Method for improving thickness uniformity of automatic spraying coating

A technology of coating thickness and automatic spraying, which is applied in coatings, devices for coating liquid on the surface, spraying devices, etc., can solve the problem of inability to ensure the uniformity of coating thickness in the left and right overlapping areas of parts, and the inability to continuously spray curved surfaces at one time and other problems to achieve the effect of improving spraying efficiency and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

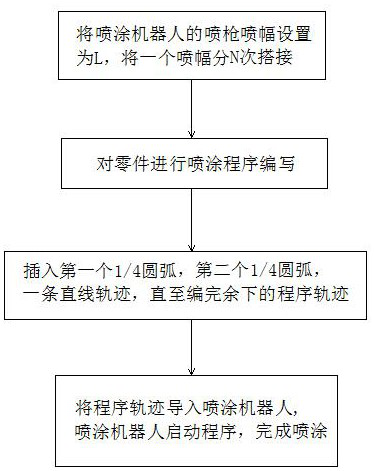

[0030] see figure 1 , a method for improving the uniformity of automatic spray coating thickness, comprising the steps of:

[0031] a. Set the spraying width of the spray gun of the spraying robot to L, divide one spraying width into N times to overlap, and determine the front and rear overlapping distance D 1 =L / N, arc radius R= D 1 / 2;

[0032] b. Write the spraying program for the parts, first determine the area to be sprayed, determine the left and right boundaries of the two different spraying areas, then insert the starting point in the area to be sprayed, and set the starting point to shoot the command, and then make a straight line trajectory, the distance between the end point of the straight trajectory and the boundary is D 2 , and at the same time insert the command to close the gun at the end of the straight line trajectory;

[0033] c. Insert the first 1 / 4 arc, and set the shooting command at the end of the arc; then insert the second 1 / 4 arc; then insert a st...

Embodiment 2

[0037] see figure 1 , a method for improving the uniformity of automatic spray coating thickness, comprising the steps of:

[0038] a. Set the spraying width of the spray gun of the spraying robot to L, divide one spraying width into N times to overlap, and determine the front and rear overlapping distance D 1 =L / N, arc radius R= D 1 / 2;

[0039] b. Write the spraying program for the parts, first determine the area to be sprayed, determine the left and right boundaries of the two different spraying areas, then insert the starting point in the area to be sprayed, and set the starting point to shoot the command, and then make a straight line trajectory, the distance between the end point of the straight trajectory and the boundary is D 2 , and at the same time insert the command to close the gun at the end of the straight line trajectory;

[0040] c. Insert the first 1 / 4 arc, and set the shooting command at the end of the arc; then insert the second 1 / 4 arc; then insert a st...

Embodiment 3

[0045] see figure 1 , a method for improving the uniformity of automatic spray coating thickness, comprising the steps of:

[0046] a. Set the spraying width of the spray gun of the spraying robot to L, divide one spraying width into N times to overlap, and determine the front and rear overlapping distance D 1 =L / N, arc radius R= D 1 / 2;

[0047] b. Write the spraying program for the parts, first determine the area to be sprayed, determine the left and right boundaries of the two different spraying areas, then insert the starting point in the area to be sprayed, and set the starting point to shoot the command, and then make a straight line trajectory, the distance between the end point of the straight trajectory and the boundary is D 2 , and at the same time insert the command to close the gun at the end of the straight line trajectory;

[0048] c. Insert the first 1 / 4 arc, and set the shooting command at the end of the arc; then insert the second 1 / 4 arc; then insert a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com