Critical edge and cave entrance protective device and fixing method of the same

A technology of protective device and fixing method, which is applied in the direction of construction, building structure, and building material processing, etc., can solve the problems of troublesome construction, high cost, and cutting corners, and achieve the effect of low cost, simple structure, and reliable fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

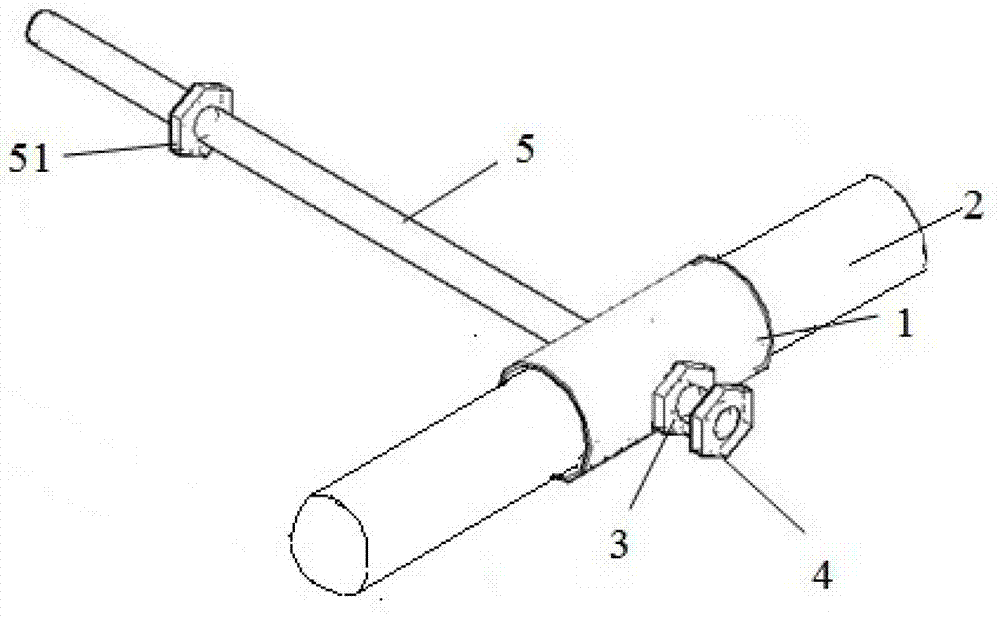

[0017] See figure 1 with figure 2 , The present invention provides an edge hole protection device, including a steel pipe body 1, a protective steel pipe 2 is inserted into the steel pipe body 1, and a locking mechanism for fixing the protective steel pipe 2 is provided on the middle side of the steel pipe body 1. The locking mechanism includes a fixing nut 3 welded to the steel pipe body 1, the screw hole of the fixing nut 3 is communicated with the pipe hole of the steel pipe body 1, and the screw hole of the fixing nut 3 is provided with a locking nut 3 Bolt 4; opposite to the other end of the locking mechanism on the steel pipe body 1 welded with a screw 5, the screw 5 is perpendicular to the steel pipe body 1, and the screw 5 away from the steel pipe body 1 is provided with a lock nut 51.

[0018] In order to make the fixation of the present invention more reliable, it is preferable that the screw 5 in this embodiment is arranged in the middle of the steel pipe body 1, and t...

Embodiment 2

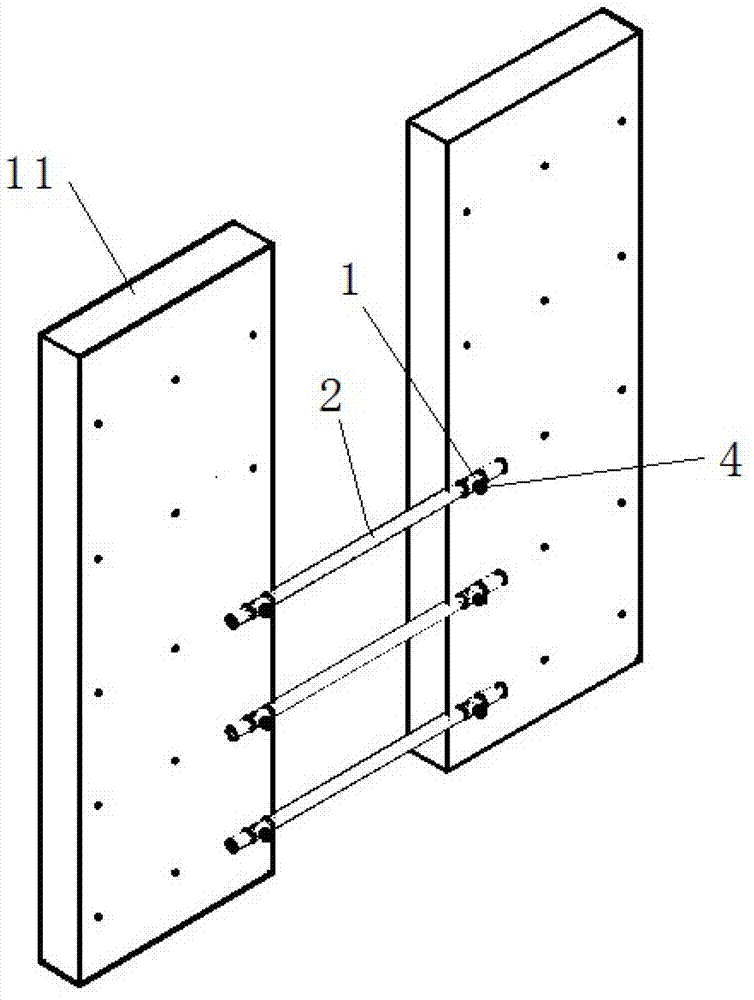

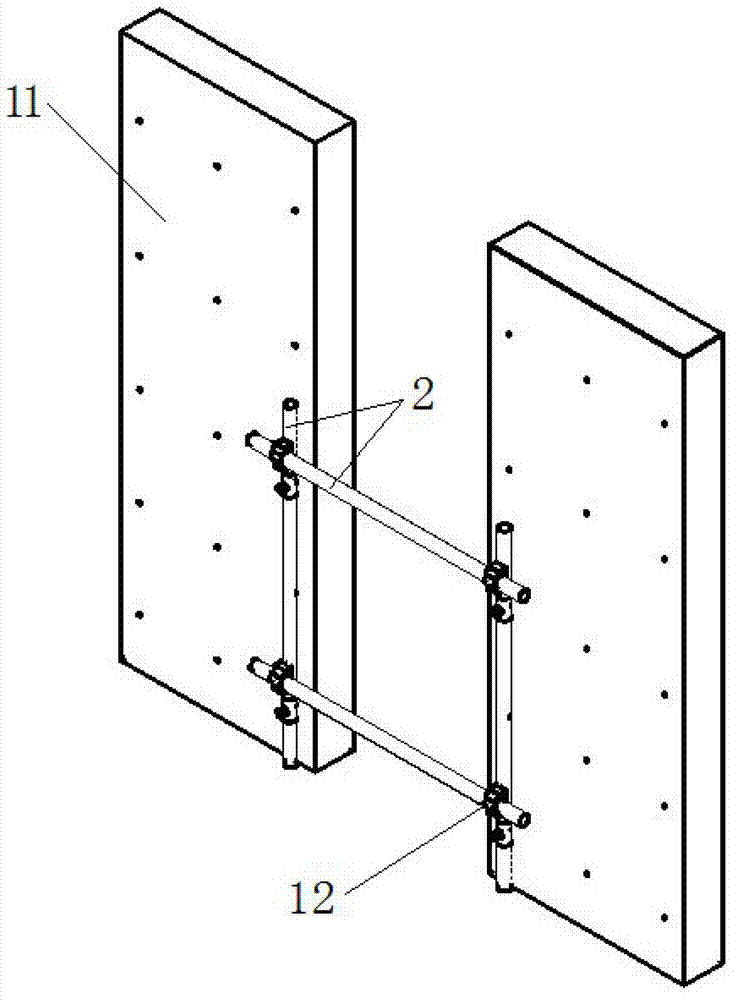

[0022] See figure 2 , Example 2 is an improvement on the method of fixing the protective device on the basis of Example 1.

[0023] In actual use, the entire device is vertically fixed on the screw hole of the shear wall 11, that is, the screw 5 is vertically inserted into the screw hole of the shear wall 11, and the lock nut 51 is used to fix it, and then the steel pipe A protective steel pipe 2 is installed vertically on the body 1, and then fixed by a locking bolt 4. A horizontal protective steel pipe 2 is added between two adjacent protective devices. Finally, a fastener 12 is used to connect the vertical protective steel pipe to the horizontal The protective steel pipe is fixedly connected.

[0024] The invention reduces the construction cost, saves materials, and the protective device has a simple manufacturing method, can be freely disassembled during installation and disassembly, is convenient to operate, greatly improves the efficiency of civilized construction work, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com