Method for detecting hollow depth of concrete under steel shell

A technology for depth detection and concrete, applied in the field of radioisotope technology, can solve the problems of affecting the calibration cycle, large deviation between water content and set water content, inaccurate calibration results, etc., to achieve accurate detection, short calibration cycle, and production cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

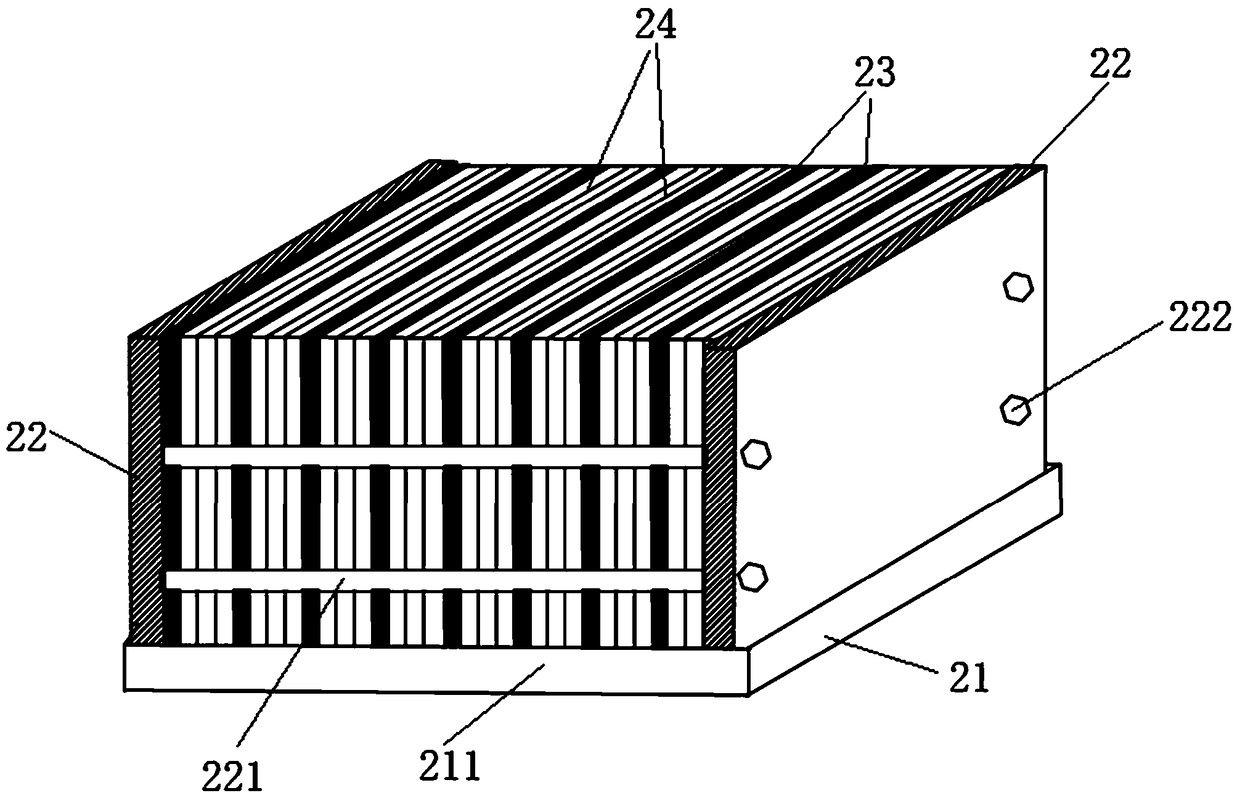

[0059] Such as figure 2 As shown, the concrete simulation standard block includes a base 21, two splints 22, a threaded guide rod 221 and several proportioning units that are repeatedly clamped and stacked vertically.

[0060] The vertical stacking thickness of several proportioning units is preferably greater than or equal to 40 cm.

[0061] The splint and the bottoms of the several proportioning units are preferably placed on the top of the base, and the splint and the tops of the several proportioning units are located on the same level.

[0062] Preferably, two parallel side baffles 211 are arranged on the base, and each side baffle is perpendicular to the splint. The side stop can limit the bottom of the proportioning units that are clamped and stacked.

[0063] The two splints are preferably clamped and fixed by threaded guide rods. The middle part of the threaded guide rod is a polished rod, which can limit the middle and top of the metal standard plates and organic...

Embodiment 2

[0073] Concrete simulation standard blocks include several proportioning units stacked horizontally repeatedly, and the thickness of horizontal stacking is greater than or equal to 40cm. The proportioning unit is preferably pressed and stacked repeatedly under the action of gravity, and splints and threaded guide rods can also be arranged on both sides of the proportioning unit.

[0074] Except that the placement direction of each proportioning unit is different, the rest is the same as that of Embodiment 1, and will not be repeated here.

[0075] A method for detecting void depth of concrete under a steel shell, comprising the following steps.

[0076] Step 1. Establish the void depth calibration curve library: by changing the void depth l between the steel plate and the concrete analog block, the thickness of the steel plate h, and the water content ω in the concrete analog block, thermal neutron detectors are used to measure the void depth Depth l is calibrated to obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com