Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Staple line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A staple line leak usually happens in the 3rd or 4th week after surgery, when a few staples pop out (usually for unknown reasons). This can allow gastric contents to leak out from the sleeve and into the abdominal cavity. Most of the time when this happens it results in a small fluid collection,...

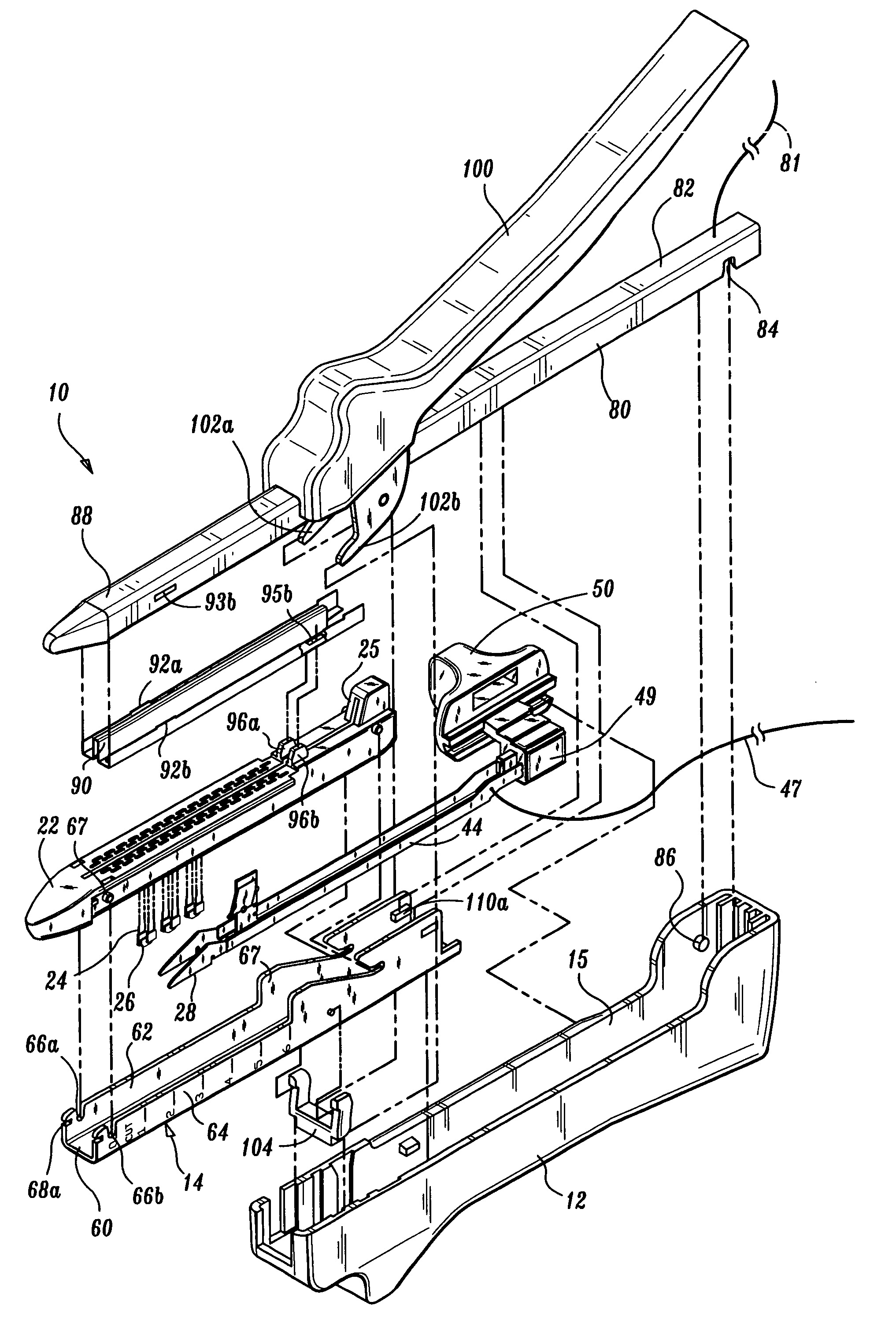

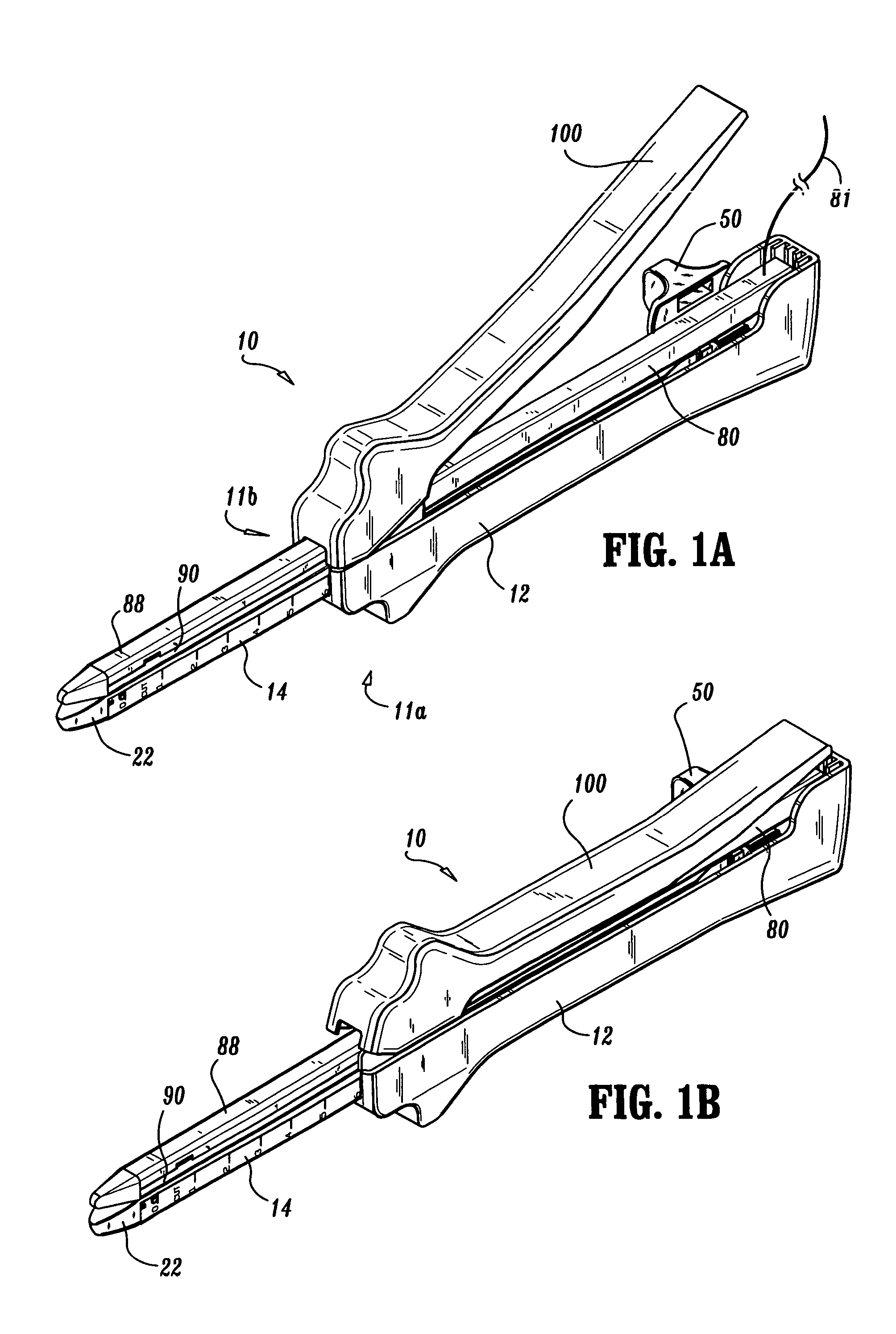

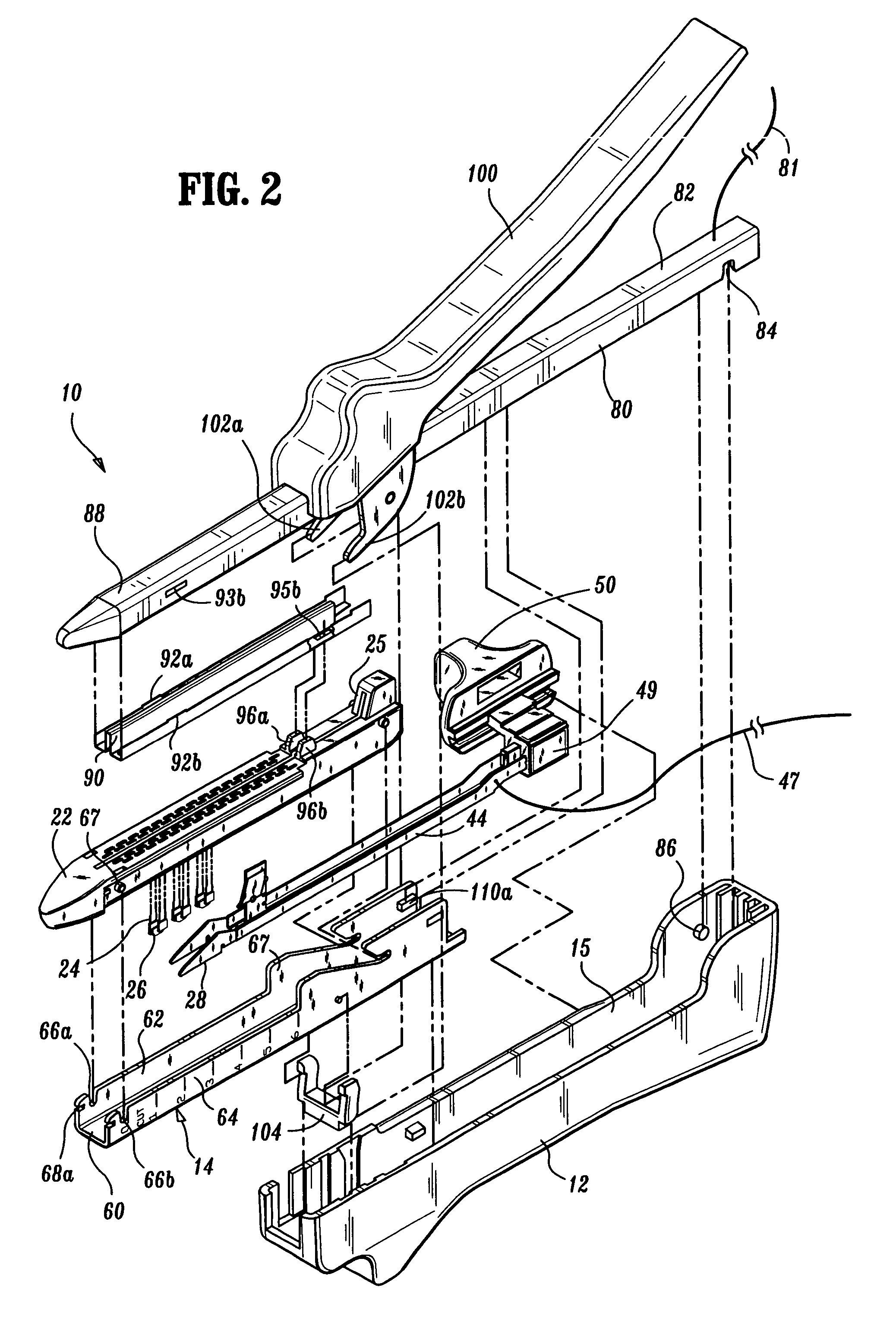

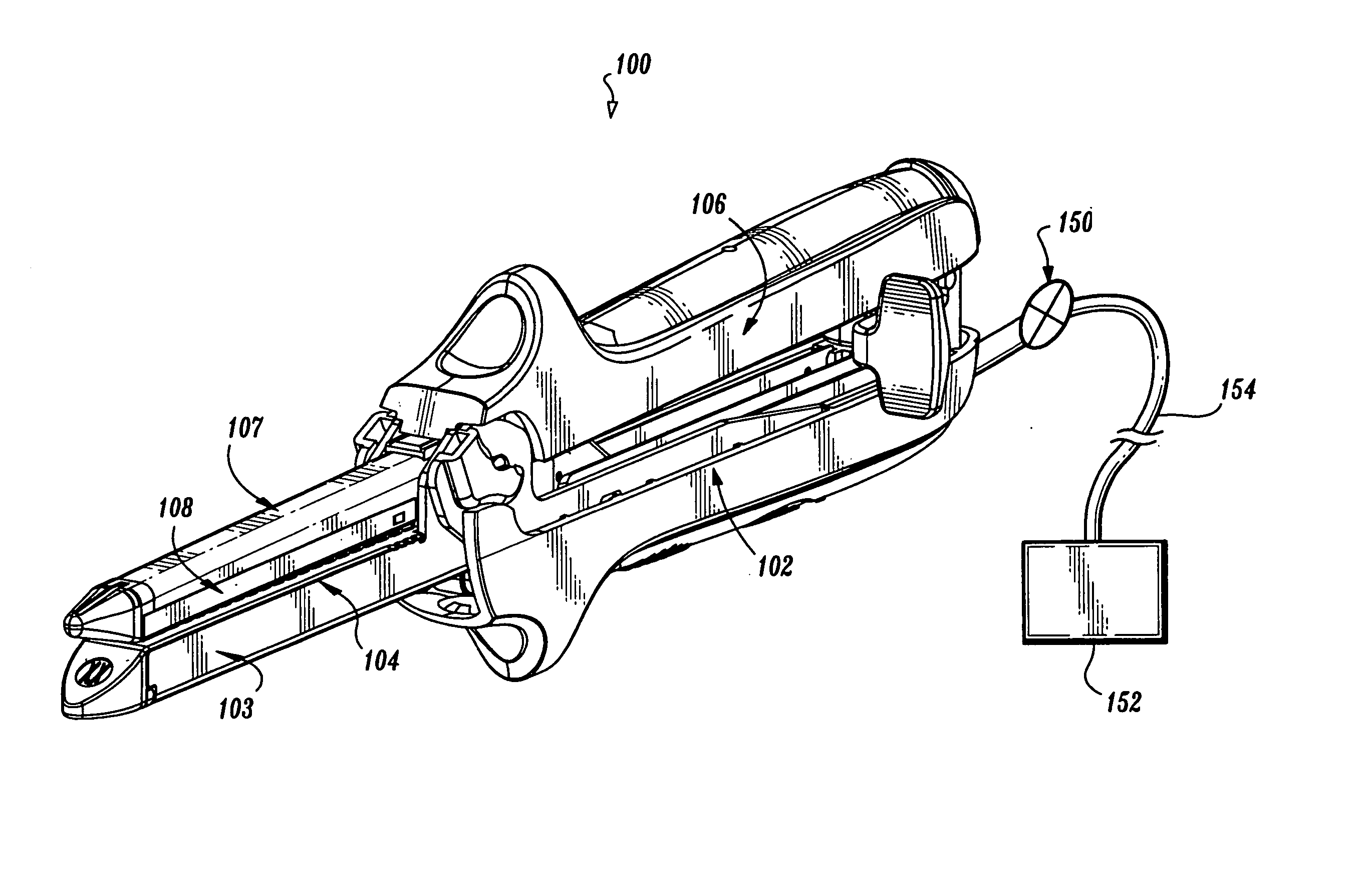

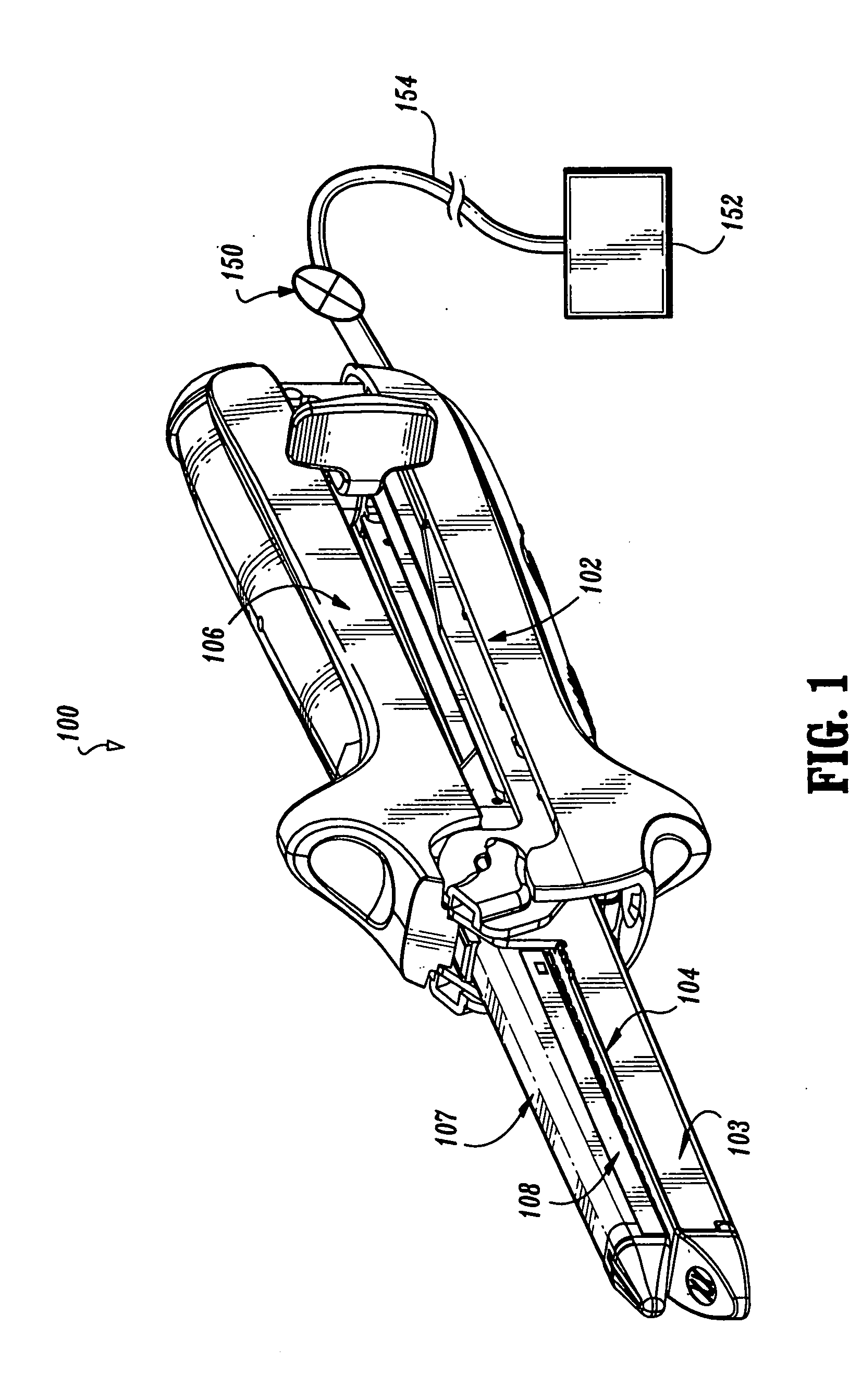

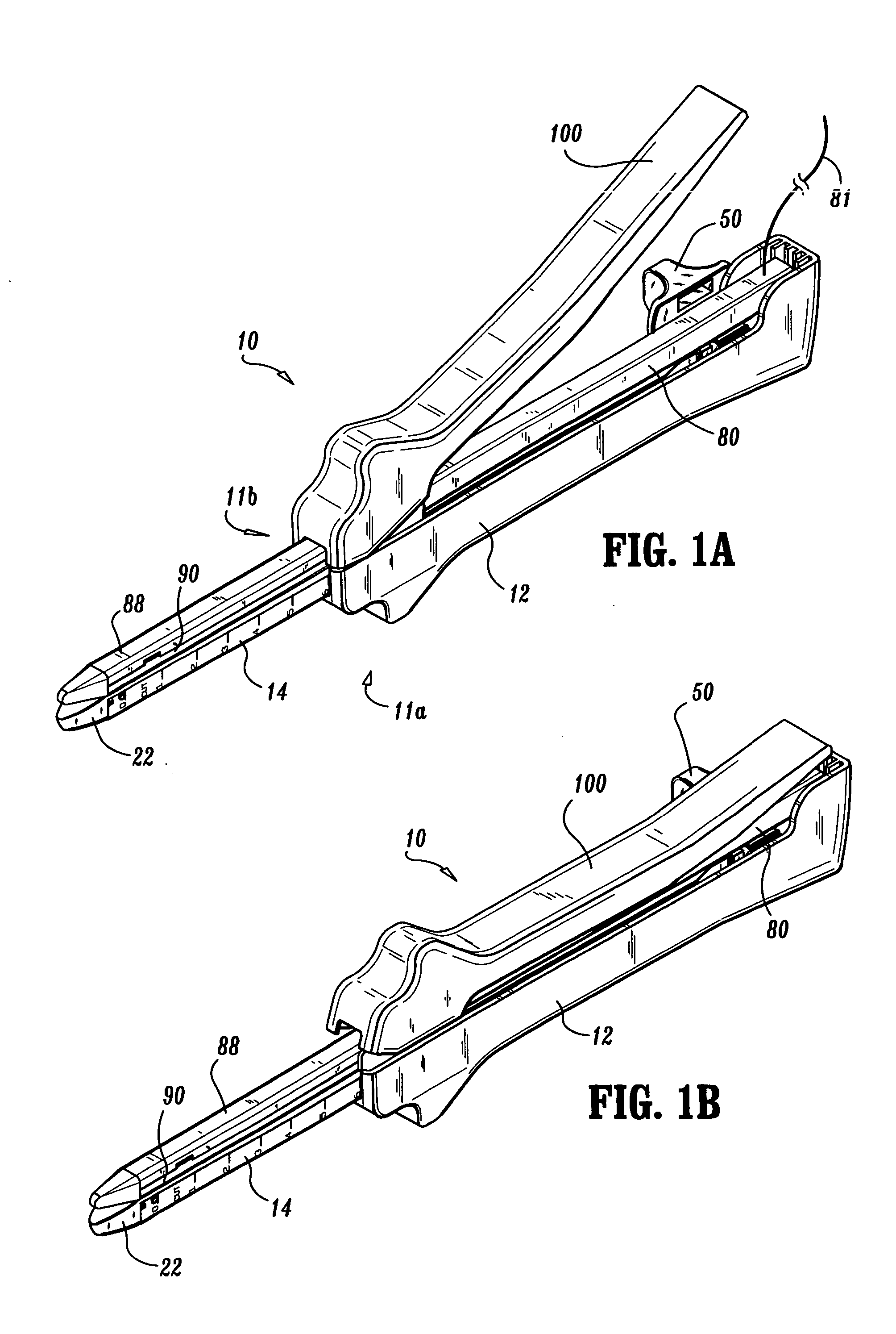

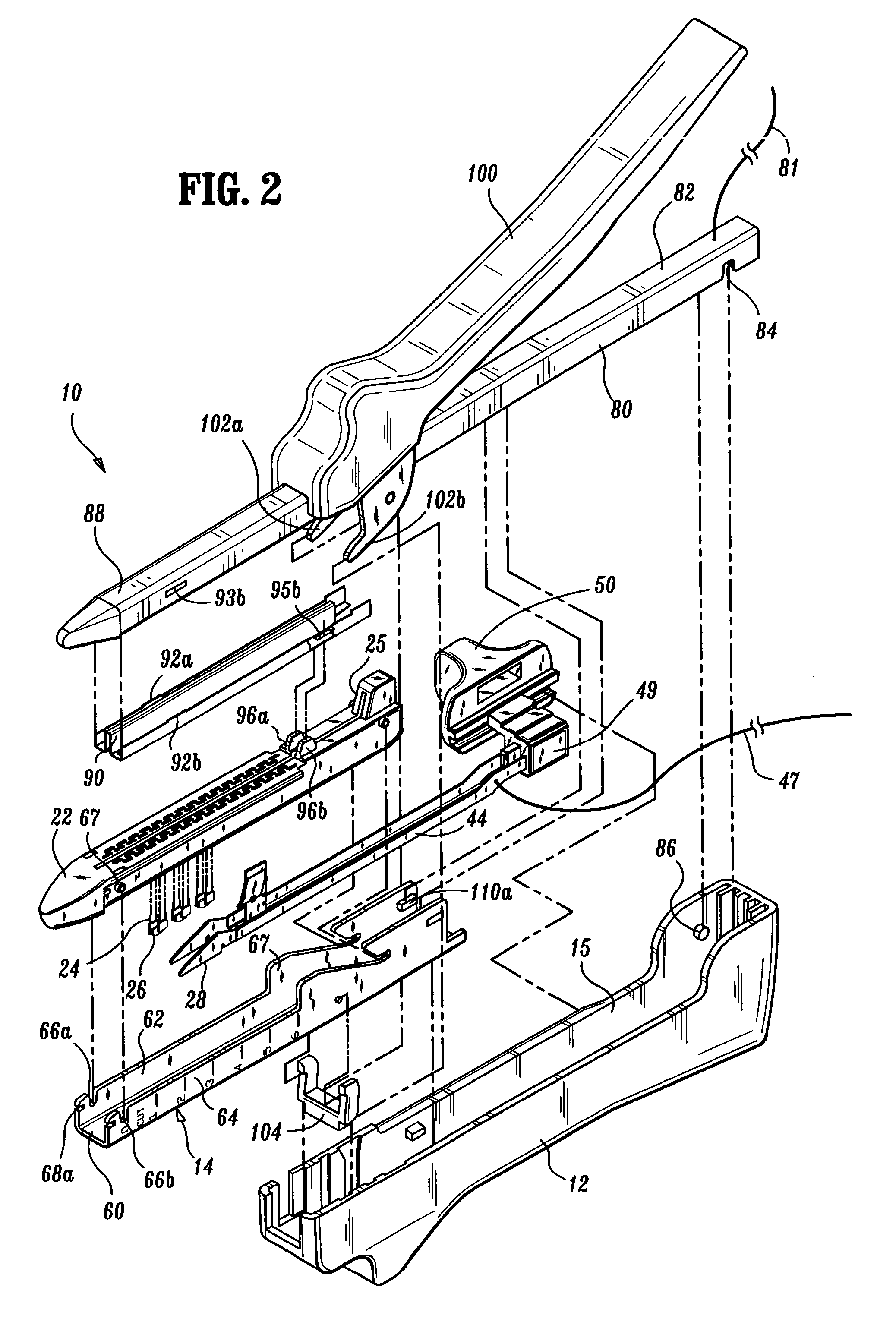

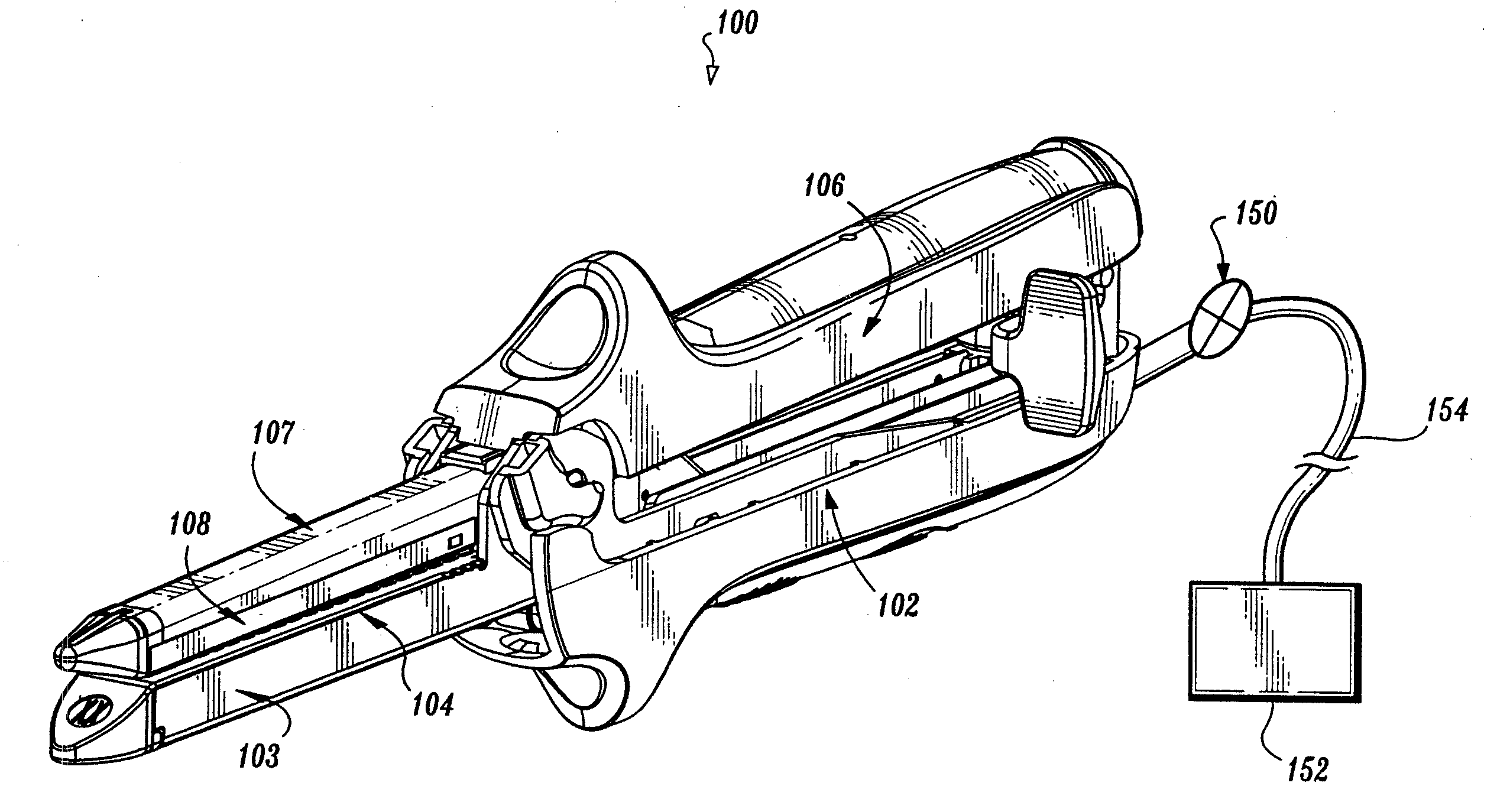

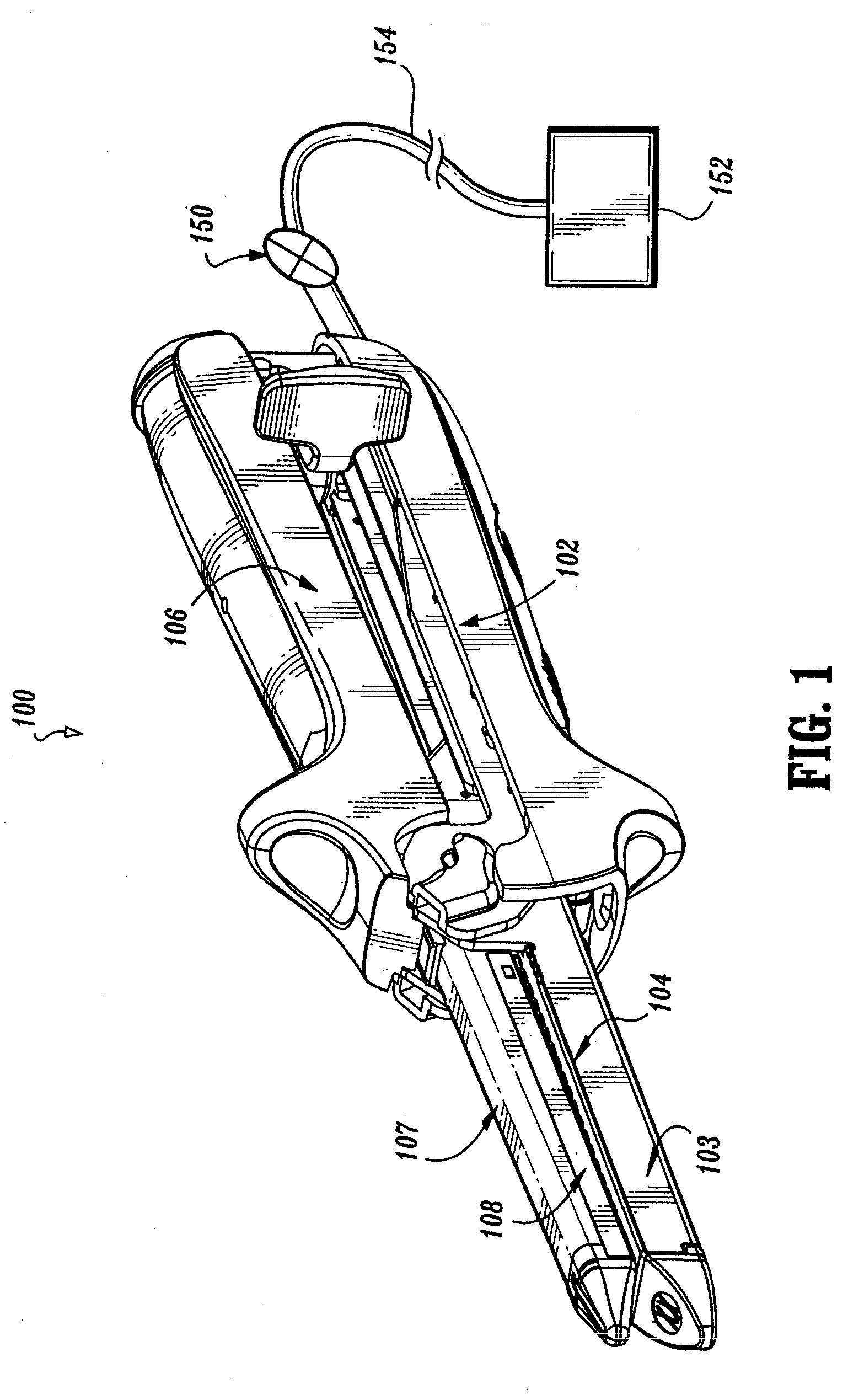

Electrosurgical stapling apparatus

InactiveUS7207471B2Reduces or prevents staple line and cut line bleedingShort and strengthSuture equipmentsStapling toolsStaple lineEngineering

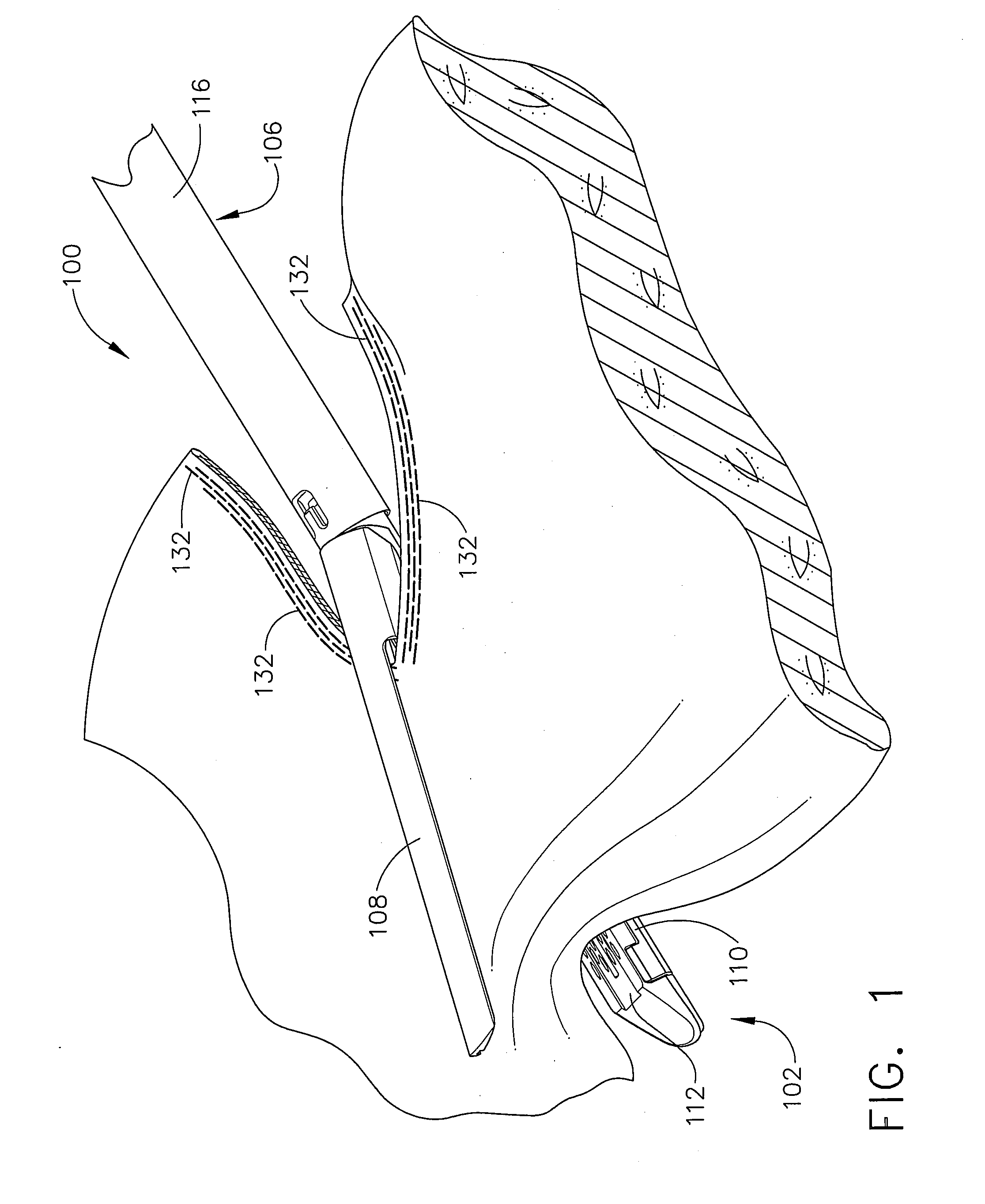

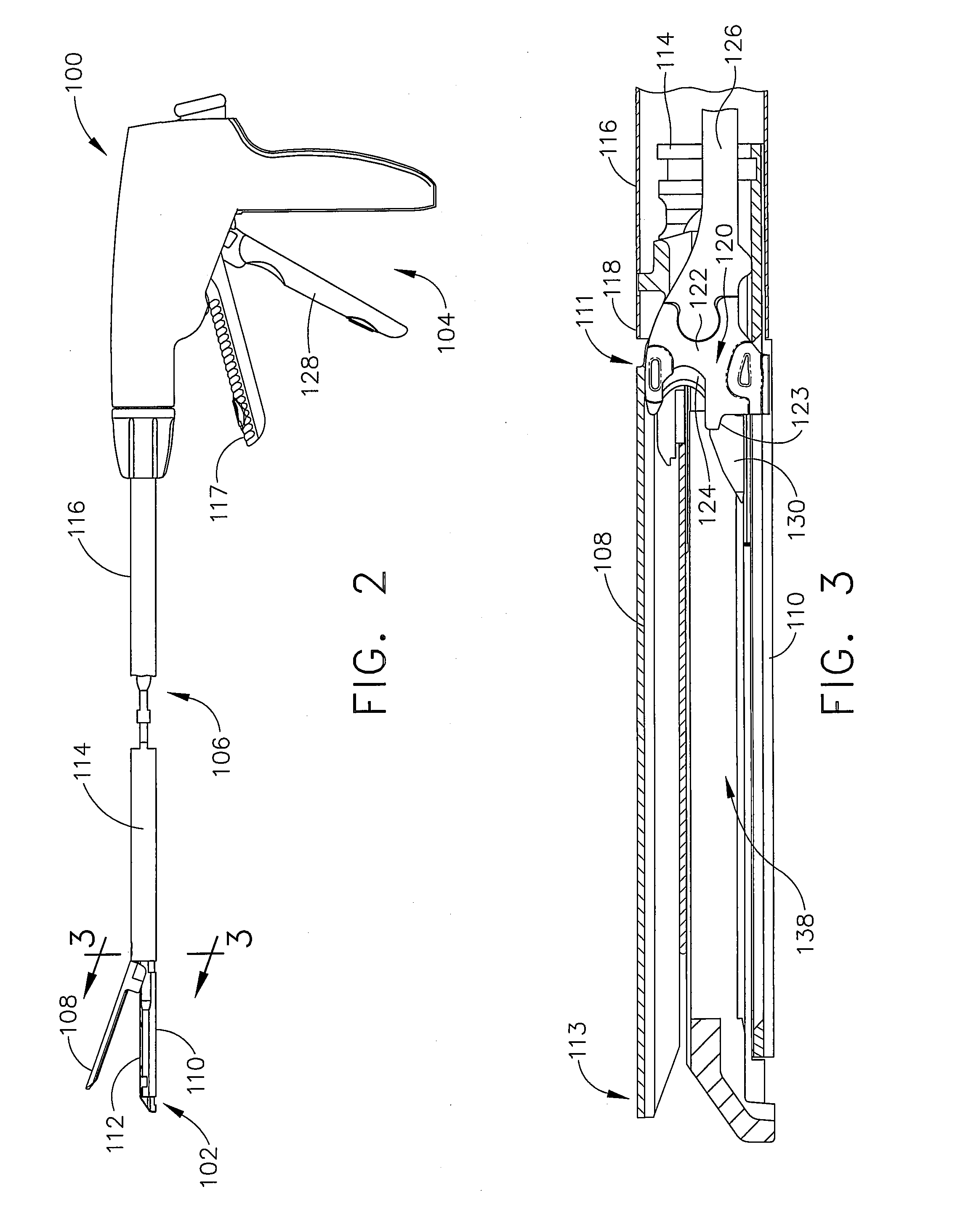

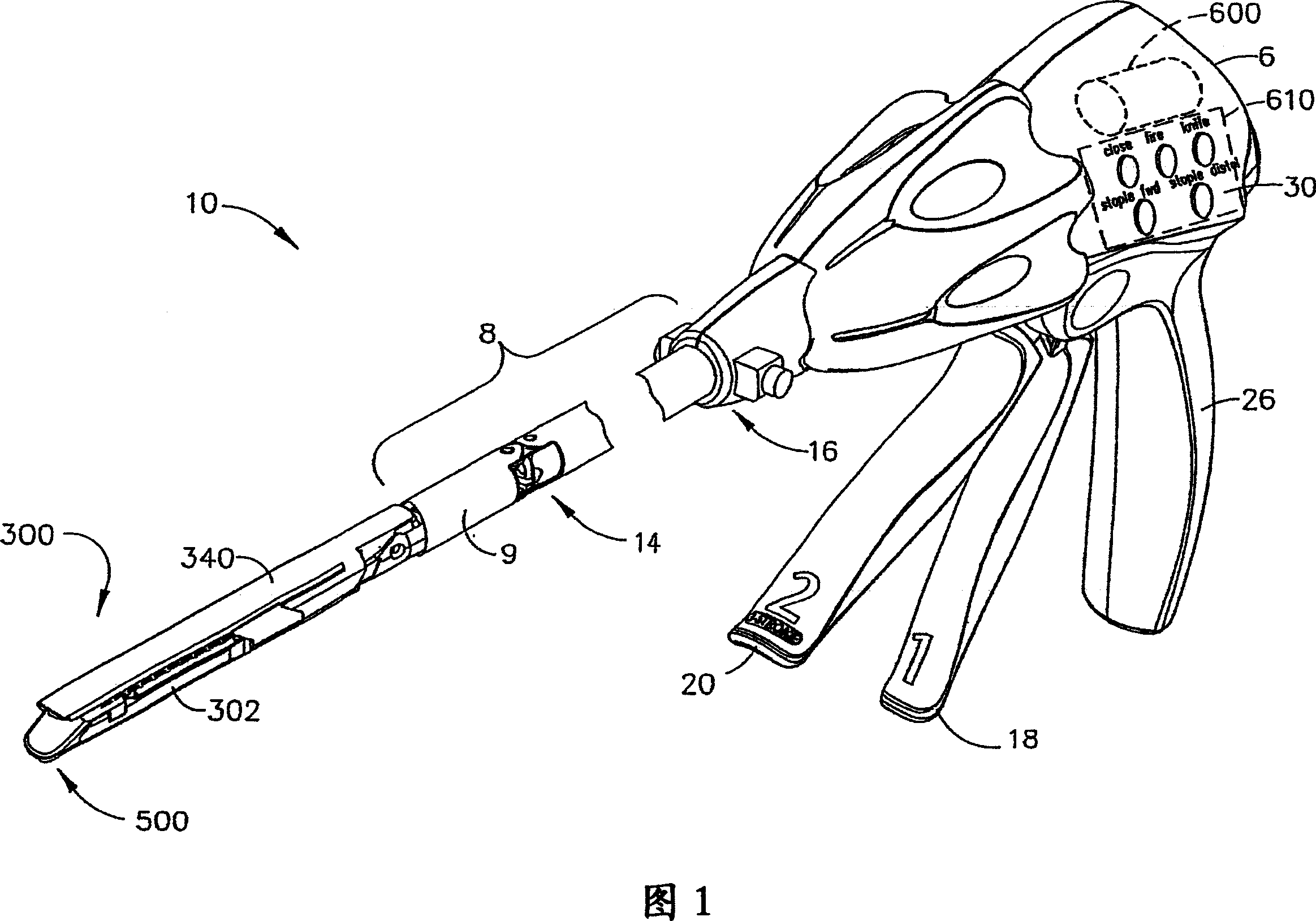

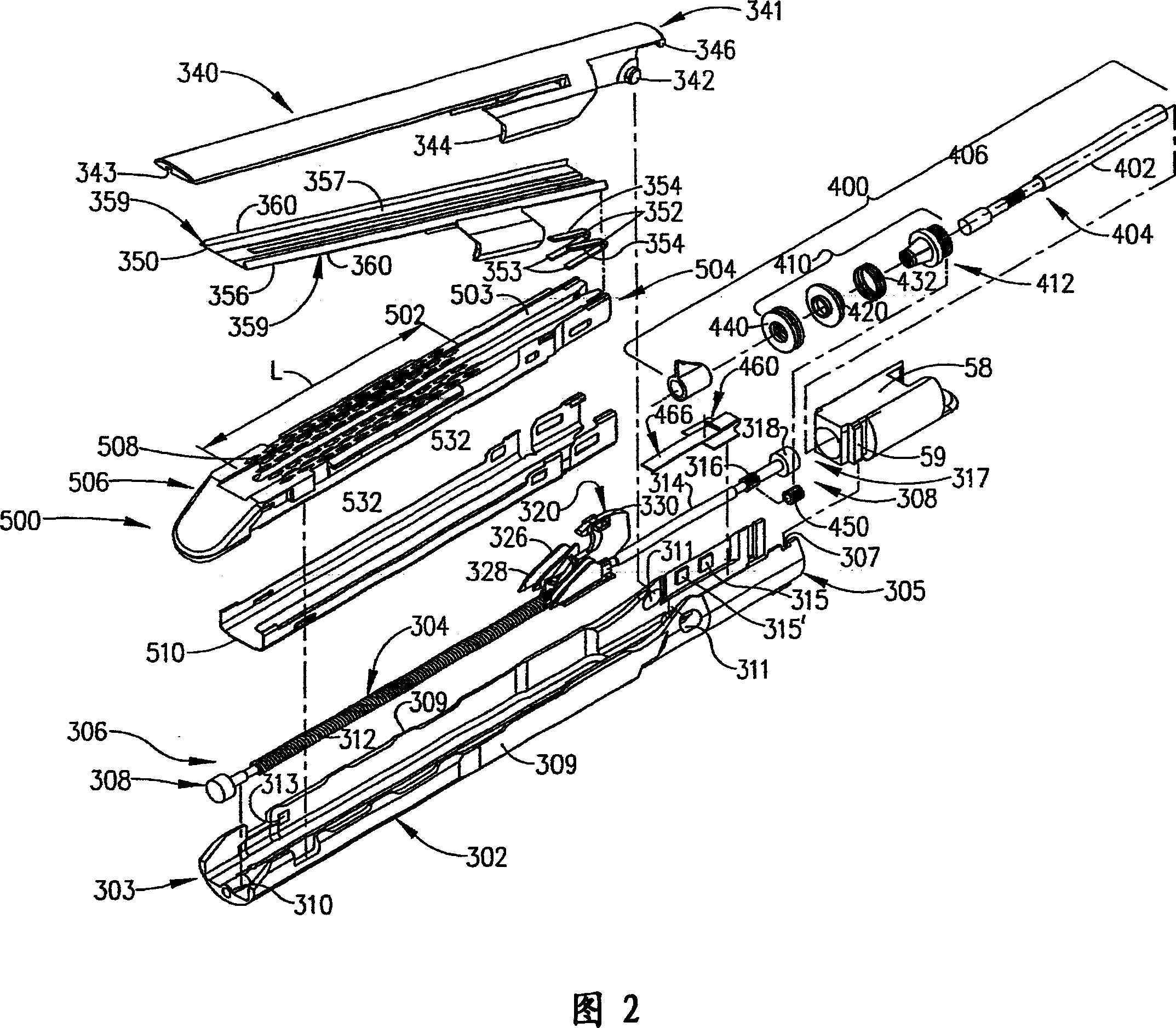

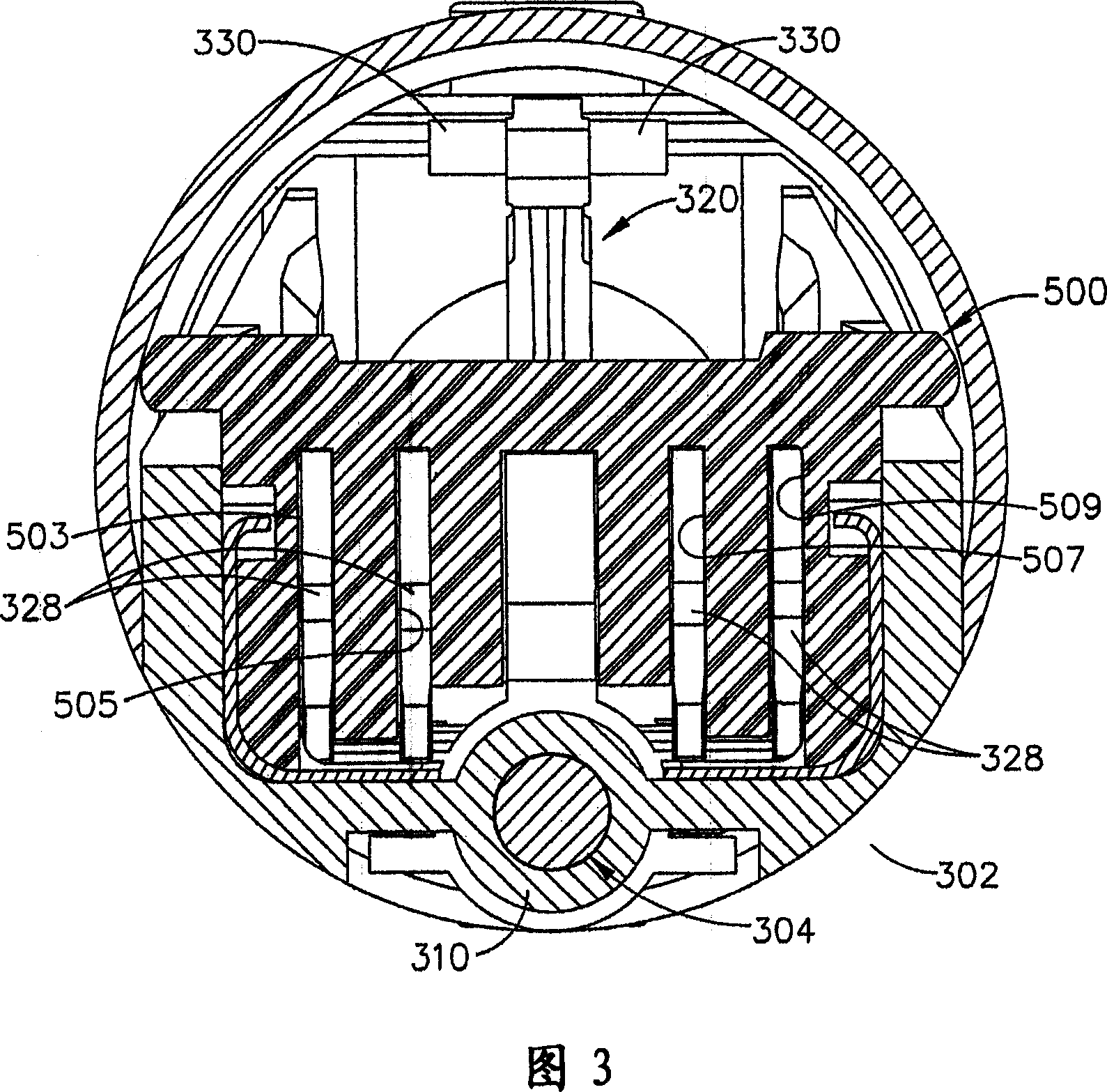

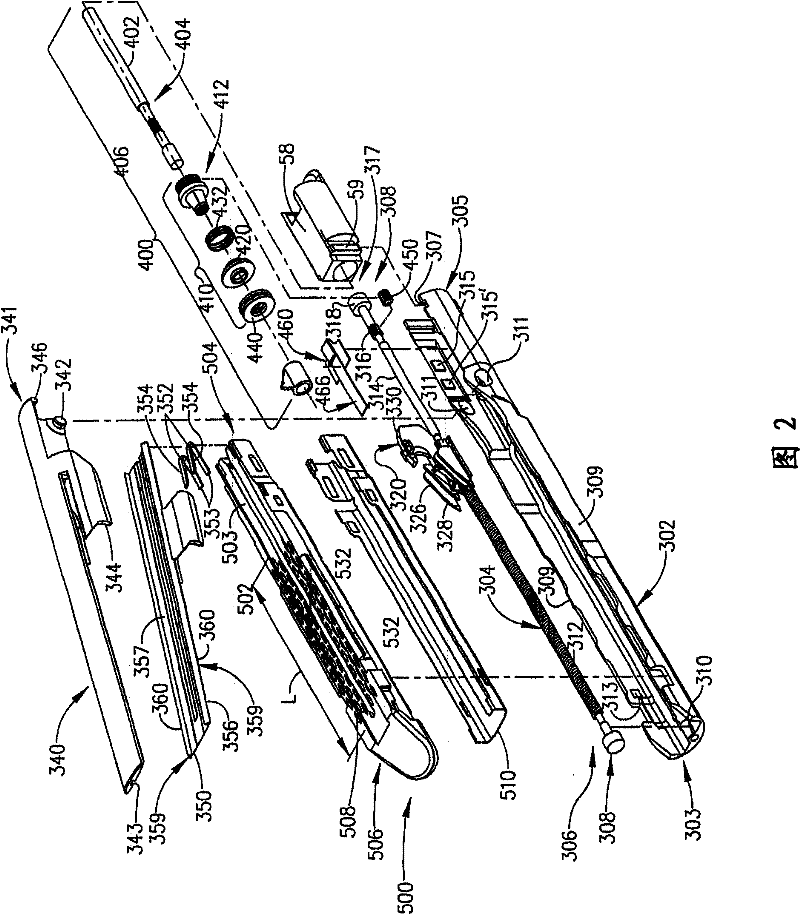

An electrosurgical stapling apparatus is provided which uses thermogenic energy as well as surgical fasteners or staples for strengthening tissue, providing hemostasis, tissue joining or welding. The thermogenic energy also strengthens tissue in proximity to a staple line and knife cut line and provides hemostasis along the staple and cut lines formed by the staples and a knife blade during surgical stapling. The use thermogenic energy provides short-term hemostasis and sealing, and reduces or prevents staple line and cut line bleeding, while the stapling features provide short and long-term tissue strength and hemostasis. The stapling apparatus further substantially reduces or prevents knife cut line bleeding by energizing a knife blade for cauterizing tissue while it is being cut. In one embodiment, energy is applied to the anvil to energize the staples as they make contact with the anvil.

Owner:TYCO HEALTHCARE GRP LP

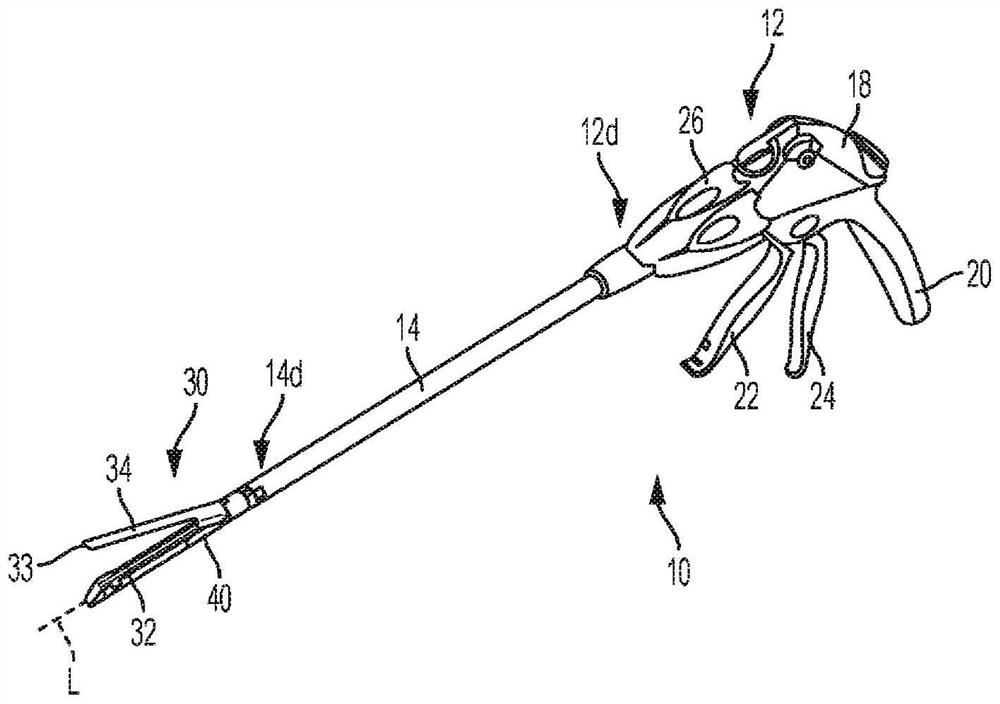

Surgical stapling device with a curved cutting member

The present invention includes a surgical stapler having a curved end-effector which is configured to deploy staples in at least one curved staple line. The surgical stapler can include a staple cartridge configured to removably store staples therein, an anvil configured to deform the staples, and a cutting member having a cutting surface. The staple cartridge and / or anvil can include a curved slot configured for receiving and guiding the cutting member wherein at least a portion of the cutting member can be defined by a curvature that substantially matches the curvature of the slot. In these embodiments, the curved cutting member can be easily moved within the curved slot thereby reducing the possibility that the cutting member will become stuck within the slot.

Owner:CILAG GMBH INT +1

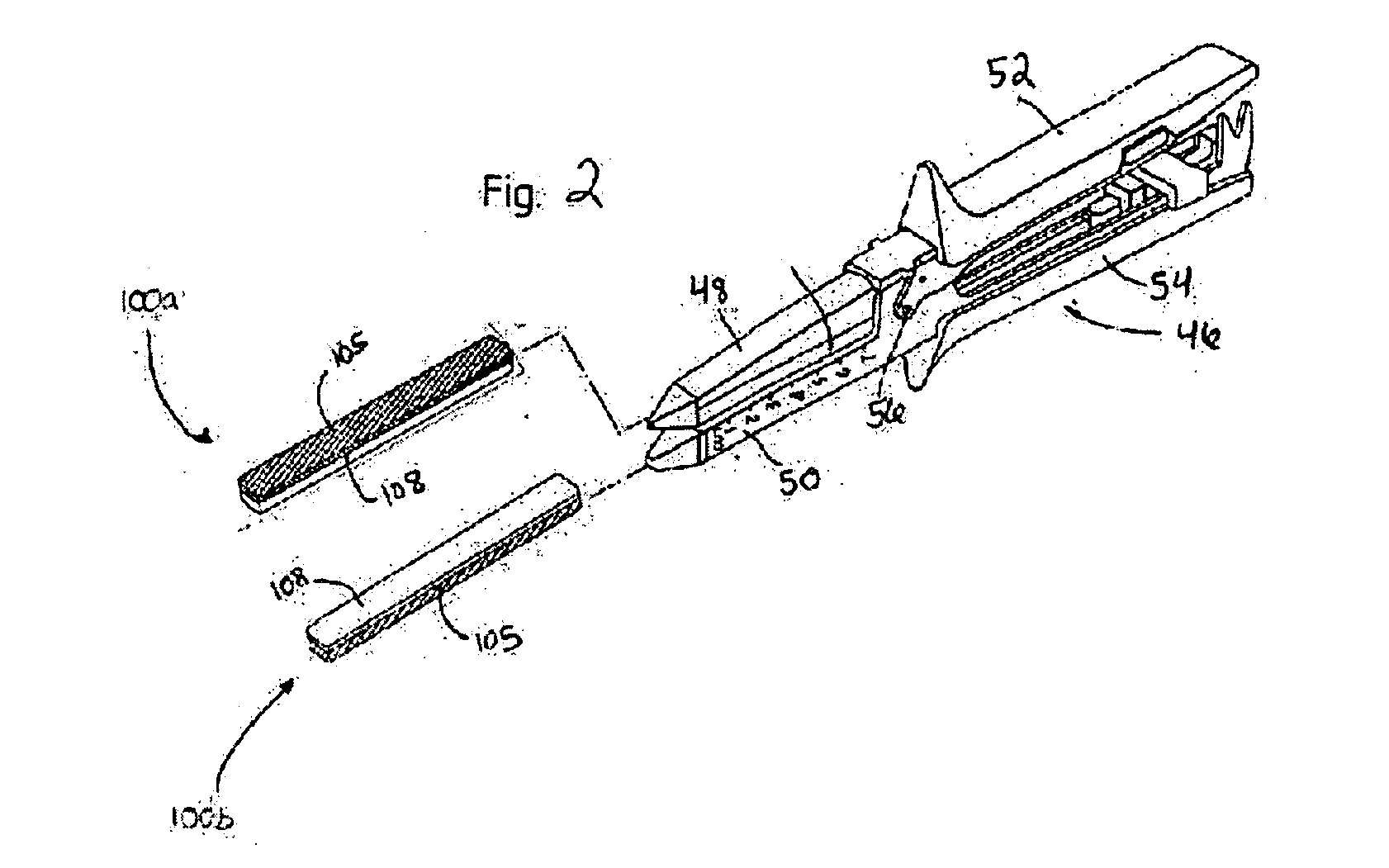

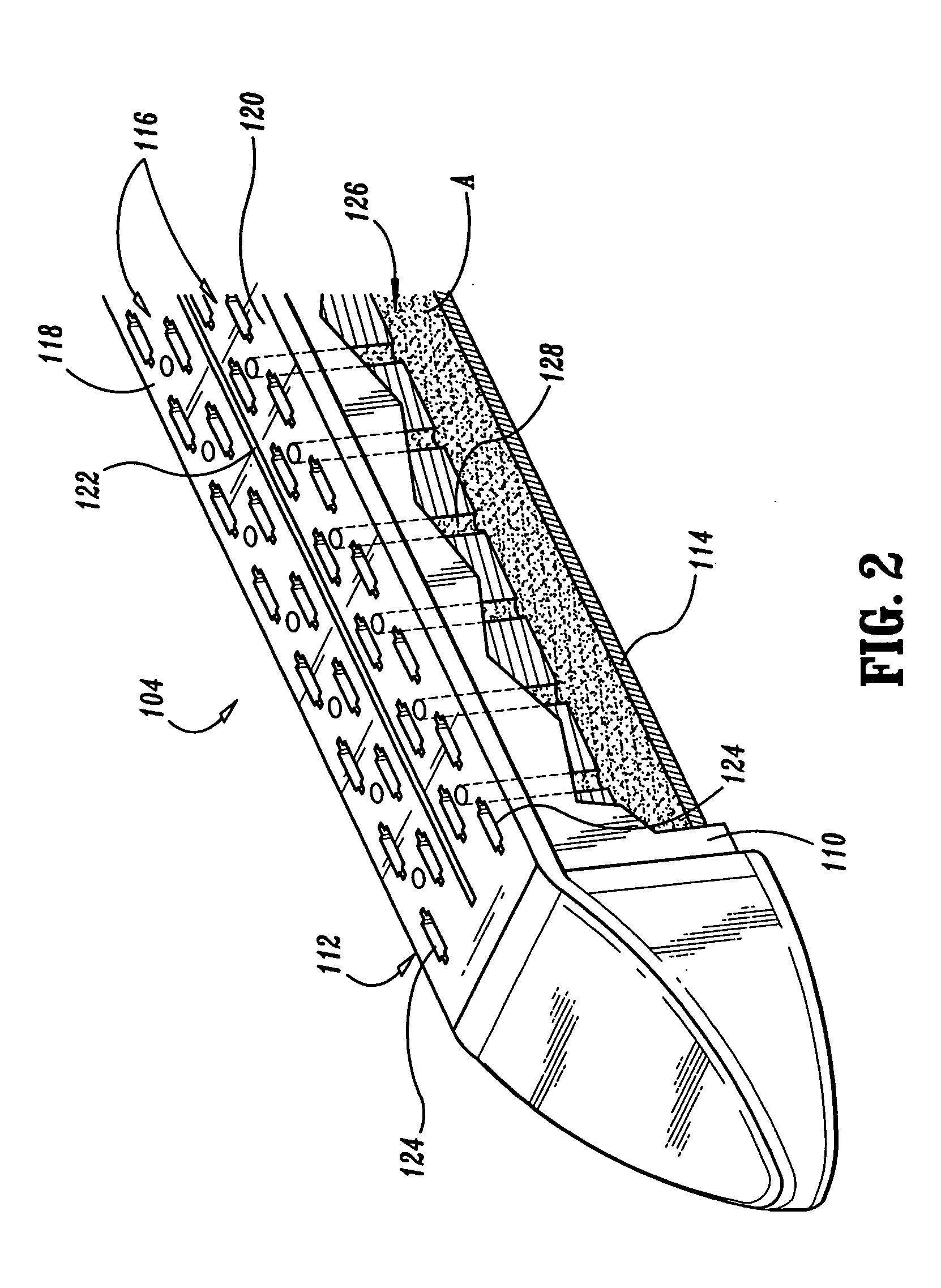

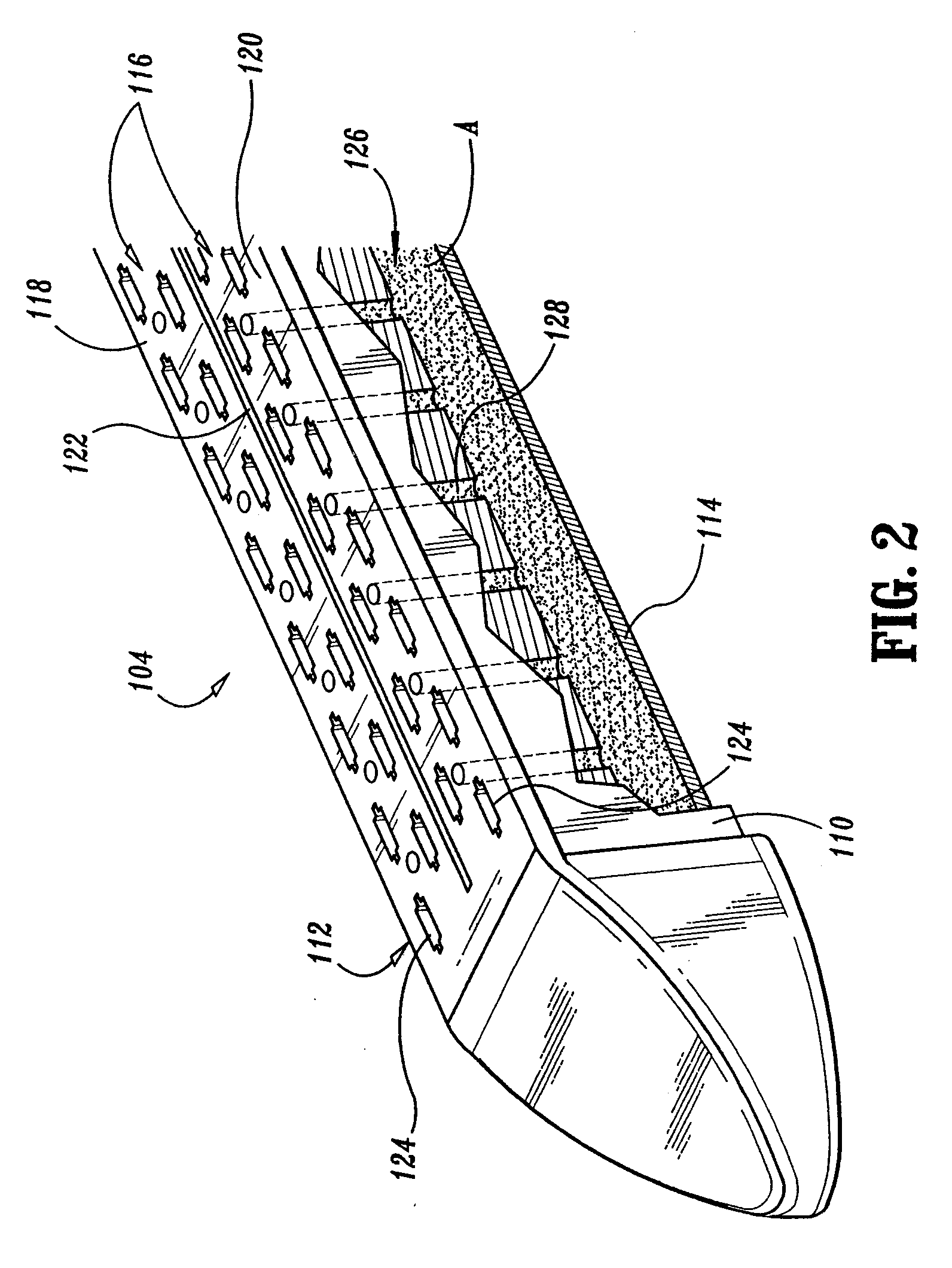

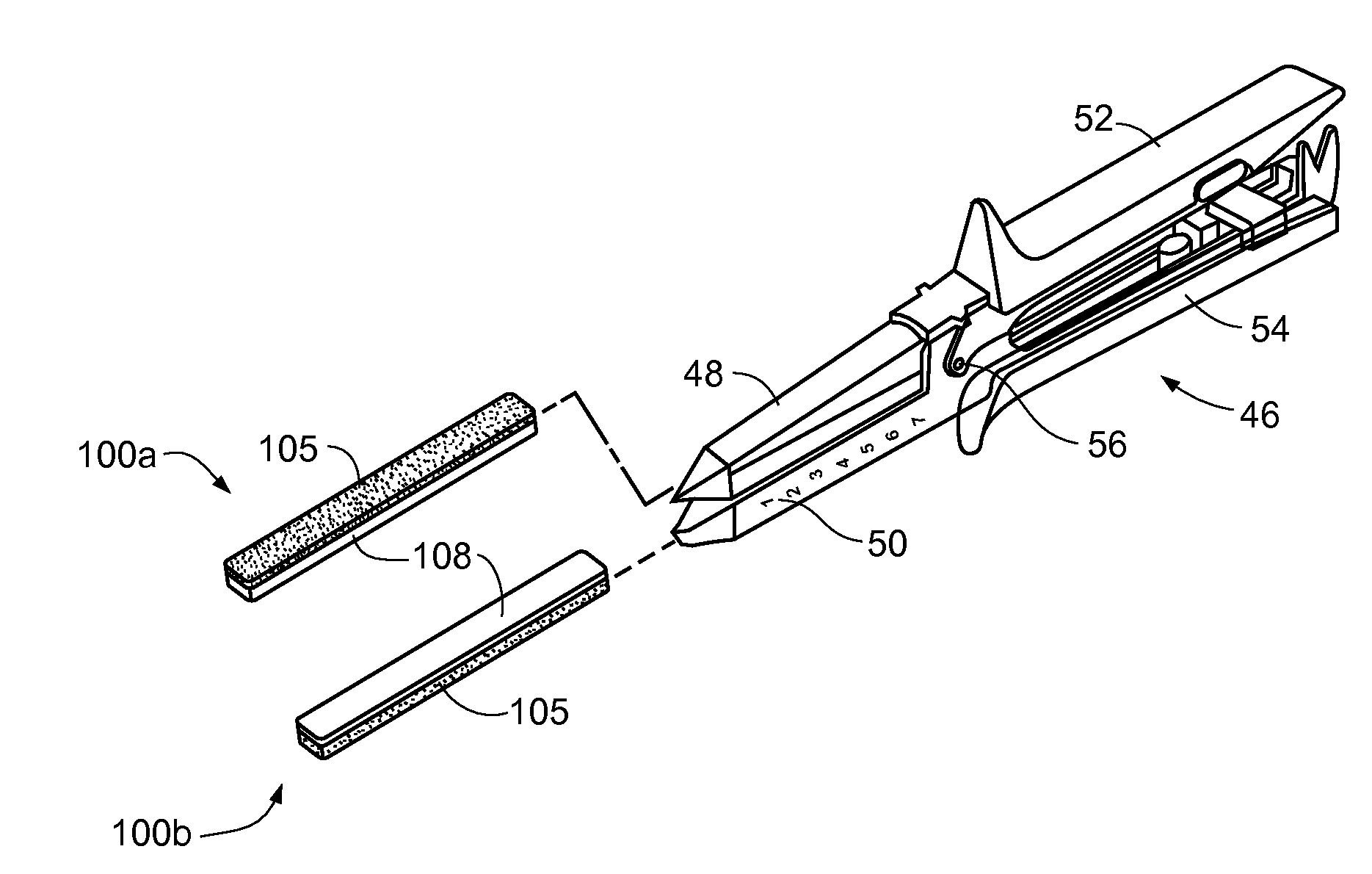

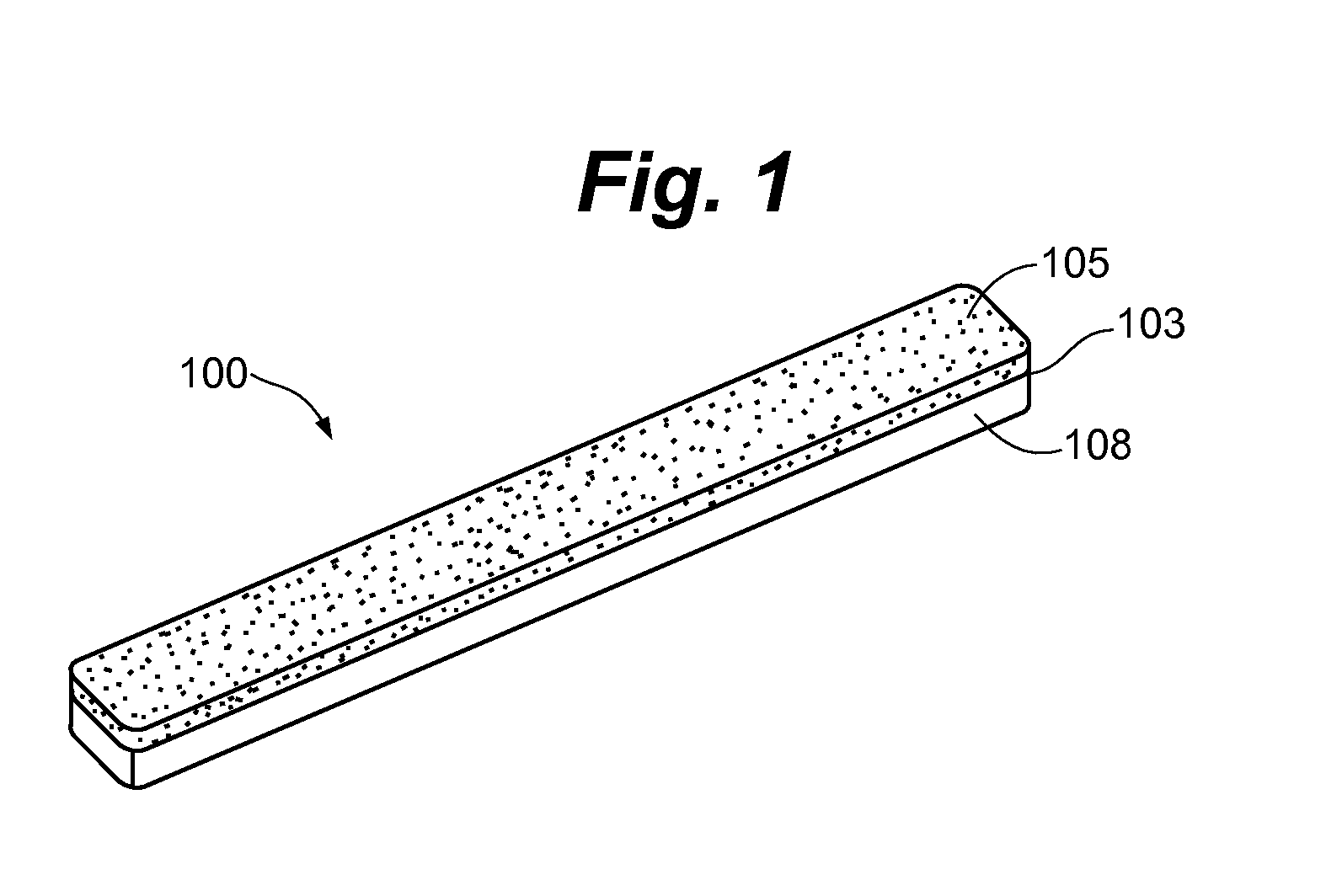

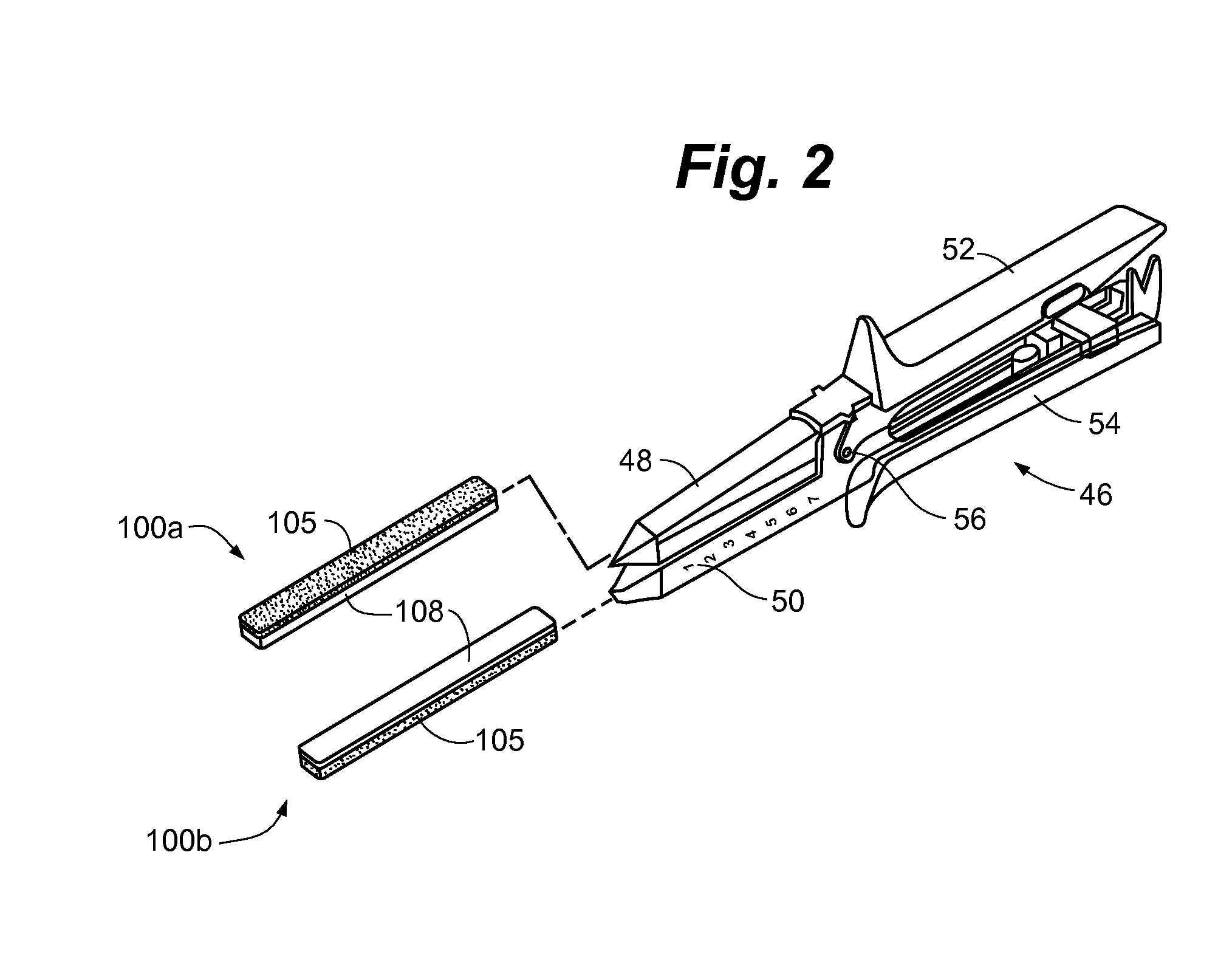

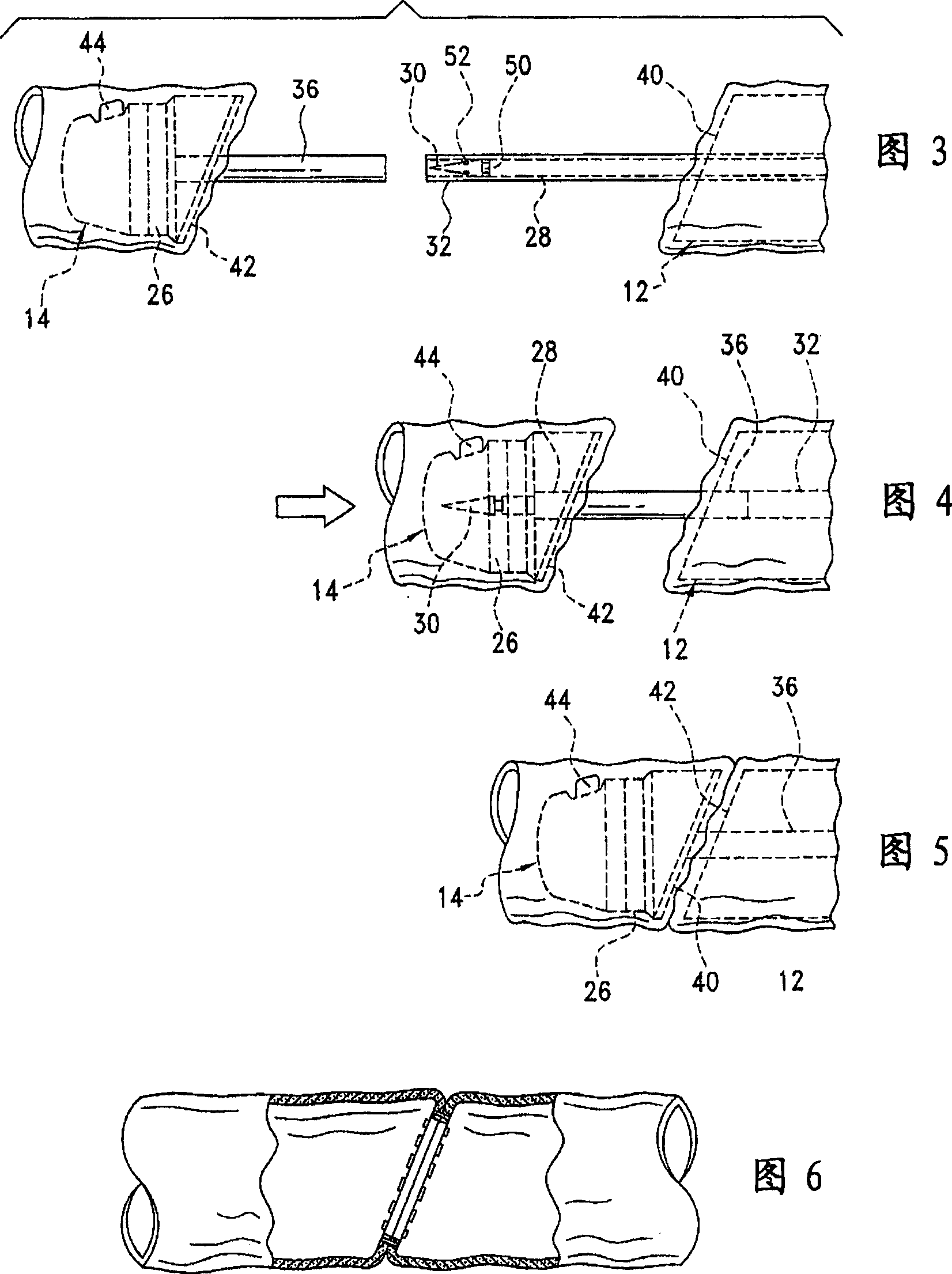

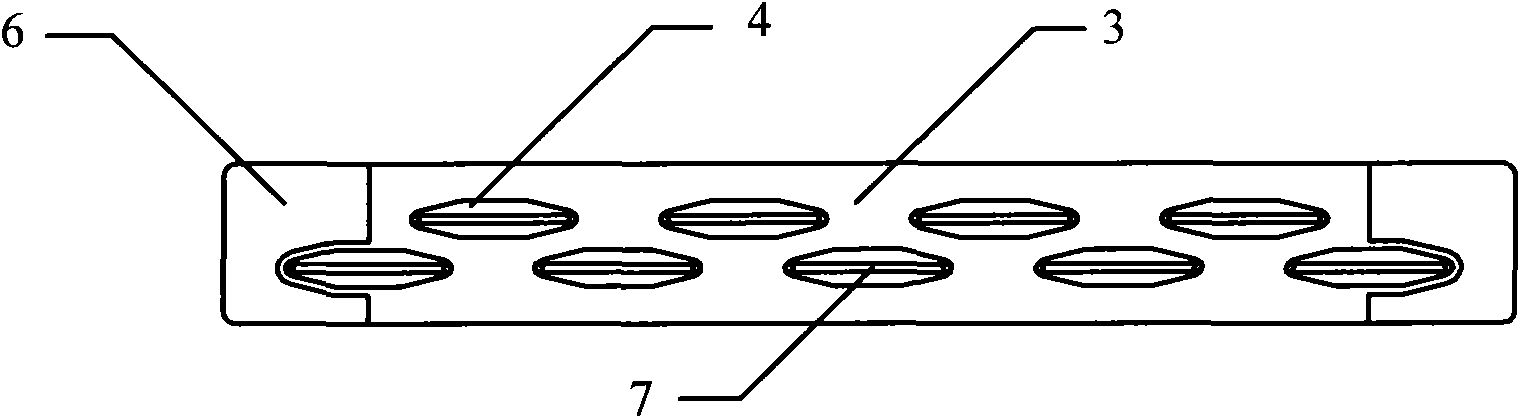

Surgical fastener buttress material

InactiveUS20060173470A1Easy to optimizeReduce misalignmentSurgical staplesWound clampsButtressStaple line

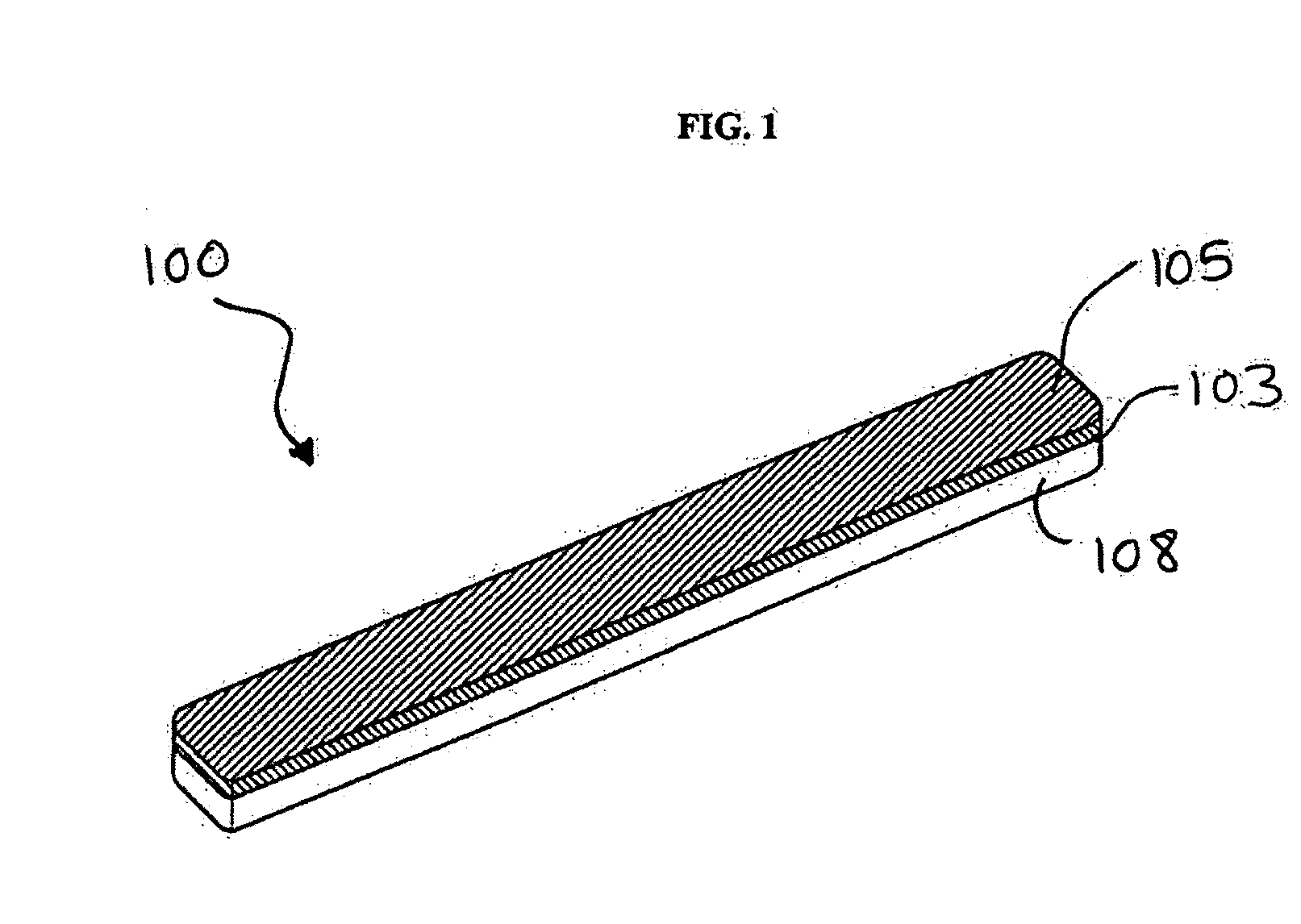

A staple line buttress material having an adhesive surface, packaged and provided in sterile, ready-to-use form. The material can be used to retrofit surgical staplers to provide an improved staple line, and with improved ease of use.

Owner:SYNOVIS LIFE TECH

Elliptical intraluminal surgical stapler for anastomosis

Owner:ETHICON ENDO SURGERY INC

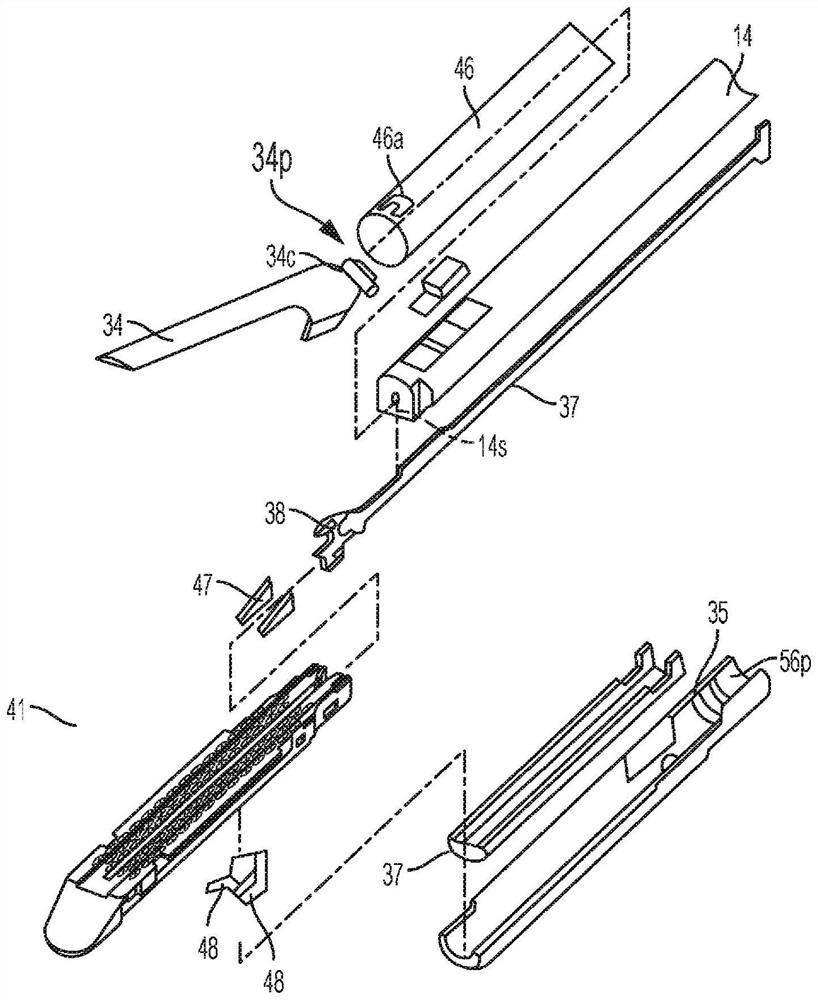

Surgical stapler and method

ActiveUS20050184121A1Less-expensive to manufactureReduce component countSuture equipmentsStapling toolsSurgical stapleStaple line

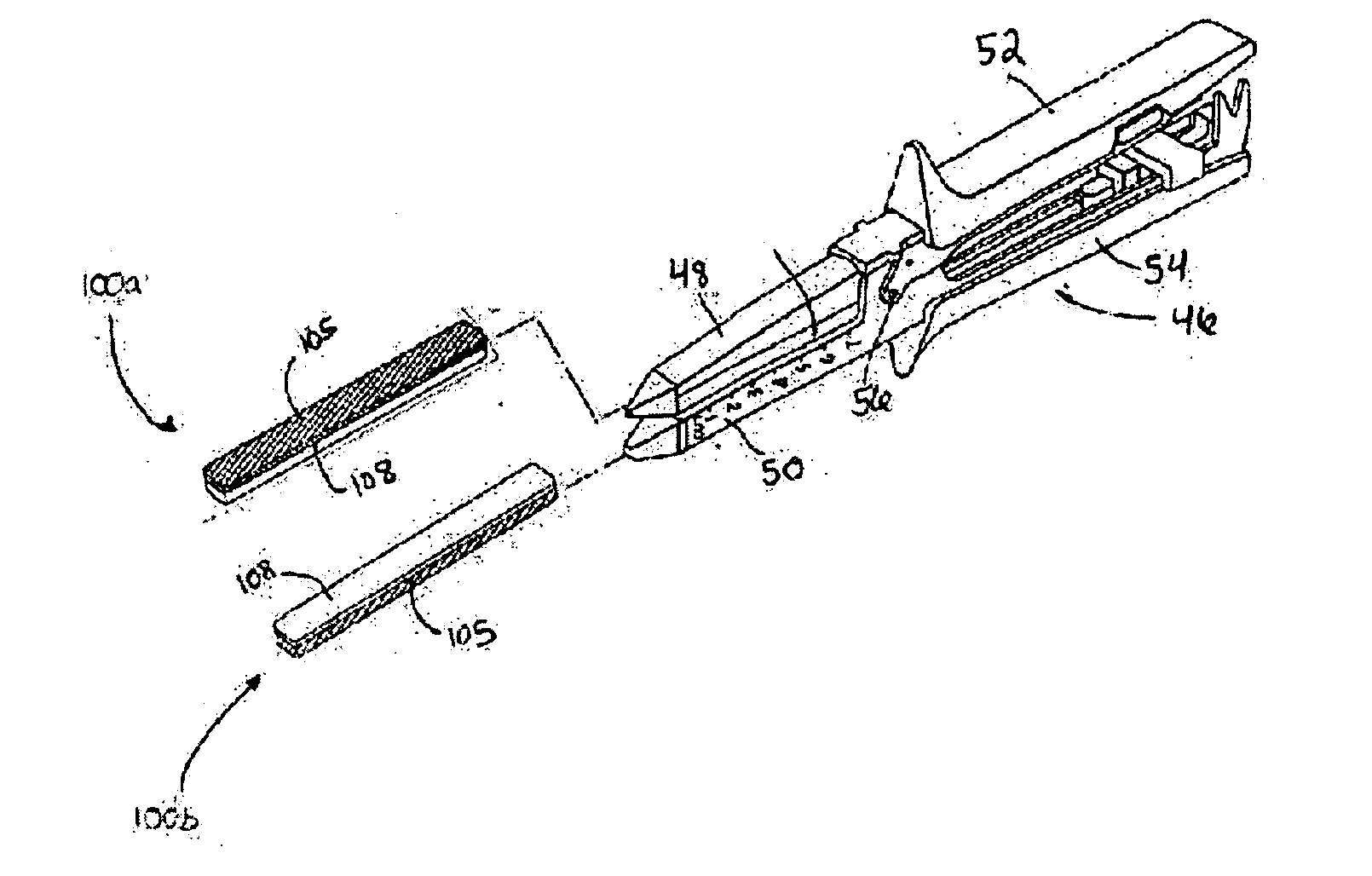

The present disclosure relates to surgical instruments including a staple anvil formed in a distal end of the surgical stapler and a staple cartridge selectively receivable in a distal end of the surgical stapler and in juxtaposition relative to the staple anvil, the staple cartridge including one or more laterally spaced apart rows of staple slots formed in an upper surface thereof, a plurality of surgical staples disposed, one each, within the staple slots, and a staple line reinforcing system configured and adapted to augment the strength of the staple line formed by the firing of the surgical staples into body tissue, wherein the surgical stapler concomitantly drives the plurality of surgical staples through the adjacent layers of body tissue to mechanically secure the body tissue and activates the reinforcing system to non-mechanically secure the adjacent layers of body tissue to one another.

Owner:TYCO HEALTHCARE GRP LP

Electrosurgical stapling apparatus

InactiveUS20050159778A1Reduces or prevents staple line and cut line bleedingShort and strengthSuture equipmentsStapling toolsStaple lineEngineering

An electrosurgical stapling apparatus is provided which uses thermogenic energy as well as surgical fasteners or staples for strengthening tissue, providing hemostasis, tissue joining or welding. The thermogenic energy also strengthens tissue in proximity to a staple line and knife cut line and provides hemostasis along the staple and cut lines formed by the staples and a knife blade during surgical stapling. The use thermogenic energy provides short-term hemostasis and sealing, and reduces or prevents staple line and cut line bleeding, while the stapling features provide short and long-term tissue strength and hemostasis. The stapling apparatus further substantially reduces or prevents knife cut line bleeding by energizing a knife blade for cauterizing tissue while it is being cut. In one embodiment, energy is applied to the anvil to energize the staples as they make contact with the anvil.

Owner:TYCO HEALTHCARE GRP LP

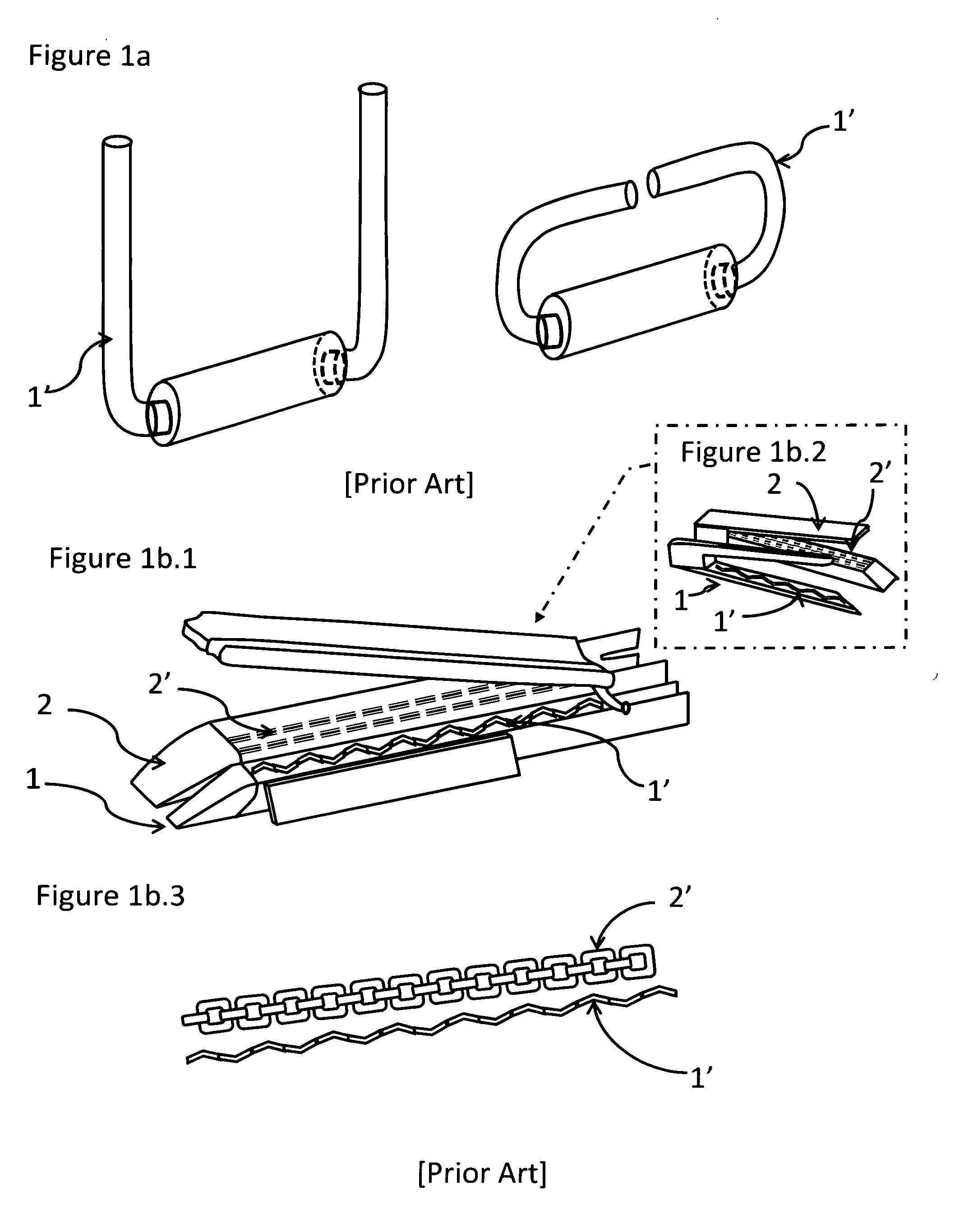

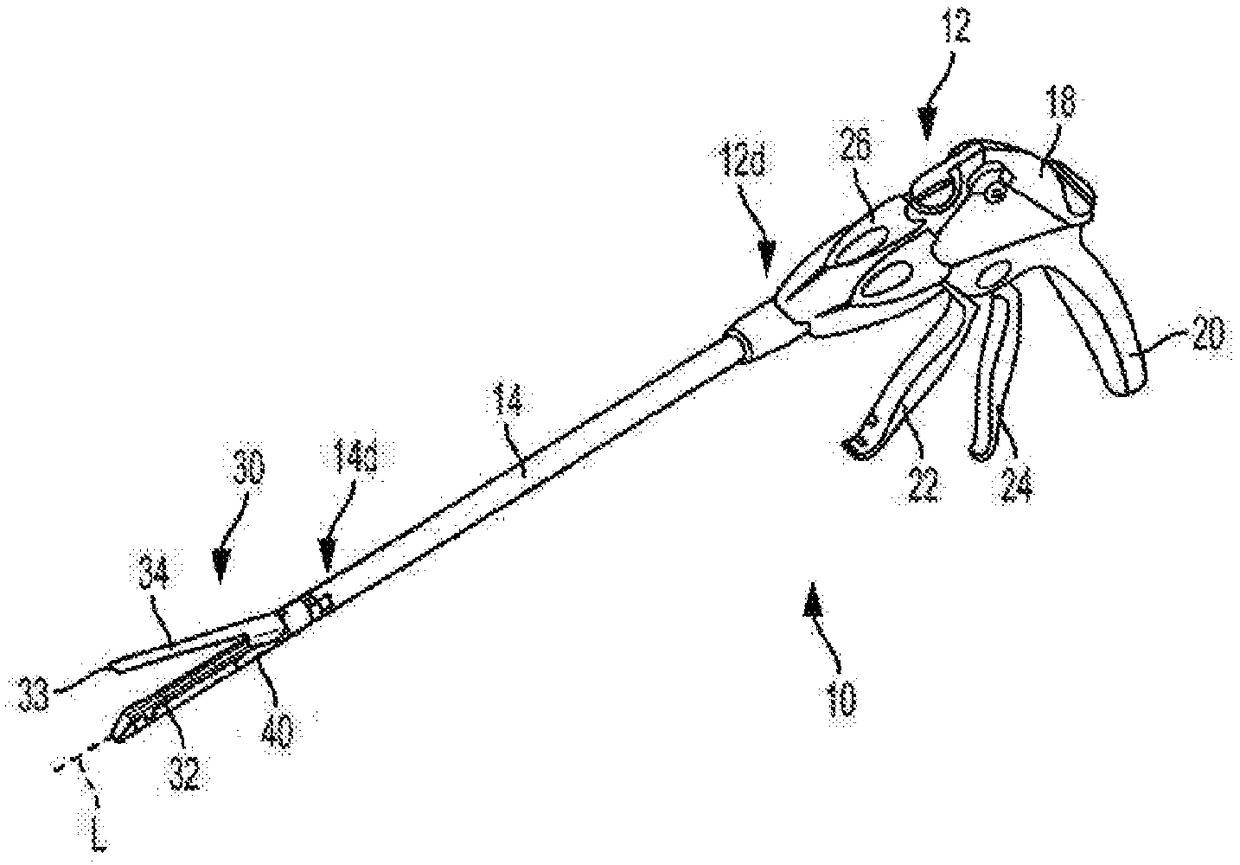

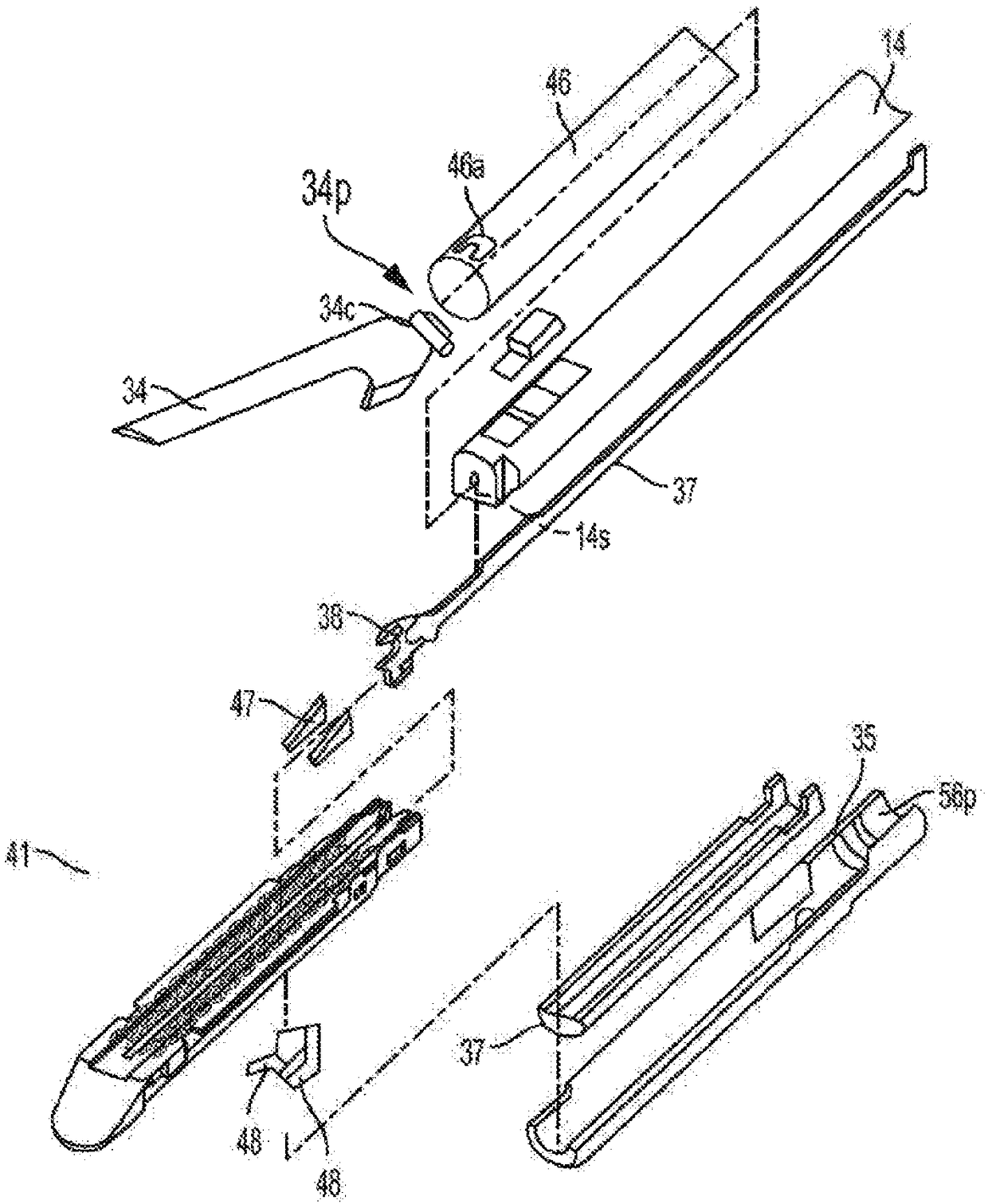

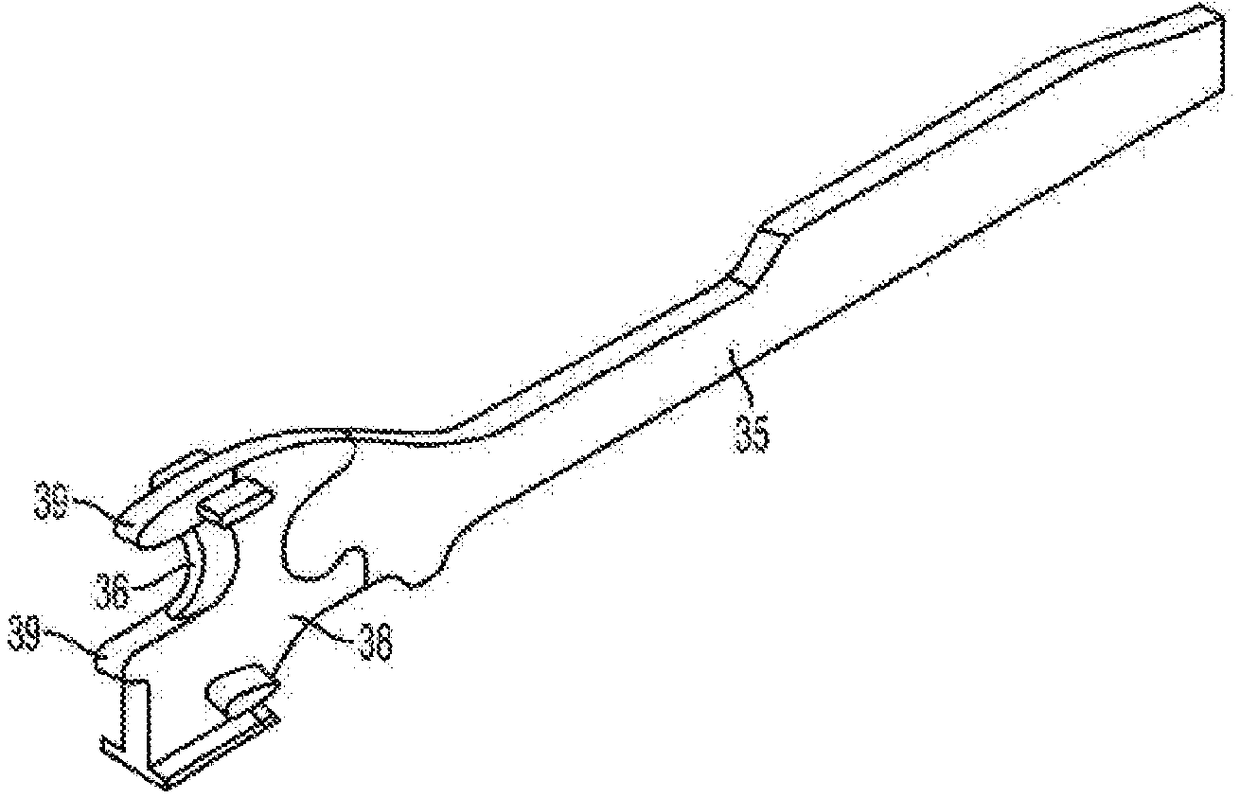

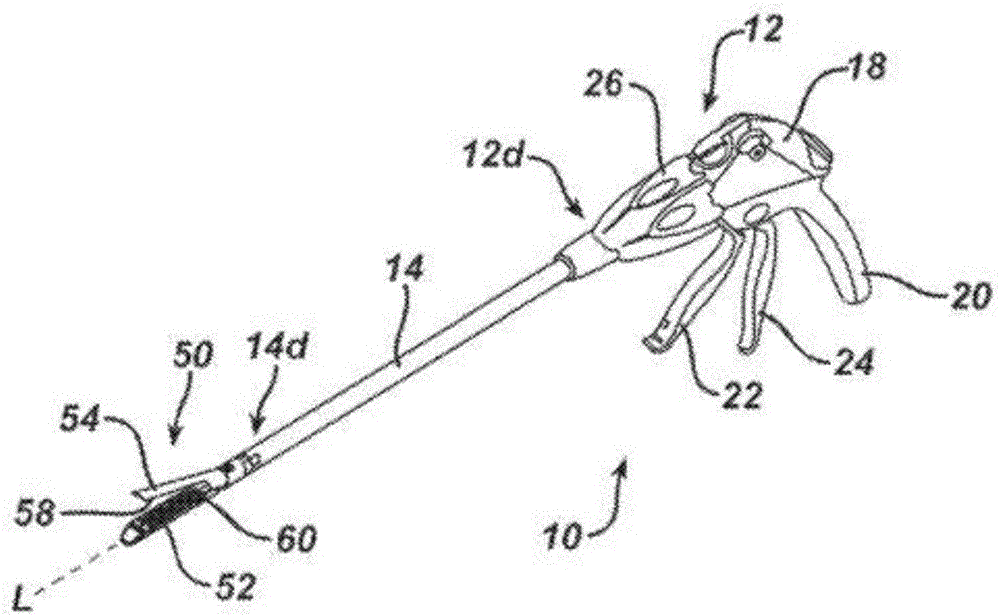

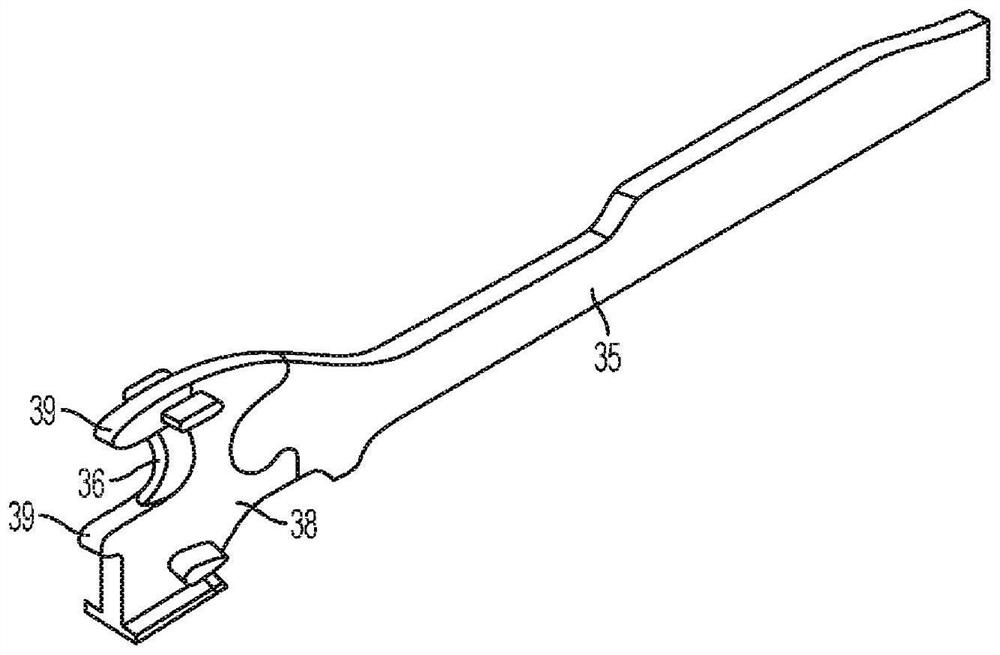

Curved end effector for a surgical stapling device

The present invention includes a surgical stapler having a curved end-effector which is configured to deploy staples in at least one curved staple line. In various embodiments, the surgical stapler includes a staple cartridge, an anvil, and a cutting member having a cutting surface wherein the cutting member is relatively movable with respect to the anvil and the staple cartridge. In one embodiment, the staple cartridge can be configured to deploy staples along different, non-parallel axes. As a result, the staples can be deployed in a significantly curved staple line. In various embodiments, the surgical stapler includes a flexible driver operably engaged with the cutting member to move the cutting member relative to the anvil and the staple cartridge. In these embodiments, the driver can include an elongate cross-section defined by a width and a height wherein its width is greater, and in some cases, substantially greater, than its height.

Owner:CILAG GMBH INT

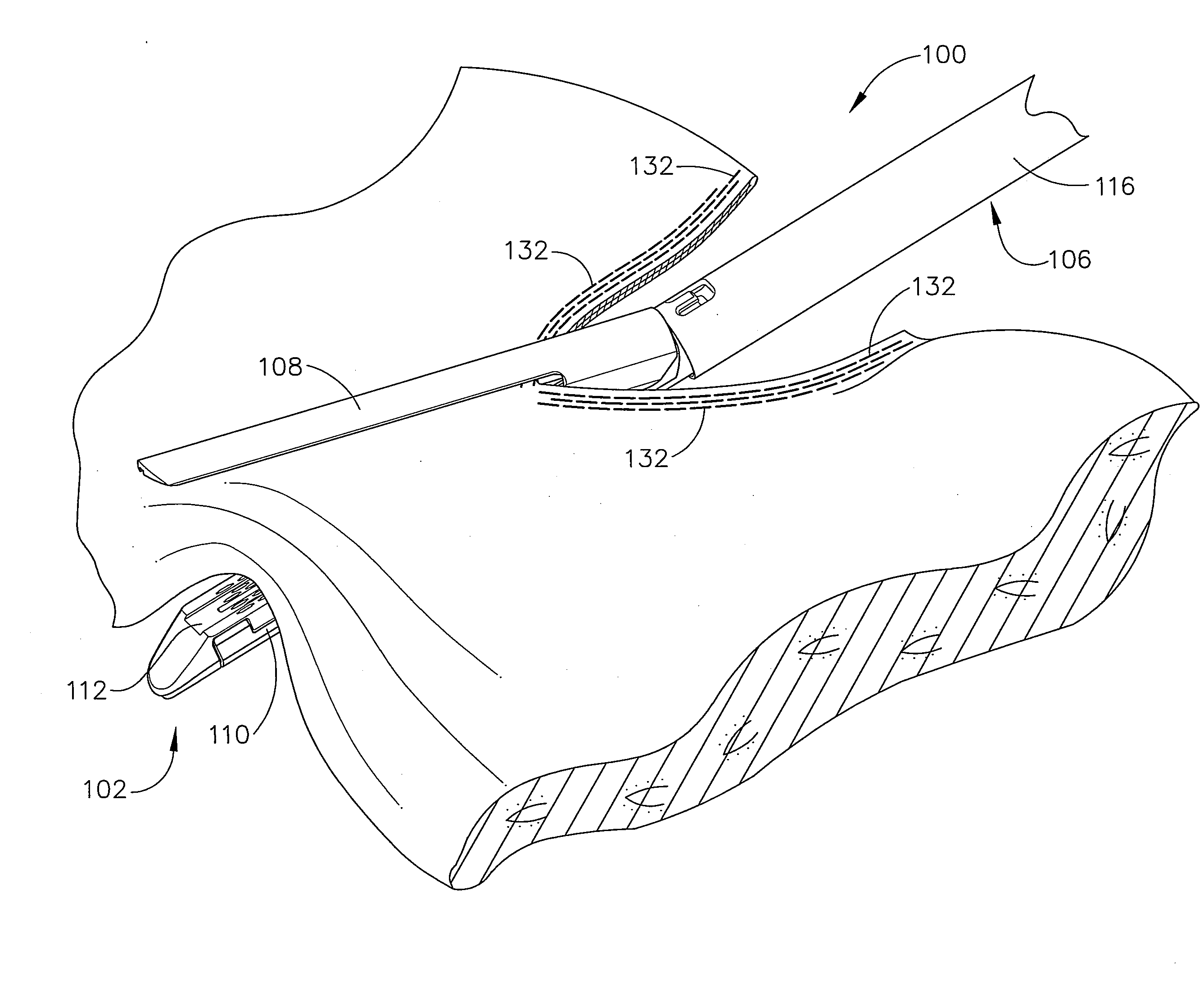

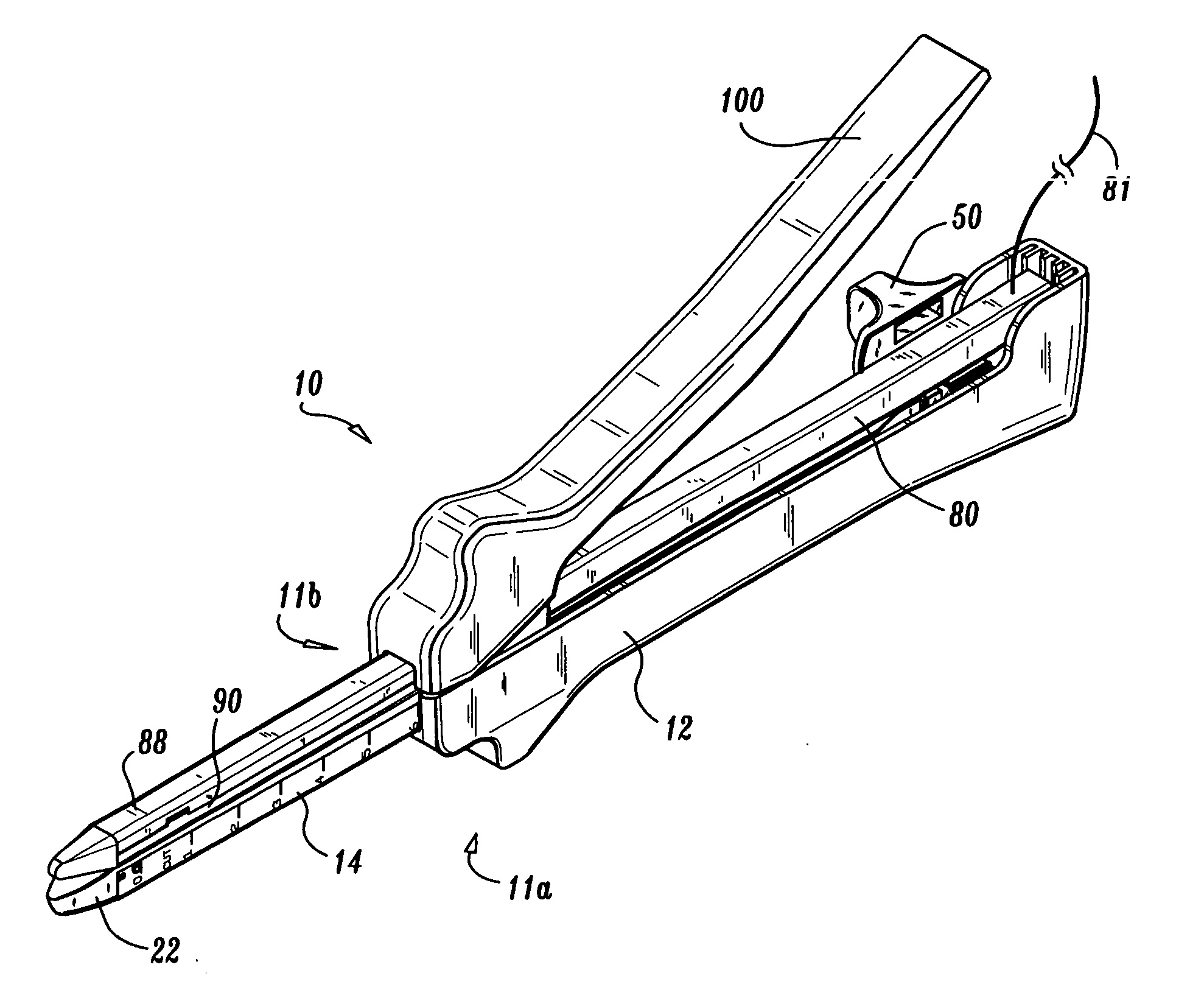

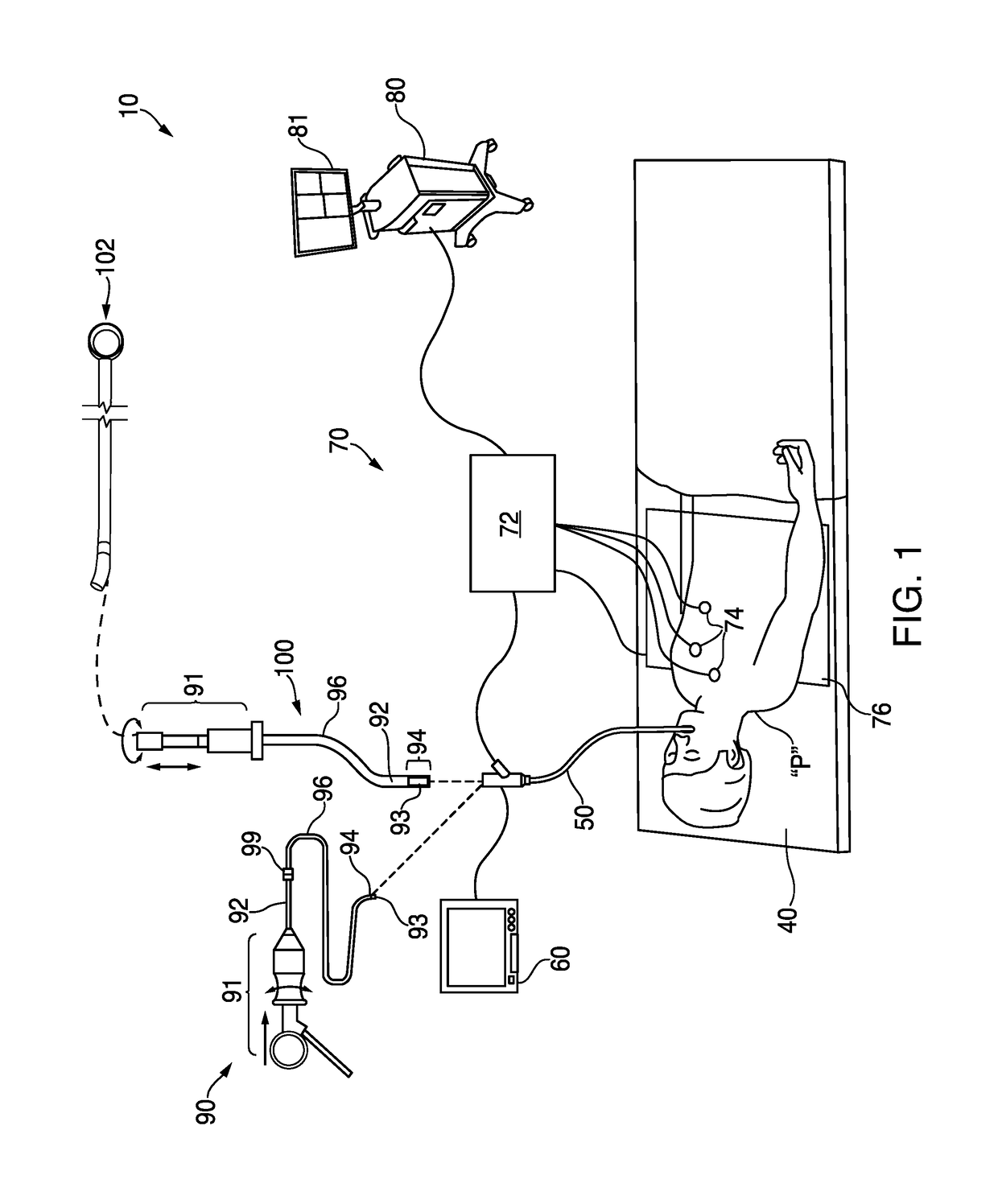

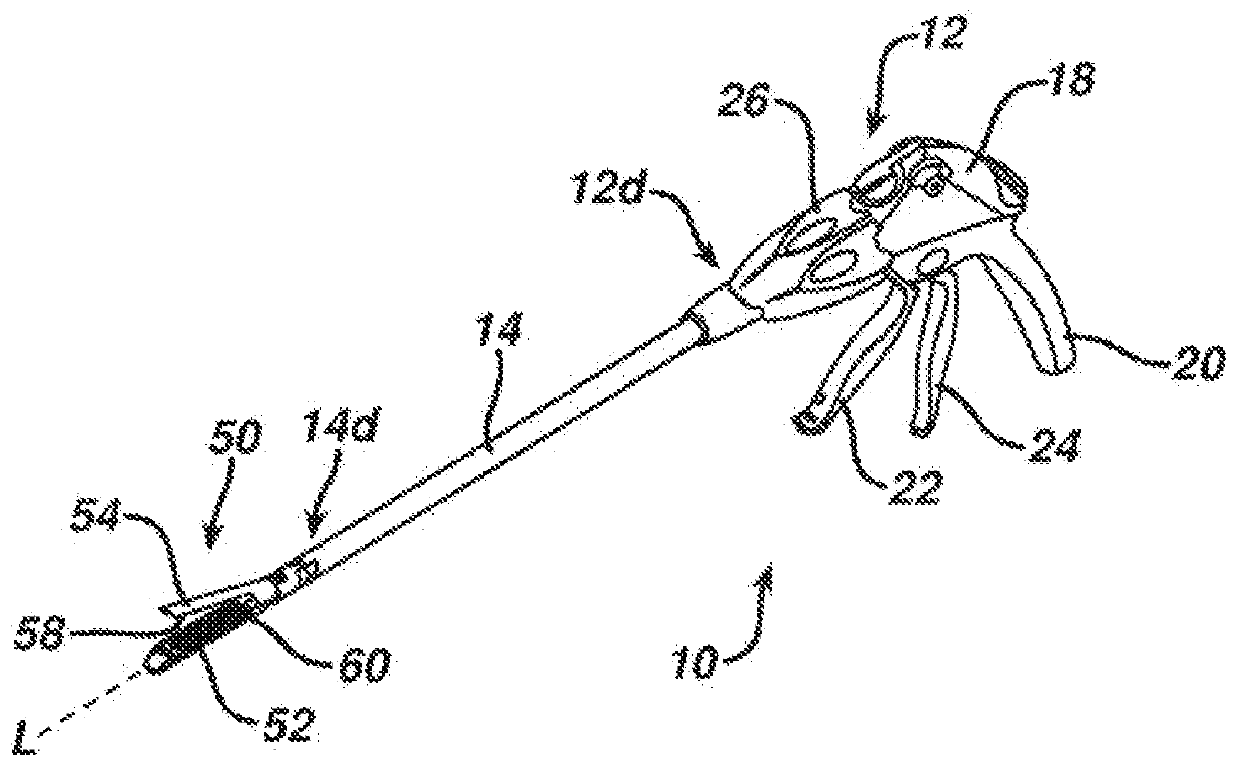

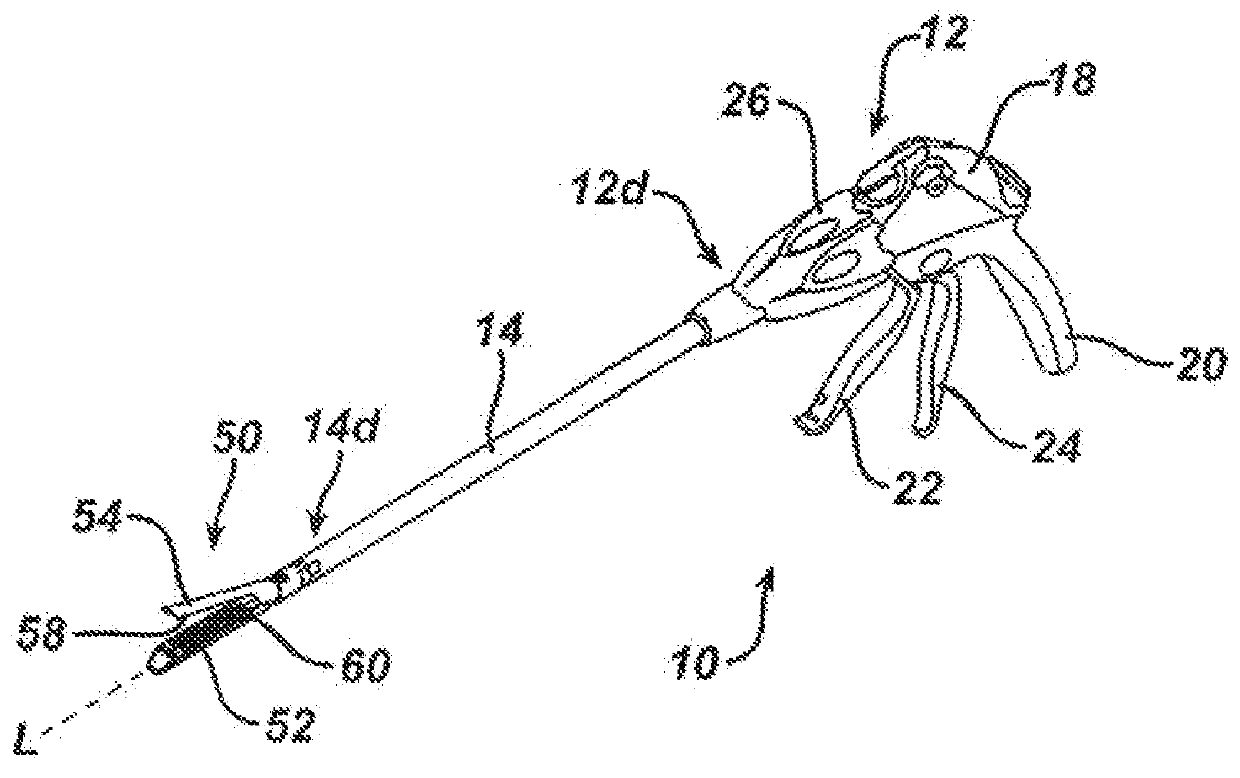

Curved cutter stapler with aligned tissue retention feature

A surgical instrument is adapted for applying a plurality of surgical fasteners to body tissue. The surgical instrument includes a frame having a proximal end and a distal end, with a handle positioned at the proximal end and an end effector positioned at the distal end. The end effector is shaped and dimensioned for supporting a cartridge housing and an anvil, the cartridge housing and anvil structure being relatively movable between a first spaced apart position and a second position in close approximation with one another. A firing mechanism is associated with the end effector and the cartridge housing for selective actuation of the fastening elements for treatment of an individual. A tissue retention feature is associated with the cartridge housing and anvil, the tissue retention feature maintaining tissue within the end effector during treatment and including a top tissue retention member and a bottom tissue retention member. The cartridge housing includes at least one staple line along a face of the cartridge housing defining the longitudinal extent of the surgical fasteners being applied via the cartridge module. The staple line includes a top and a bottom, and the top of the staple line is above the top tissue retention member and / or the bottom of the staple line is below the bottom tissue retention member.

Owner:ETHICON ENDO SURGERY INC

Surgical Stapler and Method

InactiveUS20080230583A1Enhance repairing and joiningReduce and prevent fluid leakageSuture equipmentsStapling toolsSurgical stapleStaple line

The present disclosure relates to surgical instruments including a staple anvil formed in a distal end of the surgical stapler and a staple cartridge selectively receivable in a distal end of the surgical stapler and in juxtaposition relative to the staple anvil, the staple cartridge including one or more laterally spaced apart rows of staple slots formed in an upper surface thereof, a plurality of surgical staples disposed, one each, within the staple slots, and a staple line reinforcing system configured and adapted to augment the strength of the staple line formed by the firing of the surgical staples into body tissue, wherein the surgical stapler concomitantly drives the plurality of surgical staples through the adjacent layers of body tissue to mechanically secure the body tissue and activates the reinforcing system to non-mechanically secure the adjacent layers of body tissue to one another.

Owner:TYCO HEALTHCARE GRP LP

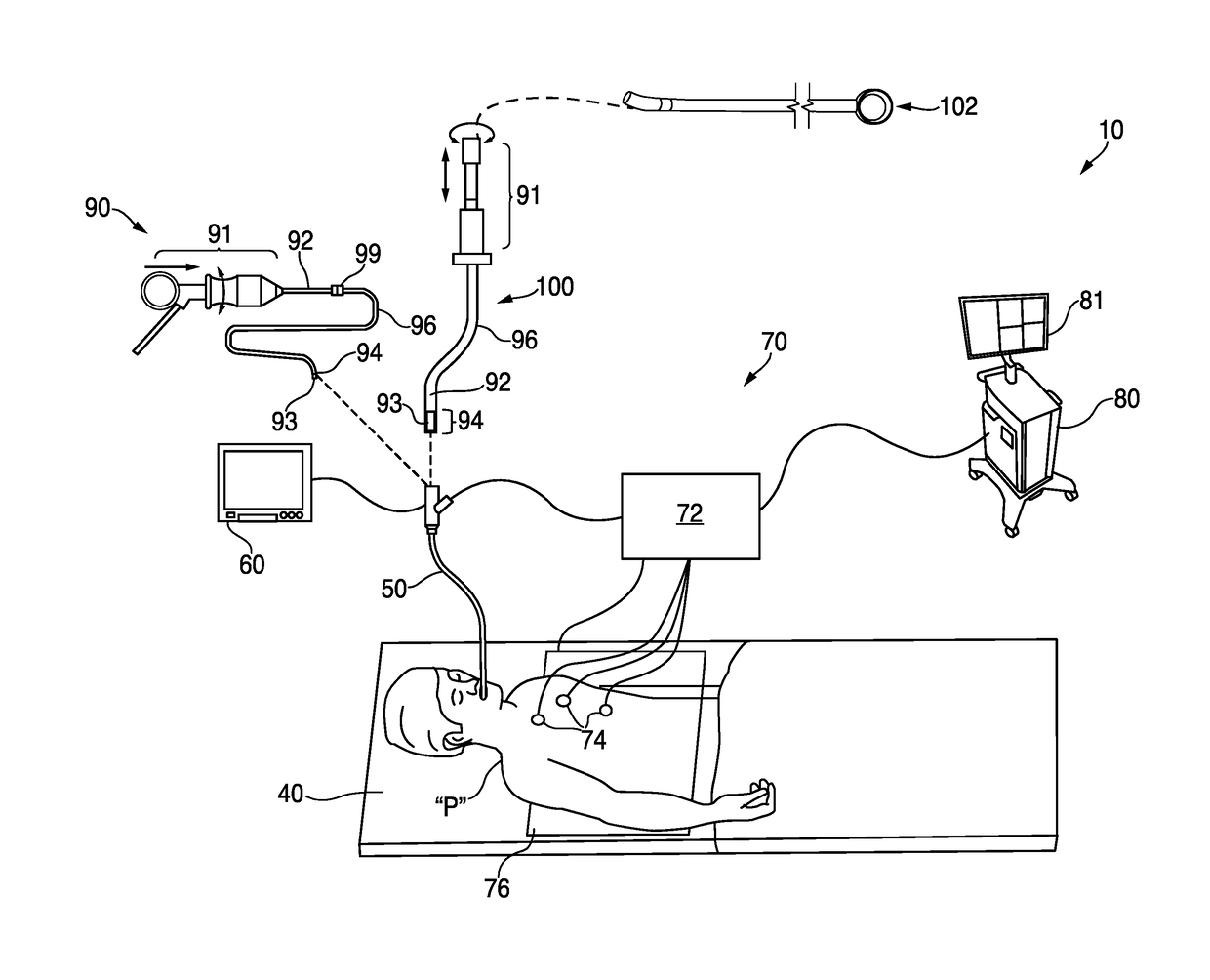

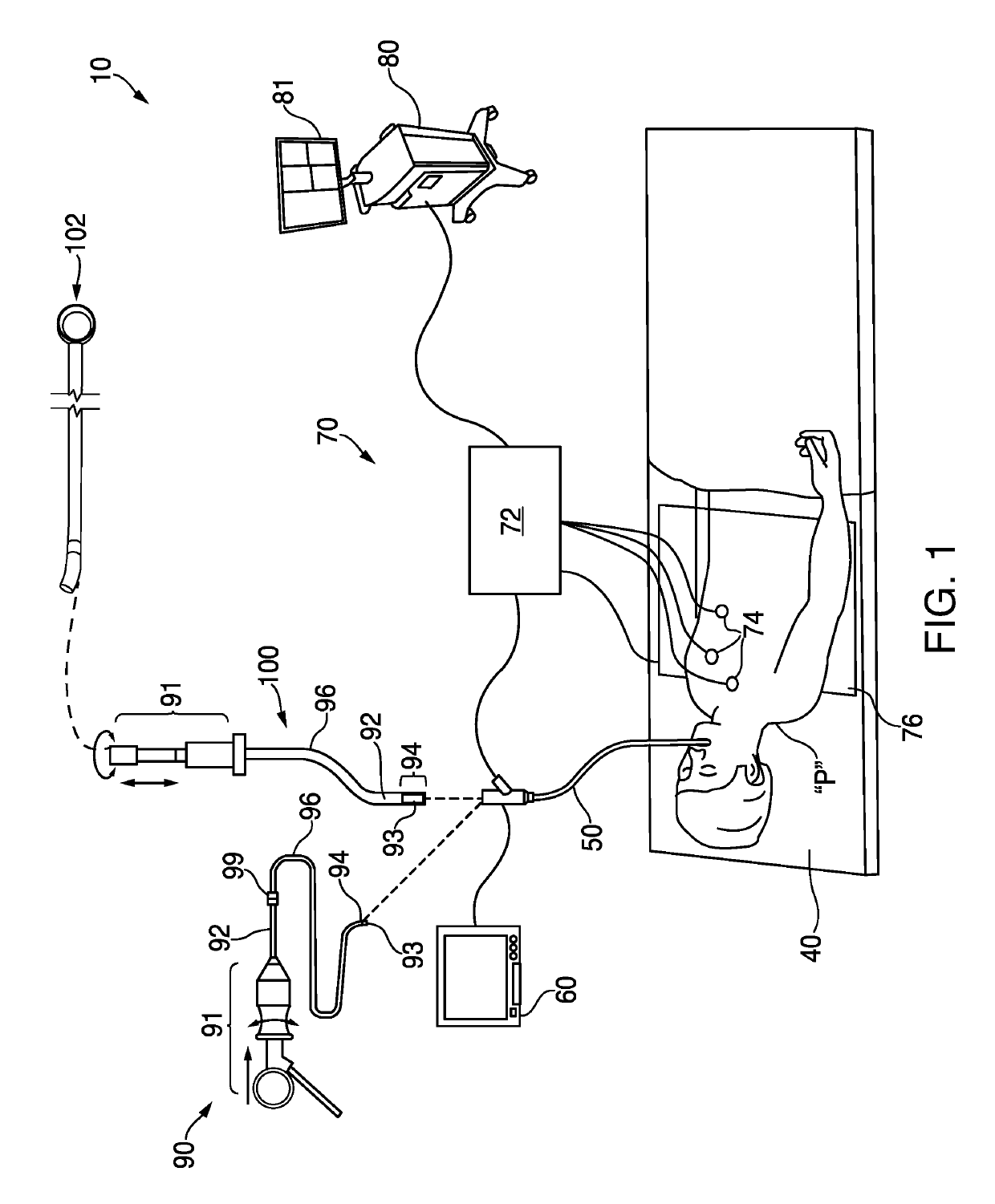

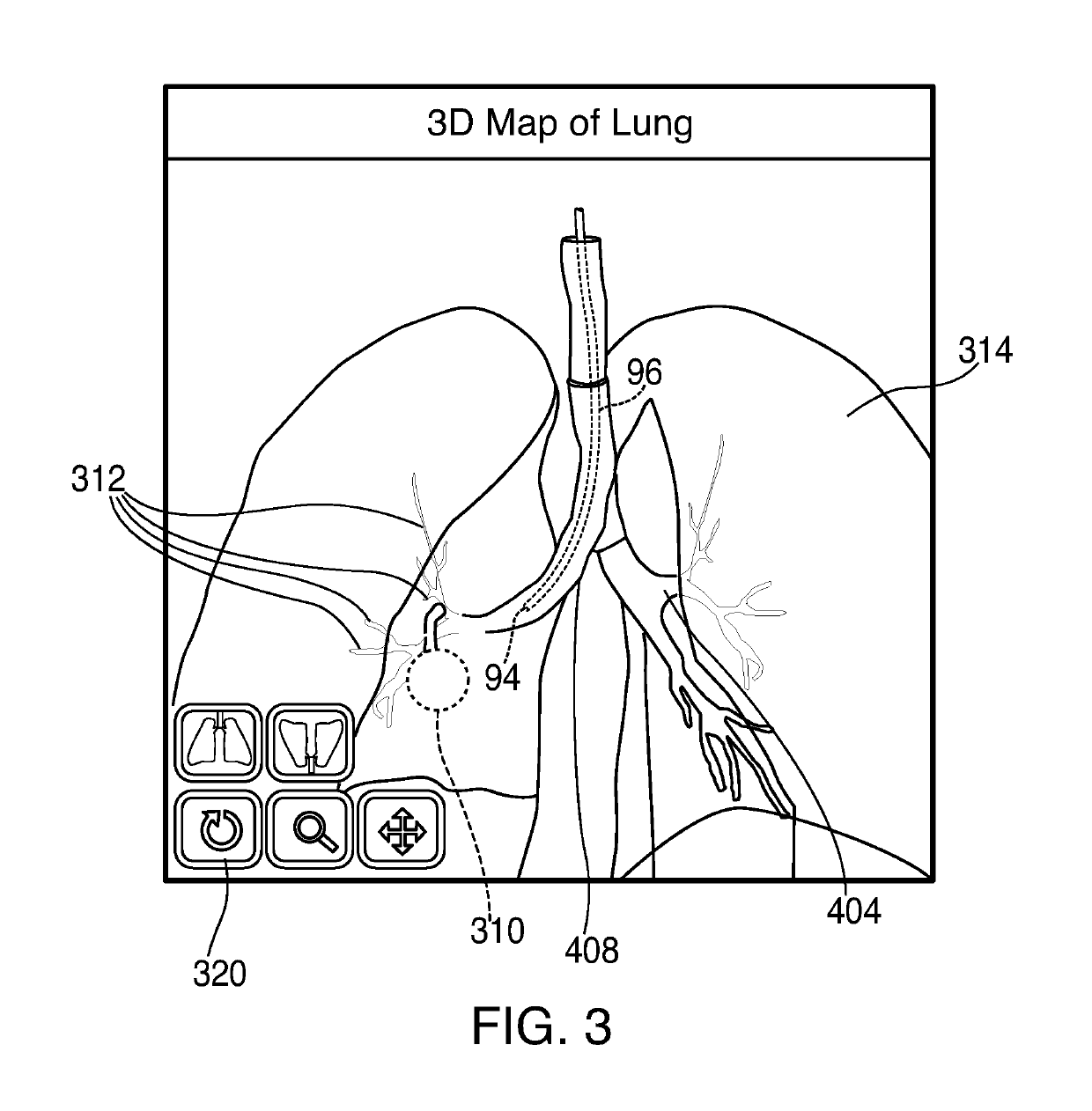

Assessment of suture or staple line integrity and localization of potential tissue defects along the suture or staple line

ActiveUS20170348067A1Ultrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsStaple lineTissue defect

A method for assessing suture line integrity includes loading a navigation plan into a navigation system, the navigation plan including a planned pathway shown in a 3D model, inserting a probe into a patient's airways, the probe including a location sensor in operative communication with the navigation system, registering a sensed location of the probe with the planned pathway, and selecting a target in the navigation plan, the target including a proposed suture line. The method further includes presenting a view of the 3D model showing the planned pathway and indicating the sensed location of the probe, navigating the probe through the airways of the patient's lungs toward the target, and imaging the proposed suture line of the target, via the probe, to determine tissue integrity surrounding the proposed suture line.

Owner:TYCO HEALTHCARE GRP LP

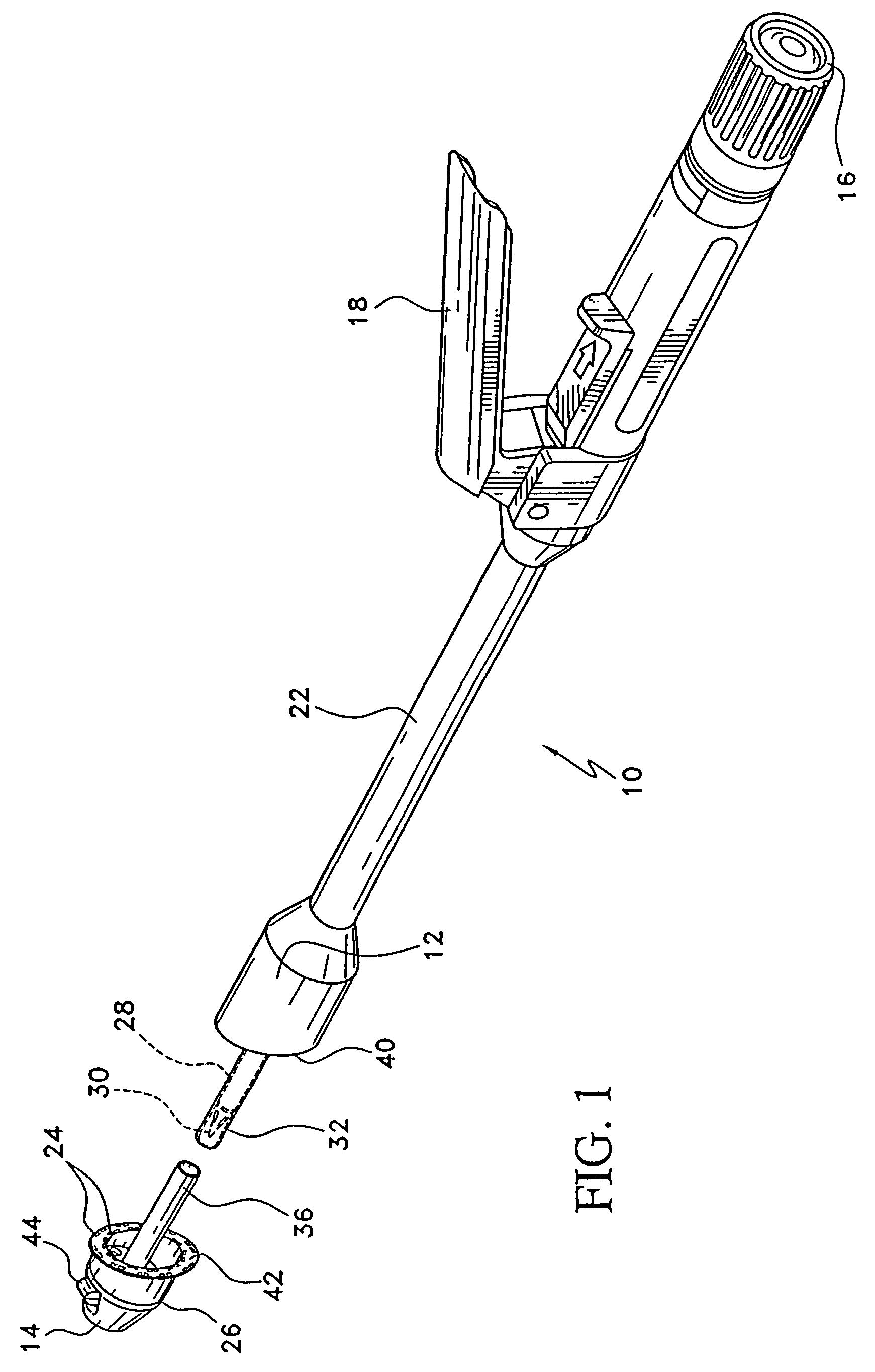

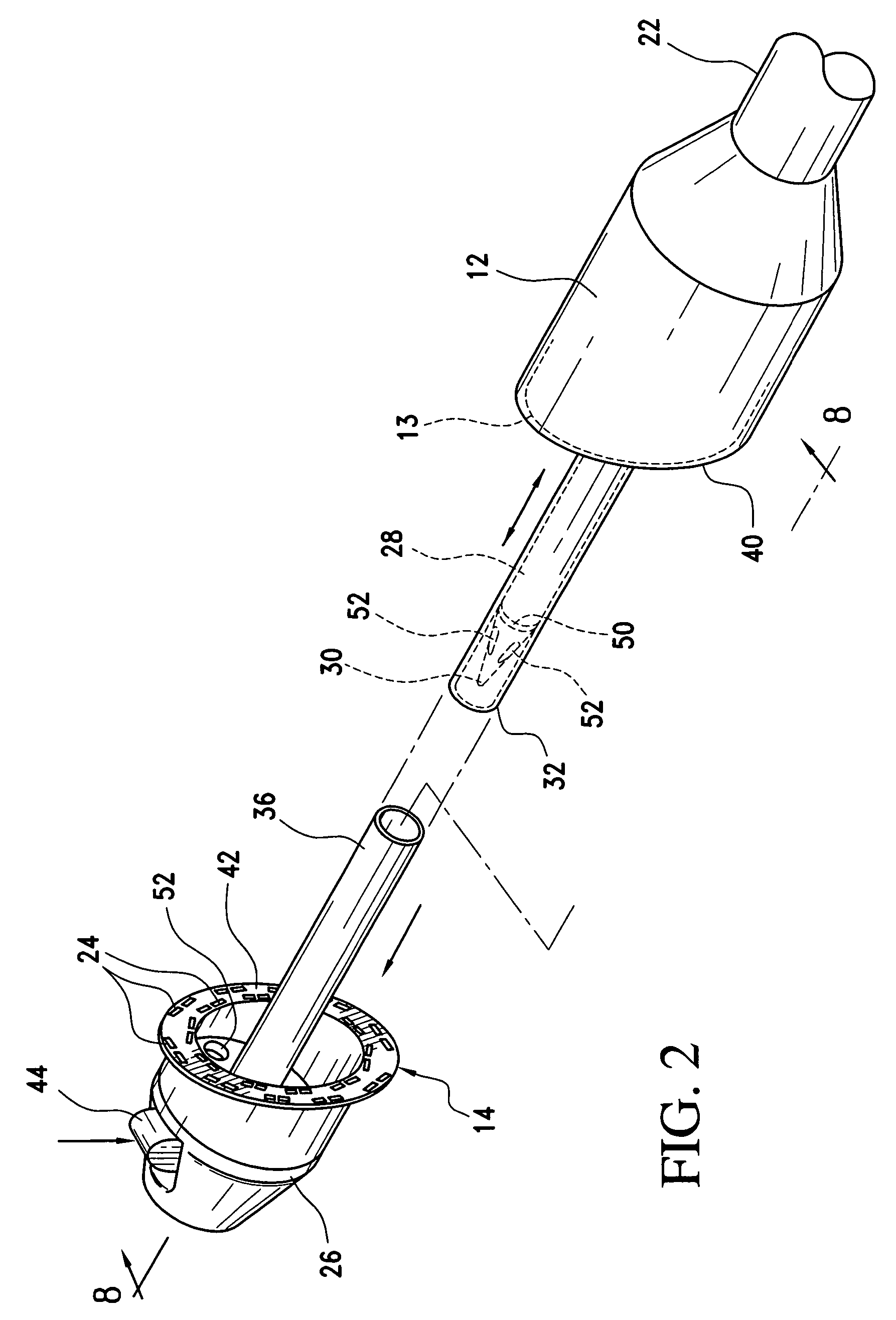

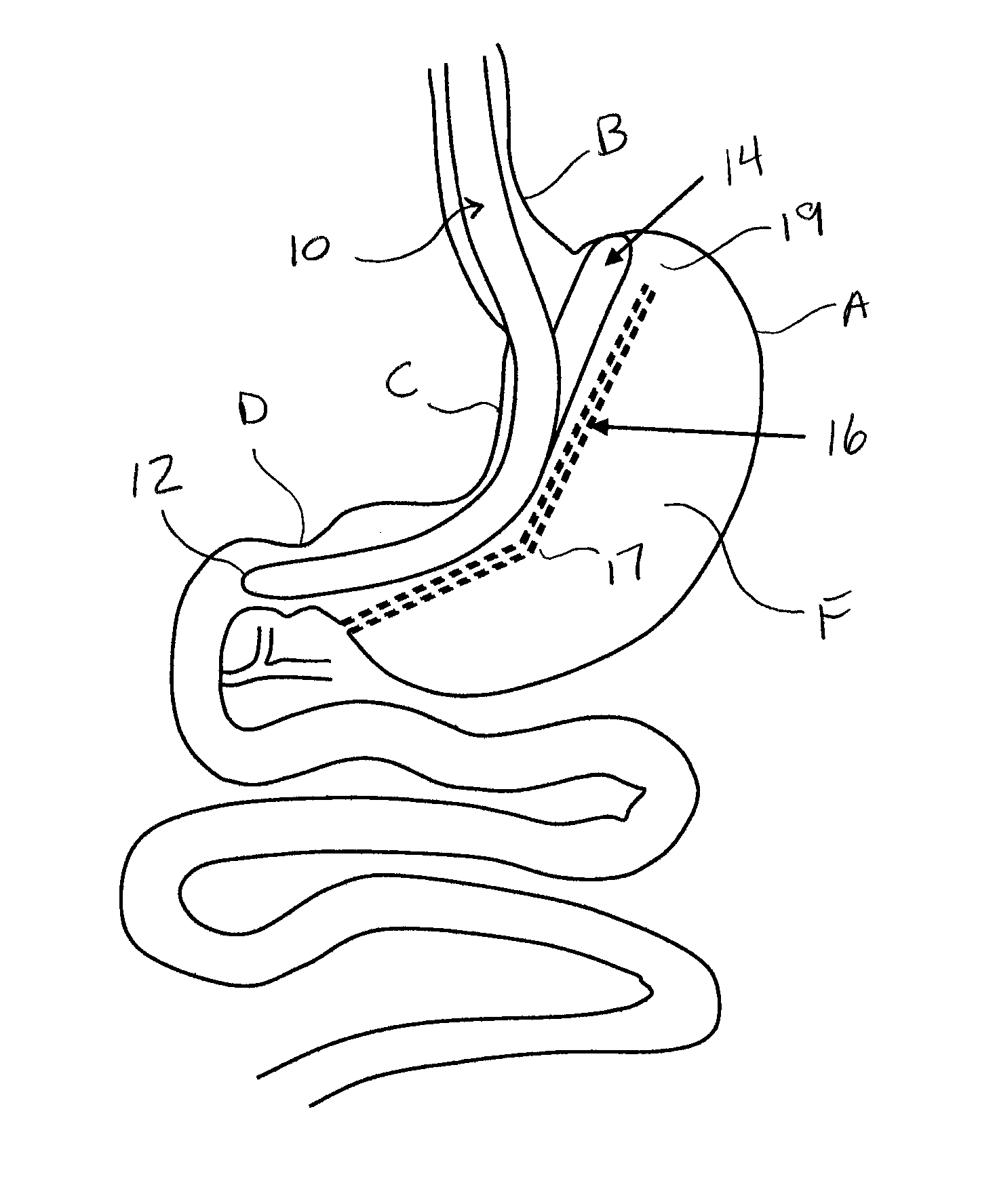

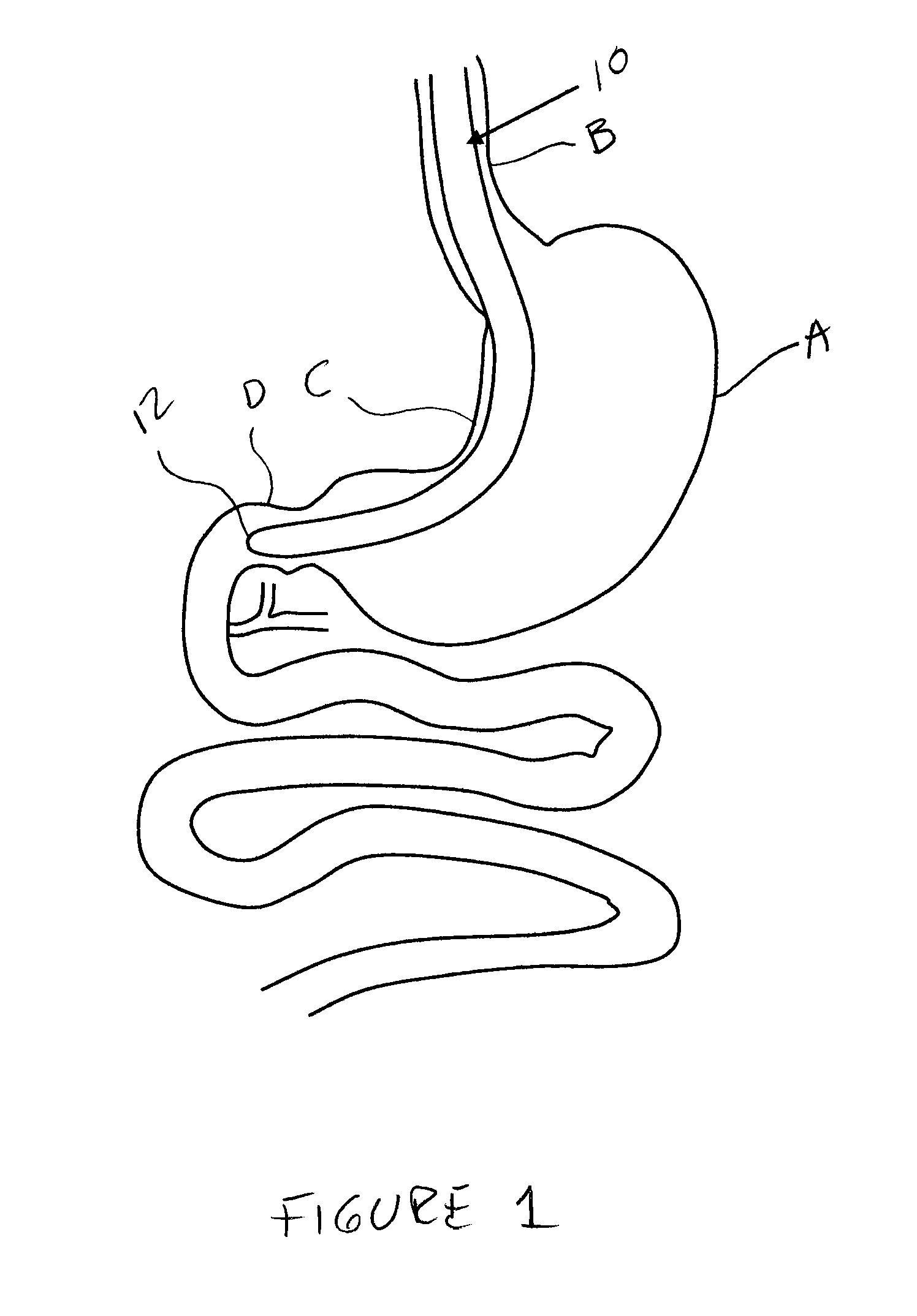

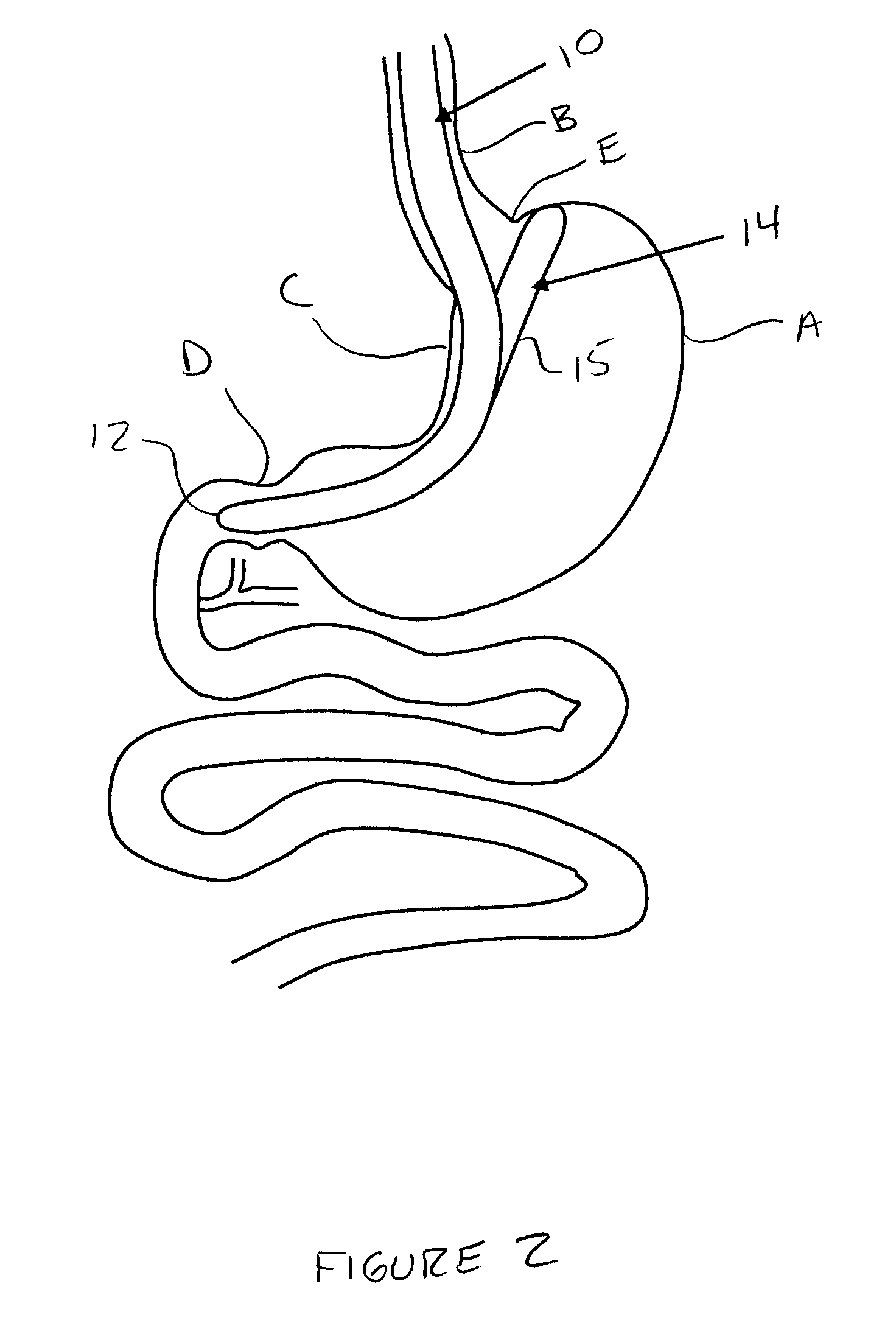

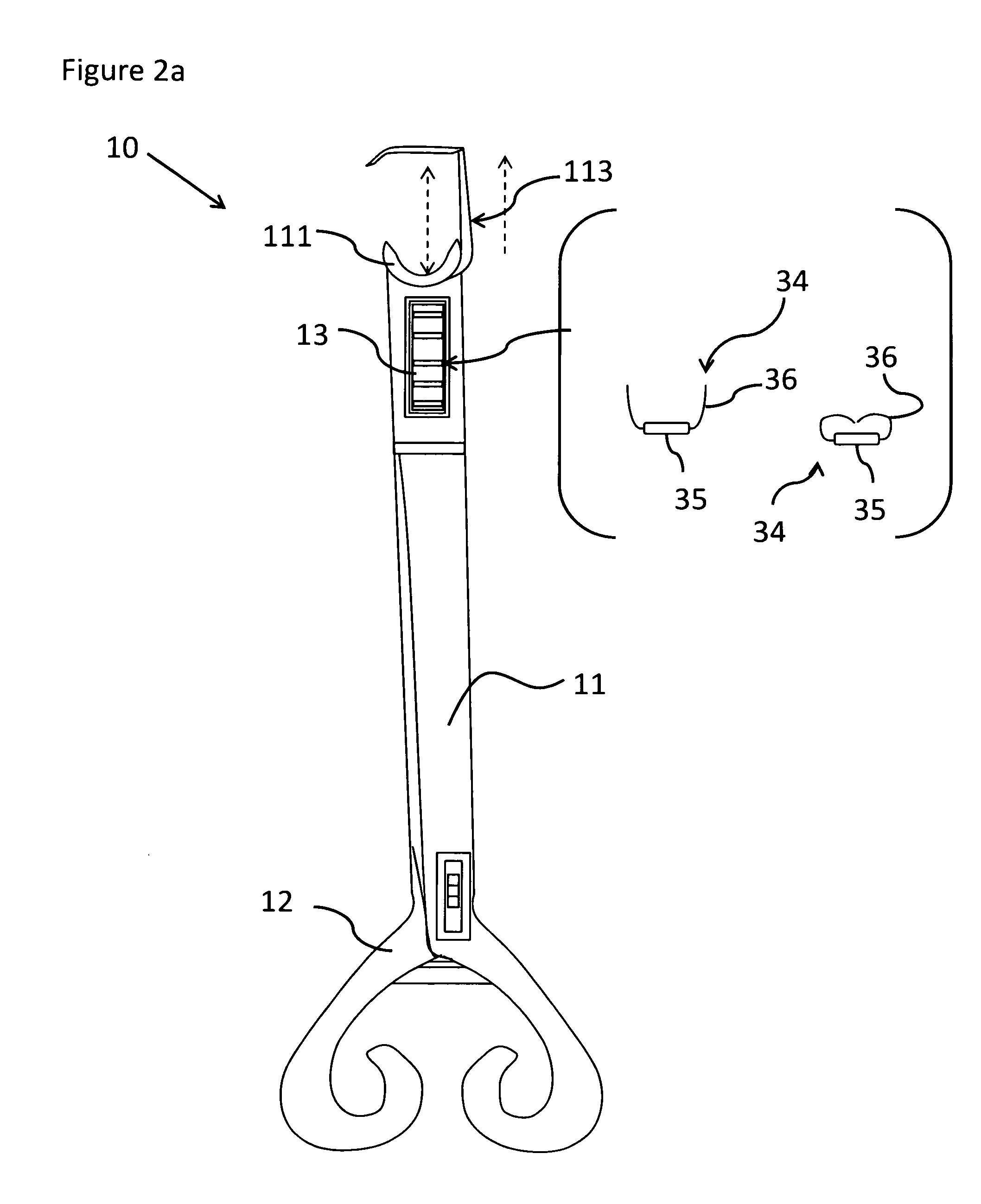

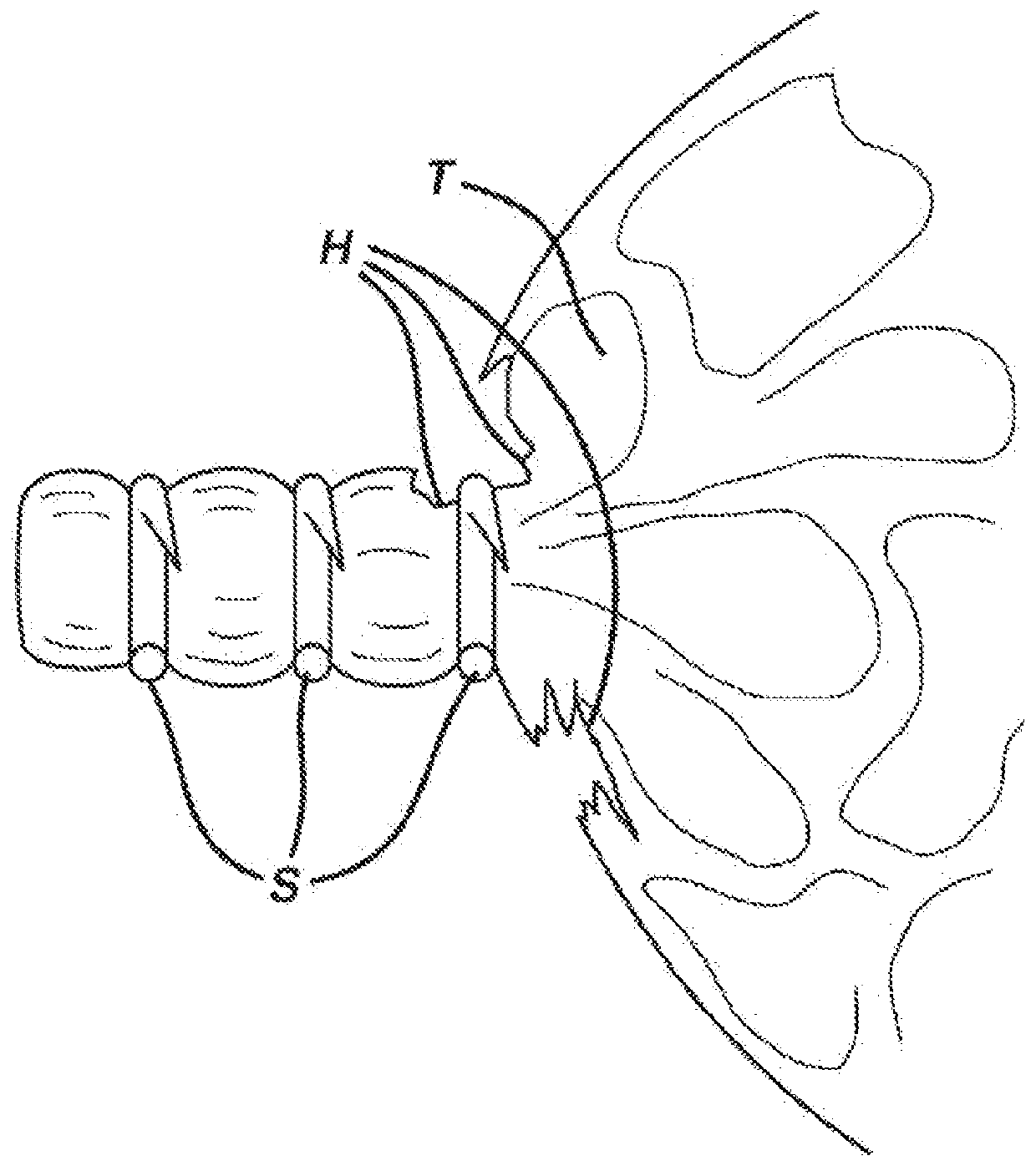

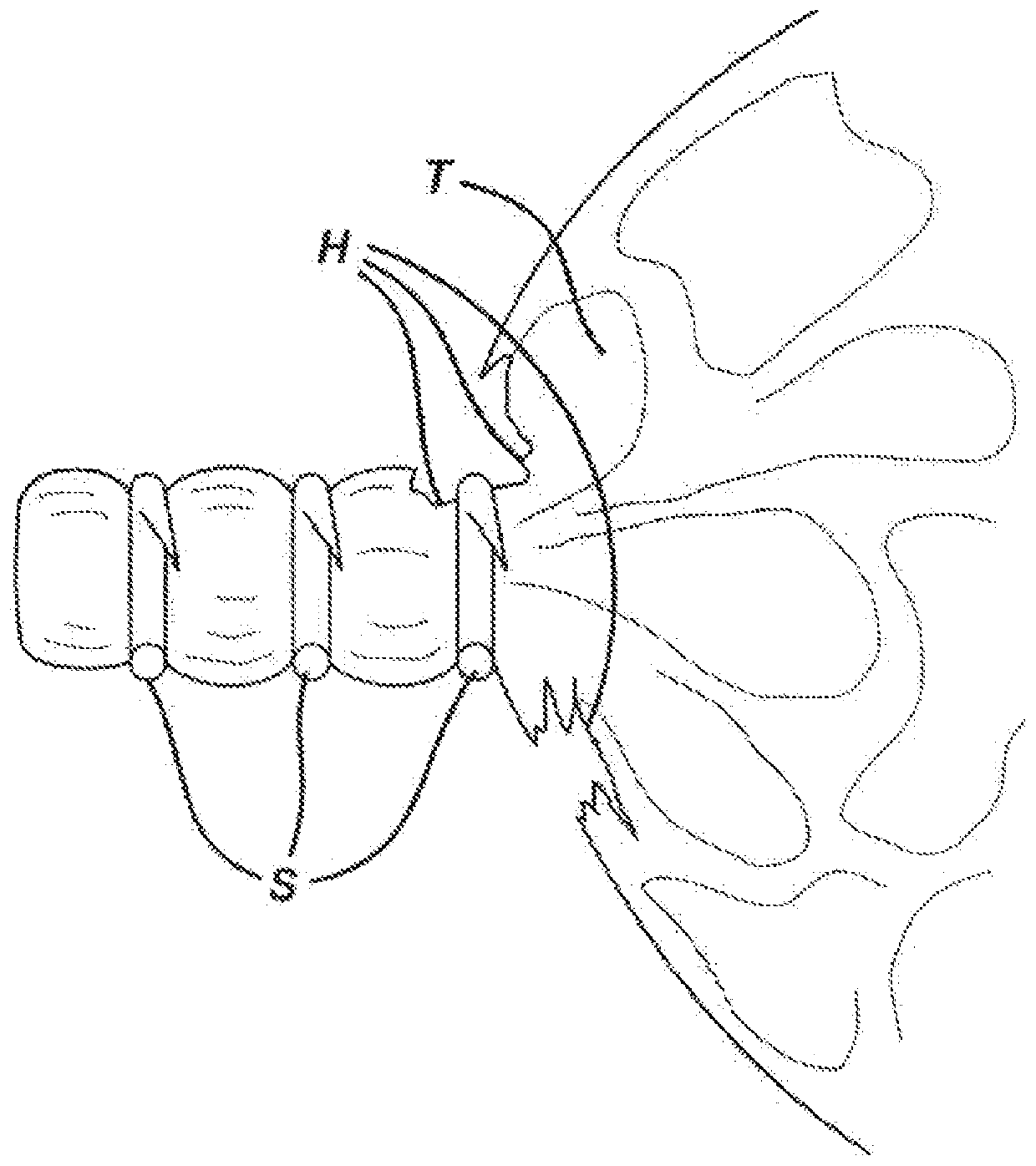

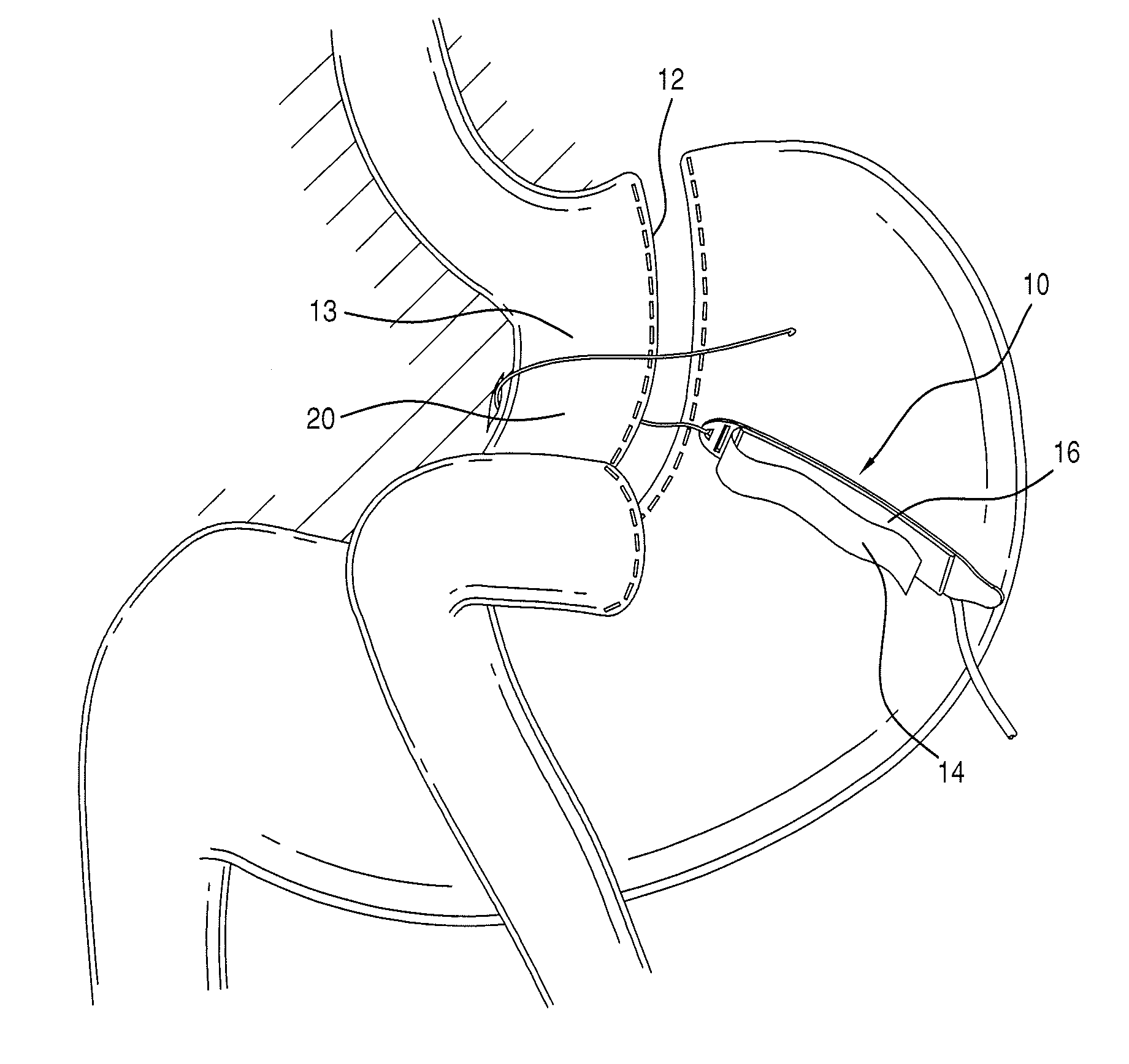

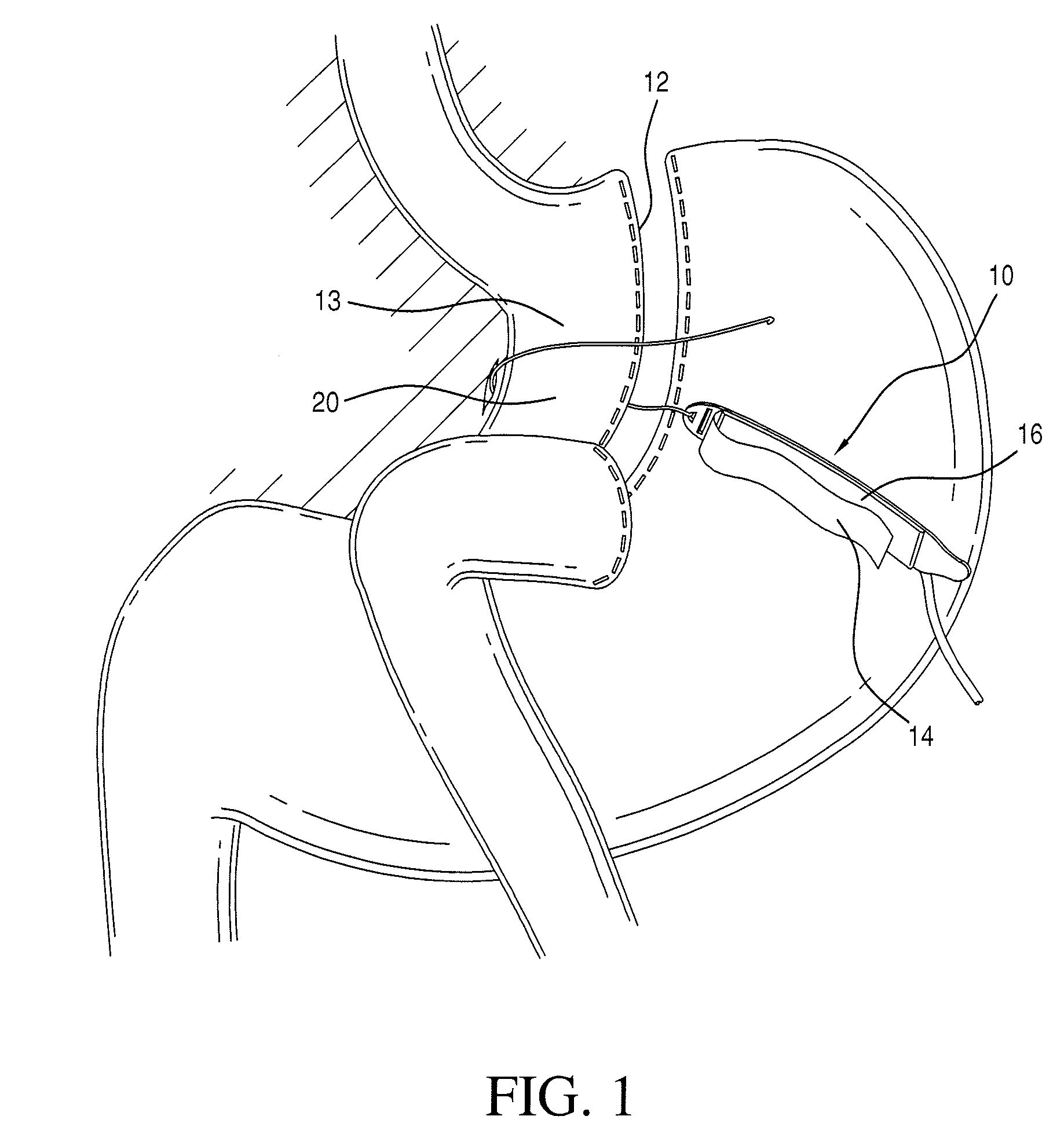

Methods and devices for performing gastroplasty

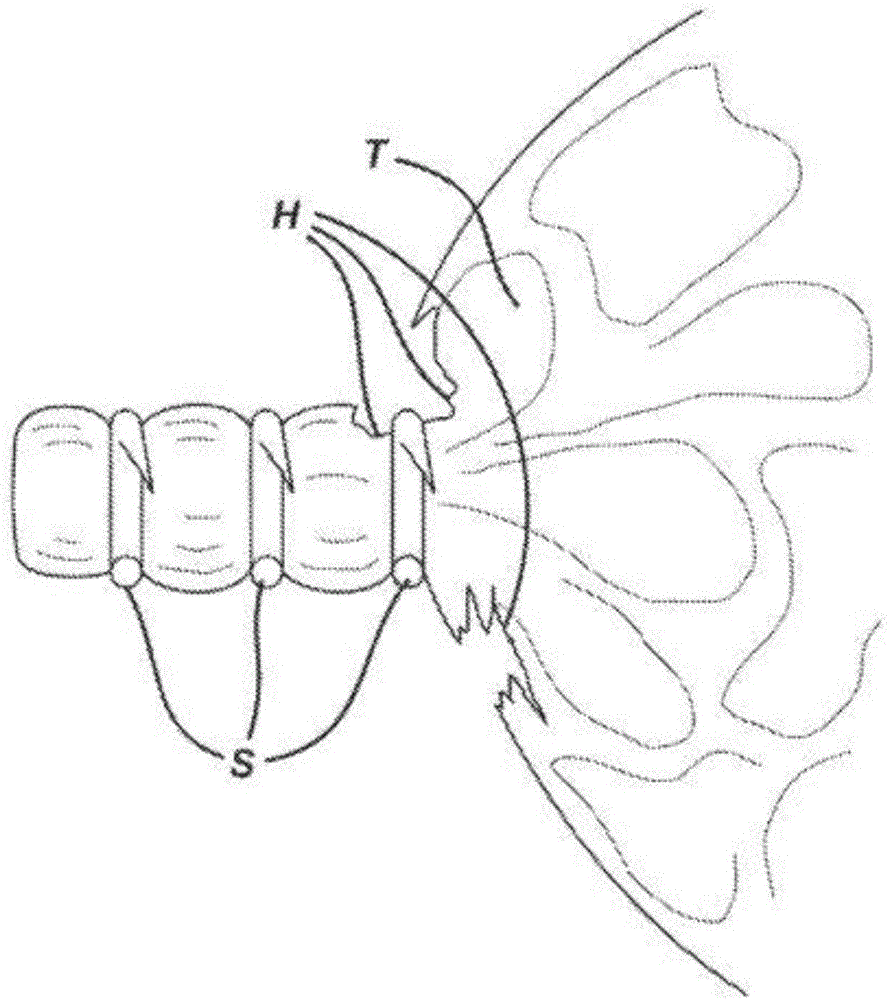

ActiveUS8663149B2Eliminate needIntravenous devicesTubular organ implantsStaple lineGastroesophageal Junction

A gastroplasty method involves a staple line that terminates prior to reaching the gastroesophageal junction such that the bypassed portion of the stomach does not require resection. Additionally, bougies are taught that assist a physician in following the improved staple line of the present invention.

Owner:BALLAST MEDICAL INC

Surgical fastener buttress material

InactiveUS20100234861A1Simple materialReduce misalignmentSuture equipmentsStapling toolsButtressStaple line

Owner:SYNOVIS LIFE TECH

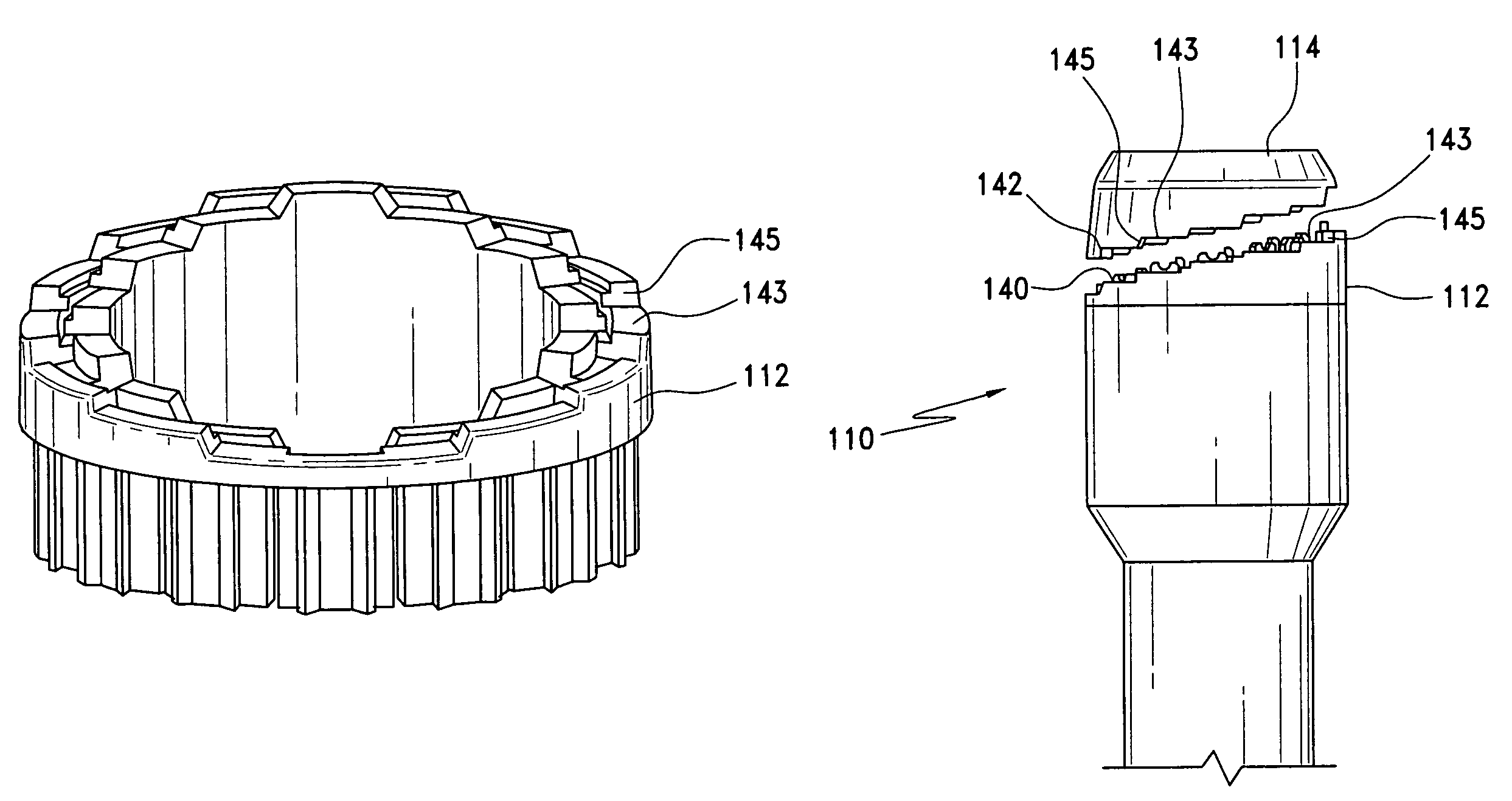

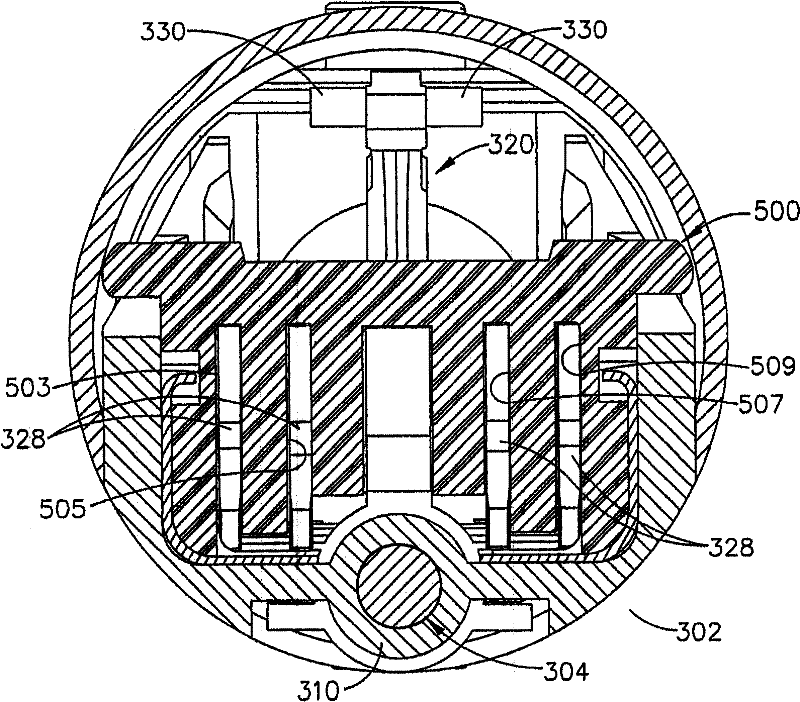

Disposable staple cartridge having an anvil with tissue locator

A disposable staple cartridge for a surgical cutting and fastening instrument. Various embodiments include a disposable anvil that is supported relative to the cartridge body and movable between open and closed positions. At least one tissue stop is provided on the disposable anvil for orienting the tissue to be cut and stapled relative to the staples supported within the cartridge body. Other embodiments relate to end effectors for surgical cutting and fastening instruments that can be used in connection with a plurality of staple cartridge bodies that each have a common length but which may different lengths of staple lines.

Owner:ETHICON ENDO SURGERY INC

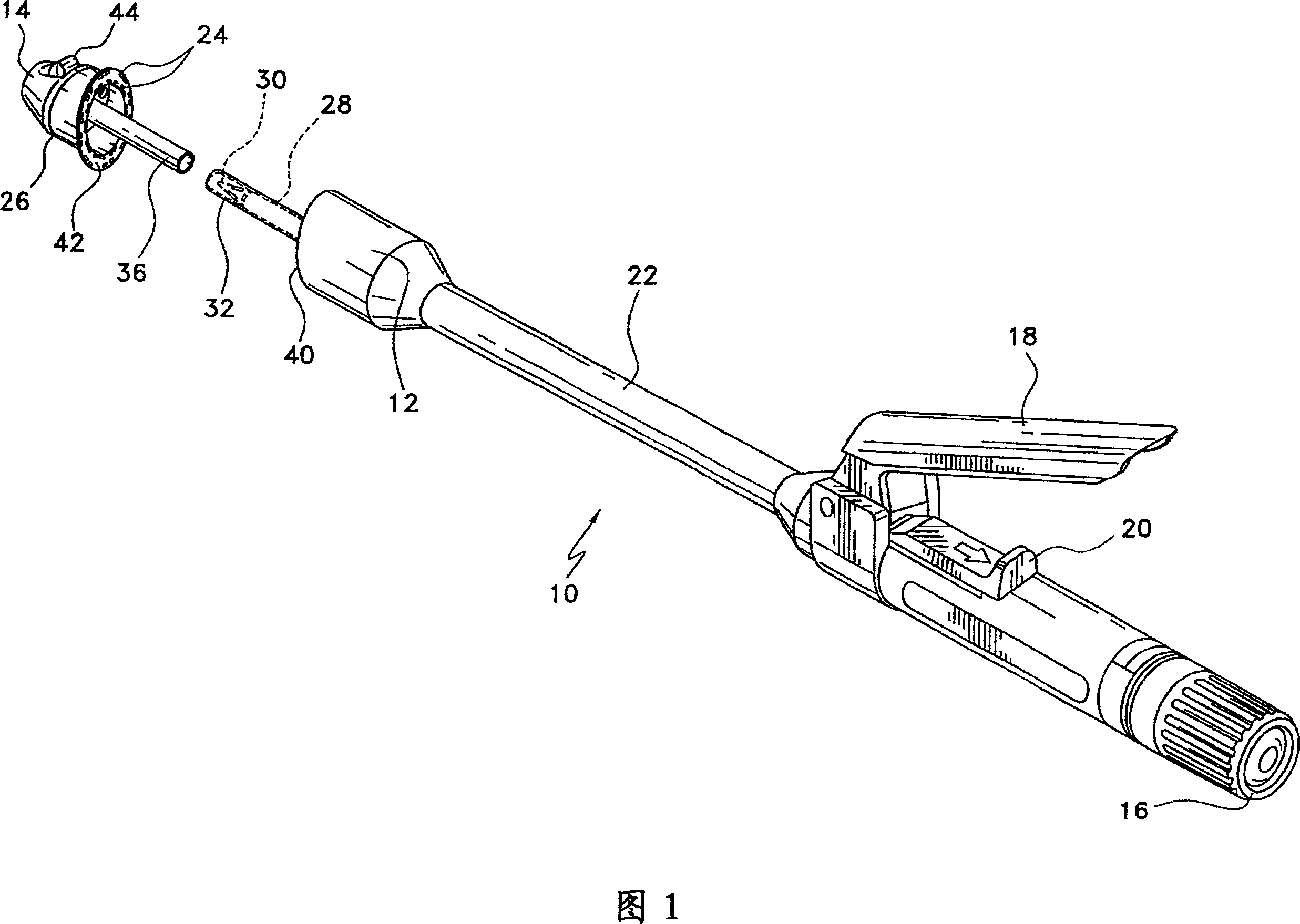

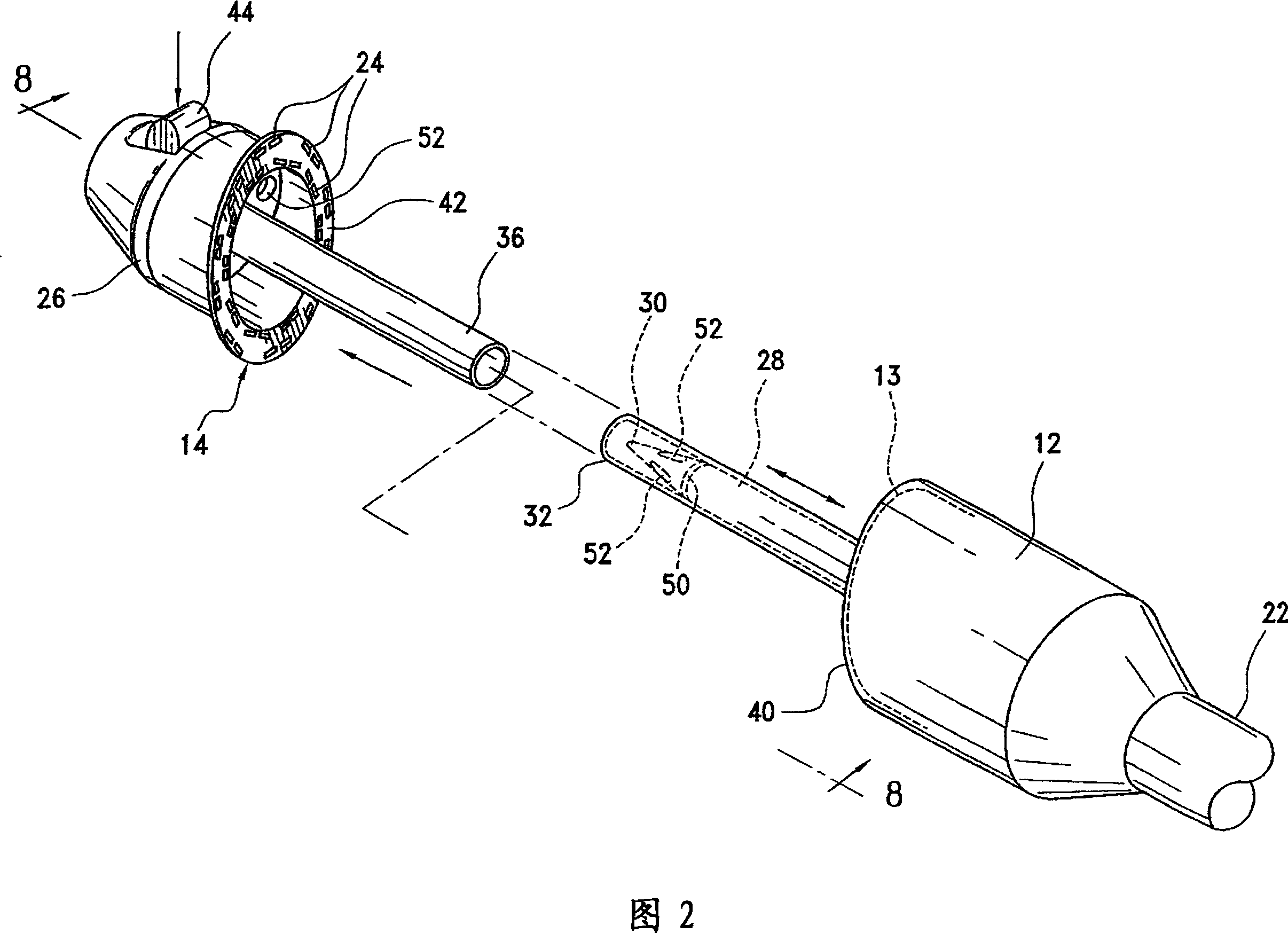

Elliptical intraluminal surgical stapler for anastomosis

A surgical stapler includes a head in which a plurality of staples are stored. The head includes a facing surface. The stapler also includes an anvil having an anvil surface shaped and dimensioned for forming the staples upon actuation of the surgical stapler, the anvil including a facing surface opposed to the facing surface of the head for mating engagement therewith. The facing surface of the head is obliquely oriented relative to a longitudinal axis of the head creating an elliptical staple line when the head is brought into contact with anvil during actuation of the surgical stapler.

Owner:ETHICON ENDO SURGERY INC

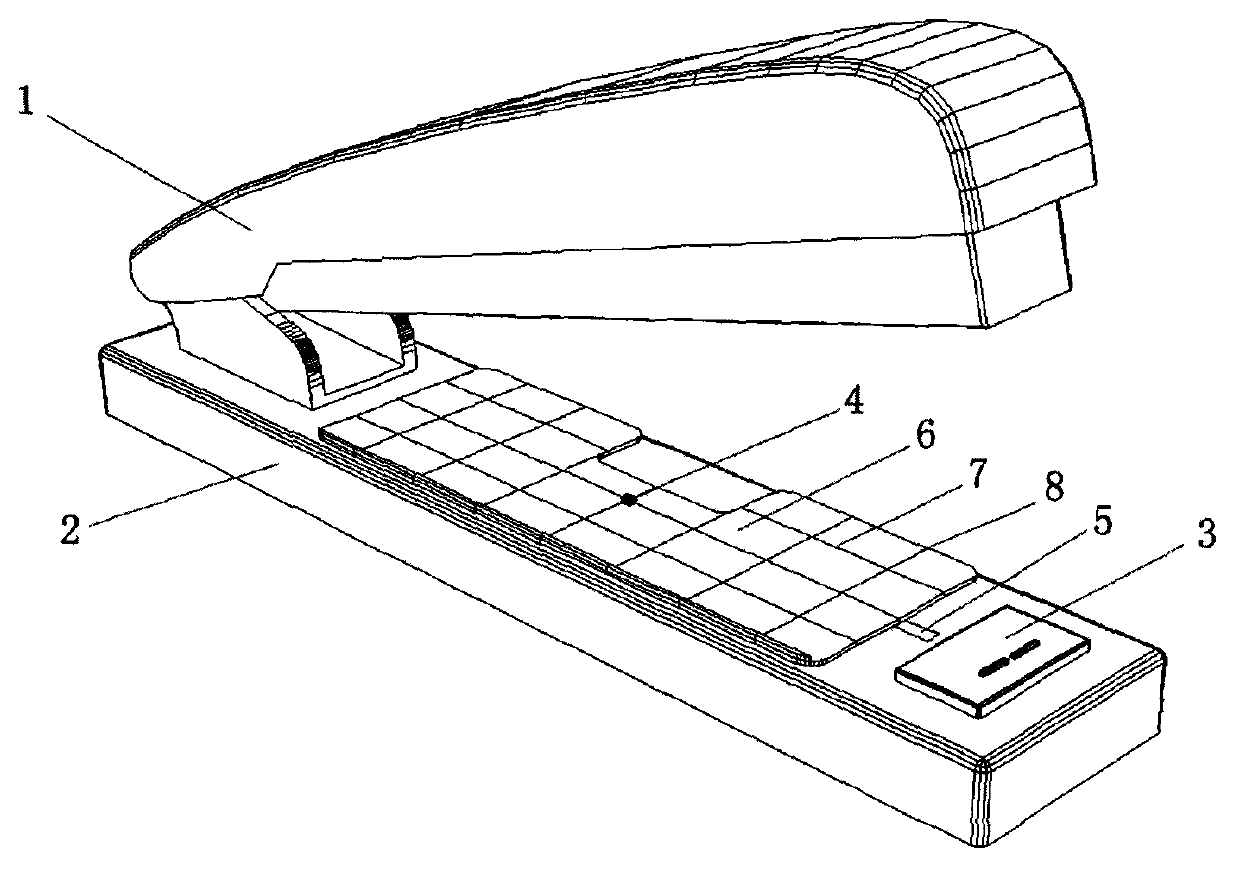

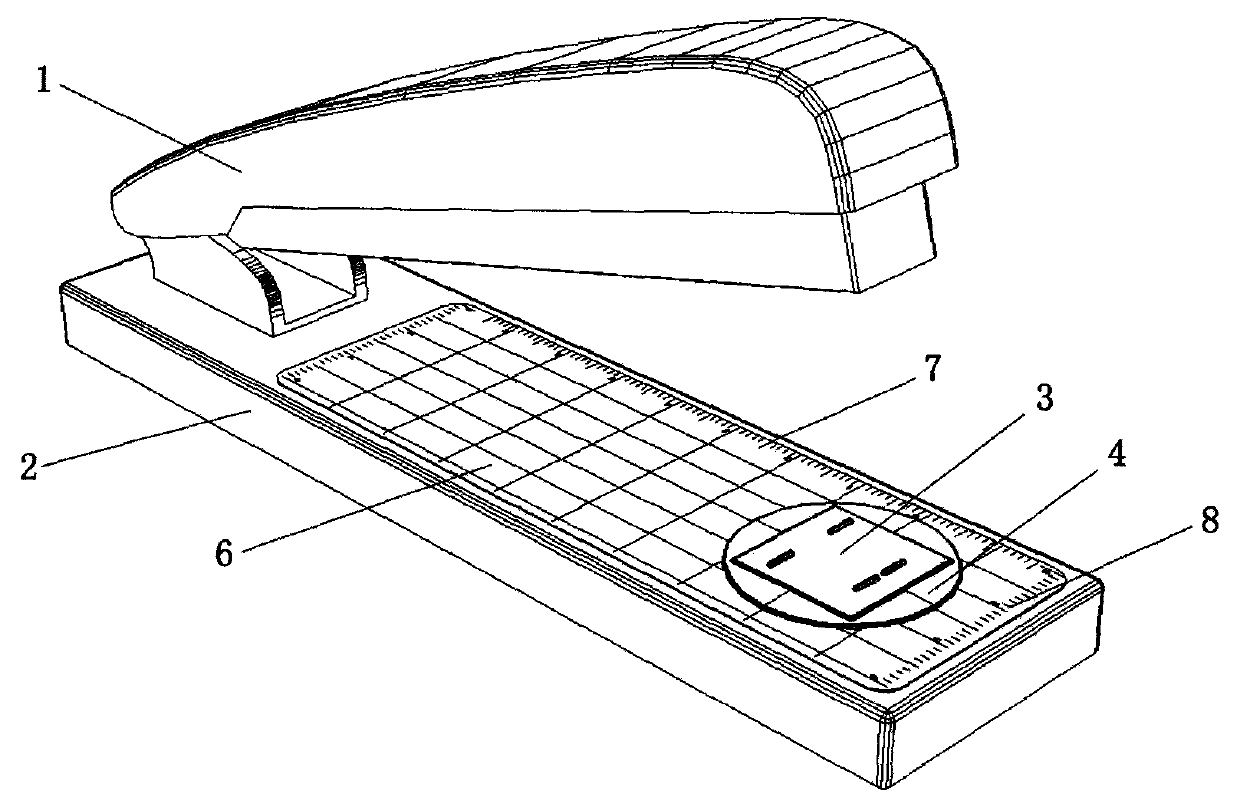

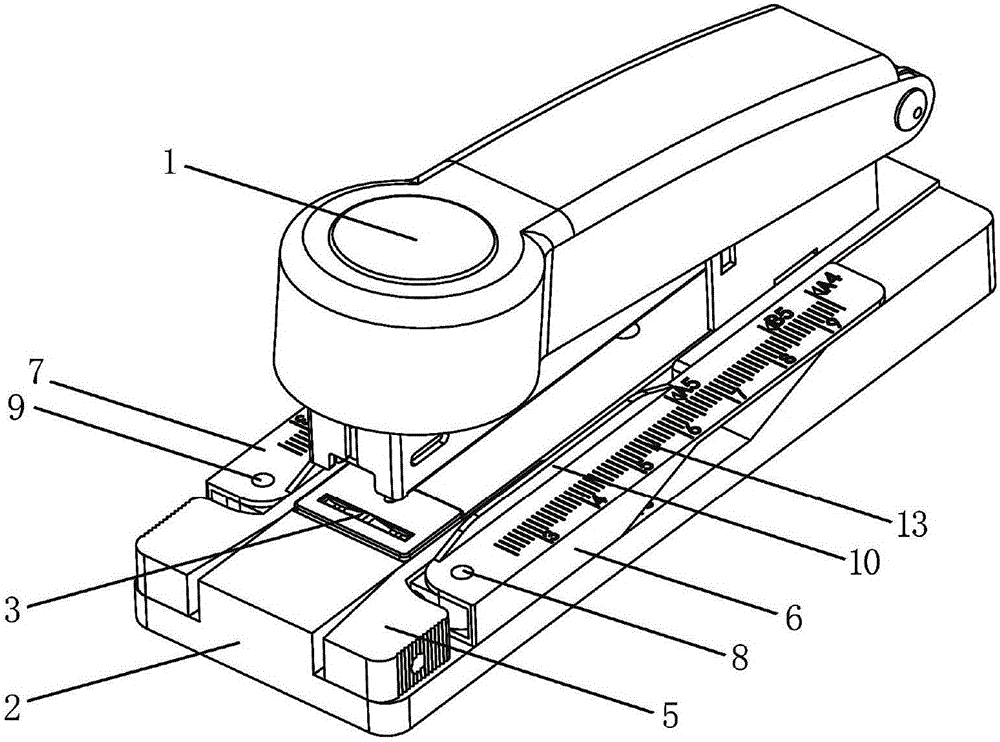

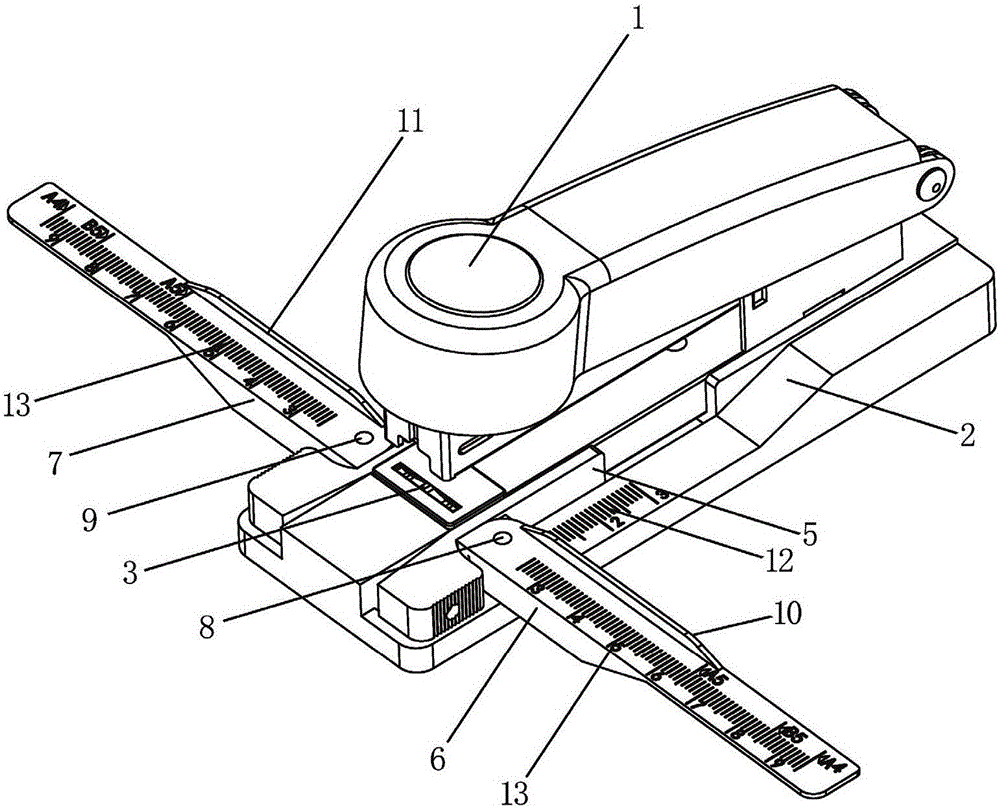

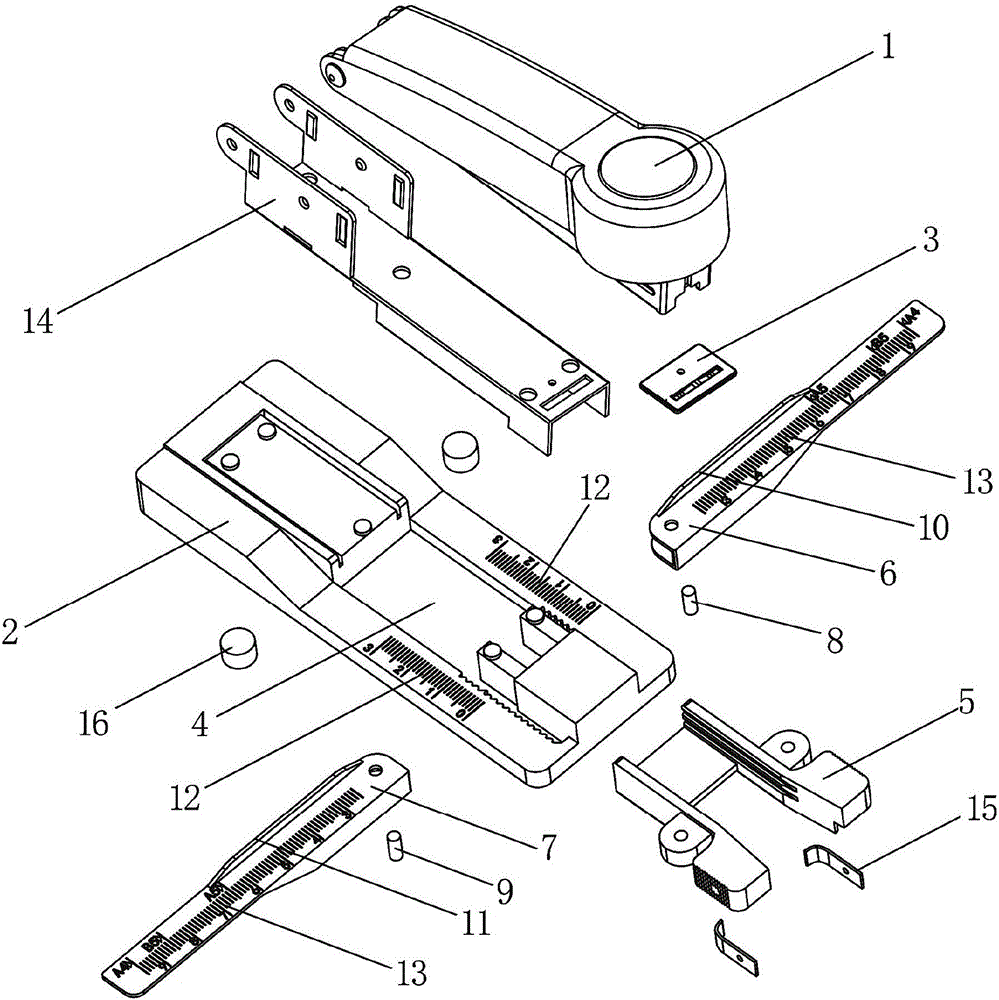

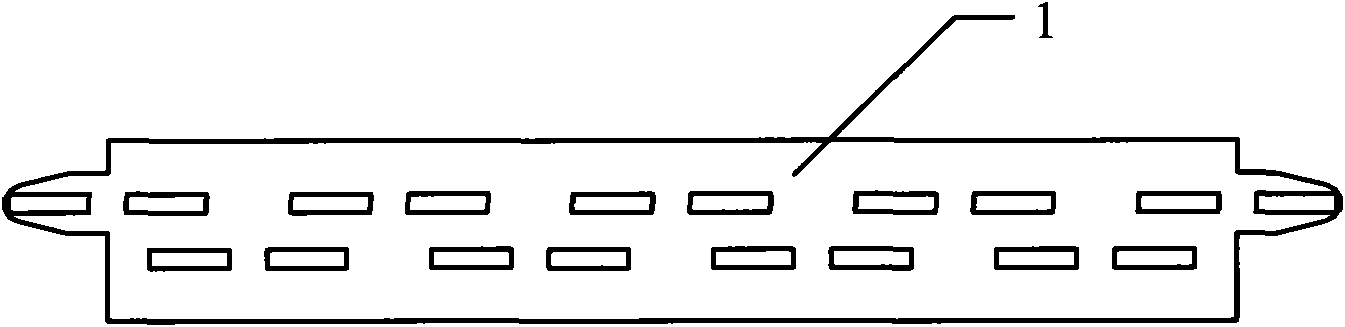

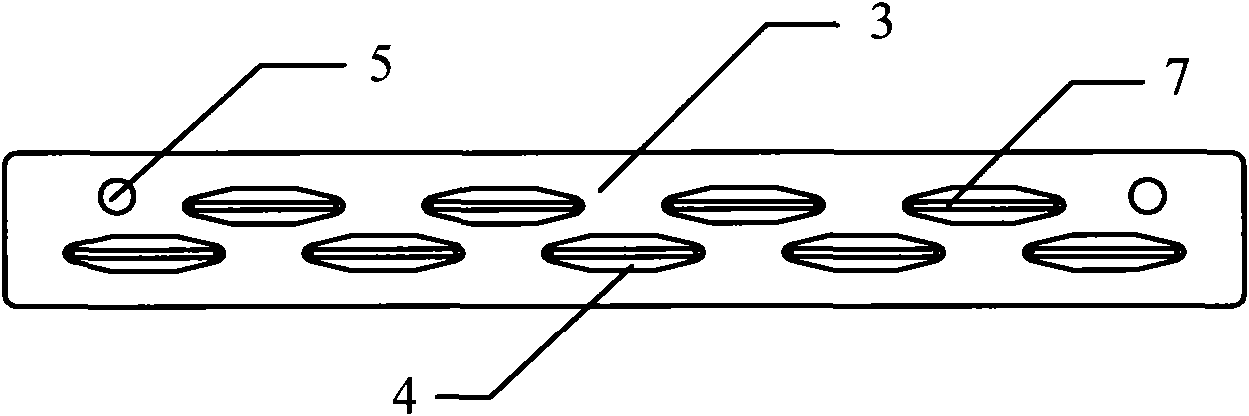

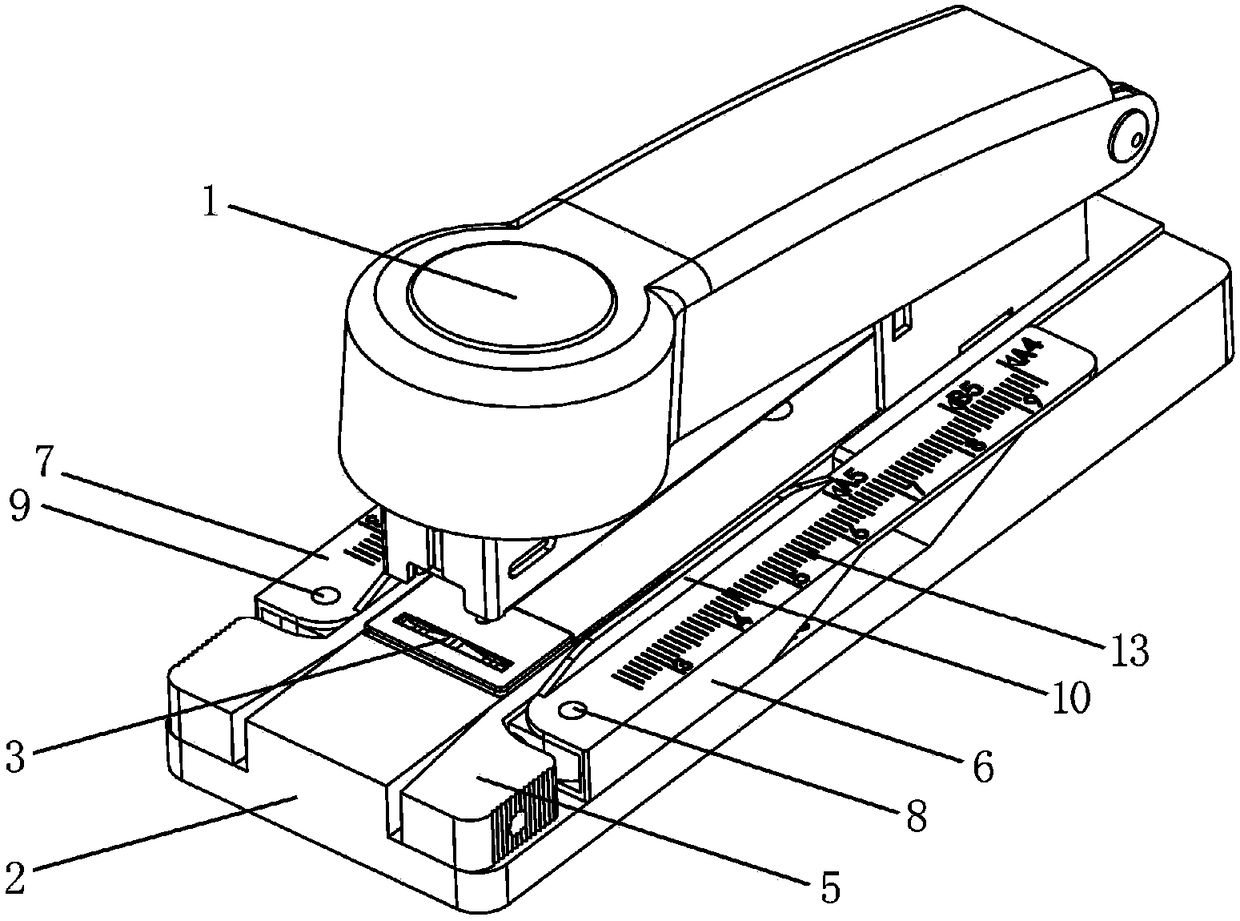

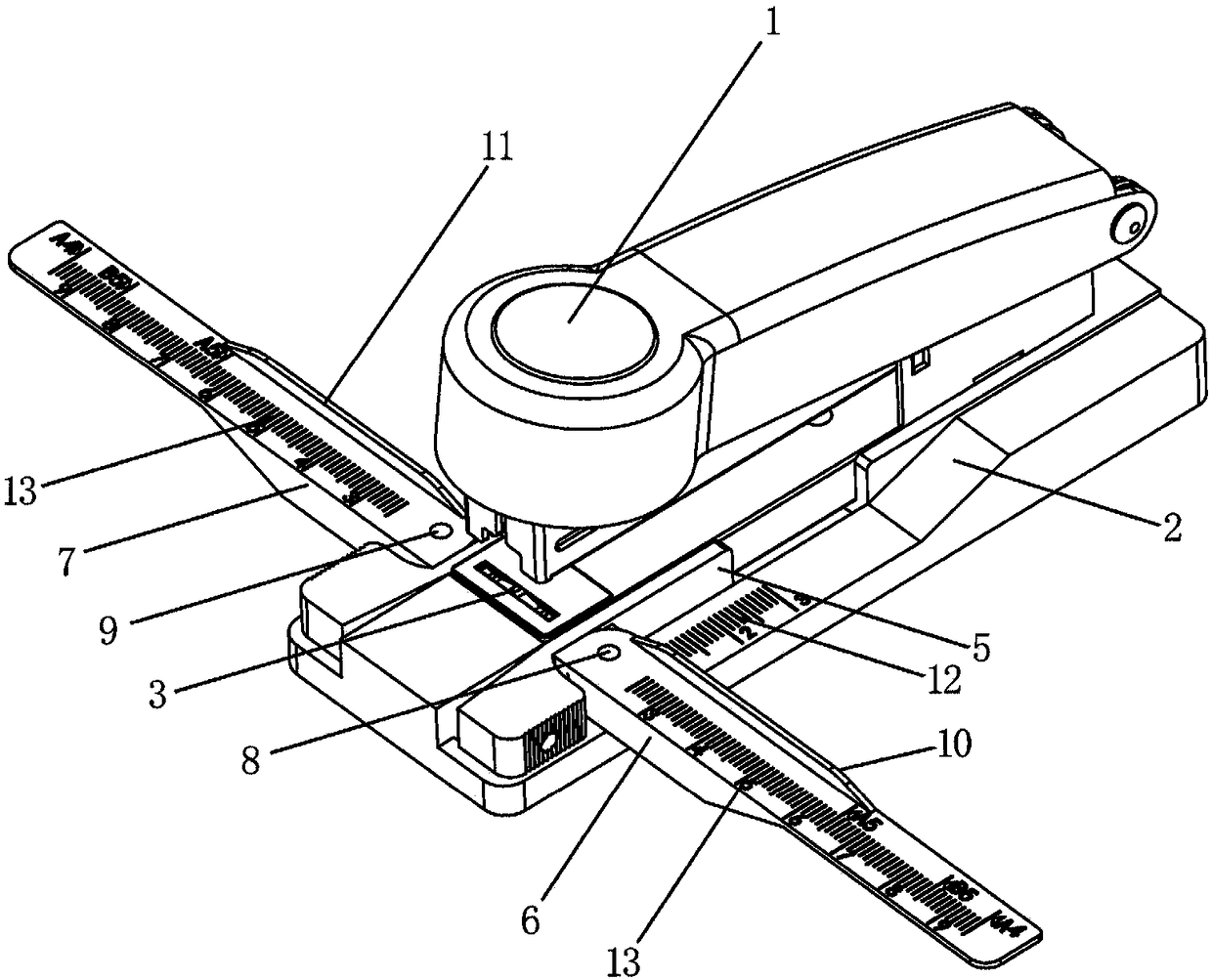

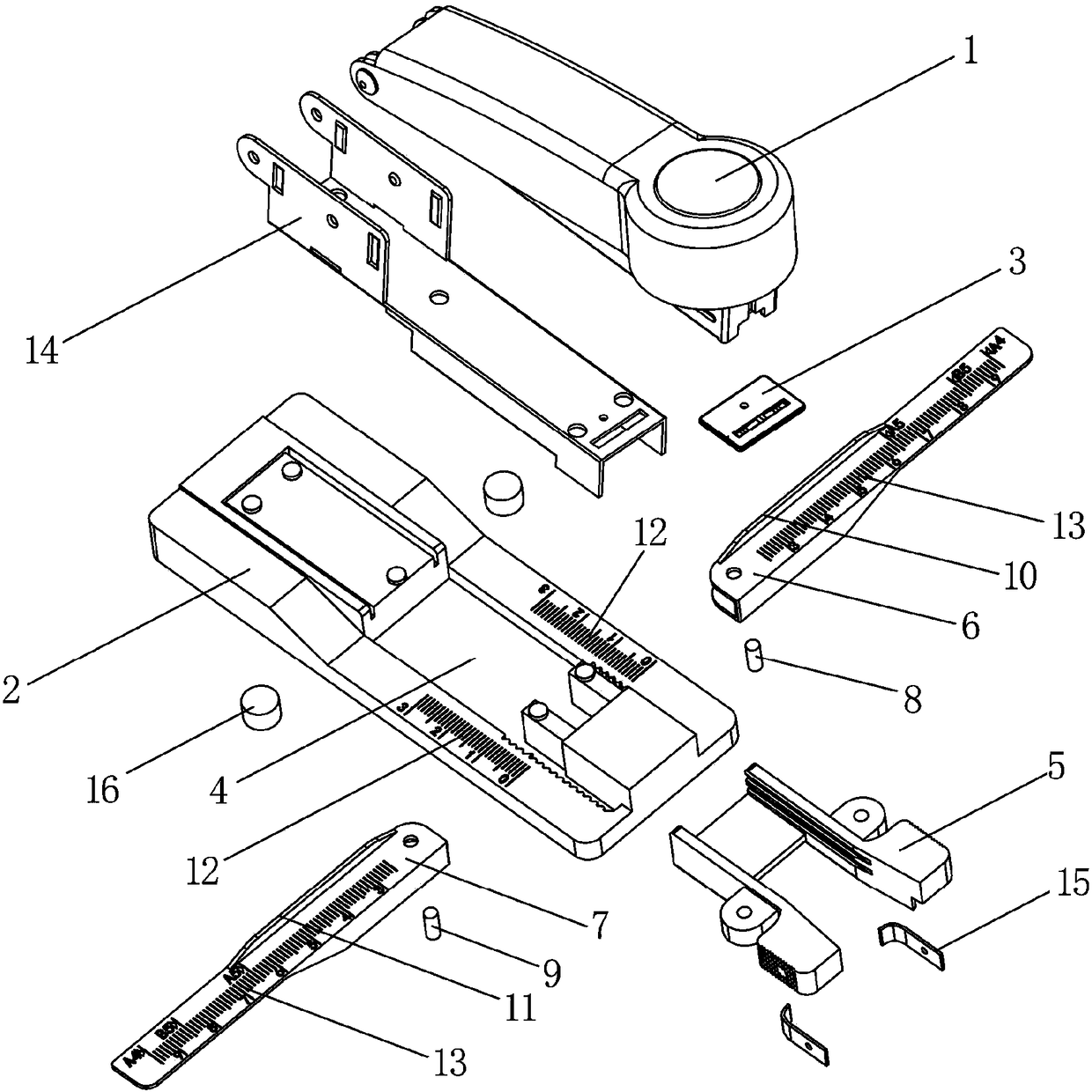

Stapler provided with stapling scale

ActiveCN104260057AAddresses an issue that does not provide a good binding position referenceMeet binding requirementsStapling toolsNailing toolsStaple lineEngineering

The invention relates to a stapler provided with a stapling scale. The stapling scale, whose length is greater than the width of a base and width is smaller than or equal to the width of the base, is mounted above the base of the stapler, and is connected to the base through axial rotation of a rotating shaft; when the stapler is not used, the stapling scale is rotated to be accommodated above the base; when the stapler is used, the stapling scale is rotated out by 90 degrees along the rotating shaft, so that the length of the stapling scale is greater than the width of the base, and the stapling scale plays a part in supporting papers and uses scale marks to provide the stapling position reference in stapling; transverse scale marks and longitudinal scale marks are arranged on the stapling scale; the transverse scale marks provide the distance reference and the parallel reference for a stapling line and the side edge of the paper to a binder, so that the distance from the stapling line to the side edge of the paper accords with the stapling requirement, and stapling nails are parallel to the side edge of the stapled paper; and the longitudinal scale marks on the stapling scale provide the distance reference for a stapling position and the upper and lower edges of the paper to the binder, so that the distance from the stapling position to the upper and lower edges of the paper accords with the stapling requirement.

Owner:苏州奕方华知识产权运营有限公司

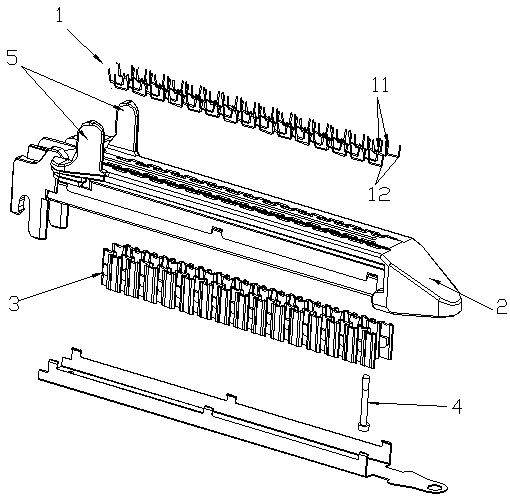

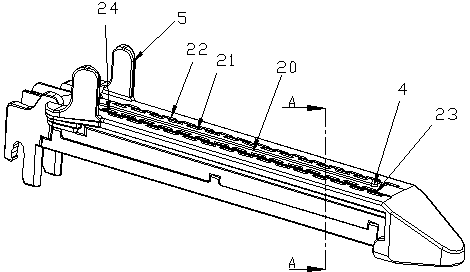

Cutting assembly of stapler

InactiveCN104027143AImprove blood supplyPromote healingIncision instrumentsSurgical staplesStaple lineTissue fluid

The invention discloses a cutting assembly of a stapler, and belongs to the field of medical instruments. Staple molding heights of suturing staples of the cutting assembly are inconsistent. By using the height difference of staple pushing grain tooth pieces, under the condition of the consistent heights of the suturing staples, the molding heights are inconsistent, and the outer molded staples are higher than the inner molded staples. The inner molded staples are low to be beneficial to stop bleeding, the outer molded staples are high to be beneficial to the blood supply for tissues to cutting edges, and the healing of the tissues is fast. A staple cartridge surface is designed into a ladder shape, the middle position is higher than the positions of the two sides, so that the squeezing force of the tissues is dispersed, the stress of the middle surface is greater to be beneficial to spread tissue fluid to the two sides, the time for compressing the tissues to the specified height is effectively shortened, and the operation time is shortened. A tissue stop stand column is used for limiting tissue pull-in positions, and interacts with tissue positioning staples to ensure that the length of staple lines always exceeds that of clamping tissues, complete suturing of the tissues is ensured, and no exposure point is generated.

Owner:SHANDONG WEIRUI SURGICAL MEDICAL PROD

Source/seed delivery surgical staple device for delivering local source/seed direclty to a staple margin

InactiveUS8579785B2Reduce the number of surgeriesPrecise deliverySuture equipmentsStapling toolsSurgical stapleStaple line

A source delivery surgical staple device delivers a source / seed to a staple margin. The surgical staple delivery device includes a main staple body segment hingedly attached to a second body segment. Each of the segments is appointed for engagement to dispense the sources / seeds and / or a surgical staple to the staple margin. The device also includes a cartridge removably attached and snapped onto the main staple body segment. The cartridge has at least one staple line appointed for housing surgical staples, and being operative to form at least one staple line of surgical staples, and at least one cut line. The cartridge also has at least one source / seed / brachy staple line forming a brachy or radioactive seeds and / or chemotherapy agent dosage source. The radioactive seeds have a radioactive and / or chemotherapy source supported by leg portions that are manipulated during insert for fastening the radioactive staples to tissue at an incision margin. With this arrangement, a hybrid of chemotherapy agent and radiation is delivered directly into the staple lines and different dosage brachy loads can be loaded in the cartridge.

Owner:SHARIATI NAZLY MAKOUI

Source/Seed delivery surgical staple device for delivering local source/seed directly to a staple margin

InactiveUS20150129633A1Reduce the number of surgeriesMitigating microscopic diseaseSuture equipmentsStapling toolsSurgical stapleStaple line

A source delivery surgical staple device delivers a source / seed to a staple margin. The surgical staple delivery device includes a main staple body segment hingedly attached to a second body segment. Each of the segments is appointed for engagement to dispense the sources / seeds for the treatment of microscopic disease to a surgical margin. The device also includes a cartridge removably attached and snapped onto the main staple body segment. The cartridge has a source / seed / brachy staple line forming a brachy or radioactive seeds and / or chemotherapy agent dosage source. The radioactive seeds have a radioactive and / or chemotherapy source supported by leg portions that are manipulated during insert for fastening the radioactive staples to tissue at an incision margin. A hybrid of chemotherapy agent and radiation is delivered directly into the surgical margin and different dosage can be loaded in the cartridge.

Owner:SHARIATI NAZLY MAKOUI

Stapler with stapling ruler

Owner:安徽众力农业装备科技有限公司

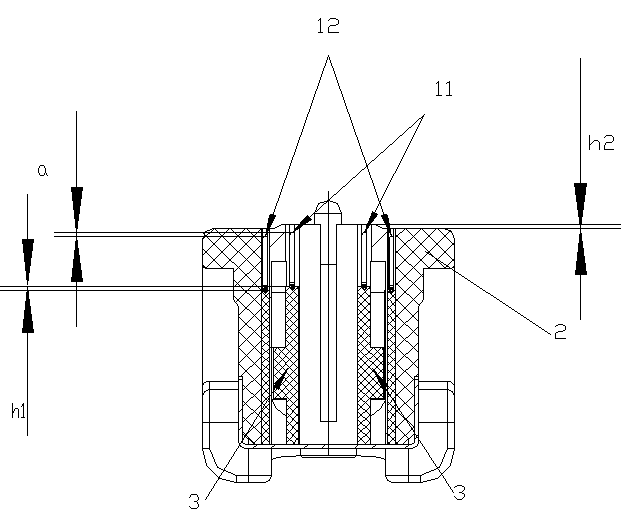

Stapling head of non-closed surgical stapling machine

InactiveCN101596120AEliminate the hidden danger of incomplete closureEliminate hidden dangersSurgical staplesStaple lineEngineering

The invention relates to a stapling head of a non-closed surgical stapling machine, belonging to the technical field of medical appliances and comprising a staple anvil, a staple pushing device and a staple chamber, wherein the staple anvil and the staple chamber are opposite to form a stapling area; at least one row of staple chamber holes is distributed on the staple chamber in linear parallelism to form a staple line; a plurality of pairs of staple grooving are distributed on the staple anvil; and the staple chamber is arranged at a far end of the staple pushing device. The stapling head is characterized in that the length of the staple line is larger than the contact length of tissues and a staple chamber surface, thereby ensuring that the broken ends of the tissues are completely closed after being stapled by the stapling machine.

Owner:TOUCHSTONE INTERNATIONAL MEDICAL SCIENCE CO LTD

Matrix metalloproteinase inhibiting adjuncts for surgical devices

The presnet invention provides various exemplary matrix metalloproteinase (MMP) inhibiting adjuncts for surgical devices. In general, an implantable adjunct can be configured to be applied to tissue by a surgical stapler in conjunction with staples. The adjunct can have at least one medicant releasably retained therein that is configured to reduce a length of the epithelialization process. In other words, the at least one medicant releasably retained in the adjunct can be configured to speed up an inflammation stage of wound healing and / or a proliferation stage of wound healing and, accordingly, reduce an amount of time before a remodeling stage of wound healing begins. The at least one medicant can be configured to be released along the staple line defined by the staples.

Owner:伊西康有限责任公司

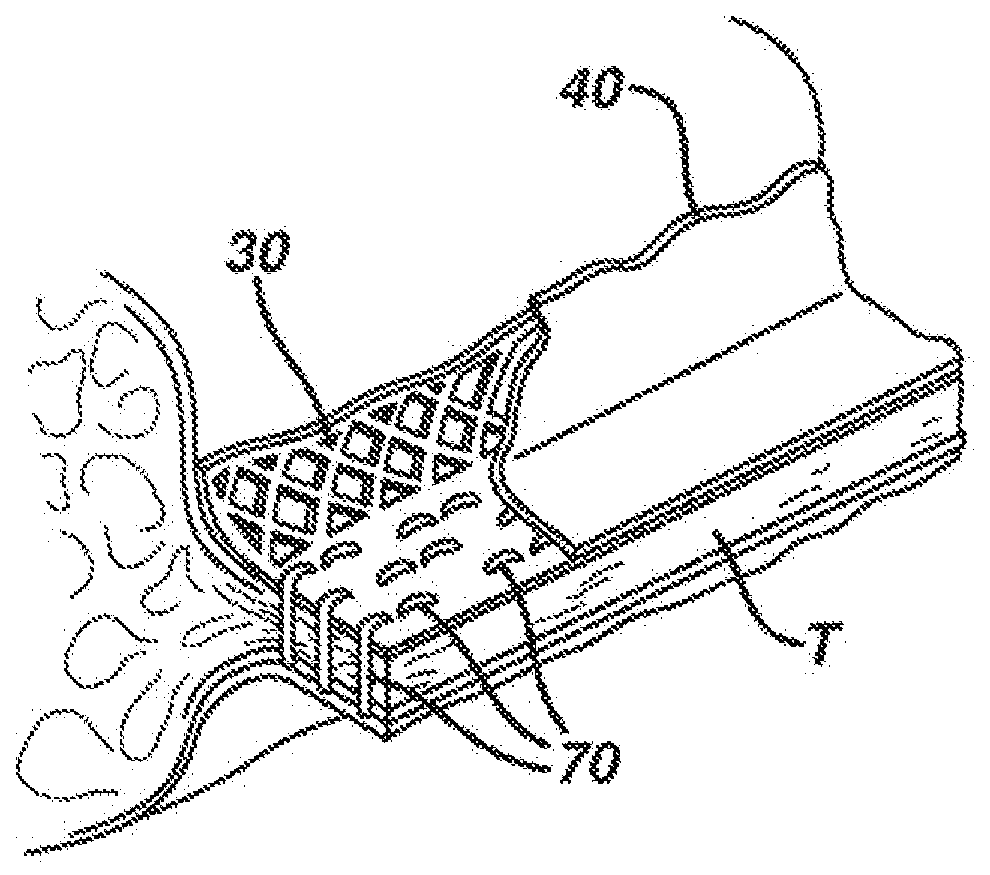

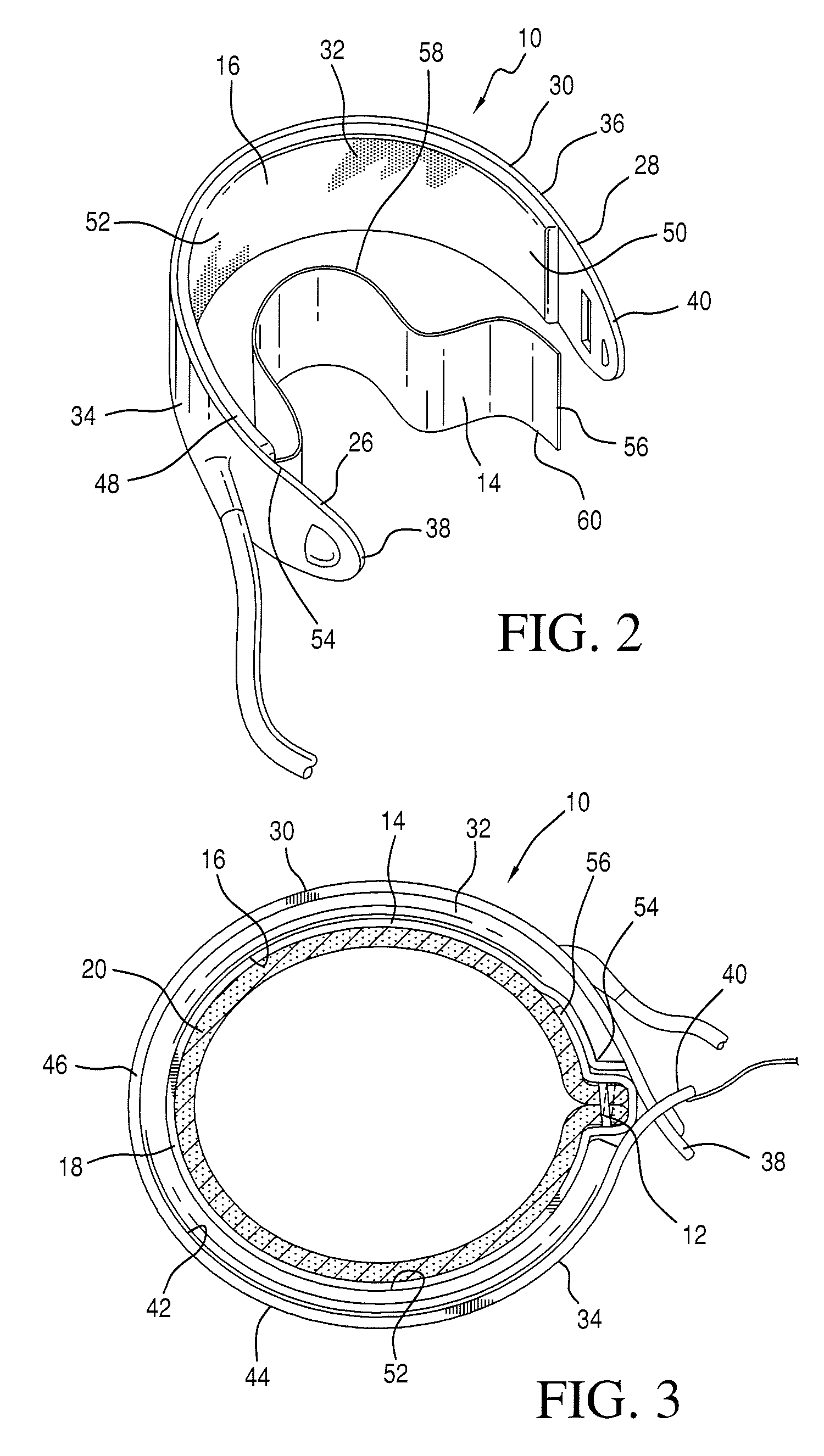

Methods and devices for reinforcing a staple line

Adjunct material and methods of using adjunct material to reinforce tissue in proximity to a staple line are provided herein. In general, the adjunct material can be used to maintain a seal in tissue, such as lung tissue, and prevent stapled tissue from tearing. This adjunct material can be coupled to a jaw of a surgical stapler, and can be deployed into tissue along with the staples. In some embodiments, the adjunct material can comprise an outer material encompassing an inner, hydrophilic swellable material. The outer material can be selectively dissolvable and / or absorbable. When the outer material is punctured by staples or otherwise penetrated, moisture is passed to the inner material which then swells and expands to transition to a predetermined shape to seal the tissue and prevent leaks from forming in the tissue. Portions of the inner material around the staple line can transition to a large radius.

Owner:ETHICON ENDO SURGERY INC

Disposable staple cartridge having an anvil with tissue locator

A disposable staple cartridge for a surgical cutting and fastening instrument. Various embodiments include a disposable anvil that is supported relative to the cartridge body and movable between open and closed positions. At least one tissue stop is provided on the disposable anvil for orienting the tissue to be cut and stapled relative to the staples supported within the cartridge body. Other embodiments relate to end effectors for surgical cutting and fastening instruments that can be used in connection with a plurality of staple cartridge bodies that each have a common length but which maydifferent lengths of staple lines.

Owner:ETHICON ENDO SURGERY INC

Device for sealing staples in tissue

This article describes devices and methods for forming an anastomosis between two body cavities. In one embodiment, an anastomosis may be formed by transecting a body lumen using a linear surgical stapler (10) delivering a plurality of sealing aids (4106, 4108) in conjunction with a plurality of surgical staples (4080) along a staple line, wherein the The plurality of sealing aids are coupled to each other by sutures (41026). A circular surgical stapler can be used to create an anastomosis across the staple line and the second body lumen. Prior to actuating the circular stapler, the proximal and distal ends of the staple line can be pulled to In the central lumen of the circular stapler, the staple line is resected when the circular stapler is actuated.

Owner:ETHICON ENDO SURGERY INC

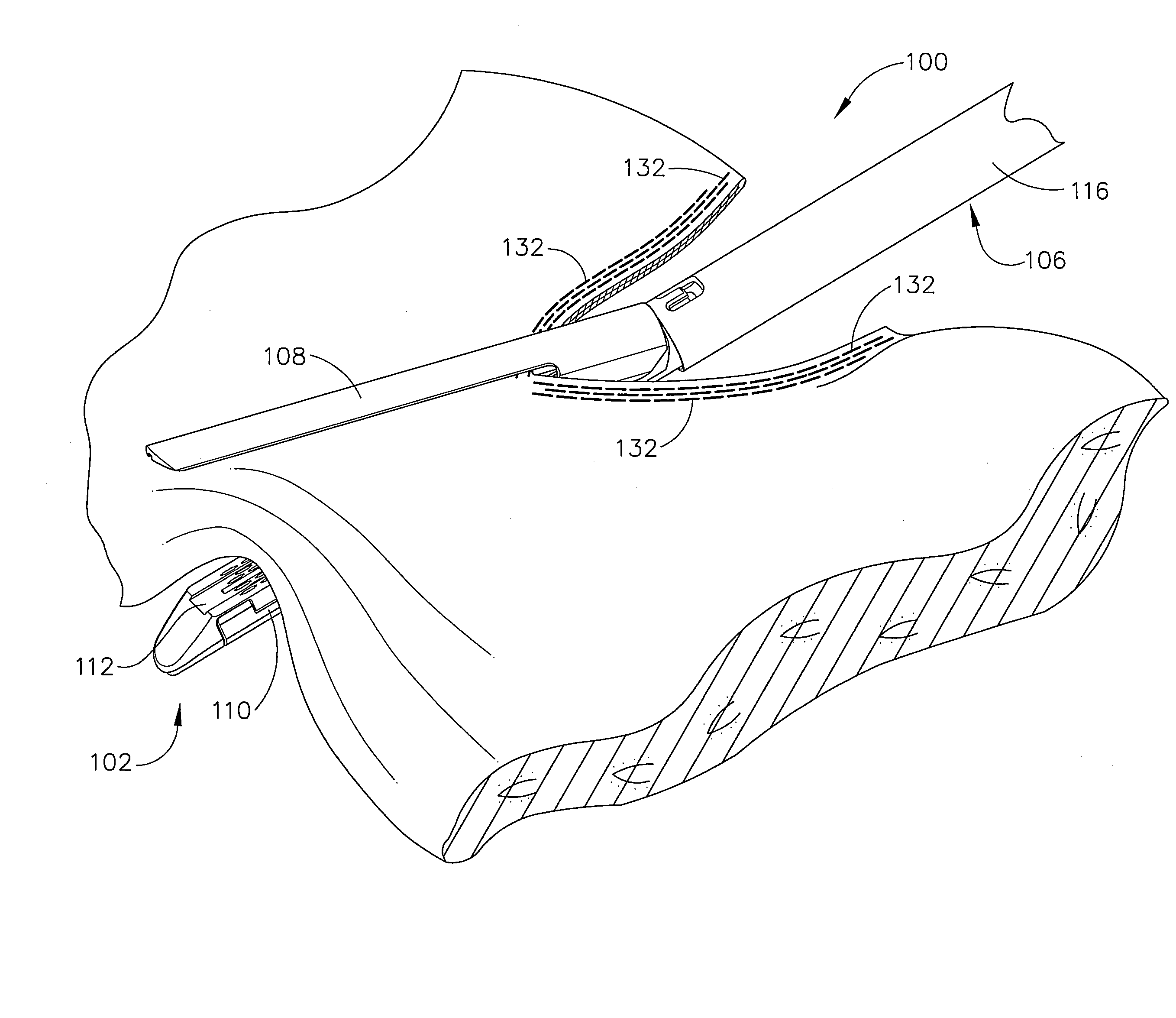

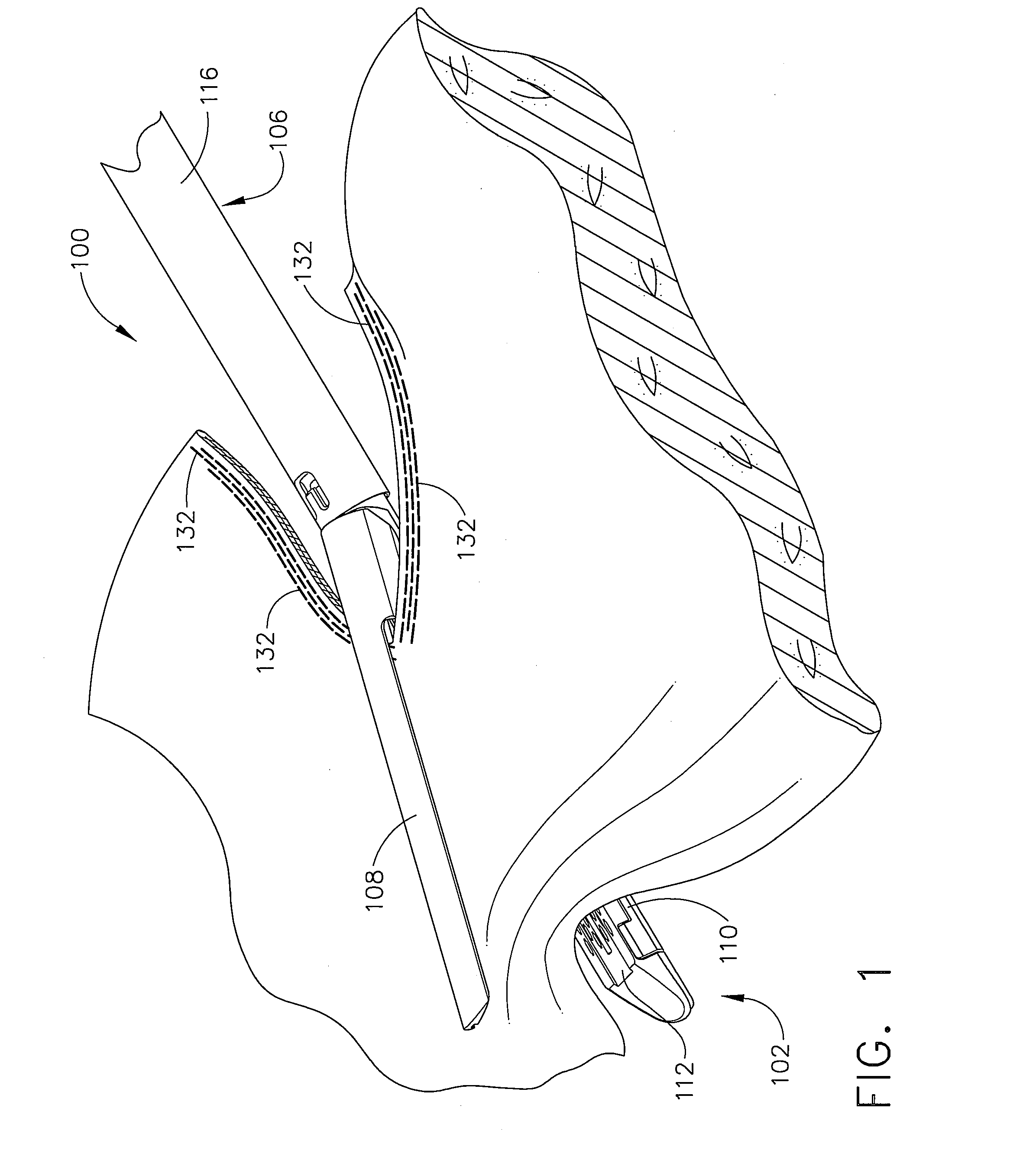

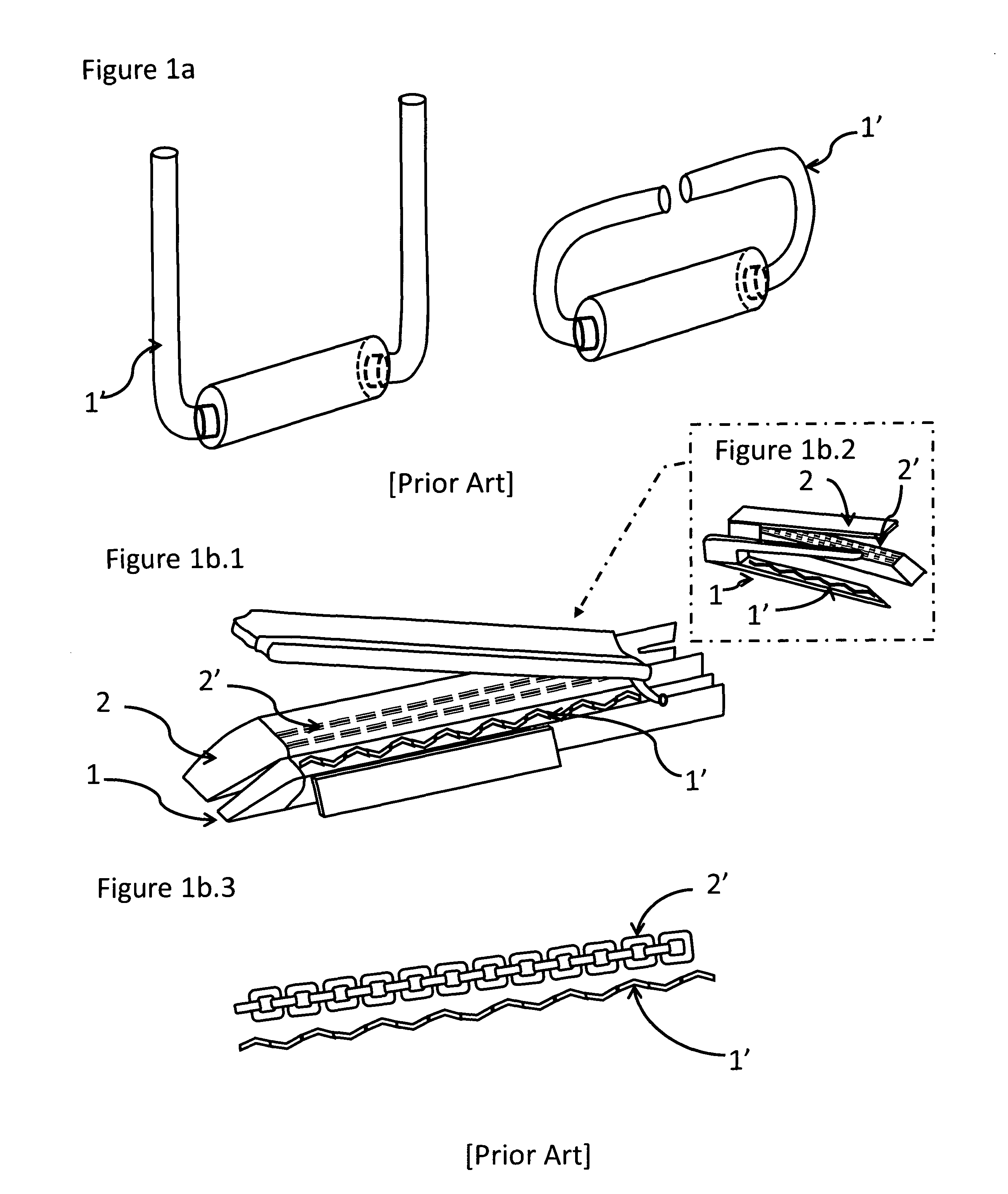

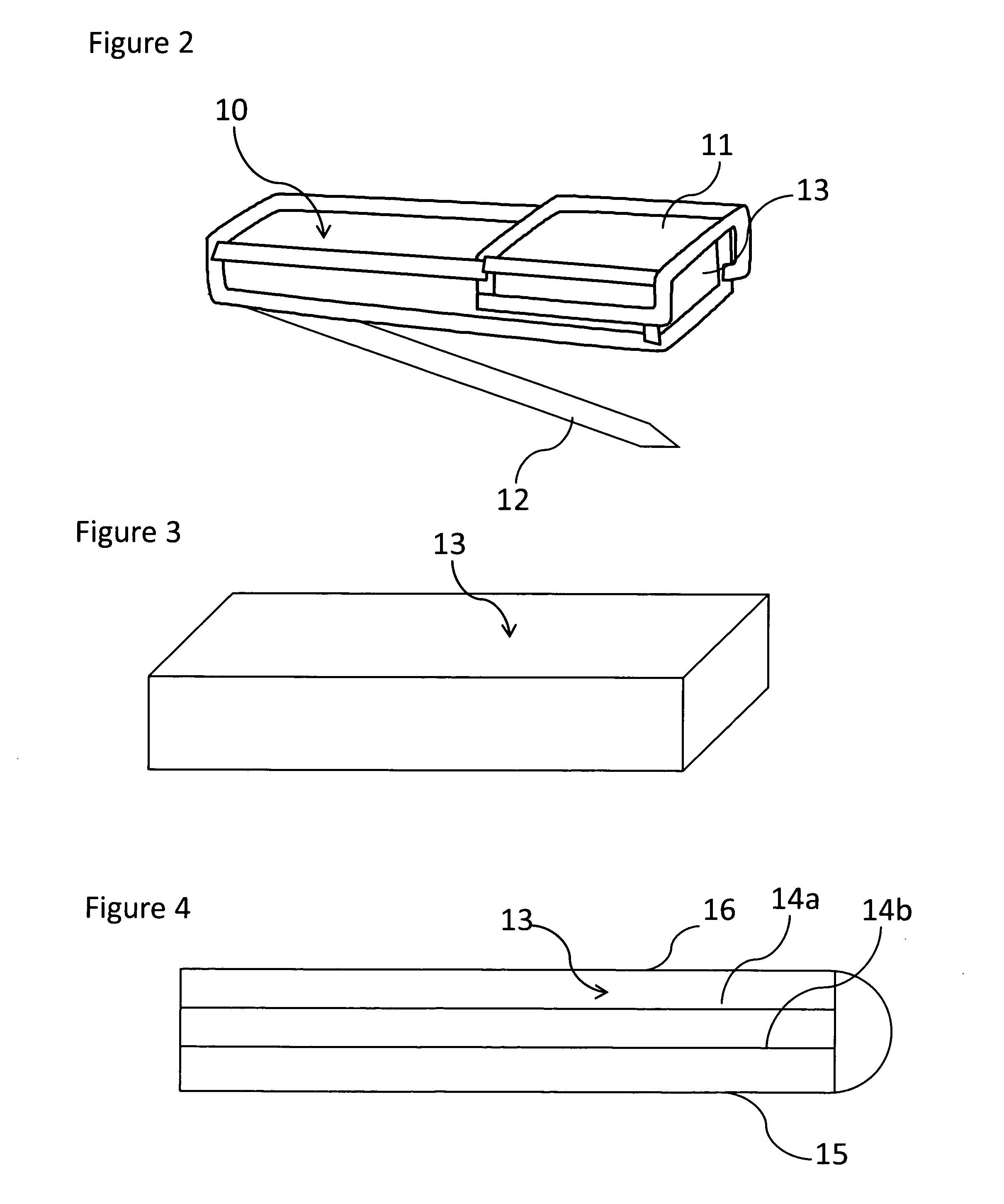

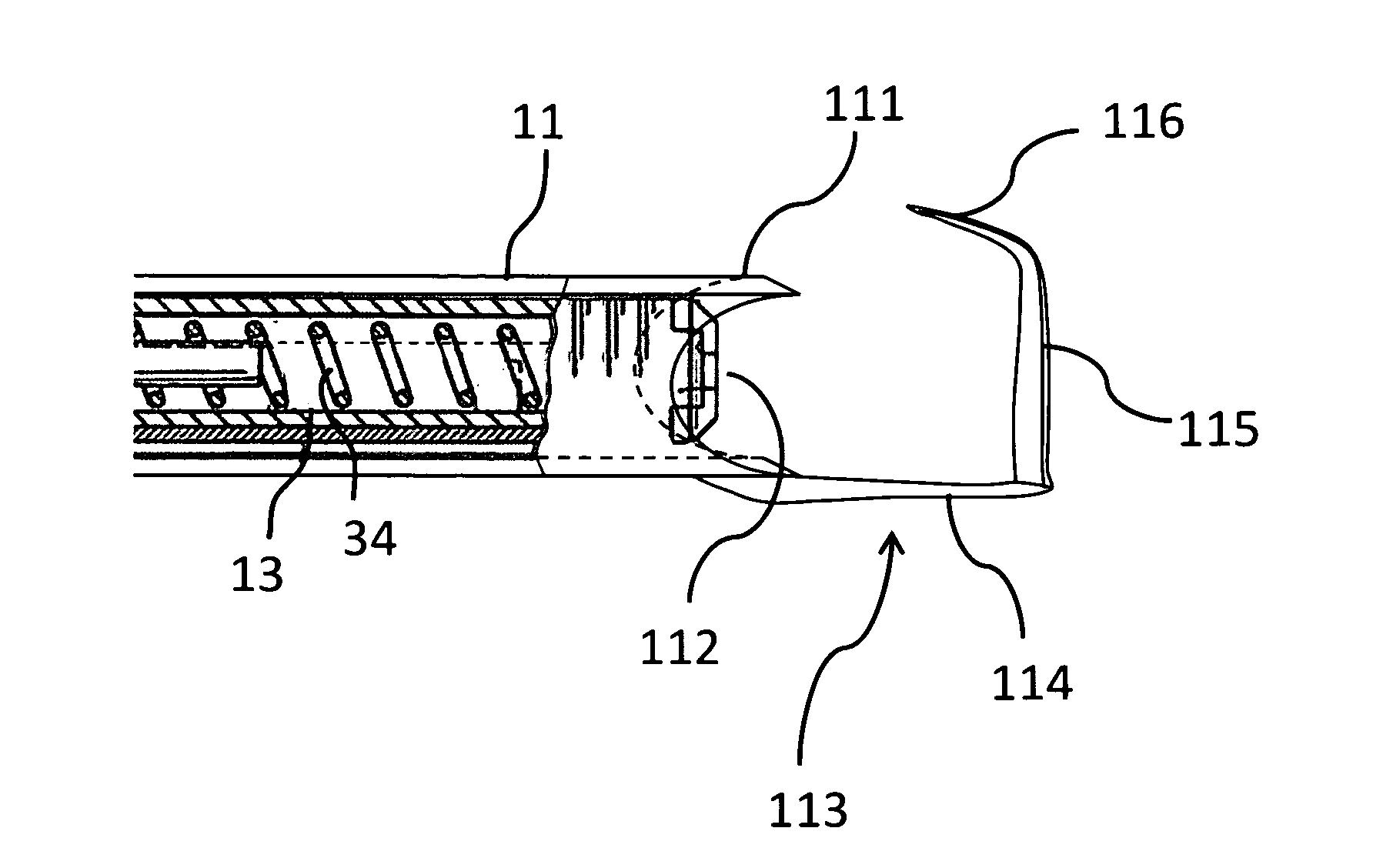

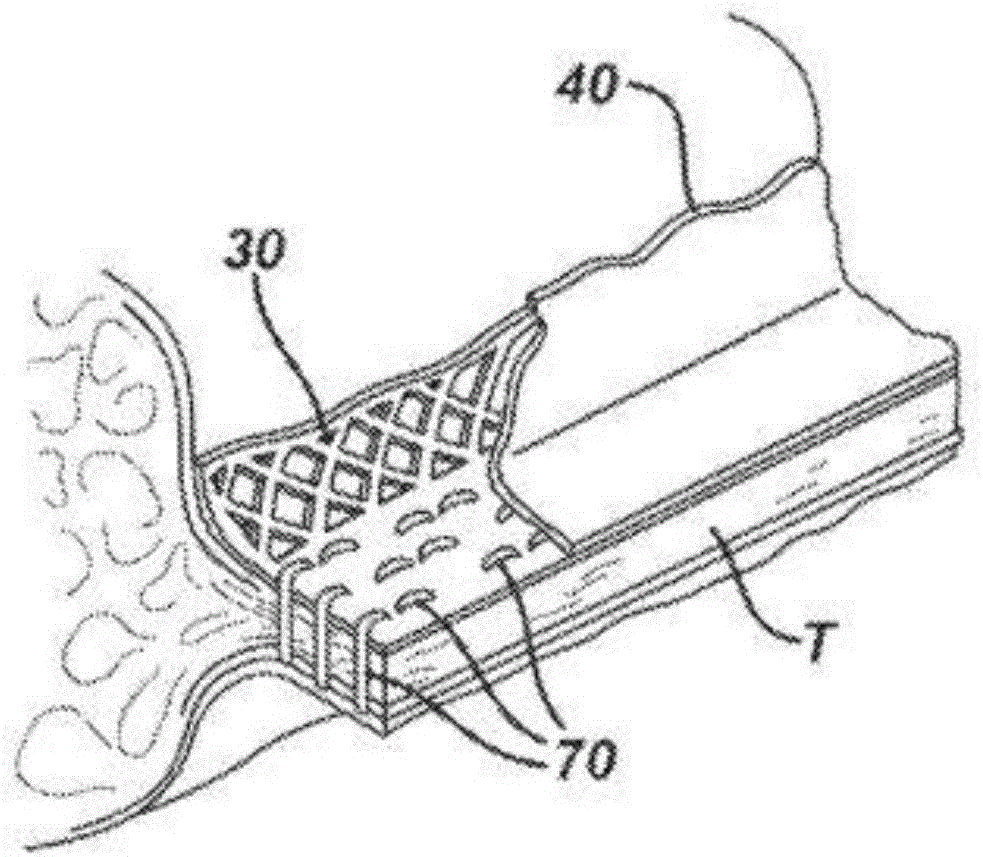

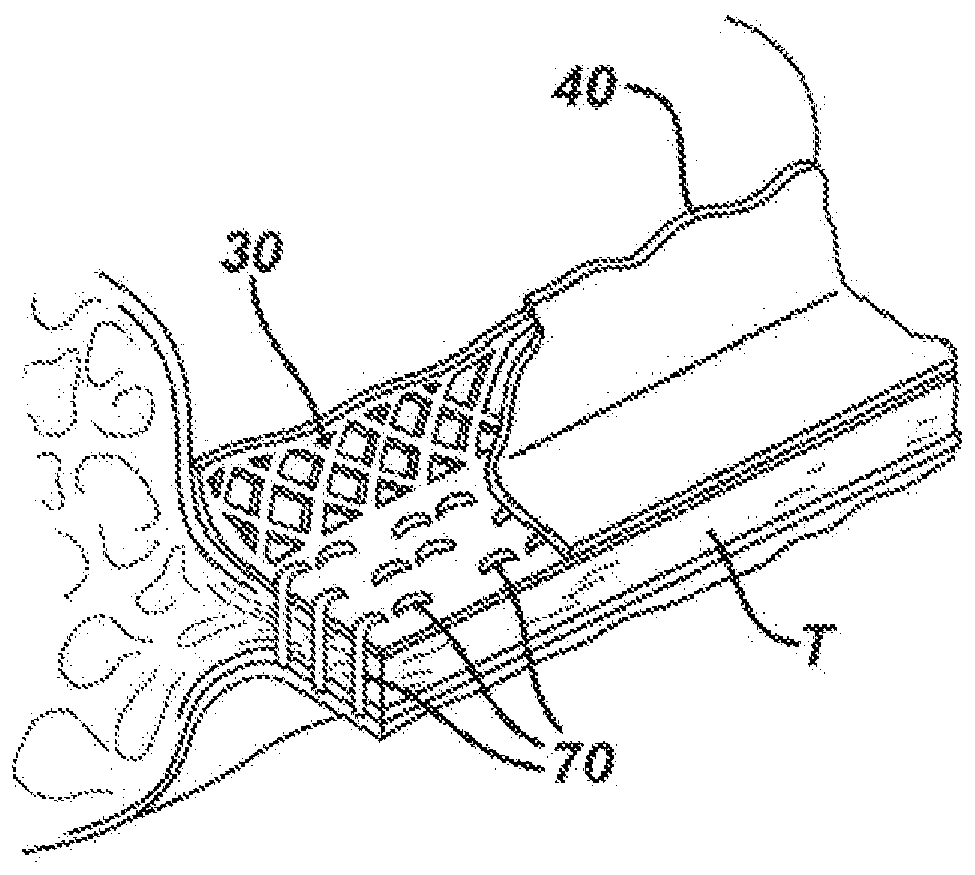

Woven and fibrous materials for reinforcing staple threads

The present invention provides an auxiliary material (3000) and a method for reinforcing a nail (70) thread using the auxiliary material (3000). In general, auxiliary material (3000) can be used to maintain a seal in tissue and can prevent the stapled tissue from tearing. Surgical stapler (10) may include jaws having auxiliary material (3000) associated therewith. Accessory material (3000) may be attached to tissue by staples (270) deployed by stapler (10, 100, 200). The auxiliary material (3000) may be a woven material having a single layer or multiple layers, and each layer may have different mechanical properties. The secondary material (3000) may have one or more layers of nonwoven material, such as stitching compressed into a three-dimensional structure.

Owner:ETHICON ENDO SURGERY INC

A stapler with a binding ruler

Owner:安徽众力农业装备科技有限公司

Implantable restriction device with spacer

An implantable restriction device includes a belt and a balloon secured to the belt for engagement with tissue when the implantable restriction device is positioned about the stomach. A spacer is associated with the belt for maintaining the restriction device in a spaced relation with a staple line employed during gastric reduction surgery.

Owner:ETHICON ENDO SURGERY INC

Assessment of suture or staple line integrity and localization of potential tissue defects along the suture or staple line

ActiveUS10470839B2Ultrasonic/sonic/infrasonic diagnosticsSurgical navigation systemsStaple lineProgram planning

Owner:TYCO HEALTHCARE GRP LP

Accessory materials for delivery to colonic tissue

Owner:伊西康有限责任公司

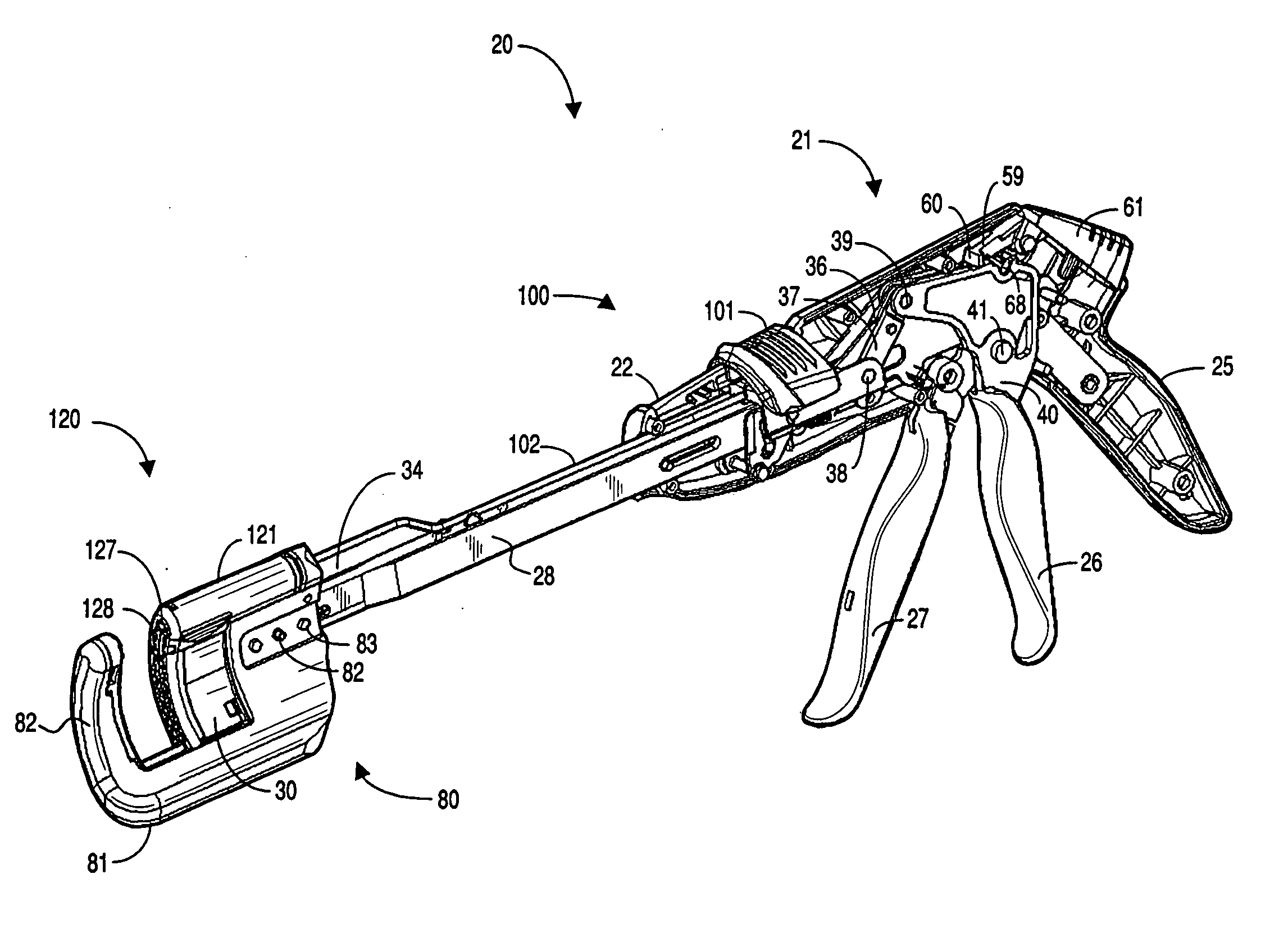

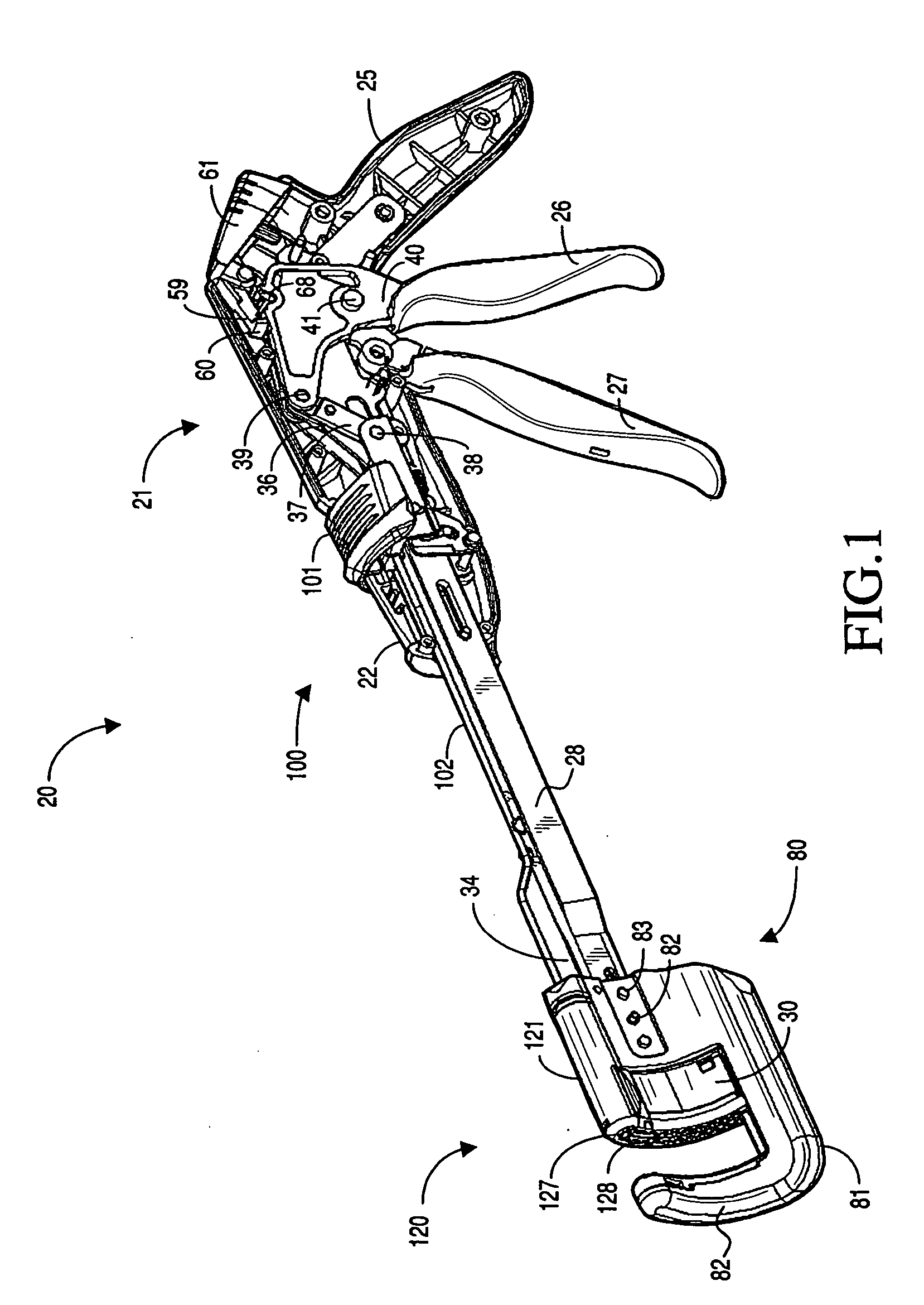

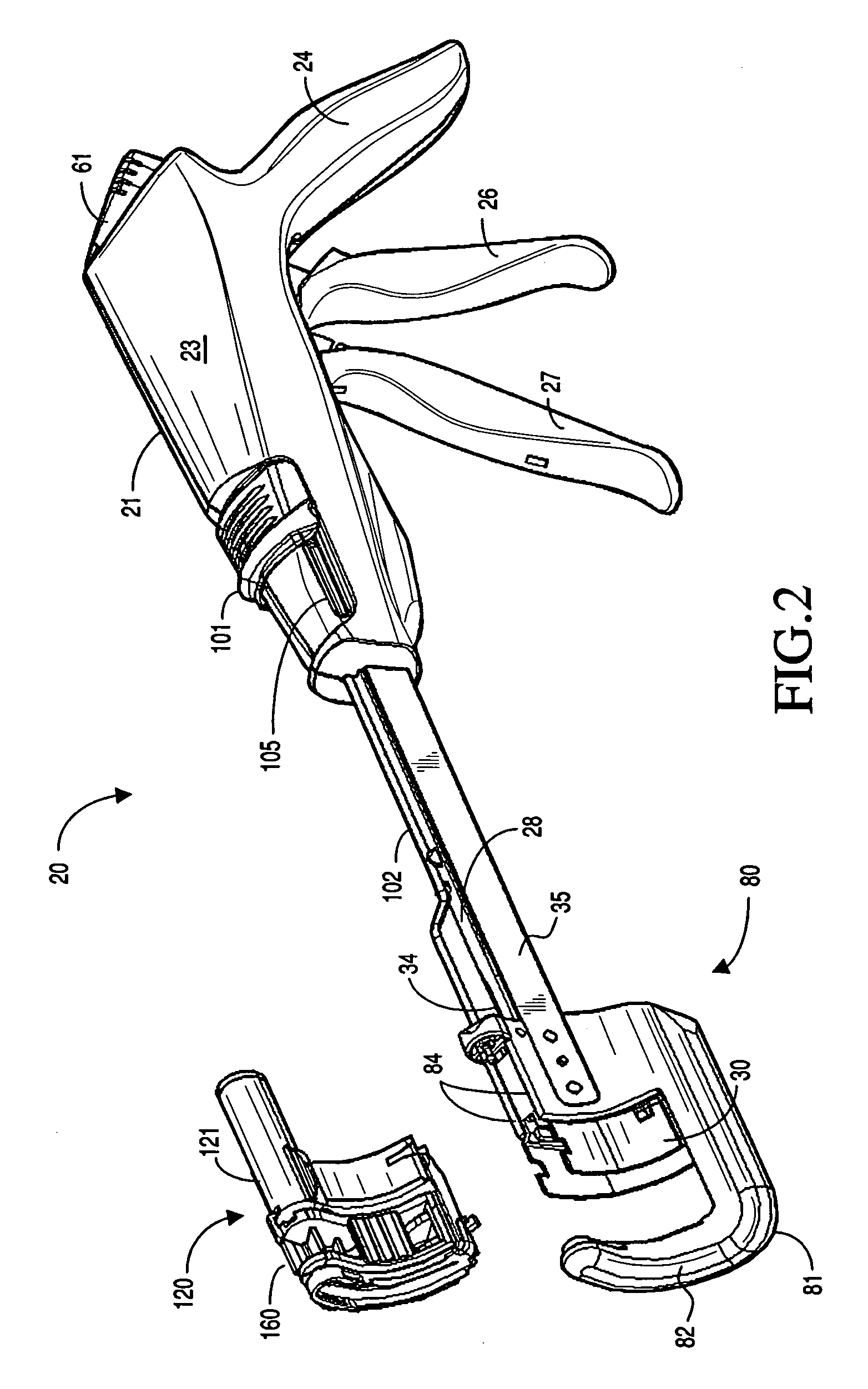

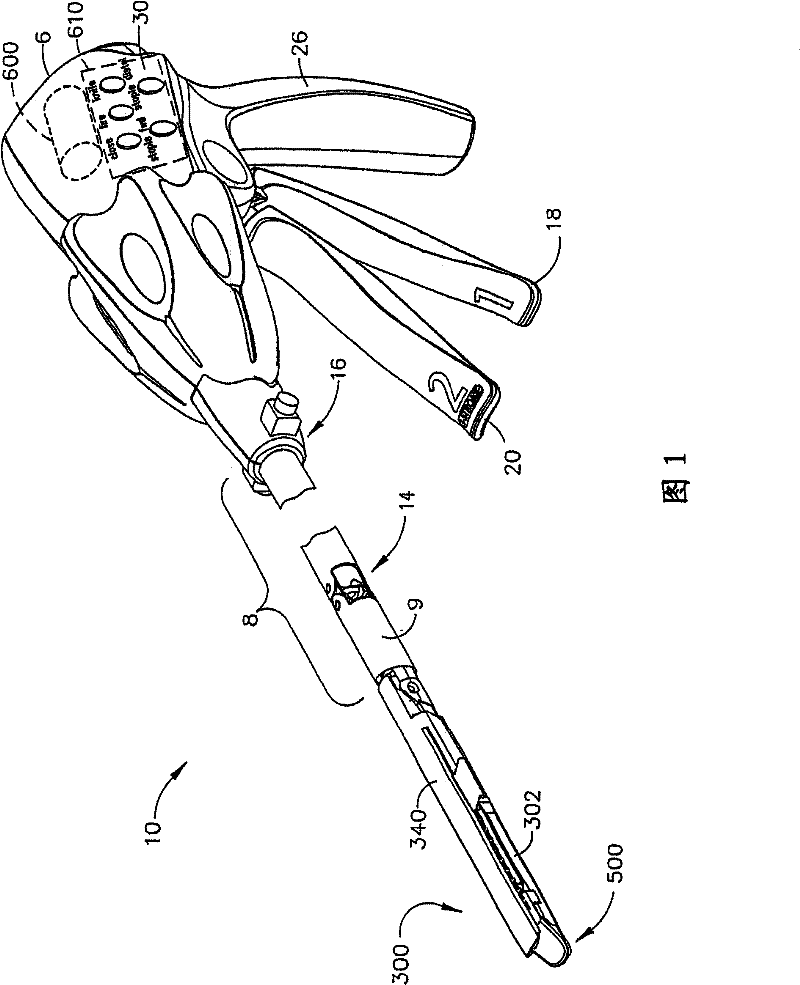

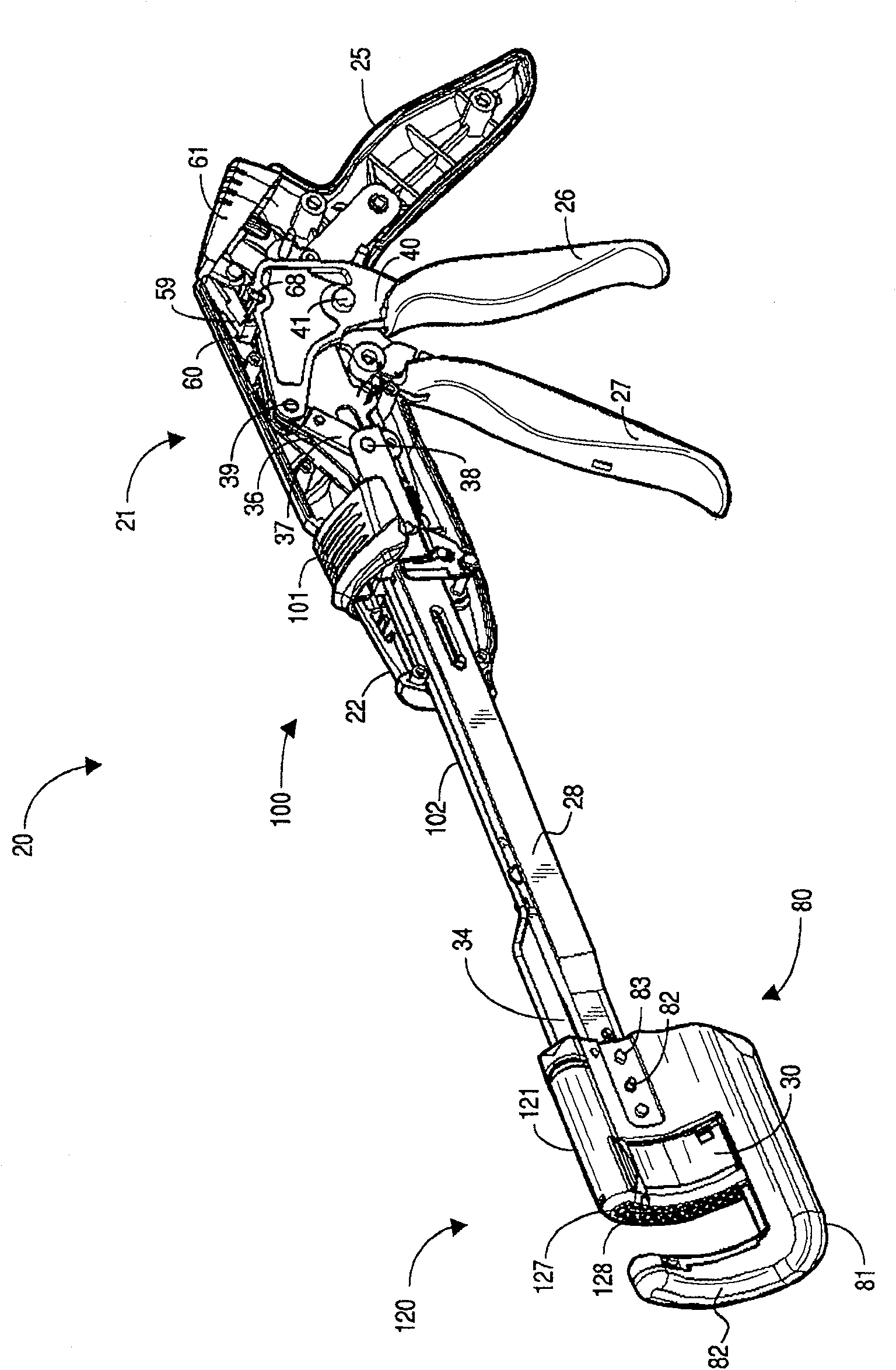

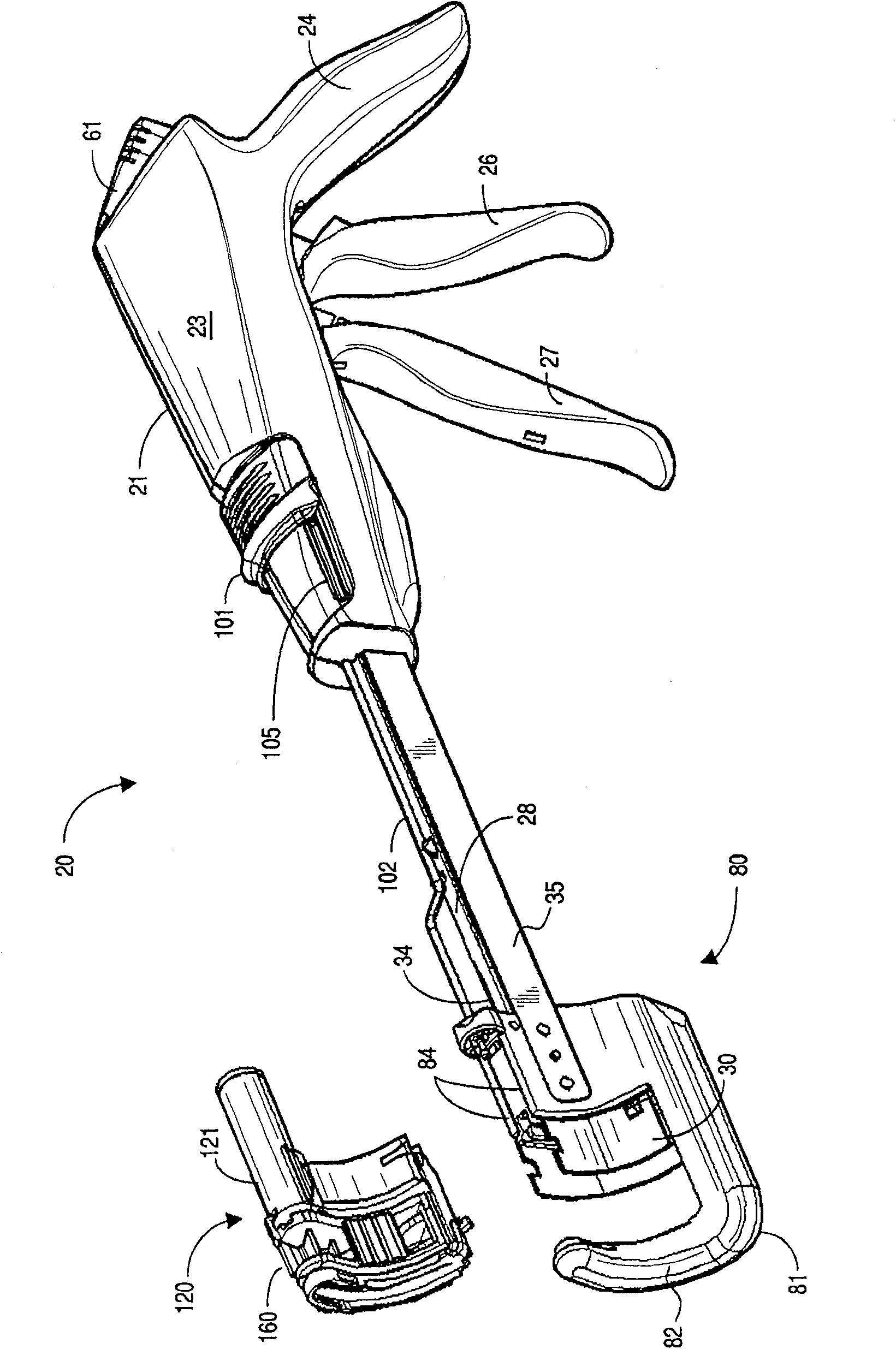

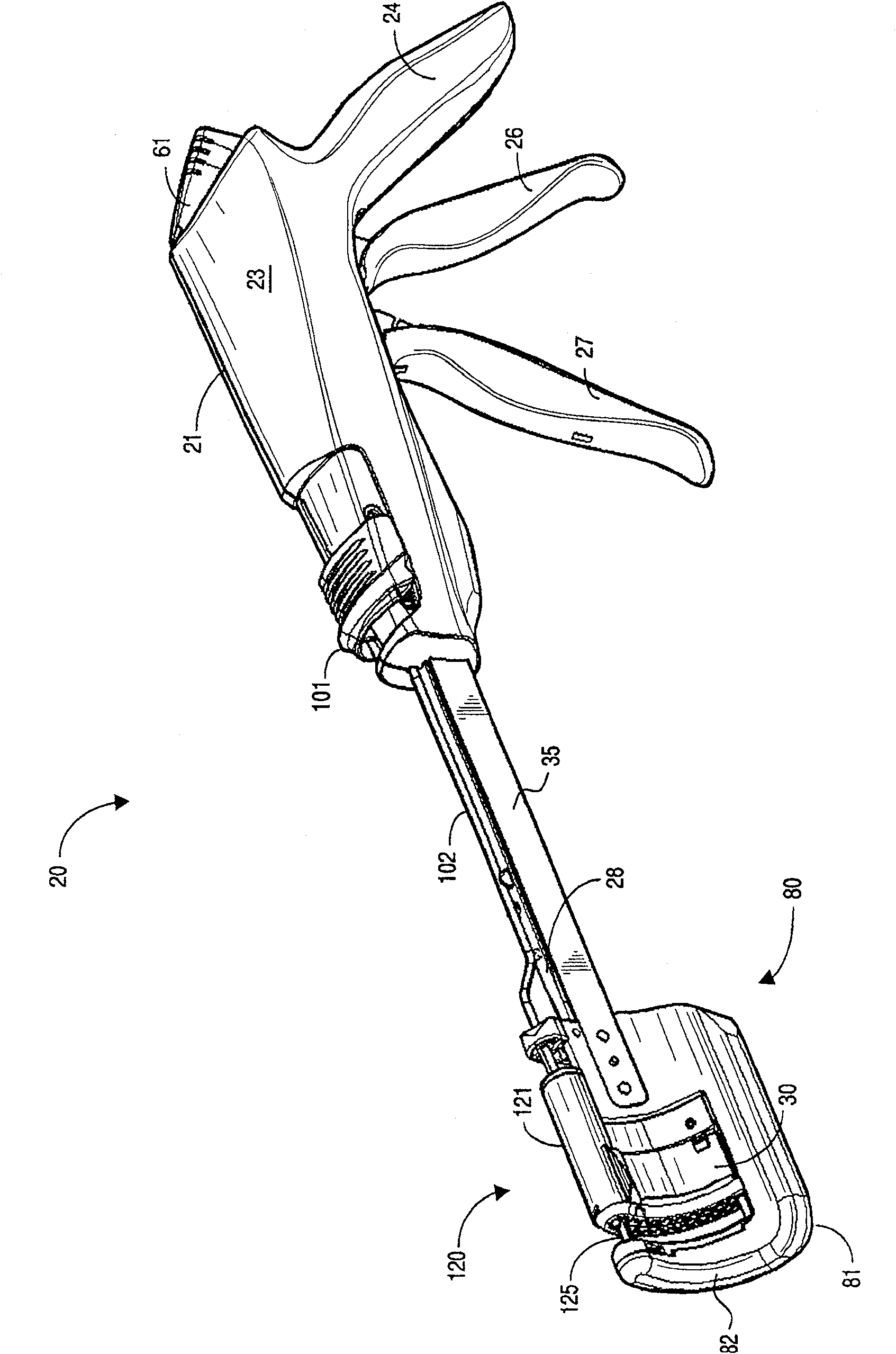

Curved cutter stapler with aligned tissue retention feature

A surgical instrument (20) adapted for applying a plurality of surgical fasteners to body tissue, the surgical instrument comprising: a frame having a proximal end and a distal end, with a handle (21) positioned at the proximal end and an end effector (80) positioned at the distal end; the end effector being shaped and dimensioned for supporting a cartridge housing (121) and an anvil (122), the cartridge housing and anvil structure being relatively movable between a first spaced apart position and a second position in close approximation with one another; a firing mechanism associated with the end effector and the cartridge housing for selective actuation of the fastening elements for treatment of an individual; and a tissue retention feature (124,125) associated with the cartridge housing and anvil, the tissue retention feature maintaining tissue within the end effector during treatment; wherein the cartridge housing includes staple lines defining the longitudinal extent of the staples being applied via the cartridge module, and the longitudinal extent of the staple line is greater than the longitudinal extent of the tissue retention feature. <IMAGE>

Owner:ETHICON ENDO SURGERY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com