Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60 results about "Hsv color model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

How to Use the HSV Color Model. The HSV color wheel sometimes appears as a cone or cylinder, but always with these three components: Hue is the color portion of the model, expressed as a number from 0 to 360 degrees: Red falls between 0 and 60 degrees. Yellow falls between 61 and 120 degrees. Green falls between 121-180 degrees.

Illumination Invariant and Robust Apparatus and Method for Detecting and Recognizing Various Traffic Signs

ActiveUS20130201334A1Easy to installImage enhancementTelevision system detailsTemplate matchingNight vision

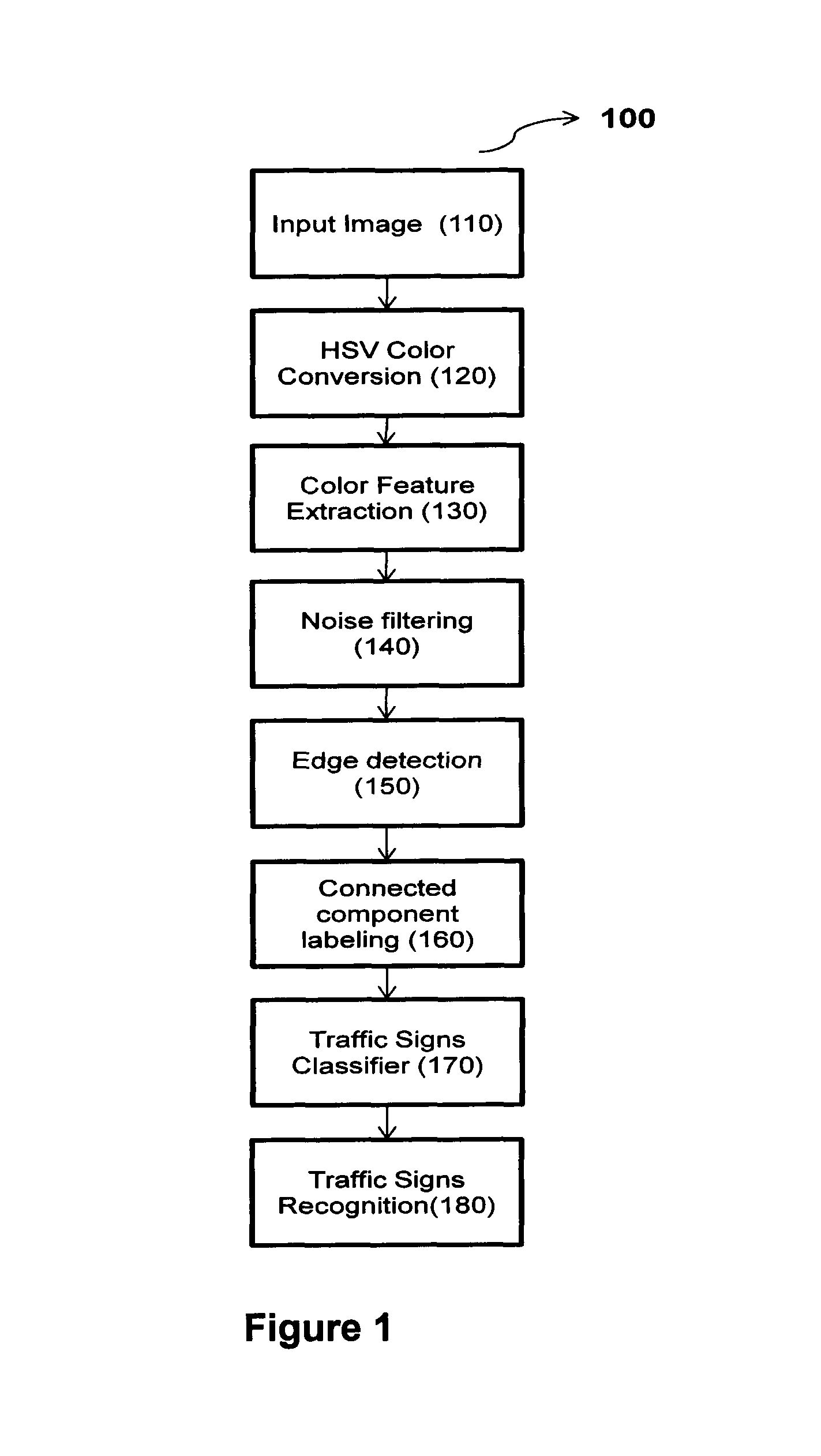

The present application provides a robust, illumination invariant apparatus and method for detecting and recognizing various traffic signs. A robust method for detecting and recognizing the traffic signs using images captured by a digital color and night vision camera, the said method characterized in being illumination invariant comprising the processor implemented steps of: transforming RGB image into HSV color model and subsequently extracting desired color components by using color quantization; filtering the noise components in the HSV color model based on object symmetrical shape property; detecting edges of the objects and subsequently detecting the distinct objects in the noise components filtered image; classifying the shapes of the traffic signs based on shape of the determined distinct objects; and recognizing the classified shapes of the traffic signs by template matching. Further, the method provides the provision for warning the driver by use of the recognized data of the traffic signs.

Owner:TATA CONSULTANCY SERVICES LTD

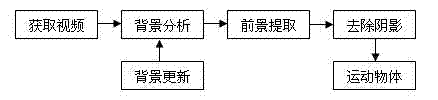

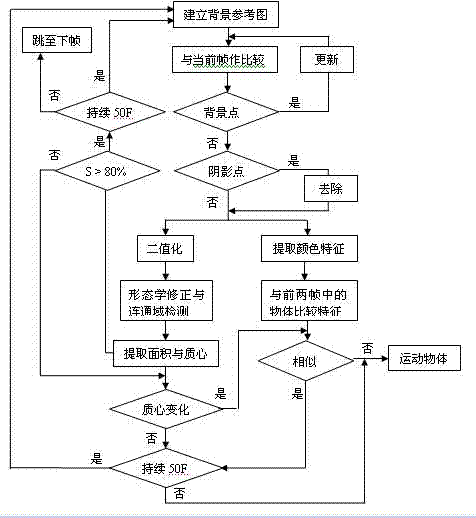

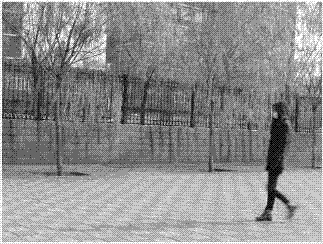

Method for monitoring moving object in natural environment

InactiveCN103208126AAccurate detectionEliminate the effects ofImage enhancementImage analysisObject pointHsv color model

The invention relates to a method for monitoring a moving object in a natural environment. Based on space-time information fusion and feature identification, the method mainly comprises background analysis, foreground extraction, shadow removal and background update. According to the thought of the method, image sequences are converted into hue, saturation and value (HSV) color models, the change rule of the parameter of each pixel point in a certain period of time is analyzed and compared, and each pixel point belonging to a background point, a moving object point or a shadow point in a certain frame can be distinguished through judgment of a judgment formula. By adopting the method, an algorithm is improved on the influence possibly caused by natural conditions such as wind, sunlight and lightning, and the background can be intelligently updated under the conditions that the illumination is abruptly changed, the moving object is still and then is blended into the background, the background object moves and the like; and the method is applied to monitoring of the moving object in the natural environment.

Owner:TONGJI UNIV

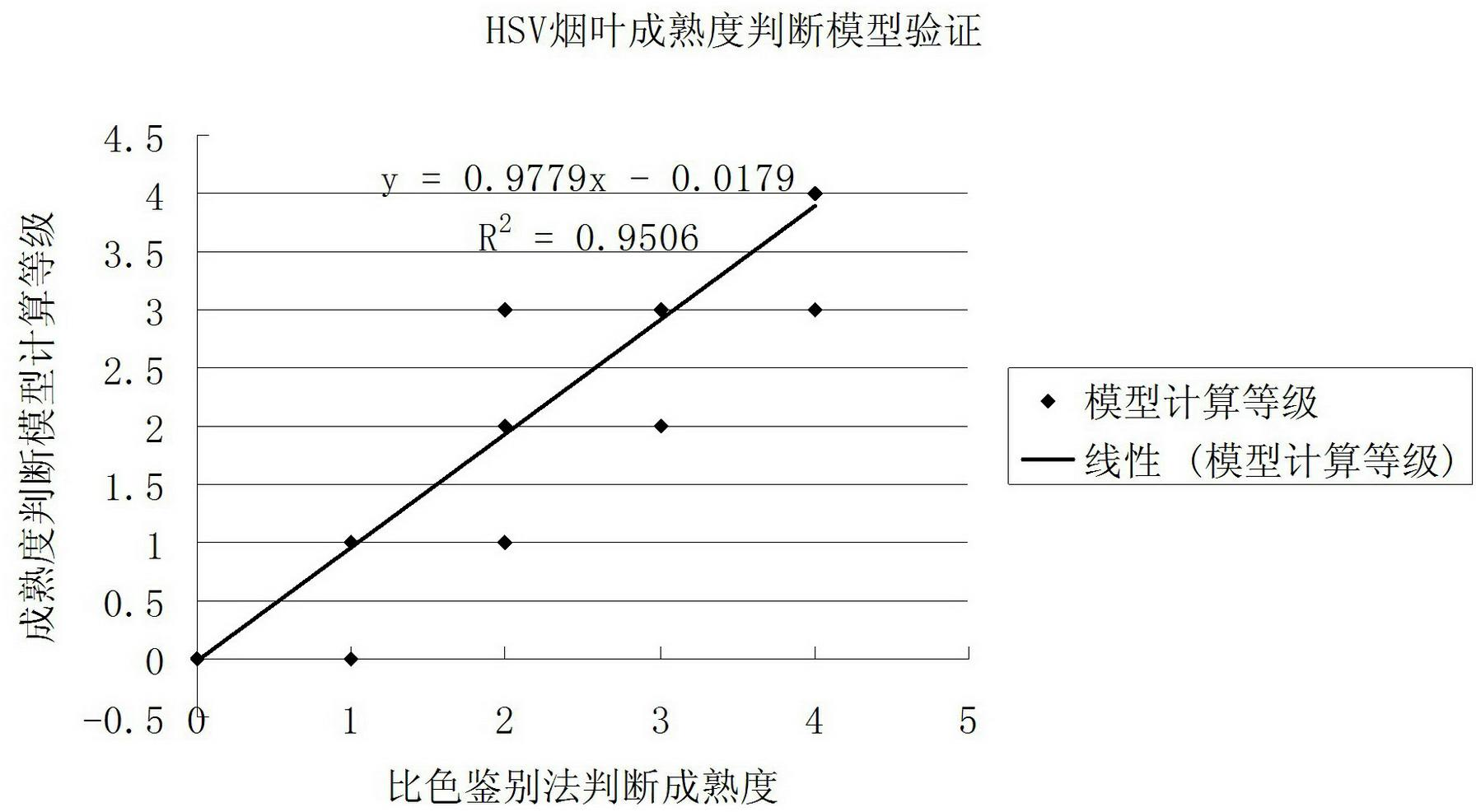

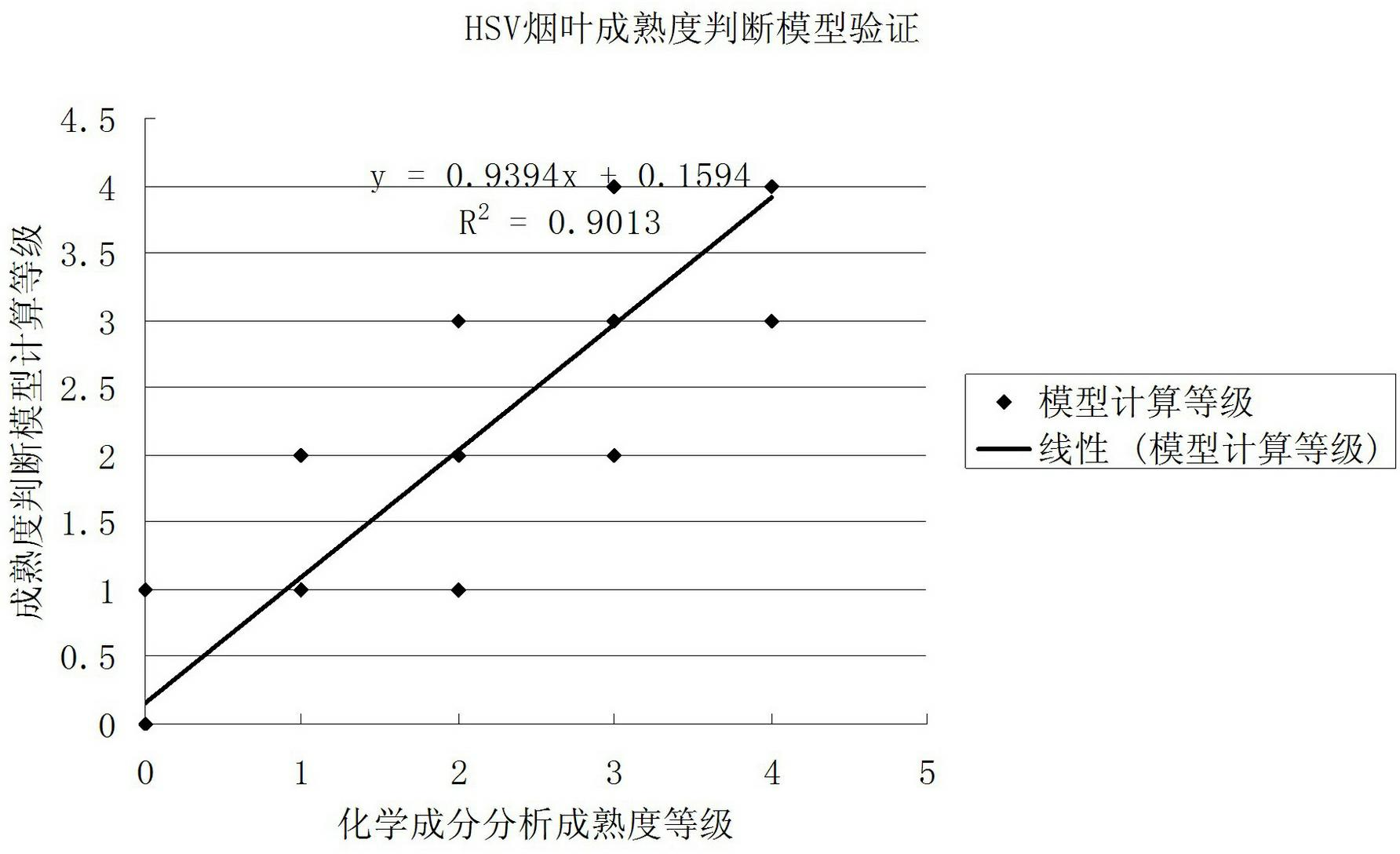

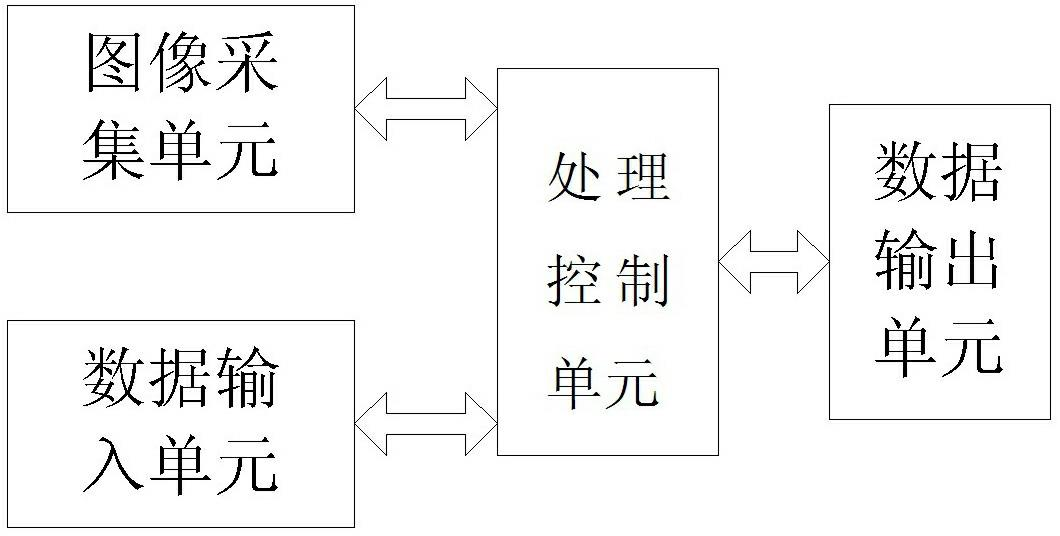

Tobacco maturity detection method and device

InactiveCN102323221AEasy to judgeJudgment quantificationColor/spectral properties measurementsPattern recognitionHsv color model

The invention relates to a tobacco maturity detection method and device. The tobacco maturity detection method comprises the steps of: acquiring an image of tobacco to be detected by an image acquiring unit, processing the image to establish or convert into an image with an HSV (Hue Saturation Value) color mode, obtaining an H color component value and an S color component value of the image; andfiguring the maturity grade MD of the tobacco to be detected according to a given mathematical model. The tobacco maturity detection method and device are used for judging the maturity of the tobaccothrough the acquired tobacco image, and have the advantage of field rapid, site and living nondestructive detection to ensure visual and quantitative judgment of the maturity of the tobacco and strong operability, and are beneficial to proper harvesting and improving of homogeneity and tobacco quality of initially baked tobacco. In the method, model parameters are judged by using the H color component value and the S color component value in an image HSV color model without the V color component value, therefore, the influence of the value of the image to the establishment of the model is eliminated.

Owner:HENAN AGRICULTURAL UNIVERSITY

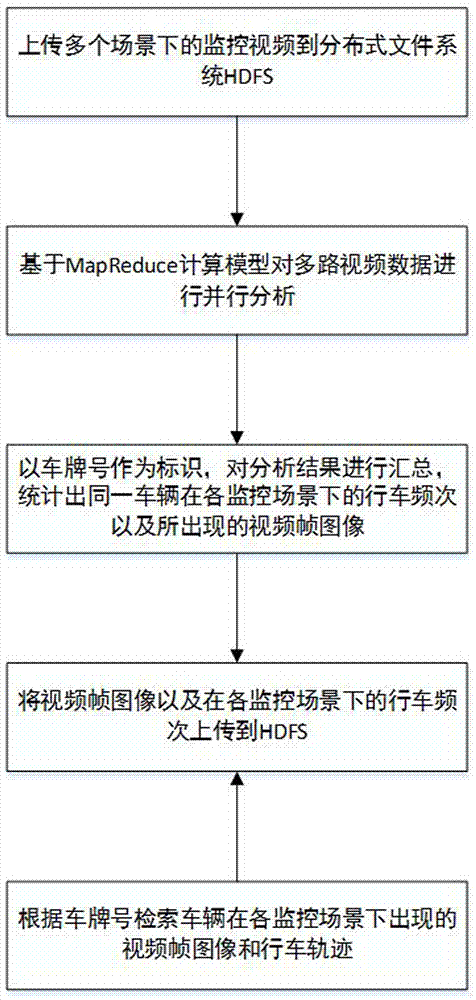

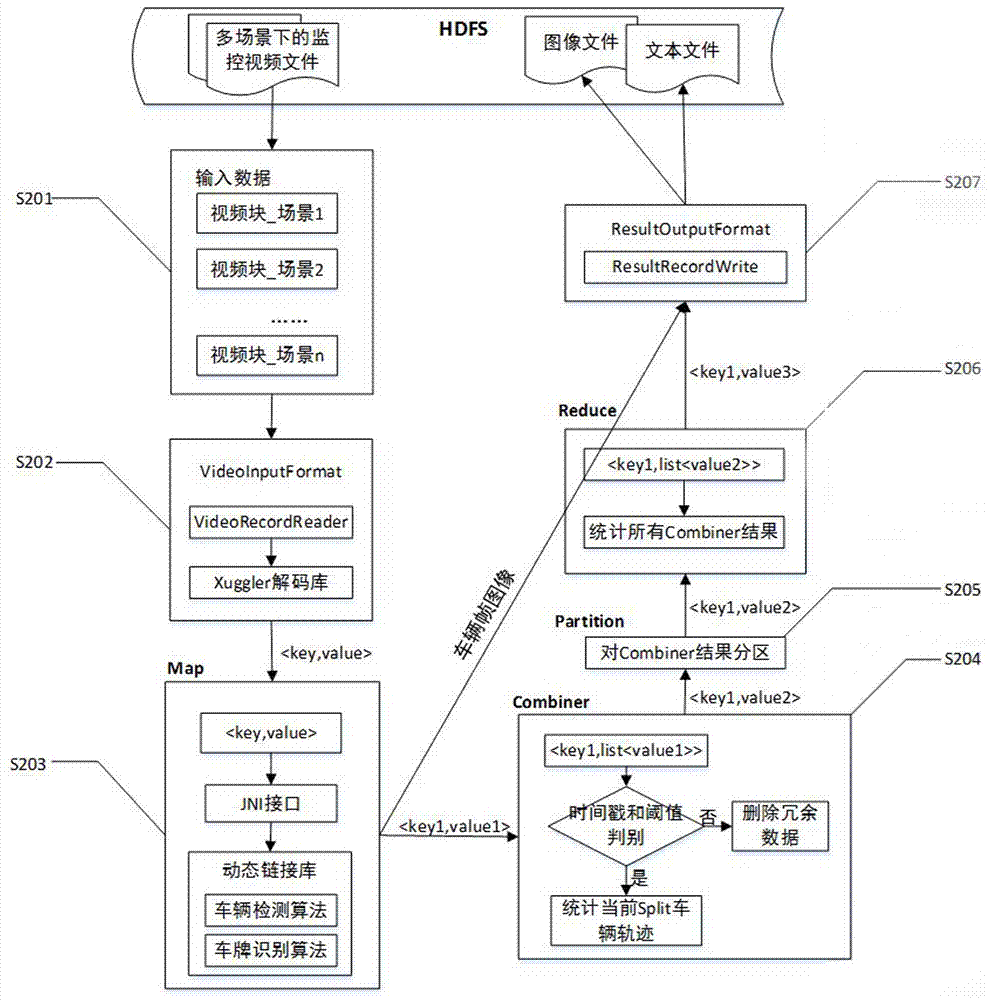

Vehicle track statistic method based on Hadoop and monitoring video streams

ActiveCN107316016ASmall amount of calculationReduce data transfer volumeVideo data indexingFile access structuresVehicle frameHsv color model

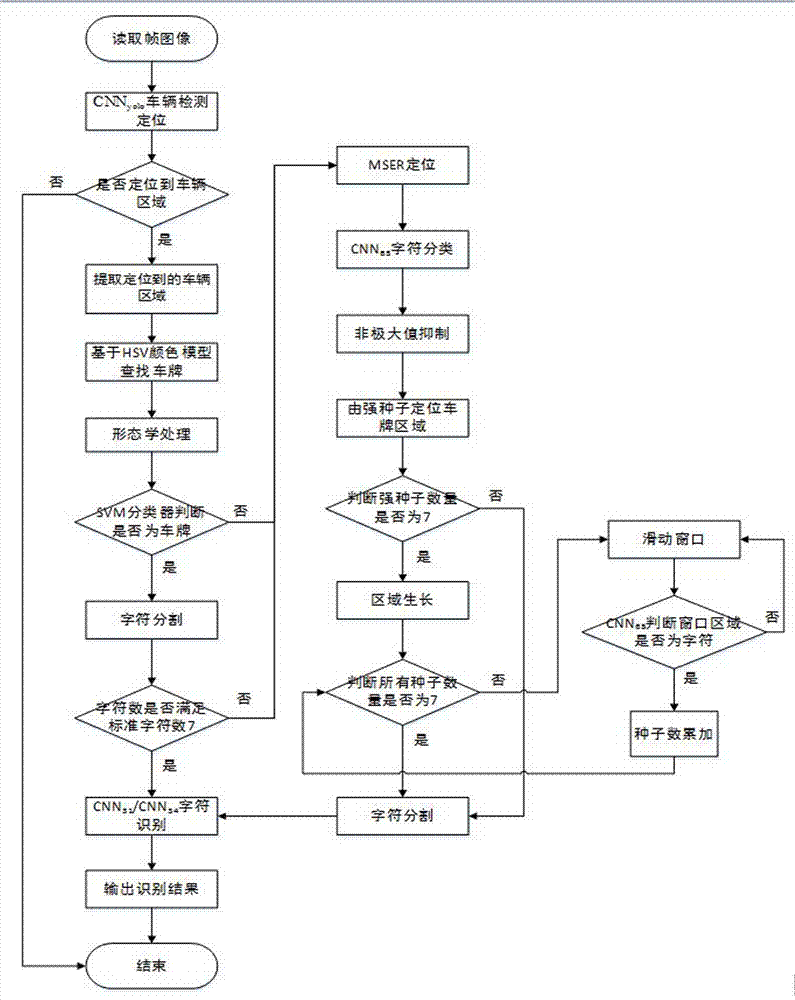

The present invention discloses a vehicle track statistic method based on Hadoop and monitoring video streams. The method involves a vehicle detection algorithm, a license plate recognition algorithm, distributed video processing and vehicle track statistics. According to the method of the invention, vehicle detection and positioning are performed on video frames on the basis of an improved tiny-yolo model; license plate regions are positioned from a positioned vehicle region on the basis of an HSV color model, an SVM classifier and a text positioning technology; license plate character recognition is performed through an improved LeNet-5 model; the processing algorithms of license plate detection and license plate recognition are compiled into a dynamic link library; the support of MapReduce for a video type format is expanded, and the Map interacts with the dynamic link library through a JNI interface, so that the distributed processing of the monitoring video streams can be realized; analysis results are summarized through three stages of Combiner, Partition and Reduce; and finally, the statistics of vehicle tracks and the storage of vehicle frames are realized. According to the method, the vehicle detection algorithm and license plate recognition algorithm have high adaptability to complex environments, and execution efficiency is higher through the interaction of the JNI interface and the MapReduce.

Owner:GUILIN UNIV OF ELECTRONIC TECH

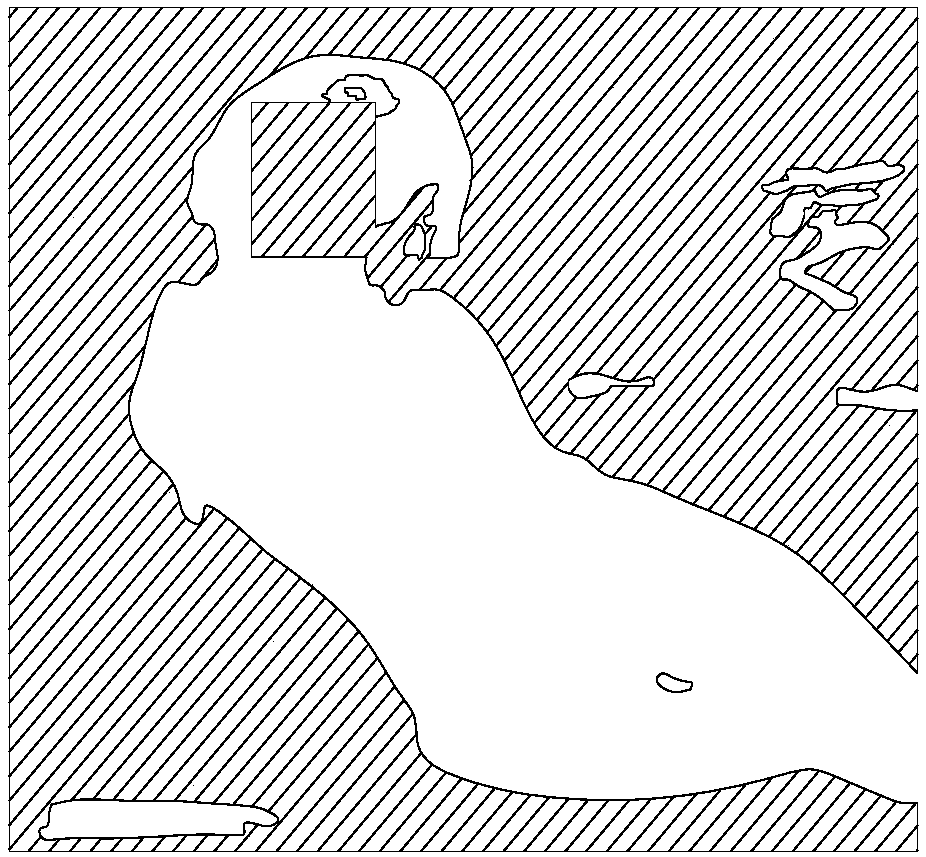

Face key part fatigue detection method

ActiveCN105844252AGood tracking effectAvoid direct contactCharacter and pattern recognitionFace detectionPattern recognition

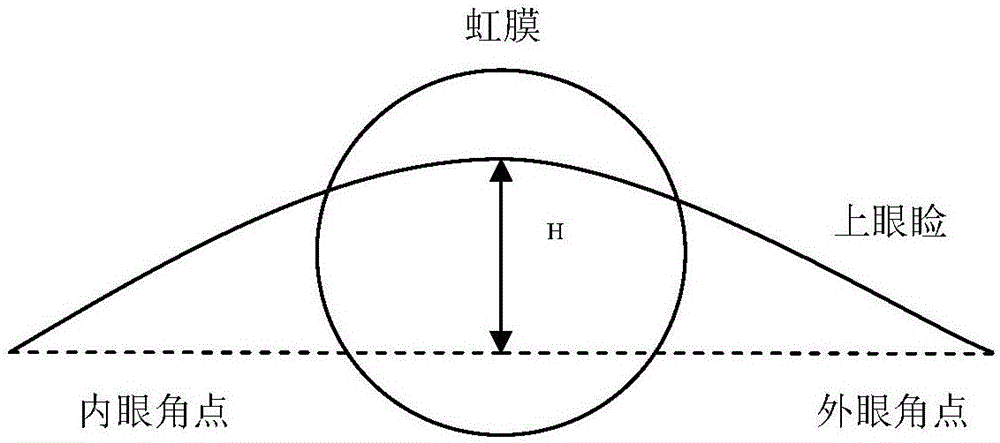

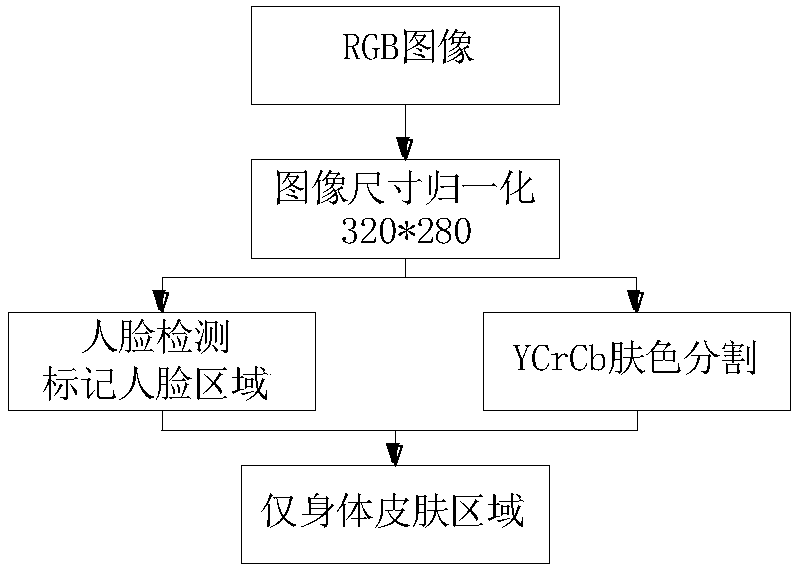

Provided is a face key part fatigue detection method, comprising: first, utilizing a skin color model to detect a face area to provide initial positioning for an AAM; performing local human eyes and mouth tracking based on the AAM to obtain eye and mouth areas; utilizing a Canny operator to accurately position two areas to obtain fatigue detection parameters; and finally realizing fatigue detection according to a PERCLOS method. Face detection based on an HSV color model is not influenced by postures and angles, but is vulnerable to background interference; while the AAM has great face key point tracking effects, but is difficult to perform initial positioning; the method combines the HSV color model and thee AAM to realize eye and mouth accurate positioning and tracking. The method avoids body direct contact, employs AAM local texture search, reduces search time and obtains more accurate results compared with an ASM algorithm. Meanwhile, the method provides a driver spirit assessment module, can perform clear determination on driver states more easily.

Owner:NANCHANG UNIV

Method for dividing plant root system image based on color characteristic

InactiveCN101324955AIntegrity guaranteedEffective segmentationImage analysisPattern recognitionInformation processing

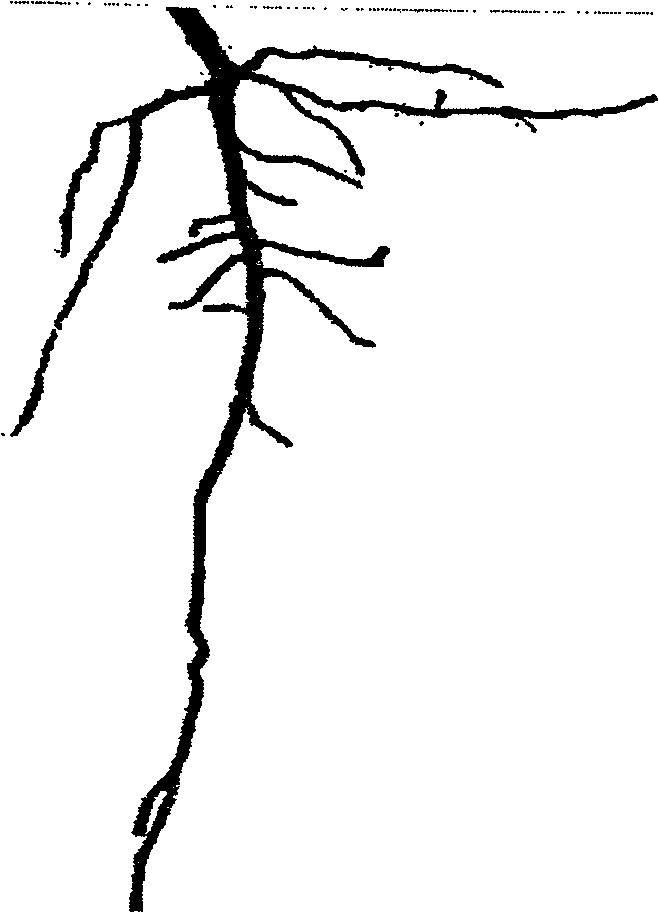

The invention relates to a method for separating plant root system images based on color features and belongs to the phytophysiology and intelligent information processing technology field. The method is used for separating a root system as a whole region from the background so as to identify the root system and measure the geometric parameters thereof. According to the features of an acquired root system image, the method adopts an HSV color model. As to a root image with single color background, the back region and the root system region are obviously different at the H value. According to the difference, dual threshold is properly set, so that the root system region and the background region are separated, and the root system is separated from the background.

Owner:KUNMING UNIV OF SCI & TECH

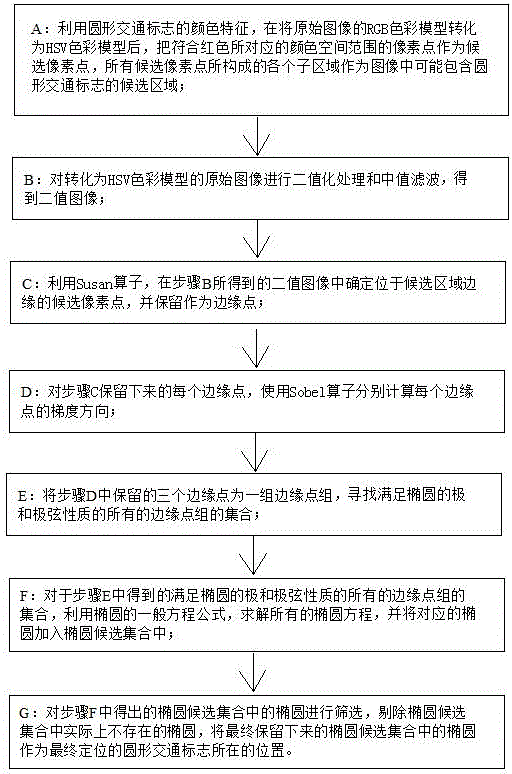

Method for positioning circular traffic signs in natural scene

The invention discloses a method for positioning circular traffic signs in a natural scene. The method comprises the steps of A, transforming an original image into an HSV color model, and determining a candidate region which possibly contains the circular traffic signs; B, performing binarization processing and median filtering; C, determining candidate pixel points located at the edge of the candidate region by using a Susan operator; D, respectively calculating the gradient direction of each edge point by using a Sobel operator; E, searching a set of all edge point groups meeting pole and polar line properties of an ellipse; F, solving all elliptic equations by using a general equation of the ellipse, and adding corresponding ellipses to an ellipse candidate set; and G, removing ellipses which do not actually exist from the ellipse candidate set, and regarding the finally reserved ellipses to be positions at which the finally positioned circular traffic signs are located. Sub-regions corresponding to circular traffic signs in an image can be accurately positioned in a complicated natural scene according to the method disclosed by the invention, and the positioning efficiency and he positioning precision are greatly improved.

Owner:HENAN UNIVERSITY

Method for identifying surface contamination condition of DC line insulator based on visible light image

InactiveCN107240095ALow running costReduce maintenance costsImage enhancementImage analysisHsv color modelImage segmentation algorithm

The invention relates to a method for identifying the surface contamination condition of a DC line insulator based on a visible light image. The method comprises the steps of preprocessing an image by adopting the visible light image segmentation algorithm, establishing the relationship between the contamination level and the visible light image, and identifying the contamination condition. According to the embodiment of the invention, the method comprises the steps of acquiring the visible light image of an insulator; preprocessing the image: including segmenting the image, removing the complex background of the image, filtering out the interference information, and ensuring the accuracy of the subsequent feature extraction and the contamination identification. The method specifically comprises the steps of converting an RGB model into an HSV color model; extracting the image color statistic features of the insulator, and evaluating the superiority-inferiority of each statistic feature according to a Fisher criterion function; forming characteristic vectors by adopting statistic features in accordance with requirements and inputting the characteristic vectors into an SVM classifier for classification; and outputting a contamination level. The method is suitable for all insulators having obvious differences from contamination color features. Therefore, the contamination levels of insulators can be effectively identified and the classification accuracy is high. The method provides a new technical means for the identification of the contamination condition.

Owner:WUHAN UNIV

Wave-soldering spot defect detection method and system

ActiveCN113724216AImprove accuracyImprove yield rateImage enhancementImage analysisColor imageHsv color model

The invention provides a wave-soldering spot defect detection method and a wave-soldering spot defect detection system, which solve the problem of non-ideal detection accuracy of the current wave-soldering spot defect detection method based on automatic optical detection.The method comprises the following steps: firstly, PCBA template image collection, preprocessing and color image threshold segmentation are carried out; then color image threshold segmentation is carried out on a detection area at the same time on the basis of R, G and B color components of the RGB color model and H, S and V color components of the HSV color model, the threshold segmentation process is optimized, effective extraction of a defect area is facilitated, a circular template matching optimization method is designed, positioning of soldering tin and a bonding pad in a wave-soldering spot is optimized; a more accurate defect area is provided for subsequent second threshold segmentation, finally, the obtained welding spot image feature parameters are compared with the original image feature parameters, a defect sample is detected, the accuracy of welding spot defect detection is improved, so that the yield of PCBA boards produced in a factory can be increased.

Owner:GUANGDONG UNIV OF TECH

Illumination invariant and robust apparatus and method for detecting and recognizing various traffic signs

ActiveUS9269001B2Easy to installTelevision system detailsImage enhancementTemplate matchingNight vision

The present application provides a robust, illumination invariant apparatus and method for detecting and recognizing various traffic signs. A robust method for detecting and recognizing the traffic signs using images captured by a digital color and night vision camera, the said method characterized in being illumination invariant comprising the processor implemented steps of: transforming RGB image into HSV color model and subsequently extracting desired color components by using color quantization; filtering the noise components in the HSV color model based on object symmetrical shape property; detecting edges of the objects and subsequently detecting the distinct objects in the noise components filtered image; classifying the shapes of the traffic signs based on shape of the determined distinct objects; and recognizing the classified shapes of the traffic signs by template matching. Further, the method provides the provision for warning the driver by use of the recognized data of the traffic signs.

Owner:TATA CONSULTANCY SERVICES LTD

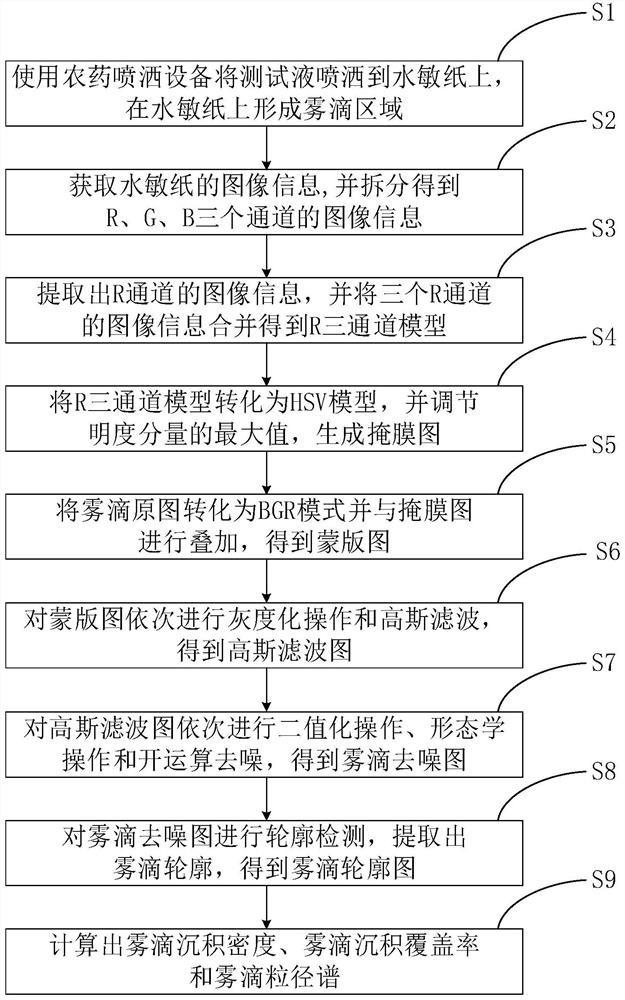

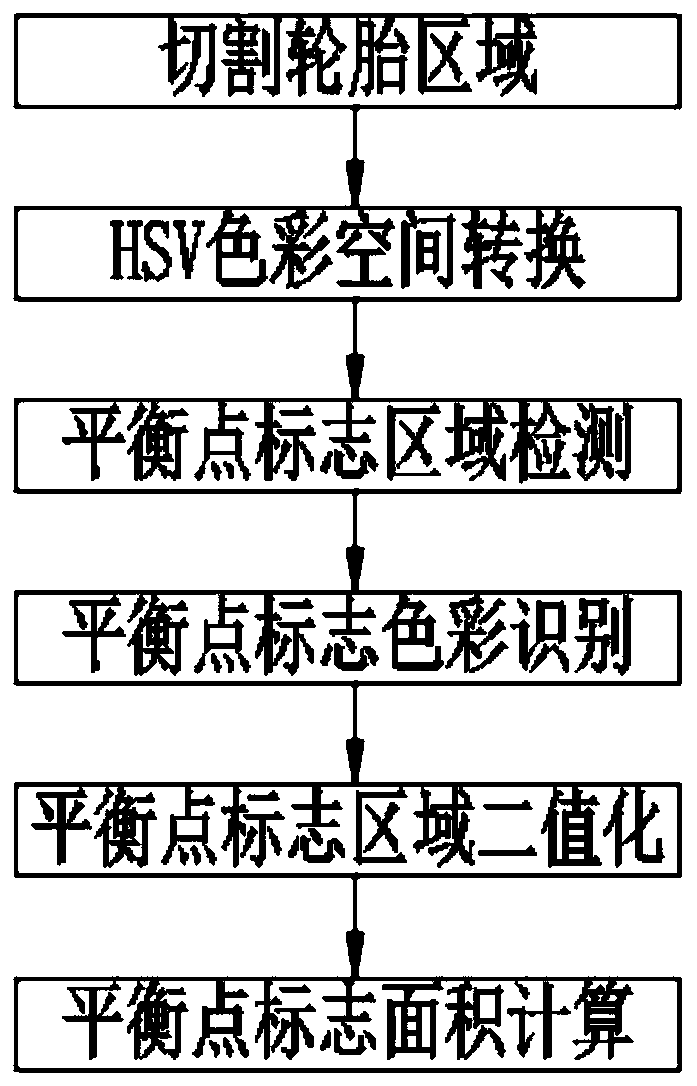

Plant protection fog drop detection method based on HSV color model

The invention relates to the field of pesticide spraying effect detection, and particularly discloses a plant protection fog drop detection method based on an HSV color model, which comprises the following steps: firstly, extracting an R channel image of a fog drop picture, processing the R channel image by using an HSV color model masking method, filtering redundant background information, binarizing to obtain a fog drop contour binary image, extracting the fogdrop contour after morphological denoising and opening operation denoising, finally, calculating the fogdrop contour surrounding shapearea, filtering redundant interference information, and acquiring a fogdrop detection result. According to the method, R three channels are combined, the HSV color model is used for generating the mask map, the mask method is used for detecting the fog drops, and important technical indexes such as the fog drop number pitch diameter, the volume pitch diameter, the deposition density and the deposition coverage rate for measuring the pesticide spraying effect can be accurately counted on the water-sensitive paper with dense fog drops. The detection process is simple.

Owner:YUNNAN TOBACCO CO LTD KUNMING BRANCH +1

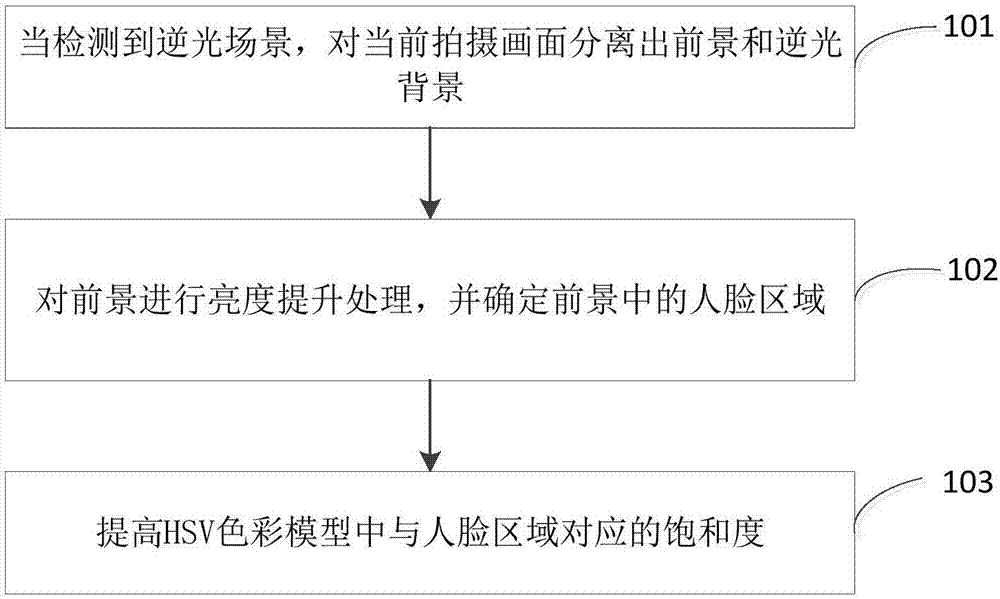

Face area processing method and device in backlight scene

ActiveCN107454315APrevent skin lighteningAvoid bloodless problemsImage enhancementTelevision system detailsHsv color modelImaging quality

The invention discloses a face area processing method and device in a backlight scene. The method comprises the steps of separating a foreground and a backlight background from a currently photographed image when the backlight scene is detected; carrying out luminance promotion on the foreground and determining a face area in the foreground; and improving saturability corresponding to the face area in an HSV color model. When the face area image under the backlight condition is heightened, the problem that the face is faded in skin color and is complexionless is solved, the image quality is improved, and moreover, the image display visual effect is ensured.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Psychoanalysis method and device based on drawing psychology

ActiveCN108392213AMeans of objective analysisObjective: the means of scientific analysis of the present inventionSensorsPsychotechnic devicesHsv color modelAnalysis method

The invention discloses a psychoanalysis method and device based on drawing psychology. The psychoanalysis method includes the steps of allowing a drawer to draw online, collecting behavioral characteristic data of the drawer during drawing, and saving the drawer's drawing after drawing; dividing an HSV (hue, saturation and value) color model through a minimal difference comparation method, and quantitatively sorting colors selected by the drawer; constructing a psychoanalysis model, and performing real-time standard processing and analyzing on the drawer's acquired behavioral characteristic data; matching user data according to the psychoanalysis model to form a psychoanalysis report for the drawer. The psychoanalysis method and device based on drawing psychology have the advantages thatdrawing psychoanalysis is automated through the computer technology so that the problem of low manual analytic efficiency is solved; a drawer's drawing data are acquired in real time via a sensing technology and subjected to drawing psychoanalysis, and the problem is solved that traditional manual analysis has poor objectiveness and accuracy; the standard analytical model is established via the machine learning algorithm so that automated drawing psychoanalysis is performed in real time.

Owner:北京态极科技有限公司

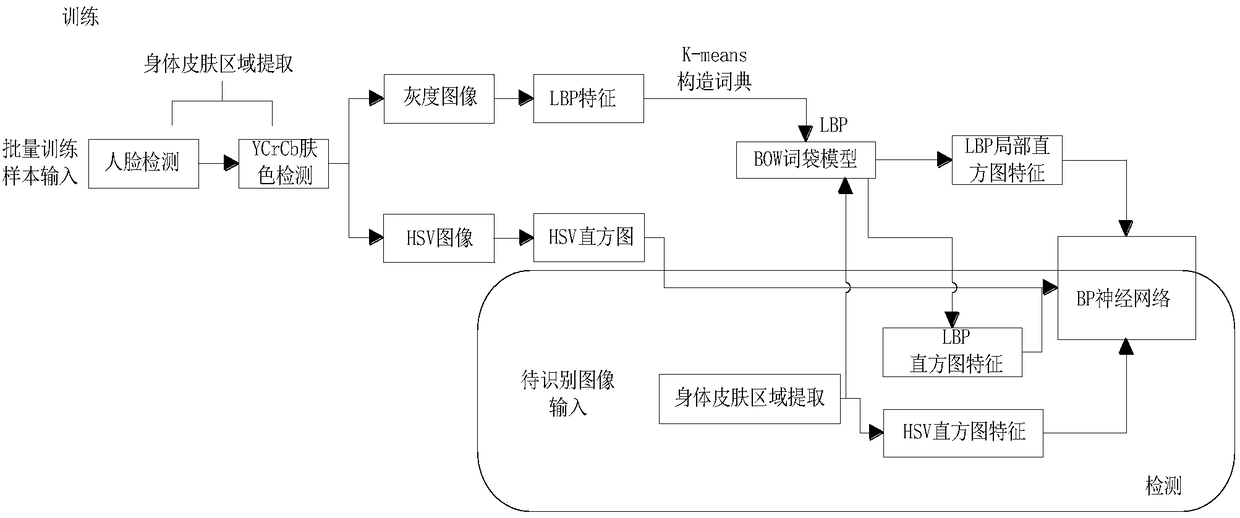

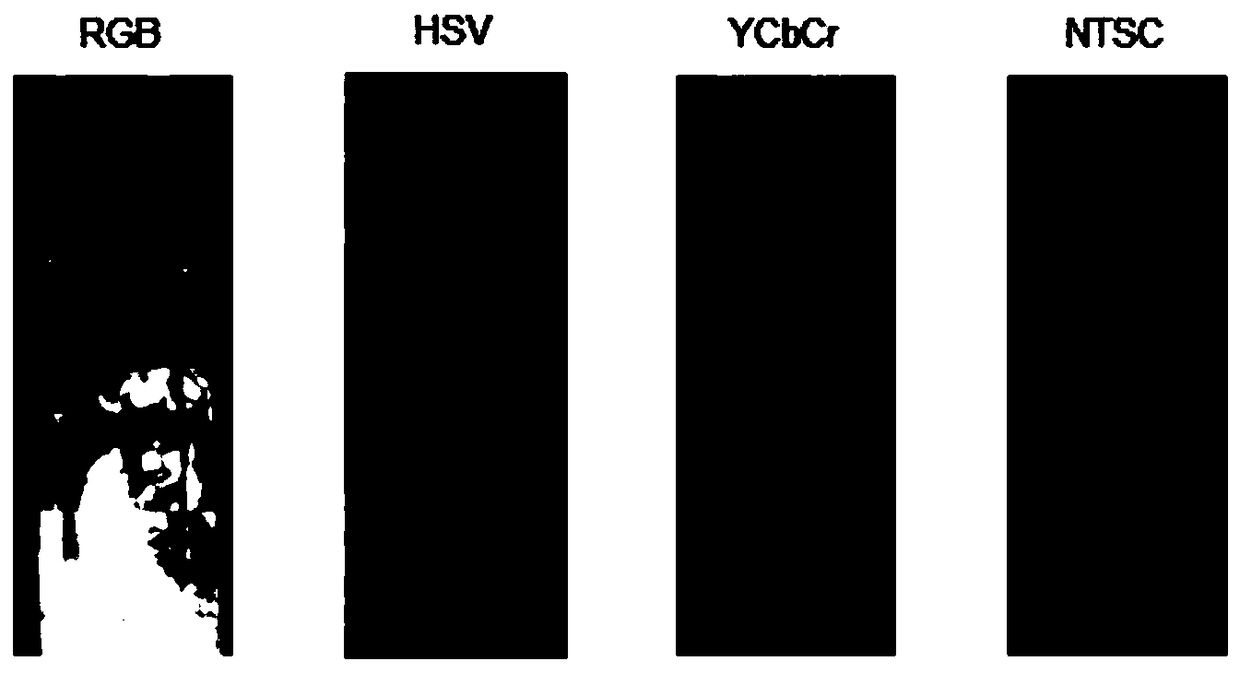

Method for recognizing sensitive images on basis of combinations of HSV (hue, saturation and value) and LBP (local binary pattern) features

PendingCN108280454ANo loss of featuresRotation invariantCharacter and pattern recognitionNeural architecturesPattern recognitionHsv color model

The invention provides a method for recognizing sensitive images on the basis of combinations of HSV (hue, saturation and value) and LBP (local binary pattern) features. The method includes acquiringskin regions of sensitive RGB (red, green and blue) images and normal RGB images; acquiring LBP visual vocabulary expression of the sensitive RGB images and the normal RGB images by the aid of LBP algorithms; acquiring HSV color features of the sensitive RGB images and the normal RGB images by the aid of HSV color models; utilizing the LBP visual vocabulary expression and the HSV color features asinput parameters and training BP (back propagation) neural networks; outputting to-be-detected image recognition results. The method has the advantages that texture information and global color information of images are used as image features, accordingly, picture feature missing can be prevented, and the method is high in accuracy and processing speed.

Owner:天津市国瑞数码安全系统股份有限公司

Non-contact on-line measurement method of aluminum ingot thickness

ActiveCN109308707ASave human effortSave moneyImage enhancementImage analysisColor imageHough transform

The invention discloses a non-contact on-line measurement method of aluminum ingot thickness. Firstly, the method simplifies the modeling of aluminum ingot mold and constructs a functional relationship between mold width and thickness, so as to convert the thickness difficult to measure in horizontal direction into the width easy to measure, and the width information is captured by a camera imagefor collection. Then, the RGB color model of the captured aluminum ingot image is converted into an HSV color model, and the color candidate regions are segmented and extracted according to the S information in the HSV color model. Then the original color image is transformed into the normalized gray-scale image. After preprocessing and gray-scale morphology operation, the width of aluminum ingotis detected by Hough transform. Finally, according to the functional relationship between the width and thickness of aluminum ingots, the thickness of aluminum ingots is measured. HSV color space selected by that invention can identify the width of the aluminum ingot more quickly and stably, thereby realizing the non-contact measurement of the thickness of the aluminum ingot.

Owner:HEBEI UNIV OF TECH

HSV, SURF and LBP feature combination-based sensitive image identification method

PendingCN108133219ANo loss of featuresImprove fault toleranceCharacter and pattern recognitionHsv color modelRgb image

The invention provides an HSV, SURF and LBP feature combination-based sensitive image identification method. The method comprises the steps of obtaining skin regions of a sensitive RGB image and a normal RGB image; obtaining SURF visual vocabulary expressions of the sensitive RGB image and the normal RGB image by using an SURF algorithm; obtaining LBP visual vocabulary expressions of the sensitiveRGB image and the normal RGB image by using an LBP algorithm; obtaining HSV color features of the sensitive RGB image and the normal RGB image by using an HSV color model; by using the SURF visual vocabulary expressions, the LBF visual vocabulary expressions and the HSV color features as input parameters, training a BP neural network; and outputting a to-be-detected image identification result. The HSV, SURF and LBP feature combination method is adopted for performing sensitive image detection, and has the characteristics of high processing speed and high accuracy.

Owner:天津市国瑞数码安全系统股份有限公司

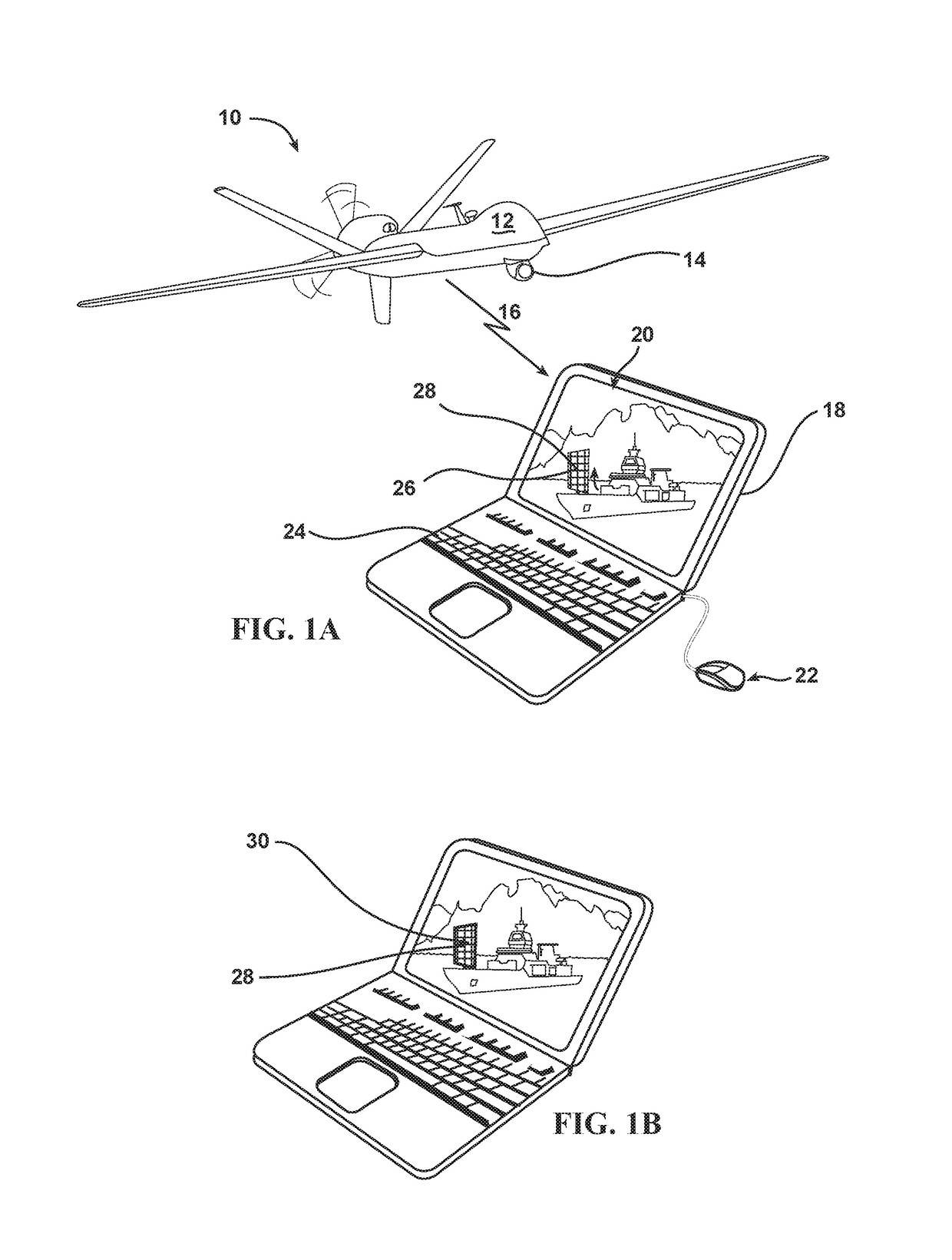

Process for recovering an unmanned vehicle

A process for recovering a vehicle includes obtaining a red green blue (RGB) image comprising a target on a recovery device. An input received from a user designates a target hue value and a target luminance value. The RGB image is converted to a hue value saturation (HSV) color model. The HSV color model is split into a hue value plane and a luminance value plane. A hue band pass filter and a luminance band pass filter are configured with appropriate thresholds. The configured hue band pass filter and the luminance band pass filter are applied to the hue value plane and the luminance value plane, respectively. The filtered hue value plane and the filtered luminance value planes are combined to yield a plurality of potential target pixel groupings. The most probable target is determined from the plurality of potential target pixels. The vehicle is directed to the target.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

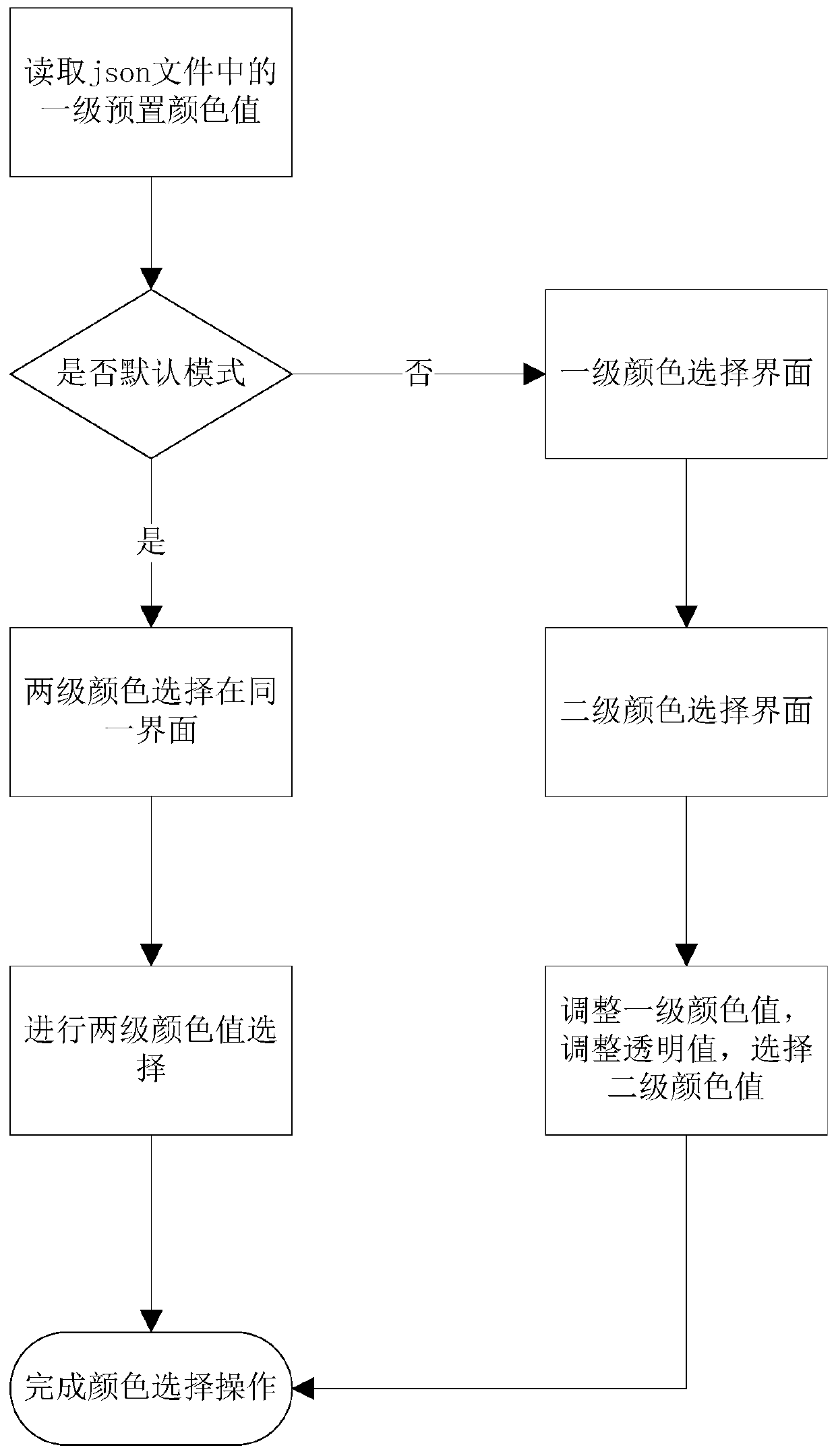

Custom color display method and custom color display system

ActiveCN111124404AEasy to operateRealize requirementsSoftware engineeringComputer graphics (images)Algorithm

The invention discloses a custom color display method and a custom color display system. The custom color display method comprises the following steps: acquiring configuration file data of a first-level color and an input first-level color value; entering a custom mode, and adjusting the input primary color value by using an HSV color model to generate a vertical progress bar of the custom palette; generating a transverse progress bar of the custom palette for the color value selected by the vertical progress bar according to different transparencies; forming a plurality of rectangular frame areas by rendering ComposeShader in a combined manner, wherein each rectangular frame area represents a secondary color generated by combining a primary color value and transparency; enabling the plurality of rectangular frame areas to generate a color combination area of the custom palette; generating the selected rectangular frame area according to the first-level color value selected by the vertical progress bar and the transparency selected by the transverse progress bar, displaying the selected rectangular frame area in an amplified mode to serve as the final display color. The requirements for convenient user operation and refined color adjustment can be met through the mode.

Owner:WUHAN HONGXIN TECH SERVICE CO LTD

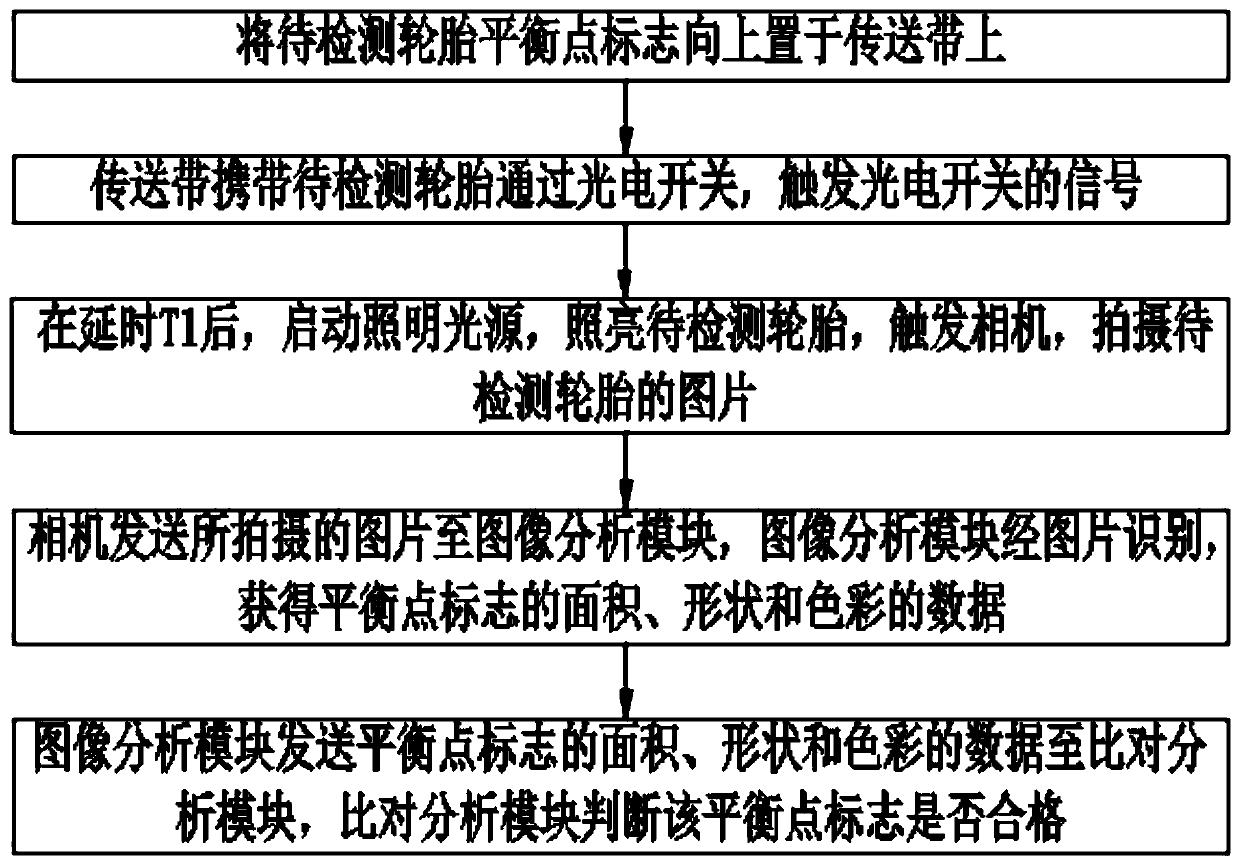

Passenger car tire balance point identification system

InactiveCN109709107AShort exposure timeImprove clarityMaterial analysis by optical meansTire balancePhotoswitch

The invention provides a passenger car tire balance point identification system, thereby solving a technical problem that the existing equipment can not be upgraded and modified by the existing spot mark detection scheme in the prior art. The system comprises a conveyor belt, a photoelectric switch, an illumination source, a camera, an image analysis module and a comparison analysis module. The photoelectric switch includes a light-emitting assembly and a receiving assembly that are arranged at the two sides of the conveyor belt; the photoelectric switch is connected to the camera and triggersthe camera to work; the illumination source and the camera are arranged above the conveyor belt; and the illumination source and the camera work cooperatively. According to the system provided by theinvention, the camera is controlled by the photogate to work; and the structure is simple and the cost is low. A few of devices are installed for the conveyor belt and modification of most of existing spot mark devices can be realized. The camera exposure time is short and the picture definition is improved; with an HSV color model, the work difficulty of the image analysis module is reduced andthe working efficiency of the image analysis module is improved; and because of an externally arranged processing module, remote control of the identification system is realized.

Owner:上海深视信息科技有限公司

Method for detecting region of interest of color image

The invention provides a method for detecting a region of interest of a color image, which is used for detecting the color image to obtain a rectangular region of interest and comprises the following specific steps of: 1, removing spare detail parts of the image by adopting a region-based fuzzy method and remaining a boundary of a foreground region and a background region, wherein an HSV (Hue, Saturation, Value) color model is adopted in the fuzzy process; 2, selecting 6 different color channels by adopting the HSV color model and a CIELUV color model for the image subjected to the fuzzy processing, respectively obtaining 6 characteristic patterns according to phase spectrums; 3, respectively detecting corresponding candidate regions of interest for the characteristic patterns so as to obtain 6 candidate rectangular regions of interest on the 6 characteristic patterns; and 4, building a remarkable pattern of the original image based on the 6 candidate rectangular regions of interest in the step 3, and detecting on the remarkable pattern to finally obtain a rectangular region of interest. The invention has high detection accuracy and robustness for the regions of interest and better application values.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

An experimental animal image calibration method based on hue saturation

PendingCN109685063ALower requirementReduce dependencyImage enhancementImage analysisPattern recognitionImage calibration

The invention discloses an experimental animal image calibration method based on hue saturation. The method is realized on the basis of OpenCV; When the extracted target is preprocessed, the target isnot converted into a grayscale image, but is converted into a HSV (Hue, Saturation, Value) color model, and a warm-toned colorant such as picric acid is applied to the target animal to distinguish itfrom other colors in the HSV color model, and the target extraction is performed on this basis.The method has the advantages that the requirement on the recognition environment is reduced, the anti-interference performance of target extraction is improved through dyeing, particularly, the influence on high light reflected by the water surface and the shadow of the corner can be ignored almost, and the target recognition accuracy is greatly improved in a similar analysis environment. The invention relates to a method for identifying a target through dyeing, which has lower dependence on the identification background, extracts a specific hue area target through color space conversion, and can resist high light on the water surface and corner shadow interference.

Owner:CHENGDU TME SOFTWARE

Method for performing visual image representation on gene information

ActiveCN106096333AEasy to readEasy to analyzeData visualisationBiostatisticsHsv color modelStream data

The invention discloses a visual image representation method for gene information. The gene information is visually converted into a visual image information representation in a byte stream image representation manner based on binary storage of the gene information. According to the method, the gene information is converted into the binary byte stream by utilizing a binary conversion method, and byte stream data is converted to form two-dimensional image data according to different color spaces, wherein the optional color space comprises RGB, HSV and GRAY single channels; a two-dimensional image matrix can adopt three modes of a fixed column, a fixed row and square fitting in structure; and when a program is applied to the execution of conversion, each base group obtains a fixed 8-bit binary number, the 8-bit binary number is multiplied by 4 to serve as an H (hue) value, 128 serves as a S (saturation) value, 128 serves as a V (value) value, an HSV color model is generated and converted into an RGB color model, and finally a visual image in a JPG format is generated.

Owner:广州麦仑信息科技有限公司

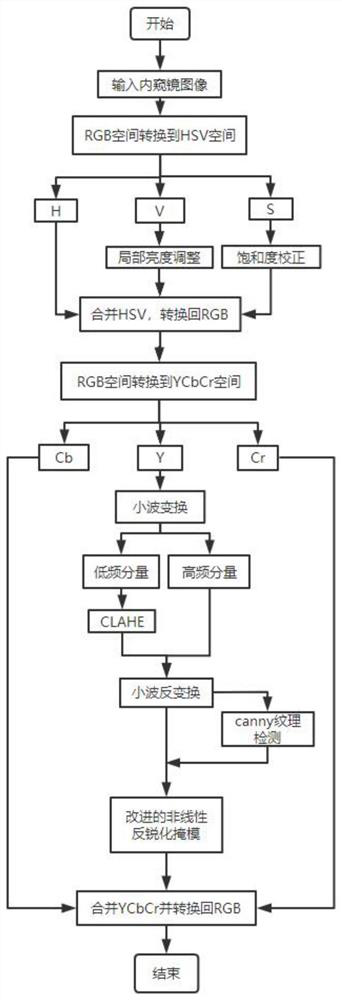

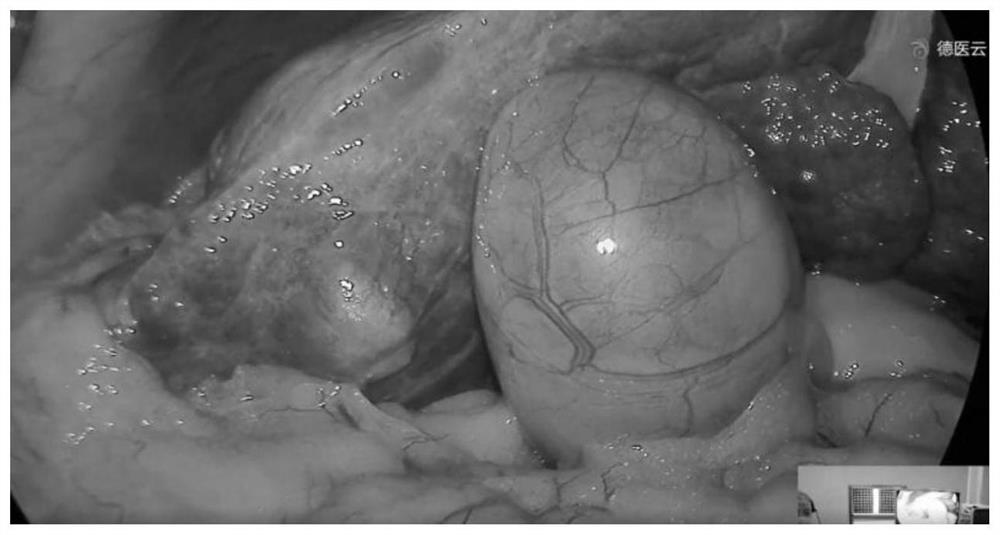

Endoscope image enhancement method based on histogram equalization and improved unsharpened mask

PendingCN113989147AIncrease contrastEnhance background detailsImage enhancementImage analysisHsv color modelImage contrast

The invention discloses an endoscope image enhancement method based on histogram equalization and improved anti-sharpening mask, which relates to the technical field of image enhancement, and comprises the following steps: acquiring an endoscope image; carrying out local brightness adjustment and saturation correction on the endoscope image by adopting an HSV color model; converting the image into a YCbCr space, and performing low-frequency background enhancement on a Y component by adopting a contrast-limited adaptive histogram equalization method; and carrying out canny texture detection, and carrying out high-frequency detail enhancement by using the improved nonlinear unsharp mask to obtain an improved endoscope enhanced image. According to the image enhancement method, a histogram equalization method, canny edge detection and an improved nonlinear anti-sharpening mask are innovatively combined, so that the low-frequency component of background intensity is effectively balanced, contour details are enhanced, the original color of the image is kept while the image contrast is naturally enhanced and detail information such as blood vessels is revealed, and the noise is reduced.

Owner:ANHUI UNIVERSITY

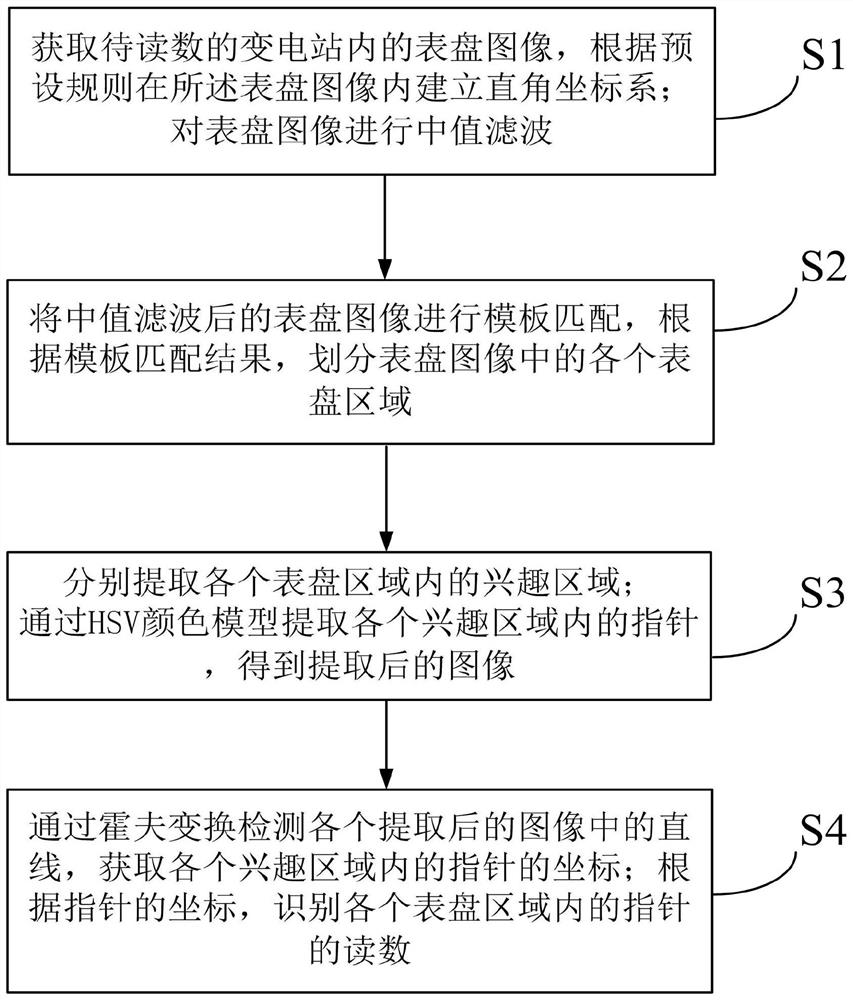

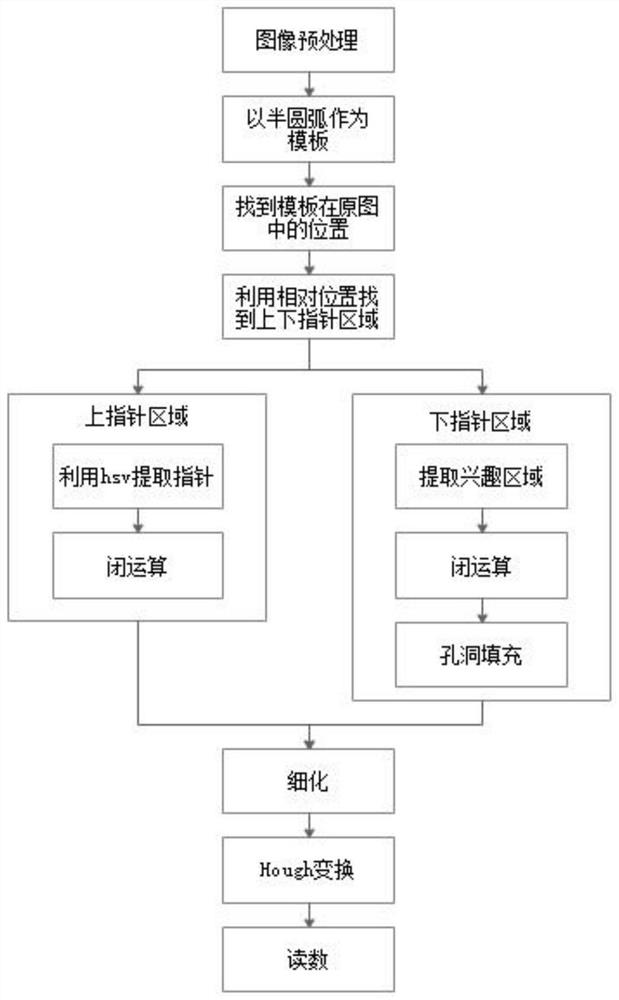

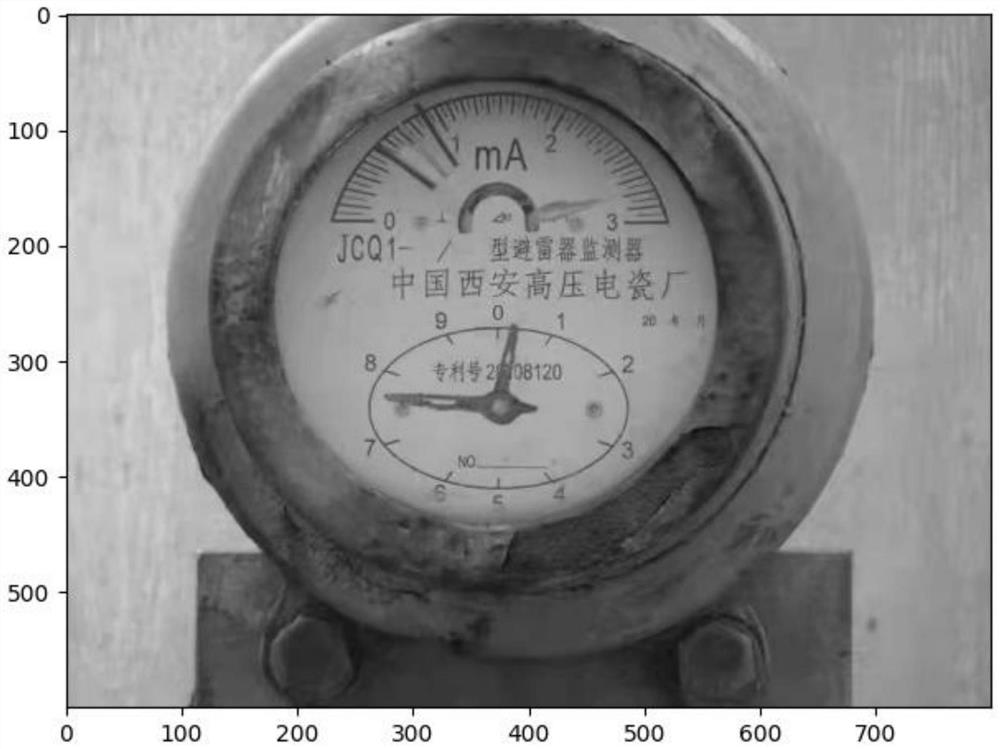

Substation multi-dial multi-pointer identification method based on template matching

PendingCN114863086AImprove accuracyCharacter and pattern recognitionInformation technology support systemAlgorithmHsv color model

The invention discloses a transformer substation multi-dial multi-pointer identification method based on template matching, and the method comprises the steps: obtaining a dial image in a to-be-read transformer substation, and building a rectangular coordinate system in the dial image according to a preset rule; performing median filtering on the dial image; performing template matching on the dial plate image after the median filtering, and dividing each dial plate area in the dial plate image according to a template matching result; respectively extracting regions of interest in each dial region; pointers in all the regions of interest are extracted through an HSV color model, and an extracted image is obtained; detecting straight lines in each extracted image through Hough transform, and obtaining coordinates of pointers in each region of interest; according to the coordinates of the pointers, the readings of the pointers in all the dial plate areas are recognized. According to the method, the reading of the multi-dial multi-pointer instrument in the transformer substation can be automatically identified, and the pointer identification accuracy of the multi-dial multi-pointer instrument is remarkably improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Novel graphical description method for power loads

PendingCN110889019AAids in missing completionAids in classificationData processing applicationsOther databases browsing/visualisationHsv color modelSimulation

The invention discloses a novel graphical description method for power loads, and belongs to the technical field of power quality analysis methods. The method comprises a new graphical description method for the power load, and a conversion method for converting load data into RGB data is designed. The sensitivity of naked eyes of people to the hue in the HSV color model is utilized, and a load image conforming to observation of people is designed on the basis of hue change. According to the load image, the load data of the object at all moments can be displayed in one image, so that the ruleof using the load by the user can be better presented. The new load data image description method is helpful for carrying out load data missing completion, user classification identification, load prediction and the like, is also helpful for applying various latest deep learning methods to an electric power system, is an important supplement to the existing load data visualization, and has very important practical significance.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

An unmanned aerial vehicle real-time detection method used in a dynamic environment

ActiveCN109948570AMeet the real-time detection requirementsReduce false detection rateImage analysisCharacter and pattern recognitionHsv color modelUncrewed vehicle

The invention discloses an unmanned aerial vehicle real-time detection method used in a dynamic environment. The unmanned aerial vehicle real-time detection method comprises the steps of 1, establishing an Otsu-HSV color model; Step 2, inputting an image into the Otsu-HSV color model; using a BING algorithm to detect, and combining an overlapping area formula to eliminate a part of detection windows with large coincidence degrees; and step 3, combining an NMS algorithm of a linear weighting method, and replacing the original confidence score of some windows needing to be suppressed with relatively low confidence by using the NMS algorithm. According to the method, the HSV space and the maximum between-cluster variance method are combined, the overlapping area and the linear weighted scoreare introduced, the improved BING / NMS algorithm is provided, and finally, on the premise that the real-time performance is met, the detection accuracy and the optimal overlapping rate of the unmannedaerial vehicle are ensured, and the false detection rate and the missing detection rate are reduced.

Owner:DALIAN UNIV

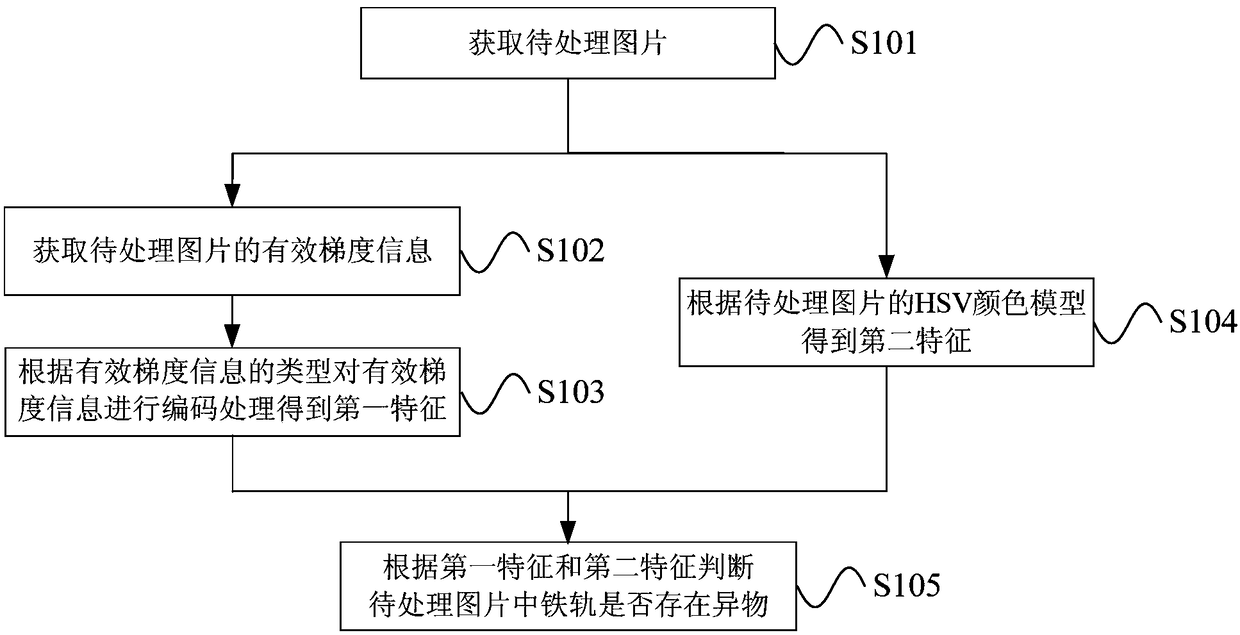

Air-based platform image-based rail foreign body monitoring method and device

The invention provides an air-based platform image-based rail foreign body monitoring method and device. The method comprises steps: a to-be-processed image is acquired, wherein the to-be-processed image is a rail image photographed by a low-altitude unmanned aerial vehicle; the effective gradient information of the to-be-processed image is acquired; according to the type of the effective gradientinformation, the effective gradient information is subjected to coding processing to obtain a first feature; according to the hue, saturation and transparency HSV color model of the to-be-processed image, a second feature is obtained; and according to the first feature and the second feature, whether a foreign body exists in the rail in the to-be-processed image can be judged. According to the air-based platform image-based rail foreign body monitoring method and device provided in the invention, the effective gradient information and the color information of the image are combined to judge whether a foreign body exists in the rail, and the rail foreign body monitoring efficiency is improved.

Owner:BEIHANG UNIV

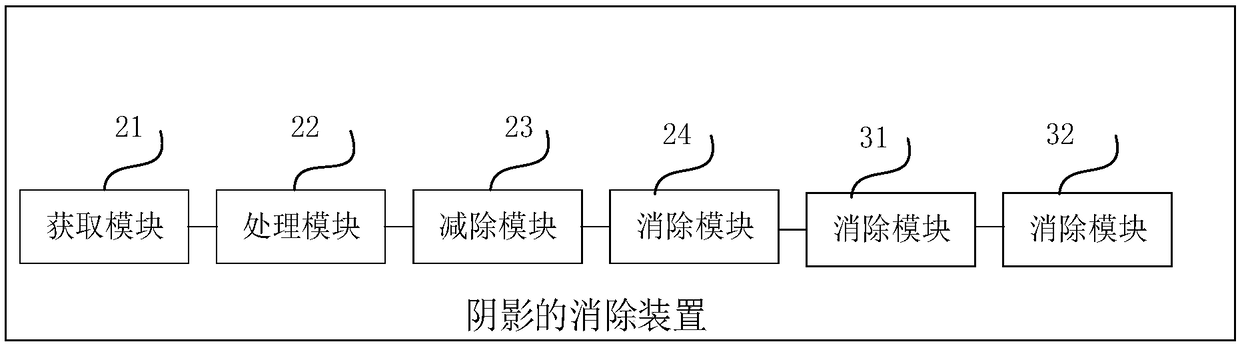

Shadow elimination method and device and storage medium

InactiveCN109166080AIncrease the speed of subtractionImprove accuracyImage enhancementImage analysisHsv color modelBrightness perception

The invention provides a shadow elimination method and device and a storage medium. The method comprises the following steps: acquiring a sequence image, wherein the sequence image comprises a plurality of frames; establishing the Gaussian mixture model according to the sequence images, and estimating the parameters of the Gaussian mixture model; according to the Gaussian mixture model after parameter estimation, subtracting the background to obtain the foreground object in the sequence image; using a tone-saturation degree-brightness HSV color model to remove shadows from foreground objects.The invention not only realizes the shadow elimination of the foreground object extracted from the sequence image, but also improves the accuracy and speed of the foreground object shadow elimination.

Owner:BAIC MOTOR CORP LTD

Method for recognizing and adjusting bulbil in precise directional ginger planting

ActiveCN110178481AEasy to operateThe process brief is clearSeed and root treatmentCharacter and pattern recognitionHsv color modelAngular deviation

The invention relates to a method for recognizing and adjusting bulbil in precise directional ginger planting. The method includes the steps of the HSV converting stage, wherein an images of an HSV color model of ginger species is collected or an image of an other-color model of the ginger species is converted into the HSV color model and then stored in a memorizer; the color splitting stage, wherein the color splitting operation is conducted on the image, and a ginger bulbil color area in the image is kept; the image binarization stage, wherein the stored image is binarized; the corrosion operation stage, wherein corrosion operation is conducted on the binarized image; the expansion operation stage, wherein expansion operation is conducted on the corroded binarized image; the image recognition stage, wherein the position of the ginger bulbil in the image is recognized; the deviation calculation stage, wherein the angular deviation of the ginger bulbil relative to the 0-degree base line is calculated; the bulbil adjustment stage, wherein the direction of the ginger bulbil is adjusted when a stepping motor adjusting device is controlled to drive the ginger species to rotate during planting.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

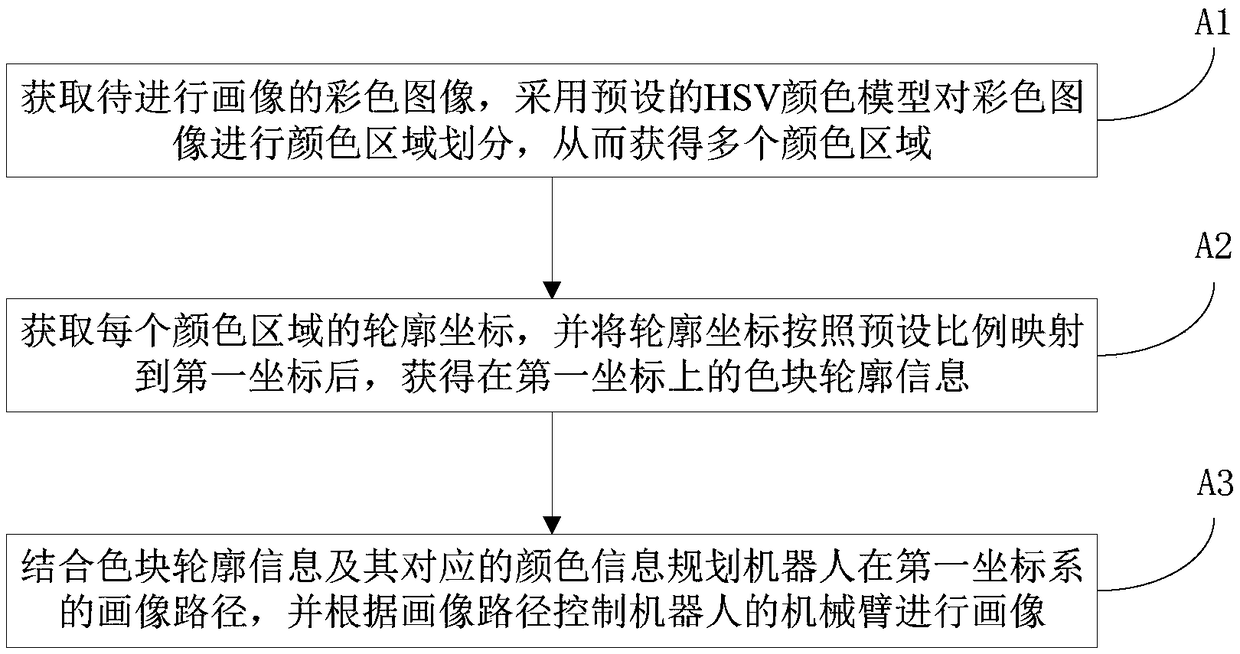

A method and a system for controlling a robot portrait

ActiveCN109087371AMeet the requirements for drawing color imagesImage analysisTexturing/coloringColor imageHsv color model

The invention discloses a method and a system for controlling a robot portrait, wherein, the method comprises the following steps: obtaining a color image of the image to be portrayed; dividing a color region of the color image by adopting a preset HSV color model, thereby obtaining a plurality of color regions; obtaining a color region of the color image by using a preset HSV color model; and obtaining a color region of the color image; obtaining contour coordinates of each color region, mapping the contour coordinates to a first coordinate system according to a preset proportion, and obtaining contour information of color blocks on the first coordinate system; combining the outline information of color block and its corresponding color information, the robot's image path in the first coordinate system being planned, and the robot's manipulator being controlled to draw according to the image path. The invention obtains a plurality of color regions through an HSV color model, and the contour coordinates of the color region are mapped to the first coordinate system, and then the robot is controlled to draw on the first coordinate system according to the contour information of the color block, so as to obtain the color portrait, which satisfies the requirements of people on the color image drawing of the portrait robot, and can be widely used in the field of robot control.

Owner:深圳市智能机器人研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com