Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Straight line trajectory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

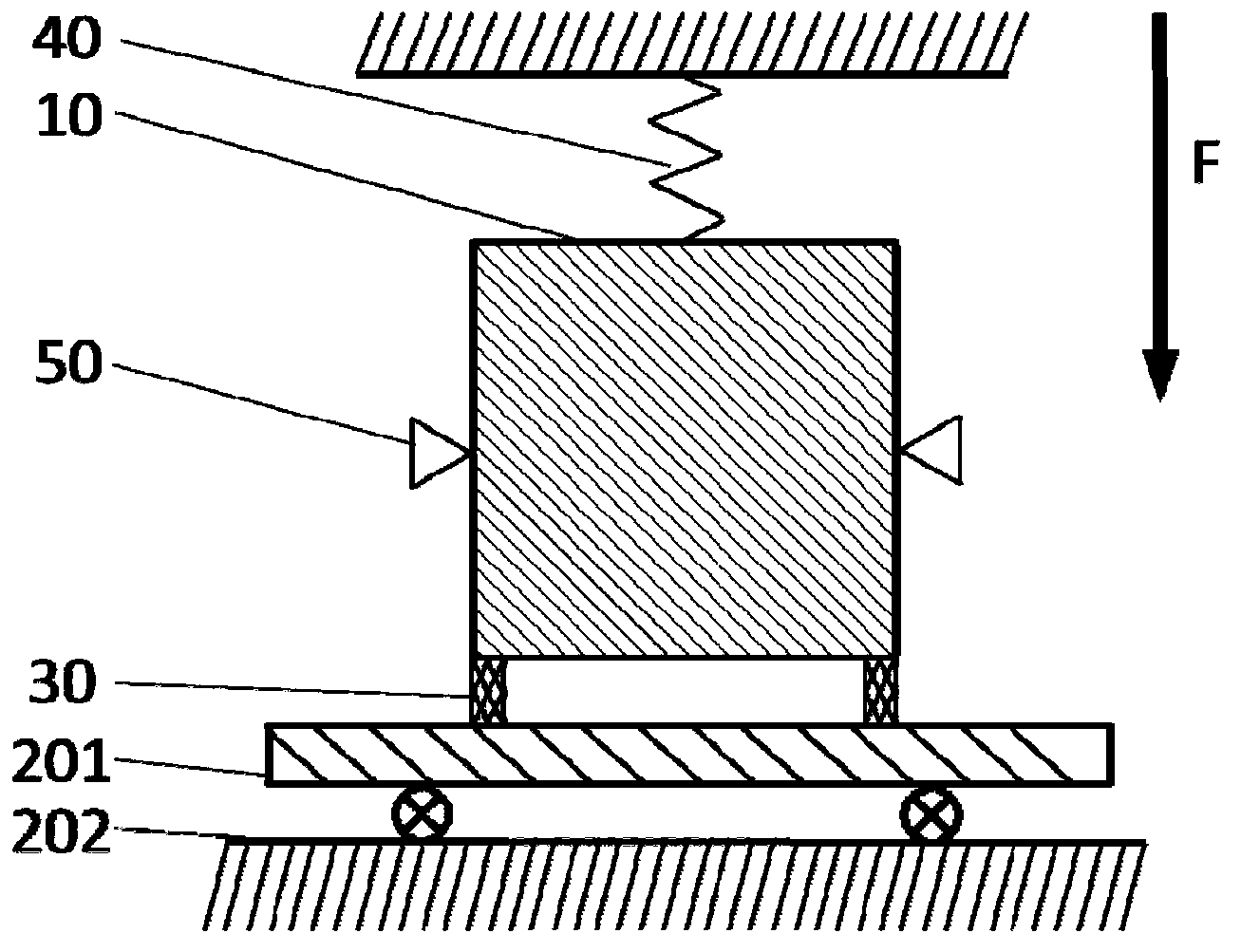

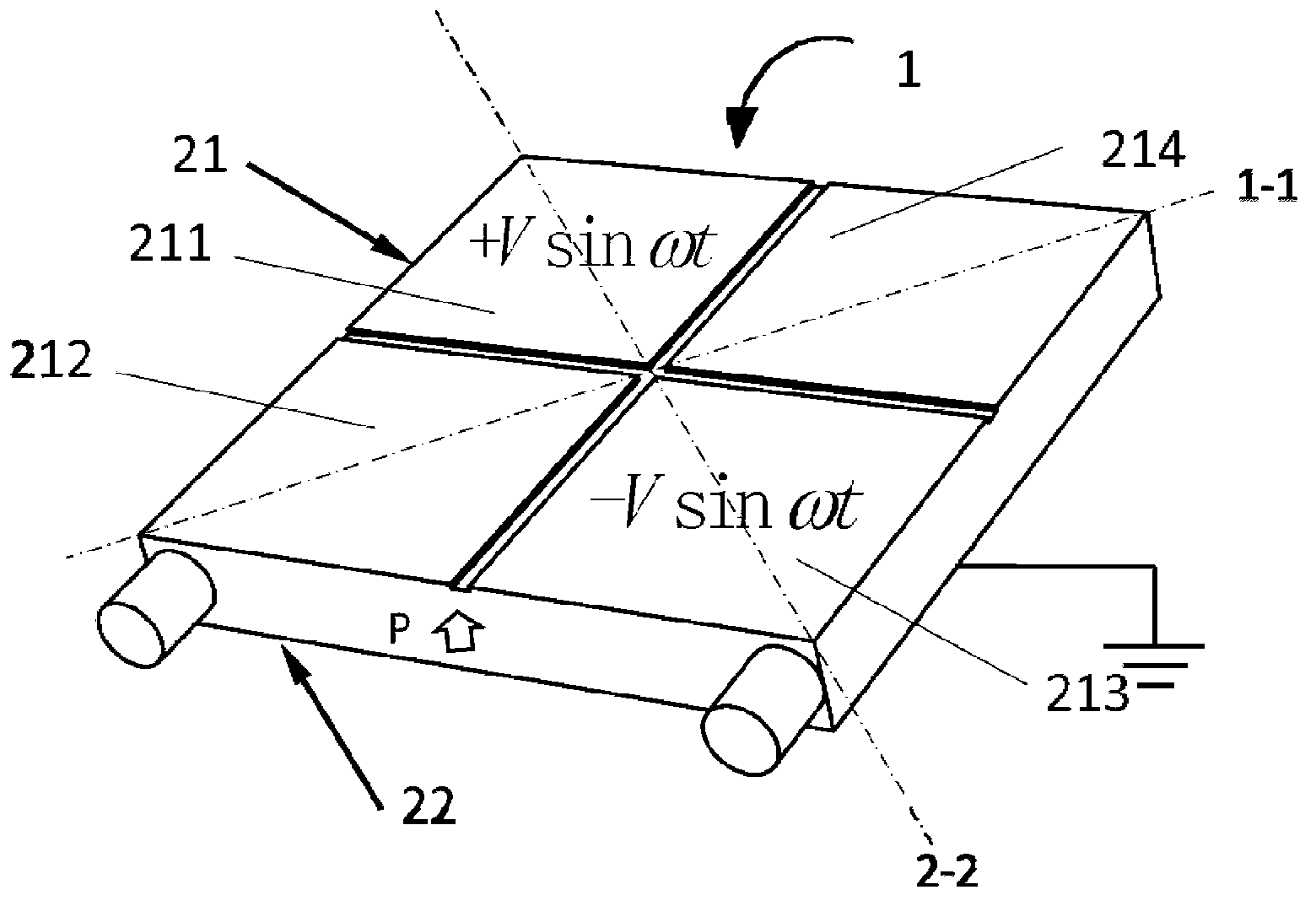

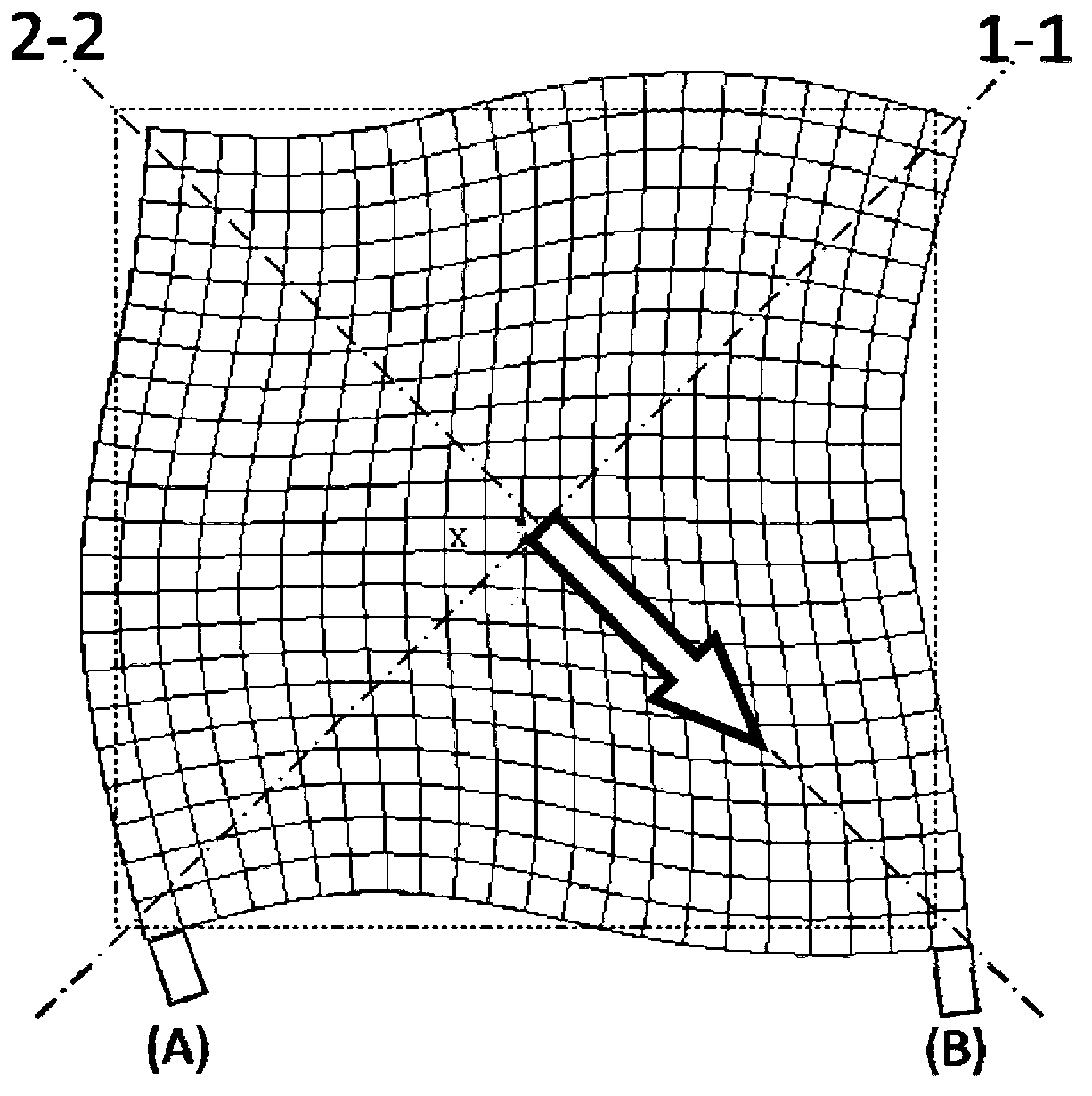

Piezoelectric actuator and piezoelectric motor

ActiveCN103259449ASimple structureEasy to manufacturePiezoelectric/electrostriction/magnetostriction machinesElectricityPiezoelectric actuators

The invention provides a piezoelectric actuator and a piezoelectric motor. The piezoelectric actuator comprises a piezoelectric body which is of a square platy structure and is polarized in the thickness direction. A first electrode layer is arranged on a main plane of a first end of the piezoelectric body in the thickness direction, a second electrode layer is arranged on a main plane of a second end of the piezoelectric body in the thickness direction, the first electrode layer comprises a plurality of electrode areas, and the second electrode layer comprises at least one electrode area. The piezoelectric actuator can work in a simple first-order bending vibration mode, generates reciprocating straight-line trajectory movement or elliptical orbit movement, is simple in structure and convenient to manufacture, and can solve problems which exist in a traditional piezoelectric actuator.

Owner:PEKING UNIV

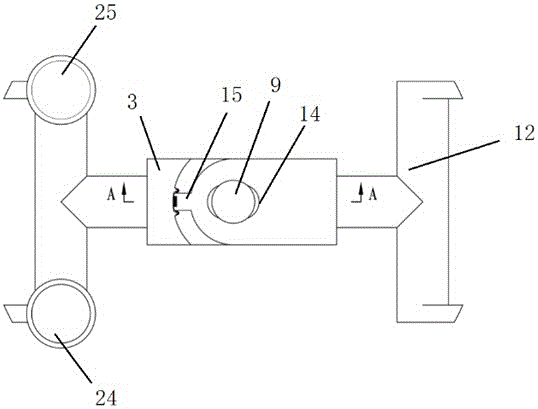

Method for recording and predicting position data for a self-propelled wheeled vehicle

ActiveUS20170347624A1Safe and precise determinationRoad vehicles traffic controlAnimal feeding devicesOn boardEngineering

A method for recording and predicting position data for a self-propelled wheeled vehicle (1) carrying a load (14) is provided whereby the vehicle (1) is caused to move along a ground surface (5) along a predominantly straight line trajectory (17) by rotating at least one load carrying wheel (3) in frictional engagement with the surface (5), angular rotation data of at least one wheel (3) is obtained, absolute position data are obtained at different predetermined fixed positions Pn of the vehicle (1) with respect to the surface (5) along the straight line trajectory (17), whereby the distance travels is measured independently and used to calibrate motion sensors on board the vehicle. The invention also comprises a delivery or pick up system, a program for an on-board computing device and an on-board computing device.

Owner:MINKPAPIR

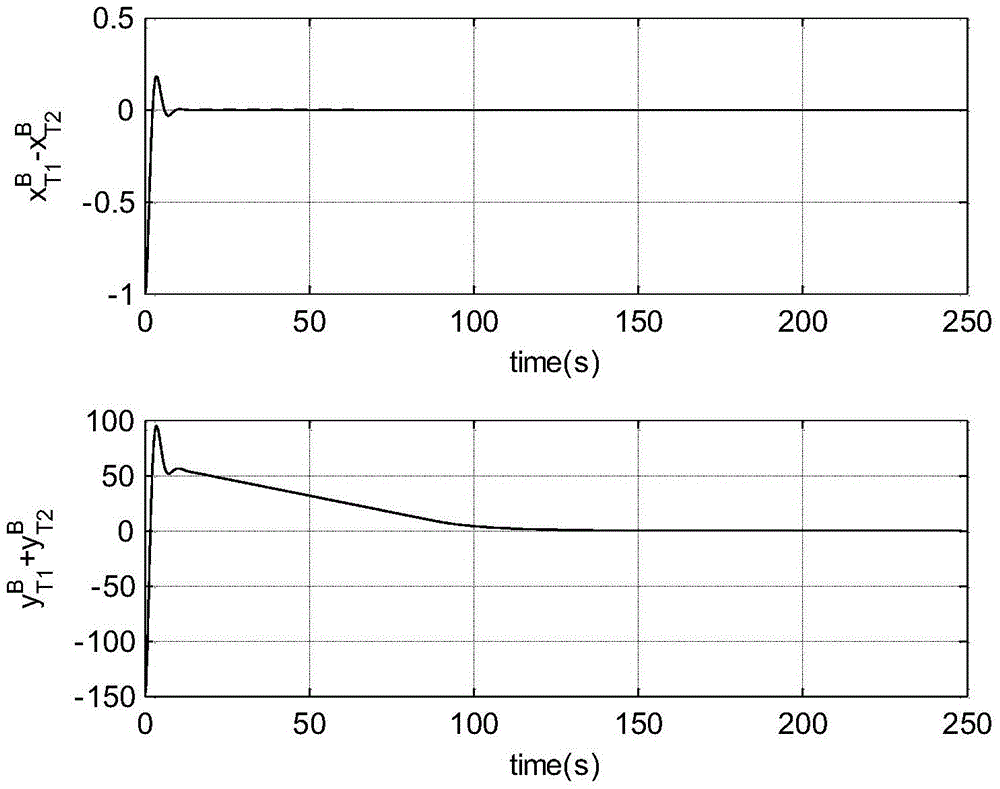

AUV inversion docking control method

InactiveCN105527967AGood speed tracking performanceEasy dockingAltitude or depth controlDocking stationTransceiver

The present invention relates to an AUV inversion docking control method, belonging to the technical field of underwater vehicle recovery and docking. The method is characterized in that the head of an AUV is equipped with a USBL transceiver, two sides of a recovery station is equipped with two USBL transponders B1 and B2; in the process that the AUV approaches a docking station, the AUV obtains the positions of the transponders in a body coordinate system through a USBL positioning system, time derivation is carried out by an AUV transponder position measurement equation, and a docking error is defined in the AUV body coordinate system. In the docking process, the AUV is in a full driving navigation mode, for a docking error, a nonlinear inversion controller is designed, thus the AUV navigates along an expected straight line trajectory until reaching the docking station. According to the method, the inversion adapted speed tracking has good speed tracking performance in a condition of parameter uncertainty, and the docking effect is good.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for implementing straight-line trajectory tracking of unmanned inspection cruiser under ocean current influence

InactiveCN108803612AGood control effectBig research prospectsPosition/course control in two dimensionsProportion integration differentiationPid control algorithm

The invention discloses a method for implementing straight-line trajectory tracking of an unmanned inspection cruiser under ocean current influence, and particularly relates to the technical field ofmariculture monitoring. According to the method for implementing the straight-line trajectory tracking of the unmanned inspection cruiser under ocean current influence, an LOS (line of sight) navigation algorithm and PID (proportion integration differentiation) control are combined for meeting factory and ecological development demands of mariculture under the ocean current influence, and the problem about the straight-line trajectory tracking of the unmanned inspection cruiser is solved. The LOS navigation algorithm is applied to course control of the unmanned inspection cruiser and finishestrajectory tracking with a PID control algorithm, so that the unmanned inspection cruiser sails to a collection point to finish water quality data collection, simulation study is performed on the method with a MATLAB, and a simulation result indicates that the method has a good control effect.

Owner:QINGDAO HUANGHAI UNIV

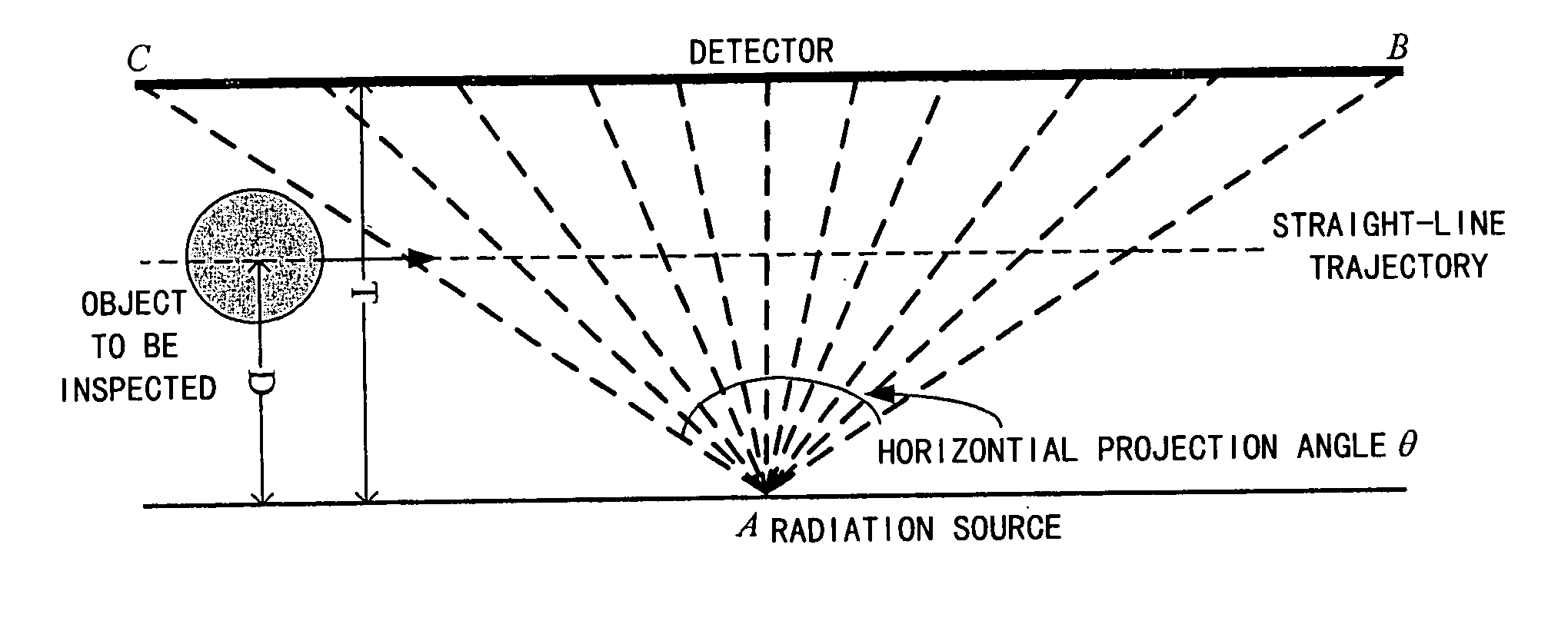

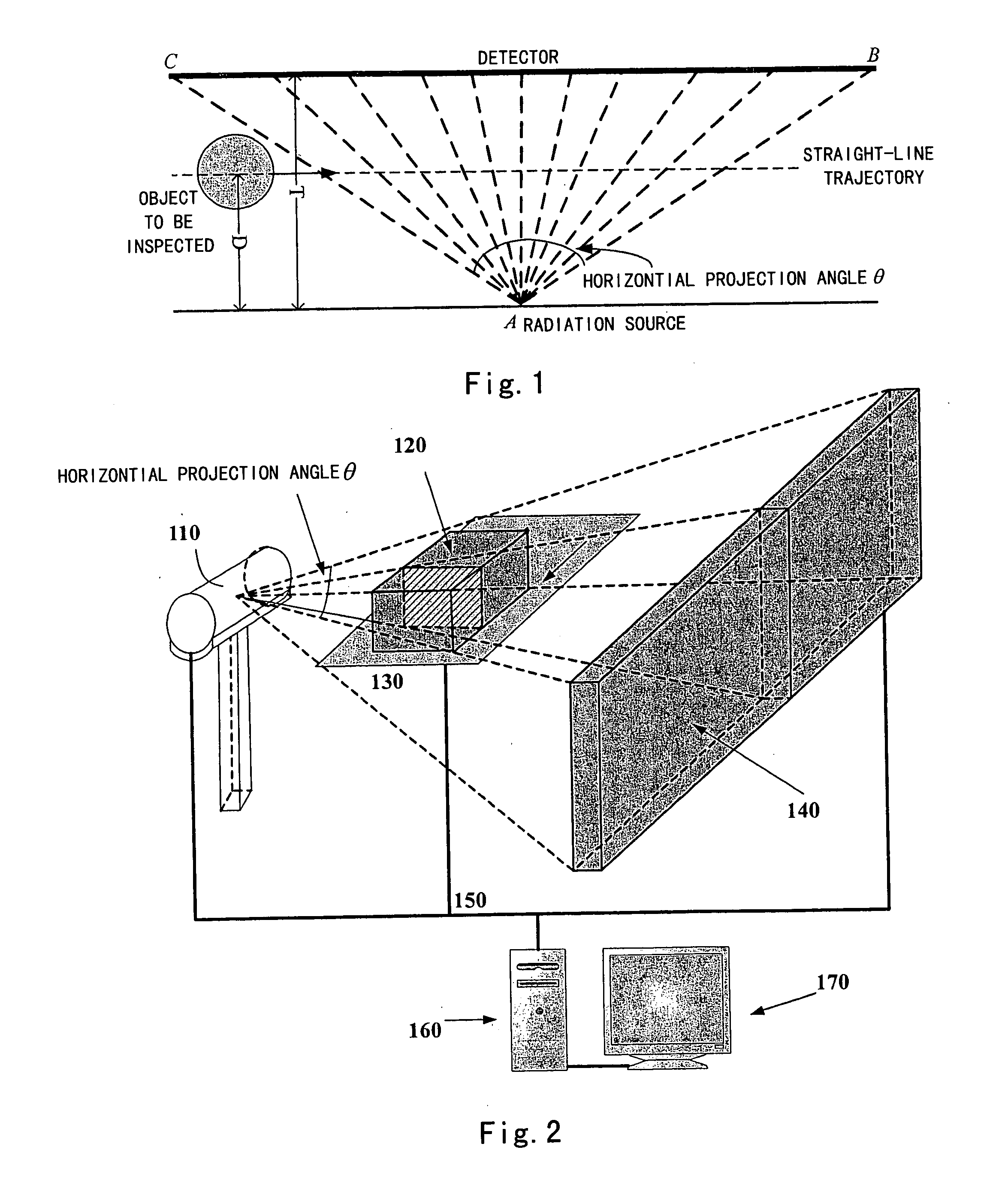

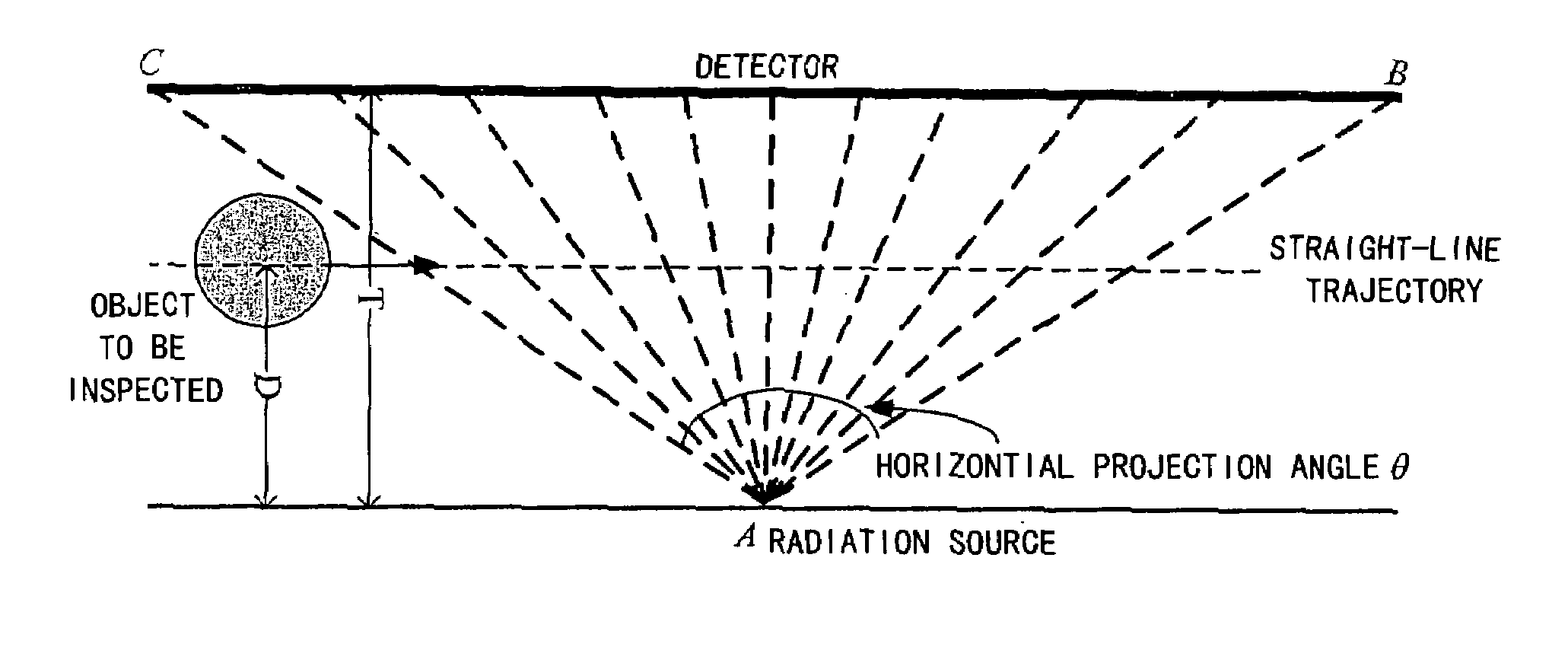

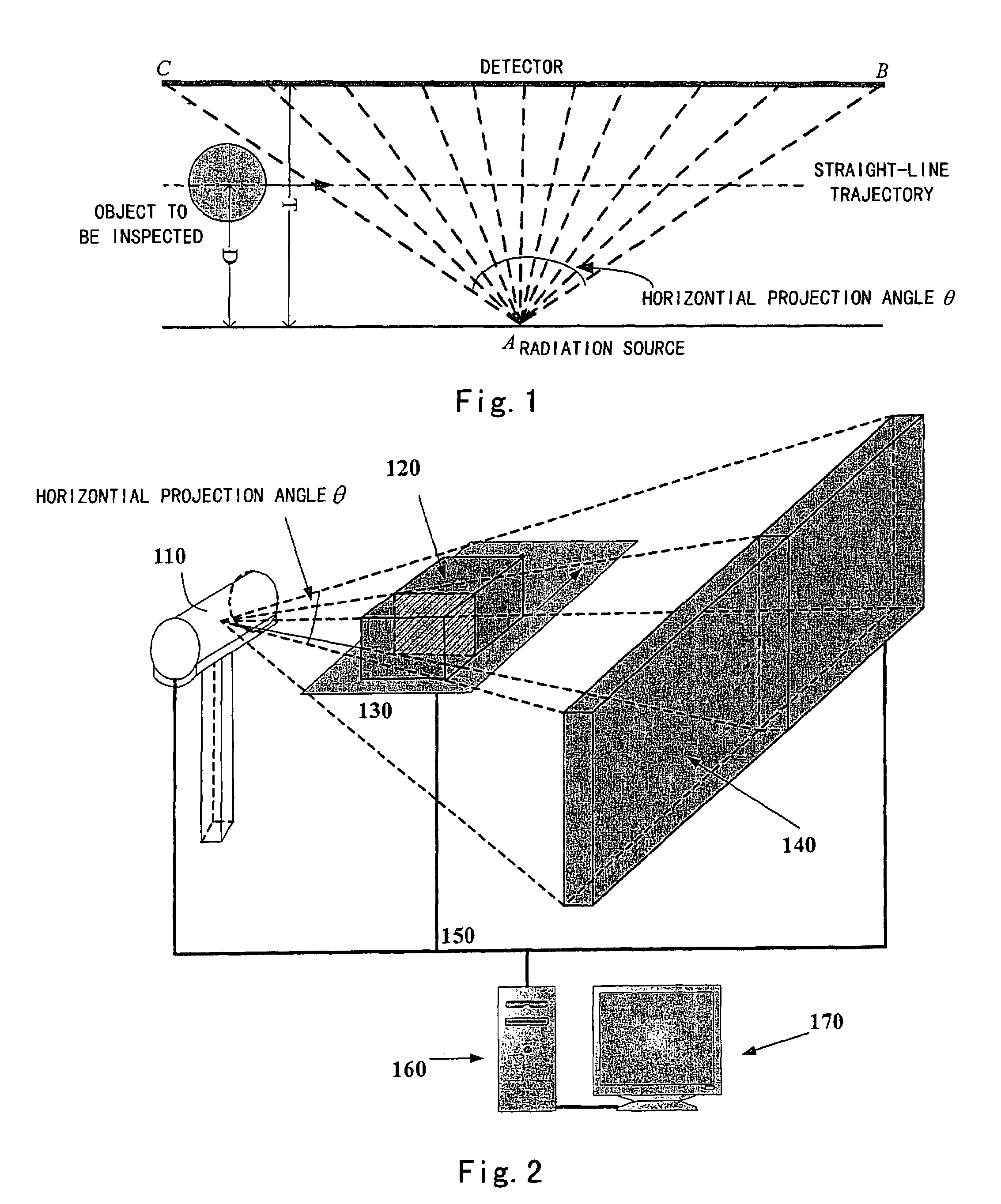

Imaging system

ActiveUS20070116177A1Quick implementationIncrease speedMaterial analysis by transmitting radiationRadiation diagnosticsImaging processingBack projection

It is disclosed an imaging system comprising: radiation generating means including at least one radiation source for generating radiations; data acquiring means including an detector matrix faced the radiation source for obtaining projection data by receiving radiations penetrated through an object to be inspected; transporting means for making the object to be inspected between the radiation source and the detector matrix linearly moving relative to the radiation source and the detector matrix; and controlling and image processing means for controlling the radiation generating means, the data acquiring means and the transporting means, and for reconstructing an image of the object to be inspected from the projection data. The imaging system according to the present invention achieves a real stereoscopic radiography by using straight-line trajectory scan and reconstructing a tomographic or stereoscopic image through a straight-line filtered back-projection algorithm. The present imaging system has advantages of fast examination speed, no rotation, and out of large cone-angle problem in a circular-orbit cone-beam CT.

Owner:TSINGHUA UNIV +1

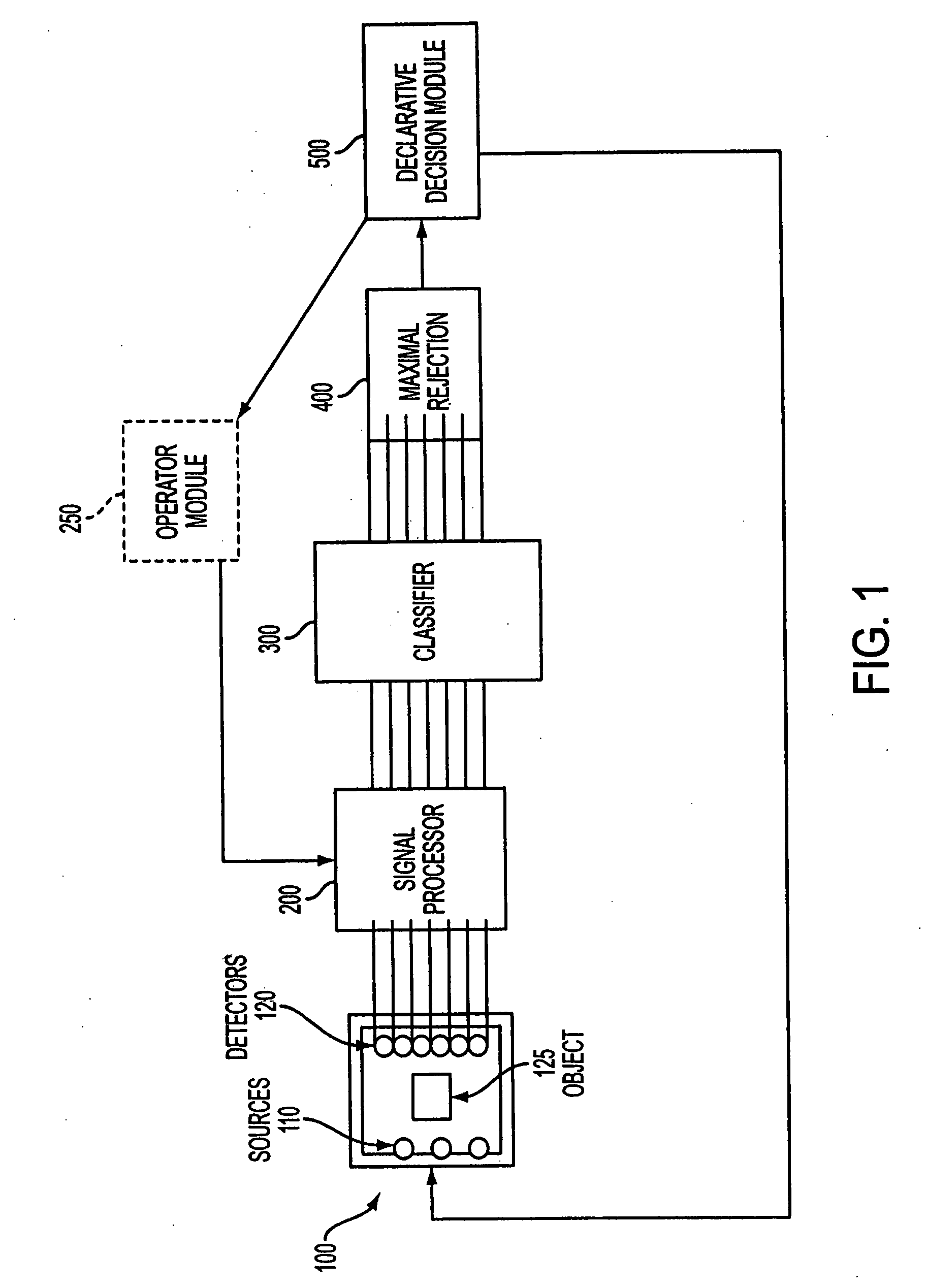

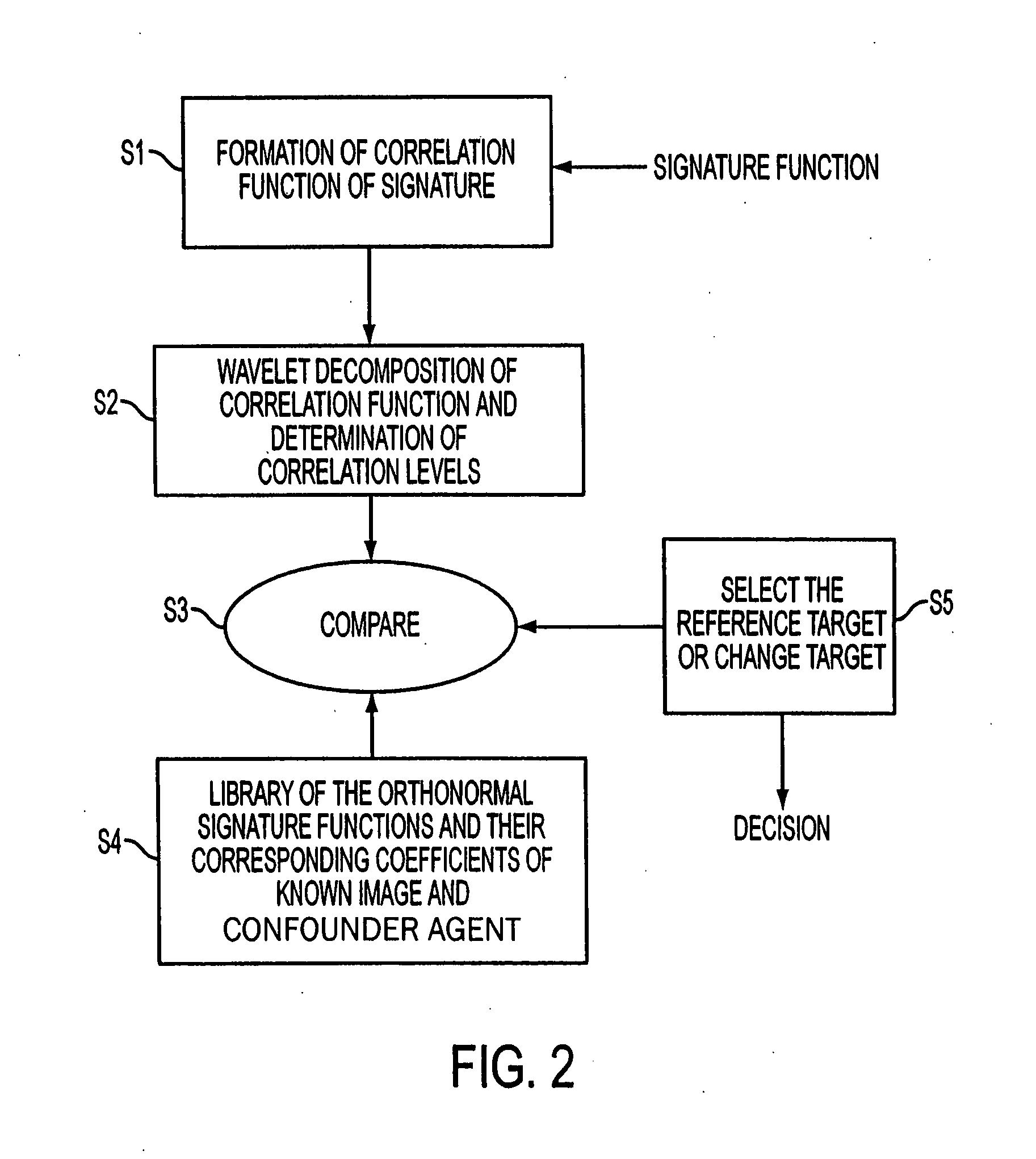

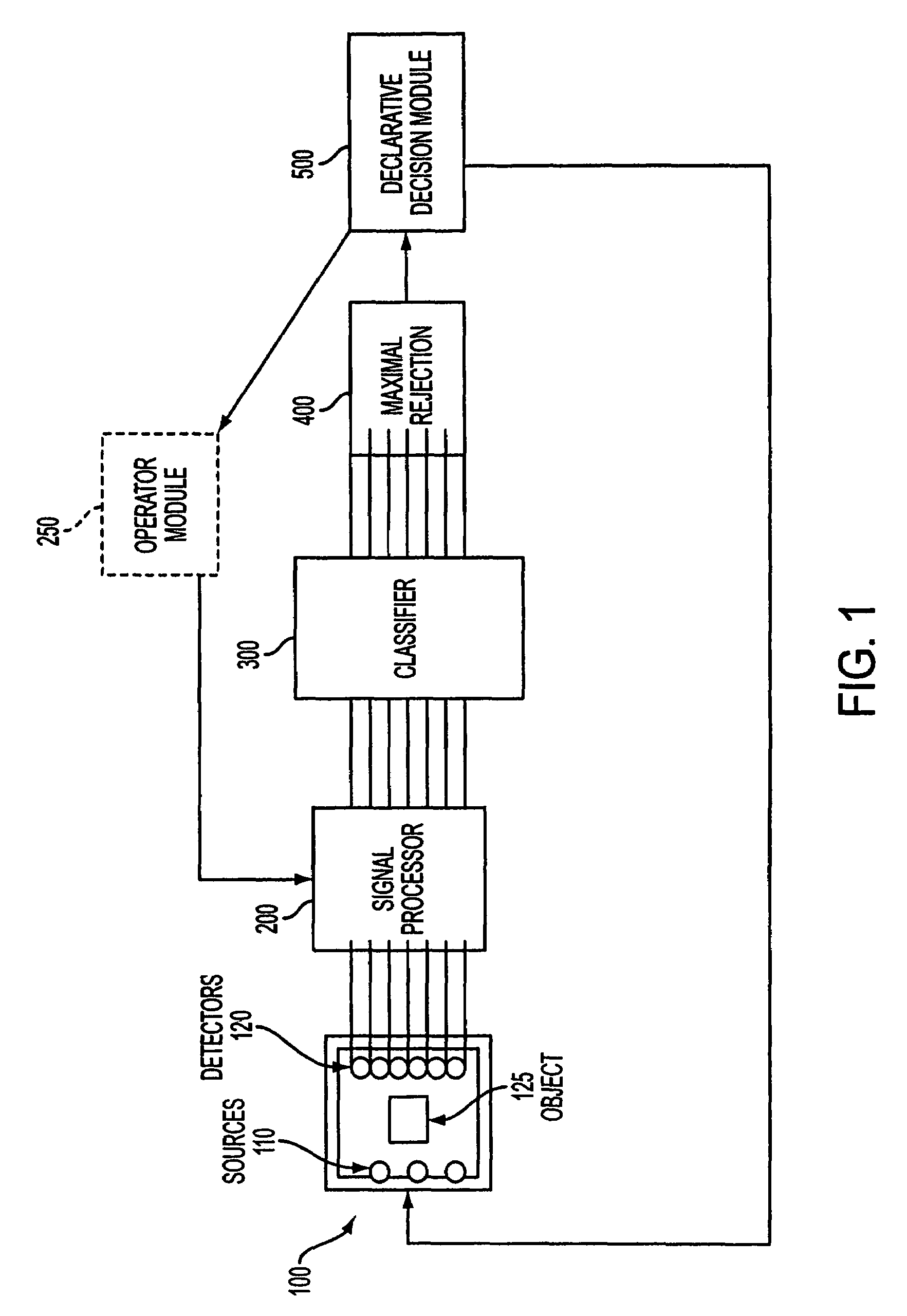

Method and apparatus for detecting and classifying explosives and controlled substances

InactiveUS20090010373A1Overcome limitationsConversion outside reactor/acceleratorsNuclear energy generationDetector arrayControl substances

A system for detecting and classifying small amounts of explosives and other controlled substances while rejecting confounders, including a source / detector array formed of a plurality of sources and a plurality of detectors, a signal processor coupled to the source / detector array for processing data received from the detectors, a classifier coupled to the signal processor for classifying data received from the signal processor according to a plurality of algorithms, a maximal rejection classifier coupled to the classifier; and a declarative decision module coupled to the maximal rejection classifier for rendering an accurate decision regarding the contents of the object is provided. The apparatus includes an enclosure, a shield layer disposed within the enclosure, a cavity disposed within the shield layer, a plurality of neutron sources and a detection array disposed within the cavity, and a transport mechanism for moving objects through the cavity past the sources and detection array. The cavity has one or more turns which preclude a straight line trajectory through the cavity. The shield layer is water-filled to prevent stray radiation from exiting the enclosure. The use of multiple lower power neutron sources and the particular geometry of the enclosure provide a compact, relatively lightweight explosive detection system which is practical for use in airports and other public locations.

Owner:FAJ INT HLDG

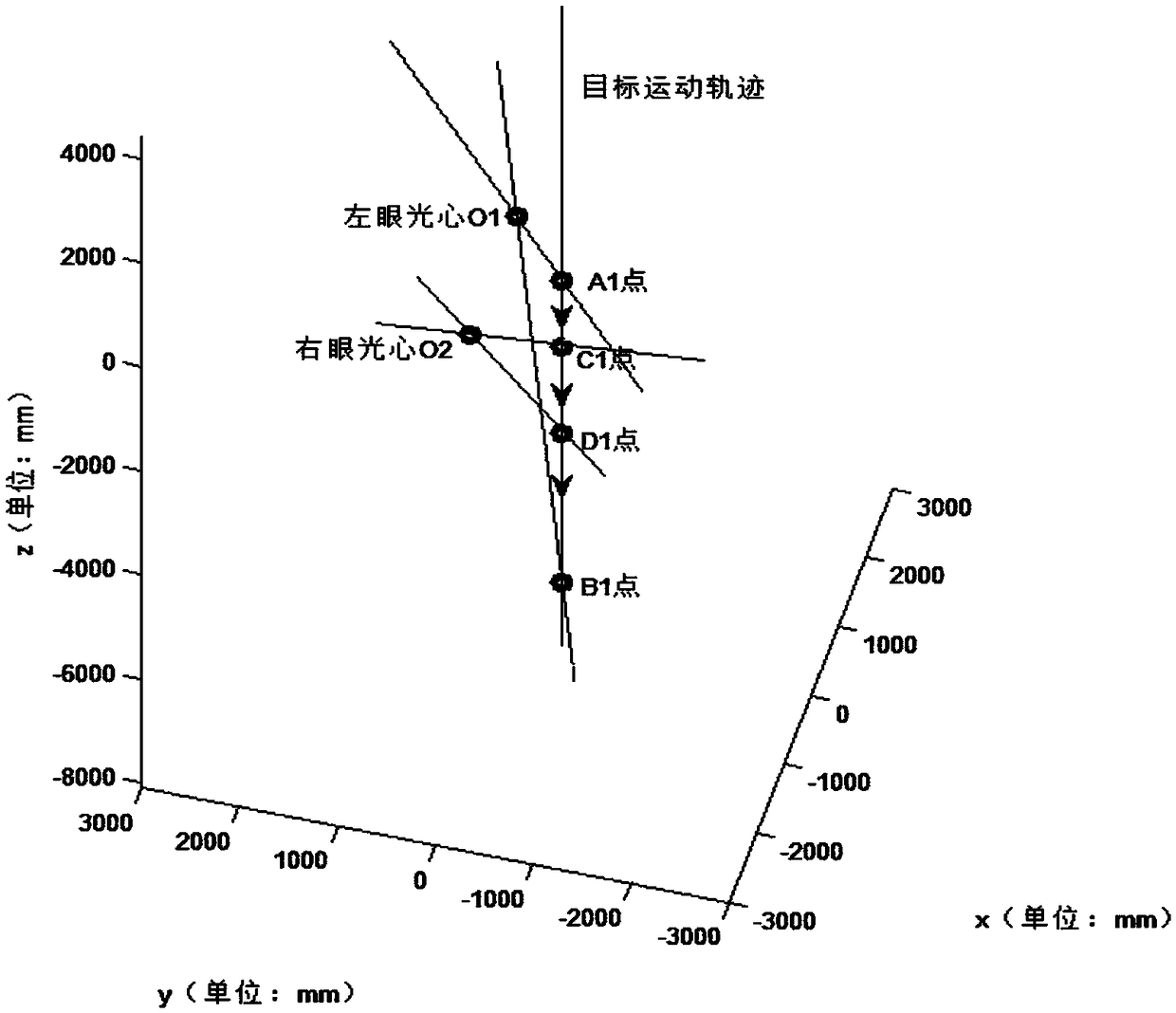

A straight line trajectory fast calculation method free of binocular synchronization

ActiveCN109285189ASolve the problem of binocular synchronization difficulty in calculating the trajectoryImage enhancementImage analysisVision basedPlane equation

The invention belongs to the technical field of stereoscopic vision based on a binocular camera, in particular to a straight line trajectory fast calculation method free of binocular synchronization.The method comprises the following steps: a binocular camera shoots a target object which moves in a straight line, left and right cameras obtain images respectively, pixel coordinates of the target object in the images are obtained, a space camera coordinate system is established with the optical center of a left eye or a right eye camera in the binocular camera as an origin, and two-dimensionalpoints in the images are converted into three-dimensional points in the space; In the camera coordinate system, the coordinates of the target points are extracted from any two images of the left-eye camera respectively, and the plane equation I is determined with the left eye center, and the coordinates of the target points are extracted from any two images of the right-eye camera respectively, and the plane equation II is determined with the right eye center, and the linear motion trajectory can be determined by intersecting the two planes. This method does not need binocular image feature point matching to calculate the linear motion trajectory, which reduces the complexity of trajectory calculation and solves the difficulty of feature point matching in the traditional binocular distancemeasurement method under high-speed camera.

Owner:HARBIN ENG UNIV

Method and apparatus for detecting and classifying explosives and controlled substances

InactiveUS7505544B2Conversion outside reactor/acceleratorsNuclear energy generationControl substancesDetector array

Owner:FAJ INT HLDG

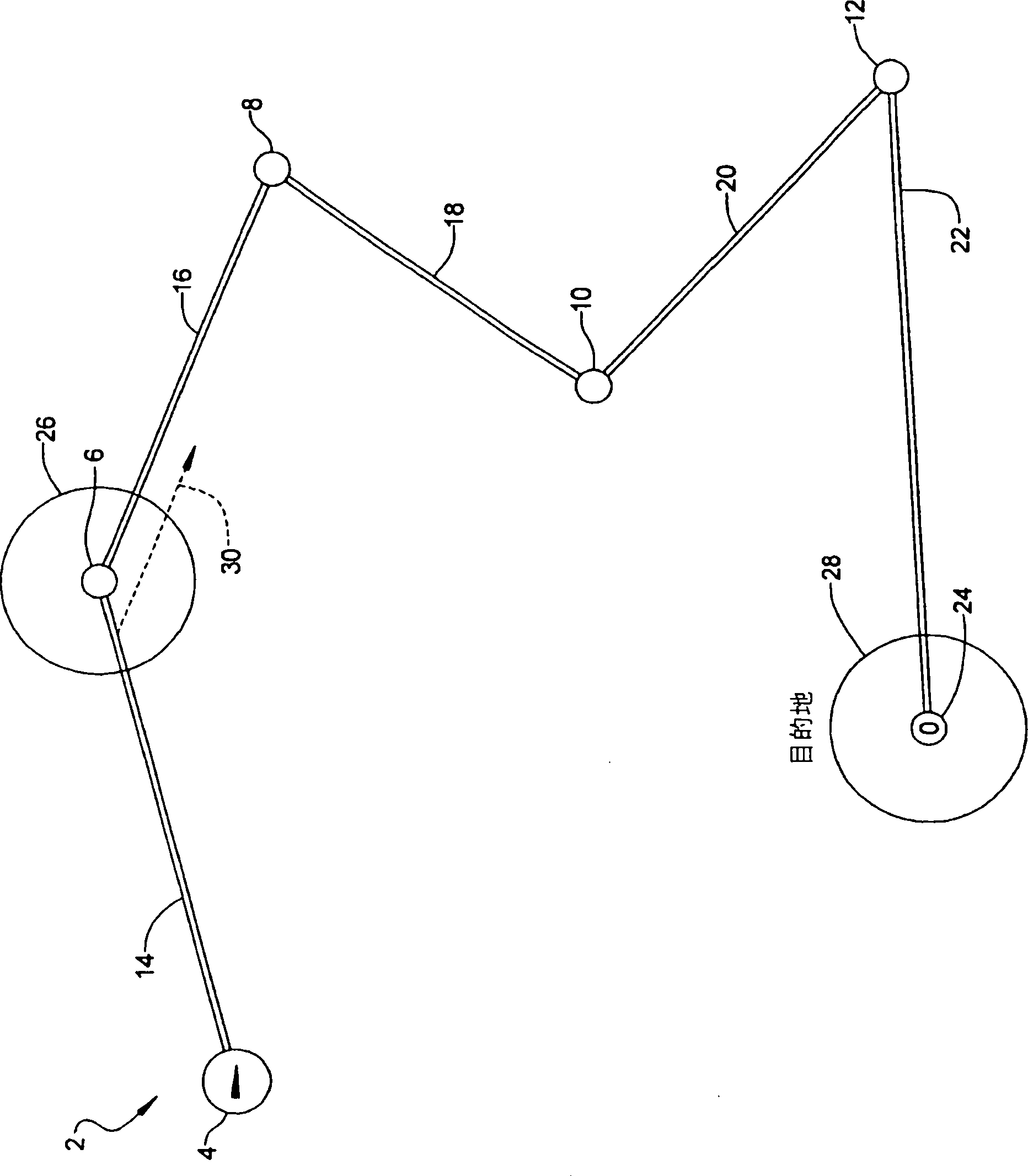

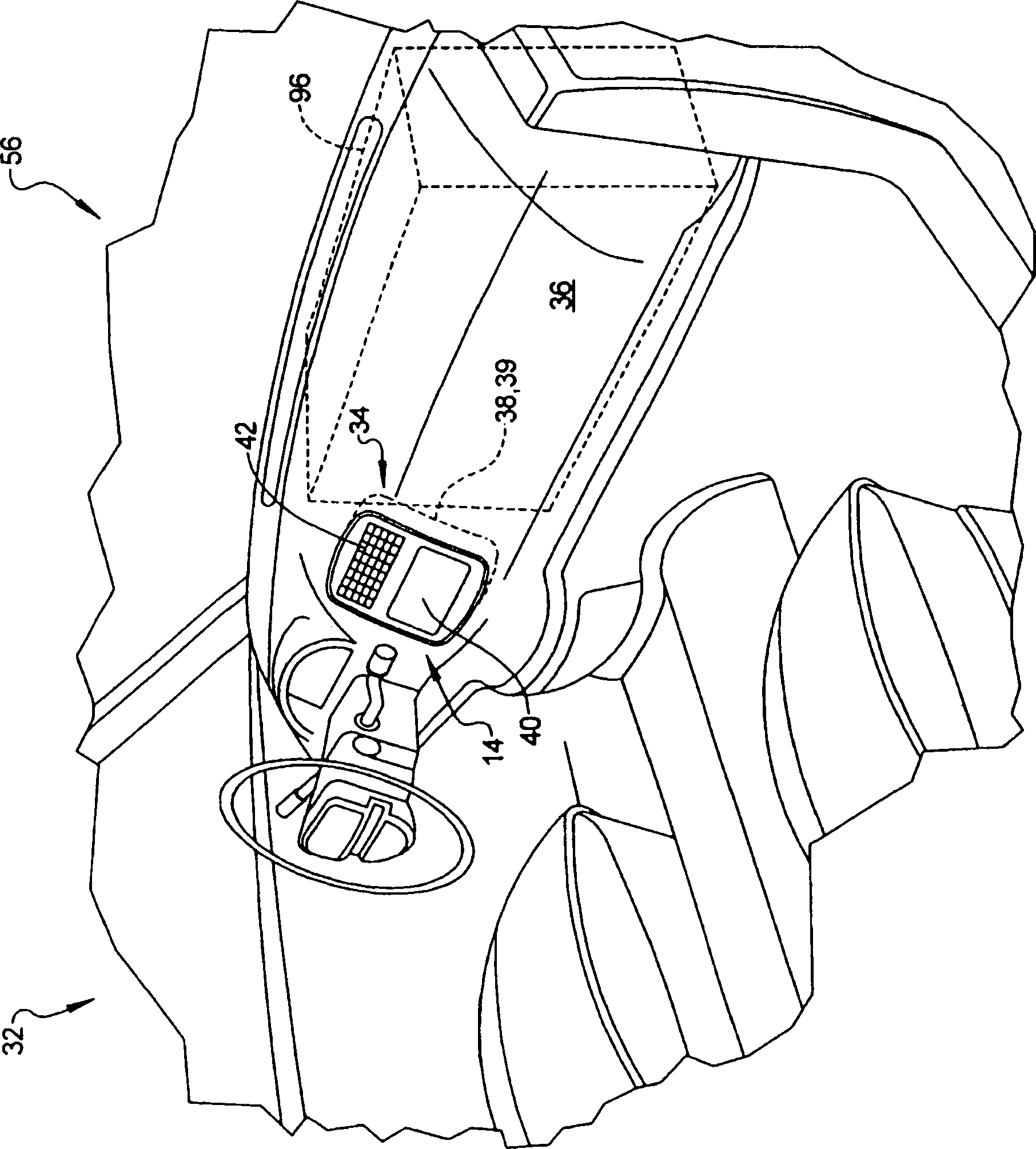

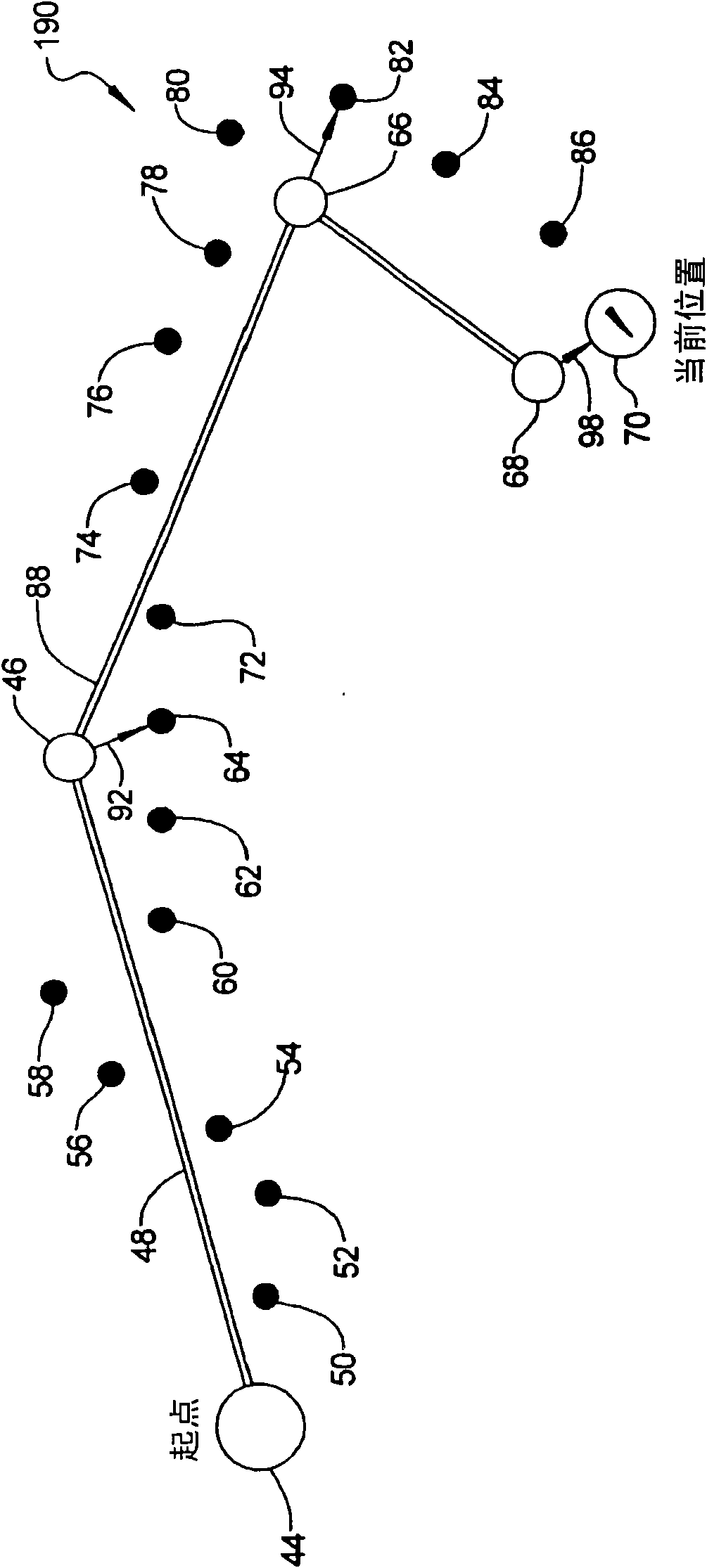

Off road navigation system

InactiveCN101936743AInstruments for road network navigationNavigational calculation instrumentsTerrainUser input

A method of operating a navigation system in a vehicle may include invoking an off-road mode of the navigation system; displaying an off-road terrain on a navigation system display; displaying a present location of the vehicle on the display, inputting a user-input off-road destination into the navigation system; inputting a user-input off-road waypoint into the navigation system; displaying straight line trajectories between the start point, the user-input off-road waypoint and the destination on a display of the navigation system and displaying a real-time path of on-screen breadcrumbs as the vehicle travels off-road in current or real-time; shifting on the display, each user-entered off-road waypoint to a closest on-screen breadcrumb of the real-time path; shifting on the display, the user-entered destination to the closest on-screen breadcrumb; and storing the real-time path in a memory of a navigation control unit.

Owner:DENSO CORP +1

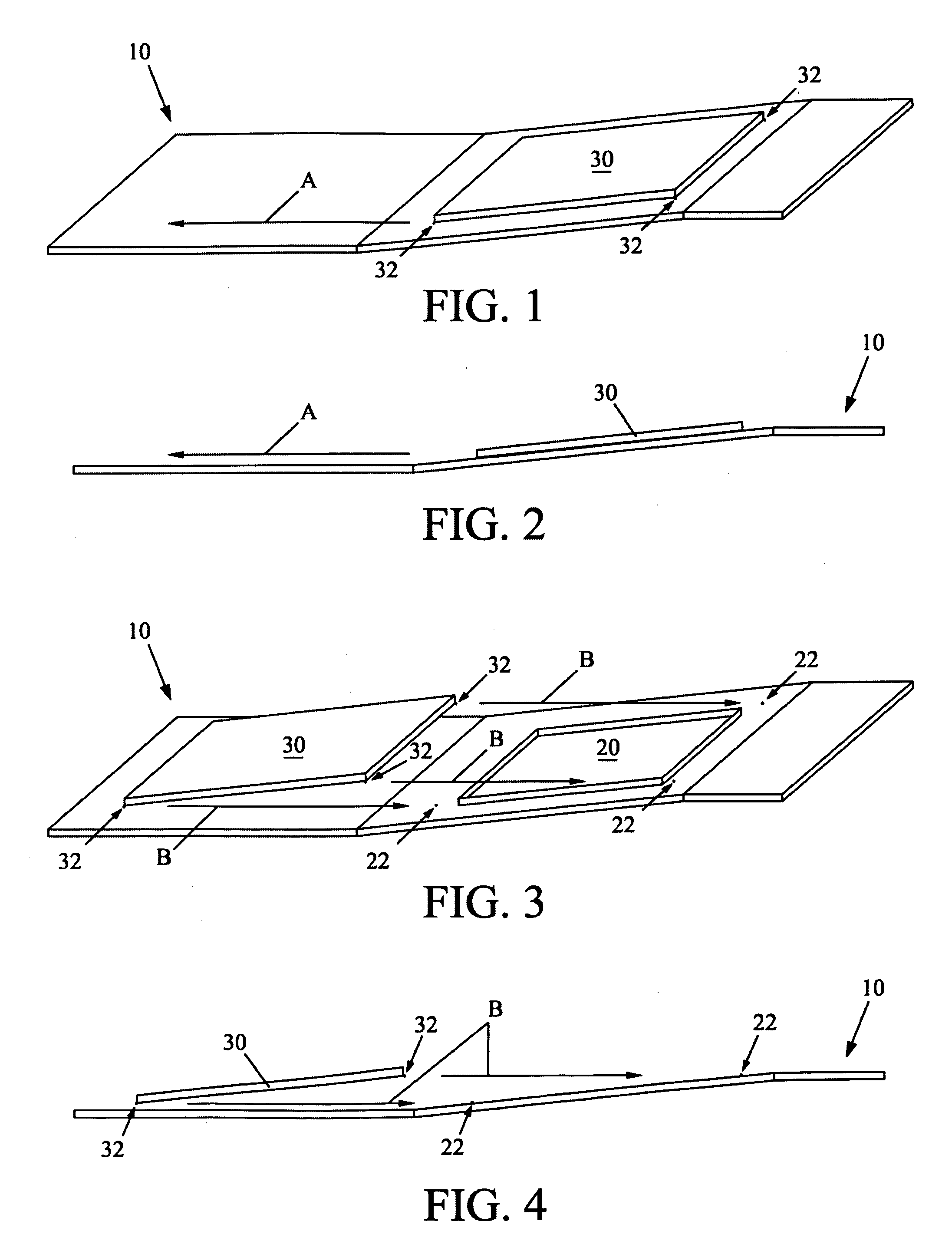

Cone beam CT circular-linear track back projection filtering reconstruction method

ActiveCN106228584AAchieve reconstructionQuality improvementReconstruction from projectionRectilinear ScanReconstruction method

The invention relates to a cone beam CT circular-linear track back projection filtering reconstruction method. M-lines are selected according to the imaging geometry characteristics of a circular-linear scanning track; a back projection integral interval is determined by calculating the endpoint coordinates of an R-line passing through the reconstruction points on the M-lines; and object reconstruction is implemented through Hilbert transform. The problem of cone angle effect during big-cone-angle scanning of a single circular track can be solved effectively. A linear scanning track is added on the basis of circular track scanning, so the conditions of perfect reconstruction are satisfied, and complete reconstruction projection data is obtained. The method can be better applied to actual scanning, effectively improves the quality of an image reconstructed at a big cone angle, and is of important practical significance to the expansion of the application range of cone beam CT scanning.

Owner:THE PLA INFORMATION ENG UNIV

Imaging system

ActiveUS7672427B2Quick implementationIncrease speedMaterial analysis by transmitting radiationRadiation diagnosticsImaging processingBack projection

It is disclosed an imaging system comprising: radiation generating means including at least one radiation source for generating radiations; data acquiring means including an detector matrix faced the radiation source for obtaining projection data by receiving radiations penetrated through an object to be inspected; transporting means for making the object to be inspected between the radiation source and the detector matrix linearly moving relative to the radiation source and the detector matrix; and controlling and image processing means for controlling the radiation generating means, the data acquiring means and the transporting means, and for reconstructing an image of the object to be inspected from the projection data. The imaging system according to the present invention achieves a real stereoscopic radiography by using straight-line trajectory scan and reconstructing a tomographic or stereoscopic image through a straight-line filtered back-projection algorithm. The present imaging system has advantages of fast examination speed, no rotation, and out of large cone-angle problem in a circular-orbit cone-beam CT.

Owner:TSINGHUA UNIV +1

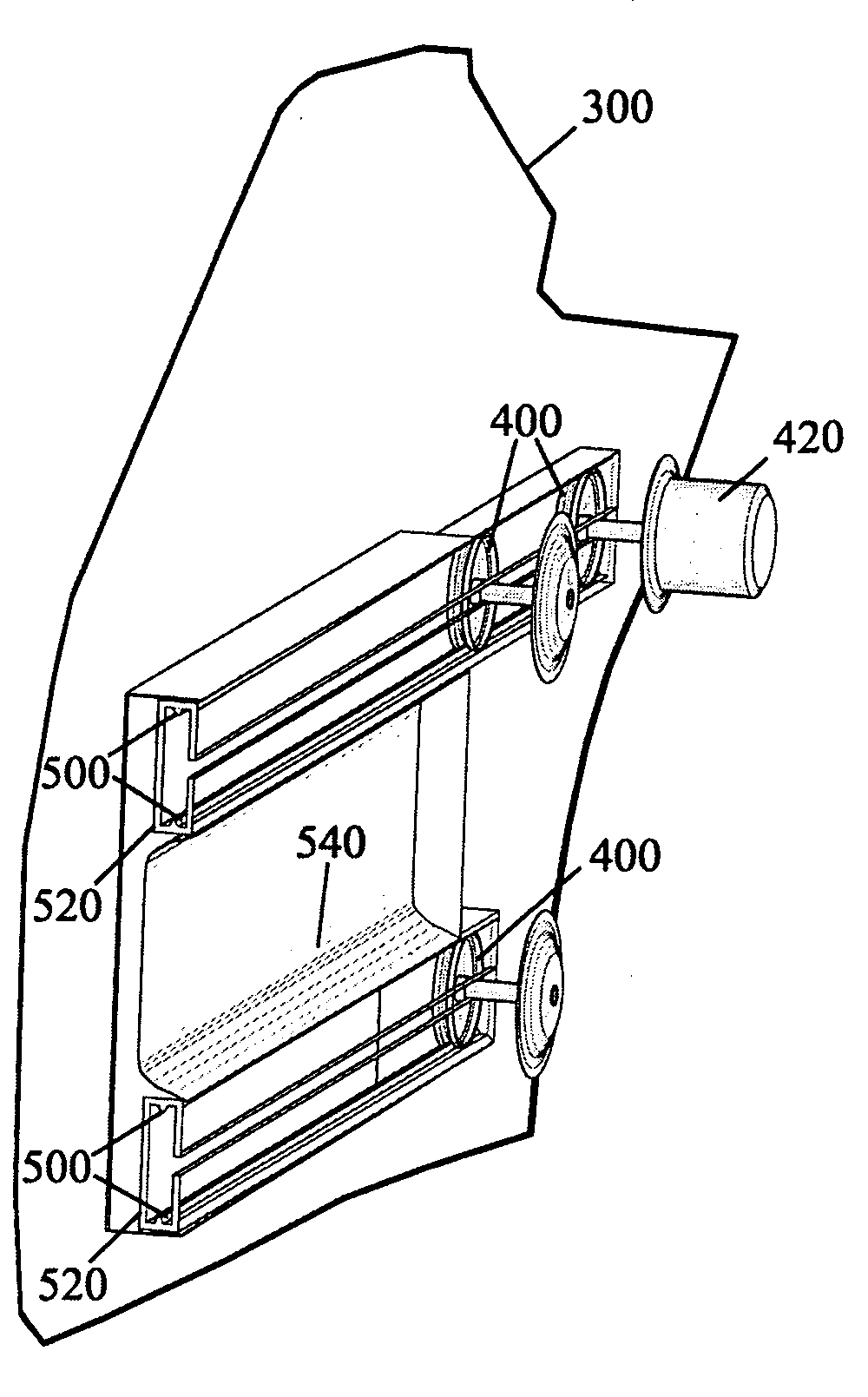

Straight trajectory sliding shutter apparatus

InactiveUS20090315362A1Readily affordablePromote sportsMonocoque constructionsVehicle bodiesEngineeringMechanical engineering

A sliding shutter apparatus comprising an opening of a predetermined shape, a shutter adapted to seal the opening in closed position and unseal the opening in opened position, and guiding means for facilitating movement of the shutter along a single straight line trajectory between opened and closed positions.

Owner:MICHNIK ALISA +1

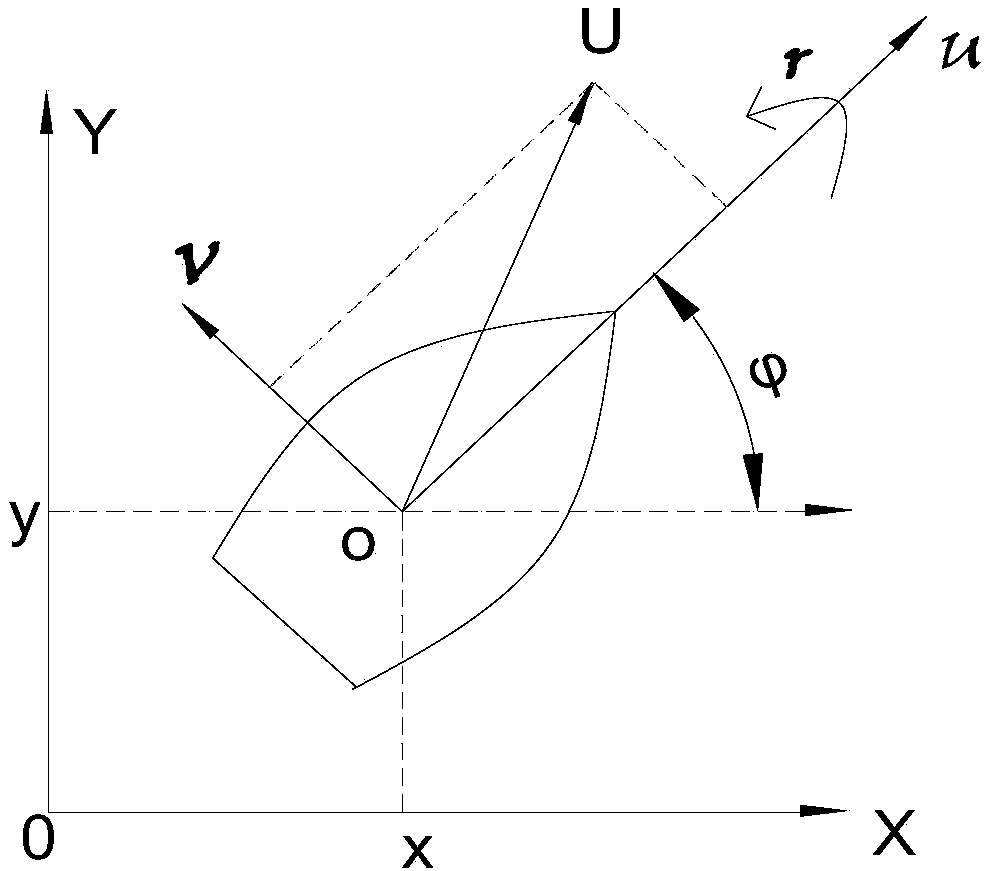

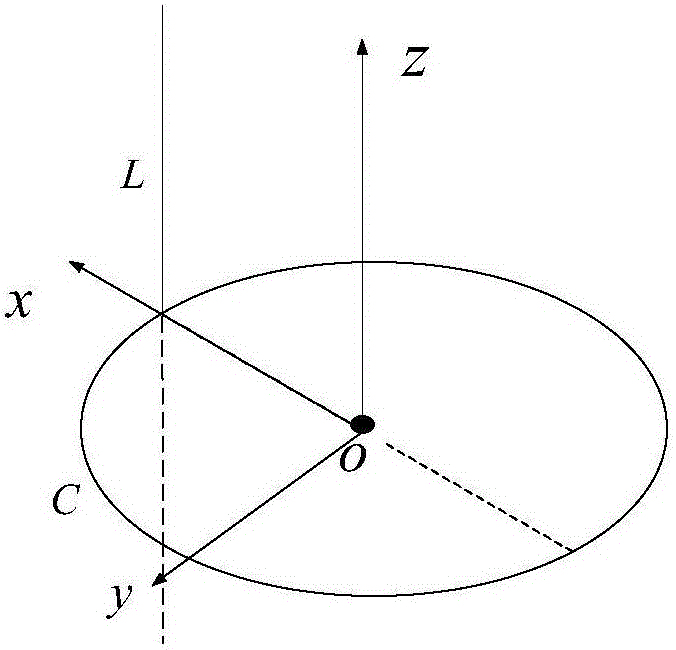

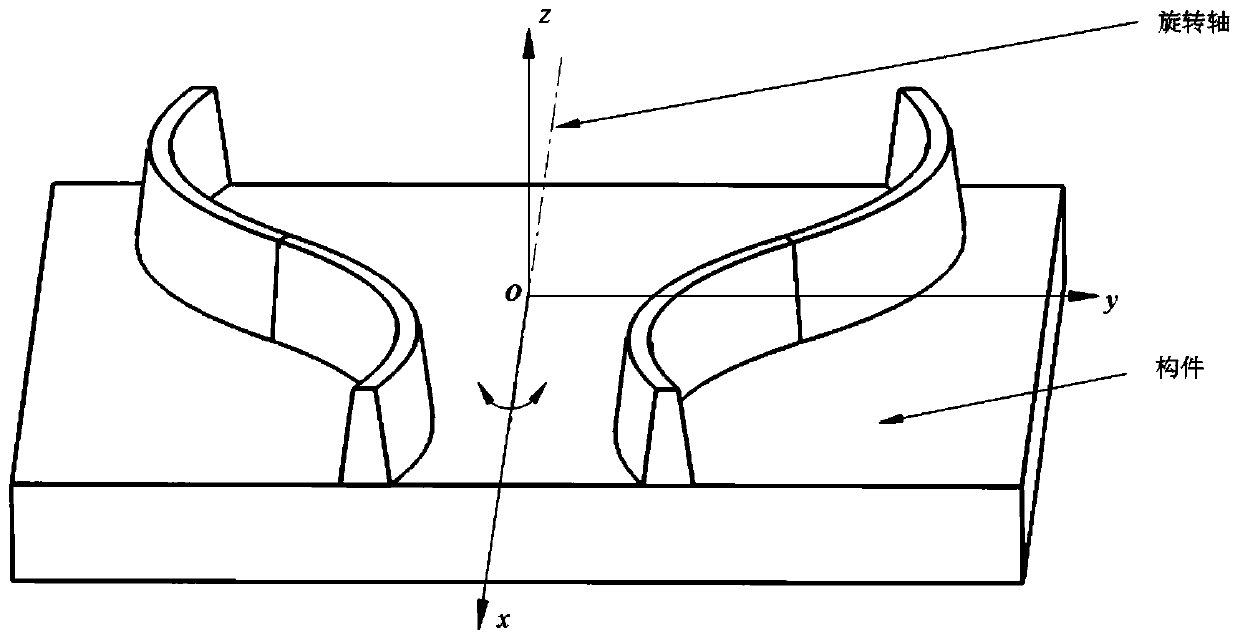

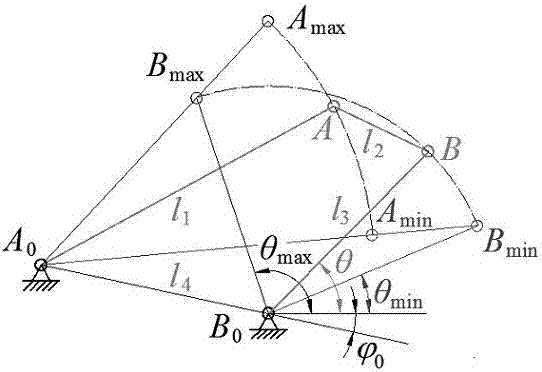

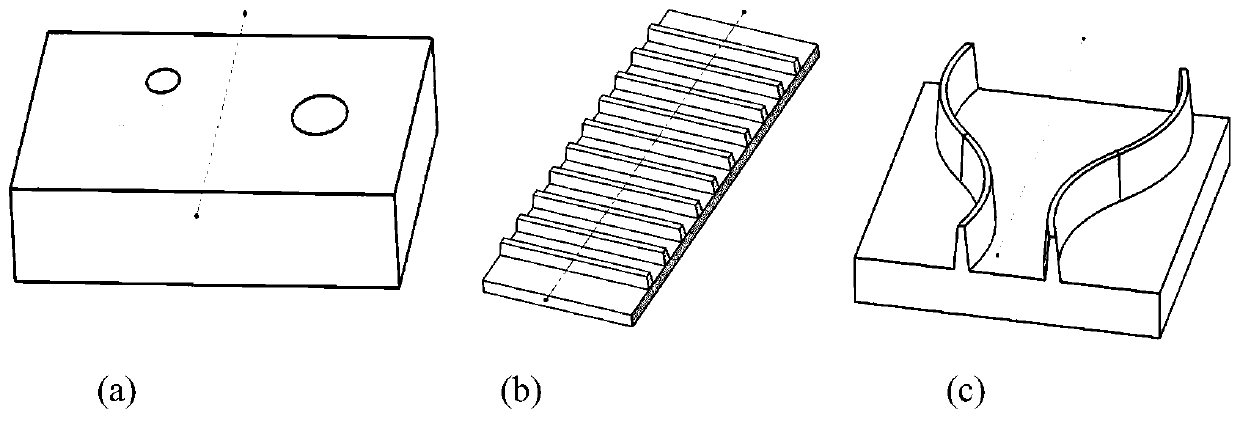

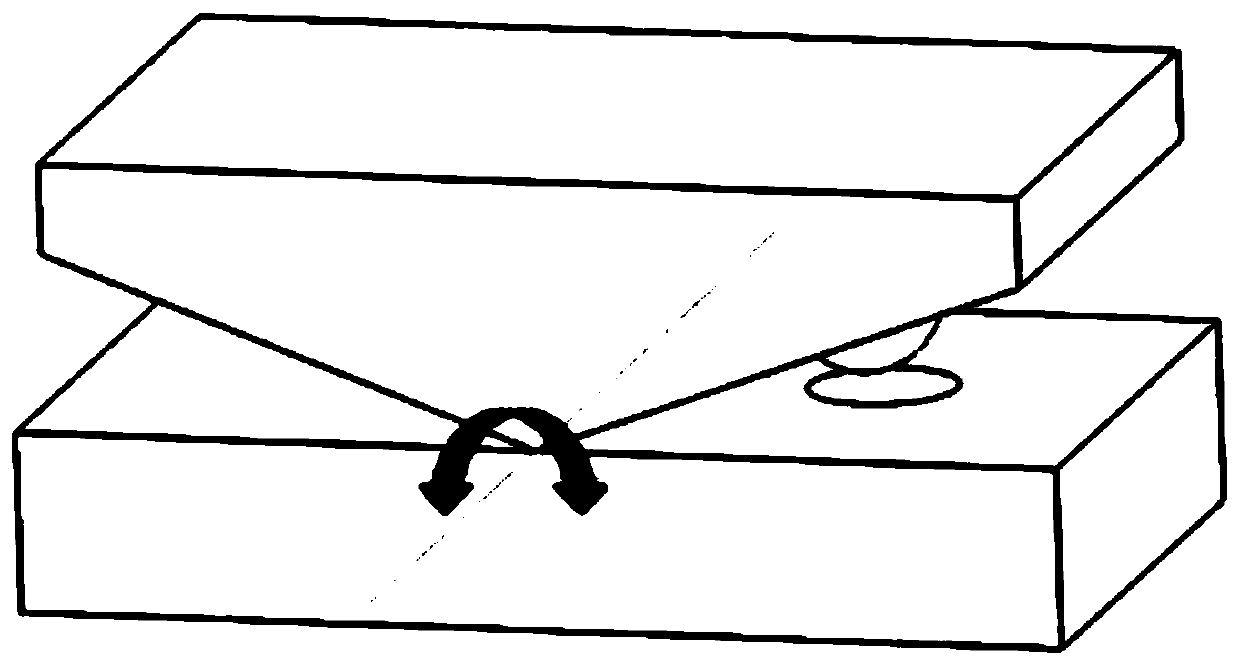

Envelope die design method for improving spatial envelope forming precision under linear track

ActiveCN110826252AGuaranteed formabilityGuaranteed forming accuracyDesign optimisation/simulationRotational axisPoint cloud

The invention relates to an envelope die design method for improving the spatial envelope forming precision under a linear trajectory. The method comprises the following steps of S1, building an O-xyzrectangular coordinate system through employing the highest plane geometric midpoint O of the upper surface of a component as the origin of coordinates; S2, generating an envelope mold design principle based on a component inversion method, and enabling the component to perform linear reciprocating swing motion around a rotating shaft; S3, dispersing and extracting the coordinates of the points on the upper surface of the component, and putting the coordinates into a set V1; S4, obtaining a point set V1' under different rotation angles from the point set V1 in the step S3 according to the movement in the step S2, wherein the set is the overall point cloud during the reverse movement process of the component, and the point cloud on the upper surface of the set is the envelope mold; and S5,extracting the upper surface points from the V1' point set by utilizing a boundary extraction algorithm, and putting the upper surface points into a point set V2, so that the point set V2 is the surface points of the envelope mold under the linear track. The envelope mold obtained by the method does not interfere with the upper surface of the component, and thus the spatial envelope forming precision of the component is improved.

Owner:WUHAN UNIV OF TECH

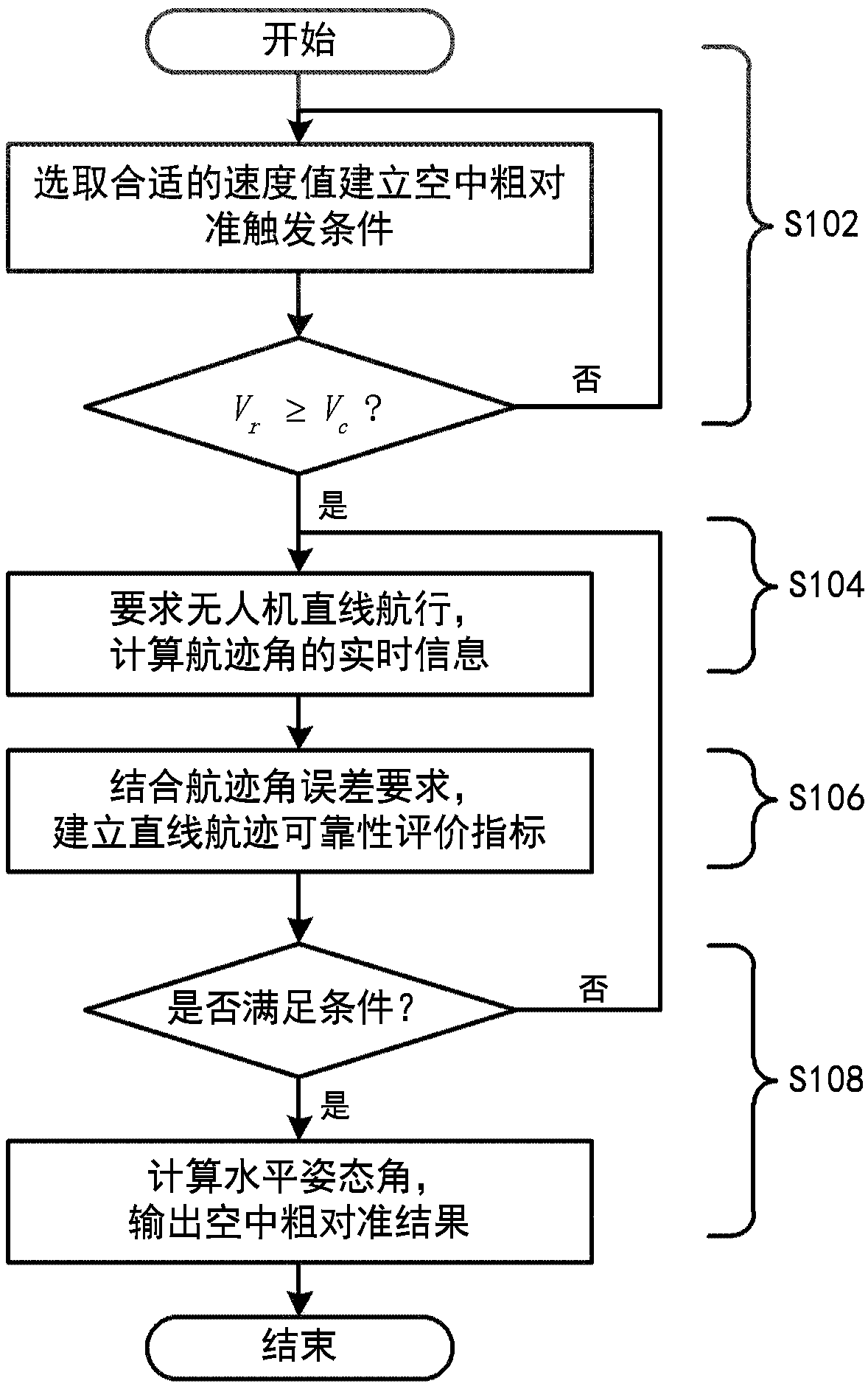

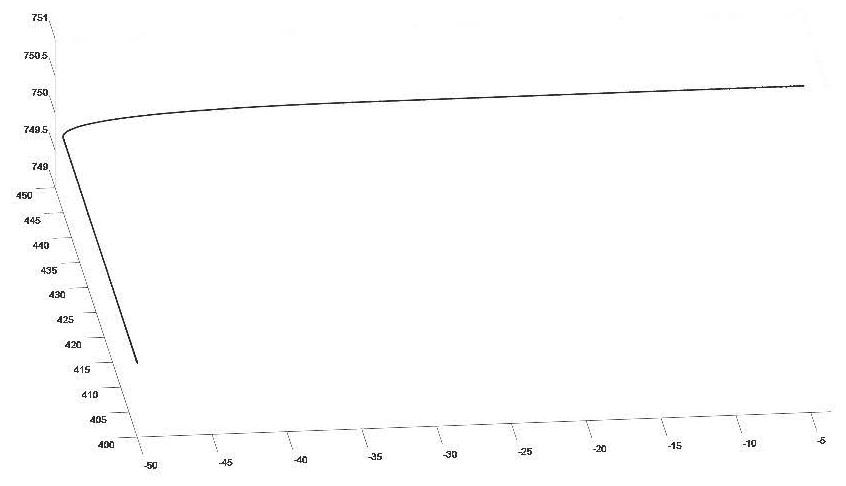

Method of air coarse alignment based on straight-line trajectory

ActiveCN109000682AAddressed issue where initial alignment was affected by wave fluctuationsImprove flight efficiencyMeasurement devicesResting timeSea waves

The invention discloses a method of air coarse alignment based on a straight-line trajectory. The method of the air coarse alignment based on the straight-line trajectory comprises the steps that an air coarse alignment triggering condition is established; after real-time speed of an unmanned aerial vehicle meets the air coarse alignment triggering condition, the unmanned aerial vehicle is required to navigate in a straight line, real-time trajectory angle information is obtained; and an effective sampling point is judged to calculate a level attitude angle by using a reliability assessment index of the straight-line trajectory, and coarse alignment is completed. According to the method of the air coarse alignment based on the straight-line trajectory, the problem that initial alignment ofa ship-borne unmanned aerial vehicle inertial navigation system is affected by sea wave fluctuating is solved, and the lifting, takeoff and straight-line operation process of the unmanned aerial vehicle are distinguished through speed threshold isolation; rest time before takeoff required for the alignment of the ship-borne unmanned aerial vehicle inertial navigation system is reduced, the alignment of initial attitude is completed by using an aircraft accelerated straight-line flight process, and the flight efficiency is well improved.

Owner:中科宇达(北京)科技有限公司

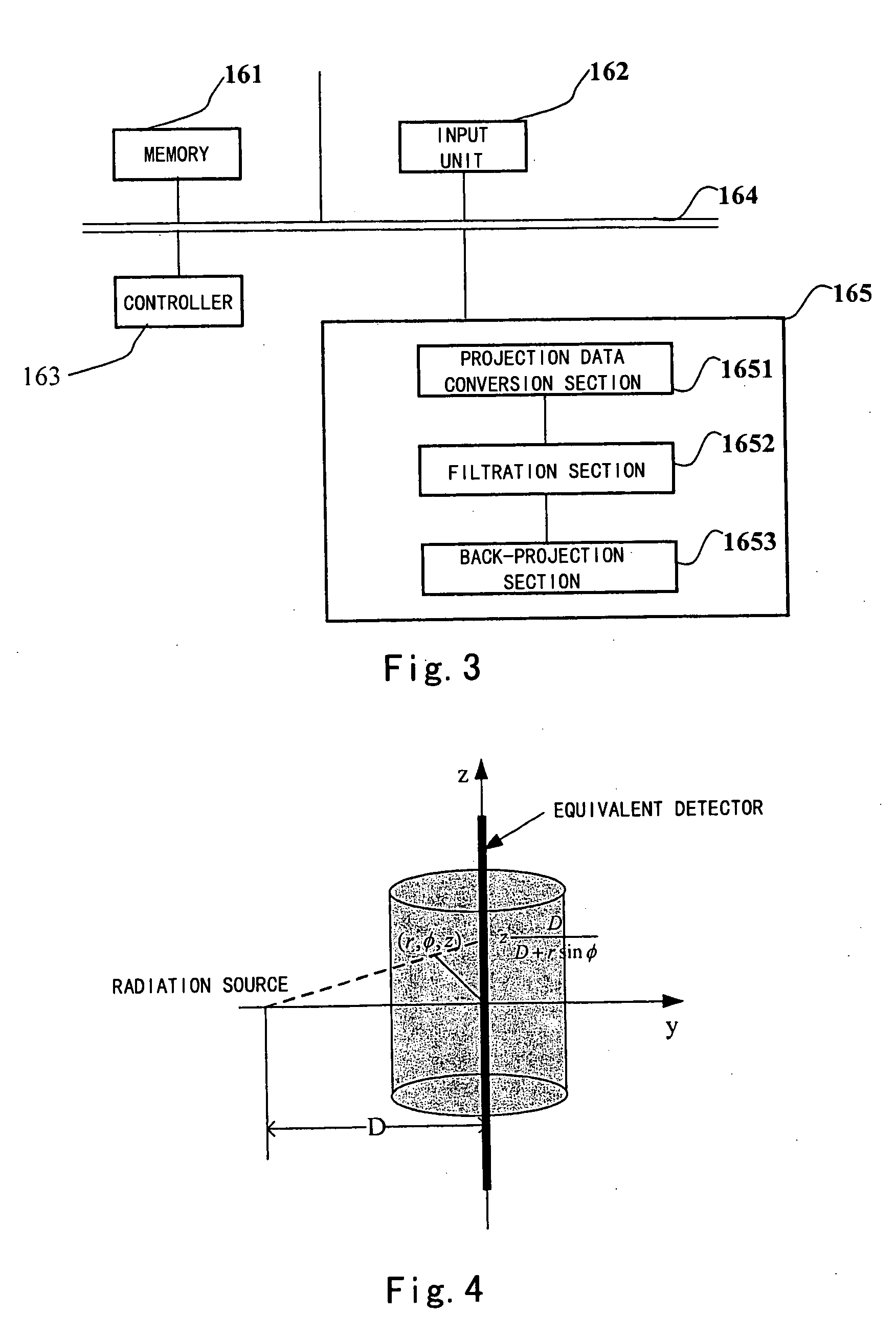

System and method for reconstructing image by using straight-line trajectory scan

ActiveUS7424089B2Improve image qualityIncrease spacingReconstruction from projectionRadiation/particle handlingFiltrationParallel beam

It is disclosed a system and a method for reconstructing an image by using a straight-line trajectory scan to avoid image spatial resolution reduction due to interpolations in angular direction and detector direction during data rebinning. This system comprises: a projection data conversion section for converting projection data from straight-line trajectory scan into projection data under quasi-parallel-beam scan; a filtration section for obtaining filtered projection data by convoluting the projection data under quasi-parallel-beam scan with a predetermined convolutional kernel; and a back-projection section for reconstructing an image by back-projecting the filtered projection data with a weighting factor. By using the inventive system and method, the spatial resolution in the reconstructed image is improved, and the influence of data truncation on the reconstructed image is reduced. The present invention applies the filtration and back-projection mode, and thus has general advantages of the filtration and back projection, such as simplicity and efficiency. And it is easy to be parallelized and accelerated.

Owner:TSINGHUA UNIV +1

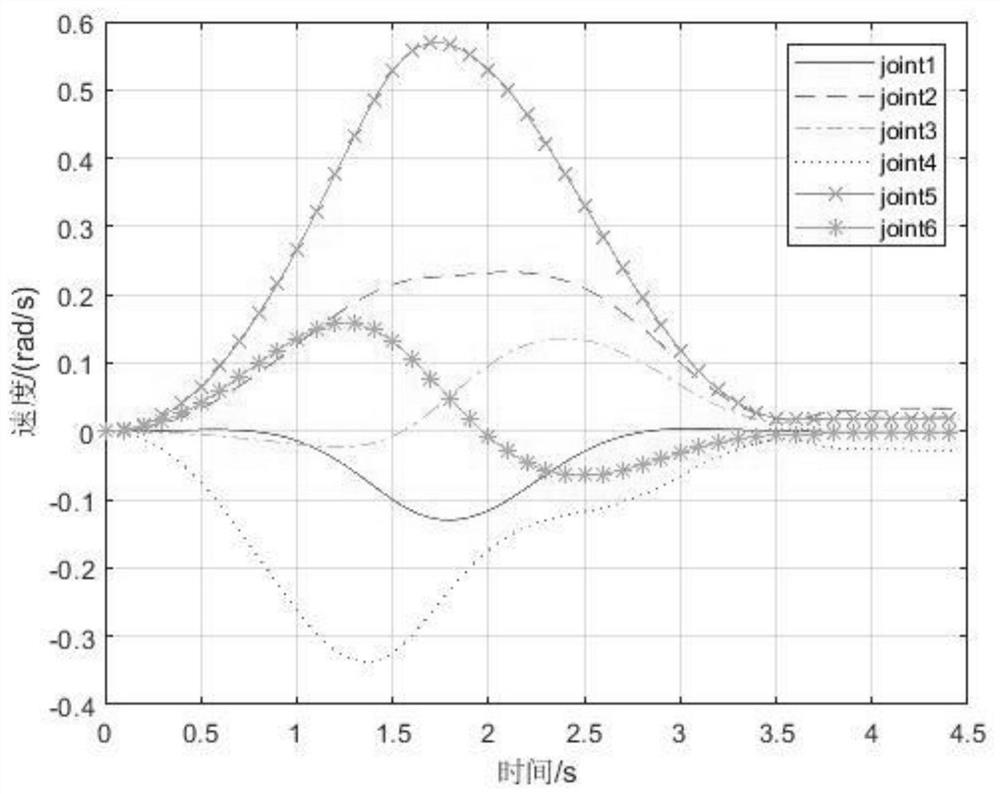

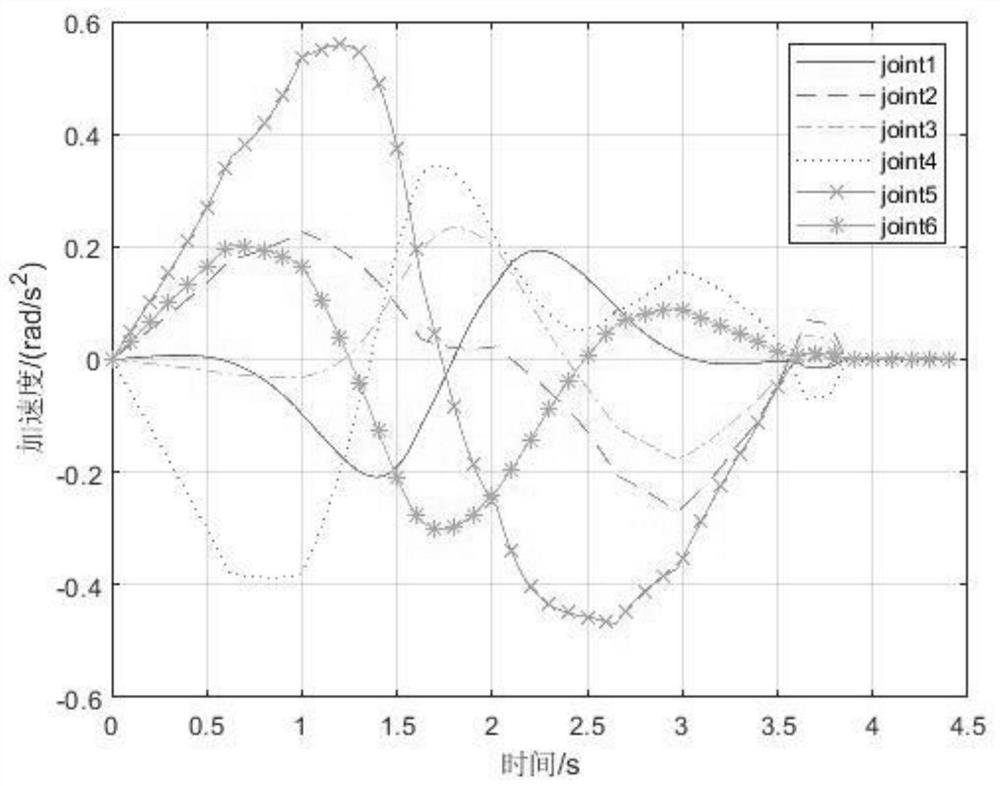

Planning method for smooth transition between linear tracks of self-driven articulated arm measuring machine

PendingCN113334385ARealize automatic online measurementReduce measurement efficiencyProgramme-controlled manipulatorClassical mechanicsIndustrial robotics

The invention relates to a planning method for smooth transition between linear tracks of a self-driven articulated arm measuring machine. Pose information and the constraint conditions are input into an acceleration and deceleration algorithm and an arc transition model to obtain a transition trajectory, and the transition trajectory is combined with a linear trajectory to obtain a complete measurement trajectory. The angle, the speed and the angular speed of each joint are obtained by means of inverse kinematics and an inverse Jacobian matrix, joint space quintic polynomial interpolation is carried out at the abrupt change position of the speed, the continuity and smoothness of the speed and the acceleration are ensured, the self-driven articulated arm measuring machine is prevented from being impacted by the abrupt change of the speed and the acceleration, and the measuring precision is improved. According to the planning method, high-precision measurement of the self-driven articulated arm measuring machine can be realized, and the method can also be applied to trajectory planning of an industrial robot.

Owner:ANHUI UNIV OF SCI & TECH

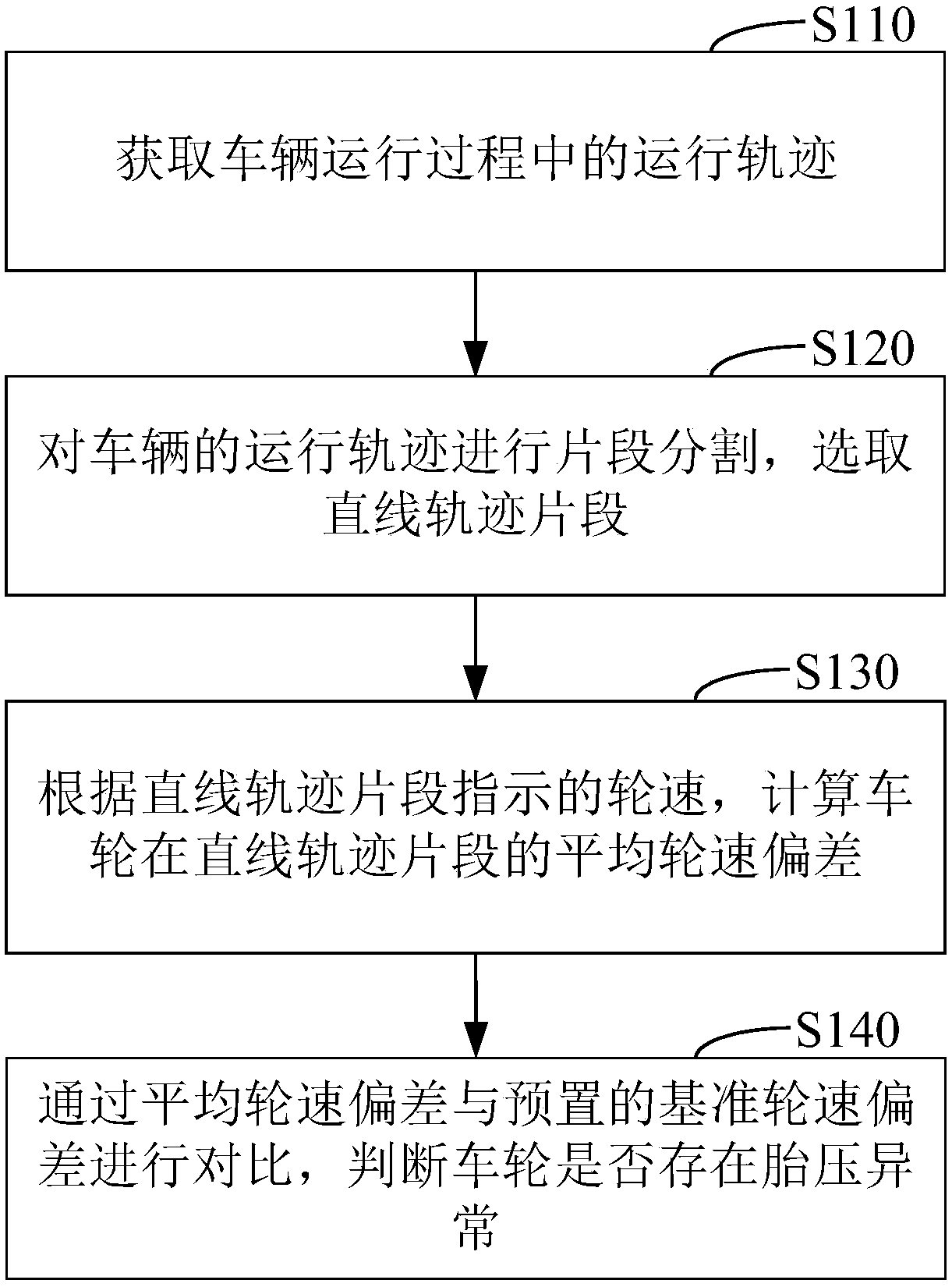

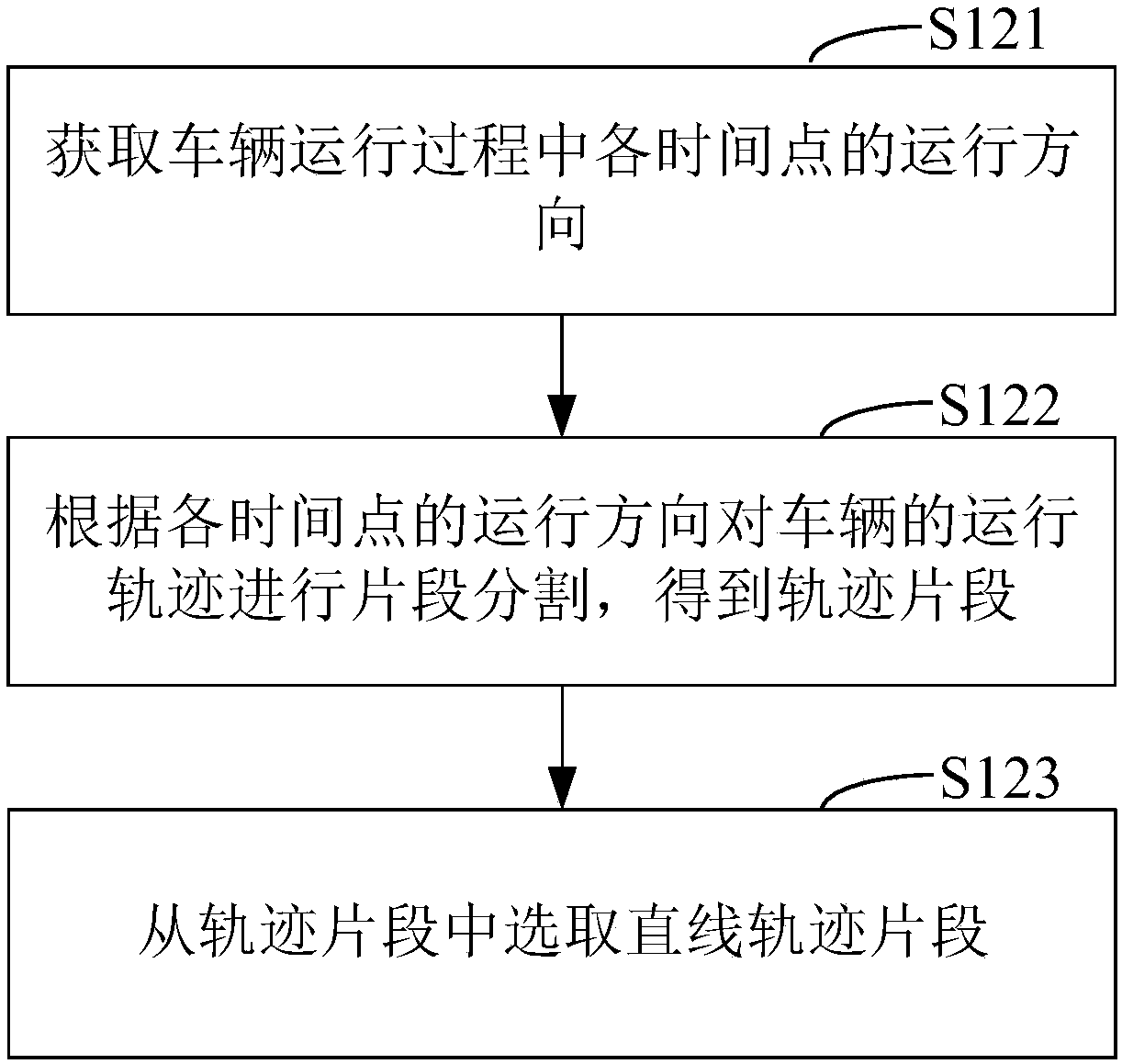

Tire pressure detection method and device and terminal

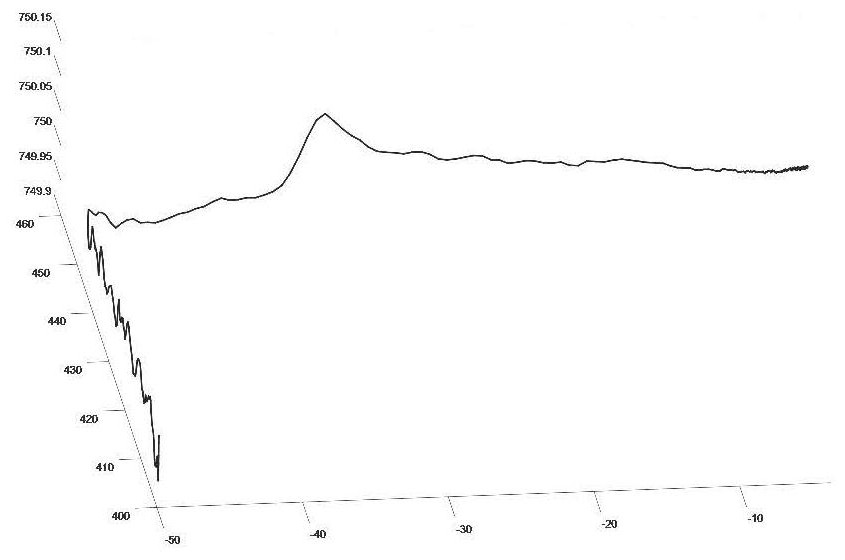

ActiveCN108454327AImprove convenienceImprove efficiencyTyre measurementsStraight line trajectoryTire pressure

The invention discloses a tire pressure detection and device and a terminal, and belongs to the technical field of computer application. The method comprises the steps that the moving trajectory in the vehicle running process is obtained, the moving trajectory of a vehicle is subjected to segmentation, and a straight line trajectory segment is selected; according to the wheel speed indicated by the straight line trajectory segment, the average wheel speed deviation of a wheel on the straight line trajectory segment is calculated, and by comparing the average wheel speed deviation with a presetreference wheel speed deviation, whether or not tire pressure abnormity exists on the wheel is judged. According to the tire pressure detection and device and the terminal, convenience and efficiencyof tire pressure detection in the vehicle running process can be improved.

Owner:LAUNCH TECH CO LTD

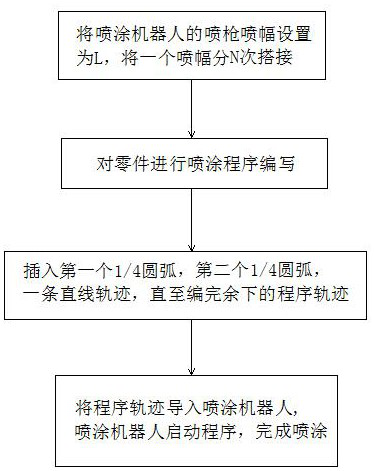

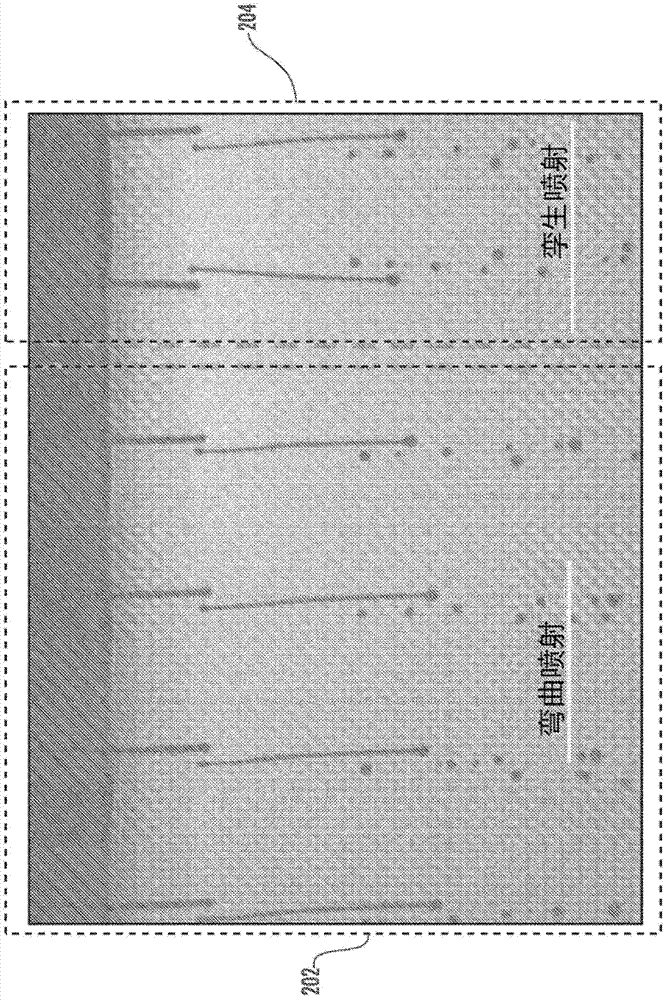

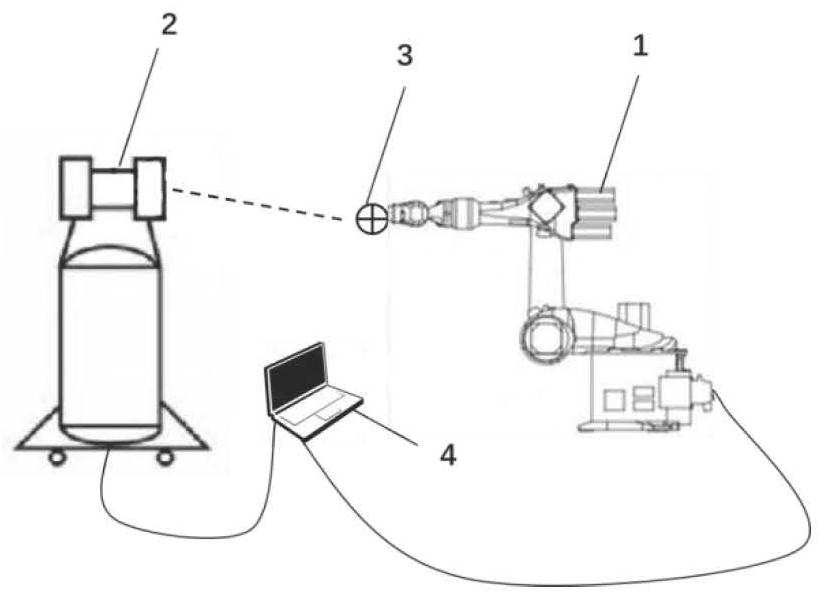

Method for improving thickness uniformity of automatic spraying coating

ActiveCN112691864AGuaranteed uniformityImprove spraying efficiencyLiquid surface applicatorsSpraying apparatusSpray coatingEngineering

The invention discloses a method for improving the thickness uniformity of an automatic spraying coating, and belongs to the technical field of robot spraying. The method is characterized by comprising the following steps that a, the spraying width of a spraying gun of a spraying robot is set to be L, and one spraying width is overlapped for N times; b, spraying program writing is performed for a part; c, a first 1 / 4 arc is inserted, and meanwhile, a gun opening instruction is set at the end point of the arc; then a second 1 / 4 arc is inserted; a straight line track is inserted again, the straight line track is parallel to the previous straight line track, and the starting point of the straight line is not provided with a gun opening and closing instruction; the operation is performed until the rest program tracks are written; and d, the program tracks are guided into the spraying robot, the part is located in a spraying area, paint is added, the spraying robot starts a program, and spraying is completed. For the concave or narrow complex part, all curved surfaces can be continuously sprayed at a time, the thickness uniformity of the coatings of the left overlapping area and the right overlapping area of the part is effectively guaranteed, and the spraying efficiency is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Method and apparatus to eject drops having straight trajectories

Described herein is a method and apparatus for driving a drop ejection device to produce drops having straight trajectories. In one embodiment, a method for driving a drop ejection device having an actuator includes building a drop of a fluid with at least one drive pulse by applying a multi- pulse waveform having the at least one drive pulse and a straightening pulse to the actuator. Next, the method includes causing the drop ejection device to eject the drop with a straight trajectory in response to the pulses of the multi-pulse waveform. The straightening pulse is designed to ensure that the drop is ejected without a drop trajectory error.

Owner:FUJIFILM DIMATIX

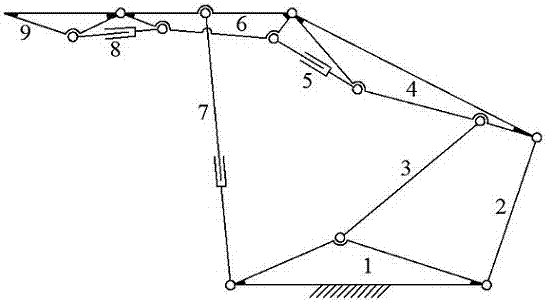

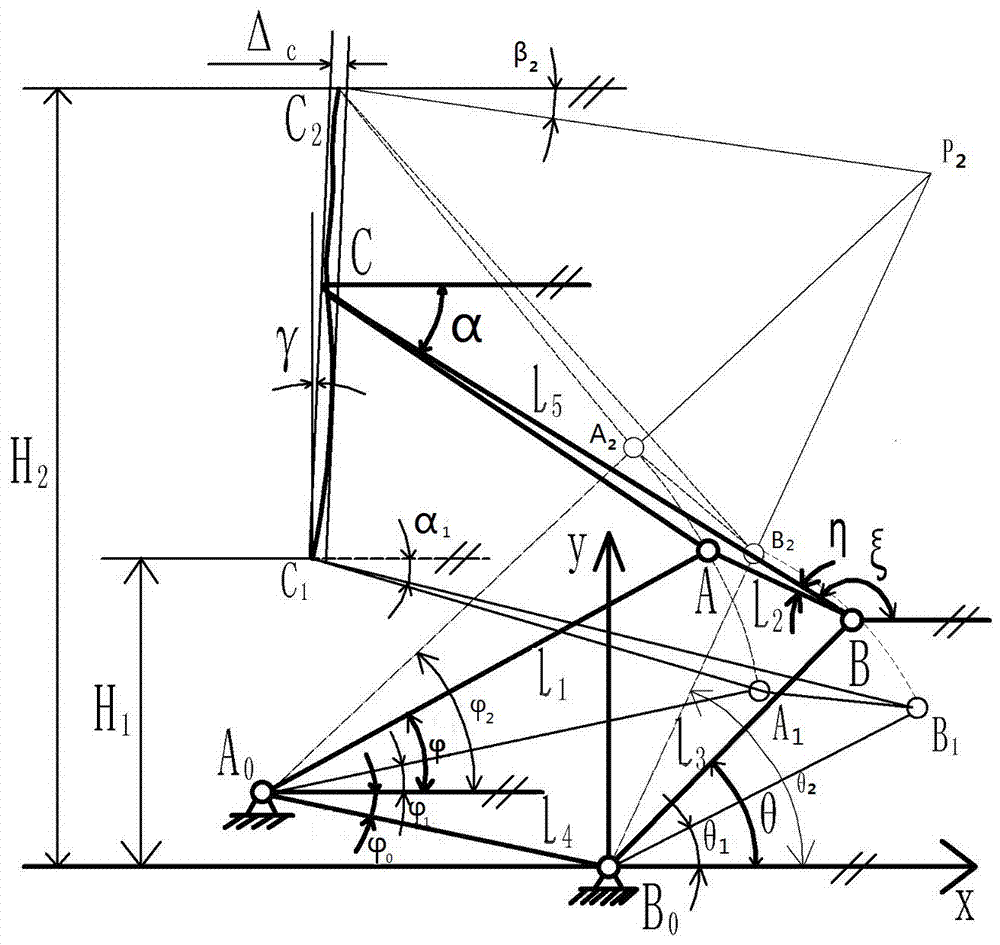

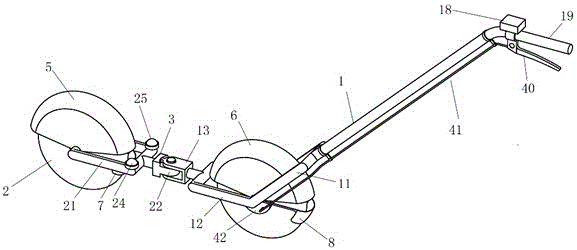

Hydraulic support approximate straight-line track four-rod mechanism

ActiveCN106948850AImproved ability to control top decksImprove abilitiesMine roof supportsWorking rangeEngineering

The invention relates to the technical field of moving mechanisms, in particular to a hydraulic support approximate straight-line track four-rod mechanism comprising a hydraulic support and a four-rod mechanism body. The hydraulic support comprises a balance jack, a rear beam, a front beam jack and a front beam. The rear beam is hinged to the front beam. The four-rod mechanism body comprises a base, a front connecting frame rod, a rear connecting frame rod and a shield beam. The front connecting frame rod and the rear connecting frame rod are both hinged between the base and the shield beam. A vertical column is arranged between the base and the rear beam. The shield beam is hinged to the rear beam. The balance jack is located at the hinging position of the shield beam and the rear beam. A front end point of the front beam is C, when the vertical column contracts to a maximum extent, the front end point C of the front beam moves downward to a point C1, and the vertical height of C1 from the ground is H1 which is equal to 935 mm. When the vertical column extends to a maximum extent, the front end point C of the front beam moves downward to a point C2, and the vertical height of C2 from the ground is H2 which is equal to 2635 mm. The track of the point C is an approximate straight line in a mining height area [H1, H2], and the horizontal oscillation range of the point C is smaller than or equal to 30 mm. According to the technical scheme, the horizontal oscillation range of the front end of the front beam in the working range can be reduced.

Owner:CHONGQING VOCATIONAL INST OF ENG

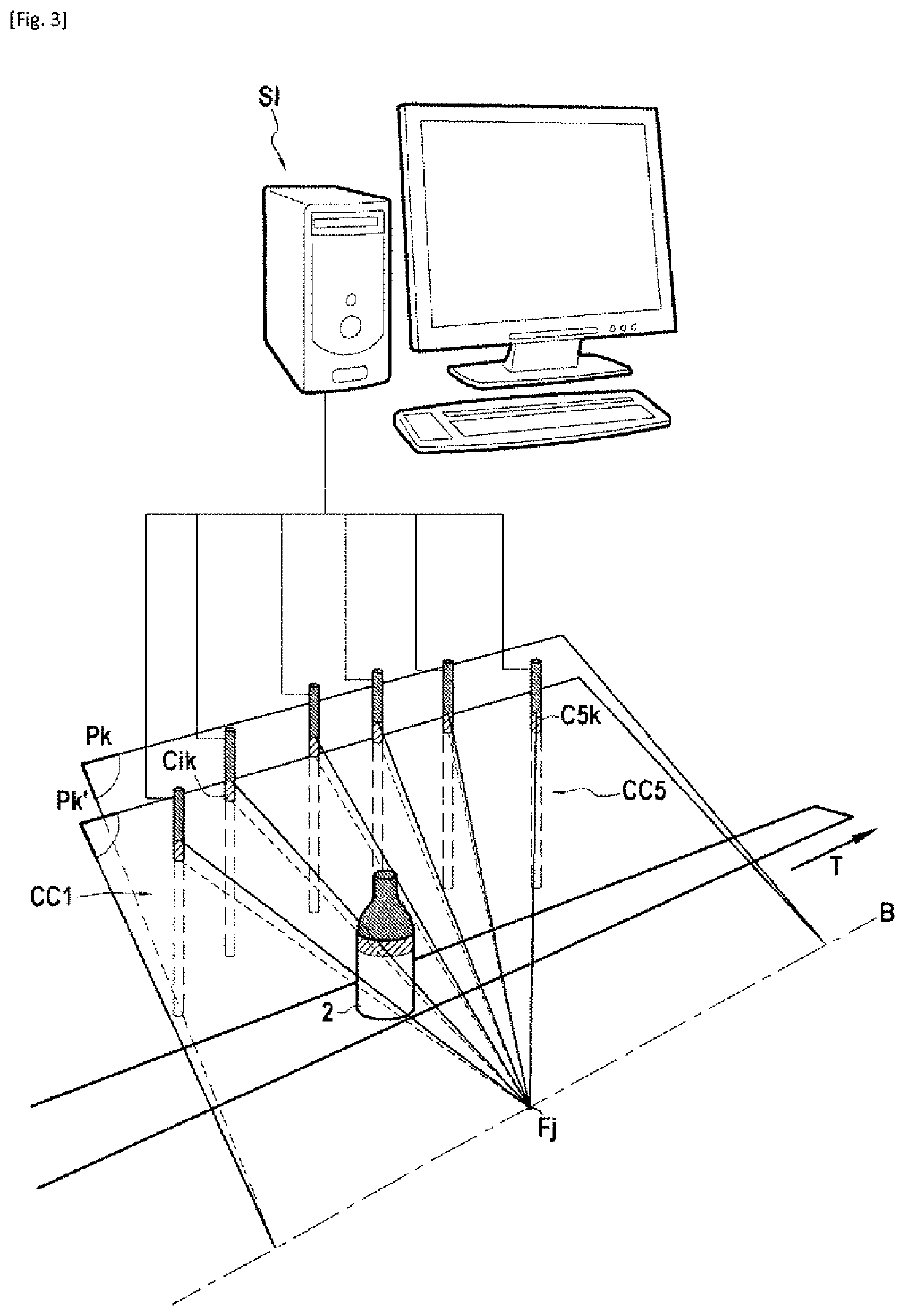

Method and installation for the in-line dimensional control of manufactured objects

PendingUS20220237761A1Television system detailsDetails involving processing stepsAlgorithmEngineering

The invention relates to a method and an installation for automatically measuring linear dimensions of manufactured objects (2) of a series comprising:the disposition of at least one focal point (Fj) of X-rays, on a same base straight line parallel to the rectilinear trajectory of displacement of the objects and of one or several image sensors (Ci);the acquisition, for each object during its displacement, of a set of one-dimensional images comprising, for a number (NK) of distinct section planes (Pk) containing the base straight line, a number (NP) of said images obtained along at least three different directions of projection (Dijk) in the section plane;for each object, and for each distinct section plane (Pk), the determination, from the images obtained, of a delineation of the object in the considered section plane (Pk).

Owner:TIAMA SOCIETE ANONYME

Multi-robot fiber placement track fixed angle design method

PendingCN110704991AReduce difficultyReduce development costsGeometric CADSimulationSoftware development

According to a multi-robot fiber placement track fixed angle design method, an out-of-plane reference line is selected, a fixed angle track is generated, the method is based on gridding curved surfacetrack planning, the application range is wide, and the method is not limited by the shape and type of the curved surface; the problem of solving a curve track on a free-form surface is converted intothe problem of solving a straight line track on a micro plane, in addition, track planning is convenient to perform due to selection of a reference line, the track planning difficulty is effectivelyreduced, and the operation efficiency is high; independent trajectory planning software can be developed according to algorithm characteristics, the development cost is low, and algorithm improvementand version upgrading are easy.

Owner:南京康德复合材料有限公司

Method for recording and predicting position data for a self-propelled wheeled vehicle

ActiveUS10729100B2Safe and precise determinationRoad vehicles traffic controlAnimal feeding devicesOn boardClassical mechanics

Owner:MINKPAPIR

A Method for Improving the Uniformity of Coating Thickness in Automatic Spraying

ActiveCN112691864BGuaranteed uniformityImprove spraying efficiencyLiquid surface applicatorsSpraying apparatusSpray coatingEngineering

The invention discloses a method for improving the uniformity of coating thickness in automatic spraying, which belongs to the technical field of robot spraying, and is characterized in that it comprises the following steps: a. Set the spraying width of the spraying gun of the spraying robot to L, divide one spraying width into N Second lap; b. Write the spraying program for the parts; c. Insert the first 1 / 4 arc, and set the shooting command at the end of the arc; then insert the second 1 / 4 arc; then insert a straight line track, the straight track is parallel to the last straight track, and the starting point of the straight line is not provided with a switch gun command; until the rest of the program track is compiled; d, the program track is imported into the spraying robot, and the parts are positioned in the spraying area, and the paint is added. The spraying robot starts the program and completes the spraying. For complex parts with concave shape or narrow space, the invention can continuously spray all the curved surfaces at one time, effectively guarantee the uniformity of the coating thickness in the left and right overlapping areas of the parts, and improve the spraying efficiency.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

A Trajectory Accuracy Analysis Method for Industrial Robots Based on Continuous Dynamic Time Warping

ActiveCN112549019BImprove accuracyAvoid the problem of mapping errorsProgramme-controlled manipulatorDynamic planningEngineering

The invention discloses a method for analyzing the trajectory accuracy of an industrial robot based on continuous dynamic time warping. Based on the idea of dynamic programming, the optimal matching point in two sequences is searched step by step. Define the cumulative distance matrix D as the similarity measure of two trajectory sequences. The two sequences are interpolated, and the regularization path satisfies a certain optimal strategy to minimize the cumulative distance, and the backtracking method is used to search from the back to the front to minimize the cumulative distance of the two sequences. The invention adopts the CDTW algorithm and analyzes the mapping between track points to solve the problem that the command track and the actual track are affected by the motion speed and motion deviation of the robot, the sampling frequency of the measurement system, and the measurement error when the plane is constructed by the non-linear track method. Mapping errors occur between points, resulting in large trajectory measurement errors. By measuring and analyzing the trajectory accuracy of industrial robots, the problem of mapping errors in the standard method can be effectively avoided and the trajectory accuracy can be improved.

Owner:BEIJING UNIV OF TECH

Method for obtaining horizon line in curved road monitoring environment

ActiveCN110675362AEasy accessImprove accuracyImage enhancementImage analysisComputer graphics (images)Engineering

The invention provides a method for obtaining a horizon line in curved road monitoring environment, and the method comprises: the step 1, dividing a background region and a movement region in a curvedroad image, and obtaining a plurality of vehicle tracks in the movement region; the step 2, screening from the plurality of vehicle tracks to obtain a vehicle linear track set and a vehicle body edgelinear set; the step 3, selecting a vehicle body edge straight line perpendicular to any vehicle straight line track in the vehicle straight line track set from the vehicle body edge straight line set to serve as a vehicle transverse edge straight line, and a vehicle transverse edge straight line set is obtained; the step 4, mapping the vehicle straight line track set and the vehicle transverse edge straight line set into a diamond space to obtain two broken line sets in the diamond space respectively, and obtaining an intersection point of the two broken line sets, namely a vanishing point in the diamond space; and the step 5, converting the vanishing points in the diamond space into an image space to obtain vanishing points (u0, v0) and (u1, v1) in the image space, and taking the extension of a connecting straight line of the vanishing points (u0, v0) and (u1, v1) as a horizon line.

Owner:CHANGAN UNIV

A Distance Measuring Vehicle with Straight Track Monitoring Function

ActiveCN104111050BSolve the inaccurate rangingImprove accuracyDistance measurementEngineeringStraight line trajectory

The invention relates to a distance measurement trolley with a linear track monitoring function. A left early-warning lamp and a right early-warning lamp are arranged at two ends of a front wheel bracket respectively, a guide block is horizontally arranged on a distance measurement wheel connection member, a left projection and a right projection are horizontally arranged in the middle of a block, the guide block abuts to the middle of the block and is located between the left projection and the right projection, a left electric contact piece is arranged on the left projection, a right electric contact piece is arranged on the right projection, an electric contact block is disposed in the middle of the guide block, the left electric contact piece is connected with the right early-warning lamp through a wire, the right electric contact piece is connected with the left early-warning lamp through a wire, and the electric contact block is connected with a battery through a wire to be respectively connected with the left early-warning lamp and the right early-warning lamp. Compared with distance measurement trolleys in the prior art, the distance measurement trolley has the advantages that the defect that pushing distance measurement of the distance measurement trolleys cannot guarantee linear tracks is overcome; linear pushing of the distance measurement trolley in the process of pushing distance measurement can be real-timely monitored, and accuracy of distance measurement is improved.

Owner:安徽兆尹安联科技有限公司

Off road navigation system

InactiveCN101936743BInstruments for road network navigationNavigational calculation instrumentsTerrainUser input

A method of operating a navigation system in a vehicle may entail invoking an off-road mode of the navigation system; displaying a first off-road terrain on a navigation system display; displaying a first present location of the vehicle on the display, inputting a first user-input off-road destination into the navigation system; inputting a first user-input off-road waypoint into the navigation system; displaying straight line trajectories between the start point, the first user-input off-road waypoint and the destination on a display of the navigation system and displaying a first real-time path of on-screen breadcrumbs as the vehicle travels off-road in current or real-time; shifting on the display, each user-entered off-road waypoint to a closest on-screen breadcrumb of the first real-time path; shifting on the display, the user-entered destination to the closest on-screen breadcrumb; and storing the first real-time path in a memory of a navigation control unit.

Owner:DENSO CORP +1

Accurate design method for space envelope forming envelope die under linear track

ActiveCN111104715AImprove design accuracyGuaranteed extraction accuracyGeometric CADDesign optimisation/simulationRectangular coordinatesEngineering

The invention relates to an accurate design method for a space envelope forming envelope die under a linear track. The accurate design method comprises the following steps: S1, establishing a rectangular coordinate system; S2, determining an envelope axis; in the xoy plane, selecting a straight line passing through a point O as an envelope axis, wherein the envelope axis cannot penetrate through the upper surface of the component, and the included angle between the envelope axis and the x axis is theta; S3, enabling the envelope axis determined in the step S2 to serve as a boundary, dividing the upper surface of the component into a left area and a right area, wherein the coordinate of any point on the upper surface of the component is (x, y, z); and S4, selecting any point M (Mx, My, Mz)of the right area, mapping the point M upwards and anticlockwise around the envelope axis, to ensure that the distances from the point M and the mapping point to the envelope axis are equal, so that the mapping point M '(M'x, M'y, M'z) is any point on the right area of an envelope mold. the enveloping mold needed in the linear track enveloping forming process of the workpiece can be obtained, andthe design precision of the enveloping die is improved.

Owner:WUHAN UNIV OF TECH

Fly-cutting trajectory planning method, fly-cutting control method and fly-cutting system

ActiveCN113296470AReduce the frequency of repeating the above action processReasonable path planningNumerical controlControl engineeringTrajectory planning

The invention relates to the technical field of component machining, in particular to a fly-cutting trajectory planning method, a fly-cutting control method and a fly-cutting system. The fly-cutting trajectory planning method comprises the following steps of screening out linear trajectory segments from a to-be-processed primitive; grouping the screened linear track segments according to whether the linear track segments are collinear or not; sequentially connecting the collinear linear trajectory sections through connecting straight lines to form at least one linear fly-cutting trajectory; when the number of the linear fly-cutting trajectory is one, taking the linear fly-cutting trajectory as a final fly-cutting trajectory; and when the number of the linear fly-cutting trajectories is multiple, connecting the adjacent linear fly-cutting trajectories in a snakelike mode through the connecting steering lines, so that a final fly-cutting trajectory is formed. According to the fly-cutting control method, control is performed according to the final fly-cutting trajectory. The fly-cutting system adopts the fly-cutting control method for cutting. According to the fly-cutting trajectory planning method, the fly-cutting control method and the fly-cutting system, more reasonable path planning is provided for a cutting head through the final fly-cutting trajectory, the machining time is saved, and the machining efficiency is improved.

Owner:ZHEJIANG RECI LASER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com