Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Multiple experts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

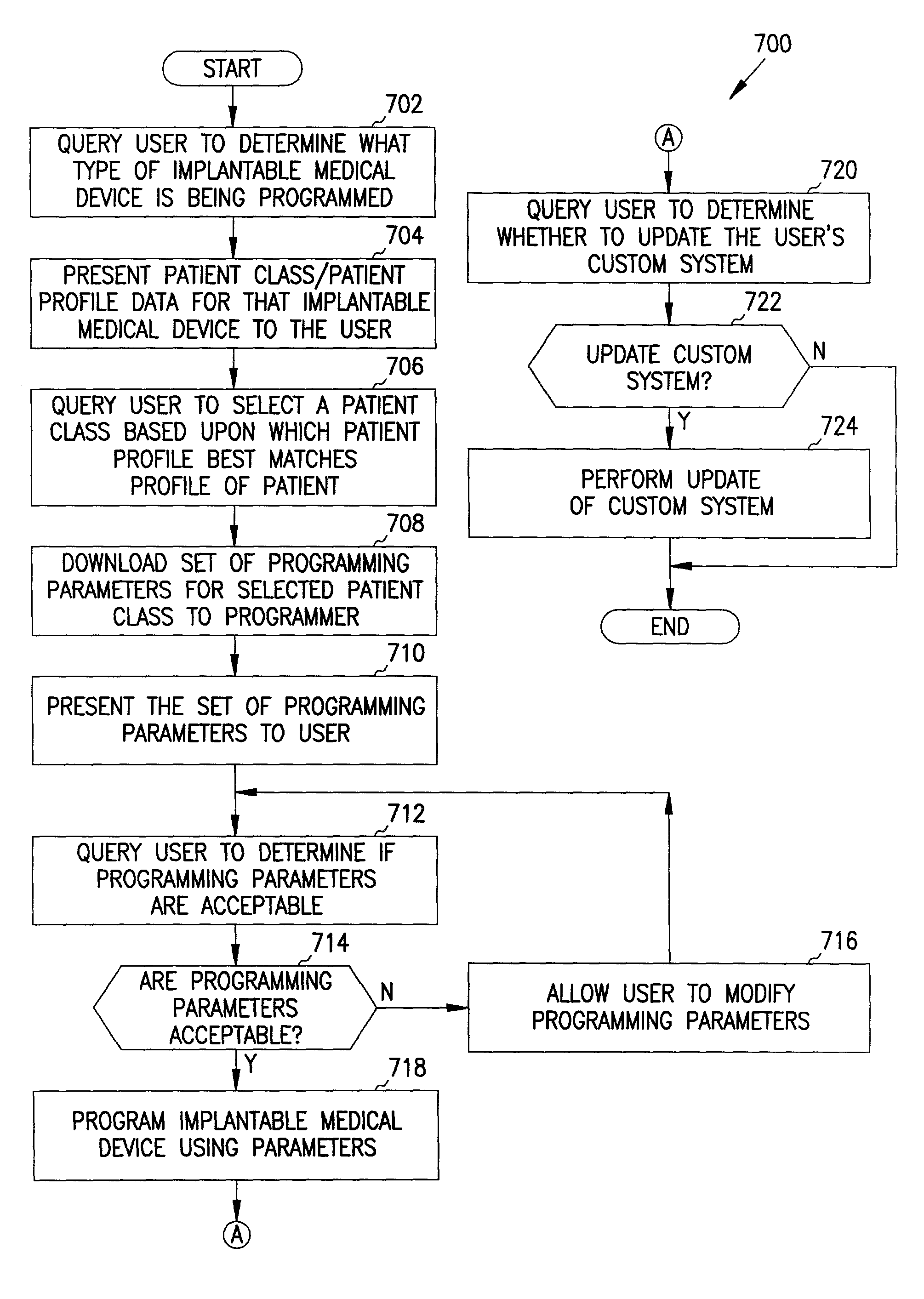

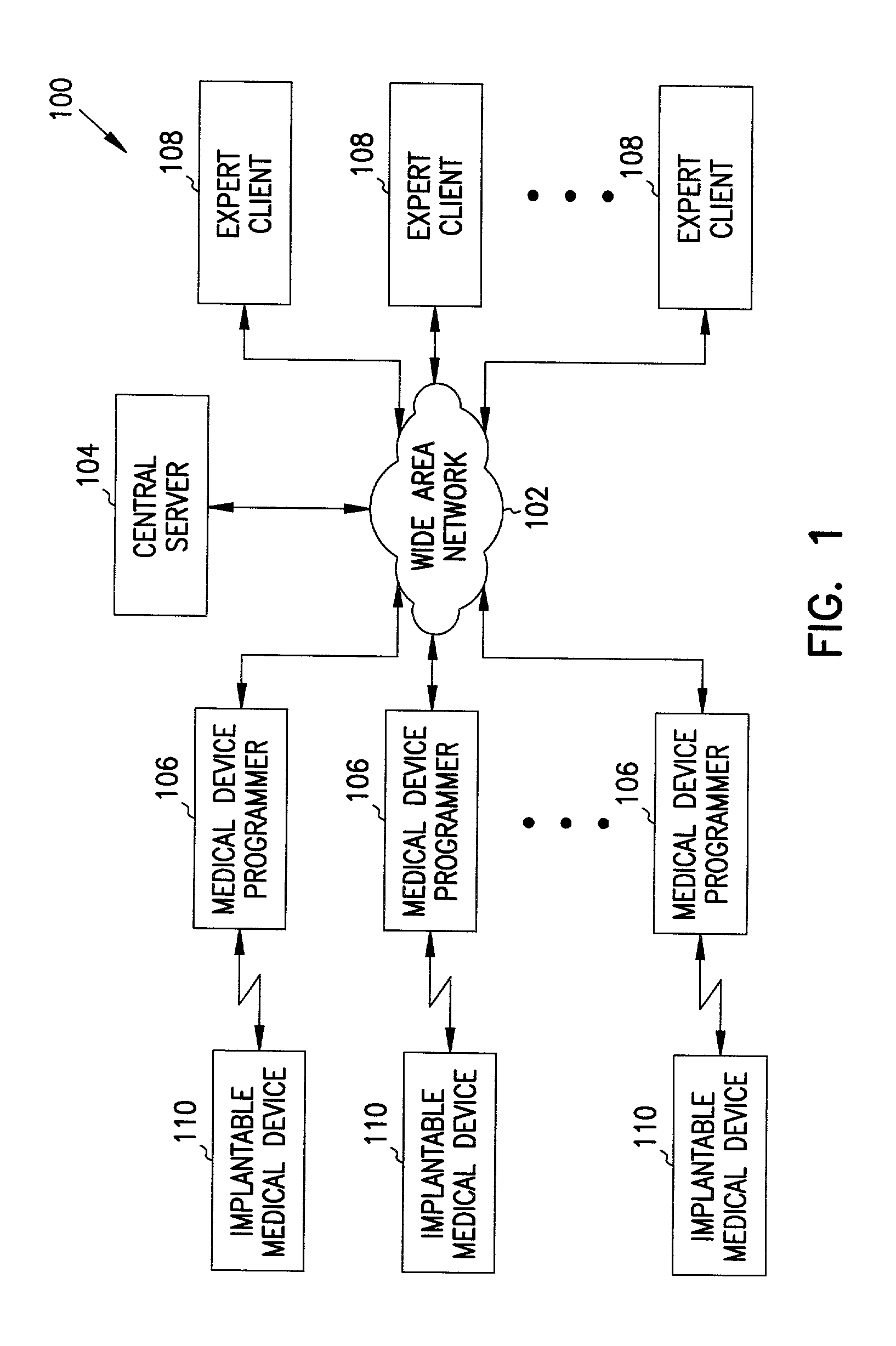

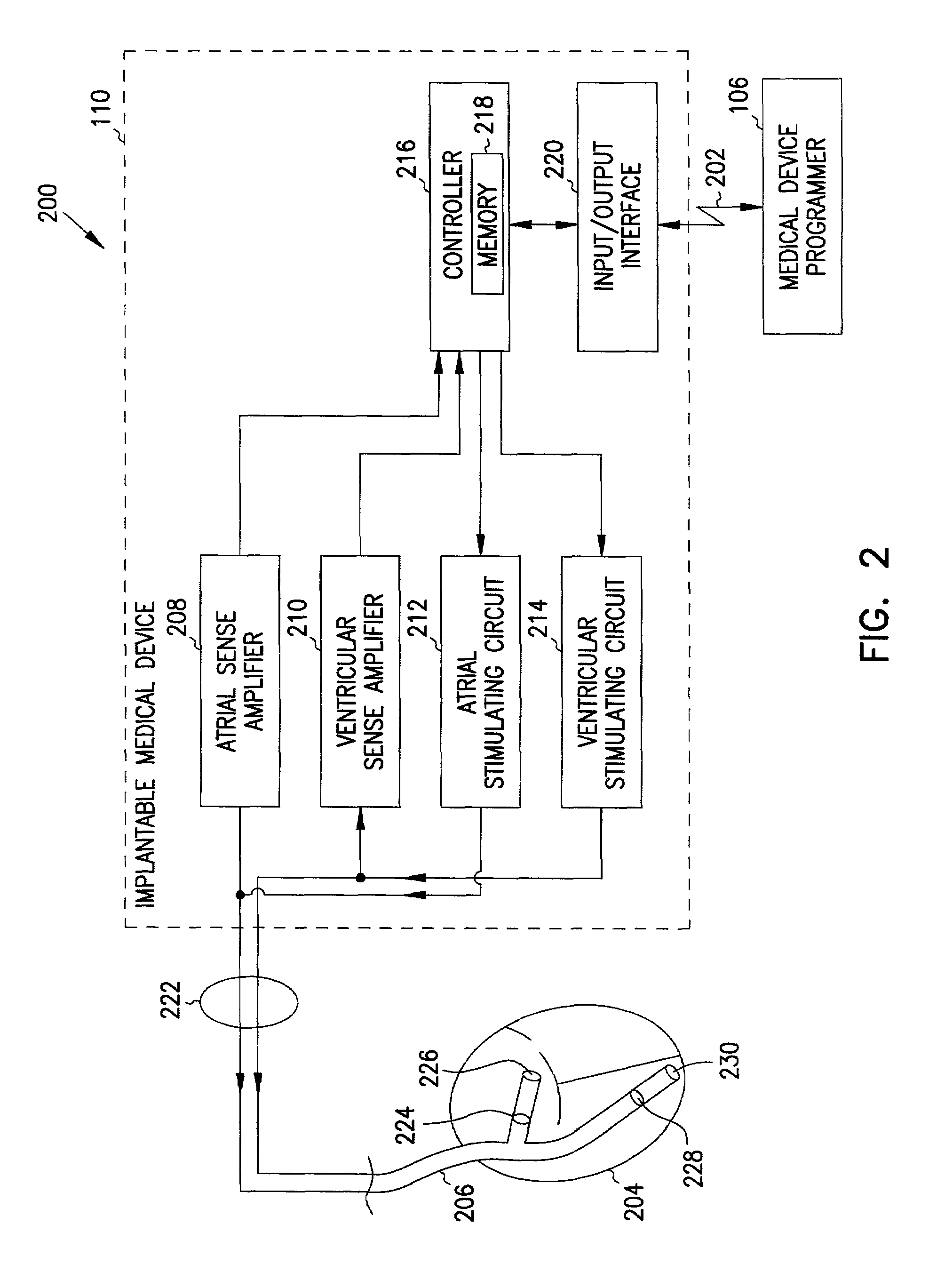

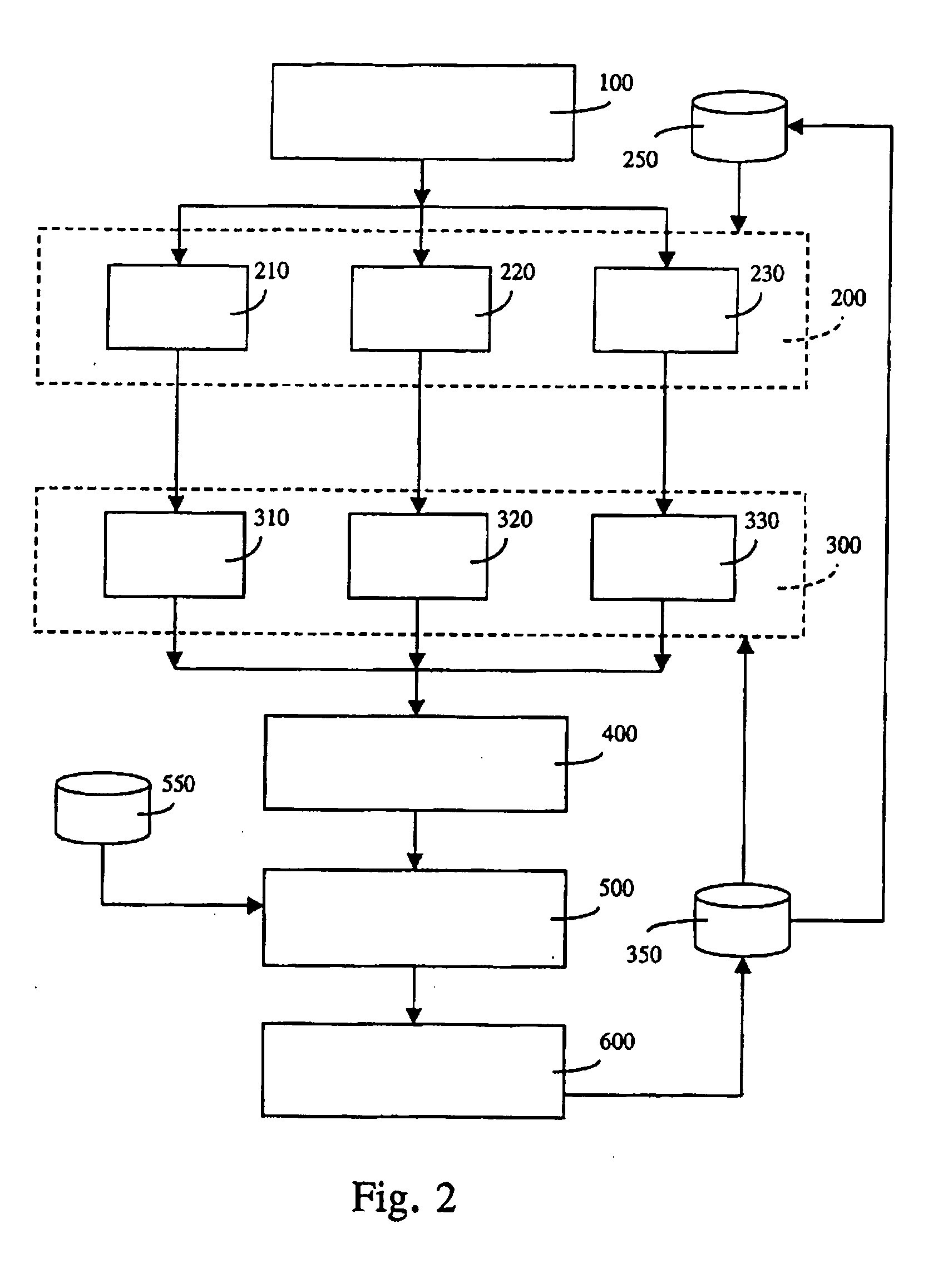

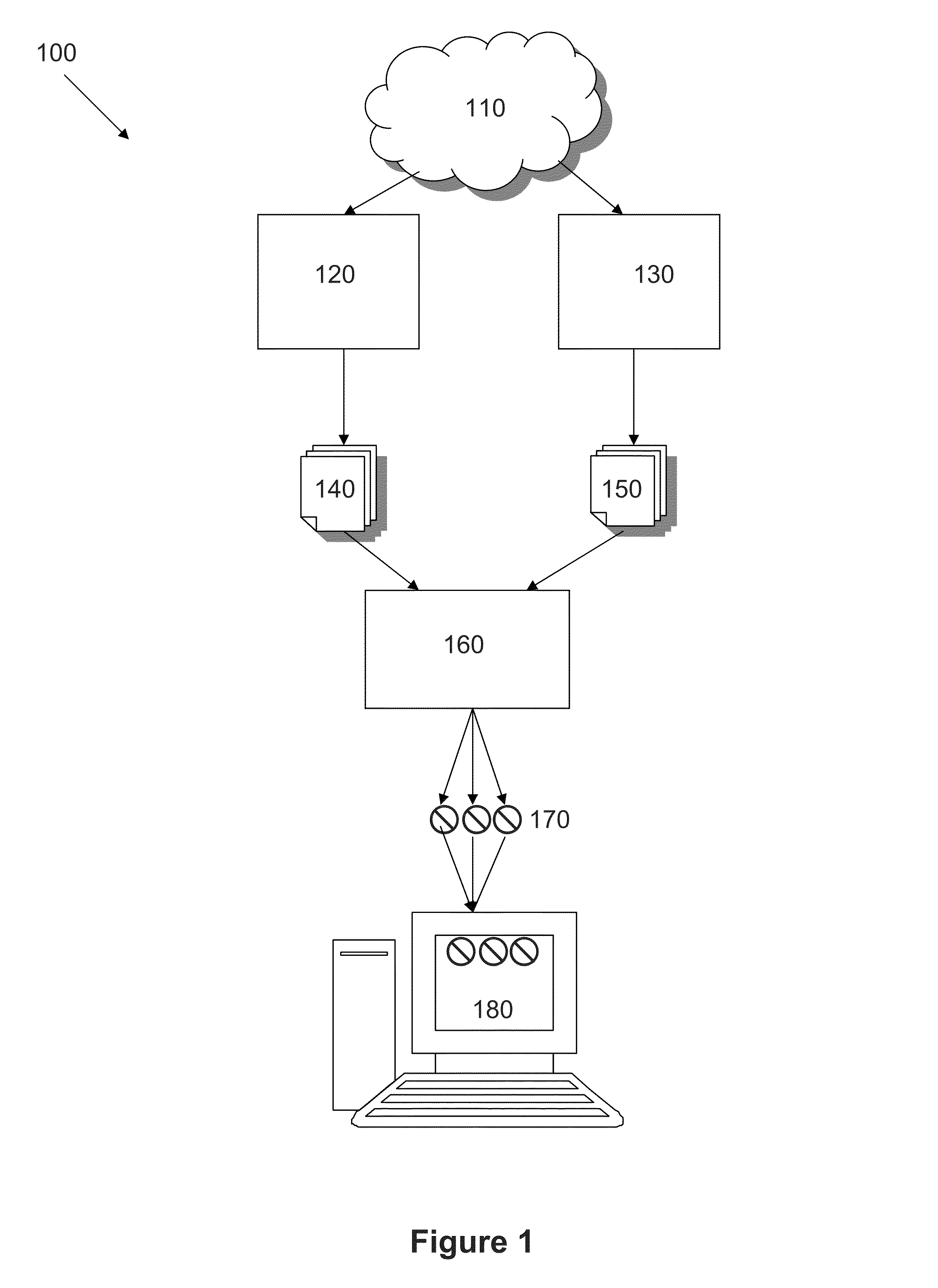

Centralized management system for programmable medical devices

InactiveUS7383088B2Physical therapies and activitiesData processing applicationsCentralized managementMedical prescription

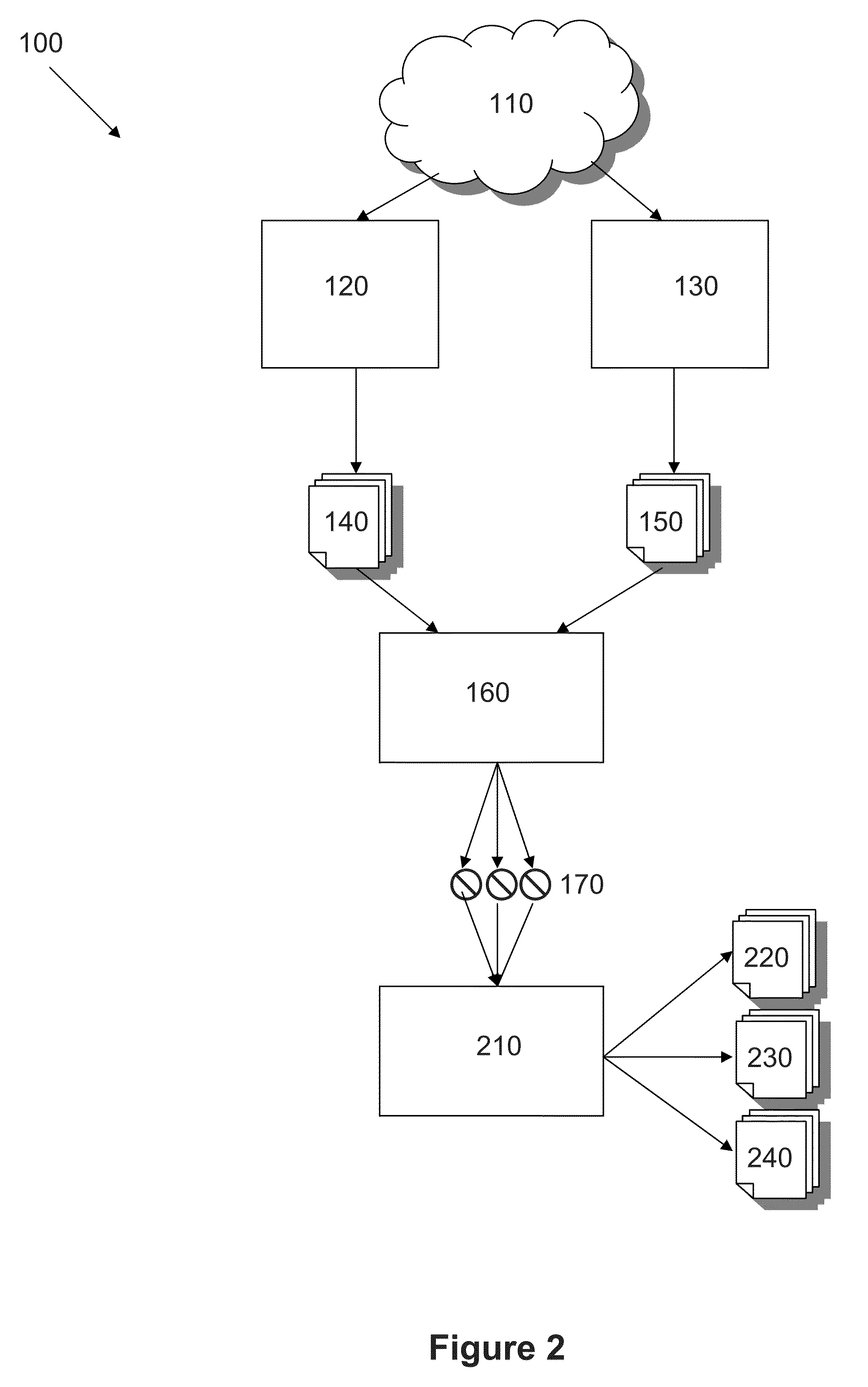

A centralized management system for medical devices includes a network, a central server coupled to the network, and a medical device programmer coupled to the network. The central server includes at least one prescription system for prescribing at least one programmable parameter of a medical device based on at least one characteristic of a patient. The medical device programmer communicates at least one characteristic of a patient to the central server via the network, receives at least one parameter from the central server via the network, and programs the medical device using the at least one parameter. In one embodiment, the central server hosts expert prescription systems defined by multiple experts, and a user selects one of the expert prescription systems. In another embodiment, the central server hosts a custom prescription system defined by the user.

Owner:CARDIAC PACEMAKERS INC

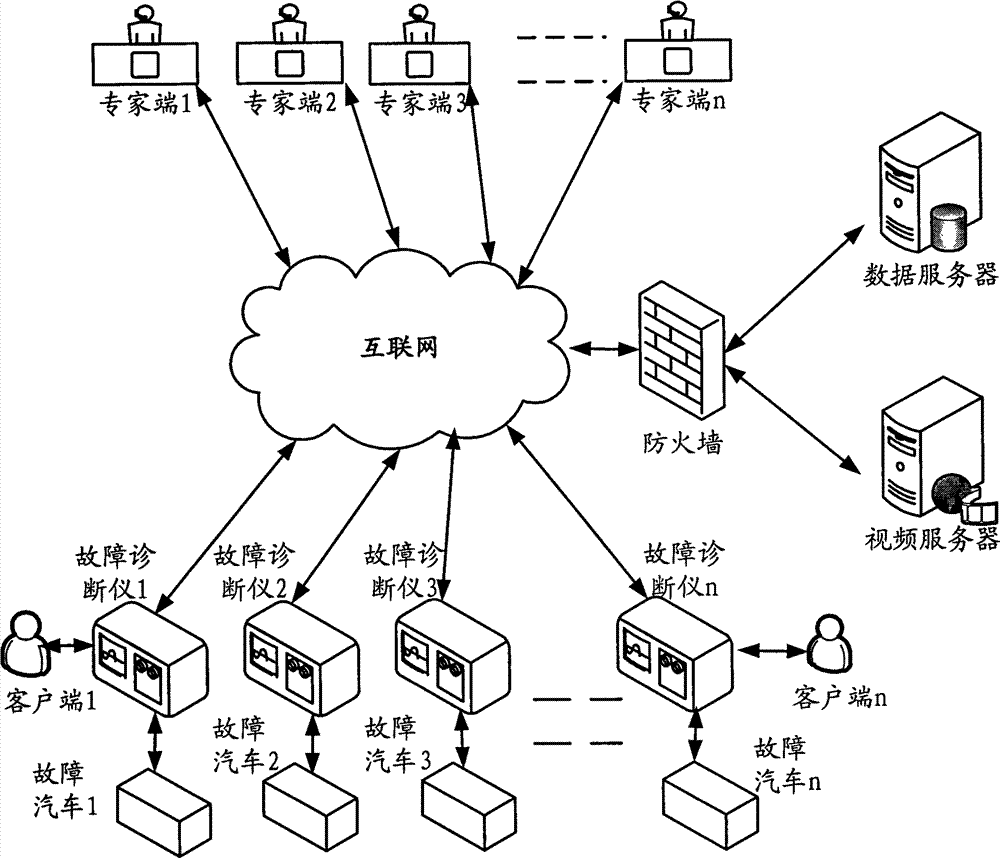

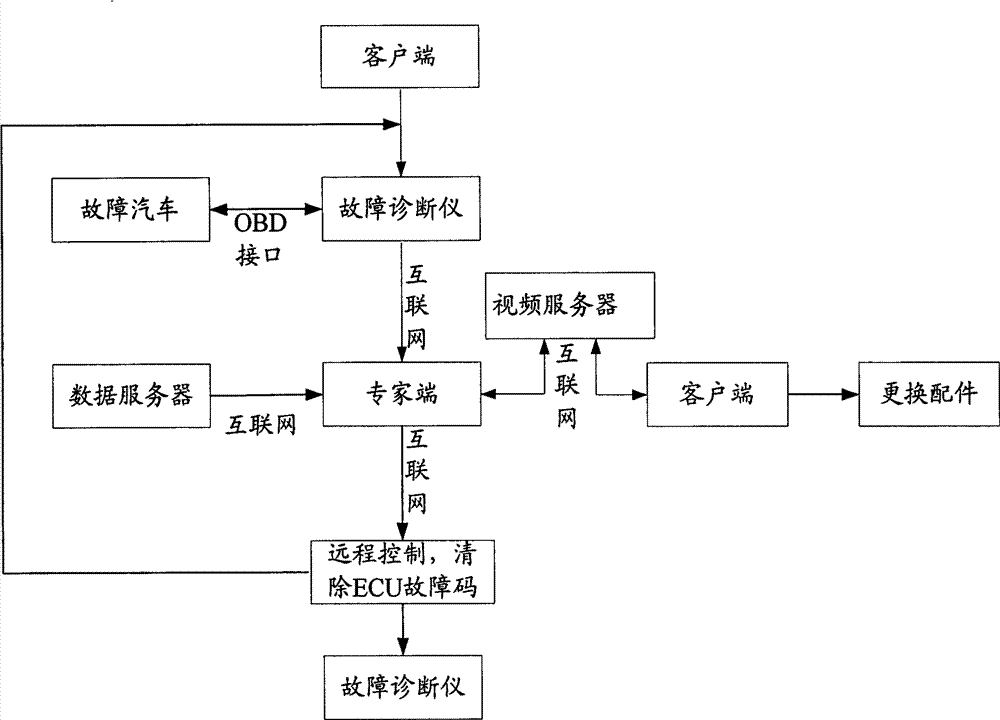

System and method of expert remote network video assistance based on automobile diagnosis device

InactiveCN102968112AImprove efficiencyConvenient and most timely maintenance assistance serviceElectric testing/monitoringDiagnostic dataNetwork connection

The invention discloses a system and method of expert remote network video assistance based on an automobile diagnosis device. An automobile fault diagnosis device with a network connecting function and a camera function sends a video to a maintaining expert, the maintaining expert in an expert remote network video assistance website of the automobile diagnosis device guides a client to operate the automobile fault diagnosis device, and by means of video communication and by checking diagnosis data of a client diagnosis device, the maintaining staff can analyze automobile faults according to detailed automobile fault phenomena until the automobile faults are removed. Compared with the prior art, when a client has problems on using the automobile diagnosis device, the client is remotely assisted to solve the technical problems of automobile maintaining are solved fast through data exchange and network video with the expert. A plurality of experts provide convenient and timely automobile maintaining assistance service simultaneously through the expert website for a large amount of clients, use efficiency of the clients for using the automobile fault diagnosis device is improved, and popularization of automobile diagnosis technology and maintaining technology is promoted.

Owner:LAUNCH TECH CO LTD

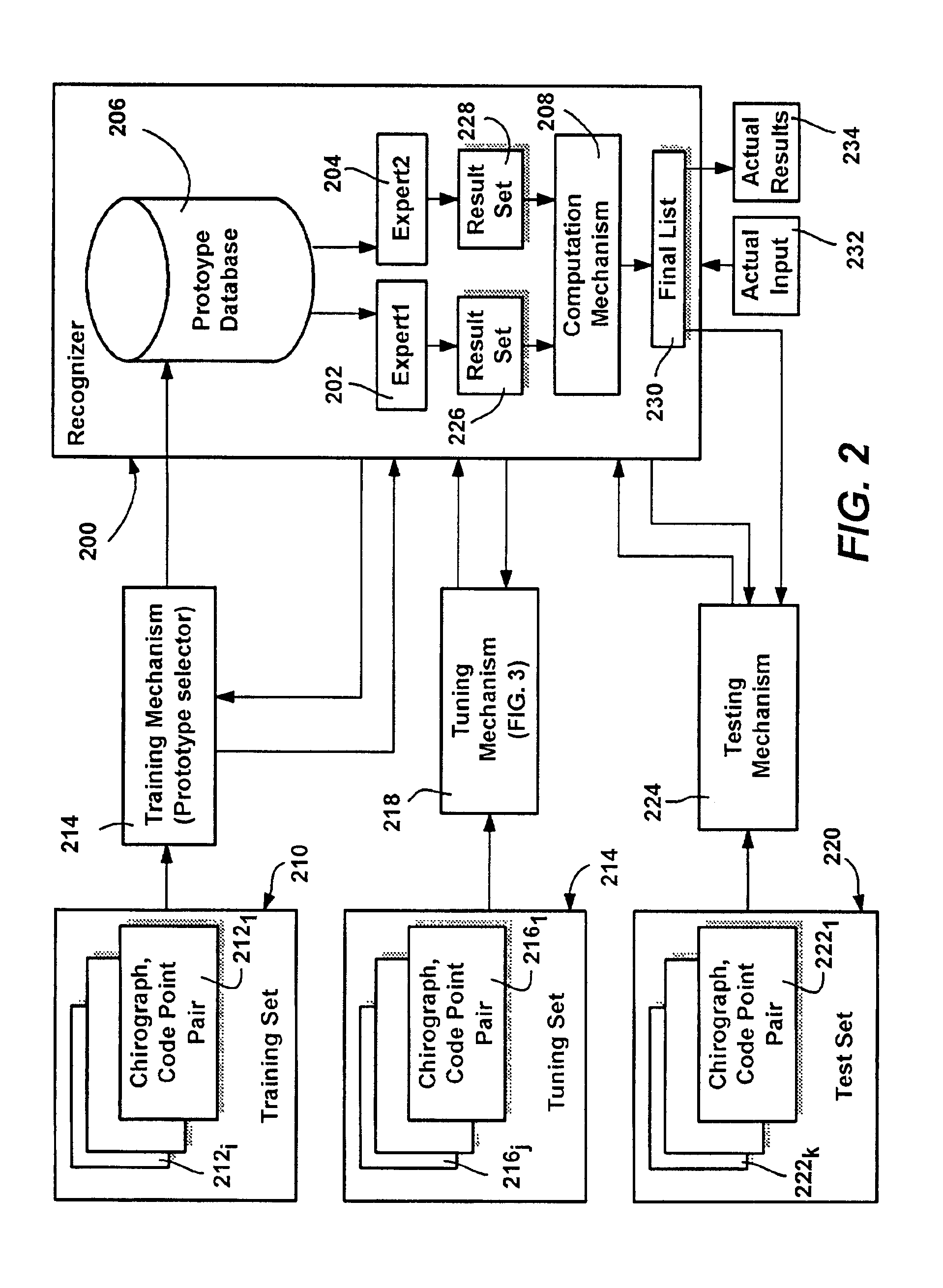

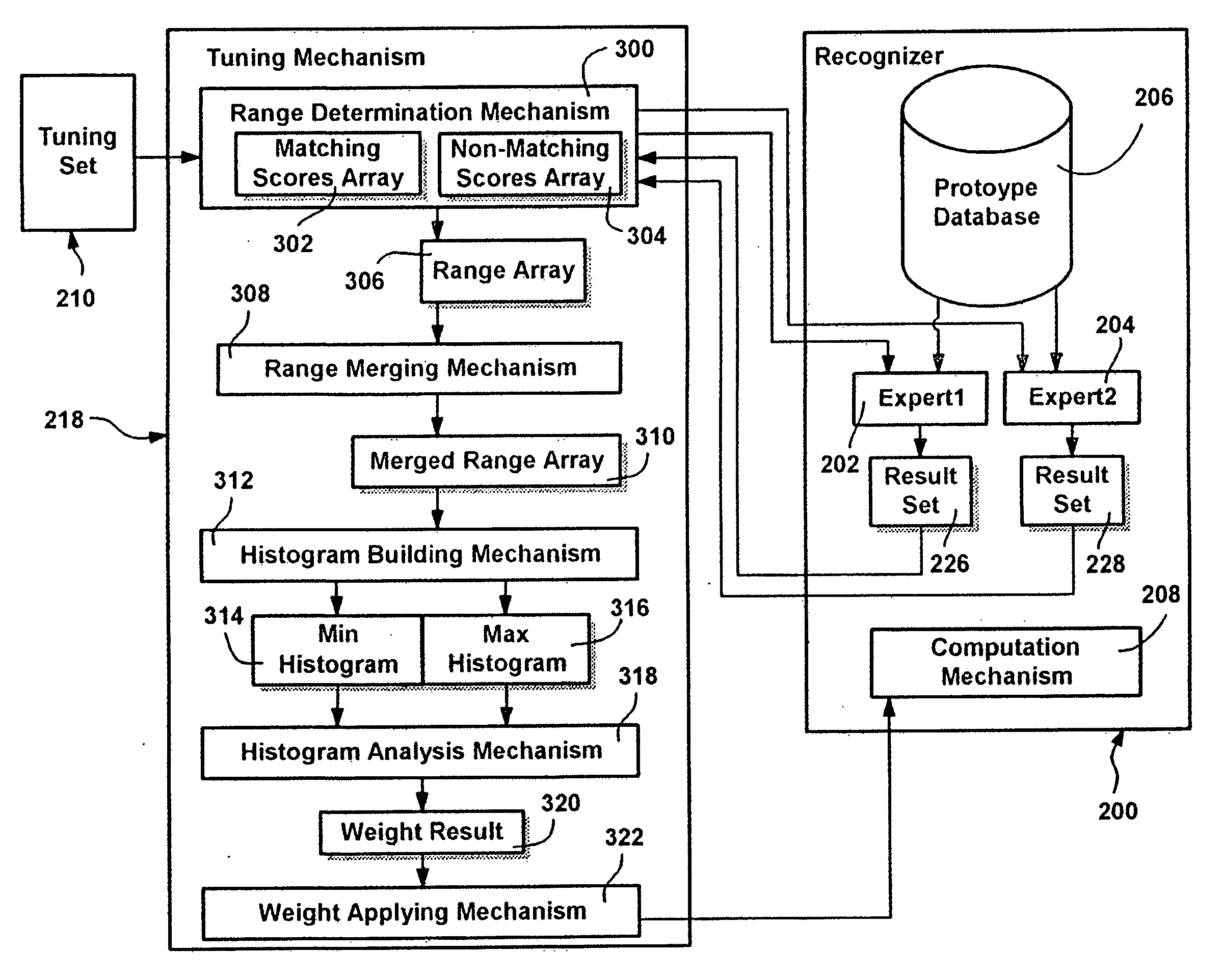

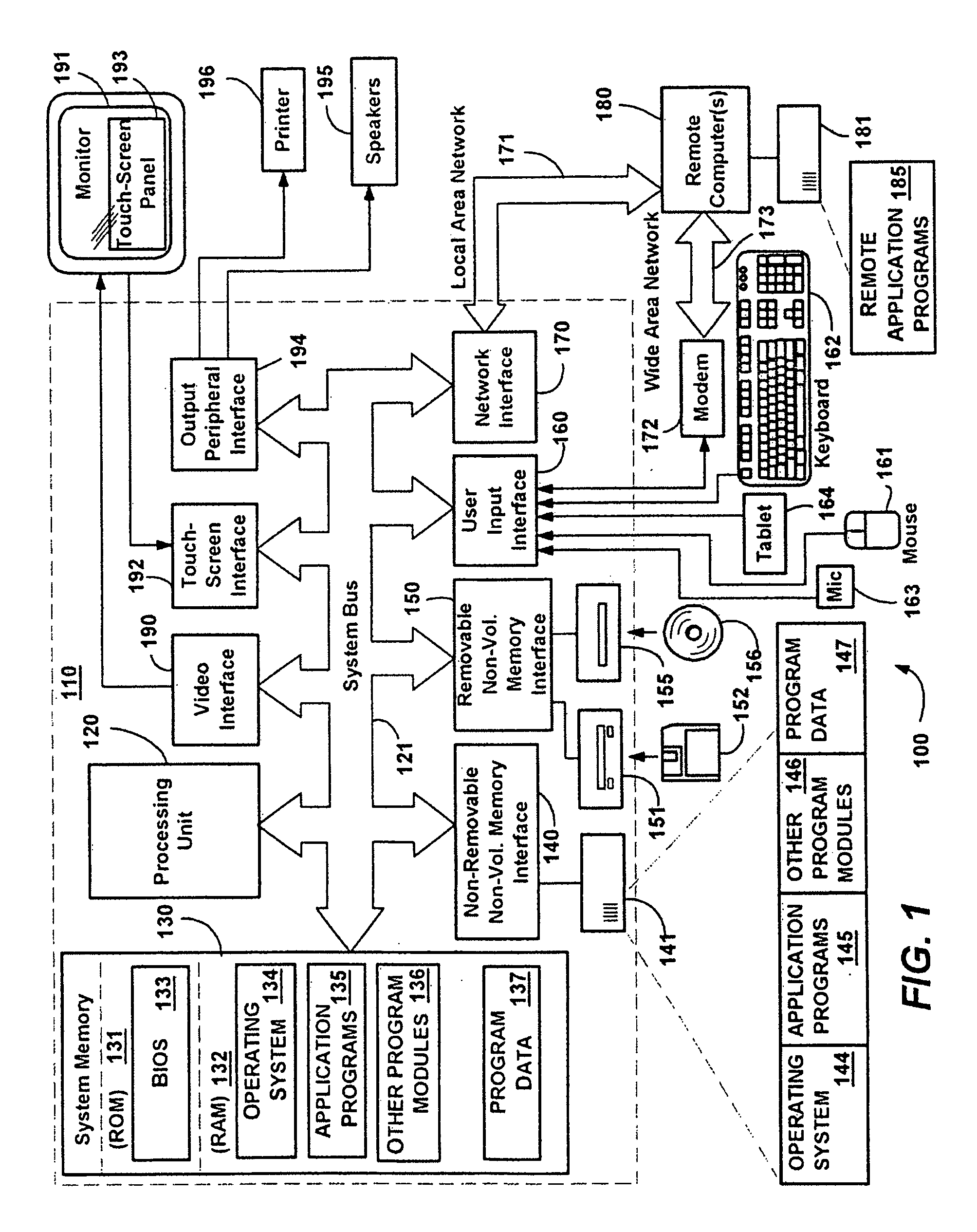

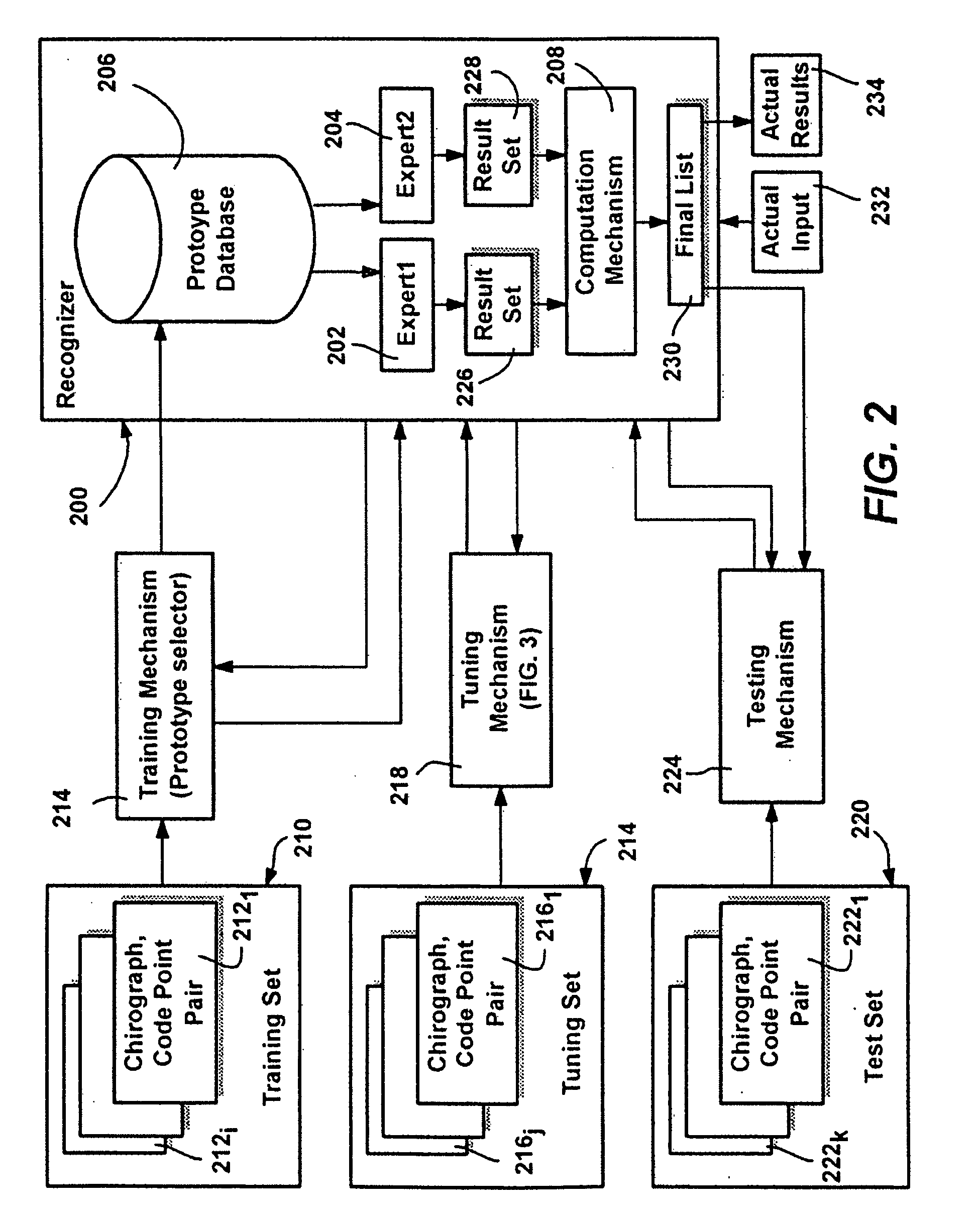

Efficient method and system for determining parameters in computerized recognition

ActiveUS6879718B2Increase valueDigital computer detailsCharacter and pattern recognitionFalse recognitionMultiple experts

In computerized recognition having multiple experts, a method and system is described that obtains an optimum value for an expert tuning parameter in a single pass over sample tuning data. Each tuning sample is applied to two experts, resulting in scores from which ranges of parameters that correct incorrect recognition errors without changing correct results for that sample are determined. To determine the range data for a given sample, the experts return scores for each prototype in a database, the scores separated into matching and non-matching scores. The matching and non-matching scores from each expert are compared, providing upper and lower bounds defining ranges. Maxima and minima histograms track upper and lower bound range data, respectively. An analysis of the histograms based on the full set of tuning samples provides the optimum value. For tuning multiple parameters, each parameter may be optimized by this method in isolation, and then iterated.

Owner:MICROSOFT TECH LICENSING LLC

Colored kiln-transformation ceramic product and manufacturing process thereof

The invention discloses a colored kiln-transformation ceramic product and a manufacturing process thereof and belongs to the field of ceramic art manufacture. The colored kiln-transformation ceramic product comprises a blank body and a glazing layer and is made by a special burning process. The invention is characterized in that: the blank paste comprises the following ingredients (by weight): 35parts of pottery clay (produced in the Zibo city), 15 parts of flint clay (produced in the Zibo city), 12 parts of quartz (produced in the Laizhou city), 12 parts of feldspar (produced in the Laizhoucity), 8 parts of soil (produced in the Datong city of the Shanxi province), 10 parts of kaolin (produced in the Yunnan province), and 8 parts of aluminum powders. The glazing material comprises the following ingredients (by weight): 35 parts of feldspar, 10 parts of dolomite, 10 parts of quartz, 3 parts of vat soil, 5 parts of barium carbonate, 5 parts of talc, 20 parts of fusion cake, 2 parts of zinc oxide, 1 part of copper oxide and 5 parts of ferric oxide. The colored kiln-transformation ceramic product is made by performing dry-method pulverization and firing in a firing atmosphere with a certain firing temperature curve. The ceramic product has rich and changeable color, integrates the visual effects of miscibility and fluidity of a variety of coloring agents, is the most beautiful ceramic treasure in ceramic history, and is called by multiple experts as a great innovation in China ceramic history.

Owner:路今铧

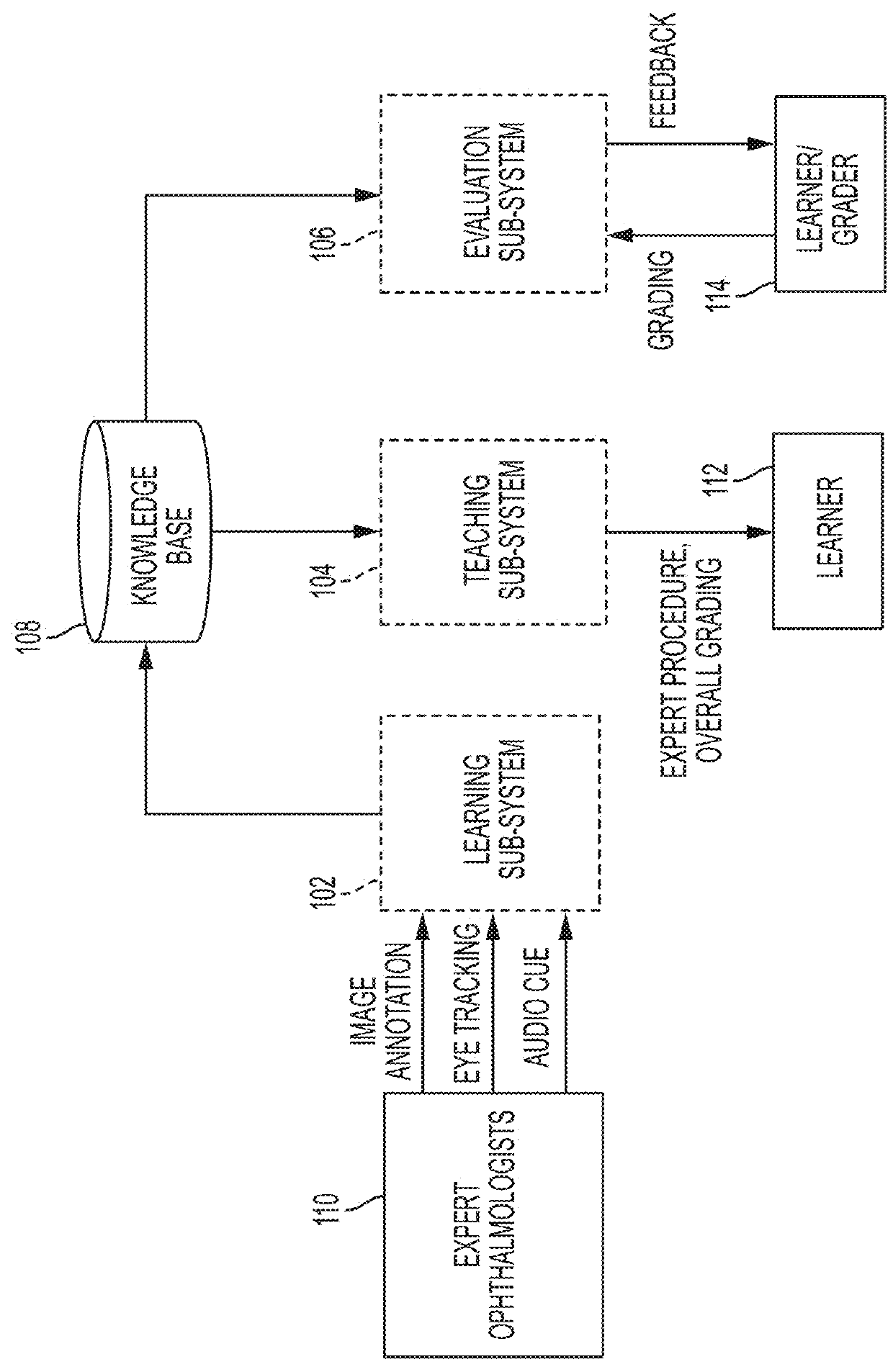

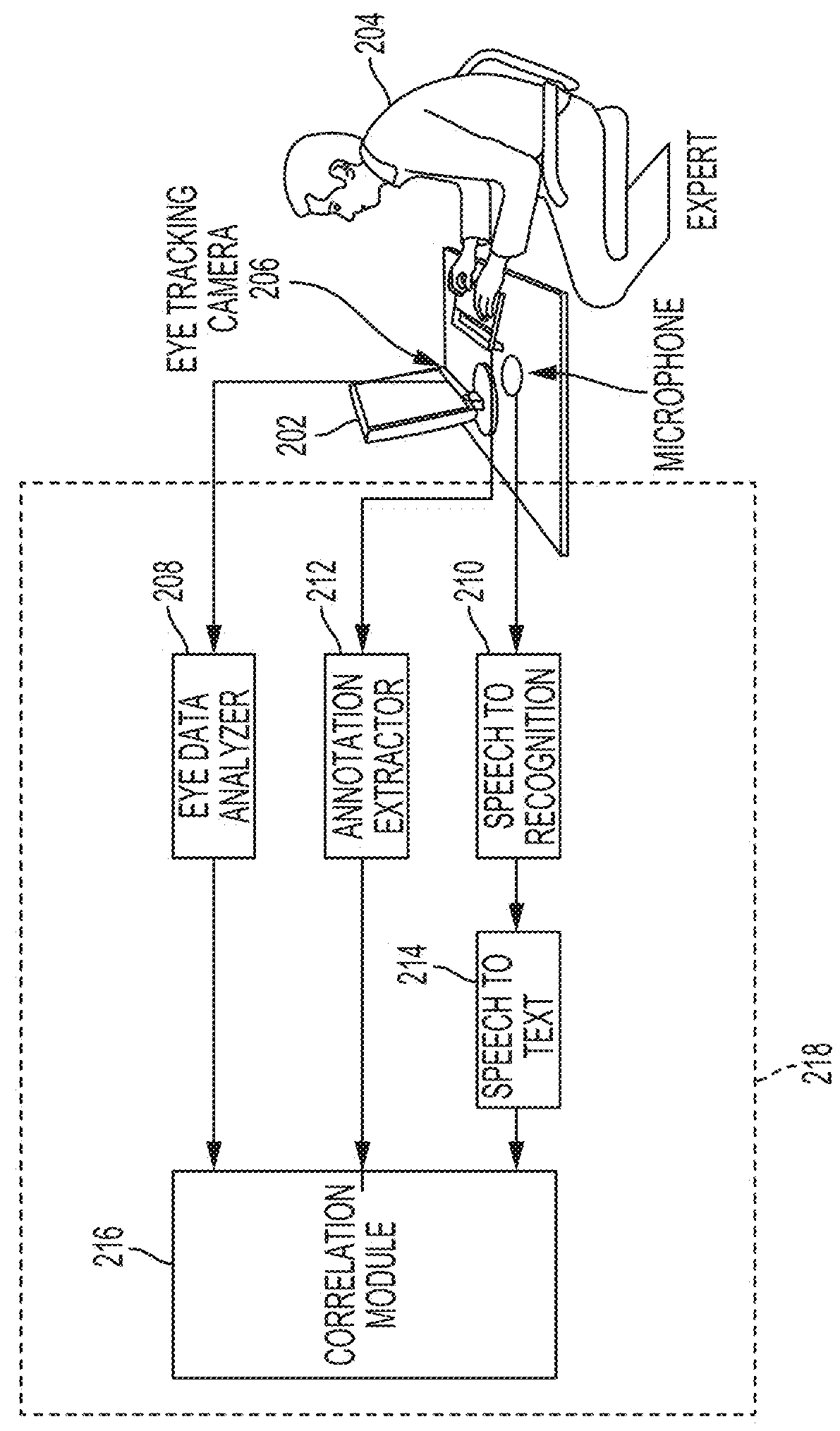

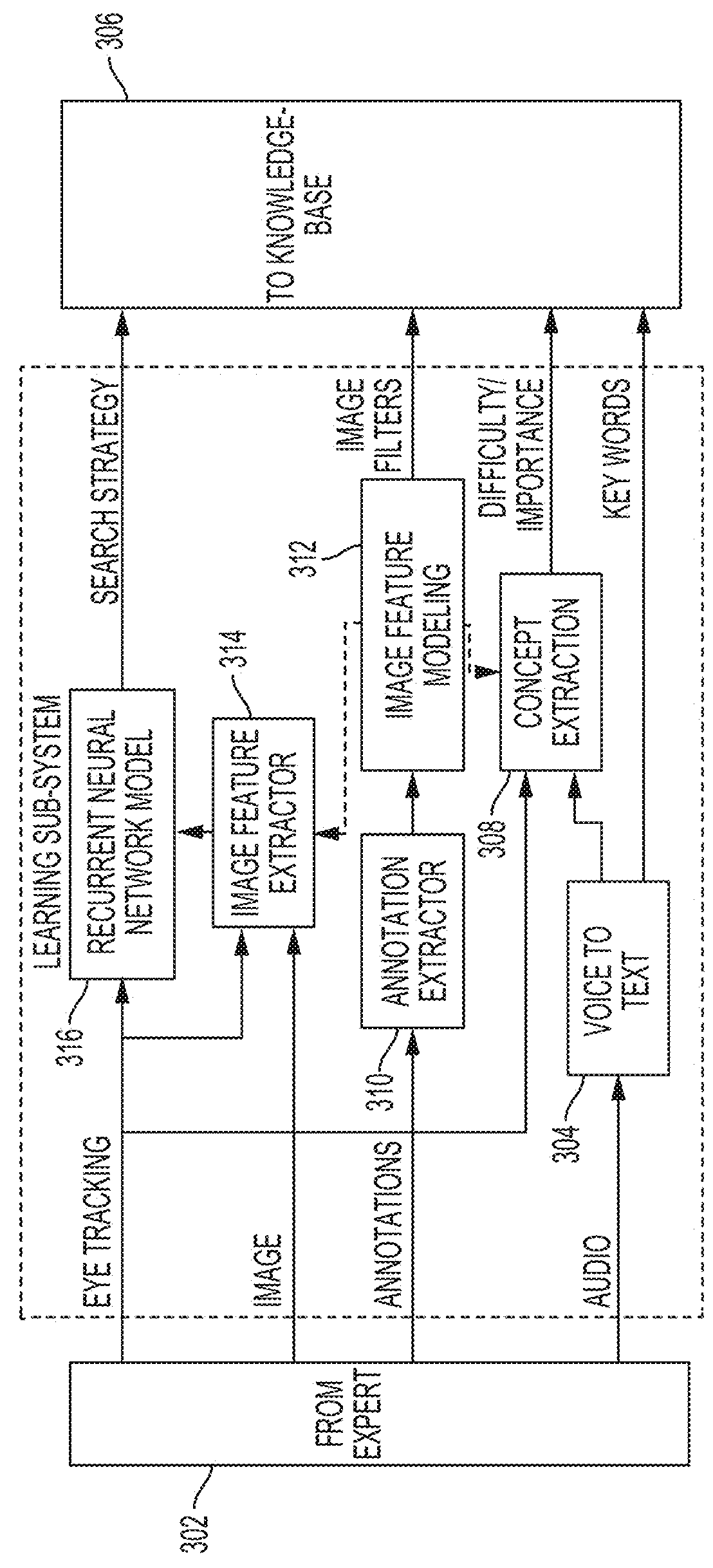

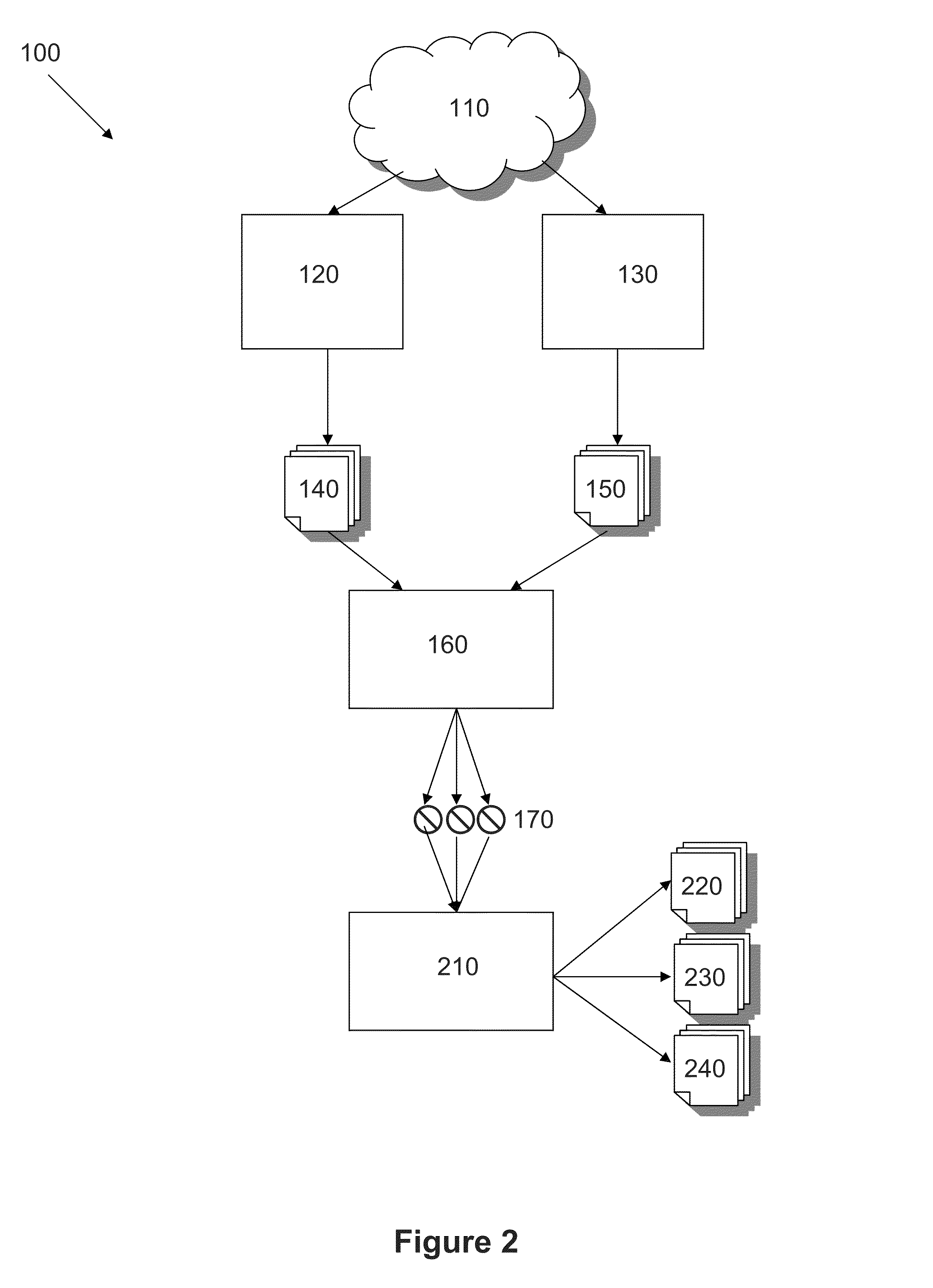

System and method to teach and evaluate image grading performance using prior learned expert knowledge base

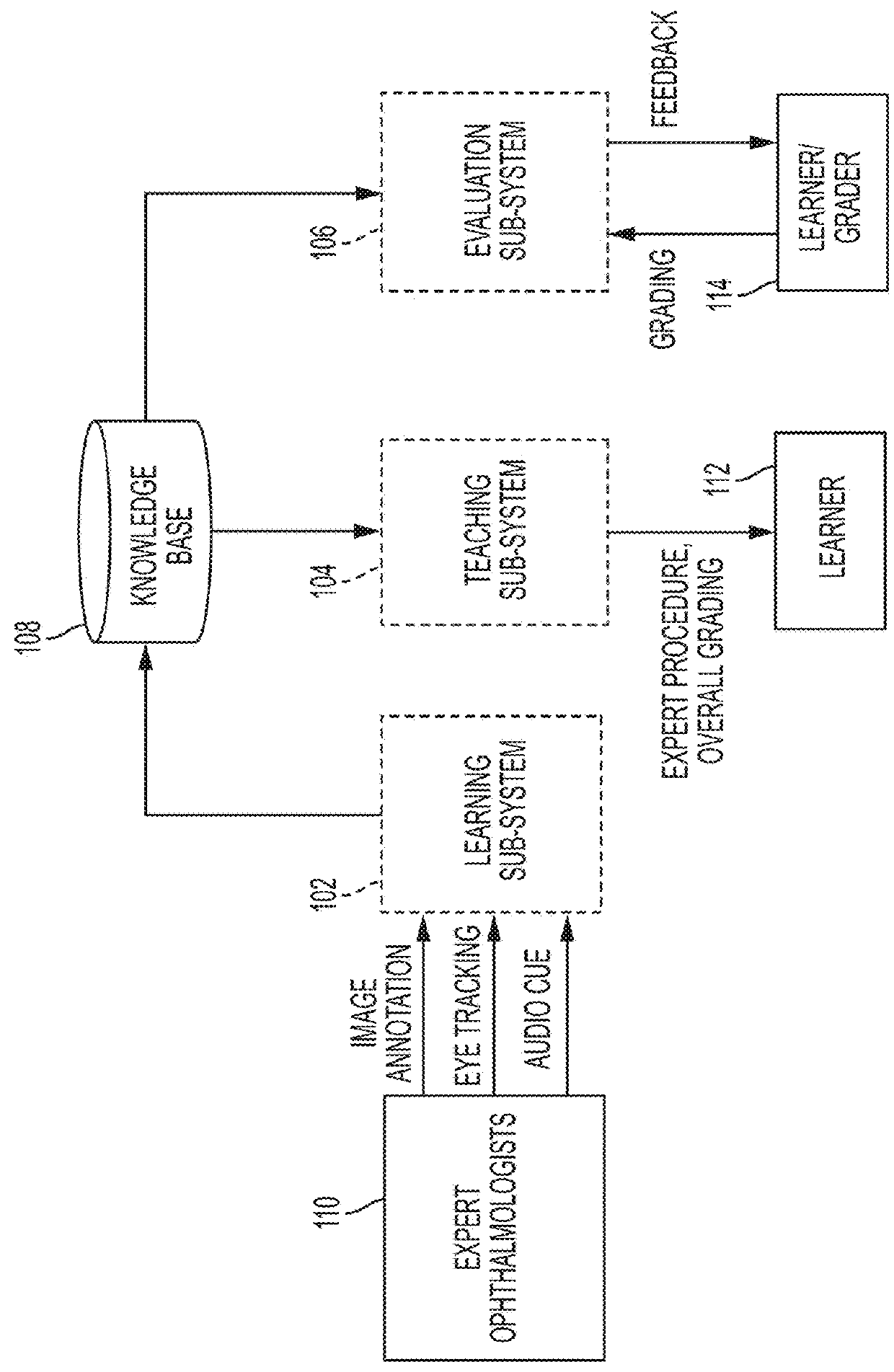

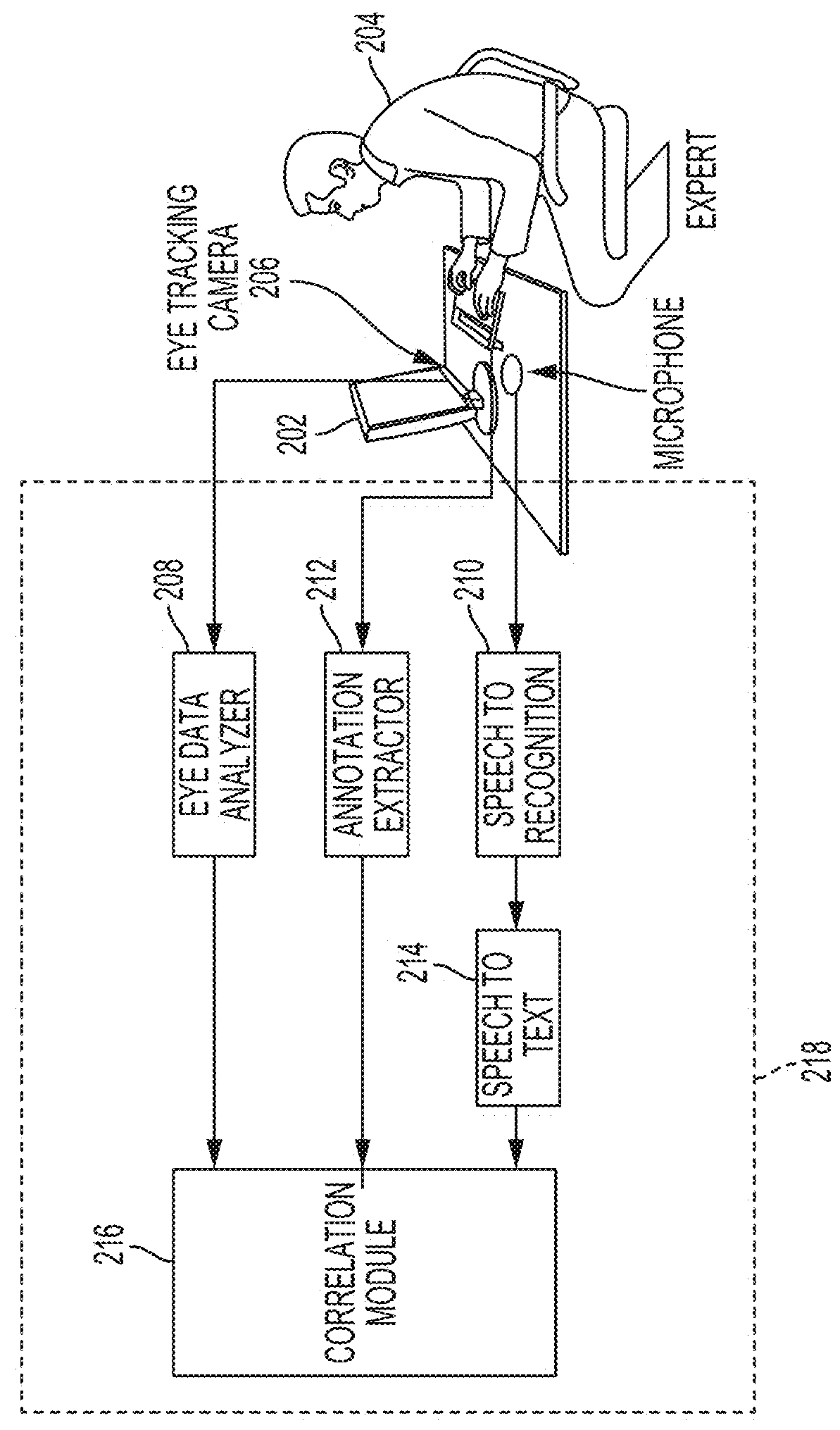

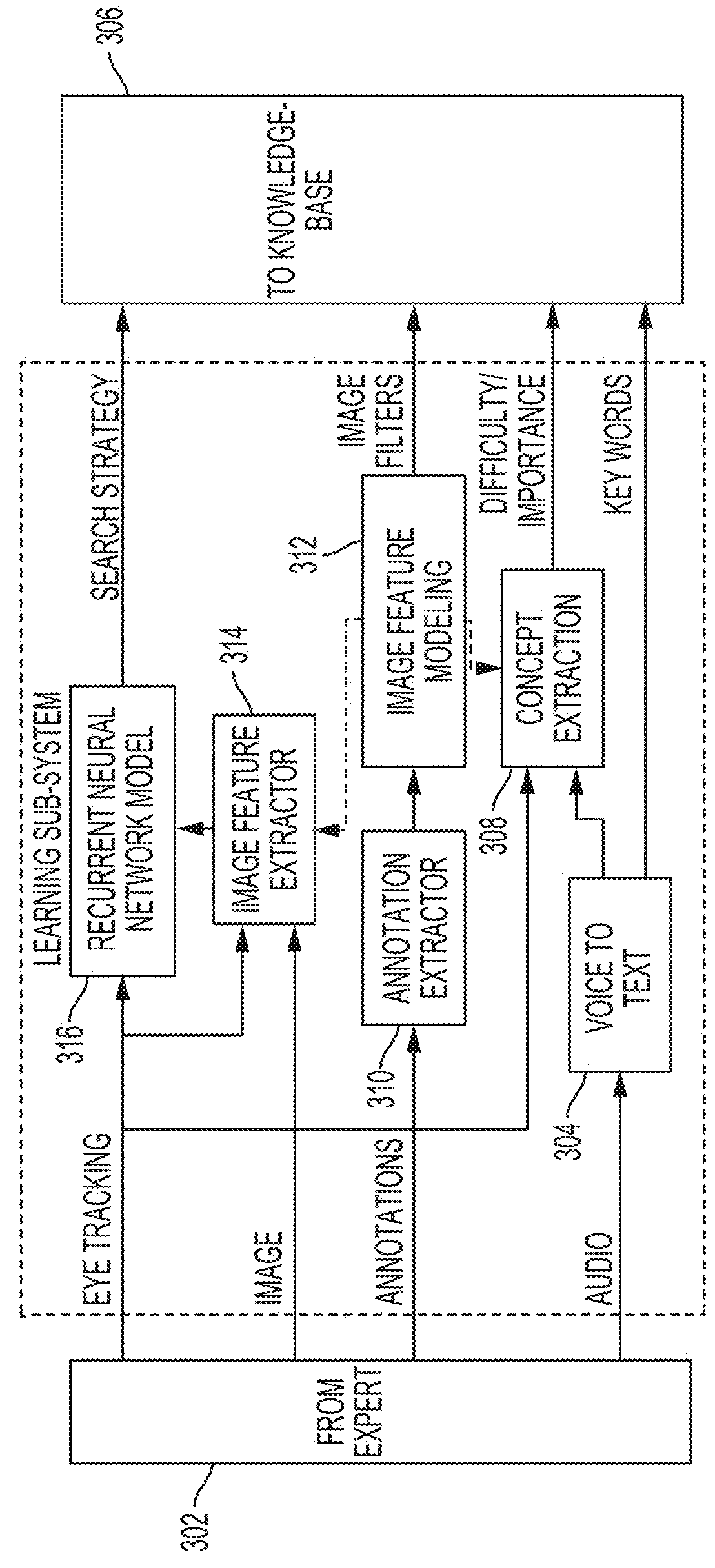

A learning sub-system models search patterns of multiple experts in analyzing an image using a recurrent neural network (RNN) architecture, creates a knowledge base that models expert knowledge. A teaching sub-system teaches the search pattern captured by the RNN model and presents to a learning user the information for analyzing an image. The teaching sub-system determines the teaching image sequence based on a difficulty level identified using image features, audio cues, expert confidence and time taken by experts. An evaluation sub-system measures the learning user's performance in terms of search strategy that is evaluated against the RNN model and provides feedback on overall sequence followed by the learning user and time spent by the learning user on each region in the image.

Owner:IBM CORP

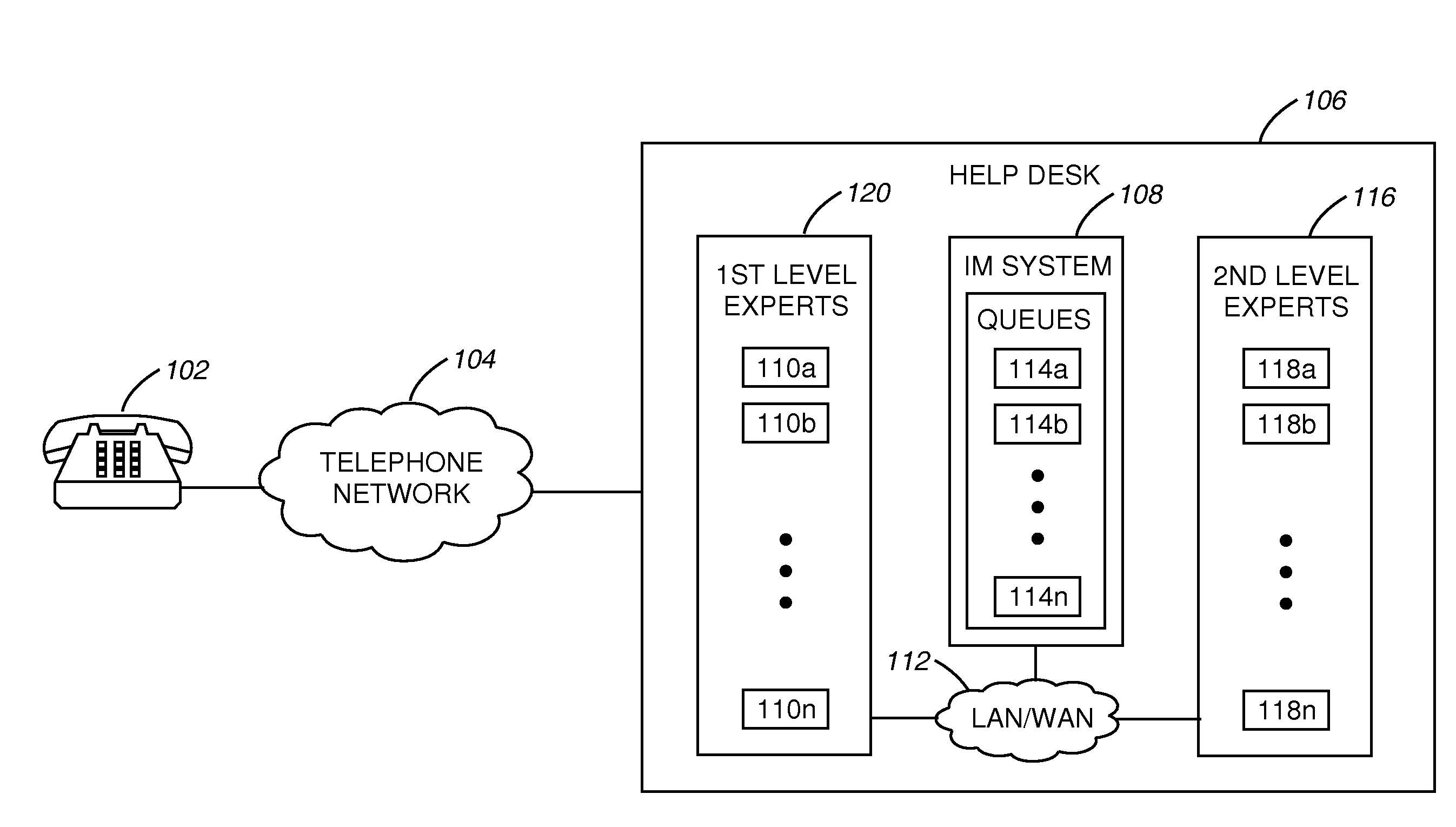

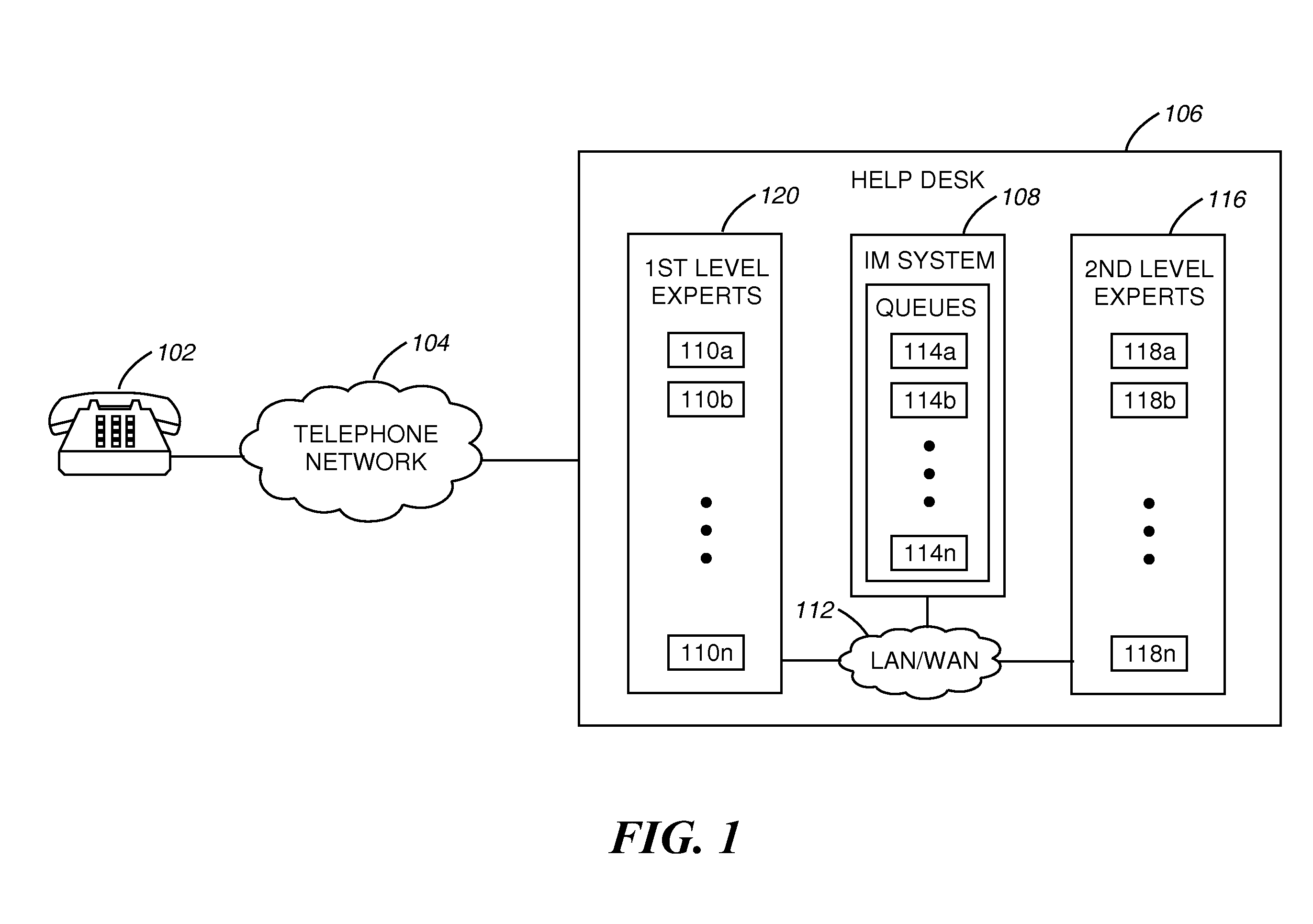

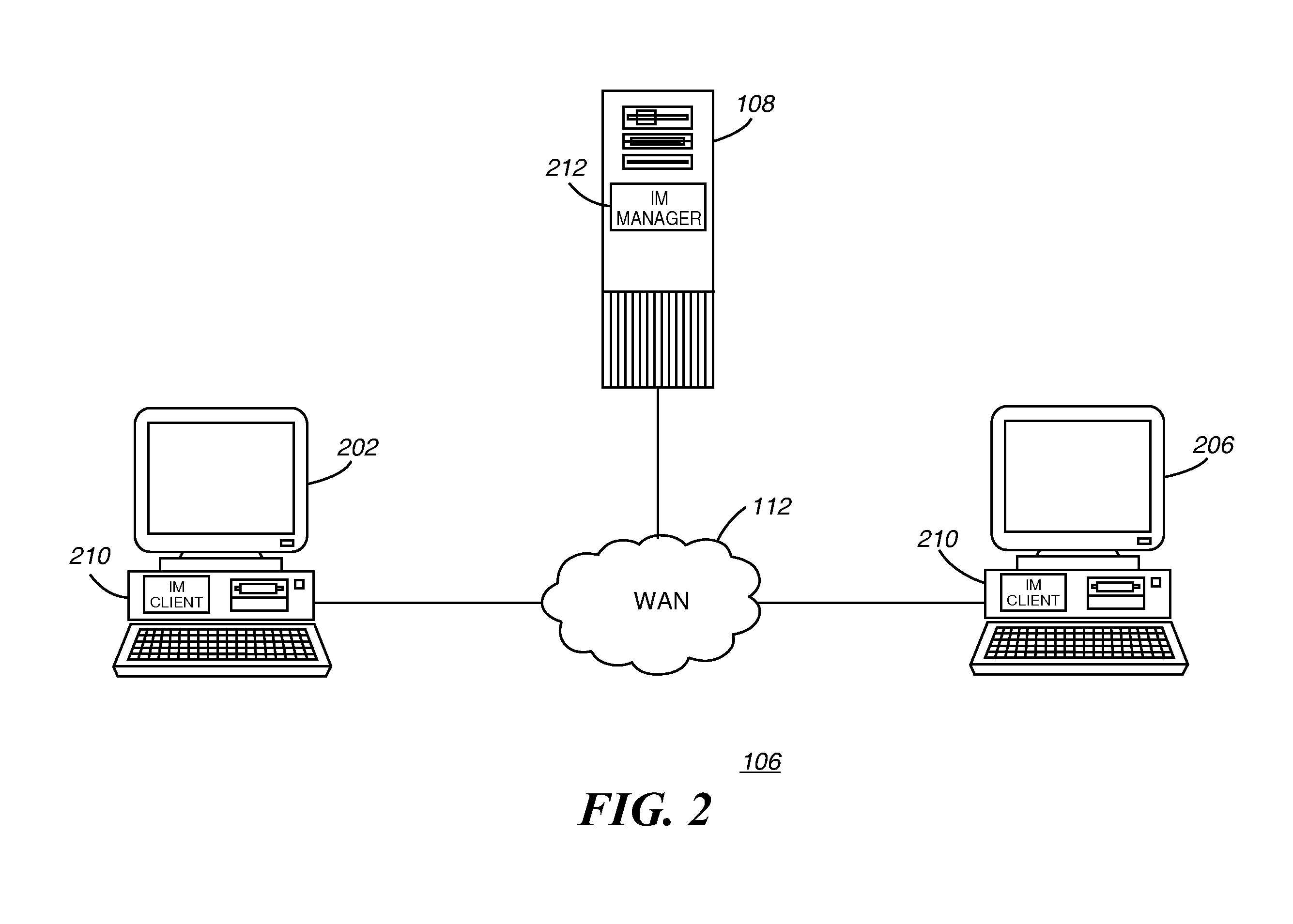

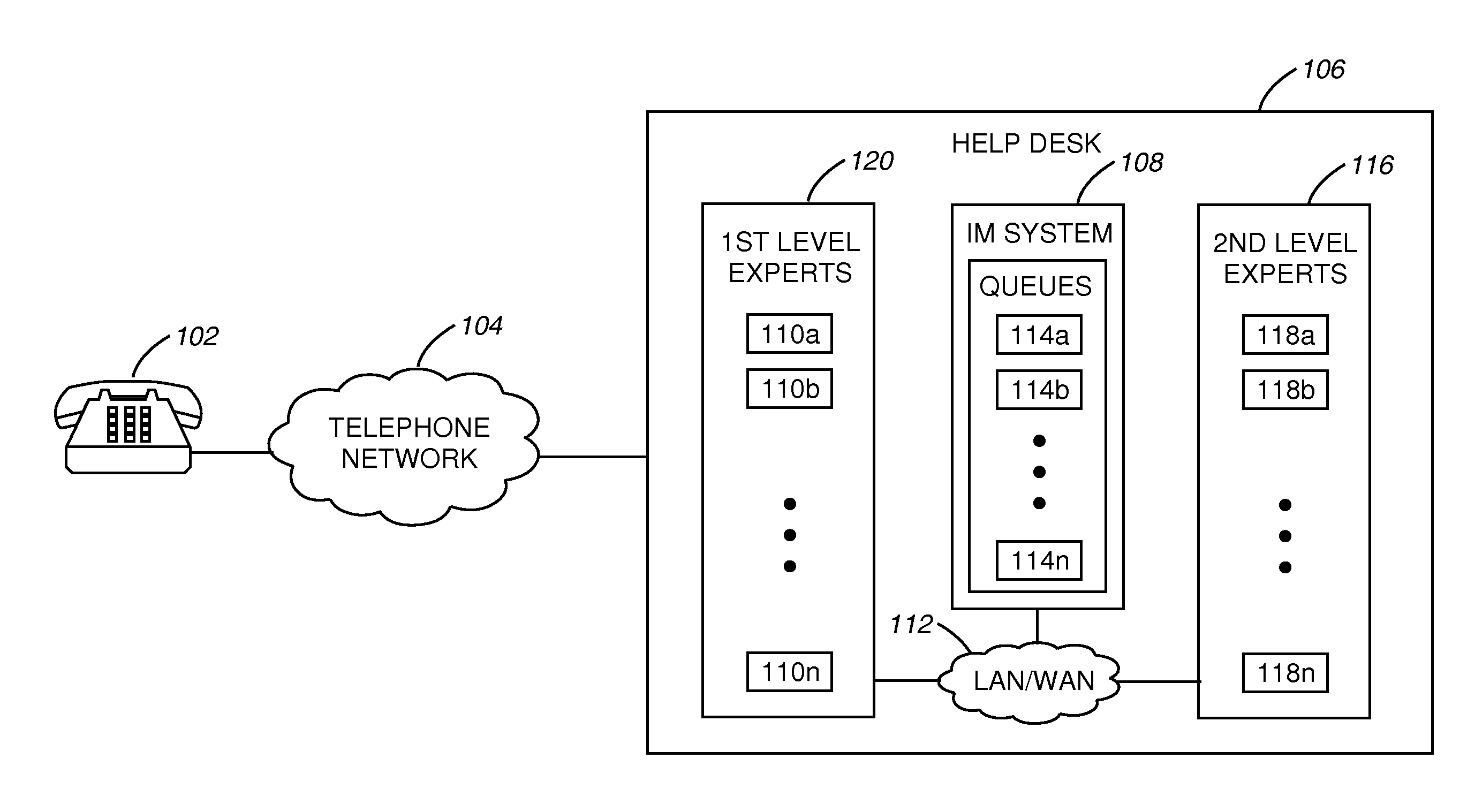

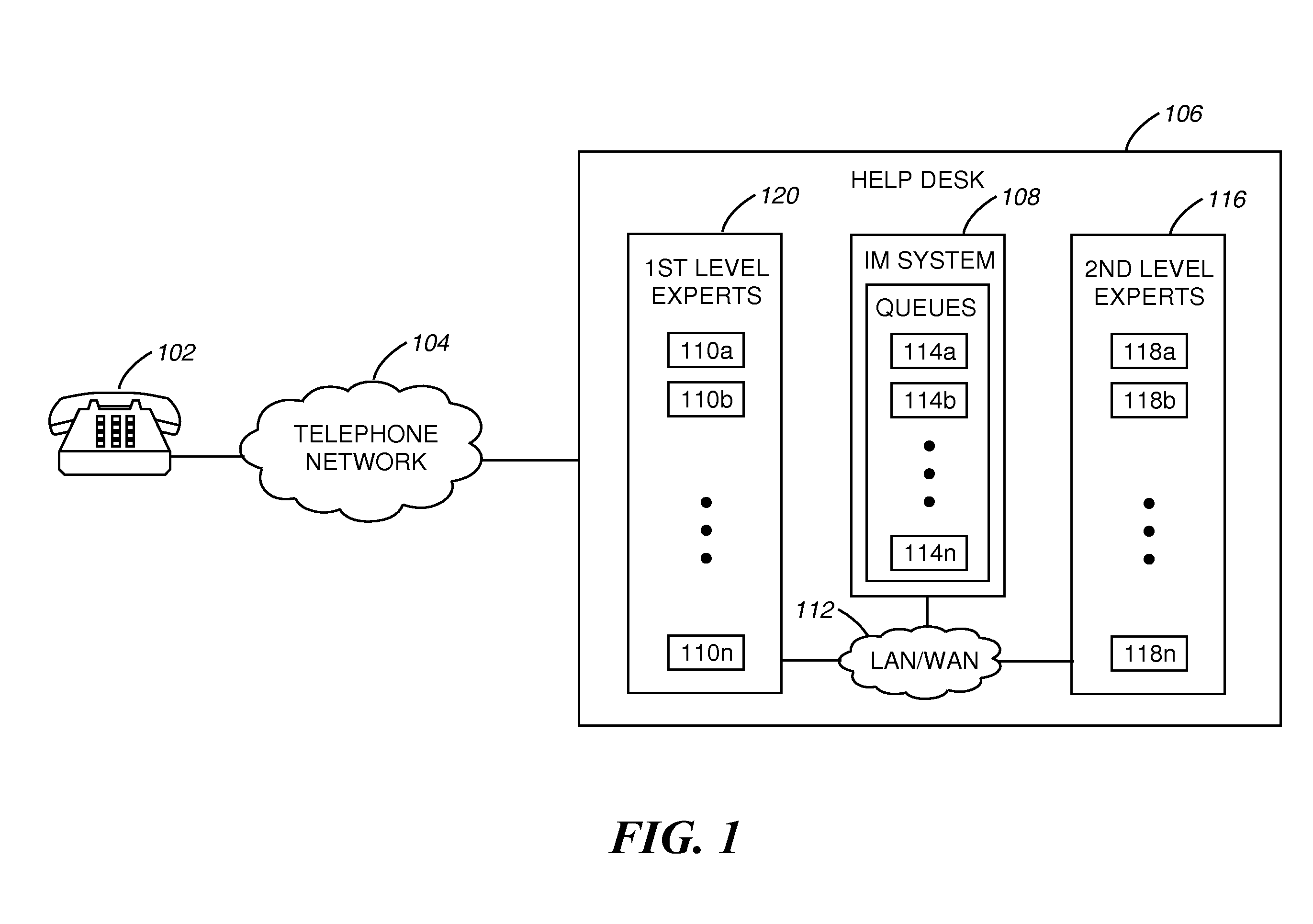

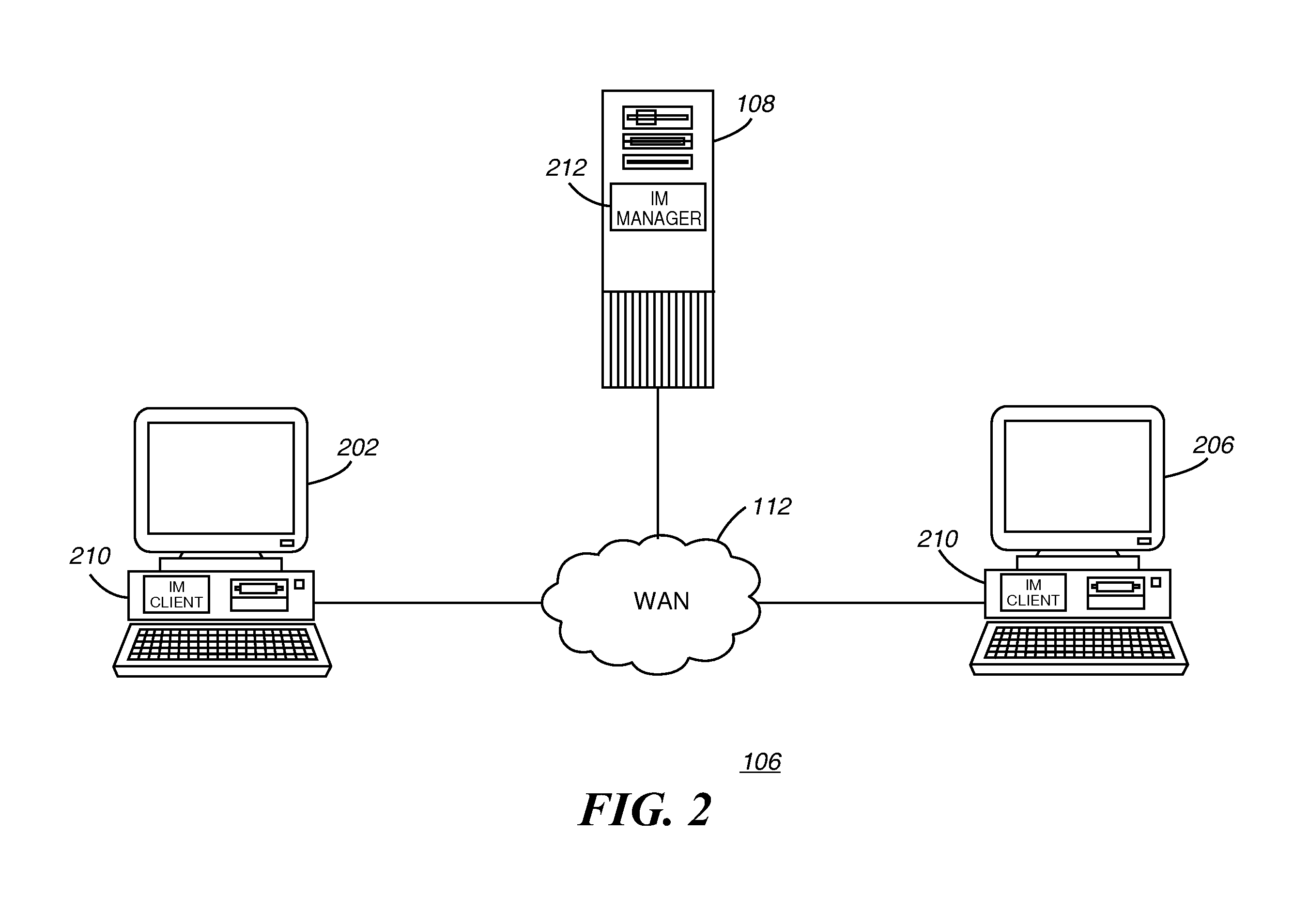

Queuing of instant messaging requests

InactiveUS20080147863A1Multiple digital computer combinationsManual exchangesAutomatic controlElectronic communication

A method and system for routing or directing calls in a call center, service center, or help desk environment includes a versatile queuing mechanism that supports instant messaging or electronic communications or mail in support of received calls taken by the help desk. The queuing mechanism provides predefined categories of different areas of expertise, automatic distribution to different skills levels of escalating expertise based on each request, multiple experts for each category monitoring the queues for new requests, and, as the requests come in, the experts can manually pull the new requests or be given the requests automatically. For each request, there is automated control of the number of instant messages any one expert is allowed to handle. The expert resolution can be used as feedback in the entire support process for evaluation.

Owner:IBM CORP

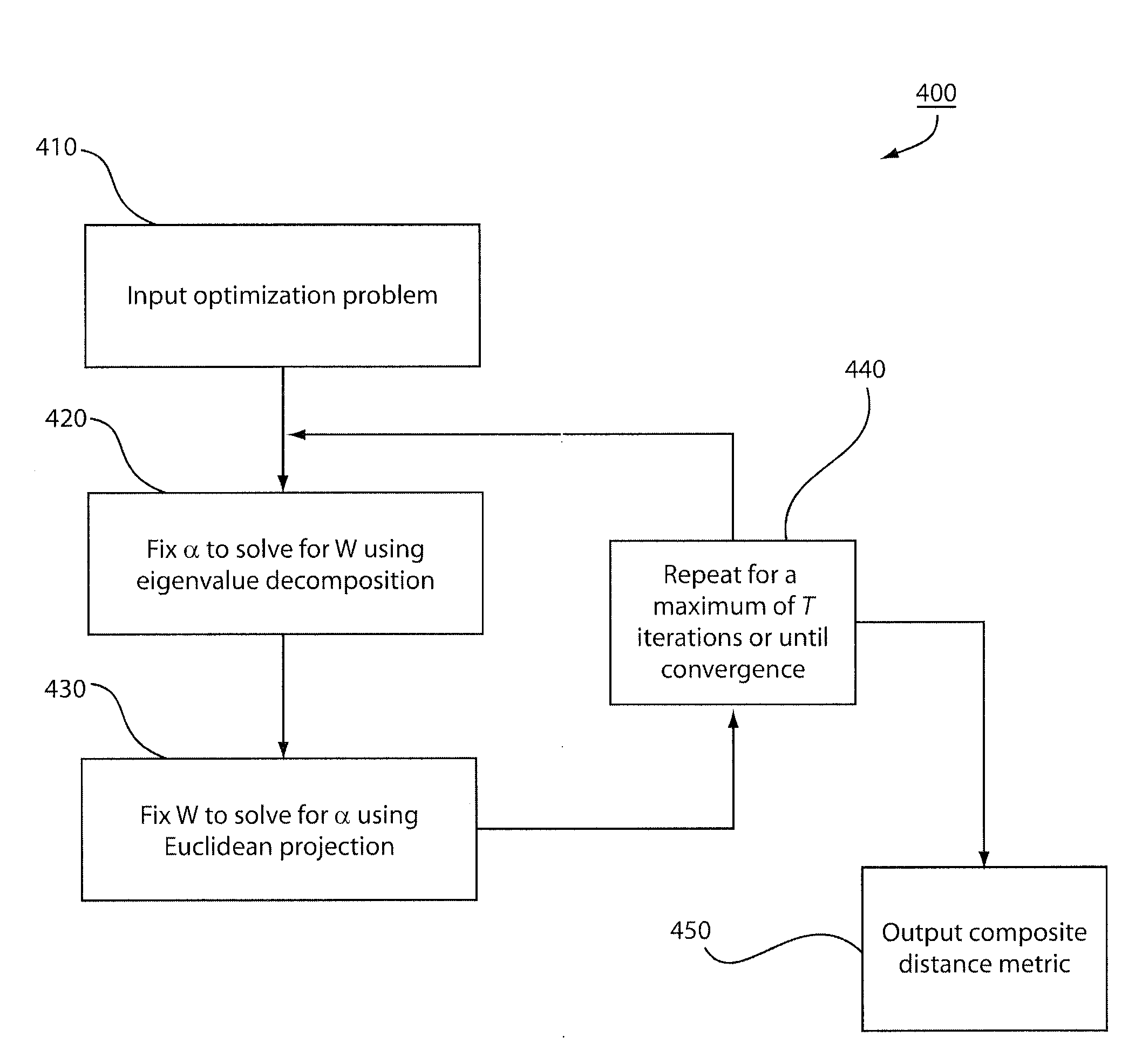

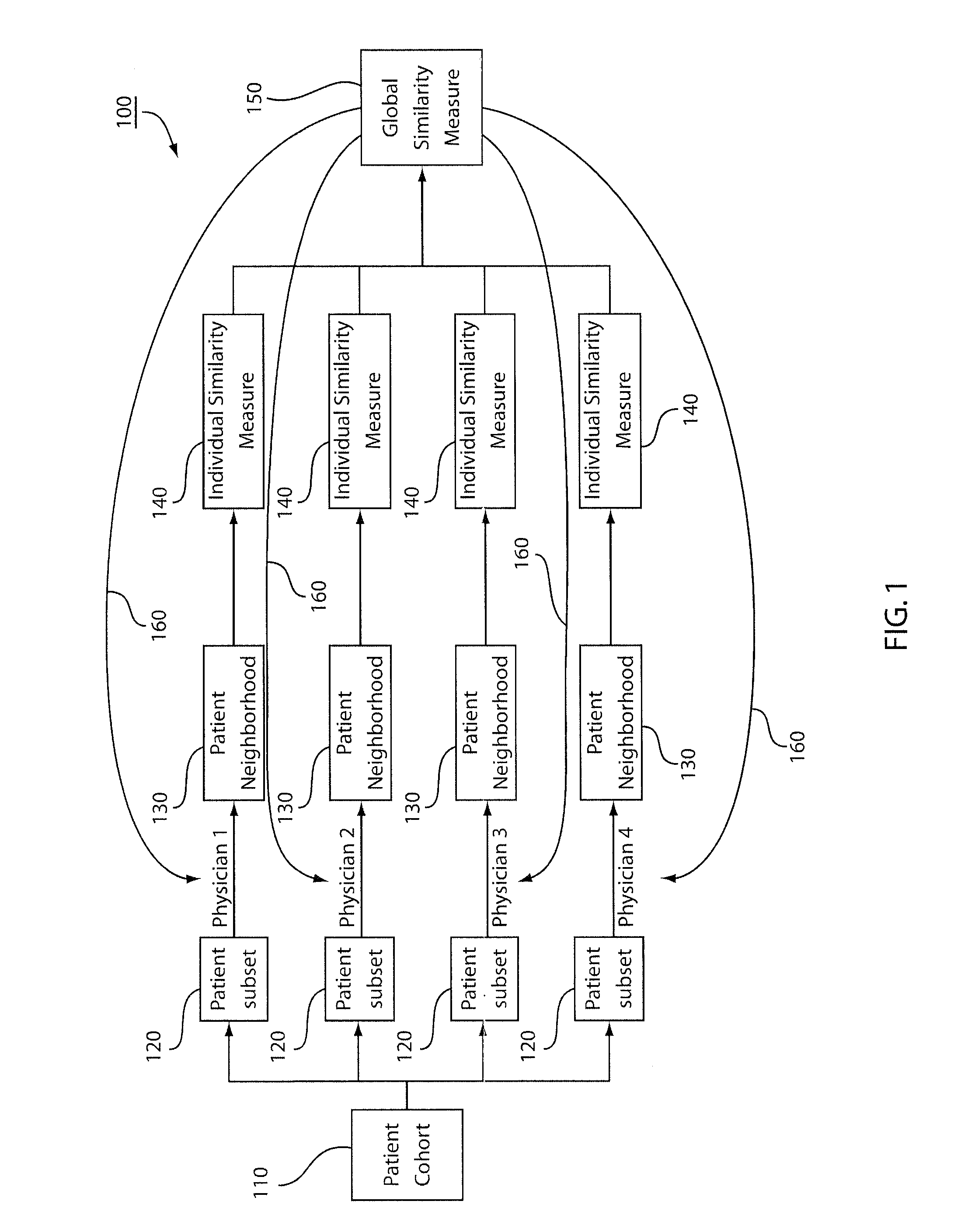

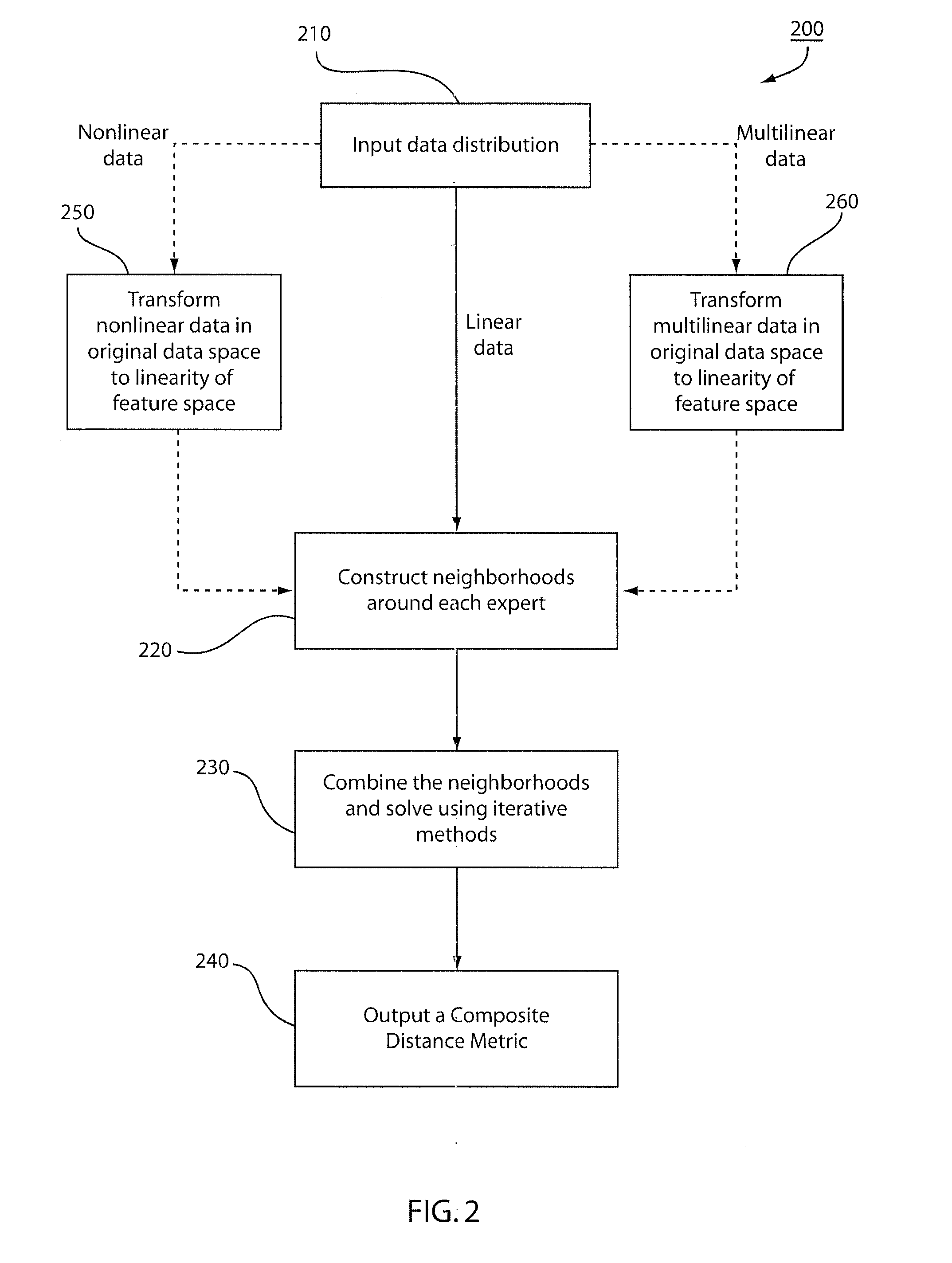

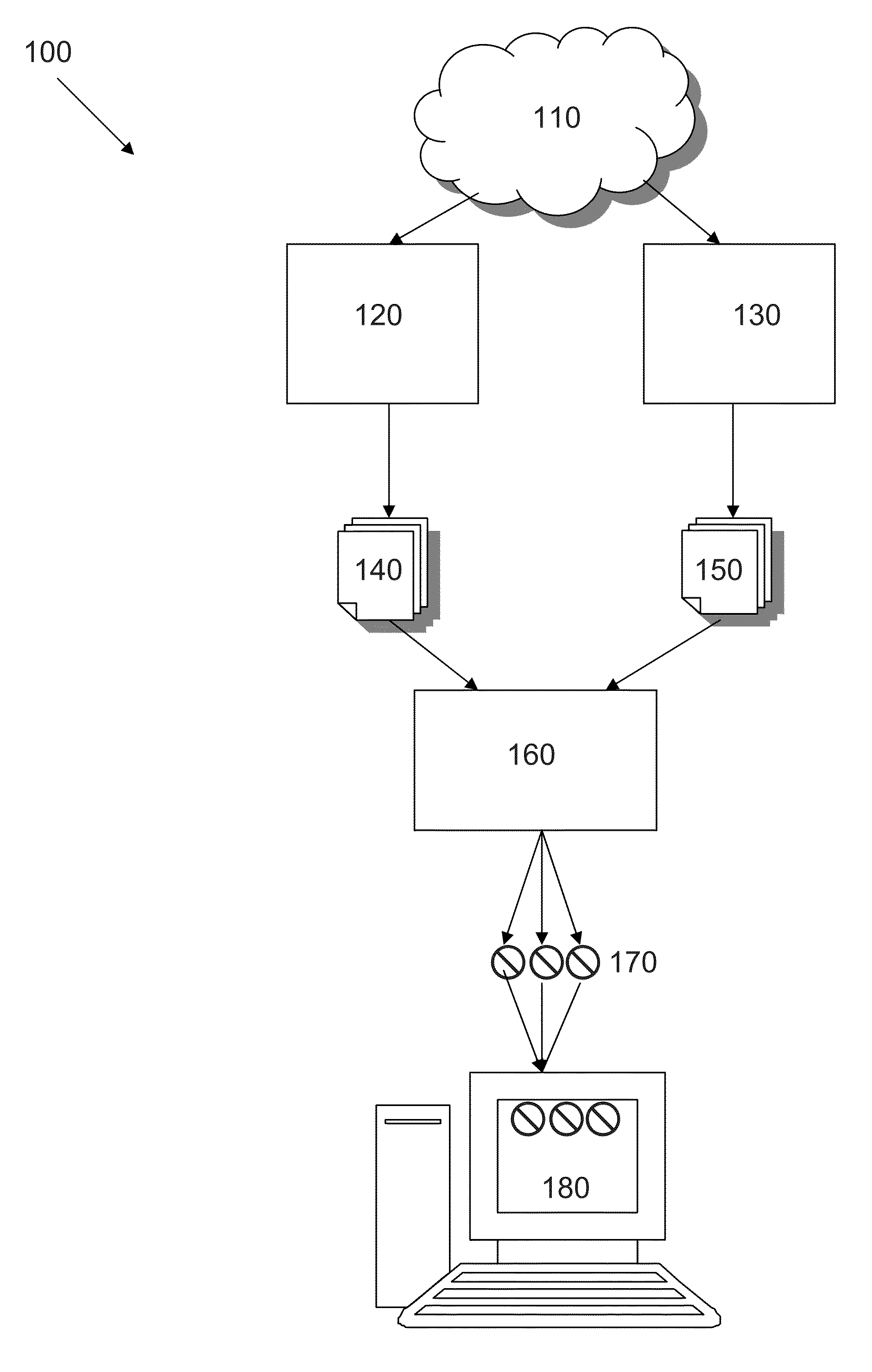

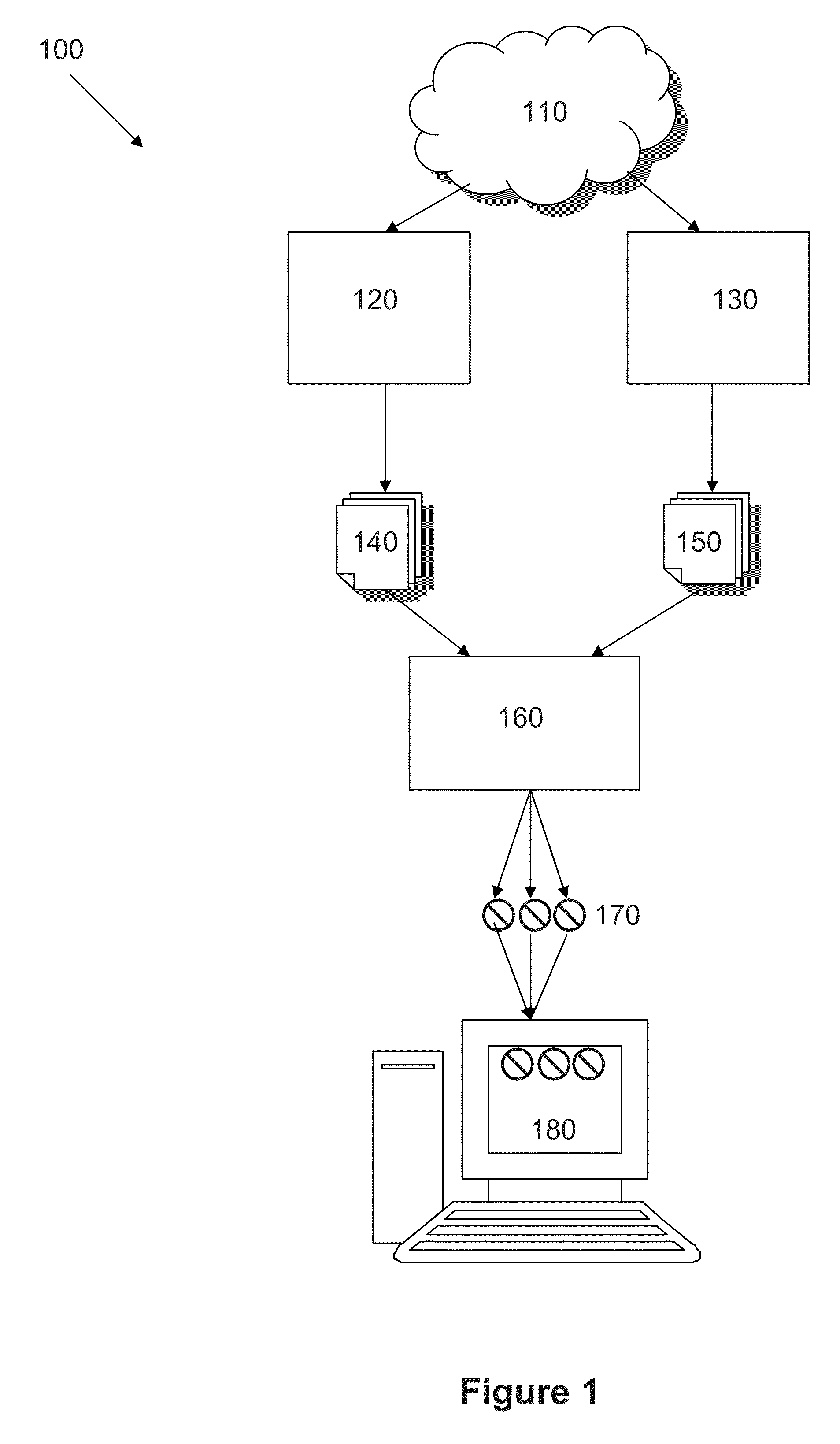

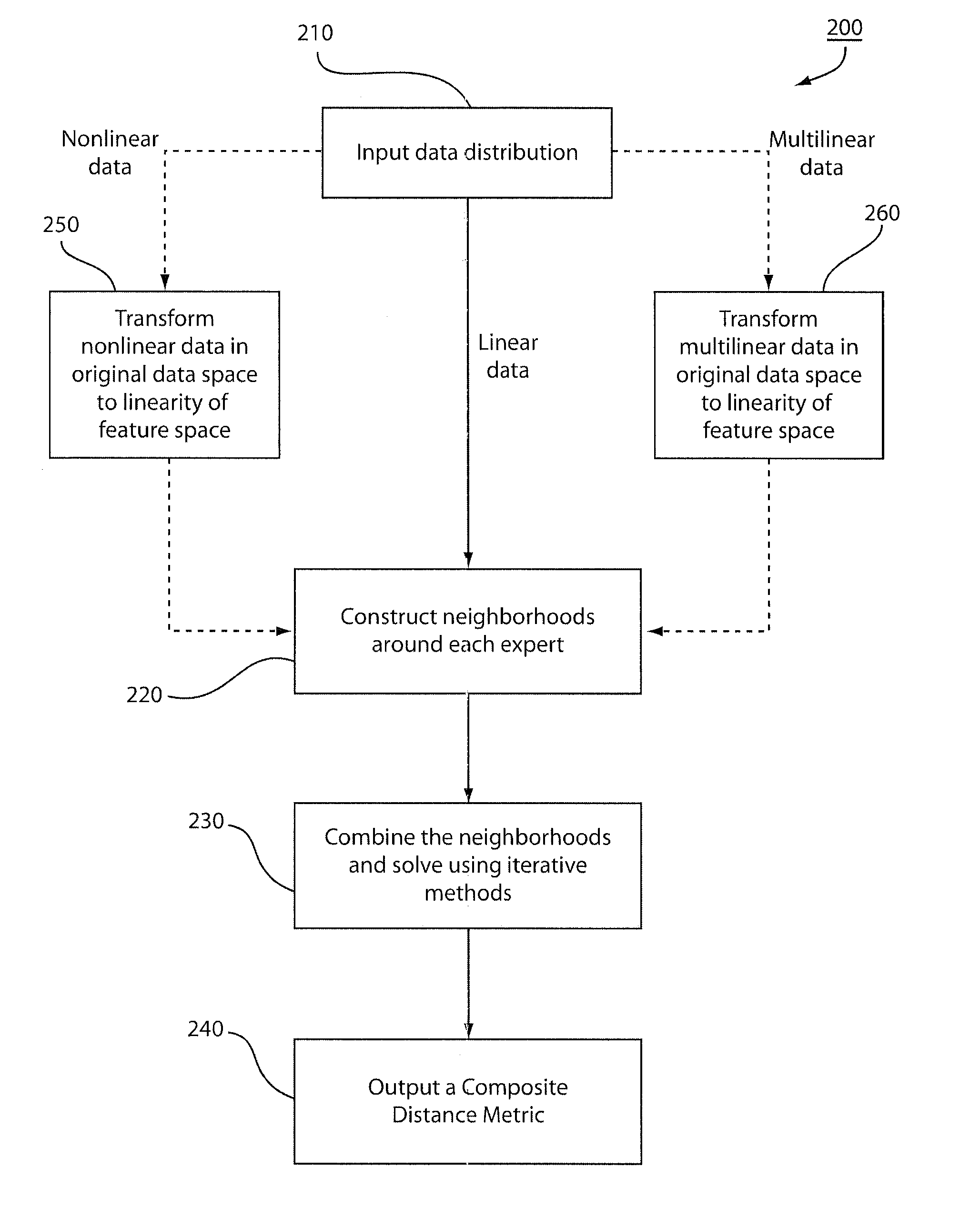

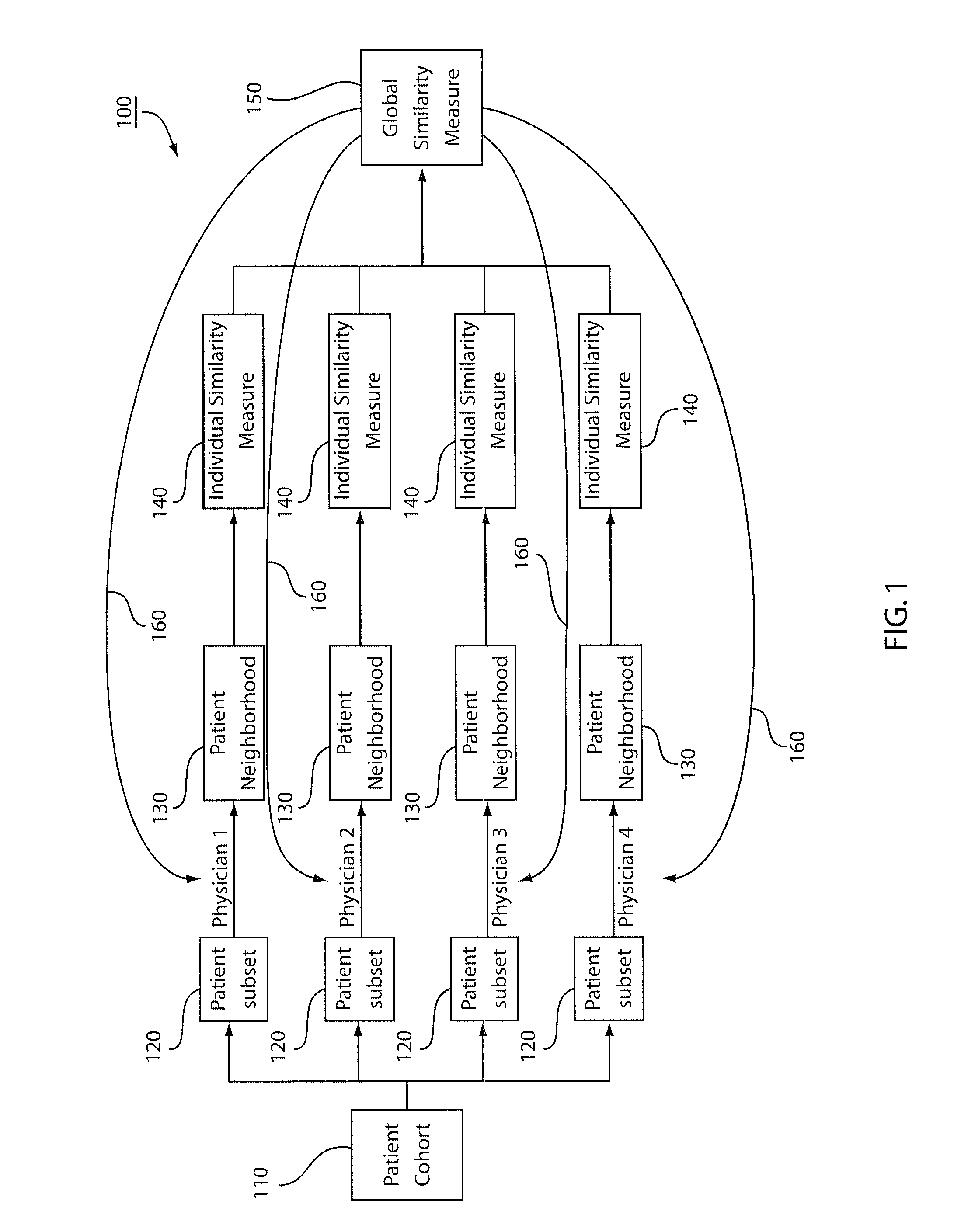

System and method for composite distance metric leveraging multiple expert judgments

A system and method for a composite distance metric leveraging multiple expert judgments includes inputting a data distribution of multiple expert judgments stored on a computer readable storage medium. Base distance metrics are converted into neighborhoods for comparison, wherein each base distance metric represents an expert. The neighborhoods are combined to leverage the local discriminalities of all base distance metrics by applying at least one iterative process to output a composite distance metric.

Owner:IBM CORP

Queuing of instant messaging requests

InactiveUS7895330B2Multiple digital computer combinationsManual exchangesAutomatic controlElectronic communication

A method and system for routing or directing calls in a call center, service center, or help desk environment includes a versatile queuing mechanism that supports instant messaging or electronic communications or mail in support of received calls taken by the help desk. The queuing mechanism provides predefined categories of different areas of expertise, automatic distribution to different skills levels of escalating expertise based on each request, multiple experts for each category monitoring the queues for new requests, and, as the requests come in, the experts can manually pull the new requests or be given the requests automatically. For each request, there is automated control of the number of instant messages any one expert is allowed to handle. The expert resolution can be used as feedback in the entire support process for evaluation.

Owner:INT BUSINESS MASCH CORP

Conflicting Expert Systems

InactiveUS20130024235A1Addressing slow performanceOptimize cross-functional conflictsResourcesTechnical standardMultiple experts

An expert system for providing optimized recommendations regarding a construction project is configured to generate conflicting optimization recommendations. Multiple expert system engines are implemented, where each engine provides one or more recommendations optimized in accordance with the priorities of a functional discipline. A conflict engine will identify conflicts between optimized recommendations and will package the conflicts into conflict objects that are presented to a conflict user interface for resolution. The user could resolve the conflicts him / herself, or could configure a cross-functional conflict object to resolve such conflicts based upon specified resolution criteria.

Owner:FLUOR TECH CORP

System and method to teach and evaluate image grading performance using prior learned expert knowledge base

A learning sub-system models search patterns of multiple experts in analyzing an image using a recurrent neural network (RNN) architecture, creates a knowledge base that models expert knowledge. A teaching sub-system teaches the search pattern captured by the RNN model and presents to a learning user the information for analyzing an image. The teaching sub-system determines the teaching image sequence based on a difficulty level identified using image features, audio cues, expert confidence and time taken by experts. An evaluation sub-system measures the learning user's performance in terms of search strategy that is evaluated against the RNN model and provides feedback on overall sequence followed by the learning user and time spent by the learning user on each region in the image.

Owner:IBM CORP

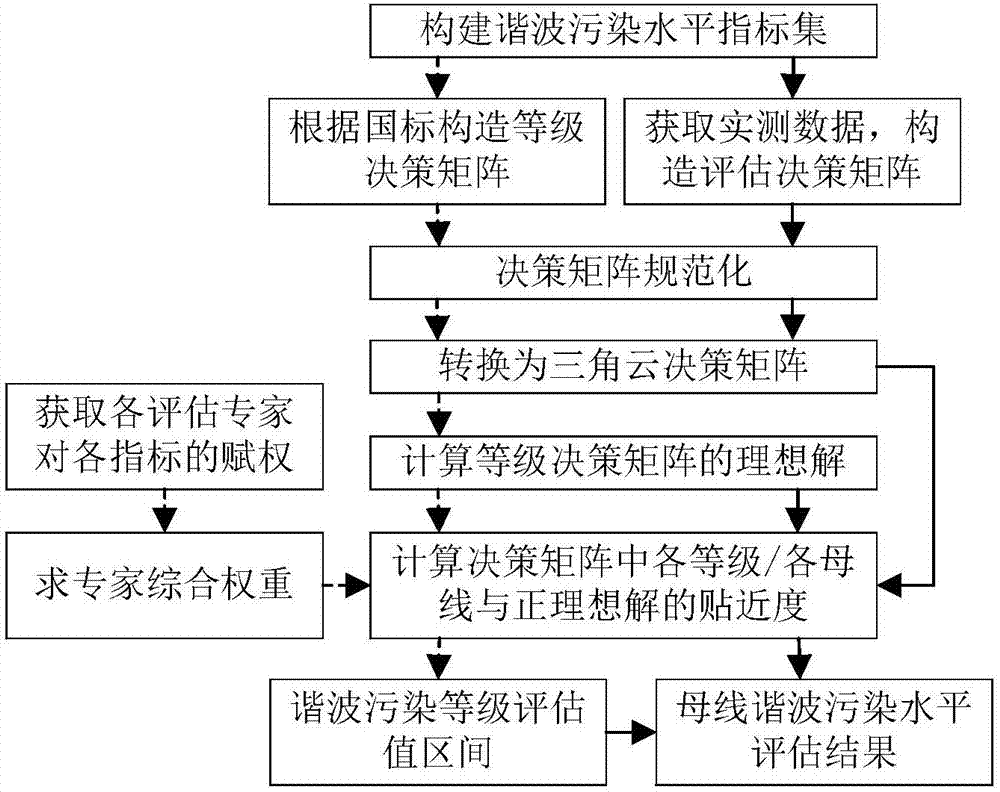

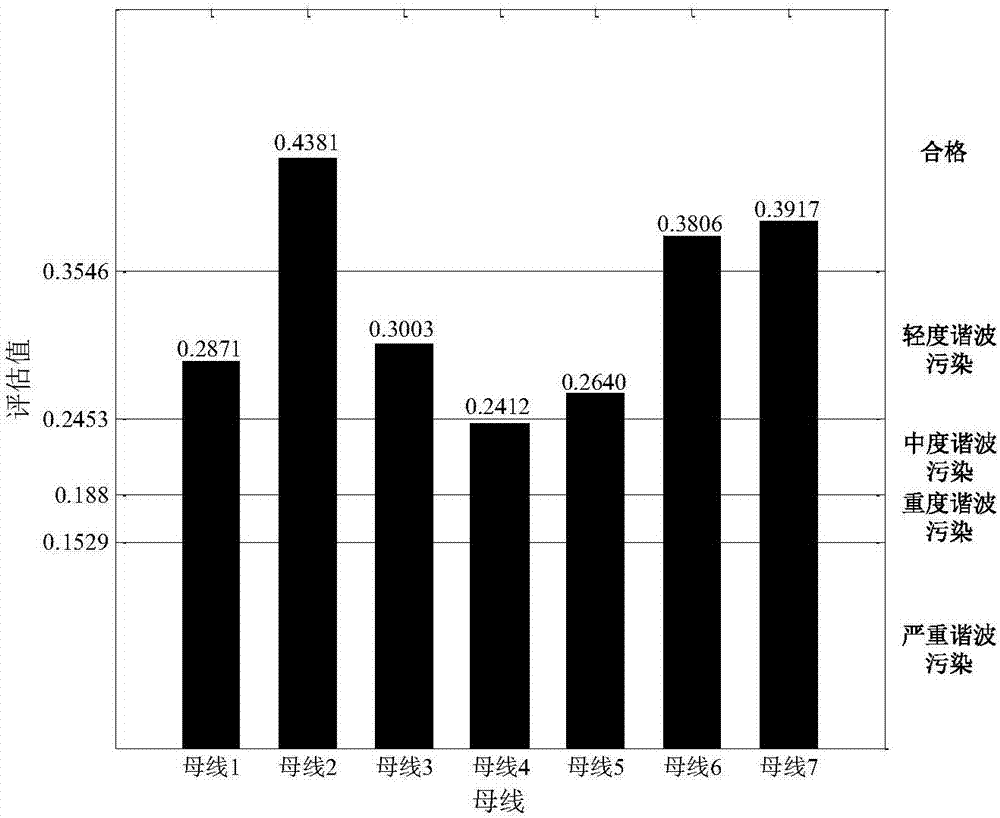

Method for assessing harmonic pollution level on basis of extended cloud similarity and similarity to ideal solution

The invention discloses a method for assessing harmonic pollution level on the basis of extended cloud similarity and similarity to ideal solution. The method comprises the following steps: firstly, establishing an assessment index system with total harmonic distortion of voltage and an effective value of harmonic current as indexes; then, integrating weight information of multiple experts with a group decision characteristic root method to obtain comprehensive weight of a harmonic pollution level assessing expert group; adopting triangular fuzzy numbers to describe fuzziness of the harmonic pollution level assessing indexes, and performing unified computation on the triangular fuzzy numbers with extended cloud similarity measure; finally, obtaining a reasonable harmonic pollution level assessing result with the method of similarity to ideal solution under the condition of construction of unified benchmark level as well as positive and negative ideal solutions. With adoption of the method, the harmonic pollution level can be assessed comprehensively, harmonic index fluctuation and assessment decision groupment in a period of time are considered, the weight information of multiple experts is integrated better, and the reasonable harmonic pollution level assessing result is obtained.

Owner:SOUTHWEST JIAOTONG UNIV

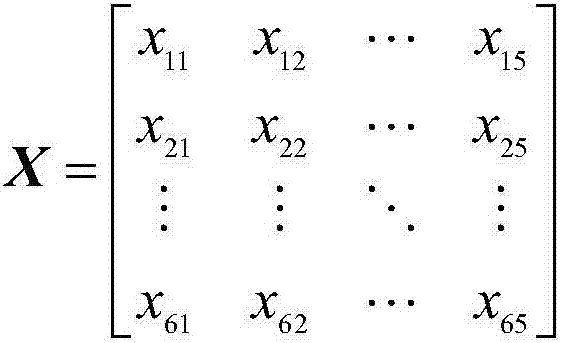

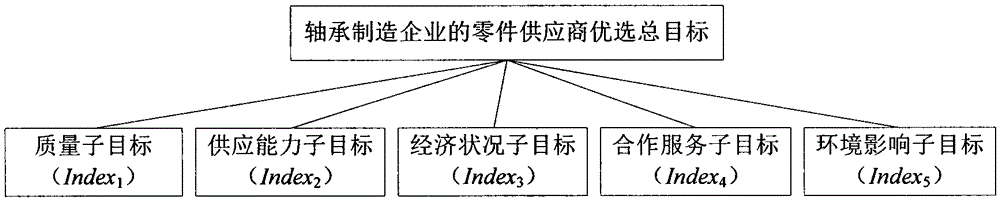

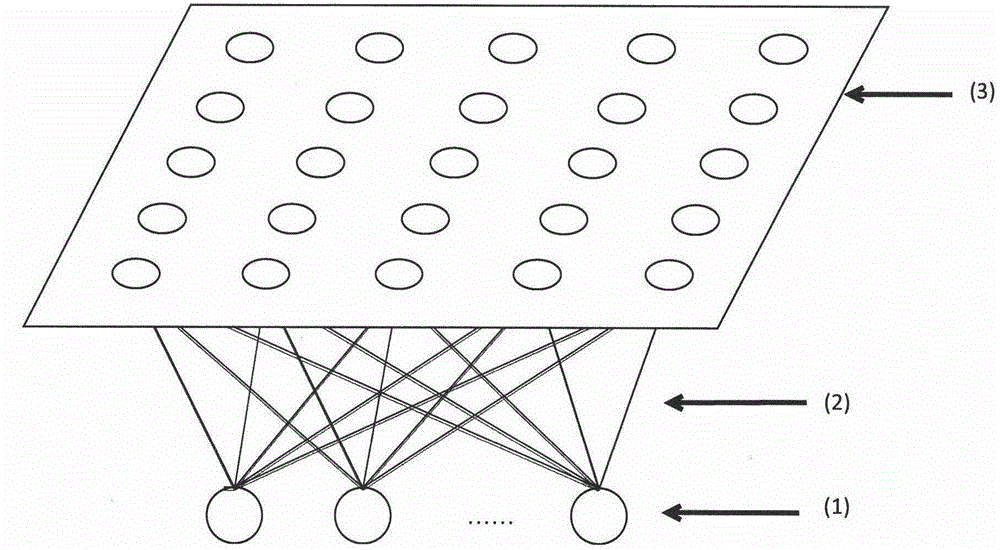

Part supplier multi-target preferable selection method orienting bearing manufacturing enterprises

InactiveCN105654175AAbility is scientific and reasonablePeep real perceptionBuying/selling/leasing transactionsNeural architecturesInformation integrationManufacturing enterprises

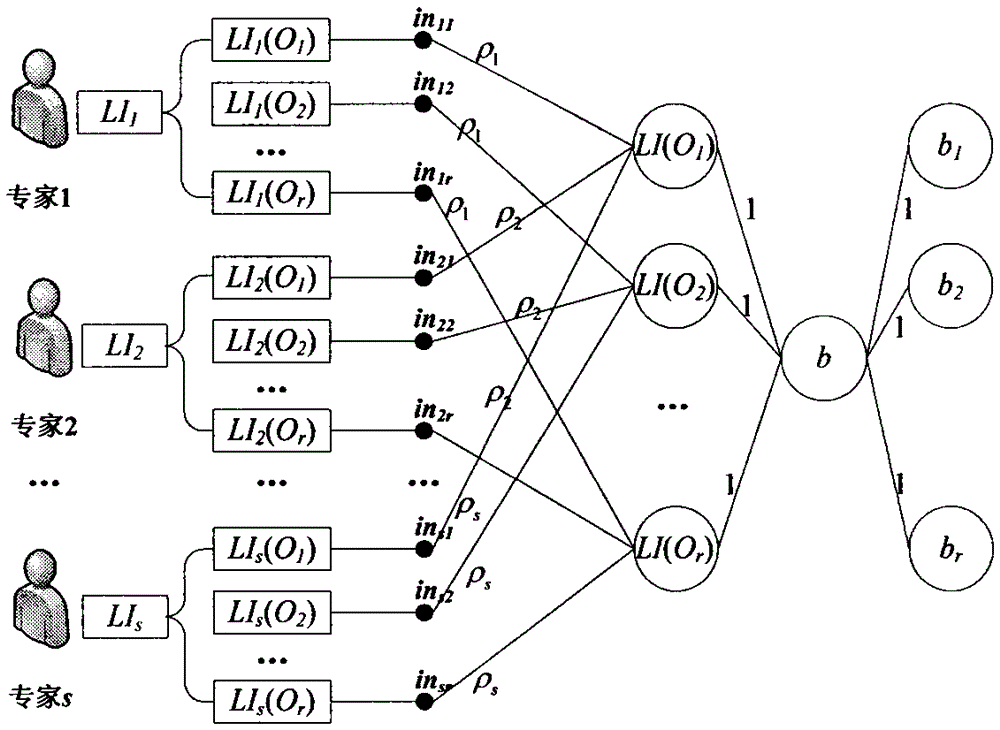

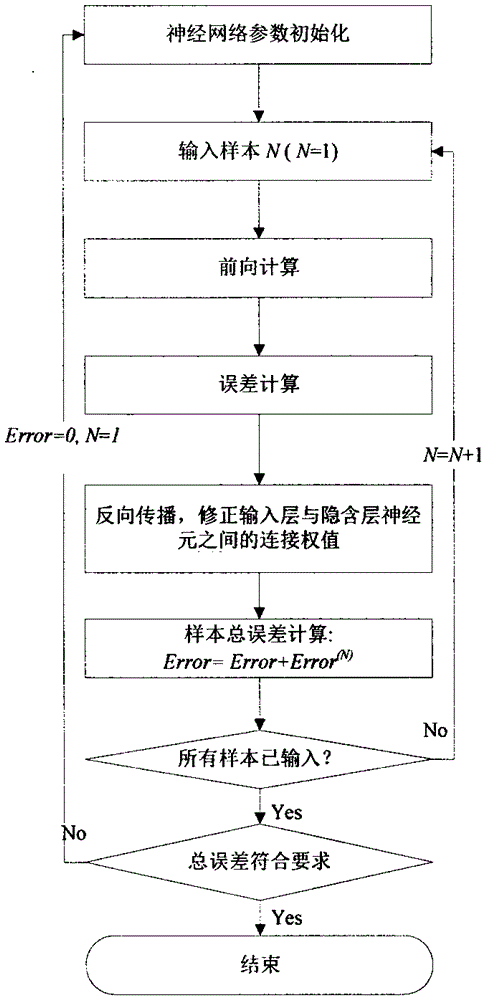

The invention provides a part supplier multi-target preferable selection method orienting bearing manufacturing enterprises. The degree of capacity of each expert is acquired from historical samples through a neural network training method by considering objective difference of the experience levels and the knowledge levels of different experts; the degree of capacity of the experts is introduced and then a multi-order fuzzy rough set integrated analytic hierarchy process with combination of an analytic hierarchy process in which fuzzy numbers replace accurate numbers and rough sets is provided so that combined processing of multiple experts for multiple part suppliers on the score result of a single indicator is realized; a multi-weight information integration model is established, and integration weights of the evaluation indicators are solved; and the part suppliers are ranked according to the indicator value of each evaluation indicator and the integration weights of the indicators of multiple part suppliers, and the optimal part supplier is obtained.

Owner:BEIFANG UNIV OF NATITIES

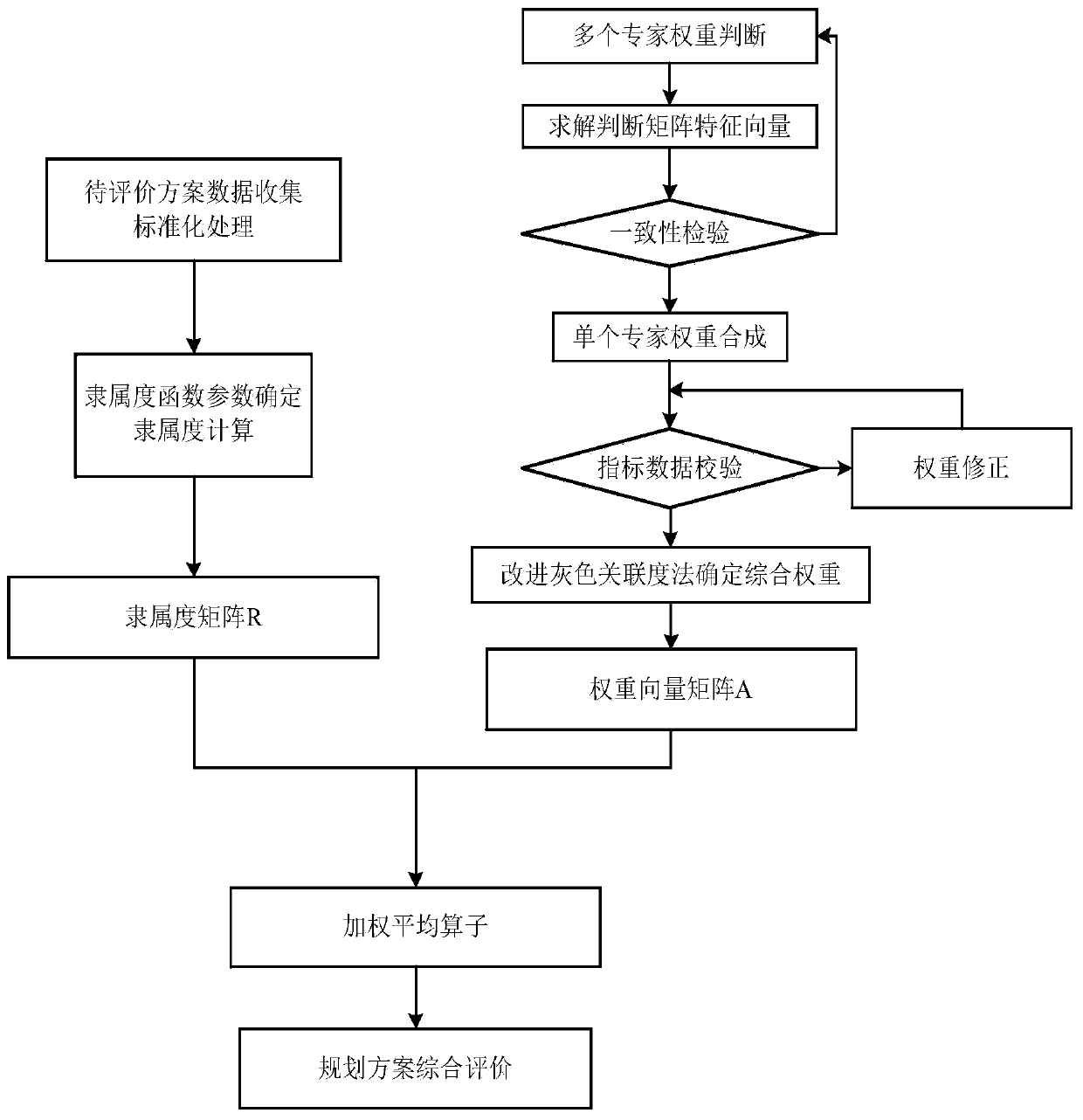

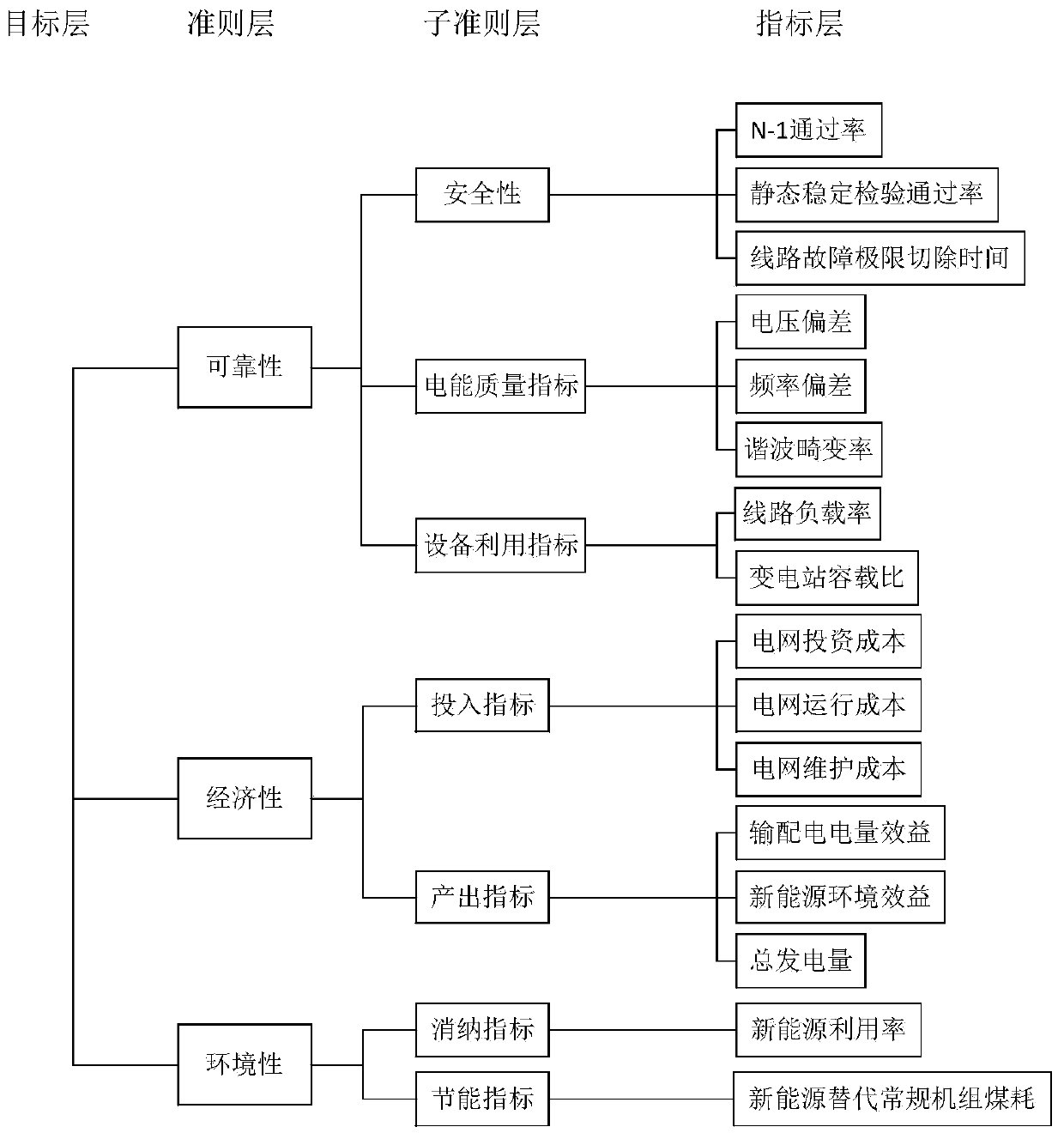

Power grid planning fuzzy comprehensive evaluation method based on comprehensive weighting

The invention belongs to the technical field of power grid comprehensive evaluation, and particularly relates to a power grid planning fuzzy comprehensive evaluation method based on comprehensive weighting, which comprises the following steps: S1, establishing a power grid planning index evaluation system suitable for electric power marketization reform; S2, determining the weight of each index inthe index system based on a comprehensive weighting method; and S3, collecting and processing each index data of the planning scheme to be evaluated, and establishing a power grid planning fuzzy comprehensive evaluation model. According to the method, subjectivity of expert weighting is considered, a comprehensive weighting method is used for processing judgment results of multiple experts, scientificity and practicability of index weight evaluation are improved, and a power grid planning scheme is comprehensively evaluated.

Owner:WUHAN UNIV

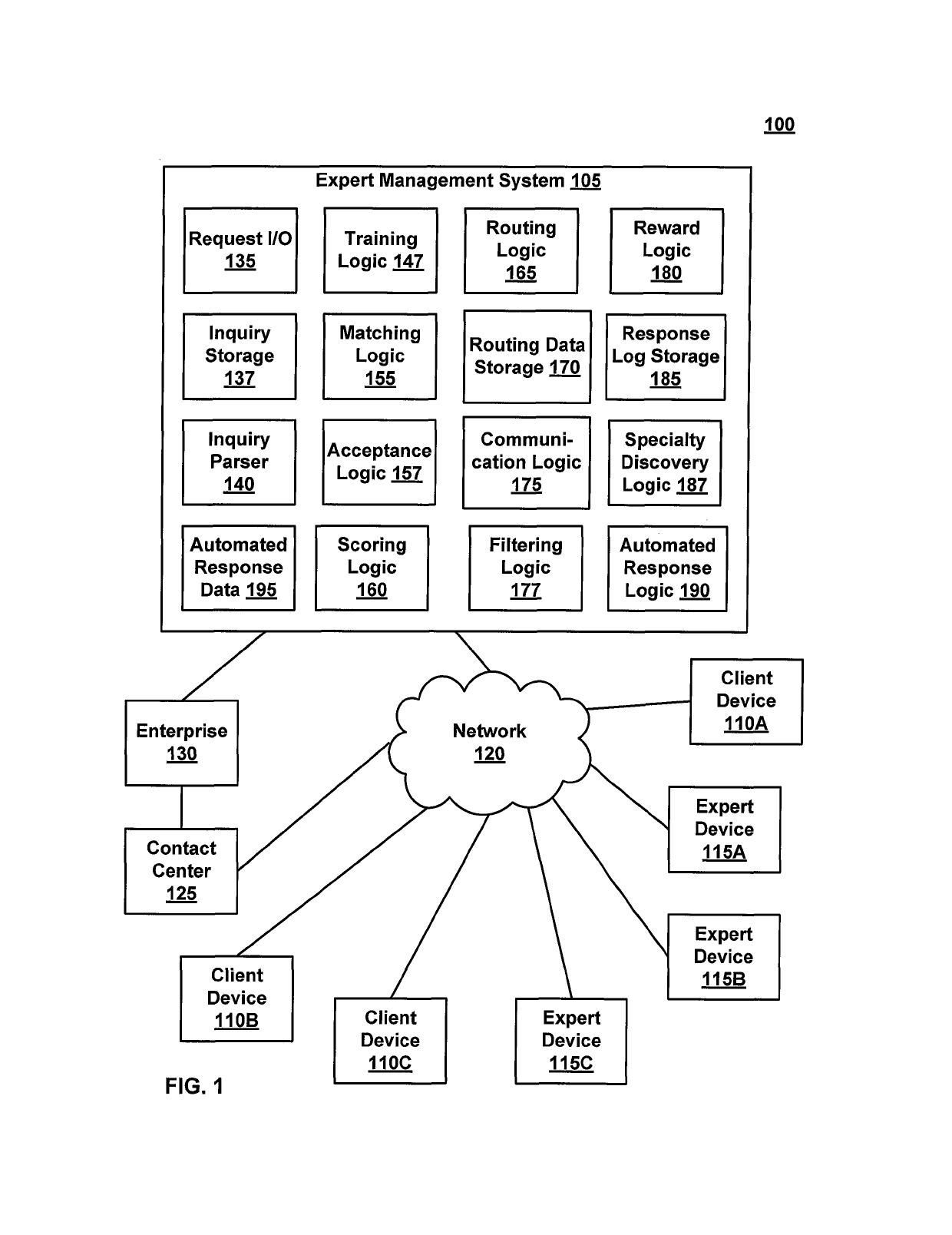

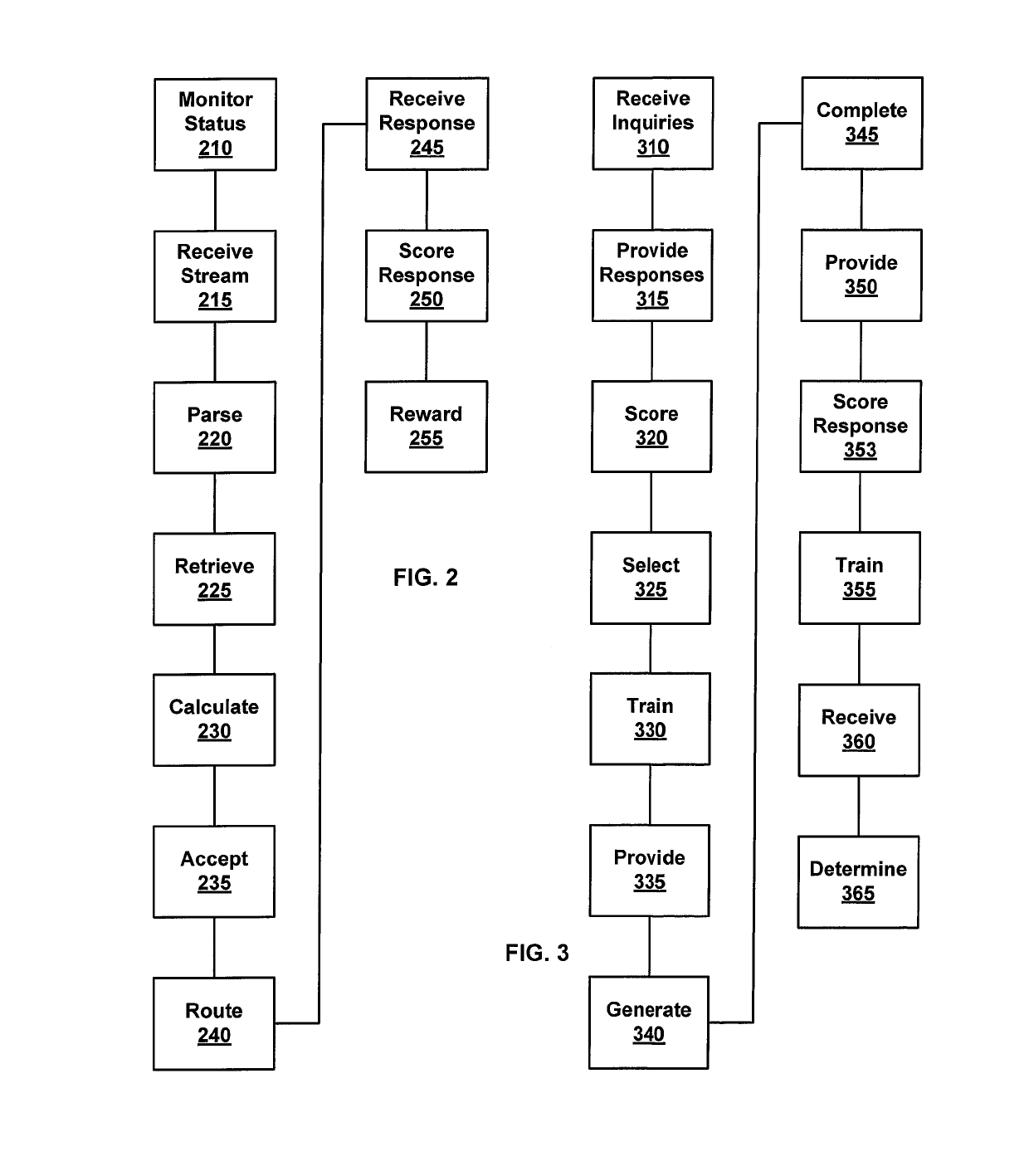

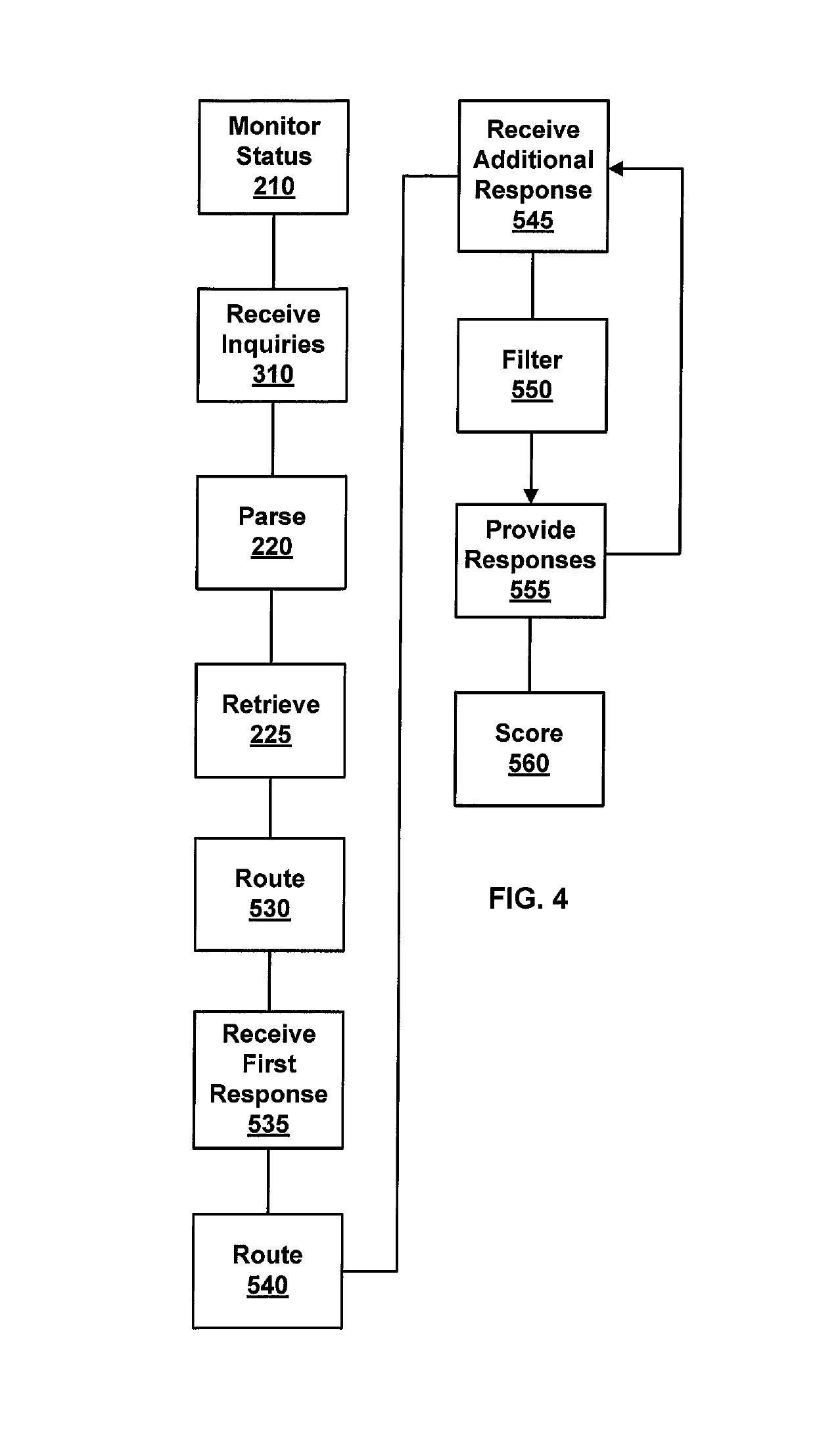

CRM including multi-thread messaging

In a crowd sourcing approach, responses to customer service inquiries are provided by routing a subset of the inquiries to an independent group of experts. The customer service inquiries are optionally routed to specific experts based on matches between identified subject matter of the inquiries and expertise of the experts. Embodiments include methods of classifying customer service inquiries, training a machine learning system, and / or processing customer service inquiries. Multiple experts may provide responses to a particular customer service inquiry, optionally within a single chat window.

Owner:ONDEMAND ANSWERS INC

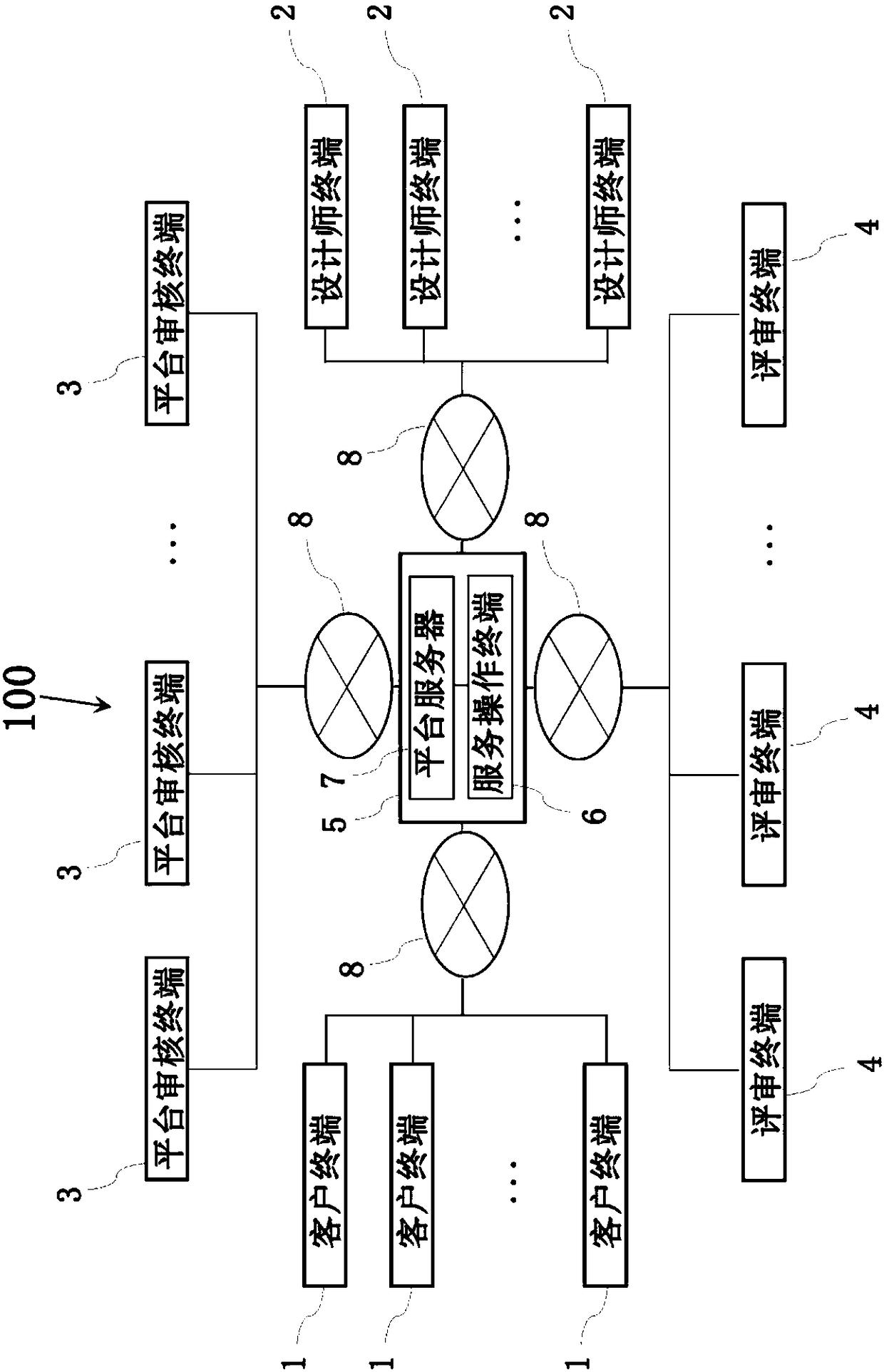

Building design bidding and tendering system

InactiveCN108520397AImprove trustIncrease motivationOffice automationTransmissionComputer terminalBuilding design

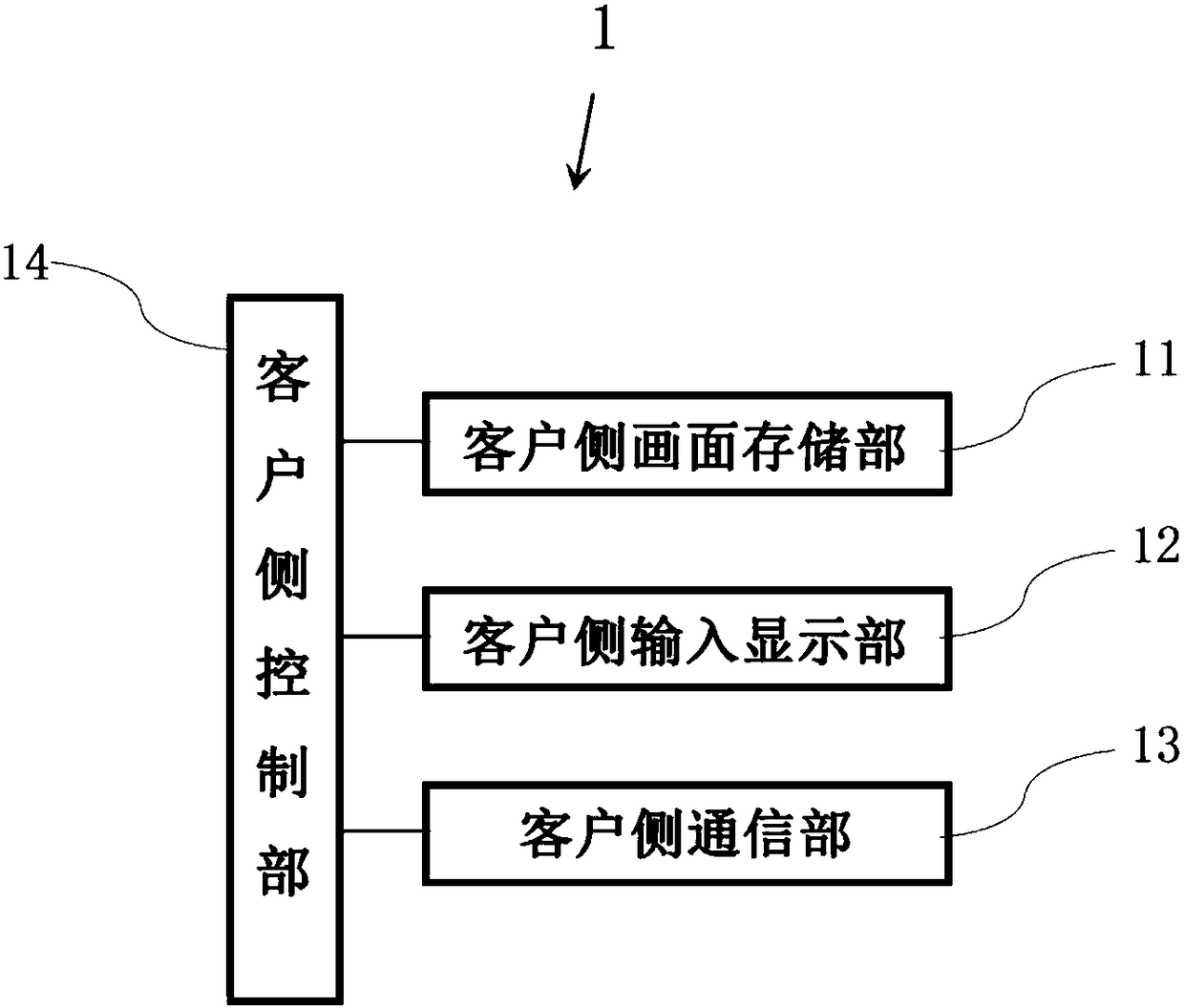

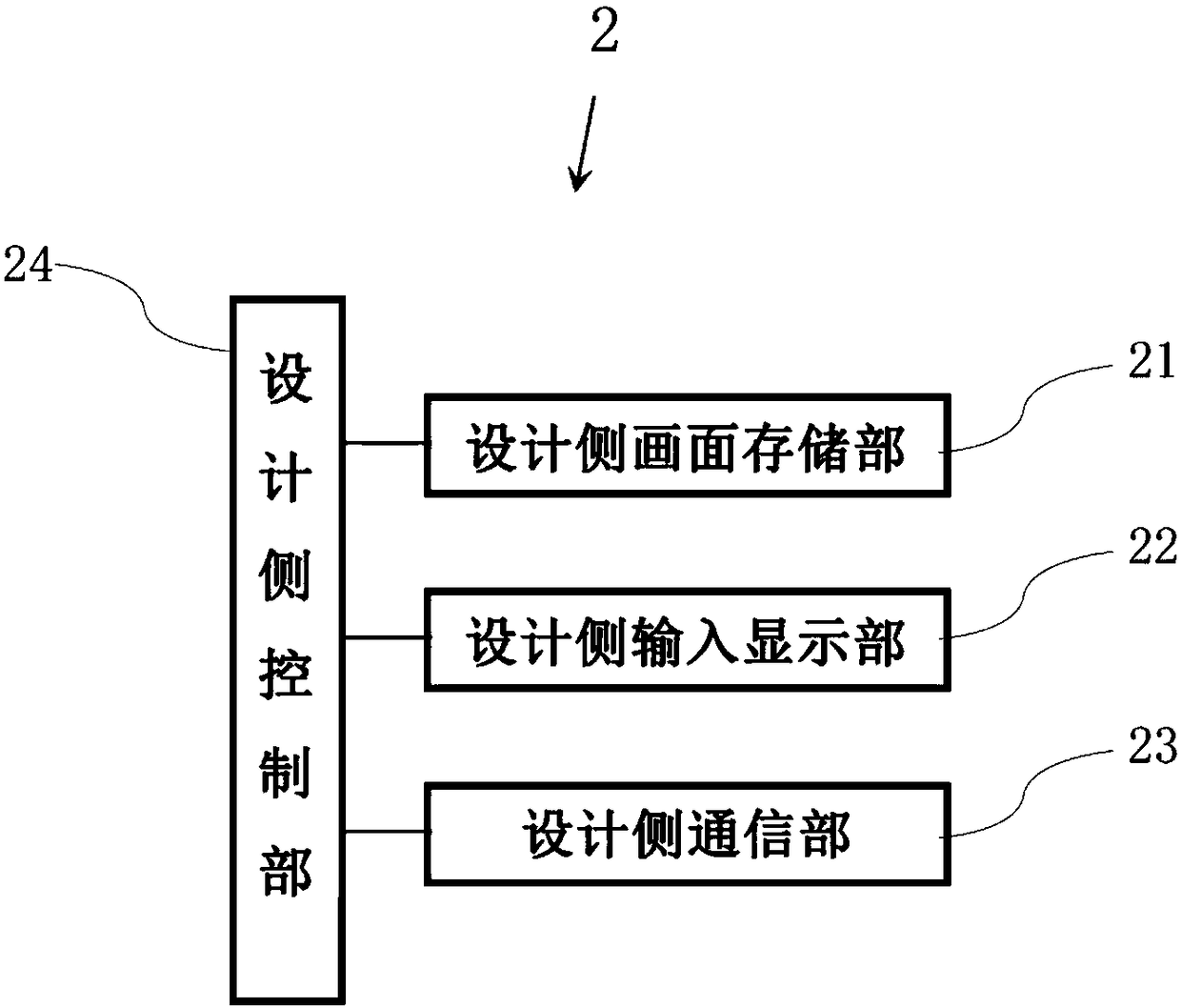

The invention provides a building design bidding and tendering system. The system comprises a plurality of client terminals, a plurality of designer terminals, at least one review terminal, and a bidding and tendering service device, the bidding and tendering service device is formed by a platform server and a service operation terminal, a service side input display portion displays a review notification image, enables a service operator to select a project name in a project selection region of the review notification image, and inputs a predetermined review day, review matters and expert information of multiple experts to an information input region, once the service operator completes selection and input, a notification control portion controls information storage and generation and transmission of a review notification, a review side input display portion displays a live broadcasting review beginning image to enable a review operator to start confirmation, a review control portion controls a review side communication portion to obtain an audio image of the live broadcasting review and sends the image to the platform server, and a design side input display portion displays a design side review live broadcasting image and displays the audio image.

Owner:施益斌

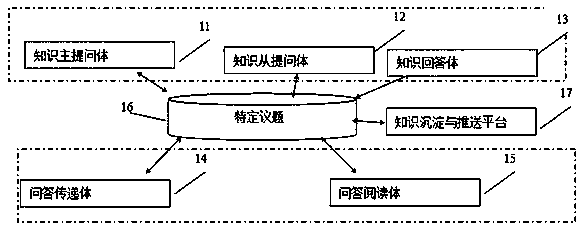

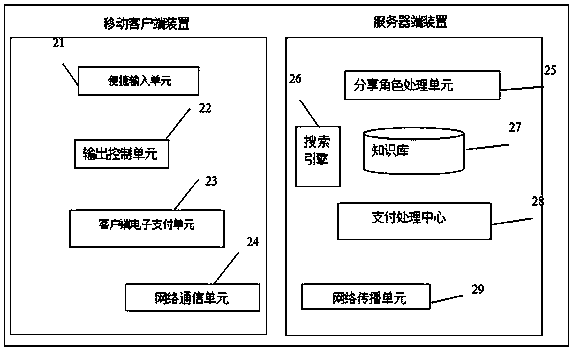

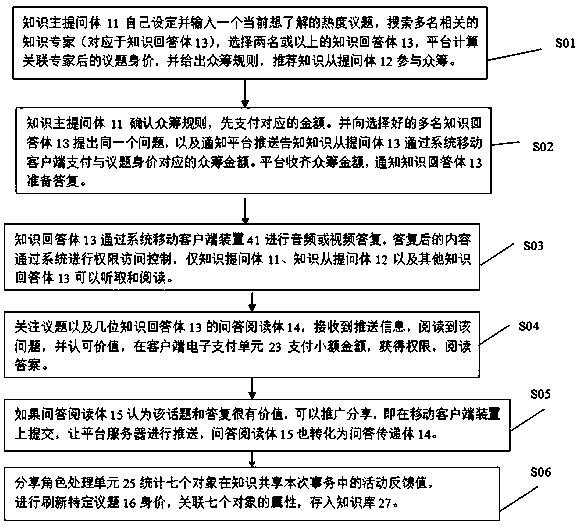

Internet-based method and device for carrying out compensated knowledge share on specific contents by multiple users

InactiveCN108628903AShared reachReach networkFundraising managementBuying/selling/leasing transactionsCrowdsKnowledge question

The invention discloses a compensated knowledge share network method and device for mining opinions, for certain specific contents, of multiple experts on the basis of mobile internet. When a knowledge primary question body sets a topic, a platform device calculates a price of the topic, gives a crowd funding rule, and recommends a knowledge secondary question bodies to participate in the crowd funding. The platform collects the crowd funding amount and notifies a knowledge answer body to give an answer. The knowledge answer body carries out audio or video answer through a mobile client device, the answered content is controlled by a system authority, and only the knowledge question bodies and the question answer have the authority. Question-answer reading bodies only can read the answer through paying a small amount at a client electronic payment unit to obtain the authority. Knowledge reading bodies popularize the topic, and the topic is pushed by a platform server so as to be converted into a question-answer transfer body. A sharing role processing unit carries out statistical analysis on feedback values of seven objects, so as to refresh the price of the specific topic, associates attributes of the seven objects and stores the topic into the knowledge base.

Owner:深圳市分享投融网络有限公司

System and method for composite distance metric leveraging multiple expert judgments

A system and method for a composite distance metric leveraging multiple expert judgments includes inputting a data distribution of multiple expert judgments stored on a computer readable storage medium. Base distance metrics are converted into neighborhoods for comparison, wherein each base distance metric represents an expert. The neighborhoods are combined to leverage the local discriminalities of all base distance metrics by applying at least one iterative process to output a composite distance metric.

Owner:INT BUSINESS MASCH CORP

Efficient method and system for determining parameters in computerized recognition

InactiveUS20050129313A1Increase valueDigital computer detailsCharacter and pattern recognitionFalse recognitionMultiple experts

In computerized recognition having multiple experts, a method and system is described that obtains an optimum value for an expert tuning parameter in a single pass over sample tuning data. Each tuning sample is applied to two experts, resulting in scores from which ranges of parameters that correct incorrect recognition errors without changing correct results for that sample are determined. To determine the range data for a given sample, the experts return scores for each prototype in a database, the scores separated into matching and non-matching scores. The matching and non-matching scores from each expert are compared, providing upper and lower bounds defining ranges. Maxima and minima histograms track upper and lower bound range data, respectively. An analysis of the histograms based on the full set of tuning samples provides the optimum value. For tuning multiple parameters, each parameter may be optimized by this method in isolation, and then iterated.

Owner:MICROSOFT TECH LICENSING LLC

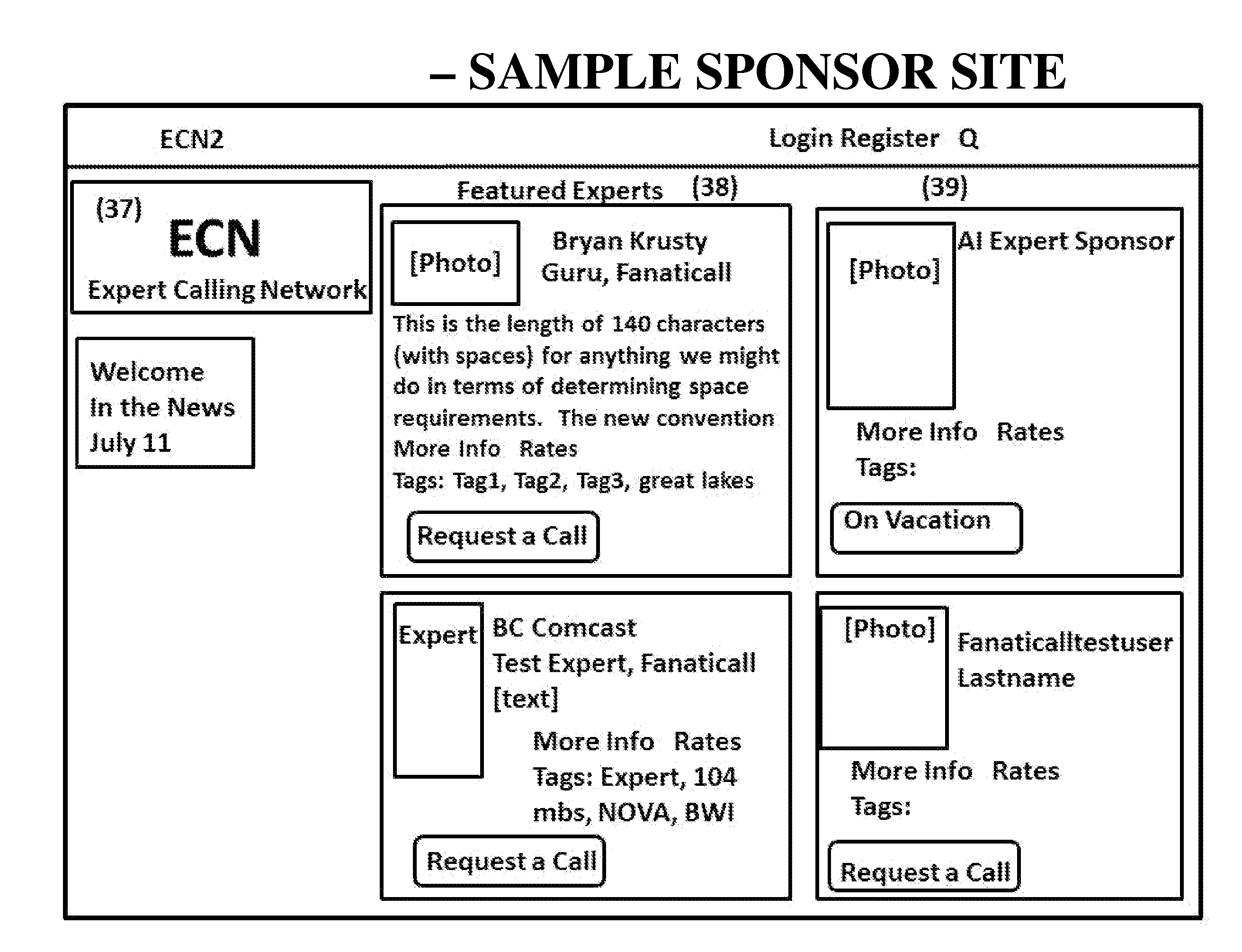

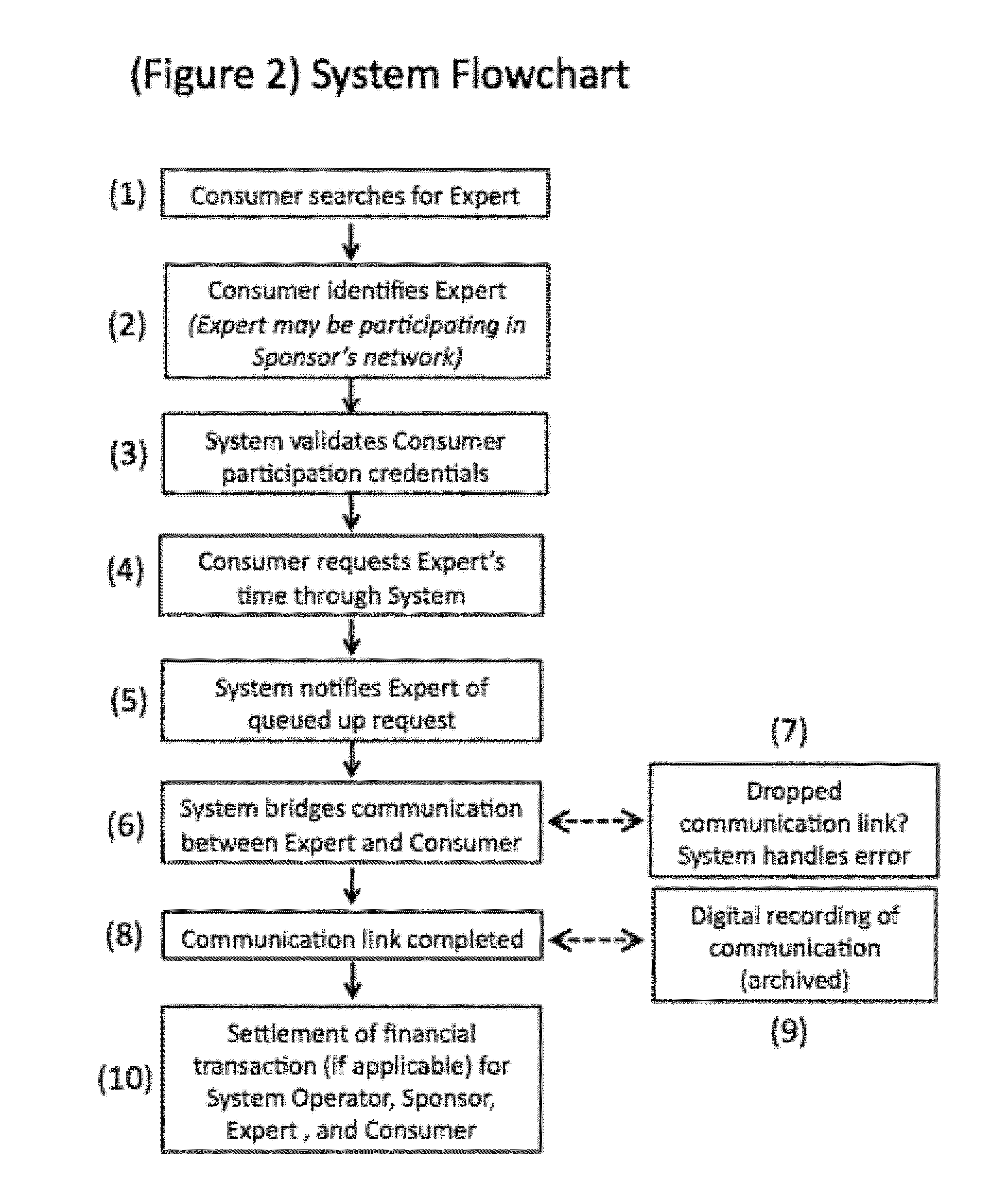

Electronic communications system for multinodal expert networks

InactiveUS20150036814A1Many of businessTechnology moreSpecial service for subscribersManual exchangesCommunications systemElectronic communication

An electronic communication system enables one or multiple parties to aggregate one or multiple experts under one or multiple brand identities and to make each unique identity publicly or privately accessible to other entities seeking to access individual or aggregated experts on a free or paid basis. This system allows one single operator to effectively power hundreds or thousands of custom branded and independently owned expert networks deployed by different network sponsors.

Owner:BUCKNER ZACH +1

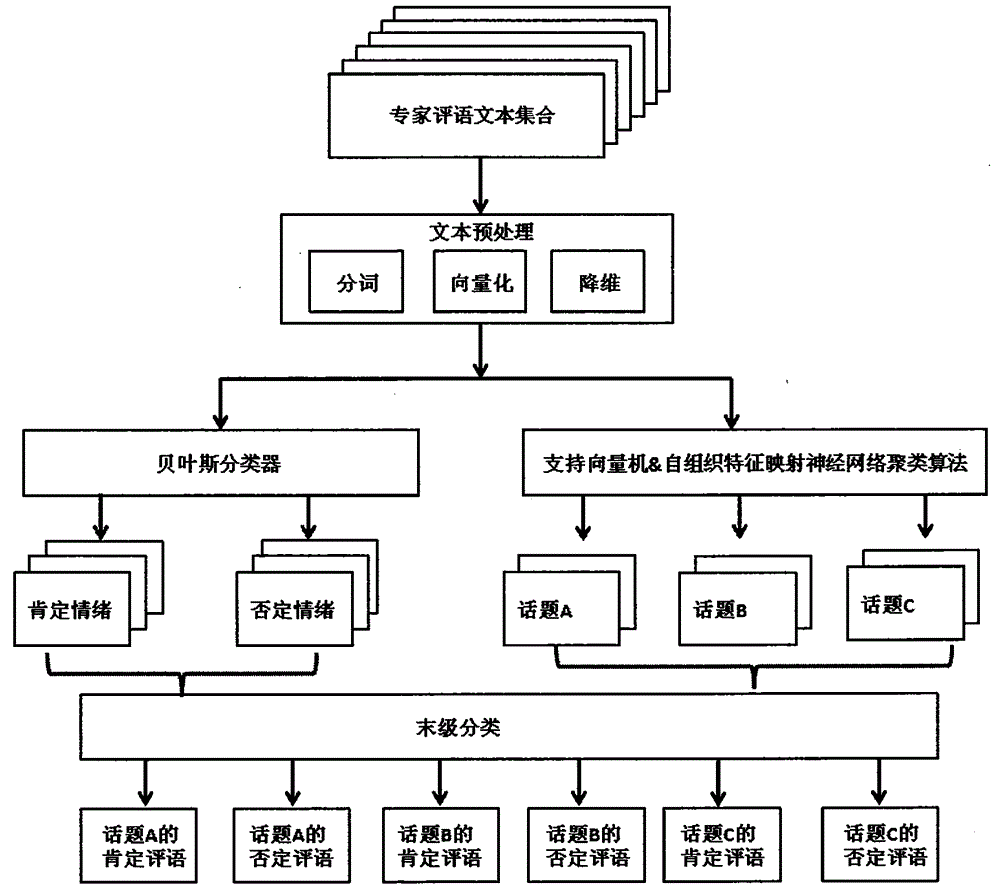

Expert comment induction algorithm based on sentiment classification and SOM clustering

InactiveCN106156184AAvoid artificial bottlenecksLow costSpecial data processing applicationsMoodInductive algorithm

The invention provides an induction and summarization algorithm which can be conducted on different comments of multiple experts on the basis of artificial intelligence. The algorithm comprises the steps that classification is conducted on the text content of the expert comments according to positive emotions or negative emotions by means of sentiment classification, clustering is conducted on topics related to all the expert comments by means of an SOM (self-organizing feature mapping neural network), and several kinds of comment clusters such as positive opinions of some topics and negative opinions of some topics are summarized from all the expert comments. According to the induction and summarization algorithm, aiming at a specific application scene that a traditional Delphi method is used for online assessment, an artificial intelligent technology is adopted for replacing the time-consuming and high-cost process that induction and summarization are conducted on the expert comments artificially in the traditional Delphi method, the efficiency of conducting online assessment through the traditional Delphi method can be improved, and the labor cost can be reduced.

Owner:苏州优估营网络科技有限公司

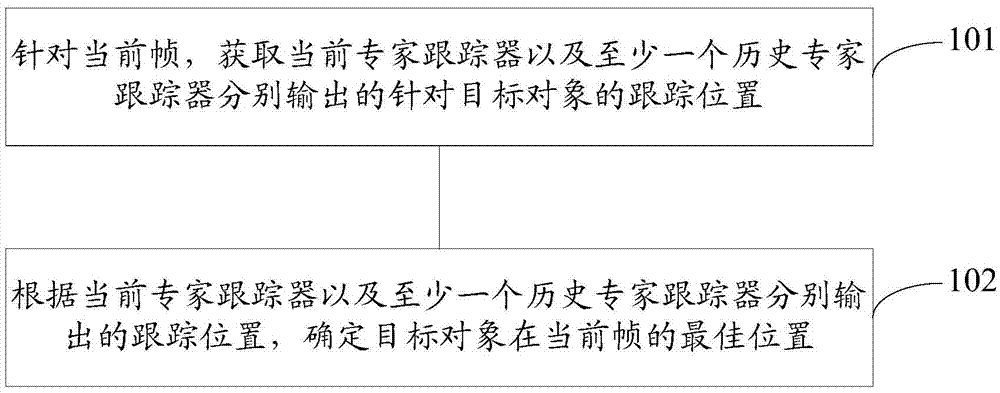

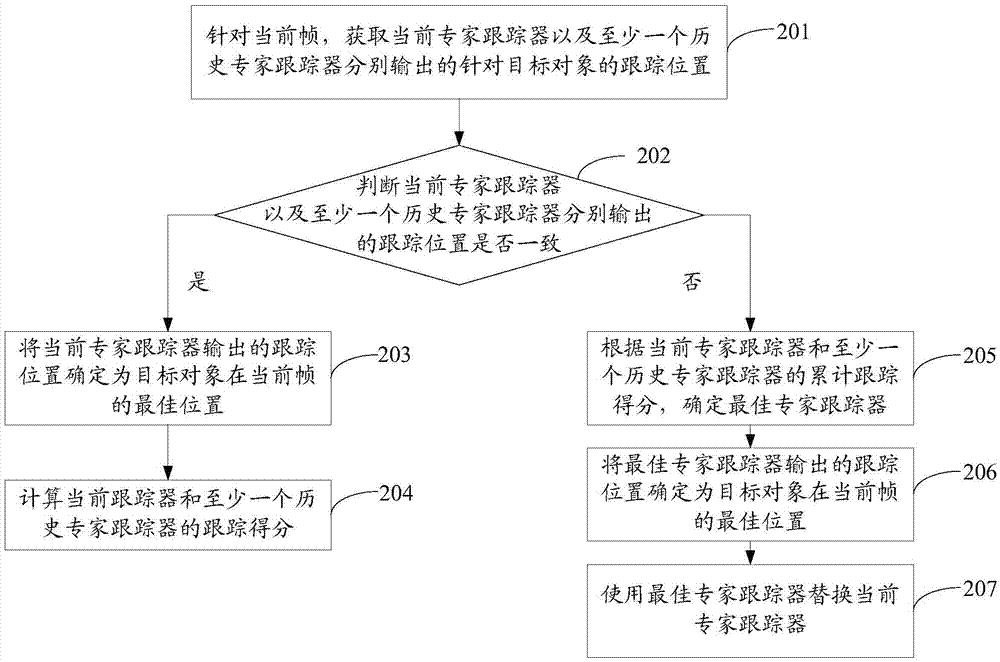

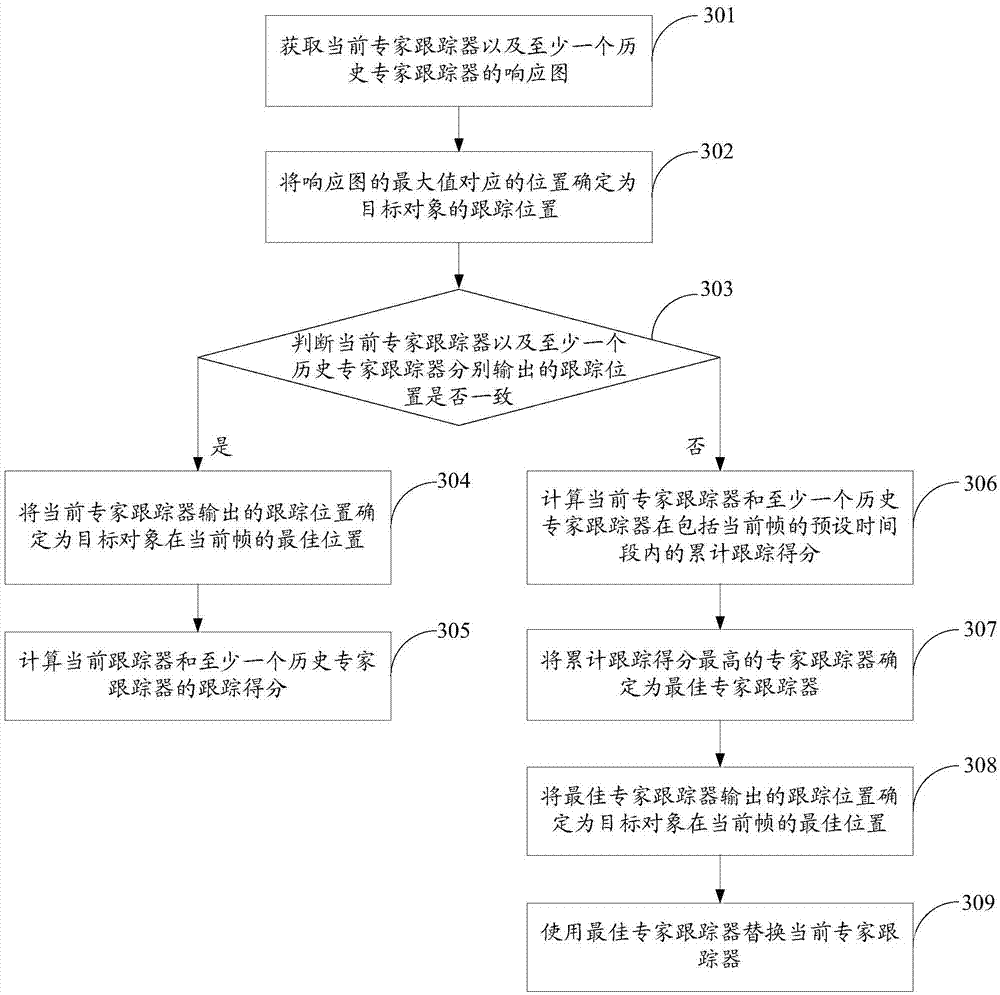

Historical-route-based target tracking method and electronic equipment

InactiveCN105447887AImprove accuracyImprove efficiencyImage enhancementImage analysisComputer visionMultiple experts

The invention, which belongs to the computer vision field, discloses a historical-route-based target tracking method and electronic equipment. The method comprises: for a current frame, tacking positions that correspond to a target object and are outputted by a current expert tracker and at least one history expert tracker respectively are obtained; and according to the tracking positions outputted by the current expert tracker and the at least one history expert tracker, an optimal position of the target object at the current frame is determined. According to the invention, because the optimal position of the target object at the current frame can be determined according to the tracking positions outputted by the current expert tracker and the at least one history expert tracker respectively, the optimal position of the target object can be determined from tracking positions outputted by a plurality of expert trackers, so that the tracking position determination becomes accurate. Meanwhile, with the multiple expert trackers, a problem of failed tracking due to factors like a disordered background, sudden movement of a target object, a shielded state of the target object, and appearance changing during the tracking process can be solved.

Owner:PALMWIN INFORMATION TECH SHANGHAI

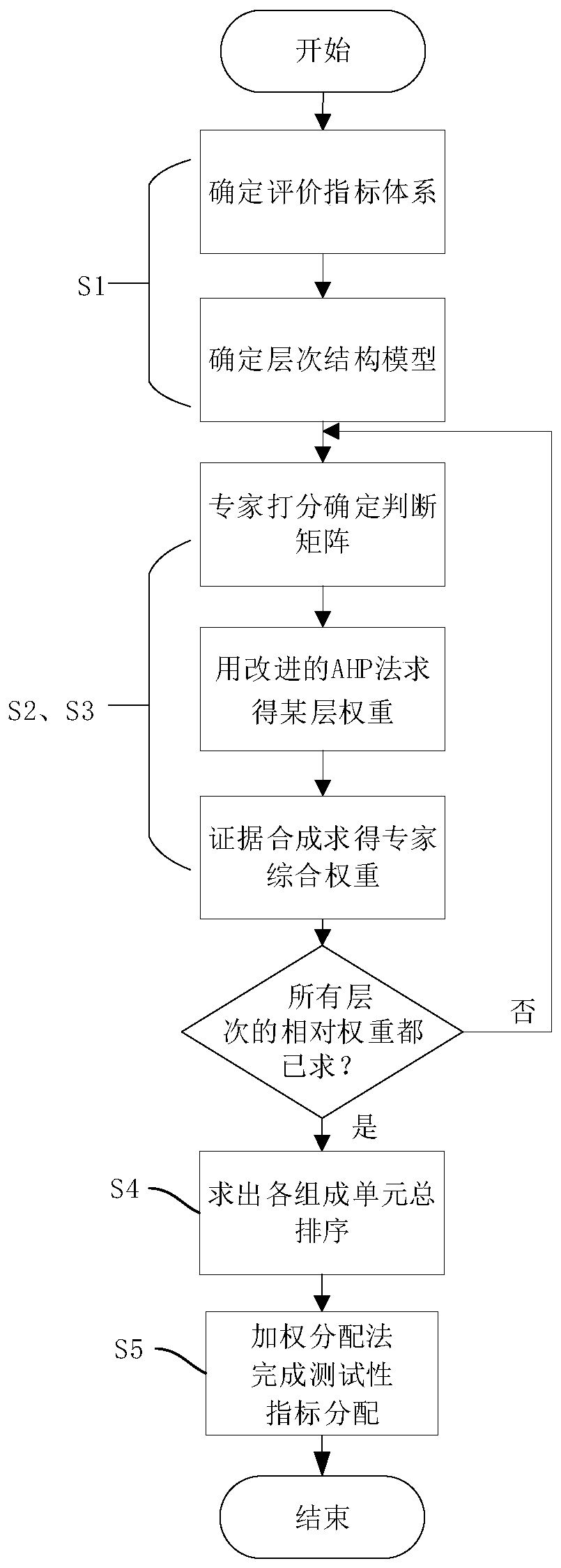

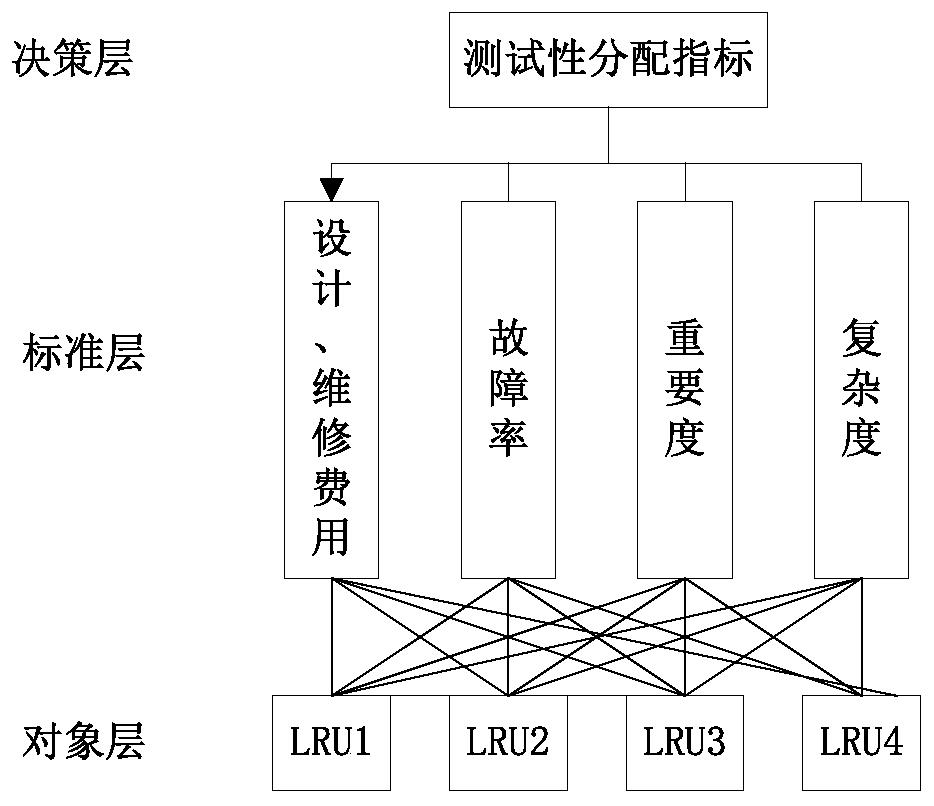

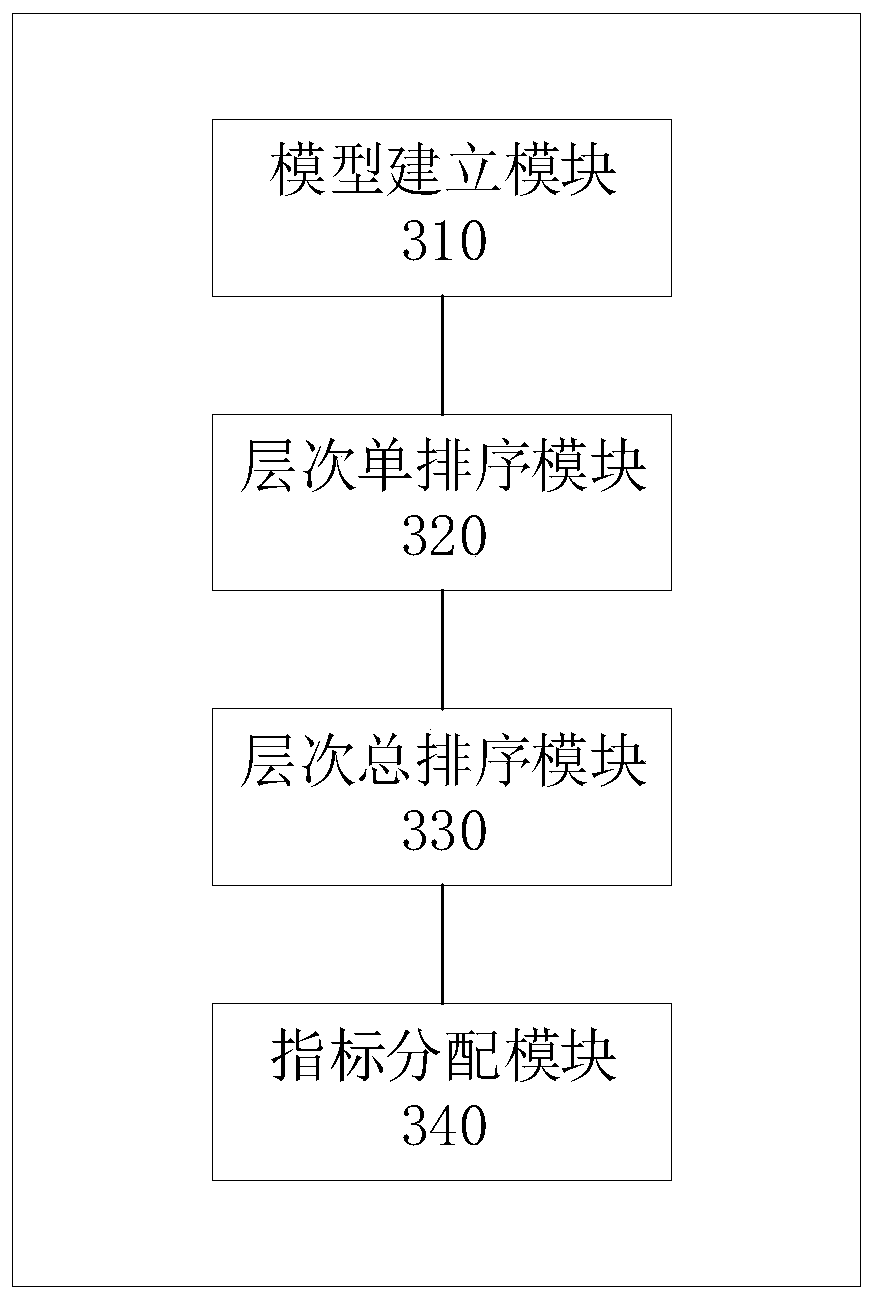

Testability index distribution method and device based on improved analytic hierarchy process

PendingCN111523746AAvoid Consistency ChecksEasy to complete the calculationHandling data according to predetermined rulesCharacter and pattern recognitionAlgorithmIndex system

The invention discloses a testability index distribution method and a testability index distribution device based on an improved analytic hierarchy process. The testability index distribution method comprises the steps of: determining an evaluation index system and a hierarchical structure model of testability index distribution; determining a judgment matrix through expert scoring, solving a weight vector of each expert by using an improved AHP method, synthesizing weight values of multiple experts by using an optimized evidence synthesis formula, and respectively calculating to obtain a weight of a standard layer to a decision-making layer and a weight of an object layer to the standard layer; calculating a total hierarchical sorting result; and completing testability index distributionby using a weighting coefficient method. According to the testability index distribution method, an analytic hierarchy process is improved, consistency verification is avoided, and operation is simplified; and a more effective evidence synthesis formula is adopted, so that the reliability and reasonability of a synthesis result are improved.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

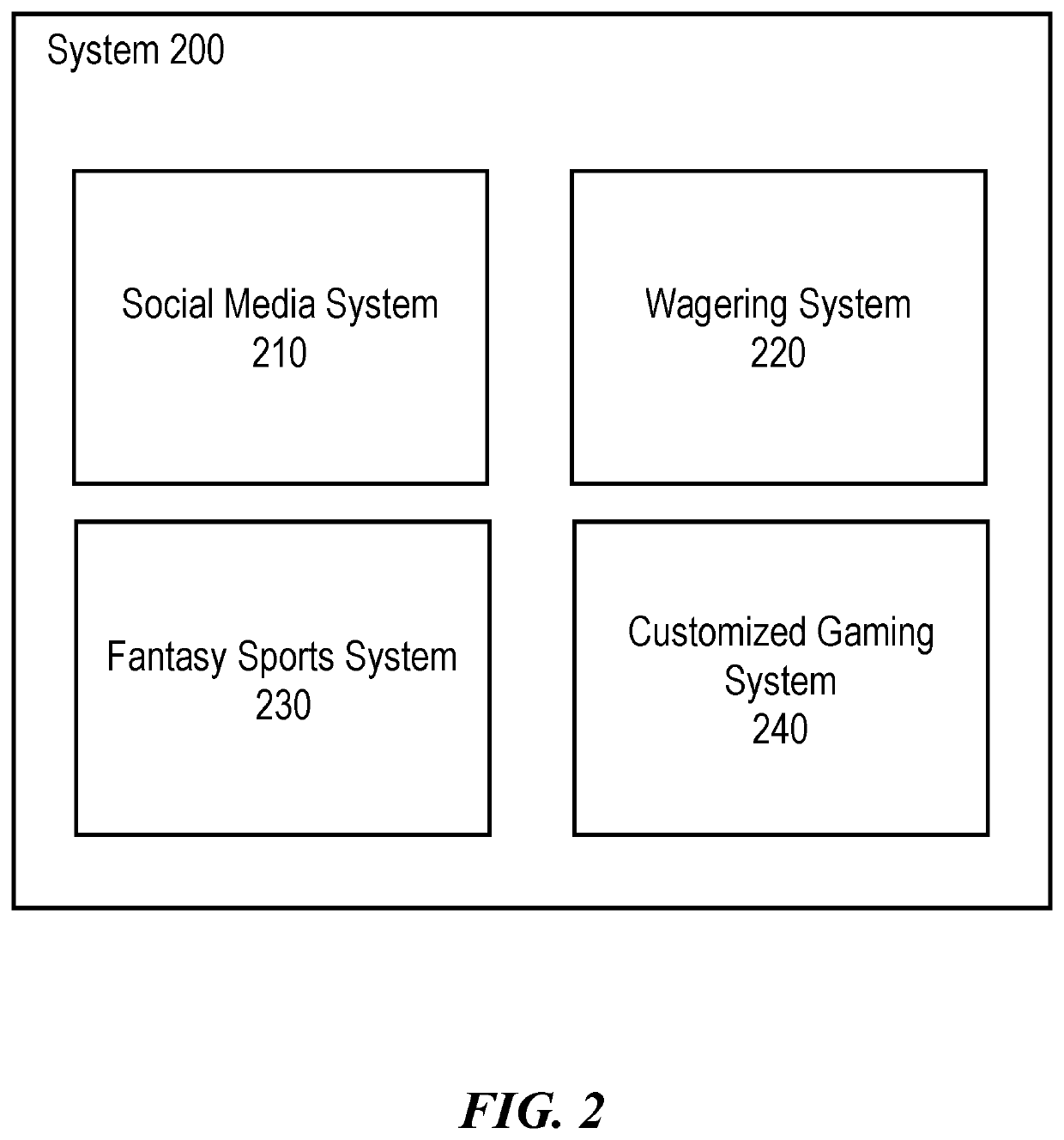

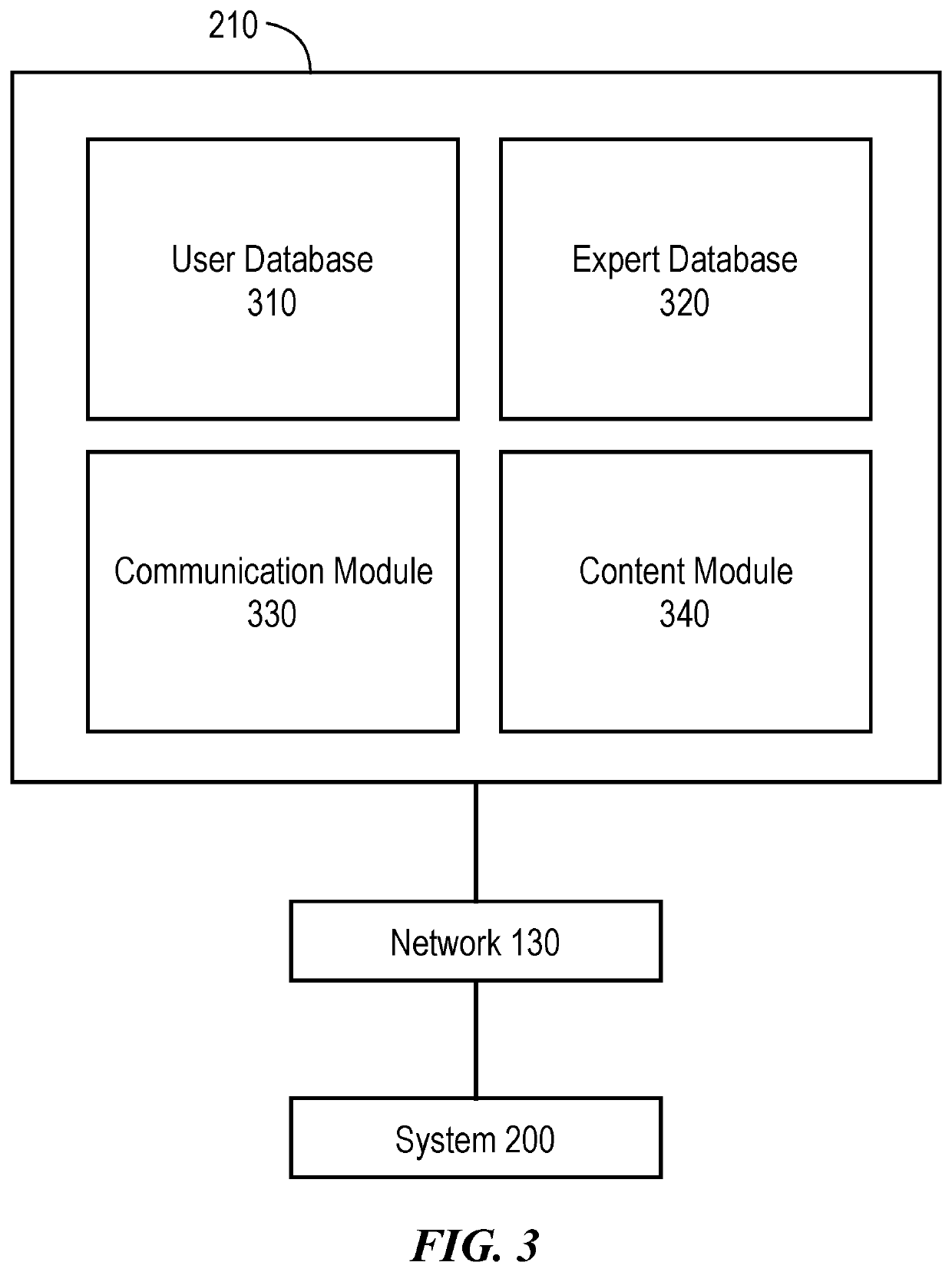

System for a sports information and betting platform

A wagering system is disclosed which includes a social media system comprising a content module operable via a processor on a computing device to display a plurality of content to a plurality of users on a mobile device and a content module to display the plurality of content on the mobile device. An evaluation system evaluates a prediction history of one or more experts and assigns a value to the one or more expert predictions. The value corresponds to a payment required for the user to receive the one or more expert predictions. A wagering system permits the creation and execution of one or more wagers and a book database to store a plurality of wager parameters. The book database is in operable communication with a wager processor to receive one or more wagers from a plurality of users, and one or more accepted wager parameters.

Owner:FLECK BLAKE

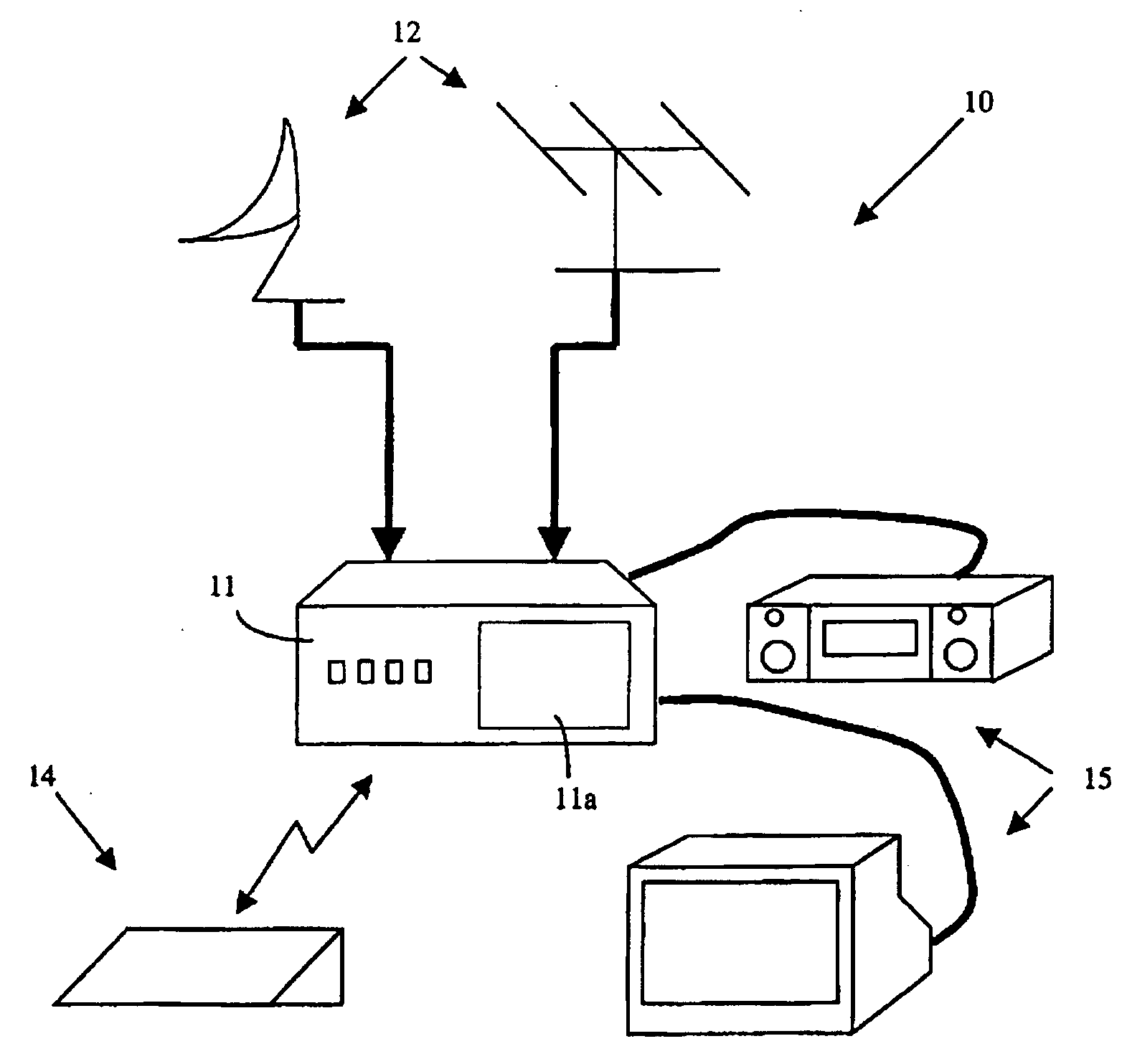

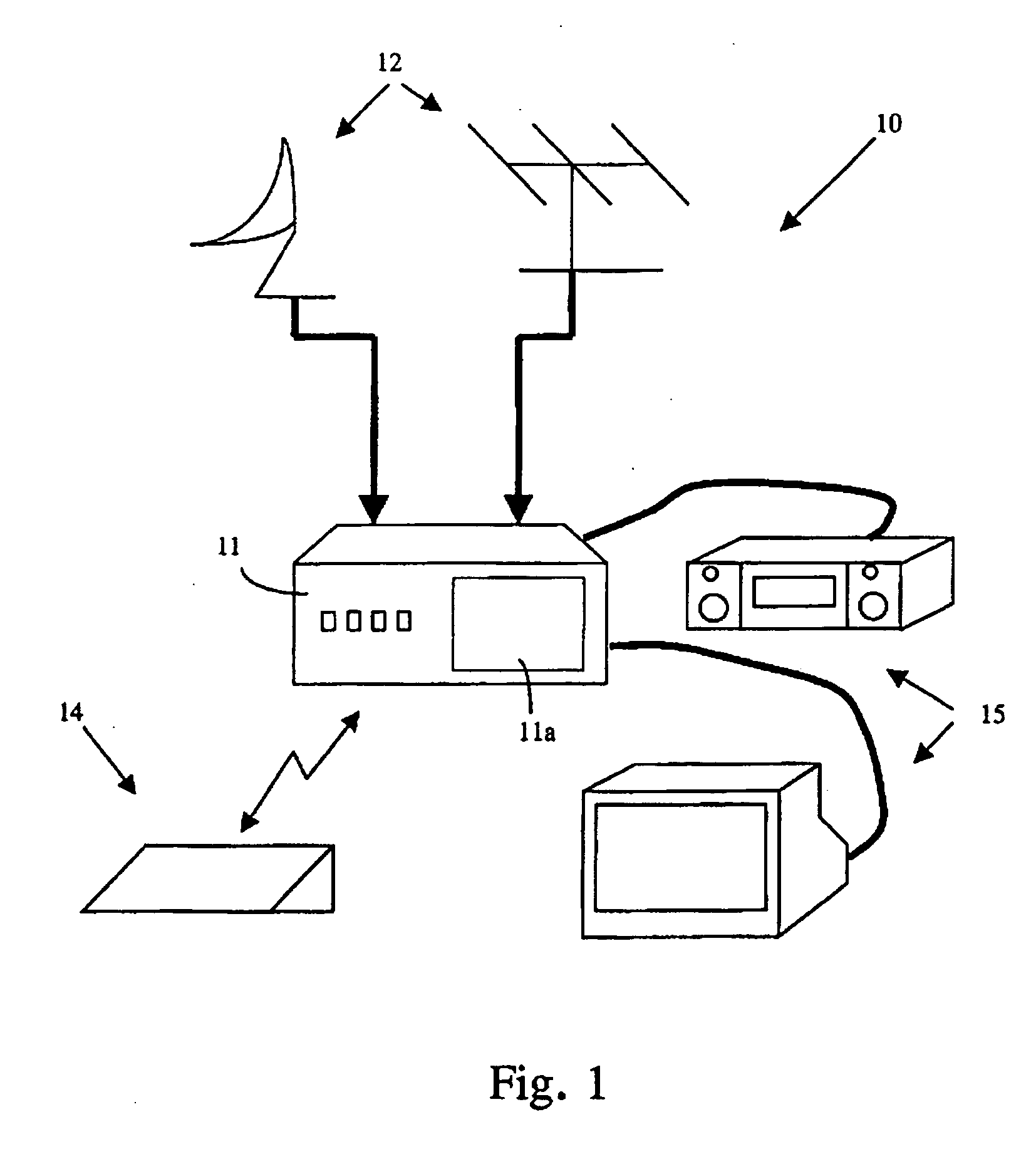

Device, system and method for programming events

InactiveUS20050022238A1Television system detailsAnalogue secracy/subscription systemsComputer scienceMultiple experts

The present invention relates to a device (11), system (10) and method for programming and reproducing events, for instance television events, wherein the device (11) is able to prearrange, based on a list of events accessible by a user and of demands expressed by the same user, a programming guide, corresponding to the expressed demands. The device (11) implements one or more modules, representative of one or more Expert modules and / or of one or more parameter class generators, and is able to combine both the Expert modules and the parameter classes to prearrange the programming guide of the events. Thanks to the capability of using multiple Experts and / or multiple parameter classes, the device (11) allows to obtain, in flexible fashion, event programming results that are particularly close to the user's demands.

Owner:TELECOM ITALIA SPA

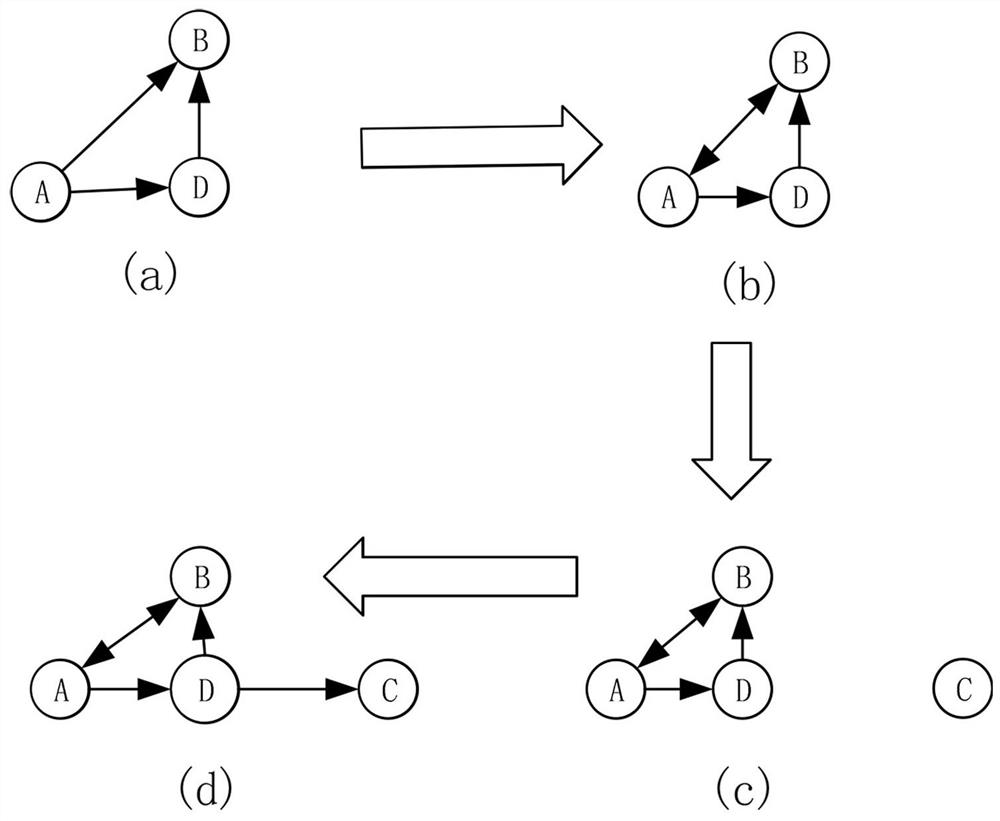

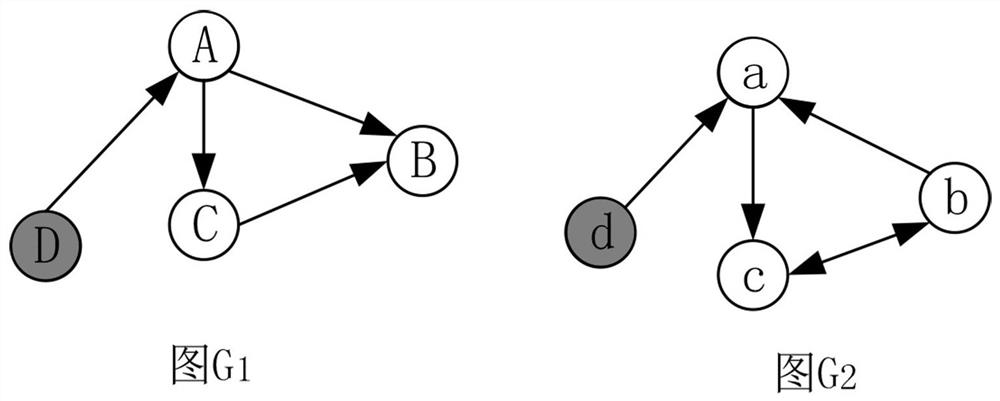

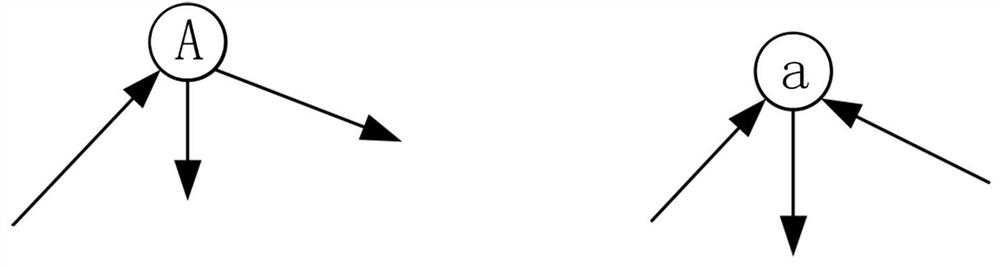

Similar directed subgraph search method and system based on subjective logic and feedforward neural network

InactiveCN113392279AEnsure objectivityGuaranteed accuracyOther databases indexingOther databases queryingDirected graphGreedy algorithm

The invention belongs to the technical field of directed subgraph similarity judgment, and particularly relates to a similar directed subgraph searching method and system based on subjective logic and a feedforward neural network. A cost function does not need to be defined, and a similarity opinion of two few-node directed graphs (containing one node or two nodes) is given by utilizing a subjective logic theory based on an observation method; then, opinions of multiple experts are synthesized by applying a subjective logic increment desire operator, the scale of similar sub-graphs is gradually expanded by adopting a greedy algorithm and a subjective logic transfer operator, the objectivity and accuracy of similarity opinions are ensured, and the uncertainty of editing distance caused by different definitions of a cost function is solved; meanwhile, the time complexity of the algorithm cannot be quickly increased along with the increase of the number of nodes contained in the two graphs.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

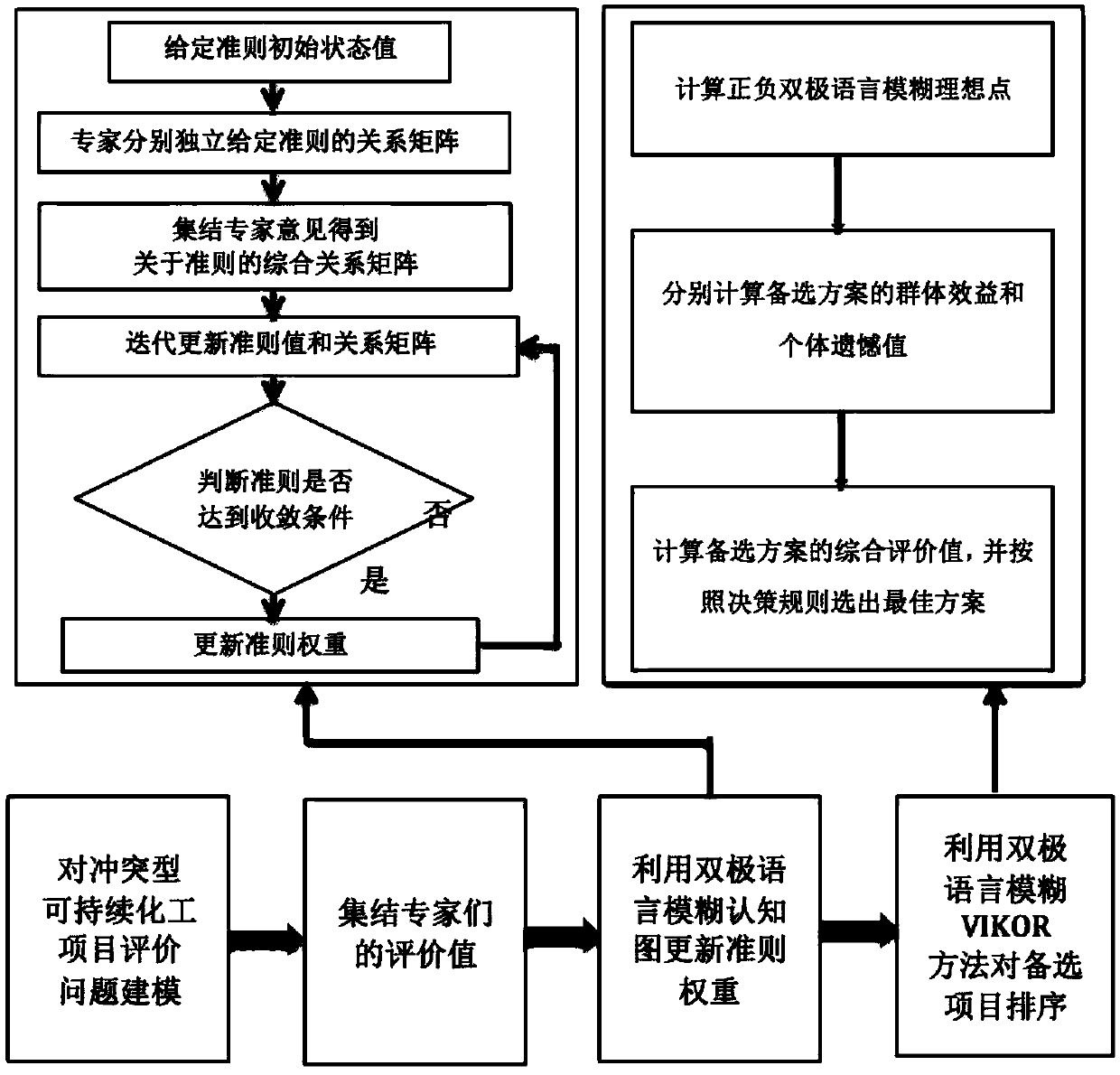

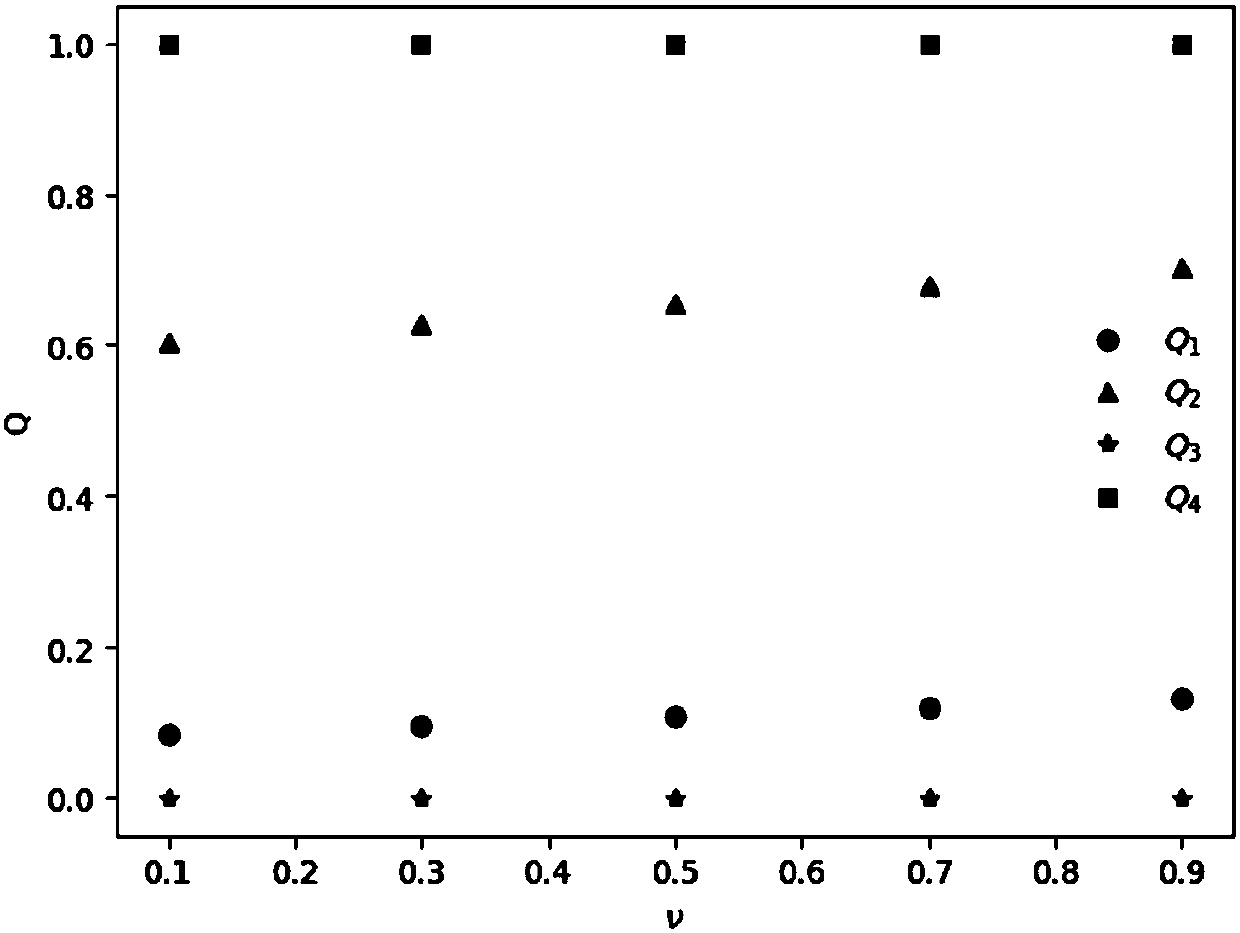

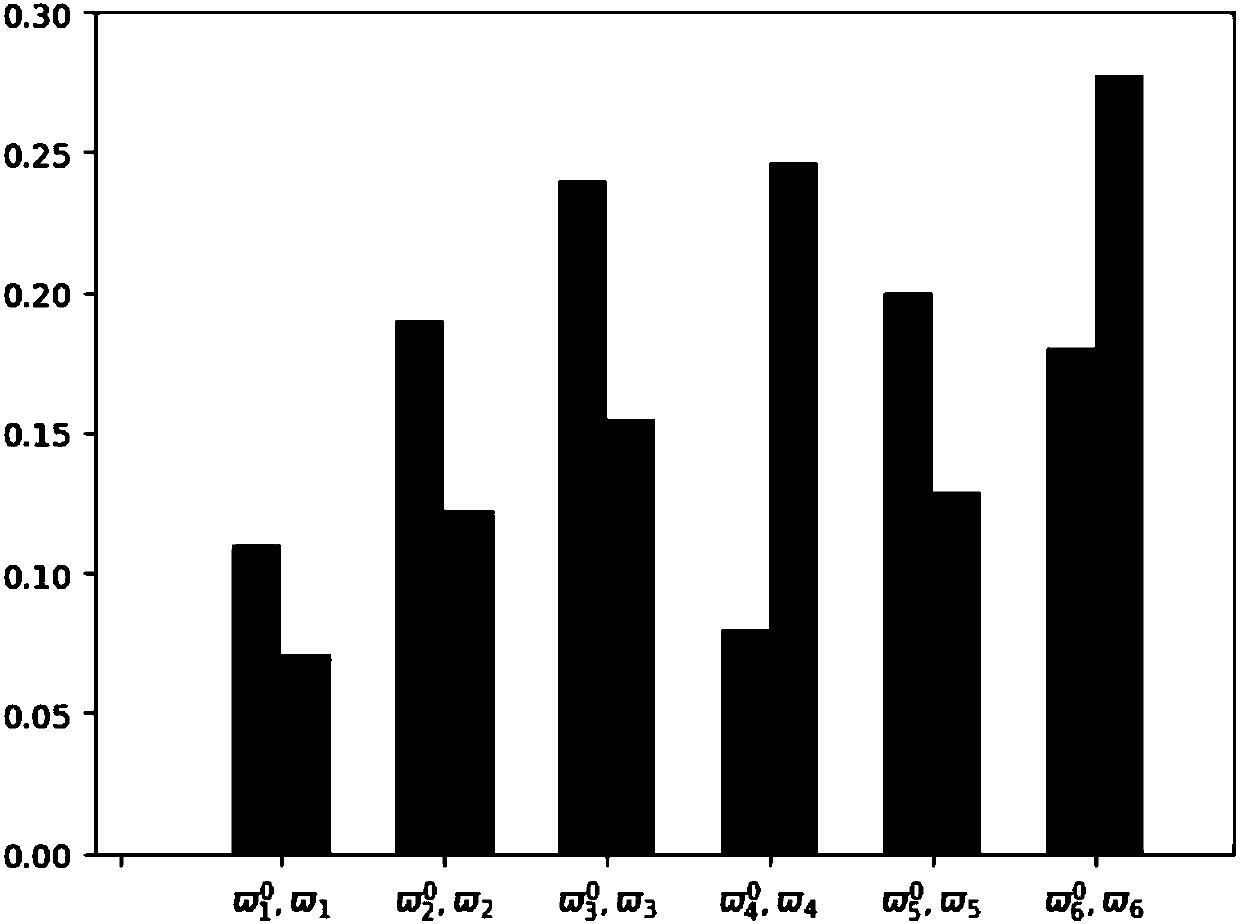

Hybrid conflict type sustainable chemical engineering evaluation method

InactiveCN107688912AAchieve protectionResourcesManufacturing computing systemsValue setFuzzy cognitive map

The invention discloses a hybrid conflict type sustainable chemical engineering evaluation method. The hybrid conflict type sustainable chemical engineering evaluation method includes the specific steps of 1, conducting mathematical modeling and aggregating bipolar language fuzziness evaluation values of to-be-selected schemes ui of all experts with respect to criteria cj by bipolar language fuzziness aggregation operators so as to obtain a comprehensive bipolar language fuzziness evaluation value set (shown in the description) of the to-be-selected schemes ui with respect to the criteria cj;2, updating the criterion weight according to bipolar language fuzziness cognitive maps; 3, ordering the schemes according to a bipolar language fuzziness VIKOR method and selecting an optimal investment project. The hybrid conflict type sustainable chemical engineering evaluation method has the advantages that the hybrid conflict type sustainable chemical engineering evaluation method, namely a comprehensive bipolar language fuzziness evaluation method, takes multiple criteria, multiple experts and relevance among the criteria comprehensively and is of great help to chemical engineering enterprises in making decisions suitable for chemical engineering development goals so as to protect the environment and energy resources.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Conflicting expert systems

InactiveUS8510142B2Addressing slow performanceOptimize cross-functional conflictsFinanceResourcesTechnical standardMultiple experts

An expert system for providing optimized recommendations regarding a construction project is configured to generate conflicting optimization recommendations. Multiple expert system engines are implemented, where each engine provides one or more recommendations optimized in accordance with the priorities of a functional discipline. A conflict engine will identify conflicts between optimized recommendations and will package the conflicts into conflict objects that are presented to a conflict user interface for resolution. The user could resolve the conflicts him / herself, or could configure a cross-functional conflict object to resolve such conflicts based upon specified resolution criteria.

Owner:FLUOR TECH CORP

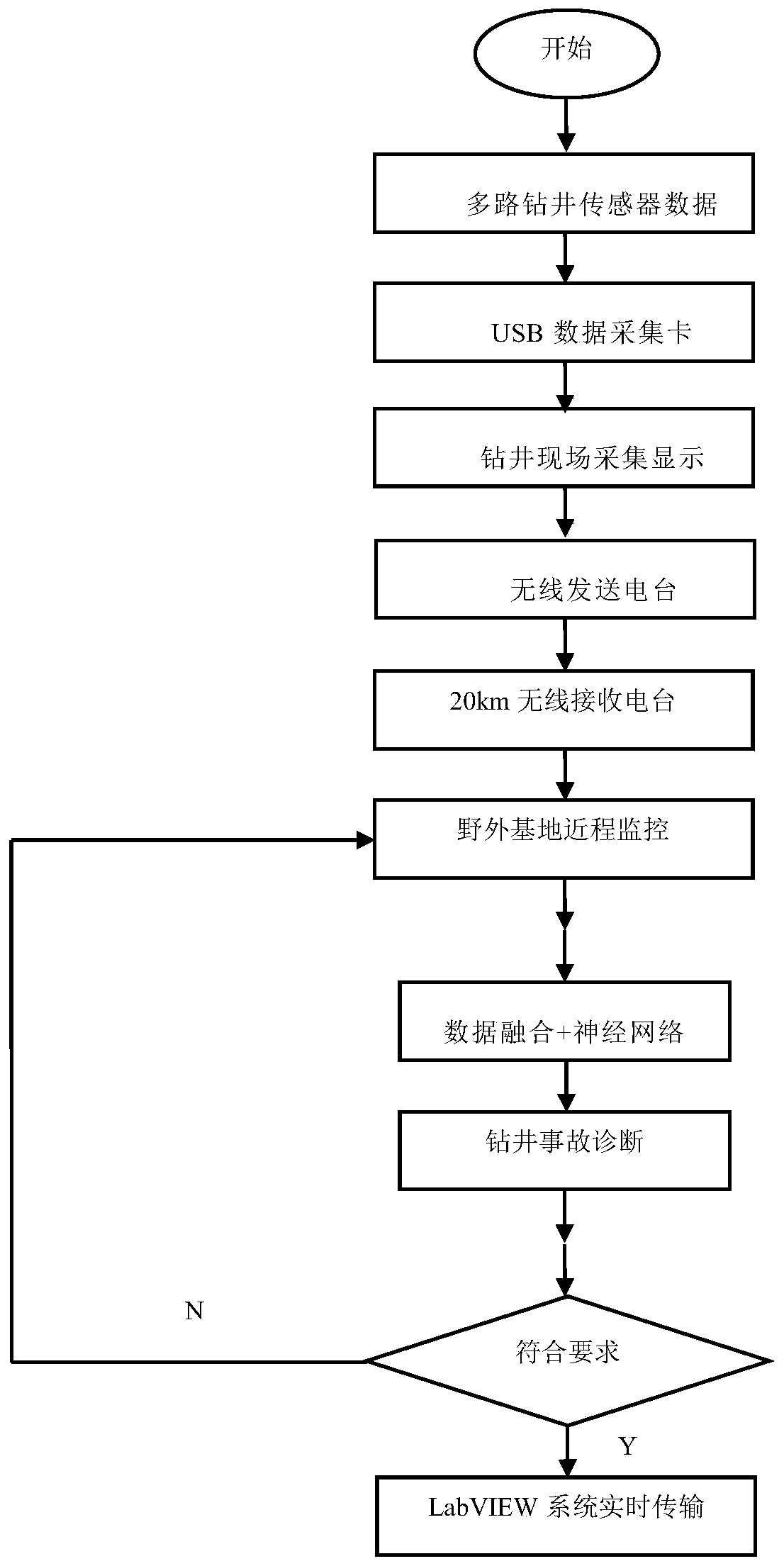

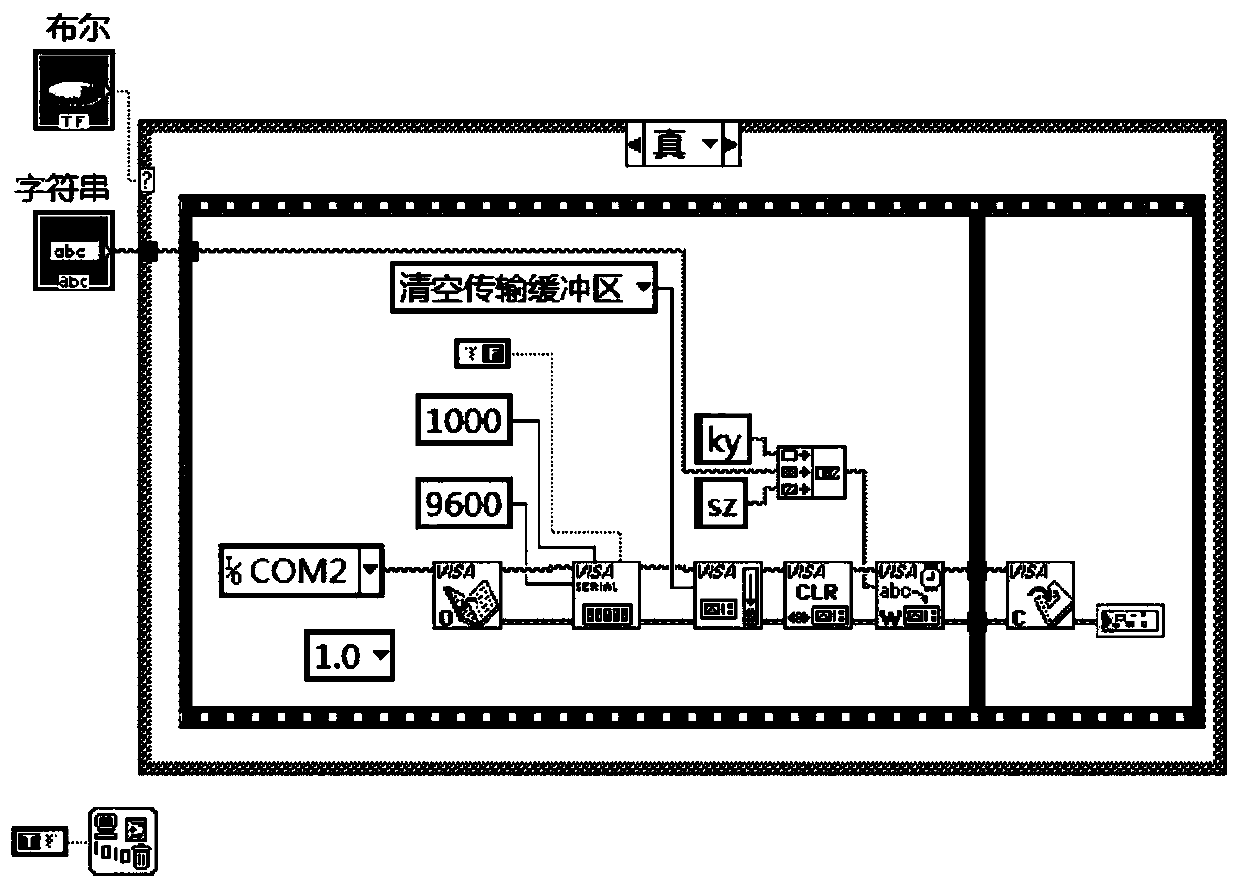

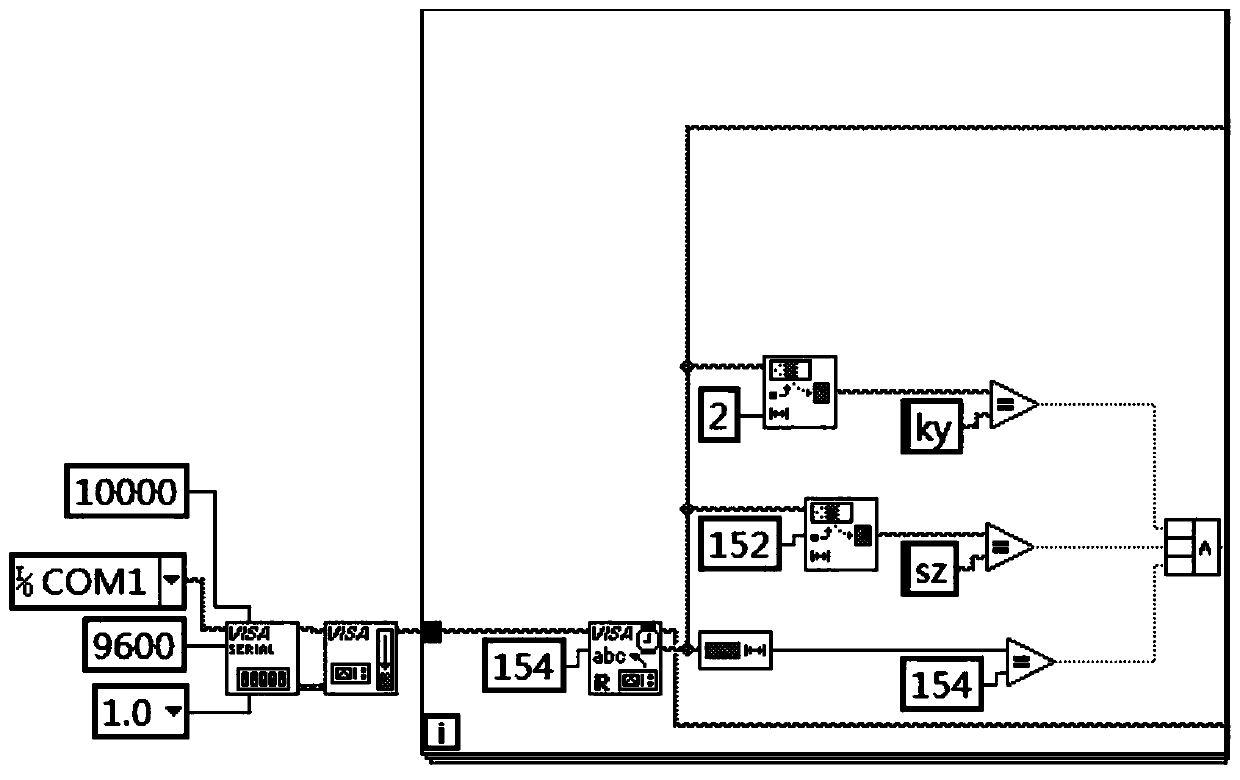

Intelligent drilling system based on LabVIEW and application thereof

ActiveCN110593847AReduced execution timeReduce memory sizeSurveyAutomatic control for drillingLabview softwareData transmission

The invention provides an intelligent drilling system based on LabVIEW and an application thereof. The application comprises the following steps of acquiring various data during drilling by using a multi-path data sensor, transmitting the acquired various data to a data acquisition card, transmitting the data in the data acquisition card to field equipment for display, and transmitting the data toa field base outside 20km through a radio station, processing related data and generating two-dimensional and three-dimensional images through LabVIEW software installed on the field base, utilizingthreshold judgment, data fusion and a neural network to realize preliminary diagnosis and prediction of accidents in real time, transmitting the preliminary diagnosis and prediction to a large-scale base with more complete equipment, completing multiple expert consultation, and finally sending consultation results to the site for efficiently and professionally completing drilling engineering. According to the intelligent drilling system based on LabVIEW and the application thereof, the identification of four complex working conditions such as well kick, well leakage, core blockage, and in-place signaling of a coring tool and the timely diagnosis of four accidents such as drill jamming, drill burying, drill burning and drill tool fracture can be realized.

Owner:INST OF EXPLORATION TECH OF CHINESE ACAD OF GEOLOGICAL SCI

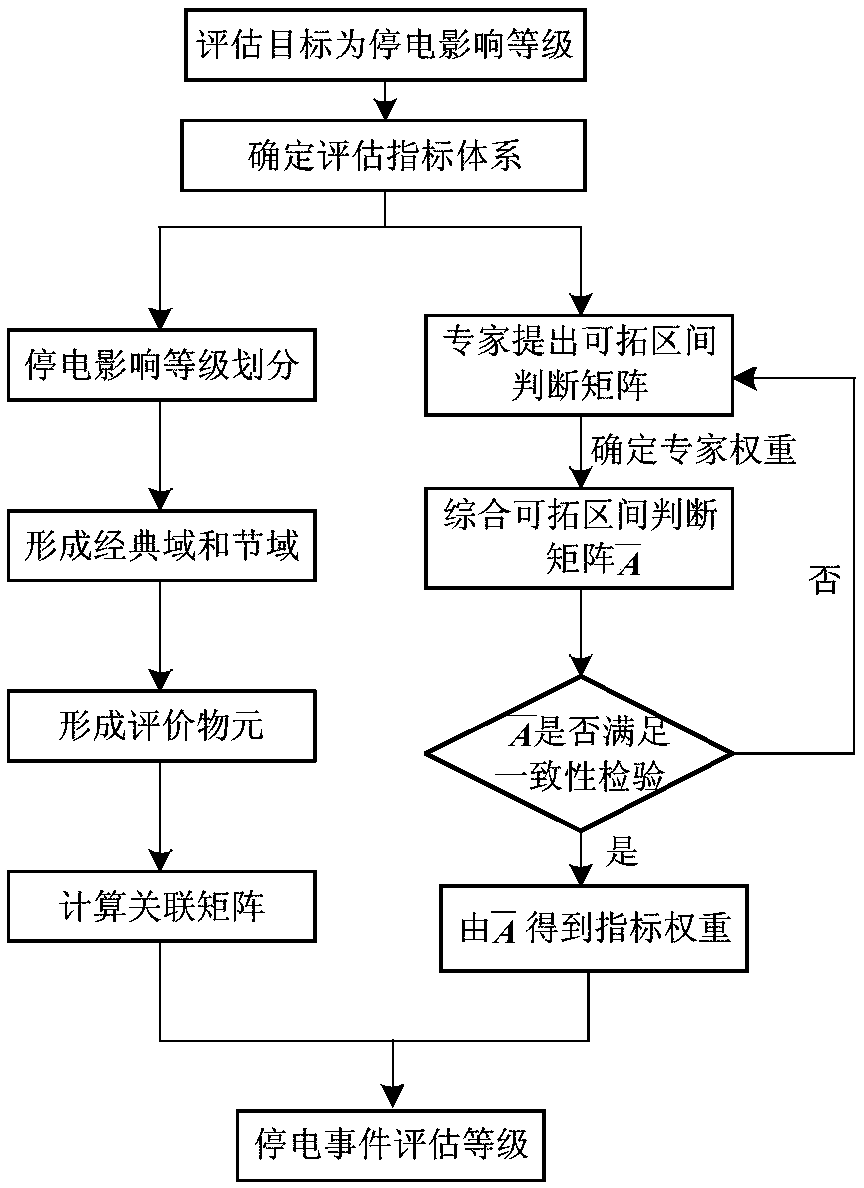

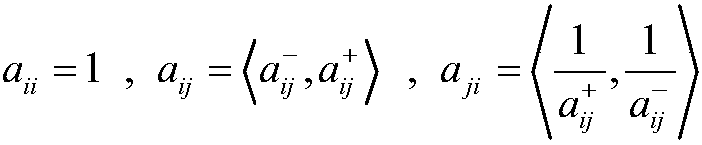

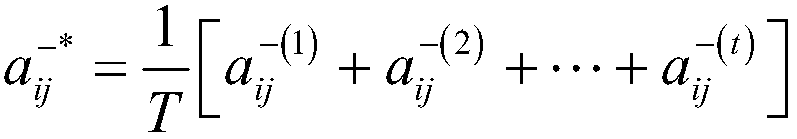

Power outage influence comprehensive evaluation method based on improved extension theory

InactiveCN108805395AOvercoming comprehensivenessOvercome limitationsResourcesExtension setExtension theory

The invention discloses a power outage influence comprehensive evaluation method based on improved extension theory. The method comprises three loops: a power outage influence evaluation matter element setting, association matrix computation and power outage influence comprehensive evaluation; a fuzzy set in an extension set theory is combined with an analytic hierarchy process to form a judgmentmatrix for representing the index relative importance by utilizing multiple experts, and the weight value of each index is computed according to the judgment matrix, thereby forming the comprehensivejudgment on the influence condition of the power outage event; and then, the comprehensive judgment matrix in the method is obtained by performing equal-weight summation through the judgment matrixesof various experts, if the cognitive level of individual expert is much different from other expert or the consistency problem is existent between the judgment matrixes, the consistency of the comprehensive judgment matrix can be influenced, and the reasonable weight value is hard to obtain.

Owner:CHINA SOUTHERN POWER GRID COMPANY

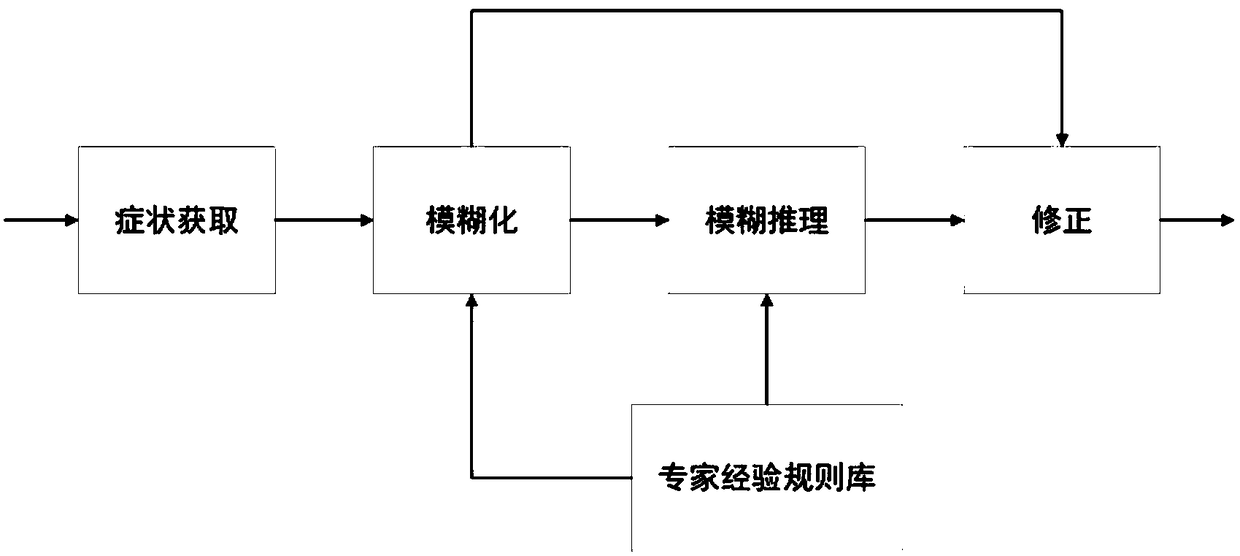

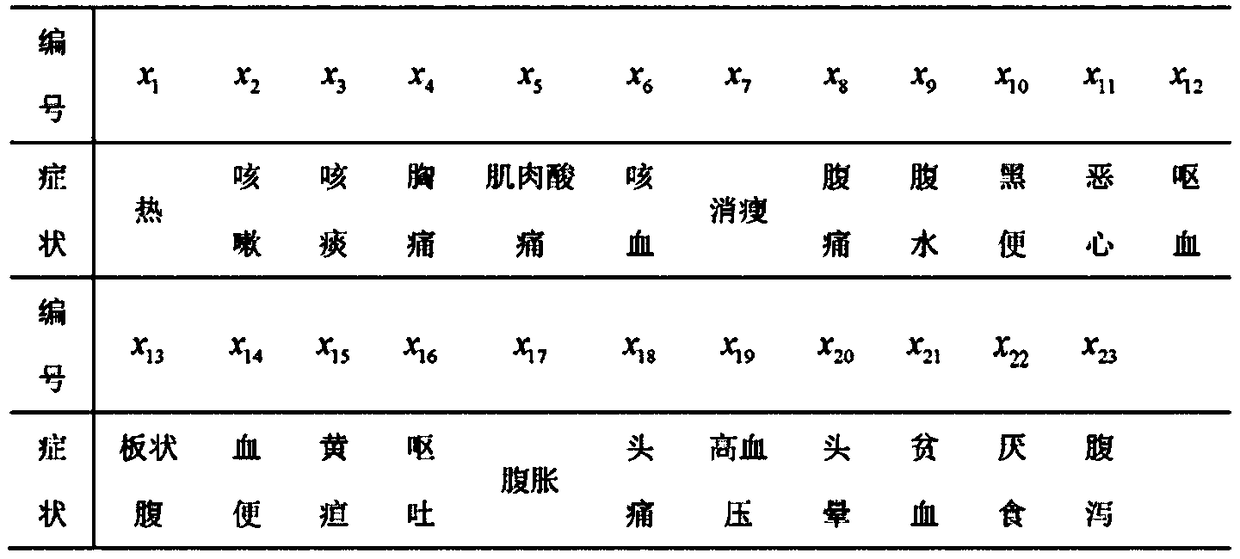

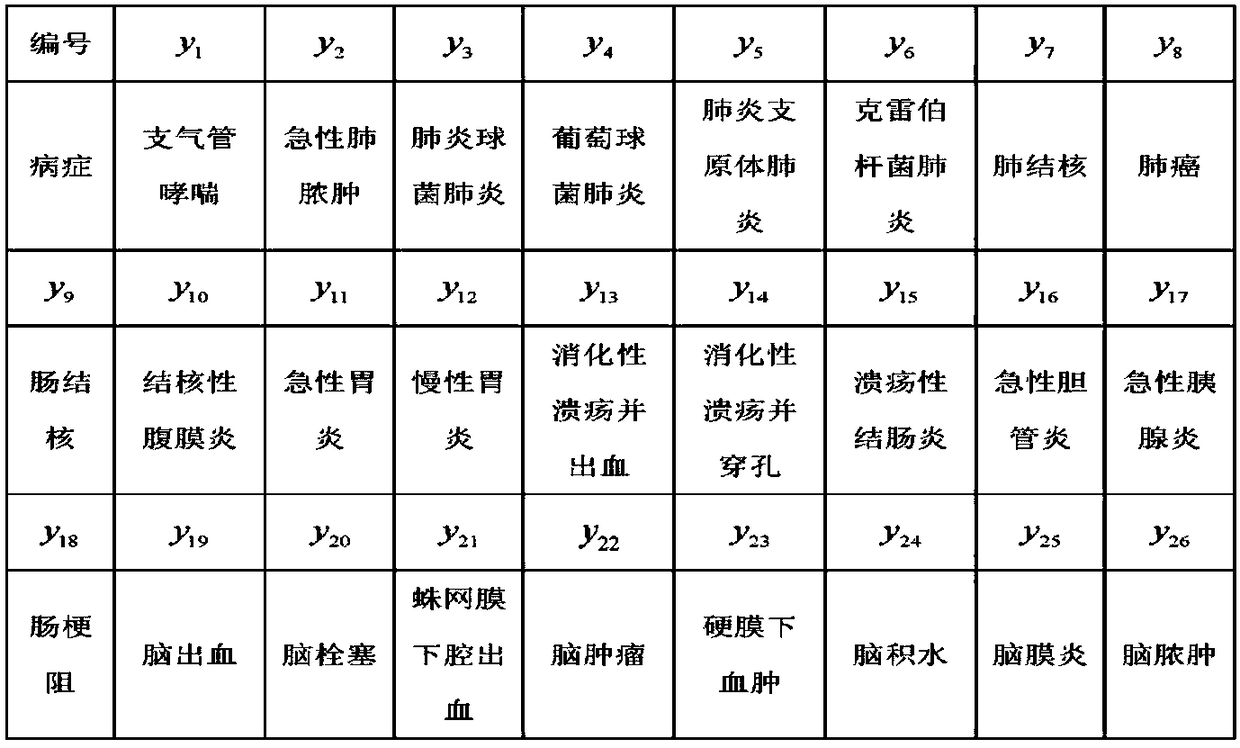

Expert experience inference system and method based on fuzzy reasoning

ActiveCN108847282AJudgment accuracy is lowMeeting triage needsMedical automated diagnosisInference methodsTriageDisease

The invention discloses an expert experience inference system based on fuzzy reasoning. The system comprises a symptom acquisition module used for obtaining the symptom information of a user, a fuzzification module, an expert experience rule database used for storing multiple expert rules, and a fuzzy reasoning module, wherein the symptom information includes the name of the symptom and the severity information of the symptom, the fuzzification module is used for fuzzifying the severity information through a membership function, the rules include a disease, symptoms of the disease and the severity of all the symptoms, and the fuzzy reasoning module is used for calculating the disease information corresponding to the symptom information of the user through utilizing fuzzy reasoning according to the fuzzy symptom information and the rules in the expert experience rule database. The invention further discloses an expert experience inference method based on fuzzy reasoning, and problems oflow accuracy of disease judgment and low efficiency of triage diagnosis are solved.

Owner:CHONGQING YOUBANJIA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com