Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

201results about "Vehicle body drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

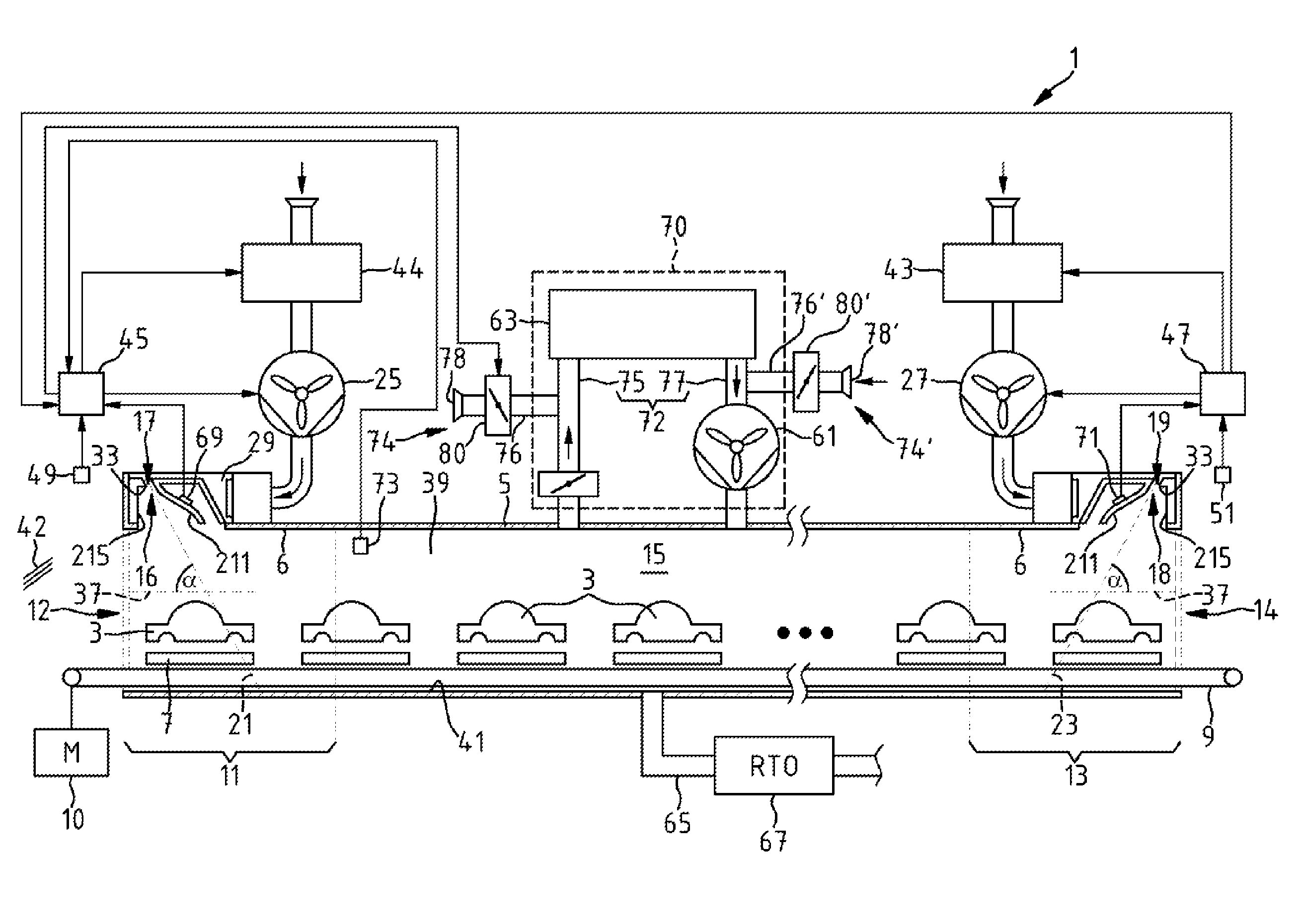

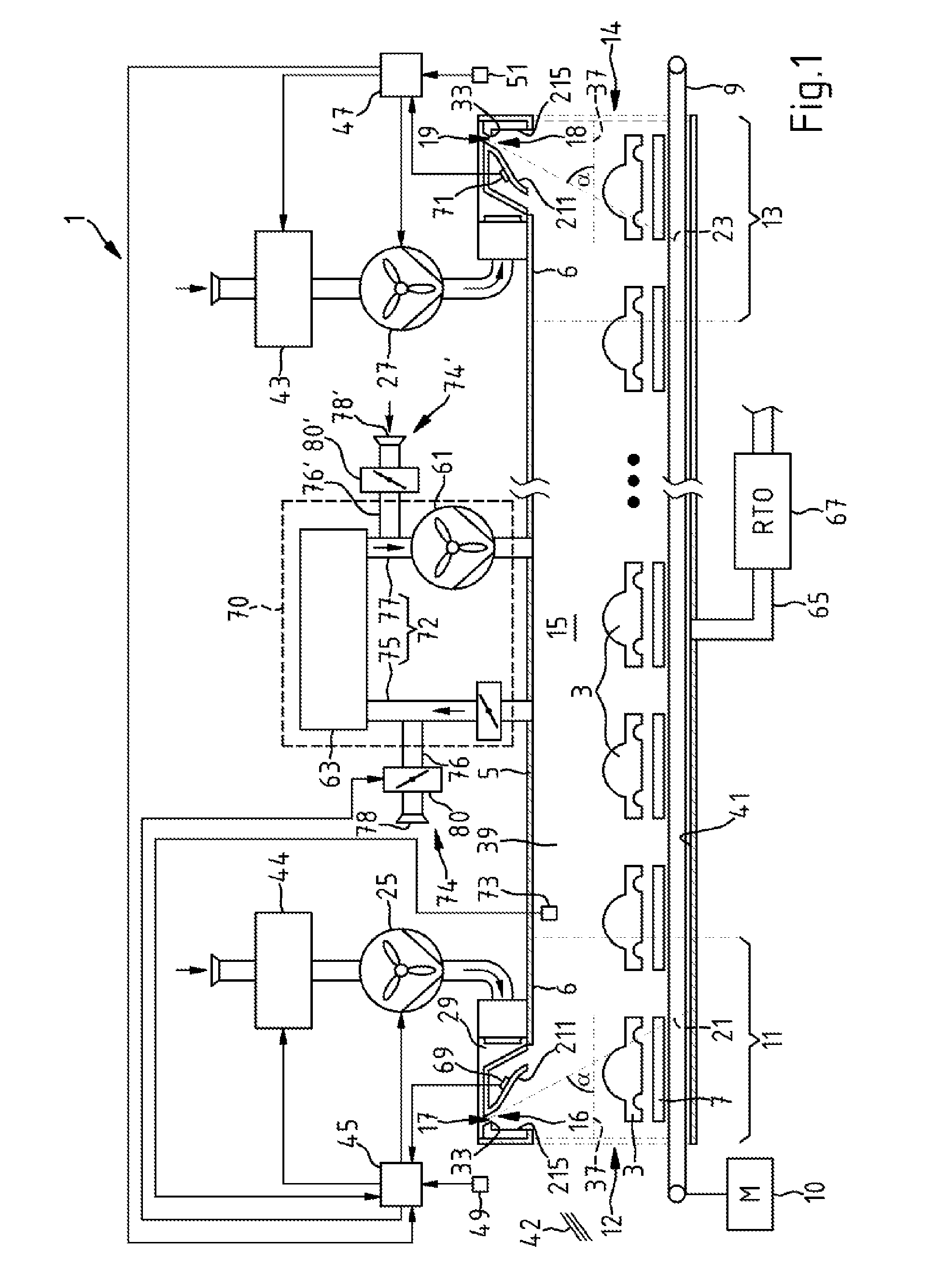

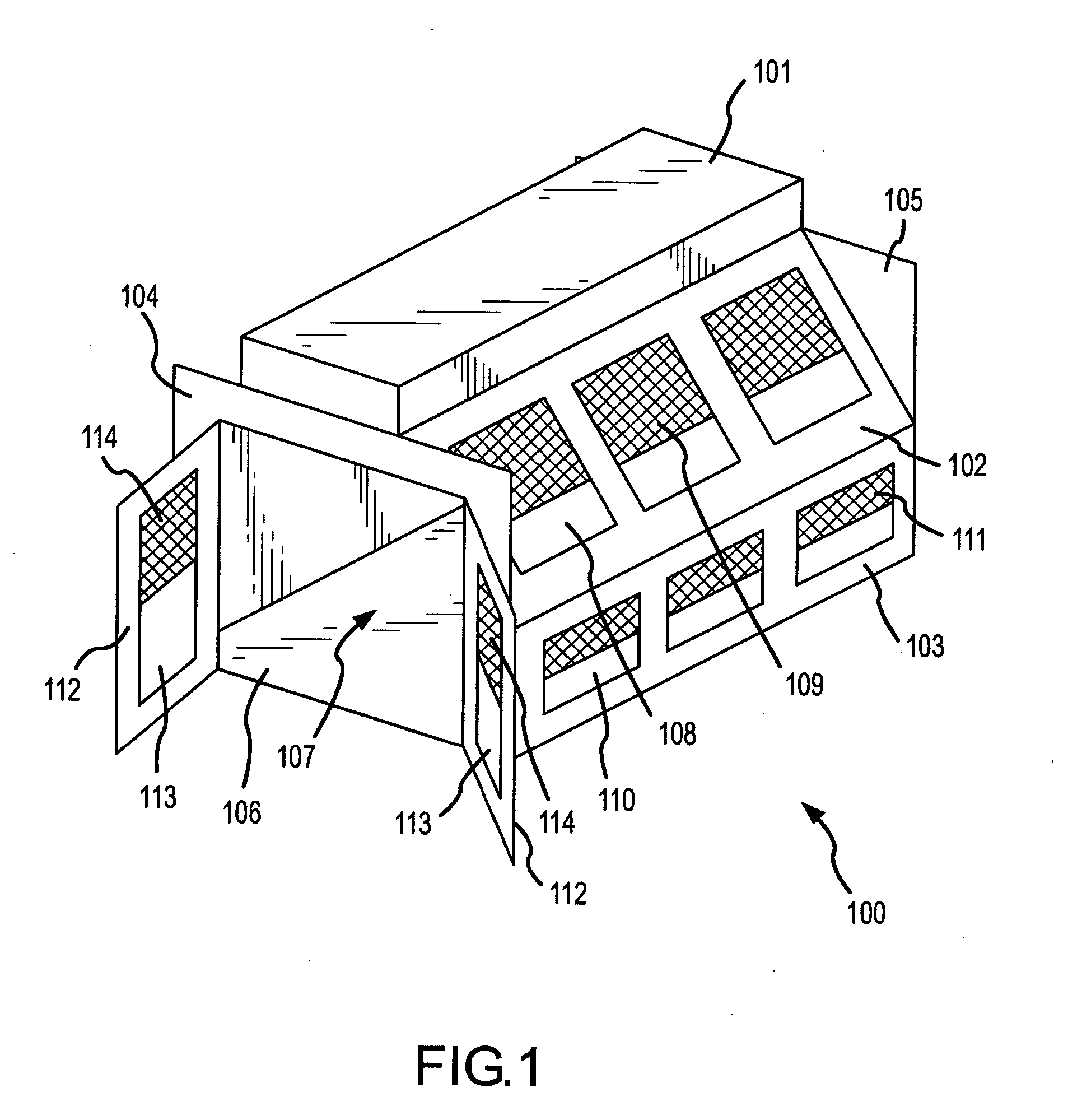

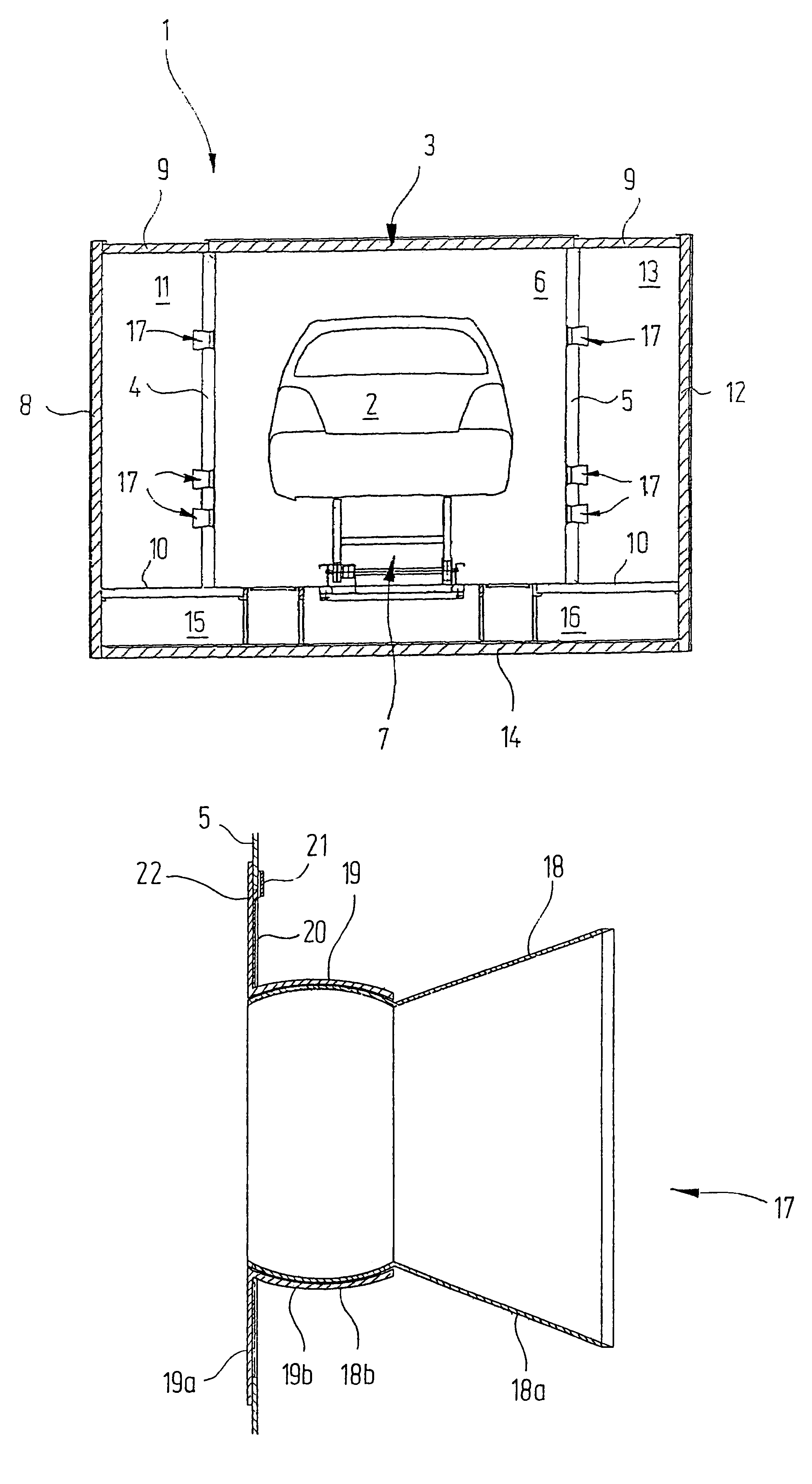

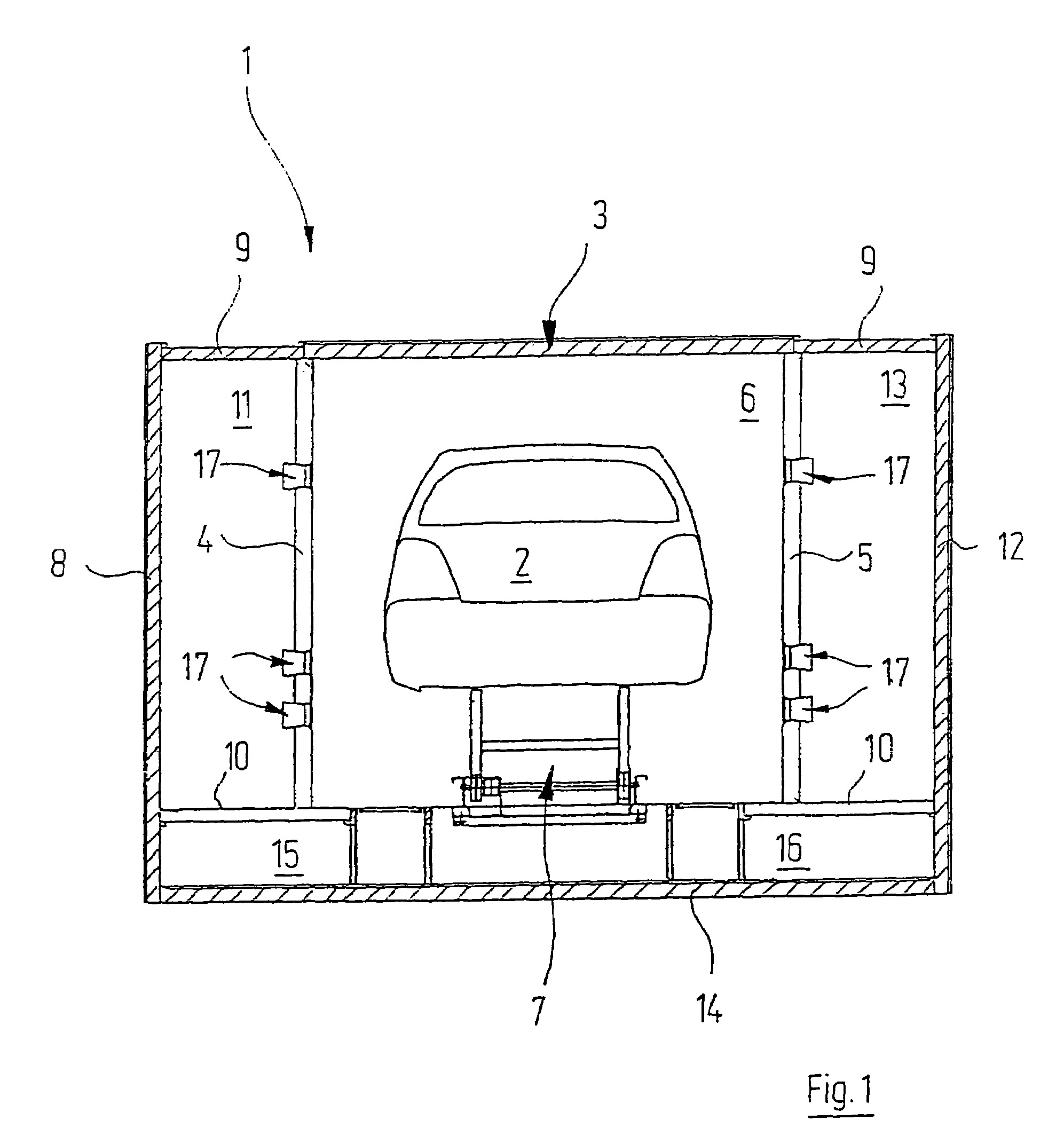

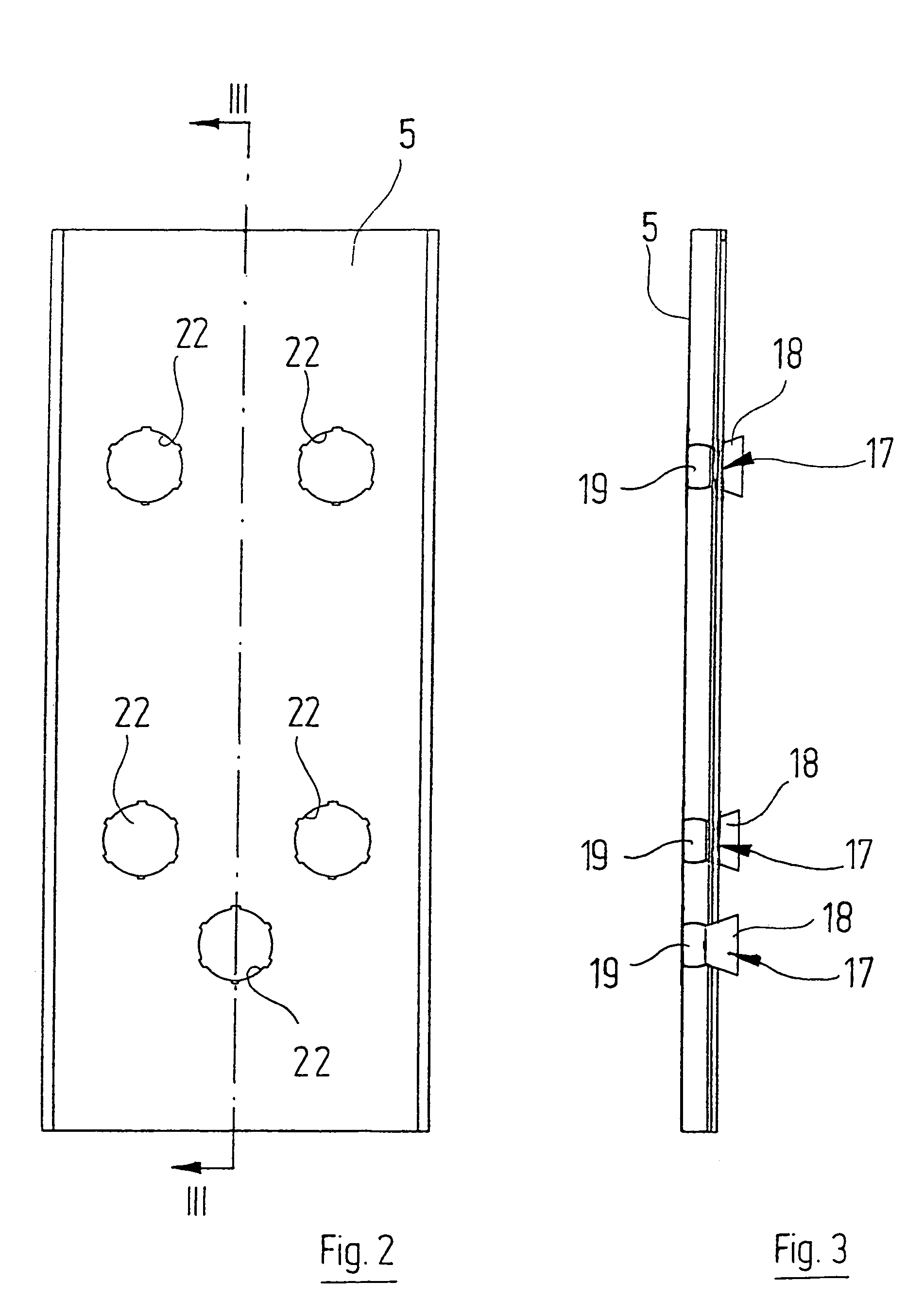

System having a process chamber for workpieces

ActiveUS20150121720A1Efficient thermal separationSimple meansDrying solid materials with heatDrying gas arrangementsSpray nozzleWaste management

The invention relates to an installation having a process chamber which comprises an inner space having a receiving region for workpieces. The process chamber has an opening for the supply or discharge of workpieces. The process chamber is constructed so as to have a device for the introduction of gaseous fluid into the inner space, which device has at least one nozzle or aperture for the production of a fluid stream curtain between the opening and the receiving region for workpieces. The process chamber has a device for supplying fresh air, with which device fresh air can be introduced into the receiving region at a side of the fluid stream curtain, which side faces away from the opening.

Owner:DUERR SYST AG

Vacuum drying method

ActiveUS7658017B1Fast curingImprove paint qualityDrying solid materials without heatVehicle body dryingSurface finishEngineering

A vacuum drying apparatus and method to dry and cure paint is disclosed. The method provides a substantially particle free environment that shortens drying time, reduces cost and improves surface finish. The apparatus includes an enclosed drying tunnel that is maintained at a reduced pressure relative to ambient conditions. Heat lamps with the drying tunnel aid in curing and provide the desired particle free environment.

Owner:LAVIOLETTE THOMAS BRIAN +1

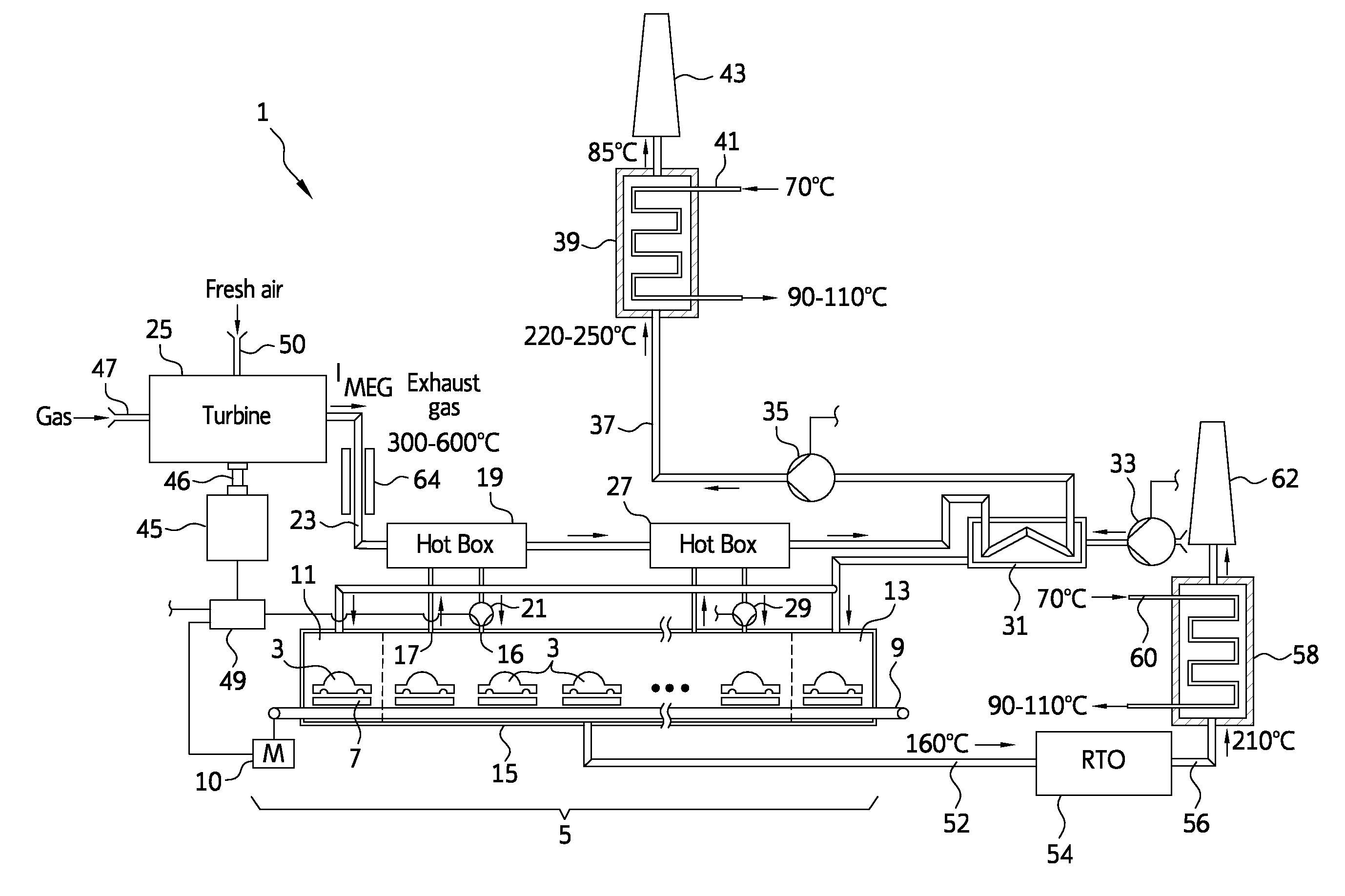

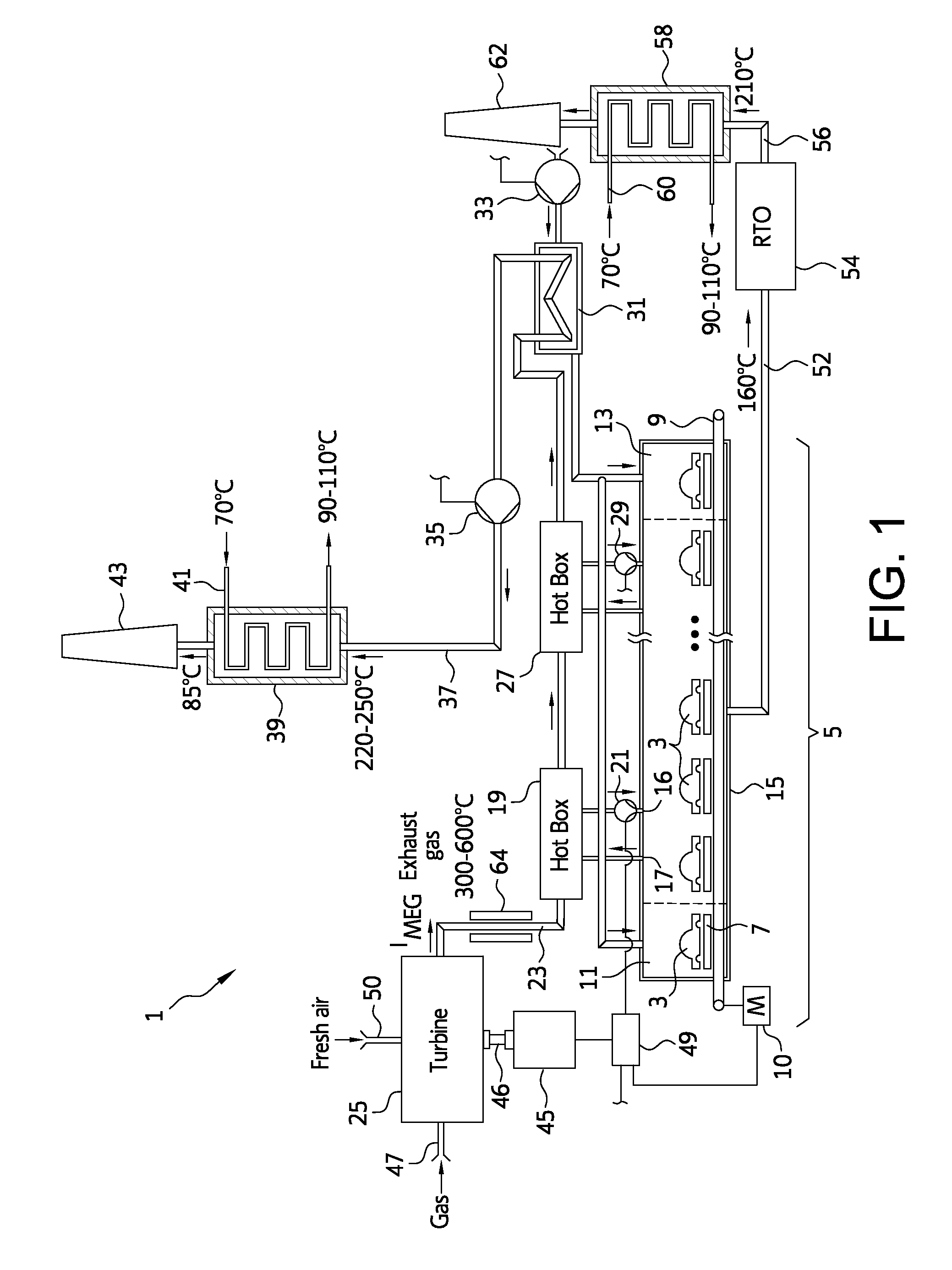

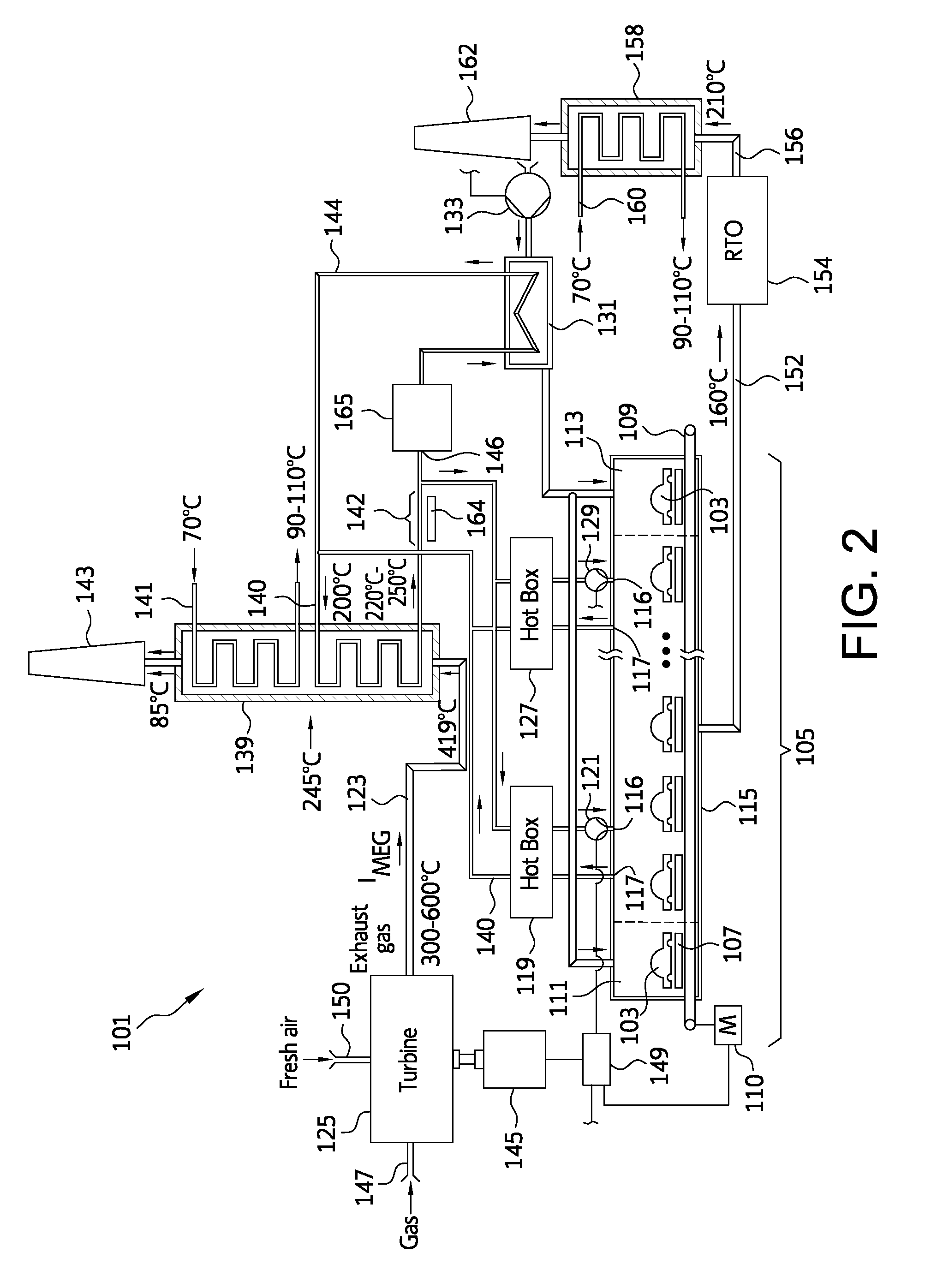

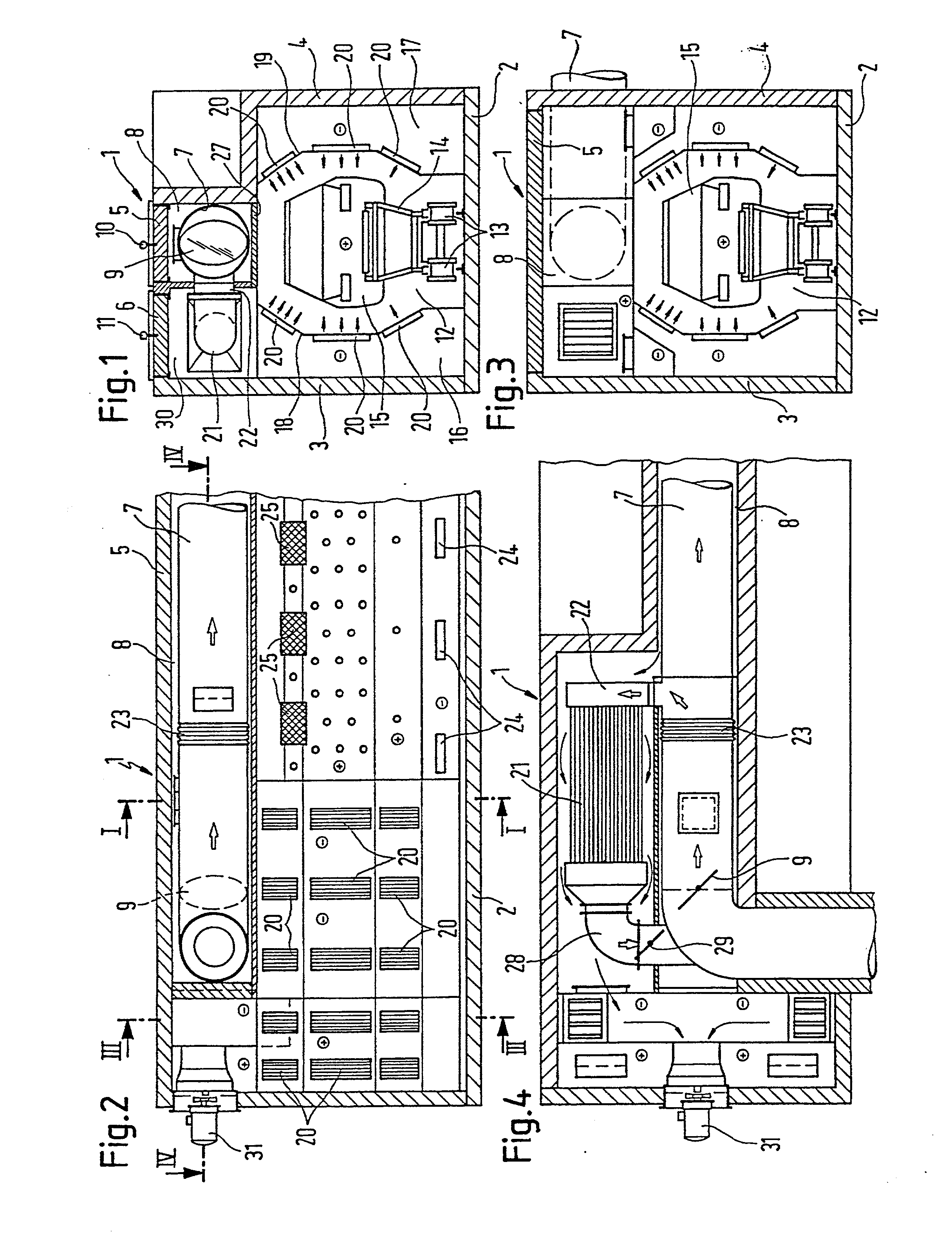

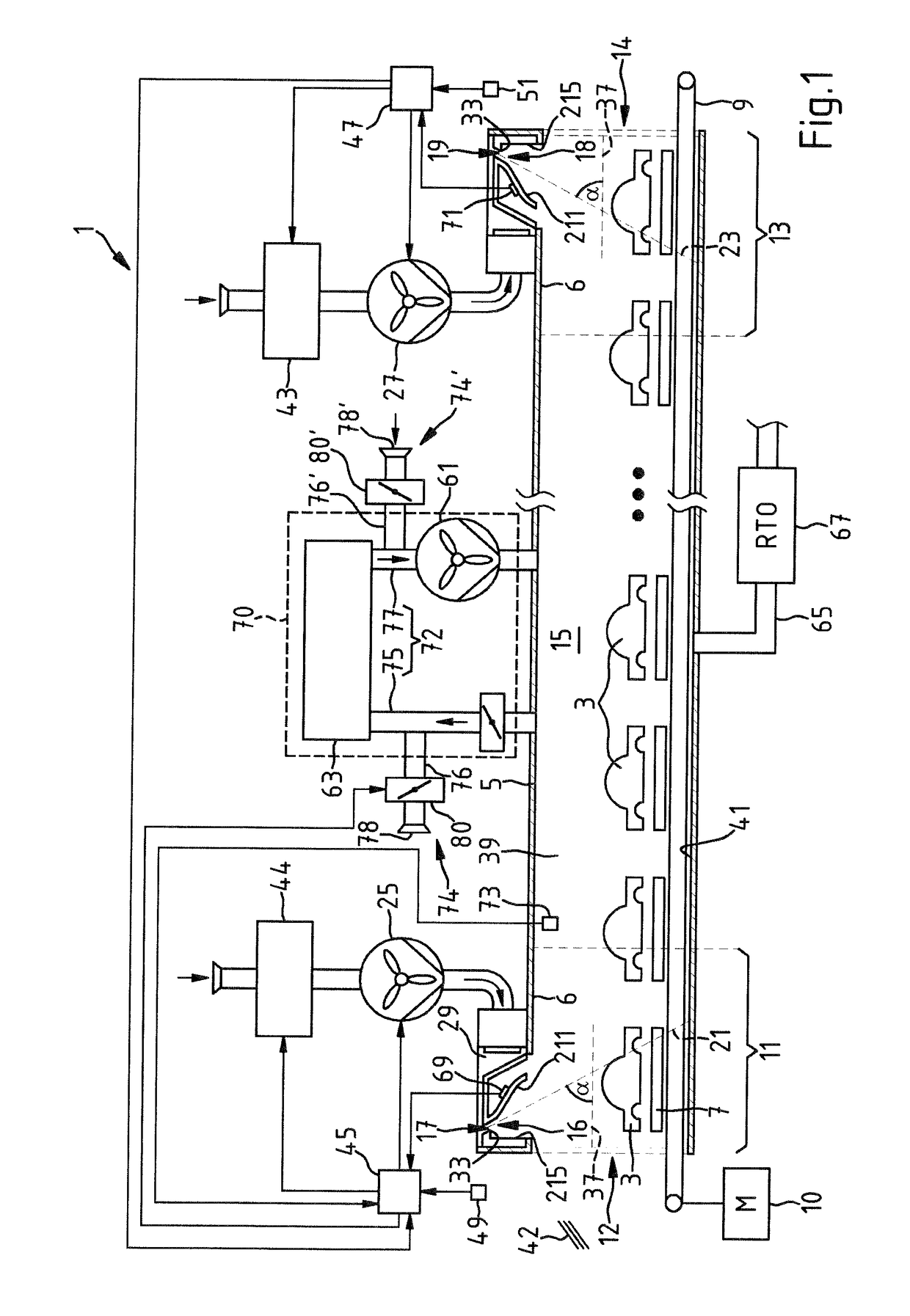

Drying System having a Thermal Engine

ActiveUS20130014406A1Guaranteed uptimeImprove system efficiencyDrying using combination processesDrying machines with progressive movementsNacelleMechanical energy

A system for drying vehicle bodies and / or for controlling the temperature thereof. The system includes a cabin and has a heater for heating hot air for the cabin. The system is equipped with a mechanical energy-consuming device, for example, a generator and / or a fan. The heater contains at least one heat exchanger. The hot exhaust gas of a thermal engine can be supplied to the heat exchanger. The thermal engine is coupled to the mechanical energy-consuming device, for example, the generator, so as to move together. Because of the coupled movement, mechanical energy can be transmitted from the thermal engine to the mechanical energy-consuming device.

Owner:DUERR SYST AG

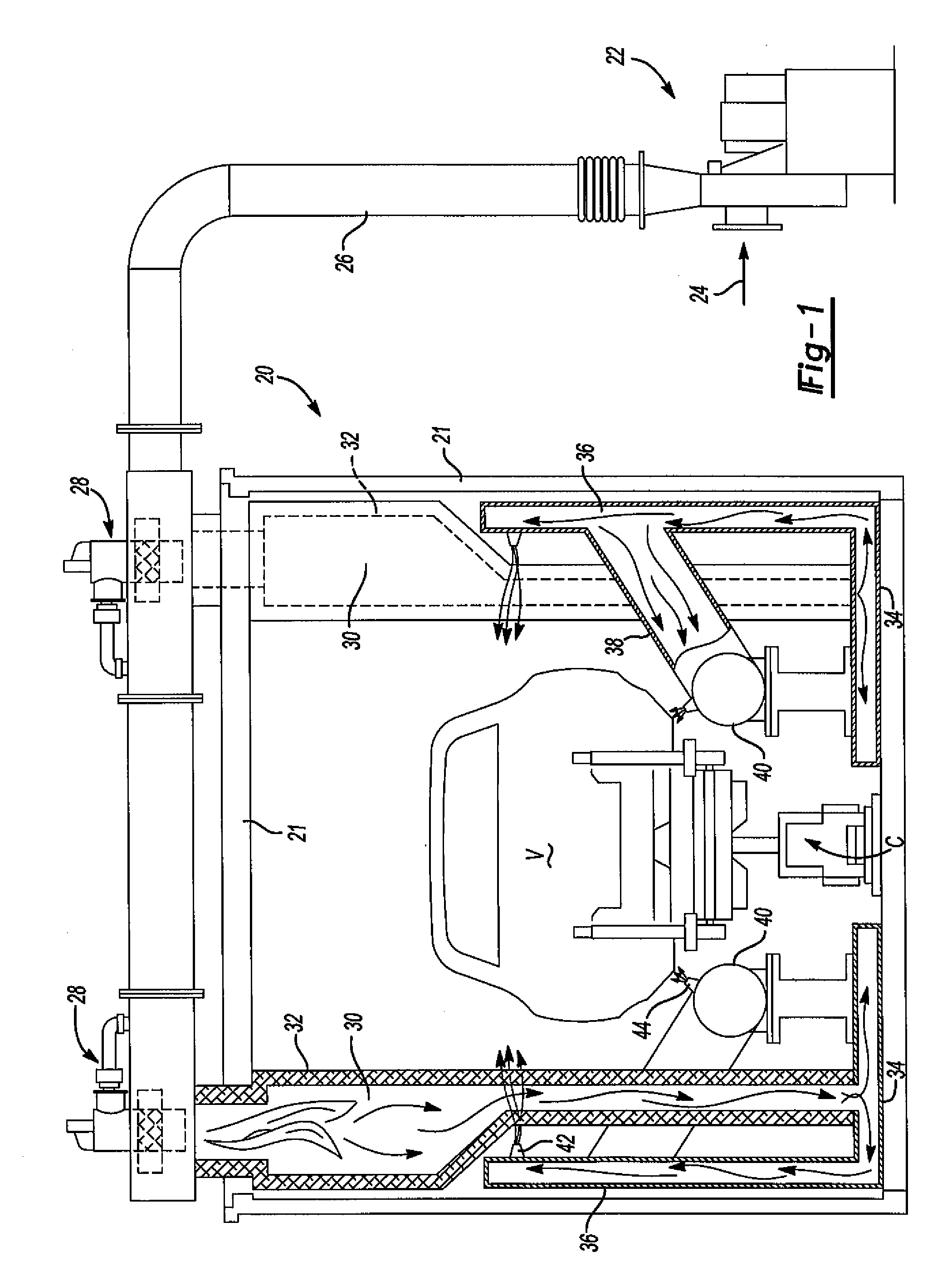

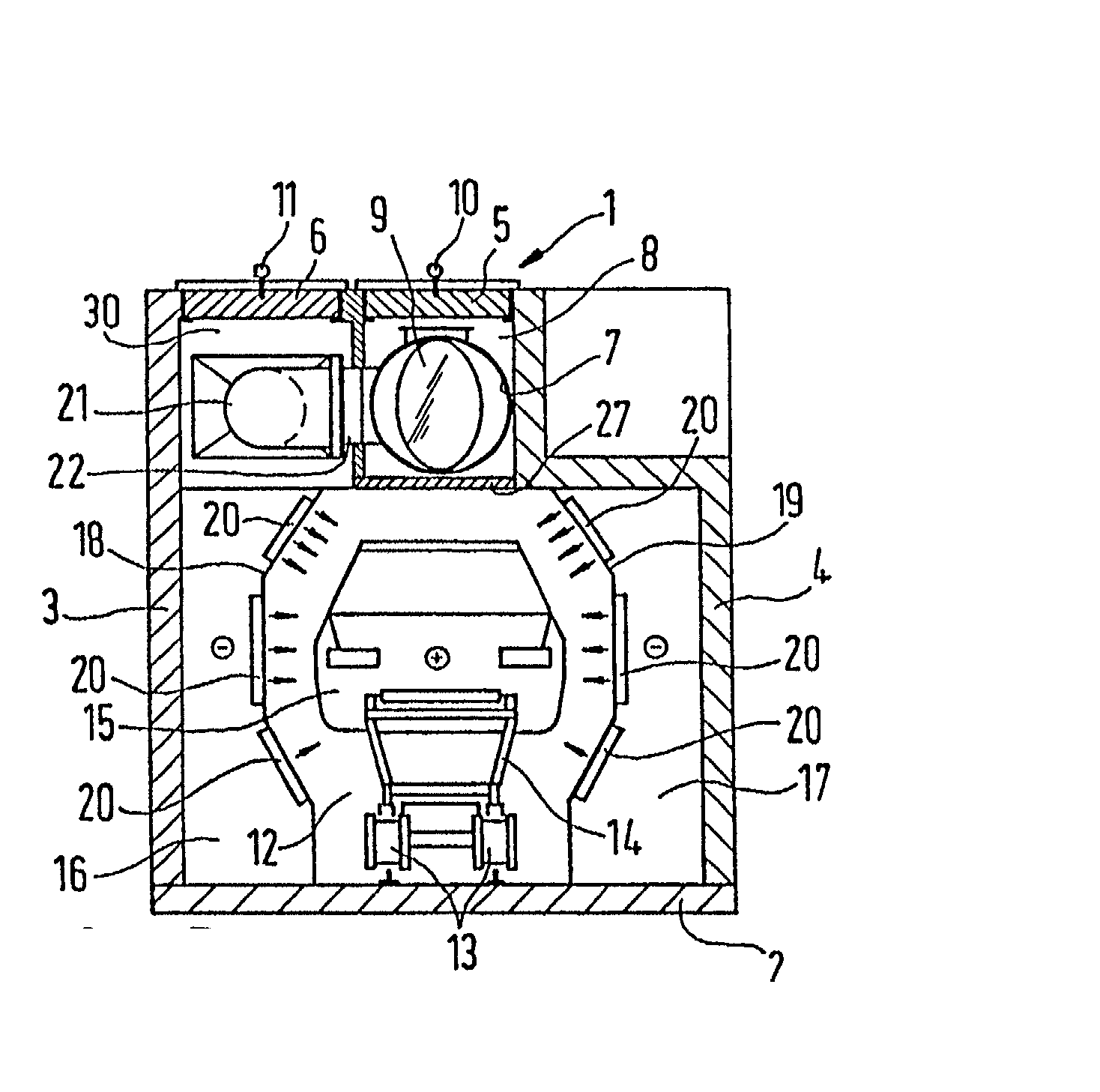

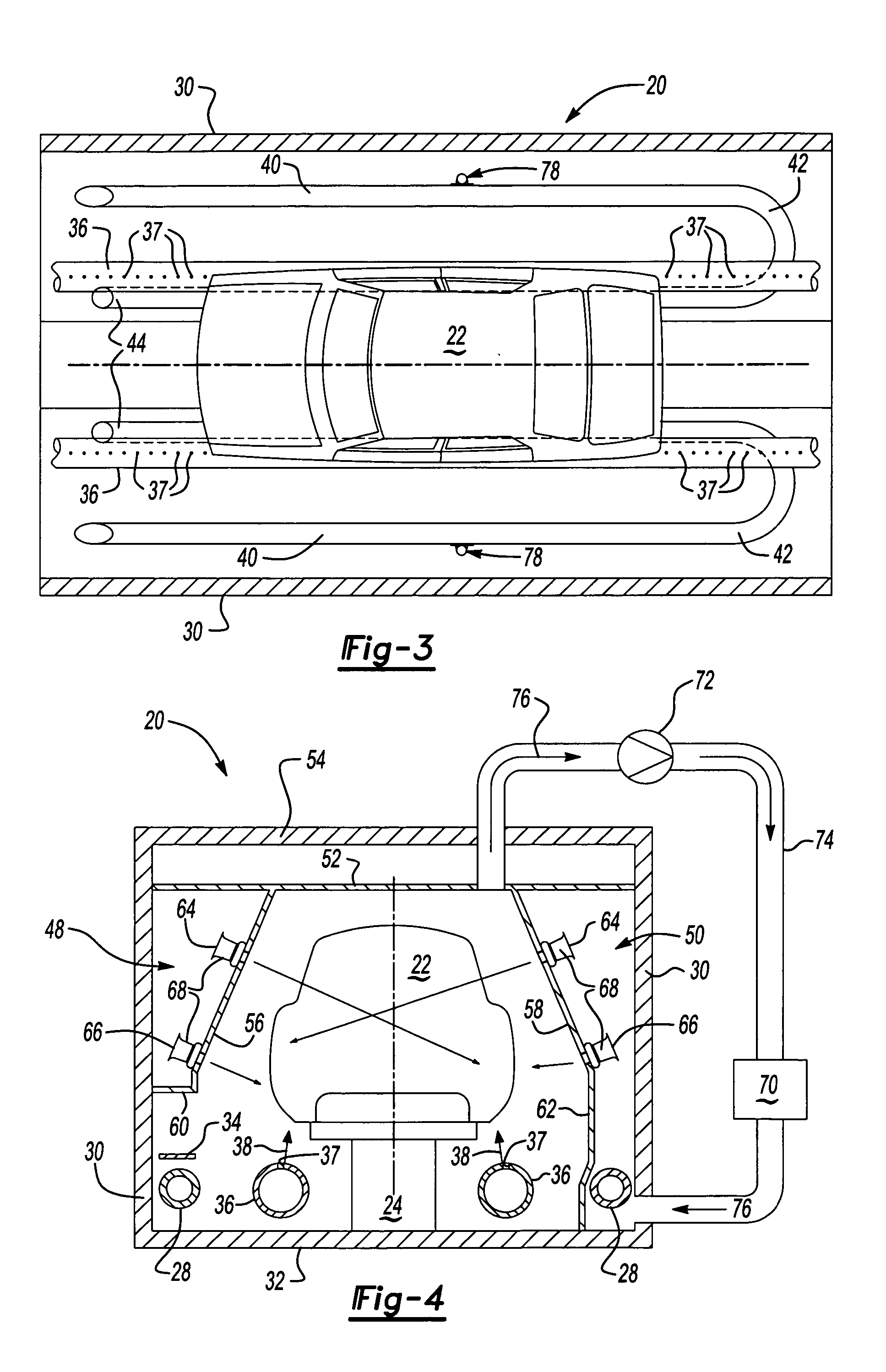

Radiant convection oven

ActiveUS20090017408A1Lower requirementDrying solid materials with heatDrying gas arrangementsCombustorEngineering

A radiant convection oven for baking a coating on an article which includes an oven enclosure receiving coating articles, a fan receiving fresh air and directing the fresh air to a burner or burners, a plurality of heat radiators each having an internal chamber receiving heated fresh air from the burner. The radiators are located within the oven opposite a coating article, radiating heat energy to the coated article, and a plurality of nozzles connected to the internal chamber of the radiators directing fresh heated onto the article, transferring convection heat energy to the coated article. In the disclosed embodiment, the radiators include radiating side and bottom walls having a relatively shallow depth, increasing the flow rate through the radiators, reducing the size and cost of the radiators and the fan.

Owner:DURR SYST INC

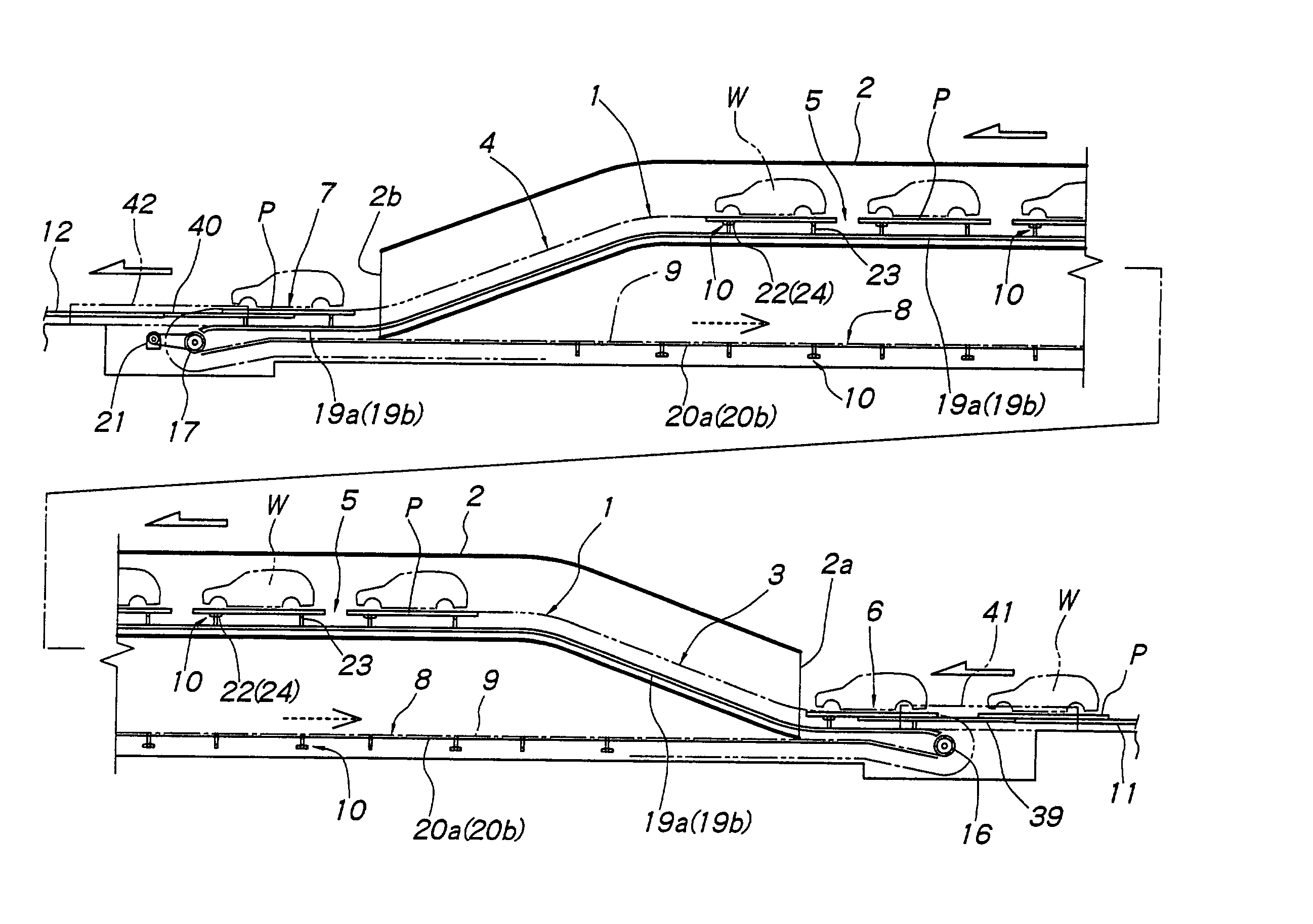

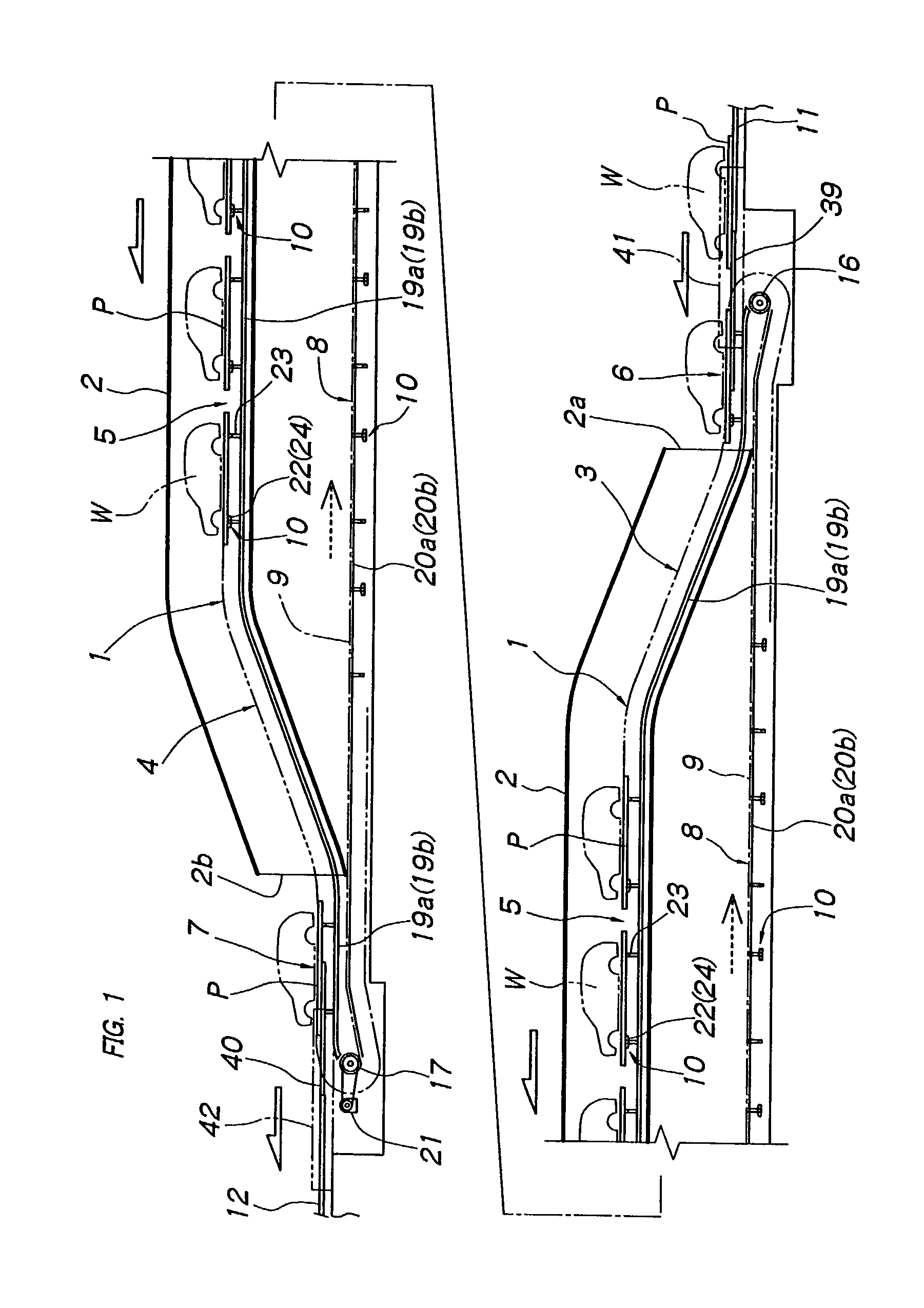

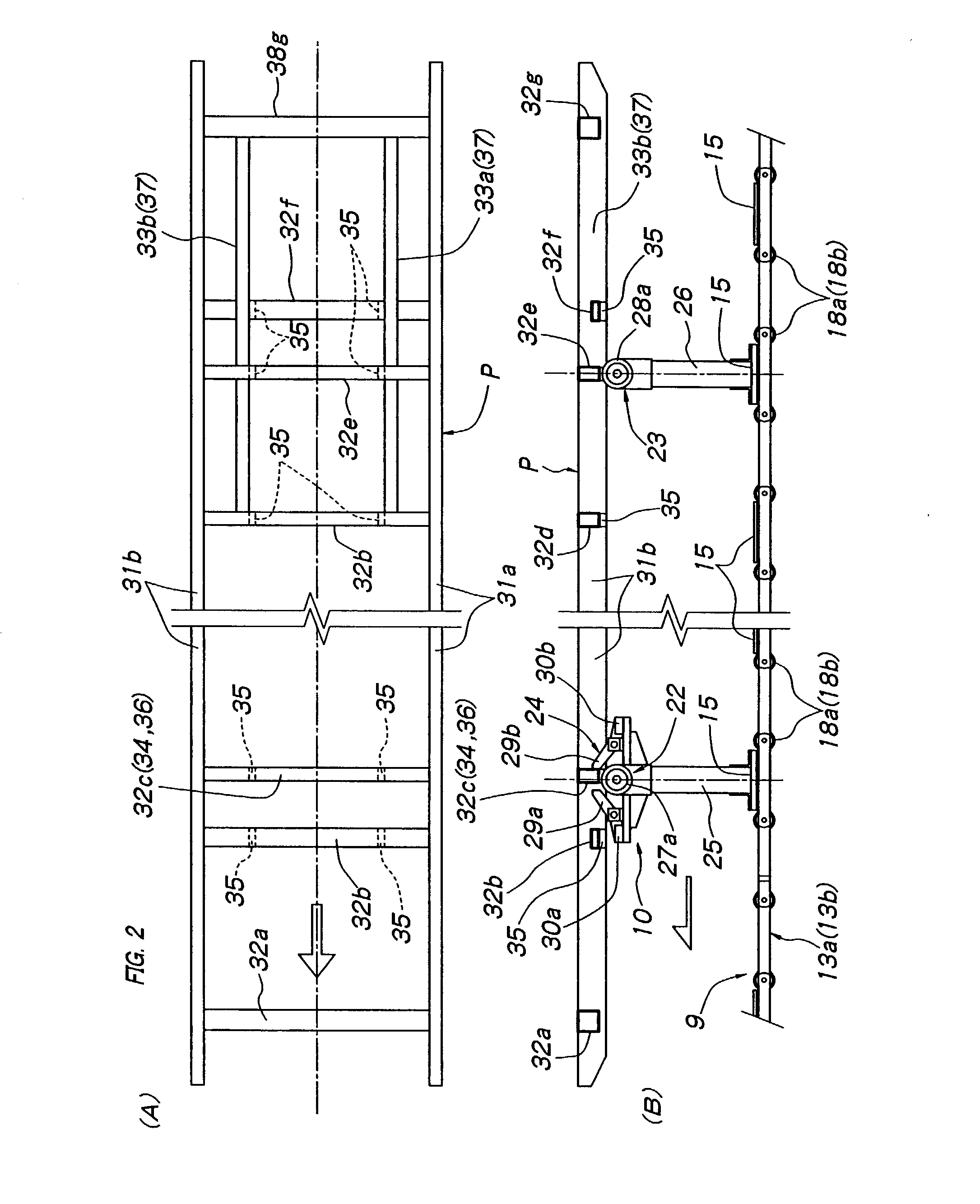

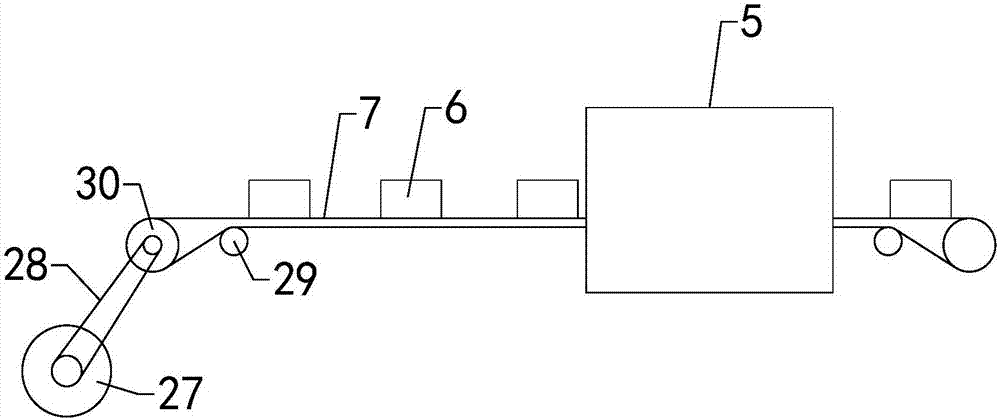

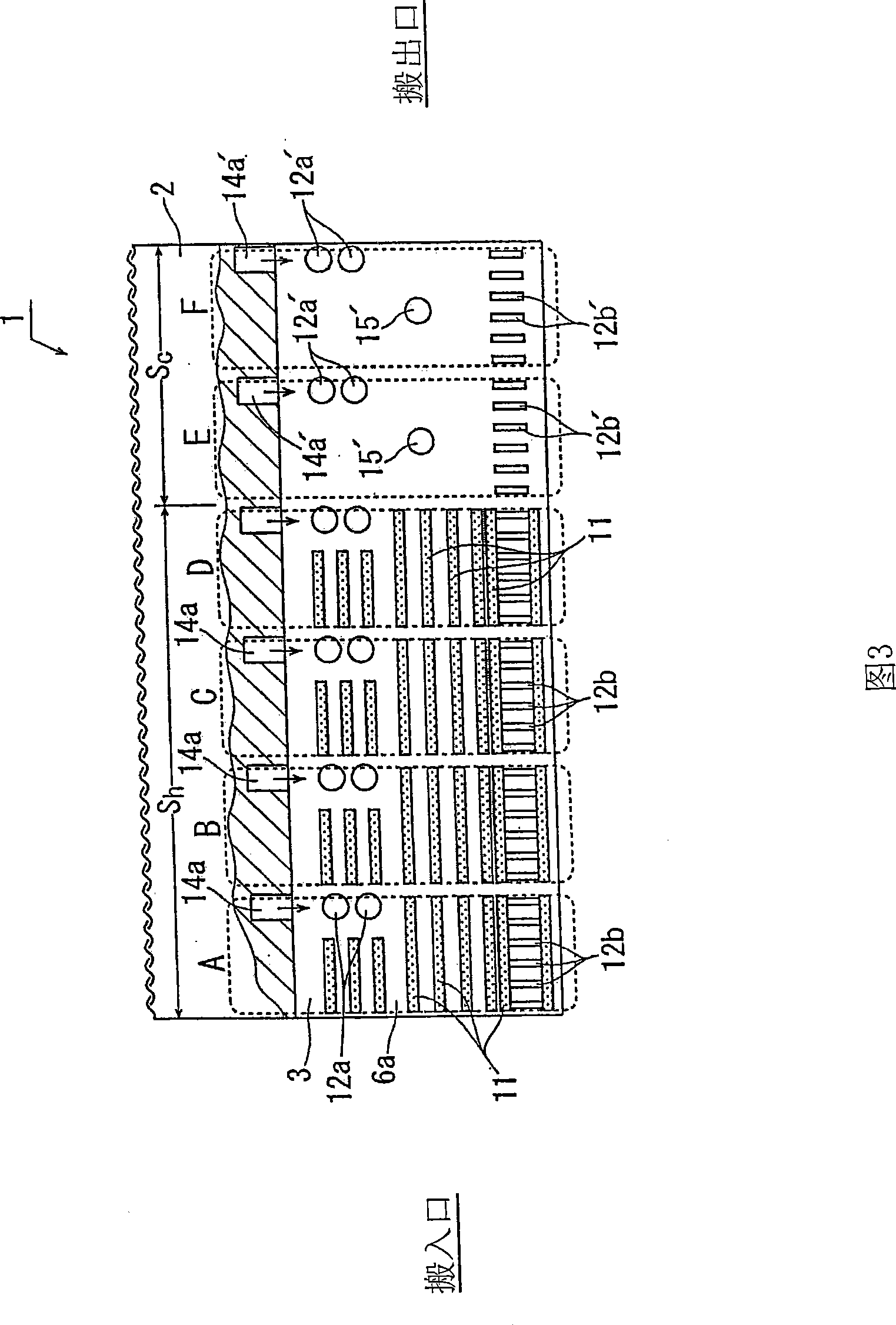

Conveying apparatus

The present invention provides a conveying apparatus for conveying in a predetermined direction loads supported on pallets in a drying furnace or the like. The conveying apparatus comprises a conveying path, a return path, an endless circulating driver and pallet supporting and driving means. The conveying path includes a horizontal inlet path, a horizontal outlet path, and an inclined path connected to at least one of the inner ends of the inlet and outlet path. The circulating driver circulates between the conveying path and return path. The supporting and driving means are mounted at intervals on the circulating driver. The pallet supporting and driving means include a front pallet support for supporting a front portion of the pallet, a rear pallet support for supporting a rear portion of the pallet, and a driving engager for automatically engaging with the pallet near the front pallet support. The pallet includes a front supported part that can be supported by the front pallet support, a rear supported part that can be supported by the rear pallet support movable relative to the pallet in the predetermined direction, and an engaged part for automatically engaging with the driving engager. The pallet conveyed to the inlet path section can be transferred onto one of the supporting and driving means, which conveys the pallet on it along the conveying path to the outlet path section.

Owner:DAIFUKU CO LTD

Paint dryer and paint dryer system

InactiveUS20020148137A1Reduce excess spaceConfiguration highLiquid surface applicatorsDrying solid materials with heatAir cycleThermodynamics

The inventive paint dryer, comprises a cabin (12) for housing objects (15) that are to be painted and dried. At least one fresh air supply (8) is provided in order to introduce fresh air into an air circulation system pertaining to the dryer (1) resulting in the circulation of said air. At least one pure gas supply line (7) is provided, wherein thermally cleaned and heated waste air is introduced as a pure gas, thereby maintaining the waste gas circulated in the circulation system at the desired temperature in such a way that objects (15) arranged in the cabin (12) can be dried by radiation and / or convection. The pure gas supply line (7) is surrounded by the fresh air supply line (8) at least along a longitudinal pipe segment and at least in said longitudinal pipe section the pure gas supply pipe (7) is constructed in such a way as to allow for the transmission of heat to fresh air flowing into the fresh air supply (8). The invention also relates to a paint dryer unit comprising several paint dryer modules which are positioned one after the other and configured as paint dryers according to the invention.

Owner:ABB FLAEKT AB

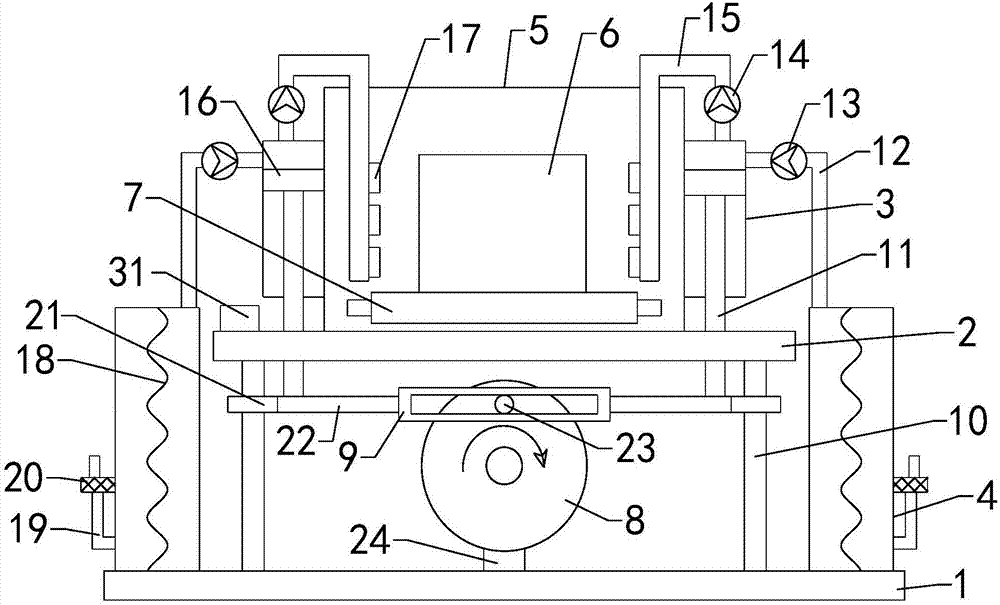

Automobile fitting intermittent drying device

InactiveCN107024099AAvoid enteringRealize the drying operationDrying gas arrangementsDrying machines with progressive movementsElectrical controlEngineering

The invention discloses an intermittent drying device for auto parts, which comprises a base, a workbench, a transfer box, a hot air box, a drying box, a conveyor belt, a rotating disc, a lifting cover plate, an electric control box and a conveying mechanism, and a hot air box. The No. 1 communication pipeline is connected to the upper top plate, and the upper inner cavity of the transfer box is connected with the other end of the No. 1 communication pipeline. A piston is arranged in the inner cavity of the transfer box, and the piston fixes the top of the push rod. There is a No. 2 communication pipeline connected to the upper top plate, and the other end of the No. 2 communication pipeline is placed in the inner cavity of the drying box. The outer ring surface of the rotating disc is fixedly equipped with a lever, and the lever is slidably set on the lifting sleeve plate. In the guide sliding cavity provided, the lifting sleeve plate is fixedly arranged on one end of the connecting rod, and the bottom end of the push rod is fixedly connected with the connecting rod. The invention has the advantages of simple structure, convenient operation, good drying effect on auto parts and high speed, greatly reduces the labor intensity of workers, and improves work efficiency.

Owner:合肥蔚然花绿化工程有限公司

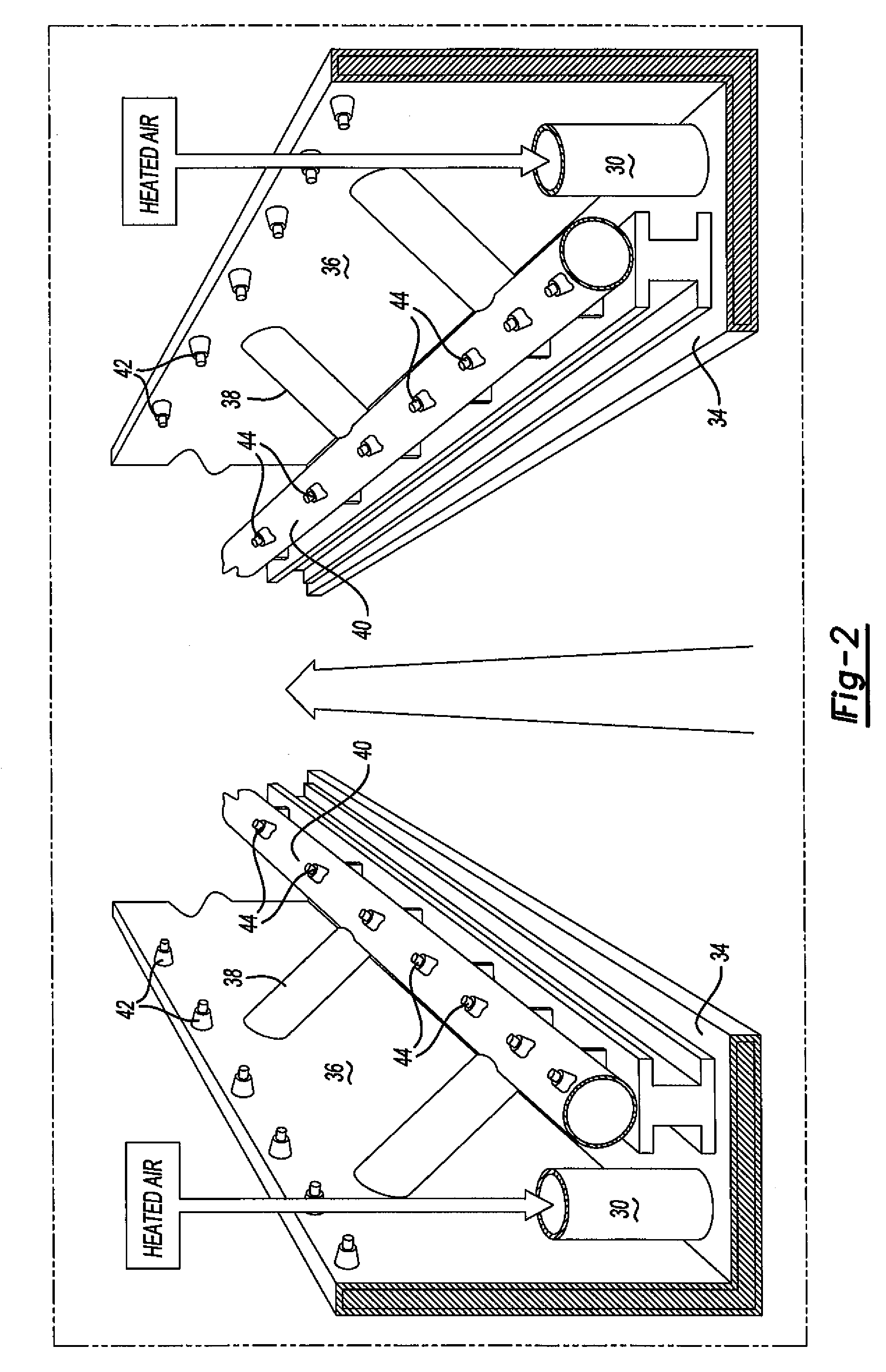

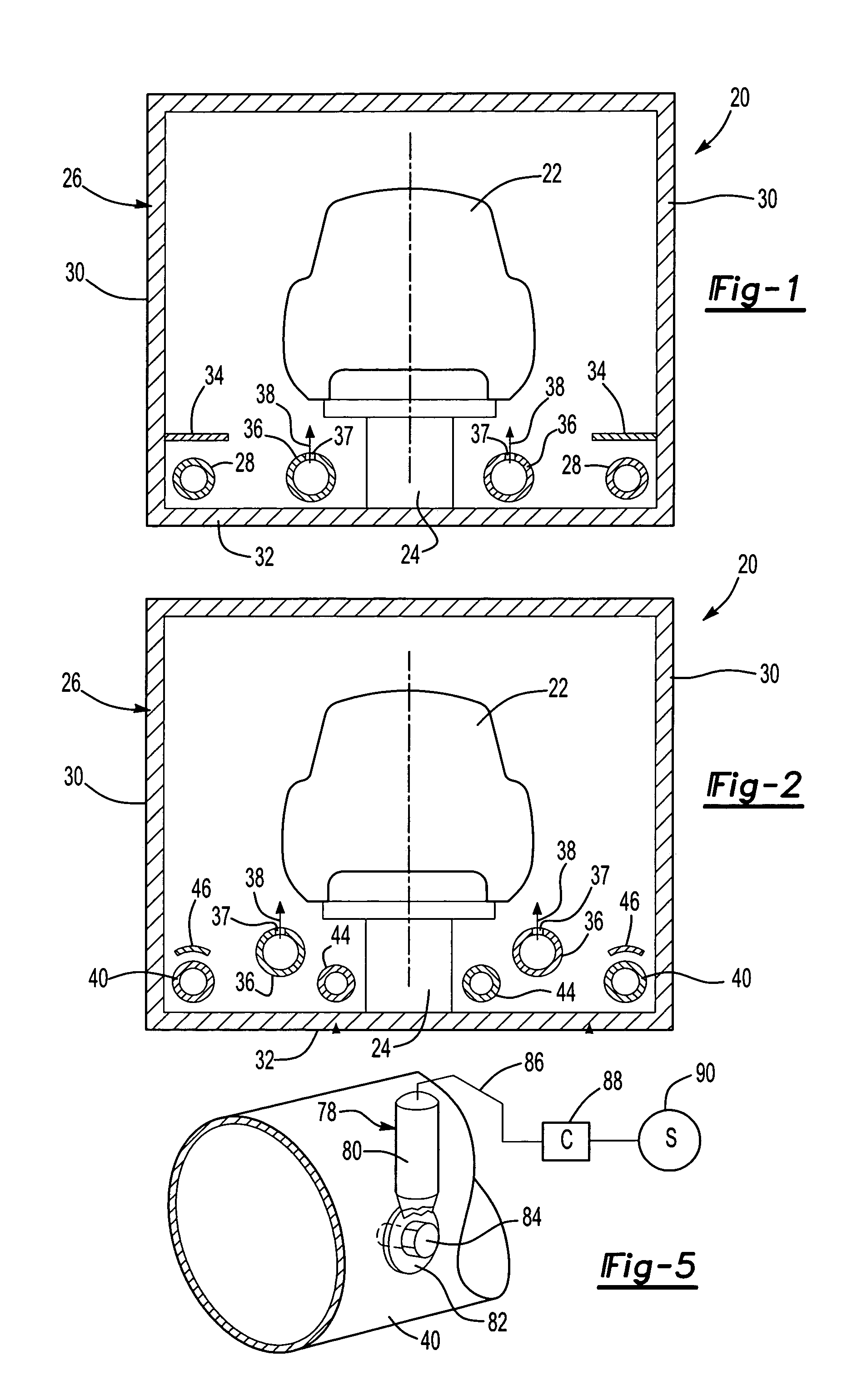

Radiant tube and convection oven

InactiveUS7063528B2Great utility and efficiencyImprove heat distributionDrying solid materials with heatDrying gas arrangementsControl systemEngineering

An oven for heating a coating on a substrate, such as a painted vehicle body, including a first zone having radiant tubes and shields above the tubes and a second zone including side heat chambers having nozzles directing heated air onto a coated substrate and a hold zone. The radiant tubes may include a first linear portion extending through the oven and return loop beneath the substrate to conserve energy and sill ducts directing heated air against the underside of the vehicle body. The temperature is controlled by sensors contacting the radiant tubes and a proportional integral control system.

Owner:GM GLOBAL TECH OPERATIONS LLC

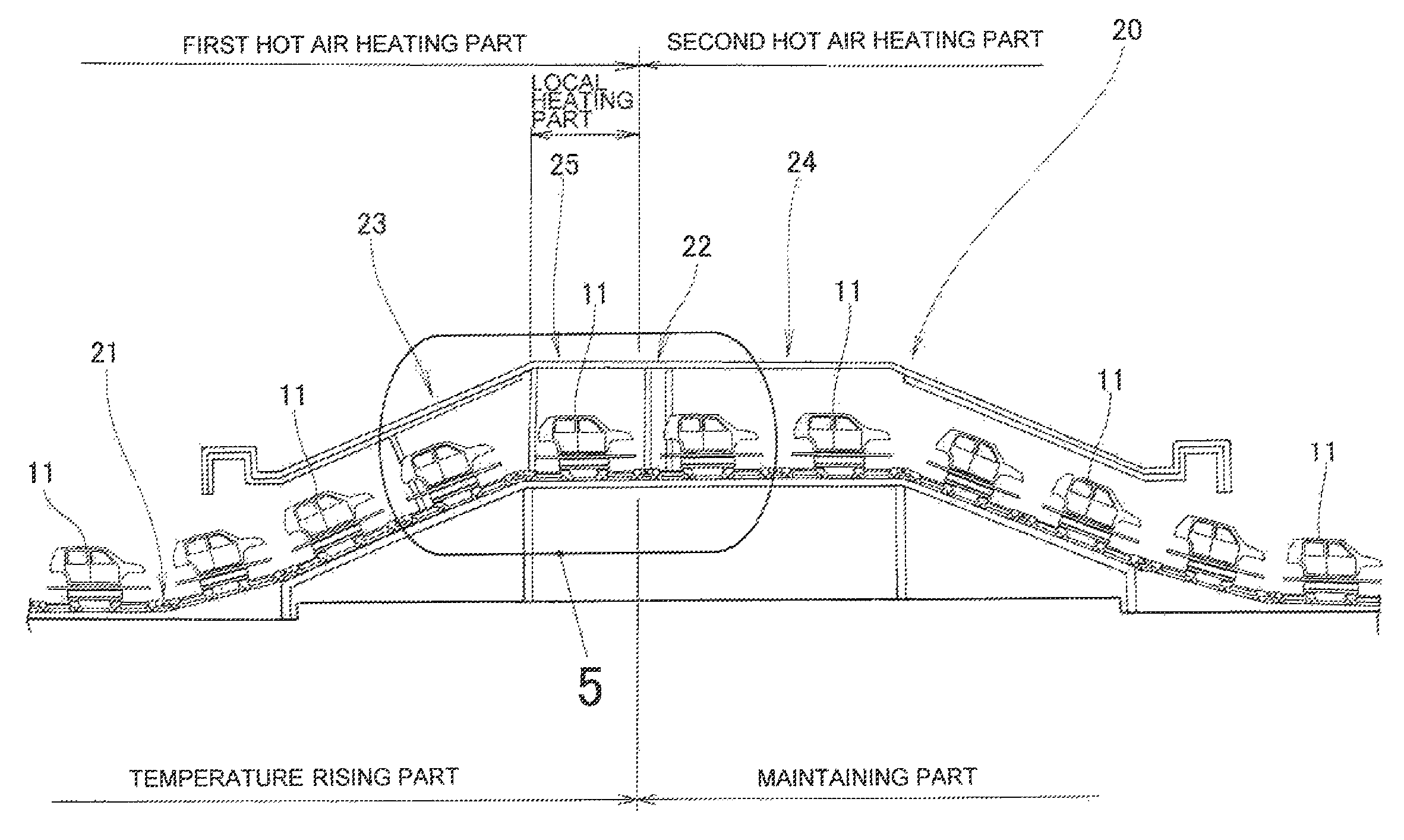

Drying furnace and drying method

InactiveUS8997374B2Reduce the amount requiredDrying using combination processesDrying solid materials with heatEngineeringRadiant heat

Owner:HONDA MOTOR CO LTD

Radiant tube and convection oven

InactiveUS20050087183A1Avoid overall overheatingAvoid explosionDomestic stoves or rangesDrying solid materials with heatControl systemEngineering

An oven for heating a coating on a substrate, such as a painted vehicle body, including a first zone having radiant tubes and shields above the tubes and a second zone including side heat chambers having nozzles directing heated air onto a coated substrate and a hold zone. The radiant tubes may include a first linear portion extending through the oven and return loop beneath the substrate to conserve energy and sill ducts directing heated air against the underside of the vehicle body. The temperature is controlled by sensors contacting the radiant tubes and a proportional integral control system.

Owner:GM GLOBAL TECH OPERATIONS LLC

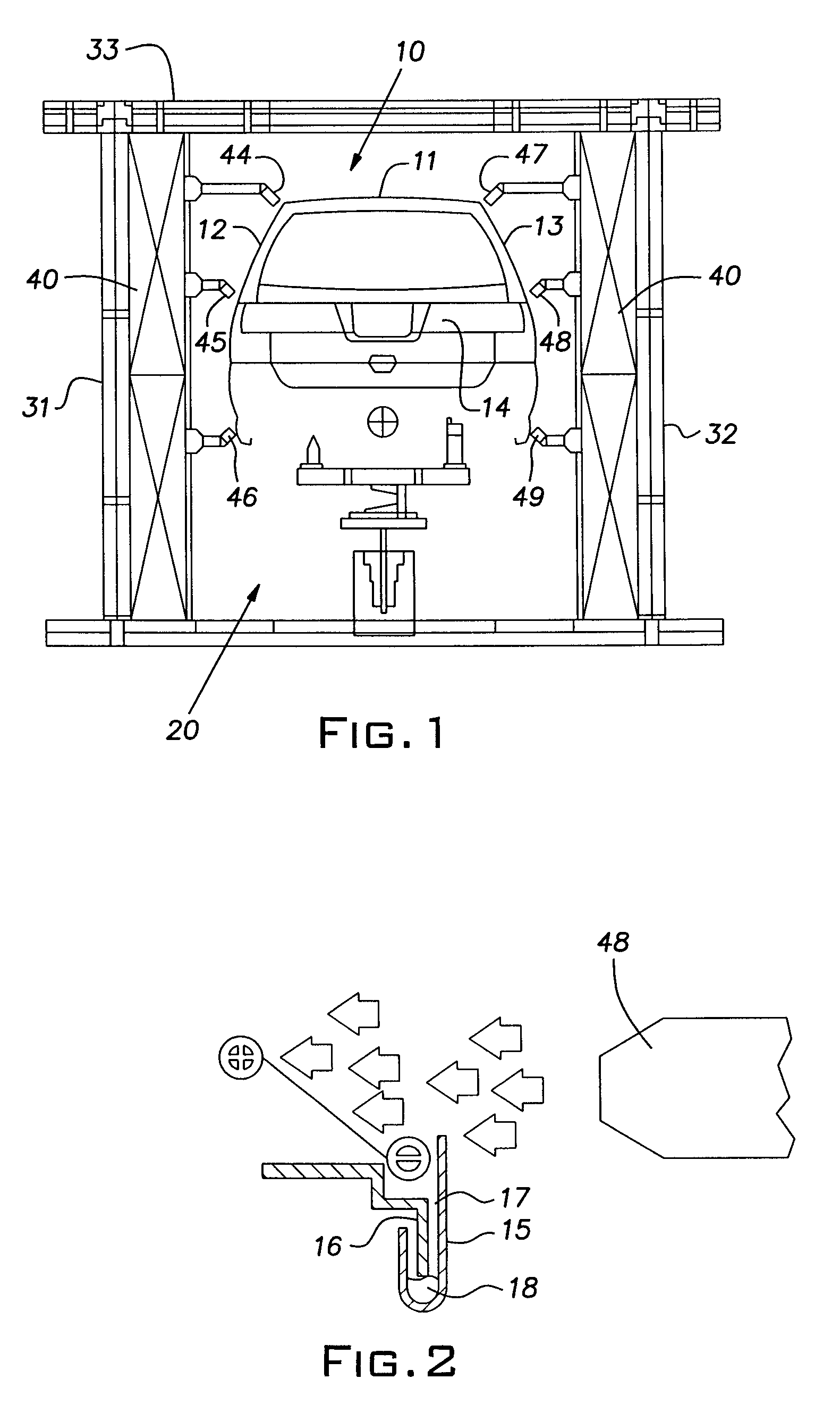

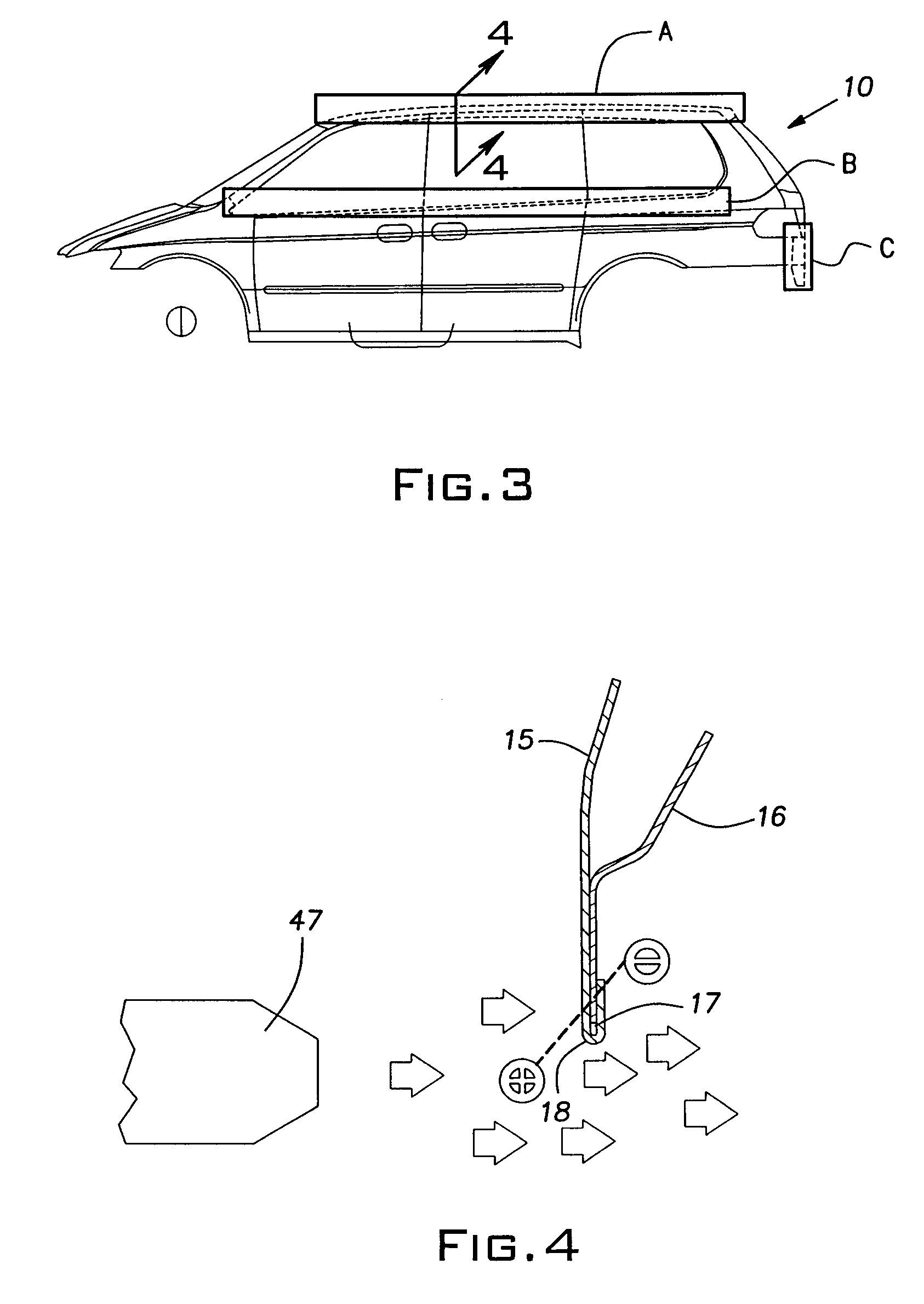

UV curing structure and process

InactiveUS20070022625A1Facilitate downdraft conditionDrying solid materials with heatDrying chambers/containersInterior spaceUV curing

A light curing structure and related methods are disclosed wherein a framework defining an interior space for containing an object having applied thereon a light-cured material is provided, and means associated with the framework for exposing the object to UV radiation from natural sunlight is used to cure the light-cured material. Preferred embodiments include a booth for applying and curing light-cured materials comprising a housing having a ceiling and walls that define an enclosed interior space for holding an object, means for applying a light-cured material to the object; means for preventing the exposure of the light-cured material to UV radiation during application of the light-cured material to the object, and means for exposing the light-cured material to UV radiation from natural sunlight after application of the light-cured material to the object. Apparatus and methods according to the invention are particularly suited for use with UV-cured paints in the automotive industry.

Owner:GARMAT USA

Drier

ActiveUS7600329B2Easy to assembleConveyorsDrying solid materials with heatDesiccantMechanical engineering

Owner:DUERR SYST AG

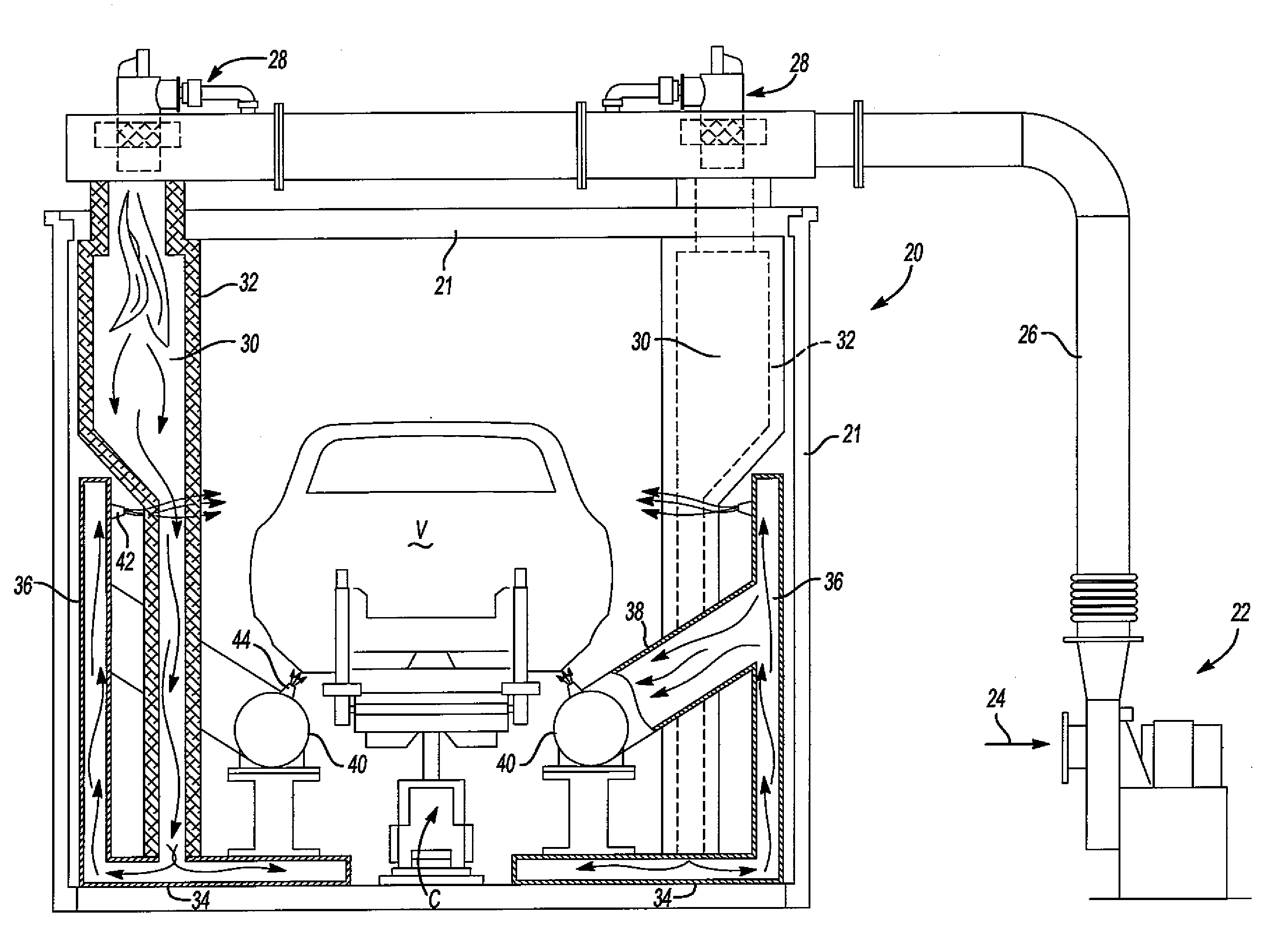

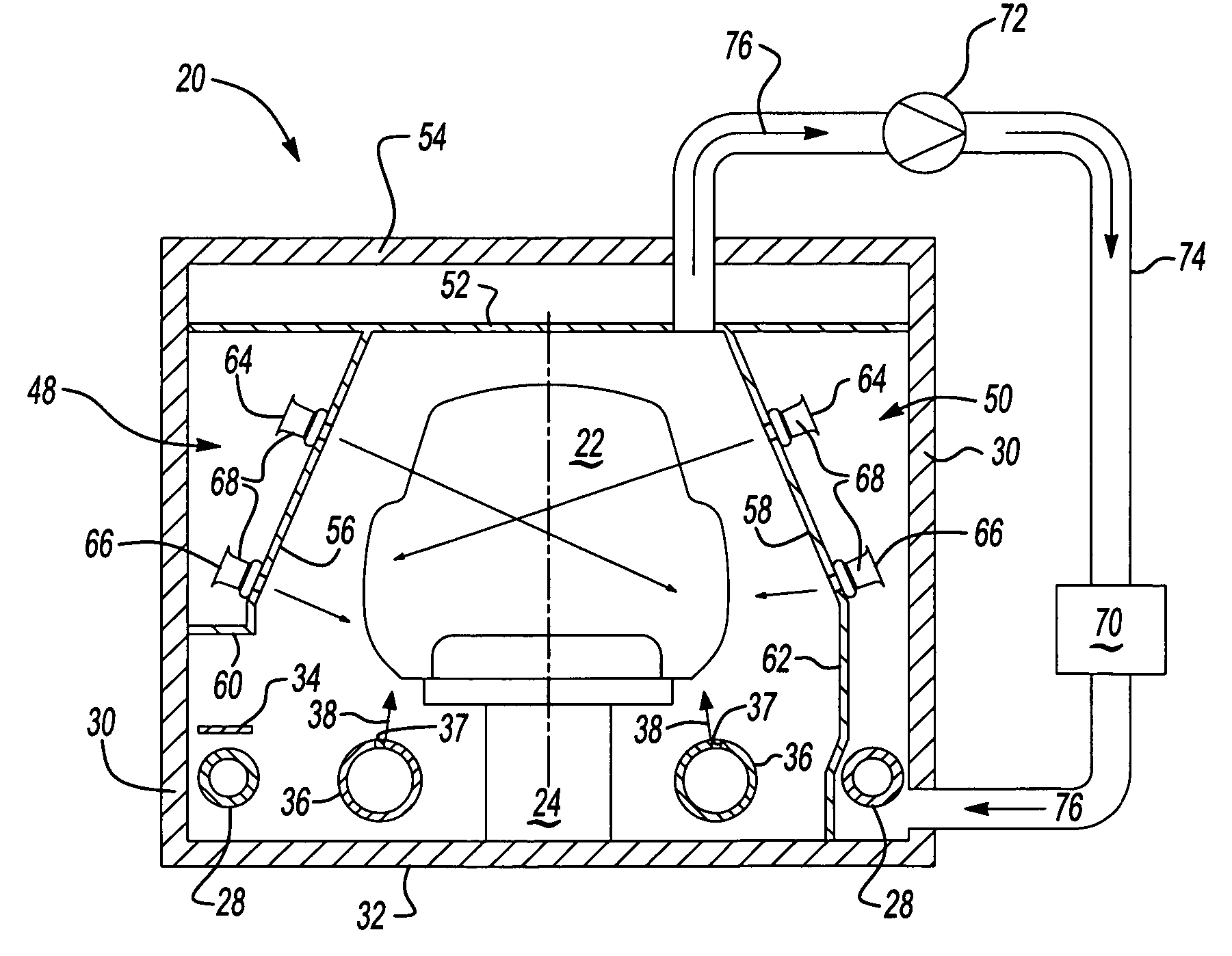

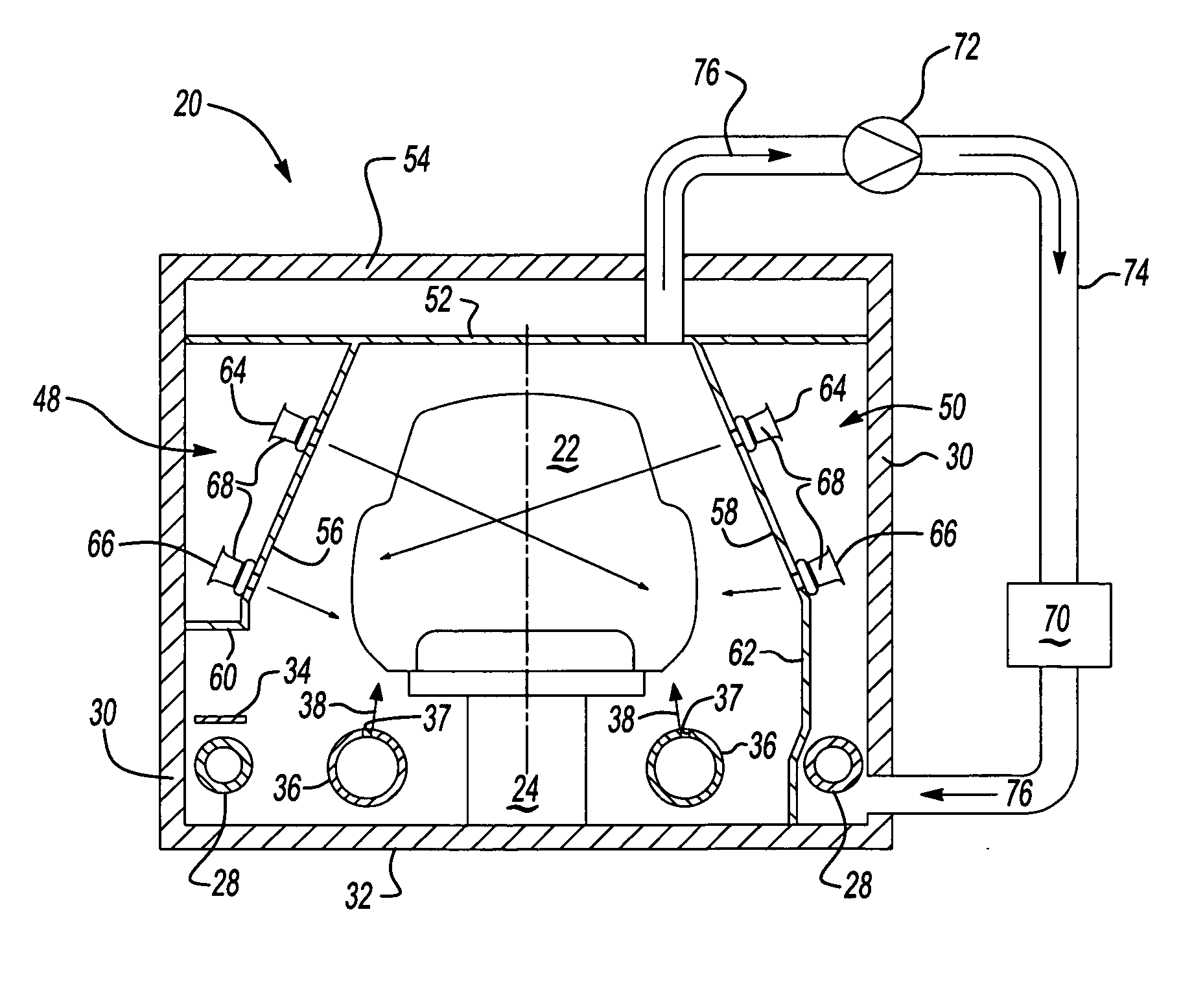

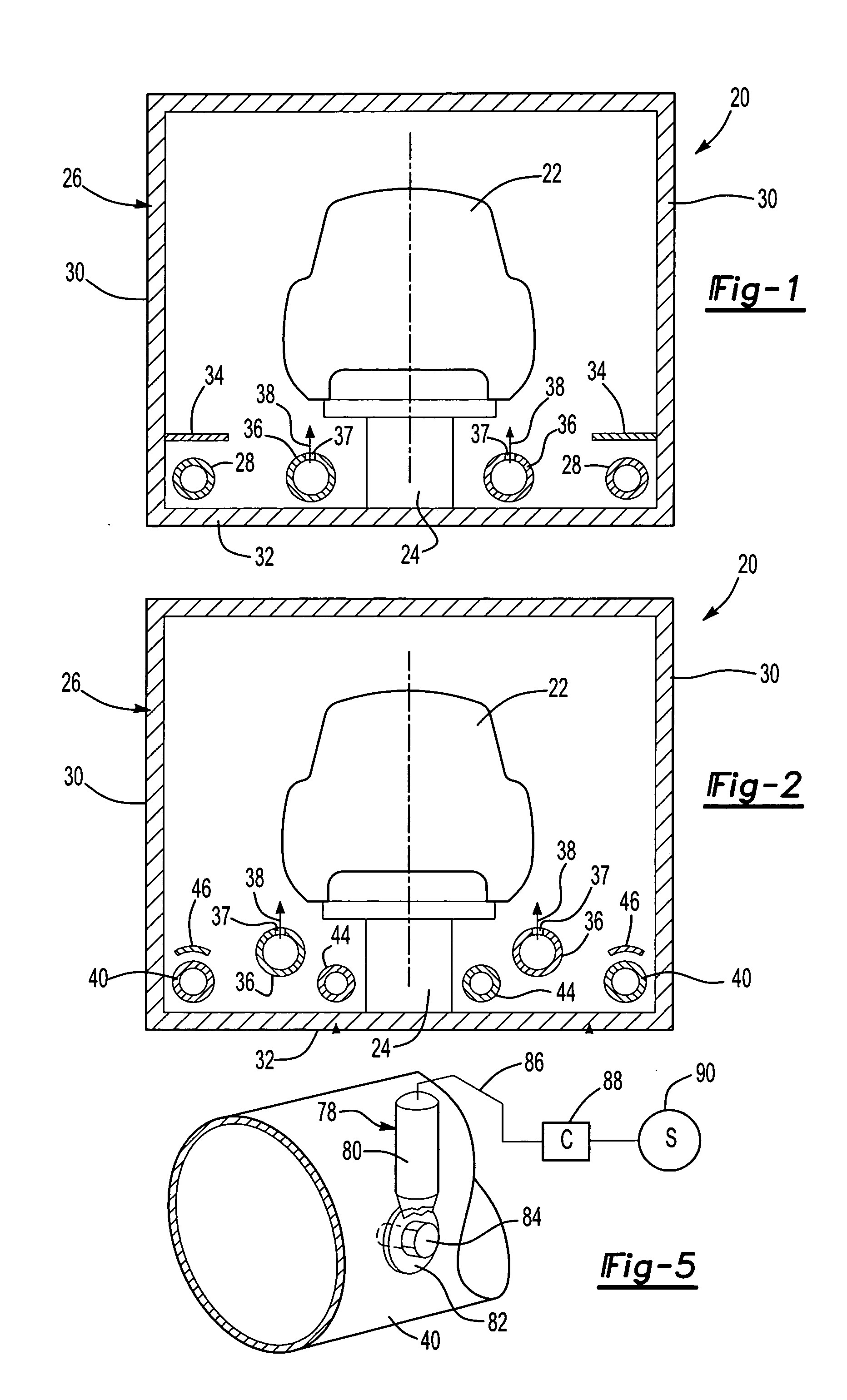

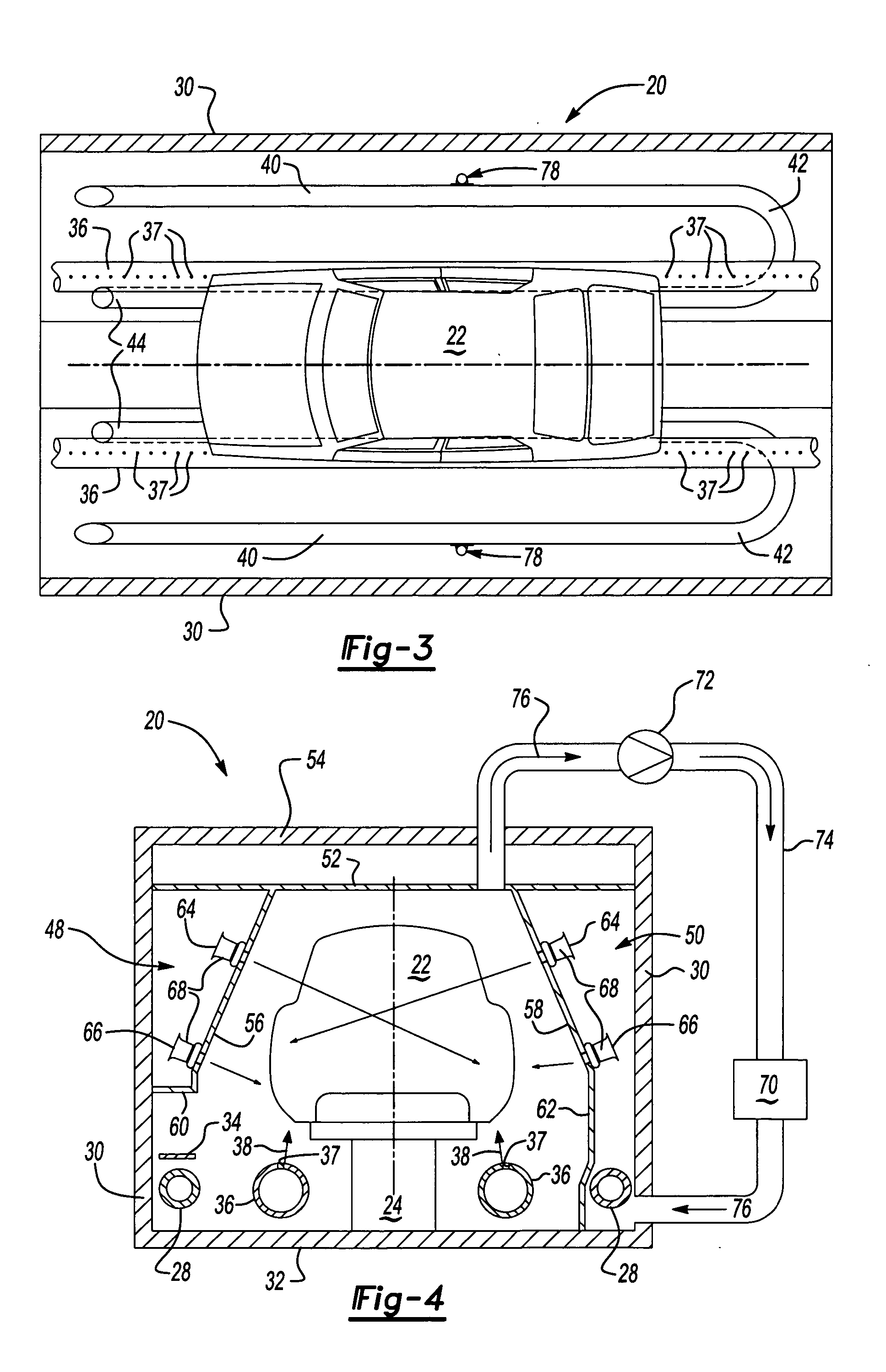

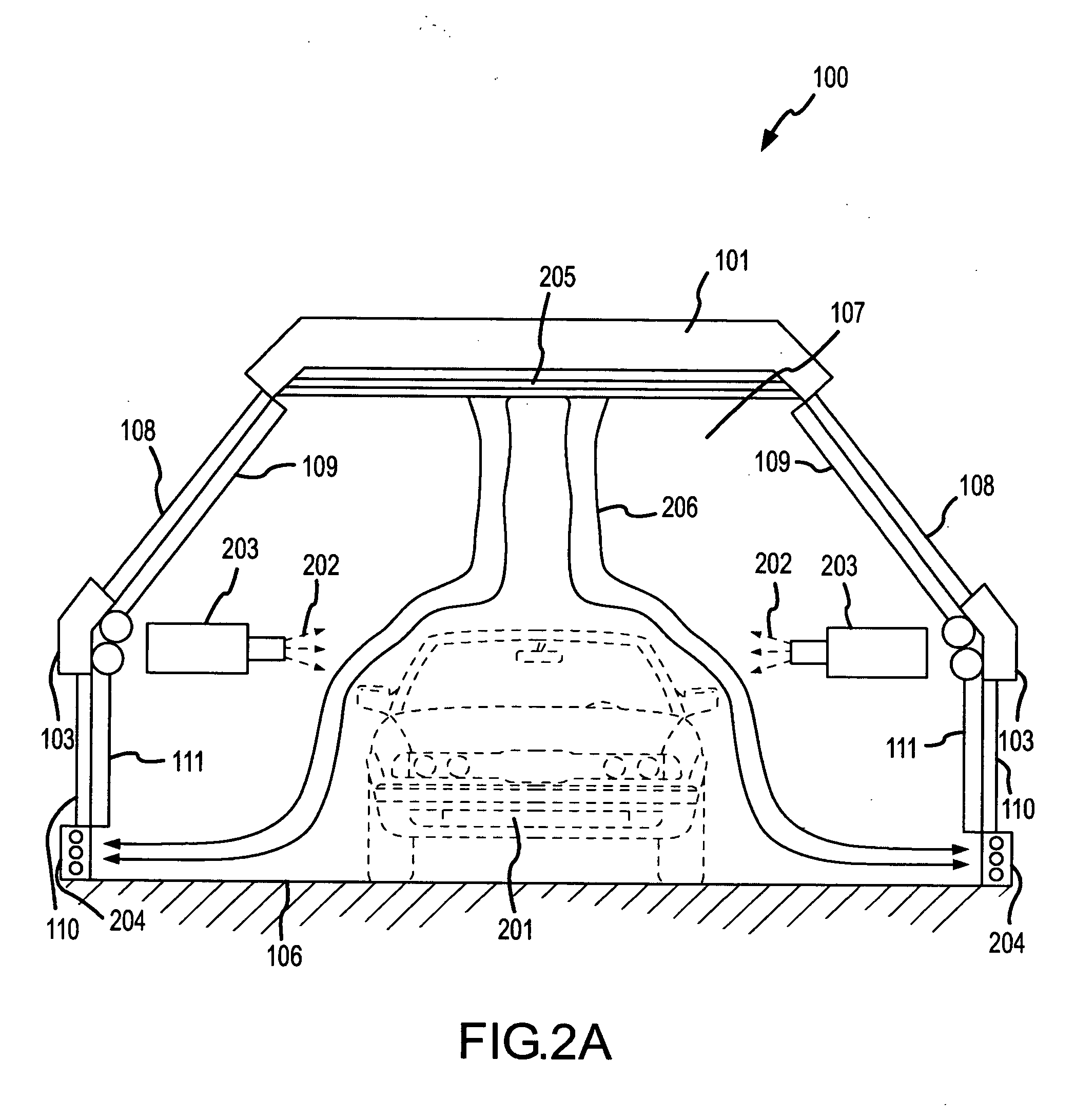

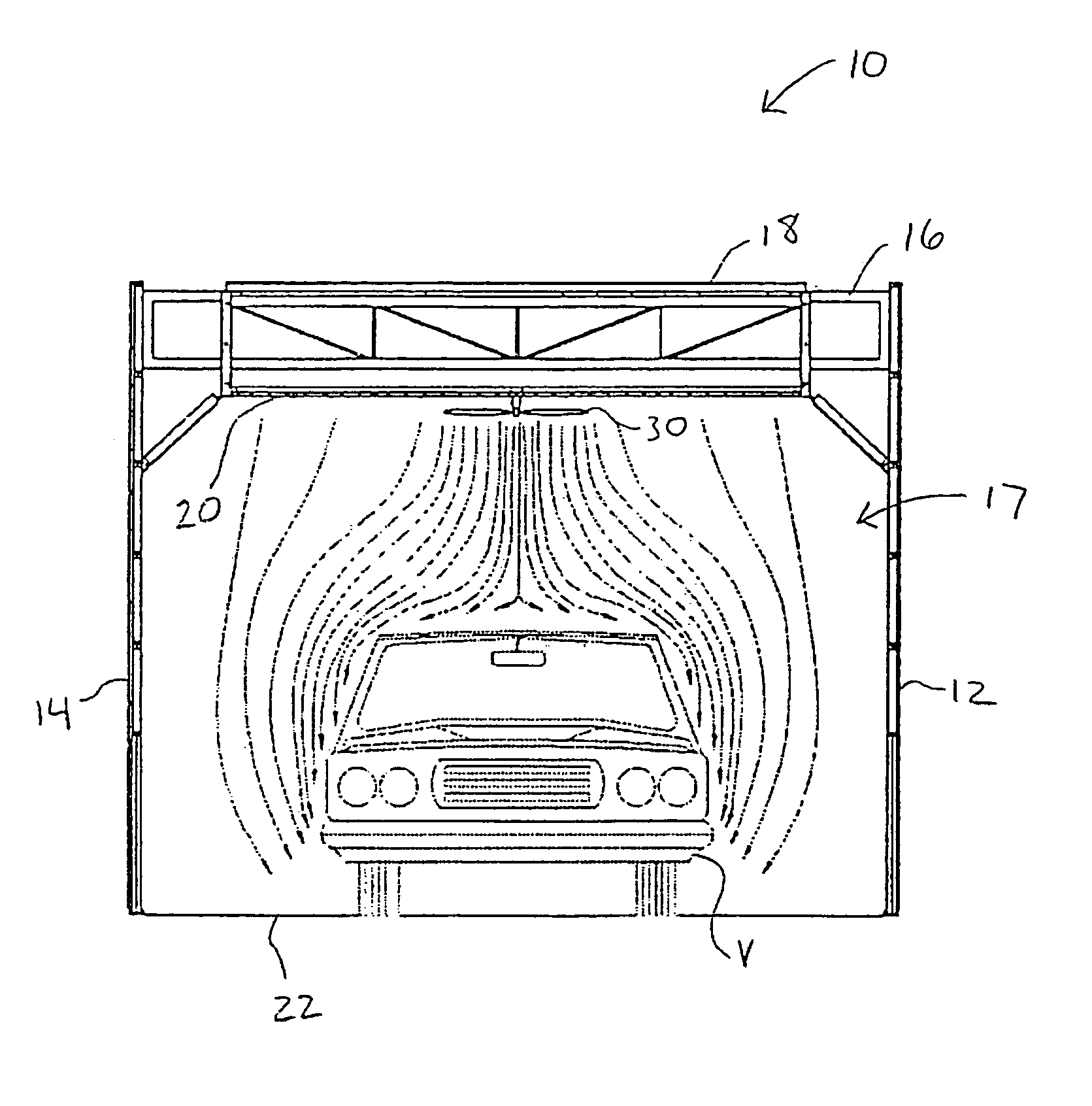

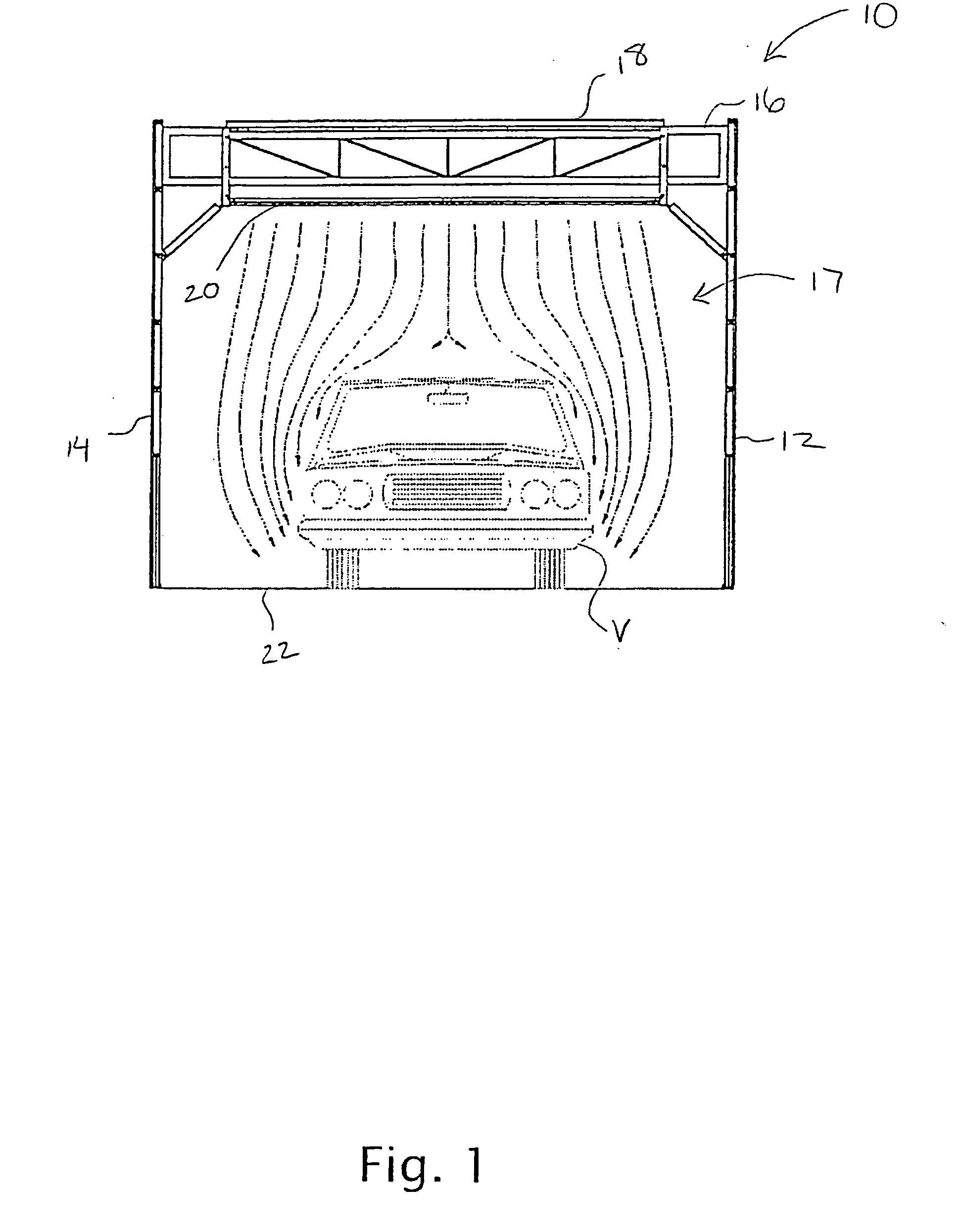

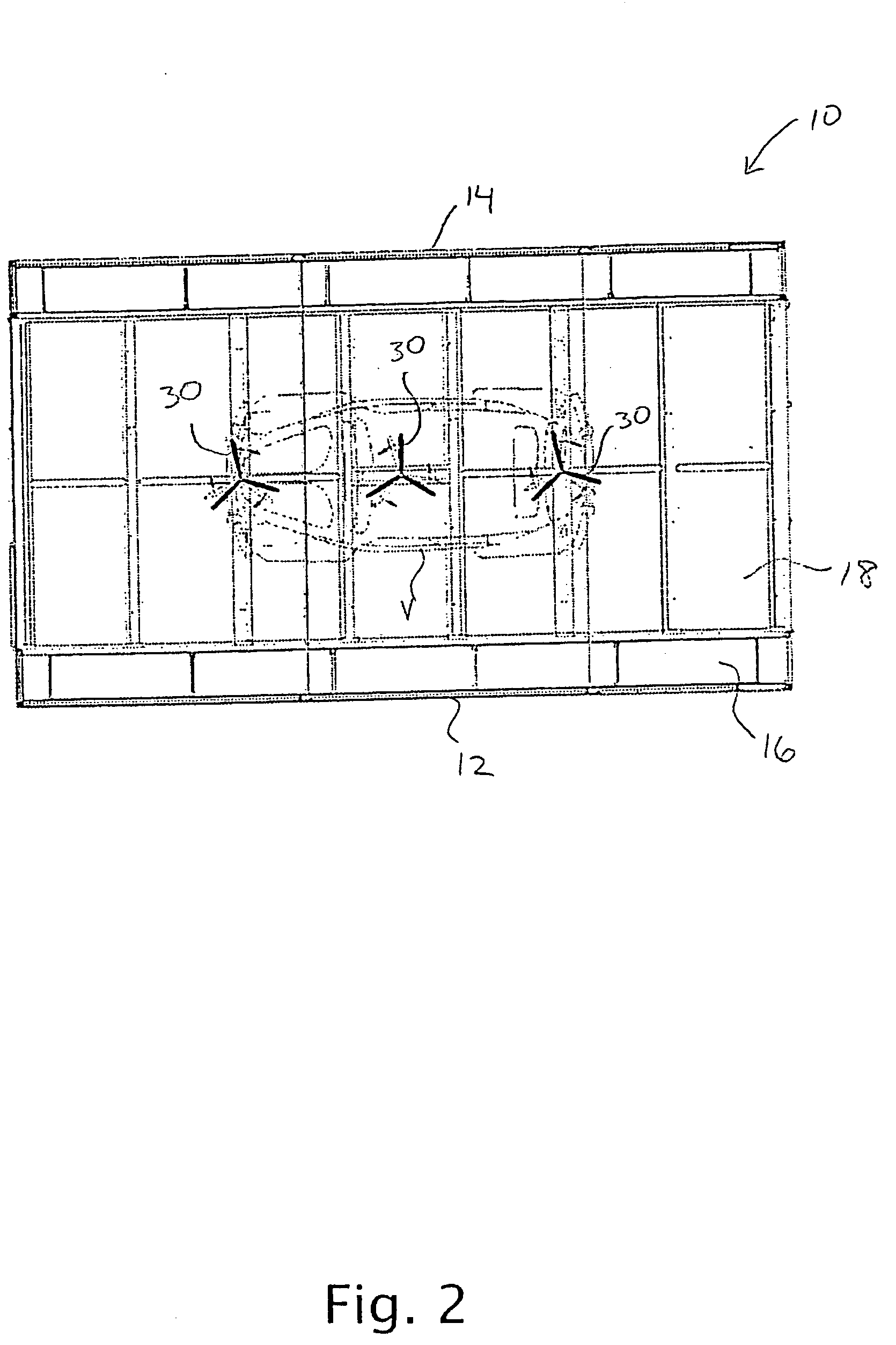

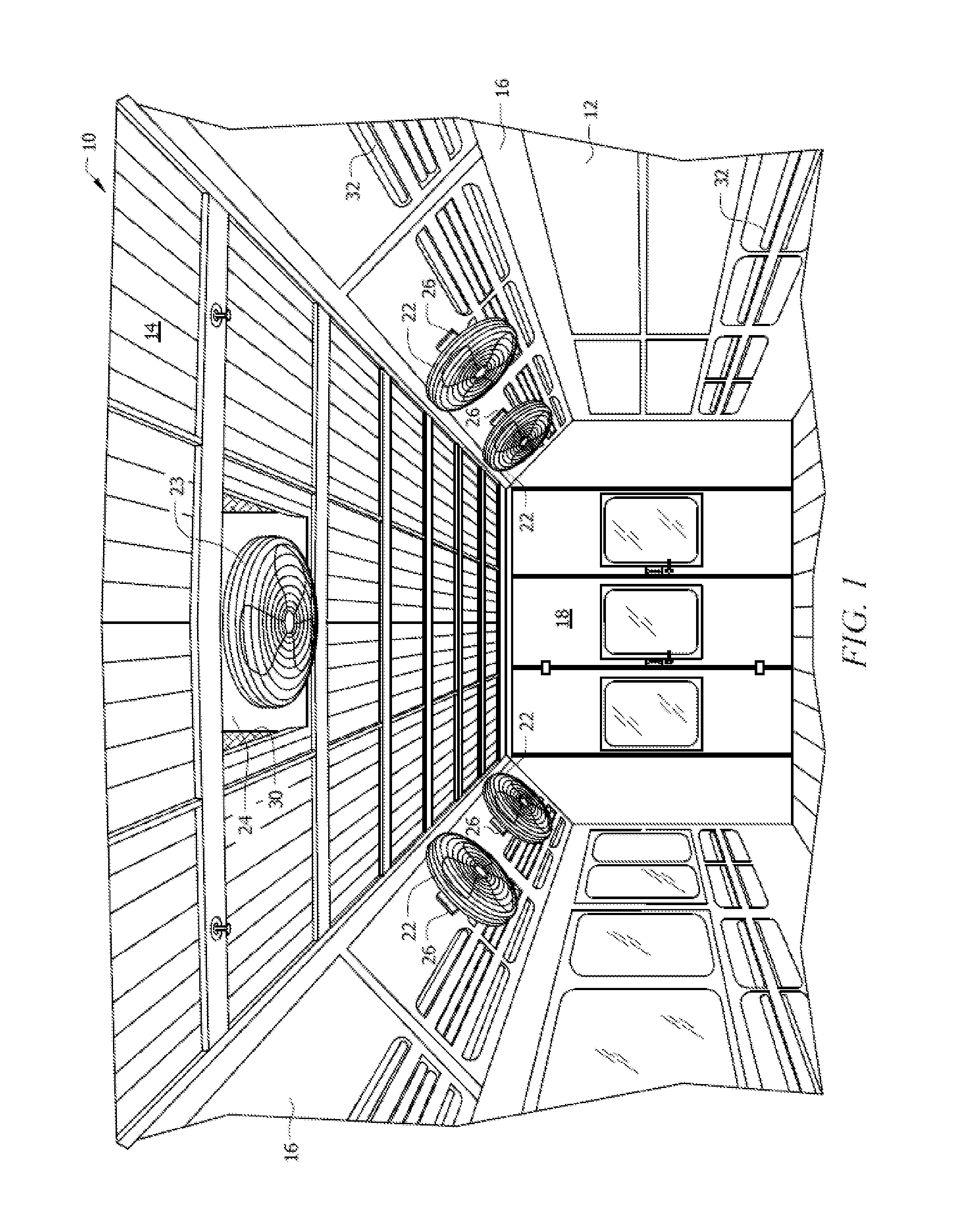

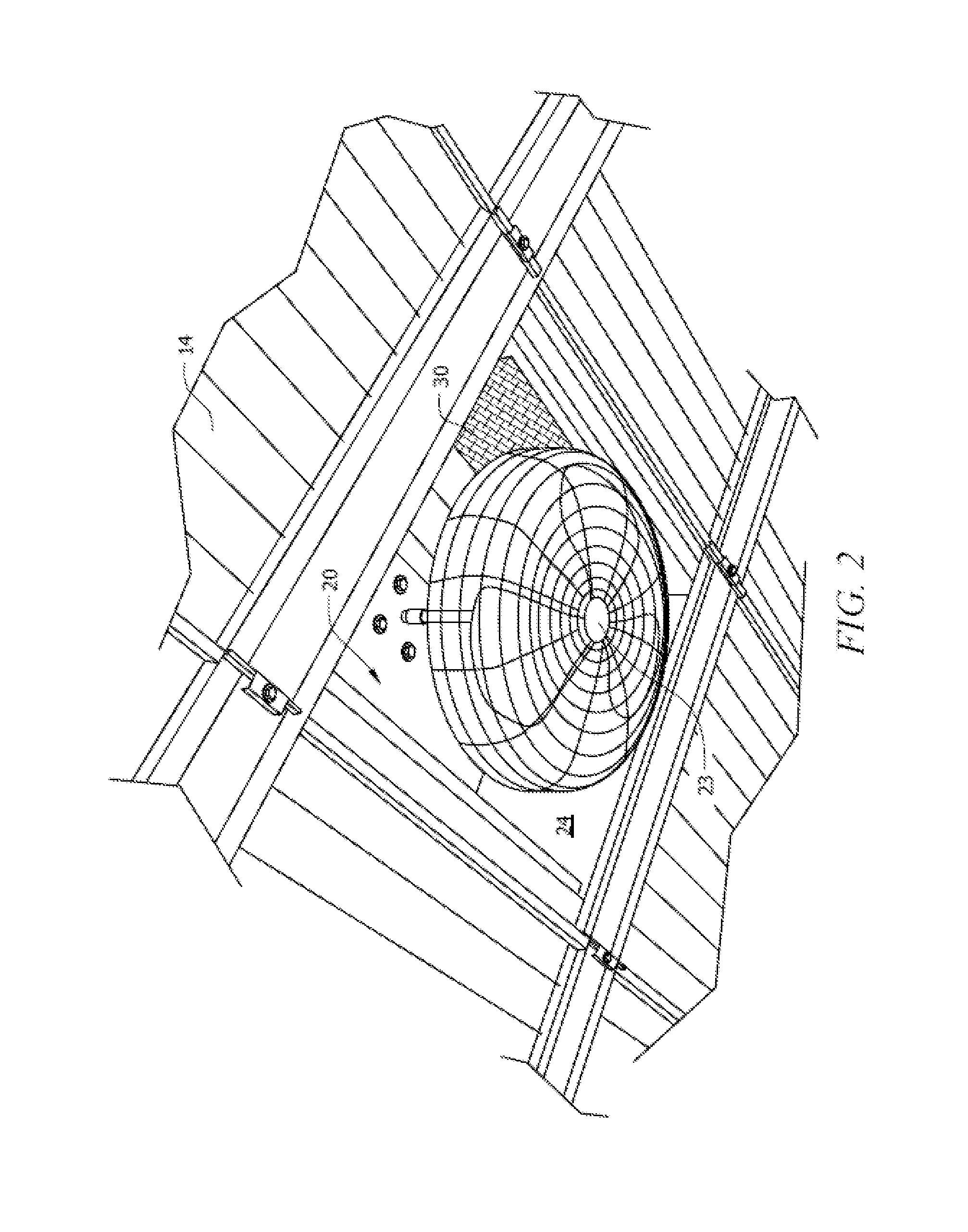

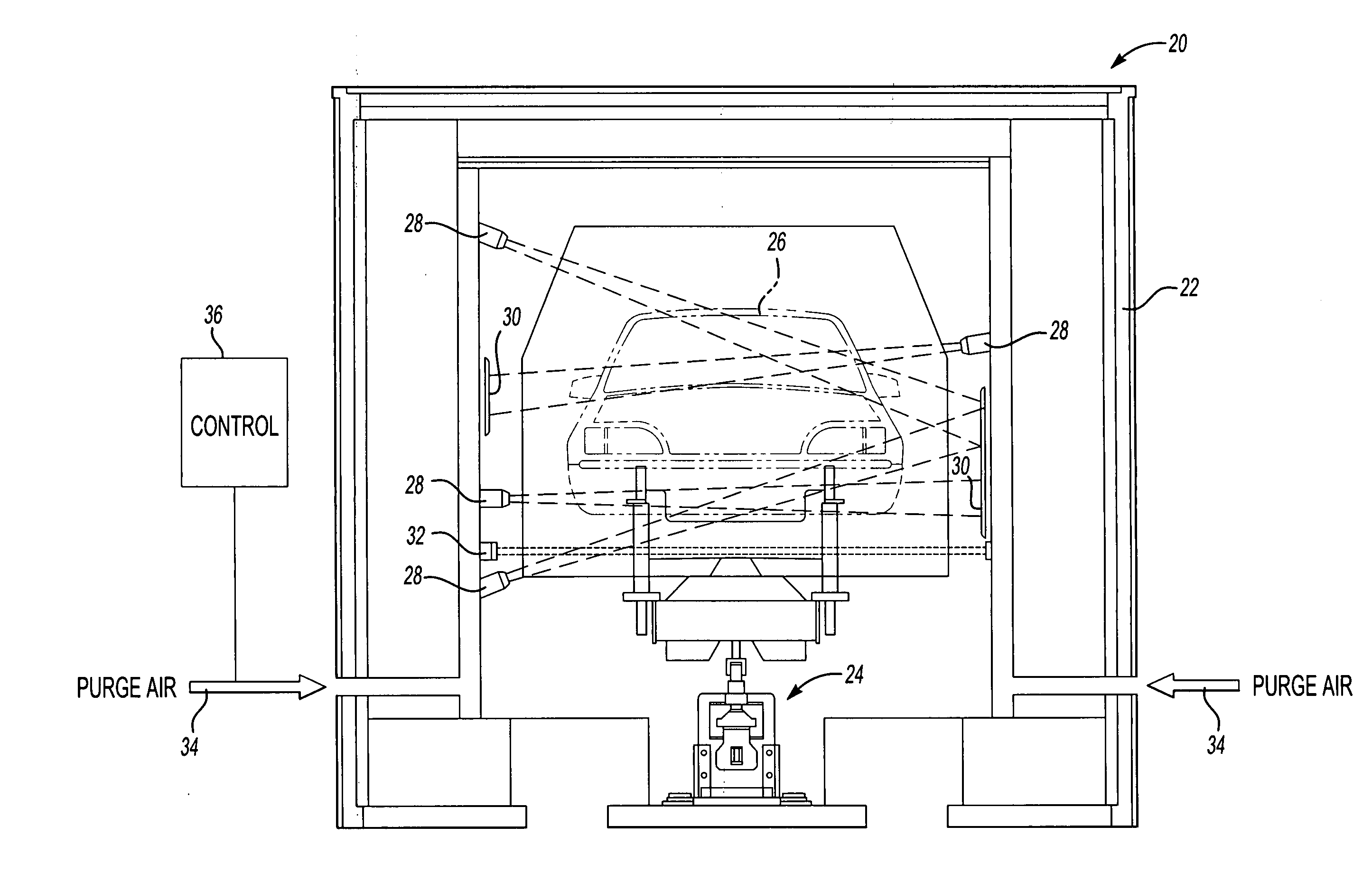

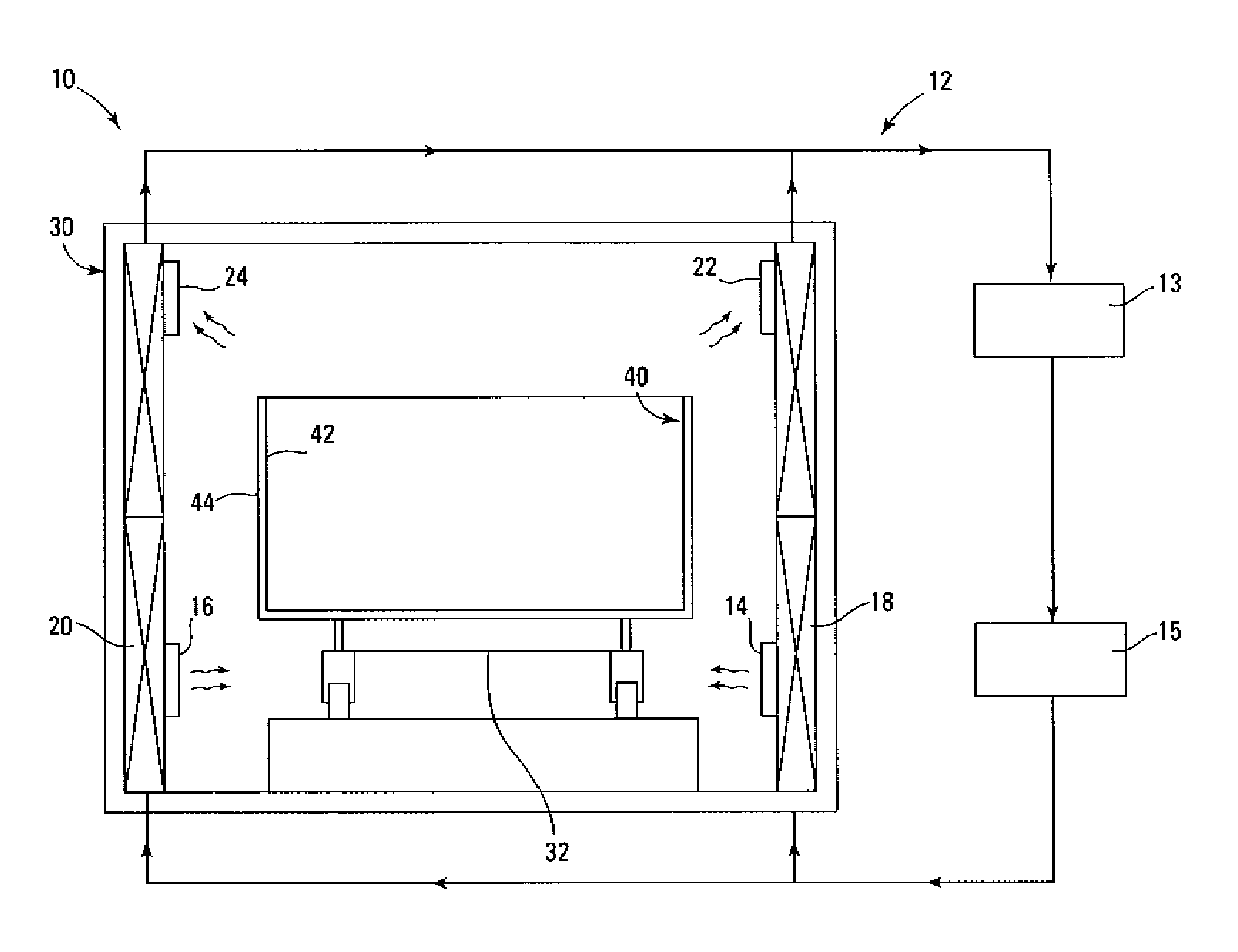

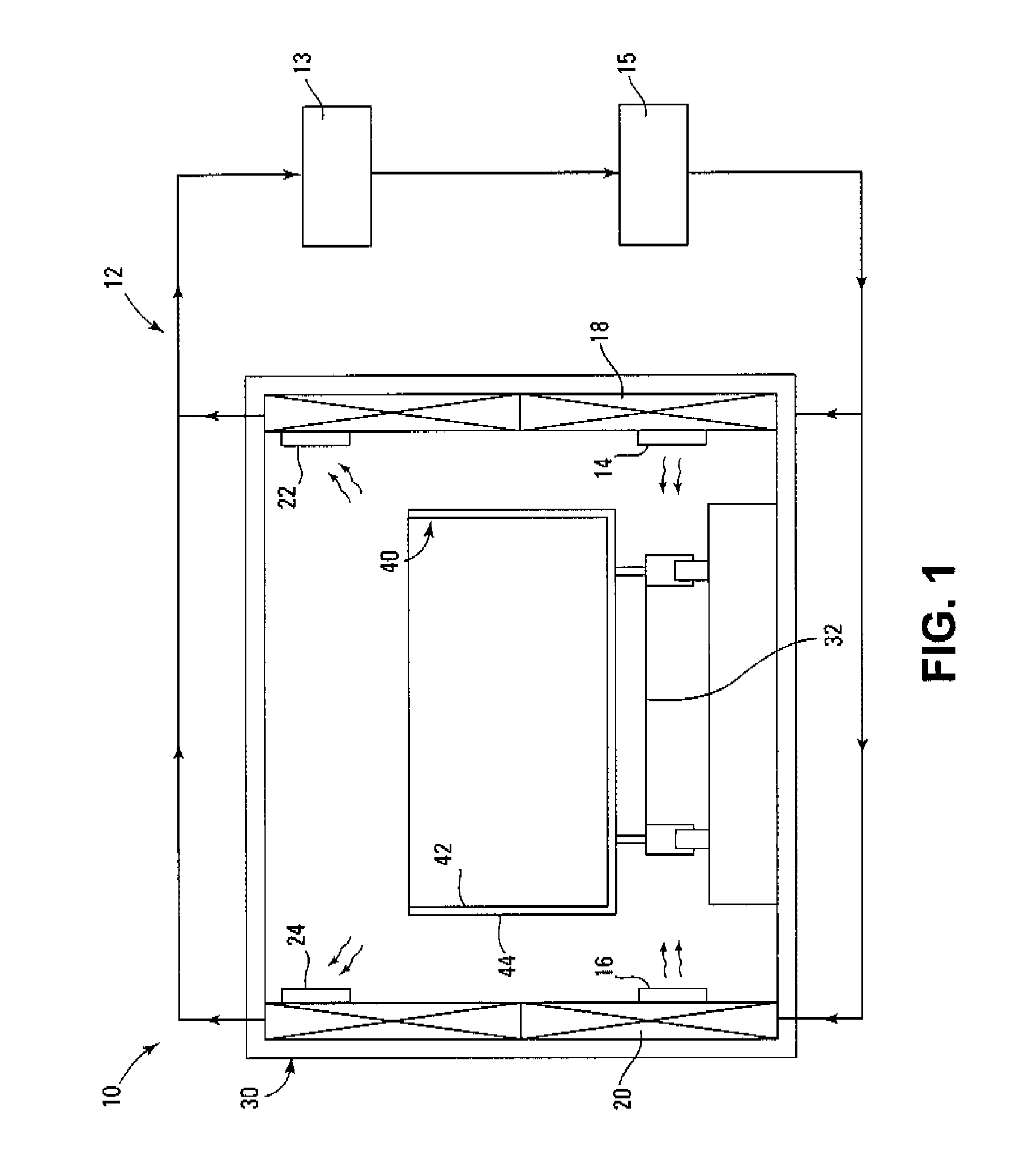

Spray booth systems and methods for accelerating curing times

ActiveUS20050120948A1Increase pressureIncrease airflowLiquid surface applicatorsDrying gas arrangementsAccelerated curingFilter media

One embodiment of the invention provides a spray booth that comprises a spray booth housing having a ceiling and side walls that define an interior for holding an object to be sprayed. A pressurized air plenum is disposed above the ceiling and is adapted to supply air into the interior. A filter media is used to filter air from the plenum before entering into the interior. At least one fan is disposed in the interior below the filter media. The fan is operable to locally increase air flows in the vicinity of the object to increase evaporation rates associated with a spray application on the object, and to enhance air flow over the object during a dry or a cure cycle.

Owner:GARMAT USA LLC

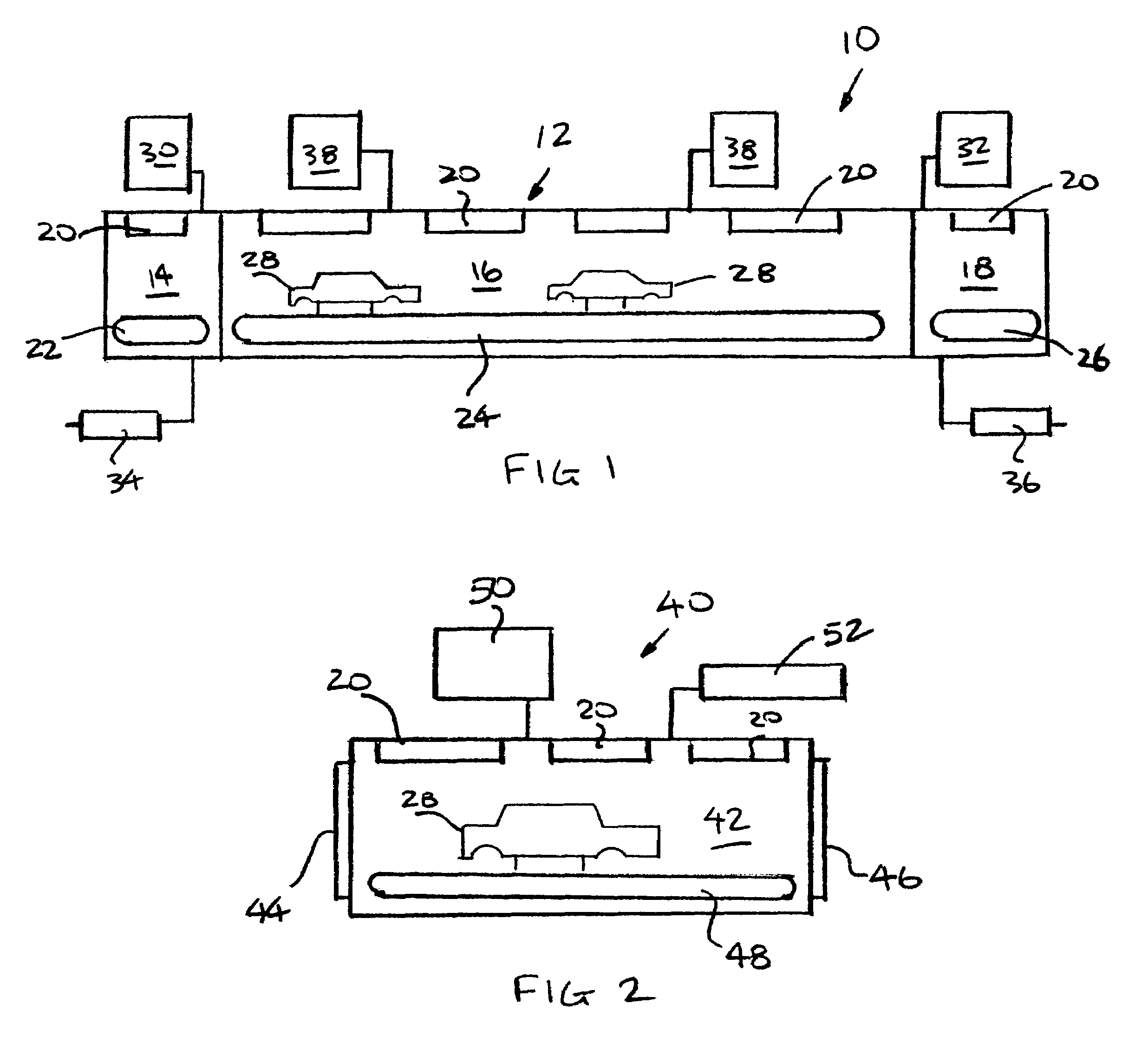

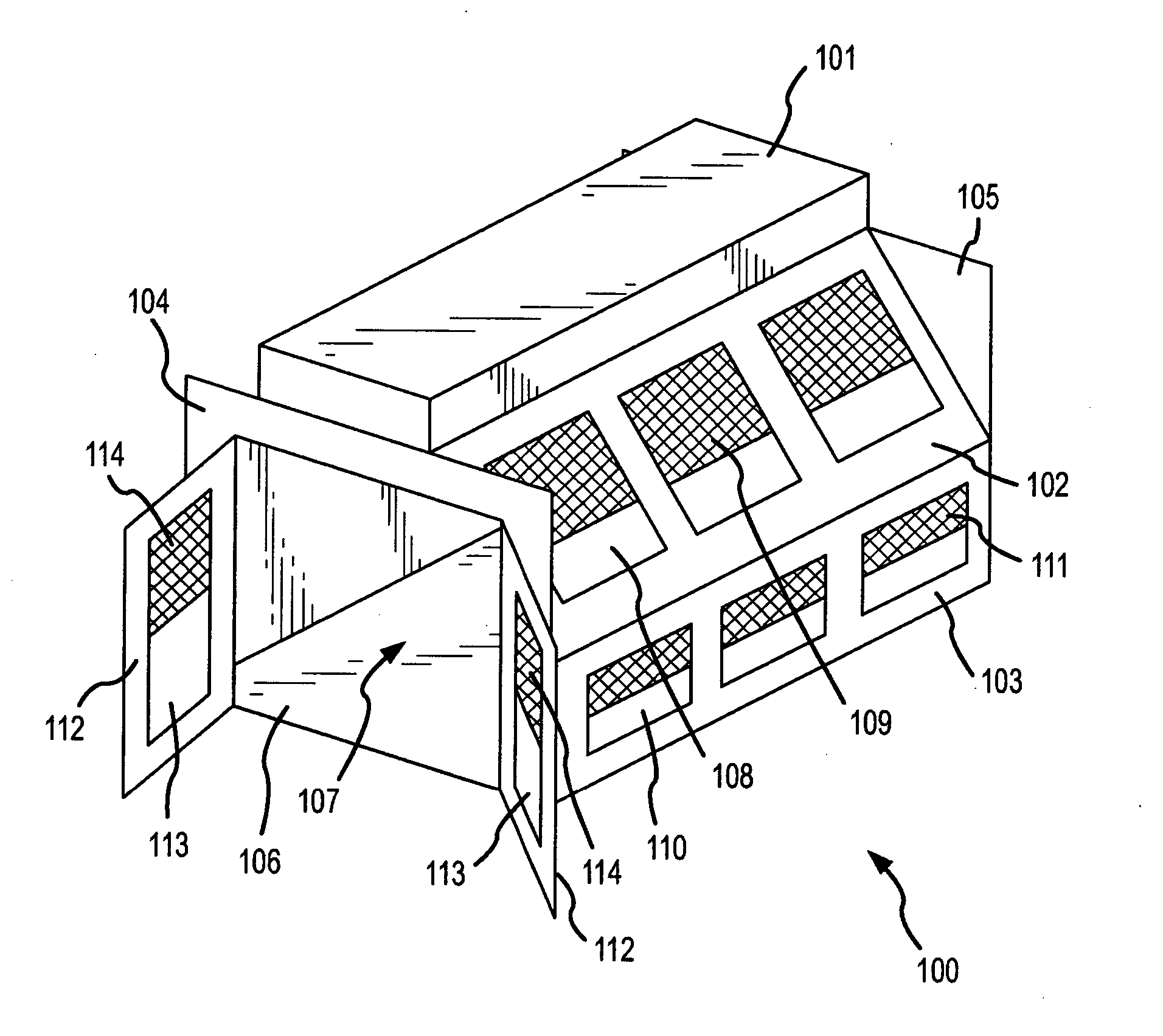

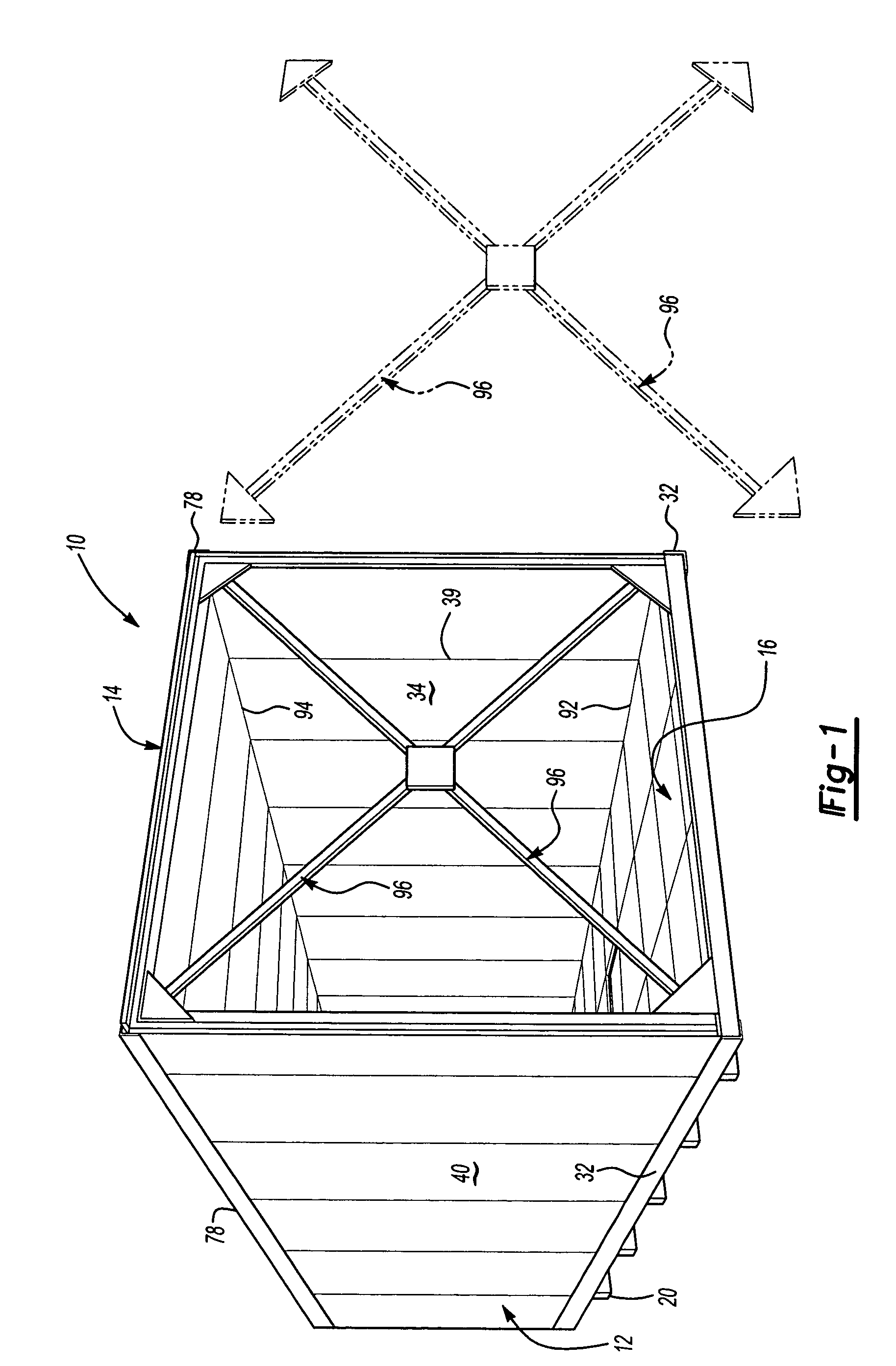

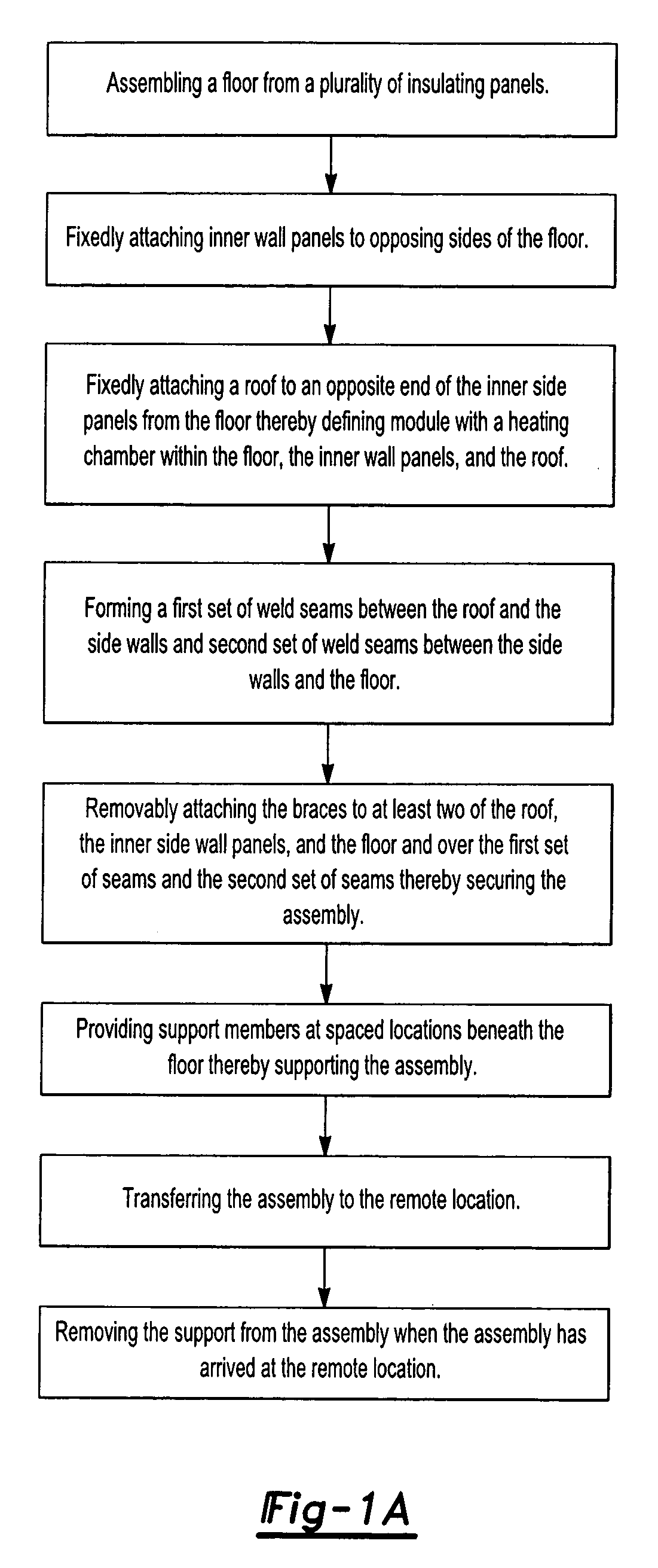

Modular paint oven

ActiveUS6990749B2Easy to manufactureDrying solid materials with heatCharge manipulationSurface plate

An oven assembly for drying paint on a product transported by a conveyor includes a plurality of modules positioned in a generally abutting relationship. Each of the modules includes a roof, side walls, and a floor having a length and a width. The floor is formed from abutting floor panels reinforced by a plurality of support members spaced along the length of the floor and having a length greater than the width of the floor. The side walls include an inner side wall panel disposed in an overlapping relationship with the floor and a side wall cladding panel supported by the support members along the width of the floor thereby concealing thermal insulating material disposed between the inner side wall panel and the side wall cladding panel.

Owner:DURR SYST INC

Spray booth system and methods

InactiveUS8756827B1Increase airflowIncrease fan speedMechanical cleaningLiquid surface applicatorsCeiling fanEngineering

The current invention discloses a novel spray booth containing a plurality of spacers disposed on the walls or ceiling, and a plurality of fans attached to the spacers. A spacer allows a fan to be disposed at an angle and at a certain distance away from the wall or ceiling, allowing sufficient airflow for spraying or curing an object within the housing. Having fans emit airflow toward both the top and the sides of an object allows optimal coating and heating of the object. A ceiling fan may also be disposed within a plenum in the ceiling of the spray booth.

Owner:THE PAINT BOOTH GUYS

Apparatus for treating articles with at least one tempered, directed air jet

InactiveUS7200953B2Easy to disassembleAccurate insertion depthDrying solid materials with heatDrying solid materials without heatWaste managementNozzle

An apparatus for treating articles, in particular vehicle bodies, with at least one tempered, directed air jet comprises a housing, in which are formed a treatment chamber and at least one pressure chamber, which is separated from the treatment chamber by a partition wall. The tempered air is suppliable to the pressure chamber and may then flow as a directed air jet into the treatment chamber through a nozzle device, which penetrates an opening of the partition wall. The nozzle device is insertable from the treatment chamber into the partition wall and fastenable from the treatment chamber to the partition wall. Consequently, subsequent work on the nozzle device, in particular an exchange thereof, may be carried out more easily.

Owner:EISENMANN MASCHINENBAU GMBH & CO KG

System having a process chamber for workpieces

ActiveUS9970706B2Efficient separationAdequate fresh air supplyDrying gas arrangementsVehicle body dryingSpray nozzleWaste management

The invention relates to an installation having a process chamber which comprises an inner space having a receiving region for workpieces. The process chamber has an opening for the supply or discharge of workpieces. The process chamber is constructed so as to have a device for the introduction of gaseous fluid into the inner space, which device has at least one nozzle or aperture for the production of a fluid stream curtain between the opening and the receiving region for workpieces. The process chamber has a device for supplying fresh air, with which device fresh air can be introduced into the receiving region at a side of the fluid stream curtain, which side faces away from the opening.

Owner:DUERR SYST AG

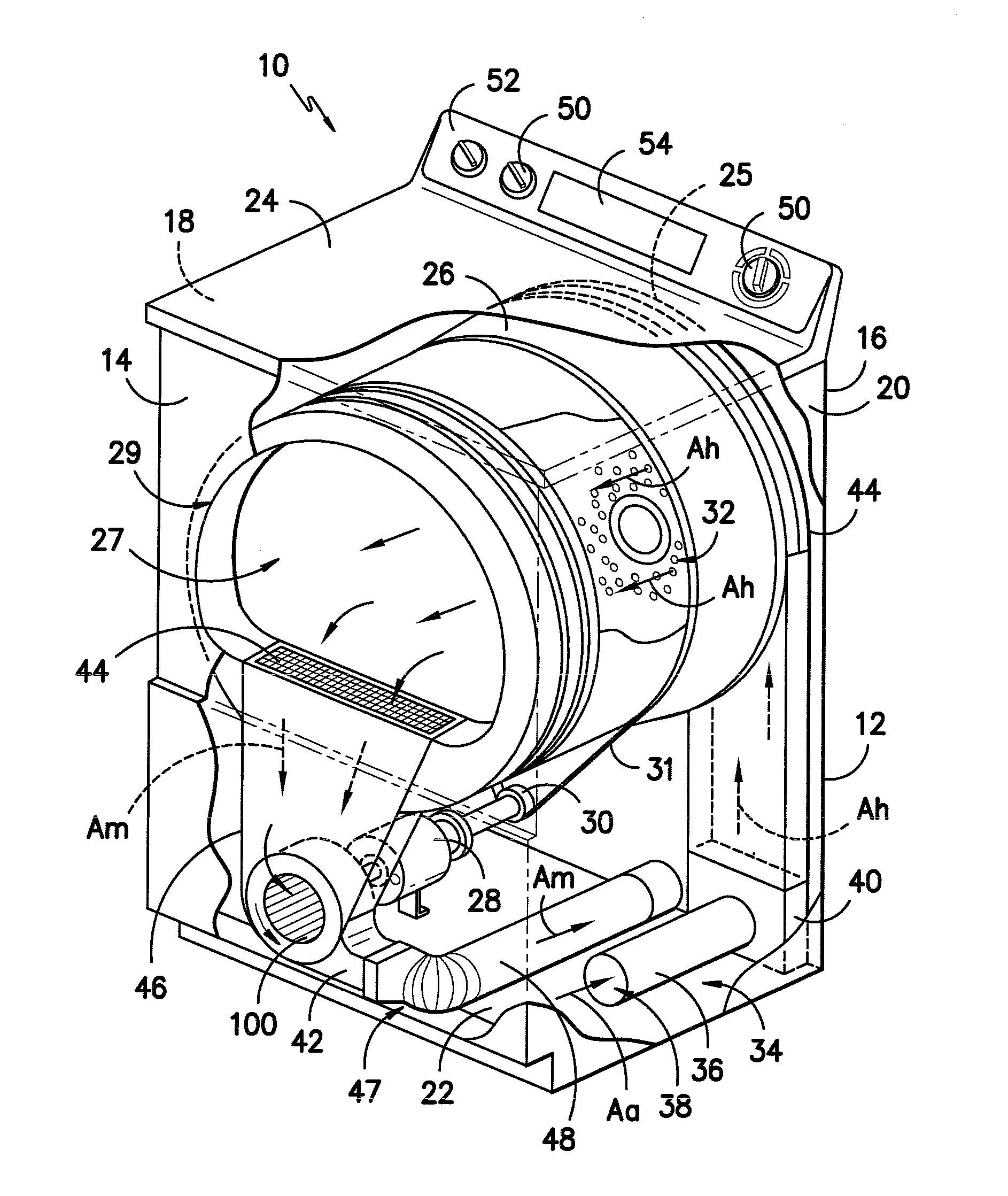

Fan assembly for an appliance

InactiveUS20140157613A1Drying solid materials with heatPump componentsEngineeringMechanical engineering

A fan assembly for an appliance is provided. The fan assembly includes a first plurality of blades and a second plurality of blades. Performance of the appliance can be improved and uniform fan assembly performance over a wide range of pressures can be provided by including the first and second pluralities of blades.

Owner:HAIER US APPLIANCE SOLUTIONS INC

Paint oven monitoring system

A paint oven including a conveyor conveying painted articles through the oven and a plurality of infrared temperature sensors directed toward and measuring the temperature of predetermined areas of the painted articles, and a control receiving a signal from the infrared temperature sensors and comparing the temperature to a predetermined standard. The disclosed embodiment further includes calibration targets opposite the infrared temperature sensors and independent temperature sensors measuring the temperature of the target for calibration of the infrared temperature sensors. The method of this invention further includes aligning the infrared temperature sensors with a coaxial light source.

Owner:DURR SYST INC

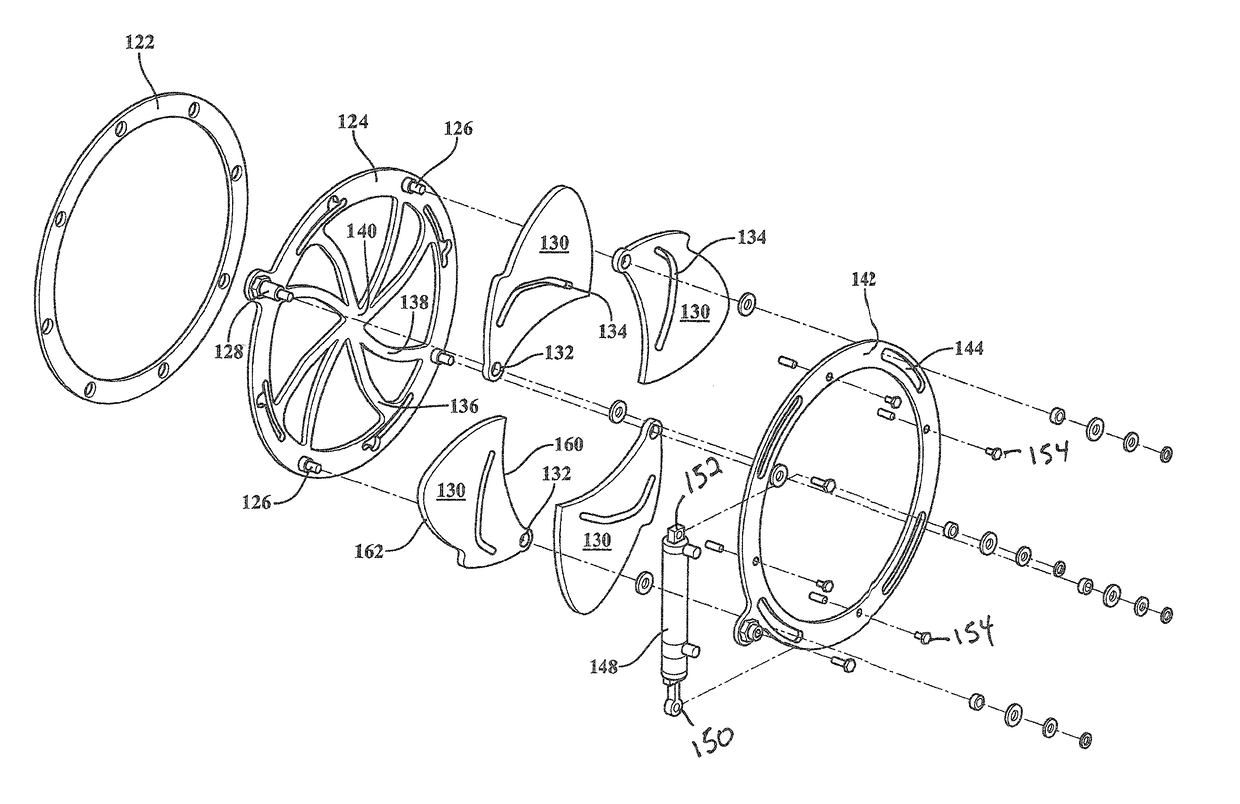

Mechanism for selectively opening/closing a vehicle wash component inlet opening

ActiveUS20170320470A1Reduce needImprove power efficiencyEngine manufacturePump componentsOperation modeEngineering

A dryer assembly for a vehicle wash system for emitting high velocity air onto a vehicle exterior includes a housing having an air inlet and an outlet. The air inlet is in communication with a motor assembly having an operating and a non-operating mode. The assembly also includes a gate mechanism in communication with the air inlet. The gate mechanism includes a plurality of pedals that are each pivotable between a first position and a second position. The gate mechanism is in communication with a controller, which directs movement of the plurality of pedals from the first position where the plurality of pedals surround the inlet opening such that air can flow into the housing and the second position where each of the plurality of pedals covers a portion of the inlet opening such that in their entirety the plurality of pedals obstruct the inlet opening to prevent air for flowing into the housing.

Owner:PISTON OPW INC

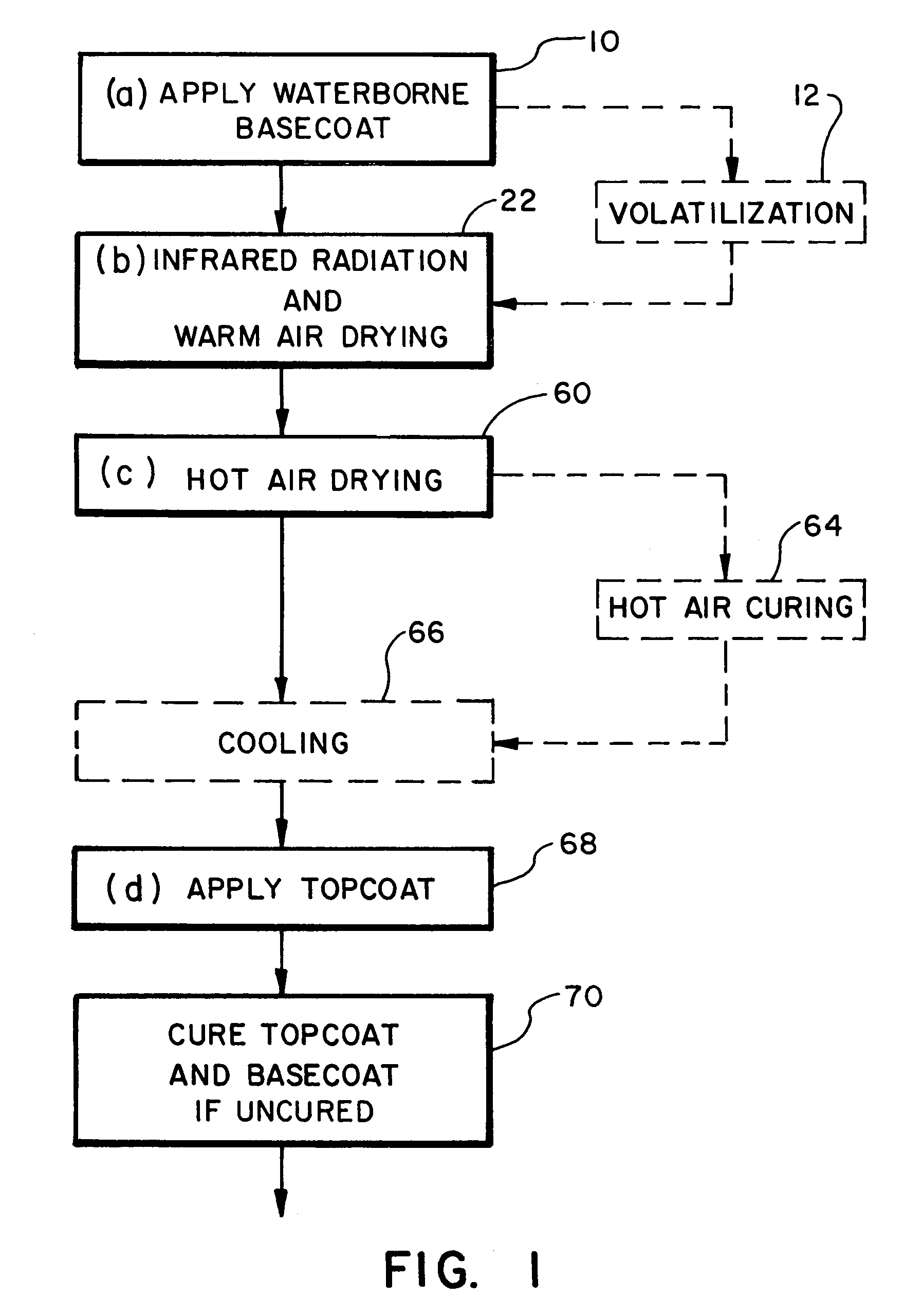

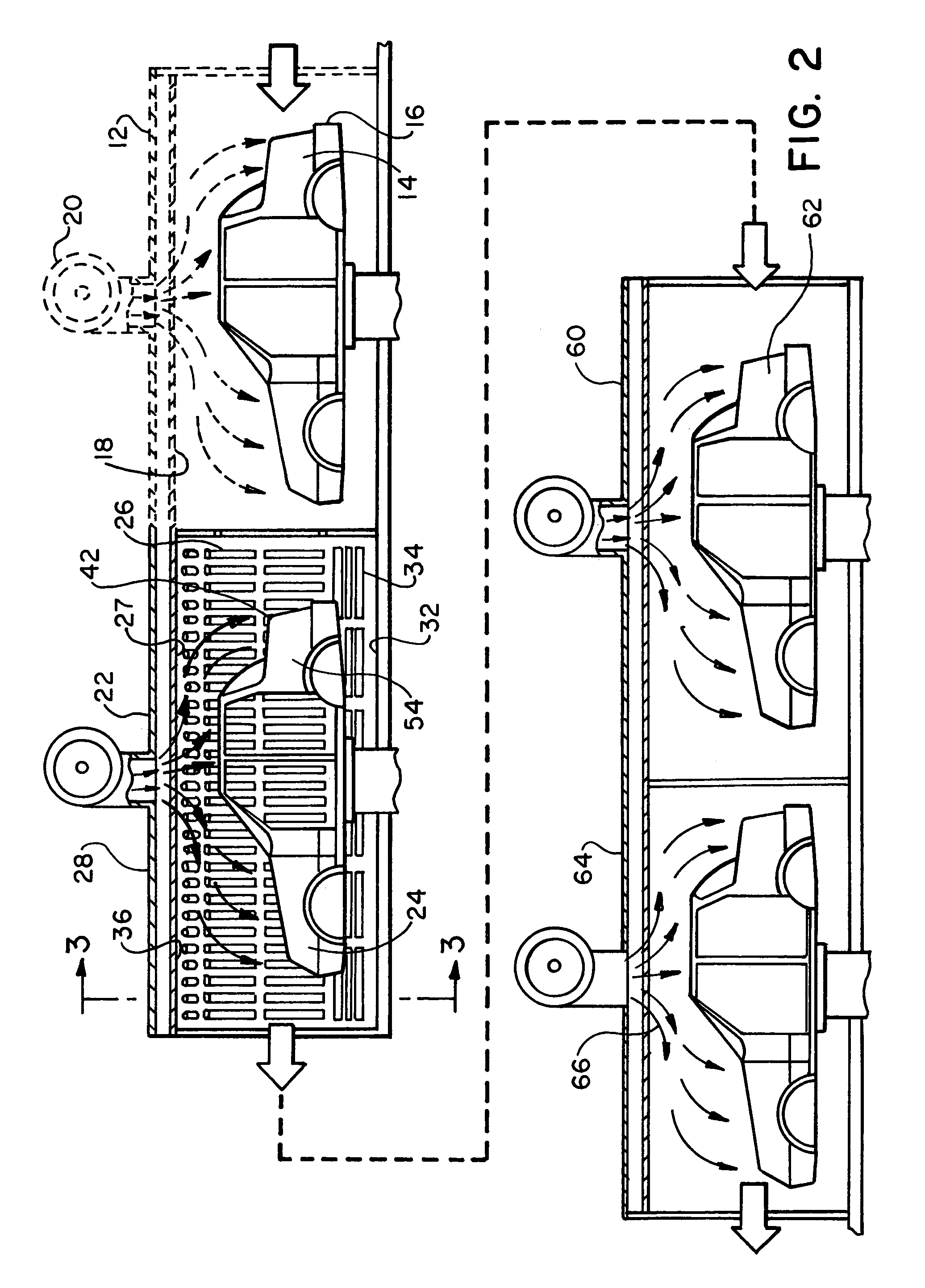

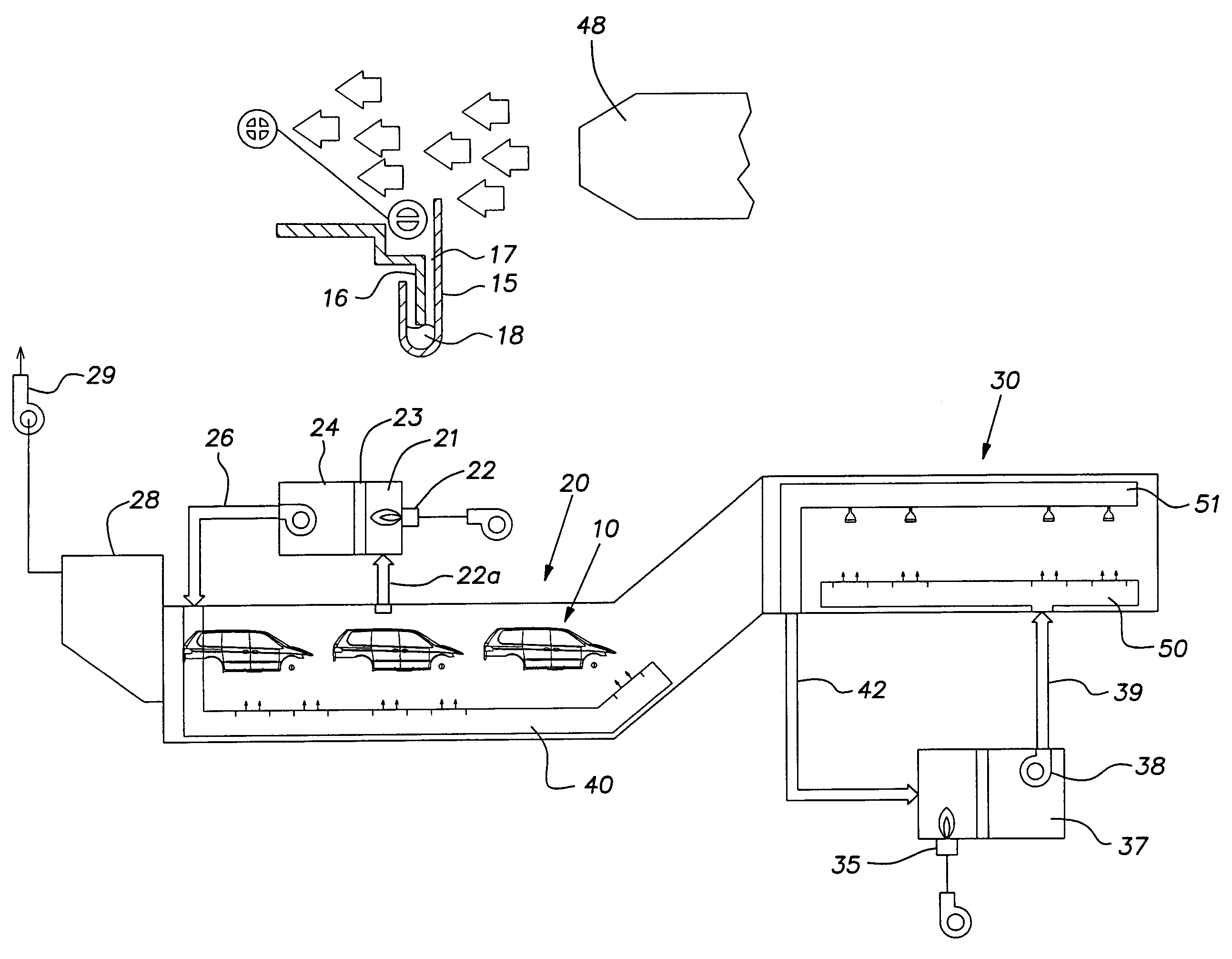

Multi-stage processes for coating substrates with multi-component composite coating compositions

InactiveUS7011869B2Drying solid materials with heatPretreated surfacesPolymer substrateVolumetric Mass Density

A process for coating a substrate is provided which includes the following steps:(a) applying a waterborne base coat composition to a surface of the substrate;(b) applying infrared radiation at a power density of 1.5–30.0 kW / m2 and a first air stream simultaneously to the base coat composition such that a pre-dried base coat is formed upon the surface of the substrate; and(c) applying a second air stream in the absence of infrared radiation to the base coat composition such that a dried base coat is formed upon the surface of the substrate.Various embodiments of the invention are disclosed including continuous, batch, and semi-batch processes, which may include additional process steps, such as subsequent application of a topcoat. The process may be used to coat a variety of metal and polymeric substrates, for example, those associated with the body of a motor vehicle.

Owner:PPG IND OHIO INC

Dehydration of body hem flanges

ActiveUS7181864B1Fast evaporationReduce air pressureDrying using combination processesDrying solid materials without heatEngineeringVaporization

As a metal assembly, which defines partially open voids in which liquid accumulates is conveyed through a heat-treating station, the hot air is blown across the open end of the void to produce a zone of low pressure at the surface of the liquid. The reduction in pressure and relatively high temperature promote rapid vaporization of the liquid while discouraging boiling of the liquid.

Owner:HONDA MOTOR CO LTD

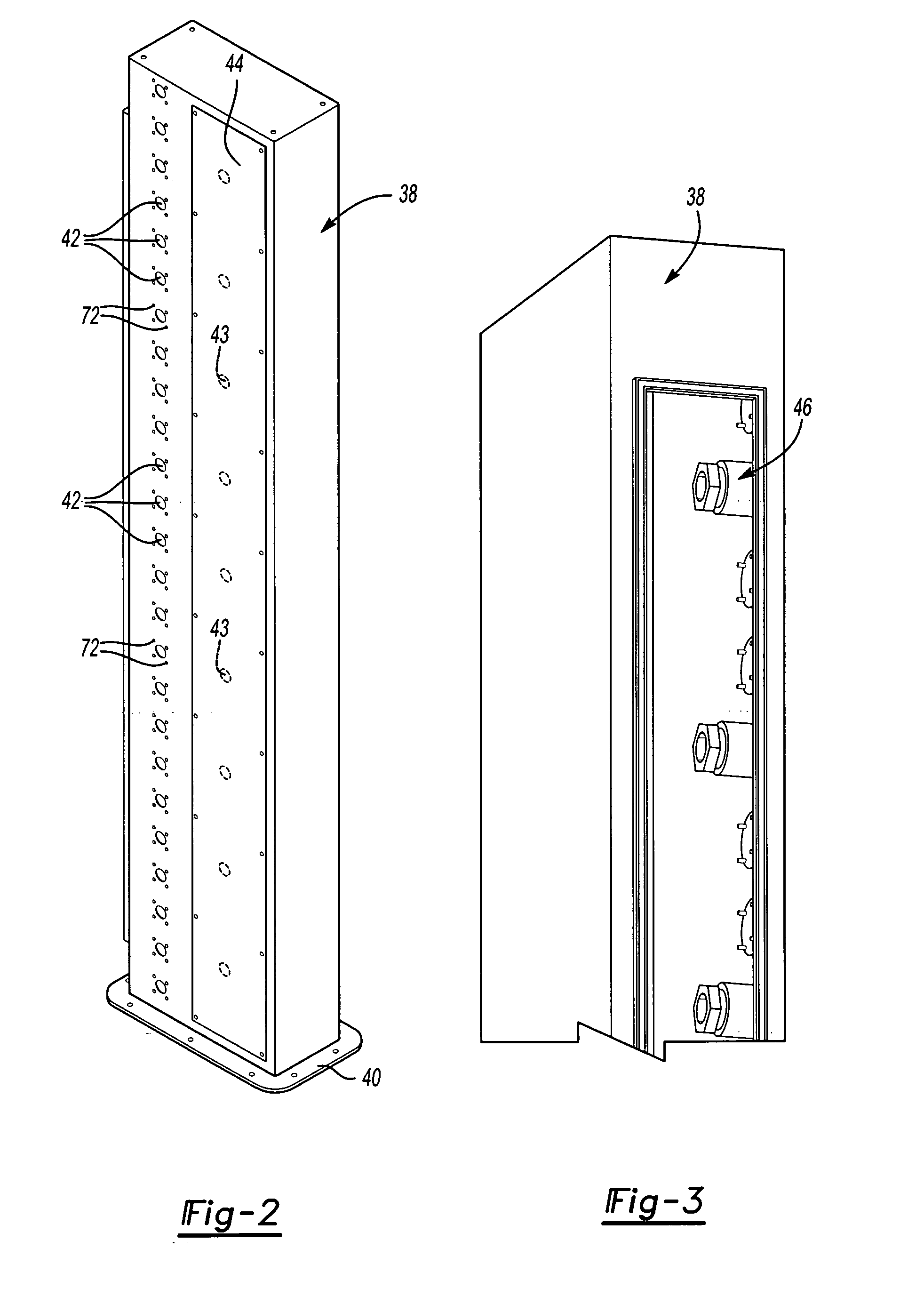

System and method having arm with cable passage through joint to infrared lamp

In one embodiment, a system is provided with a rotatable arm having a movable joint, an infrared lamp coupled to the rotatable arm, and an electrical cable extending through the rotatable arm and the movable joint. In another embodiment, a system is provided with a base and an arm coupled to the base via a first rotatable joint, wherein the arm has an arcuate shape. The system also may include a head coupled to the arm via a second rotatable joint, an infrared lamp coupled to the head, and a temperature sensor disposed adjacent the infrared lamp. Furthermore, the system may include an air flow passage extending through the first rotatable joint, the arm, and the second rotatable joint. A fan also may be pneumatically coupled to the air flow passage. In addition, an electrical cable may be disposed in the air flow passage, wherein the electrical cable extends to the infrared lamp and the temperature sensor.

Owner:CARLISLE FLUID TECH INC

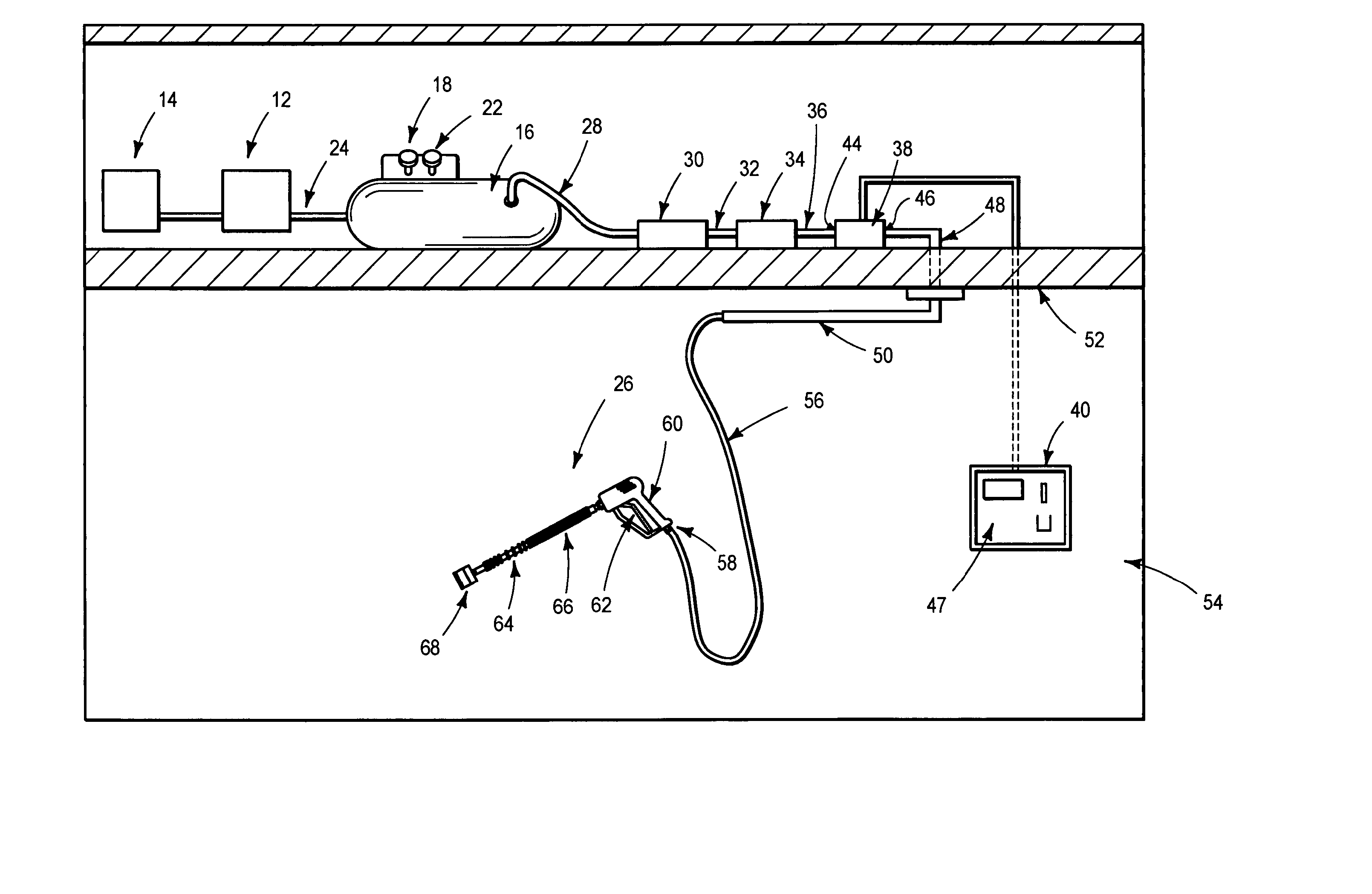

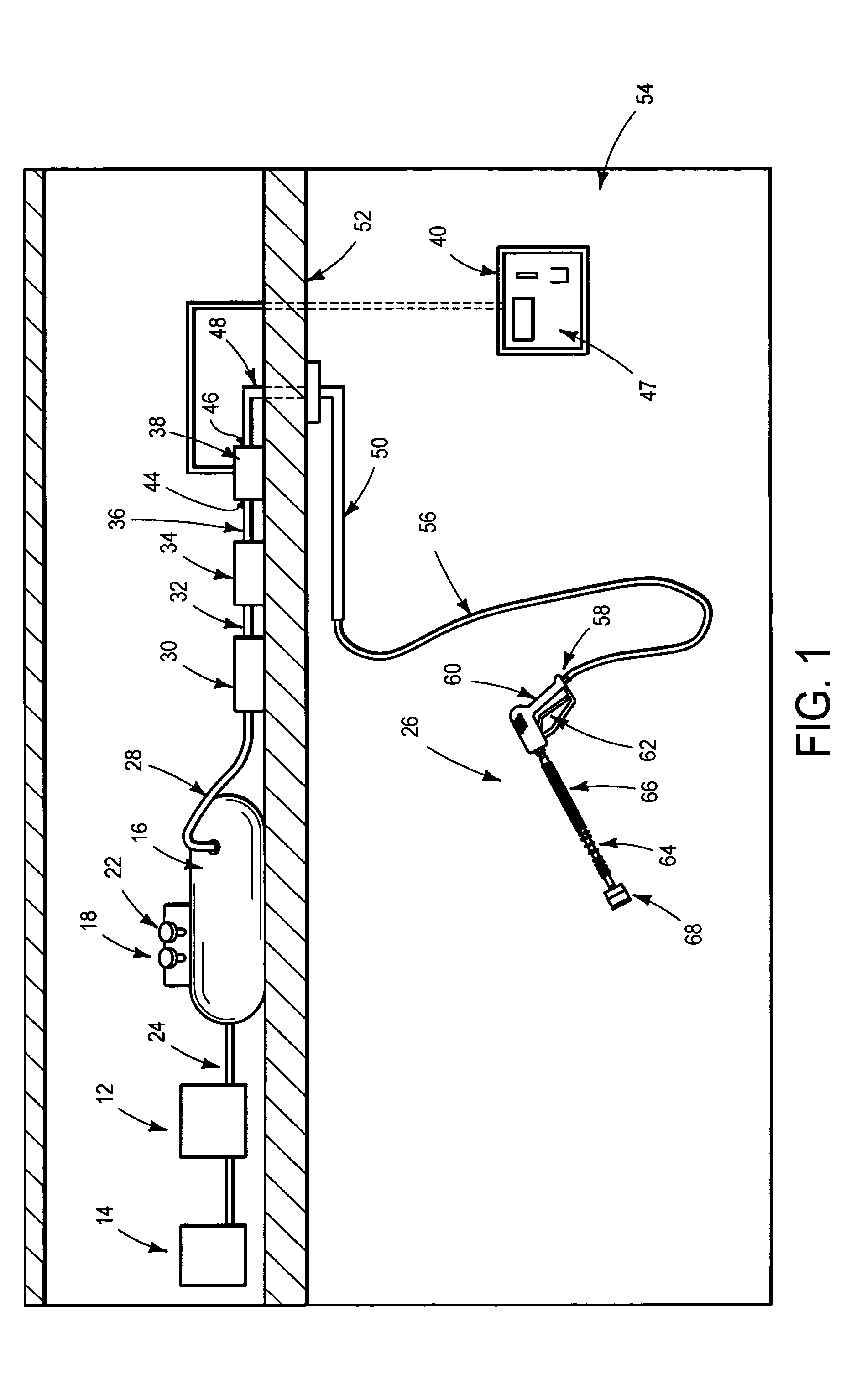

System and method for drying

InactiveUS20040143990A1Drying solid materials without heatVehicle drying apparatusCompressed-air vehicleStreamflow

The present invention relates to a system for projecting a pre-selected flow rate of dry compressed air onto a vehicle to prevent accumulation of excess water. The present invention also relates to a method for utilizing a compressed air vehicle drying system.

Owner:CAMMISANO GERLARMO P L

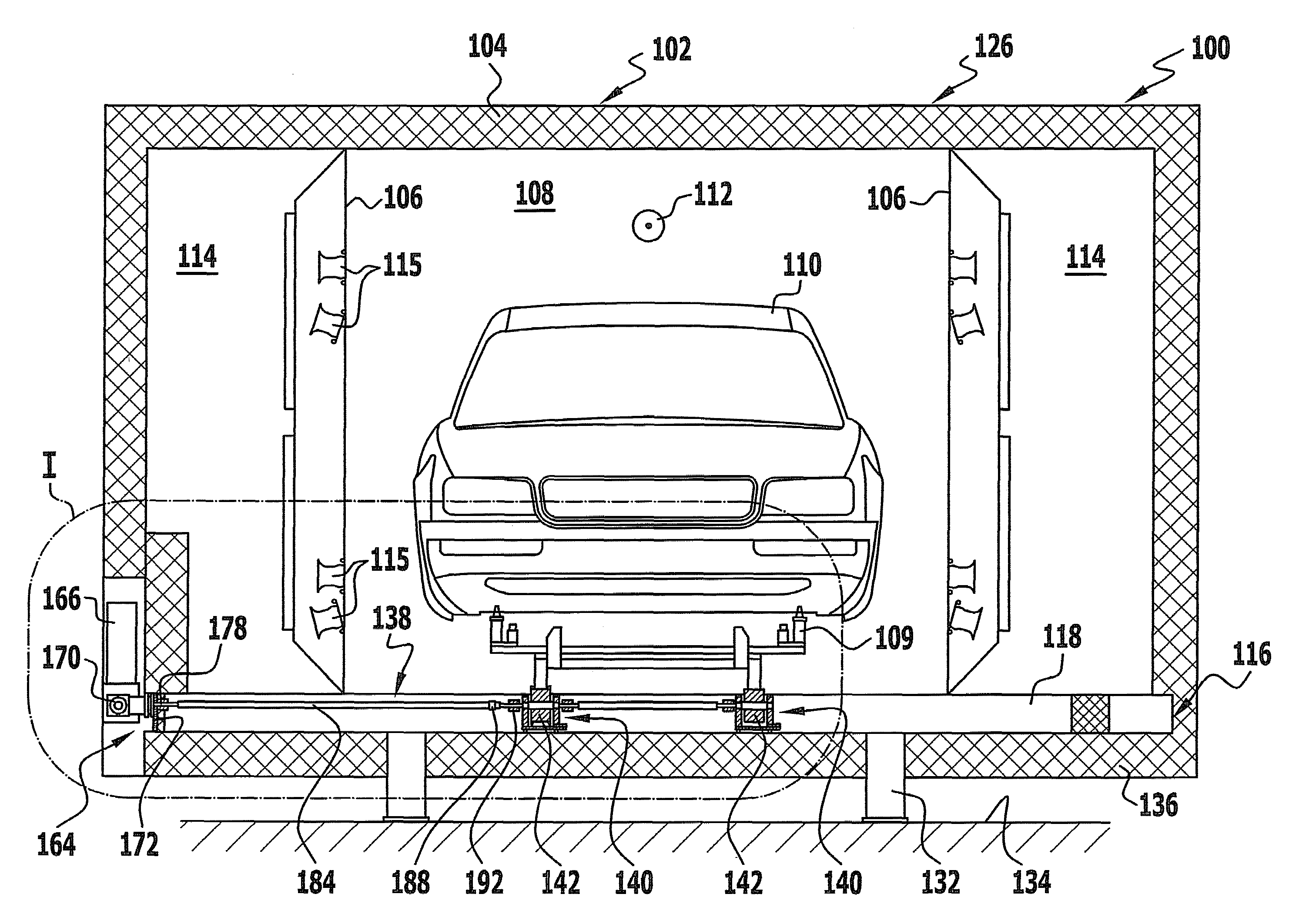

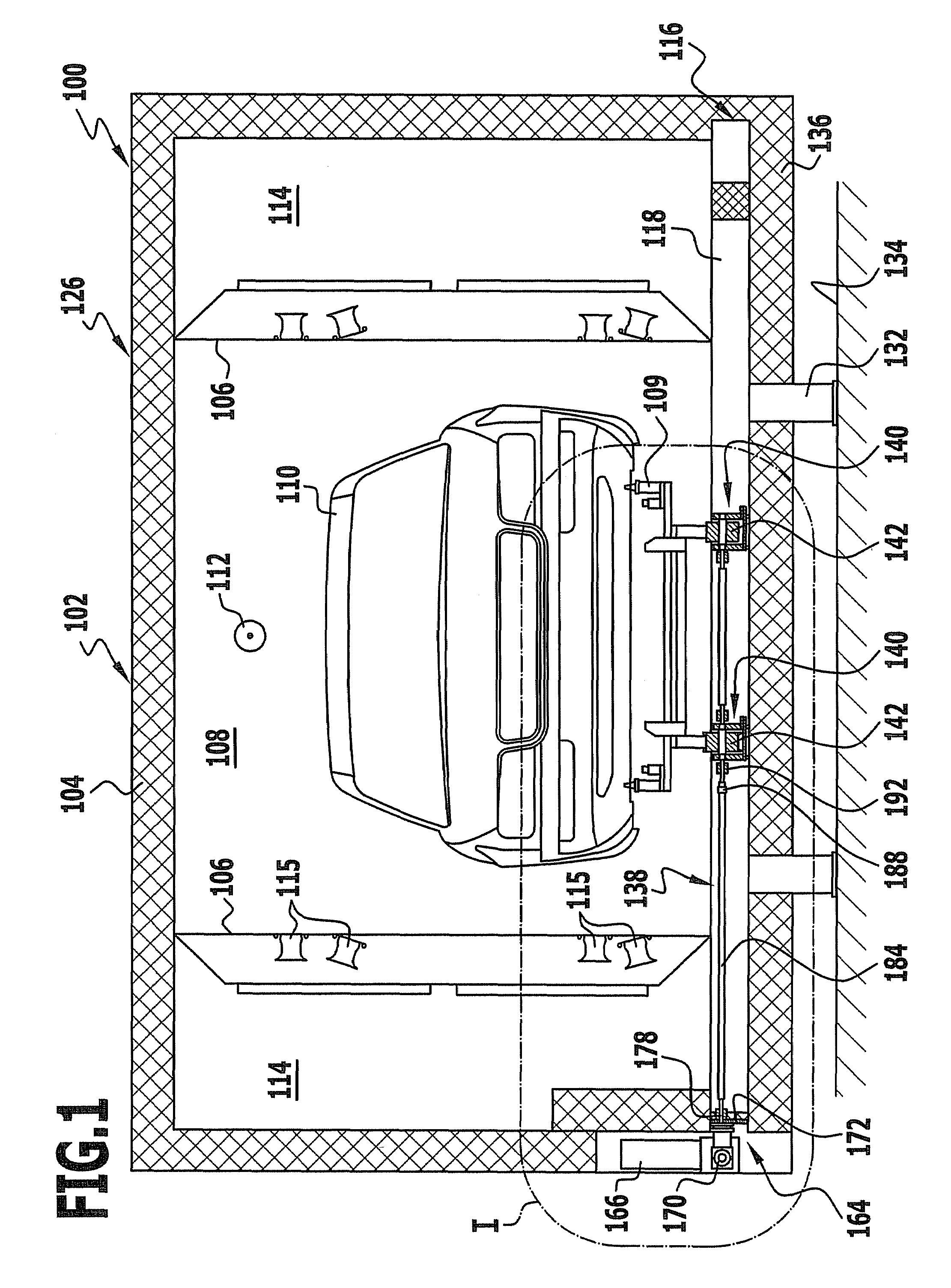

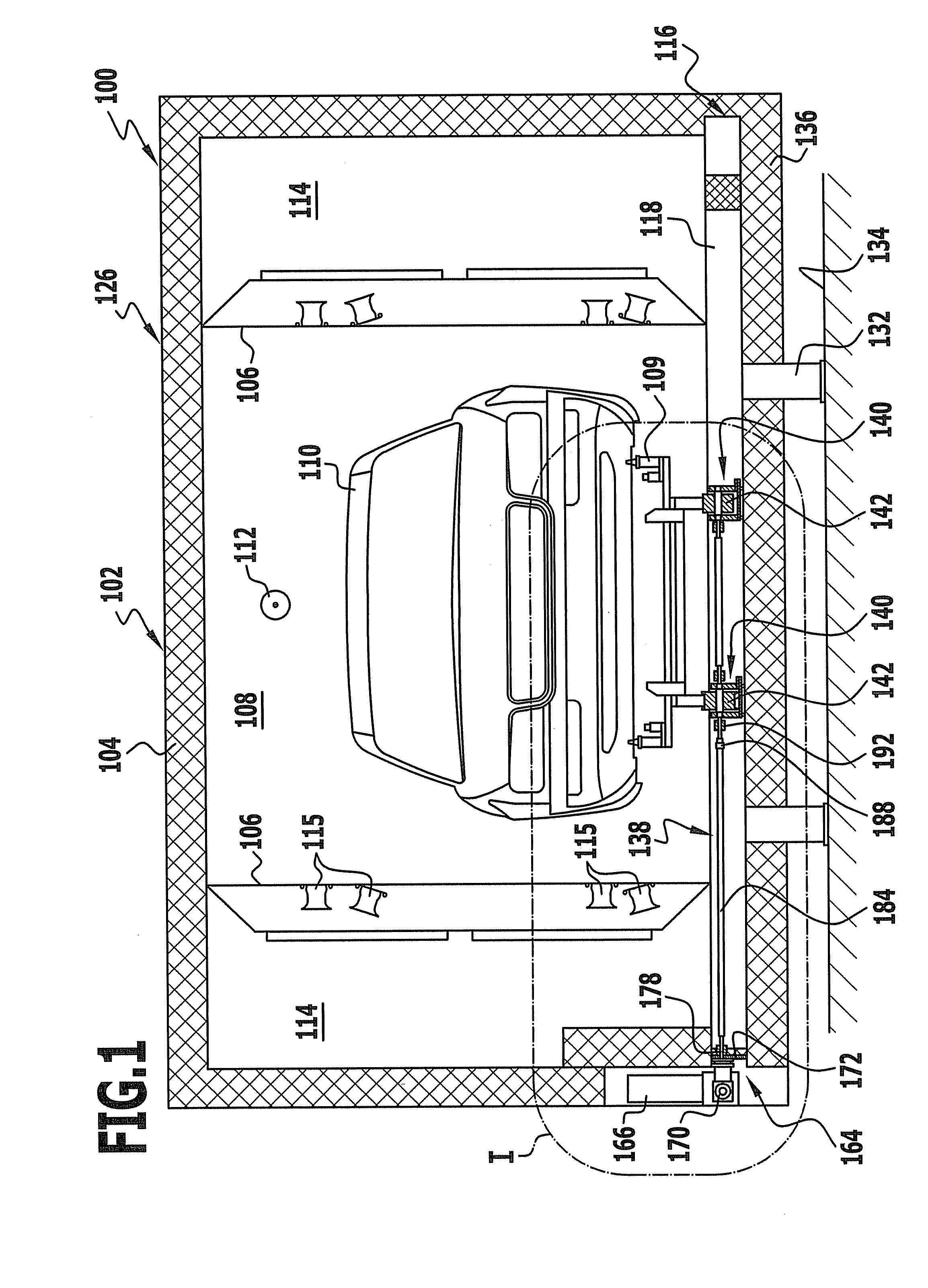

Drier

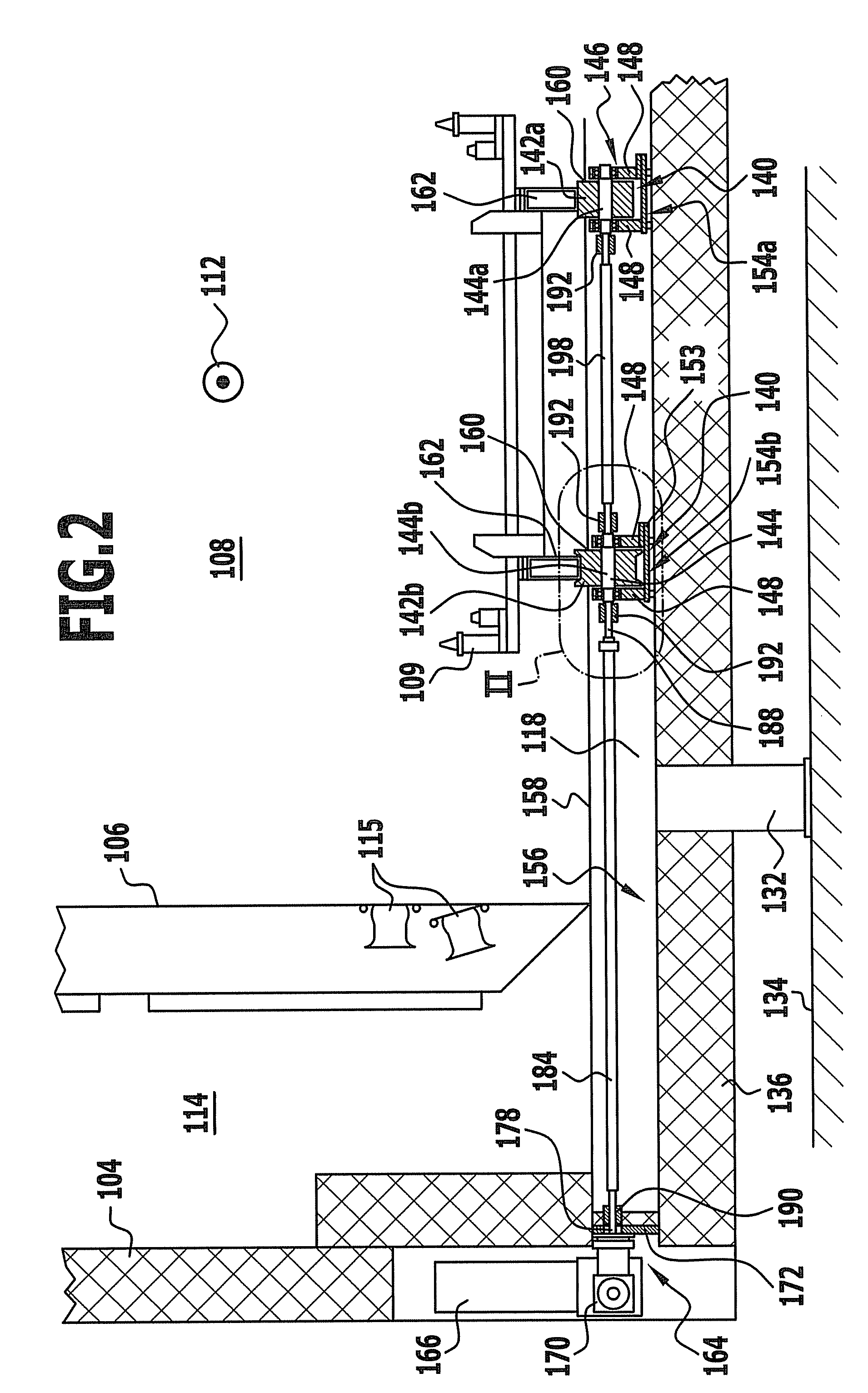

In order to provide an easy-to-assemble drier (100) for drying surface-treated workpieces, in particular vehicle bodies (110), which are each disposed on a respective workpiece carrier (109), comprising a drier housing (102) having a drier tunnel (108), through which the workpieces are moved along a conveying direction (112) and which is delimited in a downward direction by a drier floor (116) comprising a plurality of floor elements (118), and a conveying device (138) that conveys the workpieces through the drier tunnel (108), it is proposed that the conveying device (138) comprises a plurality of carrying roller units (140), which are disposed successively in the conveying direction (112) and each comprise at least one carrying roller (142), on which the workpiece carriers (109) rest as they are conveyed through the drier tunnel (108), wherein the carrying roller units (140) are each mountable separately on a respective floor element (118) of the drier floor (116).

Owner:DUERR SYST AG

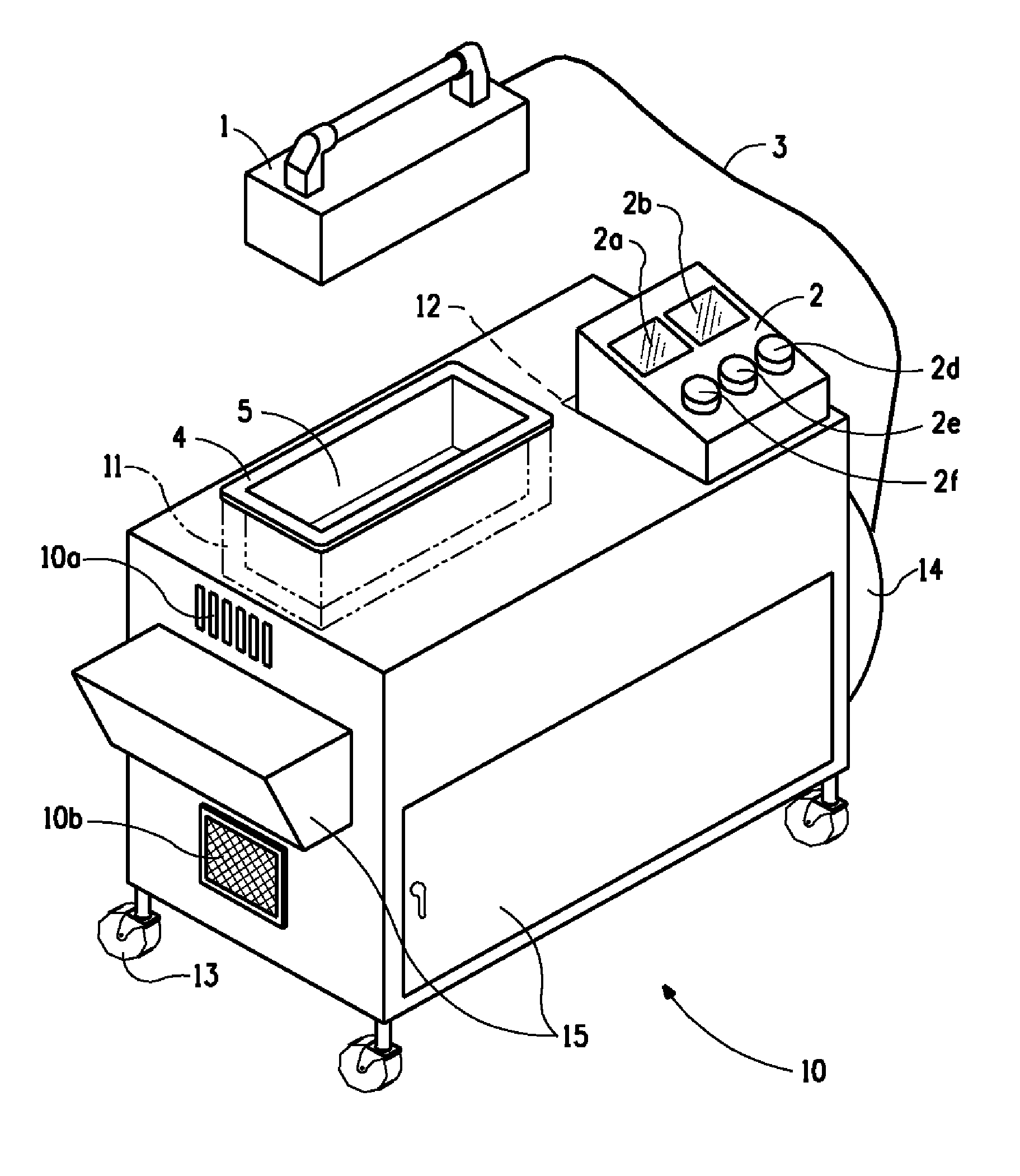

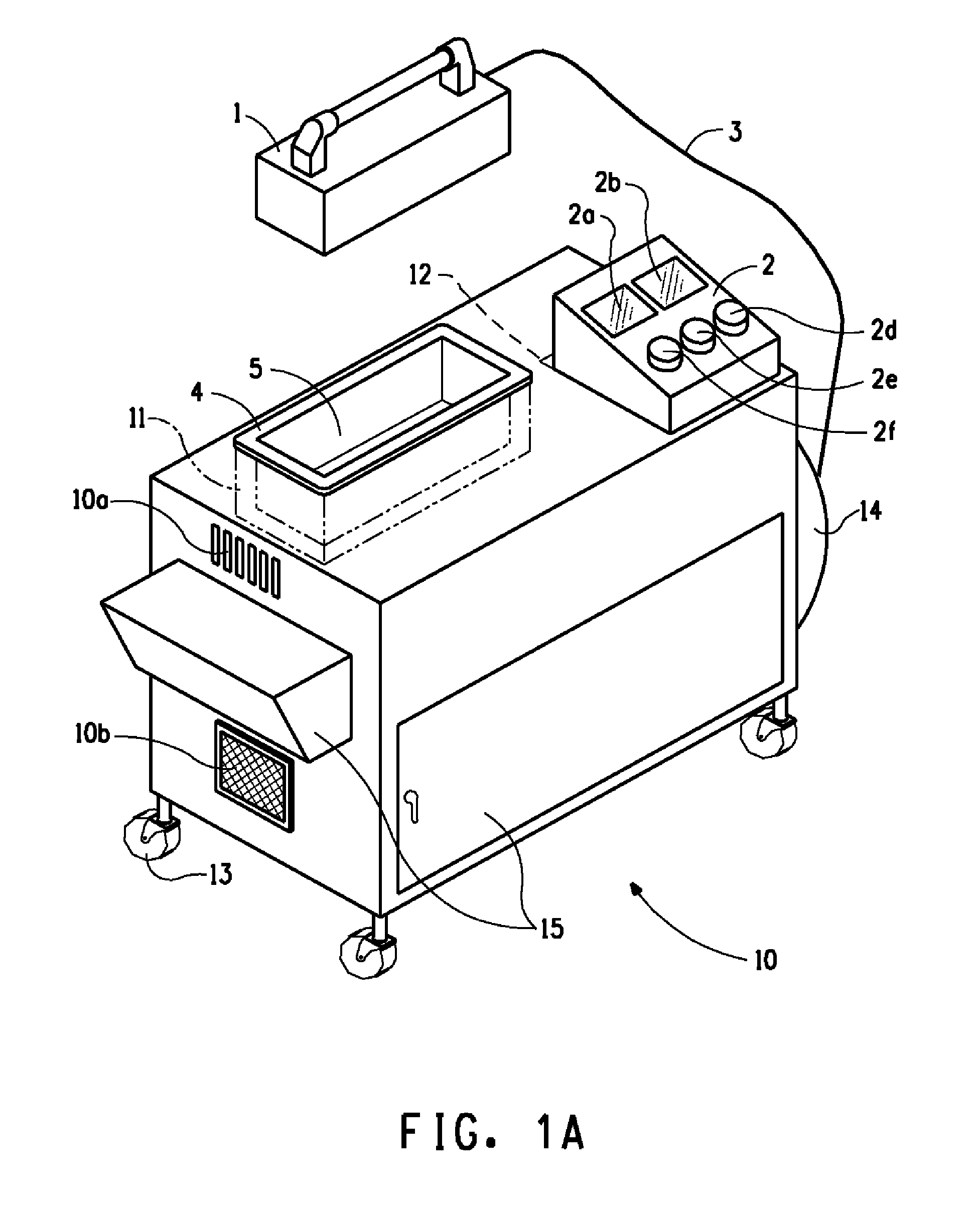

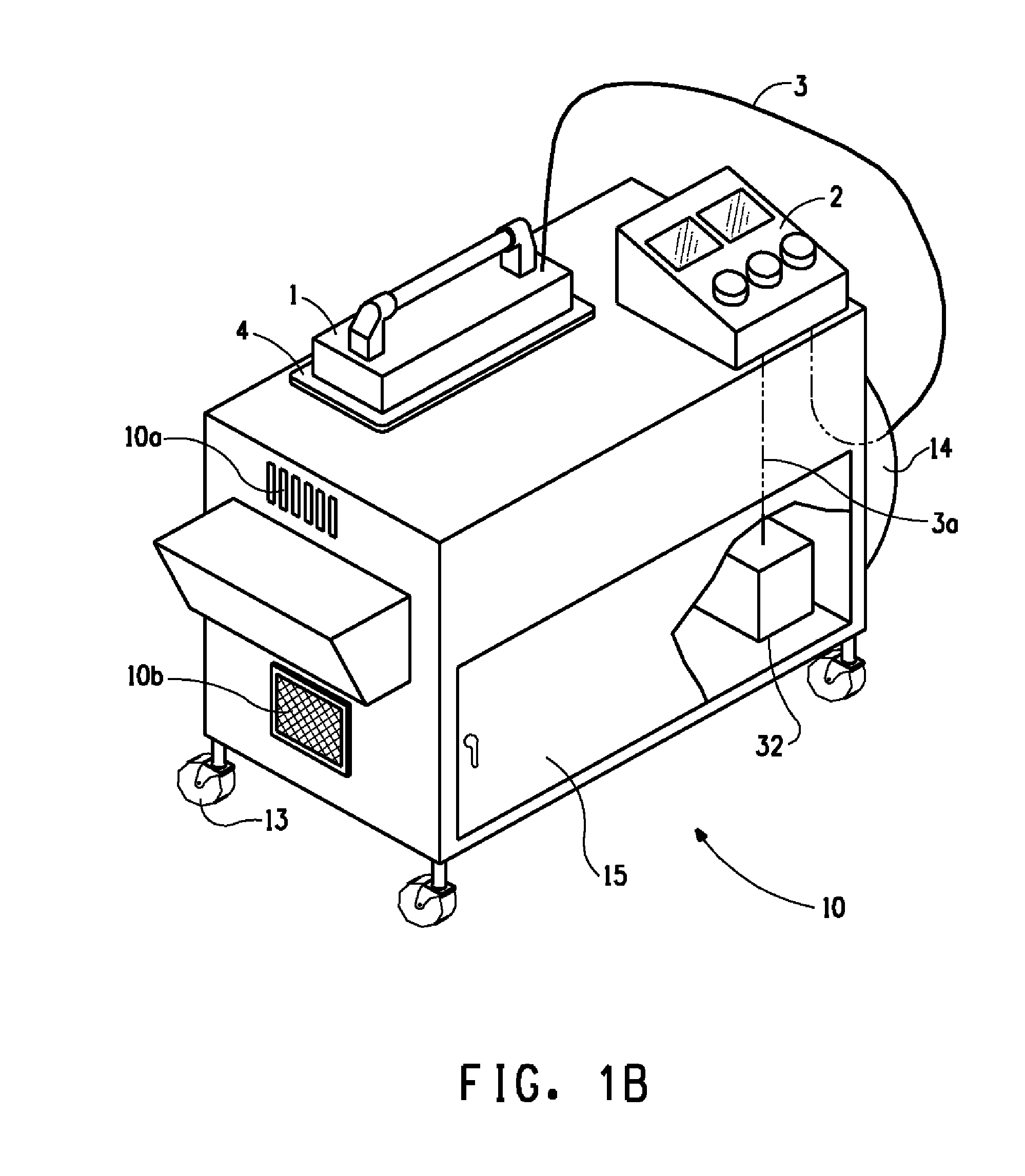

Mobile uva curing system for collision and cosmetic repair of automobiles

InactiveUS20140246602A1Drying solid materials with heatPretreated surfacesLength waveSeated Positions

The present invention is directed to a mobile radiation system that comprises a mobile radiation device coupled to a control unit; a radiation blocker having an adaptor opening for receiving said mobile radiation device when said mobile radiation device is in a seated position on said radiation blocker; and a mobile carrier comprising a first compartment for housing said radiation blocker, a second compartment for housing said control unit, and one or more carrier motion devices. The adaptor opening can dimensionally fit the mobile radiation device to block radiations from the mobile radiation device when said mobile radiation device is in the seated position. The mobile radiation device can produce radiation having peak radiation wavelength in a range of from 250 nm to 450 nm and can have a peak irradiation power in a range of from 0.5 W / cm2 to 10 W / cm2.

Owner:SPDI

Spray booth systems and methods for accelerating curing times

ActiveUS7045013B2Increase airflowIncrease evaporation rateLiquid surface applicatorsDrying gas arrangementsAccelerated curingFilter media

One embodiment of the invention provides a spray booth that comprises a spray booth housing having a ceiling and side walls that define an interior for holding an object to be sprayed. A pressurized air plenum is disposed above the ceiling and is adapted to supply air into the interior. A filter media is used to filter air from the plenum before entering into the interior. At least one fan is disposed in the interior below the filter media. The fan is operable to locally increase air flows in the vicinity of the object to increase evaporation rates associated with a spray application on the object, and to enhance air flow over the object during a dry or a cure cycle.

Owner:GARMAT USA LLC

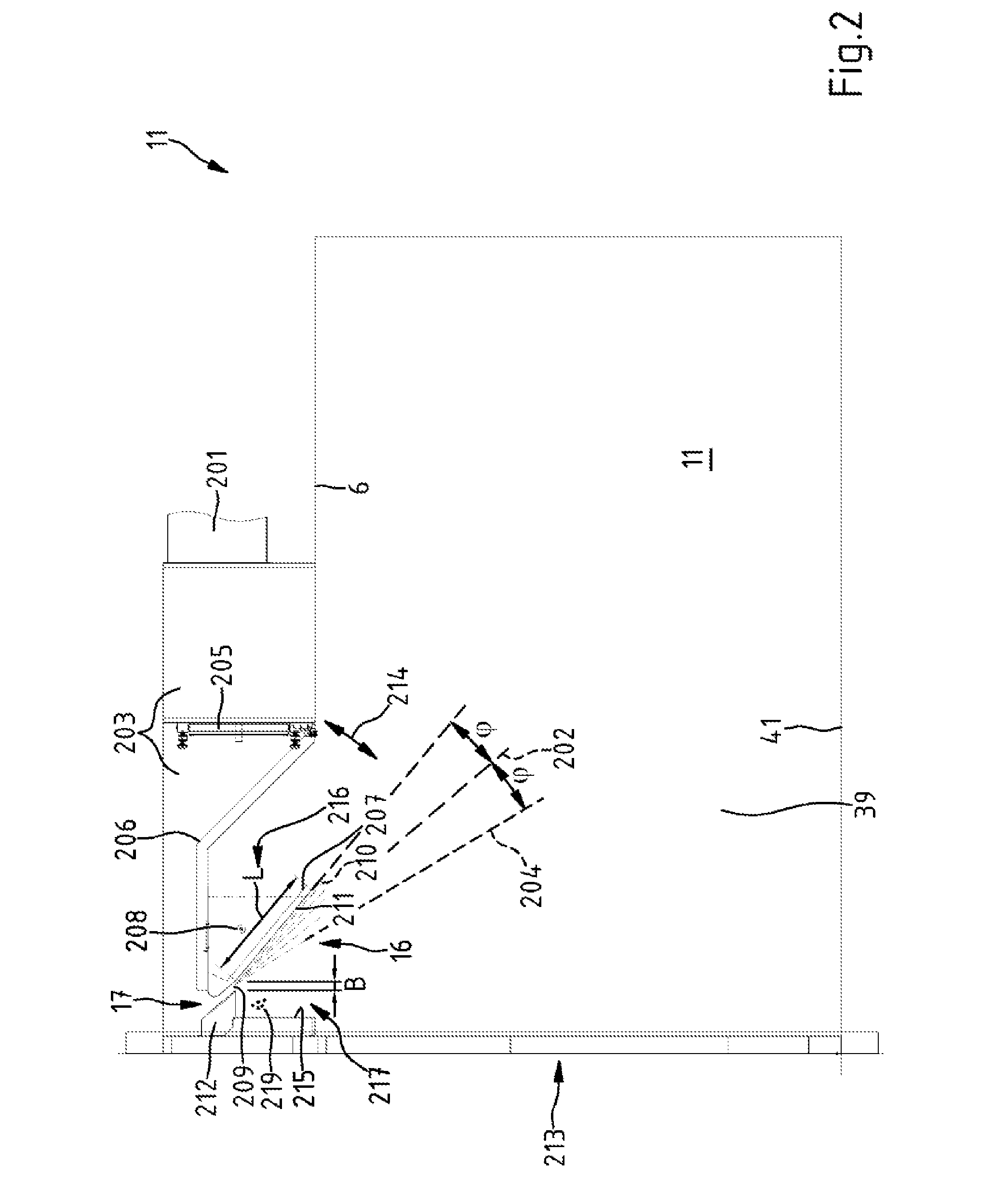

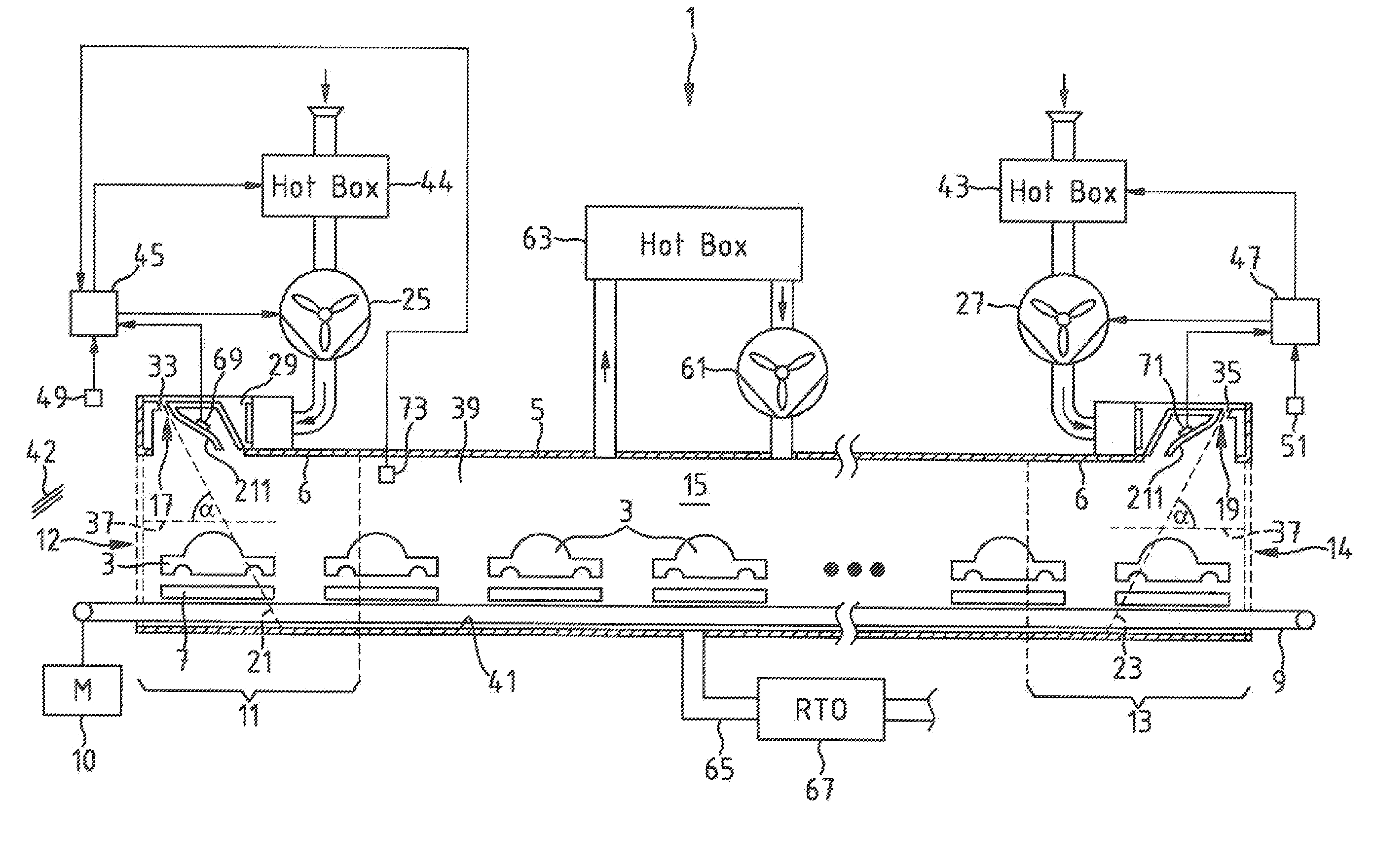

Process chamber incorporating an arrangement for injecting gaseous fluid thereinto

ActiveUS9316406B2Reduce energy consumptionNot to damageOptical rangefindersCircuit elementsInterior spaceEngineering

A process chamber (5) has an interior space (39). In the interior space (39), there is a receiving region (15) for workplaces (3). The process chamber (5) has an opening (12, 14) for the entry and exit of workplaces (3). The process chamber includes an arrangement (17, 19, 25, 29, 33, 37, 35) for injecting gaseous fluid into the interior space (39). The arrangement for injecting gaseous fluid has at least one nozzle (17, 19) for producing a fluid flow curtain (21, 23) between the opening (12, 14) and the receiving region (15) for workplaces (3).

Owner:DUERR SYST AG

Water-based coating compositions and systems with improved sag resistance and related methods

InactiveUS20130105473A1High viscosityExtended drying timeSpraying apparatusDrying gas arrangementsWater basedCoating system

The present invention provides a water-based coating and / or coating system that can be used to form sag resistant wet layers or coatings on a wide range of substrates. The coating system is particularly effective for protecting metal-containing substrates, such as intermodal cargo containers, against corrosion. As an overview, the present invention provides water-based compositions suitable to form primer coats on substrates. Desirably, the primer incorporates a high level of one or more CAS agents for excellent sag resistance while drying in a broad range of relative humidity environments. Alternatively, modifications can be made to control temperature and humidity during spray application and drying as a way to increase sag resistance of the coating.

Owner:VALSPAR SOURCING INC

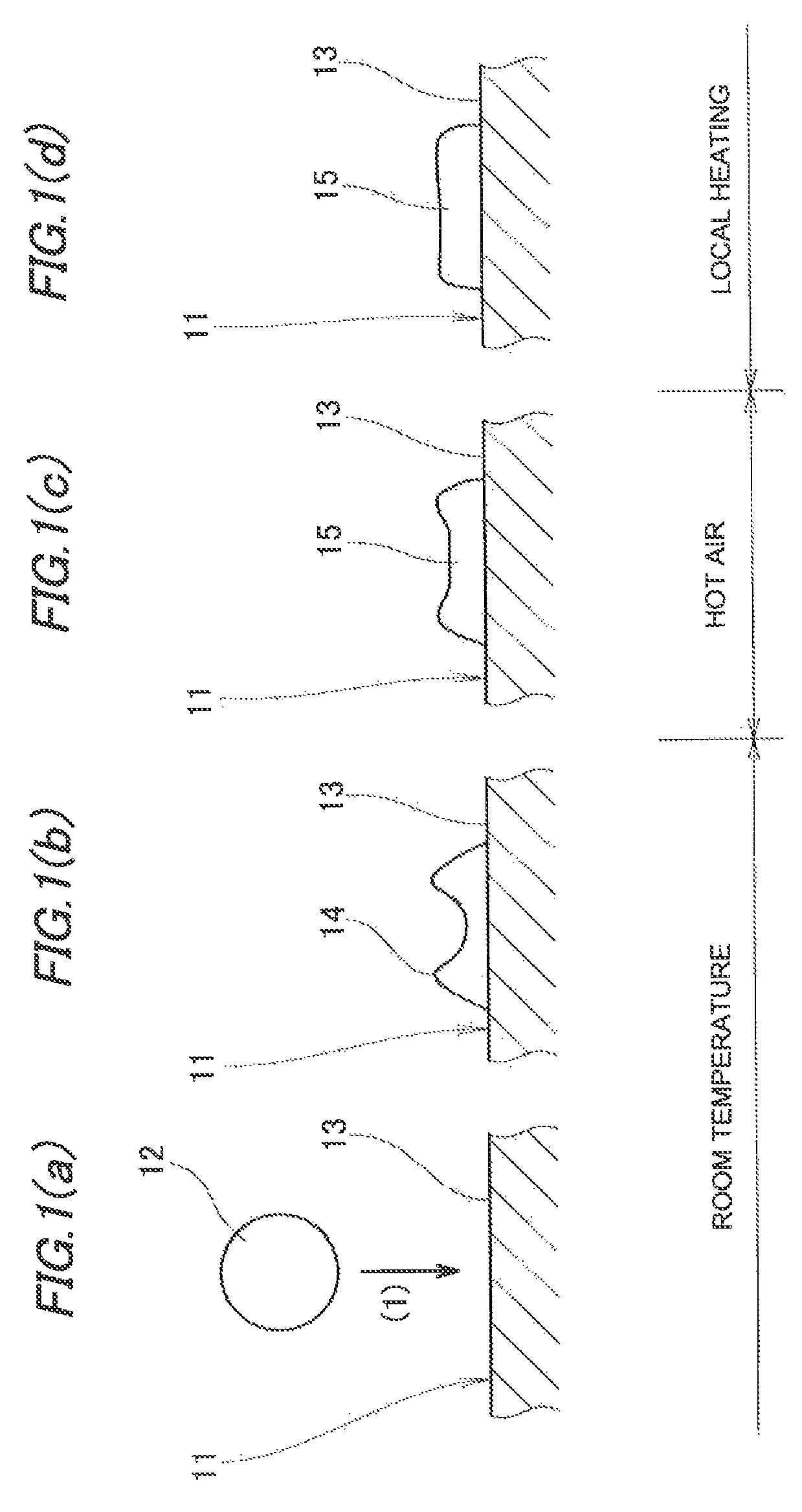

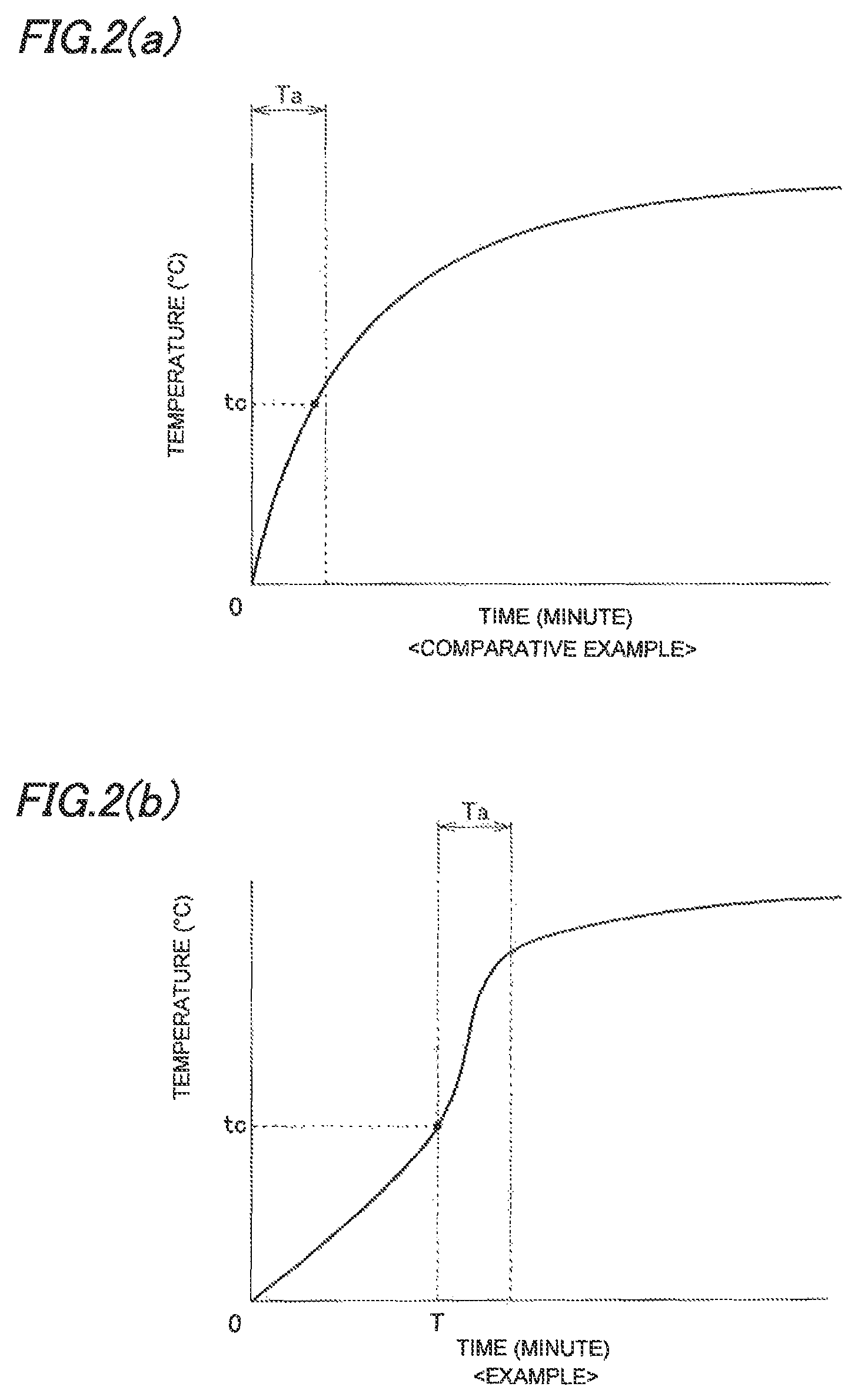

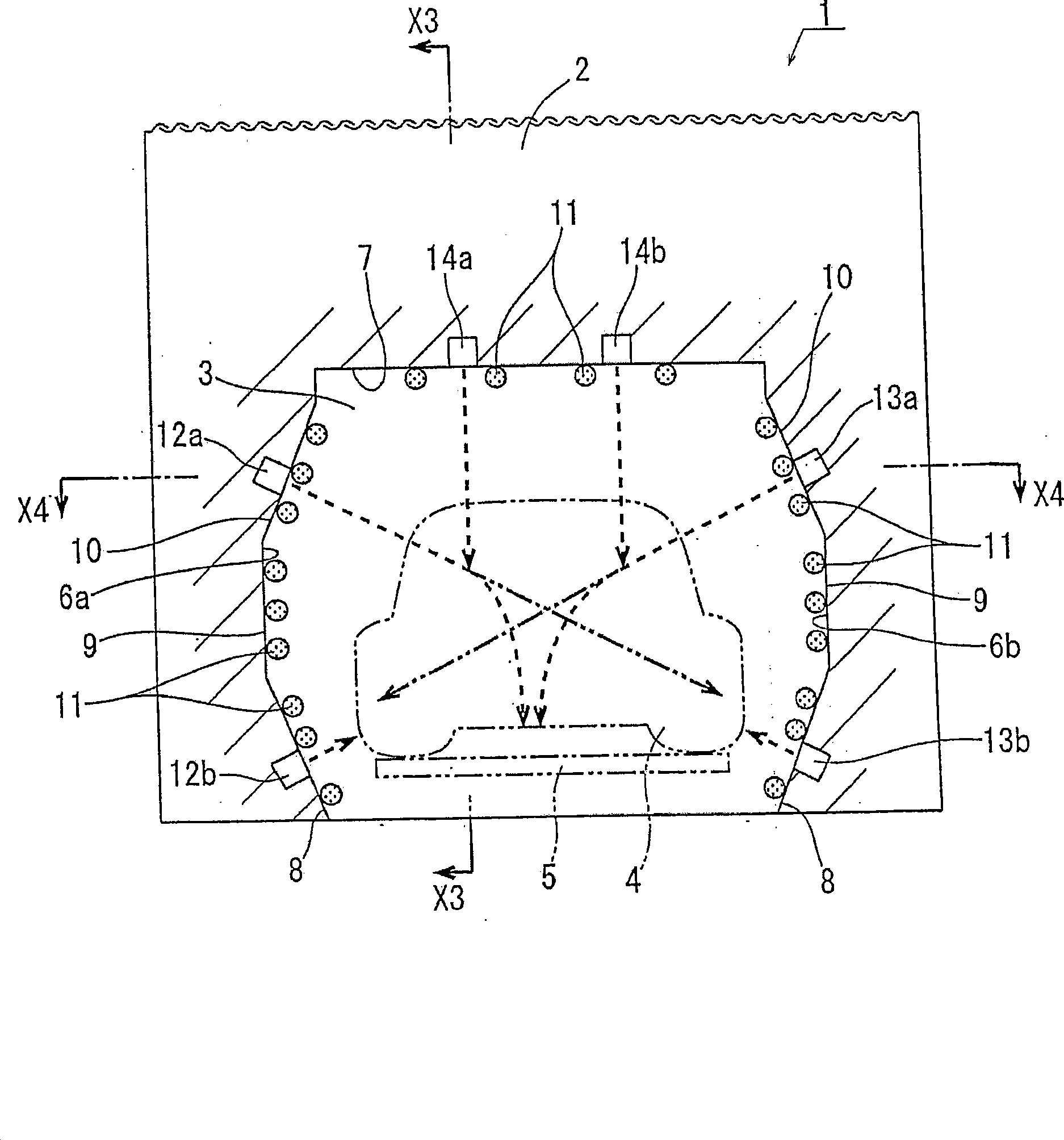

Coating film drying method and coating film drying apparatus

InactiveCN101435653APrevent hardeningAvoid damageDrying using combination processesDrying solid materials with heatEngineeringCoating

Disclosed is a method and apparatus for drying a coating film (4a) on an exterior panel of a box-shaped workpiece (4), wherein radiant rays, and warm air having a temperature less than a hardening temperature of the coating film (4a), are supplied simultaneously and directly to the coating film (4a). The method and apparatus of the present invention can dry the coating film (4a) on the exterior panel of the workpiece (4) within a relatively short period of time, without causing a negative effect on a surface quality of the coating film (4a).

Owner:TAIKISHA LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com