Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Achieve neatness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

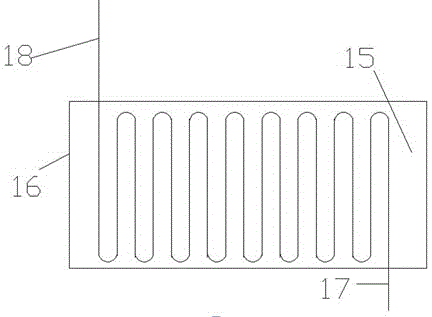

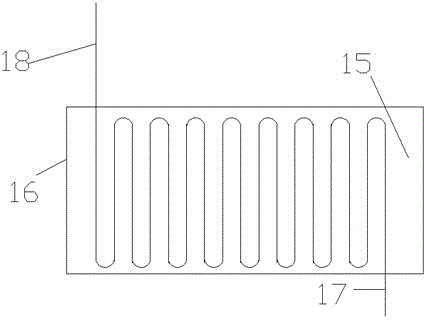

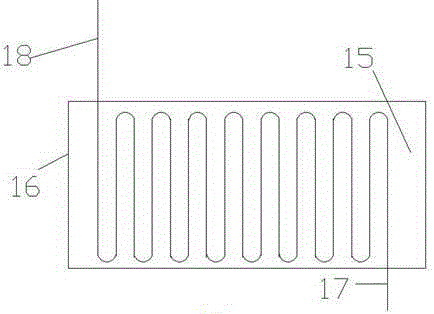

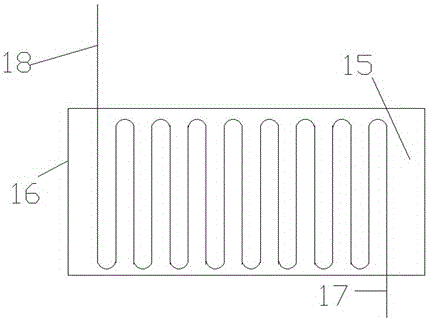

Heat storage heat exchanger and fresh air system thereof

ActiveCN104807355AEven heat absorptionAvoid uneven heat absorptionHeat storage plantsSpace heating and ventilation detailsEngineeringRecuperator

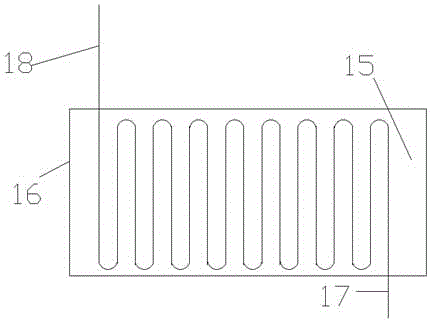

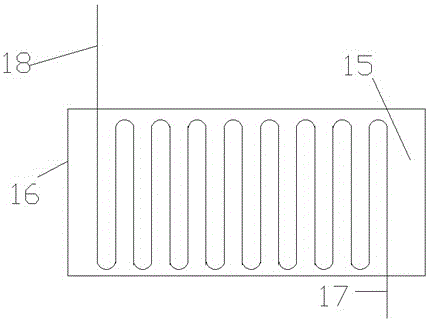

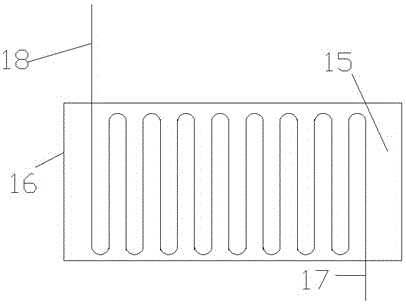

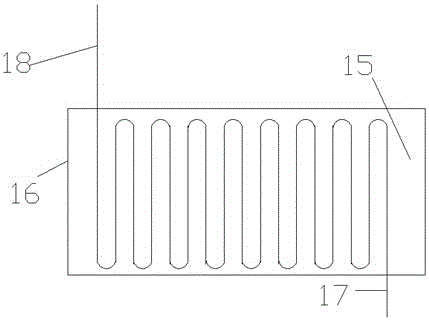

The invention relates to a heat storage heat exchanger and an air supply system comprising same. The heat exchanger comprises a shell, a heat storage medium and a fluid passage, wherein the heat storage medium is arranged in the shell, the fluid passage is arranged in the heat storage medium, the fluid passage is provided with a fluid inlet and a fluid outlet, the heat storage capacity of the heat storage heat exchanger is S, the heat storage capacity S is set as a function which is x away from the fluid inlet, i.e. S=f(x), in the heat storage heat exchanger, f(x) is more than 0, and f(x) is a first derivative of f(x). The heat storage medium integrally and uniformly absorbs the heat in the flowing direction of the fluid, and the situation such as non-uniformity in heat absorption can be avoided.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Heat storage heat exchanger and fresh air system with automatic electrostatic precipitation control function

ActiveCN104930895AEven heat absorptionAvoid uneven heat absorptionSpace heating and ventilation safety systemsSpace heating and ventilation control systemsPlate heat exchangerAutomatic control

Disclosed is a heat storage heat exchanger. The heat exchanger comprises a shell, heat storage medium and a fluid passage, wherein the heat storage medium is located in the shell; the fluid passage is located in the heat storage medium and provided with a fluid inlet and a fluid outlet; the heat storage capacity of the heat storage heat exchanger is gradually increased in the flowing direction of fluid. The heat storage medium is uniform in overall heat absorption in the flowing direction of fluid, and therefore the phenomenon of uneven heat absorption is avoided.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Heat storage heat exchanger and fresh air system with same

ActiveCN104807354AEven heat absorptionAvoid uneven heat absorptionHeat storage plantsSpace heating and ventilation detailsPlate heat exchangerFresh air

The invention relates to a heat storage heat exchanger. The heat exchanger comprises a shell, a heat storage medium and a fluid passage, wherein the heat storage medium is arranged in the shell, the fluid passage is arranged in the heat storage medium, the fluid passage is provided with a fluid inlet and a fluid outlet, and the heat storage medium is a phase-changing heat storage medium. By adopting the heat storage heat exchanger, the capacity of the phase-changing material for absorbing a great amount of potential heat and capable of being recycled for a long time is utilized, so that the consumption of unnecessary additional energy is avoided, and the temperature of fresh air is more comfortable; the system is high in heat exchanging efficiency, pollution-free, energy-saving and environment-friendly.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

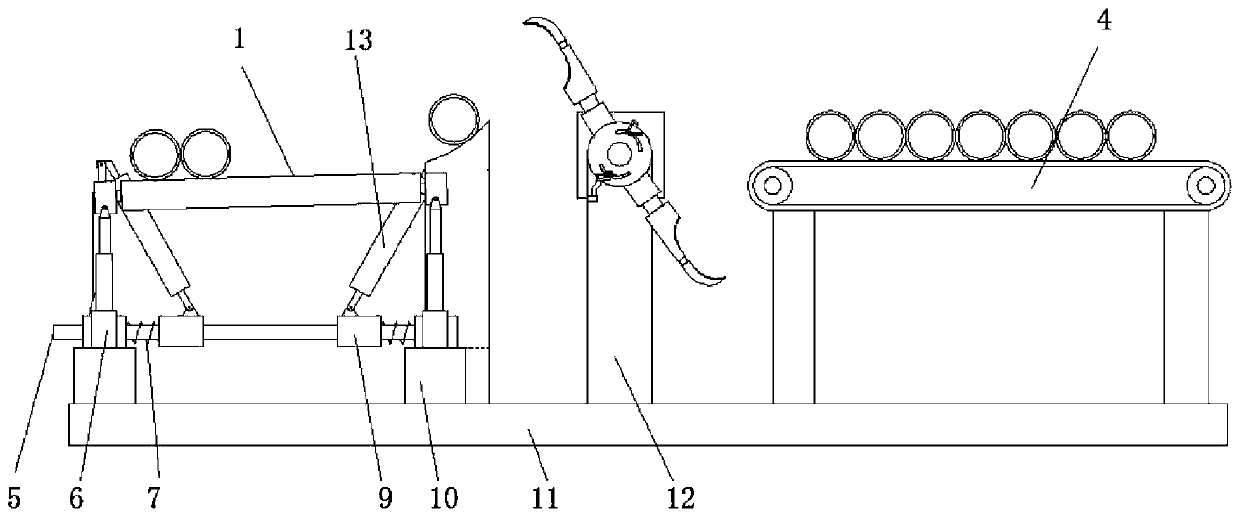

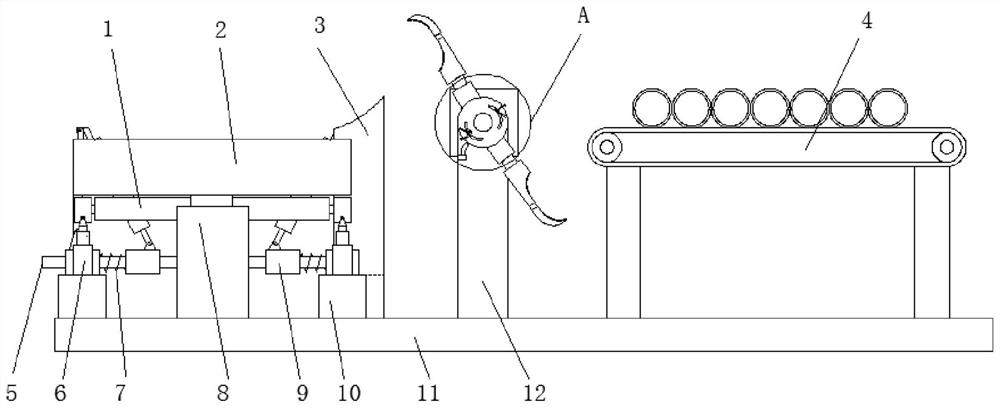

Stacking machine used for stacking steel pipes

ActiveCN111498510AEasy to clamp and supportAchieve magnetic fixationConveyorsStacking articlesElectric machineryPalletizer

The invention discloses a stacking machine used for stacking steel pipes. The stacking machine used for stacking the steel pipes comprises a steel pipe conveying belt, a bottom plate, a stacking mechanism, a material pushing mechanism and a steel pipe magnetic suction device; the material pushing mechanism consists of a push plate and a second electric telescopic rod; the stacking mechanism comprises multiple groups of supporting plates, a limiting frame, multiple groups of first fixing seats, multiple groups of limiting rods and multiple groups of second fixing seats; the steel pipe magneticsuction device comprises an upright, a motor, a rotating seat and a material supporting part; and the material supporting part comprises a third electric telescopic rod, a first placing plate, a cylinder and a second placing plate. According to the stacking machine used for stacking the steel pipes, the magnetic suction fixing of the material supporting part to the steel pipe can be effectively realized through the material supporting part and electromagnetic suction of the material supporting part; the contact between an elastic shifting sheet and an extruding plate can be effectively realized through the position of the elastic shifting sheet in an arc slide groove; the steel pipes can be effectively stacked one by one through obliquely arranged supporting plates; and the steel pipes canbe effectively stacked layer by layer by adjusting the telescopic quantity of a first electric telescopic rod.

Owner:LIAOCHENG ANTAI PETROLEUM MACHINERY

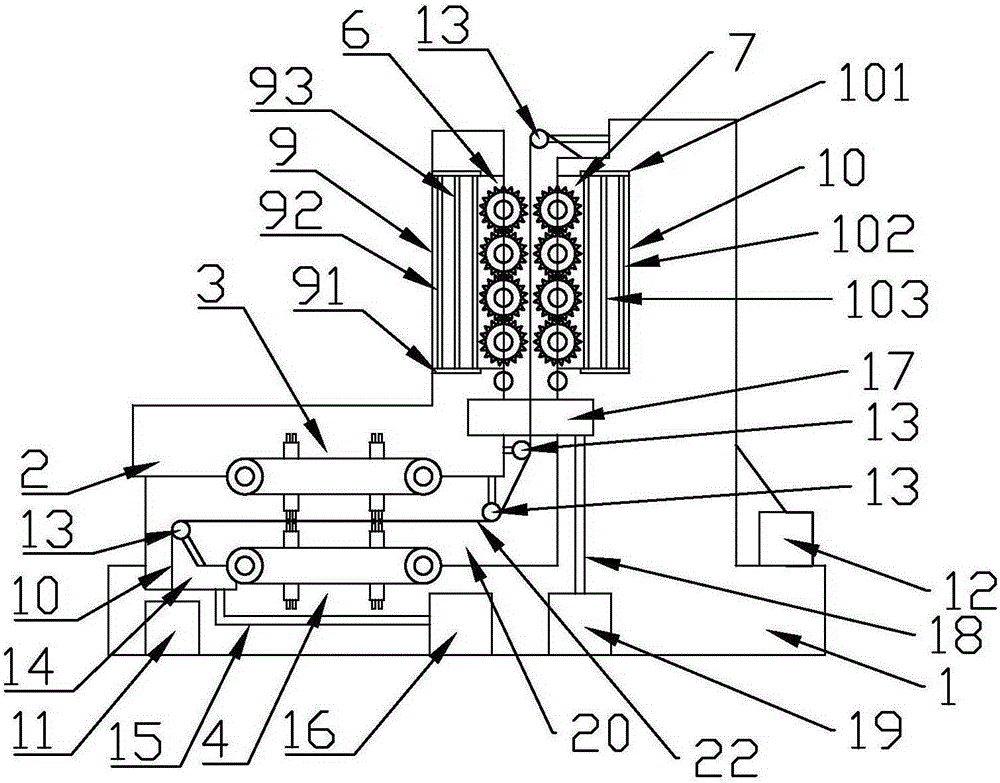

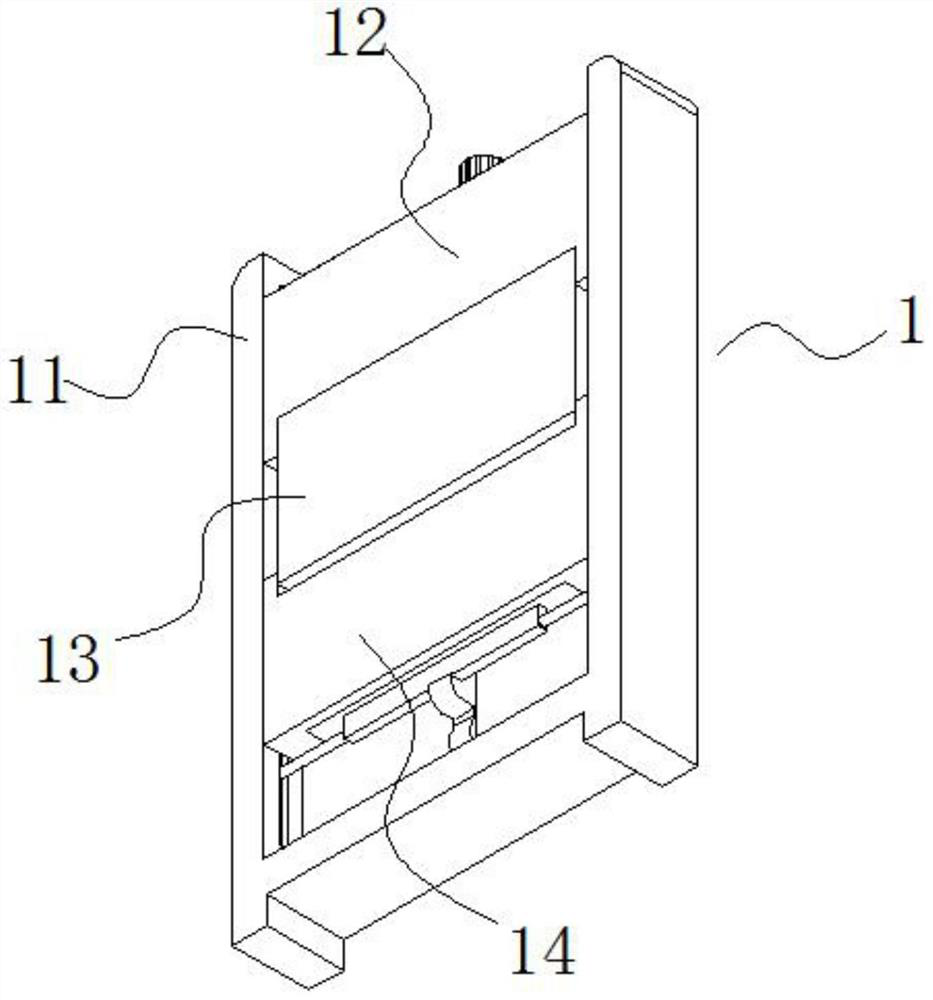

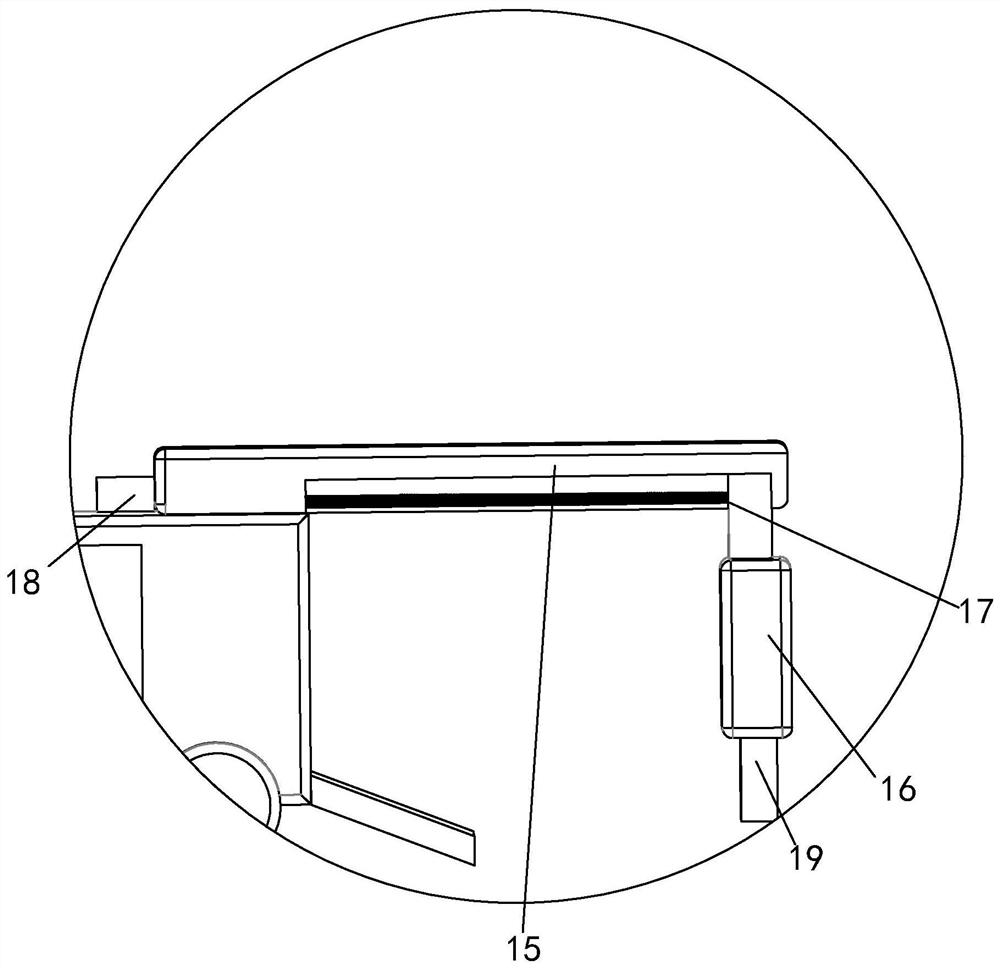

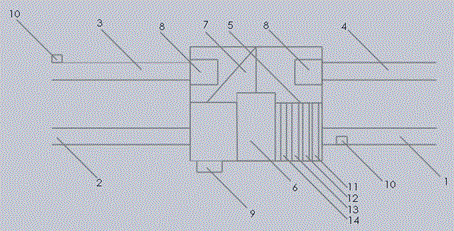

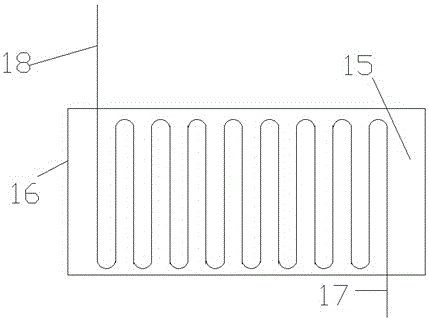

Cloth inspecting dust removing system applied to clothing production

ActiveCN105170499ASimple structureTargetedCleaning using toolsElectrostatic chargesEngineeringTextile

The invention discloses a cloth inspecting dust removing system applied to clothing production. The cloth inspecting dust removing system applied to clothing production comprises a cloth inspecting rack and a dust removing rack. A dust removing channel is formed between the cloth inspecting rack and the dust removing rack and is internally provided with dust removing cloth and dust removing devices. The dust removing devices comprise the horizontal dust removing device and the vertical dust removing device. The horizontal dust removing device comprises an upper dust removing mechanism, a lower dust removing mechanism and a horizontal driving mechanism. The upper dust removing mechanism and the lower dust removing mechanism are both connected with the horizontal driving mechanism. The vertical dust removing device comprises a left dust removing mechanism, a right dust removing mechanism and a vertical driving mechanism. The left dust removing mechanism and the right dust removing mechanism are both connected with the vertical driving mechanism. The horizontal dust removing device and the vertical dust removing device are used for performing dust removal on the upper surface and the lower surface of the dust removing cloth two times respectively, the dirt, dust and electrostatic effect of the cloth is eliminated, the eliminating rate can reach up to 98%, and therefore the purposes that a cloth cover is clean and tidy, product quality is improved, the product yield rate is increased, the reject ratio is reduced, and product cost is reduced can be achieved.

Owner:HAIAN RUNDE CLOTHING CO LTD

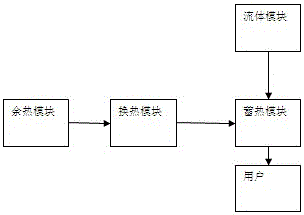

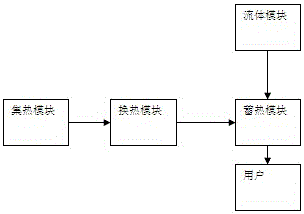

Solar phase change heat storage system

ActiveCN104896773AContinuous heat utilizationRealize centralized utilizationSolar heating energySolar heat devicesEngineeringPhase change

A solar heat storage system comprises a heat collection module, a heat exchange module, a heat storage module and a fluid module, wherein the heat collection module absorbs solar energy and transfers the solar energy to the heat storage module by the heat exchange module, the fluid module comprises a fluid channel, and the fluid channel and the heat storage module exchange heat to transfer the heat to fluid in the fluid channel. The solar heat can be stored and reused, energy is saved, and the aims of energy conservation and environment protection are achieved.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

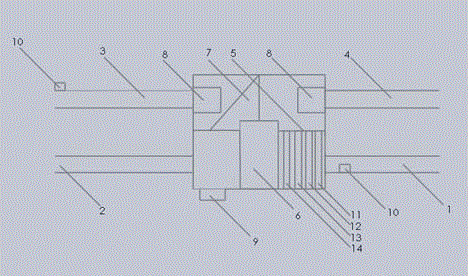

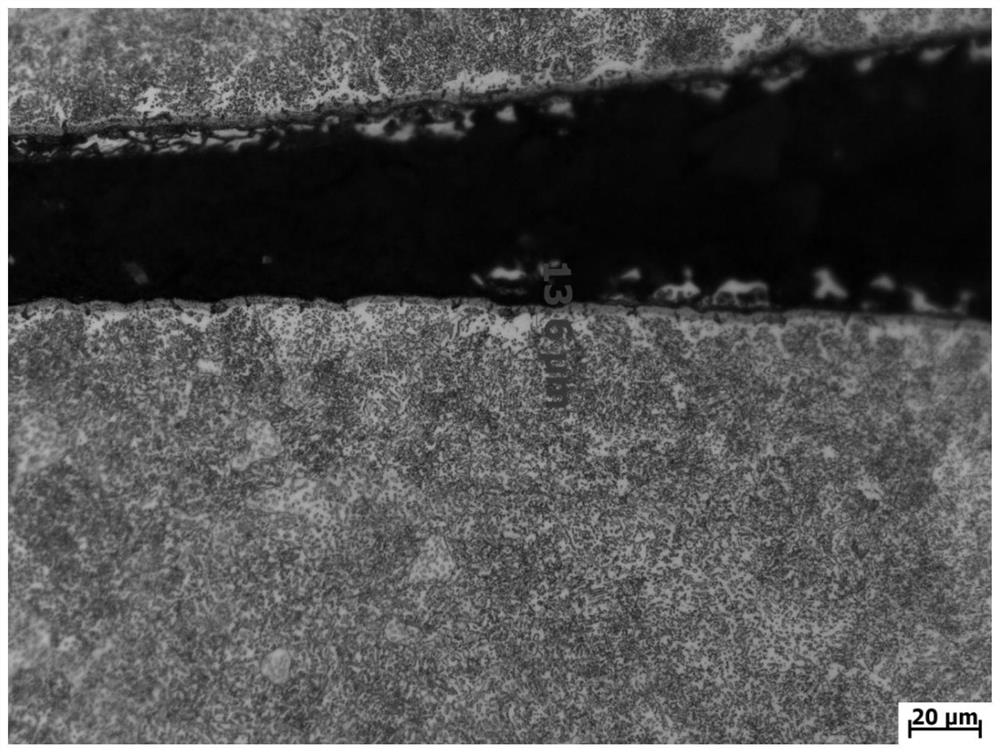

Large-specification high-carbon chromium bearing steel hot-rolled wire rod and high-speed wire rod production method thereof

ActiveCN112355054ADowngradeReduce the cost of spheroidizing annealingTemperature control deviceProcess efficiency improvementWire rodProduction line

The invention provides a large-specification high-carbon chromium bearing steel hot-rolled wire rod and a high-speed wire rod production method thereof. The method comprises the following steps that (1) a continuous casting square billet is heated in a heating furnace, the temperature of a preheating section ranges from 830 DEG C to 880 DEG C, the temperature of a heating section ranges from 1150DEG C to 1210 DEG C, and the temperature of a soaking section ranges from 1190 DEG C to 1220 DEG C; (2) the continuous casting square billet is subjected to heat preservation in a high-temperature section, and the heat preservation time is larger than or equal to 120 min; (3) the continuous casting square billet is rolled through a high-speed rolling mill, the initial rolling temperature is controlled to be 1090-1120 DEG C, the spinning temperature is controlled to be 860-900 DEG C, the swing amplitude of a spinning machine is controlled, and the continuous casting square billet is rolled intoa hot-rolled wire rod; (4) the rolled hot-rolled wire rod is cooled to be larger than or equal to 550 DEG C at the cooling speed of 0.7-0.9 DEG C / s, the speed of a Stelmor line roller way is controlled, coil collection is carried out, and then air cooling is carried out to reach the room temperature; (5) surface quality inspection, finishing and sampling are carried out on the collected hot-rolled wire rod; and (6) the finished hot-rolled wire rod is quickly packaged online. According to the high-speed wire rod production method, the bearing steel hot-rolled wire rod with phi 21-25 mm is produced.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

Device for dedusting circuit board

The invention provides a device for dedusting a circuit board. The device comprises a bracket, wherein an outer frame is fixedly arranged on the bracket; the outer frame is arranged in a half-sealing mode; one surface of the outer frame is provided with an opening; electrostatic isolation leather is arranged at the opening, is fixed on the outer frame and covers the opening; a circuit board bearing panel is arranged at the bottom of an inner cavity of the outer frame; an exhaust fan device is fixed at the bottom of the outer frame; and the exhaust fan device is matched with the circuit board bearing panel and is connected with a dust collection device through a dust adsorption pipe. Due to matching between the exhaust fan device and the outer frame, the dust can be effectively removed from the circuit board, so that the circuit board has a neat surface, and the health of an operator is protected.

Owner:欧朗电子科技有限公司

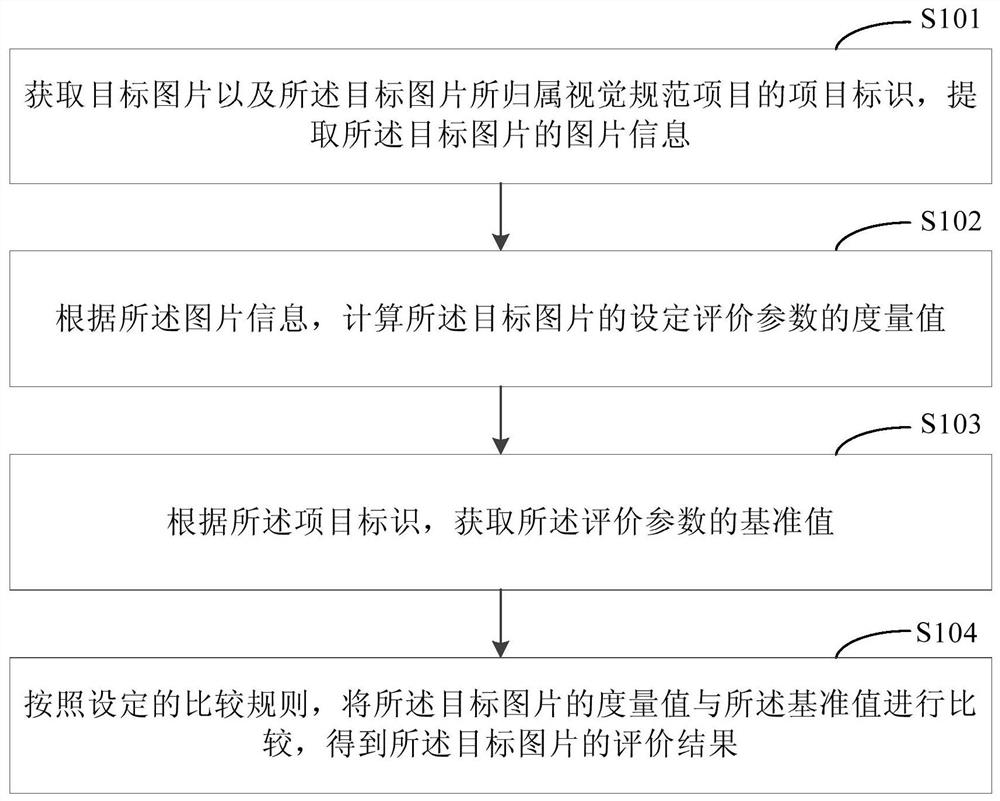

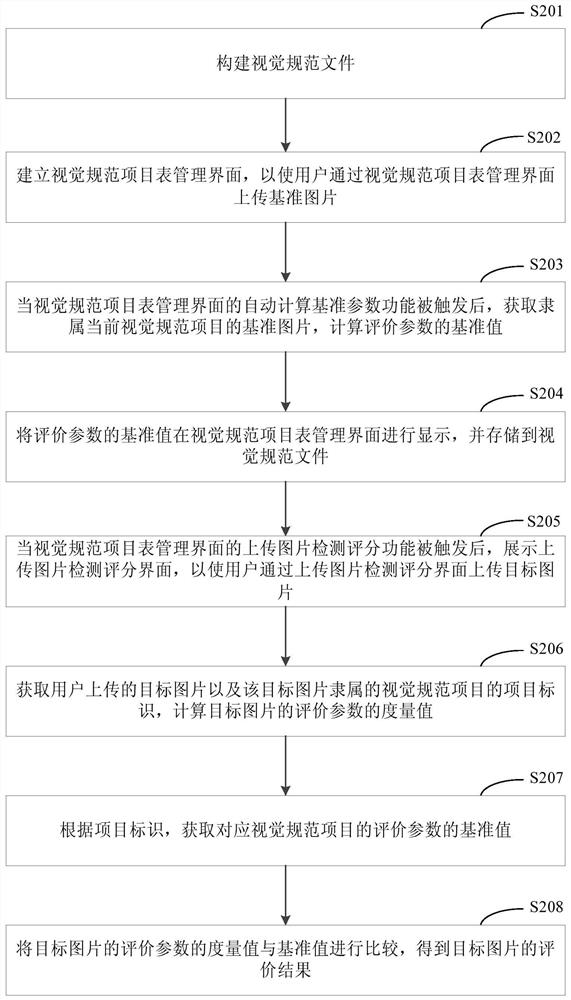

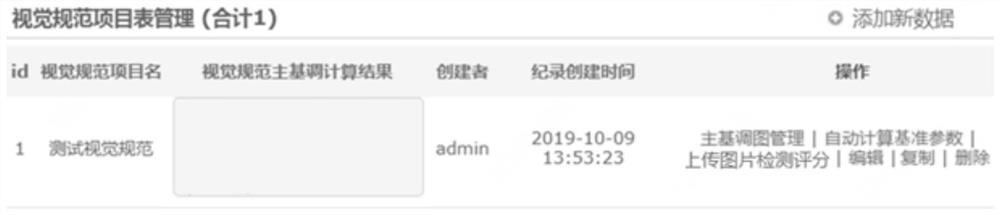

Picture quality evaluation method and system

PendingCN111798406AGo digitalRealize automated evaluationImage enhancementImage analysisEvaluation resultVisual specification

The invention discloses a picture quality evaluation method and system, and relates to the technical field of computers. A specific embodiment of the method comprises: obtaining a target picture and aproject identifier of a visual specification project to which the target picture belongs, and extracting picture information of the target picture; according to the picture information, calculating ametric value of a set evaluation parameter of the target picture; obtaining a reference value of the evaluation parameter according to the project identifier, wherein the reference value is determined by calculating metric values of evaluation parameters of a plurality of reference pictures; and comparing the metric value of the target picture with the reference value according to a set comparison rule to obtain an evaluation result of the target picture. According to the embodiment, by extracting the picture information of the target picture, generating the digital evaluation parameter and then comparing the digital evaluation parameter with the reference value of the evaluation parameter, automatic evaluation of the picture quality is realized, the evaluation efficiency is improved, andthe evaluation result is objective and fair.

Owner:BEIJING JINGDONG SHANGKE INFORMATION TECH CO LTD +1

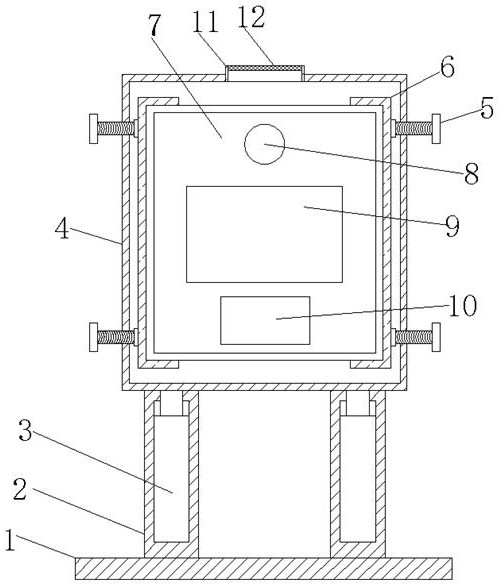

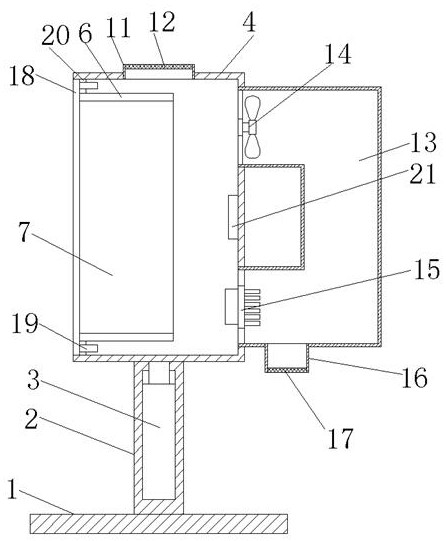

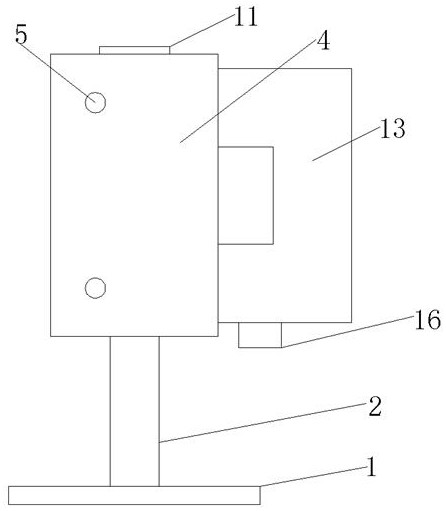

Vehicle-mounted full-payment intelligent terminal

InactiveCN112185032AEasy to cleanAchieve neatnessCash registersModifications by conduction heat transferIn vehicleEngineering

The invention discloses a vehicle-mounted full-payment intelligent terminal. The intelligent terminal comprises a bottom plate, two symmetrically-distributed supporting columns are fixed to the outerwall of the top of the bottom plate, built-in grooves are reserved in the two supporting columns, air cylinders are fixed to the inner walls of the built-in grooves, and piston rods of the air cylinders extend to the outer walls of the tops of the supporting columns. The same fixing box is fixed to the top ends of piston rods of the two air cylinders, an opening is formed in the outer wall of oneside of the fixing box, baffles are fixed to the inner wall of the top and the outer wall of the bottom, close to the opening, of the fixing box, and two symmetrically-distributed threaded holes are formed in the outer walls of the two sides of the fixing box. A transparent window is arranged on the surface of the intelligent payment terminal, an operator can clean the intelligent payment terminalconveniently while payment is not hindered, cleanliness of the whole device is achieved, meanwhile, the height of the intelligent payment terminal can be adjusted through operation of the air cylinders, the intelligent payment terminal is suitable for crowds with different heights, and the humanized design is embodied.

Owner:深圳市迈圈信息技术有限公司

Flowerpot with tray

InactiveCN101422116AAchieve aestheticsAchieve neatnessReceptacle cultivationFlower-pot saucersEngineeringFlowerpot

The invention discloses a flowerpot with a tray, which consists of a flowerpot opening, a flowerpot body and a flowerpot base. The bottom part of the flowerpot base is provided with the tray which is in a concave shape; the outer edge of the tray turns over to the upper side by a certain height; the tray and the flowerpot body are integrally baked and shaped. In the invention, the tray and the flowerpot are integrally baked and shaped, the residual water falls into the depression part of the tray, thereby preventing the irrigated residual water from affecting the environment caused by running over the flowerpot, thus achieving the effects of beauty and cleanness.

Owner:张爱银

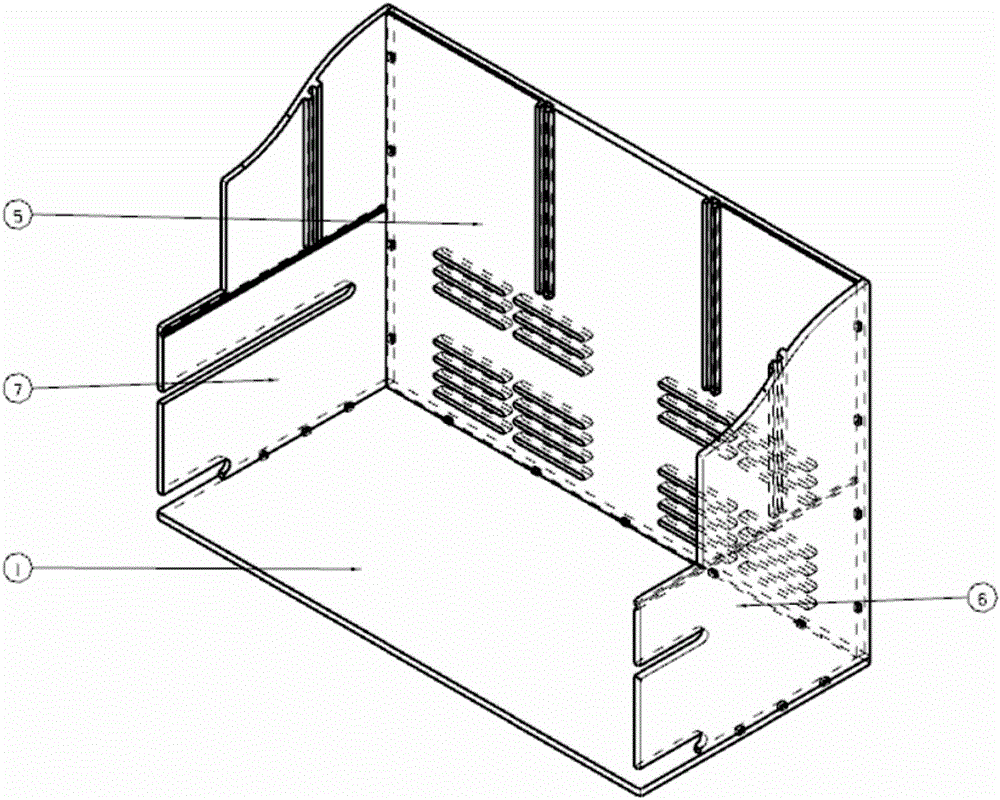

Multifunctional computer data line storage box

InactiveCN106724200AEasy to storeOrderly storageOffice tablesOther accessoriesBusiness cardRemote control

The invention relates to a multifunctional computer data line storage box which comprises a double-layer data line storage layer, storage cells and a main outer frame. The whole double-layer data line storage layer and the main outer frame are combined in a plugged mode. The whole storage cells and the main outer frame are combined in slot plugged mode as well. The multifunctional computer data line storage box can contain data lines and office articles and can conveniently store a power module, a power line, a computer accessory-keyboard, mouse and other data lines of a portable computer (notebook computer) in use, and quickly and conveniently store various small office supplies such as business cards, notebooks, pens, USB flash disks, remote-control units and the like in the plugged mode to achieve the comprehensive purposes of decreasing data lines on a desk top, making office supplies stored orderly and making the desk top tidy.

Owner:CHANGZHOU INST OF MECHATRONIC TECH

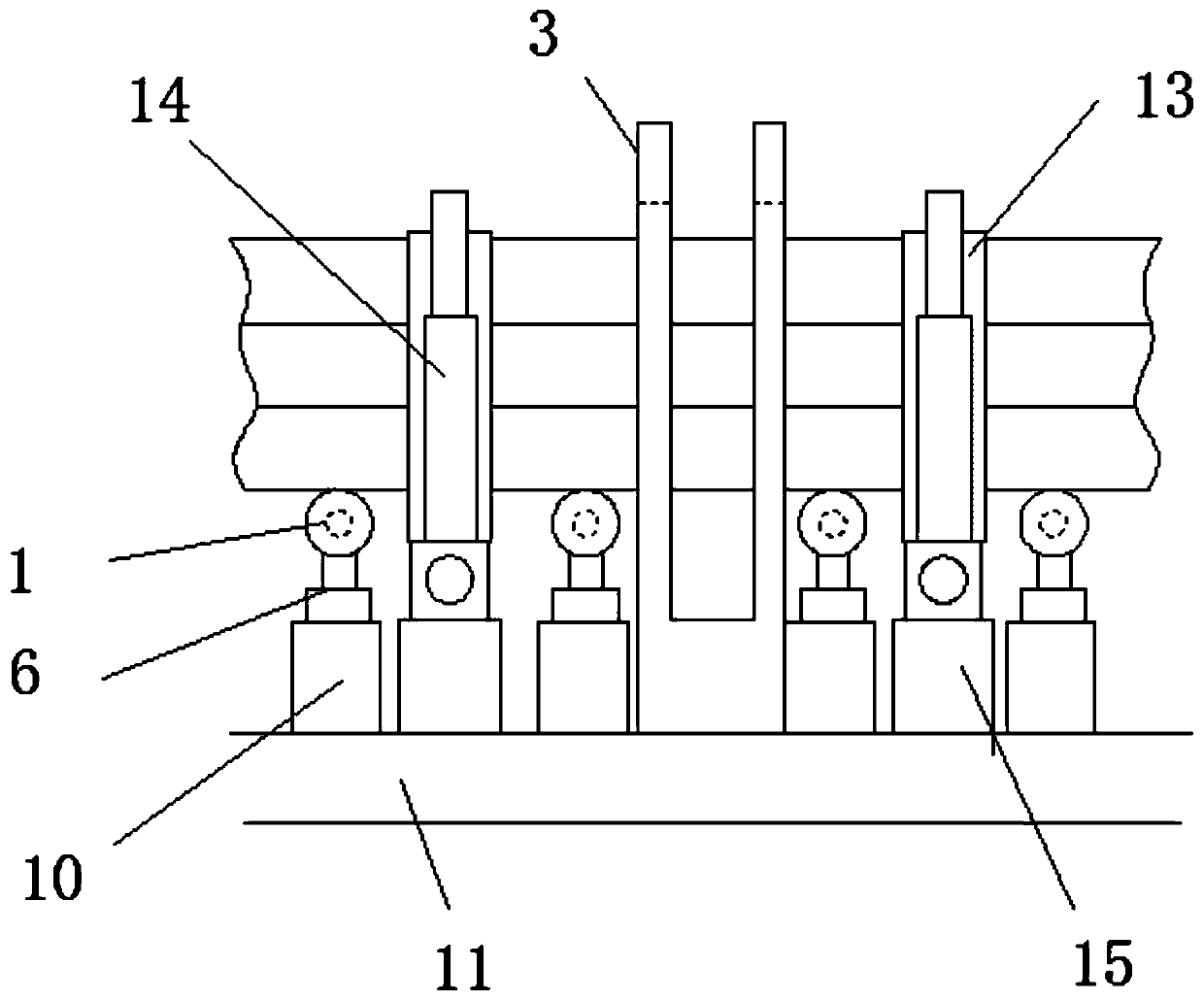

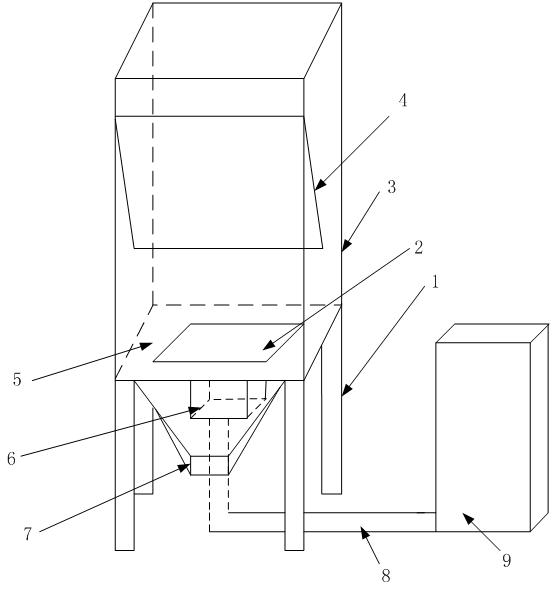

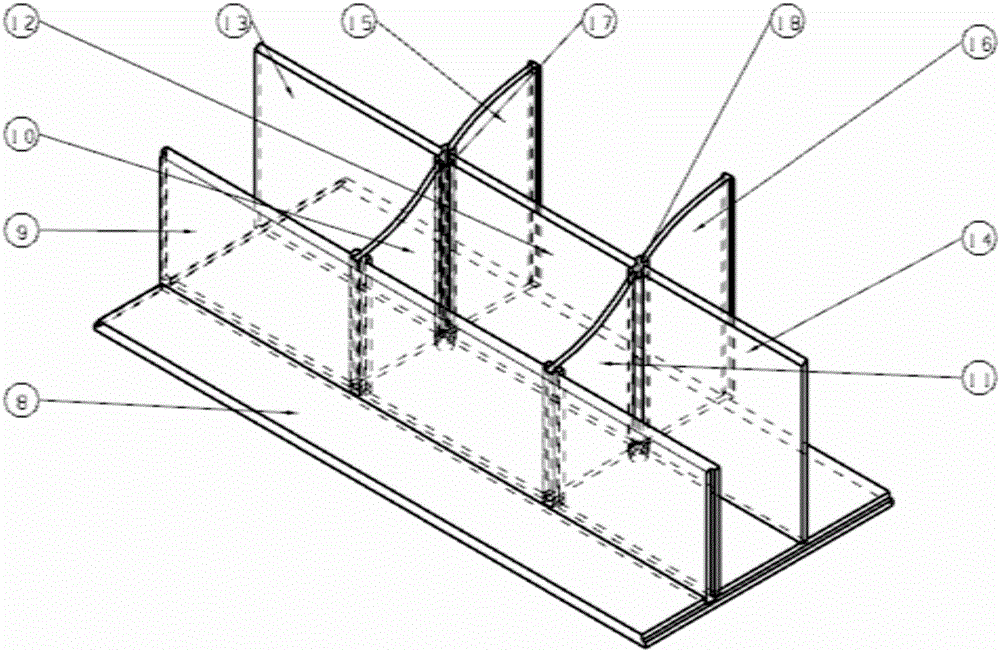

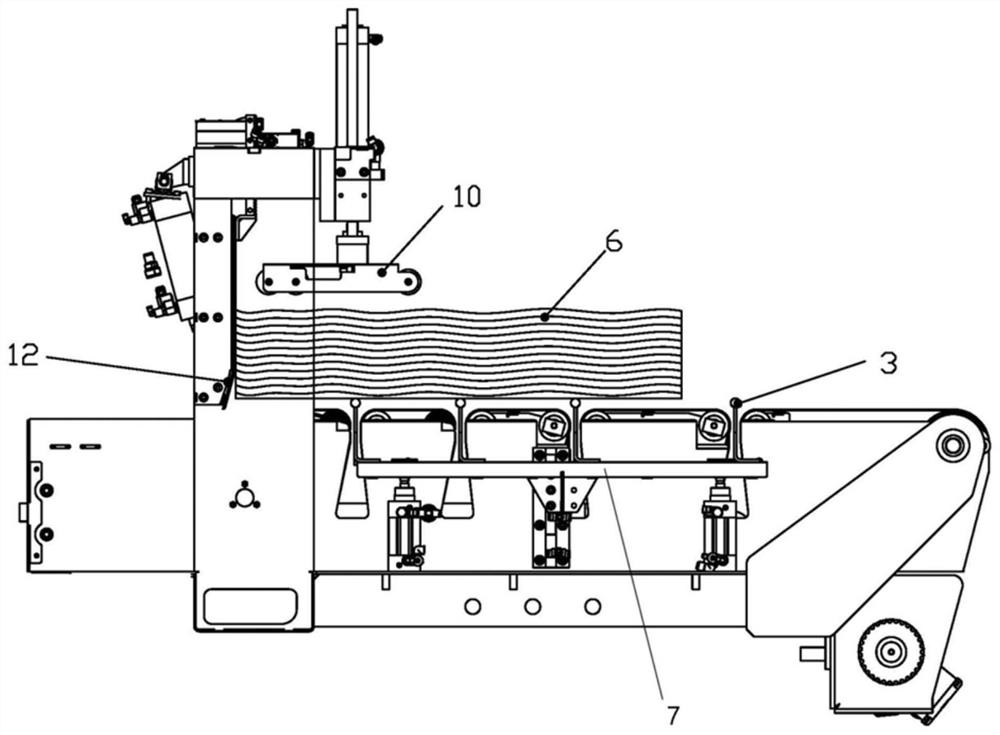

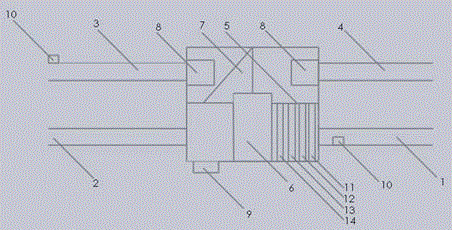

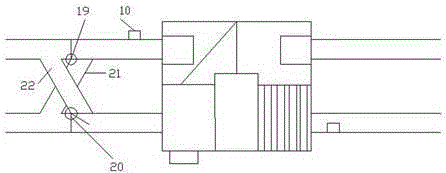

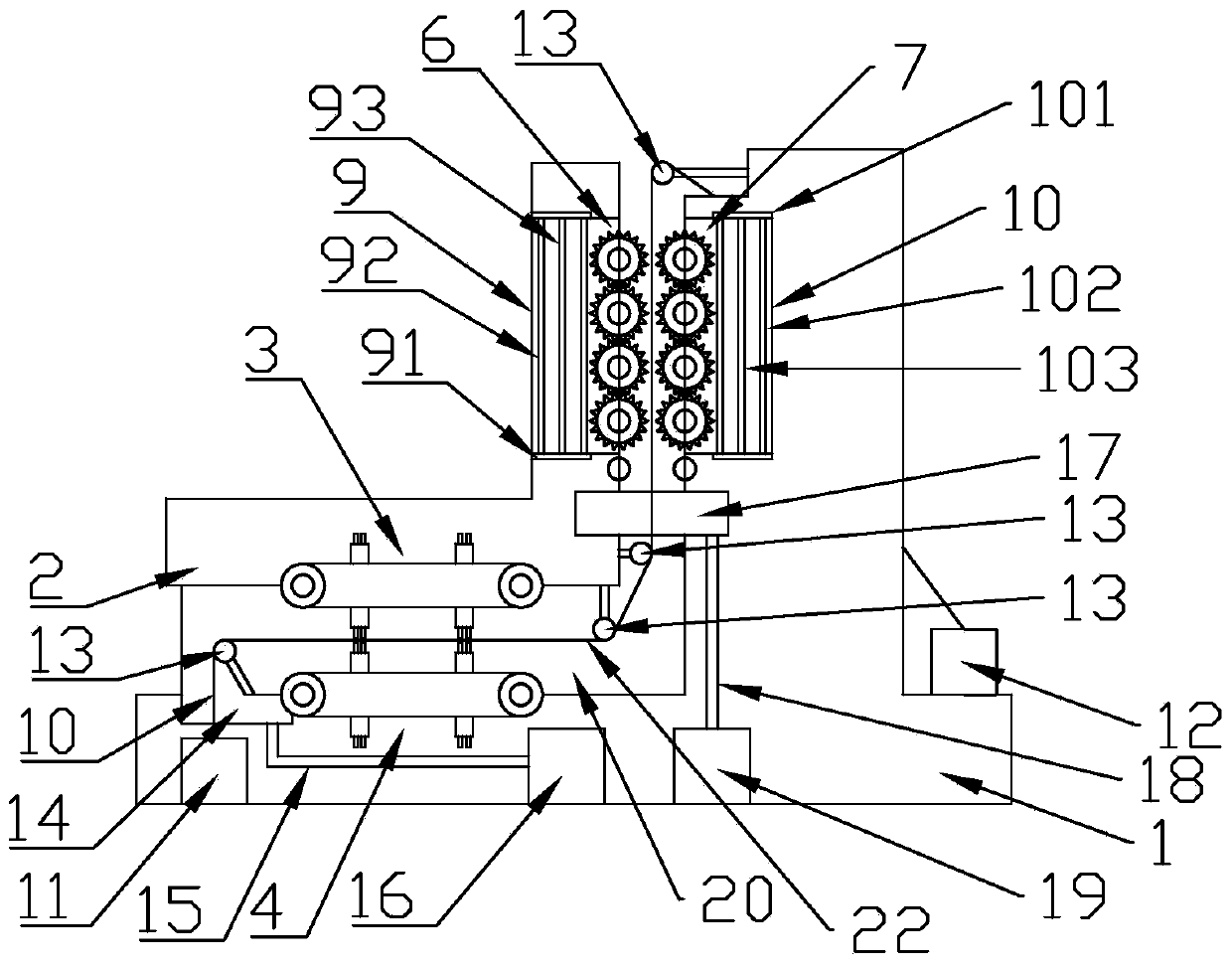

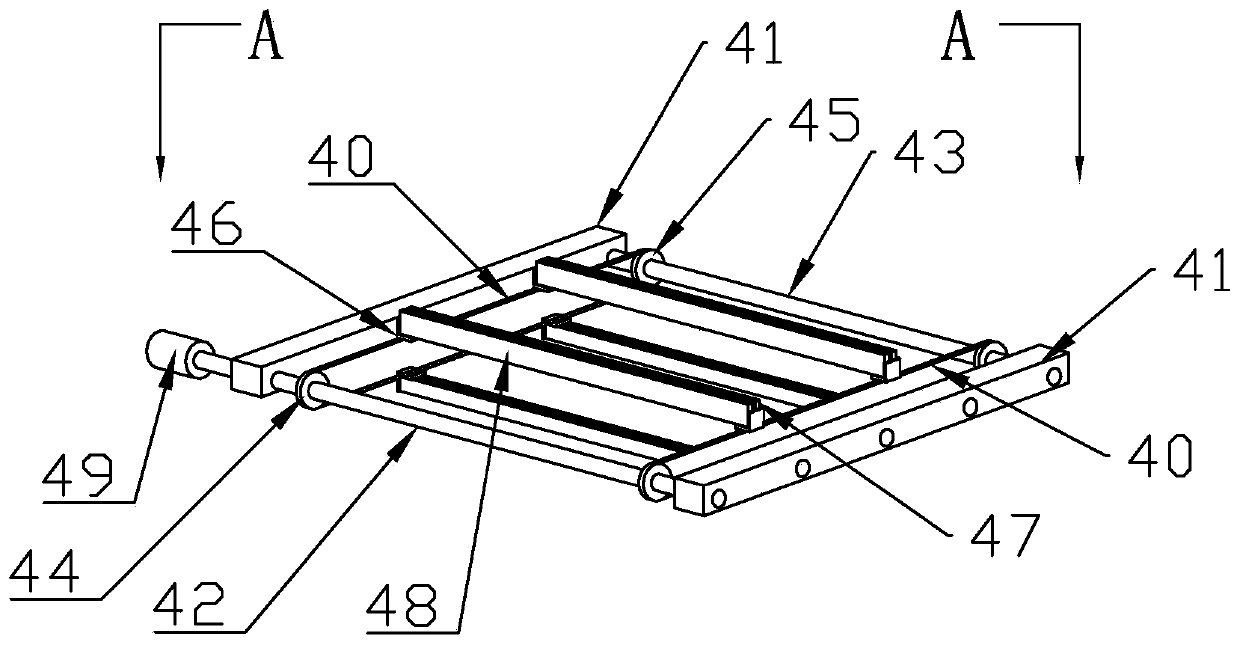

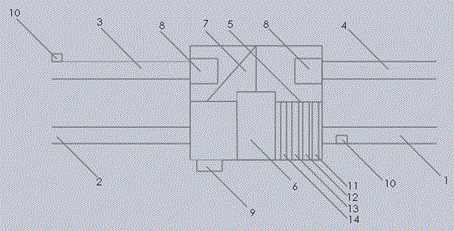

Paper arranging device used before corrugated paper laying of paper feeder

PendingCN112441442AAchieve neatnessSmooth feedingArticle separationStructural engineeringIndustrial engineering

The invention relates to a paper arranging device before corrugated paper laying of a paper feeder. The paper arranging device comprises a machine frame (9), a side beating mechanism, a belt conveyingmechanism for conveying a paper stack (6) and a paper supporting rod supporting mechanism (7) are connected onto the machine frame (9), wherein the side beating mechanism is positioned above the beltconveying mechanism, a plurality of grooves are arranged in the belt conveying mechanism, paper supporting rods (3) are arranged in the grooves, the paper supporting rods (3) are connected to the paper supporting rod supporting mechanism (7) and is driven by the paper supporting rod supporting mechanism (7), the belt conveying mechanism drives the paper stack (6) to stop after the paper stack (6)is input to a designated position, then the paper supporting rod supporting mechanism (7) drives the paper supporting rod (3) to drive the paper stack (6) to ascend, after the paper stack (6) ascends, the paper supporting rod supporting mechanism (7) stops, the side beating mechanism acts, the two sides of the paper stack (6) are beat to be aligned, and paper arrangement is completed. Compared with the prior art, the paper arranging device has the advantages of being good in paper arranging effect, high in paper feeding stability, high in device stability and the like.

Owner:SHANGHAI ETERNAL MACHINERY

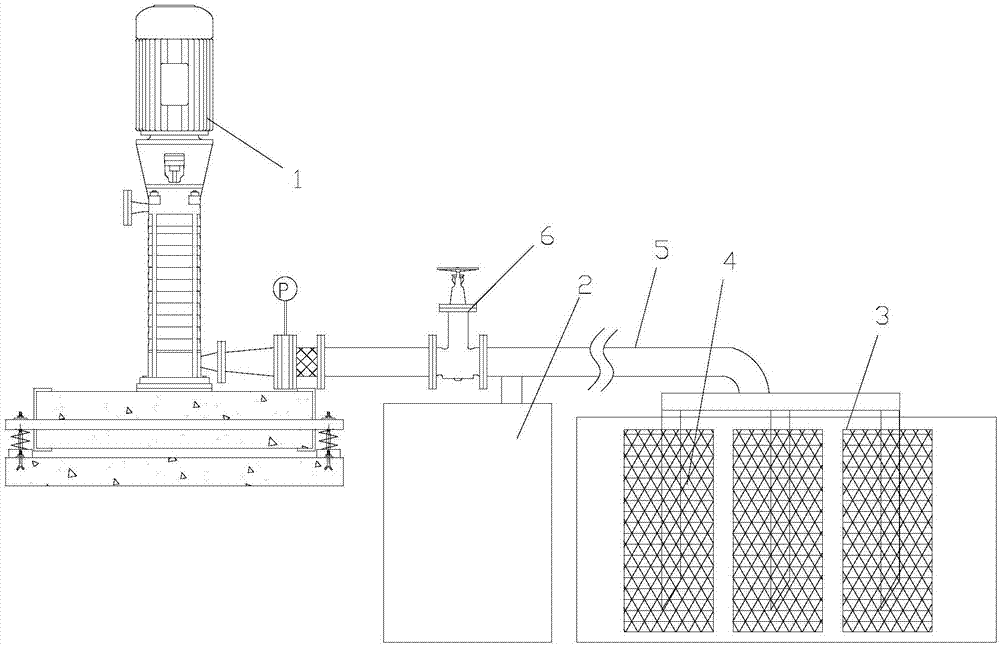

Mud on-site separation device and separation method

PendingCN107970659AAchieve neatnessMovableStationary filtering element filtersWater storageWater storage tank

The invention relates to the technical field of waterproofness and anti-permeability in the building field, and particularly relates to a mud on-site separation device. The mud on-site separation device comprises a vacuum pump, a water storage tank, a support cage, filter cloth and a water pumping pipe, the vacuum pump is communicated with one end of the water pumping pipe, the water storage tankis connected onto the side wall of the water storage tank through a pipeline, the other end of the water pumping pipe extends into the bottom part of the support cage, and the filter cloth is wrappedat the outer part of the support cage. The building mud is processed by a mud dehydration recycle device, an effluent is recycled to serve as production water for the construction site, the water resource is saved, the aggregate is reused as a resource, and a mud cake is used as backfilling earthwork. After the building mud is treated, the moisture content is reduced to about 27% from 61%, the weight loss ratio of the volume of the mud is 47%, and the goal of minimization is achieved.

Owner:TIANJIN DIVINE WING AIRCRAFT TECH

Air supply system with accumulator

ActiveCN104807355BEven heat absorptionAvoid uneven heat absorptionHeat storage plantsSpace heating and ventilation detailsEngineeringHeat exchanger

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

A cloth inspection and dust removal system applied to clothing production

ActiveCN105170499BSimple structureSolve the problem of dust removalCleaning using toolsElectrostatic chargesEngineeringYield rate

The invention discloses a cloth inspection and dust removal system used in clothing production, which includes a cloth inspection frame and a dust removal frame. A dust removal channel is formed between the cloth inspection frame and the dust removal frame. A dust removal cloth and a dust removal channel are provided in the dust removal channel. The dust removal device includes a horizontal dust removal device and a vertical dust removal device. The horizontal dust removal device includes an upper dust removal mechanism, a lower dust removal mechanism and a horizontal driving mechanism. The upper dust removal mechanism and the lower dust removal mechanism are both connected to the horizontal driving mechanism. The vertical dust removal device includes a left dust removal device. mechanism, the right dust removal mechanism and the vertical drive mechanism, the left dust removal mechanism and the right dust removal mechanism are both connected to the vertical drive mechanism. Through the horizontal dust removal device and the vertical dust removal device, the upper and lower surfaces of the dust removal cloth are subjected to two dust removal treatments respectively to eliminate dirt, dust and static electricity on the dust removal cloth. The elimination rate can reach 98%, thereby achieving a clean cloth surface and improving the product quality. The purpose is to improve product quality, improve product yield, reduce scrap rate, and reduce product cost.

Owner:HAIAN RUNDE CLOTHING CO LTD

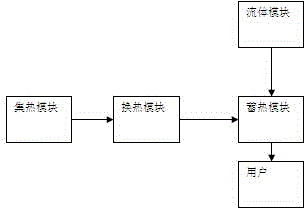

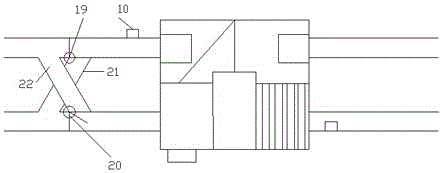

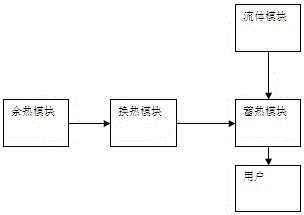

Phase change heat storage system for residual heat of ignition stove

ActiveCN104990107AContinuous heat utilizationRealize centralized utilizationDomestic stoves or rangesStorage heatersEngineeringPhase change

A heat storage system for an ignition stove comprises a residual heat module, a heat exchange module, a heat storage module and a fluid module, wherein the residual heat module is used for absorbing residual heat of the ignition stove, and transmitting the residual heat to the heat storage module through the heat exchange module; the fluid module comprises a fluid passage which exchanges heat with the heat storage module, so as to transmit heat to a fluid in the fluid passage. The heat storage system has the advantages that the heat of the ignition stove can be stored and then utilized, so that the energy is saved, and the purpose of energy conservation and environment protection are realized.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

A heat storage heat exchanger and a fresh air system with automatic control of electrostatic dust removal

ActiveCN104930895BEven heat absorptionAvoid uneven heat absorptionSpace heating and ventilation safety systemsSpace heating and ventilation control systemsAutomatic controlEngineering

Disclosed is a heat storage heat exchanger. The heat exchanger comprises a shell, heat storage medium and a fluid passage, wherein the heat storage medium is located in the shell; the fluid passage is located in the heat storage medium and provided with a fluid inlet and a fluid outlet; the heat storage capacity of the heat storage heat exchanger is gradually increased in the flowing direction of fluid. The heat storage medium is uniform in overall heat absorption in the flowing direction of fluid, and therefore the phenomenon of uneven heat absorption is avoided.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

A large-scale high-carbon chromium bearing steel hot-rolled wire rod and its high-speed wire rod production method

ActiveCN112355054BDowngradeReduce the cost of spheroidizing annealingTemperature control deviceProcess efficiency improvementWire rodTemperature control

The invention provides a large-scale high-carbon chromium bearing steel hot-rolled wire rod and its high-speed wire rod production method, comprising the following steps: (1) heating the continuous casting billet in a heating furnace, the temperature in the preheating section is 830-880°C, The temperature in the heating section is 1150-1210°C, and the temperature in the soaking section is 1190-1220°C; (2) The continuous casting billet is kept warm in the high temperature section, and the holding time is ≥120min; (3) The continuous casting billet is rolled by a high-speed rolling mill , control the rolling start temperature at 1090-1120°C, and the spinning temperature at 860-900°C, control the swing amplitude of the laying machine, and roll the continuous casting billet into a hot-rolled wire rod; Cool the strips at a cooling rate of 0.7-0.9°C / s to ≥550°C, control the speed of the Stelmore wire roller table and collect the coils, and then air-cool to room temperature; Surface quality inspection, finishing, sampling; (6) Quickly pack the finished hot-rolled wire rod online. The invention utilizes a high-speed wire rod production line to produce a Φ21-25mm bearing steel hot-rolled wire rod.

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

A phase-change heat storage system for residual heat from a ignition stove

ActiveCN104990107BContinuous heat utilizationRealize centralized utilizationDomestic stoves or rangesStorage heatersEngineeringPhase change

A heat storage system for an ignition stove comprises a residual heat module, a heat exchange module, a heat storage module and a fluid module, wherein the residual heat module is used for absorbing residual heat of the ignition stove, and transmitting the residual heat to the heat storage module through the heat exchange module; the fluid module comprises a fluid passage which exchanges heat with the heat storage module, so as to transmit heat to a fluid in the fluid passage. The heat storage system has the advantages that the heat of the ignition stove can be stored and then utilized, so that the energy is saved, and the purpose of energy conservation and environment protection are realized.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Workbench capable of being rotatably adjusted and expanded for computer software development

ActiveCN113729397AAchieve foldingAchieve stretchBook cabinetsSuspended tablesDrive wheelSoftware engineering

The invention discloses a workbench capable of being rotatably adjusted and expanded for computer software development, and relates to the technical field of software development. The workbench comprises two supporting mechanisms which are oppositely arranged; a bearing assembly and a storage assembly are clamped to the surface of a fixing rod; a first expansion table is rotationally connected with a supporting assembly, the top of a second expansion table is rotationally connected with the bottom of the first expansion table, the bottom of the second expansion table is rotationally connected with the top of an expansion suite, and the expansion suite is in sliding fit with the supporting assembly. Through the design of a folding storage groove, a slide way, amovement hole channel, a threaded rod, a driving wheel, the first expansion table, the second expansion table, the expansion suite and the matching wheel, the threaded rod rotates to drive the driving wheel to slide along the movement hole channel, and then the driving wheel is used for pushing the matching wheel to move synchronously, so that folding and stretching among the first expansion table, the second expansion table and the expansion suite are achieved, and the area of the workbench can be flexibly adjusted according to needs.

Owner:JINAN KEMING DIGITAL TECH

Express moving device based on intelligent control

InactiveCN112572268AReach mobileEasy to watchItem transportation vehiclesCleaning using gasesPhysicsSmart control

The invention discloses an express moving device based on intelligent control. The device comprises a moving device body and a moving assembly, wherein a side wall of the moving device body is fixedlyprovided with a guide plate which is used for enabling an express to enter a box; a cleaning brush is arranged in the moving device body and connected with a dust collection assembly to be arranged in the moving device body, a disinfection assembly used for disinfecting express items is fixed to the inner wall of the moving device body, and a first conveying assembly is fixed to the inner wall ofthe moving device body; a second conveying assembly is fixed to the top of the moving device body, a pushing assembly used for pushing the express items is arranged on the inner wall of the moving device body in a sliding mode, and a weighing assembly used for weighing the express items is fixed to the inner wall of the moving device body. The device is advantaged in that problems that dust removal and disinfection cannot be conducted on expresses, and weighing and screening cannot be conducted on the expresses are solved.

Owner:NINGBO POLYTECHNIC

A heat storage heat exchanger and a fresh air system with switching air ducts

ActiveCN104879855BEven heat absorptionAvoid uneven heat absorptionMechanical apparatusLighting and heating apparatusFresh airEngineering

A heat storage heat exchanger comprises a shell, a heat storage medium and a fluid channel. The heat storage medium is located in the shell. The fluid channel is located in the heat storage medium and provided with a fluid inlet and a fluid outlet. The heat storage capability of the heat storage heat exchanger is gradually improved along with the flowing direction of fluid. According to the heat storage heat exchanger, the capabilities of absorbing a large amount of latent heat and long-term circulation use of a phase-change material are fully utilized, unnecessary extra energy consumption is avoided, and the temperature of fresh air makes people feel comfortable; a system is high in heat exchanging efficiency, free of pollution, environmentally friendly and capable of saving energy.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

A bicycle with a small wheel diameter that can be pushed after being folded vertically

ActiveCN104309748BSimple structural designRegular and reasonable structural designFoldable cyclesVehicle frameH shaped

Owner:张建民

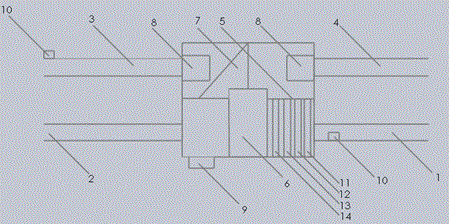

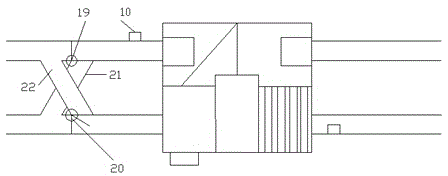

An ultra-low energy consumption building system

ActiveCN104895349BFulfill heating needsHeating demand does not requireCombination devicesSolar heating energyThermal energyConservation energy

The invention relates to an ultralow-energy-consumption building system. The ultralow-energy-consumption building system comprises a solar system, a kitchen ventilator system, an ignition stove waste heat system, an air supply system, an exterior wall heat insulation system and an energy-saving window system. The ultralow-energy-consumption building system comprehensively utilizes various heat energies to achieve the goal of saving energy, the heating demand in winter can be substantively realized and no radiator is needed for heating.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

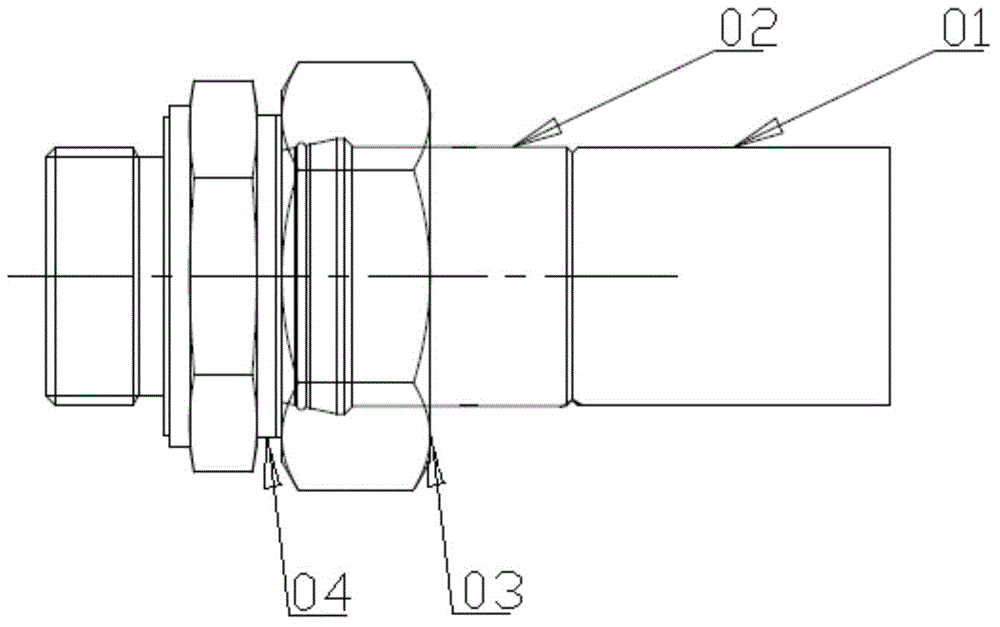

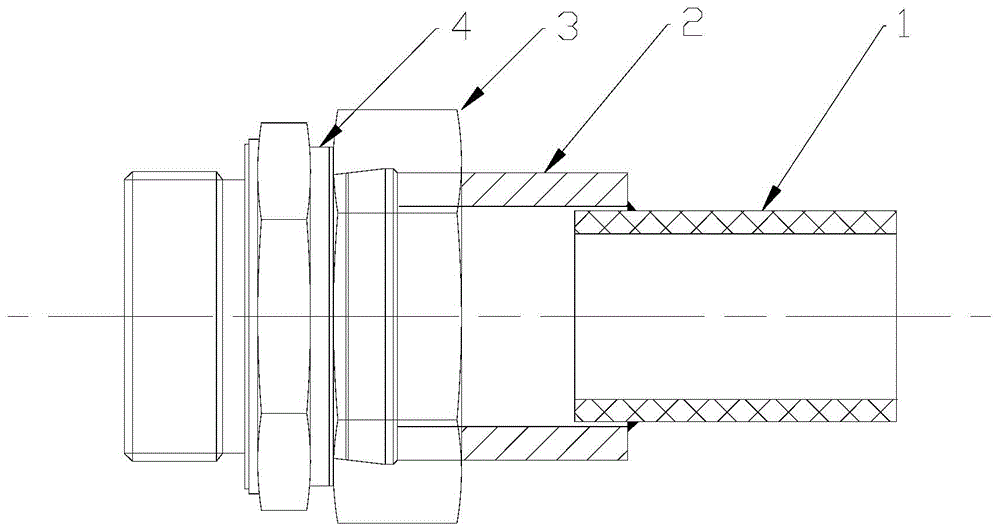

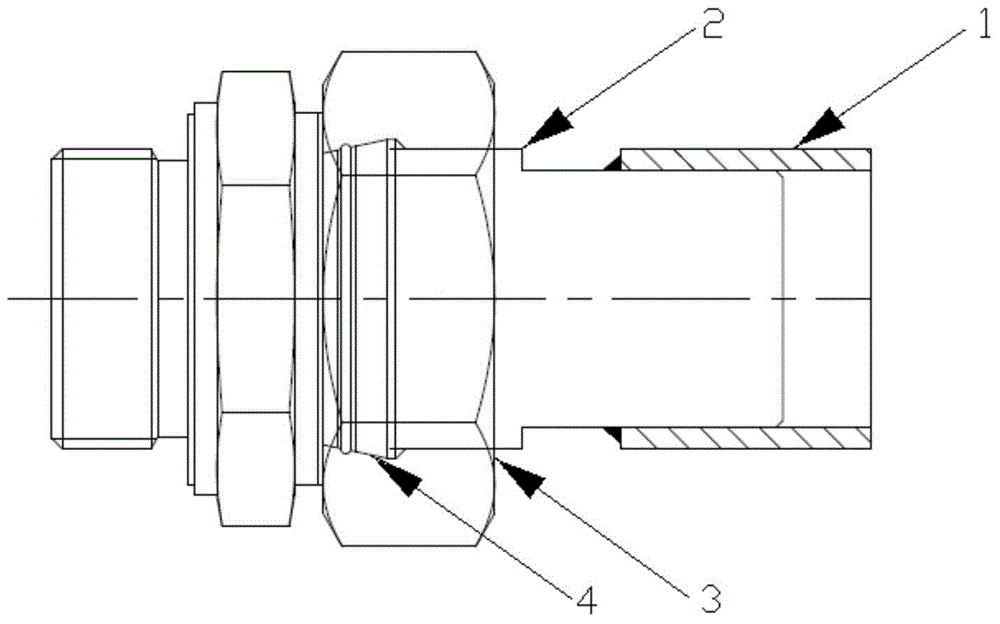

Pressure lubrication system and welded type tube joint device thereof

InactiveCN105485446AAccurate connectionShorten the timeNon-disconnectible pipe-jointsEngineeringLubrication

The invention discloses a welded type tube joint device. The welded type tube joint device comprises a connecting tube, a joint body and a hard tube. The first end of the connecting tube is connected with the joint body. The second end of the connecting tube and the first end of the hard tube can move relatively and are in nested connection with each other so that the connecting tube and the hard tube can move in a telescopic mode. The length of the hard tube is indirectly adjusted in the moving process, and the accuracy of the relative length of the hard tube can be still guaranteed during connection even if the cutting size of the hard pipe is not accurate, so that the cutting time of the hard tube is shortened, and the cutting efficiency of the hard tube is improved. The invention further discloses a pressure lubrication system which comprises the welded type tube joint device. The cutting efficiency of the hard tube of the pressure lubrication system can be effectively improved, and meanwhile the regularity of a tube array in the pressure lubrication system is achieved.

Owner:WORLD TRANSMISSION TECH TIANJIN SHARE LTD

A thermal storage system integrating the residual heat system and the air supply system of the ignition stove

ActiveCN104896643BContinuous heat utilizationRealize centralized utilizationEnergy recovery in ventilation and heatingMechanical apparatusAir exchangeOperations management

The invention relates to an ignition stove waste heat system and air supply system combined heat storage system. The ignition stove waste heat system and air supply system combined heat storage system comprises an ignition stove waste heat module, a heat exchange module, a heat storage module, an air supply module, a heat exchange module and an air return module, wherein the waste heat module absorbs waste heat, then the waste heat is transmitted to the heat storage module through the heat exchange module, the air supply module supplies fresh air, the air return module delivers air in rooms of end users to the outside, the fresh air and the air exchange heat in the heat exchange module, and the fresh air absorbs the heat of the air, enters the heat storage module, and then enters the rooms of end users. The ignition stove waste heat system and air supply system combined heat storage system has the advantages that the heat of ignition stoves and the indoor hot air can be stored, then the heat is utilized, the energy is saved and the goals of saving the energy and protecting the environment are achieved.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

A palletizer for stacking steel pipes

ActiveCN111498510BEasy to clamp and supportAchieve magnetic fixationConveyorsStacking articlesElectric machinePalletizer

Owner:LIAOCHENG ANTAI PETROLEUM MACHINERY

Heat storage system integrated with solar energy system and air supply system

ActiveCN104913530BContinuous heat utilizationRealize centralized utilizationEnergy recovery in ventilation and heatingSolar heating energyThermal energy storageEngineering

Provided is a heat storage system integrating a solar energy system with an air supply system. The heat storage system comprises a solar heat collection module, a heat transfer module, a heat storage module, an air supply module, a heat exchange module and an air return module. The heat collection module absorbs solar energy which is transmitted to the heat storage module by the heat transfer module. The air supply module is used for conveying fresh air. The air return module is used for conveying air in a room of an end user to the outside. Heat transfer between fresh air and air is carried out in the heat exchange module. Heat absorbed by fresh air enters the heat storage module and then enters the room of the end user.The heat storage system integrating the solar energy system with the air supply system is capable of storing solar heat and heat of hot indoor air and then utilizing the heat, thereby saving energy and fulfilling the purpose of energy conservation and environmental protection.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

A heat storage heat exchanger and a fresh air system with a filter device

ActiveCN104833254BEven heat absorptionAvoid uneven heat absorptionHeat storage plantsSpace heating and ventilation detailsEngineeringMicro heat exchanger

The invention discloses a heat accumulation heat exchanger and a primary air system with a filtering device. The heat exchanger comprises a shell, a heat accumulation medium and a fluid channel. The heat accumulation medium is located in the shell, the fluid channel is located in the heat accumulation medium, the fluid channel is provided with a fluid inlet and a fluid outlet, and the heat accumulation capability of the heat accumulation heat exchanger is gradually increased in the flowing direction of fluid. The heat accumulation medium integrally absorbs heat evenly in the fluid flowing direction, and the situation of uneven heat absorbing is avoided.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com