Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about "Hydraulic programme control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

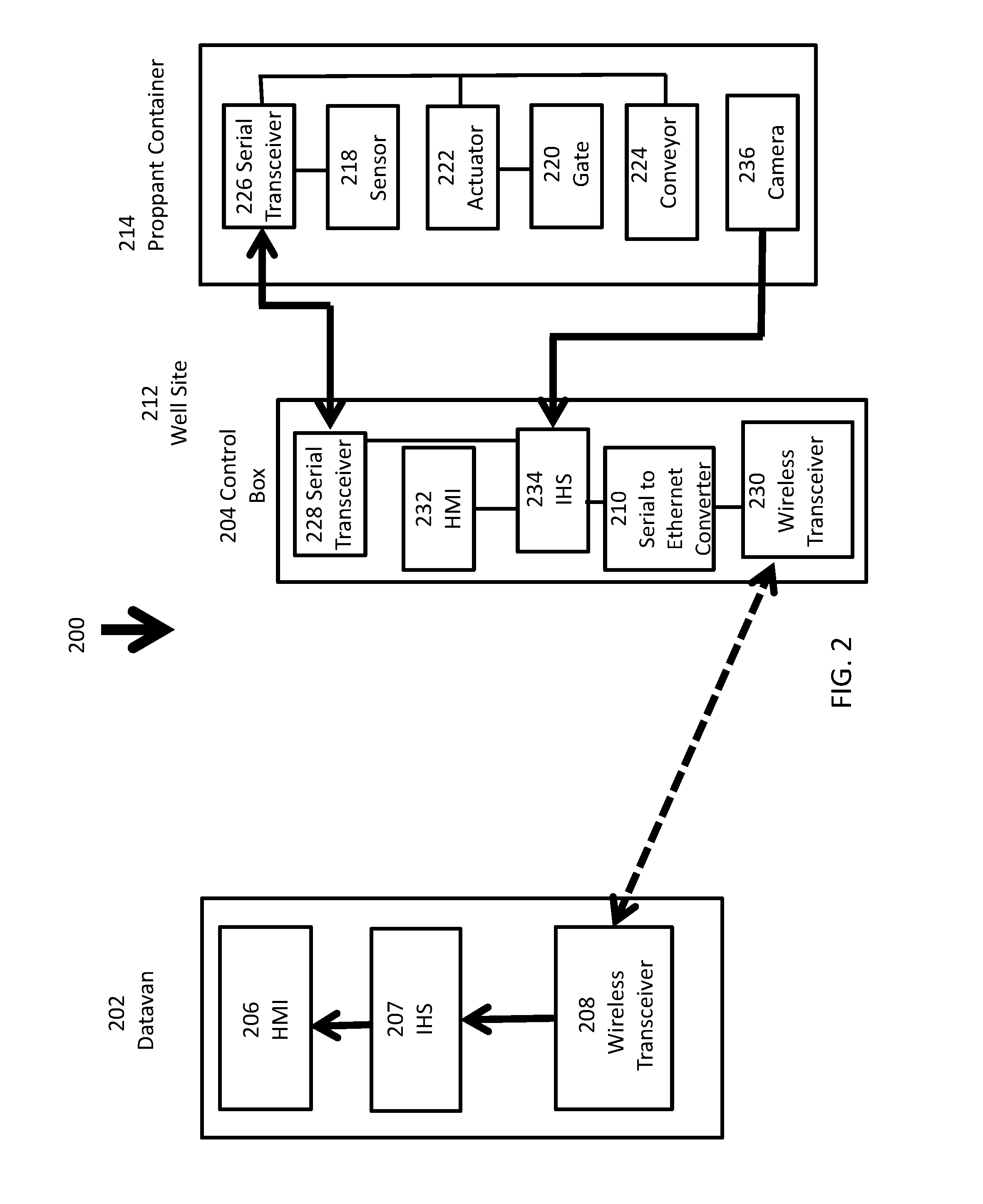

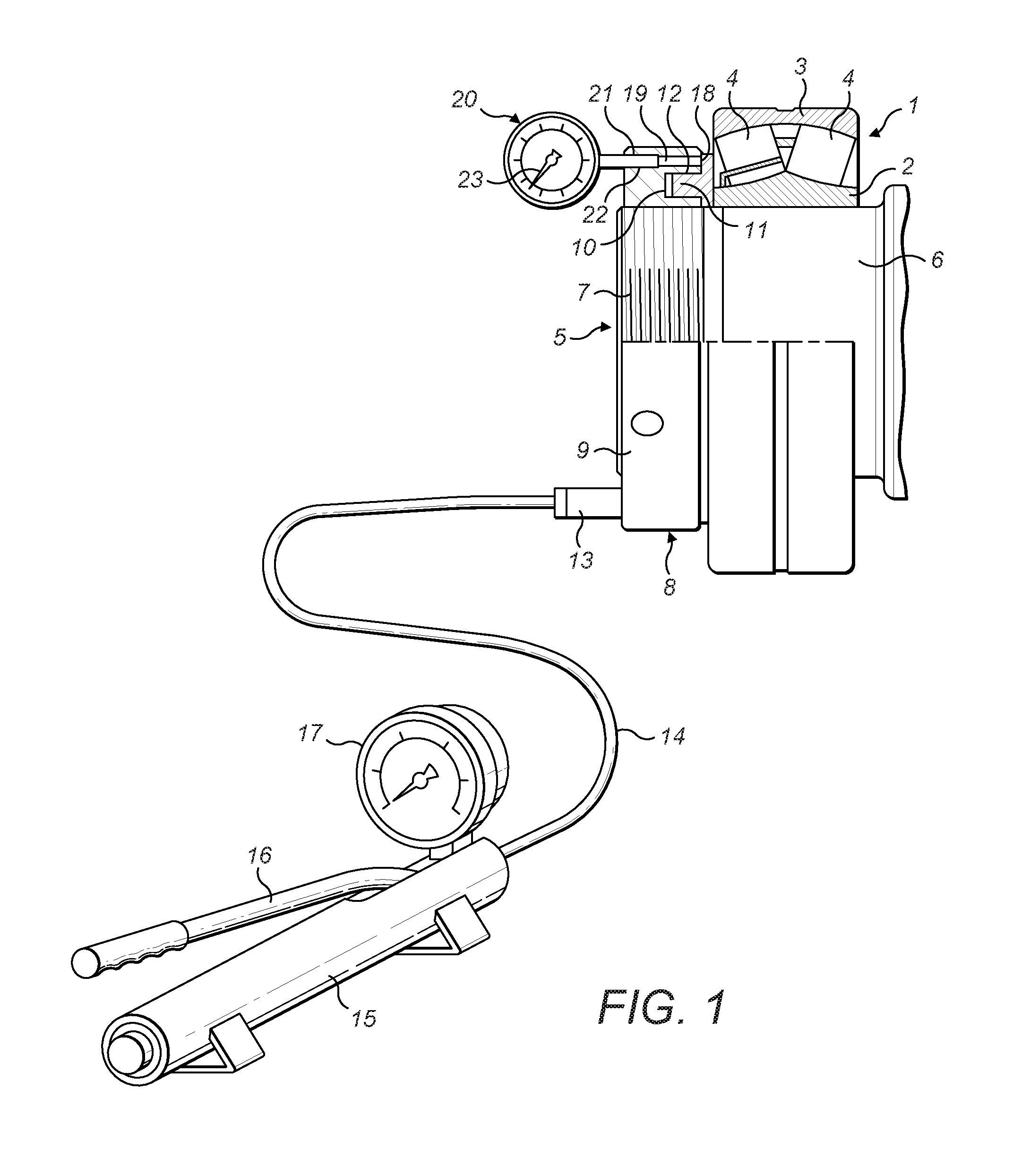

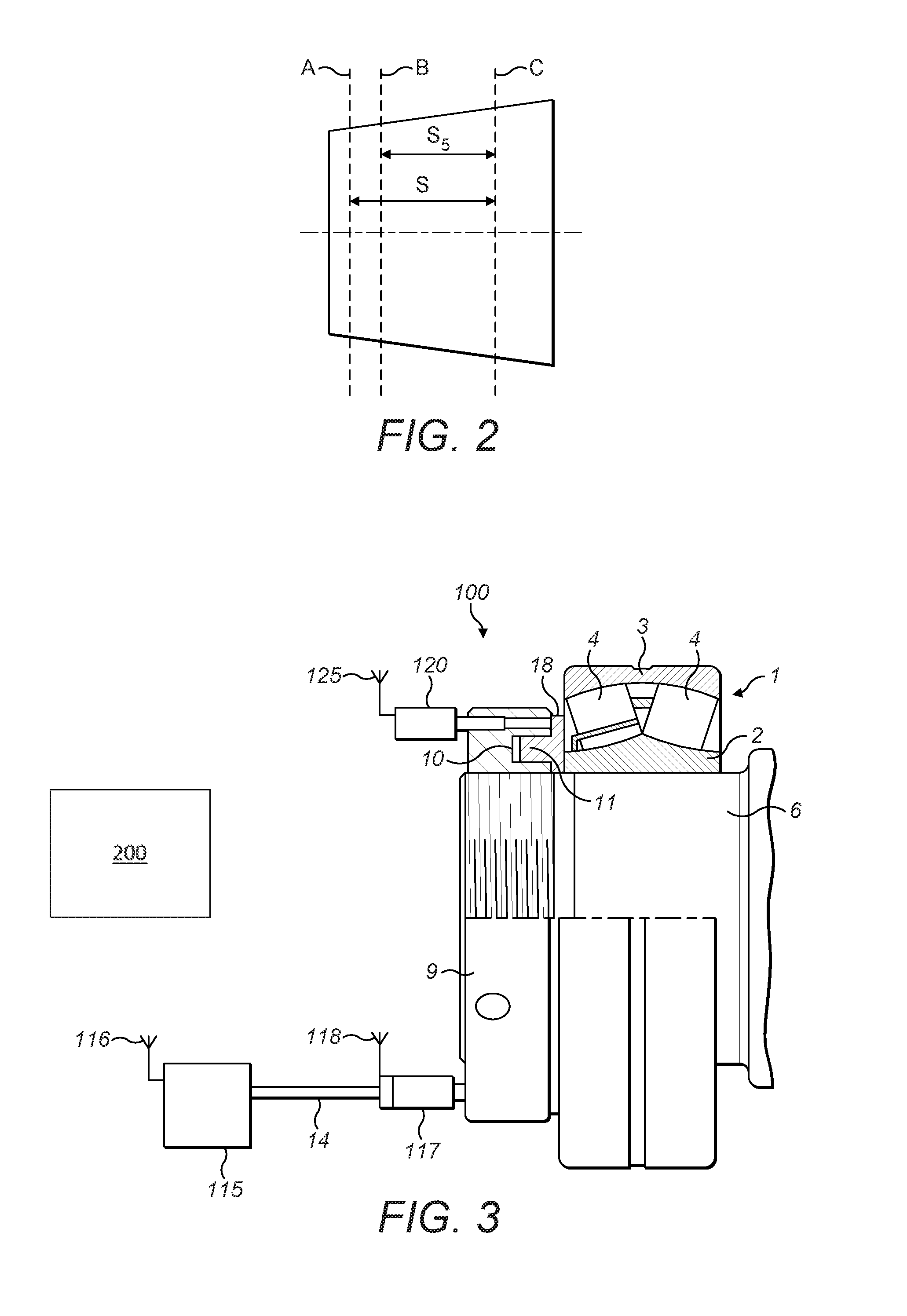

Monitoring and control of proppant storage from a datavan

ActiveUS10254732B2Automate processingHydraulic programme controlComputer controlTime informationDisplay device

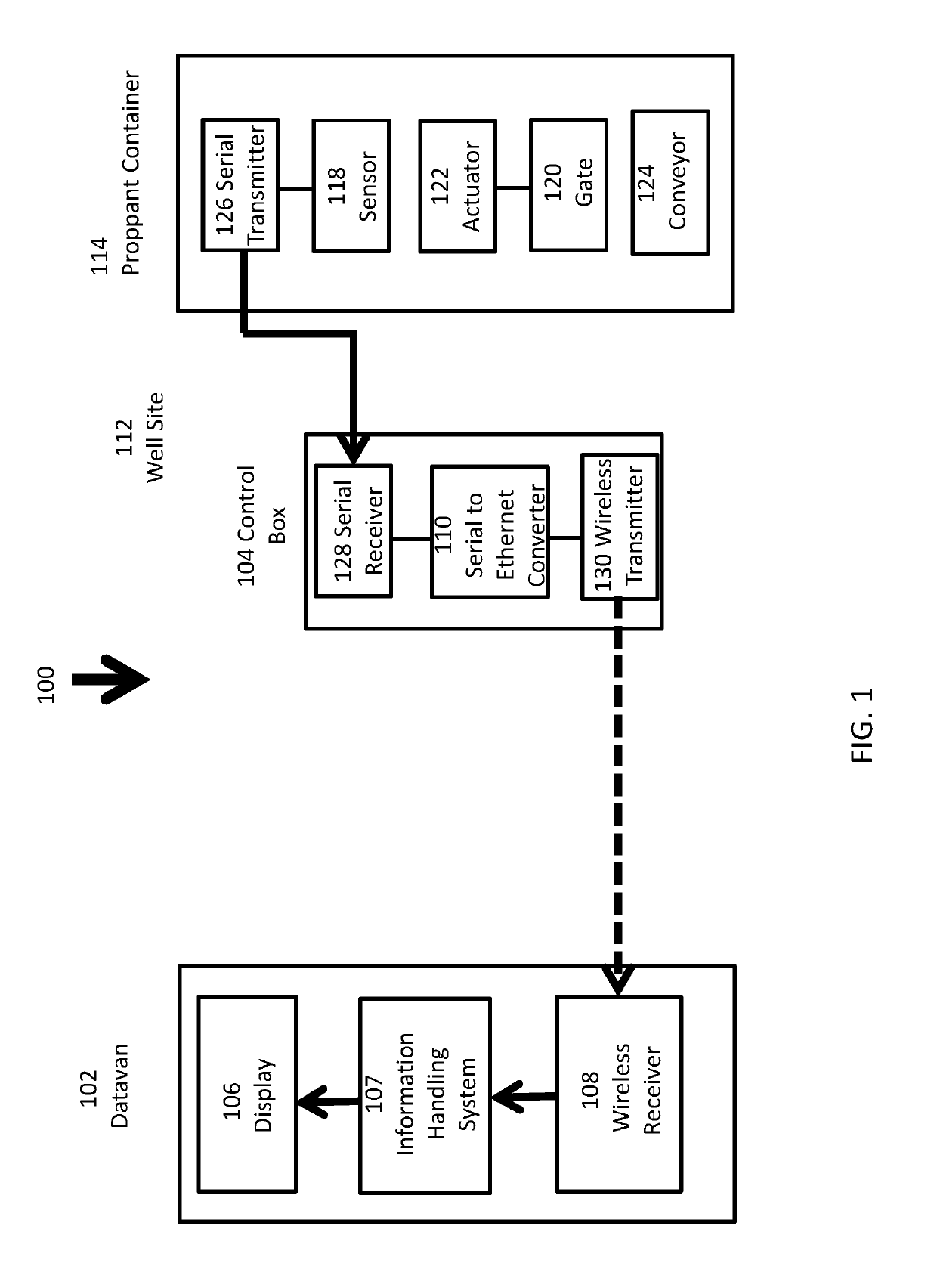

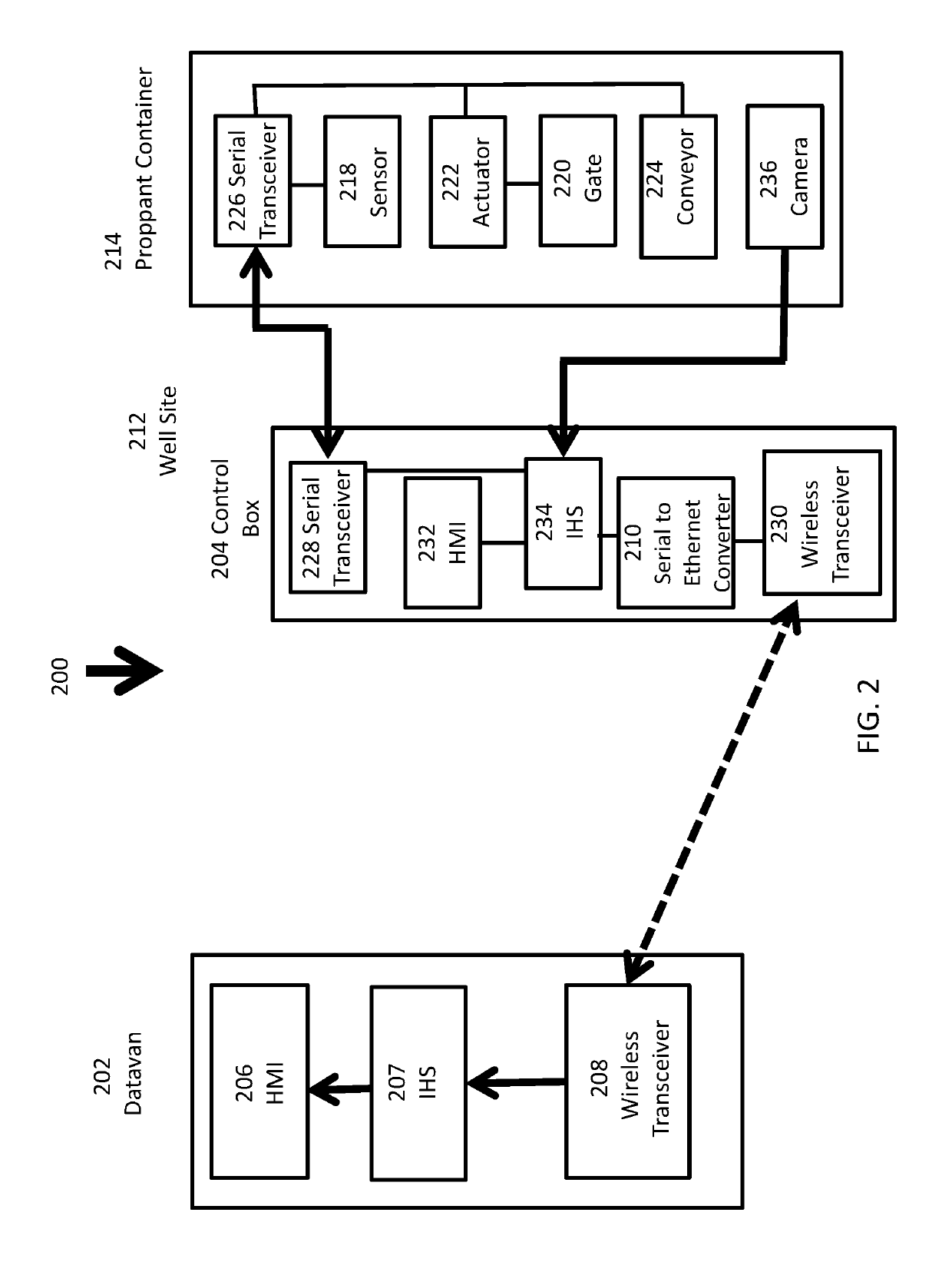

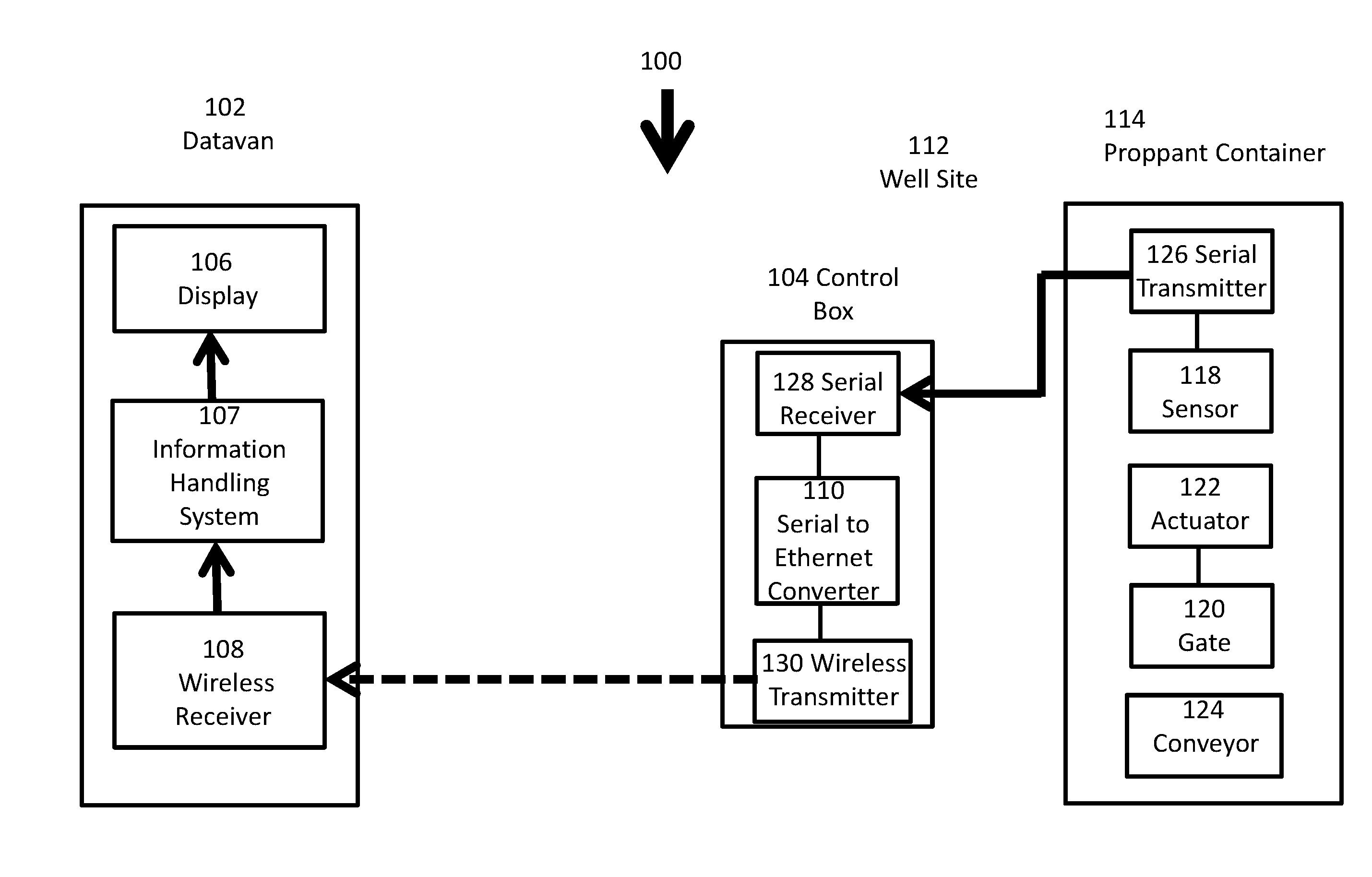

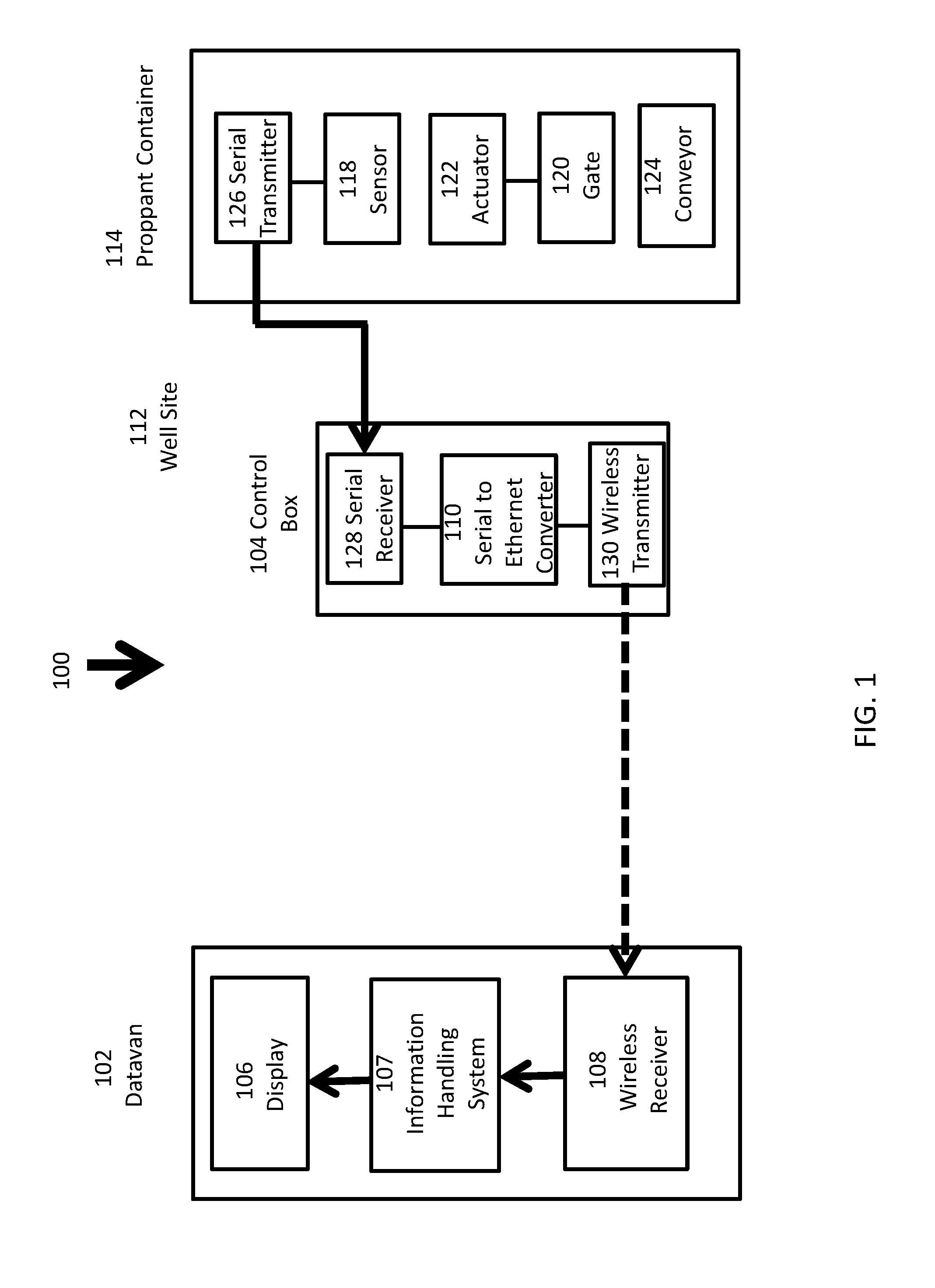

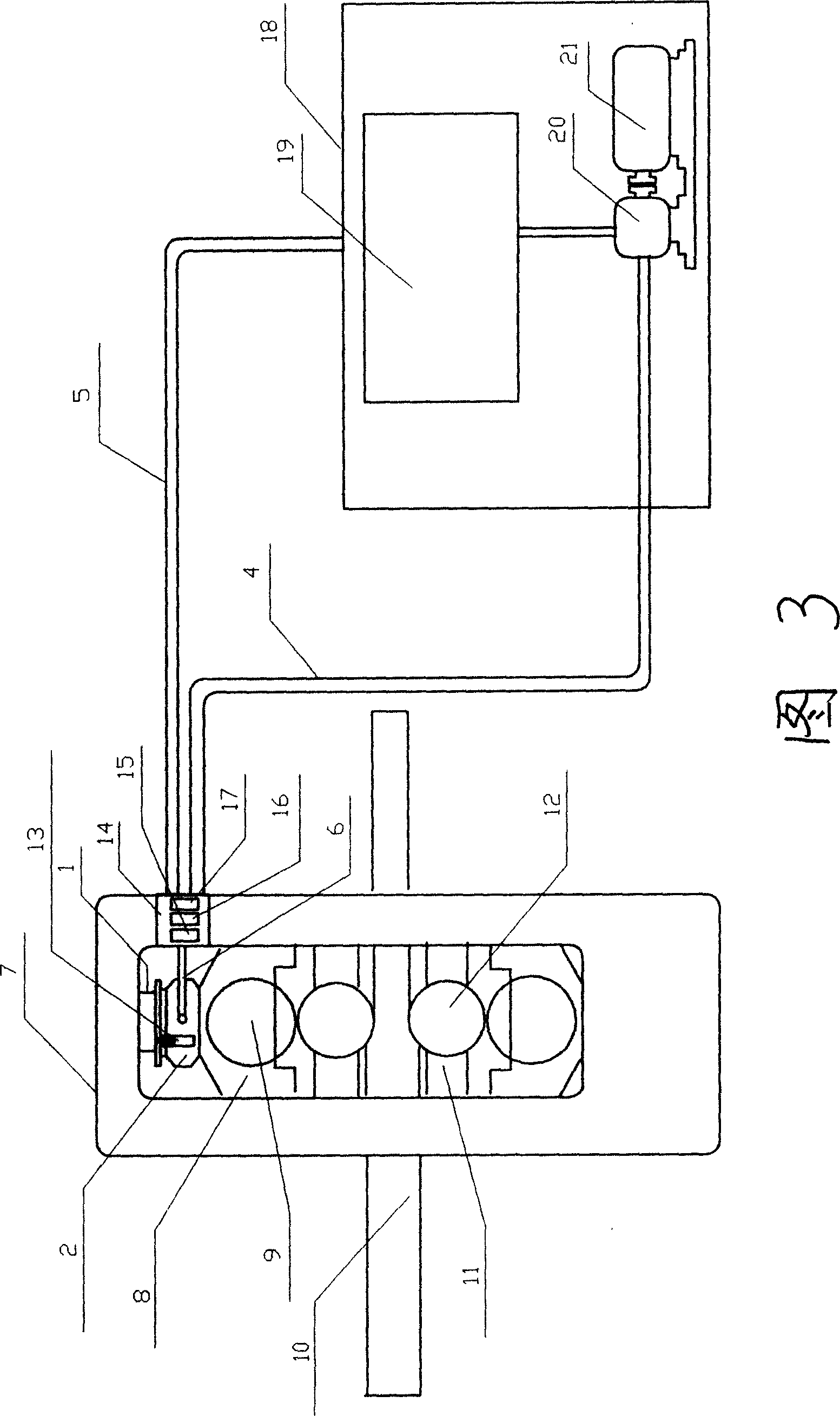

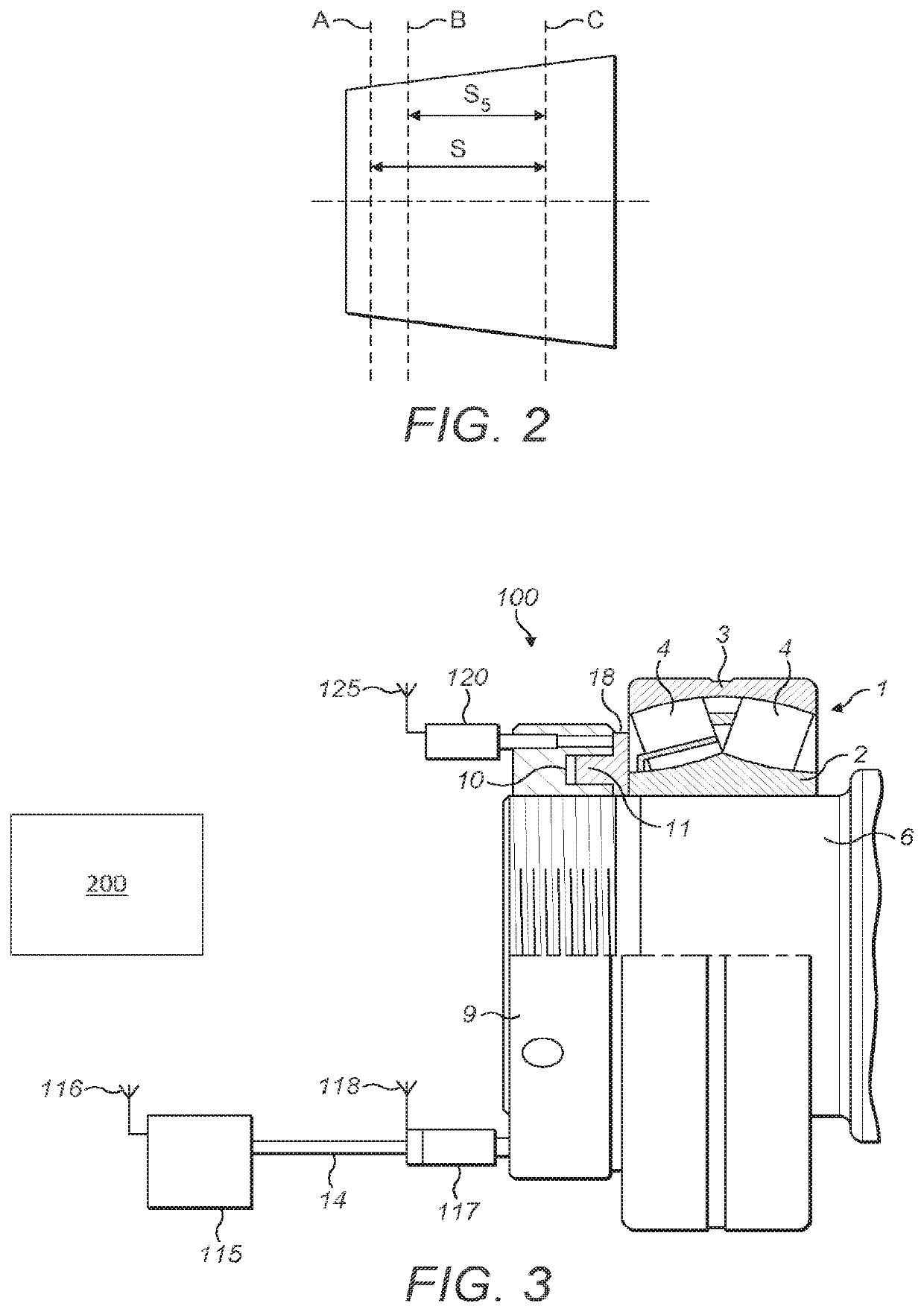

A system and method that remotely monitors and controls proppant usage in a fracturing operation. The system and method allow operators to wirelessly monitor and control proppant storage units from inside a datavan through sensors and control mechanisms that interface with fracturing software to schedule the flow of the proppant. A sensor monitors the weight, container level, or volume of the proppant being used to keep the induced hydraulic fracture open. A serial to Ethernet converter converts this information and sends it wirelessly to a datavan. A user at the datavan controls the proppant usage through a display in the datavan of the storage units with the appropriate weight. The container monitoring software links with the fracturing software, providing real-time information about proppant usage so that the user can properly schedule proppant flow to the well through valves, conveyor belts, and other control mechanisms.

Owner:US WELL SERVICS LLC

Monitoring and Control of Proppant Storage from a Datavan

ActiveUS20160349728A1Automate processingHydraulic programme controlComputer controlTime informationDisplay device

A system and method that remotely monitors and controls proppant usage in a fracturing operation. The system and method allow operators to wirelessly monitor and control proppant storage units from inside a datavan through sensors and control mechanisms that interface with fracturing software to schedule the flow of the proppant. A sensor monitors the weight, container level, or volume of the proppant being used to keep the induced hydraulic fracture open. A serial to Ethernet converter converts this information and sends it wirelessly to a datavan. A user at the datavan controls the proppant usage through a display in the datavan of the storage units with the appropriate weight. The container monitoring software links with the fracturing software, providing real-time information about proppant usage so that the user can properly schedule proppant flow to the well through valves, conveyor belts, and other control mechanisms.

Owner:US WELL SERVICS LLC

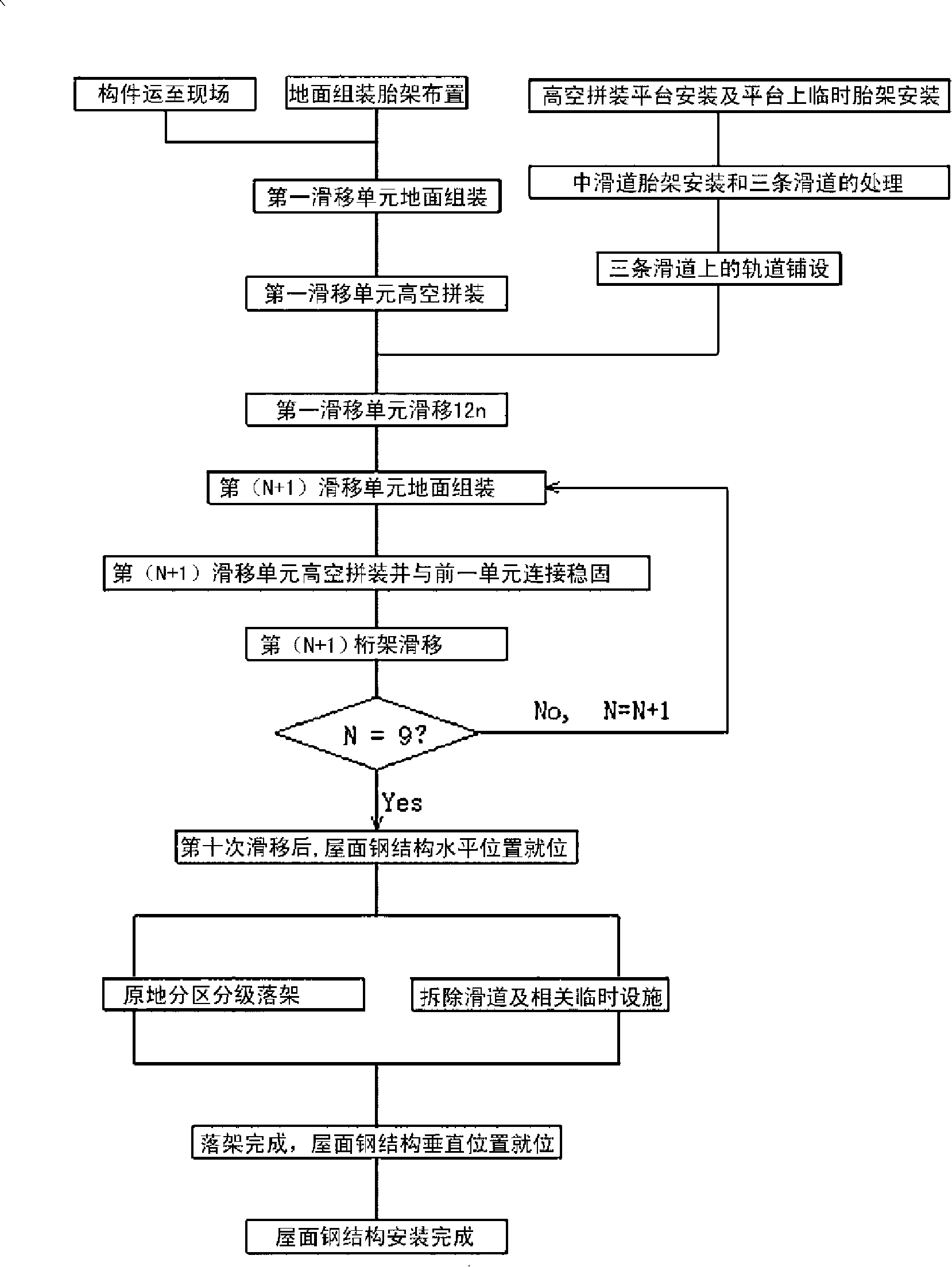

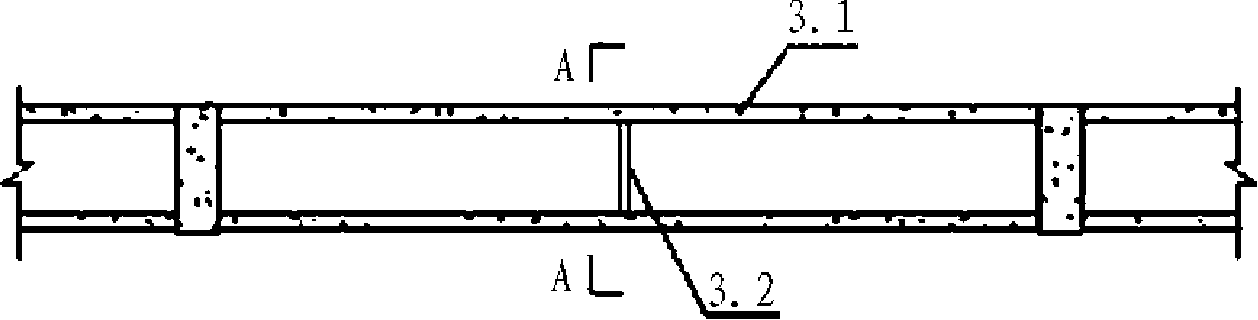

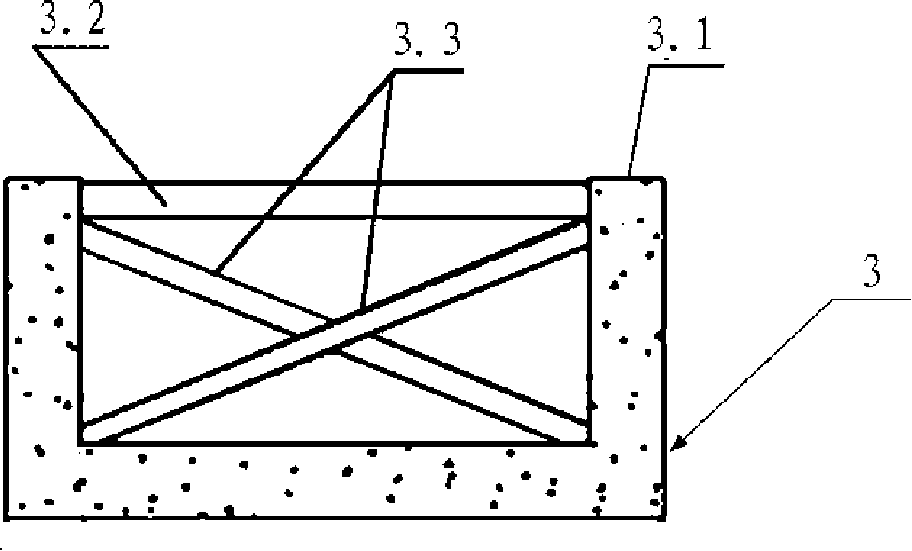

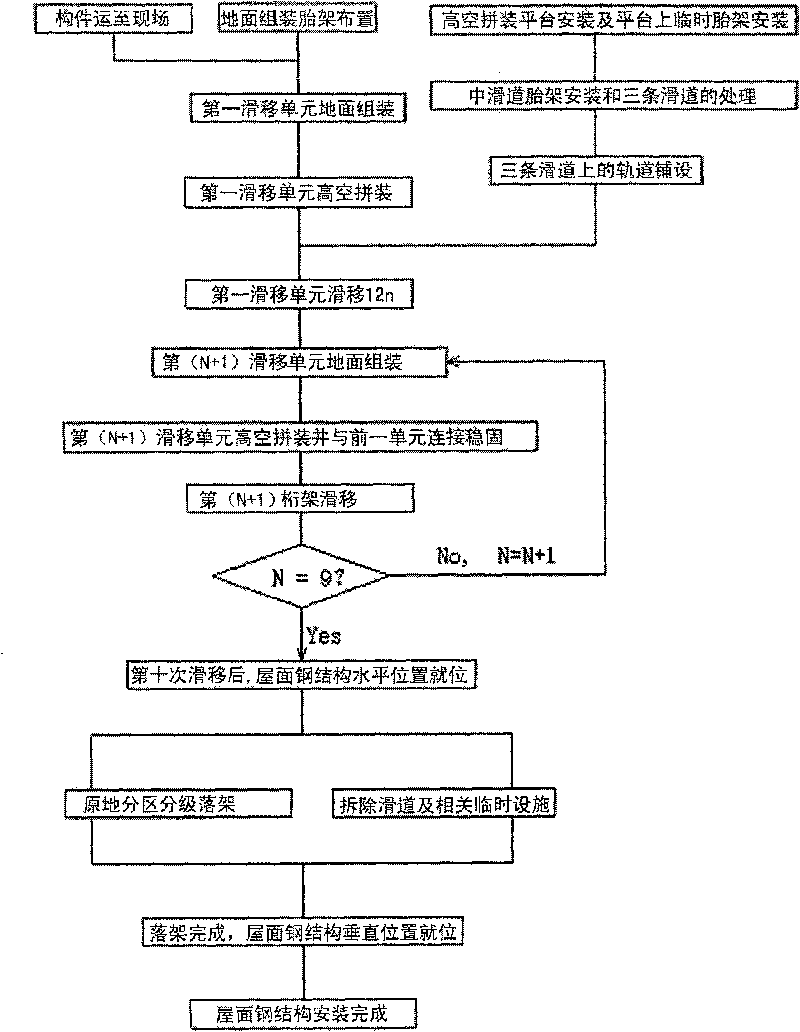

Multi-point pushing cumulative-gliding construction method for steel roof truss

ActiveCN101200959AReduce adverse effectsReduce downswingBuilding roofsHydraulic programme controlSupporting systemControl system

The invention provides a multipoint incremental launching accumulative sliding construction method for steel roof truss. First, a slide support system of three chutes and six rails is set up; a high altitude assembly platform is set up beside the main structure; and a temporary support jig of the middle chute is set up along the midline of the main structure, using the concrete trough beam as the side chute. Then steel truss components are assembled on the ground, and are hoisted to the high altitude assembly platform to assemble a first sliding unit, and then the first sliding unit is connected with a hydraulic synchronous multipoint incremental launching mechanism; the hydraulic synchronous multipoint incremental launching mechanism consists of eight hydraulic crawl devices, three hydraulic pump stations and a synchronous incremental launching control system; after the first sliding unit is pushed, a second sliding unit is assembled and connected with the first sliding unit, and then a second time sliding is performed. Via such an assembly structure, the sliding movement is performed for n times, and then the backout bracket is unloaded, the high altitude assembly platform and the temporary support jig of the middle chute are dismounted. The invention solves the difficulty of safe and stable installation and emplacement in synchronous sliding of the steel roof truss, and at the same time reduces the engineering cost and shortens the construction period without affecting the construction of other structures.

Owner:BEIJING URBAN CONSTR GROUP +1

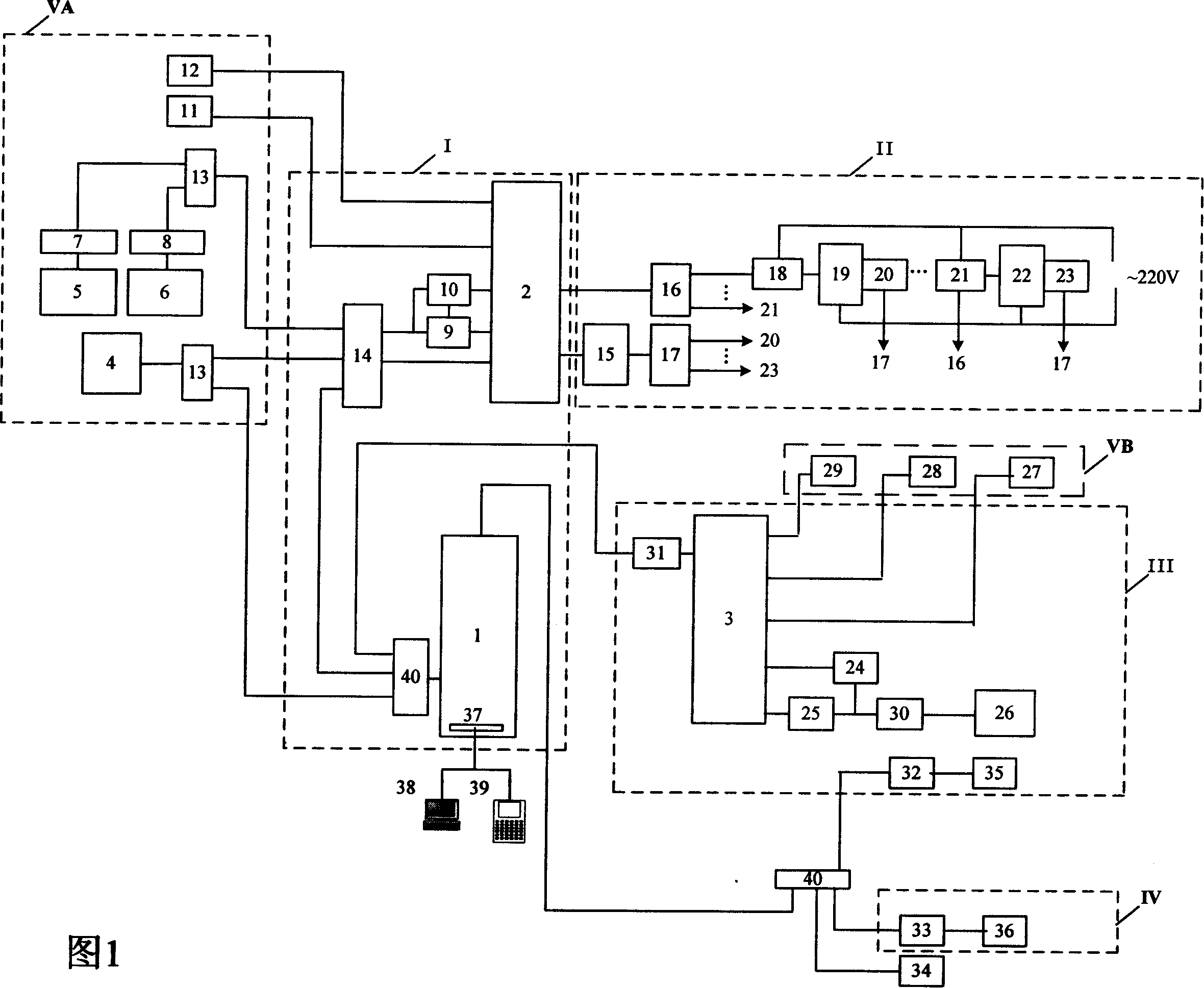

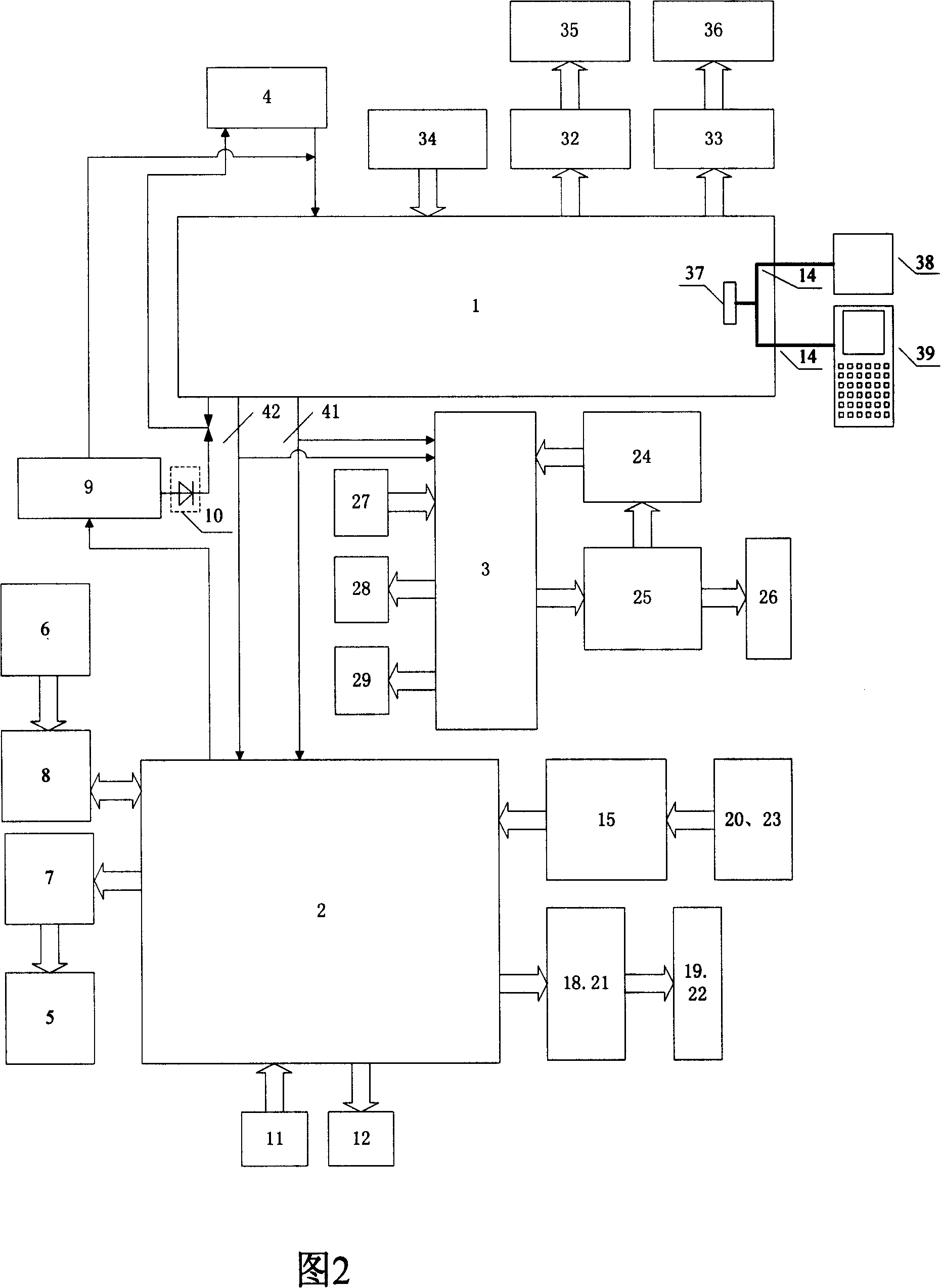

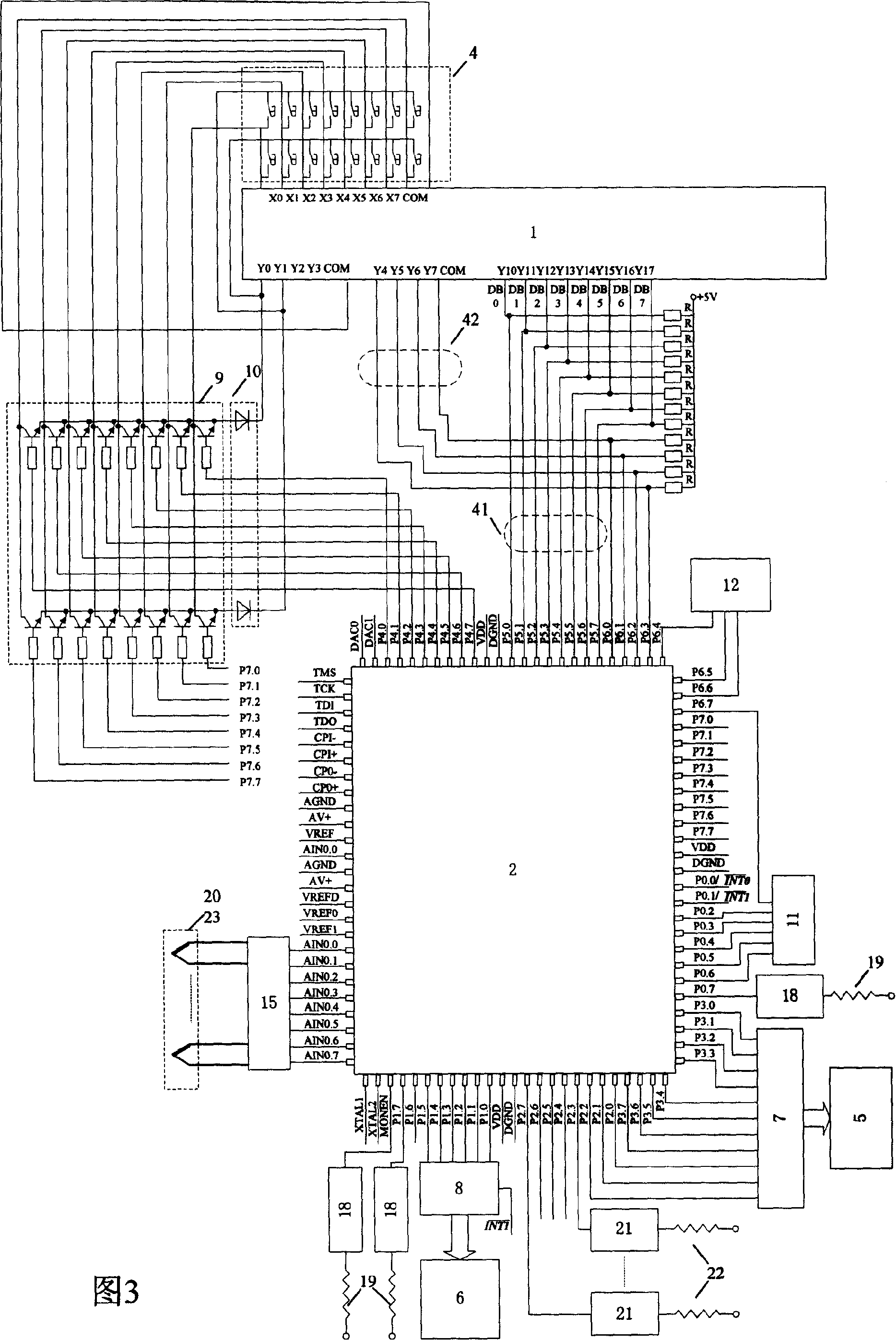

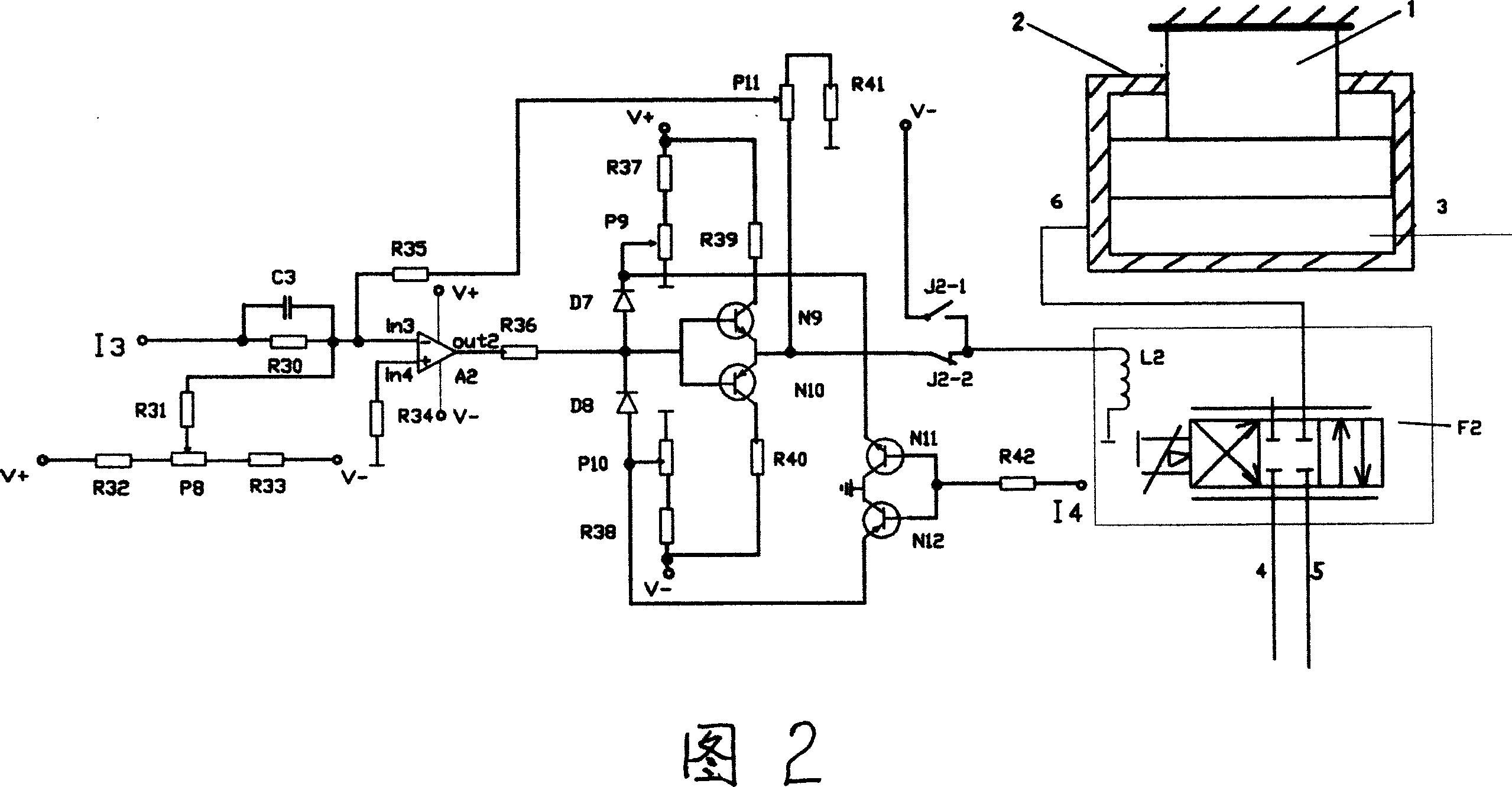

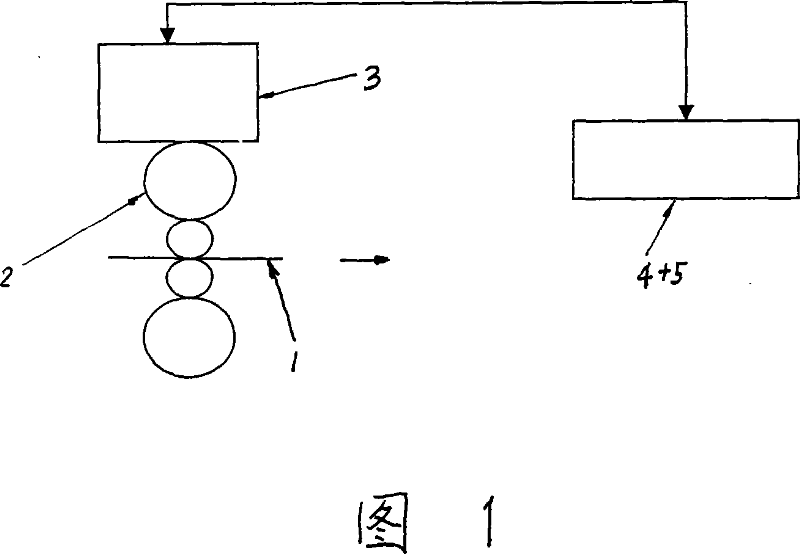

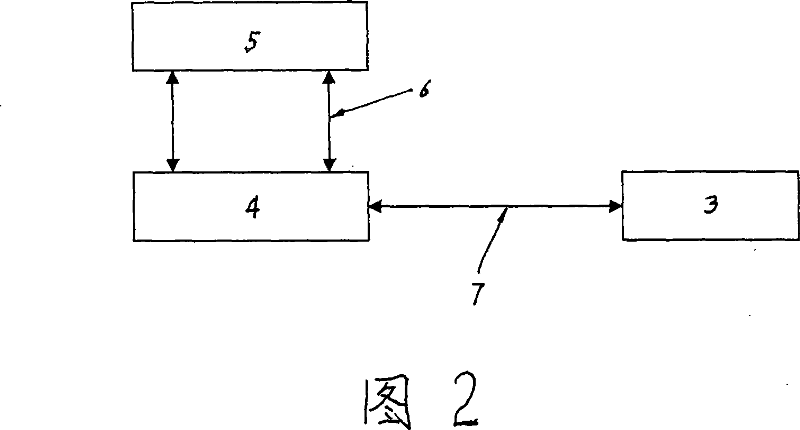

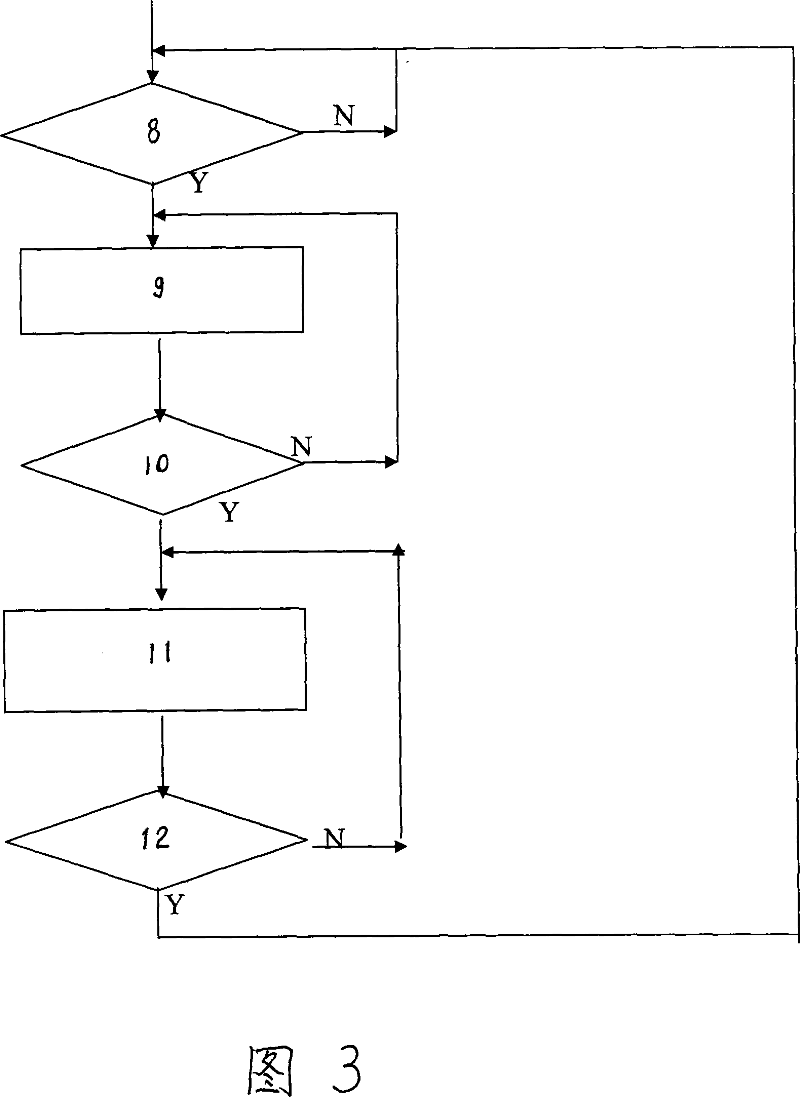

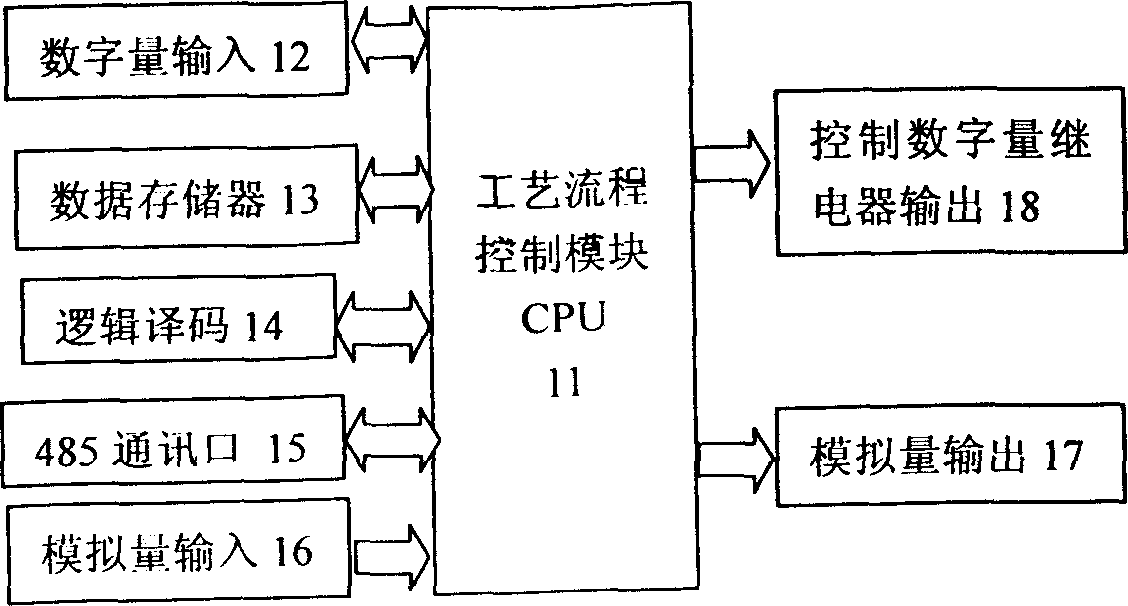

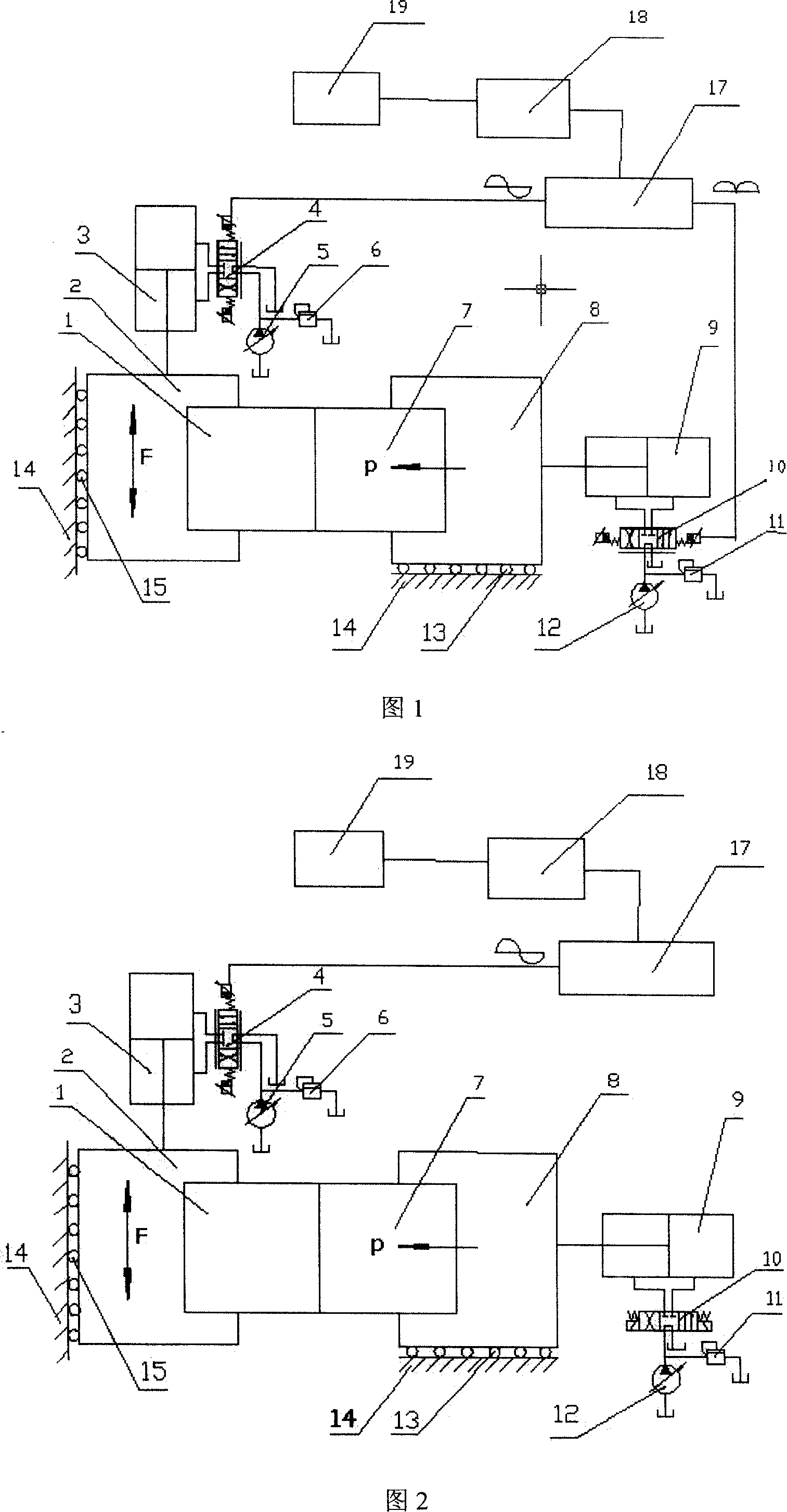

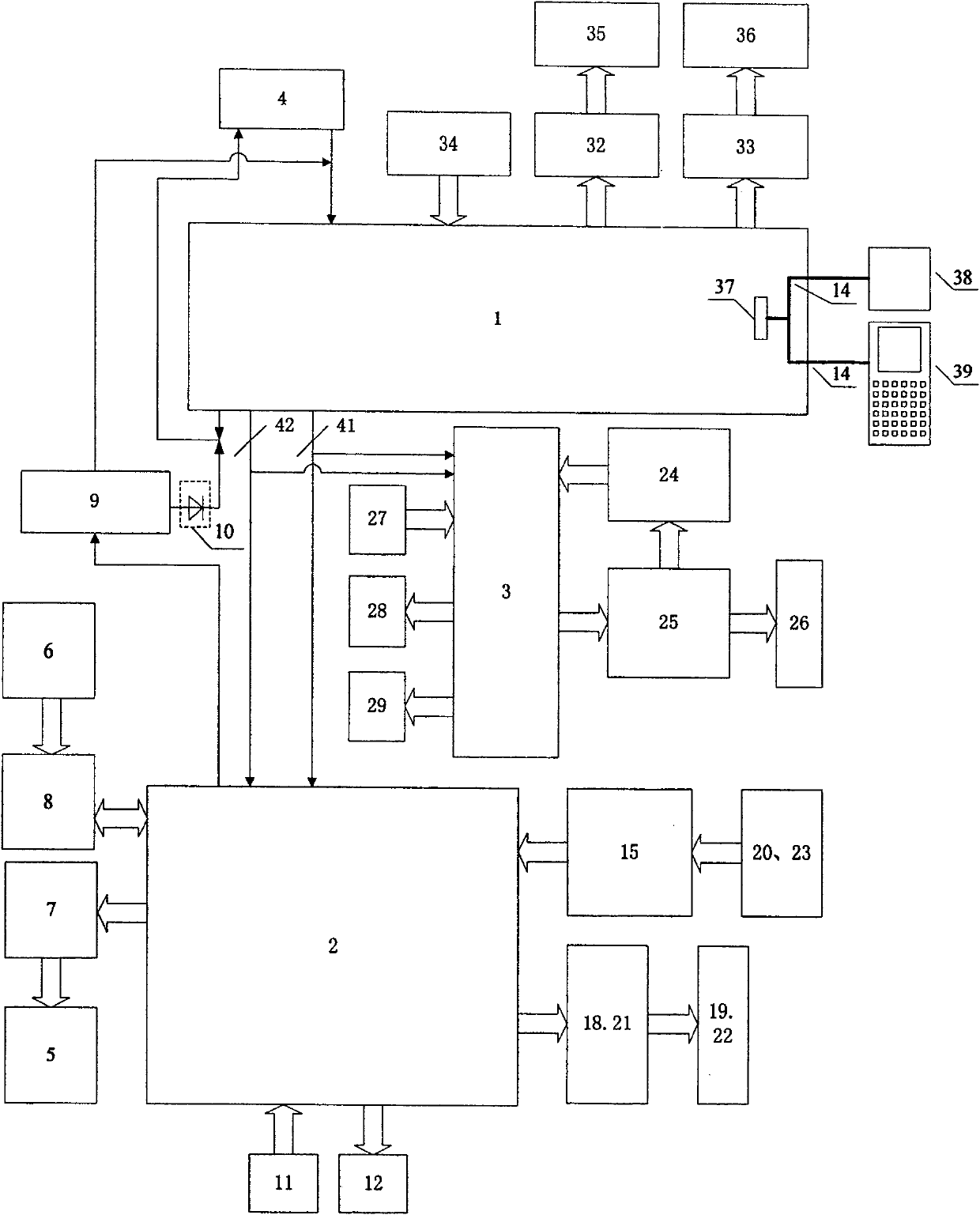

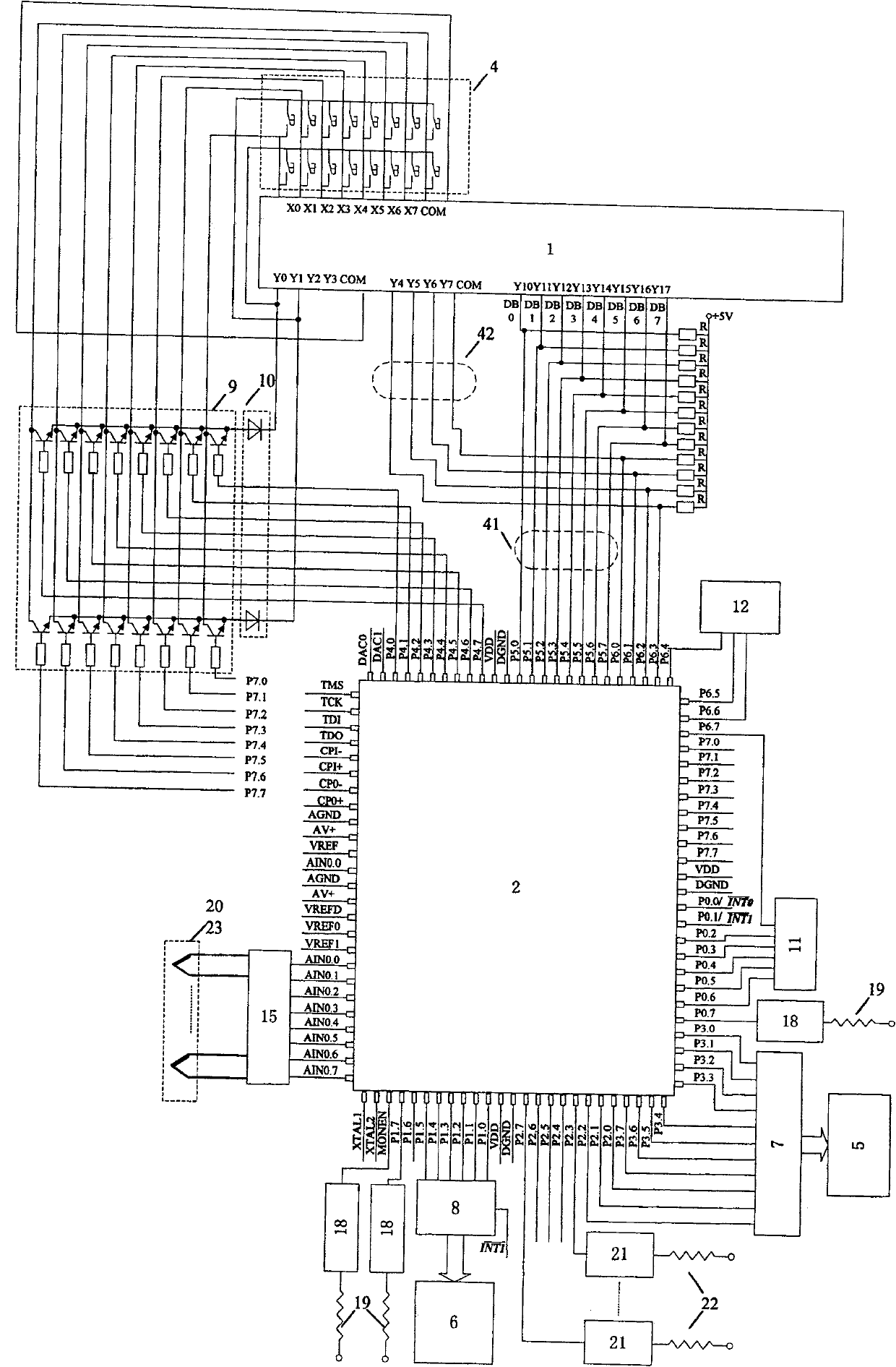

Full-automatic injecting blowing plastic hollow molding machine control device and cybernation method thereof

InactiveCN101138884AImprove control effectImprove precision controlHydraulic programme controlTemperature control using electric meansAutomatic controlProportioning valve

A control of a full-automatic plastic filling and blowing and hollow molding machine of a PLC-high speed singlechip-PIC singlechip includes a PLC- high speed singlechip system which consists of a PLC, a high speed singlechip, a level conversion circuit and a current direction control circuit, a temperature control module which consists of a signal magnifying circuit of a N-path temperature sensor and a driving circuit of a N-path heating device, a hydraulic pressure control system which consists of a PIC singlechip and a driving system of a hydraulic pressure control device, a pneumatic control module and a control panel. The method of using the device of the present invention to automatically control the filling and blowing process of the full-automatic plastic filling and blowing and hollow molding machine includes obtaining the system information, controlling the mechanical motion, controlling the temperature during the process of filling and blowing and controlling a hydraulic pressure flux and constant current of electric current of an electro-liquid proportional valve, and the obtaining of the system information has two routes of a PLC control procedure and a touch-screen interruption disposal. The control has high automatization degree and reliability, friendly human-machine interface, high cost performance of the system and the simple, convenient and practical method.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

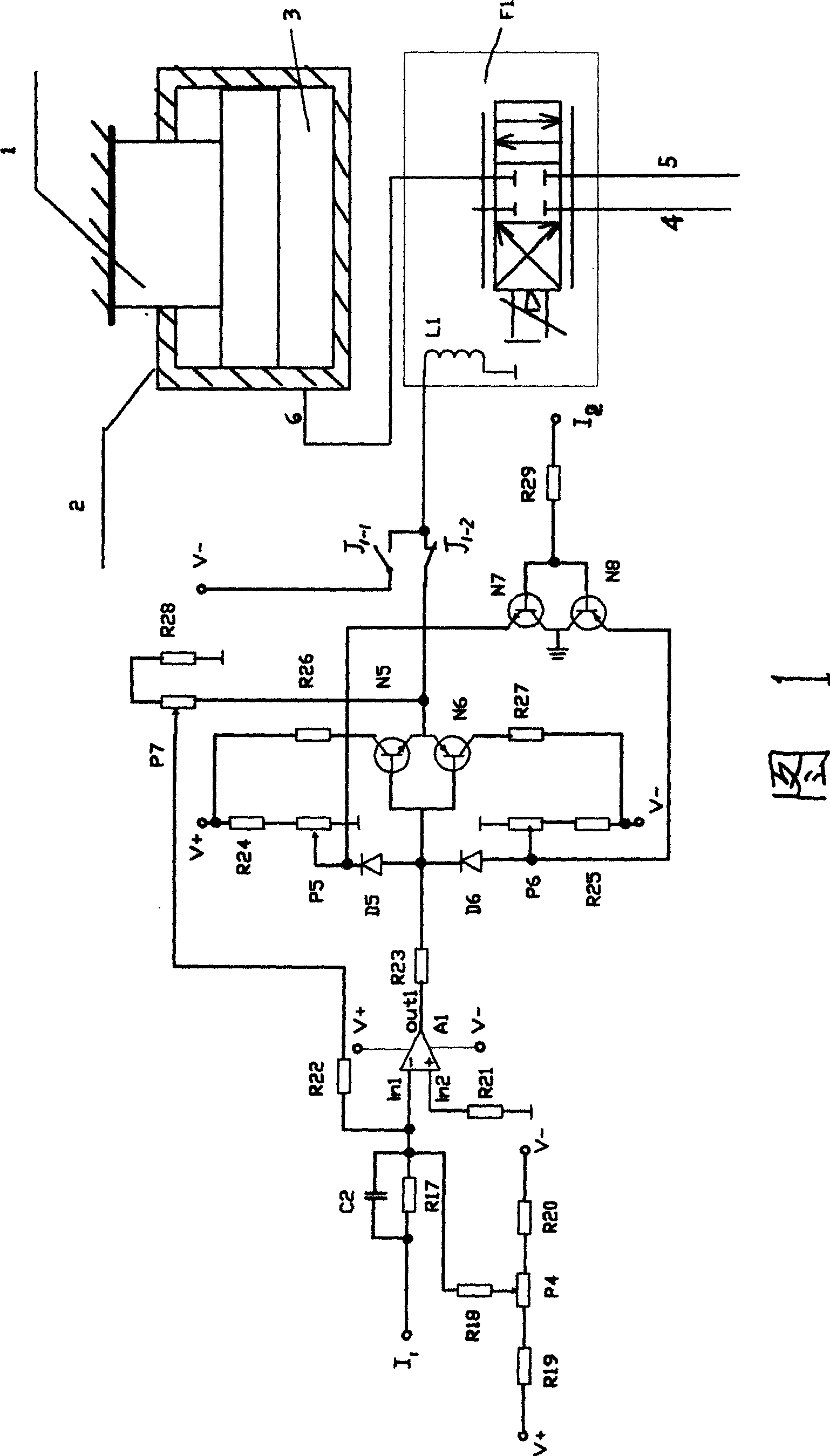

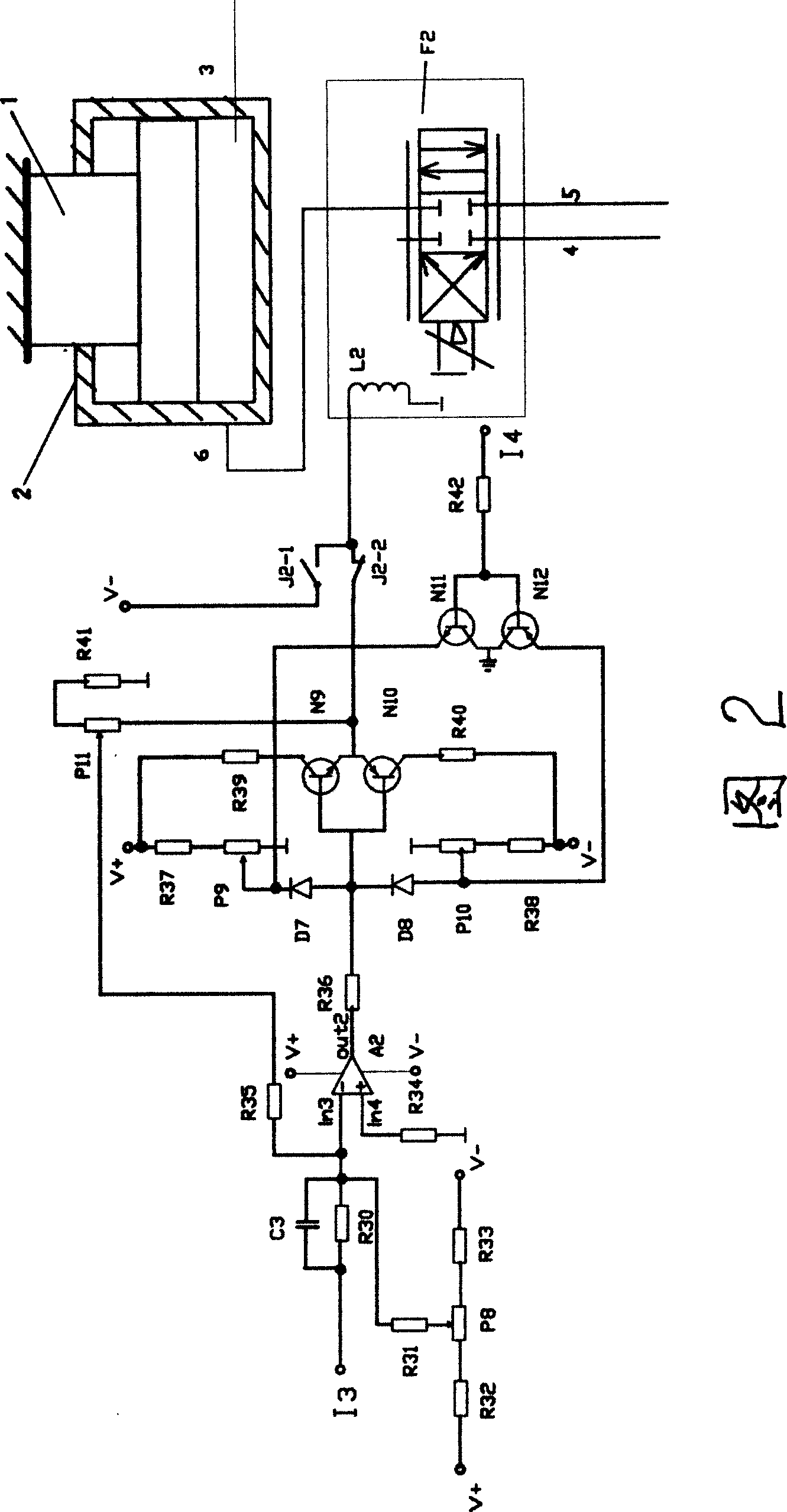

Method and device for synchro controlling high precision screwdown at two side during rolling steel plate

InactiveCN101003062AHigh precisionHigh technology contentHydraulic programme controlComputer controlSynchronous controlPush pull

A method for controlling the high-precision synchronous press-down at both sides of rolled plate features that a technique for high-precision two-stage synchronous control to press-down speed and the in-line real-time computer control to automatic complementary linkage of high-precision synchronizing are used. Its apparatus is composed of two high-precision two-stage press-down speed controlling mechanisms with hydraulic mechanism, computer, push-pull switching circuit and electro-hydraulic servo valve.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

No flow detection means for sensorless pumping control applications

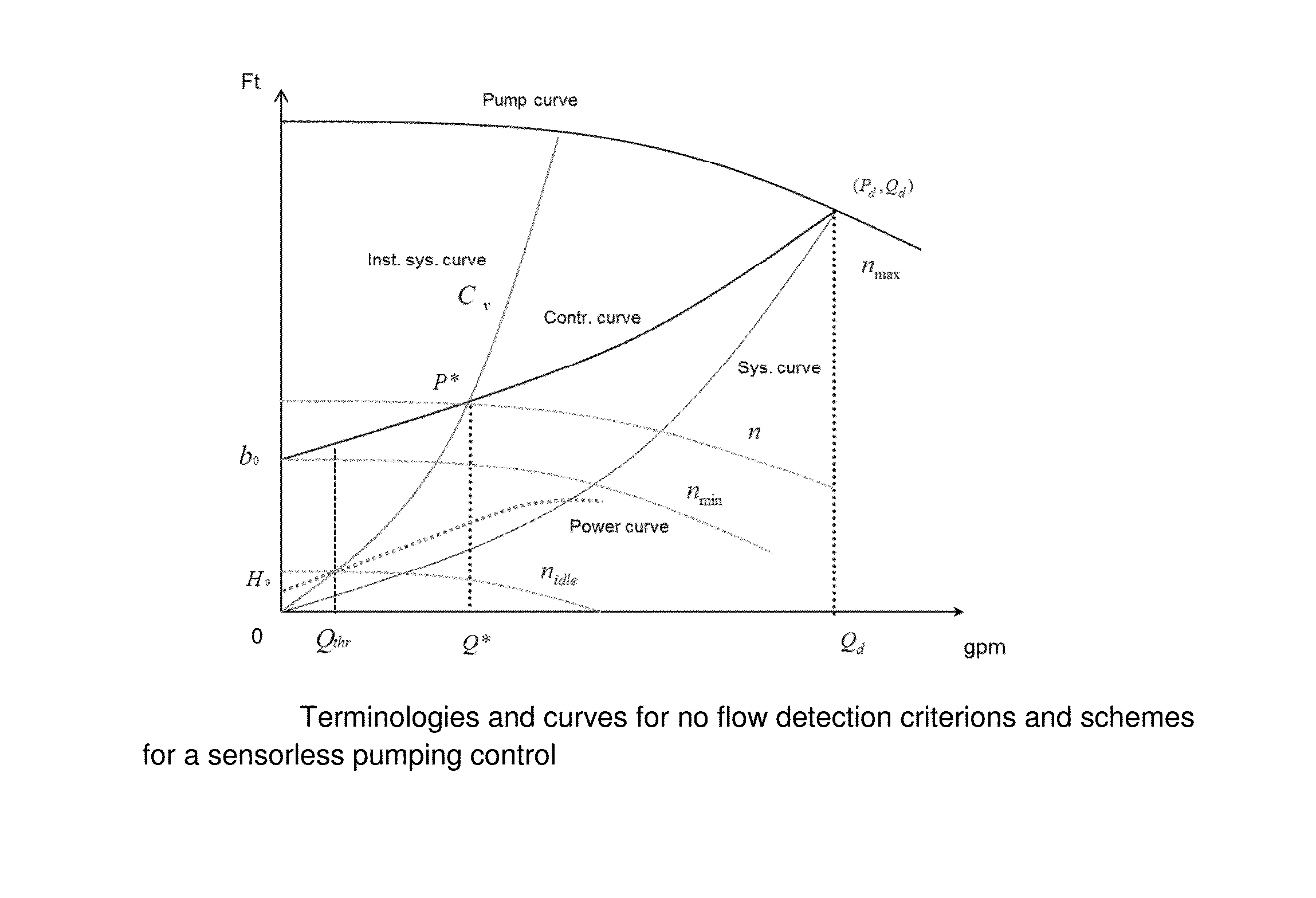

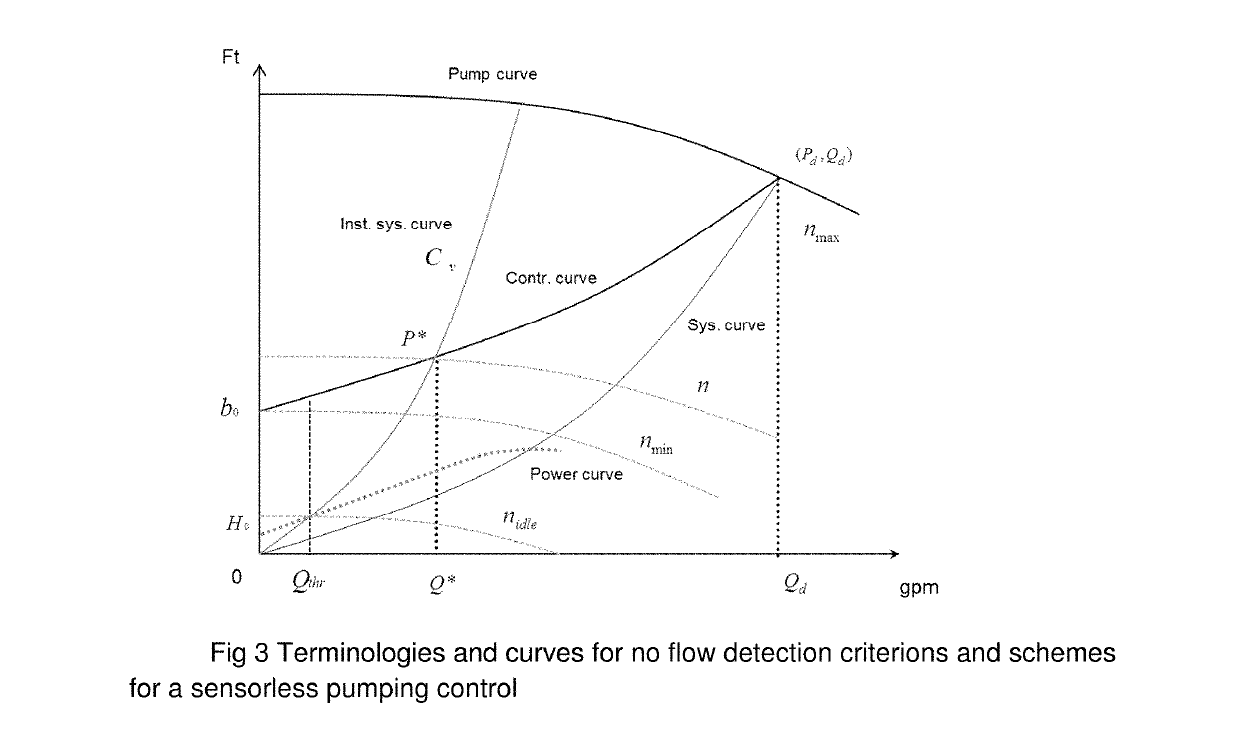

ActiveUS20160246290A1Save pump operation energyHydraulic programme controlComputer controlComputer moduleIdle speed

Apparatus is provided featuring a signal processor or processing module configured to receive signaling containing information about a pump no flow idle (NFI) state when the pump is running at a pump idle speed; and determine corresponding signaling containing information about whether the pump should remain in a no flow shutdown (NFSD) state or the pump NFI state, based upon the signaling received. The signal processor or processing module is configured to provide the corresponding signaling containing information about whether the pump should remain in the NFSD state or the NFI state.

Owner:FLUID HANDLING

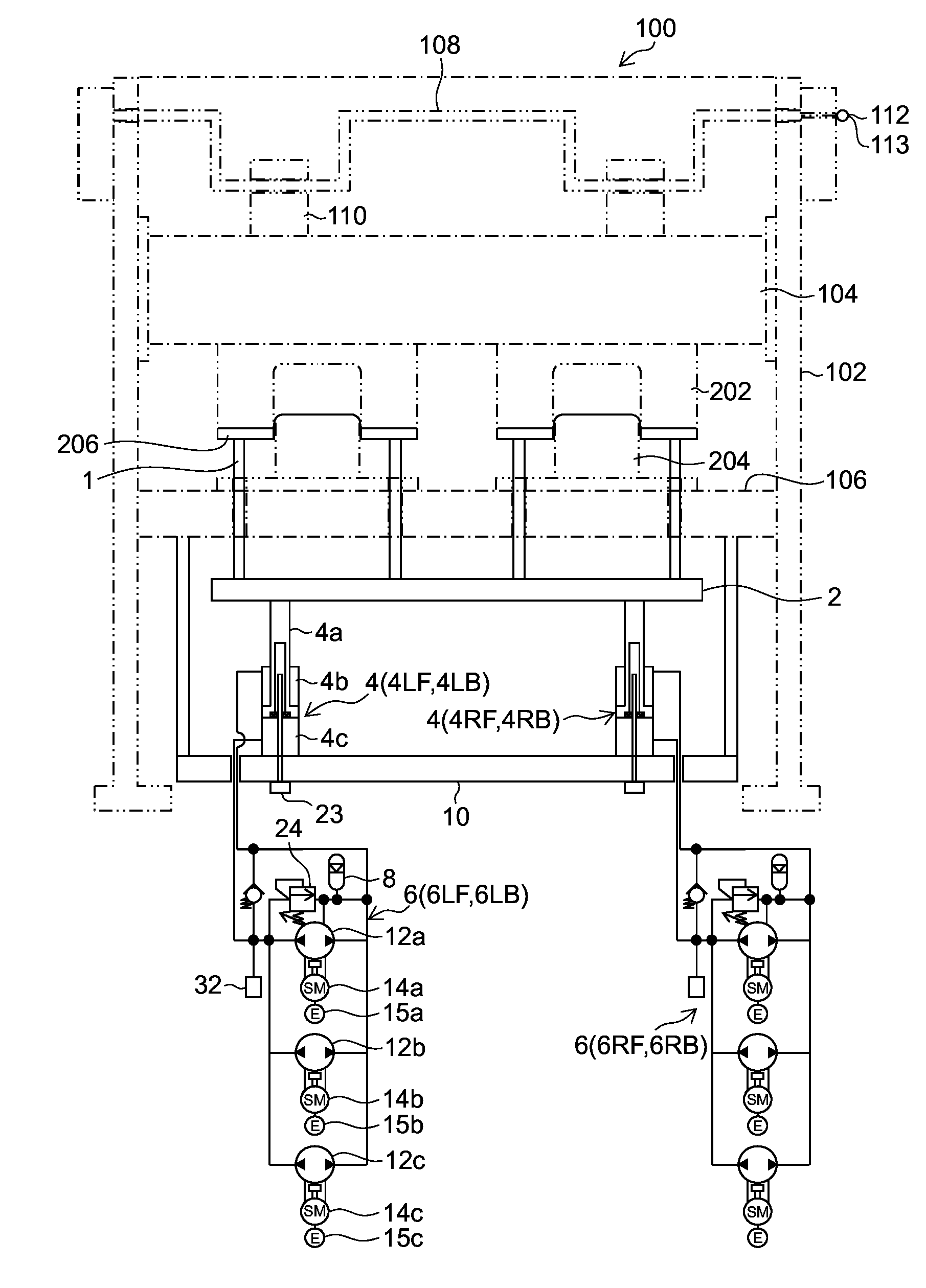

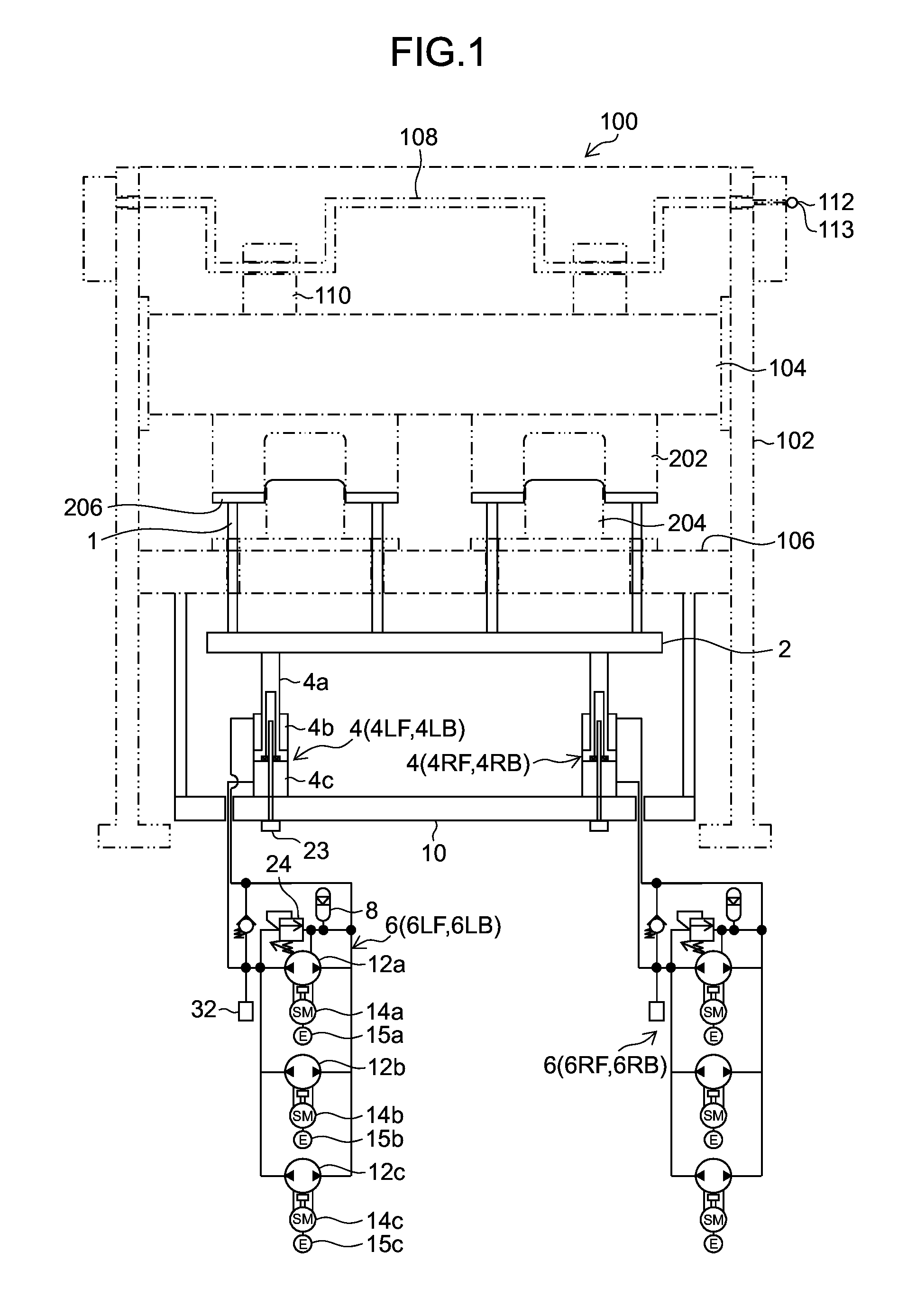

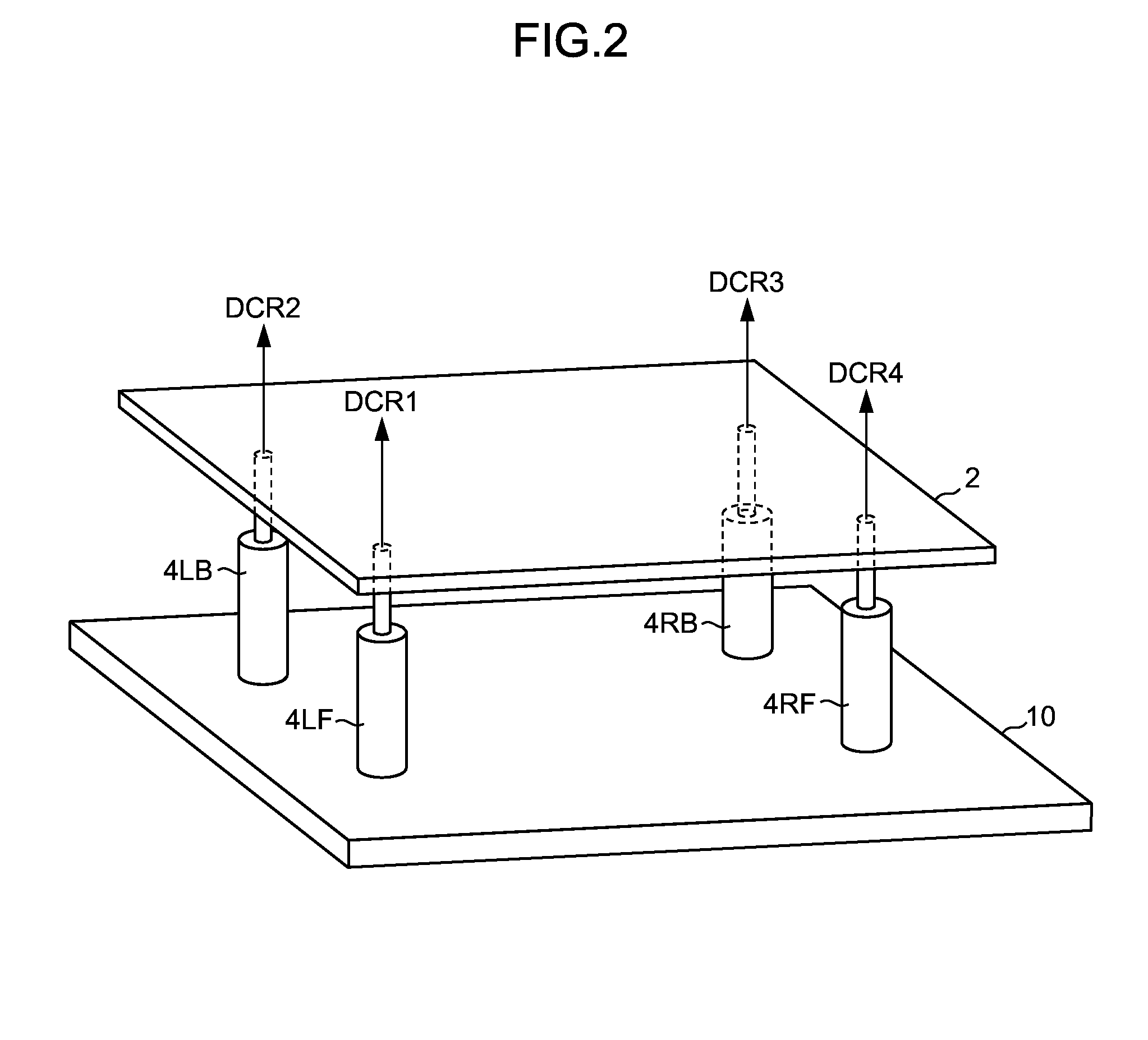

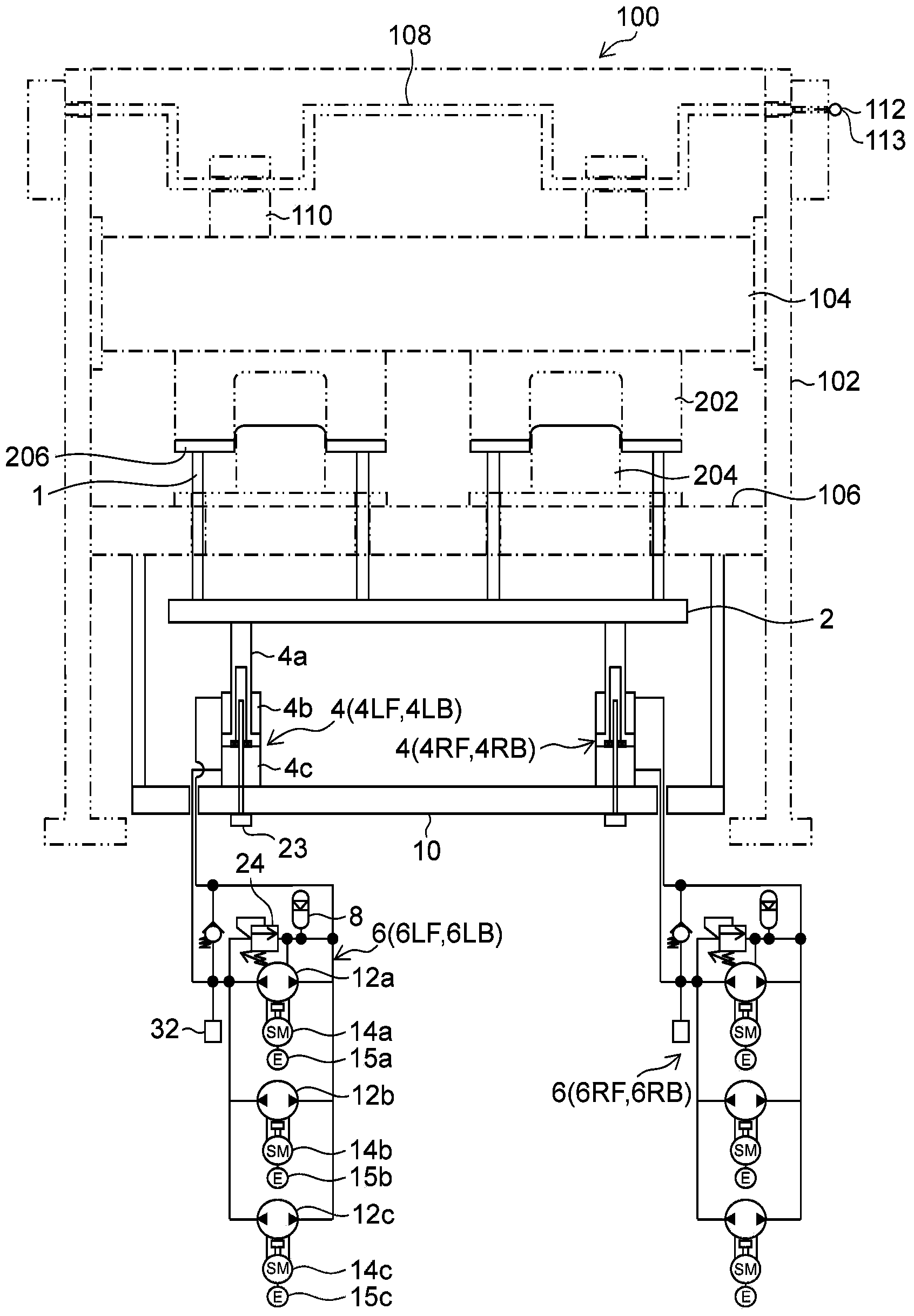

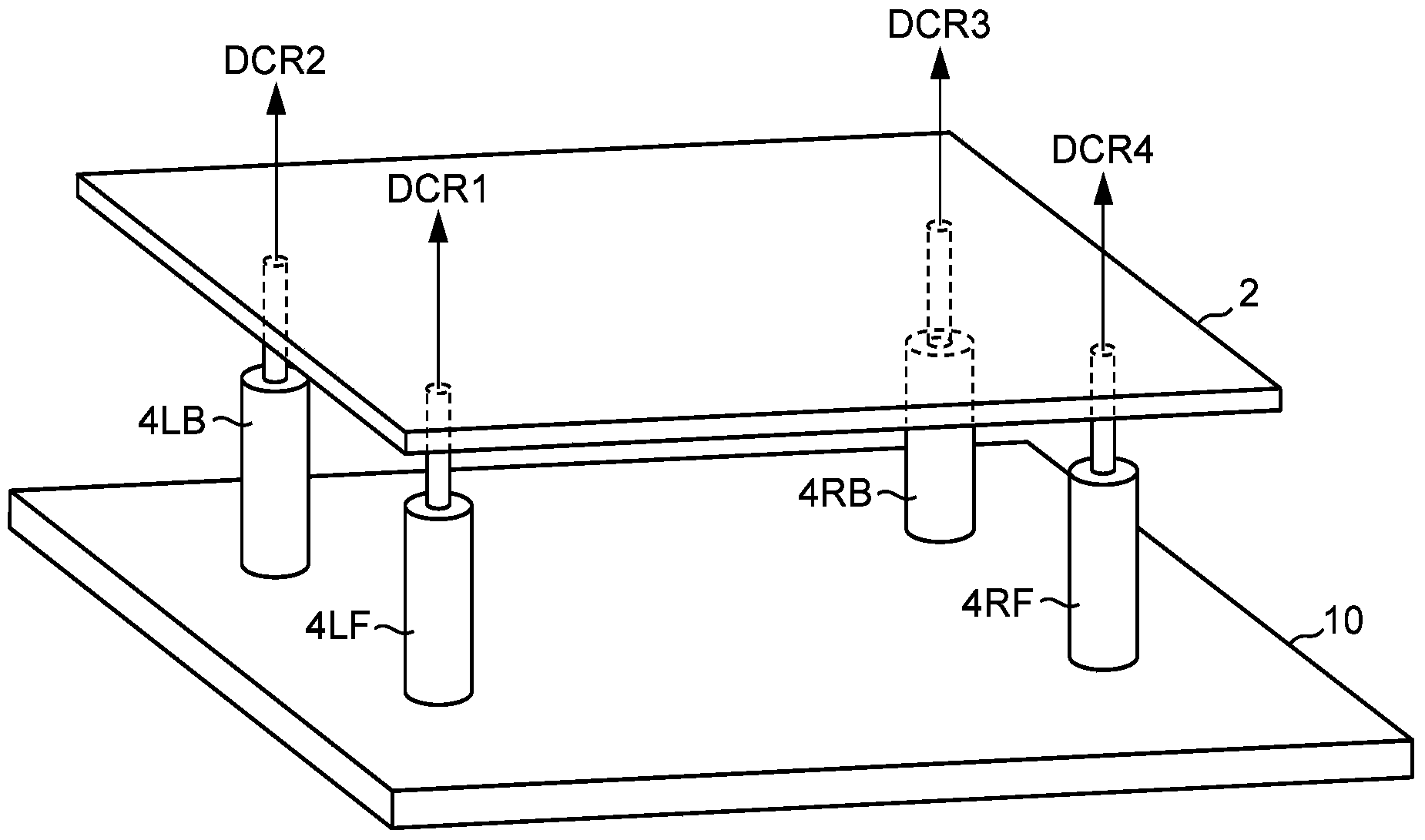

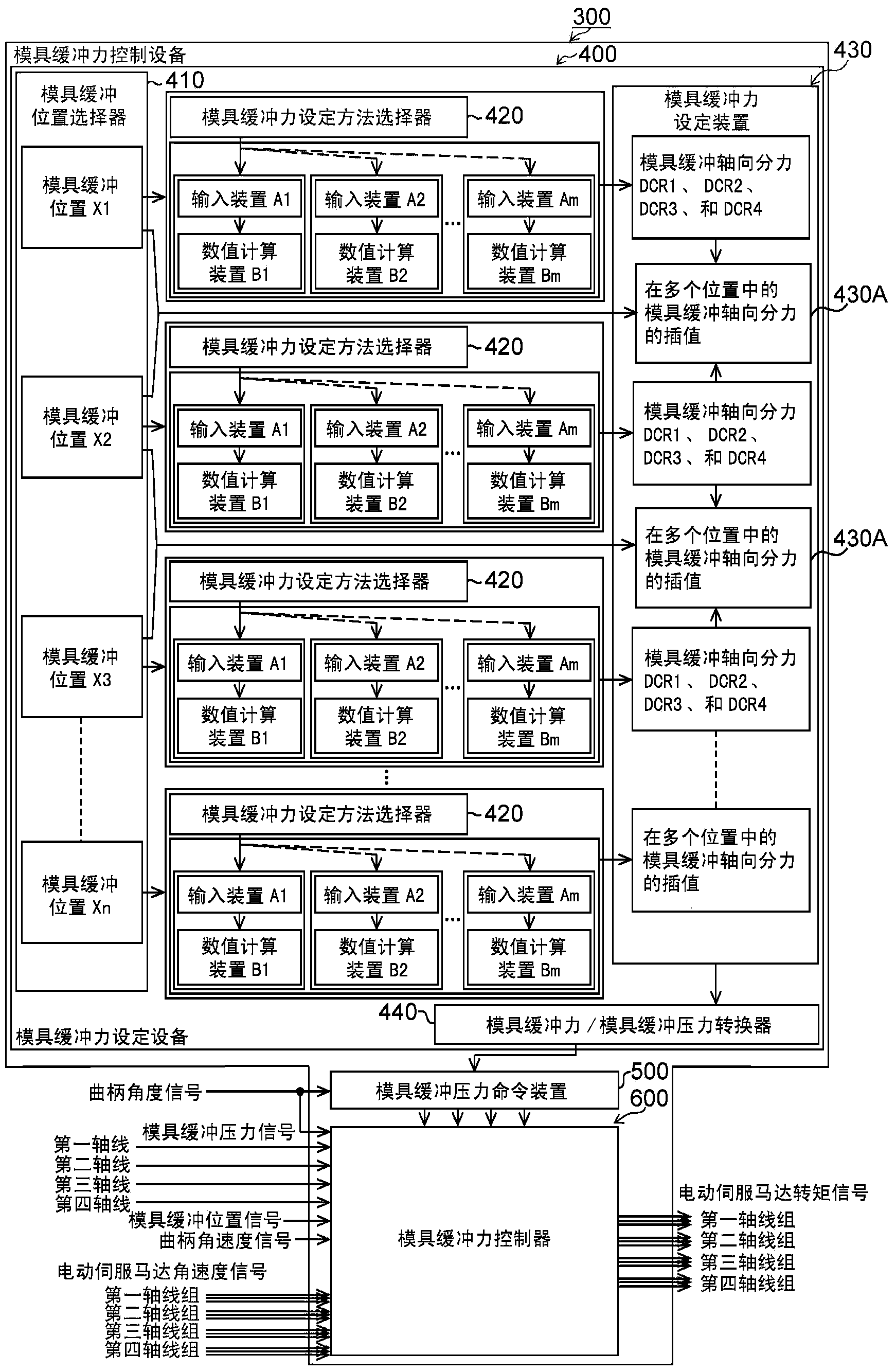

Die cushion force setting apparatus

ActiveUS20140366606A1Method is suitableEasy accessHydraulic programme controlForging press detailsHydraulic cylinderEngineering

The die cushion force setting apparatus according to an aspect of the present invention allows die cushion forces (component forces) acting on plural driving shafts to be set easily, makes it easy to apply strong or weak die cushion forces to a complex-shaped drawn part in a plane of a cushion pad, and provides a smooth die cushion force distribution. An operator manually enters a total die cushion force, axial component force of a left front hydraulic cylinder, and center-of-force position by operating an input device. Based on the information entered via the input device, the numerical computing device B1 calculates axial component forces of three hydraulic cylinders through numerical computations. The one axial component force thus entered and three axial component forces thus computed numerically are set as the axial component forces of four hydraulic cylinders.

Owner:AIDA ENG LTD

Control method of special hot rolled sheet to plus pressure

InactiveCN101036922ARealize automated productionAdvanced technologyHydraulic programme controlRoll force/gap control deviceAutomatic controlTime delays

A control method of special steel hot-rolling variable gain reduction of the invention, belongs to steel rolling technique field, the method is a steel rolling method that the special steel (including stainless steel, silicon steel and so on) strip steel automatically controlled by computer and software program is rolled by the finishing mill to realize variable gain reduction control, including: 1. completing set, storage, management, control of the parameter model and transferring to rolling mill control step computer based on the rolling steel kind and specification, rolling strip steel thickness, width and biting steel time delay, variable gain reduction and so on series parameter definite thereout by the parameter management step computer; 2. realizing reduction position, reduction position bounce amount, strip steel time delay biting steel and so on strip steel variable gain reduction control steel rolling method controlling automatically rolling mill by the rolling mill control step computer, the method makes finishing mill hydraulic pressure reduction control automatic, continuous, precise and eliminates phenomenon of vibration of the rolling mill stand, abnormal action of the reduction and loop, hydraulic pipeline and equipments easy to be damaged, ensuring safe production and equipment, the special steel rolling method controlled by the computer realizes producing automation, product with high quality, rolling mill with safety, the new steel rolling method is technique independent innovation and improves technique and lever of rolling the special steel.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

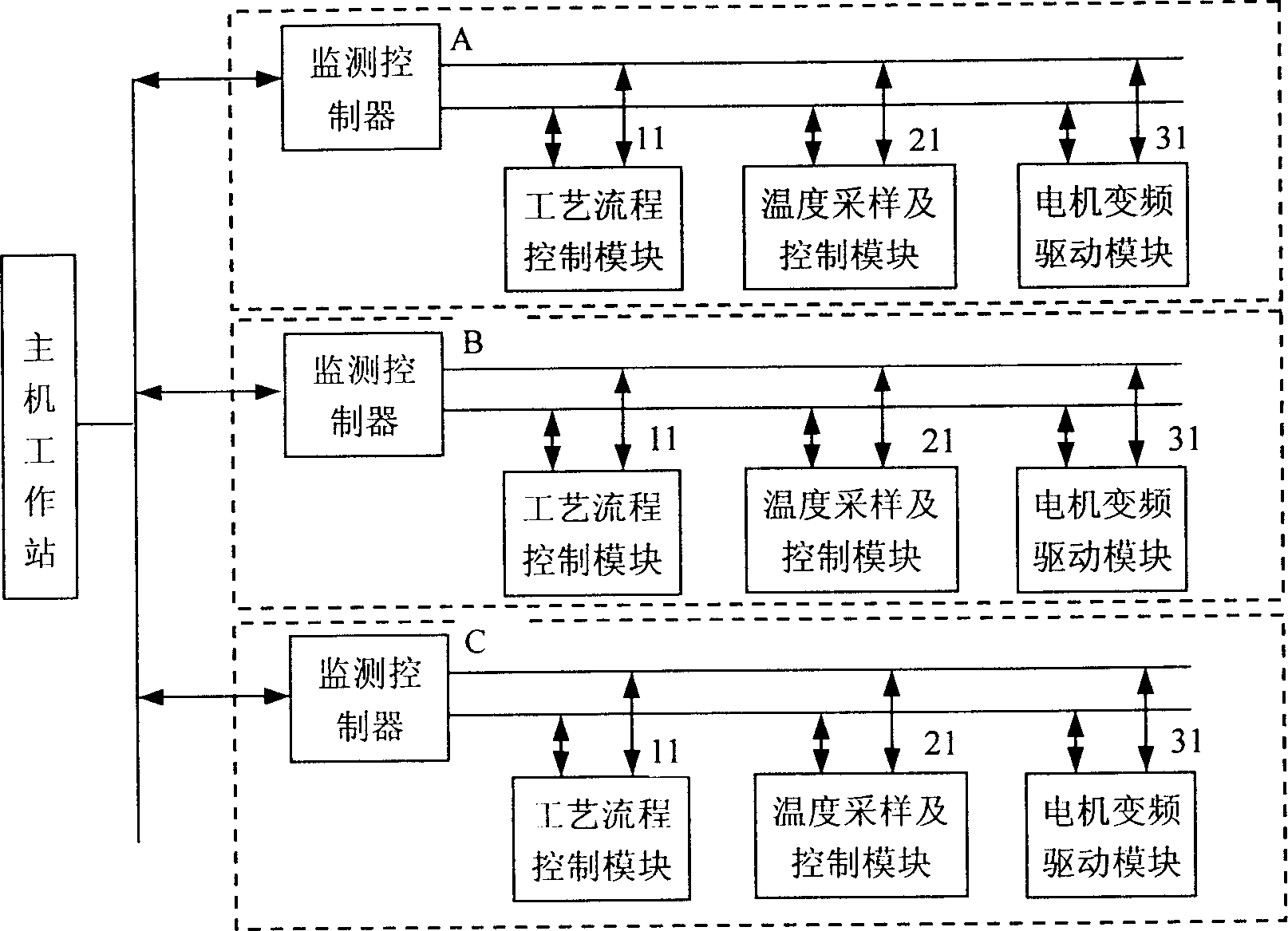

Energy saving control system of rubber injection shaping machine

InactiveCN1824490ARealize data exchangeCentralized management of productionHydraulic programme controlTotal factory controlControl systemComputer module

The present invention relates to a rubber injection moulding machine energy-saving control system. It includes frequency converter drive motor, liquid pressure and flow rate sensor, temperature sensor and power supply circuit. Its energy-saving control system is formed from monitoring controller, technological process control module, temperature sampling and control module and frequency converter drive control module. Said invention also provides the working principle and operation method of said system.

Owner:宁波千普机械制造有限公司

Friction pressure loading unit of linear friction welding machine and loading method thereof

InactiveCN1994651ASmall driving forceHydraulic programme controlServomotor componentsFriction weldingPhase shifted

The invention relates to a friction pressure loader of linear friction welding machine, wherein it uses computer to output one group of one-way vibration signals with same frequency, amplitude as vibrant sine signal, but pi / 2 phase shift; uses DA output plate to convert it into analogue signal; uses amplifier to V / I convert and amplify; controls servo valve to cylinder piston horizontally move repeated to generate pulp. The invention also discloses a relative loading method, which comprises that: using sine signal to control the vibration servo valve; using one-way vibration signal to control the moving servo valve, to generate friction pressure between work-piece and moving work piece into pulp; therefore, it can reduce driving force.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

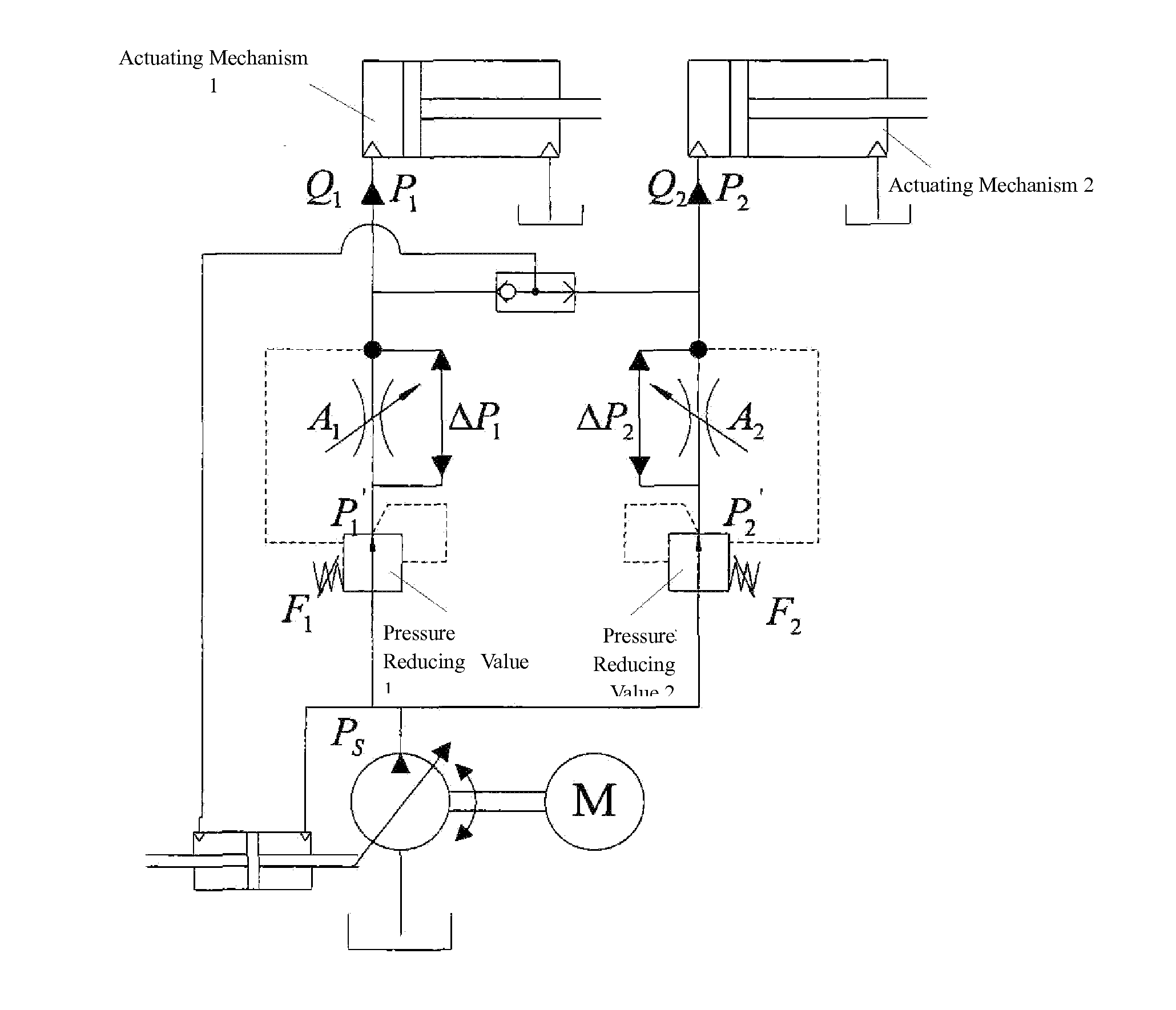

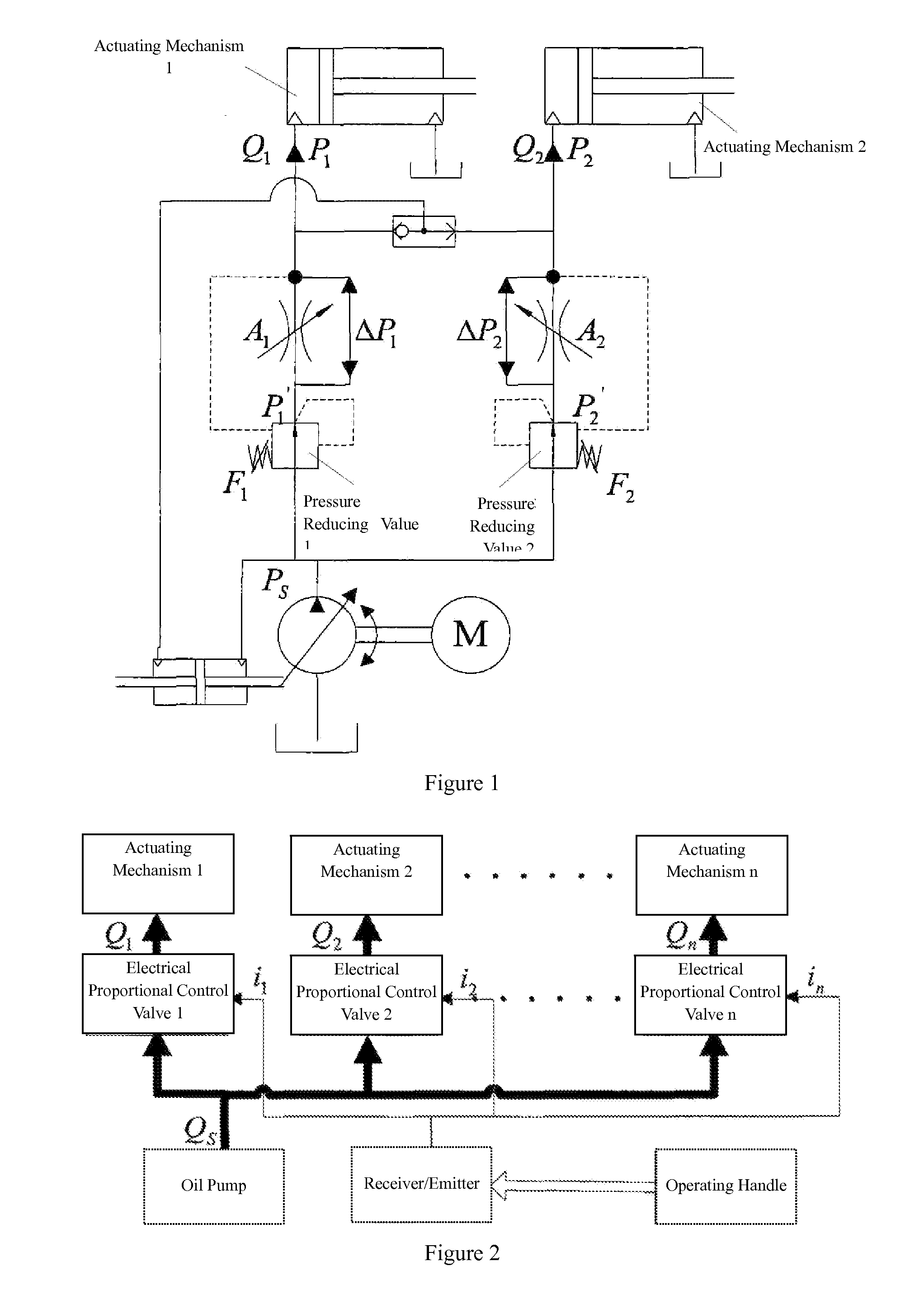

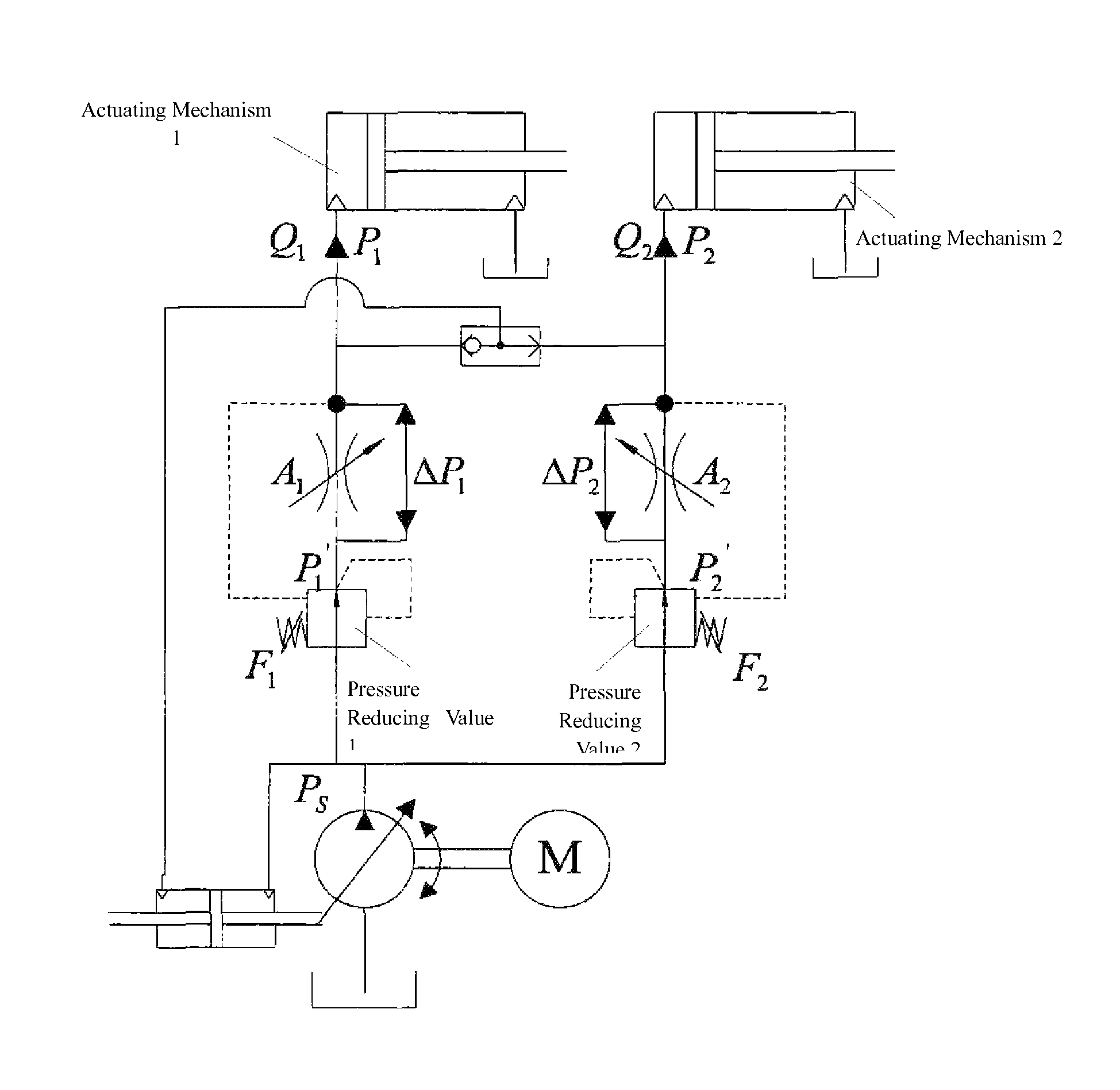

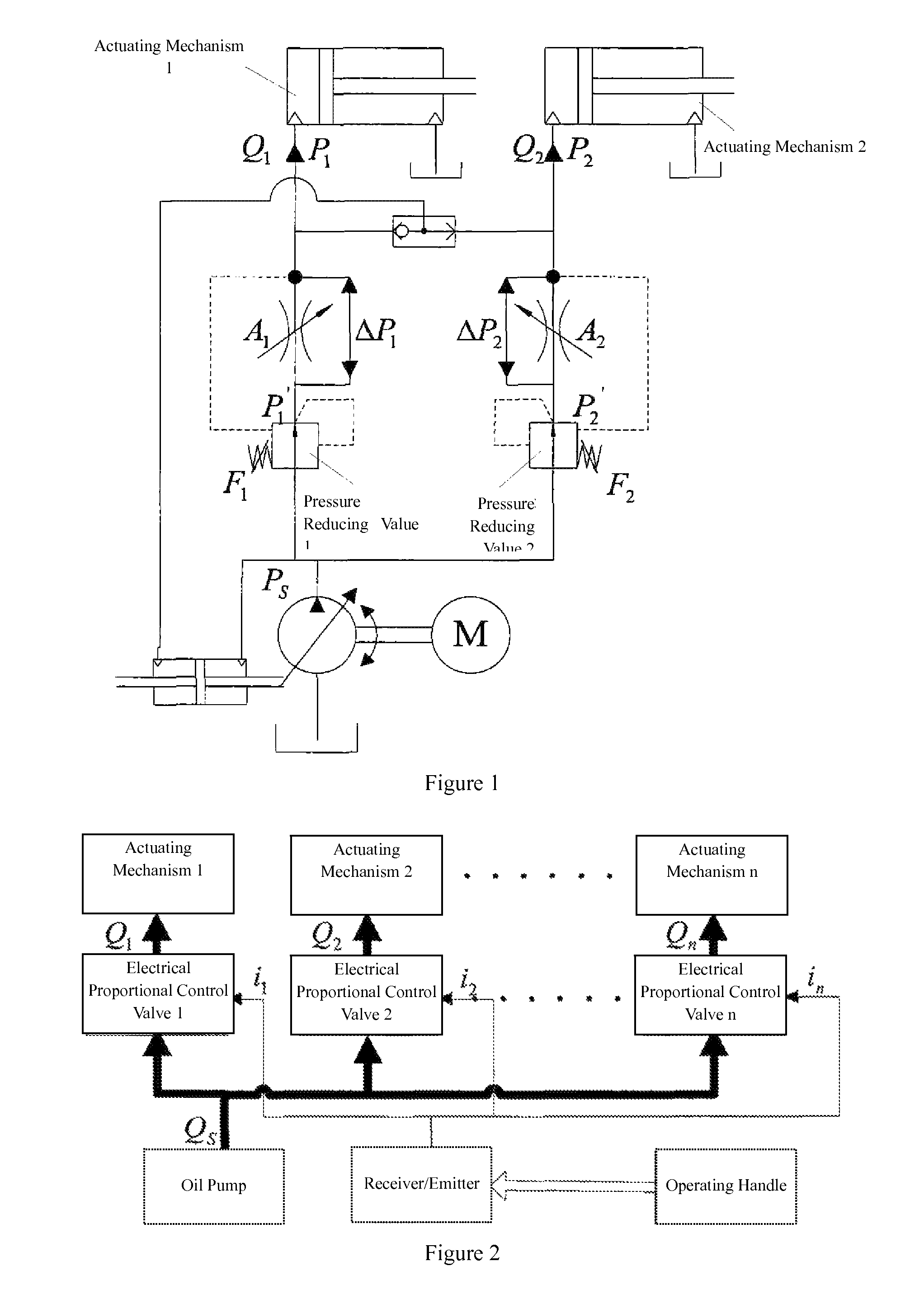

Concrete distributing device and control method, control system and electrical control system for composite motion of boom thereof

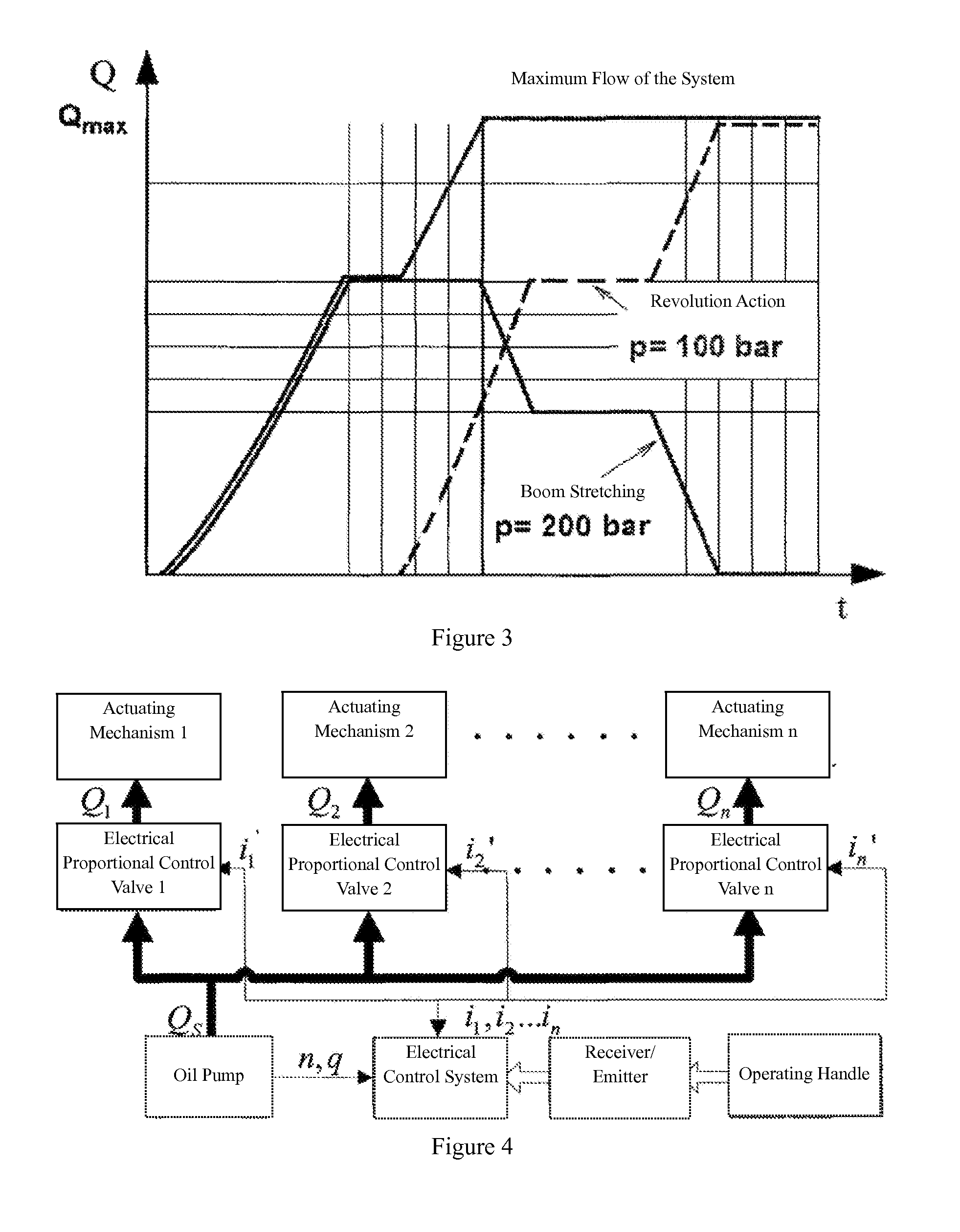

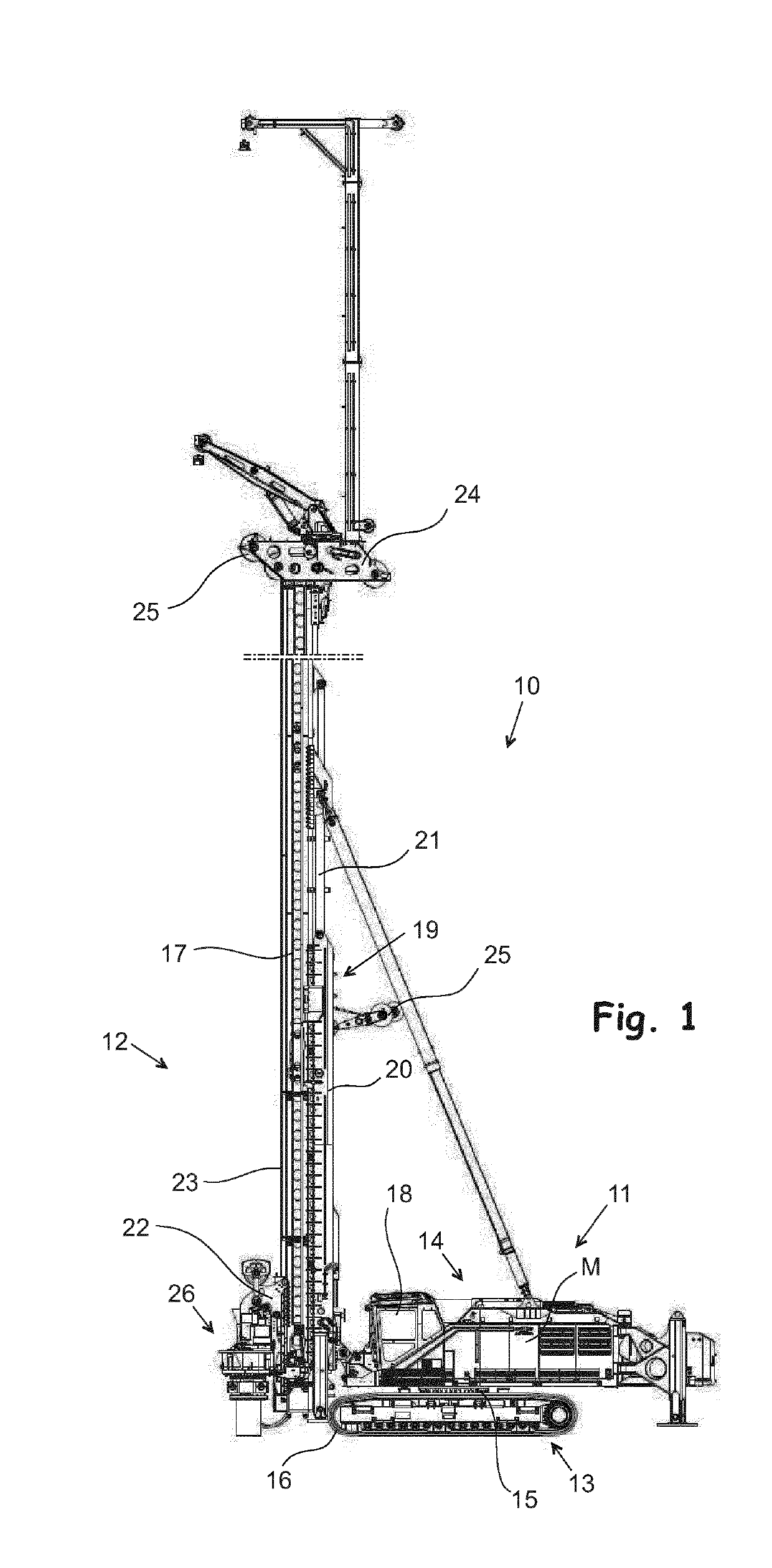

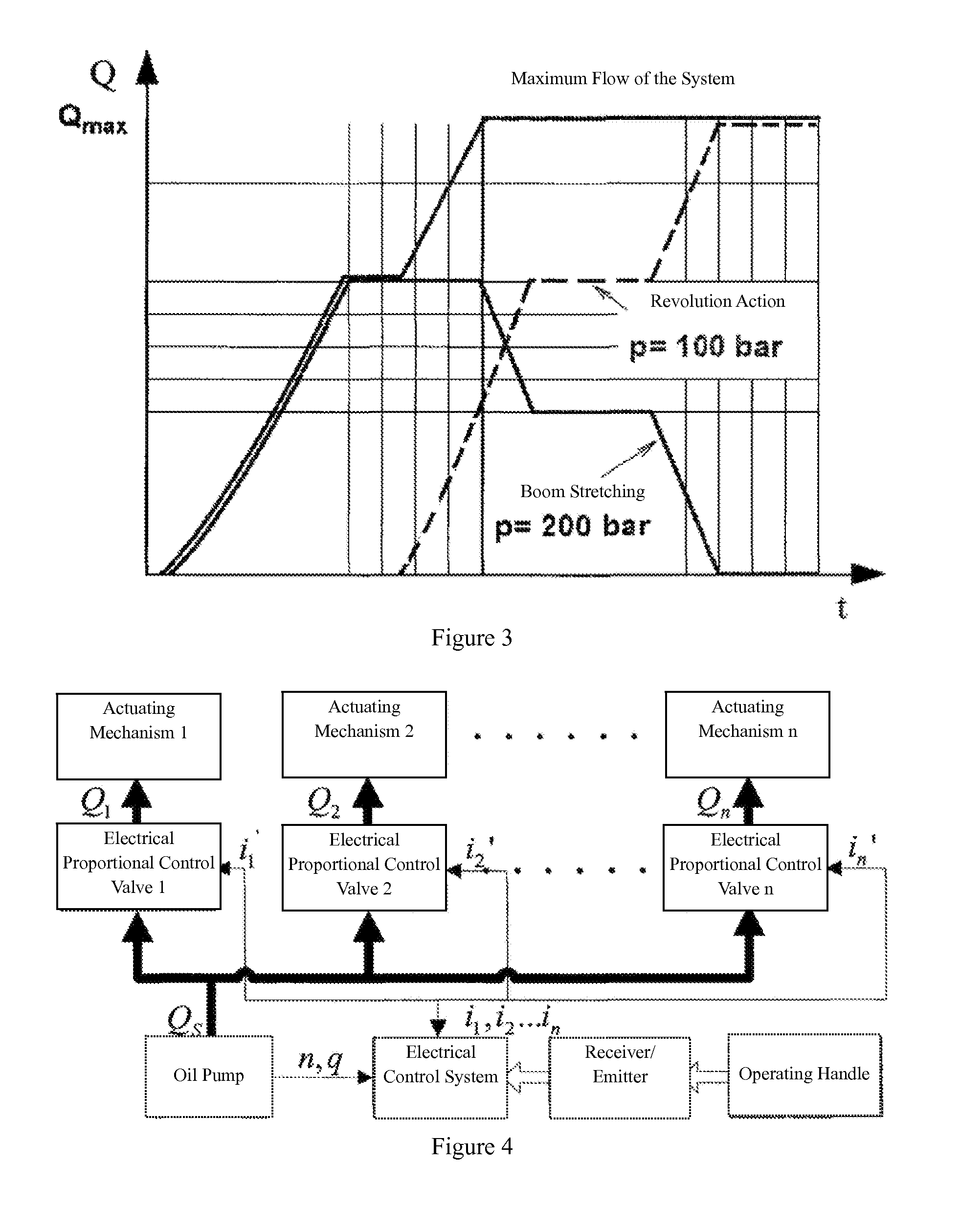

ActiveUS20120253528A1Track controlReduce movement speedHydraulic programme controlServometer circuitsProportional controlControl signal

Disclosed are a concrete distributing device and a control method, a control system and an electrical control system for composite motion of a boom thereof. The control method comprises the steps as follows: calculating the flow of a boom pump when an operating handle sends a command; according to the command sent by the operating handle, calculating theoretical demand flow of all actuating mechanisms of the boom and theoretical control signals of all electronic proportional control valves; comparing the total theoretical demand flow of the actuating mechanisms with the flow of the boom pump; providing the theoretical control signals to all the electronic pro portional control valves when the flow of the boom pump is greater than or equal to the total theoretical demand flow of the actuating mechanisms, otherwise, providing actual control signals smaller than the theoretical control signals to all the electronic proportional control valves and reducing the movement speeds of all the actuating mechanisms proportionally. In this way, when undersaturation of system occurs to the composite motion of the boom, the movement speeds of all the actuating mechanisms are reduced proportionally independent of the load difference of the actuating mechanisms, thereby ensuring that the boom can move in a motion track expected by an operator.

Owner:ZOOMLION HEAVY IND CO LTD +1

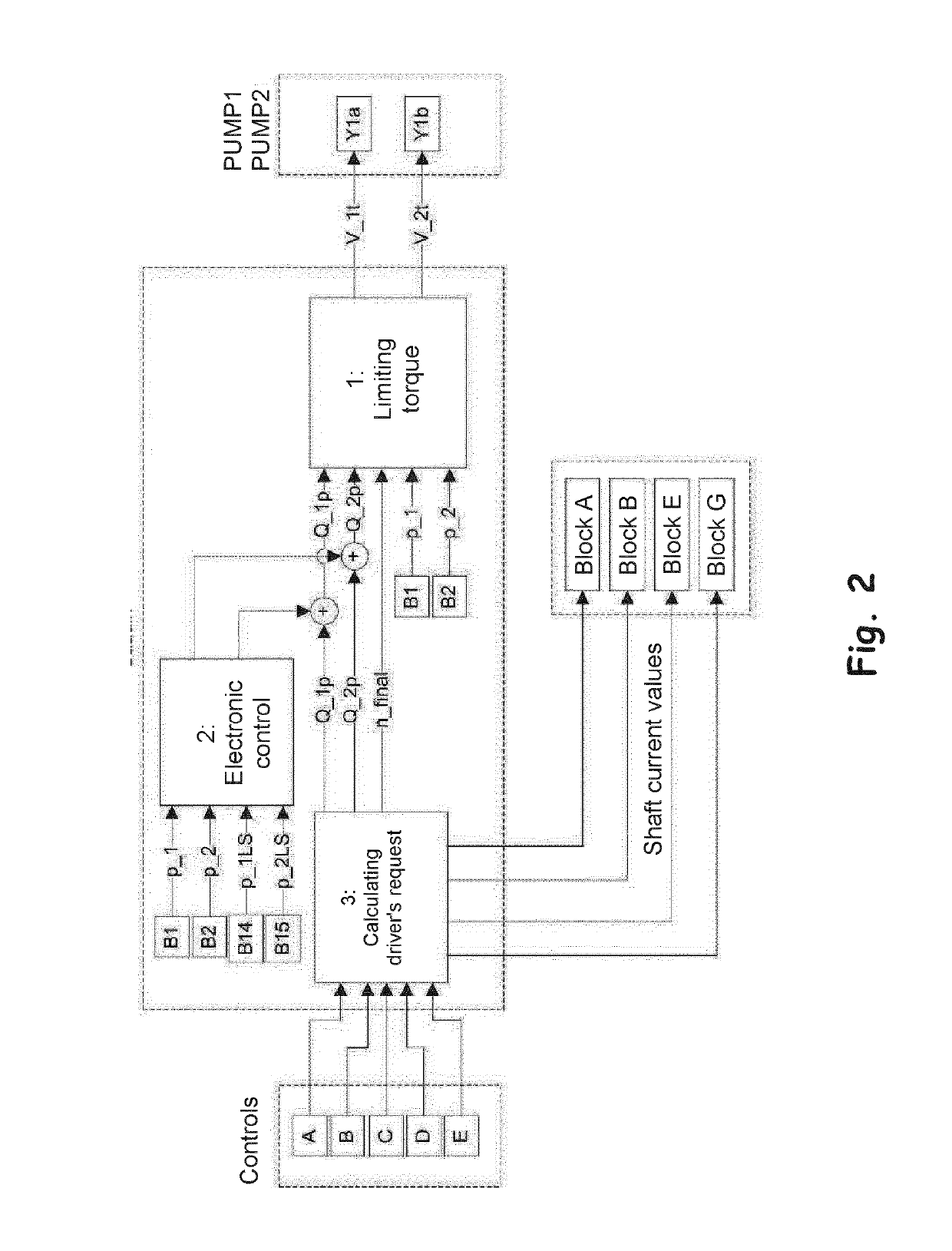

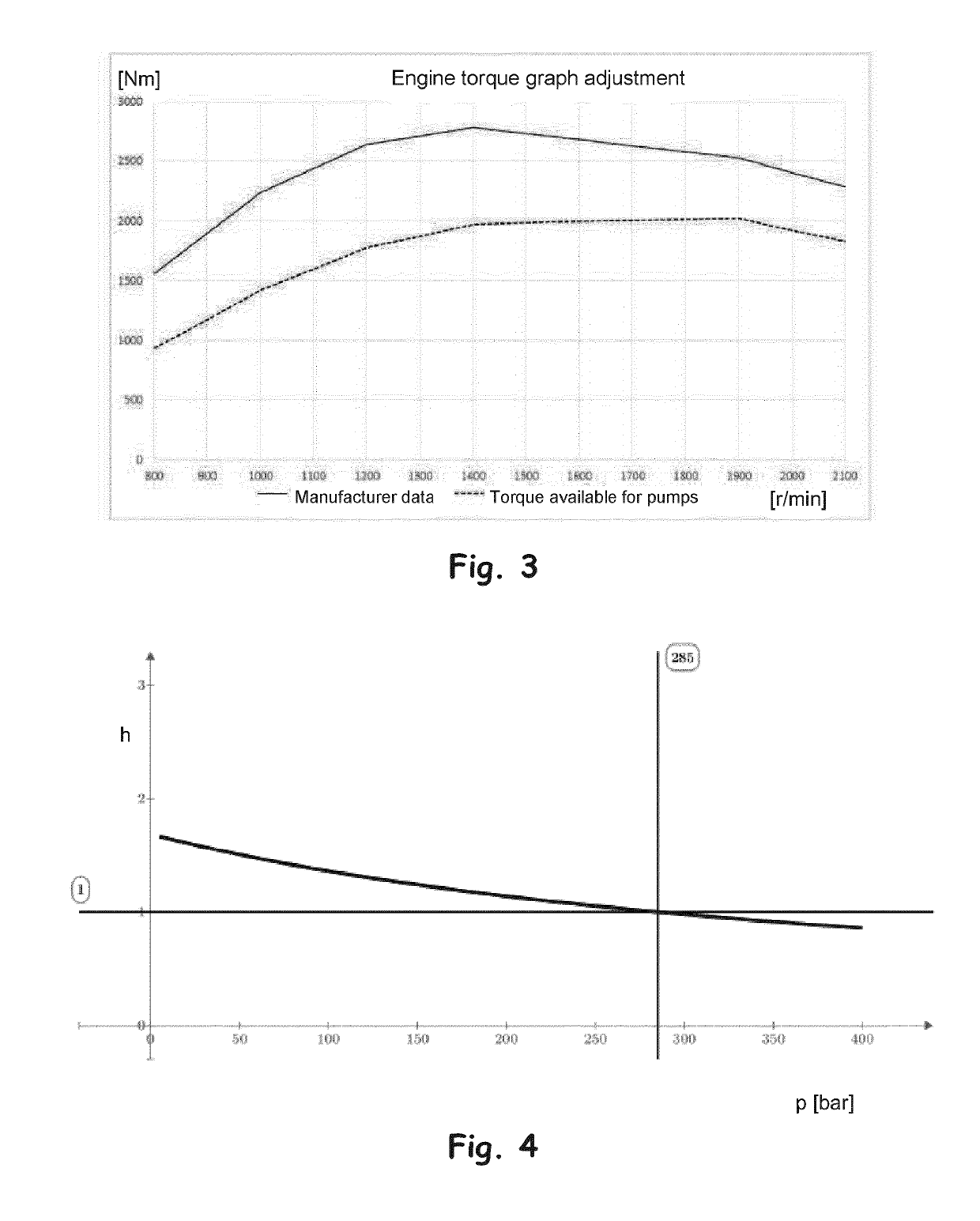

A method and a system for controlling the driving engine and hydraulic pumps of a hydraulic machine, as well as a pile driving rig

InactiveUS20190162211A1Reduce energy consumptionImprove energy efficiencyHydraulic programme controlServomotorsWorking pressureHydraulic pump

The invention relates to a method for controlling the driving engine (M) and hydraulic pumps (PUMP1, PUMP2) of a hydraulic machine (10), the method comprising: —driving at least one hydraulic variable displacement pump (PUMP1, PUMP2) that supplies pressurized medium to the hydraulic system of the machine by the driving engine (M), —determining the working pressure pi, p2) and volume flow (Qip, Q2p) output from at least one hydraulic pump (PUMP1, PUMP2), —determining the torque (T-ip, T2p) required of at least one hydraulic pump (PUMP1, PUMP2) or the total torque (Tpk0k) required by two or more hydrau¬lic pumps (PUMP1, PUMP2) by means of the working pressure (p-i, p2) and volume flow (Qip, Q2p) of pressurized medium output from at least one hydraulic pump (PUMP1, PUMP2), as well as the rotation speed (i) of the driving engine (M); —controlling the rotation speed (i) of the driving engine (M) and the dis¬placement (V1p, V2p) of at least one hydraulic pump (PUMP1, PUMP2) auto¬matically so that the torque (Td, Tdeff) produced by the driving engine approaches the torque (Tip, T2p) required by at least one hydraulic pump (PUMP1, PUMP2) driven by the driving engine (M), or the total torque (Tpk0k) of two or more hydraulic pumps (PUMP1, PUMP2) in such a way that the volume flow (Q1p, Q2p) produced by at least one hydraulic pump (PUMP1, PUMP2) will remain unchanged. The invention also relates to a system for controlling the driving engine (M) and hydraulic pumps (PUMP1, PUMP2) of a hydraulic machine (10), as well as a pile driving rig comprising the system according to the invention.

Owner:JUNTTAN OY

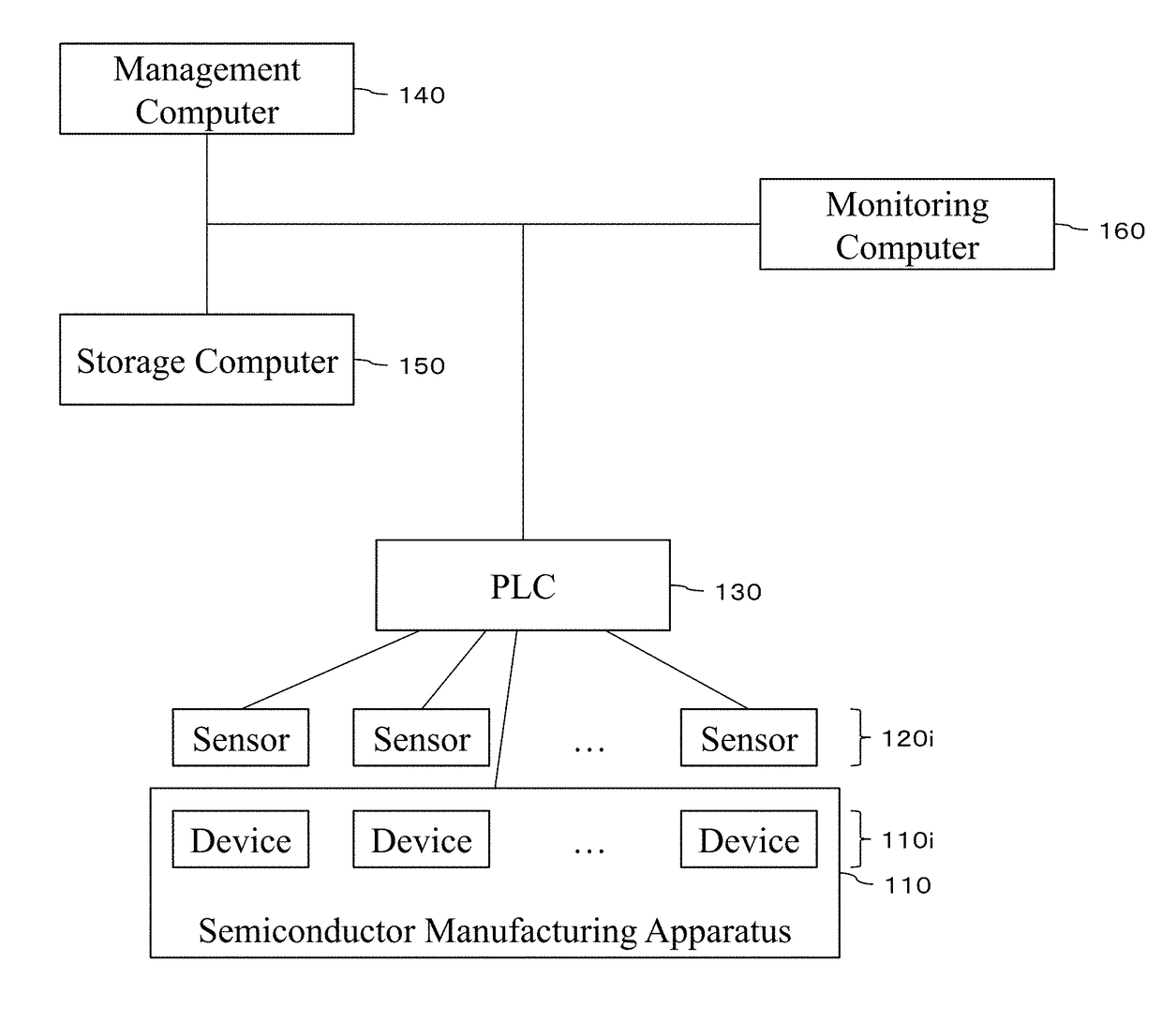

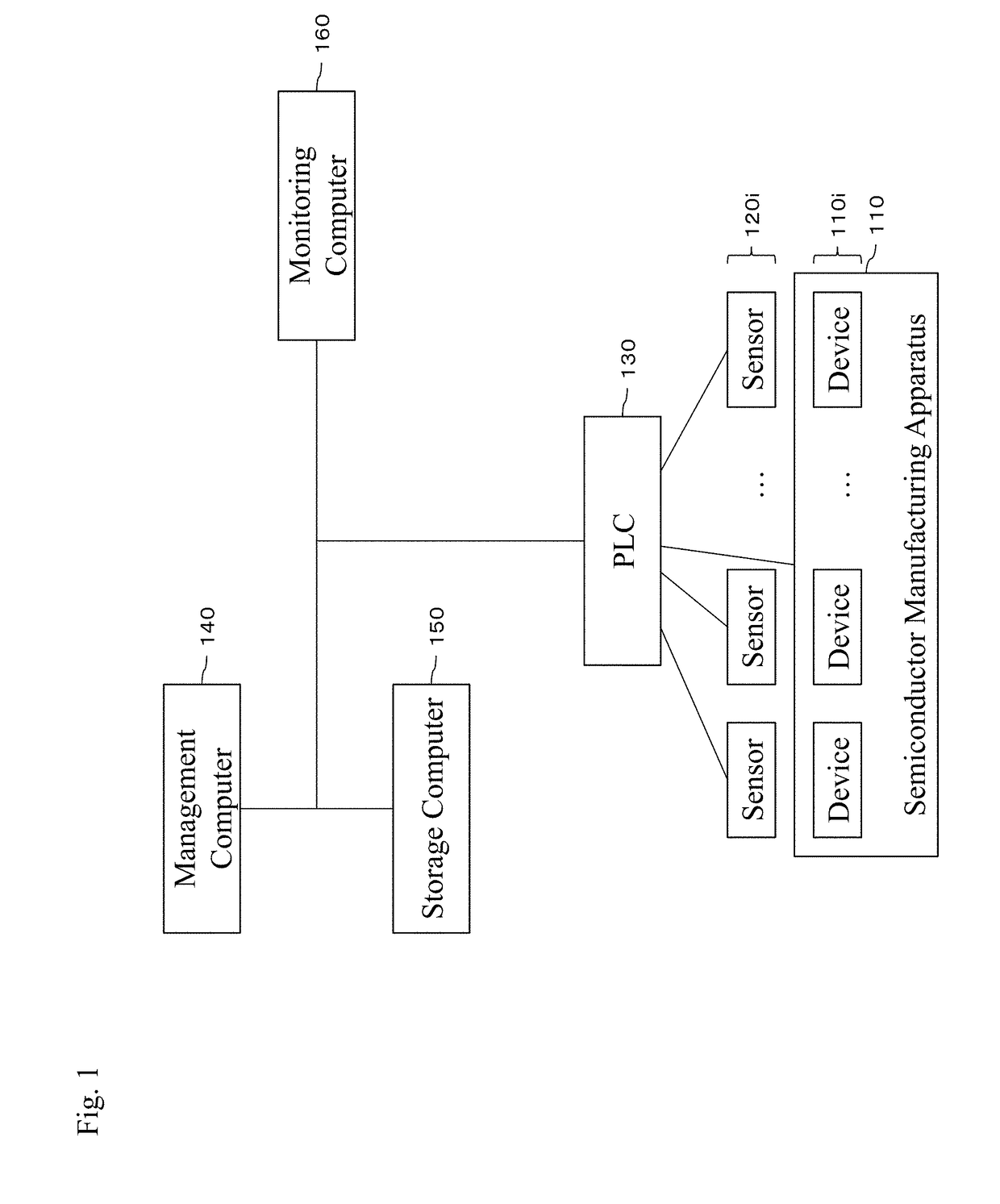

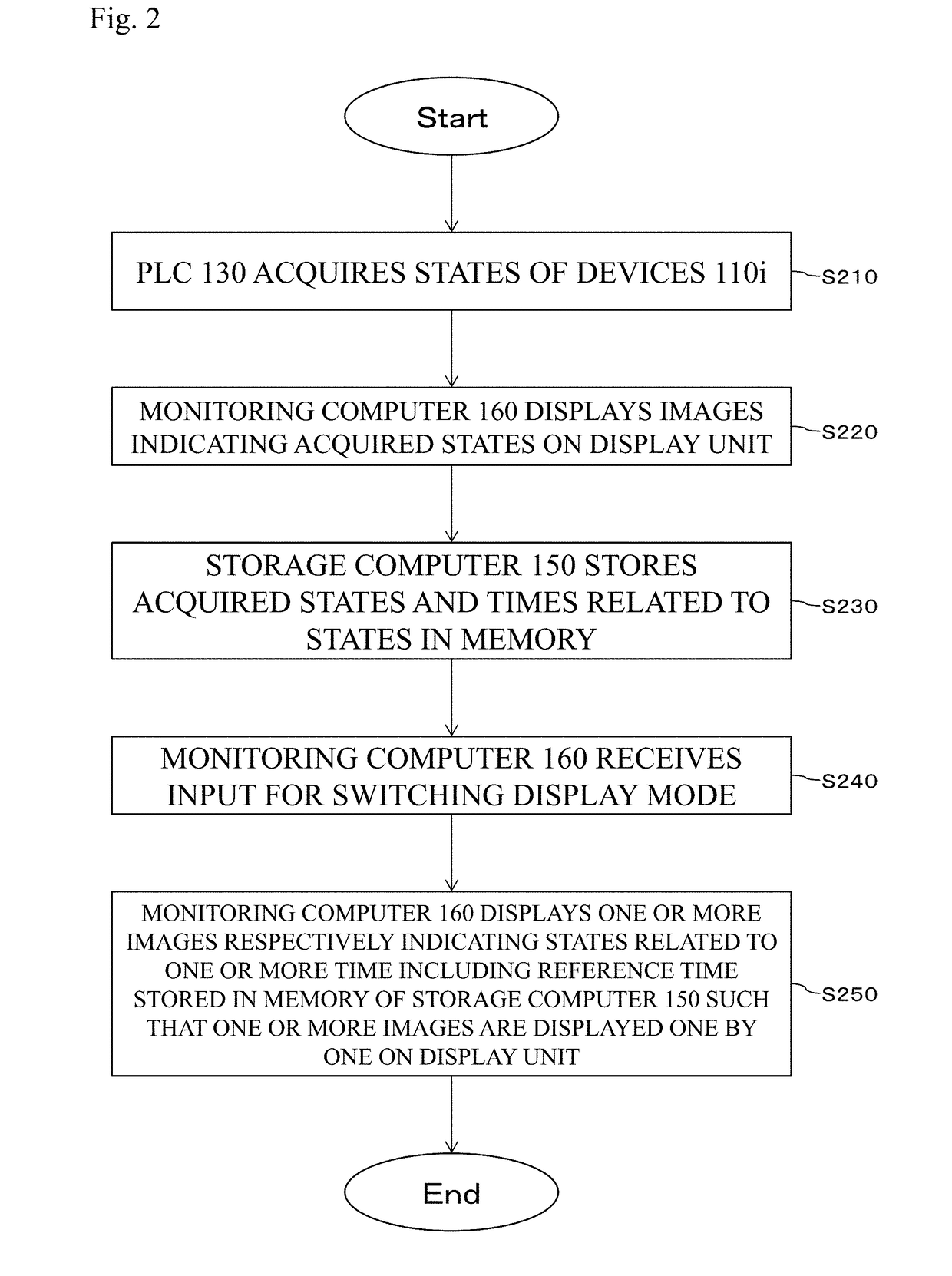

Method of controlling display of operation of semiconductor manufacturing apparatus and non-transitory computer readable storage medium therefor, and system for performing display concerning operation of semiconductor manufacturing apparatus

A method is provided, the method including: repeatedly acquiring a state of one or more devices included in the semiconductor manufacturing apparatus; providing a first animation indicating an operation of the semiconductor manufacturing apparatus by displaying at least an image indicating the state of one or more devices on a display unit each time the state is acquired; storing, in a memory, the acquired state of one or more devices and a time related to the state; receiving an input for switching a display mode; and providing a second animation of the semiconductor manufacturing apparatus by displaying, one by one on the display unit, at least one or more images respectively indicating the state of one or more devices related to one or more times including a reference time stored in the memory, after receiving the input for switching a display mode.

Owner:EBARA CORP

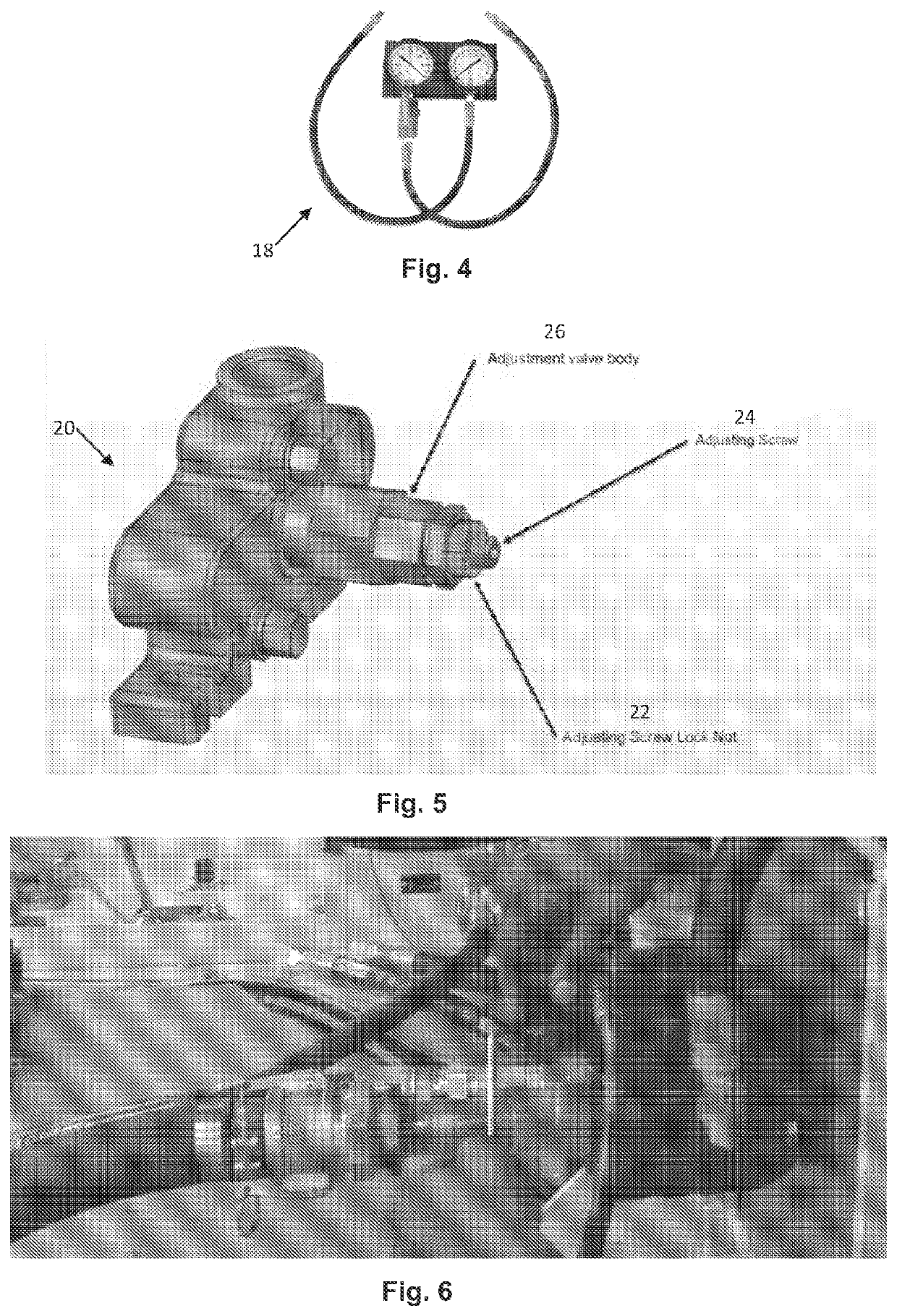

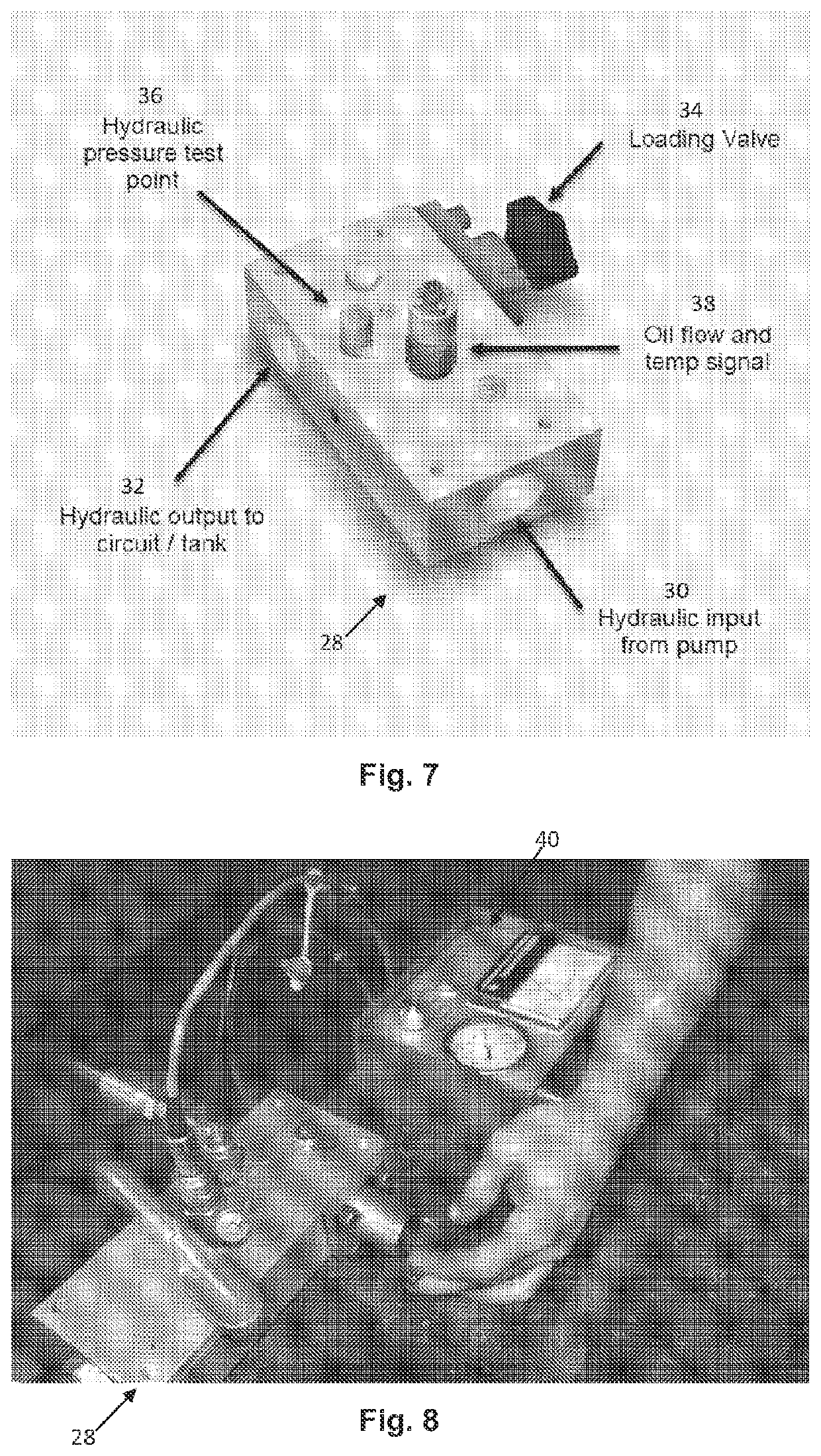

Testing of safety devices

ActiveUS20170268695A1Avoid excessive movementFluid-pressure actuator safetyFluid-pressure actuator testingValve actuatorEngineering

Many operators choose not to utilise partial-stroke testing arrangements even when the equipment required for it to be performed is available, due to a perceived risk of over-travel and / or spurious trip. To alleviate this, we describe a safety valve system comprising a valve operable to move between an operating state and a safe state, a valve actuator operatively connected to the valve to control its state, and including a bias toward the safe state, a pair of drive members powered by a pressure media, each acting against the bias to urge the valve toward the operating state, a first control valve arranged to selectively convey pressure media to both drive members and to withdraw supply on receipt of a safety trigger, and a second control valve arranged to selectively convey pressure media to one drive member only of the pair and to withdraw supply on receipt of a test signal. In this way, a partial stroke test is possible via the second control valve, but the other drive member of the pair will remain active thus acting as a buffer that prevents excessive movement of the valve.

Owner:IMTEX CONTROLS

Die cushion force setting apparatus

ActiveUS9669446B2Easy to set upEfficient use ofHydraulic programme controlPress ramHydraulic cylinderEngineering

The die cushion force setting apparatus according to an aspect of the present invention allows die cushion forces (component forces) acting on plural driving shafts to be set easily, makes it easy to apply strong or weak die cushion forces to a complex-shaped drawn part in a plane of a cushion pad, and provides a smooth die cushion force distribution. An operator manually enters a total die cushion force, axial component force of a left front hydraulic cylinder, and center-of-force position by operating an input device. Based on the information entered via the input device, the numerical computing device B1 calculates axial component forces of three hydraulic cylinders through numerical computations. The one axial component force thus entered and three axial component forces thus computed numerically are set as the axial component forces of four hydraulic cylinders.

Owner:AIDA ENG LTD

Concrete distributing device and control method, control system and electrical control system for composite motion of boom thereof

ActiveUS9045316B2Reduce movement speedHydraulic programme controlSoil-shifting machines/dredgersProportional controlControl signal

Disclosed are a concrete distributing device and a control method, a control system and an electrical control system for composite motion of a boom thereof. The control method comprises the steps as follows: calculating the flow of a boom pump when an operating handle sends a command; according to the command sent by the operating handle, calculating theoretical demand flow of all actuating mechanisms of the boom and theoretical control signals of all electronic proportional control valves; comparing the total theoretical demand flow of the actuating mechanisms with the flow of the boom pump; providing the theoretical control signals to all the electronic proportional control valves when the flow of the boom pump is greater than or equal to the total theoretical demand flow of the actuating mechanisms, otherwise, providing actual control signals smaller than the theoretical control signals to all the electronic proportional control valves and reducing the movement speeds of all the actuating mechanisms proportionally. In this way, when undersaturation of system occurs to the composite motion of the boom, the movement speeds of all the actuating mechanisms are reduced proportionally independent of the load difference of the actuating mechanisms, thereby ensuring that the boom can move in a motion track expected by an operator.

Owner:ZOOMLION HEAVY IND CO LTD +1

No flow detection means for sensorless pumping control applications

Apparatus is provided featuring a signal processor or processing module configured to receive signaling containing information about a pump no flow idle (NFI) state when the pump is running at a pump idle speed; and determine corresponding signaling containing information about whether the pump should remain in a no flow shutdown (NFSD) state or the pump NFI state, based upon the signaling received. The signal processor or processing module is configured to provide the corresponding signaling containing information about whether the pump should remain in the NFSD state or the NFI state.

Owner:FLUID HANDLING

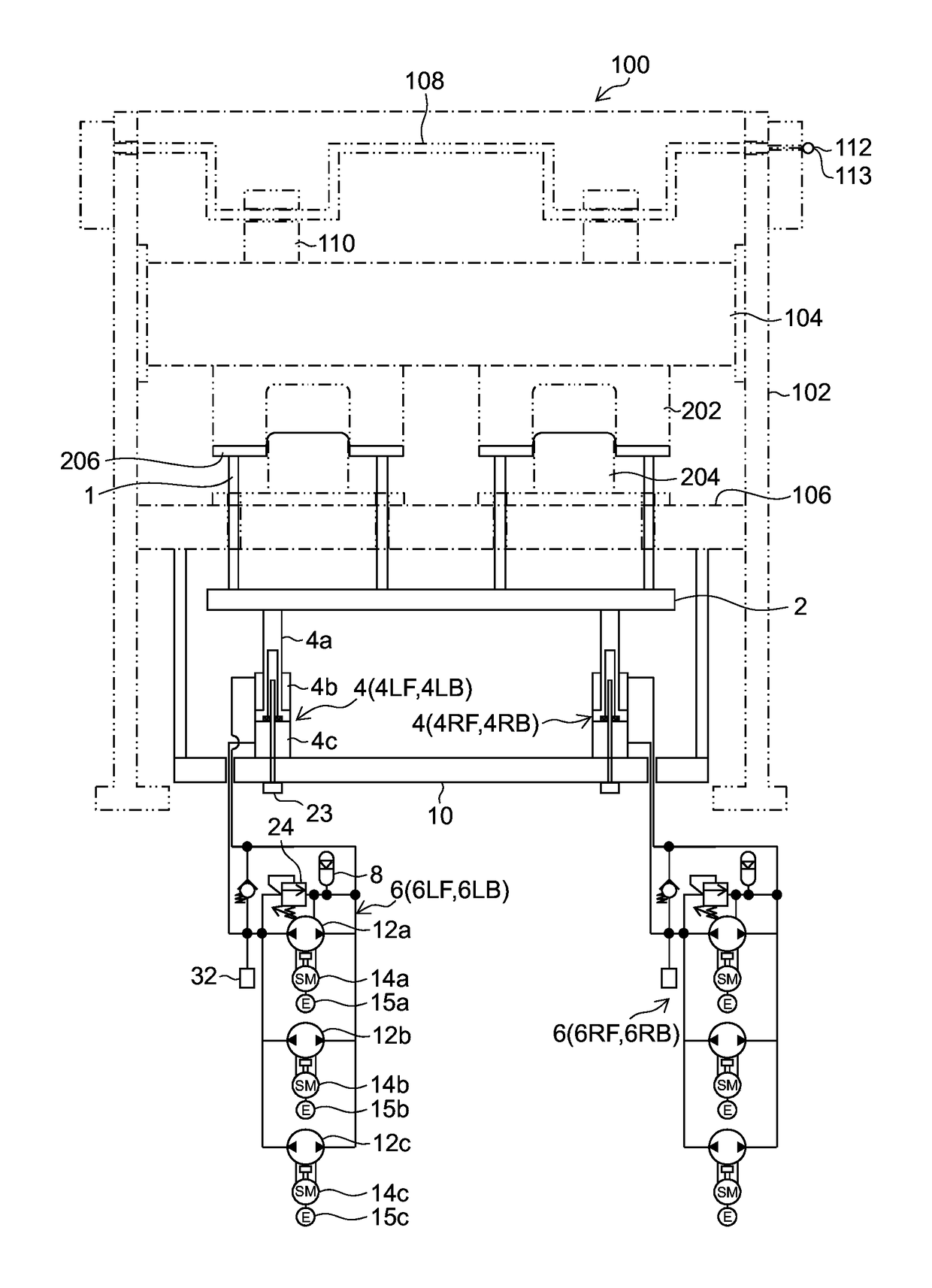

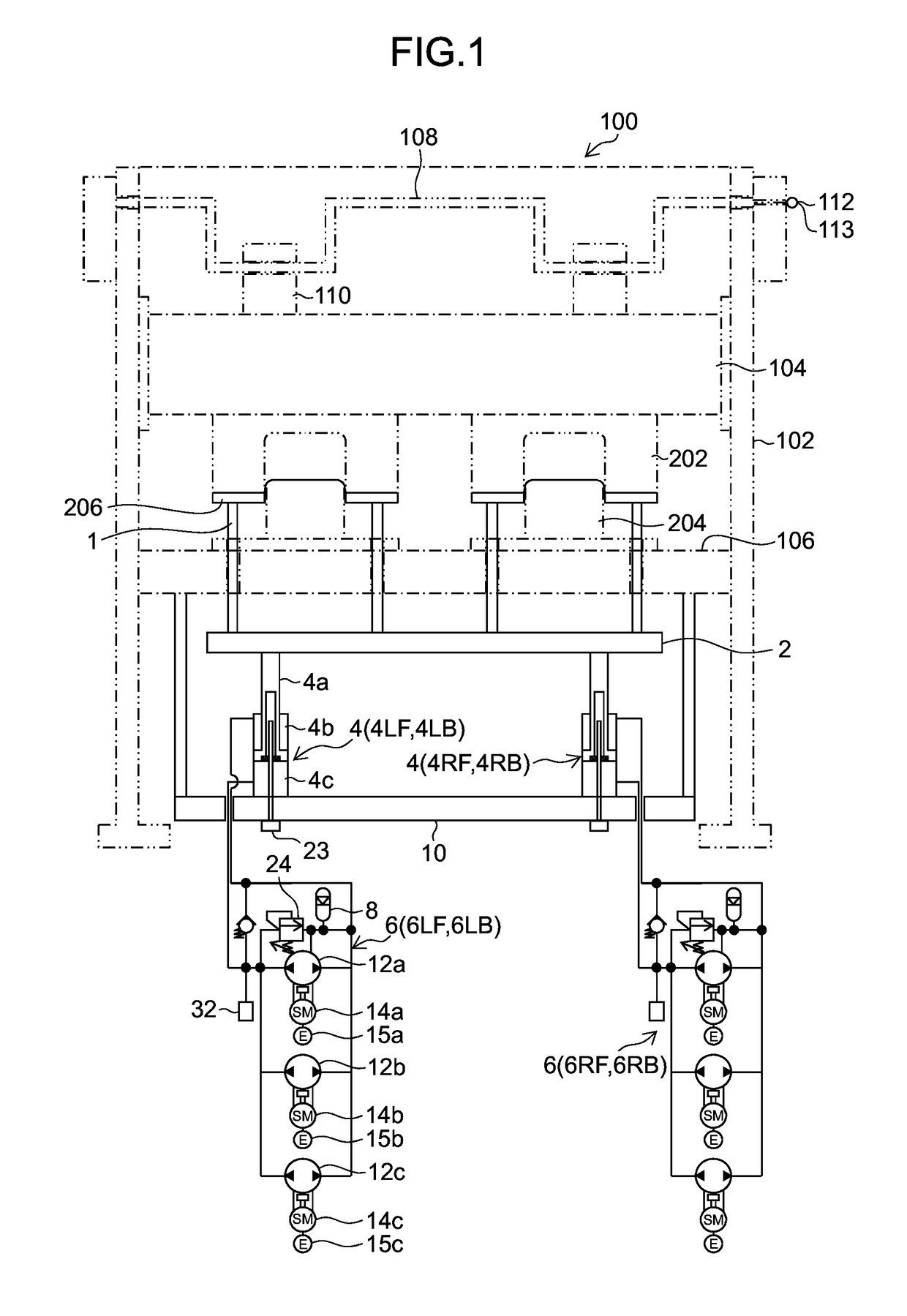

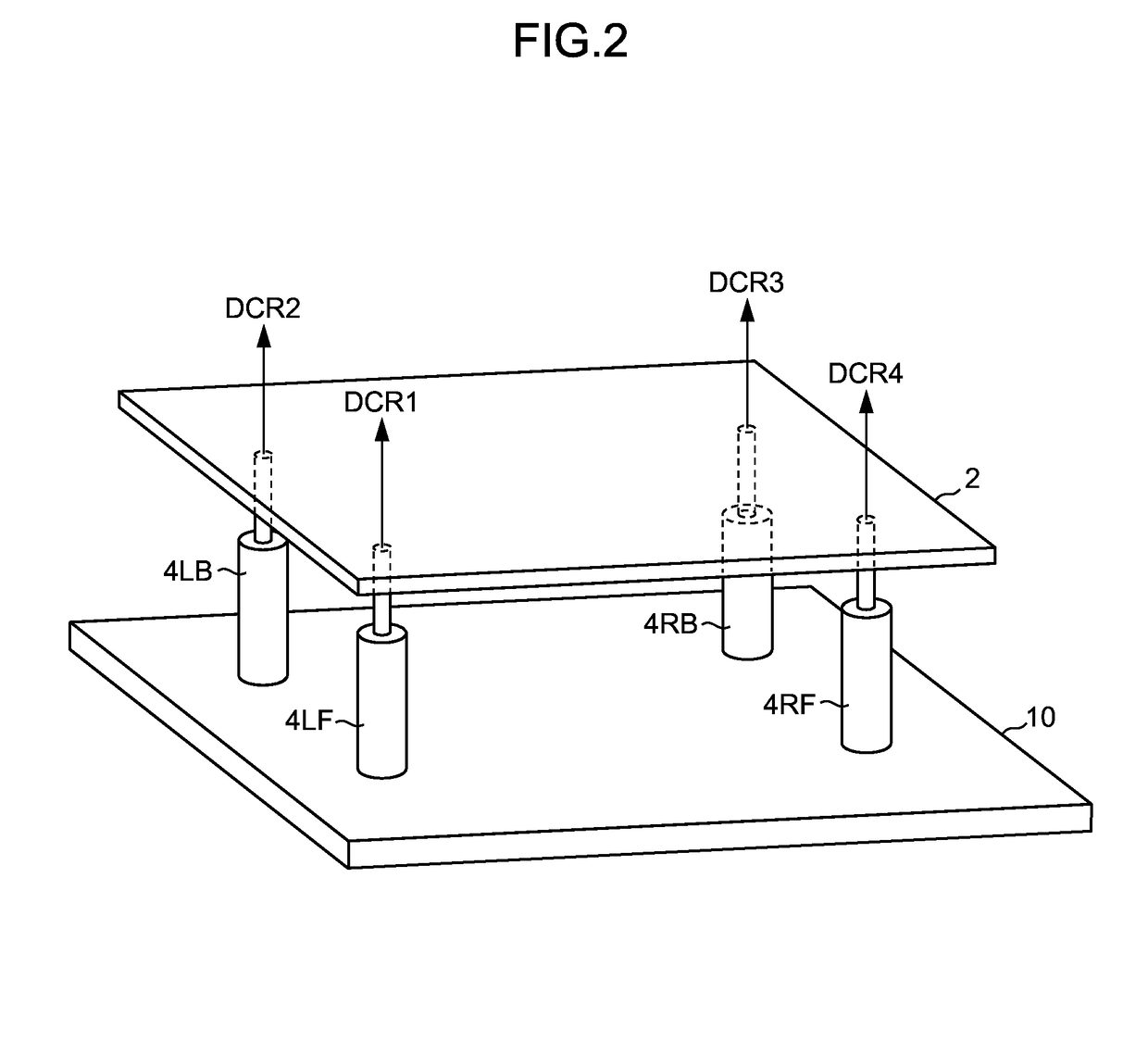

Die cushion force setting apparatus

ActiveCN104226772ASmooth cushion force distributionSimple inputHydraulic programme controlPress ramHydraulic cylinderEngineering

The die cushion force setting apparatus according to an aspect of the present invention allows die cushion forces (component forces) acting on plural driving shafts (4a) to be set easily, makes it easy to apply strong or weak die cushion forces to a complex-shaped drawn part in a plane of a cushion pad (2), and provides a smooth die cushion force distribution. An operator manually enters (step S18A) a total die cushion force, axial component force of a left front hydraulic cylinder (4LF), and center-of-force position by operating an input device (A1). Based on the information entered via the input device (A1), the numerical computing device B1 calculates (step S18B) axial component forces of three hydraulic cylinders (4LB, 4RF, 4RB) through numerical computations. The one axial component force thus entered and three axial component forces thus computed numerically are set (step S18C) as the axial component forces of four hydraulic cylinders (4LF, 4LB, 4RF, 4RB).

Owner:AIDA ENG LTD

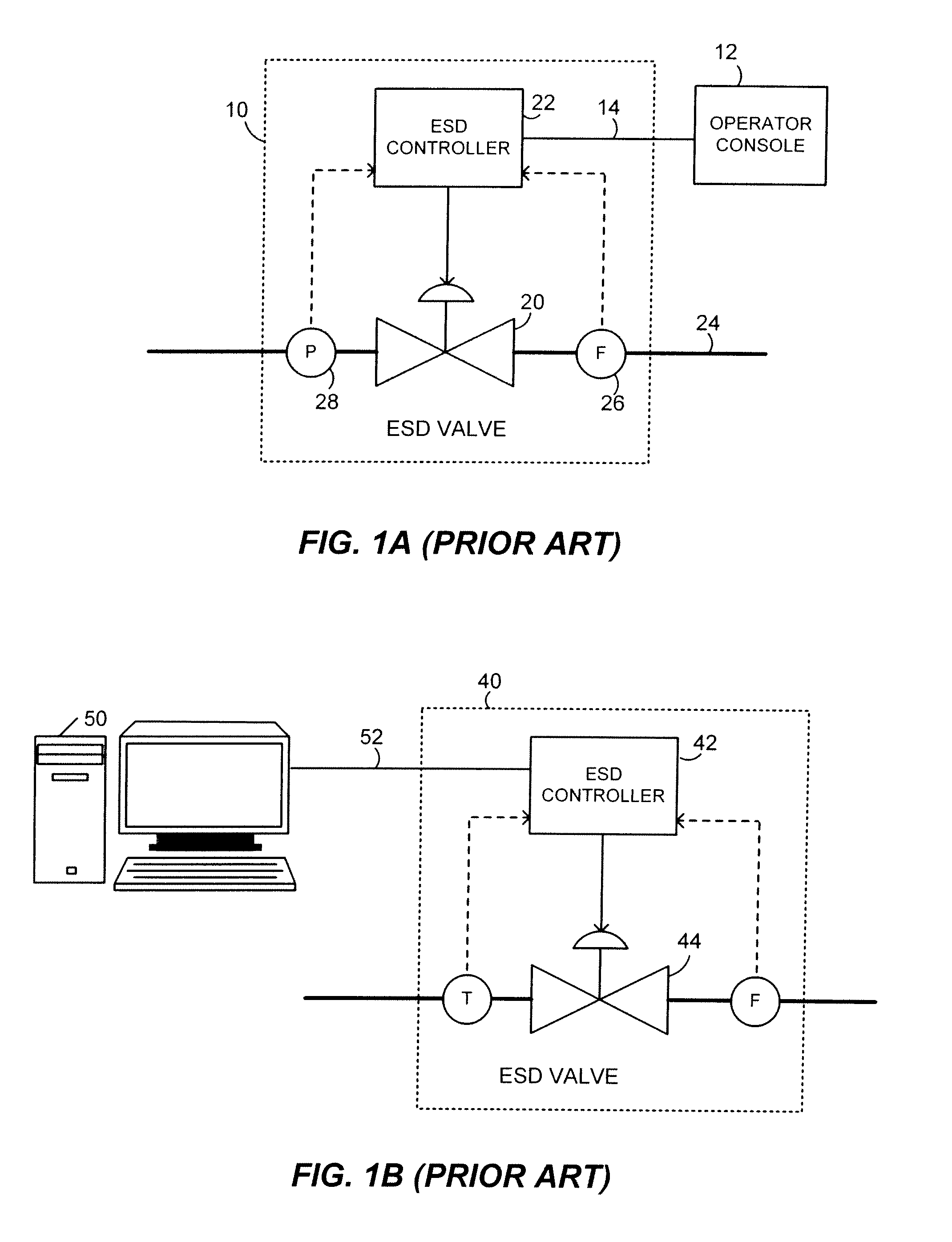

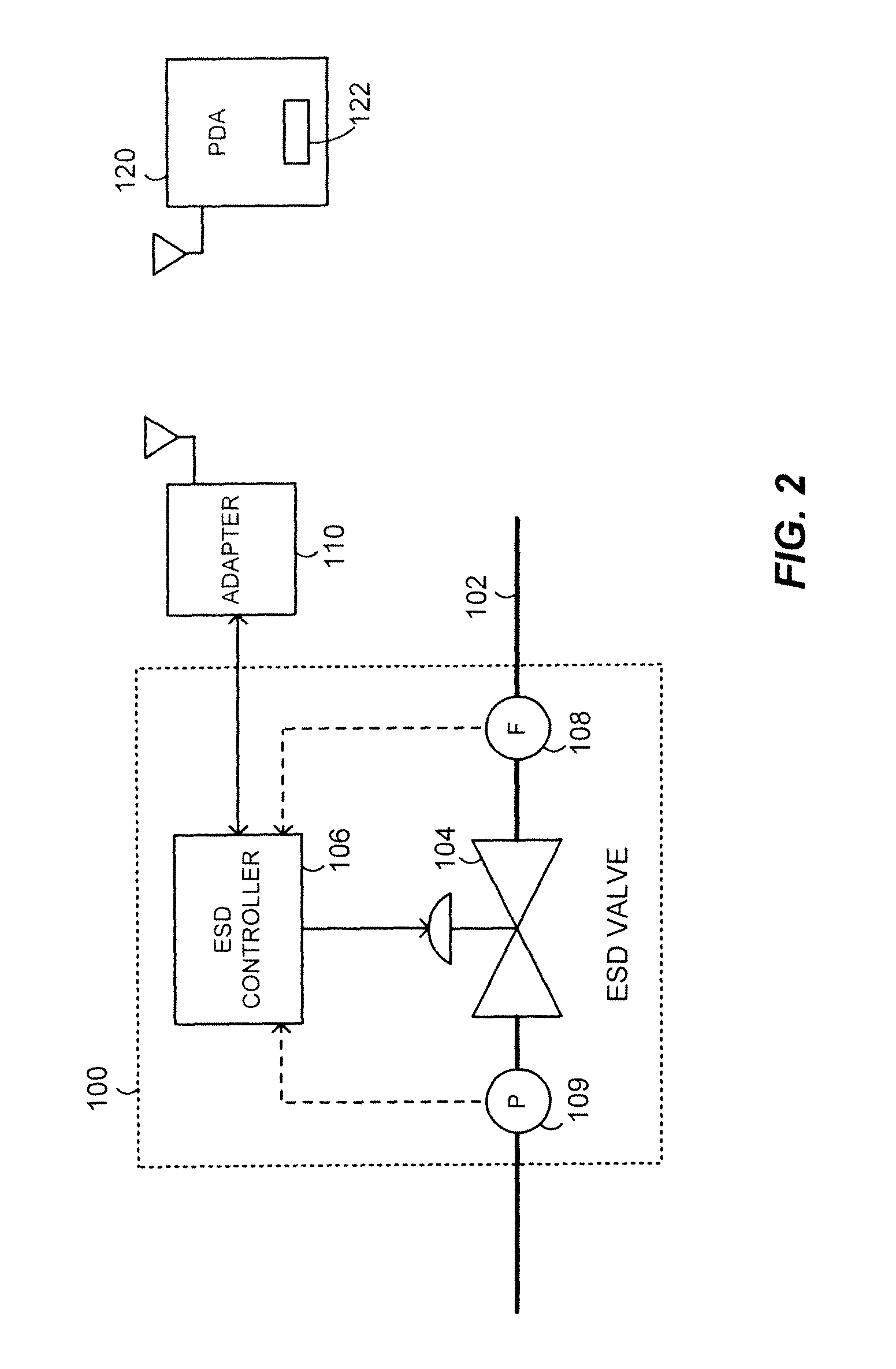

Method and apparatus for partial stroke testing of an emergency shutdown valve

ActiveUS9080683B2Valve arrangementsHydraulic programme controlTelecommunications linkCommunication link

A method for conducting a partial stroke test of an emergency shutdown valve includes receiving a request to initiate the partial stroke test from a user interface or another source, establishing a direct or an indirect wireless communication link with the emergency shutdown valve, and generating one or more commands of a digital industrial automation protocol to be transmitted to the emergency shutdown valve via the wireless communication link, so that a partial stroke test of the emergency shutdown valve is initiated in response to these commands.

Owner:FISHER CONTROLS INT LLC

Multi-point pushing cumulative-gliding construction method for steel roof truss

ActiveCN101200959BReduce volumeLight weightBuilding roofsHydraulic programme controlSupporting systemControl system

The invention provides a multipoint incremental launching accumulative sliding construction method for steel roof truss. First, a slide support system of three chutes and six rails is set up; a high altitude assembly platform is set up beside the main structure; and a temporary support jig of the middle chute is set up along the midline of the main structure, using the concrete trough beam as theside chute. Then steel truss components are assembled on the ground, and are hoisted to the high altitude assembly platform to assemble a first sliding unit, and then the first sliding unit is connected with a hydraulic synchronous multipoint incremental launching mechanism; the hydraulic synchronous multipoint incremental launching mechanism consists of eight hydraulic crawl devices, three hydraulic pump stations and a synchronous incremental launching control system; after the first sliding unit is pushed, a second sliding unit is assembled and connected with the first sliding unit, and thena second time sliding is performed. Via such an assembly structure, the sliding movement is performed for n times, and then the backout bracket is unloaded, the high altitude assembly platform and the temporary support jig of the middle chute are dismounted. The invention solves the difficulty of safe and stable installation and emplacement in synchronous sliding of the steel roof truss, and at the same time reduces the engineering cost and shortens the construction period without affecting the construction of other structures.

Owner:BEIJING URBAN CONSTR GROUP +1

Method and device for synchro controlling high precision screwdown at two side during rolling steel plate

InactiveCN101003062BHigh precisionHigh technology contentHydraulic programme controlComputer controlSynchronous controlPush pull

A method for controlling the high-precision synchronous press-down at both sides of rolled plate features that a technique for high-precision two-stage synchronous control to press-down speed and the in-line real-time computer control to automatic complementary linkage of high-precision synchronizing are used. Its apparatus is composed of two high-precision two-stage press-down speed controlling mechanisms with hydraulic mechanism, computer, push-pull switching circuit and electro-hydraulic servo valve.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

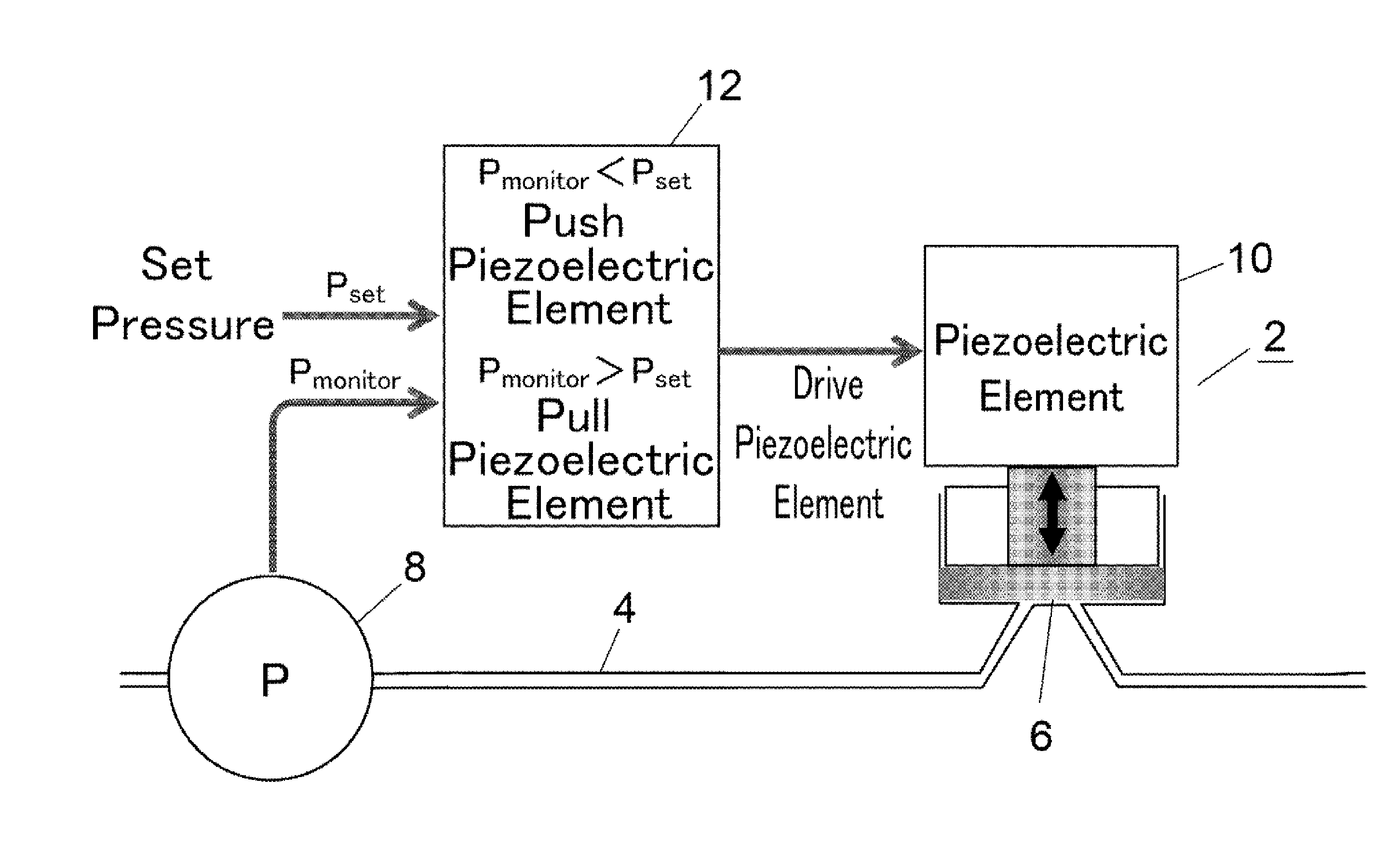

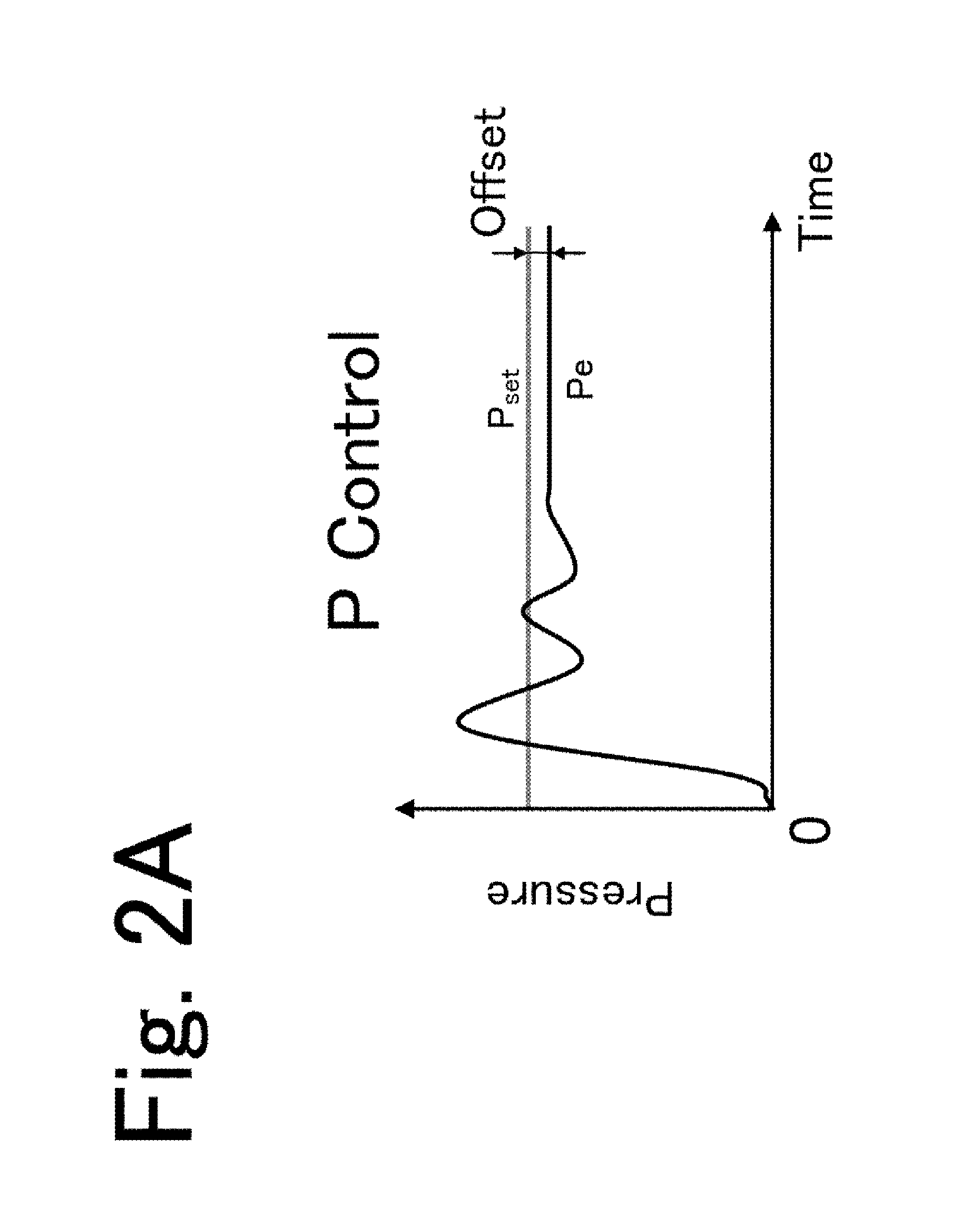

Feedback control device

ActiveUS20170045482A1Stability of feedback is highComplicated processing can be easilyHydraulic programme controlComponent separationFeedback controlControl circuit

A feedback control apparatus includes: a detector configured to detect an output value based on a controlled object; a P control circuit including a differential amplifier circuit and an analog circuit, the differential amplifier circuit being configured to receive a detection value of the detector and a target value, the analog circuit being configured to output a P control component VP to an output of the differential amplifier circuit; an I control unit configured to output an I control component VI by integrating a deviation of the detection value from the target value by digital processing; and a driver element configured to be driven based on the P control component VP from the P control circuit and the I control component VI from the I control unit to control the controlled object.

Owner:SHIMADZU CORP

System for mounting an annular component on a shaft

InactiveUS20160224019A1Reduce dependenceThe process is fast and accurateFluid parameterRoller bearingsAxial displacementRemote control

A system for mounting an annular component on a shaft, comprising (a) a hydraulic nut having an annular coaxial cavity and a ring-like piston, displaceable within the cavity; (b) a displacement sensor for providing a displacement signal indicating the axial displacement of the piston within the cavity; (c) a wireless displacement transmitter for transmitting the displacement signal; (d) a pressure sensor for providing a pressure signal indicating a pressure within the cavity; (e) a wireless pressure transmitter for transmitting the pressure signal; (f) a pump arranged to pump fluid into the cavity; and (g) a remote control device having a communications device arranged to receive transmitted pressure and displacement signals, wherein the remote control device is arranged to output control information for controlling the pump.

Owner:AB SKF

Method for operating hydraulic drive

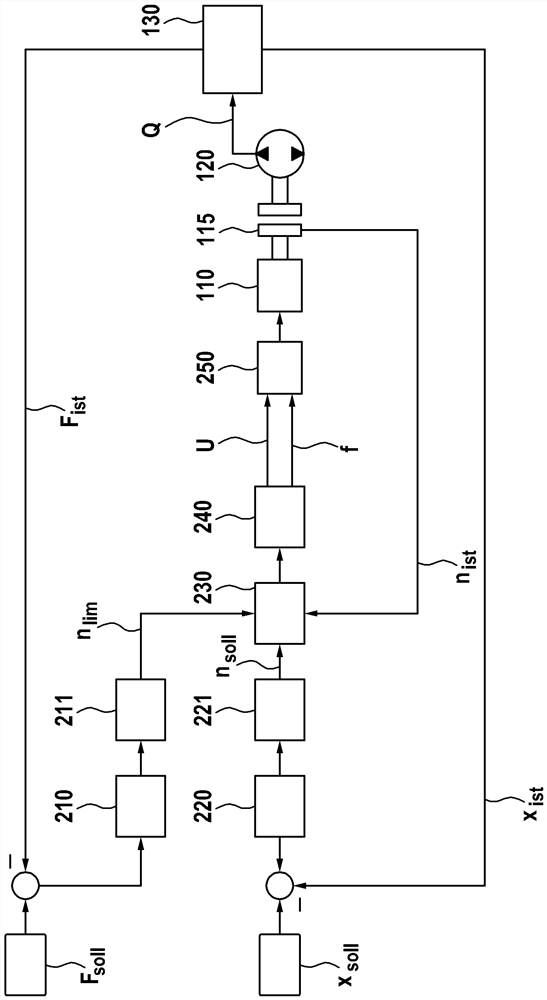

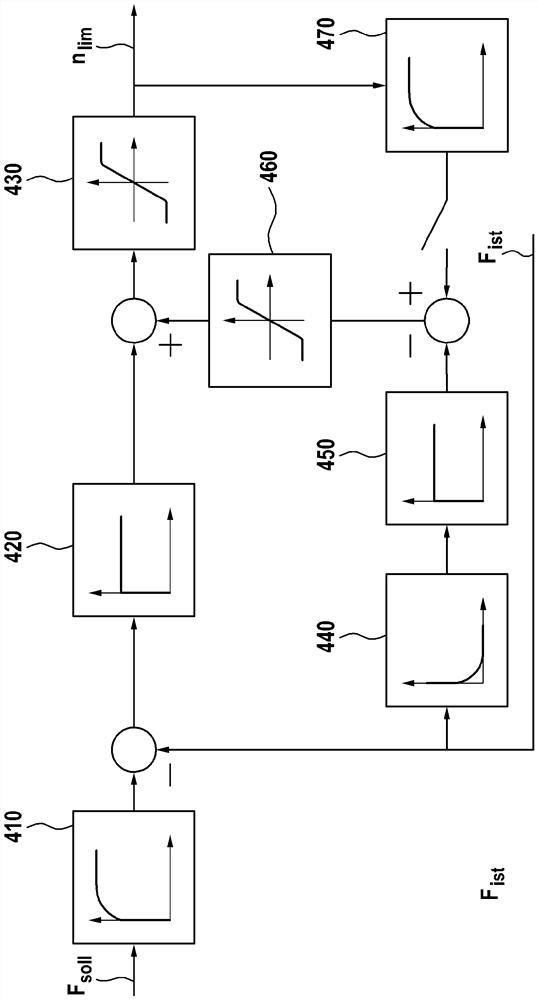

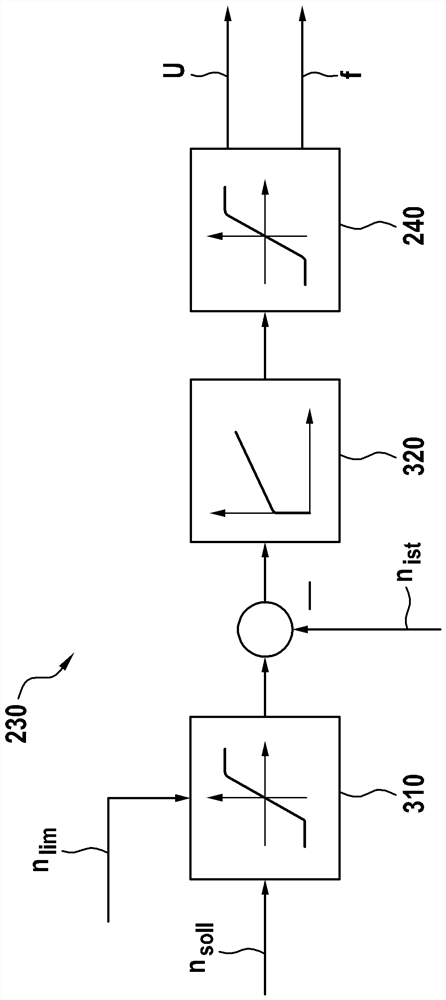

PendingCN113251031AAdjust tensionPrecisely regulate or limit extrusion forceHydraulic programme controlTelemotorsHydraulic pumpMotronic

The invention relates to a method for operating a hydraulic drive. The drive comprises a hydraulic pump (120) driven by a variable-speed electric motor (110) and a hydraulic consumer (130) connected to the hydraulic pump (120) and comprising positionable elements, wherein the positions of a positionable elements of the hydraulic consumer (130) are adjusted as control variables by means of a position controller (220) through a rotational speed of the electric motor (110), and a pressure on the positionable elements of the hydraulic consumer (130) or a force exerted by the positionable elements of the hydraulic consumer (130) is adjusted by means of a pressure or force controller (210), and a predetermined rotational speed of the electric motor (110) is adjusted by means of a predetermined cycle frequency (f) and / or a predetermined voltage (U) of a magnetic field of a stator of the electric motor (110).

Owner:ROBERT BOSCH GMBH

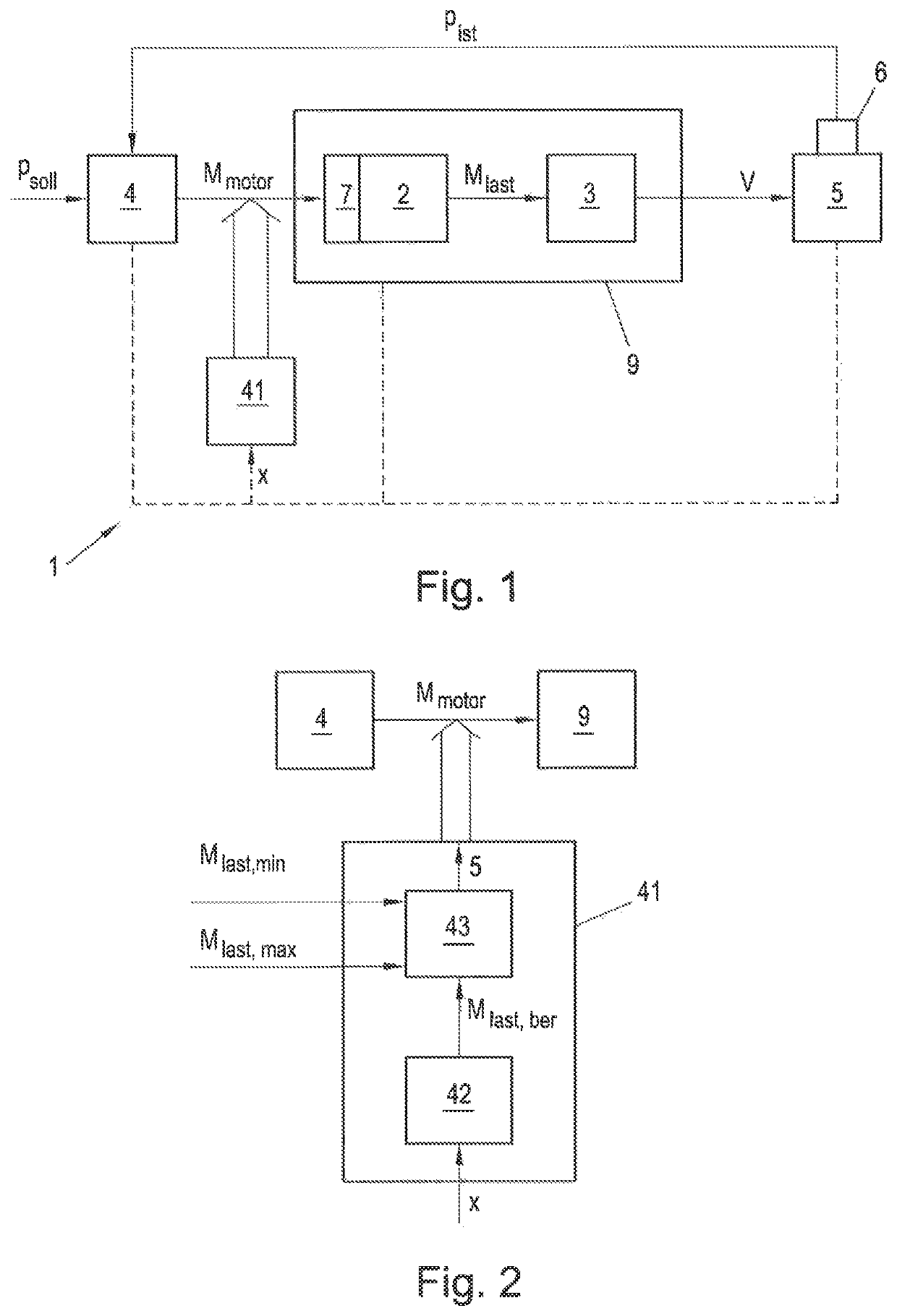

Hydraulic system with servo drive and hydraulic load and control unit for the hydraulic system

ActiveUS10837466B2Reduce mechanical loadLimit the motor torqueHydraulic programme controlServomotorsLoad torqueSystem pressure

To utilize and protect a mechanical load torque range of a servo drive in combination with a pump, a control unit is given a target system pressure as a reference variable and an actual system pressure as a control variable. An electric motor torque acting on a pump of the servo drive is specified by the control unit to an electric motor of the servo drive, a volume flow at the hydraulic load is generated by the pump, by which a mechanical load torque sets it at the electric motor and the actual system pressure is produced in the hydraulic load via the volume flow. A dynamic system variable of the hydraulic system is transmitted to the limiting unit. The limiting unit limits the motor torque transmitted by the control unit to the electric motor as a function of the value of the system variable.

Owner:B&R IND AUTOMATION GMBH

Remotely controlling a hydraulic system

PendingUS20220260958A1Sampled-variable control systemsFluid-pressure actuator testingEngineeringActuator

Owner:KOODAIDERI INNOVATION & TECH PTY LTD

Full-automatic injecting blowing plastic hollow molding machine control device and cybernation method thereof

InactiveCN100588534CImprove control effectImprove precision controlHydraulic programme controlTemperature control using electric meansLevel shiftingMicrocontroller

A control of a full-automatic plastic filling and blowing and hollow molding machine of a PLC-high speed singlechip-PIC singlechip includes a PLC- high speed singlechip system which consists of a PLC,a high speed singlechip, a level conversion circuit and a current direction control circuit, a temperature control module which consists of a signal magnifying circuit of a N-path temperature sensorand a driving circuit of a N-path heating device, a hydraulic pressure control system which consists of a PIC singlechip and a driving system of a hydraulic pressure control device, a pneumatic control module and a control panel. The method of using the device of the present invention to automatically control the filling and blowing process of the full-automatic plastic filling and blowing and hollow molding machine includes obtaining the system information, controlling the mechanical motion, controlling the temperature during the process of filling and blowing and controlling a hydraulic pressure flux and constant current of electric current of an electro-liquid proportional valve, and the obtaining of the system information has two routes of a PLC control procedure and a touch-screen interruption disposal. The control has high automatization degree and reliability, friendly human-machine interface, high cost performance of the system and the simple, convenient and practical method.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

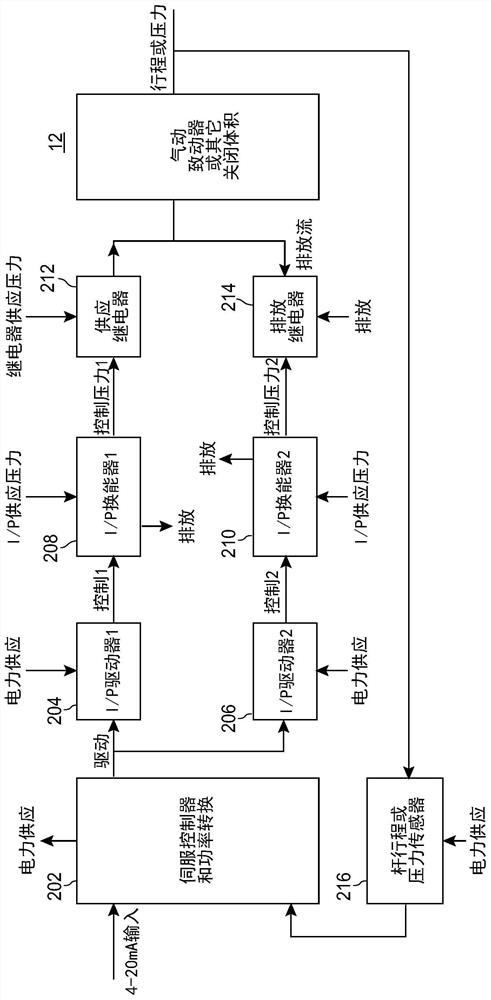

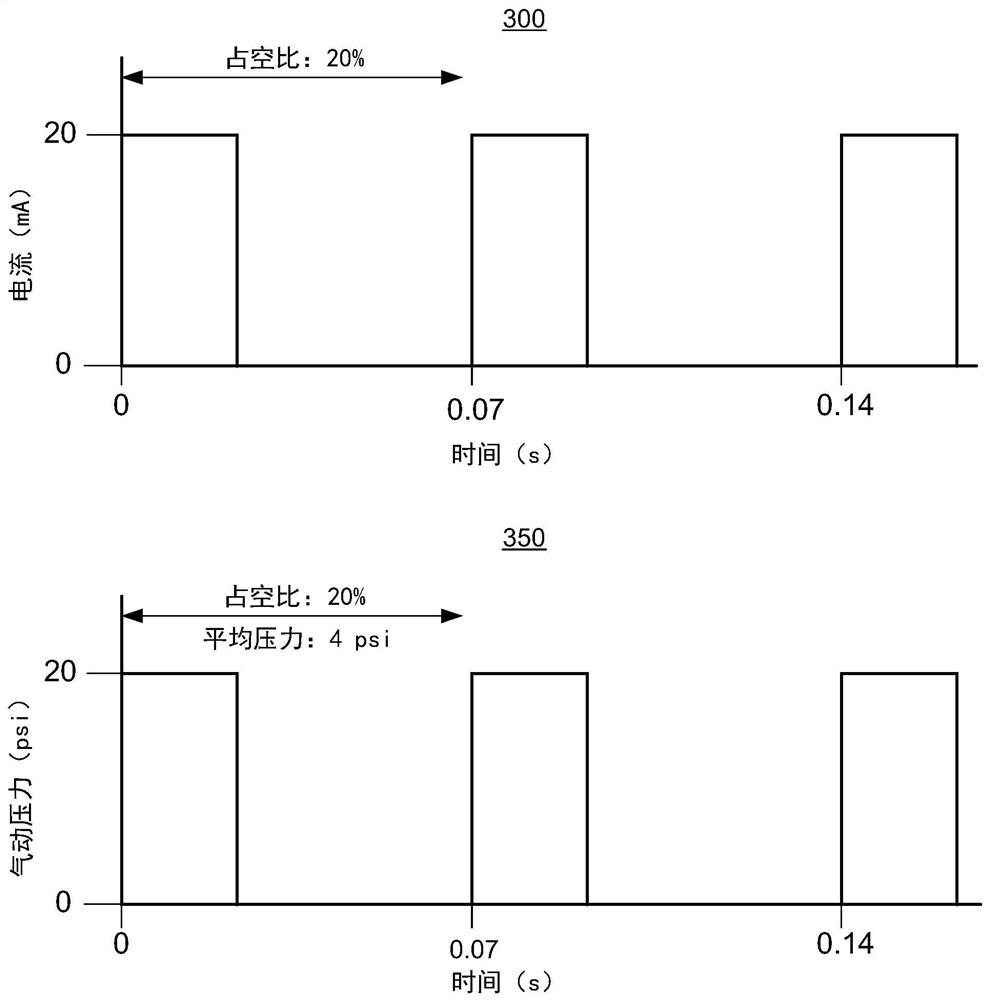

Feature set and methods for digital positioner

PendingCN113700928AAC motor controlOperating means/releasing devices for valvesConvertersEngineering

A digital positioner for a valve includes a valve controller configured to obtain a set point value for a valve travel of a valve, and generate a pulse-width modulated current signal based on the set point value. The digital positioner also includes a current-to-pressure converter configured to receive the pulse-width modulated current signal from the valve controller, convert the pulse-width modulated current signal to a pulse-width modulated pressure signal, and provide the pulse-width modulated pressure signal to a pneumatic actuator in the valve to adjust a position of the valve.

Owner:FISHER CONTROLS INT LLC

System for mounting an annular component on a shaft

ActiveUS20200240472A1Reduce dependenceFluid parameterRoller bearingsAxial displacementRemote control

A system for mounting an annular component on a shaft, comprising (a) a hydraulic nut having an annular coaxial cavity and a ring-like piston, displaceable within the cavity; (b) a displacement sensor for providing a displacement signal indicating the axial displacement of the piston within the cavity; (c) a wireless displacement transmitter for transmitting the displacement signal; (d) a pressure sensor for providing a pressure signal indicating a pressure within the cavity; (e) a wireless pressure transmitter for transmitting the pressure signal; (f) a pump arranged to pump fluid into the cavity; and (g) a remote control device having a communications device arranged to receive transmitted pressure and displacement signals, wherein the remote control device is arranged to output control information for controlling the pump.

Owner:AB SKF

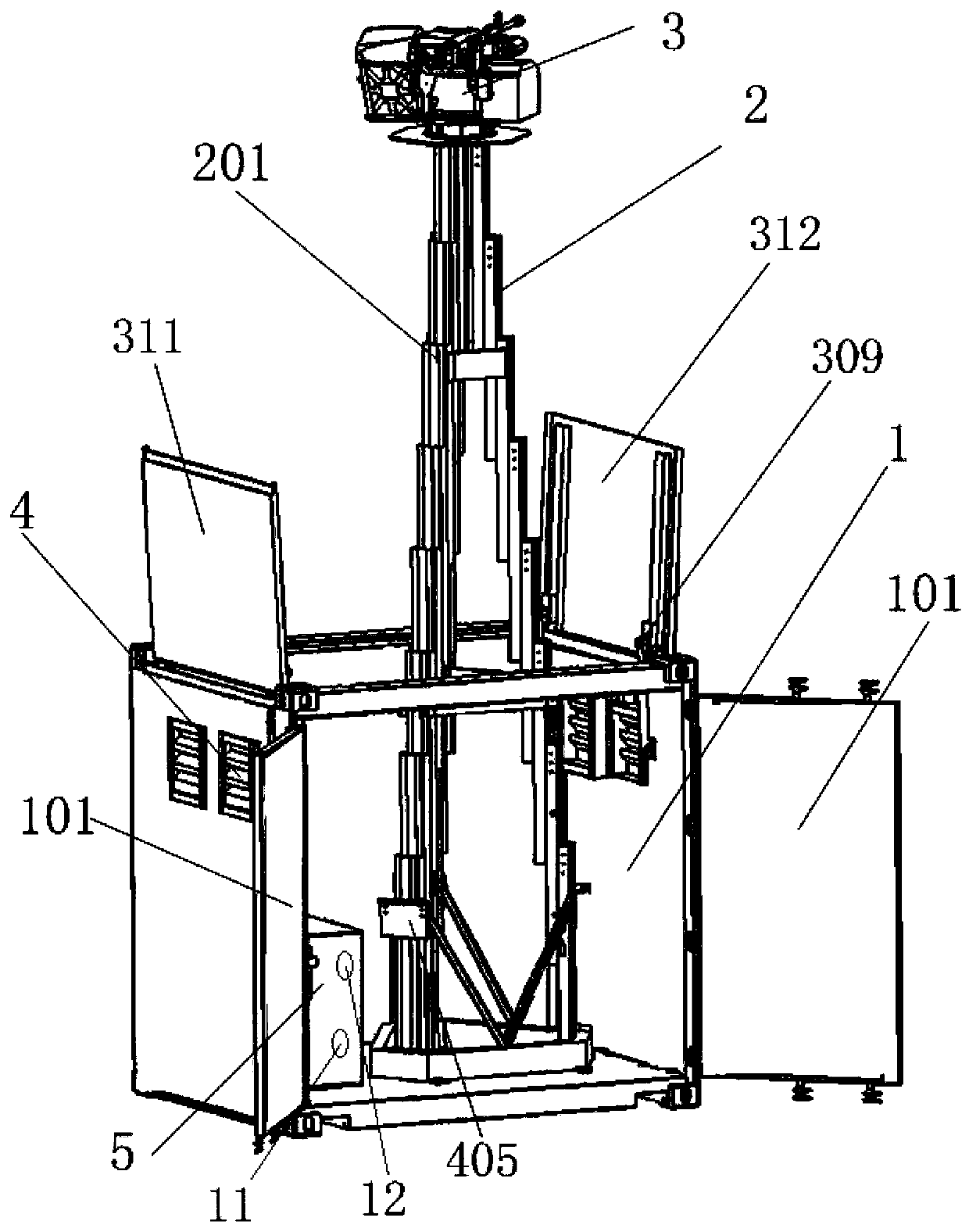

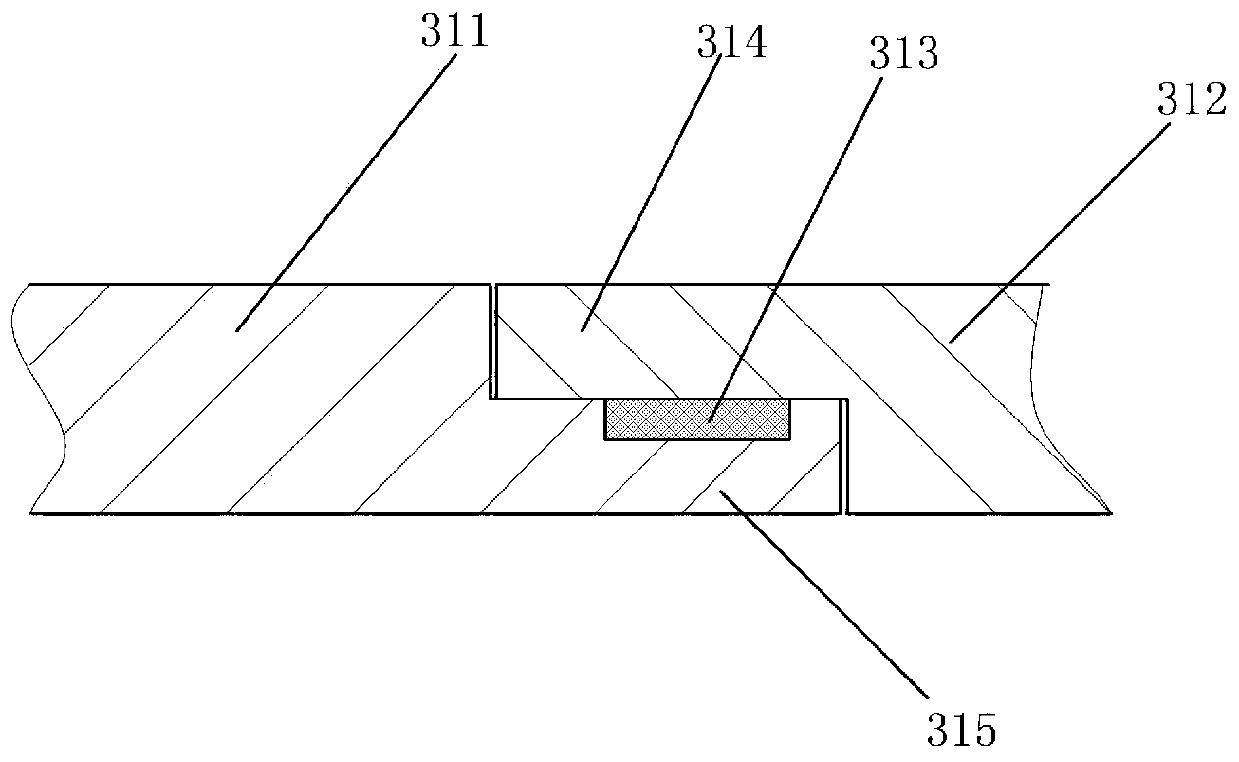

Rapid and automatic arrangement and control container type weapon station and load platform control method

PendingCN110220420AImprove target observationHigh protection levelHydraulic programme controlLifting devicesBodies oilControl system

The invention discloses a rapid and automatic arrangement and control container type weapon station and a load platform control method. The rapid and automatic arrangement and control container type weapon station comprises a box body and further comprises a hydraulic lifting tower, a weapon, an electrical control system and a hydraulic system which are arranged in the box body. The top of the boxbody is provided with an upper opening type top cover controlled by a top plate oil cylinder. The hydraulic lifting tower comprises a lifting support and a tower body oil cylinder, and the weapon isarranged on a load platform on the top of the lifting support. The electrical control system controls a top cover opening and closing hydraulic subsystem and a tower body lifting hydraulic subsystem to work, the tower body oil cylinder and the top plate oil cylinder are made to act, and top cover opening and closing and lifting support lifting are achieved according to the set sequence. A container is adopted as a platform assembly, rapid ascending and descending of the automatic weapon station platform are achieved through an external power system or standby power system, the deploying / hidingtime is short, the height of the automatic weapon station platform can be increased to several meters to tens of meters according to needs, the weapon target observing, obtaining and firepower effects are improved, and the protection level of a protected object is obviously improved.

Owner:陕西雷神智能装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com