Preparation method of whole-bean soybean milk taking high-pressure homogenization as main process

A high-pressure homogenization, soybean milk technology, applied in dairy products, milk substitutes, applications, etc., can solve the problems of cumbersome pulverization and fine homogenization steps, very large energy consumption, high soybean nutrition loss rate, and reduce the soaking system. equipment, shortening the pre-processing time, and reducing the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The present embodiment provides a kind of preparation method of whole soybean soymilk, it comprises the following steps:

[0035] 1) After the soybeans are screened and impurities are removed, 10kg is weighed, and the soybeans are roasted using a soybean roaster (microwave infrared roasting, roasting temperature 80°C, roasting time 7 minutes, microwave power 11kW), and then cooled rapidly to ≤30°C; quickly use a soybean peeling machine to peel the soybeans after cooling, so that the soybeans become two petals, and the peeling rate is 92%.

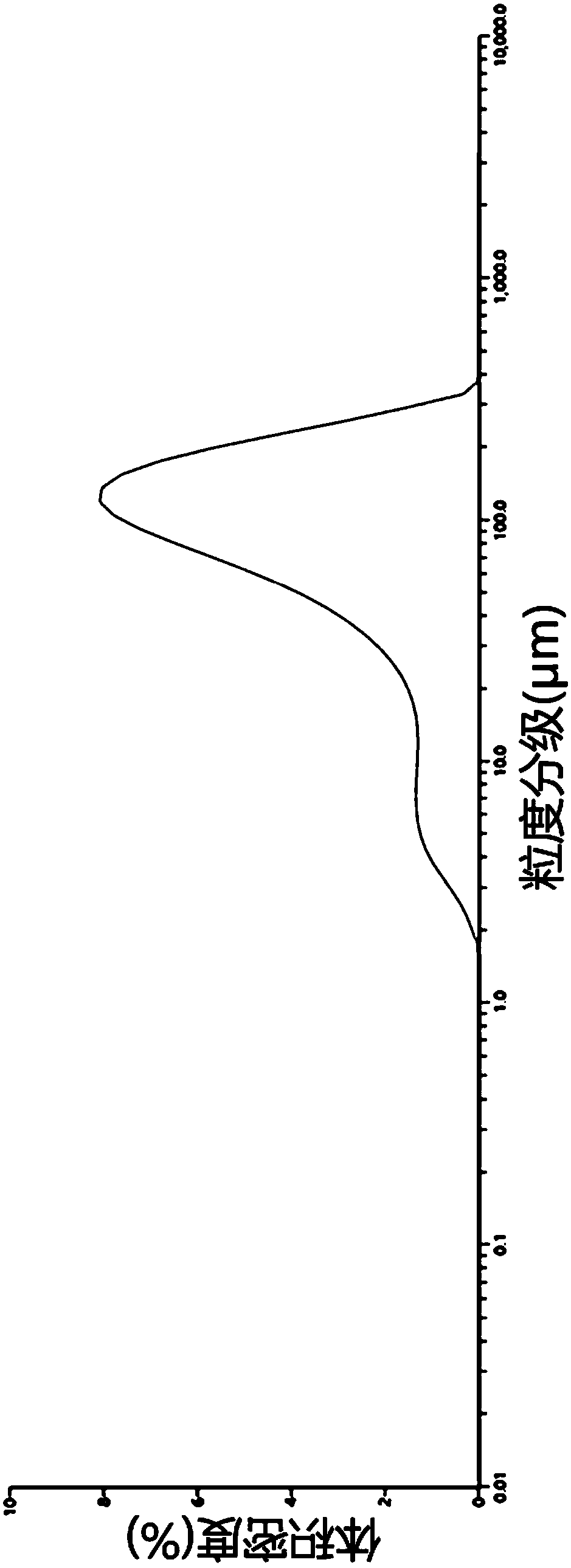

[0036] 2) Use a dry refiner to refine the dehulled soybeans and 90°C hot water at a ratio of 1:7.45, and the average particle size of the raw pulp is 96.4 μm (refer to figure 1 ).

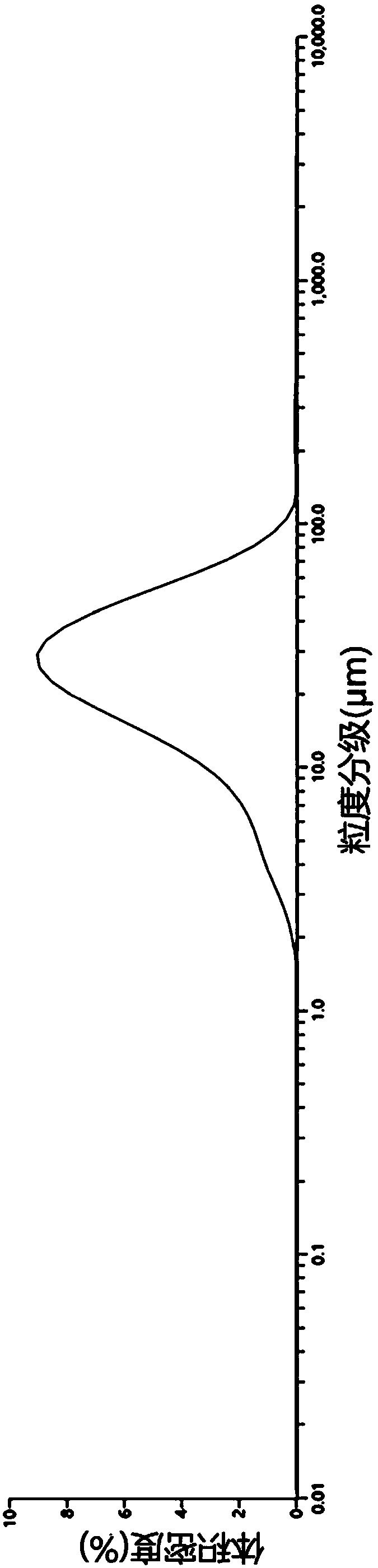

[0037] 3) Use a high-pressure homogenizer to carry out high-pressure homogenization to the raw pulp after refining, the homogenization pressure is 800bar, and the average particle size of the raw pulp obtained after homogenization is 28.9 μm (reference f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com