Automatic insertion device for motor stator insulated slot wedge

A motor stator, automatic insertion technology, applied in the direction of electromechanical devices, use/manufacture slot locking devices, electric components, etc., to achieve high production efficiency and improve the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

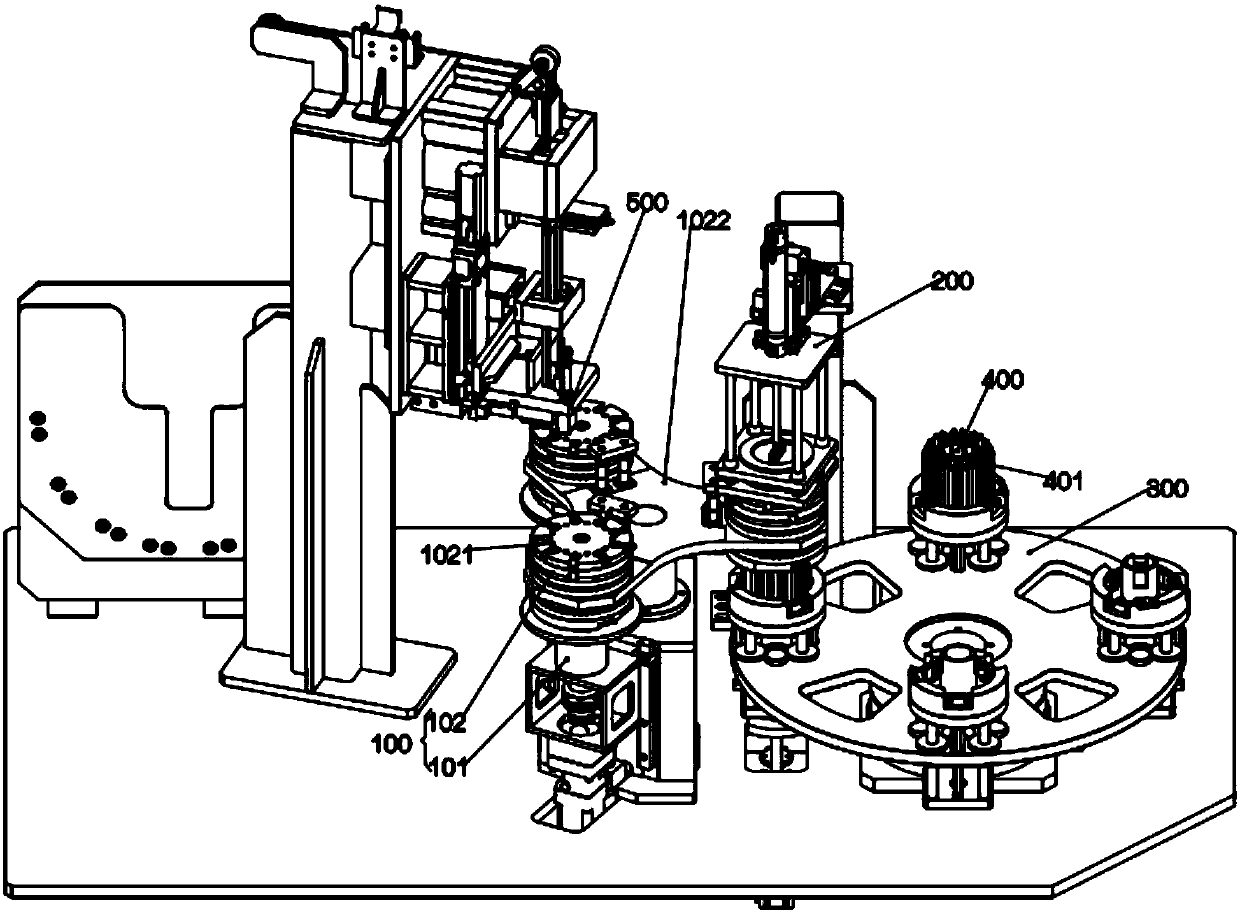

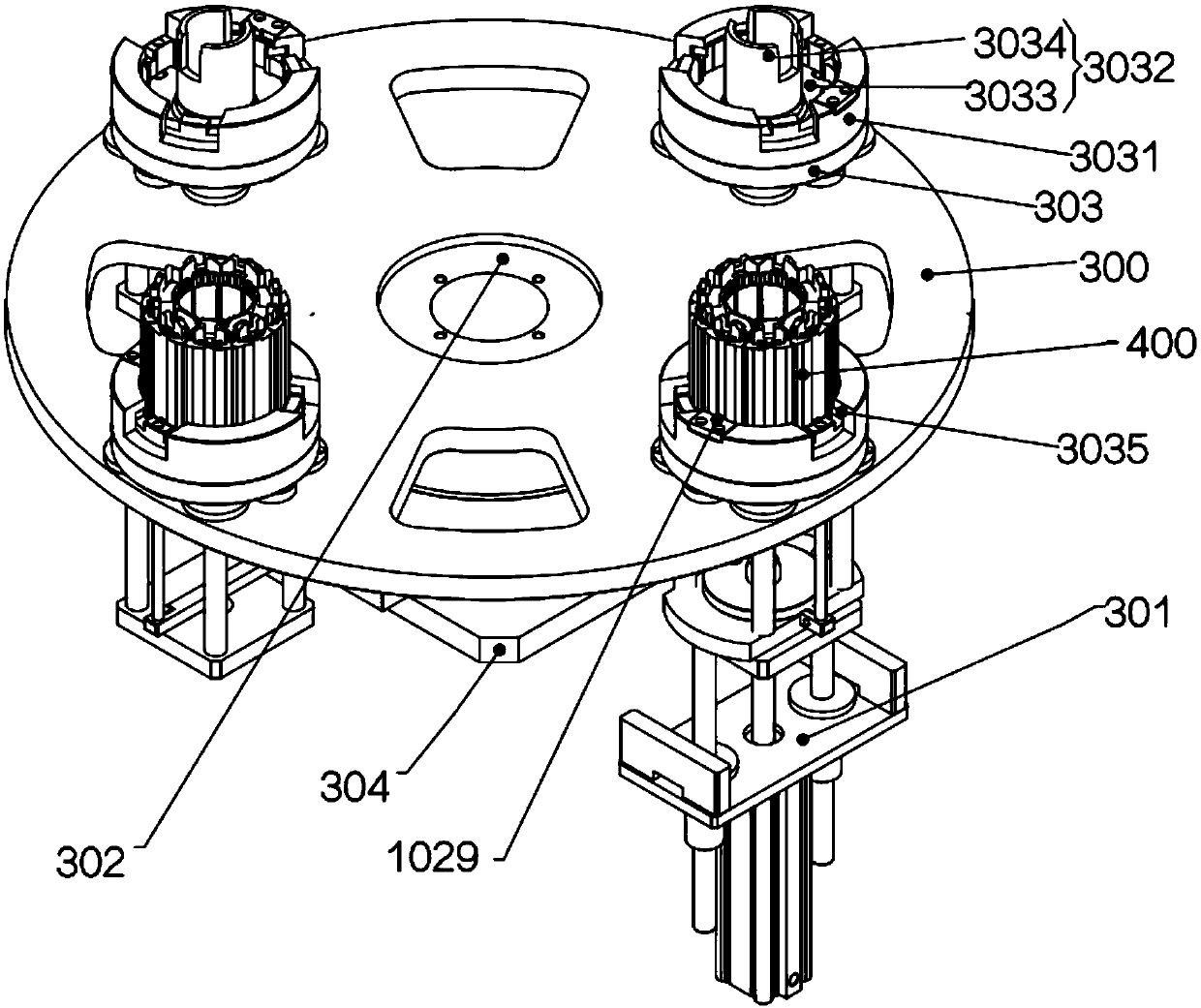

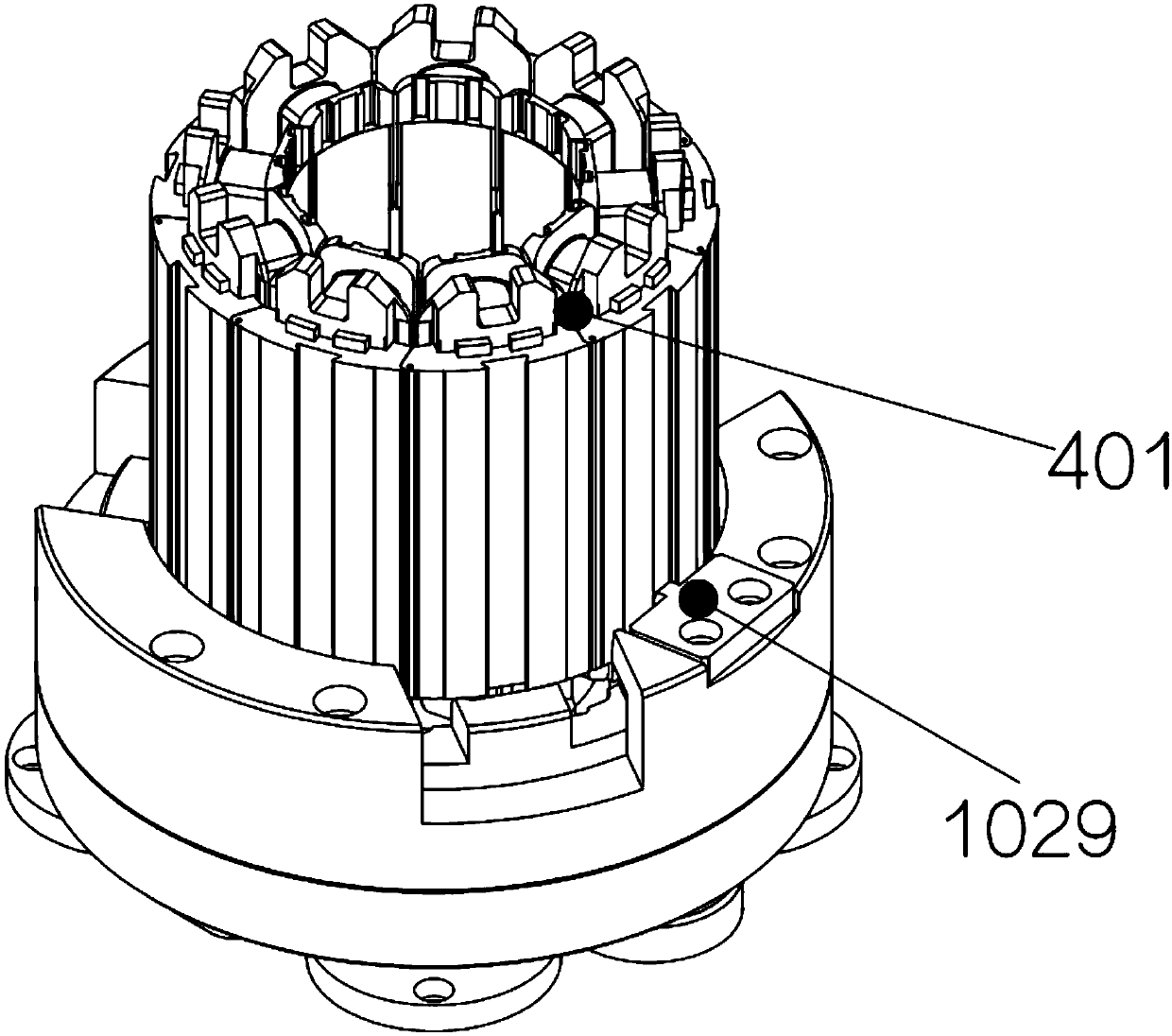

[0045] Such as Figure 1 to Figure 12 As shown, this embodiment provides a motor stator insulation slot wedge automatic insertion device, including a workpiece mounting plate 300, a control unit and a feeding device 500 connected to the control unit, a pre-insertion indexing mechanism 100 and an insertion mechanism 200; The mounting plate 300 is used to install the motor stator 400; the pre-insertion indexing mechanism 100 includes a temporary storage device 102, and the temporary storage device 102 is provided with a temporary storage hole 1021 at a position corresponding to the slot wedge installation hole 401 of the motor stator 400, and the feeding device 500 It is used to put the slot wedge 600 into the temporary storage hole 1021; the temporary storage device 102 is provided with a turntable 1022 capable of revolving itself and the turntable 1022 is connected to the control unit; the insertion mechanism 200 is used to drive the slot in the temporary storage hole 1021 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com