Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "Critical edge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In: Critical Edge. Critical Edge in Soul Edge (Soul Blade) Critical Edge is the name given to attacks used by all Standard Characters (and Soul Edge) characters in Soul Edge (Soul Blade).

Method, an apparatus and a storage medium for locating QR codes

ActiveUS7273175B2Code conversionCharacter and pattern recognitionCharacteristic ratioArtificial intelligence

Owner:CANON KK

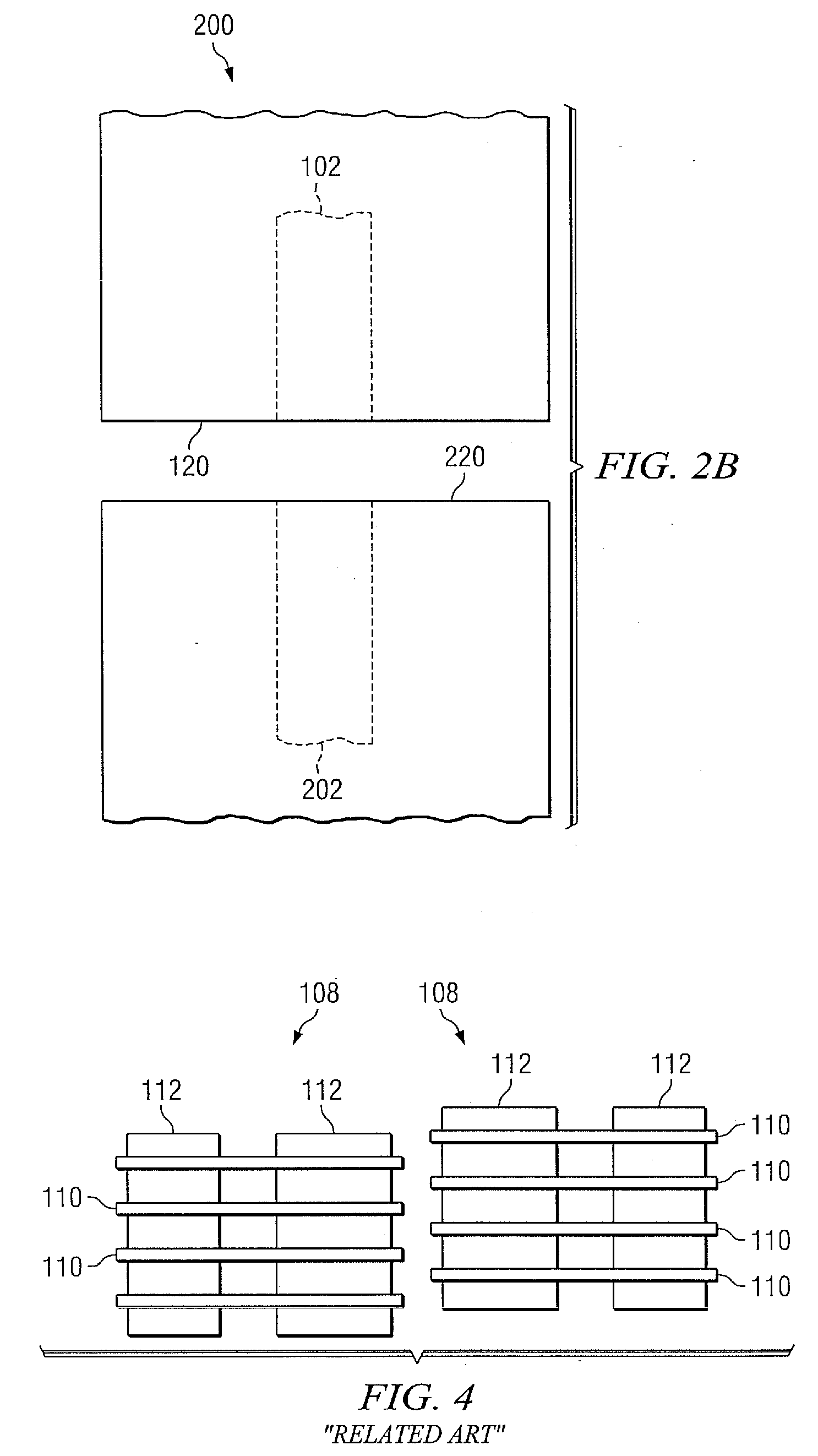

Method and apparatus for determining mask layouts for a multiple patterning process

ActiveUS20080244504A1Improve toleranceIncreasing trenchOriginals for photomechanical treatmentSpecial data processing applicationsEngineeringDesign intent

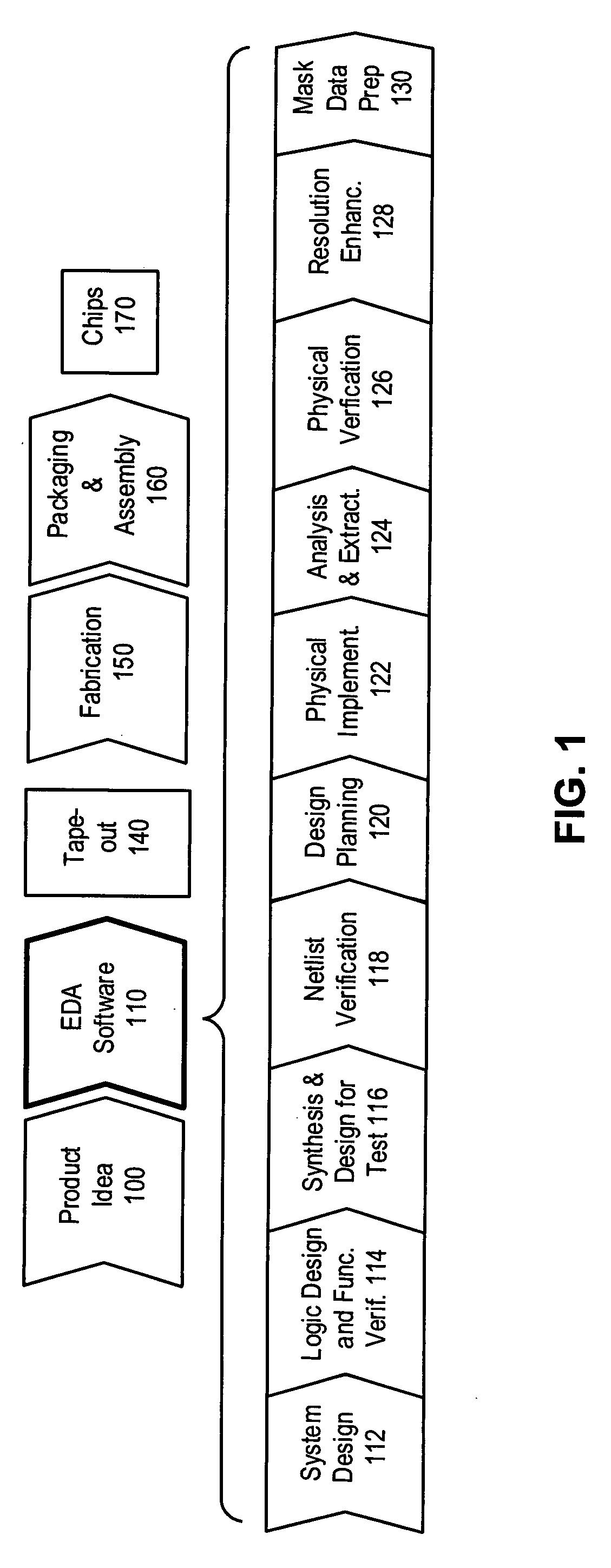

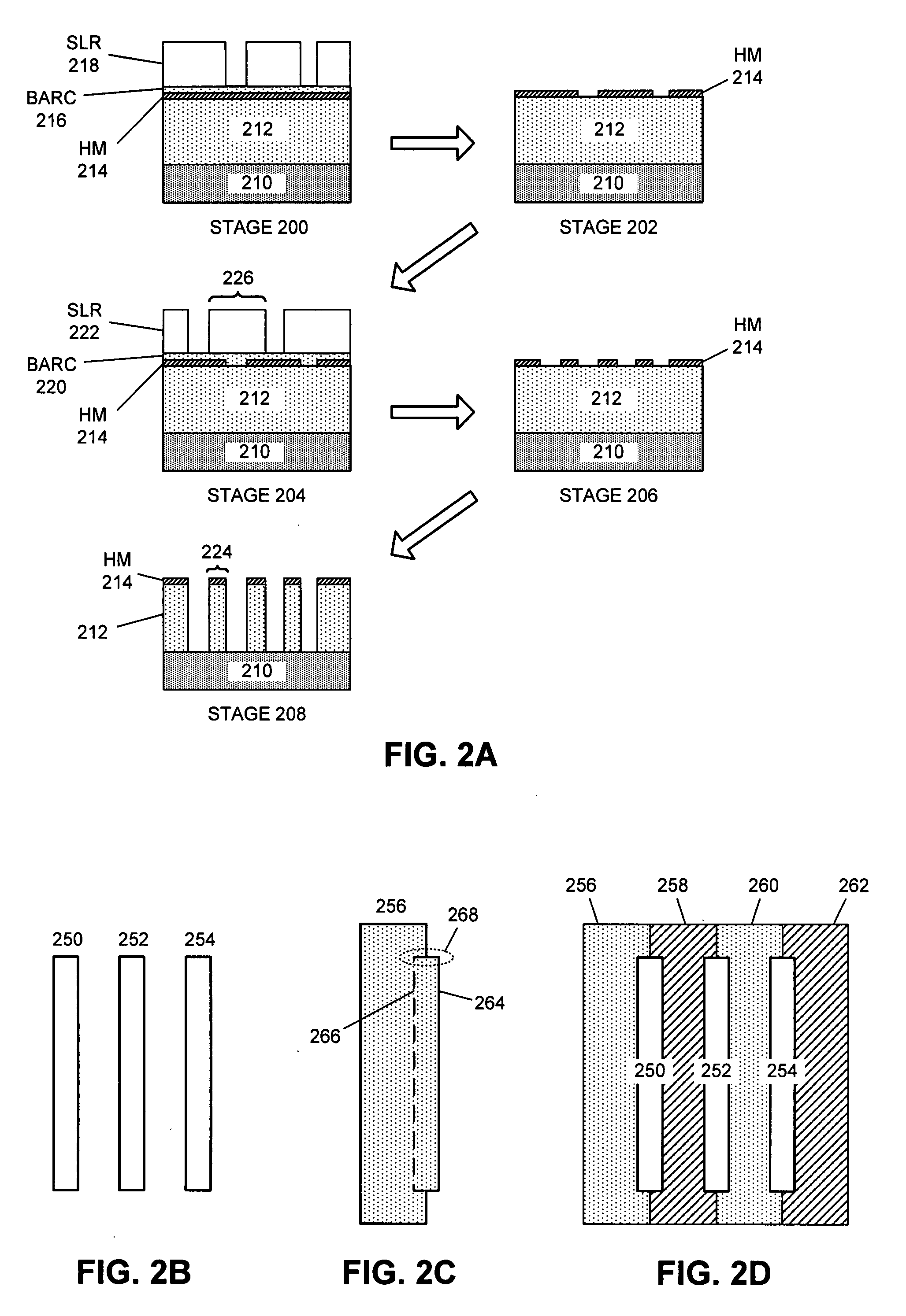

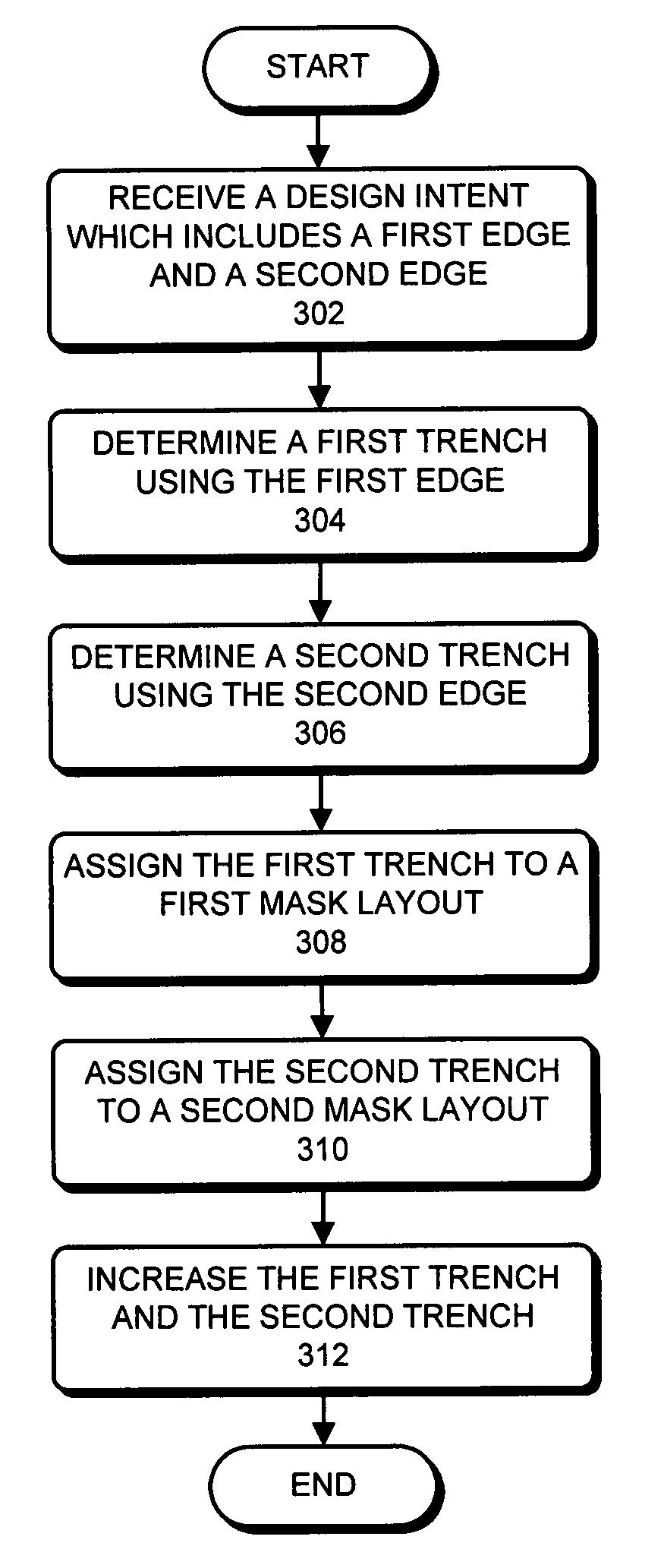

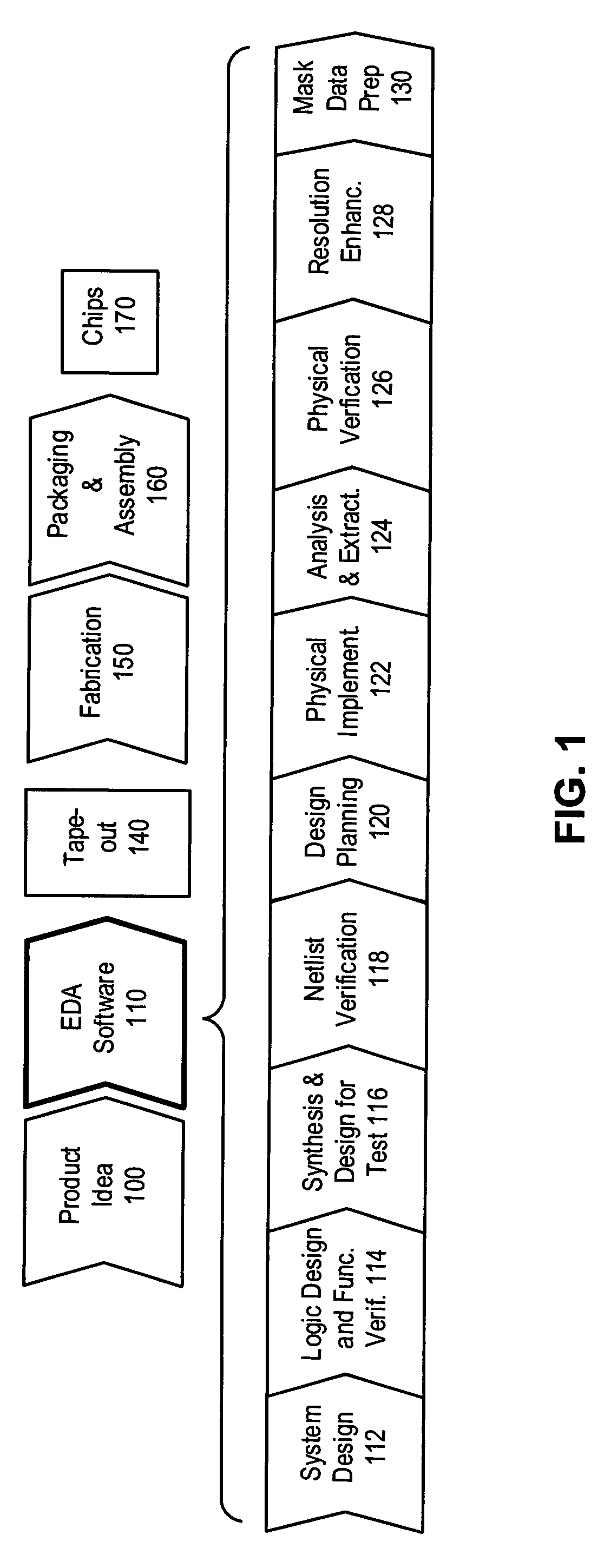

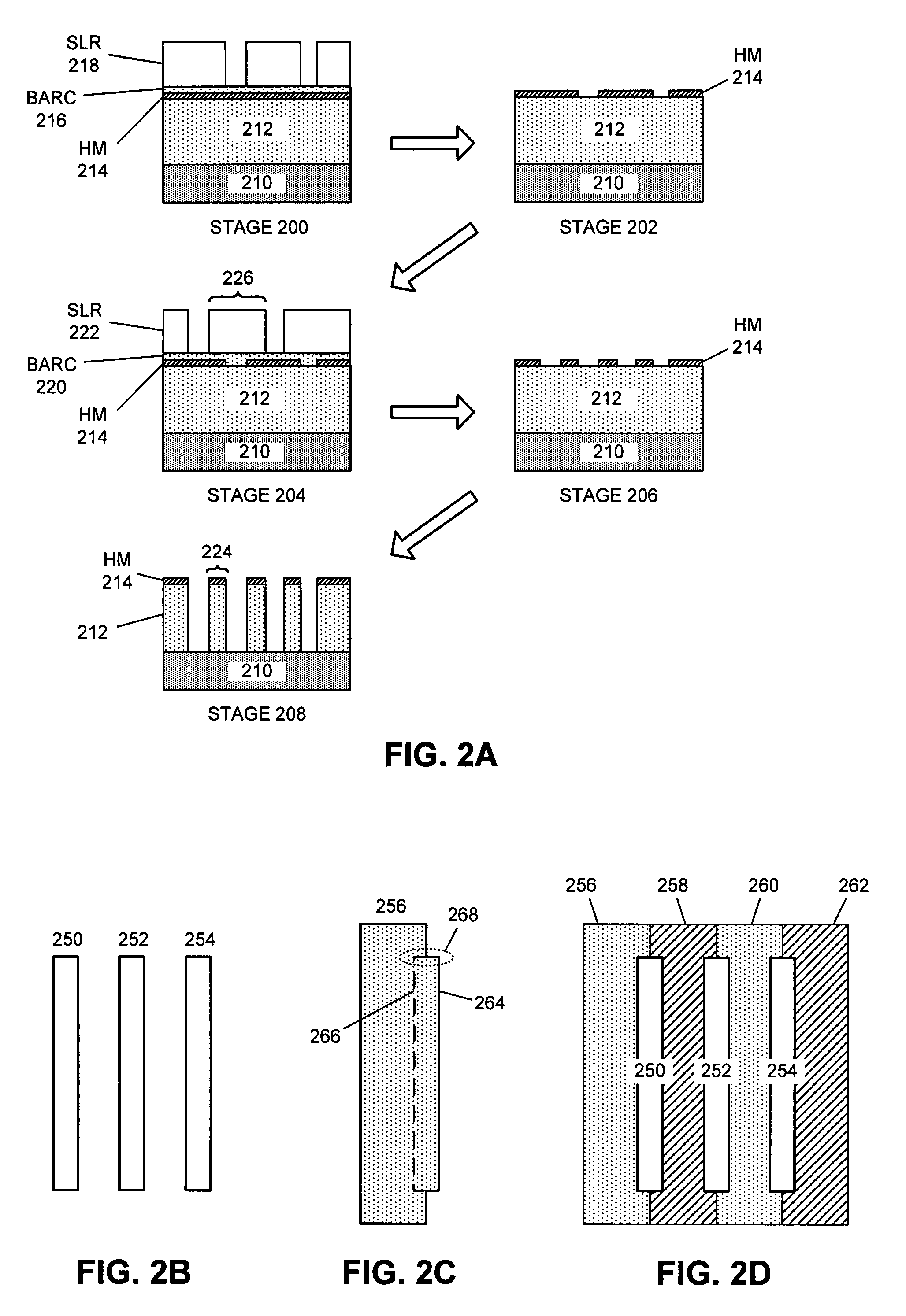

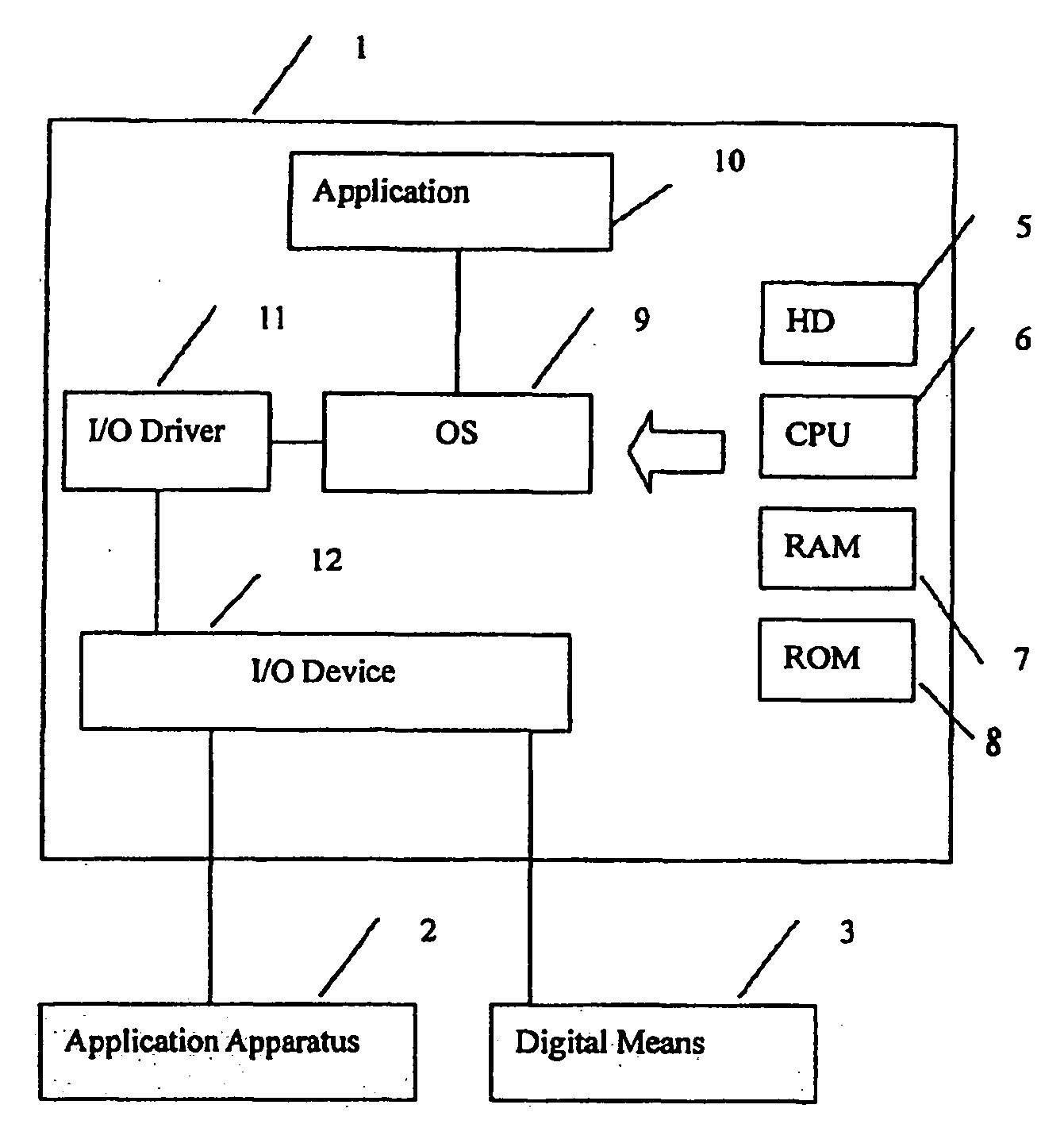

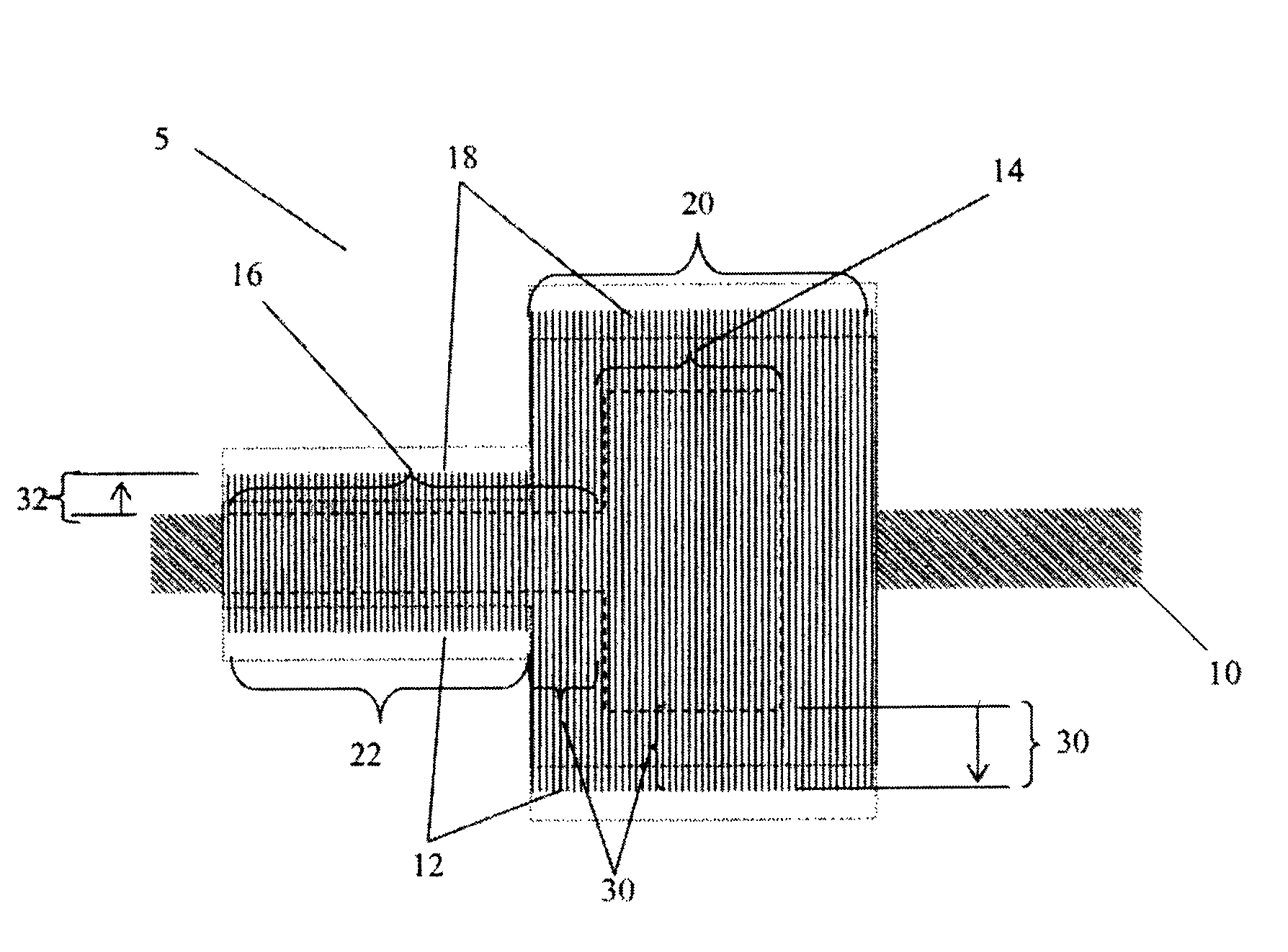

One embodiment provides a method for determining mask layouts. During operation, the system can receive a design intent. Next, the system can determine a set of critical edges in the design layout, and select a first edge and a second edge. The system can then determine a first trench and a second trench using the first edge and the second edge, respectively. Note that an edge of the first trench may substantially overlap with the first edge, and an edge of the second trench may substantially overlap with the second edge. Next, the system may assign the first trench and the second trench to the first mask layout and the second mask layout, respectively. The system can then increase the first trench and the second trench, thereby improving pattern fidelity. The resulting mask layouts may be used in a double patterning process.

Owner:SYNOPSYS INC

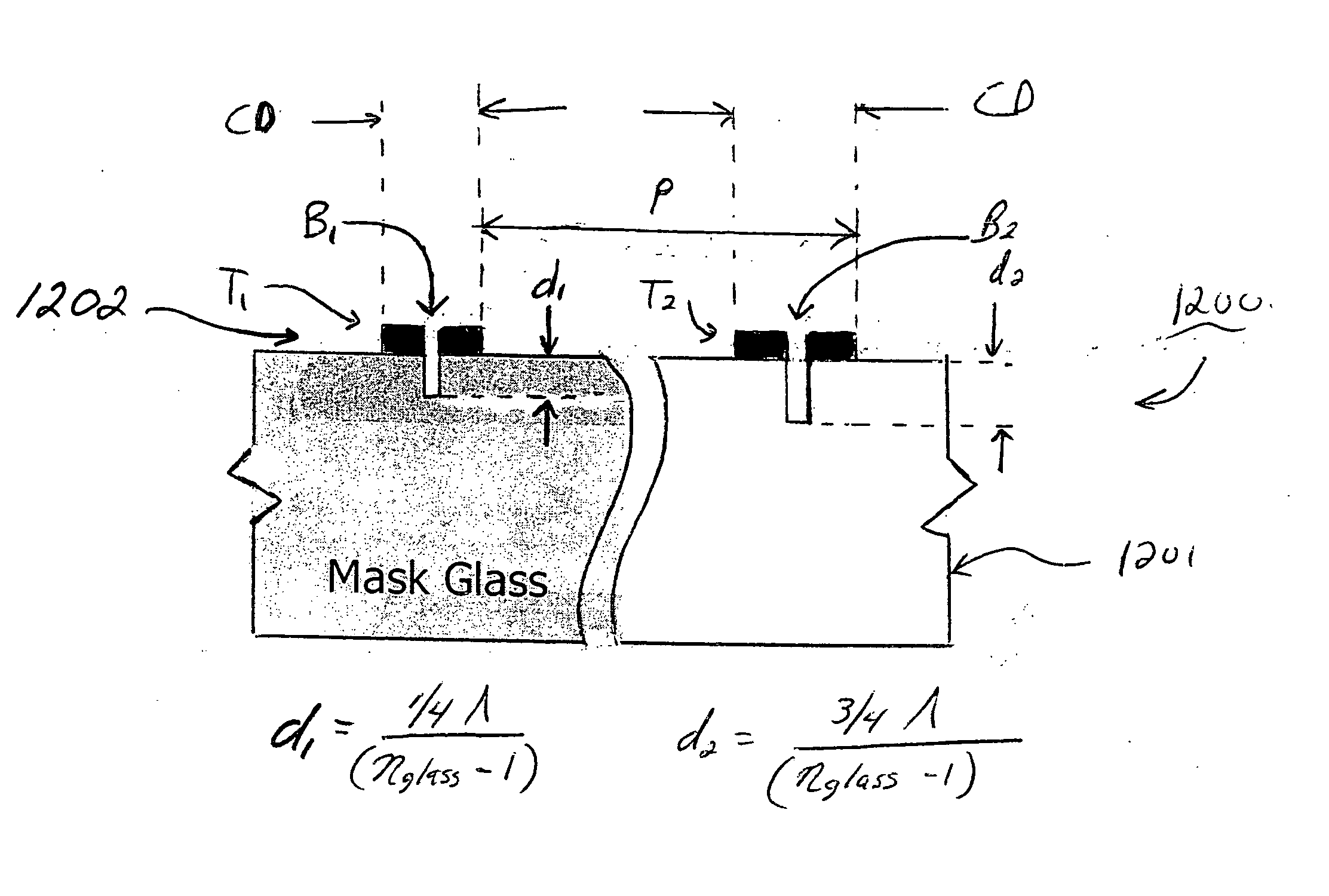

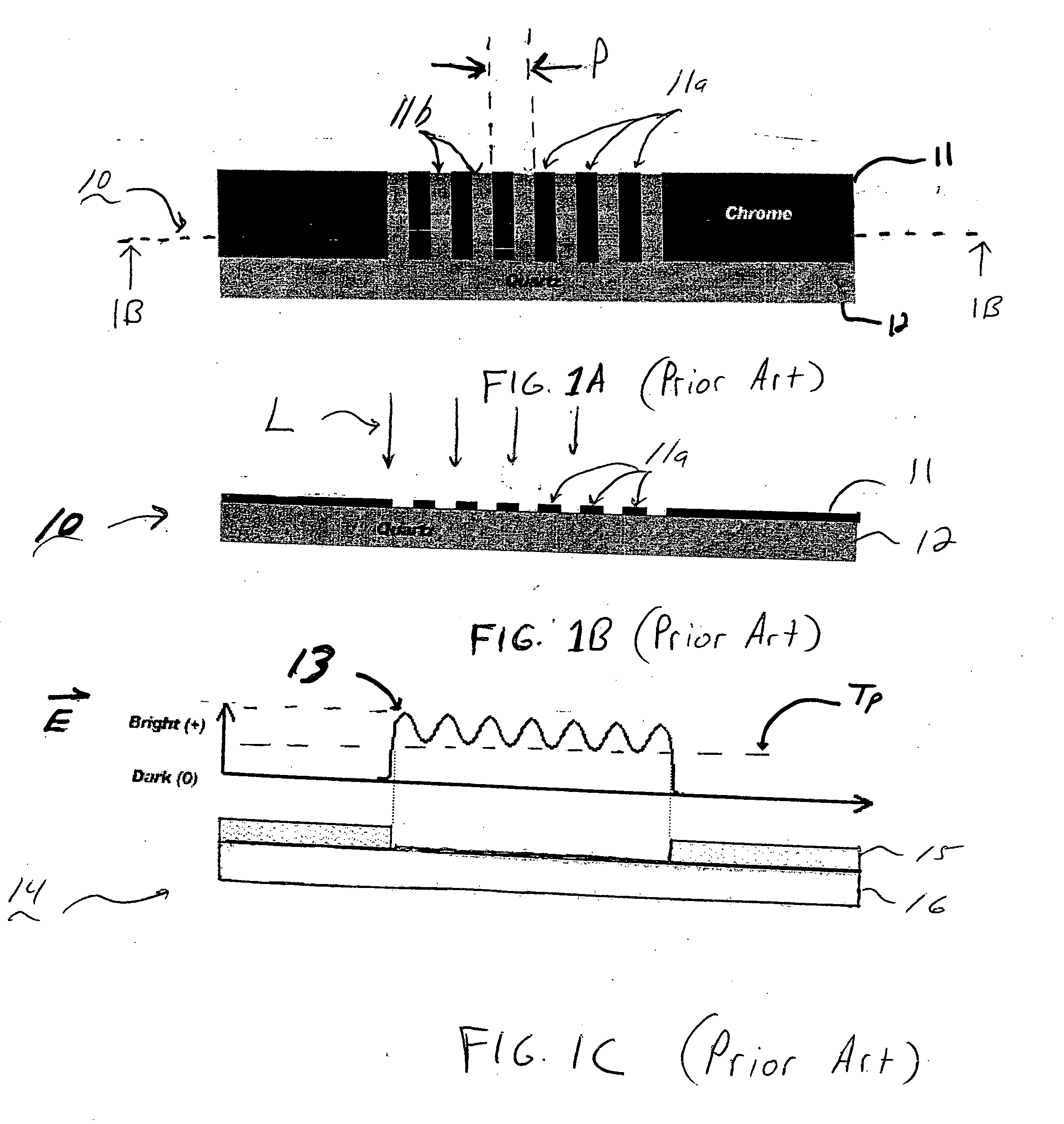

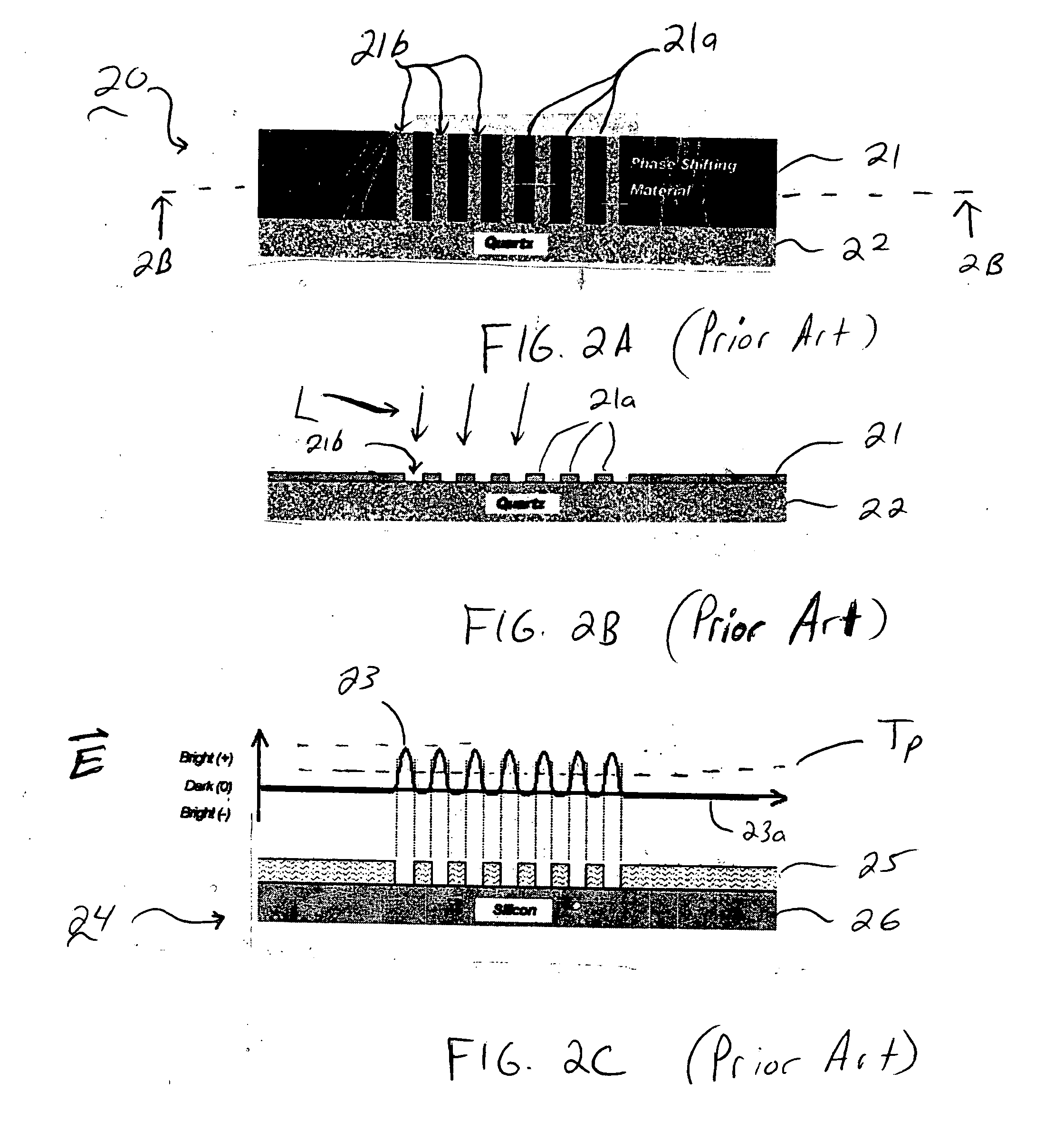

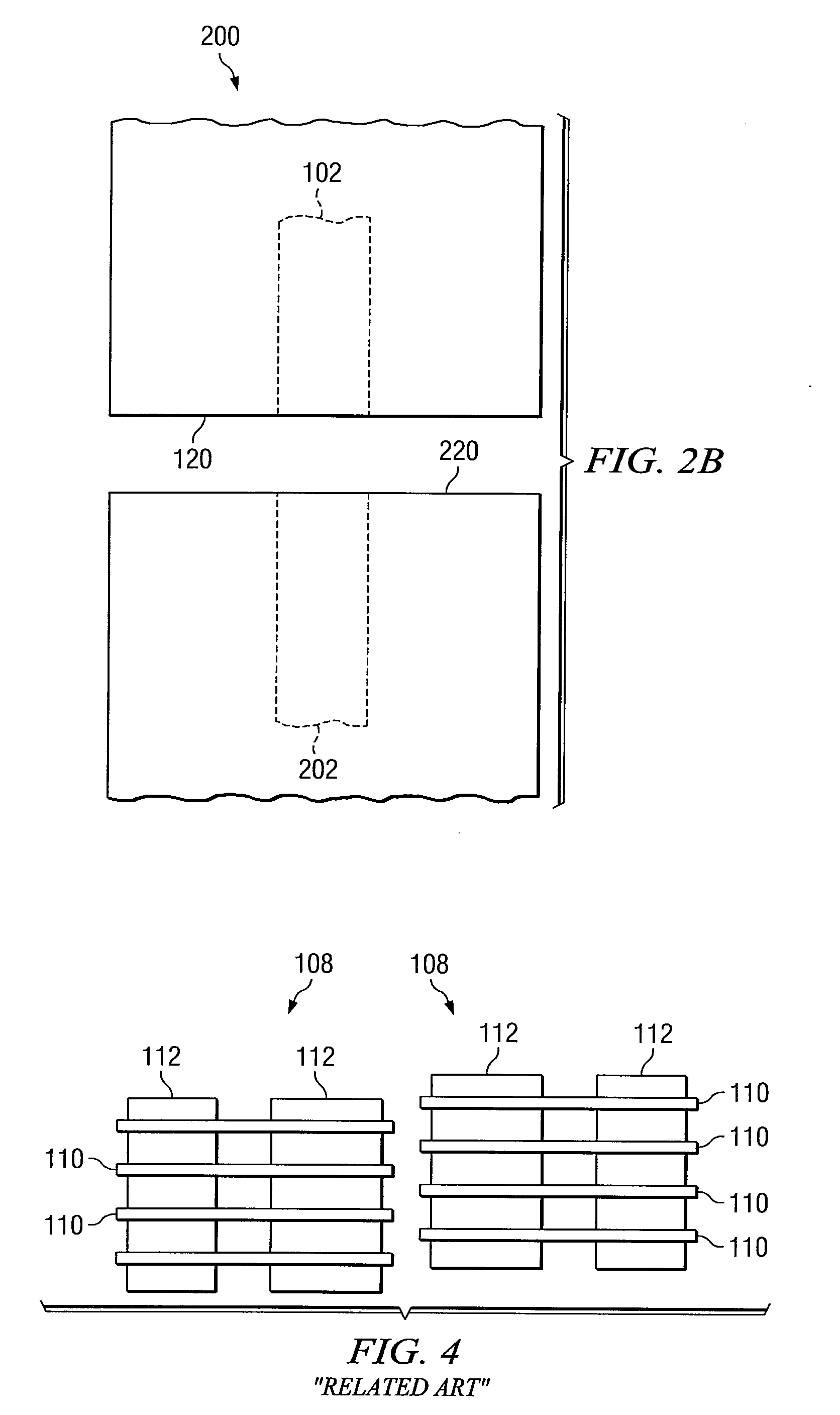

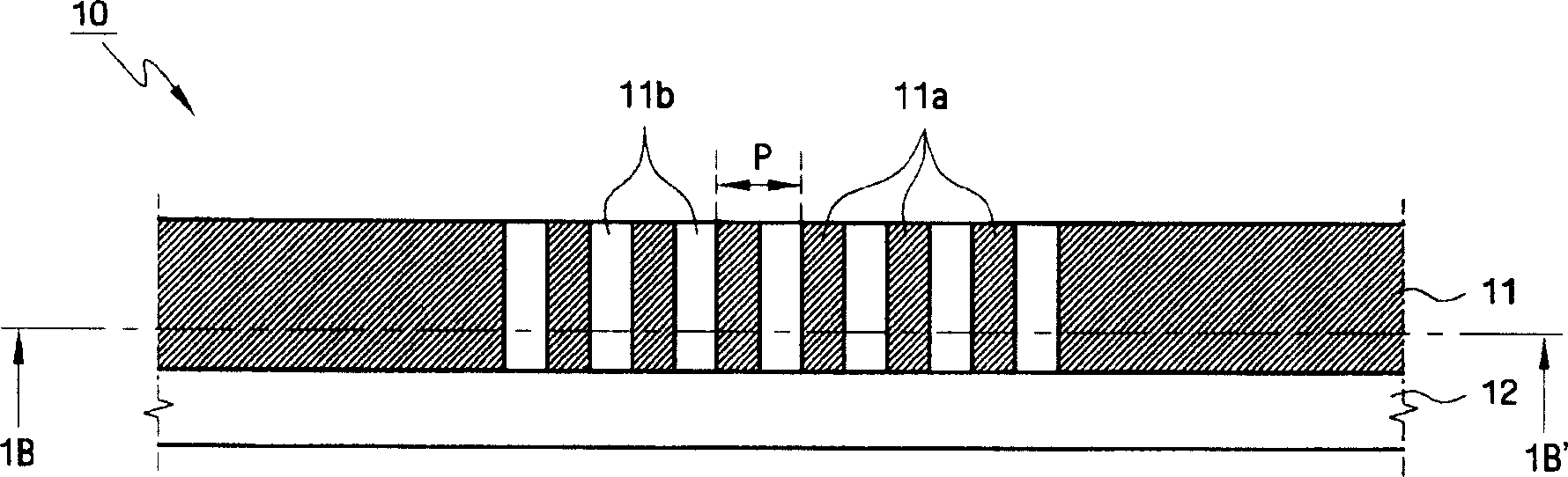

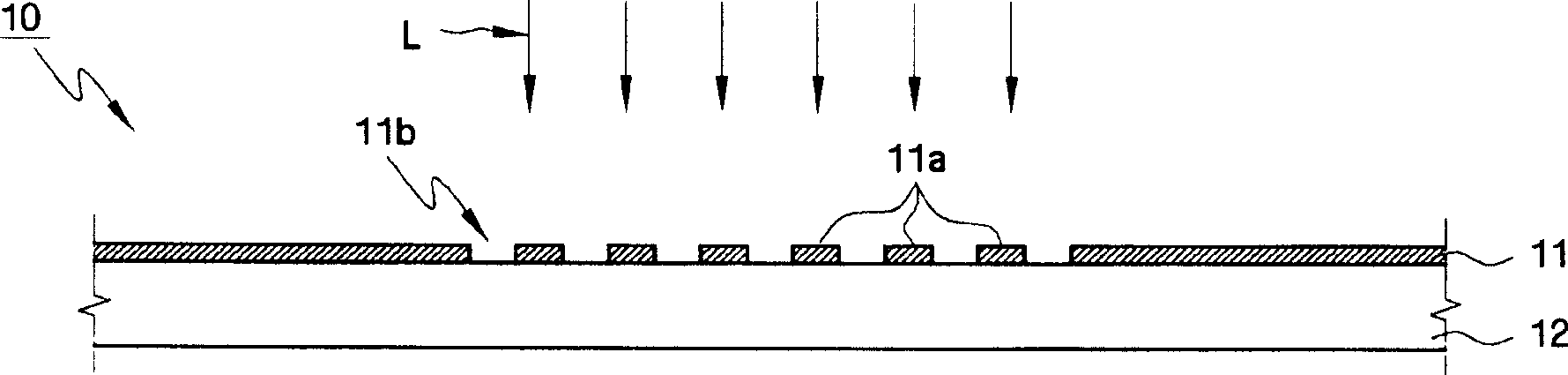

Photomask structures providing improved photolithographic process windows and methods of manufacturing same

InactiveUS20060234137A1Improve image contrastImprove lithographic processPhotomechanical apparatusOriginals for photomechanical treatmentLithography processImage contrast

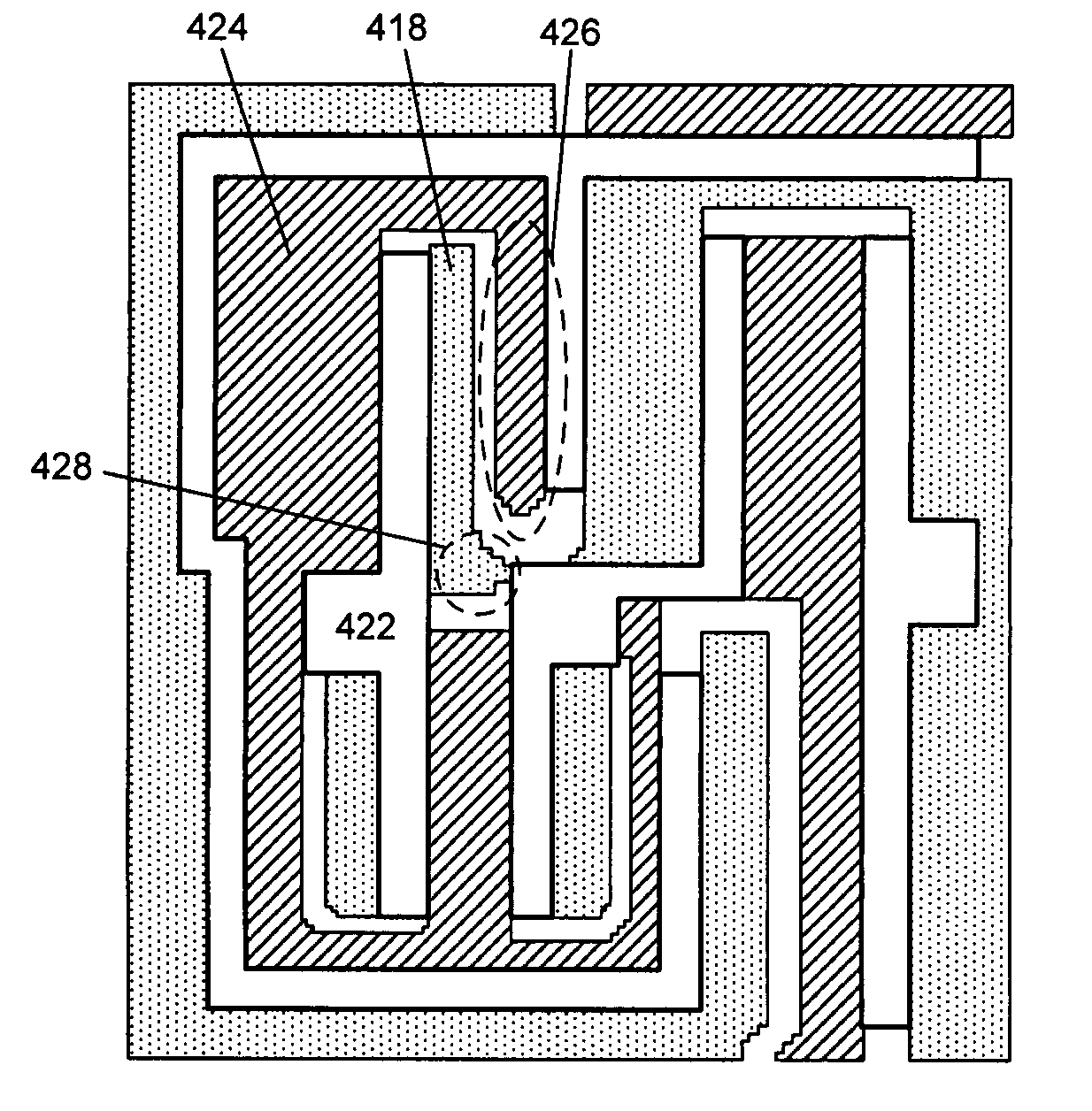

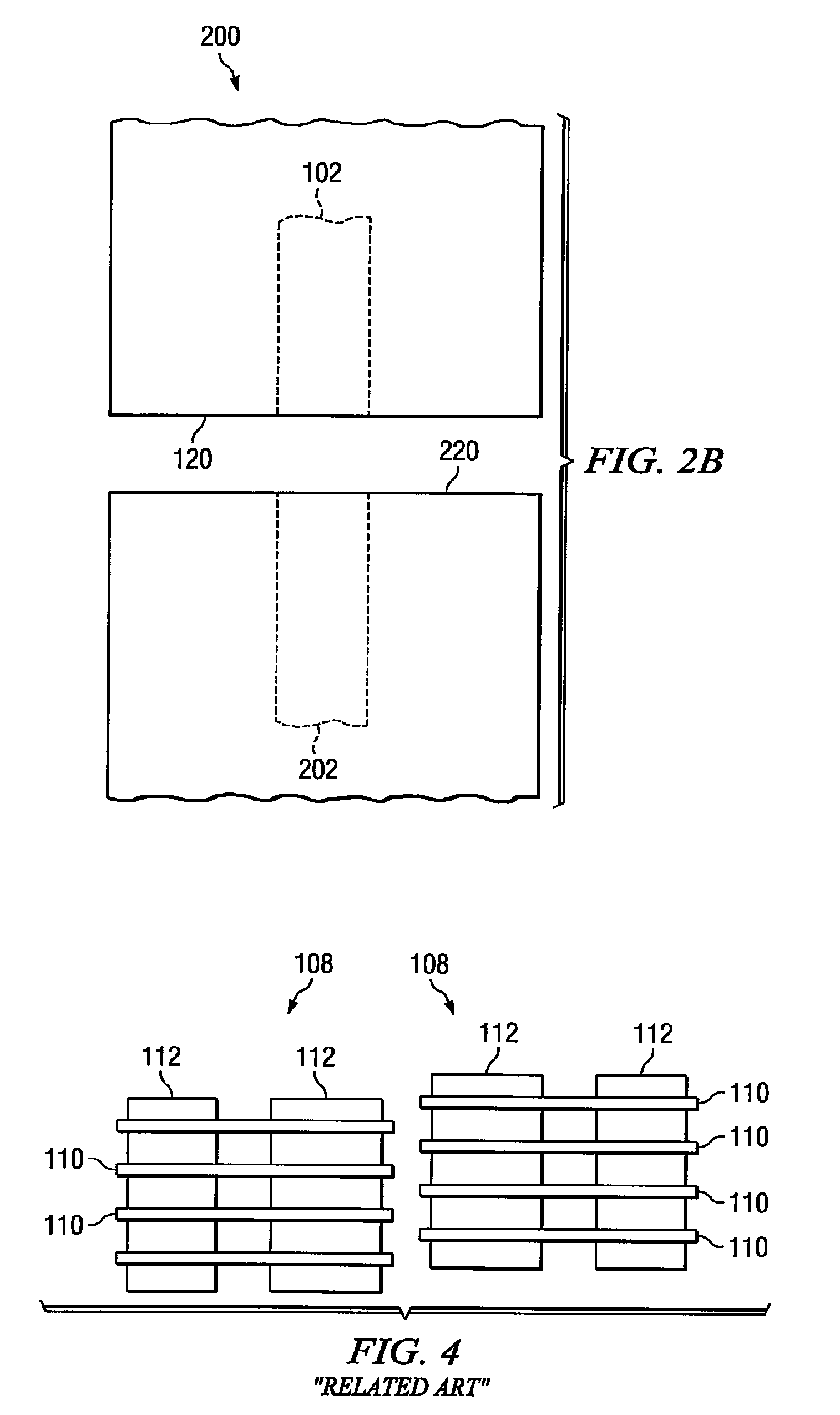

Photolithographic methods for semiconductor manufacturing are provided wherein photomask structures are designed to provide increased lithographic process windows for printing sub-wavelength features. In one aspect, a photomask includes a mask substrate transparent to exposure light of a given wavelength, and a mask pattern formed on a surface of the substrate. The mask pattern comprises a printable element defined by a first and second critical edge, wherein the printable element includes an inner, non-printing feature formed between the first and second critical edges. The inner, non-printing feature is adapted to enhance image contrast at the first and second critical edges of the printable element for the given wavelength of exposure light during a photolithographic process. The non-printing feature comprises a space feature that exposes a region of the mask substrate aligned to the printable element between the first and second critical edges, and a trench feature that is formed in the mask substrate and aligned to the space feature.

Owner:SAMSUNG ELECTRONICS CO LTD

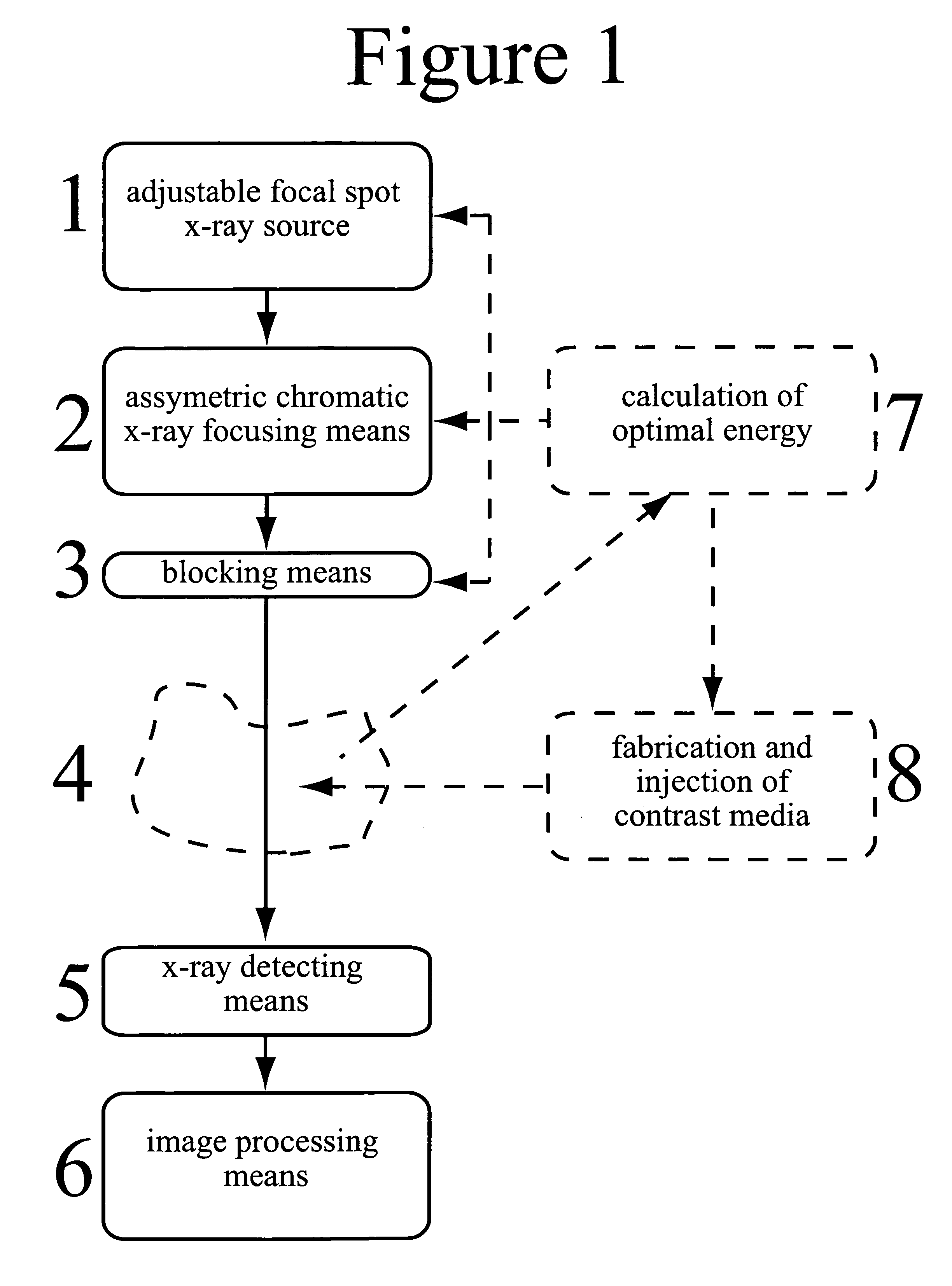

X-ray imaging arrangement

InactiveUS20070121784A1Compensation effectIncrease contrastTomographyAngiographySignal-to-noise ratio (imaging)X-ray optics

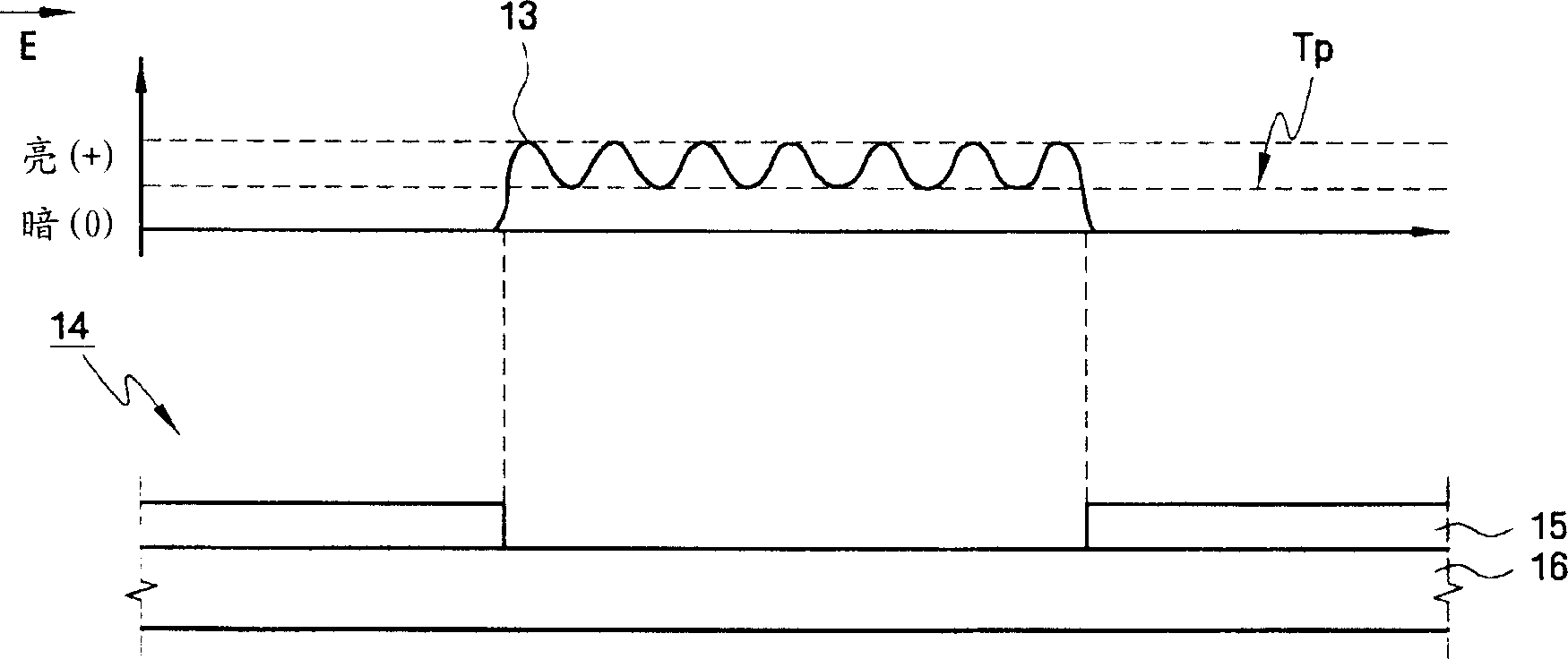

An x-ray system for narrow bandwidth imaging of in particular small objects is provided. X-radiation from an x-ray source (1) is focused by chromatic x-ray optics (2) on an x-ray energy dependent distance from the optics. Asymmetric focusing of the x-ray optics is compensated for by choosing an asymmetric focal spot of the source. The energy selective focusing makes possible blocking unwanted x-ray energies (3) from reaching an object (4). In that way optimization of the energy according to the size of the object can be done to minimize dose and maximize signal-to-noise ratio (7). Furthermore, a critical edge subtraction image can be obtained at the object dependent optimal energy if the object is injected with a contrast agent having an absorption edge close to the optimal energy (8). Radiation is registered (5) and processed (6) to combine structural and energy subtraction images.

Owner:SECTRA MAMEA

Method and apparatus for determining mask layouts for a multiple patterning process

ActiveUS8028253B2Increasing trenchImprove toleranceOriginals for photomechanical treatmentSpecial data processing applicationsEngineeringDesign intent

One embodiment provides a method for determining mask layouts. During operation, the system can receive a design intent. Next, the system can determine a set of critical edges in the design layout, and select a first edge and a second edge. The system can then determine a first trench and a second trench using the first edge and the second edge, respectively. Note that an edge of the first trench may substantially overlap with the first edge, and an edge of the second trench may substantially overlap with the second edge. Next, the system may assign the first trench and the second trench to the first mask layout and the second mask layout, respectively. The system can then increase the first trench and the second trench, thereby improving pattern fidelity. The resulting mask layouts may be used in a double patterning process.

Owner:SYNOPSYS INC

Method, an apparatus and a storage medium for locating QR codes

ActiveUS20060082475A1Code conversionCharacter and pattern recognitionCharacteristic ratioArtificial intelligence

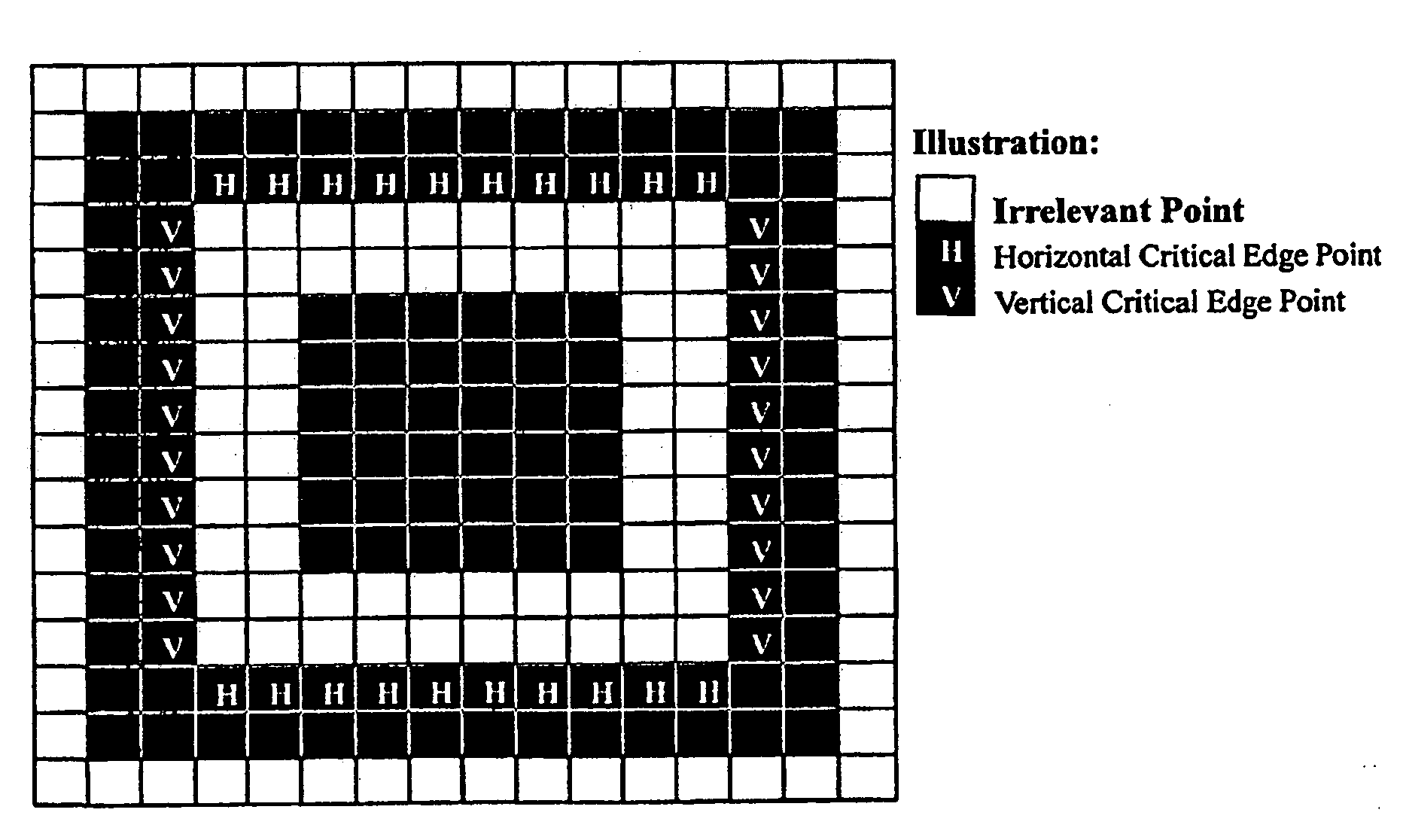

The present application relates to a method, an apparatus and a storage medium for locating QR codes. For automatically locating a plurality of QR codes in image of any size, the invention provides an apparatus for locating at least one QR code in an image, comprising: characteristic ratio detection means for detecting the potential QR code location symbol areas by carrying out a plurality of detections for detecting the characteristic ratio of the QR code; critical edge detection means for detecting the critical edges of the potential QR code location symbol areas so that the false areas are excluded; location symbol grouping means for matching the detected QR code location symbol areas into potential QR codes; and verification means for excluding the false QR codes. The invention also provides a corresponding method for locating at least one QR code.

Owner:CANON KK

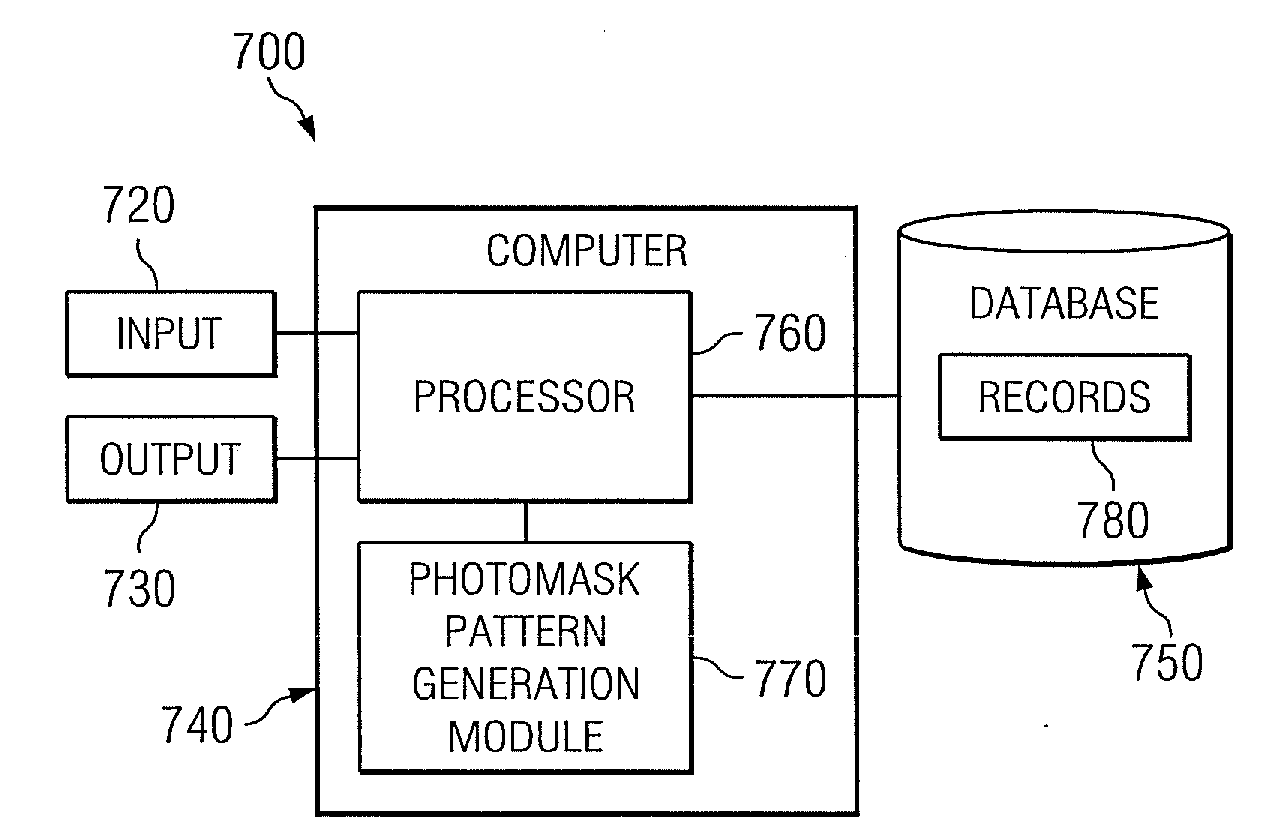

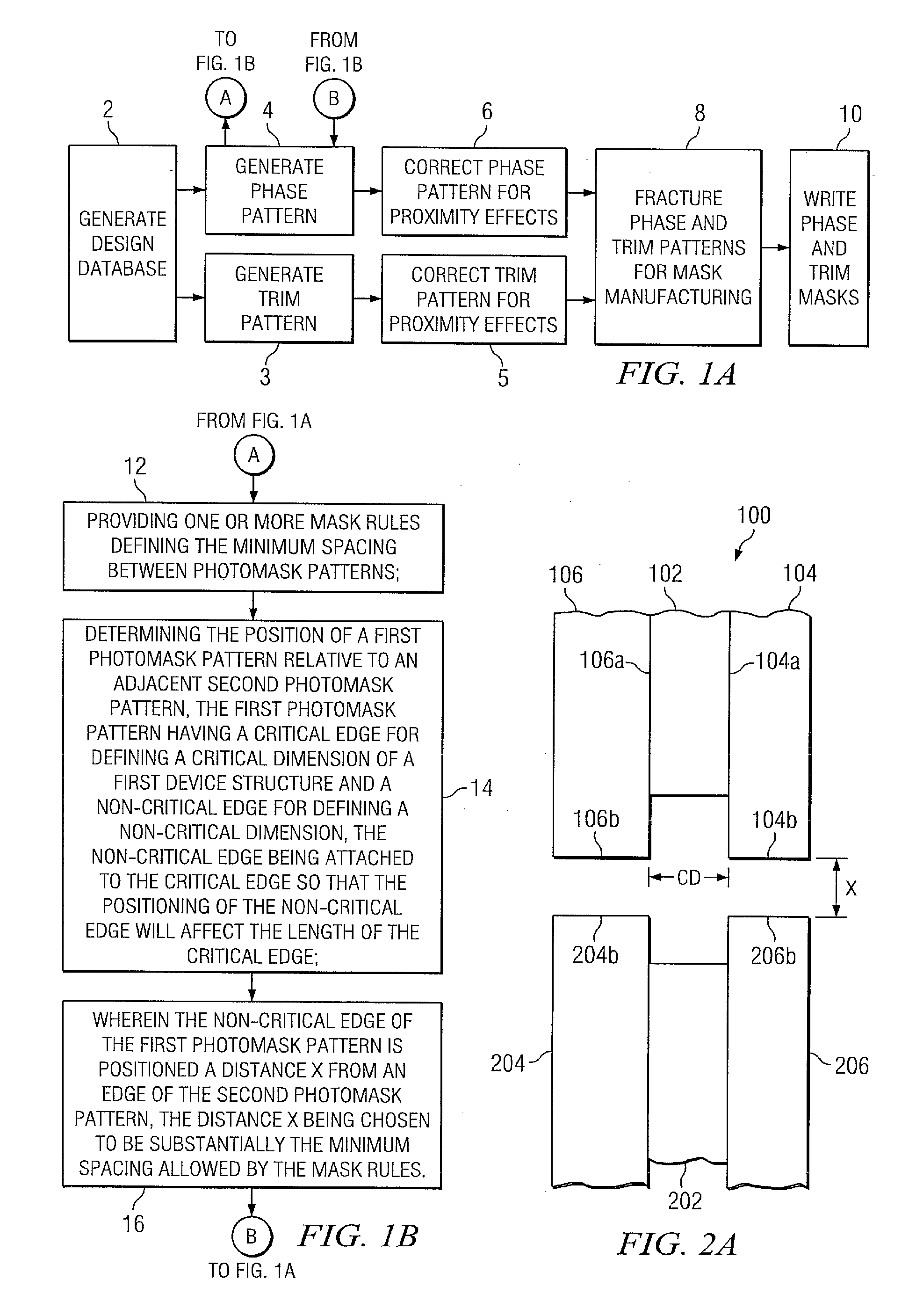

System and method for making photomasks

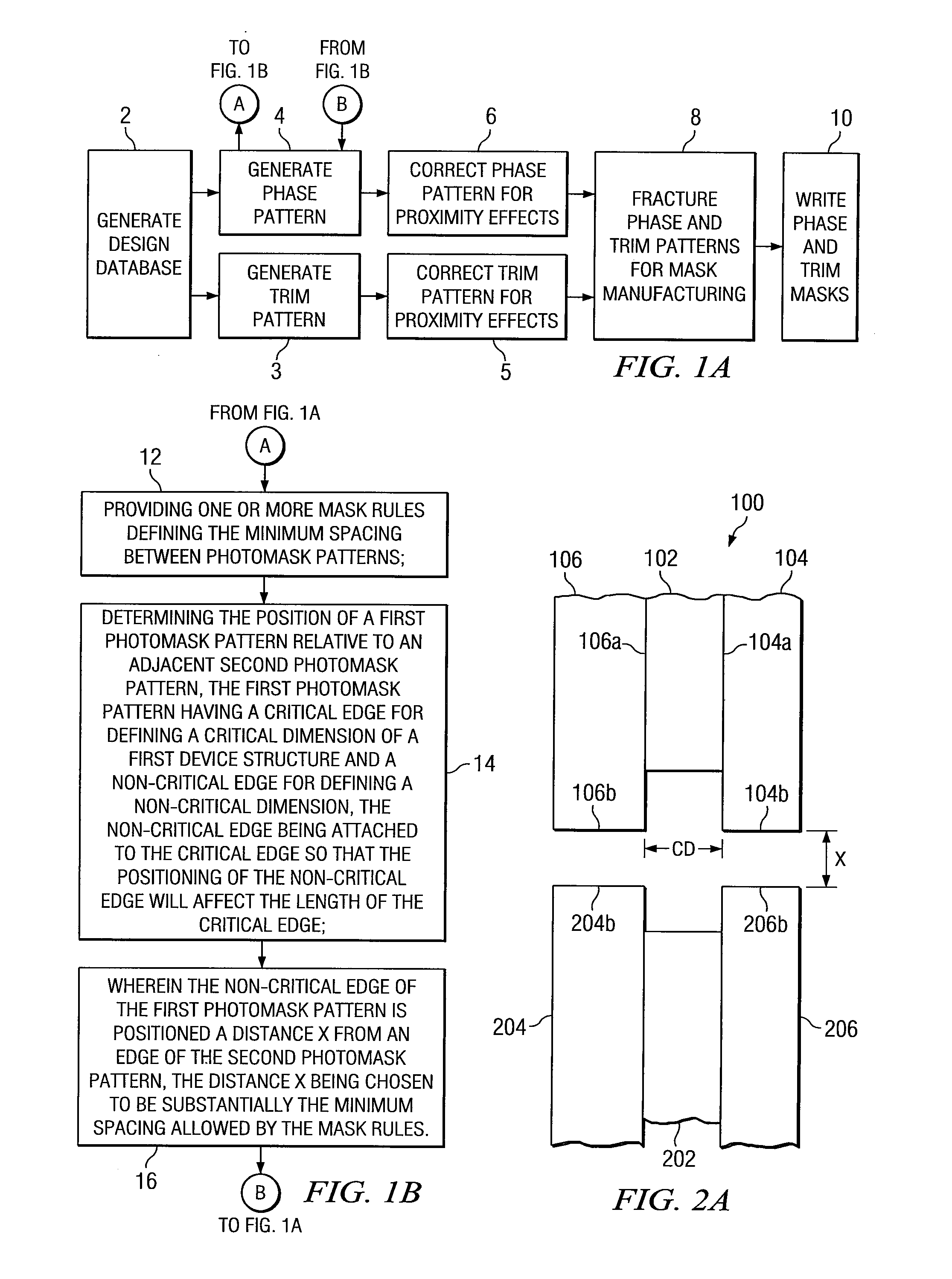

ActiveUS20090128788A1Length can be affectedUsing optical meansOriginals for photomechanical treatmentEngineeringCritical dimension

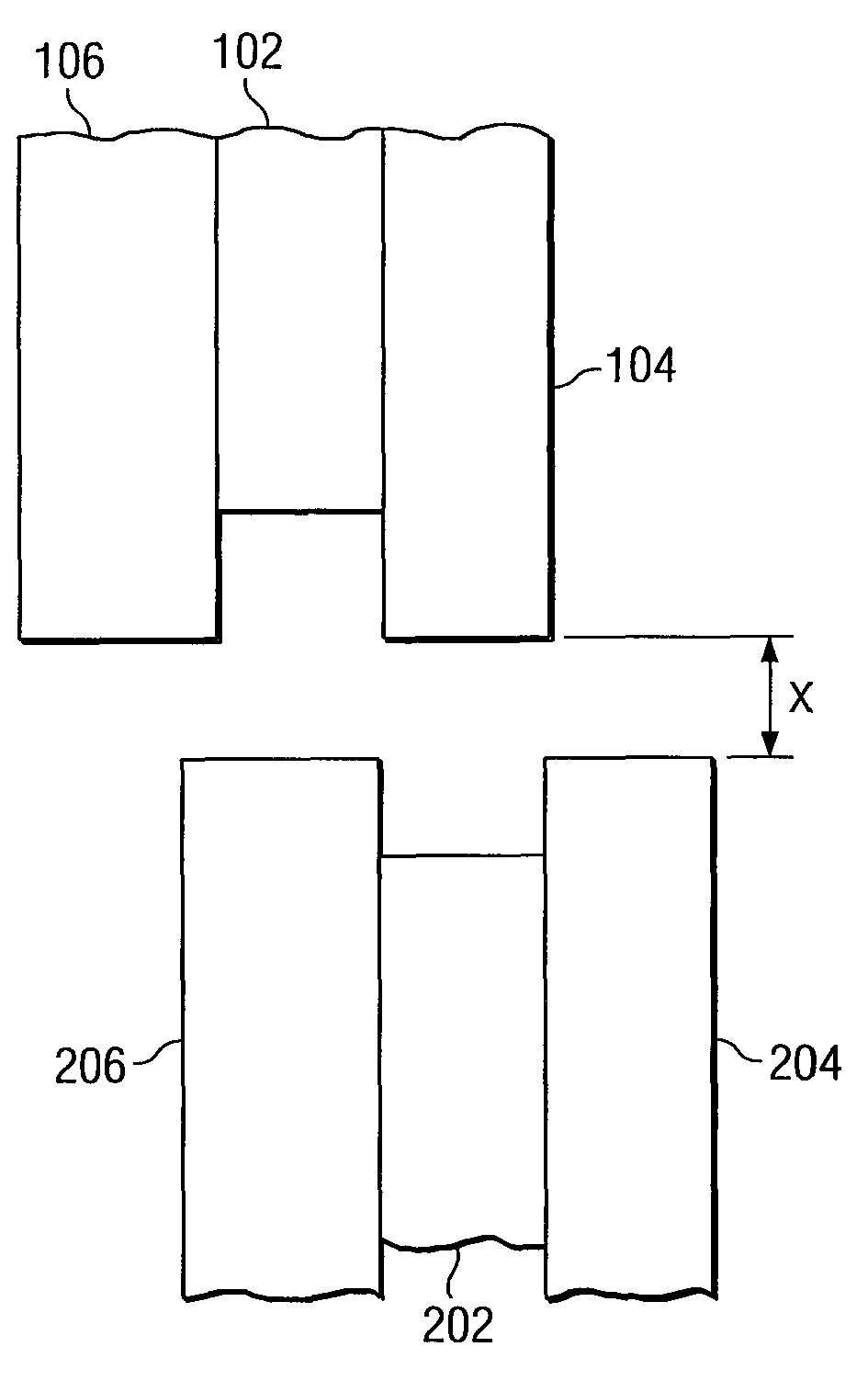

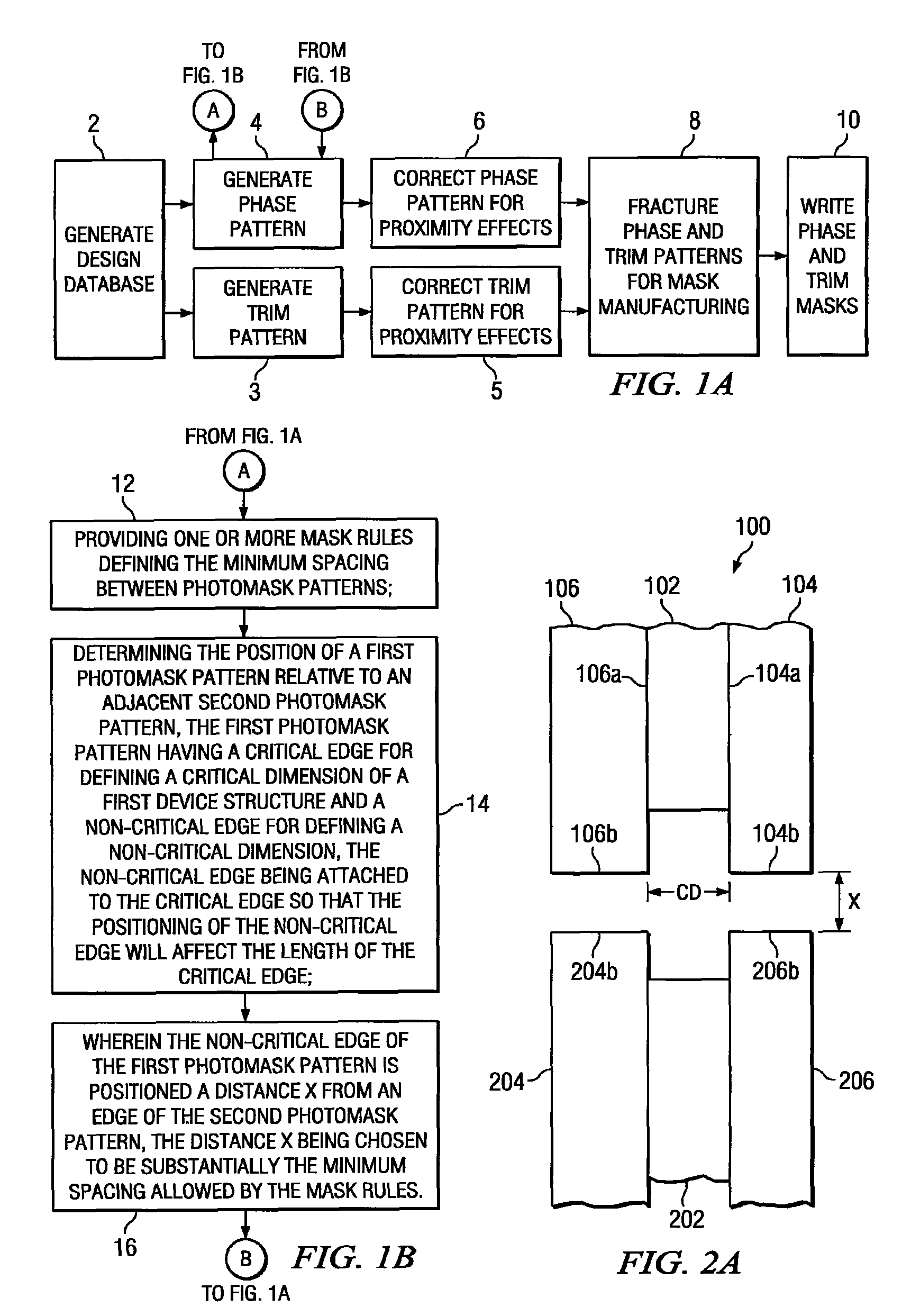

The present application is directed a method for determining the position of photomask patterns in a mask making process. The method comprises providing one or more mask rules defining the minimum spacing between photomask patterns. The method further comprises determining the position of a first photomask pattern relative to an adjacent second photomask pattern, the first photomask pattern having a critical edge for defining a critical dimension of a first device structure and a non-critical edge for defining a non-critical dimension. The non-critical edge is attached to the critical edge so that the positioning of the non-critical edge will affect the length of the critical edge. The non-critical edge of the first photomask pattern is positioned a distance X from an edge of the second photomask pattern, wherein the distance X is chosen to be substantially the minimum spacing allowed by the mask rules. Embodiments directed to software modules for implementing the method and patterning processes employing the method are also disclosed.

Owner:TEXAS INSTR INC

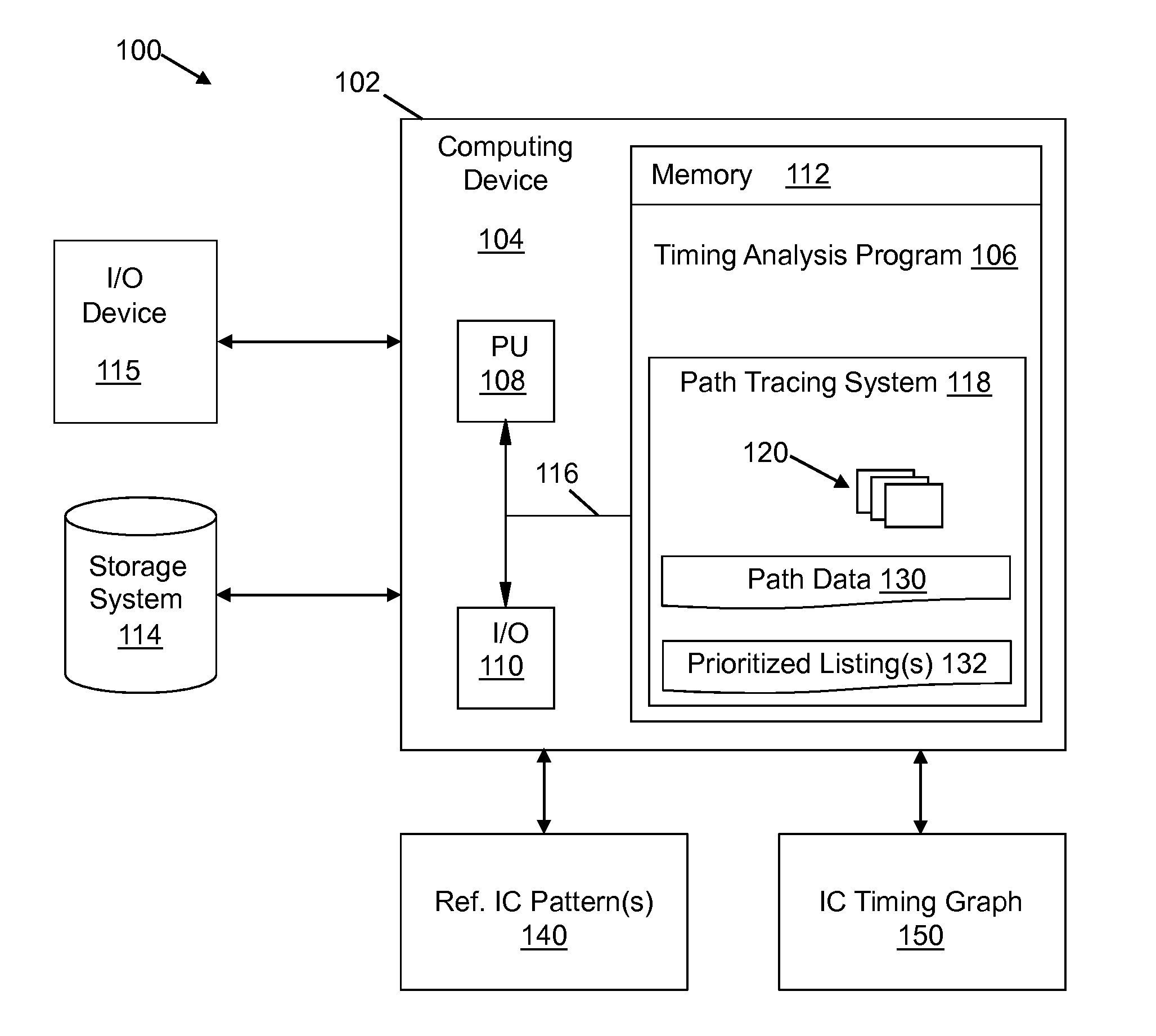

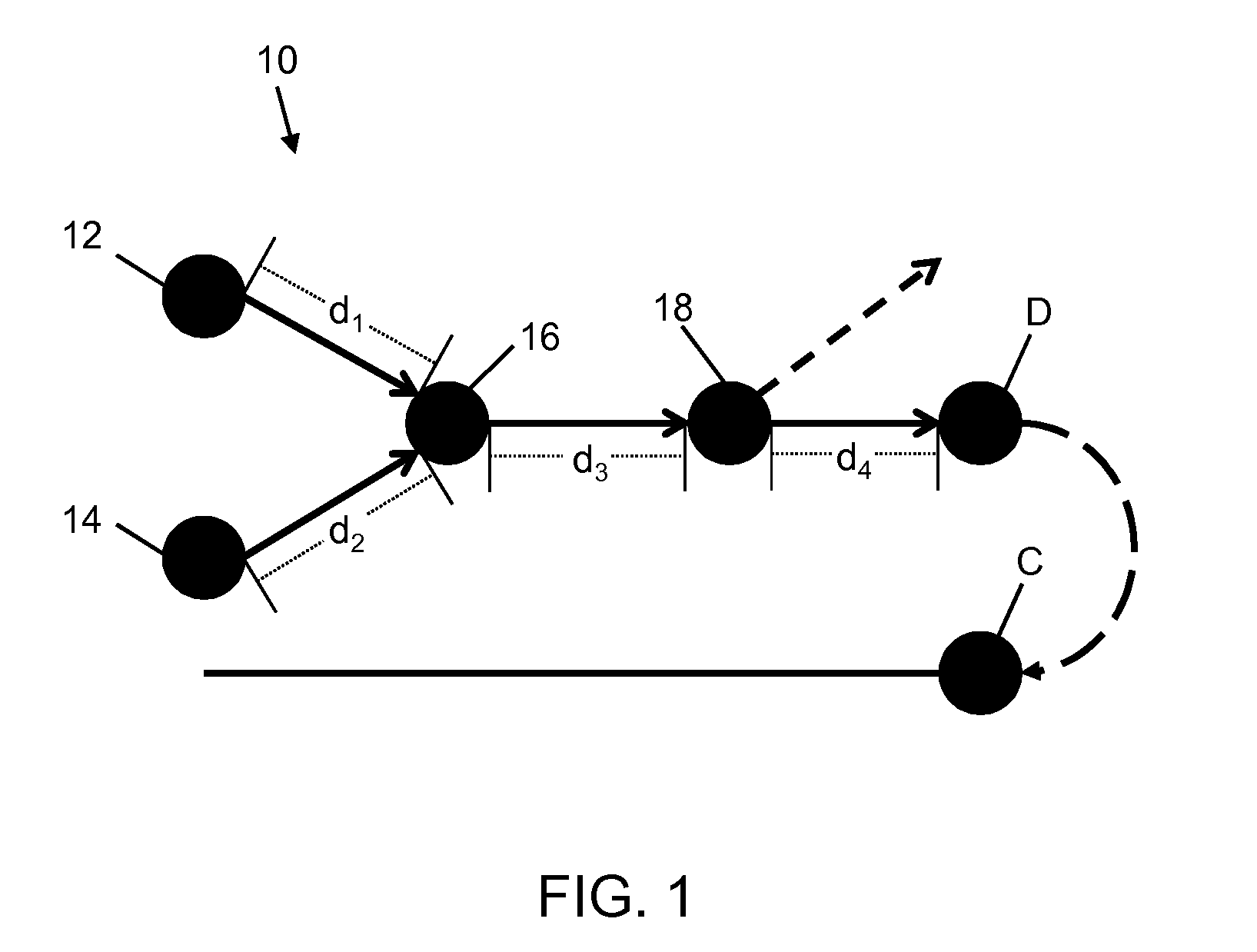

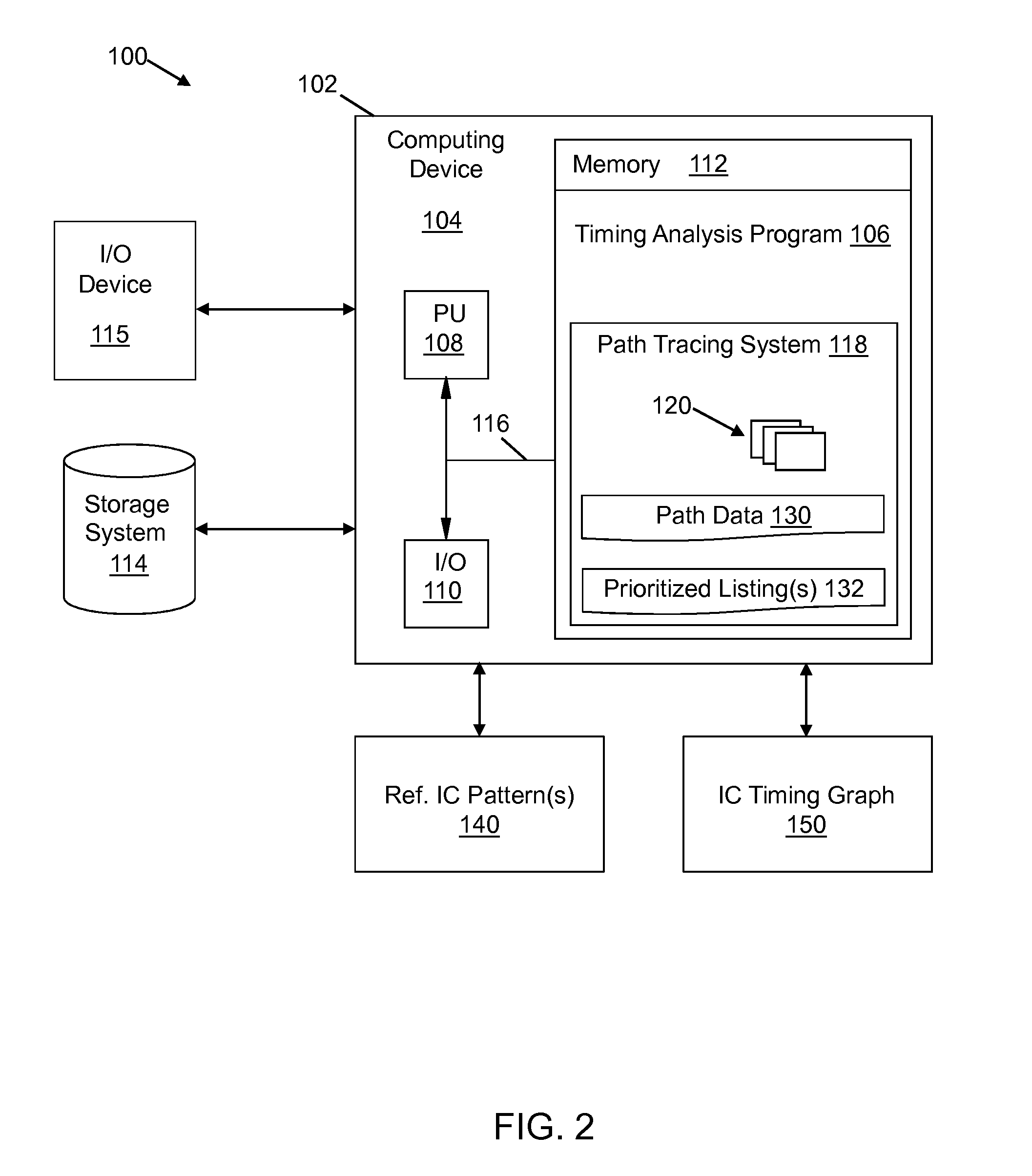

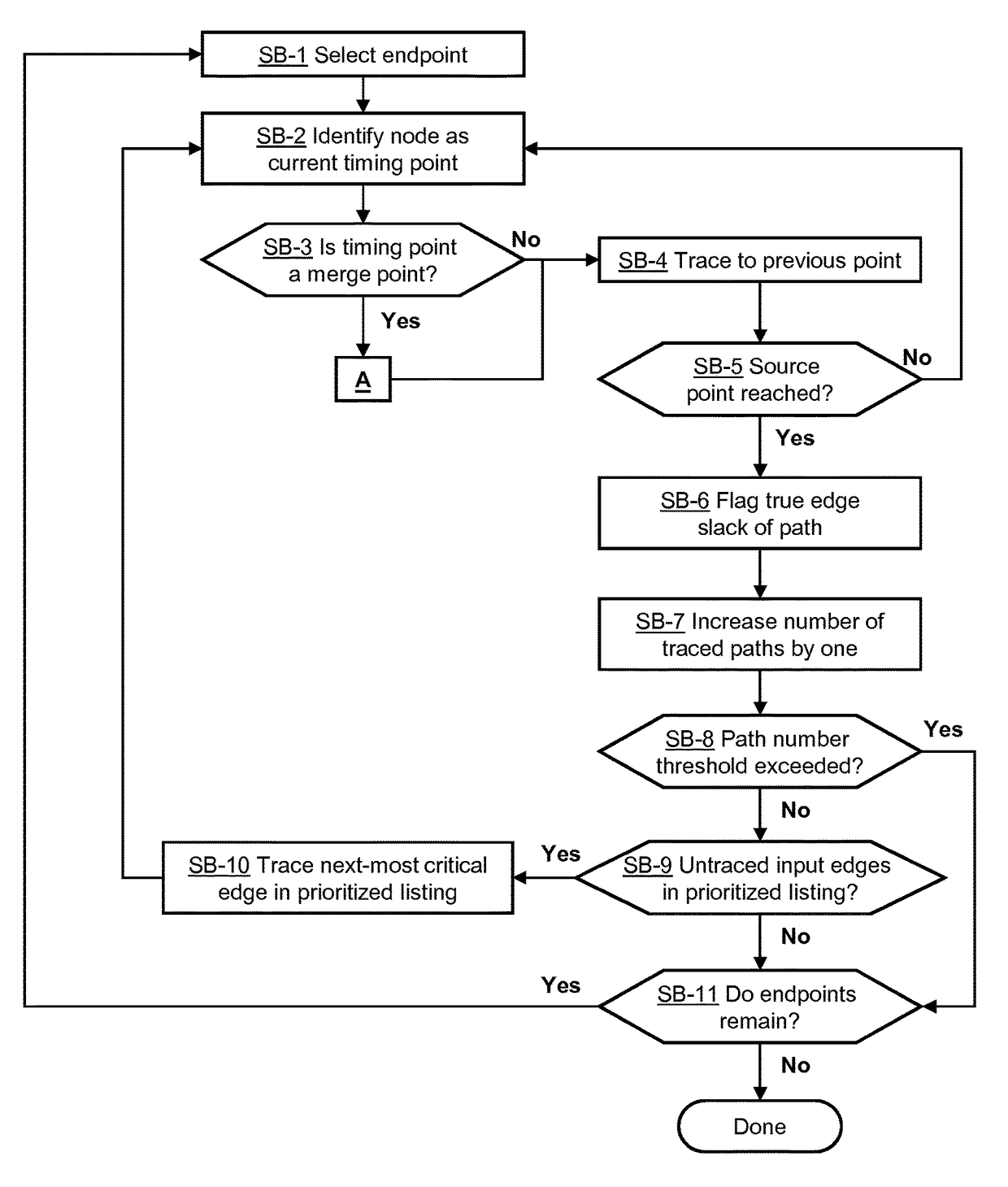

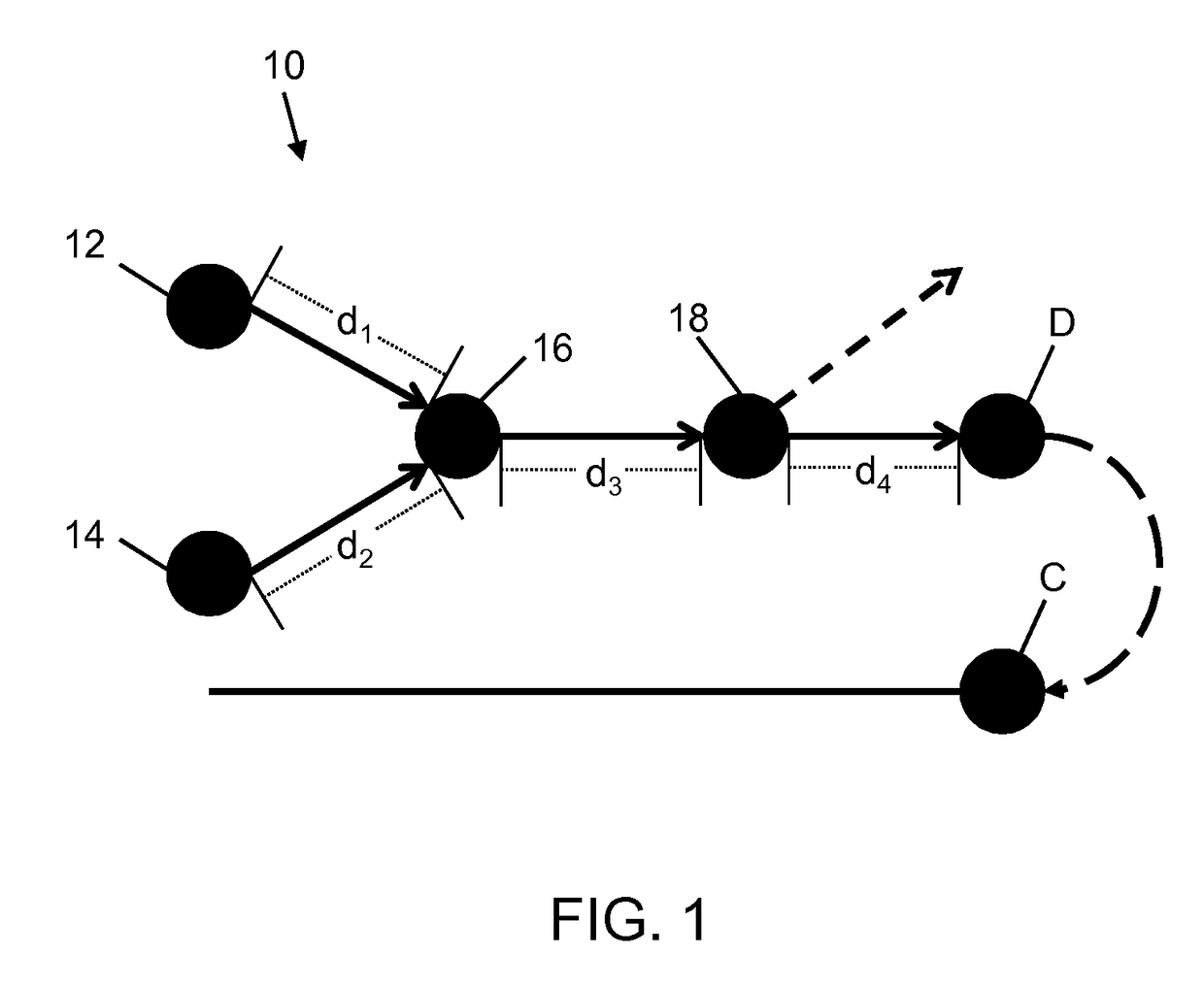

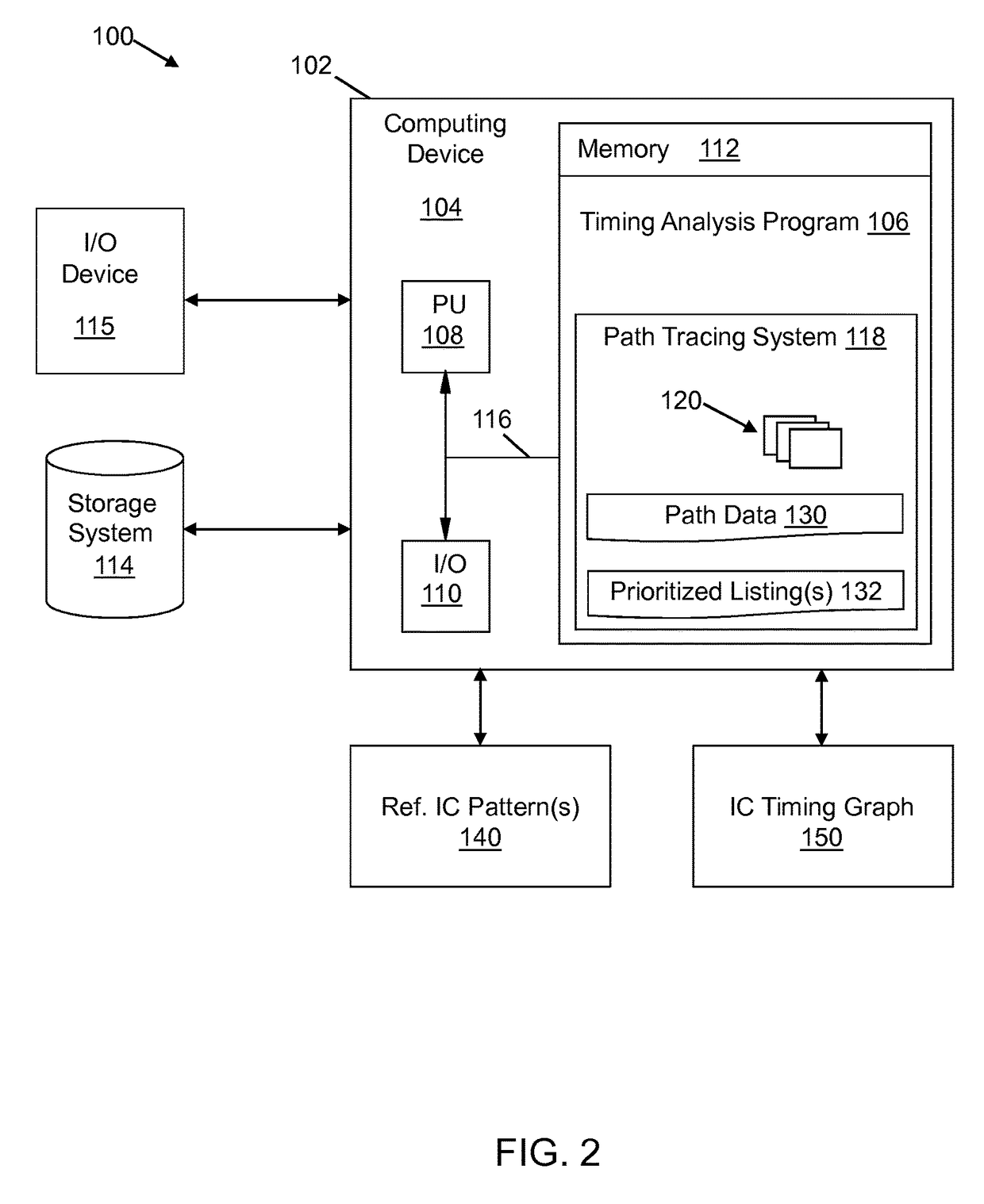

Prioritized path tracing in statistical timing analysis of integrated circuits

Methods of the present disclosure can include methods for prioritized path tracing in a statistical timing analysis of integrated circuits. Methods of the present disclosure can include: determining a required arrival time for a merge point in a statistical timing graph, the merge point having a plurality of associated input edges; calculating a plurality of edge slack distributions for each of the plurality of input edges and the required arrival time at the merge point; projecting a representative edge slack from each of the plurality of edge slack distributions; identifying a most critical input edge based on the plurality of representative edge slacks; generating a prioritized listing of input edges from lowest-value representative edge slack to highest-value representative edge slack; and tracing a next-most critical input edge of the prioritized listing, subsequent to tracing a path from the most critical edge to a source point.

Owner:IBM CORP

System and method for making photomasks

InactiveUS20090004573A1Length can be affectedSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringCritical dimension

The present application is directed a method for determining the position of photomask patterns in a mask making process. The method comprises providing one or more mask rules defining the minimum spacing between photomask patterns. The method further comprises determining the position of a first photomask pattern relative to an adjacent second photomask pattern, the first photomask pattern having a critical edge for defining a critical dimension of a first device structure and a non-critical edge for defining a non-critical dimension. The non-critical edge is attached to the critical edge so that the positioning of the non-critical edge will affect the length of the critical edge. The non-critical edge of the first photomask pattern is positioned a distance X from an edge of the second photomask pattern, wherein the distance X is chosen to be substantially the minimum spacing allowed by the mask rules. Embodiments directed to software modules for implementing the method and patterning processes employing the method are also disclosed.

Owner:TEXAS INSTR INC

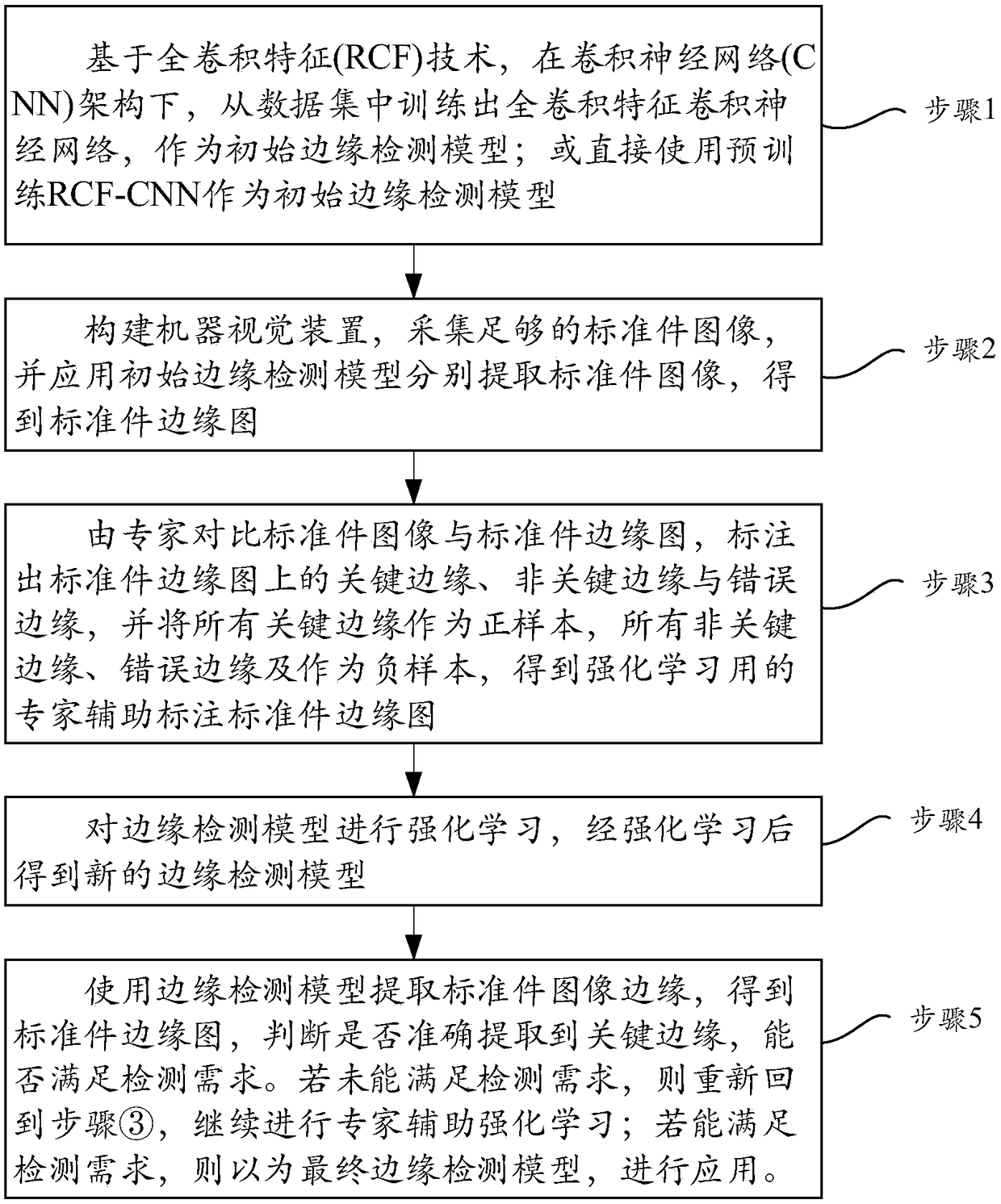

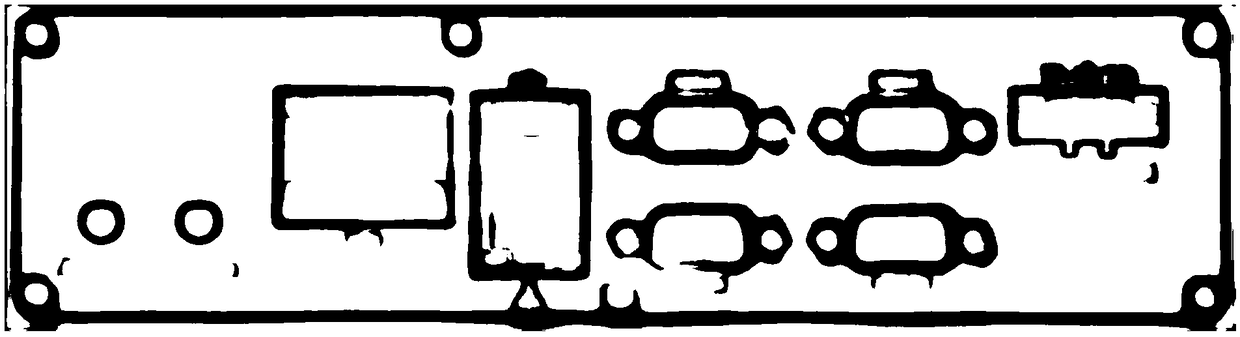

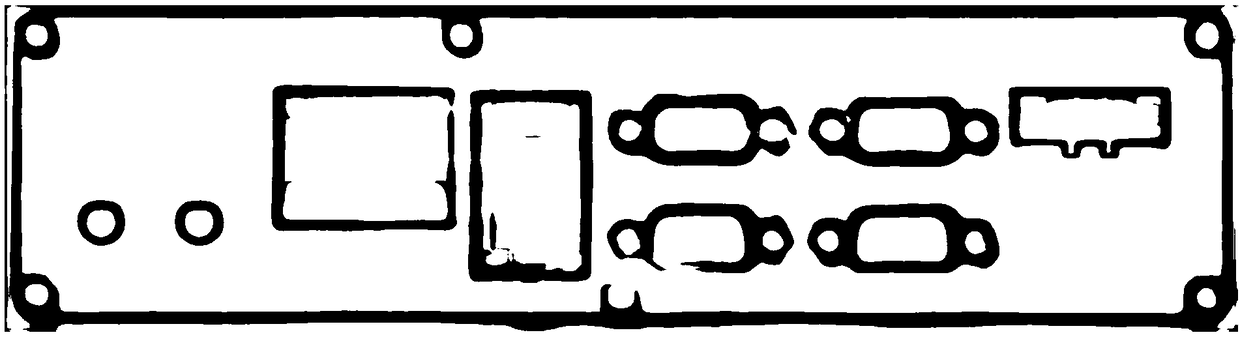

A method for edge detection of full-depth convolution feature of standard parts

A method for edge detection of full-depth convolution feature of standard parts, which includes training full convolution feature neural network, As an initial edge detection model (img file= 'DDA0001789553820000011. TIF' wi= '171' he= '95' / ), I2, I3... In... IN, where n is [1, N], n is Z, The images of standard parts were extracted from the original edge detection model (img file = 'DDA0001789553820000012. TIF' wi= '139' he= '88' / ), The standard part edge map (img file= 'DDA0001789553820000013. TIF' wi= '683' he= '91' / ) is obtained to compare the standard part image In with the standard partedge map (img file= 'DDA00017895 53820000014. TIF 'wi=' 125 'he=' 89 ' / ) Key points on standard part edge plot (img file=' DDA0001789553820000015. TIF 'wi=' 99 'he=' 89 ' / ) Edge (img file= 'DDA0001789553820000016. TIF' wi= '150' he= '96' / ) Non-critical edge (img file= 'DDA0001789553820000017. TIF' wi= '128' he= '93' / ) with the wrong edge (img file= 'DDA0001789553820000018. TIF' wi= '147' he= '94' / ) and set the critical edge (img file= 'DDA0001 789553820000019. TIF 'wi=' 115 'he=' 93 ' / ) as a positive sample, Non-critical edges (img file= 'DDA00017895538200000110. TIF' wi= '133' he= '88' / ) andincorrect edges (img file= 'DDA00017895538200000111. TIF 'wi=' 118 'he=' 88 ' / ) as a negative sample, Expert-aided edge map (img file = 'DDA00017895538200000112. TIF' wi= '700' he= '60' / ) is obtainedto reinforce the initial edge detection model. The new edge detection model (img file= 'DDA00017895538200000113. TIF' wi= '163' he= '97' / ) was obtained using the edge detection model (img file= 'DDA0001789553820 0000114. TIF 'wi=' 139 'he=' 97 ' / ) extract image edges of standard part, Obtain the standard part edge map (img file= 'DDA00017895538200000115. TIF' wi= '657' he= '88' / ) and judge whetherthe key edge is accurately extracted (img file= 'DDA000178955 38200000116. Re-execute Step C if TIF 'wi=' 700 'he=' 80 ' / ) and the extracted key edges can meet the requirements, if the requirements cannot be met; To meet the detection requirements, the (img file = 'DDA00017895538200000117. TIF' wi= '138' he= '98' / ) is used as the final edge detection model MEdge.

Owner:SOUTH CHINA UNIV OF TECH

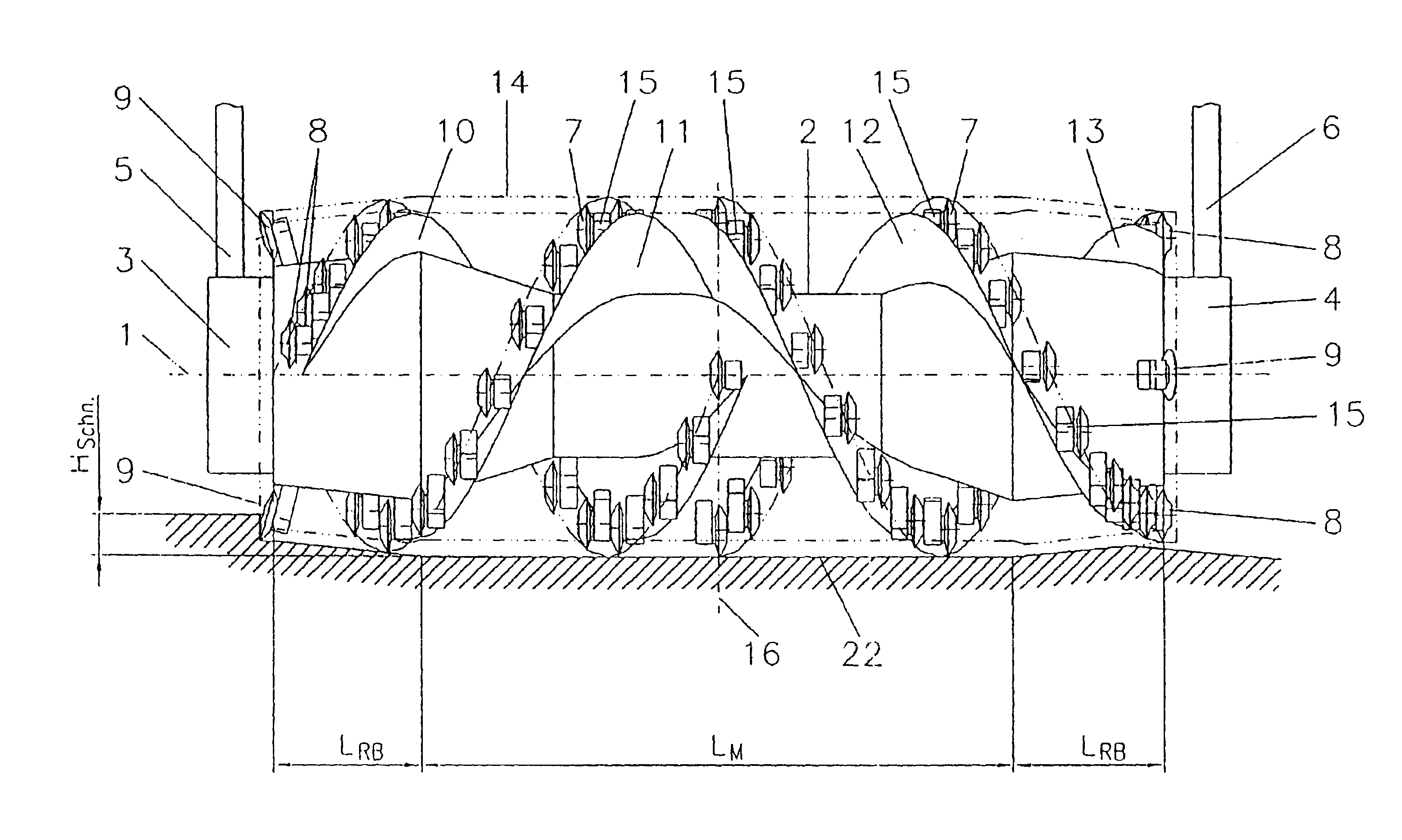

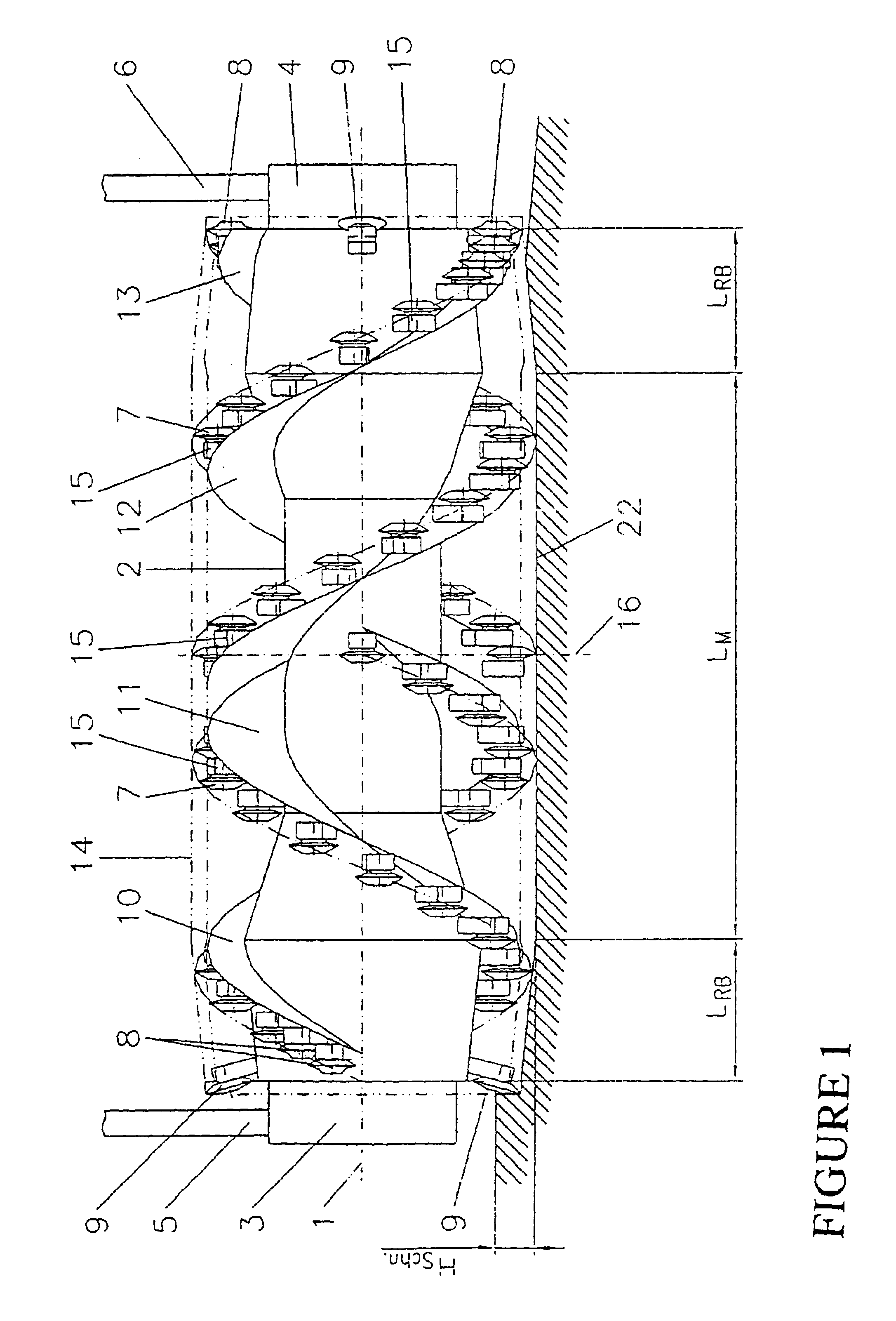

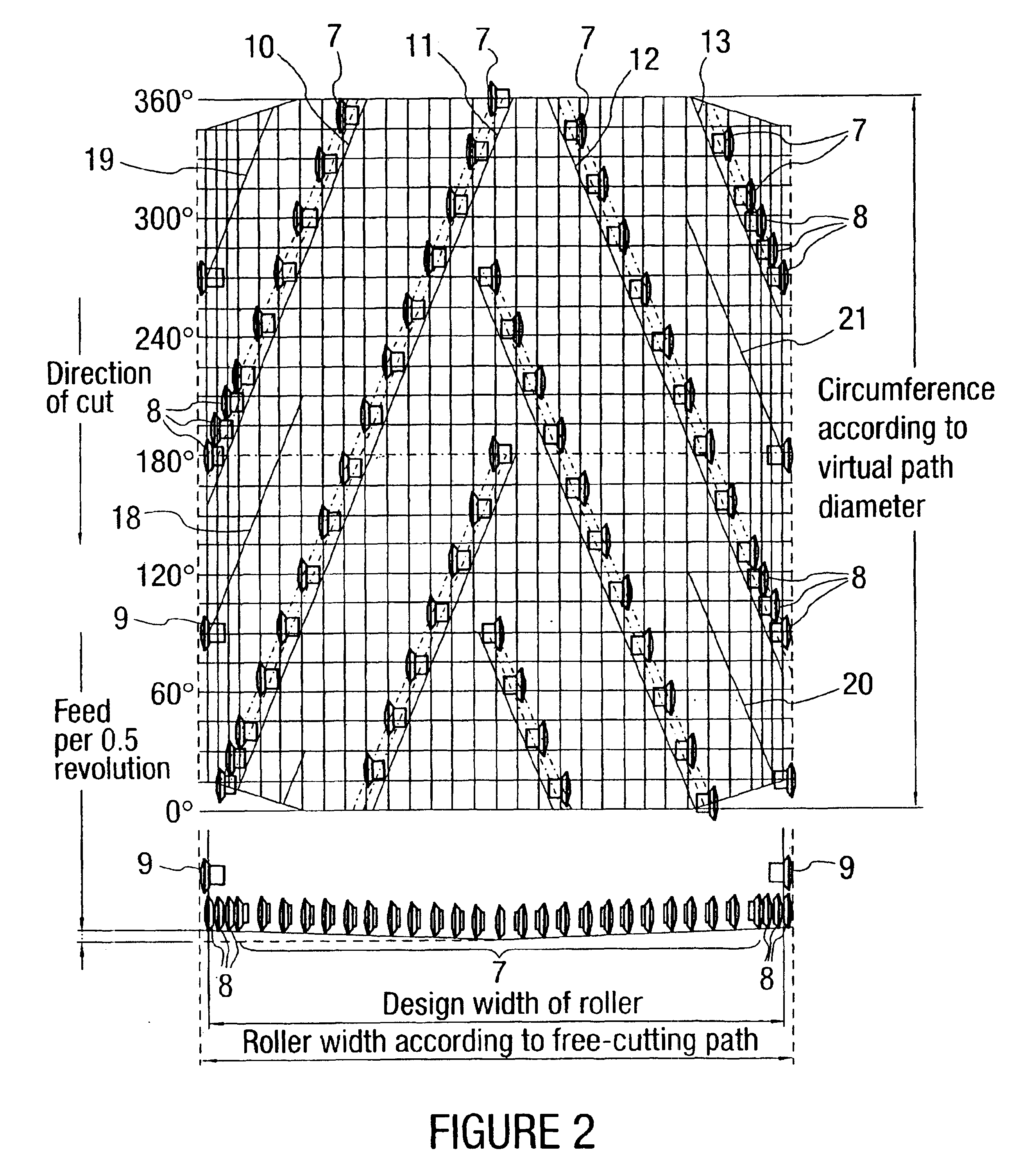

Cutting roller for a continuously operating surface miner

InactiveUS6948779B2Cleanly clearHigh strengthMechanical machines/dredgersOpen-pit miningCircular discHigh intensity

A mining member designed as a cutting roller for a continuously operating surface miner for mining mineral raw materials of high strength. The roller body is equipped for this purpose with mini-disk bits of identical design. Since different conditions occur over the entire width of the roller during the separation of the material from the soil, the roller body is designed correspondingly, and the arrangement of the mini-disk bits is adapted to these conditions. The mini-disk bits in the edge areas are placed at a greater density than are the mini-disk bits (7) in the middle area. In addition, mini-disk bits are directed obliquely toward the outside as free-cutting bits at the two outer edges of the cutting roller. The height of the mini-disk bits is selected to be such that their individual virtual rolling paths together form a virtual cutting roller body, which comprises a middle cylinder, which is joined on both sides by outwardly tapering frusta. This solution is associated with the advantages that more mini-disk bits are available per unit area in the critical edge areas for separating the material and for cutting the roller free, and the cutting height HSchn is smaller there.

Owner:MAN TAKRAF FORDERTECHN

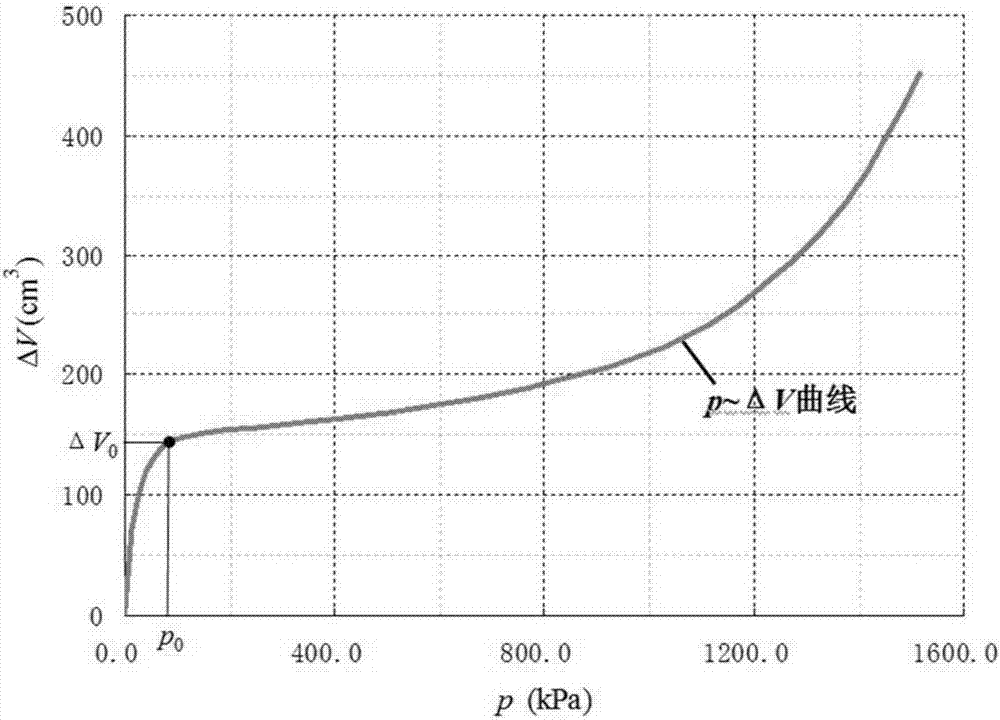

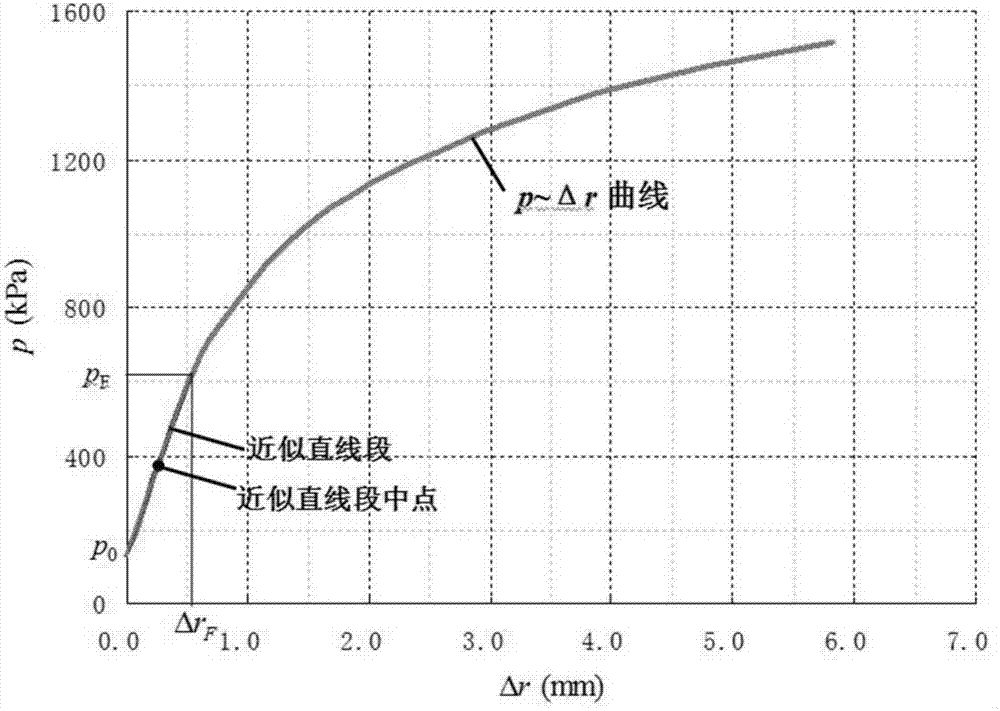

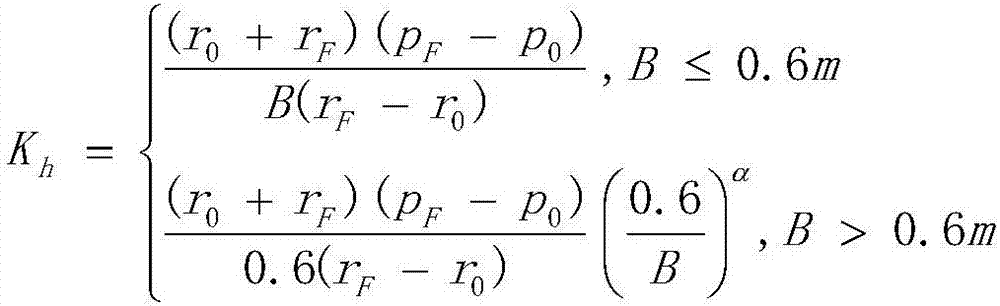

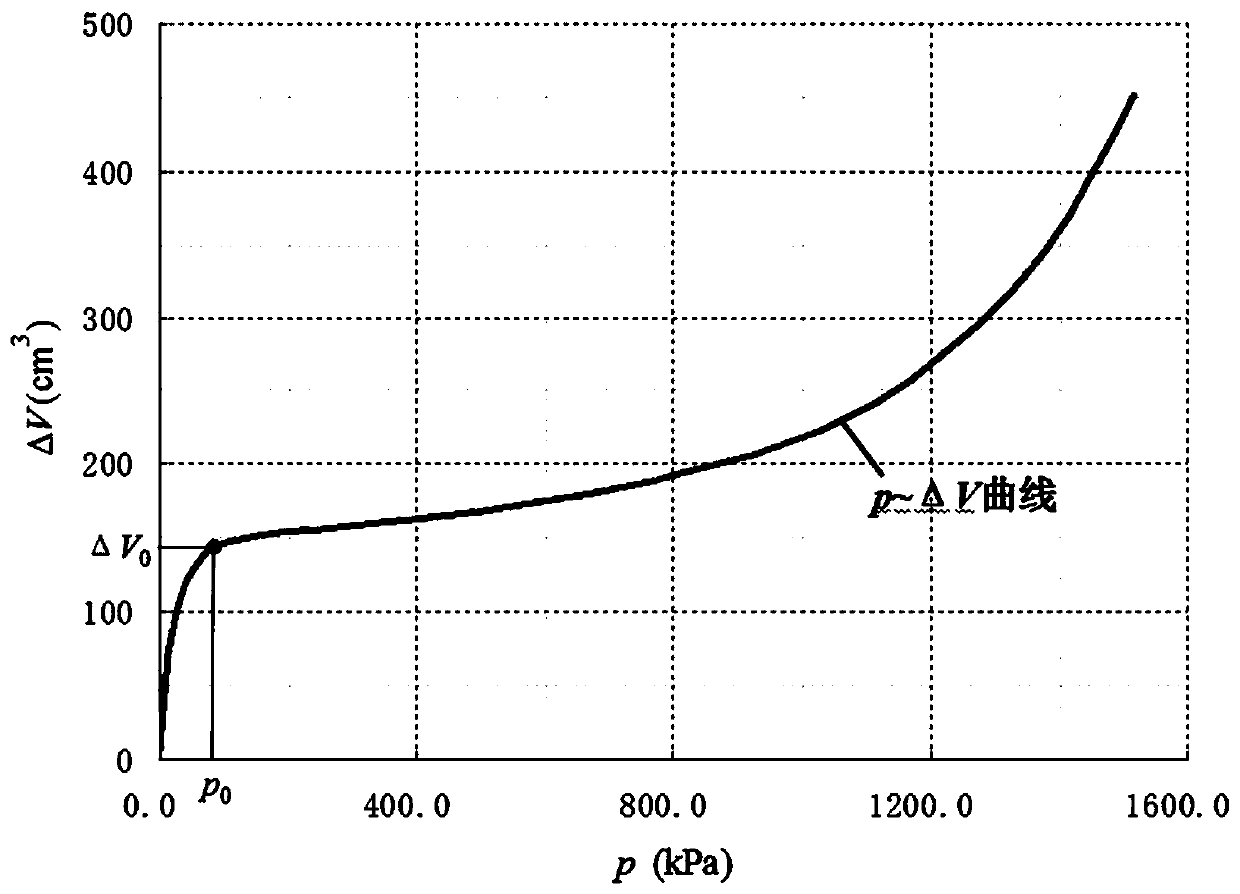

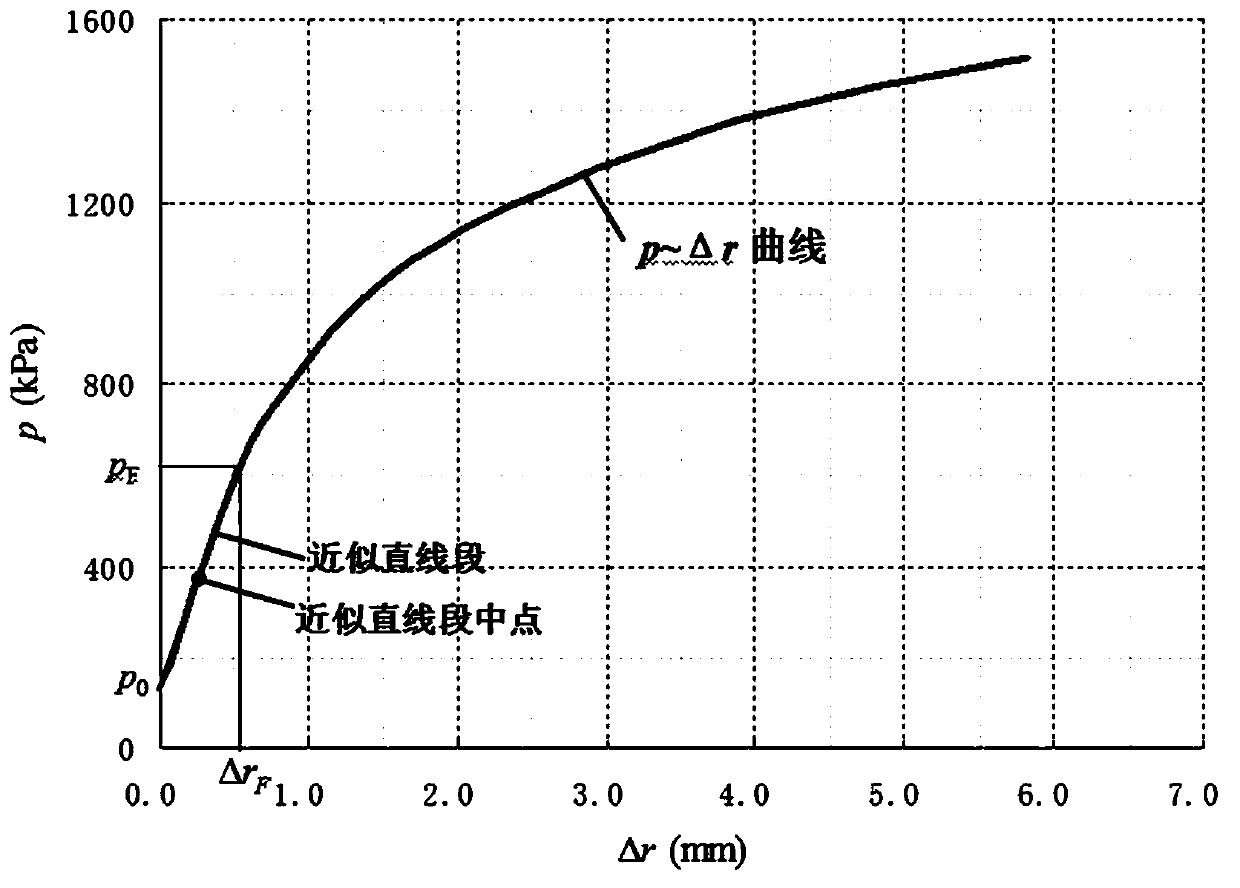

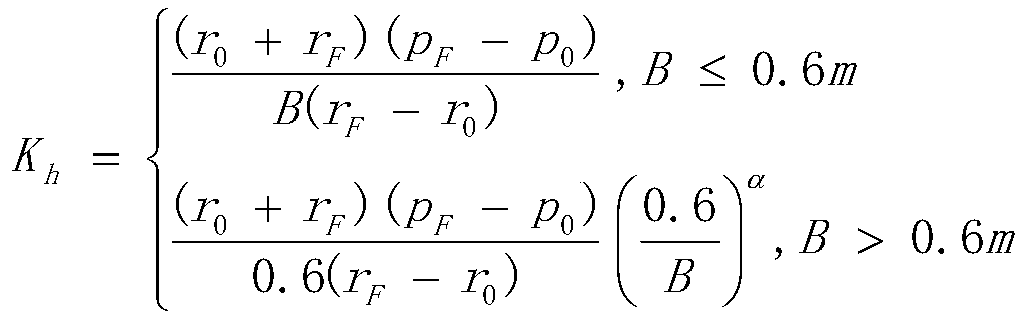

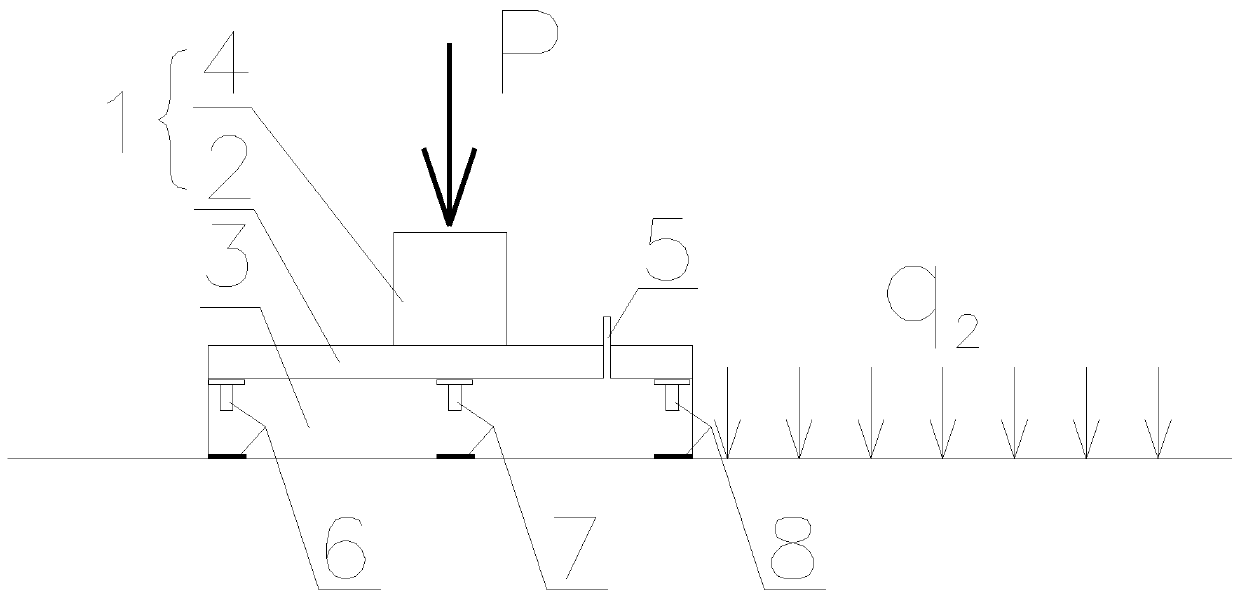

Method for determining pressuremeter test horizontal bedding coefficient

ActiveCN107016204AEnsure safetyHigh precisionGeometric CADDesign optimisation/simulationRadial displacementDrill hole

The invention relates to the technical field of geotechnical engineering investigation, in particular to a method for determining a pressuremeter test horizontal bedding coefficient. The method comprises the steps of drilling holes in a test site, arranging special mud protection walls for the drilled holes, measuring the relation of pressure and pressuremeter sizes, obtaining a p - delta r curve through conversion, then according to the p - delta r curve, obtaining initial pressure p0, critical edge pressure pF and respective corresponding pressuremeter radial displacements r0 and rF, and according to the parameters, calculating the horizontal bedding coefficient of the soil body. The whole test method is simple and fast, the difficulty for determining the horizontal bedding coefficient through a pressuremeter test can be drastically lowered, the precision of the horizontal bedding coefficient test is improved, and the method is beneficial to large-scale application and promotion.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

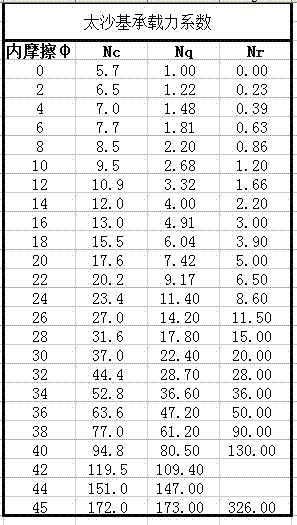

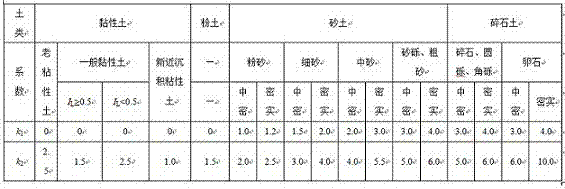

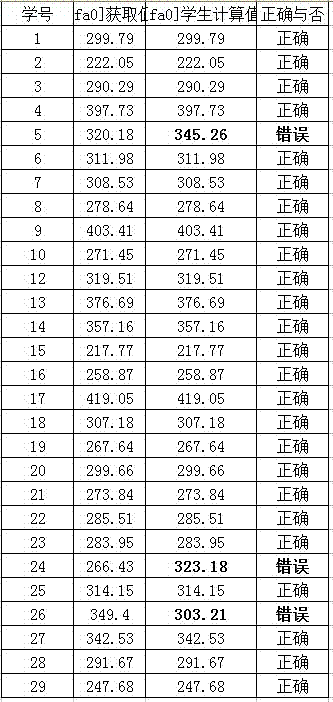

Verification method for foundation bearing capacity determination

InactiveCN106930335AOvercome the disadvantage of only being able to verify a single dataReduce labor intensityFoundation testingOriginal dataCritical load

The invention discloses a verification method for foundation bearing capacity determination. The verification method comprises the following steps that firstly, an original data worksheet is built, and original data are input in the worksheet; secondly, a calculation sheet workbook is built, specifically, the calculation workbook comprises a basic data setting area, a critical edge load calculation area, a critical load calculation area and a data comparison area, the areas are endowed with the corresponding positions, a calculation program of the critical edge load, namely, pcr, p1 / 3, p1 / 4 and Pu of Terzaghi is written, values are assigned to the areas of the calculation sheet workbook, the obtained data are compared, and a reasonable value is selected to obtain a final calculation result; thirdly, a set of original data is selected to conduct test-calculation, whether a program formula is accurate or not is checked; fourthly, an input area sheet is written and verified and makes one to one correspondence with corresponding table cells of a calculation sheet; and fifthly, a macroprogram is written and loaded, big data input and verified result presentation are achieved, and the result is presented in an operation result area. The defect that in former soil mechanics foundation bearing capacity synthesis training, teachers need to verify the accuracy of data calculated by students one by one is overcome, one-step type verification of the data of classes and even a whole major is achieved, read-over difficulty is reduced, and the working efficiency is improved.

Owner:LIAONING TECHNICAL UNIVERSITY

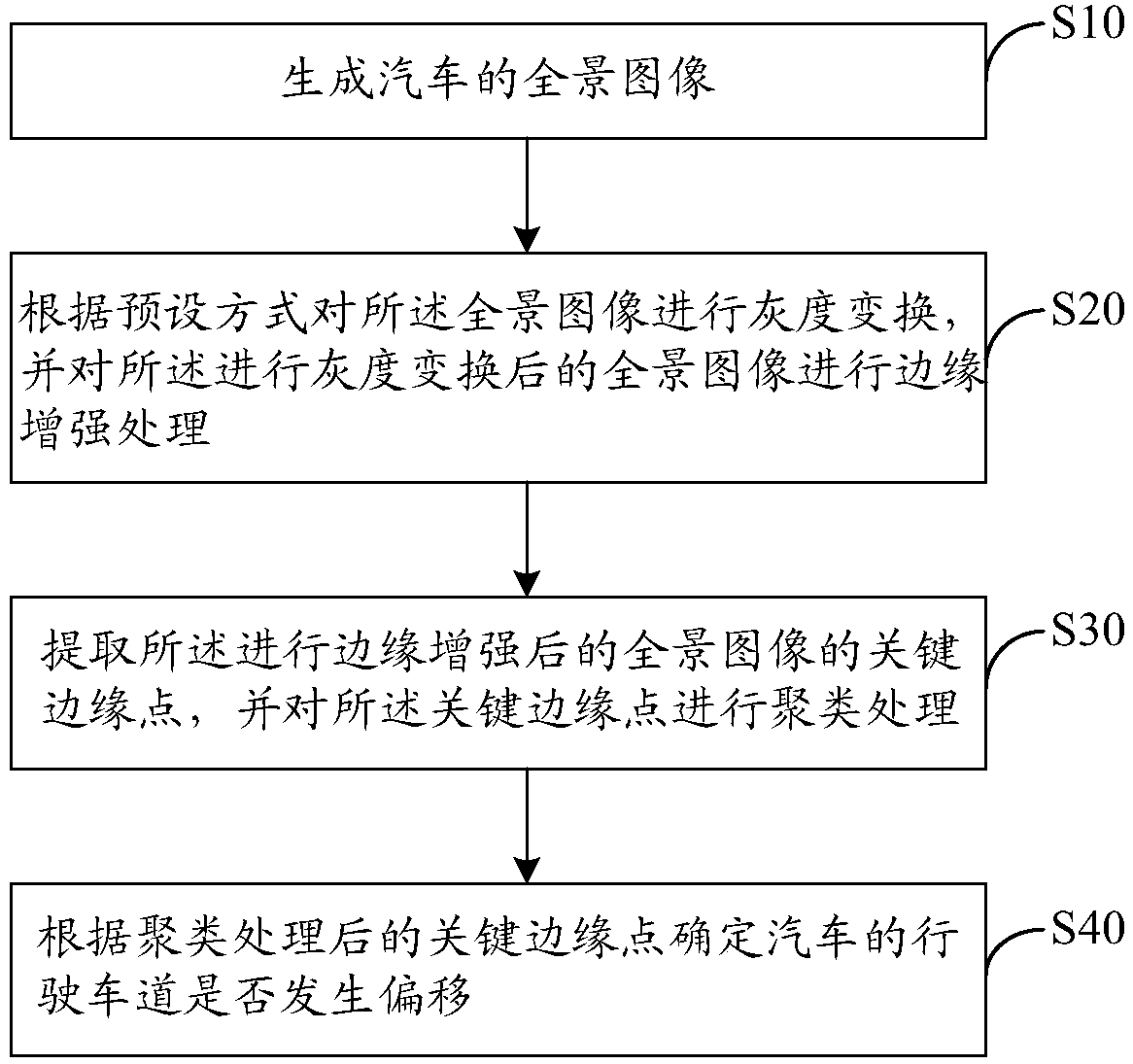

Lane offset determination method and automobile

InactiveCN108256470AImprove the accuracy of offset detectionHighly integratedImage enhancementImage analysisComputer visionEdge enhancement

The invention belongs to the automobile field and provides a lane offset determination method and an automobile. According to the method, firstly, a panorama image of an automobile is generated, secondly, grey transformation of the panorama image is carried out in a preset mode, edge enhancement processing of the panorama image after grey transformation is carried out, key edge points of the panorama image after edge enhancement are extracted, clustering processing on the key edge points is carried out, and whether a driving lane of the automobile is offset is determined according to the key edge points after clustering processing. The method is advantaged in that on the basis of a panorama system, lane offset detection is carried out in the panorama mode, lane offset detection accuracy isimproved, and a purpose of improvement of the integration degree of the ADAS technology is realized.

Owner:鹰驾科技(深圳)有限公司

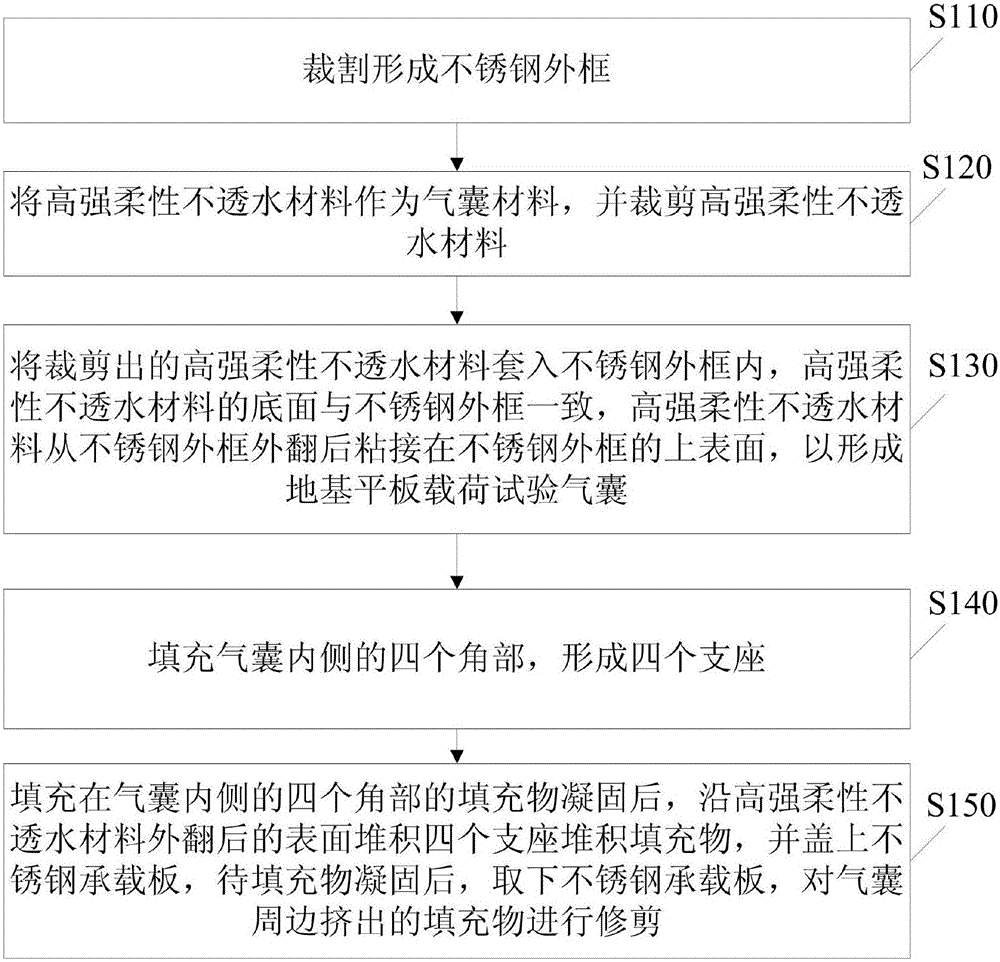

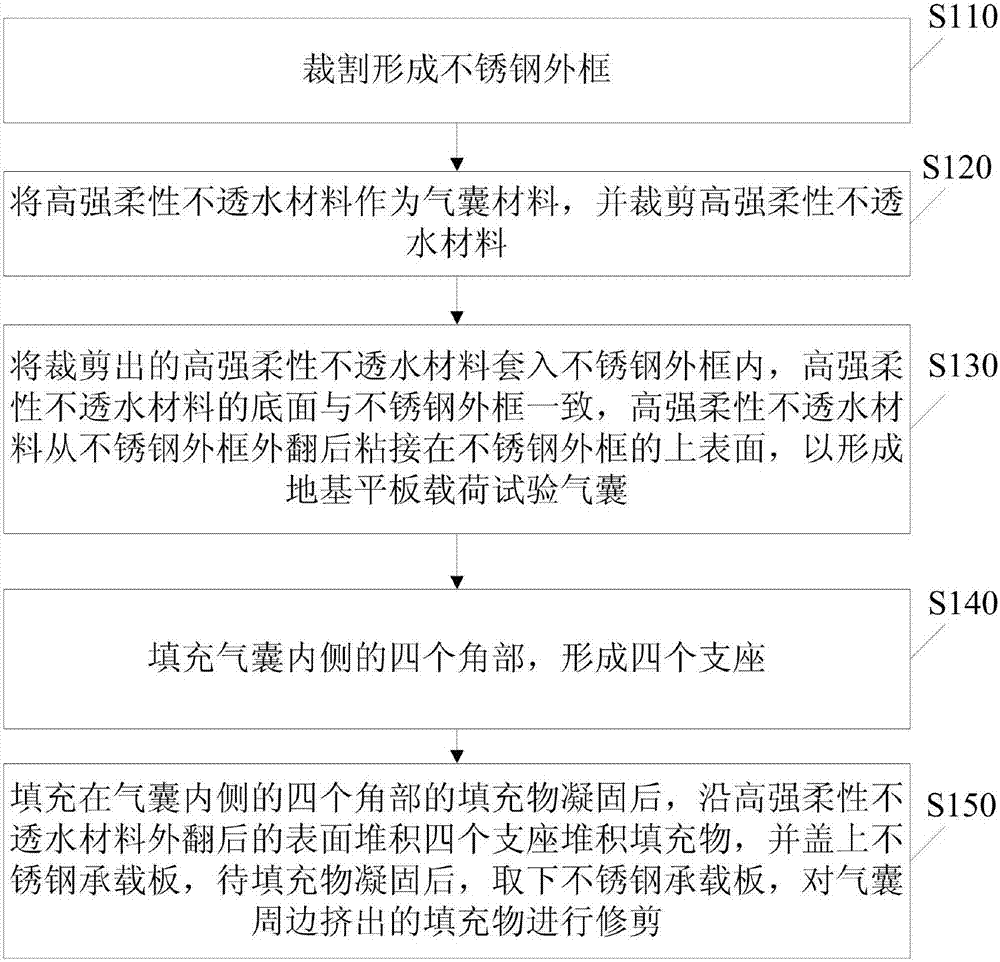

Method for manufacturing airbag for plate loading test of foundation

ActiveCN105714754AEasy to assemble and disassembleEvenly distributedIn situ soil foundationMetallurgyDeformation modulus

The invention provides a method for manufacturing an airbag for plate loading test of a foundation. The method comprises the following steps: cutting to form a stainless steel outer frame; taking a high-strength flexible impervious material as an airbag material, and cutting the material; sleeving the cut high-strength flexible impervious material by the stainless steel outer frame, enabling the bottom surface of the high-strength flexible impervious material to be consistent with the stainless steel outer frame, and after outwardly turning the high-strength flexible impervious material from the stainless steel outer frame, bonding the high-strength flexible impervious material onto the upper surface of the stainless steel outer frame to form the airbag; filling four corners on the inner side of the air bag to form four supports; and after solidification of a filler filling the four corners on the inner side of the airbag, stacking filler on the surface (four peripheries) of the outwardly turned high-strength flexible impervious material and on the four supports, covering with a stainless steel bearing plate, taking down the stainless steel bearing plate after solidification of the filler, and trimming the filler extruded out of the periphery of the airbag. The method can solve the problem that the critical edge pressure and the deformation modulus of the foundation, which are tested by plate loading test of the foundation, have big errors.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Photomask

InactiveCN1854893ASemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusImage contrastEngineering

Photolithographic methods for semiconductor manufacturing are provided wherein photomask structures are designed to provide increased lithographic process windows for printing sub-wavelength features. In one aspect, a photomask includes a mask substrate transparent to exposure light of a given wavelength, and a mask pattern formed on a surface of the substrate. The mask pattern comprises a printable element defined by a first and second critical edge, wherein the printable element includes an inner, non-printing feature formed between the first and second critical edges. The inner, non-printing feature is adapted to enhance image contrast at the first and second critical edges of the printable element for the given wavelength of exposure light during a photolithographic process. The non-printing feature comprises a space feature that exposes a region of the mask substrate aligned to the printable element between the first and second critical edges, and a trench feature that is formed in the mask substrate and aligned to the space feature.

Owner:SAMSUNG ELECTRONICS CO LTD

System and method for making photomasks

ActiveUS7818711B2Originals for photomechanical treatmentSpecial data processing applicationsEngineeringCritical dimension

The present application is directed a method for determining the position of photomask patterns in a mask making process. The method comprises providing one or more mask rules defining the minimum spacing between photomask patterns. The method further comprises determining the position of a first photomask pattern relative to an adjacent second photomask pattern, the first photomask pattern having a critical edge for defining a critical dimension of a first device structure and a non-critical edge for defining a non-critical dimension. The non-critical edge is attached to the critical edge so that the positioning of the non-critical edge will affect the length of the critical edge. The non-critical edge of the first photomask pattern is positioned a distance X from an edge of the second photomask pattern, wherein the distance X is chosen to be substantially the minimum spacing allowed by the mask rules. Embodiments directed to software modules for implementing the method and patterning processes employing the method are also disclosed.

Owner:TEXAS INSTR INC

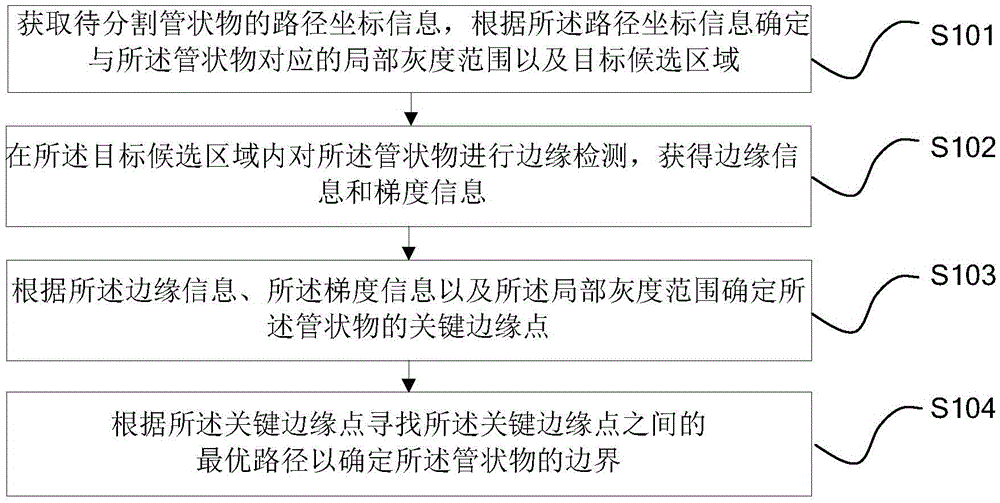

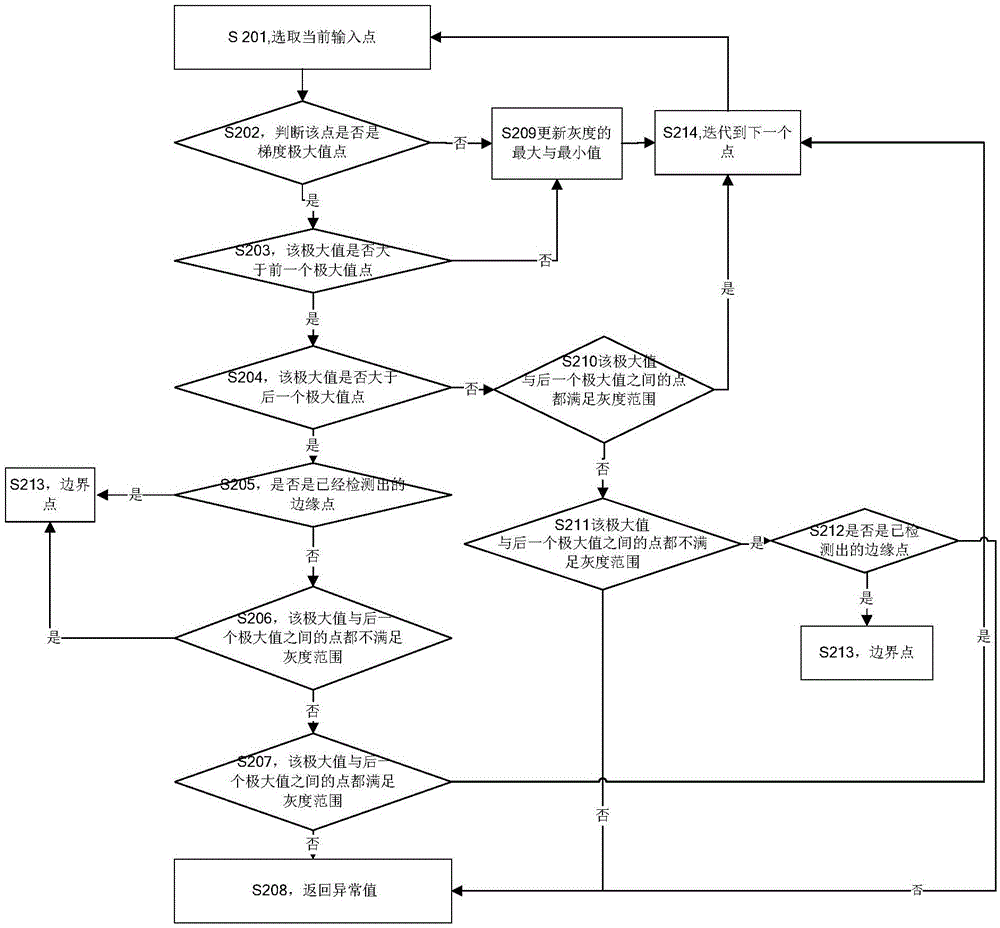

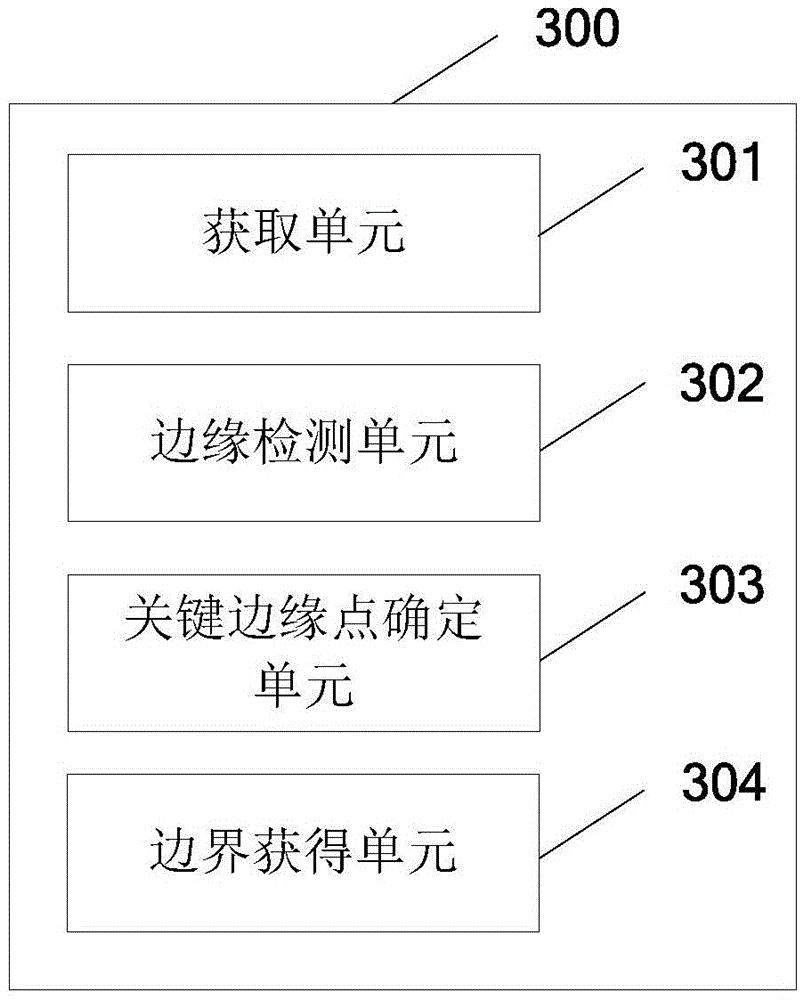

Tubular object segmentation method, device and equipment

ActiveCN105631869AImprove accuracyThe extraction result is accurateImage enhancementImage analysisComputer visionComputer science

The embodiment of the invention provides a tubular object segmentation method, device and equipment. The method comprises the steps that path coordinate information of a tubular object to be segmented is acquired, and local grayscale range and a target candidate area corresponding to the tubular object are determined according to the path coordinate information; edge detection is performed on the tubular object in the target candidate area so that edge information and gradient information are acquired; the key edge points of the tubular object are determined according to the edge information, the gradient information and the local grayscale range; and an optimal path between the key edge points is searched according to the key edge points so as to determine the border of the tubular object. Segmentation accuracy of the tubular object can be effectively enhanced by the tubular object segmentation method, device and equipment.

Owner:NEUSOFT CORP

Reduced mask count gate conductor definition

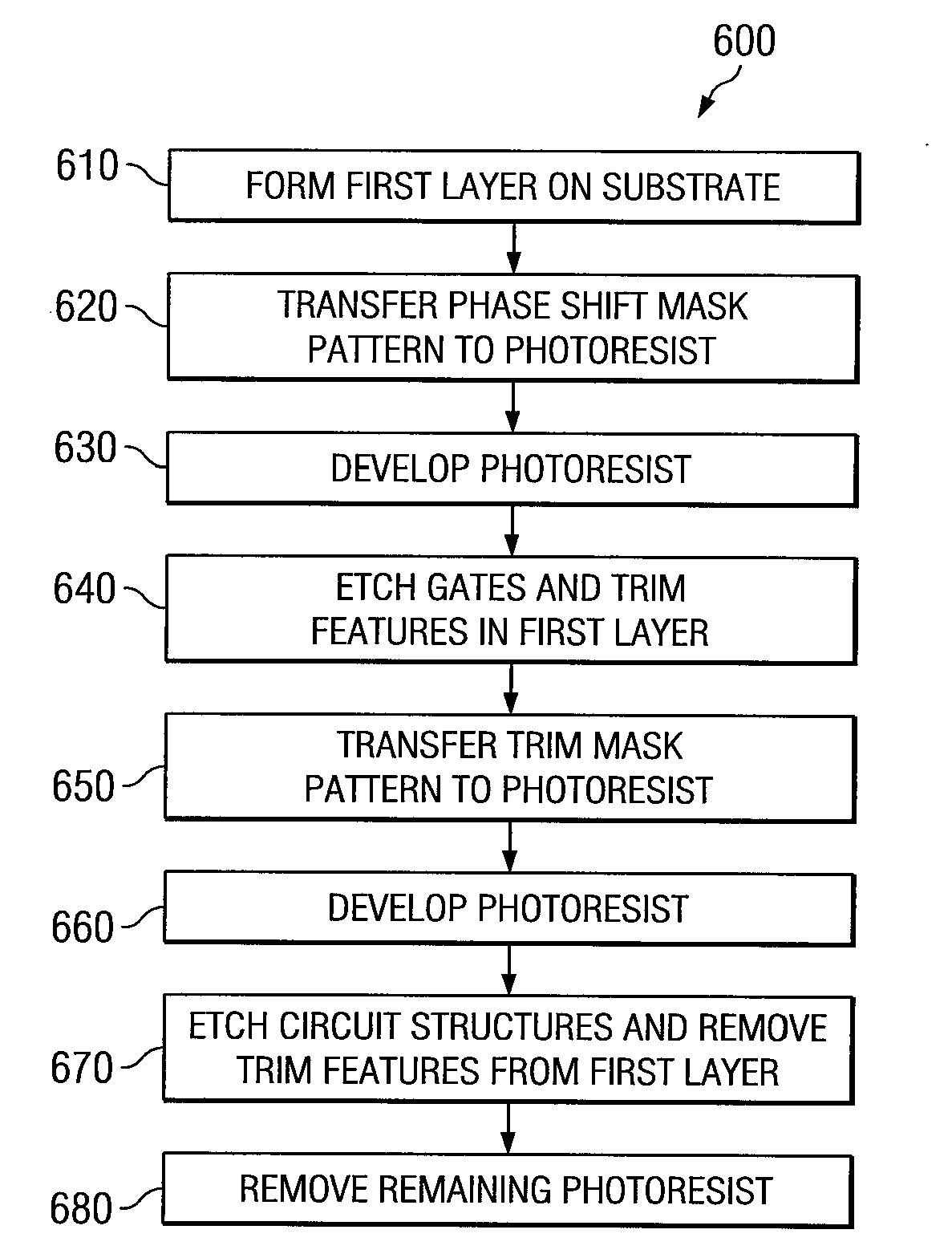

InactiveUS7771604B2Vacuum gauge using ionisation effectsDecorative surface effectsElectrical conductorEngineering

Owner:GLOBALFOUNDRIES INC

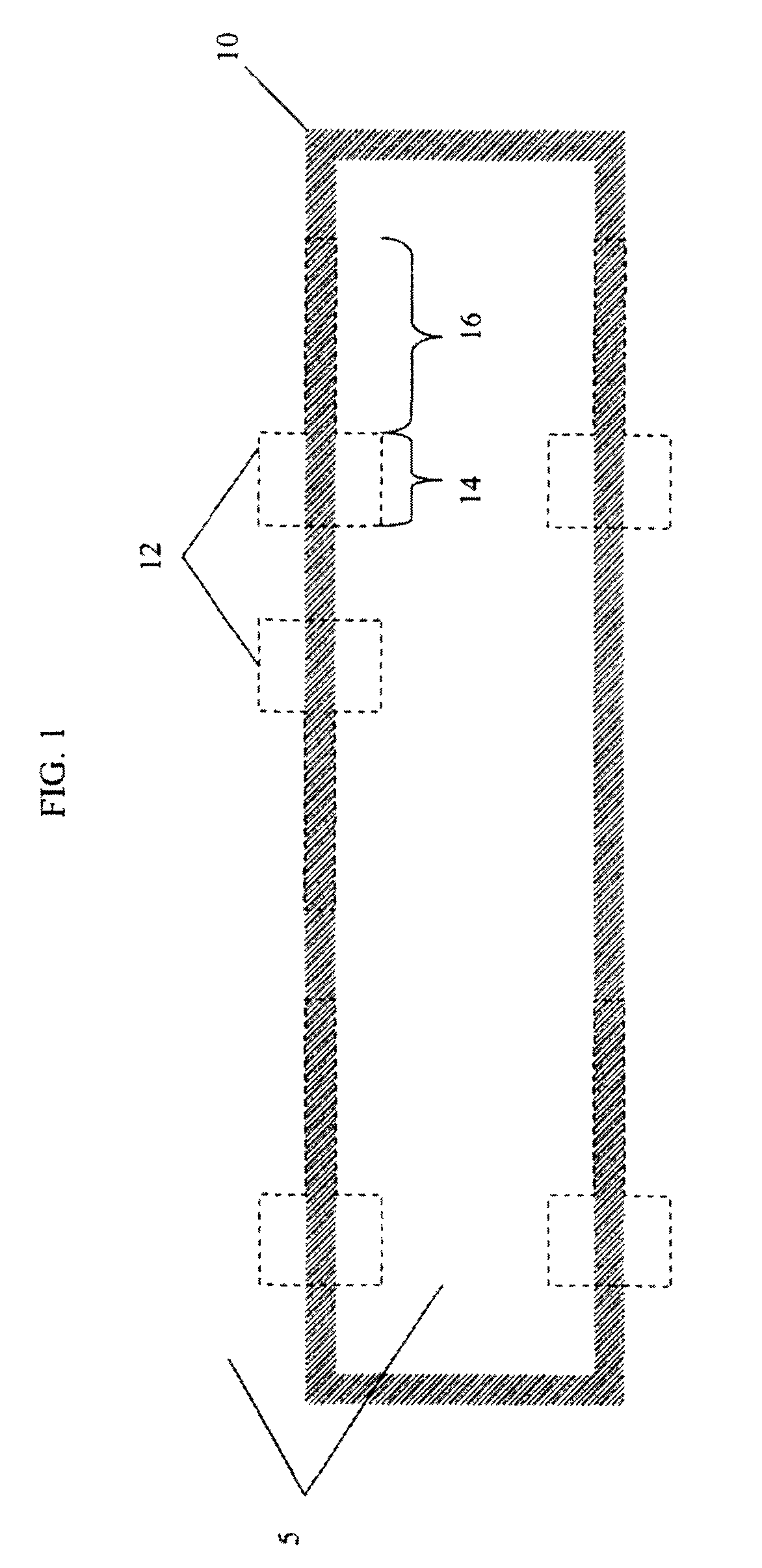

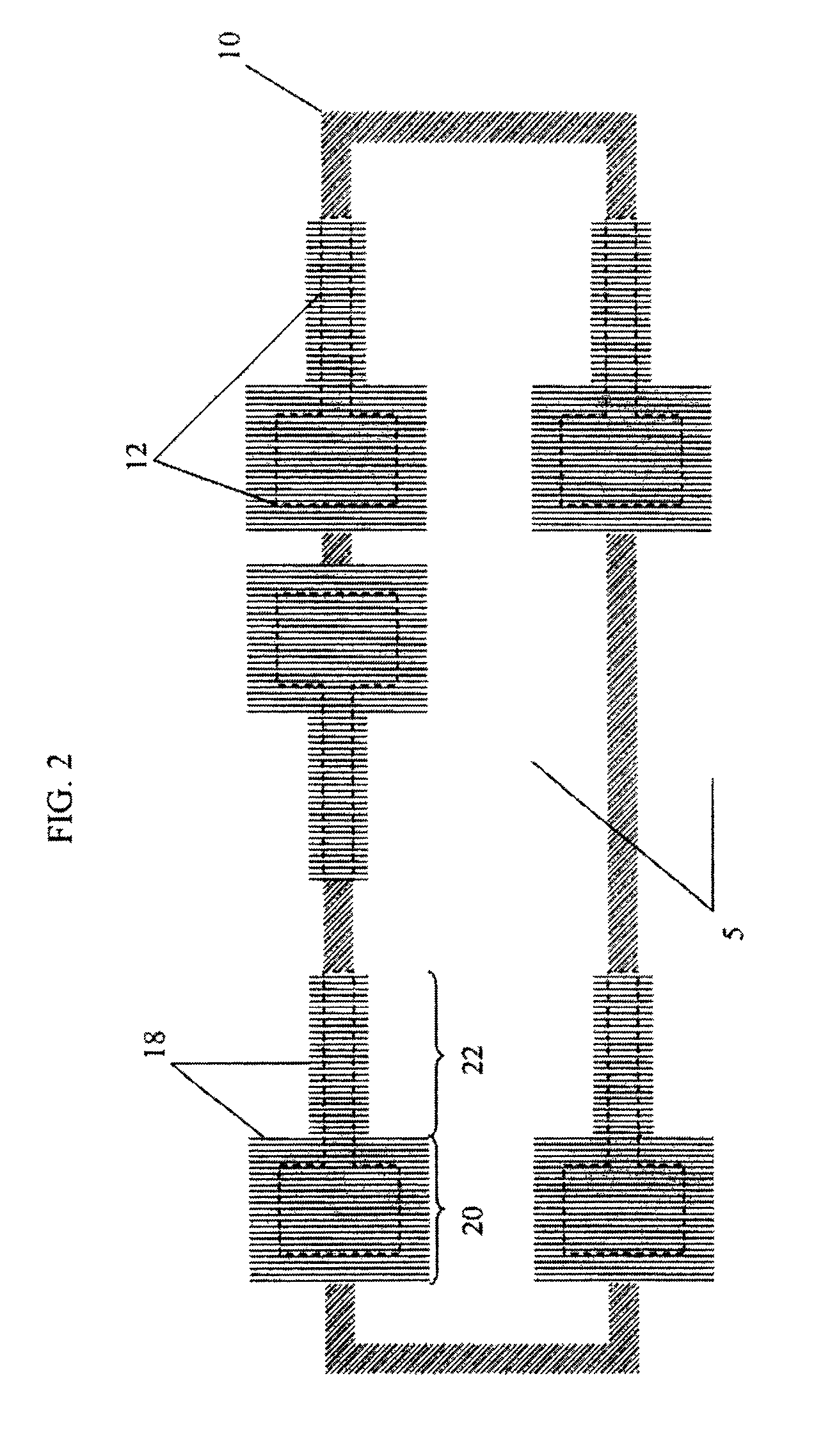

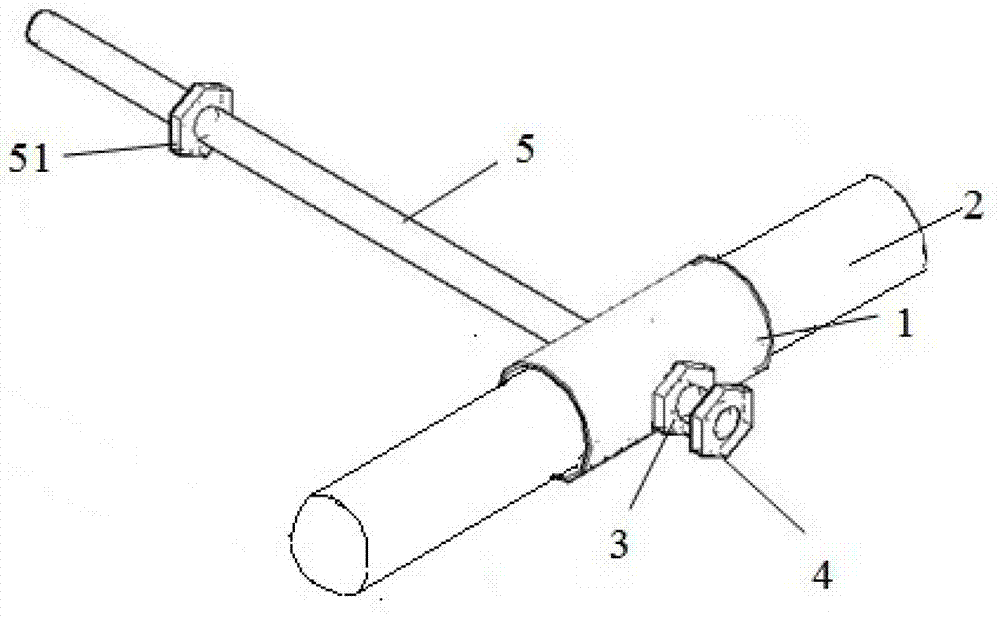

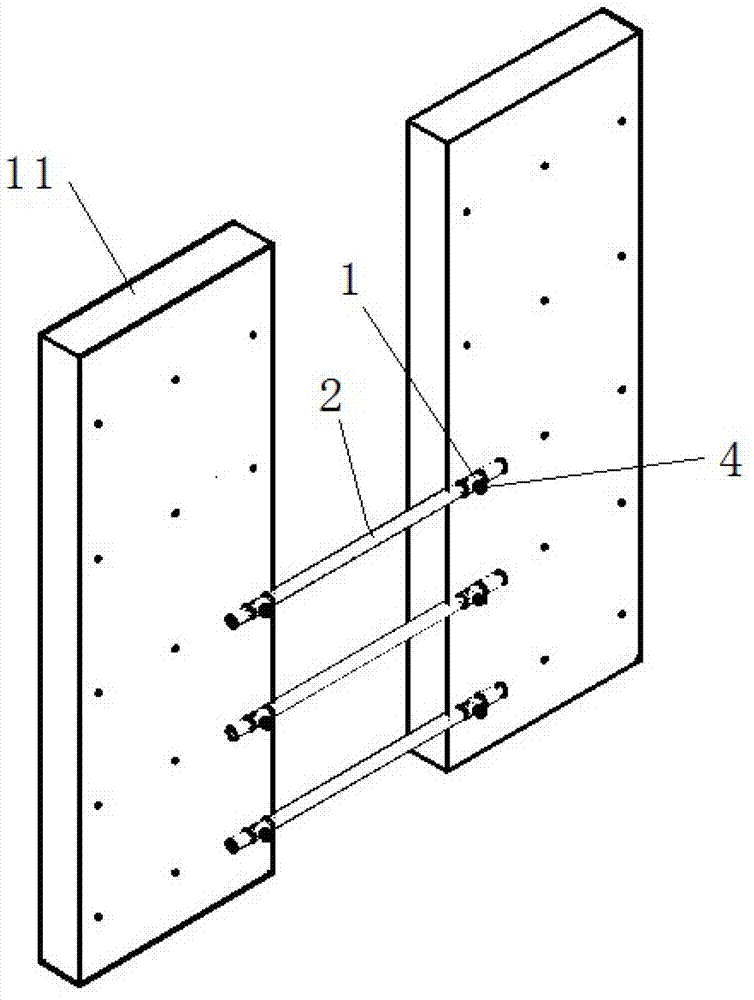

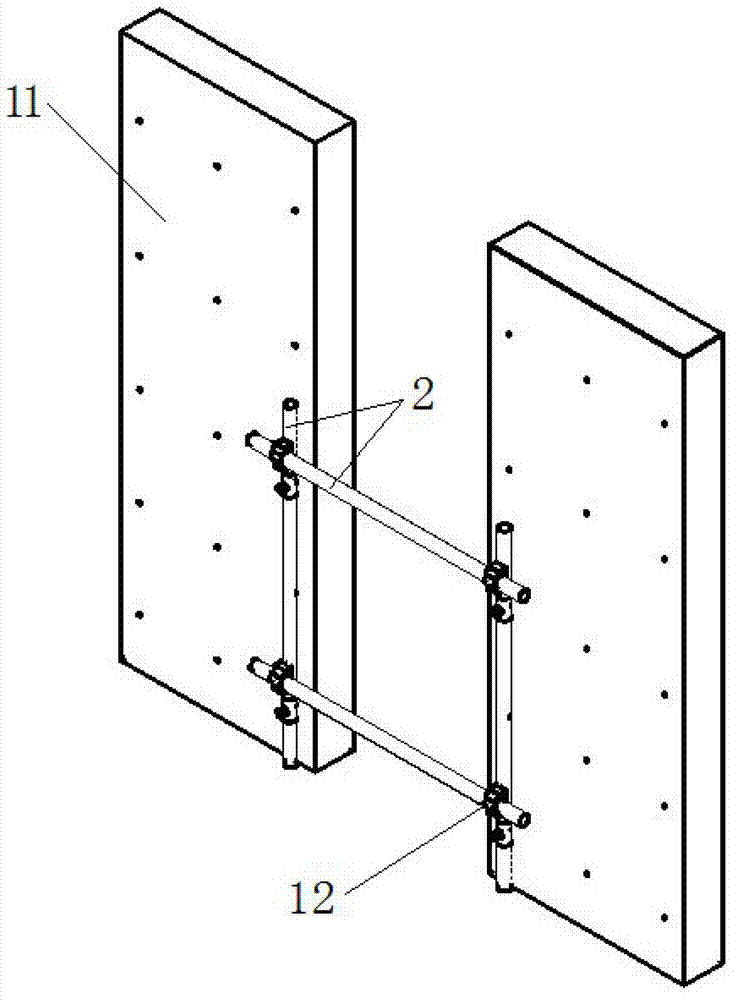

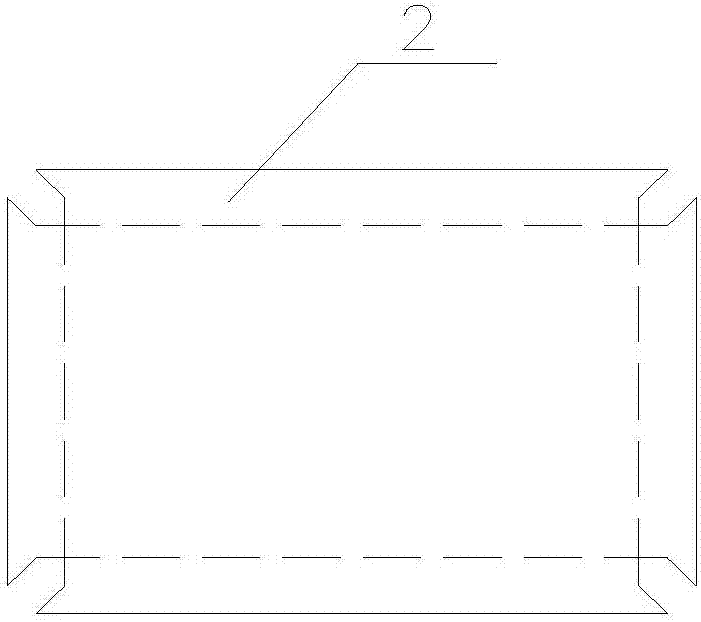

Critical edge and cave entrance protective device and fixing method of the same

InactiveCN103161321ASimple structureEasy to fixBuilding material handlingLocking mechanismArchitectural engineering

The invention discloses a critical edge and cave entrance protective device and a fixing method of the critical edge and cave entrance protective device. The critical edge and cave entrance protective device and the fixing method of the critical edge and cave entrance protective device comprise a steel pipe body. A protective steel pipe penetrates through the steel pipe body. A locking mechanism used for fixing the protective steel pipe is placed on one side of the middle of the steel pipe body, and comprises a fixing nut welded on the steel pipe body. A threaded hole of the fixing nut is communicated with a pipe hole of the steel pipe body. A locking bolt with a nut is placed in the threaded hole of the fixing nut. A screw is welded, relative to the other end of the locking mechanism, on the steel pipe body. The screw is placed perpendicular to the steel pipe body. A locking nut is placed at the end, away from the steel pipe body, of the screw. When in construction, the screw is inserted in a screw hole of a shear wall, and is locked by the locking nut. The critical edge and cave entrance protective device is simple in structure, convenient to fix, capable of being repeatedly used and low in cost.

Owner:ZHONGTIAN CONSTR GROUP

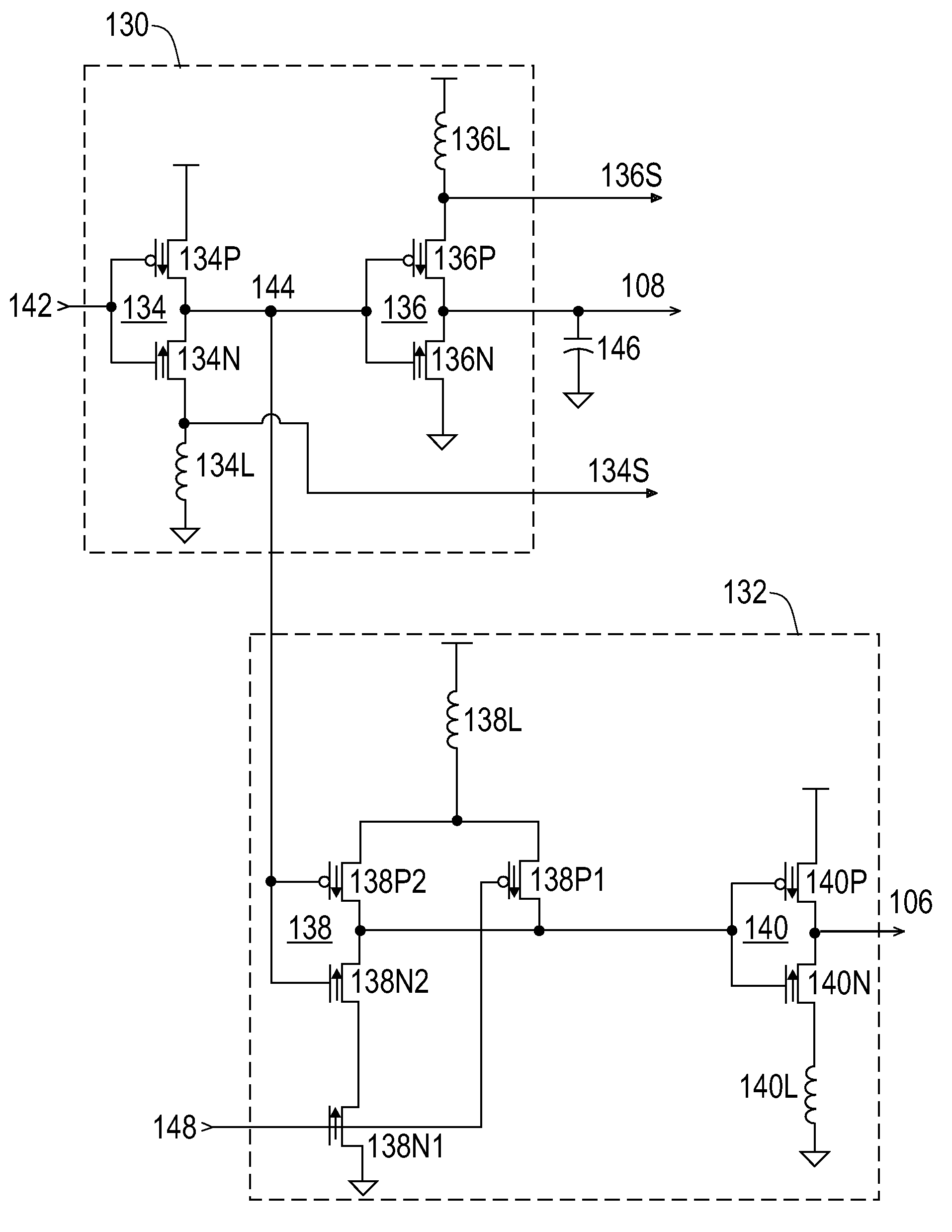

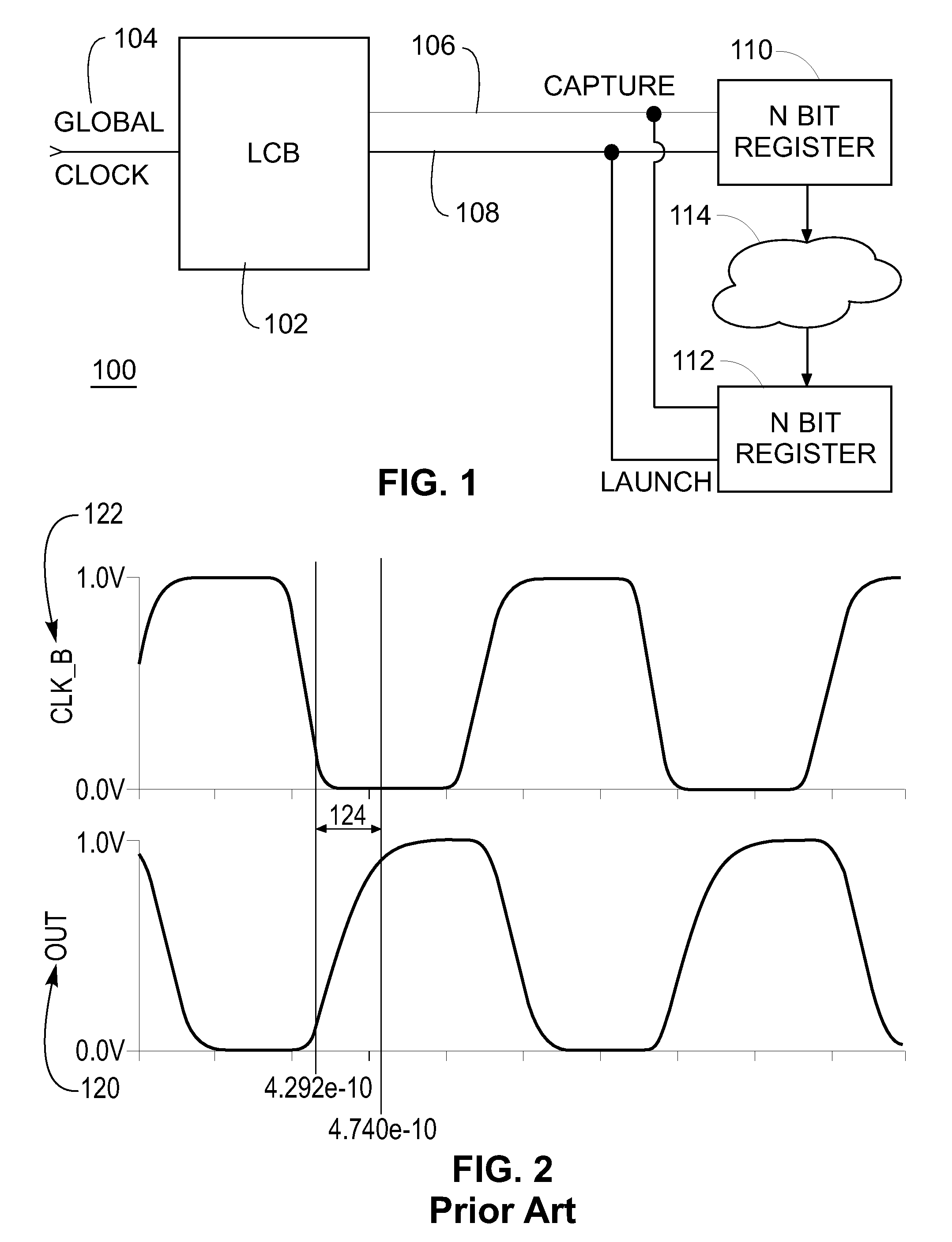

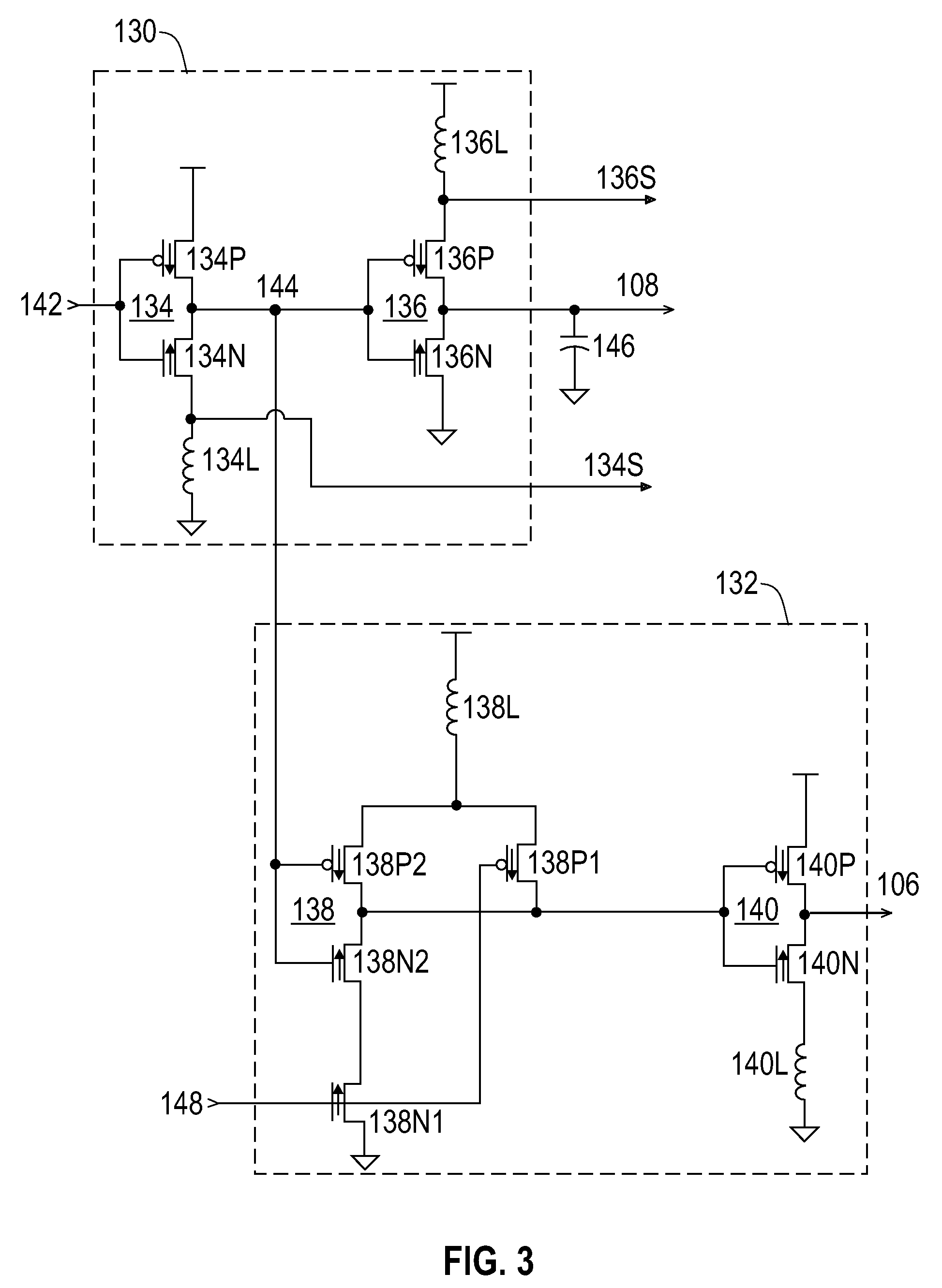

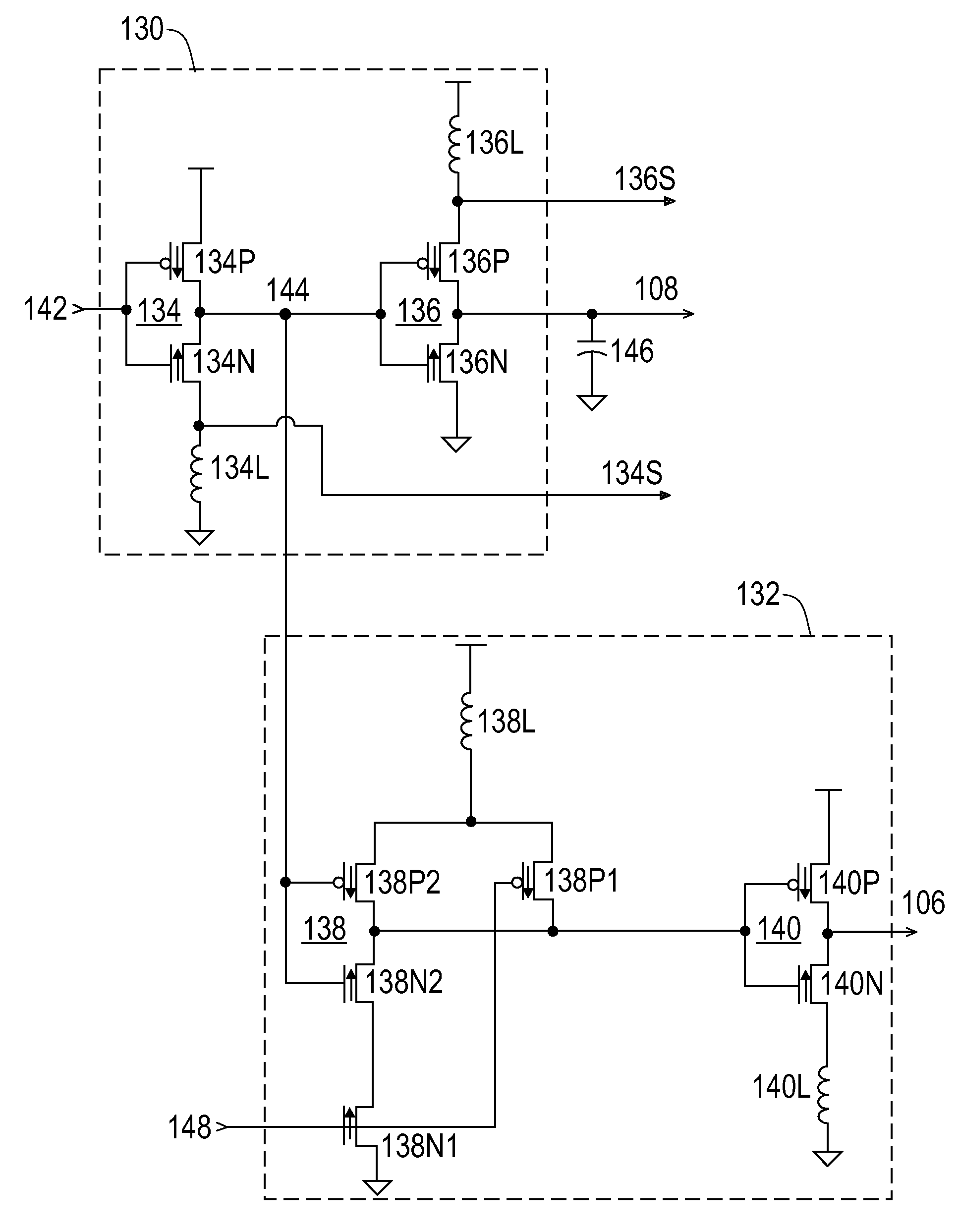

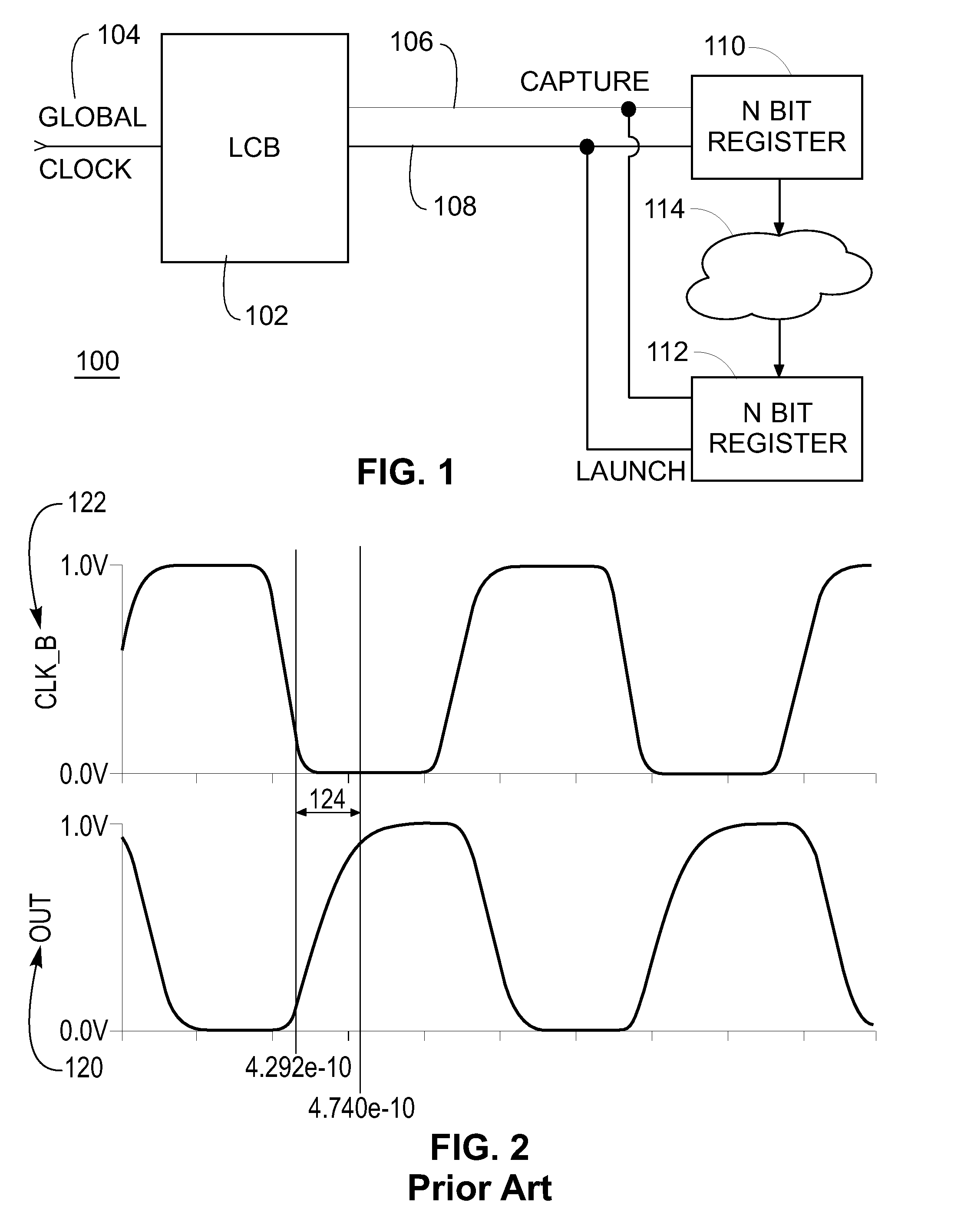

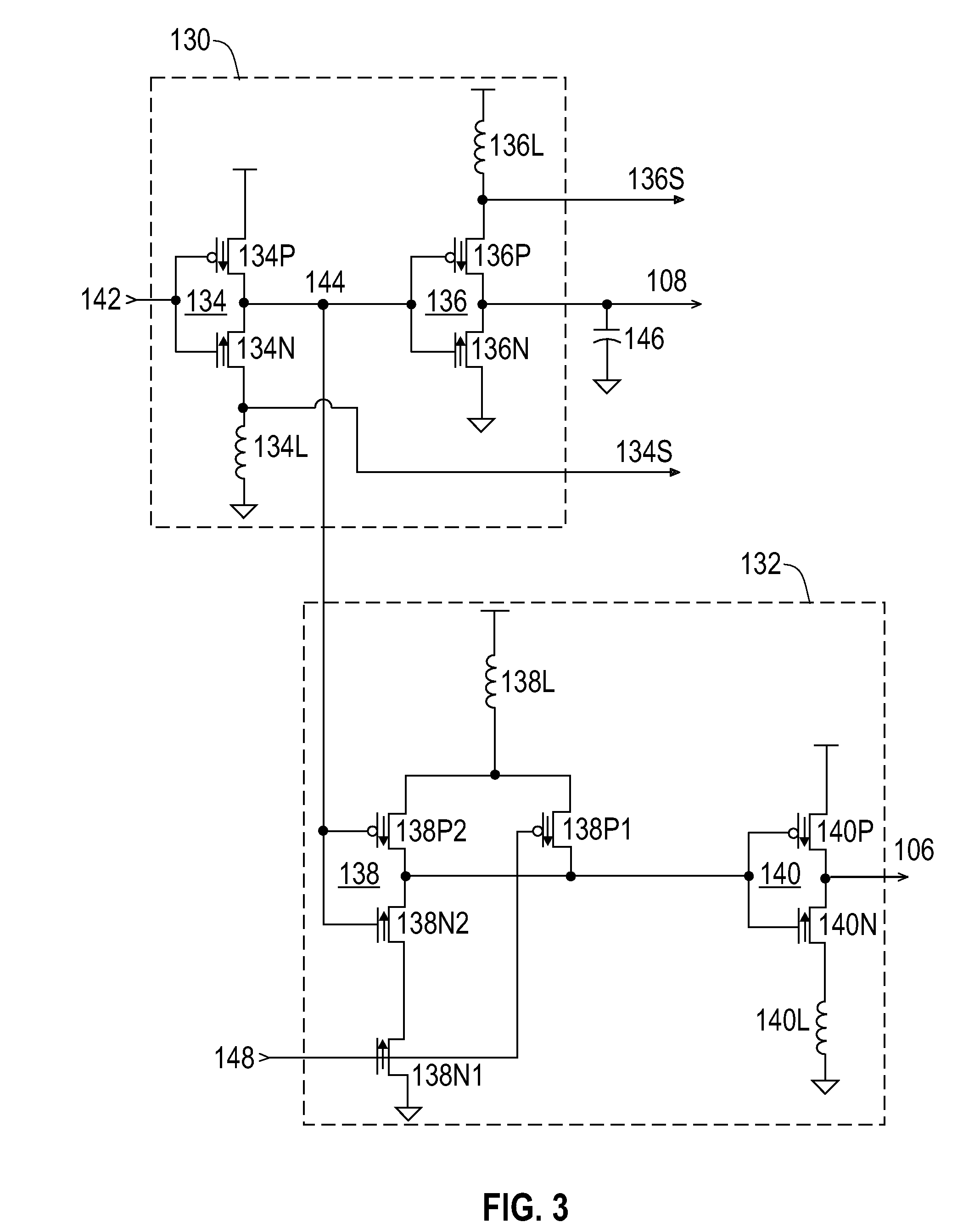

Local clock buffer (LCB) with asymmetric inductive peaking

InactiveUS20080238484A1Reduce IC chip powerReduce the required powerLogic circuitsProcessor registerPeak value

A Local Clock Buffer (LCB), an IC chip including registers, some of which may include master / slave latches, locally clocked by the LCB, e.g., providing a launch clock and a capture clock each with an identified critical edge. The LCB includes asymmetrically inductively peaked series connected logic gates (e.g., inverters and / or NAND gates), each with an inductor between gate devices and supply (Vdd) or ground. The series connected gates alternate between having the inductor located between gate devices and the supply and located between gate devices and ground, providing asymmetric inductive peaking to maintain the sharpness of the critical edges. Optionally, corresponding logic gates in multiple LCBs may share the same inductor. Asymmetric inductive peaking allows reducing LCB power without degrading performance.

Owner:IBM CORP

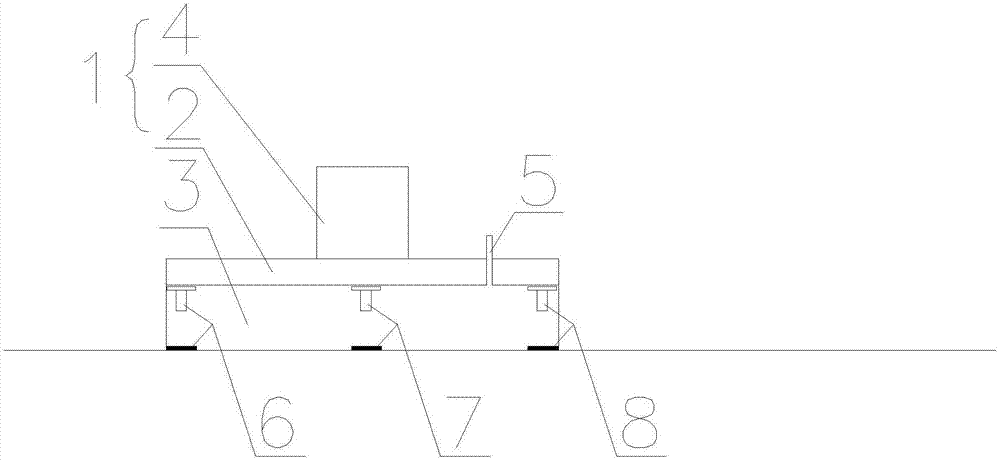

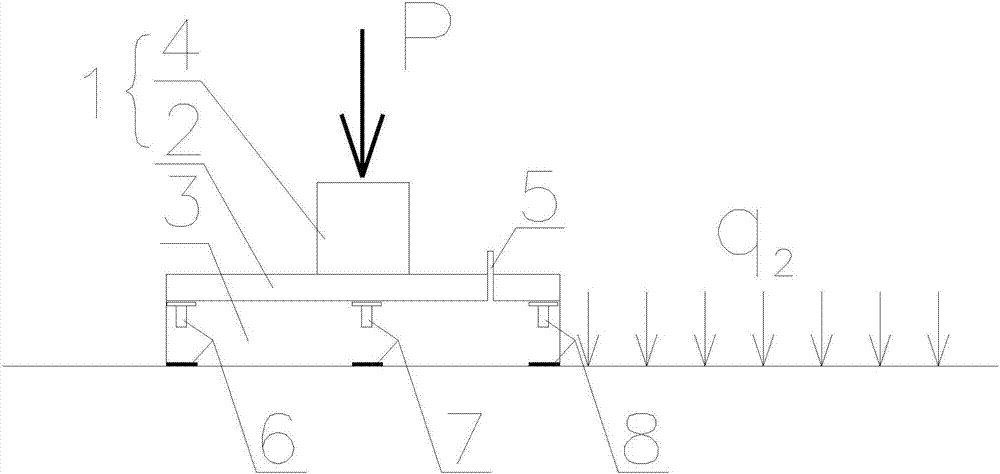

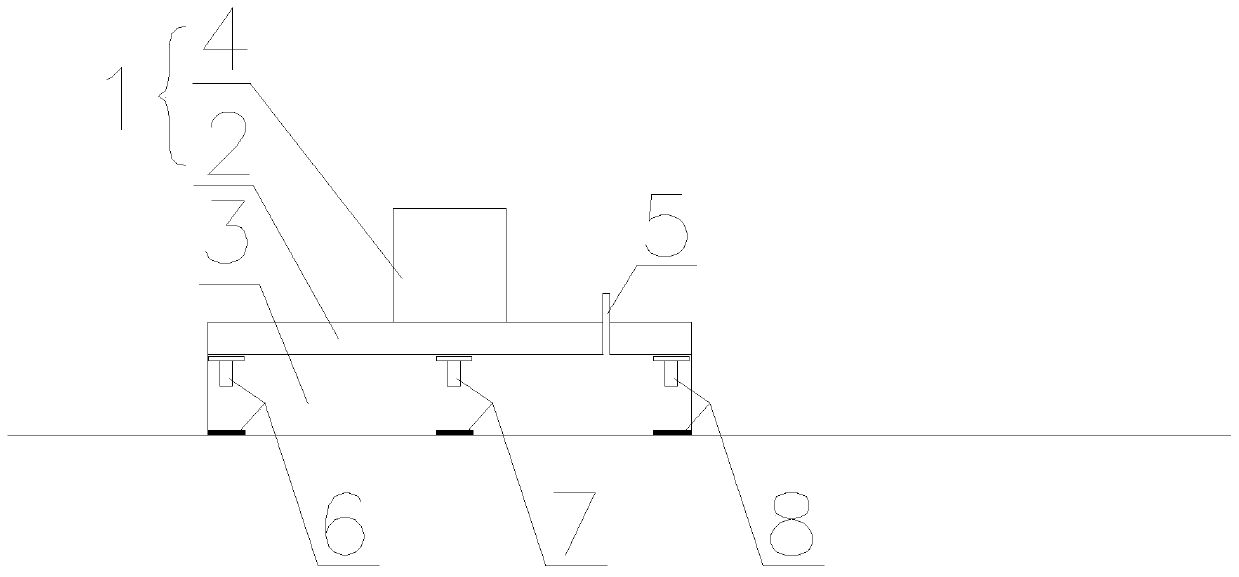

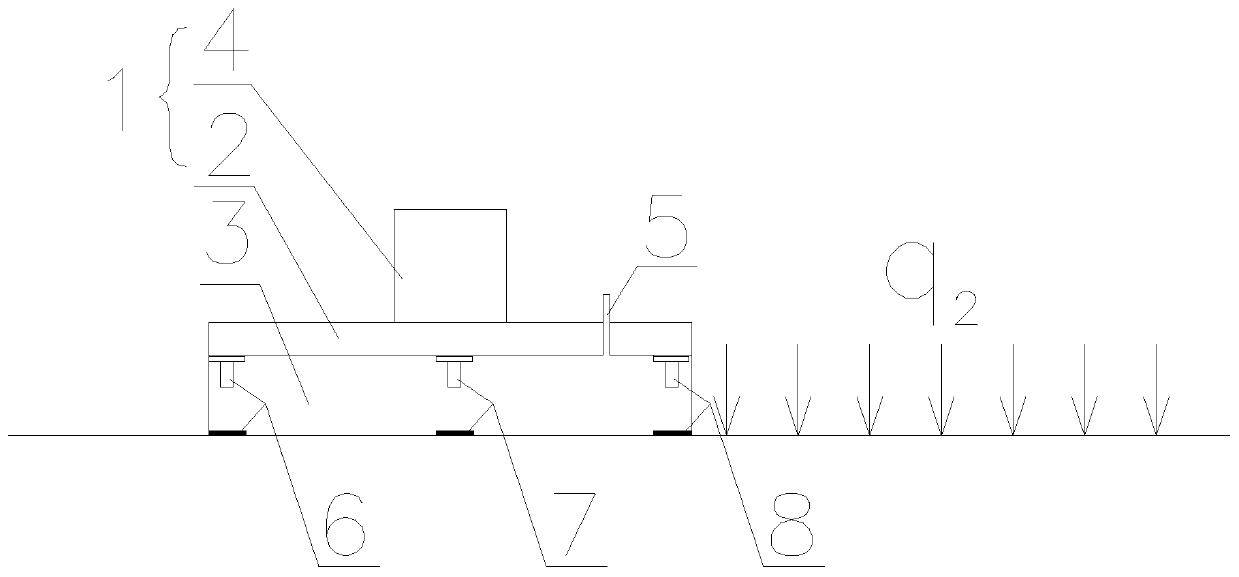

Soil shear strength parameter testing method based on critical edge loading formula

ActiveCN107884285ALow operating skill requirementsThe test result is accurateMaterial strength using steady shearing forcesEngineeringEarth surface

The invention discloses a soil shear strength parameter testing method based on a critical edge loading formula. The shear strength parameter of soil can be tested in an accurate, rapid, and economicmode. A loading test of the loading plate is developed, two different earth surface load values q1 and q2 are applied at two sides of the loading plate, critical edge load values pcr1 and pcr2 are respectively tested according to the different earth surface load values q1 and q2, and soil cohesive force value c and a soil internal friction angle value Phi are subjected to inverse computation by apcr formula.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

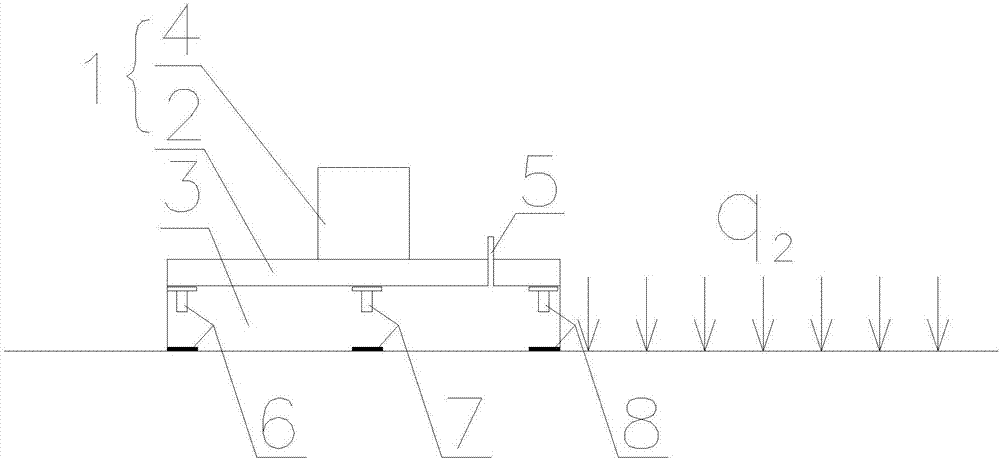

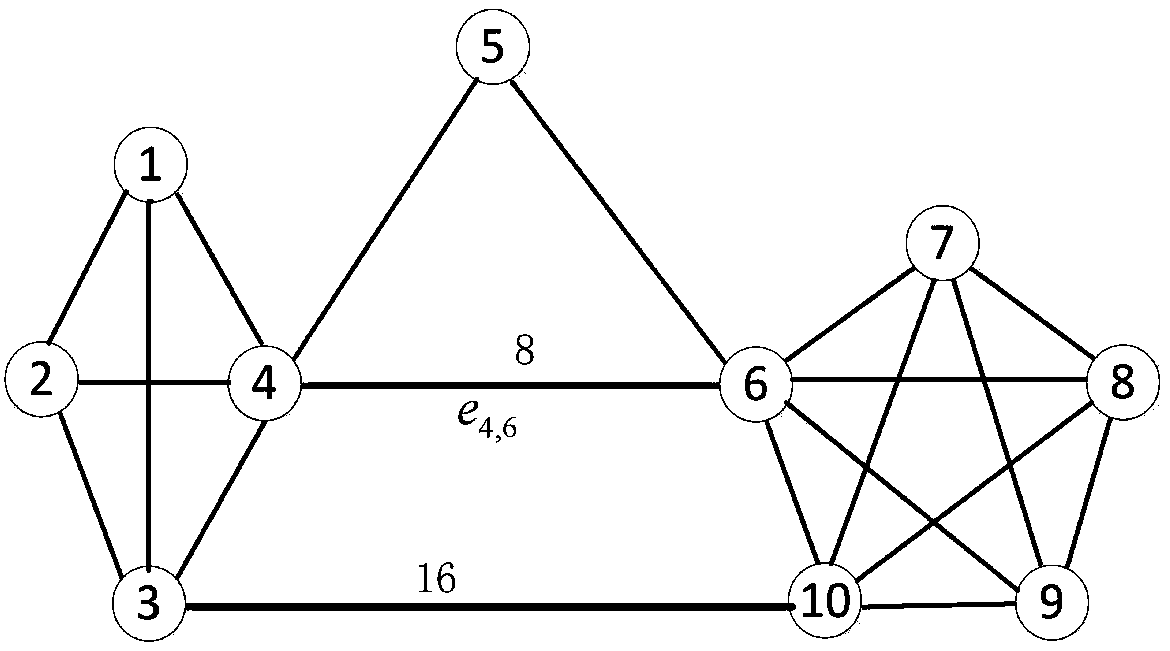

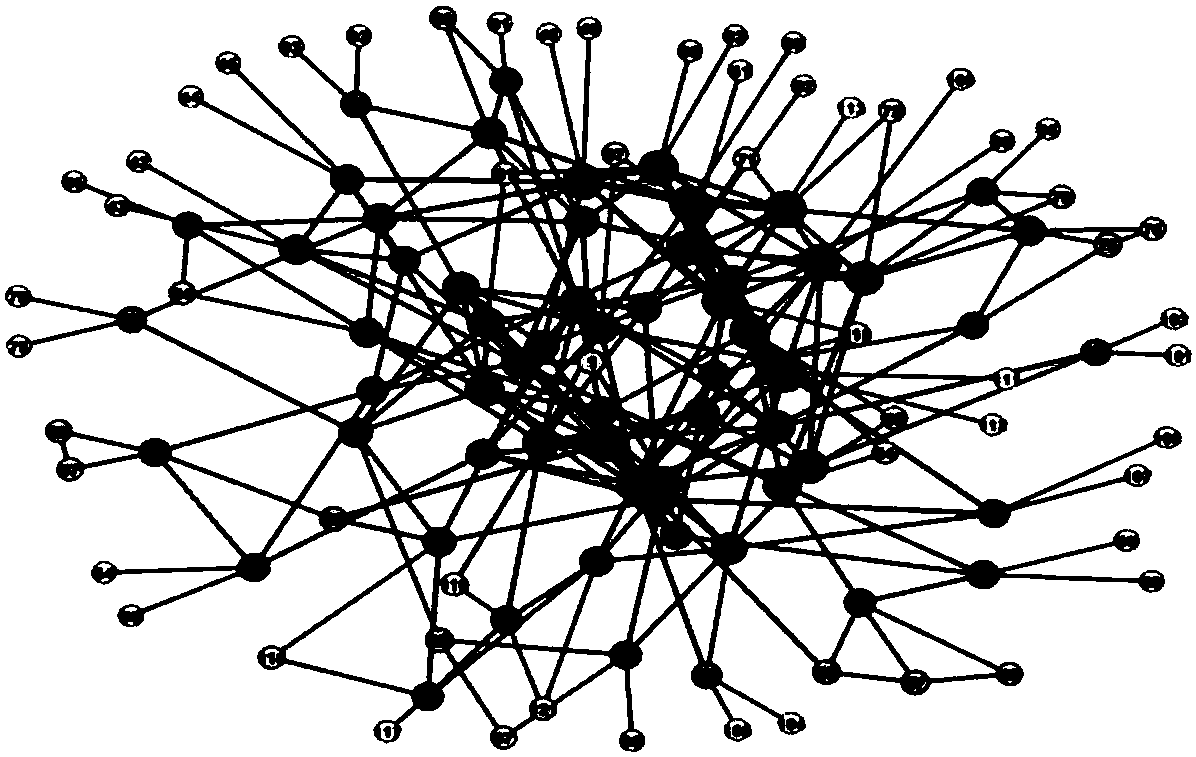

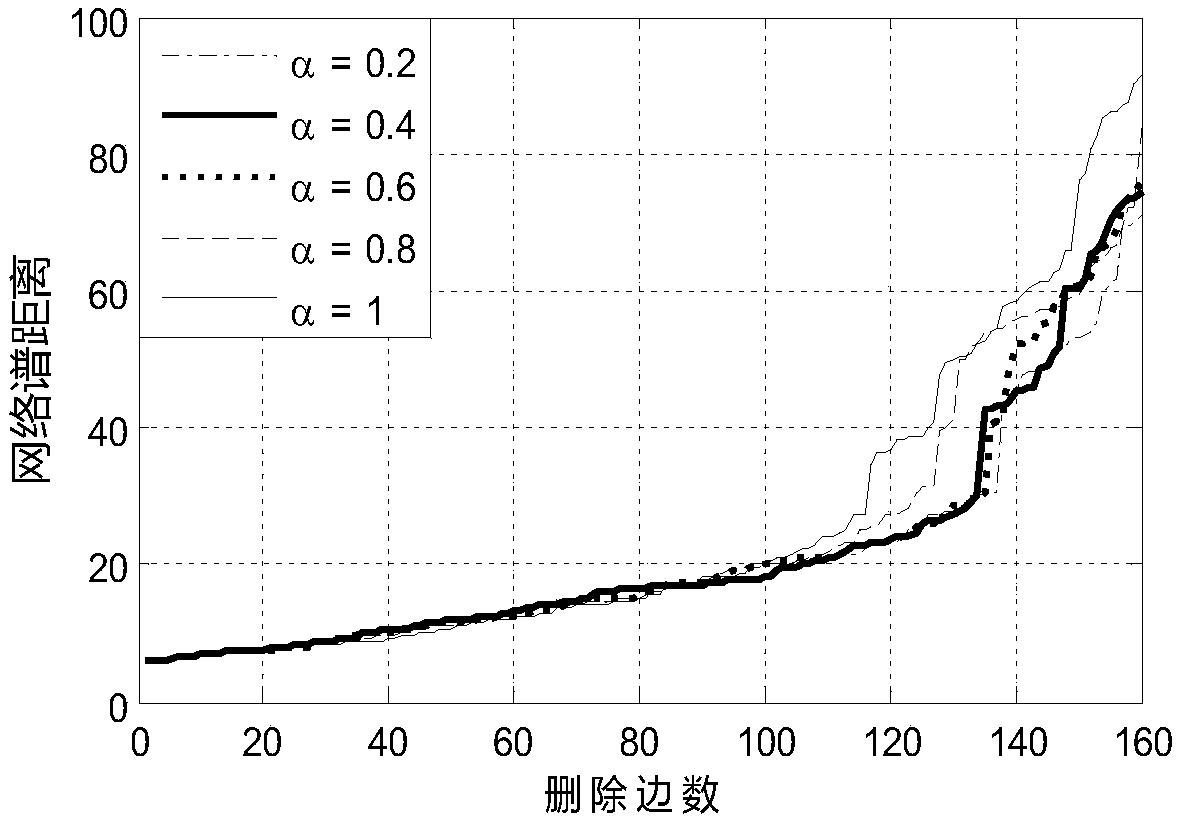

Bridging coefficient-based command and control network bridge edge identification method

ActiveCN108259245AImprove survivabilityAccurate identificationData switching networksStatistical analysisCommand and control

Owner:DALIAN UNIVERSITY

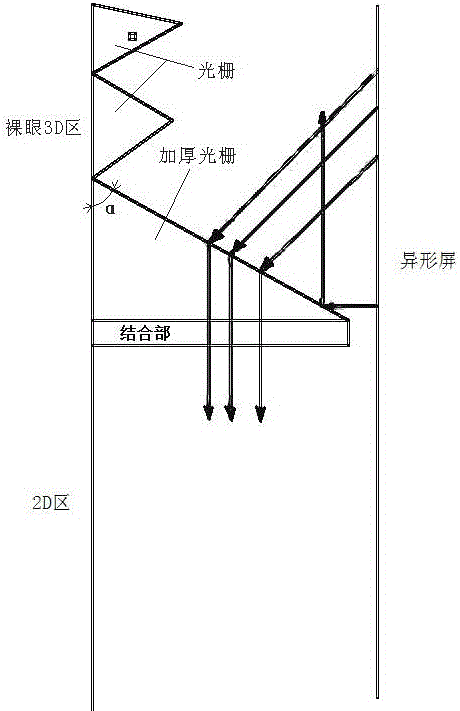

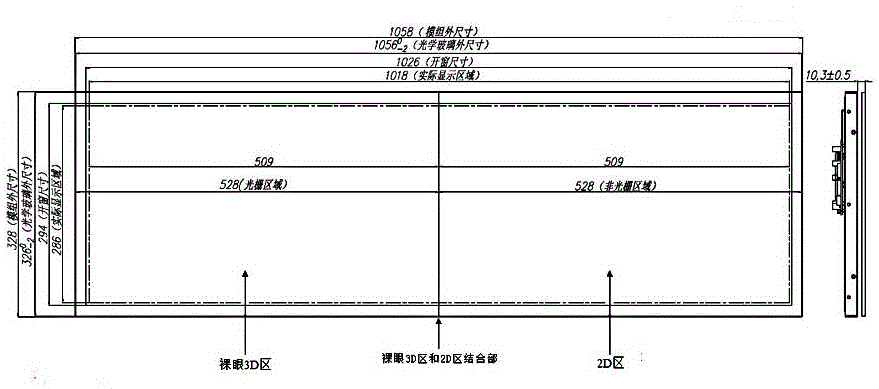

A 2D and glasses-free 3D split-screen playback display based on a special-shaped screen

ActiveCN104601973BReduce resolutionEasy procedureSteroscopic systemsOptical elementsGratingImage resolution

The invention discloses a naked-eye 2D and 3D split-screen display based on a special-shaped screen; the naked-eye 2D and 3D split-screen display comprises the special-shaped screen formed by cutting a standard liquid crystal screen in a partial clock signal removal manner as well as a corresponding backlight module; the special-shaped screen is provided with naked-eye 3D and 2D frequency-division display areas, wherein a bearing material is attached to the front part of the naked-eye 3D area and an optical grating is attached on the bearing material of the naked-eye 3D area; the optical grating attached at the joint of the naked-eye 3D area and the naked-eye 2D area is thicker and the bevel edge of this optical grating has an angle Alpha with the surface of the bearing material; the angle Alpha is taken as proper when the light from the surface of the special-shaped screen is parallel with the screen surface and then is refracted. With adoption of the above scheme, the naked-eye 2D and 3D multi-area display is realized on hardware and the original programs and software are simplified; because videos do not need to be subjected to compression and reduction of resolution ratios, the naked-eye 2D and 3D split-screen display is more reliable and pictures are better and more comfortable; with the processing of the critical edge (joint) of the 3D and 2D display, the display is uniform in the whole transition and stronger in zoning property.

Owner:ANNAX SUZHOU RAIL SYST

A Method of Determining the Coefficient of Horizontal Subgrade in Side Pressure Test

ActiveCN107016204BEnsure safetyHigh precisionGeometric CADDesign optimisation/simulationRadial displacementDrill hole

The invention relates to the technical field of geotechnical engineering investigation, in particular to a method for determining a pressuremeter test horizontal bedding coefficient. The method comprises the steps of drilling holes in a test site, arranging special mud protection walls for the drilled holes, measuring the relation of pressure and pressuremeter sizes, obtaining a p - delta r curve through conversion, then according to the p - delta r curve, obtaining initial pressure p0, critical edge pressure pF and respective corresponding pressuremeter radial displacements r0 and rF, and according to the parameters, calculating the horizontal bedding coefficient of the soil body. The whole test method is simple and fast, the difficulty for determining the horizontal bedding coefficient through a pressuremeter test can be drastically lowered, the precision of the horizontal bedding coefficient test is improved, and the method is beneficial to large-scale application and promotion.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

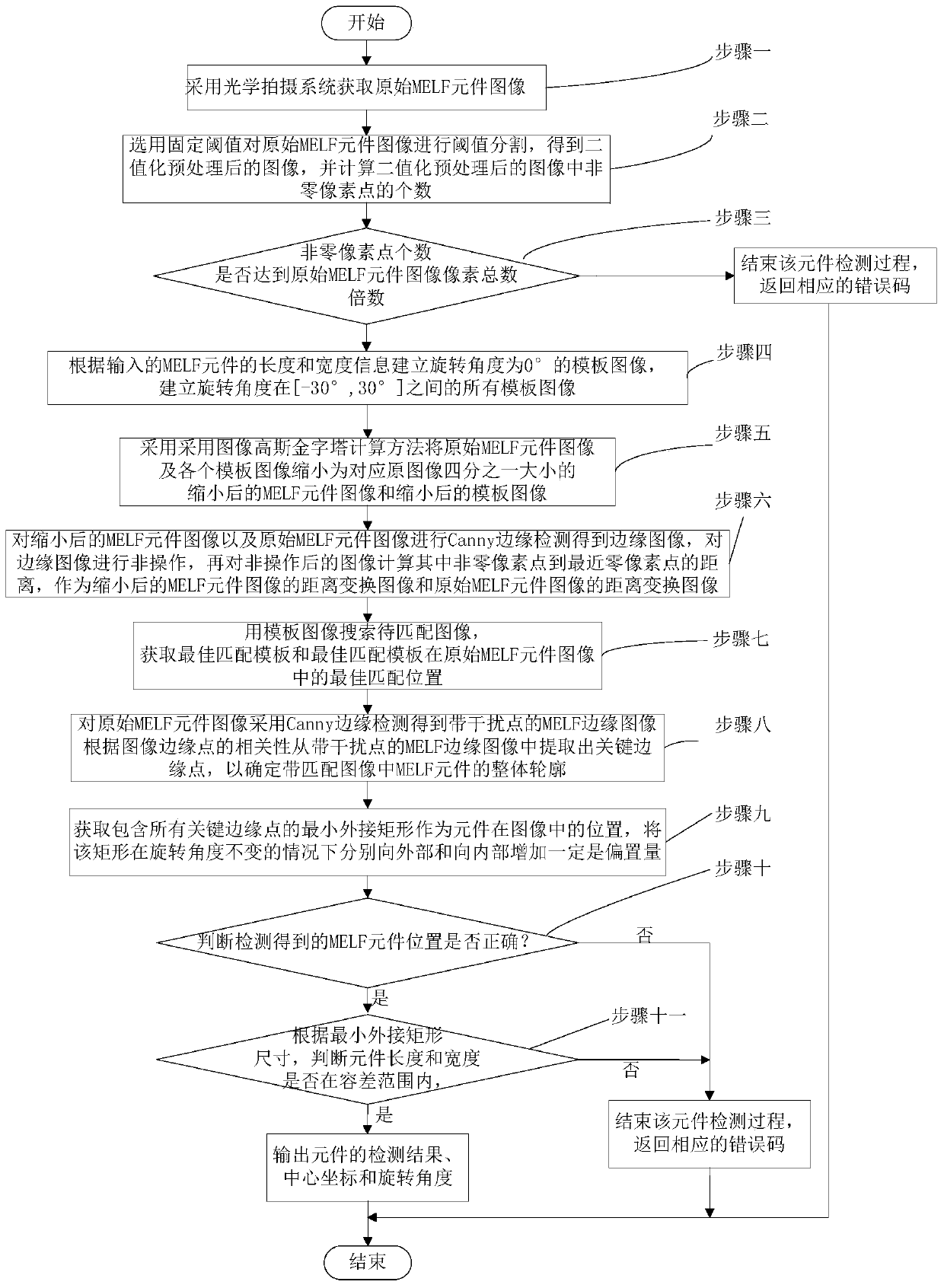

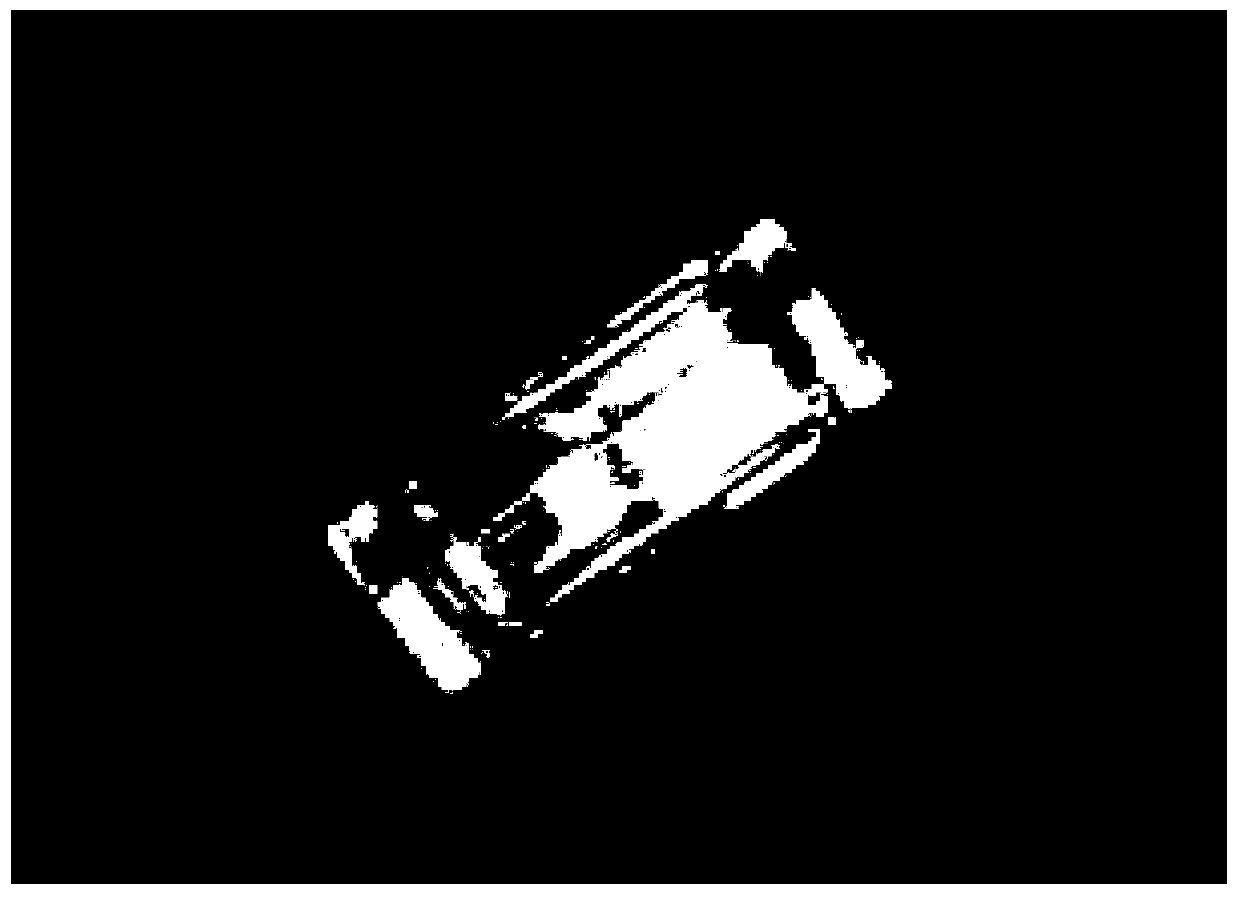

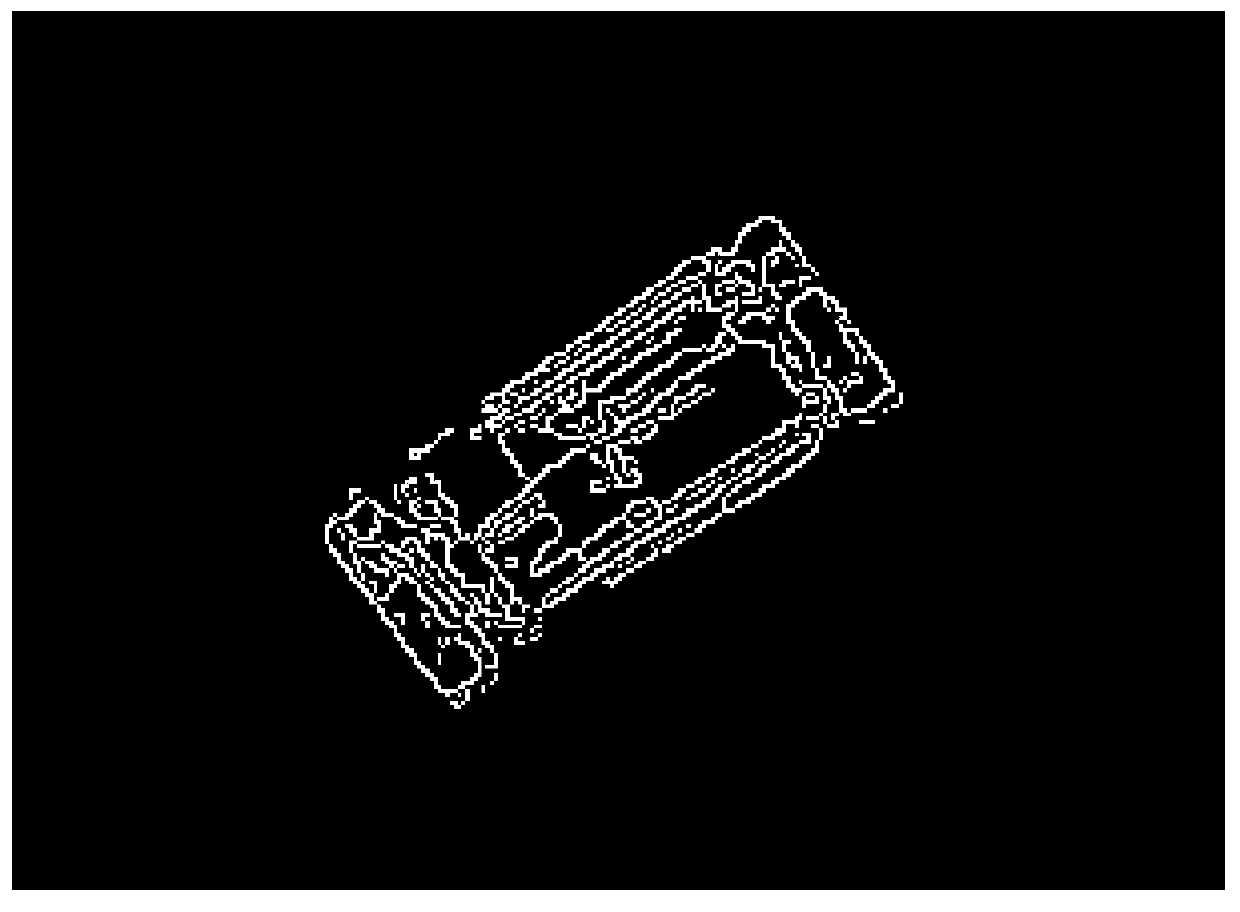

Method of localization and detection of melf components based on template matching

ActiveCN105046271BAvoid affecting the detection processReduce searchImage enhancementImage analysisTemplate matchingMinimum bounding rectangle

The invention relates to a template matching-based MELF element location and detection method, which belongs to the field of element location and detection. The traditional template matching algorithm has a large amount of calculation and slow execution speed when detecting components with rotation angles, resulting in slow component positioning and detection speed. A MELF component positioning and detection method based on template matching, by establishing a template image with an angle, obtaining the reduced component image, obtaining the distance transformed image of the reduced component image and the distance transformed image of the original component image, and obtaining the final The best matching template image and the best matching position, extract key edge points in the edge image with interference points and form the minimum circumscribed rectangle, set the number of internal non-zero pixels after the offset according to the minimum circumscribed rectangle, and obtain When the position of the component is correct and the length and width of the component are within the tolerance range, the positioning and detection process is completed and the component position information is output. The invention can reduce the number of search positions for template matching calculation and matching calculation amount, improve the template matching calculation efficiency, and the accuracy rate of positioning and detection reaches 95-98%.

Owner:宁波智能装备研究院有限公司

Manufacturing method of airbag for foundation plate load test

ActiveCN105714754BEasy to assemble and disassembleEvenly distributedMaterial strength using tensile/compressive forcesIn situ soil foundationDeformation modulusPlate load test

The invention provides a method for manufacturing an airbag for plate loading test of a foundation. The method comprises the following steps: cutting to form a stainless steel outer frame; taking a high-strength flexible impervious material as an airbag material, and cutting the material; sleeving the cut high-strength flexible impervious material by the stainless steel outer frame, enabling the bottom surface of the high-strength flexible impervious material to be consistent with the stainless steel outer frame, and after outwardly turning the high-strength flexible impervious material from the stainless steel outer frame, bonding the high-strength flexible impervious material onto the upper surface of the stainless steel outer frame to form the airbag; filling four corners on the inner side of the air bag to form four supports; and after solidification of a filler filling the four corners on the inner side of the airbag, stacking filler on the surface (four peripheries) of the outwardly turned high-strength flexible impervious material and on the four supports, covering with a stainless steel bearing plate, taking down the stainless steel bearing plate after solidification of the filler, and trimming the filler extruded out of the periphery of the airbag. The method can solve the problem that the critical edge pressure and the deformation modulus of the foundation, which are tested by plate loading test of the foundation, have big errors.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Testing method of soil shear strength parameters based on temporary plastic load formula

ActiveCN107884285BLow operating skill requirementsThe test result is accurateMaterial strength using steady shearing forcesEngineeringEarth surface

The invention discloses a soil shear strength parameter testing method based on a critical edge loading formula. The shear strength parameter of soil can be tested in an accurate, rapid, and economicmode. A loading test of the loading plate is developed, two different earth surface load values q1 and q2 are applied at two sides of the loading plate, critical edge load values pcr1 and pcr2 are respectively tested according to the different earth surface load values q1 and q2, and soil cohesive force value c and a soil internal friction angle value Phi are subjected to inverse computation by apcr formula.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Local clock buffer (LCB) with asymmetric inductive peaking

InactiveUS20080290893A1Reduce synchronous IC chip power consumedLower performance requirementsReliability increasing modificationsElectronic switchingProcessor registerInductor

A Local Clock Buffer (LCB), an IC chip including registers, some of which may include master / slave latches, locally clocked by the LCB, e.g., providing a launch clock and a capture clock each with an identified critical edge. The LCB includes asymmetrically inductively peaked series connected logic gates (e.g., inverters and / or NAND gates), each with an inductor between gate devices and supply (Vdd) or ground. The series connected gates alternate between having the inductor located between gate devices and the supply and located between gate devices and ground, providing asymmetric inductive peaking to maintain the sharpness of the critical edges. Optionally, corresponding logic gates in multiple LCBs may share the same inductor. Asymmetric inductive peaking allows reducing LCB power without degrading performance.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com