Processing method for dairy cake on large scale

A processing method and milk cake technology are applied in the field of industrial production of milk cakes, which can solve the problems of whether the product can be industrialized, short shelf life, poor sanitary conditions, etc., and achieve excellent flavor and fragrance, good taste and flavor, The effect of optimizing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

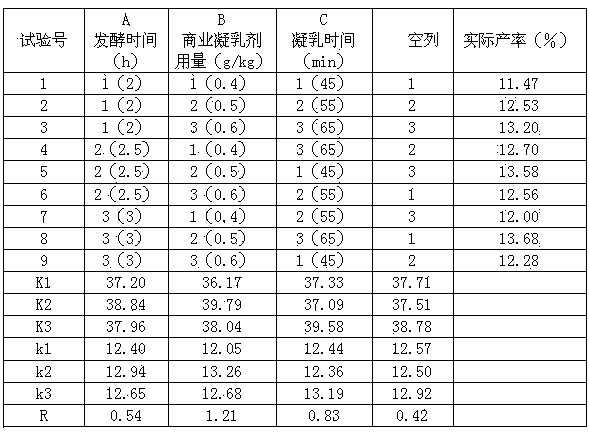

Examples

Embodiment 1

[0038] A kind of processing method of industrialized production milk cake is characterized in that: comprise the processing step of following order:

[0039] (1) Raw material pretreatment: Fresh milk is processed by centrifugation to adjust the total solids content of the fresh milk to 11% of its mass (the insufficient part is made up with milk powder), and sterilized at 63°C for 30 minutes;

[0040](2) Inoculation fermentation: Cool the milk to 42°C, inoculate the starter with 2% of its mass, stir well, and let it stand for fermentation for 2 hours;

[0041] Wherein, the starter is prepared by the following method: take 2 milk fans from Dali, Yunnan Province as samples, take a little sample by aseptic operation, and insert it into M 17 In liquid culture medium, culture at 37°C for 24 hours, after diluting with sterile saline, select 10 -8 、10 -9 、10 -10 Three dilutions were poured into plates using M 17 Solid culture is based on culture at 37°C for 72 hours, 24 character...

Embodiment 2

[0058] A kind of processing method of industrialized production milk cake is characterized in that: comprise the processing step of following sequence:

[0059] (1) Raw material pretreatment: fresh milk is treated by centrifugation, and the total solid content of the fresh milk is adjusted to 10.5% of its mass (if the total solid content is insufficient, make up with milk powder), and sterilized at 61°C for 30 minutes;

[0060] (2) Fermentation by inoculation: Cool the milk to 40°C, inoculate the starter with 1.5% of its mass, stir well, and leave it to ferment for 2 hours. The screening method of the starter is the same as in Example 1;

[0061] (3) Curd milk: Cool down the fermented milk in step (2) to 33°C, add Danisco rennet according to 0.05% of its mass, and curd the milk for 45 minutes to obtain a curd, cut the curd into 1cm 3 The granules are then raised to 73°C at a rate of 1°C per 3 minutes, kept at a temperature of 10 minutes, blanched and stretched to remove whey, ...

Embodiment 3

[0063] A kind of processing method of industrialized production milk cake is characterized in that: comprise the processing step of following sequence:

[0064] (1) Raw material pretreatment: fresh milk is treated by centrifugation, and the total solid content of the fresh milk is adjusted to 11.5% of its mass (if the total solid content is insufficient, use milk powder to make up for it), and sterilized at 65°C for 30 minutes;

[0065] (2) Inoculate the starter: cool the milk to 44°C, inoculate the starter with 2% of its mass, stir well, and leave it to ferment for 2 hours. The screening method of the starter is the same as in Example 1;

[0066] (3) Curd milk: cool down the fermented milk in step (2) to 37°C, add Danisco rennet according to 0.04% of its mass, and curd the milk for 65 minutes to obtain curd, cut the curd into granules, and then Raise the temperature to 77°C at a rate of 1°C every 3 minutes, keep it warm for 10 minutes, perform blanching and stretching, remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com