Method and apparatus to eject drops having straight trajectories

A technology of droplets and equipment, applied in the field of spraying droplets with straight trajectories, can solve problems such as image quality deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

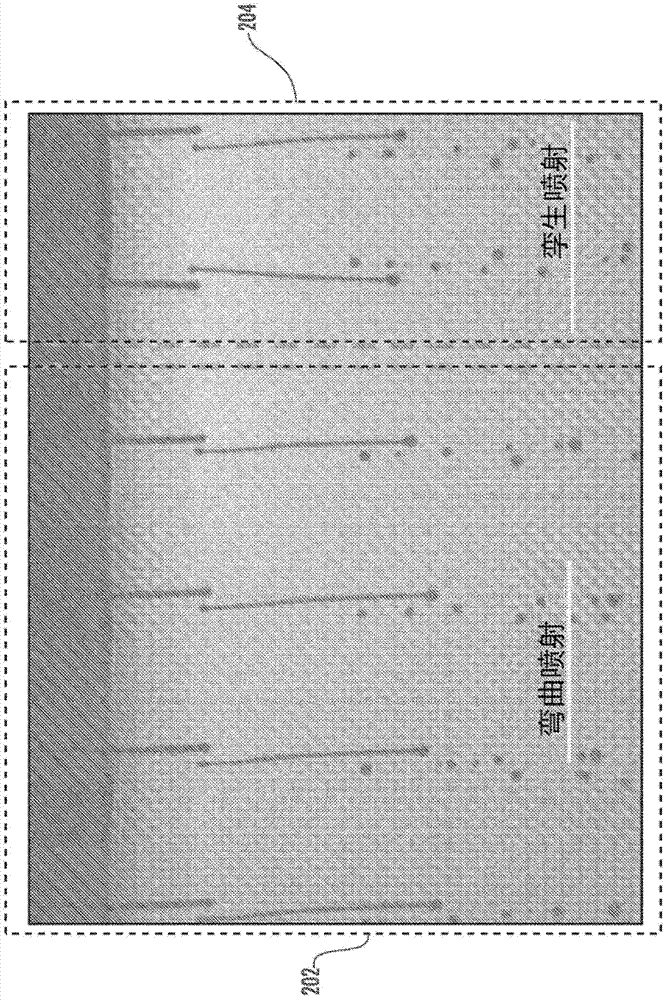

Image

Examples

Embodiment Construction

[0028] Described herein is a method and apparatus for driving a drop ejection device to produce droplets ejected in a straight line trajectory. In one embodiment, a method for driving a droplet ejection device having an actuator comprises building a fluid with at least one drive pulse by applying a multi-pulse waveform having at least one drive pulse and a straightening pulse to the actuator. of droplets. Next, the method includes causing the droplet ejection device to eject a droplet having a linear trajectory in response to the pulses of the multi-pulse waveform. Straightening pulses are designed to ensure that droplets are ejected without droplet trajectory errors.

[0029] To reduce potential droplet trajectory errors, the straightening pulse causes straightening of the droplet formed by the at least one drive pulse by raising the meniscus position of the fluid past the nozzle. The straightening pulse also reduces asymmetric wetting problems by changing the properties of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com