Halogen-free transparent flame-retardant photovoltaic encapsulating material and preparation method of halogen-free transparent flame-retardant photovoltaic encapsulating material

A packaging material, photovoltaic technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as easy overflow, affecting the appearance and power generation performance of components, and easy overflow to the front of crystalline silicon cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

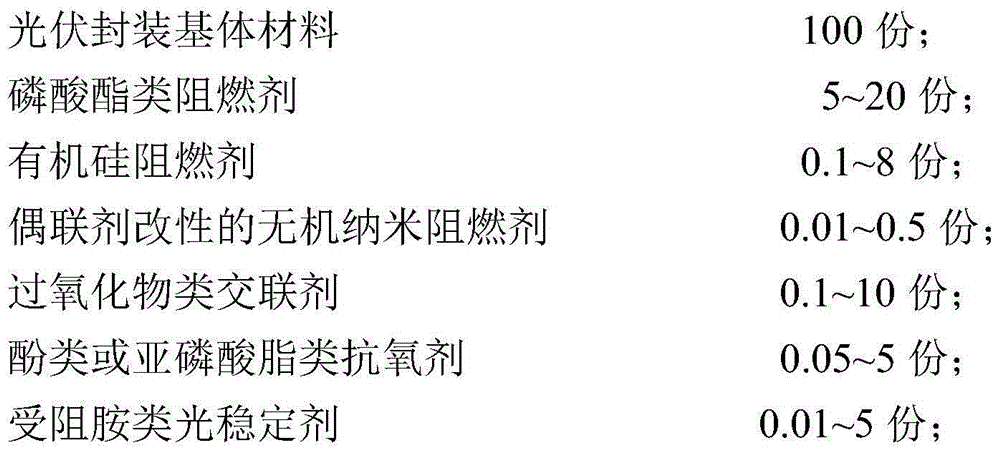

[0026] A halogen-free transparent flame-retardant flame-retardant photovoltaic encapsulation material, in parts by weight, its main raw material composition is as follows: 100 parts of ethylene-vinyl acetate copolymer (U.S. DuPont, VA mass fraction is 33%), 8 parts of phosphoric acid ester BDP-like flame retardant, 0.1 part of silicone flame retardant RM4-7105 (Dow Corning, USA), 0.5 part of nano-zinc oxide modified by silane coupling agent KH550, 0.1 part of hindered amine light stabilizer sebacic acid bis-2 , 2,6,6-tetramethylpiperidinol ester (Shanghai Yanjia Plastic Chemical Co., Ltd.), 0.2 parts of antioxidant 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6 -Dimethylbenzyl)-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione and tris(2,4,-di-tert-butylphenyl) Phosphate ester compound (mass ratio 1:2, Tianda Tianhai Technology Development Co., Ltd.), 0.2 parts of crosslinking agent tert-butyl peroxyisopropyl carbonate (Bailingwei Technology Co., Ltd.), 0.1 part of UV absorber 2, 2-Tetramethylen...

Embodiment 2

[0034] A halogen-free transparent flame-retardant photovoltaic encapsulation material, in parts by weight, its composition is as follows: 100 parts of ethylene vinyl acetate copolymer (U.S. DuPont, VA mass fraction is 16%), 5 parts of RDP, 8 parts of RM4-7081 (U.S. Dow Corning Corporation), 0.01 part of silane coupling agent KH550 modified aluminum hydroxide, 0.1 part of hindered amine light stabilizer sebacic acid bis-2,2,6,6-tetramethyl piperidinol ester (Shanghai Yanjia Plastic Chemical Co., Ltd.), 0.2 parts of antioxidant 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl)-1,3,5-tris Oxazine-2,4,6-(1H,3H,5H)-trione / tris(2,4,-dicumylphenyl)pentaerythritol diphosphite compound (mass ratio 1:4, Tiandatianhai Science and Technology Development Co., Ltd.), 1.5 parts of cross-linking agent 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (Shanghai Base Free Biotechnology Co., Ltd.), 0.1 part of UV absorber Agent 2,2-tetramethylenebis(3,1-benzoxazin-4-one) (Nanjing Zhonghesheng Te...

Embodiment 3

[0042] A halogen-free transparent flame-retardant photovoltaic encapsulation material, in parts by weight, its composition is as follows: 100 parts of ethylene-vinyl acetate copolymer (U.S. DuPont Company, VA mass fraction is 40%), 20 parts of TPP and DMMP composite resistance Burning agent (the mass ratio of the two is 1:1), 3 parts of SFR-100 (General Electric Company of the United States), 0.05 part of magnesium hydroxide modified by silane coupling agent KH570, 0.1 part of hindered amine light stabilizer bis(1 ,2,2,6,6-Pentamethyl-4-piperidinyl) aquilate / Methyl-1,2,2,6,6-pentamethyl-4-piperidinyl abrate Compound (mass ratio 1:1, Beijing Tiangang Co., Ltd.), 0.2 parts of antioxidant 1,3,5-tris(4-tert-butyl-3-hydroxy-2,6-dimethylbenzyl )-1,3,5-triazine-2,4,6-(1H,3H,5H)-trione / tris(2,4,-dicumylphenyl)pentaerythritol diphosphite compound ( Mass ratio 1:4, Tianda Tianhai Science and Technology Development Co., Ltd.), 1.5 parts of crosslinking agent 1-bis(tert-butyl peroxide)-3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com