Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87 results about "Thermal neutron detector" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

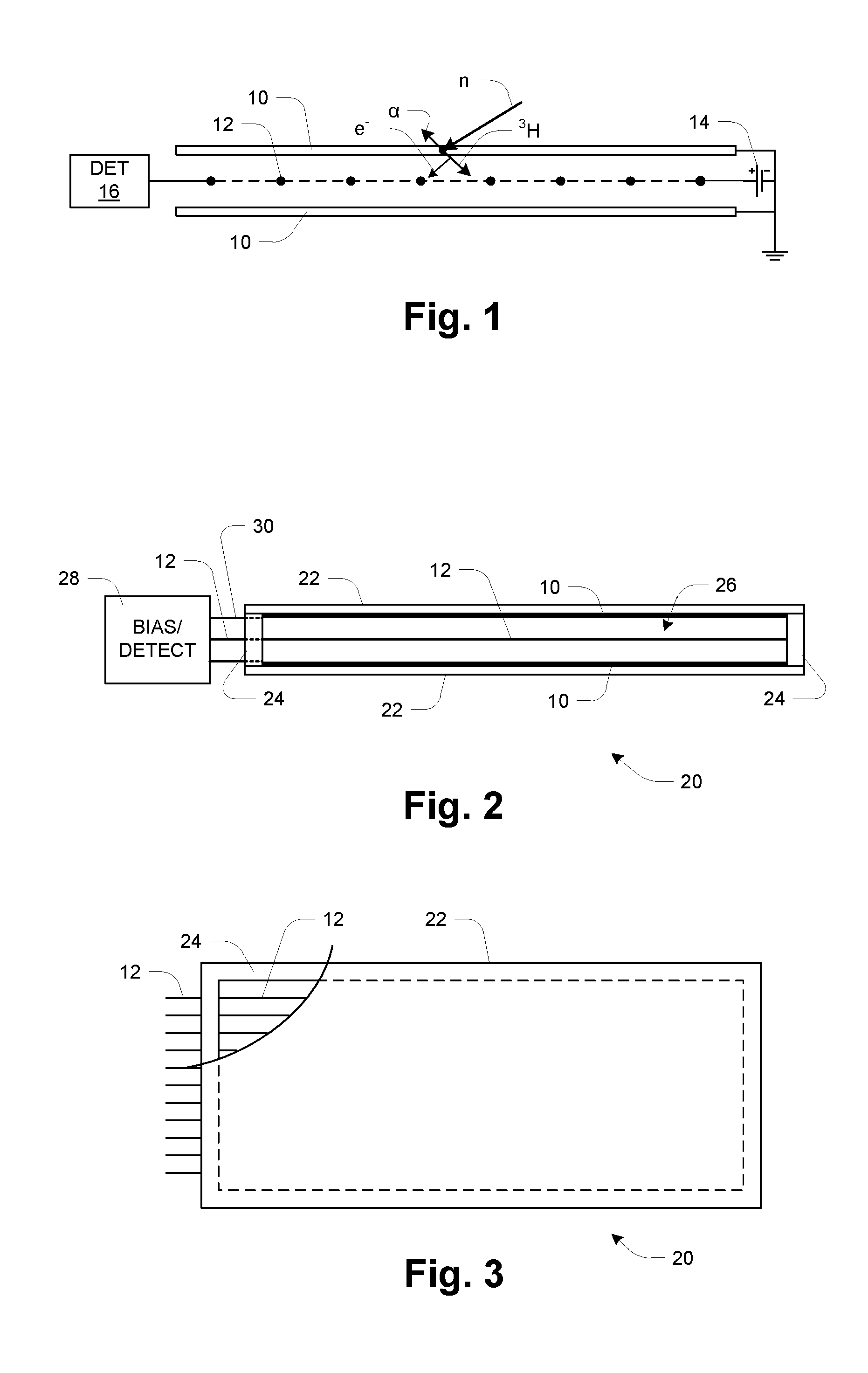

Solid-state thermal neutron detector

InactiveUS7372009B1Measurement with semiconductor devicesMicrobiological testing/measurementElectricityOhmic contact

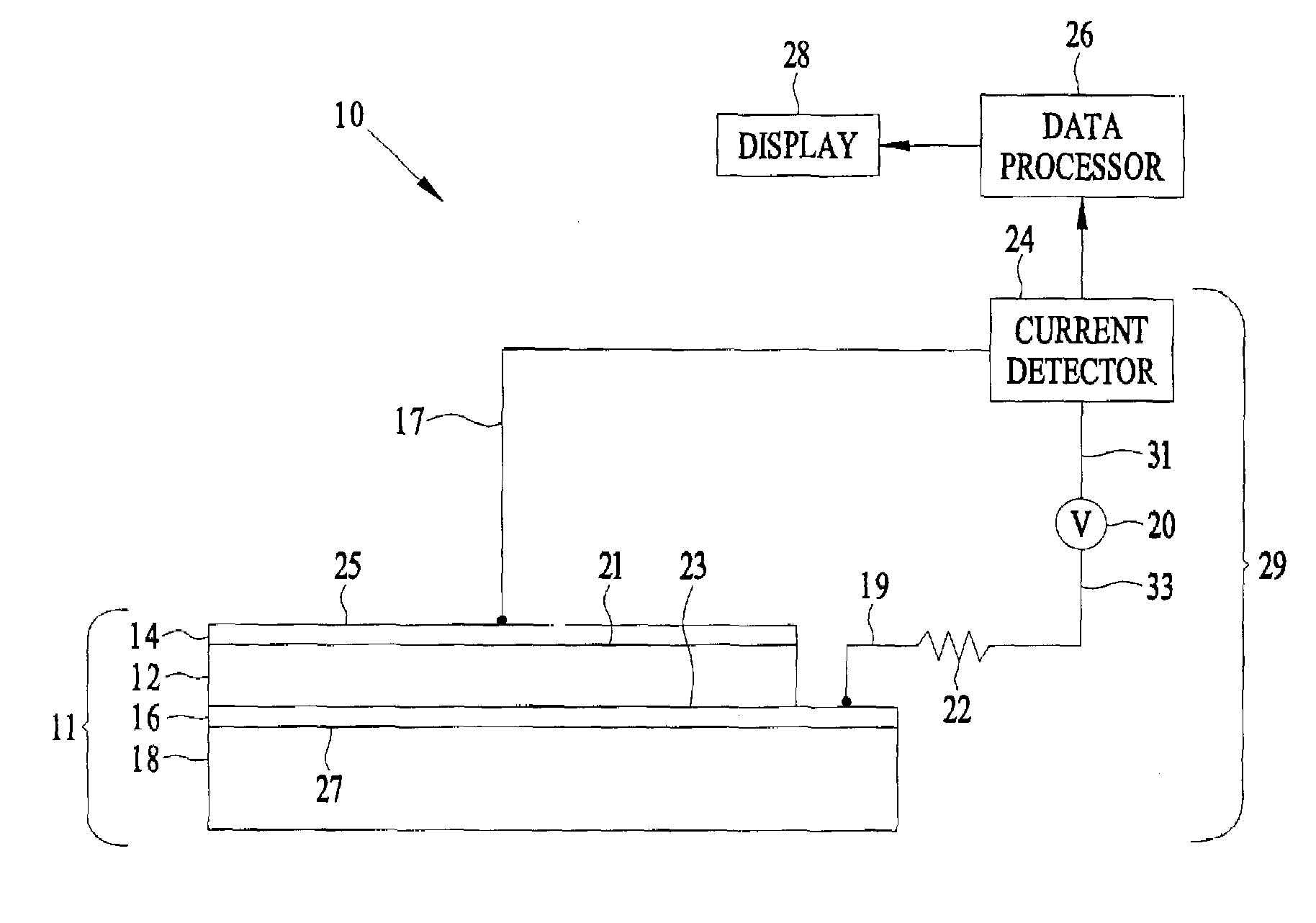

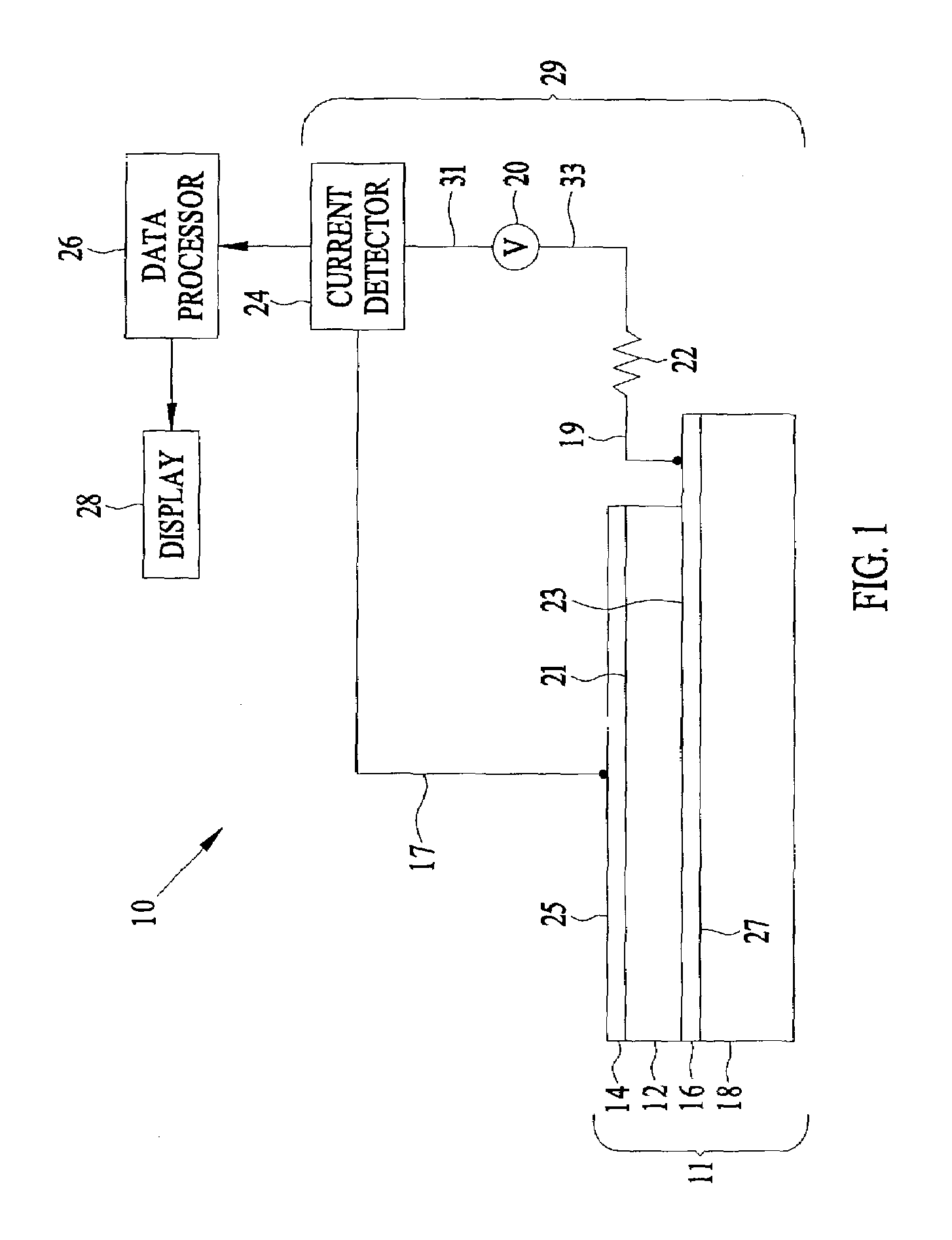

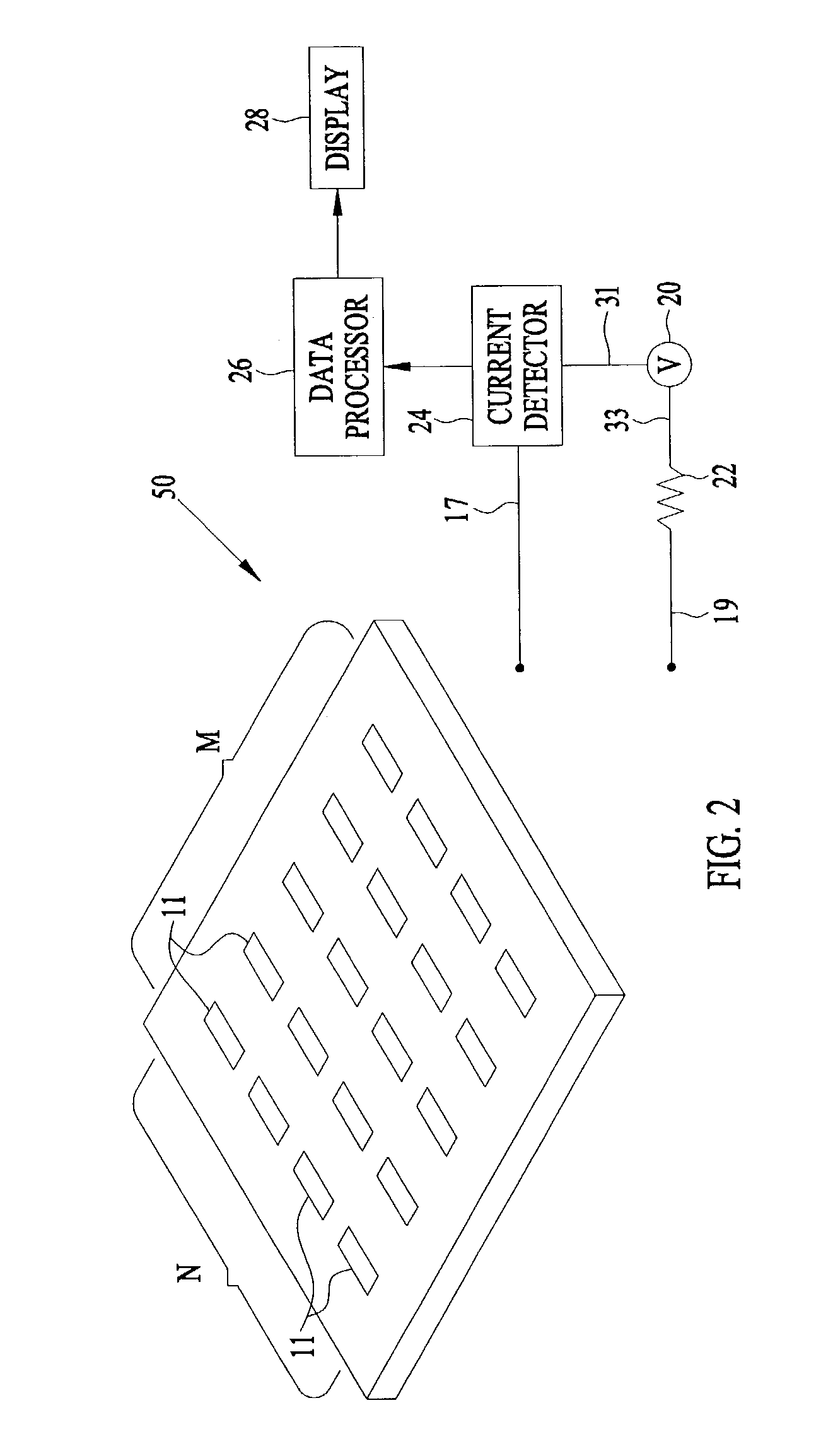

A solid-state thermal neutron detector comprises: a layered structure that includes; an electrically insulating substrate; a first electrode affixed to the substrate; a neutron-reactive layer affixed to and in ohmic contact with the first electrode; and a second electrode affixed to and in ohmic contact with the neutron-reactive layer; a voltage source electrically coupled to the first and second electrodes; and an electrical current detector electrically coupled in series between the layered structure and the voltage source.

Owner:NAVY SEC OF THE UNITED STATES +1

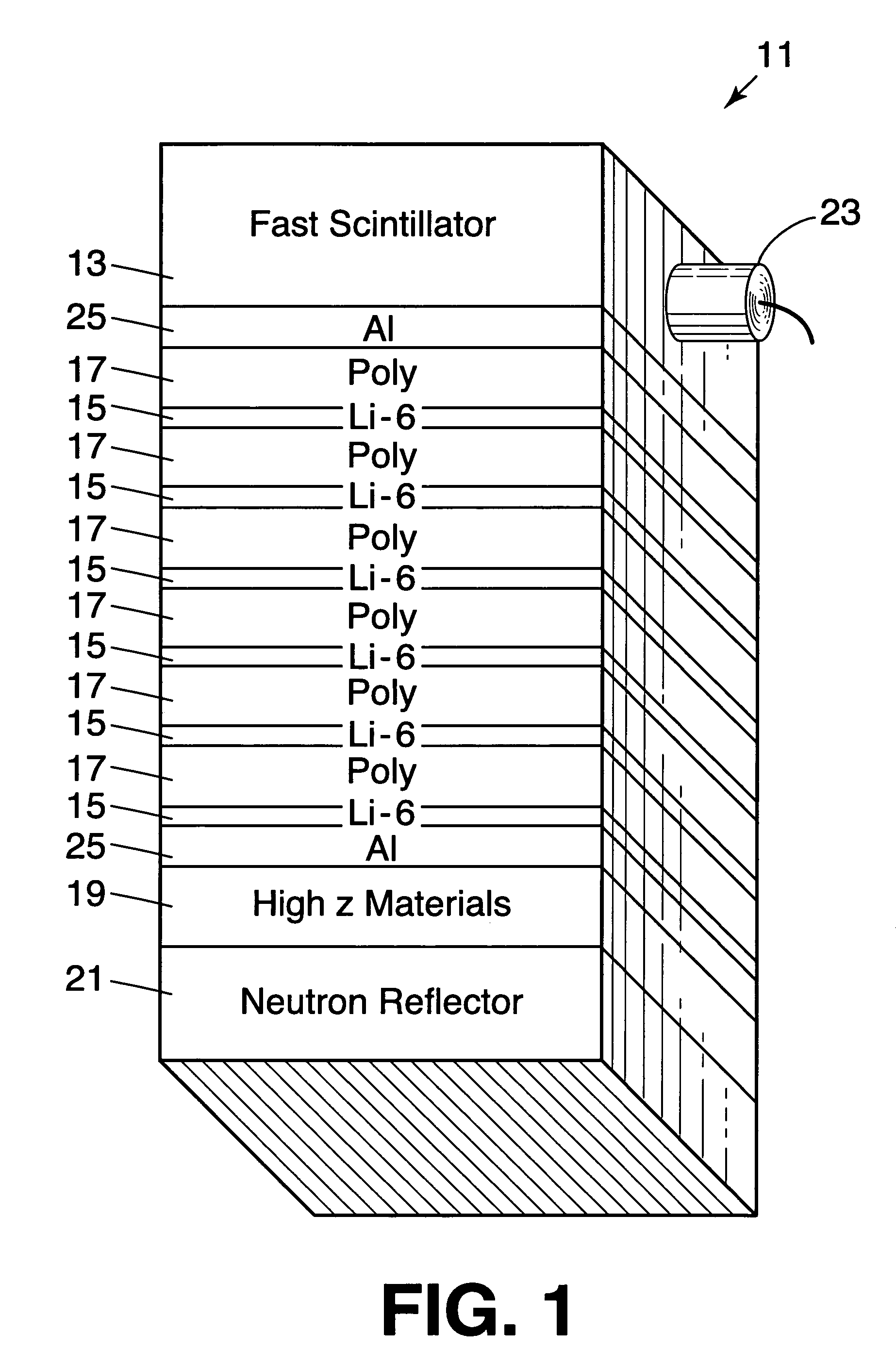

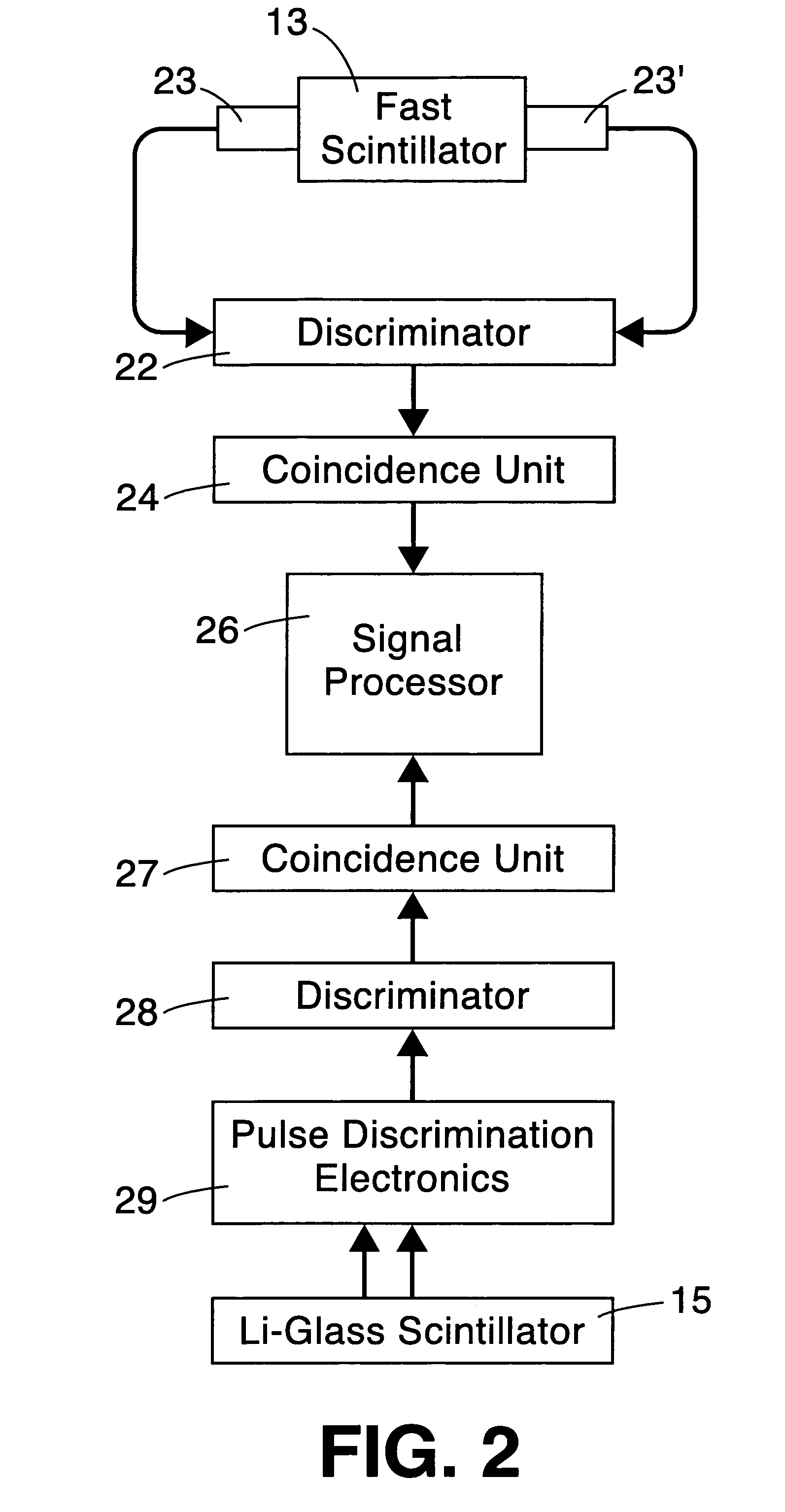

Fiber optic thermal/fast neutron and gamma ray scintillation detector

InactiveUS7141799B1Measurement with scintillation detectorsMaterial analysis by optical meansGlass fiberFiber

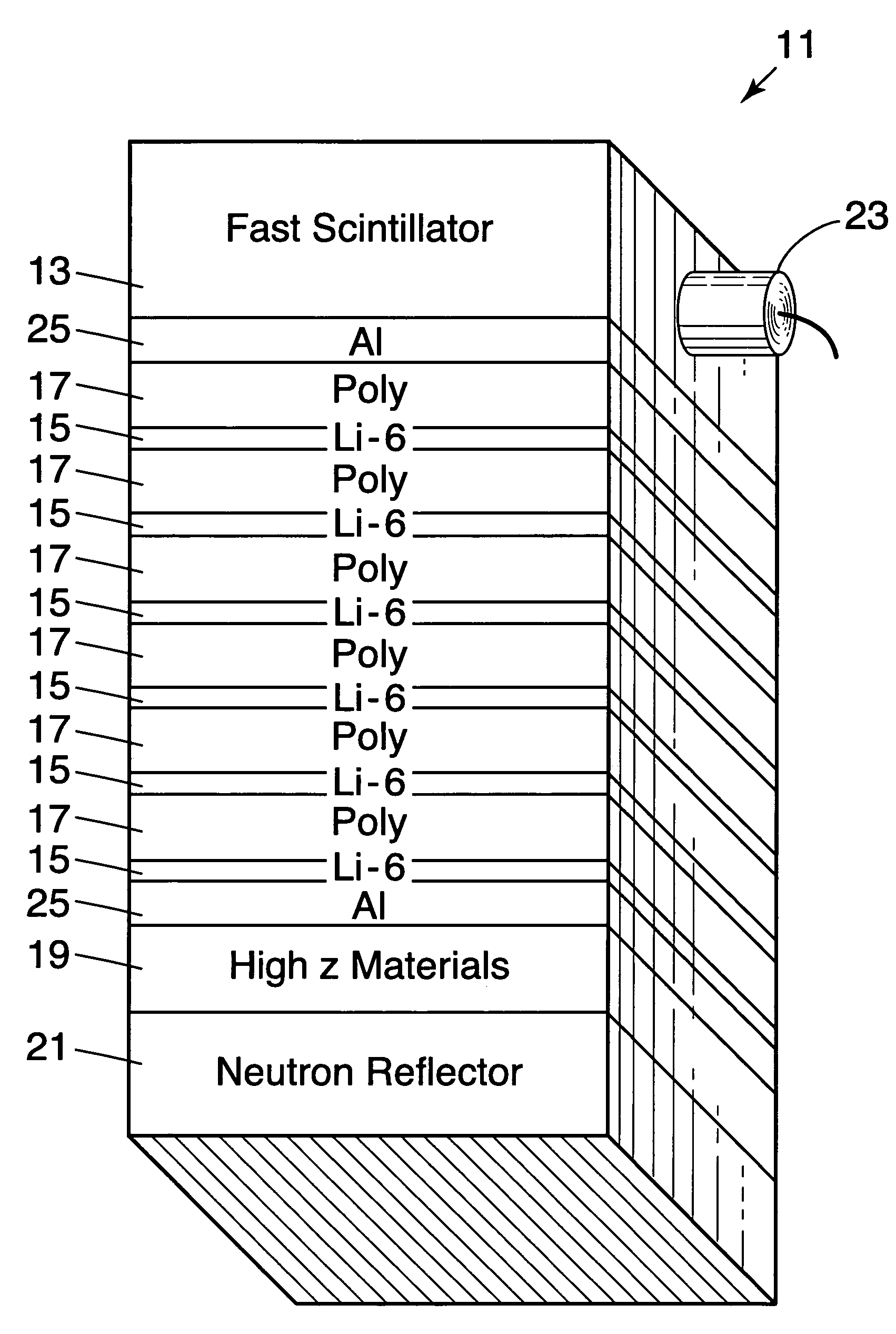

A detector system that combines a 6Li loaded glass fiber scintillation thermal neutron detector with a fast scintillation detector in a single layered structure. Detection of thermal and fast neutrons and ionizing electromagnetic radiation is achieved in the unified detector structure. The fast scintillator replaces the polyethelene moderator layer adjacent the 6Li loaded glass fiber panel of the neutron detector and acts as the moderator for the glass fibers. Fast neutrons, x-rays and gamma rays are detected in the fast scintillator. Thermal neutrons, x-rays and gamma rays are detected in the glass fiber scintillator.

Owner:UT BATTELLE LLC

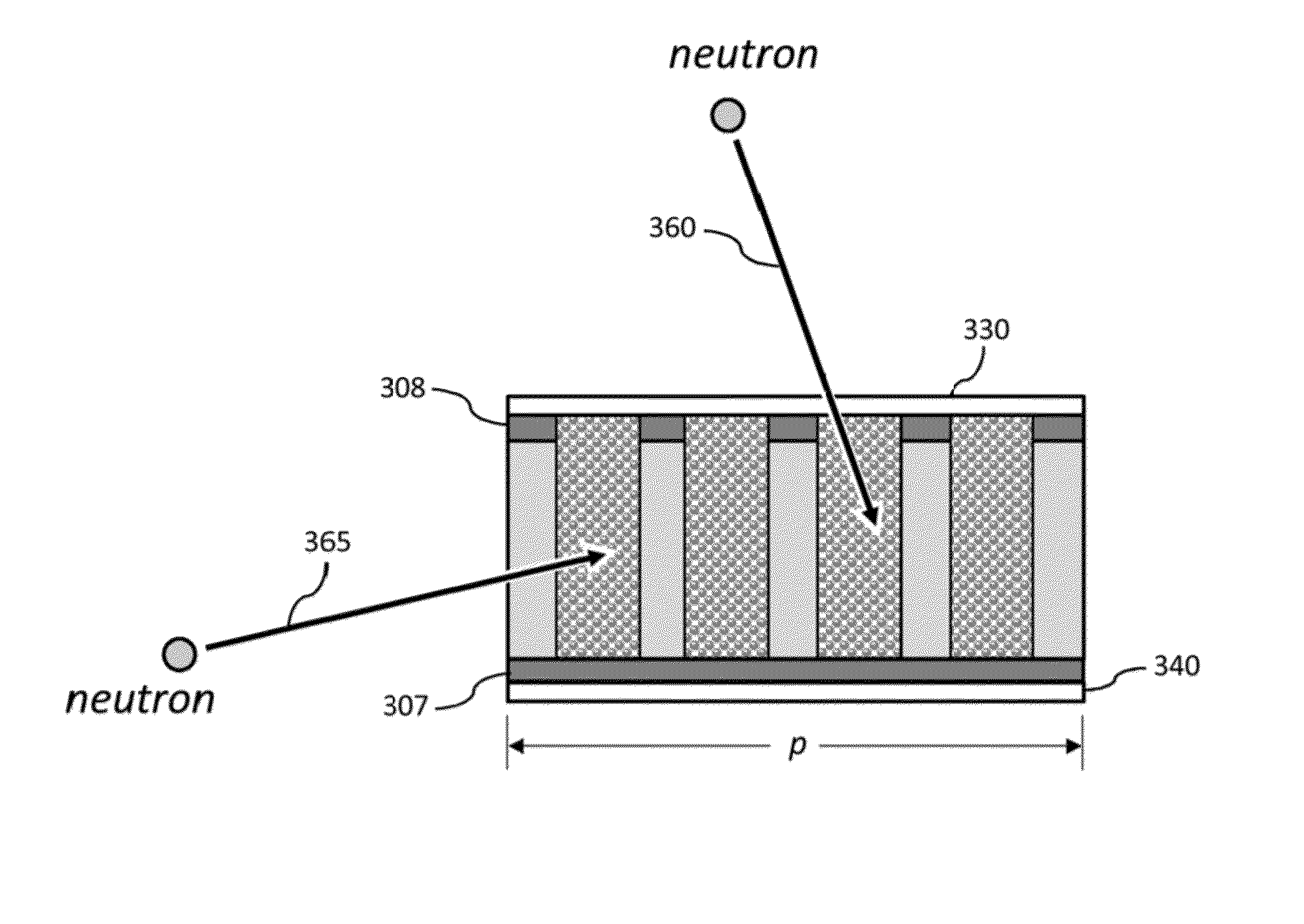

Three-dimensional boron particle loaded thermal neutron detector

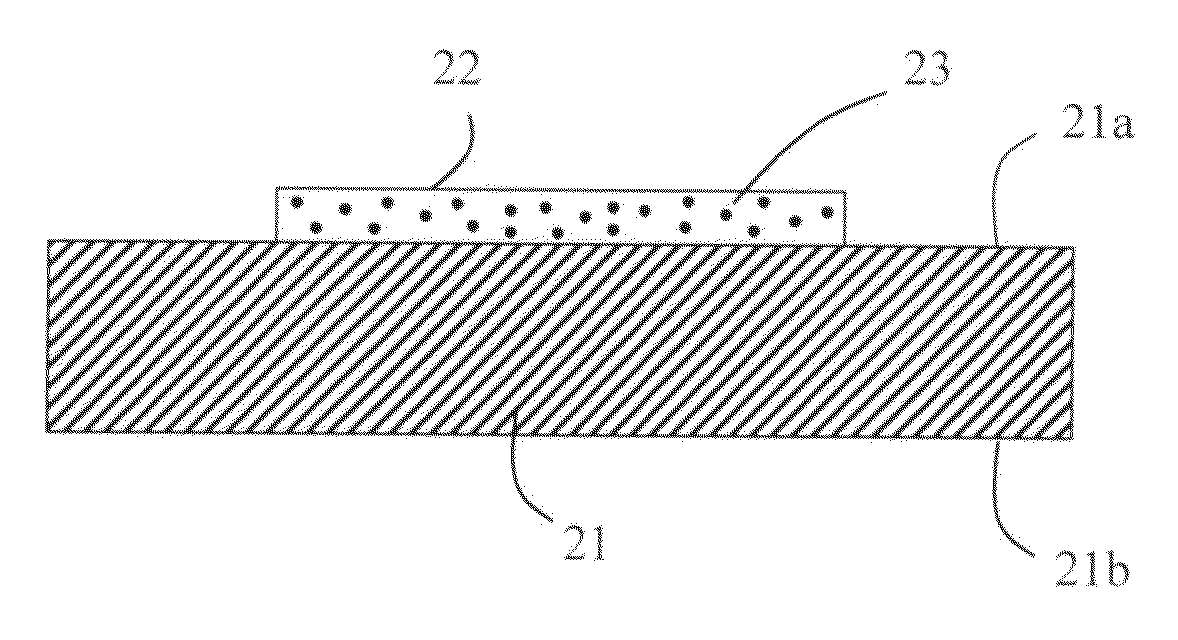

ActiveUS20130075848A1Simple and low-costImprove efficiencyMeasurement with semiconductor devicesSemiconductor/solid-state device manufacturingBoronNanometre

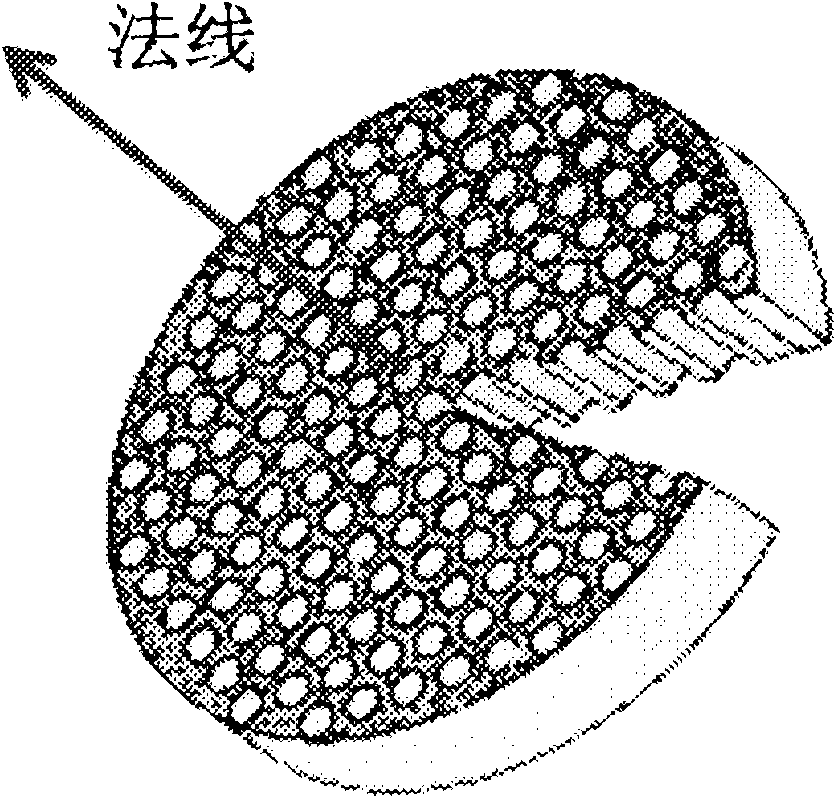

Three-dimensional boron particle loaded thermal neutron detectors utilize neutron sensitive conversion materials in the form of nano-powders and micro-sized particles, as opposed to thin films, suspensions, paraffin, etc. More specifically, methods to infiltrate, intersperse and embed the neutron nano-powders to form two-dimensional and / or three-dimensional charge sensitive platforms are specified. The use of nano-powders enables conformal contact with the entire charge-collecting structure regardless of its shape or configuration.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

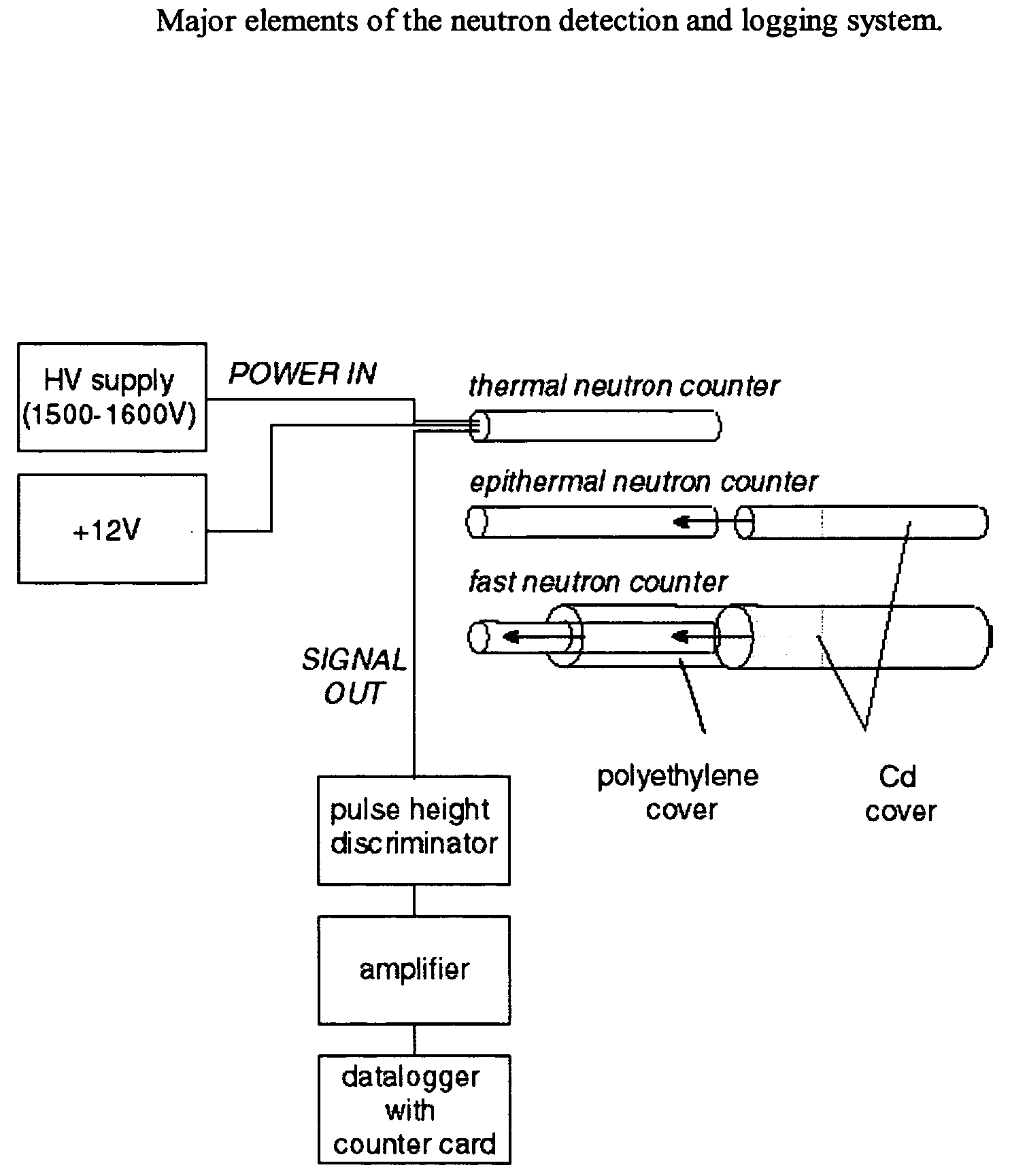

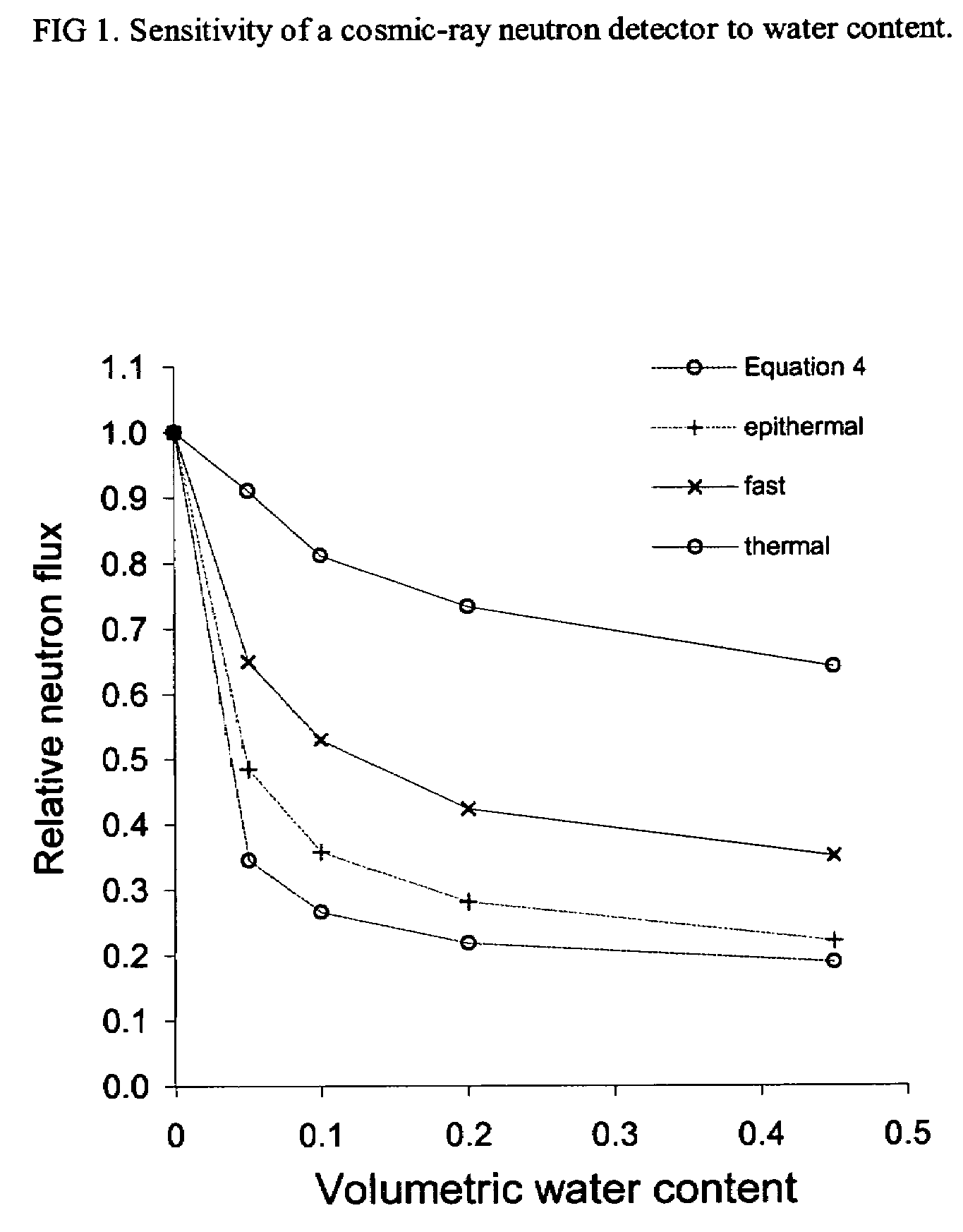

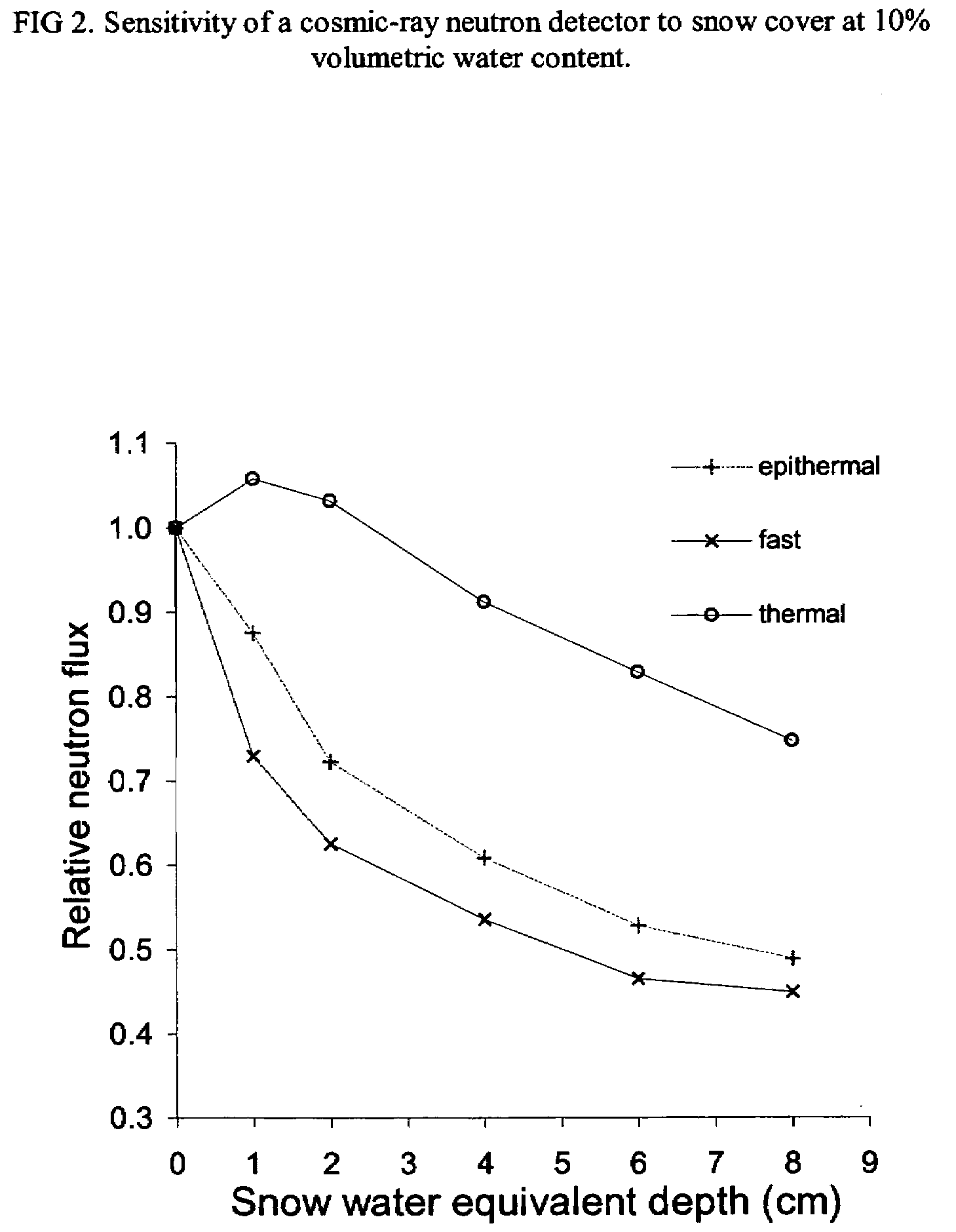

Non-invasive method for measuring soil water content or snow water equivalent depth using cosmic-ray neutrons

InactiveUS20080087837A1Weaken energySlow rate of increaseMaterial analysis by optical meansMaterial analysis using radiation diffractionSnowpackThermal energy

The present invention is directed toward the determination of soil water content and the water equivalent depth of snow deposited on top of the ground. The apparatus for measuring soil water content consists of one or more cosmic-ray neutron detectors located above the soil surface. The detectors record neutrons in the thermal, epithermal or fast energy bands. Snow water equivalence is determined by using a thermal neutron detector and an epithermal or fast neutron detector. Neutron count rates for all three energy bands decrease monotonically with increasing soil water content. Epithermal and fast neutron count rates decrease monotonically with increased snow water equivalent depth, but thermal neutron count rates increase at first and then decrease with increasing snow cover.

Owner:ARIZONA BOARD OF REGENTS ON BEHALF UNLV OF ARIZONA

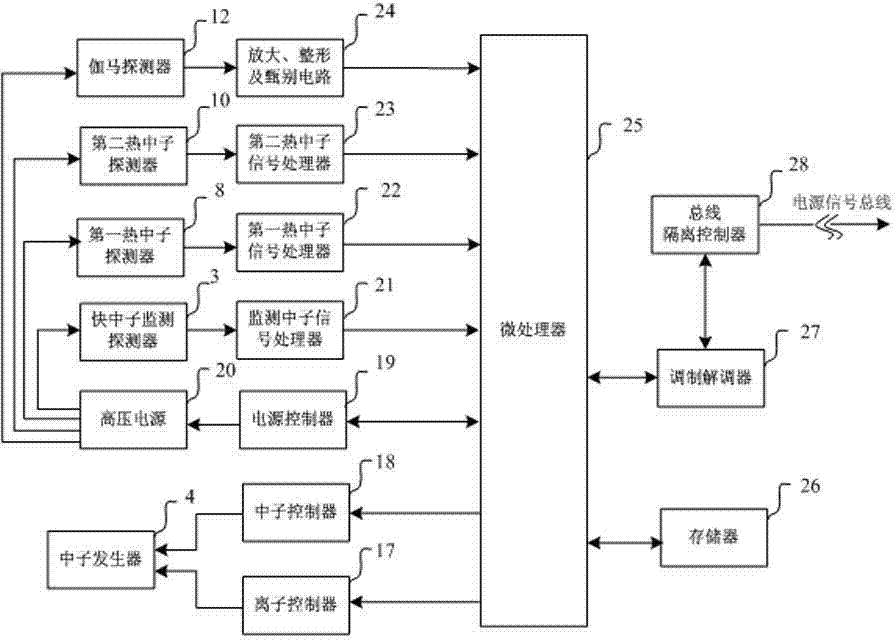

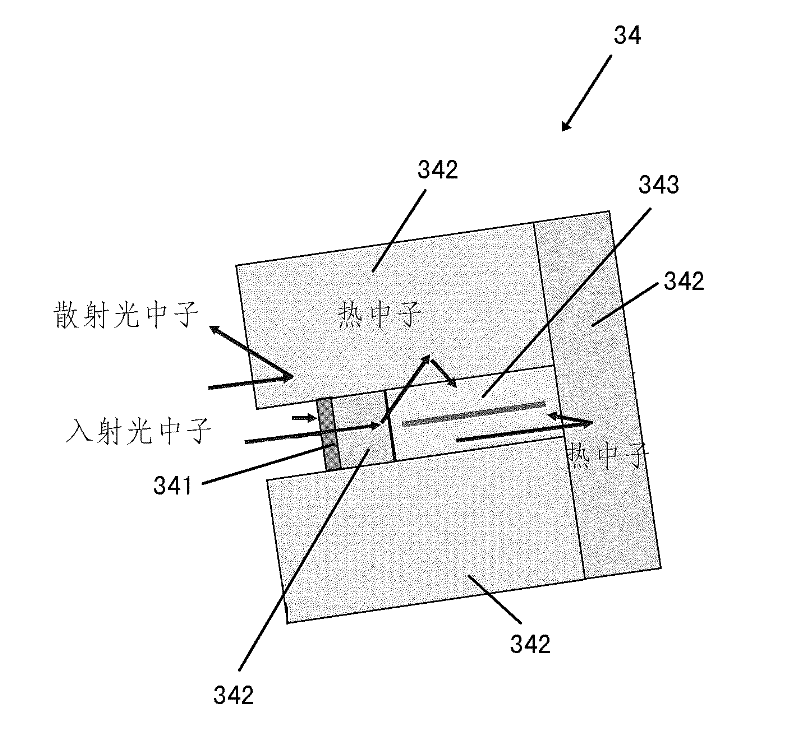

Continuous neutron spectrum real-time detection system

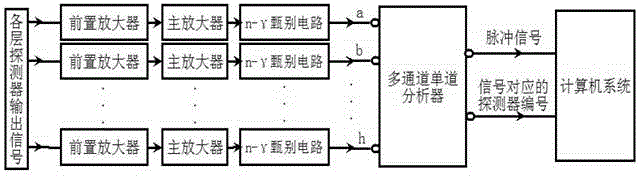

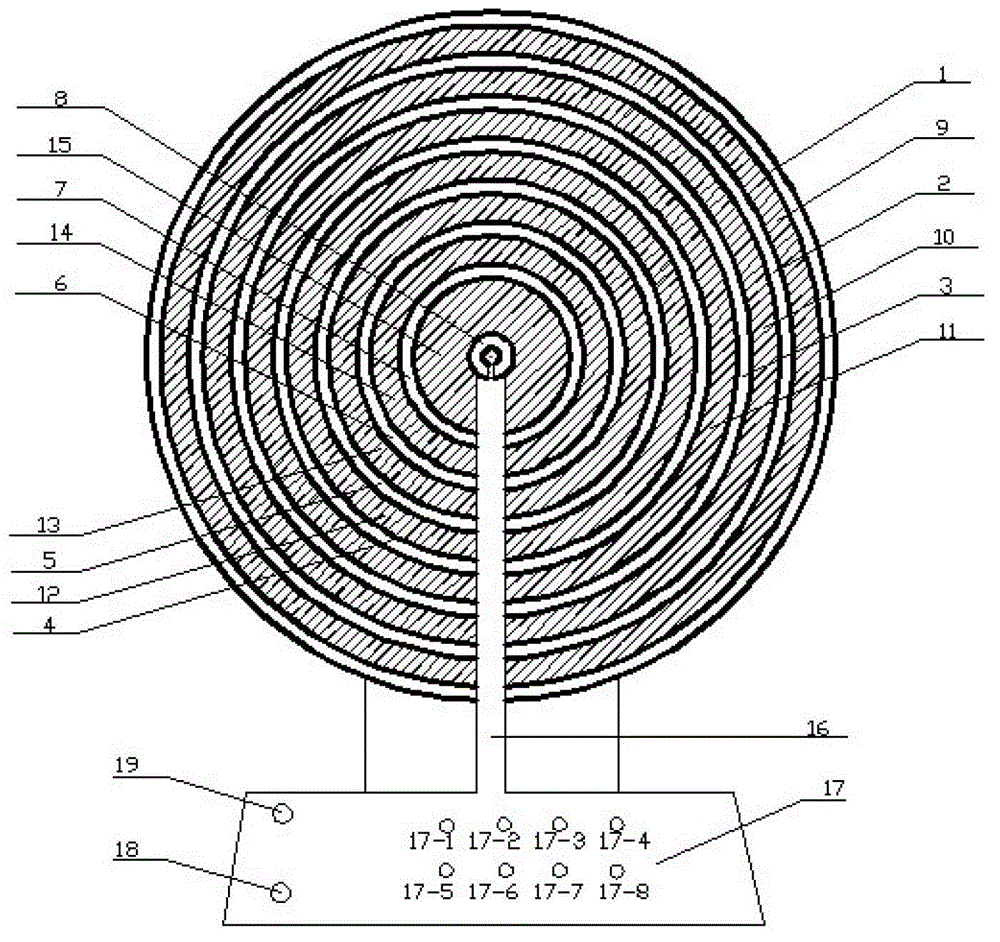

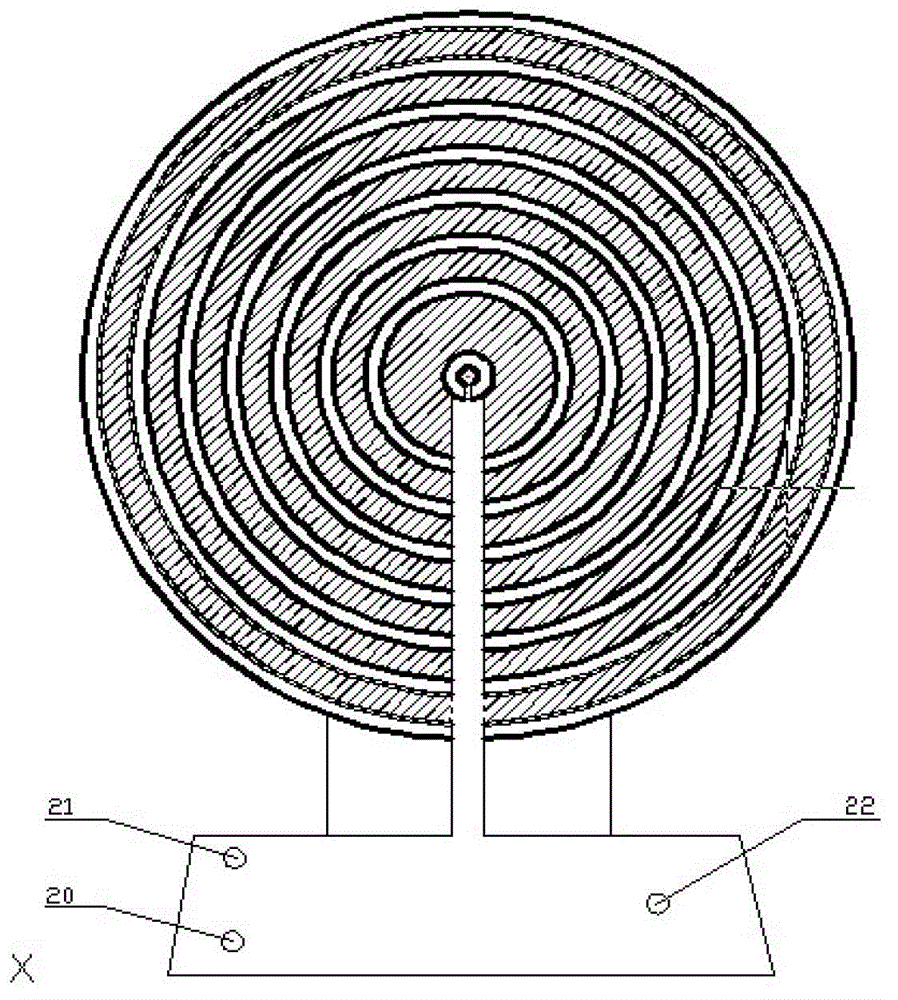

InactiveCN102866416AAccurate measurementReduce volumeNeutron radiation measurementNeutron energy spectrumElectronic systems

A continuous neutron spectrum real-time detection system comprises a plurality of spherical-shell polyethylene moderation layers, a plurality of spherical-shell thermal-neutron detector systems, an electronics system, a computer system, an input power supply interface, a signal output interface, a display panel and a switch; and after neutrons with different energies enter the detection system, the neutrons are moderated by different moderation layers to thermal neutrons to be finally detected by the detector system of one layer, a pulse signal is transmitted to the electronics system, the electronics system analyzes and outputs relevant signals according to signals inputted by different detection layers, finally the computer system outputs a corresponding energy value according to different signals outputted by the electronics system and draws and records an energy spectrum. The continuous neutron spectrum real-time detection system is small in size and capable of precisely measuring neutron energy spectrum on one position.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

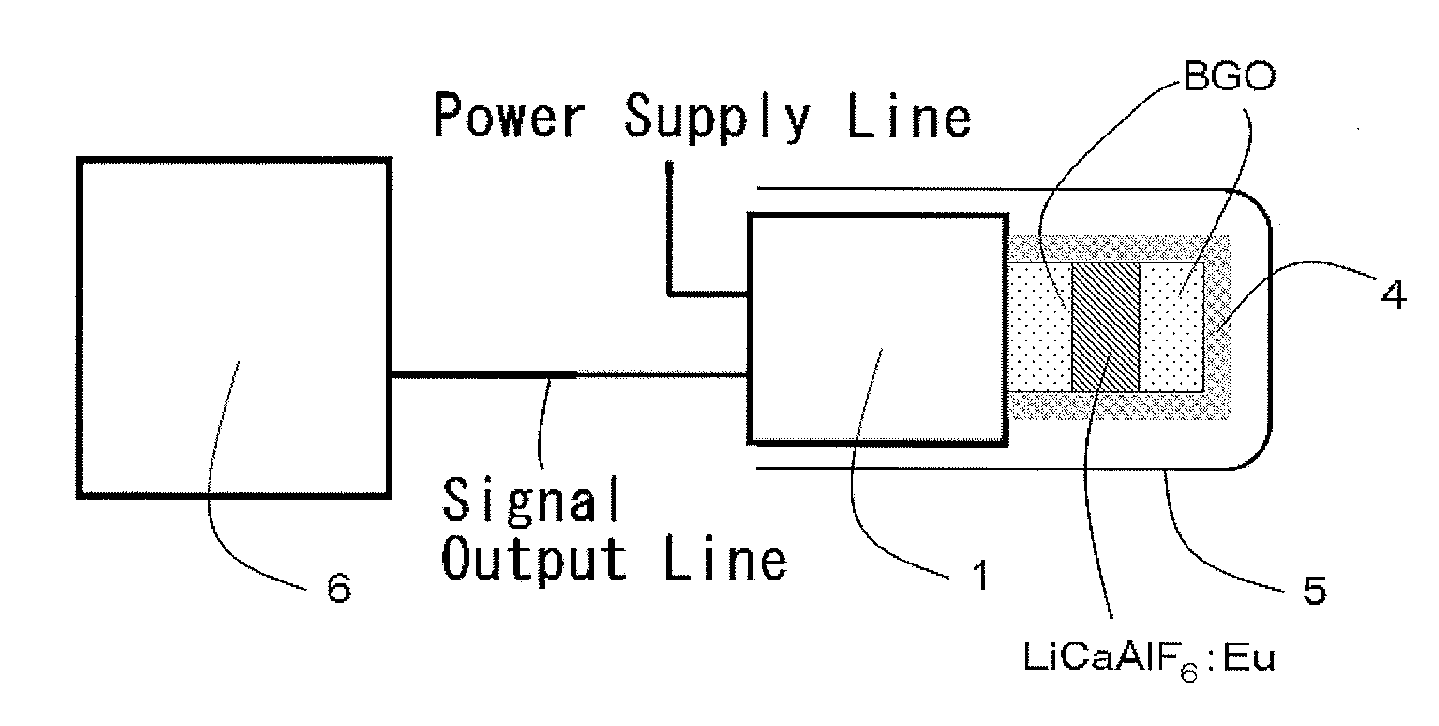

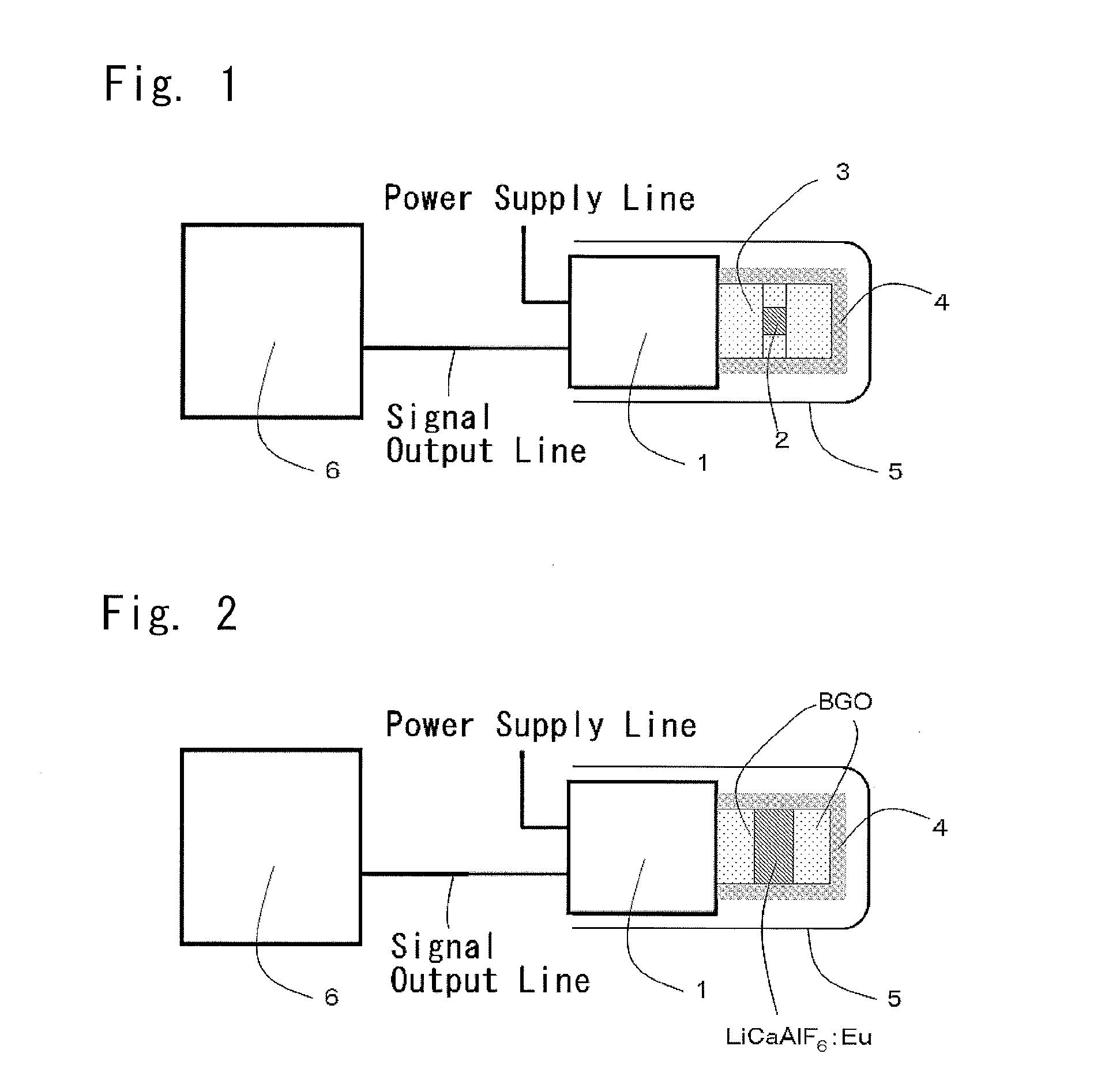

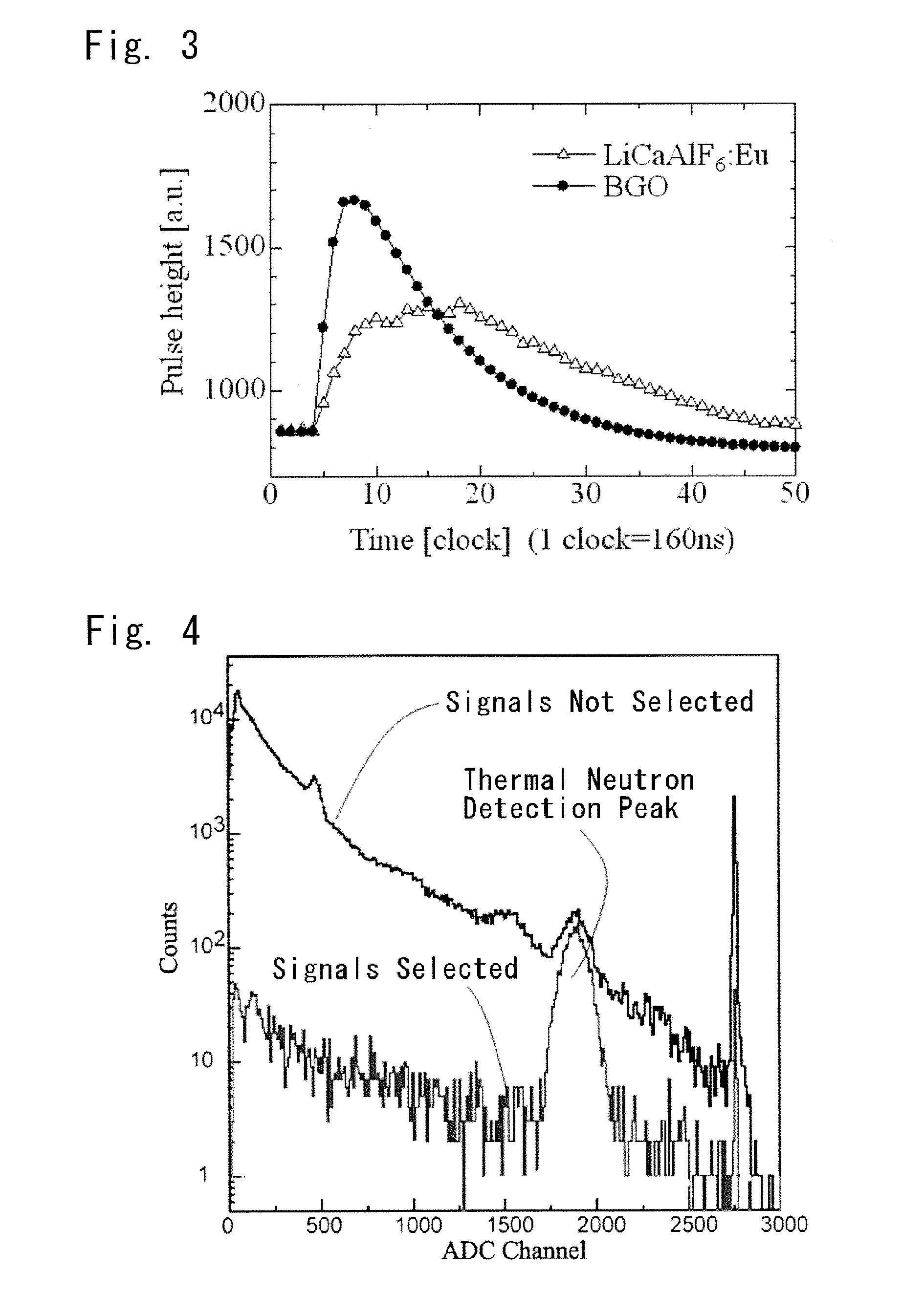

Phoswich thermal neutron detector

InactiveUS20130112885A1Easily discriminatedPolycrystalline material growthMeasurement with scintillation detectorsLithiumSignal on

[Problems to be Solved] A phoswich radiation detector, which can easily discriminate between detection signals on gamma rays and thermal neutrons, and which can selectively acquire signals on thermal neutrons, is provided.[Means to Solve the Problems] In a phoswich radiation detector having two scintillators and discriminating between thermal neutrons and gamma rays, the detector comprises a scintillator for detecting thermal neutrons, such as LiCaAlF6:Eu, which has a light yield of more than 1500 photons / neutron, and a scintillator for detecting gamma rays, which has a permeable end on a shorter wavelength than the light emission wavelength of the thermal neutron scintillator. The scintillator for detecting gamma rays is characterized by being either an organic solid scintillator, such as a plastic scintillator, which does not contain a total amount of 10 mol % or more of elements selected from 6Li, 10B and Gd, or an inorganic single crystal scintillator, such as lithium glass (containing 6Li and Ce) or BGO, which has an effective atomic number Zeff of 30 or larger and which does not contain a total amount of 10 mol % or more of elements selected from 6Li, 10B and Gd.

Owner:HIROSHIMA UNIVERSITY +2

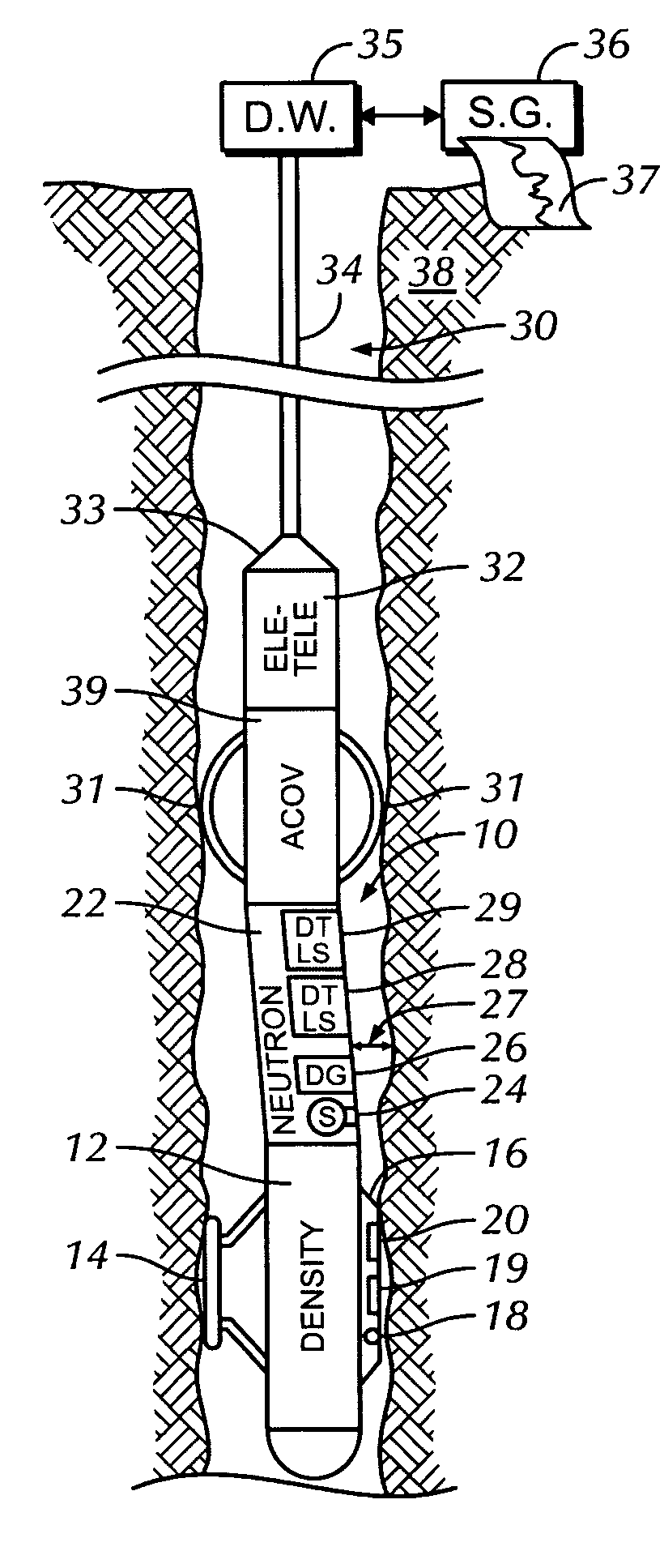

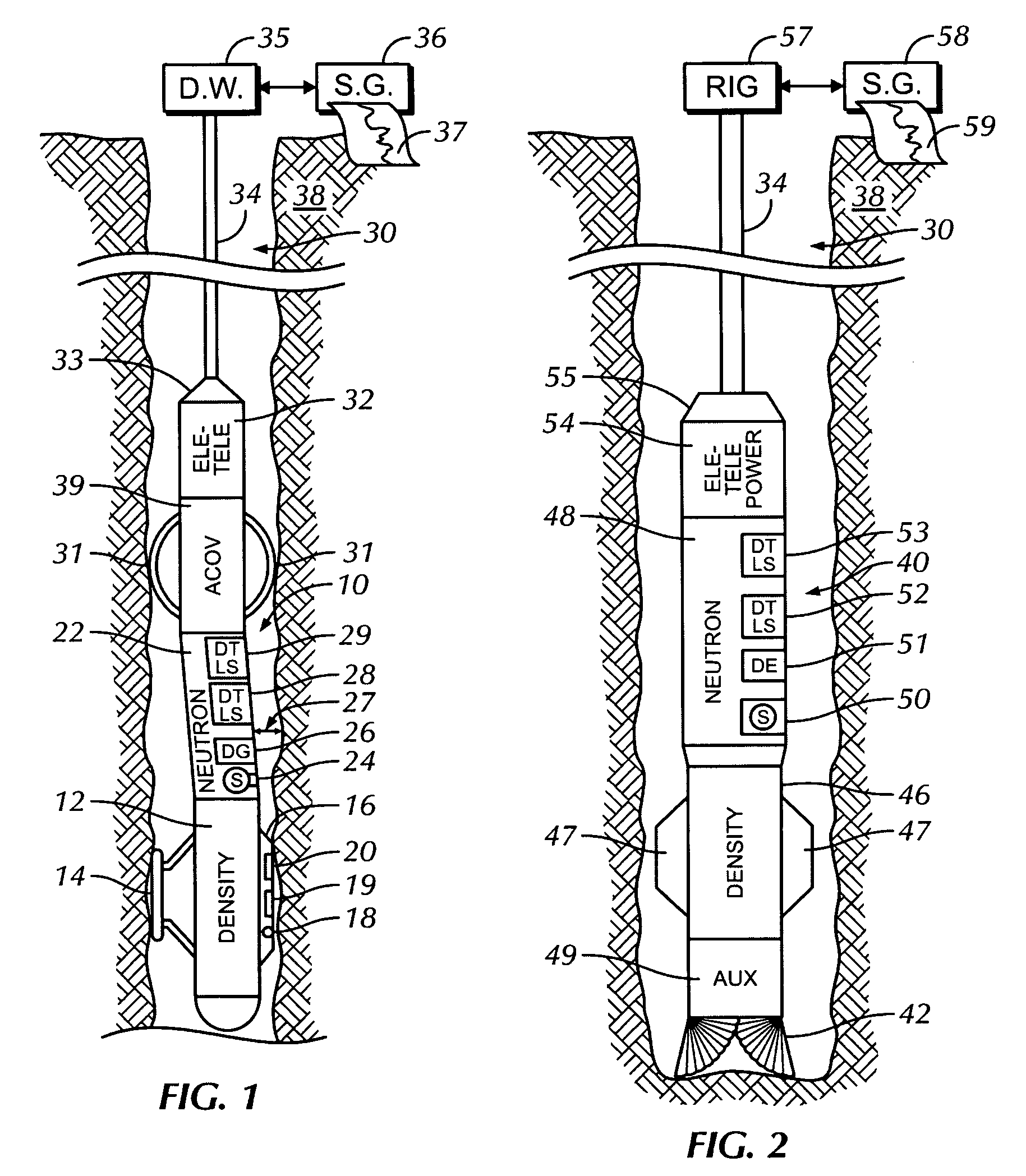

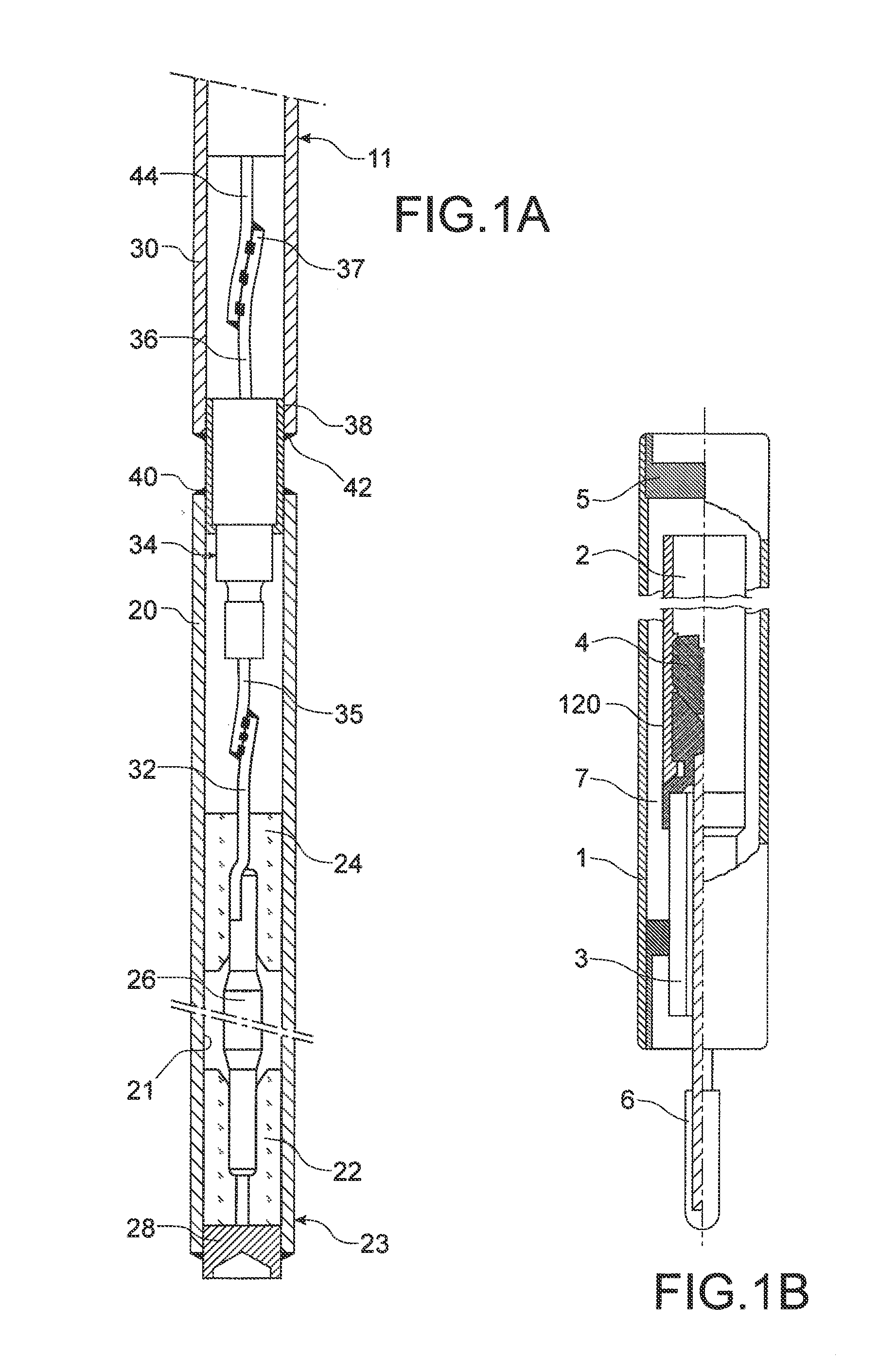

Borehole imaging and standoff determination using neutron measurements

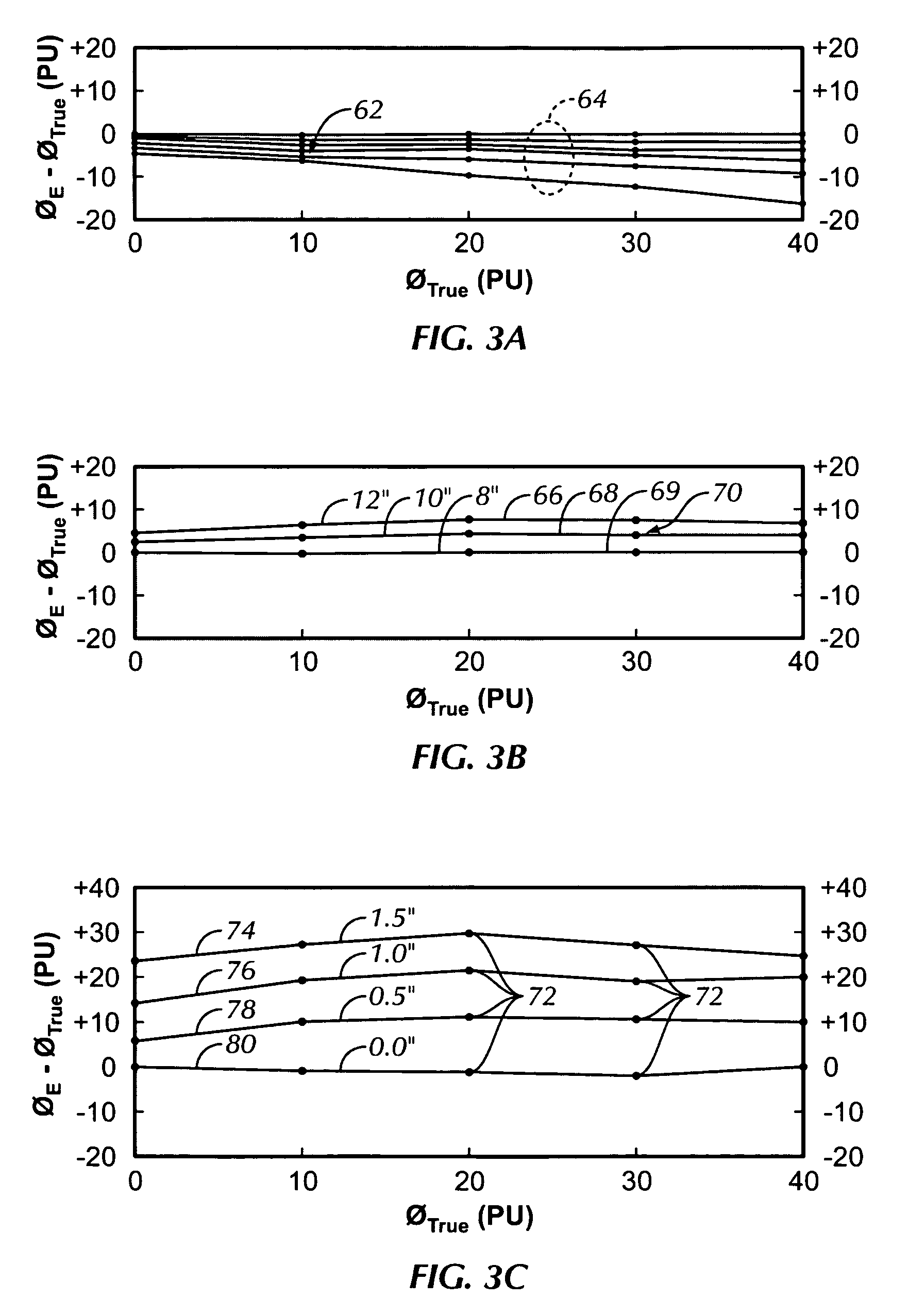

Apparatus and methods for determining borehole diameter and standoff for neutron porosity logging systems. The apparatus comprises an isotopic neutron source, a single epithermal neutron detector and two thermal neutron detectors, where all detectors are at different axial spacings from the neutron source. Thermal neutron porosity is determined from the combined response of the thermal neutron detectors. Epithermal neutron porosity is determined from the response of the single epithermal neutron detector. Embodied as a wireline system, a difference between thermal neutron porosity and epithermal neutron porosity is used to compute a tool standoff, which in turn is used to correct the thermal neutron porosity for effects of standoff. Borehole size measurements are made independently and preferably with a mechanical caliper of a density tool subsection. Embodied as a LWD system, the difference between thermal neutron porosity and epithermal neutron porosity is used to correct the thermal neutron porosity measurement for both borehole diameter and radial position (standoff) of the tool within the borehole.

Owner:WEATHERFORD TECH HLDG LLC

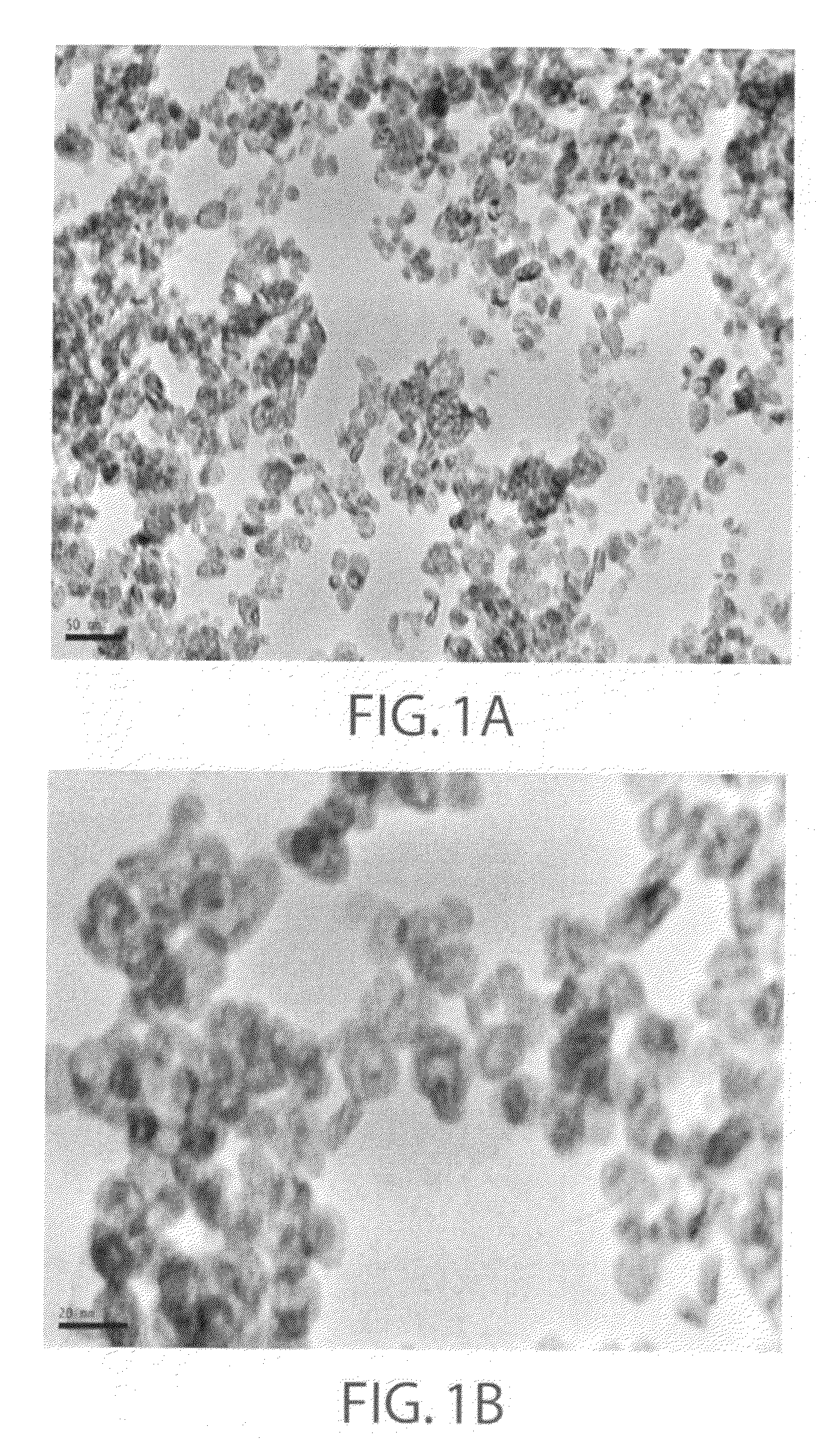

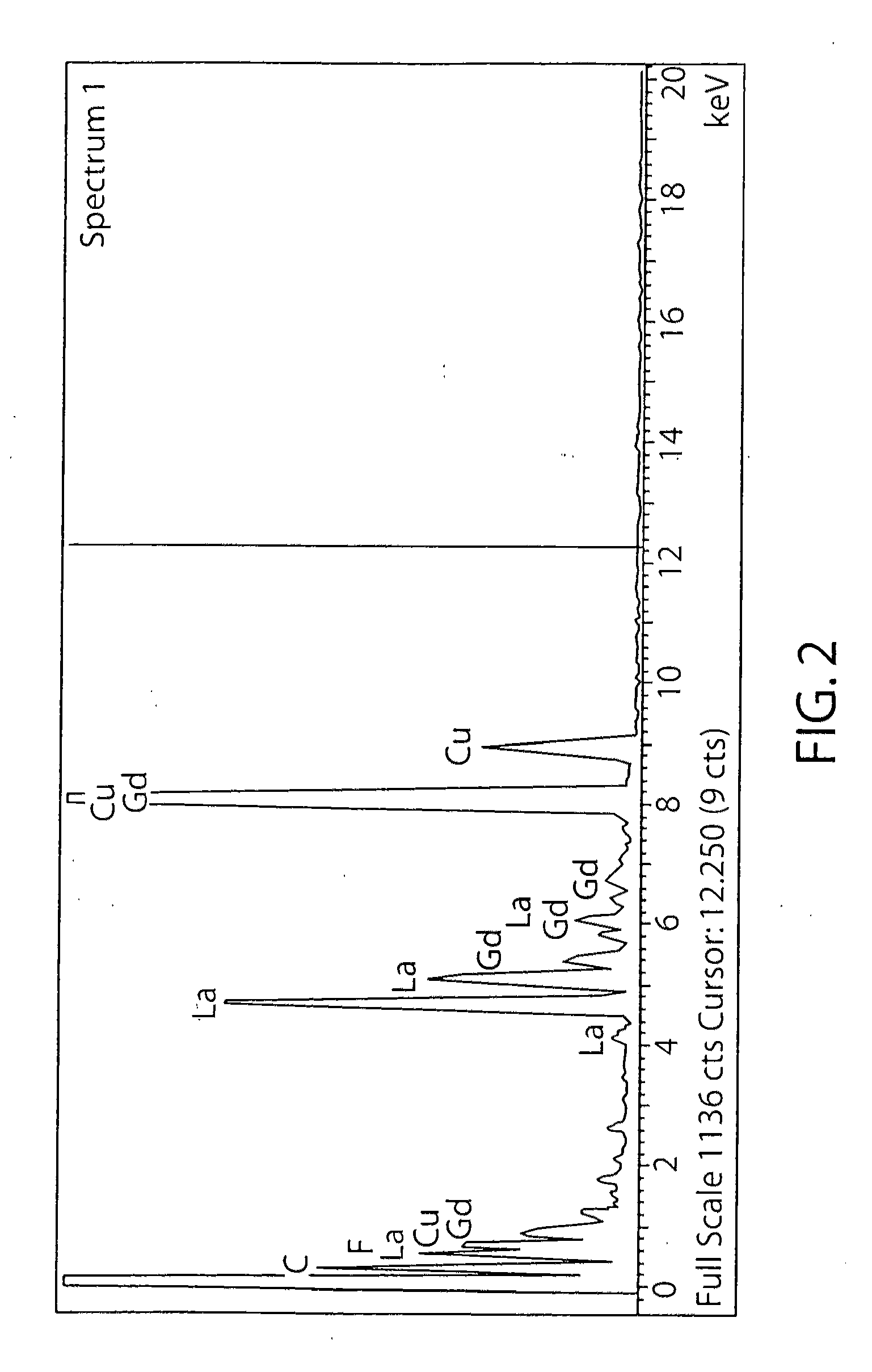

Thermal neutron detectors based on gadolinium-containing nanoscintillators

ActiveUS20120286166A1Measurement with scintillation detectorsMaterial analysis by optical meansGadoliniumNeutron radiation

A thermal neutron detector and method employ Gd-containing nanoscintillators. Thermal neutron radiation is detected by observing scintillation events from the nanoscintillators.

Owner:STC UNM

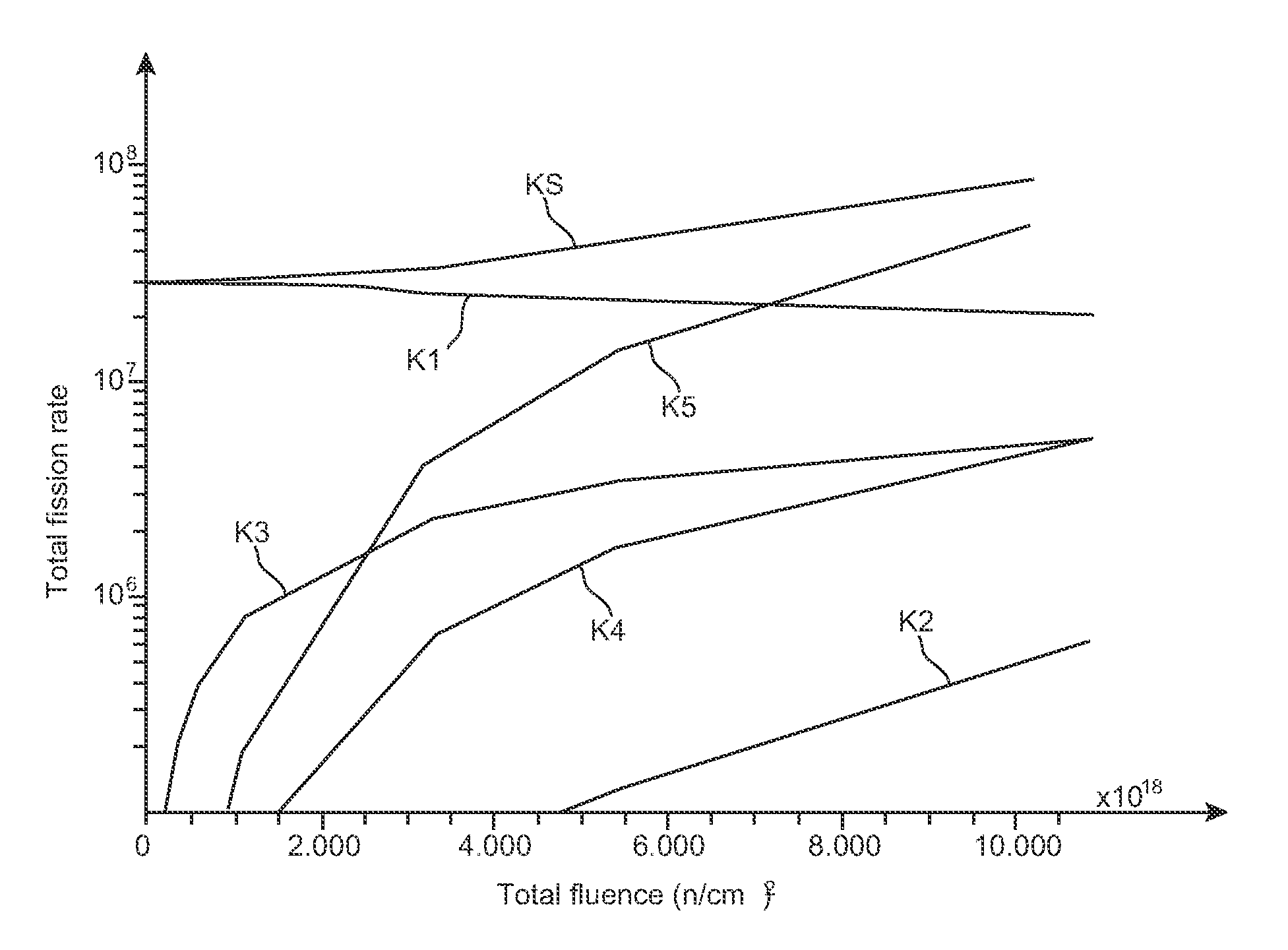

Device for online measurement of a flow of fast and epithermal neutrons

InactiveUS20110274230A1Nuclear energy generationNuclear monitoringThermal neutron detectorEpithermal neutron

A device for online measurement of a flow of fast and epithermal neutrons. The device has a fast and epithermal neutron detector (DNR) able to detect principally fast and epithermal neutrons; a thermal neutron detector (DNT) able to detect principally thermal neutrons; a first circuit (C1) for processing the signal delivered by the fast neutron detector; a second circuit (C2) for processing the signal delivered by the thermal neutron detector; a means (CE, PMM) suitable for determining the progressive sensitivity to the fast neutrons and to the thermal neutrons of each of the neutron detectors, and a computer (CALC) which computes the flow of fast and epithermal neutrons on the basis of the said progressive sensitivities and of the signals delivered by the first and second processing circuits.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

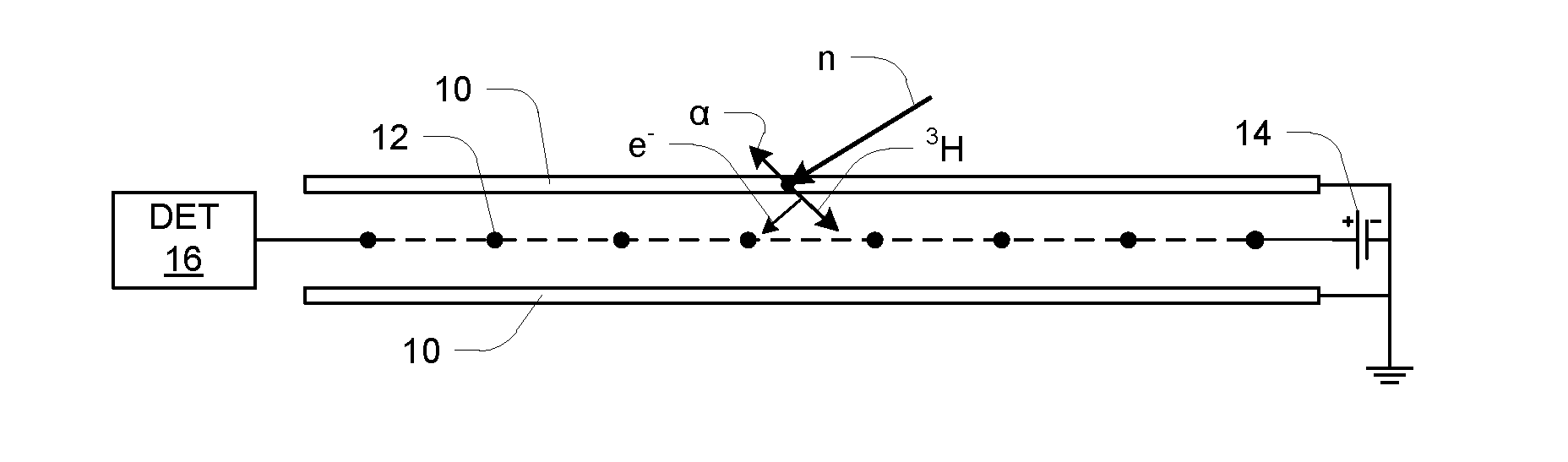

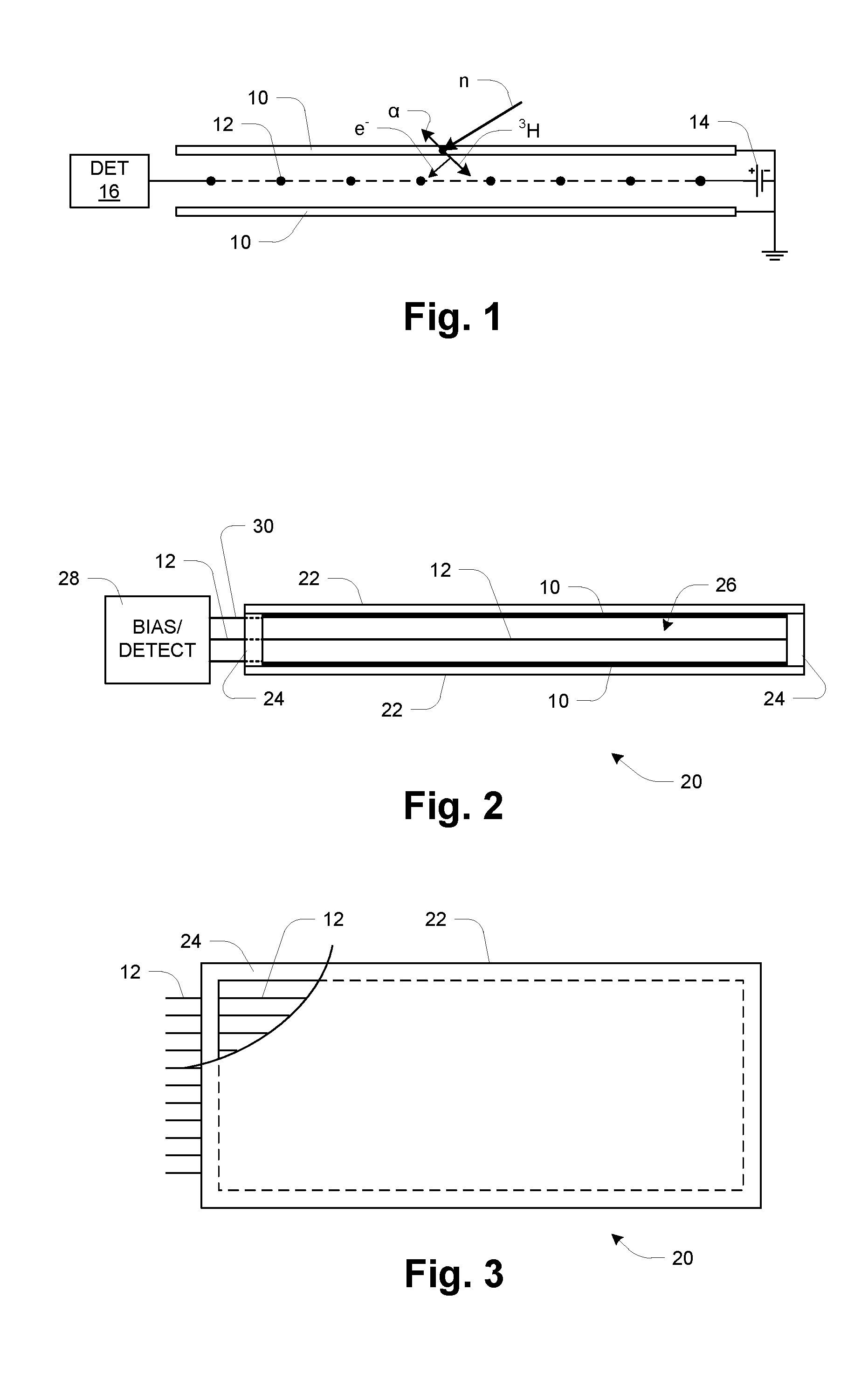

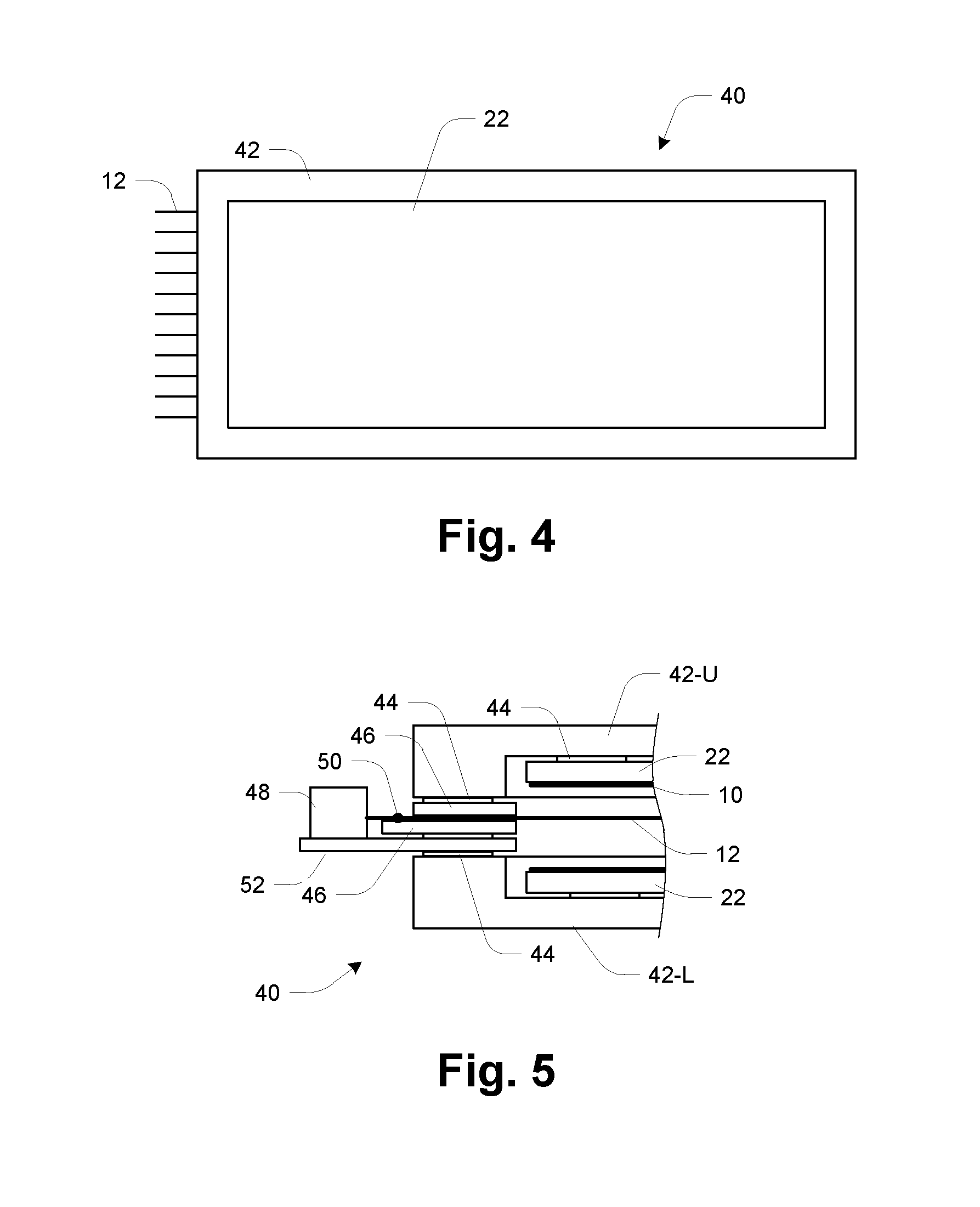

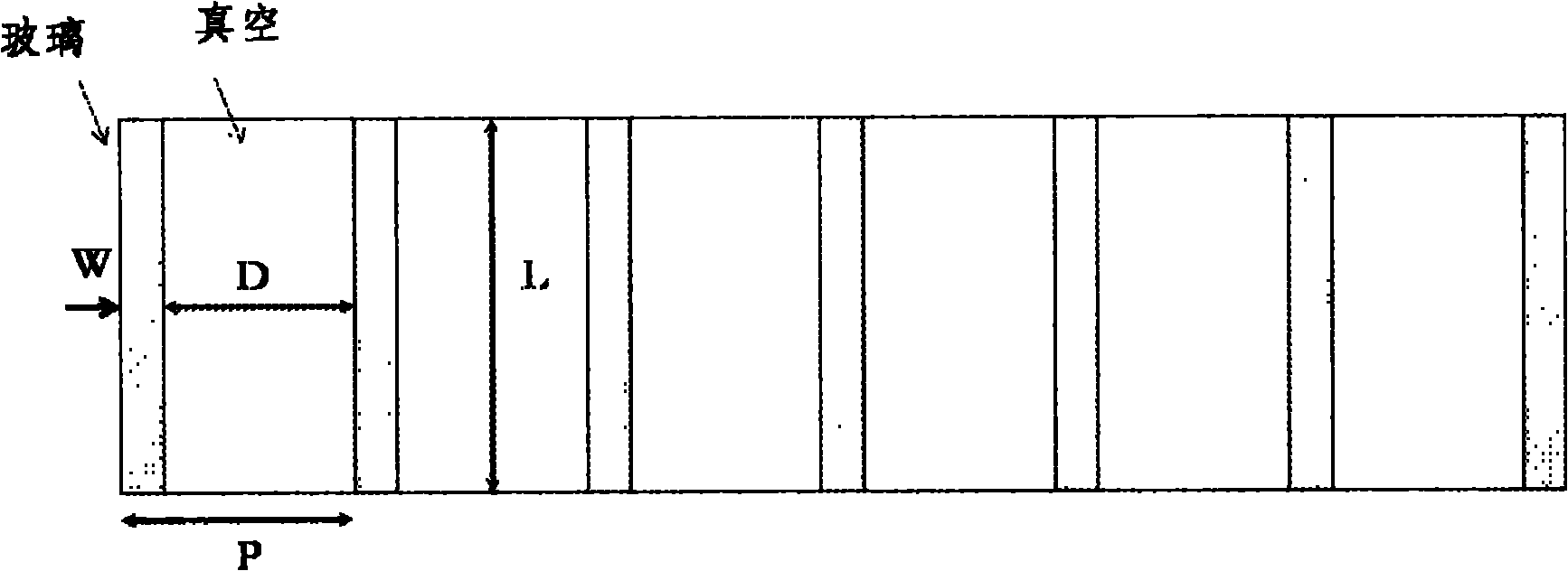

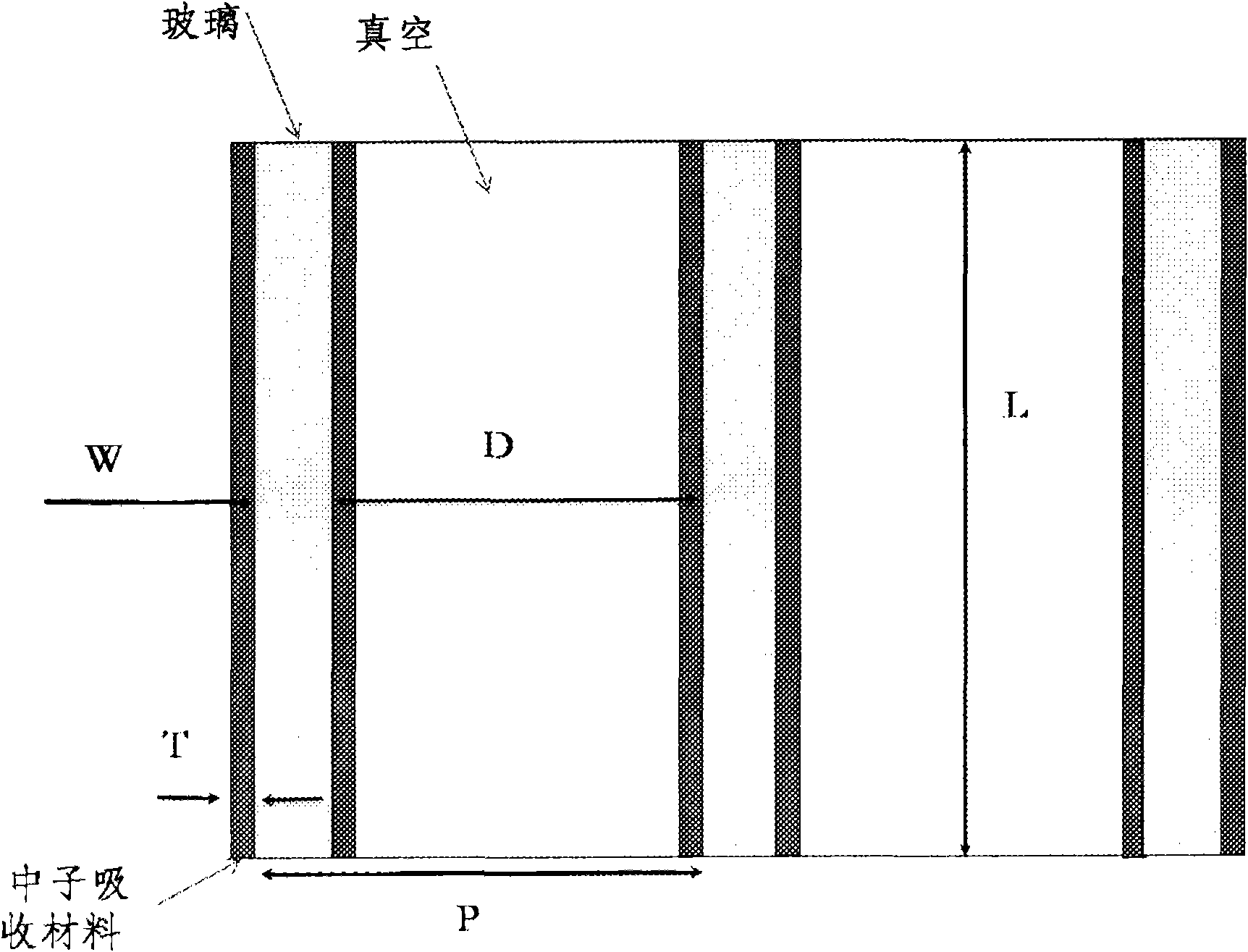

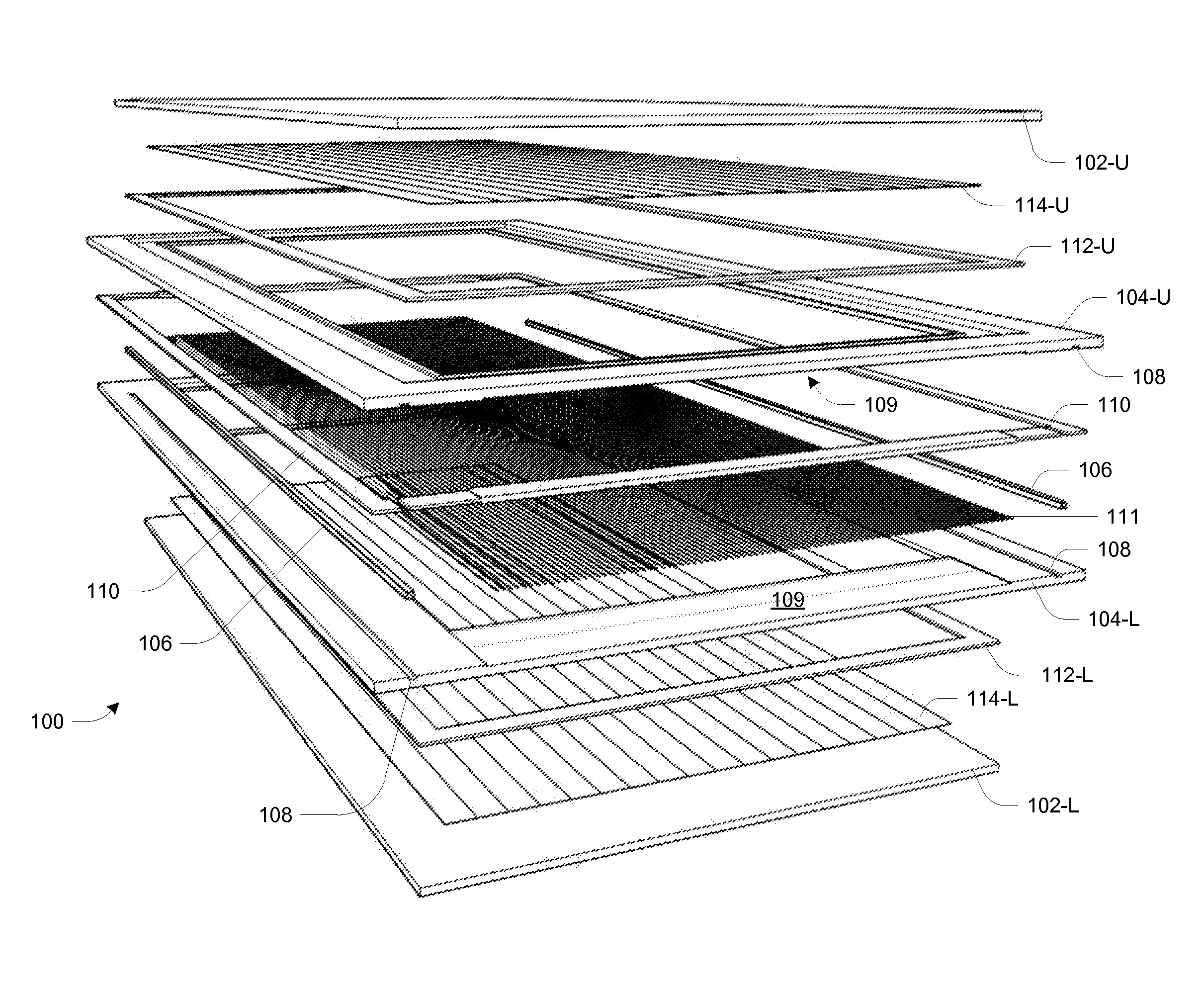

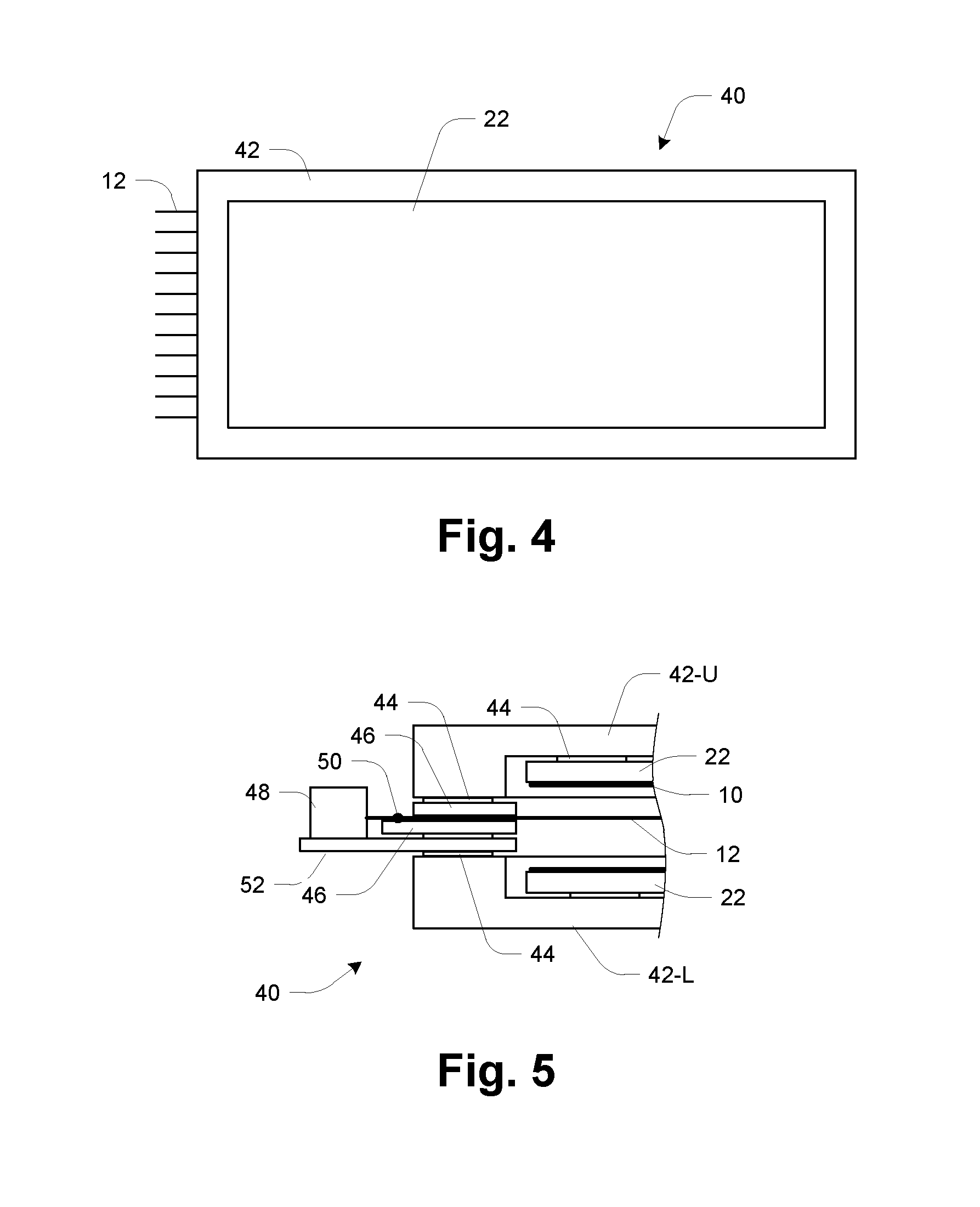

Glass-panel lithium-6 neutron detector

InactiveUS20140077091A1Leverage cost and design and durability and performanceMost efficientElectric discharge tubesMaterial analysis by optical meansNeutron emissionElectron multiplication

A thermal neutron detector includes a planar detector housing having two glass panels spaced apart by a gas-tight seal defining a detection chamber including an inert detection gas and lithium foils adhered to inner surfaces of the glass panel(s). The lithium foils emit alpha particles and tritons in response to incident thermal neutrons, and the inert detection gas is ionized by the particles to generate drift electrons. A planar array of detection wires is spaced apart from the lithium foils and extends outside the detection chamber. Electronic bias applies a field voltage between the wires and the lithium foils to establish a drift electric field in the detection chamber effective to attract the drift electrons to the wires and provide a large electric field near the anode wires to cause electron multiplication near the wire resulting in large numbers of electrons and positive ions for each initial electron. Detection circuitry detects electric signals in wires generated by the drift of positive ions away from the wires and interpret the electrical signals as incidence of thermal neutrons on the detector.

Owner:TRUSTEES OF BOSTON UNIV

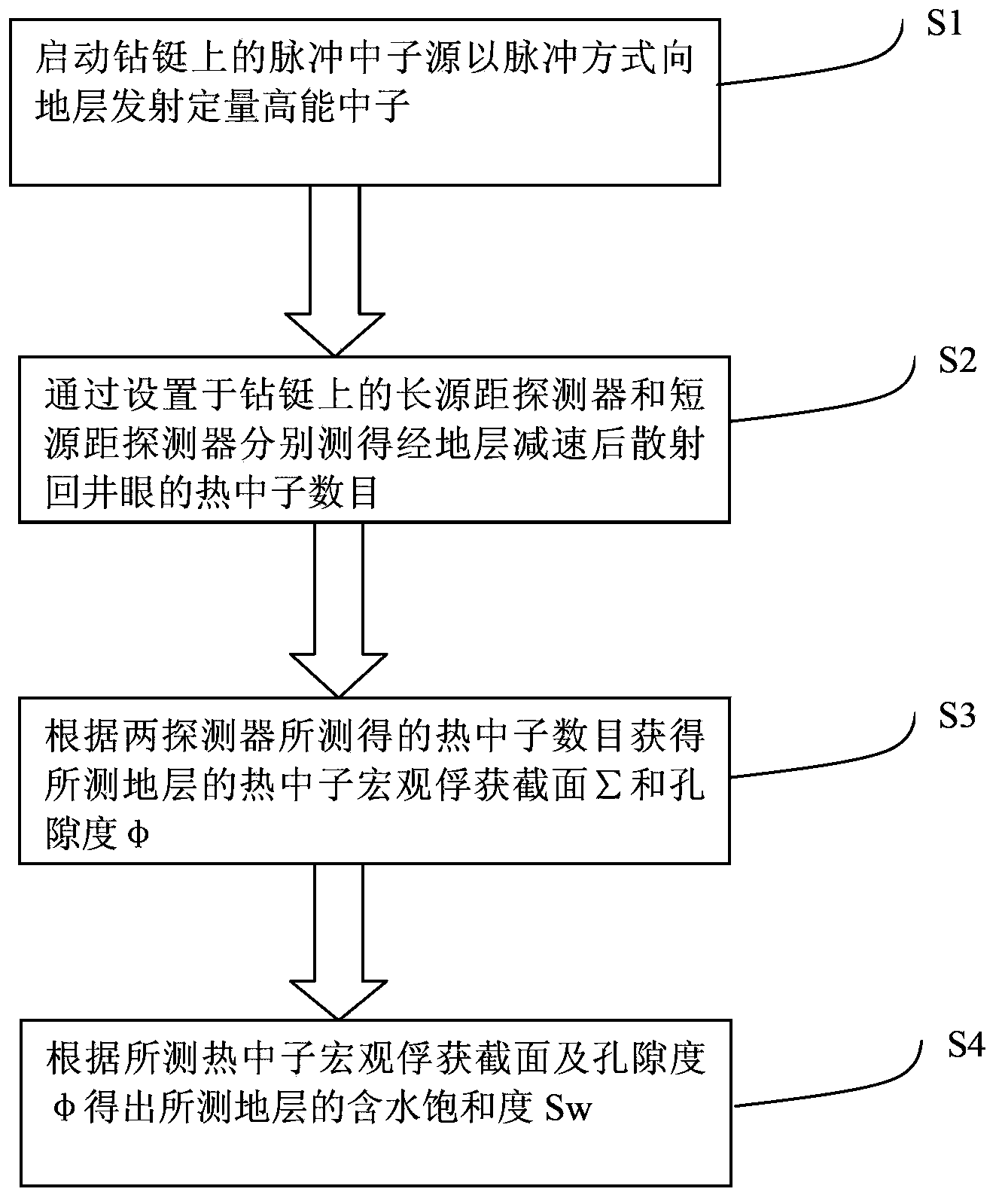

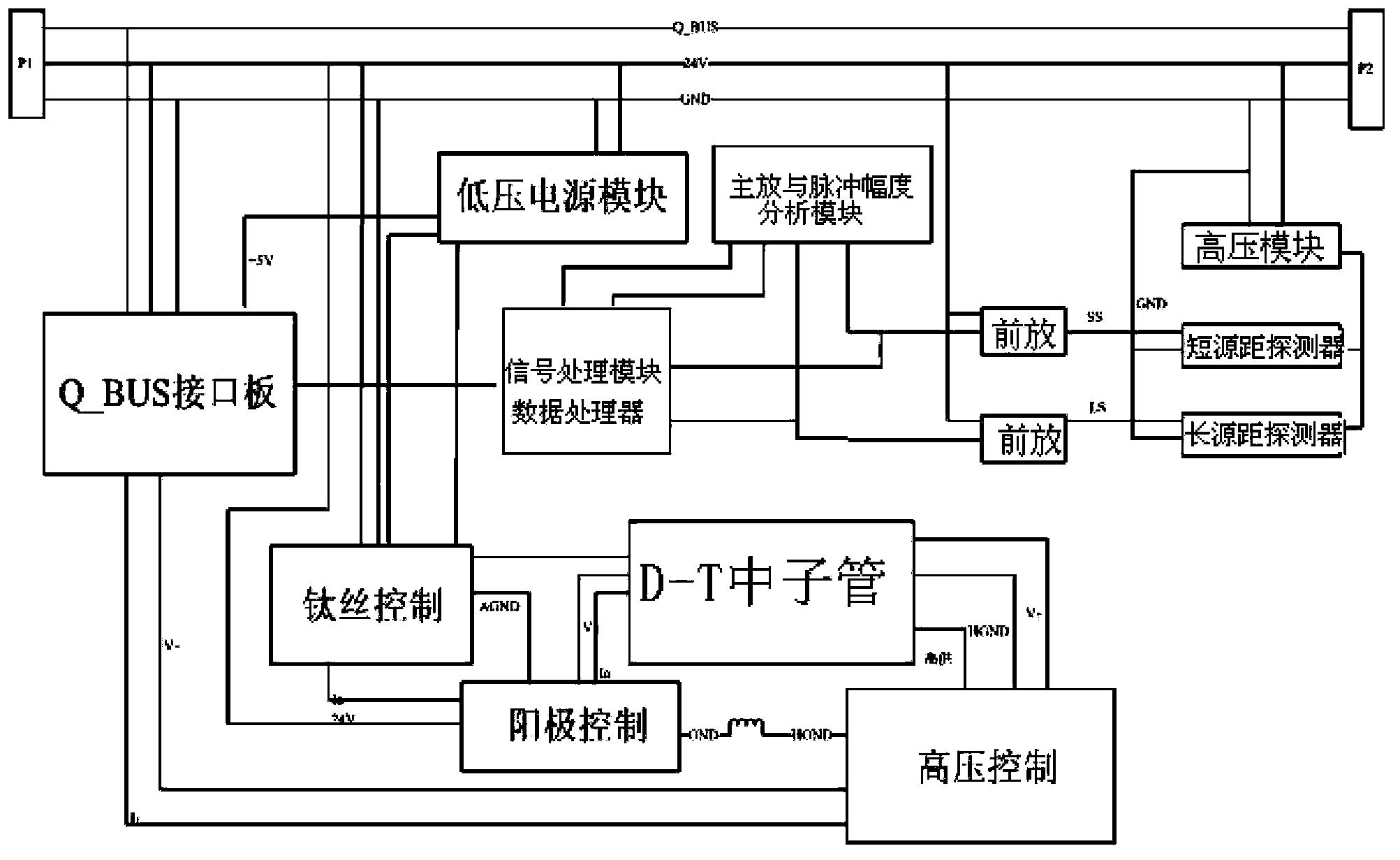

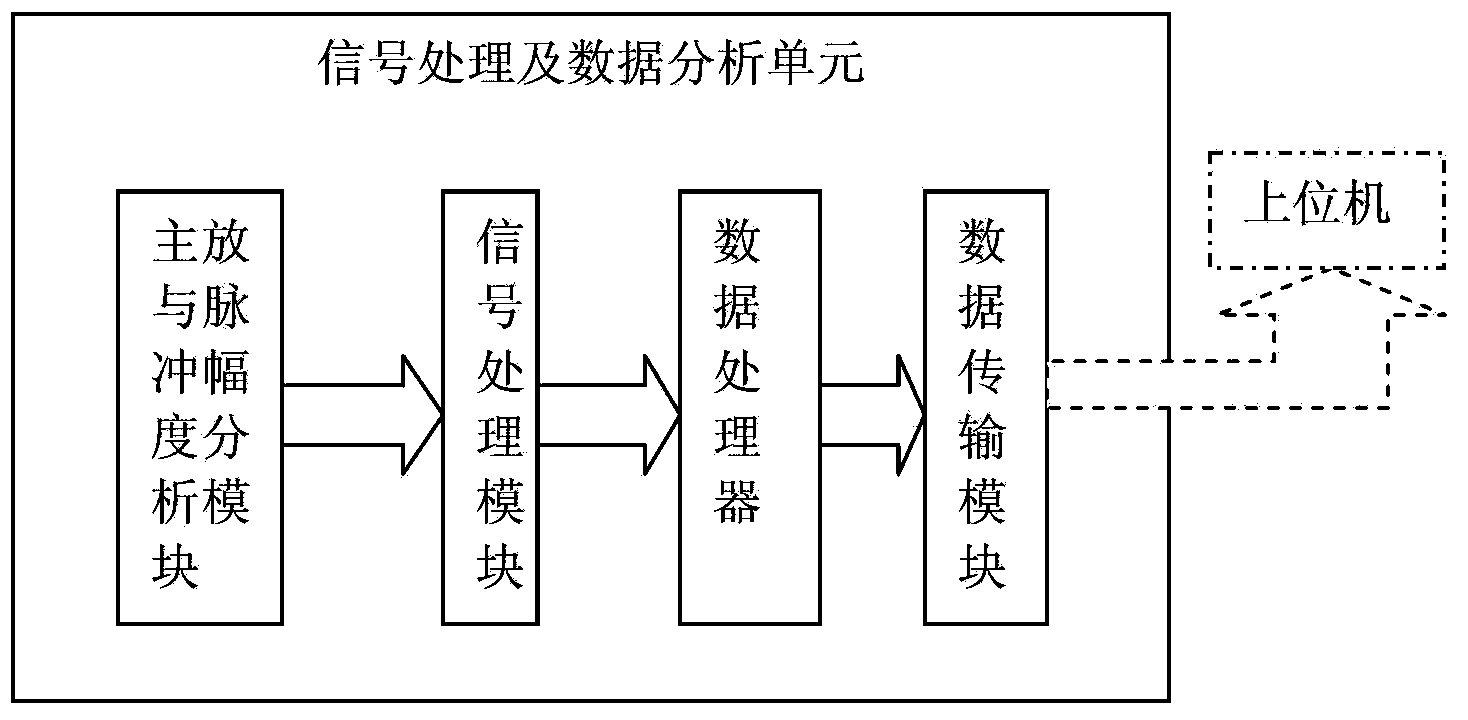

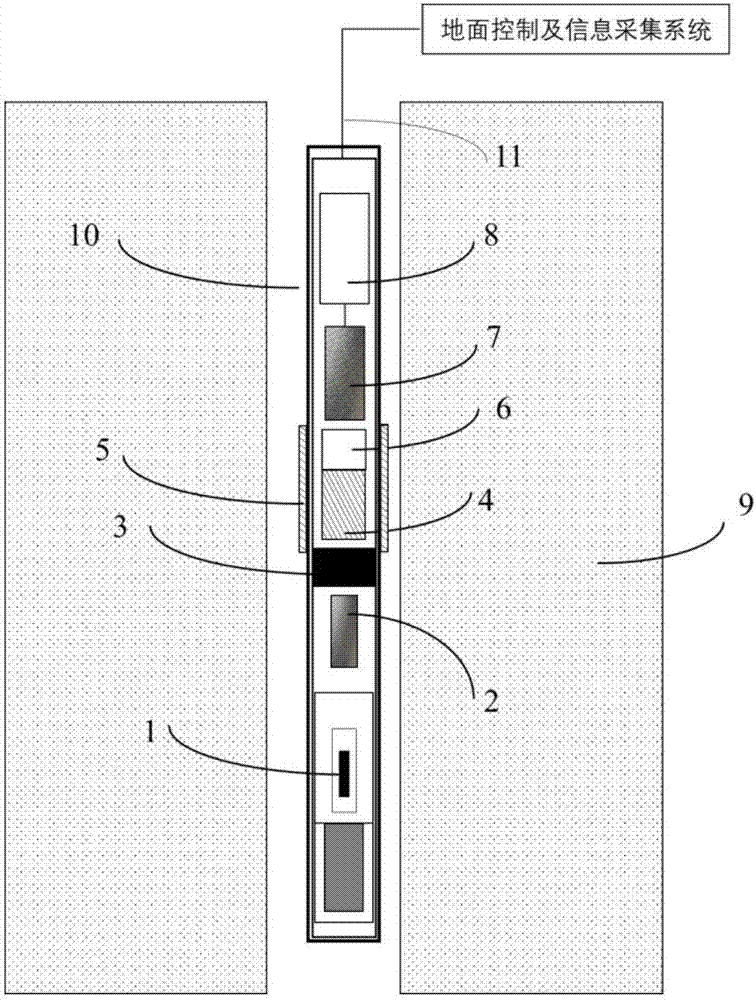

Method and instrument for controllable source neutron logging during drilling

ActiveCN103527181AReduce the numberIncrease count rateDrilling rodsDrilling casingsLong spacingHigh energy

The invention discloses a method and instrument for controllable source neutron logging during drilling. The method comprises the steps that a pulse neutron source on a drill collar is started and quantitative high-energy neutrons are emitted to a stratum in a pulse mode; the number of thermal neutrons with the speed reduced by the stratum is measured through a long spacing detector and a short spacing detector which are arranged on the drill collar respectively, wherein the thermal neutrons are scattered back to a well hole; according to the number, measured through the two spacing detectors, of the thermal neutrons, the macroscopic capture cross section sigma of the thermal neutrons and the porosity phi of the stratum are obtained; the stratum water saturation Sw is obtained according to the macroscopic capture cross section of the thermal neutrons and the porosity phi. The instrument comprises the pulse neutron source, a detection unit, a signal processing and data analyzing unit and a power module used for supplying power for the detection unit and the signal processing and data analyzing unit. The thermal neutrons are detected through the long spacing <3>He thermal neutron detector and the short spacing <3>He thermal neutron detector, two sets of parameters including the porosity and the macroscopic capture cross section of the thermal neutrons and are obtained, and therefore the measurement of the water saturation and the porosity of the stratum with a relatively low degree of mineralization is achieved. Due to the use of the pulse neutron source, damage, caused by a radioactive source, to human and the environment is eliminated.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

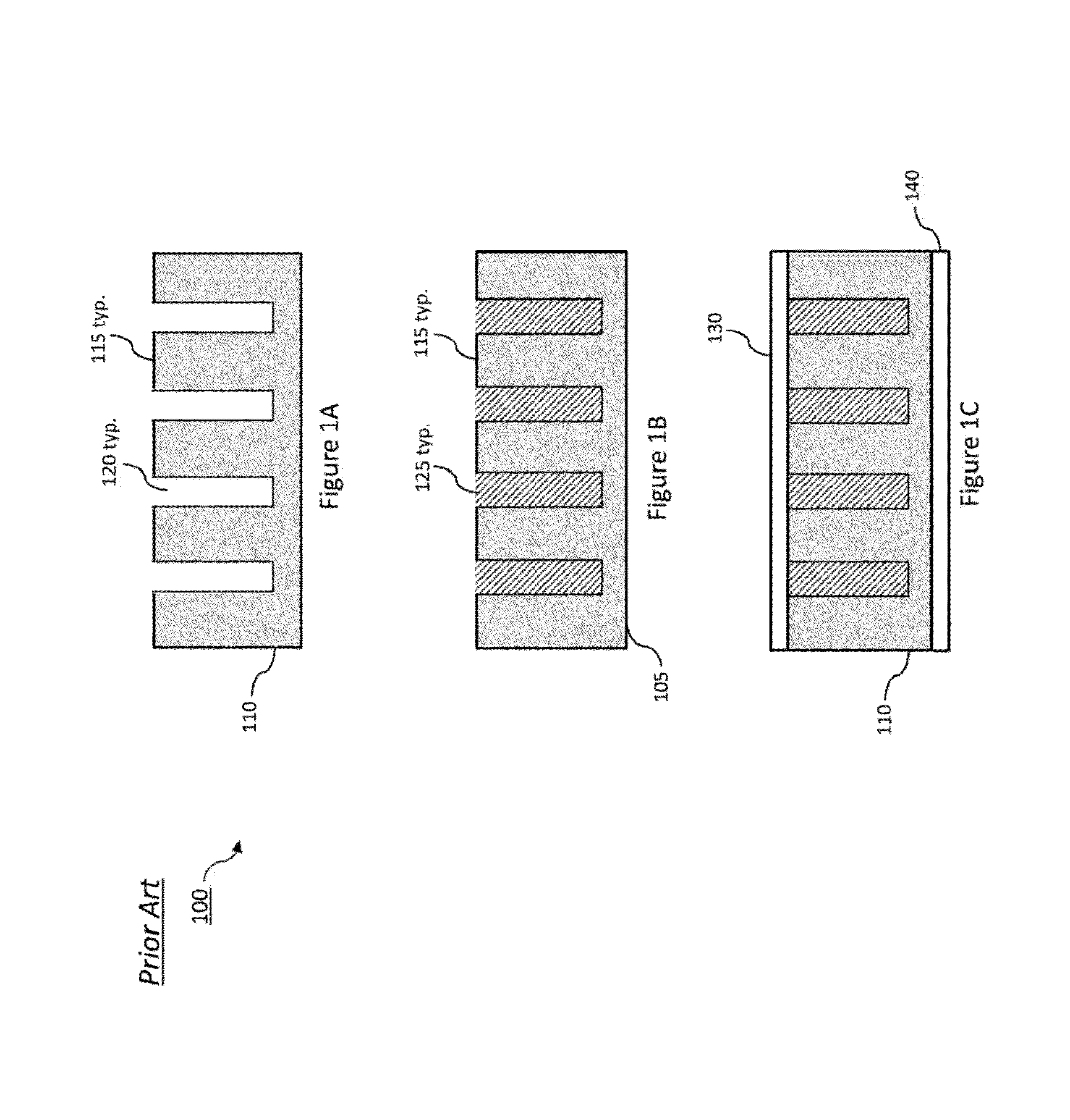

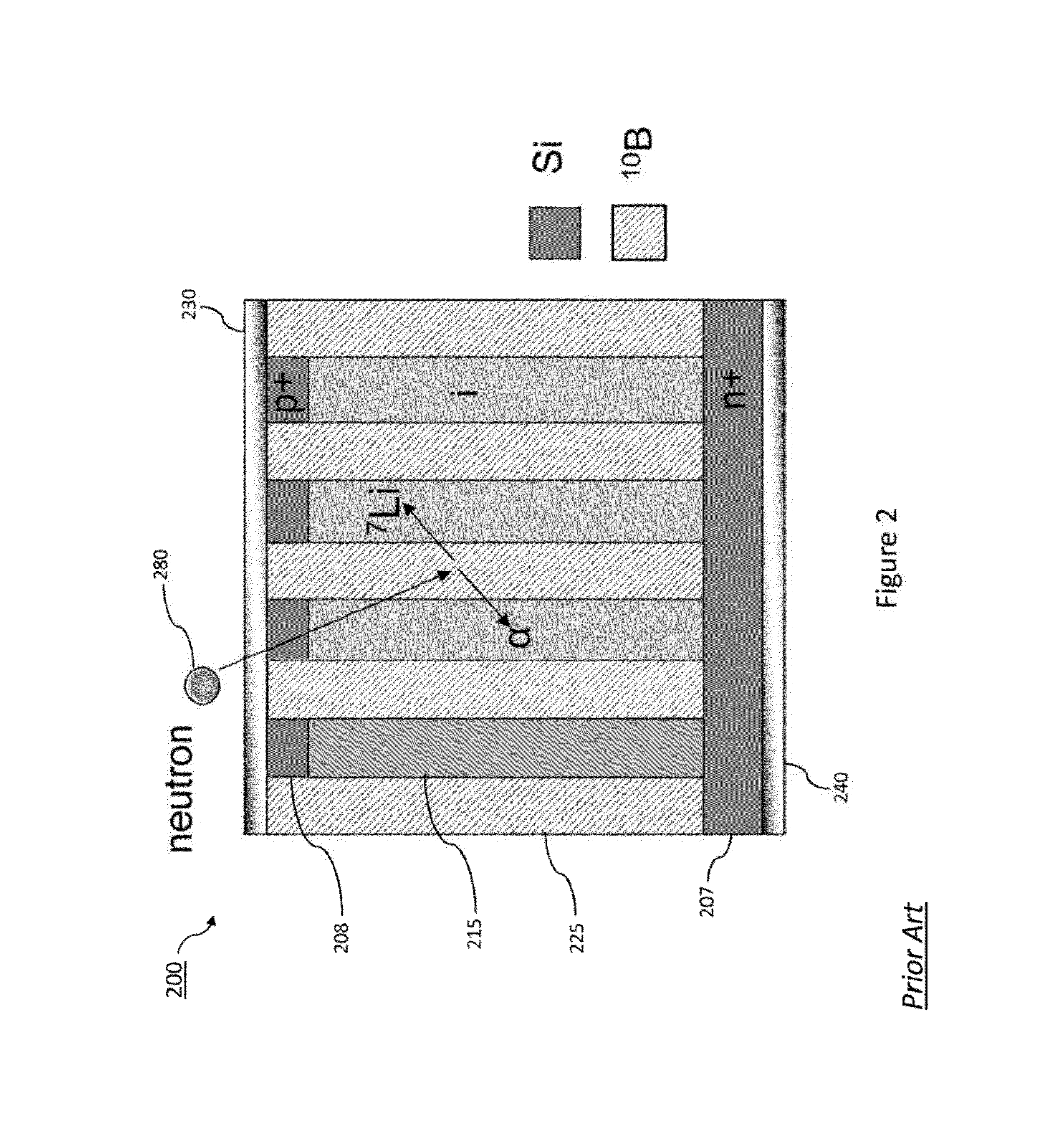

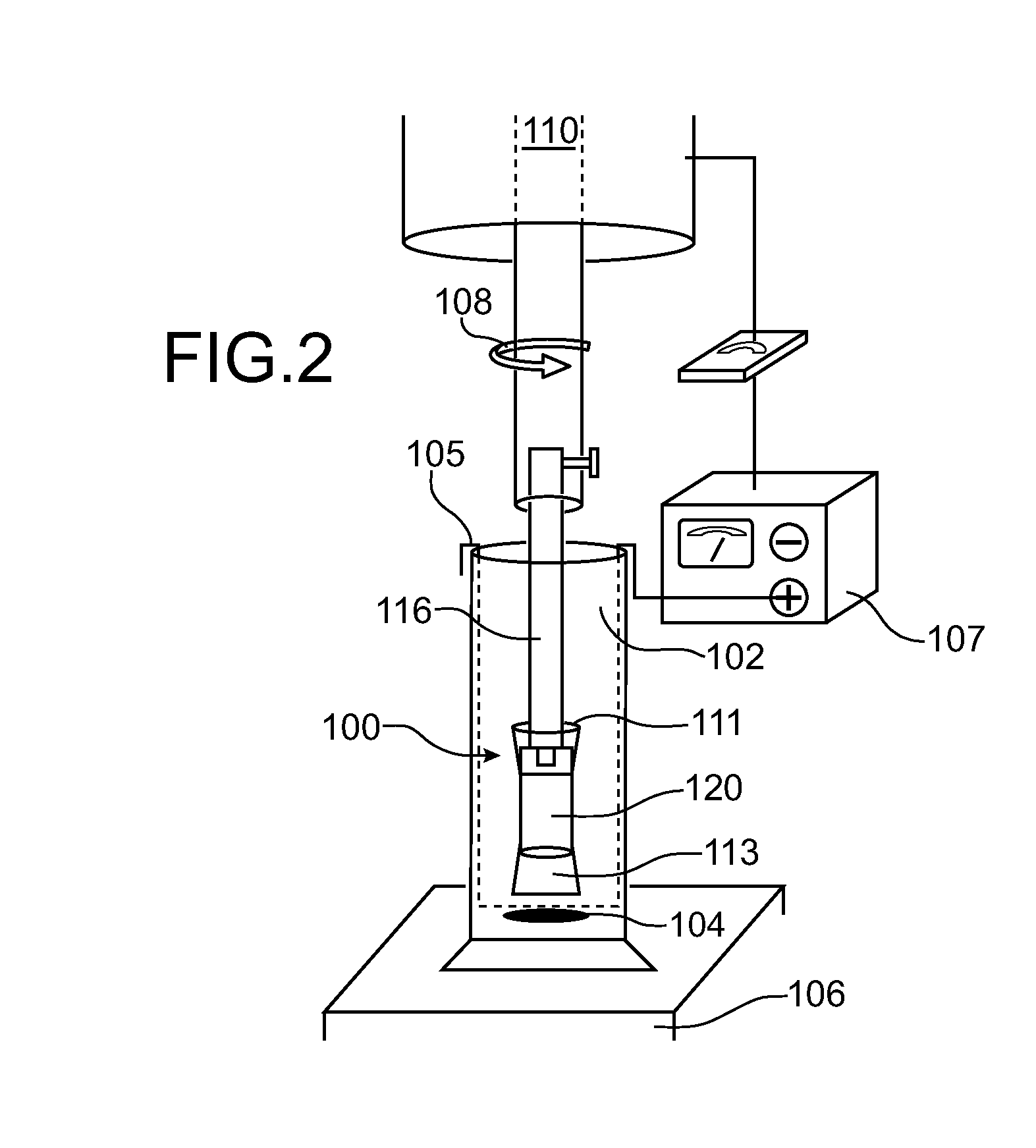

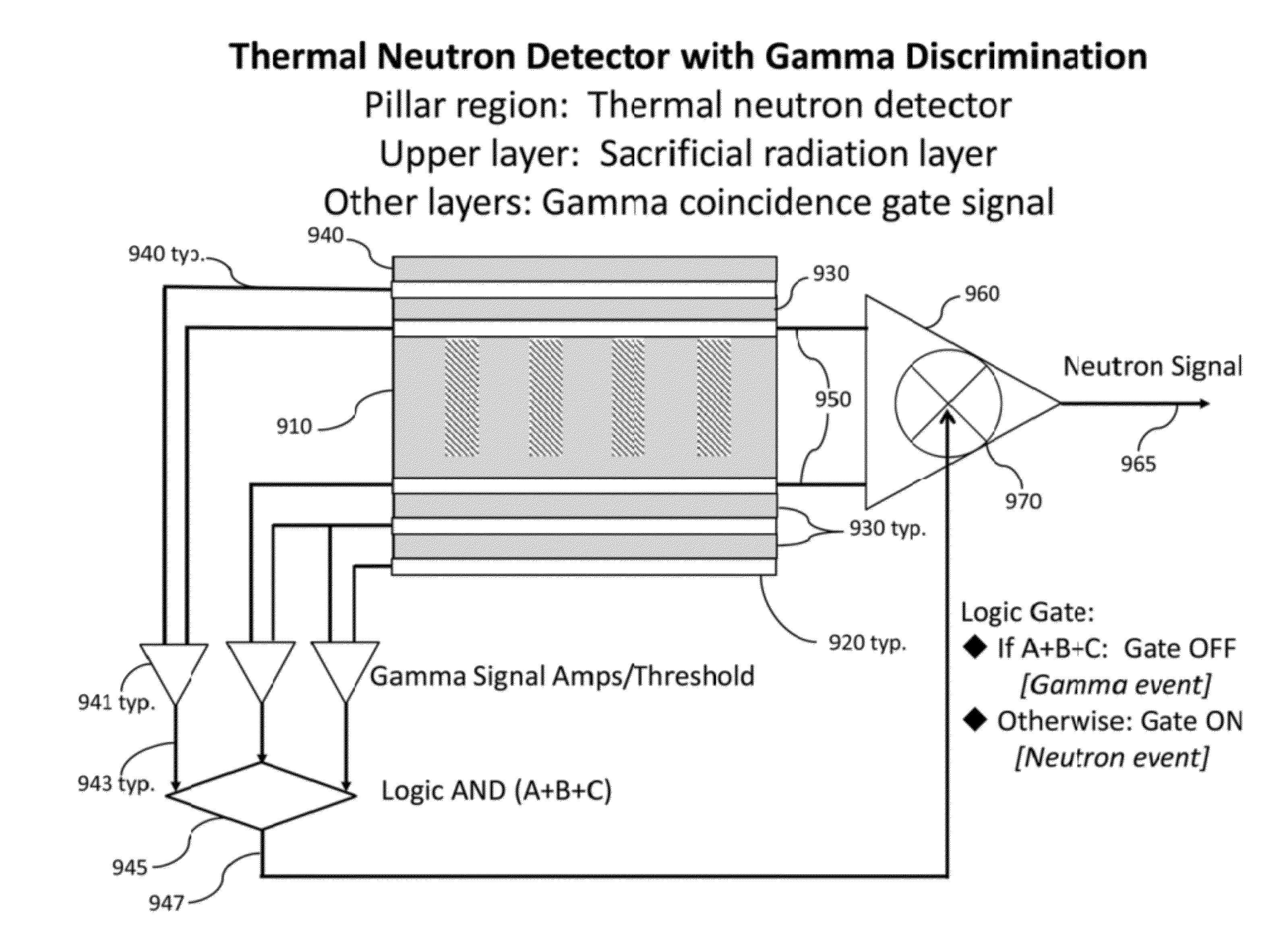

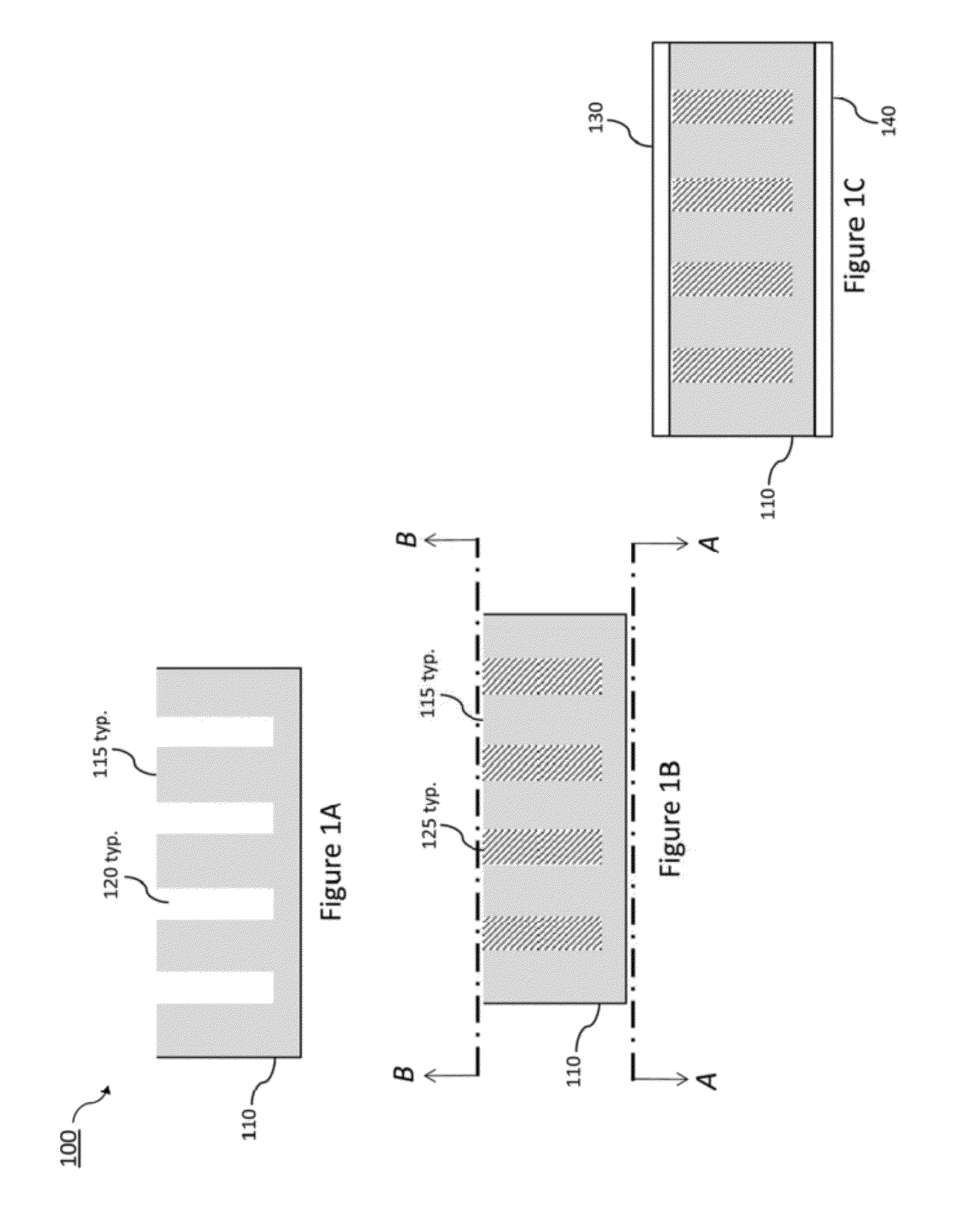

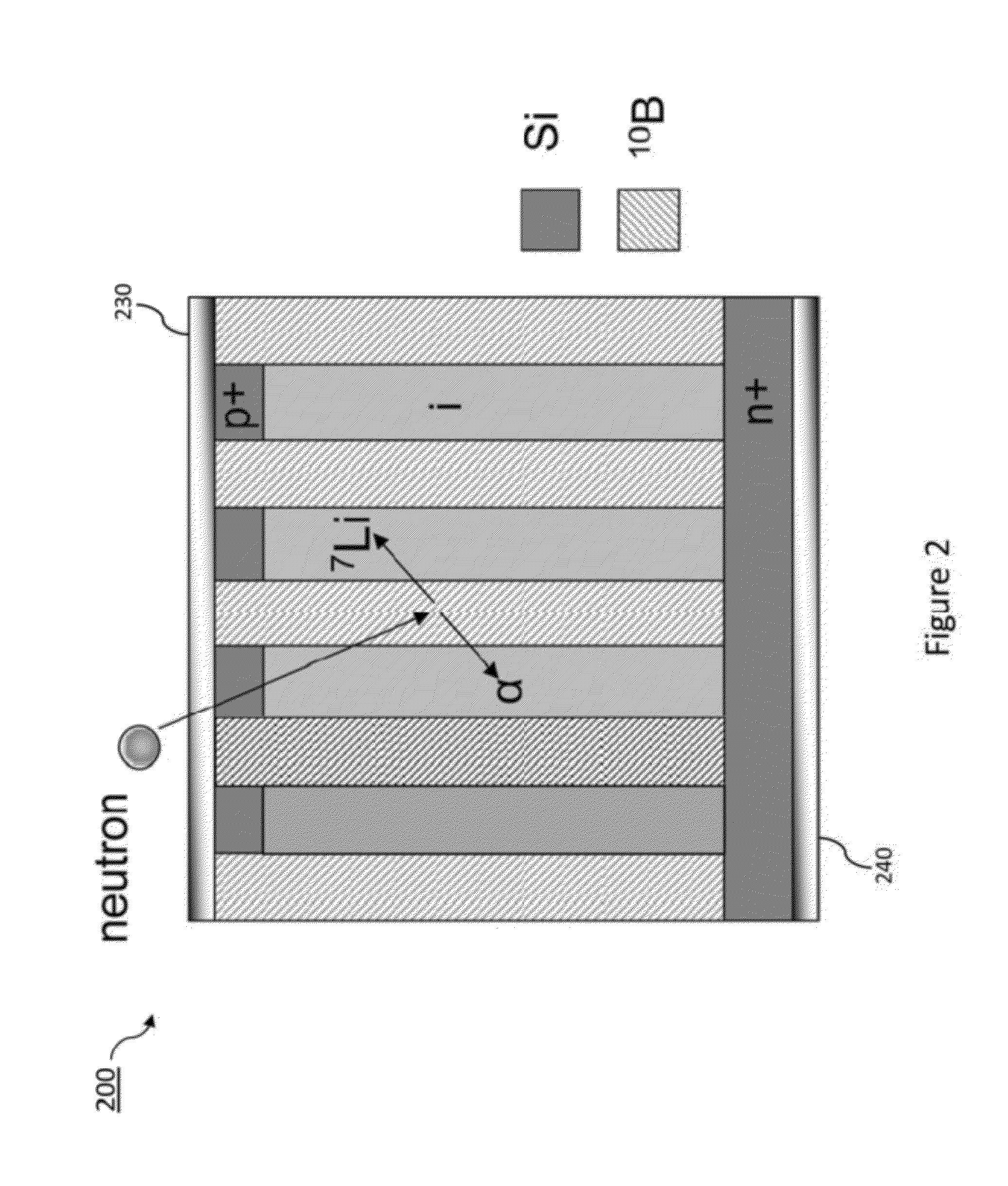

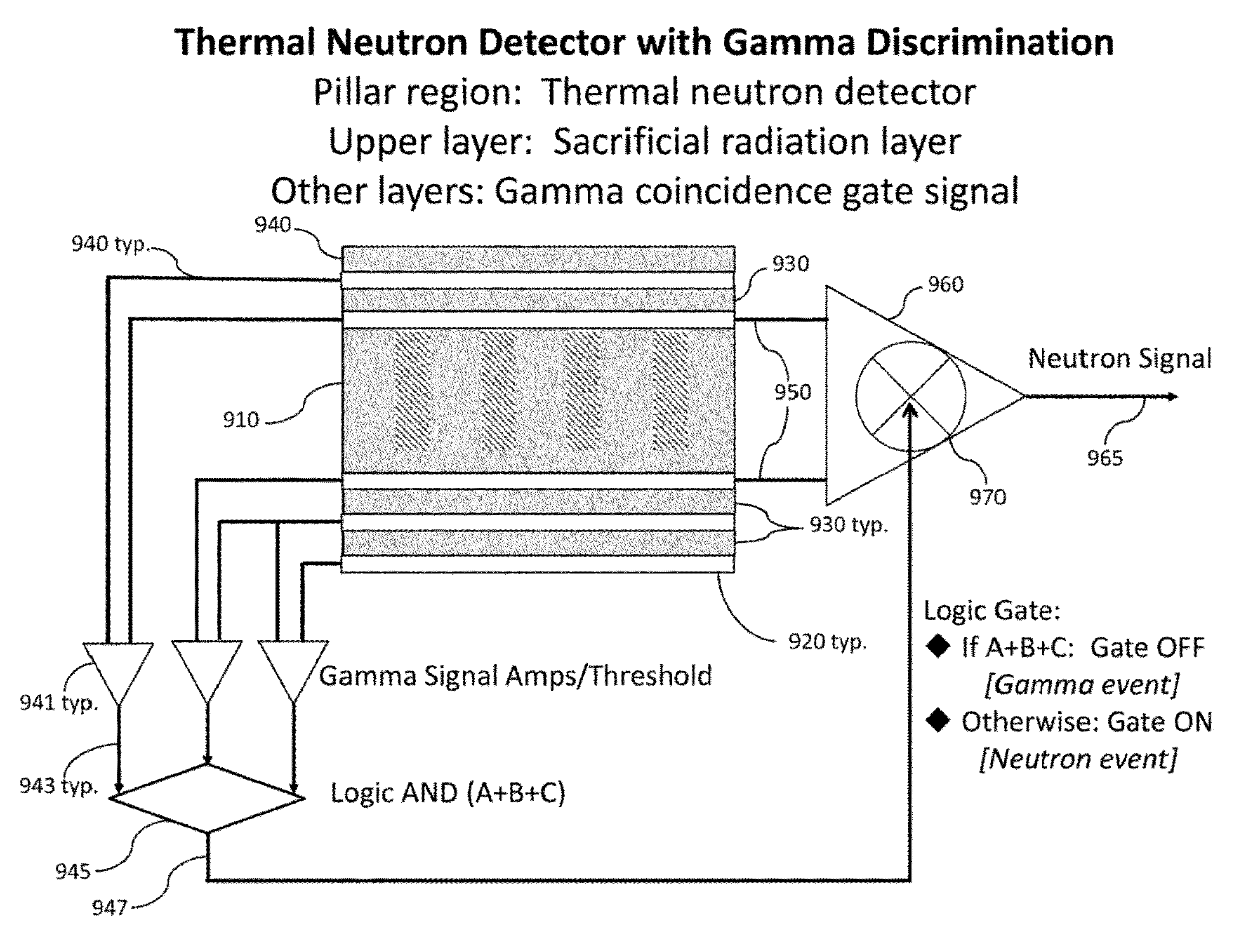

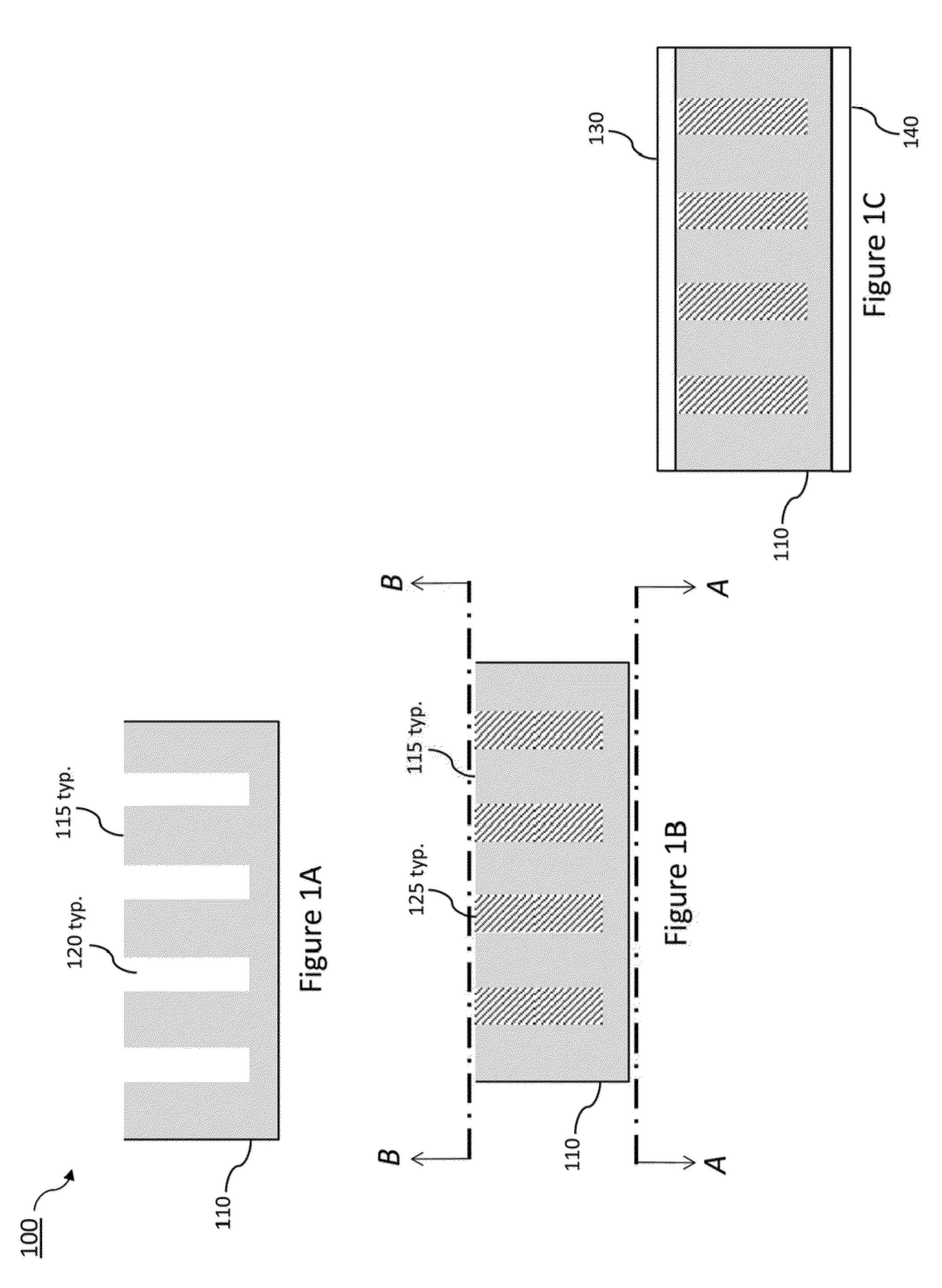

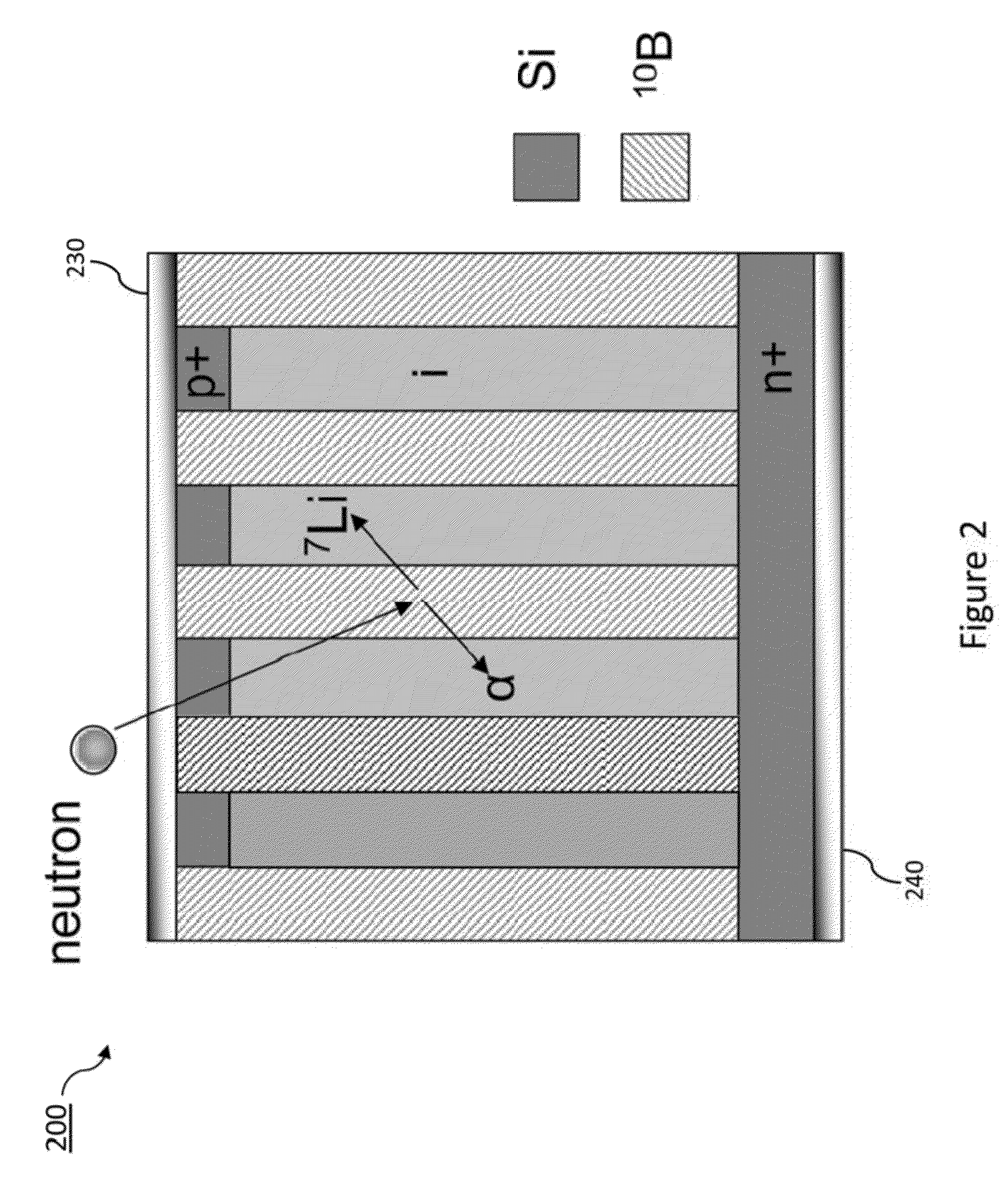

Method for manufacturing solid-state thermal neutron detectors with simultaneous high thermal neutron detection efficiency (>50%) and neutron to gamma discrimination (>1.0e4)

ActiveUS20120235260A1High thermal neutron detection efficiencyReduce areaMeasurement with semiconductor devicesMaterial analysis by optical meansNuclear physicsThermal neutron detector

Methods for manufacturing solid-state thermal neutron detectors with simultaneous high thermal neutron detection efficiency (>50%) and neutron to gamma discrimination (>104) are provided. A structure is provided that includes a p+ region on a first side of an intrinsic region and an n+ region on a second side of the intrinsic region. The thickness of the intrinsic region is minimized to achieve a desired gamma discrimination factor of at least 1.0E+04. Material is removed from one of the p+ region or the n+ region and into the intrinsic layer to produce pillars with open space between each pillar. The open space is filed with a neutron sensitive material. An electrode is placed in contact with the pillars and another electrode is placed in contact with the side that is opposite of the intrinsic layer with respect to the first electrode.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

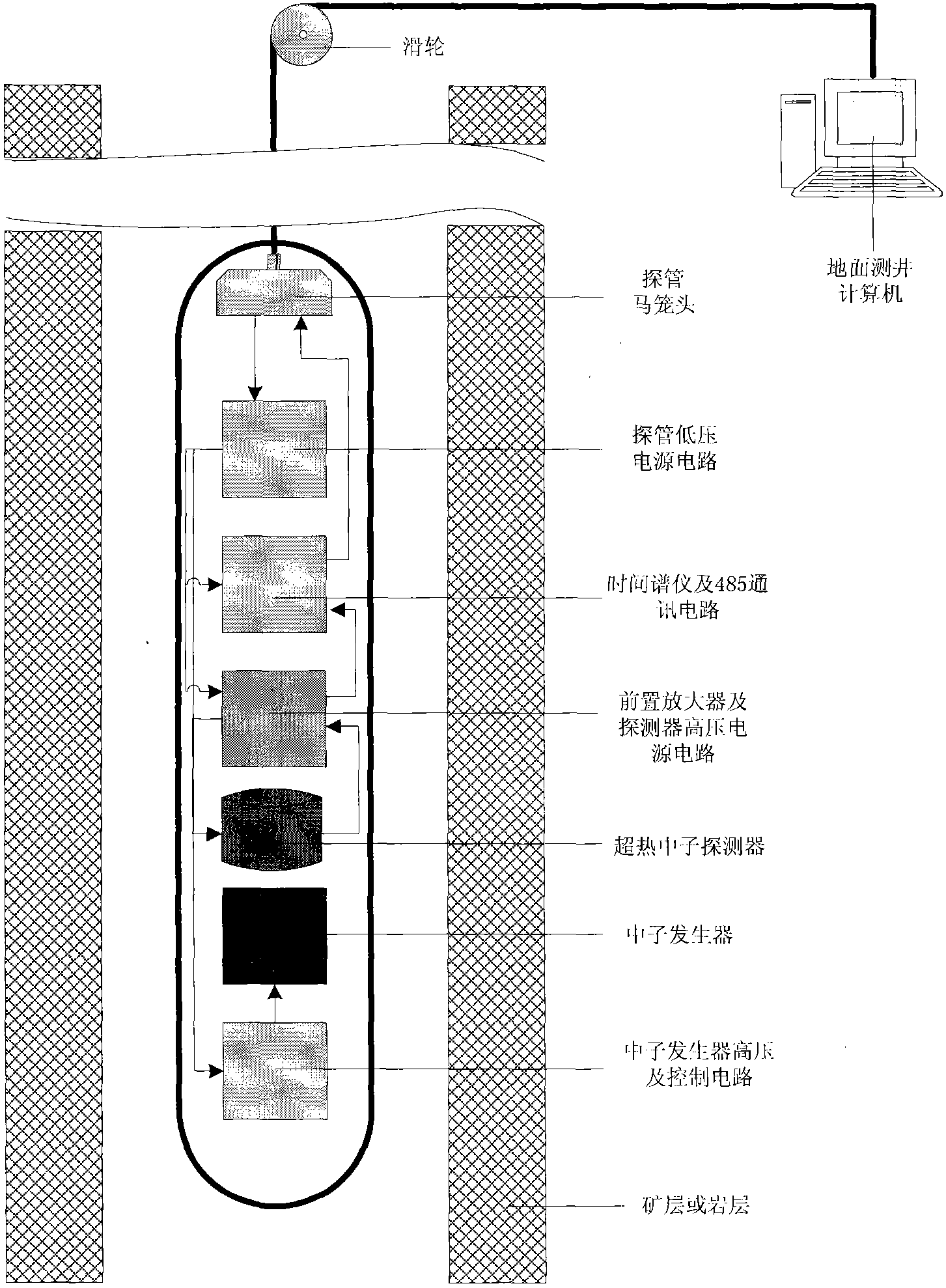

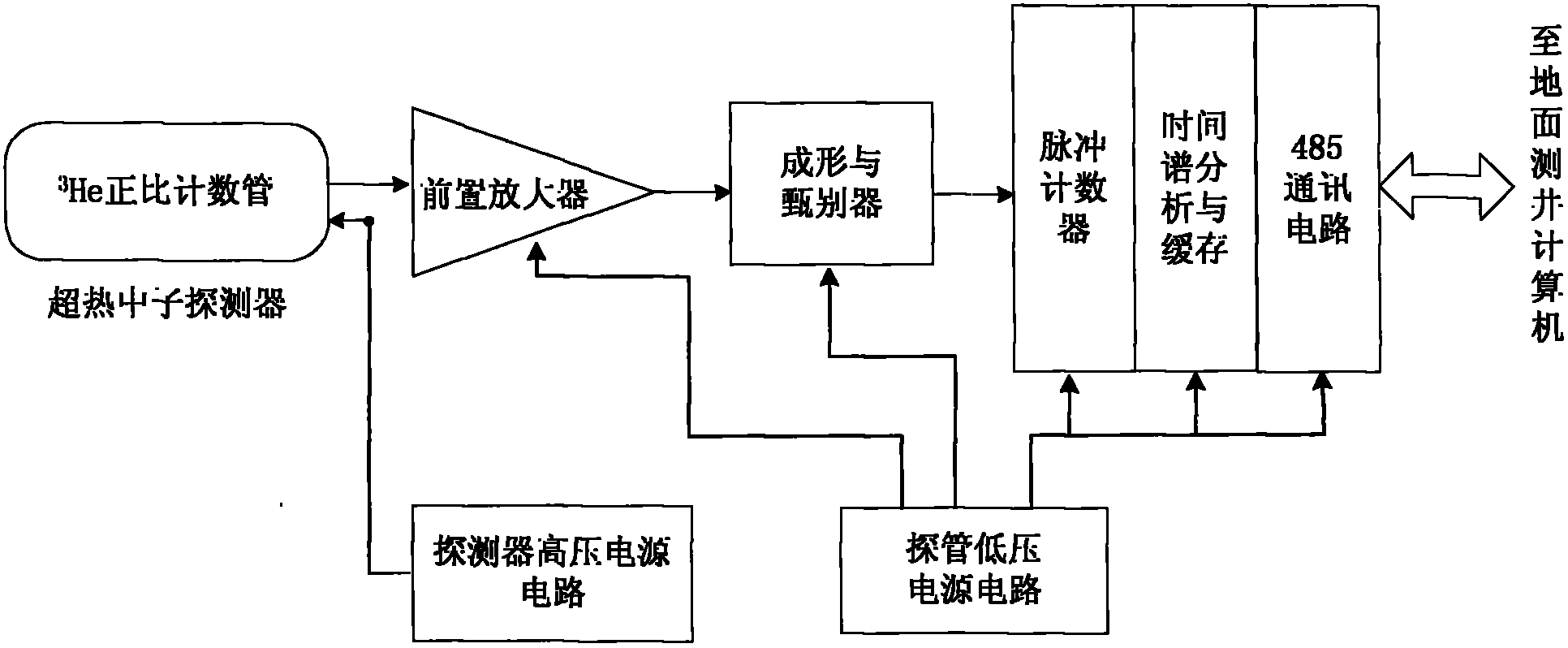

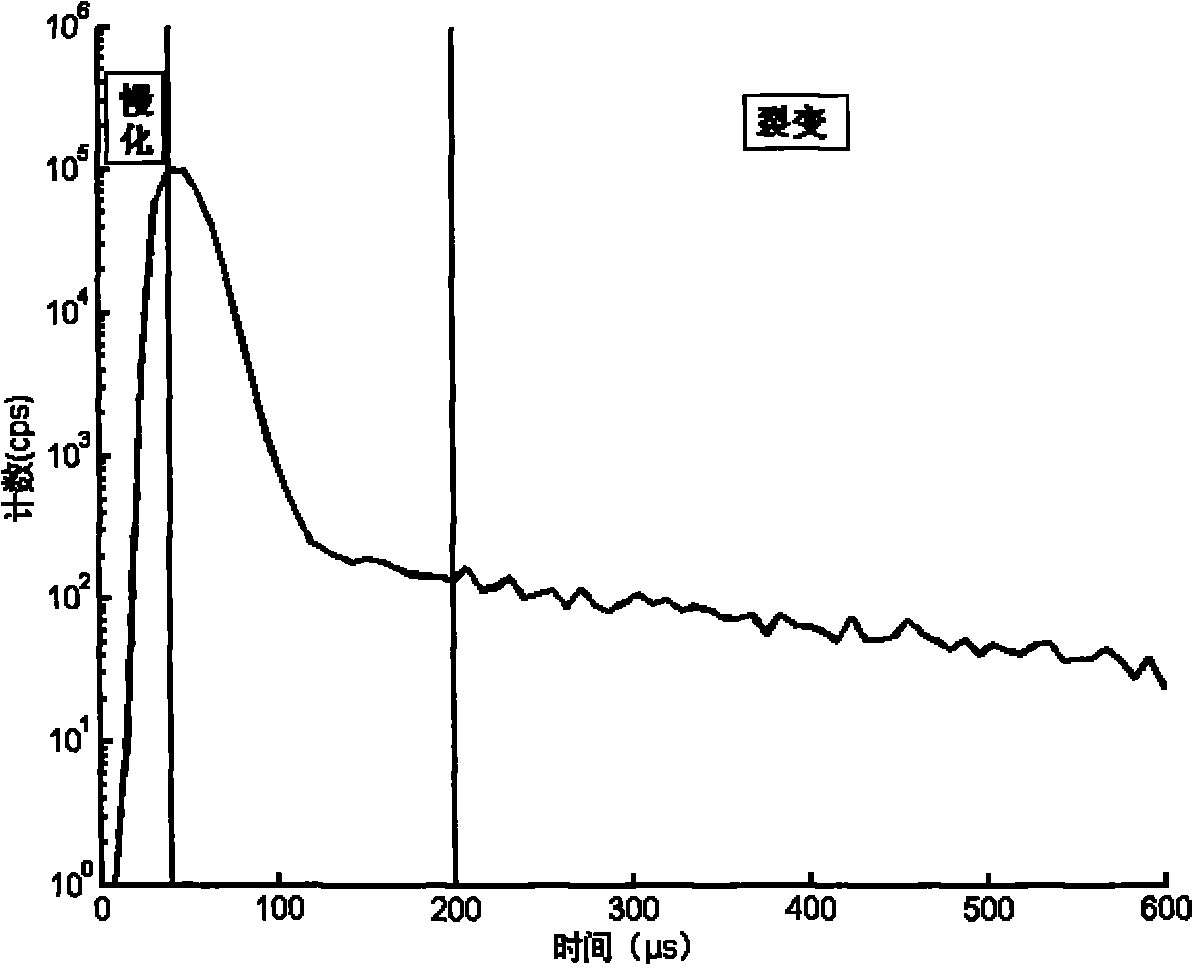

Prompt neutron logging and uranium ore quantity determining technology based on above-thermal neutron time spectrum

The invention discloses a prompt neutron logging and uranium ore quantity determining technology based on an above-thermal neutron time spectrum. Specifically, fast neutrons, i.e. virgin neutrons are emitted to stratum rock in a drilled hole in a pulse way, the virgin neutrons are moderated to thermal neutrons, and the thermal neutrons induce 235U to be fissioned and radiate uranium fission prompt neutrons, i.e. secondary neutrons. The virgin neutrons and the secondary neutrons are moderated to above-thermal neutrons and thermal neutrons with time; then the above-thermal neutron time spectrum is recorded, two coefficients, i.e. 1 / t2 and 1 / t1 which indicate the virgin neutron moderating capacity and the uranium fission sustaining capacity are extracted, nE(t1) / nE(t2) is defined as a fission / moderation ratio and a stratum rock uranium quantity determining algorithm is established according to the fission / moderation ratio. The invention additionally discloses an above-thermal neutron detector and a time spectrometer which are used for uranium ore pulsed neutron logging, and a real-time uranium quantity determining algorithm based on the above-thermal neutron time spectrum and an ore formation.

Owner:EAST CHINA UNIV OF TECH

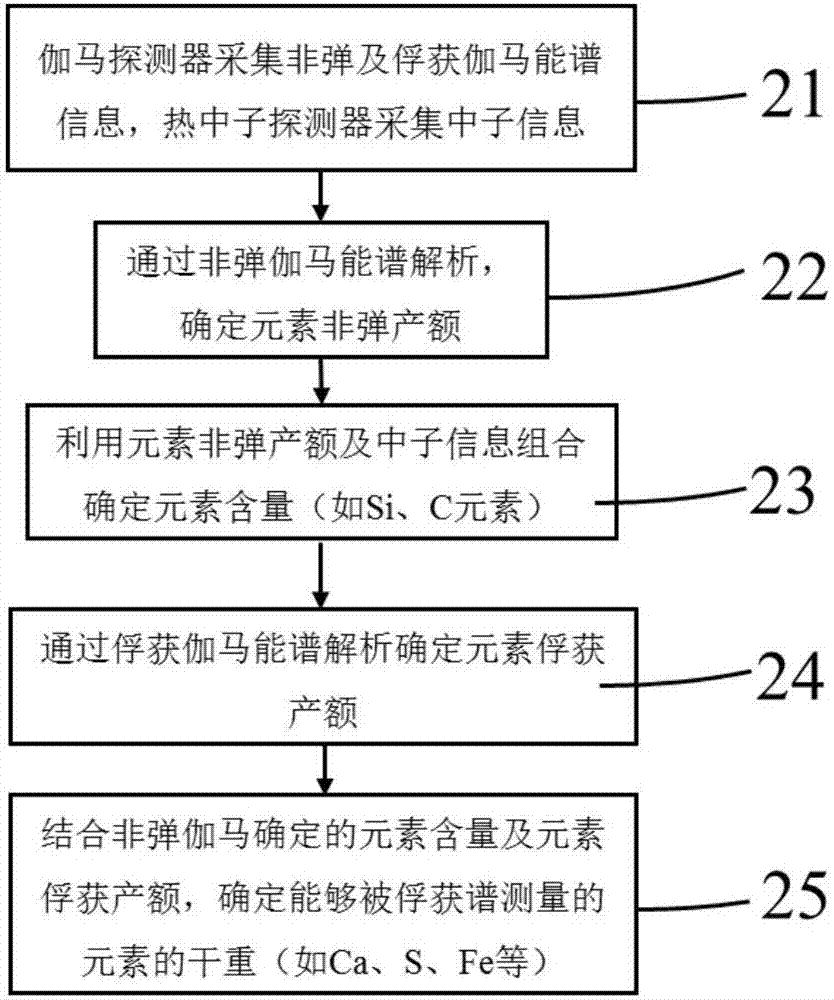

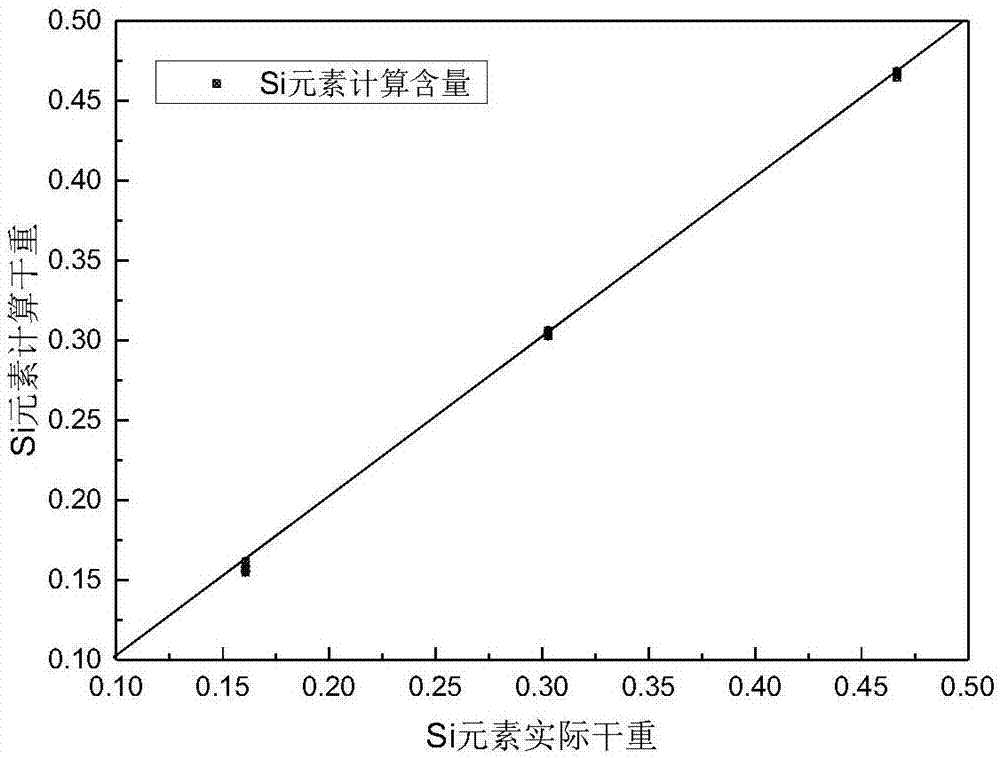

Controllable-neutron three-detector element well logging device and method

The invention discloses a controllable-neutron three-detector element well logging device and method, which specifically relate to the field of oil and natural gas exploration. The device uses a D-T controllable neutron source, a near He-3 neutron detector, a LaBr3 crystal gamma detector, and a super far He-3 thermal neutron detector. The two He-3 neutron detectors collect the time spectrum of neutrons and the total count of neutrons. The LaBr3 gamma detector collects inelastic and capture gamma time spectrums, and measurement information is uploaded to ground equipment through a telemetry pipe nipple of the instrument. The method includes the following steps: first, processing the inelastic gamma energy spectrum, calculating the inelastic gamma yield of elements, and calculating the dry weights of Si, C and other elements according to the inelastic yield of elements, the near-to-super far neutron counting ratio and other information; and then, processing the capture gamma energy spectrum, calculating the capture yield of elements, and calculating the contents of elements which can be measured by the capture gamma energy spectrum, such as Ca, S and Fe, according to the contents of elements determined by inelastic gamma and the capture yield.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Thermal neutron detector and manufacturing method thereof

InactiveCN102313898AImprove detection efficiencyImprove spatial resolutionNeutron radiation measurementImage resolutionNeutron

The invention discloses a thermal neutron detector and a manufacturing method thereof. The thermal neutron detector comprises a microchannel plate, wherein the microchannel plate comprises a plurality of glass tubes forming a microchannel, and a film layer containing thermal neutron absorbing material is coated on the inner wall of the microchannel. Higher detecting efficiency, favorable spatial resolution and better thermal neutron / gamma suppression ratio can be realized through coating the film layer containing the thermal neutron absorbing material on the inner wall of the microchannel by using a mature film coating technology without changing the glass components of the glass tubes of the microchannel plate, therefore, the preparation process of the microchannel plate can not be influenced, and the common microchannel plate capable of being obtained commercially can be utilized.

Owner:TSINGHUA UNIV +1

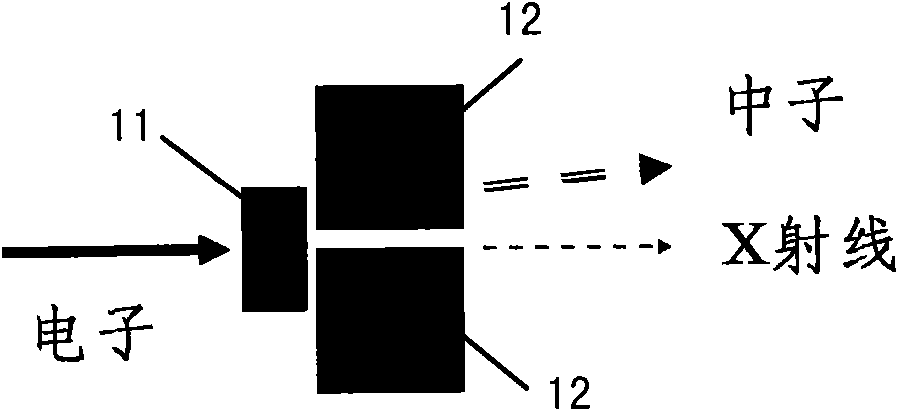

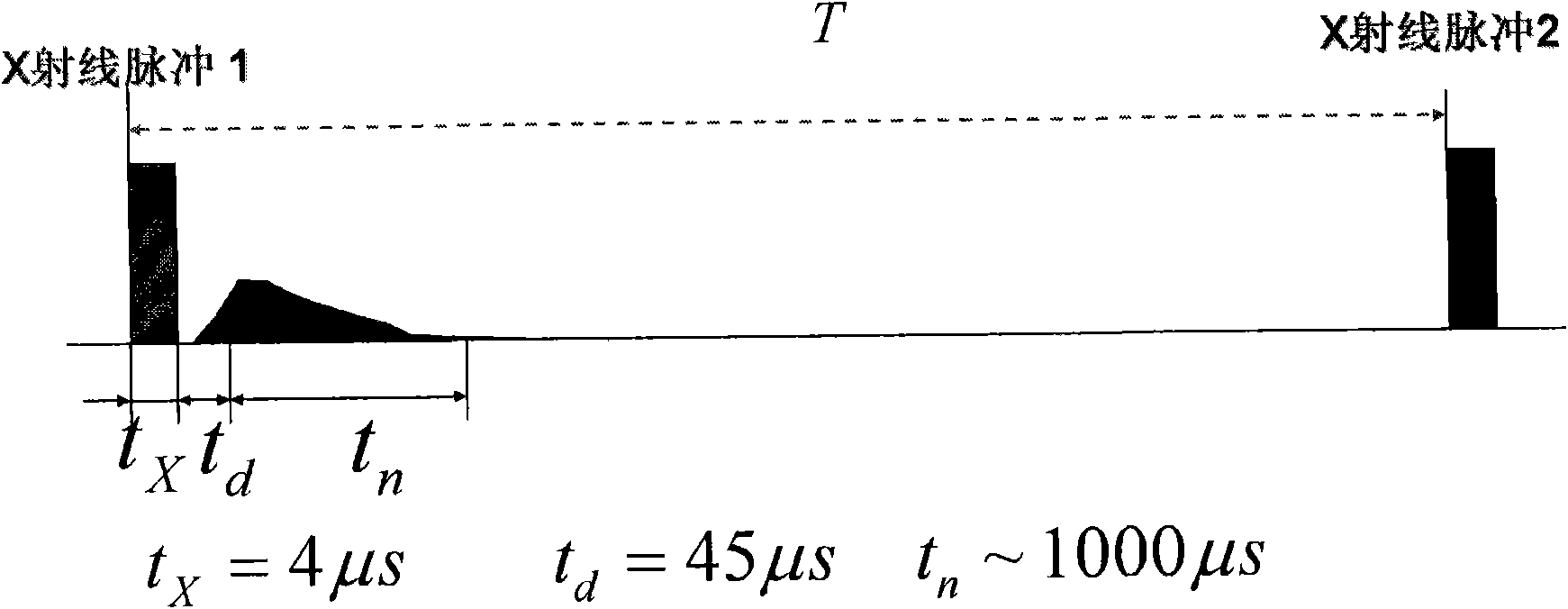

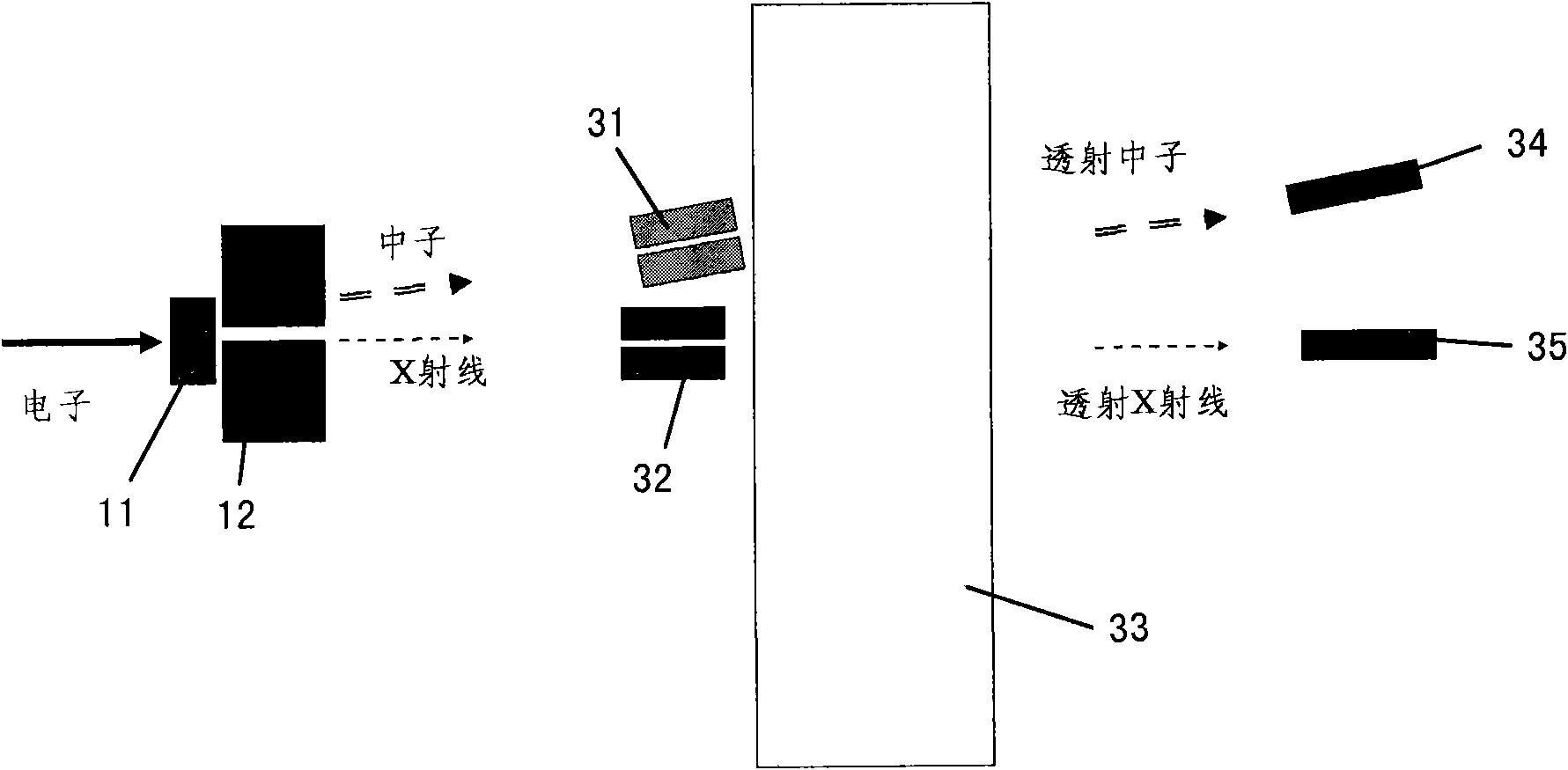

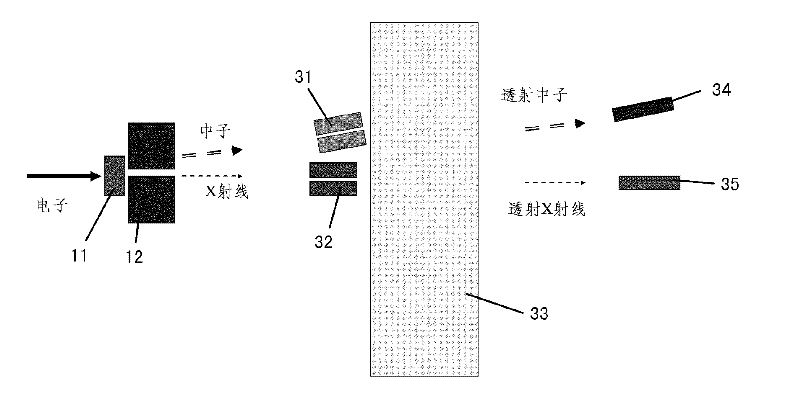

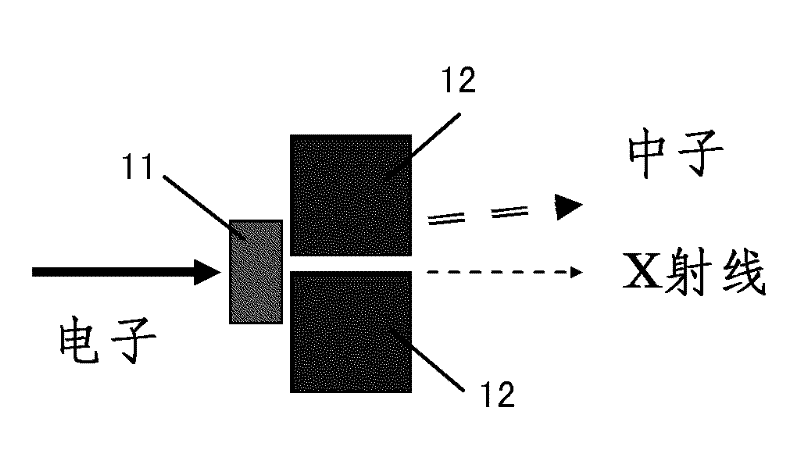

Fast neutron detection method, substance identification methods and neutron detector

ActiveCN102109607AImprove accuracyNeutron radiation measurementMaterial analysis by transmitting radiationSoft x rayUltrasound attenuation

The invention discloses a fast neutron detection method, which is used for detecting fast neutrons with X-rays, and comprises the following steps: passing the fast neutrons through a neutron slowing body to absorb the X-rays and slow the fast neutrons into thermal neutrons; and detecting the thermal neutrons by using a thermal neutron detector to obtain the information on the fast neutrons. The invention also discloses a method for identifying substances by using photoneutrons, a method for identifying substances by using X-rays and the photoneutrons, and a neutron detector. The neutron detector comprises the neutron slowing body which is suitable for absorbing the X-rays therein and slowing the fast neutrons into the thermal neutrons; and the thermal neutron detector which is suitable for detecting the thermal neutrons to obtain the information on the fast neutrons. In the invention, the interference of the X-rays with the fast neutron measurement can be eliminated by arranging the neutron slowing body, so the accuracy of the neutron measurement is improved. And as the attenuation information of the X-rays and the attenuation information of the neutrons, which are different, are obtained at the same time, the capability of identifying detected objects is improved.

Owner:NUCTECH CO LTD +1

Glass-panel lithium-6 neutron detector

InactiveUS9018594B2Leverage cost and design and durability and performanceMost efficientElectric discharge tubesMaterial analysis by optical meansLithiumNeutron emission

A thermal neutron detector includes a planar detector housing having two glass panels spaced apart by a gas-tight seal defining a detection chamber. Lithium foils adhered to inner surfaces of the glass panel emit alpha particles and tritons in response to incident thermal neutrons, and an inert detection gas is ionized to generate drift electrons. A planar array of detection wires is spaced from the lithium foils and extends outside the detection chamber. Electronic bias applies a field voltage between the wires and the lithium foils to establish a drift electric field to attract the drift electrons to the wires and provide a large electric field to cause electron multiplication. Detection circuitry detects electric signals in the wires generated by the drift of positive ions away from the wires and interprets the electrical signals as incidence of thermal neutrons on the detector.

Owner:TRUSTEES OF BOSTON UNIV

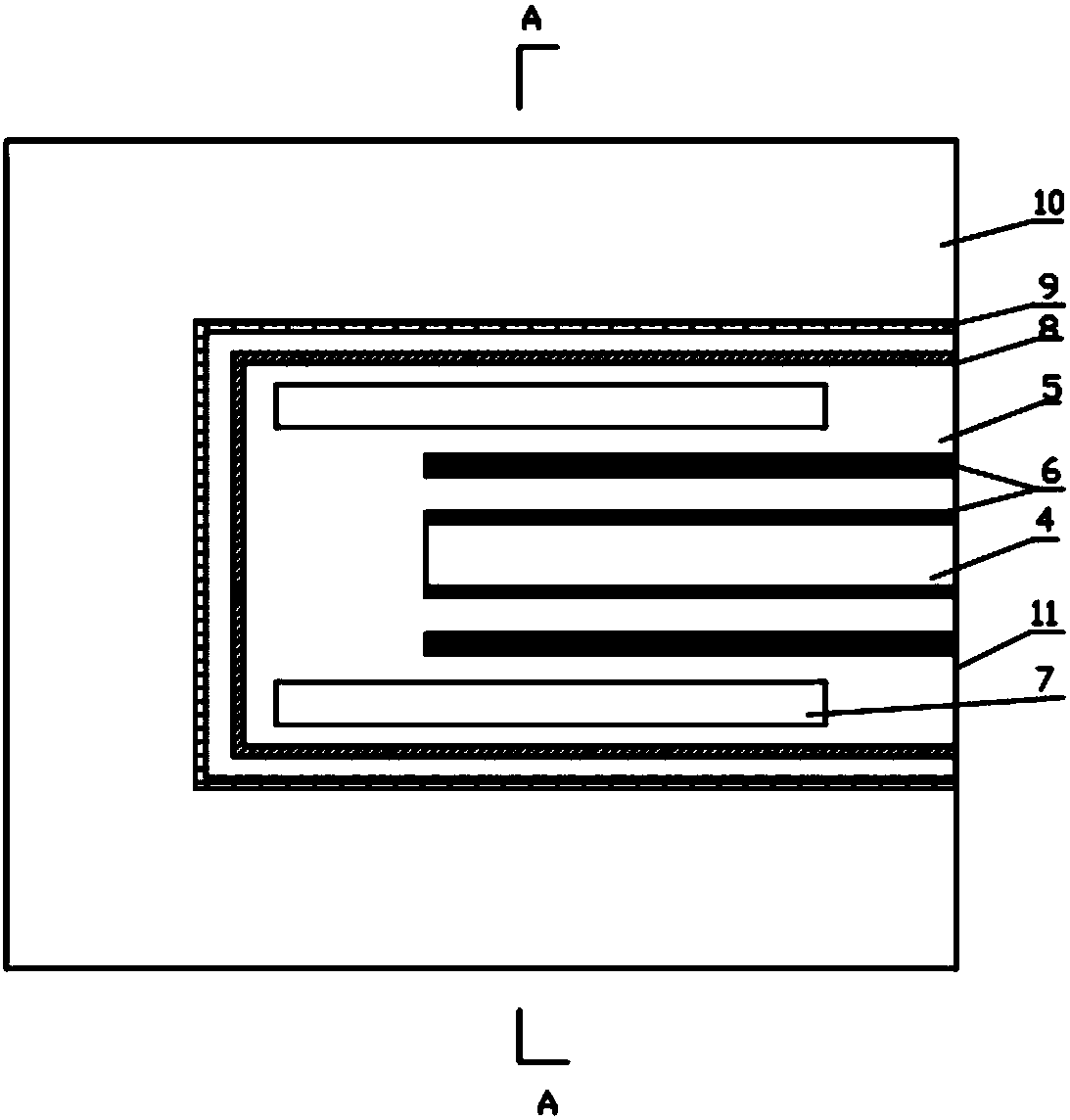

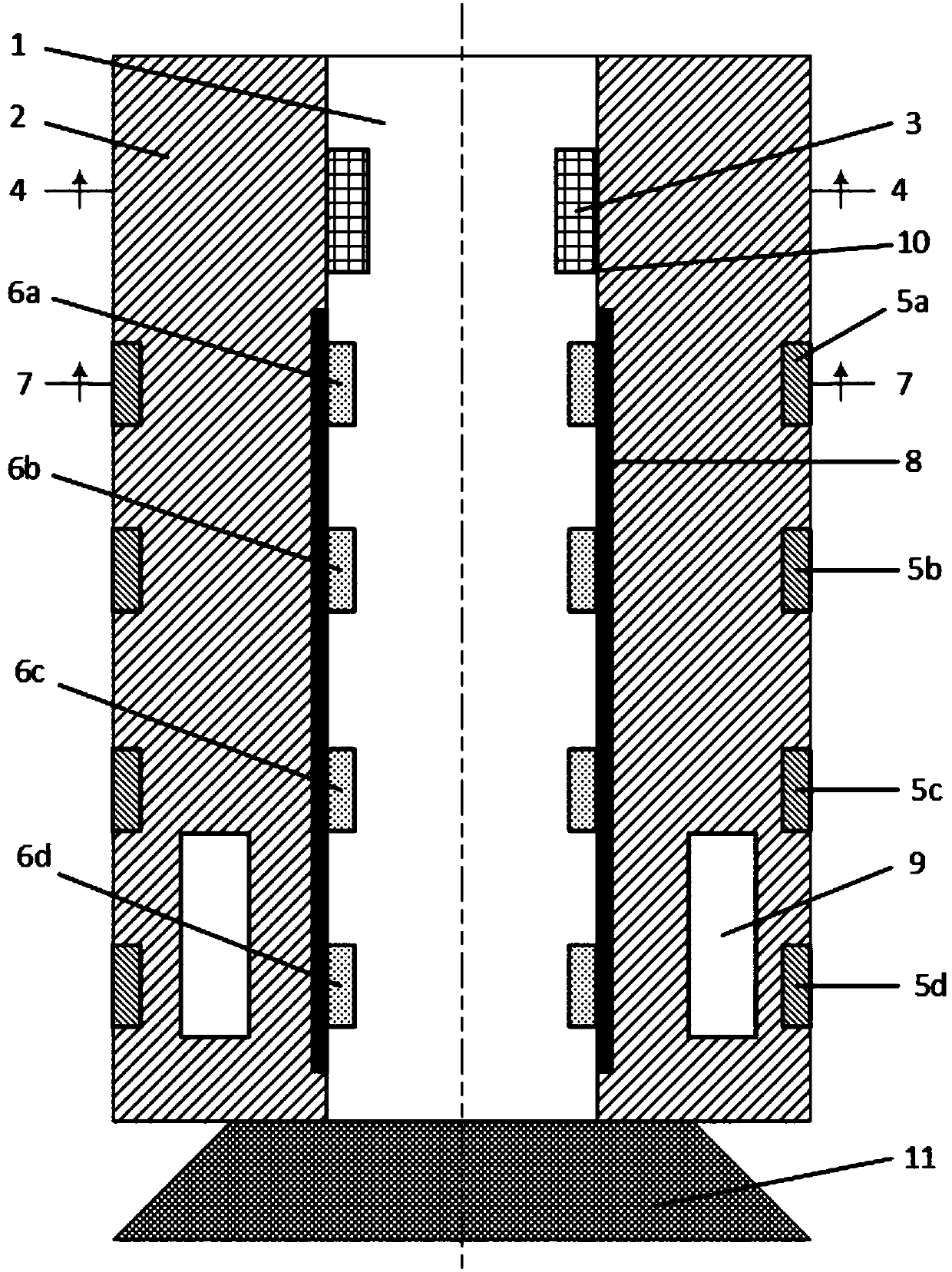

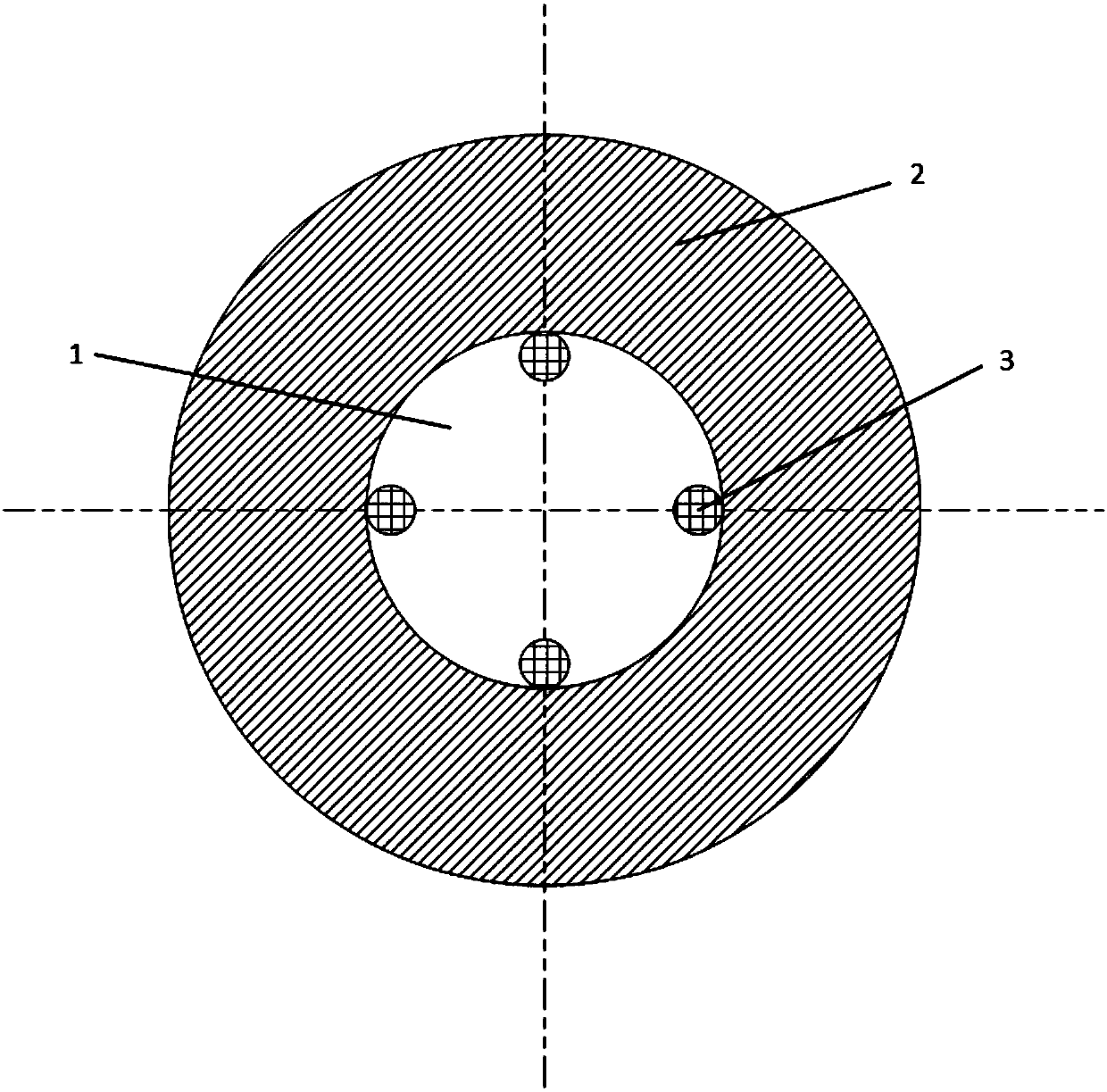

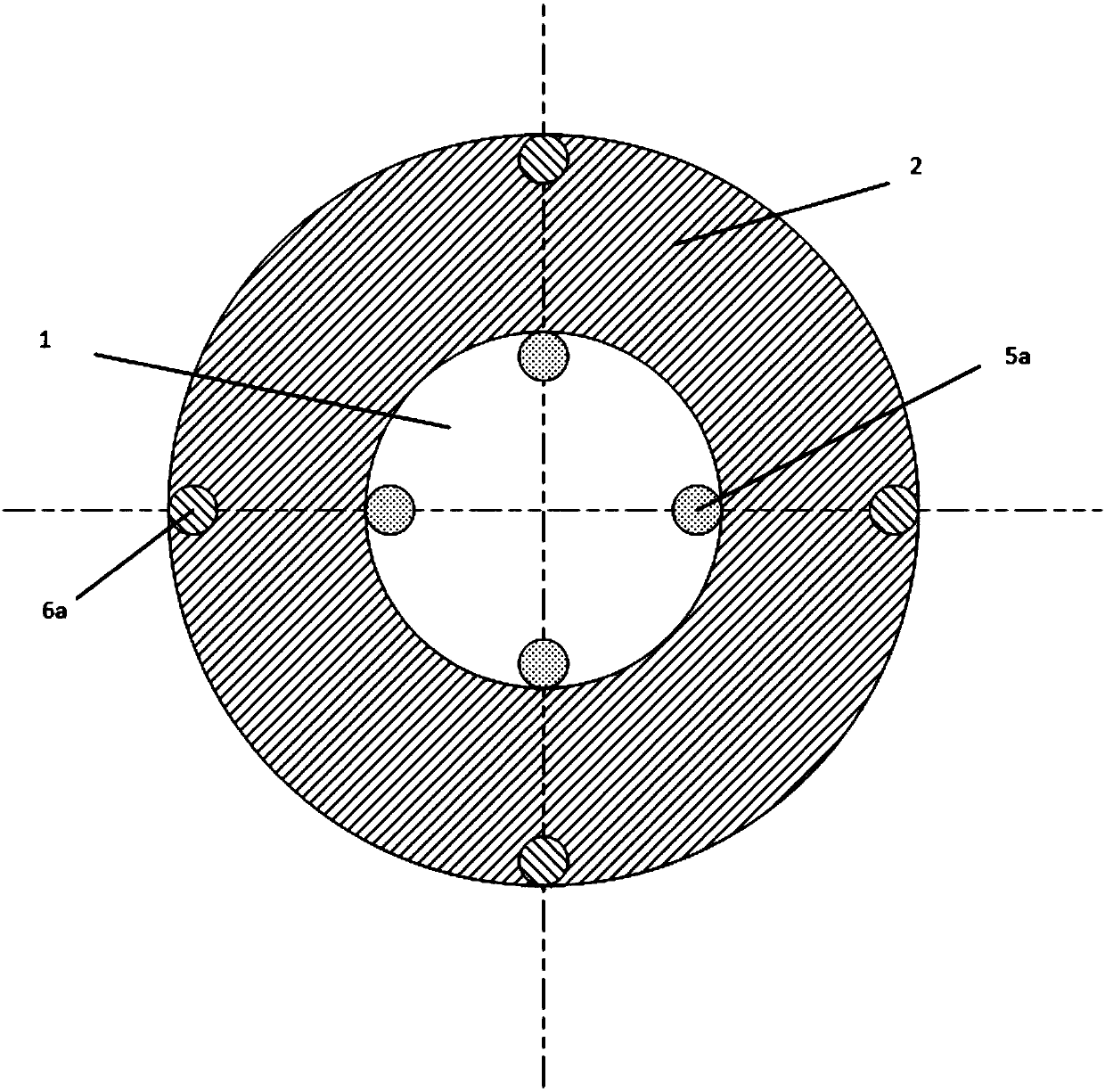

Stratum density measuring while drilling instrument based on deuterium-tritium accelerator neutron source

InactiveCN104747179AReduce usageReduce Radiation HazardsBorehole/well accessoriesGamma rayNeutron yield

The invention provides a stratum density measuring while drilling instrument based on a deuterium-tritium accelerator neutron source. The stratum density measuring while drilling instrument is used for measuring the density of a stratum around a well hole in the well drilling process, and meanwhile can measure the neutron porosity. According to the stratum density measuring while drilling instrument, a U-shaped groove is formed in one side of a drill collar, a fast neutron monitoring detector and a neutron generator are arranged inside a neutron generator module compression resistance cylinder, a neutron shielding body, a first thermal neutron detector, a neutron shielding body, a second thermal neutron detector, a gamma ray shielding body, a gamma detector and a control processing circuit are sequentially installed inside a detector installation skeleton from top to bottom, and the neutron generator module compression resistance cylinder and the detector installation skeleton are connected and fixed into the U-shaped groove through a coupling connector. The stratum density measuring while drilling instrument adopts the deuterium-tritium accelerator neutron source for measuring the stratum density, a chemical gamma radioactive source is prevented from being used, damage to people and environment is eliminated, and the measuring precision is effectively improved by monitoring the neutron yield in real time.

Owner:CHINA PETROCHEMICAL CORP +1

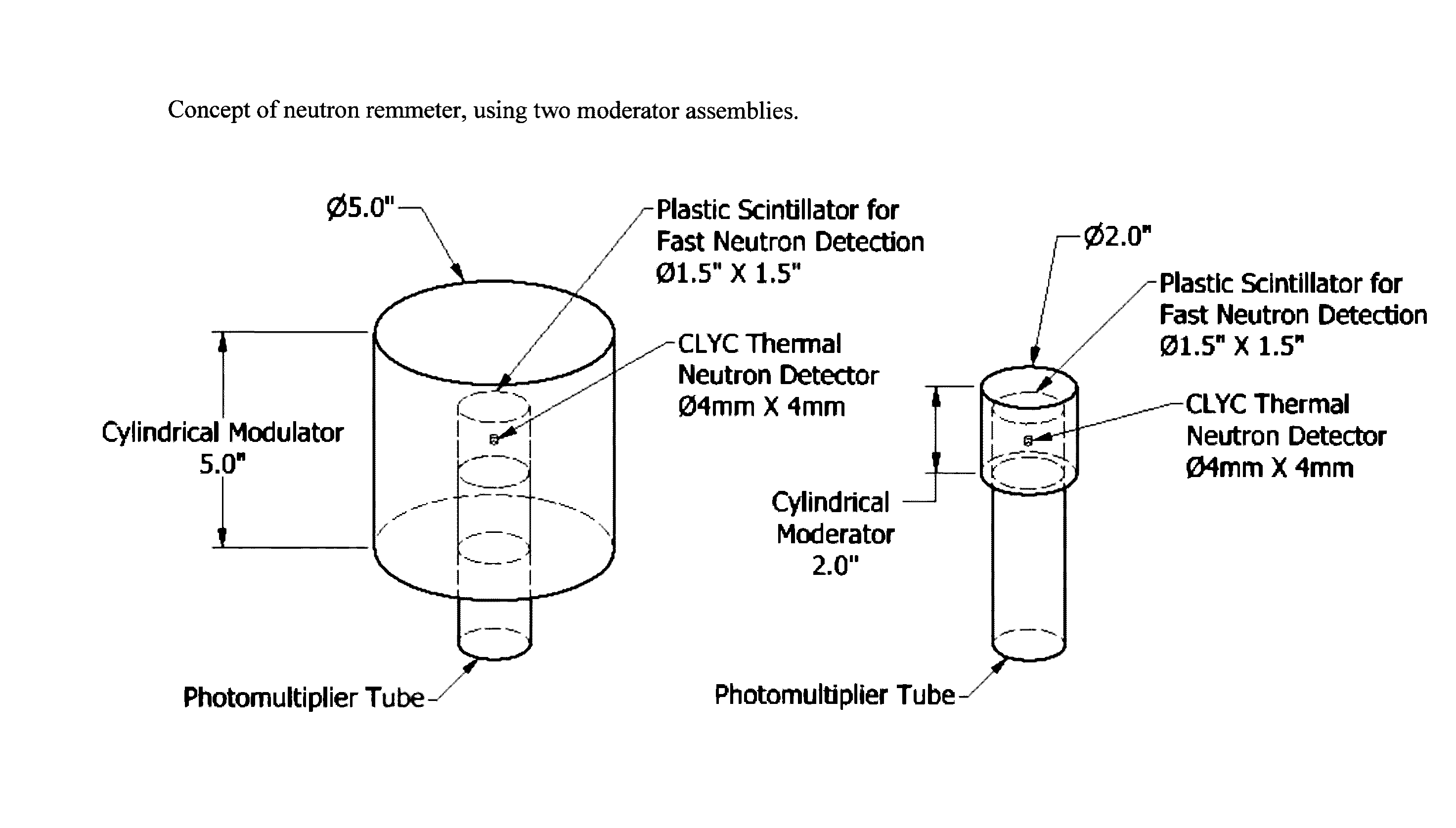

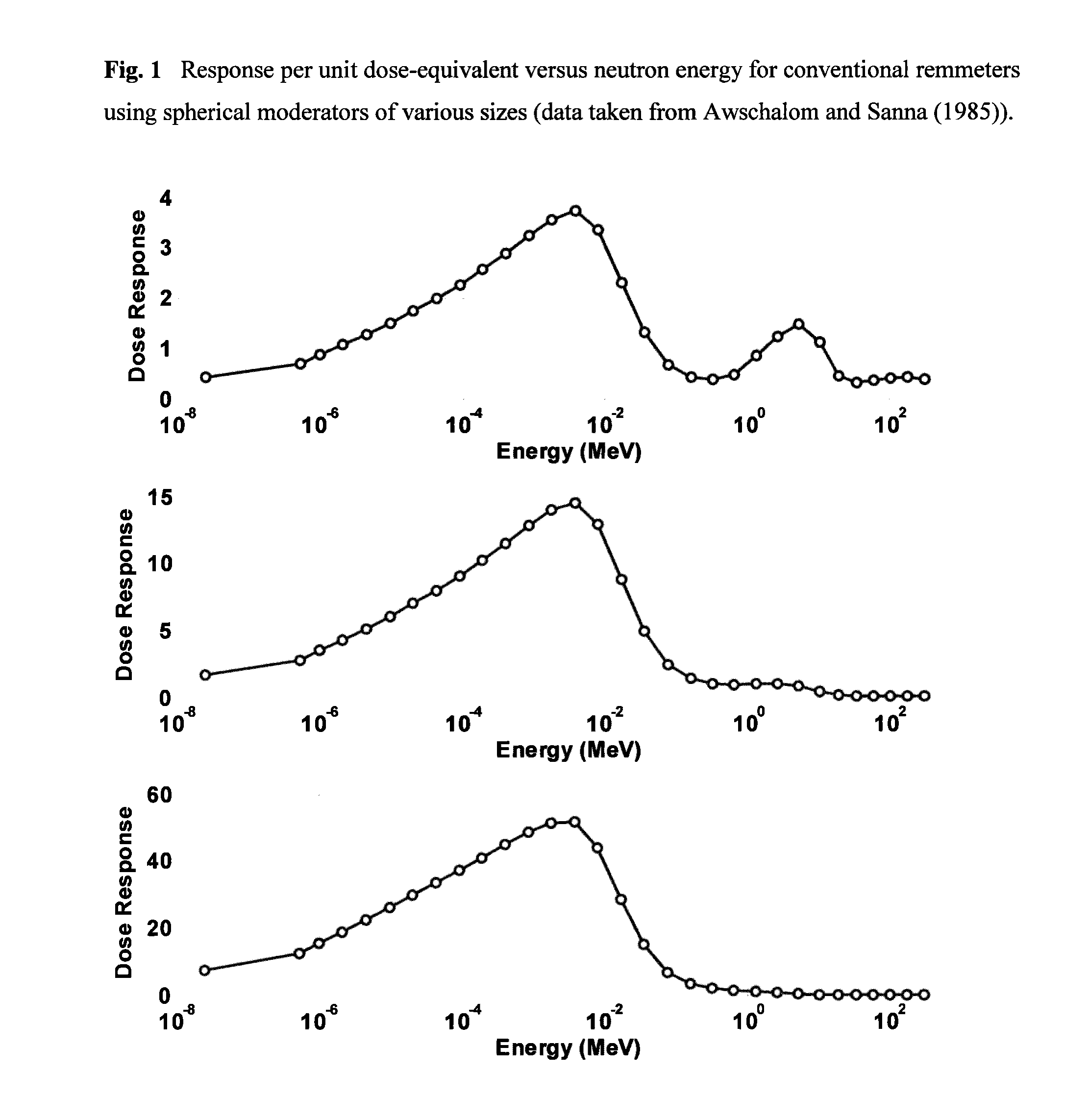

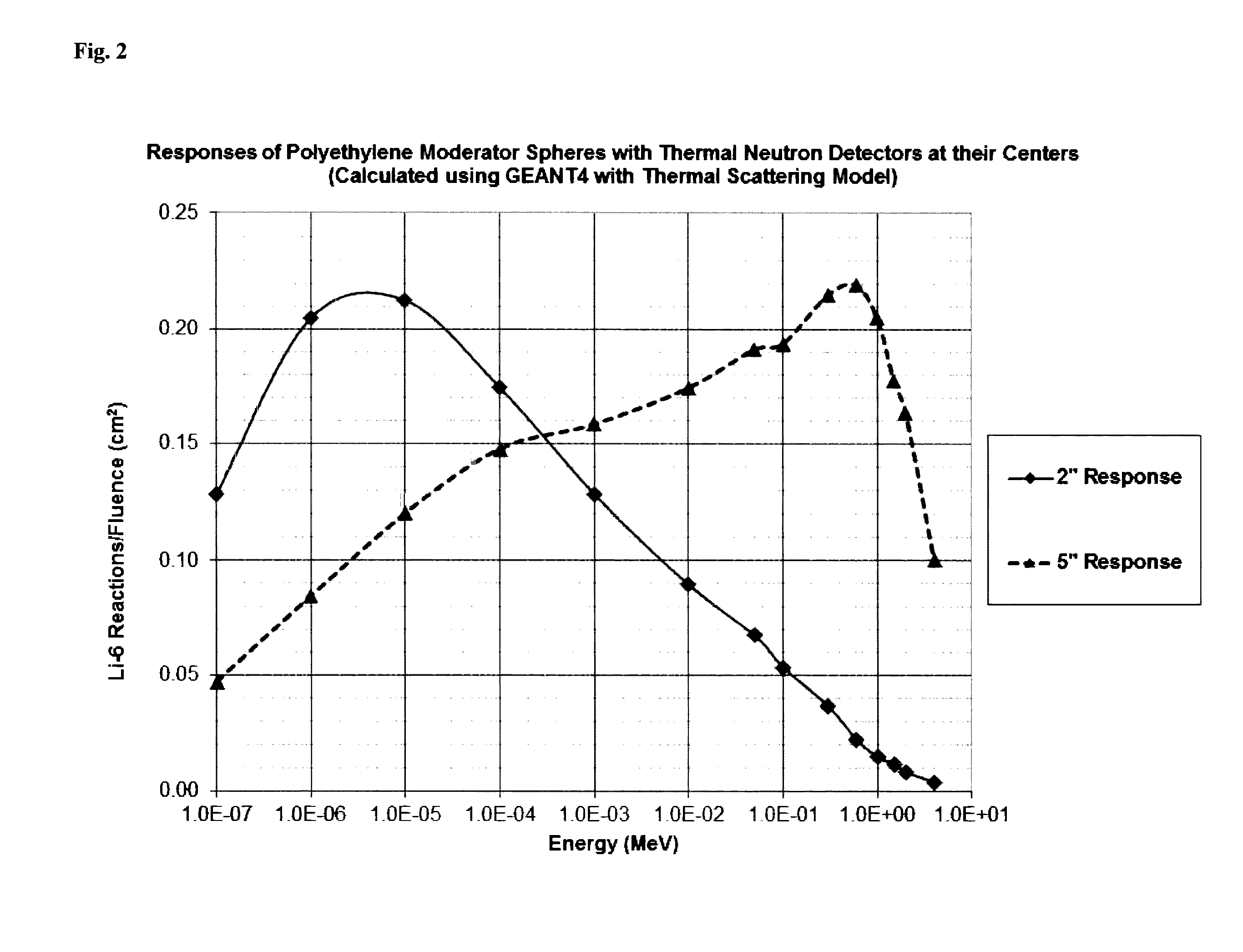

Accurate Light-Weight Broad-Energy Neutron Remmeter and use Thereof

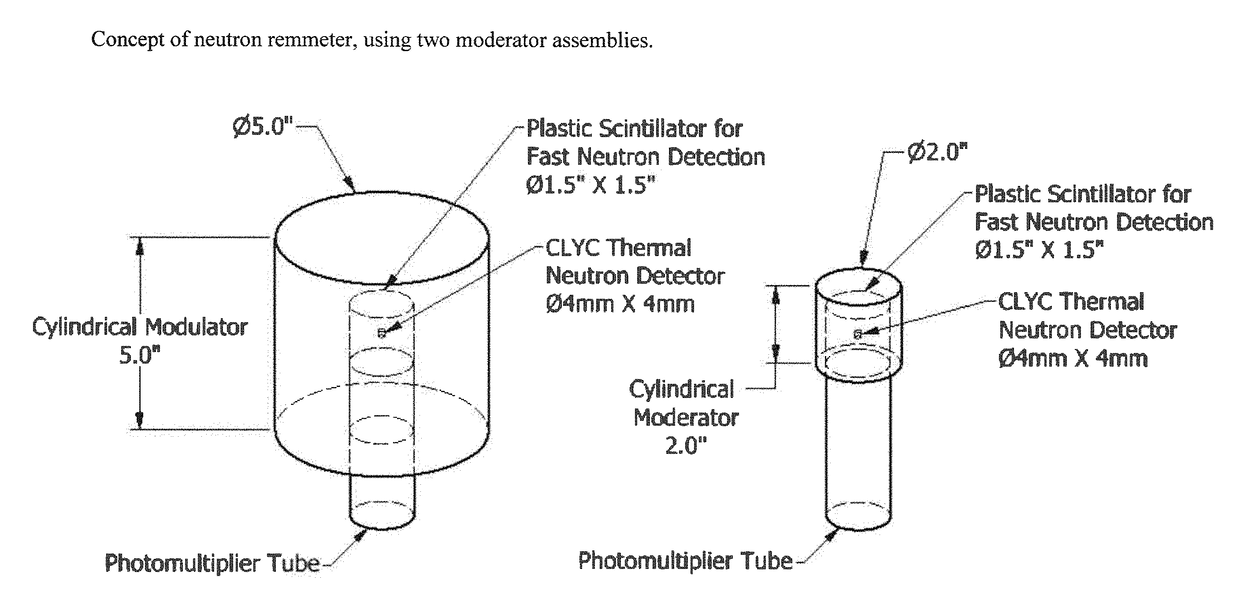

ActiveUS20170059723A1Comparable and good neutron dosimetry accuracyComparable and good and sensitivityDosimetersMeasurement with scintillation detectorsThermal neutron captureDose conversion

This invention describes a remmeter that is based on the use of an assembly comprising two or more different-sized hydrogenous moderators, each hydrogenous moderator incorporating a hydrogenous spectroscopic fast neutron detector and a thermal neutron detector in order to provide more accurate neutron dosimetry across a wide range of neutron energies (thermal neutrons to >15 MeV) in a form factor that is lighter than conventional remmeters. The new remmeter utilizes the principle of spectral dosimetry, where the energy or energy distribution of the incident neutrons is first measured and then this energy information (along with the measured fluence) is used to establish the dosimetric quantity using the various fluence-to-dose conversion curves (e.g. H*(10) (ICRP (1997)), NCRP-38 (1971)). Using the method of spectral dosimetry, the large variation in response in these curves as a function of neutron energy (especially over the region 1 keV to 1 MeV) is largely mitigated through the use of the energy and fluence information, and the appropriate fluence-to-dose conversion curve to calculate the dose.

Owner:BUBBLE TECH INDS

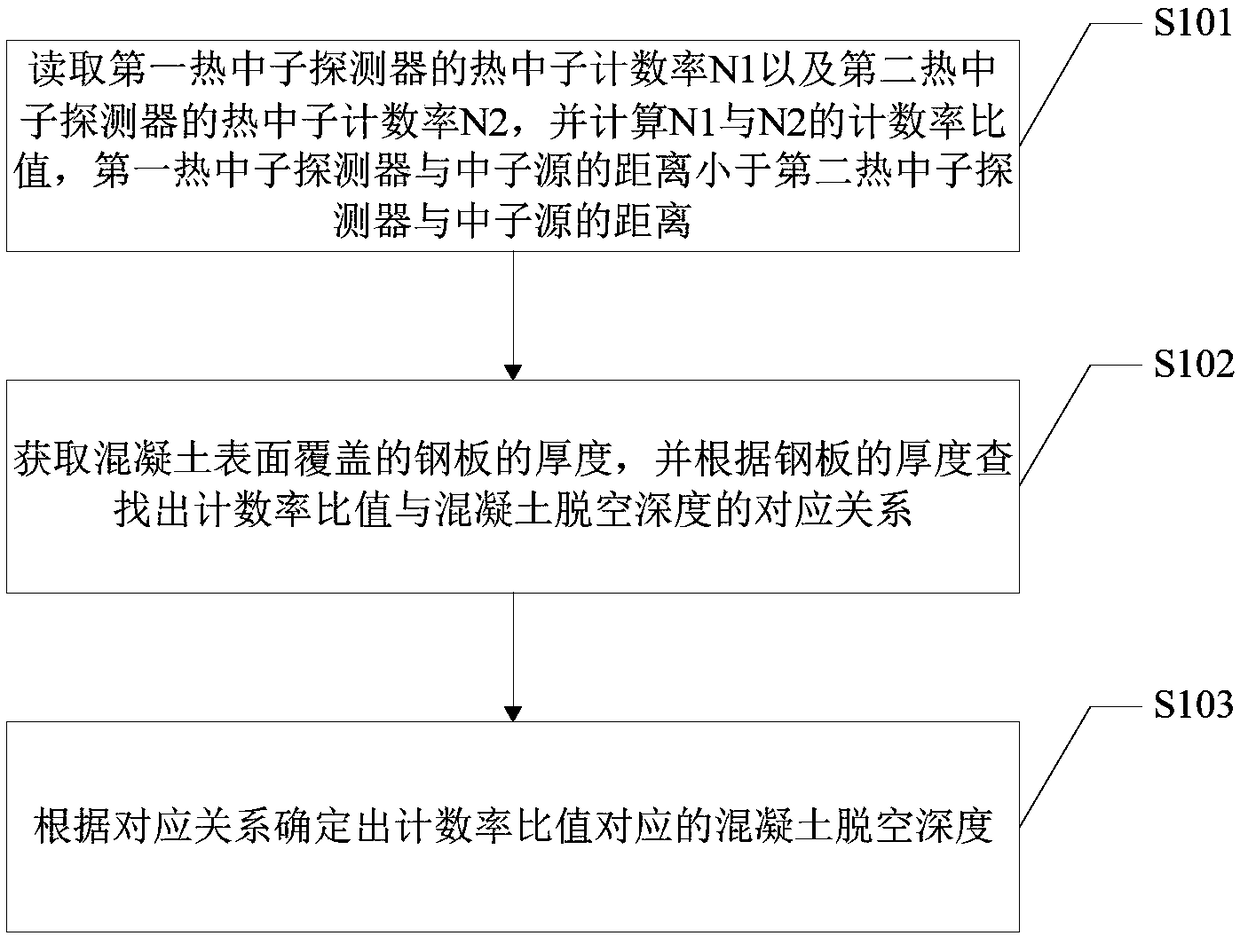

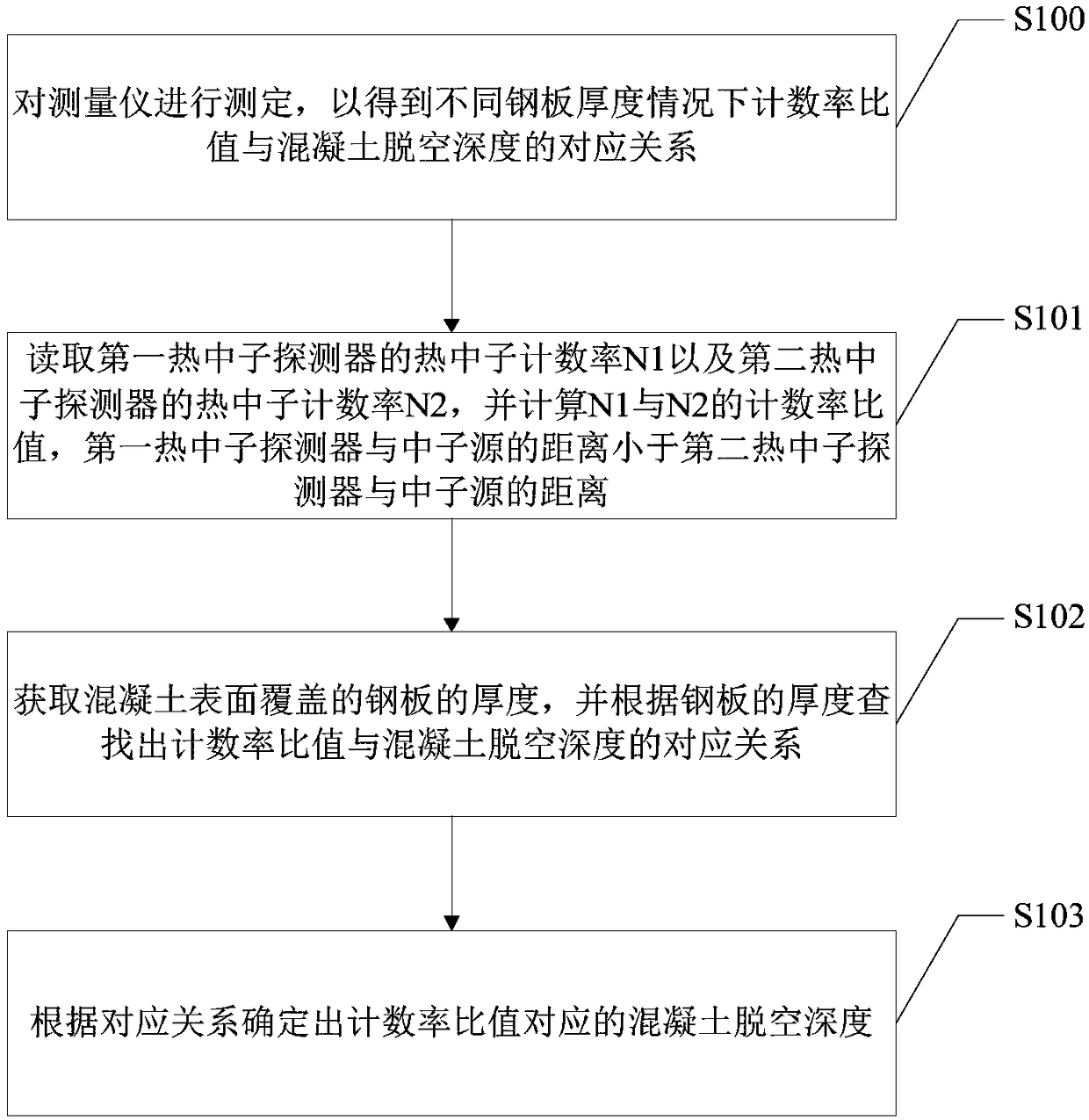

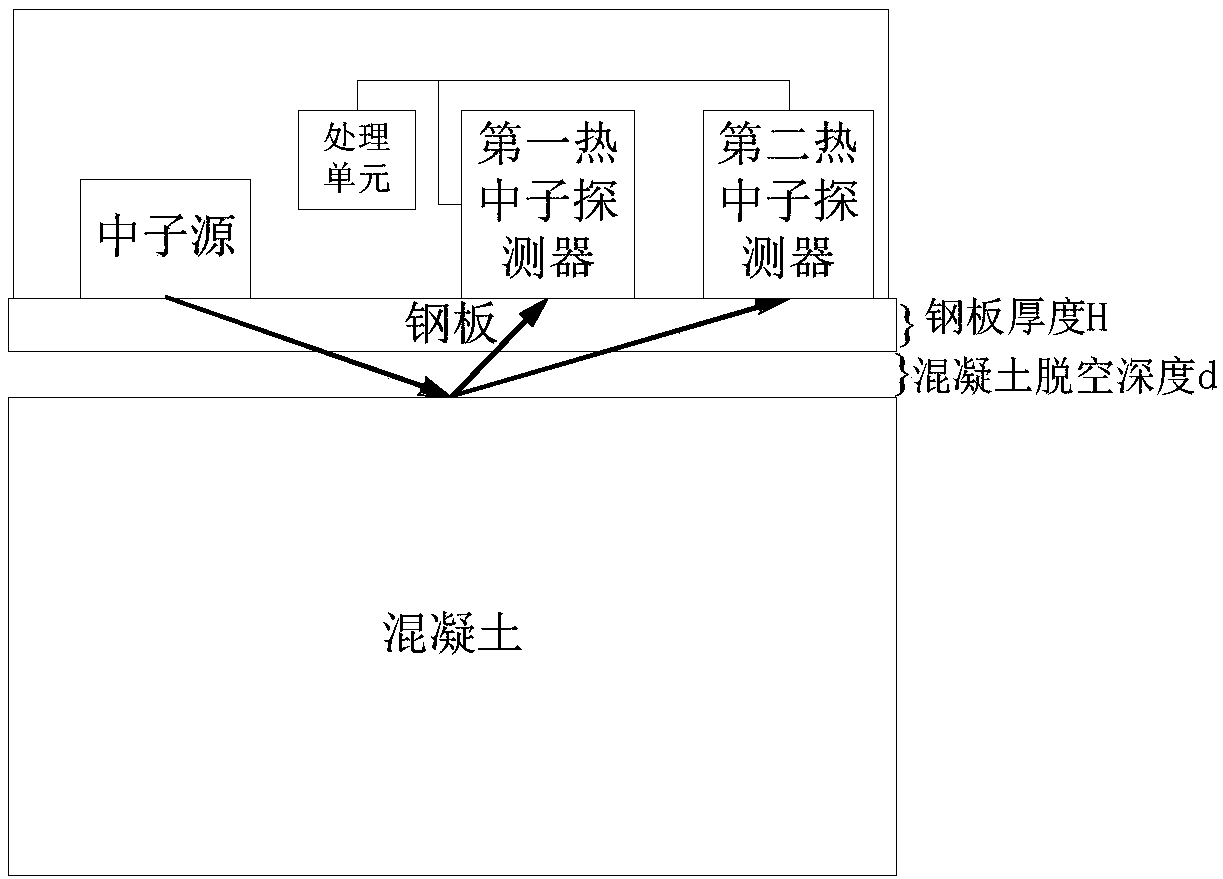

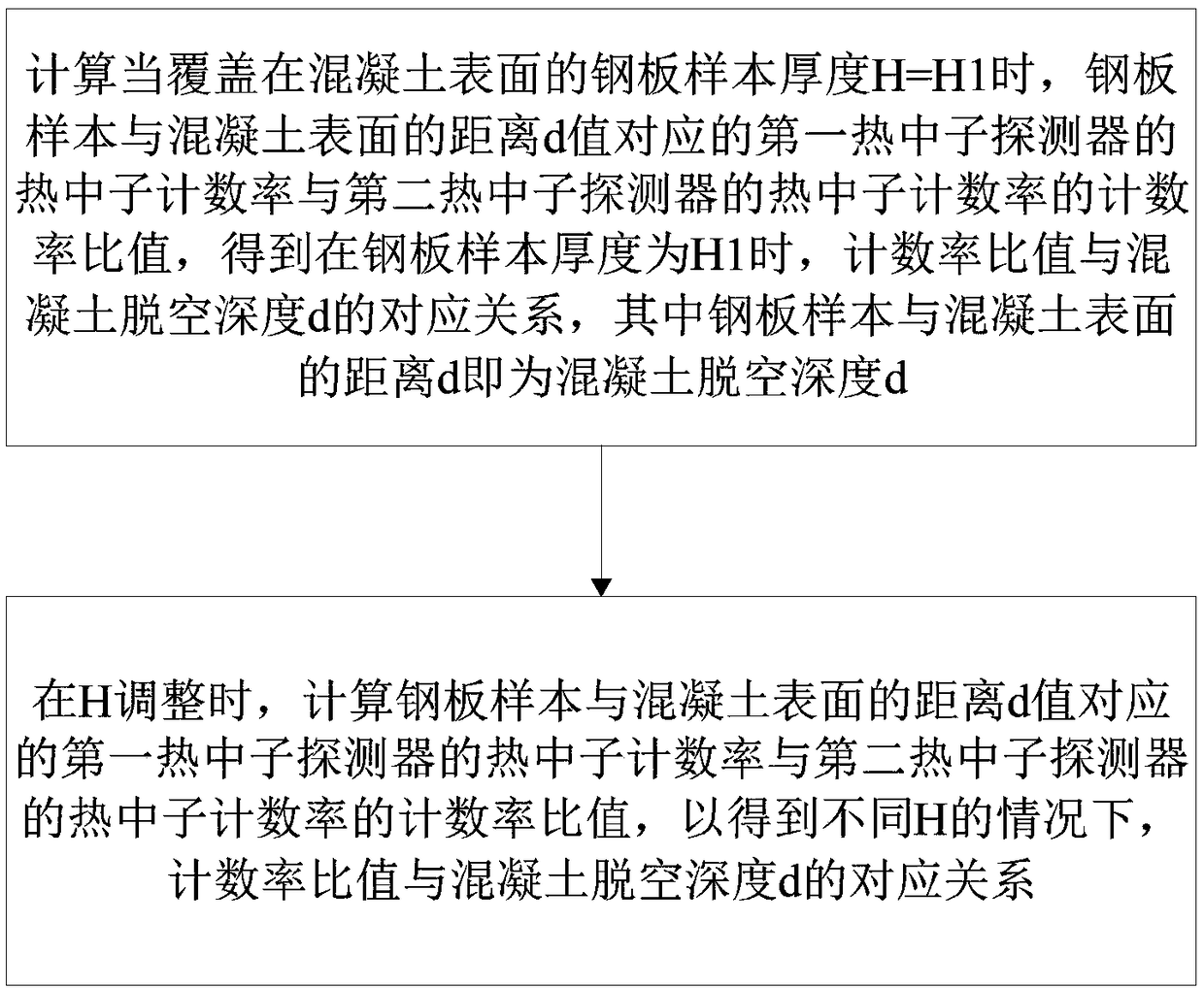

Concrete emptying detection method, device, and terminal equipment

ActiveCN108548833AMoisture content eliminationEnables direct detectionMaterial analysis by transmitting radiationMaterial analysis using radiation diffractionCounting rateNeutron count

The invention belongs to the technical field of neutron detection, and provides a concrete emptying detection method, device, and terminal equipment. The method comprises following steps: reading thethermal neutron counting rate N1 of a first thermal neutron detector and the thermal neutron counting rate N2 of a second thermal neutron detector, calculating the counting rate ratio of N1 to N2, wherein the distance between the first thermal neutron detector and a neutron source is smaller than the distance between the second thermal neutron detector and the neutron source; obtaining the thickness of a steel plate that covers the surface of concrete, based on the thickness of the steel plate, finding the corresponding relationship between the counting rate ratio and concrete emptying depth;and based on the corresponding relationship, determining the concrete emptying depth corresponding to the counting rate ratio. The method has the advantages that a large amount of tedious operation isreduced, and the efficiency on measuring the concrete emptying depth is largely improved.

Owner:SHENZHEN SINO NUCLEAR CO CREATION TECH CO LTD

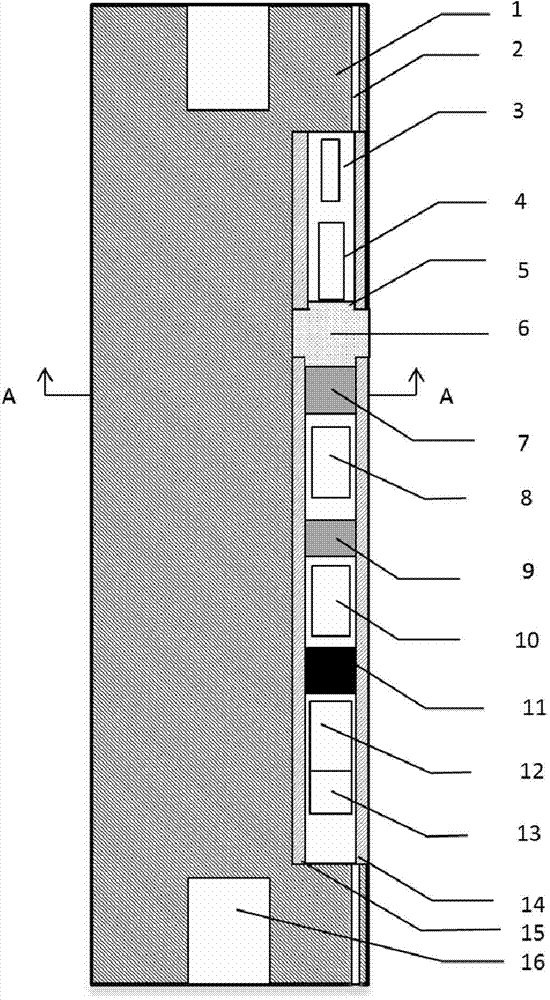

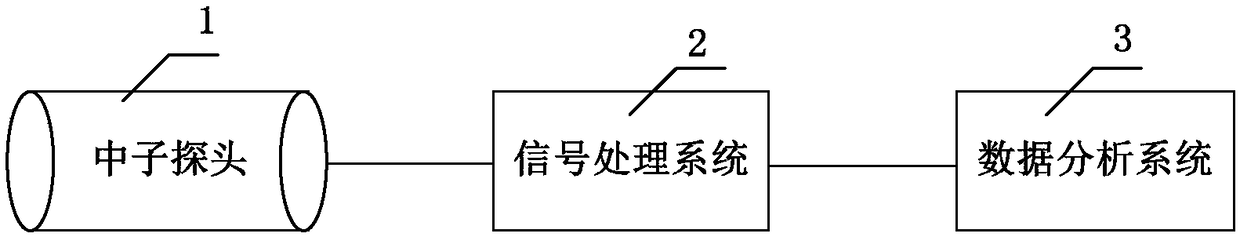

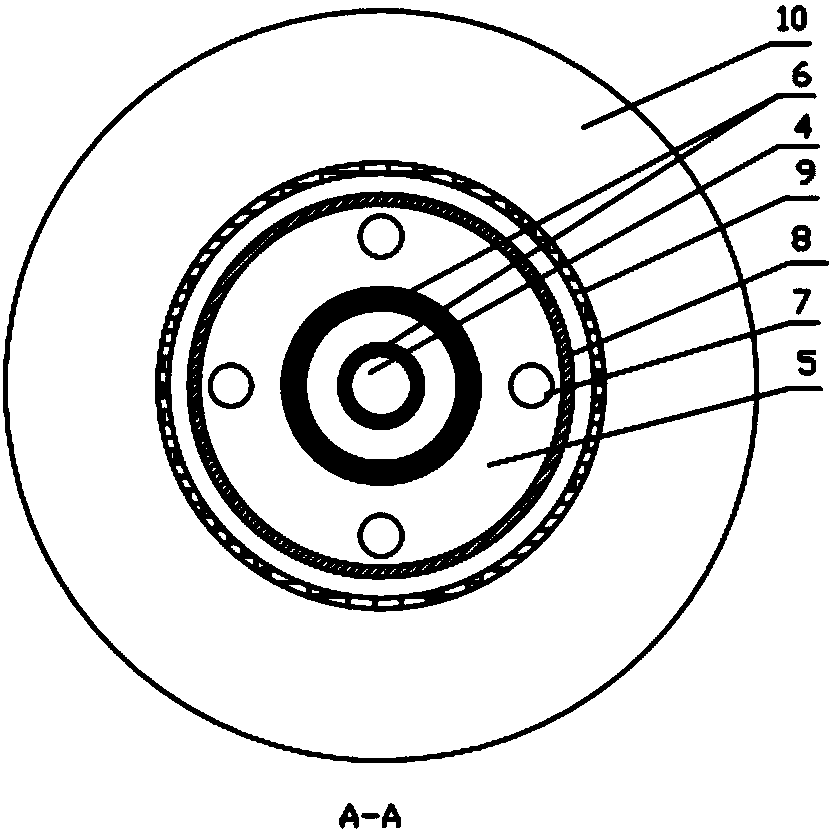

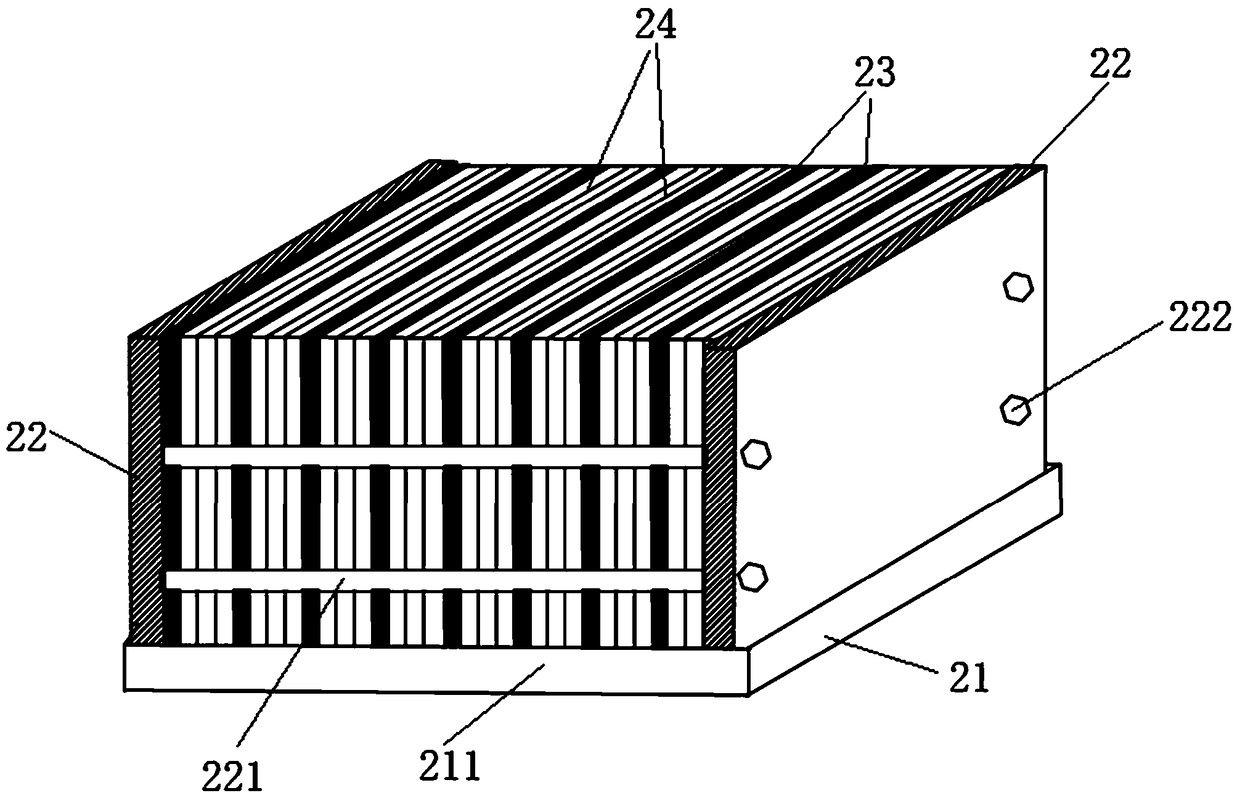

Heavy-metal-multiplication wide-energy neutron source intensity measurement system

ActiveCN108562929AHigh energyTaking into account the needs of radiation field measurementNeutron radiation measurementData analysis systemNeutron radiation

The invention discloses a heavy-metal-multiplication wide-energy neutron source intensity measurement system, which can be suitable for single-energy or wide-energy neutron radiation field source intensity measurement and value transfer of a high-energy accelerator and a reactor and the like. The system comprises a neutron probe, a signal processing system and a data analysis system. The neutron probe is formed by a central thermal neutron detector, an inner-layer moderator, a neutron multiplication layer, a peripheral thermal neutron detector, a reflecting layer, a lateral thermal neutron absorber, an external-layer moderator and a forward thermal neutron absorber. The central thermal neutron detector adopts a position-sensitive neutron detector to obtain energy spectrum information of aradiation field; and an energy weighting factor is set to compensate for energy response of the central thermal neutron detector, thereby improving measurement precision. The system is novel in structure, wide in energy range and good in angle response performance, can carry out energy response compensation and is high in source intensity measurement precision and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

A chlorine spectrometry logging method

InactiveCN1595202ASimple structureReduce logging costsNuclear radiation detectionDouble differenceSalt water

This invention relates to a chlorin spectrometry logging method for measuring under-well saturation moisture content during the brine layer oil injection period in oil exploration. It adopts thermal neutron detector and gamma detector to measure the thermal neutron and elastic gamma information generated in the reaction of the neutron emitting source and earth layer and it calculates the apparent porosity and water saturation in the pay through the measurement the difference between the neutron and the neutron gamma relative saturation fresh water or oil earth layer. So it overcomes the influence of the mud and frame in the earth layer and the double difference method can improve the responding accuracy in the measurement of the ground water mineralization rate.

Owner:中国石油集团测井有限公司技术中心

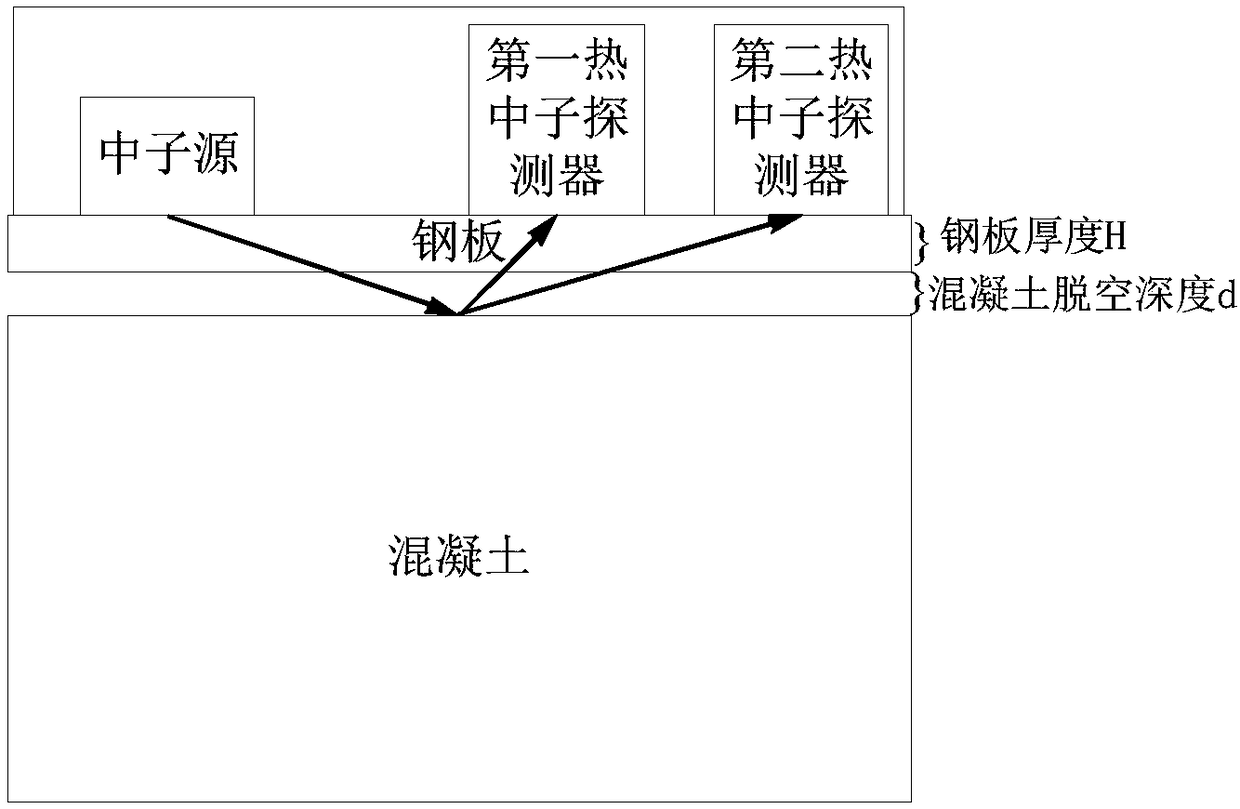

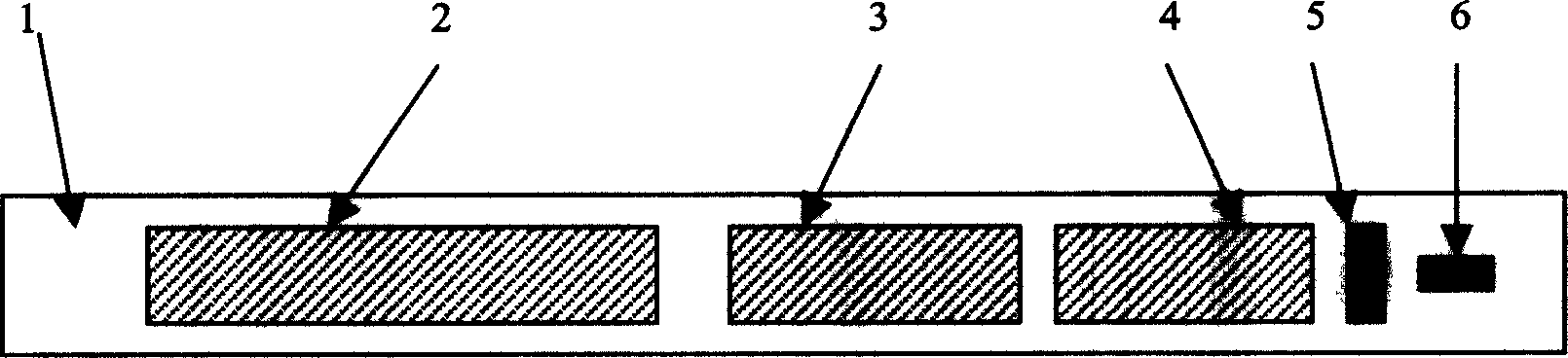

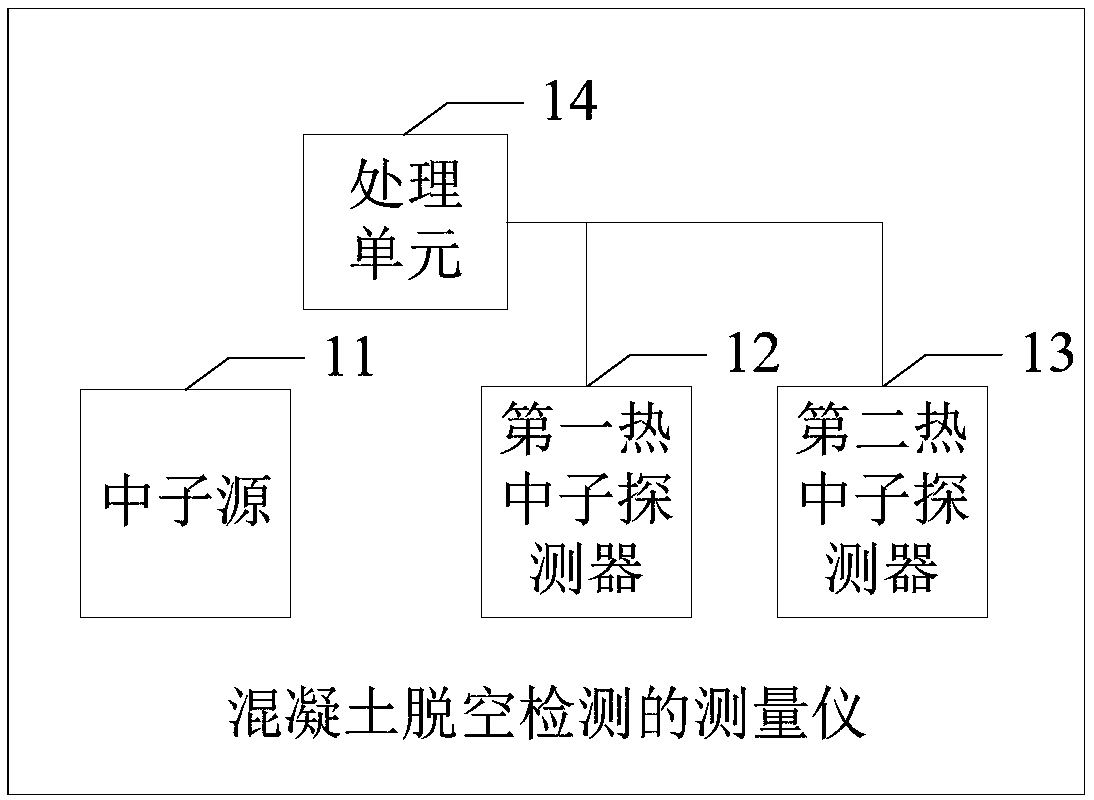

Measuring instrument for concrete void detection

ActiveCN108693201AMoisture effectImprove the efficiency of void depth measurementMaterial analysis by transmitting radiationCounting rateNeutron count

The invention provides a measuring instrument for concrete void detection, the measuring instrument is applicable to the technical field of neutron detection, and the measuring instrument comprises aneutron source, a processing unit, a first thermal neutron detector and a second thermal neutron detector; the neutron source is used for transmitting fast neutrons to concrete covered with a steel sheet; the first thermal neutron detector and the second thermal neutron detector are used for obtaining heat neutron counting rate N1 and heat neutron counting rate N2 at two locations, with differentdistances from the neutron source, on the steel sheet covering the surface of the concrete; the processing unit is configured to calculate the counting rate ratio of heat neutron counting rate N1 to heat neutron counting rate N2; the processing unit is further configured to obtain the thickness of the steel sheet covering the surface of the concrete, according to the thickness of the steel plate,a corresponding relationship between the counting rate ratio and a concrete void depth is found, and the concrete void depth corresponding to the counting rate ratio is determined according to the corresponding relationship. The measuring instrument saves a lot of cumbersome operation and greatly improves the efficiency of actual concrete void depth measurement.

Owner:SHENZHEN SINO NUCLEAR CO CREATION TECH CO LTD

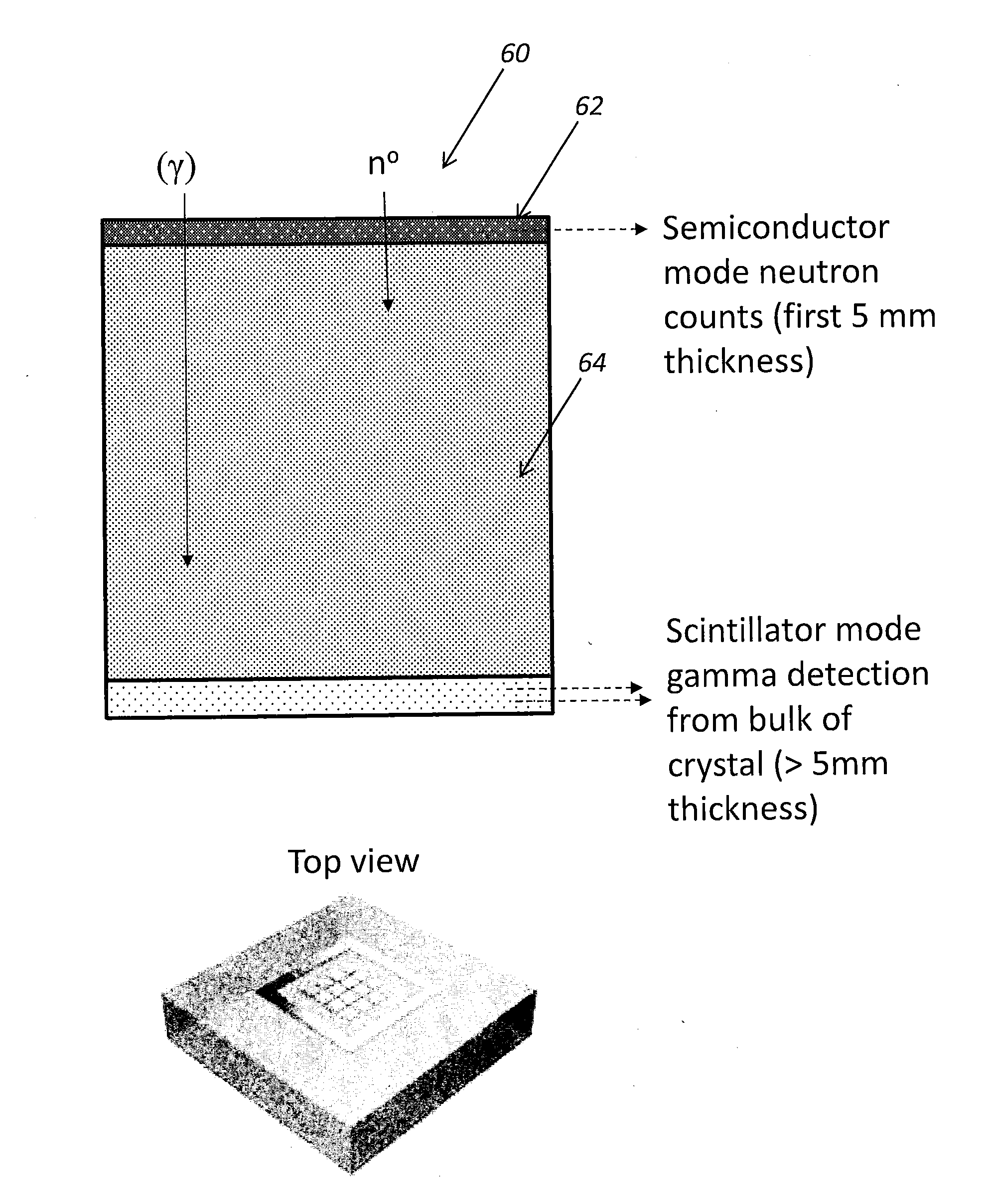

Thermal neutron detector and gamma-ray spectrometer utilizing a single material

ActiveUS20160146953A1High gamma-to-neutron discriminationLow costPolycrystalline material growthX-ray spectral distribution measurementPhotodetectorOptical spectrometer

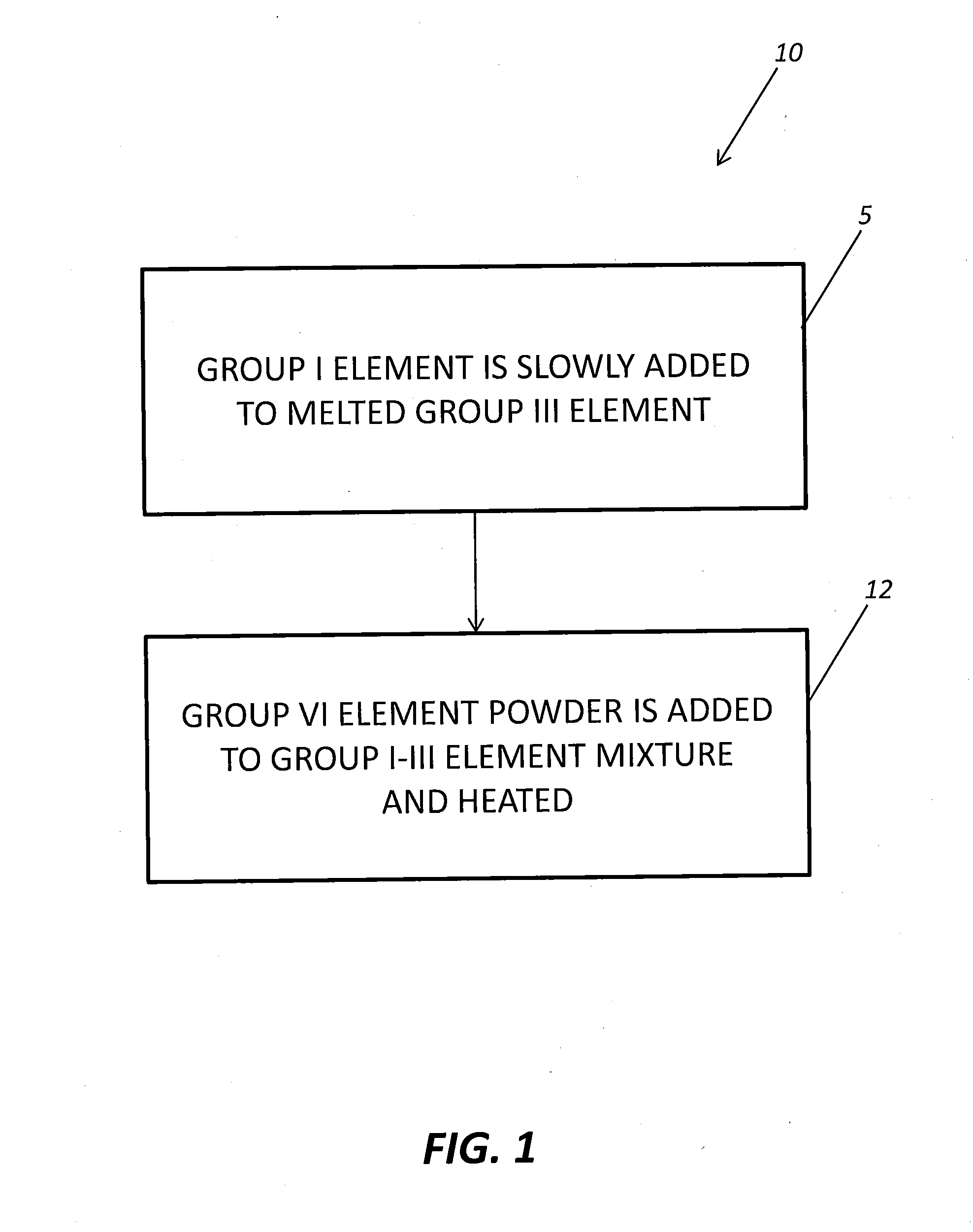

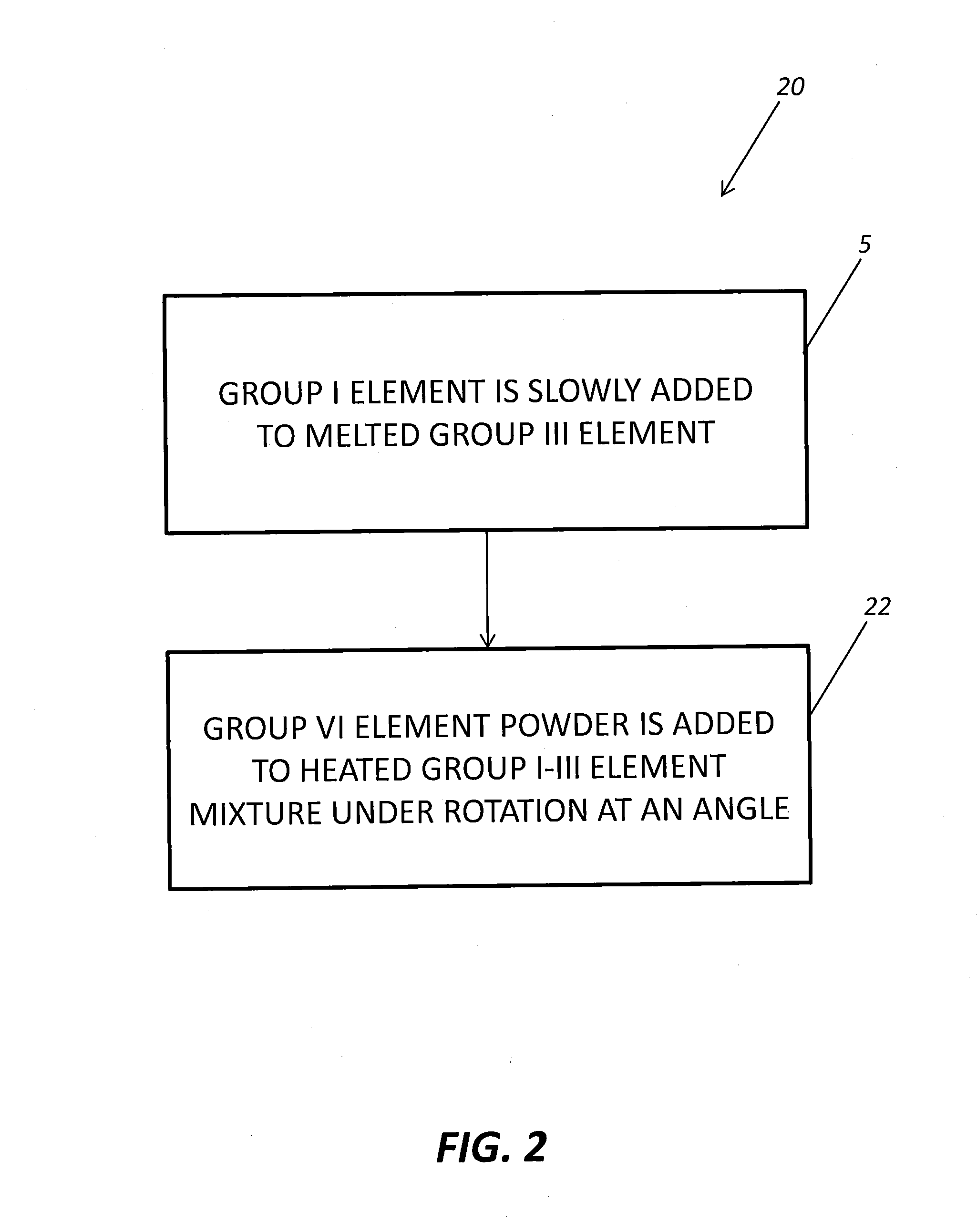

A combined thermal neutron detector and gamma-ray spectrometer system, including: a detection medium including a lithium chalcopyrite crystal operable for detecting thermal neutrons in a semiconductor mode and gamma-rays in a scintillator mode; and a photodetector coupled to the detection medium also operable for detecting the gamma rays. Optionally, the detection medium includes a 6LiInSe2 crystal. Optionally, the detection medium comprises a compound formed by the process of: melting a Group III element; adding a Group I element to the melted Group III element at a rate that allows the Group I and Group III elements to react thereby providing a single phase I-III compound; and adding a Group VI element to the single phase I-III compound and heating; wherein the Group I element includes lithium.

Owner:CONSOLIDATED NUCLEAR SECURITY +2

Accurate light-weight broad-energy neutron remmeter and use thereof

ActiveUS9939538B2Minimal weightAccurately doneDosimetersMeasurement with scintillation detectorsDosimetry radiationThermal neutron capture

A remmeter includes two or more different-sized hydrogenous moderators, each incorporating a hydrogenous spectroscopic fast neutron detector and a thermal neutron detector to provide more accurate neutron dosimetry across a wide range of neutron energies (thermal neutrons to >15 MeV) in a form factor that is lighter than conventional remmeters. The remmeter utilizes the principle of spectral dosimetry, where the energy or energy distribution of the incident neutrons is first measured and then this energy information (along with the measured fluence) is used to establish the dosimetric quantity using the various fluence-to-dose conversion curves (e.g. H*(10) (ICRP(1997)), NCRP-38(1971)). Using the method of spectral dosimetry, the large variation in response in these curves as a function of neutron energy (especially over the region 1 keV to 1 MeV) is largely mitigated through the use of the energy and fluence information, and the appropriate fluence-to-dose conversion curve to calculate the dose.

Owner:BUBBLE TECH INDS

Method for manufacturing solid-state thermal neutron detectors with simultaneous high thermal neutron detection efficiency (>50%) and neutron to gamma discrimination (>1.0E4)

ActiveUS8558188B2Measurement with semiconductor devicesMaterial analysis by optical meansNuclear engineeringAtomic physics

Methods for manufacturing solid-state thermal neutron detectors with simultaneous high thermal neutron detection efficiency (>50%) and neutron to gamma discrimination (>104) are provided. A structure is provided that includes a p+ region on a first side of an intrinsic region and an n+ region on a second side of the intrinsic region. The thickness of the intrinsic region is minimized to achieve a desired gamma discrimination factor of at least 1.0E+04. Material is removed from one of the p+ region or the n+ region and into the intrinsic layer to produce pillars with open space between each pillar. The open space is filed with a neutron sensitive material. An electrode is placed in contact with the pillars and another electrode is placed in contact with the side that is opposite of the intrinsic layer with respect to the first electrode.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

Neutron detector

The invention discloses a neutron detector. The neutron detector comprises a neutron moderating body and a thermal neutron detector, wherein the neutron moderating body is suitable for absorbing X rays passing through the neutron moderating body and moderating fast neutrons into thermal neutrons; and the thermal neutron detector is suitable for detecting the thermal neutrons to acquire information about the fast neutrons. Through the neutron moderating body, interference of the X rays to fast neutron measurement can be eliminated, so that the neutron measurement accuracy is improved. The identification capacity of a detected object is improved by simultaneously acquiring two types of different attenuation information of the X rays and the neutrons.

Owner:NUCTECH CO LTD +1

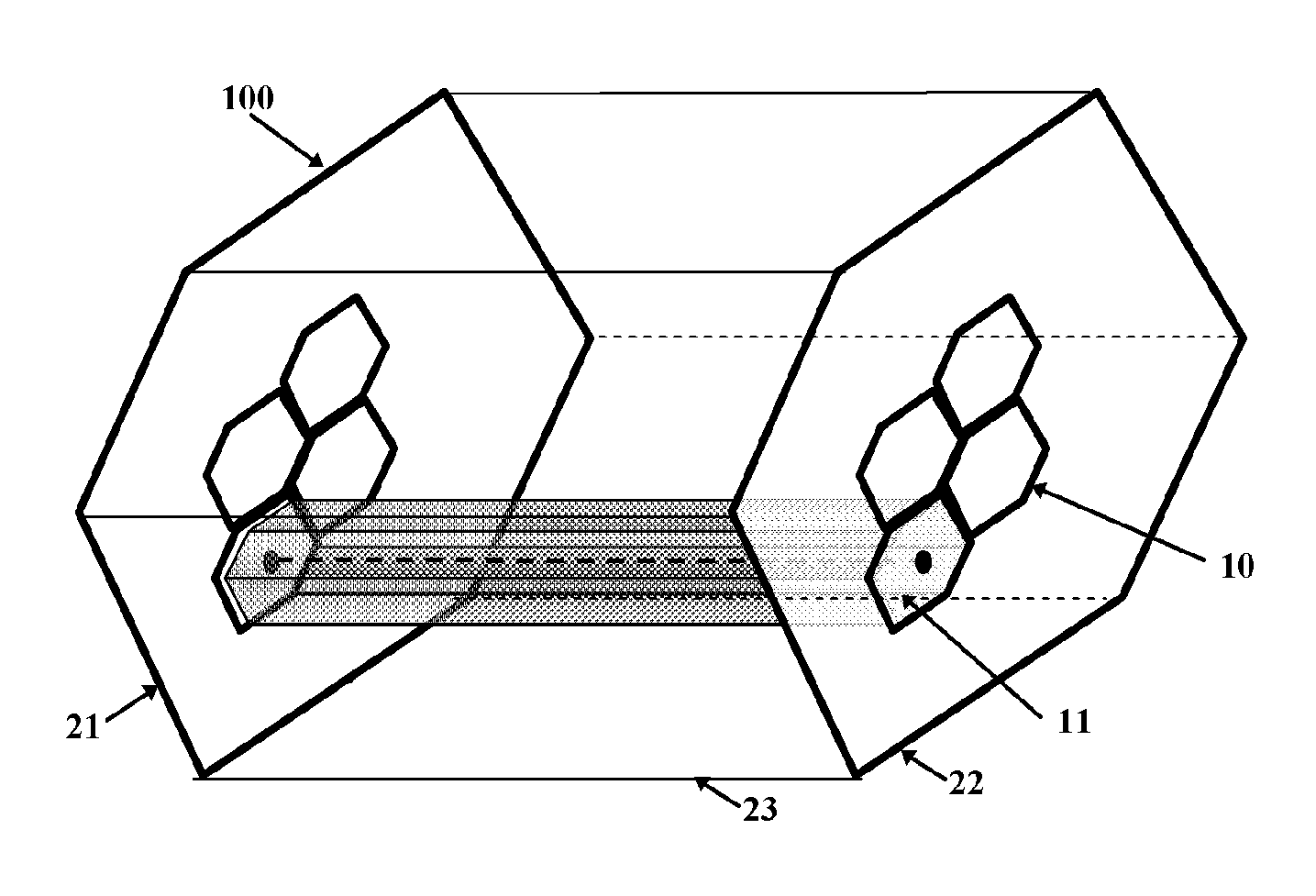

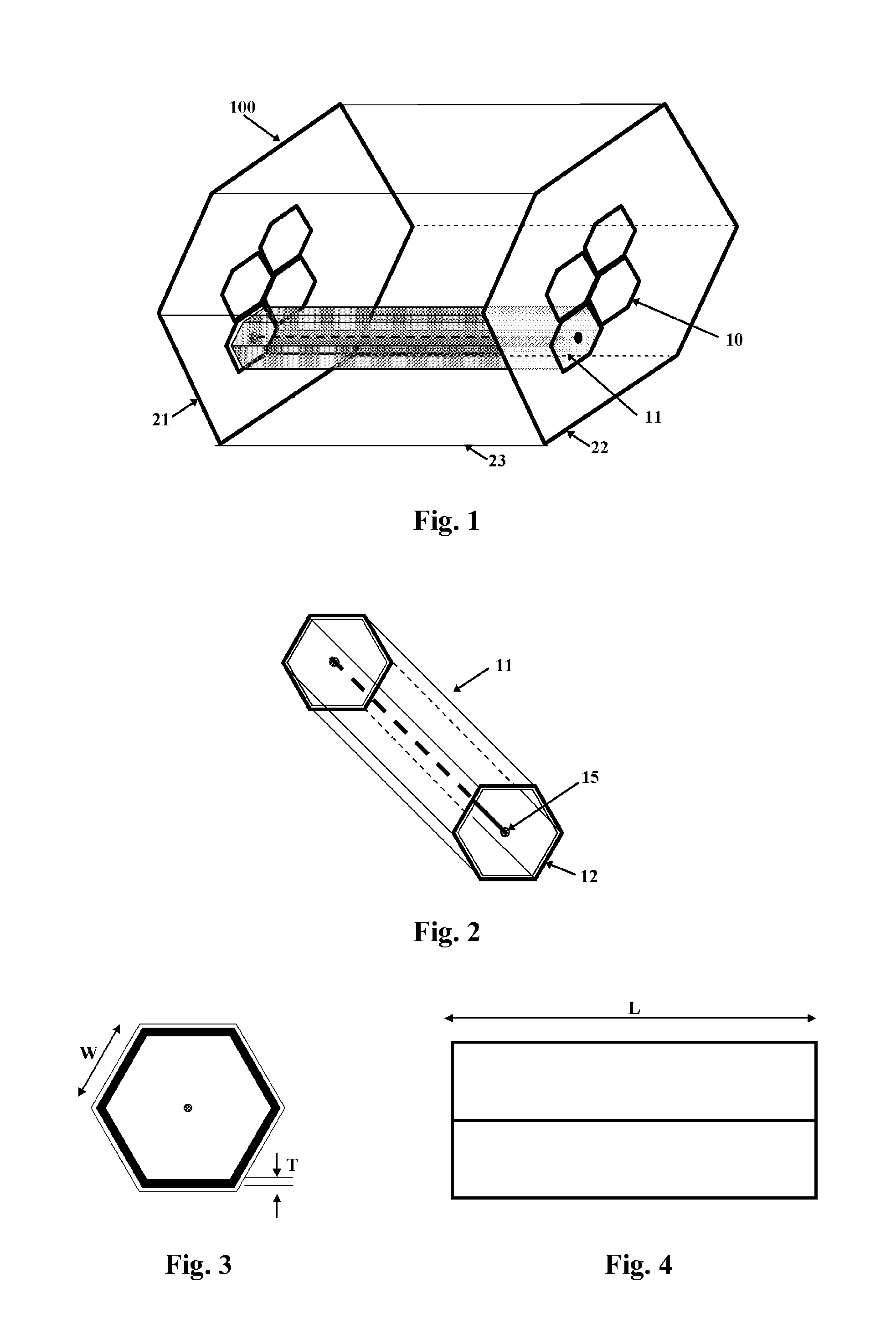

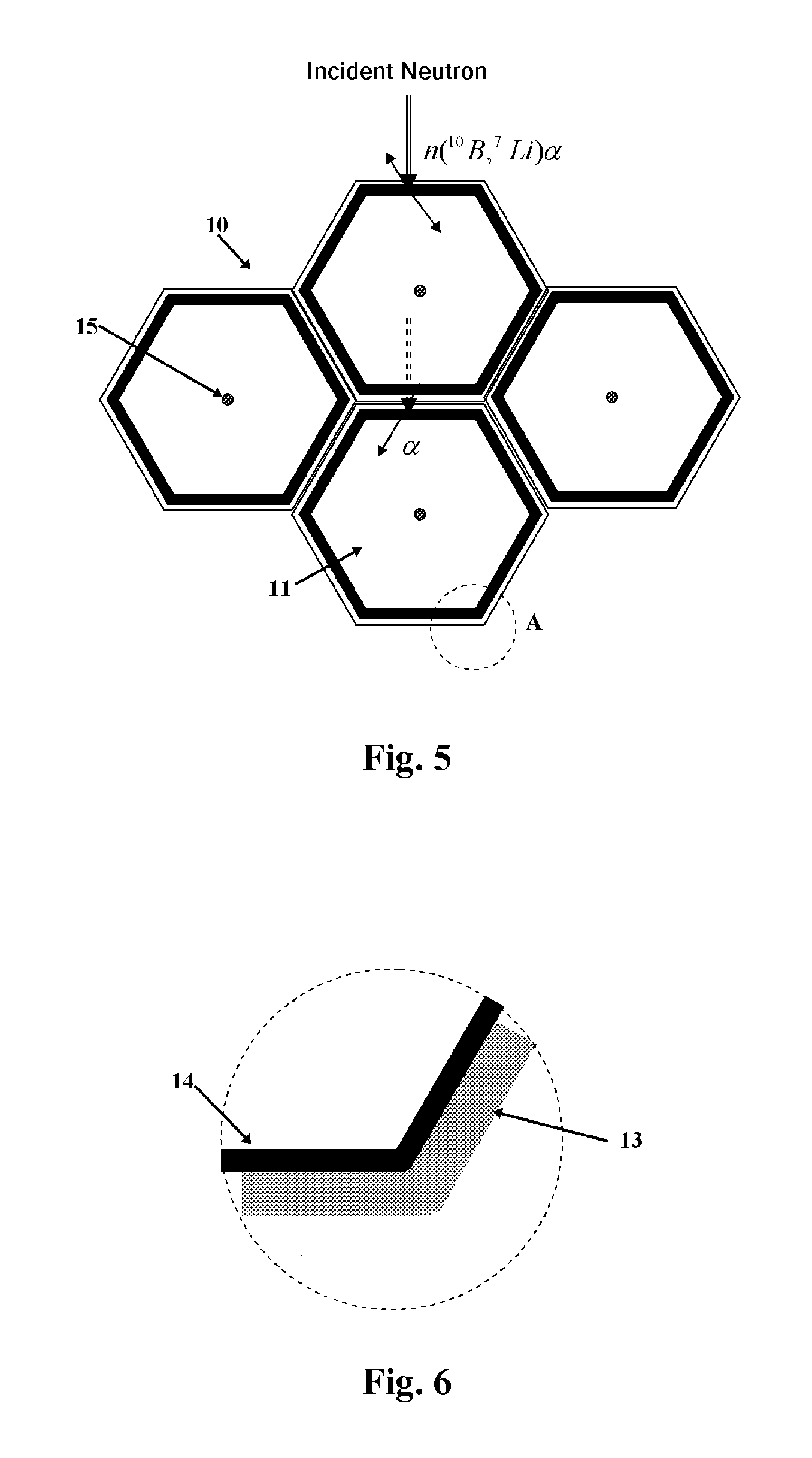

Cellular thermal neutron detector

ActiveUS20130168565A1Reduce manufacturing costReduced or eliminated neutron detection dead zoneMaterial analysis by optical meansNeutron radiation measurementEngineeringHoneycomb structure

The present invention provides a cellular thermal neutron detector, comprising: a cellular structure comprised of one or more hollow regular hexagonal prism-shaped cellular units, wherein a neutron absorbing material is coated on an inner side of a pipe wall of each of the cellular units. Since the neutron-sensitive cellular structure is employed, the present invention can perform thermal neutron detection without using the scarce nuclide 3He, and effectively reduce the manufacture costs of the thermal neutron detector. Further, the present invention has characteristics such as a reduced or eliminated neutron detecting dead zone.

Owner:NUCTECH CO LTD +1

Multi-source spacing measurement device and method for neutron porosity during drilling

ActiveCN107829728AGuaranteed accuracyCorrection and Compensation EffectsSurveyMeasurement deviceNeutron emission

The invention discloses a multi-source spacing measurement device and method for neutron porosity during drilling. The measurement device includes a non-magnetic drill collar, a neutron emission unit,a fast neutron monitoring unit, a hot neutron detecting unit and a control unit; the neutron emission unit contains multiple accelerator neutron sources, the fast neutron monitoring unit includes multiple fast neutron monitor groups, the hot neutron detecting unit includes multiple hot neutron detector groups, and the control unit is connected to the neutron emission unit, the fast neutron monitoring unit and the hot neutron detecting unit separately. The multi-source spacing measurement device and method for the neutron porosity during drilling overcome the defects in the prior art, ensure the flexibility and data accuracy of detecting instruments under a complex geologic condition, effectively reduce the influences of well hole parameters, vibration, impact and random fluctuation of measurement data on the measurement result, solve problems in prior art, remove limitations in the prior art, and achieve accurate acquirement of stratum porosity parameters.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Method for detecting hollow depth of concrete under steel shell

PendingCN109444176AAccurate detectionQuick checkUsing wave/particle radiation meansMaterial analysis using neutronsOmegaCalibration curve

The invention discloses a method for detecting the hollow depth of concrete under a steel shell. The method comprises the steps as follows: step 1, establishing a hollow depth calibration curve library: by changing hollow depth 1 between a steel plate and a concrete simulation standard block, thickness h of the steel plate and water content omega of the concrete simulation standard block, calibrating the hollow depth 1 by a thermal neutron detector to obtain the hollow depth calibration curve library, wherein the hollow depth calibration curve library comprises multiple hollow depth calibration curve units with different water contents, and each hollow depth calibration curve unit comprises three hollow calibration curves with different steel plate thicknesses; step 2, arranging detectionpoints; step 3, selecting and determining hollow depth calibration curves; step 4, measuring and determining the hollow depth. The hollow depth calibration curves are established, effects of water content of concrete on the hollow depth are fully considered, and different calibration curves are adopted for different steel plate thicknesses and water content of concrete, so that the detection of the hollow depth is more accurate and rapid.

Owner:NANJING HYDRAULIC RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com