Non-contact on-line measurement method of aluminum ingot thickness

A measurement method, non-contact technology, applied in the field of metal thermal processing, can solve the problems of inaccurately reflecting the true thickness of aluminum ingots, sloshing of aluminum liquid, and less aluminum ingots, so as to save manpower, increase speed, and improve thickness measurement accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The method of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0032] The specific implementation steps will be described in detail below.

[0033] Step 1: Model the aluminum ingot mold, find the mathematical relationship between the thickness of the aluminum ingot and the width of the upper surface of the aluminum liquid, so as to facilitate subsequent conversion of the width of the aluminum ingot into thickness information. This step needs to actually measure the mold and find the corresponding relationship after modeling;

[0034] Step 2: Take pictures of the aluminum ingot site and crop the original images, and cut out unnecessary parts to reduce the amount of data that needs to be calculated, so as to increase the processing speed;

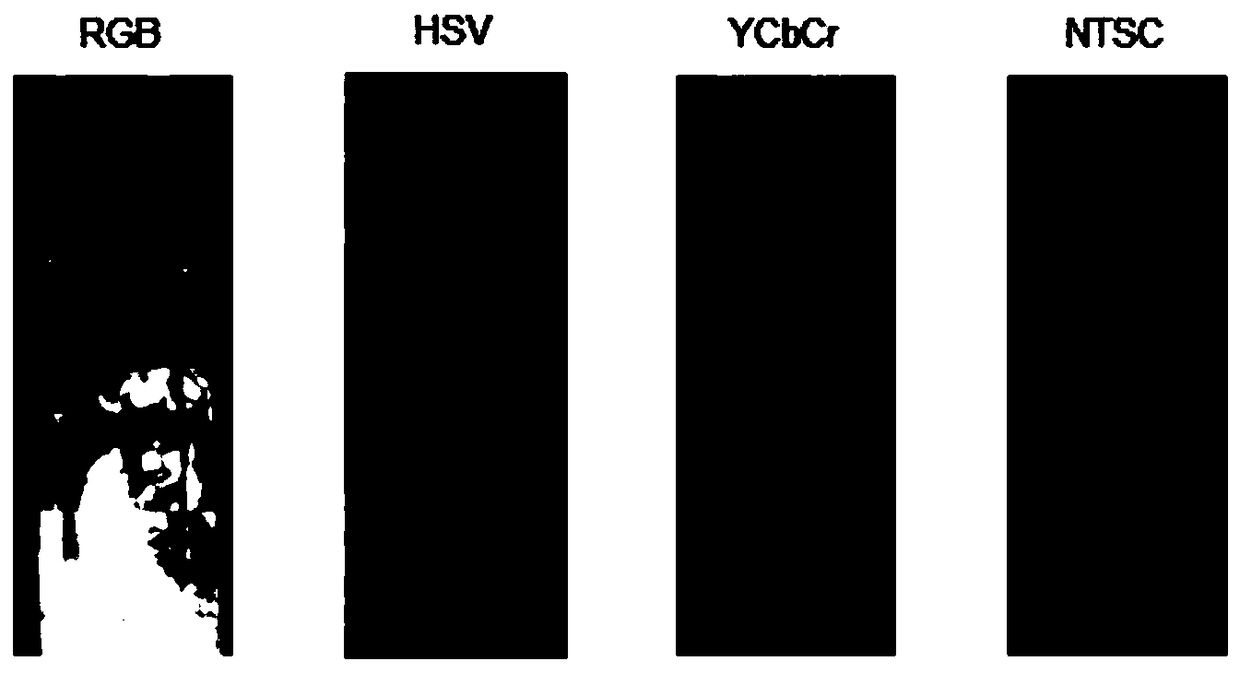

[0035] Step 3: Compare the cropped images under different color models, as shown in Figure 3, it can be seen that the HSV color model can better highlight the required measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com