Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Feedforward systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

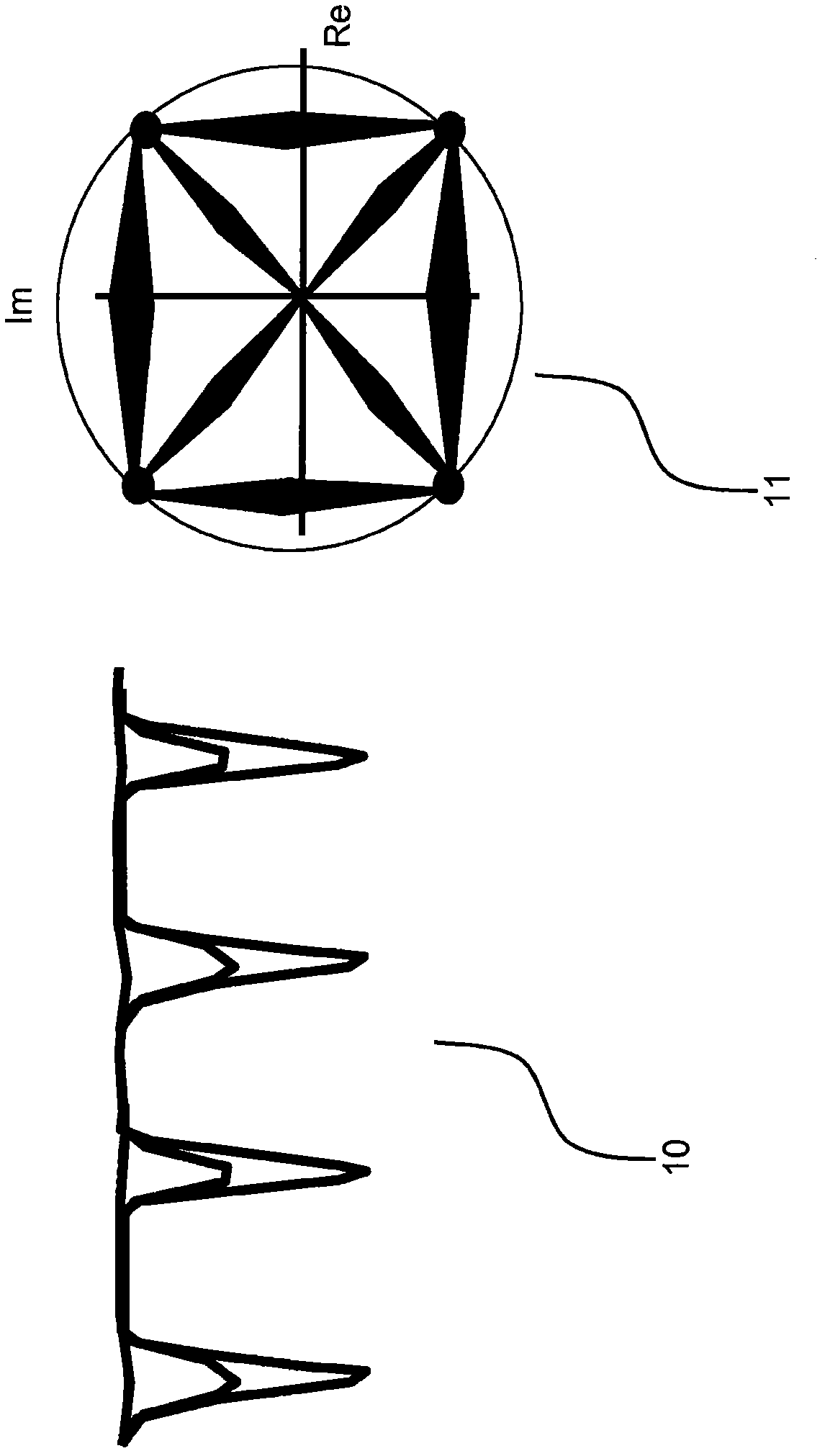

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Feedforward control system. Feedforward control measures one or more inputs of a process, calculates the required value of the other inputs and then adjusts it. Feedforward control has to predict the output as it does not measure output. So, it is sometimes called as PREDICTIVE CONTROL.

Noise-canceling headphone

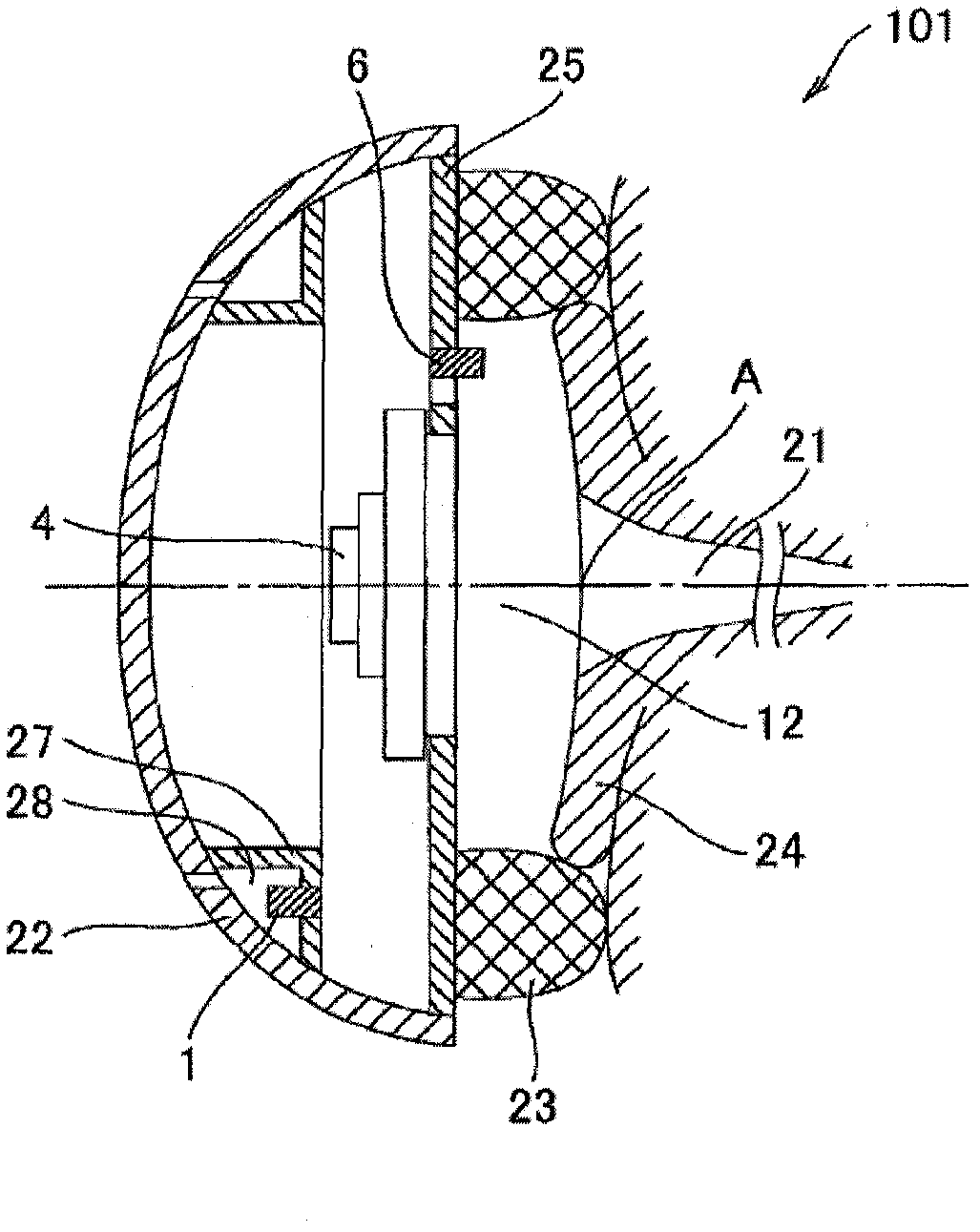

InactiveUS20120014532A1Improve noise reductionCancel noiseEar treatmentNoise generationNoise-cancelling headphonesEngineering

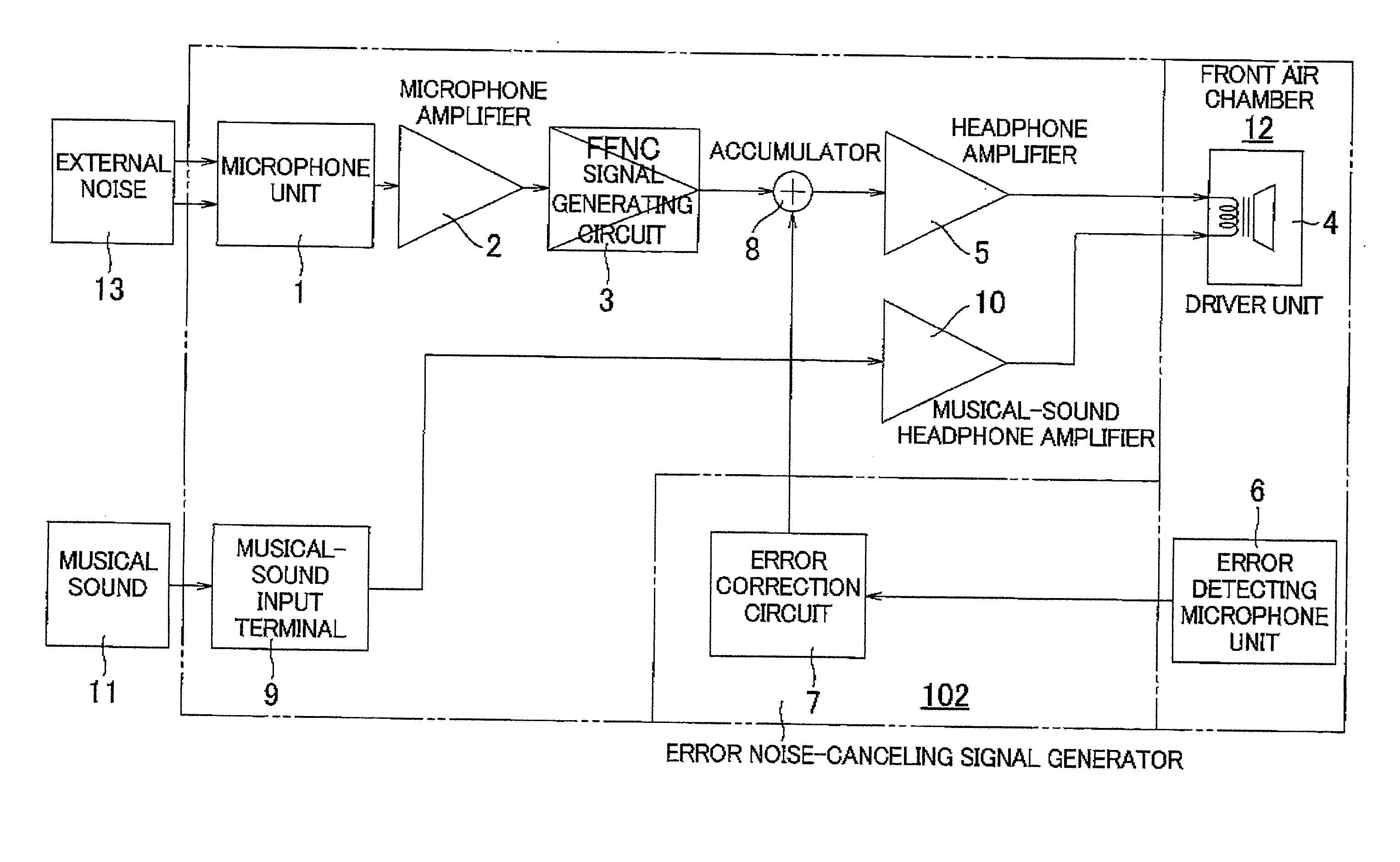

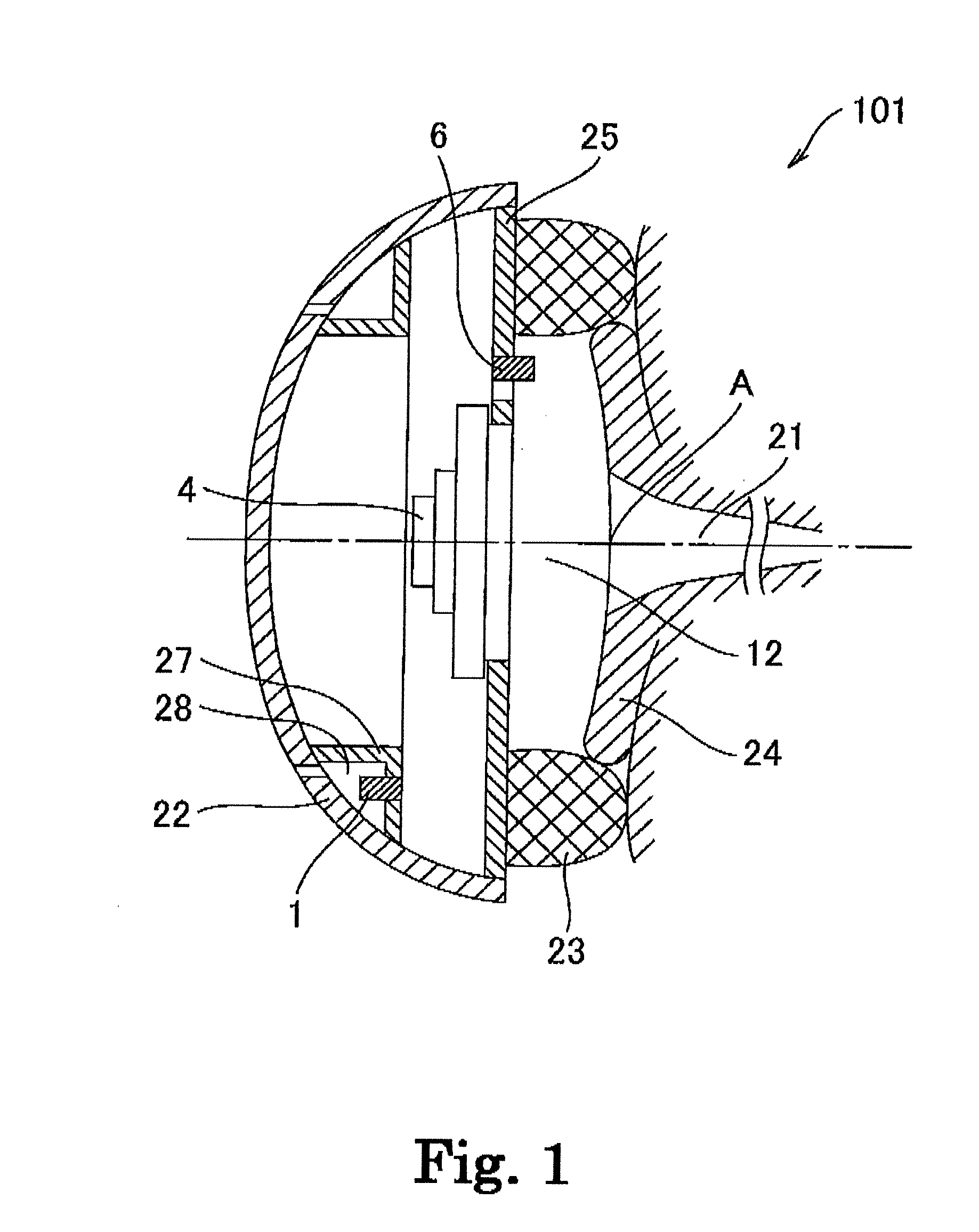

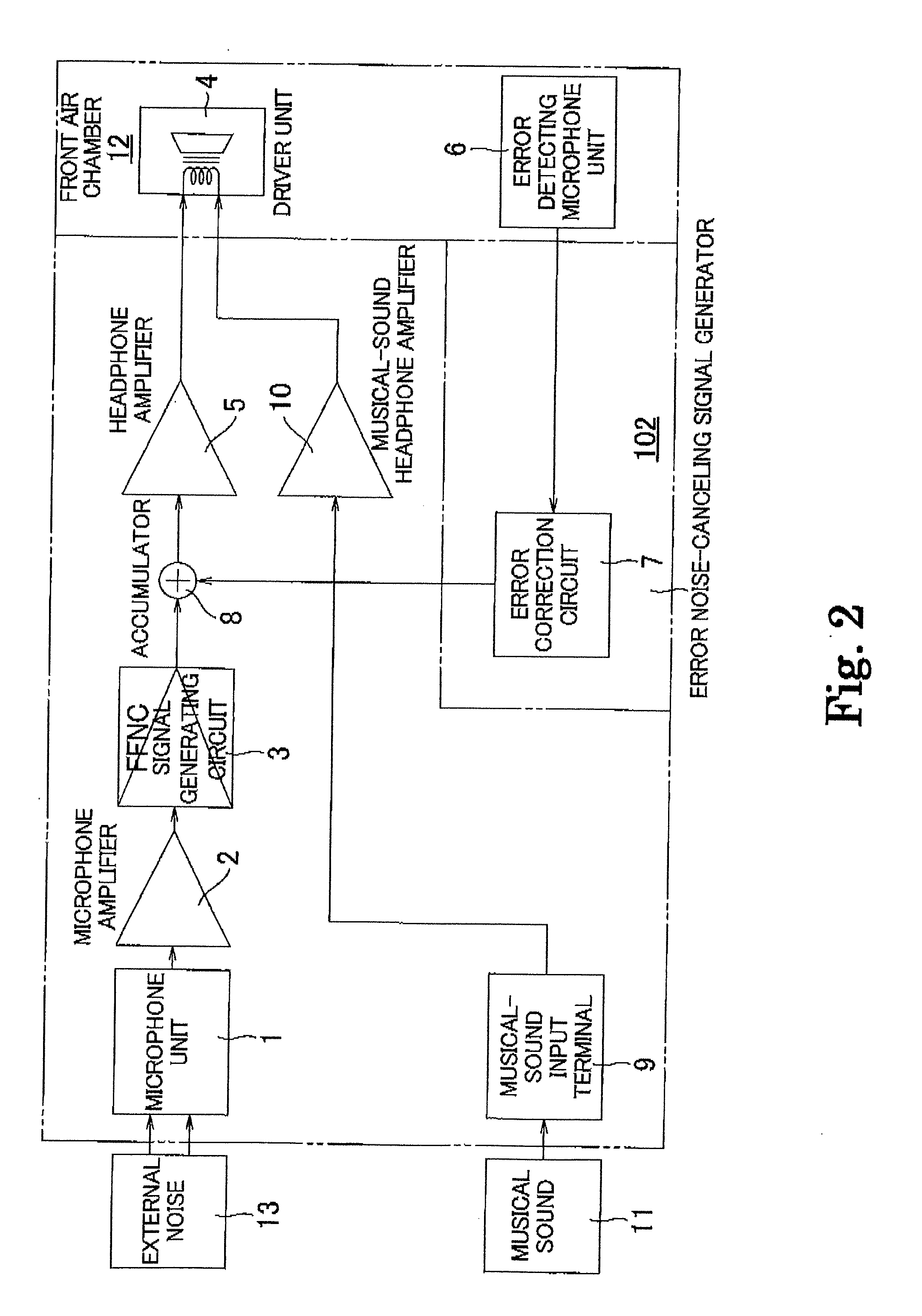

A noise-canceling headphone that cancels external noise with a feedforward system includes a driver unit disposed in a housing, a microphone unit that is outwardly disposed in the housing and collects the external noise, and canceling signal generator that generates a noise-canceling signal having a phase opposite to the noise entering through the headphone. The noise-canceling headphone includes an error detecting microphone unit that detects error noise uncanceled by the feedforward system, and error noise-canceling signal generator that generates an error correction signal to cancel the error noise with a feedback system.

Owner:AUDIO-TECHNICA

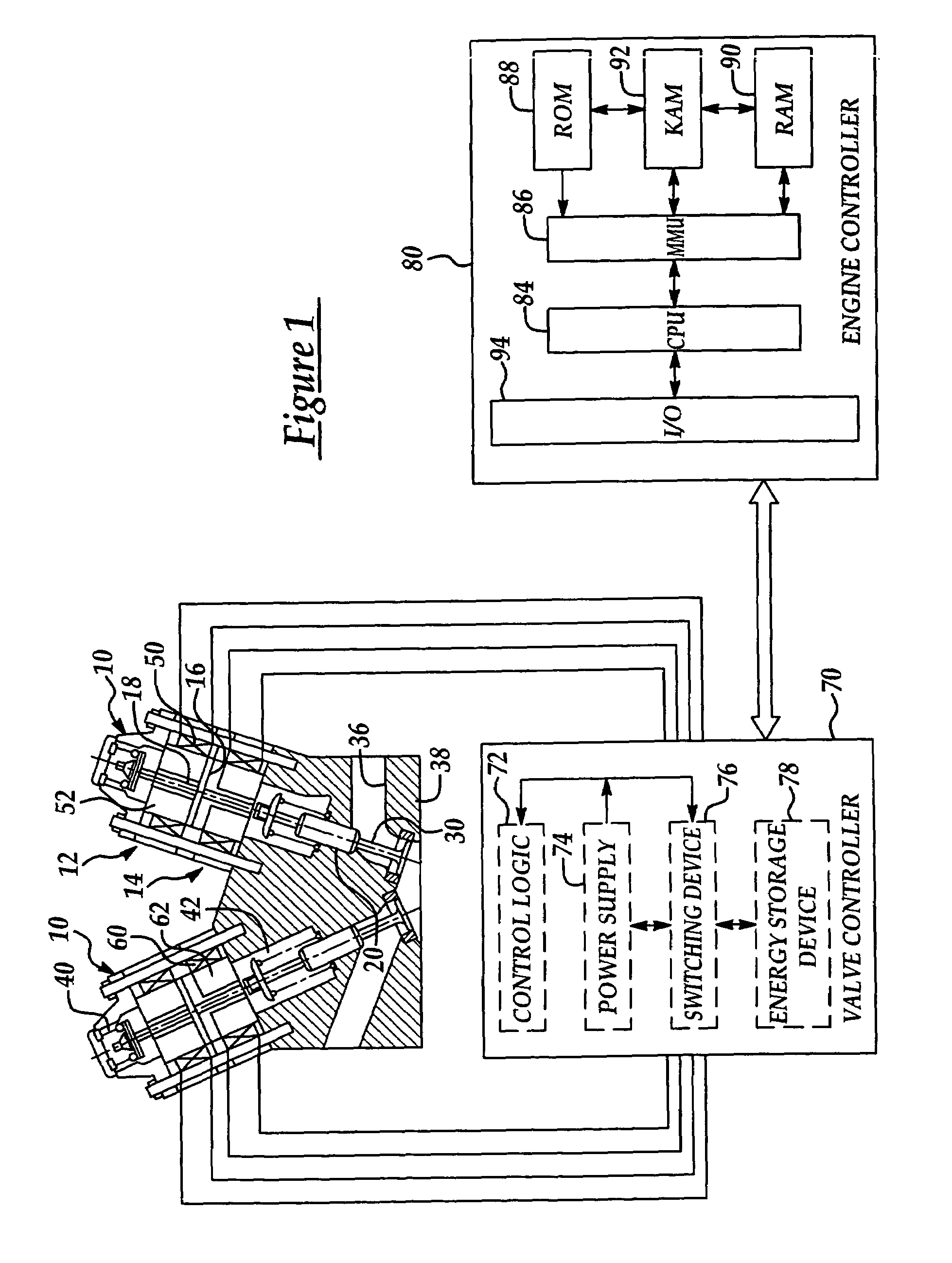

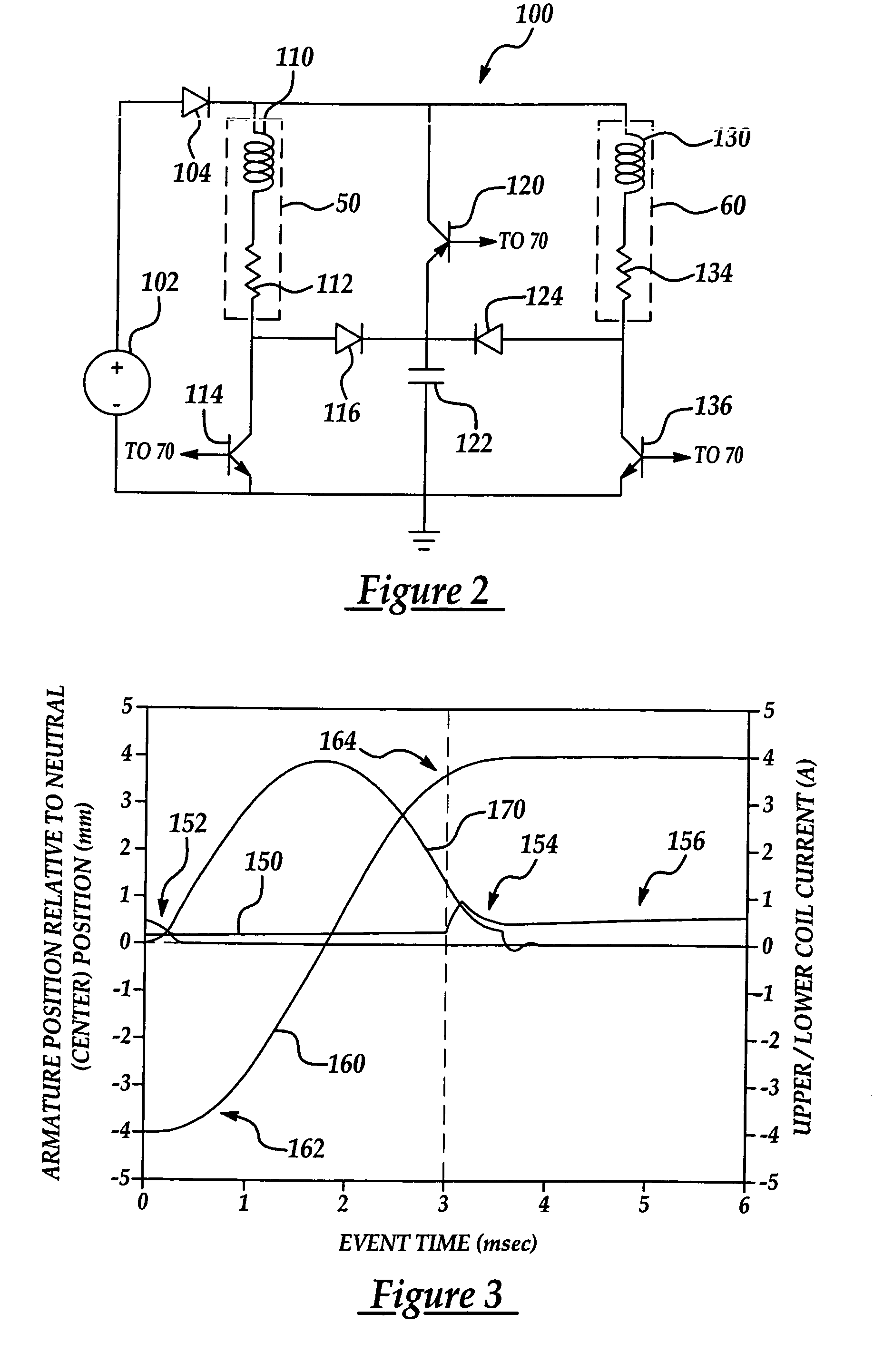

Electromagnetic valve actuation

ActiveUS6948461B1Loss of forceRapidly quench the coil currentOperating means/releasing devices for valvesElectric switchesCombustion chamberControl system

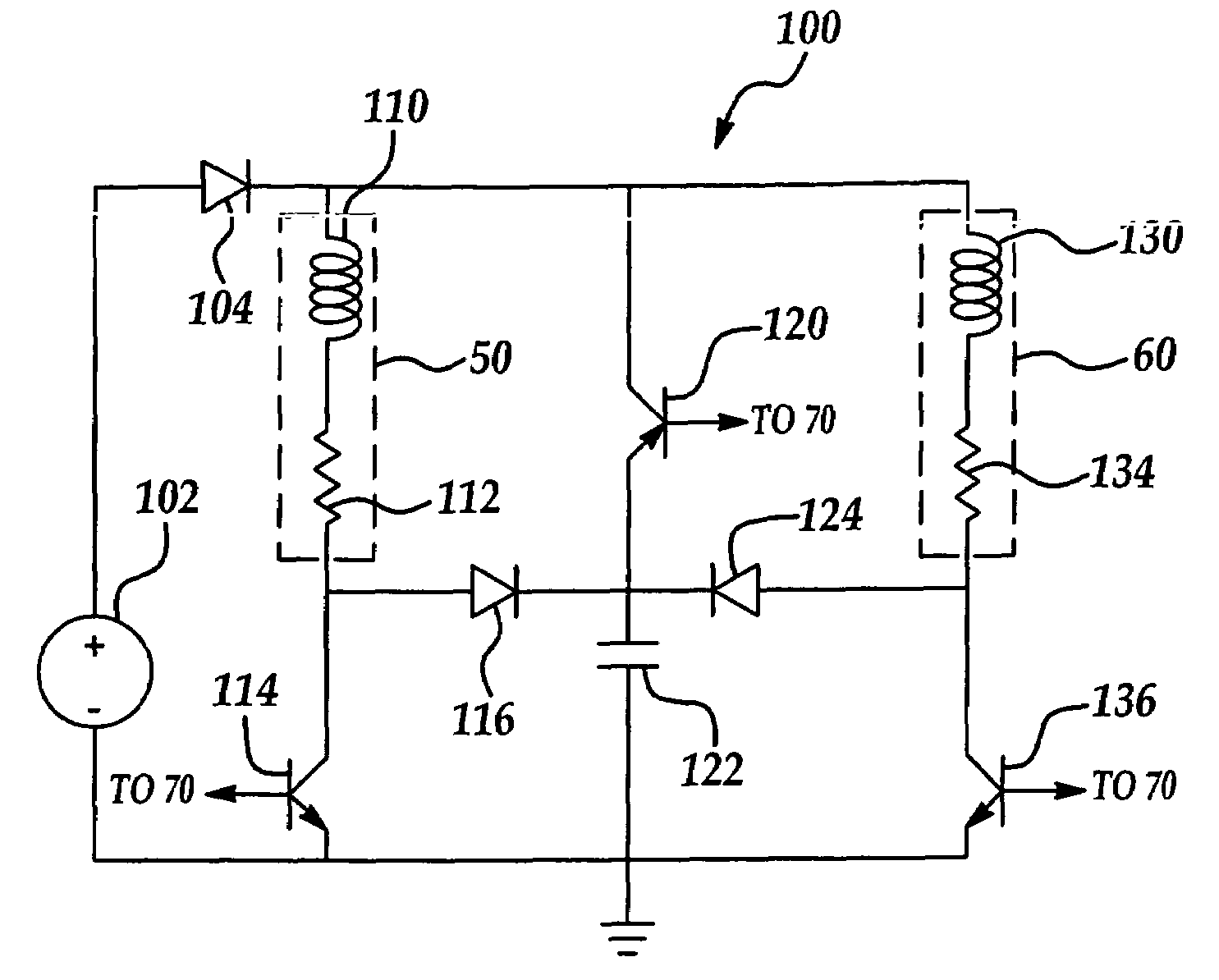

A system and method for controlling an internal combustion engine provide valve actuation that selectively couples an energy storage device to a launching coil to recover energy stored in the magnetic field and valve spring of the launching coil, decouples the energy storage device during a valve opening or closing event to control energy supplied to the catching coil, and couples the energy storage device to the catching coil to transfer energy from the storage device to the catching coil to provide a repeatable soft landing. A nonlinear feedback controller incorporates a feedforward system with an observer to control the rate of energy into the magnetic field of the catching coil while compensating for system losses and work to overcome gas forces within the combustion chamber. Feedback linearization techniques improve stability of the control system.

Owner:FORD GLOBAL TECH LLC

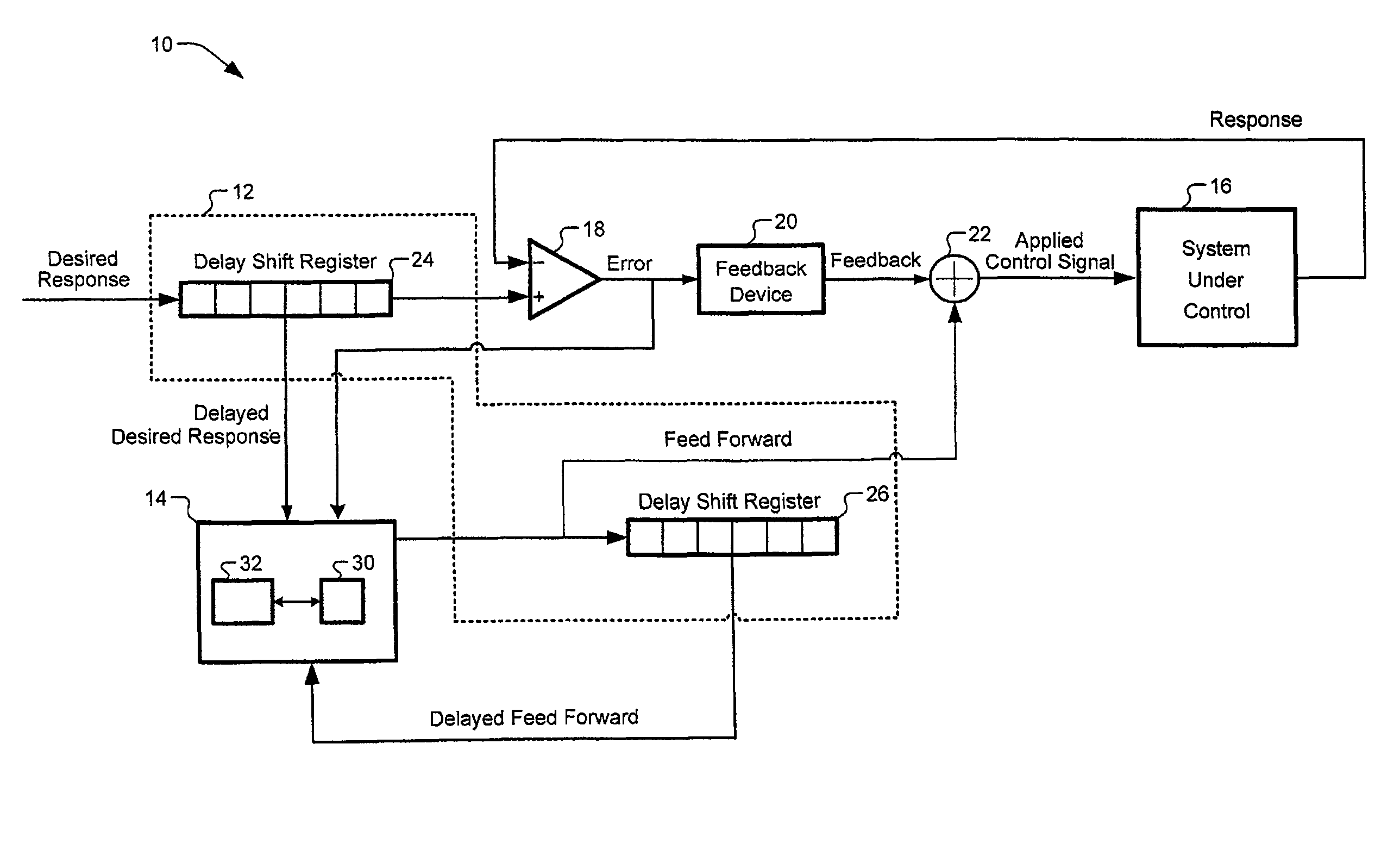

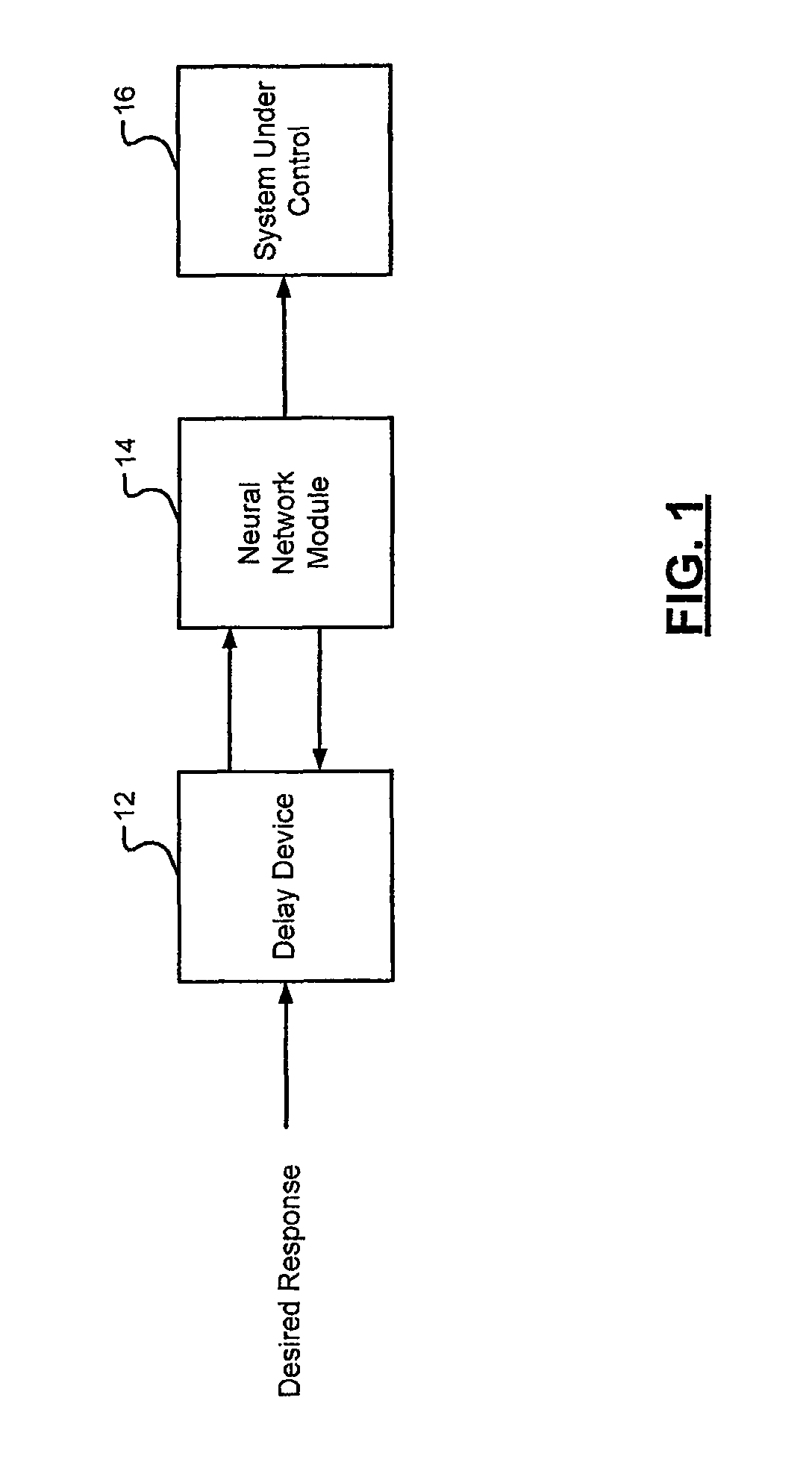

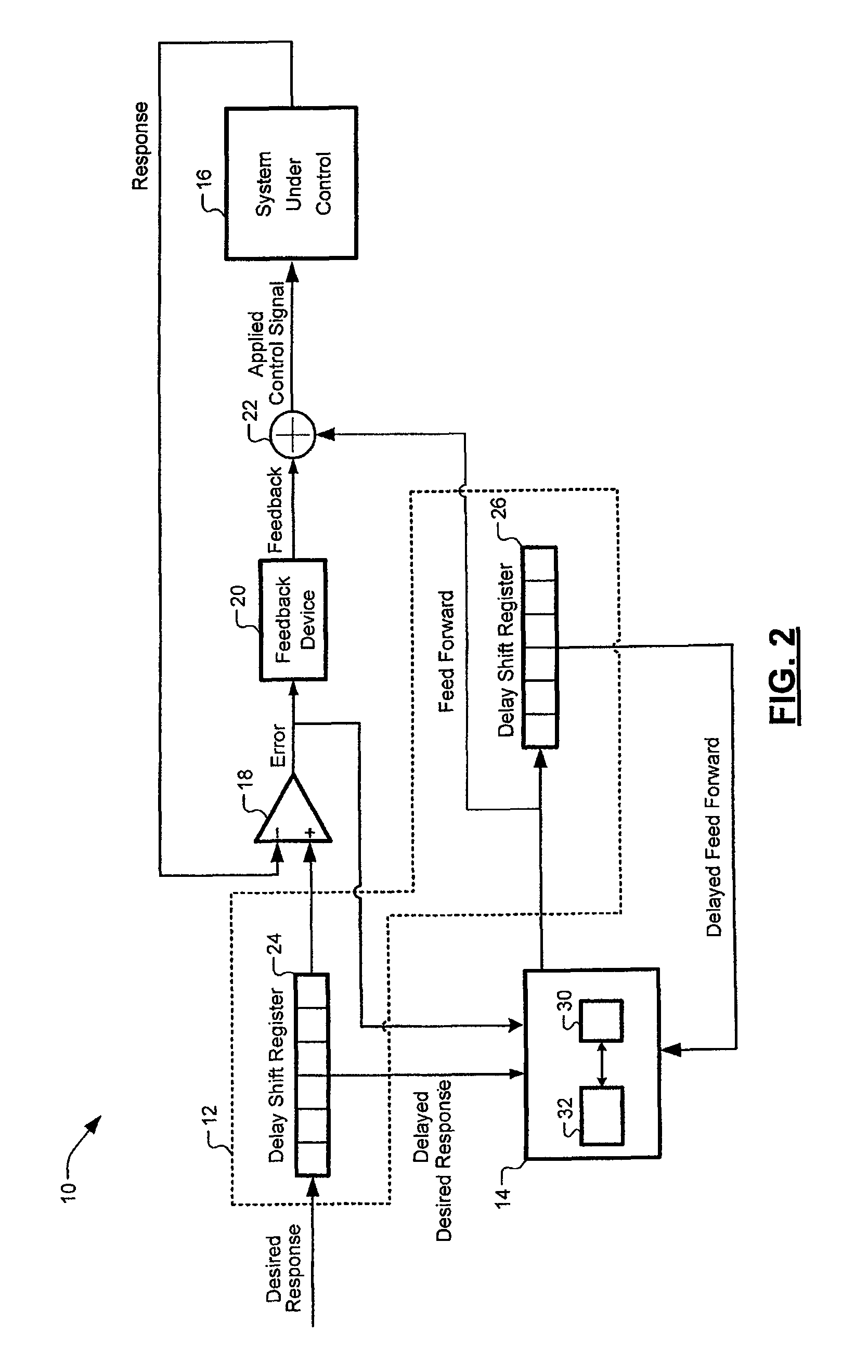

Adaptive neural net feed forward system and method for adaptive control of mechanical systems

A feed forward system includes an input device configured to receive a desired response of the mechanical system and a trainable system configured to generate a feed forward signal that drives the mechanical system based on the desired response. The trainable system is trained based on a plurality of measured responses of the mechanical system.

Owner:MARVELL ASIA PTE LTD

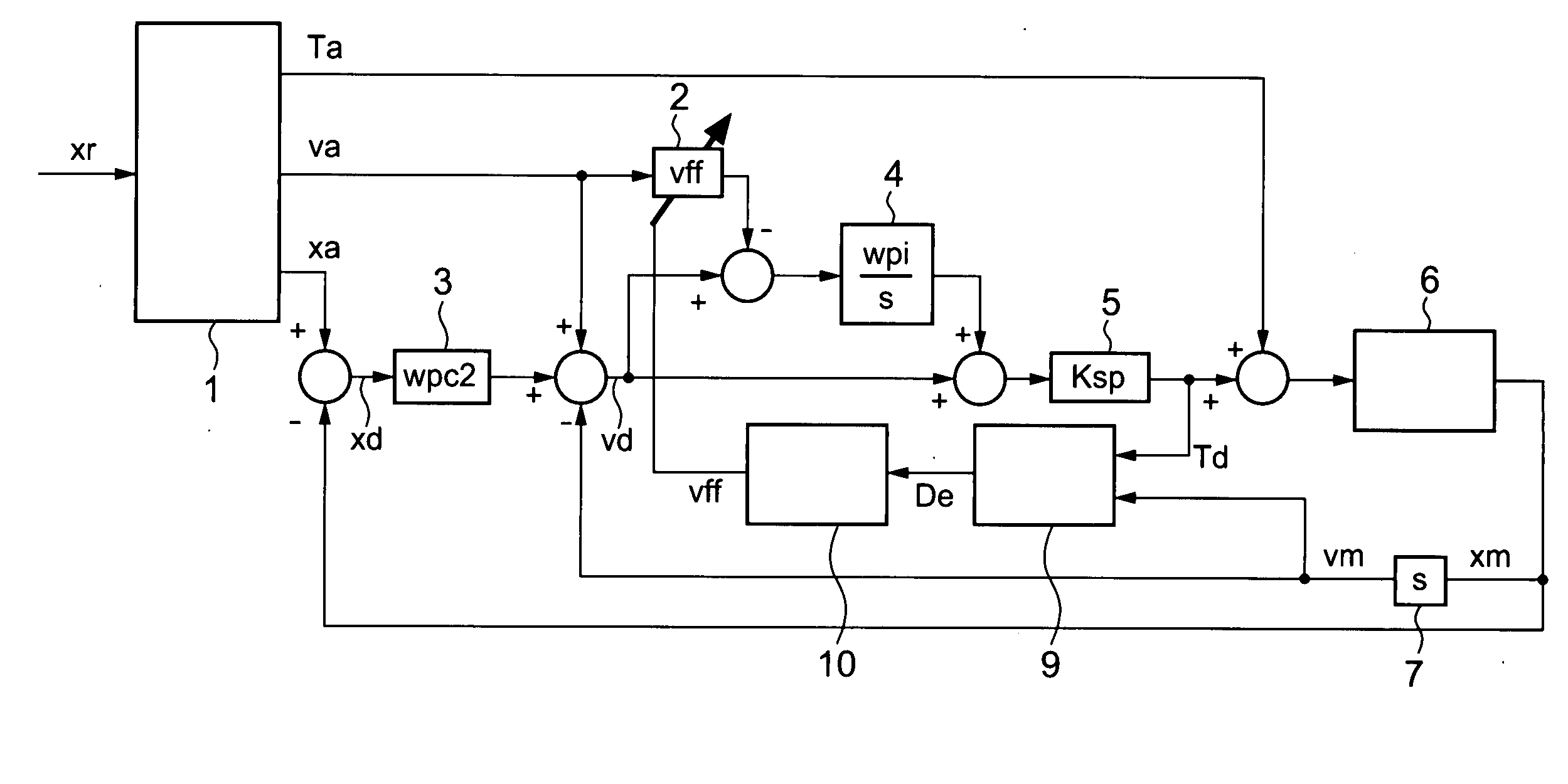

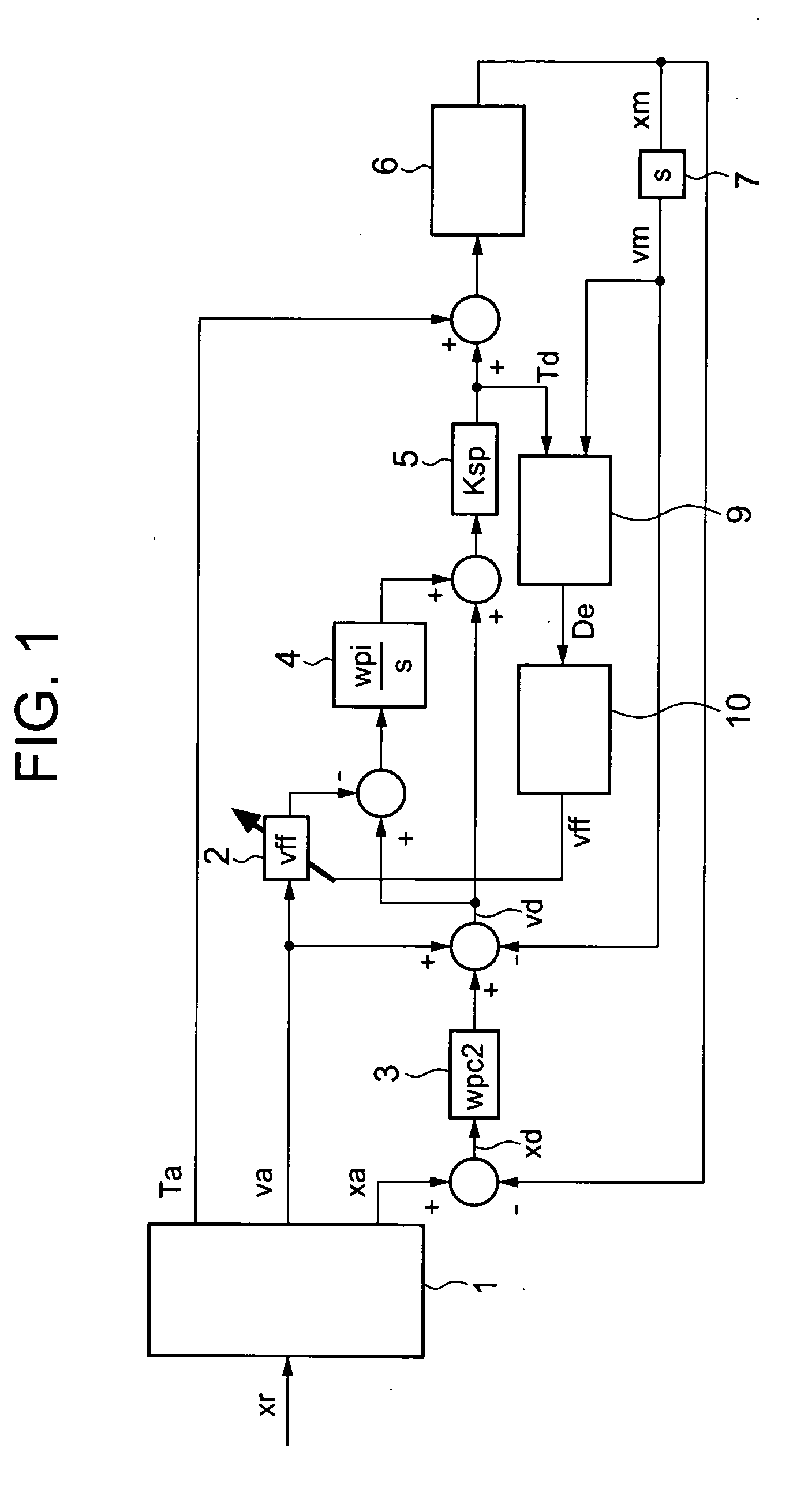

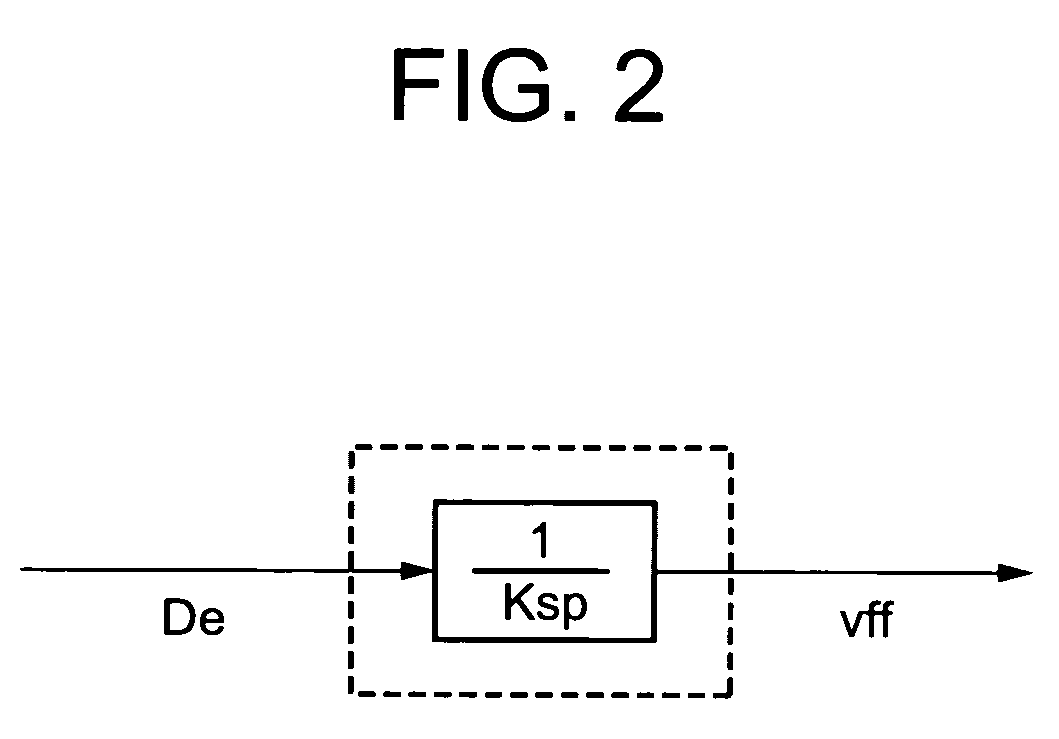

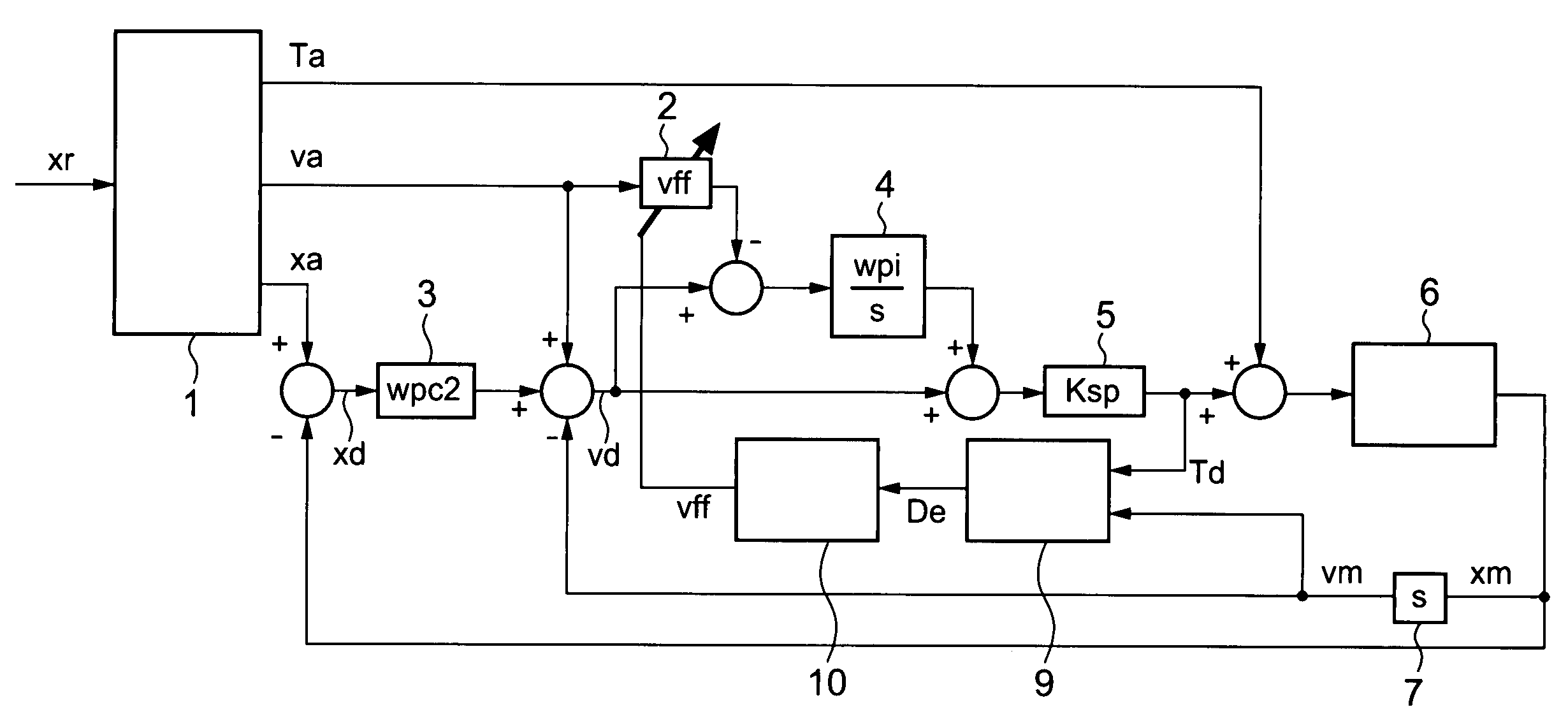

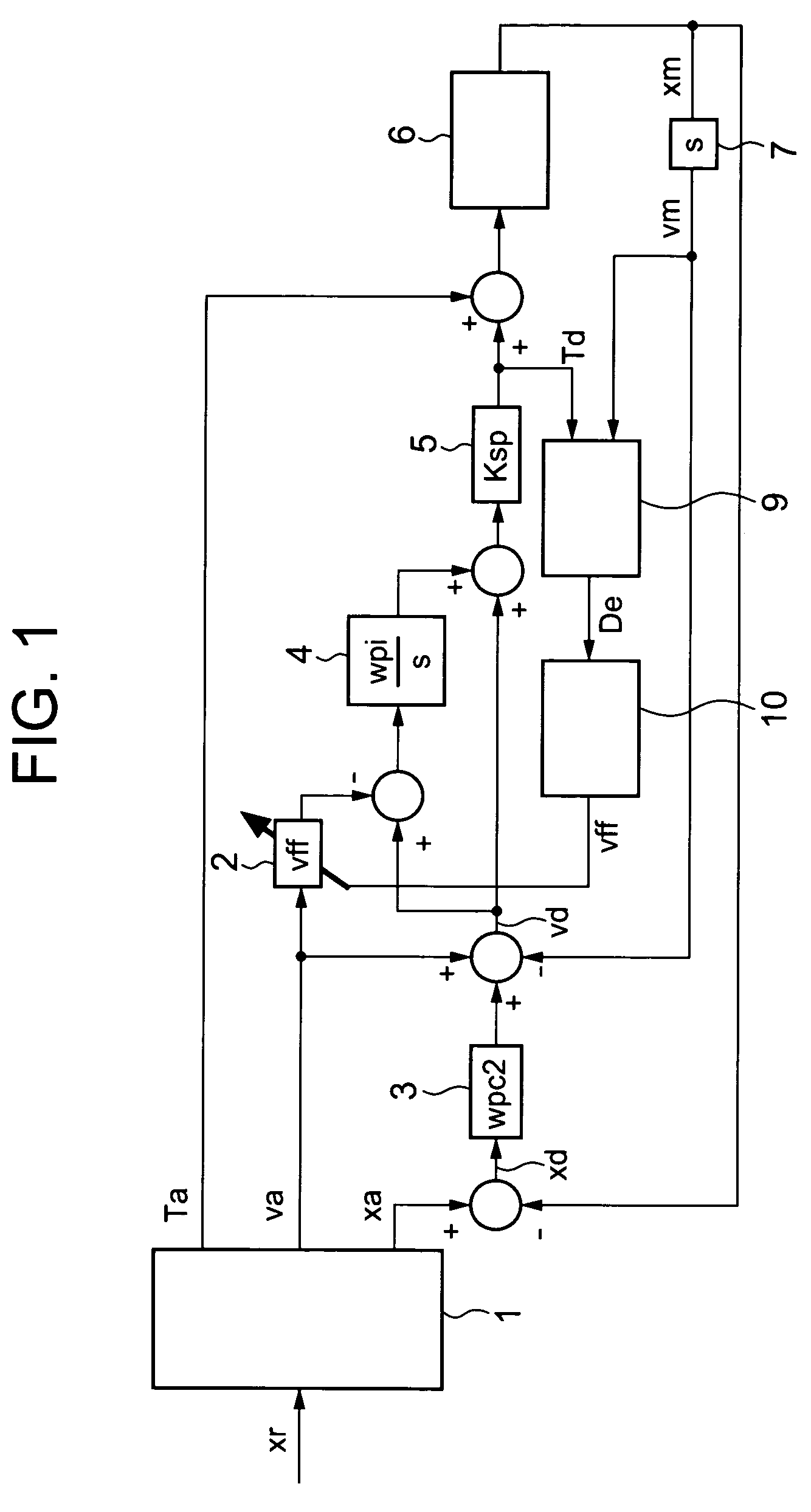

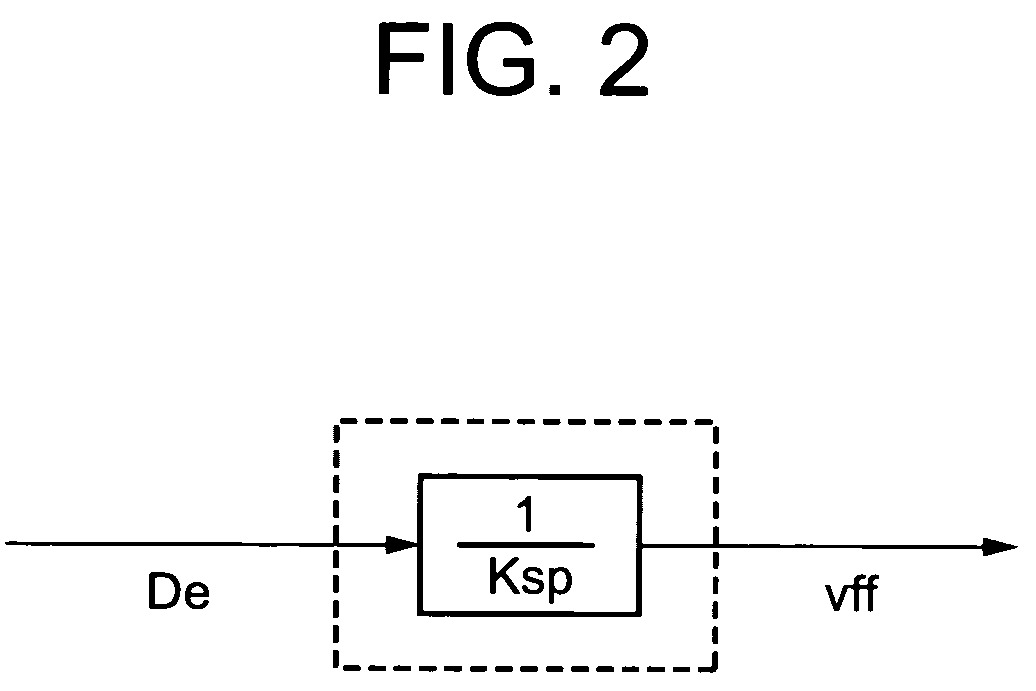

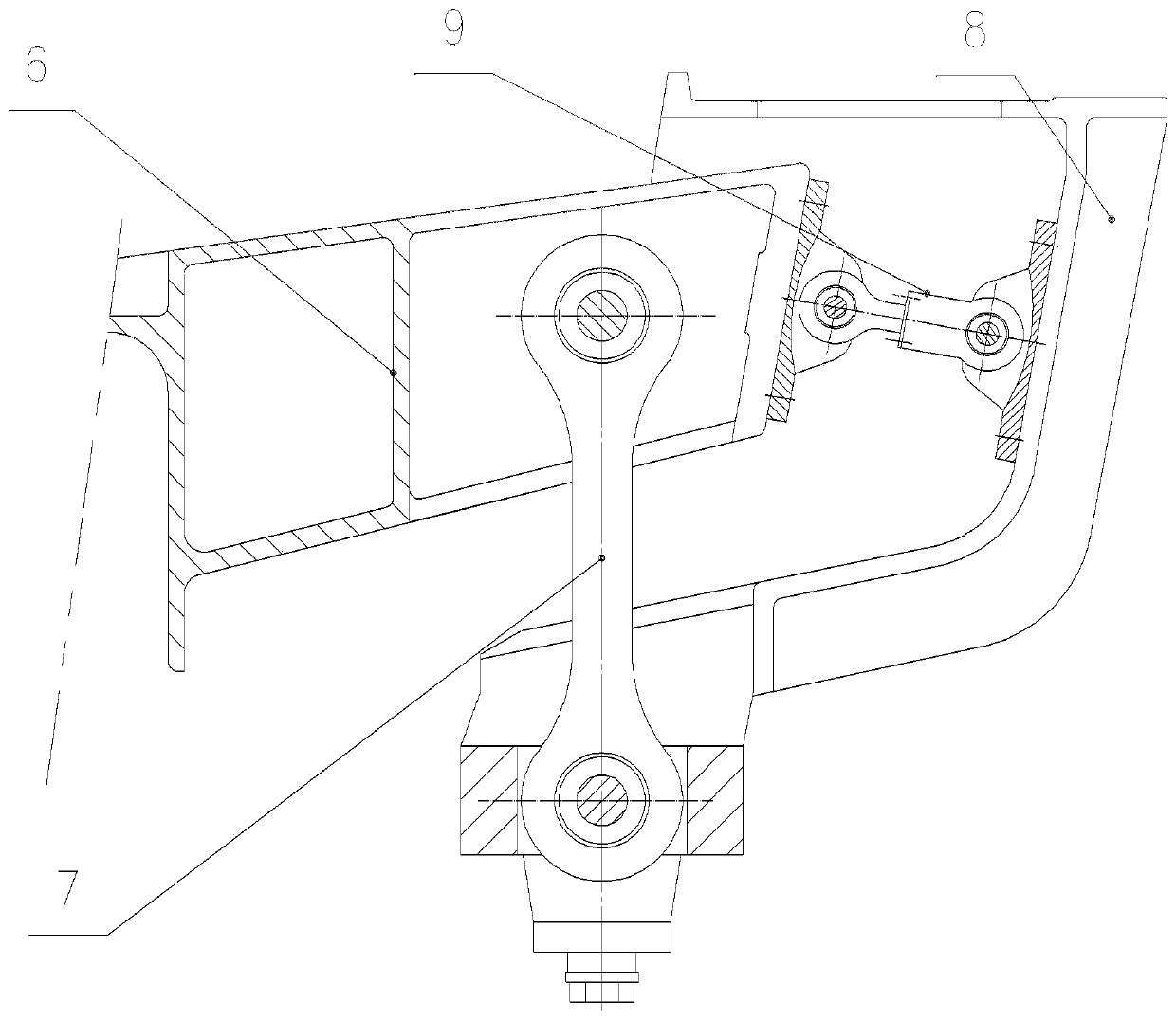

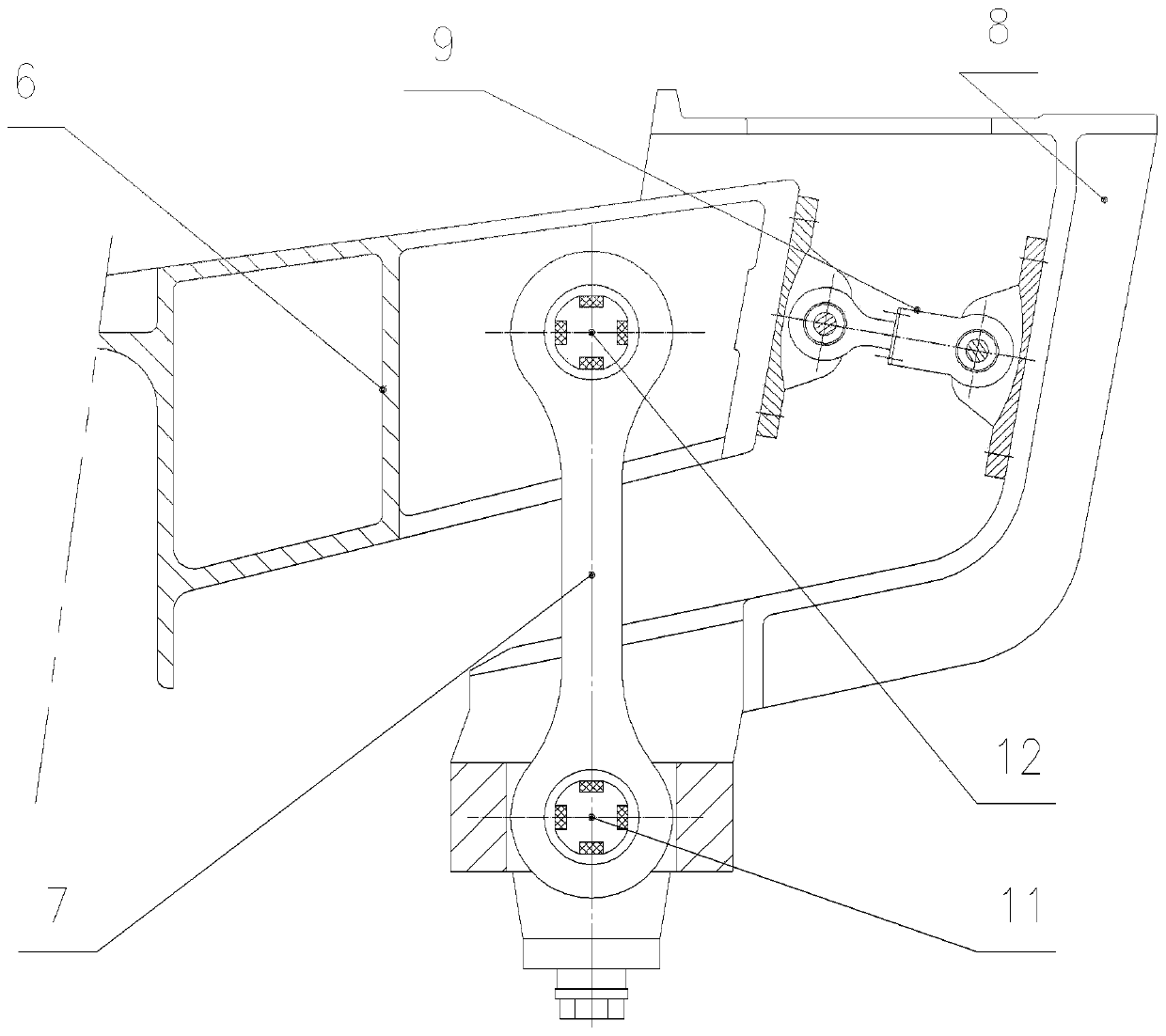

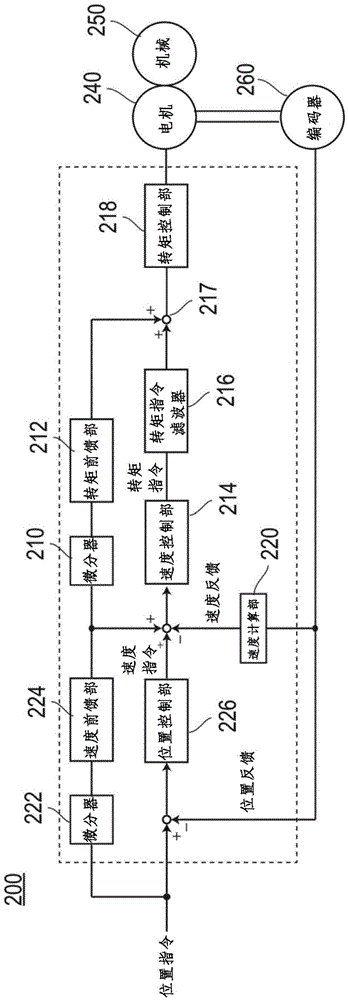

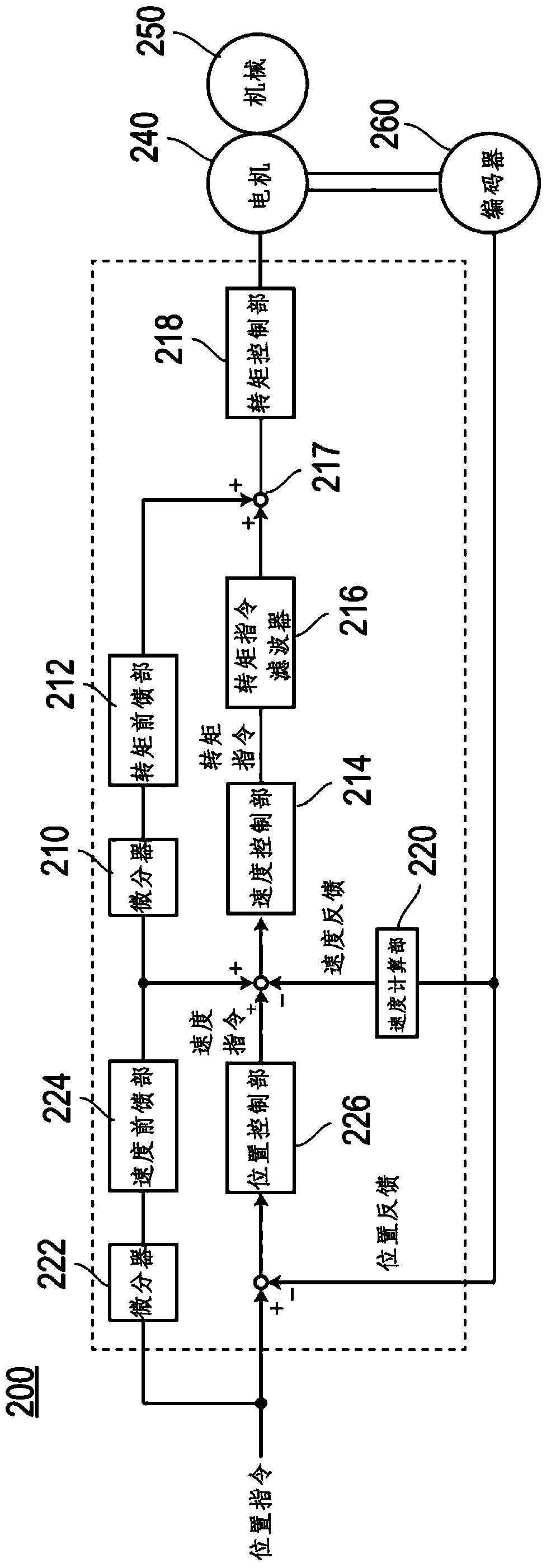

Position controller and controlling method therefor

ActiveUS20070007927A1Decrease feedforwardPossibility of generating mechanical resonances is smallProgramme controlElectric motor controlValue setPosition control

An objective is to obtain a high robust position controller and a controlling method therefor, with respect to their technique in which control gain, in order to prevent an overshoot due to frictions, is most suitably adjusted. The position controller having a feedforward system includes: a friction-coefficient-estimated-value setting unit for setting arbitrary friction-coefficient-estimated-values; an overshoot-prevention-gain calculator for determining speed-integral-term feedforward gain, based on estimated friction-coefficient values set by the friction-coefficient-estimated-value setting unit; and a speed feedforward multiplying unit for calculating the product of the speed-integral-term feedforward gain multiplied by a feedforward command value that is based on a positional command; the multiplication product from the speed feedforward multiplying unit being used to reduce the feedforward term.

Owner:MITSUBISHI ELECTRIC CORP

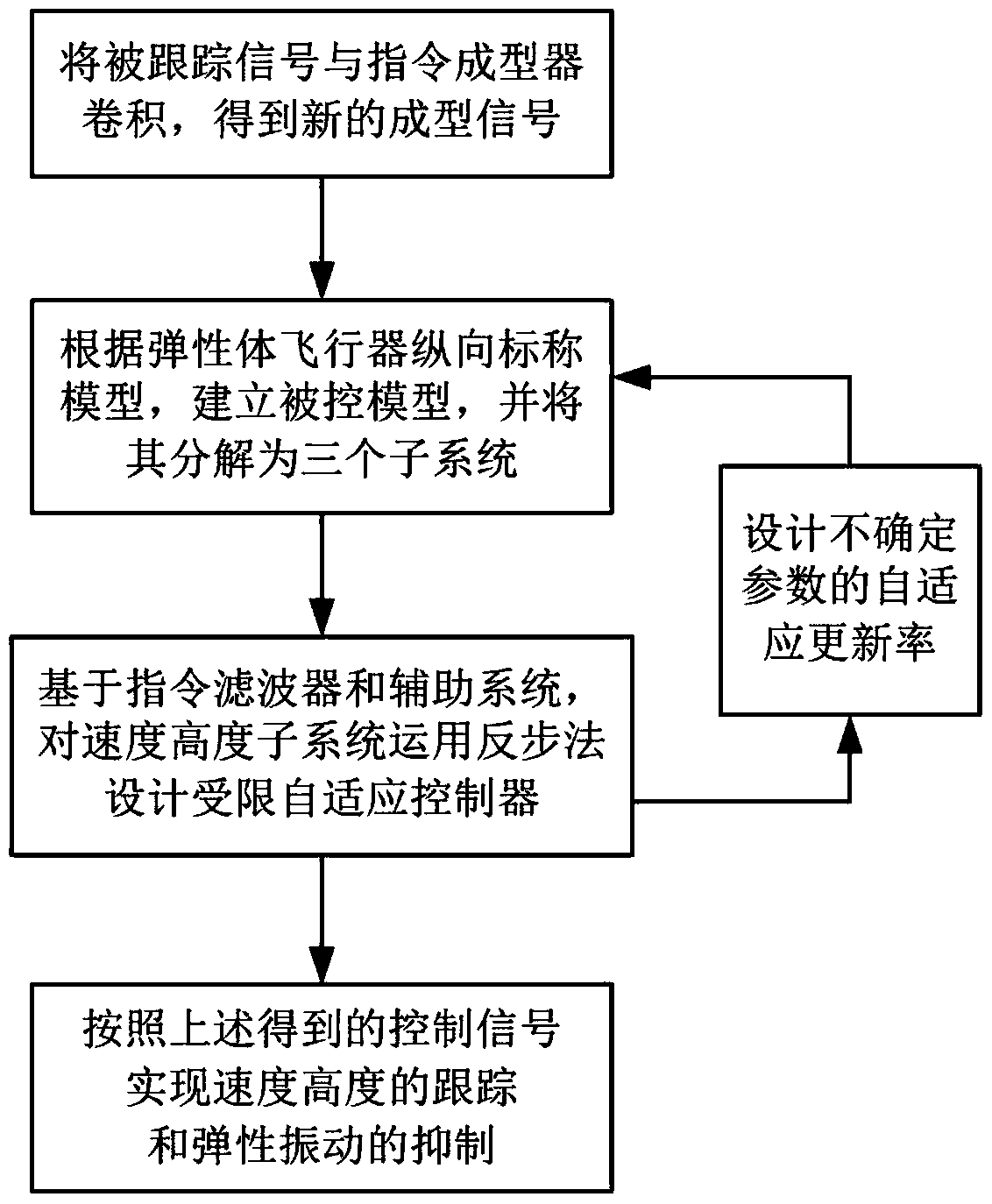

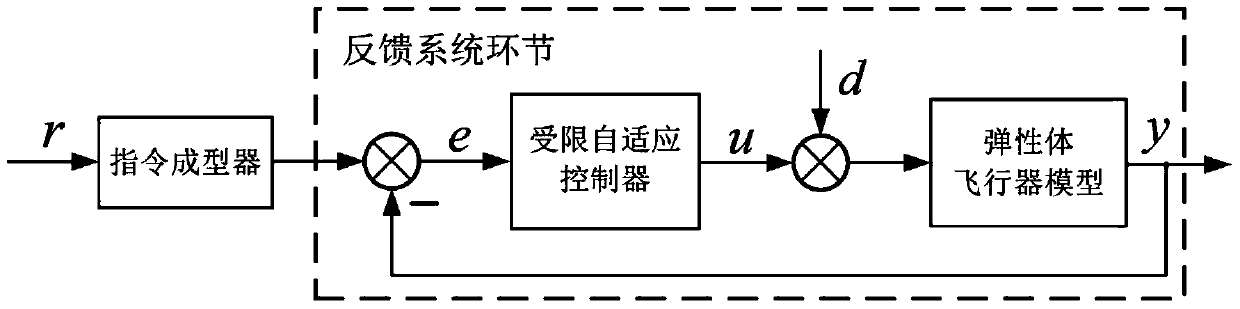

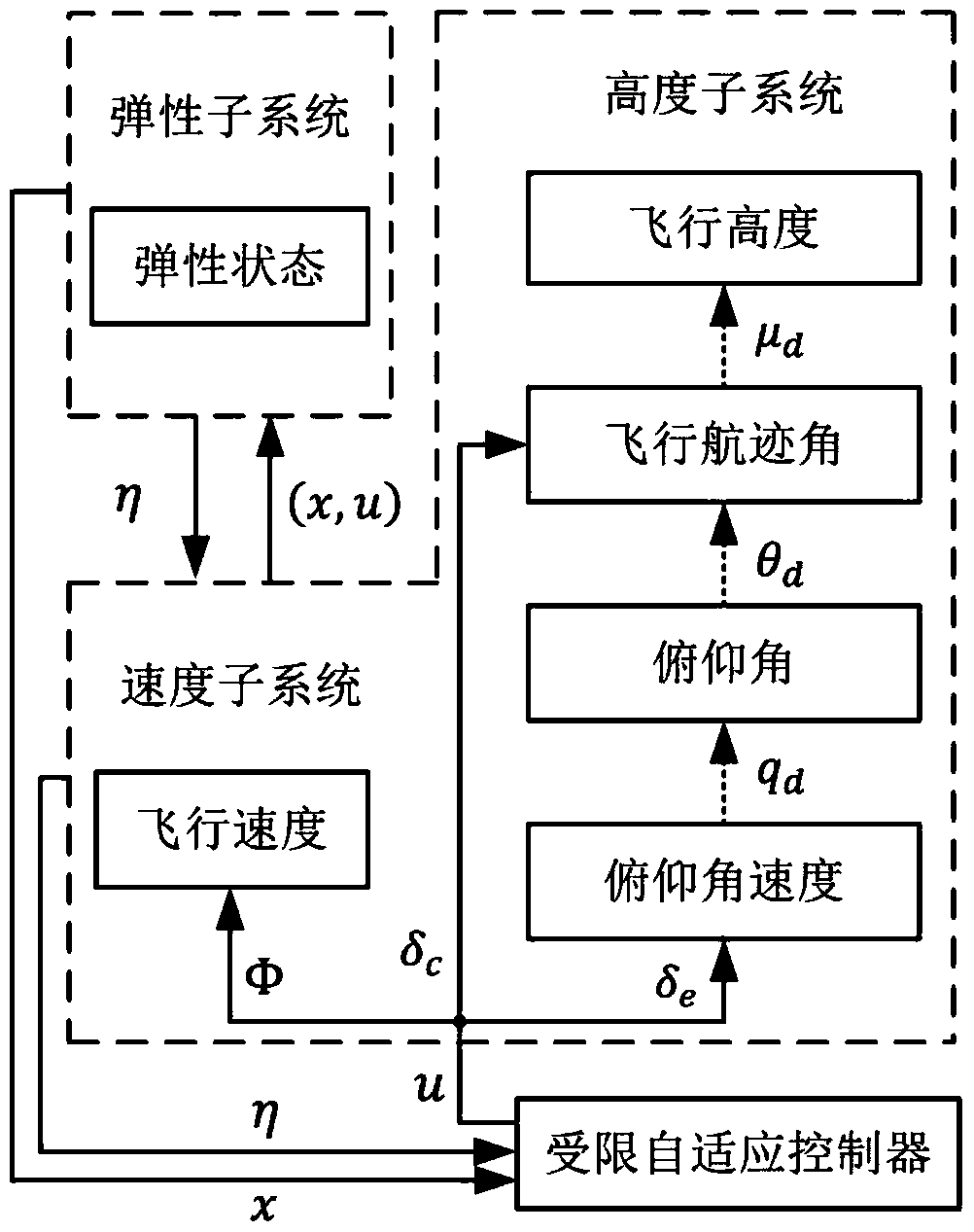

Elastic body aircraft adaptive constrained tracking control indirect method

InactiveCN105182742AReduce residual vibrationDoes not destroy tracking control effectAdaptive controlPosition/course control in three dimensionsElastomerDiagnostic Radiology Modality

The invention discloses an elastic body aircraft adaptive constrained tracking control indirect method. The objective of the invention is to solve the technical problem of low possibility of realizing adaptive tracking of reference instruction signals when an elastic body aircraft has input and state saturation constraints. The method includes the following steps that: a feedforward system is designed based on an instruction former, and tracked signals and the pulses of the former are subjected to convolution, so that new forming signals can be obtained and are adopted as the input of a subsequent feedback system; the design of the feedback system is decomposed into a velocity subsystem, a height subsystem and an elasticity subsystem, and the influence of elastic modality in rigid body dynamic is considered as elastic interference, and uncertain parameters and an external disturbance introduction nominal model are used in combination, and therefore, a controlled system can be obtained; and a saturation constrained adaptive control method can be realized for the controlled system through utilizing an instruction filter and an auxiliary system, and tracking for the forming signals in the feedforward system can be realized, and closed-loop system signals can be uniformly and ultimately bounded, and suppression on elastic modality deformation and vibration can be realized.

Owner:BEIHANG UNIV

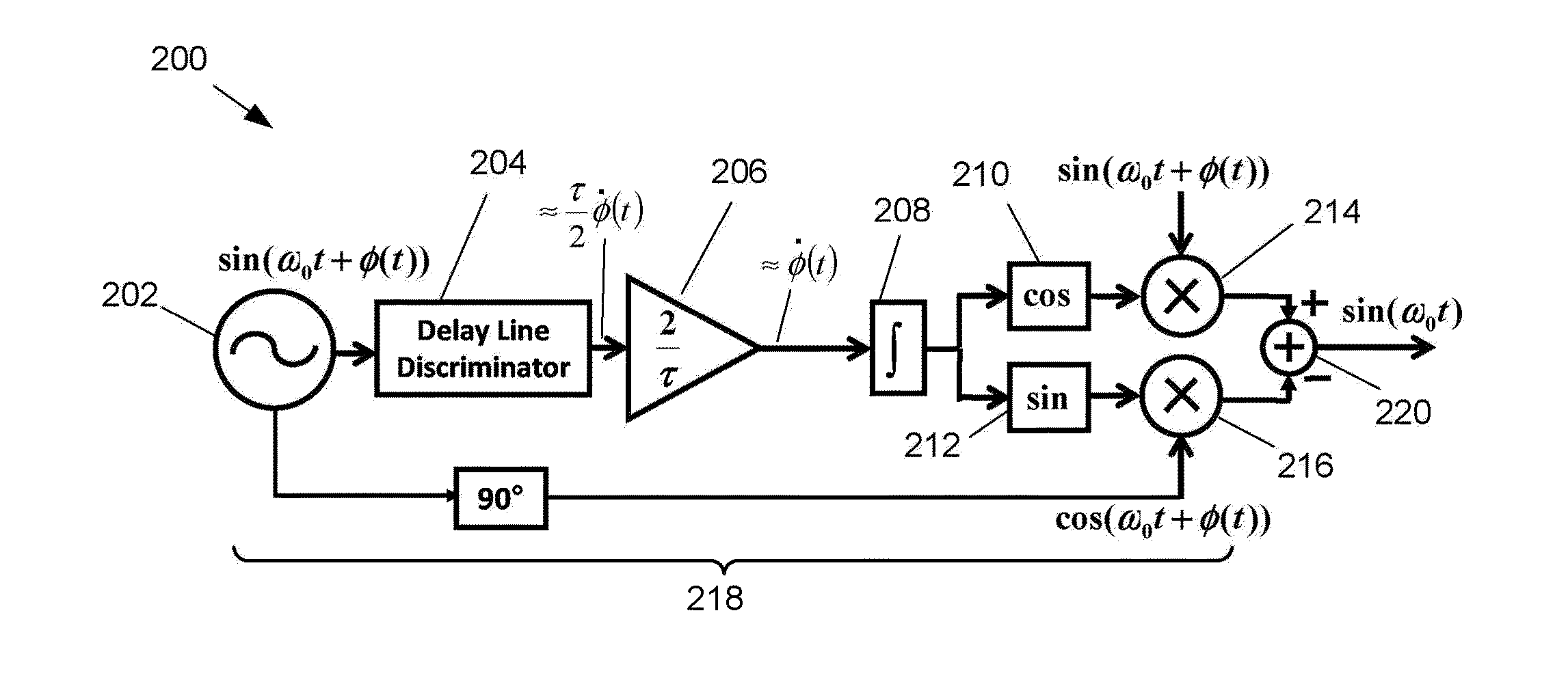

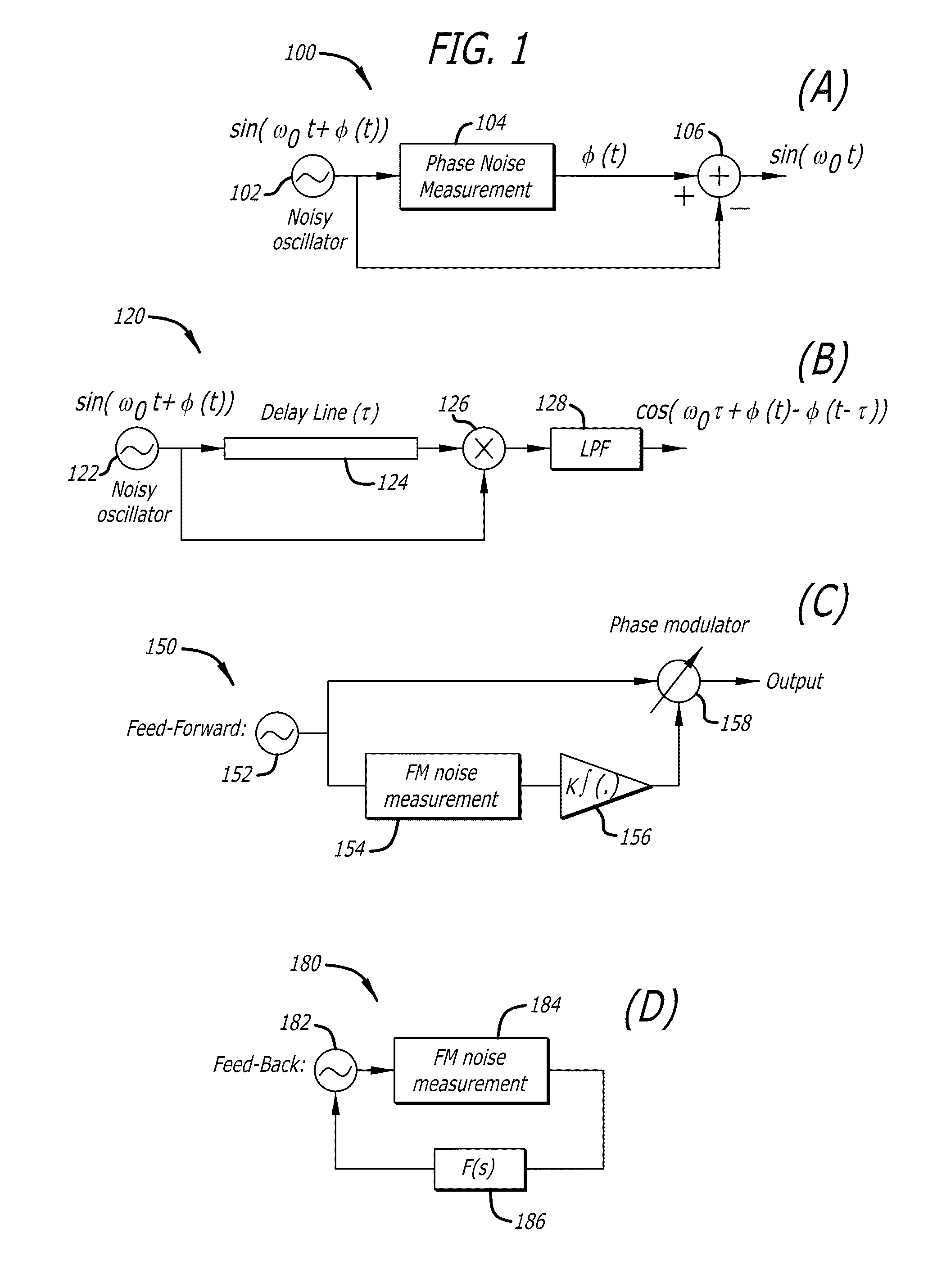

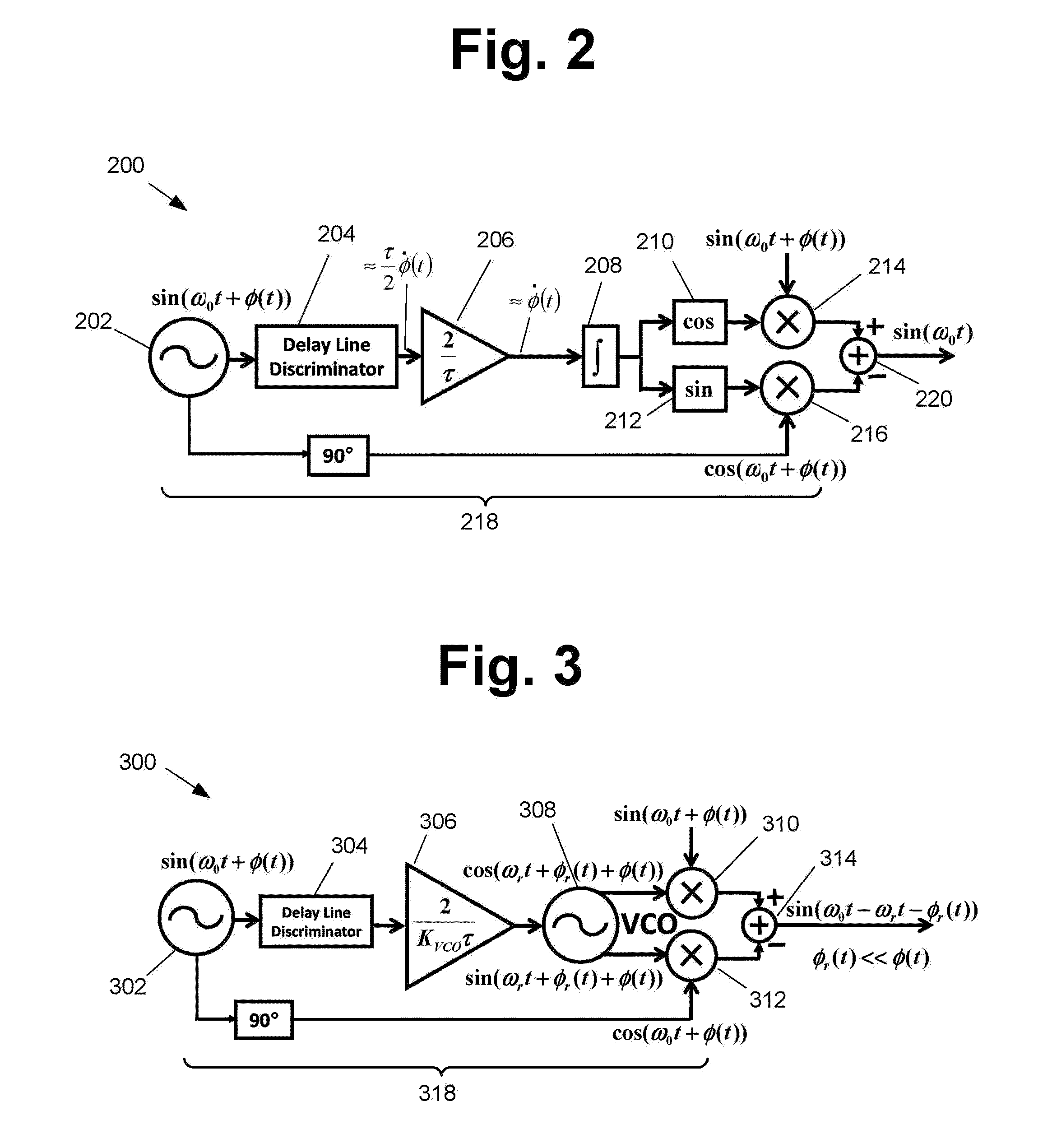

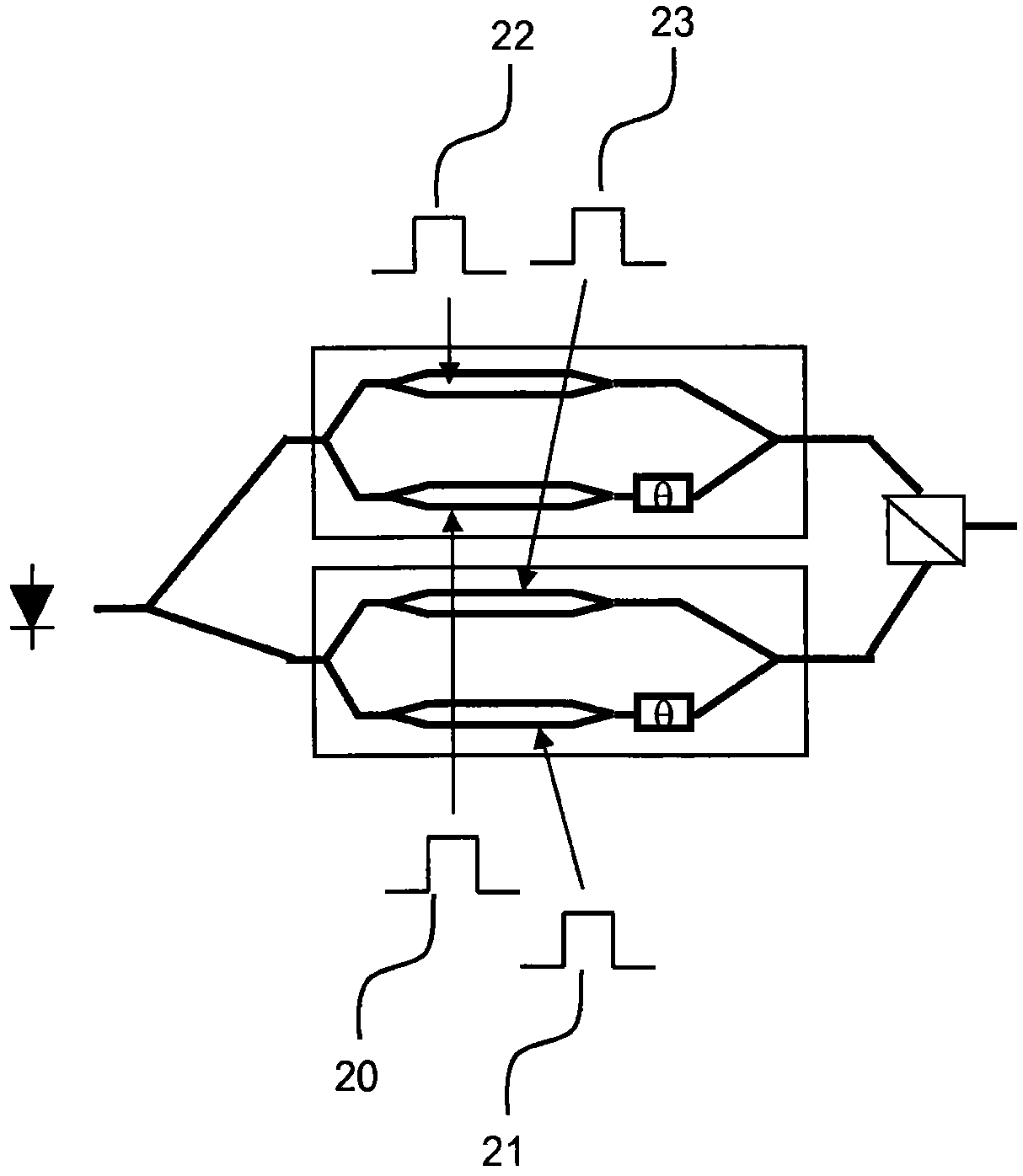

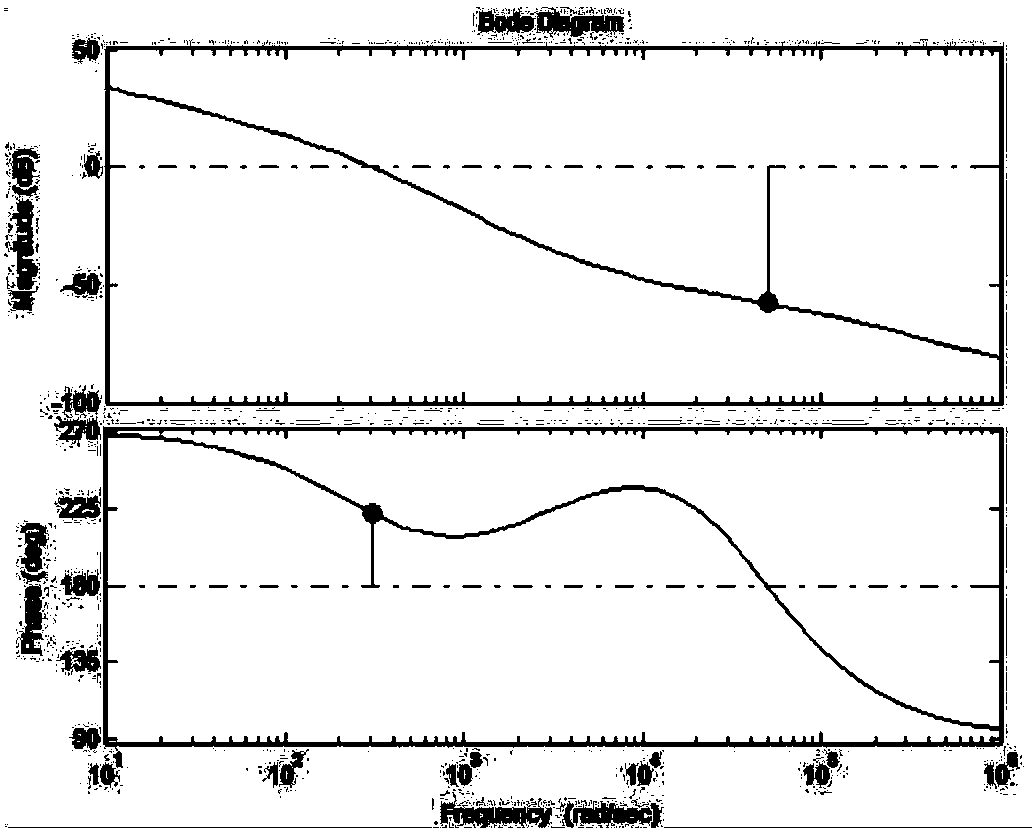

Feed-back and feed-forward systems and methods to reduce oscillator phase-noise

ActiveUS20100237958A1Low signalMultiple-port networksPulse automatic controlPhase noiseFrequency spectrum

Systems, methods, and apparatus are described that provide for low phase-noise, spectrally-pure, and low-jitter signals from electrical oscillators. An aspect of the present disclosure includes utilization of an open-loop feed-forward phase-noise cancellation scheme to cancel phase noise, or jitter, of an electrical oscillator. Phase noise can be measured and then subtracted, with the phase noise measurement and subtraction being performed at a speed faster than phase noise variations of the oscillator. Another aspect of the present disclosure includes use of a feedback scheme for phase noise reduction. A feedback scheme can be used alone or in conjunction with a feed-forward scheme. Related phase-noise cancellation and / or reduction methods are described. Notch filter and RF amplifier circuits are also described.

Owner:UNIV OF SOUTHERN CALIFORNIA

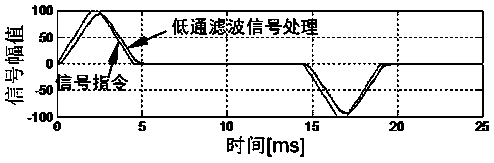

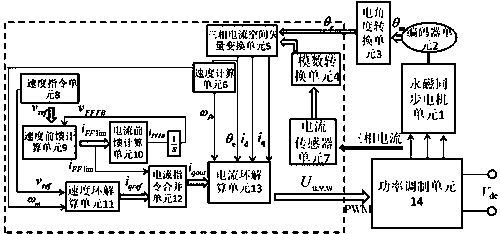

Current feedforward control method and device based on proportional integral coefficient adjustment

ActiveCN108712131AImprove the response characteristics of the speed loopPrevent deviationElectronic commutation motor controlVector control systemsControl systemFeedback control

Embodiments of the invention relate to a current feedforward control method and device based on proportional integral coefficient adjustment for improving the response speed of a speed ring of an AC servo drive control system. The current feedforward structure can realize the independent calculation of a current feedforward instruction without being affected by the external disturbance, referenceis made to a feedback control system model in the establishment of a current feedforward model, the calculation accuracy of the current feedforward instruction of the control system is improved, and compared with the traditional current feedforward system based on flow pass filtering, the novel current feedforward system has better instruction tracking capability, eliminates the distortion causedby the low pass filtering feedforward to the instruction filtering and effectively improves the response speed tracking capability of the control system.

Owner:上海频控科技有限公司

Noise-canceling headphone

InactiveCN102340717AImprove the noise reduction effectEarpiece/earphone noise reductionTransducer circuitsNoise-cancelling headphonesEngineering

A noise-canceling headphone that cancels external noise with a feedforward system includes a driver unit disposed in a housing, a microphone unit that is outwardly disposed in the housing and collects the external noise, and canceling signal generator that generates a noise-canceling signal having a phase opposite to the noise entering through the headphone. The noise-canceling headphone includes an error detecting microphone unit that detects error noise uncanceled by the feedforward system, and error noise-canceling signal generator that generates an error correction signal to cancel the error noise with a feedback system.

Owner:AUDIO-TECHNICA

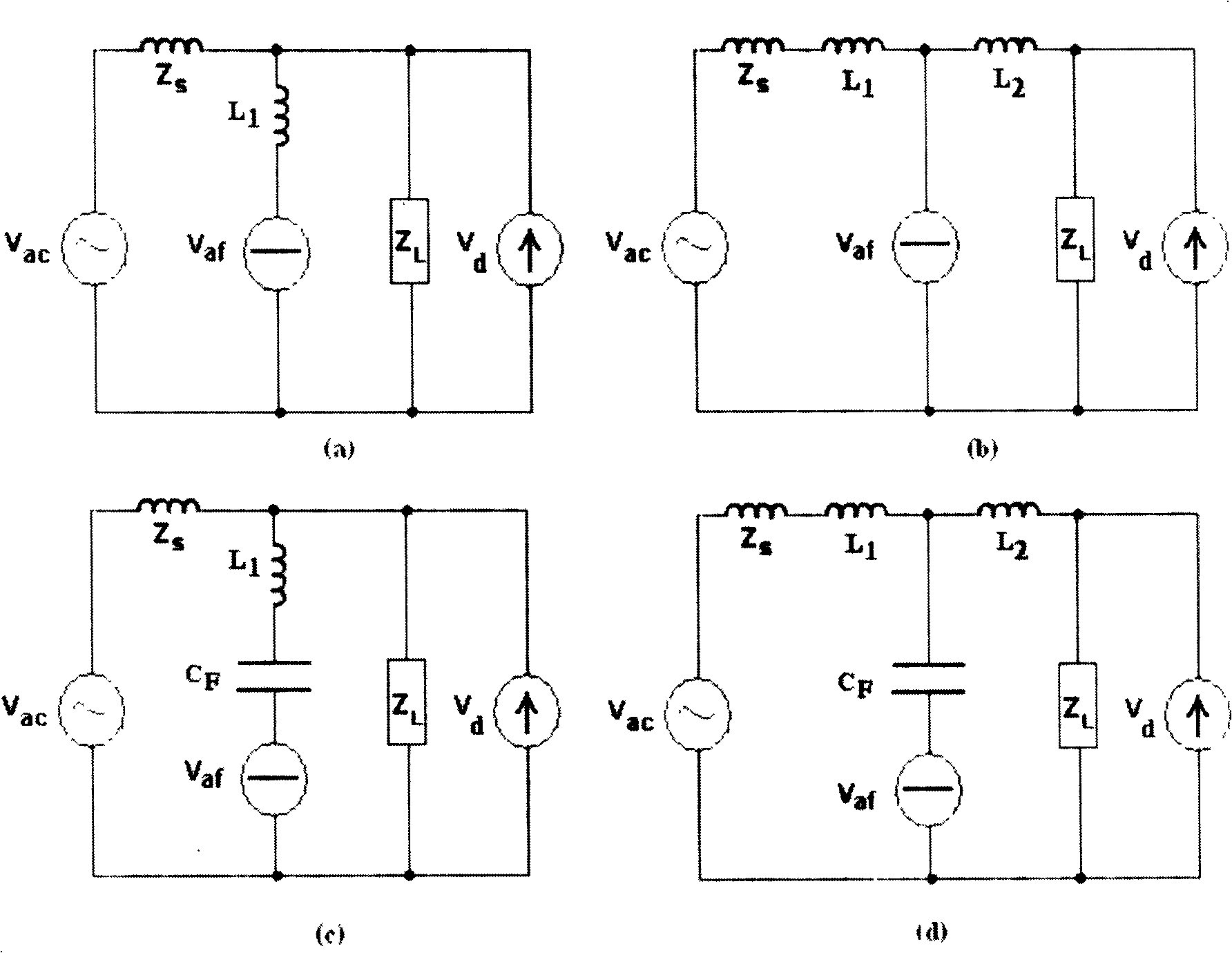

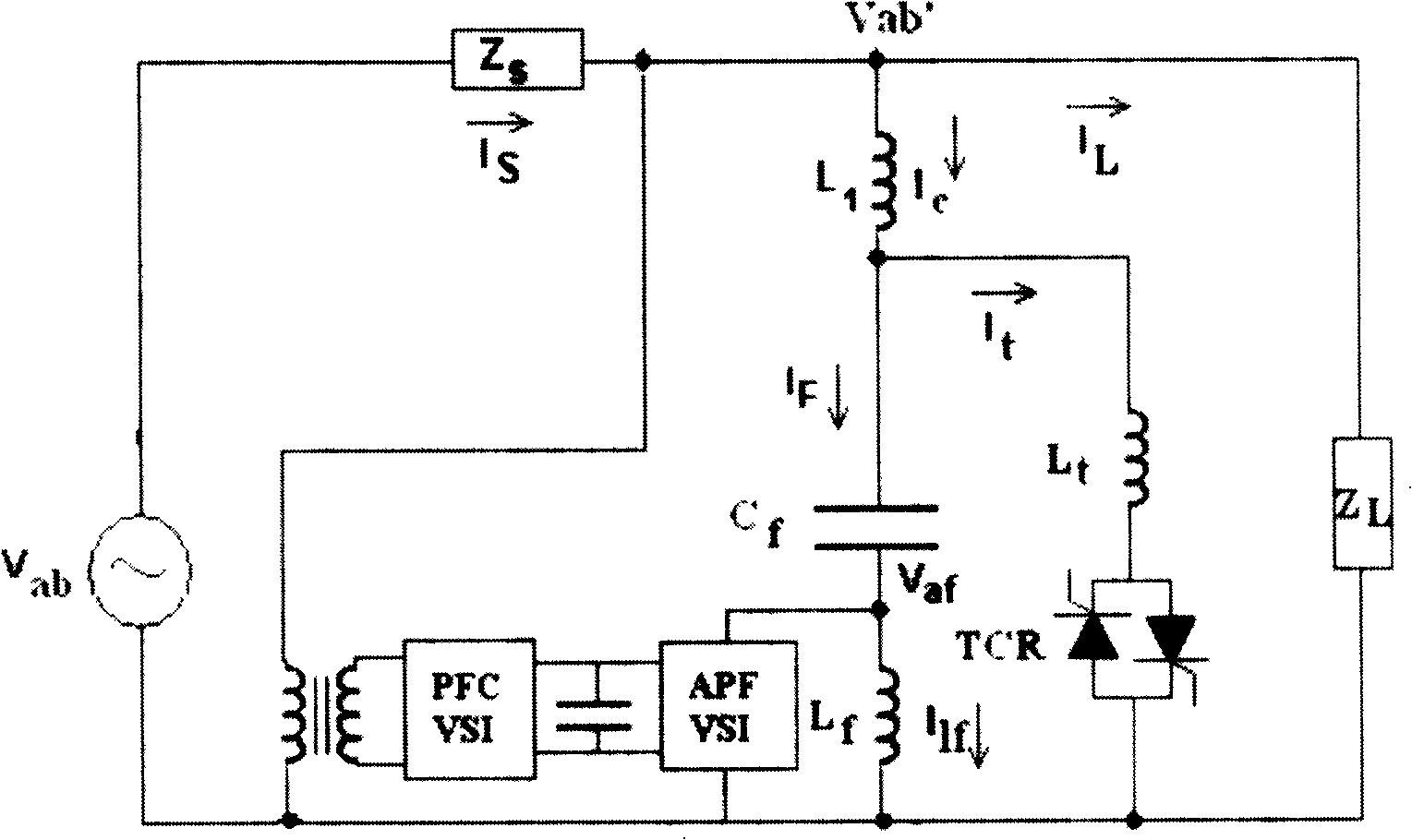

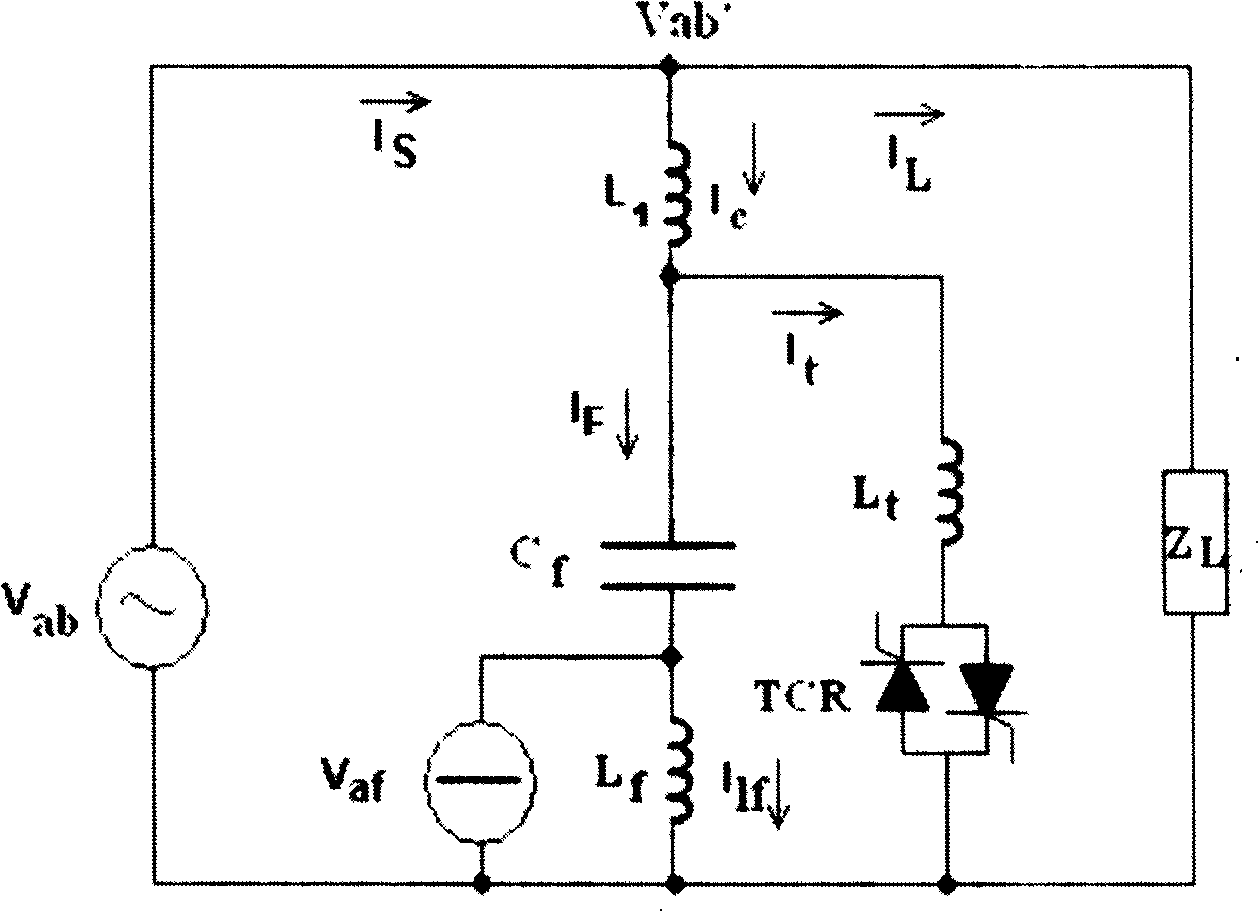

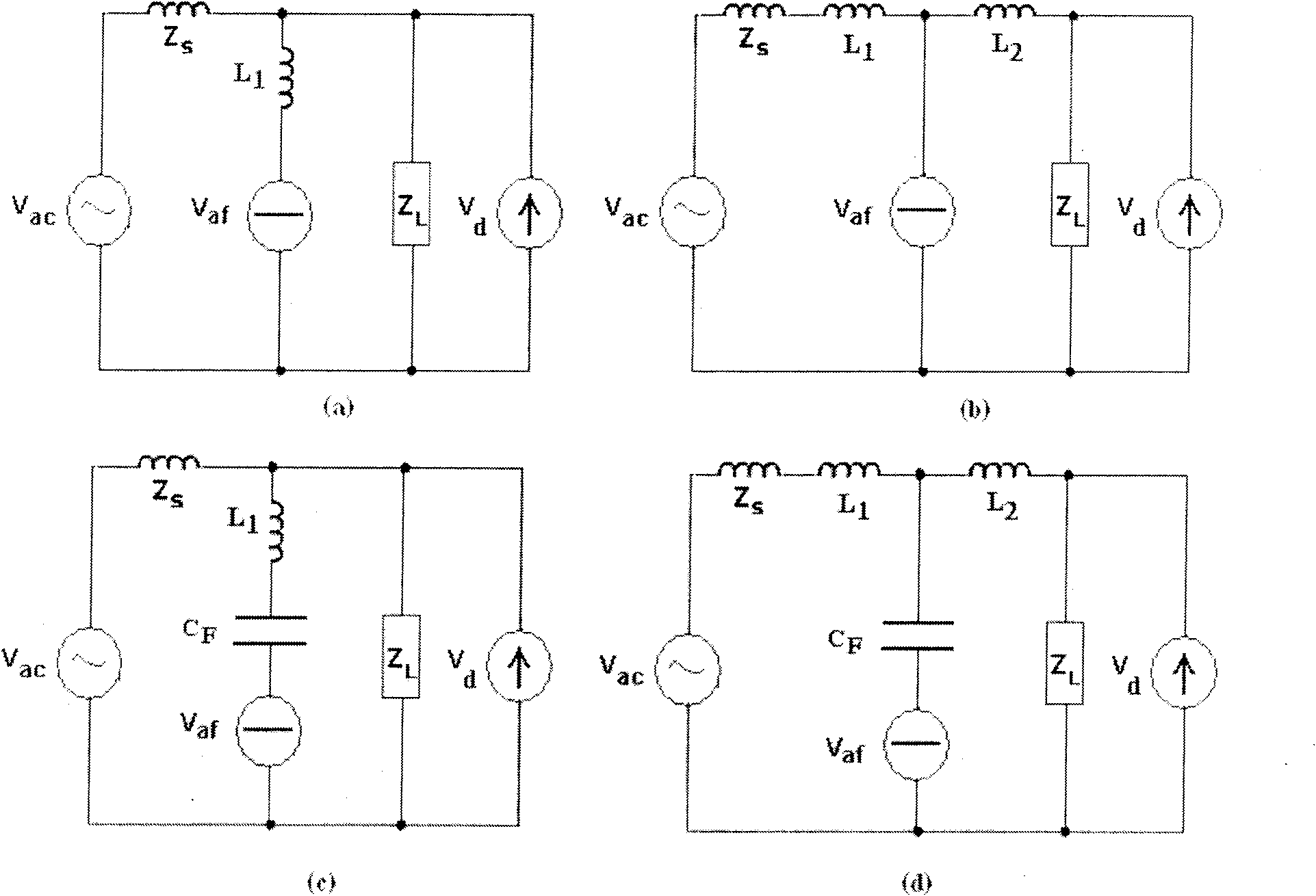

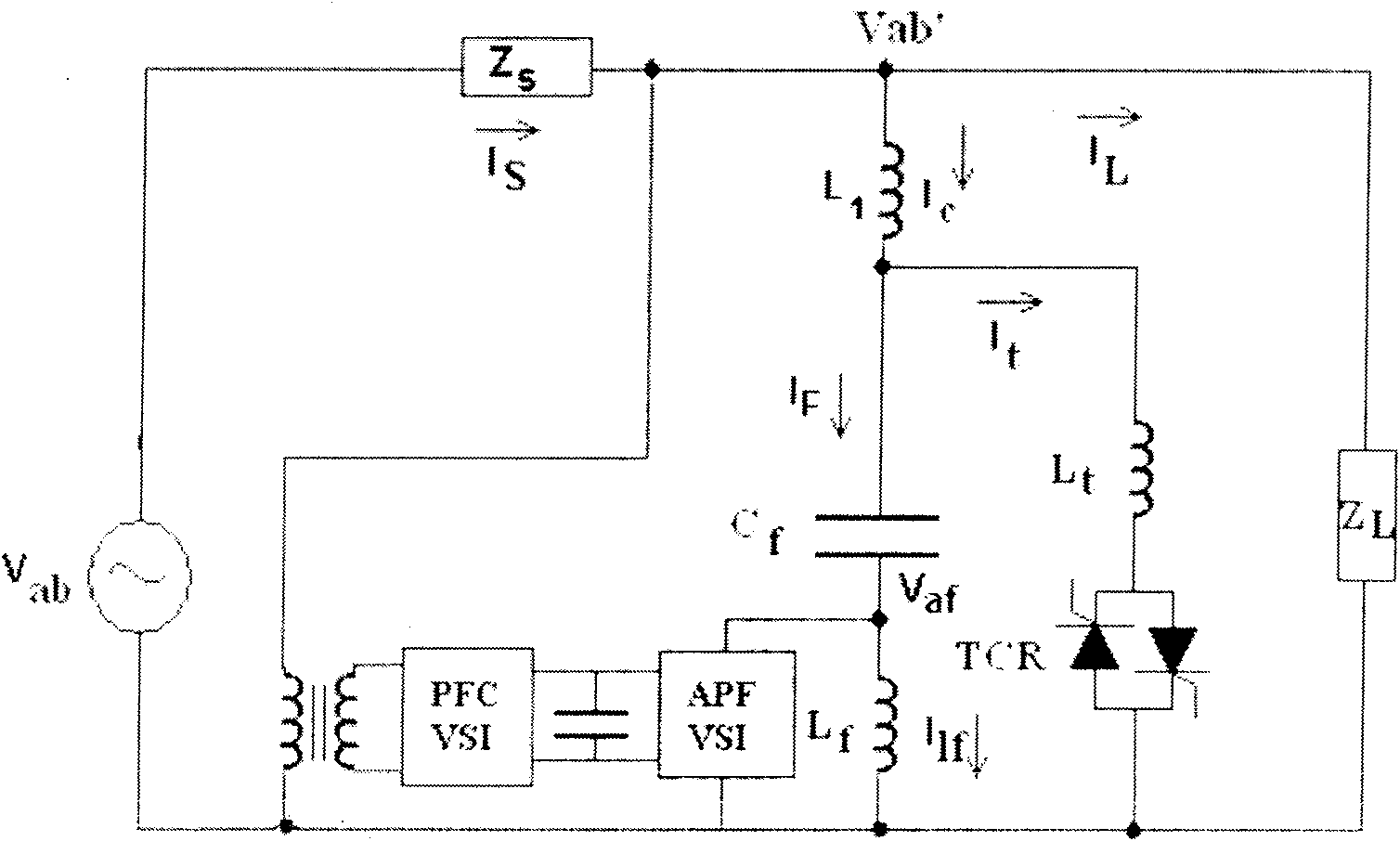

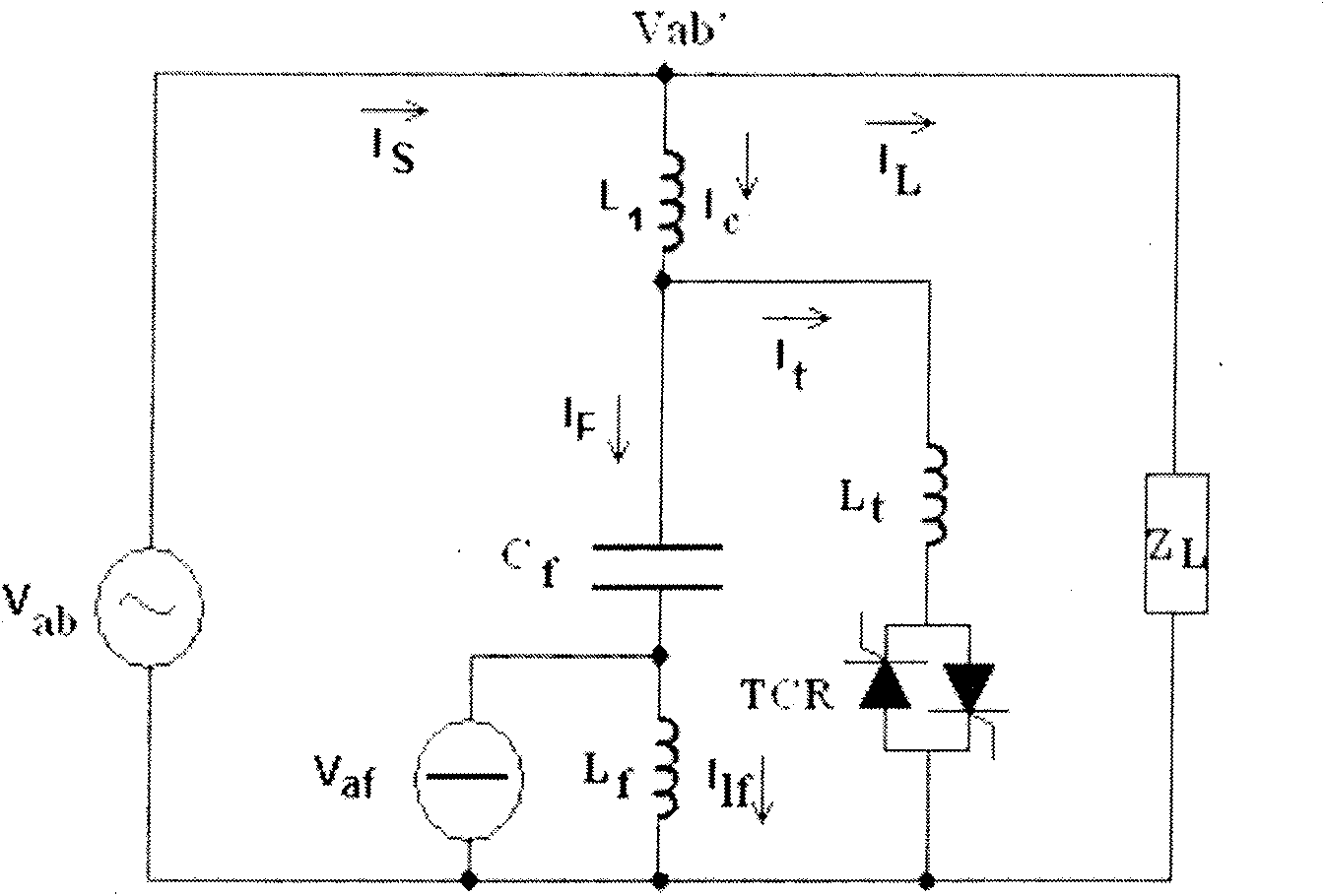

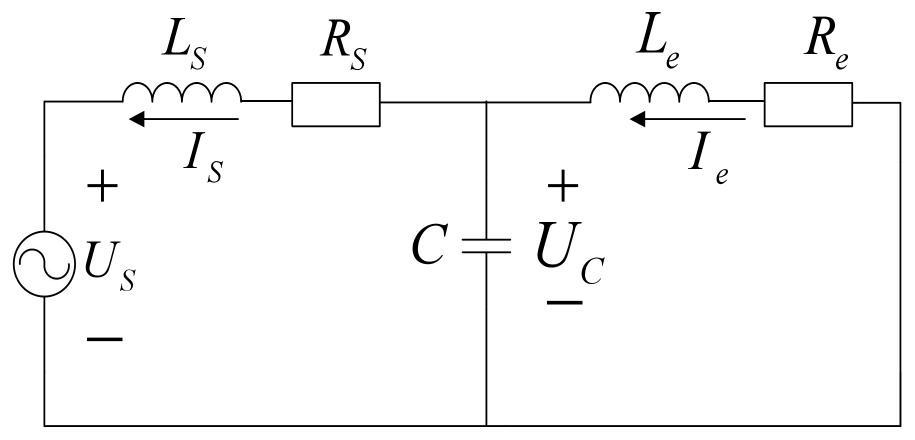

A TCR static passive compensation device with T active power filter structure

InactiveCN101262132AGood compensationGuaranteed uptimeFlexible AC transmissionActive power filteringHigh resistanceVoltage source inverter

The invention discloses a design of a TCR static var compensator (SVC) provided with a T-shaped active power filter (APF) and a control method thereof. The var compensator adopts a hybrid SVC composed of the T-shaped active power filter and an SVC and is connected with a power factor corrector of a small-sized voltage source inverter type (PFC-VSI). A harmonic compensation control loop of the APF part in the device consists of two parts, namely, a direct feedback control loop and a feedforward system; the active power filter part of the system consists of a capacitor Cf, an inductor Lf and an APF-VSI connected with the inductor Lf in parallel. The TCR part is mainly applied in absorbing harmonic current and adjusting reactive power. For the T-shaped active power filter is adopted, the inductor Lt of the TCR branch has high resistance during ultraharmonics and can naturally filter part ultraharmonics. Compared with the prior harmonic filter different from the harmonic filter provided by the invention which works together with the voltage source inverter of low bandwidth, and therefore the control of the system is simpler than common harmonic filters and not affected by the inherent delay of one period when DSP is executed.

Owner:北京博旺天成科技发展有限公司

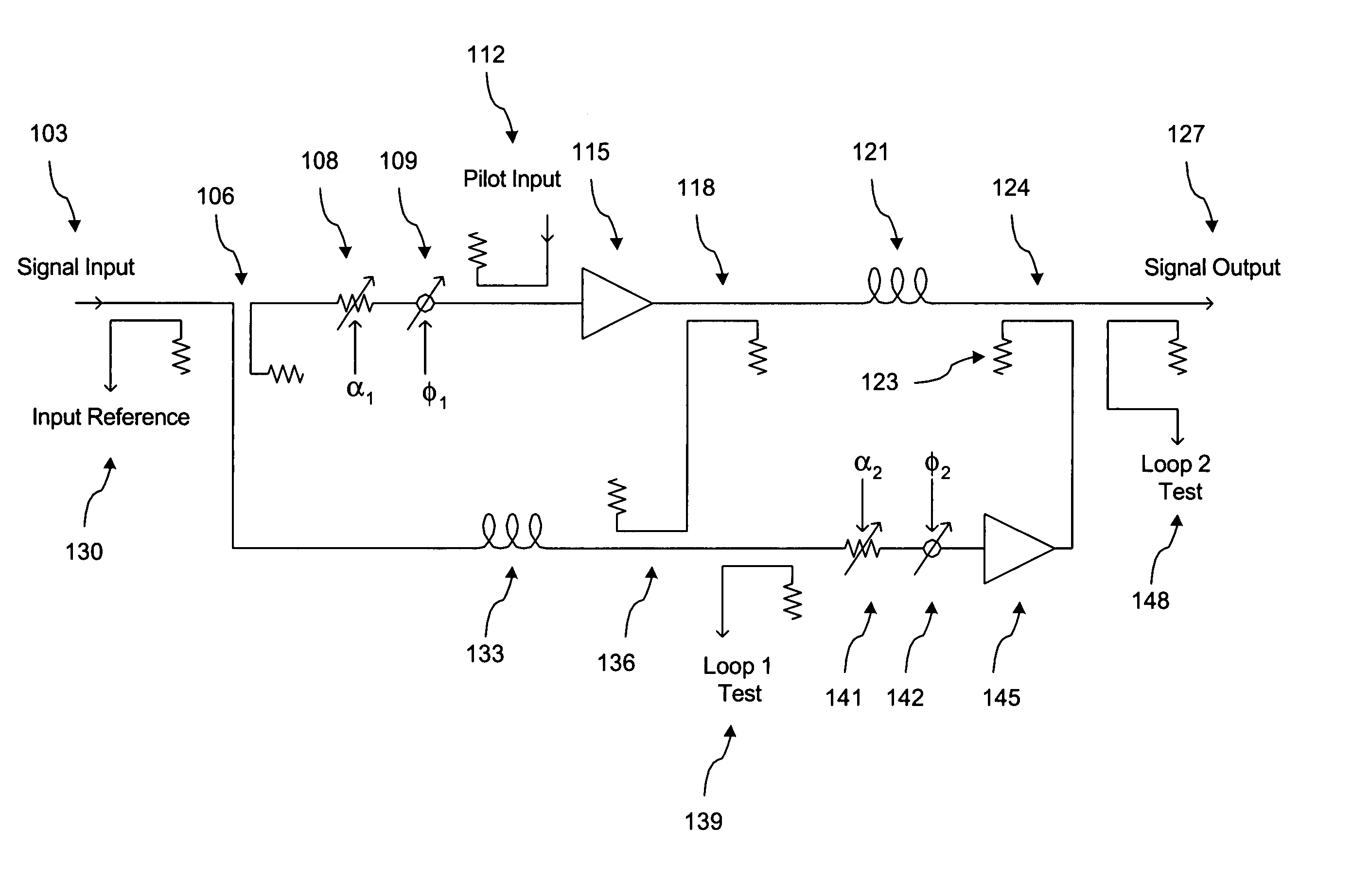

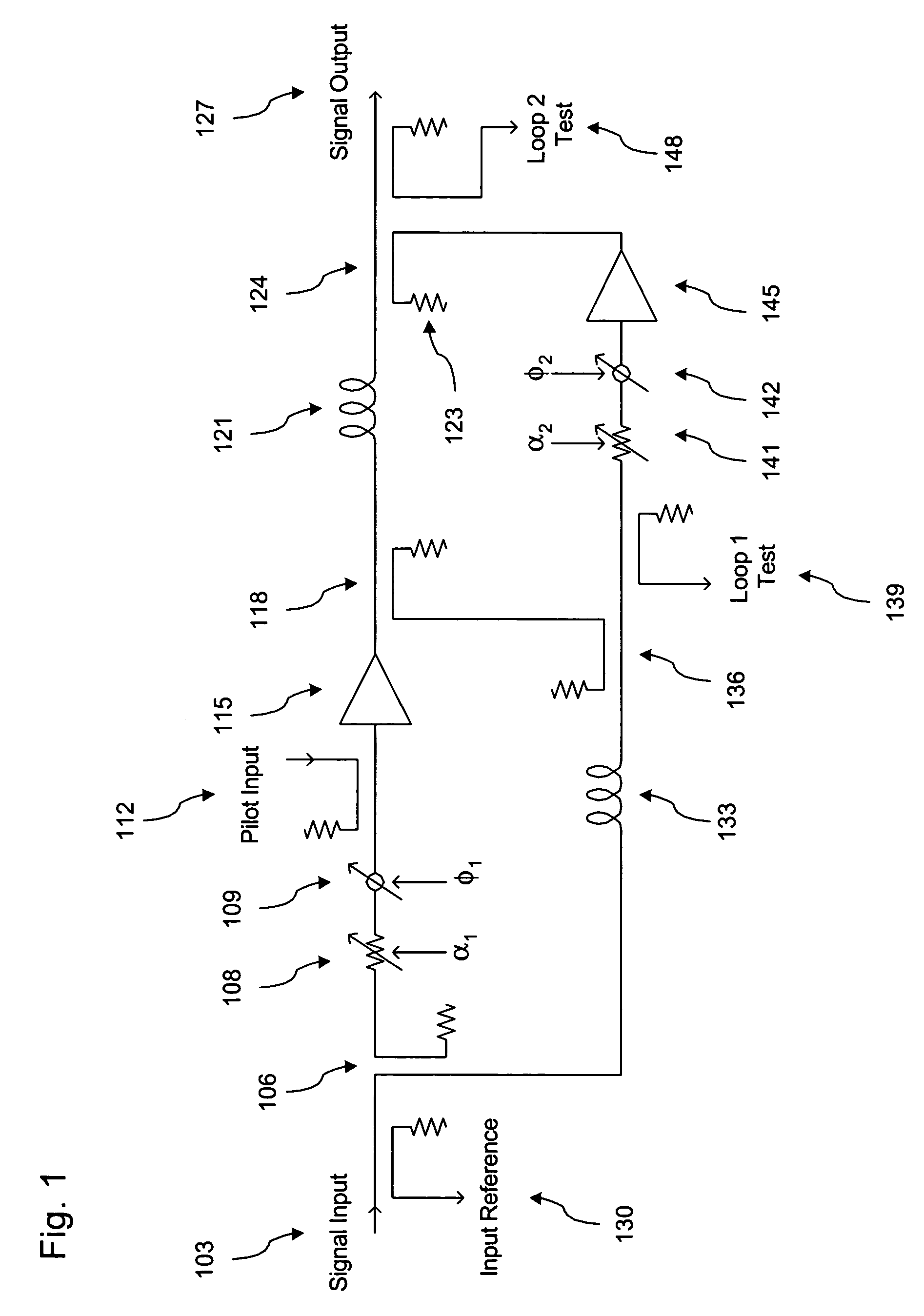

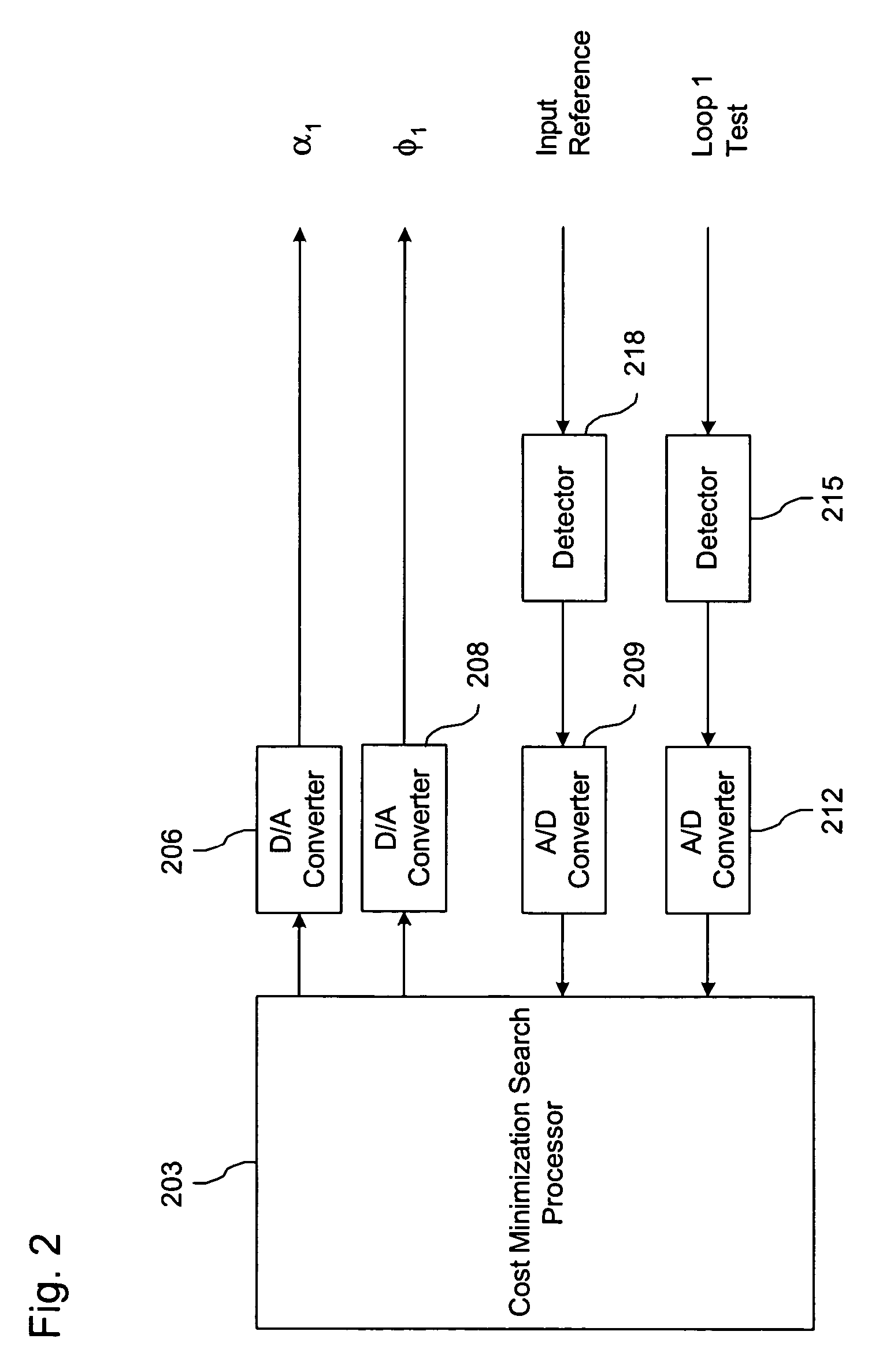

Feed forward amplifier system using penalties and floors for optimal control

InactiveUS6998916B2Minimizes valueAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce noise influenceOptimal controlCarrier signal

A feed forward amplifier employing a new adaptive controller and method is disclosed. The controller aligns both a gain adjuster and phase adjuster of a first cancellation loop. The phase adjuster may be controlled following a standard approach. However, the gain adjuster is offset intentionally causing an incomplete cancellation, increasing the signal power passing through the error amplifier. If the gain adjuster is offset low, below the gain adjustment required to maximize carrier cancellation, peak power output from the main amplifier is reduced while the second loop maintains constant system output power. If the gain adjuster is offset high, peak power output from the error amplifier is reduced while the second loop maintains constant system output power. By controlling the gain adjuster offset from full first loop cancellation, the feed forward amplifier can be optimized for the power handling capabilities of the main and error amplifiers. A system and method of specifying and controlling the steady-state offset of the first loop gain adjuster is also disclosed. By altering the cost function of the first loop gain, the desired gain adjuster offset becomes the steady-state adjustment. Floors and penalties are incorporated into the first loop gain minimization approach to allow precise specification of the gain adjuster offset. The gain adjuster offset can be controlled at will to optimize the feed forward system even when the operating conditions or goals are varying.

Owner:INTEL CORP

Position controller and controlling method therefor

ActiveUS7560890B2Decrease feedforwardPossibility of generating mechanical resonances is smallProgramme controlElectric motor controlValue setControl theory

Owner:MITSUBISHI ELECTRIC CORP

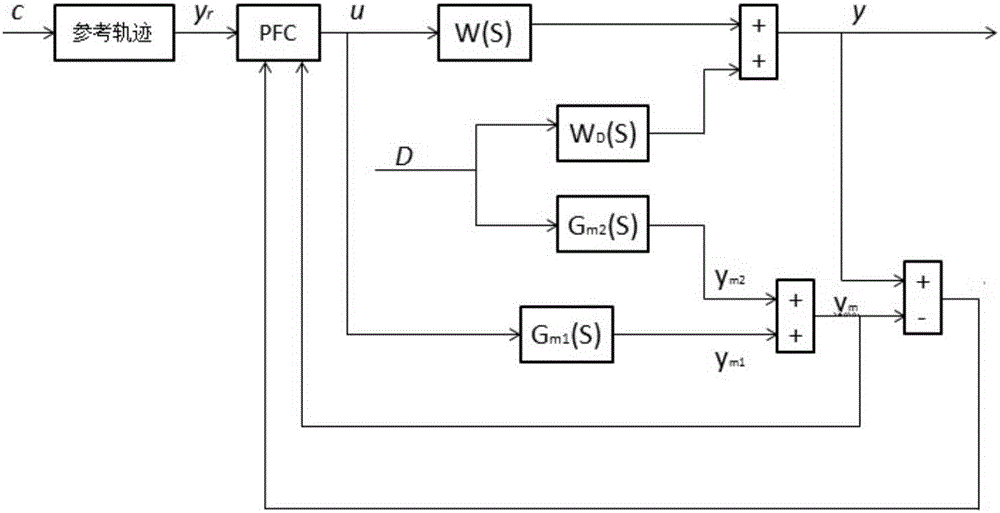

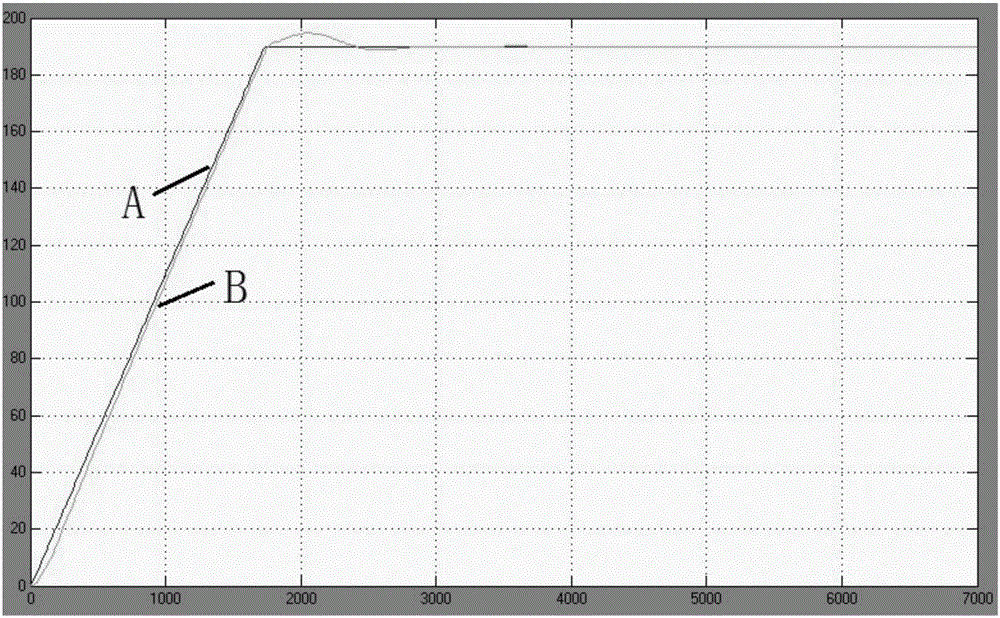

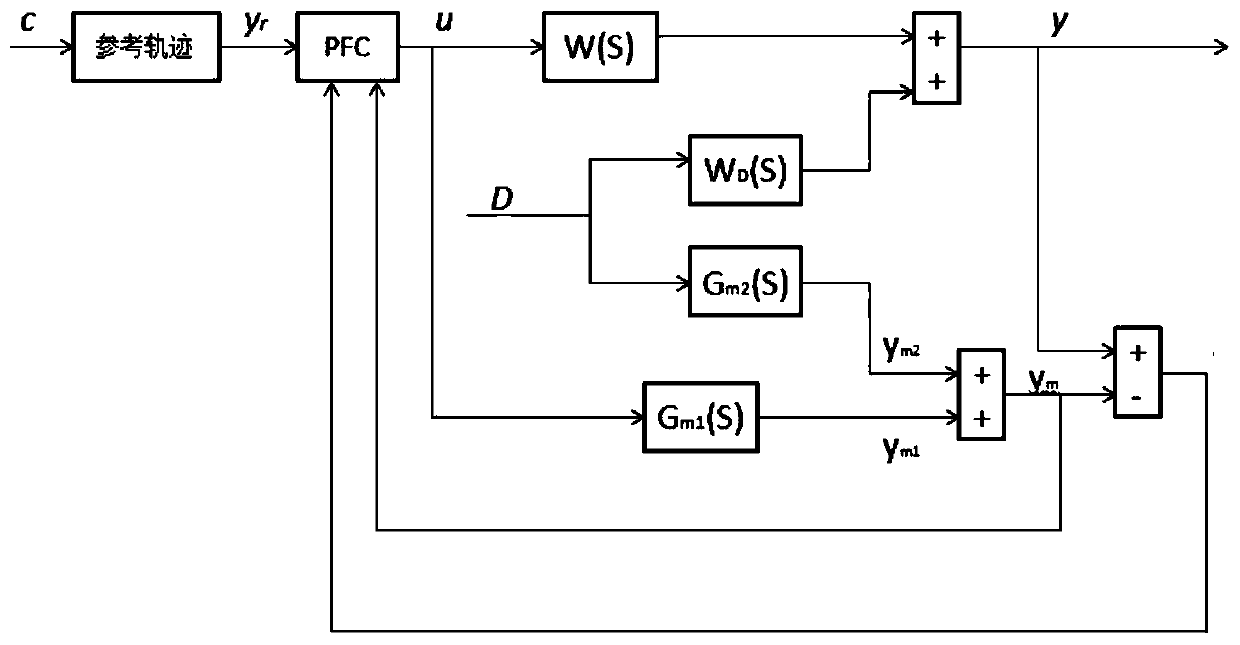

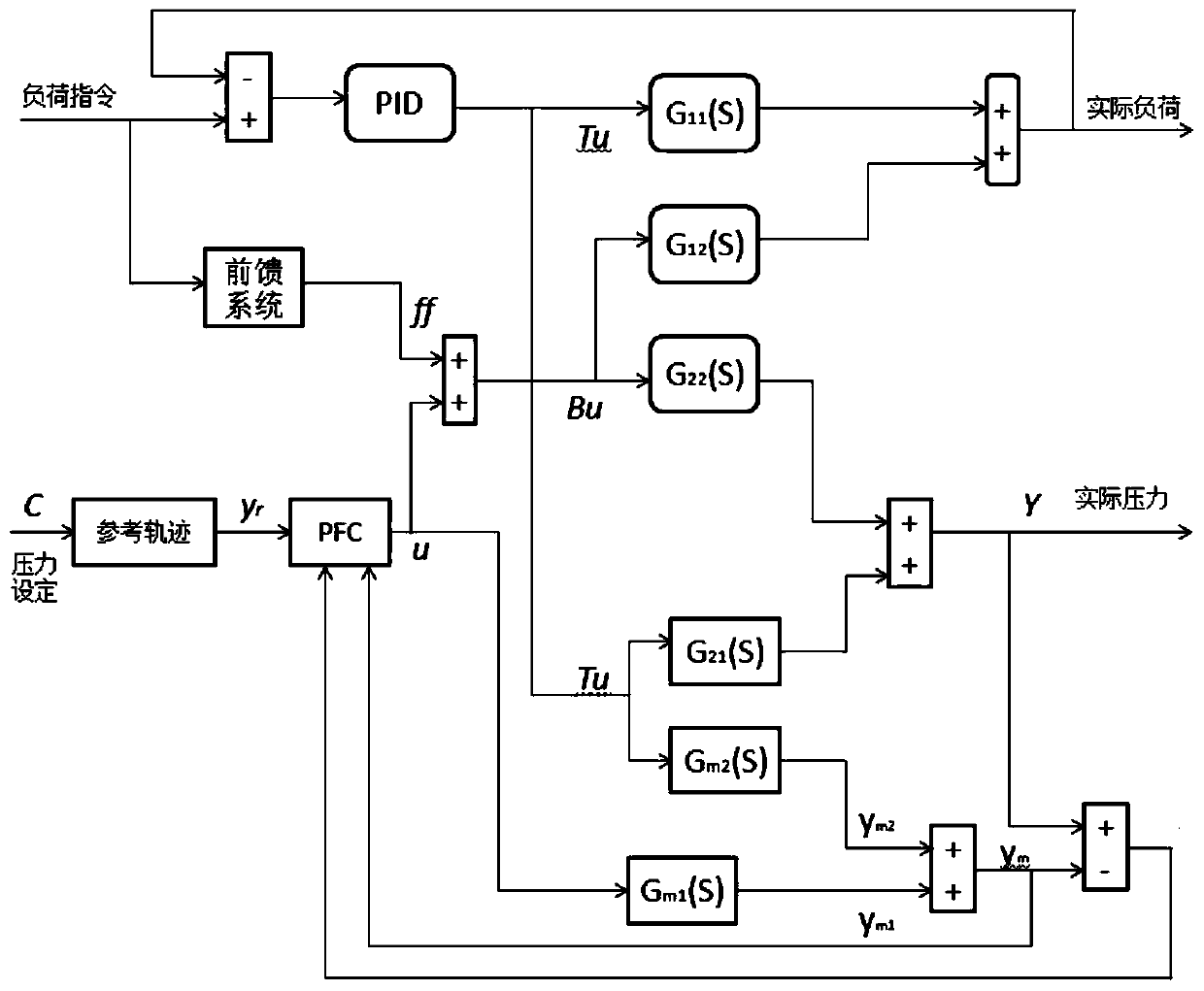

Subcritical unit coordination prediction function control algorithm based on leading disturbance model

ActiveCN106647240AProve excellent performanceEase couplingControllers with particular characteristicsLoad instructionControl system

The invention discloses a subcritical unit coordination prediction function control algorithm based on a leading disturbance model. The conventional PID control system can not consider both the load quickness and the pressure stability, and the quality of a coordination control system needs to be improved. The prediction function control is applied to a pressure closed loop of the subcritical unit coordination control system, a prediction function control system is formed, and the pressure closed loop has a delay inertial link; the load closed loop of the subcritical unit coordination control system adopts PID control, and a load instruction adopts a datum line plus differential mode for a coal quantity feedforward system; an actual turbine control valve instruction serves as a disturbance signal source, and the optimal control law is acquired according to a prediction model of the prediction function control system; and simplification is carried out on the basis of the optimal control law, and a simplified optimal control law is obtained. The control quality of the subcritical unit coordination control system is improved, and both the load quickness and the pressure stability can be considered.

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

Hewlett packard development co (us)

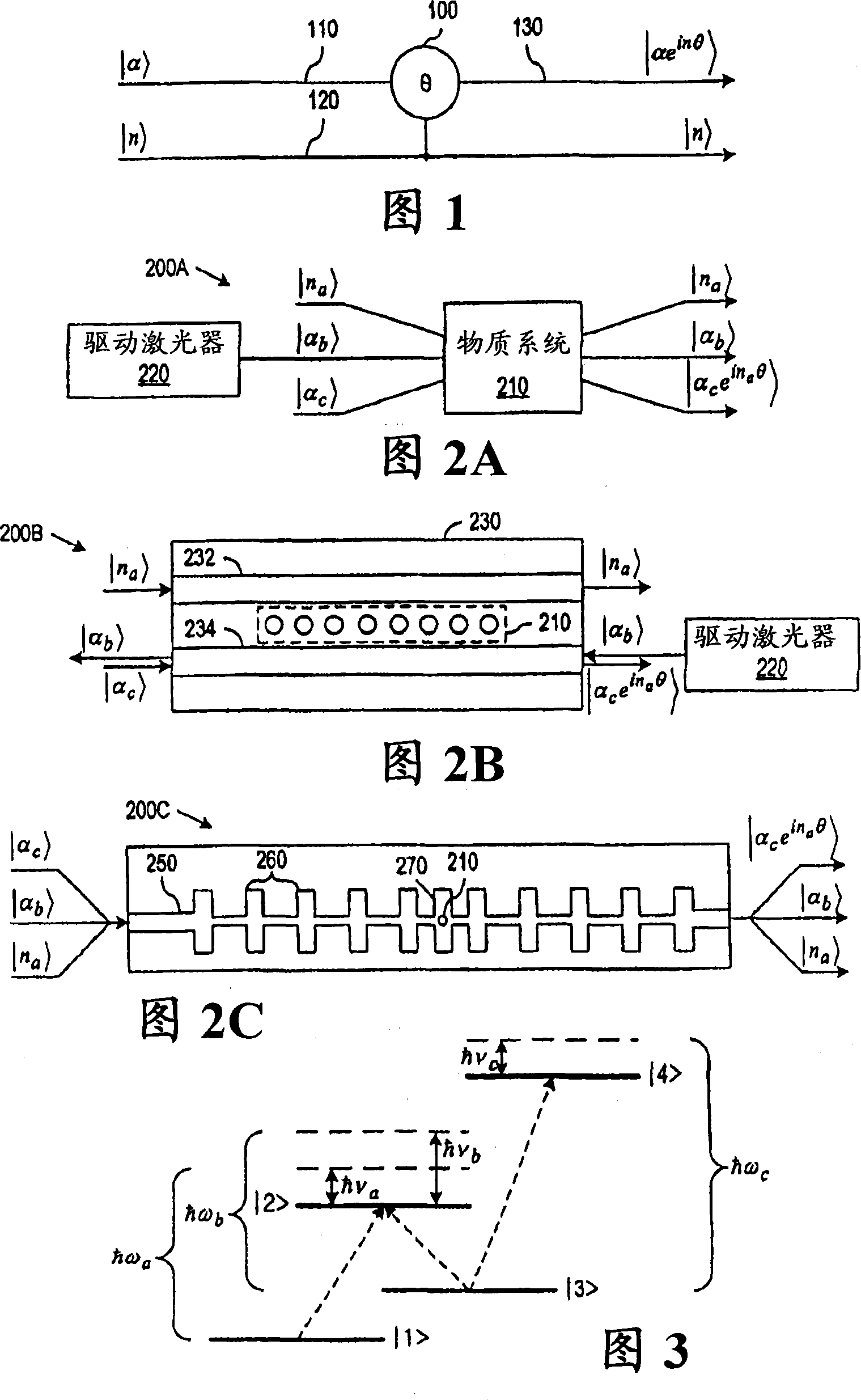

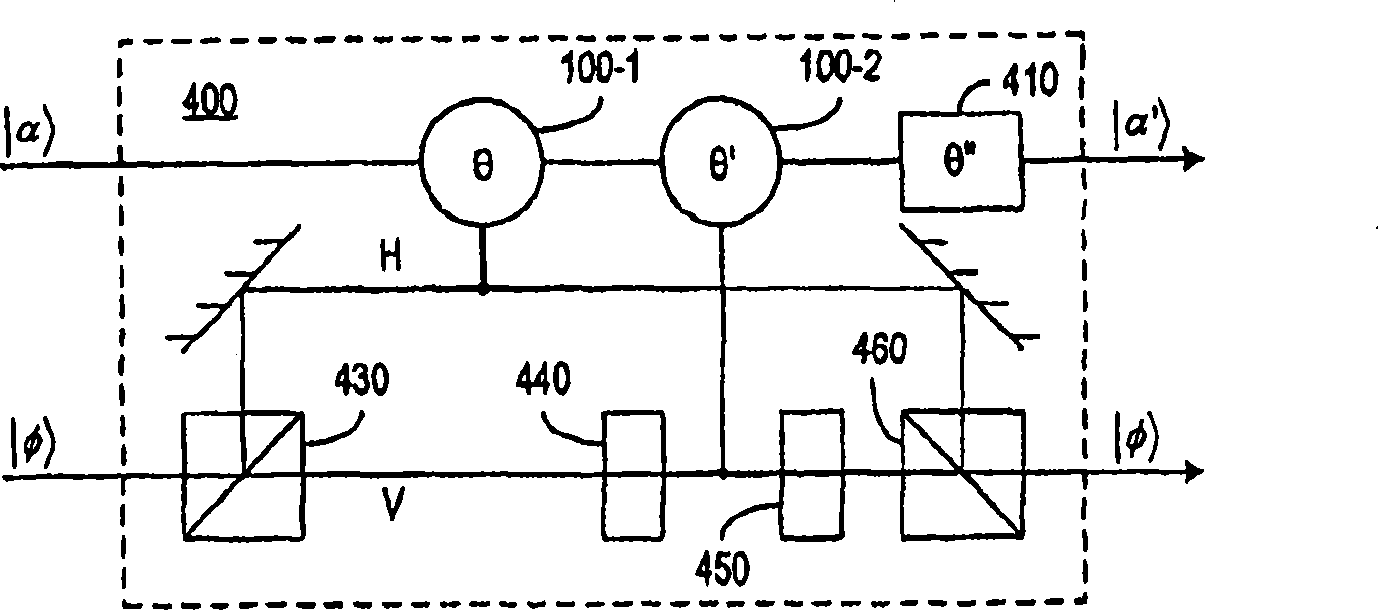

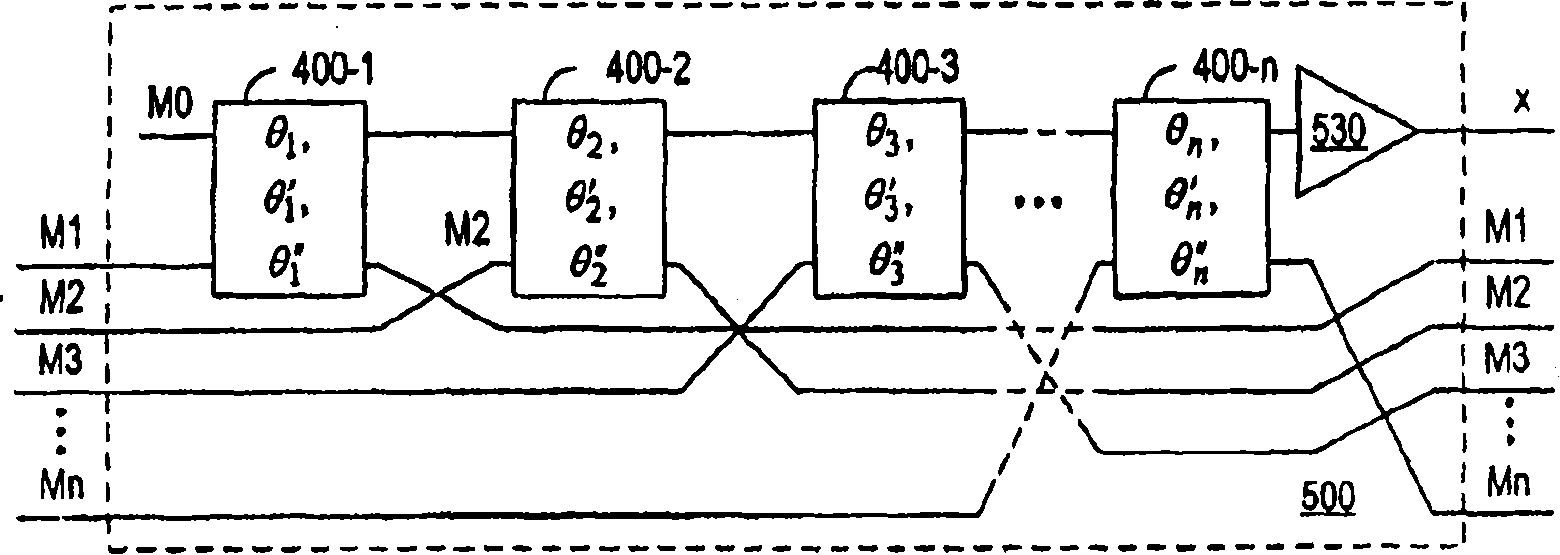

Nonlinear electromagnetic elements can efficiently implement quantum information processing tasks such as controlled phase shifts, non-demolition state detection, quantum subspace projections, non-demolition Bell state analysis, heralded state preparation, quantum non-demolition encoding, and fundamental quantum gate operations. Direct use of electromagnetic non-linearity can amplify small phase shifts and use feed forward systems in a near deterministic manner with high operating efficiency. Measurements using homodyne detectors can cause near deterministic projection of input states on a Hilbert subspace identified by the measurement results. Feed forward operation can then alter the projected state if desired to achieve a desired output state with near 100% efficiency.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

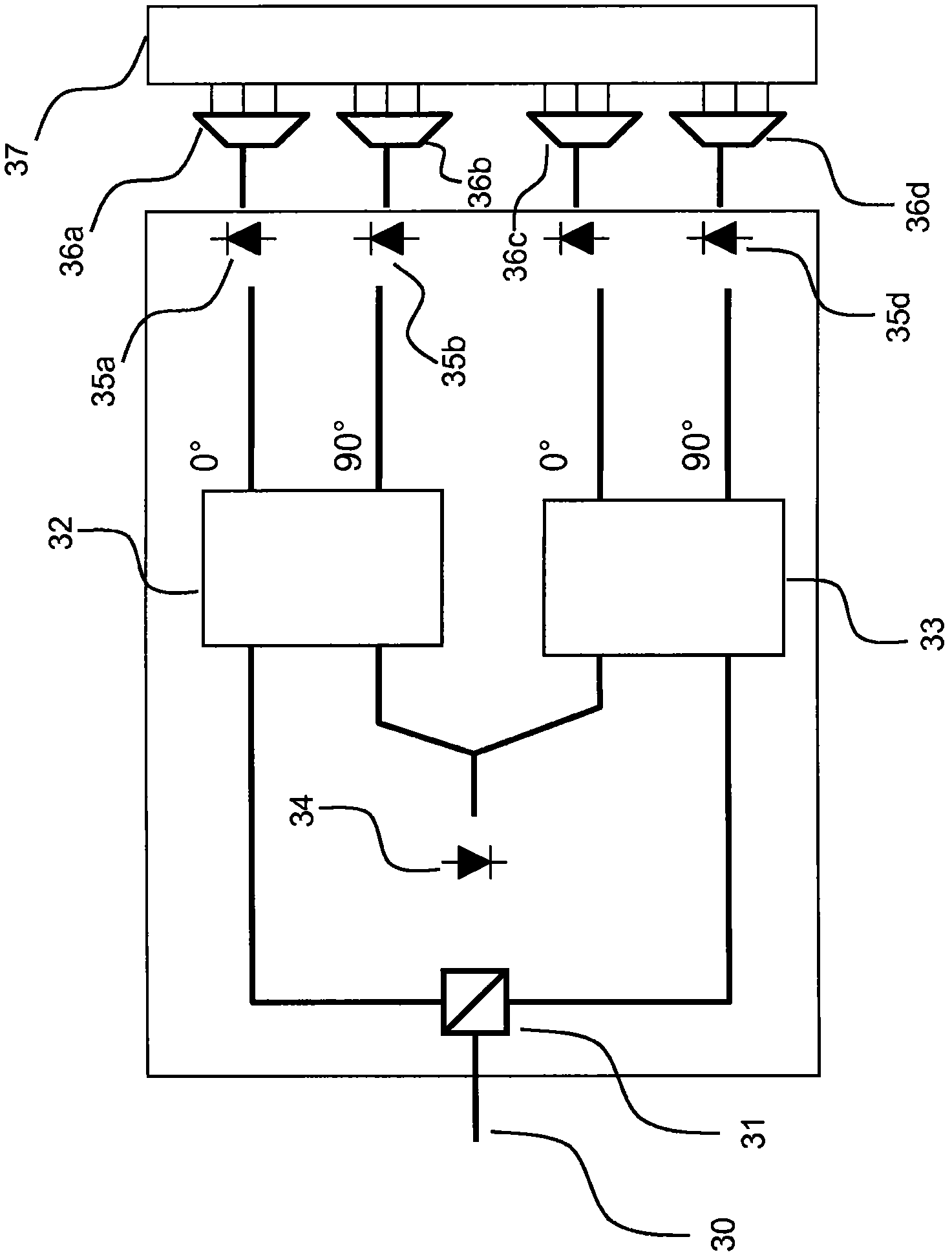

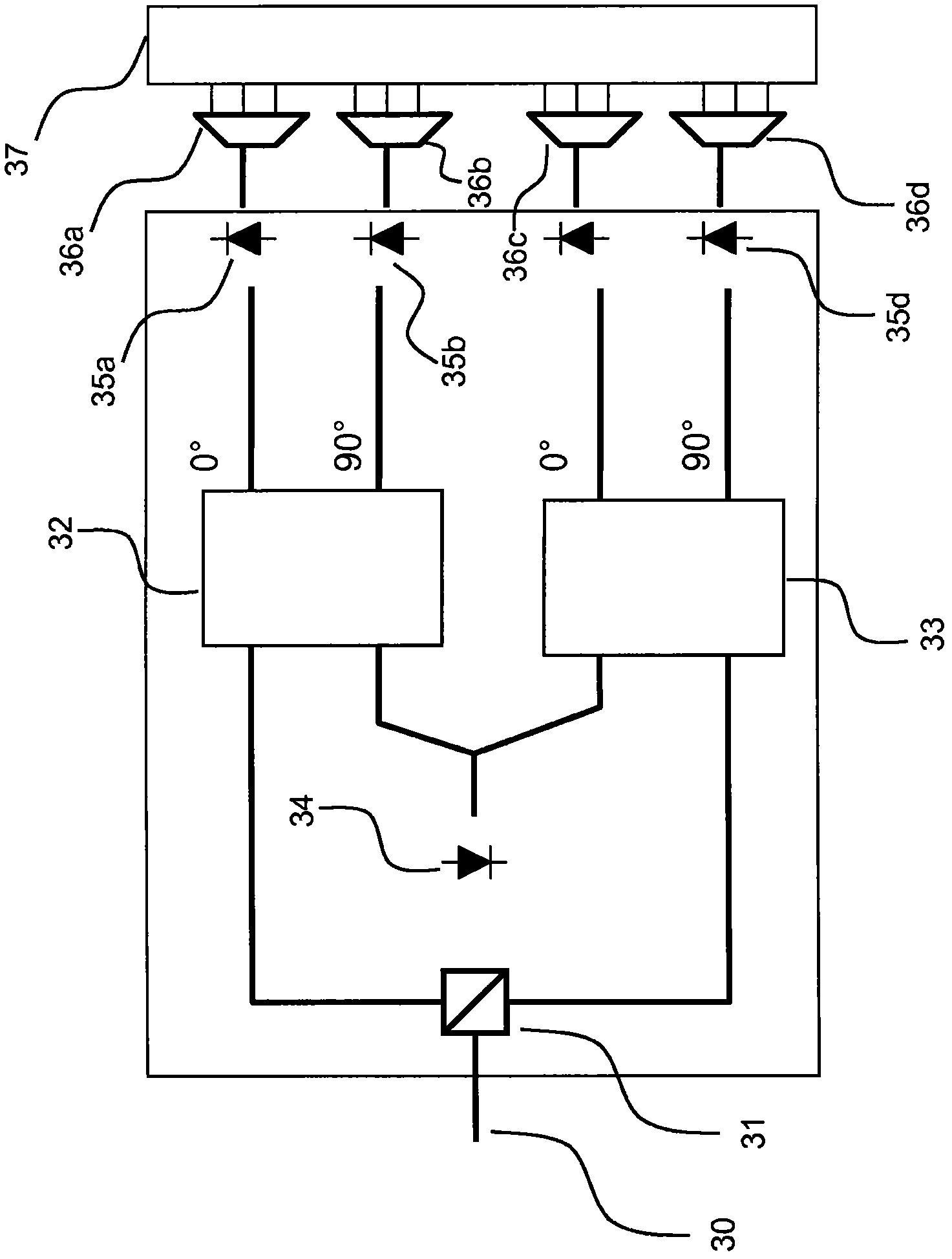

Clock recovery for optical transmission systems

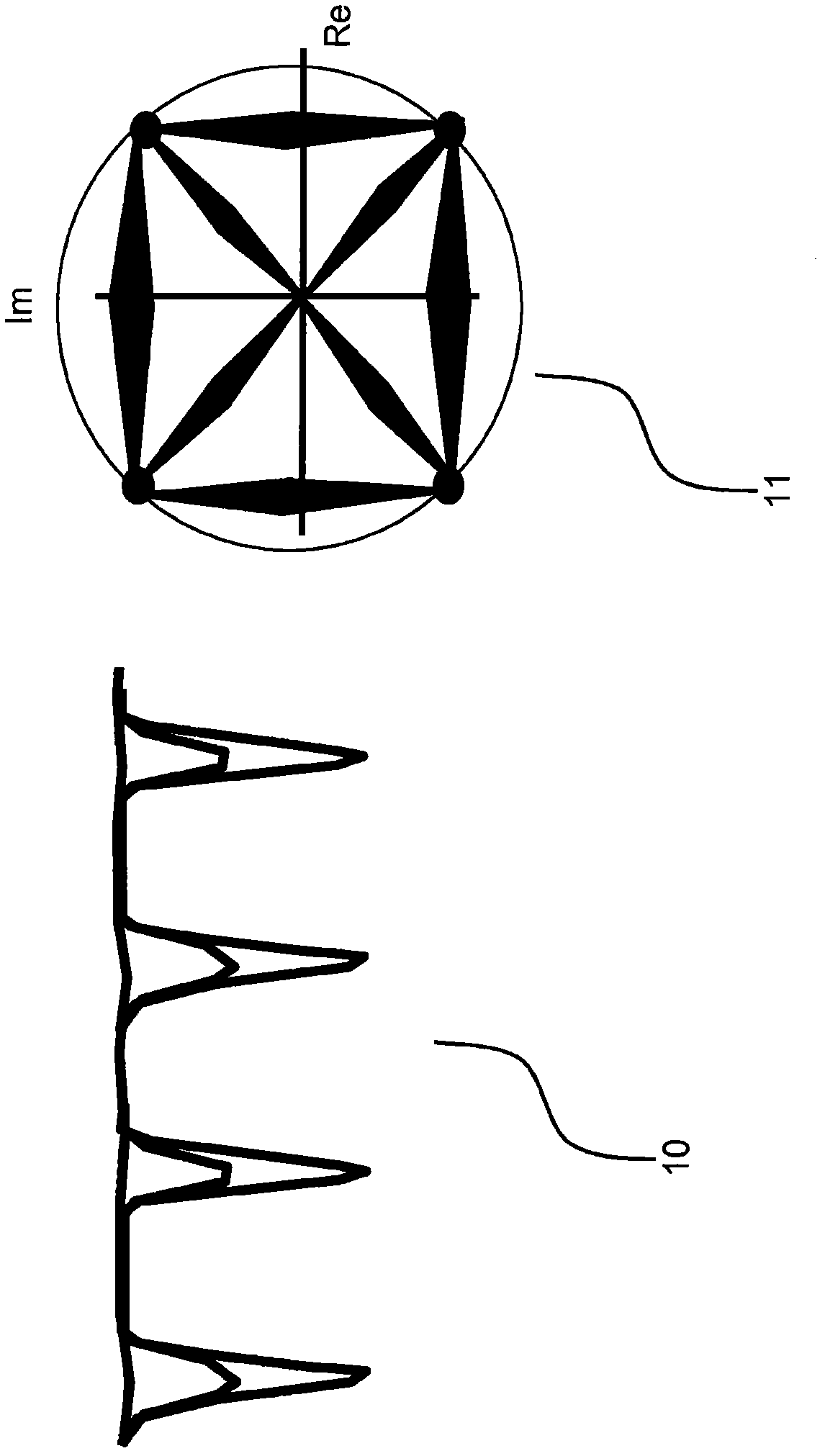

ActiveCN102577183AElectromagnetic receiversSynchronising arrangementPhase detectorCommunications system

A receiver for an optical communications system which corrects distortion of a received signal. A clock recovery system utilising a feedback and feedforward system are provided. The feedback loop comprises a phase detector and a clock source, while the feedforward loop comprises the phase detector and a delay element for delaying the output of distortion correction system. The feedback loop has a significantly lower bandwidth than the feedforward path. There are also provided methods of optimising tap weights and of acquiring initial tap weights.

Owner:CISCO TECH INC

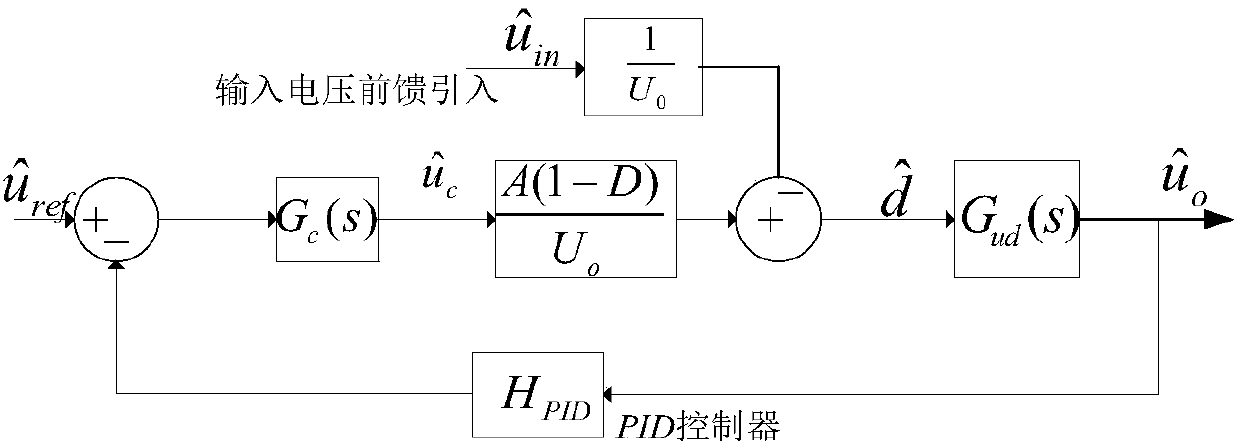

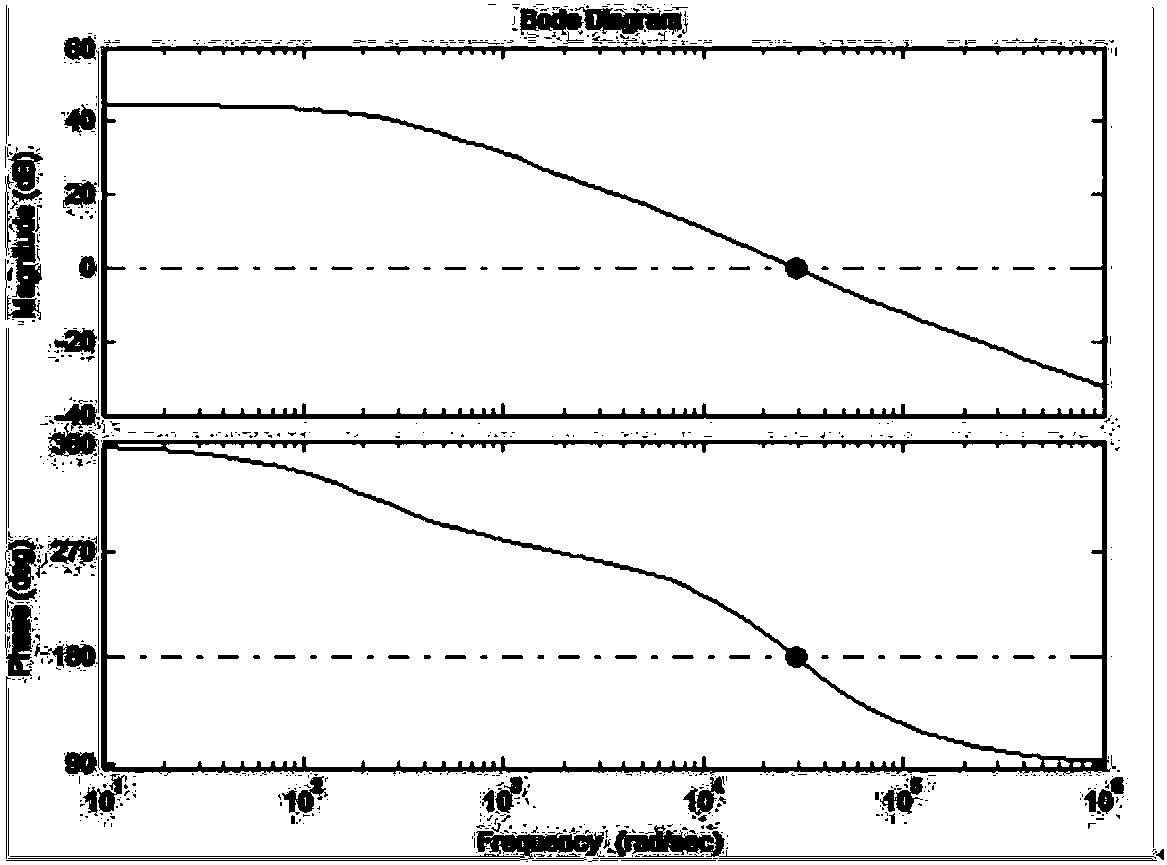

Boost converter-based anti-input voltage and anti-load fluctuation control system

InactiveCN107707101AEasy to implementSolve the anti-input disturbancePower conversion systemsControl systemEngineering

The invention relates to a boost converter-based anti-input voltage and anti-load fluctuation control system, including an input voltage feedforward system, a boost converter control system and a verification system, wherein the input voltage feedforward system is used for adding feedback to the boost converter control system before input voltage, and the verification system performs collection and verification on control system parameters after feedback is added, and adjusts a power switch duty ratio D in the boost converter and a transfer function of a compensation network according to a verification result. The boost converter-based anti-input voltage and anti-load fluctuation control system adopts a strategy of adding feedforward control at the input end, introduces variation oppositeto input disturbance to counteract input side change, and by adoption of a novel derivation mode, an established model is very simple and is easy to realize.

Owner:BEIJING MECHANICAL EQUIP INST

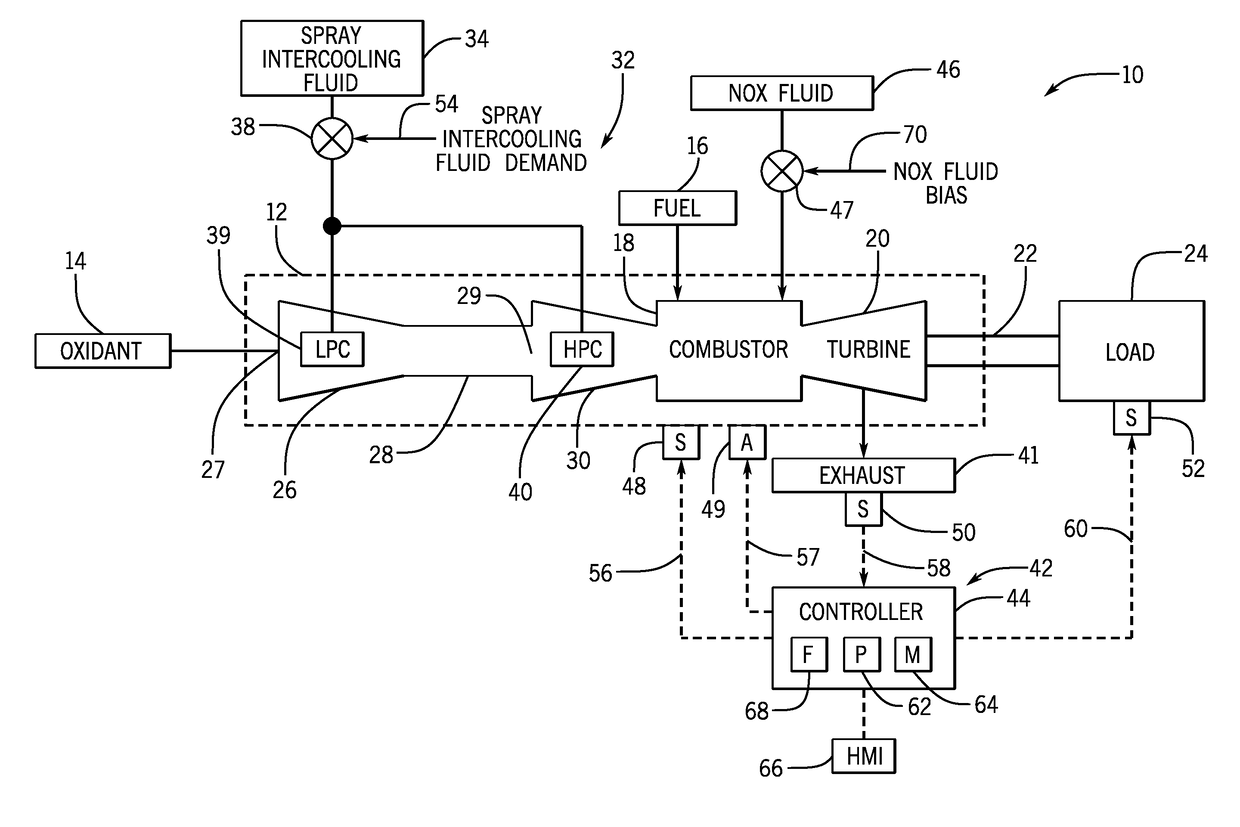

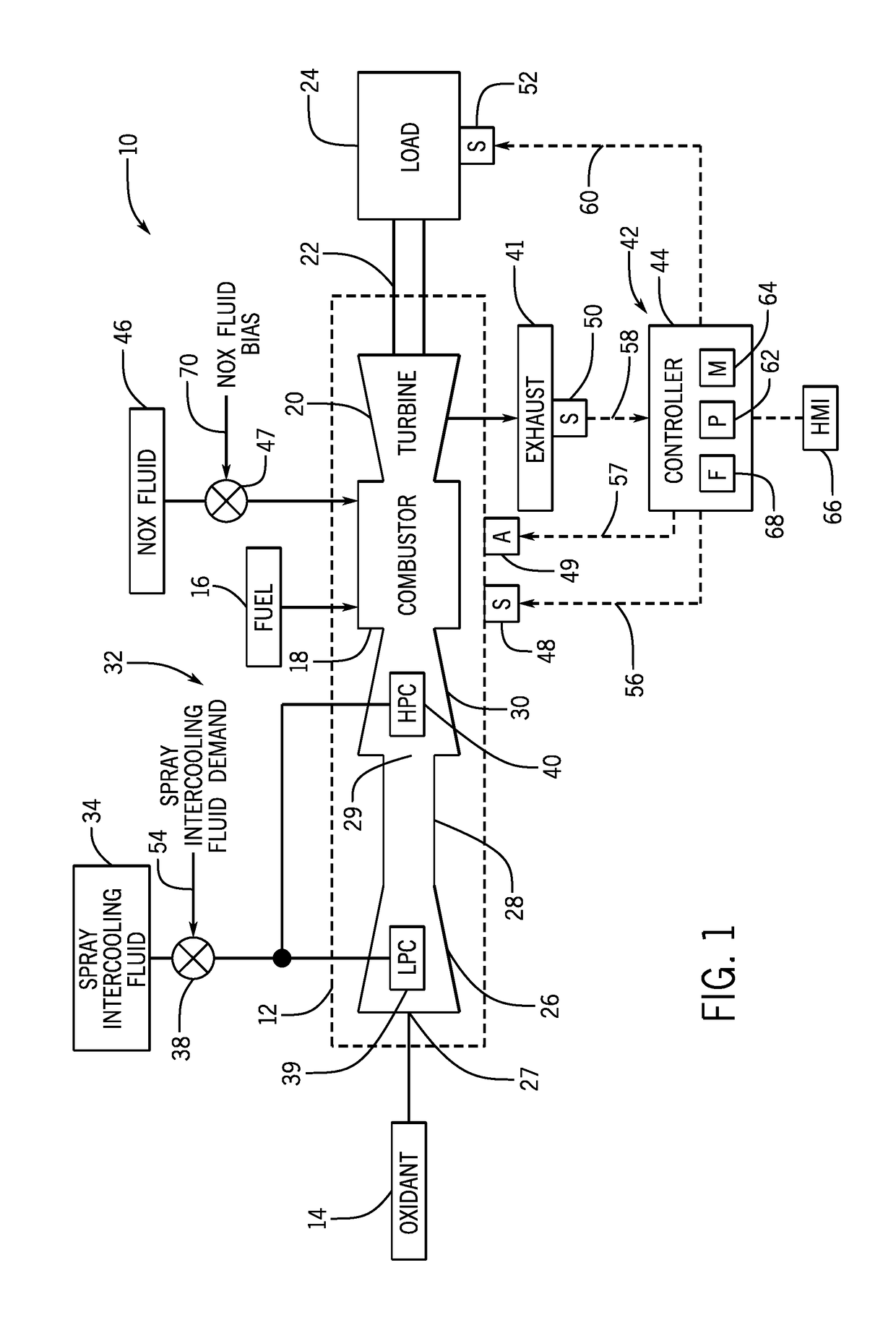

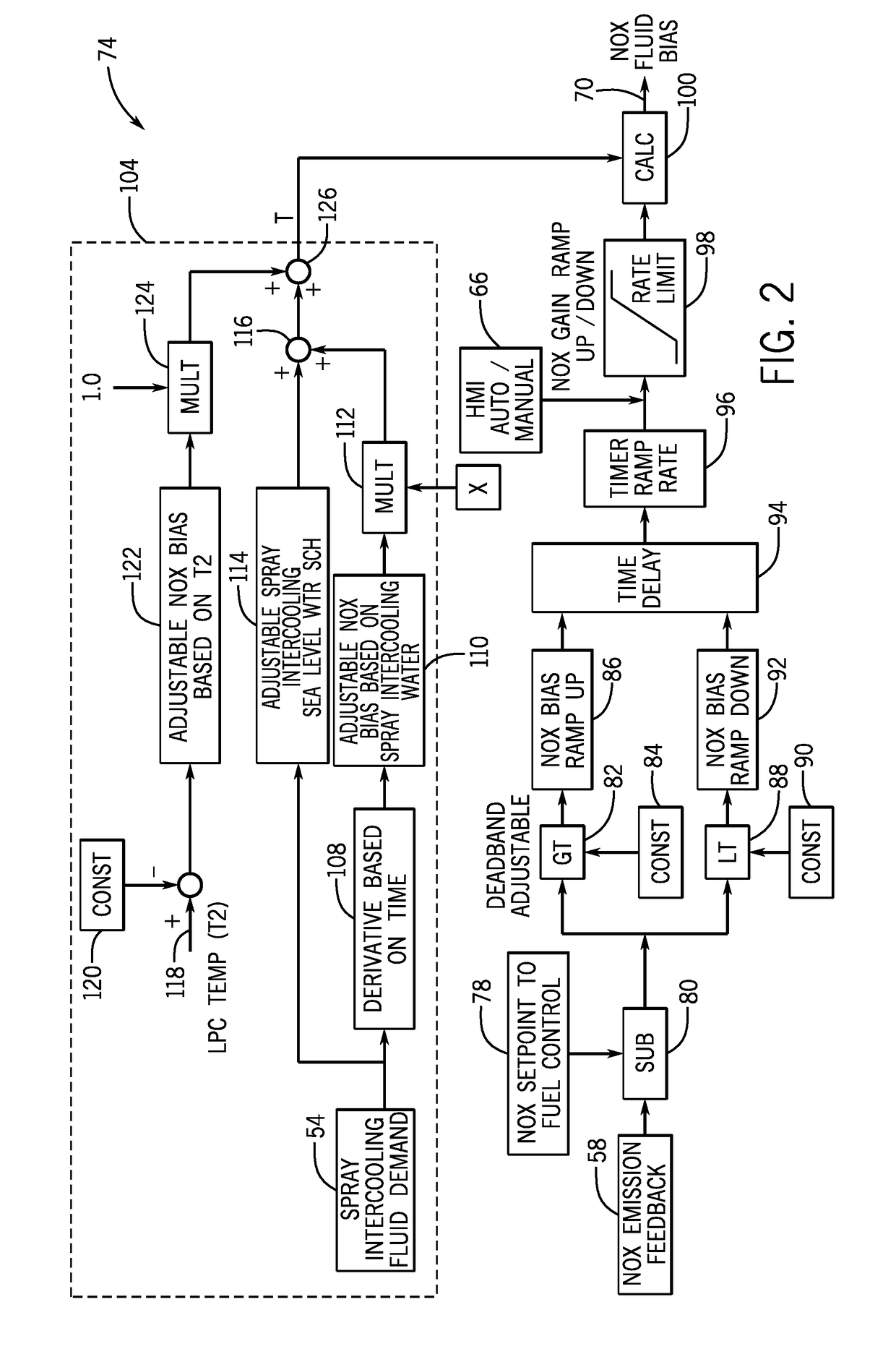

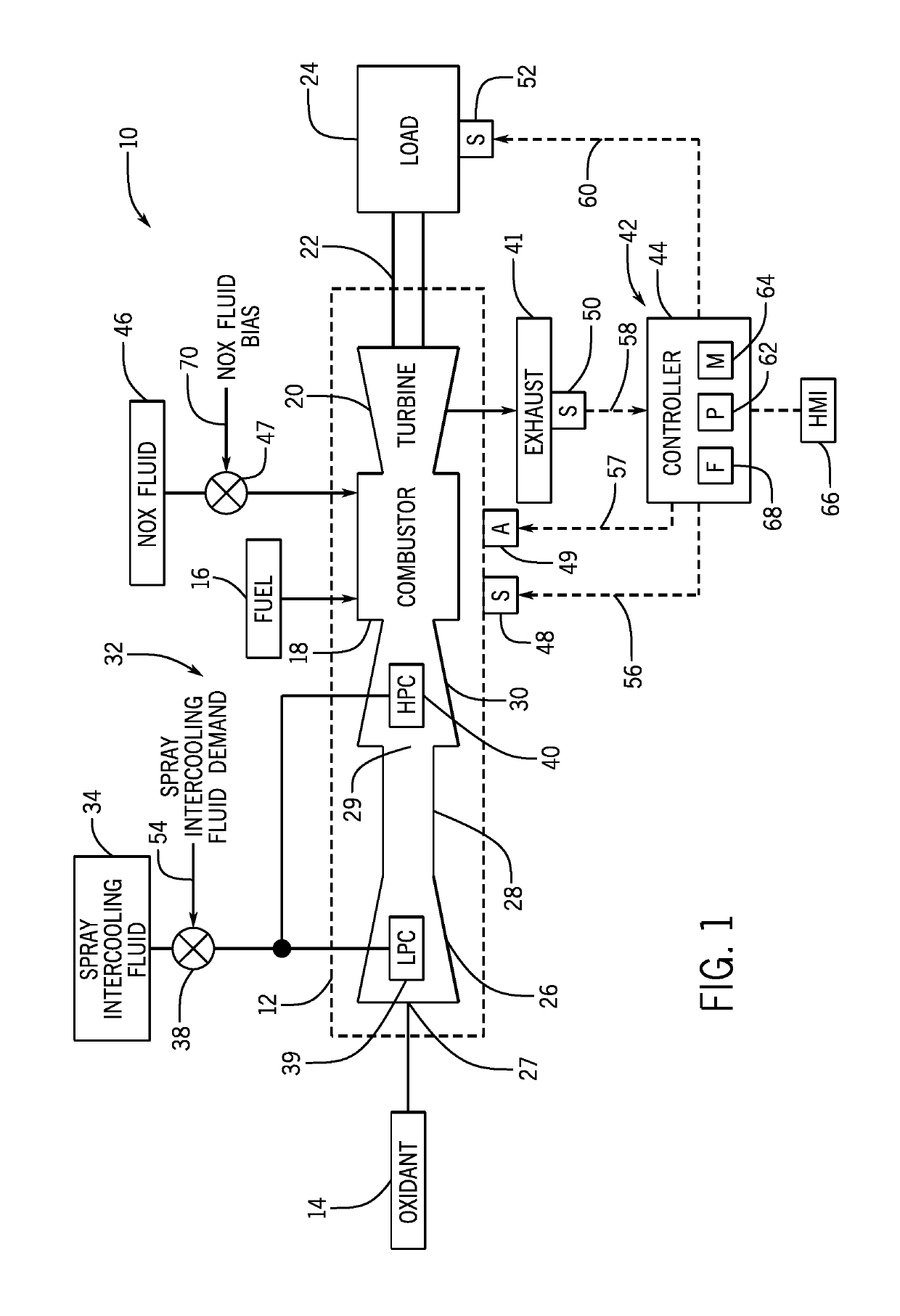

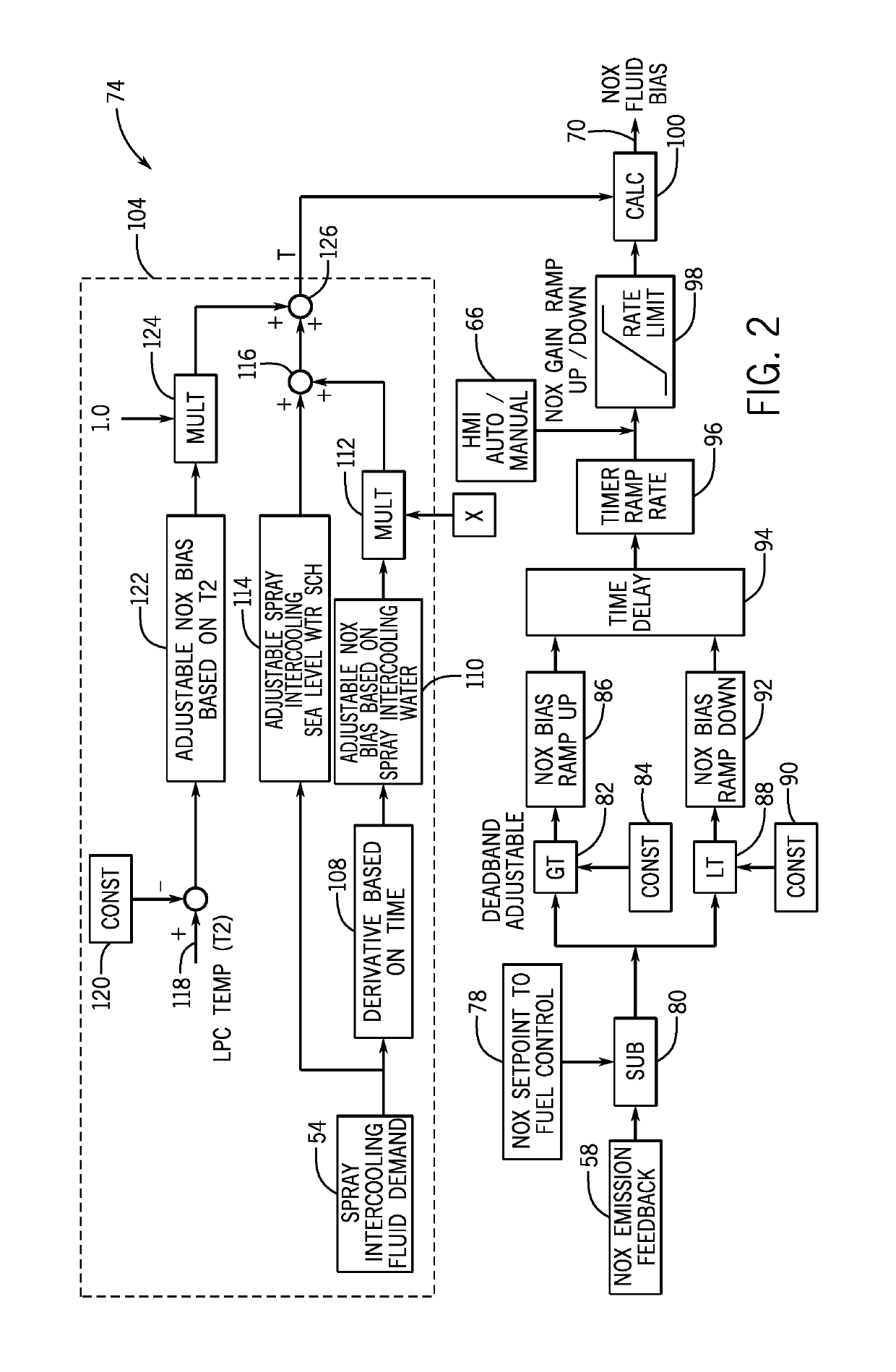

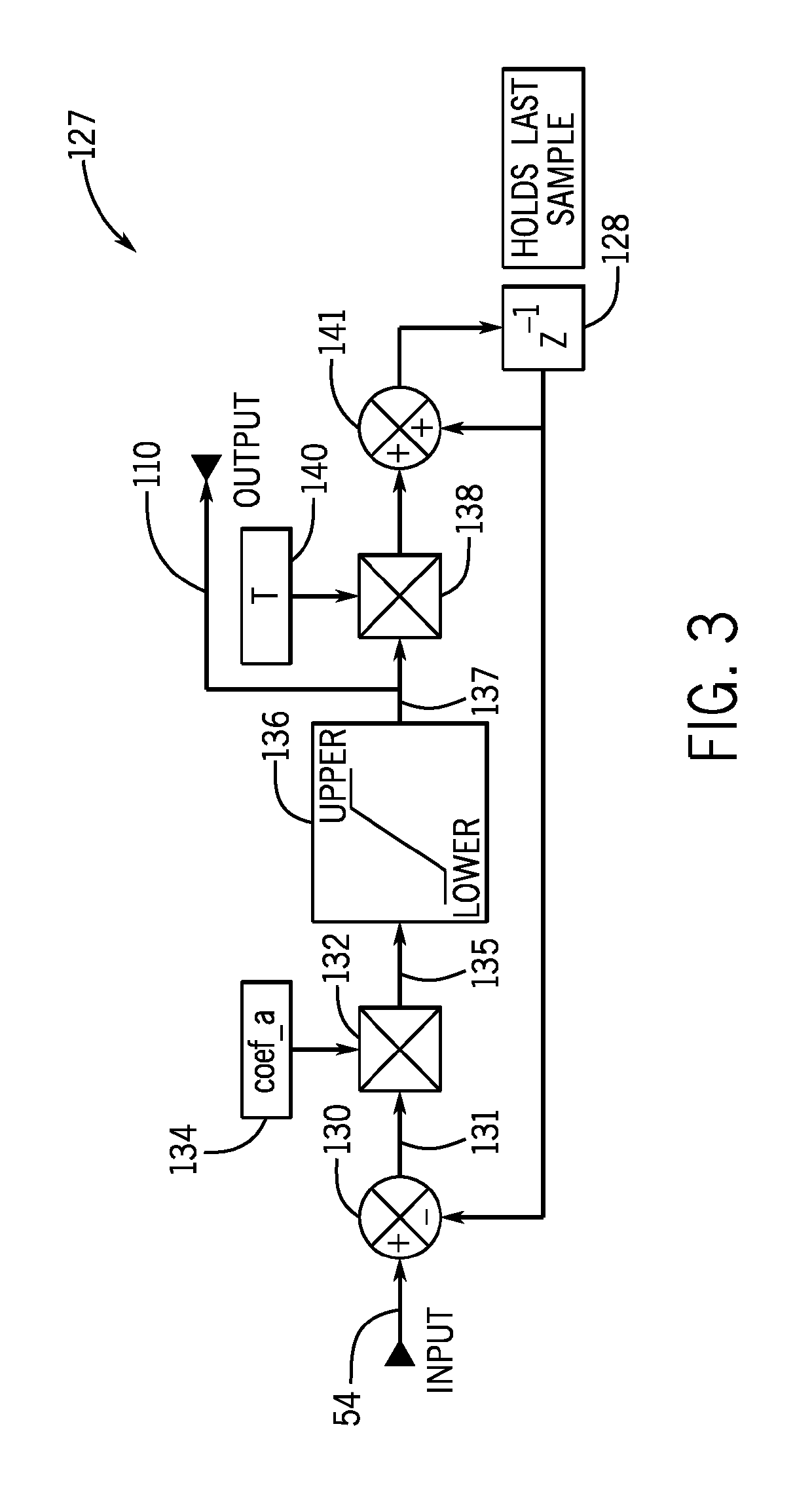

Feedforward systems and methods for spray intercooling fluid flows

ActiveUS20170363005A1Reduce nitrogen oxide emissionsGas turbine plantsEngine controlControl flowNitrogen oxides

A system for a gas turbine includes a control system comprising a processor. The processor is configured to receive a signal indicating spray intercooling fluid demand of the gas turbine. The processor is configured to determine a rate of change of the spray intercooling fluid demand. The processor is configured to control flow of a nitrogen oxide (NOX) minimization fluid that reduces NOX emissions from the gas turbine based at least in part on the rate of change of the spray intercooling fluid demand.

Owner:GENERAL ELECTRIC CO

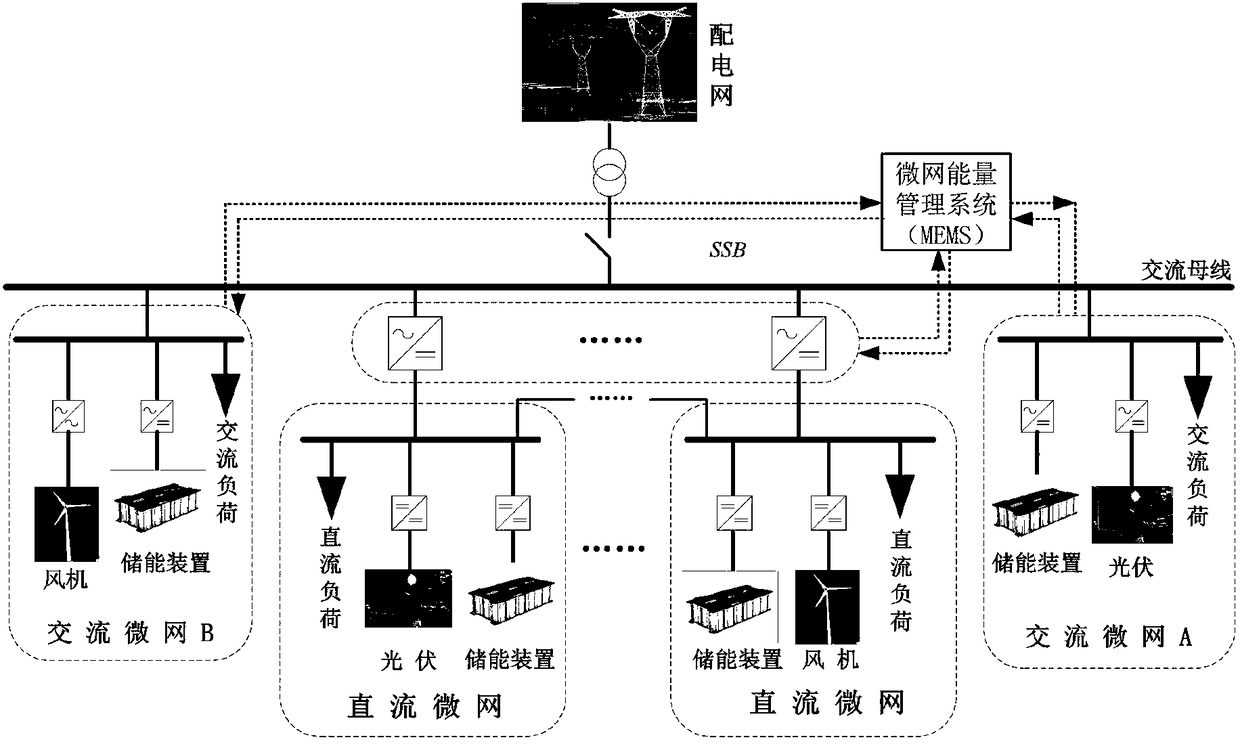

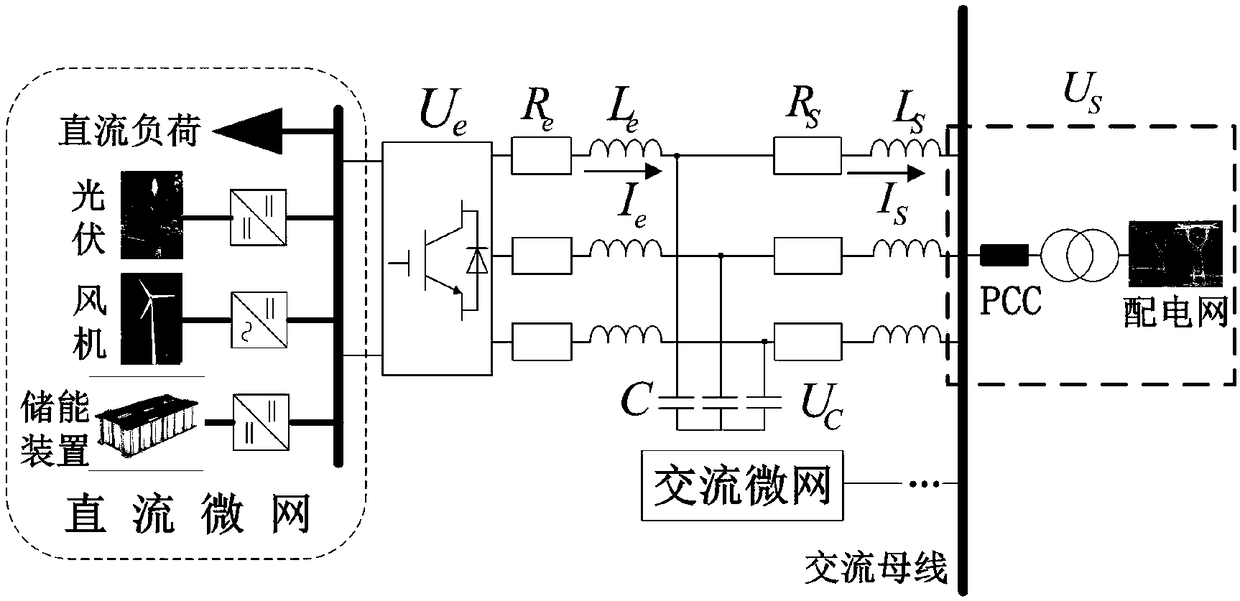

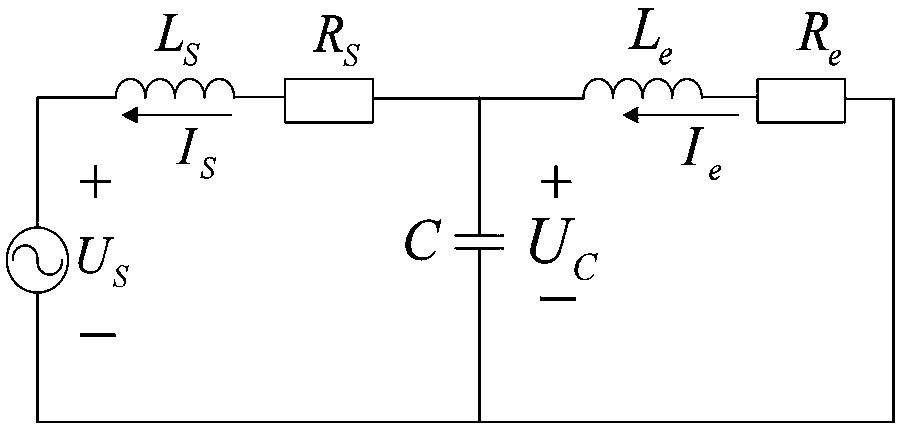

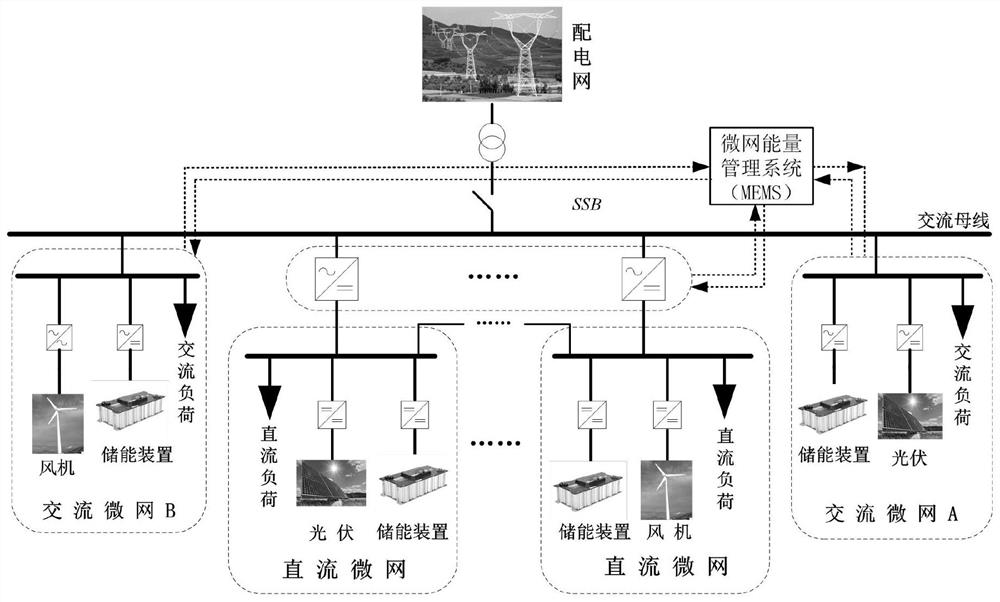

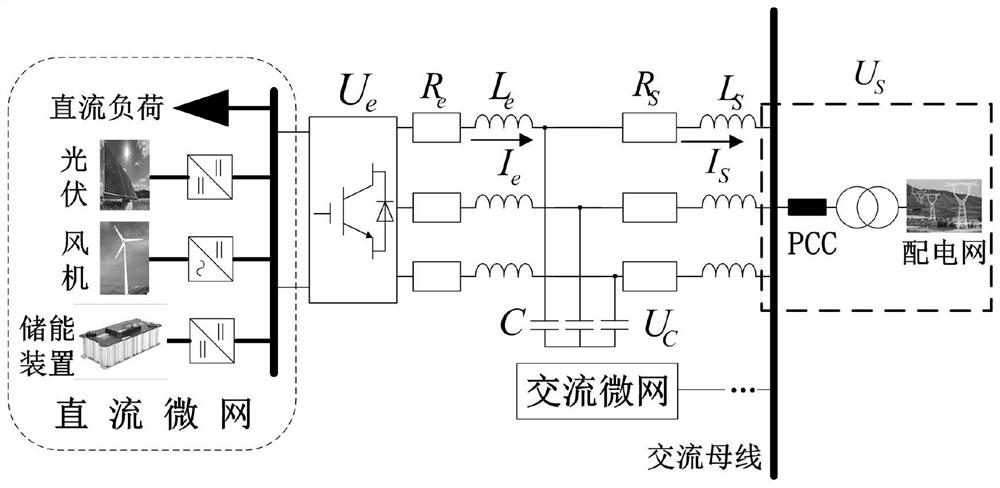

AC/DC hybrid micro-grid grid connection robust control method taking uncertainty into consideration

ActiveCN108521143ARealize flexible grid connectionImprove robustnessSingle network parallel feeding arrangementsCapacitanceOvercurrent

Provided is an AC / DC hybrid micro-grid grid connection robust control method taking uncertainty into consideration. The method includes the following steps: on the basis of the superposition theorem,establishing an AC / DC hybrid micro-grid grid connection mathematical model and a feed-forward system mathematical model in accordance with an AC / DC hybrid micro-grid grid connection topological structure; independently controlling a DC sub-micro-grid and providing a reference voltage to a filter capacitor in an AC / DC hybrid micro-grid; and constructing an AC / DC hybrid micro-grid grid connection robust controller and AC / DC hybrid micro-grid grid connection is achieved, so the robust performance of the AC / DC hybrid micro-grid is improved. The method of the invention avoids overcurrents in grid connection points during AC / DC hybrid micro-grid grid connection, realizes seamless switching, and enables AC / DC hybrid microgrids still to be normally connected in a condition of certain parameter perturbation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

Control system of magnetic levitation vehicle

PendingCN110155099AControl lateral vibrationReduce lateral vibrationRailway tunnelsSliding/levitation railway systemsSupporting systemControl system

Owner:UNIV OF SCI & TECH OF CHINA

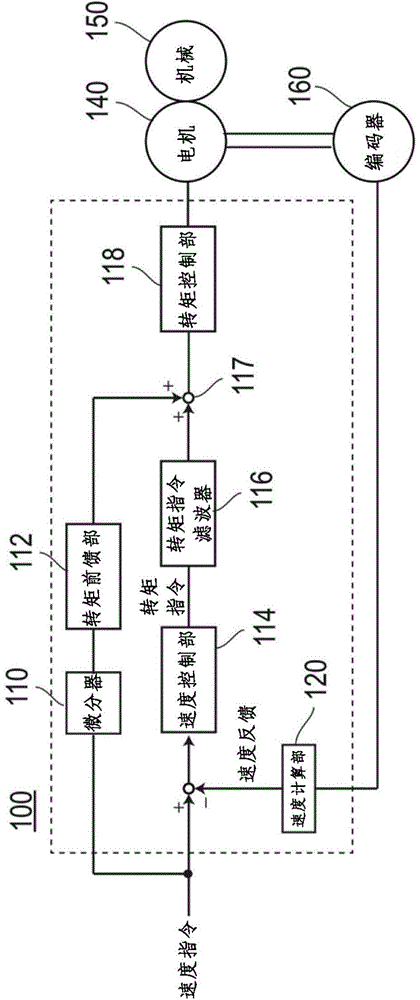

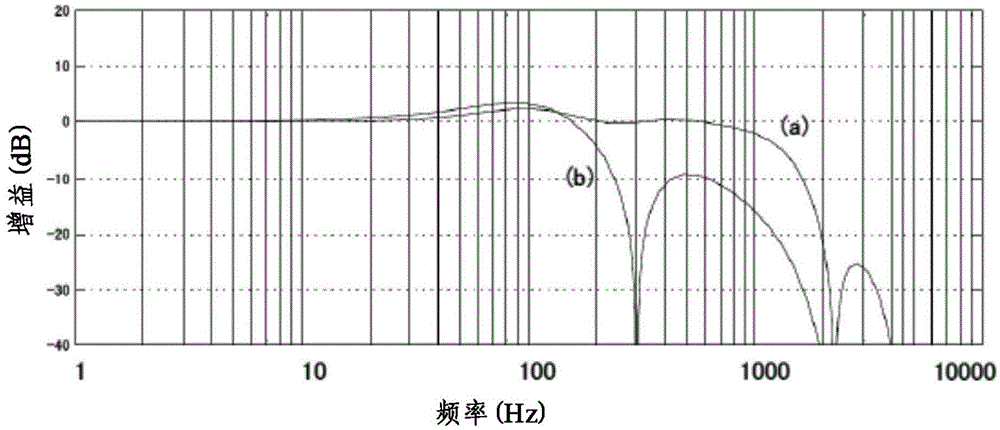

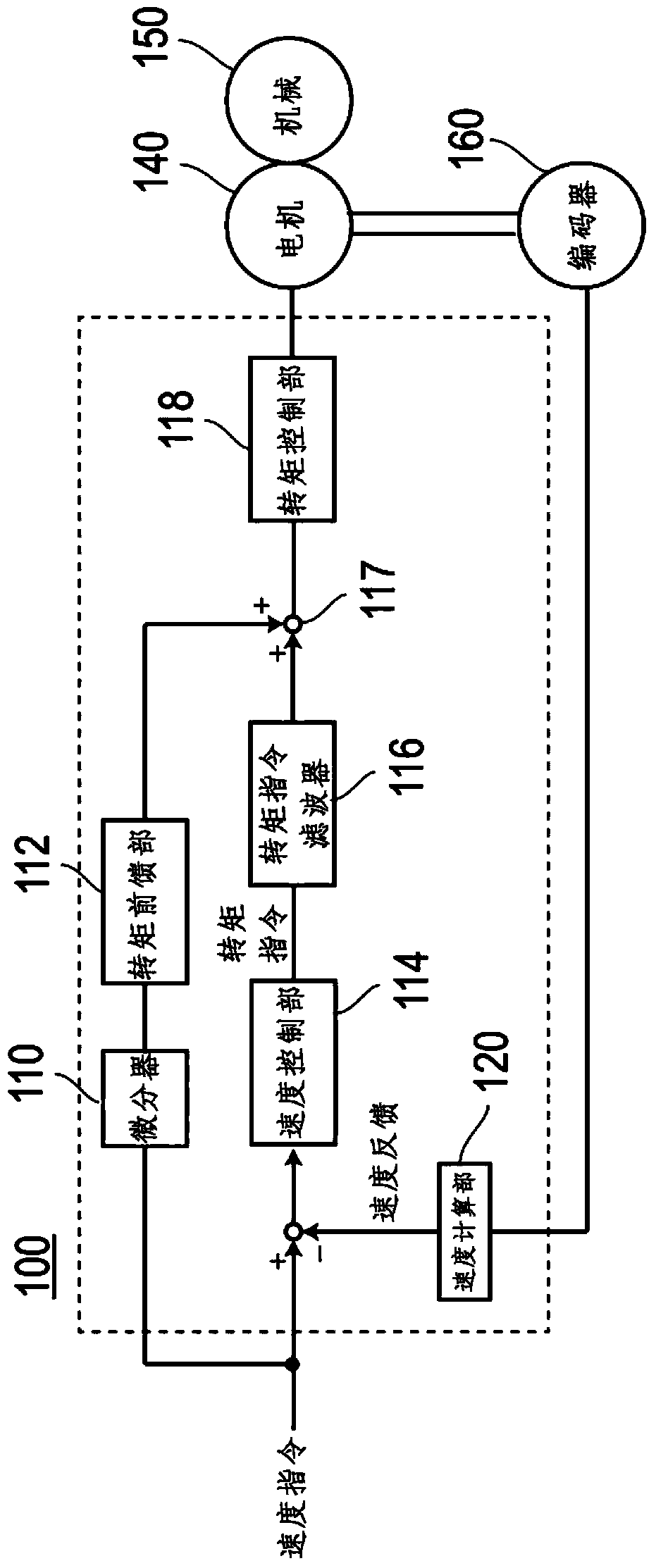

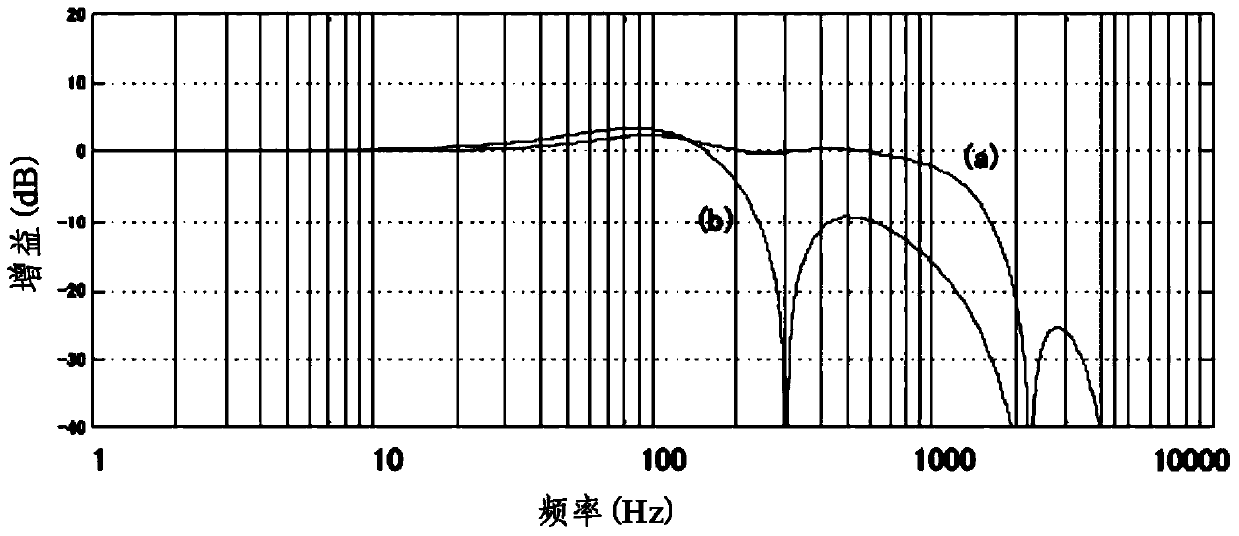

Motor controller

ActiveCN104702158AAchieve traceabilityElectric motor controlVector control systemsDifferentiatorResonance

The invention provides motor controller capable of improving instruction traceability; the motor controller (100) comprises the following elements: a differentiator differentialing externally inputted speed instruction; a torque feedforward portion (112) used for generating a first torque indication for the feedforward system according to the differential speed instruction; a speed control portion (114) used for generating a second torque indication according to deviation between the externally inputted speed indication and the speed feedback; a torque indication filter (116) used for preventing machinery resonance and encoder quantization wave of the second torque indication; an addition operation point used for carrying out addition operation for the first torque indication and the second torque indication outputted from the torque indication filter (116), thus generating a third torque indication; a torque control portion (118) using the third torque indication to control the motor motions.

Owner:SANYO DENKI CO LTD

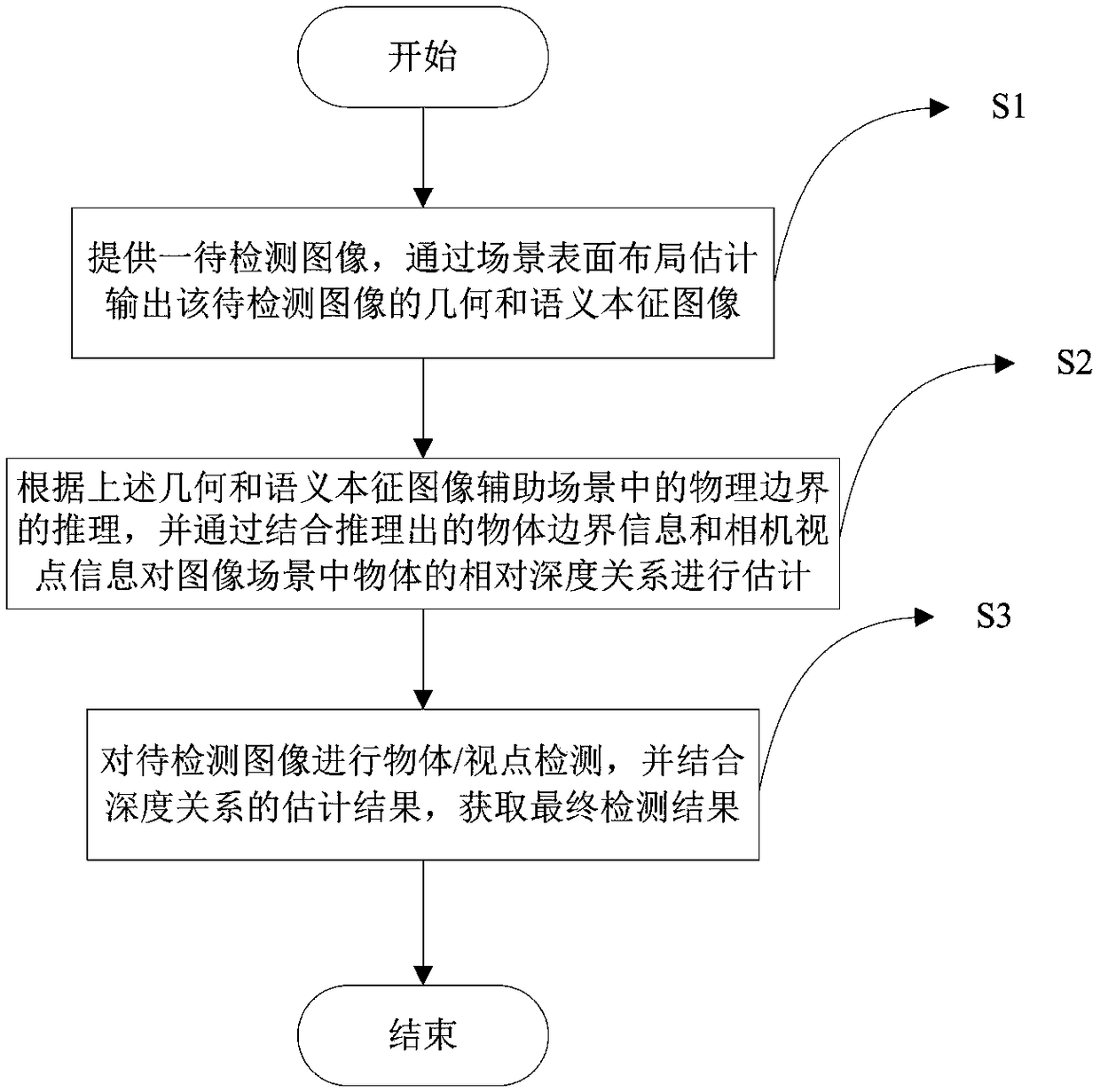

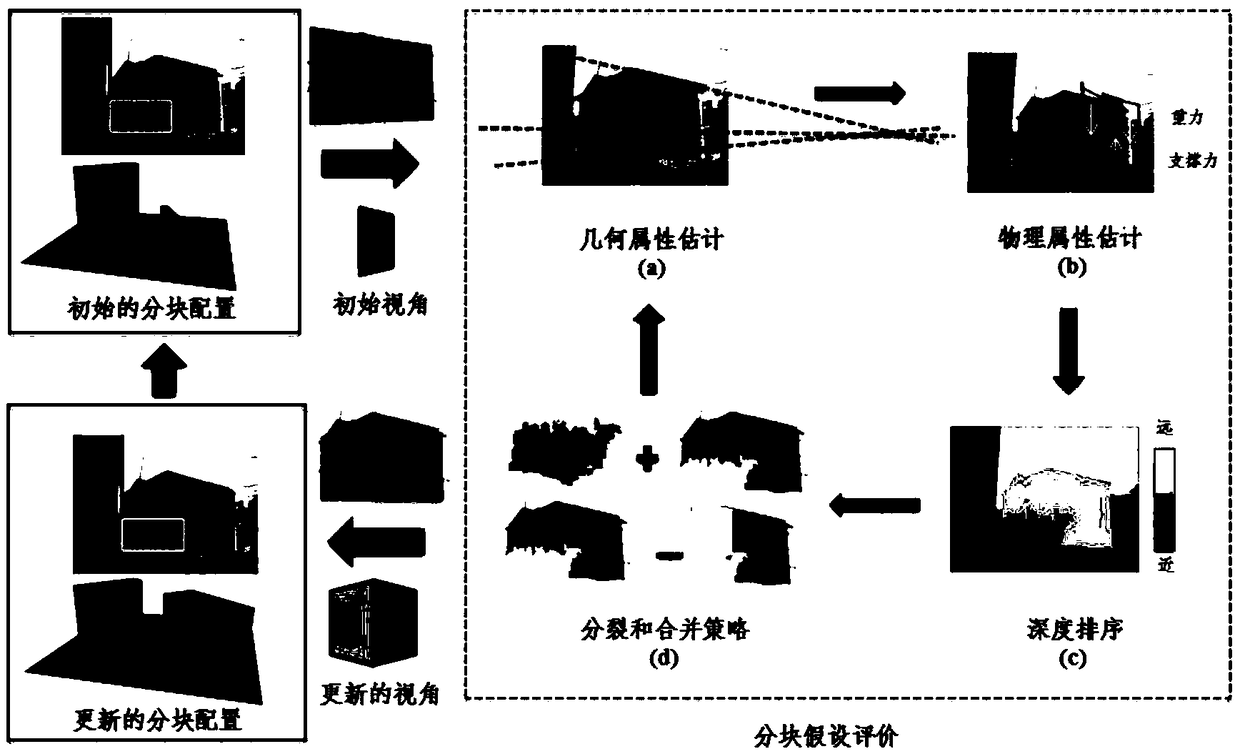

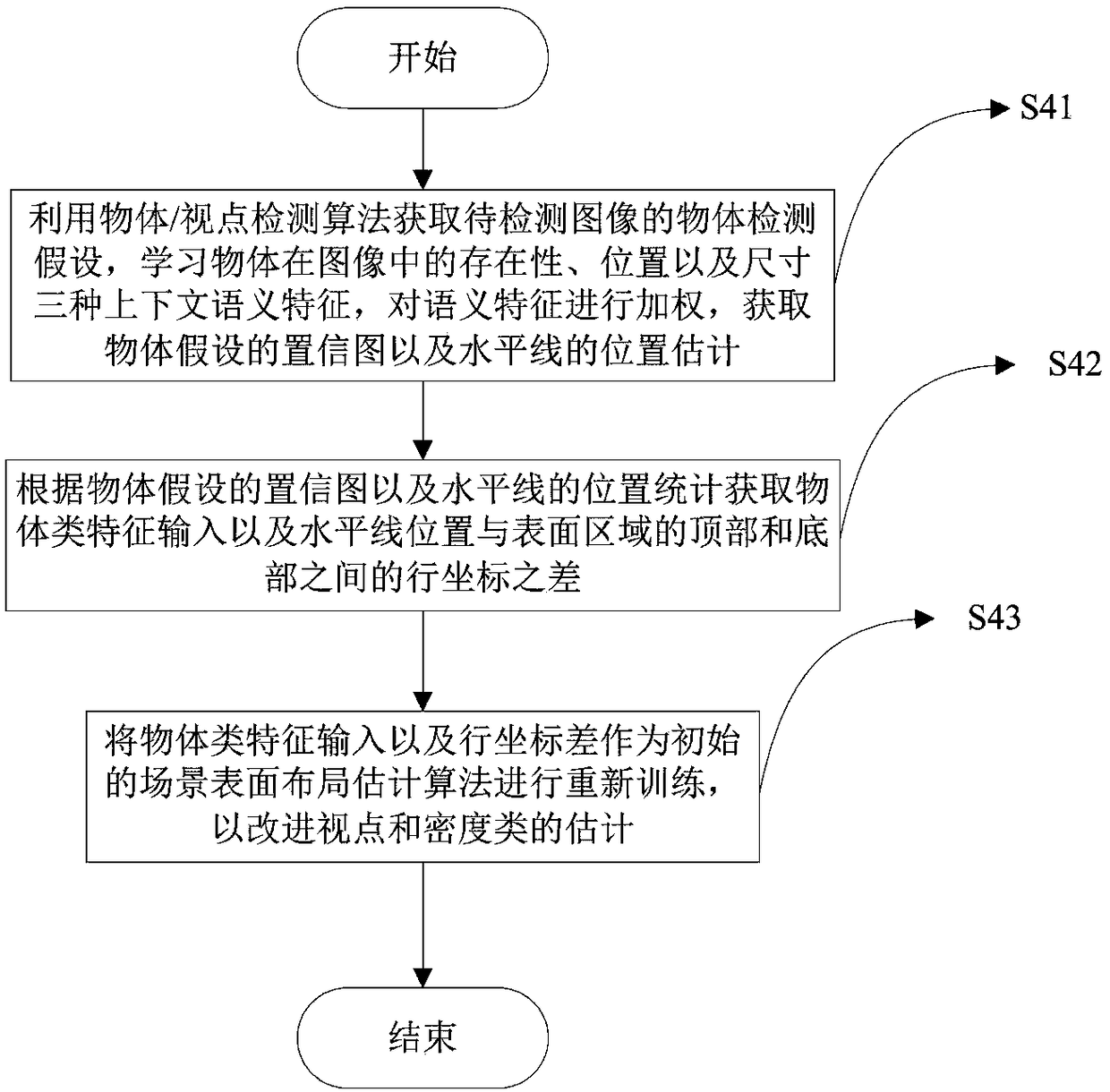

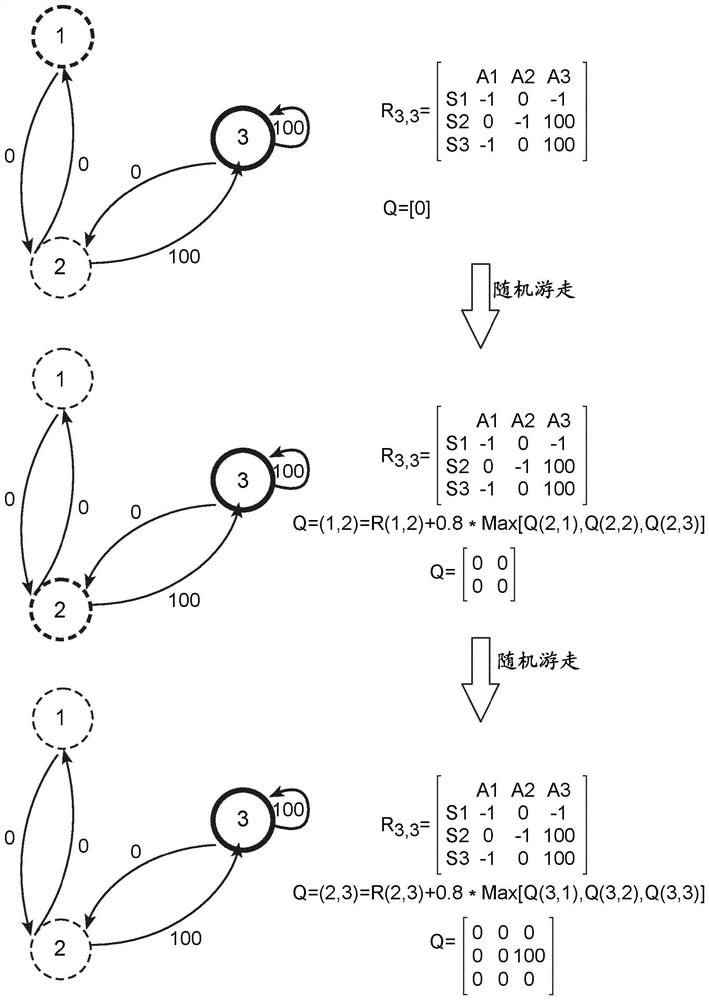

A recursive scene understanding method based on multiple semantic interactions

InactiveCN109344771AInsufficient improvementStrong scalabilityCharacter and pattern recognitionPattern recognitionViewpoints

The invention provides a recursive scene understanding method based on multiple semantic interactions. The method comprises the following steps: providing an image to be detected; estimating and outputting geometric and semantic eigenimages of the image to be detected through the surface layout of the scene; and outputting the geometric and semantic eigenimages of the image to be detected. According to the geometrical and semantic eigenimages, the relative depth of the object in the scene is estimated by combining the inferred object boundary information and the camera viewpoint information. Object / viewpoint detection is performed on the image to be detected, and the final detection result is obtained by combining the estimation result of depth relationship. This feedback design based on eigeninformation interaction can effectively improve the shortcomings of the feedforward system, and has good scalability.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

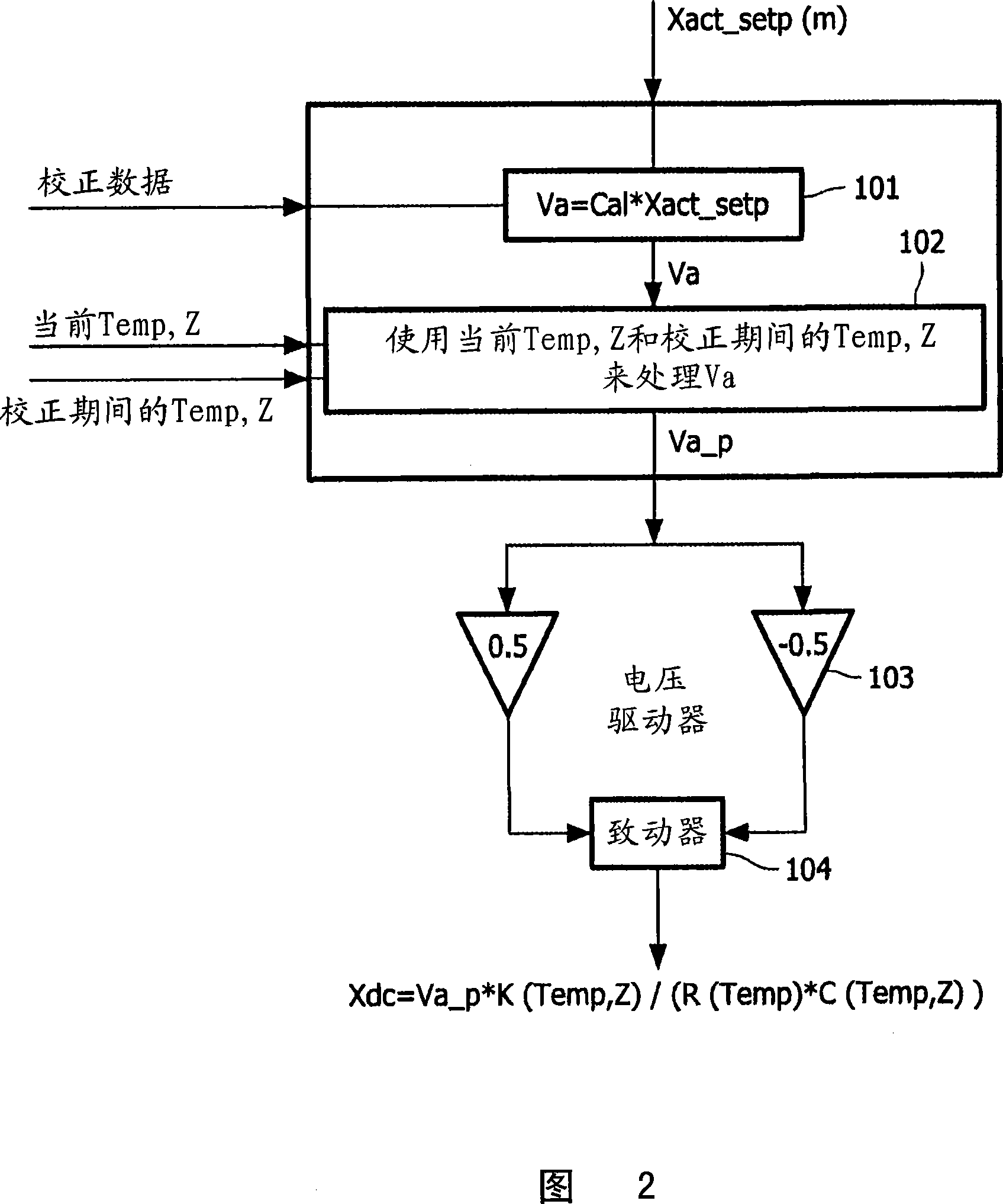

Method and device for sensitivity compensation

Method and device for generating a control voltage for a position actuator of a disk drive system for displacing a lens of a pick-up unit to a given X-position. The actuator is operated by an open loop control system. First, parameters of the control system are calibrated so that the control system produces a control voltage (Va) from an input position signal (Xact setp). Then, the control voltage is processed in a feed forward system for generating a processed control signal (Va_p) which is fed to the position actuator for displacing said lens to the X-position. A Z- value corresponding to the axial distance of the lens from a calibrated axial position and a temperature of the pick-up unit are measured. The position actuator operates according to the formula: Xdc = Va_p * K(Temp,Z) / (R(Temp) * C(Temp,Z)) in which: Xdc = position signal for said given position Va_p = Va processed K = property of 'actuator' 21 : Newton / Ampere R = resistance of 'actuator' coil C = Spring constant in Newton / meter. The Va_p is calculated according to the following formula: Va_p = Xact_set*Cal*S(Tem_cal,Z_cal) / S(Tem_write,Z_write) in which CaI is the result of the calibration S(Temp,Z) = (A_T+B_T*Temp+C_T*TempA2 )*(A_Z+B_Z*Vz+C_Z*VzA2) wherein A T, B T, C T, A Z, B Z, C Z are constants; Vz is the voltage across the Z actuator, Temp cal and Vz cal are the temperature and Vz, respectively, during calibration, Temp write and Vz write are the temperature and Vz, respectively, during writing.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Coordinated Predictive Functional Control Algorithm for Subcritical Units Based on Leading Disturbance Model

ActiveCN106647240BEase couplingImprove robustnessControllers with particular characteristicsClosed loopOptimal control

Owner:ELECTRIC POWER RES INST OF STATE GRID ZHEJIANG ELECTRIC POWER COMAPNY +1

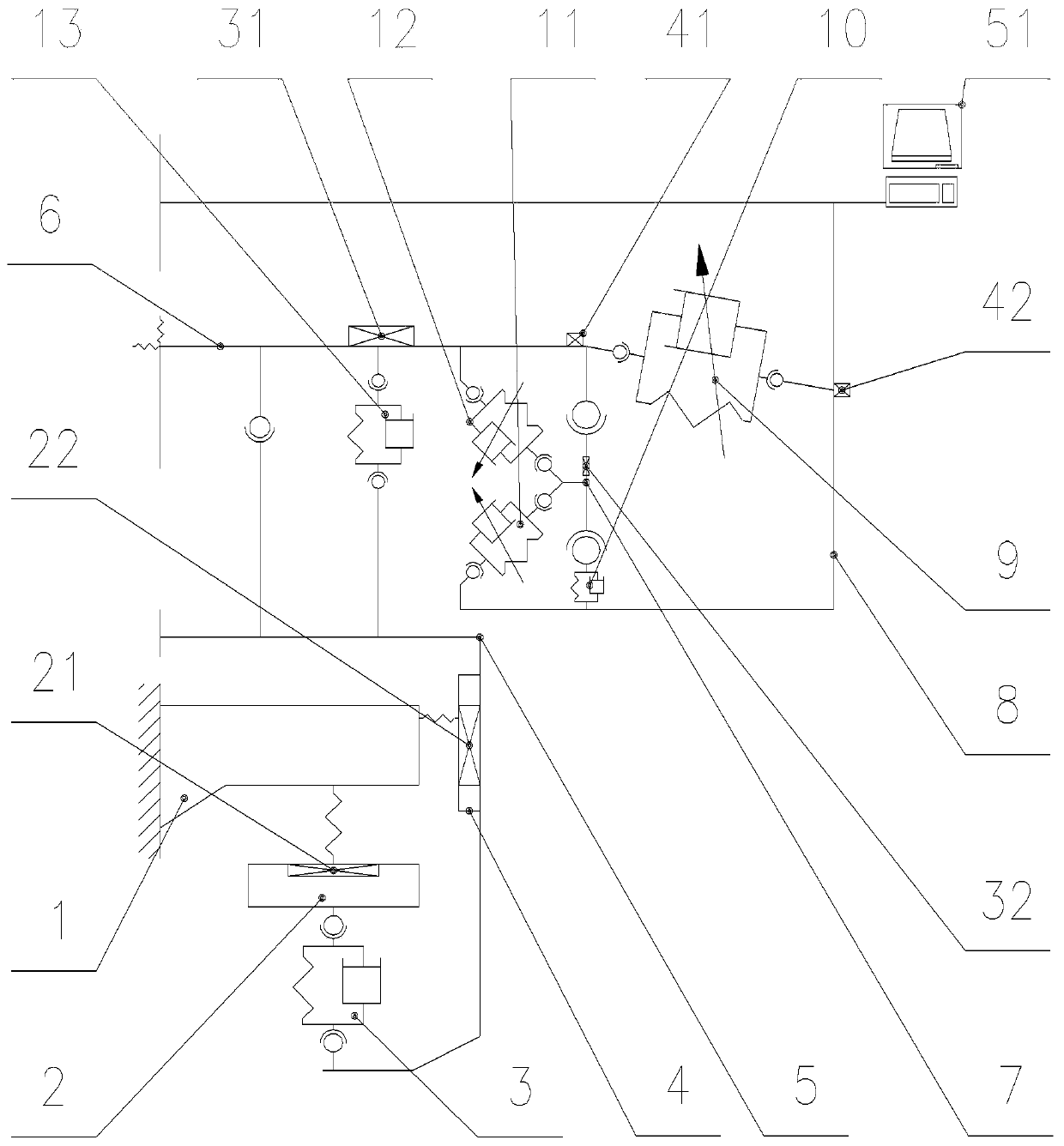

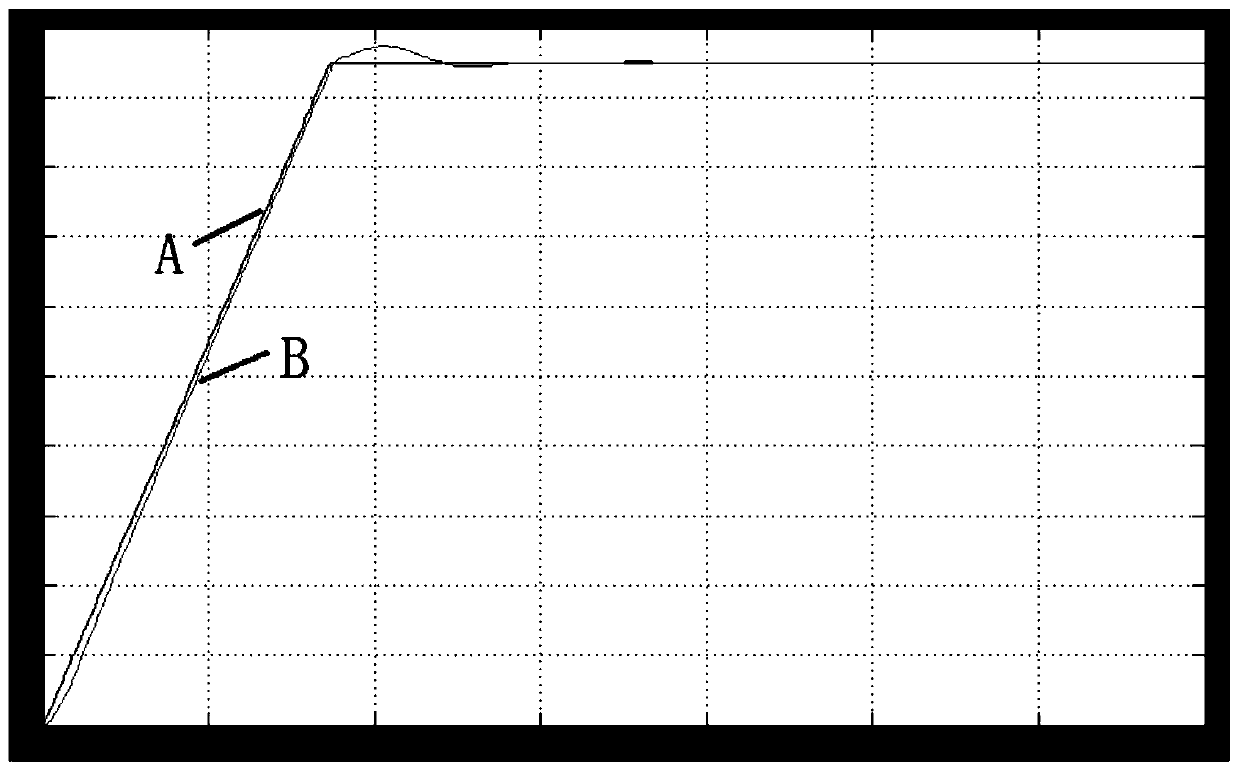

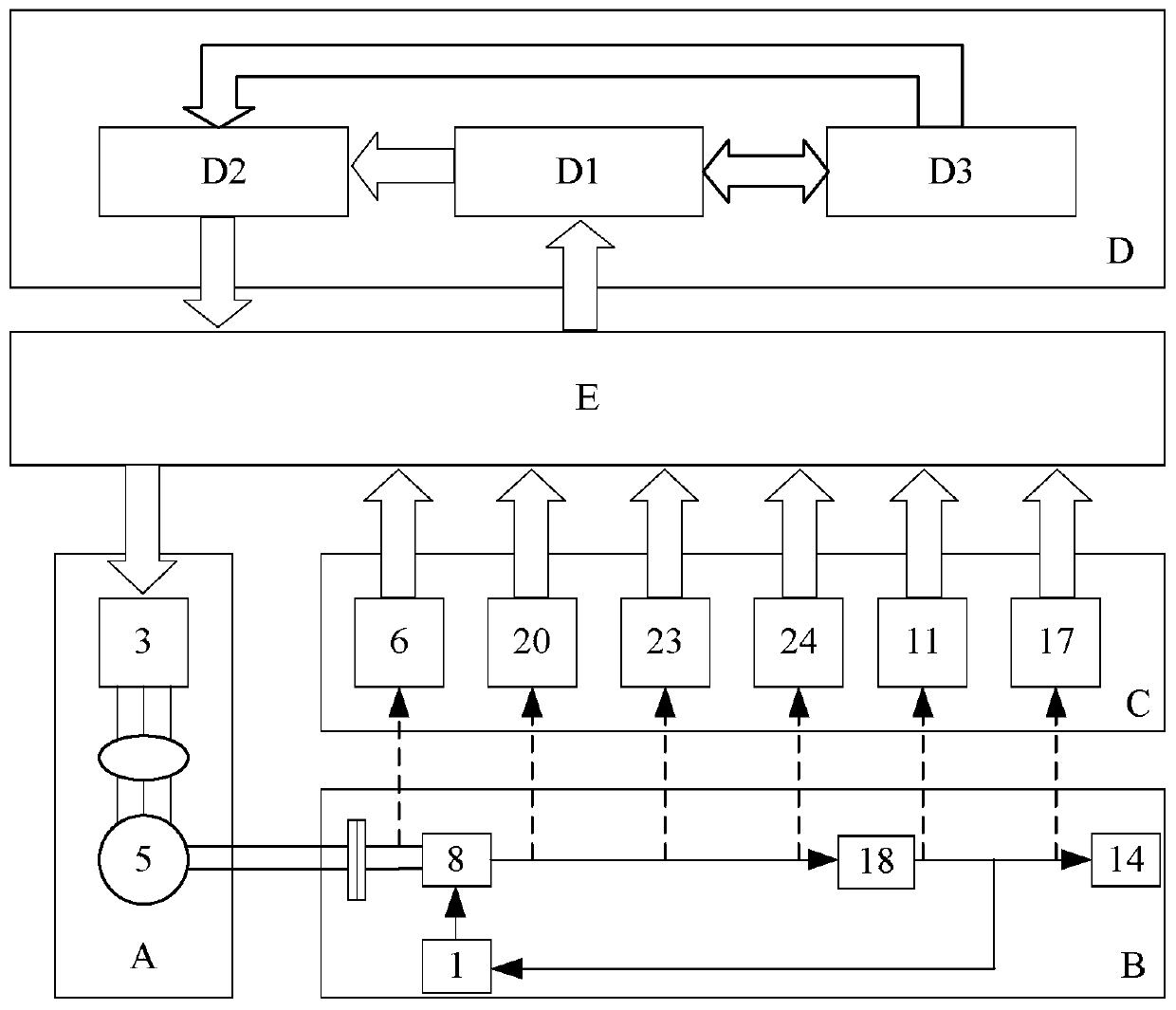

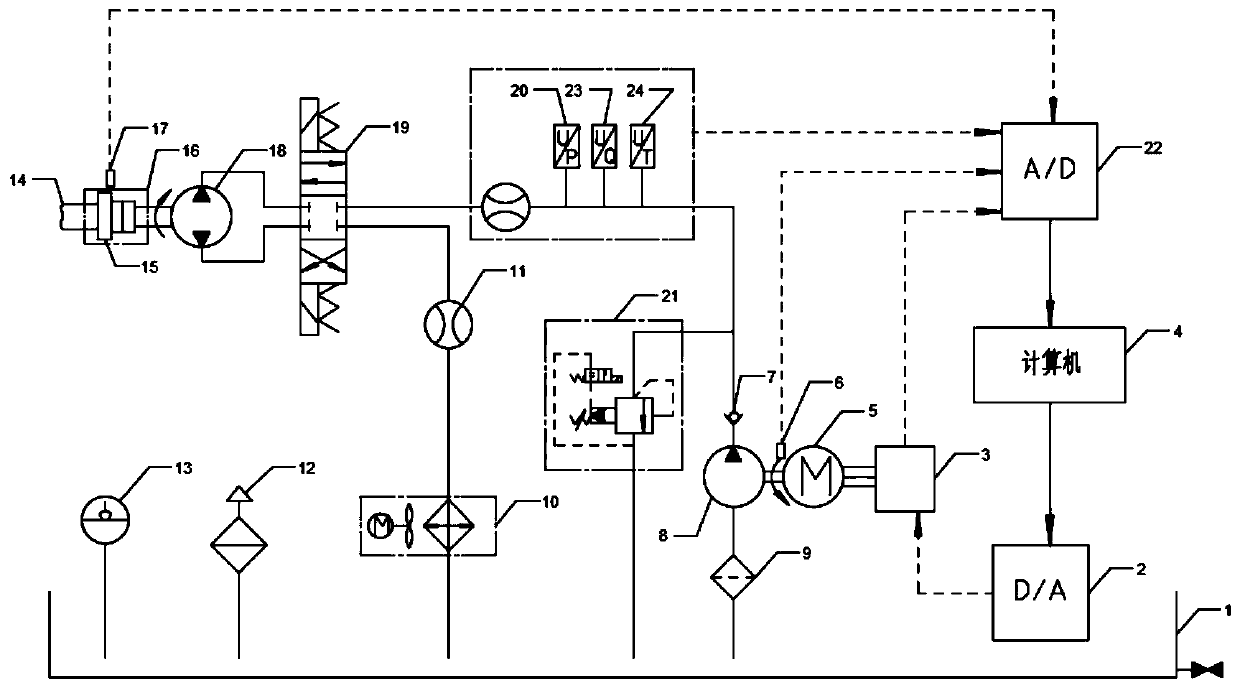

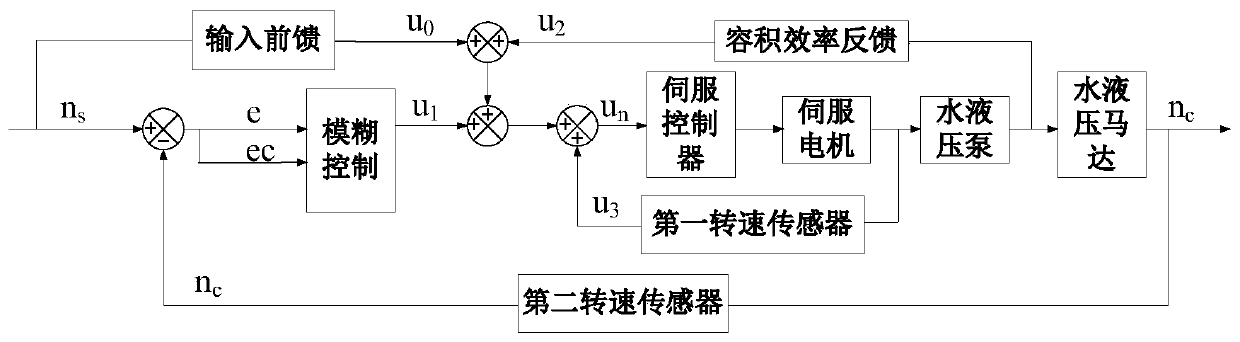

A water hydraulic motor speed control system and method

Owner:HANGZHOU DIANZI UNIV

motor control unit

ActiveCN104702158BAchieve traceabilityElectric motor controlVector control systemsDifferentiatorResonance

The invention provides motor controller capable of improving instruction traceability; the motor controller (100) comprises the following elements: a differentiator differentialing externally inputted speed instruction; a torque feedforward portion (112) used for generating a first torque indication for the feedforward system according to the differential speed instruction; a speed control portion (114) used for generating a second torque indication according to deviation between the externally inputted speed indication and the speed feedback; a torque indication filter (116) used for preventing machinery resonance and encoder quantization wave of the second torque indication; an addition operation point used for carrying out addition operation for the first torque indication and the second torque indication outputted from the torque indication filter (116), thus generating a third torque indication; a torque control portion (118) using the third torque indication to control the motor motions.

Owner:SANYO DENKI CO LTD

Feedforward systems and methods for spray intercooling fluid flows

A system for a gas turbine includes a control system comprising a processor. The processor is configured to receive a signal indicating spray intercooling fluid demand of the gas turbine. The processor is configured to determine a rate of change of the spray intercooling fluid demand. The processor is configured to control flow of a nitrogen oxide (NO.sub.X) minimization fluid that reduces NO.sub.X emissions from the gas turbine based at least in part on the rate of change of the spray intercooling fluid demand.

Owner:GE INFRASTRUCTURE TECH INT LLC

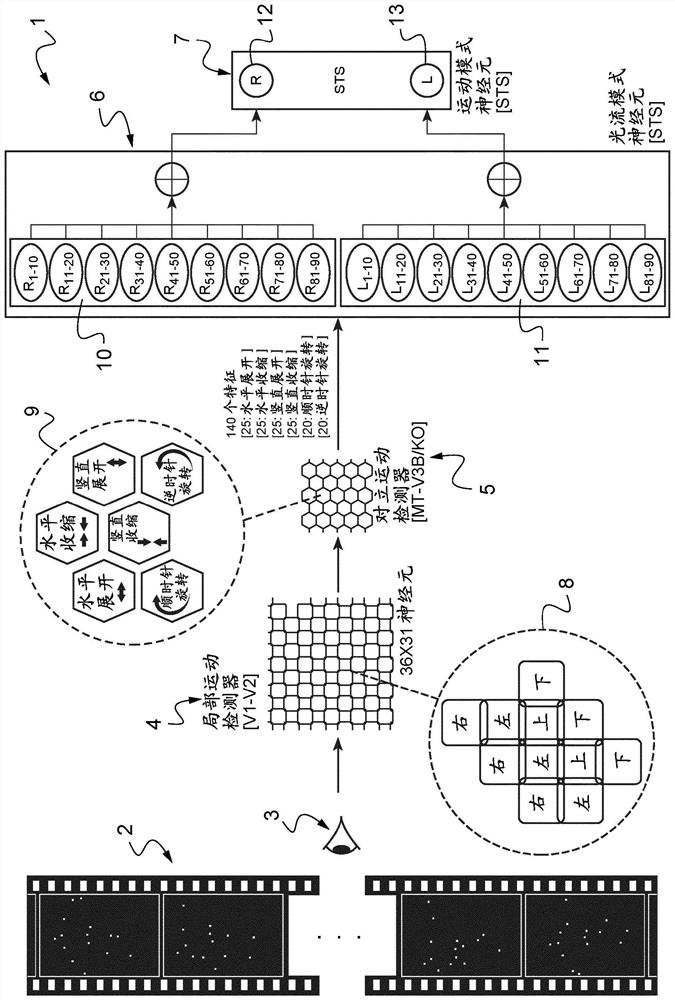

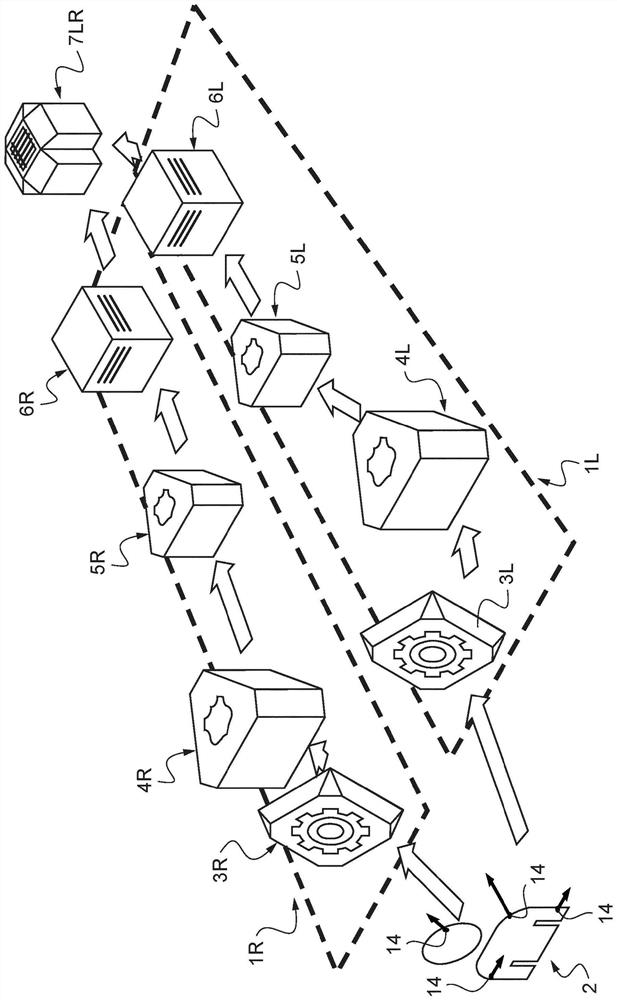

System for simulating decision-making process in brain of mammal with respect to visually observed movement of body

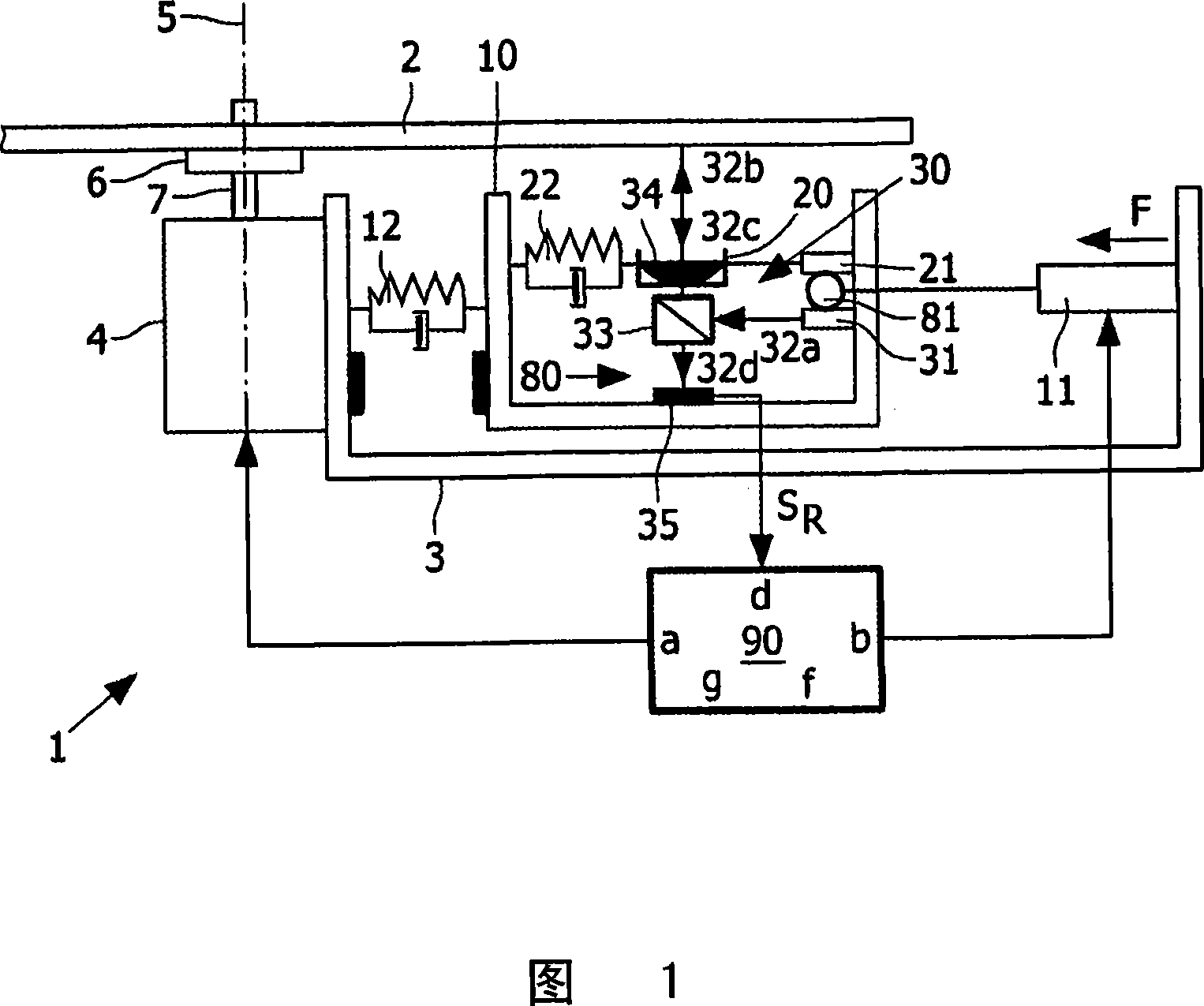

The invention is a system (1) that simulates a decision process in a mammalian brain with respect to a motion characteristic relating to a visually observed body posture of a body by means of a simulated visual path comprising an interface towards a simulated neuronal structure, the system includes an interface that converts at least luminescence information of the observed body into an optical flow data stream that delivers information relating to the visually observed body and that can be processed in the simulated neuron structure, the system being a feed-forward system that can be coupled to the simulated neuron structure. And from the visual observation that the decision comprises hierarchically: the simulated visual path and its interface (3, 3L, 3R); a simulated local motion direction detection neuron structure (4, 4L, 4R) for detecting the motion direction by means of a receptive field; a simulated opposition motion detection neuron structure (5, 5L, 5R) for detecting opposition motion at least relating to expansion and contraction; a simulated complex pattern detection neuron structure (6, 6L, 6R) for globally detecting an optical flow pattern over the entire visual observation and according to the evolution of the entire visual observation during the time, the detectable pattern being a prototype pattern; and a simulated motion pattern detection neuron structure (7, 7LR) for detecting a motion pattern and providing a decision regarding a motion characteristic. According to the invention, the neurons of the simulated motion pattern detection neuron structure (7, 7LR) comprise a forgetting ability that is a function of the delay and for each neuron an activity of the neuron.

Owner:UNIV DE MONTREAL +1

A TCR static passive compensation device with T active power filter structure

InactiveCN101262132BGood compensationGuaranteed uptimeFlexible AC transmissionActive power filteringHigh resistanceVoltage source inverter

The invention discloses a design of a TCR static var compensator (SVC) provided with a T-shaped active power filter (APF) and a control method thereof. The var compensator adopts a hybrid SVC composed of the T-shaped active power filter and an SVC and is connected with a power factor corrector of a small-sized voltage source inverter type (PFC-VSI). A harmonic compensation control loop of the APFpart in the device consists of two parts, namely, a direct feedback control loop and a feedforward system; the active power filter part of the system consists of a capacitor Cf, an inductor Lf and anAPF-VSI connected with the inductor Lf in parallel. The TCR part is mainly applied in absorbing harmonic current and adjusting reactive power. For the T-shaped active power filter is adopted, the inductor Lt of the TCR branch has high resistance during ultraharmonics and can naturally filter part ultraharmonics. Compared with the prior harmonic filter different from the harmonic filter provided by the invention which works together with the voltage source inverter of low bandwidth, and therefore the control of the system is simpler than common harmonic filters and not affected by the inherentdelay of one period when DSP is executed.

Owner:北京博旺天成科技发展有限公司

Clock recovery for optical transmission systems

ActiveCN102577183BElectromagnetic receiversSynchronising arrangementPhase detectorCommunications system

A receiver for an optical communications system which corrects distortion of a received signal. A clock recovery system utilising a feedback and feedforward system are provided. The feedback loop comprises a phase detector and a clock source, while the feedforward loop comprises the phase detector and a delay element for delaying the output of distortion correction system. The feedback loop has a significantly lower bandwidth than the feedforward path. There are also provided methods of optimising tap weights and of acquiring initial tap weights.

Owner:CISCO TECH INC

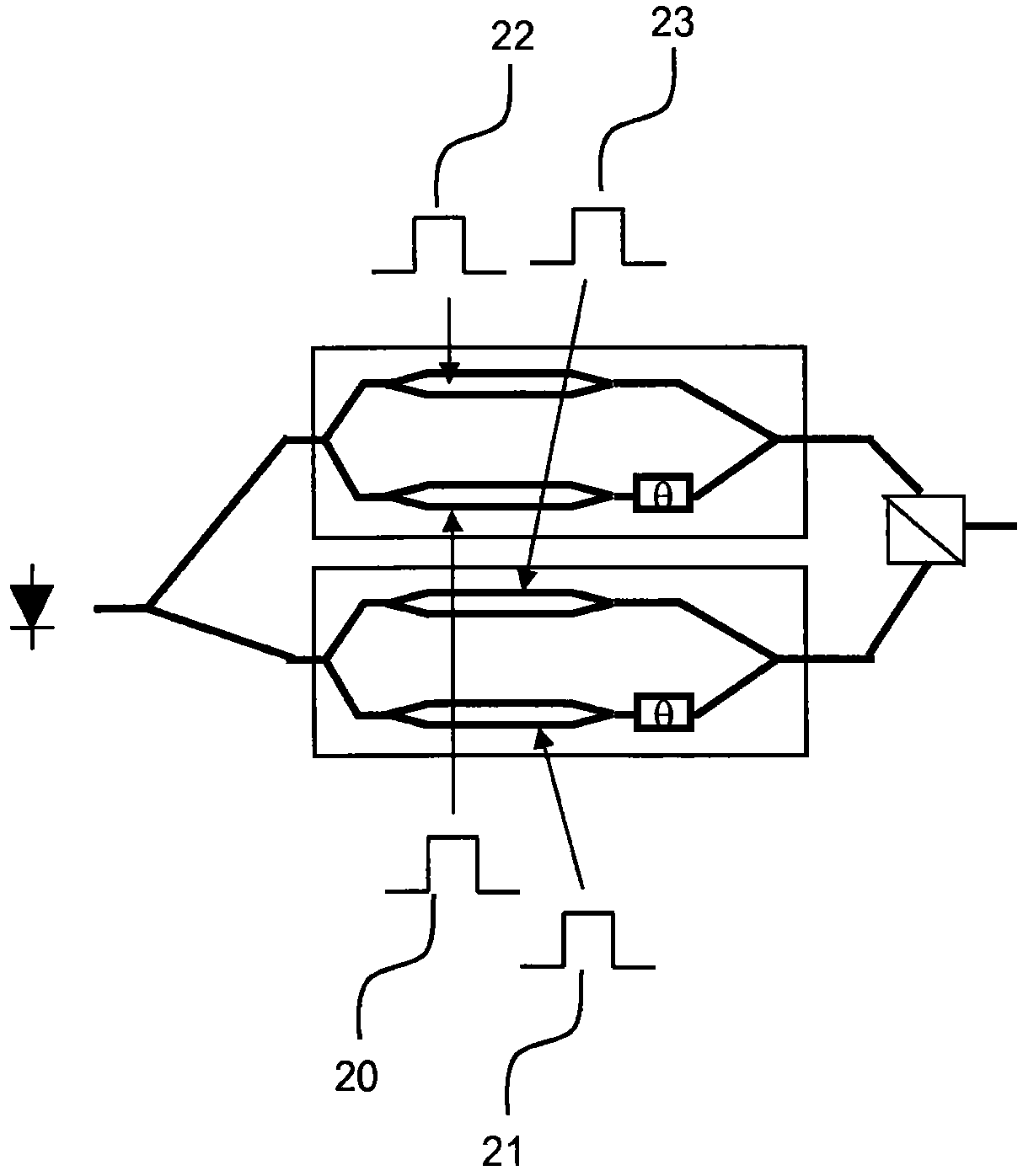

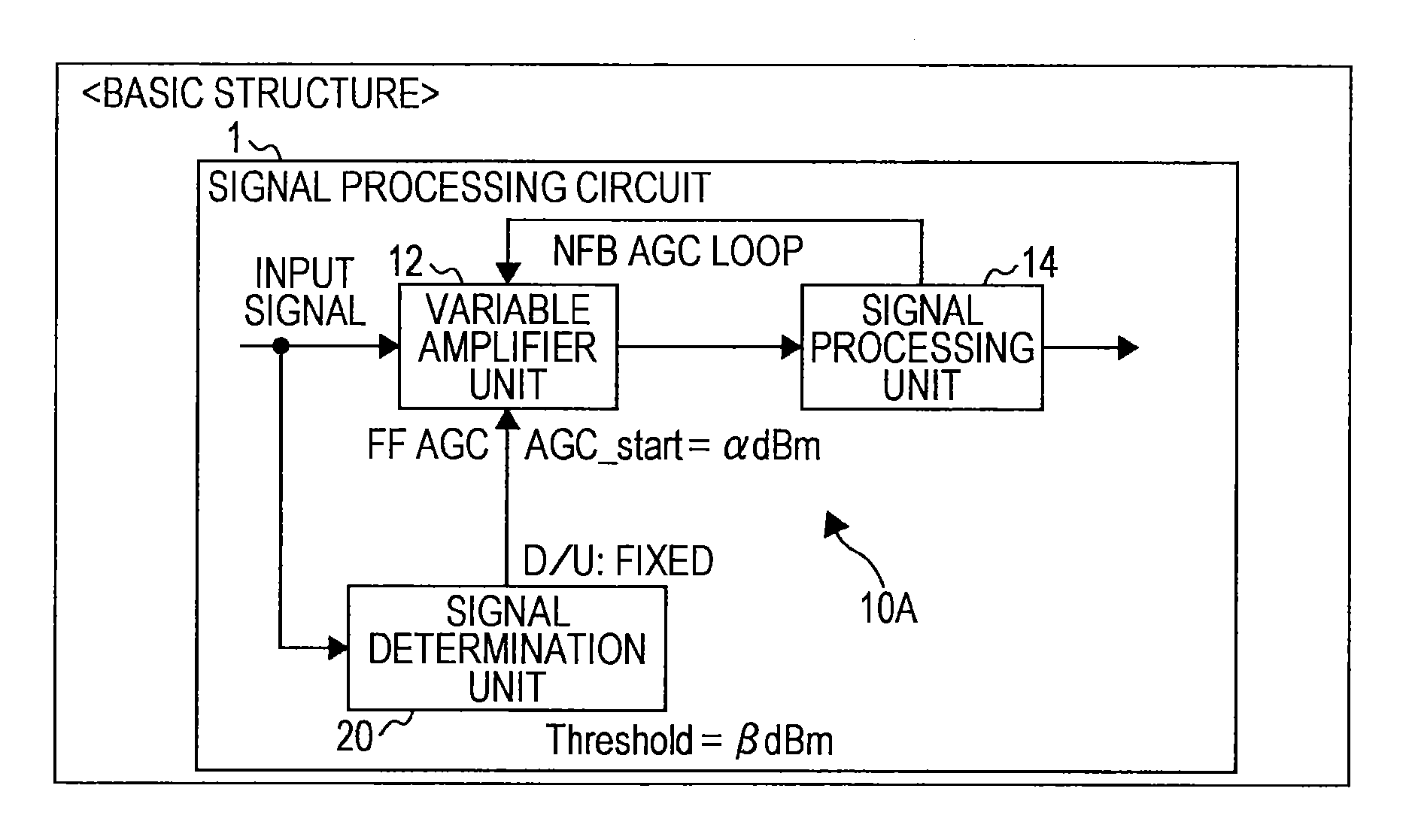

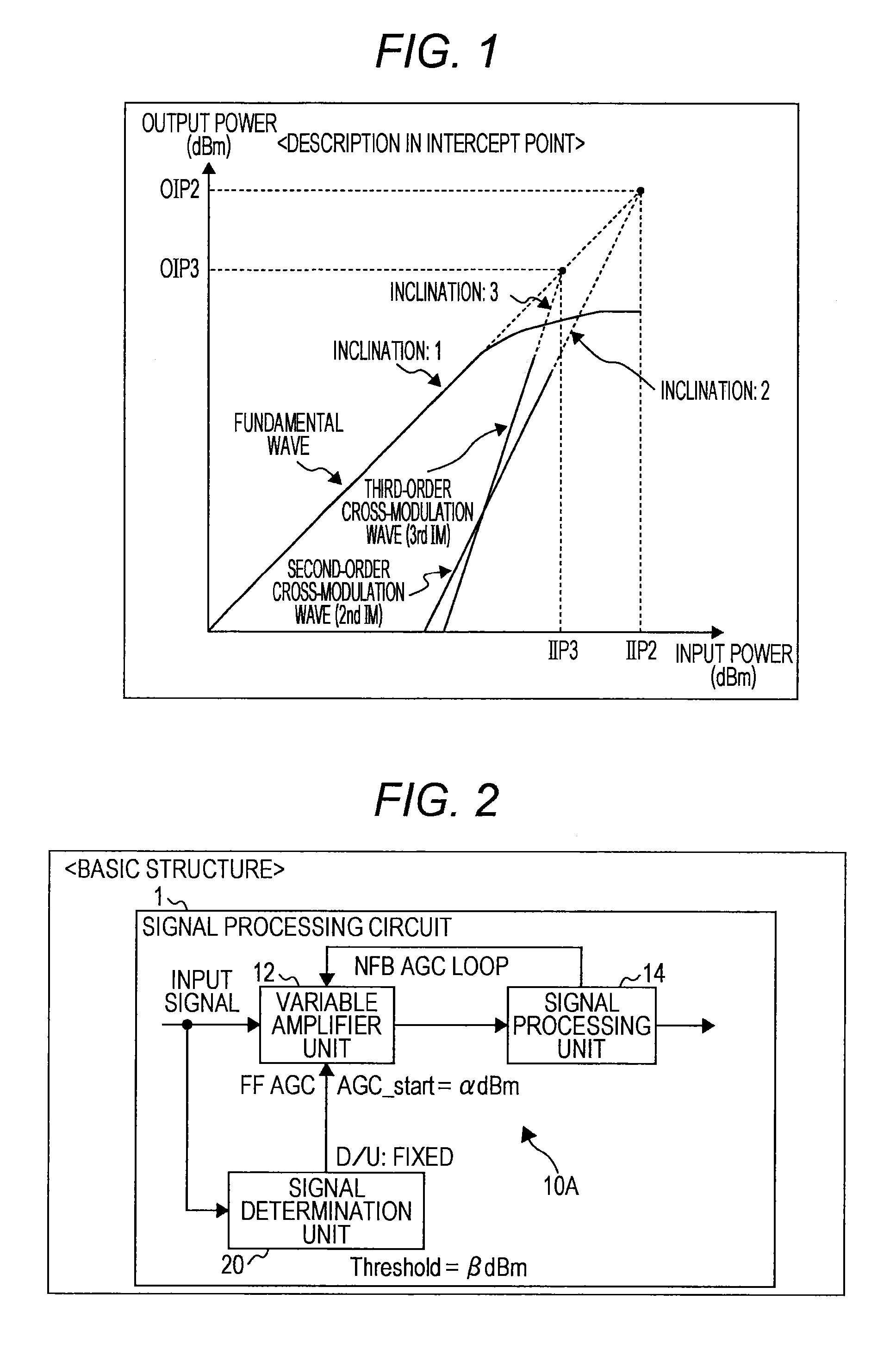

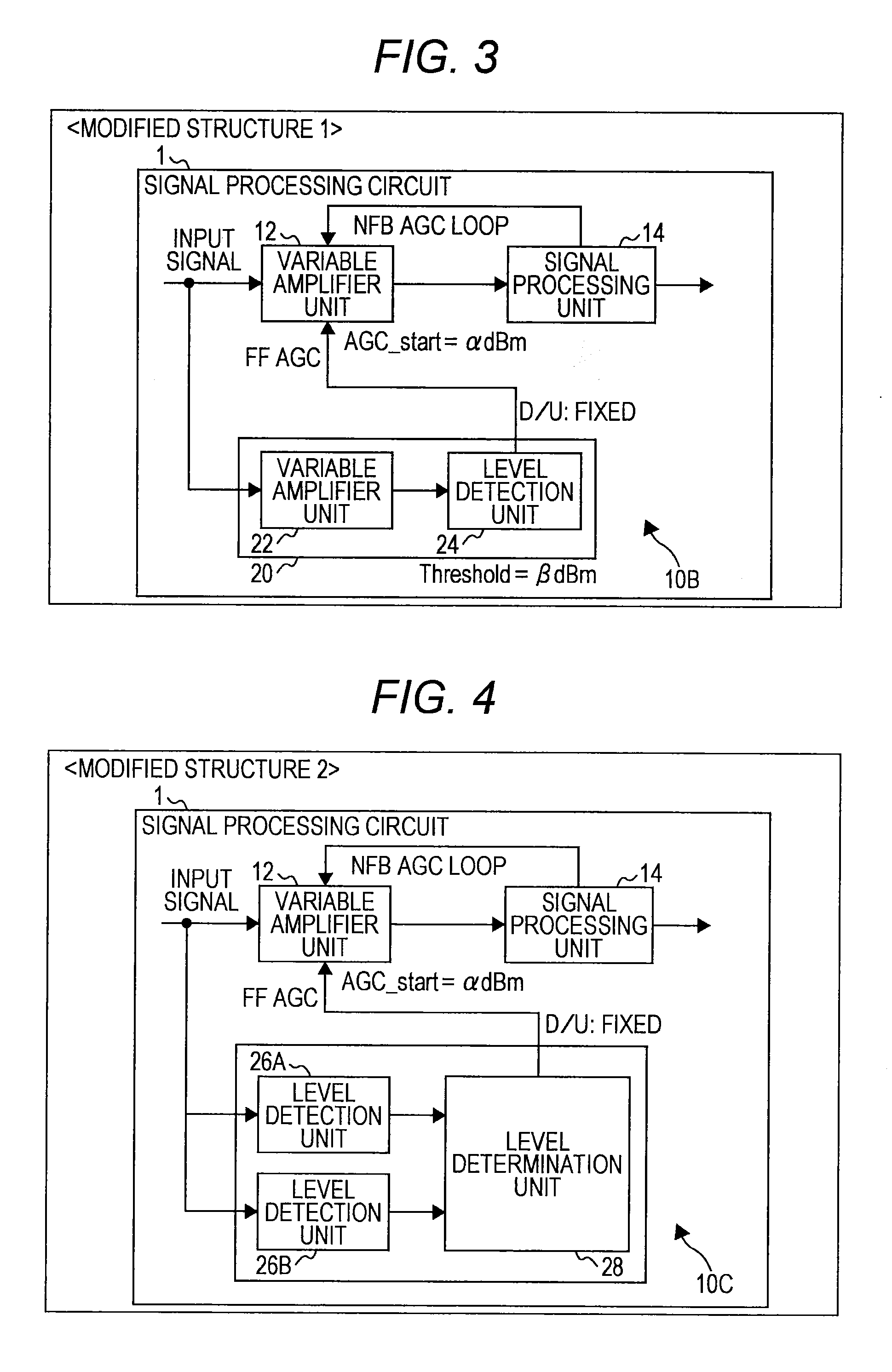

Gain control circuit, communication device, electronic appliance, and gain control method

ActiveUS9184718B2Gain controlAmplifier with semiconductor-devices/discharge-tubesAudio power amplifierEngineering

The present technology relates to a gain control circuit, a communication device, an electronic appliance, and a gain control method which aim to provide a technology capable of suppressing intermodulation distortion. The gain control circuit includes a first amplifier for amplifying an input signal, and a signal determination unit for determining an input signal to be input to the first amplifier, and controlling an amplification factor of the first amplifier based on the determination result. The communication device includes a first amplifier for amplifying a received signal, a receiving unit for performing a receiving process based on a signal output from the first amplifier, and a signal determination unit for determining a received signal to be input to the first amplifier, and controlling the amplification factor of the first amplifier based on the determination result. In the gain control method, an input signal to be input to a first amplifier for amplifying an input signal is determined, and the amplification factor of the first amplifier is controlled by a feed forward system based on the determination result.

Owner:SONY CORP

A grid-connected robust control method for AC/DC hybrid microgrid considering uncertainty

ActiveCN108521143BGrid connection is normalNo overcurrent phenomenonSingle network parallel feeding arrangementsCapacitanceMicrogrid

Provided is an AC / DC hybrid micro-grid grid connection robust control method taking uncertainty into consideration. The method includes the following steps: on the basis of the superposition theorem,establishing an AC / DC hybrid micro-grid grid connection mathematical model and a feed-forward system mathematical model in accordance with an AC / DC hybrid micro-grid grid connection topological structure; independently controlling a DC sub-micro-grid and providing a reference voltage to a filter capacitor in an AC / DC hybrid micro-grid; and constructing an AC / DC hybrid micro-grid grid connection robust controller and AC / DC hybrid micro-grid grid connection is achieved, so the robust performance of the AC / DC hybrid micro-grid is improved. The method of the invention avoids overcurrents in grid connection points during AC / DC hybrid micro-grid grid connection, realizes seamless switching, and enables AC / DC hybrid microgrids still to be normally connected in a condition of certain parameter perturbation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com