Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about "Attachable planing devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

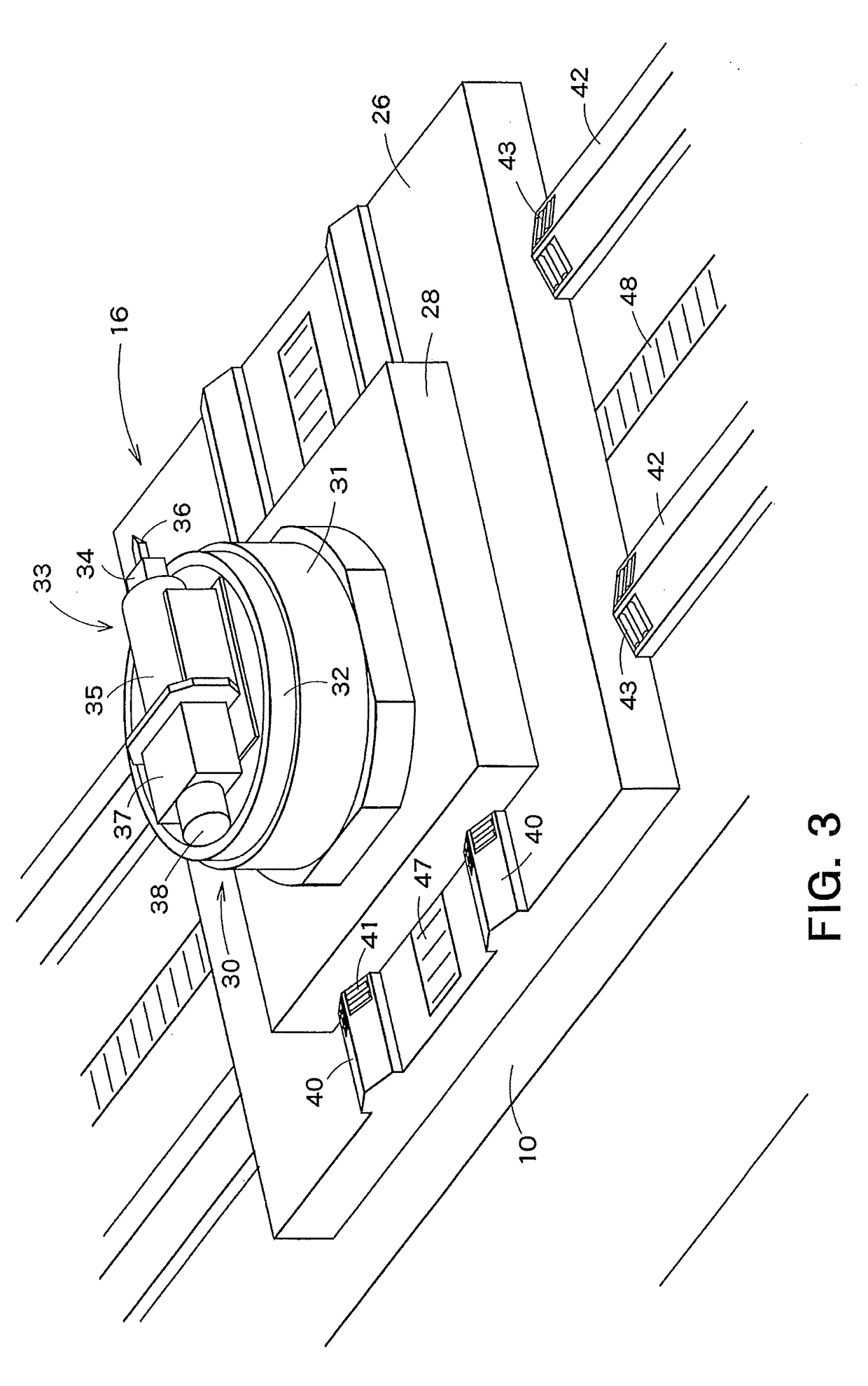

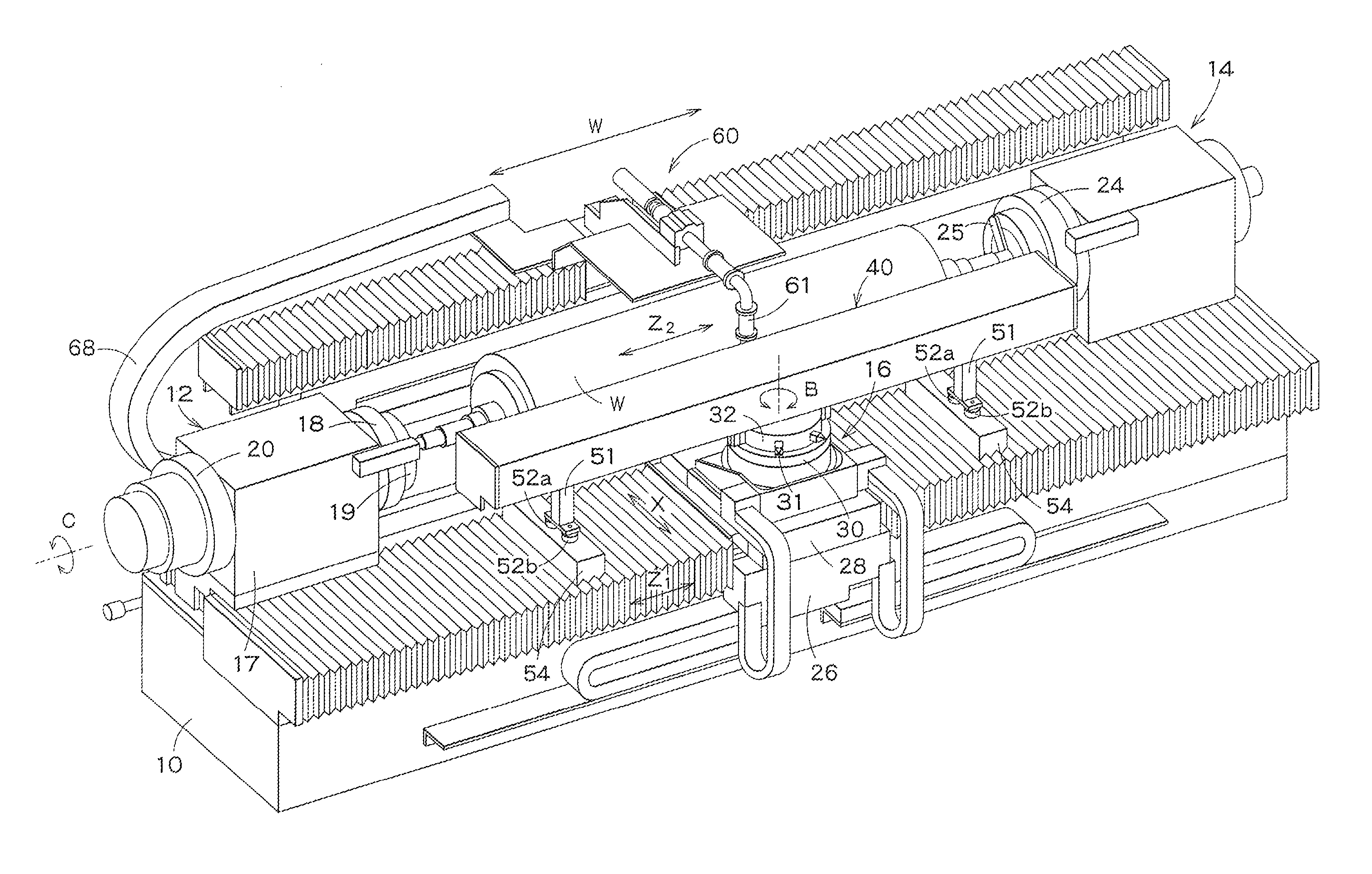

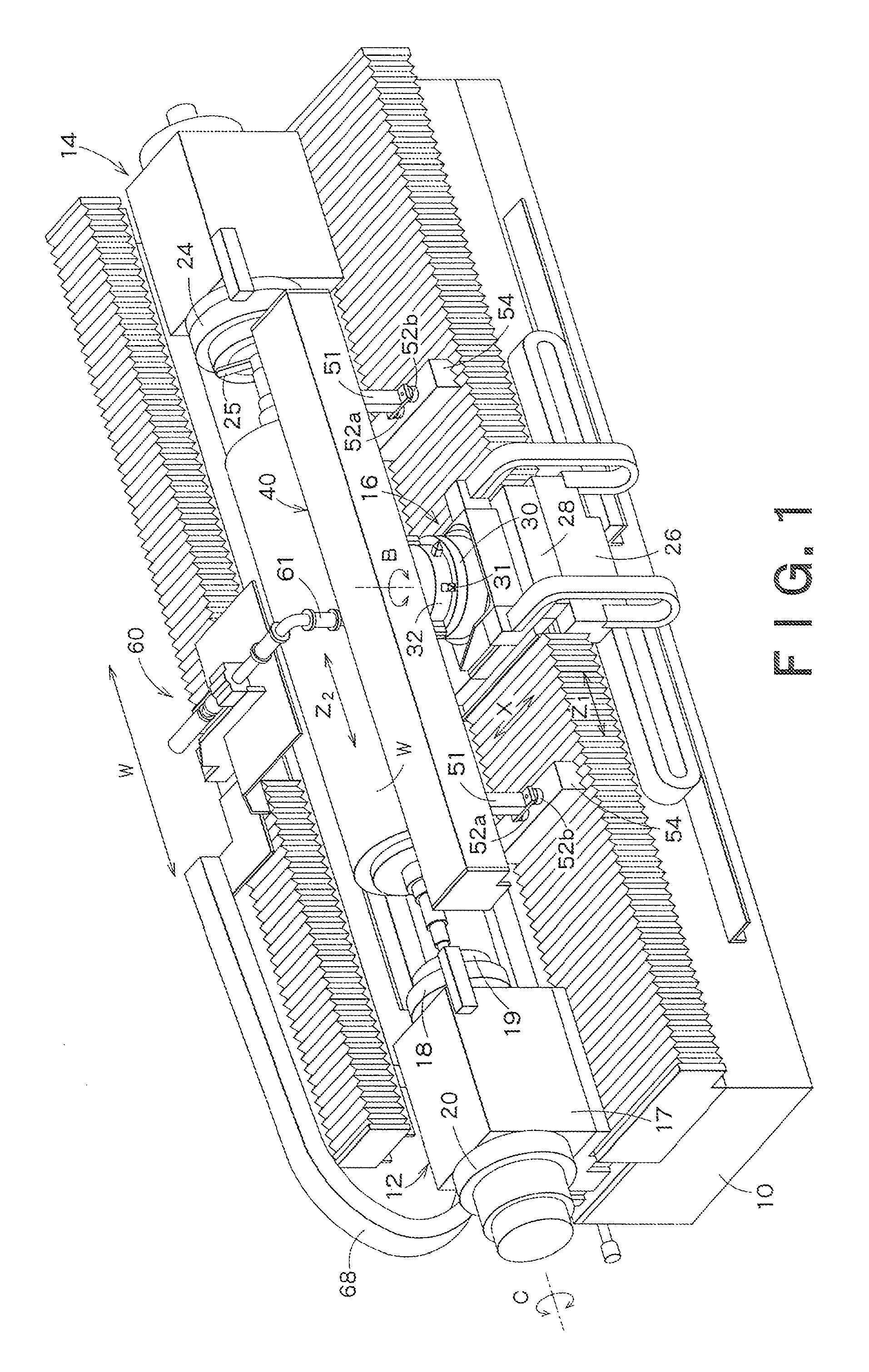

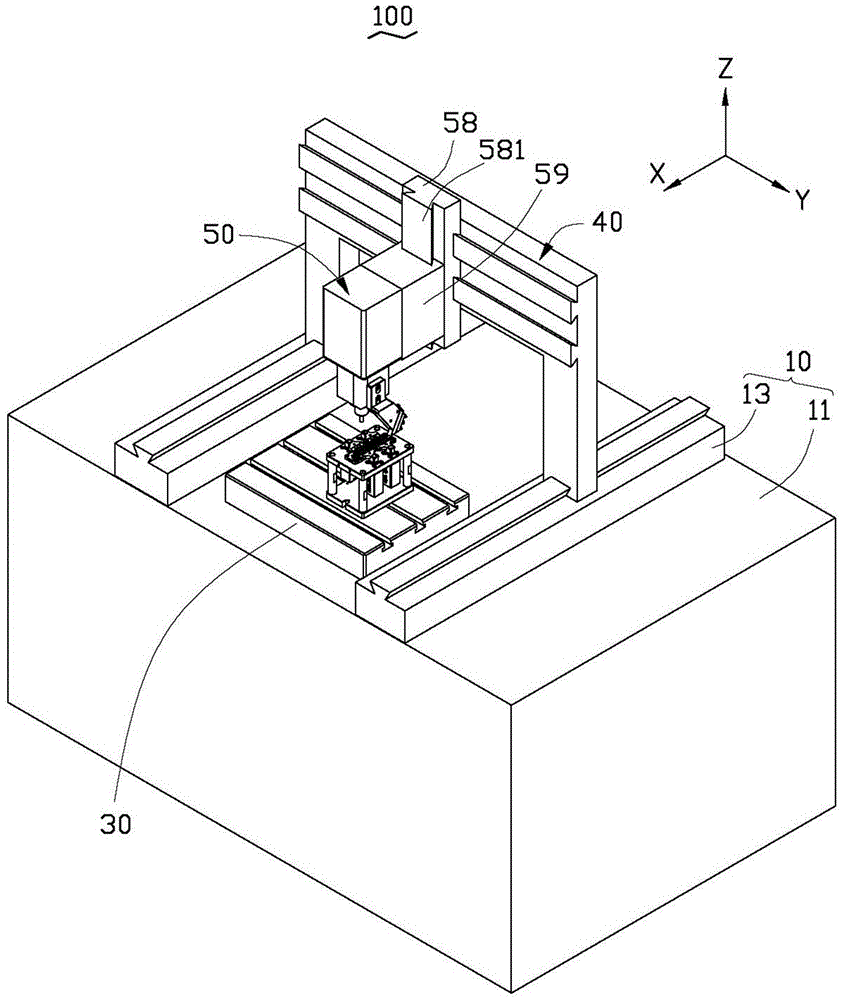

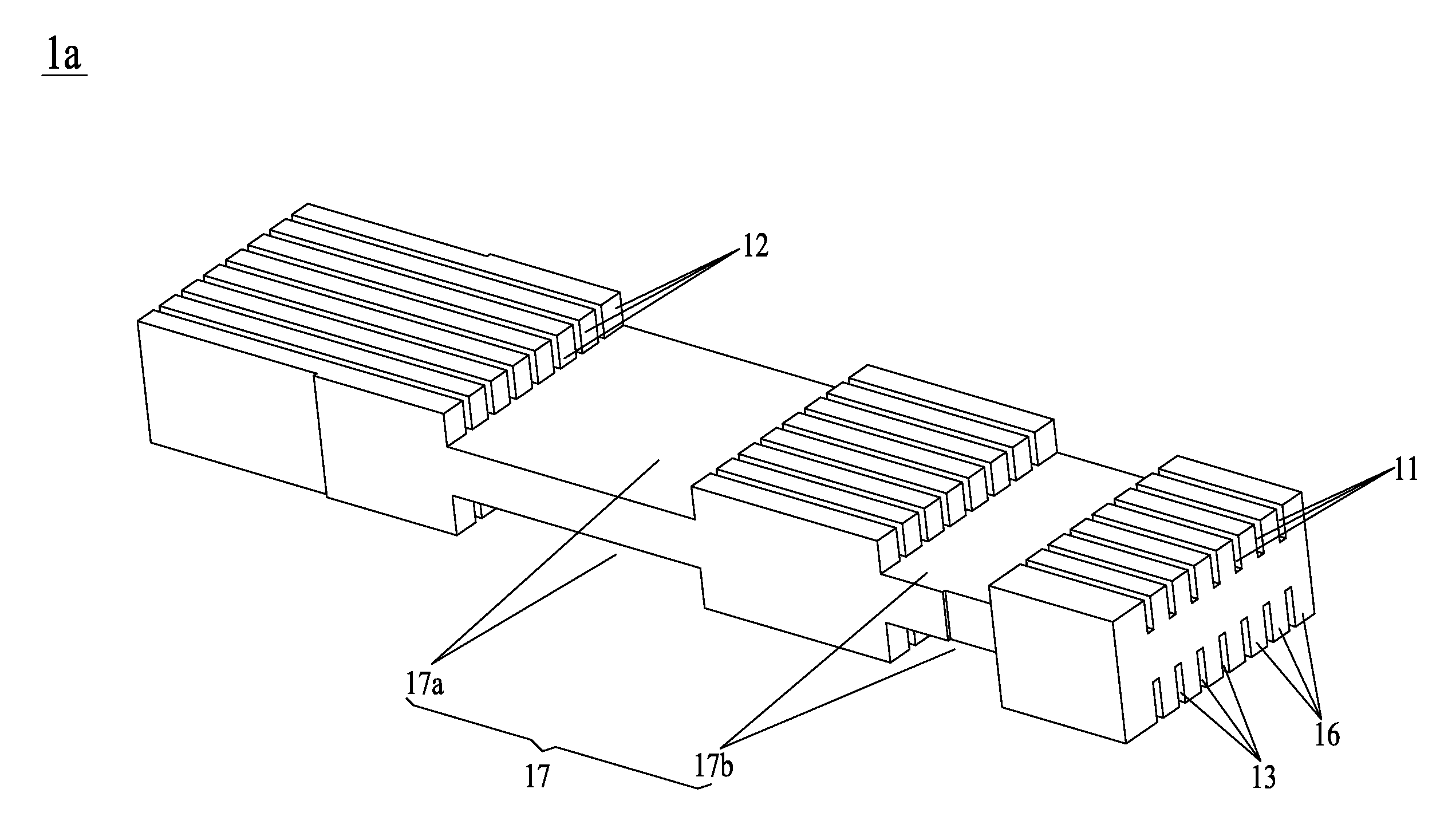

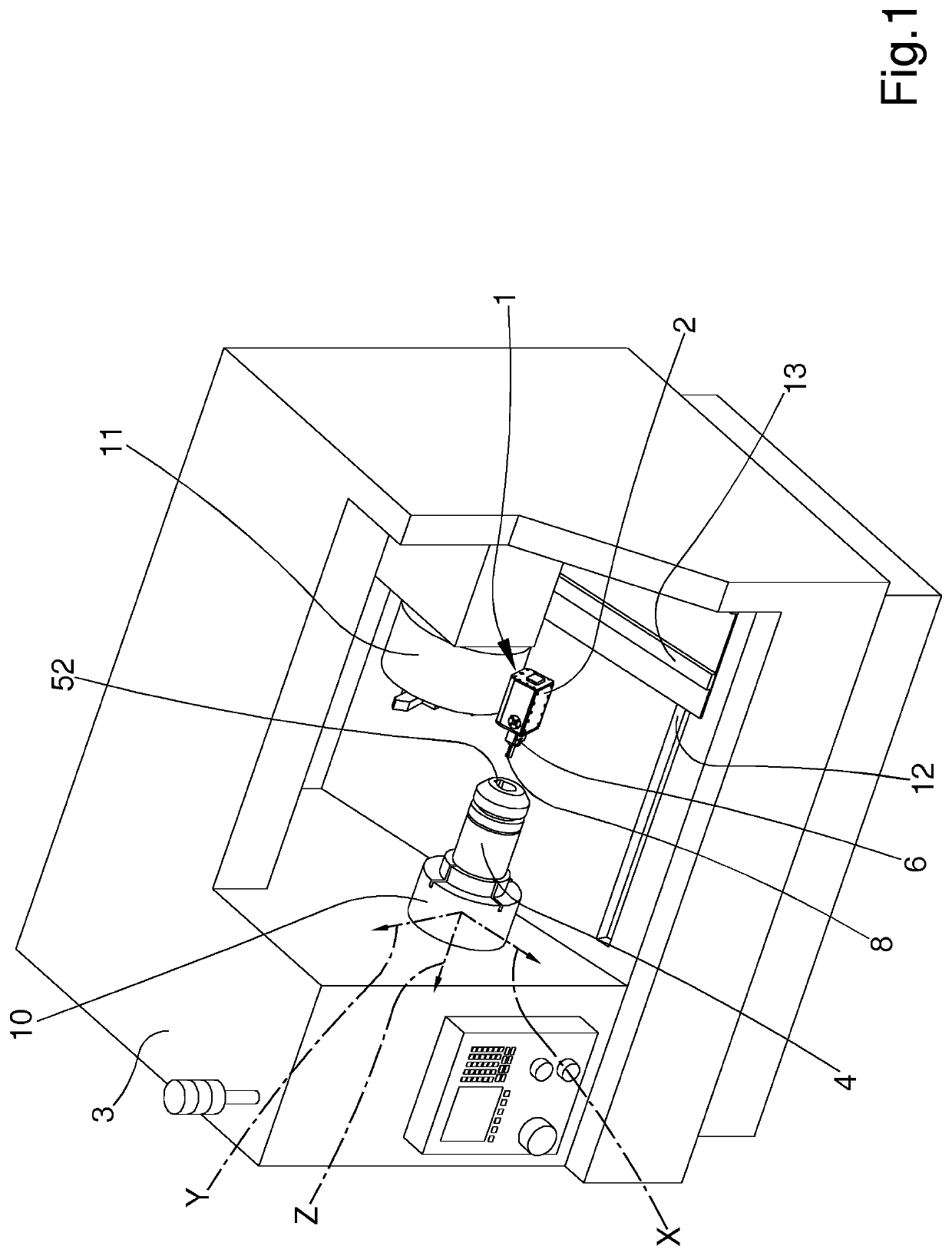

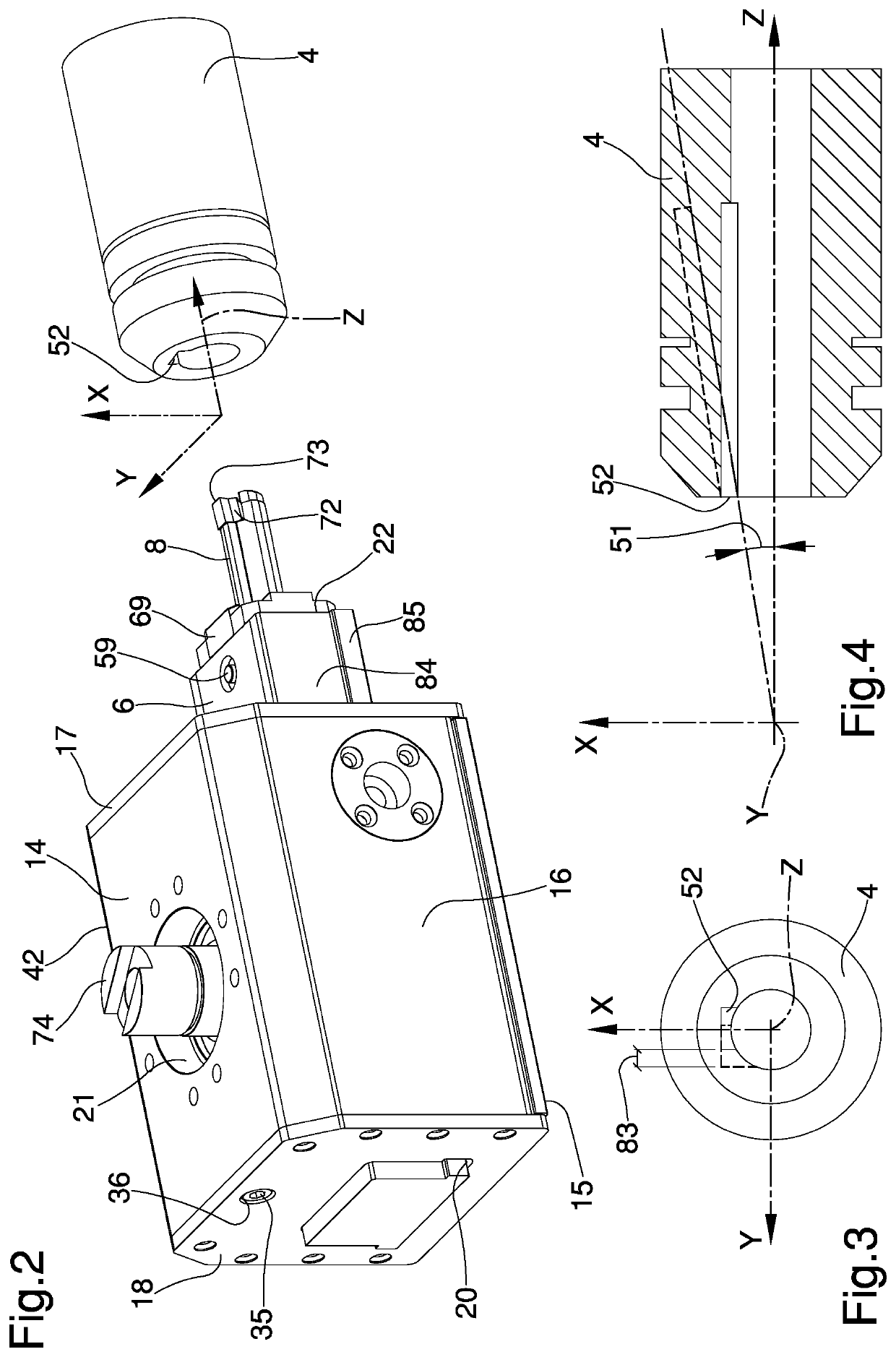

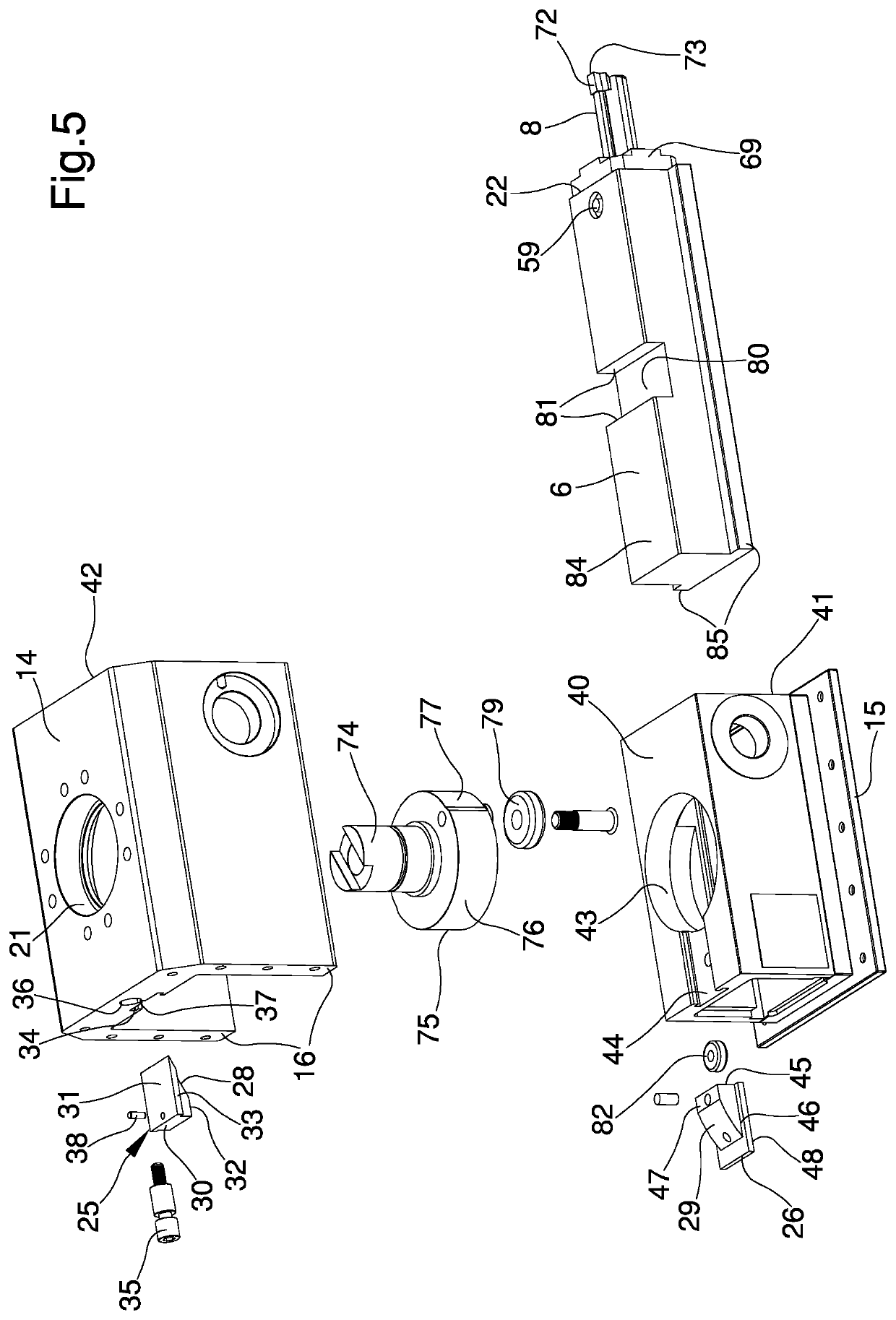

Machine tool with lathe tool and scraping cutter

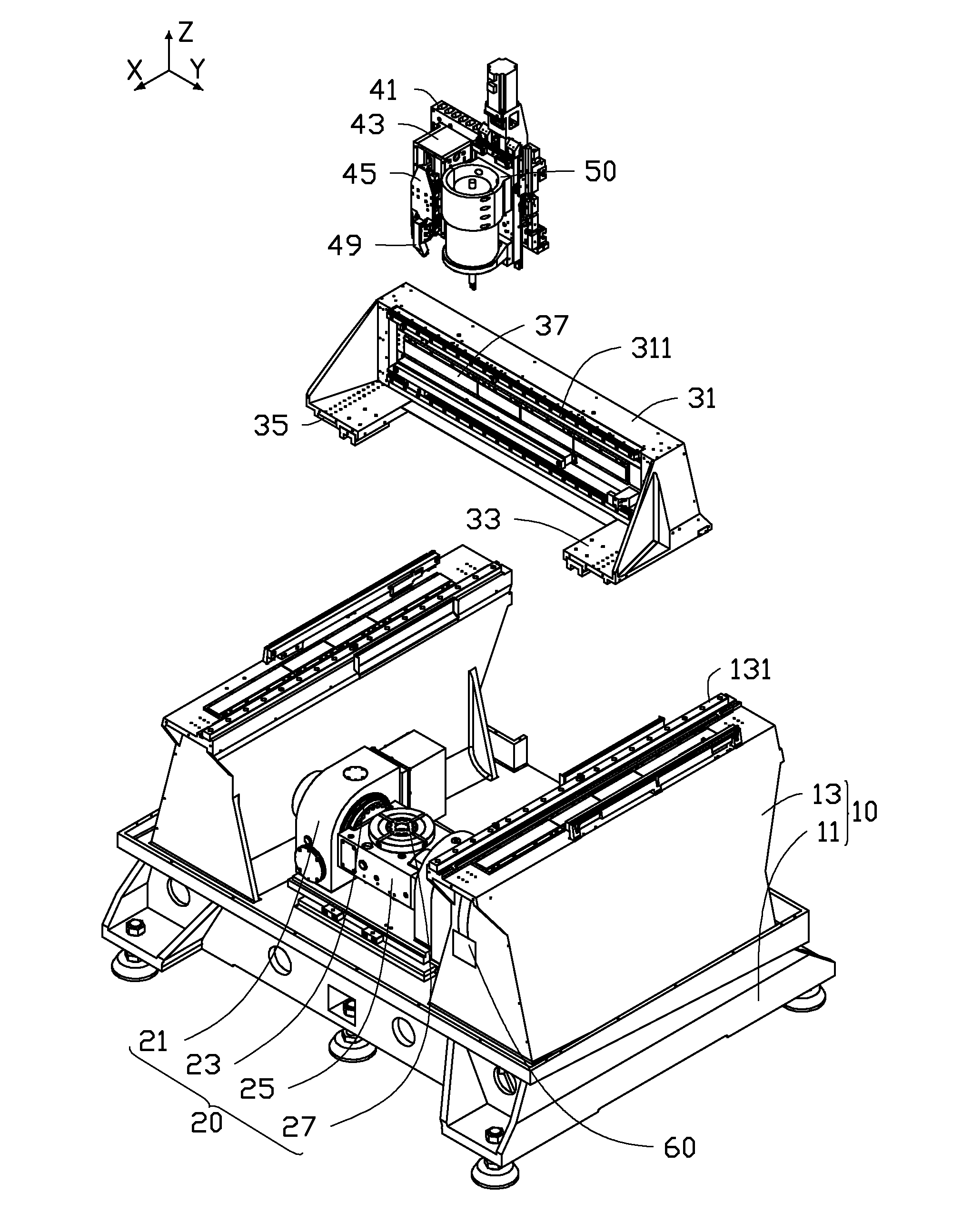

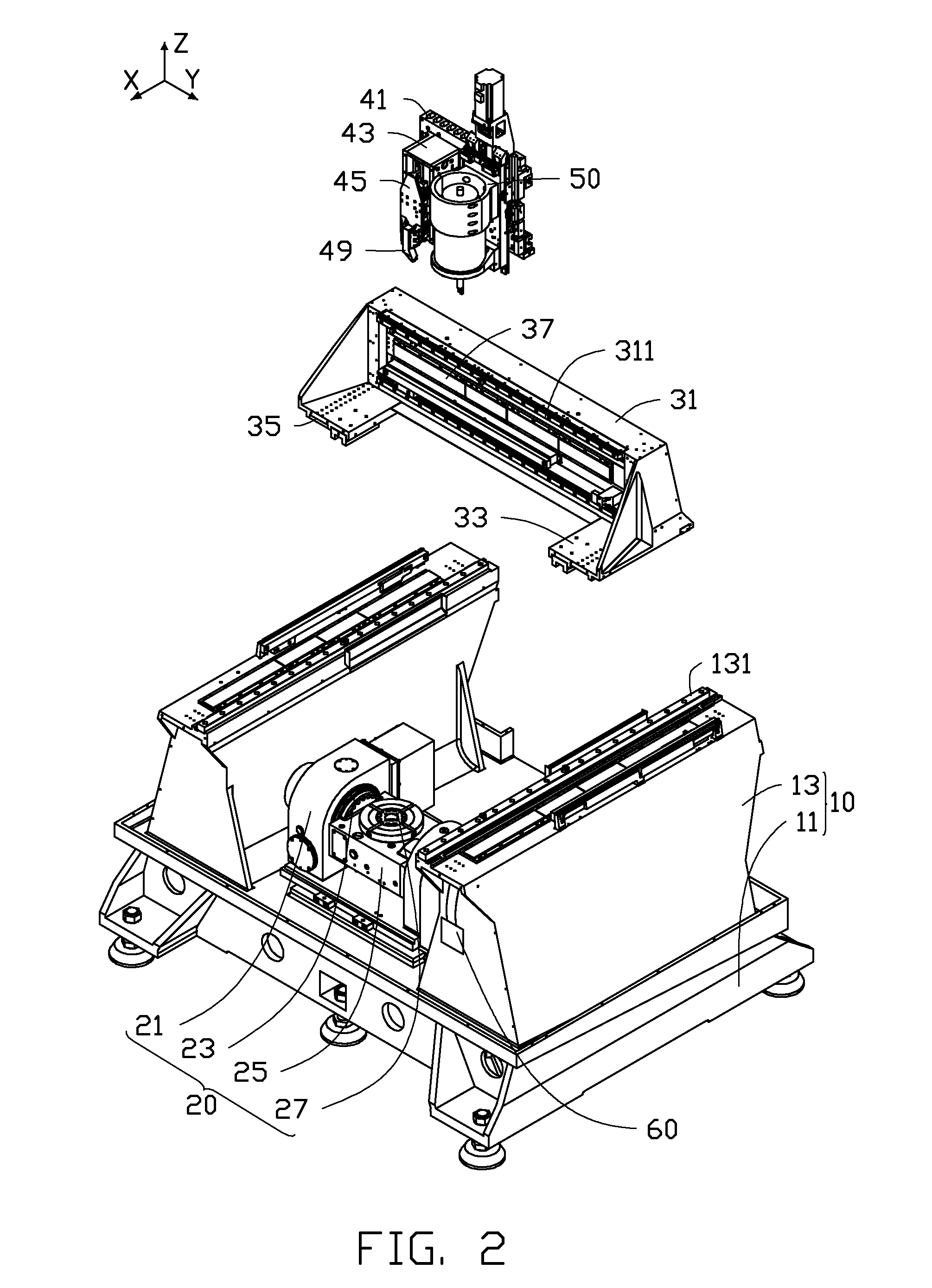

A machine tool with lathe tool and scraping cutter includes a machine support, a worktable, a moving device, a lathe feeding mechanism and a scraping feeding mechanism. The worktable is positioned on the machine support. The moving device is slidably assembled to the machine support along a first direction and located above the worktable. The lathe feeding mechanism and the scraping feeding mechanism are slidably assembled to the moving device along a second direction perpendicular to the first direction, the lathe feeding mechanism includes a feeding assembly and a lathe tool connected to the feeding assembly, the feeding assembly is configured for driving the lathe tool to move along a third direction substantially perpendicular to the first and second direction reciprocally, the scraping feeding mechanism includes a scraping cutter and is configured for driving the scraping cutter to move along the third direction.

Owner:FU DING ELECTRONICSAL TECH JIASHAN +1

Method for processing profiled core prints

InactiveCN101579699AHigh positioning accuracyHigh dimensional accuracyExtrusion diesAttachable planing devicesNumerical controlEngineering

The embodiment of the invention discloses a method for processing profiled core prints, which comprises the following steps of: selecting die steel for blanking according to the diameter of a die; roughly lathing the excircle and thickness of the die according to the paper size; if the blank amount of the core print and the diffluent hole is larger than the blank set amount, marking off the shape and position of the diffluent hole and the core print of a top die by a marker, roughly machining by a plain-milling machine, conducting transverse alignment according to the excircle, semifinishing core print working tape by a numerical control milling machine, and processing the root of the core print and the diffluent hole according to the paper size; otherwise, conducting transverse alignment according to the excircle to directly process the core print working tape, and processing the root of the core print and the diffluent hole according to the paper size; carrying out heat treatment on the die, plainly grinding the upper plane and lower plane of the die, and conducting finish turning on the excircle of the core print according to the paper size; conducting transverse alignment according to the excircle, and conducting finish machining on the core print working tape by the numerical control milling machine according to the paper size; grinding and polishing the core print and assembling with a lower die and die cushion. The invention improves the processing quality of the core print, reduces the cost and shortens the processing time.

Owner:SOUTHWEST ALUMINUM GRP

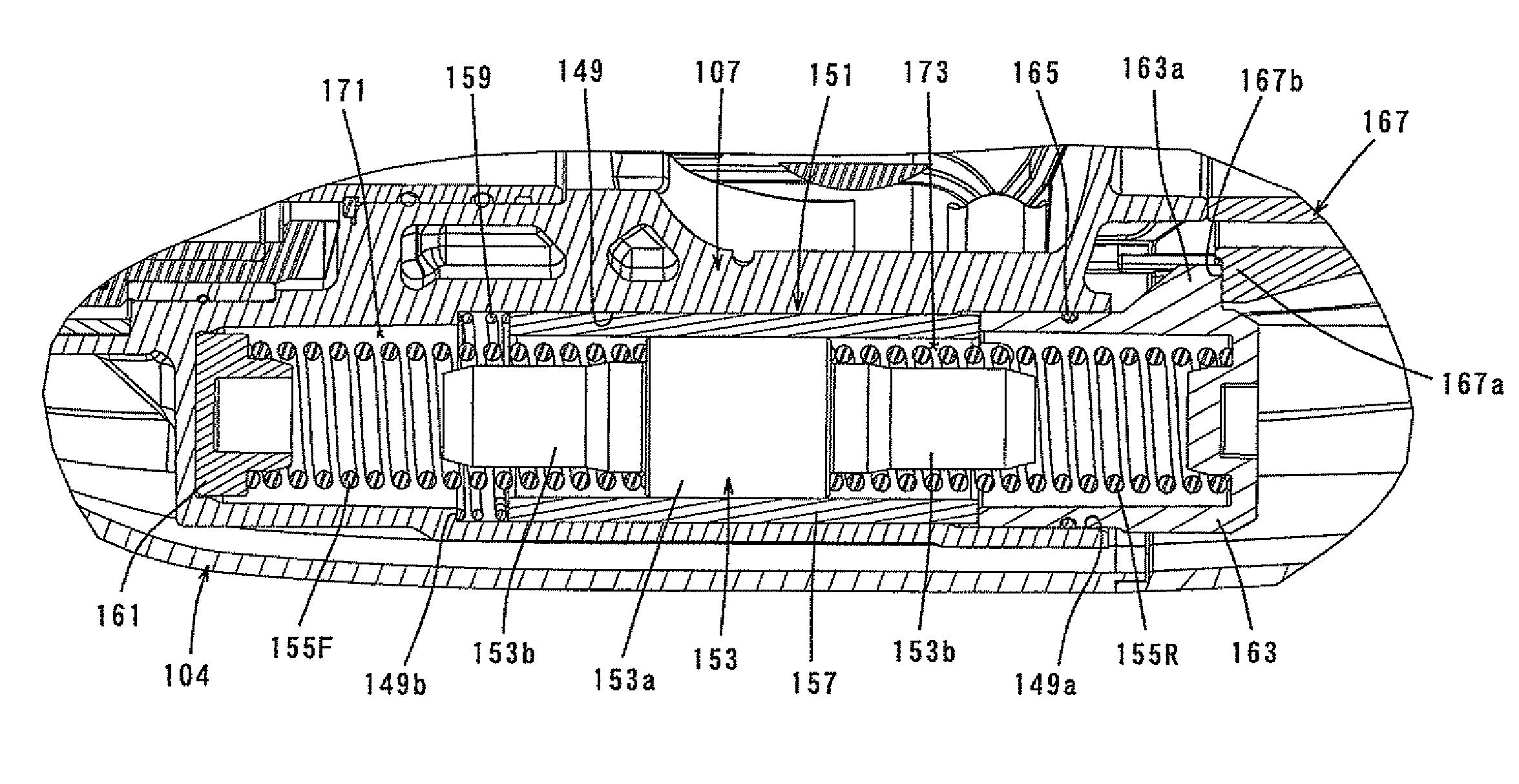

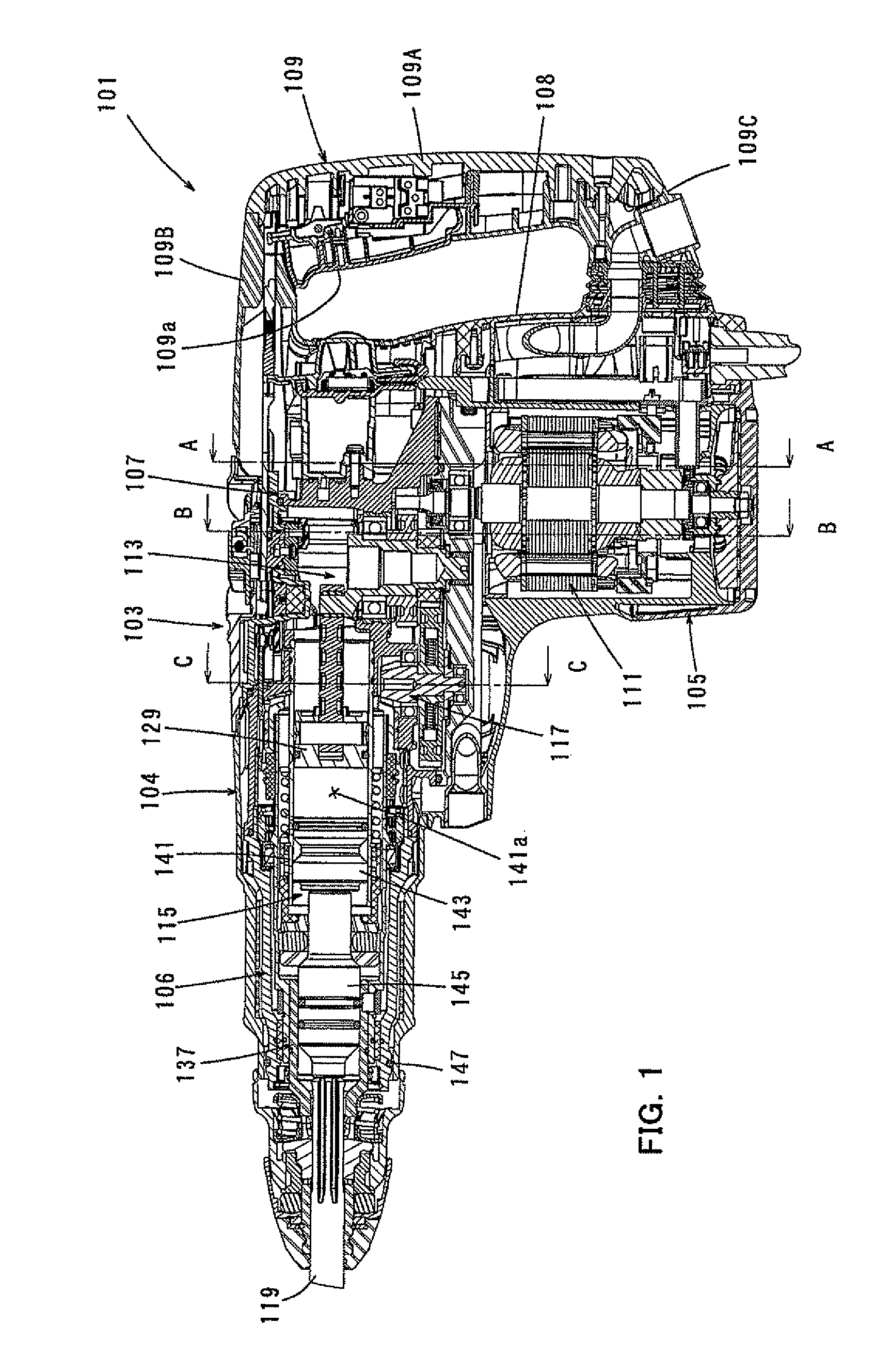

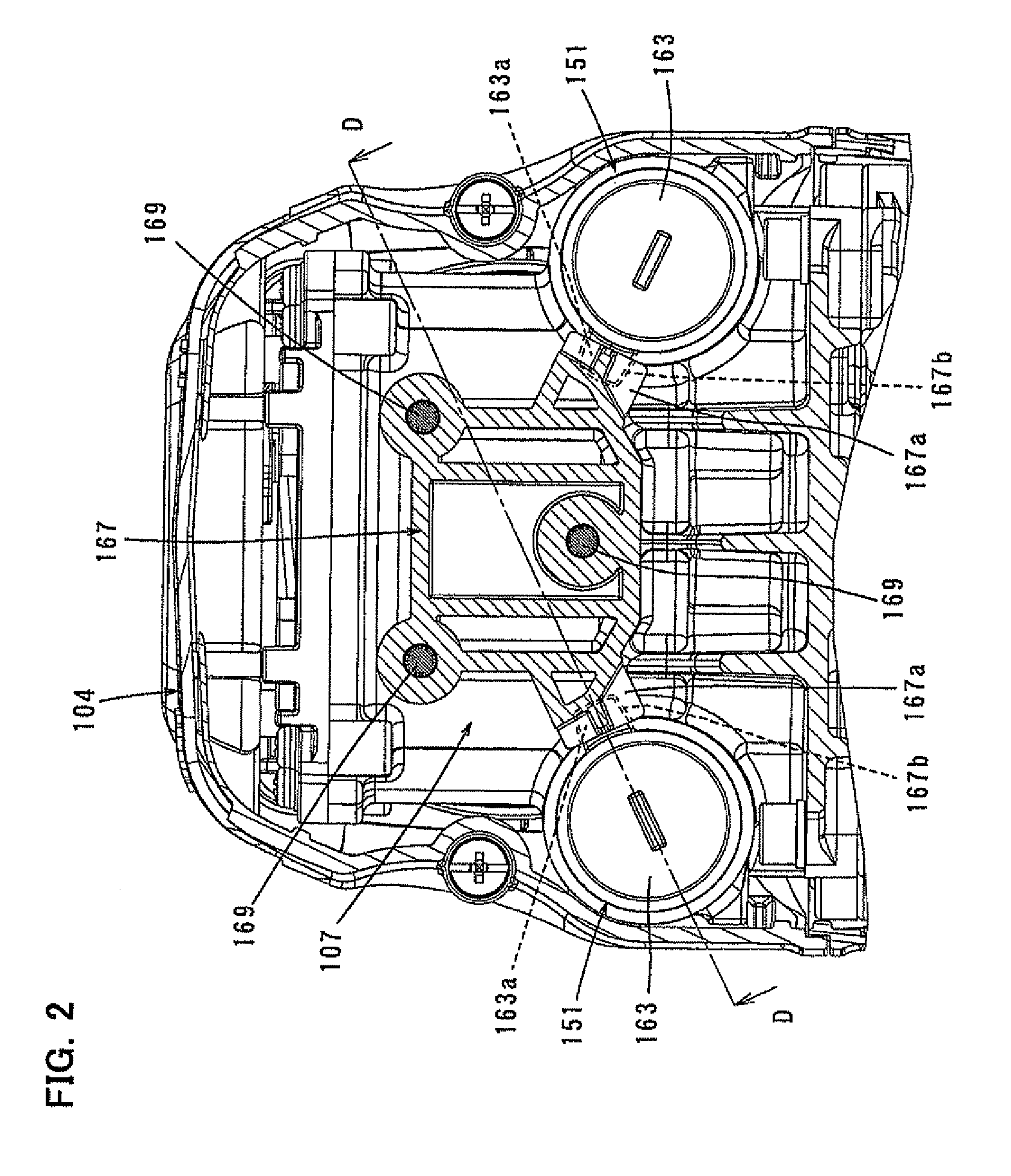

Power tool

ActiveUS8844647B2Reduce stepsReduce the number of partsDrilling rodsConstructionsLinear motionReducer

A representative power tool according to the invention performs a predetermined operation on a workpiece at least by axial linear movement of a tool bit 119 coupled to a front end region of a housing 103. The power tool includes driving mechanisms 113, 115 that are housed within the housing 103 and linearly drives the tool bit 119, and a dynamic vibration reducer 151 that has a weight 153 which is allowed to linearly move under a biasing force of an elastic element, and reduces vibration caused during operation, by movement of the weight 153 in the axial direction of the tool bit. A dynamic vibration reducer housing space 149 for housing the weight 153 and the elastic element of the dynamic vibration reducer 151 is integrally formed with the housing 103.

Owner:MAKITA CORP

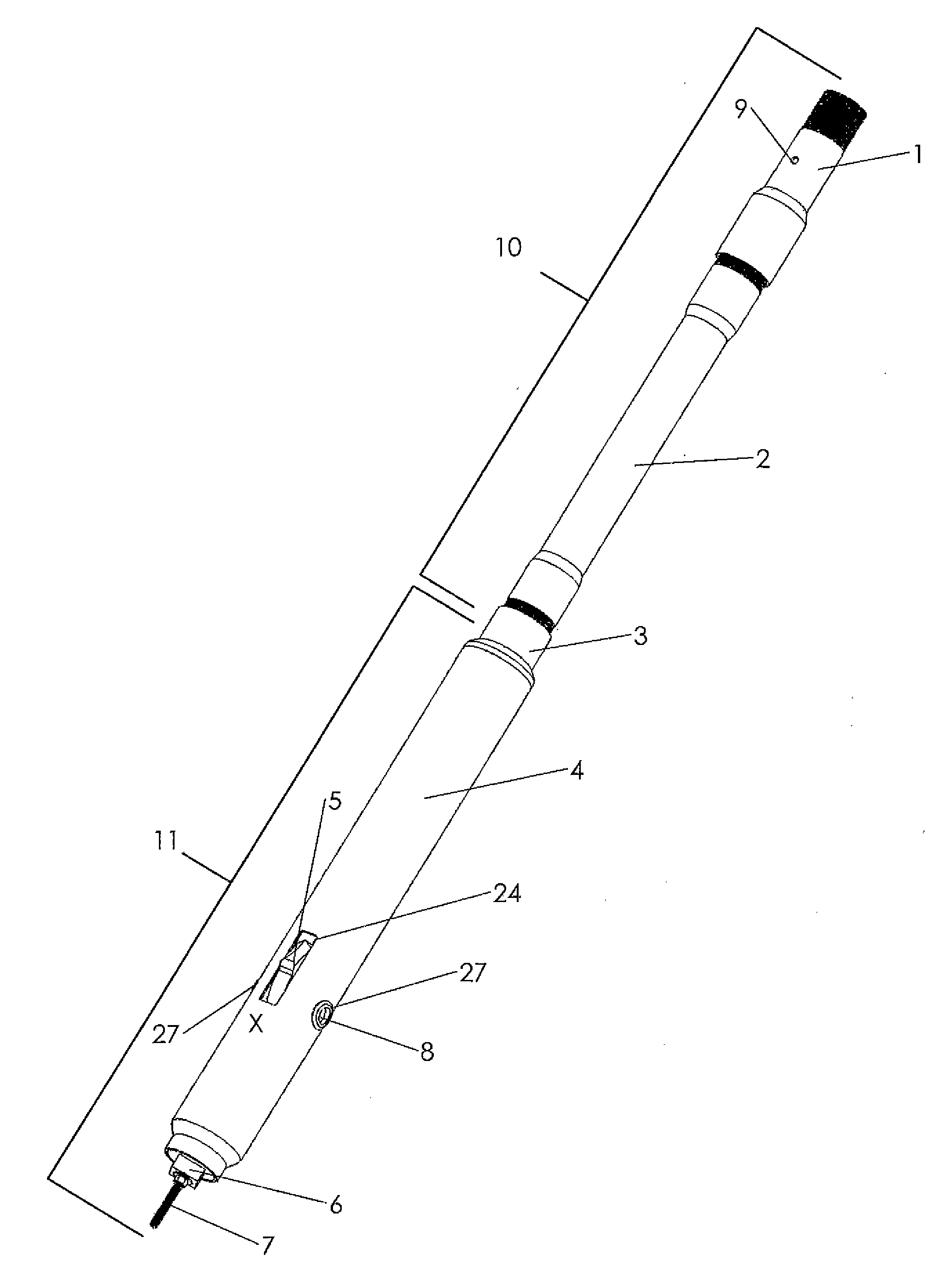

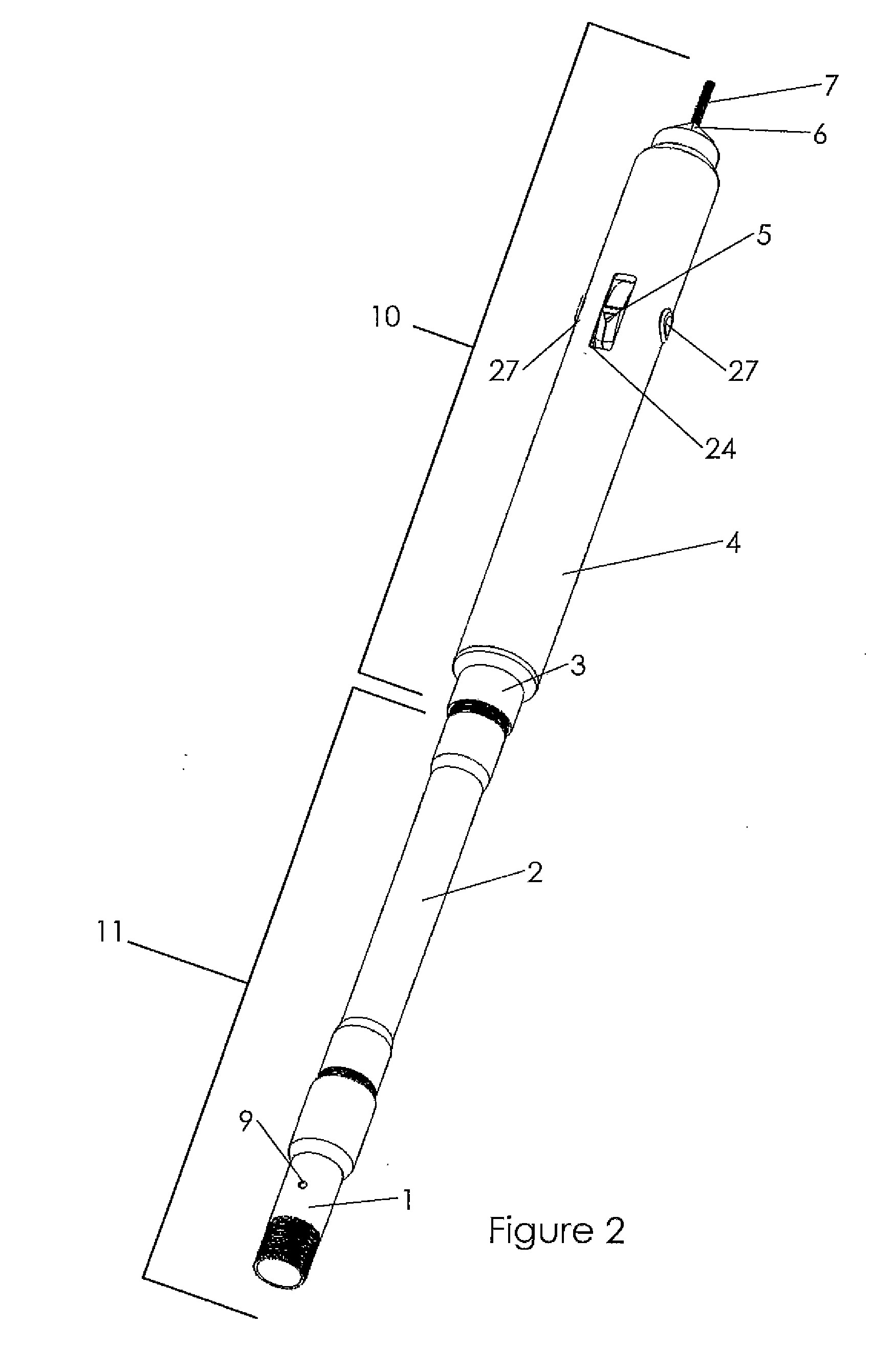

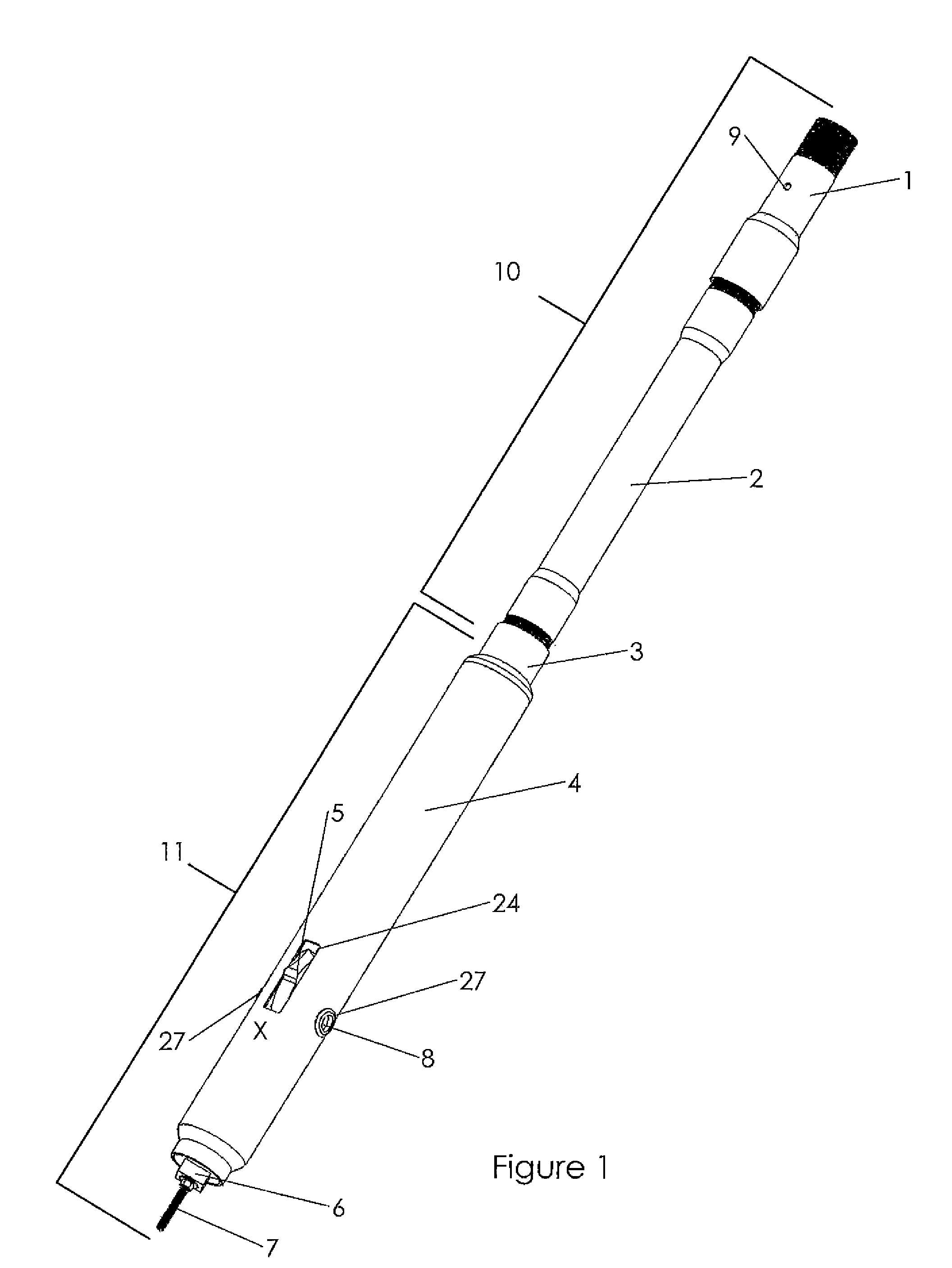

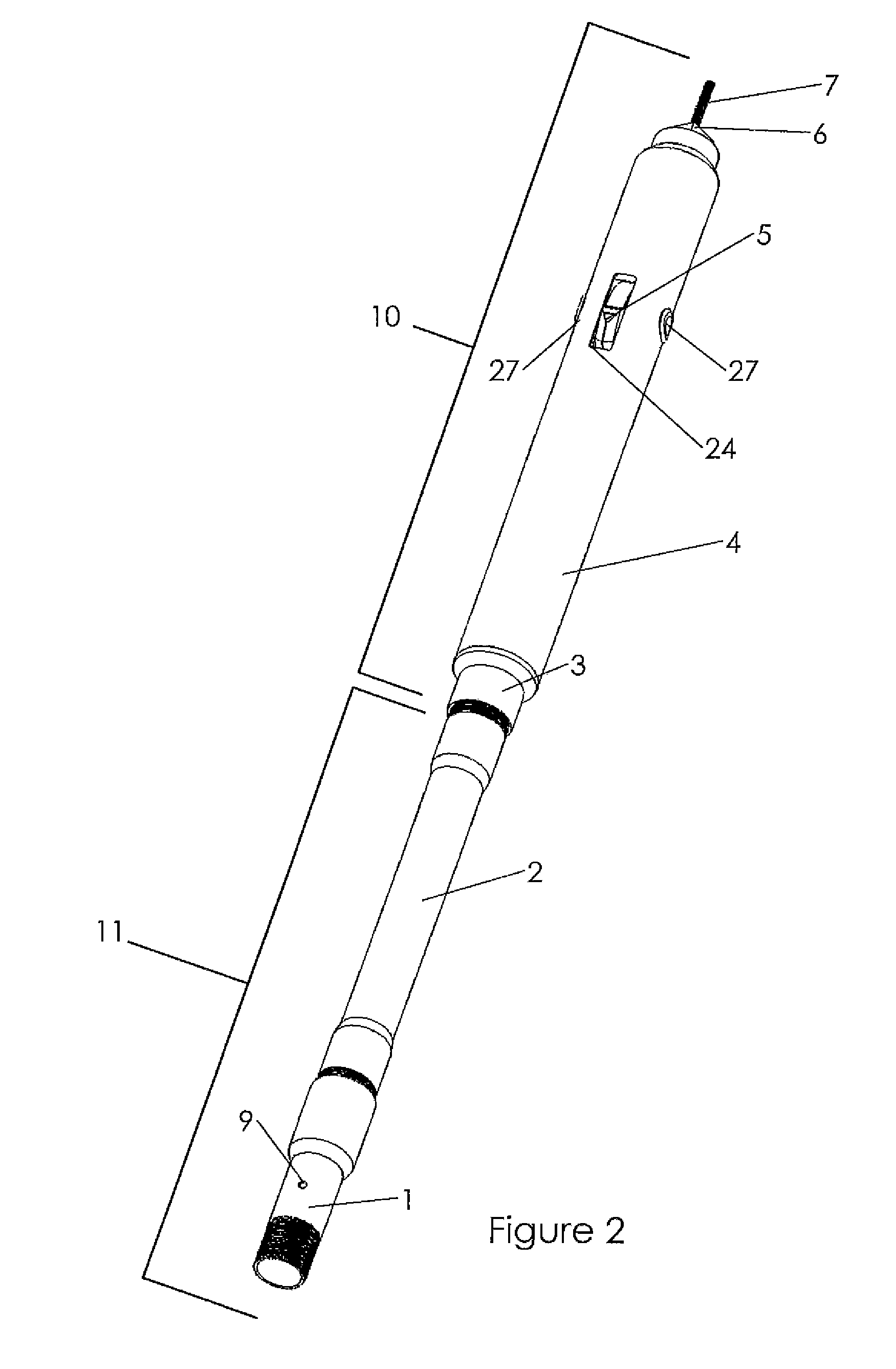

Production casing ripper

Owner:LIQUID GOLD WELL SERVICE

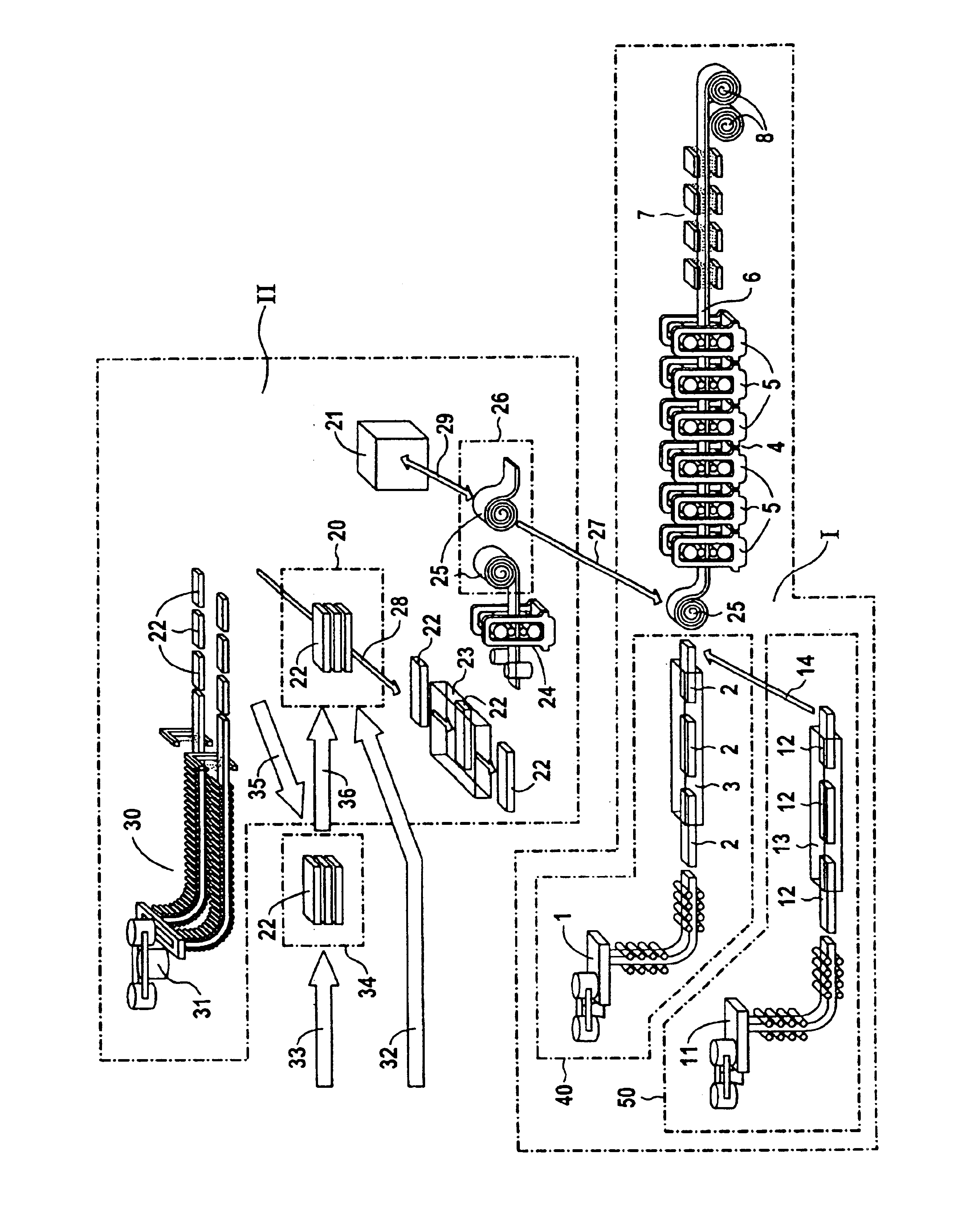

Method for operating a casting-rolling plant

InactiveUS6941636B2Improve throughputMetal rolling stand detailsAttachable planing devicesProduction lineRolling mill

A casting-rolling plant and a method of operating a casting-rolling plant are disclosed. At least one slab production line (40, 50) and at least one mill train (4) as well as at least one slab feeding device (20) that is independent of the slab production line (40, 50) with respect to the production process are provided. In order to achieve a higher throughput in the production of strip material, the slab feeding device (20) takes over slab feed to the mill train (4) during a production break of the slab production line (40, 50) in accordance with logistic and / or manufacturing standards up to a maximum output possible.

Owner:PRIMETALS TECH GERMANY

Production casing ripper

A production casing ripper comprising a swedge; spring housing; coupling; main housing; end piece; blade; and means for connecting the blade to the plunger; wherein the blade is situated inside of the main housing; wherein a plunger is situated inside of the main housing; wherein a primary spring is situated inside of the spring housing; wherein a primary pull rod is connected to the primary spring at one end and to the plunger at the other end; wherein when hydraulic pressure is introduced through the swedge, the plunger moves downward inside of the main housing and causes the blade to extend through an aperture in the main housing; and wherein when the hydraulic pressure is released, the primary spring causes the plunger to return to its original position, thereby causing the blade to retract.

Owner:LIQUID GOLD WELL SERVICE

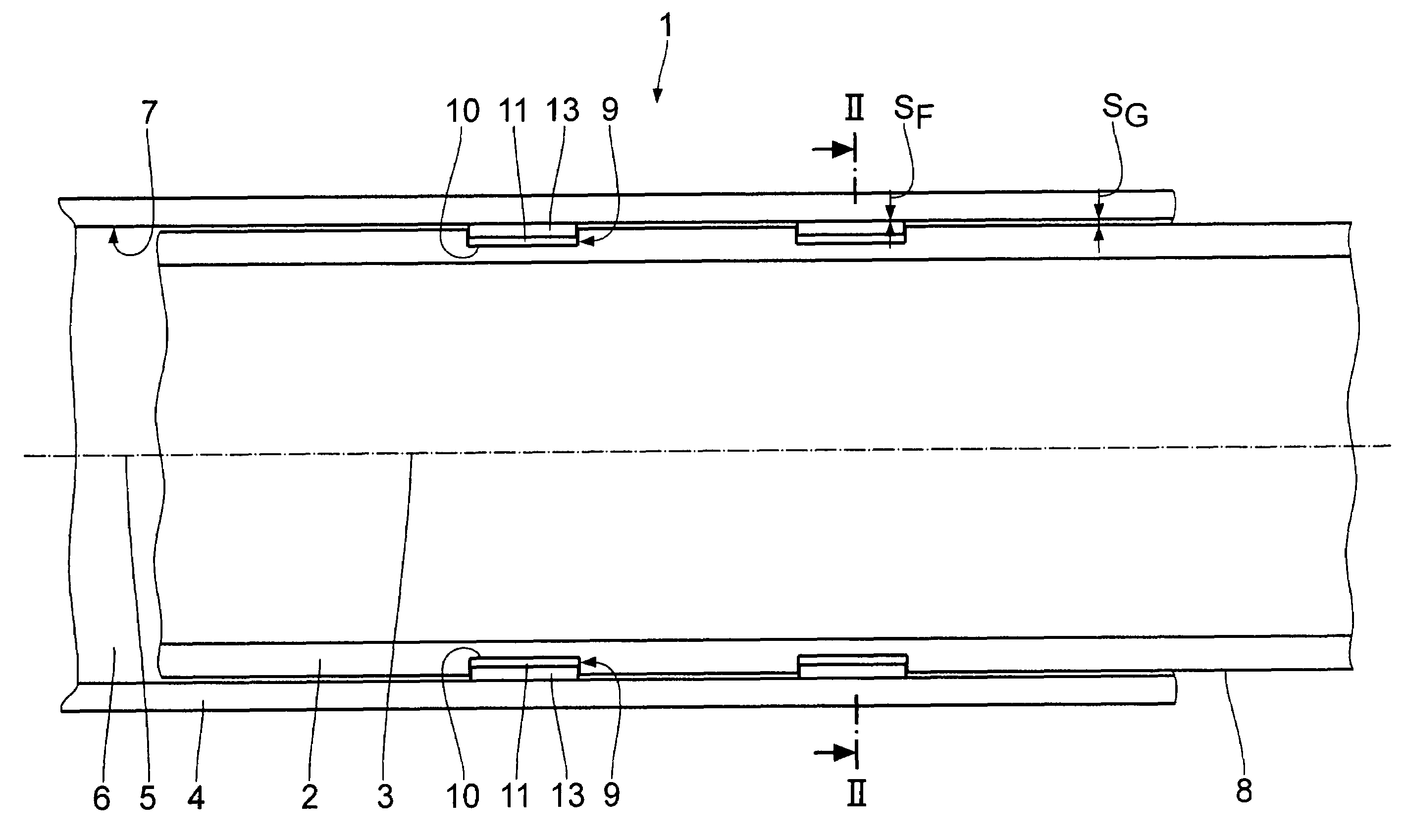

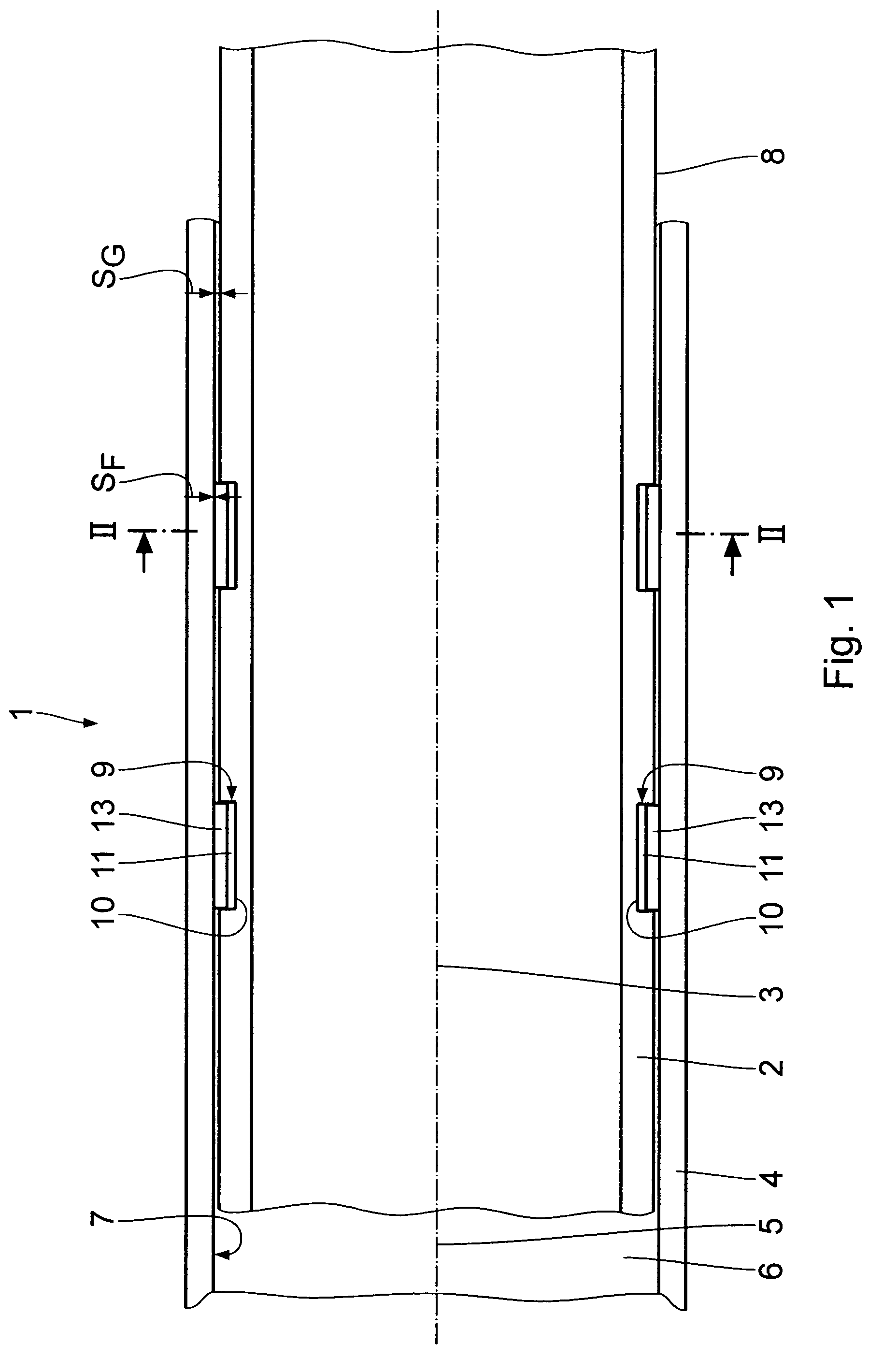

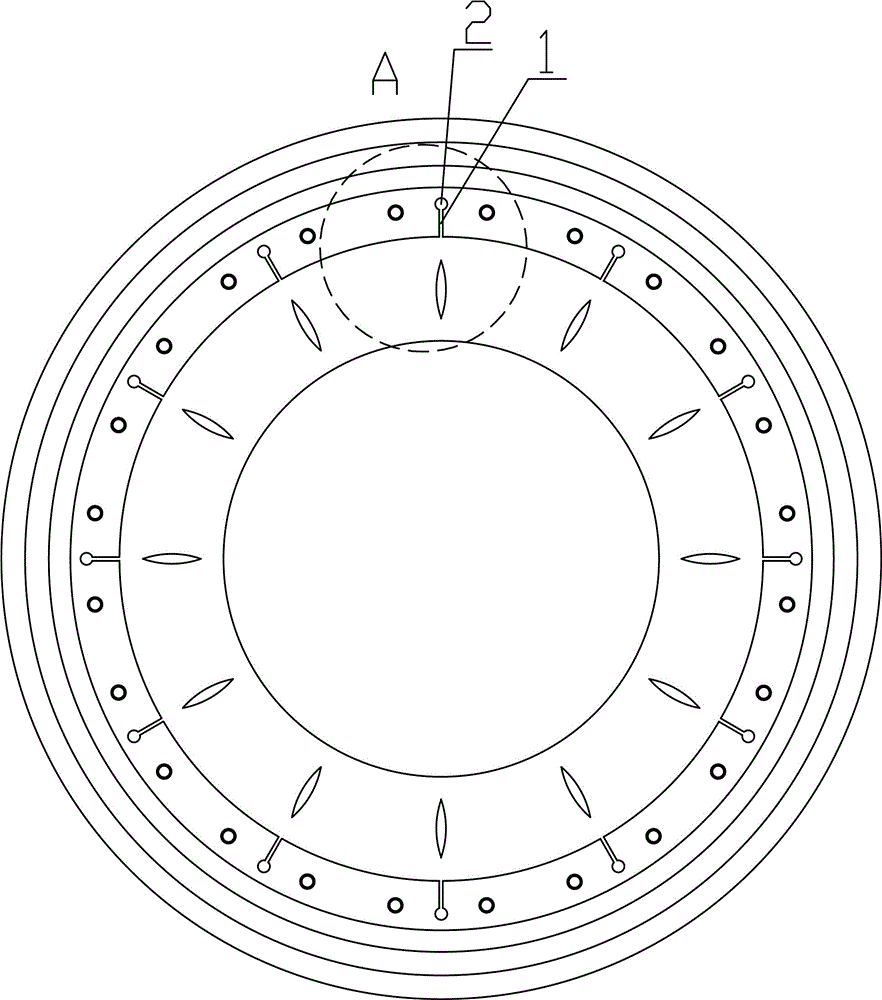

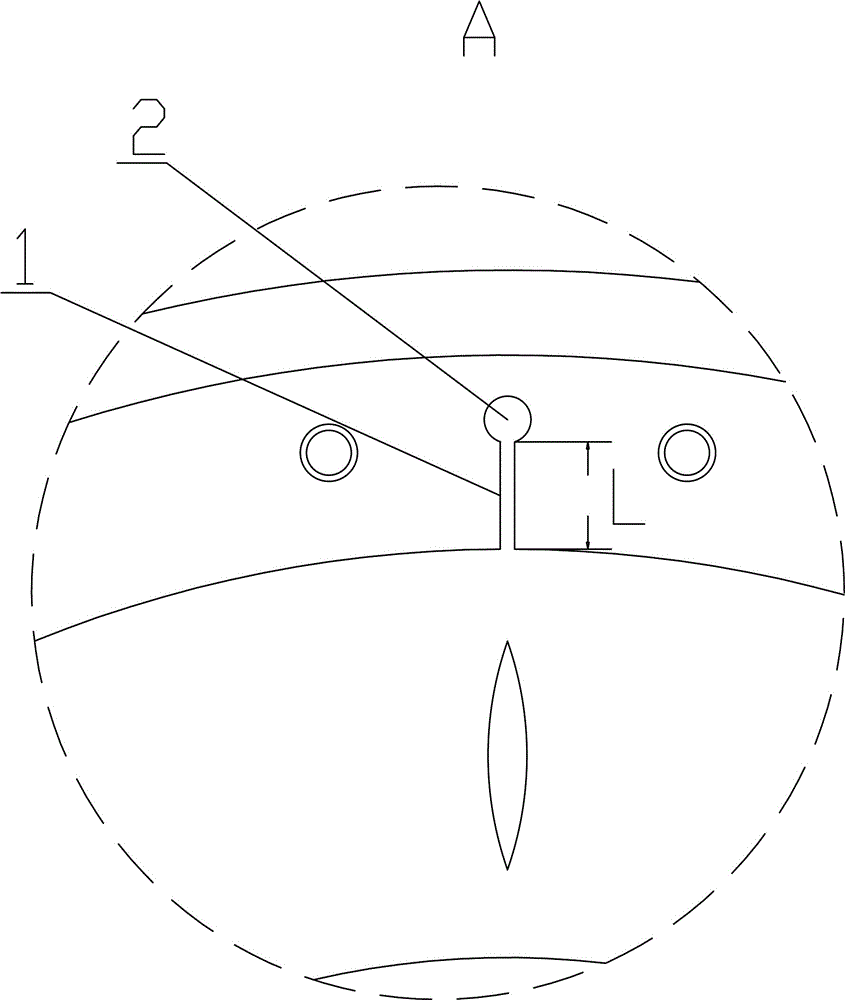

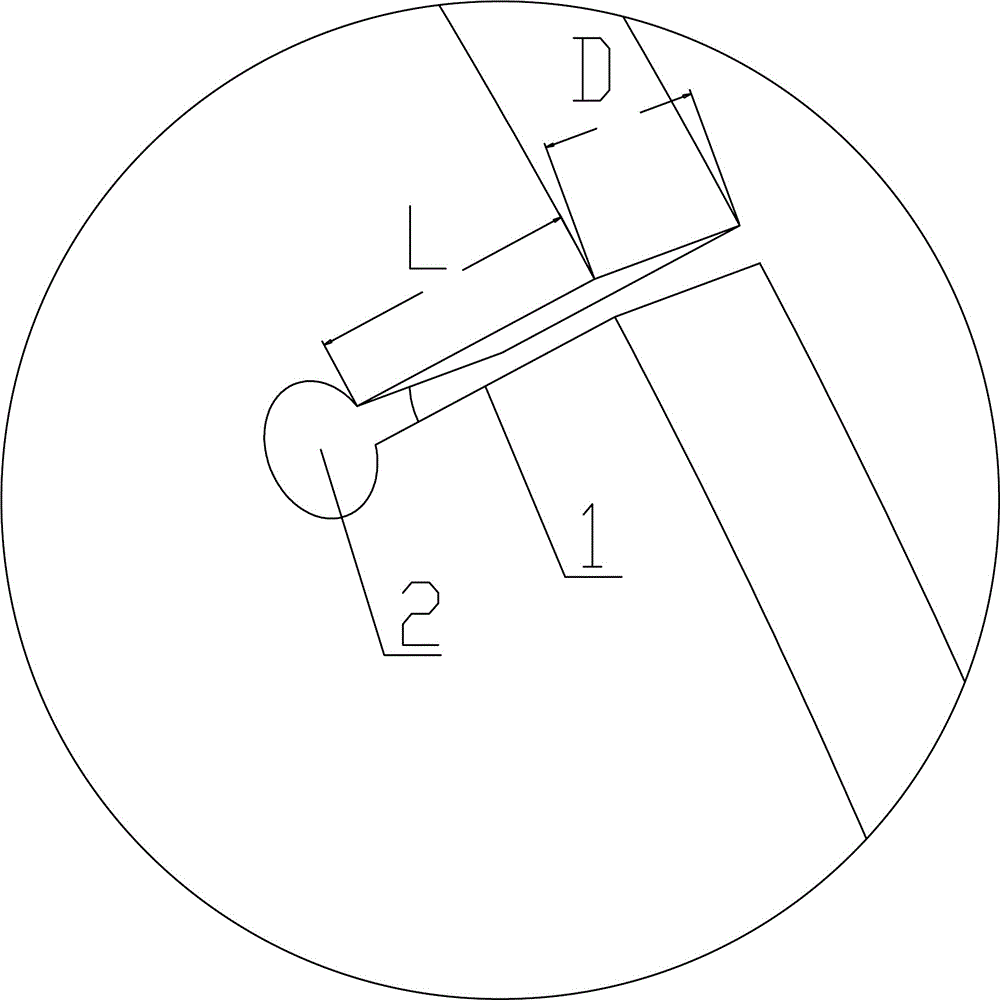

Sliding bearing and method for the manufacture thereof

InactiveUS7497014B2Low costRotary bearingsAttachable planing devicesEngineeringMechanical engineering

A sliding bearing for axial and / or radial arrangement of a first bearing member in relation to a second bearing member, comprises a second bearing member, which has a bearing recess provided with a second slide face; a first bearing member, which is lodged in the bearing recess and which is mounted axially and / or radially, the first bearing member having a first slide face, which is opposite the second slide face and spaced therefrom by a clearance; at least one sliding / guiding element, which is disposed between the first and the second bearing members and fixed in relation to one bearing member, for guidance of a motion of the first relative to the second bearing member; an equalizing compound, which is disposed between the at least one sliding / guiding element and the bearing member relative to which is fixed the at least one sliding / guiding element, for adaptation of the guide clearance between the at least one sliding / guiding element and the slide face that is displaceable in relation thereto, the equalizing compound being solid in the operating state of the sliding bearing and free-flowing prior thereto.

Owner:SUSPA

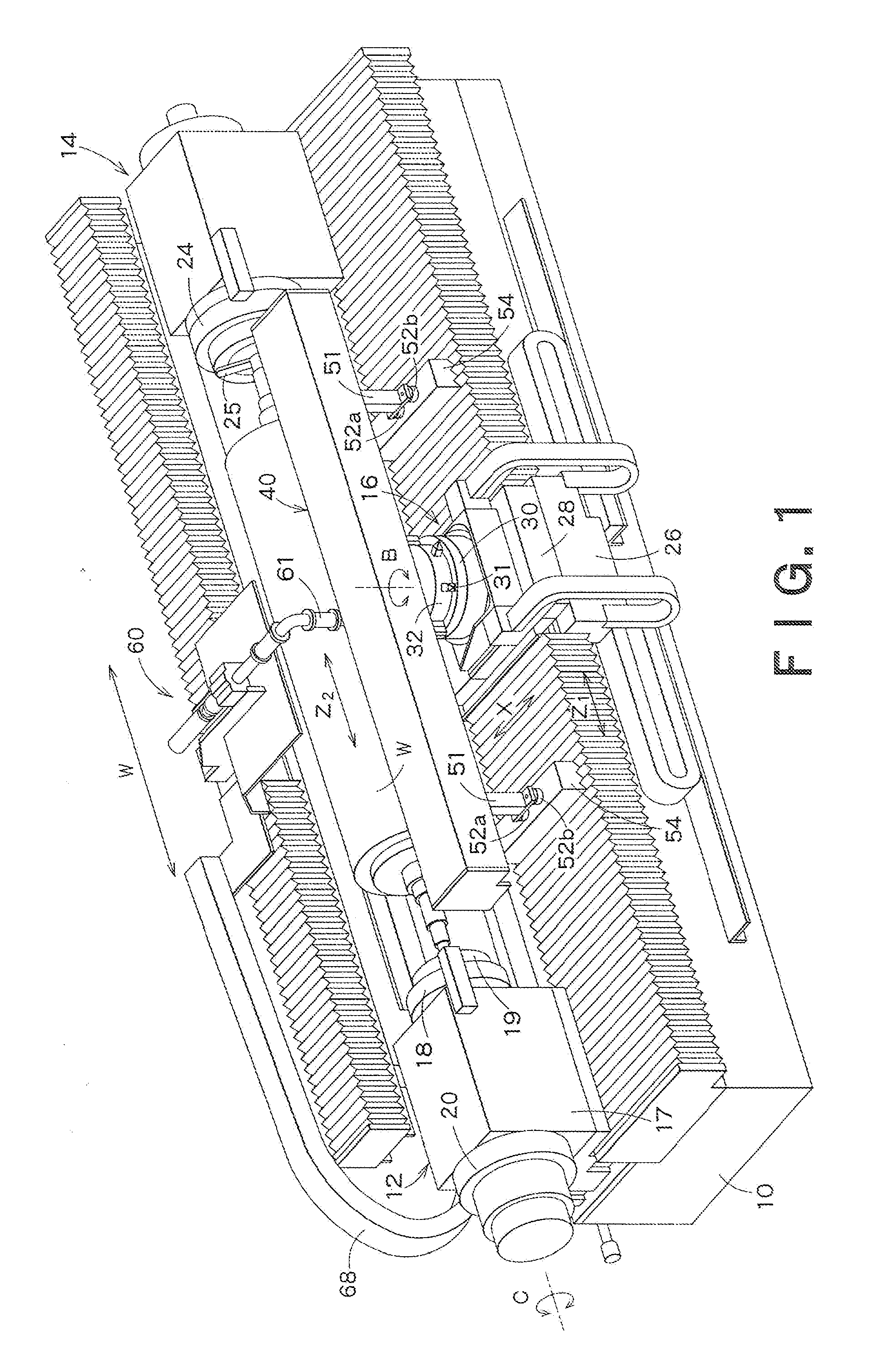

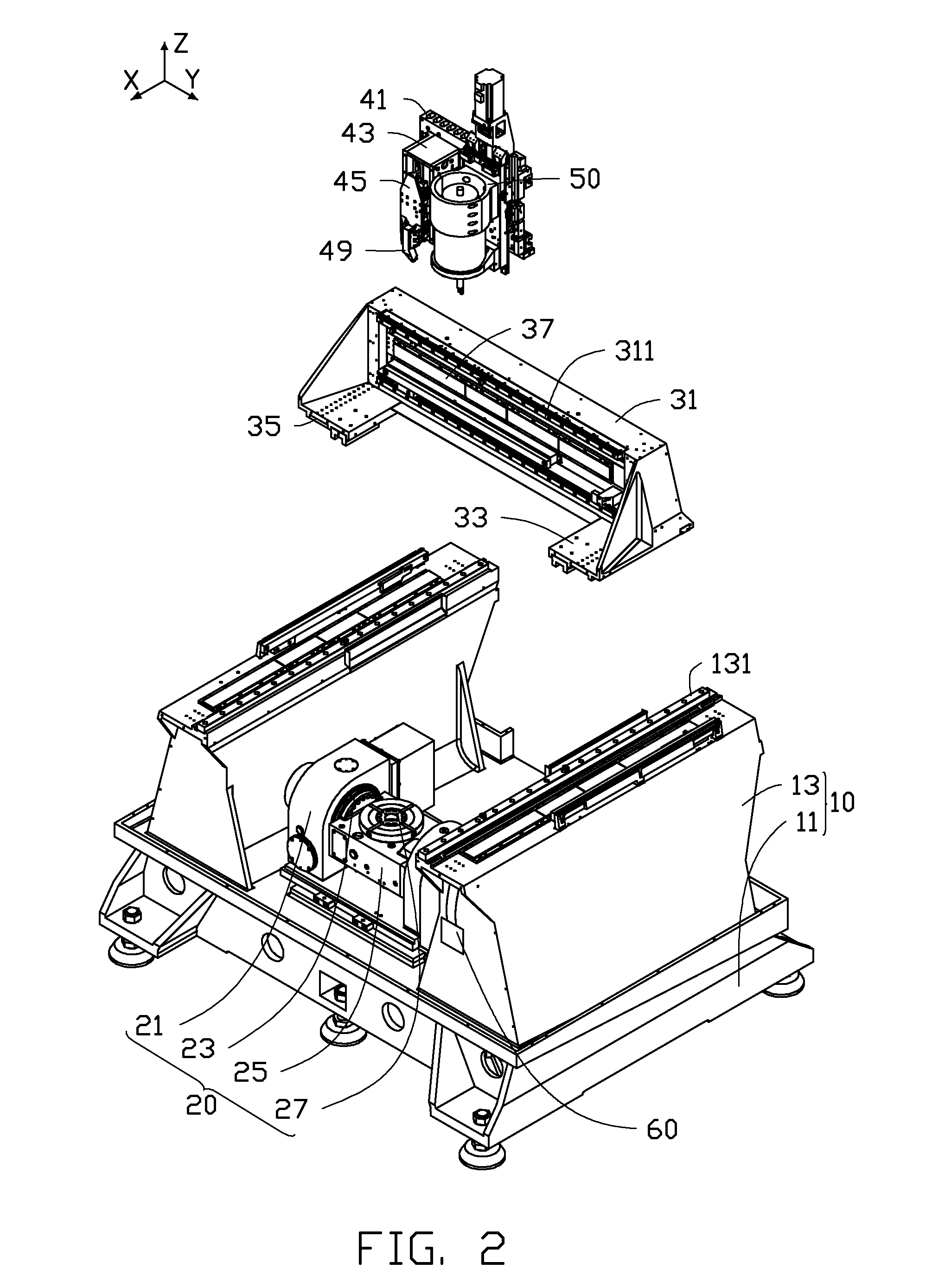

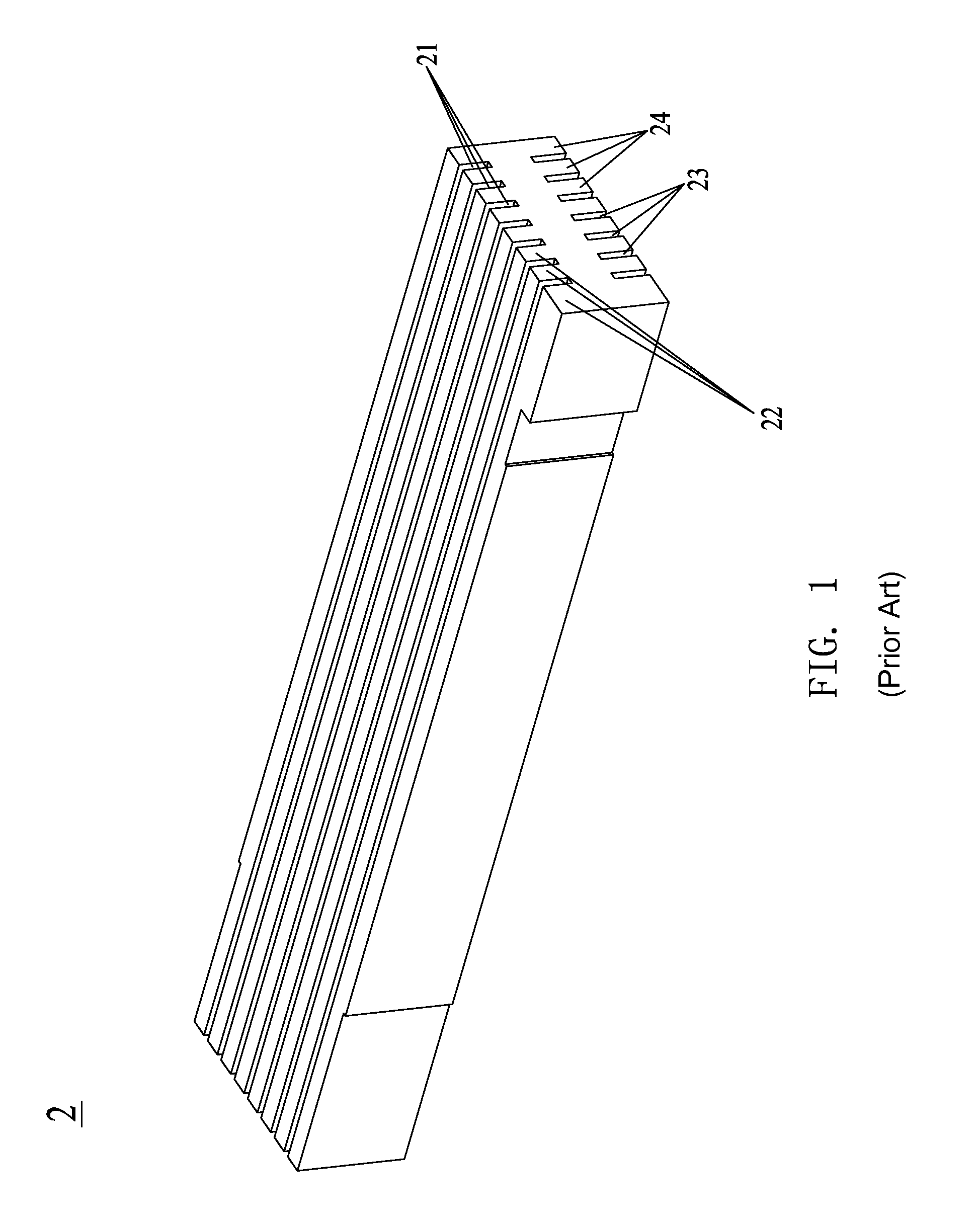

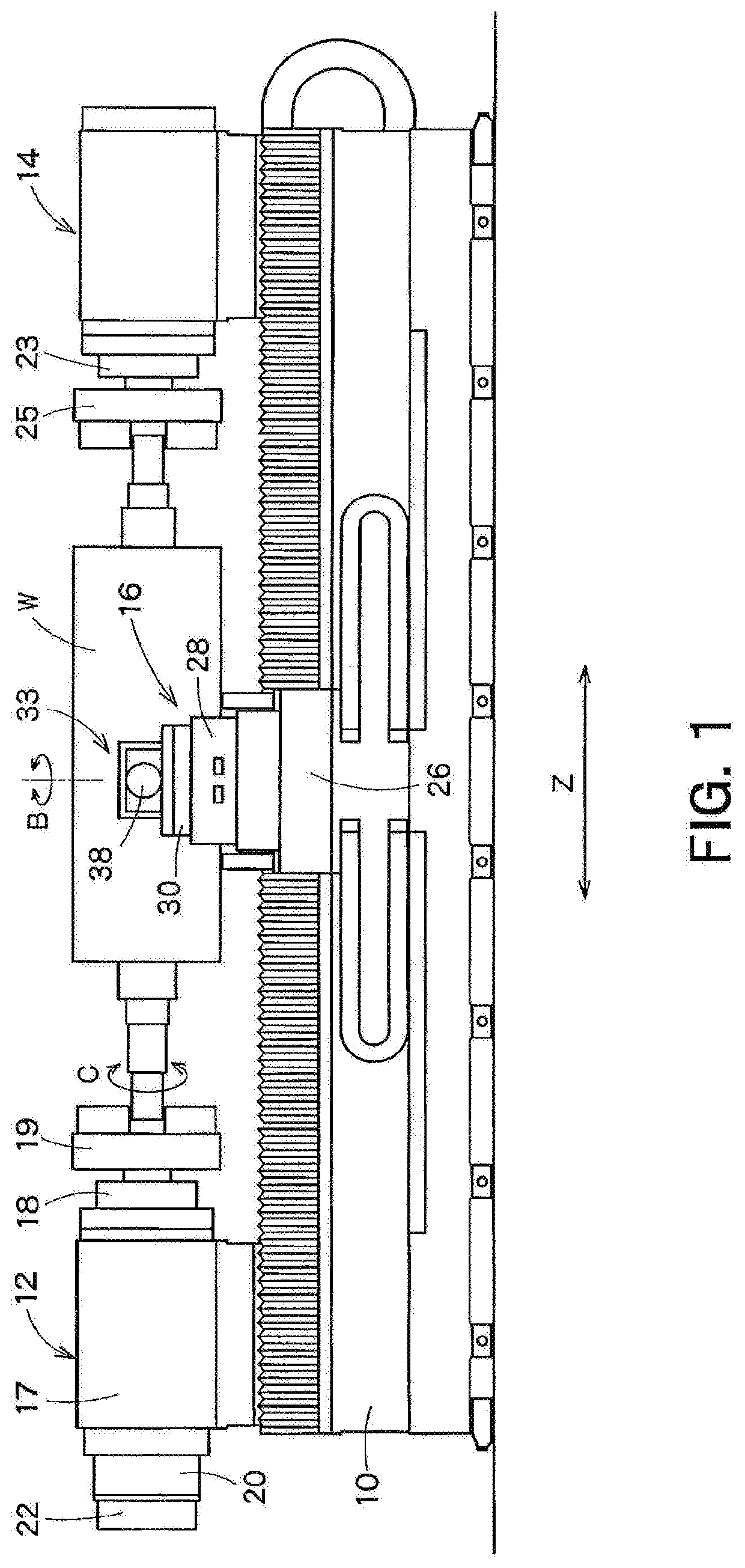

Precision roll turning lathe

ActiveUS20090120250A1Reduce time spentIncrease speedLathesAutomatic/semiautomatic turning machinesEngineeringLinear motor

There is provided a precision roll turning lathe which can perform machining of fine grooves at a dramatically higher speed as compared to conventional roll turning lathes, thus significantly shortening time taken for machining one groove. The precision roll turning lathe includes: a bed; a headstock, mounted on the bed, having a main spindle for rotating a roll as a workpiece while holding one end of the roll by means of a chuck; a tail stock, mounted on the bed and disposed opposite the headstock, for rotatably supporting the other end of the roll; a carriage including a saddle mounted on the bed movably in the longitudinal direction of the roll, and a table mounted on the saddle movably in a direction perpendicular to the longitudinal direction of the roll; and an air slide apparatus, mounted on the table, including a guide rail extending parallel to the roll in the longitudinal direction, an air slider having a diamond tool, capable of traveling in a floating state on the guide rail, and a linear motor for driving the air slider.

Owner:TOSHIBA MASCH CO LTD

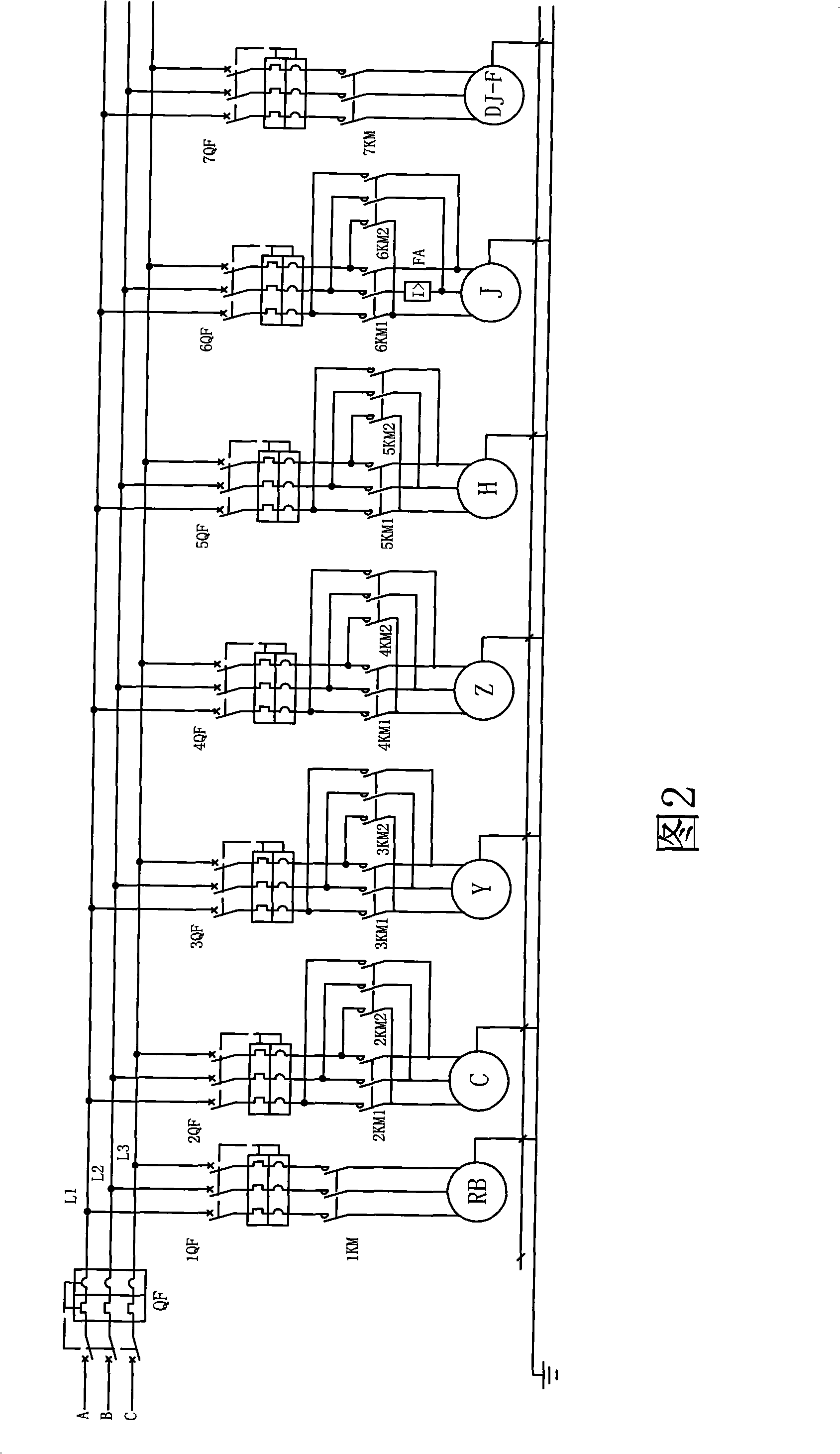

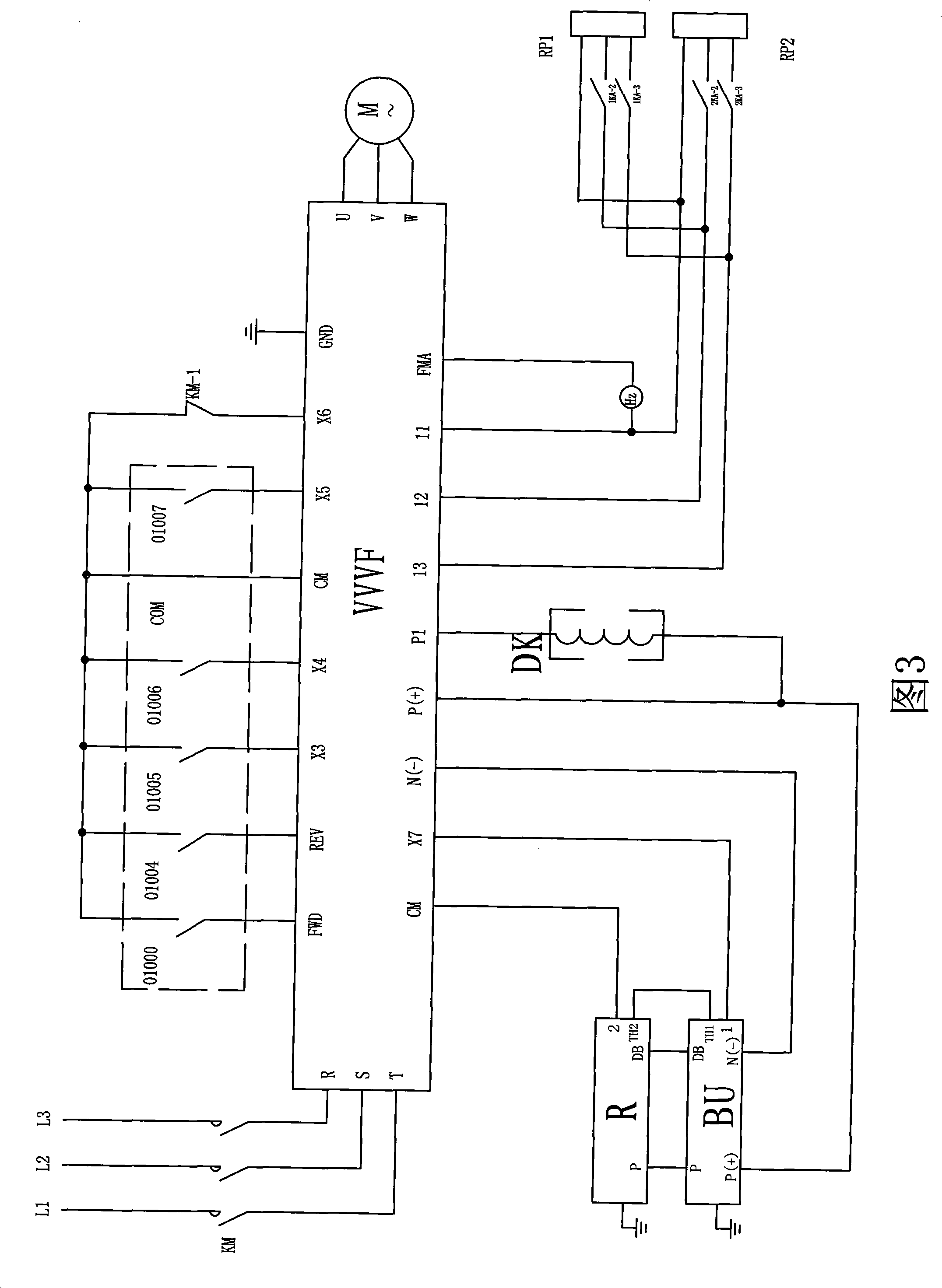

Power-saving control system of double housing planer

InactiveCN101829806ASimple and convenient speed adjustmentRealize stepless speed regulationAttachable planing devicesControl systemElectric machinery

The invention discloses a power-saving control system of a double housing planer, which comprises a cabinet body, a main loop unit, a frequency converter VVVF control unit, a programmable controller (PLC) input and output unit, a cutter lifting and indicating lamp unit and a relay protection unit, wherein all the units are arranged in the cabinet body; a main circuit is connected with a lubricating motor RB, a vertical turret motor C, a right turret motor Y, a left turret motor Z, a cross beam lifting motor H and a cross beam clamping motor J through circuit breakers 1QF-7QF and contactors 1KM respectively; the frequency converter VVVF output is connected to a main motor M; and the PLC input and output unit consists of an input part and an output part. The power-saving control system of the double housing planer has the advantages of simple structure, strong reliability, convenient speed adjustment, energy conservation, running speed improvement and cutting efficiency improvement, and can be widely applied to cutting mechanical equipment.

Owner:SHENYANG LIGONG UNIV

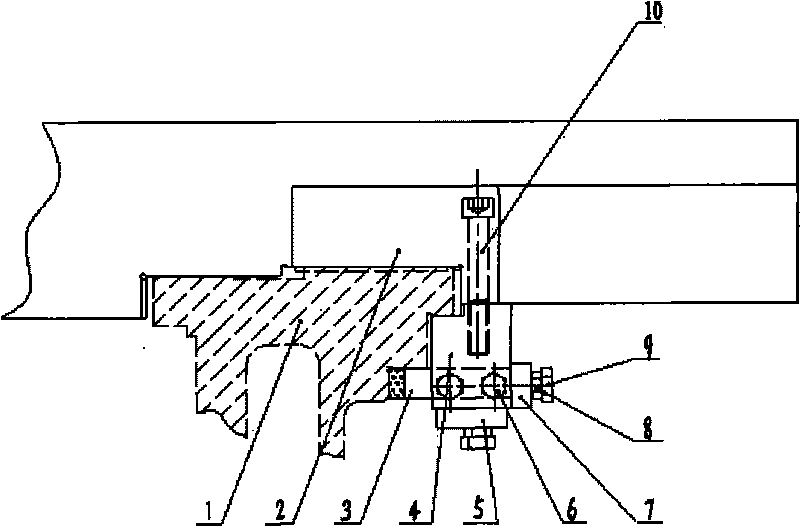

Device for correcting precision of rack installation surface of lathe body of lathe

InactiveCN101745684APositional tolerances are easily guaranteedImprove processing efficiencyAttachable planing devicesNumerical controlPosition tolerance

The invention relates to a device for correcting the precision of a rack installation surface of a lathe body of a lathe, which is arranged on a lathe saddle of the lathe in the assembling process for correcting the rack installation surface of the lathe body of the lathe. The invention is suitable for large and heavy numerical control lathes with high installation precision requirement and long length specification. The device comprises a cutter clamp, wherein the cutter clamp is distributed and arranged on the lathe saddle of the lathe, a wide edge plane cutter is arranged in the cutter clamp, the cutter is regulated to a proper position through a regulation screw bolt arranged on a regulation plate, and then, the cutter is tightly pressed, the cutter clamp moves synchronously along with an electric tail seat of the lathe for realizing the correction on the rack installation surface of the lathe body of the lathe, the position tolerance between the corrected rack installation surface of the lathe body and the reference surface can be easily ensured, the precision requirement of the product drawing can be ensured, the work intensity of workers can be reduced, and the production efficiency can be improved.

Owner:ANYANG XINSHENG MACHINE TOOL

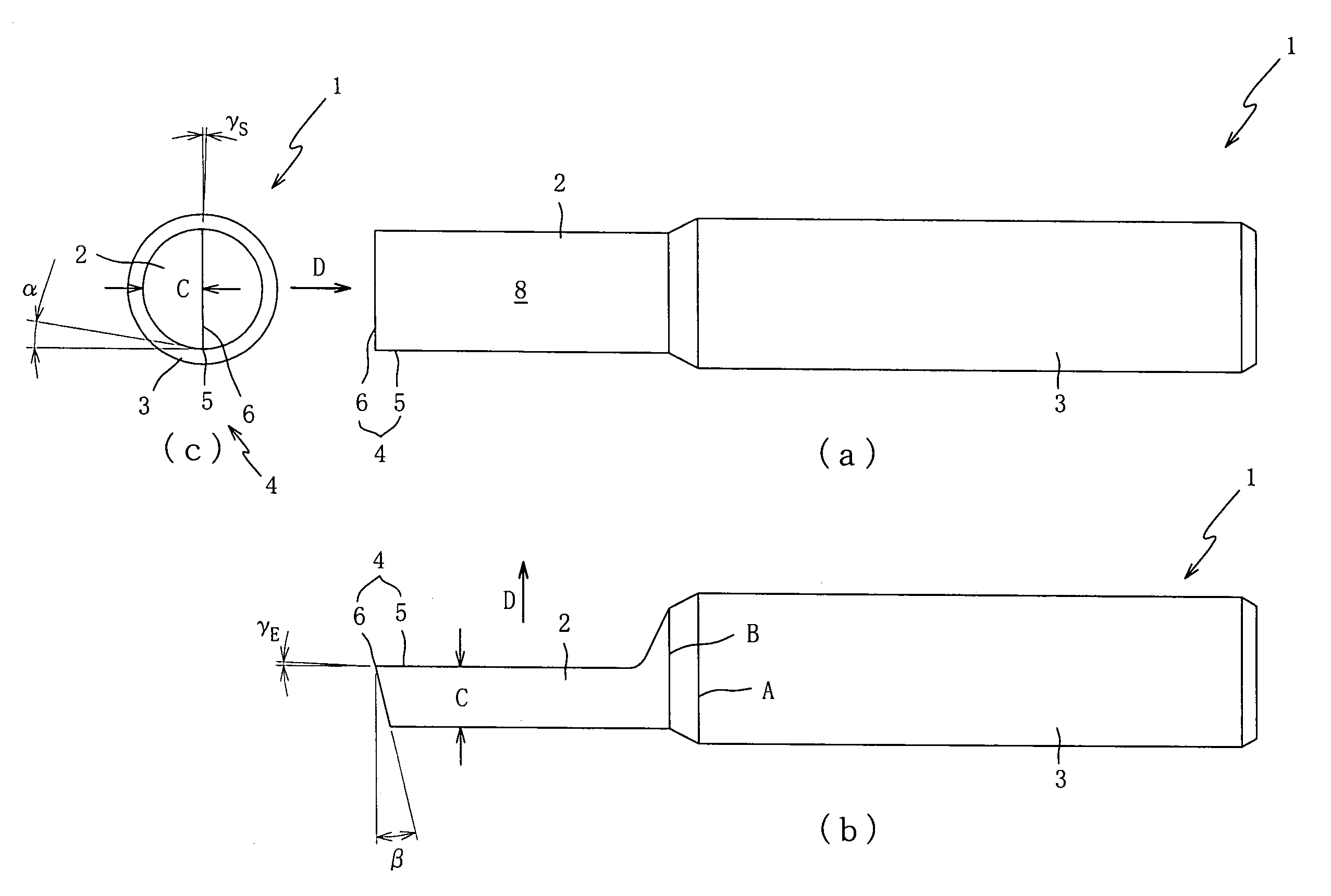

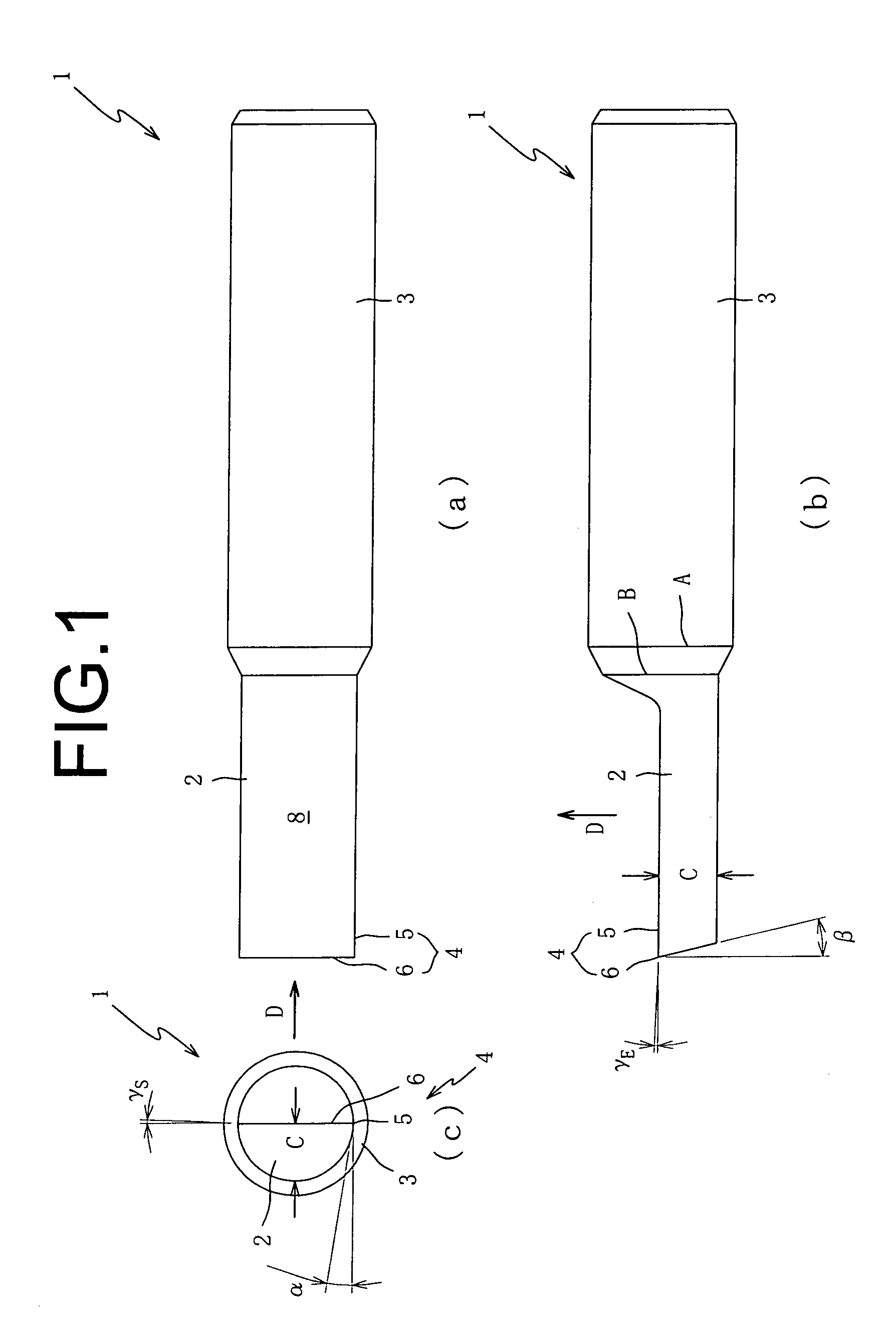

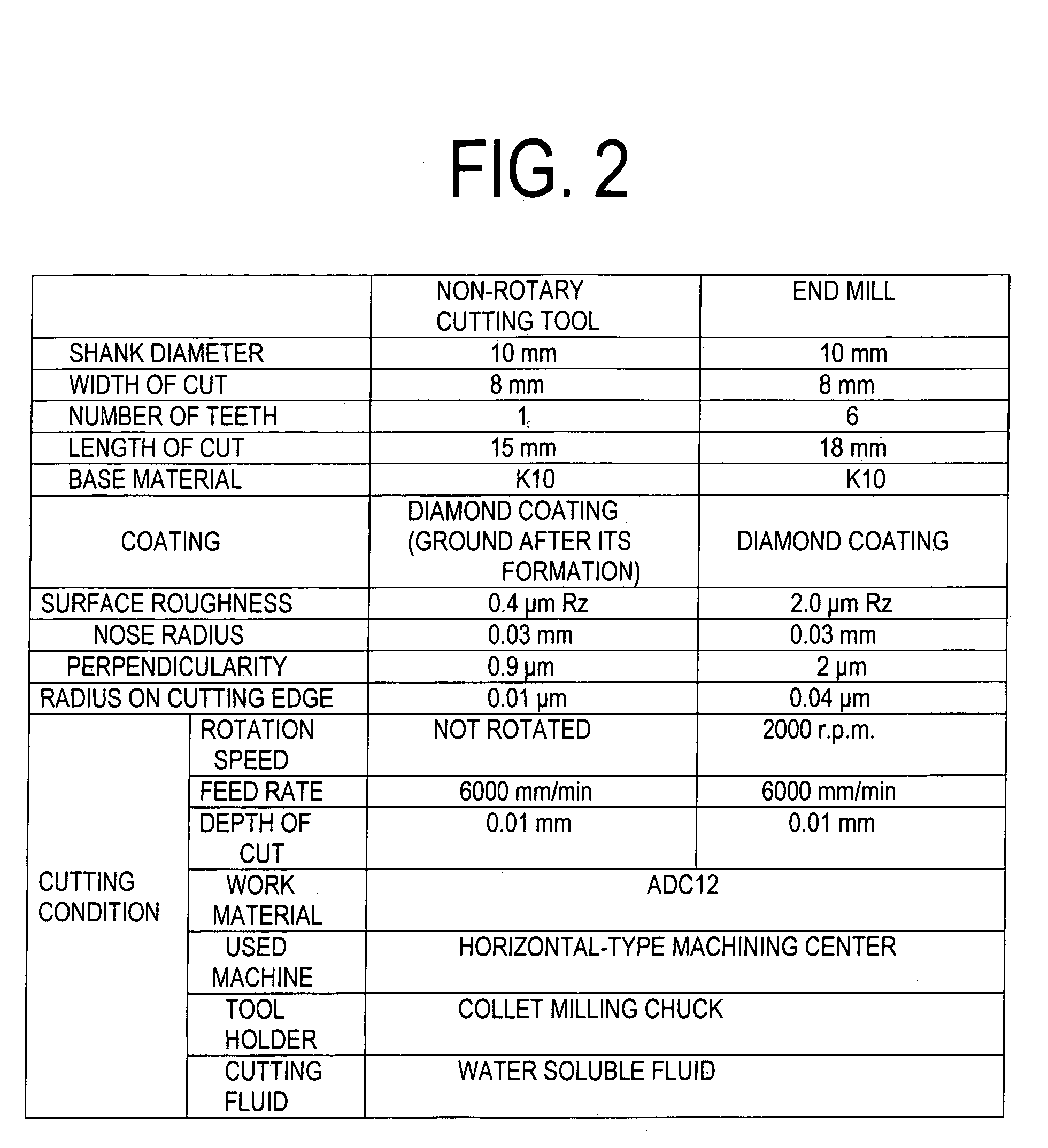

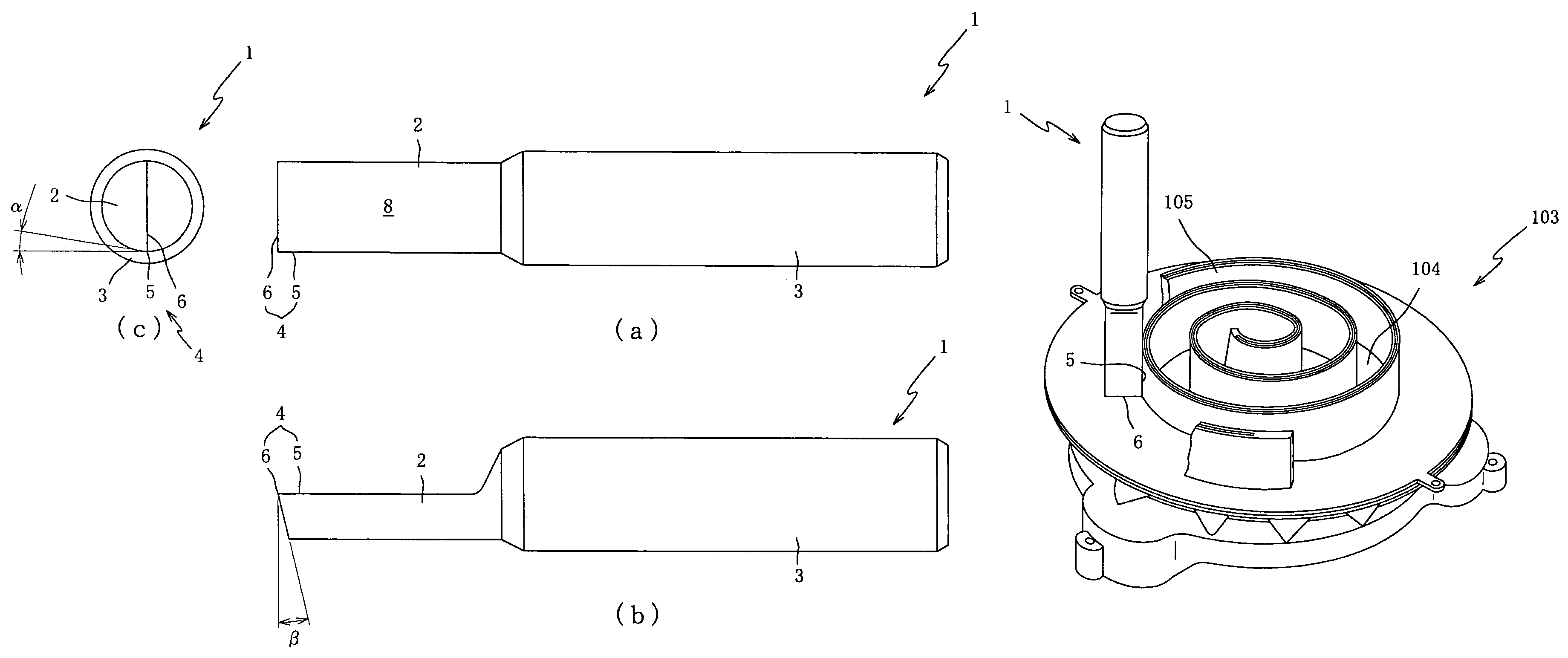

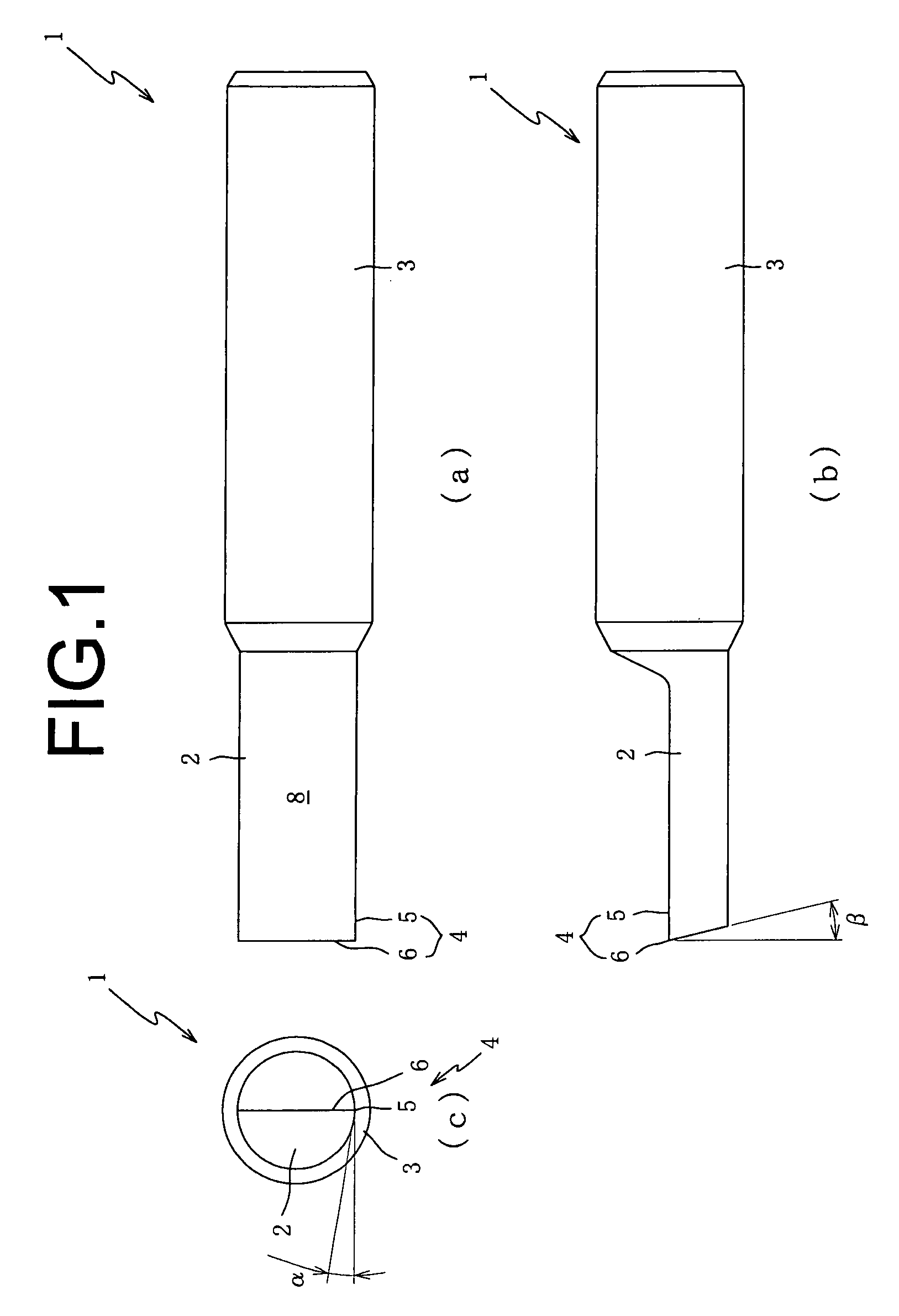

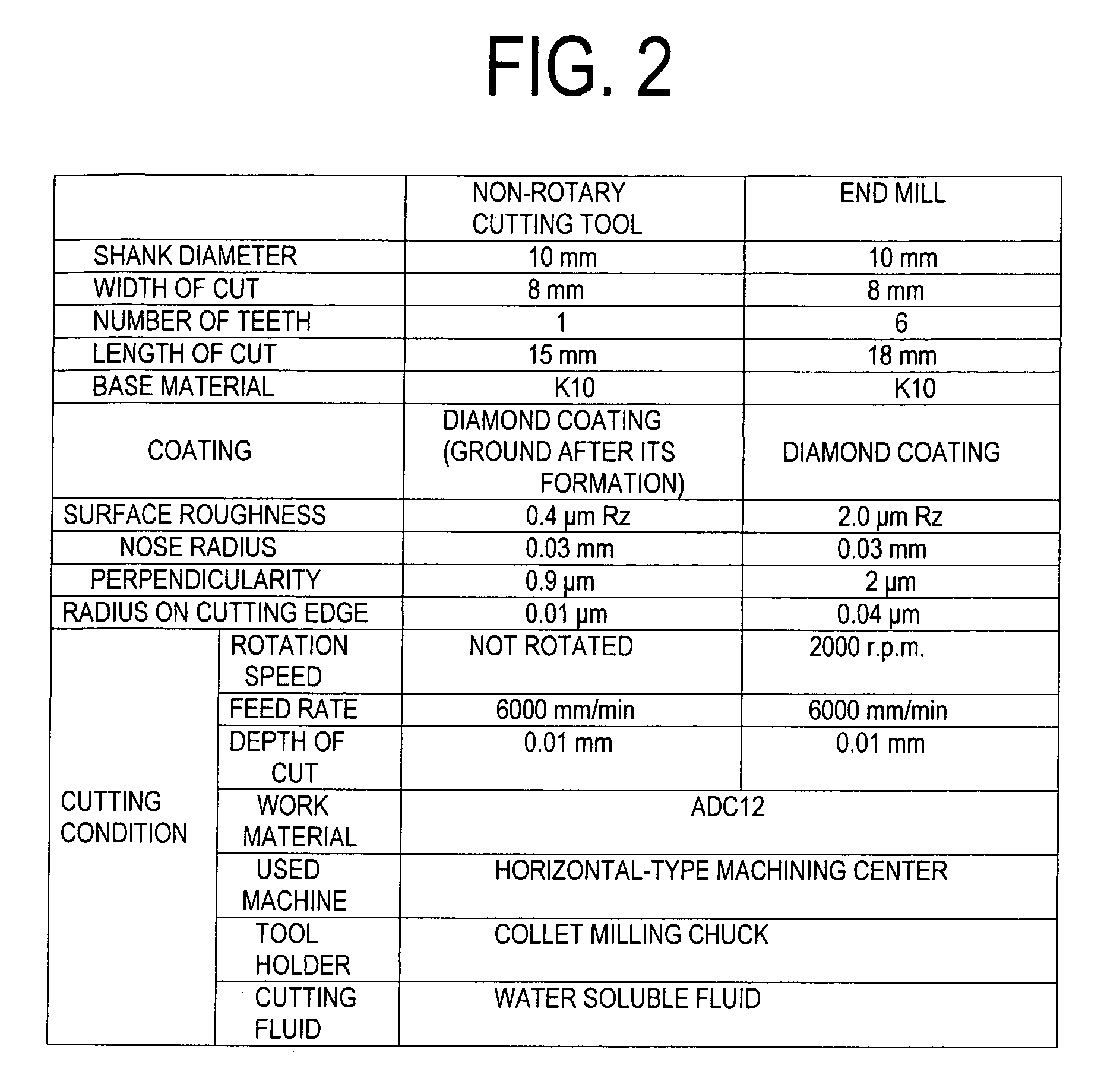

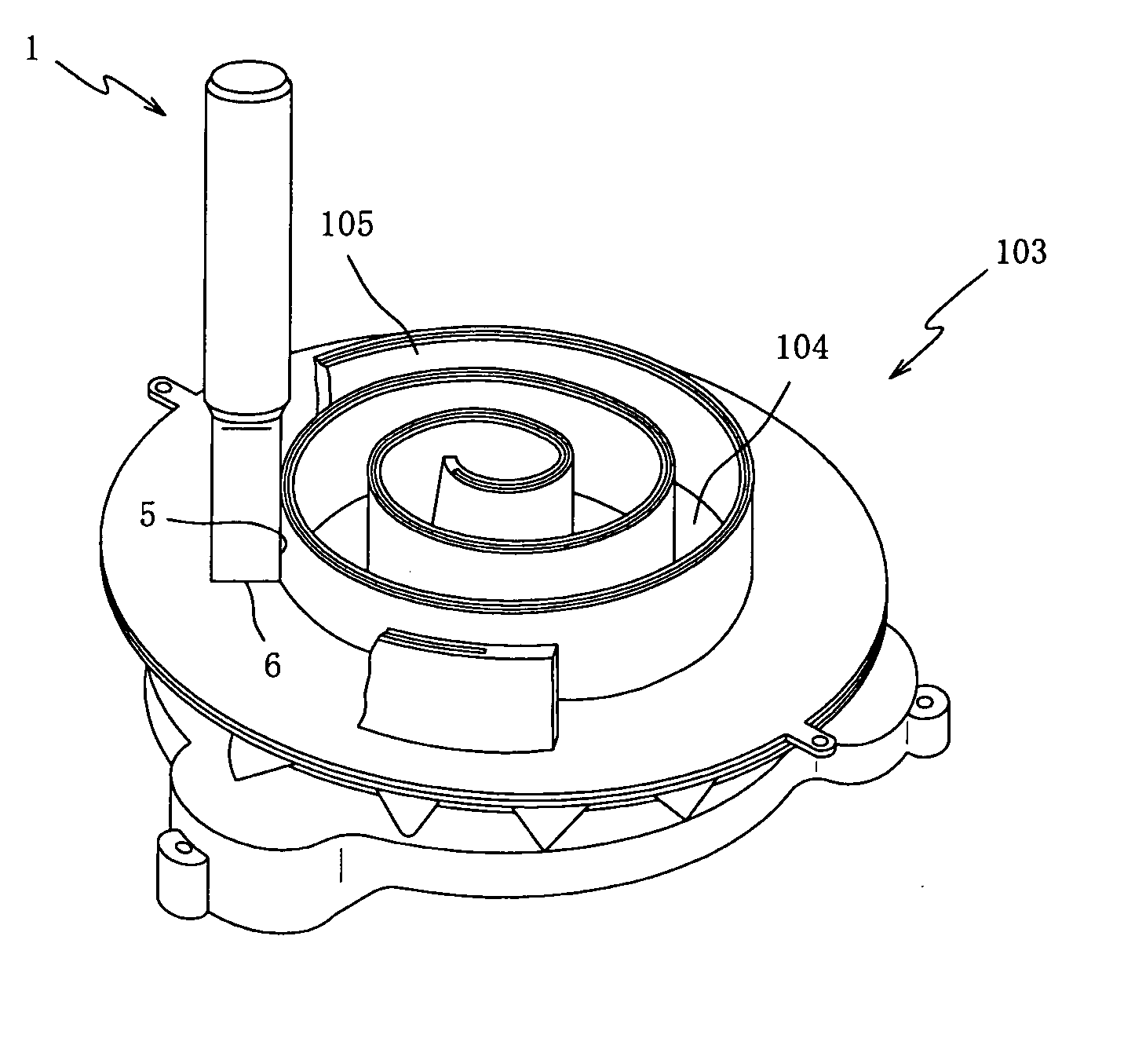

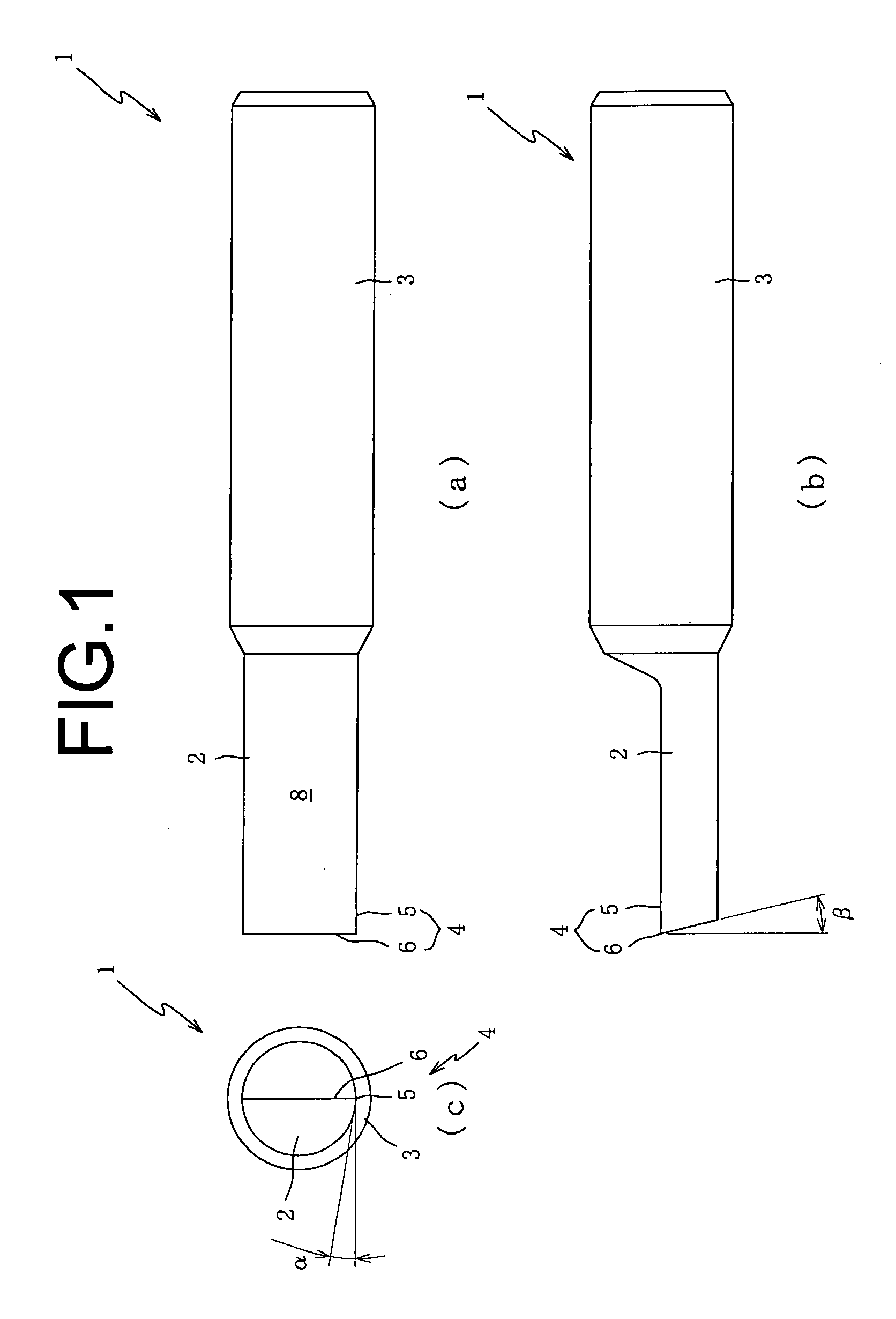

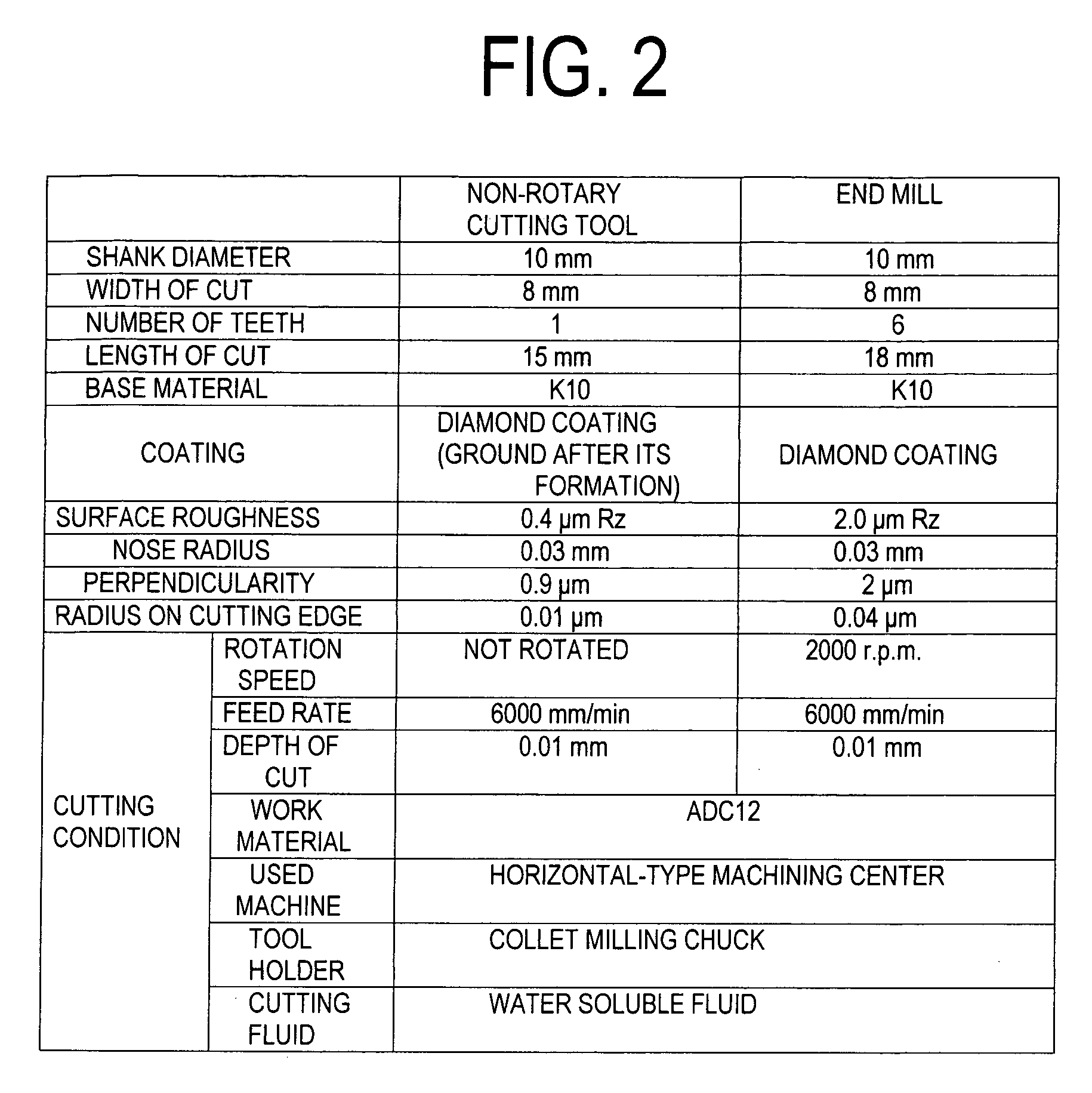

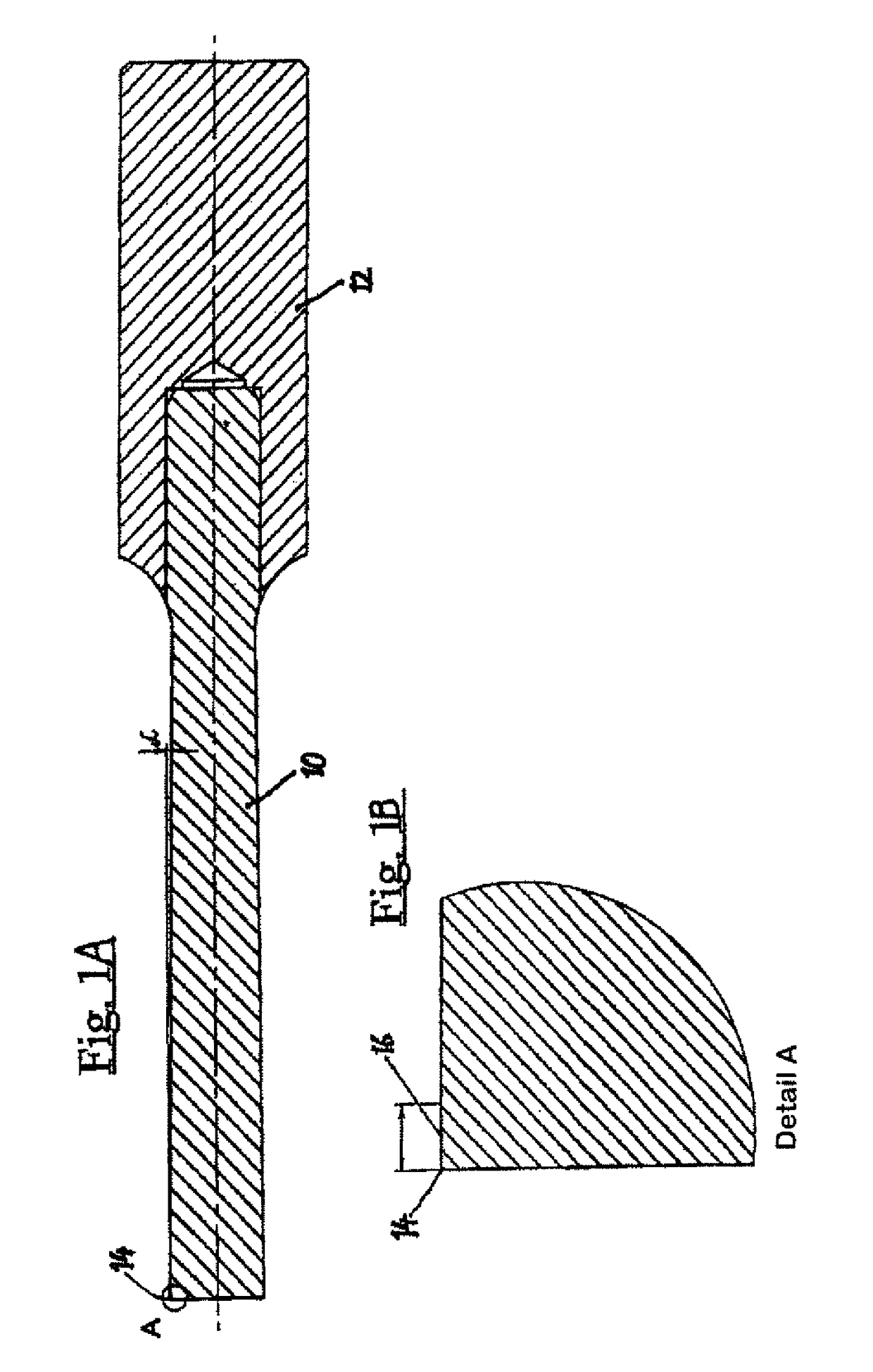

Non-rotary cutting tool and process of machining scroll member by using the same

ActiveUS7293945B2Convenient and accurateHigh precisionAttachable planing devicesCutting insertsEngineeringMechanical engineering

A non-rotary cutting tool which is to be moved relative to a workpiece in a predetermined direction for cutting the workpiece, with its rake face being held substantially perpendicular to the predetermined direction. The cutting tool includes (a) a generally cylindrical shank portion, and (b) a generally semi-cylindrical body portion which has an outer circumferential surface constituted by the rake face and a semi-cylindrical surface. The semi-cylindrical body portion has a cutting edge which is defined by an edge of the rake face and which is covered with a diamond coating. Also disclosed is a process of machining a scroll member of a scroll compressor by using this non-rotary cutting tool.

Owner:PANASONIC CORP +1

High-speed grooving method

ActiveUS20190061008A1Efficient processingImprove machine efficiencyAttachable planing devicesAuxillary equipmentEngineeringMachining

A high-speed grooving method includes: a dummy machining step of machining a dummy groove in the surface of the workpiece by moving the cutting tool relative to the workpiece in a first direction, then turning the cutting tool 180 degrees, and subsequently further machining the dummy groove by moving the cutting tool in a second direction opposite to the first direction; a step of measuring a displacement of the cutting edge of the cutting tool, caused by the inversion of the cutting tool, from the dummy groove formed in the surface of the workpiece; a forward-stroke machining step of machining a groove with the cutting tool in the surface of the workpiece by moving the cutting tool relative to the workpiece in the first direction; a cutting tool inversion step of turning the cutting tool 180 degrees after completion of the forward-stroke machining step, thereby setting the direction of the cutting edge of the cutting tool to a direction opposite to the first direction so that the workpiece can be machined during a return stroke of the cutting tool; a correction step of correcting the relative position between the workpiece and the cutting tool so as to eliminate the displacement; and a return-stroke machining step of further machining the groove, which has been machined in the forward-stroke machining step, with the cutting tool by moving the cutting tool relative to the workpiece in the direction opposite to the first direction.

Owner:TOSHIBA MASCH CO LTD

Process of machining scroll member by using non-rotary cutting tool

ActiveUS7237992B2Convenient and accurateHigh precisionLathesAttachable planing devicesMechanical engineeringCoating

A process of machining a scroll member of a scroll compressor by using a non-rotary cutting tool. The non-rotary cutting tool is moved relative to a workpiece in a predetermined direction for cutting the workpiece, with its rake face being held substantially perpendicular to the predetermined direction. The cutting tool includes (a) a generally cylindrical shank portion, and (b) a generally semi-cylindrical body portion which has an outer circumferential surface constituted by the rake face and a semi-cylindrical surface. The semi-cylindrical body portion has a cutting edge which is defined by an edge of the rake face and which is covered with a diamond coating. The rake face has a planar surface and a constant width throughout the cutting edge.

Owner:PANASONIC CORP +1

Method for machining narrow groove in planing mode by numerical control boring and milling machine

ActiveCN105458384ASolve processing problemsImprove processing efficiencyAttachable planing devicesPlaning/slotting machinesIn planeNumerical control

The invention provides a method for machining a narrow groove in a planing mode by a numerical control boring and milling machine. The method comprises the steps of 1, clamping a work-piece and enabling the machining face to be parallel with a main shaft of the numerical control boring and milling machine and the length direction of the narrow groove to be parallel with the direction of the main shaft; 2, clamping and correcting a cutter and enabling the machining direction of the boring cutter to be parallel with the length direction of the narrow groove and the feed direction to be parallel with the thickness direction of the narrow groove; 3, fixing the main shaft; 4, carrying out programming machining, wherein a numerical control shaft parallel with the length direction of the narrow groove to be machined does the main cutting motion, a numerical control shaft parallel with the depth direction of the narrow groove to be machined does the feed motion and then a program is started for machining. Through the steps, the numerical control boring and milling machine can be used for machining the narrow groove in the planing mode. By adopting the numerical control boring and milling machine for machining the narrow groove, the machining efficiency is improved, the machining quality is guaranteed, the operation is simple, convenient and practicable, and the width of the groove is easy to control. By adopting the method, the efficiency of machining the narrow groove is 2-5 times that of machining the narrow groove by an end mill, and the economic benefit of machining the groove with the width ranging from 2 mm to 4 mm is the most remarkable.

Owner:YICHANG MARINE DIESEL ENGINE

Machine tool with lathe tool and scraping cutter

A machine tool with lathe tool and scraping cutter includes a machine support, a worktable, a moving device, a lathe feeding mechanism and a scraping feeding mechanism. The worktable is positioned on the machine support. The moving device is slidably assembled to the machine support along a first direction and located above the worktable. The lathe feeding mechanism and the scraping feeding mechanism are slidably assembled to the moving device along a second direction perpendicular to the first direction, the lathe feeding mechanism includes a feeding assembly and a lathe tool connected to the feeding assembly, the feeding assembly is configured for driving the lathe tool to move along a third direction substantially perpendicular to the first and second direction reciprocally, the scraping feeding mechanism includes a scraping cutter and is configured for driving the scraping cutter to move along the third direction.

Owner:FU DING ELECTRONICSAL TECH JIASHAN +1

Process of machining scroll member by using non-rotary cutting tool

ActiveUS20050166739A1Easy to processHigh precisionLathesAttachable planing devicesEngineeringMechanical engineering

A process of machining a scroll member of a scroll compressor by using a non-rotary cutting tool. The non-rotary cutting tool is to be moved relative to a workpiece in a predetermined direction for cutting the workpiece, with its rake face being held substantially perpendicular to the predetermined direction. The cutting tool includes (a) a generally cylindrical shank portion, and (b) a generally semi-cylindrical body portion which has an outer circumferential surface constituted by the rake face and a semi-cylindrical surface. The semi-cylindrical body portion has a cutting edge which is defined by an edge of the rake face and which is covered with a diamond coating.

Owner:PANASONIC CORP +1

Precision roll turning lathe

ActiveUS8272302B2Reduce time spentIncrease speedLathesAutomatic/semiautomatic turning machinesLinear motorTailstock

There is provided a precision roll turning lathe which can perform machining of fine grooves at a dramatically higher speed as compared to conventional roll turning lathes, thus significantly shortening time taken for machining one groove. The precision roll turning lathe includes: a bed; a headstock, mounted on the bed, having a main spindle for rotating a roll as a workpiece while holding one end of the roll by means of a chuck; a tail stock, mounted on the bed and disposed opposite the headstock, for rotatably supporting the other end of the roll; a carriage including a saddle mounted on the bed movably in the longitudinal direction of the roll, and a table mounted on the saddle movably in a direction perpendicular to the longitudinal direction of the roll; and an air slide apparatus, mounted on the table, including a guide rail extending parallel to the roll in the longitudinal direction, an air slider having a diamond tool, capable of traveling in a floating state on the guide rail, and a linear motor for driving the air slider.

Owner:TOSHIBA MASCH CO LTD

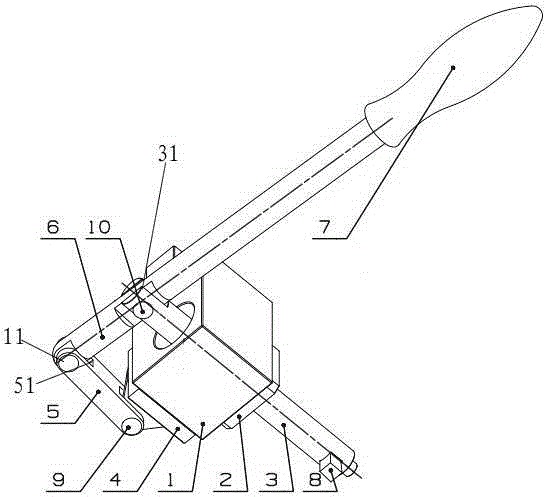

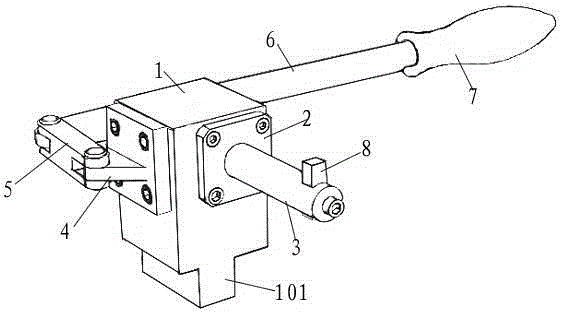

Manual slotting tool for lathe

InactiveCN105149673AImprove processing efficiencyGenerate high efficiencyAttachable planing devicesNumerical controlEngineering

The invention discloses a manual slotting tool for a lathe. The manual slotting tool comprises a base and a slotting cutter rod; a through hole is formed in the base, and the slotting cutter rod is arranged in the through hole in a penetrating manner; a slotting cutter bit is arranged at one end of the slotting cutter rod, and the other end of the slotting cutter rod is connected to a rocking rod; one end of the rocking rod is movably connected to the base, and the rocking rod swings around the connecting position of the rocking rod and the slotting cutter rod; and the base is fixed to the lathe, and the rocking rod swings so as to drive the slotting cutter rod to axially move. According to the manual slotting tool for the lathe, a common lathe or a numerical control lathe can complete slotting machining of a key groove, and original cutting functions of a slotting machine can be partly completed; particularly, under the single piece or small batch production condition, the machining efficiency of an inner key groove can be greatly improved, and the generation benefits are improved.

Owner:SUZHOU INST OF INDAL TECH

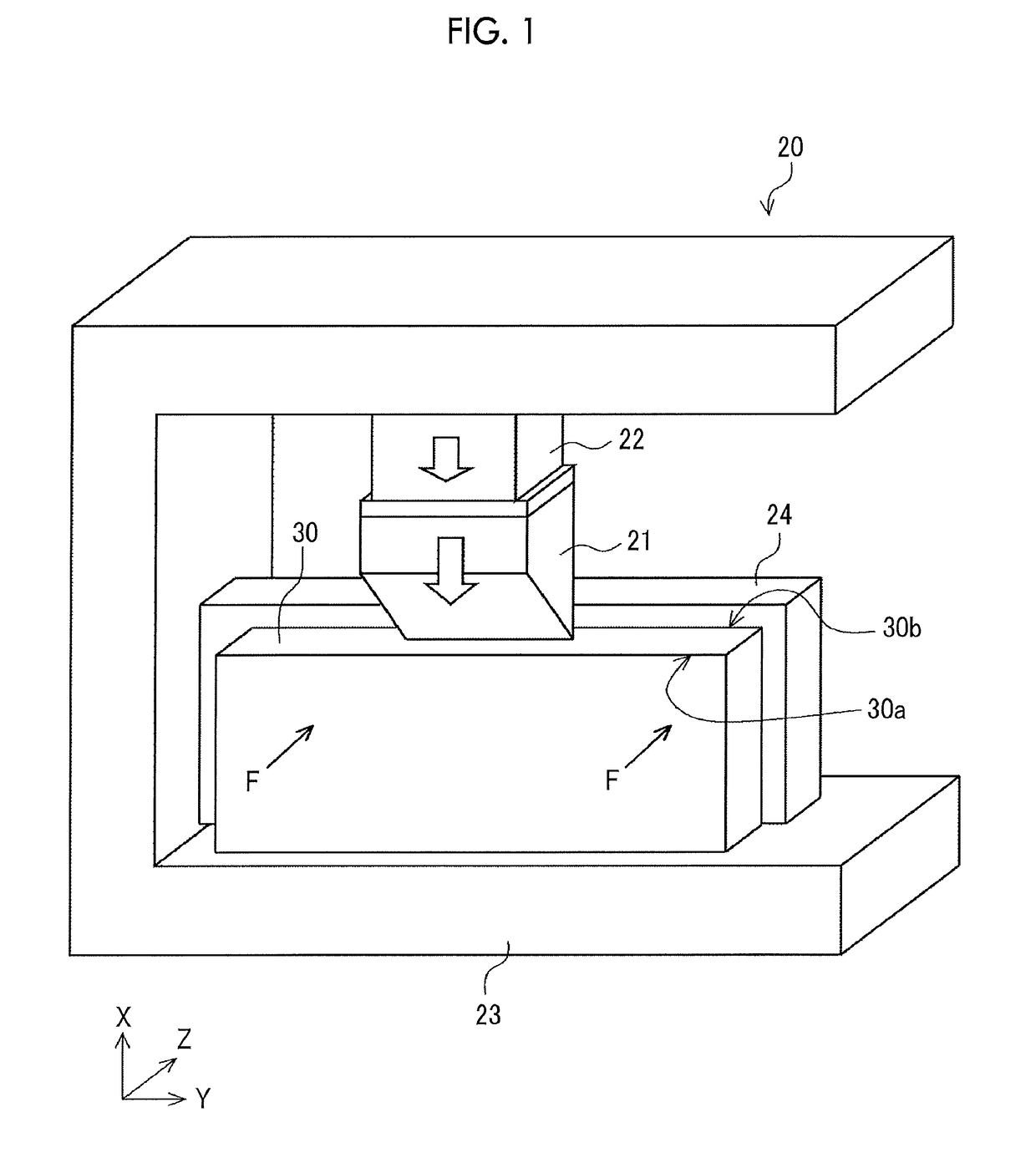

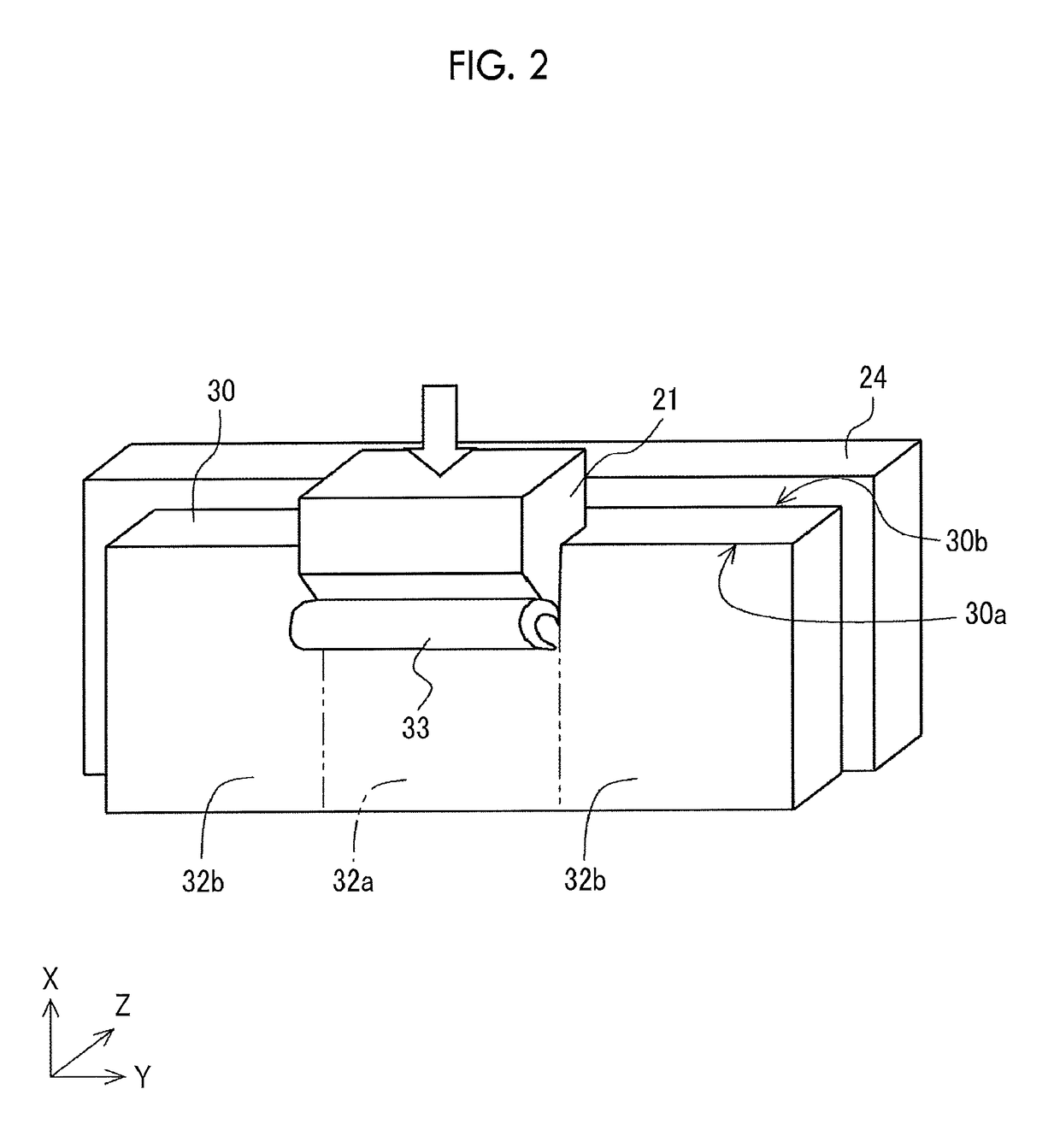

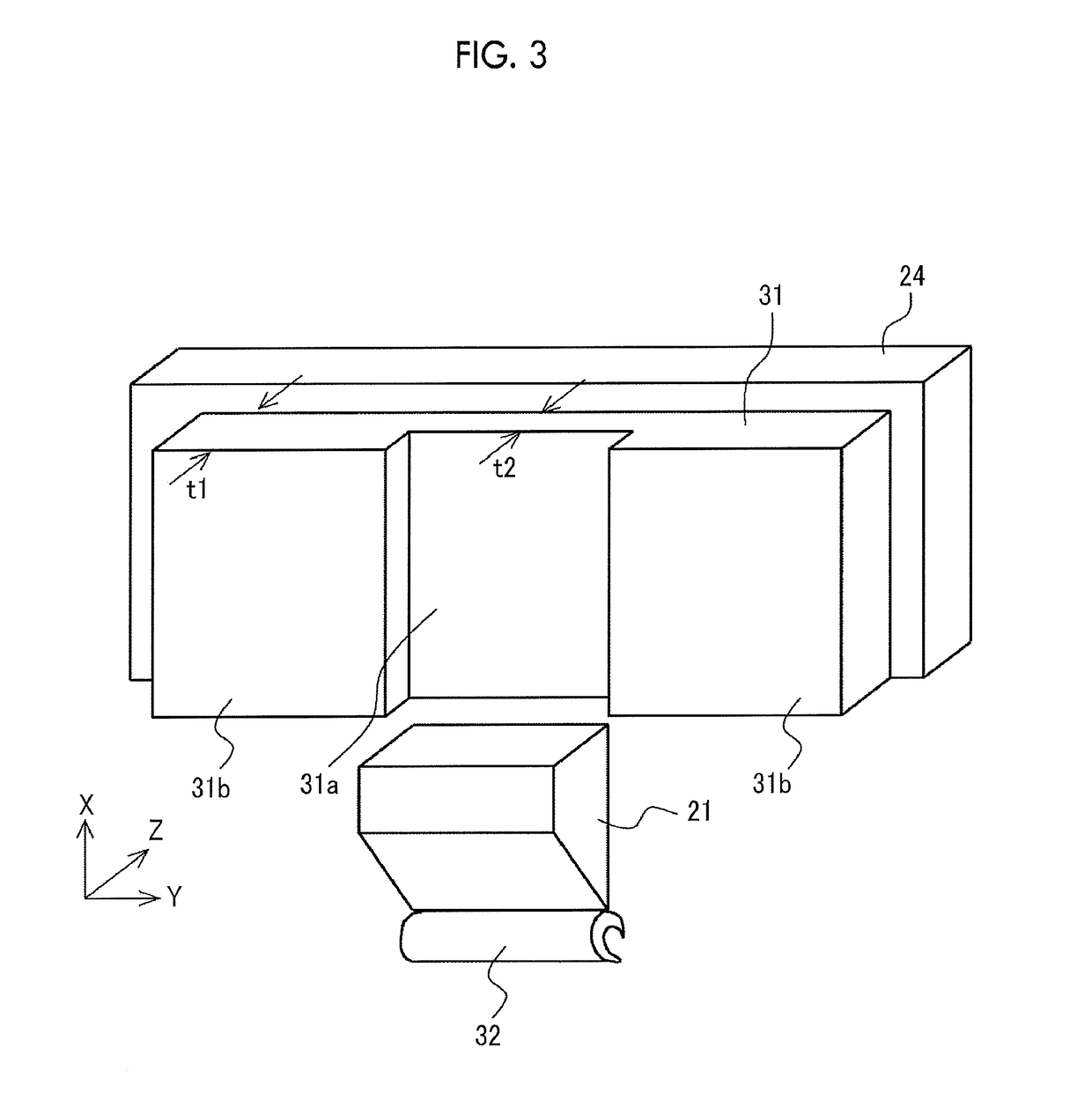

Manufacturing method of metal member

InactiveUS20180369936A1Work is suppressedReduce weightAttachable planing devicesMilling cuttersMetal

A manufacturing method of a metal member includes performing first shaving on a first surface perpendicular to a thickness direction of a metal plate, in a first portion of the metal plate by moving a cutting edge in a direction along the first surface. In the metal plate, the thickness of the first portion is reduced to be smaller than the thickness of a second portion by the first shaving.

Owner:TOYOTA JIDOSHA KK

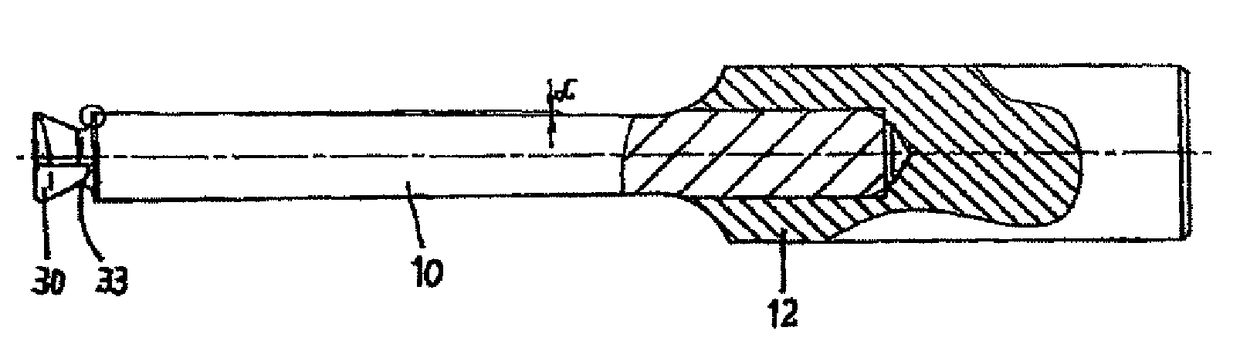

Method and tool for producing an exact-fit cylindrical bore by removal of material from an existing bore with a finishing allowance

InactiveUS9919389B2Reduce processing timeLoss in precision qualityPerforating toolsInternal combustion piston enginesEngineeringReamer

The provided method and material-removing tool serve for producing an exact-fit cylindrical bore with a high degree of surface quality and a length that may be a multiple of the diameter from an existing bore with a finishing allowance. In order to reduce the time taken for the finishing by means of a reamer to be performed, it is proposed to use a tool in the form of an impact die, which is formed at the front end with a circular or substantially circular cutting edge, the diameter of which corresponds to the nominal diameter of the bore to be produced, and which tapers from directly behind the cutting edge or behind a front region of a certain length.

Owner:AUDI AG +1

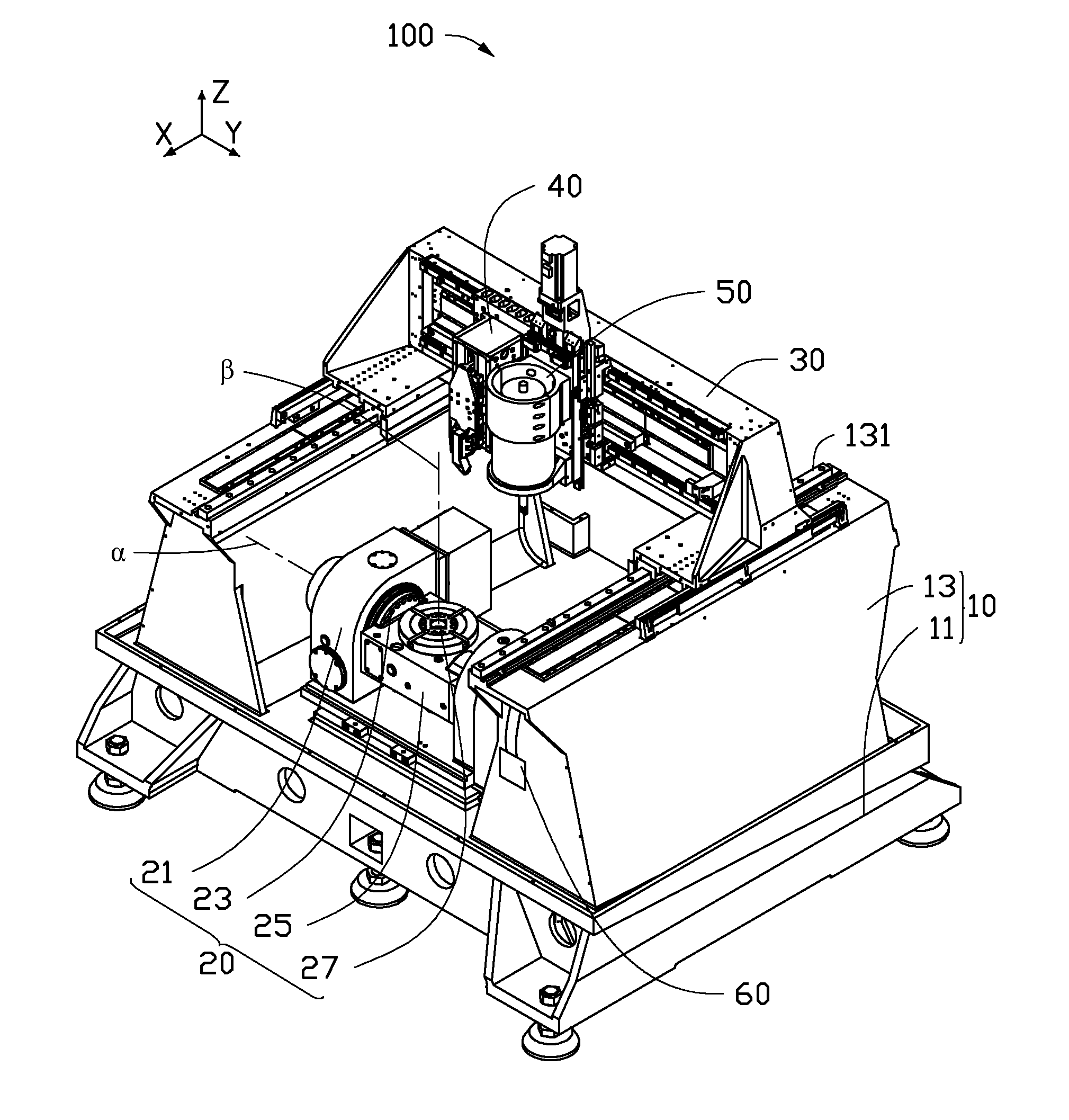

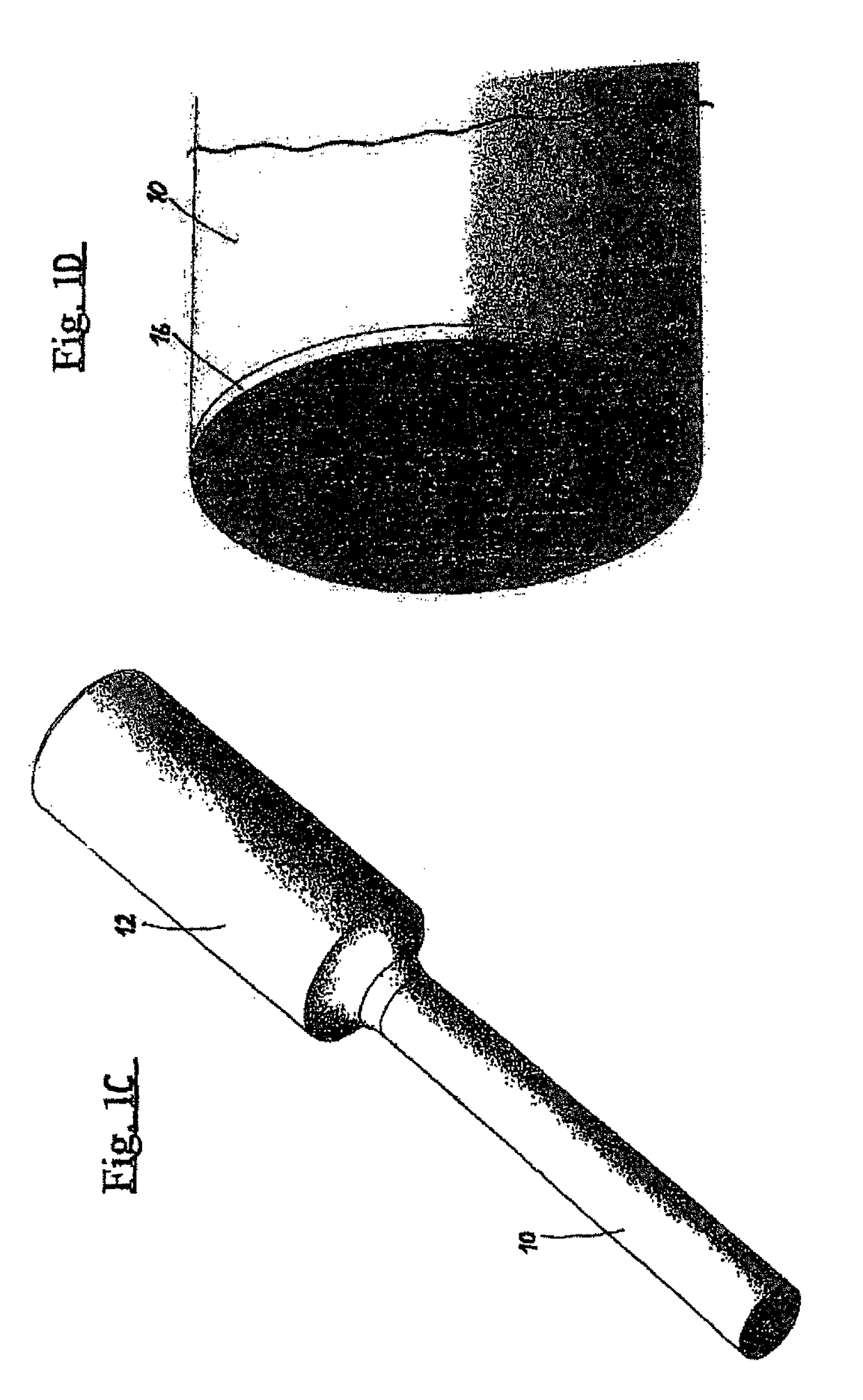

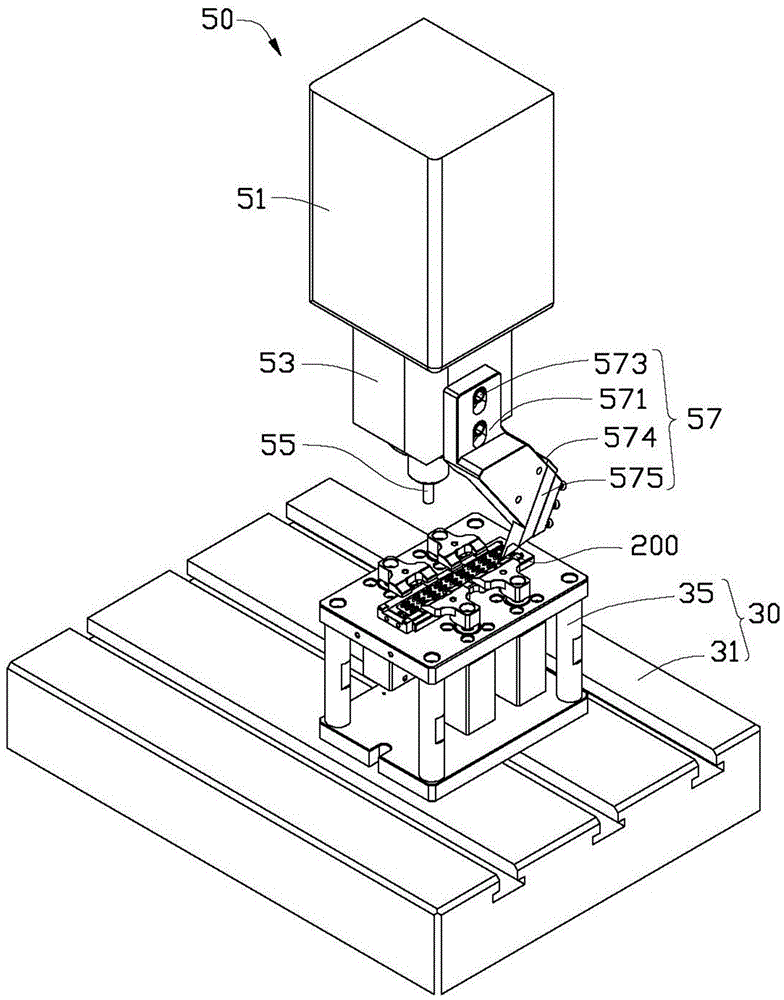

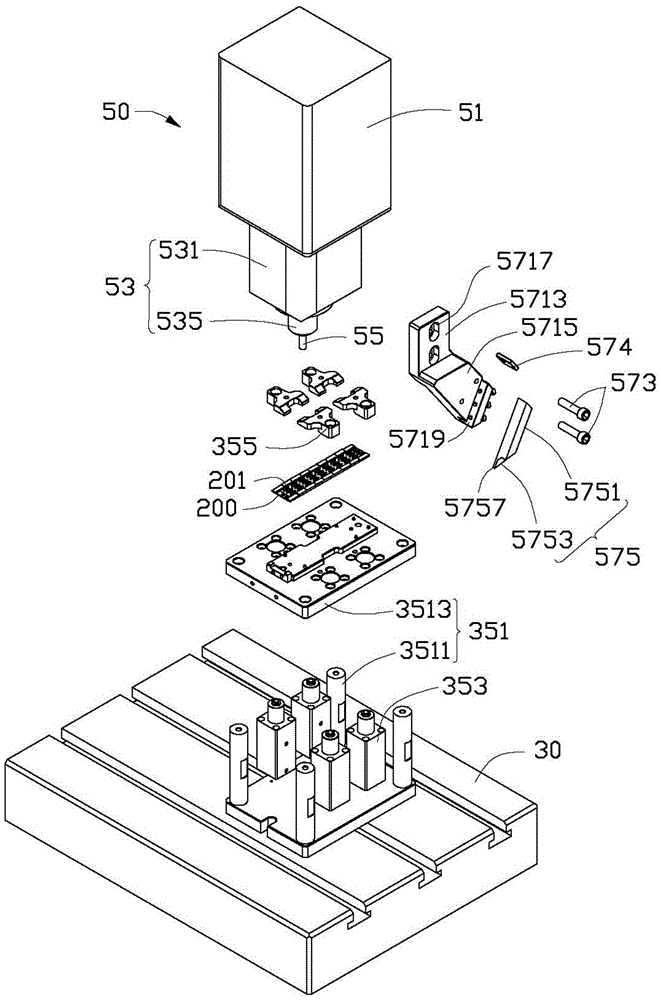

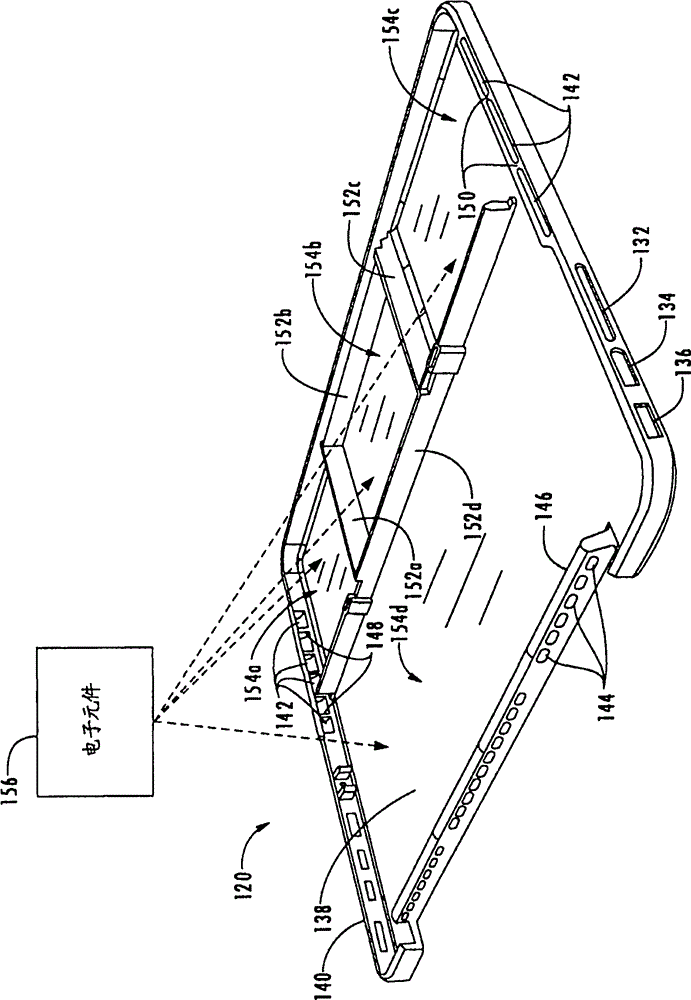

Feeding device, machine tool adopting feeding device and machining method thereof

ActiveCN104097065ARemove surfaceImprove processing efficiencyAttachable planing devicesFeeding apparatusMilling cutterEngineering

The invention provides a feeding device. The feeding device comprises a connection seat, a main shaft arranged on the connection seat and a milling cutter, wherein the main shaft comprises a fixed part and a rotary part which is in rotary connection with the fixed part; the fixed part is connected with the connection seat; the milling cutter is fixedly connected with the rotary part. The feeding device is characterized by further comprising a plane cutter assembly arranged on the fixed part; the plane cutter assembly comprises a tool rest and a plane cutter which is fixedly arranged on the tool rest; the tool rest comprises a connection part and a mounting part which is formed by extending from one end of the connection part in a certain angle; the connection part is fixedly connected with the fixed part; the plane cutter is arranged at one end, which is far away from the connection part, of the mounting part; the plane cutter extends in a direction far away from the connection part, and a certain angle is formed between the plane cutter and the mounting part; a profiled cutting edge is arranged at one end, which is far away from the tool rest, of the plane cutter. The invention further provides a machine tool adopting the feeding device and a machining method thereof.

Owner:富联科技(山西)有限公司

A machining method for slotting of key slots by a numerical control apparatus

The invention relates to the technical field of key slot machining and provides a machining method for slotting of key slots by a numerical control apparatus. The machining method for efficient slotting of key slots by a numerical control apparatus is characterized in that a numerical control milling center replaces a traditional manual slotting apparatus and the slotting machining of a plurality of key slots is performed by using the indexing function of the numerical control apparatus with one-time clamping; the problems of poor machining precision, low machining efficiency and high workload of the manual slotting apparatus are solved.

Owner:FLIGHT AUTOMATIC CONTROL RES INST

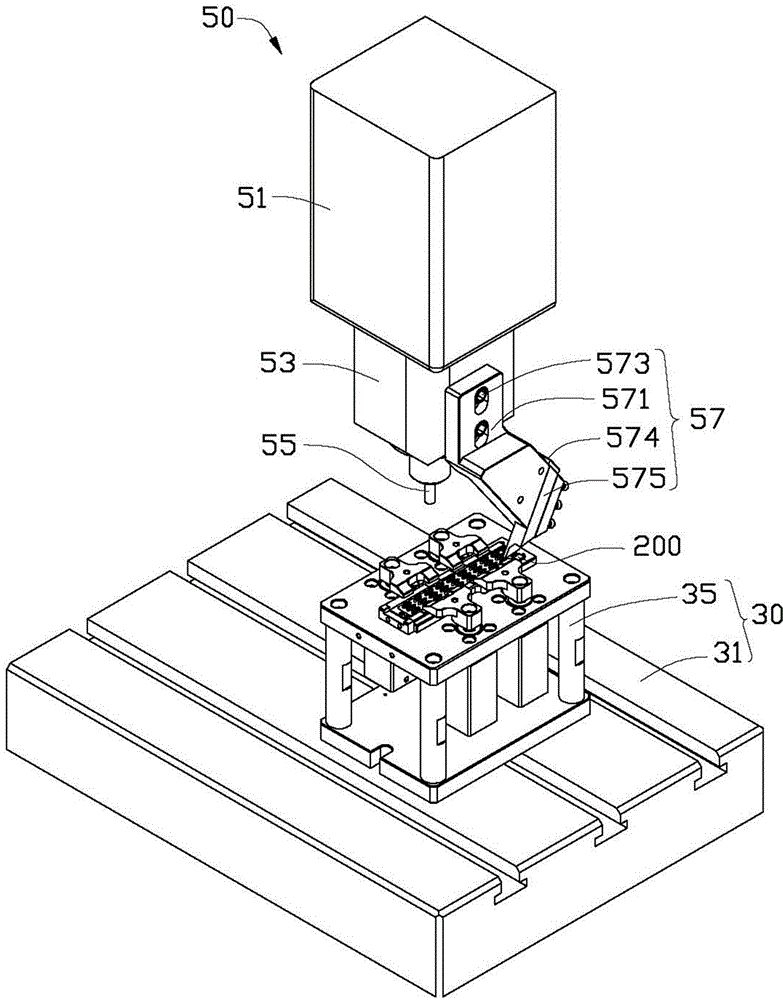

Electrically controlled mechanical cutting machine

InactiveCN112453548AAvoid affecting the working environmentAvoid re-pinning situationsAttachable planing devicesShearing machinesActivated carbon filtrationElectrical control

The invention discloses an electrically-controlled mechanical cutting machine, and belongs to the technical field of mechanical cutting machines. According to the cutting machine, a movable frame is slidably connected to the top of a cabinet body, a cutting mechanism used for mechanical cutting is connected to the movable frame, a cavity is formed in the cabinet body, a motor in positioning connection with a placing plate is arranged in the cavity, and the motor can drive the placing plate to rotate in the circumferential direction on the plane; in addition, a purification tank with an activated carbon filter screen is further arranged in the cavity, and the purification tank can extract and filter cutting dust through an induced draft fan and a conveying pipe and then discharge the cutting dust; and according to the cutting machine, the angle of a product can be adjusted according to the cutting position of the product, it is avoided that when the product is cut at different positions, the position needs to be adjusted and fixed again after the product is detached, time is saved, work efficiency is improved, dust splashed during product cutting can be exhausted from the two sidesof the product through the conveying pipe, the situation that dust is accumulated on the workbench to influence the working environment is avoided, and practicability is high.

Owner:PAGMAN TECH (TAICANG) CO LTD

Feed device, machine tool using the feed device and processing method thereof

ActiveCN104097065BRemove surfaceImprove processing efficiencyAttachable planing devicesFeeding apparatusMilling cutterEngineering

A feeding device, which includes a connecting seat, a main shaft installed on the connecting seat, and a milling cutter, the main shaft includes a fixed part and a rotating part connected to the fixed part in rotation, and the fixed part is connected to the connecting seat , the milling cutter is fixedly connected with the rotating part, the feeding device also includes a planer assembly mounted on the fixed part, the planer assembly includes a knife holder, a planer fixed on the knife holder and a positioning block, The tool holder includes a connecting portion and a mounting portion formed by extending at a certain angle from one end of the connecting portion. The connecting portion is fixedly connected to the fixing portion. The connecting portion extends and forms a certain angle with the mounting portion, and the end of the planer away from the tool holder has a profiling cutting edge. The positioning block is installed on the mounting portion and abuts against an end of the planer away from the cutting edge. The invention also provides a machine tool using the feeding device and a processing method thereof.

Owner:富联科技(山西)有限公司

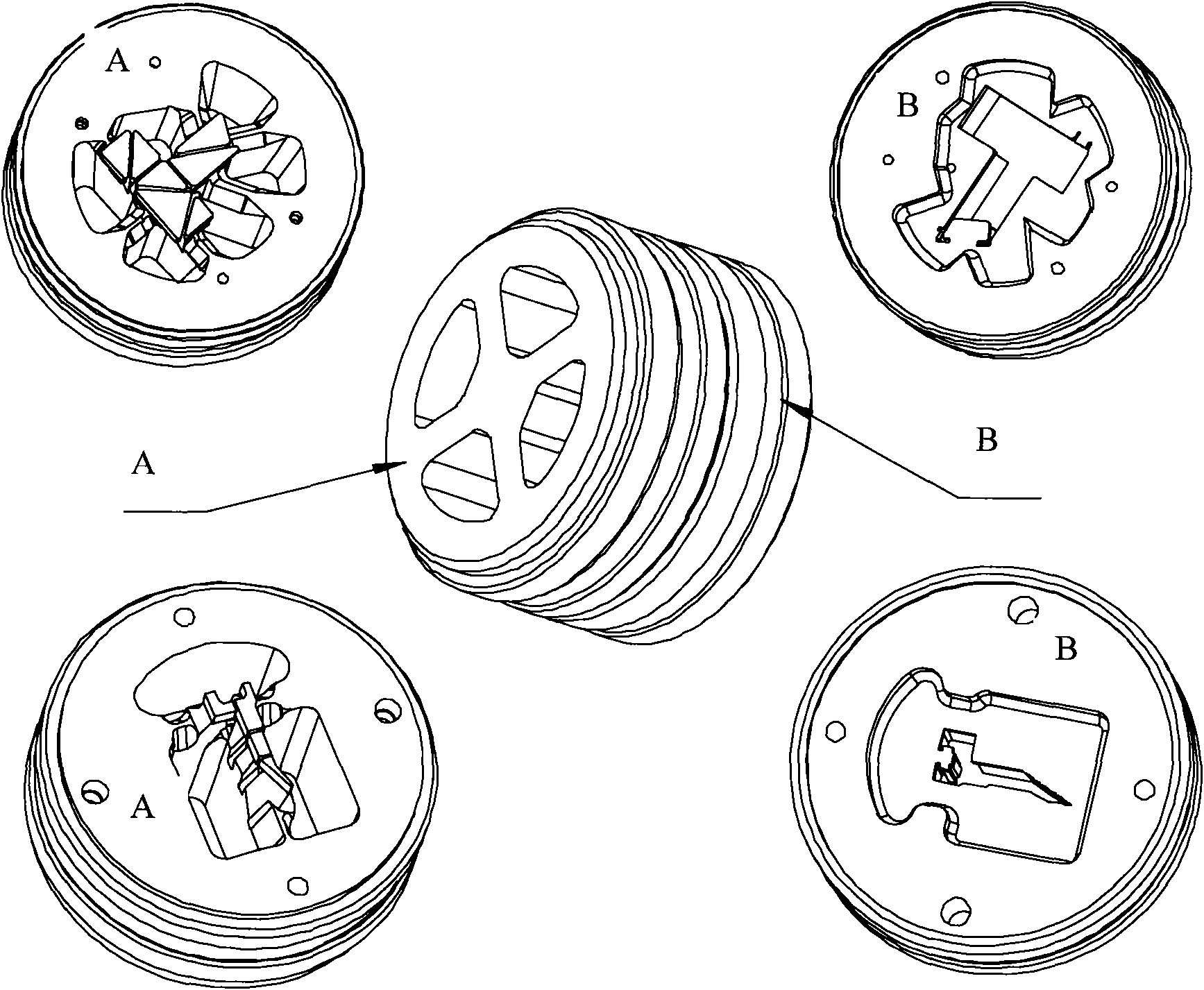

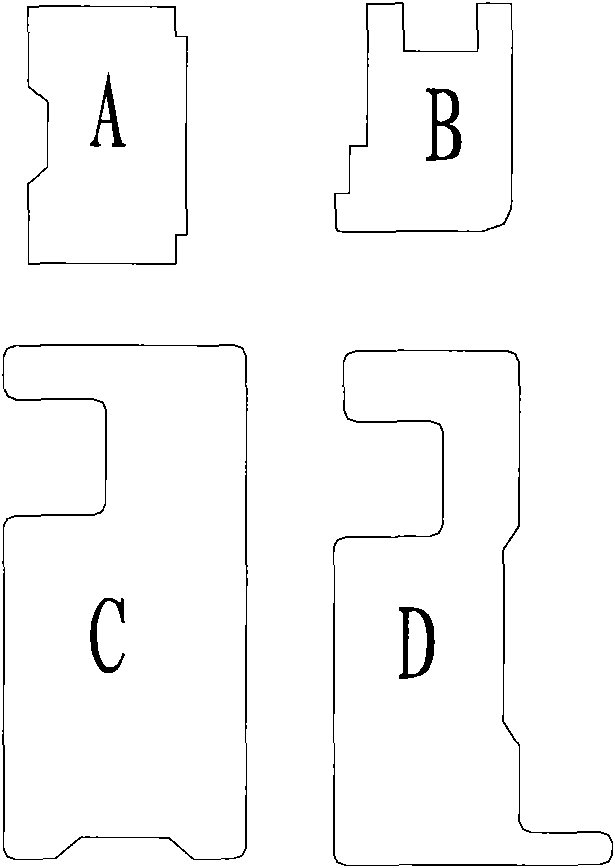

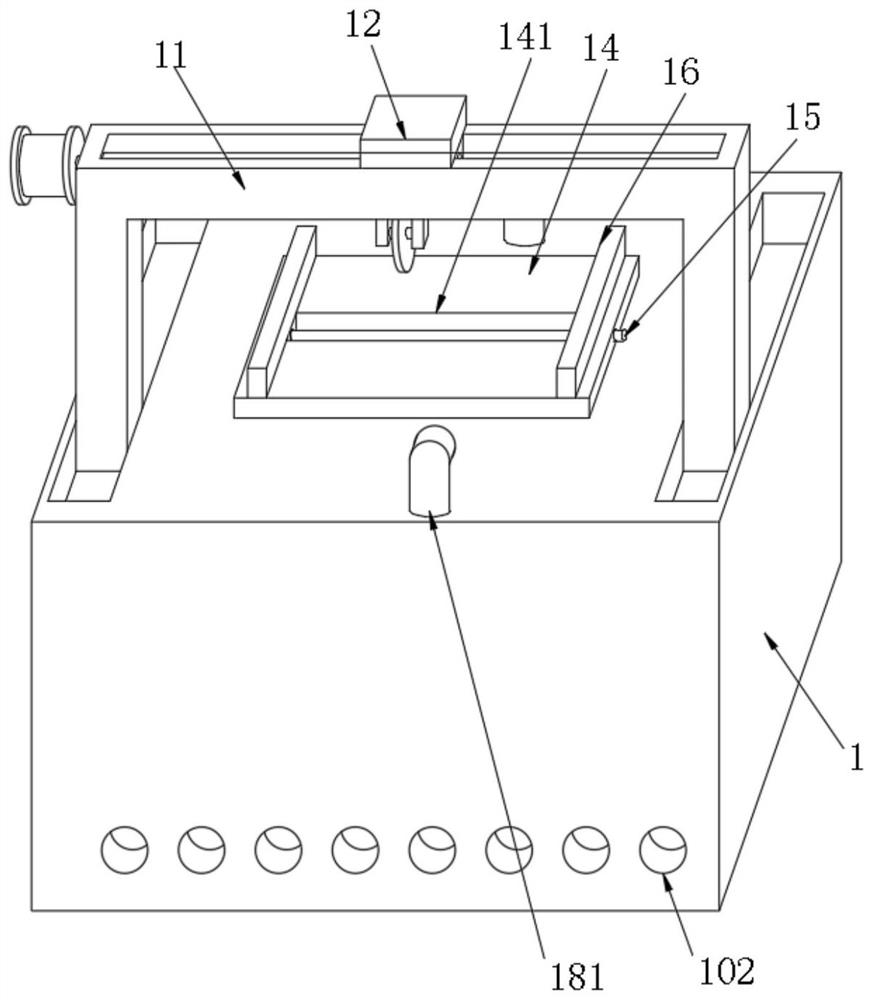

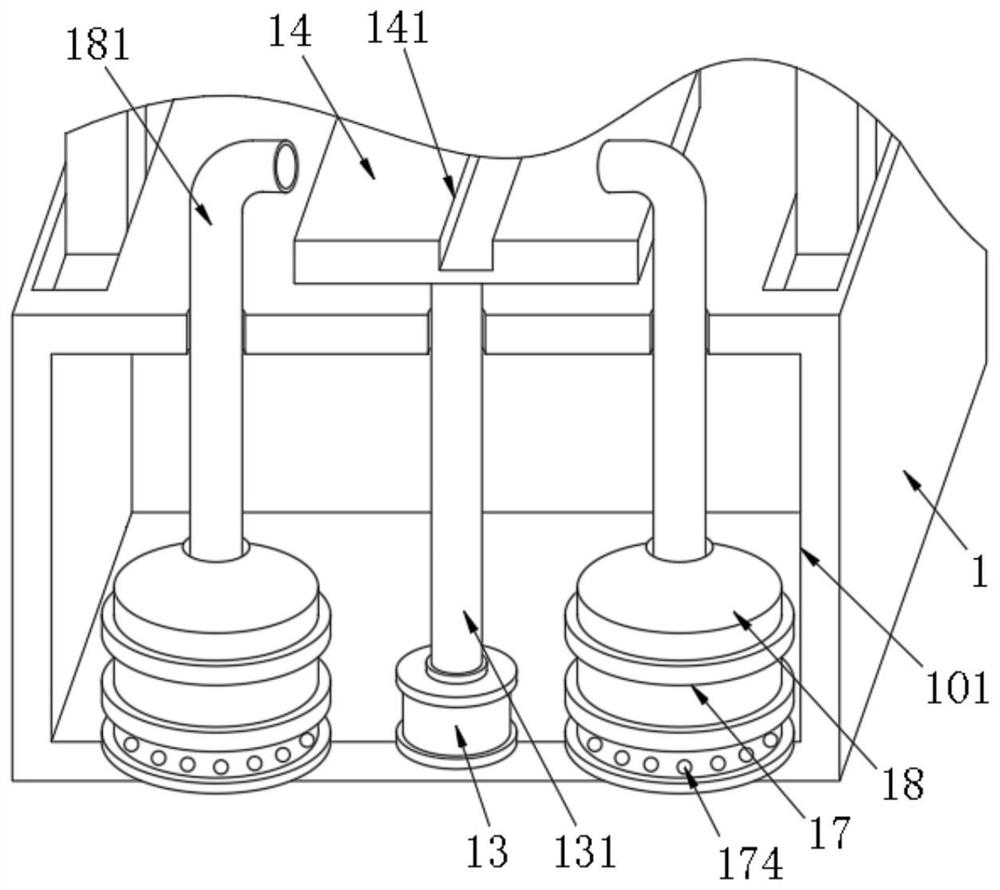

Mold of removing chips

InactiveUS20120079927A1High strengthLow production costAttachable planing devicesPlaning/slotting toolsEngineeringProcessing accuracy

Provided is a mold of removing chips for machining a product with center pins. The mold includes a plurality of first forming grooves disposed on an upper end thereof, a plurality of second forming grooves disposed on a lower end thereof, and at least two chip-removing grooves separately disposed on the upper and lower ends thereof. The first and second forming grooves separately divide the upper and lower ends into a plurality of upper and lower cores. The chip-removing grooves are separately cutting the first and second forming grooves. The chip-removing grooves can make the chips be easily removed out of the mold for preventing the chips from blocking up the first and second forming grooves and avoiding the deformation of the upper and lower cores, thereby enhancing the strength of the mold, elongating the useful life thereof and ensuring the machining precision of the product.

Owner:CHENG UEI PRECISION IND CO LTD

Power-saving control system of double housing planer

InactiveCN101829806BSimple and convenient speed adjustmentRealize stepless speed regulationAttachable planing devicesFrequency changerControl system

The invention discloses a power-saving control system of a double housing planer, which comprises a cabinet body, a main loop unit, a frequency converter VVVF control unit, a programmable controller (PLC) input and output unit, a cutter lifting and indicating lamp unit and a relay protection unit, wherein all the units are arranged in the cabinet body; a main circuit is connected with a lubricating motor RB, a vertical turret motor C, a right turret motor Y, a left turret motor Z, a cross beam lifting motor H and a cross beam clamping motor J through circuit breakers 1QF-7QF and contactors 1KM respectively; the frequency converter VVVF output is connected to a main motor M; and the PLC input and output unit consists of an input part and an output part. The power-saving control system of the double housing planer has the advantages of simple structure, strong reliability, convenient speed adjustment, energy conservation, running speed improvement and cutting efficiency improvement, andcan be widely applied to cutting mechanical equipment.

Owner:SHENYANG LIGONG UNIV

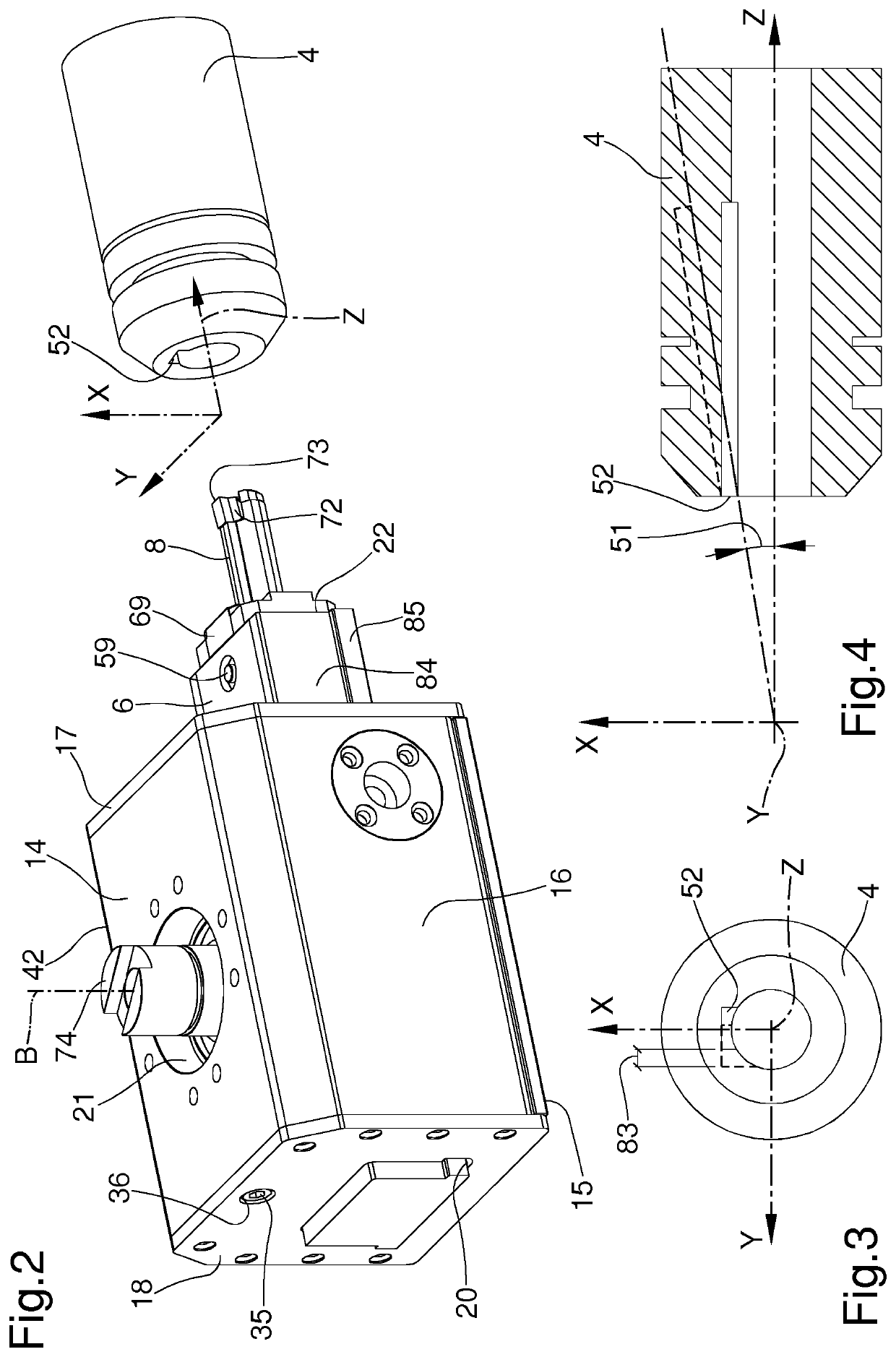

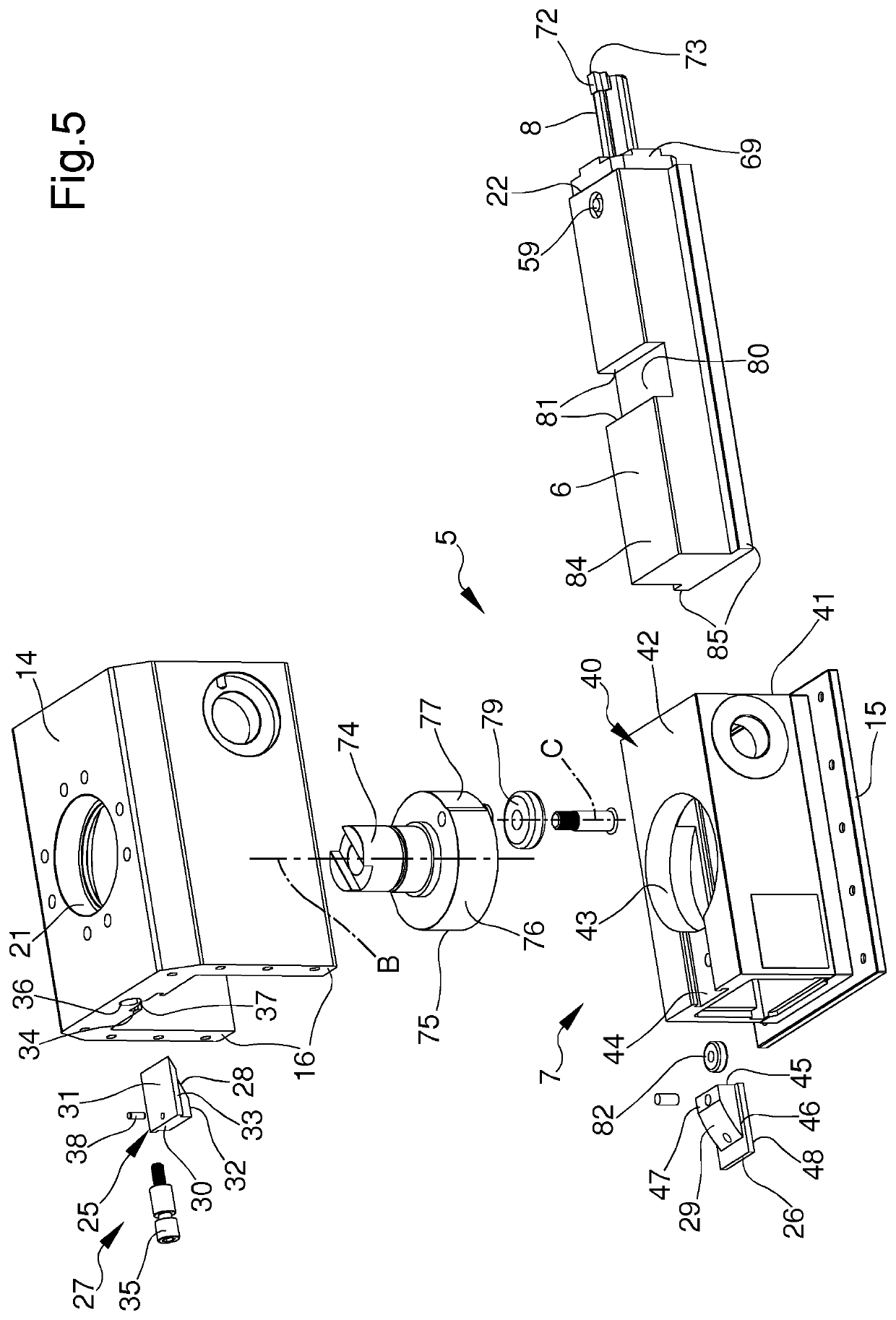

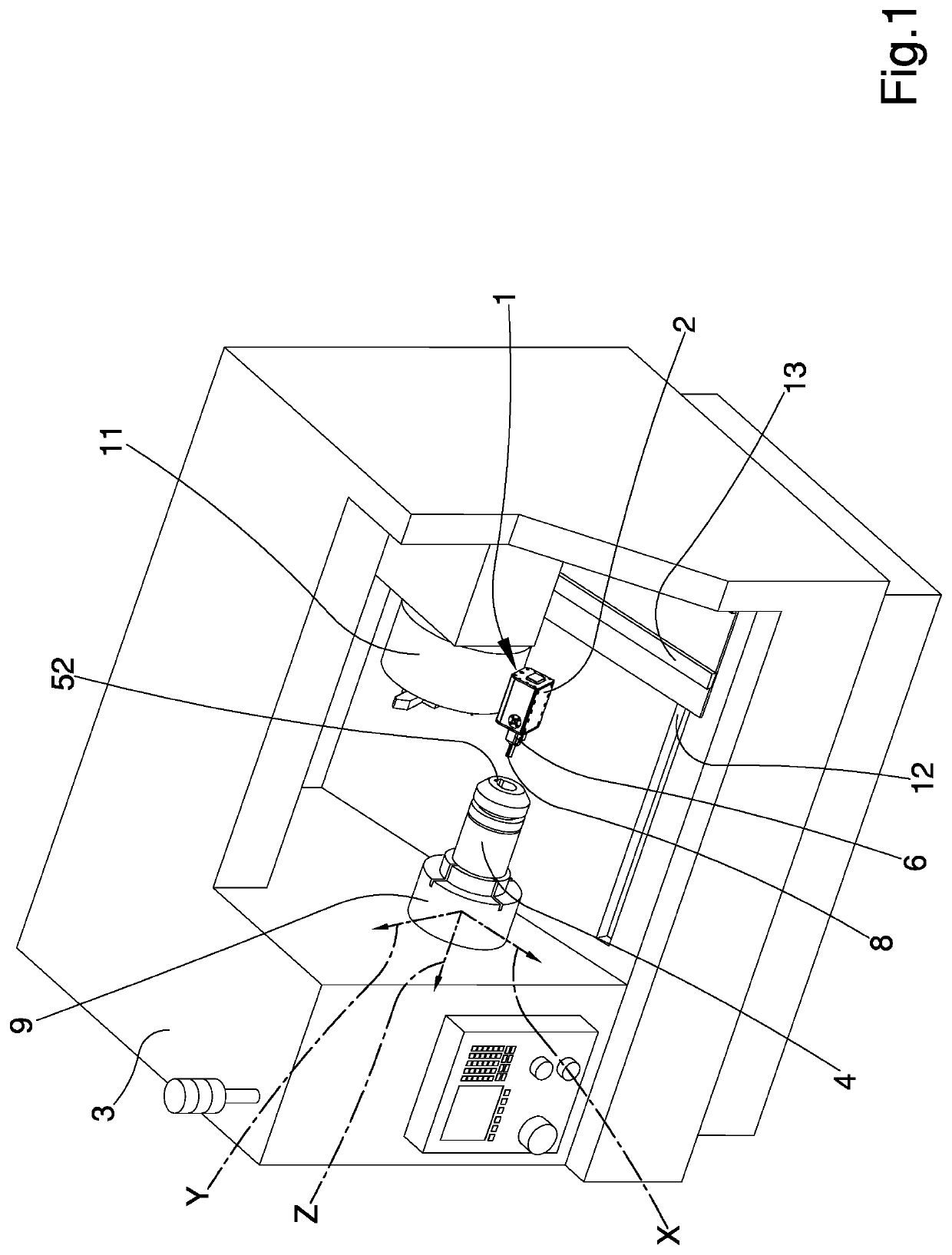

Tool holder device for broaching and slotting

ActiveUS11325197B2Effective and easy to useLow costAutomatic/semiautomatic turning machinesBroaching toolsEngineeringMachine

The tool holder device for broaching and slotting, comprising: one main frame associated with one machine adapted to machine one workpiece; one working assembly associated with the main frame and comprising one supporting bar movable longitudinally along a first axis and a guiding mechanism for the supporting bar movable longitudinally along the first axis; one tool associated with the supporting bar and adapted to machine the workpiece; angular adjustment mechanism for adjusting the supporting bar, interposed between the main frame and the guiding mechanism and adapted to rotate the supporting bar around a second axis substantially orthogonal with respect to the first axis; and straight adjustment mechanism for adjusting the tool with respect to the supporting bar, interposed between the tool and the supporting bar, the straight adjustment mechanism being adapted to adjust the position of the tool along the second axis.

Owner:REV S R L UNIPERSONALE

High-speed grooving method

ActiveUS10675688B2Efficient processingImprove machine efficiencyAuxillary equipmentAttachable planing devicesEngineeringMachining

A method for machining grooves in the surface of a workpiece in which a dummy groove is machined in the surface of the workpiece by moving a cutting tool relative to the workpiece in a first machining direction of the workpiece, then orienting the cutting tool 180 degrees as compared to the first machining, and subsequently second machining the dummy groove by moving the cutting tool in a second direction opposite to the first direction. A displacement of a cutting edge of the cutting tool, caused by the first and second machining of the dummy groove is measured. A groove is machined with the cutting tool in a forward stroke and then a return stoke with the cutting tool rotated 180 degrees between the strokes. A relative position between the workpiece and the cutting tool during the forward and return strokes is corrected so as to eliminate the displacement.

Owner:TOSHIBA MASCH CO LTD

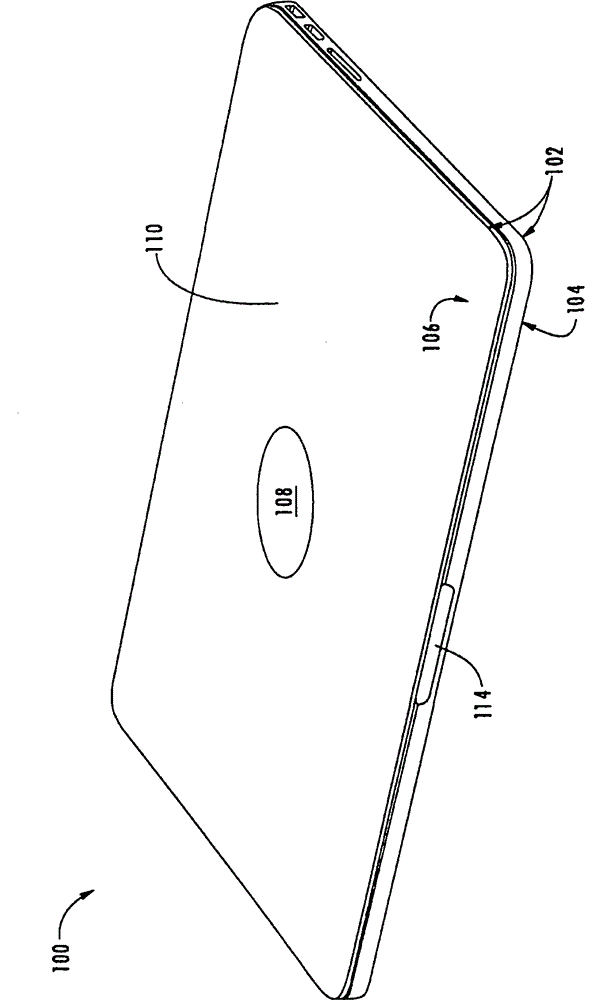

Retrofit for current CNC machines to allow for 'shaping' style machining process

An apparatus configured to convert a rotary machine to a non-rotary machine is provided. The apparatus may include a tool body that engages a rotary head of a CNC mill and a rotation restraint member that is fixed at a stationary position relative to a rotational axis of the rotary head. An arm of the tool body may engage the rotation restraint member to prevent rotation of the tool body. A cutting tool may be coupled to the tool body such that rotation thereof is also fixed. The arm of the tool body may include an elongated aperture that allows for slight pivoting of the tool body and the cutting tool to facilitate chip removal and cutting in opposing directions. Related methods are also provided.

Owner:APPLE INC

Tool holder device for broaching and slotting

ActiveUS20200164448A1Effective and easy to useLow costBroaching toolsAttachable planing devicesStructural engineeringMachine

The tool holder device for broaching and slotting, comprising: —one main frame associated with one machine adapted to machine one workpiece; —one working assembly associated with the main frame and comprising one supporting bar movable longitudinally along a first axis and guiding means of the supporting bar movable longitudinally along the first axis; —one tool associated with the supporting bar and adapted to machine the workpiece; —angular adjustment means for adjusting the supporting bar, interposed between the main frame and the guiding means and adapted to rotate the supporting bar around a second axis substantially orthogonal with respect to the first axis; and —straight adjustment means for adjusting the tool with respect to the supporting bar, interposed between the tool and the supporting bar, the straight adjustment means being adapted to adjust the position of the tool along the second axis.

Owner:REV S R L UNIPERSONALE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com