Rotor coil shaping device

A technology of shaping device and rotor coil, applied in electromechanical devices, using/manufacturing slot locking devices, manufacturing motor generators, etc., can solve the problems of high labor intensity and low efficiency of workers, reduce labor intensity of workers and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below according to the accompanying drawings and specific embodiments.

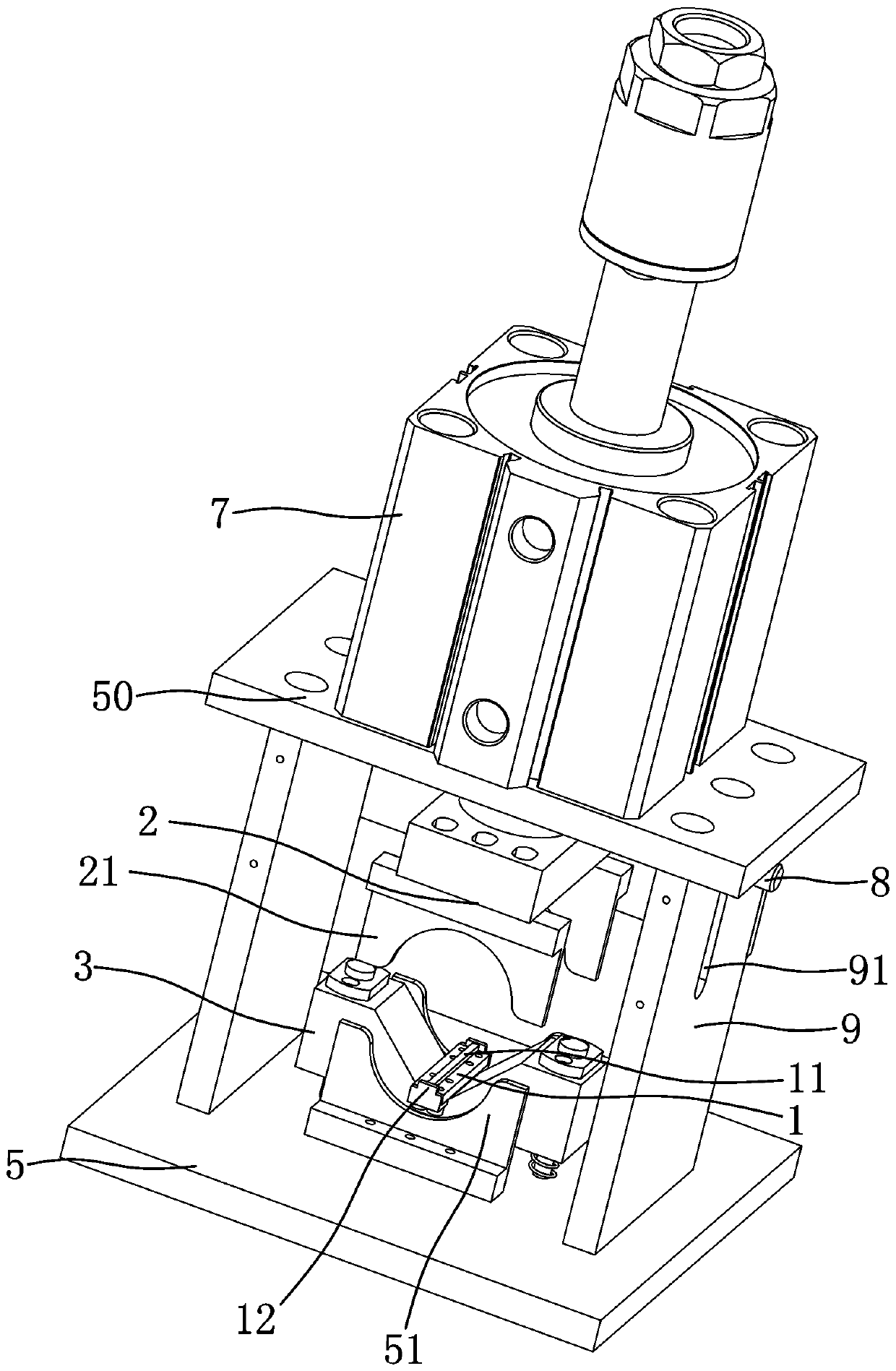

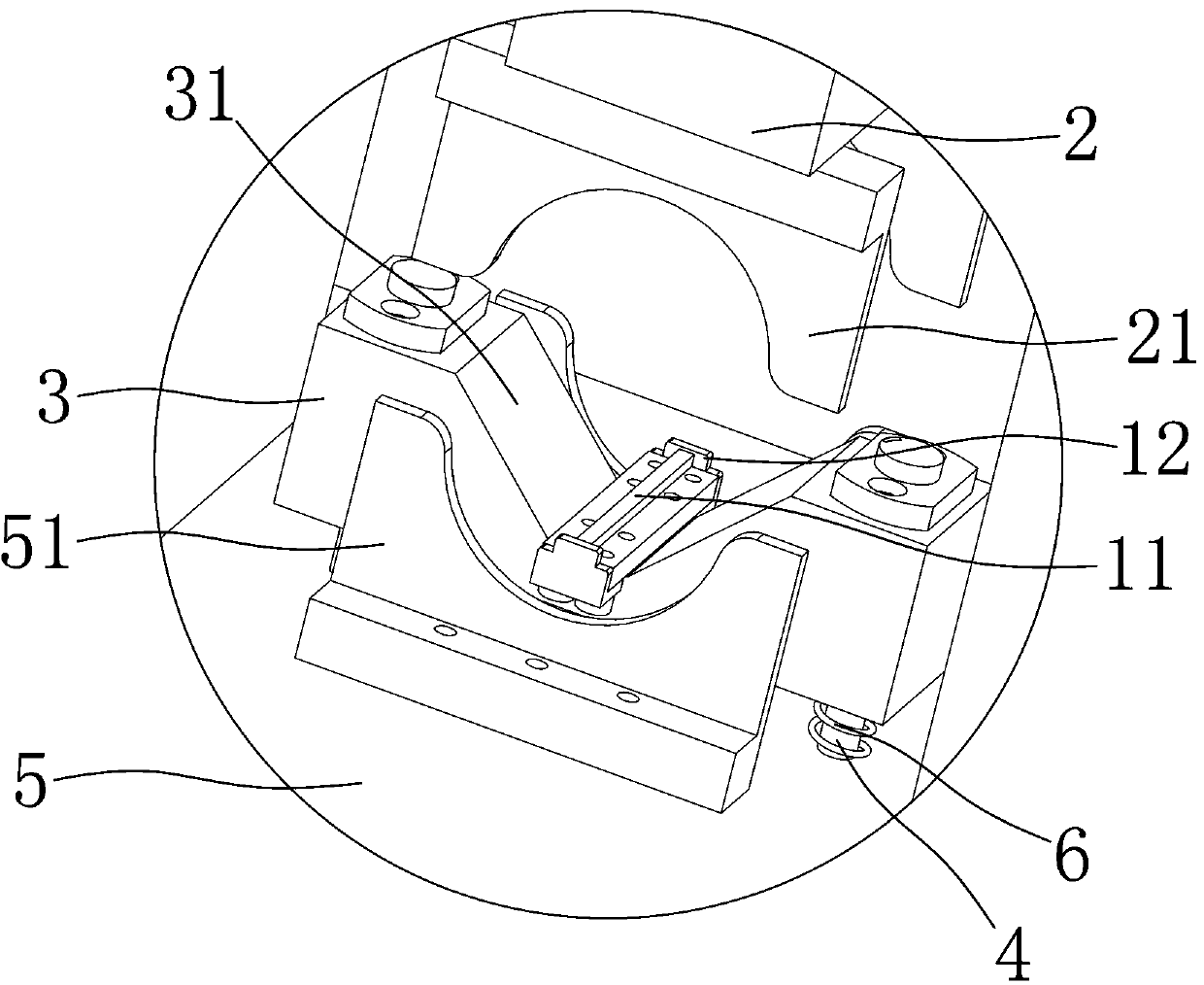

[0015] Depend on figure 1 , figure 2 As shown, a rotor coil shaping device of the present invention includes a positioning block 1 and a pressing block 2 located above the positioning block 1. The middle of the positioning block 1 is provided with a positioning protrusion 11 extending upward and arranged in the front-rear direction. The positioning protrusion The width of 11 is the same as the width of the rotor slot opening of the rotor. Both the front and rear ends of the positioning block 1 have upwardly extending limit protrusions 12. Has an arcuate slot that opens downwards.

[0016] The positioning block 1 is detachably fixed on the positioning seat 3 through screws. The positioning seat 3 is sleeved on the two vertically arranged guide rods 4. There is a spring 6, the spring 6 is sleeved on the guide rod 4, the bottom plate 5 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com