A large-scale high-carbon chromium bearing steel hot-rolled wire rod and its high-speed wire rod production method

A high-carbon chromium bearing steel and hot-rolled wire rod technology, which is applied in metal rolling, metal rolling, workpiece heating devices, etc., can solve the problem of increasing the cost of the downstream spheroidizing annealing process, high grade of network carbide, and package shape Poor regularity and other problems, to achieve the effect of reducing the cost of spheroidizing annealing, reducing anisotropy, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

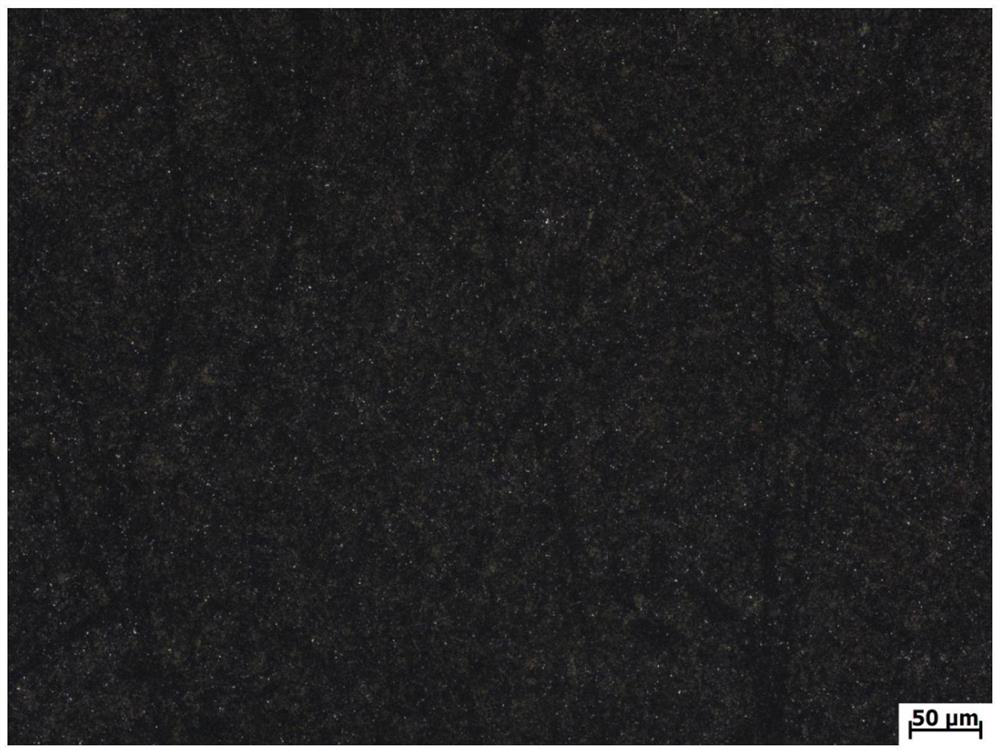

Image

Examples

Embodiment 1

[0034] Select 150*150mm GCr15 continuous casting billet, the chemical composition is shown in Table 1.

[0035] Table 1 Chemical composition of bearing steel GCr15 (%)

[0036]

[0037] (1) The size of the continuous casting billet in converter smelting: 150*150mm, the billet passes through the preheating section at 830°C and the second heating section at 1160°C in the heating furnace to reach the soaking section at 1195°C.

[0038] (2) Heat preservation for 120min in the range of 1160~1200℃ in the high temperature section.

[0039] (3) The continuous casting billet comes out of the heating furnace, and after descaling by high pressure water, the rolling temperature is 1090℃, the laying temperature is 865℃, the swing amplitude of the laying machine is 5%, and it is rolled into a hot-rolled wire rod of Φ21mm.

[0040] (4) After spinning, cool down to about 570°C at a speed of 0.9°C / s, and collect the hot-rolled wire rods in a bundle; the running speed of the roller table is...

Embodiment 2

[0045] Select 160*160mm GCr15 continuous casting billet, the chemical composition is shown in Table 2.

[0046] Table 2 Chemical composition of bearing steel GCr15 (%)

[0047]

[0048] (1) The size of the continuous casting billet in converter smelting: 160*160mm, the billet passes through the preheating section at 855°C and the second heating section at 1190°C in the heating furnace to reach the soaking section at 1205°C.

[0049] (2) Heat preservation in the range of 1180-1210℃ in the high temperature section for 120min.

[0050] (3) The continuous casting billet comes out of the heating furnace, and after descaling by high pressure water, the rolling temperature is 1105℃, the laying temperature is 880℃, the swing amplitude of the laying machine is 4%, and it is rolled into a hot-rolled wire rod of Φ23mm.

[0051] (4) After spinning, cool down to about 585°C at a speed of 0.8°C / s, and collect the hot-rolled wire rod in a bundle. The running speed of the roller table is:...

Embodiment 3

[0057] Select 160*160mm GCr15 continuous casting billet, the chemical composition is shown in Table 3.

[0058] Table 3 Chemical composition of bearing steel GCr15 (%)

[0059]

[0060] (1) The size of the continuous casting billet in converter smelting: 160*160mm, the billet passes through the preheating section at 880°C and the second heating section at 1200°C in the heating furnace to reach 1220°C in the soaking section.

[0061] (2) Heat preservation for 130min in the range of 1190~1220℃ in the high temperature section.

[0062] (3) The continuous casting billet comes out of the heating furnace, and after descaling by high pressure water, the rolling temperature is 1120℃, the laying temperature is 900℃, the swing amplitude of the laying machine is 3%, and it is rolled into a hot-rolled wire rod of Φ25mm.

[0063] (4) After spinning, it is cooled to about 590°C at a speed of 0.7°C / s, and the hot-rolled wire rod is collected in a bundle. The running speed of the roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com