Stator manufacturing method, stator, and motor

A manufacturing method and stator technology, which are applied in the field of electric motors, can solve the problems of decreasing the occupancy rate and increasing the insulating parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] One embodiment of the present invention will be described below with reference to the drawings.

[0029] Such as figure 1 As shown, the motor housing 2 of the motor 1 has: a cylindrical casing 3 formed in a bottomed cylindrical shape; figure 1 Middle left) the opening is closed. In addition, on the back side of the cylindrical case 3 ( figure 1 A circuit storage box 5 is installed on the end portion of the middle right side), and power circuits such as circuit boards are stored in the circuit storage box 5 .

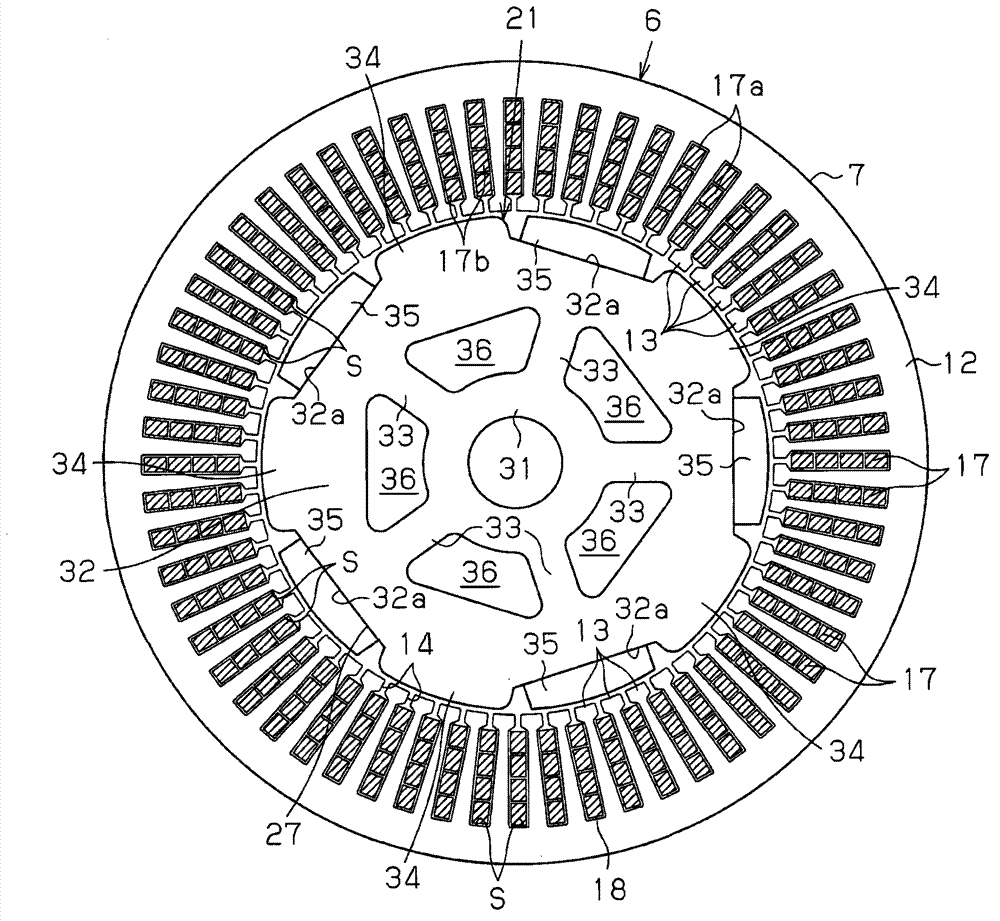

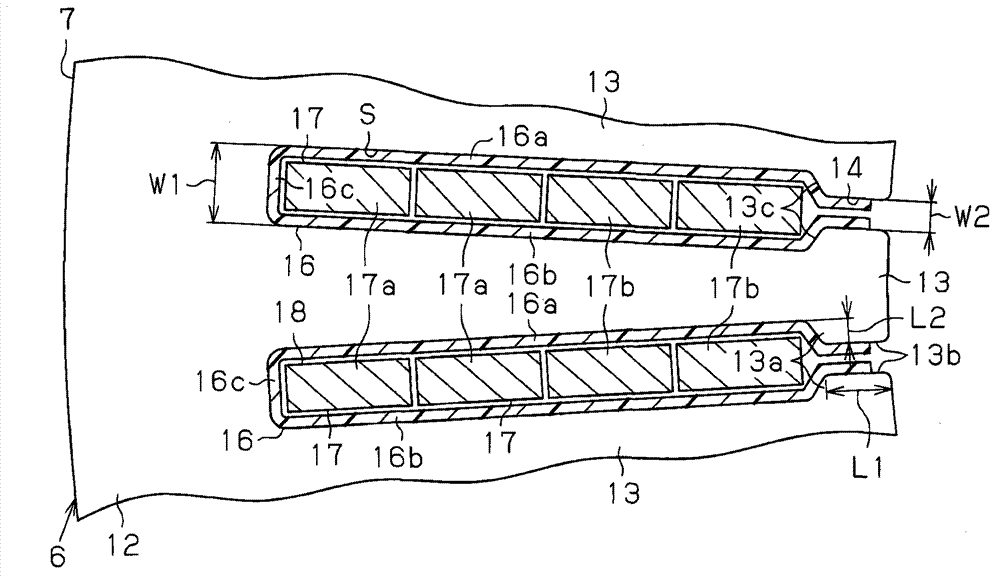

[0030] A stator 6 is fixed to the inner peripheral surface of the cylindrical case 3 . The stator 6 has an armature core 7 . The armature core 7 is formed by laminating a plurality of chips 11 . The chip 11 has a plate shape and is made of a steel plate. And, if figure 2 As shown, the armature core 7 has: an annular portion 12 formed in an annular shape; and a plurality of teeth 13 arranged in the circumferential direction. A plurality of teeth 13 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com