Stapler with stapling ruler

A stapler and ruler technology, applied in the direction of nailing U-shaped nail tools, nailing tools, manufacturing tools, etc., can solve the problems of difficult limit and distance reference, no design of binding ruler, no scale, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

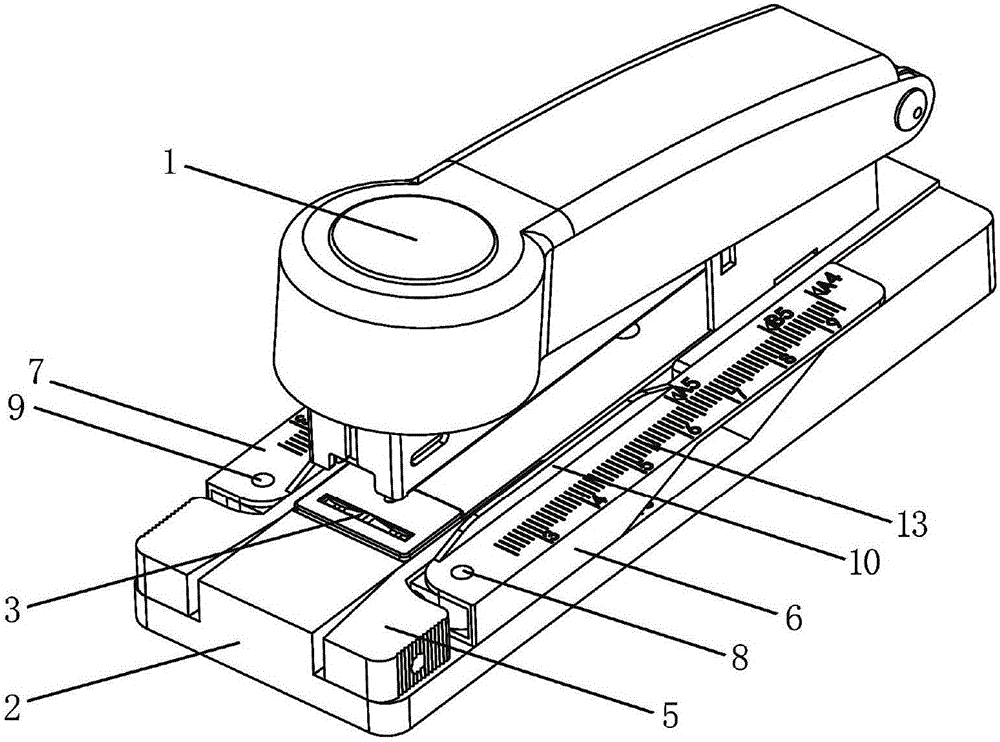

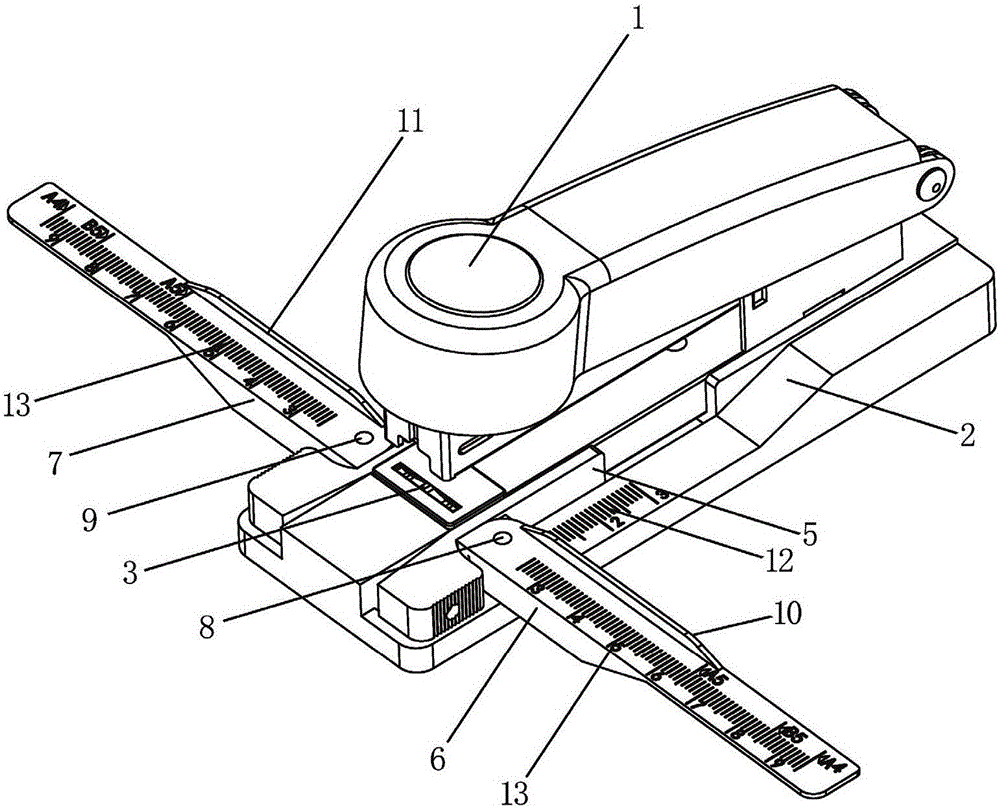

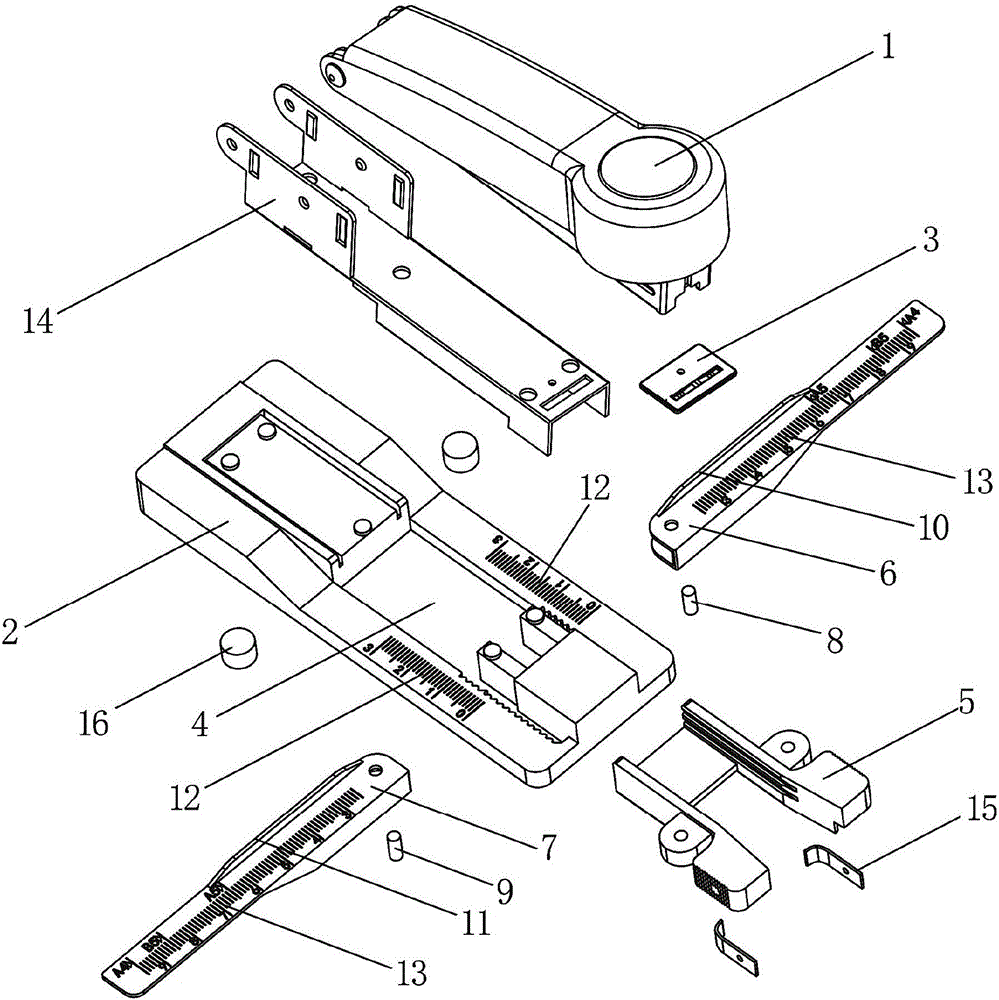

[0014] Control attached figure 1 , 2 , 3, figure 1 is a perspective view of one of the embodiments of the present invention, figure 2 is a three-dimensional view of the use state of one of the embodiments of the present invention, image 3 is an exploded view of one of the embodiments of the present invention. This embodiment is that the present invention has the stapler of push-pull binding scale. In this embodiment, the middle part of the base 2 of the stapler is sunken to form a track 4, and the slide block 5 is placed in the track 4. The rigid base 14 is positioned above the slide block 5 and presses the slide block 5. The left side of the slide block 5 There is a left rotating shaft 8, a left scale 6 is installed above, a right rotating shaft 9 is arranged on the right side, a right scale 7 is installed above, a left baffle 10 is arranged on the left scale 6, and a right baffle 11 is arranged on the right scale 7, There are A4, B5, A5 scales and horizontal scales 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com