Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

132results about "Applying/manufacturing slot closures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

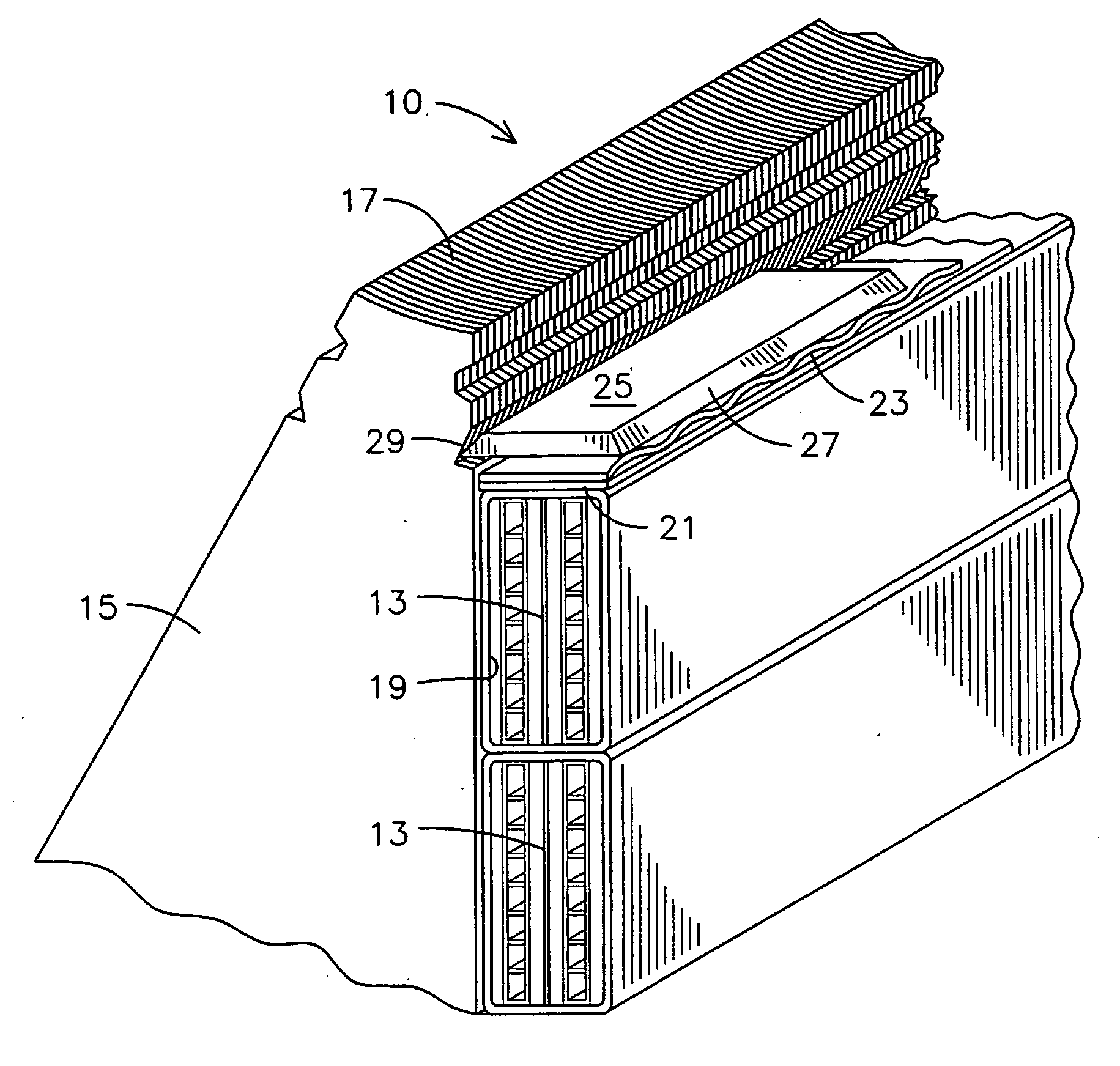

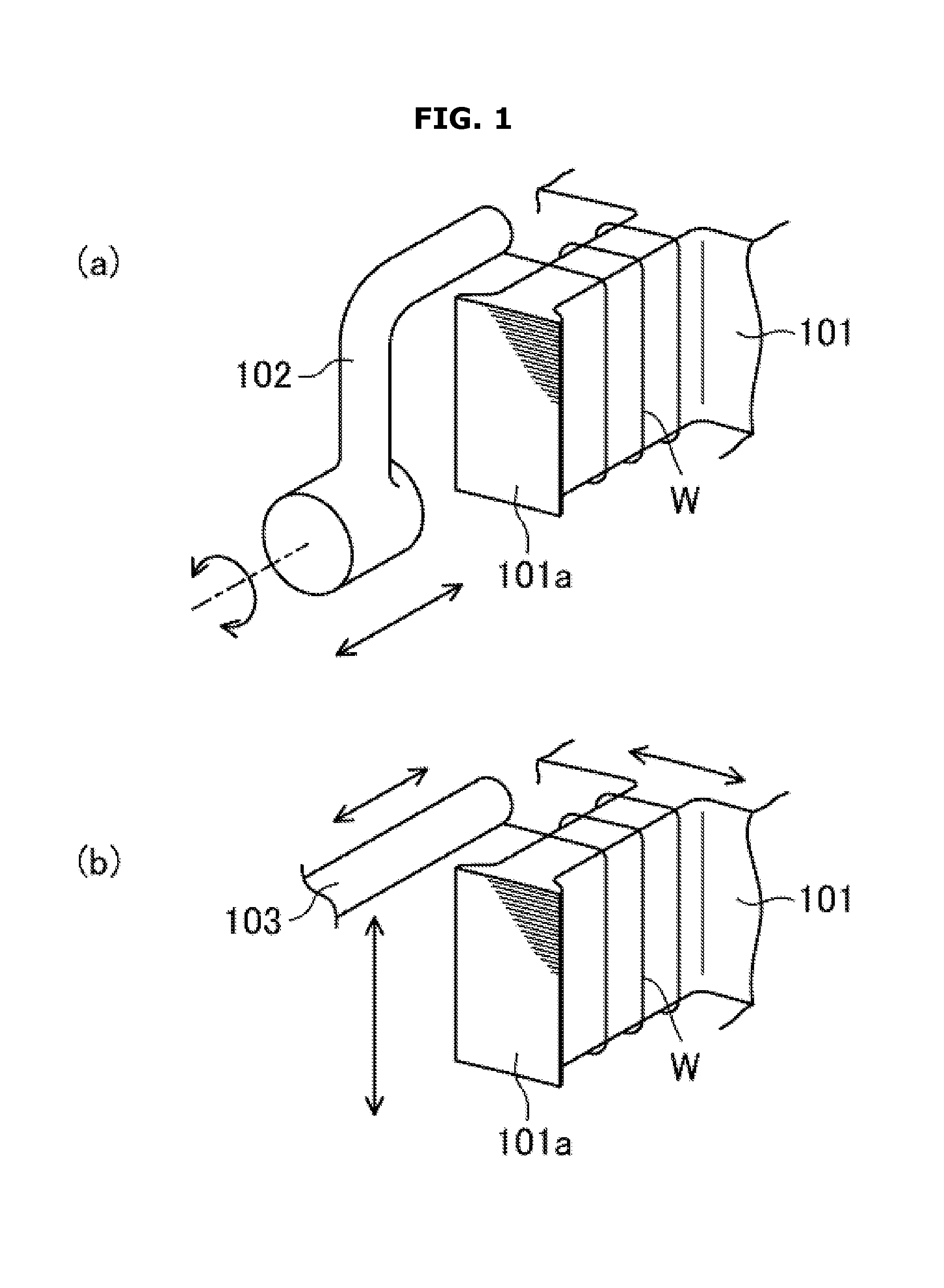

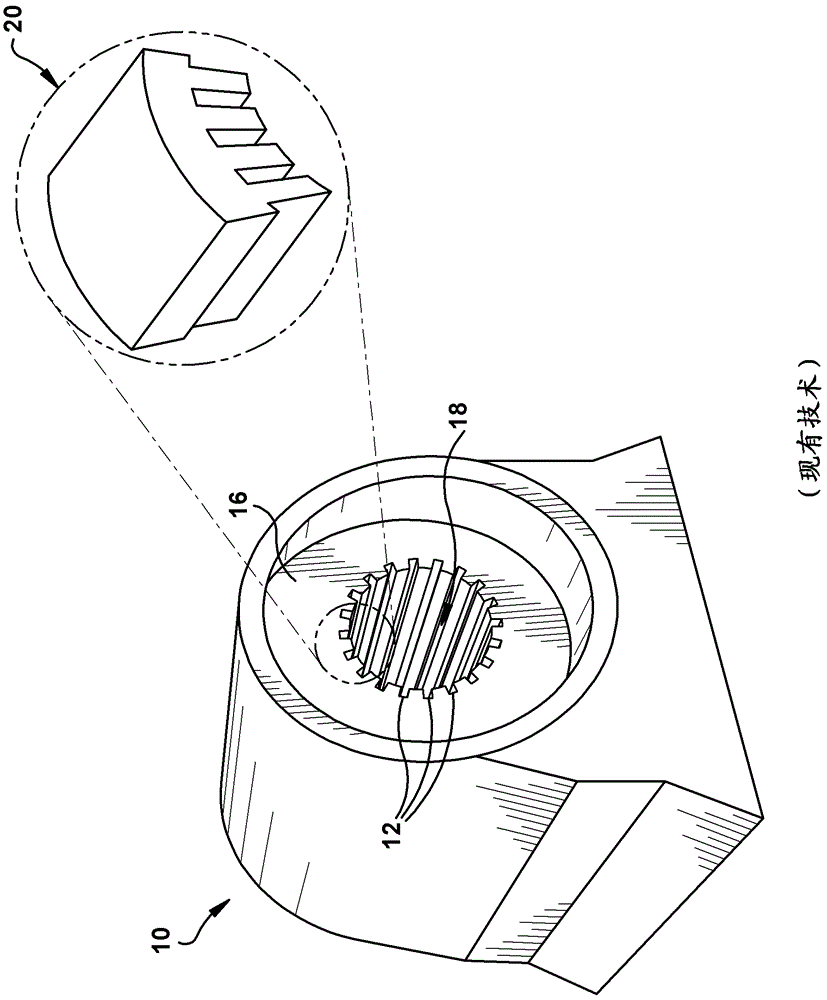

Automated remote carriage for tightening generator wedges

ActiveUS7866421B2Increase widthDigital data processing detailsColor television detailsRemote controlMachine maintenance

Owner:SIEMENS ENERGY INC

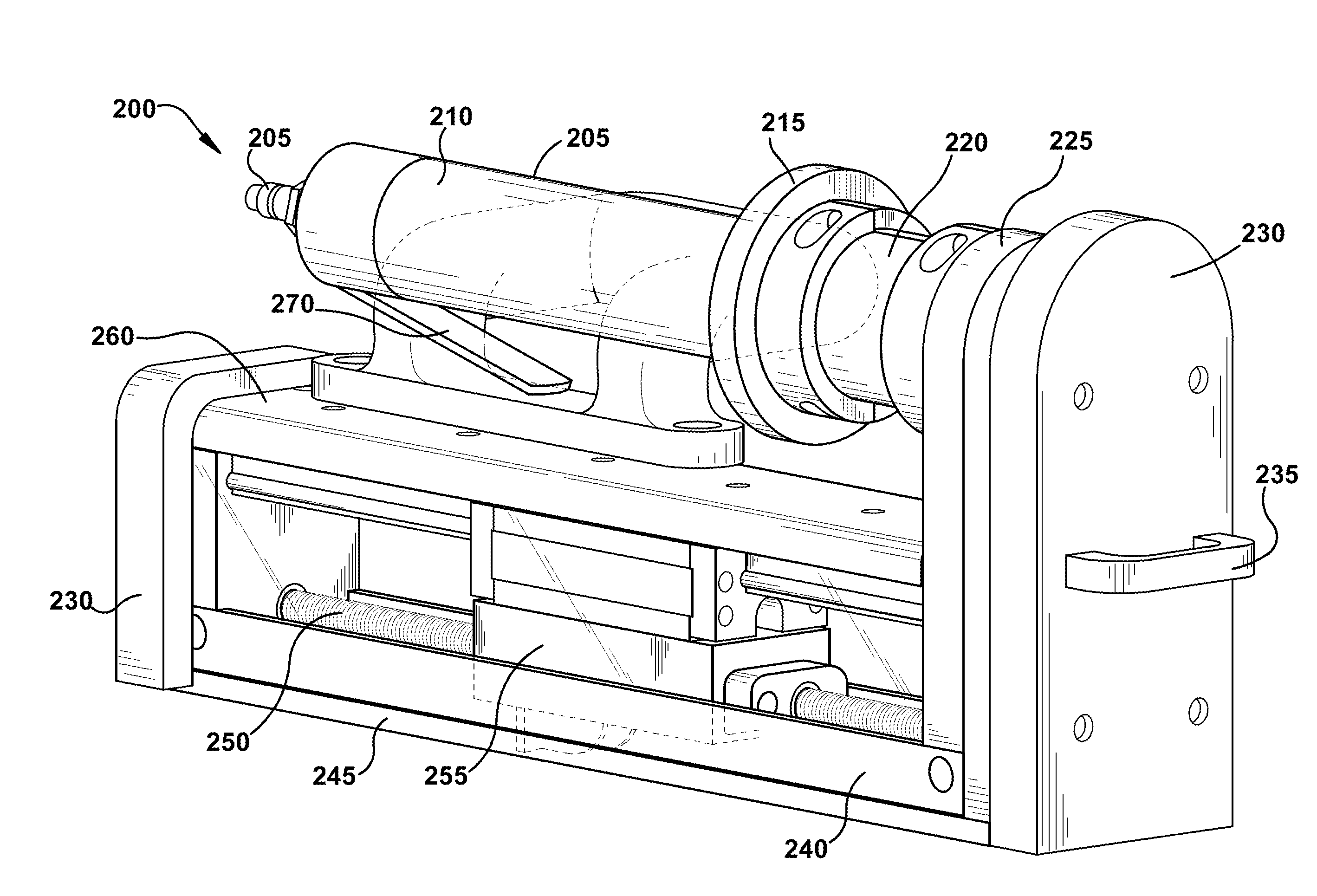

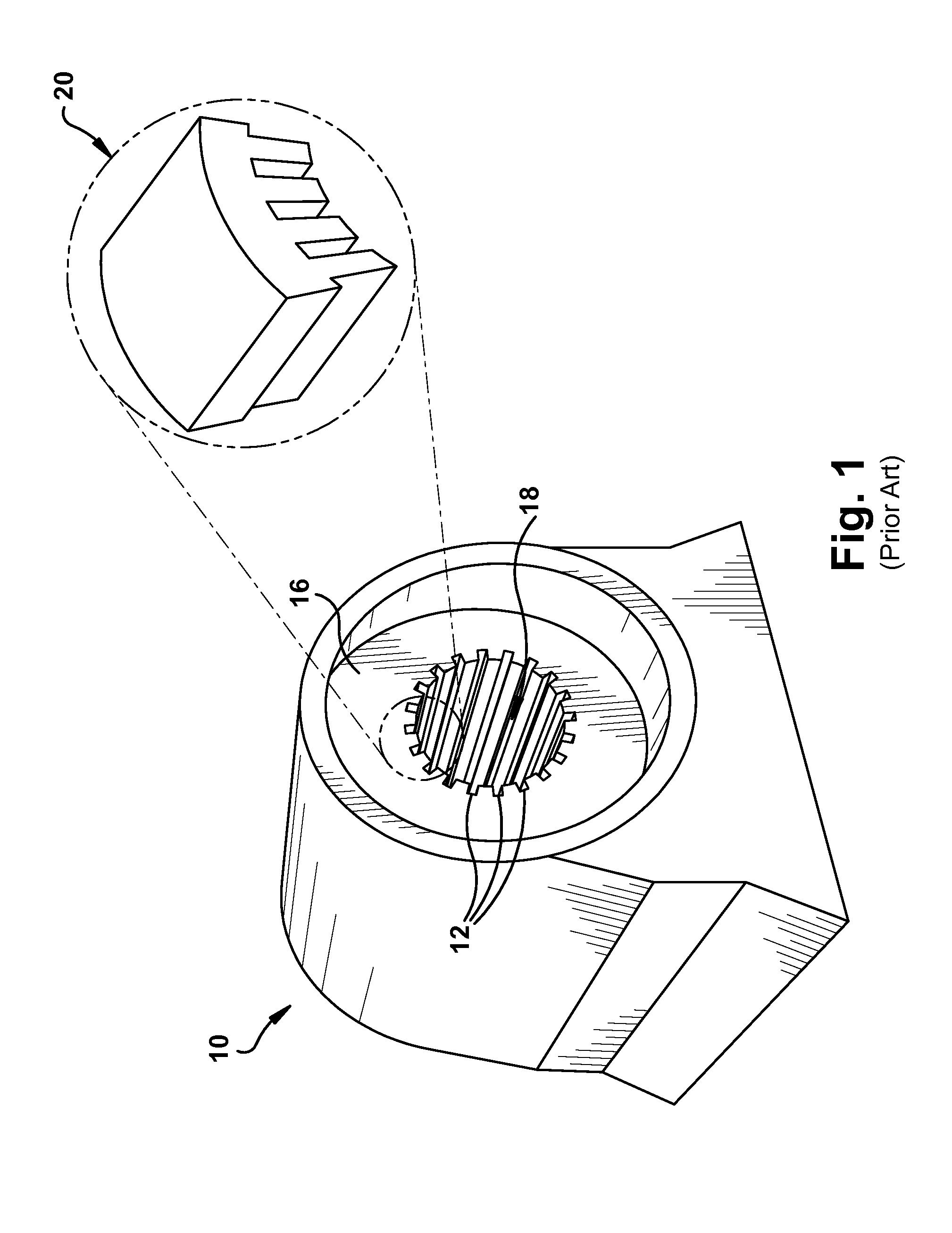

Apparatus and methods for removing wedges of a stator core of an electrical machine

The wedge removal apparatus includes an elongated frame having telescopic elements at opposite ends with cylinders to engage pads along opposite sides of the frame against diametrically opposed wedges of stator core slots. The frame mounts a linear drive assembly carrying a carriage for longitudinal movement relative to the drive assembly and frame. The carriage mounts diametrically opposed heads and a cylinder displaces the heads radially outwardly to engage the wedges and compress underlying ripple springs. Saws carried by the heads cut through the wedges as the carriage is displaced along the frame and without binding because of the force applied to the wedges compressing the ripple springs. The linear drive assembly is rotated to discrete circumferential positions to cut the wedges of additional diametrically opposed slots.

Owner:GENERAL ELECTRIC CO

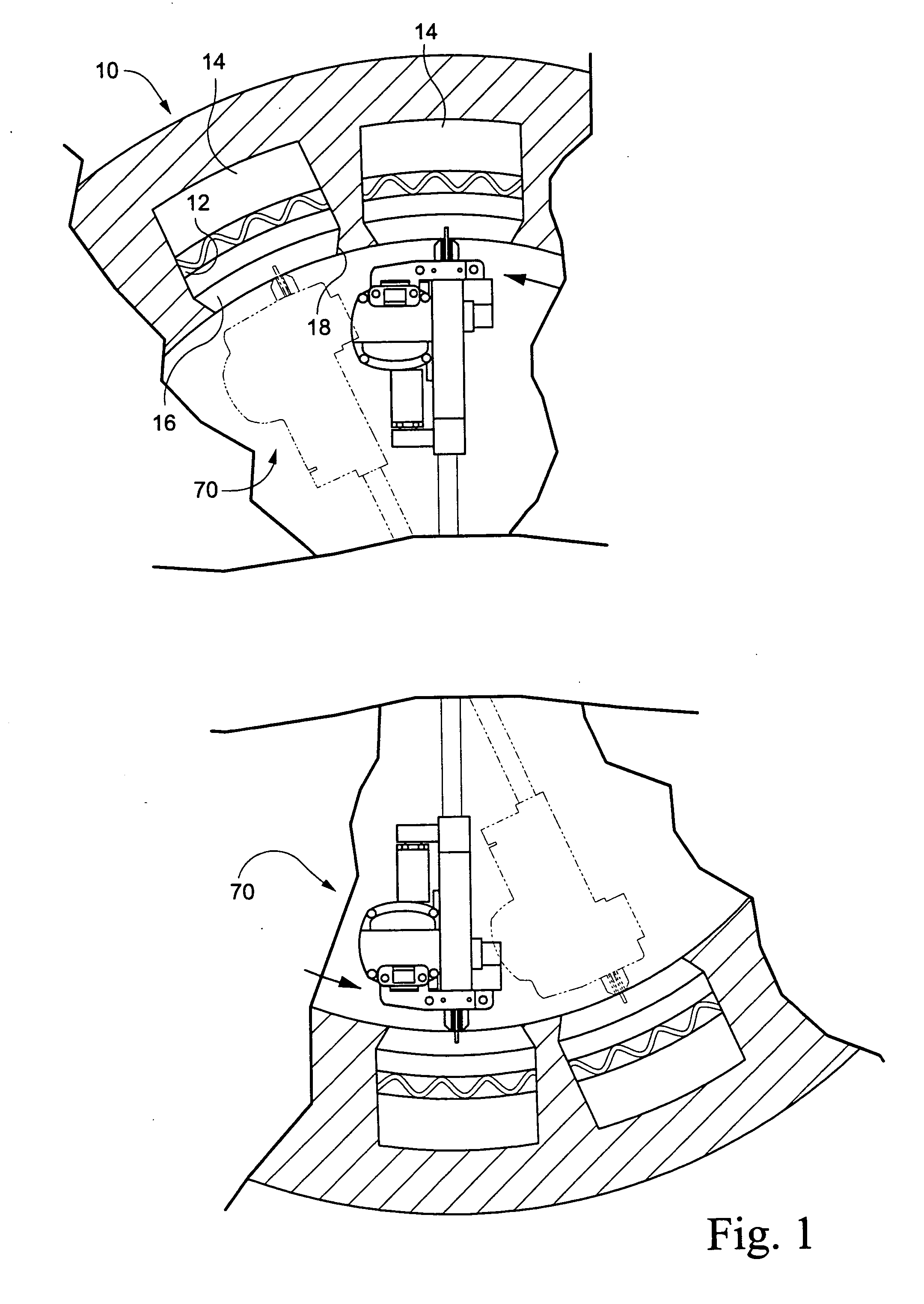

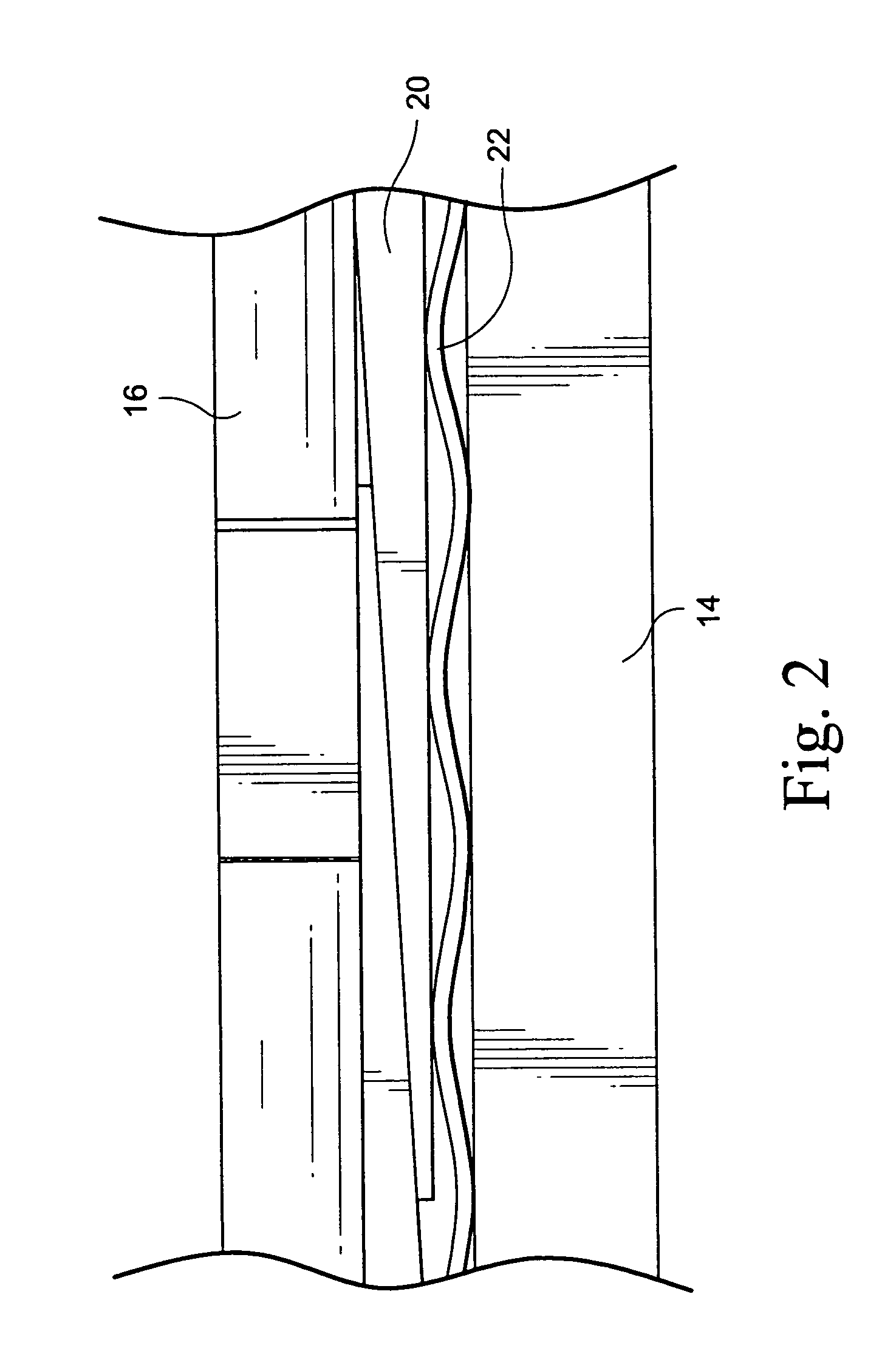

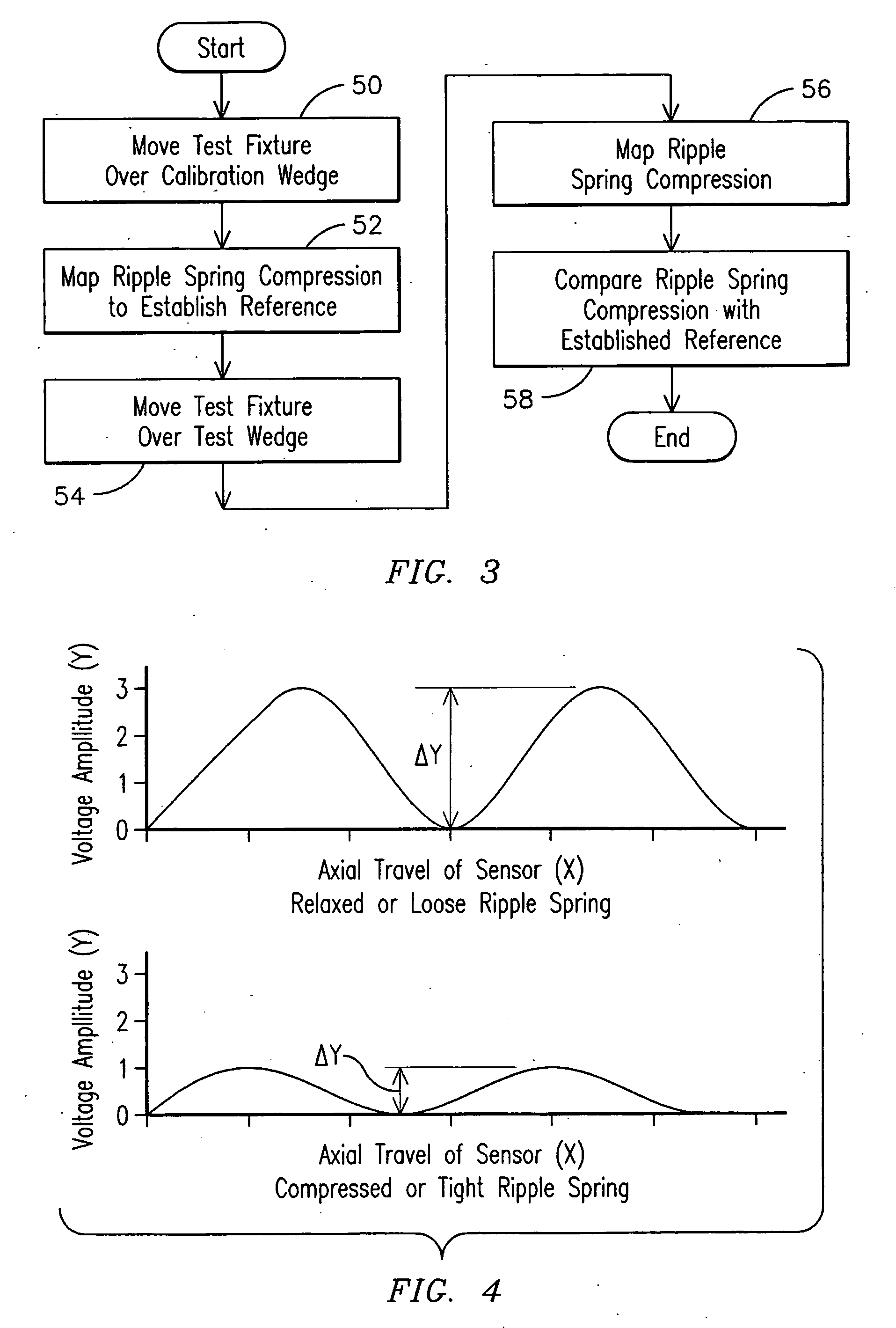

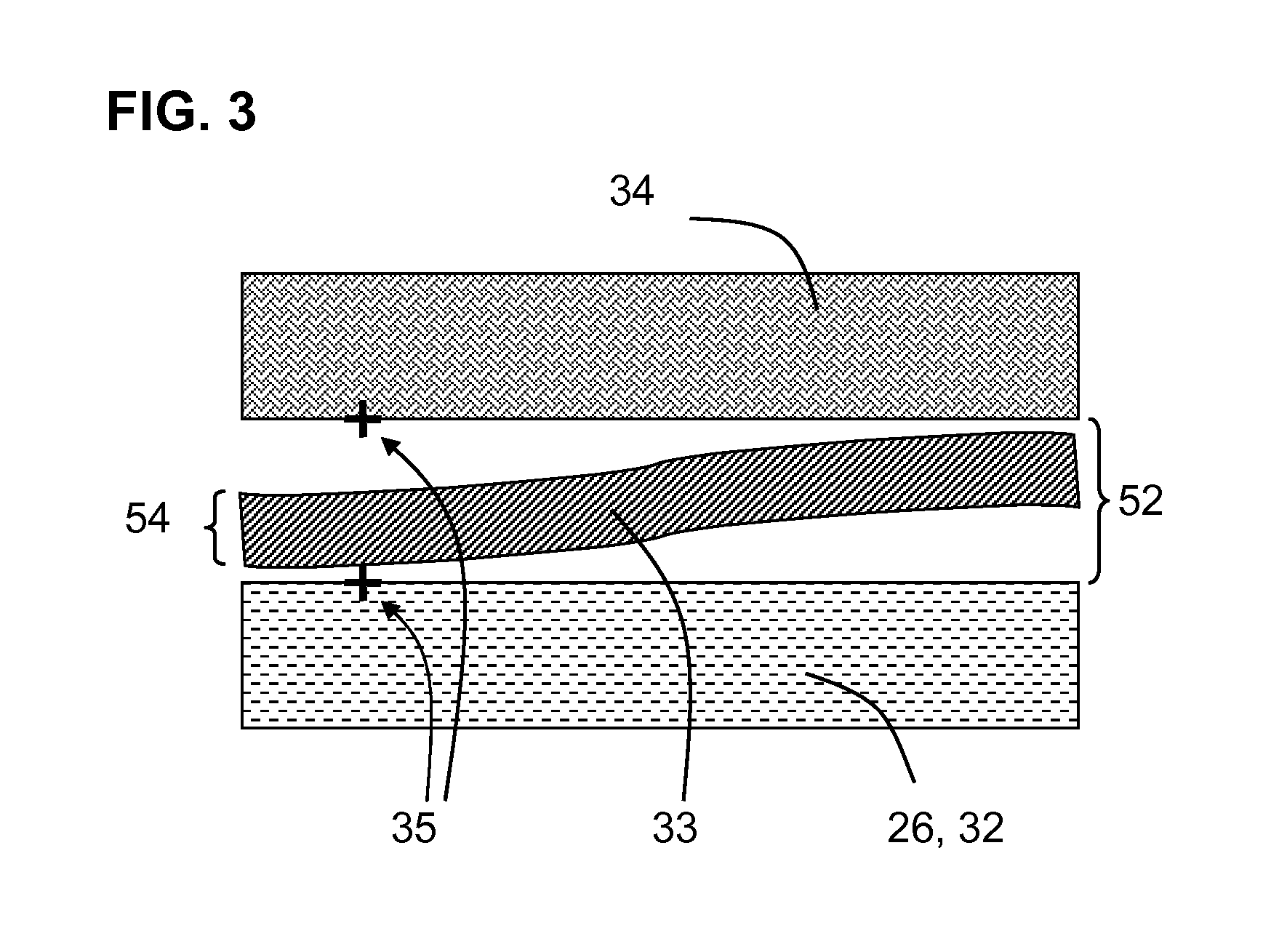

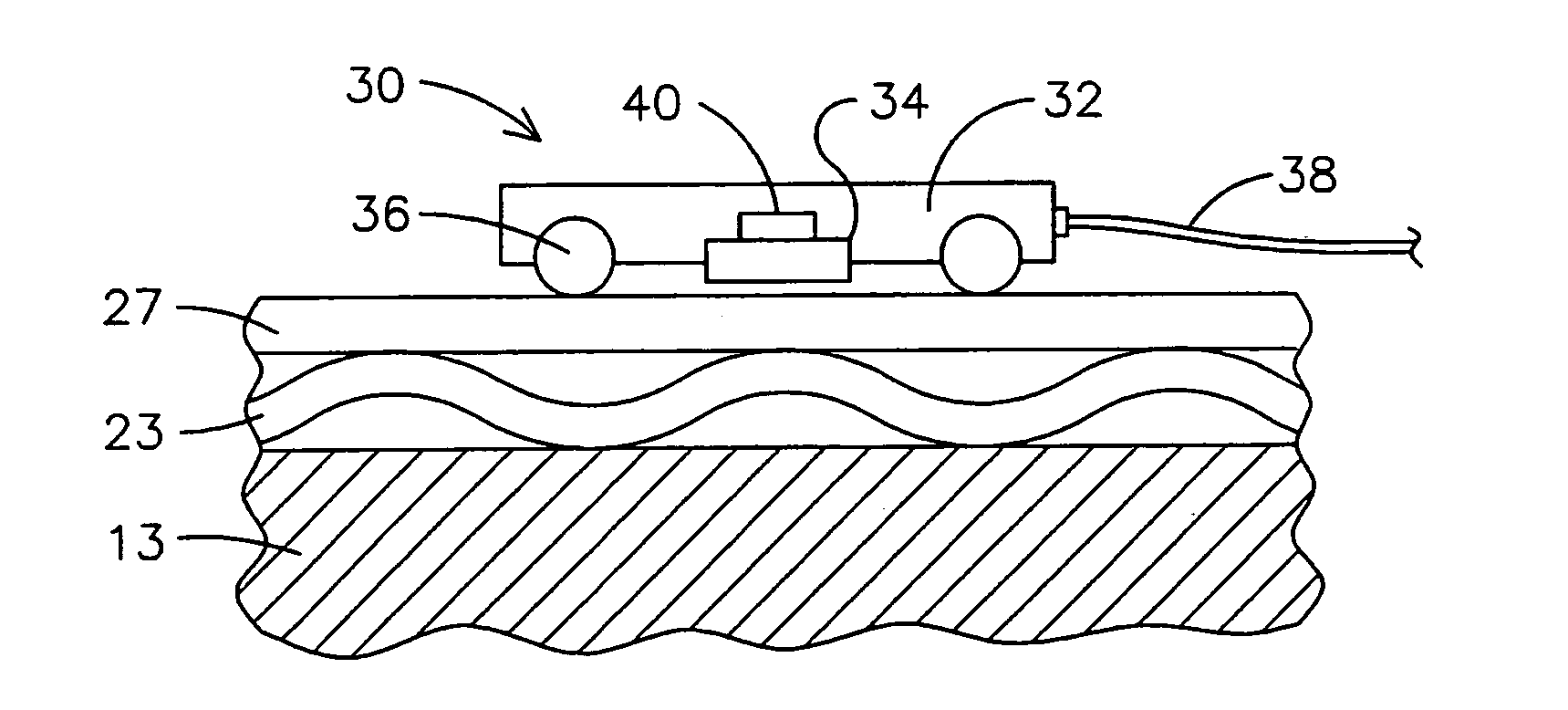

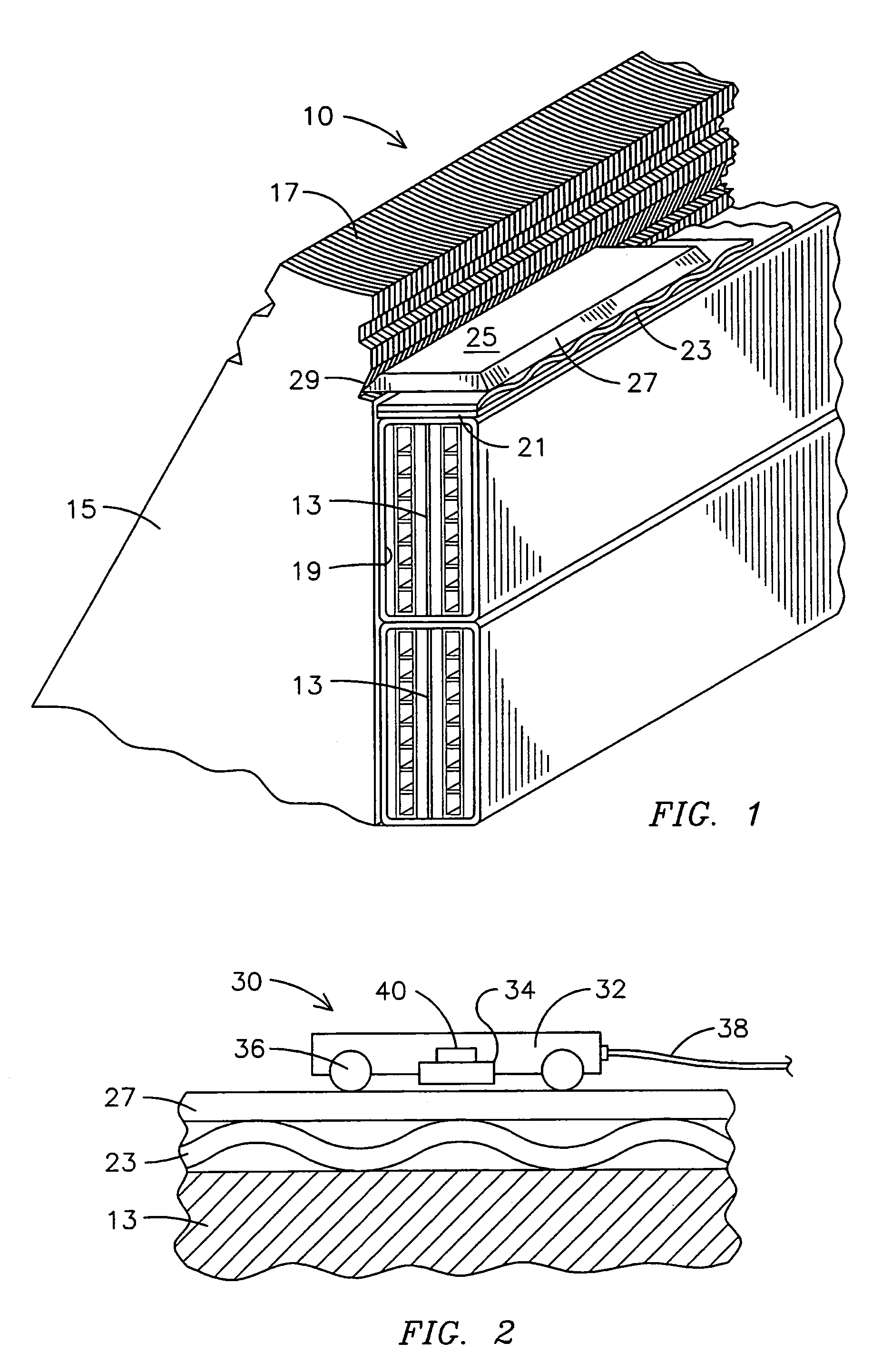

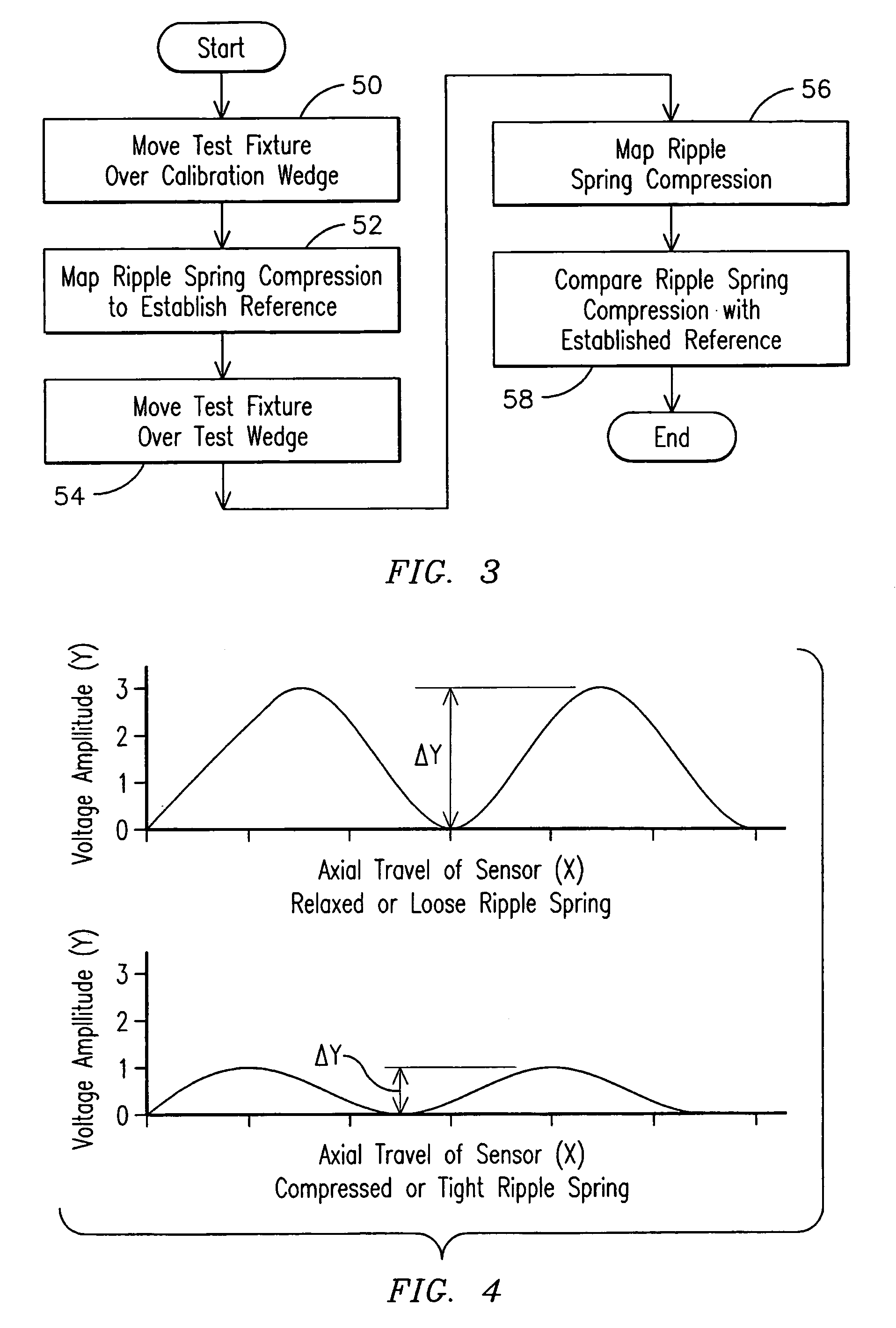

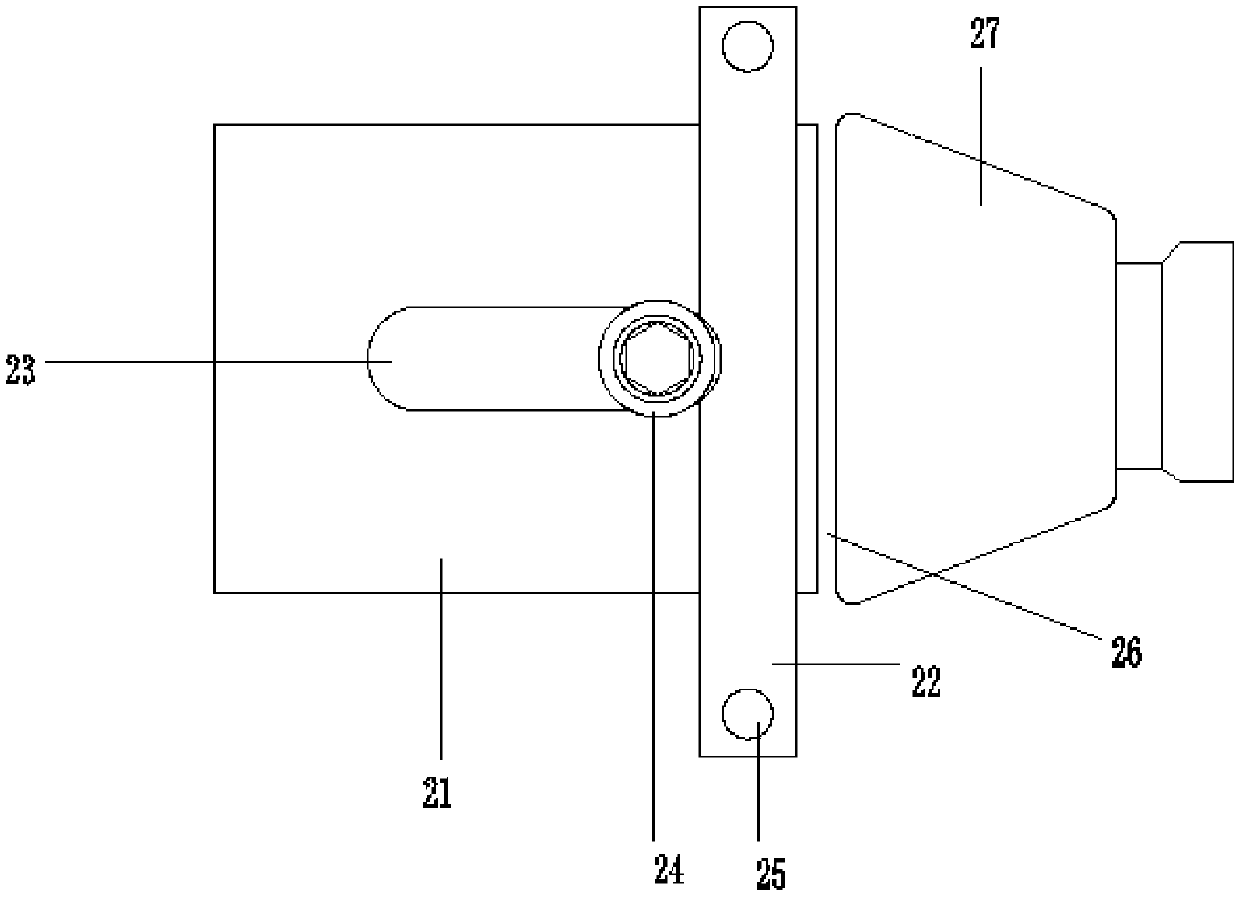

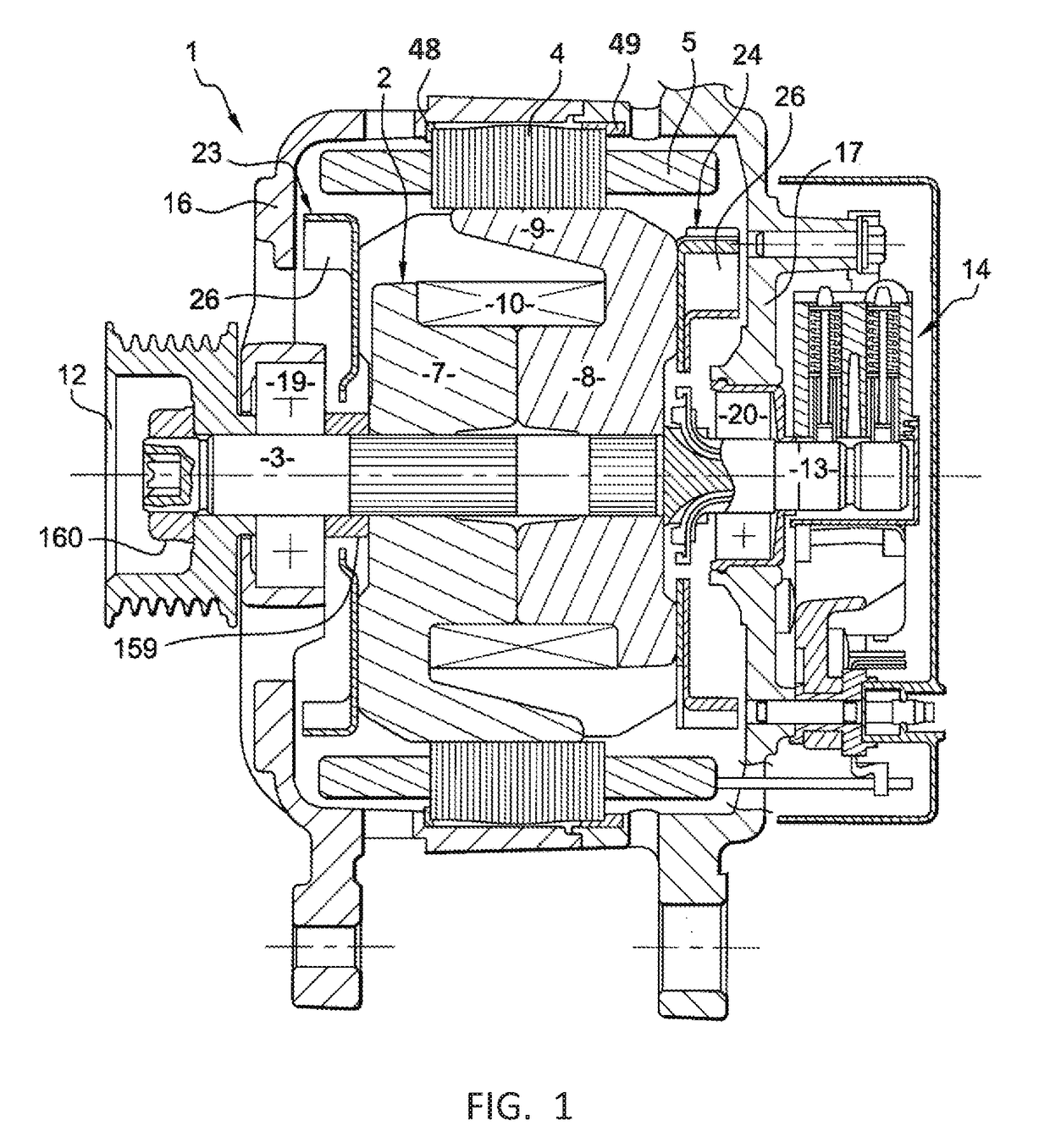

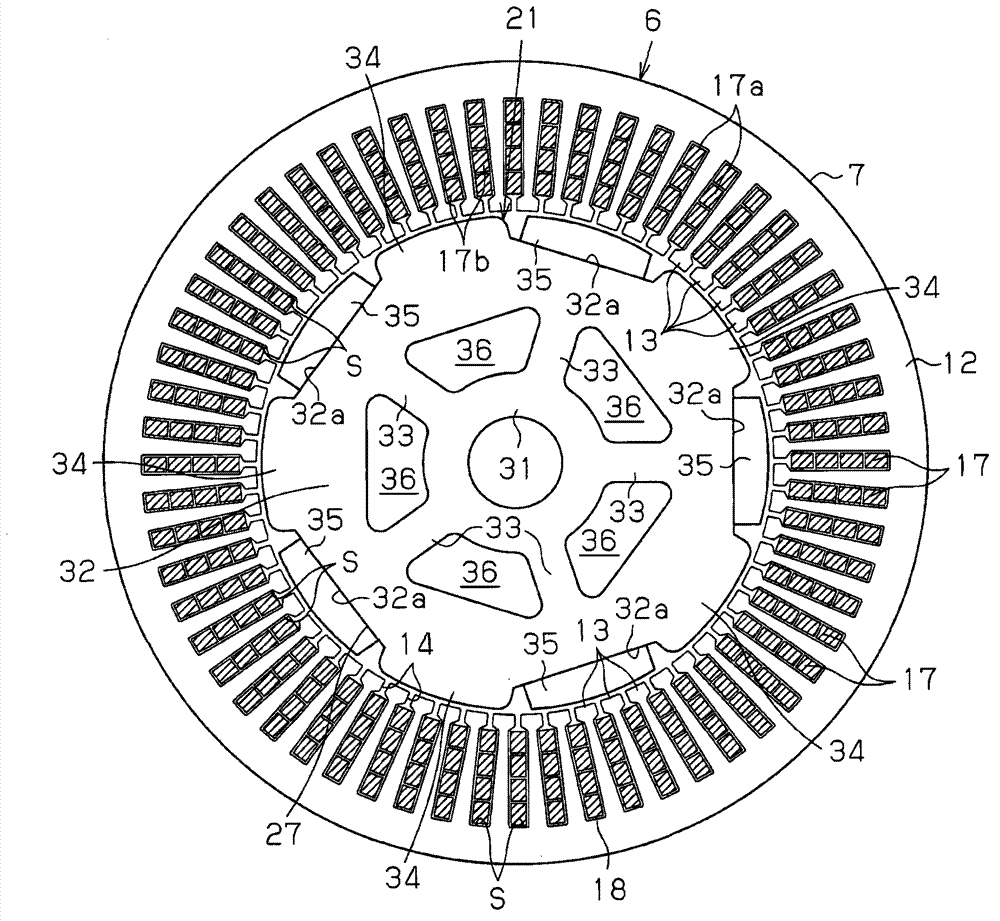

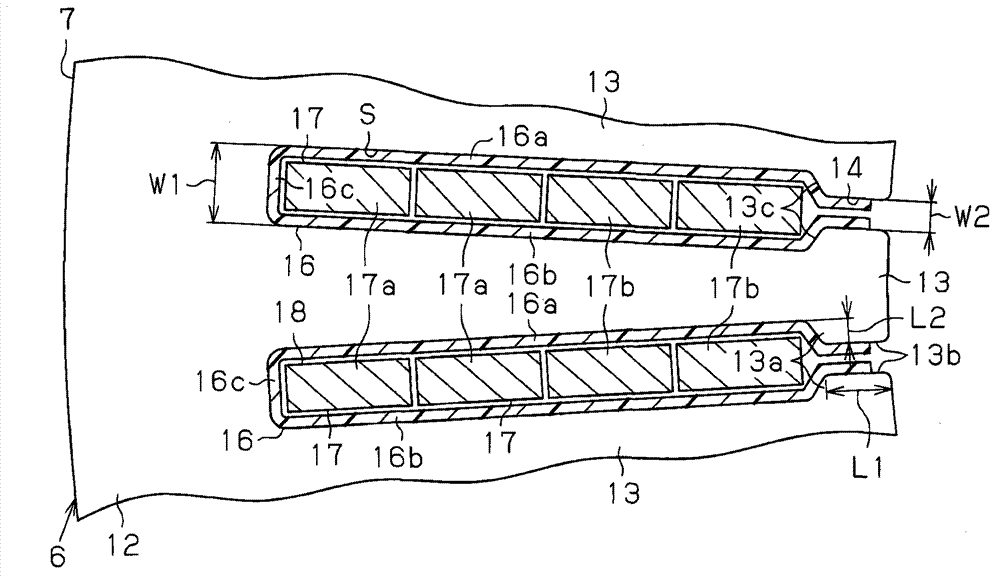

Method and system for ripple-spring compression assessment

InactiveUS20060283234A1WindingsMaterial strength using tensile/compressive forcesProximity sensorEngineering

A method and system for directly measuring the compression of a ripple spring (23) in a dynamoelectric machine through a corresponding wedge (27). A compression-assessment tool (3) is provided that includes a carriage (32) for supporting a proximity sensor (34). The carriage (32) enables the proximity sensor (34) to be passed over the length of the ripple spring (23), which produces an output signal that is representative of the compression of the ripple spring (23).

Owner:SIEMENS ENERGY INC

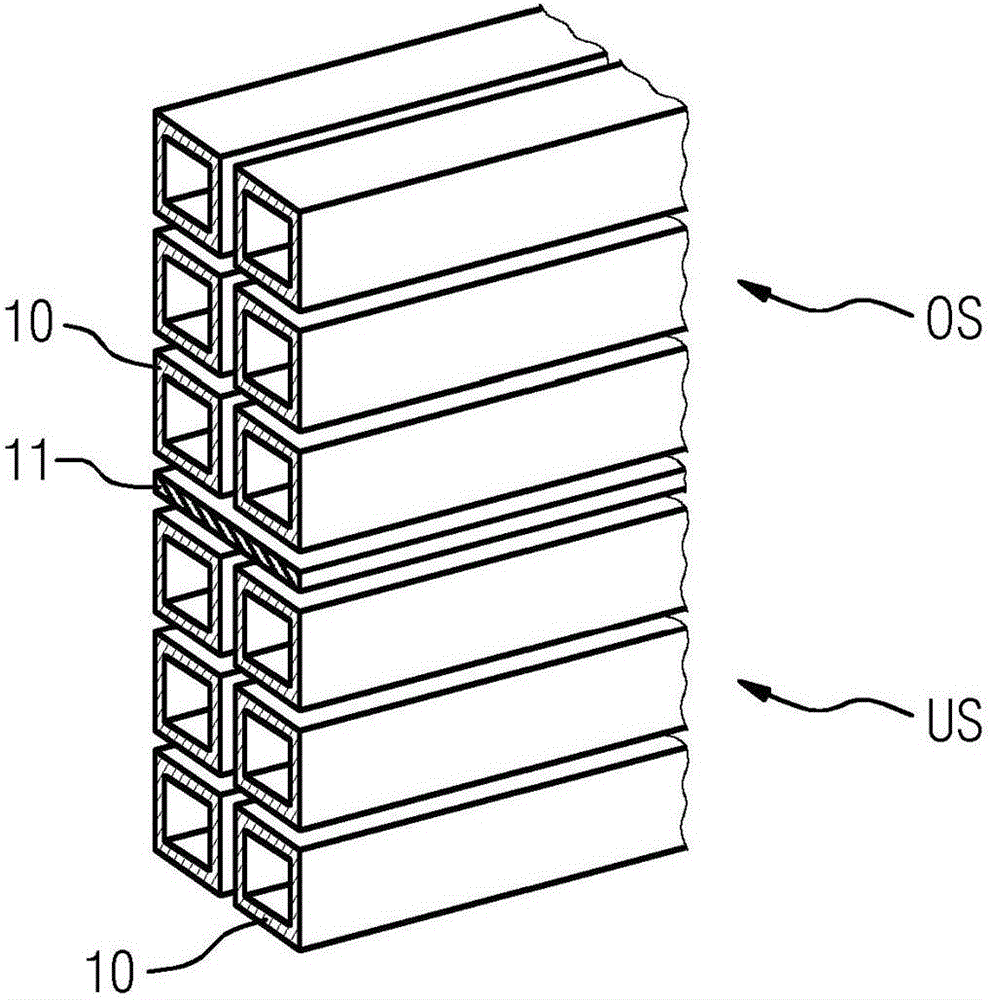

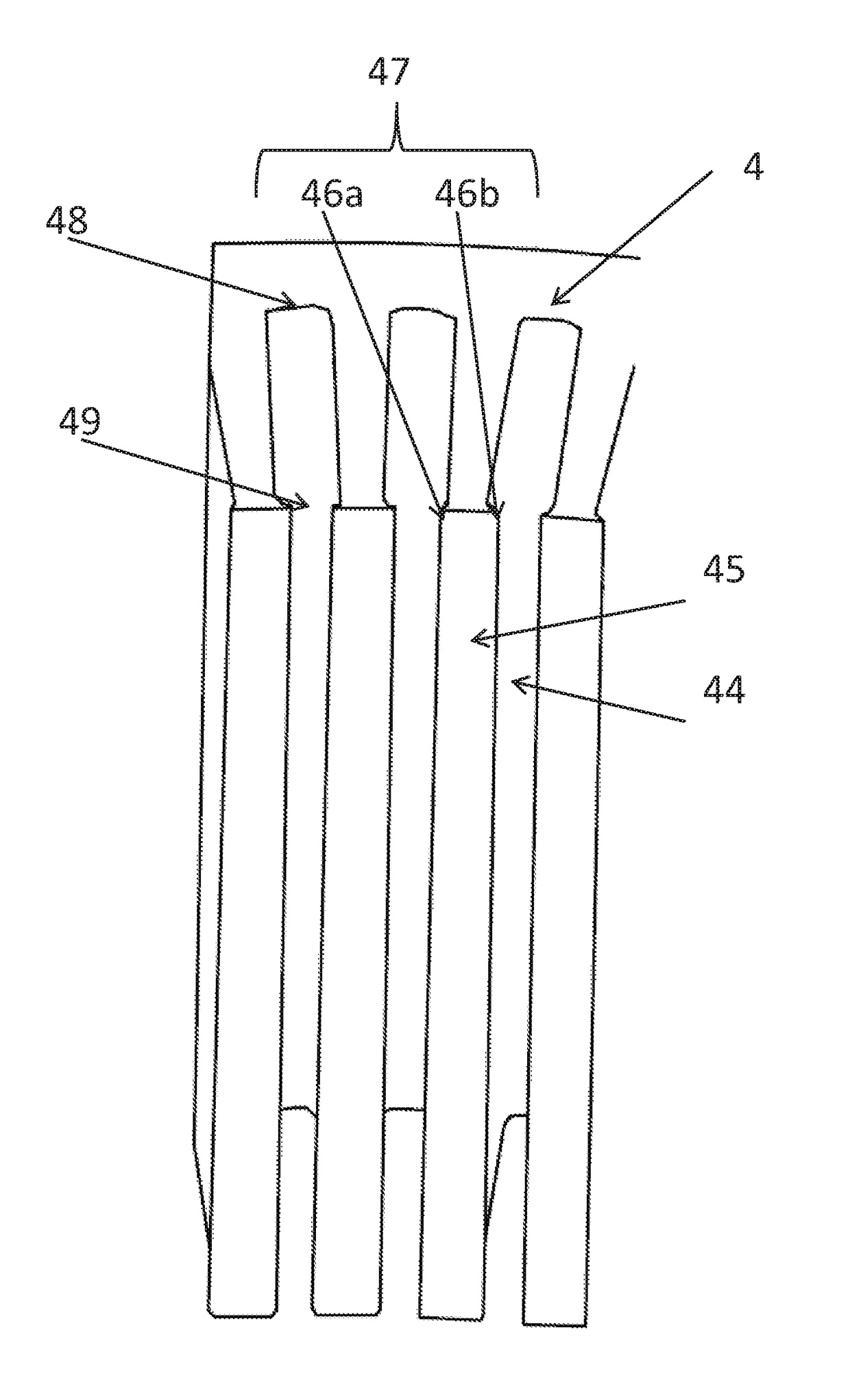

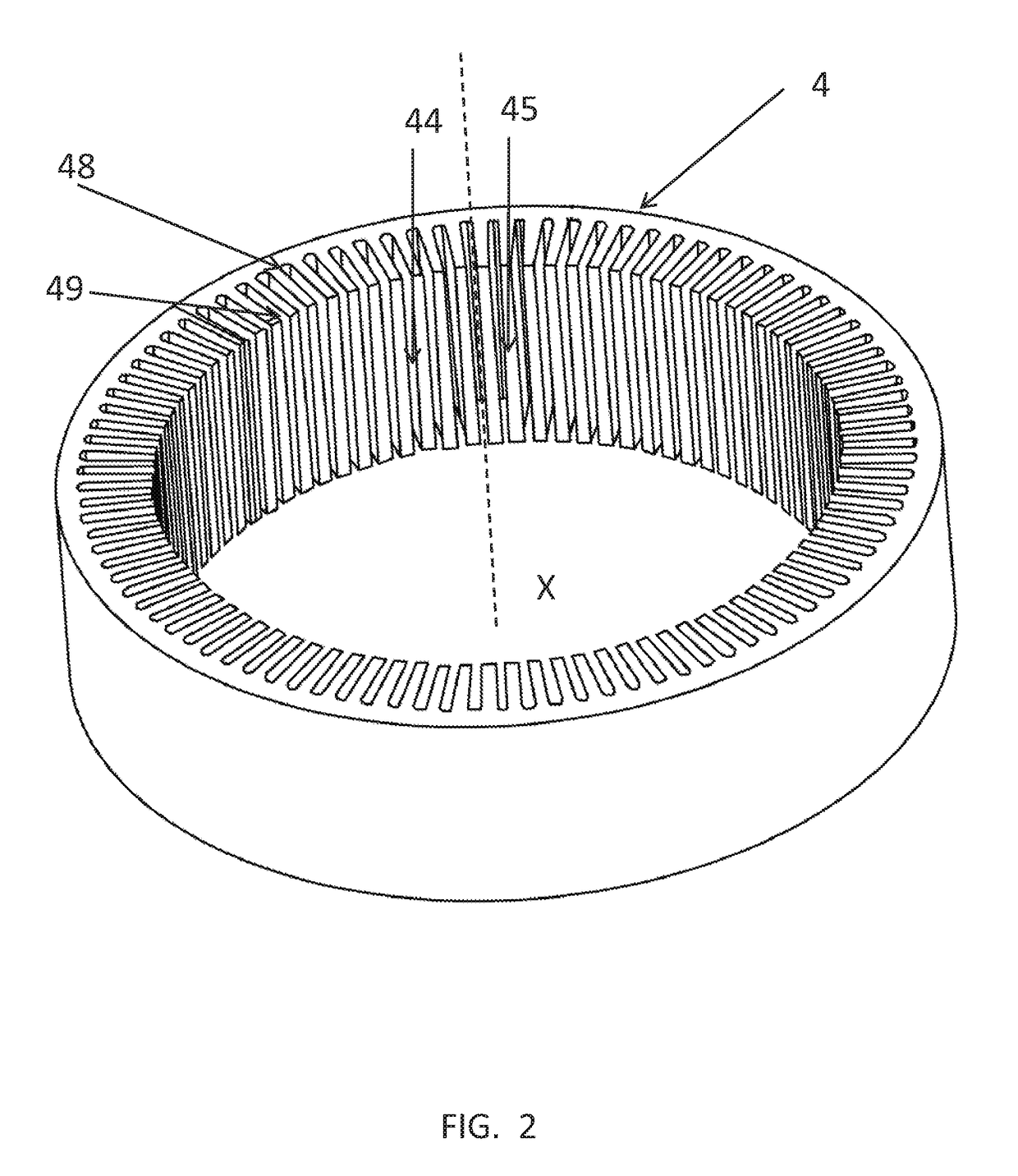

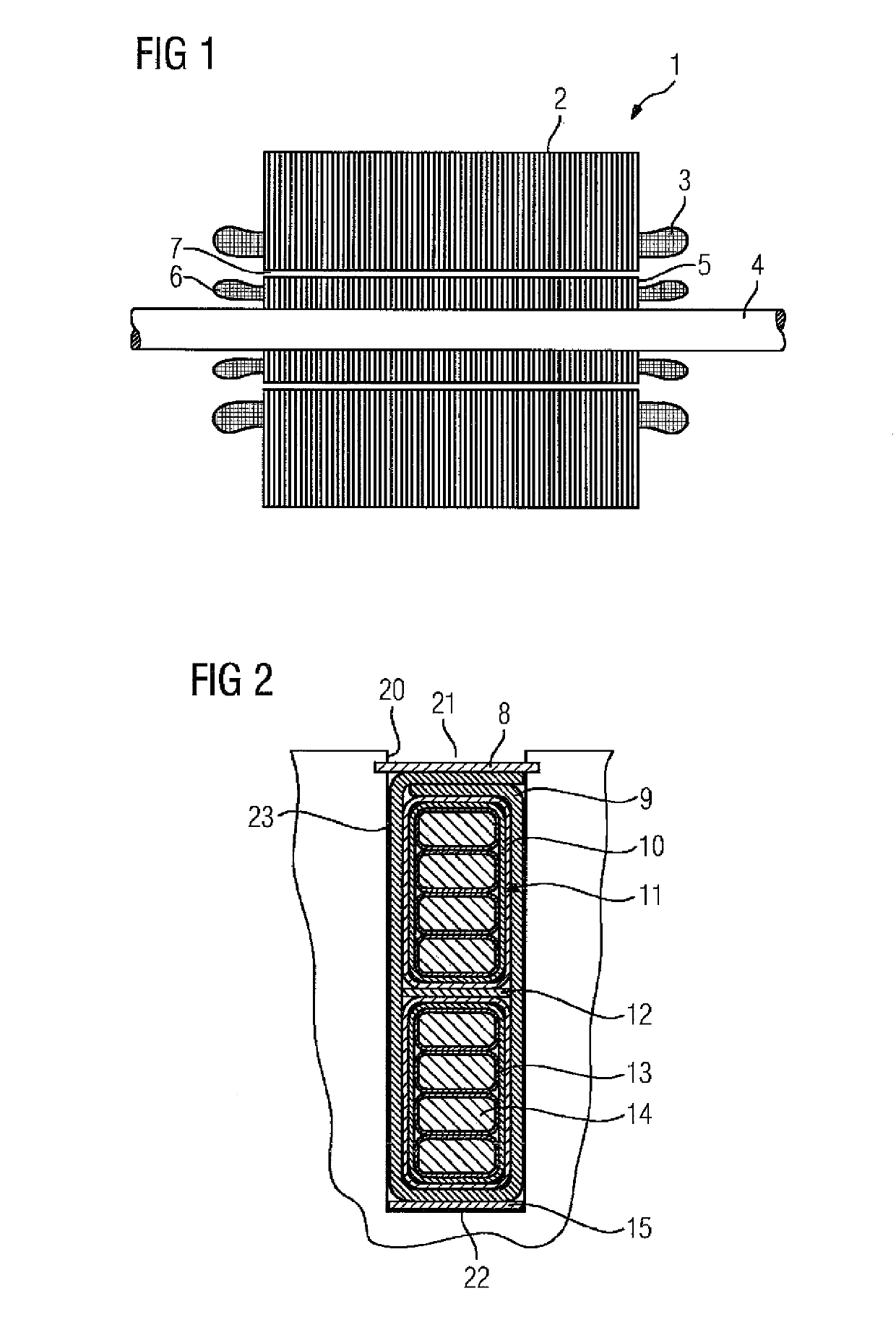

Stator of an electric machine and production thereof

ActiveCN106233576AWindings insulation materialWindings insulation shape/form/constructionElectric machineElectrical and Electronics engineering

The invention relates to a stator (100) of a rotating electric machine, the stator (100) comprising: a laminate stack (104) having a plurality of slots (106) open towards an air gap between the stator (100) and a rotor of the electric machine; and a winding (102) having a plurality of coils, the turns of said winding each passing through slots (106) of the laminate stack (104). In this case, the turns of the coils within the slots (106) are electrically insulated from one another and from the laminate stack (104) by a ceramic material. In addition, the invention relates to a method for the automated production of a winding (102) of a stator (100) of a rotating electric machine.

Owner:SIEMENS AG

Visual inspection-based generator retention assembly tightness detection

A method and apparatus for visually detecting and measuring retention assembly tightness are disclosed. In an embodiment, an optical device is used to obtain at least an image of a retention assembly, the optical device being insertable into a slot between two stator core laminations and directable toward a side view of the retention assembly. The image is displayed on a display, and a measurer is used to determine a tightness of a retention assembly.

Owner:GENERAL ELECTRIC CO

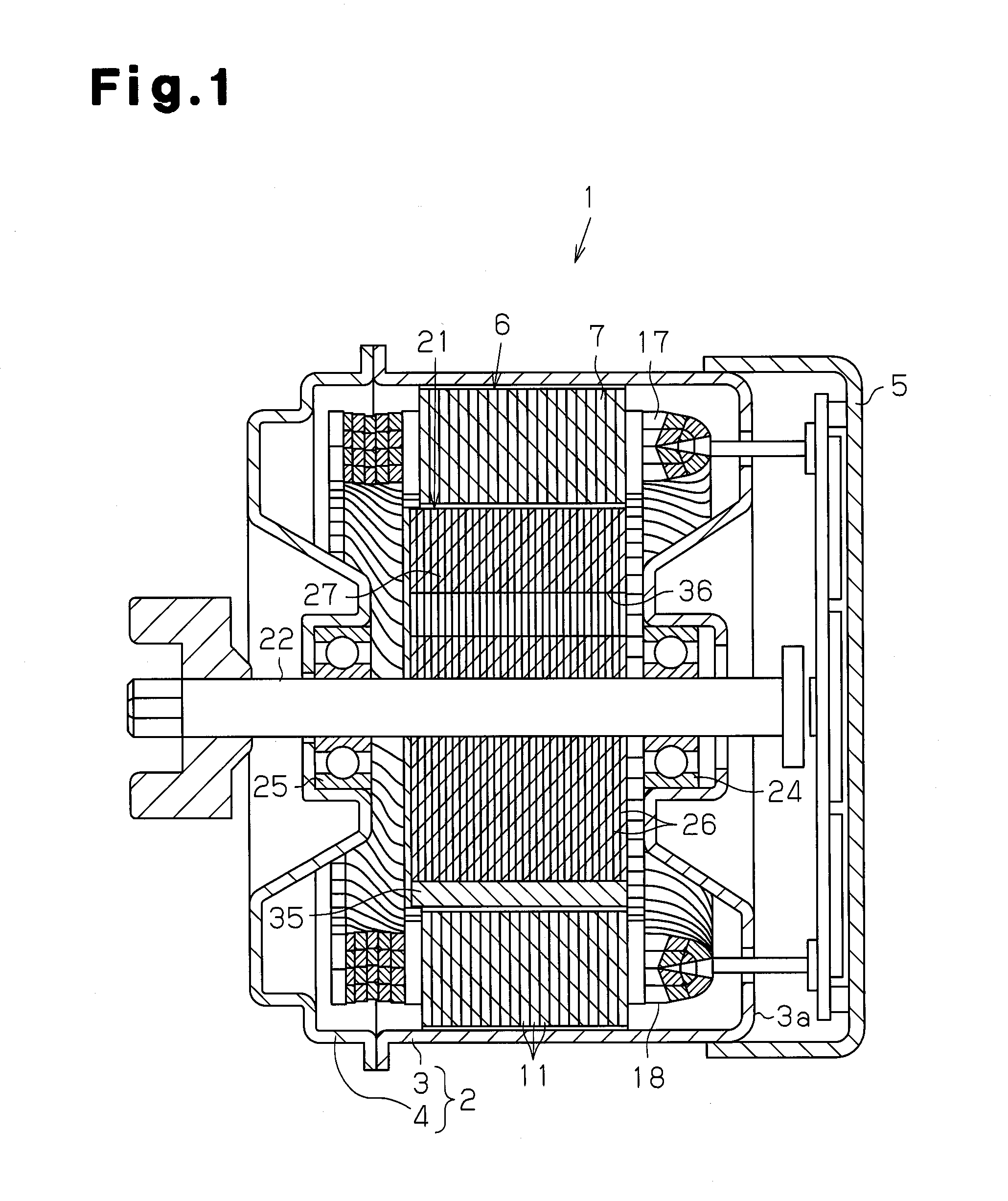

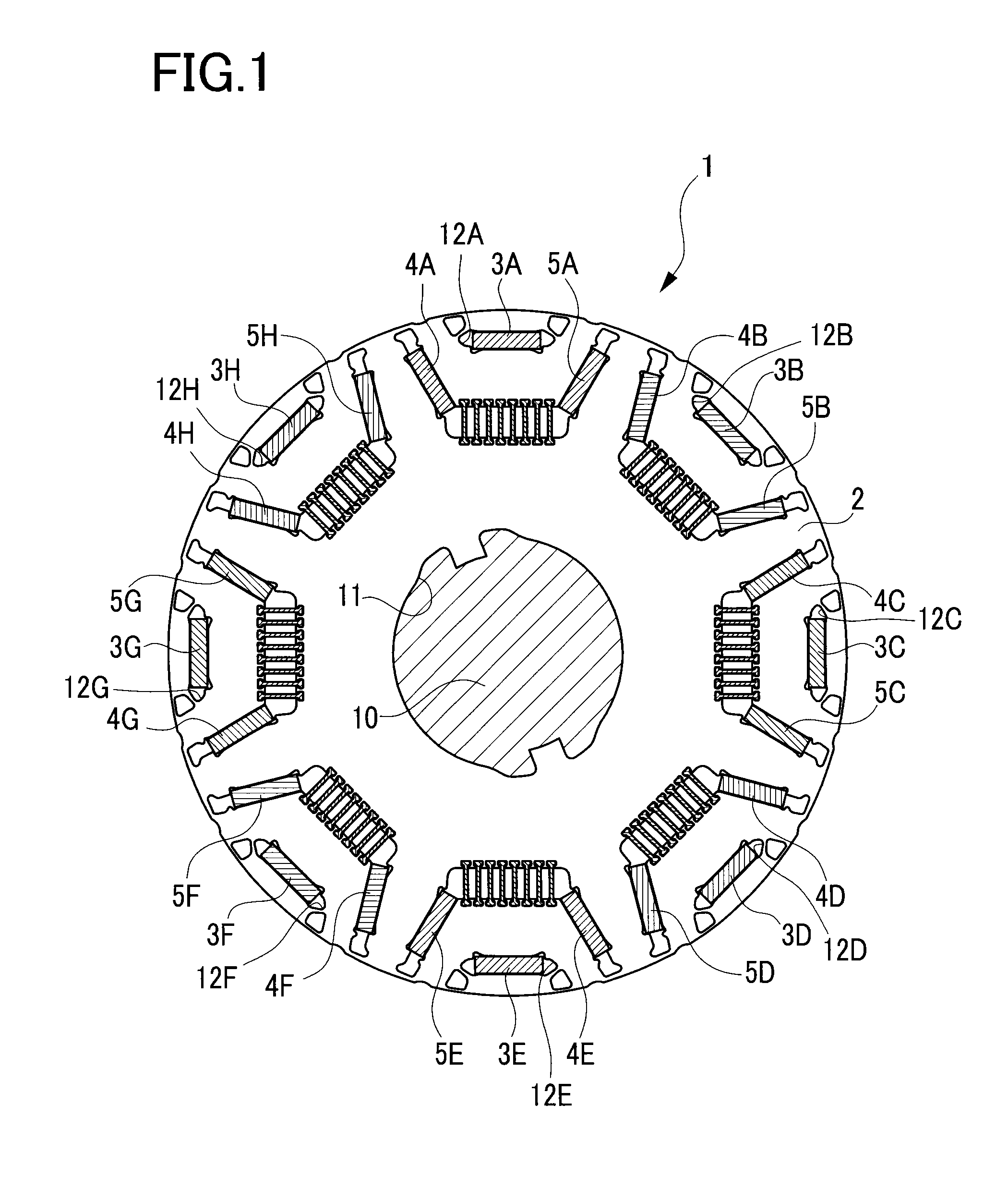

Rotating electrical machine

InactiveCN101989772AHigh duty cycleWindingsMagnetic circuit rotating partsElectric machineEngineering

The invention provides a rotating electrical machine. A tooth main body is connected with tooth tip edge portions by connecting portions with slits being formed in the coil sides of the connecting portions; and the slits extend from opening portions towards the centers of the tooth tip edge portions in circumferential direction, and are formed so that their tooth main body sides and their tip edge portion sides, that together define the opening portions of the slits, contact one another; with the gaps between adjacent ones of the tooth tip edge portions in circumferential direction being smaller than a width of the slot. The high duty ratio of the iron core in the iron core groove is high, the coil winding is simplified and the electronic characteristic is excellent.

Owner:HITACHI LTD

Method and system for ripple-spring compression assessment

InactiveUS7418858B2WindingsMaterial strength using tensile/compressive forcesProximity sensorEngineering

A method and system for directly measuring the compression of a ripple spring (23) in a dynamoelectric machine through a corresponding wedge (27). A compression-assessment tool (3) is provided that includes a carriage (32) for supporting a proximity sensor (34). The carriage (32) enables the proximity sensor (34) to be passed over the length of the ripple spring (23), which produces an output signal that is representative of the compression of the ripple spring (23).

Owner:SIEMENS ENERGY INC

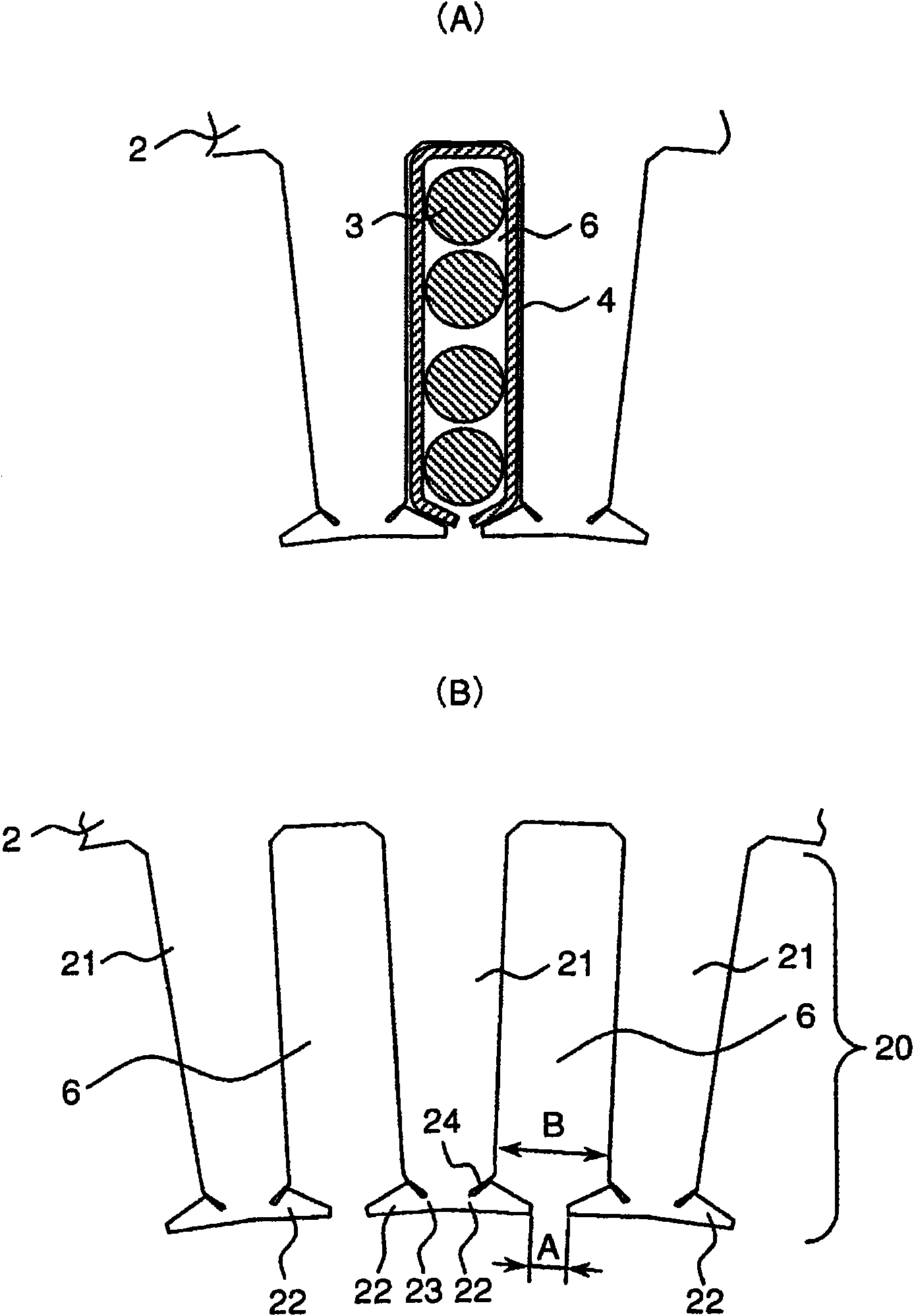

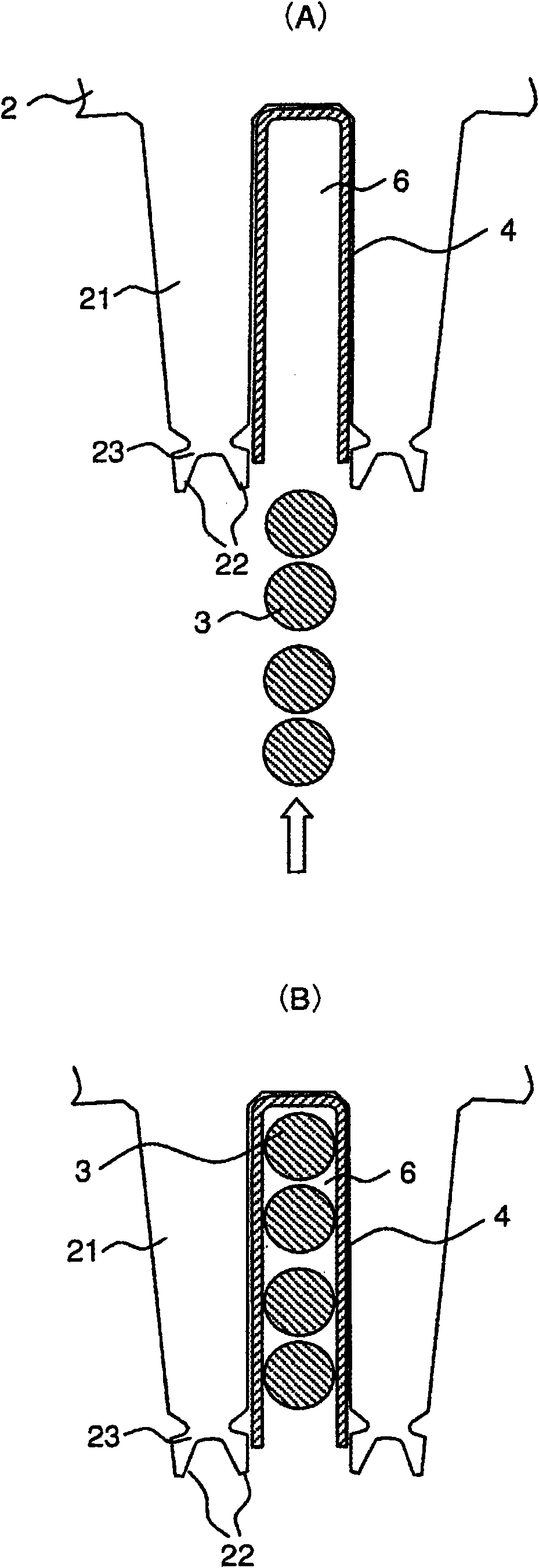

Stator manufacturing method, stator, and motor

InactiveUS20120326550A1Without lowering in occupancy rateEnsure insulationWindings insulation shape/form/constructionMagnetic circuitElectrical conductorEngineering

A stator manufacturing method includes the steps of preparing an armature core, forming an insulating member including two opposing portions from a sheet-like insulating material, and deforming the insulating member to move the two opposing portions toward each other. The method also includes the step of inserting distal parts of the two opposing portions into the corresponding slit from the axial direction thereby covering an inner surface of each of the slot with the insulating member. Further, the method includes the steps of inserting a conductor forming a winding into each of the slots between the two opposing portions.

Owner:ASMO CO LTD

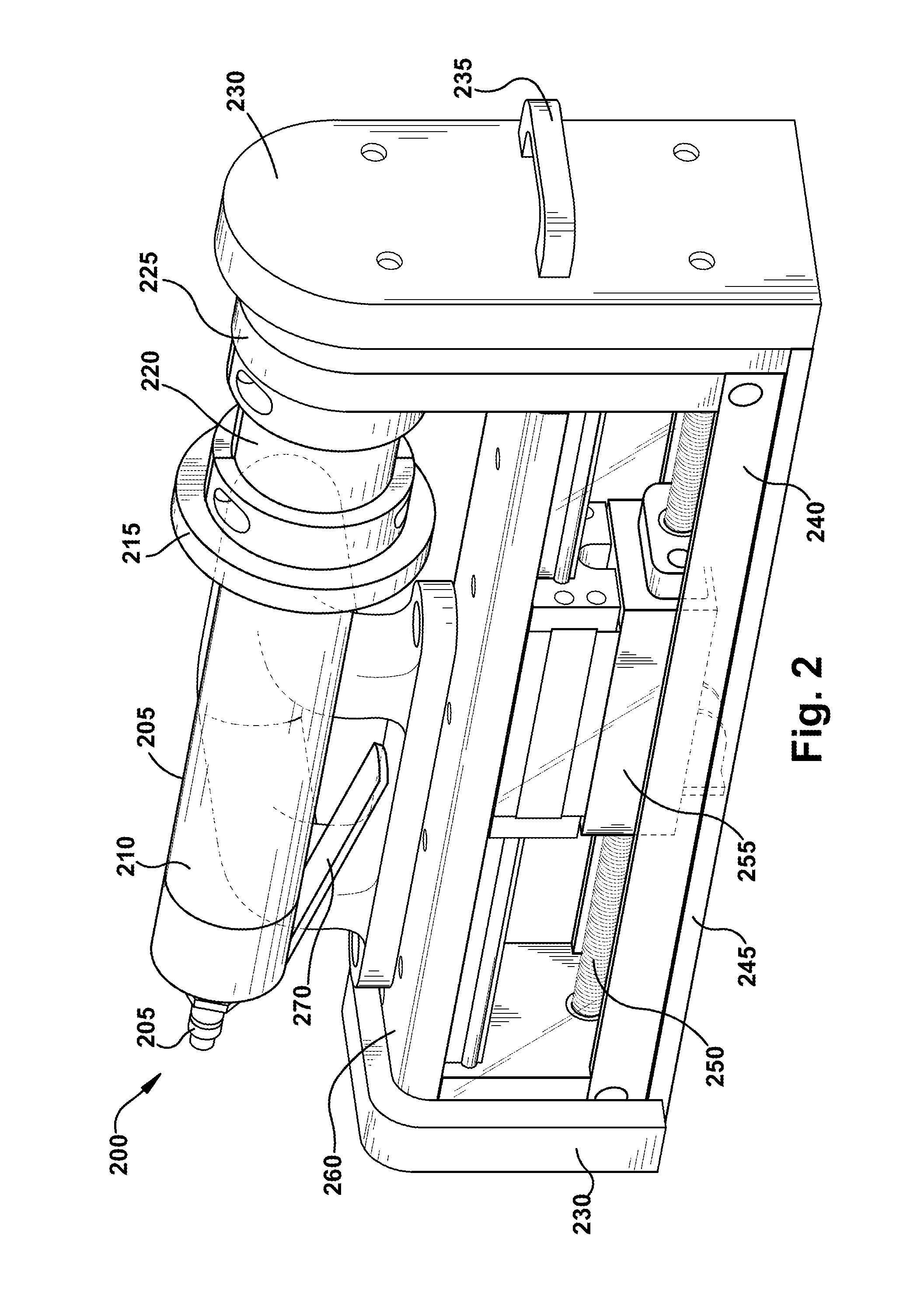

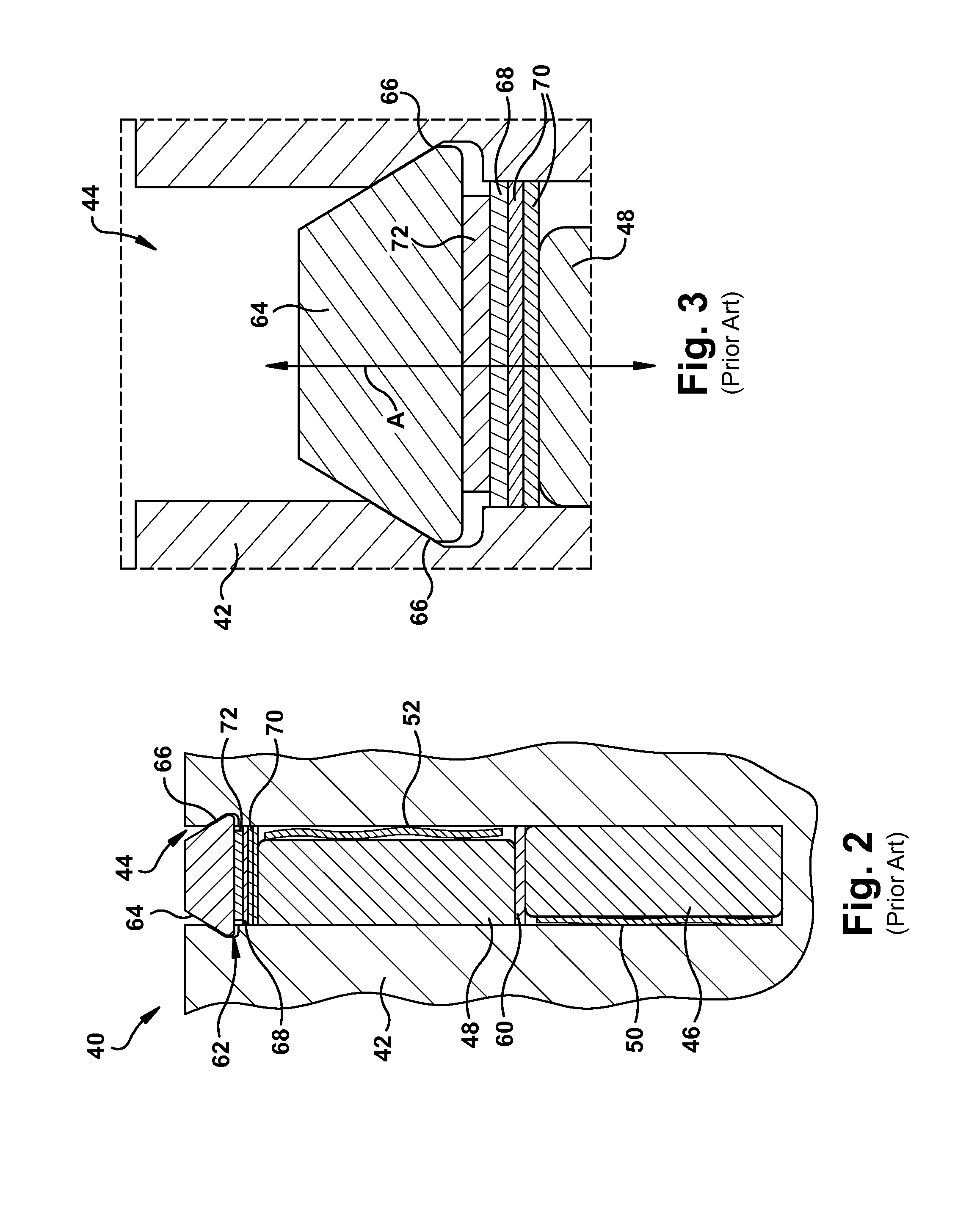

Tool for driving wedges or slides

InactiveUS20090031557A1Substantial eliminationReduce deflectionApplying/manufacturing slot closuresOther manufacturing equipments/toolsEngineeringMechanical engineering

A tool is provided for driving a slide or wedge within a slot of an armature or field of a dynamoelectric machine. The armature or field includes a core, and the core includes one or more vent slots for facilitating ventilation of the armature or field. The tool includes a drive for applying a driving force, and a push block is connected to the drive. At least one guide rail is configured to cooperate with the push block. The drive operates on the push block to drive a slide or wedge. The at least one guide rail reduces deflection or skew of the push block during a driving operation.

Owner:GENERAL ELECTRIC CO

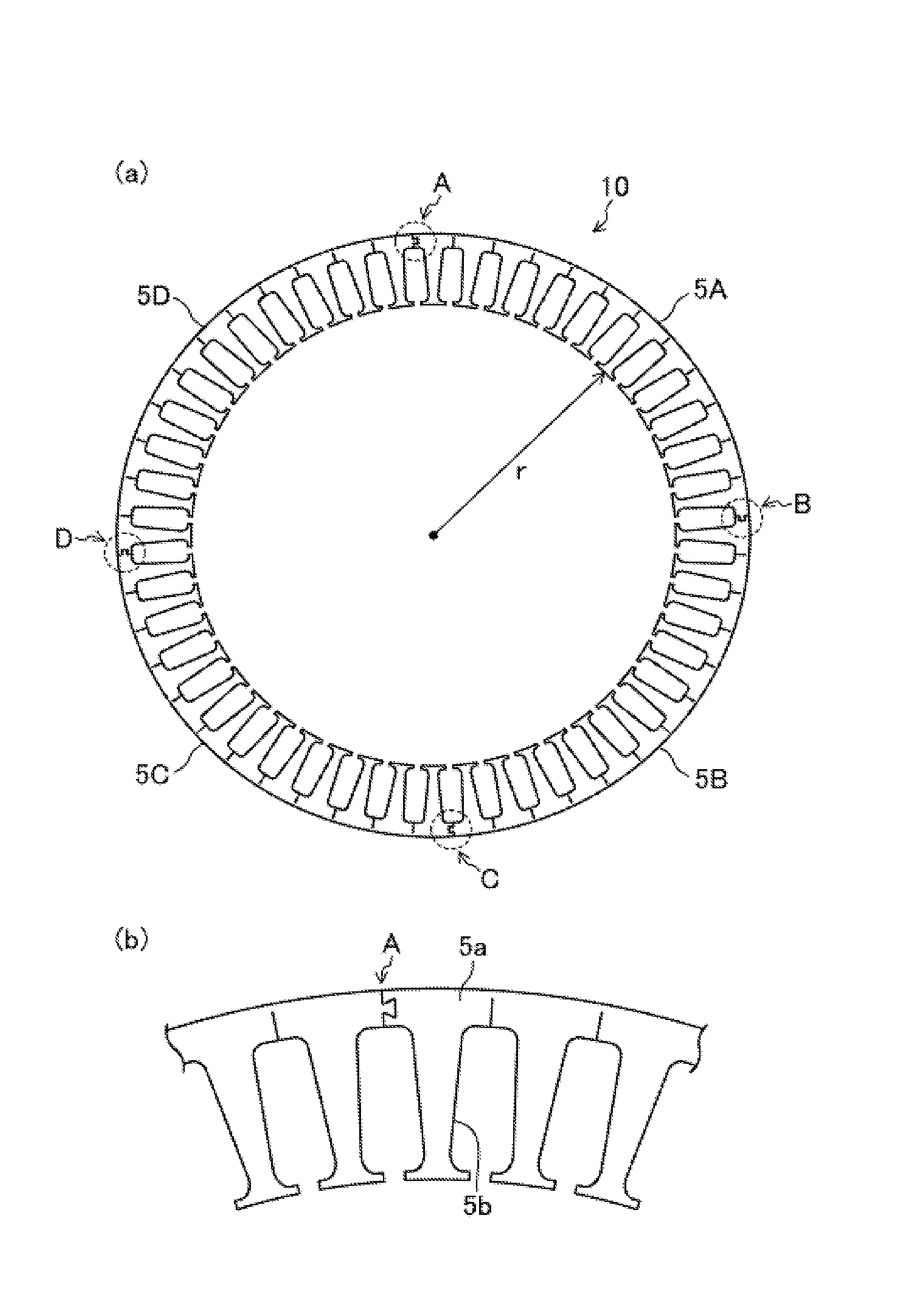

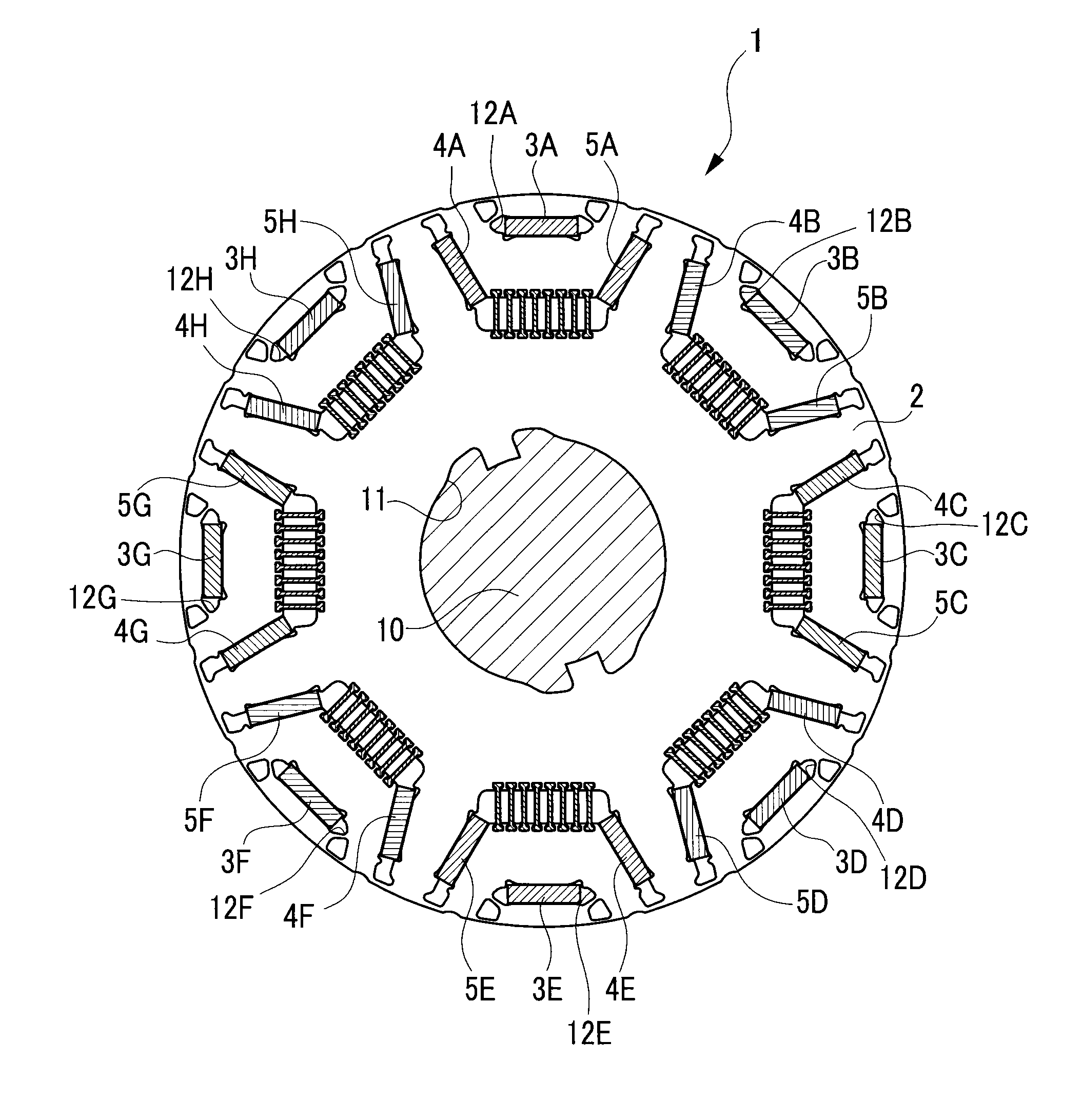

Motor with stiffened stator core, manufacturing method thereof, and washing machine including the motor

ActiveUS10673289B2Low profileWindings insulation shape/form/constructionMagnetic circuit rotating partsLaundry washing machineElectric machine

Provided is a high-powered low profile motor. The motor includes a stator (20) facing a rotor (50) while having a gap from the rotor (50). The stator (20) includes a ring-shaped connection core (10) formed by connecting a plurality of divided cores (5a) and an insulator (24) formed as if surrounding the connection core (10) by resin molding by an insertion forming. An inner diameter (r) of the connection core (10) is set smaller than inner diameters (R) of the divided cores (5a) bent in a half moon shape when connected.

Owner:SAMSUNG ELECTRONICS CO LTD

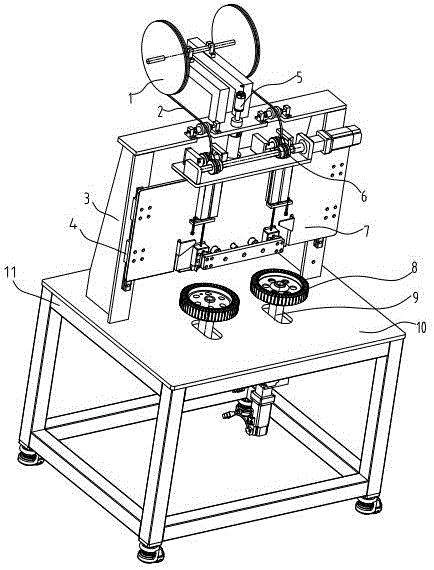

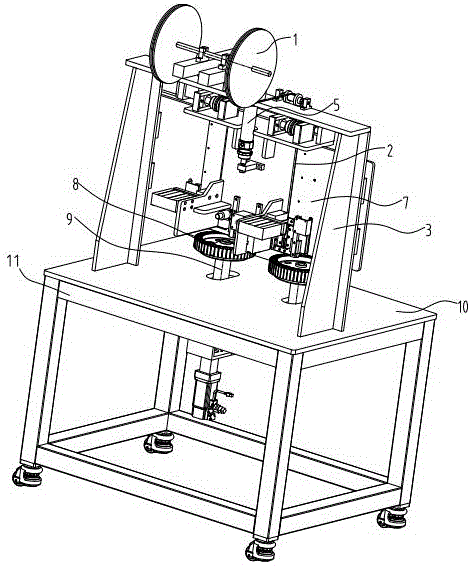

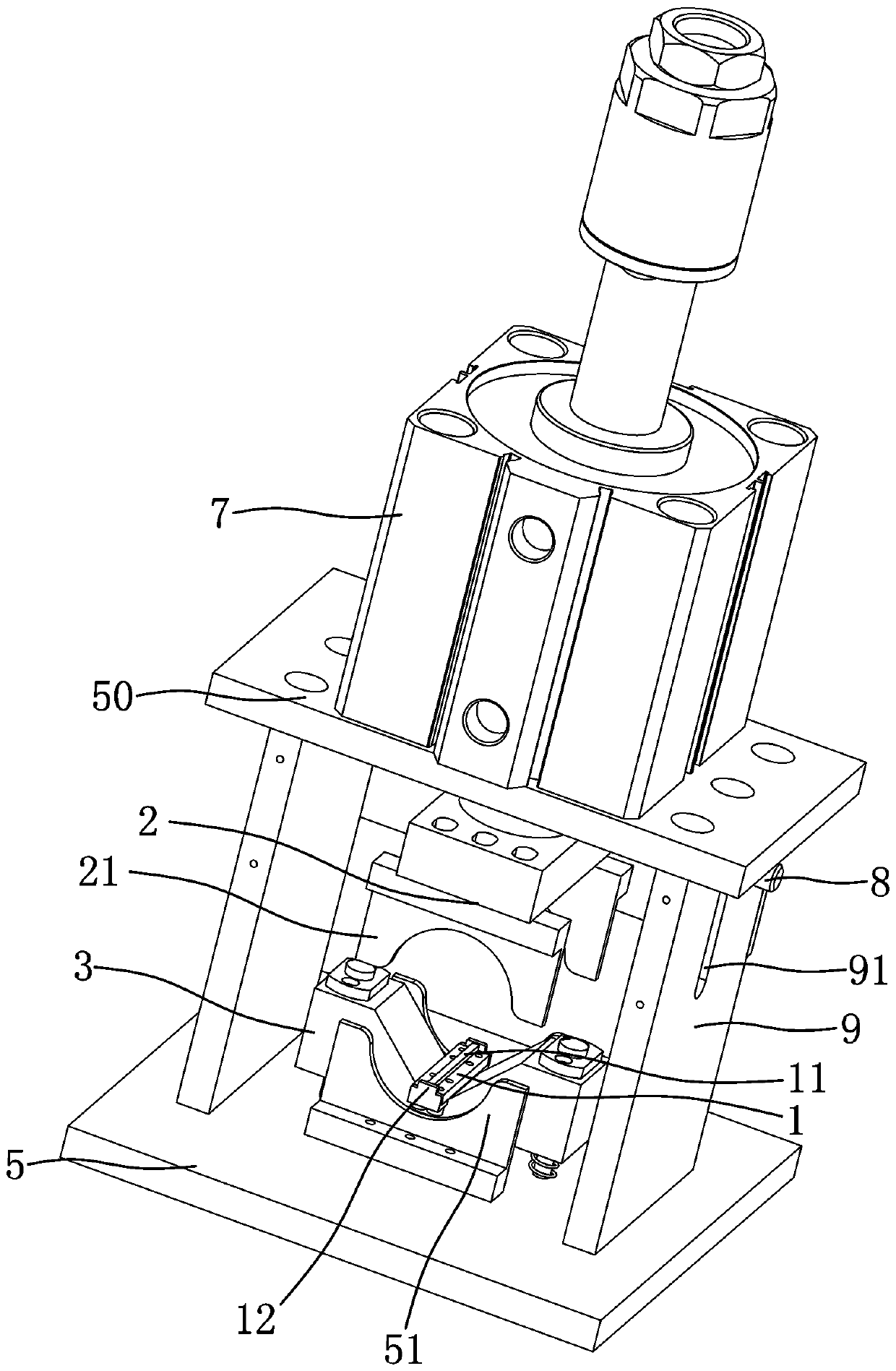

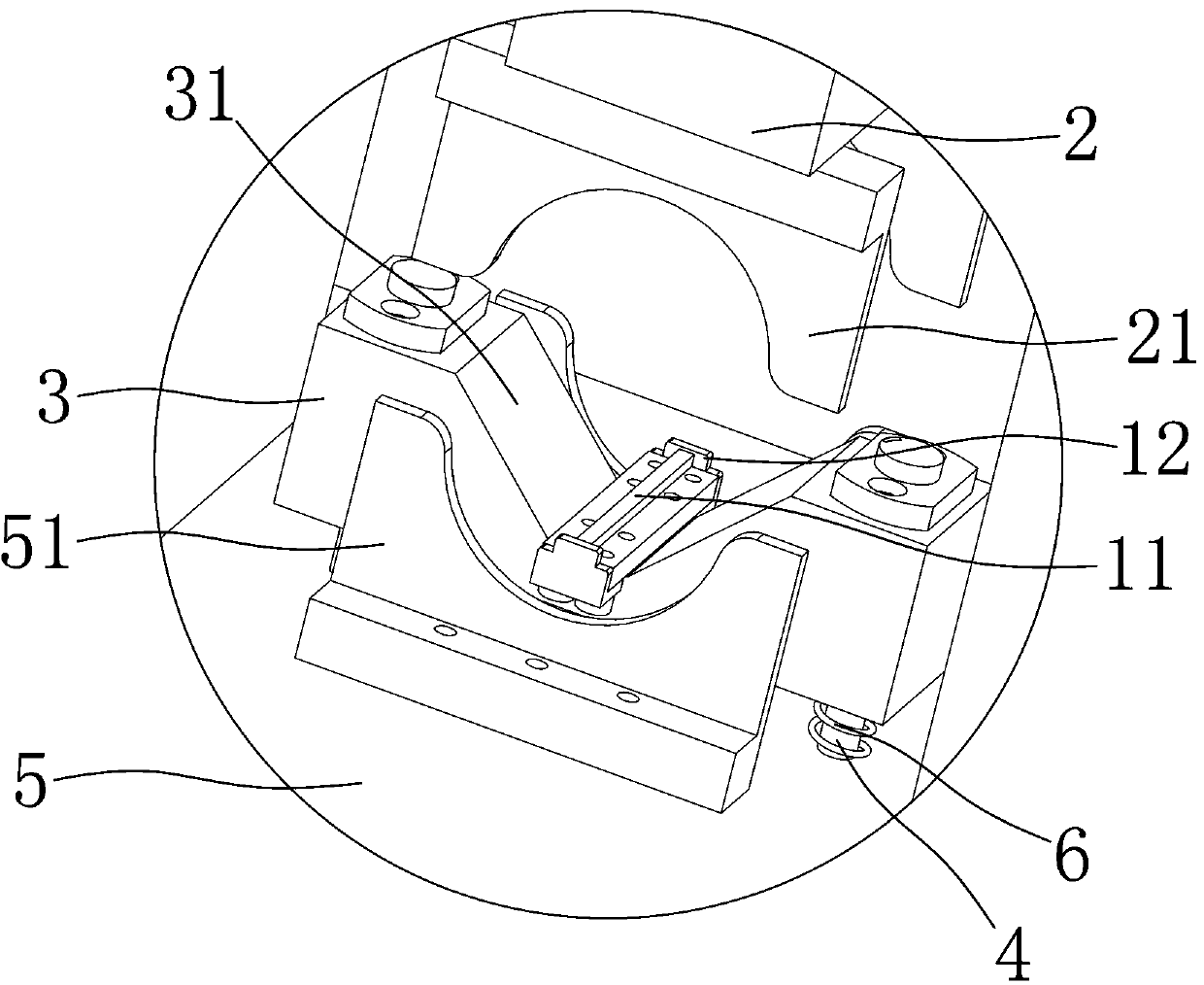

Motor stator slot-sealing mechanism and motor stator slot-sealing machine

ActiveCN105762993ASimple actionCompact structureApplying/manufacturing slot closuresPulp and paper industryAutomation

Owner:HANGZHOU TIANMING TECH CO LTD

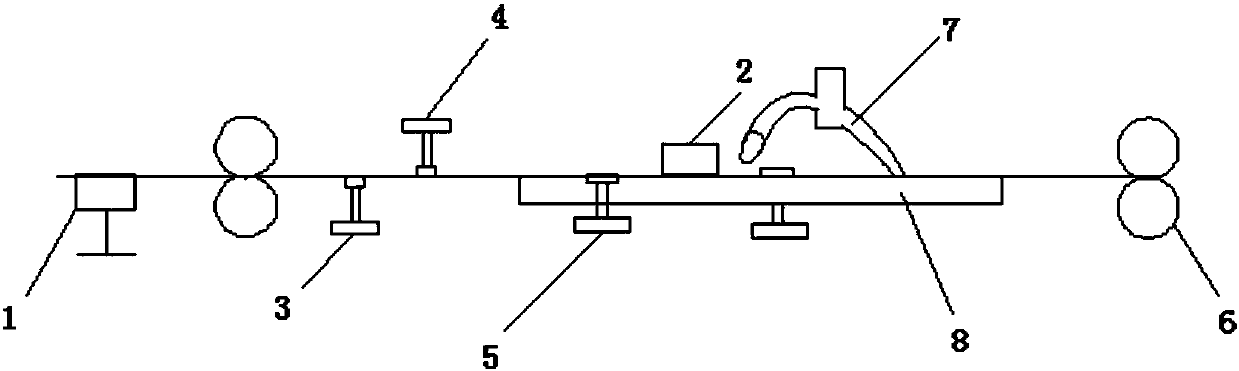

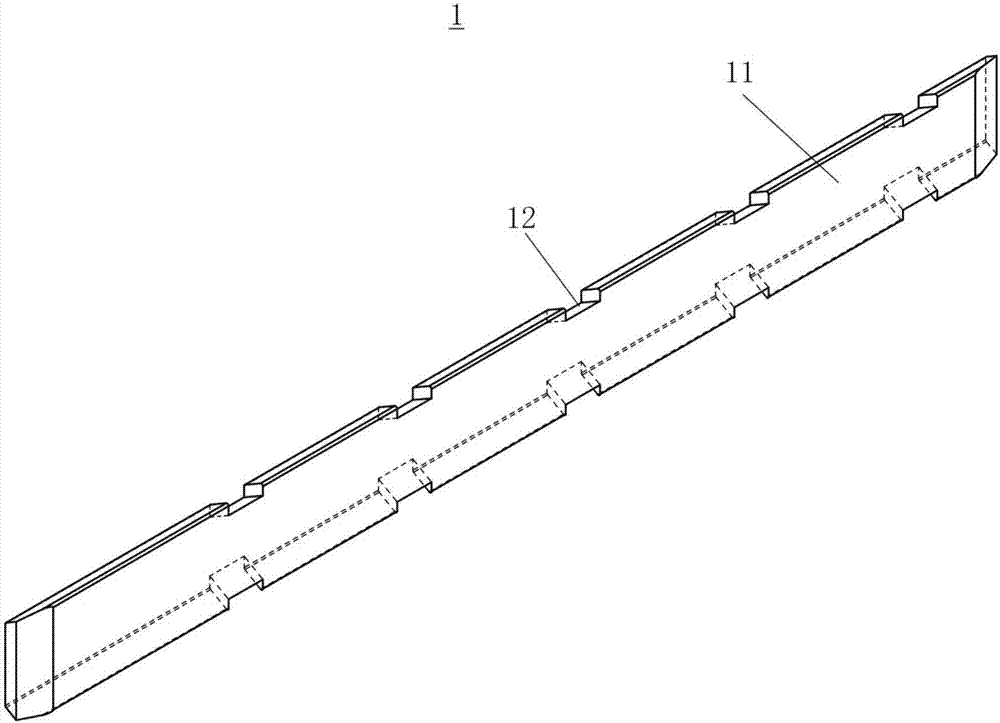

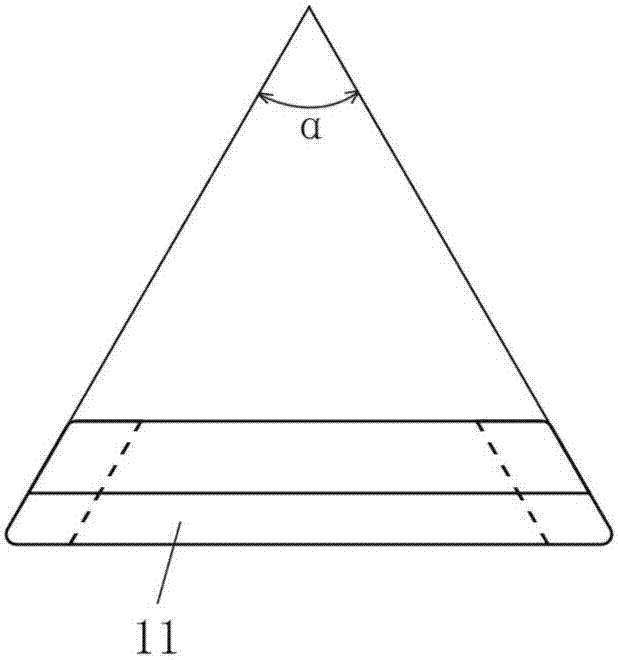

Slot wedge processing device adapt to different widths

InactiveCN108054882AAvoid offsetAvoid it happening againApplying/manufacturing slot closuresMilling cutterEngineering

The invention provides a slot wedge processing device adapt to different widths. The slot wedge processing device comprises a clamping device, a polishing device, a milling device, a delivering device, and a width adjusting device. The clamping device comprises a positioning platform, a positioning plate, a connection rod, and an adjusting device. The polishing device comprises a first milling cutter and a second milling cutter. The milling device comprises a plurality of milling machines. The delivering device comprises multiple roller pairs and guide rails. The width adjusting device comprises a baffle plate and a movable press plate. A pressing device is used to tightly press a slot wedge strip under a delivery state so as to prevent the deviation of the slot wedge strip during the delivery process, the width adjusting device adjust the width of the slot wedge strip under a delivery state, and the processing device has the advantages of high automatic degree and high safety, can prevent the generation of sparks, and is capable of eliminating waste scraps in time.

Owner:安徽省盛鑫绝缘材料有限公司

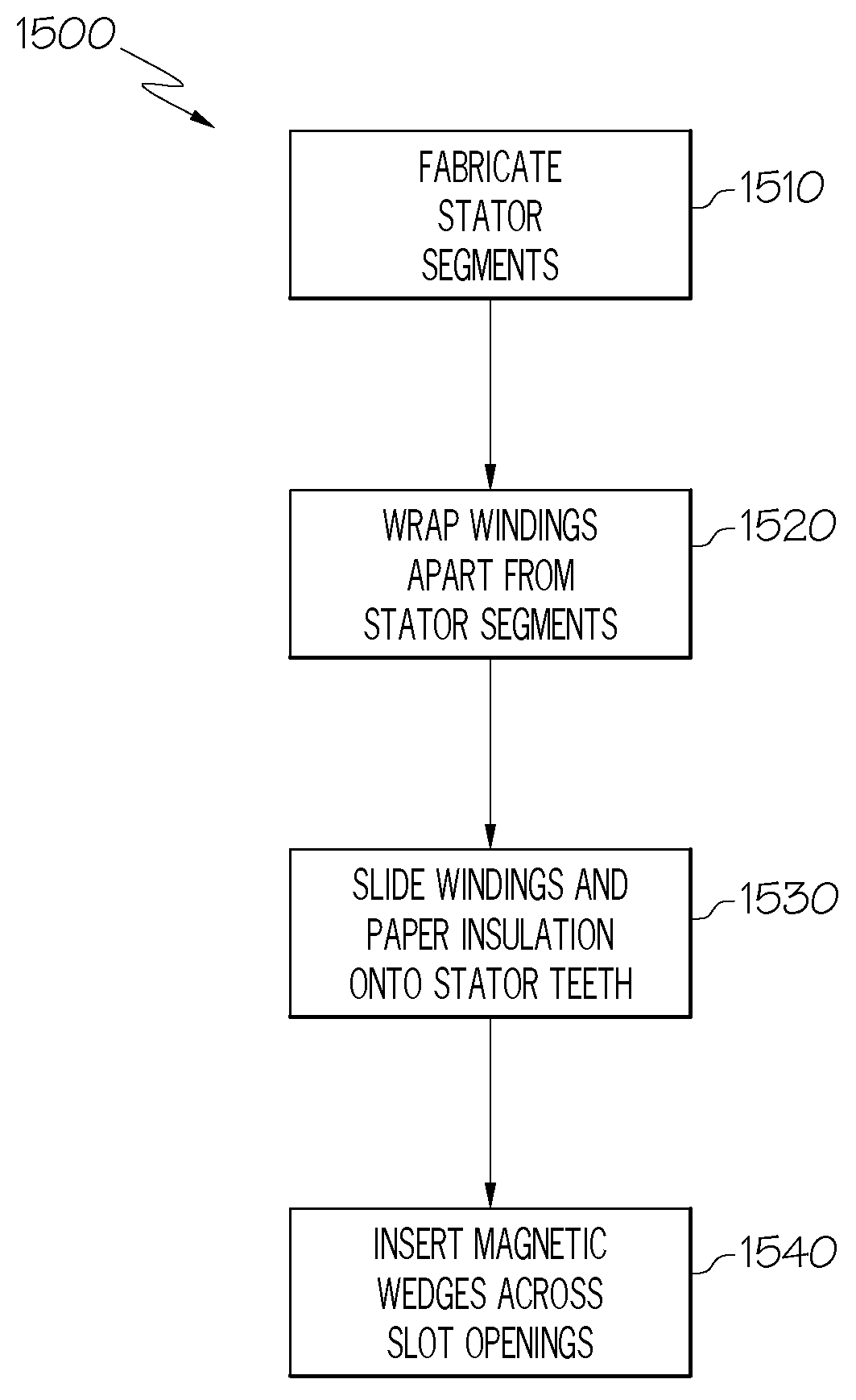

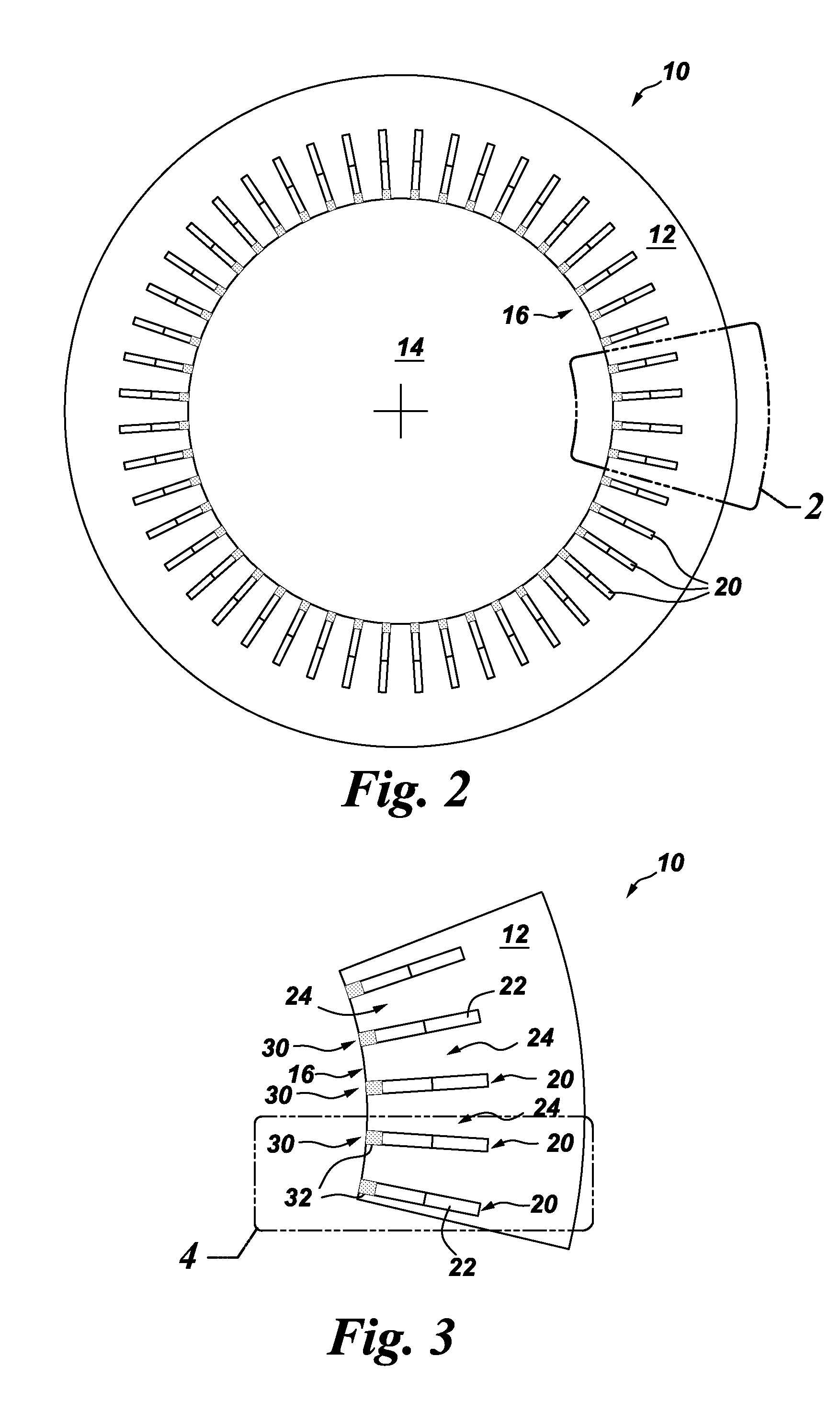

Concentrated winding machine with magnetic slot wedges

InactiveUS20080282531A1Improve operating characteristicsWindingsApplying/manufacturing slot closuresWinding machineEngineering

Methods and apparatus are provided for improving operational characteristics of a concentrated winding machine. According to an example embodiment, a method comprises fabricating a magnetic slot wedge that is adapted to be joined to a first stator tooth and a second stator tooth, the first and second stator tooth part of a fixed-tooth stator that does not allow relative movement between the first stator tooth and the second stator tooth.

Owner:GM GLOBAL TECH OPERATIONS LLC

Rotary electrical machine provided with a stator

InactiveUS20170133893A1Improve distributionRelieve pressureWindingsMagnetic circuit stationary partsElectric machineMetal sheet

A stator of a rotary electrical machine has a stator body formed by a stack of metal sheets. The stator body is delimited by inner and outer radial surfaces. Notches in the stator body extend axially. Each notch has a notch base and a notch opening, and the notch opening is on the side of the inner radial surface. A stator winding is supported by the stator body, and the winding has a plurality of winding parts. Each part is accommodated in one of the notches. Each of the notches at the notch opening has a closure element. Each winding par in a notch is retained between the notch base and the closure element. The closure elements are formed by offsetting at least one of the metal sheets of an adjacent notch in the direction of the notch.

Owner:VALEO EQUIP ELECTRIC MOTEUR

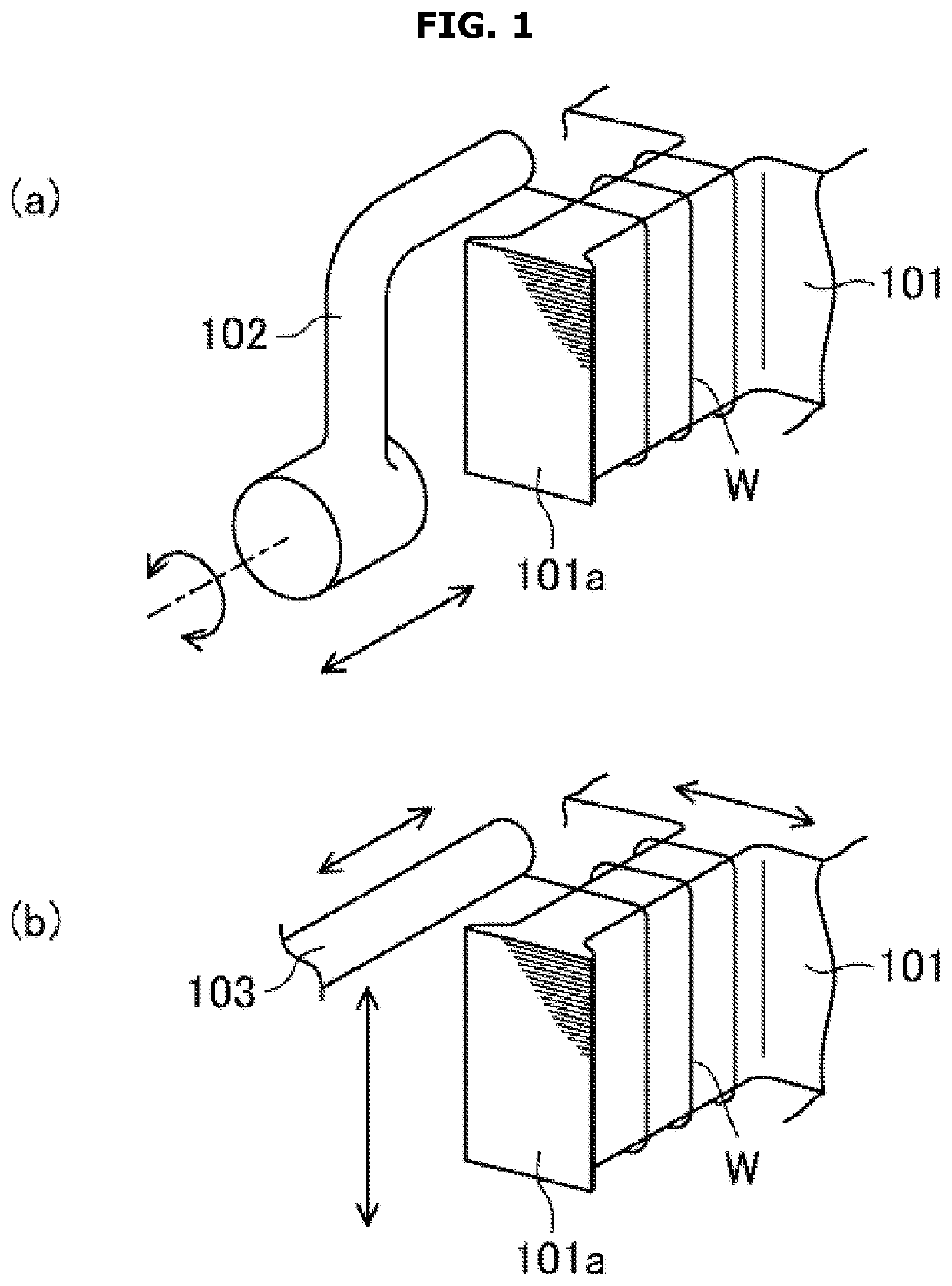

Rotary Electric Machine and Manufacturing Method for Rotary Electric Machine

ActiveUS20190207460A1Improve motor efficiencySmall lossWindingsApplying/manufacturing slot closuresElectric machineEngineering

Please substitute the new Abstract submitted herewith for the original Abstract: Provided is a rotary electric machine that achieves high motor efficiency with little loss. This rotary electric machine is equipped with: a stator core arranged opposing the circumferential surface of a rotor, and in which multiple slots, wherein openings opening toward the rotor are formed, are formed in the circumferential direction; and coils inserted into the slots. A mixture of a soft magnetic powder and a resin material is formed in the openings of the slots, and the relative permeability of the mixture is 5-35.

Owner:HITACHI IND EQUIP SYST CO LTD

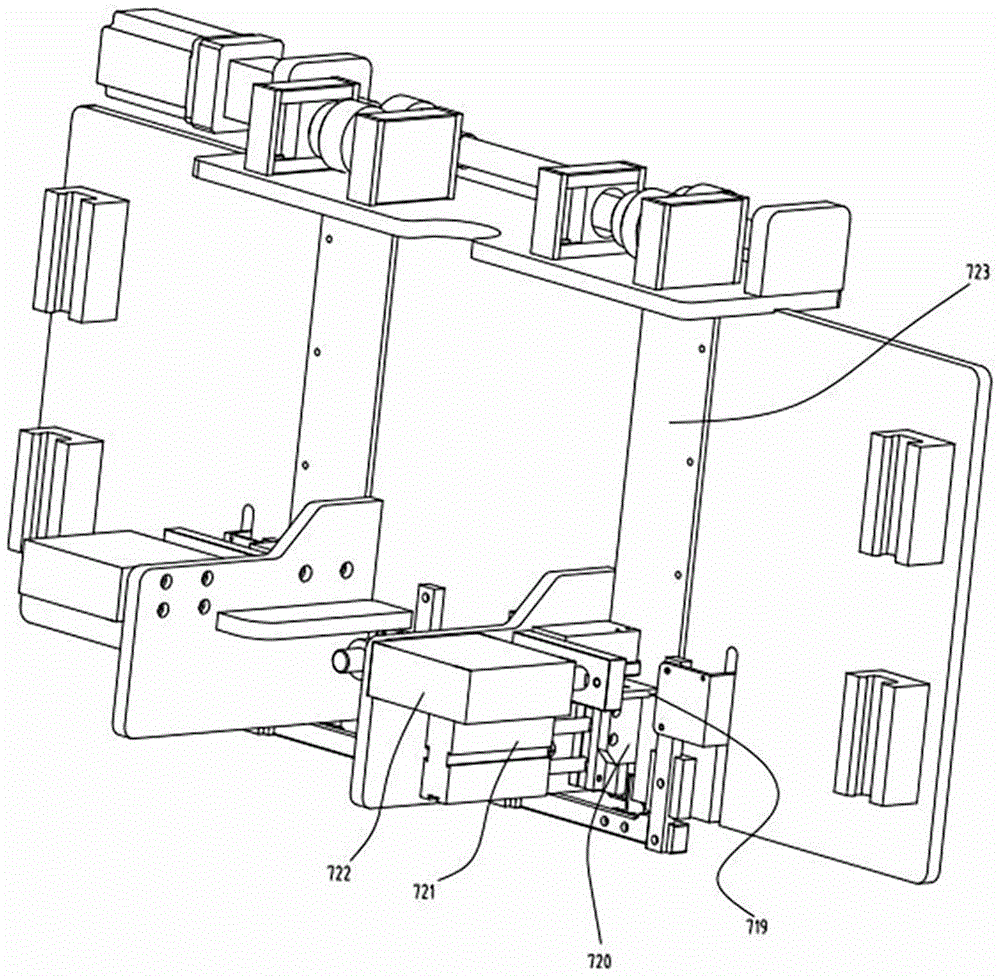

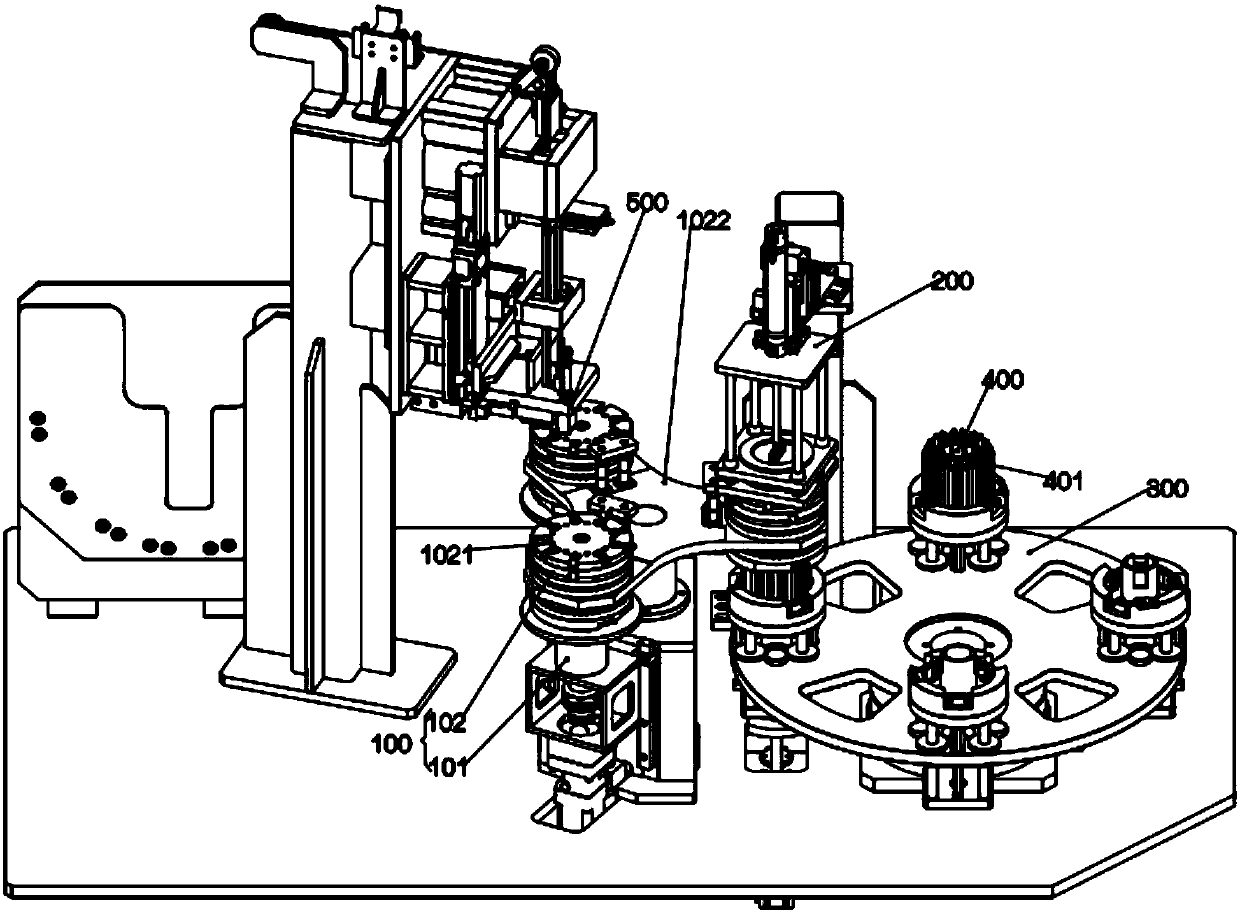

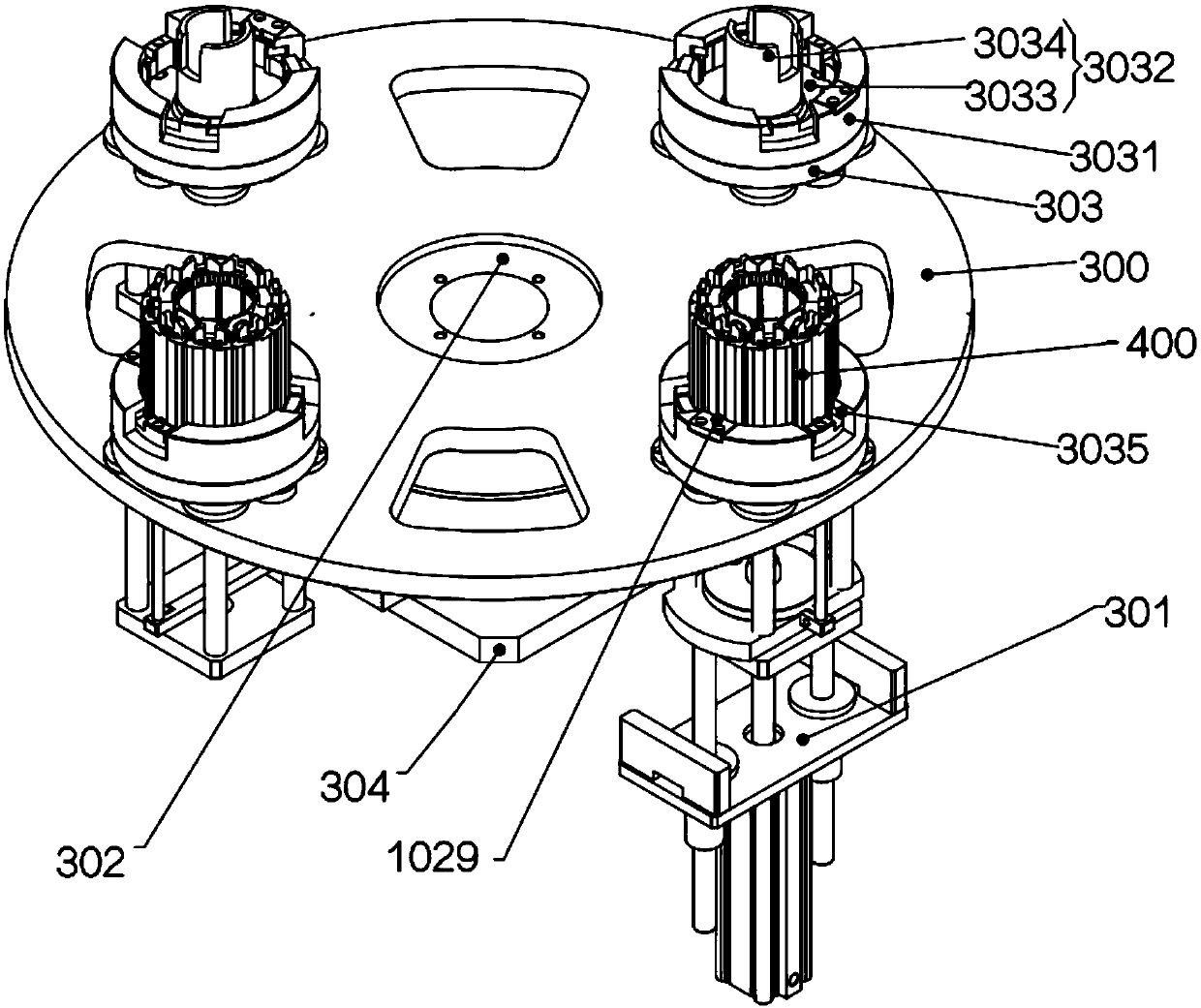

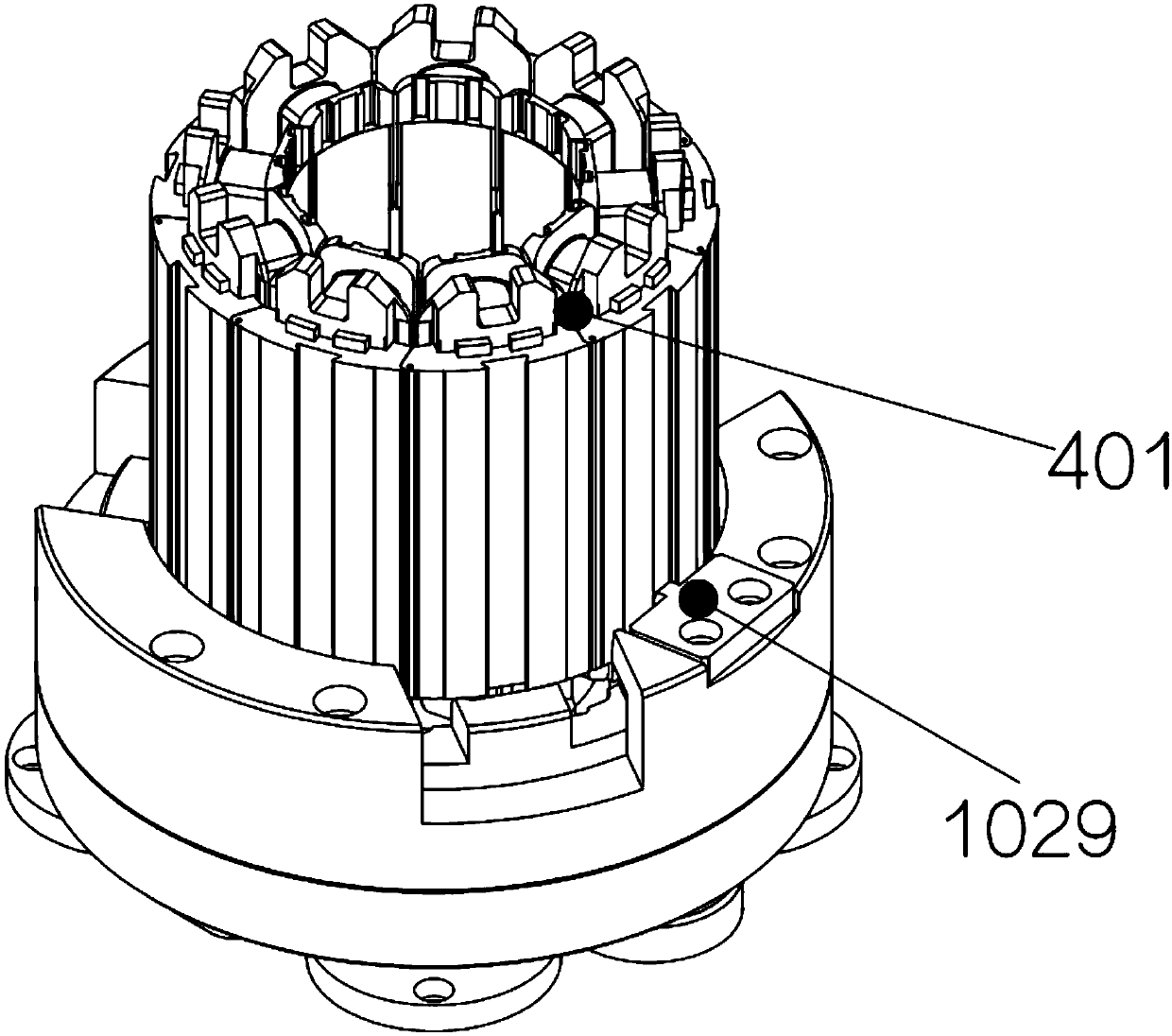

Automatic insertion device for motor stator insulated slot wedge

PendingCN109546814AIncrease productivityImprove pass rateWindingsApplying/manufacturing slot closuresEngineeringInsertion device

The invention relates to the field of a motor stator for a compressor and in particular to an automatic insertion device for a motor stator insulated slot wedge. The automatic insertion device comprises a workpiece mounting plate, a control unit and a group connected with the control unit and including a loading device, a pre-insertion indexing mechanism and an insertion mechanism. The workpiece mounting plate is used for installing a motor stator. The pre-insertion indexing mechanism comprises a temporary storage device provided with a temporary storage hole at a position corresponding to themotor stator slot wedge mounting hole. The loading device is used for loading the slot wedge into the temporary storage hole. The temporary storage device is provided with a turntable capable of revolving itself and connected with the control unit. The insertion mechanism is used for inserting the slot wedge in the temporary storage hole into the motor stator slot wedge mounting hole. The loadingdevice inserts the slot wedge into the temporary storage hole, and then the turntable rotates so that the temporary storage hole on the temporary storage device and the motor stator wedge mounting hole face each other. The slot wedge in the temporary storage hole is inserted by the insertion mechanism into the motor stator slot wedge mounting hole. The automatic insertion device has high production efficiency, avoids missing the slot wedge insertion or bending the slot wedge during an insertion process, and improves the qualified rate of the motor stators.

Owner:GUANGZHOU TRAYI PRECISION MASCH CO LTD

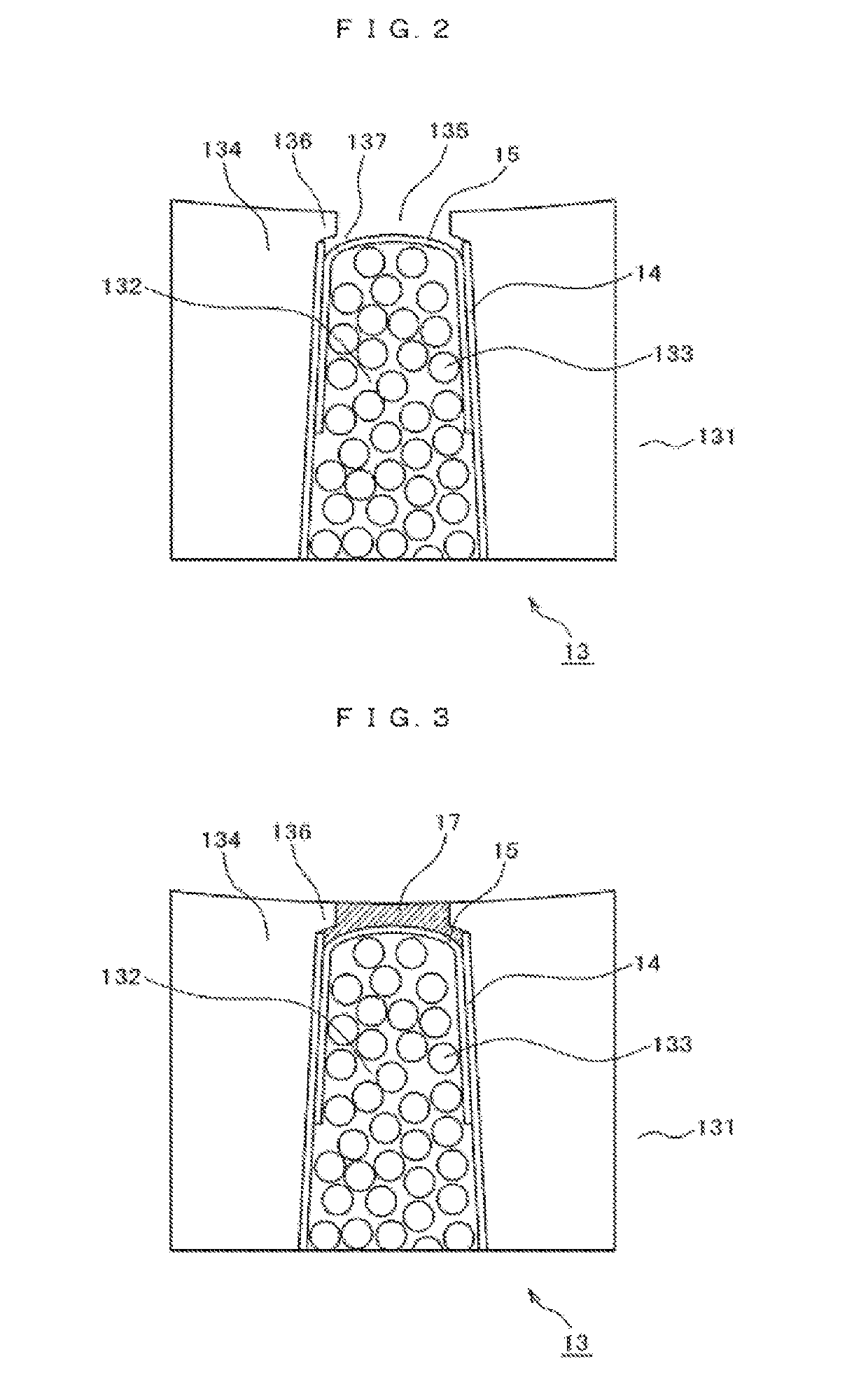

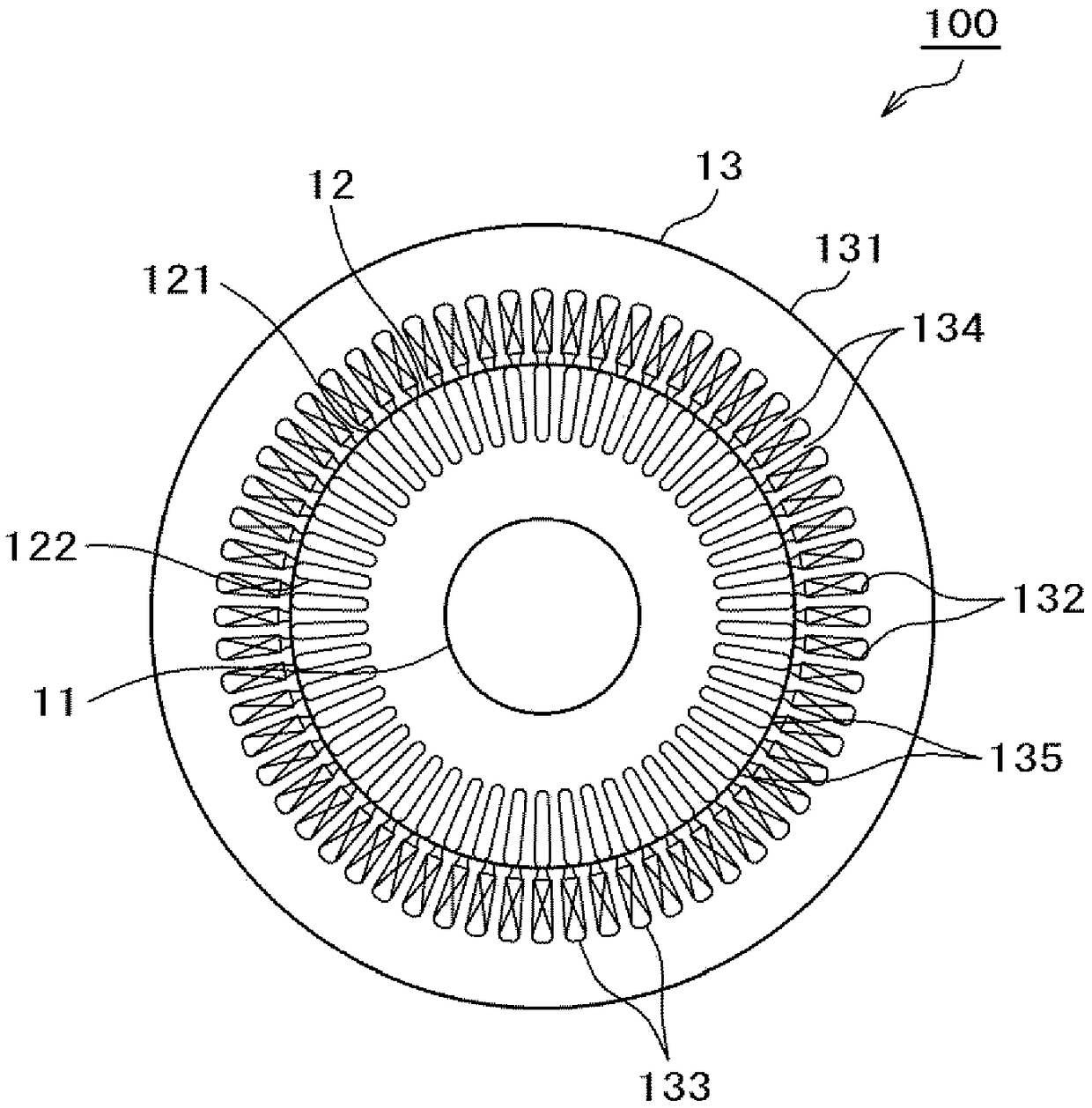

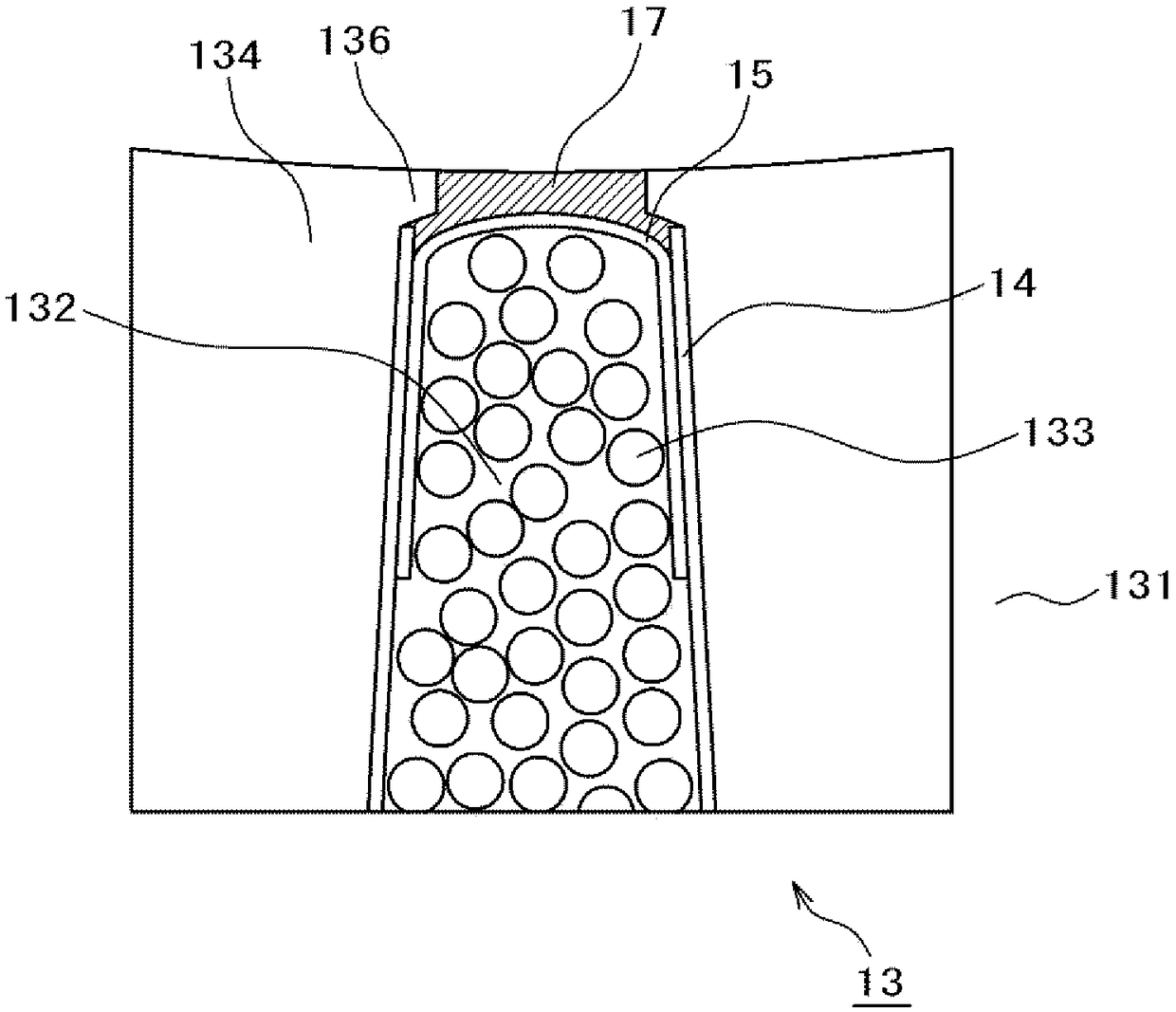

Rotary electric machine and manufacturing method for rotary electric machine

ActiveCN109417327AReduce lossImprove motor efficiencyWindingsApplying/manufacturing slot closuresElectric machineRelative permeability

Provided is a rotary electric machine that achieves high motor efficiency with little loss. This rotary electric machine is equipped with: a stator core 131 arranged opposing the circumferential surface of a rotor 12, and in which multiple slots 132, wherein openings 135 opening toward the rotor 12 are formed, are formed in the circumferential direction; and coils 133 inserted into the slots 132.A mixture 17 of a soft magnetic powder and a resin material is formed in the openings 135 of the slots 132, and the relative permeability of the mixture 17 is 5-35.

Owner:HITACHI IND EQUIP SYST CO LTD

Motor, manufacturing method thereof, and washing machine

Provided is a high-powered low profile motor. The motor includes a stator (20) facing a rotor (50) while having a gap from the rotor (50). The stator (20) includes a ring-shaped connection core (10) formed by connecting a plurality of divided cores (5a) and an insulator (24) formed as if surrounding the connection core (10) by resin molding by an insertion forming. An inner diameter (r) of the connection core (10) is set smaller than inner diameters (R) of the divided cores (5a) bent in a half moon shape when connected.

Owner:SAMSUNG ELECTRONICS CO LTD

Stator manufacturing method, stator, and motor

InactiveCN102857046AGuaranteed insulation performanceWindings insulation shape/form/constructionMagnetic circuit stationary partsElectrical conductorElectric motor

The invention provides a stator manufacturing method, a stator, and a motor which can ensure the insulation between a conductor and a armature core and can suppress the reducing of the fill-in ratio. The stator manufacturing method includes the steps of preparing an armature core, forming an insulating member including two opposing portions from a sheet-like insulating material, and deforming the insulating member to move the two opposing portions toward each other. The method also includes the step of inserting distal parts of the two opposing portions into the corresponding slit from the axial direction thereby covering an inner surface of each of the slot with the insulating member. Further, the method includes the steps of inserting a conductor forming a winding into each of the slots between the two opposing portions.

Owner:ASMO CO LTD

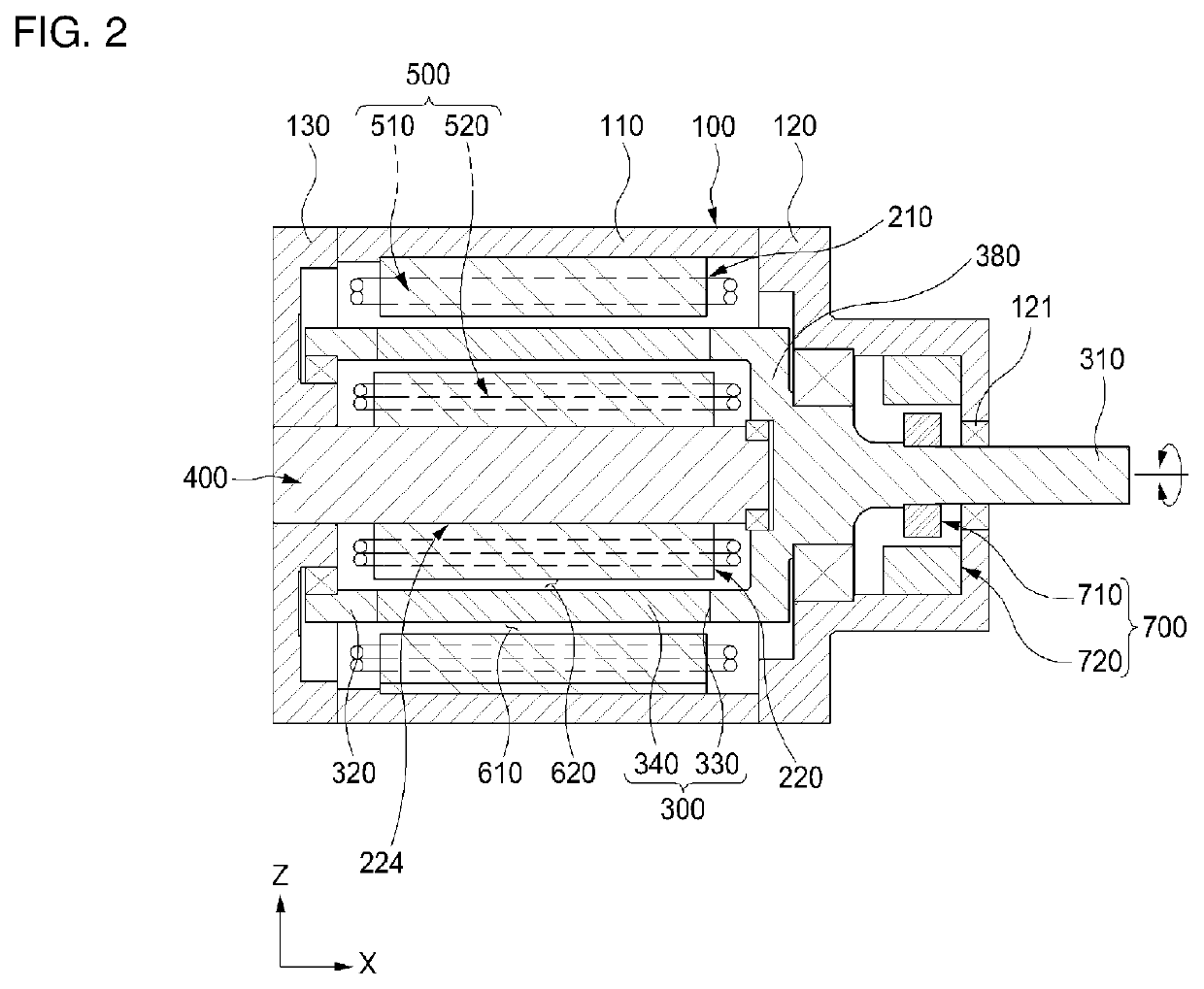

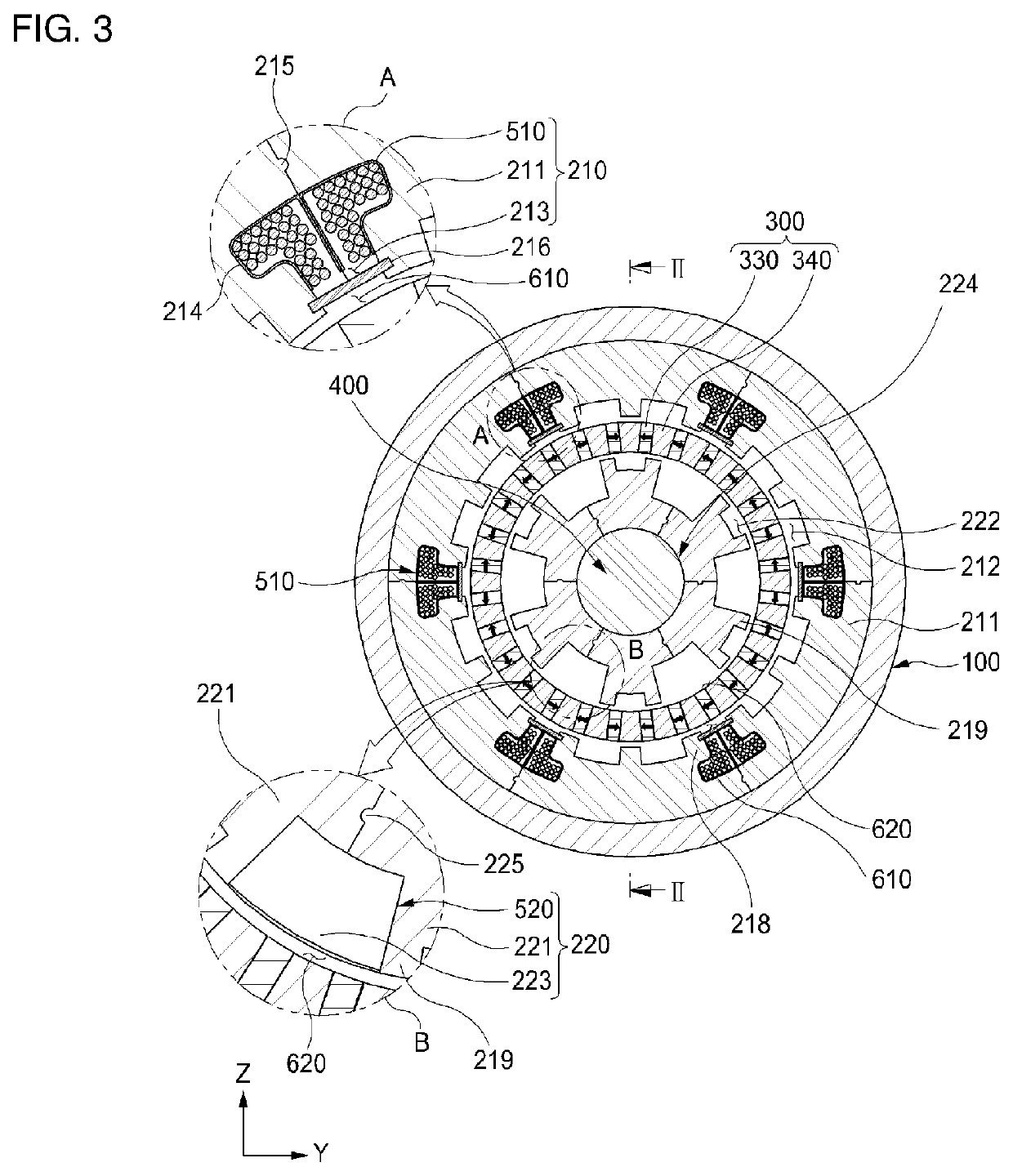

Rotating electric device

ActiveUS20200303973A1Increase output powerIncrease the generating areaMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsStator

A rotating electric device comprising: an outer stator (210) comprising an outer stator iron core (211) having a plurality of outer stator winding slots (213) formed on the inner peripheral surface thereof at a predetermined interval in the circumferential direction, and an outer winding (510) wound around an outer stator iron core tooth (218) relatively formed by a pair of outer stator winding slots (213) adjacent to each other; an inner stator (220) comprising an inner stator iron core (221) having a plurality of inner stator winding slots (223) formed on the outer peripheral surface thereof at a predetermined interval in the circumferential direction; and a rotor (300) having, between the outer stator (210) and the inner stator (220).

Owner:VAM CO LTD

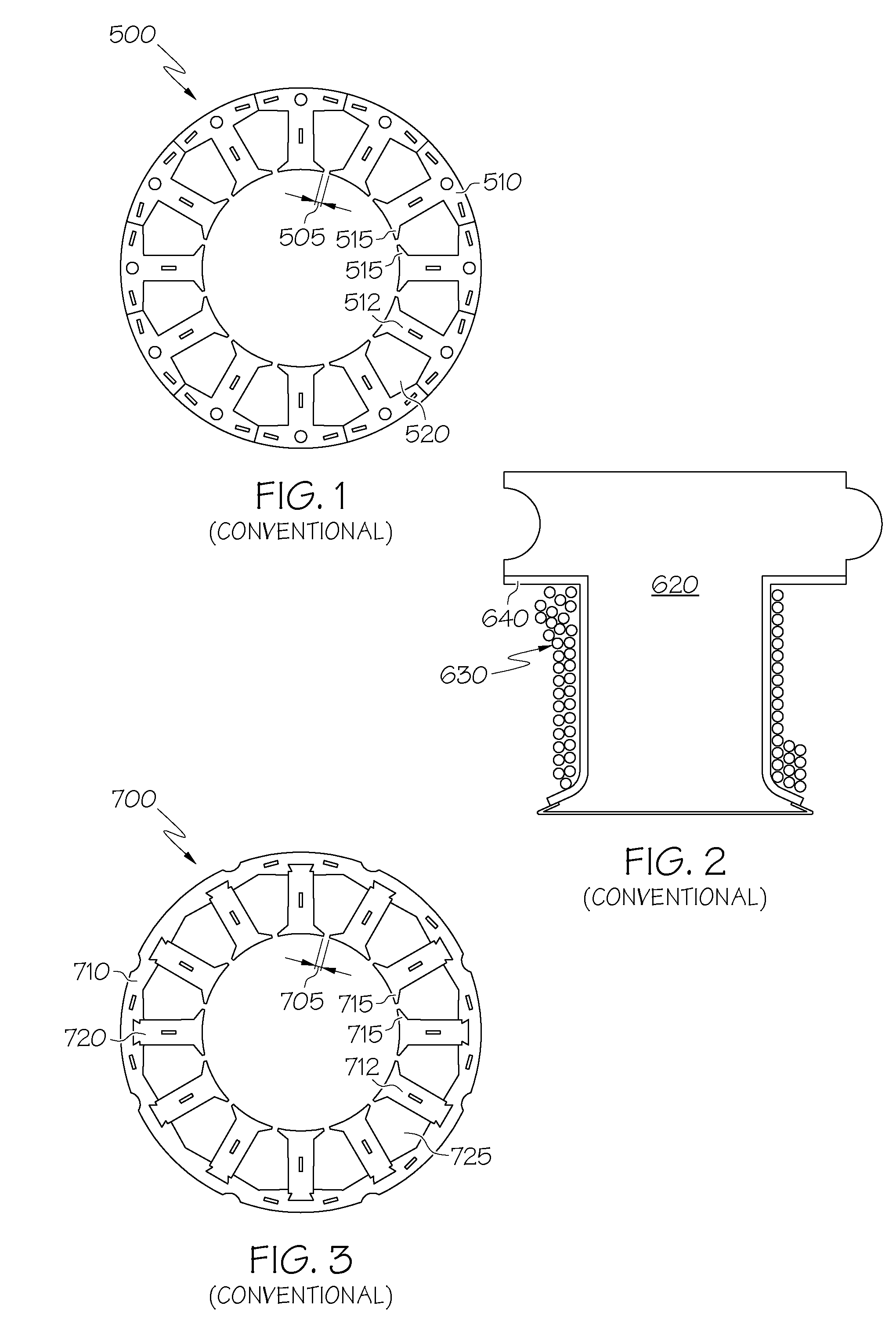

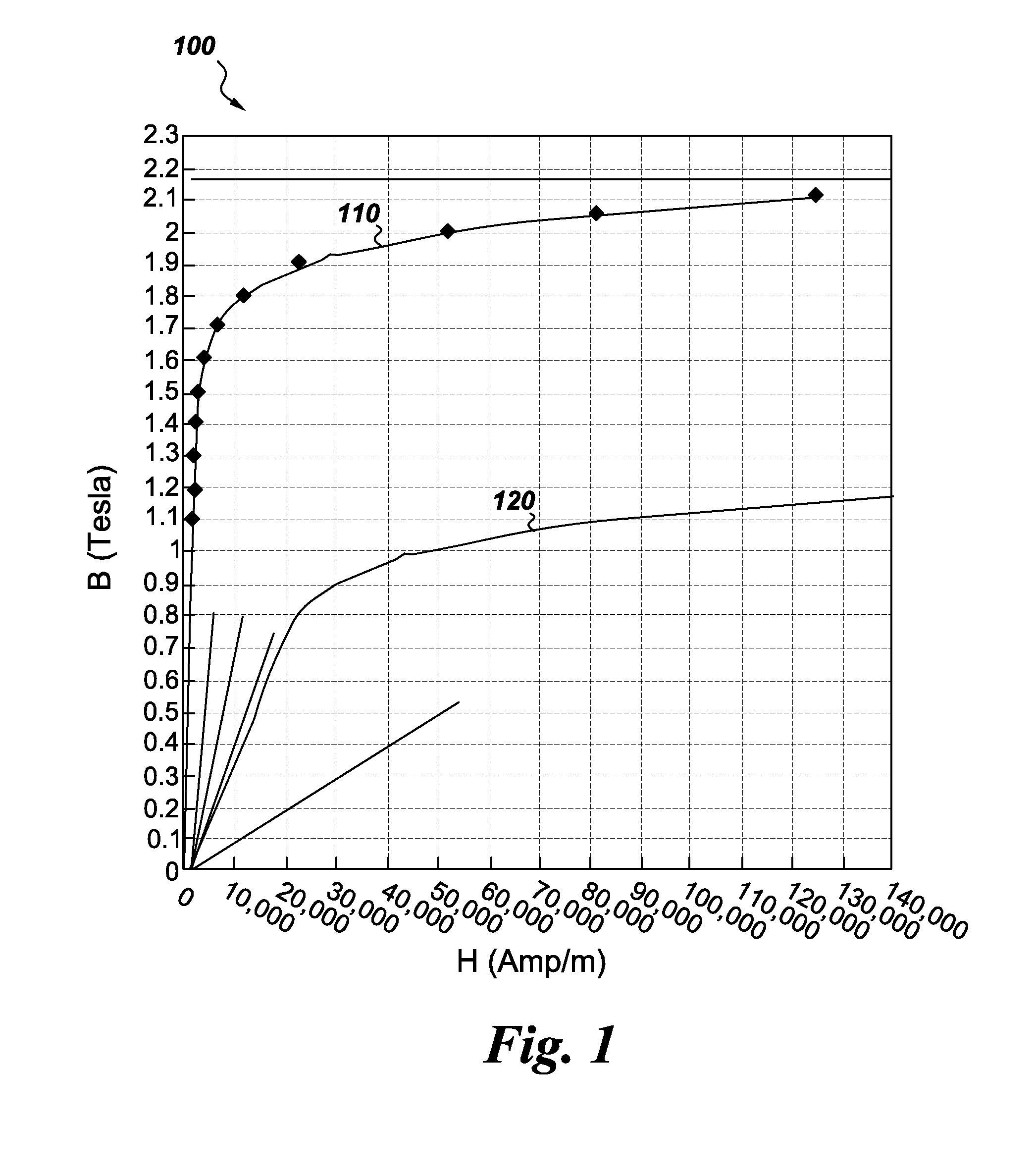

Electric machine stator lamination with dual phase magnetic material

ActiveUS20160087503A1Increase speedImprove power factorMagnetic circuitSynchronous machinesMagnetic phaseDouble phase

A stator lamination for an electric machine has a circular lamination with an annular bore therethrough; winding slots therethrough; and, slot closures disposed adjacent to the winding slots. The stator lamination is formed of a dual magnetic phase material, such that the magnetic property of the lamination can have a first state and a magnetic property in a second state, wherein the second state is different than the first state. The slot closures regions are treated so as to transition to the second state. A method of manufacturing an electric machine component is also disclosed.

Owner:GENERAL ELECTRIC CO

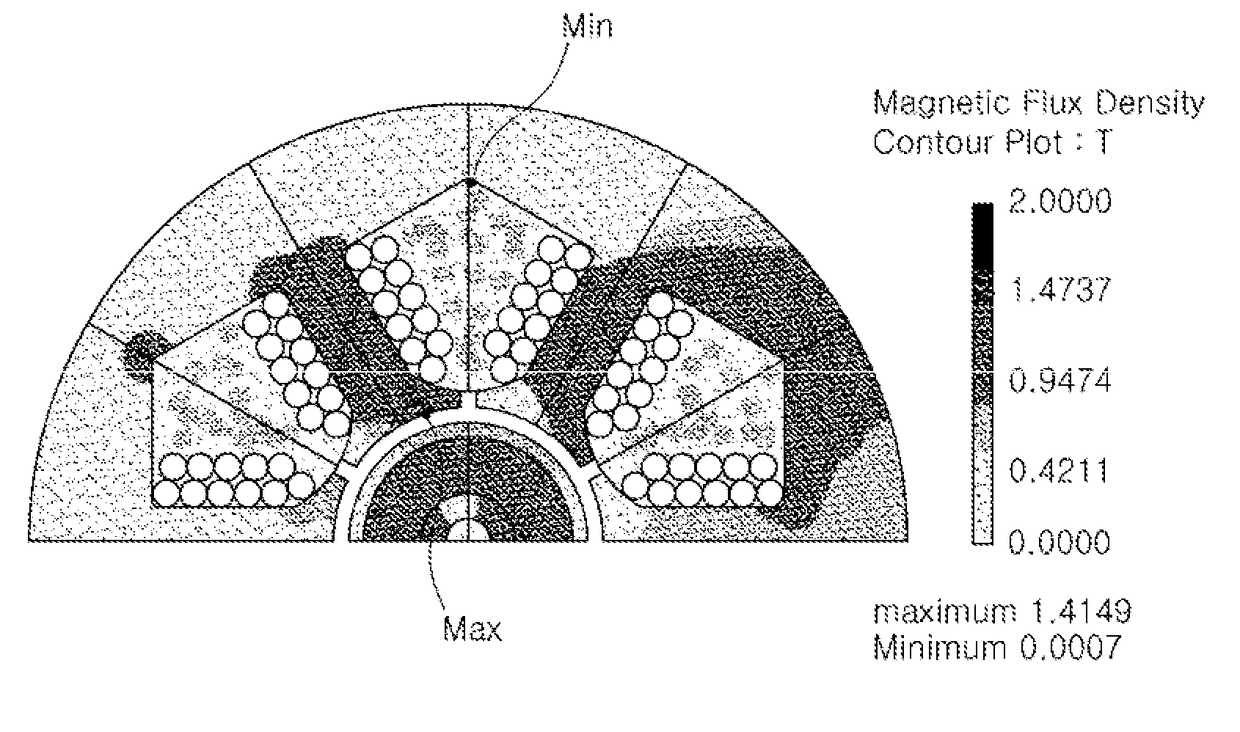

Stator for a high efficiency motor and manufacturing methods thereof

ActiveUS20180115227A1Minimize magnetic flux leakageMinimize iron lossWindings insulation shape/form/constructionMagnetic circuit stationary partsAdhesiveEngineering

A stator for a high efficiency motor and a manufacturing method of a stator for a high efficiency motor are disclosed. The method includes: preparing filling powder by coating a surface of soft magnetic powder with an insulating layer; providing a stator core partitioned into a center hole and inner spaces, the stator core including a yoke portion and a plurality of teeth; coiling coils around the plurality of teeth located in the inner spaces, respectively; and filling the inner spaces with a mixture of the filling powder and an adhesive, and curing the mixture of the filling powder and the adhesive.

Owner:HYUNDAI MOTOR CO LTD

Method for producing a rotor

ActiveUS20160126814A1Prevent leakageReduce the amount requiredMagnetic circuit rotating partsApplying/manufacturing slot closuresEngineeringNon magnetic

In a method for producing a rotor including a leak prevention hole formed in a rotor core to prevent leakage of magnetic flux from a permanent magnet; an outer-circumferential-side dovetail groove formed in an outer-circumferential-side inner wall of the leak prevention hole, an inner-circumferential-side dovetail groove formed, opposite the outer-circumferential-side dovetail groove, in an inner-circumferential-side inner wall of the leak prevention hole; and a non-magnetic bridge having both end portions engageable with the dovetail grooves, an external force is applied to bring the outer-circumferential-side inner wall close to the inner-circumferential-side inner wall, the non-magnetic bridge is inserted in the dovetail grooves while keeping the rotor core in an elastically deformed state, and, after inserting, the external force is released.

Owner:TOYOTA JIDOSHA KK

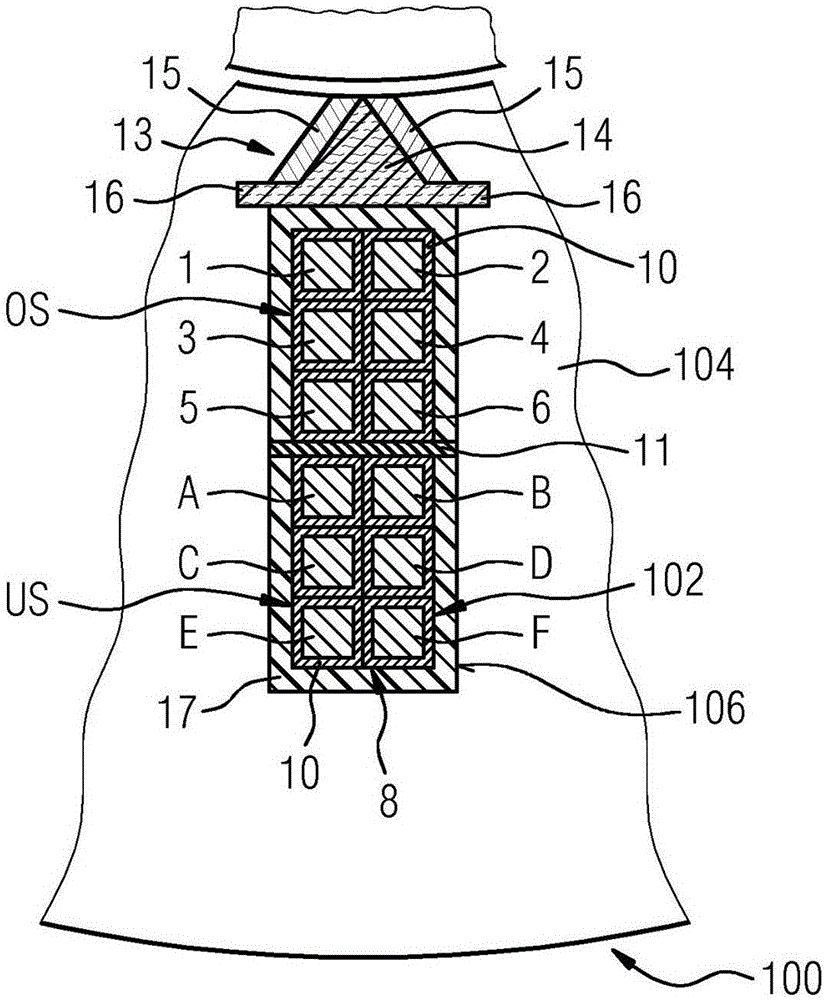

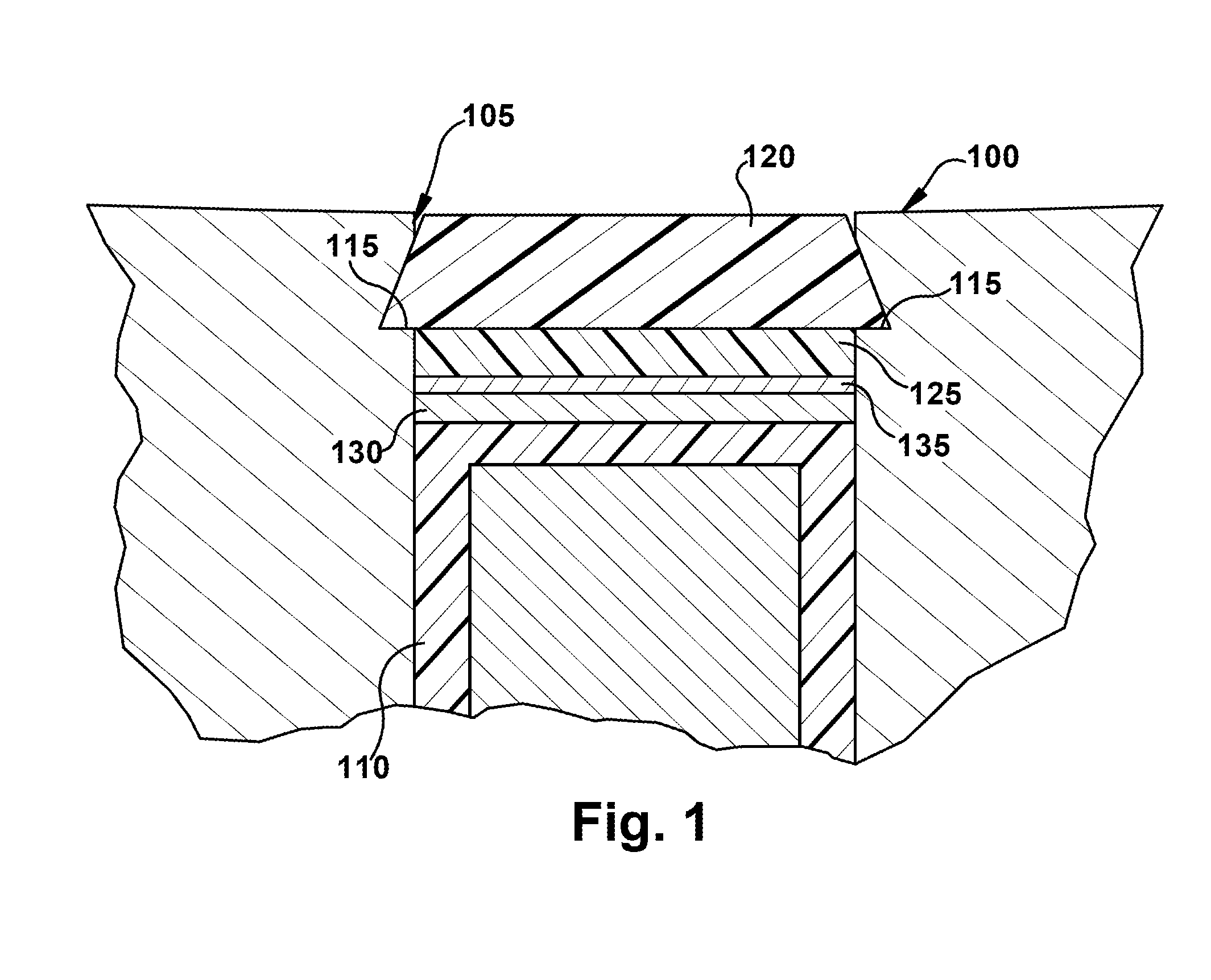

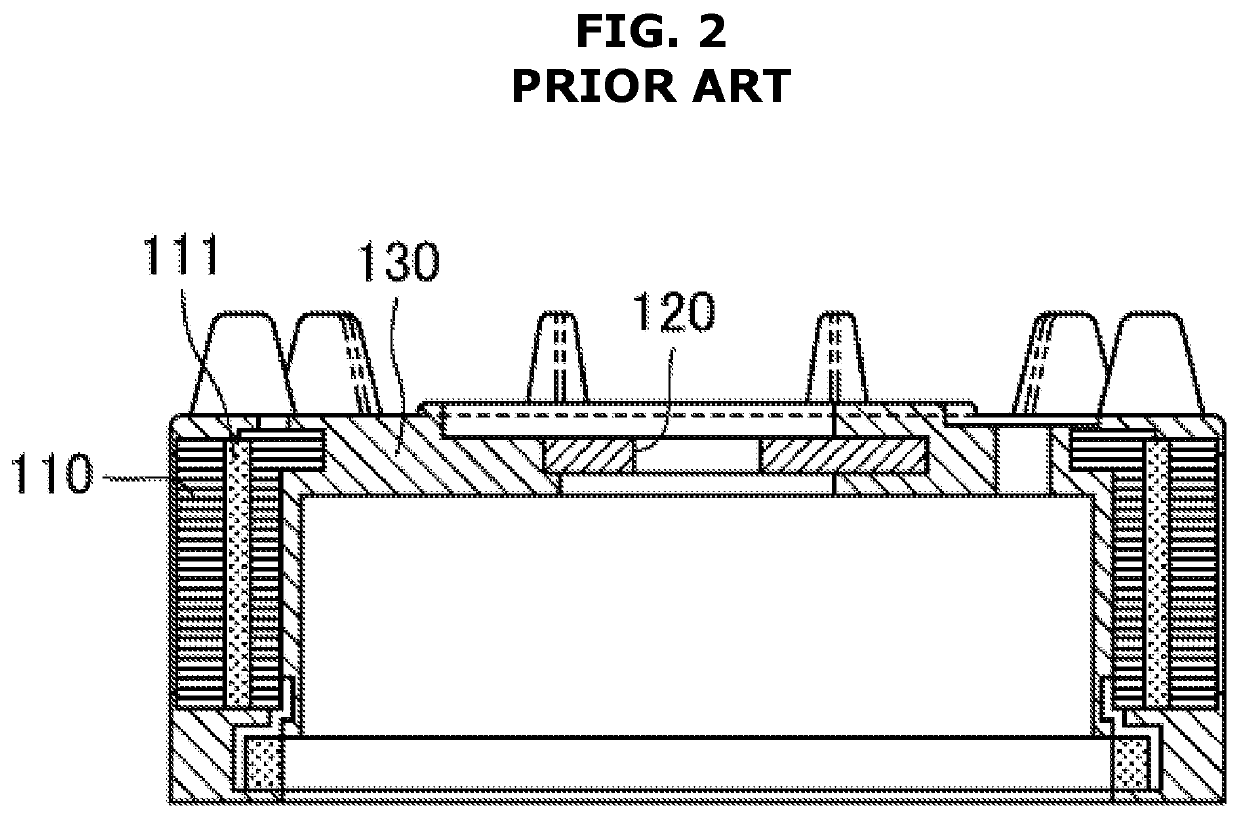

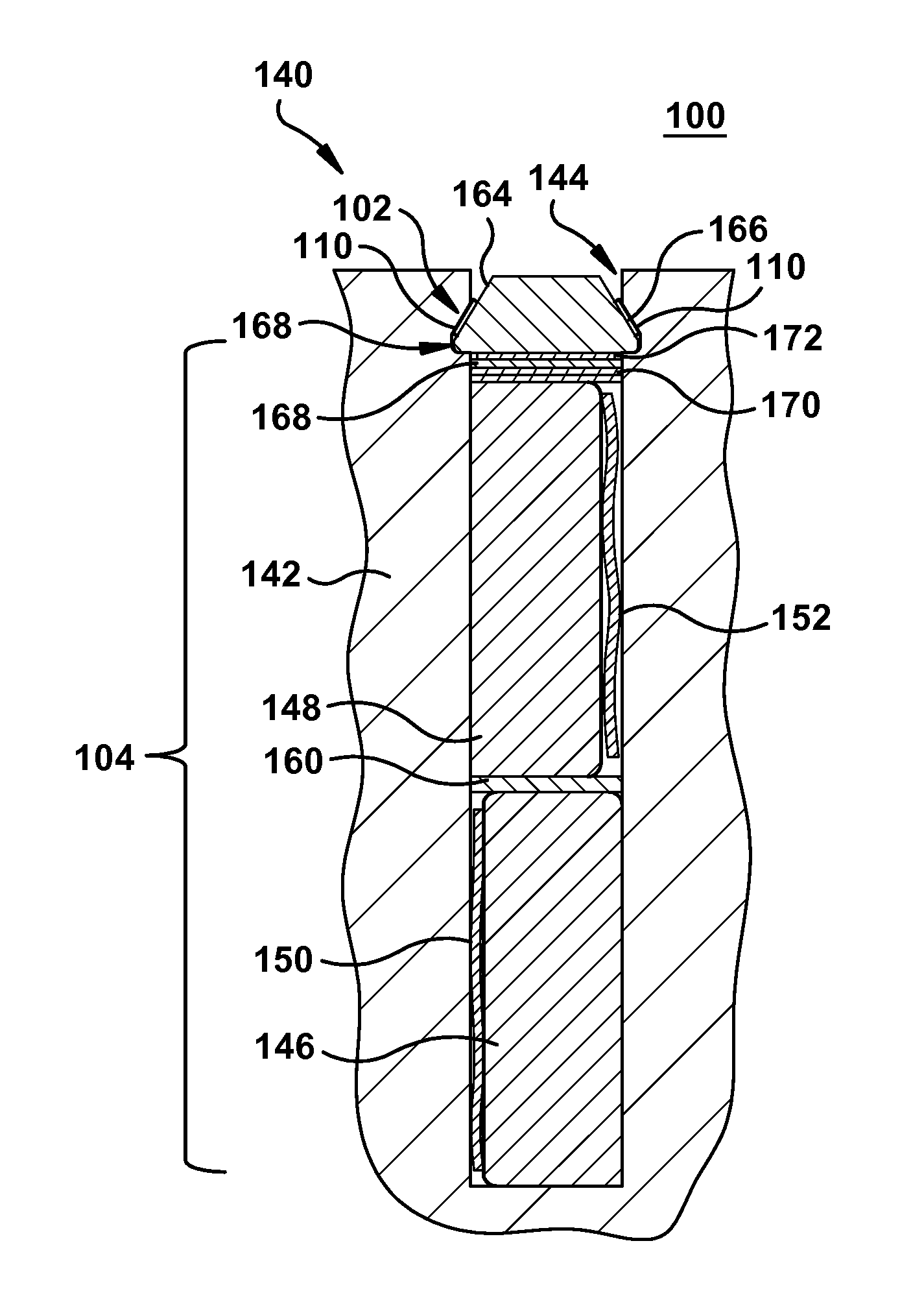

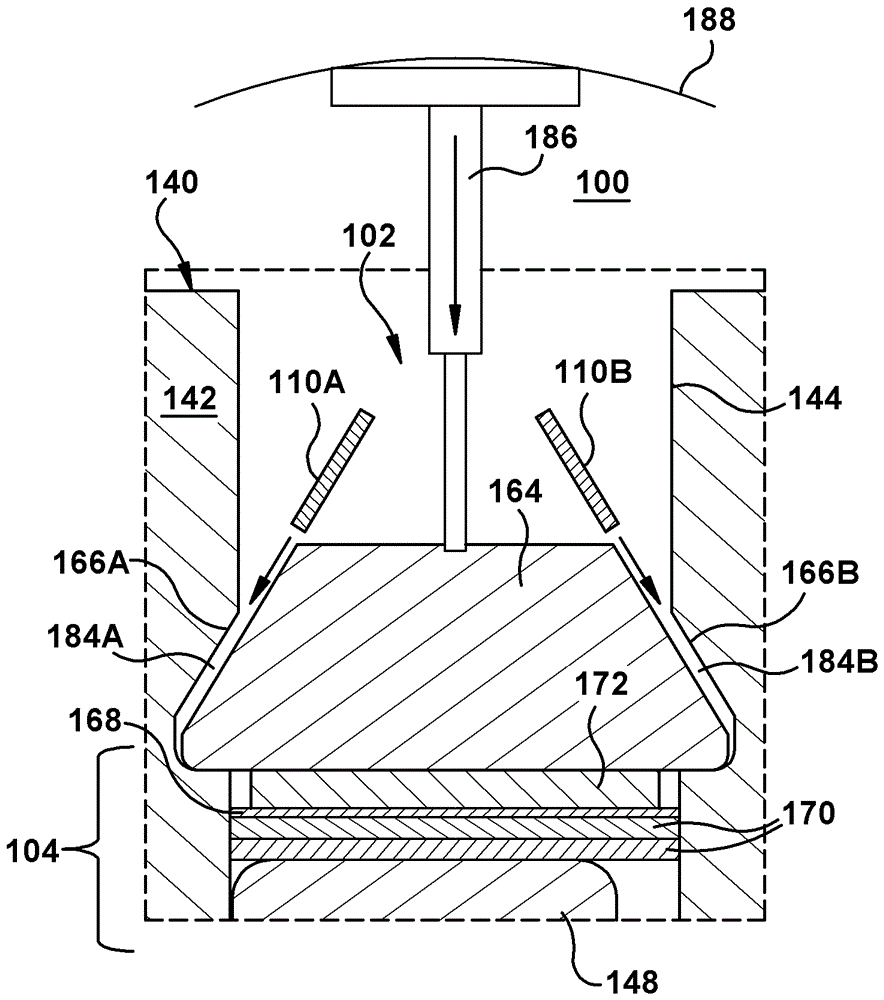

Retention assembly for stator bar using shim with stator wedge and related method

ActiveUS20160359385A1Excessive compressionWindingsMagnetic circuit stationary partsElectric machineMechanical engineering

A retention assembly for retaining a plurality of elements in a stator slot of an electric machine is provided. The retention assembly may include a stator wedge fixedly positioned in a dovetail in the stator slot to retain the plurality of elements; a top ripple spring between the plurality of elements and the stator wedge; and at least one shim positioned between the stator wedge and a load bearing surface of the dovetail. A method may include compressing the stator wedge in the stator slot from a first position thereof relative to the dovetail of the stator slot, the compressing creating a gap between the stator wedge and the dovetail. A shim may be inserted in the gap; the compressing released such that the shim retains the stator wedge in a second position that is more compressed relative to the plurality of elements in the stator slot compared to the first position.

Owner:GENERAL ELECTRIC CO

Method for producing a dynamoelectric rotary machine, and dynamoelectric rotary machine

ActiveUS10424985B2Not easy to make mistakesMore time-savingWindings insulation shape/form/constructionMagnetic circuit rotating partsWind systemConductive materials

The invention relates to a method for producing a rotor and / or a stator of a dynamoelectric rotary machine by means of the following steps: —producing pre-formed coils from an integral electrically conductive material or pre-insulated or coated electrically conductive wires, —fixing spacers to the pre-formed coil at predefinable intervals, —inserting the pre-formed coil, which is provided with spacers, into slots in a laminated core of a stator or rotor, —making contact with the individual pre-formed coils to form groups of coils and forming a winding system of a rotor and / or stator in accordance with a predefined circuit plan, —insulating the pre-formed coils or the winding system in the slots by complete encapsulation, in particular by complete vacuum encapsulation.

Owner:FLENDER GMBH

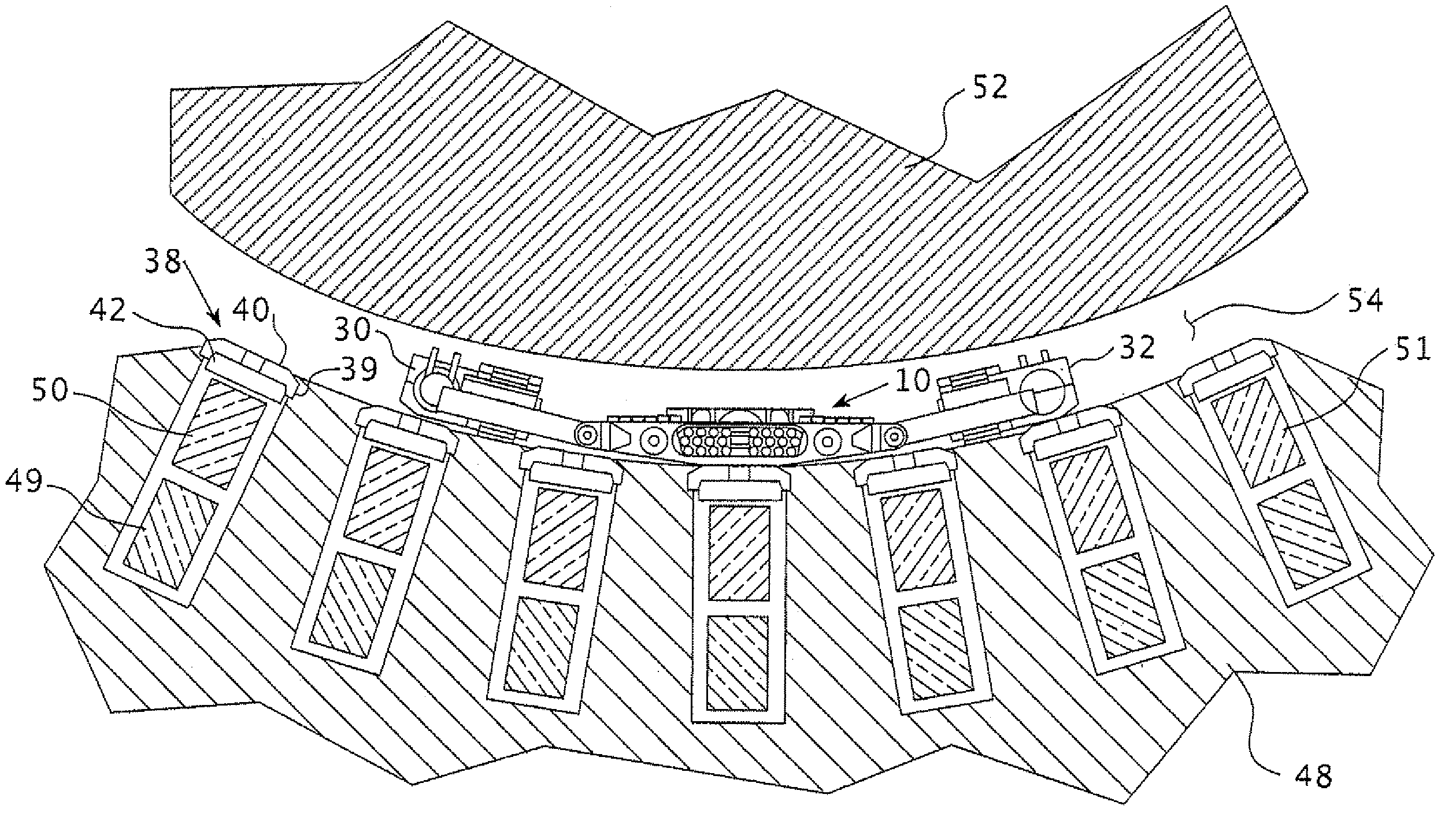

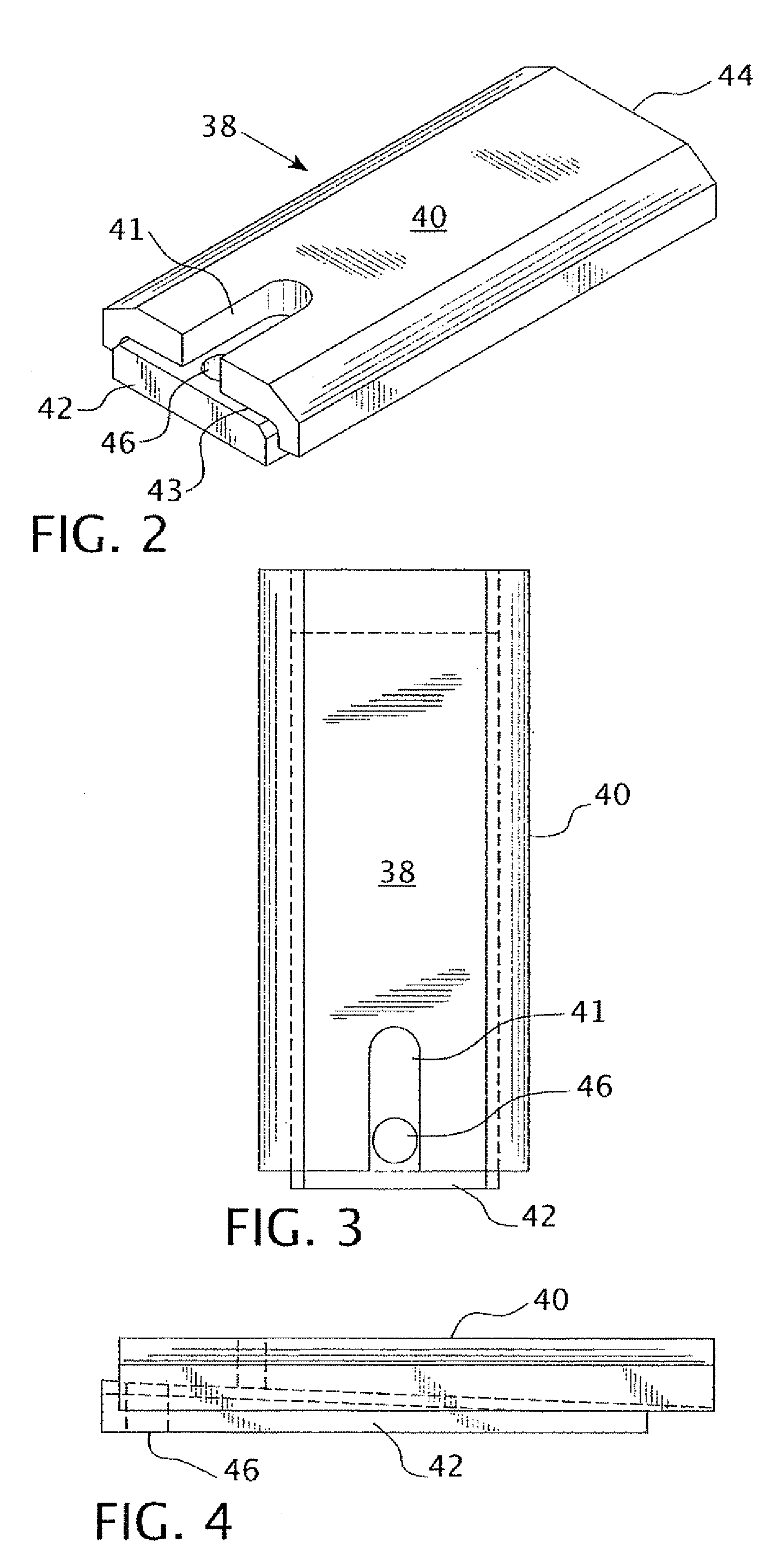

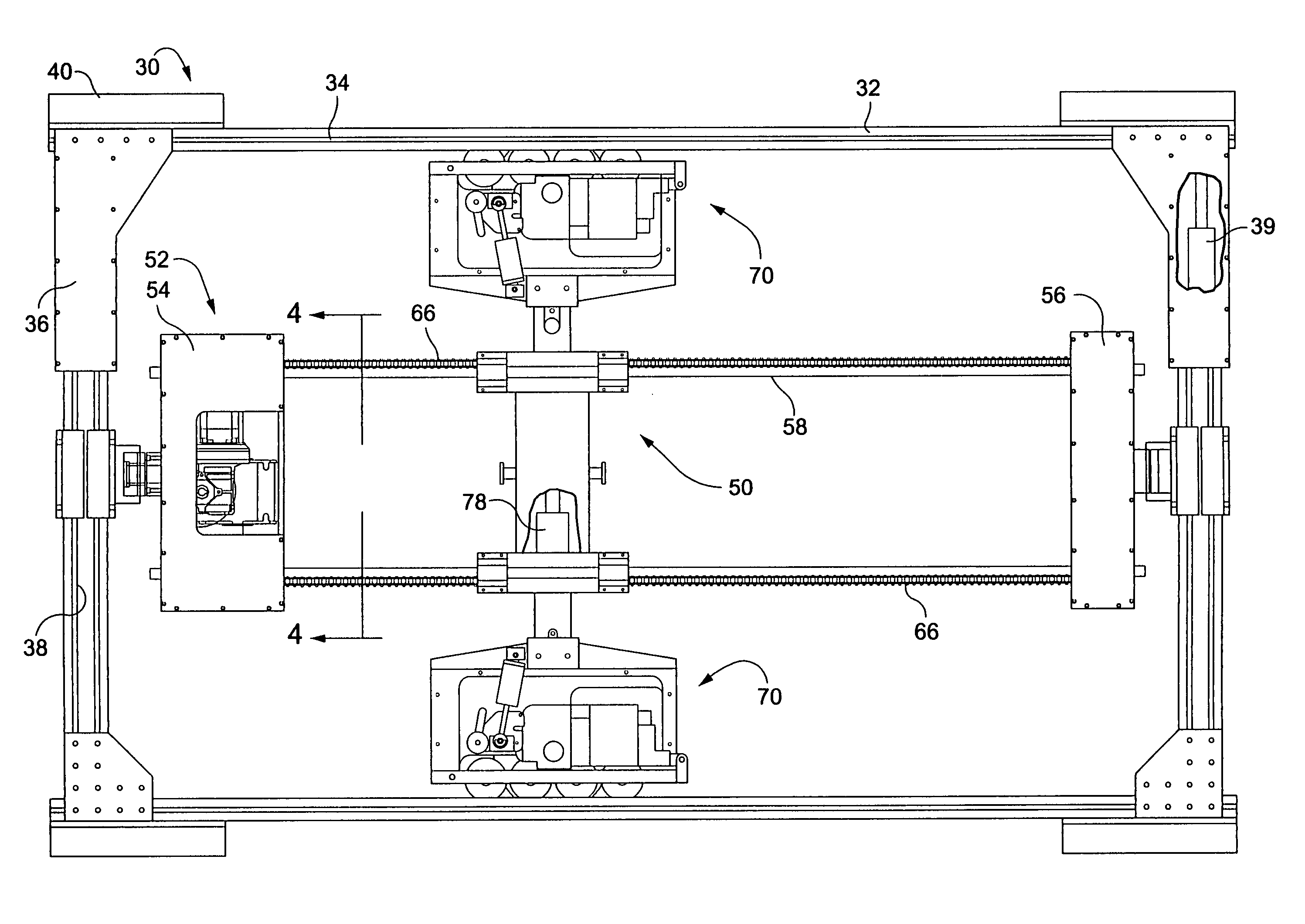

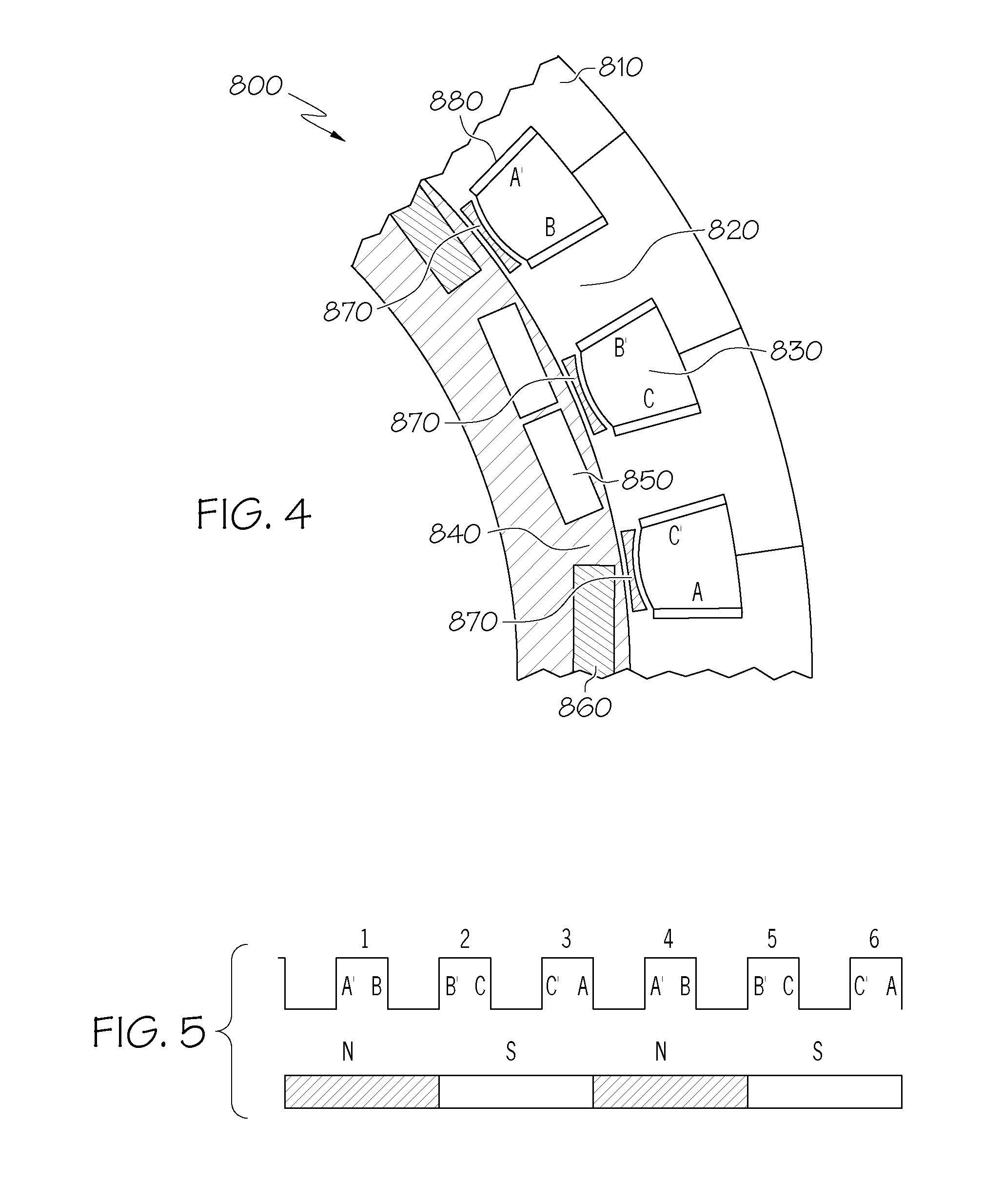

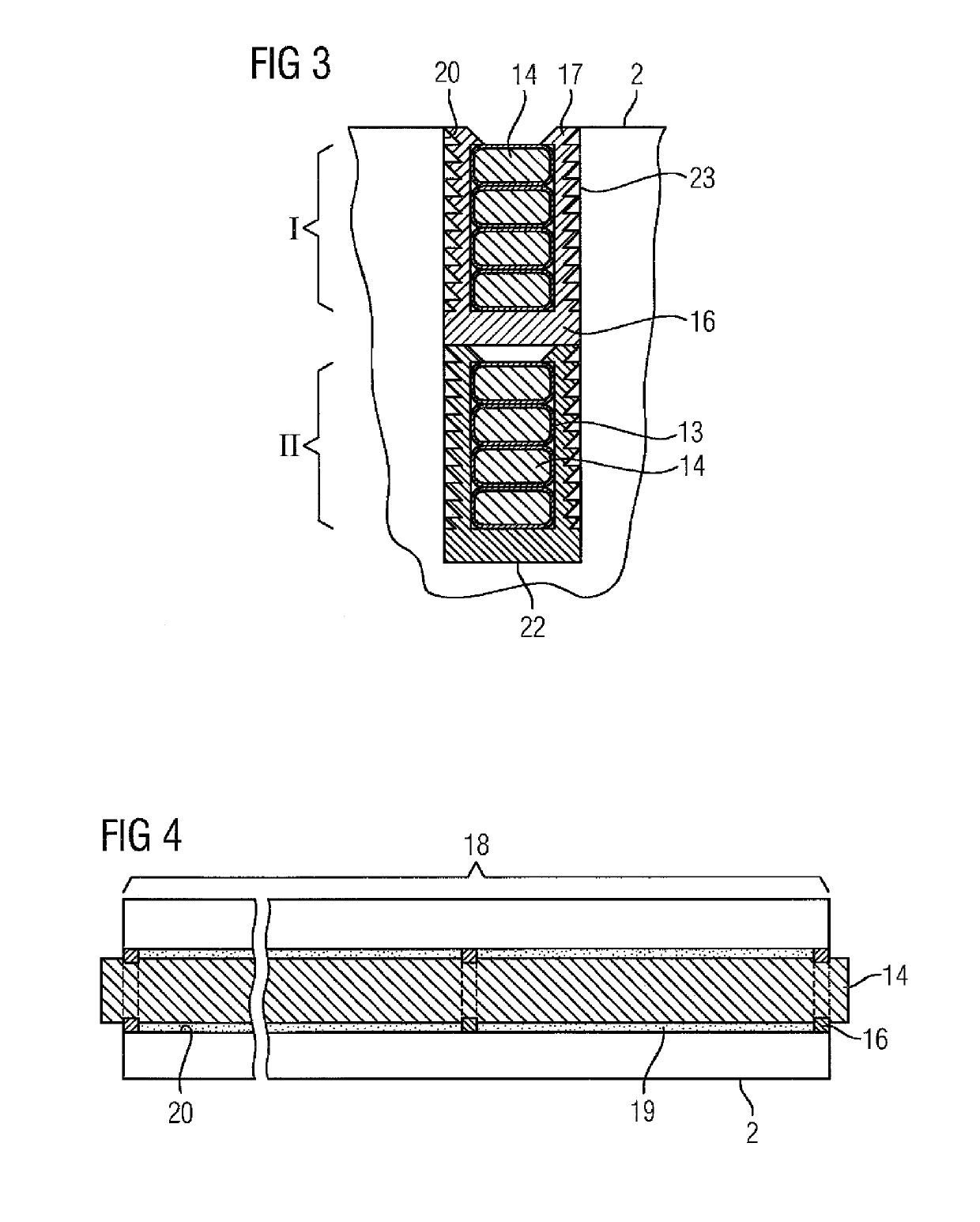

Automated Remote Carriage for Tightening Generator Wedges

ActiveUS20090194346A1Increase widthDigital data processing detailsColor television detailsMachine maintenanceRemote control

A remote-controlled dynamoelectric machine maintenance vehicle that can fit and travel within the air gap between a stator and rotor of a dynamoelectric machine. The maintenance vehicle has an effectuator that can remotely attach to an adjustable wedge within a coil slot of the stator and tighten the wedge in position and then move on to repeat the process until all the wedges on the stator are secured.

Owner:SIEMENS ENERGY INC

Rotor coil shaping device

PendingCN110739815AReduce labor intensityIncrease productivityApplying/manufacturing slot closuresMechanical engineeringPhysics

Owner:HENGDIAN GRP INNUOVO ELECTRIC

Retention assembly for stator bar using shim with stator wedge and related method

A retention assembly (102) for retaining a plurality of elements (104) in a stator slot (144) of an electric machine (100) is provided. The retention assembly (102) may include a stator wedge (164) fixedly positioned in a dovetail (166) in the stator slot (144) to retain the plurality of elements (104); a top ripple spring (168) between the plurality of elements (104) and the stator wedge (164); and at least one shim (110) positioned between the stator wedge (164) and a load bearing surface (165) of the dovetail (166). A method may include compressing the stator wedge (164) in the stator slot (144) from a first position thereof relative to the dovetail (166) of the stator slot (144), the compressing creating a gap (184B) between the stator wedge (164) and the dovetail (166). A shim (110) may be inserted in the gap (184B); the compressing released such that the shim (110) retains the stator wedge (164) in a second position that is more compressed relative to the plurality of elements (104) in the stator slot (144) compared to the first position.

Owner:GENERAL ELECTRIC TECH GMBH

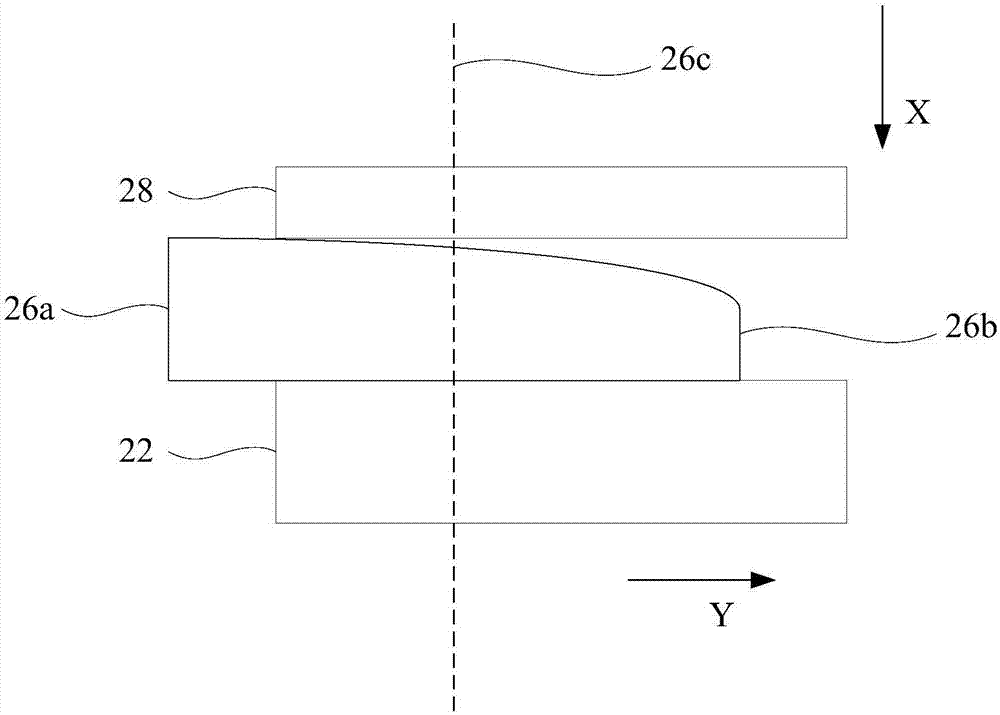

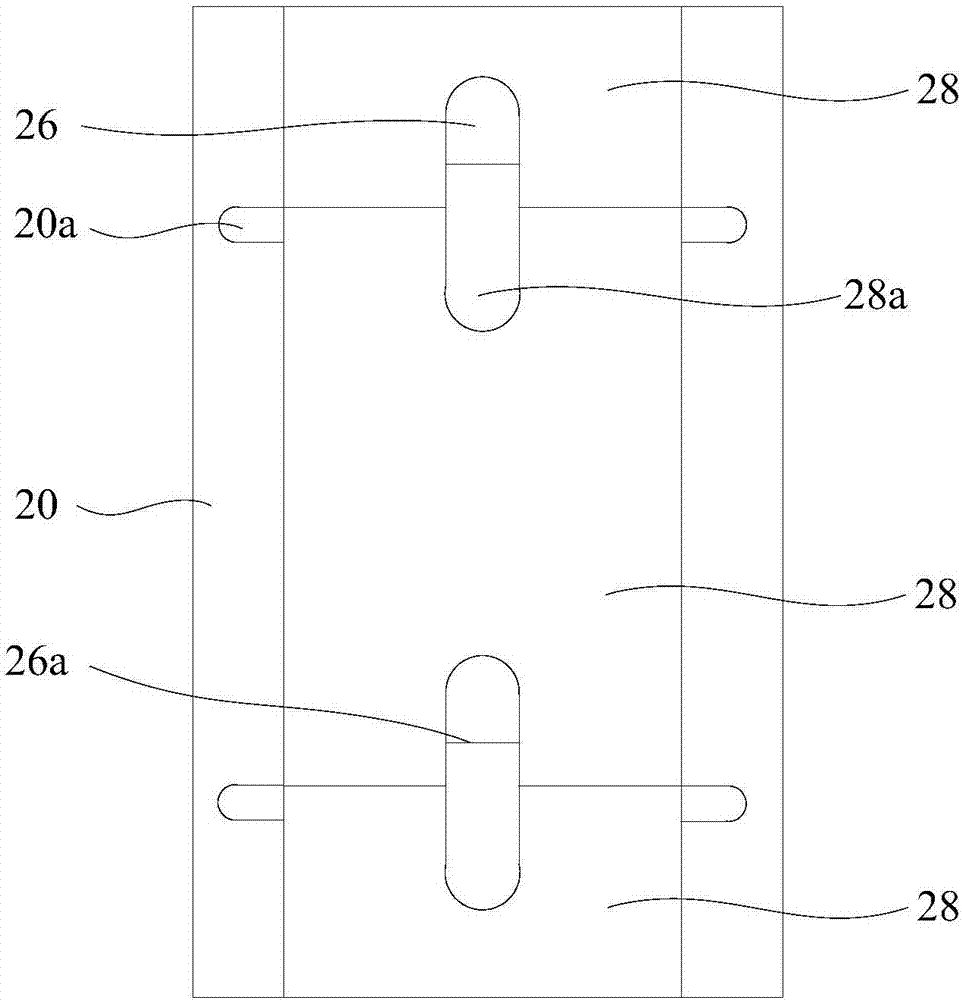

Slot wedge, stator and motor, and method for manufacturing slot wedge

InactiveCN107979203AReduce temperature riseImprove cooling effectWindingsApplying/manufacturing slot closuresElectrical and Electronics engineeringAir gap flux

Owner:XINJIANG GOLDWIND SCI & TECH

A walking robot and a method thereof for processing slot wedge loosening

ActiveCN107332400APlay the role of tightening the coilImproving the Efficiency of Overhauling GeneratorsWindingsApplying/manufacturing slot closuresEngineeringHuman power

The invention relates to a walking robot and a method thereof for processing slot wedge loosening. The walking robot includes a vehicle body and a striking part, and the vehicle body is used for being adsorbed on an iron core of a stator and capable of moving relative to the stator. The striking part is disposed on the vehicle body and capable of moving in a radial direction of the stator relative to the vehicle body to pass through an insertion hole of a slot wedge. The striking part can also move in the axial direction of the stator relative to the vehicle body to strike a spacer within the insertion hole. The walking robot can directly enter the gap between the stator and a rotor and can move above a loose slot wedge. After the striking part is inserted into the insertion hole of the slot wedge, the striking part can strike the spacer along the axial direction of the stator to enable the spacer to move along the axial direction of the stator for a certain distance to realize tightening through expending in the slot wedge, thereby realizing an effect of fastening a coil. The loose slot wedge is processed through utilization of the walking robot to avoid waste of a lot of time and manpower caused by drawing through the rotor and handling of loosening by human power, thereby substantially raising the efficiency of inspection and repairing a motor.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com