Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

315results about "Pressure exchangers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

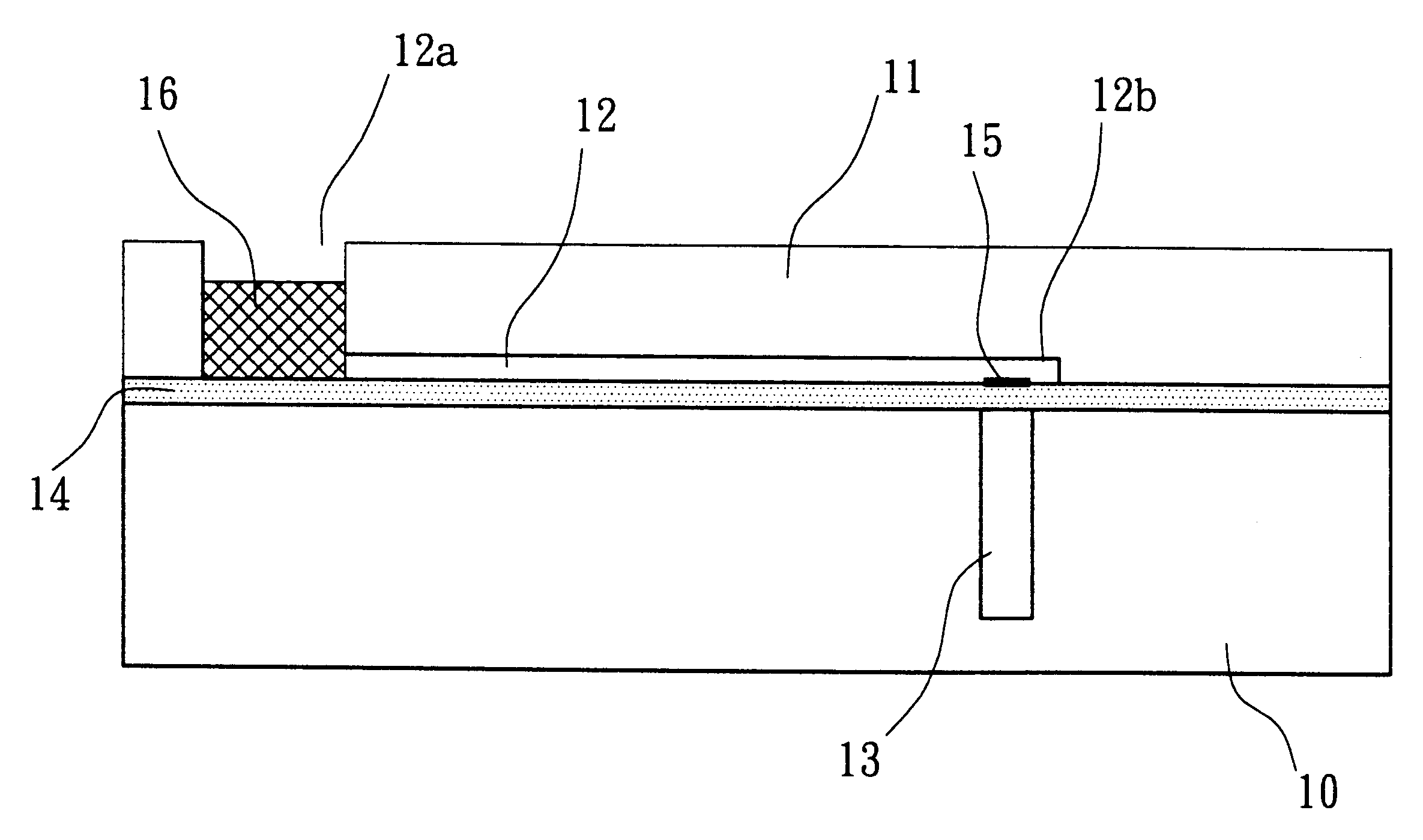

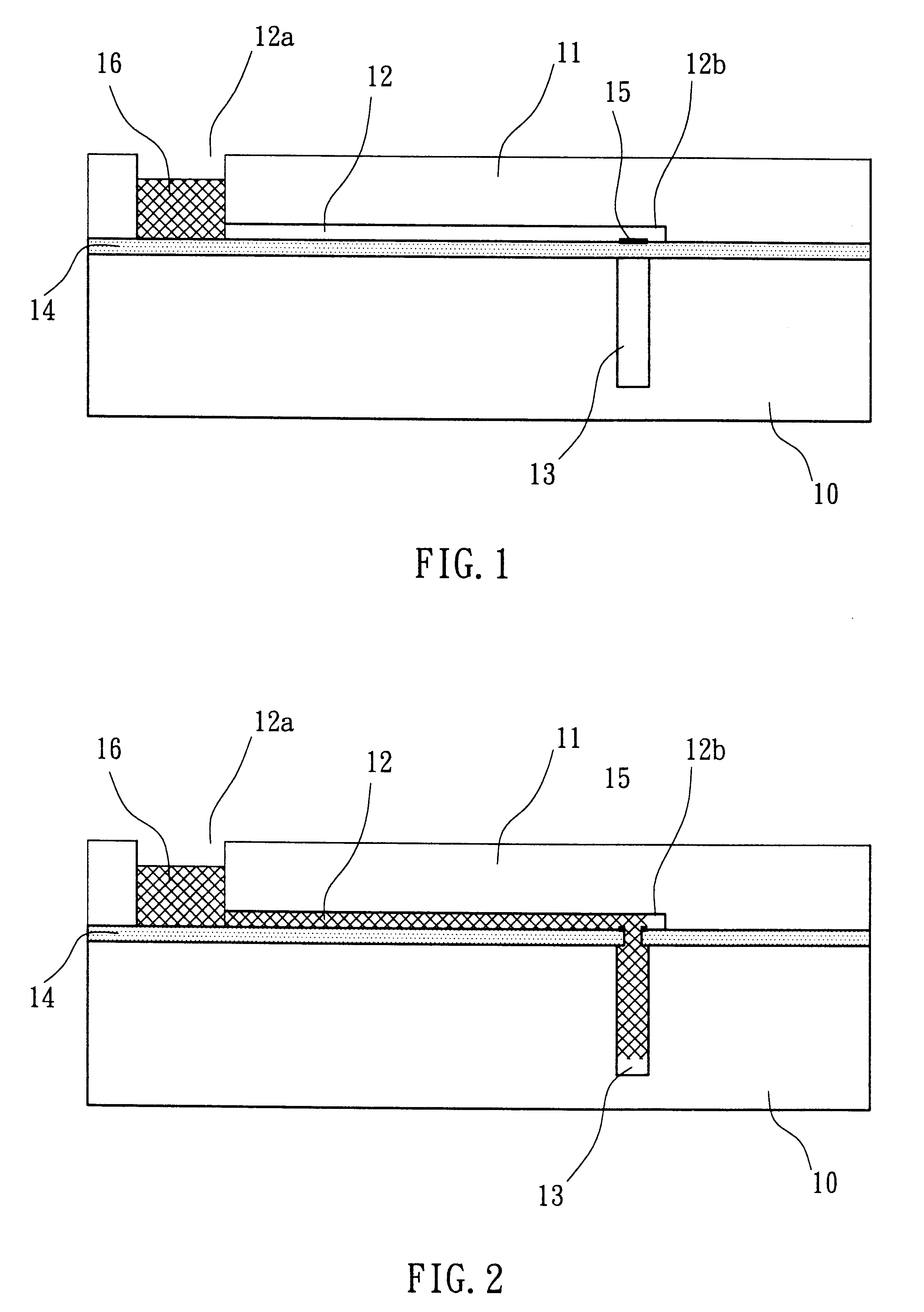

Microfluidic actuator

InactiveUS6521188B1Easy to prepareLow costCircuit elementsPressure pumpsEngineeringAtmospheric pressure

A simple microfluidic actuator includes a sealed vacuum chamber actuated by providing a current to a thin film heater, which in turn weakens and, under the atmospheric pressure differential, breaks a diaphragm sealing said vacuum chamber whereby the vacuum inside said chamber is released. By applying the microfluidic actuator to a microfluidic network the resulting pressure differential can be used to generate a pumping force with the microfluidic network. The chamber may be prepared in a silicon, glass, or plastic substrate. The diaphragm may be a metallic gas-impermeable film. A releasing member comprising a thin-film metallic heater is then microfabricated on the diaphragm. The assembly so prepared may be bonded to a glass or plastic substrate that contains a network of microchannels. The microfluidic actuator is suited for a microfluidic platform in generating driving powers for operations including pumping, metering, mixing and valving of liquid samples.

Owner:IND TECH RES INST

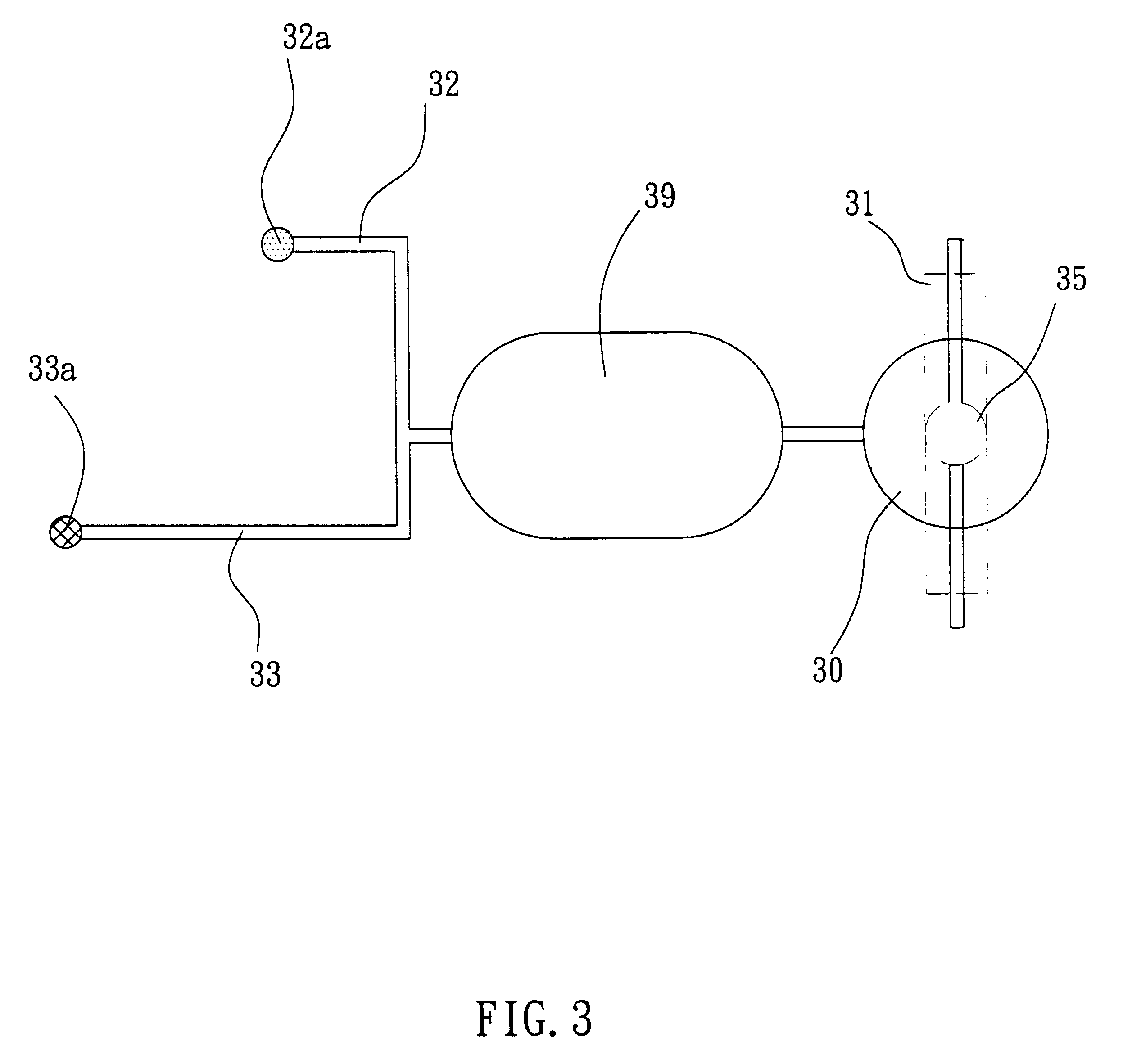

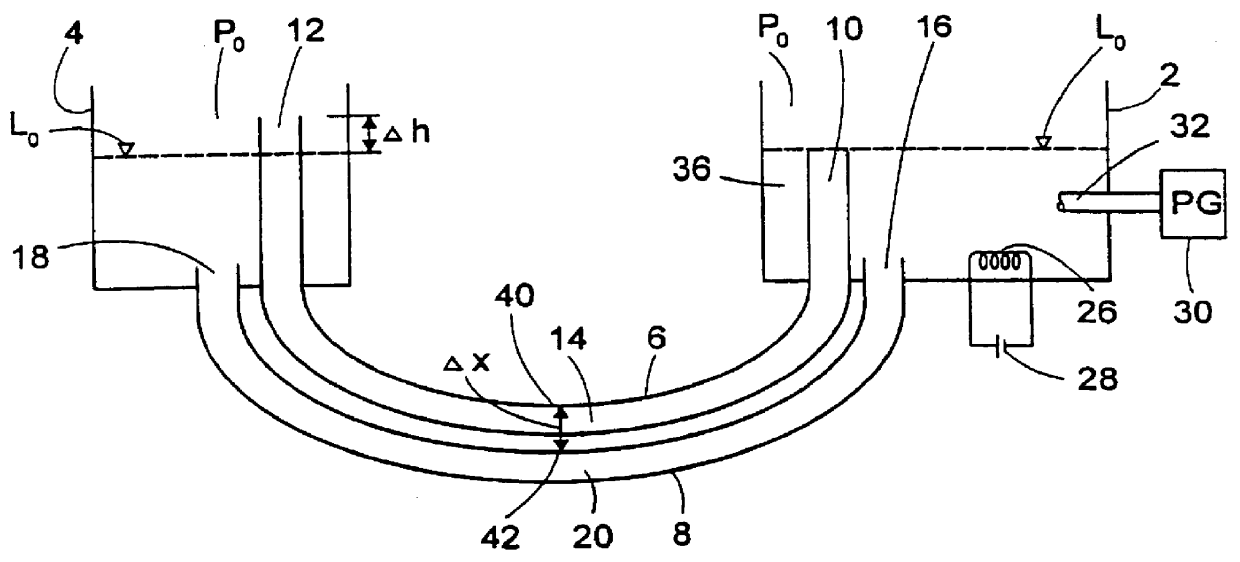

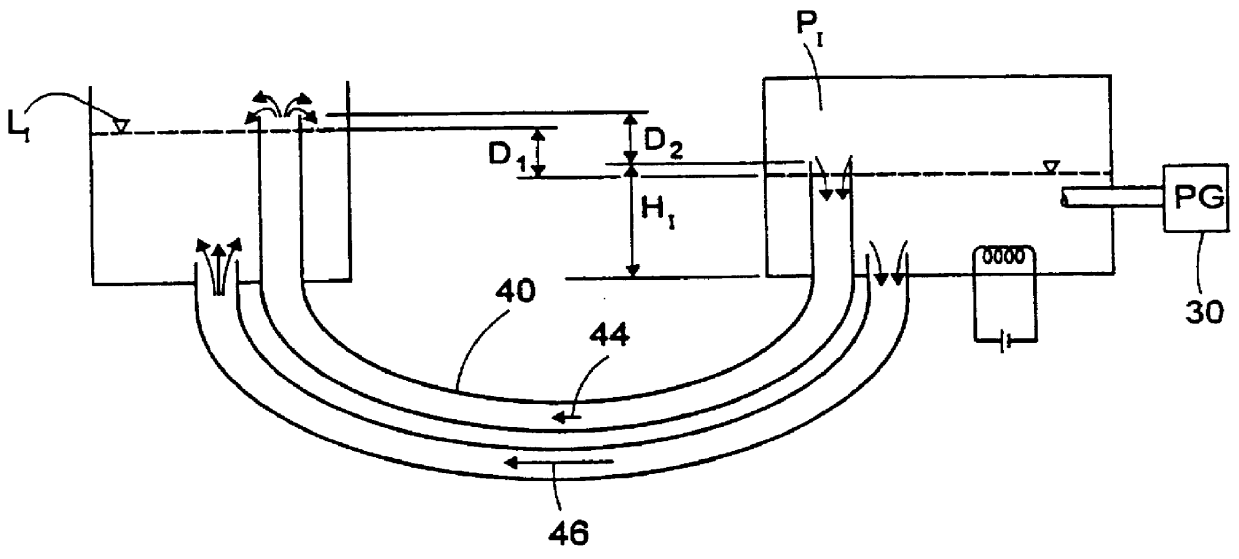

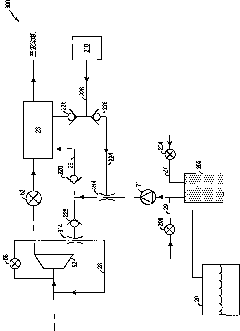

Pneumatic control of formation and transport of small volume liquid samples

A process and system are provided for forming and transporting precise small volumes of liquid samples by means of controlled gas pressures. As the controlled gas pressures are changed at a multiplicity of control points in the fluid circuit, transitions take place involving the transport of small liquid samples. This transport is arrested by the geometry of the fluid circuit to produce a new state, which state remains stable until another transition is initiated by a change in the multiplicity of controlled gas pressures. Various combinations of control elements are described for effecting formation of fixed liquid volumes, transporting, mixing, and removing entrained bubbles from small liquid samples.

Owner:APPL BIOSYSTEMS INC

Fluid displacement system

In a fluid displacement system having a pressure vessel, an expansion vessel, first and second tubes in fluid communication with the two vessels, and an energy source, fluid contained within the system is transferred from one vessel to the other by activating the energy source, which in turn generates pressure in the pressure vessel. The generated pressure in the pressure vessel, in turn, displaces the fluid in the expansion vessel, and the system advantageously has no moving parts.

Owner:T D I THERMO DYNAMICS ISRAEL

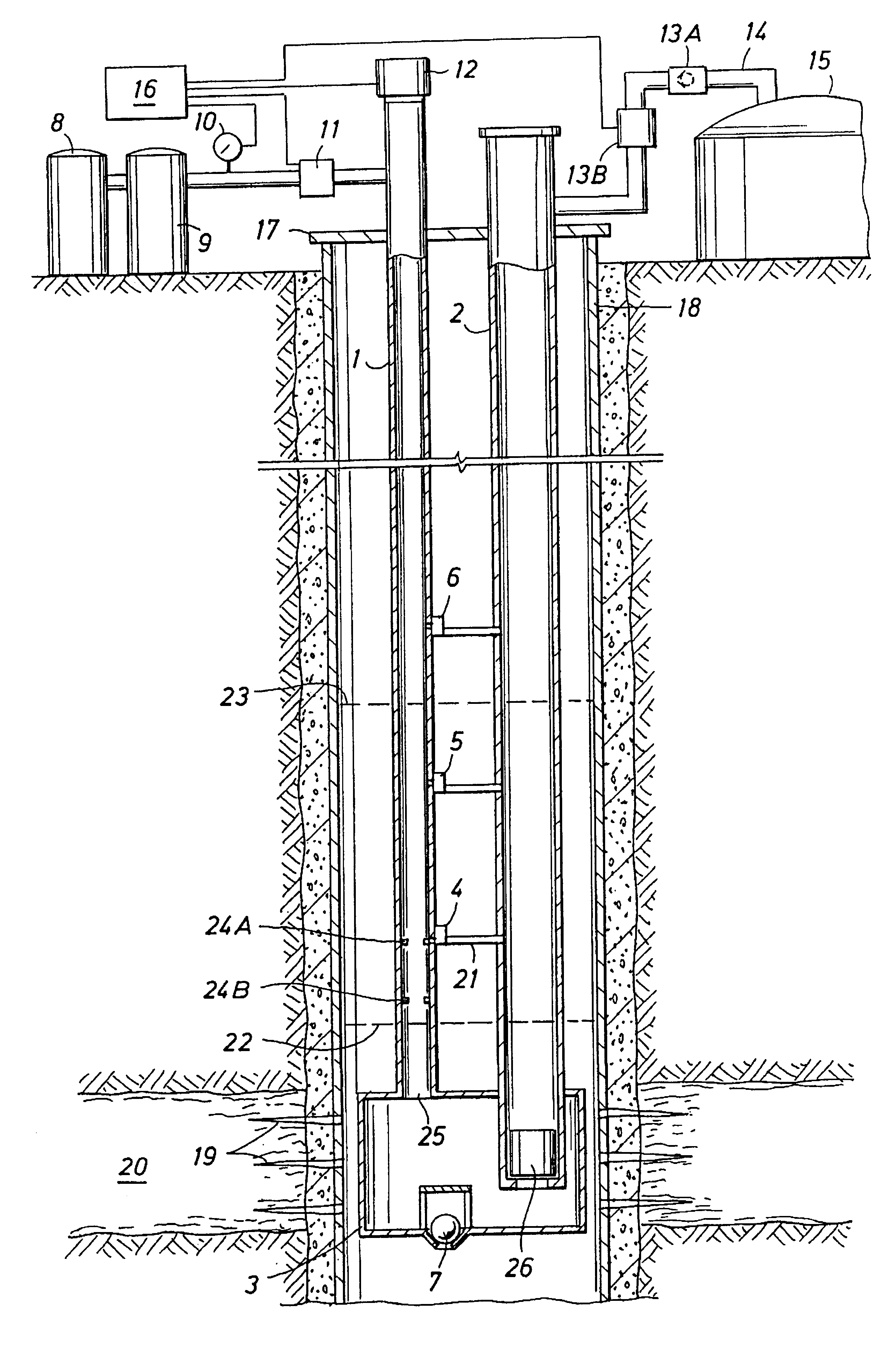

Method and apparatus for gas lift system for oil and gas wells

An intermittent gas lift well pumping system containing an accumulator, a gas line, a liquid discharge line, and a battery operated controller. By using one or more constrictions in the gas line and acoustical techniques, accurate liquid level is determined in the pumping system for optimum production. Bypasses are connected between the gas line and the liquid discharge line. Each contains a valve that opens at a preset absolute pressure in the gas line, an orifice, and a one-way valve. The bypasses are strategically placed to prevent overloading of the system. A liquid slug sensor on the upper end of the liquid discharge line and a rabbit in this line enables optimum production and gas conservation.

Owner:BUCKMAN SR WILLIAM G

Electromagnetic wave absorbing materials

Electromagnetic wave absorbing materials comprising magnetic alloy particles and an insulating matrix are disclosed. The magnetic alloy particles comprise a transition metal such as Fe and / or Co, and further comprise at least one refractory metal such as Ti, V, Cr, Zr, Nb, Mo, Hf, Ta and W. The magnet alloy particles may further include Ni and / or Al, or other alloying additions which provide the desired absorption characteristics. In a preferred embodiment, the magnetic alloy particles comprise an Fe-Cr-Ni-Al alloy. The insulating matrix of the electromagnetic wave absorbing material may comprise a water miscible polysilicate or a refractory cement. The materials may be provided in the form of coatings that are applied to a substrate, such as the hot engine exhaust area of an aircraft. The electromagnetic wave absorbing materials are capable of functioning at very high temperatures for extended periods of time while retaining satisfactory electromagnetic wave absorbing properties.

Owner:LOCKHEED MARTIN CORP

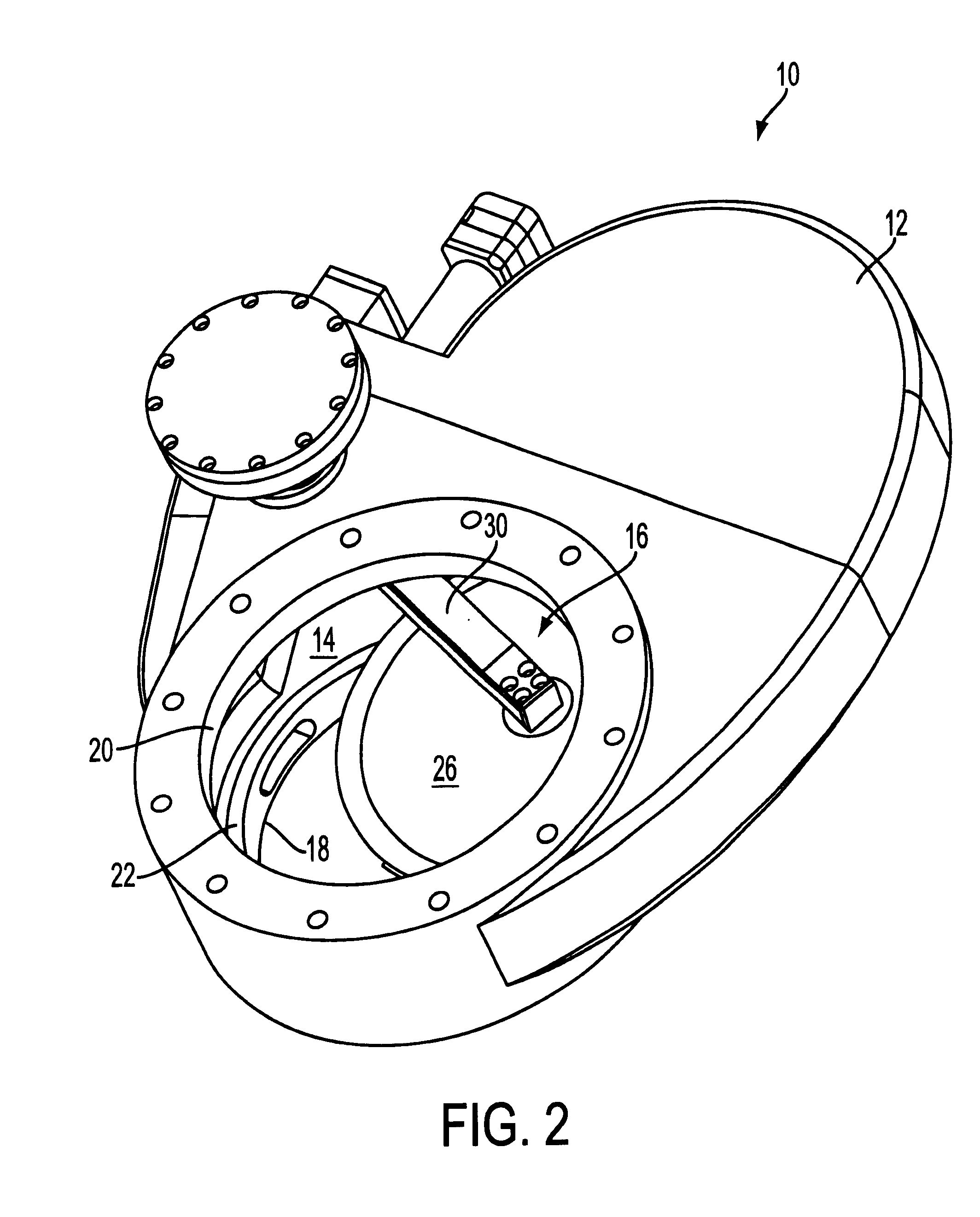

Dual pendulum valve assembly

InactiveUS6328051B1Easy to controlOperating means/releasing devices for valvesPositive displacement pump componentsInterior spaceVacuum pressure

A dual pendulum valve assembly including a housing having an interior space and first and second openings through which fluid can enter and exit the interior space; valve seats disposed in the interior space around the edges of the openings; and first and second pendulum valves for opening and closing, respectively, the first and second openings. Each pendulum valve is independently movable and includes a valve body mounted relative to the housing so that the valve body is movable between a completely opened position wherein fluid is allowed to pass through its respective opening and a completely closed position wherein the valve body seals the opening so that fluid can not pass therethrough. Each pendulum valve also includes a shaft fixedly coupled to the valve body through at least one pivot arm and at least partially mounted within the housing so that the valve body can rotate about a longitudinal axis of the shaft between a first angular position where the first valve body is in the completely opened position and a second angular position where the valve body is substantially axially aligned with its respective opening, and move substantially parallel to the longitudinal axis of the shaft, so that the valve body can move between the second angular position and the completely closed position as the pendulum valve continues to rotate. The present disclosure also provides a method of precisely controlling vacuum pressure within a process chamber of a semi-conductor wafer fabricator.

Owner:MKS INSTR INC

Motor-compressor

ActiveUS20070196215A1Increased complexityReliable timePressure pumpsMagnetic bearingsEngineeringElectric motor

Motor-compressor comprising a compressor, an electric motor directly connected to said compressor, wherein the compressor and the electric motor are integrated in a single unit, housed in a single box or casing.

Owner:NUOVO PIGNONE TECH SRL

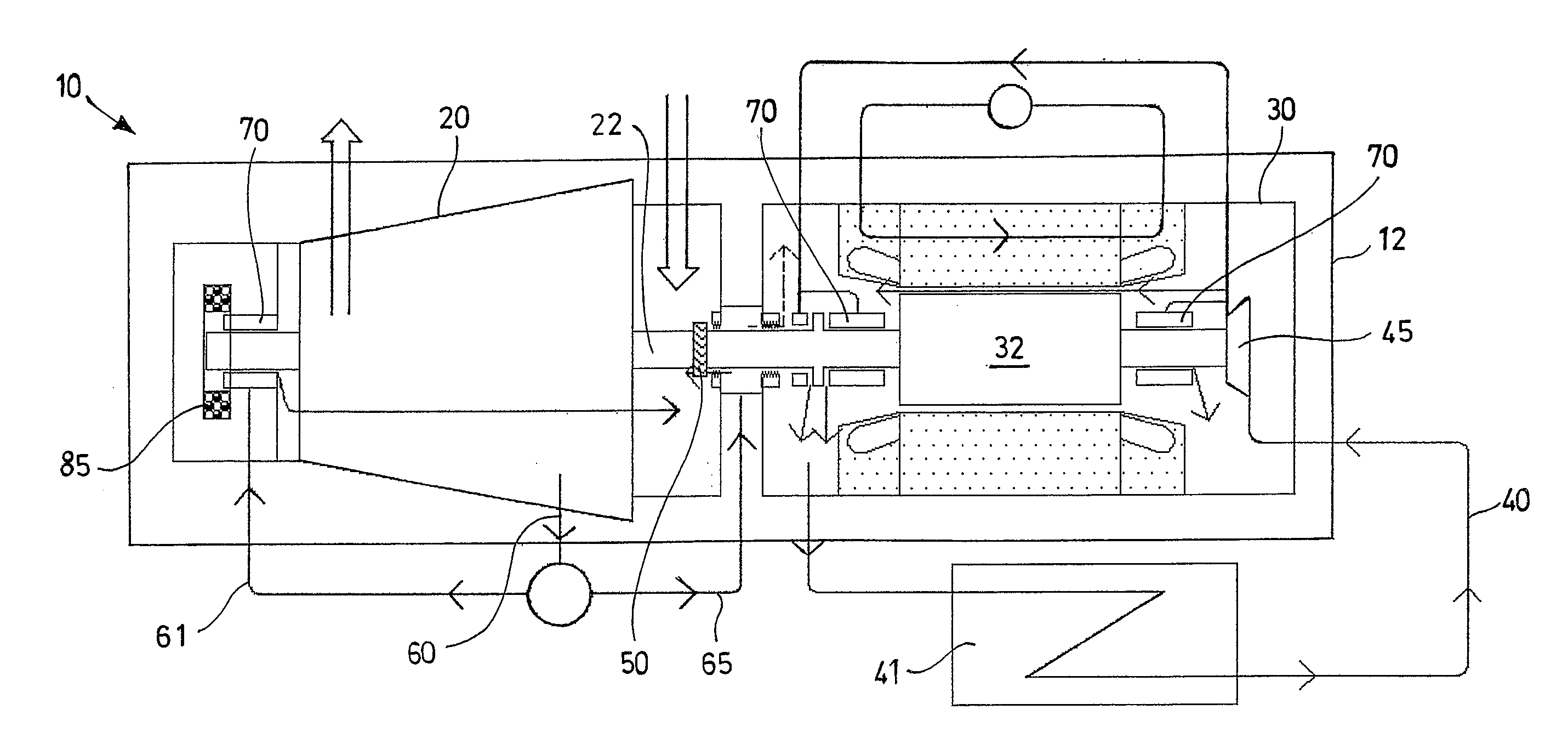

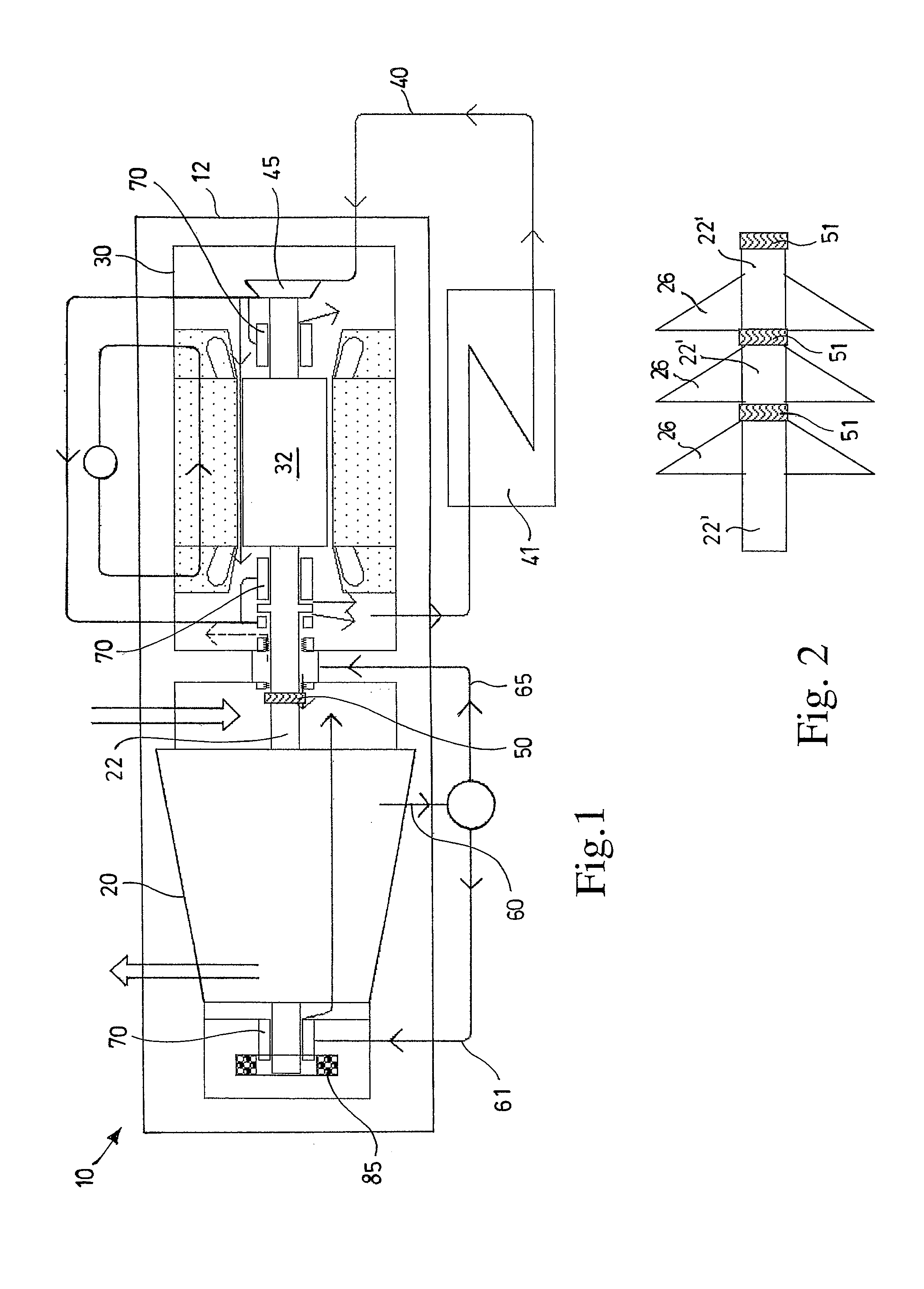

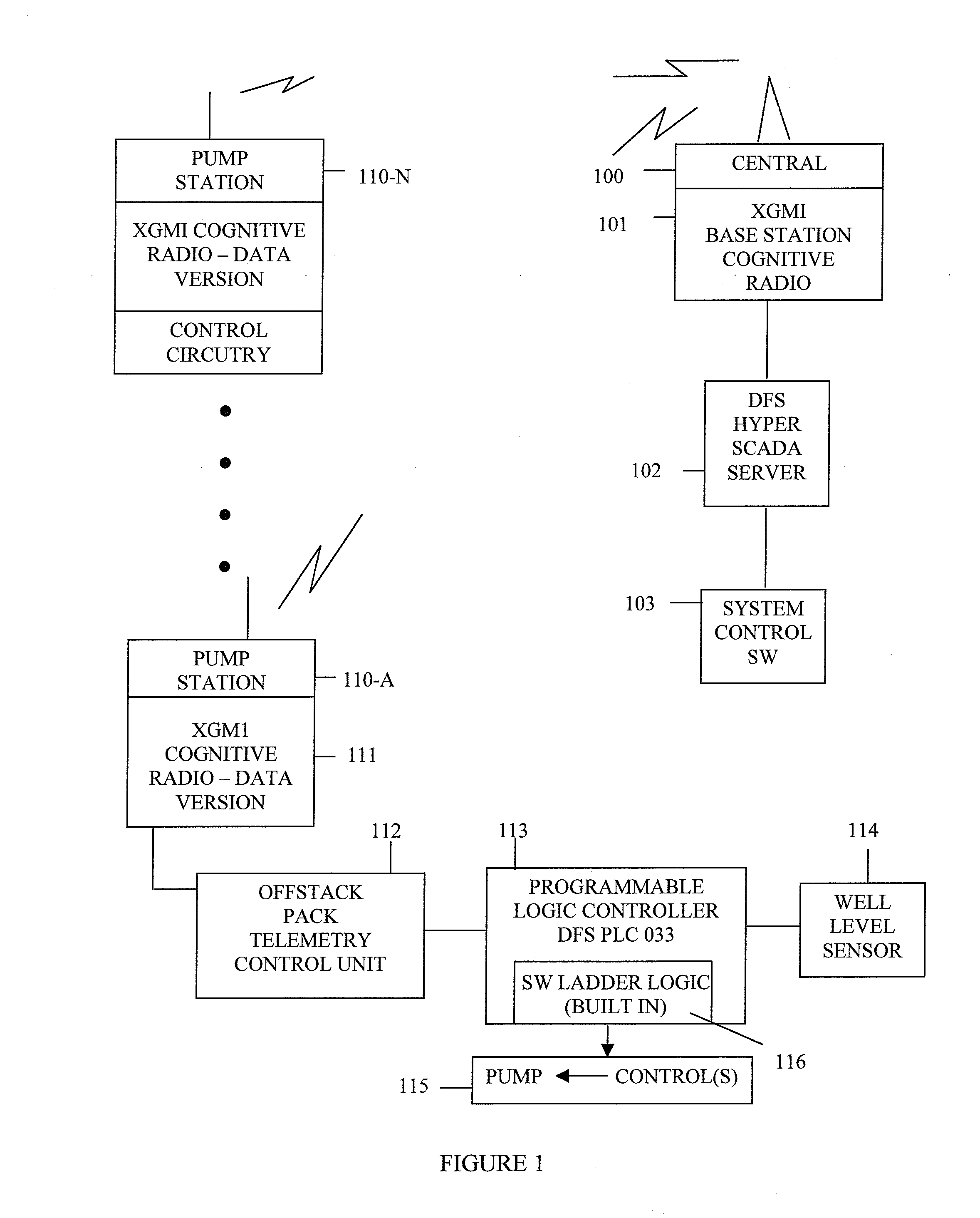

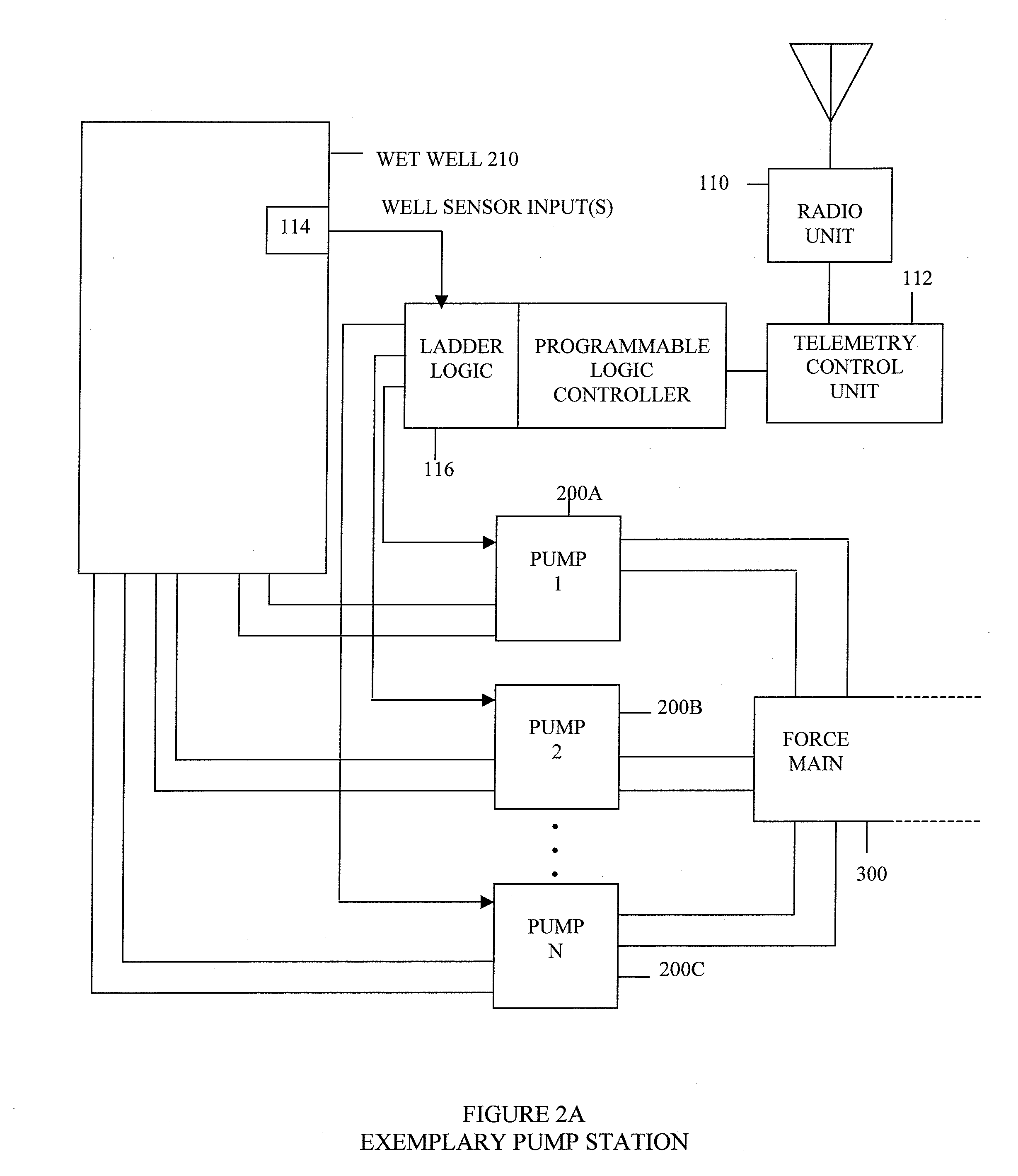

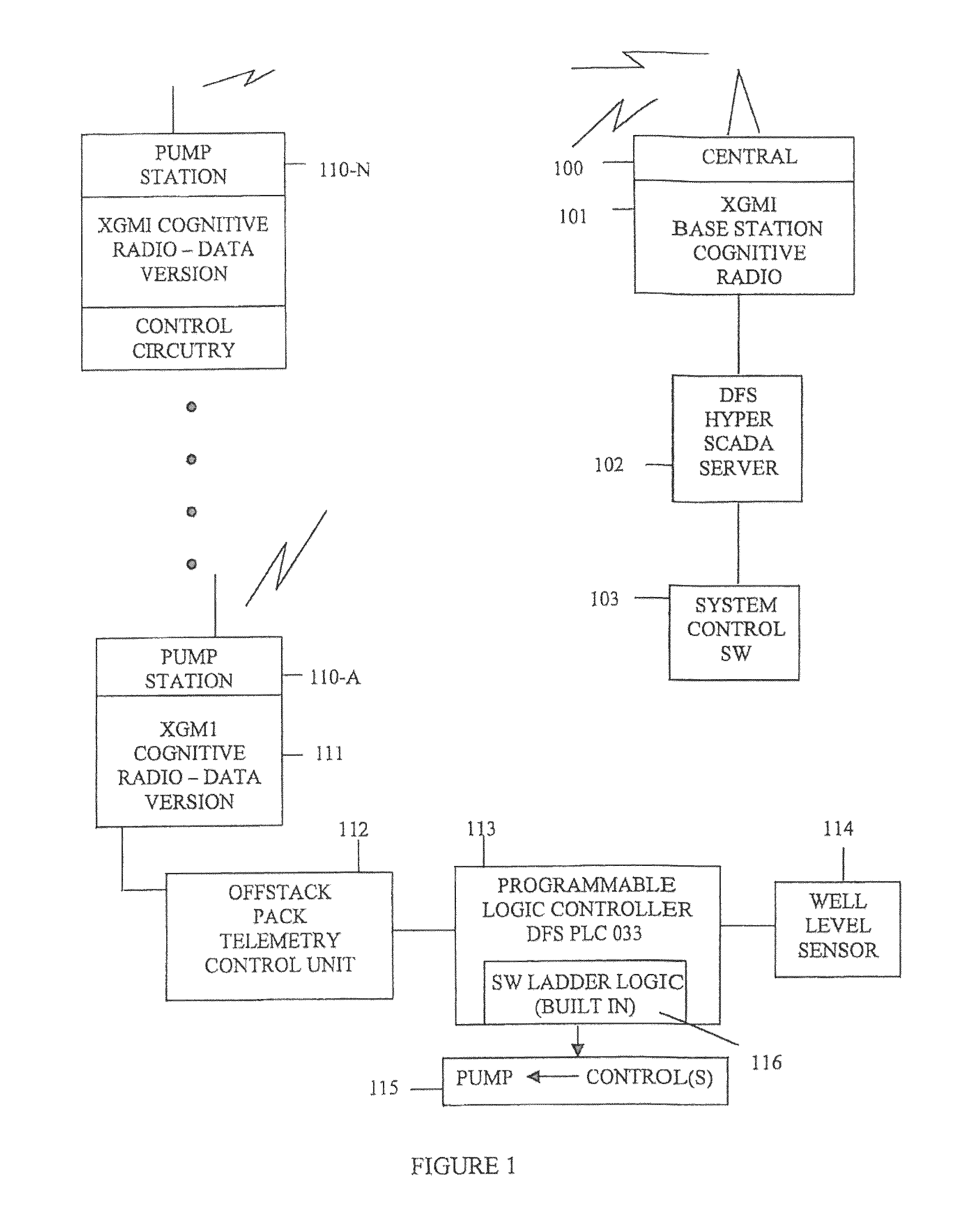

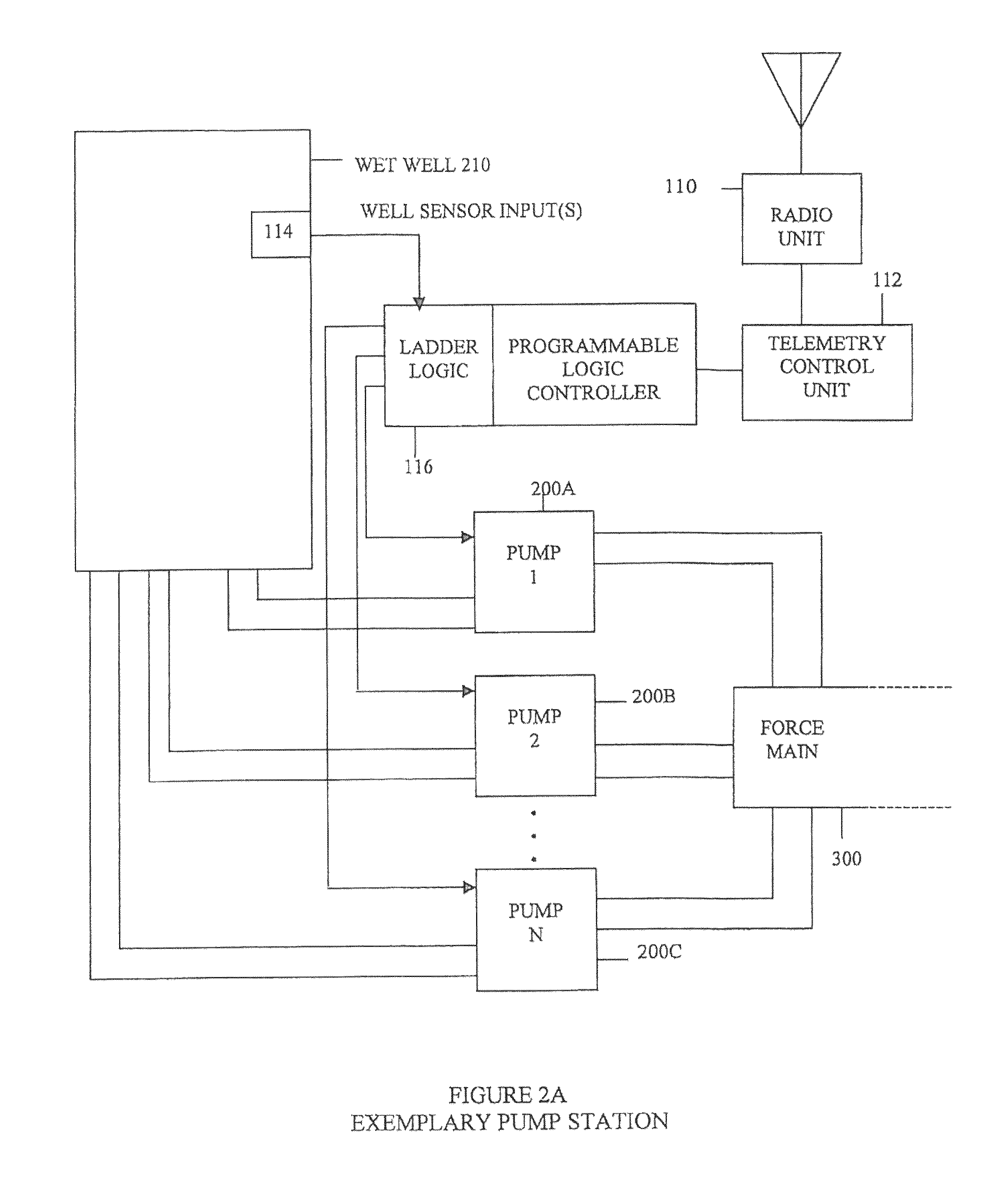

Wastewater collection flow management system and techniques

ActiveUS8594851B1Reduce maintenanceIncrease threshold level of activationFuel supply regulationLevel controlPeak valueEnergy expenditure

Reductions in energy consumption and maintenance requirements for operating a wastewater treatment plant are achieved by controlling the operation of pumps at pump stations along a force main in a systematic fashion. The operation of the pumps is controlled to manage the flow of wastewater along the force main to minimize energy consumption, to eliminate sediment, to manage peak pressures encountered by smaller pumps and to avoid septic conditions.

Owner:DATA FLOW SYST

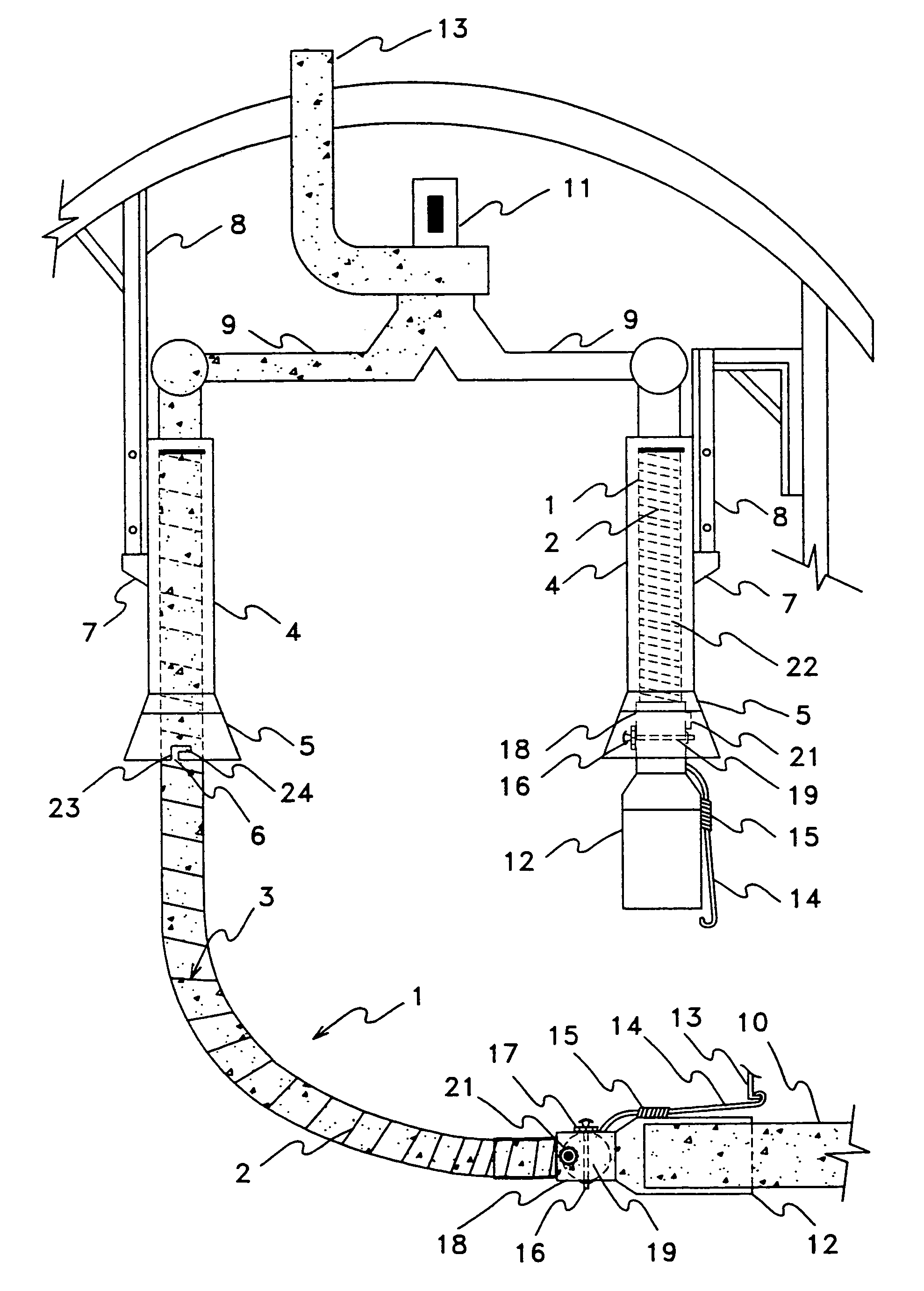

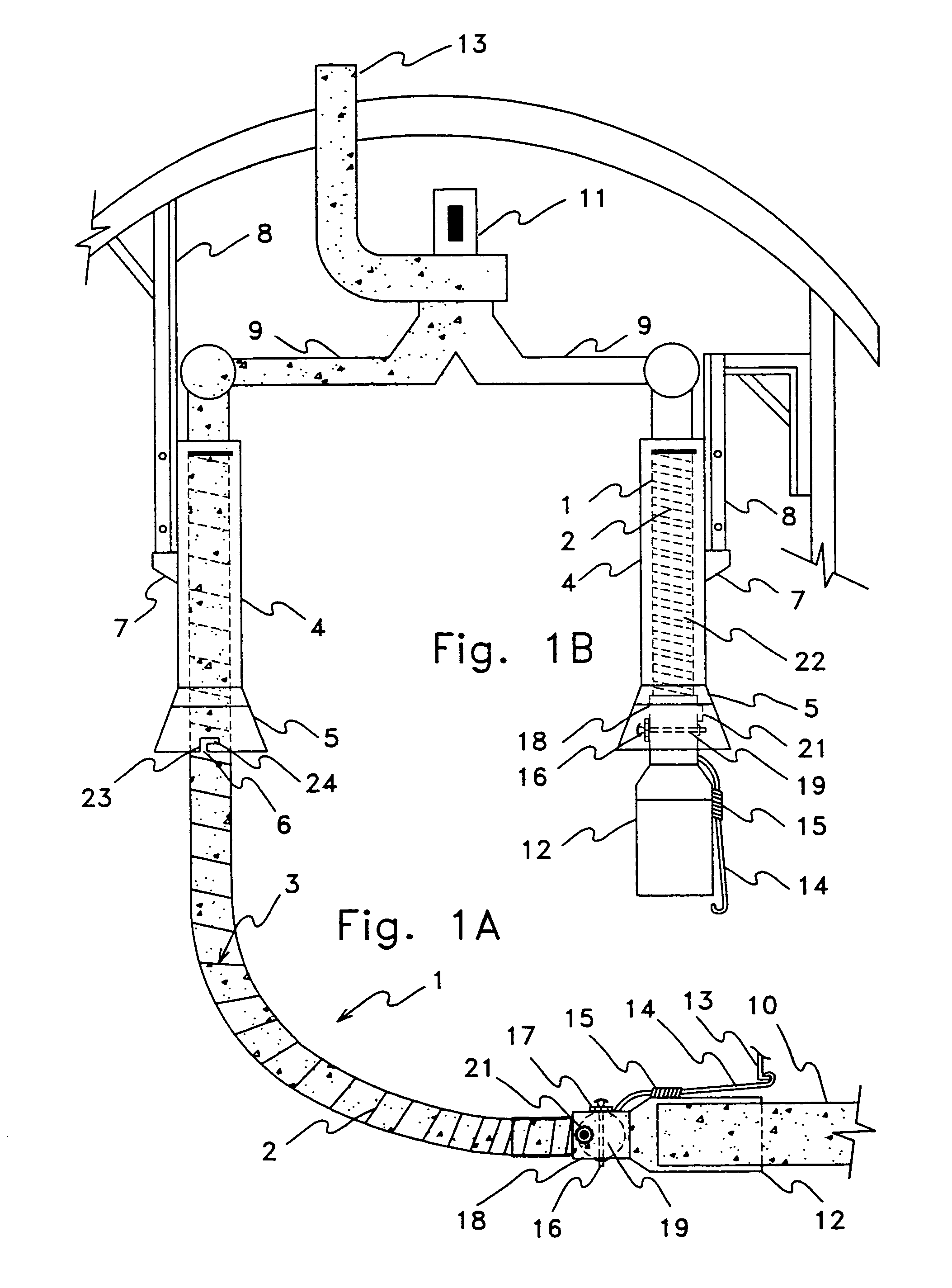

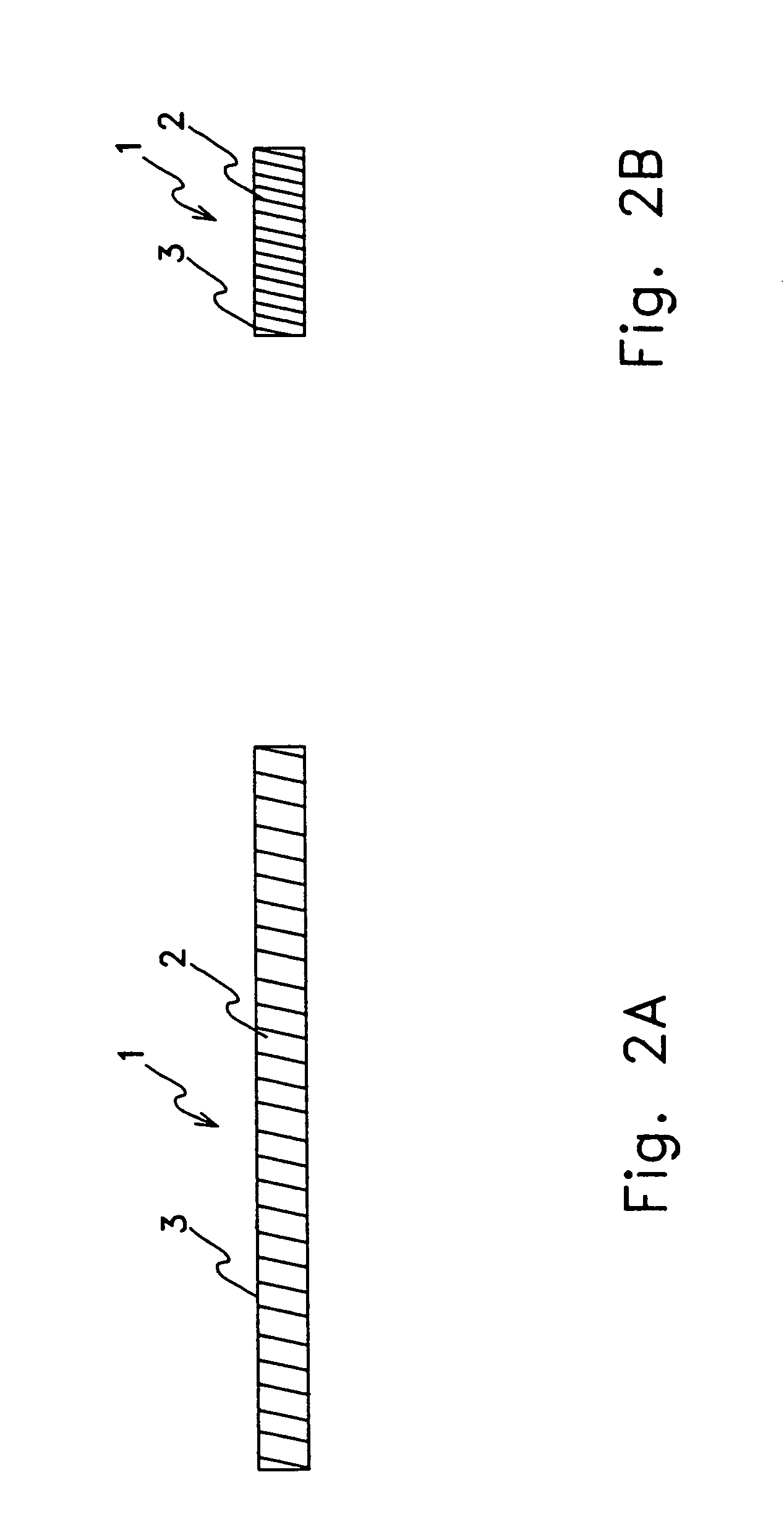

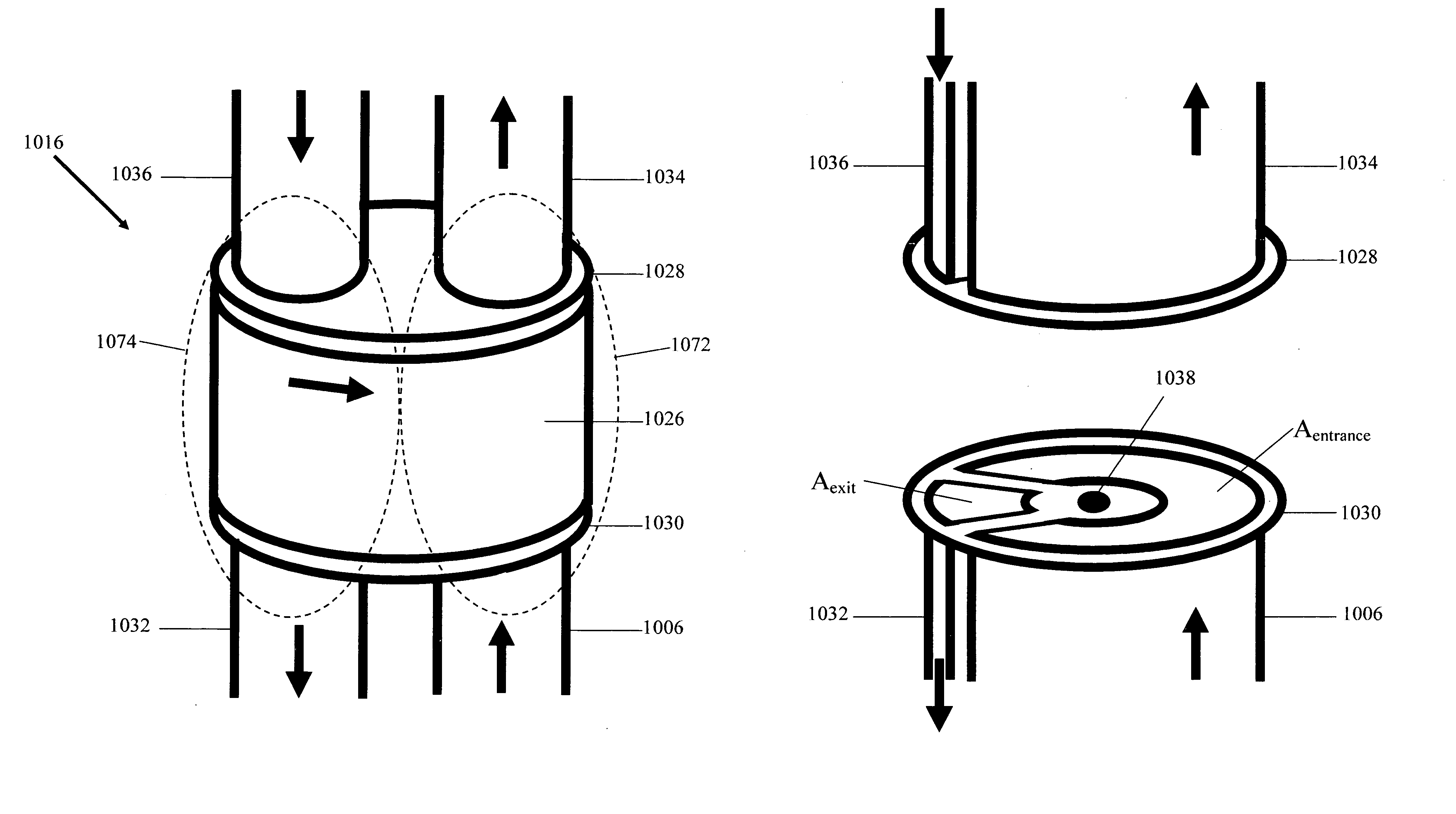

Pressure differential distribution system

InactiveUS6983757B1Improve aestheticsImprove usabilityDomestic stoves or rangesSpace heating and ventilationDistribution systemEngineering

An pressure differential distribution system which offers an pressure differential reaction element (1) made of a comfortable, flexible pressure differential interface (2) that is attached to a support element (3), which in conjunction with a difference in pressure between the interior volume of the differential reaction element (1) can conform to various extended or reduced conformers. The flexible pressure differential interface (2) may retract within an enclosure(4). An emission removal adaptor (12) or terminal interface (23) may be coupled to a substance source (10) to capture or move substances on a pressure differential from a first zone to a second zone.

Owner:ASCENT SYST

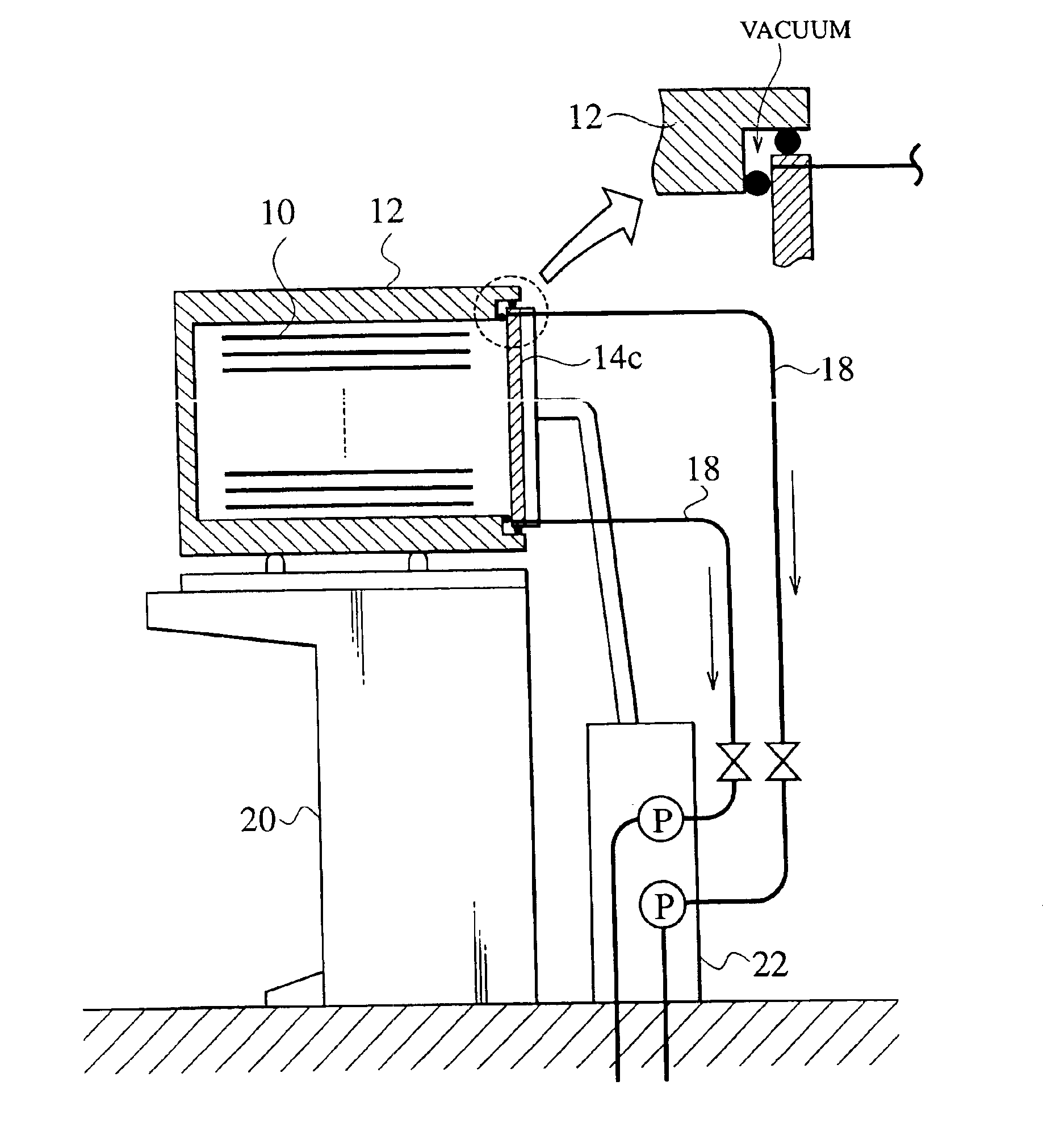

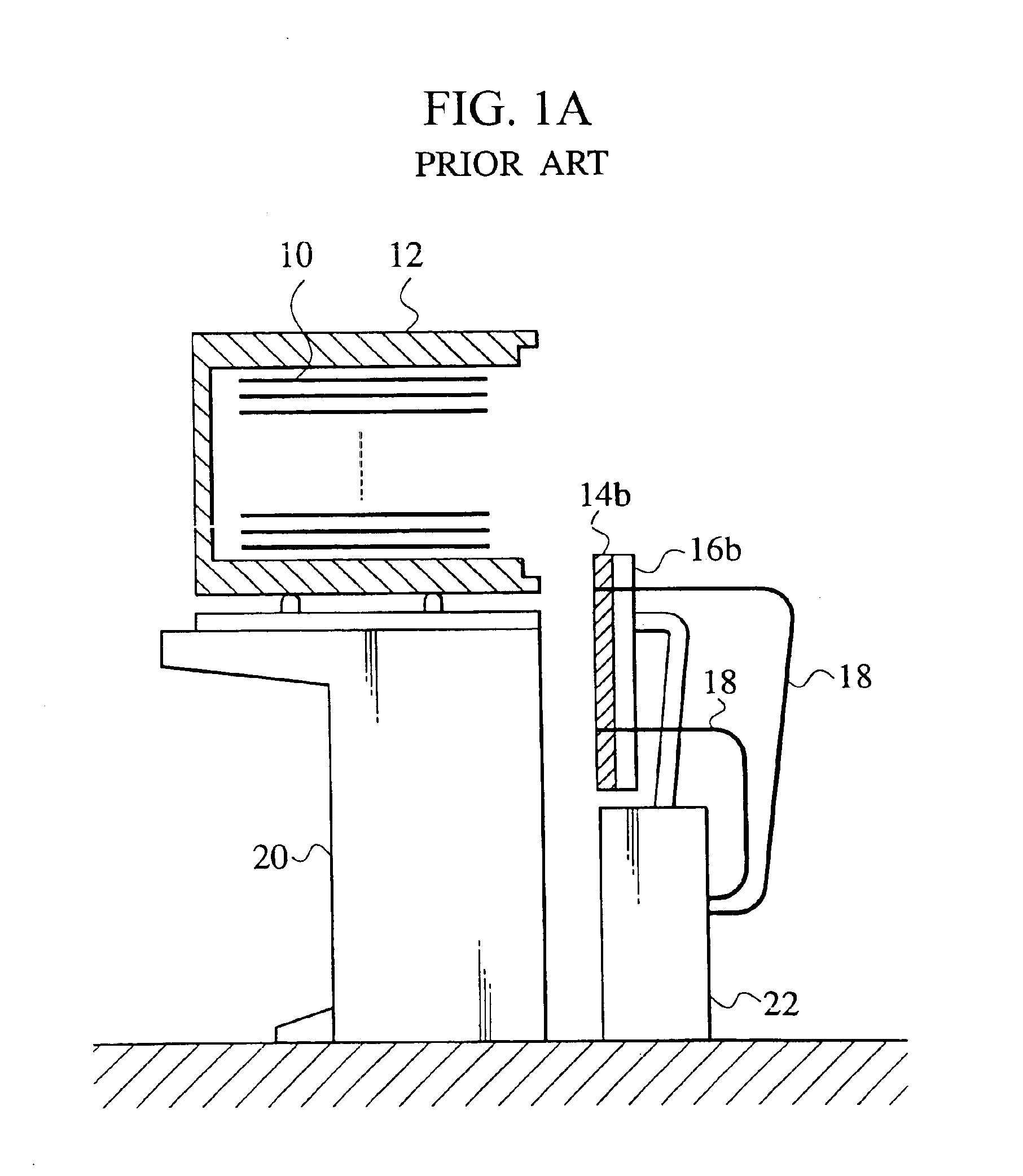

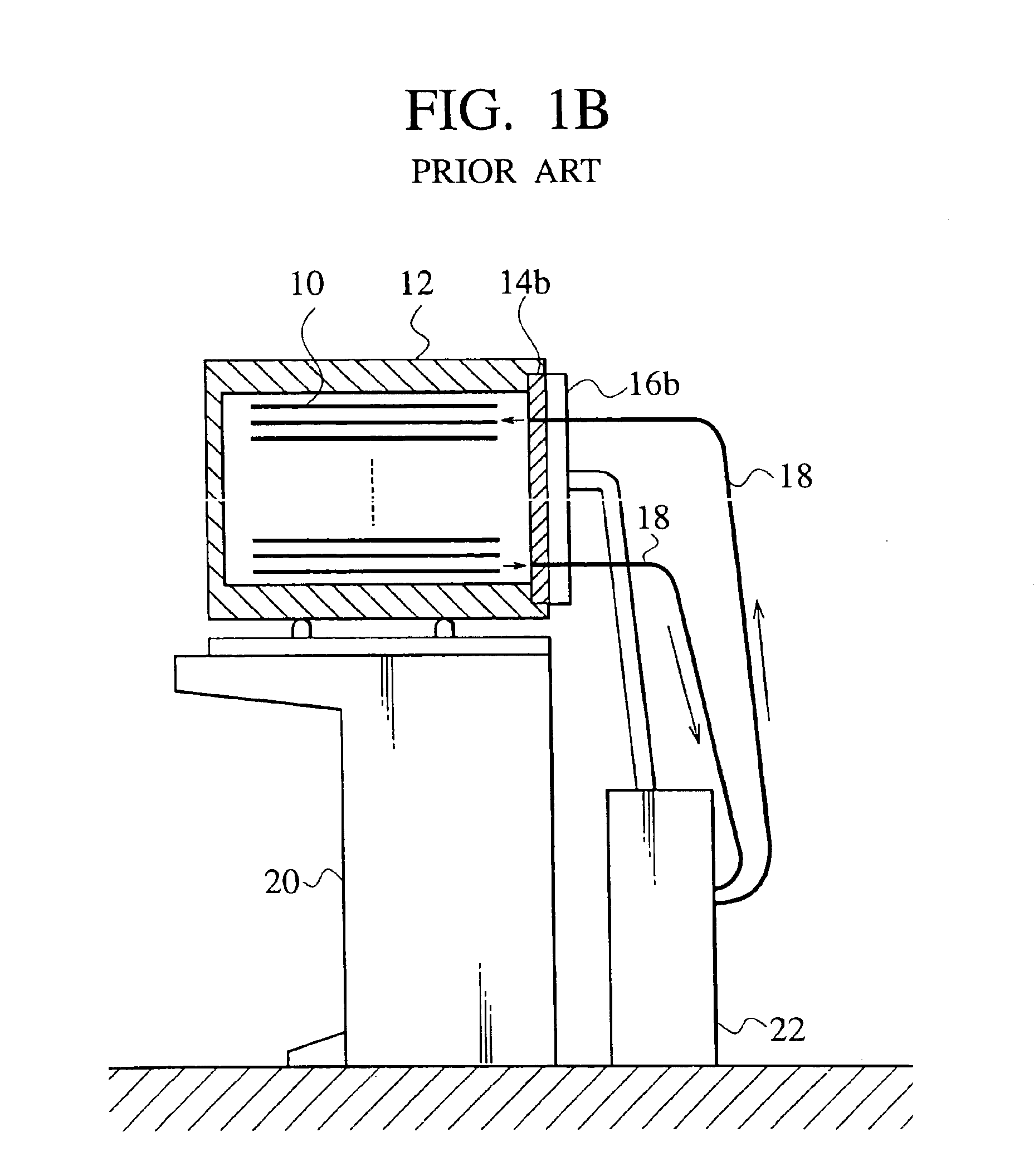

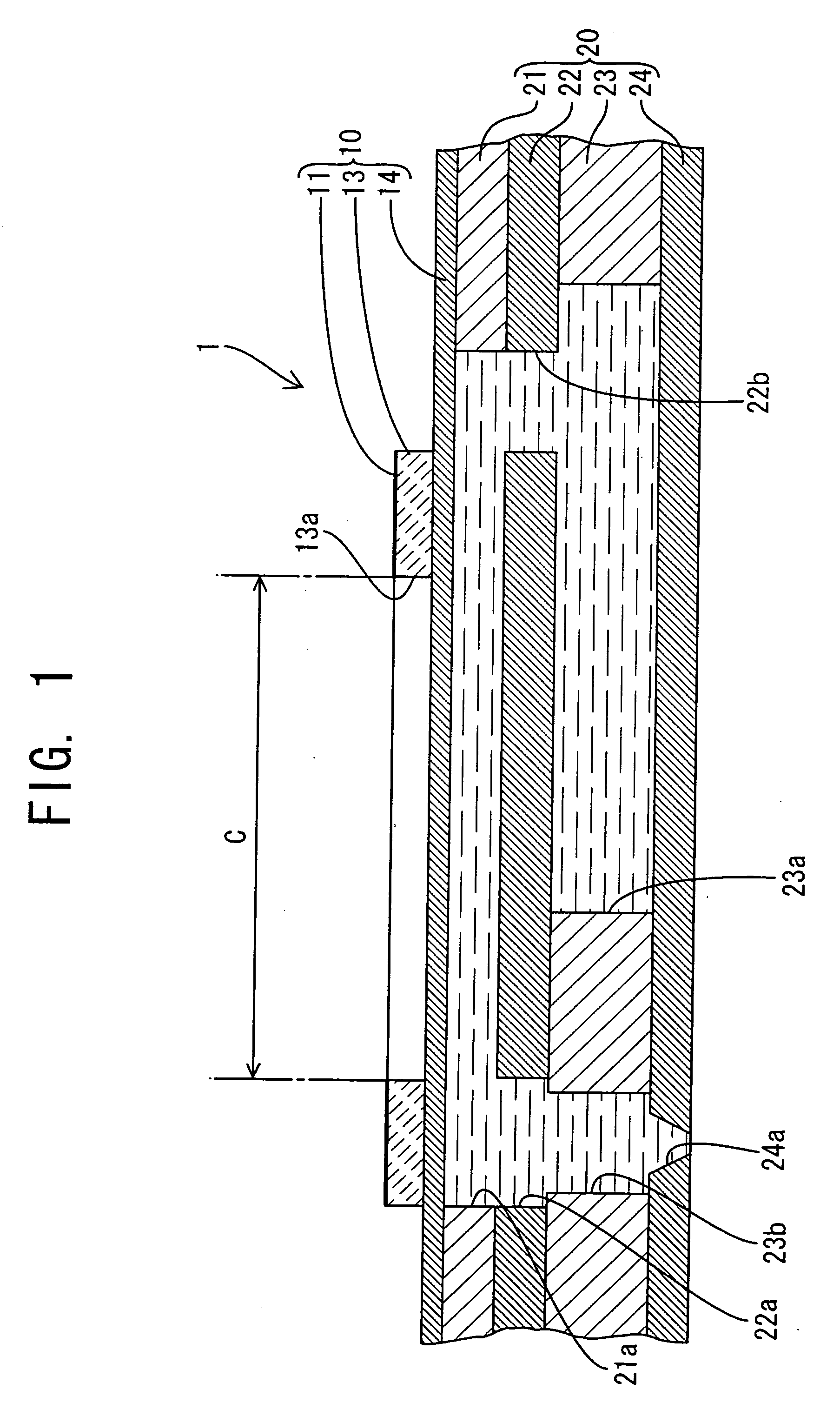

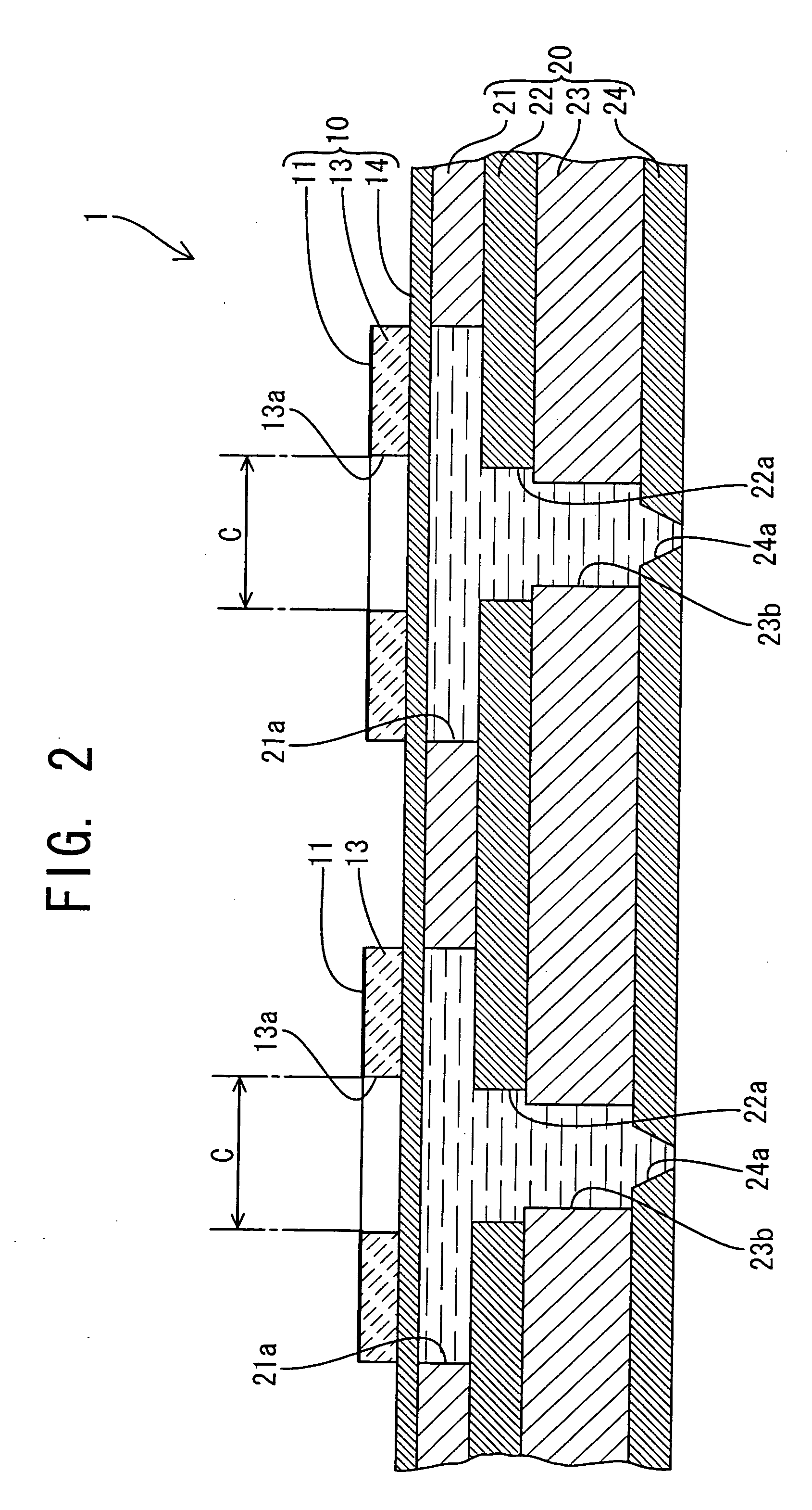

Wafer container

InactiveUS6883539B2Shorten cycle timeIncrease productivityLiquid fillingPressure pumpsEngineeringCycle time

A container for storing substrates capable of shortening the cycle time of the production, improving the production efficiency and reducing the production cost is provided. The container for storing substrates is composed of a box for accommodating the substrates, and a closure member for sealingly closing the box by tightly fixing the closure member to the opening of the box. The container for storing substrates is provided with means for temporarily storing a sealing gas and introducing the sealing gas into the box. Also, the container for storing substrates is provided with means for means for temporarily forming a low pressure space for the purpose of evacuating the gas inside of the box by transferring the gas to the low pressure space.

Owner:KK TOSHIBA

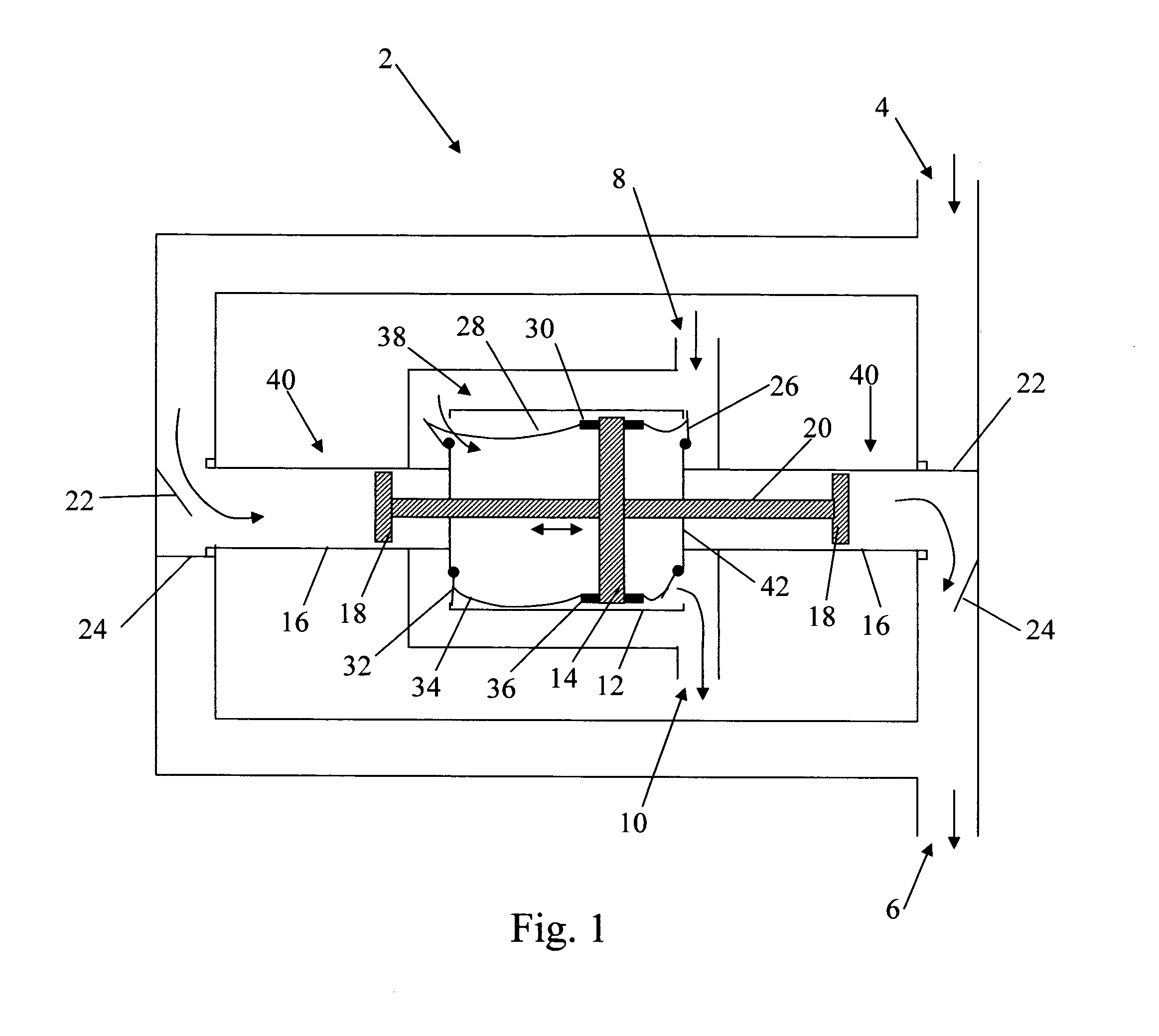

Double block valve with proving system

A double block valve and a valve proving system are disclosed. The double block valve is actuated by a single actuator and includes a valve body housing a cavity. The cavity defines an upstream portion with a fluid inlet and a downstream portion with a fluid outlet. A seating assembly is interposed between the upstream and the downstream portions. A first and a second blocking element are disposed in the valve body and are both movable within the cavity between opened and closed positions. With the first and second blocking elements both contacting the seating assembly, the space therebetween defines an enclosed space with a finite volume. The proving system is used for two safety shut-off valves on a valve train, such as a double block valve. The proving system connects to an enclosed space established between the two safety shut-off valves and includes a pair of three-way valves, oppositely biased pressure switches, and a pump, all of which are interconnected through pneumatic conduits. The proving system uses pressure accumulation and timed decay to determine the integrity of the two safety shut-off valves of the valve train.

Owner:ASCO CONTROLS LP

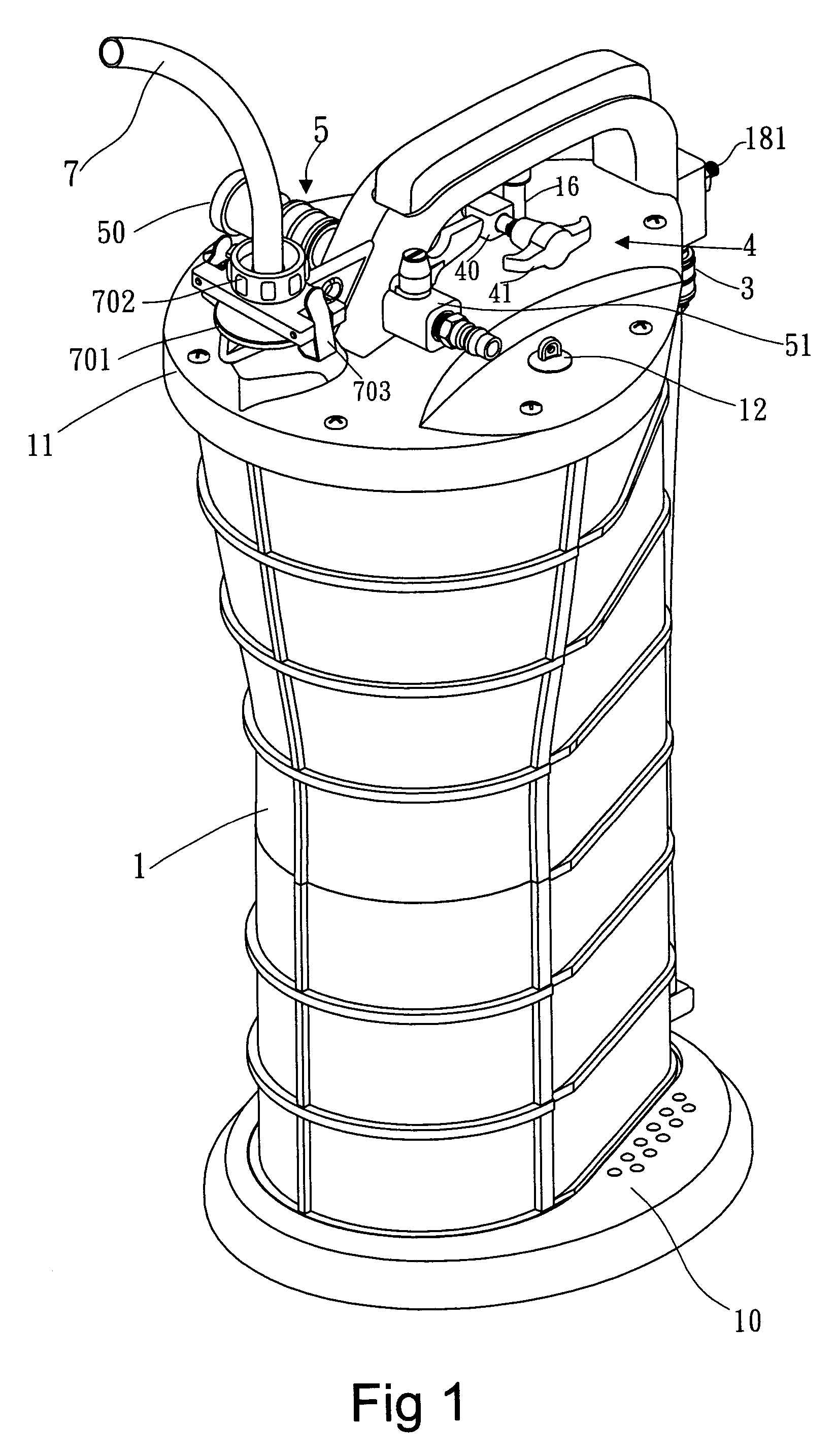

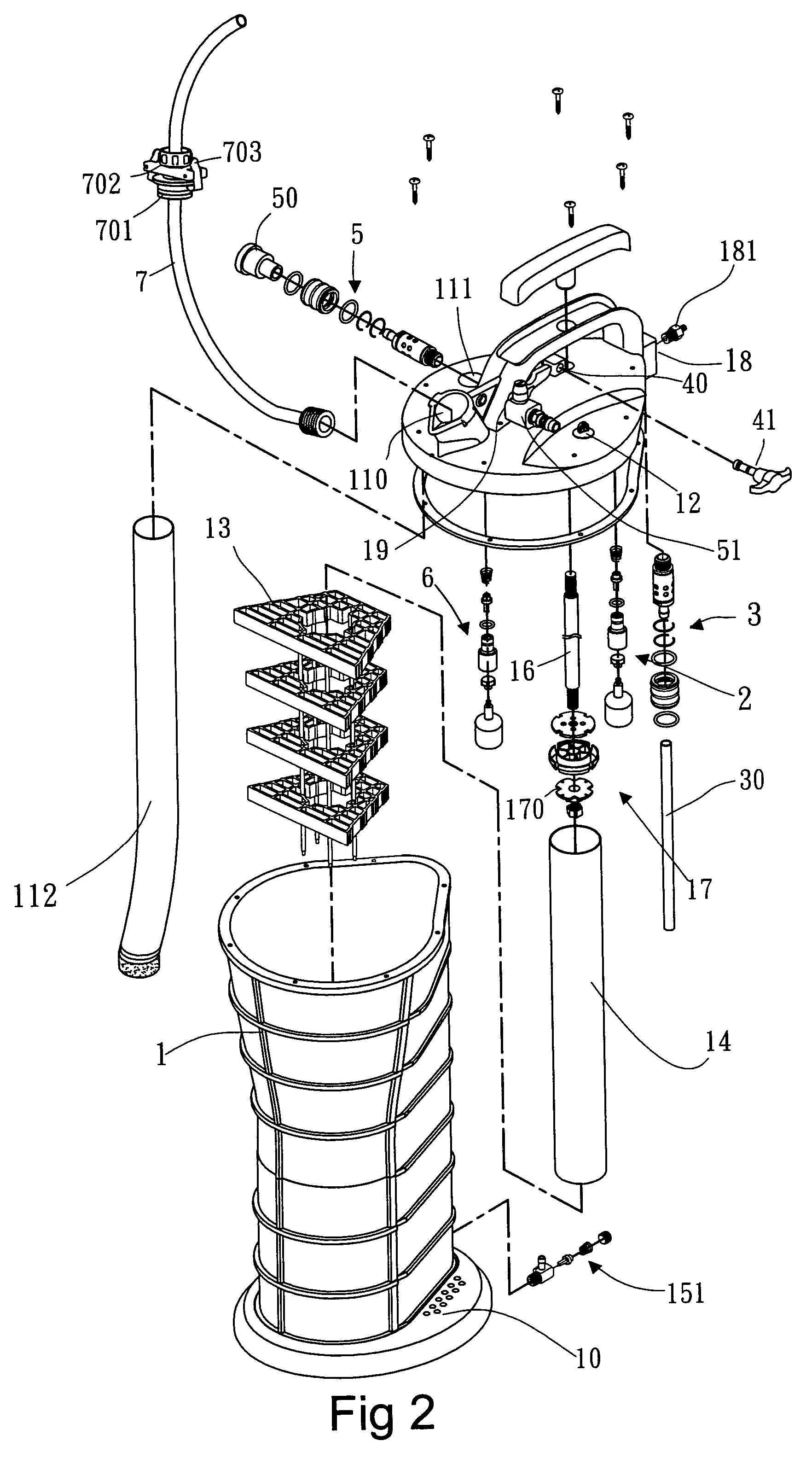

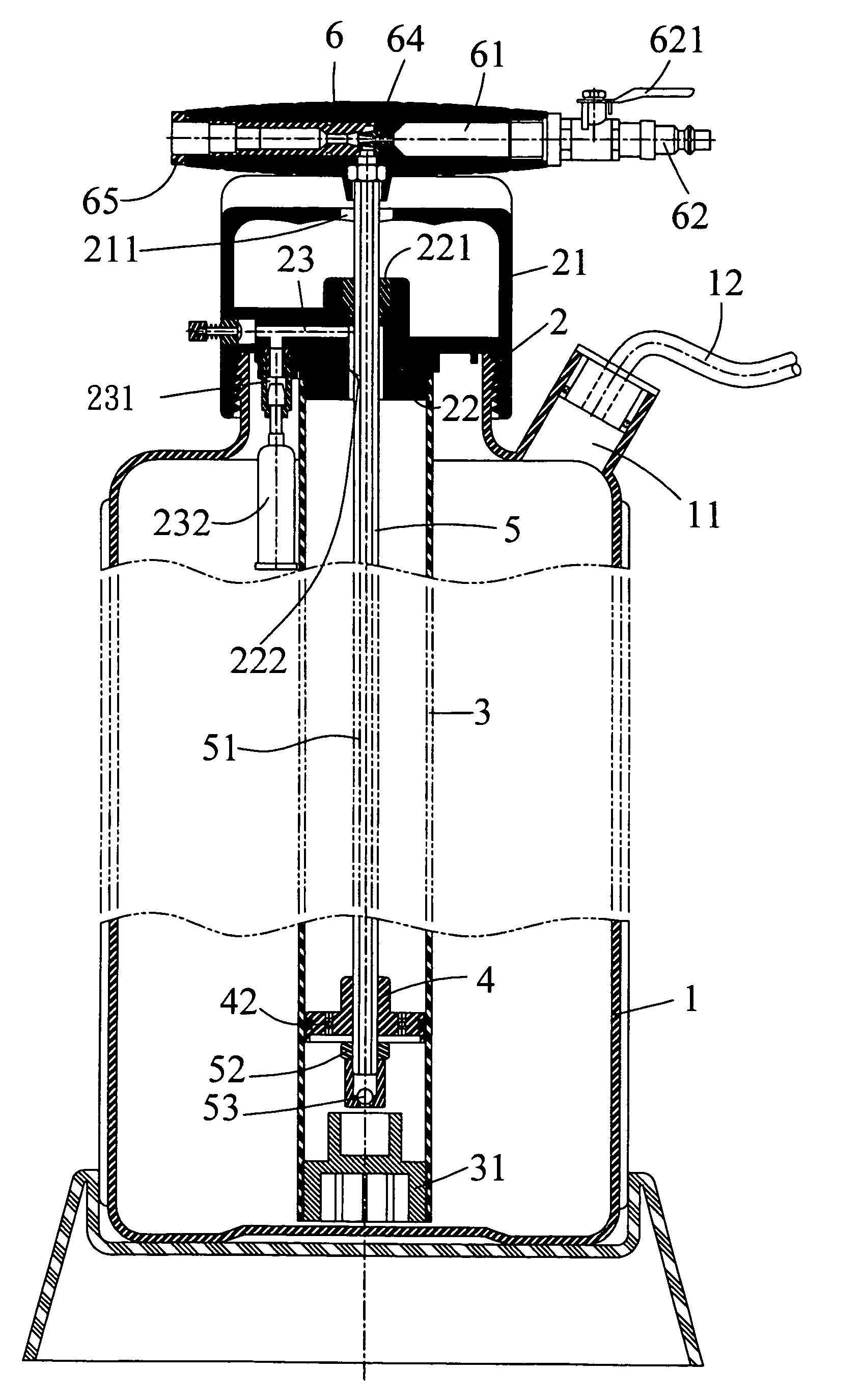

Pumping device

A pumping device includes a container having a cover structure. A piston is movably received in the container and is manually operable. The cover structure has an air inlet valve and a slide switch, which, when properly set, allow air to be sucked into or expelled out of the container by the manual operation of the piston to increase or decrease the internal pressure of the container for oil suction and oil drainage. The pumping device also includes another slide switch, whereby when both slide switches are properly set, the internal pressure of the container is increased or decreased due to the supply of pressurized air from an external source and oil can be sucked into and drained out of the container accordingly.

Owner:LIH YANN INDAL

Liquid pumping device

ActiveUS7093624B2Improve versatilityCrankshaftsFilling using suctionEngineeringMechanical engineering

A liquid pumping device includes a barrel, a cylinder, a conducting rod, a piston, an operation lever, and a cover. Thus, the liquid pumping device is operated automatically by the power source or operated manually by the operation lever to suck the liquid from the suction pipe into the inside of the barrel rapidly, so that the liquid pumping device is operated automatically and manually, thereby greatly enhancing the versatility of the liquid pumping device.

Owner:YO LEE MFG

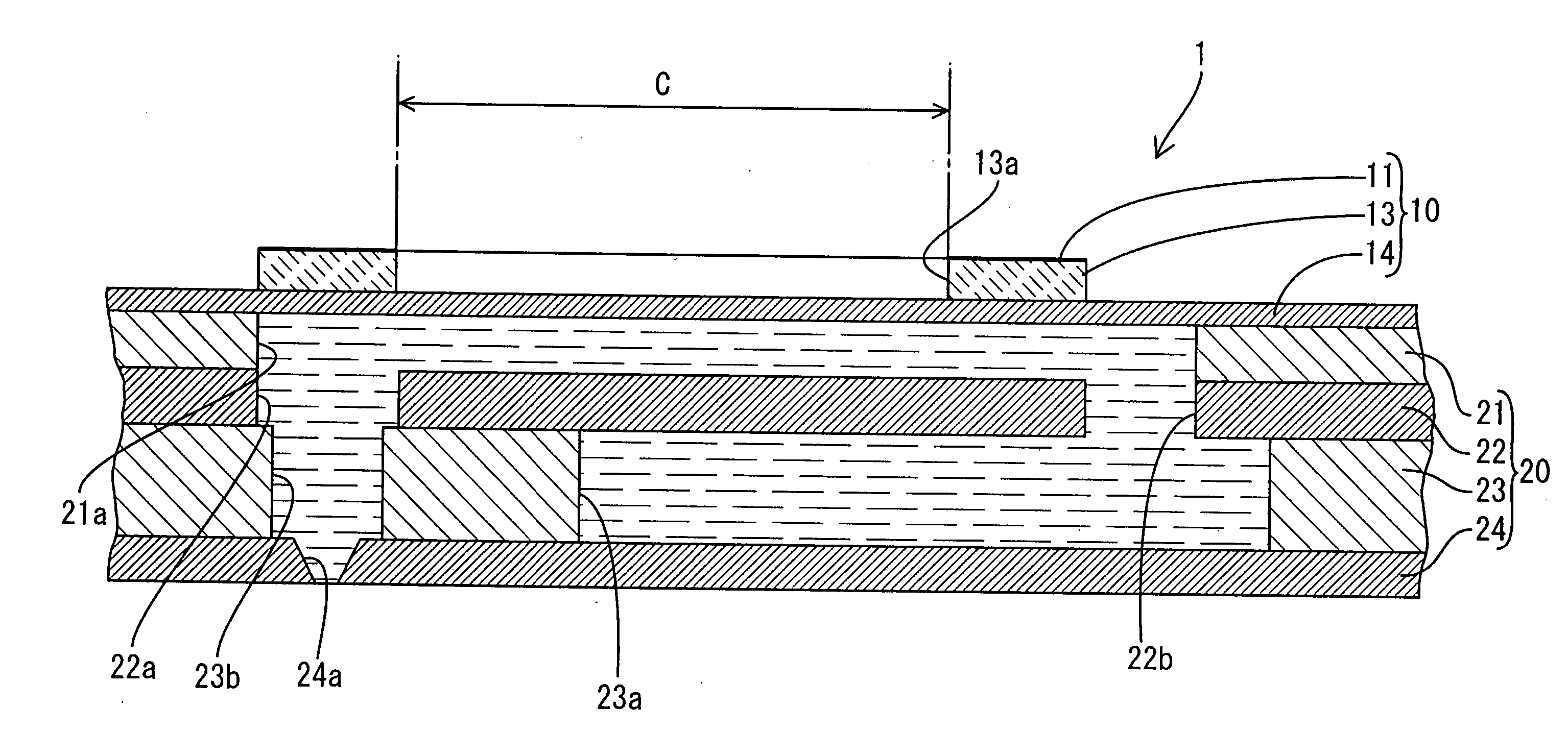

Liquid delivery apparatus

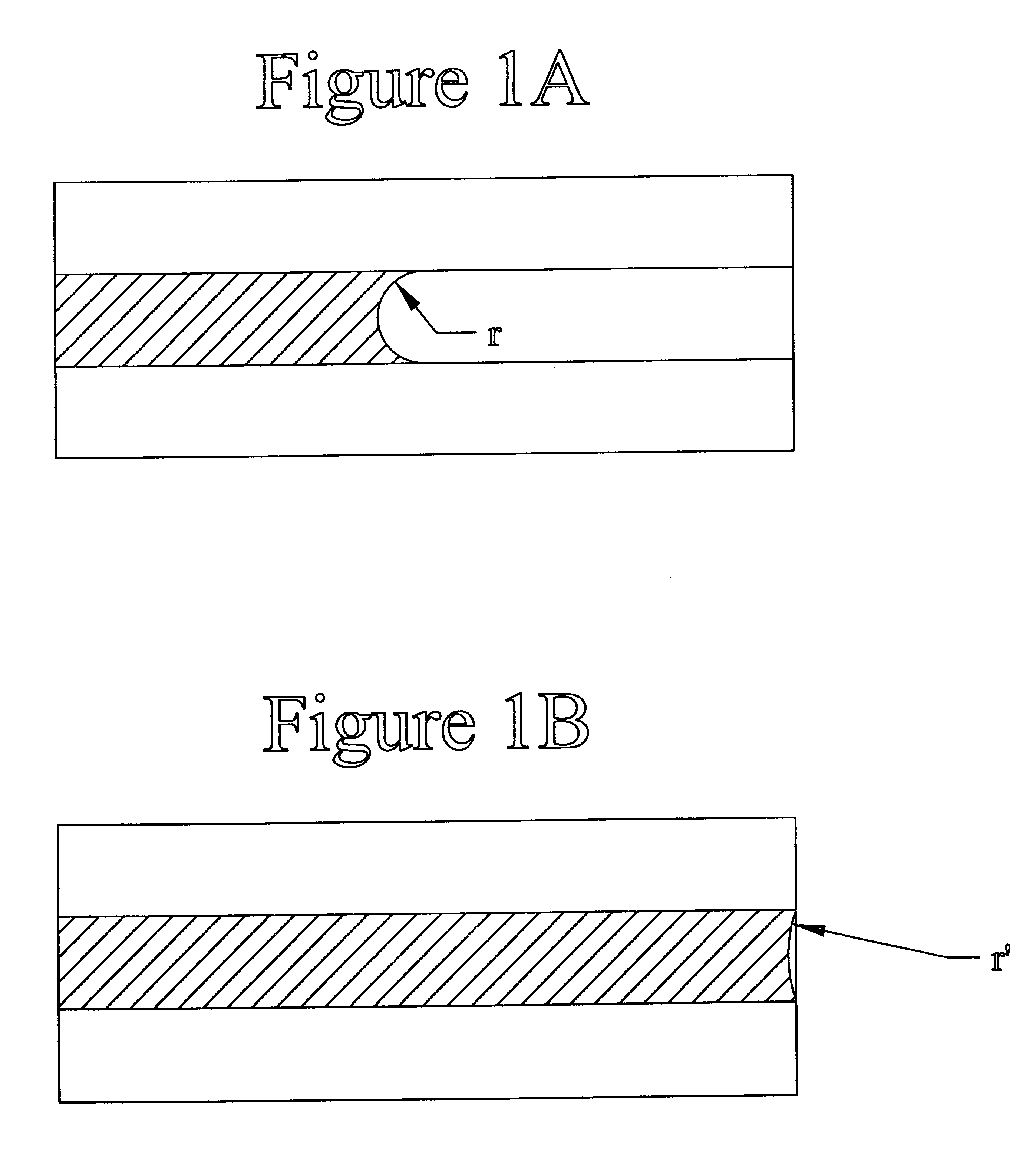

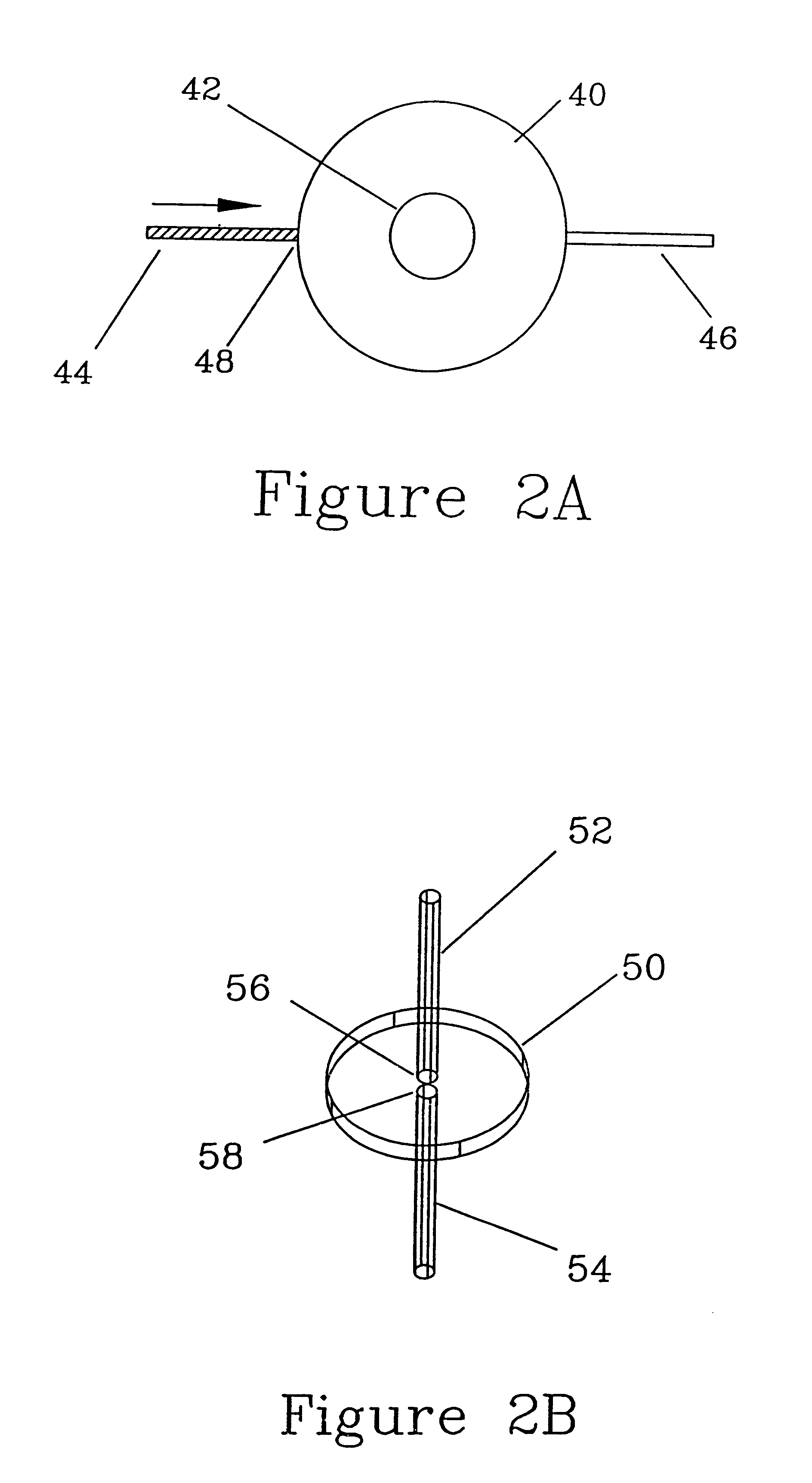

ActiveUS20050069430A1Increase displacementReduce stiffnessPressure pumpsFlexible member pumpsPiezoelectric actuatorsEngineering

A liquid delivery apparatus comprises a pressure chamber accommodating a liquid, and a piezoelectric actuator plate which is disposed to close the pressure chamber and is deformed to deliver the liquid through an opening in communication with the pressure chamber. The actuator plate has a laminated structure including a piezoelectric layer which is deformable at least in a planar direction thereof by an application of an electric field to the piezoelectric layer, and a planar diaphragm laminated on the piezoelectric layer. A rigidity of the piezoelectric actuator plate is lower at a portion thereof over an inner side of an inner peripheral part of the pressure chamber than at a portion thereof over the inner peripheral part of the pressure chamber.

Owner:BROTHER KOGYO KK

Method and system of operating a fuel vapor recovering system and its engine system

A method of operating a boosted engine system is described in which a vacuum generator coupled with a fuel vapor purging system can generate vacuum during both purging and non-purging conditions, and during both boosted and non-boosted conditions. The vacuum can therefore be used to power vacuum actuated brakes, and / or other vacuum actuators, irrespective of the purging conditions, and irrespective of boost levels and irrespective of vacuum. The vehicle fuel economy and exhaust can be improved.

Owner:FORD GLOBAL TECH LLC

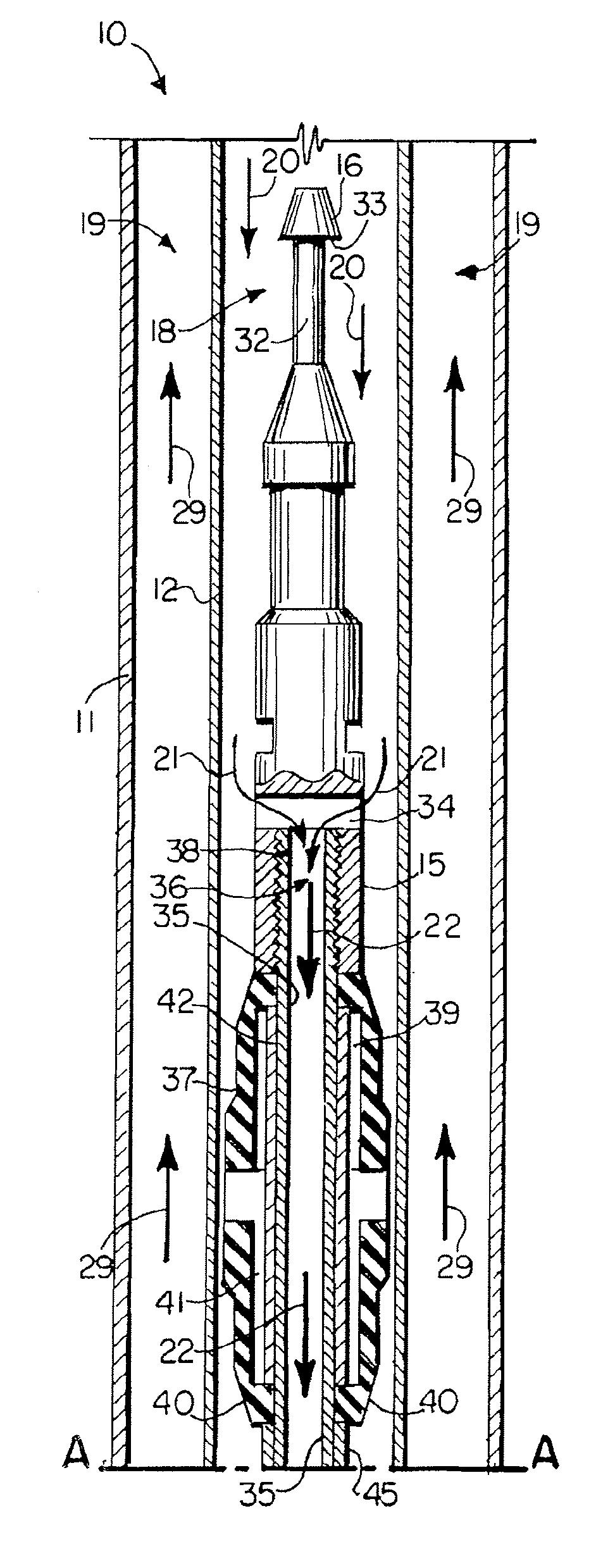

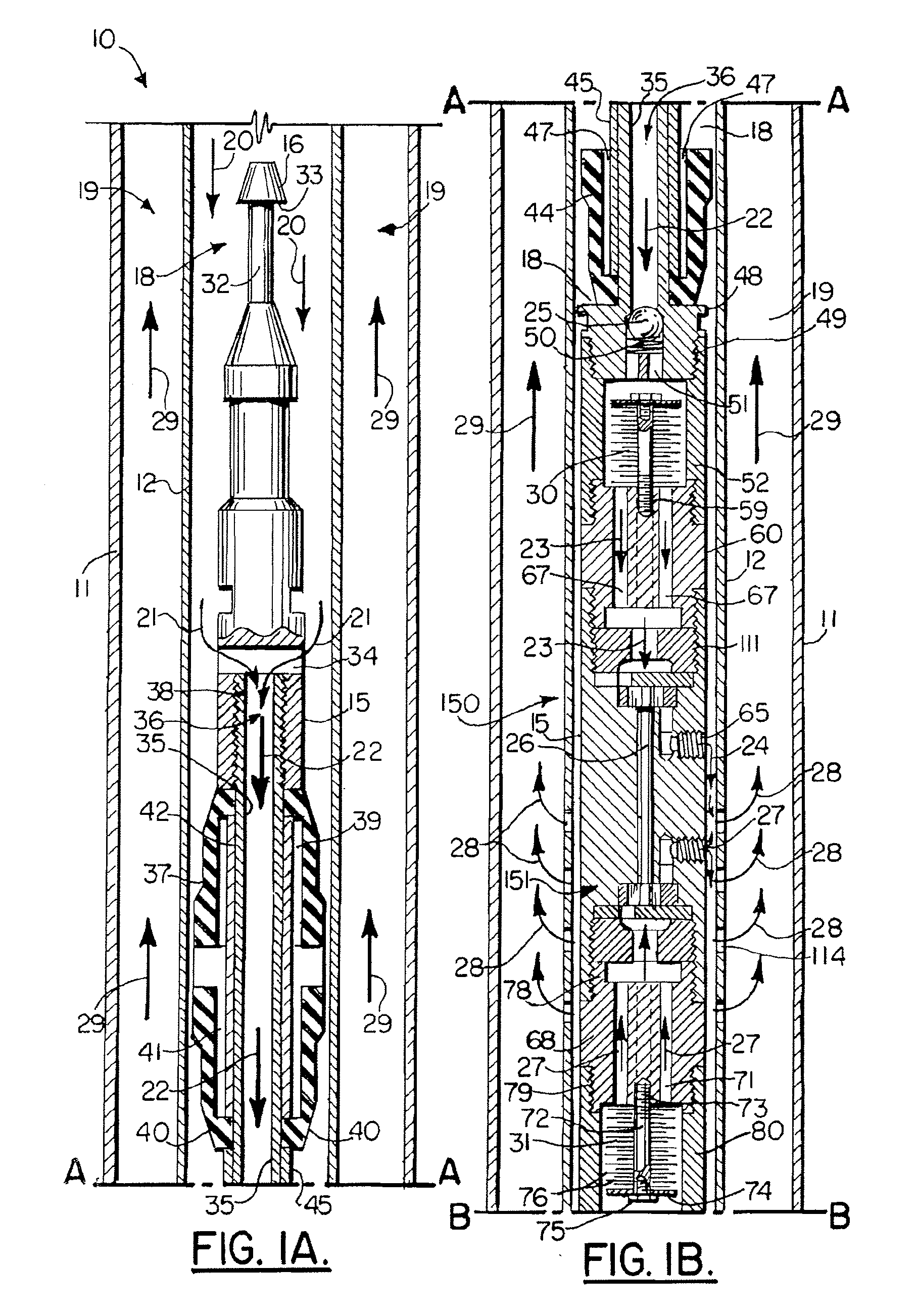

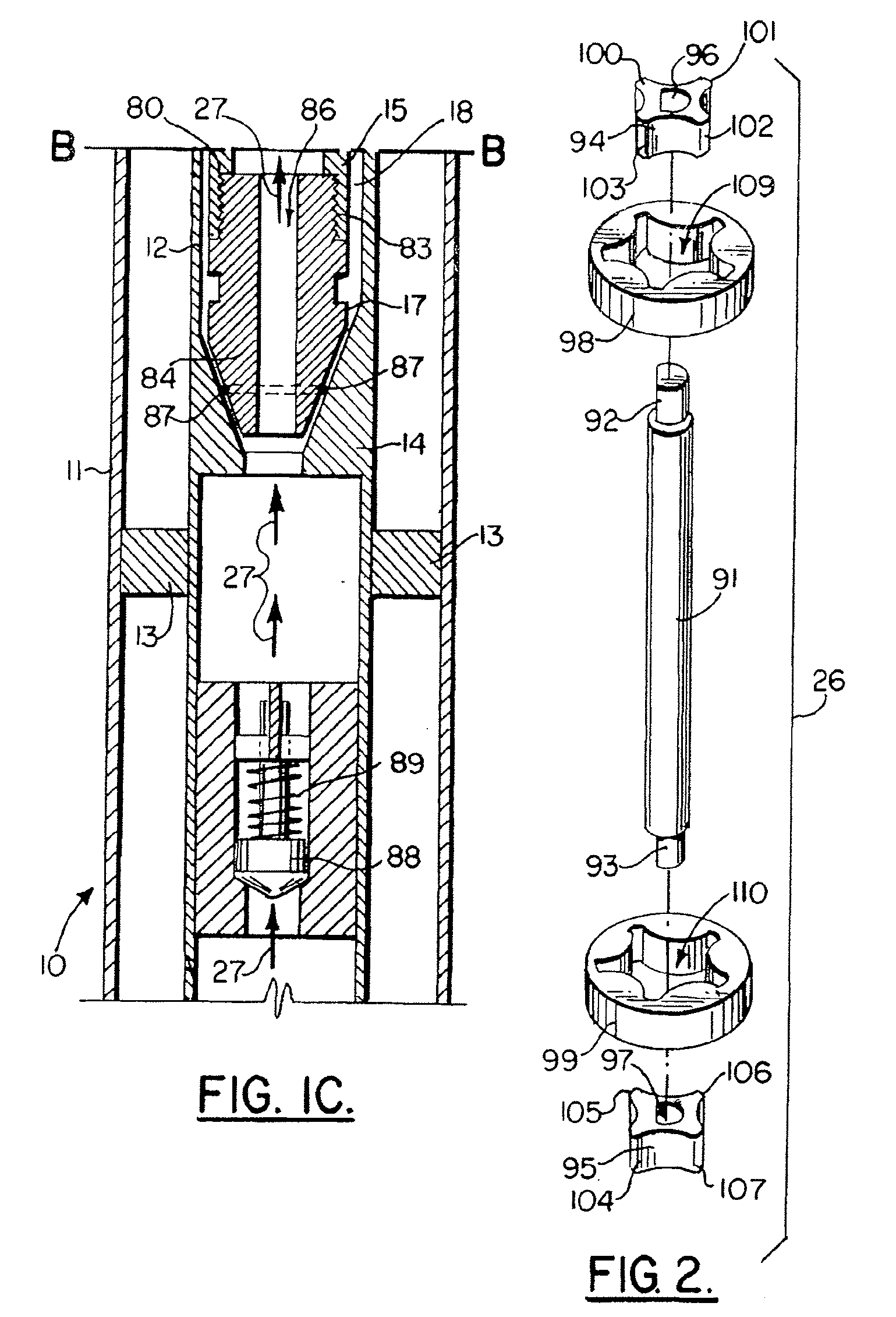

Oil well pump apparatus

An oil well pumping apparatus for pumping oil from a well to a wellhead provides a tool body that is sized and shaped to be lowered into the production tubing string of the oil well. A working fluid is provided that can be pumped into the production tubing. A prime mover is provided for pumping the working fluid. A flow channel into the well bore enables the working fluid to be circulated from the prime mover via the production tubing to the tool body at a location in the well and then back to the wellhead area. A pumping mechanism is provided on the tool body, the pumping mechanism including upper and lower spur gear or gears. The upper spur gear is driven by the working fluid. The lower spur gear is rotated by the first spur gear. The upper and lower spur gears are connected with a common shaft. If upper pairs and lower pairs of spur gears are employed, each upper and lower gear are connected via a common shaft. The tool body has flow conveying portions that mix the working fluid and the produced oil as the oil is pumped. The pumping mechanism transmits the commingled fluid of oil and working fluid to the wellhead area where they are separated and the working fluid recycled.

Owner:DAVIS RAYMOND C

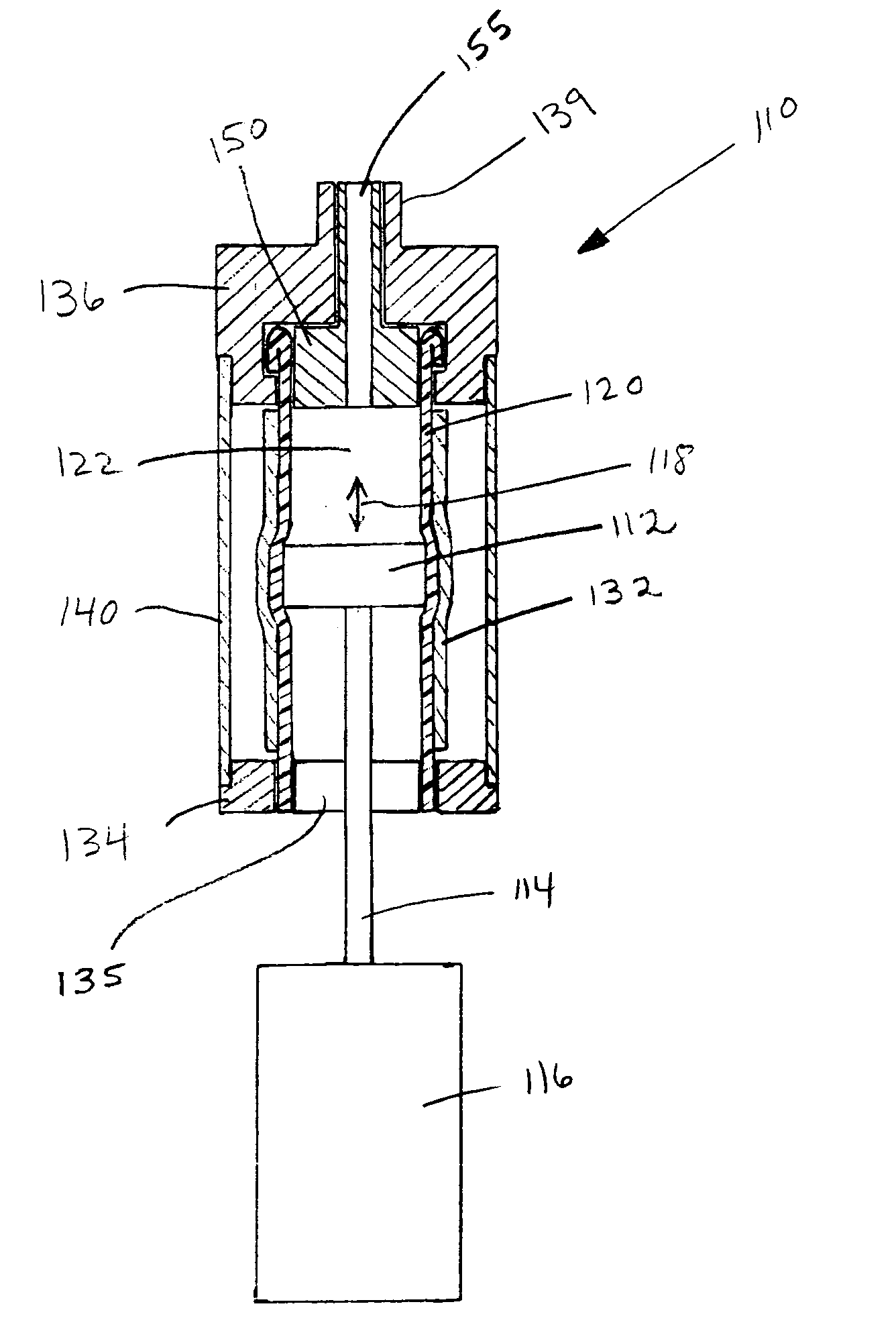

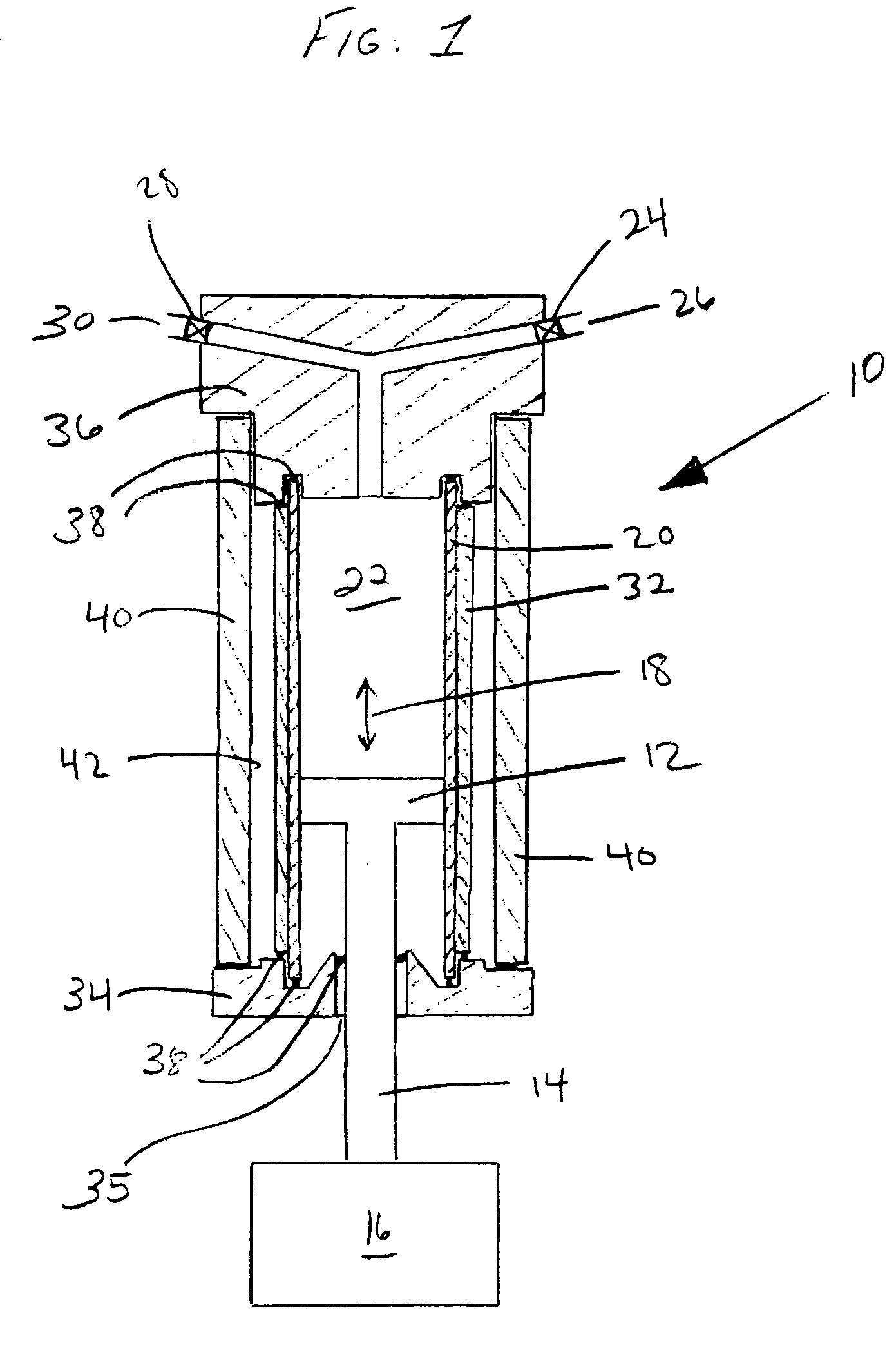

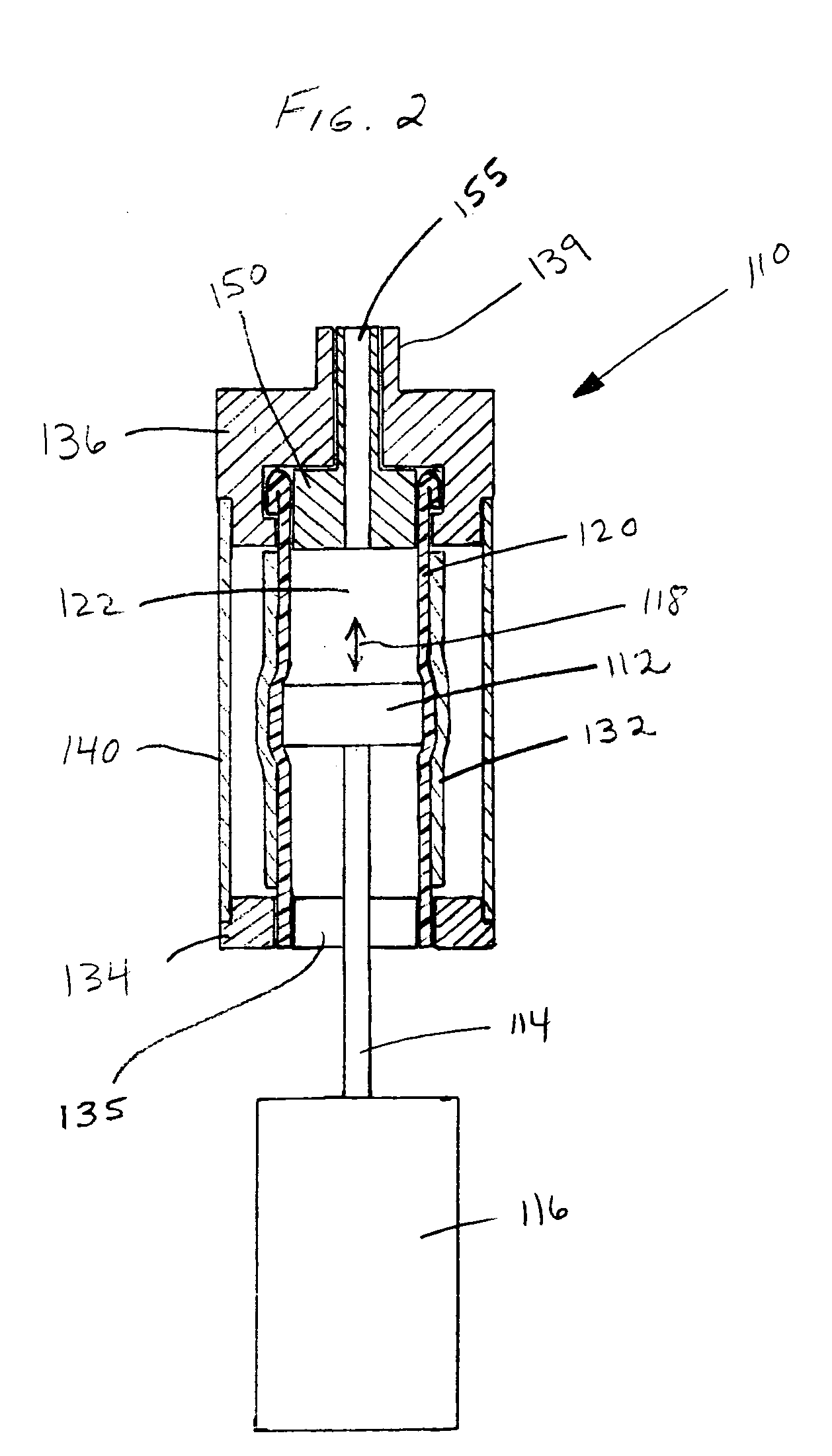

Flexible sleeve syringe and system

InactiveUS20050196287A1Improve the immunityLow pumpingPositive displacement pump componentsInfusion syringesEngineeringBiomedical engineering

A syringe having an elastic sleeve which defines a fluid chamber, and a plunger positioned within the elastic sleeve. The outer diameter of the plunger is greater than the inner diameter of the elastic sleeve such that the plunger elastically deforms the sleeve during use. A syringe pump system is also provided.

Owner:DIBA IND

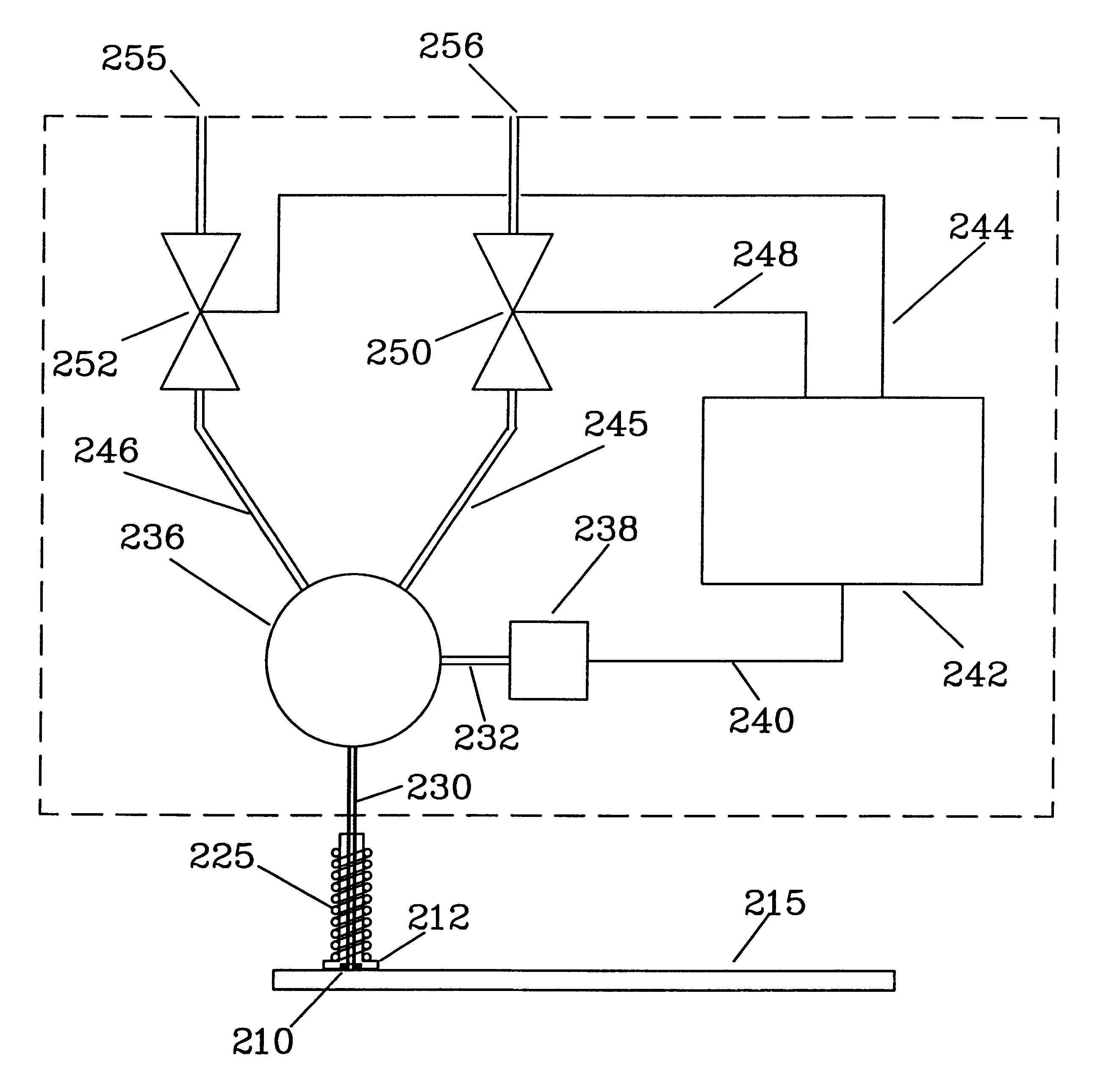

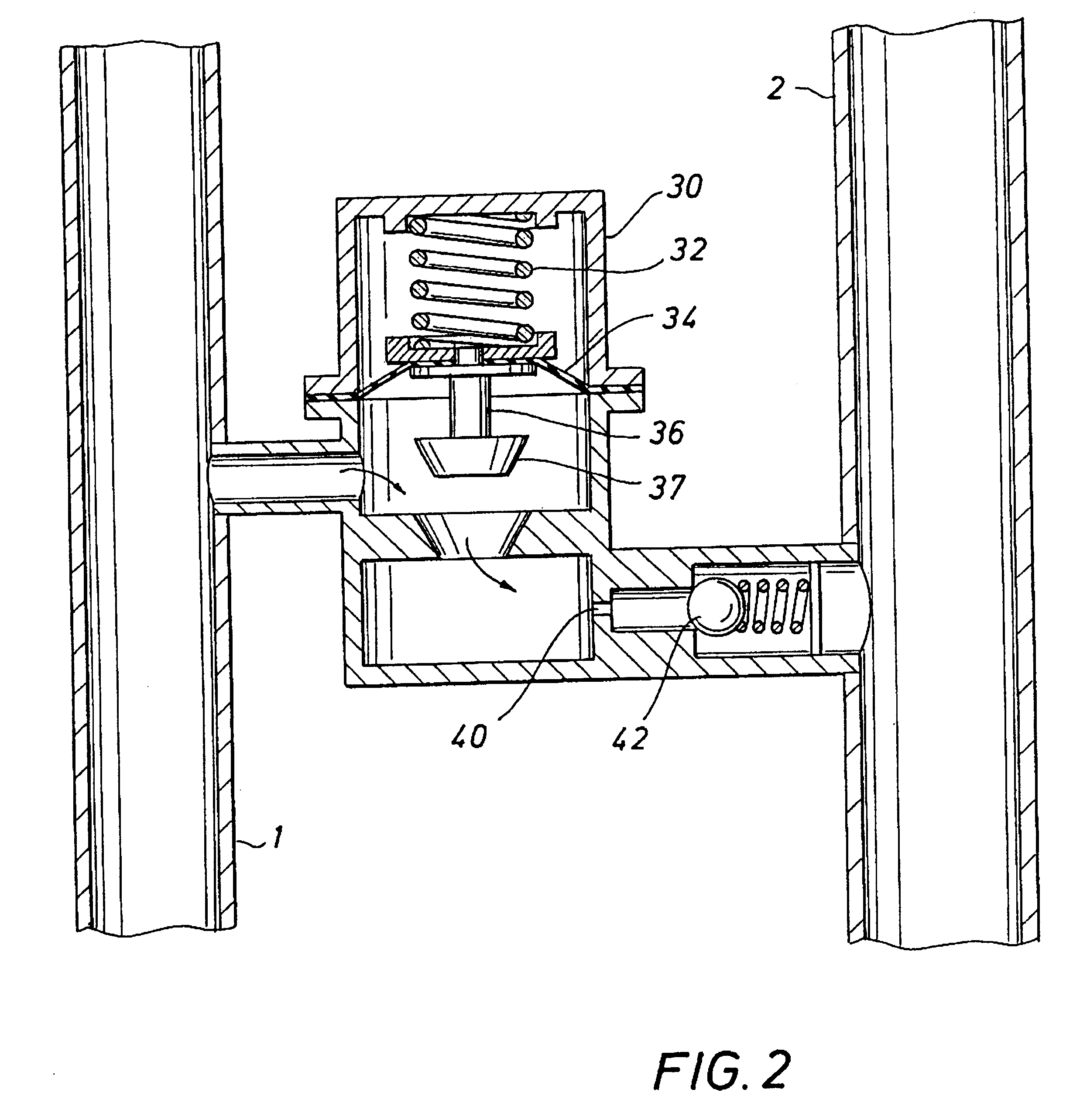

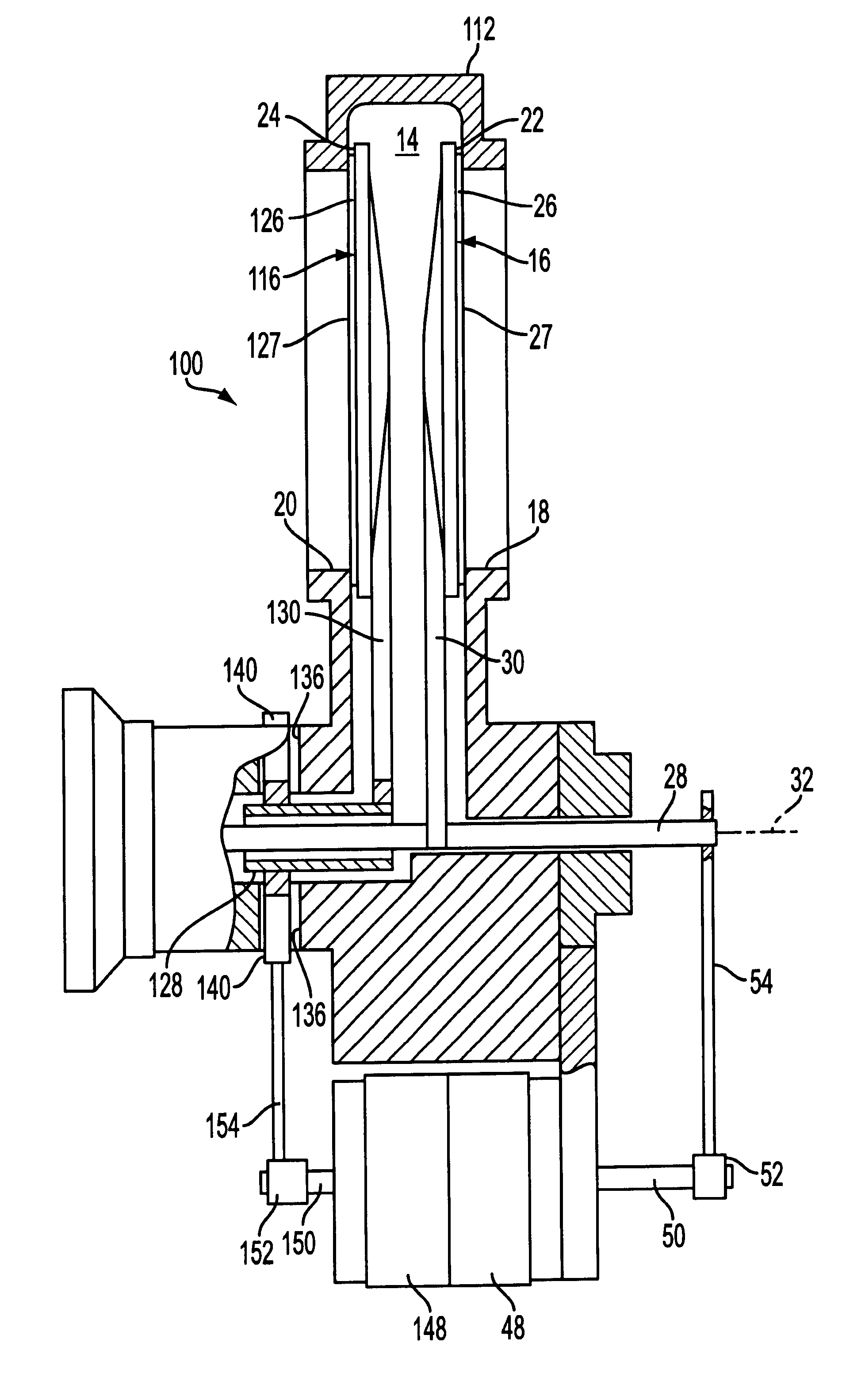

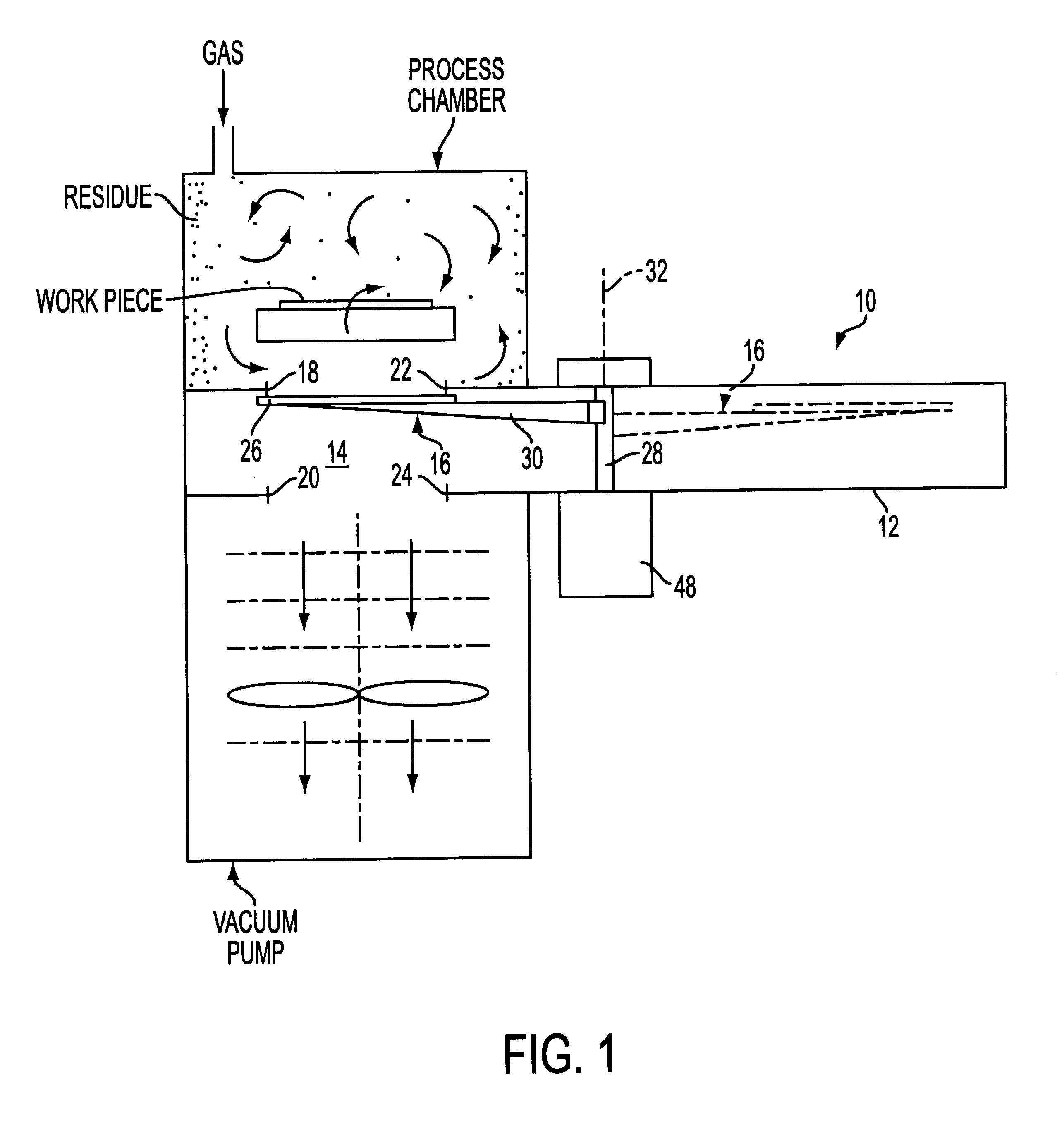

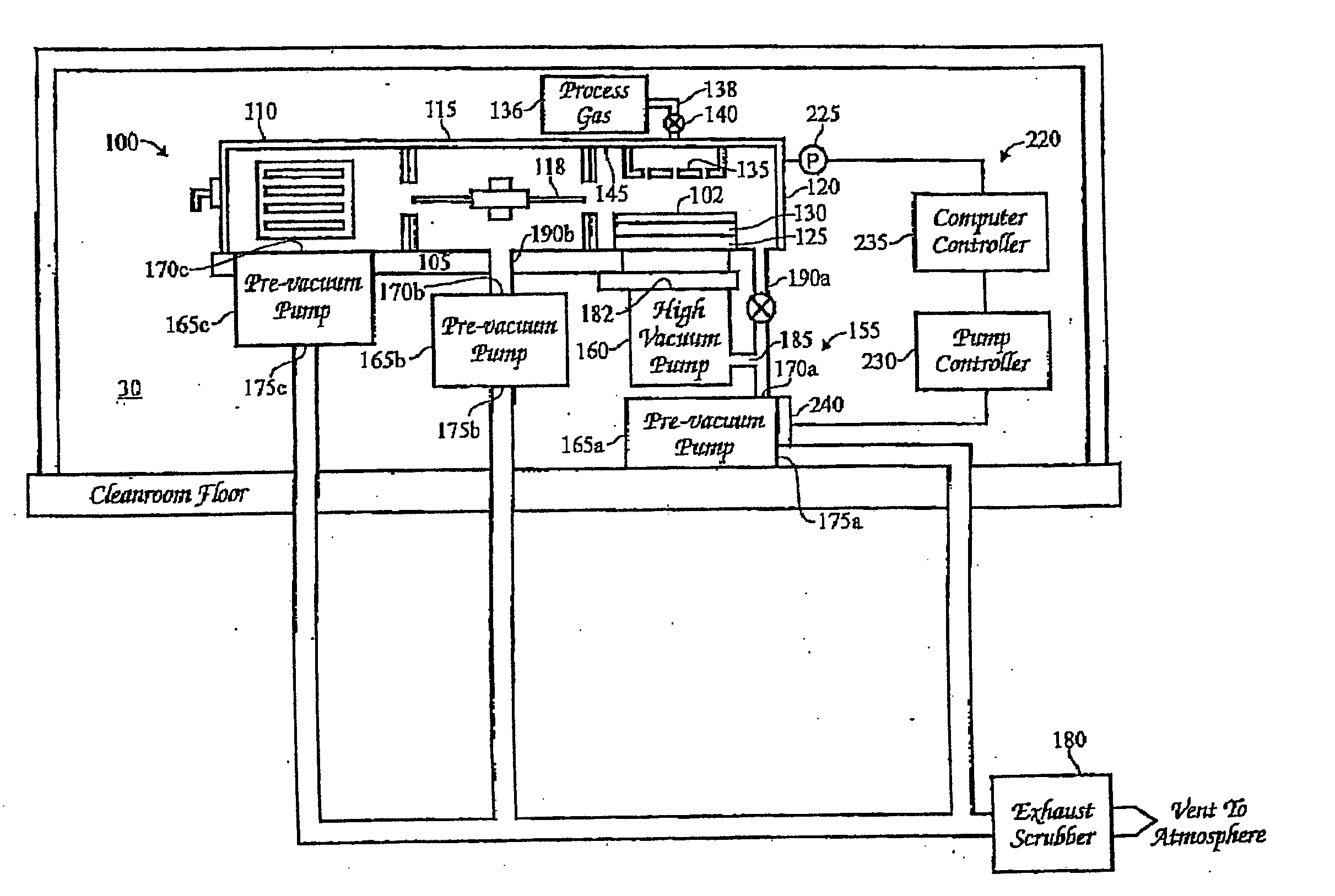

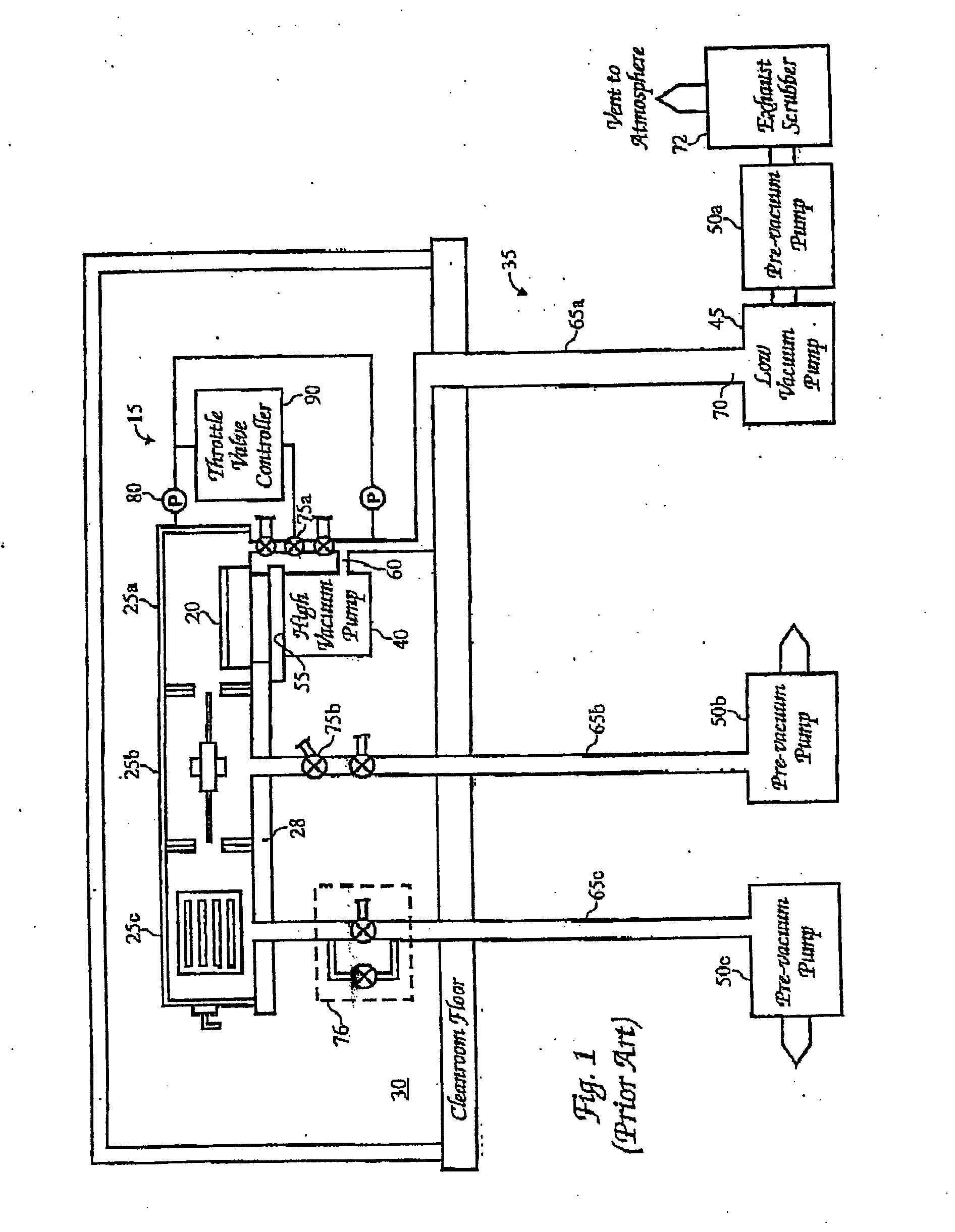

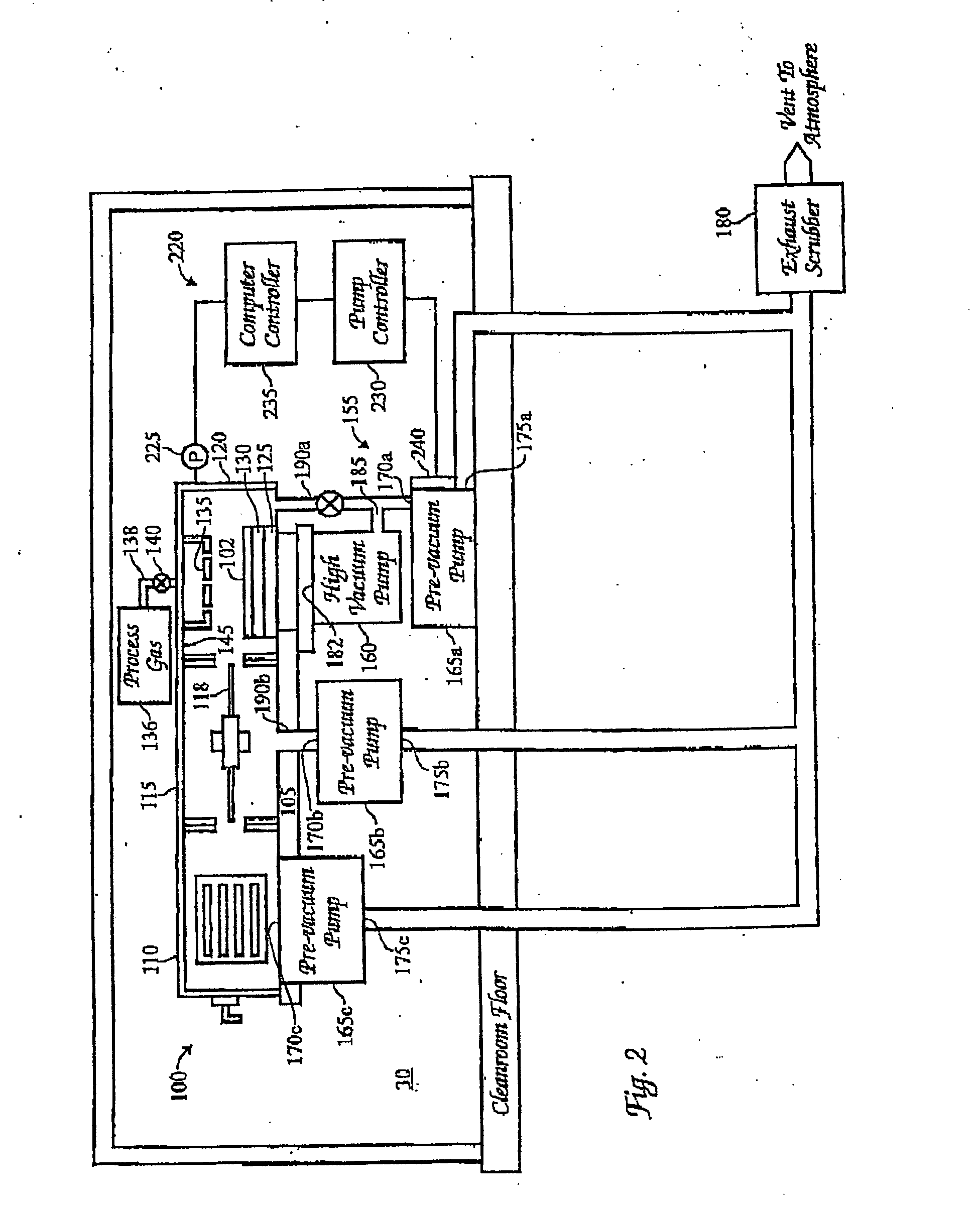

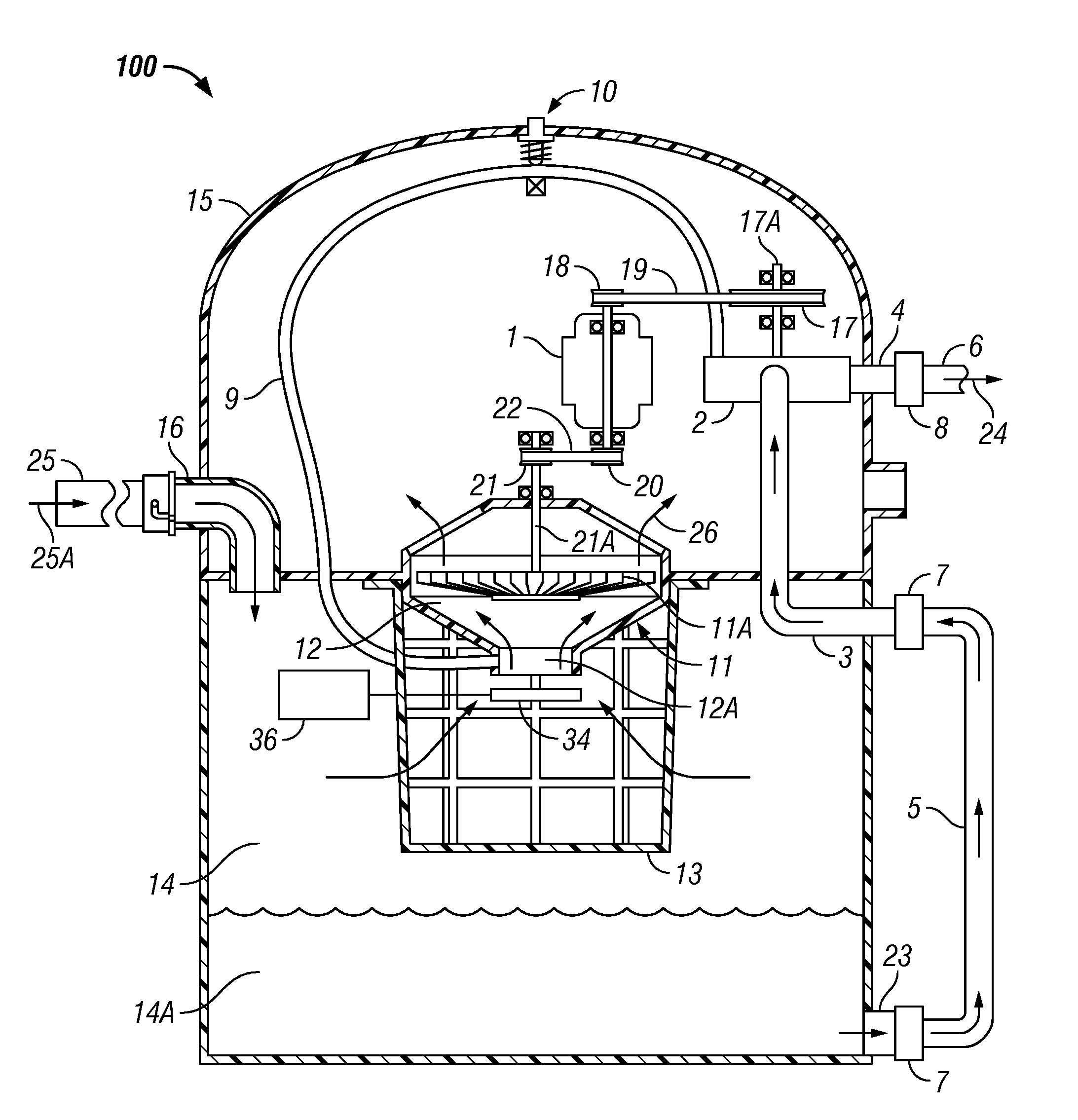

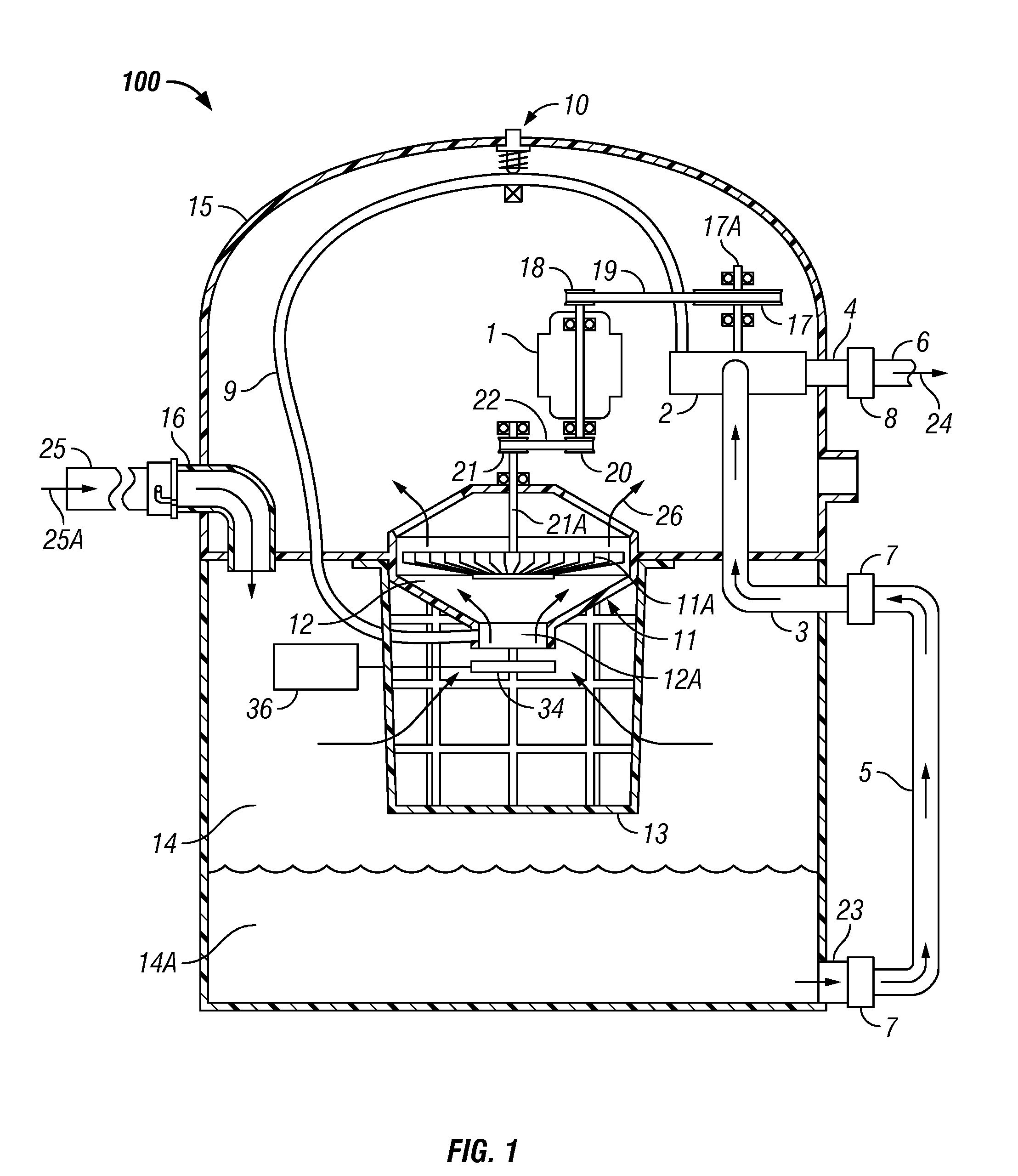

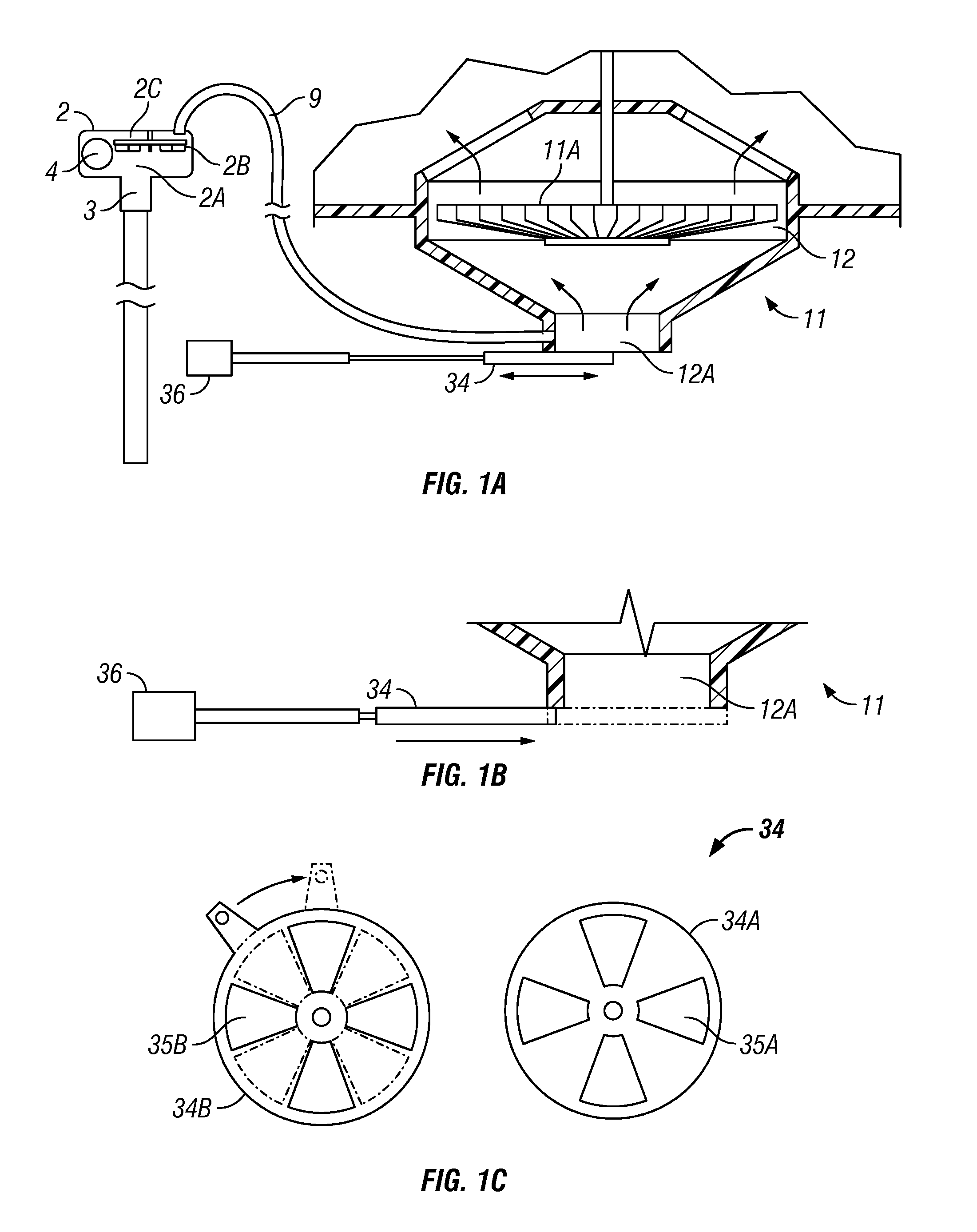

Processing apparatus having integrated pumping system

InactiveUS20050034767A1Improve space efficiencyPressurized chemical processContainer filling methodsNoise levelLow vacuum

An apparatus 115 for processing a substrate 20, comprises an integrated pumping system 155 having a high operating efficiency, small size, and low vibrational and noise levels. The apparatus 115 comprises a chamber, such as a load-lock chamber 110, transfer chamber 115, or process chamber 120. An integrated pump 165 is abutting or adjacent to one of the chambers 110, 115, 120 for evacuating gas from the chambers. In operation, the pump is located within the actual envelope or footprint of the apparatus and has an inlet 170 connected to a chamber 110, 115, 120, and an outlet 175 that exhausts the gas to atmospheric pressure. Preferably, the integrated pump 165 comprises a pre-vacuum pump or a low vacuum pump and is housed in a noise reducing enclosure having means for moving the pump between locations and means for stacking pumps vertically in use.

Owner:APPLIED MATERIALS INC

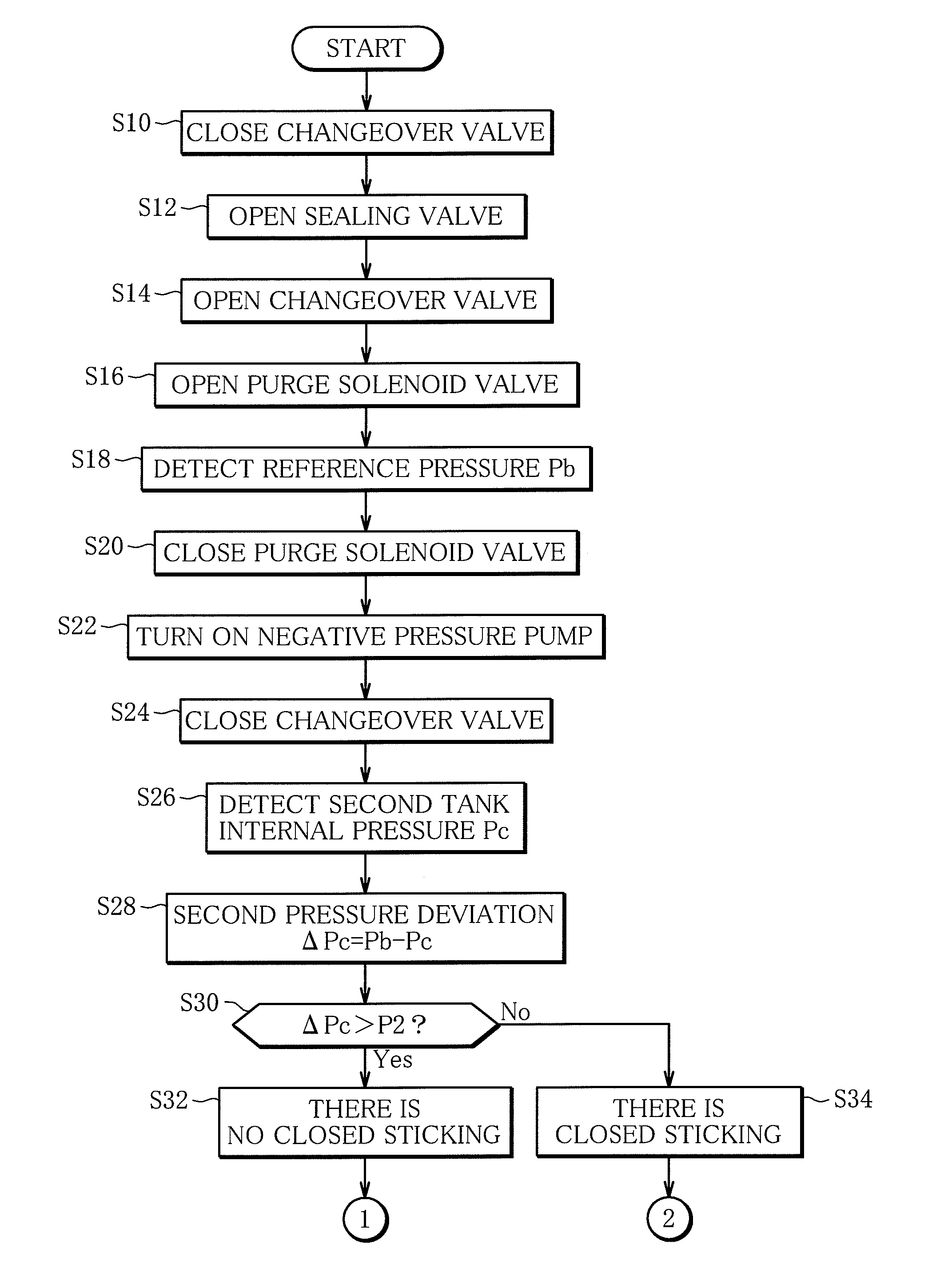

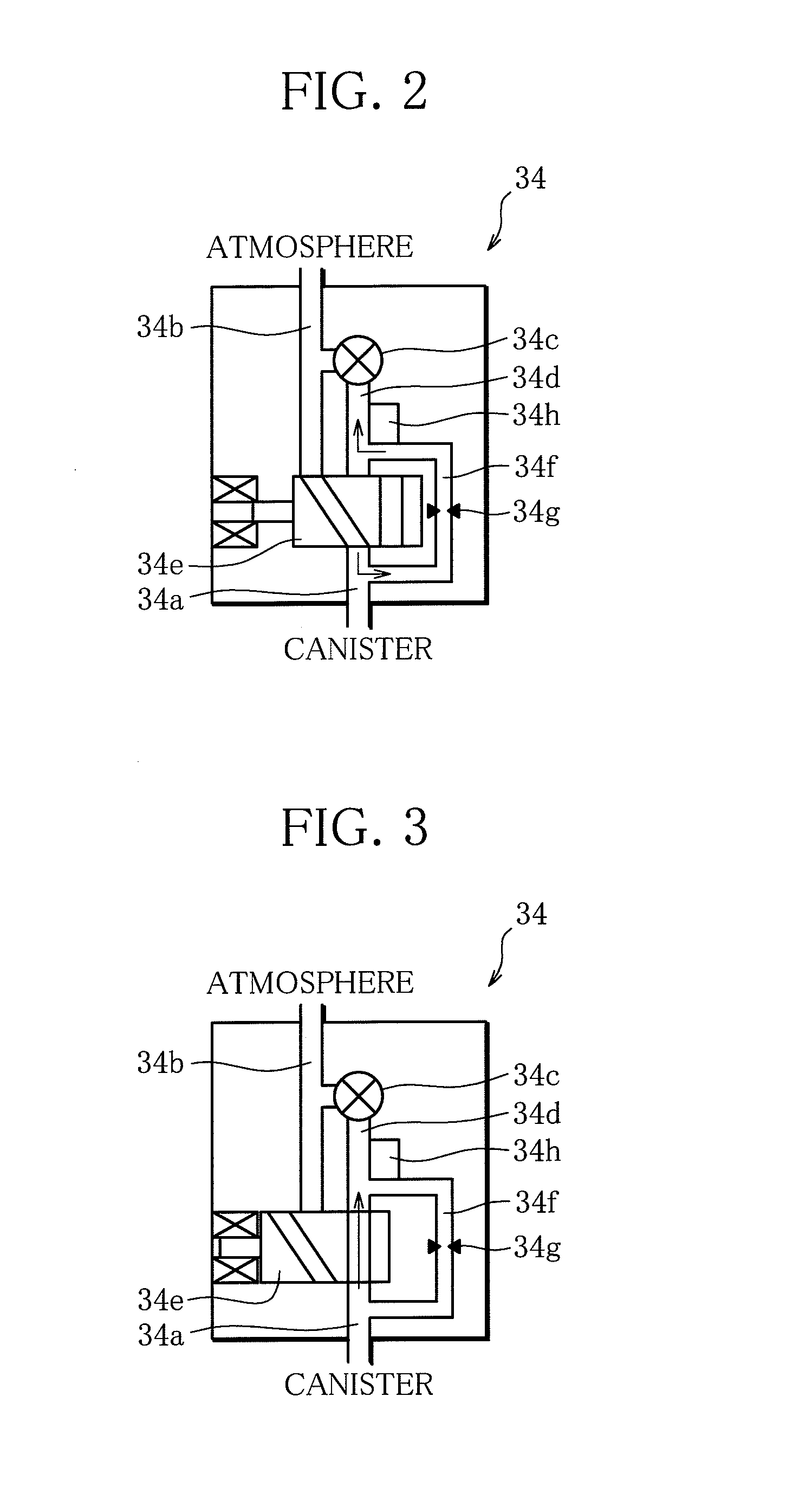

Apparatus for suppressing fuel evaporative gas emission

ActiveUS20140174573A1Reduce the possibilityReliably stickingNon-fuel substance addition to fuelPressure pumpsInternal pressureSolenoid valve

A purge solenoid valve is opened to introduce an atmospheric pressure into a fuel tank, the purge solenoid valve is closed to operate a negative pressure pump, and set an internal pressure of the tank to a reference pressure Pb. Then, a changeover valve is closed, and the purge solenoid valve is opened to cause a canister to communicate with an intake passage. Further, the changeover valve is opened, and the purge solenoid valve is closed. Then, a first tank internal pressure Po is detected and subtracted from the reference pressure Pb. If a calculated first pressure deviation ΔPo is larger than a first threshold ΔP1, it is determined that there is no open sticking in a sealing valve.

Owner:MITSUBISHI MOTORS CORP

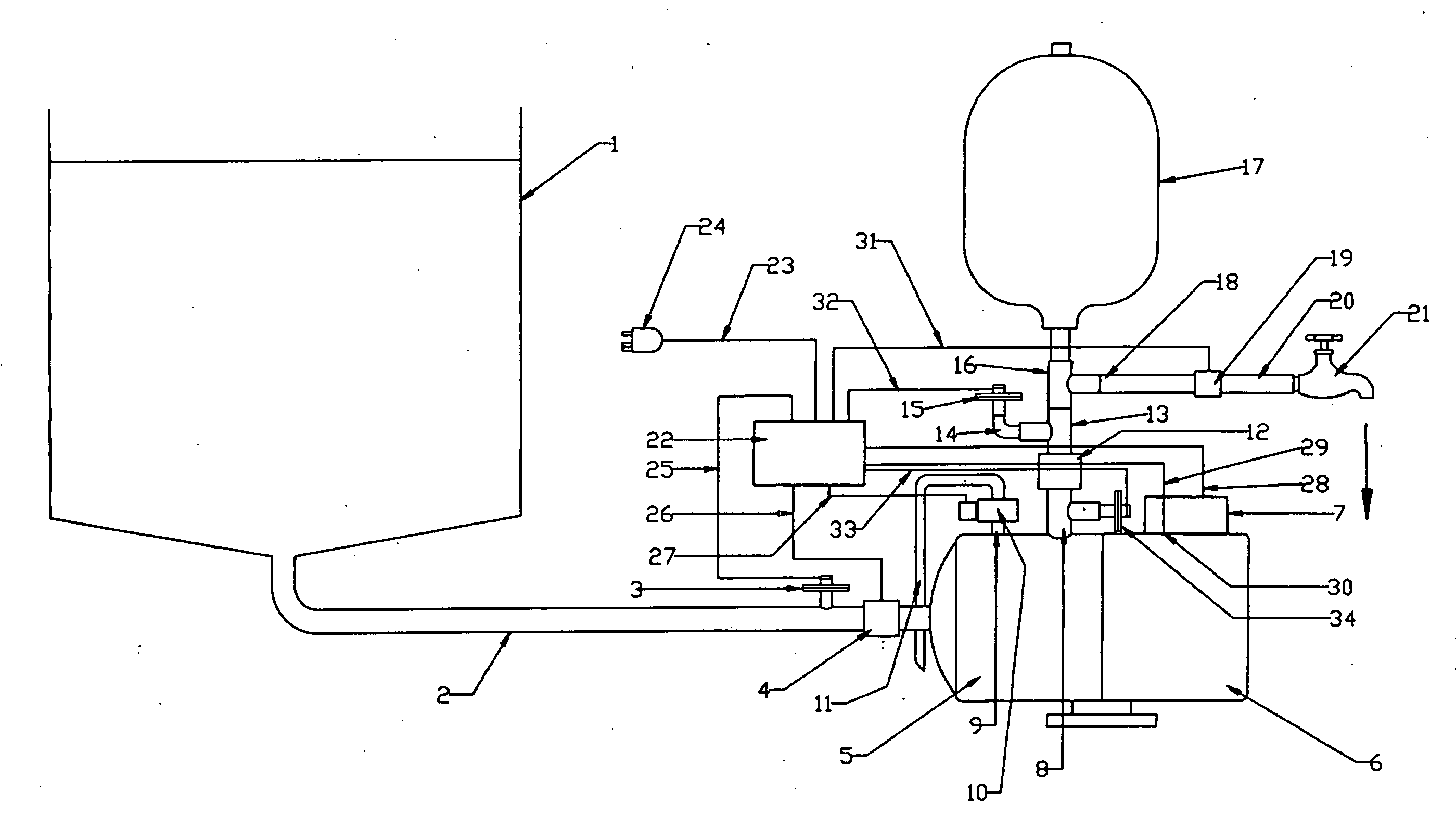

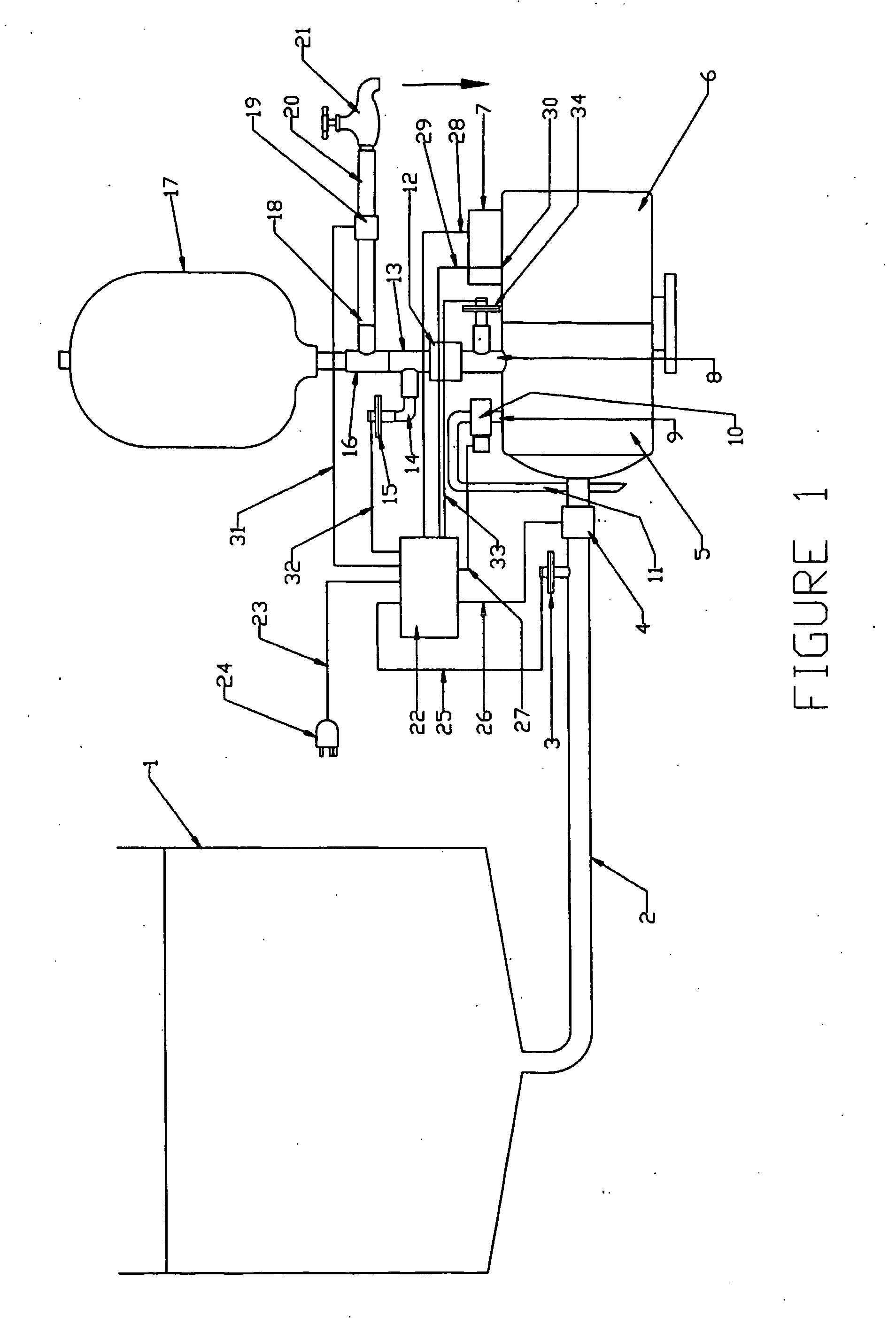

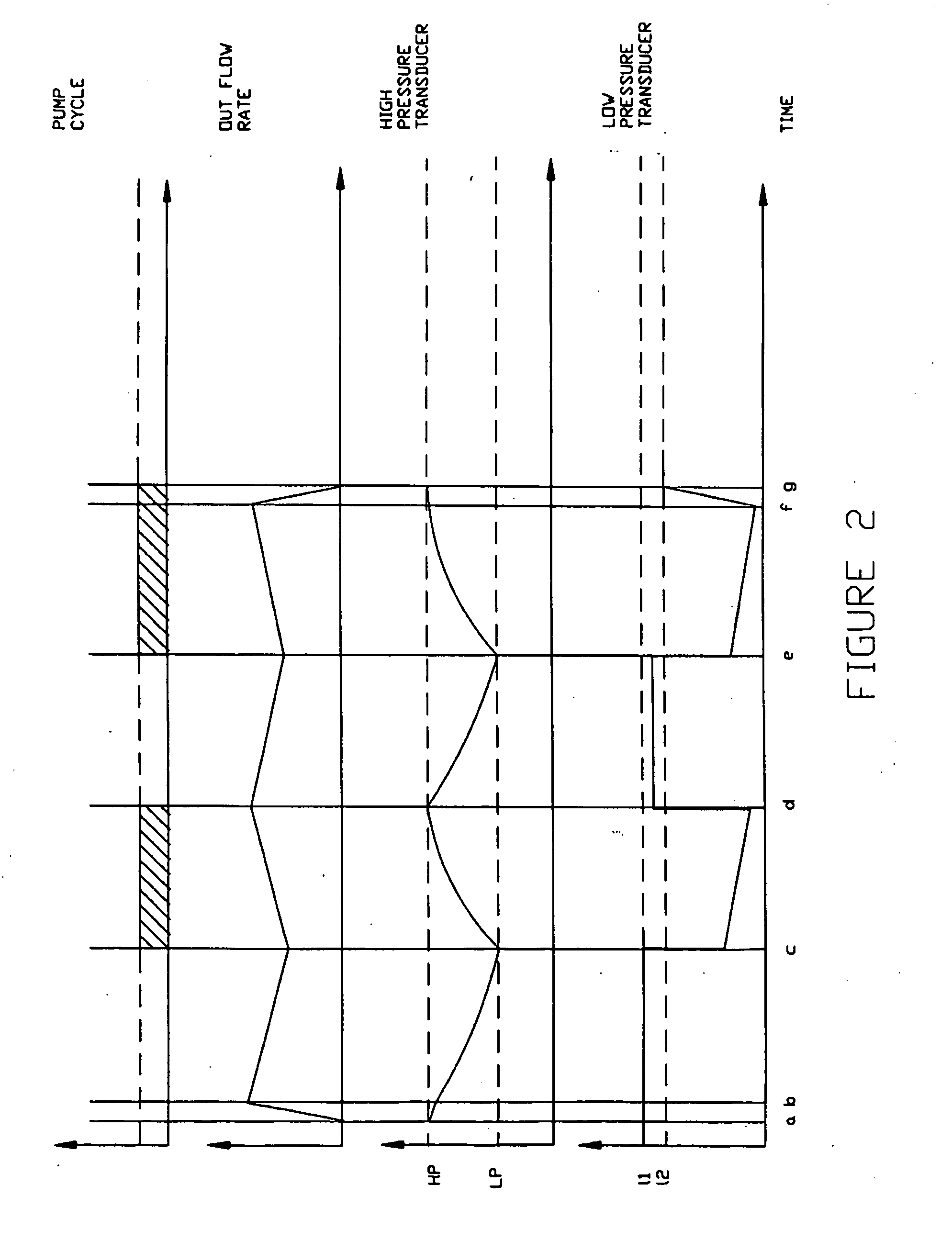

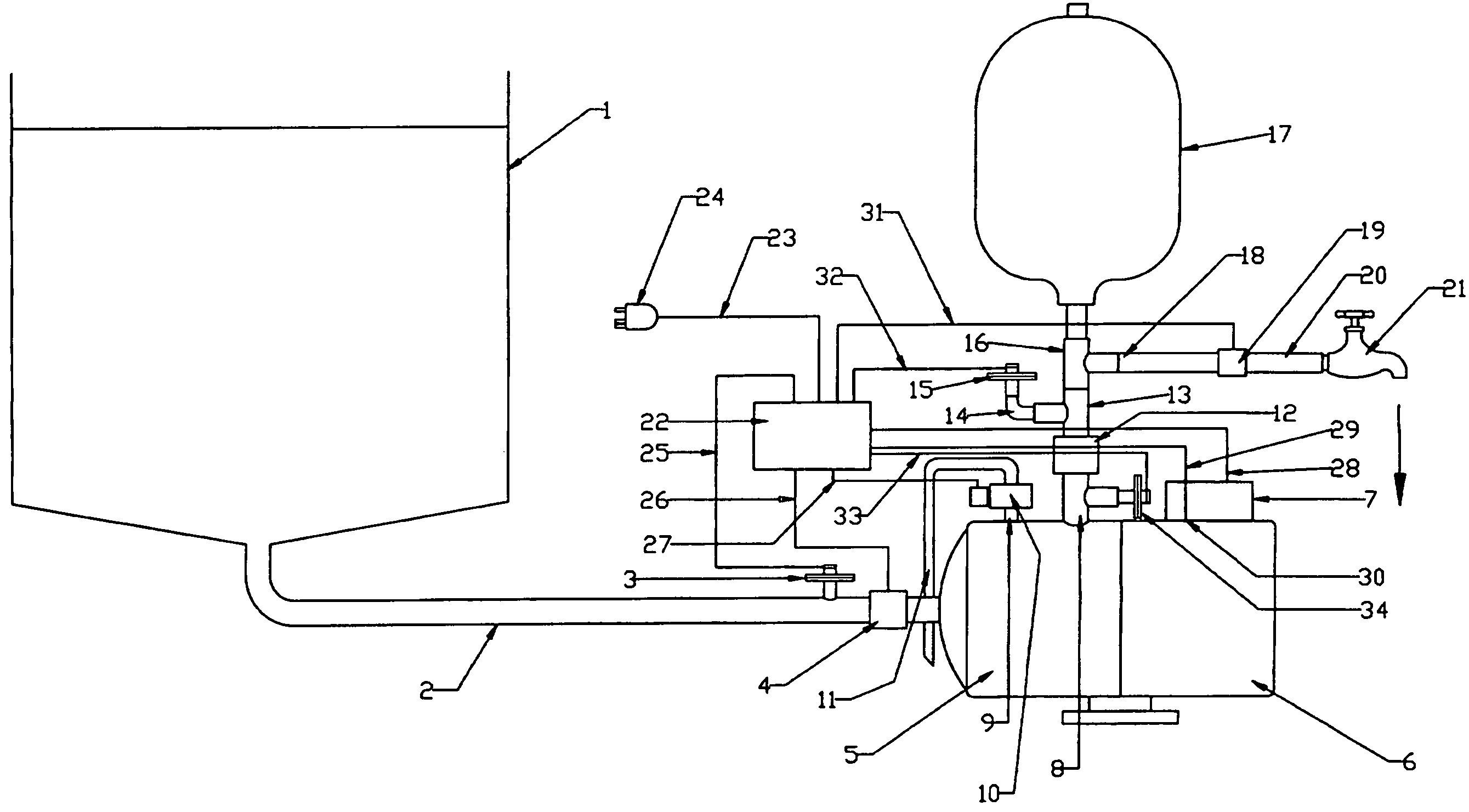

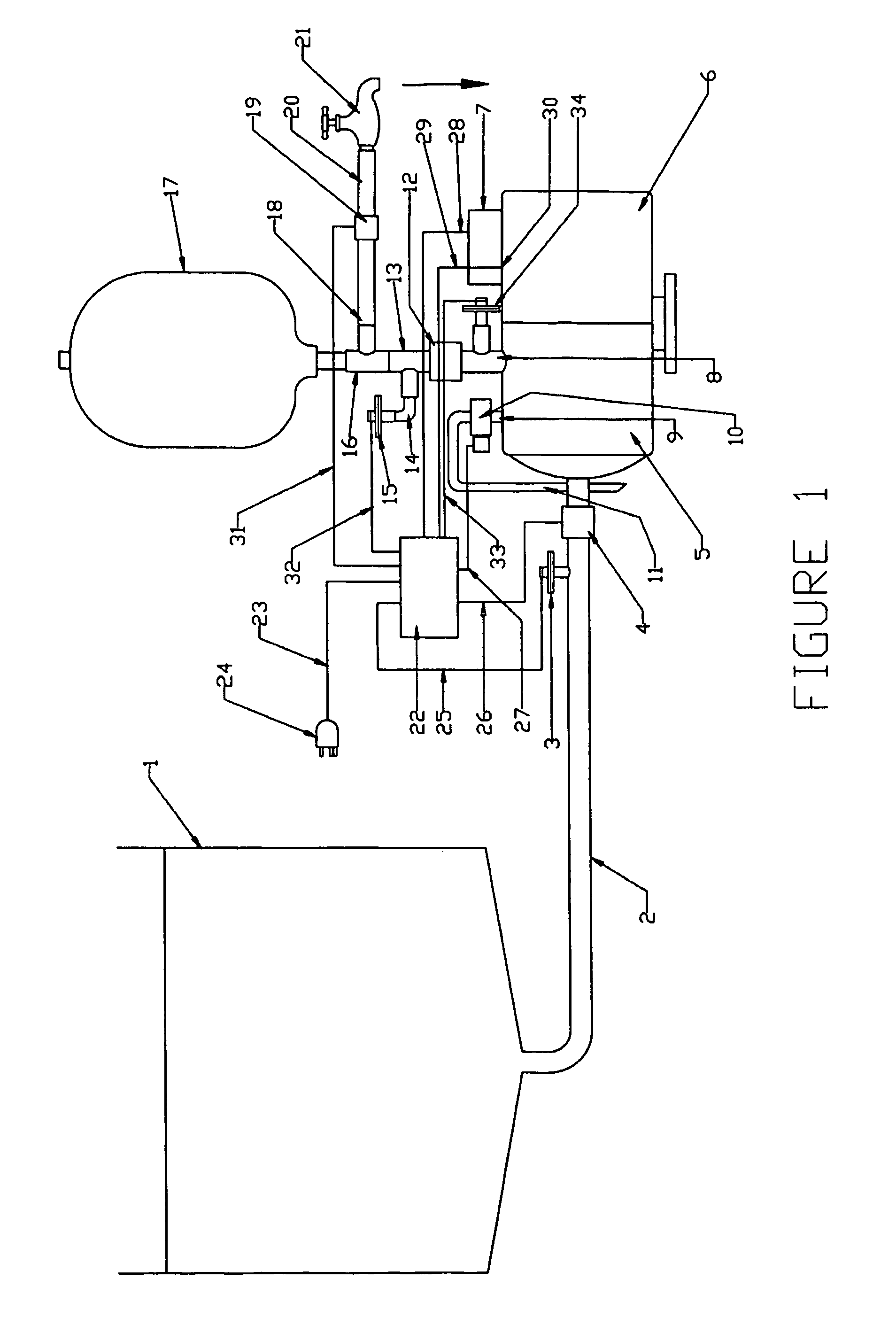

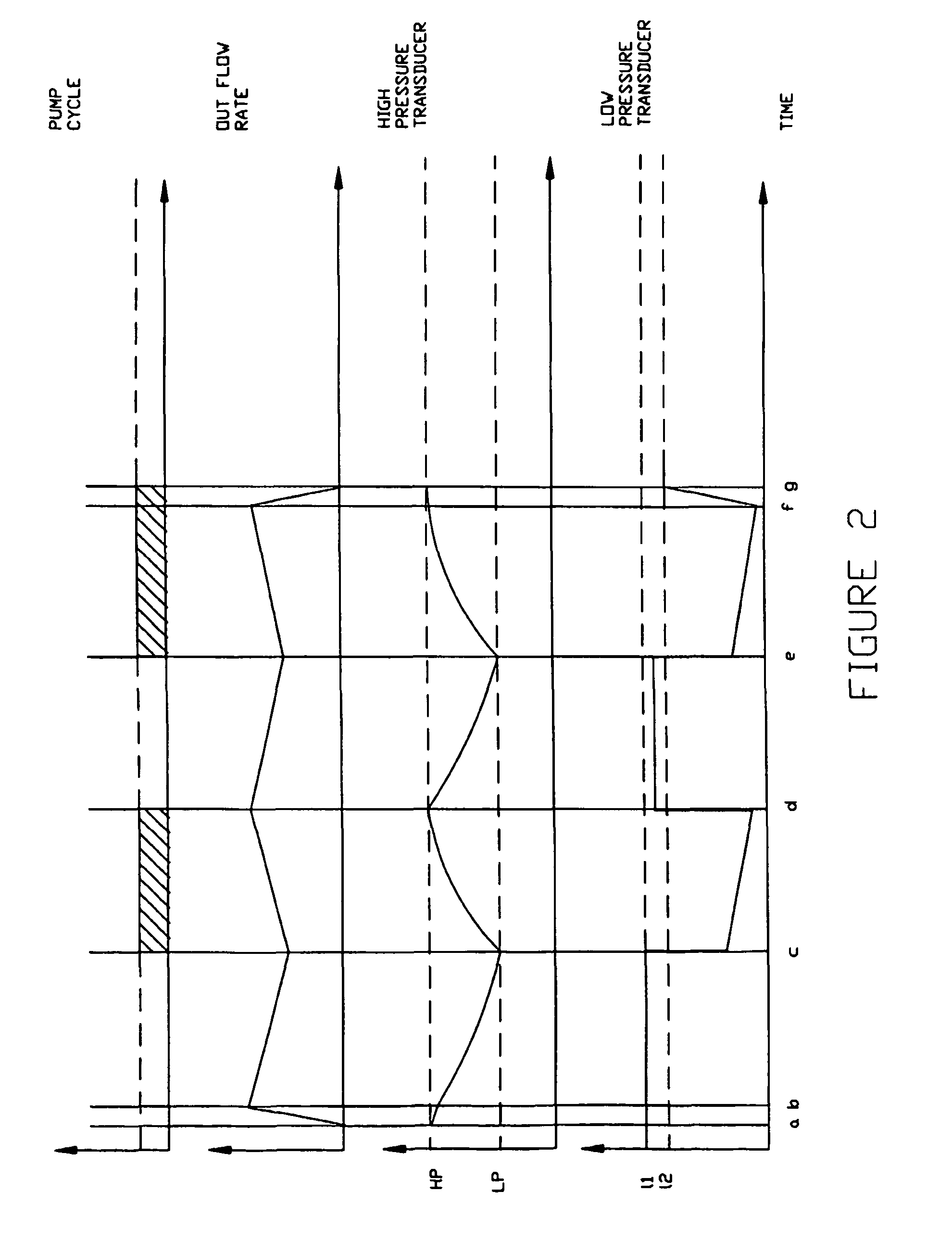

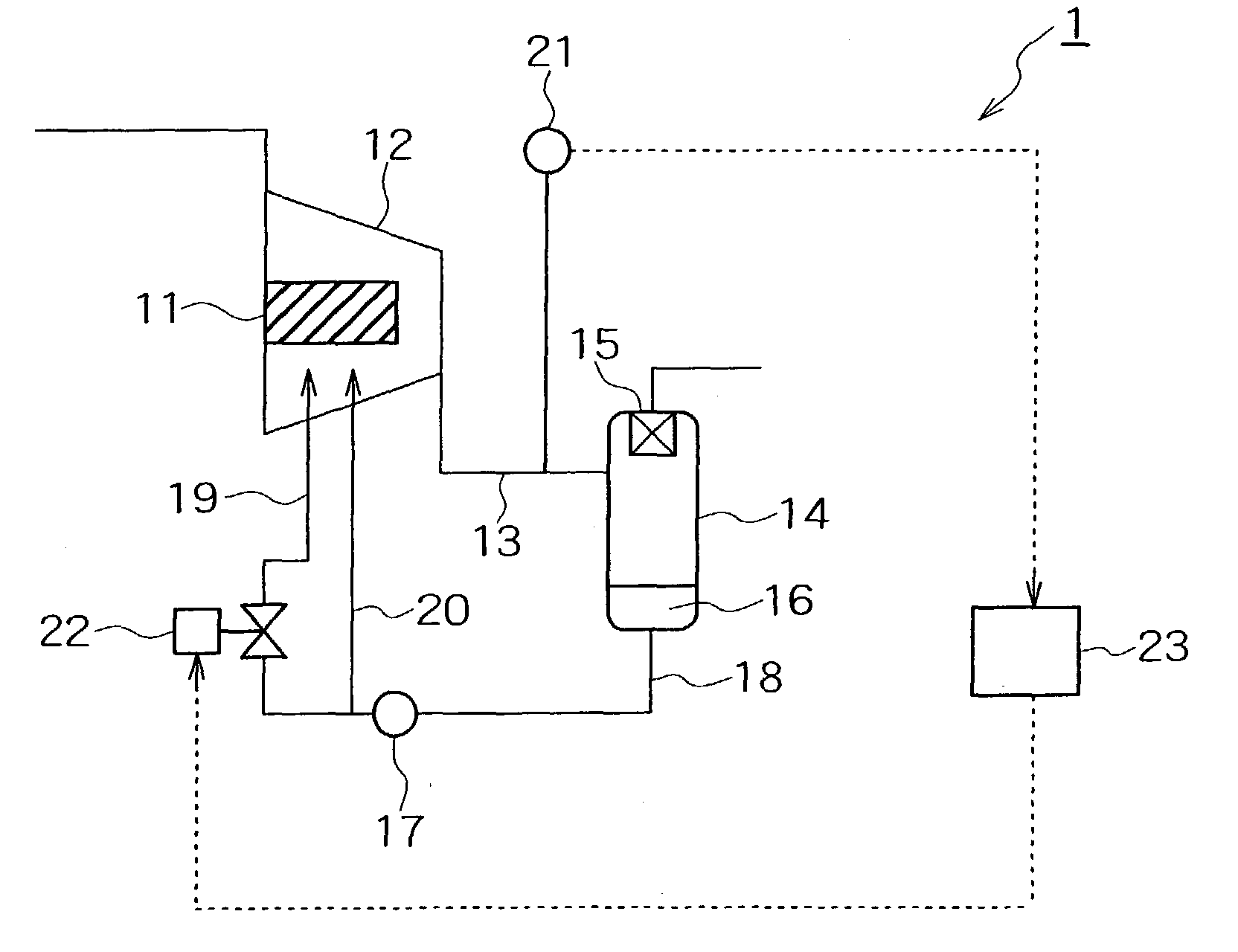

Pump Control System

InactiveUS20080317608A1Adequate determinationSignificant comprehensive benefitsPressure pumpsPriming pumpFlow transducerControl system

A pumping system in which a pump (5) is controlled by a programmed controller (22) in response to input signals from an inlet pressure transducer (3) and an outlet pressure transducer (15) and in certain circumstances inputs from various flow sensors (4,19). The controller (22) can be programmed to allow the pump (5) to prematurely operate before an outlet pressure reaches a low pressure threshold, when usage of the liquid is high. The controller (22) can be programmed to detect a lack of prime of the pump (5), to restore prime once the pump (5) has lost prime, and to prevent successive on / off pump cycles when the outlet flow is continuous and at a moderate or low level.

Owner:GRAY

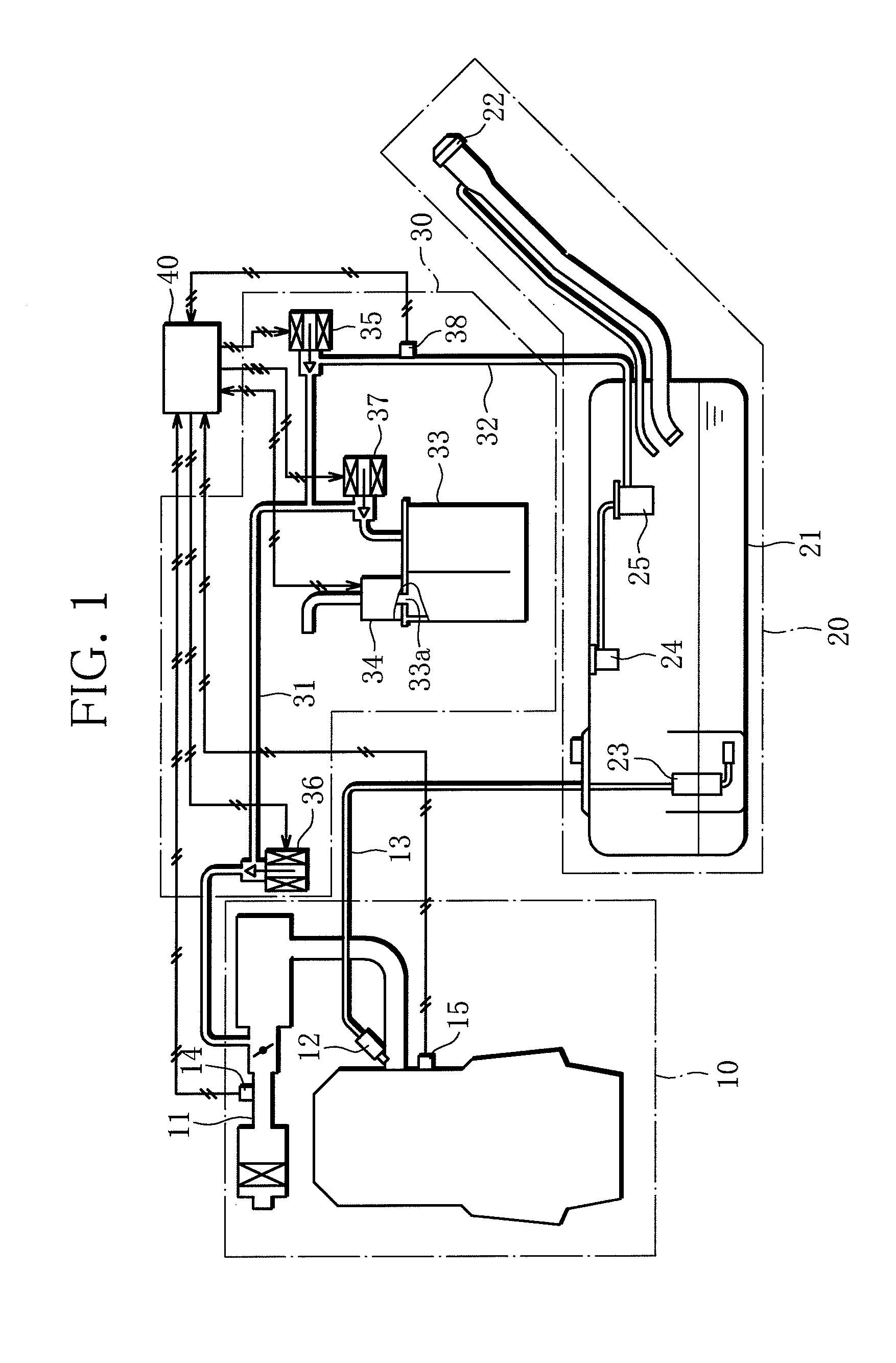

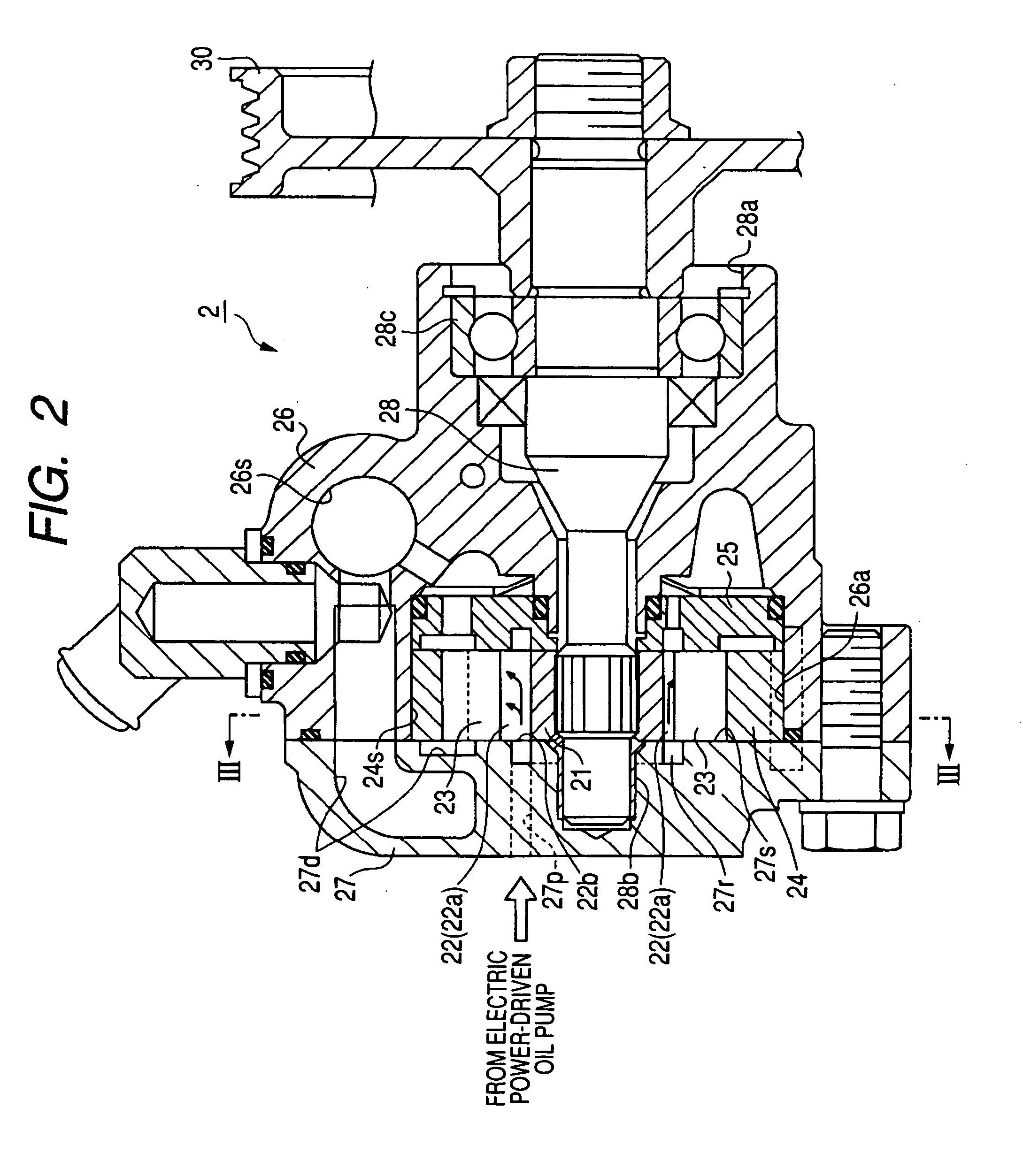

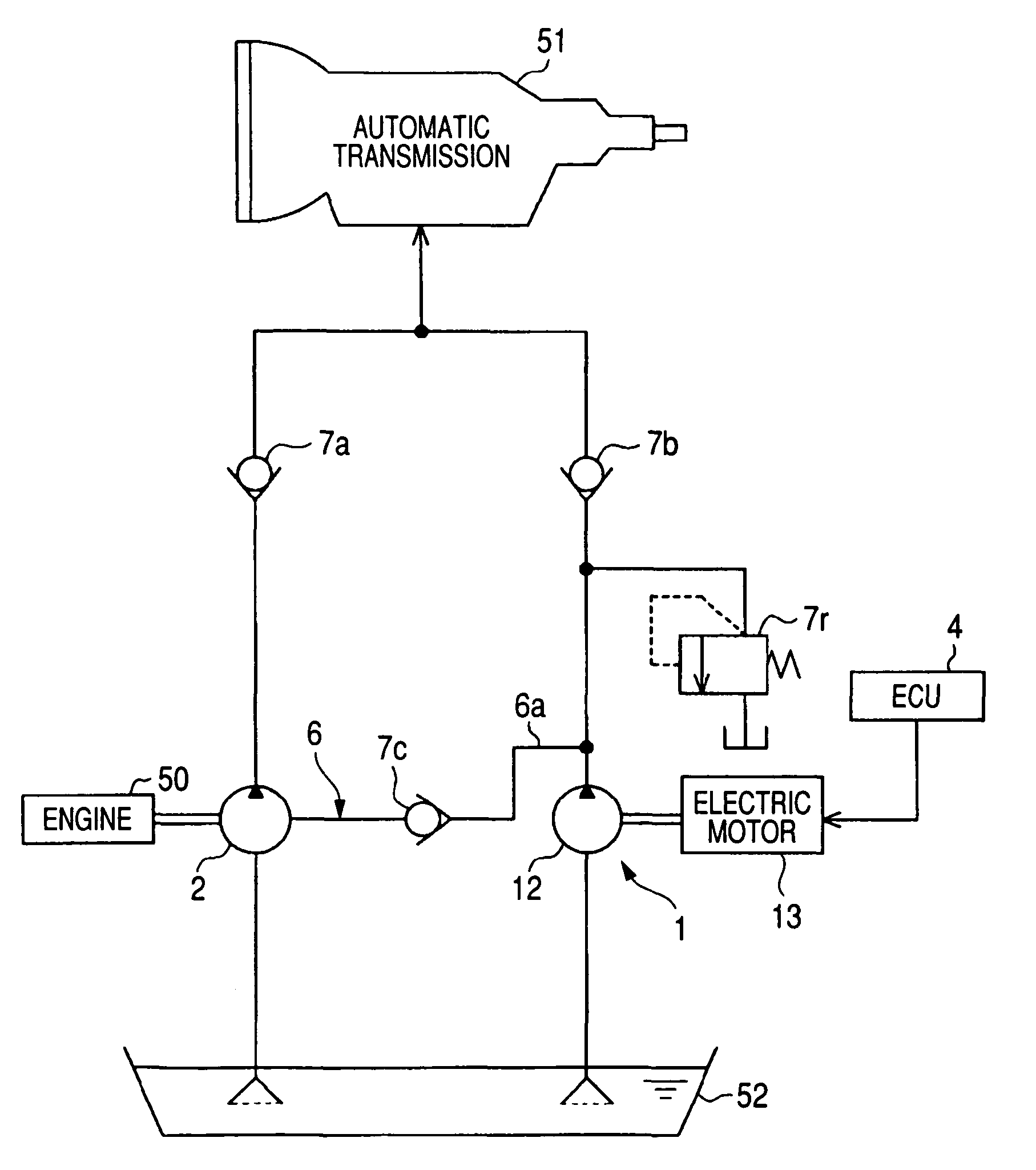

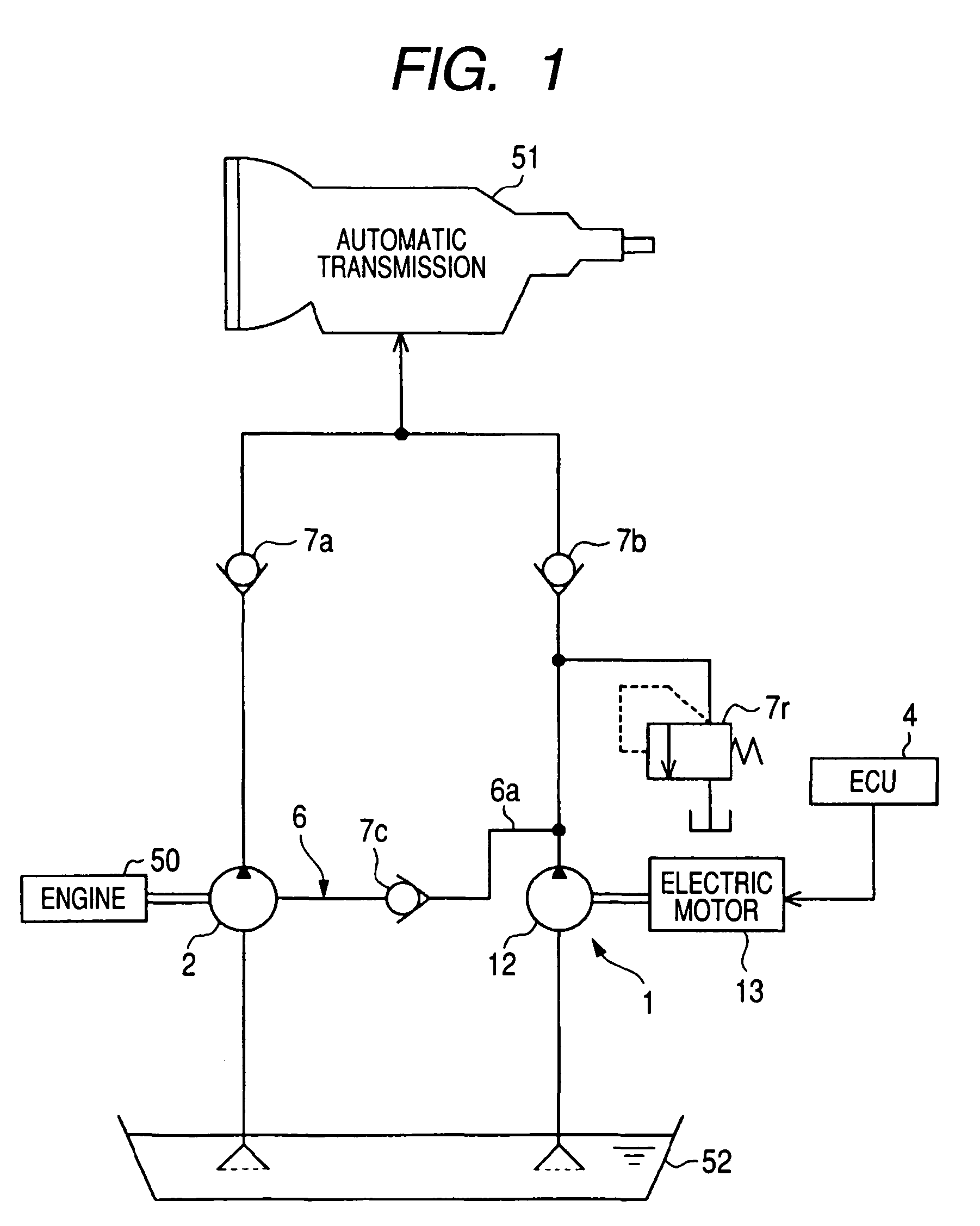

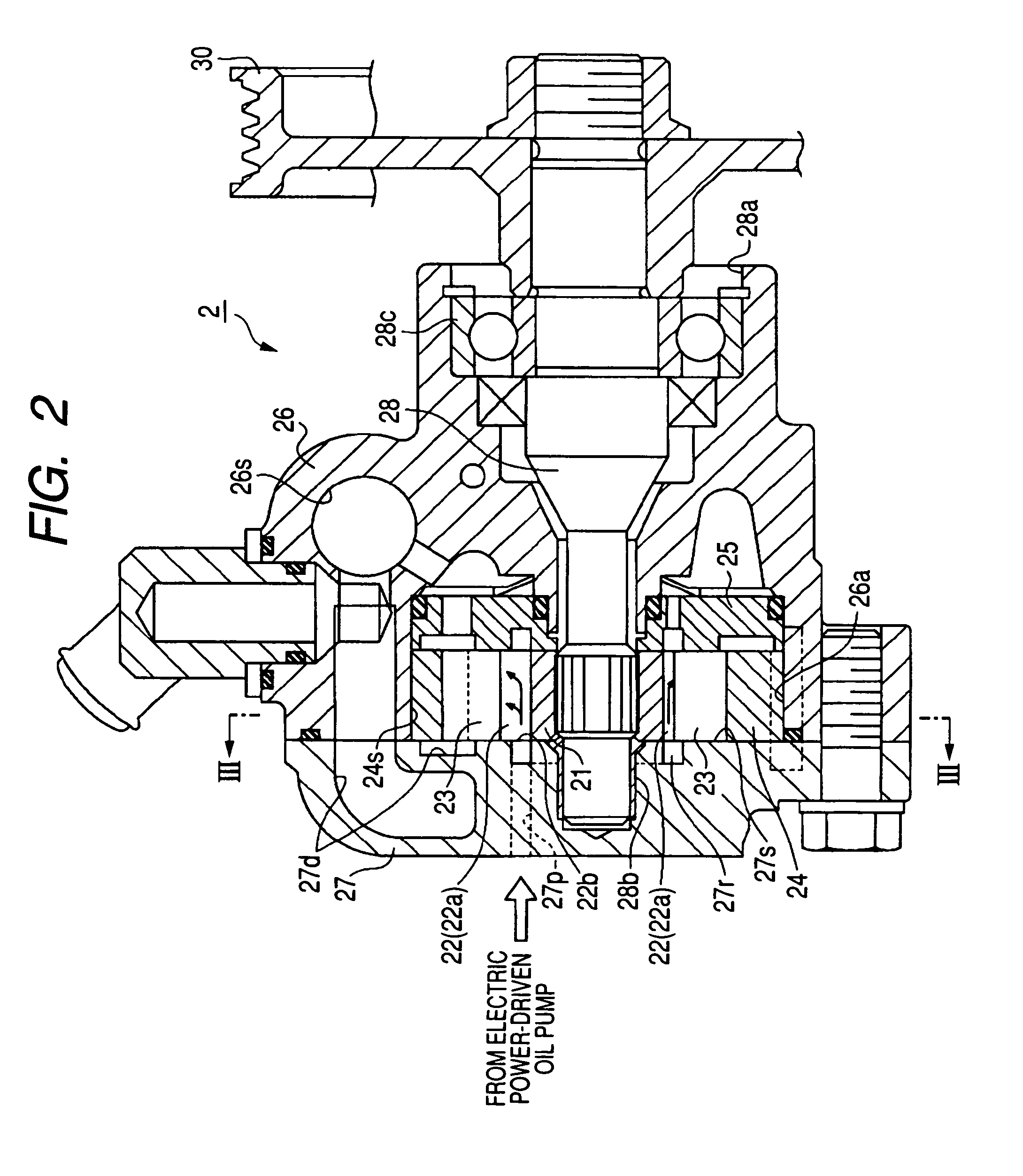

Oil pump system for vehicle

ActiveUS20080286123A1Constant flow rate characteristicSmall pulsationPressure pumpsGearing controlAutomatic transmissionIdle speed

An oil pump system for a vehicle includes: a vane pump having a plurality of vanes which respectively project retractably from a plurality of vane accommodating grooves provided in a rotor so as to be brought into sliding contact with a cam surface, the vane pump being adapted to supply a hydraulic fluid to an automatic transmission; an electric power-driven oil pump for assisting the hydraulic pressure of the hydraulic fluid during an idling stop of the automobile; and an ECU for controlling its operation. During an idling stop, the hydraulic fluid is fed to the automatic transmission by the operation of the electric power-driven oil pump to assist the hydraulic pressure, while the hydraulic fluid is fed with pressure also to the vane accommodating grooves to press the vanes against the cam surface.

Owner:JTEKT CORP

Oil pump system for vehicle

An oil pump system for a vehicle includes: a vane pump having a plurality of vanes which respectively project retractably from a plurality of vane accommodating grooves provided in a rotor so as to be brought into sliding contact with a cam surface, the vane pump being adapted to supply a hydraulic fluid to an automatic transmission; an electric power-driven oil pump for assisting the hydraulic pressure of the hydraulic fluid during an idling stop of the automobile; and an ECU for controlling its operation. During an idling stop, the hydraulic fluid is fed to the automatic transmission by the operation of the electric power-driven oil pump to assist the hydraulic pressure, while the hydraulic fluid is fed with pressure also to the vane accommodating grooves to press the vanes against the cam surface.

Owner:JTEKT CORP

Pump control system

InactiveUS7901190B2Adequate determinationSignificant comprehensive benefitsPressure pumpsPump controlControl systemTransducer

A pumping system in which a pump (5) is controlled by a programmed controller (22) in response to input signals from an inlet pressure transducer (3) and an outlet pressure transducer (15) and in certain circumstances inputs from various flow sensors (4,19). The controller (22) can be programmed to allow the pump (5) to prematurely operate before an outlet pressure reaches a low pressure threshold, when usage of the liquid is high. The controller (22) can be programmed to detect a lack of prime of the pump (5), to restore prime once the pump (5) has lost prime, and to prevent successive on / off pump cycles when the outlet flow is continuous and at a moderate or low level.

Owner:GRAY

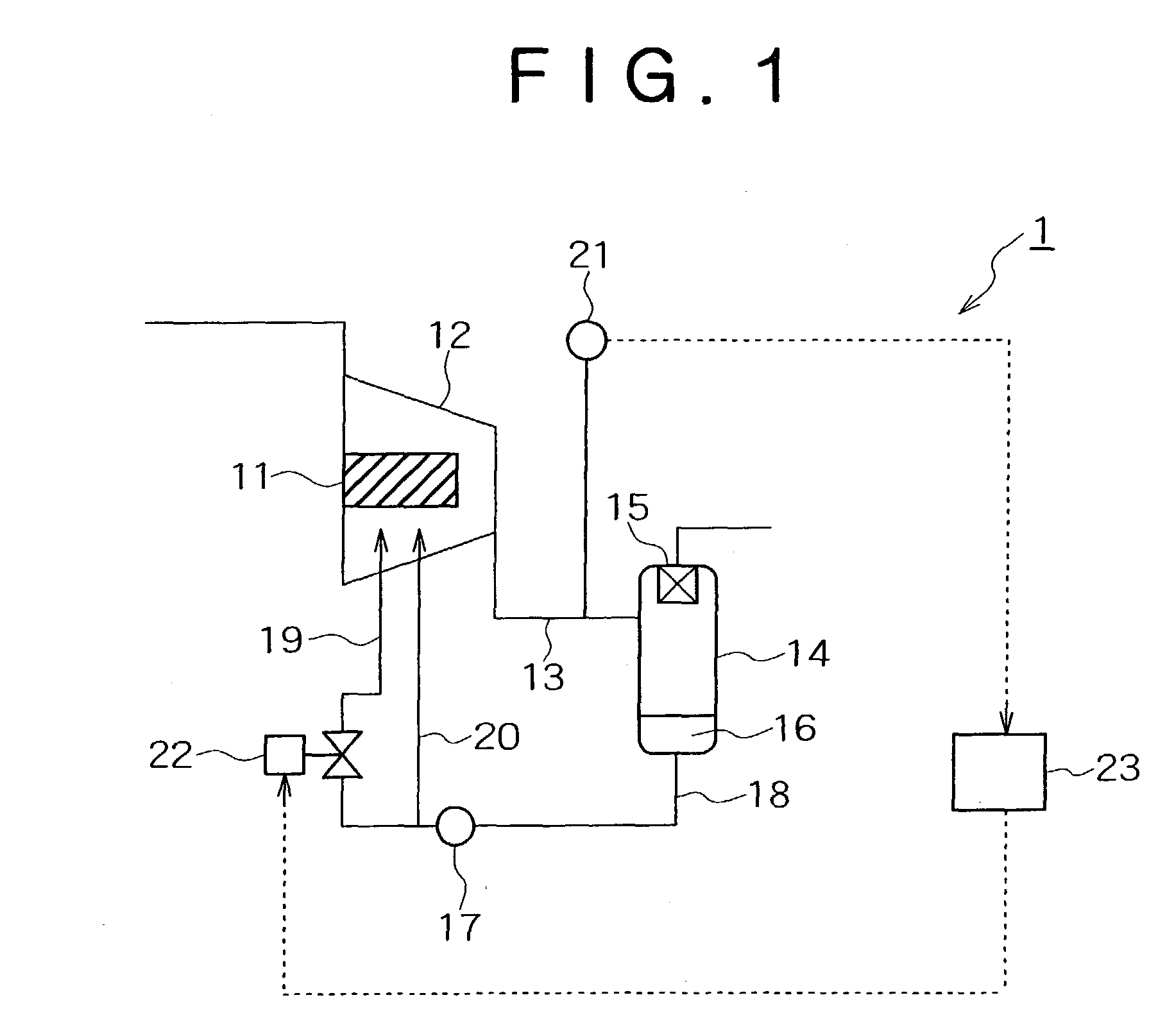

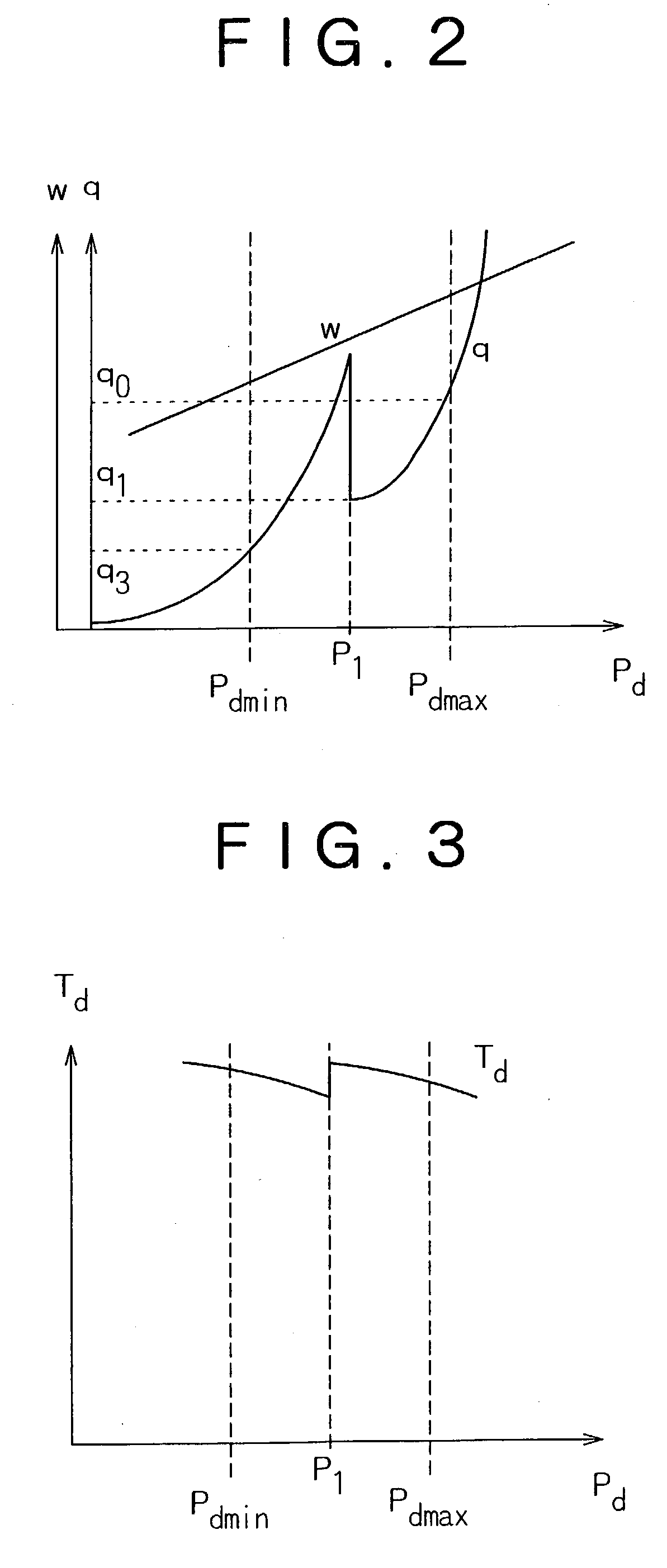

Oil-cooled compressor

An oil-cooled screw compressor which can maintain the discharge temperature of discharge gas at an appropriate level is provided. The oil-cooled screw compressor comprises a compressor body, an oil separation / recovery unit disposed in a discharge path extending from a discharge port of the compressor body, and an oil feed path extending from the oil separation / recovery unit and communicating with the compressor body 12. The oil feed path is branched at an intermediate position thereof into a first feed path portion and a second feed path portion. An opening / closing valve is disposed in the first feed path portion, a pressure gauge is disposed in the discharge path, and a control unit is provided to control opening and closing of the opening / closing valve on the basis of a correlation between a discharge pressure detected by the pressure gauge and a predetermined pressure.

Owner:KOBELCO COMPRESSORS CORP

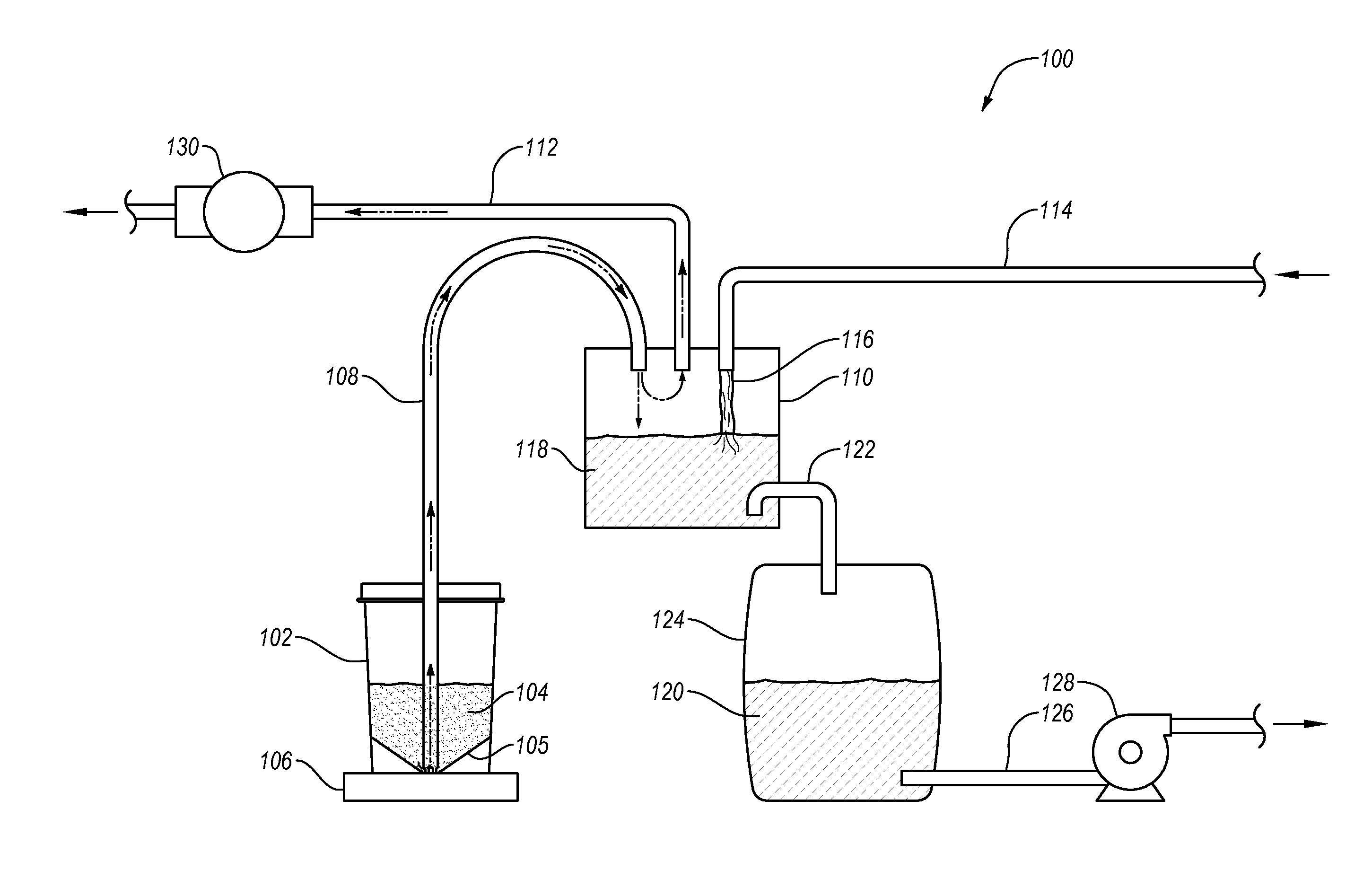

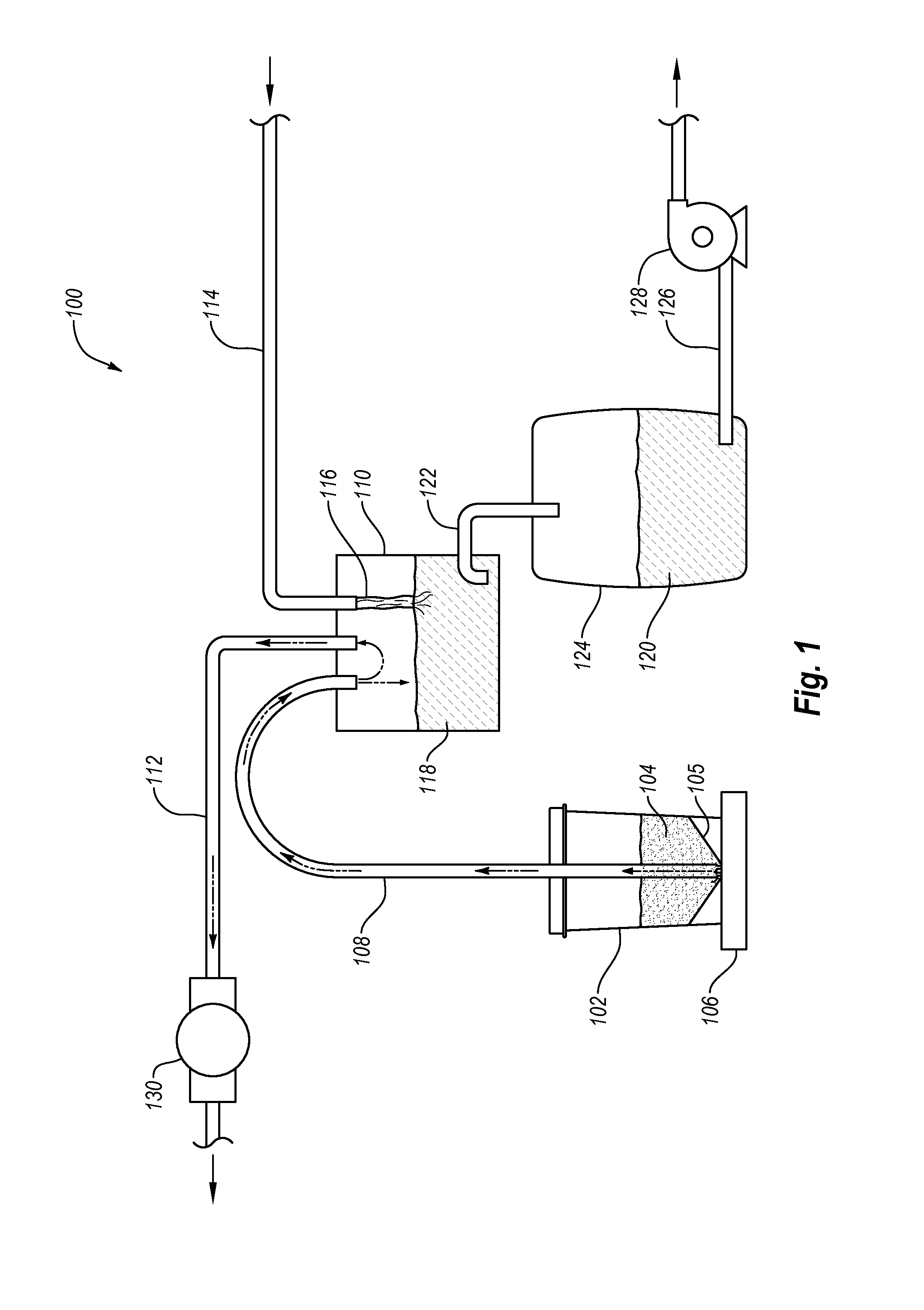

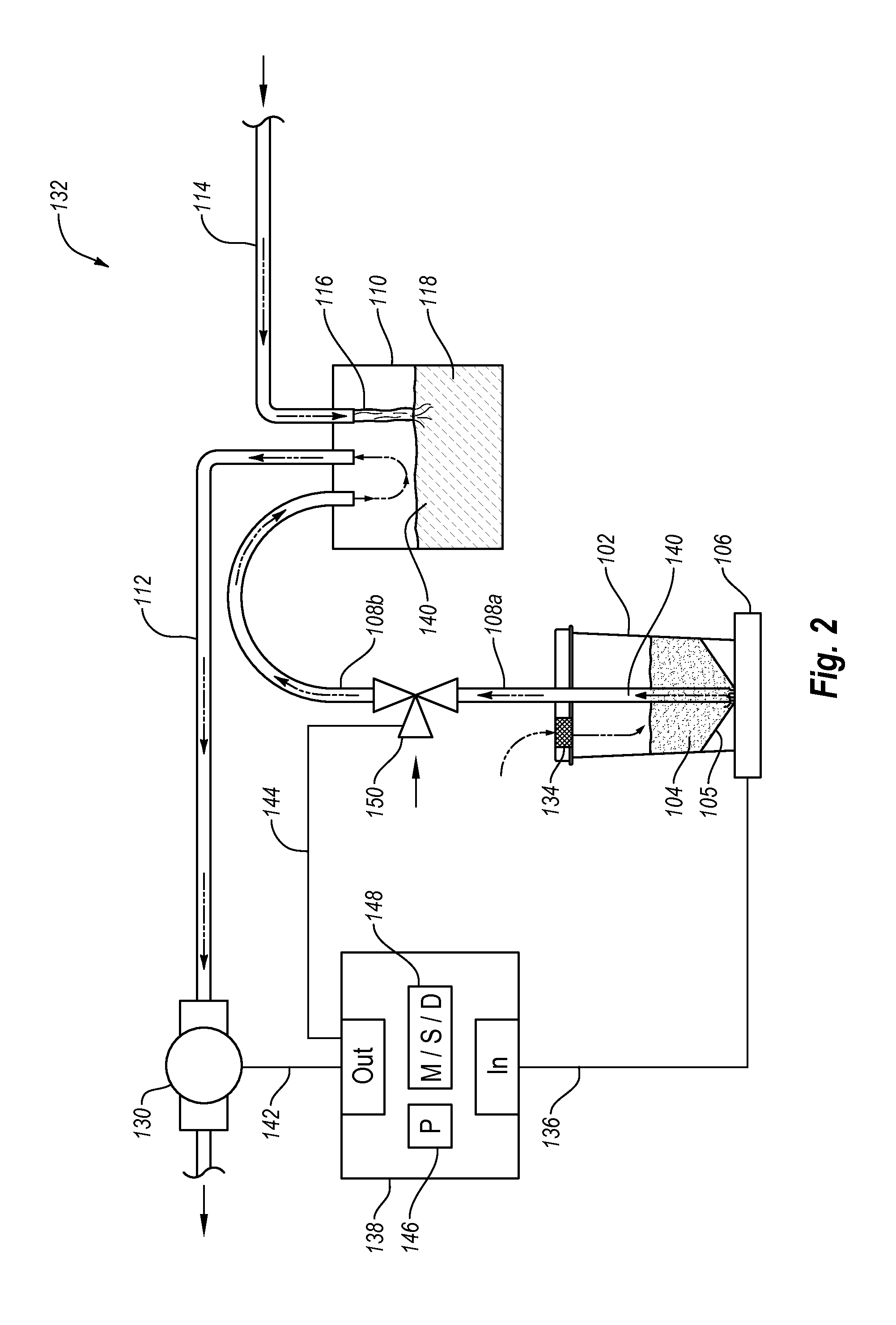

Priming apparatus for a centrifugal pump

InactiveUS7334600B2Reduce surging and turbulenceReduce morbidityLighting and heating apparatusPressure pumpsVacuum assistedAtmospheric air

A vacuum assisted priming system for a fluid pump including a housing defining a hopper that communicates with a pump inlet. The housing mounts a first port that communicates with the source of vacuum and a second port that communicates with atmosphere. A check valve allows atmospheric air to flow into the housing under certain operating conditions but inhibits reverse flow. A valve member pivotally mounted within a valve chamber carries first and second sealing elements that are engageable with first and second seats. The lever arm is operatively connected to a float via a lost motion connection. When the fluid level in the hopper rises to a predetermined level, an actuating rod moves the lever arm to a first sealing position. When the fluid level falls to a predetermined level, the actuating rod moves the lever arm to a second sealing position. A baffle located at an inlet to the hopper reduces surging and turbulence in the hopper and defines a circuitous path through which the fluid must flow in order to enter the hopper.

Owner:GORMAN RUPP COMPANY THE

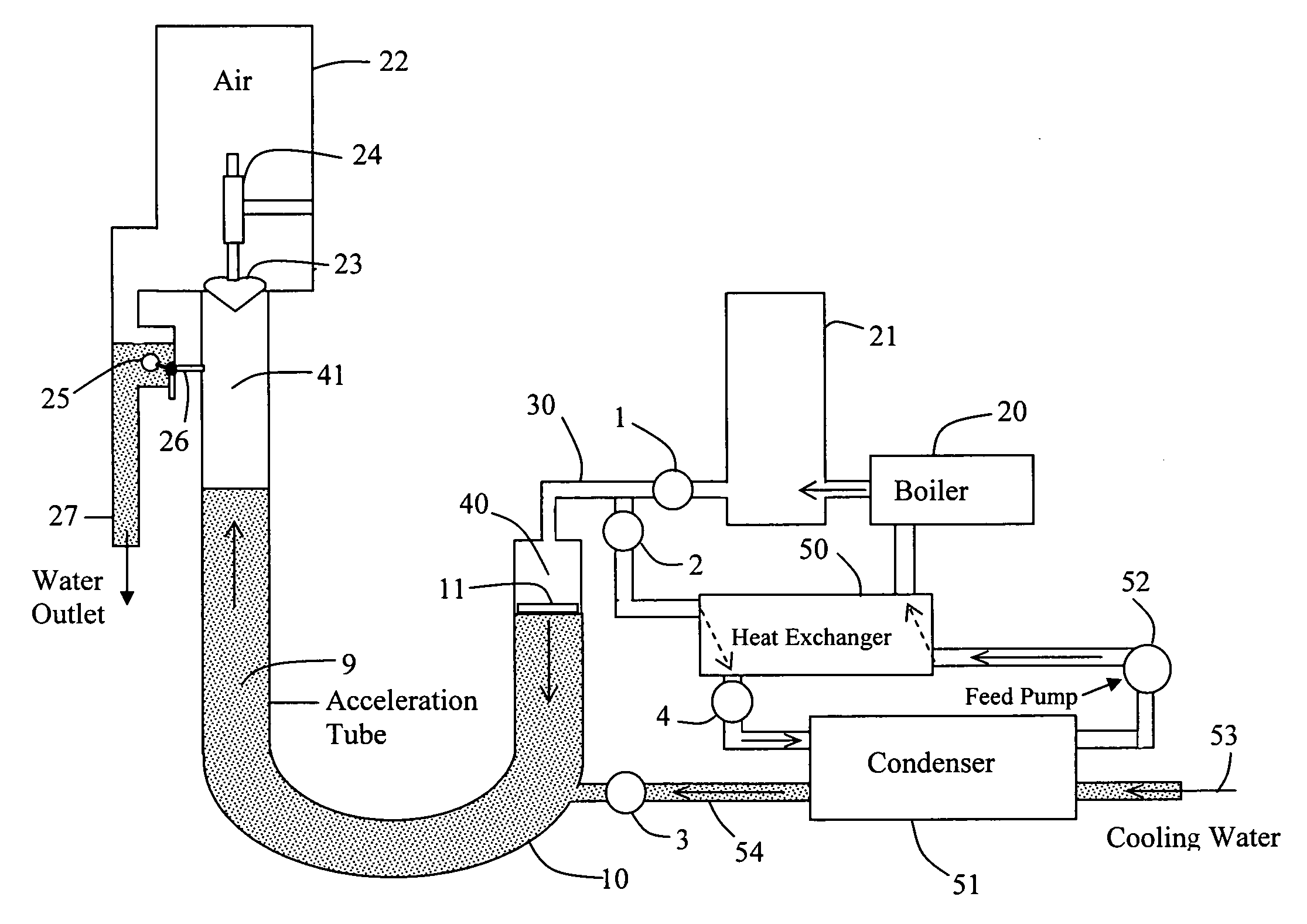

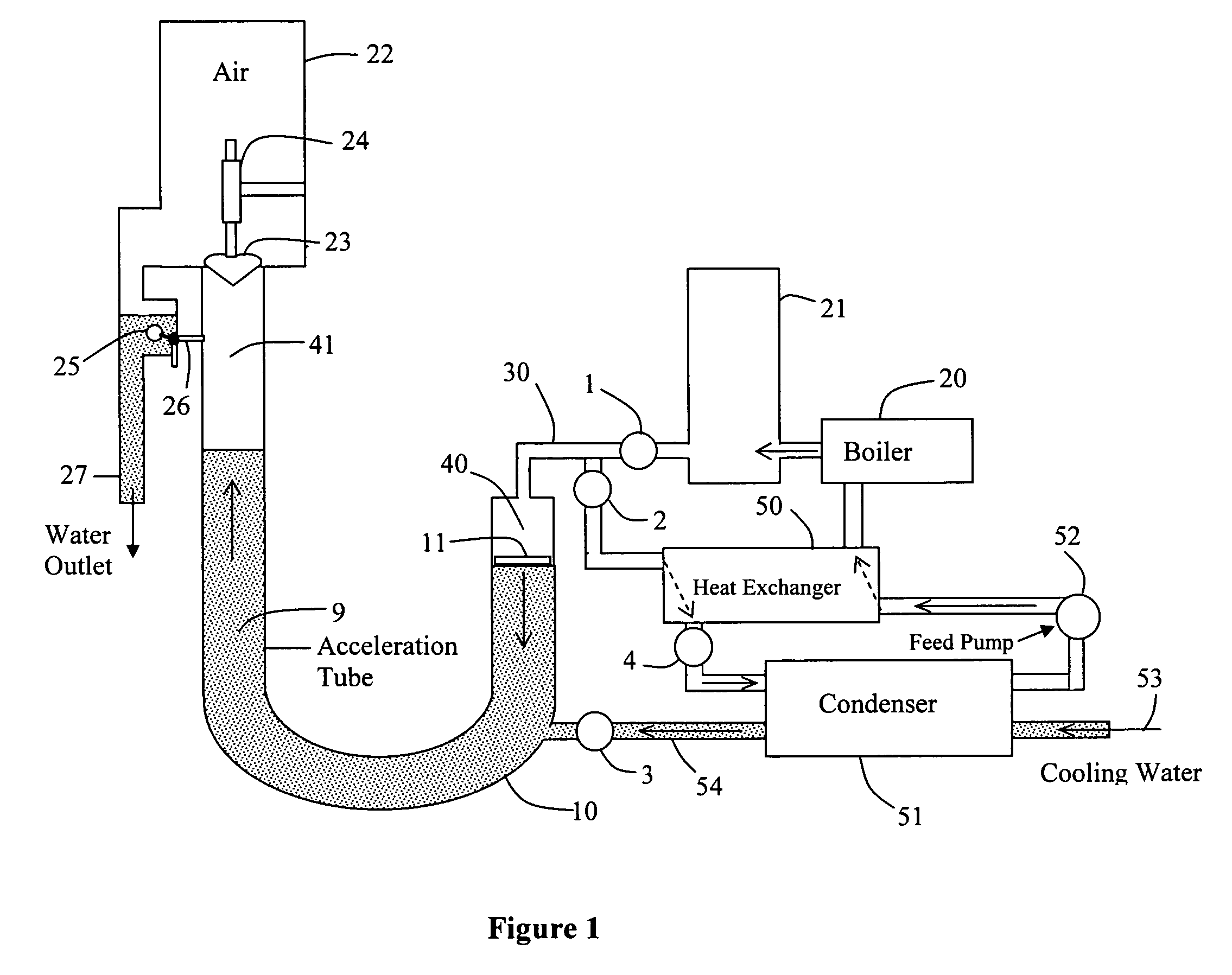

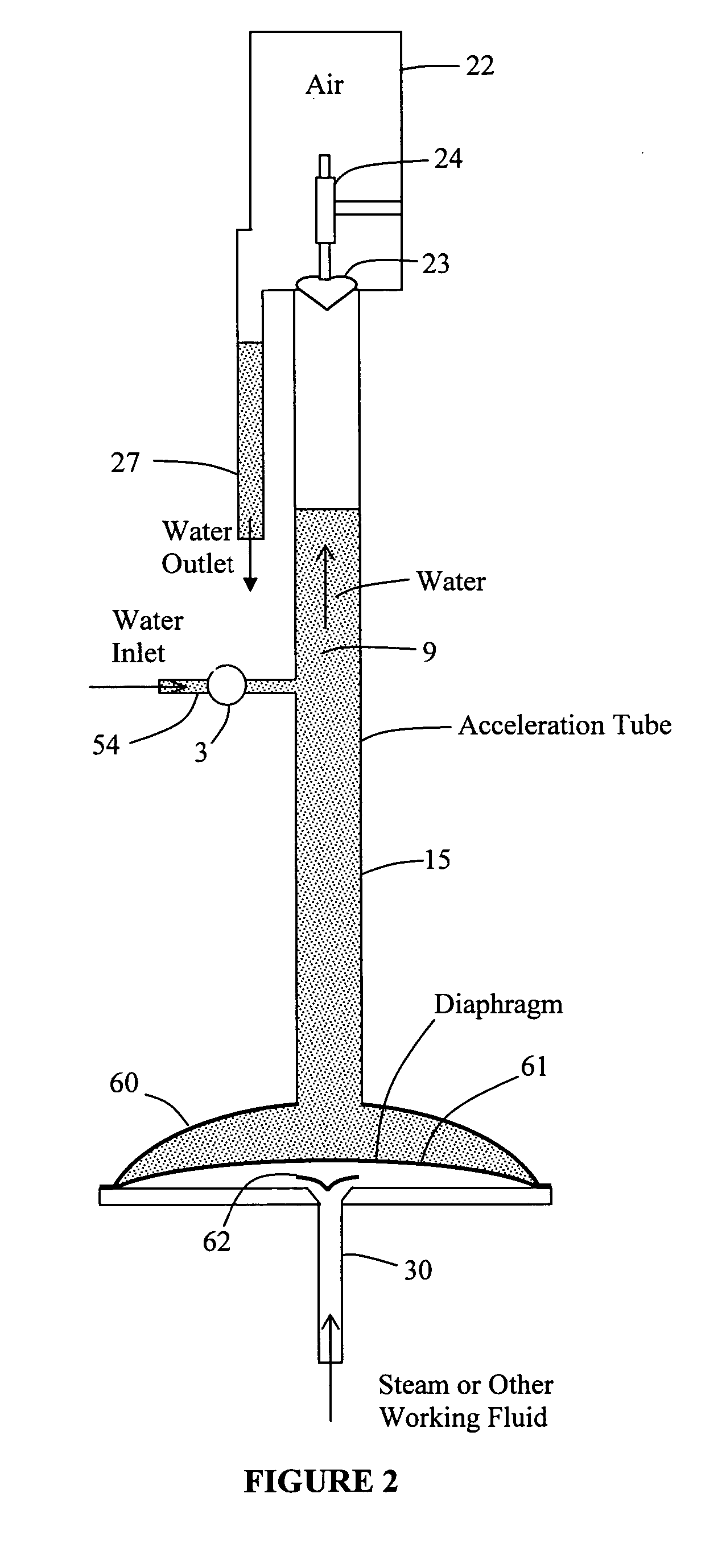

Vapor-powered kinetic pump

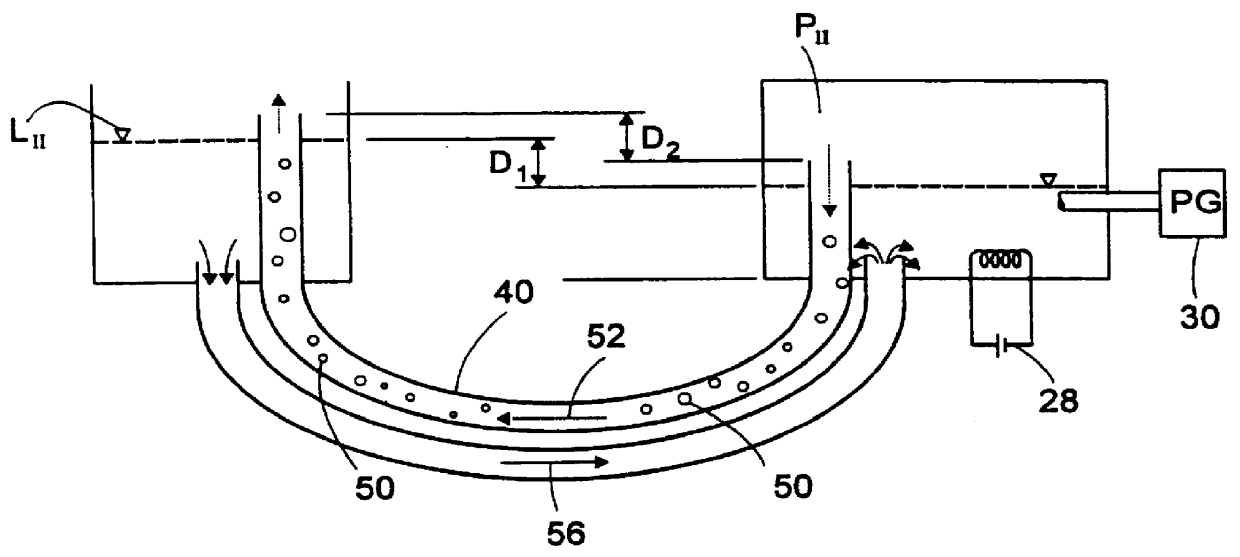

InactiveUS7021900B2Travel distance is limitedAvoid steam condensationPositive displacement pump componentsFlexible member pumpsSurge tankProduct gas

A kinetic pump and method of pumping a liquid comprising providing an acceleration tube for the acceleration of a liquid contained therein by an introduced high-pressure vapor or gas, receiving the liquid from the acceleration tube with a compressed-air surge tank, admitting the liquid from the acceleration tube into the compressed-air surge tank via a check valve, draining the liquid from the compressed-air surge tank from an outlet, and adding additional liquid to the acceleration tube via an inlet, wherein during each first half cycle of the method, the vapor or gas forces the liquid to accelerate in the acceleration tube, whereby a portion of the liquid is forced into the compressed-air surge tank, and wherein during each second half cycle of the pump, the vapor or gas is substantially removed from the acceleration tube and the liquid flows back to its original location and the additional liquid is added to the liquid.

Owner:PRUEITT FAMILY TRUST S PRUEITT TRUSTEE

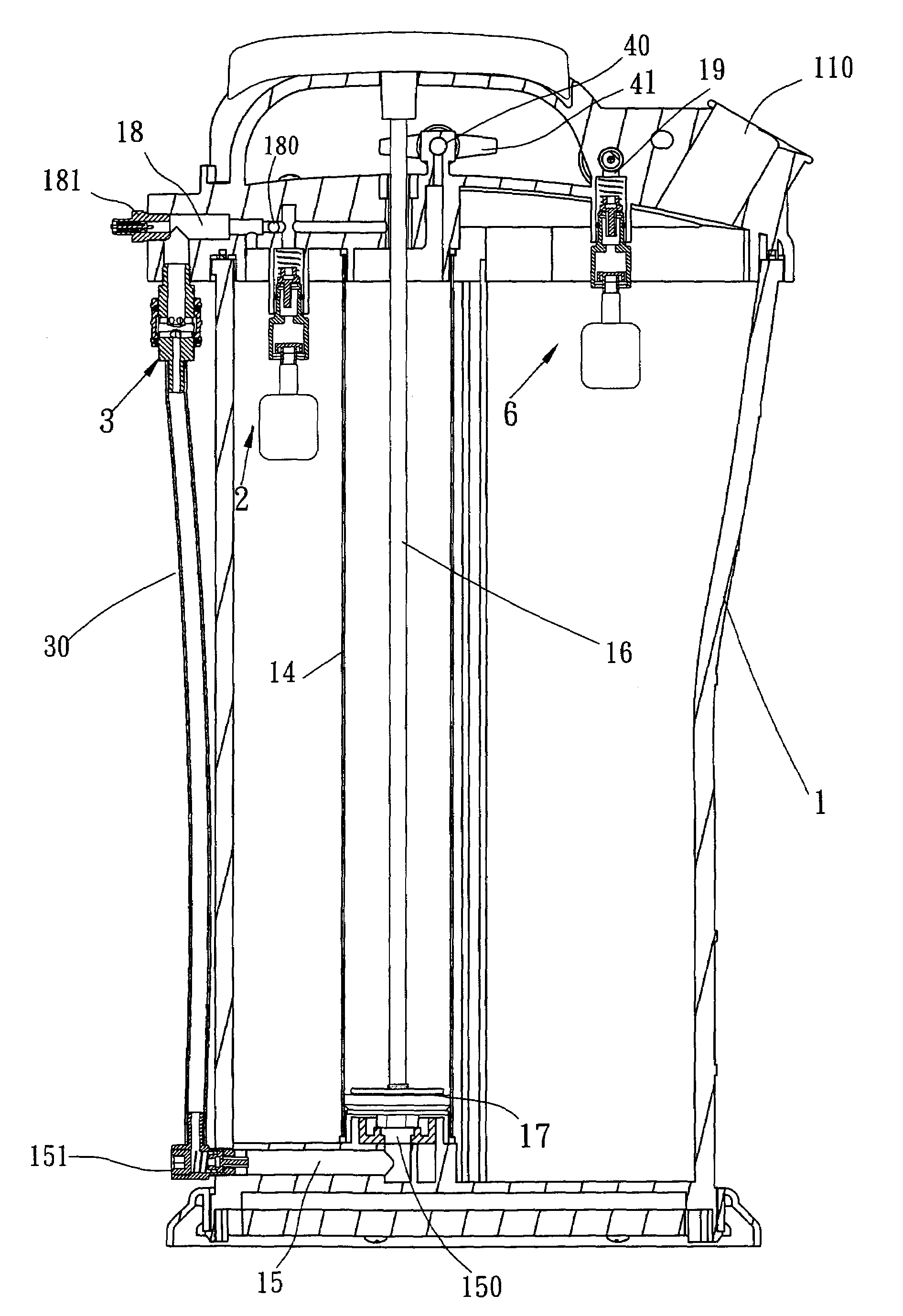

Method and apparatus of driving multiple shafts in a wet/dry vacuum and liquid pump

InactiveUS20090123293A1Improve performanceMotor fan assembly mountingFlexible member pumpsVacuum cleanerElectrical and Electronics engineering

The present disclosure provides a method and system to supply pumping capabilities to a wet and dry vacuum cleaner. A single motor can operate a vacuum unit and the pump distinct from the vacuum unit. A port in the vacuum flow path can act as a vacuum tap to prime the pump when necessary. The pump can directly pump the fluids without having to flow first into the drum container of the vacuum cleaner. The system can allow independent operation of the vacuum unit and the pump and at different, more optimal speeds for each, allowing a higher performance on each of the vacuum unit and the pump, since maximum power for the system can be provided to either the operating device while the other one is not operating. Accordingly, the disclosure further provides a system and method for separately engaging and disengaging the vacuum unit and the pump.

Owner:EMERSON ELECTRIC CO

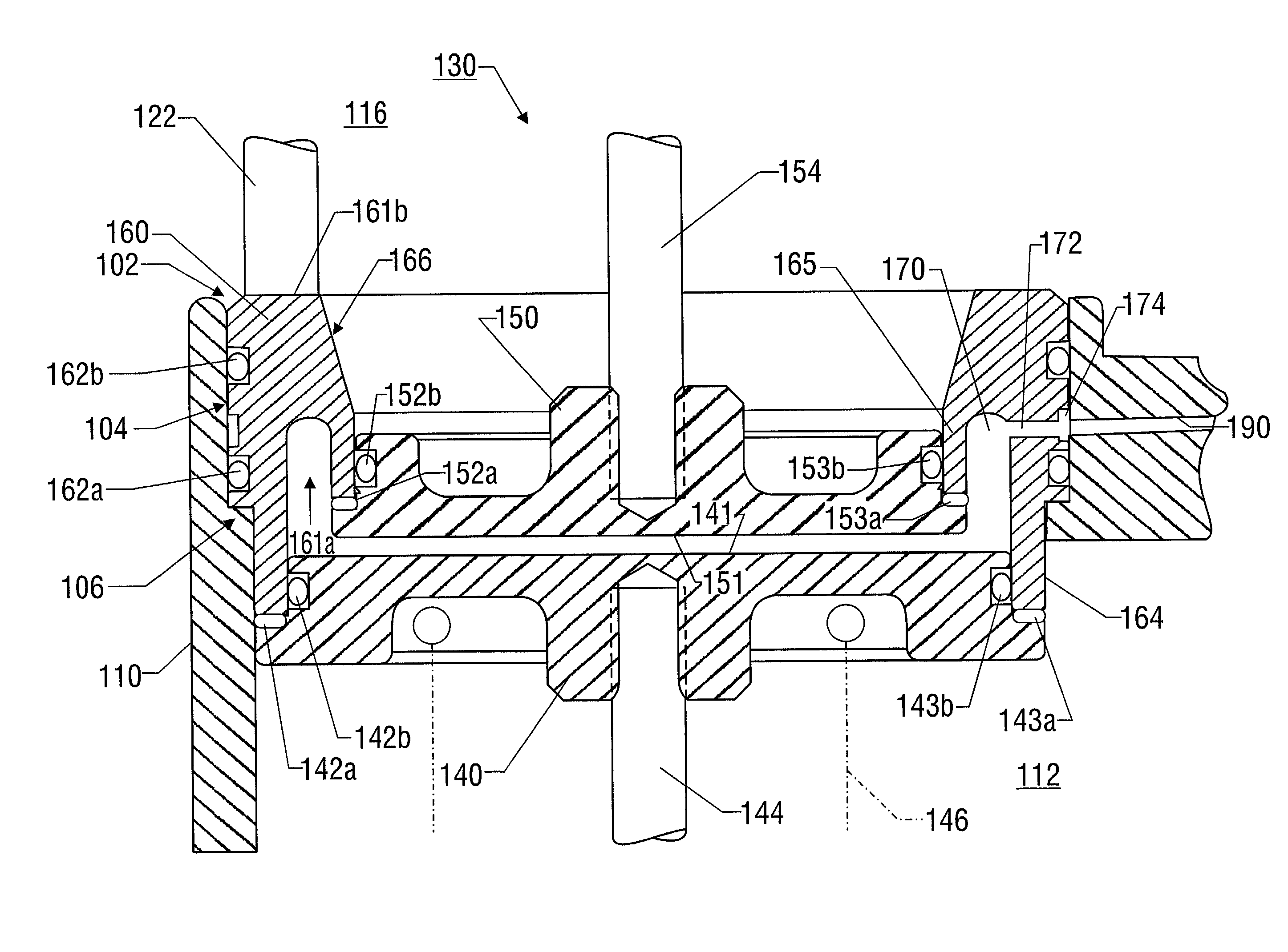

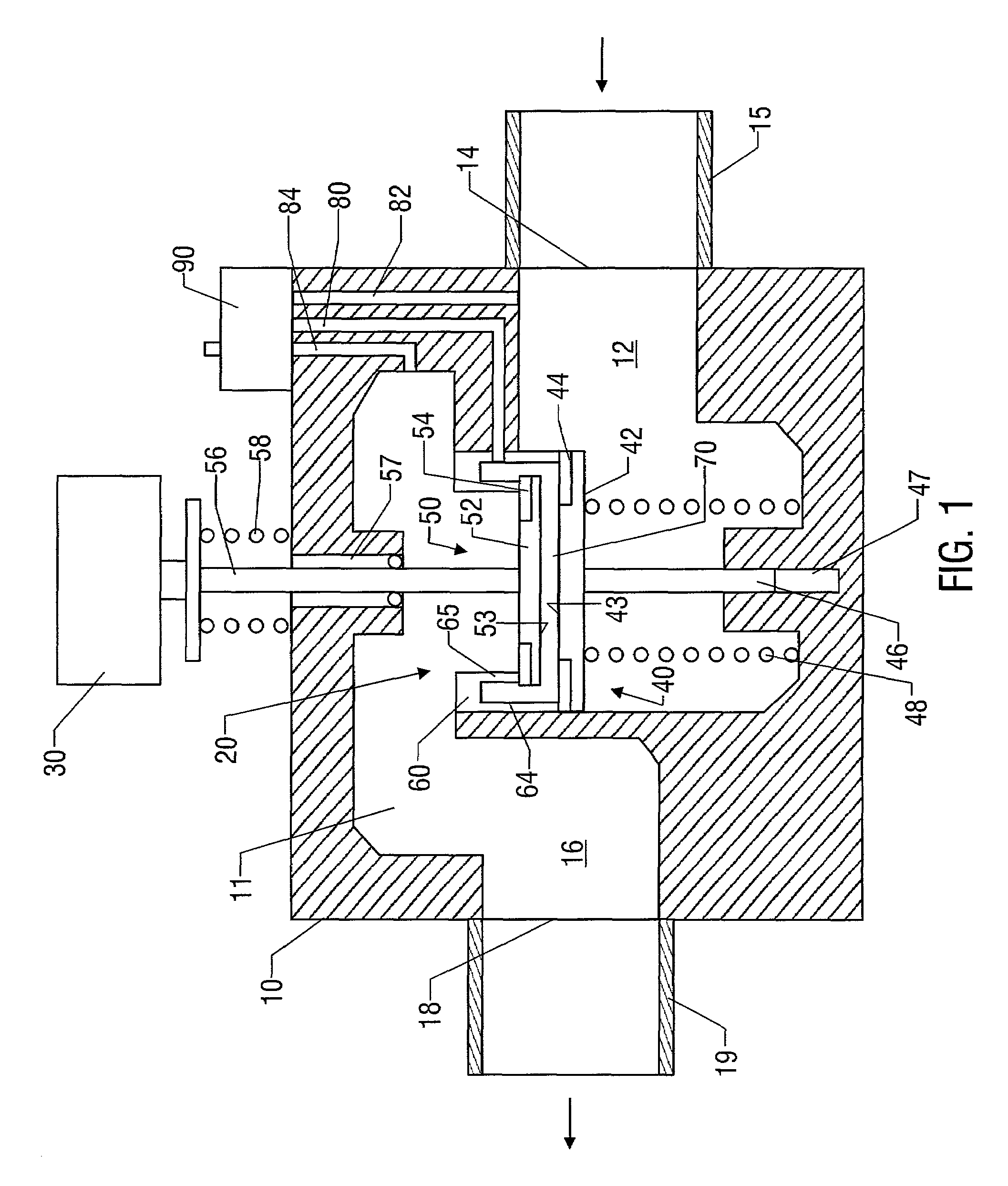

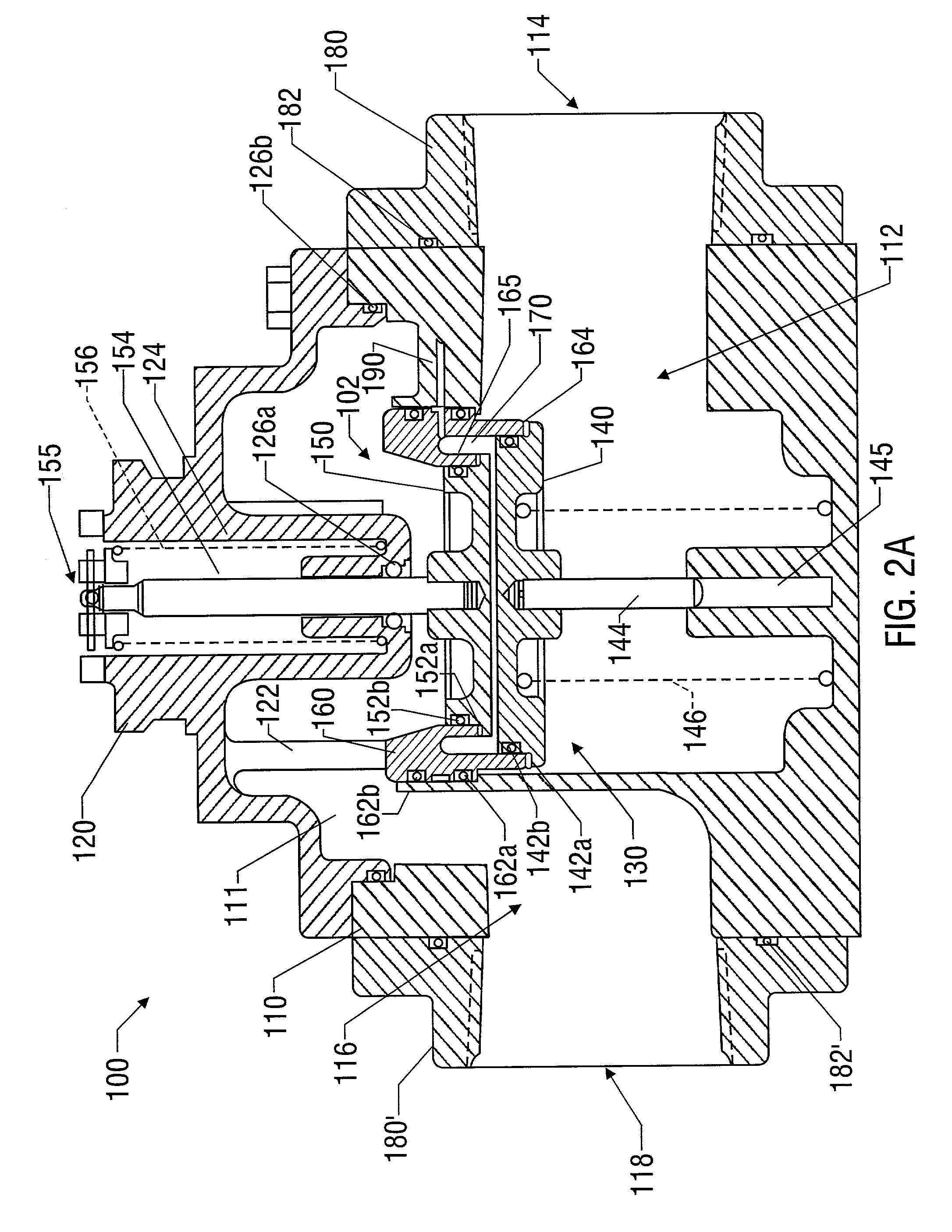

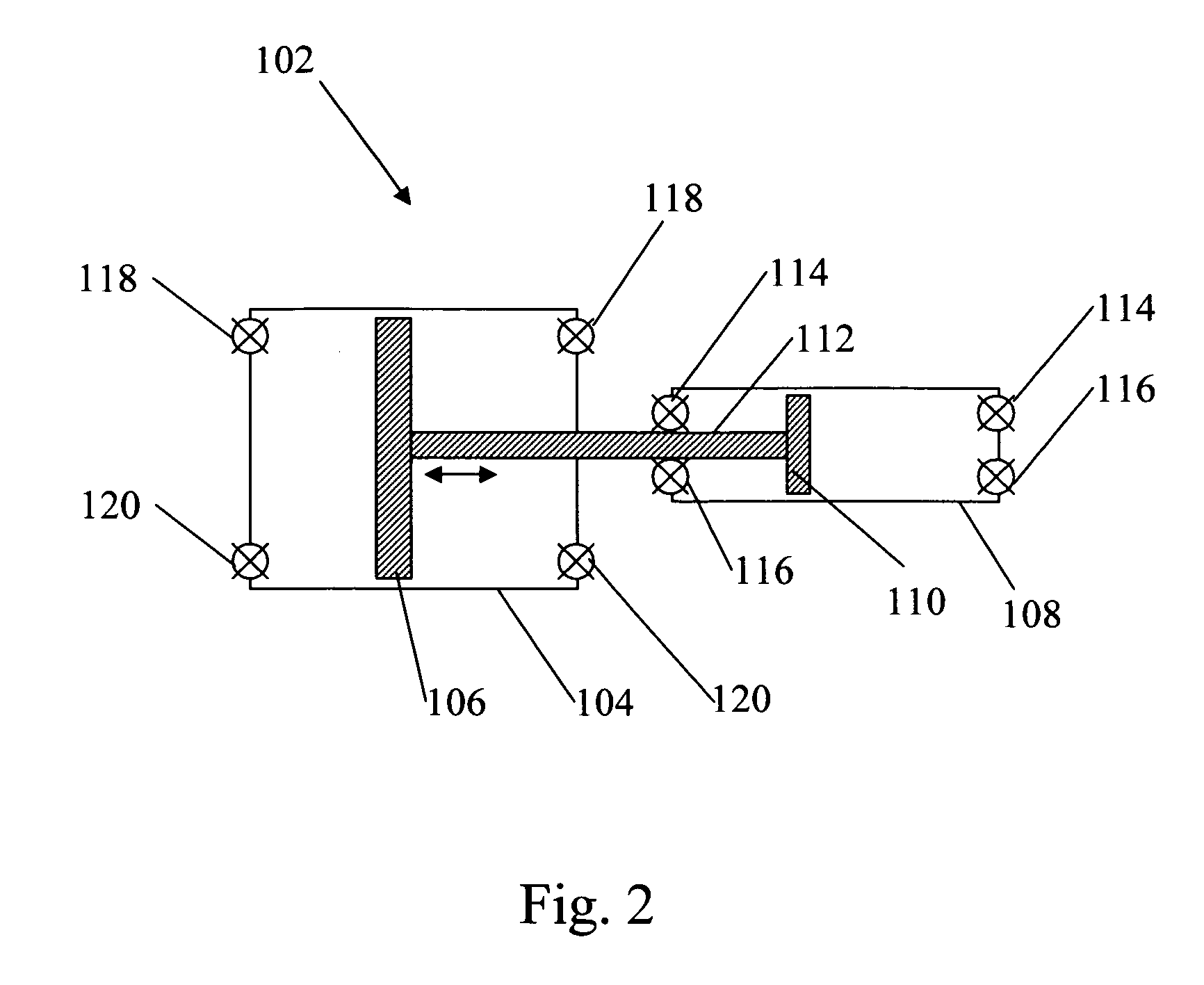

Pressurizer for a rocket engine

InactiveUS7194853B1Increased complexityAdd additional massPressure pumpsPiston pumpsReactor pressure vesselEngineering

A pump for pressurizing a fluid includes an engine portion including a first pressure vessel, a first piston movable inside the first pressure vessel, at least two pressurant entrance valves connected to the first pressure vessel, and at least two pressurant exit valves connected to the first pressure vessel. The valves are configured to be opened and closed automatically and directly as a function of a position of the first piston inside the first pressure vessel. The valves are also configured to be automatically opened and closed out of phase with each other. The pump also includes a pump portion including a second pressure vessel, a second piston connected to the first piston and movable inside the second pressure vessel, at least two fluid entrance valves connected to the second pressure vessel, and at least two fluid exit valves connected to the second pressure vessel.

Owner:KNIGHT ANDREW F

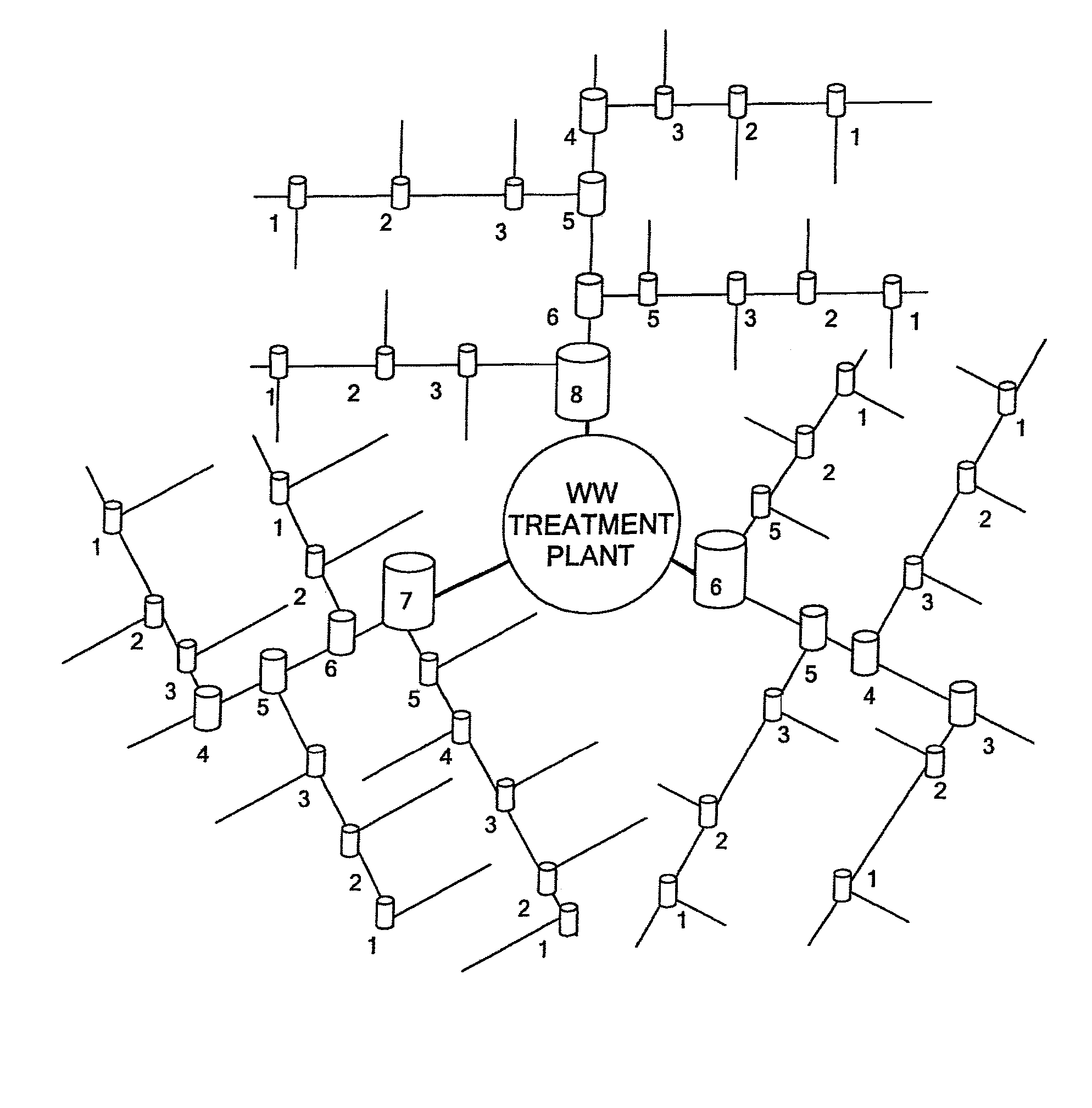

Fluid flow management through a wastewater level manipulation system and associated methods

ActiveUS8983667B2Efficient deliveryEasy to useBiological treatment regulationPressure pumpsWater levelFluid management

A system is provided to control fluid flow in a wastewater treatment system through wastewater level manipulation. The wastewater treatment system may include a wastewater treatment plant connected to a plurality of pump stations by a main. Each of the plurality of pump stations may include a wet well with a pump therein. The system may include a central server in communication with a sensor to sense a level of wastewater within the wet well. The pump may be automatically moved to an on position when the level of the wastewater in the wet well is at or above a first level and may be automatically moved to an off position when the level of the wastewater in the respective wet well is at or below a pump cutoff level. The central server may systematically manipulate the first level to selectively set the level of wastewater within the wet well.

Owner:DATA FLOW SYST

Chemical solution mixing and dispensing apparatus

InactiveUS20140269153A1Allocation is accurateControlling ratio of multiple fluid flowsFlow mixersChemical solutionEngineering

Example embodiments of the present invention provide a chemical solution mixing a dispensing system for making a customized chemical solution for industrial applications. For example, the embodiments of the present invention can include a chlorination system that mixes and then dispenses a chlorine solution into a water supply line for the treatment or sanitation of the water in the water supply line.

Owner:EZCHLOR LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com