Process for preparing perfluoroalkyl group by telomerization

A perfluoroalkyl iodide and perfluoroalkyl technology, which is applied in the field of telomerization to synthesize perfluoroalkyl iodide, can solve the problems of wide carbon chain distribution of telomer products, difficulty in telomerization degree in tank reactors, and tubular reactors. Low reaction efficiency and other problems, to achieve the effect of no hydrogen-containing by-products, simple production equipment, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

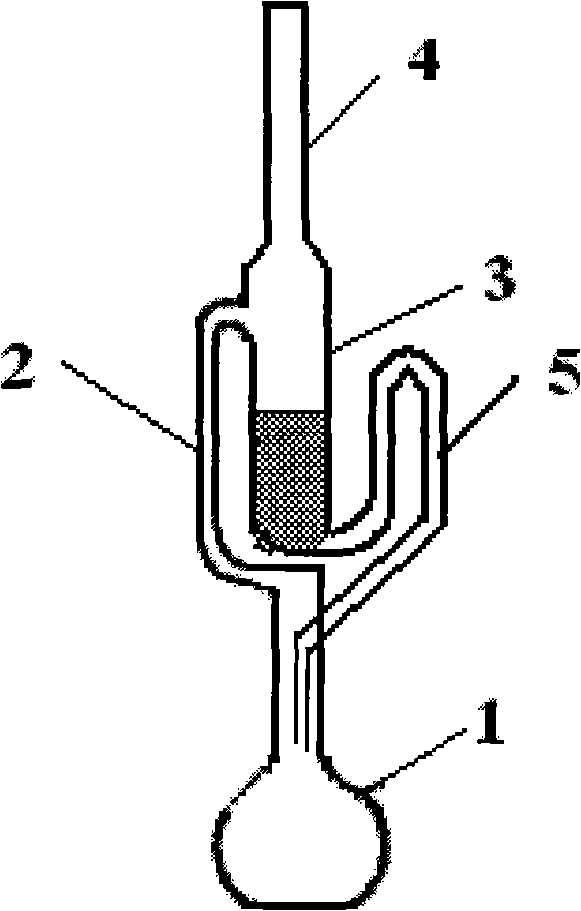

[0024]The telomerization test was carried out in an extraction tower reactor composed of a stainless steel reflux cooling tube with an inner diameter of 10mm and a height of 800mm; an extraction tower with an inner diameter of 40mm and a height of 400mm, and a product collection tank with a volume of 1.2L. The catalyst packing is a 5-mesh spherical active copper catalyst, and the height of the catalyst bed is 300 mm. The reflux cooling pipe is equipped with an outer jacket, which is cooled by a refrigerant inside, and the extraction tower and product collection kettle are also equipped with an outer jacket, and are heated by low-pressure steam. During the reaction, add 1500g C to the product collection kettle earlier. 2 f 5 I. Then pass industrial water to the jacket of the reflux cooling pipe, and pass low-pressure water vapor to the jacket of the extraction tower and the product collector, and control the temperatures of the middle part of the reflux cooling pipe, the extr...

Embodiment 2

[0026] The telomerization test was carried out in an extraction tower reactor composed of a stainless steel reflux cooling pipe with an inner diameter of 10mm and a height of 1500mm; an extraction tower with an inner diameter of 10mm and a height of 1300mm, and a product collection tank with a volume of 1.2L. The catalyst packing is a 50-mesh spherical active copper catalyst, and the height of the catalyst bed is 1000mm. The reflux cooling pipe is equipped with an outer jacket, which is cooled by refrigerant inside, and the extraction tower and product collection kettle are also equipped with outer jacket pipes, which are heated by low-pressure steam. Add 1500g C from the top of the tower 2 f 5 I. Industrial water is passed through the jacket of the reflux cooling pipe, and low-pressure water vapor is passed through the jacket of the extraction tower and product collection kettle. Then add C at a rate of 30g / h 2 f 4 , Continue feeding for 4h, stop the reaction after 2h of...

Embodiment 3

[0028] The telomerization test was carried out in an extraction tower reactor composed of a stainless steel reflux cooling tube with an inner diameter of 10mm and a height of 800mm; an extraction tower with an inner diameter of 40mm and a height of 400mm, and a product collection tank with a volume of 1.2L. The catalyst filler is a 10-mesh spherical active copper-nickel alloy catalyst, the mass ratio of copper to nickel is 3:7, and the height of the catalyst bed is 300mm. The reflux cooling pipe is equipped with an outer jacket tube, which is cooled by a refrigerant inside, and the extraction tower and product collection kettle are also equipped with an outer jacket tube, which is heated by low-pressure steam. After replacing the oxygen in the system with high-purity nitrogen, add 800g C from the top of the tower 2 f 5 I. Industrial water is passed through the jacket of the reflux cooling pipe, and low-pressure water vapor is passed through the jacket of the extraction tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com