Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99 results about "Dairy servings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In general, here are the servings of dairy foods that count as 1 cup: 1 cup of milk. 1 cup of yogurt. 1 cup of soy milk. 1 ½ ounces of natural cheese.

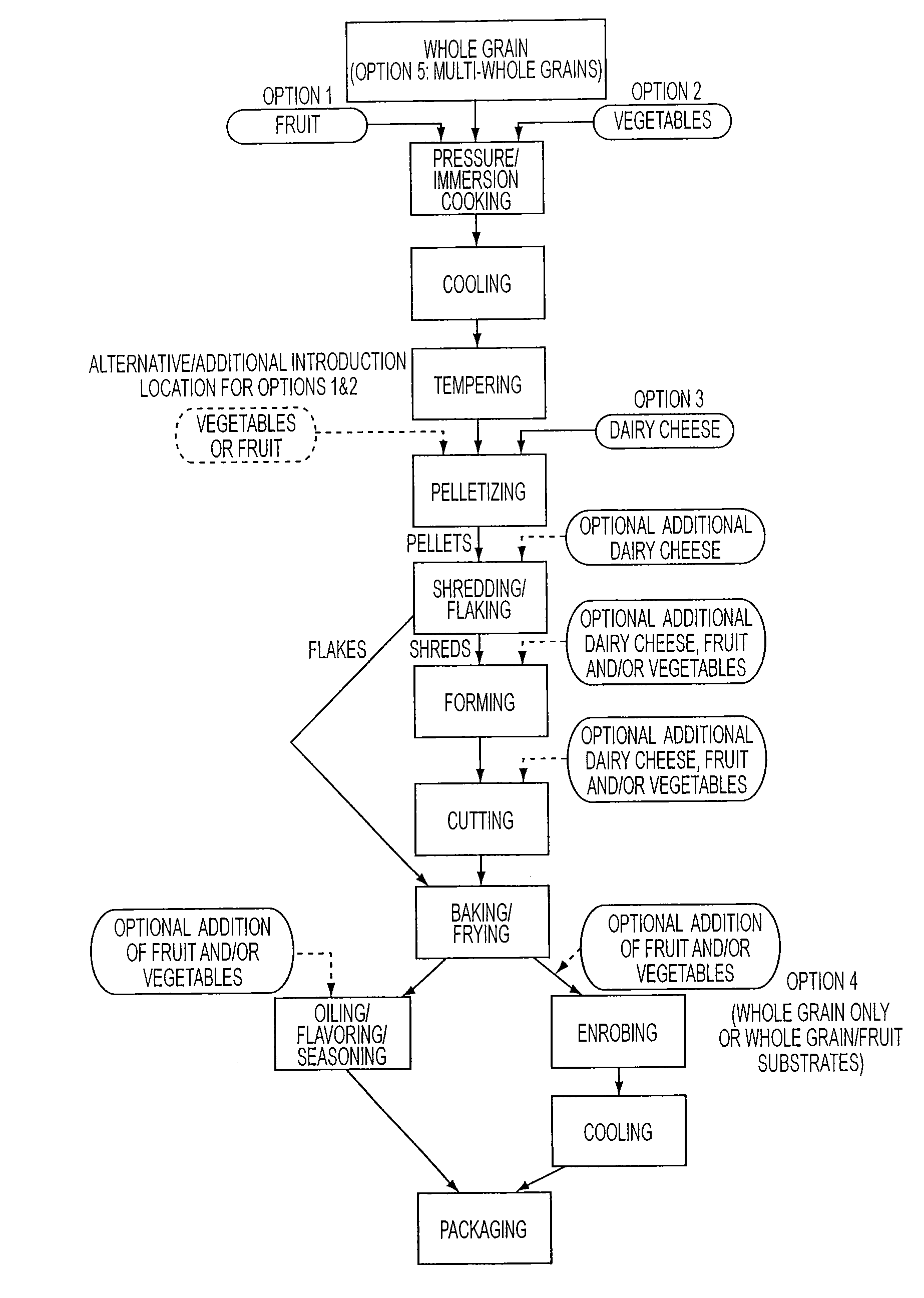

Production of shredded or flaked whole grain-containing composite food products

ActiveUS20060246202A1Eliminating and minimizing problemConveniently formedCocoaBakery productsBiotechnologySweetness

Shredded or flaked whole grain-containing composite food products, such as ready-to-eat cereals, and sweet and savory snacks, are continuously produced by pelletizing cooked, tempered, whole cereal grain particles in the presence of vegetables, fruit, or dairy cheese. In another aspect, an enrobing coating containing chocolate is applied to a baked shredded laminate product of the pelletization, wherein the shredded product may further optionally include fruit added and present during pelletization.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

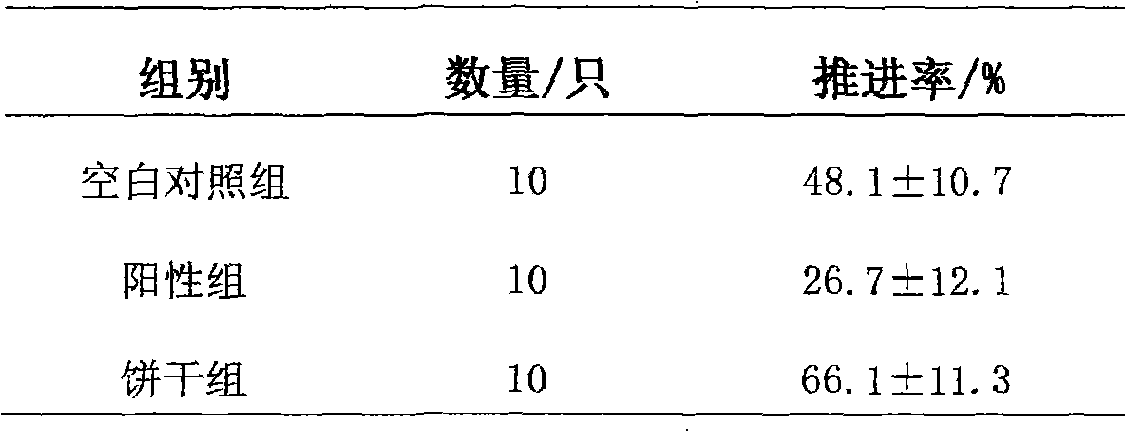

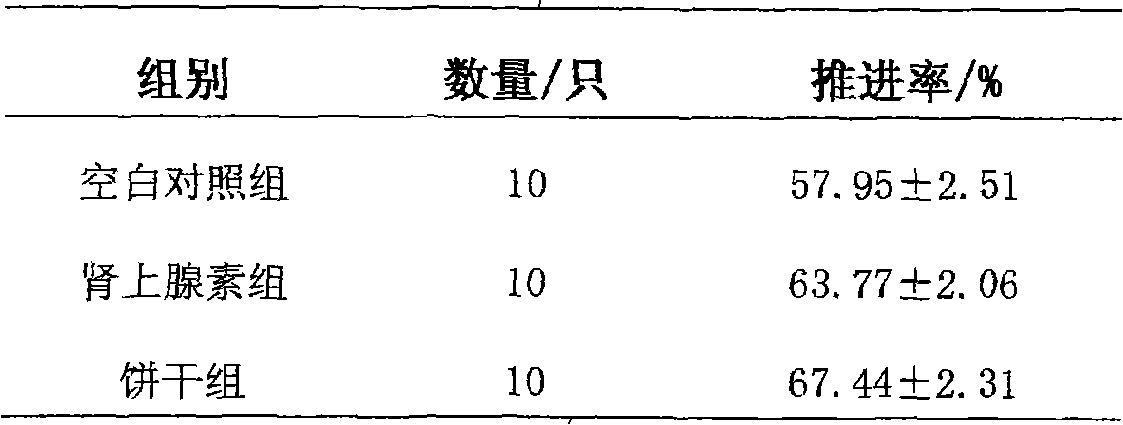

Cookies formula with catharsis effect and preparation method thereof

The invention relates to a formula of a cookie for improving constipation laxation and a preparation method. The medical ingredients are as follows: cassia seed, fructus cannabis, cinnamon and radish seed. Extracts are obtained by using the preparation method such as squeezing and water extraction; the extracts are used with wheat flour, sugar (with or without), fat, dairy and egg as the main ingredients; emulsifier, raising agent, modifier and other excipients are added; and the cookie is made by flour mixing, forming, baking, cooling, or sandwiching, or coating and packaging process. The formula has a reasonable component; all the added Chinese herbal medicines can be used as medicine or food which can be eaten and can prevent and cure diseases; the process is advanced and practical; the made cookie has better flavor and can be used for people with constipation.

Owner:SILANG FOODS HUAIBEI

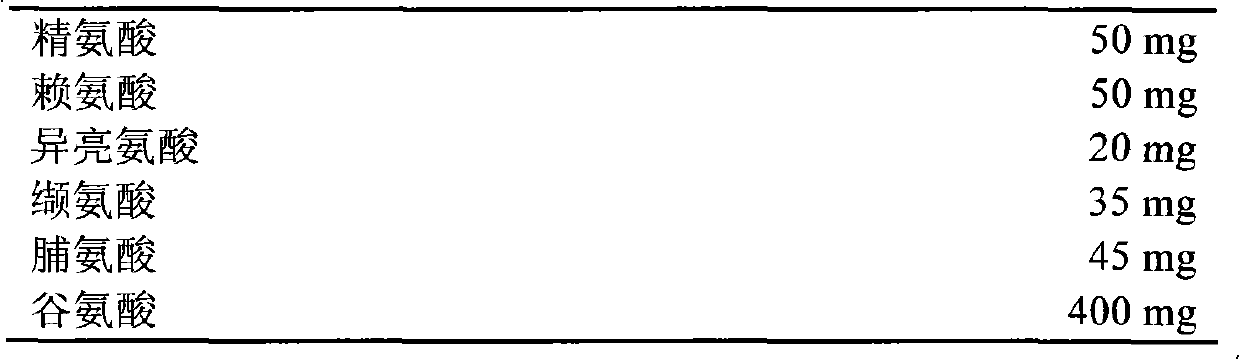

Food ingredient having milk taste-enhancing action, production method thereof, method of enhancing milk taste of food or seasoning and milk taste-enhanced milk-based hard candy

InactiveCN102028176AEnhanced Milky FlavorEnhances Natural Dairy FlavorConfectionerySweetmeatsBiotechnologyArginine

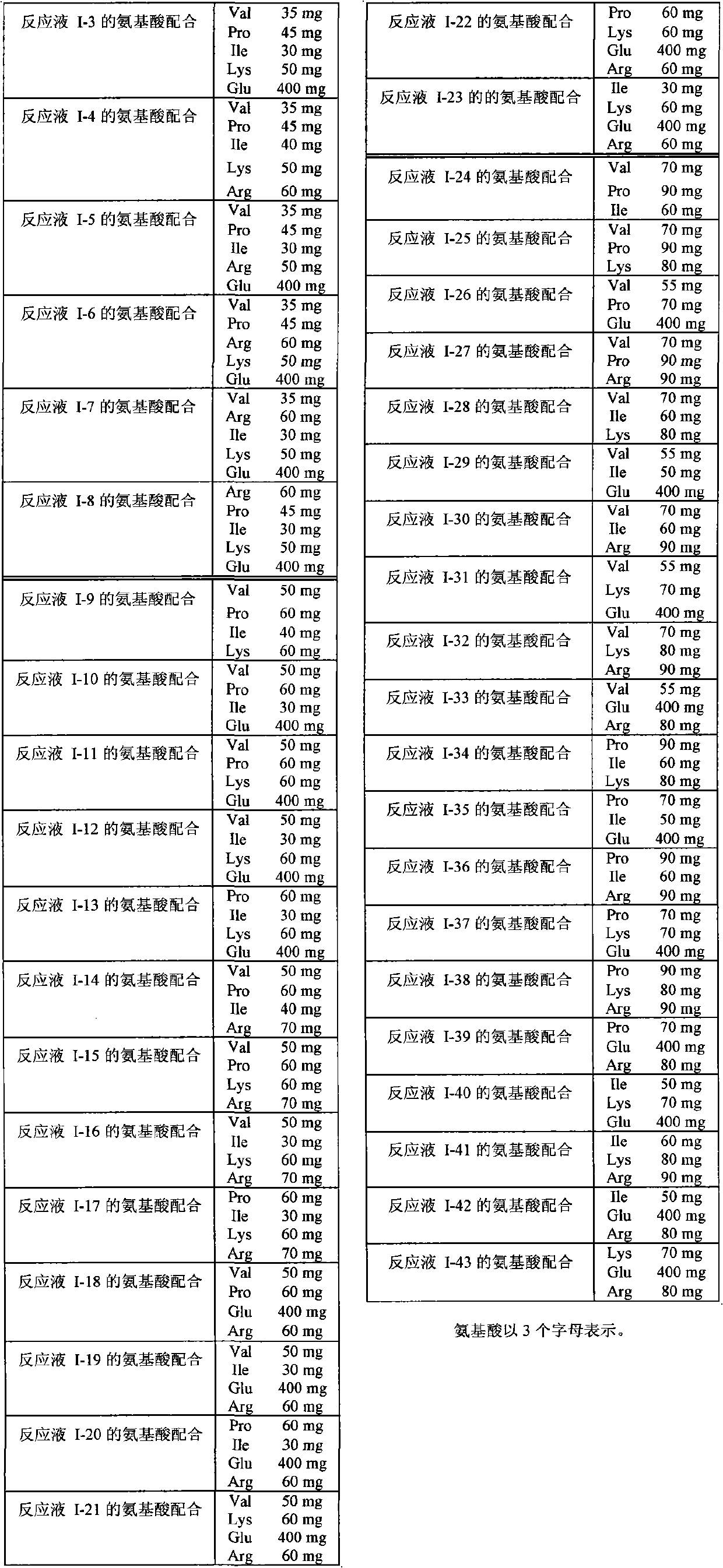

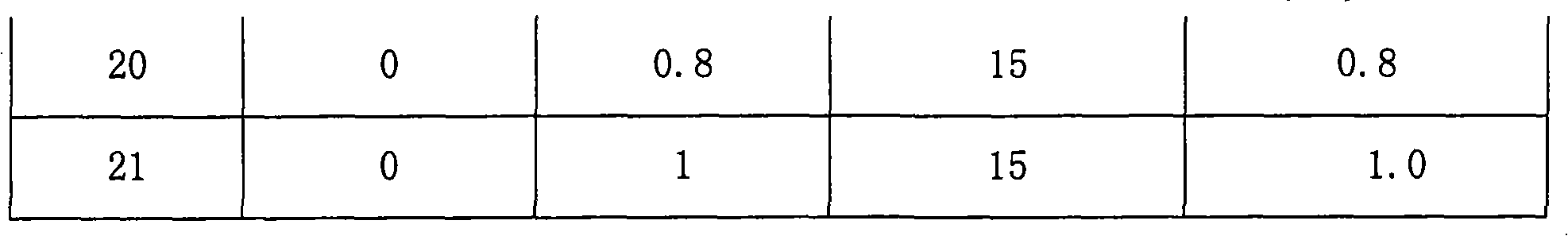

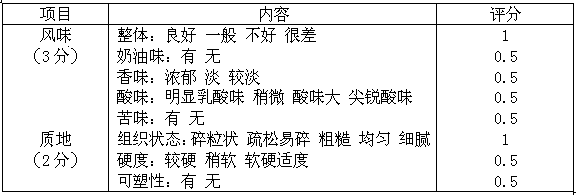

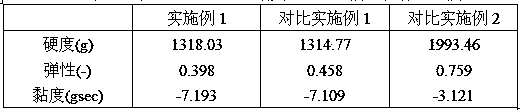

An object of the invention is to provide a food ingredient having strong milk taste-enhancing action without providing coarse taste, a production method thereof, a method of improving milk taste, a milk-based hard candy, in particular a milk-based nonsugar hard candy, having a delicious milk taste that is produced with a food ingredient that can replace part or most of the dairy product at low cost. The present invention relates to a food ingredient having milk taste-enhancing action, prepared by heating an aqueous solution containing an amino acid mixture containing at least three kinds of amino acids selected from valine, proline, isoleucine, lysine, glutamic acid and arginine as the principal components and a carbohydrate. The total amount of the at least three kinds of amino acids selected from valine, proline, isoleucine, lysine, glutamic acid, and arginine is preferably 70 wt % or more with respect to the total amount of all amino acids.

Owner:UHA MIKAKUTO CO LTD

Chocolate flavor manipulation

InactiveUS20040191403A1Optimization of asset utilizationLow costConfectionerySweetmeatsChocolate FlavorCaramel Flavor

A process for manipulating the flavor of a single mass of chocolate by adding a flavor effective amount of a non-cocoa and / or milk / dairy flavor attribute to the chocolate mass wherein the flavor provides any of the following attributes: roasted, sweet, bitter, crumb, caramel, fruity, floral, biscuit, baked, bready, cereal, malty, astringent or praline.

Owner:NESTEC SA

Supplemented sesame ice cream

The invention provides a supplemented desert comprising a sweetened dairy composition containing sesame seed paste, roasted sesame seed, and an effective amount of at least one nutraceutical. Specifically, the invention provides a supplemented vanilla ice cream containing from about 850 to about 946 ml of a vanilla ice cream, from about 1 to about 3 ounces of black sesame seed paste, from about 1 to about 3 ounces of roasted sesame seed, from about 1 to about ¼ teaspoon of vanilla extract; and an effective amount of a nutraceutical.

Owner:ESGHIPOUR MEHRDAD

Pre-mix formulations comprising ingredients for dairy products

Compositions and methods of using the compositions to prepare dairy food products are disclosed. The ingredients may include milk protein concentrates, fat containing powders and other mixtures including sweeteners, flavorings, preservatives, salt and emulsifiers. Food products prepared according to the invention include yogurt, cheese, soft cheese, spreads, nutritional bars, cream cheese, dairy desserts and yoghurt.

Owner:FONTERRA COOP GRP LTD

Liquid dairy product containing linoleic acid and linolenic acid and preparation method thereof

The invention provides a liquid dairy product containing linoleic acid and linolenic acid. The linoleic acid exists in the liquid dairy product in a plant oil form; and the liquid dairy product comprises the following components by weight: 400 to 900 portions of liquid milk, 30 to 50 portions of plant oil, 4 to 6 portions of linolenic acid, 1.0 to 3.5 portions of emulsifier and 0.5 to 1.5 portionsof thickening agent. The liquid dairy product is added with the linoleic acid and the linolenic acid, and is added with the emulsifier and the thickening agent in proper proportion to successively solve the problem that the quality of the components added is not stable in the ultra-temperature liquid milk, so that the product has normal flavor and mouthfeel and stable quality.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Manipulation of chocolate flavor

InactiveUS20040191389A1Optimization of asset utilizationLow costCocoaAdditive ingredientChocolate Flavor

A process for manipulating the flavor of a single mass of chocolate which comprises first reducing or removing the natural flavor from the chocolate ingredients or the chocolate mass and then adding an effective amount of a flavor to the chocolate mass. The flavor provides any of the following attributes: cocoa / dairy, roasted, sweet, bitter, crumb, caramel, fruity, floral, biscuit, baked, bready, cereal, malty, popcorn, astringent or praline.

Owner:NESTEC SA

Process of making a homogeneous cheese

Owner:LEPRINO FOODS

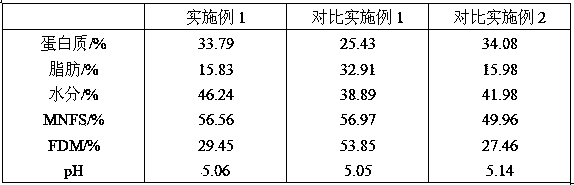

Low-fat cheddar cheese containing lactobacillus casei generating exopolysaccharides and preparation method of low-fat cheddar cheese

The invention relates to the field of processing of dairy products, and specifically relates to low-fat cheddar cheese containing lactobacillus casei generating exopolysaccharides and a preparation method of the low-fat cheddar cheese. Under the condition that any fat substituents and glue additives are not added, the defect that character and fusing property of low-fat cheddar cheese are poor due to lipopenia is improved by means of natural exopolysaccharide generating bacteria, and the low-fat cheddar cheese approaches whole fat cheddar cheese. The fat content of the low-fat cheddar cheese provided by the invention is reduced by over 50% compared with a normal whole fat group. The cheese prepared by the invention is not only low in fat content, but also is easy to accept by consumers in character and taste. The product is suitable for crowds and children with obesity and diabetes to eat. In addition, the cheese is beneficial for preventing diseases such as obesity and cardia-cerebrovascular diseases for common crowds.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

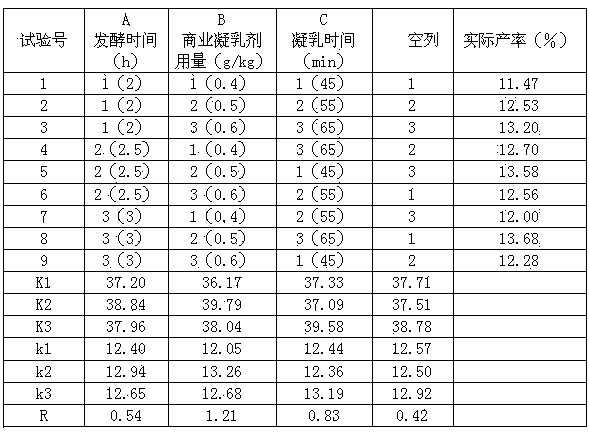

Method for preparing milk curd of composite cheese of soybean and cow's milk

InactiveCN101366414AImprove textureInsufficient reliefCheese manufactureFood preparationCow milkingVolume concentration

The invention relates to a method for preparing clabber for composite cheese of soybean and cow milk. The method comprises the following steps: boiling fresh soymilk first; adding coagulator CaCl2 aqueous solution with soybean mass of between 0.05 and 5.0 percent into the soymilk to promote the soymilk quickly clabbered and cooled, when the temperature is reduced to between 60 and 90 DEG C; then inoculating ferment into the cow milk which is sterilized and cooled, with the inoculum concentration accounting for 0.5 to 5.0 percent of volume concentration; adding the soymilk into the cow milk for commonly rennet curdling, when the pH value reaches between 5.5 and 6.5; and after clabber is formed, obtaining Chinese cheese which has soymilk dosage of between 25 and 35 percent and excellent quality, and is applicable to Chinese taste through cutting, forming, salting, maturating and other processes. Therefore, the method not only can relieve the problem of milk source lack in China, and completely develop the soybean resource for China, but also can provide a novel milk product with rich nutrition for consumers, and provide certain technical support and theoretical foundation for industrial production of the composite cheese of the soybean and the cow milk.

Owner:JILIN AGRICULTURAL UNIV

Simplified preparation method of low-lactose milk powder

The invention provides a simplified preparation method of low-lactose milk powder, and belongs to the technical field of dairy product production. According to the invention, a pasteurizing process and a lactose degradation process of the milk are carried out synchronically. In the initial stage of the pasteurizing process of the milk, lactase is added into the milk, and the enzyme hydrolysis process and the pasteurizing process are carried out simultaneously. The equipment used for common milk production processes is not increased, such that equipment investment is relatively reduced. Also, the chance for secondary pollution is reduced. Because the enzyme has a characteristic of high activity, the lactose hydrolysis process is achieved simultaneously during the pasteurizing process. Therefore, the production period of the low-lactose milk is shortened, and the production efficiency is improved. With the enzyme, during the lactose hydrolysis process, galactooligosaccharide with relatively high yield is obtained, such that the nutritive value of the milk is improved.

Owner:山东东兴生物科技股份有限公司

A kind of preparation method of compound bacterial strain fermented milk flavor essence

The invention discloses a method for preparing composite strain fermented milk flavor essence. The method comprises the following steps of: dissolving, fermenting for the first time, sterilizing for the first time, separating for the first time, adjusting, fermenting for the second time, sterilizing for the second time, separating for the second time and texturing. In the step of fermenting for the first time, lactobacillus strains are used, and in the step of fermenting for the second time, yeast strains are used; the obtained milk flavor essence has strong volatile fragrance and fermented mouthfeel, and can be modified into milky white or butter yellow paste products according to the requirement; and the milk flavor essence has the strong and natural fragrance of milk and butter, has the characteristics of stable flavor and high applicability, and can be applied to food such as dairy products, drinks, cold drinks, candies, bakery products and the like.

Owner:南京汇肽生物科技有限公司

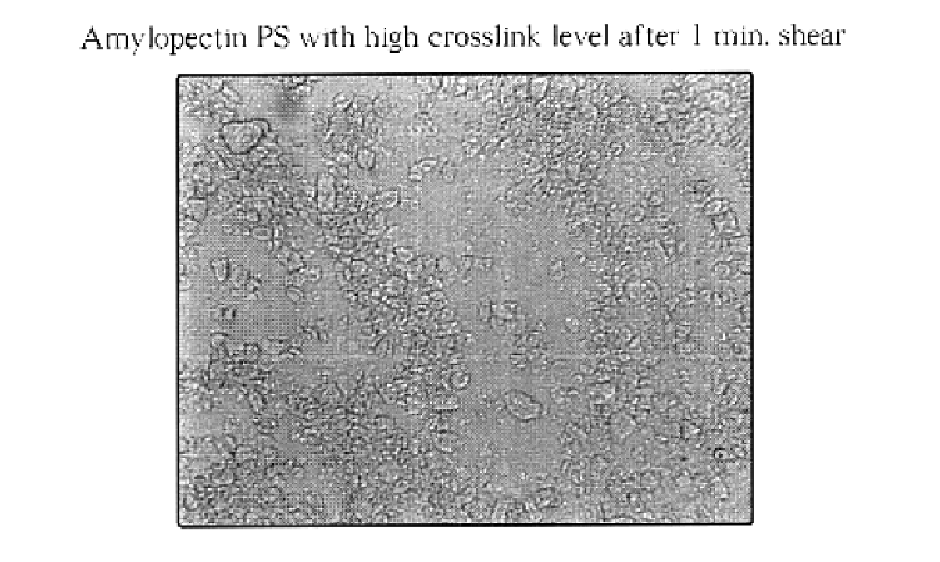

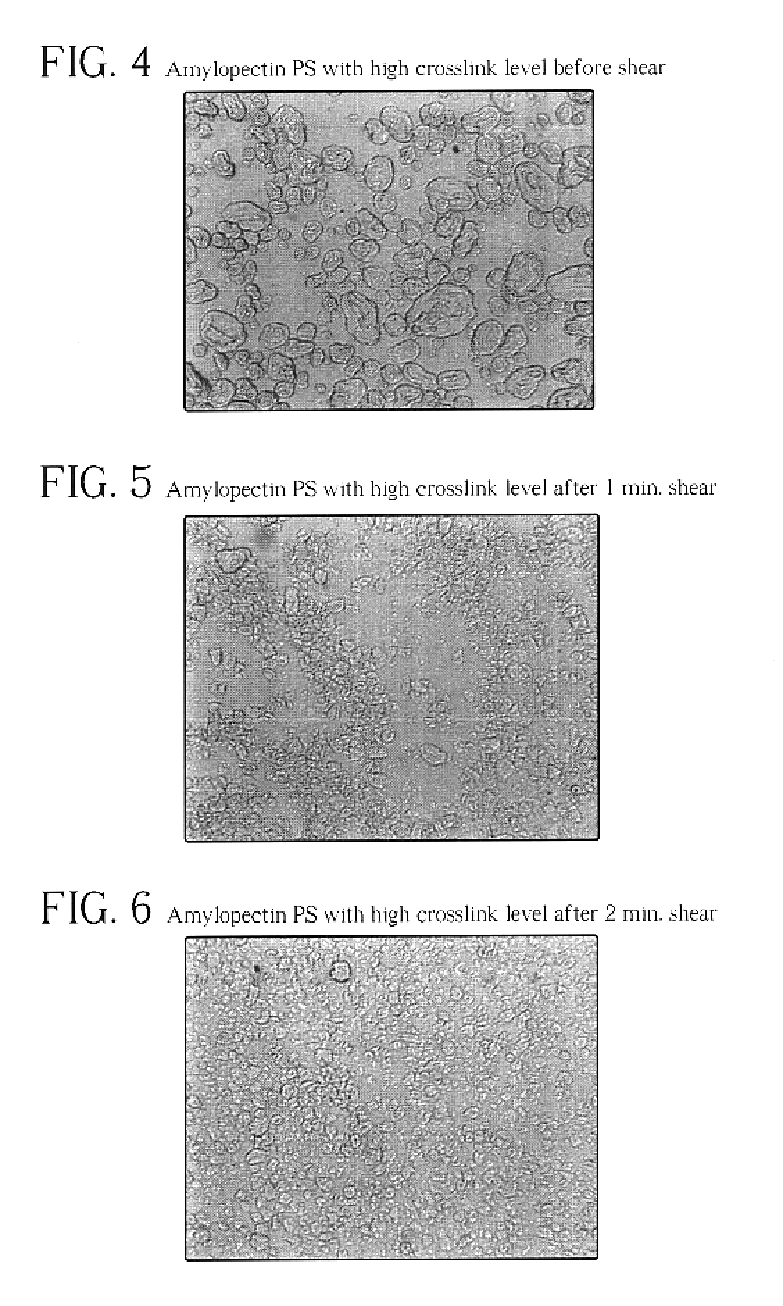

Foodstuff containing discrete starch particles

InactiveUS6899913B1Short and smooth textureMilk preparationFood preparationFood industryProlonged treatment

The invention relates to starch used in the food industry, more specifically to starch used in processed foodstuff that, at least in one processing step, is subject to heat and, or shear treatment. The invention provides use of modified starches and methods to use these in foodstuffs (soups, (dairy) desserts, sauces, creams, dressings, fillings and such), that, when used in preparing foodstuff that is subject to heat and / or shear treatment, provide said foodstuff with the so desired smooth, short textures and shiny appearance, even after prolonged treatment where use of other starches would render the product slimy, coarse or dull.

Owner:COOP AVEBE U A

Stabilization of Milk-Based Products

Dairy-derived food products, particularly beverages, such as milk / juice blends, yogurt-based drinks, fermented milk beverages, and soft drinks, are disclosed. These compositions contain a stabilizing mixture comprising metal (in the form of ions, salts or oxides) such as zinc or magnesium, either alone or together with an adjunct component such as ascorbic acid. These beverage products do not form off-flavors when they are exposed to sunlight or fluorescent light. This provides for more efficient and inexpensive manufacture of the products and eliminates the need for expensive opaque packing materials.

Owner:WILD FLAVORS INC

Processing method for dairy cake on large scale

The invention discloses a processing method for dairy cake on a large scale, and belongs to the technical field of dairy product processing. The processing method of the dairy cake comprises the following sequential steps of (1) pretreating of raw materials: subjecting fresh milk to centrifugal milk purification, regulating a total solid content in the fresh milk to 10.5-11.5% of the mass of the milk and sterilizing for 30 minutes at a temperature of 61-65 DEG C; (2) inoculating a leavening agent: cooling the milk to a temperature of 40-44 DEG C and inoculating the leavening agent according to a mass of 1.5-2% that of the of the milk; and (3) curding the milk: cooling the milk fermented by the step (2) to a temperature of 33-37 DEG C, adding Danisco chymosin with a mass of 0.04-0.06% that of the milk, curding for 45-65 minutes to obtain curds, and shaping by squeezing the curds to obtain the dairy cake. The prepared dairy cake tastes fine and smooth with mellow fragrance, does not loose when being diced, has stable quality, is healthy, has a long quality guarantee period, is suitable for large-scale production, and meets requirements of QS signs.

Owner:YUNNAN HUANGSHI LESSON DAIRY IND

Preparation method of sugar-removing milk

InactiveCN101380042AIncrease the cohesion densityResidue reductionMilk preparationFlavorUltrafiltration

The invention provides a method for removing lactose from milk, and more particularly relates to lactose removed milk products prepared by degreasing or not, deposition, ultrafiltration, re-dissolving, mixing, restoration, and the like, and taking the milk as raw materials. The lactose removed milk can be produced into liquid milk or solid milk powder. The lactose removed milk products produced by the method has the advantages of keeping the flavor, taste, nutritious substance of the original milk and can be combined with other products, thus preparing non lactose or low lactose healthy foods.

Owner:SHANGHAI SHANGLONG DAIRY

Dairy-based sugar substitute

The invention includes an all-natural dairy-based sugar substitute composition including a dairy-derived ingredient, a high-potency sweetening ingredient, and a flavor-balancing ingredient, and optionally including a grain hull ingredient, that can be used to replace sugar in any food, cosmetic, or pharmaceutical product.

Owner:SWEETSCIENCE LLC

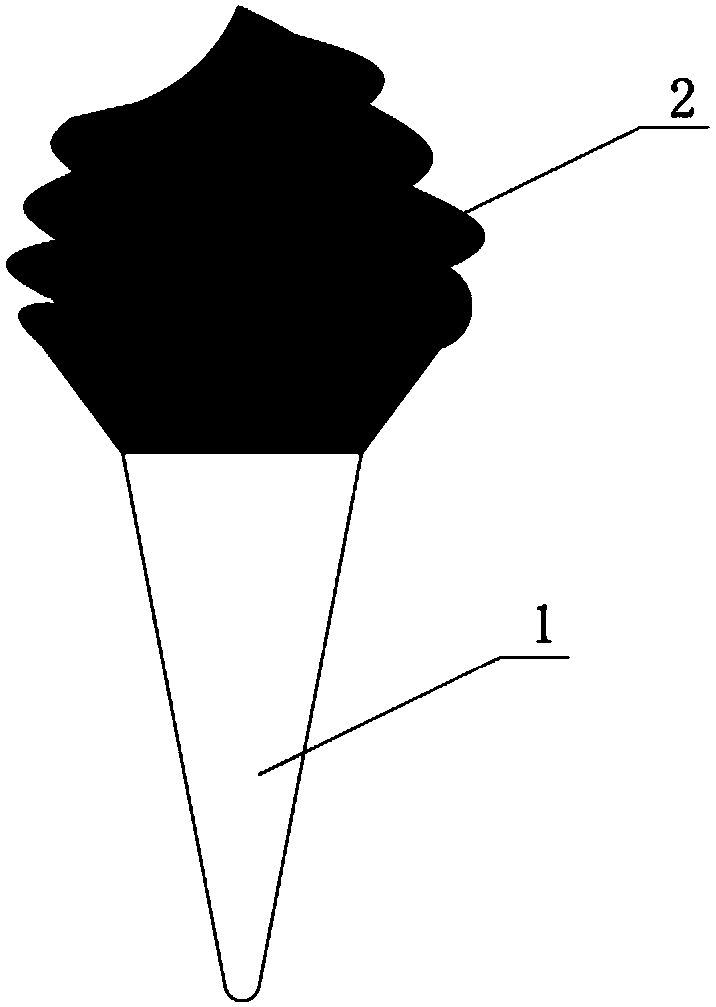

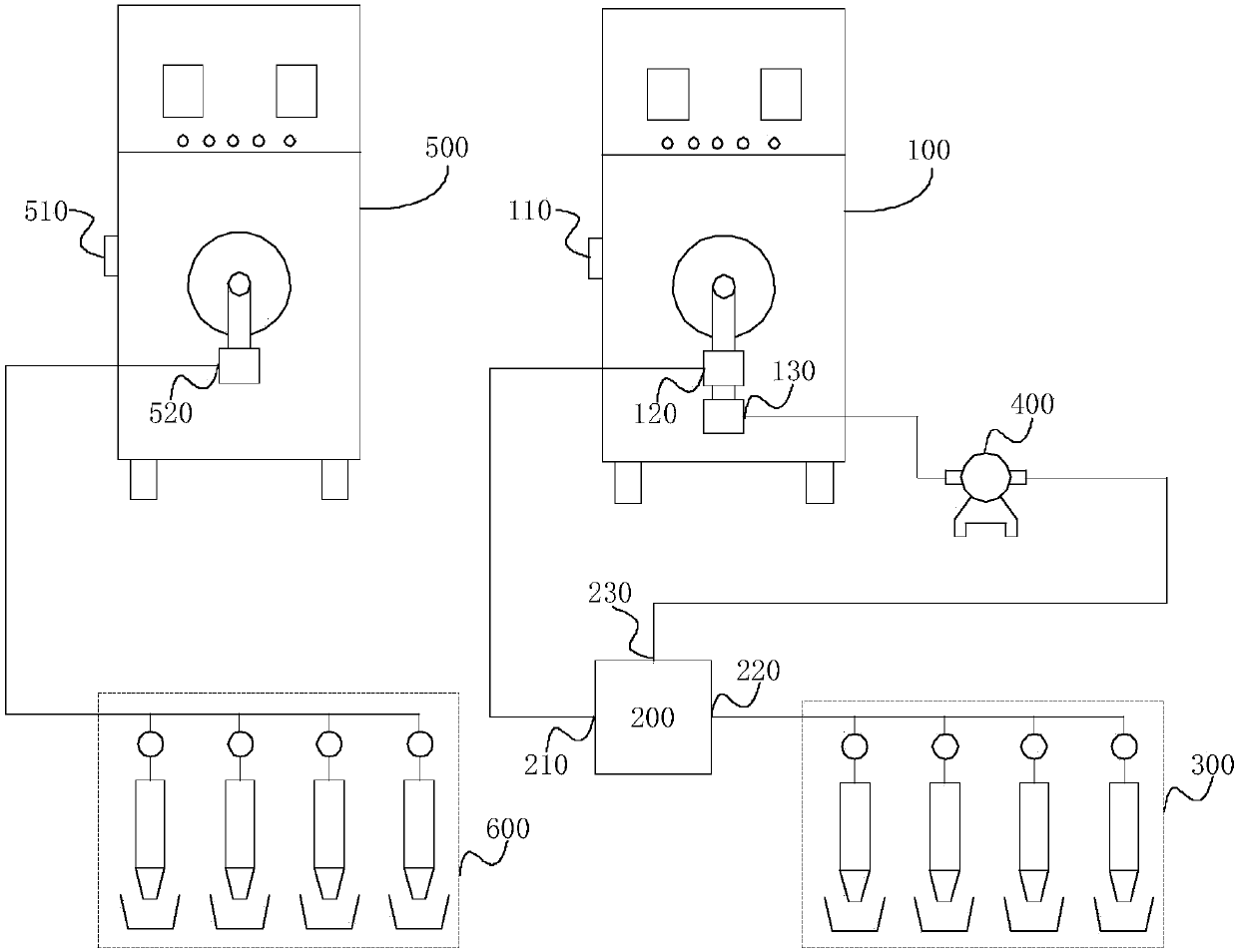

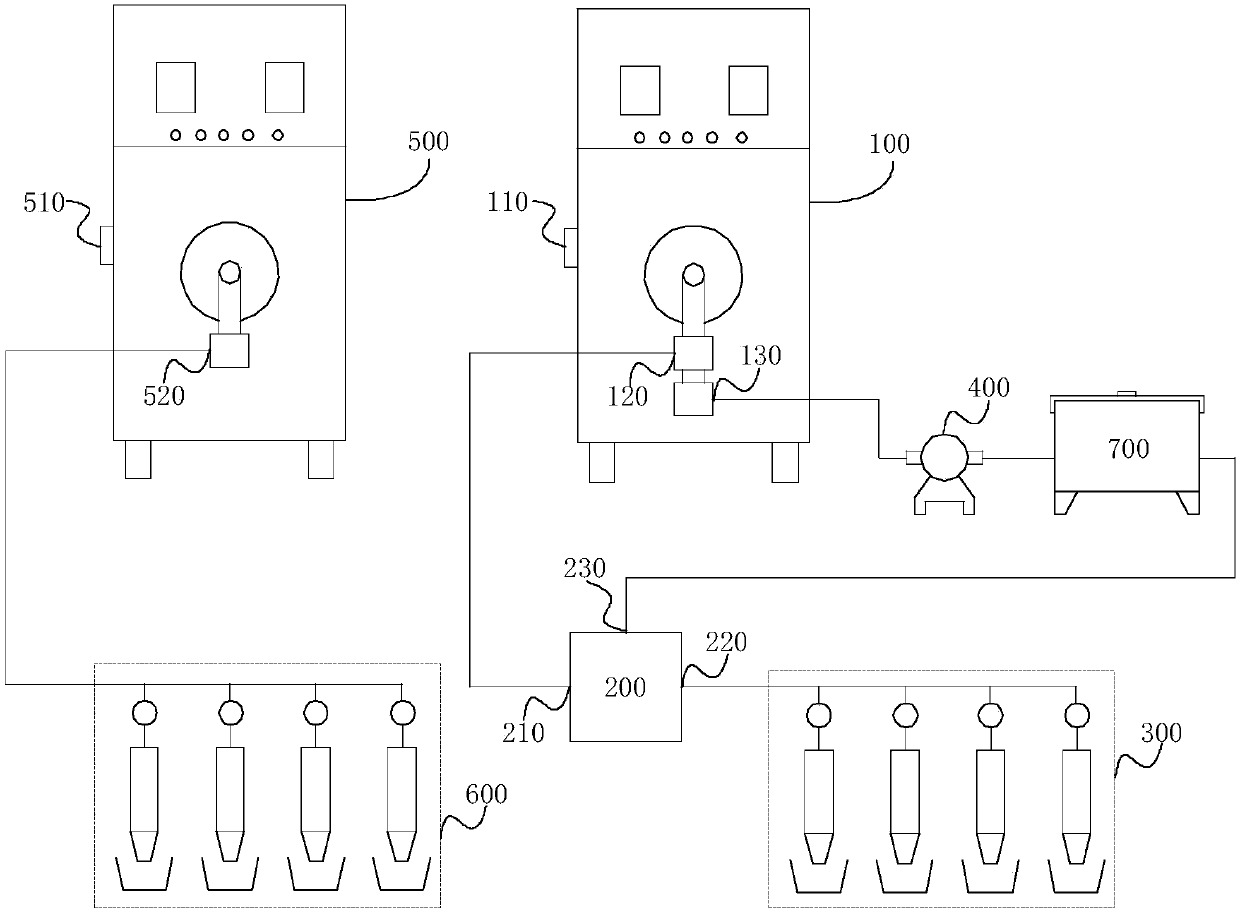

Double-color double-taste torch-shaped frozen beverage and making method and system thereof

PendingCN107811110ARealize continuous productionAvoid pollutionSugar food ingredientsFrozen sweetsFruit juiceVisual perception

The invention provides a double-color double-taste torch-shaped frozen beverage and a making method thereof. The frozen beverage comprises an egg roll, a first ice cream core and a second ice cream core, wherein the first ice cream core is poured in the egg roll; the second ice cream core is poured on the first ice cream core and is connected with the first ice cream core; the first ice cream coreand the second ice cream core respectively and independently comprise 5-60 parts by weight of raw milk and / or dairy products, 10-30 parts by weight of a sweetness material, 0-35 parts by weight of fruit juice and / or jam, 0-10 parts by weight of edible fat, 0.1-0.8 part by weight of a stabilizing agent and 0.1-0.6 part by weight of a sourness adjusting agent; and besides, the first ice cream coreand the second ice cream core are different in color and taste. New experience can be provided for consumers in visual sense and mouth feel, and further much consumption experience can be driven.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Casein Based Puffed Products, Their Preparation And Their Use In Food Products

InactiveUS20080279987A1High nutritional valueEdible oils/fats ingredientsFrozen sweetsDried foodIce cream

Casein based puffed products, their preparation and their use in food products. These casein based puffed product include a matrix made of extruded and expanded casein salt and additional nutritional elements which are dispersed throughout the matrix mass. They can be used for providing or delivering additional nutritional elements within the food products, for example as inclusions in food products such as dry food products like cereal flakes or bars, chocolate or confectionery, or wet food products such as ice-creams, milk based desserts or chilled dairy products like yogurts, curds or fresh cheese. A process for their preparation and food products comprising the casein based puffed product are also disclosed.

Owner:NESTEC SA

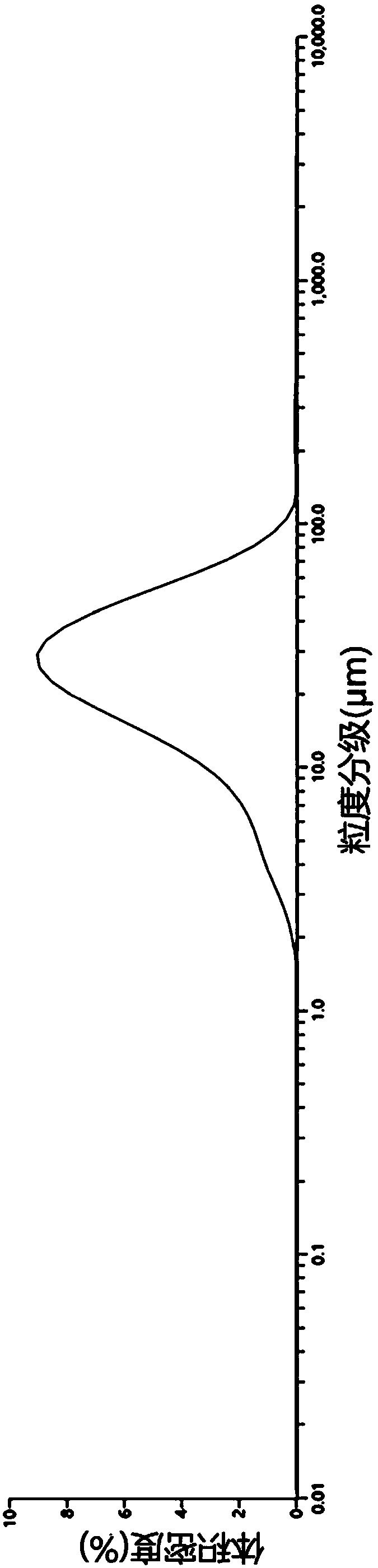

Preparation method of whole-bean soybean milk taking high-pressure homogenization as main process

InactiveCN111134194AAvoid the potential risk of breedingReduce processing timeMilk substitutesFood scienceEngineeringProcess engineering

The invention provides a preparation method of whole-bean soybean milk taking high-pressure homogenization as a main process. The preparation method of the whole-bean soybean milk taking the high-pressure homogenization as the main process comprises the following steps: baking soybeans so as to have husk of the soybeans separated; mixing the husk-separated soybeans with hot water, and carrying outdry pulp-grinding so as to obtain an original soybean milk solution; performing high-pressure homogenizing on the original soybean milk solution; and then, cooking the original soybean milk solutionsubjected to the high-pressure homogenizing, and carrying out enzyme inactivation so as to obtain the whole-bean soybean milk. The invention further provides the whole-bean soybean milk prepared by the preparation method. The preparation method of the whole-bean soybean milk provided by the invention takes the dry pulp-grinding as the main pulp grinding means and the high-pressure homogenizing asthe main crushing means, so that high-capacity production requirements in modern enterprises can be met; and moreover, the capacity of the preparation method of the whole-bean soybean milk can be basically the same as the capacities of common normal-temperature dairy product preparation methods. In addition, the preparation method of the whole-bean soybean milk is greatly optimized in processing steps, and greatly reduced in processing steps and energy consumption; and moreover, the preparation method is shortened in processing time, and reduced in excessive loss of soybean nutrients caused bylong-time high temperature in the process of soybean milk preparation.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Dairy gluten free no sugar added coconut milk frozen desert compositions and products

Described in preferred embodiments are dairy gluten free no sugar added coconut milk frozen desert compositions including a unique coconut milk, which have organoleptic qualities comparable to high fat frozen desserts such as ice cream. The compositions are composed of organic coconut milk comprising organic coconut solids and water, a sweetening agent and vegetable glycerin. Also described are dairy gluten free no sugar added flavors and inclusion compositions and methods for their production and incorporation into the dairy gluten free no sugar added coconut milk frozen desserts. Also provided are methods of making the frozen desert products.

Owner:ZAHORA EDWARD P +3

Probiotic fermented yoghurt cover tea and preparation method thereof

InactiveCN111758778ASolve the problem that it is difficult to suspend on the top of the tea soup for a long timeExtended storage timeMilk preparationTea extractionBiotechnologySucrose

The invention belongs to the technical field of dairy product processing, and provides probiotic fermented yoghurt cover tea and a preparation method thereof. The probiotic fermented yoghurt cover teacomprises a yoghurt cover and tea soup, wherein the yoghurt cover comprises the following components in percentage by weight: 60%-85% of fresh milk, 6%-9% of sucrose, 6%-9% of single cream, 0.5%-2.0%of whey protein concentrate, 0.5%-2.5% of whole milk protein powder, 0.1%-2.0% of cheese powder, 0.15%-0.25% of edible salt, 0.5%-1.5% of a compound thickening agent, 0.003%-0.005% of probiotic fermentation agent, 0.0002%-0.001% of cheese essence, and the balance of deionized water, and the total percentage by weight of the components is 100%, and the tea soup comprises the following components in percentage by weight: 0.5%-5.0% of tea leaves, 3.0%-7.0% of high fructose corn syrup and the balance of deionized water, and the total percentage by weight of the components is 100%. Through the technical scheme, the problem that in the prior art, a milk cover in milk cover tea is difficult to suspend at the top of tea soup for a long time is solved.

Owner:HEBEI BROS ILONG FOOD TECH LLC

Milk-based infant formula liquid milk containing active protein and preparing method of liquid milk

The invention discloses milk-based infant formula liquid milk containing active protein and a preparing method of the liquid milk, and belongs to the technical field of dairy products. According to the milk-based infant formula liquid milk and the preparing method, fresh milk is taken as a main raw material, according to the requirements in national standards and standards of breast milk, the proportion of protein, fat and carbohydrates in the milk is adjusted, vitamins and minerals are added, and the infant formula liquid milk which is convenient to drink is developed. More importantly, the influence of different heat treatment processes on the active protein is compared, immune globulin, lactoferrin and low-abundance protein in whey are mainly involved, finally, a pasteurization method is adopted for sterilizing the milk, and the pasteurization-type milk-based infant formula liquid milk containing active protein is developed.

Owner:JIANGNAN UNIV

Method for preparing novel fermented soybean milk products

The invention relates to a method for preparing novel fermented soybean milk products, such as fermented soybean milk, fermented mixed soybean milk, fermented dried tofu and the like, which prepares the produces such as soybean milk, fermented mixed soybean milk, dried tofu or dried tofu paste and the like by obtaining lactic acid bacteria by using vitality of alpha acetolacetate decearboxylase (ALDC) as an index and fermenting soybean milk or mixed milk containing the soybean milk by using one ore more lactic acid bacteria. The prepared products have a good flavor and are easy to be acceptedby consumers.

Owner:YANGZHOU UNIV

Organic plant protein powder and preparation method thereof

InactiveCN111374220AImprove work efficiencyEasy to eatPre-extraction tea treatmentCocoaBiotechnologyLactase

The invention relates to organic plant protein powder. The organic plant protein powder comprises 50-90 parts of plant protein powder and 5-10 parts of synthetic digestion enzyme, wherein the plant protein powder comprises pumpkin seed powder, flaxseed powder, quinoa flour and pea protein powder. The synthetic digestion enzyme comprises amylase, protease, lipase, lactase, and cellulase. The organic plant protein powder is a comprehensive high protein dietary supplement beverage which is capable of providing effective and complete 20 essential amino acids for the human body and is completely free of dairy and lactose components, while also free of gluten and soybean, and is a low-sensitivity high-quality protein powder. The product is low in fat, low in heat and high in fiber, and is very suitable for children, adult people, old people and fitness groups. The protein powder is smooth in mouth feel, is rich in a large amount of digestive enzymes, and helps to improve the working efficiency of the digestion system.

Owner:汪冰

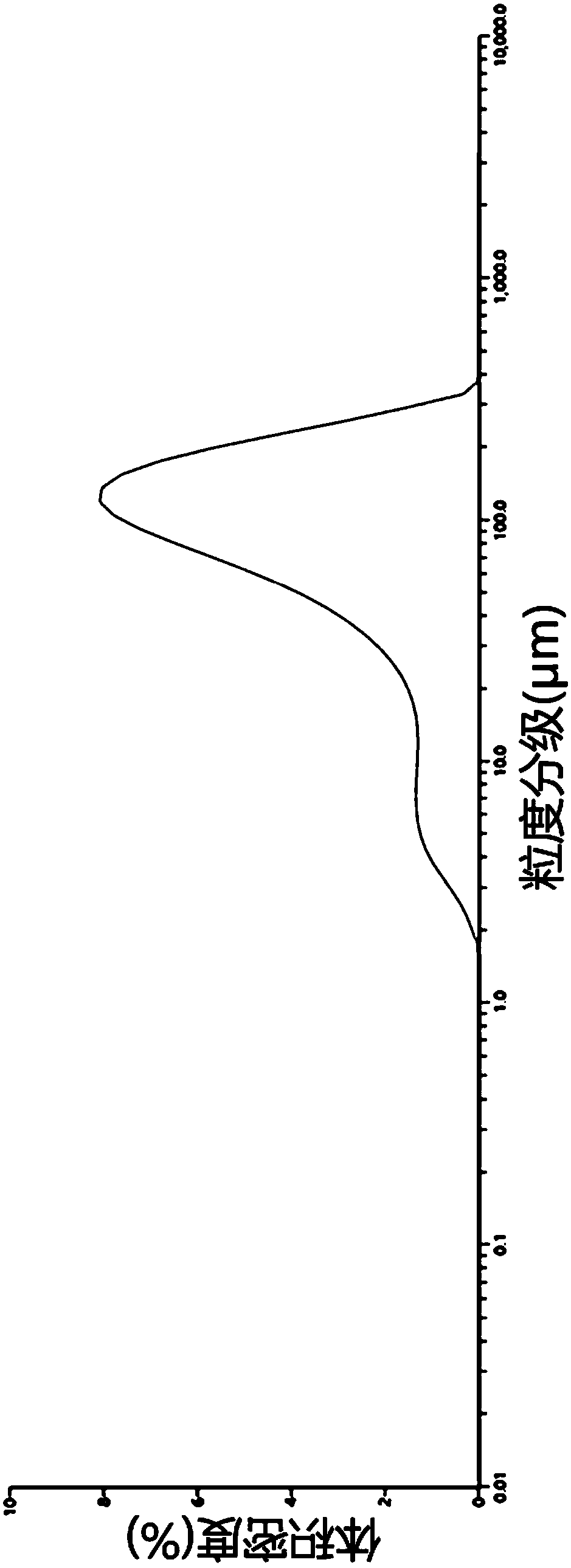

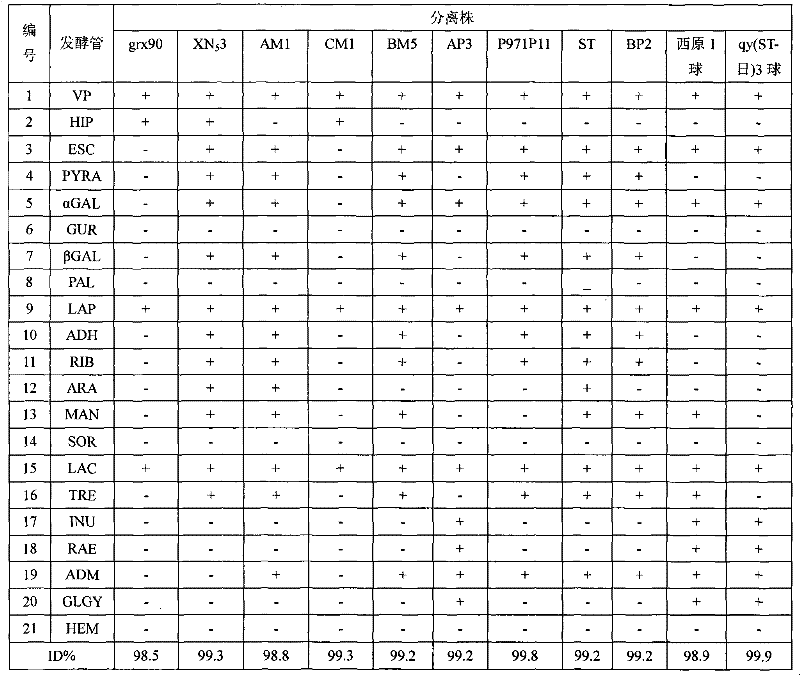

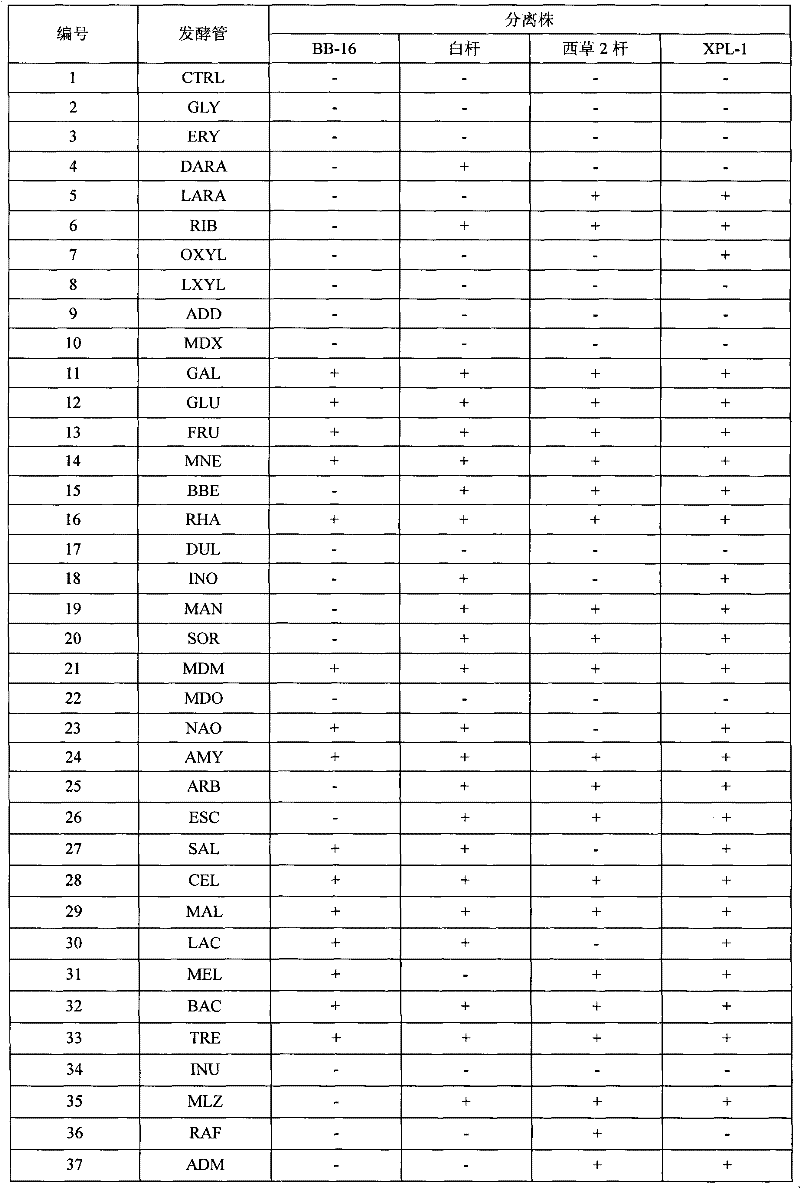

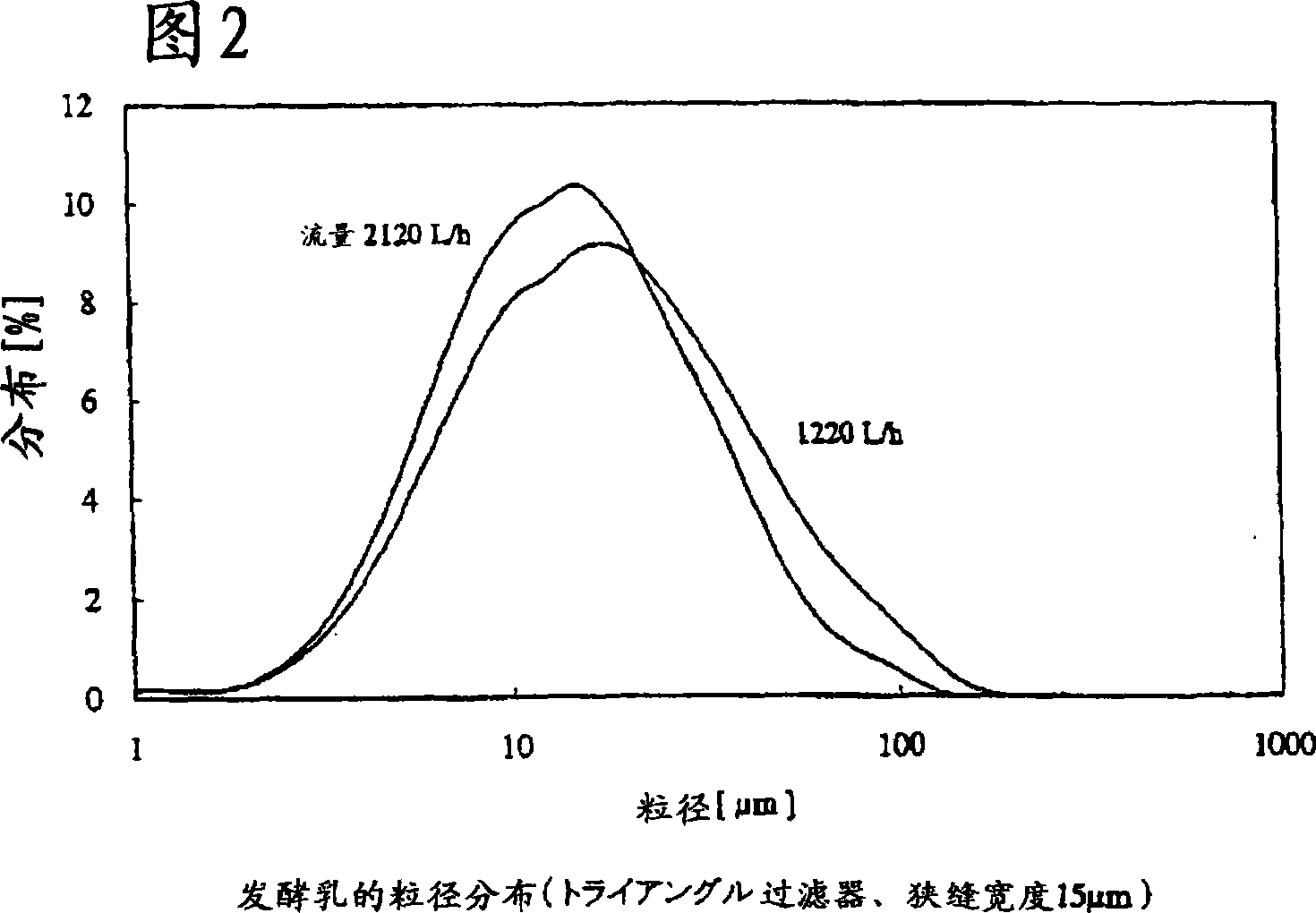

Method of producing fermented milk product and permented milk product produced thereby

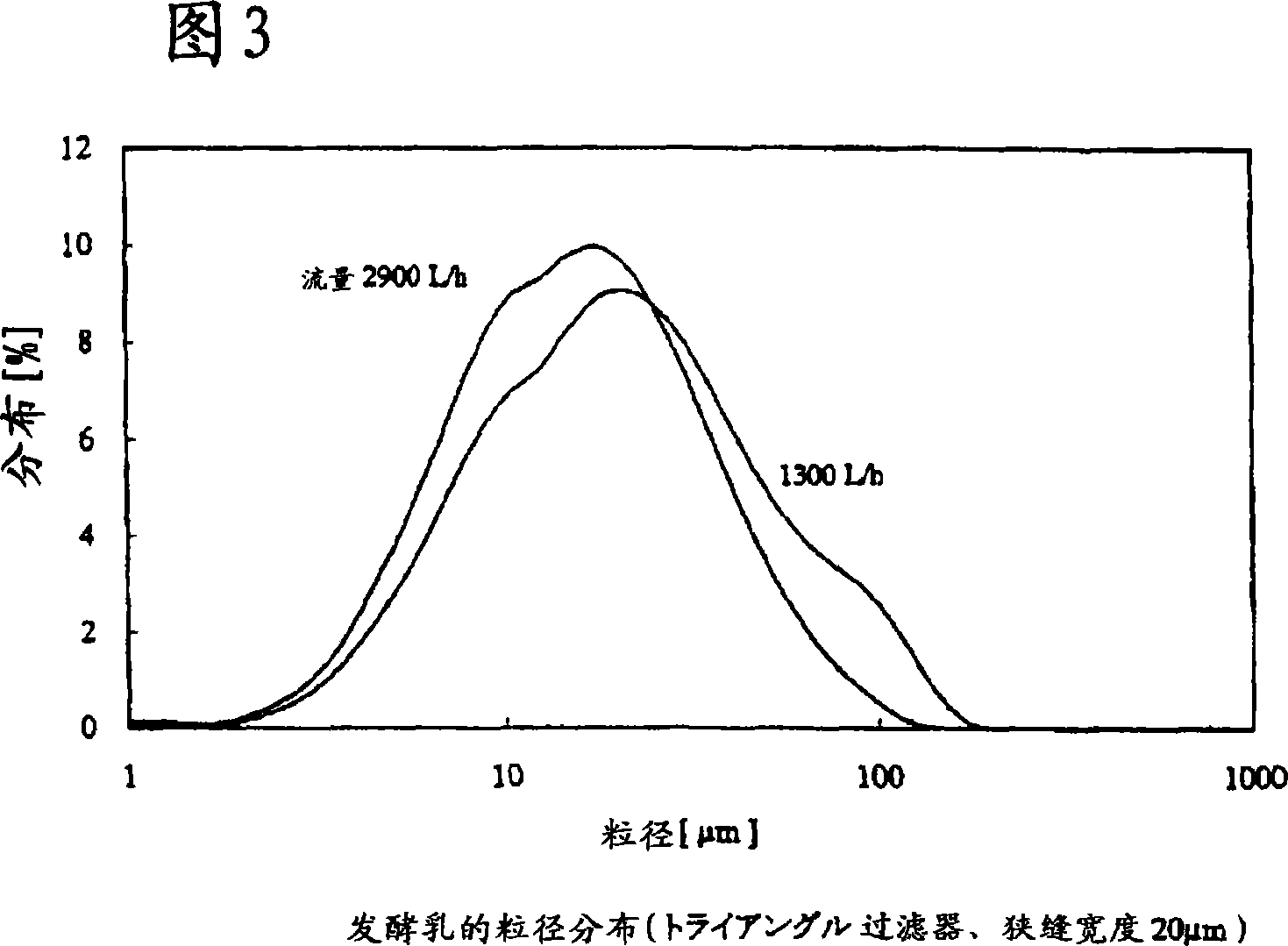

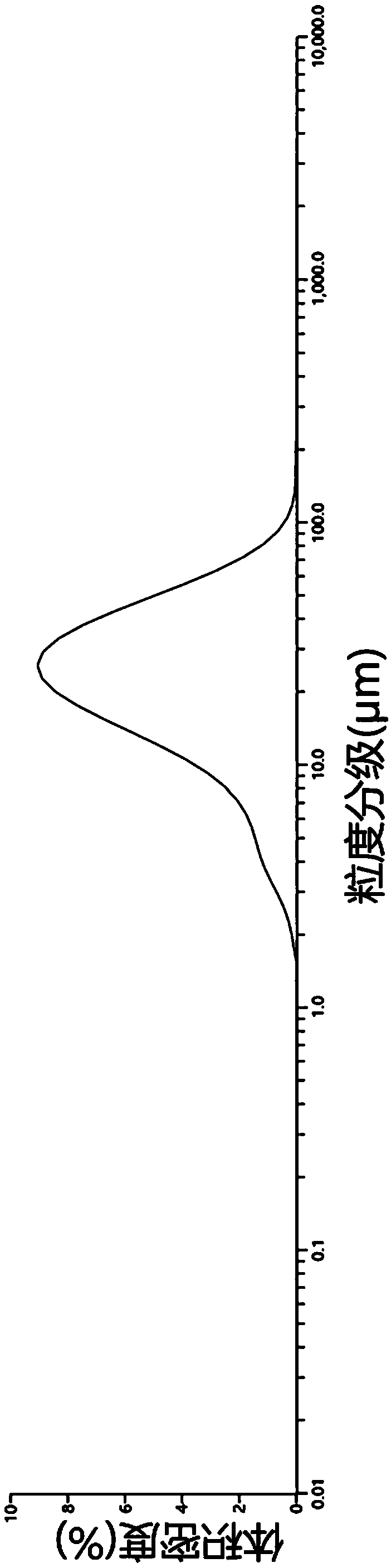

ActiveCN101065020AViscosity does not particularly decreaseProduction viscosity does not particularly decreaseMilk preparationSoured milkMilk protein

The invention provides a method of producing a fermented milk product having a favorable particle size distribution state, wherein the particle sizes fall within a definite range centering around a desired value and the particle size distribution is not so widespread, without specially lowering the viscosity, and a fermented milk product produced thereby. A method of producing a fermented milk product involving the step of milling a fermented milk curd obtained by fermenting a yogurt mix containing at least one member selected from among milk, milk products and milk protein, wherein the step of milling the fermented milk curd is performed by extruding the fermented milk curd through multiple openings of from 325-mesh to 1300-mesh in size (in accordance with sieve size standards defined in JIS), and a fermented milk product produced thereby.

Owner:MEIJI CO LTD

Liquid milk with fructose and milk power and preparation thereof

A lactopectose liquid milk and its milk powder for preventing constipation, improving physique and taking care of intestinal health are prepared from the liquid milk through converting the lactose in liquid milk to lactopectose or adding lactopectose to the liquid milk while removing the residual lactopectose. It has high output rate of lactopectose.

Owner:徐跃

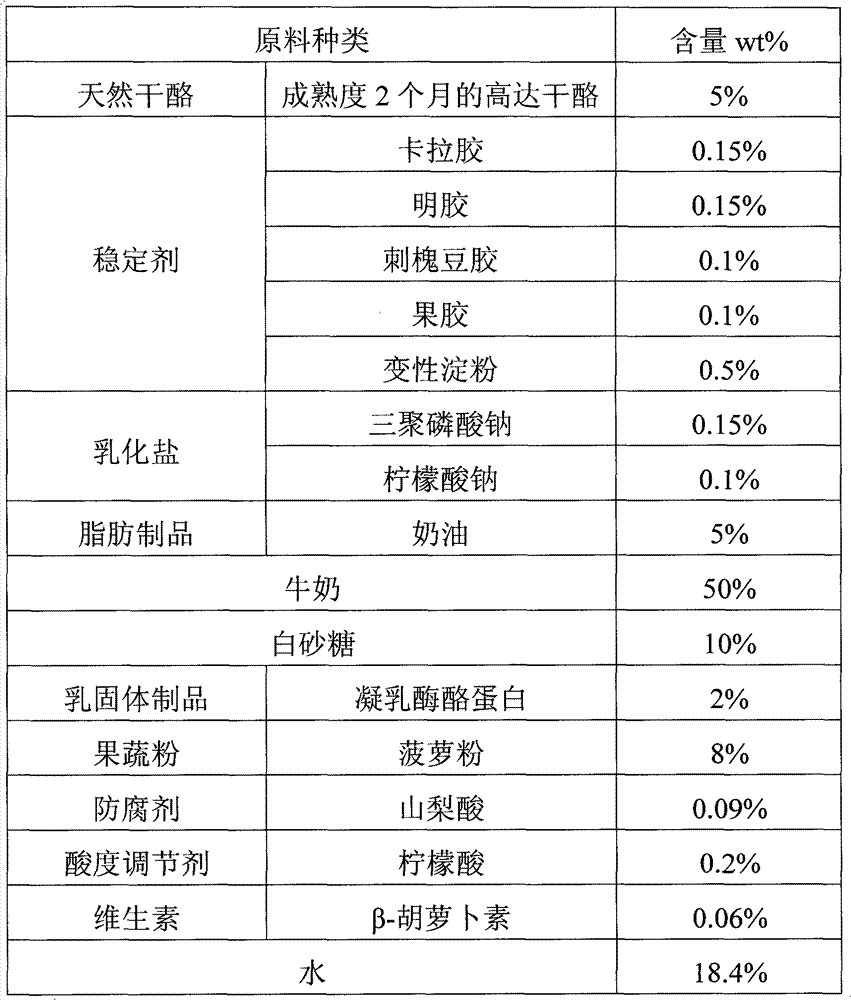

Processed cheese and its preparation method

ActiveCN102239927BImproves tangy and pungent flavorsCater to light tasteCheese manufactureFlavorSugar

The invention discloses a processed cheese and its preparation method. The preparation method comprises the following steps: uniformly mixing a stabilizing agent with white sugar, milk which accounts for 0% - 50% of total mass of raw materials, and water which accounts for 30% - 60% of total mass of raw material water, mixing and emulsifying the obtained mixture with natural cheese, emulsifying salt, fat product and rest water, homogenizing and sterilizing; wherein, the stabilizing agent, natural cheese and emulsifying salt are particularly preferred. When the consumption of the milk is zero,and the fat product contains dilute cream, the dilute cream is uniformly mixed with the stabilizing agent or other fat products. The processed cheese prepared by the method has characteristics of fashion like pudding and nutrition like cheese, and simultaneously is capable of improving the strong stimulated flavor of the cheese, catering to the light taste of Chinese people and making up the blank of cold chain dairy desserts in retail markets, so that the processed cheese is concerned and loved by consumers, and promotes the growth of high-quality advanced dairy products such as cheese in Chinese markets.

Owner:BRIGHT DAIRY & FOOD CO LTD

Whole soybean milk preparation method with high-pressure jet homogenization as main process

InactiveCN111134195AAvoid the potential risk of breedingReduce processing timeMilk substitutesFood scienceSoybean hullsProcess engineering

The invention provides a whole soybean milk preparation method with high-pressure jet homogenization as a main process. The method comprises the following steps: baking soybeans and performing soybeanhull separation; mixing the obtained soybeans after soybean hull separation with hot water, and performing dry refining; performing high-pressure jet homogenization on the soybean milk raw pulp obtained by dry refining; and performing pulp-boiling and enzyme inactivation on the soybean milk raw milk after high-pressure jet homogenization to obtain the whole soybean milk. The invention also provides the whole soybean milk prepared by the method. The invention provides the whole soybean milk preparation method using dry refining as a main refining manner and high-pressure jet homogenization asa main crushing manner. The method can meet high-capacity production of enterprises at present, and the production capacity of the method can be basically the same as that of common normal-temperaturedairy products. At the same time, the processing steps are greatly optimized, and the processing steps and energy consumption are greatly reduced. At the same time, the processing time is shortened,and the excessive loss of soybean nutrients caused by long-term high temperature in the process is reduced.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com