Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Preparation by halogenatd hydrocarbon disproportionation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

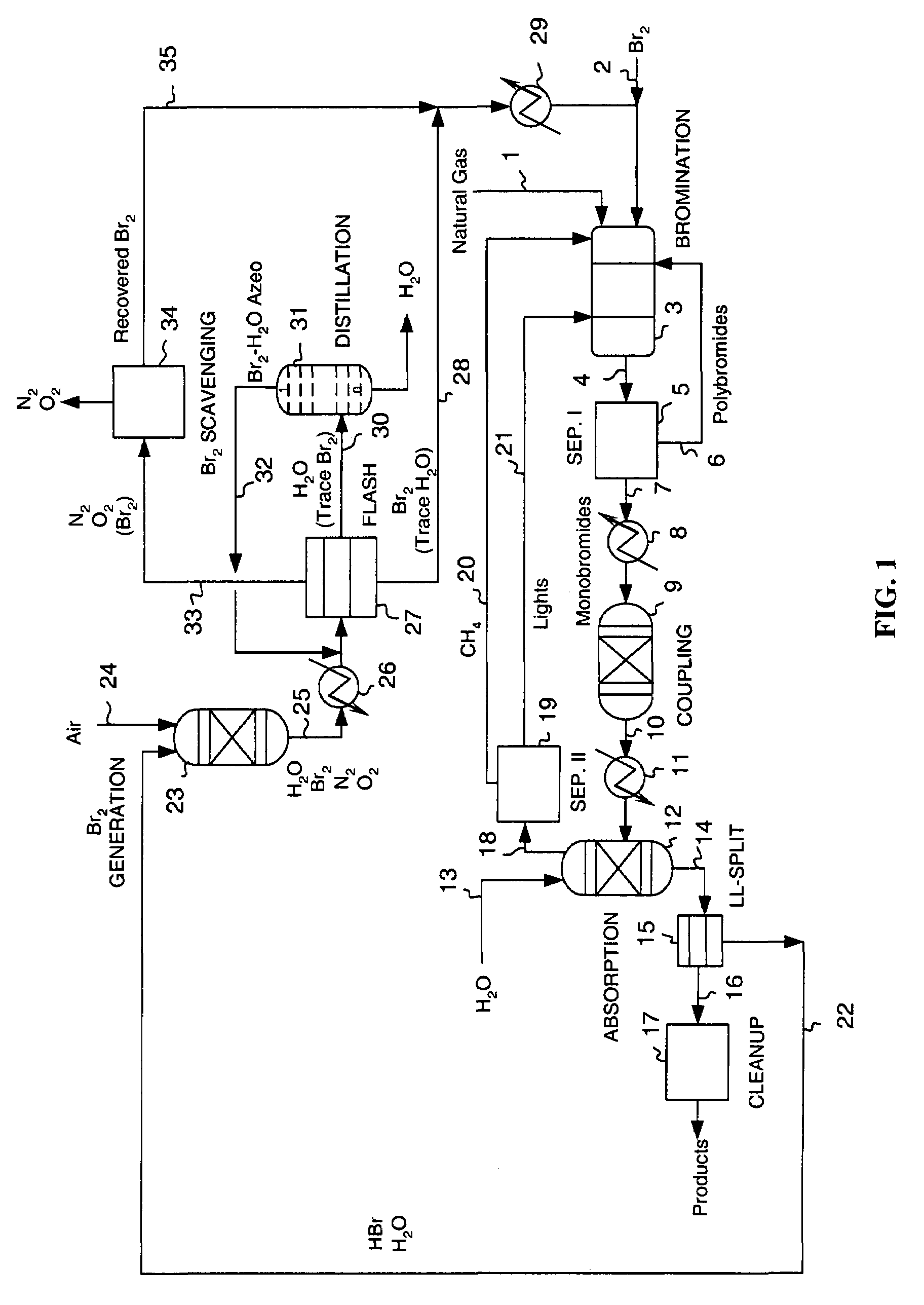

Continuous process for converting natural gas to liquid hydrocarbons

InactiveUS20070238909A1Easily toleratedContinuous regenerationMolecular sieve catalystLiquid hydrocarbon mixture recoveryAlkaneOxygen

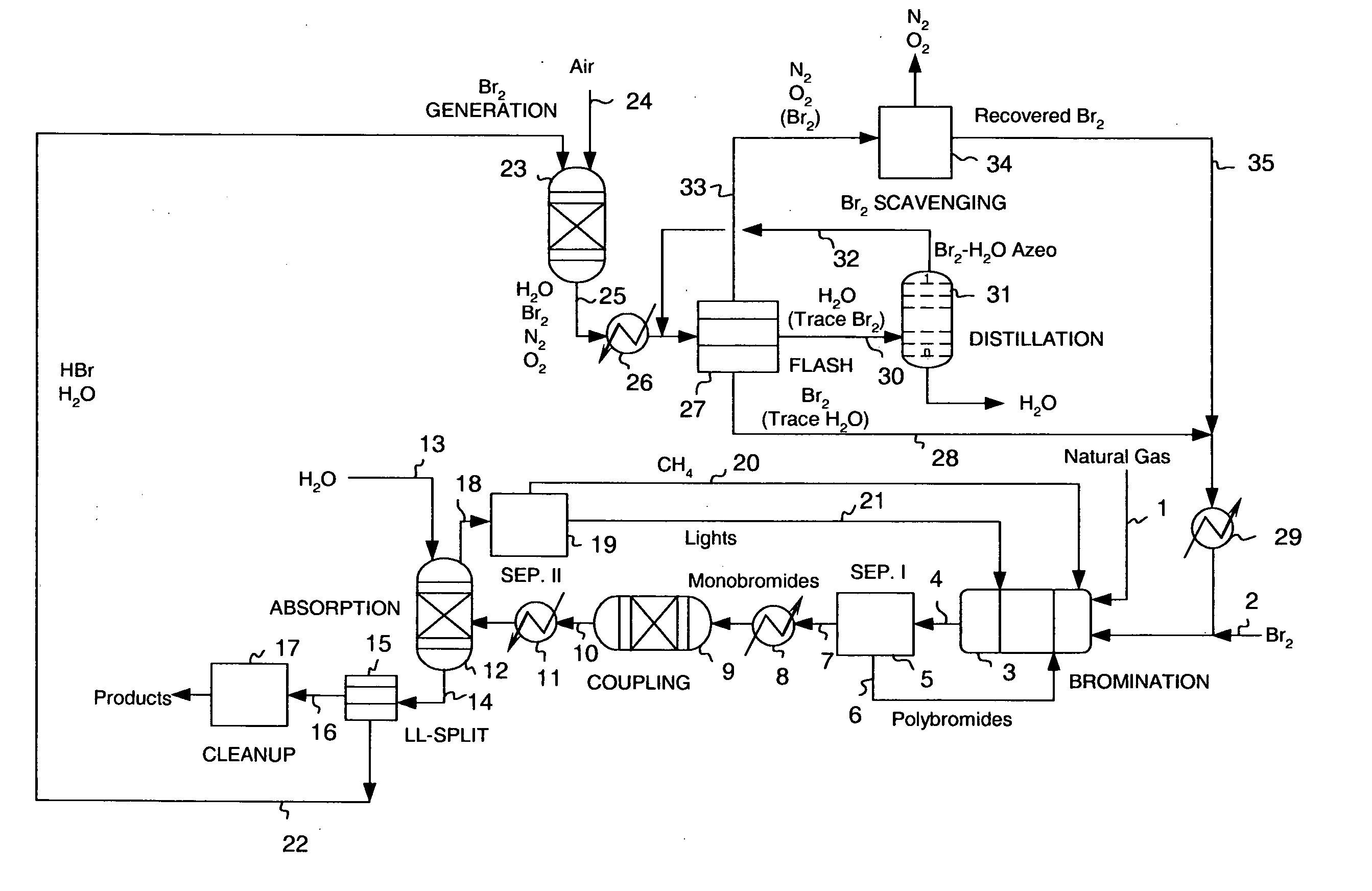

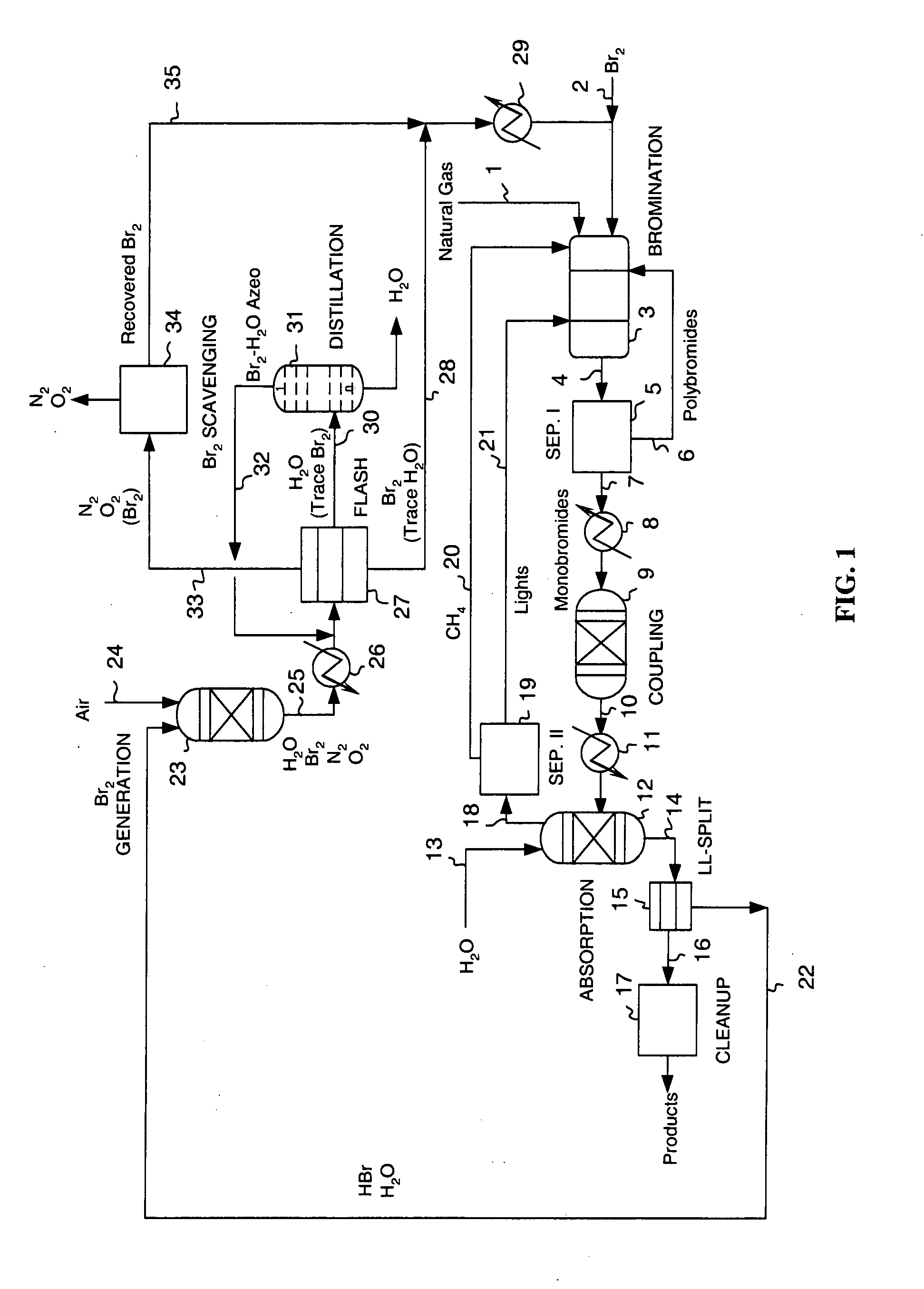

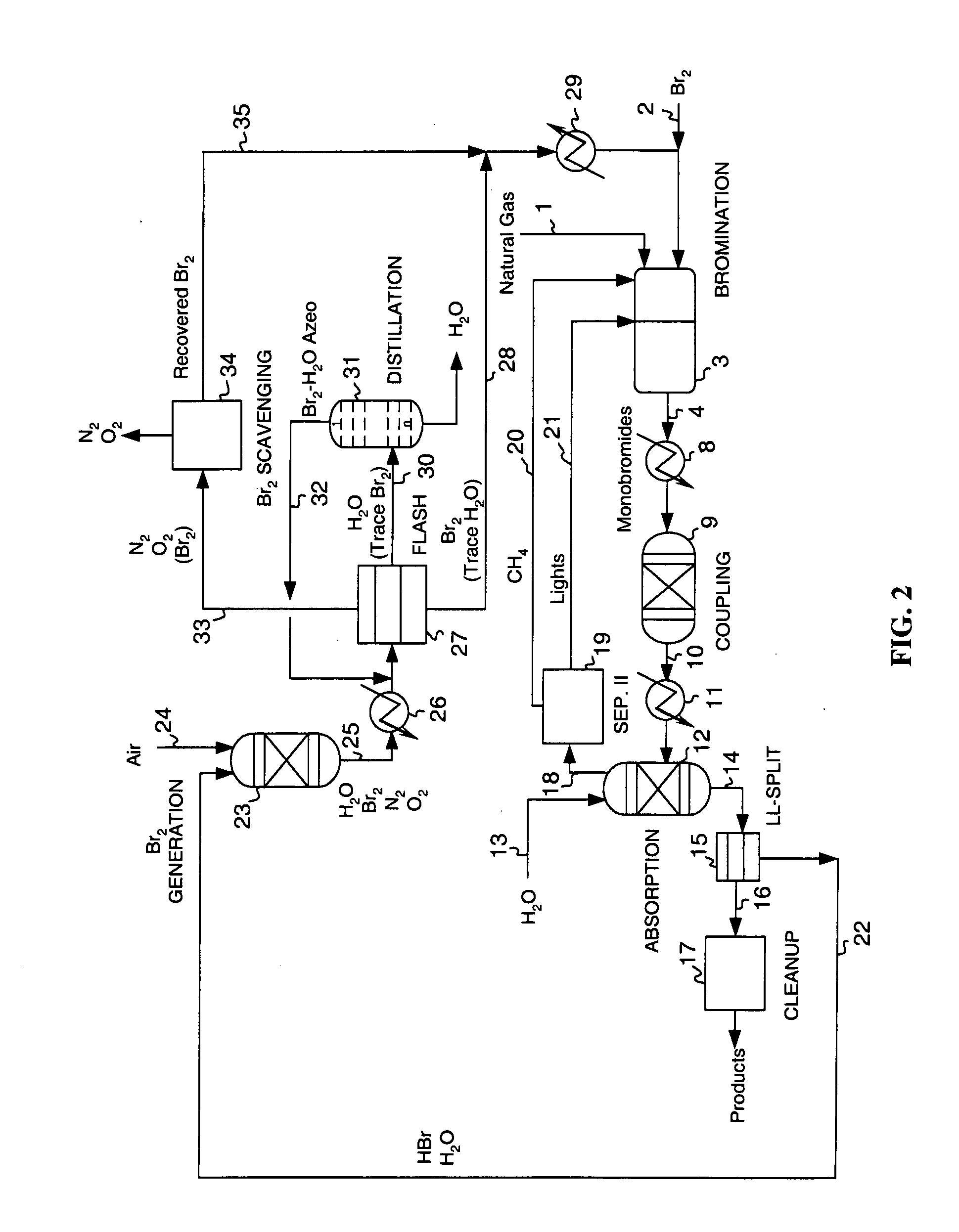

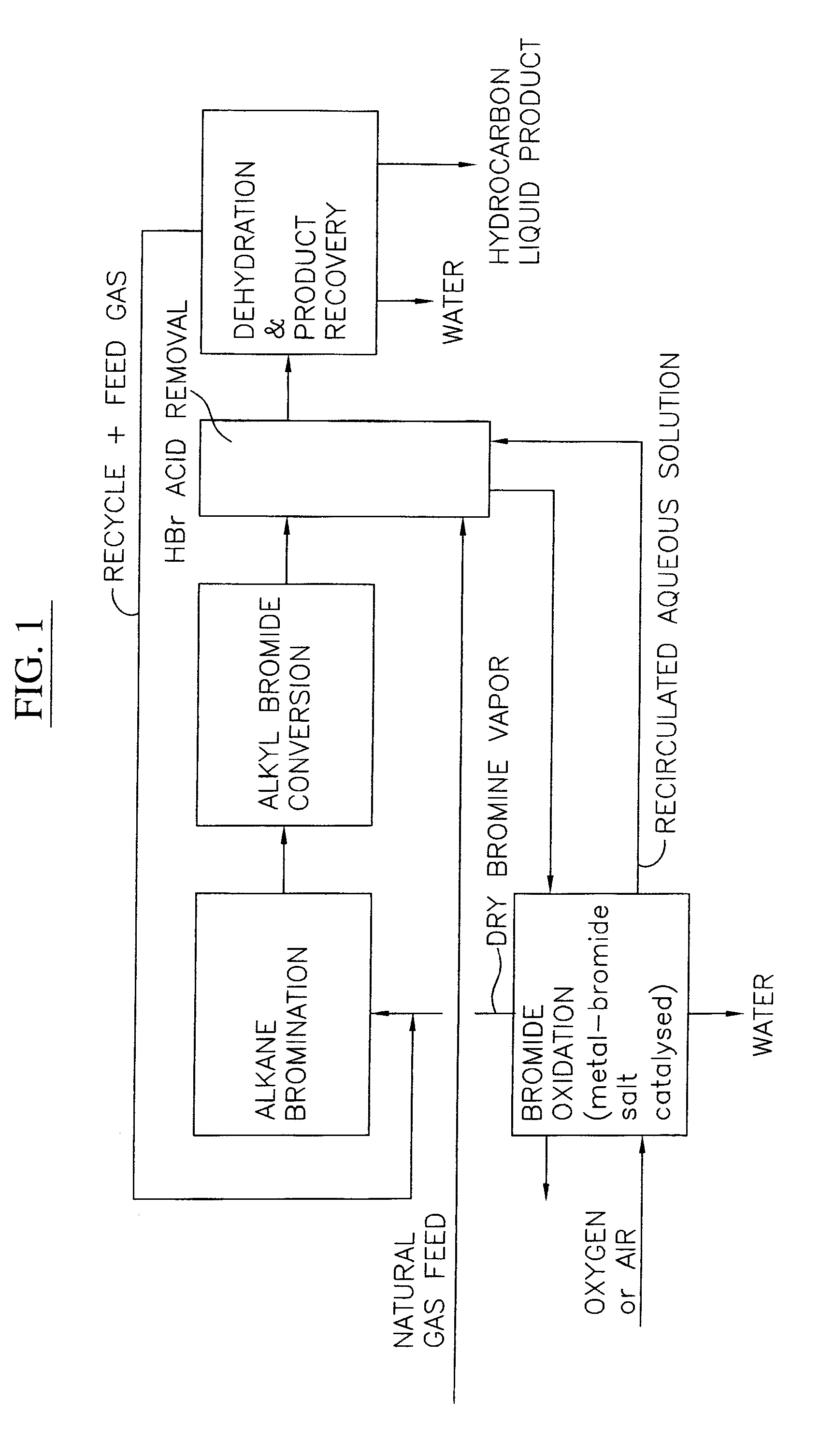

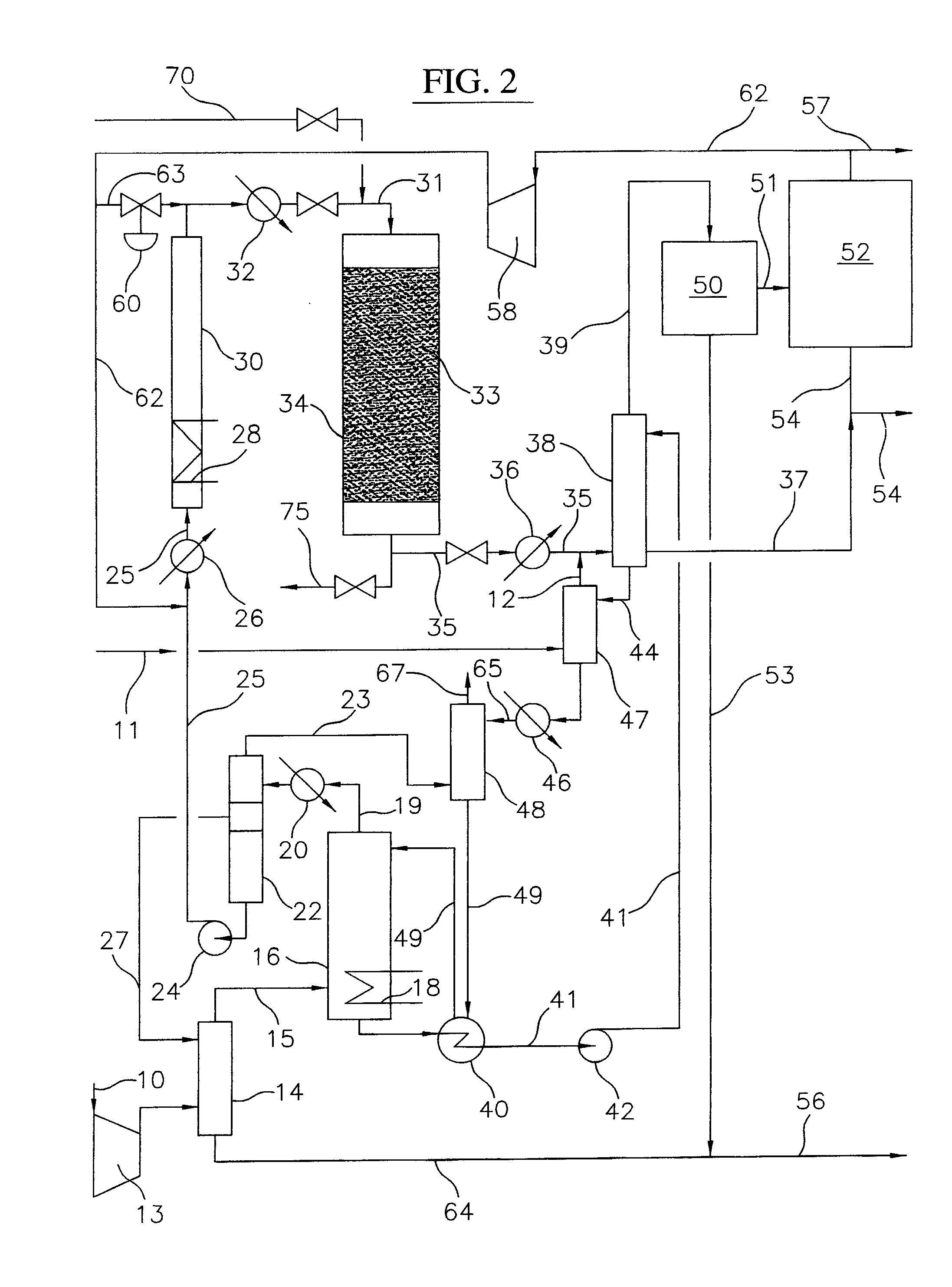

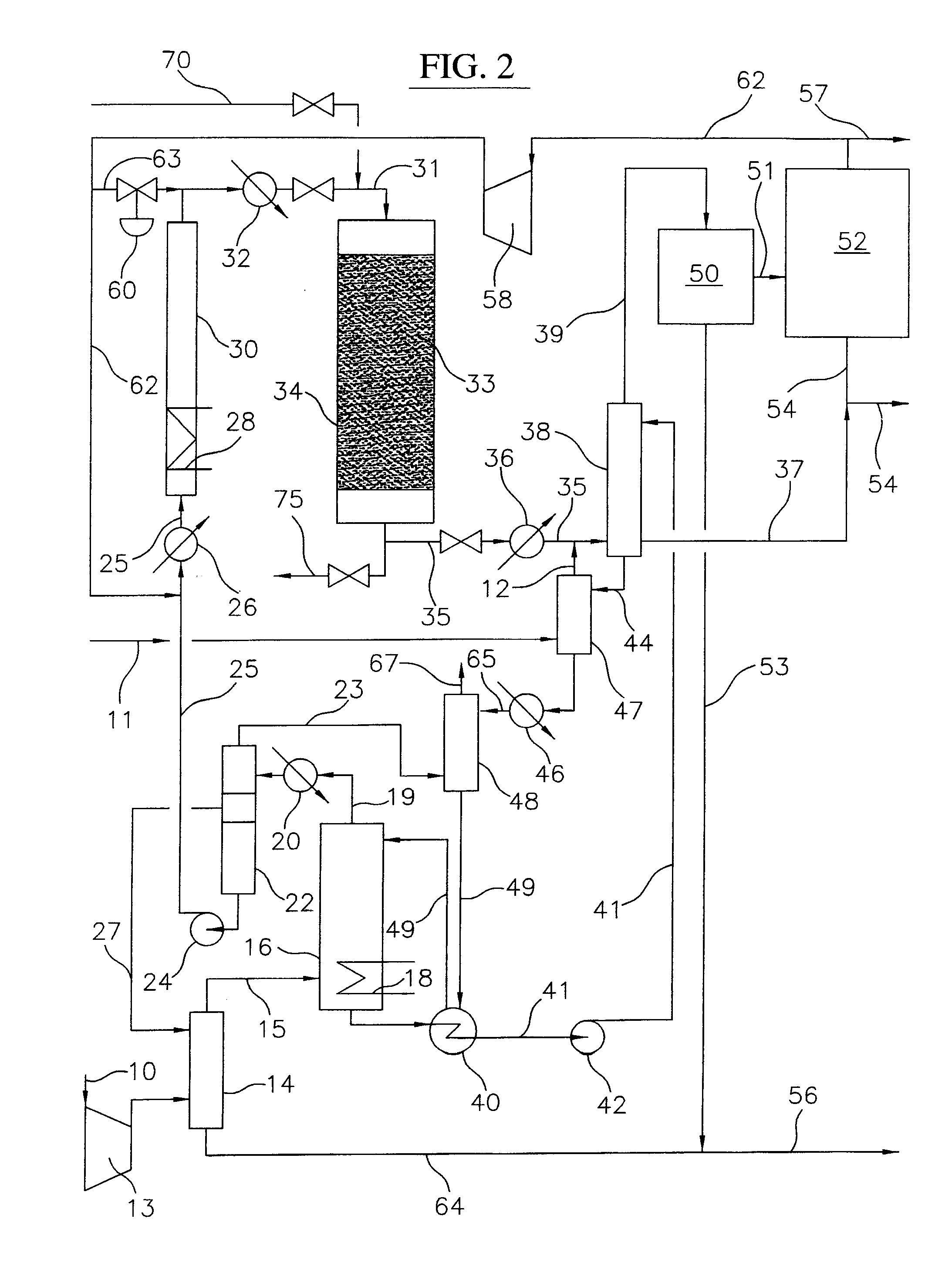

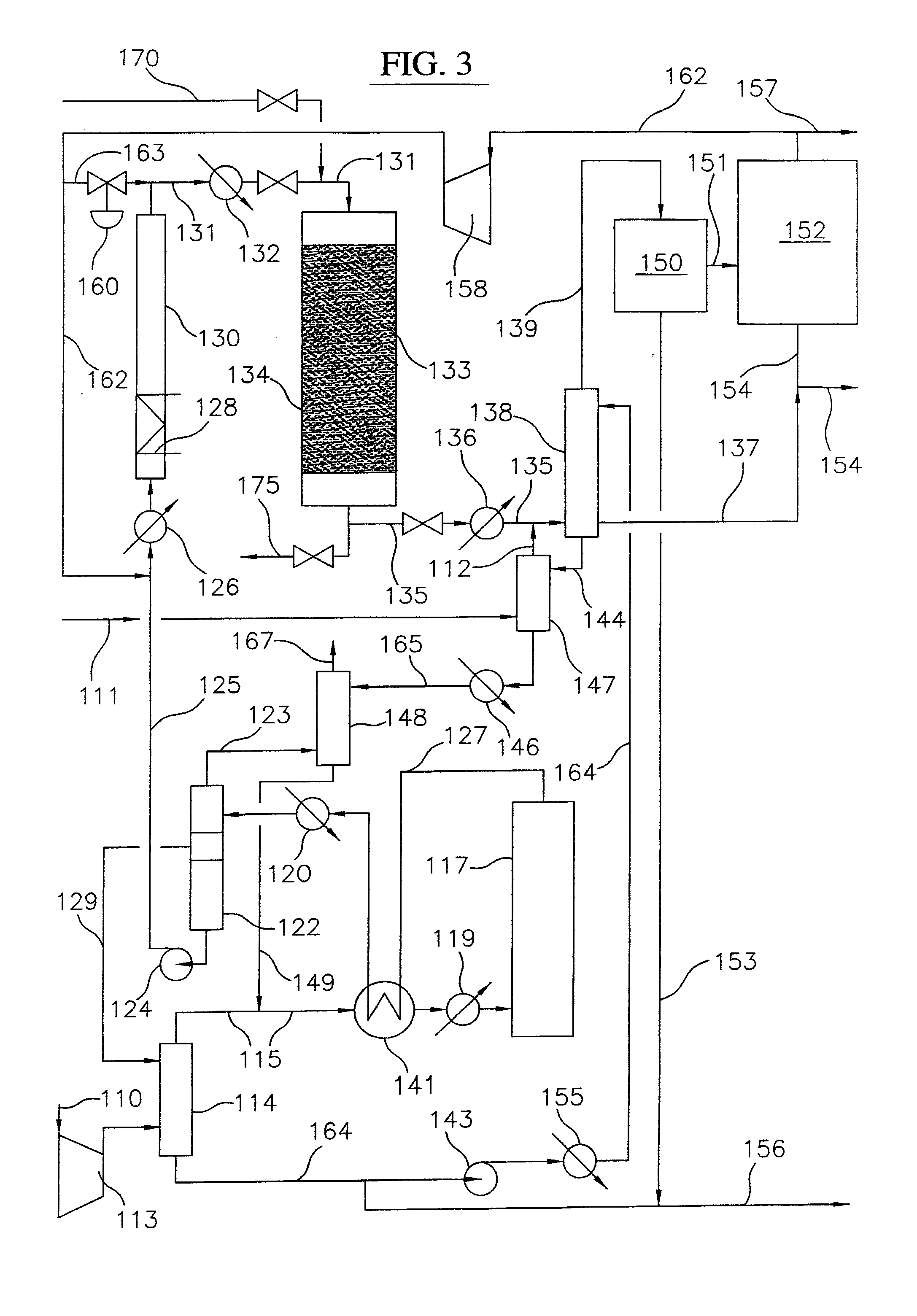

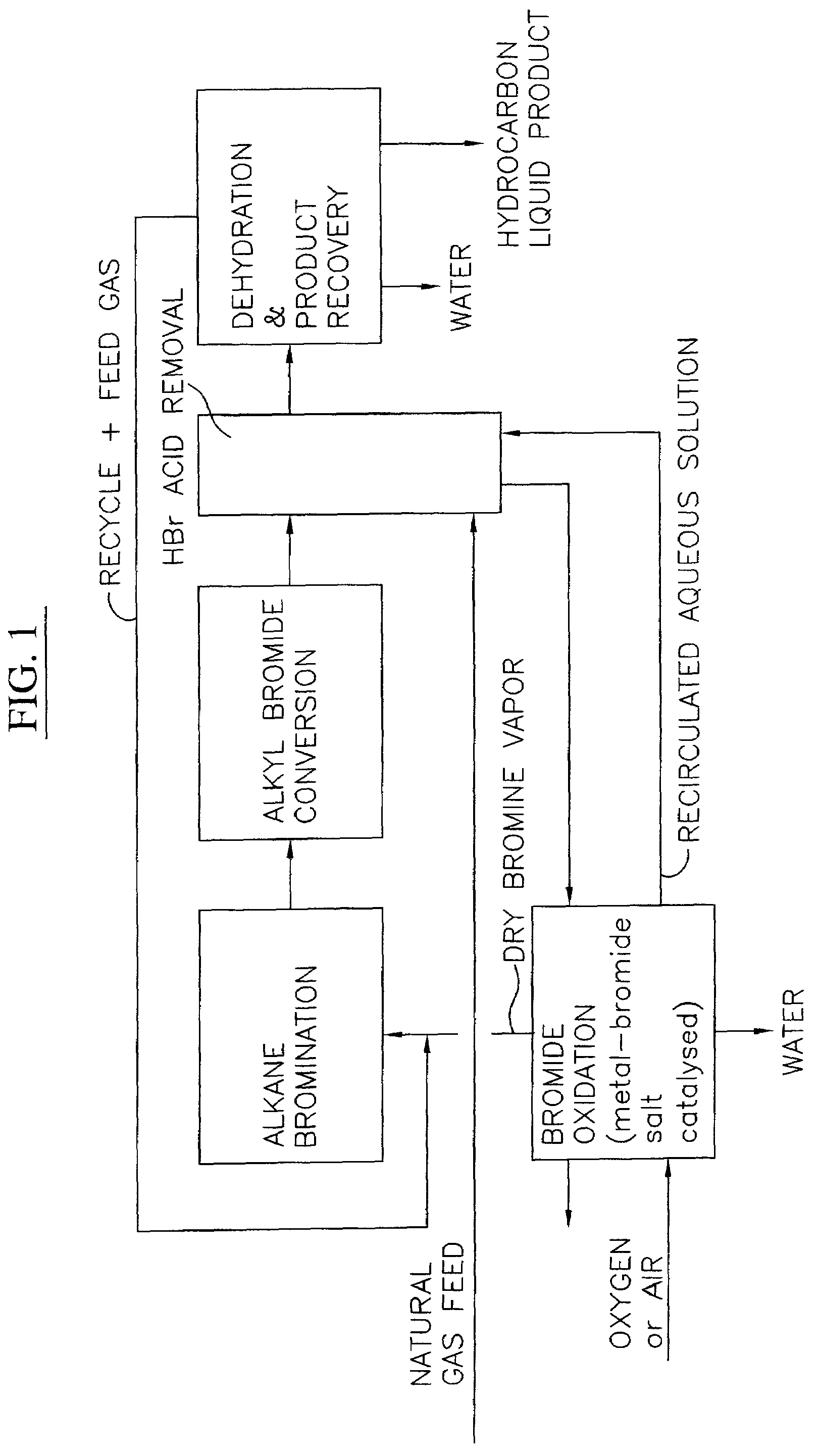

An improved continuous process for converting methane, natural gas, or other hydrocarbon feedstocks into one or more higher hydrocarbons or olefins by continuously cycling through the steps of alkane halogenation, product formation (carbon-carbon coupling), product separation, and regeneration of halogen is provided. Preferably, the halogen is continually recovered by reacting hydrobromic acid with air or oxygen. The invention provides an efficient route to aromatic compounds, aliphatic compounds, mixtures of aliphatic and aromatic compounds, olefins, gasoline grade materials, and other useful products.

Owner:REACTION 35 LLC

Processes for converting gaseous alkanes to liquid hydrocarbons

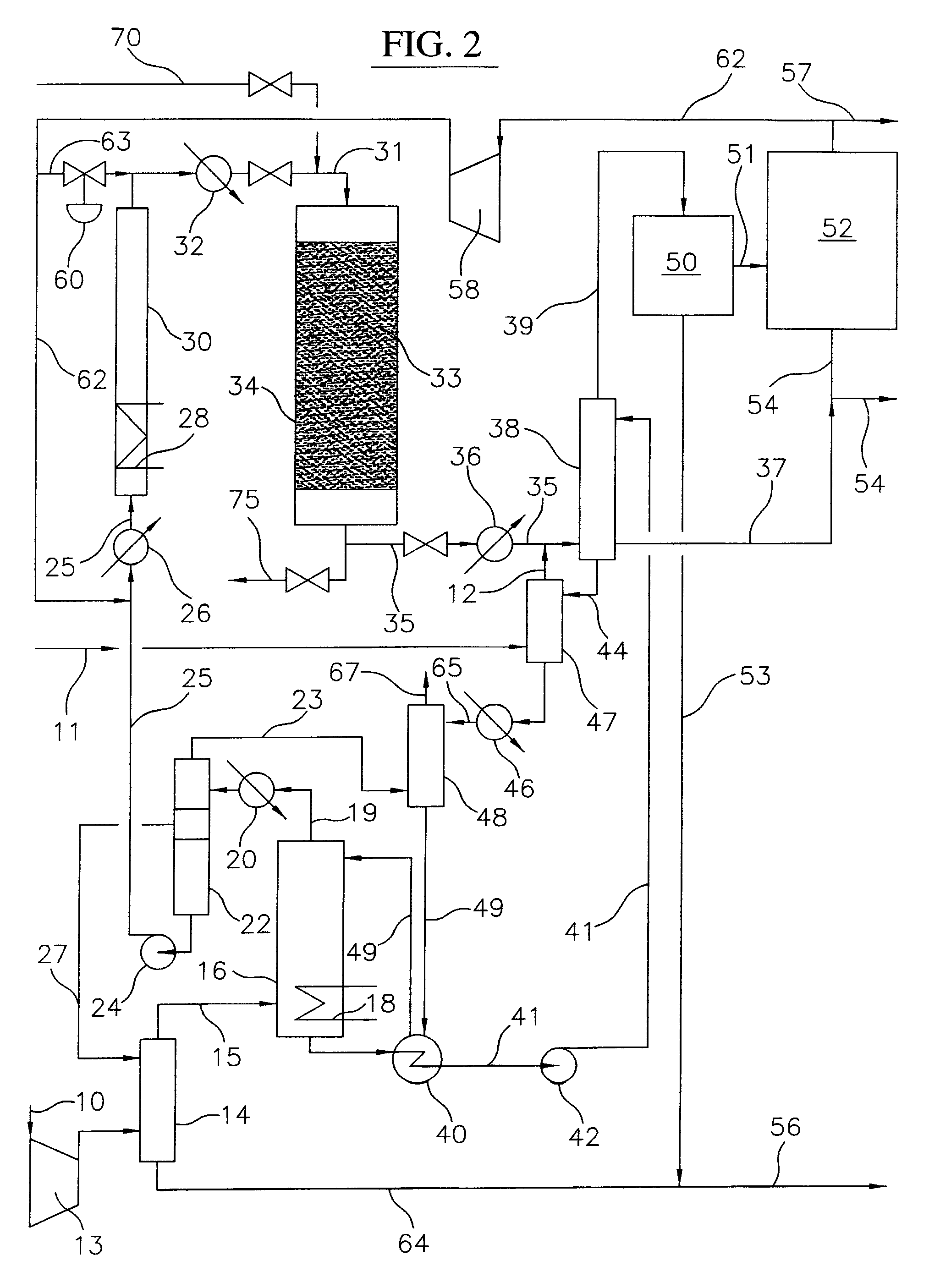

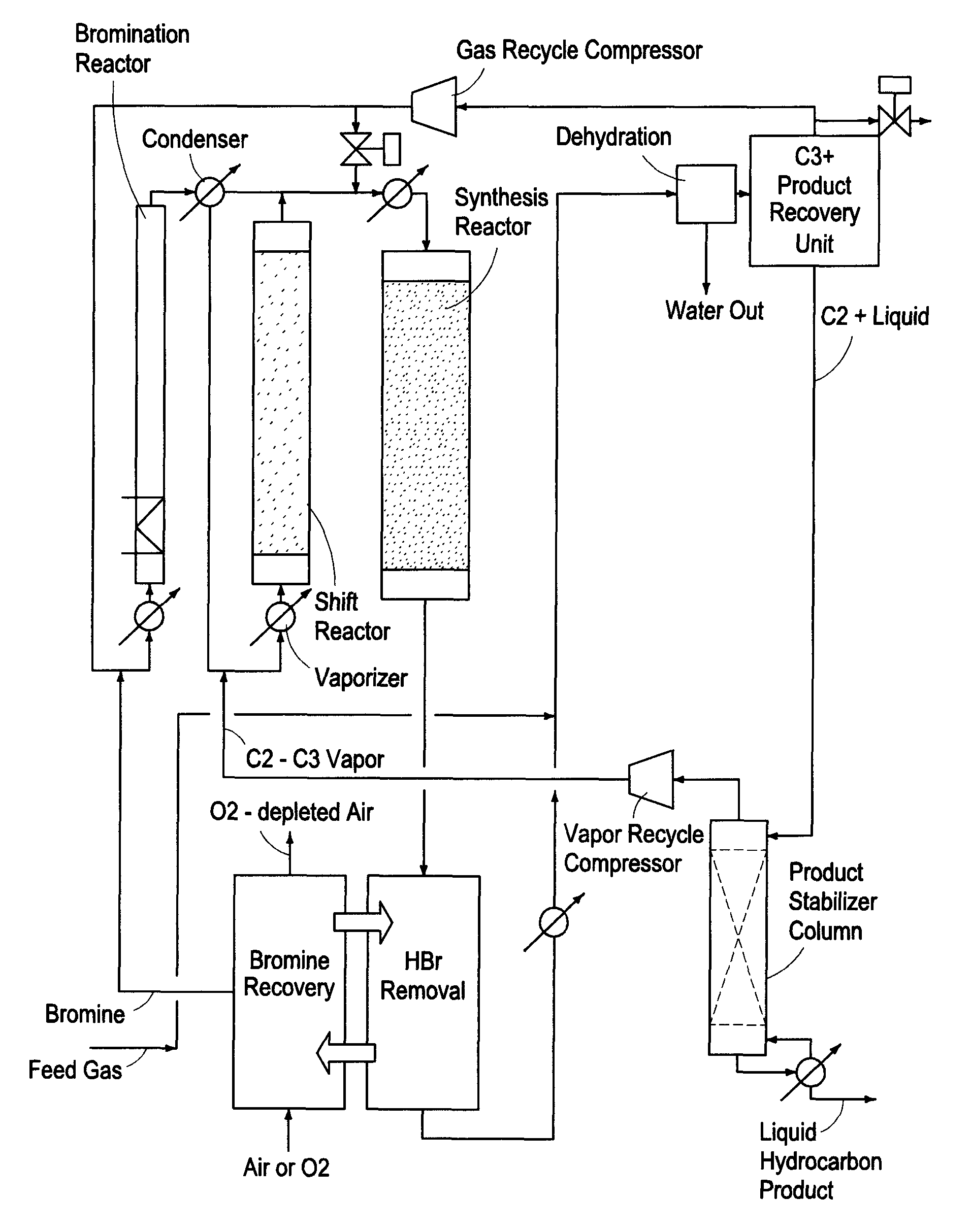

A process for converting gaseous alkanes to olefins, higher molecular weight hydrocarbons or mixtures thereof wherein a gaseous feed containing alkanes is thermally reacted with a dry bromine vapor to form alkyl bromides and hydrogen bromide. Poly-brominated alkanes present in the alkyl bromides are further reacted with methane over a suitable catalyst to form mono-brominated species. The mixture of alkyl bromides and hydrogen bromide is then reacted over a suitable catalyst at a temperature sufficient to form olefins, higher molecular weight hydrocarbons or mixtures thereof and hydrogen bromide. Various methods are disclosed to remove the hydrogen bromide from the higher molecular weight hydrocarbons, to generate bromine from the hydrogen bromide for use in the process, and to selectively form mono-brominated alkanes in the bromination step.

Owner:SULZER MANAGEMENT AG

Processes for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to olefins, higher molecular weight hydrocarbons or mixtures thereof wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid is then reacted over a suitable catalyst at a temperature sufficient to form olefins, higher molecular weight hydrocarbons or mixtures thereof and hydrobromic acid vapor. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons, to generate bromine from the hydrobromic acid for use in the process, and to selectively form monobrominated alkanes in the bromination step.

Owner:SULZER MANAGEMENT AG

Processes for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to olefins, higher molecular weight hydrocarbons or mixtures thereof wherein a gaseous feed containing alkanes is reacted with a dry bromine vapor to form alkyl bromides and hydrobromic acid vapor. The mixture of alkyl bromides and hydrobromic acid is then reacted over a suitable catalyst at a temperature sufficient to form olefins, higher molecular weight hydrocarbons or mixtures thereof and hydrobromic acid vapor. Various methods are disclosed to remove the hydrobromic acid vapor from the higher molecular weight hydrocarbons, to generate bromine from the hydrobromic acid for use in the process, and to selectively form monobrominated alkanes in the bromination step.

Owner:SULZER MANAGEMENT AG

Synthesis of hexafluoropropylene

ActiveUS6924403B2Increase productionAvoid production lossPreparation by hydrogen halide split-offOrganic chemistry methodsHexafluoropropyleneNickel alloy

The present invention relates to the process of pyrolyzing tetrafluoroethylene to hexafluoropropylene by carrying out the pyrolysis in a tubular reactor that is lined with either nickel or nickel alloy which contains no greater than 8 wt % chromium.

Owner:THE CHEMOURS CO FC LLC

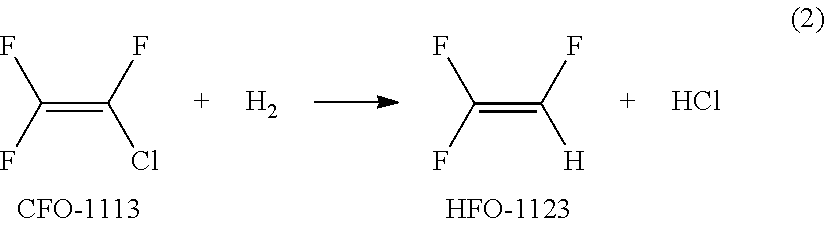

Method for purifying fluid that includes trifluoroethylene, and method for producing trifluoroethylene

ActiveUS20160347693A1Efficient removalEfficient productionPreparation by dehalogenationPreparation by hydrogen halide split-offAlkaneHydrogen atom

To provide a method for purifying trifluoroethylene, by which from a fluid containing trifluoroethylene, a C1-5 alkane or alkene (excluding trifluoroethylene) in which at least one hydrogen atom may be substituted with a chlorine atom or a fluorine atom can be efficiently removed, and a method for producing trifluoroethylene by which trifluoroethylene can be efficiently produced.A fluid containing trifluoroethylene is brought into contact with at least one type of synthetic zeolite selected from synthetic zeolites 3A, 4A and 5A.

Owner:ASAHI GLASS CO LTD

Processes for converting gaseous alkanes to liquid hydrocarbons

A process for converting gaseous alkanes to olefins, higher molecular weight hydrocarbons or mixtures thereof wherein a gaseous feed containing alkanes is thermally reacted with a dry bromine vapor to form alkyl bromides and hydrogen bromide. Poly-brominated alkanes present in the alkyl bromides are further reacted with methane over a suitable catalyst to form mono-brominated species. The mixture of alkyl bromides and hydrogen bromide is then reacted over a suitable catalyst at a temperature sufficient to form olefins, higher molecular weight hydrocarbons or mixtures thereof and hydrogen bromide. Various methods are disclosed to remove the hydrogen bromide from the higher molecular weight hydrocarbons, to generate bromine from the hydrogen bromide for use in the process, and to selectively form mono-brominated alkanes in the bromination step.

Owner:SULZER MANAGEMENT AG

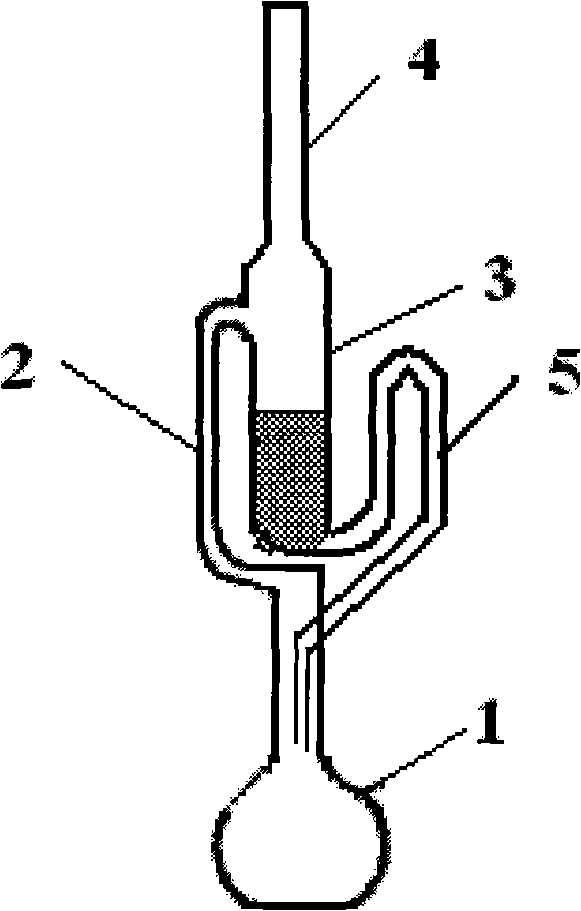

Process for preparing perfluoroalkyl group by telomerization

InactiveCN101306977ASimple production equipmentProcess parameter control is simplePreparation by halogenatd hydrocarbon disproportionationIodideOperations security

The invention discloses a method for synthesizing perfluoro-alkyl iodide through telomerization. The method is as follows: short-carbon chain perfluoro-alkyl iodide and tetrafluoroethylene are added in an extraction column reactor filled with catalyst filler inside an extraction tower or a rectification tower reactor taking catalyst as filler so as to carry out reaction with the molar ratio between short-carbon chain perfluoro-alkyl iodide and tetrafluoroethylene of between 3:1 and 50:1 at a reaction temperature of between 40 and 200 DEG C, thereby obtaining perfluoro-alkyl iodide. The method takes the lead in taking the extraction column filled with catalyst filler inside the extraction tower or the rectification tower taking catalyst as filler as a reactor which is used in the telomerization of perfluoro-alkyl iodide; moreover, compared with the prior disclosed art, the method has the advantages of simple production equipment, easily controlled technological parameter, better operational safety, ideal reaction selectivity, high product purity and no hydrogen-containing byproducts, etc.

Owner:JUHUA GRP

Continuous process for converting natural gas to liquid hydrocarbons

InactiveUS7579510B2Easily toleratedContinuous regenerationMolecular sieve catalystLiquid hydrocarbon mixture recoveryAlkaneOxygen

An improved continuous process for converting methane, natural gas, or other hydrocarbon feedstocks into one or more higher hydrocarbons or olefins by continuously cycling through the steps of alkane halogenation, product formation (carbon-carbon coupling), product separation, and regeneration of halogen is provided. Preferably, the halogen is continually recovered by reacting hydrobromic acid with air or oxygen. The invention provides an efficient route to aromatic compounds, aliphatic compounds, mixtures of aliphatic and aromatic compounds, olefins, gasoline grade materials, and other useful products.

Owner:REACTION 35 LLC

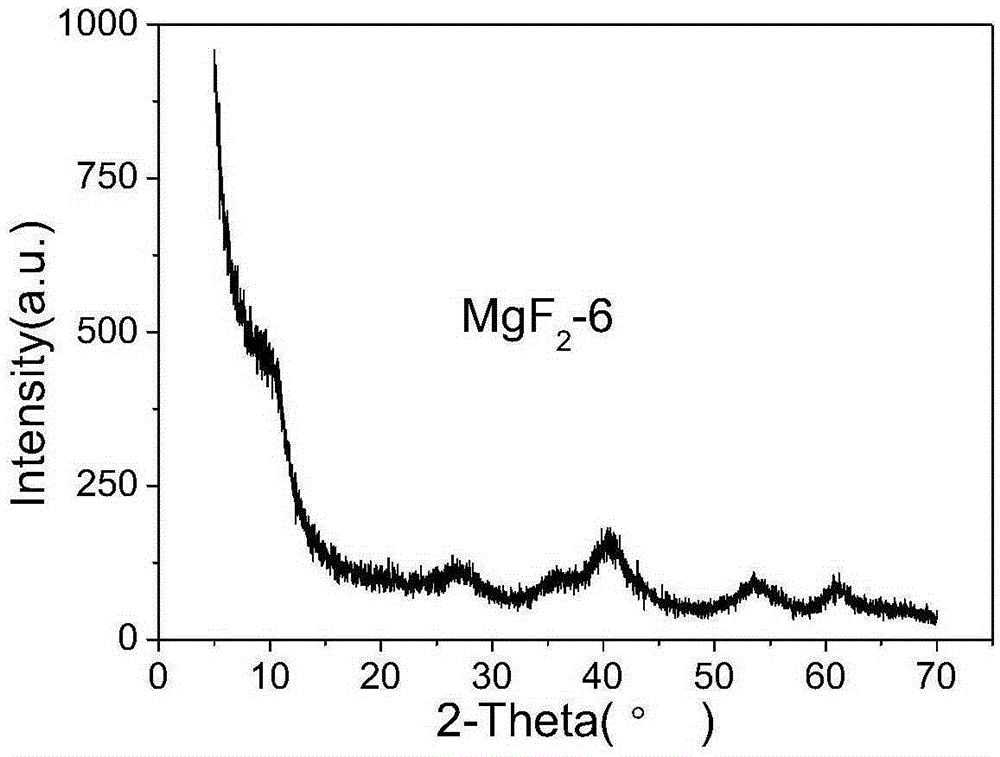

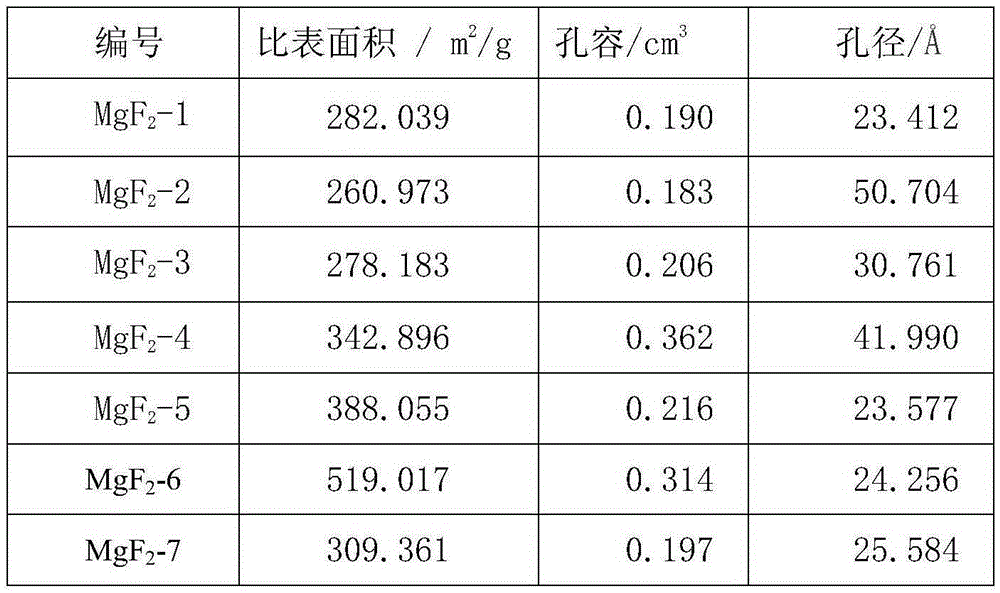

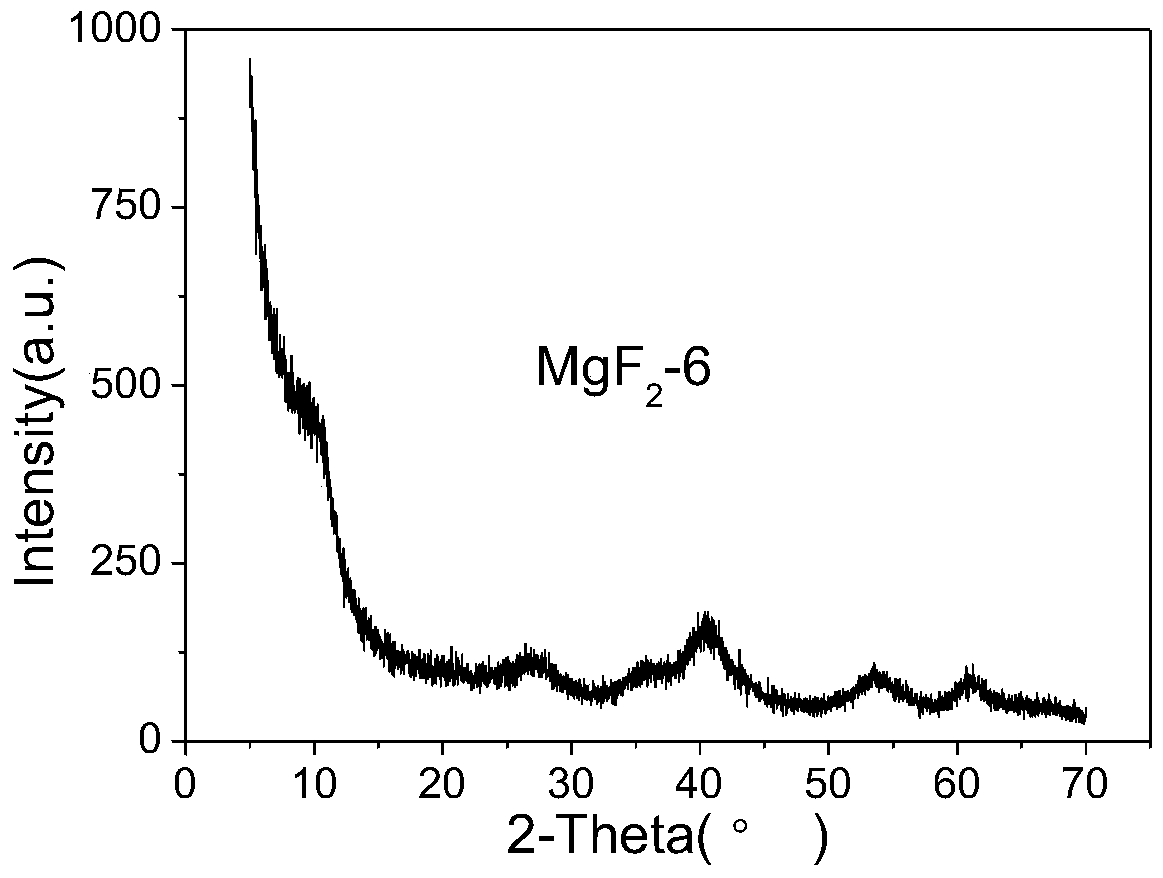

Magnesium fluoride catalyst and its preparation method and use

ActiveCN106669742ALarge specific surface areaAppropriate aperturePreparation by hydrogen halide split-offPhysical/chemical process catalystsMagnesium fluorideDehydrohalogenation

The invention discloses a magnesium fluoride catalyst. The magnesium fluoride catalyst has carbon content of less than 10% and a specific surface area of more than 130 m<2> / g. The magnesium fluoride catalyst provided by the invention has high catalytic activity and strong stability in the dehydrohalogenation reaction, fluorine-chlorine exchange reaction, disproportionation reaction or hydrofluorination reaction.

Owner:陕西中化蓝天化工新材料有限公司 +2

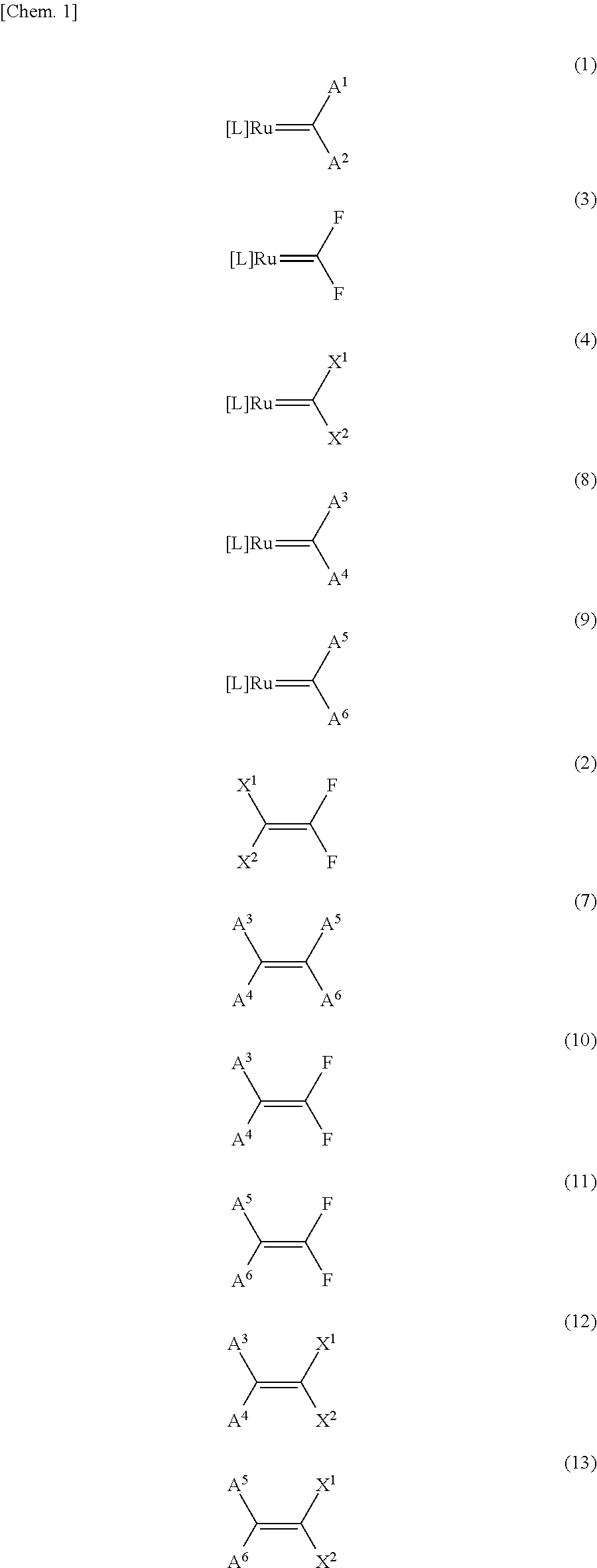

Method for producing fluorine-containing olefin

ActiveUS20160176791A1Simply and efficiently producedRuthenium organic compoundsOrganic compound preparationCombinatorial chemistryAlkene

Owner:ASAHI GLASS CO LTD

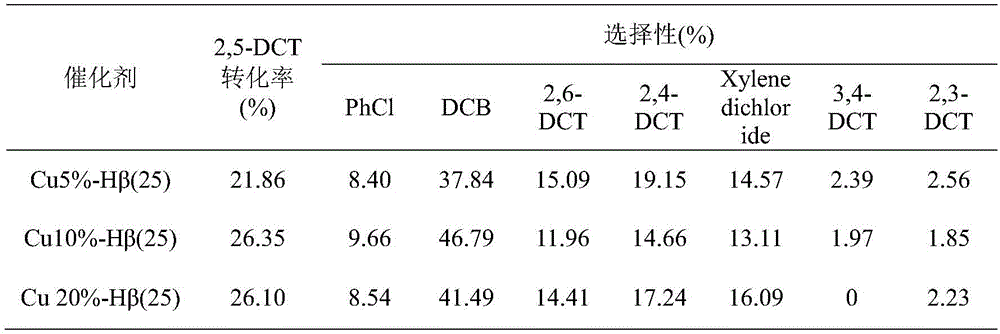

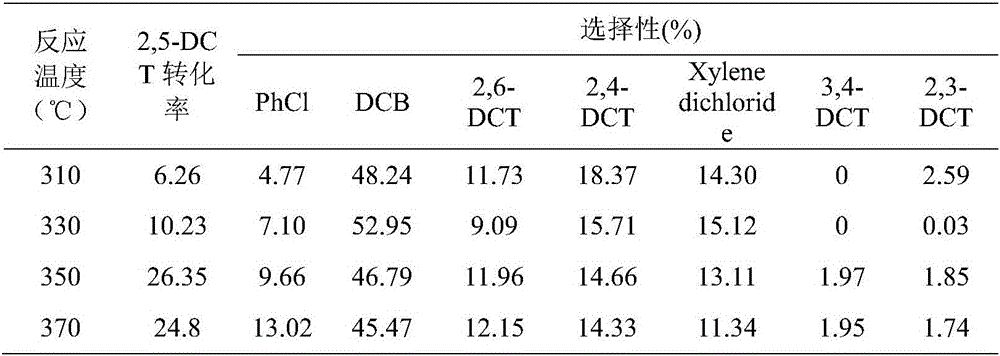

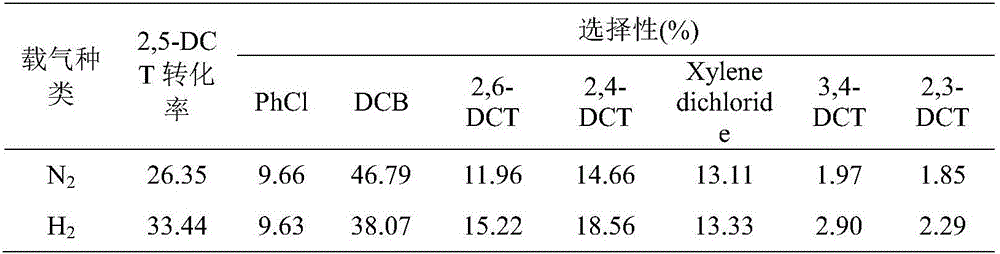

Method for catalyzing 2,5-dichlorotoluene reaction by modified H type molecular sieve

ActiveCN106831318ANo need to deal withLow costMolecular sieve catalystsPreparation by halogenatd hydrocarbon disproportionationMolecular sievePtru catalyst

The invention relates to a method for catalyzing 2, 5-dichlorotoluene reaction by a modified H type molecular sieve, and belongs to the technical field of chlorotoluene derivatives. The method comprises the following steps: dissolving Cu(NO3)2 3H2O into distilled water, fully mixing and stirring with an H type molecular sieve after completely dissolving, standing for 12 hours under a condition that the environment temperature is 110 DEG C after standing and drying, and drying in a muffle furnace of which the temperature is 400 DEG C for 2 hours; performing a modified molecular sieve, grinding, sieving, and selecting sieved molecular sieve particles as a catalyst; filling a constant-temperature zone of a fixed bed reactor with the catalyst; conveying raw materials to the fixed bed reactor through a constant flow pump, and continuously bringing rapidly vaporized raw material steam in the constant-temperature zone into a catalyst bed layer through a gas; finally collecting a product through water bath condensation. According to the method disclosed by the invention, the modified H type molecular sieve is adopted as the catalyst, no toxicity and no harm exist, better stability and higher catalytic activity are obtained, cyclic and repeated utilization can be carried out, and sustained industrial production is facilitated.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

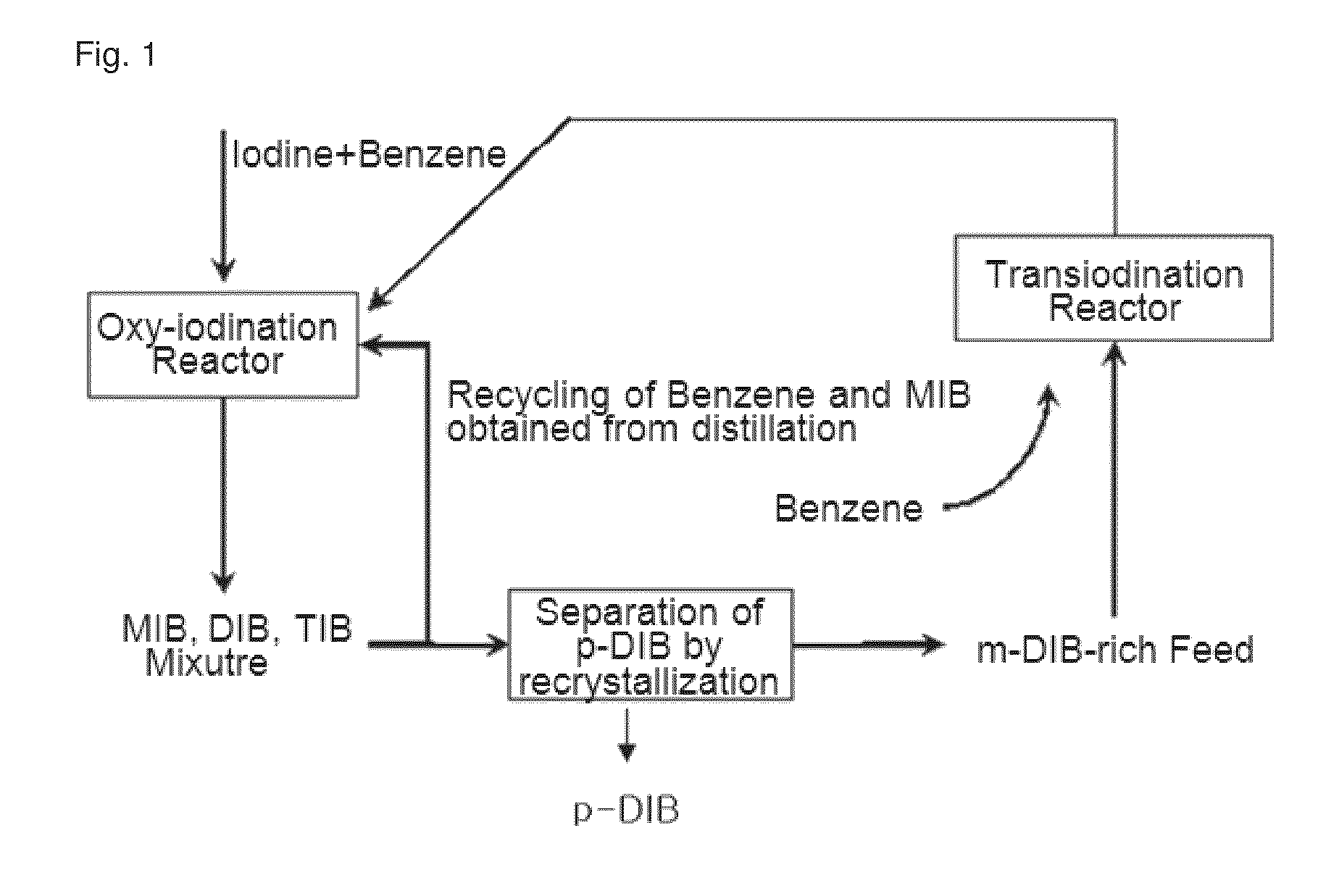

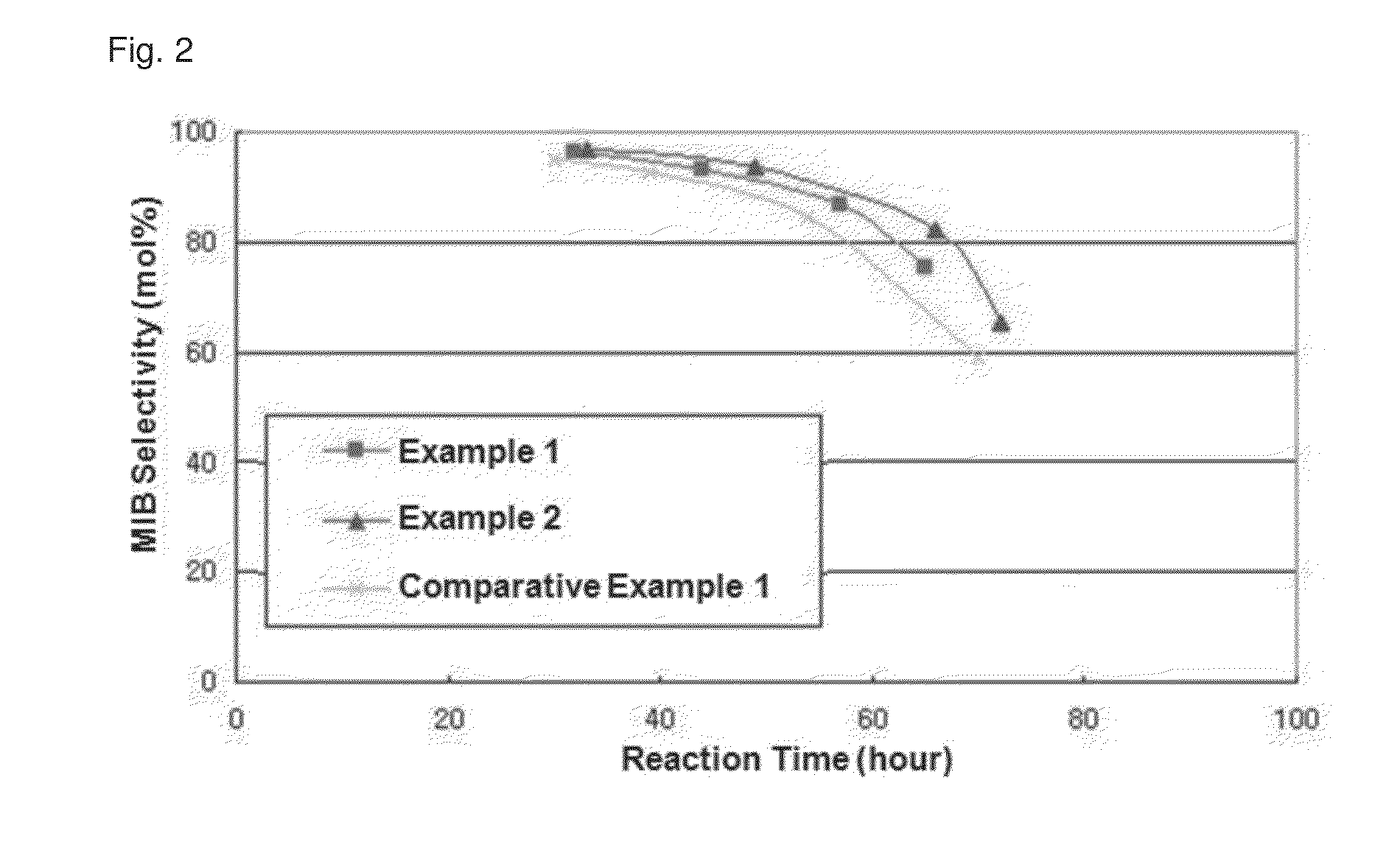

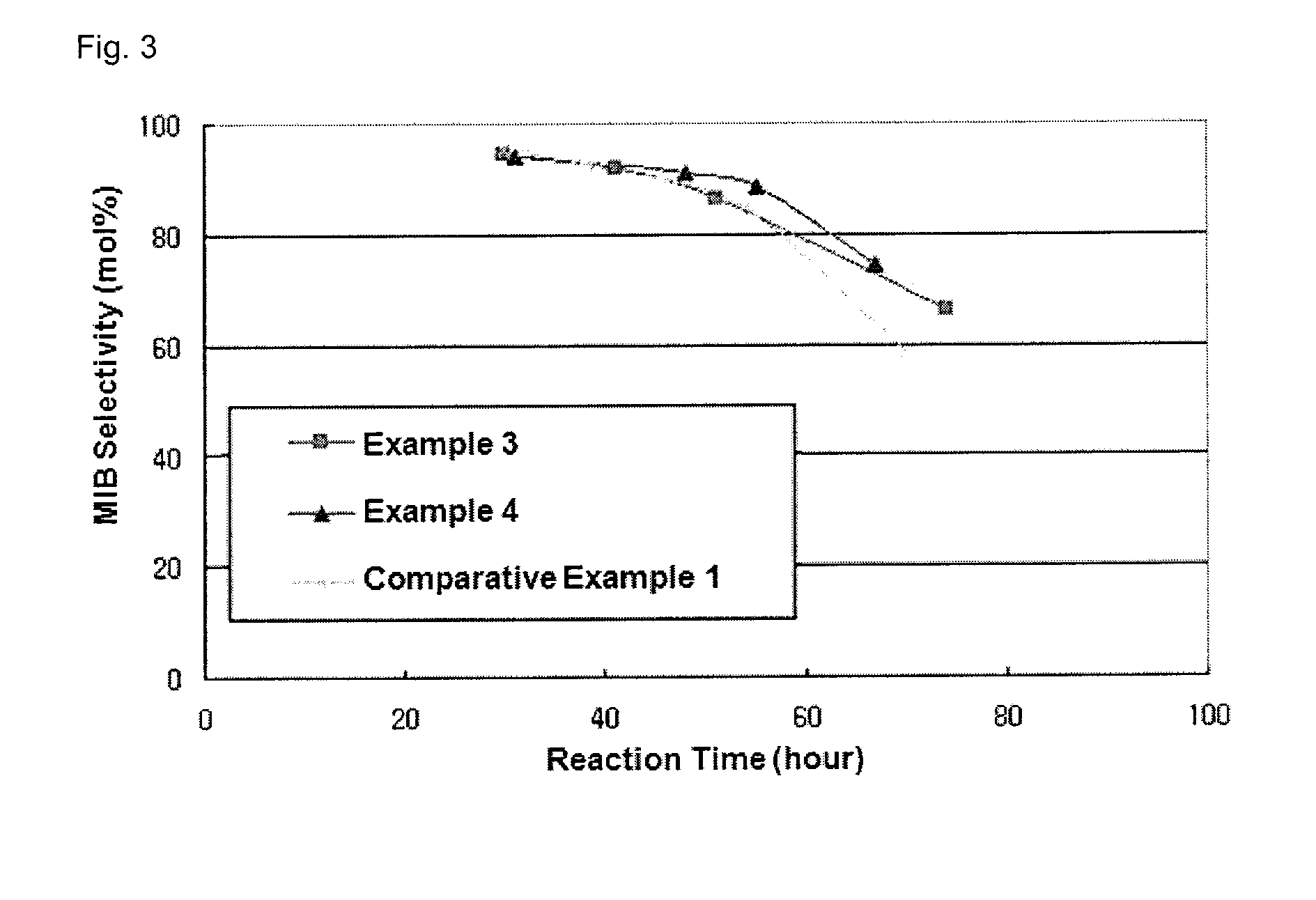

Cation-exchanged zeolite catalyst and process for producing mono-iodo benzene through transiodination by using it

InactiveUS20130116484A1Molecular sieve catalystsPreparation by halogenatd hydrocarbon disproportionationBenzeneAlkaline earth metal

The present invention relates to a cation-exchanged zeolite catalyst for an transiodination and a process for producing mono-iodo benzene by using it. Particularly, the cation-exchanged zeolite catalyst has a molar ratio of Si / Al from 5 to 100 and is ion-exchanged with an alkali metal or an alkaline earth metal in range of 2% to 50% of ion exchange capacity.Further, the process for producing mono-iodo benzene of the present invention comprises the step of performing a transiodination by using the cation-exchanged zeolite catalyst to produce mono-iodo benzene from reactants including benzene and one or more multi-iodo benzenes selected from the group consisting of di-iodo benzene and tri-iodo benzene.

Owner:SK CHEM CO LTD

Cation-exchanged zeolite catalyst and process for producing mono-iodo benzene through transiodination by using it

The present invention relates to a cation-exchanged zeolite catalyst for an transiodination and a process for producing mono-iodo benzene by using it. Particularly, the cation-exchanged zeolite catalyst has a molar ratio of Si / Al from 5 to 100 and is ion-exchanged with an alkali metal or an alkaline earth metal in range of 2% to 50% of ion exchange capacity.Further, the process for producing mono-iodo benzene of the present invention comprises the step of performing a transiodination by using the cation-exchanged zeolite catalyst to produce mono-iodo benzene from reactants including benzene and one or more multi-iodo benzenes selected from the group consisting of di-iodo benzene and tri-iodo benzene.

Owner:SK CHEM CO LTD

Process for the preparation of hexafluoro-2-butyne

ActiveUS8524955B2Preparation by dehalogenationPreparation by hydrogen halide split-offHalogenHydrogen

Disclosed is a process for making hexafluoro-2-butyne comprising the steps of: (a) providing a composition comprising CF3CX═CXCF3, where X=halogen; and (b) treating CF3CX═CXCF3 with a dehalogenation catalyst in the presence of a halogen acceptor compound Y, where Y is not hydrogen. The halogen acceptor compound Y is a material capable of being halogenated, preferably a compound having a multiple bond, such as an alkyne, alkene, allene, or carbon monoxide. Another suitable material capable of being halogenated is a cyclopropane. A catalyst effectively transfers halogen from CF3CX═CXCF3 to the halogen acceptor compound. Since Y is not hydrogen, the formation of CF3CX═CHCF3 is greatly reduced or eliminated.

Owner:HONEYWELL INT INC

Process for the preparation of hexafluoro-2-butyne

ActiveUS20110288348A1Preparation by dehalogenationPreparation by hydrogen halide split-offHydrogenHalogen

Disclosed is a process for making hexafluoro-2-butyne comprising the steps of: (a) providing a composition comprising CF3CX═CXCF3, where X=halogen; and (b) treating CF3CX═CXCF3 with a dehalogenation catalyst in the presence of a halogen acceptor compound Y, where Y is not hydrogen. The halogen acceptor compound Y is a material capable of being halogenated, preferably a compound having a multiple bond, such as an alkyne, alkene, allene, or carbon monoxide. Another suitable material capable of being halogenated is a cyclopropane. A catalyst effectively transfers halogen from CF3CX═CXCF3 to the halogen acceptor compound. Since Y is not hydrogen, the formation of CF3CX═CHCF3 is greatly reduced or eliminated.

Owner:HONEYWELL INT INC

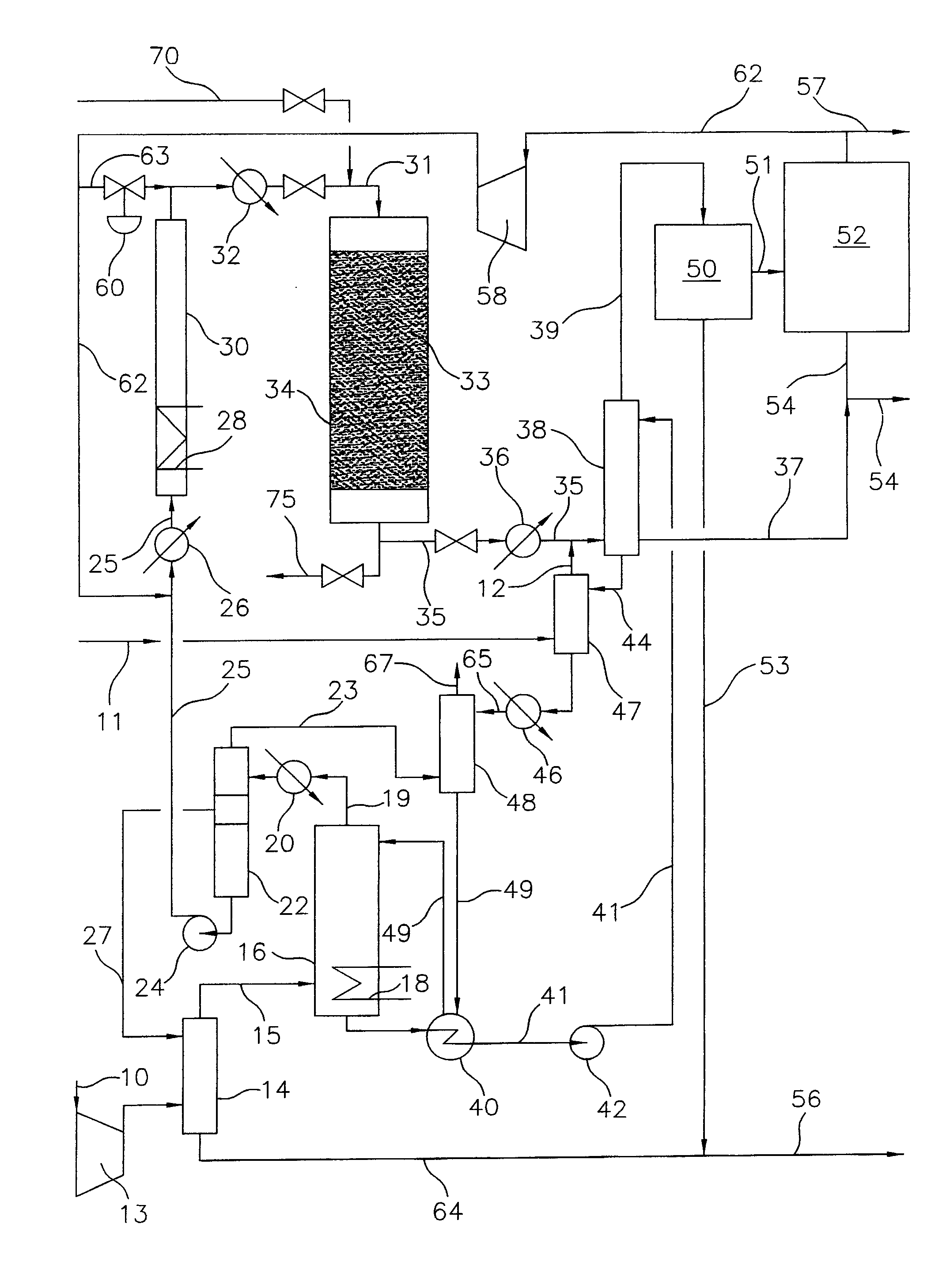

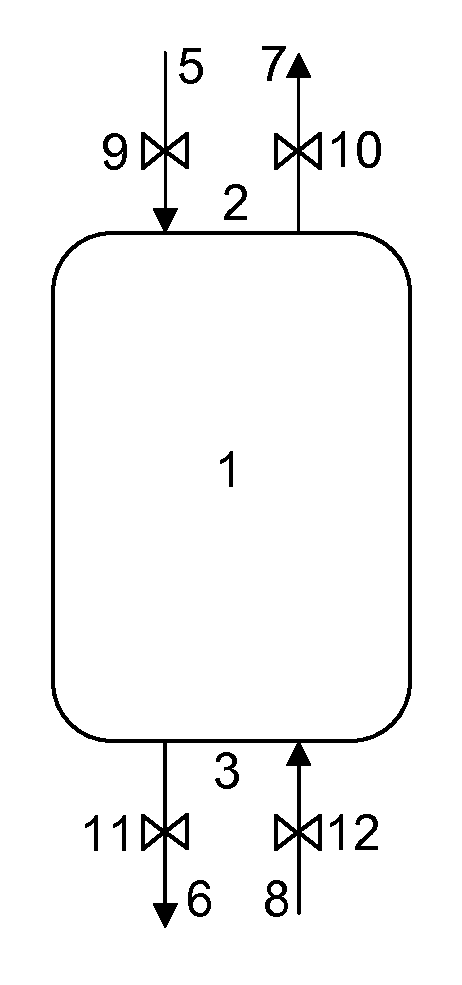

Catalytic reaction with reverse-flow regeneration

ActiveUS9259707B2Lower overall pressure dropOrganic compound preparationPreparation by halogenatd hydrocarbon disproportionationChemical reactionReaction chamber

The invention concerns a chemical reaction process performed in a reaction chamber (1) which contains a catalyst bed, the reaction chamber (1) comprising a first end (2) and a second end (3), opposite the first end (2), the process involving alternately: a reaction phase, in which a reaction flow passes through the reaction chamber (1) from its first end (2) towards its second end (3); and a catalyst-regeneration phase, in which a regeneration flow passes through the reaction chamber (1) from its second end (3) towards its first end (2). The reaction chamber (1) preferably consists of a plurality of separate reaction compartments containing a catalyst bed and a heat-exchange system for exchanging heat therebetween.

Owner:ARKEMA FRANCE SA

Method for producing fluorine-containing olefin

ActiveUS9598335B2Simply and efficiently producedRuthenium organic compoundsOrganic compound preparationFluorine containingMedicinal chemistry

Owner:ASAHI GLASS CO LTD

Method for purifying fluid that includes trifluoroethylene, and method for producing trifluoroethylene

ActiveUS9862660B2Efficient removalEfficient productionPreparation by dehalogenationPreparation by hydrogen halide split-offAlkaneHydrogen atom

To provide a method for purifying trifluoroethylene, by which from a fluid containing trifluoroethylene, a C1-5 alkane or alkene (excluding trifluoroethylene) in which at least one hydrogen atom may be substituted with a chlorine atom or a fluorine atom can be efficiently removed, and a method for producing trifluoroethylene by which trifluoroethylene can be efficiently produced.A fluid containing trifluoroethylene is brought into contact with at least one type of synthetic zeolite selected from synthetic zeolites 3A, 4A and 5A.

Owner:ASAHI GLASS CO LTD

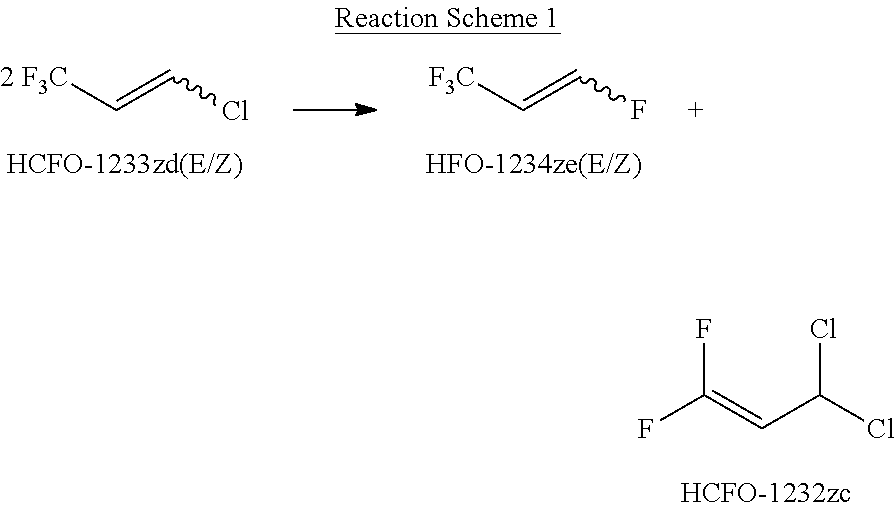

METHOD FOR PRODUCING 1,3,3,3-TETRAFLUOROPROPENE (HFO-1234ze) FROM 1-CHLORO-3,3,3-TRIFLUOROPOPENE (HCFO-1233zd)

ActiveUS20190152882A1Preparation by halogen replacementPreparation by halogenatd hydrocarbon disproportionationHydrogen fluoridePresent method

A method for producing 1,3,3,3-tetrafluoropropene (HFO-1234ze, or 1234ze) from 1-chloro-3,3,3-trifluoropopene (HCFO-1233zd, or 1233zd). In one embodiment, HFO-1233zd is subjected to a disproportionation reaction in the presence of a catalyst at an elevated temperature to produce HFO-1234ze as well as 3,3-dichloro-1,1-difluoropropene (HCFO-1232zc). The catalyst may be at least one of a chromium oxyfluoride catalyst, a chromium oxide catalyst, or a metal fluoride catalyst. The reaction may be conducted in the vapor phase at a temperature between 100° C. and 450° C. Advantageously, in the present method, substantially no hydrogen fluoride (HF) is used as a reactant, and substantially no HF is produced as a product.

Owner:HONEYWELL INT INC

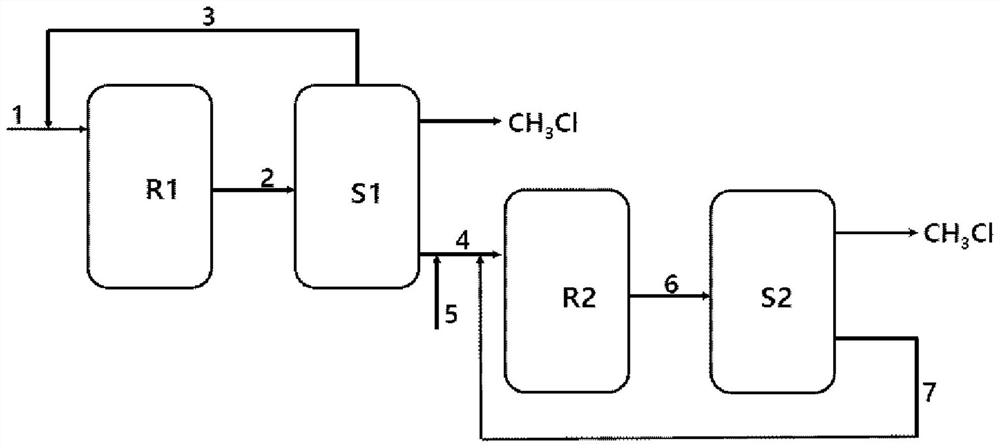

Method of producing methyl chloride by multistage reactions

PendingCN112739674AIncrease productionGuaranteed outputMolecular sieve catalystCatalystsWater chlorinationChloride

The present invention relates to a method of producing methyl chloride by multistage reactions. The method of the present invention comprises: a) a chlorination step for sufficiently increasing the conversion rate of methane, which is an initial reactant; and b) a subsequent reaction step for actively utilizing hydrogen chloride (HCl), which is a hazardous byproduct of chlorination, such that the method can efficiently treat harmful hydrogen chloride, and at the same time, can improve the overall production of methyl chloride.

Owner:KOREA RES INST OF CHEM TECH

Production method for fluorine-containing olefin compound

ActiveUS20170369402A1Easily and efficiently producedOrganic chemistry methodsPreparation by halogenatd hydrocarbon disproportionationCompound aCompound (substance)

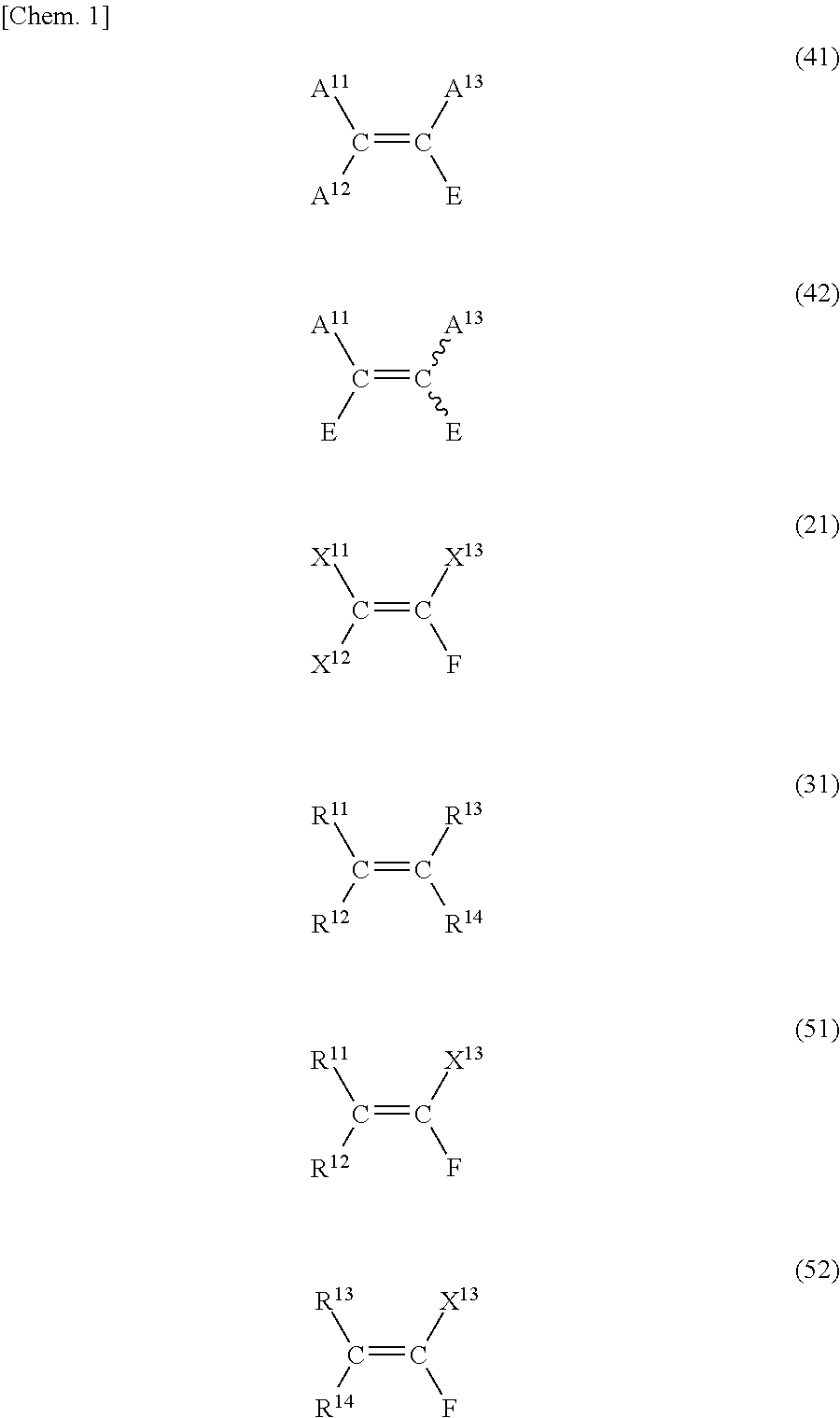

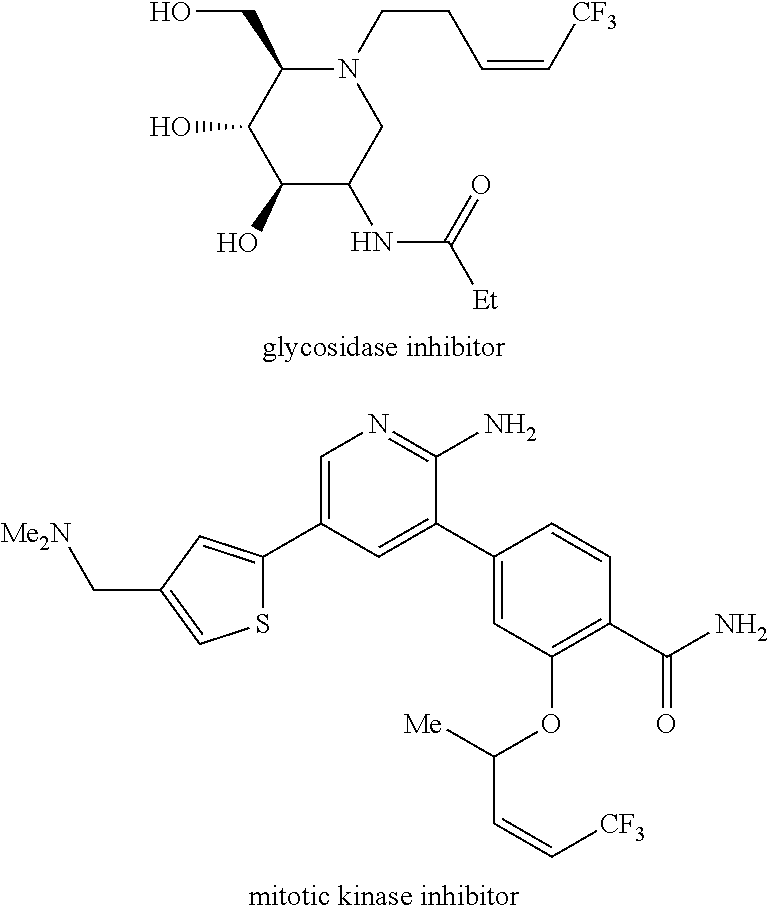

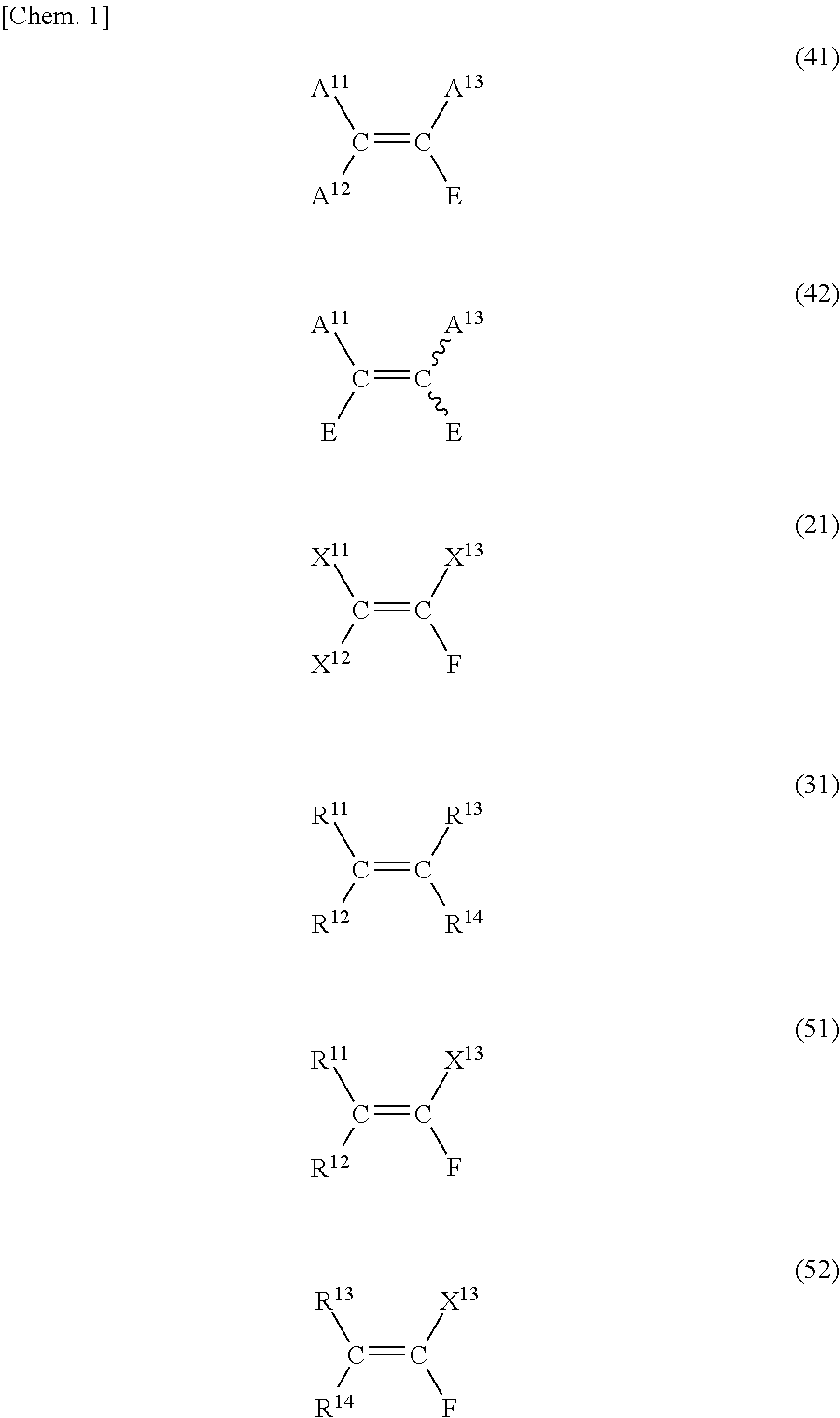

A method for producing at least one compound of a fluorine-containing olefin compound (51) or a fluorine-containing olefin compound (52) includes performing a reaction of a fluorine-containing olefin compound (21) with an olefin compound (31) in the presence of a metal-carbene complex compound having an olefin metathesis reaction activity and an olefin compound (41) or (42).

Owner:ASAHI GLASS CO LTD

Method for modifying fluorine distribution in a hydrocarbon compound

ActiveUS11459286B2Reduce corrosionIncrease contentPreparation by hydrogen halide split-offPreparation by halogen replacementPtru catalystPhysical chemistry

The present invention relates to a process for modifying the fluorine distribution in a hydrocarbon compound, comprising a step of making contact between said hydrocarbon compound and a catalytic composition comprising a chromium-based catalyst, said process being performed in a reactor made of a material comprising a base layer made of a material M1 and an inner layer made of a material M2, said base layer and said inner layer being laid against each other by bonding.

Owner:ARKEMA FRANCE SA

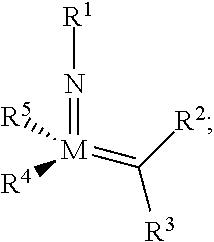

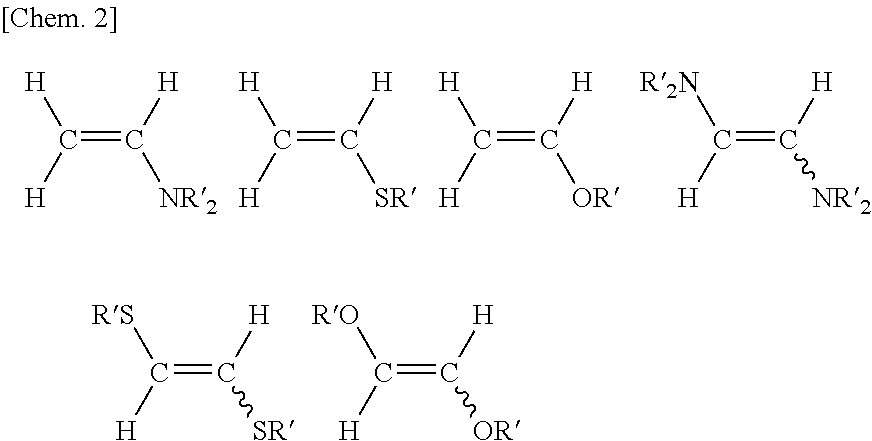

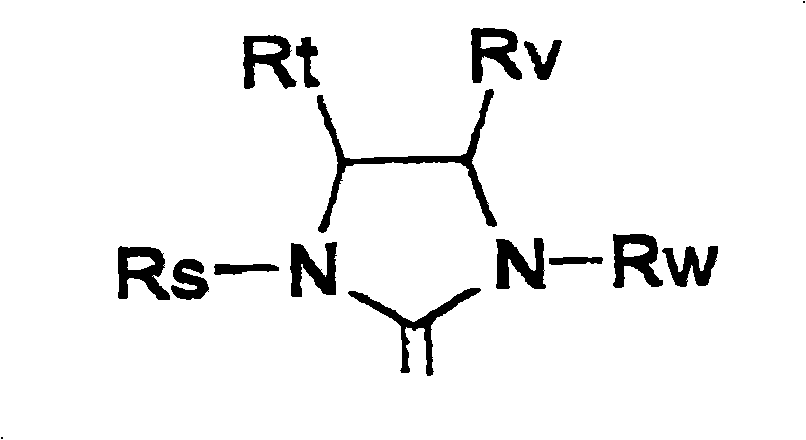

Halogen-containing metathesis catalysts and methods thereof

ActiveUS20190314799A1Easy accessHigh stereoselectivitySilicon organic compoundsAmino preparation from aminesHalogenFluoride

The present disclosure provides compounds, compositions, and methods for preparing alkenyl halides and / or haloalkyl-substituted olefins with Z-selectivity. The methods are particularly useful for preparing alkenyl fluorides such as CF3-substituted olefins by means of cross-metathesis reactions using halogen-containing molybdenum and tungsten complexes.

Owner:BOSTON COLLEGE +1

Method for producing fluorine-containing olefin compound

ActiveUS10252959B2Easily and efficiently producedOrganic chemistry methodsPreparation by halogenatd hydrocarbon disproportionationCompound aAlkene

A method for producing at least one compound of a fluorine-containing olefin compound (51) or a fluorine-containing olefin compound (52) includes performing a reaction of a fluorine-containing olefin compound (21) with an olefin compound (31) in the presence of a metal-carbene complex compound having an olefin metathesis reaction activity and an olefin compound (41) or (42).

Owner:ASAHI GLASS CO LTD

A kind of magnesium fluoride catalyst, its preparation method and application

ActiveCN106669742BLarge specific surface areaAppropriate aperturePreparation by hydrogen halide split-offPhysical/chemical process catalystsHydrogen halidePtru catalyst

Owner:陕西中化蓝天化工新材料有限公司 +2

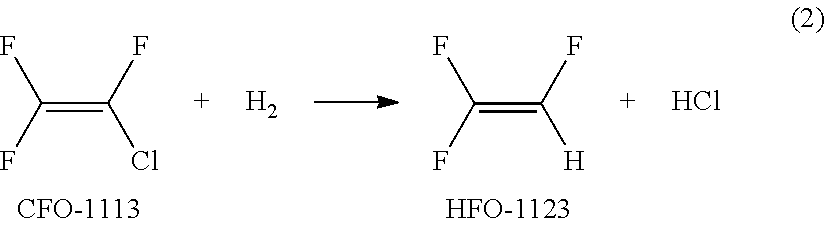

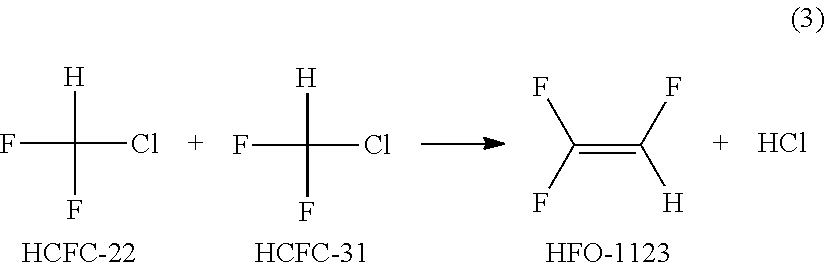

Method for producing trifluoroethylene

InactiveCN105339330AEfficient preparationGWP) smallPreparation by halogenatd hydrocarbon disproportionationDistillationPhotochemistry

Provided is an economically advantageous method for efficiently and at a high purity producing HFO-1123, which is industrially useful, by means of a synthesis reaction that uses easily acquired starting materials, does not use a catalyst, and accompanies pyrolysis, in a manner such that the generation is suppressed of by-products difficult to separate by means of distillation from HFO-1123, particularly HFO-1132(E). The method for producing HFO-1123 from R31, R22, and TFE has (a) a step for supplying R31, R22, and TFE to a reaction vessel in a separate or pre-mixed manner, (b) a step for supplying a heat medium to the reaction vessel, and (c) a step for generating HFO-1123 by contacting R31, R22, TFE, and the heat medium together in the reaction vessel in the state of the temperature of within the reaction vessel being controlled to 400-950 DEG C.

Owner:ASAHI GLASS CO LTD

A kind of method that modified h-type molecular sieve catalyzes 2,5-dichlorotoluene reaction

ActiveCN106831318BNo need to deal withLow costMolecular sieve catalystsPreparation by halogenatd hydrocarbon disproportionationMolecular sievePtru catalyst

The invention relates to a method for catalyzing 2, 5-dichlorotoluene reaction by a modified H type molecular sieve, and belongs to the technical field of chlorotoluene derivatives. The method comprises the following steps: dissolving Cu(NO3)2 3H2O into distilled water, fully mixing and stirring with an H type molecular sieve after completely dissolving, standing for 12 hours under a condition that the environment temperature is 110 DEG C after standing and drying, and drying in a muffle furnace of which the temperature is 400 DEG C for 2 hours; performing a modified molecular sieve, grinding, sieving, and selecting sieved molecular sieve particles as a catalyst; filling a constant-temperature zone of a fixed bed reactor with the catalyst; conveying raw materials to the fixed bed reactor through a constant flow pump, and continuously bringing rapidly vaporized raw material steam in the constant-temperature zone into a catalyst bed layer through a gas; finally collecting a product through water bath condensation. According to the method disclosed by the invention, the modified H type molecular sieve is adopted as the catalyst, no toxicity and no harm exist, better stability and higher catalytic activity are obtained, cyclic and repeated utilization can be carried out, and sustained industrial production is facilitated.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

Metathesis synthesis of pheromones or their components

InactiveCN100528829CPreparation rom asymmetrical anhydridesOrganic compound preparationDiamondback mothMicrobiology

The present invention relates to metathesis syntheses for insect sex-attractant pheromones or their components, such as E-5-decenyl acetate, the major component of the Peach Twig Borer pheromone; (5R, 6S)-6-acetoxy-5-hexadecanolide, the mosquito oviposition attractant pheromone; E9, Z11-hexadecadienal, the pecan nut casebearer moth pheromone; 9-tetradecenyl formate, an analog of the Diamondback Moth (DBM) pheromone; 11-tetradecenyl acetate, the Omnivorous Leafroller (OLR) pheromone; E-4-tridecenyl acetate, the major component of the Tomato Pinworm (TPW) pheromone; E,E-8,10-dodecadienol, the Codling Moth (CM) pheromone. The syntheses preferably employ a Class I-IV metathesis catalyst, entail few reaction steps, use generally commercially available starting materials, and have relatively short process times. These syntheses produce good yields without the need for expensive or sophisticated equipment. The invention also provides an inexpensive route for producing omega-haloalkenols by cross-metathesizing alpha-omega-diacetoxy alkenes and alpha-omega-dihalides to yield omega-haloalkenols, which are easily converted into omega-haloalkanols under traditional hydrogenation methods.

Owner:R·L·佩德森 +1

Pyrolysis process

ActiveUS6958422B2High yieldIncrease valuePreparation by hydrogen halide split-offPreparation by halogenatd hydrocarbon disproportionationTetrafluoroethyleneReaction zone

The present invention relates to the pyrolysis of hydrochlorofluorocarbons to form fluoromonomers such as tetrafluoroethylene, the pyrolysis being carried out in a reaction zone lined with nickel and mechanically supported by a jacket of other corrosion resistant metal, the nickel lining providing an improved yield of valuable reaction products.

Owner:THE CHEMOURS CO FC LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com