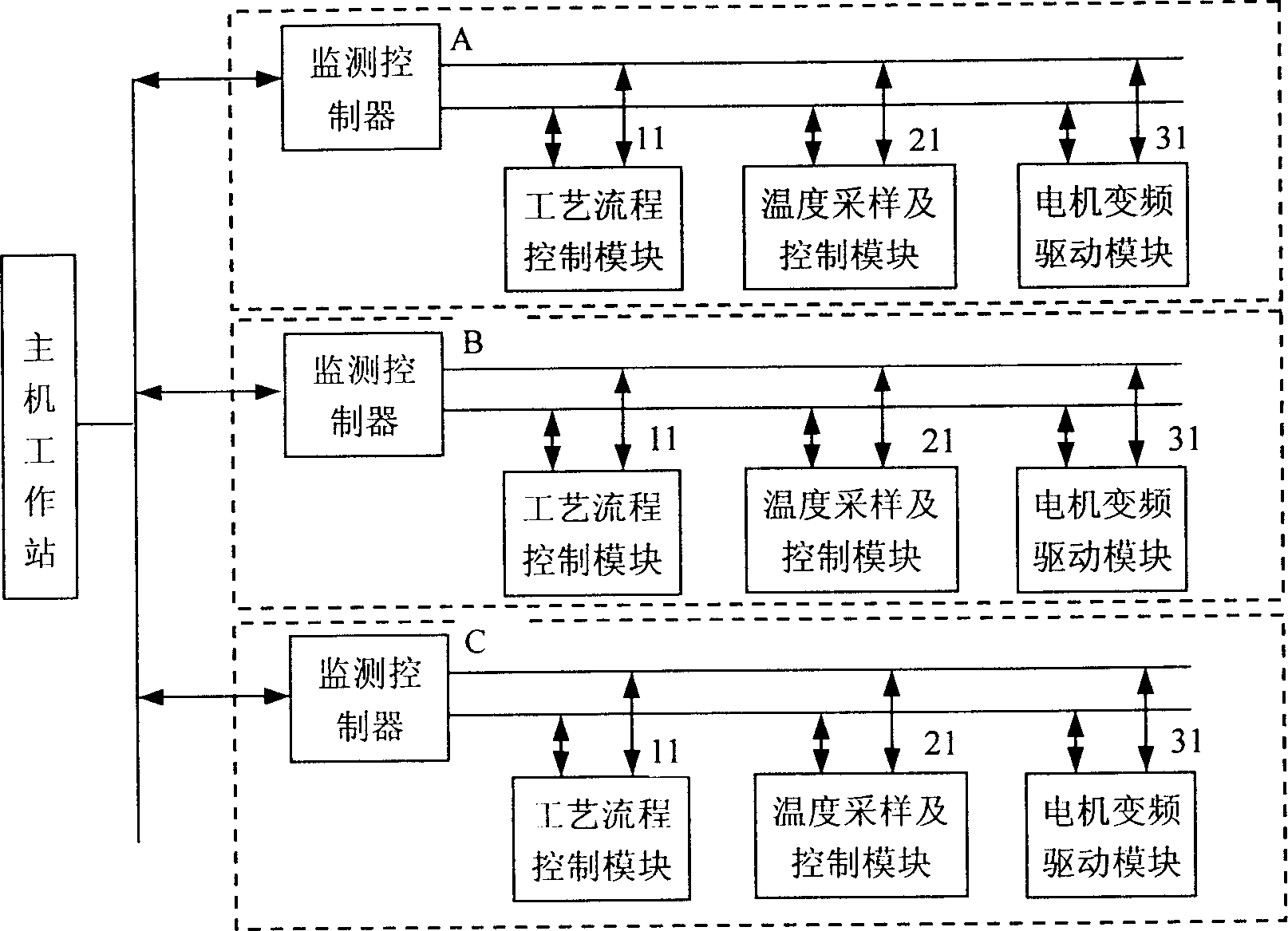

Energy saving control system of rubber injection shaping machine

An energy-saving control system and rubber injection technology, applied in the direction of jet flow program control, comprehensive factory control, comprehensive factory control, etc., to achieve the effect of on-site digital management, fast response of frequency conversion speed regulation, and remote control of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

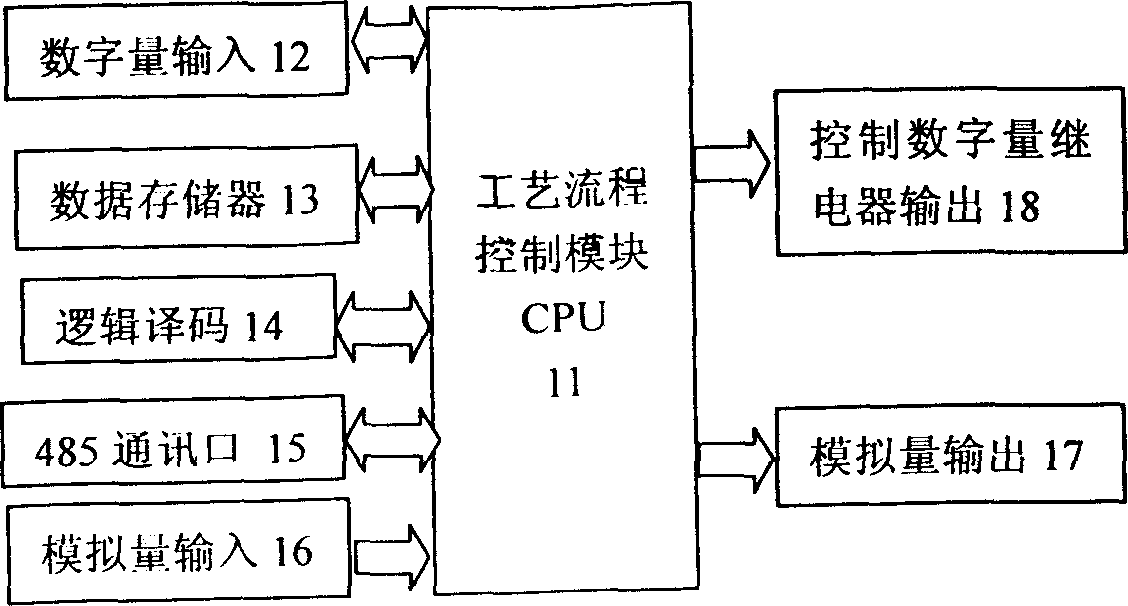

[0030] Monitoring controller (A, B, C...) structure, see figure 2 and image 3 The monitoring controller 1 is composed of reset circuit 2, data memory 3, logic decoding 4, 485 communication port 5, LCD display 6, network interface 7 and keyboard indicator light 8 respectively connected to its input terminal and output terminal.

[0031] Monitoring and control main chip circuit 1: CPU chip is INTER80196KC.

[0032] Reset circuit 2: The reset circuit mainly uses IMP809 and diode D20, which can reset the system under abnormal conditions, so as to ensure the normal operation of the system.

[0033] Data memory 3: use memory chip 27C512 to expand program space, and use chip 28C256 to expand mold parameter storage space.

[0034] Logic decoding 4: use the chip GAL16V8 of LT Company for logic decoding, and select each chip to work.

[0035] 485 communication port 5: The interface uses chip 75LBC184, resistors R51, R52, R53, R54, R55, R56, R57, capacitors C51, C52 to form a standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com