Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Blade geometry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term blade geometry refers to the physical properties of a sword blade: cross-section (or grind) and taper.

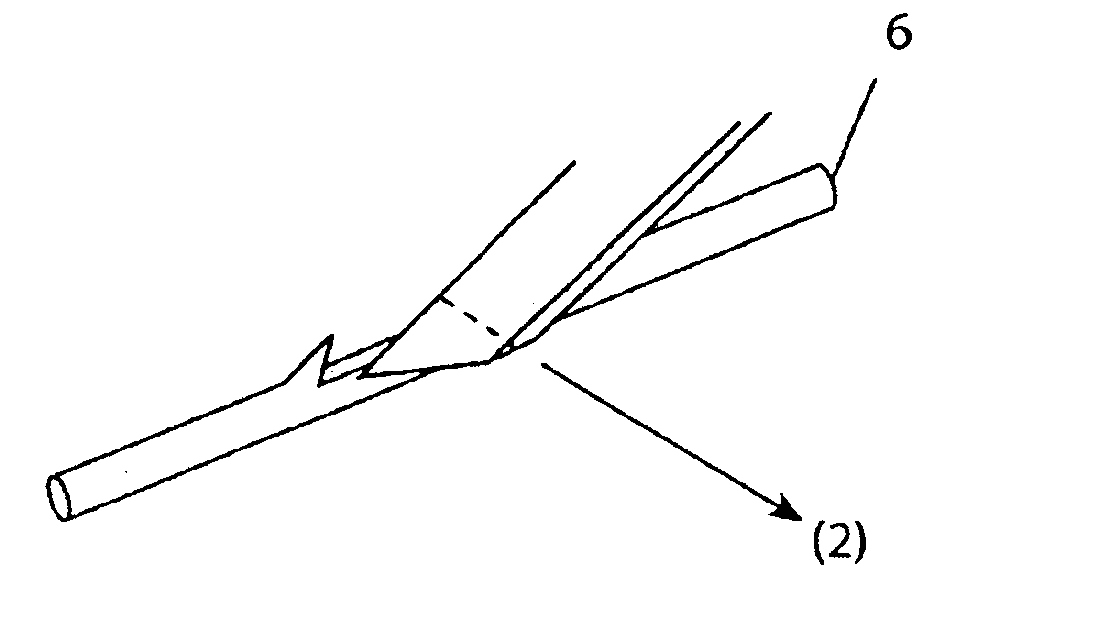

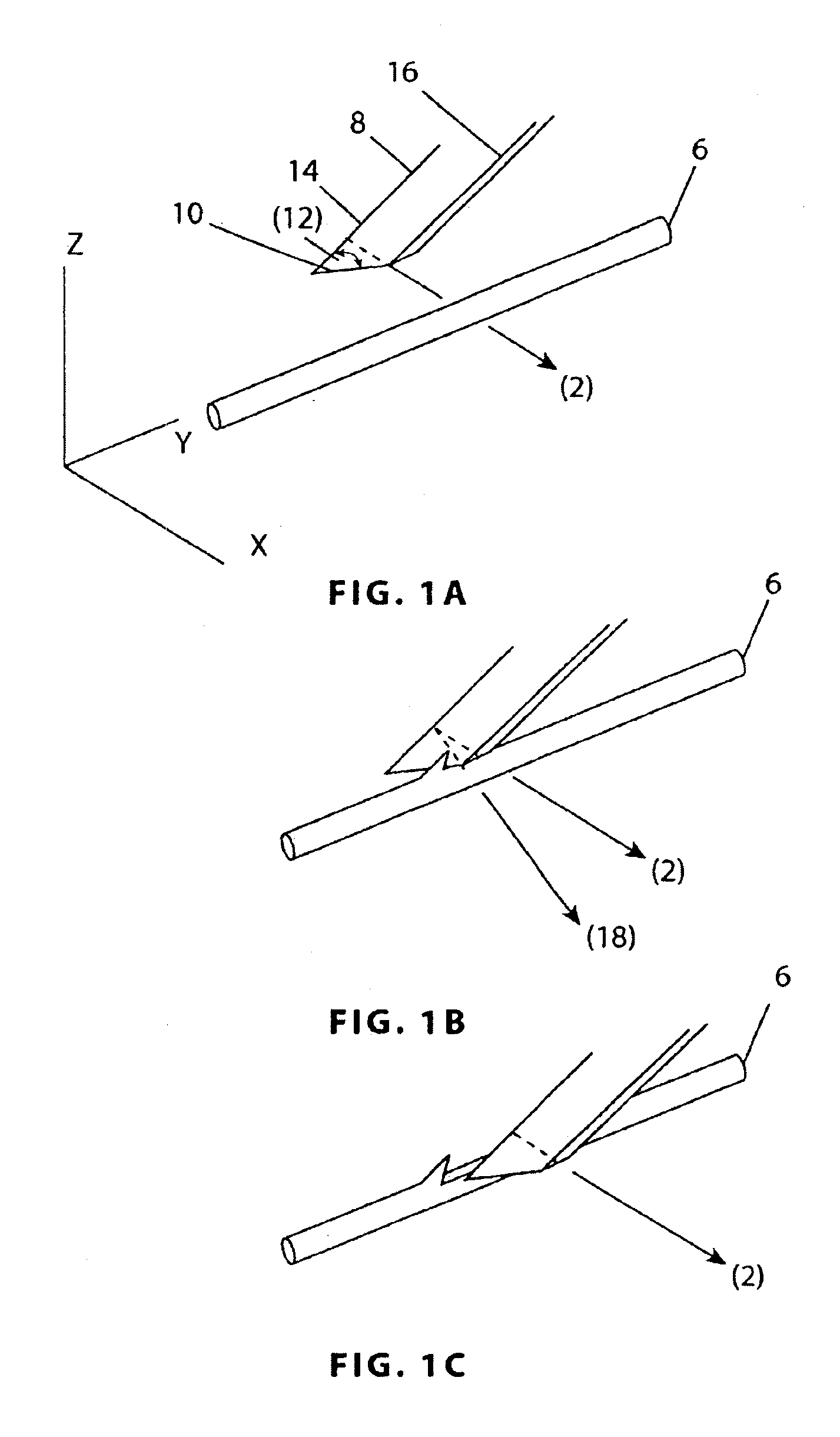

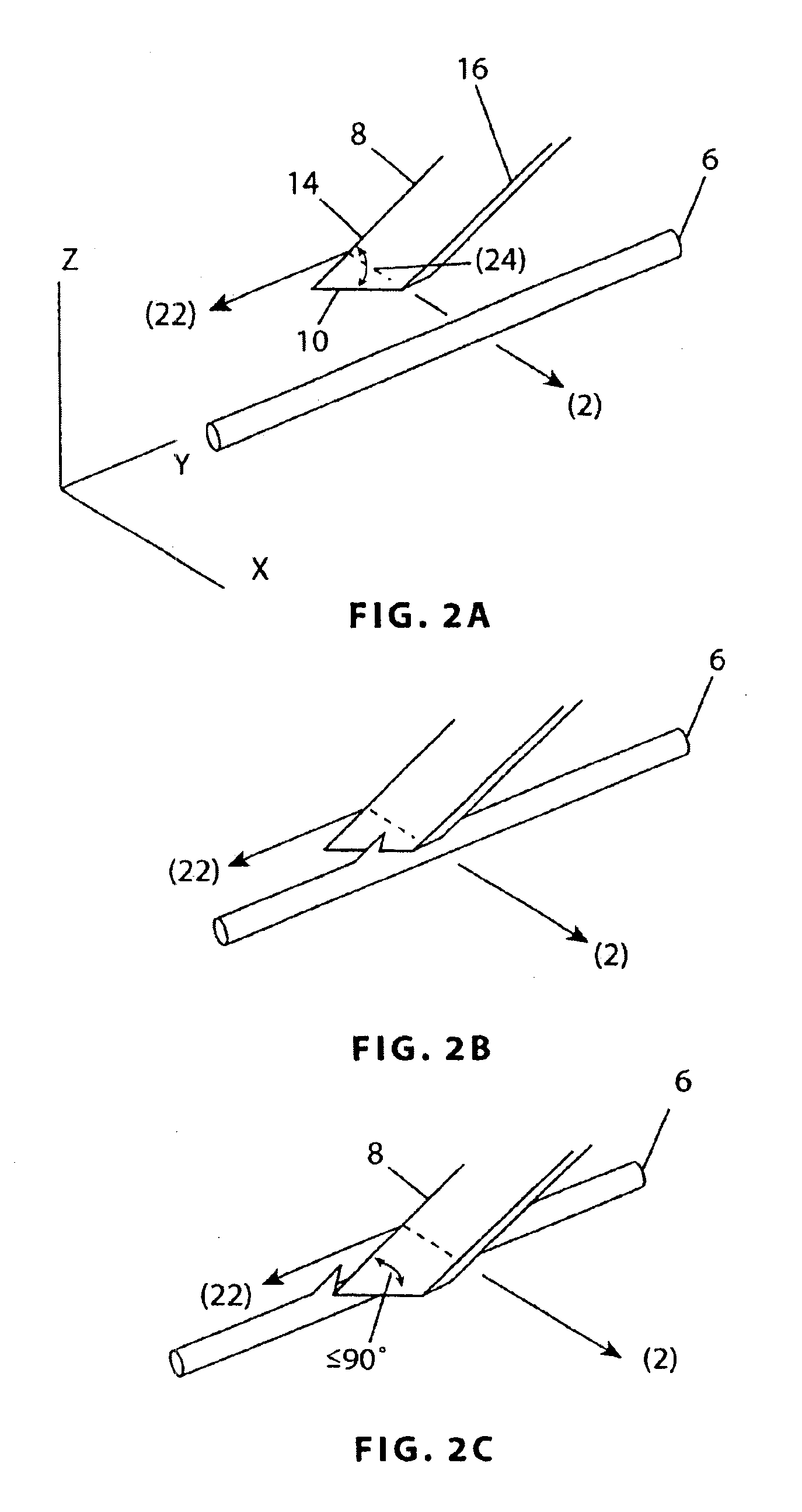

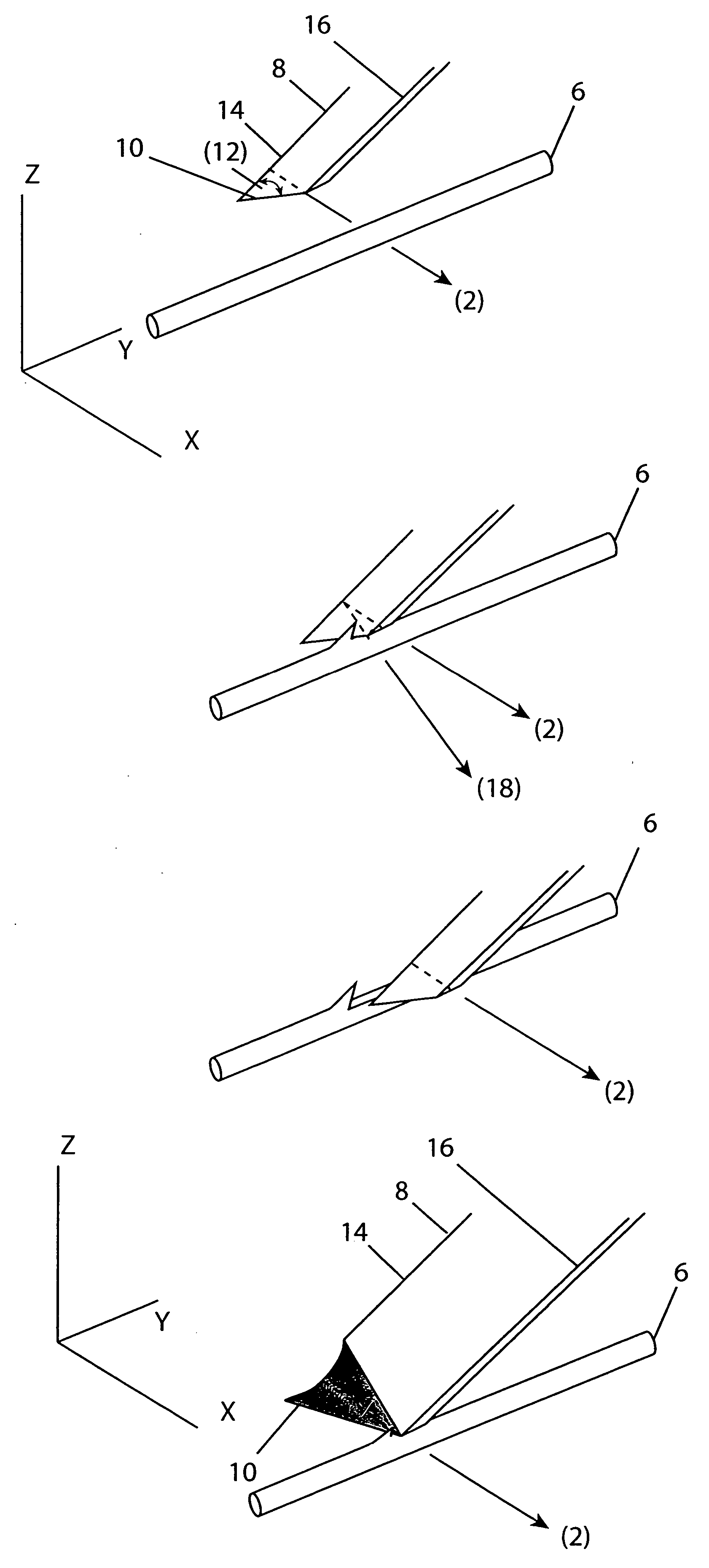

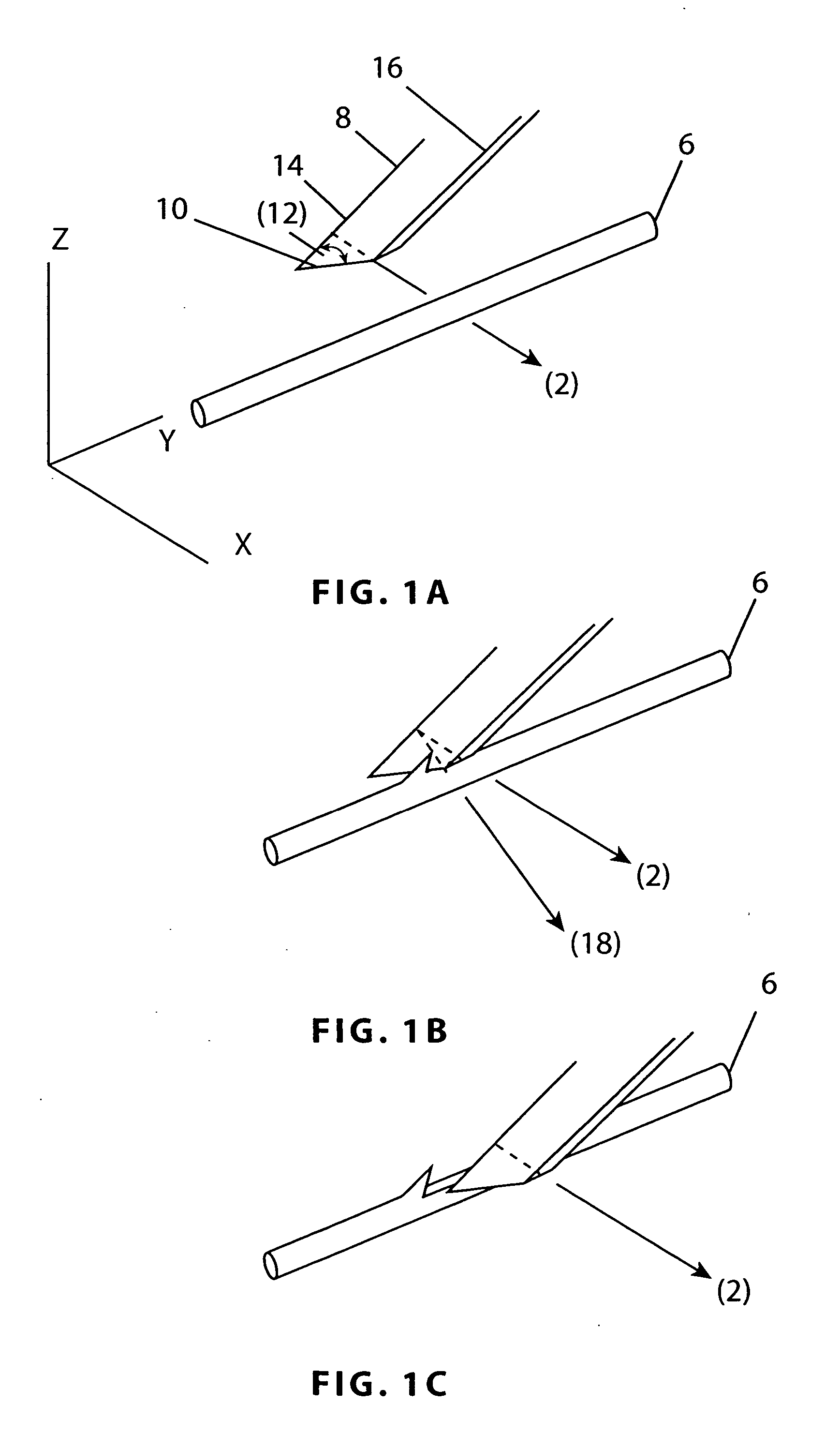

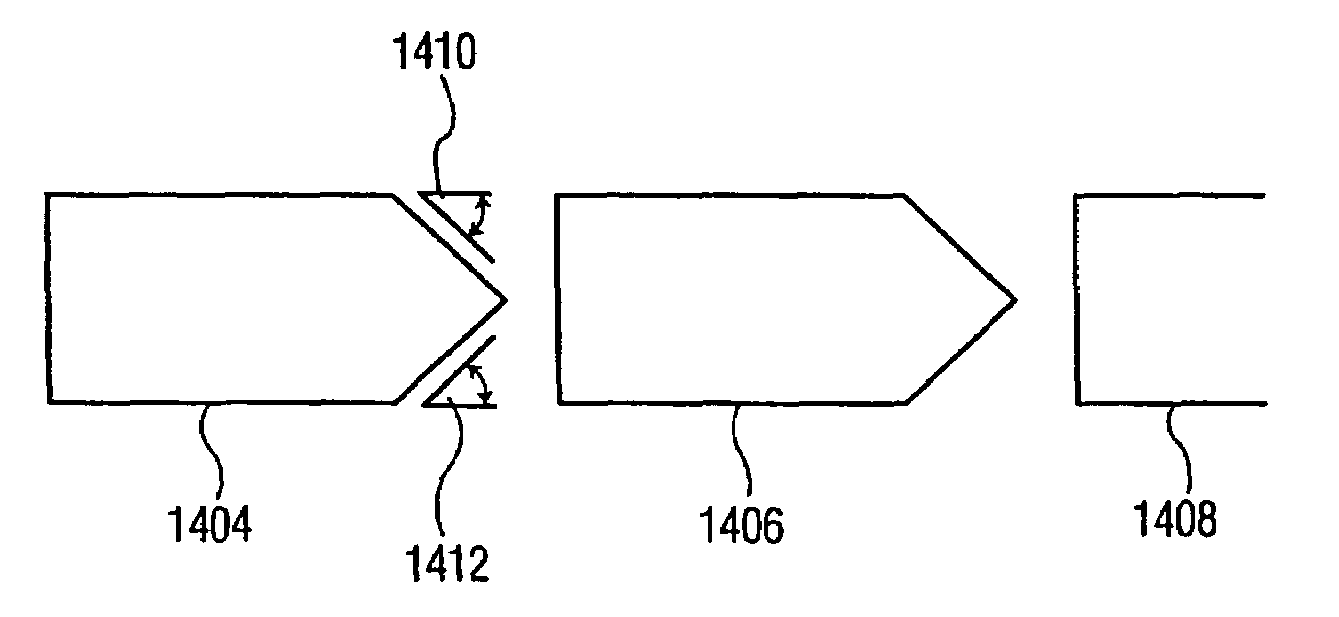

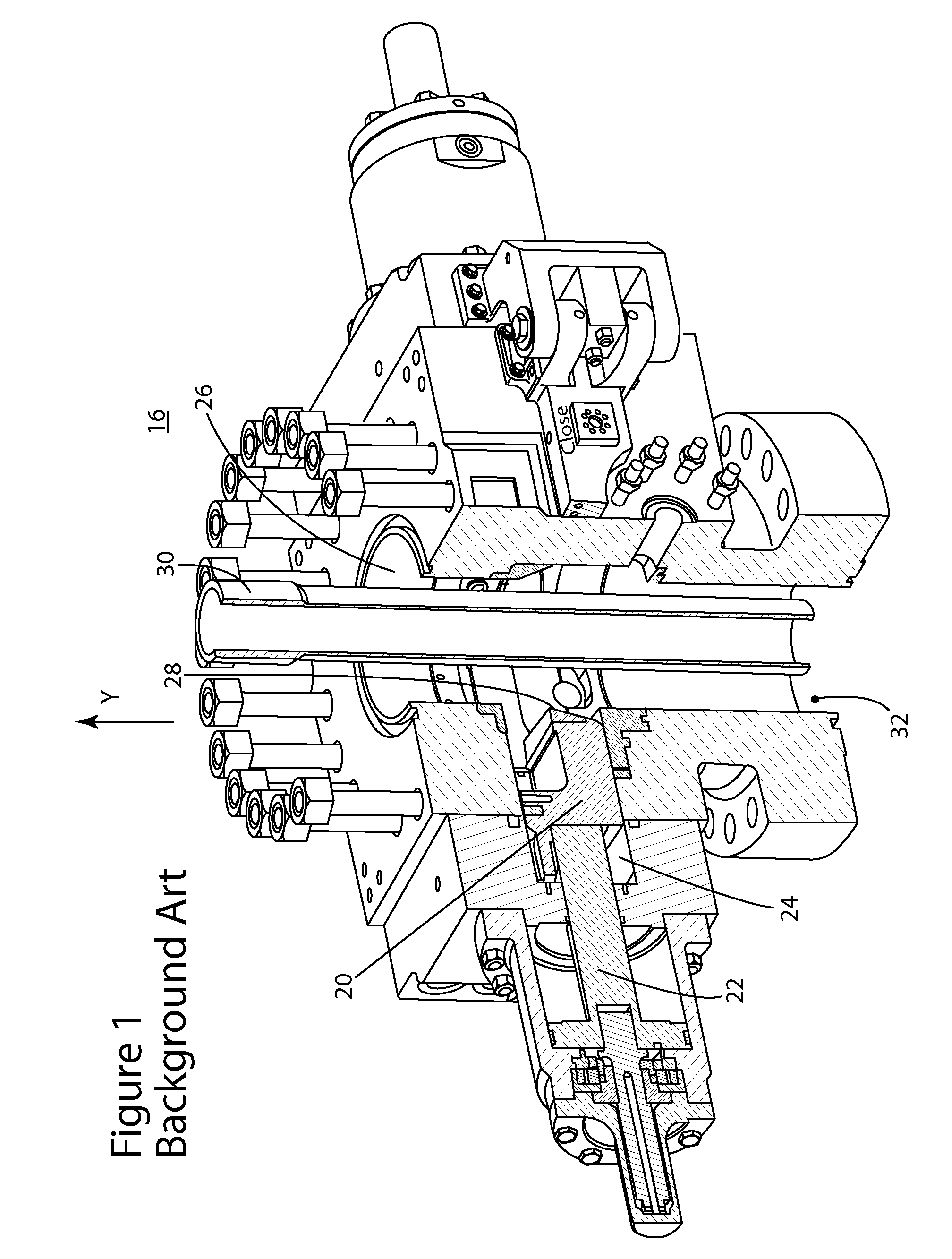

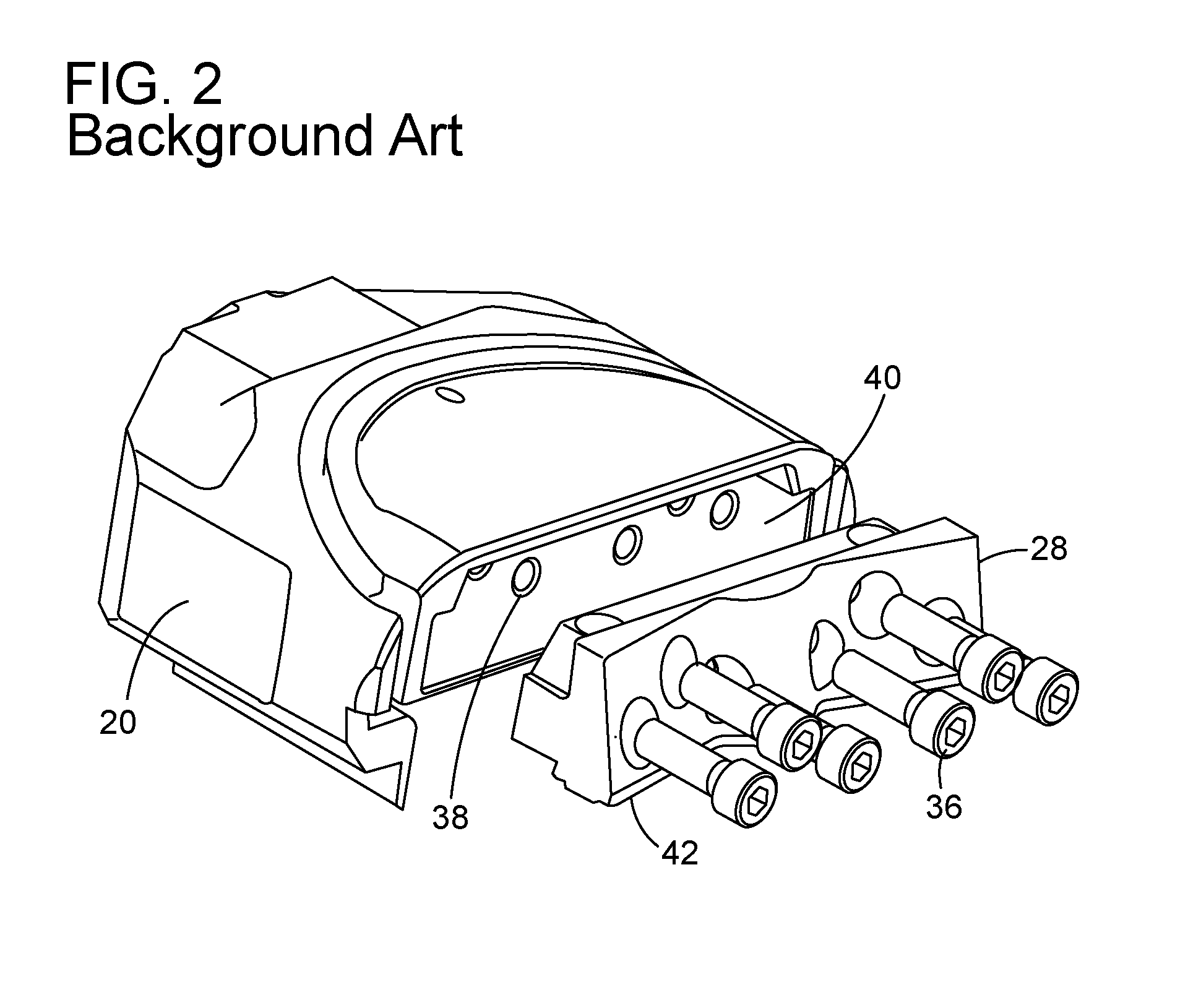

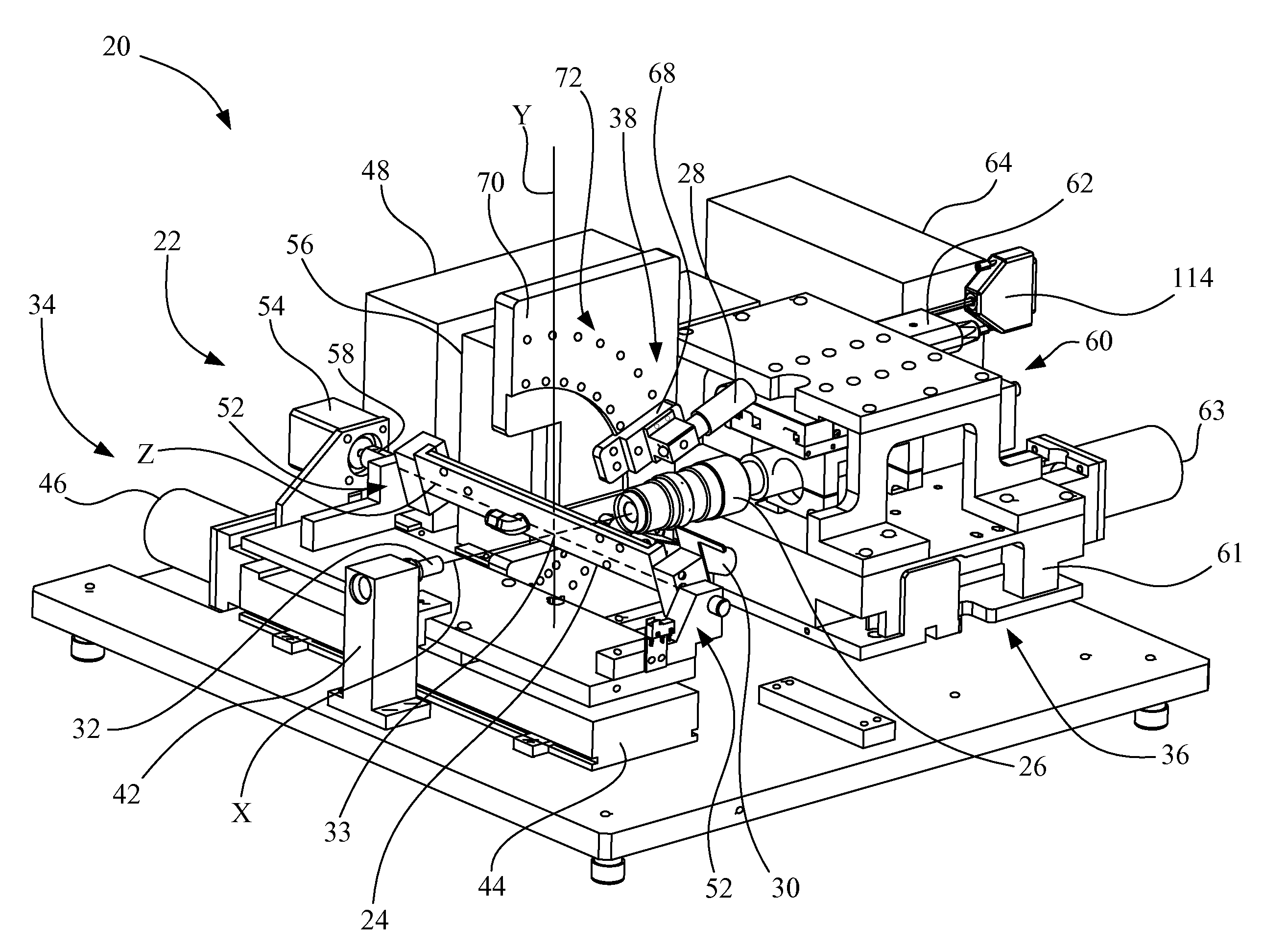

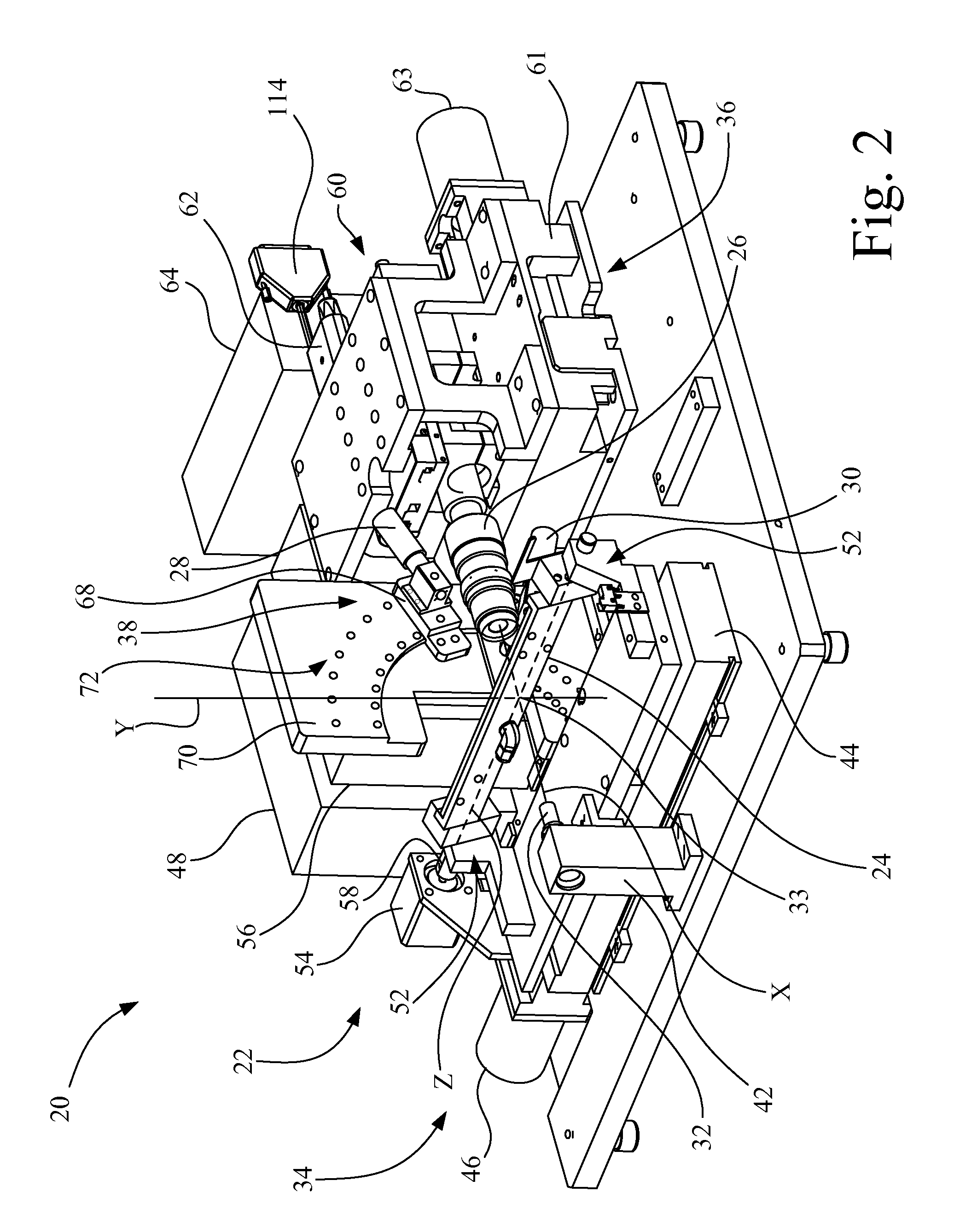

Method of forming barbs on a suture and apparatus for performing same

InactiveUS6848152B2Maximum anchoring propertyMore suitedSuture equipmentsSurgical needlesEngineeringBlade geometry

A method of making a barbed suture by varying the blade geometry and / or the movement of the blade when cutting a suture. The method can also be accomplished with a cutting device to create a plurality of barbs on the exterior of surgical suture. The barbs produced using the method with the cutting device can be the same or random configurations.

Owner:CILAG GMBH INT

Method of forming barbs on a suture and apparatus for performing same

ActiveUS20040237736A1Maximum anchoring propertyMore suitedSuture equipmentsSurgical needlesEngineeringBlade geometry

A method of making a barbed suture by varying the blade geometry and / or the movement of the blade when cutting a suture is disclosed. The method can also be accomplished with a cutting device to create a plurality of barbs on the exterior of surgical suture. The barbs produced using the method with the cutting device can be the same or random configurations.

Owner:CILAG GMBH INTERNATIONAL

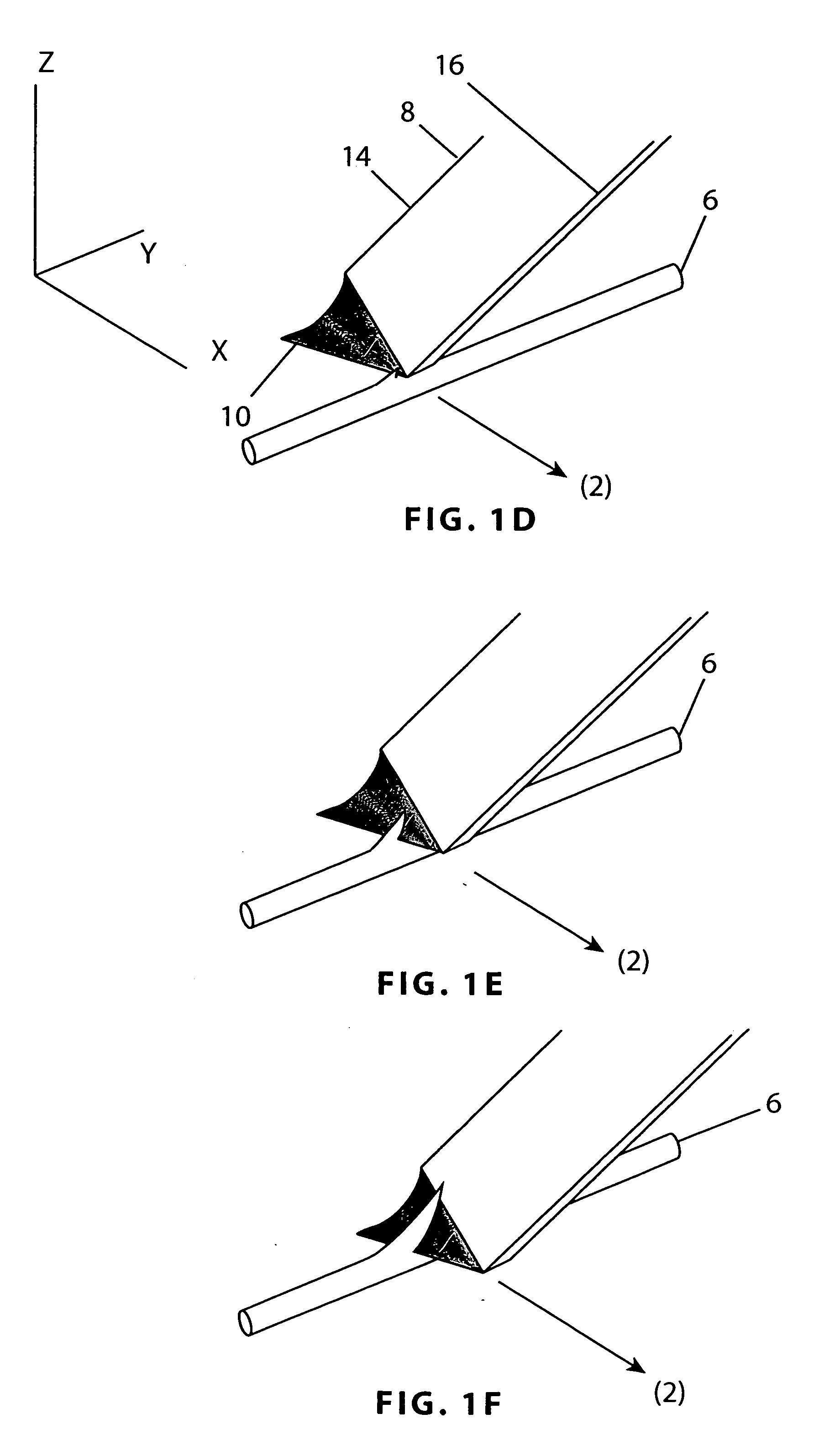

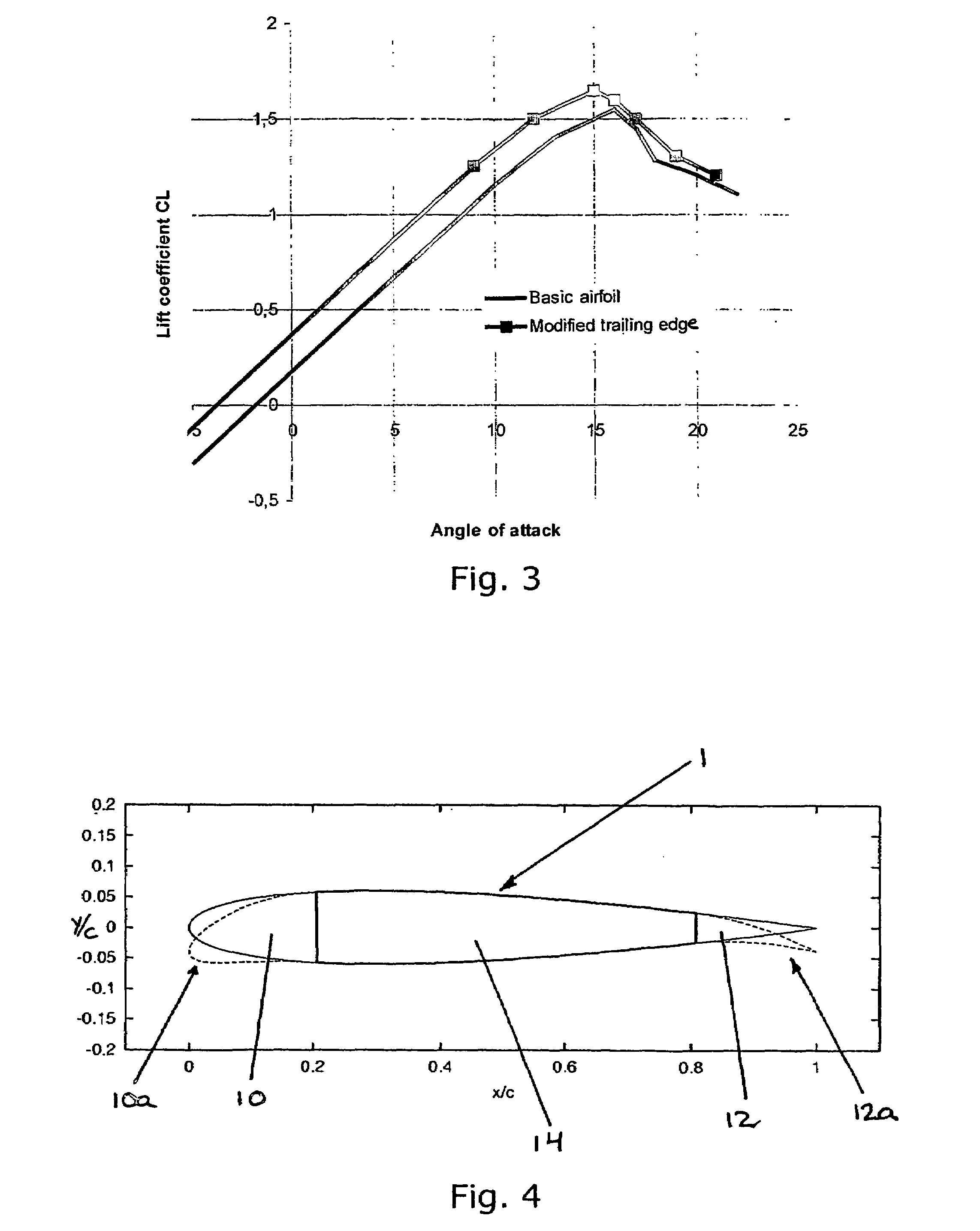

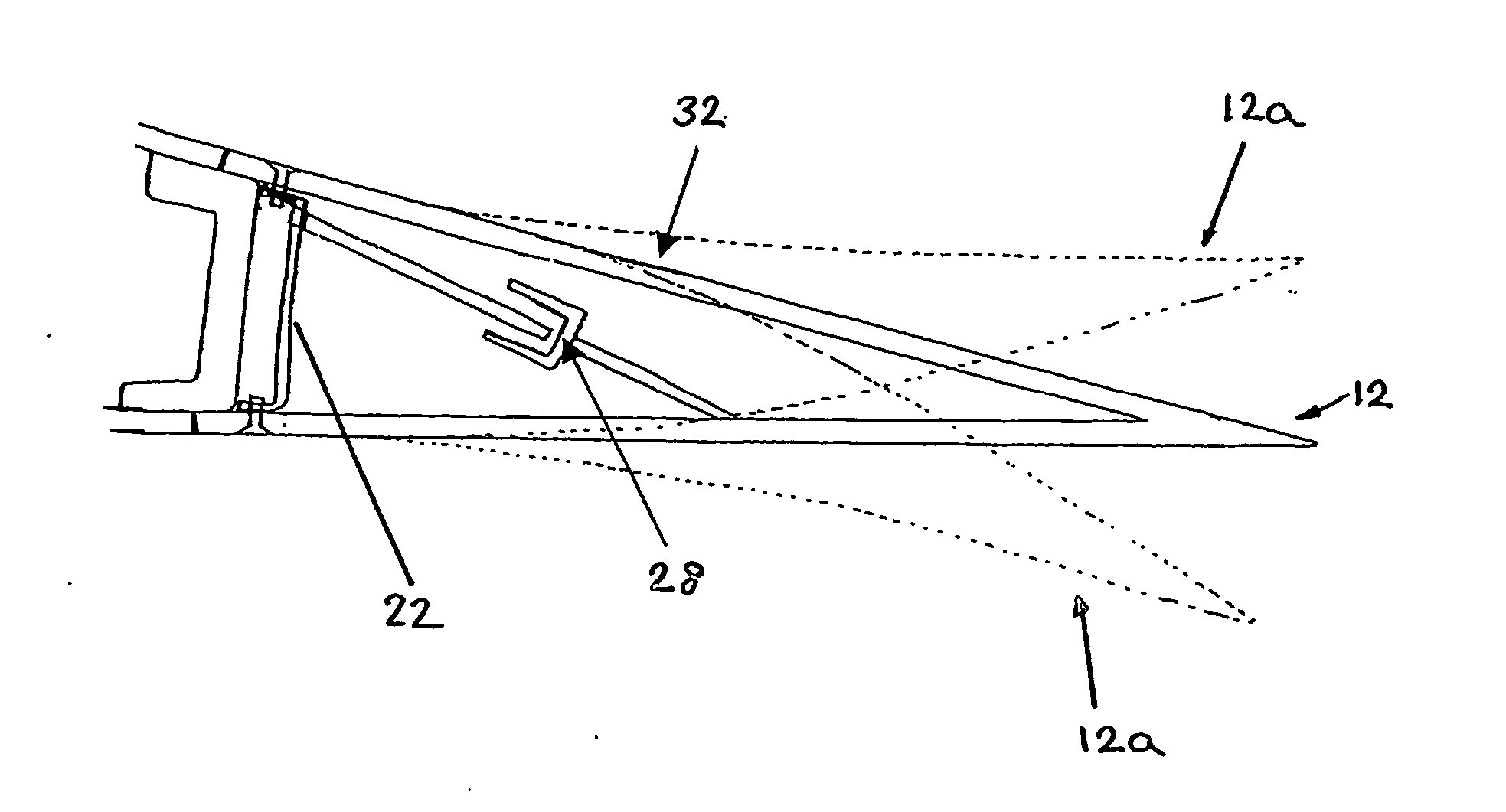

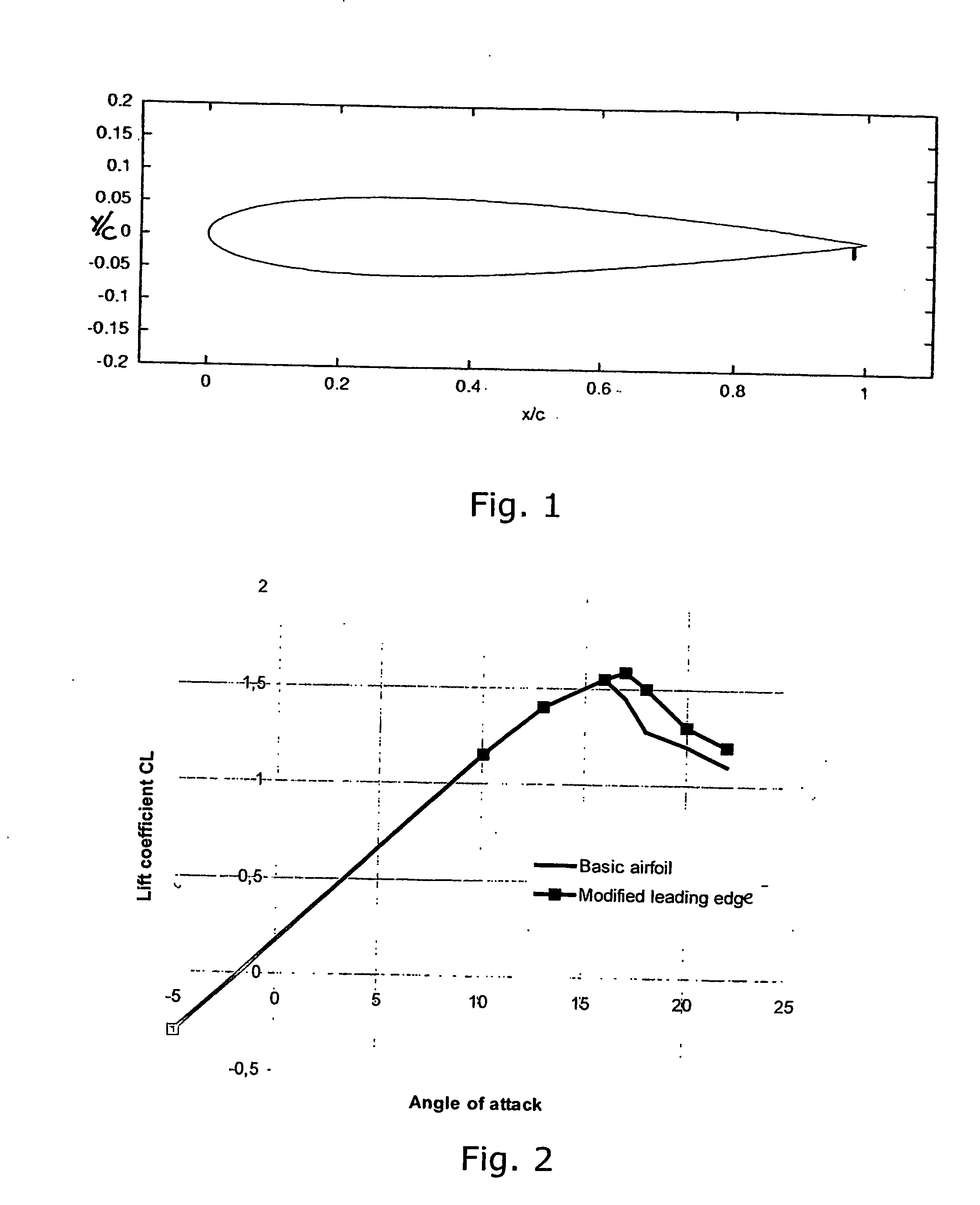

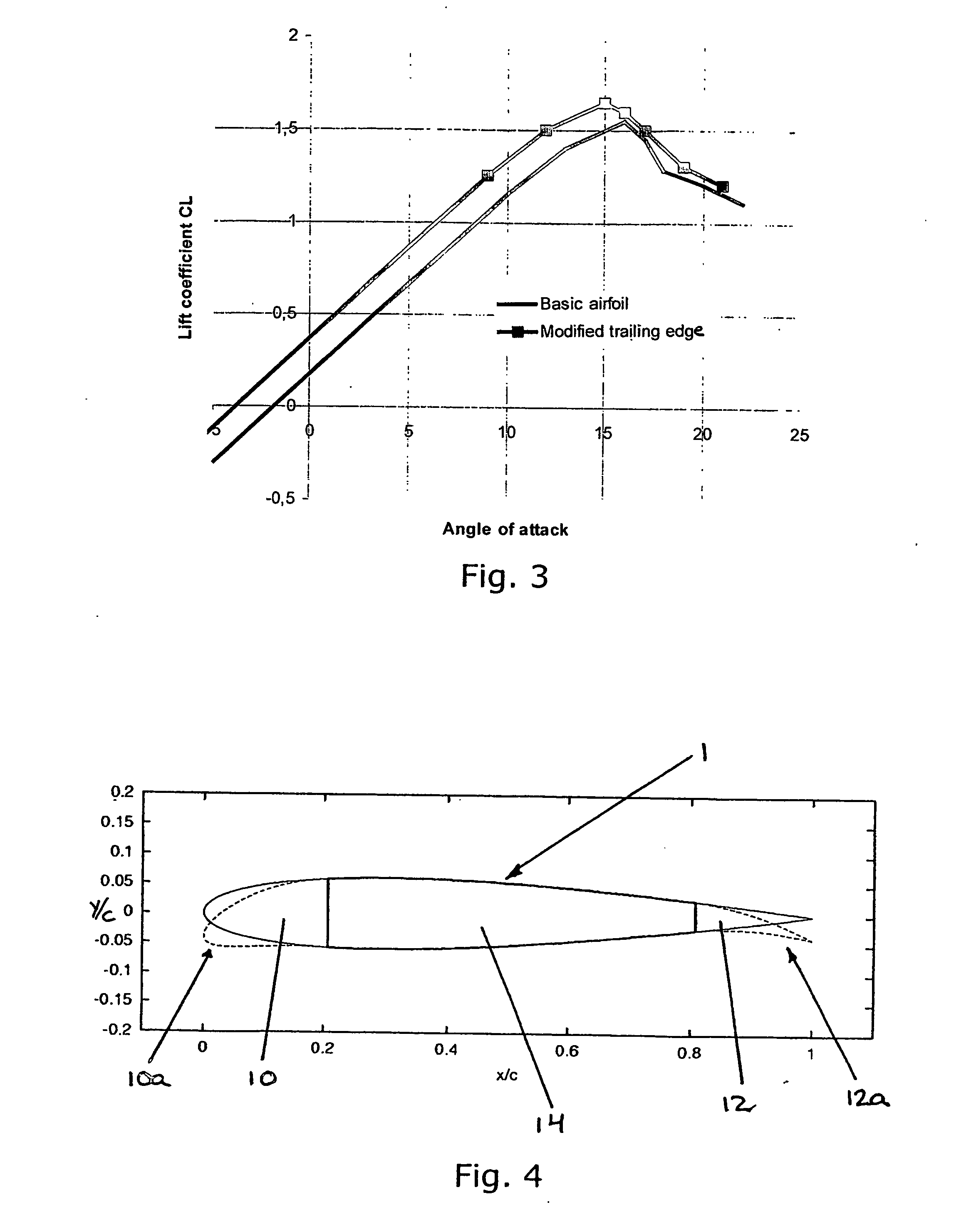

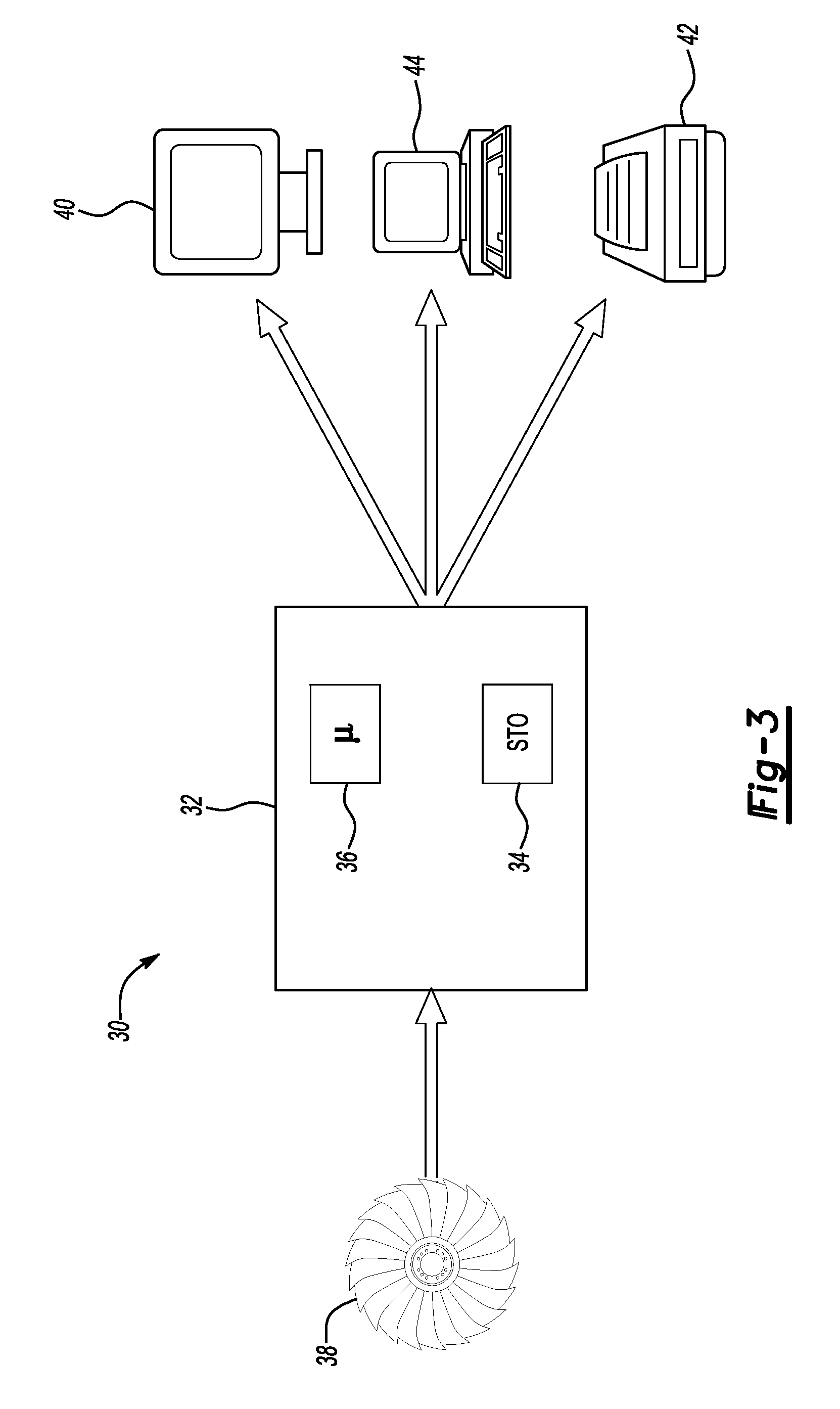

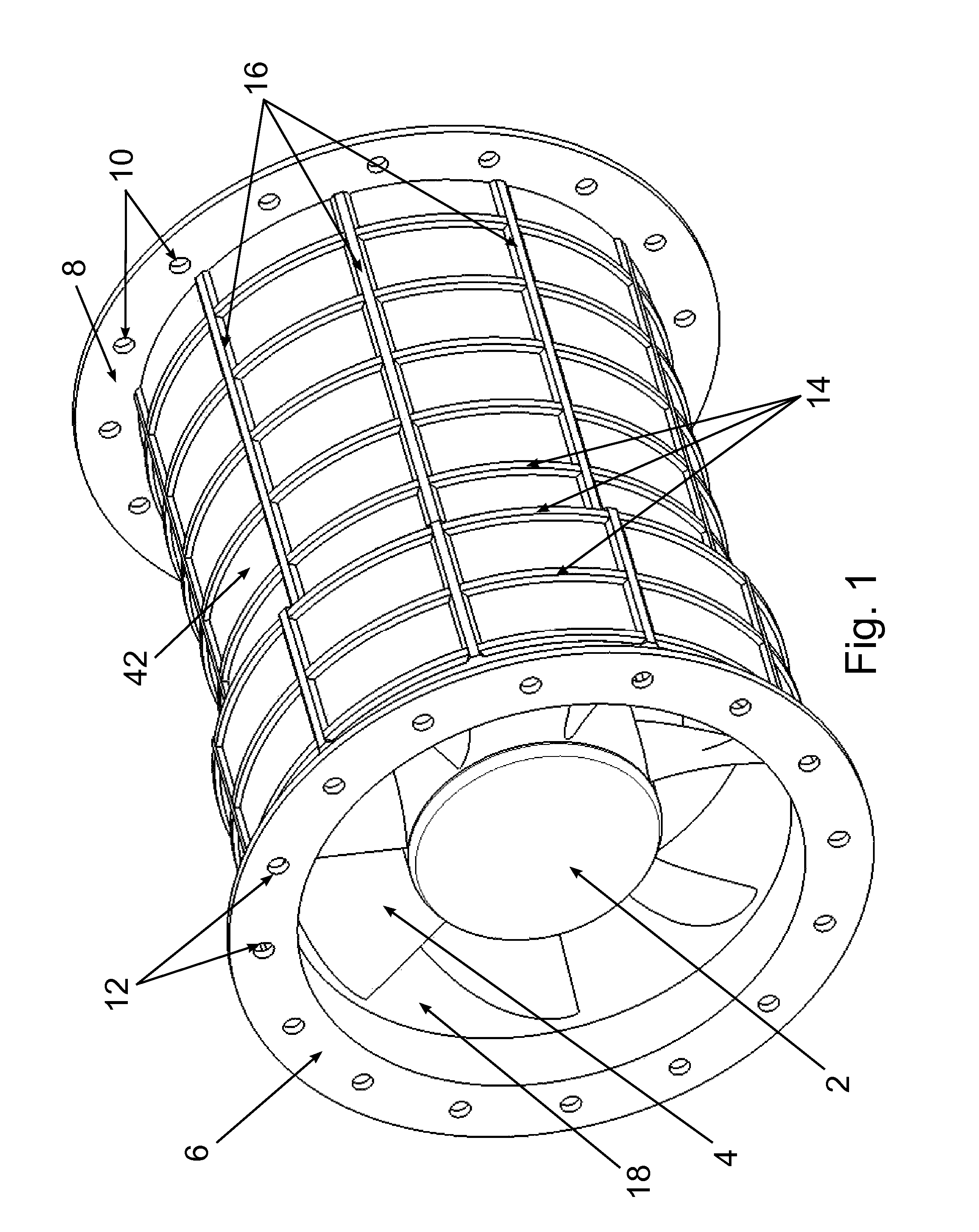

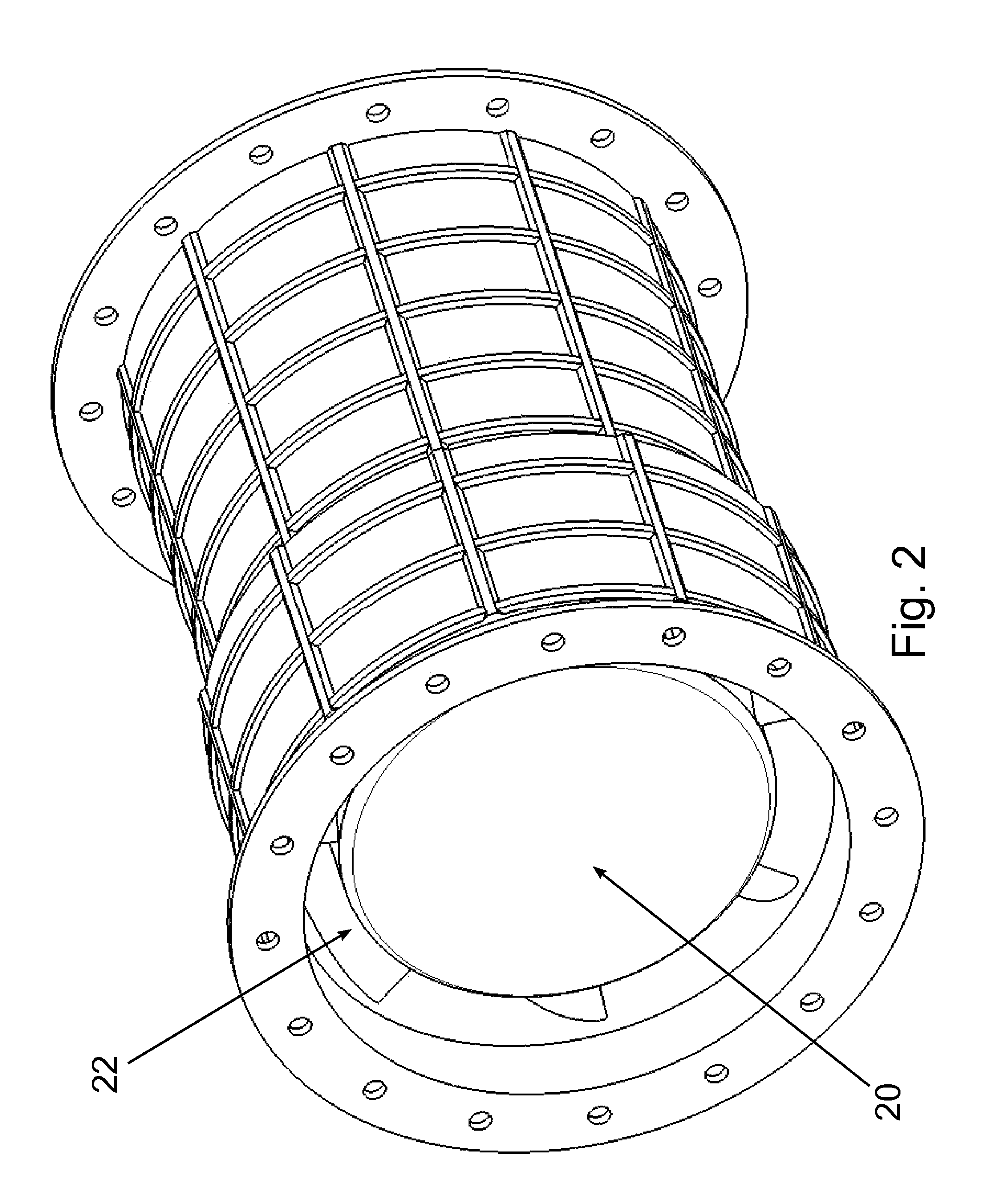

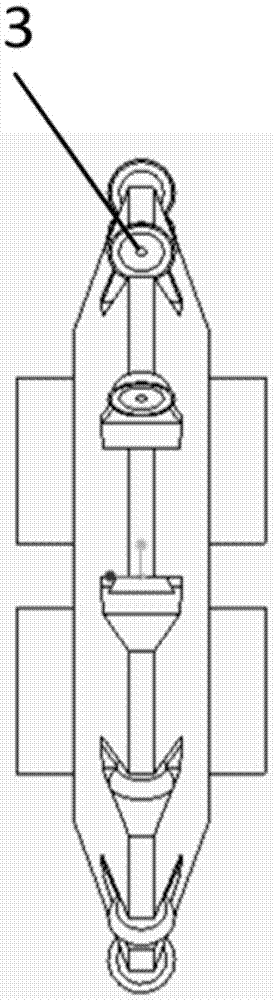

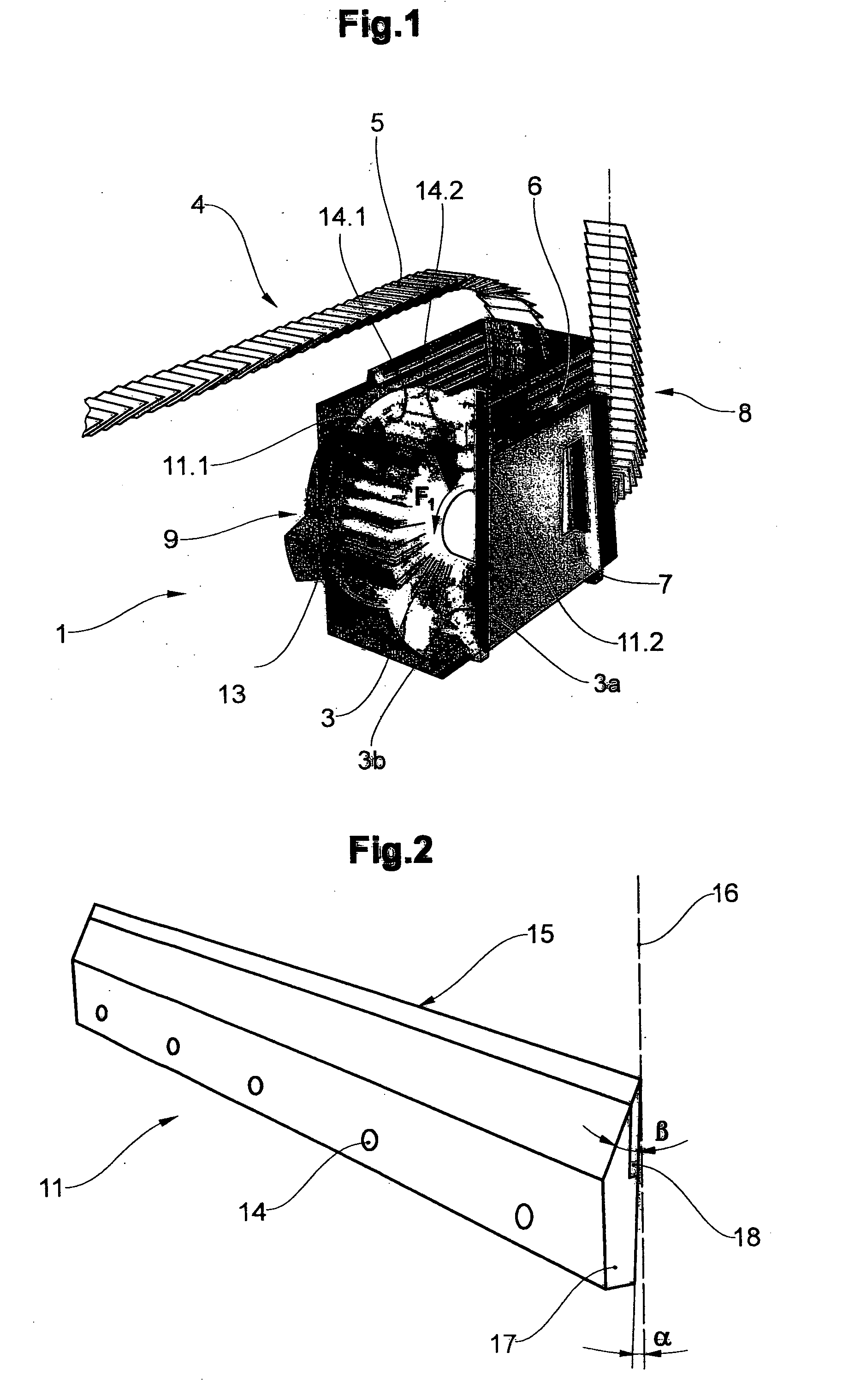

Control of power, loads and/or stability of a horizontal axis wind turbine by use of variable blade geometry control

Owner:DANMARKS TEKNISKE UNIV

Control of power, loads and/or stability of a horizontal axis wind turbine by use of variable blade geometry control

The present invention relates to a design concept by which the power, loads and / or stability of a wind turbine may be controlled by typically fast variation of the geometry of the blades using active geometry control (e.g. smart materials or by embedded mechanical actuators), or using passive geometry control (e.g. changes arising from loading and / or deformation of the blade) or by a combination of the two methods. The invention relates in particular to a wind turbine blade, a wind turbine and a method of controlling a wind turbine.

Owner:DANMARKS TEKNISKE UNIV

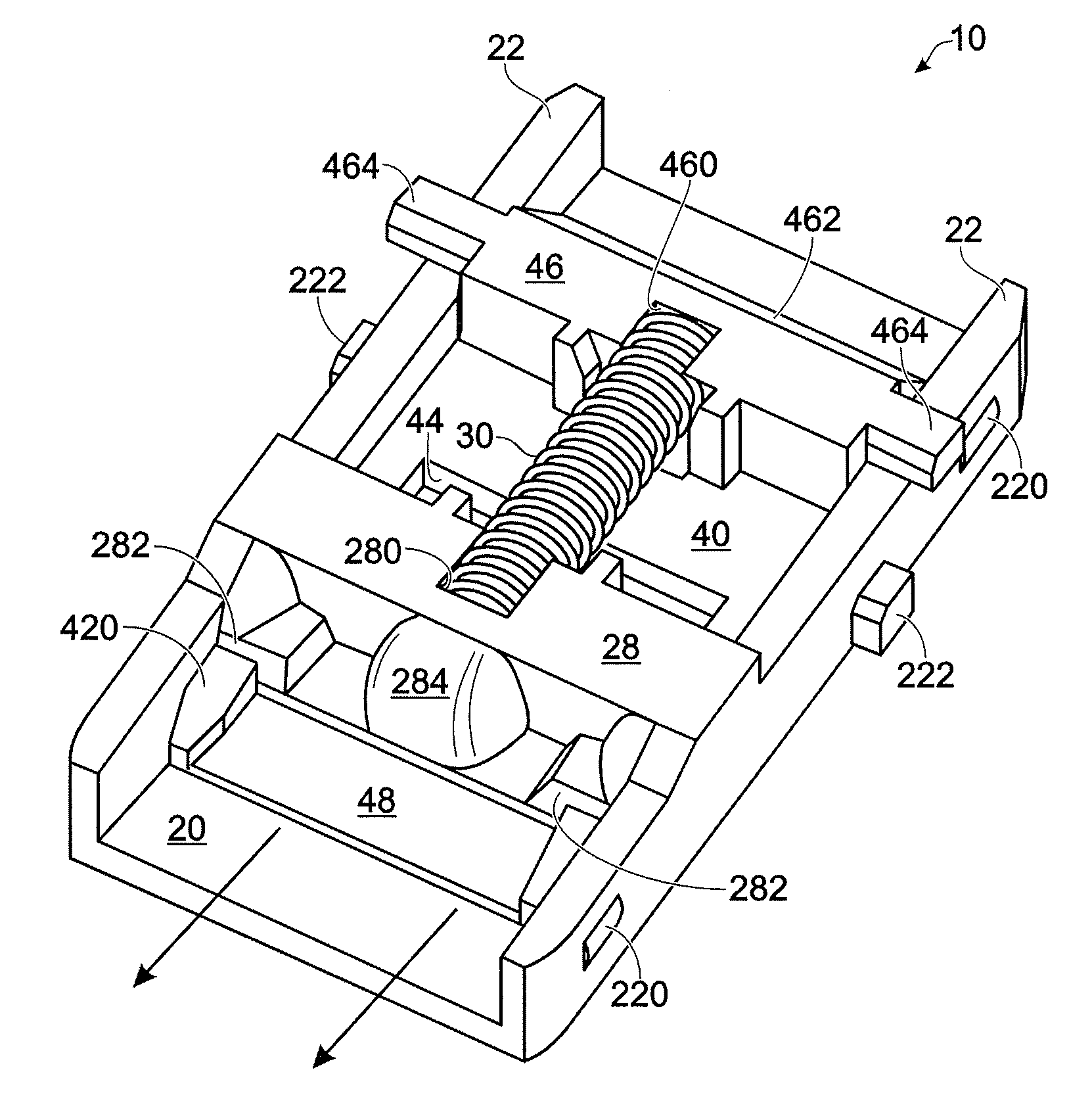

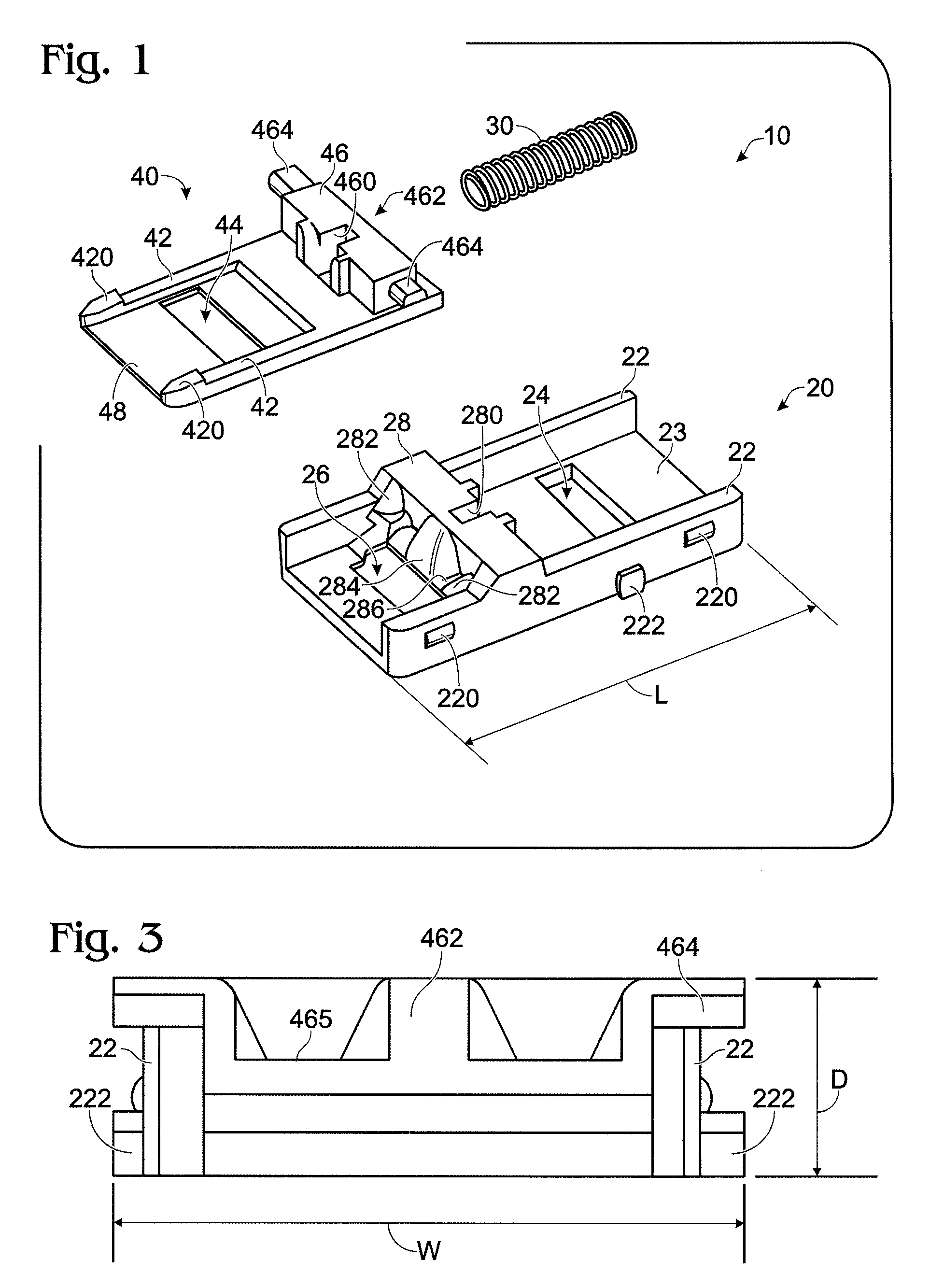

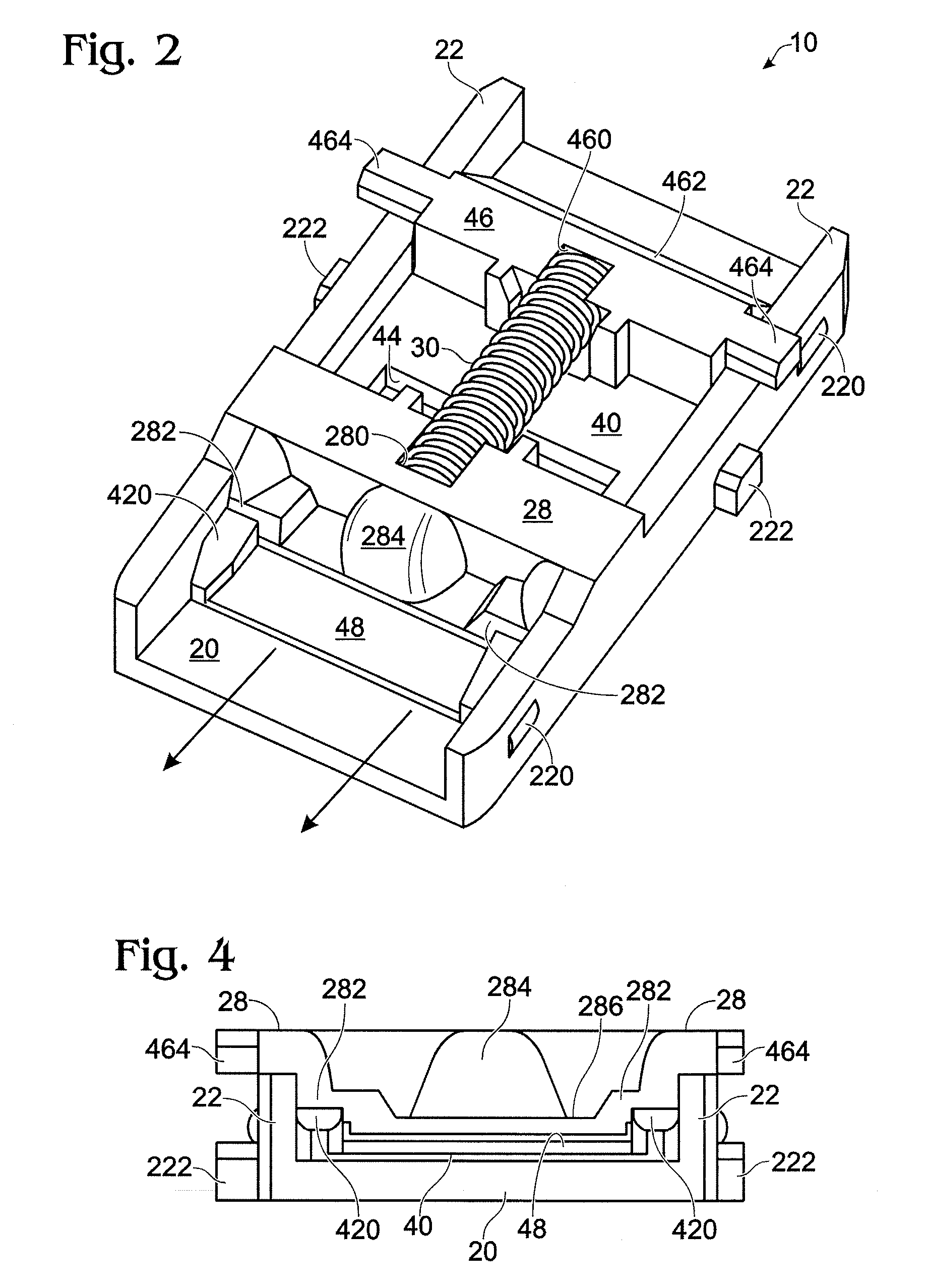

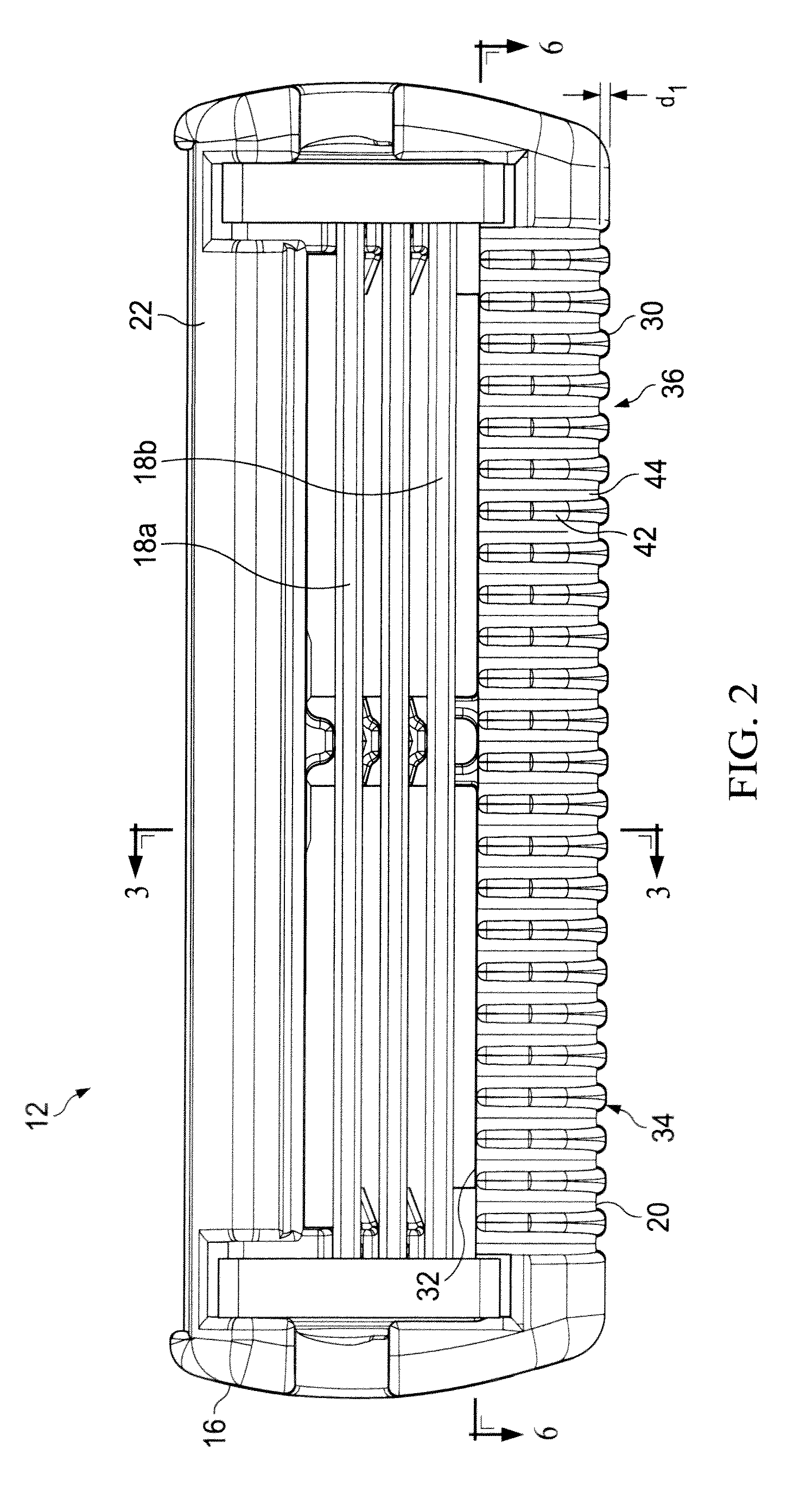

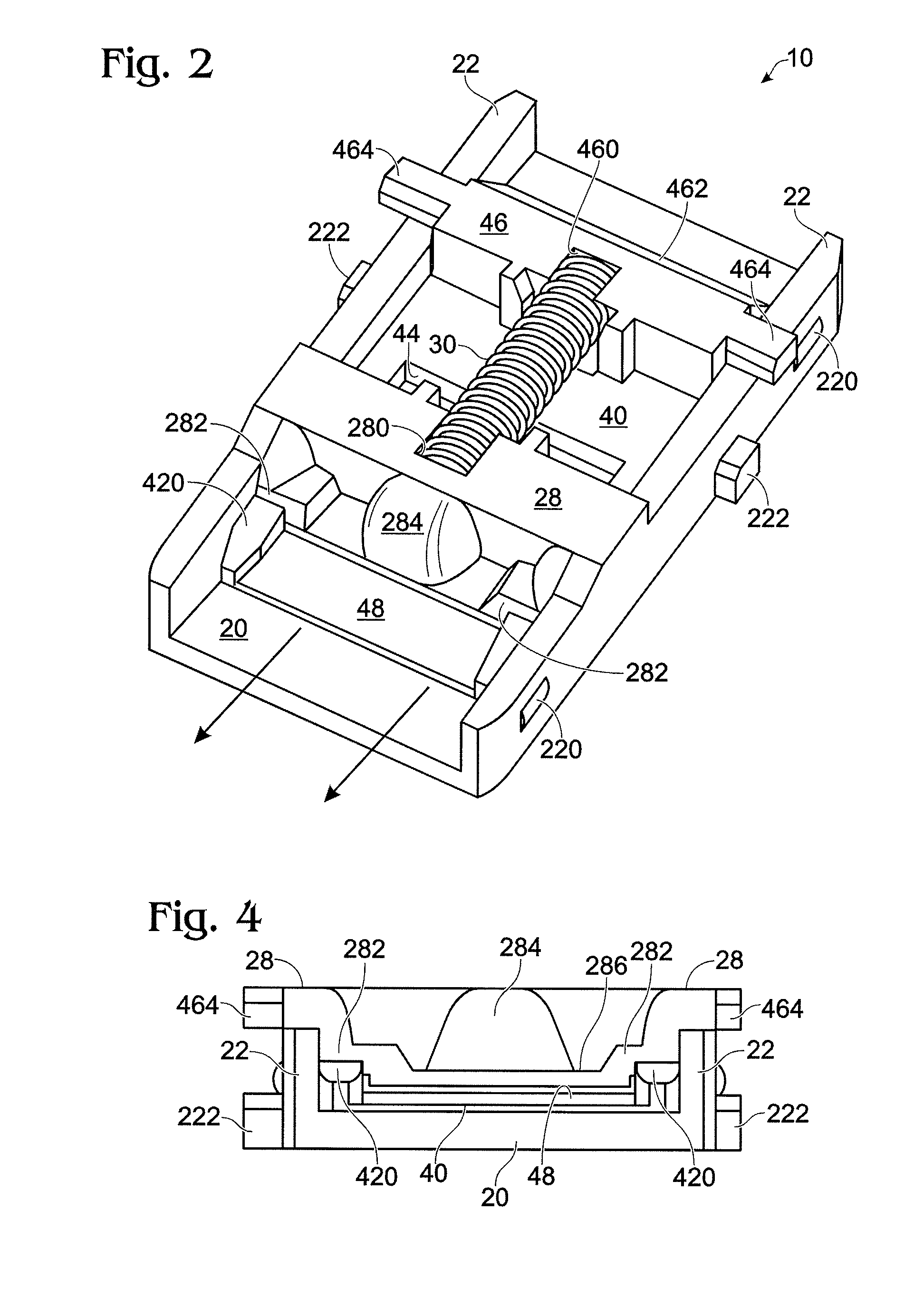

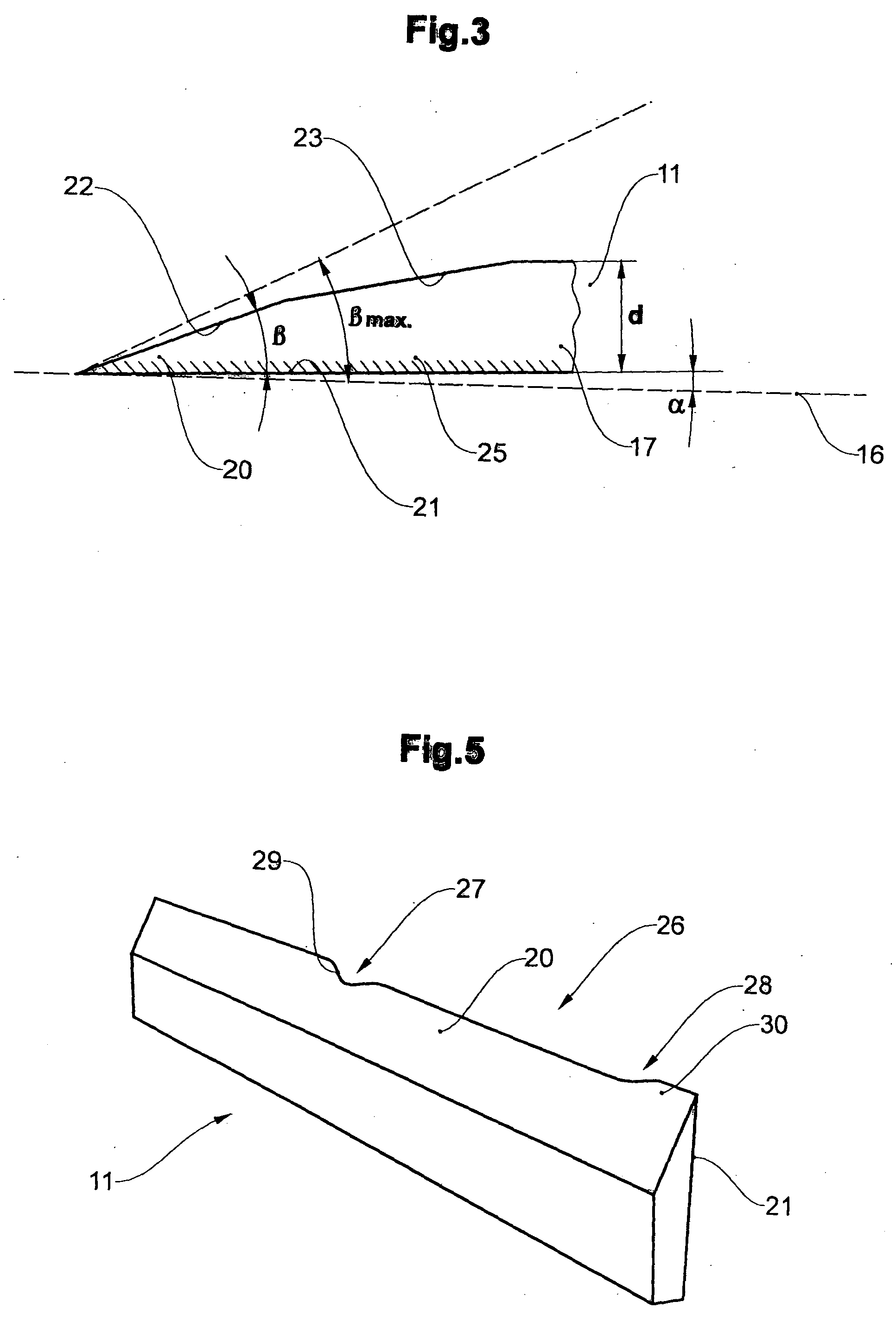

Protective device with tamper resistant shutters

InactiveUS7312394B1Switch operated by falling currentCasings/cabinets/drawers detailsWindow shutterEngineering

The present invention is directed to a protective shutter assembly for use within a cover assembly of an electrical wiring device. The assembly includes a frameless shutter sub-assembly movable between a closed position and an open position. The frameless shutter sub-assembly is configured to move from the closed position to the open position in response to engaging at least one plug blade having a predetermined plug blade geometry. A spring member is disposed within the frameless shutter sub-assembly. The spring member is configured to bias the frameless shutter sub-assembly in the closed position. At least one retainer element is disposed in the frameless shutter sub-assembly. The at least one retainer element being configured to retain the spring member within the frameless shutter sub-assembly. At least one registration member is disposed on the frameless shutter sub-assembly, the at least one registration member being configured to position and align the protective shutter assembly within the cover assembly.

Owner:PASS SEYMOUR

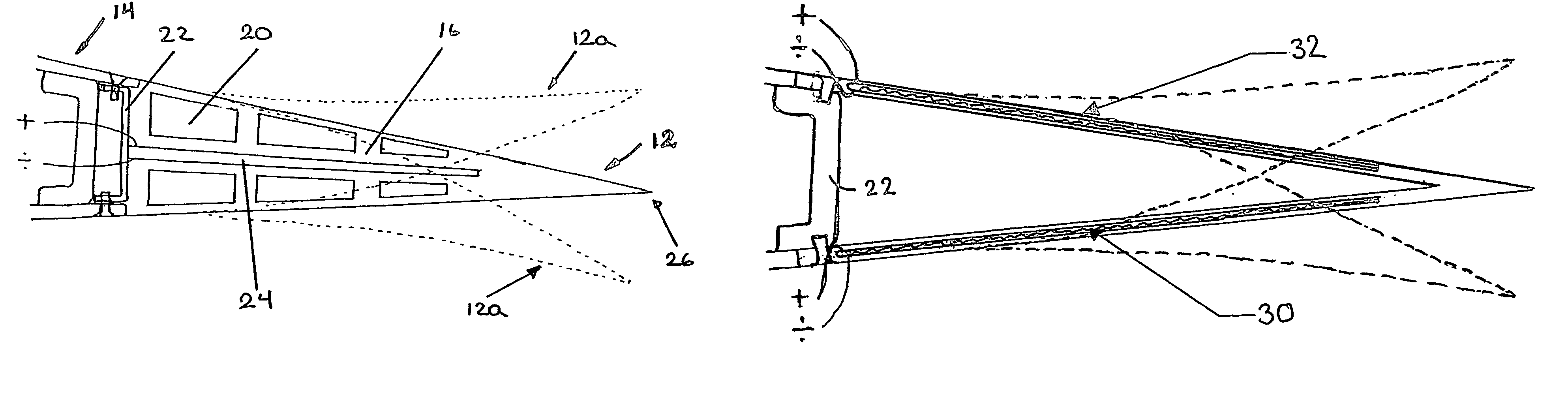

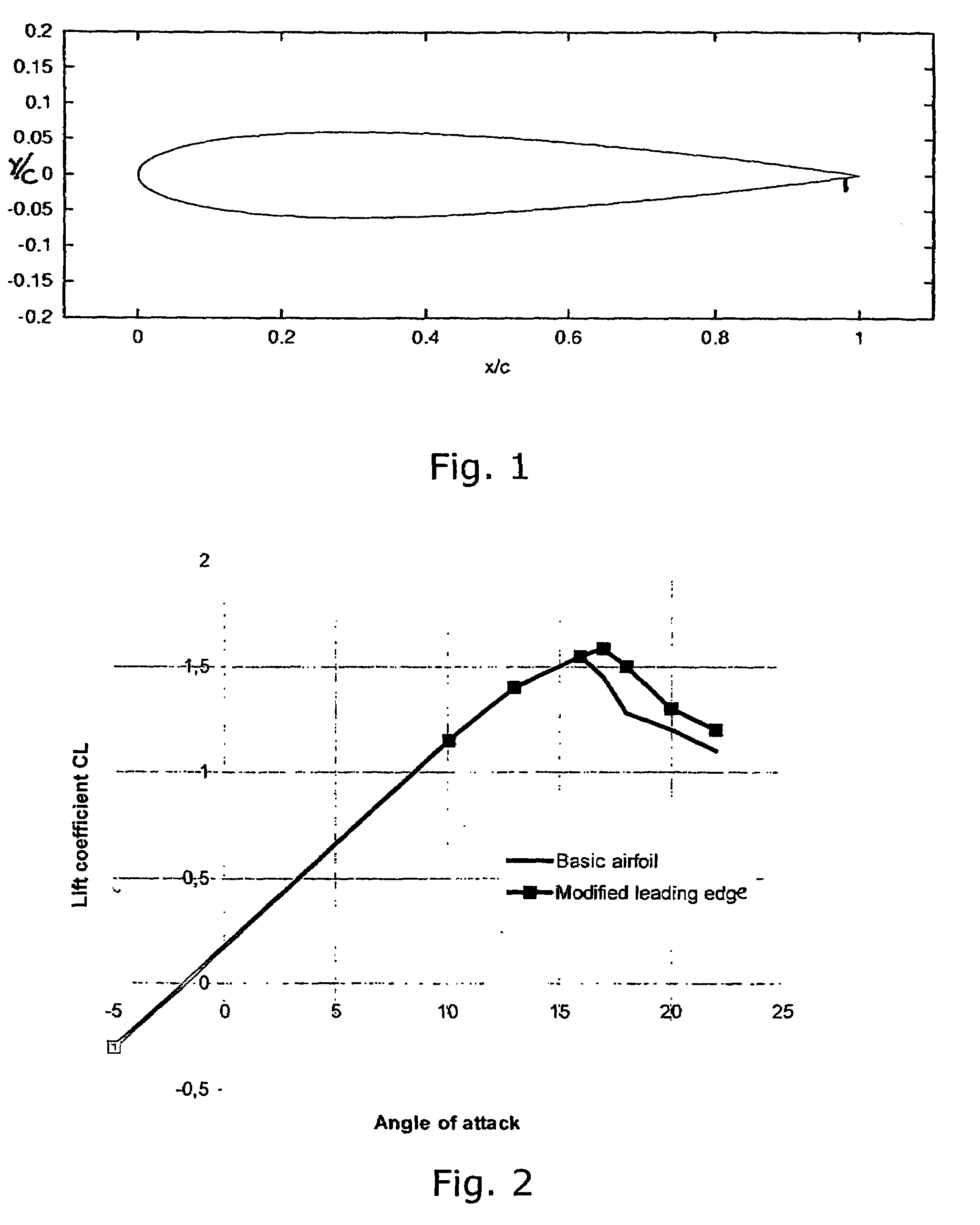

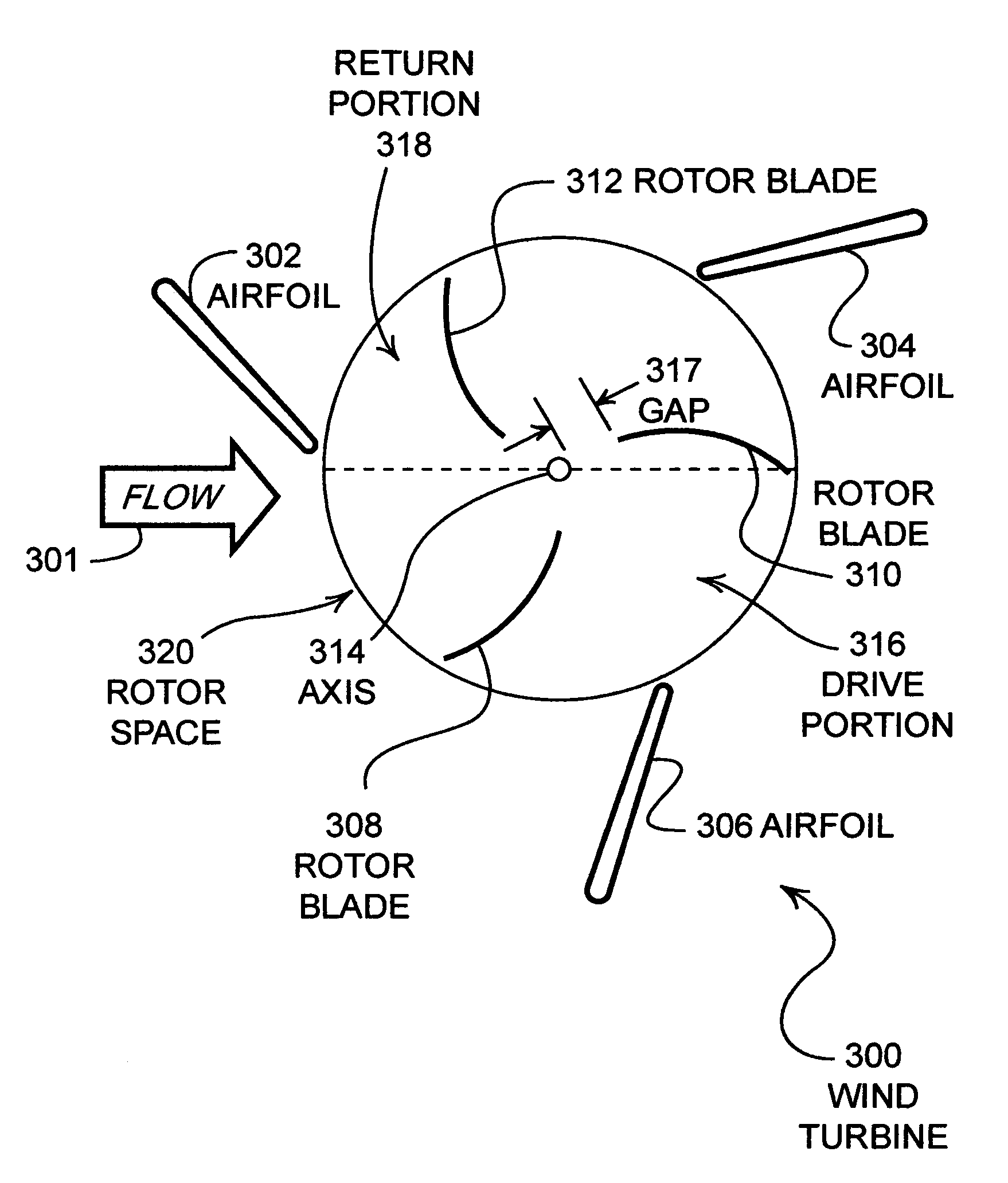

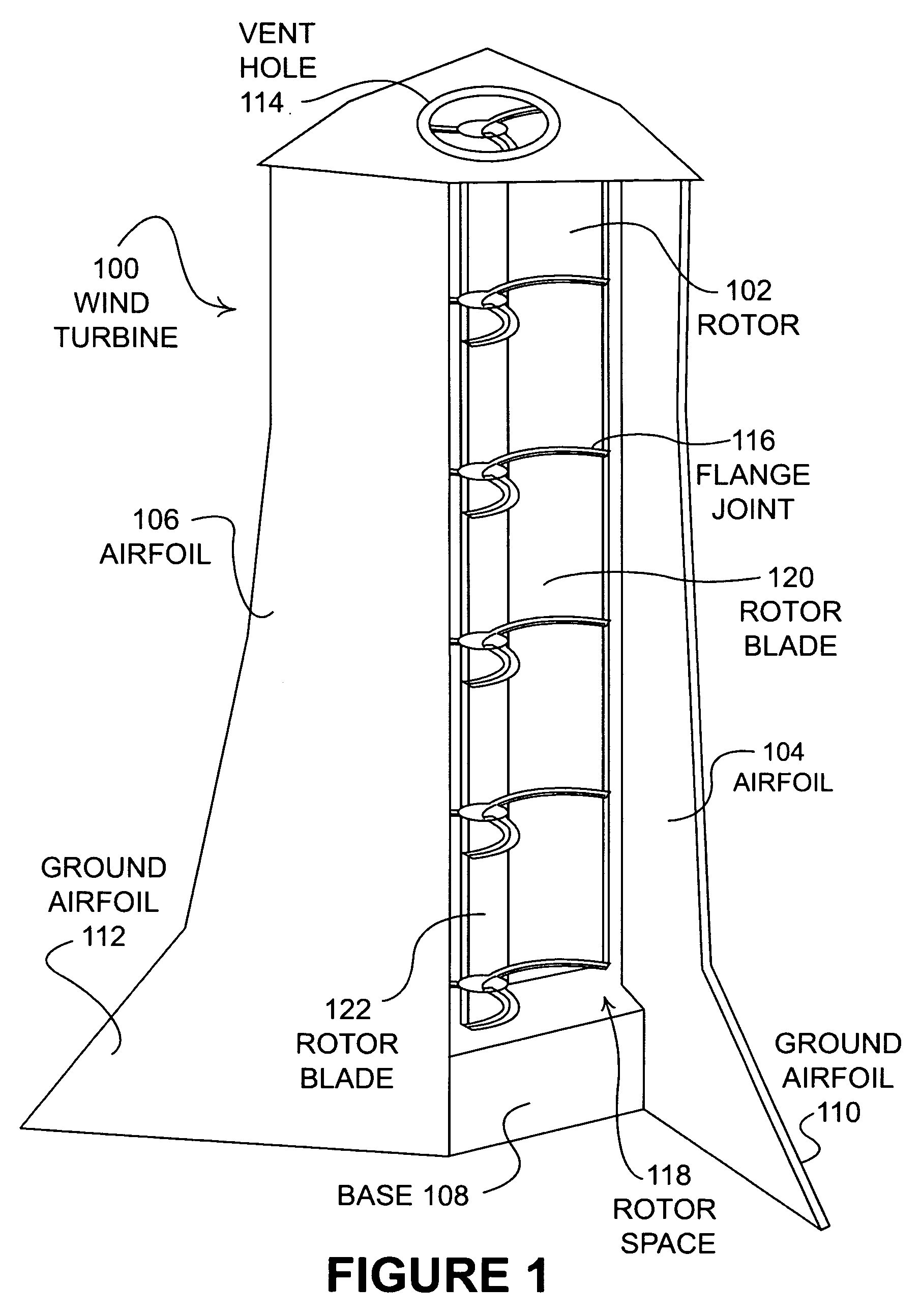

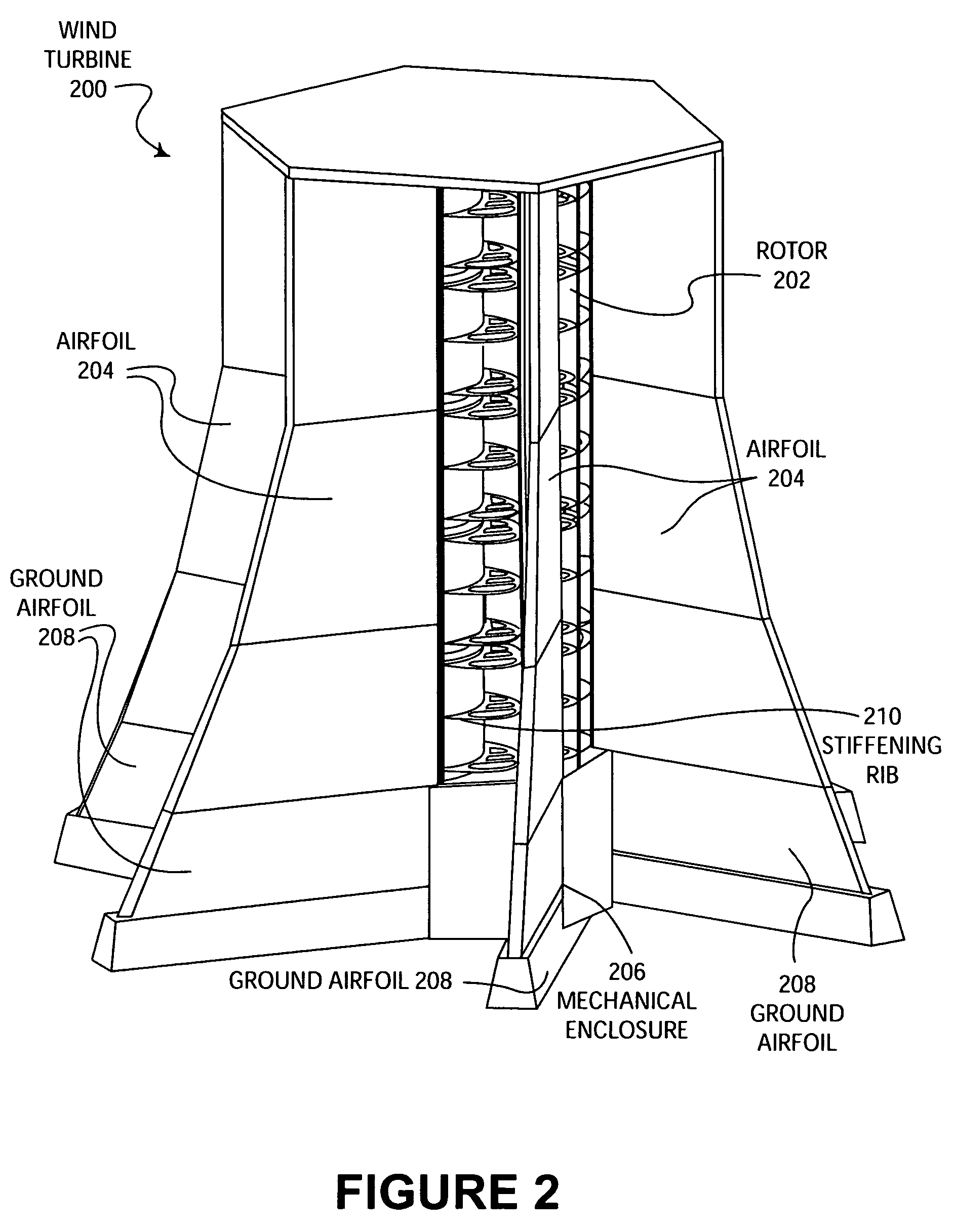

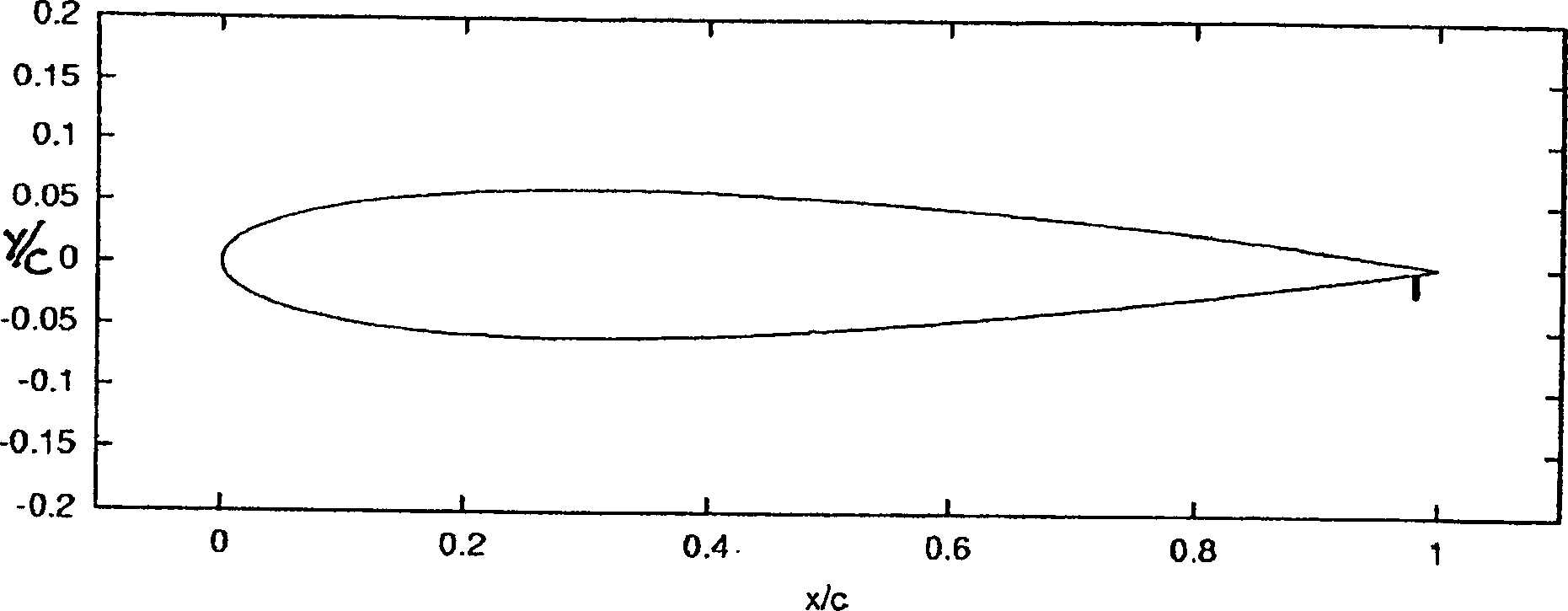

Wind turbine having airfoils for blocking and directing wind and rotors with or without a central gap

InactiveUS6966747B2Safe and visually appealingImprove efficiencyPump componentsFinal product manufactureAir volumeMoment of inertia

A wind turbine device of increased efficiency is comprised of a set of fixed airfoils that direct wind into a rotor having a plurality of blades. The fixed airfoils may extend to the ground to increase the amount of wind directed into the rotor and may be manufactured from concrete. The rotor blades have a vented portion near the axis of rotation that has been found to increase efficiency for certain blade geometries. For other blade geometries, increased efficiency is observed with no gap at the axis of rotation. The rotor may also be manufactured from composite materials to increase strength while decreasing the moment of inertia for the rotor.

Owner:TERRA MOYA AQUA

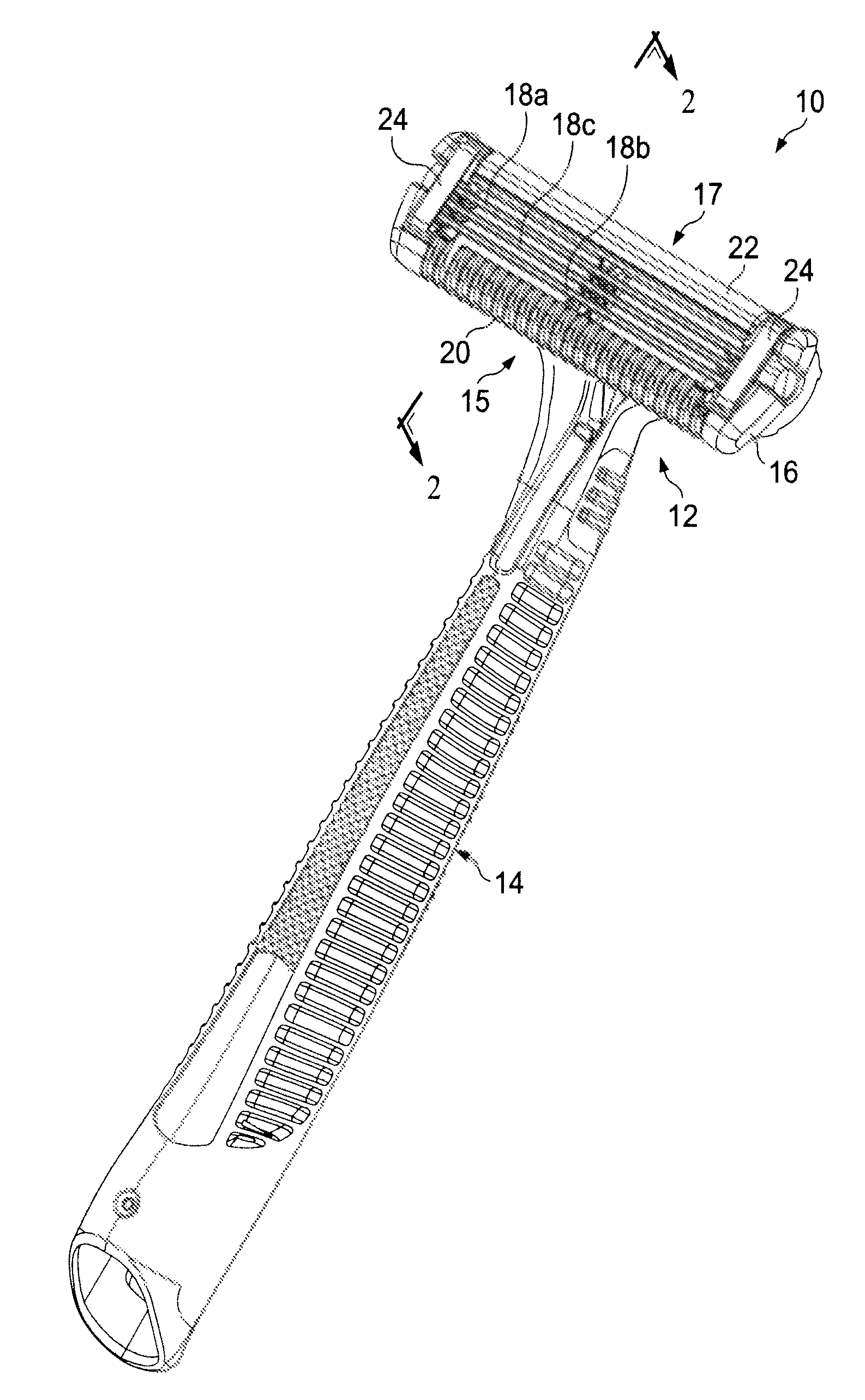

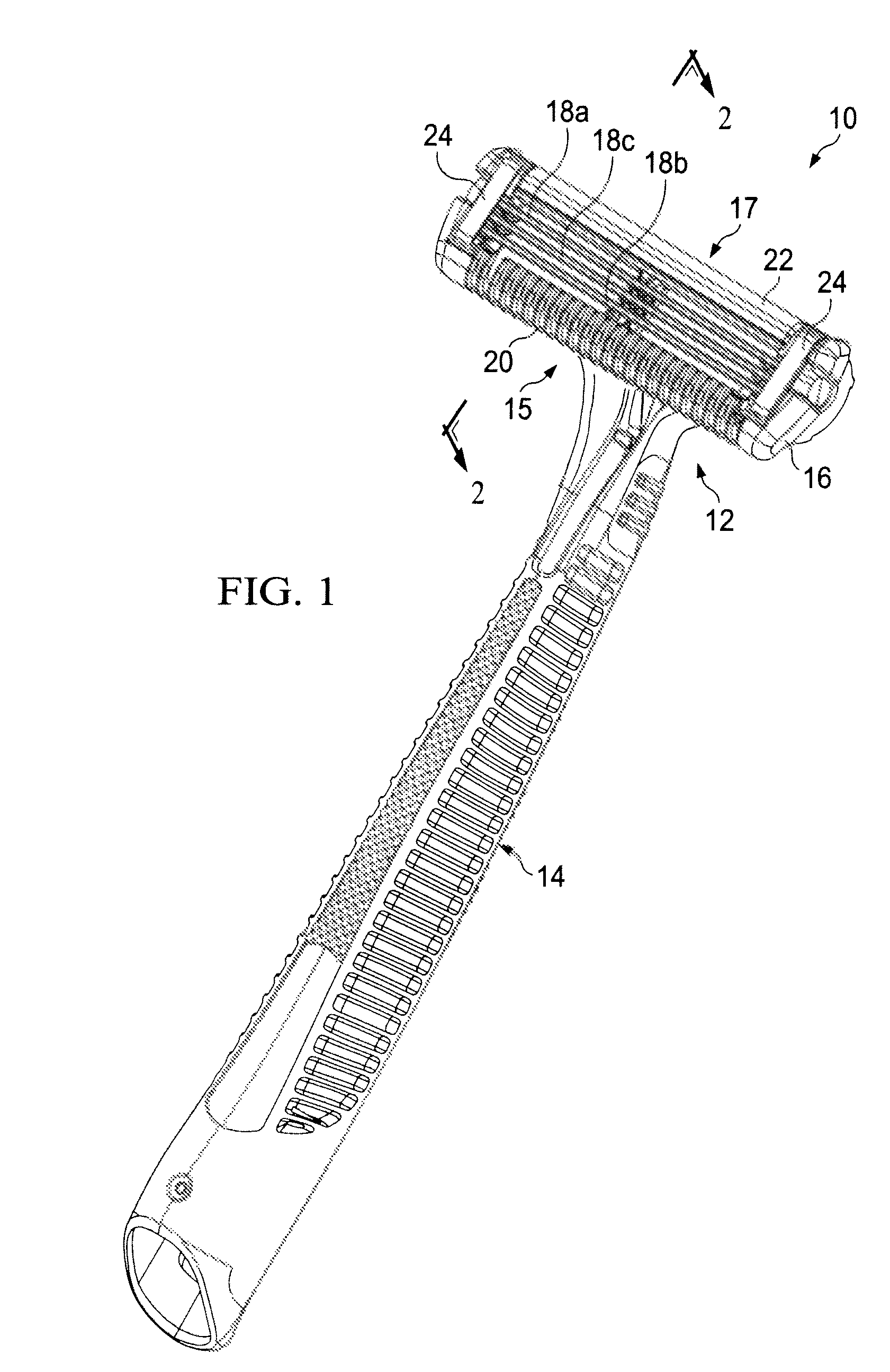

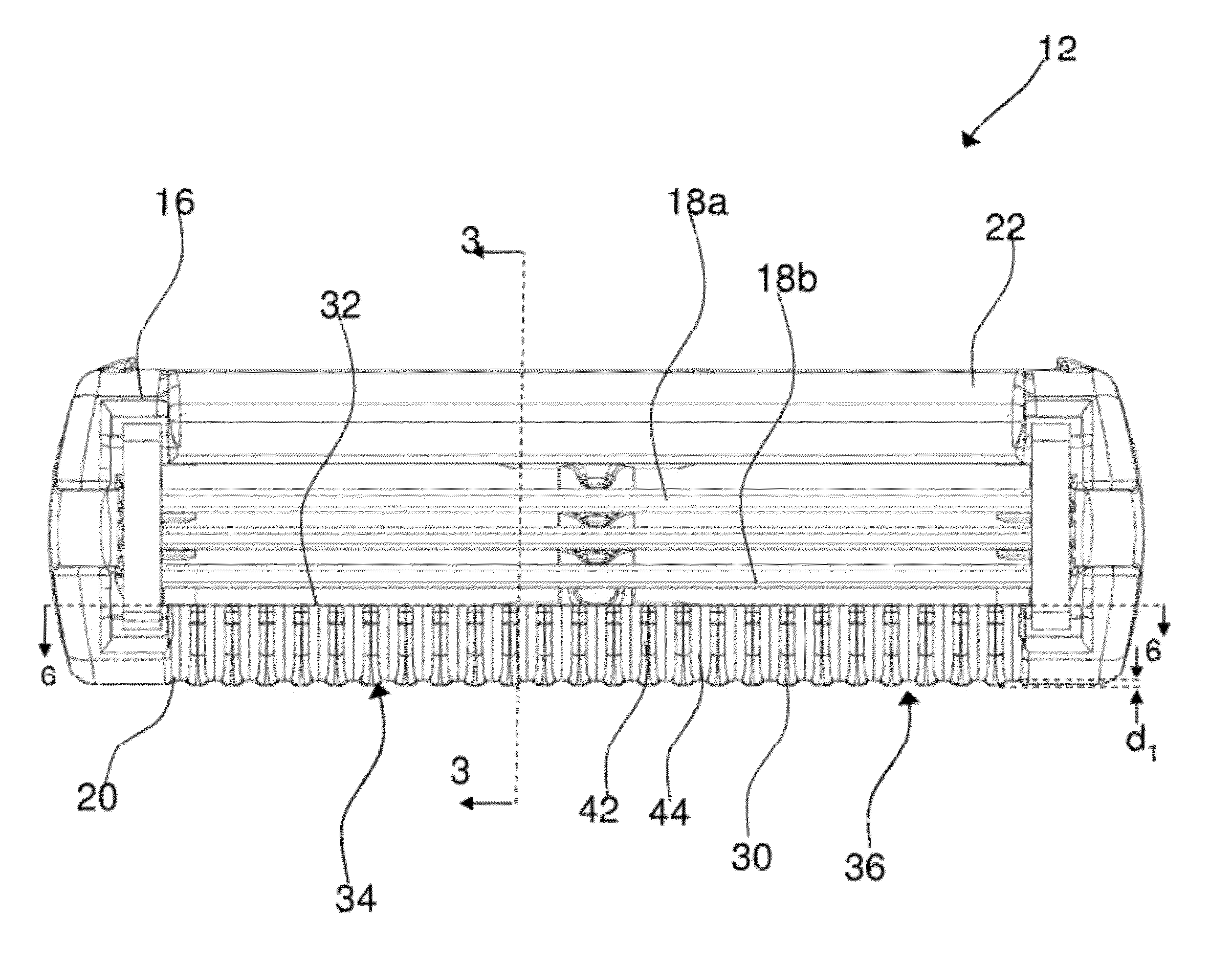

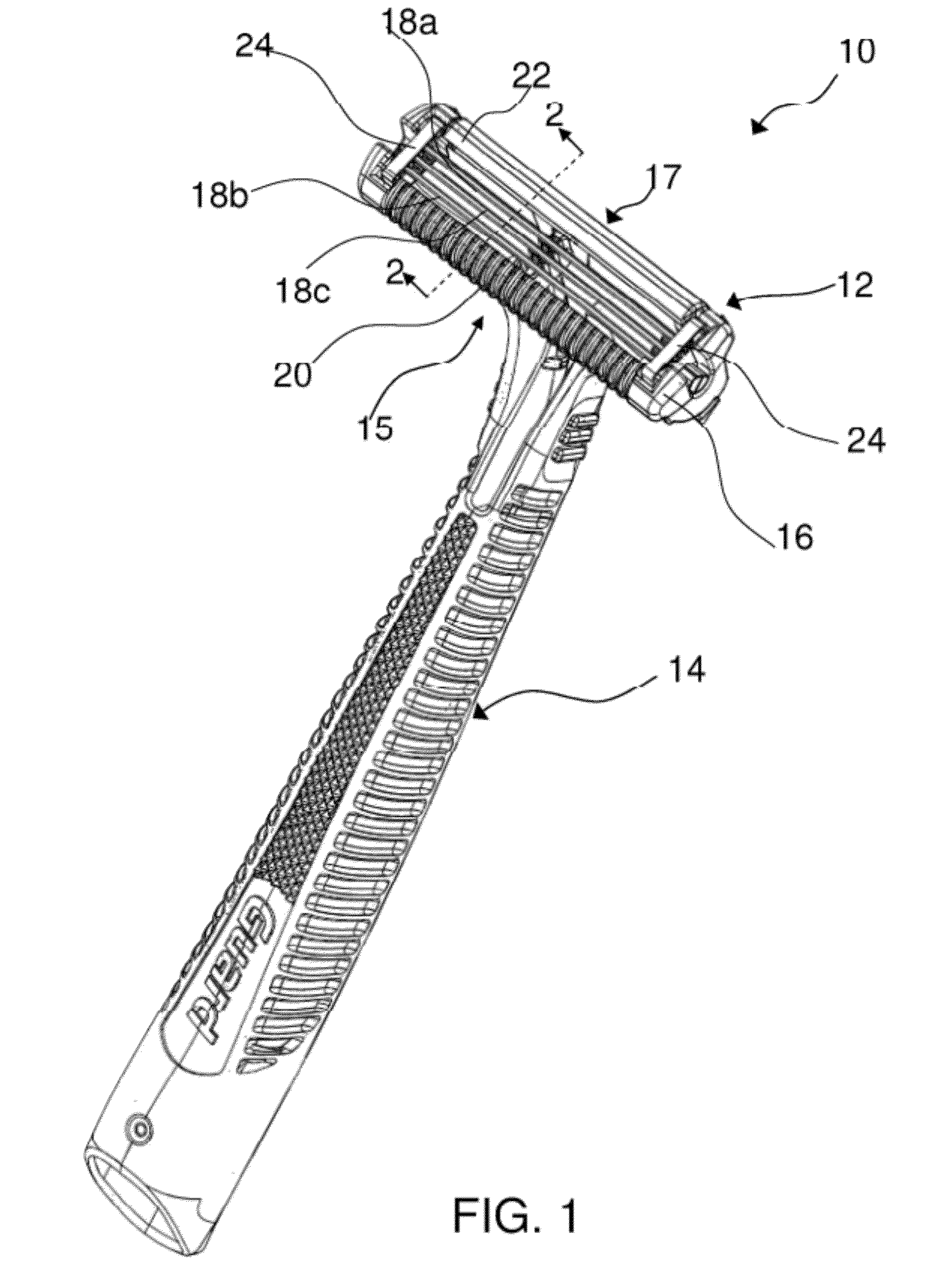

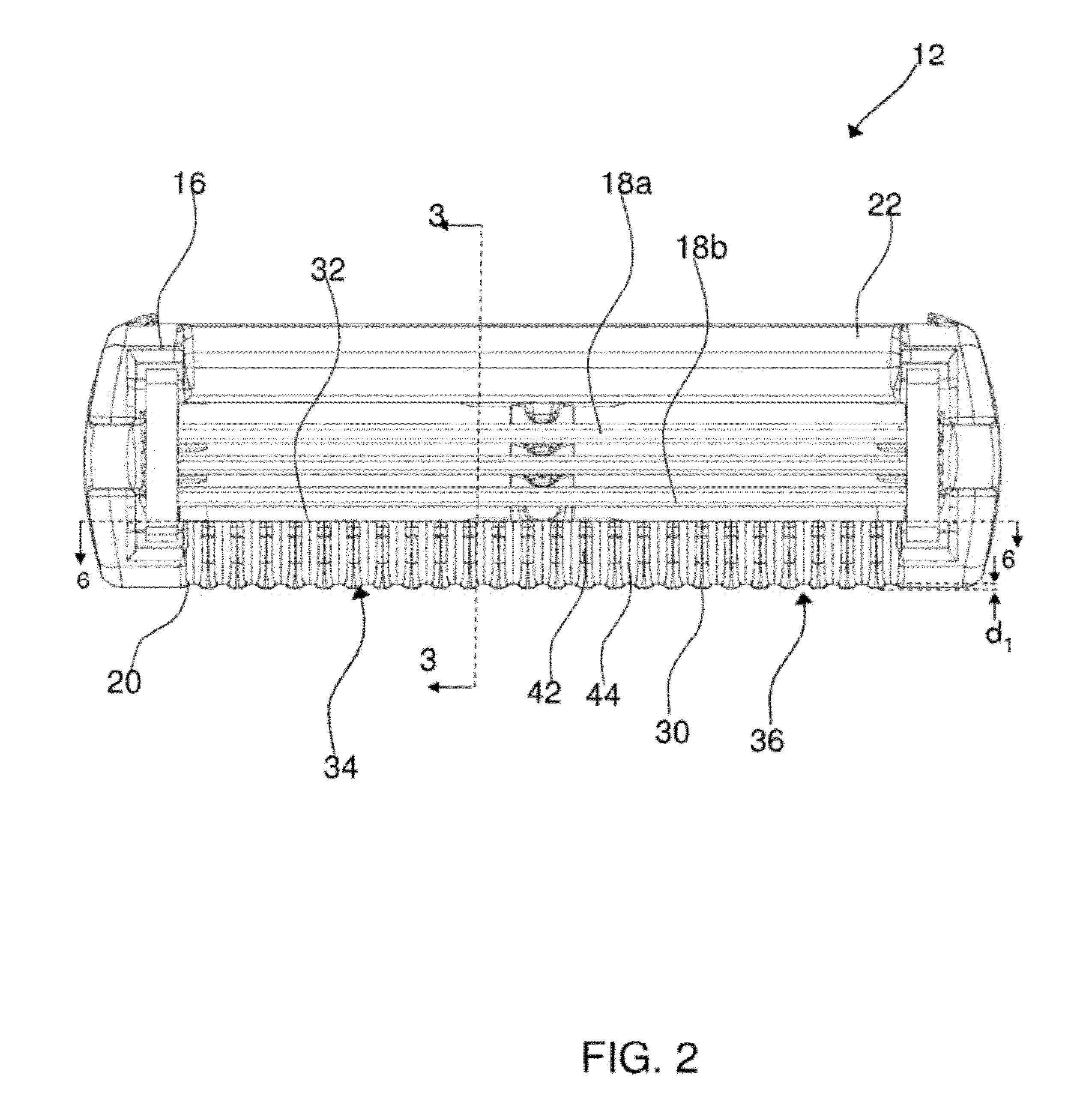

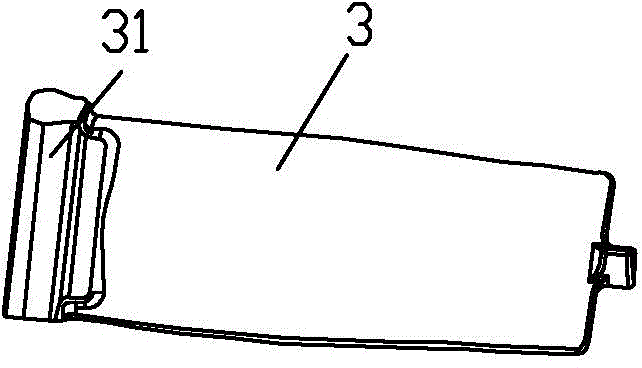

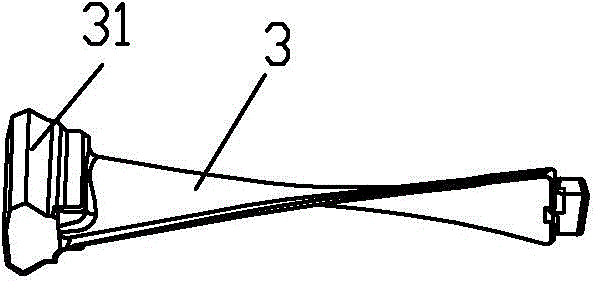

Shaving cartridge with supressed blade geometry

Owner:THE GILLETTE CO

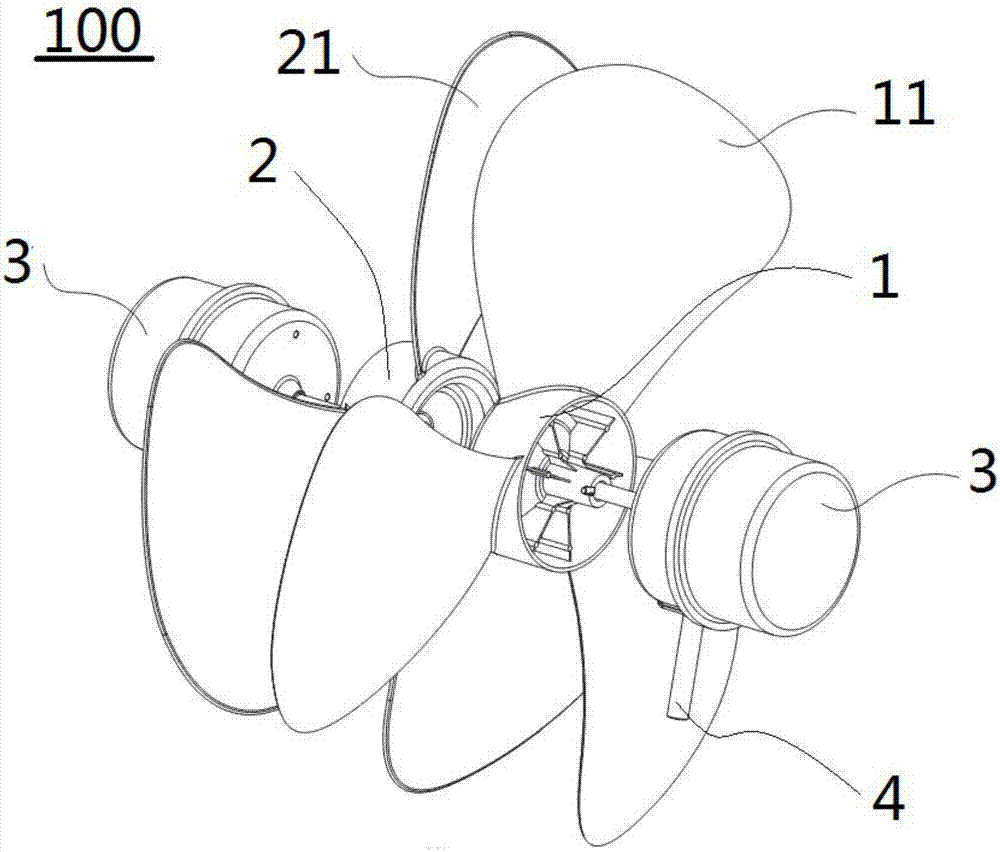

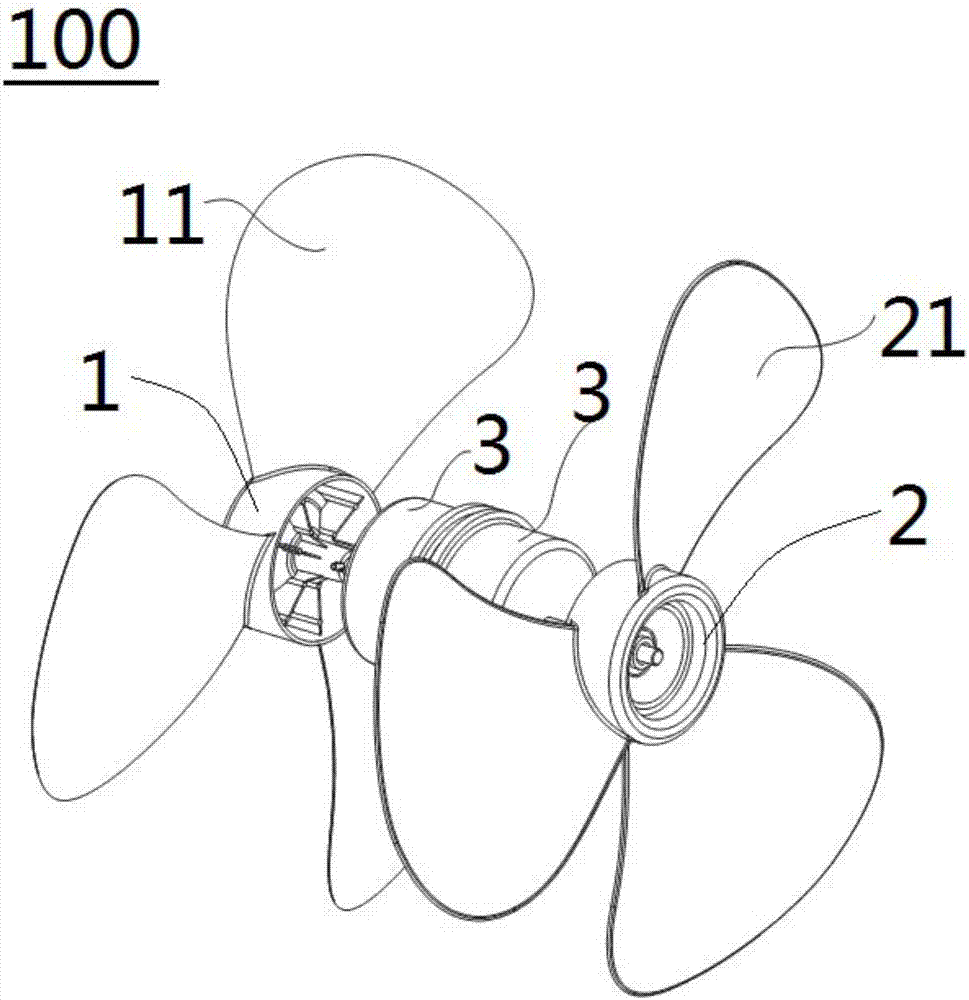

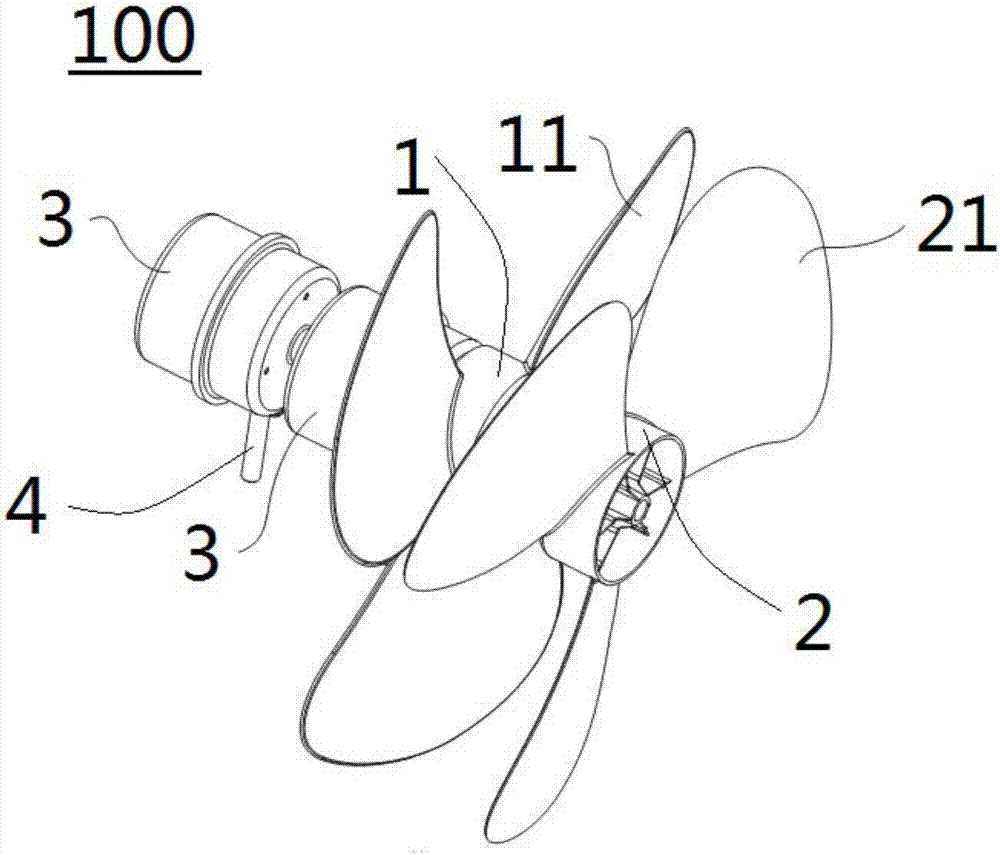

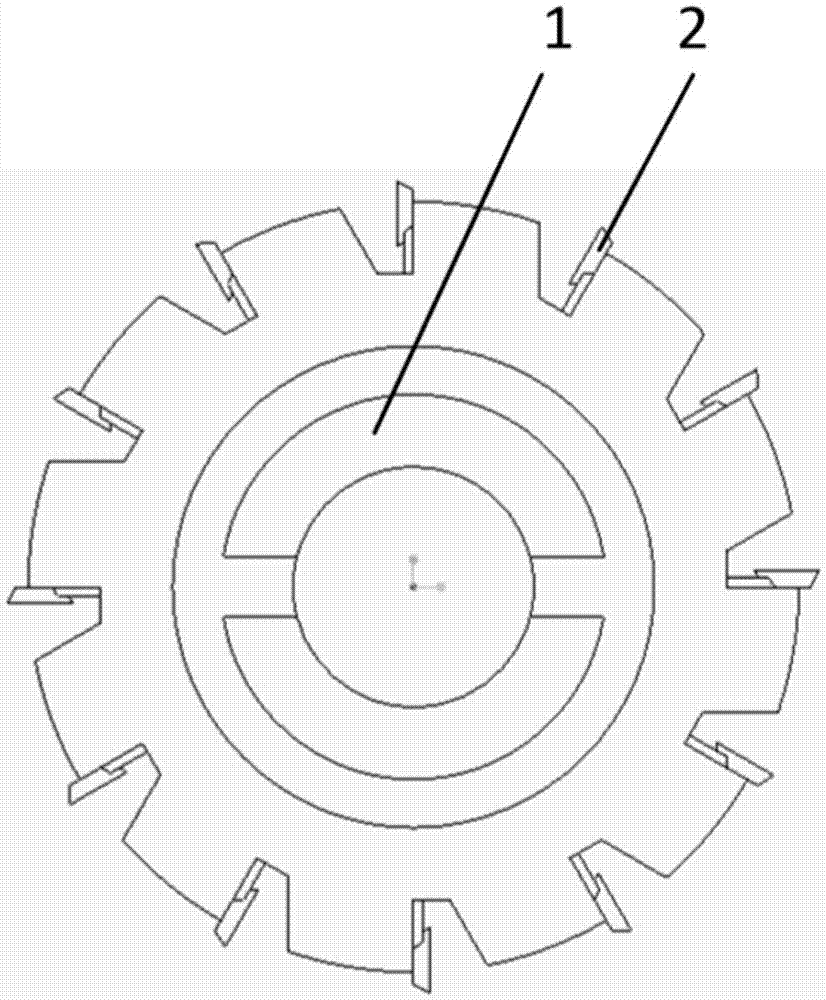

Axial flow fan

InactiveCN106968973AImprove performanceSmall geometryPump componentsPump installationsTurbine bladeEngineering

The invention discloses an axial flow fan, comprising: a first axial flow wind wheel, on which a first fan blade is arranged; a second axial flow wind wheel, on which the second axial flow wind wheel is arranged on the first On the air outlet side of the axial flow rotor, the second axial flow rotor is provided with a second fan blade, the bending direction of the first fan blade is opposite to that of the second fan blade; and a driving assembly, the driving assembly is the same as the first The axial flow wind wheel and the second axial flow wind wheel are respectively connected to drive the first axial flow wind wheel and the second axial flow wind wheel to rotate, the first axial flow wind wheel rotates around the first direction, and the second axial flow wind wheel rotates around the first direction Rotate in two directions, the second direction is opposite to the first direction. According to the axial flow fan of the present invention, the operating speed and noise can be greatly reduced, or the air supply volume can be increased, or the geometric dimensions such as the diameter of the fan blade can be reduced, so as to improve the performance of the axial flow fan. At the same time, the reverse air supply can be effectively realized, and the two-way reversible fan can be realized.

Owner:MIDEA GRP CO LTD

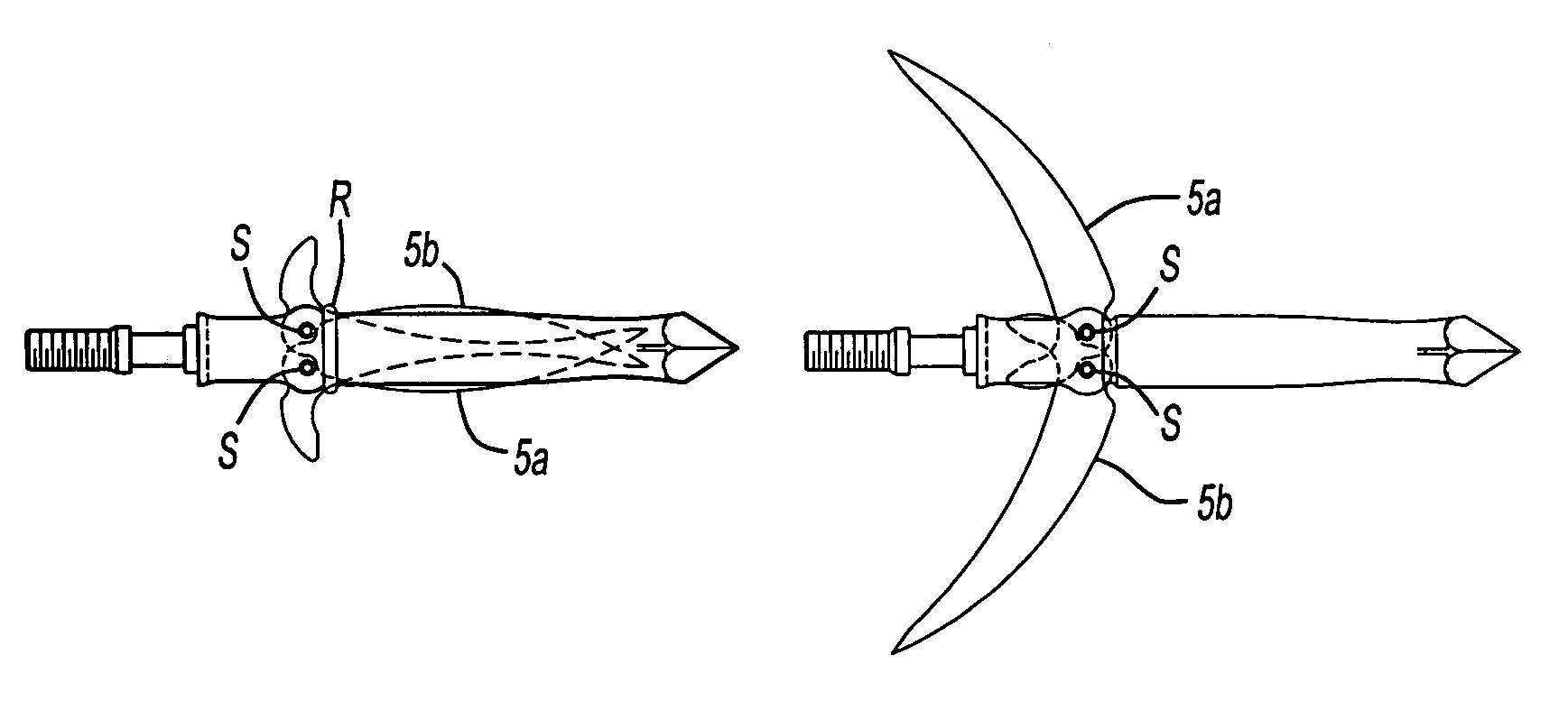

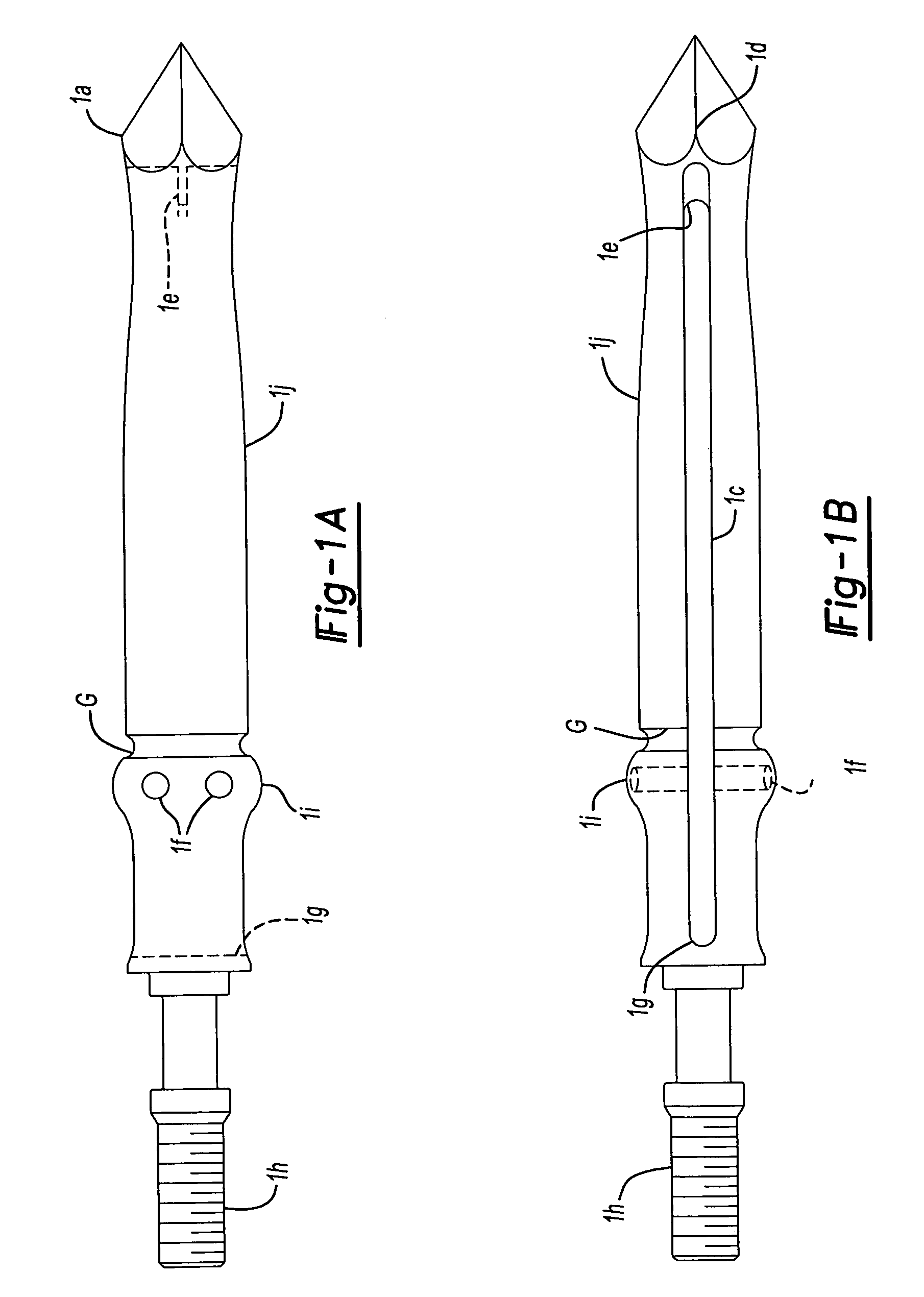

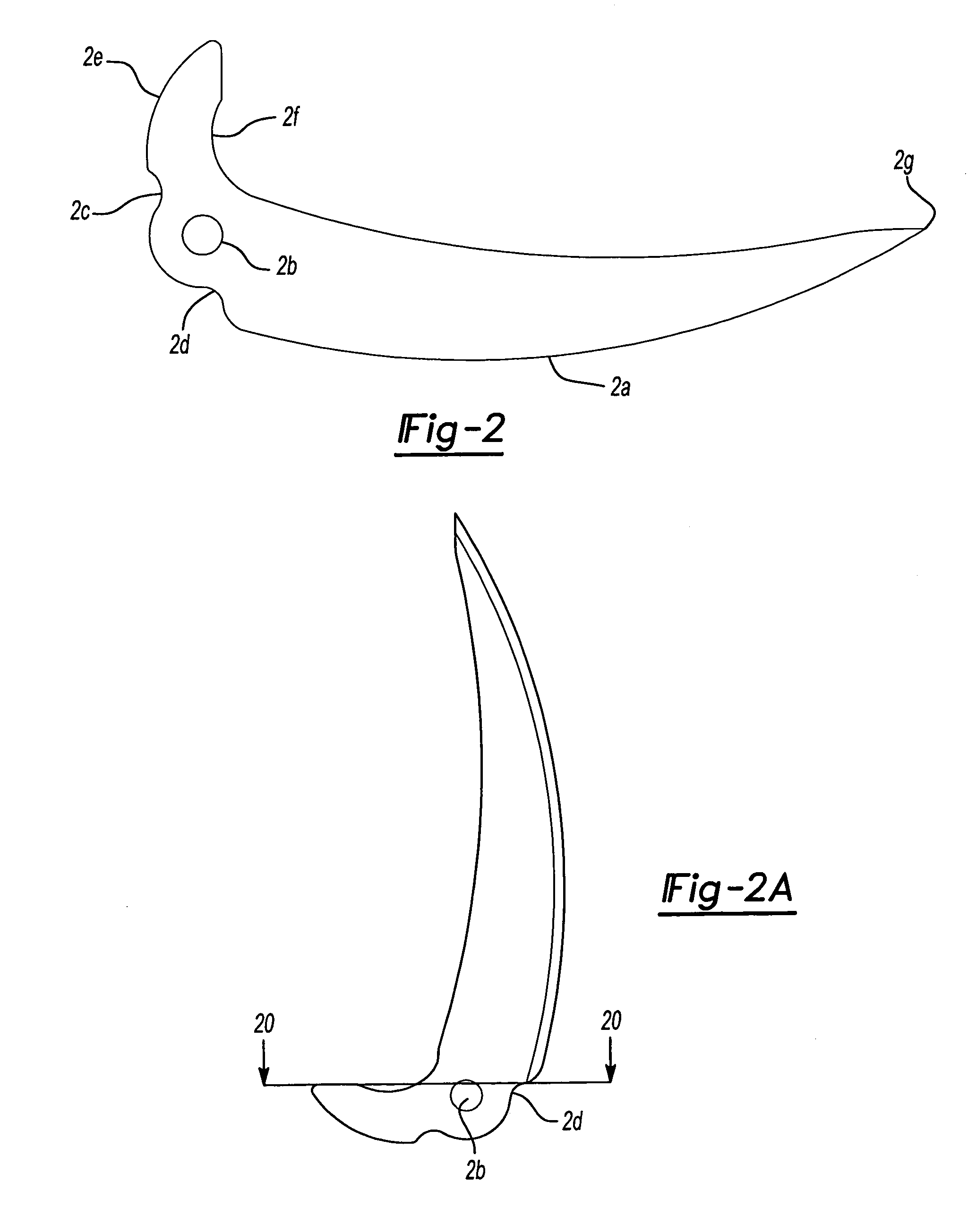

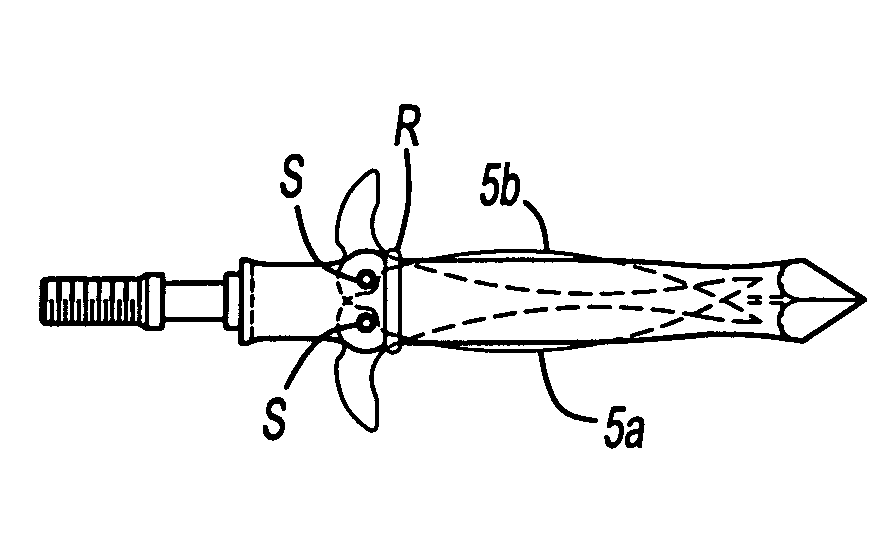

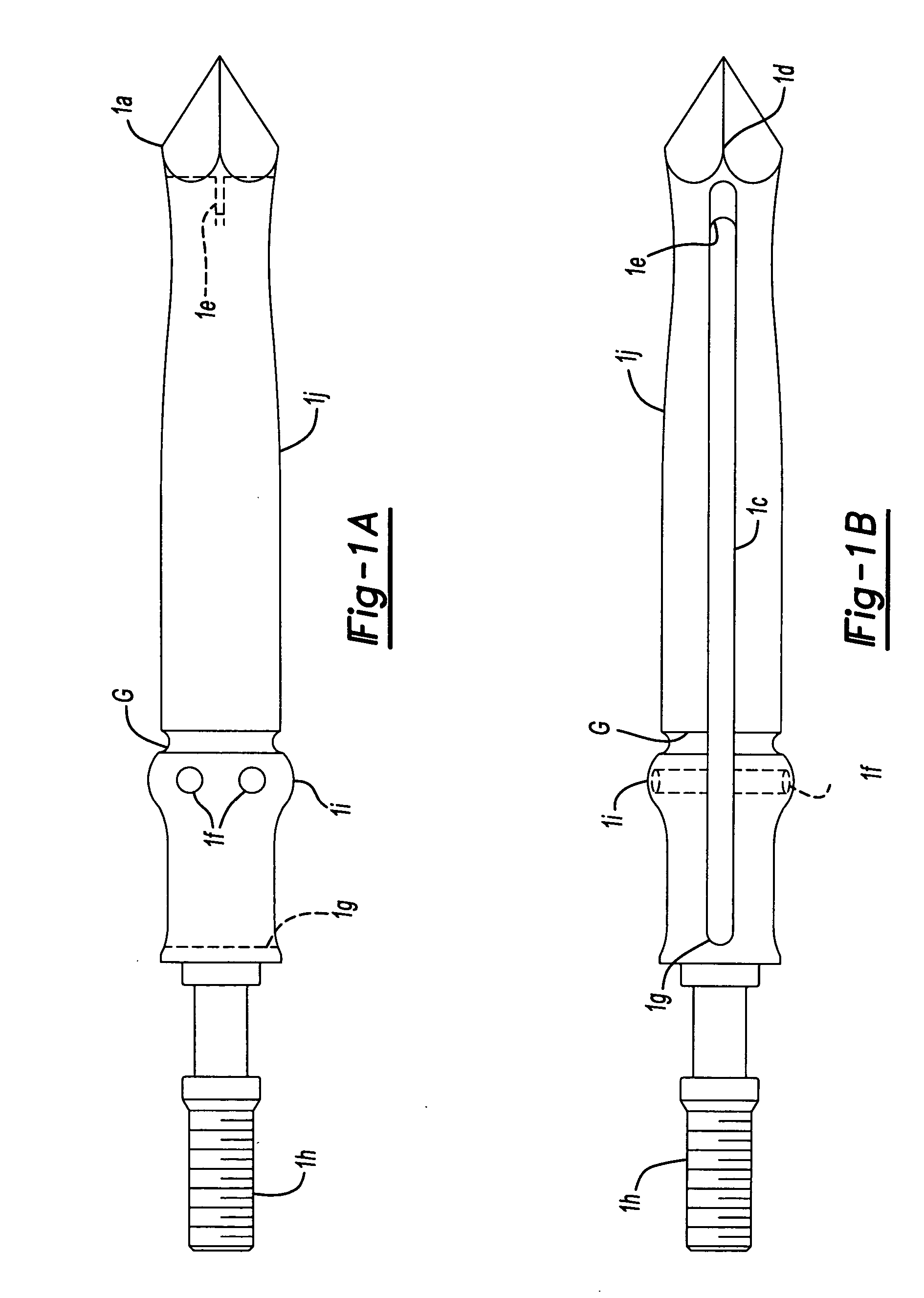

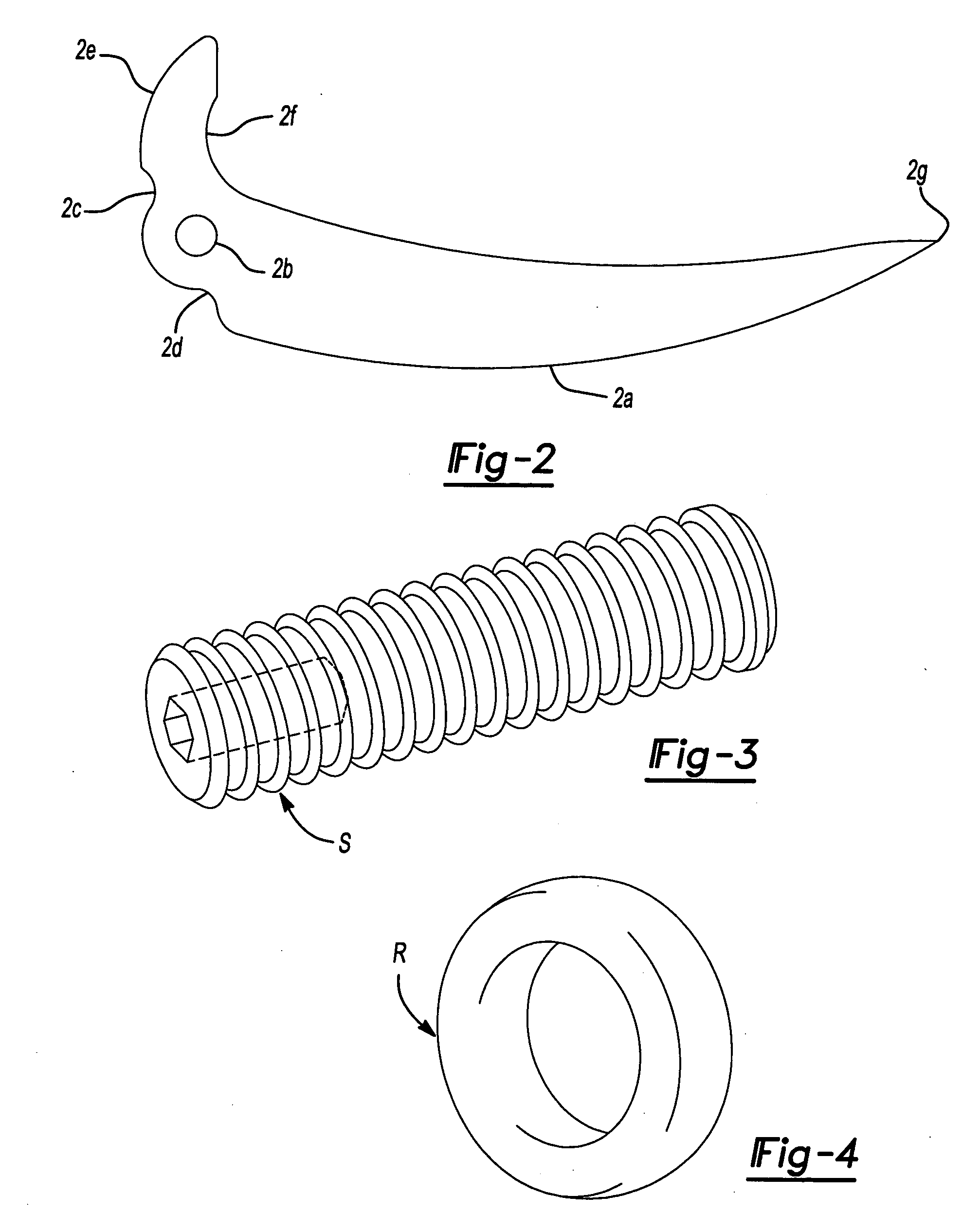

Mechanical anti-wedging and controlled deployment broadhead

ActiveUS7377869B2Reduce the amount of solutionLimited ability to articulateThrow gamesArrowsGravity centerCircular segment

An anti-wedging, controlled deployment broadhead with an over-center of gravity blade geometry for bow-hunting that has the ability to penetrate bone and soft tissue deeply before deploying its blades while conserving the highest possible amount of kinetic energy in flight and at target. The inventive device includes the one-piece body, specially aligned and faceted cutting tip, blades, O-ring, and set screws. The blades have independent pivots that also act as travel limiters, are arch shaped with very sharp leading edges and a J-shaped lever. The center of gravity of each of the blades is oriented so as to insure retaining each blade in its respective retracted position during acceleration and assisting in deployment thereof during deceleration. The device with its special body and blade geometry now allows for more energy and blade area to be delivered to the vital organs of game to facilitate a faster and more humane harvest.

Owner:KOREKUT TECH LLC

Control of power, loads and/or stability of a horizontal axis wind turbine by use of variable blade geometry control

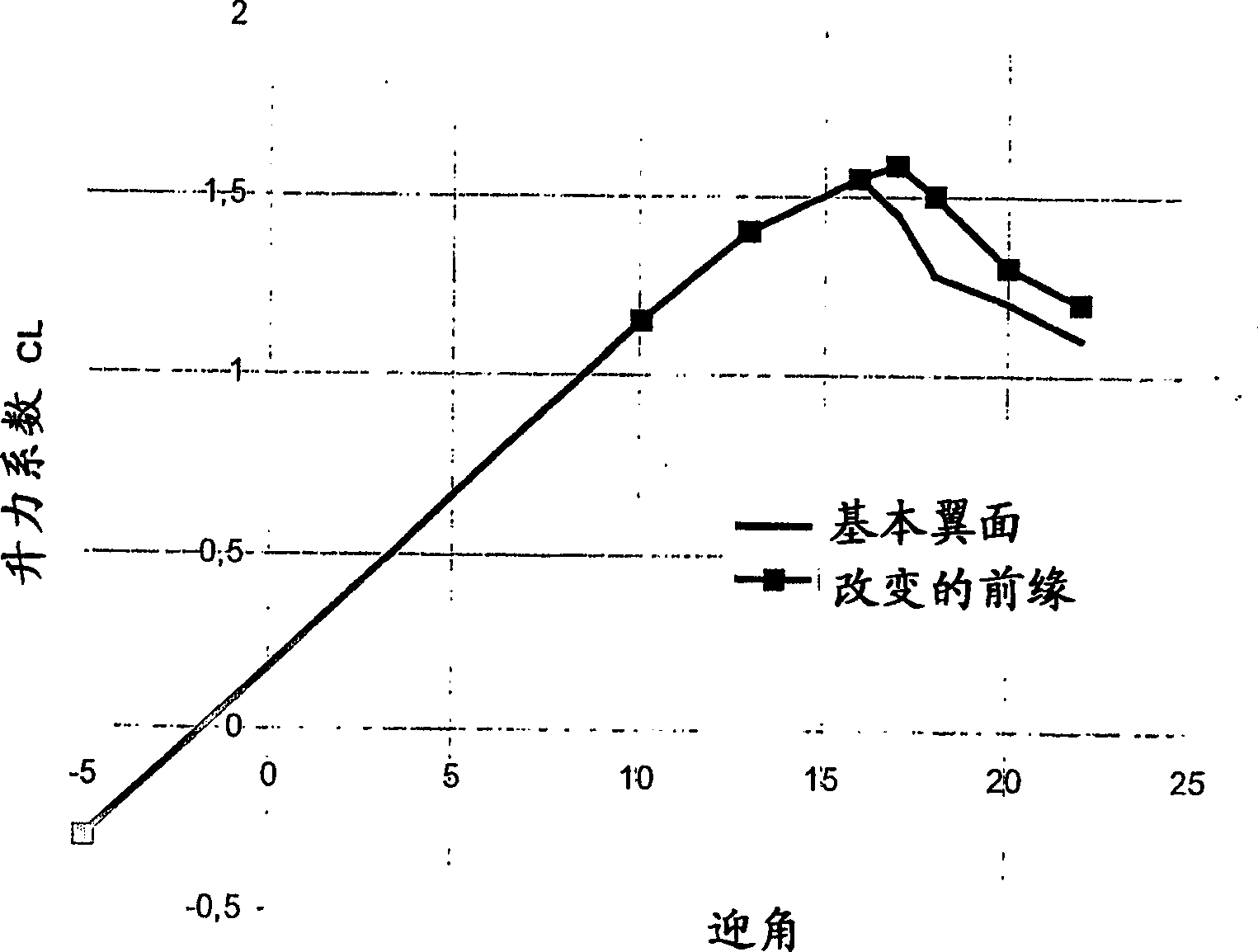

InactiveCN1780983AReduce loadReduce aerodynamic noiseWind motor controlEngine fuctionsTurbine bladeHorizontal axis

The present invention relates to a design concept according to which, by using active geometry control (for example, smart materials or embedded mechanical actuators), or using passive geometry control (for example caused by the loading and / or deformation of the blade) changes), or a combination of these two methods, allows rapid changes in the blade geometry to control the power, load and / or stability of the wind turbine. In particular the invention relates to a wind turbine blade, a wind turbine and a method of controlling a wind turbine.

Owner:DANMARKS TEKNISKE UNIV

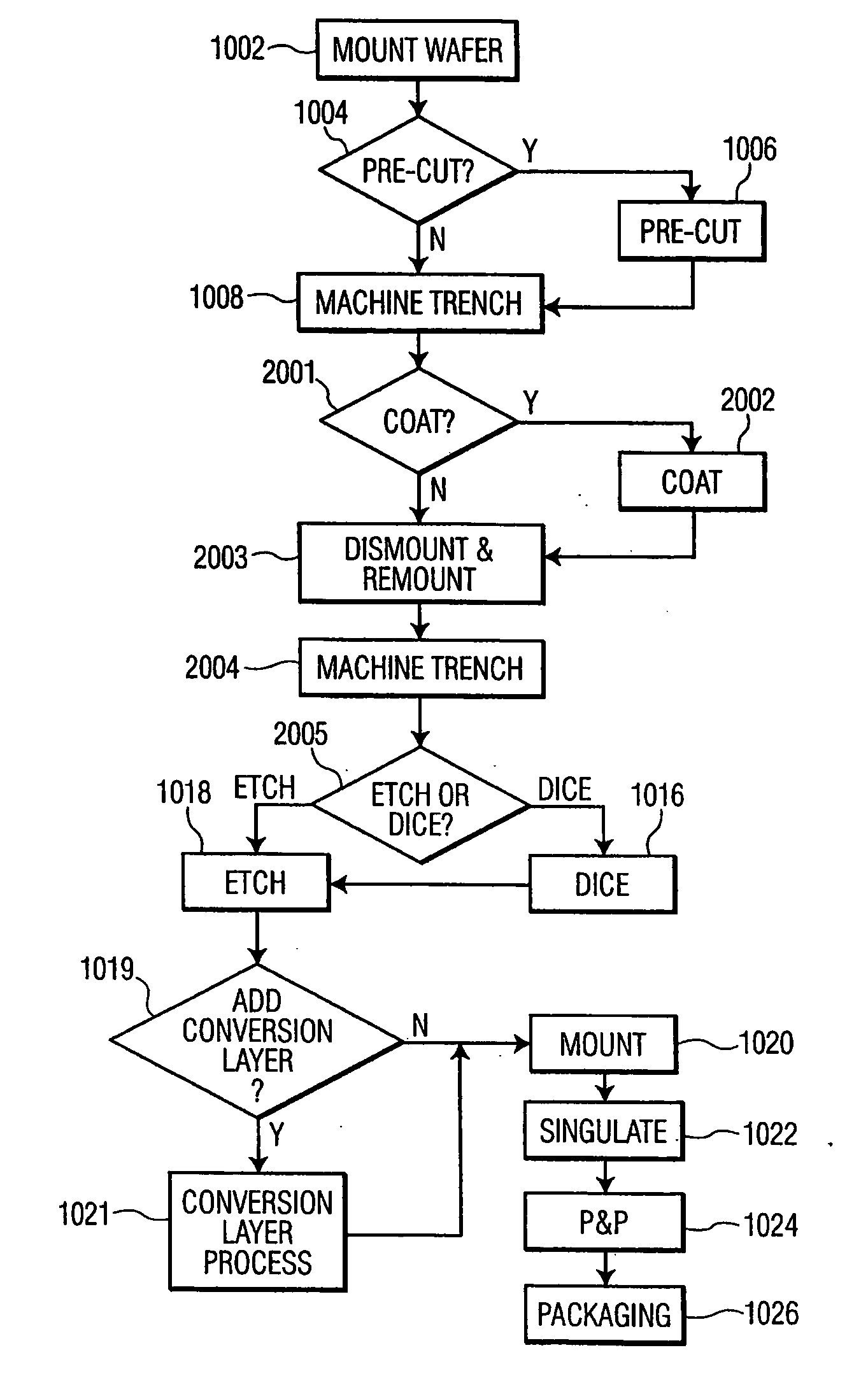

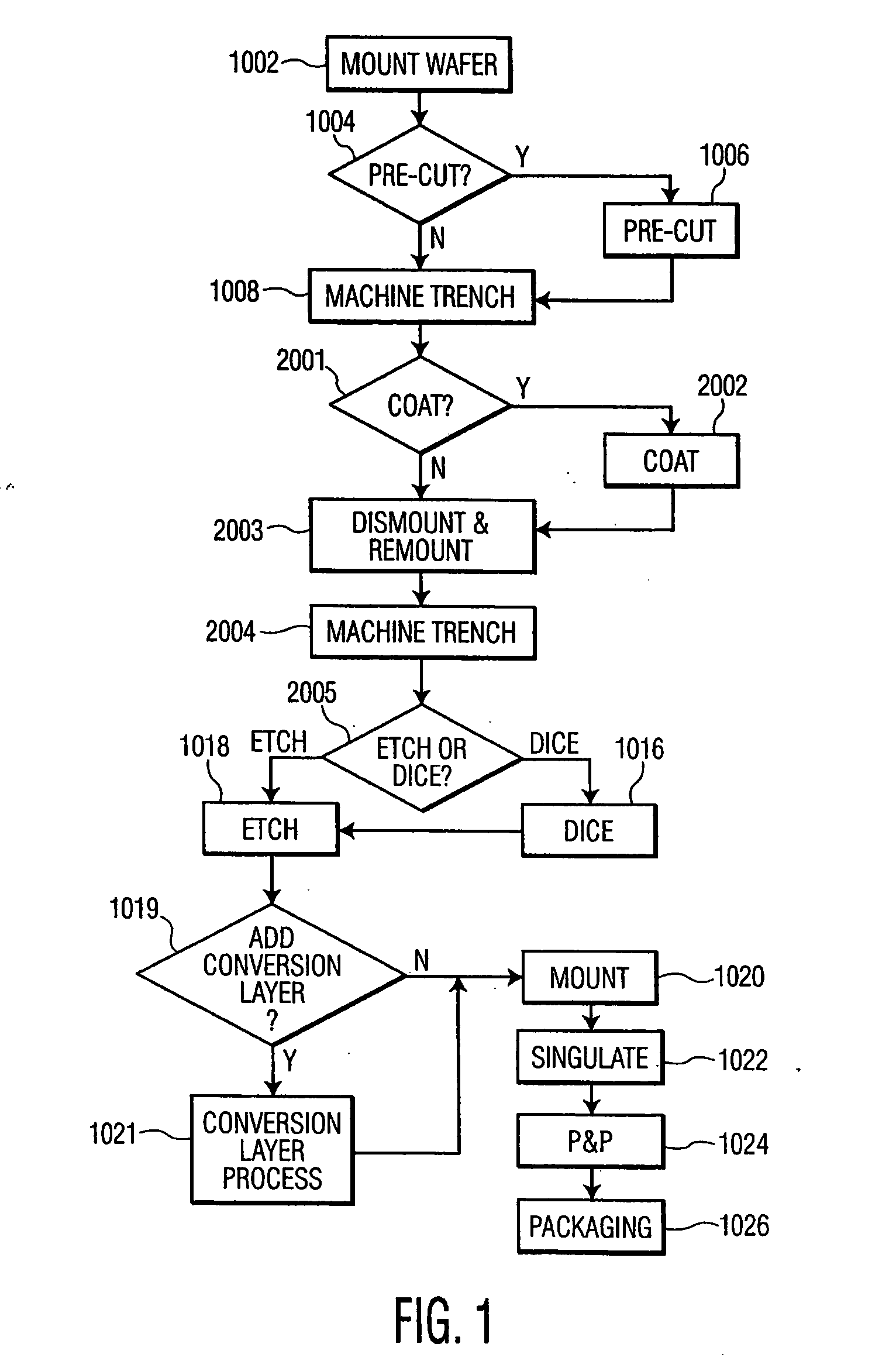

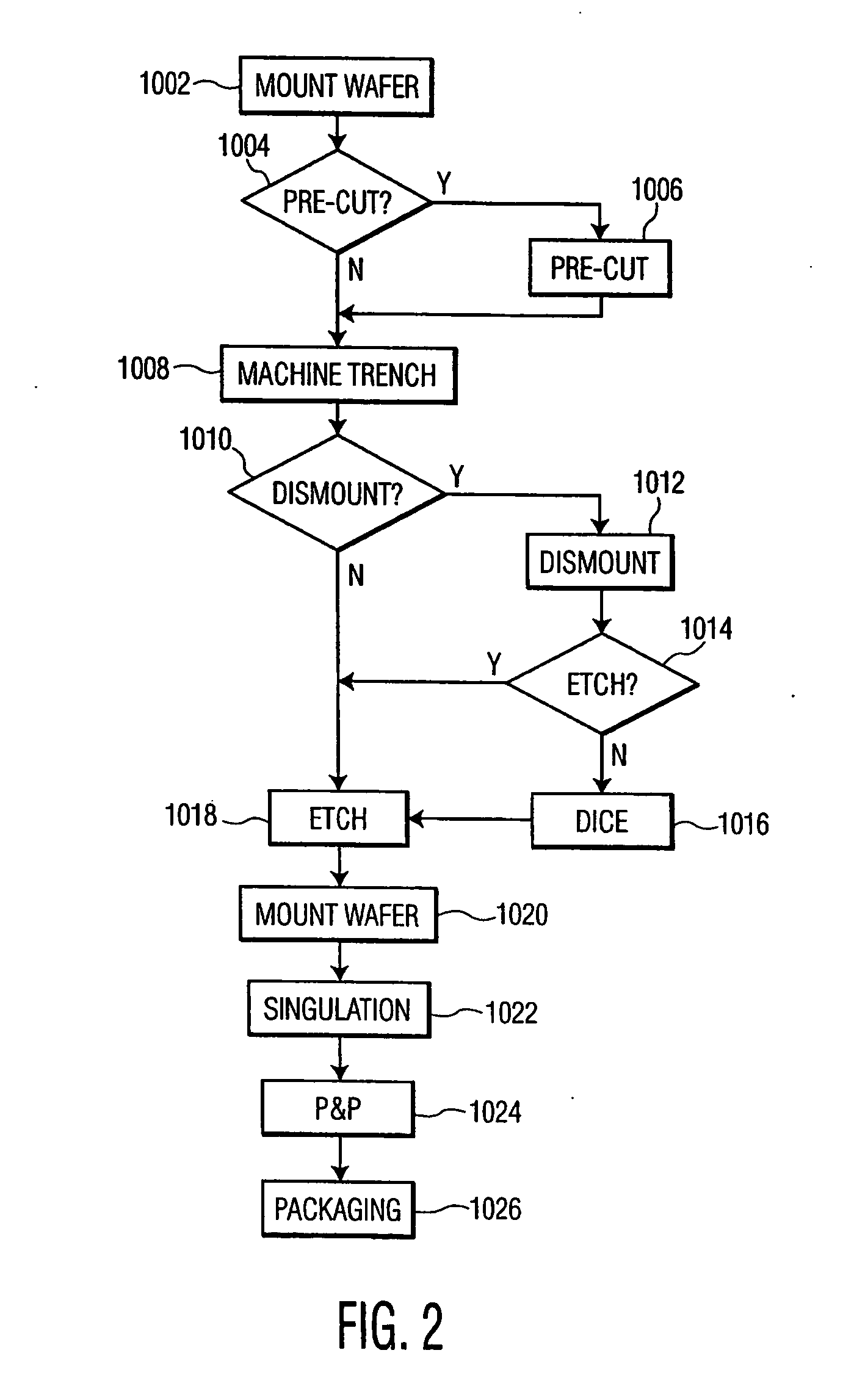

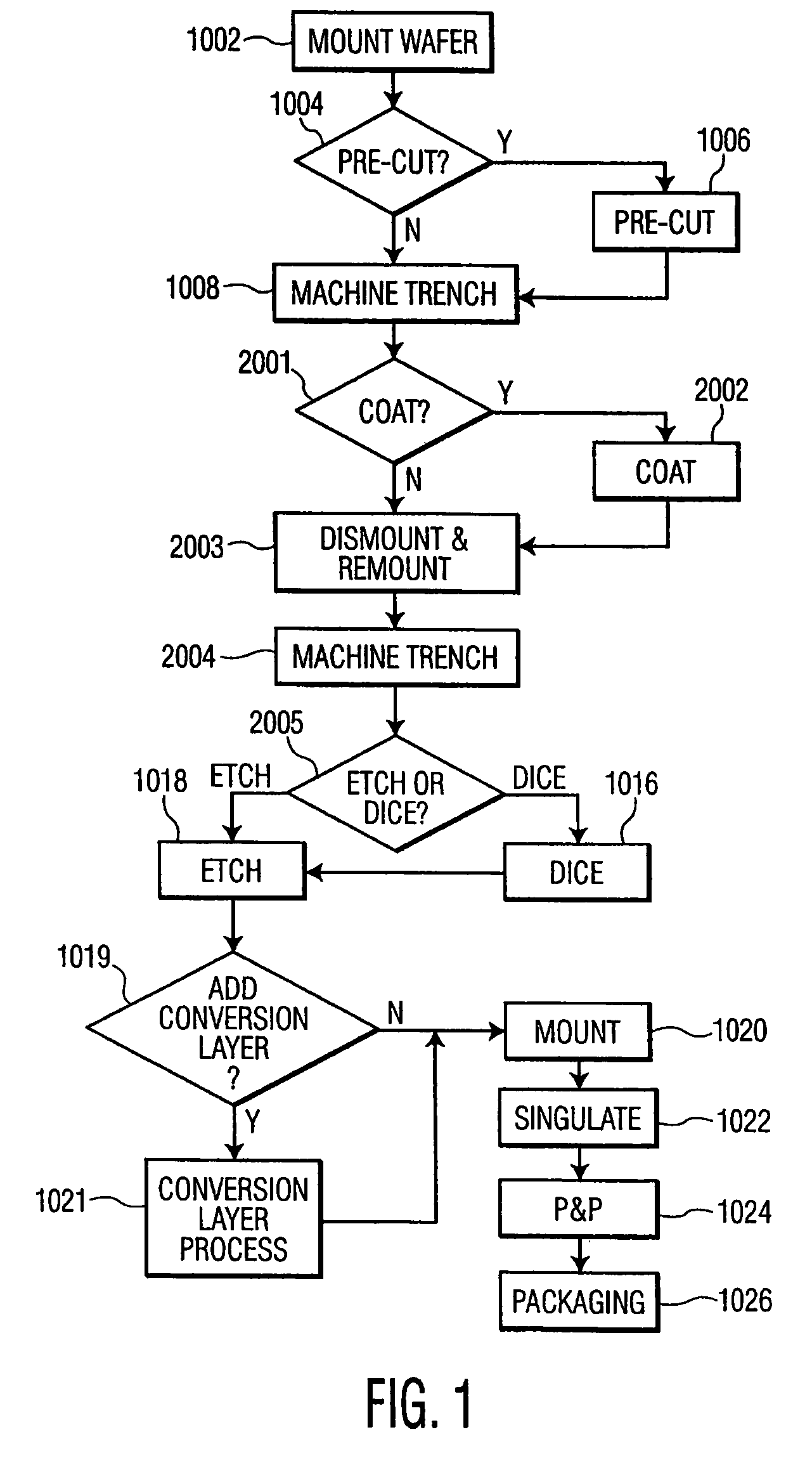

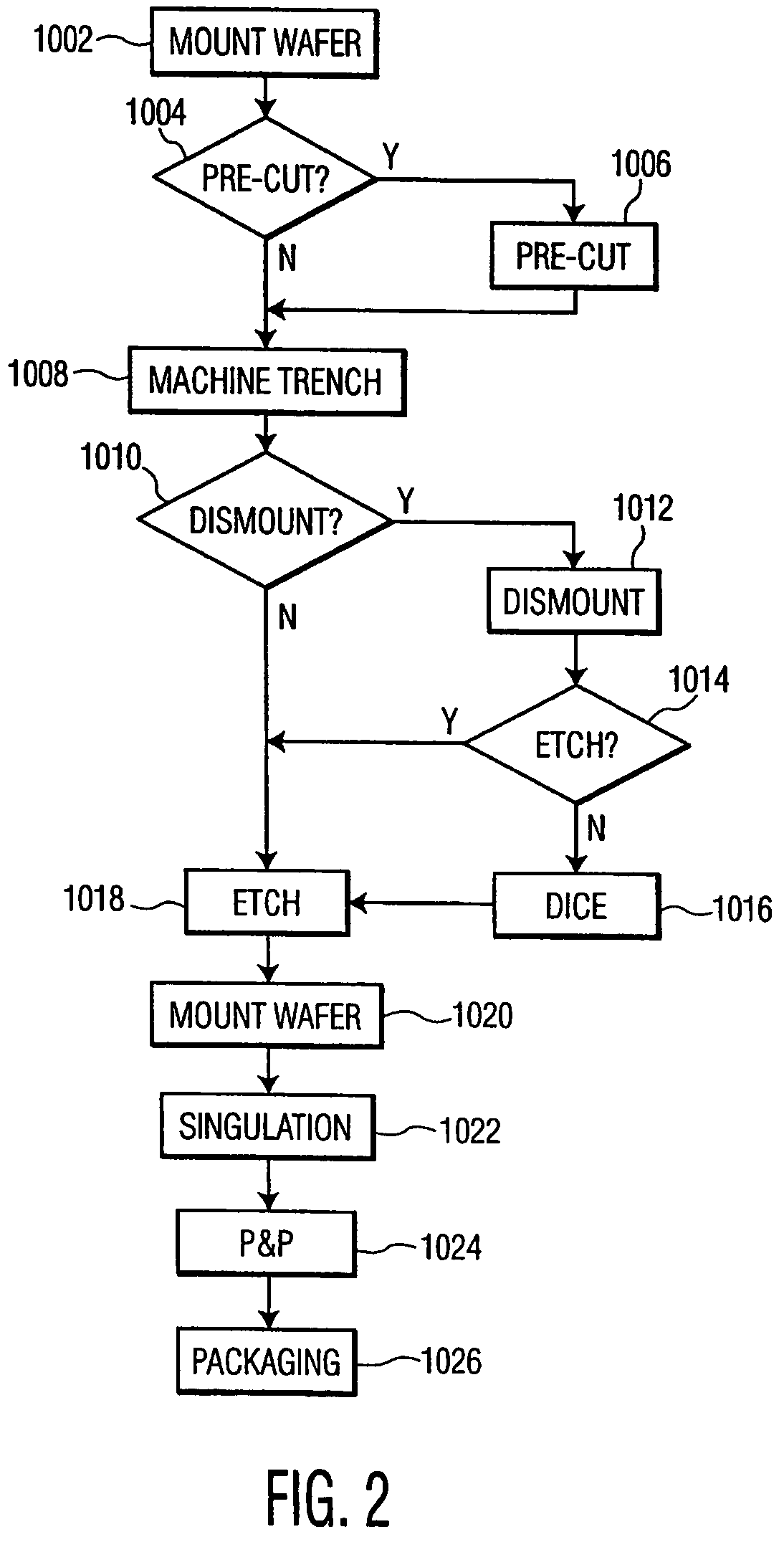

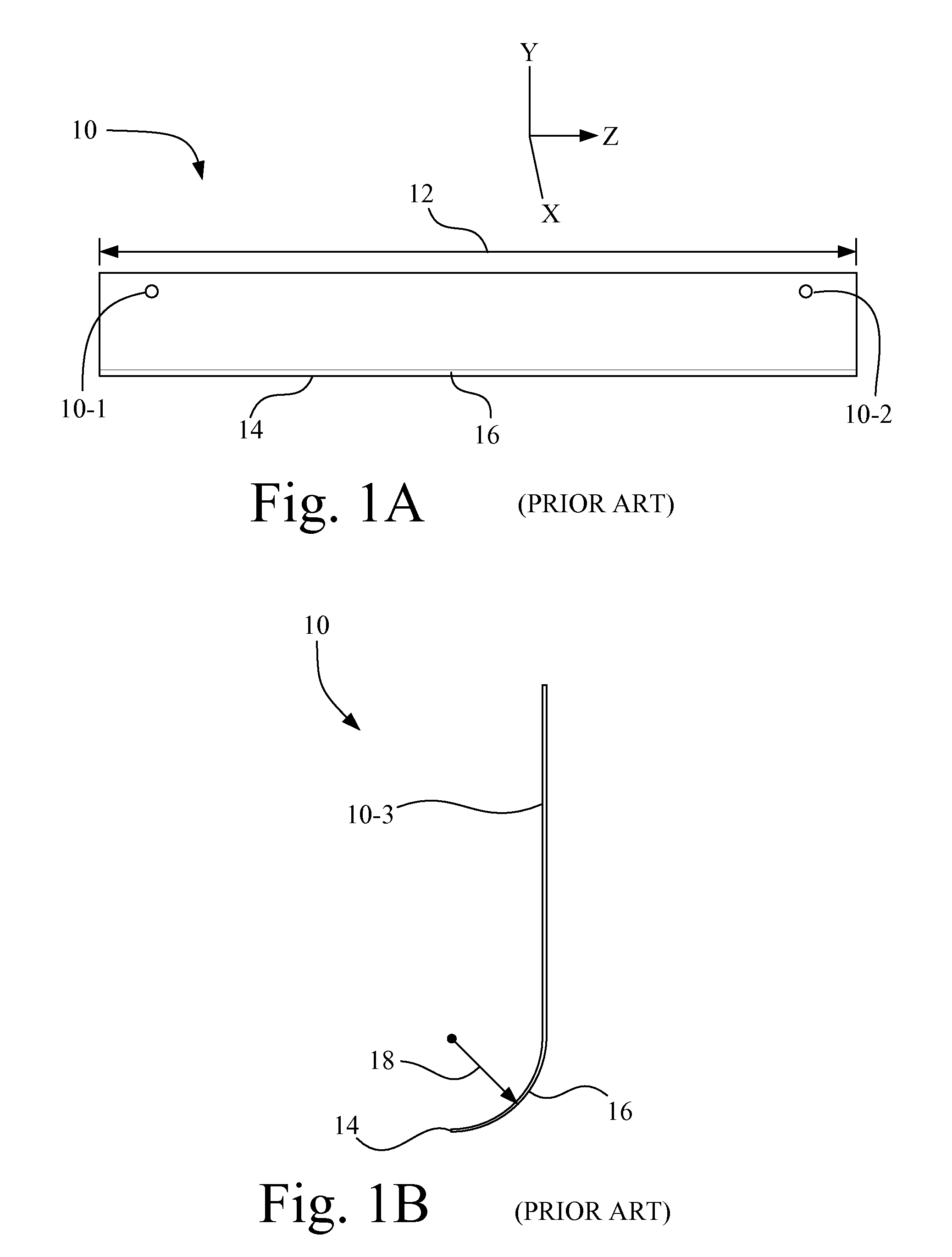

Methods of fabricating complex blade geometries from silicon wafers and strengthening blade geometries

ActiveUS20050266680A1High strengthEasy to controlIncision instrumentsDecorative surface effectsSurgical bladeEngineering

Ophthalmic surgical blades are manufactured from either a single crystal or poly-crystalline material, preferably in the form of a wafer. The method comprises preparing the single crystal or poly-crystalline wafers by mounting them and etching trenches into the wafers using one of several processes. Methods for machining the trenches, which form the bevel blade surfaces, include a diamond blade saw, laser system, ultrasonic machine, a hot forge press and a router. Other processes include wet etching (isotropic and anisotropic) and dry etching (isotropic and anisotropic, including reactive ion etching), and combinations of these etching steps. The wafers are then placed in an etchant solution which isotropically etches the wafers in a uniform manner, such that layers of crystalline or poly-crystalline material are removed uniformly, producing single, double or multiple bevel blades. Nearly any angle can be machined into the wafer, and the machined angle remains after etching. The resulting radii of the blade edges is 5-500 nm, which is the same caliber as a diamond edged blade, but manufactured at a fraction of the cost. A range of radii may be 30 to 60 nm, with a specific implementation being about 40 nm. The blade profile may have an angle of, for example, about 60°. The ophthalmic surgical blades can be used for cataract and refractive surgical procedures, as well as microsurgical, biological and non-medical, non-biological purposes. Surgical and non-surgical blades and mechanical devices manufactured as described herein can also exhibit substantially smoother surfaces than metal blades.

Owner:BEAVER VISITEC INT US

Shaving cartridge with supressed blade geometry

A shaving cartridge with a housing, a cap, and a guard. The guard has an upper surface. The cap has a top surface, a front edge, and an arcuate surface connecting the top surface and the front edge. A first blade between the cap and the guard has a cutting edge nearest the cap. A second blade between the cap and the guard has a cutting edge nearest the guard. The first and second blades define a blade plane tangent to the cutting edges. The blade plane is positioned below both (i) the surface of the guard and (ii) an intersection point of the front edge and the top surface of the cap.

Owner:THE GILLETTE CO

Methods of fabricating complex blade geometries from silicon wafers and strengthening blade geometries

ActiveUS7396484B2Quality improvementUniform radiusIncision instrumentsDecorative surface effectsSurgical bladeSingle crystal

Ophthalmic surgical blades are manufactured from either a single crystal or poly-crystalline material, preferably in the form of a wafer. The method comprises preparing the single crystal or poly-crystalline wafers by mounting them and etching trenches into the wafers using one of several processes. Methods for machining the trenches, which form the bevel blade surfaces, include a diamond blade saw, laser system, ultrasonic machine, a hot forge press and a router. Other processes include wet etching (isotropic and anisotropic) and dry etching (isotropic and anisotropic, including reactive ion etching), and combinations of these etching steps. The wafers are then placed in an etchant solution which isotropically etches the wafers in a uniform manner, such that layers of crystalline or poly-crystalline material are removed uniformly, producing single, double or multiple bevel blades. Nearly any angle can be machined into the wafer, and the machined angle remains after etching. The resulting radii of the blade edges is 5-500 nm, which is the same caliber as a diamond edged blade, but manufactured at a fraction of the cost. A range of radii may be 30 to 60 nm, with a specific implementation being about 40 nm. The blade profile may have an angle of, for example, about 60°. The ophthalmic surgical blades can be used for cataract and refractive surgical procedures, as well as microsurgical, biological and non-medical, non-biological purposes. Surgical and non-surgical blades and mechanical devices manufactured as described herein can also exhibit substantially smoother surfaces than metal blades.

Owner:BEAVER VISITEC INT US

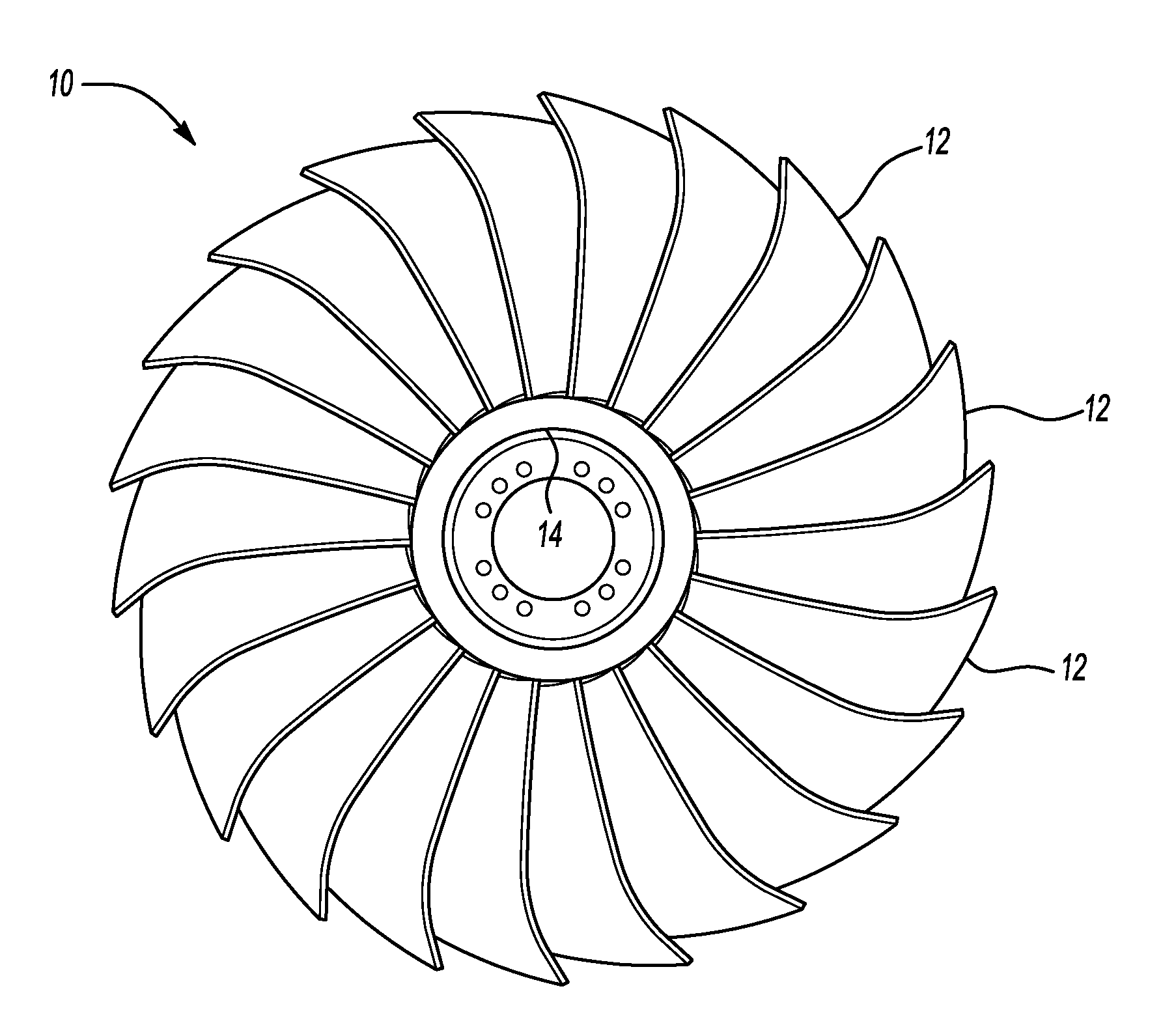

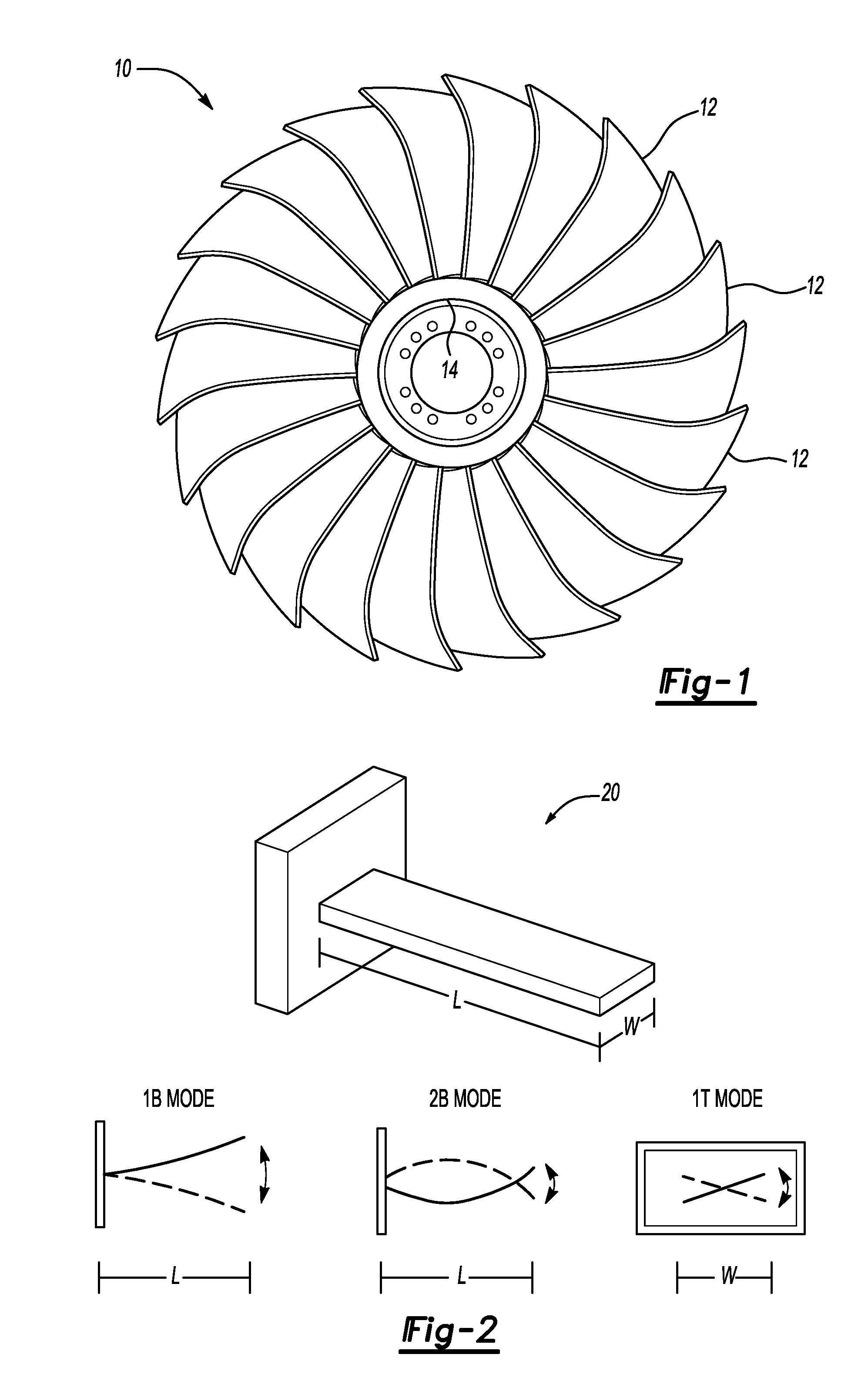

Aeroelastic model using the principal shapes of modes (AMPS)

ActiveUS20090099796A1Reduce in quantityEasy to predictVehicle testingElectrical testingEngineeringBlade geometry

The Aeroelastic Model using the Principal Shapes of modes (AMPS) is a method used to predict flutter in gas turbine engines. Modern gas turbine engines often include rotors with flexible disks and / or significant blade geometry variations. The AMPS method accounts for the varying blade mode shapes associated with flexible disks as well as changing blade geometry, providing accurate flutter predictions for a large number of modes from a relatively small number of CFD (computational fluid dynamics) simulations. The AMPS method includes determining a smaller set of principal shapes that approximates a larger set of structural modes of interest. Using linear superposition, aerodynamic forces associated with the vibration of the principal shapes can be used to construct the full aerodynamic coupling matrix associated with the structural modes of interest. An eigenvalue equation is solved to determine a damping distribution associated with the structural modes of interest. The damping distribution is predictive of flutter.

Owner:RAYTHEON TECH CORP

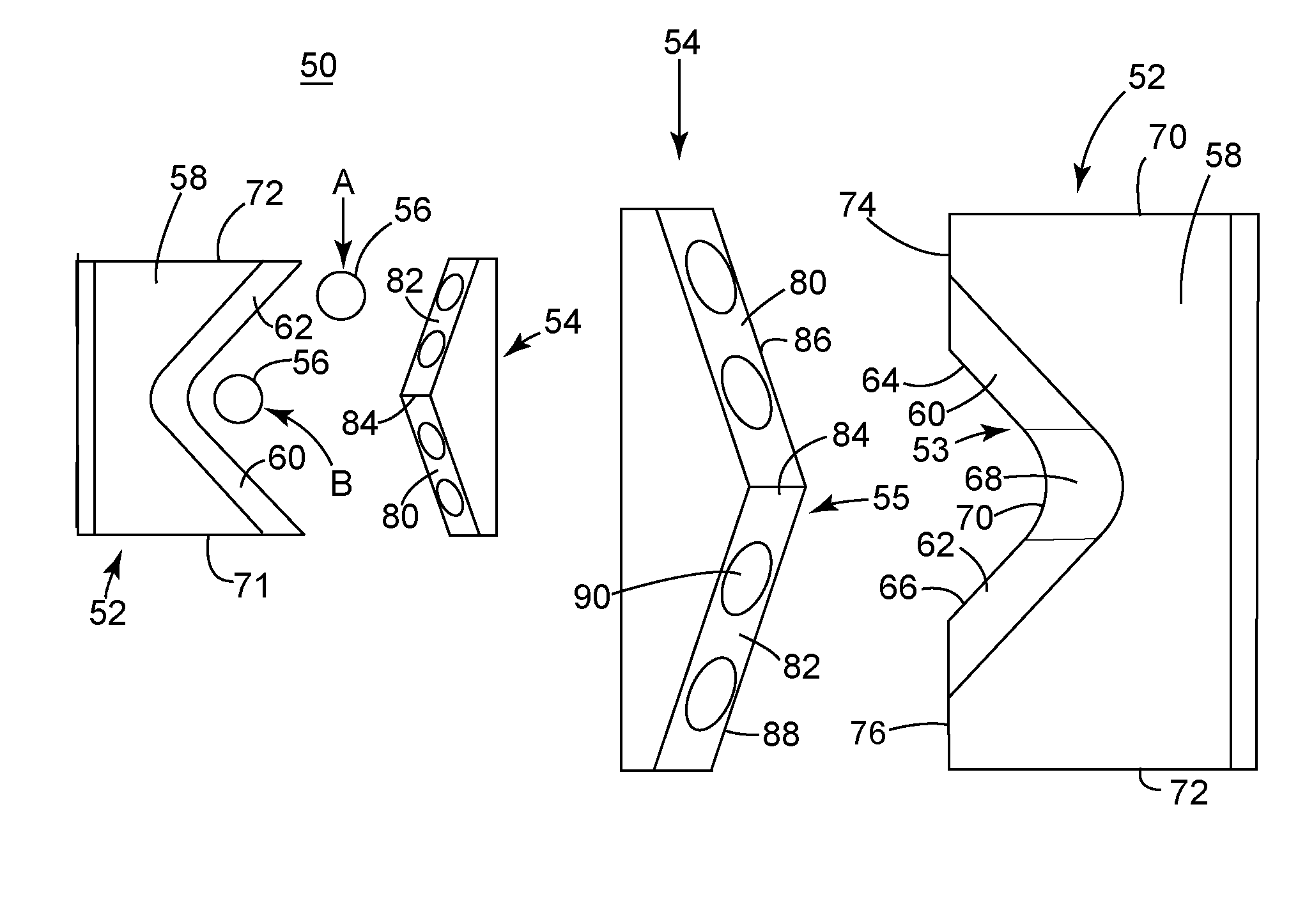

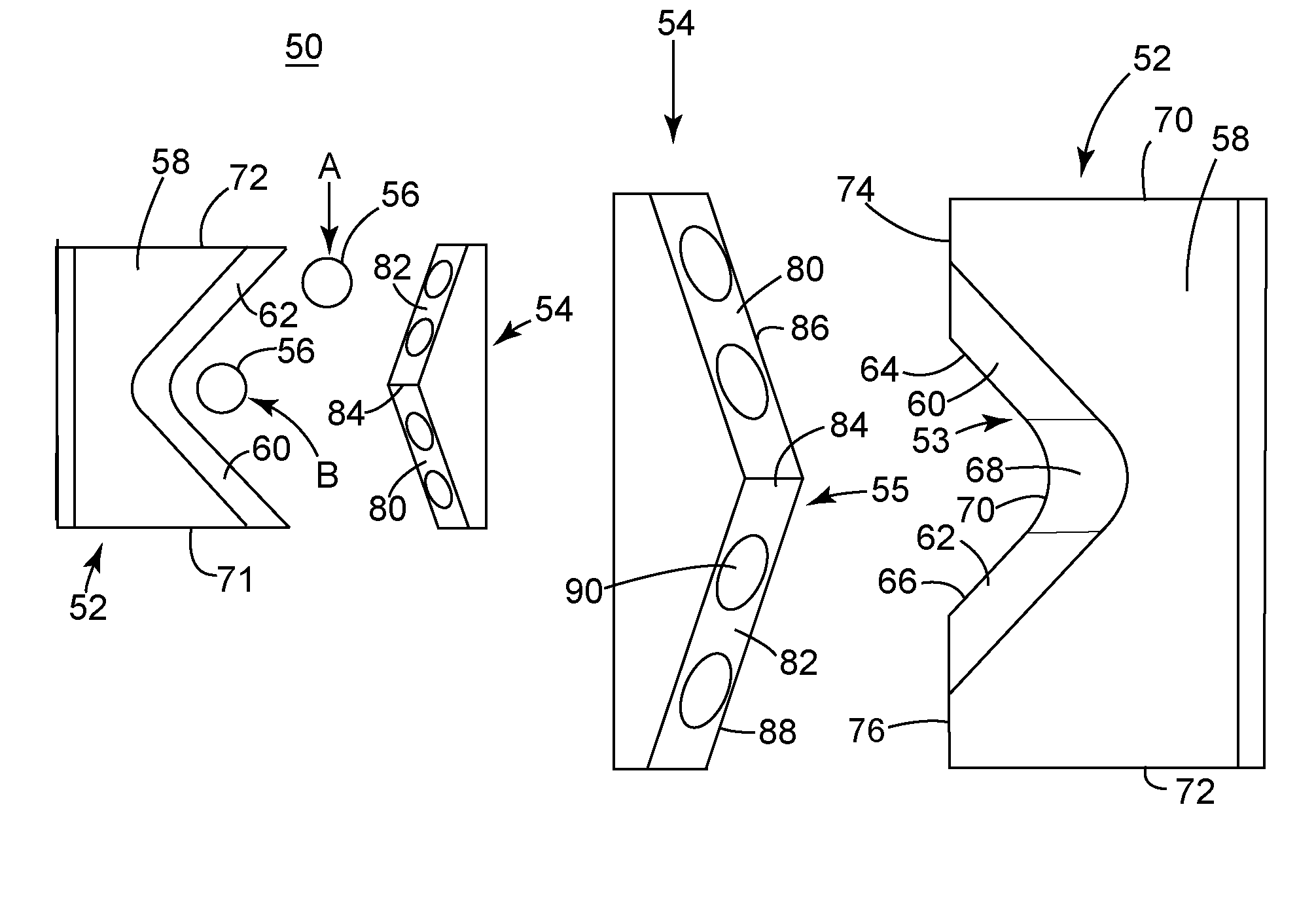

Shear Blade Geometry and Method

A pair of shear blades and a blowout preventer having the pair of shear blades. The shear blades are configured to cut a tubular inside the blowout preventer. The shear blades have different geometries of the front cutting surfaces. One geometry promotes a secure positioning of the tubular relative to the first blade while the second geometry promotes a puncturing of the tubular by the second blade.

Owner:HYDRIL USA DISTRIBUTION LLC

Shear Blade Geometry and Method

A pair of shear blades and a blowout preventer having the pair of shear blades. The shear blades are configured to cut a tubular inside the blowout preventer. The shear blades have different geometries of the front cutting surfaces. One geometry promotes a secure positioning of the tubular relative to the first blade while the second geometry promotes a puncturing of the tubular by the second blade.

Owner:HYDRIL USA DISTRIBUTION LLC

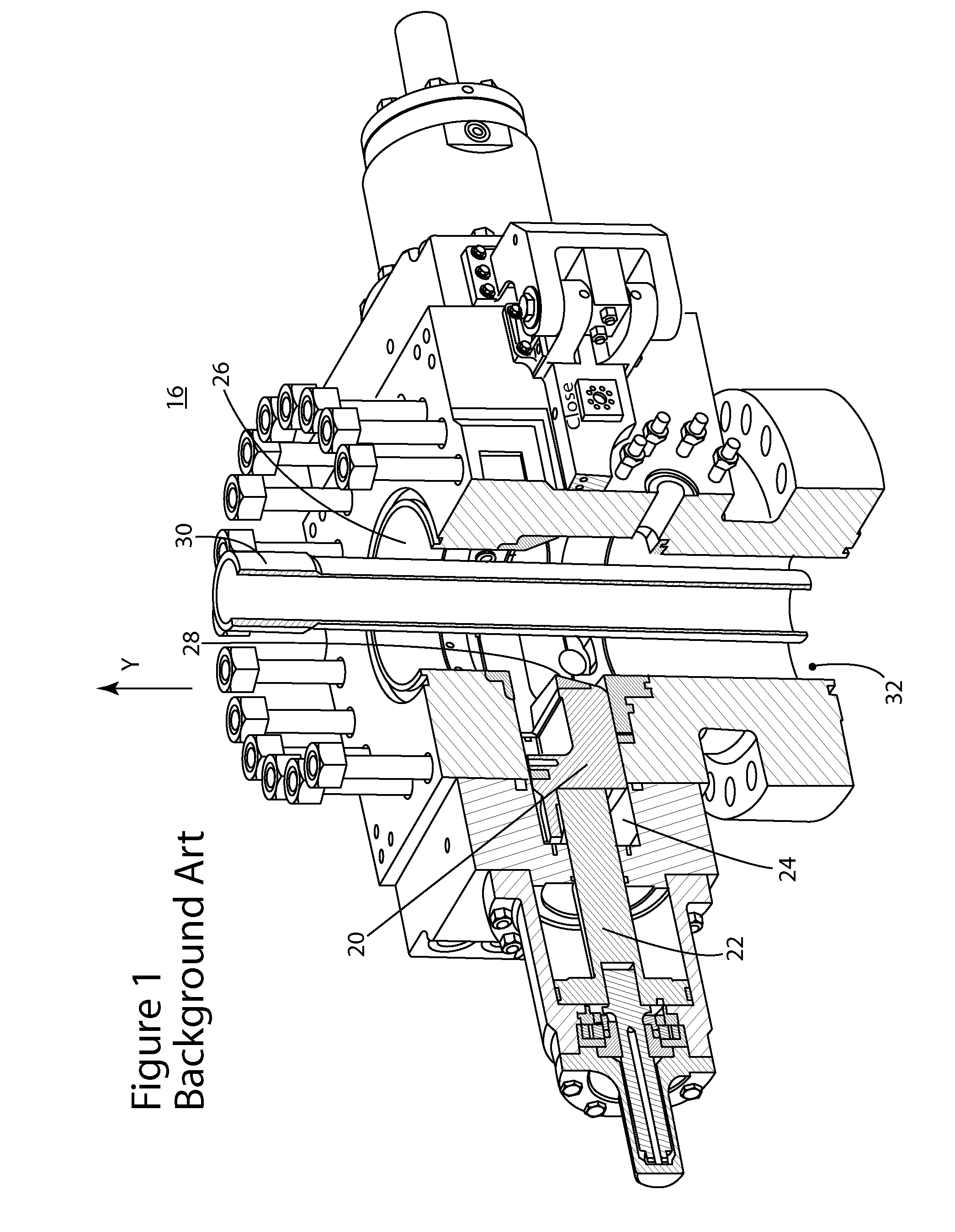

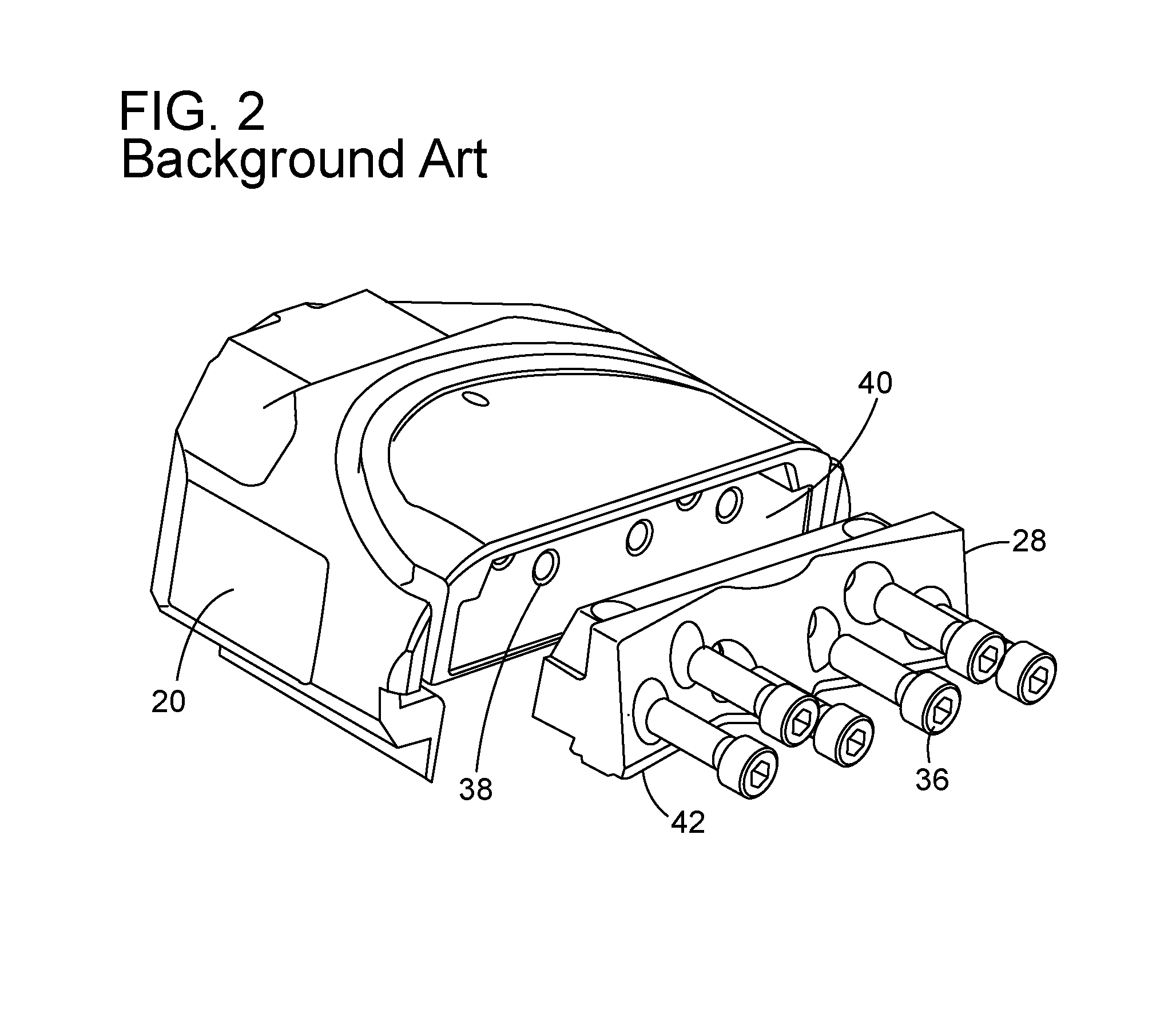

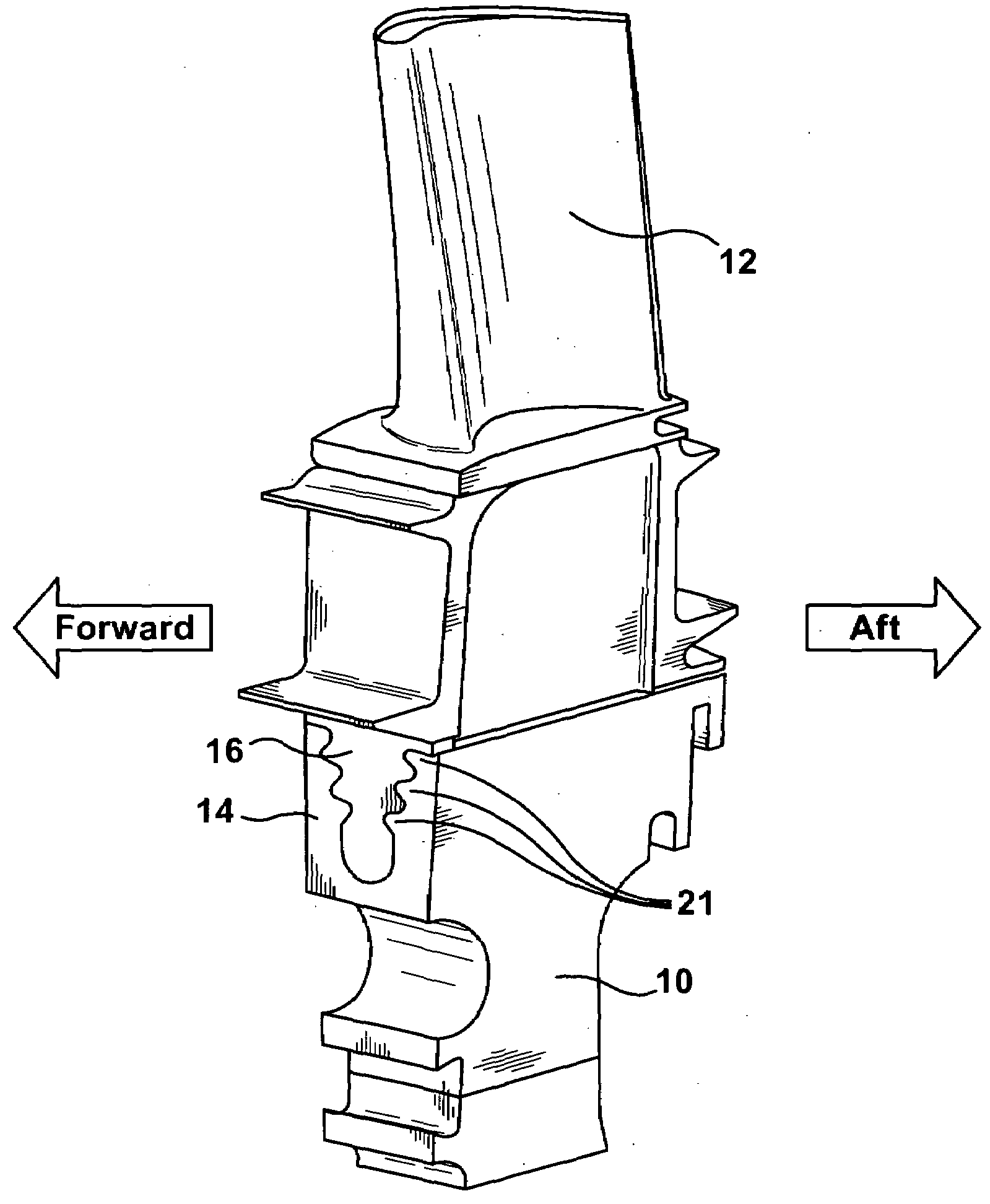

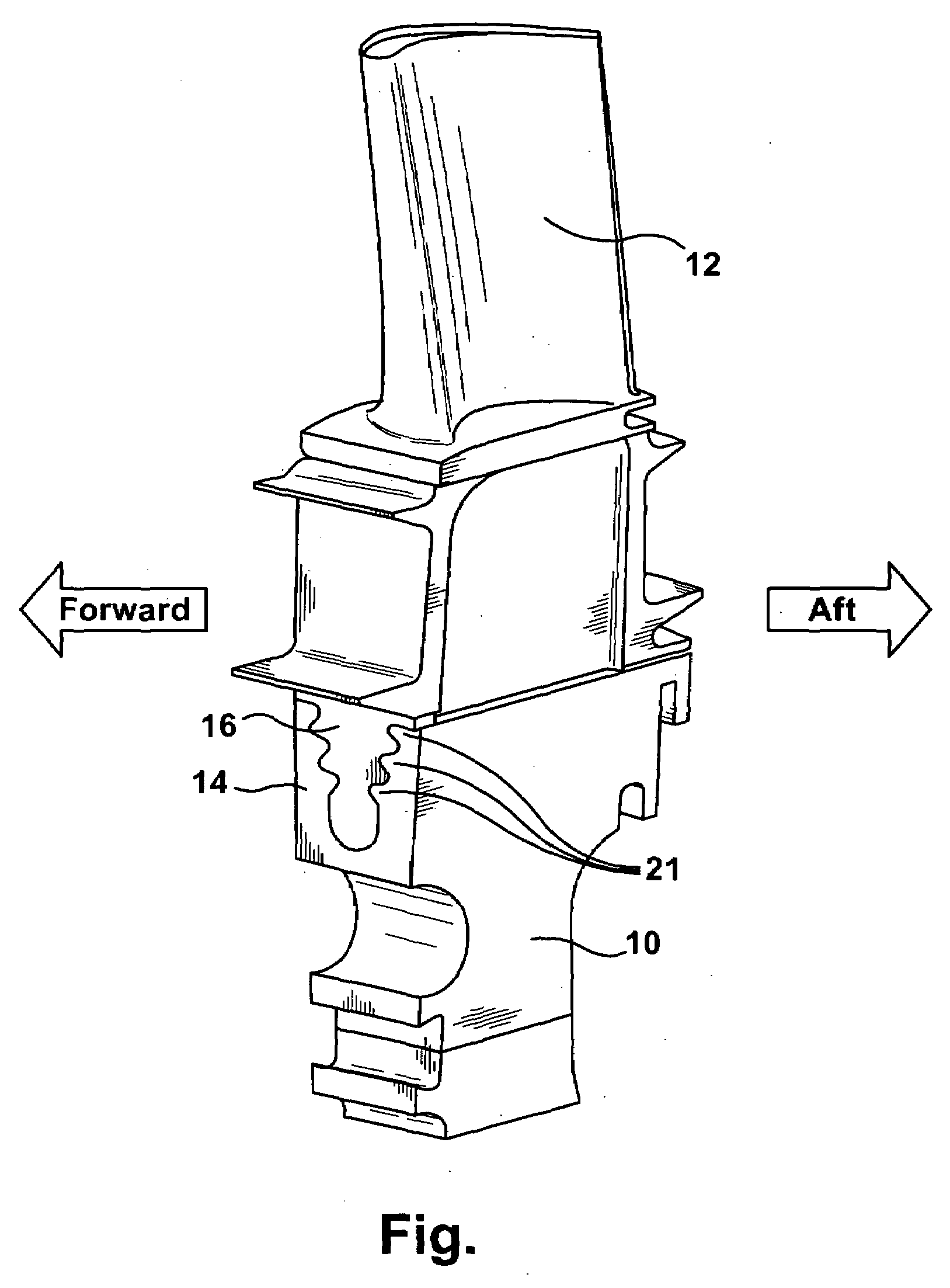

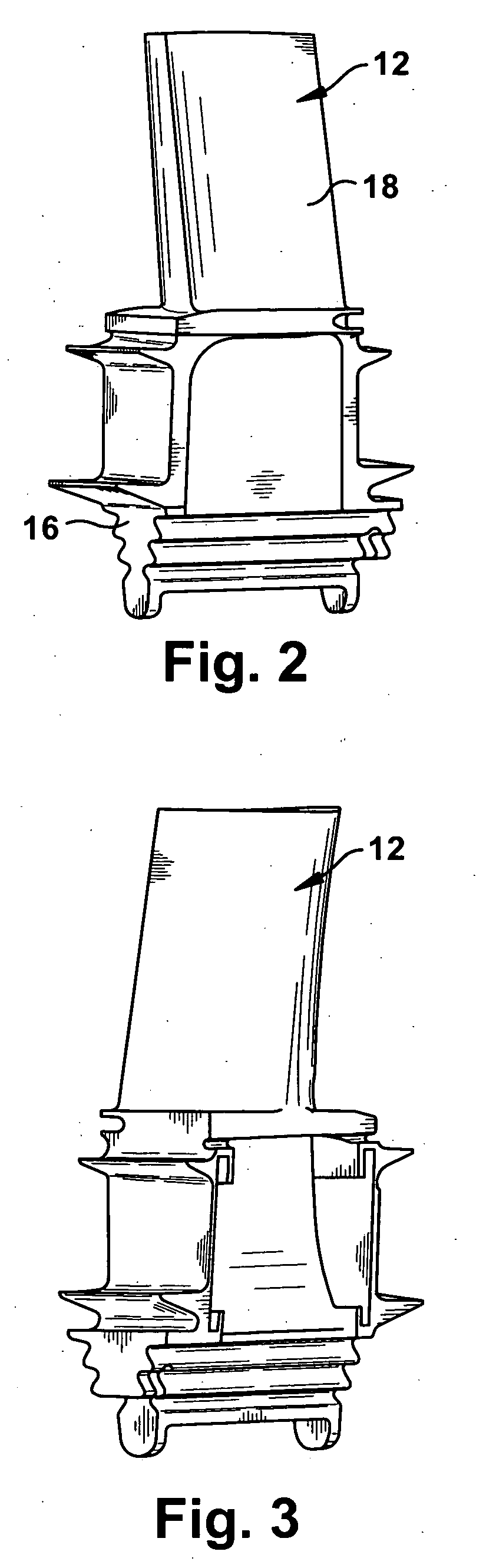

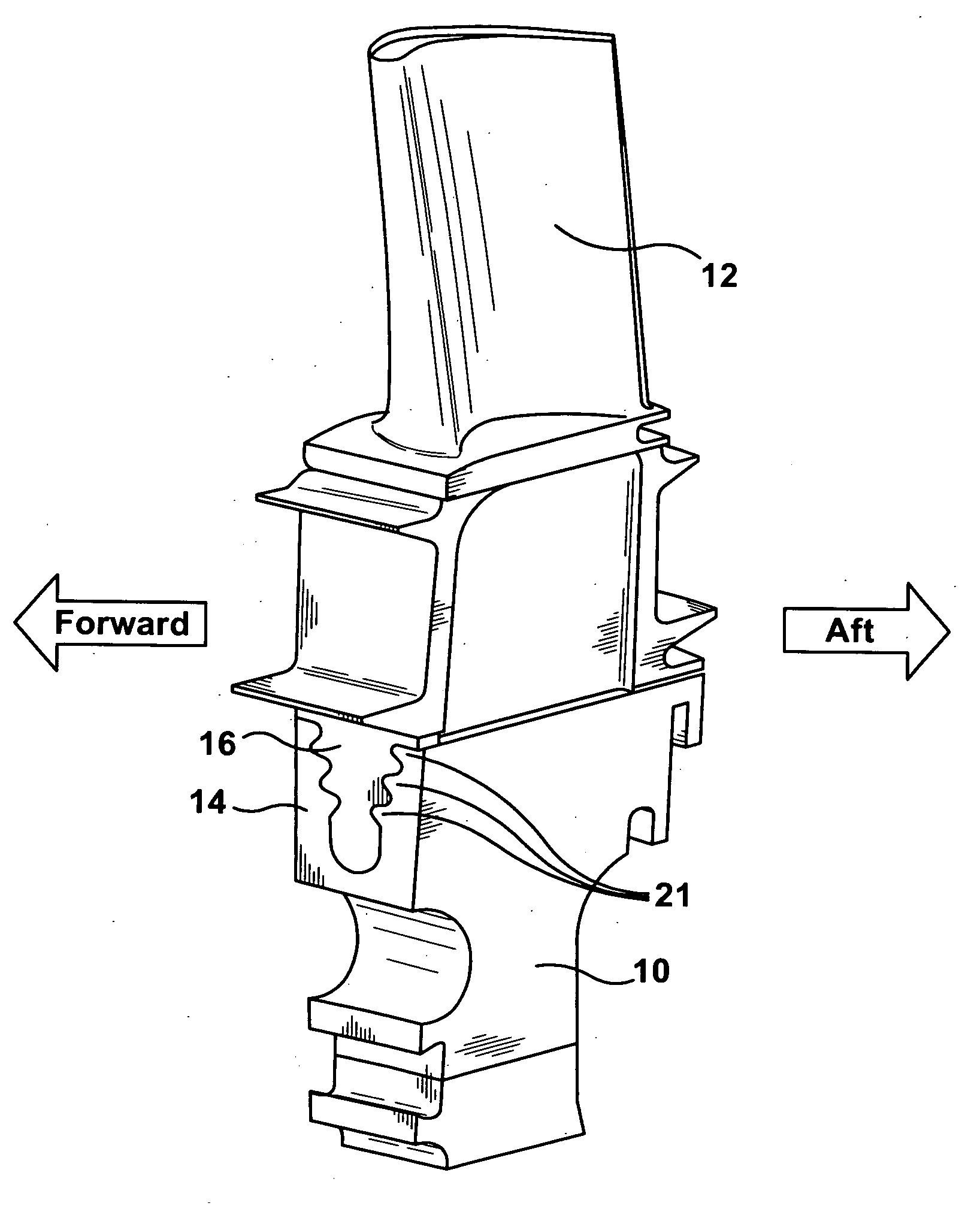

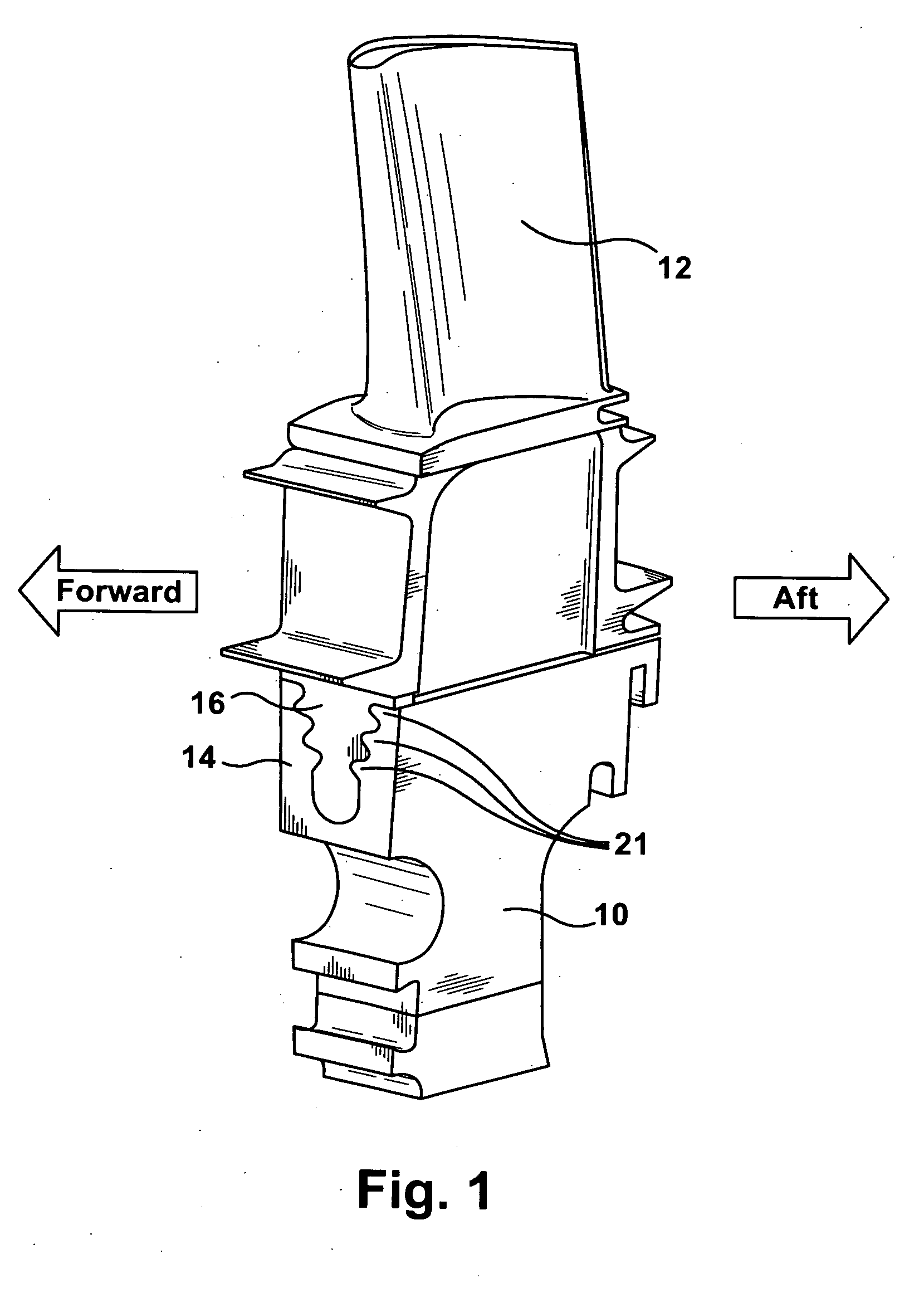

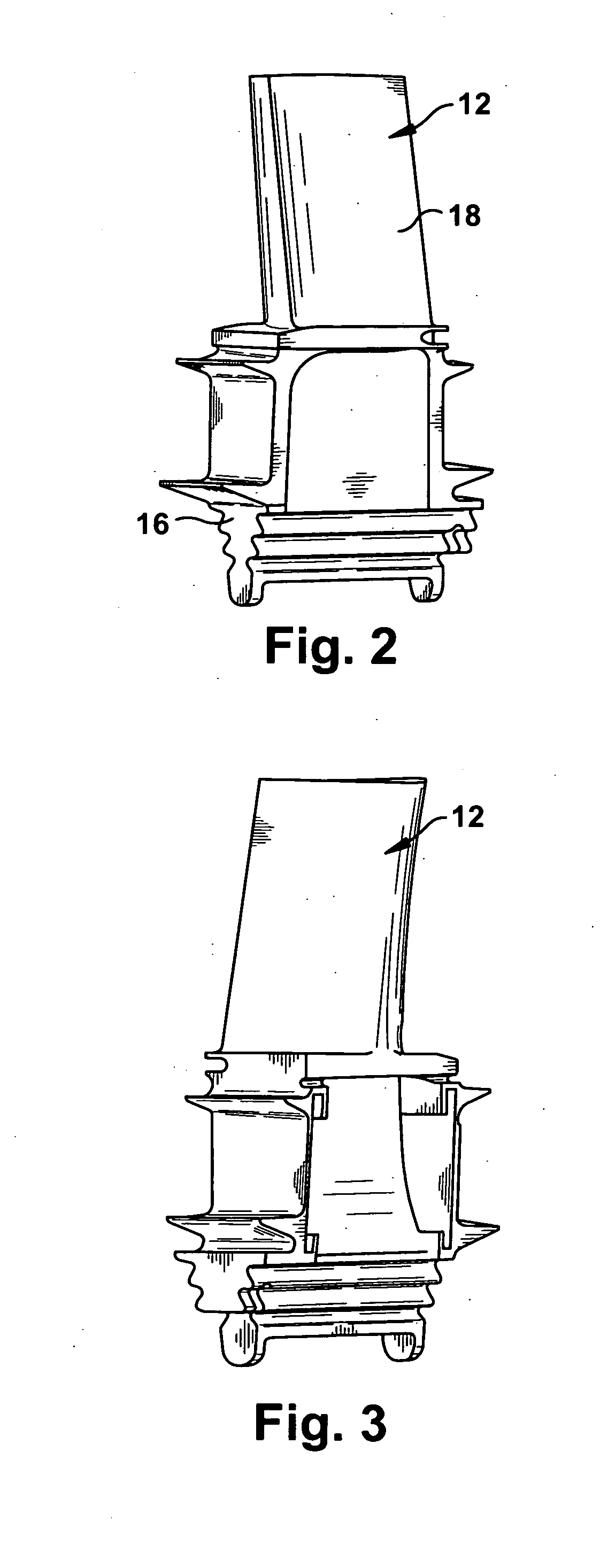

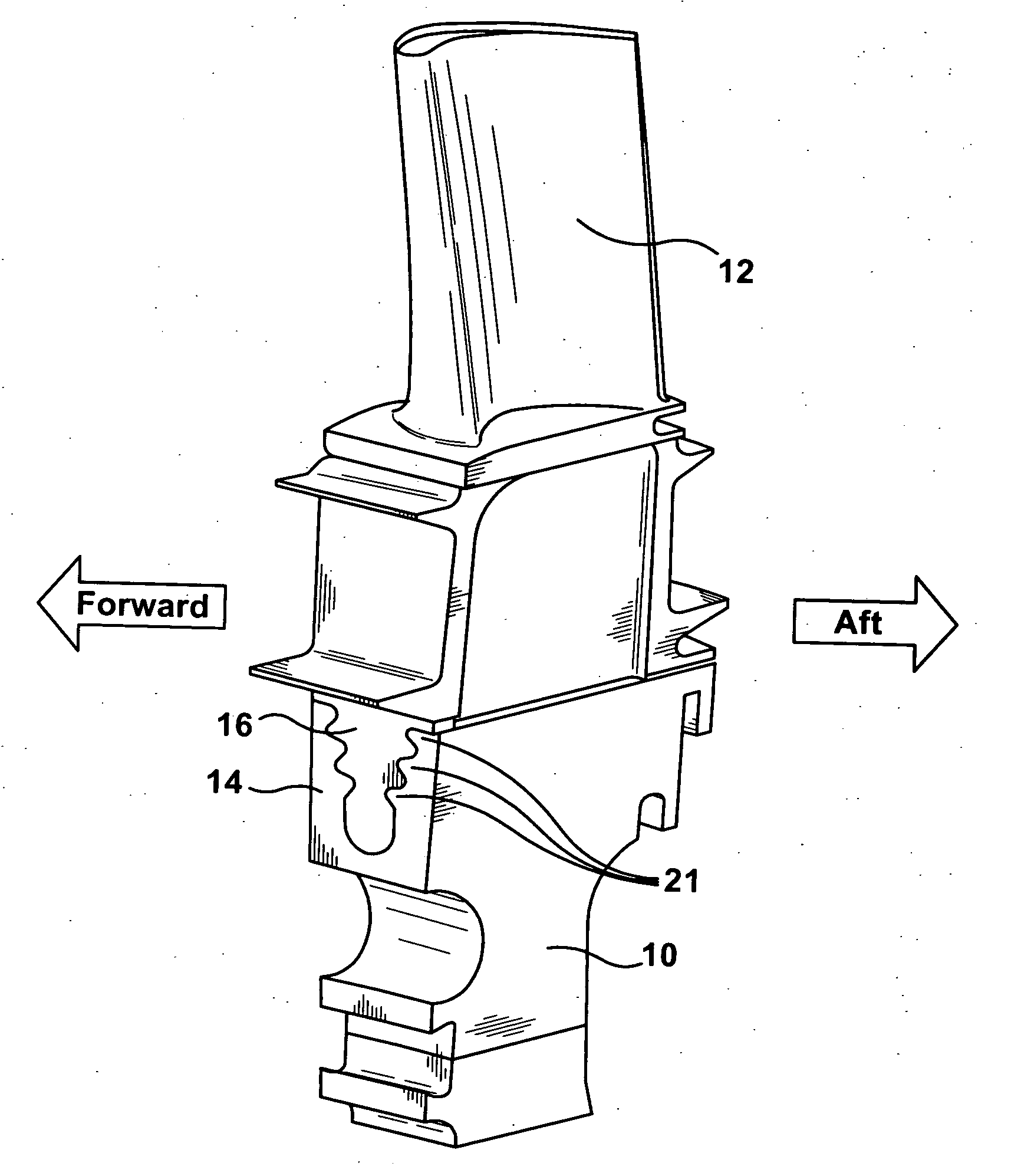

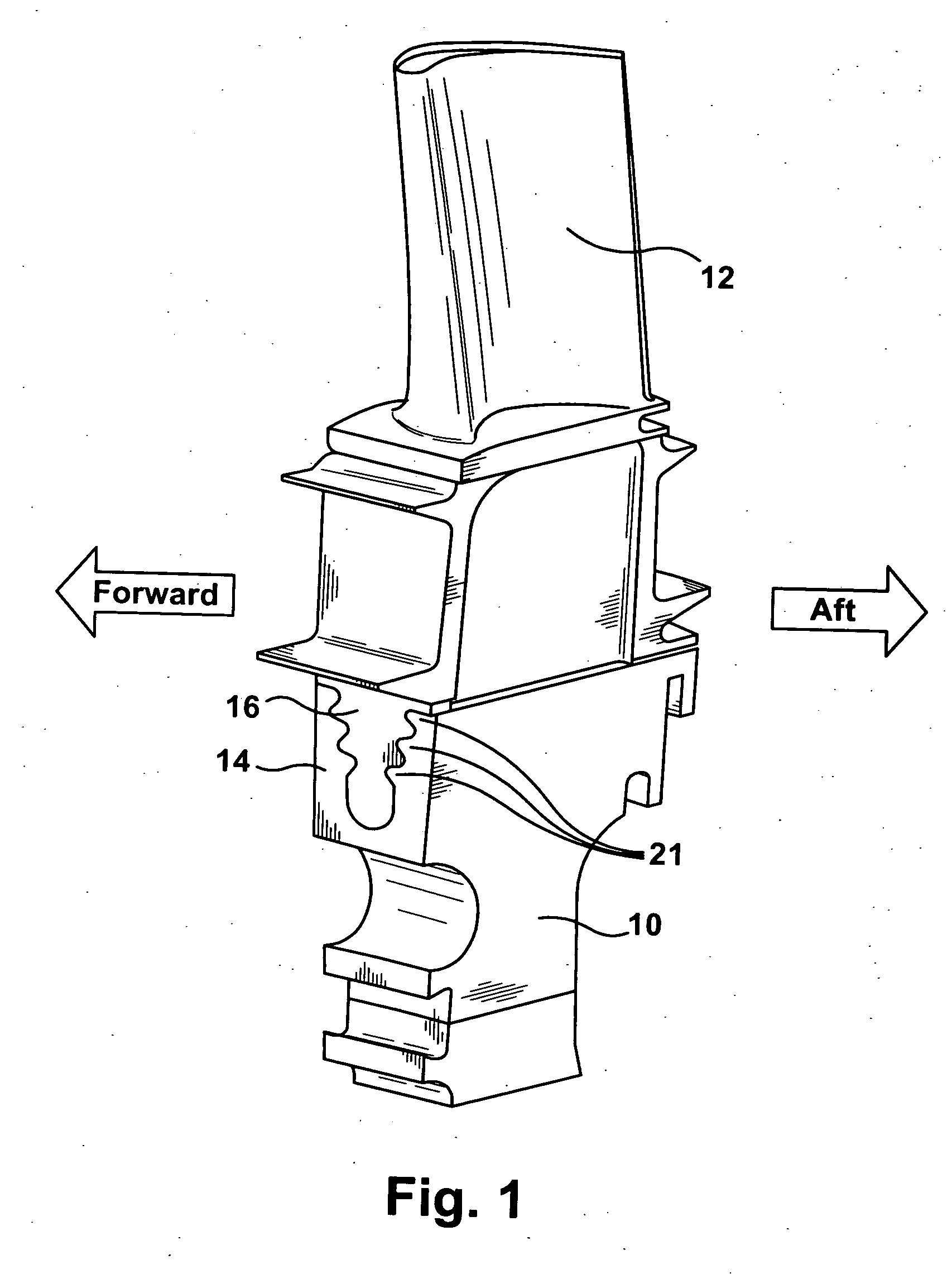

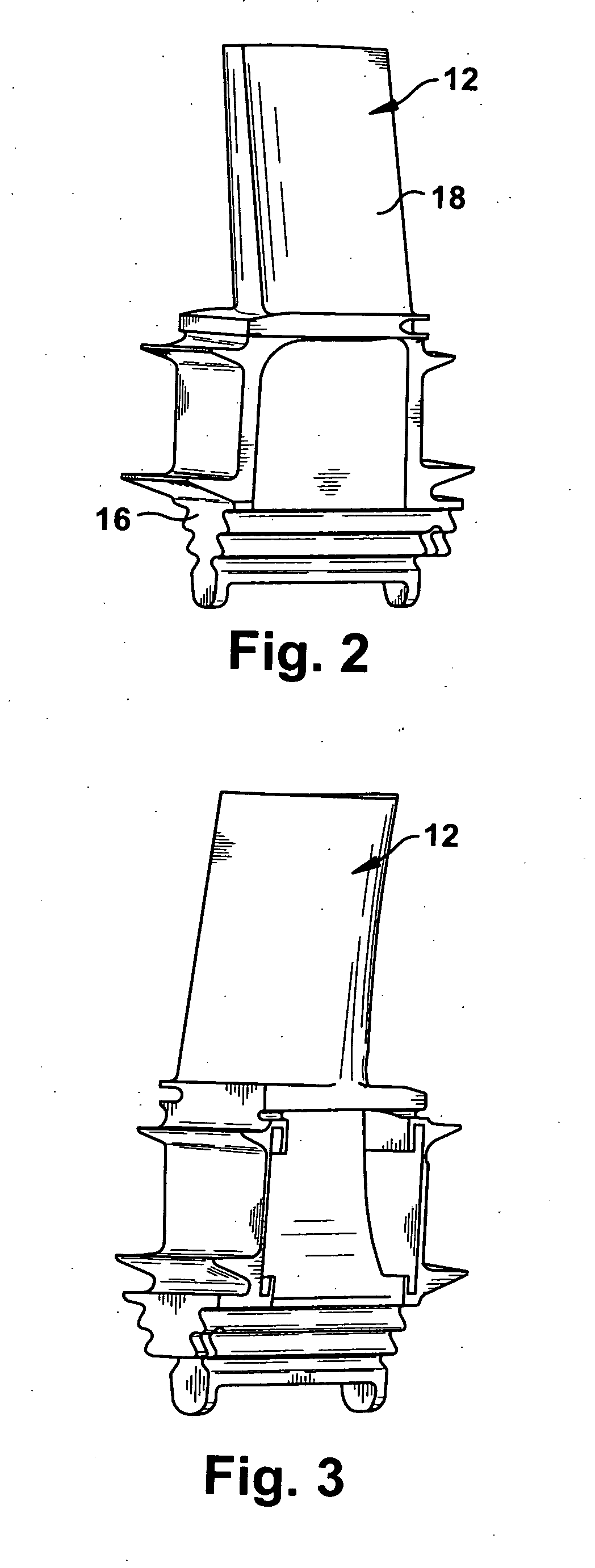

Blade/disk dovetail backcut for blade/disk stress reduction (7FA, stage 2)

InactiveUS20080101939A1Relieve pressureMaximize balancePropellersPump componentsCircular discTurbine blade

A turbine blade that may include an airfoil and a blade dovetail, the blade dovetail being shaped corresponding to a dovetail slot in a turbine disk. The blade dovetail may include a dovetail backcut sized and positioned according to blade geometry to maximize a balance between stress reduction on the disk, stress reduction on the blade, a useful life of the turbine blade, and maintaining or improving the aeromechanical behavior of the turbine blade. A start point of the dovetail backcut, which defines a length of the dovetail backcut along a dovetail axis, may be determined relative to a datum line positioned a fixed distance from a forward face of the blade dovetail along a centerline of the dovetail axis. The start point of the dovetail backcut may be at least approximately 1.215 inches in an aft direction from the datum line.

Owner:GENERAL ELECTRIC CO

Control method for a gas turbine blade forging stock geometry and testing model

ActiveCN104406502ASimple structureReduce weightMechanical counters/curvatures measurementsProduction modelGraphics

The invention discloses a gas turbine blade geometry forging stock control methods and a testing model. The method includes the model of production and specific inspection, the model produced by the cross-sectional model making, model making and model axis combinations, axial cross-sectional model making production model are by cutaway model of the blade-shaped three-dimensional model of two-dimensional graphics, the graphics were produced by two-dimensional cross-sectional axis model and model both inside and outside the arc, and then combined to form inside and outside the arc than the fixed model with a model than by combining visual and feeler the methods were inside and outside the arc blades comparison checks. Model by a number of cross-section than the production model by forming an axis model fishbone-shaped cross-section and the axis of the model than the model on the side blade-shaped formation. The beneficial effect of the invention is a method which can detect the test results obtained in several parts of the blade, simple operation, high accuracy and high detection efficiency; check the model structure is simple, low labor intensity is detected, the detection of low skill requirements.

Owner:CHONGQING CHANGZHENG HEAVY IND

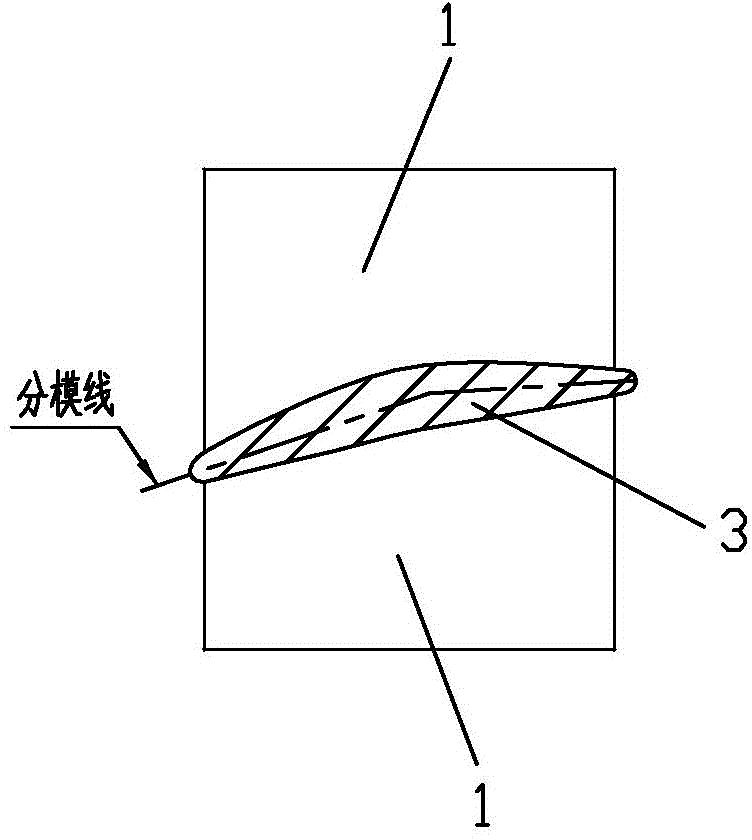

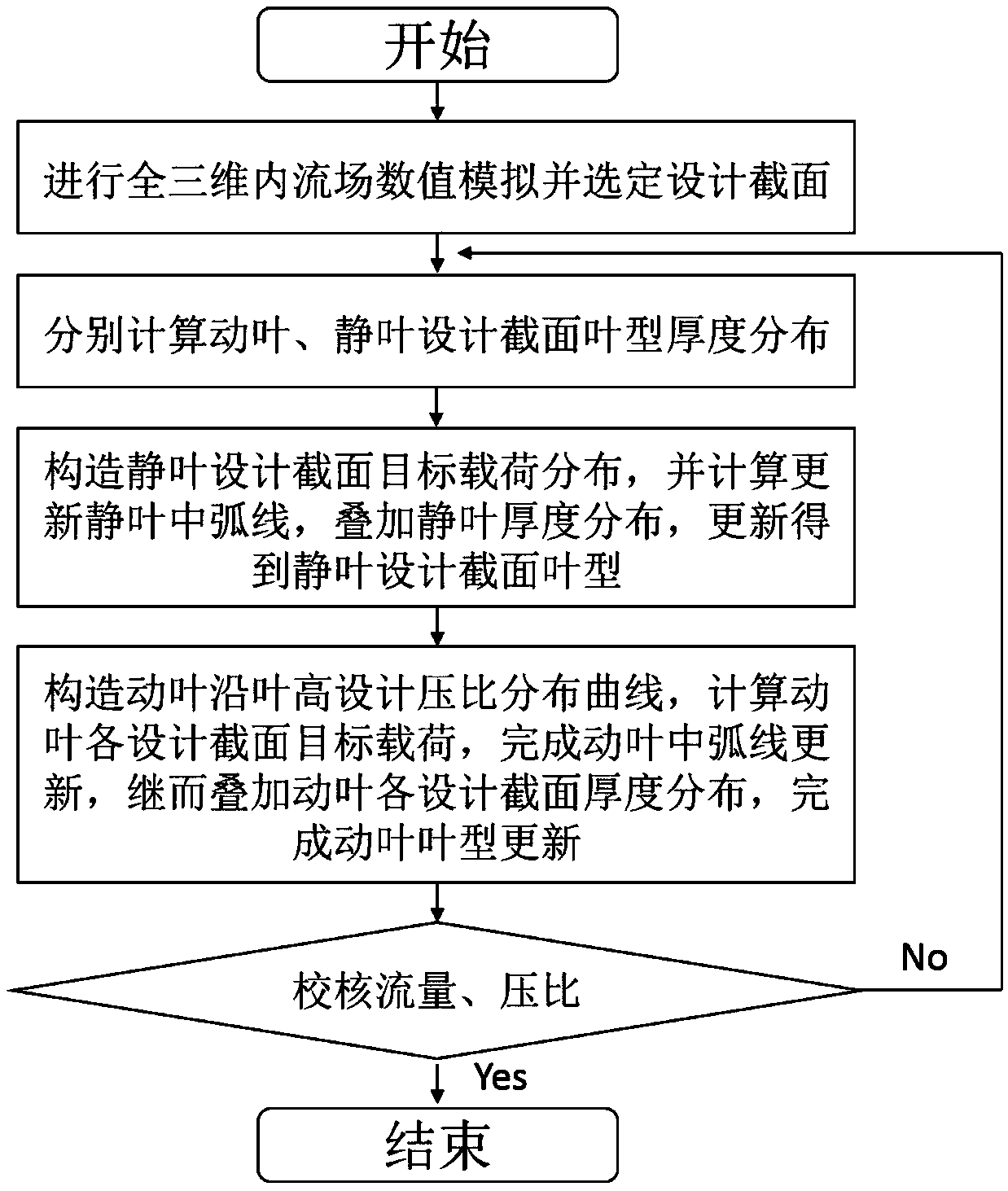

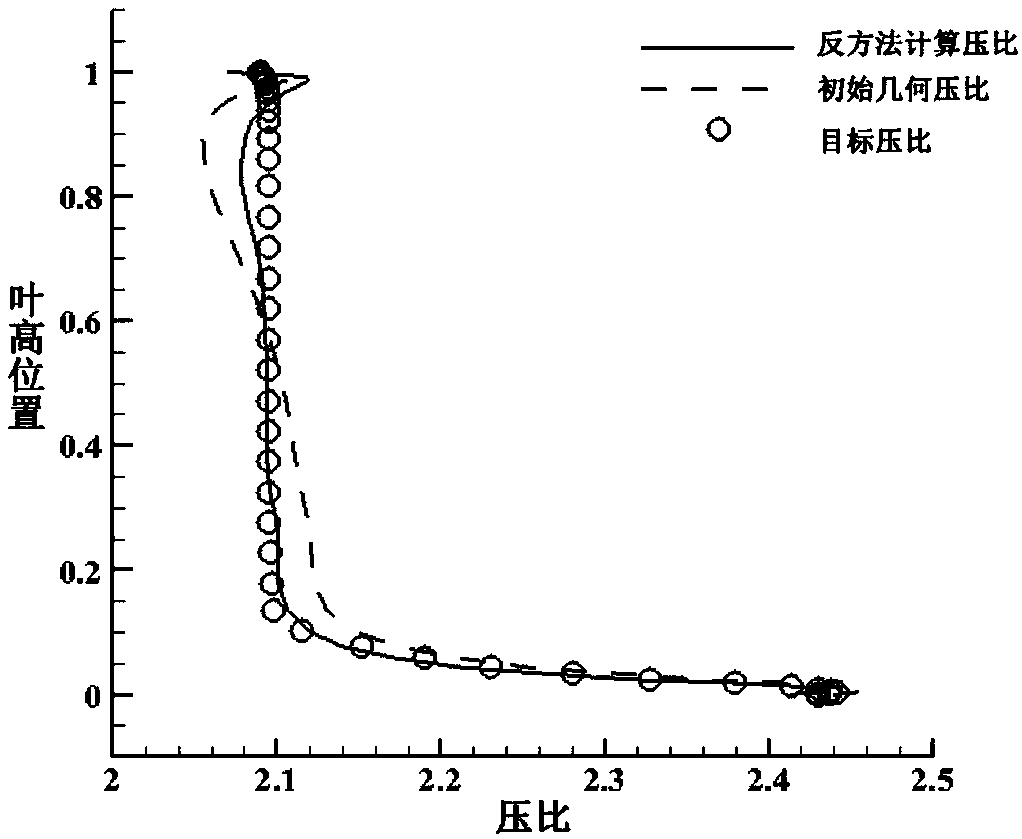

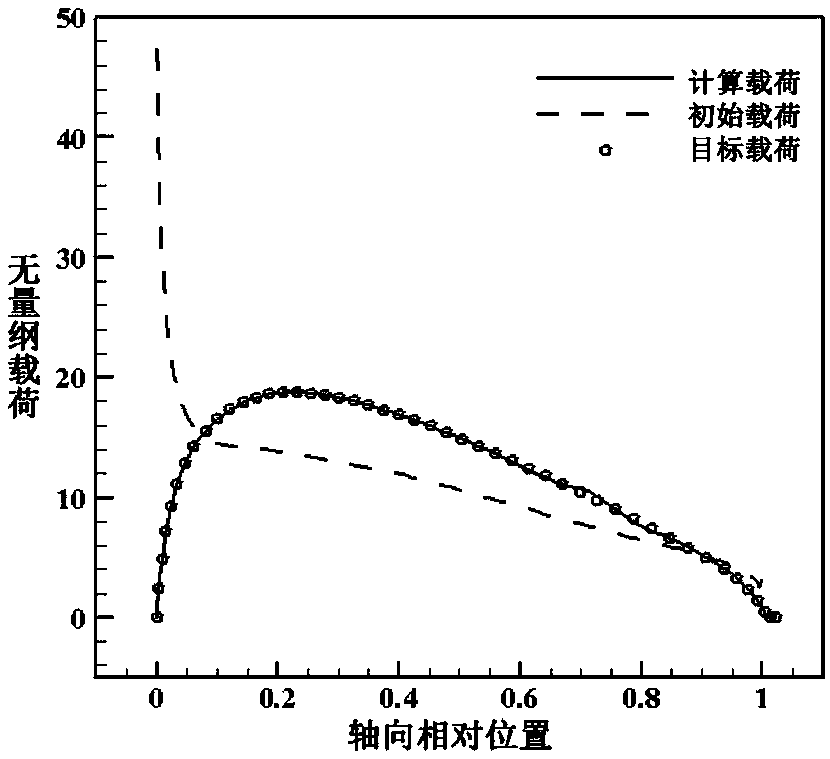

A method for optimizing aerodynamic matching between full three-dimensional stages of an axial flow compressor

ActiveCN109165440AImprove insulation efficiencyIdeal aerodynamic matching effectGeometric CADSpecial data processing applicationsAxial compressorEngineering

A method for optimizing aerodynamic matching between full three-dimensional stages of an axial flow compressor is provided. For a given axial compressor blade geometry, the RANS method is adopted, a 3-D viscous internal flow field is numerically simulated, and according to the numerical simulation results, the design target loads of each design section of the stator blade are constructed. For therotor, the target load distribution of the design section of the rotor blade is calculated, and the outlet flow boundary condition is given to ensure that the flow rate remains unchanged before and after optimization, that is to say, the purpose of completing the whole stage matching modification design of the compressor is achieved. The method can simultaneously complete quantitative design for swirl angle distribution and rotor pressure ratio distribution of an axial flow compressor stator outlet under a full three-dimensional environment. As a result, the axial compressor rotor and stator can be modified at the same time, the limitation that the traditional axial compressor aerodynamic matching modification technology can not simultaneously modify the rotor and stator blades is broken through, and an ideal aerodynamic matching effect is obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Variable performance vaneaxial fan with high efficiency

Owner:CORNERSTONE RES GROUP

Mechanical anti-wedging and controlled deployment broadhead

ActiveUS20050130774A1Rule out the possibilityReduce chanceThrow gamesArrowsGravity centerCircular segment

An anti-wedging, controlled deployment broadhead with an over-center of gravity blade geometry for bow-hunting that has the ability to penetrate bone and soft tissue deeply before deploying its blades while conserving the highest possible amount of kinetic energy in flight and at target. The inventive device includes the one-piece body, specially aligned and faceted cutting tip, blades, O-ring, and set screws. The blades have independent pivots that also act as travel limiters, are arch shaped with very sharp leading edges and a J-shaped lever. The center of gravity of each of the blades is oriented so as to insure retaining each blade in its respective retracted position during acceleration and assisting in deployment thereof during deceleration. The device with its special body and blade geometry now allows for more energy and blade area to be delivered to the vital organs of game to facilitate a faster and more humane harvest.

Owner:KOREKUT TECH LLC

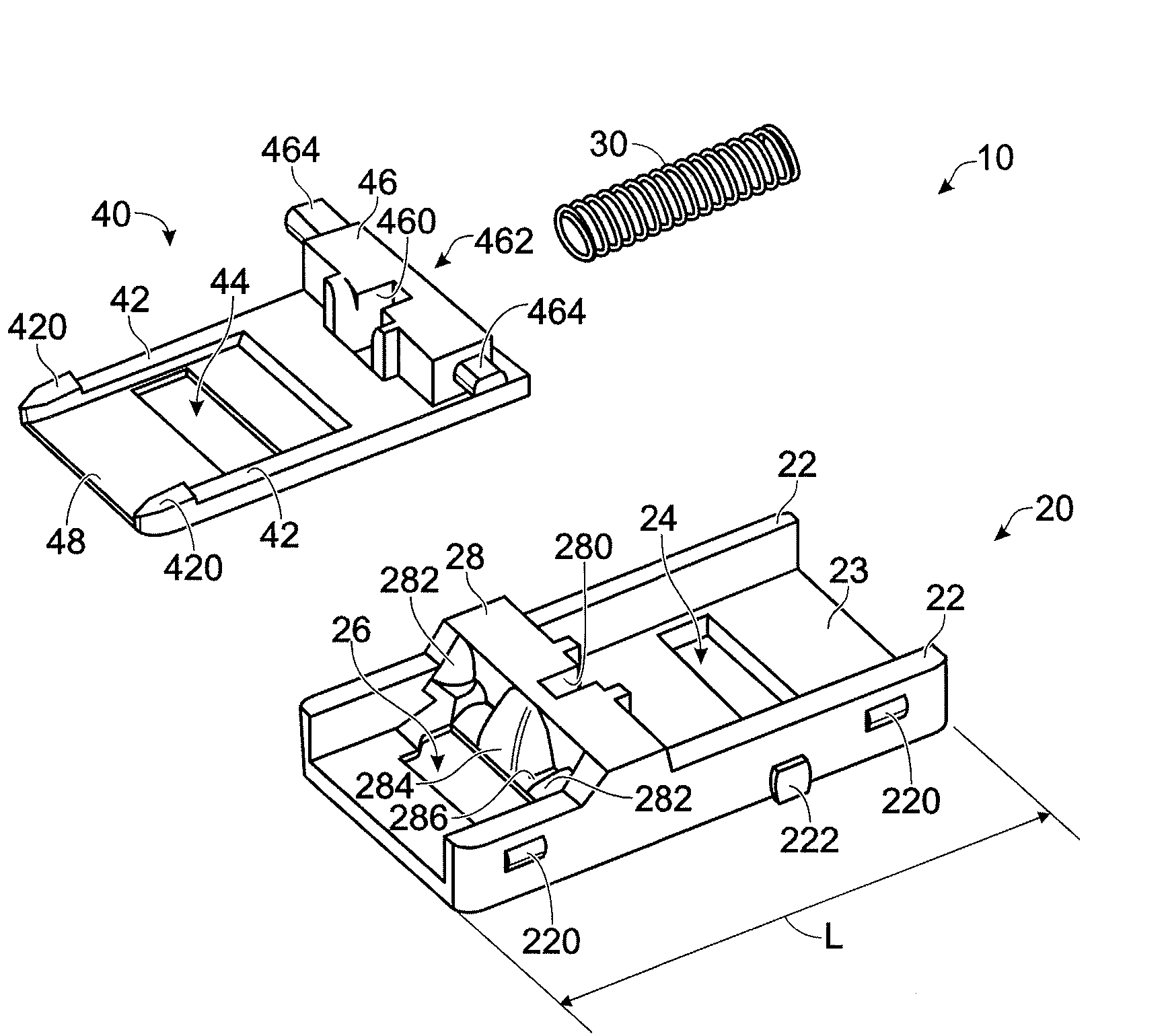

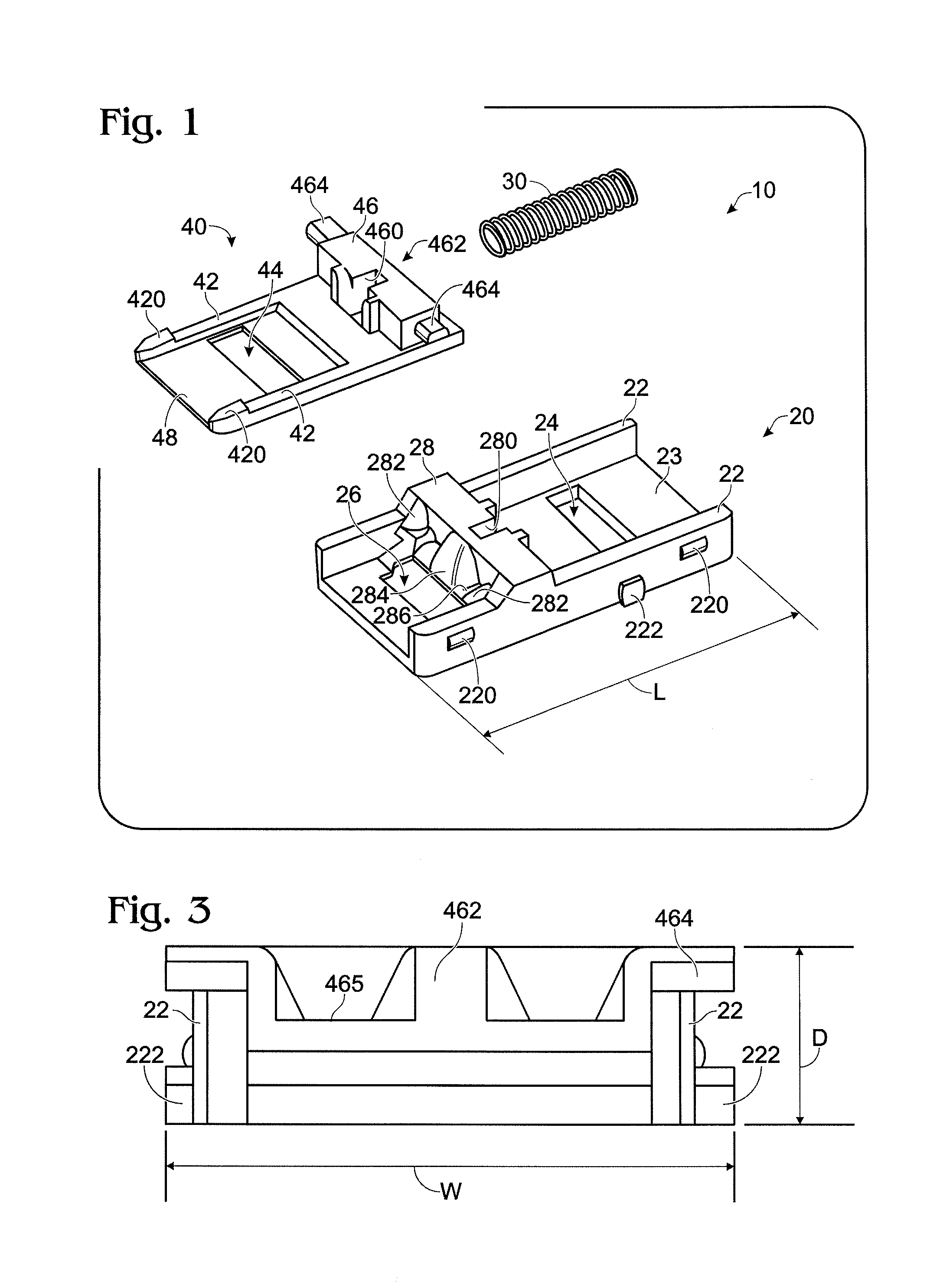

Method For Measuring Doctor Blade Geometric Deviations

A method for measuring geometric deviations of a doctor blade using an apparatus, including initializing the apparatus, mounting the doctor blade to a doctor blade holding device, illuminating the doctor blade with light, positioning a first portion of the doctor blade at an optical axis of a camera, obtaining a first image signal from the camera that corresponds to the first portion of the doctor blade, generating a first doctor blade geometry value associated with the first image signal, and determining if a first geometric deviation of the doctor blade is within acceptable tolerance using the first doctor blade geometry value.

Owner:LEXMARK INT INC

Protective Device with Tamper Resistant Shutters

ActiveUS20090052120A1Substation/switching arrangement detailsSwitch operated by falling currentWindow shutterEngineering

The present invention is directed to a protective shutter assembly for use within a cover assembly of an electrical wiring device. The assembly includes a frameless shutter sub-assembly movable between a closed position and an open position. The frameless shutter sub-assembly is configured to move from the closed position to the open position in response to engaging at least one plug blade having a predetermined plug blade geometry. A spring member is disposed within the frameless shutter sub-assembly. The spring member is configured to bias the frameless shutter sub-assembly in the closed position. At least one retainer element is disposed in the frameless shutter sub-assembly. The at least one retainer element being configured to retain the spring member within the frameless shutter sub-assembly. At least one registration member is disposed on the frameless shutter sub-assembly, the at least one registration member being configured to position and align the protective shutter assembly within the cover assembly.

Owner:PASS SEYMOUR

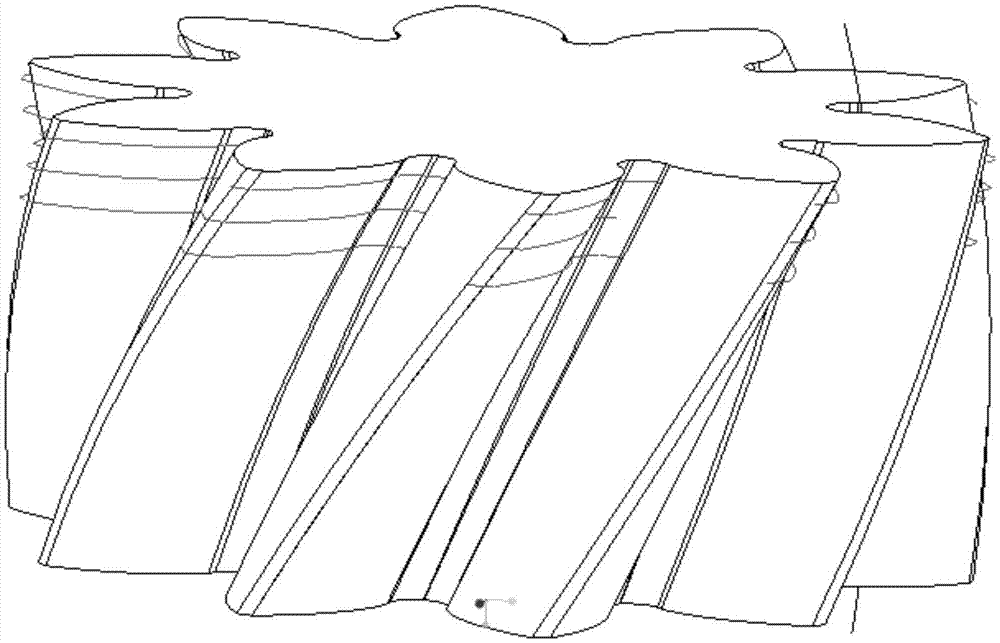

Method for processing hard tooth surface of medium-precision large-modulus cylindrical gear

ActiveCN105436623AGood fixationImprove cutting rigidityGear teeth manufacturing toolsGear teethDynamic stiffnessHelical line

A method for processing a hard tooth surface of a medium-precision large-modulus cylindrical gear is characterized in that a double-parameter non-instantaneous-pole enveloping method is carried out to perform tooth surface generating enveloping and hard milling, namely, a cutter is used for performing weft enveloping along the circumference contour direction of the gear and then performing warp enveloping along a helical line direction of the tooth surface of the gear. According to the method, a large-diameter disc milling cutter, which is provided with a large-space chip storing groove and is high in cutting stiffness and convenient and reliable in blade fixing manner, is utilized, so that a cutter disc is outstanding in comprehensive high-speed hard milling performance; a coated carbide blade is used for achieving high-speed hard milling of hardened steel; the form of the geometric structure of the blade can effectively improve the dynamic stiffness and thermal stiffness and can also reduce the influence of force and heat on a workpiece and the blade, and as a result, the durability of the blade can be improved.

Owner:NANJING GONGDA CNC TECH +1

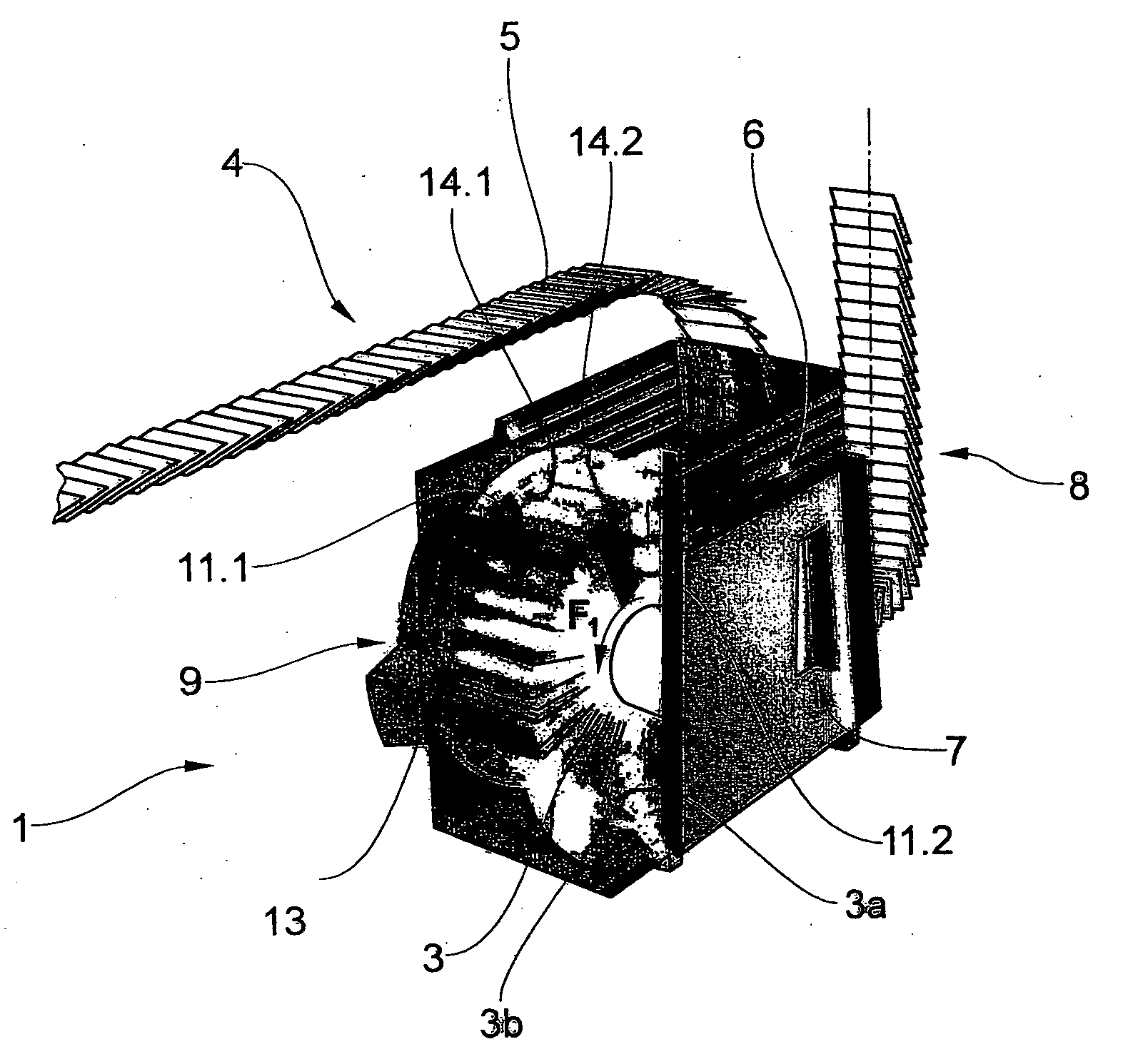

Cutting device and cutting method for printed products

InactiveUS20100126319A1Improve the problemExtension of timeShearing machinesMetal working apparatusKinematicsBlade geometry

The invention relates to a cutting device for cutting continuously conveyed printed products (5). The cutting device has multiple conveying elements (3) which run around a closed path for conveying at least one single printed product (5) or printed product groups (5′). The printed products (5, 5′) are moved along their conveyance path past at least one cutting station (10). In each cutting station, at least one edge of the printed product (5) is cut by knife blades (11, 12) and counter blades (13, 14) in a shear cut. For this shear cut, according to the invention, multiple self-sharpening blades (11, 12) come into cutting engagement with at least one counter blade (13, 14). Alternatively, multiple counter blades (13, 14) come into cutting engagement with at least one self-sharpening blade (11, 12). A significant improvement in edge retention and cutting quality is achieved by means of targeted blade kinematics, blade arrangement, product guidance, and blade geometry.

Owner:FERAG AG

Heavy type cutting rotary turning and milling composite blade

InactiveCN108655427AImprove impact resistanceStable cutting processMilling cuttersCutting insertsSet screwEdge strength

A blade is mainly applied to the field of heavy type cutting, and the problems that during heavy type machining of large special-shaped pieces, since the cutting parameters are large and the machinedcomponent surface state is complex, the blade is likely to vibrate, and failures happen need to be solved. For the large special-shaped piece machining complex work condition, a heavy type cutting rotary turning and milling composite blade is developed and designed. The blade is provided with a linear cutting edge and an arc cutting edge; and meanwhile, the large parameters during heavy type cutting are considered, so that negative chamfer is designed, and the cutting edge strength of the blade can be improved. Streamline protrusions and conical abrasion reducing protrusions are designed on the upper cutter face, and during machining, the functions that the cutting temperature is reduced and scrap rolling and discharging are assisted can be achieved, and meanwhile the anti-vibration capability of the blade is improved. An octangle groove and a set screw hole are designed in the geometric center of the blade, an annular heat dissipation groove is designed in the bottom, the blade and air contact area can be increased while cutting fluid is stored, the heat dissipation function is achieved during blade cutting, and meanwhile the blade strength is improved. The whole blade structure is complete, the production cost is low, and the heavy type cutting rotary turning and milling composite blade is suitable for being used for heavy type turning and milling machining.

Owner:HARBIN UNIV OF SCI & TECH

Blade/disk dovetail backcut for blade/disk stress reduction (9FA, stage 1)

InactiveUS20080101937A1Relieve pressureMaximize balancePropellersEngine manufactureCircular discTurbine blade

A turbine blade that may include an airfoil and a blade dovetail, the blade dovetail being shaped corresponding to a dovetail slot in a turbine disk. The blade dovetail may include a dovetail backcut sized and positioned according to blade geometry to maximize a balance between stress reduction on the disk, stress reduction on the blade, a useful life of the turbine blade, and maintaining or improving the aeromechanical behavior of the turbine blade. A start point of the dovetail backcut, which defines a length of the dovetail backcut along a dovetail axis, may be determined relative to a datum line positioned a fixed distance from a forward face of the blade dovetail along a centerline of the dovetail axis. The start point of the dovetail backcut may be at least approximately 1.539 inches in an aft direction from the datum line.

Owner:GENERAL ELECTRIC CO

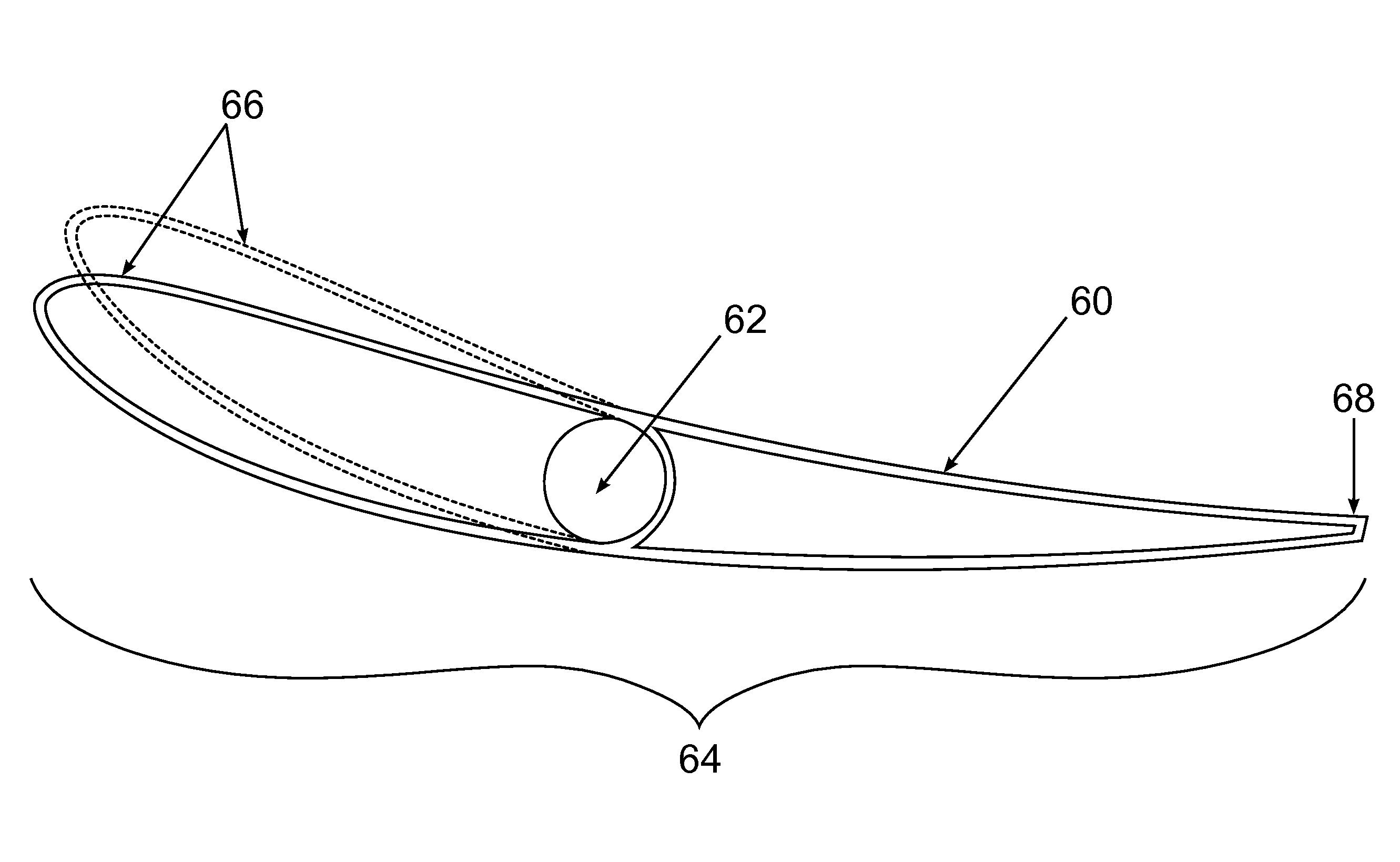

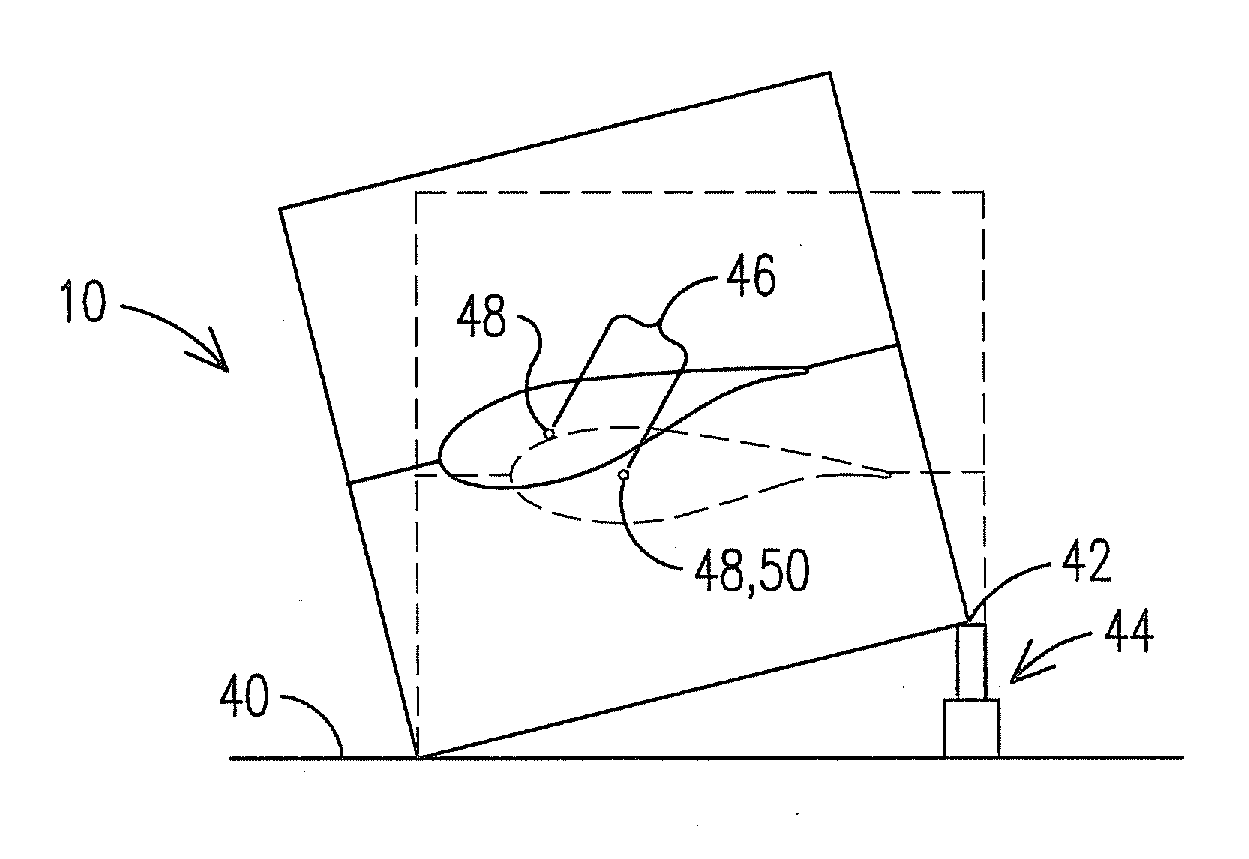

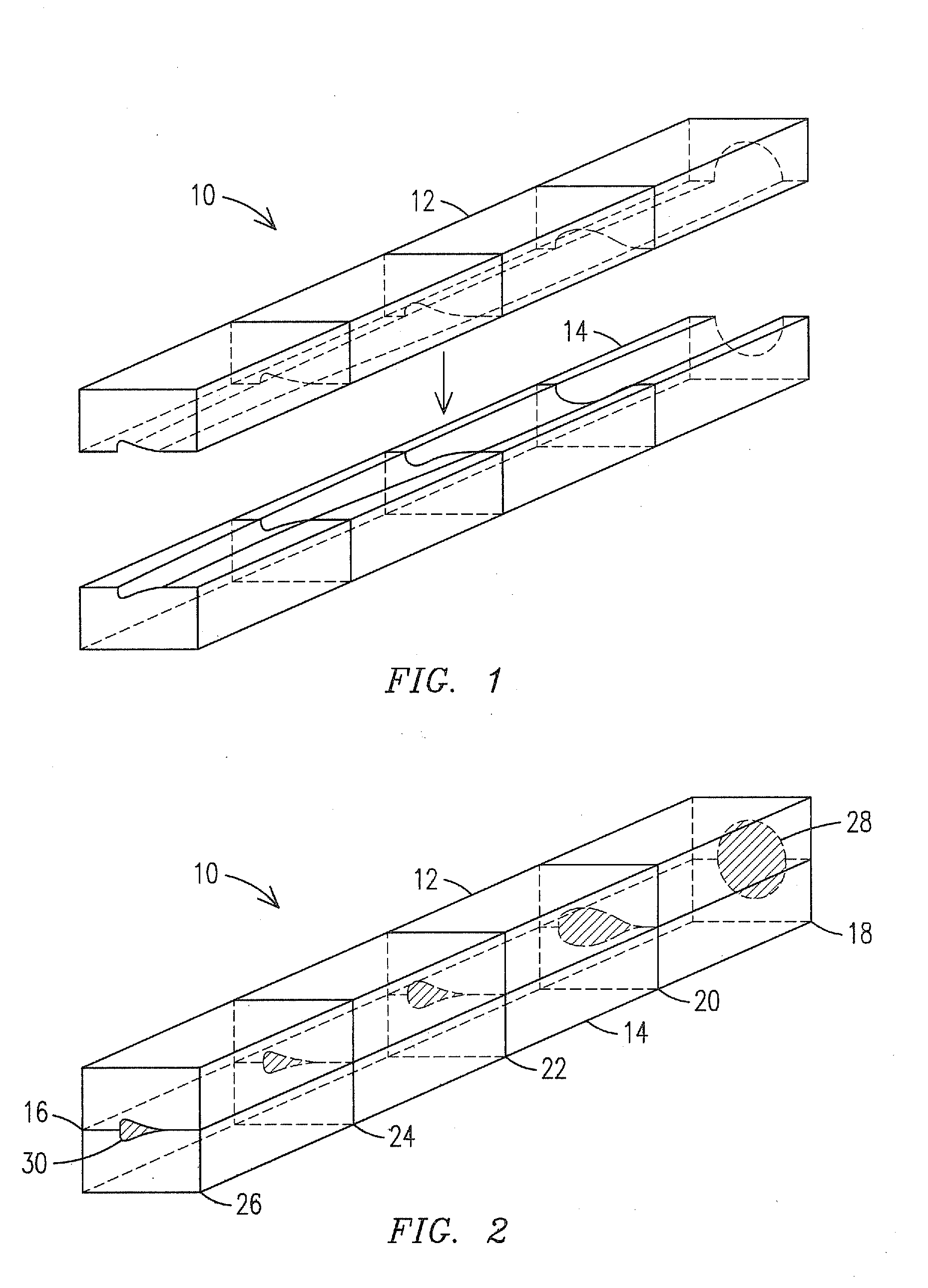

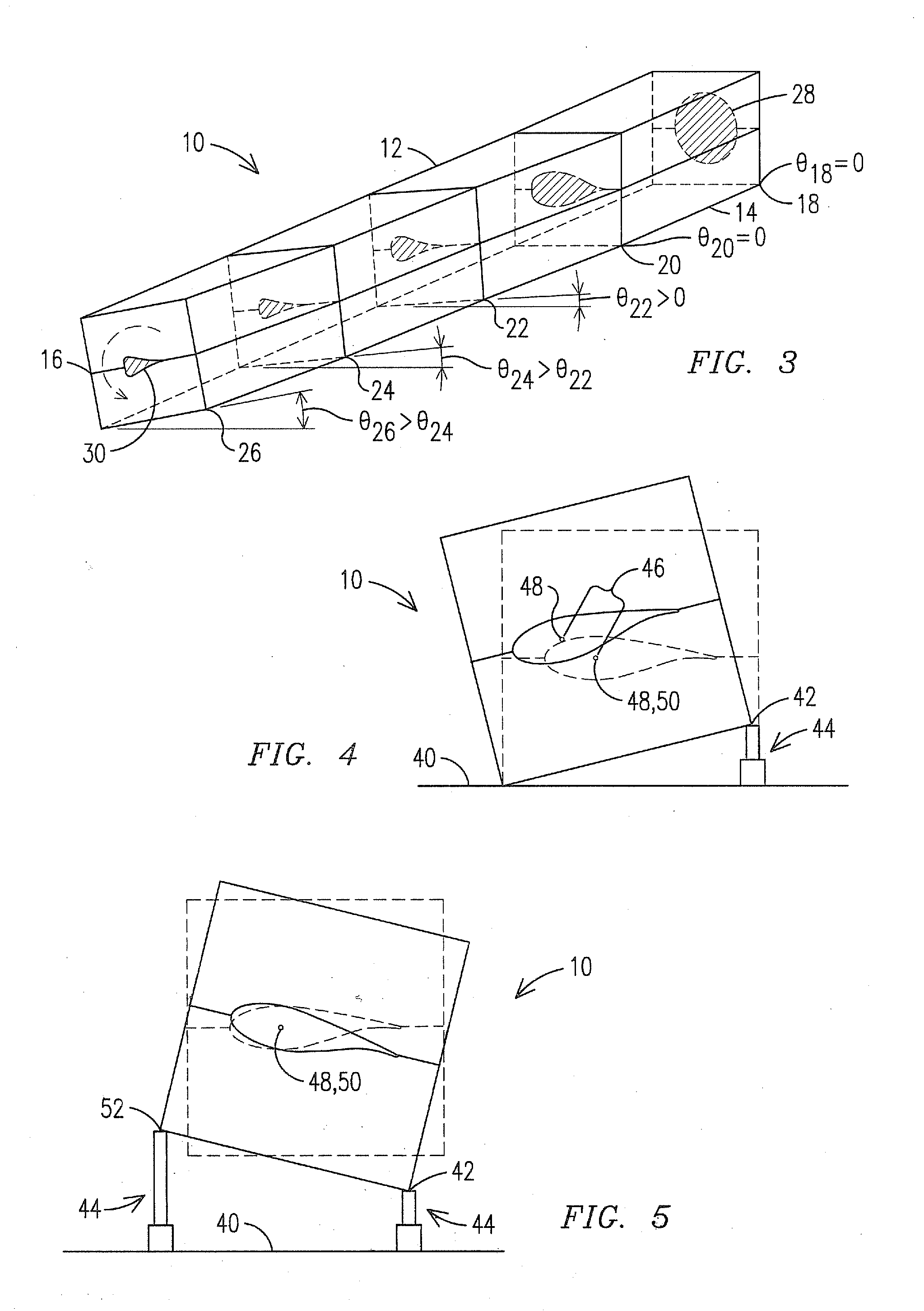

Arrangement and method for manufacturing a wind turbine blade

A closed mold arrangement for manufacturing a wind turbine blade, including: a closed outer mold (10); a mechanism (44) to selectively flex the outer mold (10) across a range of outer geometries; and a first inner mold (92, 120). The first inner mold (92, 102, 120, 140) is used in the closed outer mold (10) when the closed outer mold (10) is in a first outer geometry and thereby defines a first blade geometry. Alternatively a second inner mold (102, 140) is used in the closed outer mold (10) when the closed outer mold (10) is flexed to a second outer geometry different than the first outer geometry and thereby defines a second blade geometry.

Owner:SIEMENS AG

Blade/disk dovetail backcut for blade/disk stress reduction (7FA, stage 1)

InactiveUS20080101938A1Relieve pressureMaximize balancePropellersPump componentsCircular discTurbine blade

A turbine blade that may include an airfoil and a blade dovetail, the blade dovetail being shaped corresponding to a dovetail slot in a turbine disk. The blade dovetail may include a dovetail backcut sized and positioned according to blade geometry to maximize a balance between stress reduction on the disk, stress reduction on the blade, a useful life of the turbine blade, and maintaining or improving the aeromechanical behavior of the turbine blade. A start point of the dovetail backcut, which defines a length of the dovetail backcut along a dovetail axis, may be determined relative to a datum line positioned a fixed distance from a forward face of the blade dovetail along a centerline of the dovetail axis. The start point of the dovetail backcut may be at least approximately 1.645 inches in an aft direction from the datum line.

Owner:GENERAL ELECTRIC CO

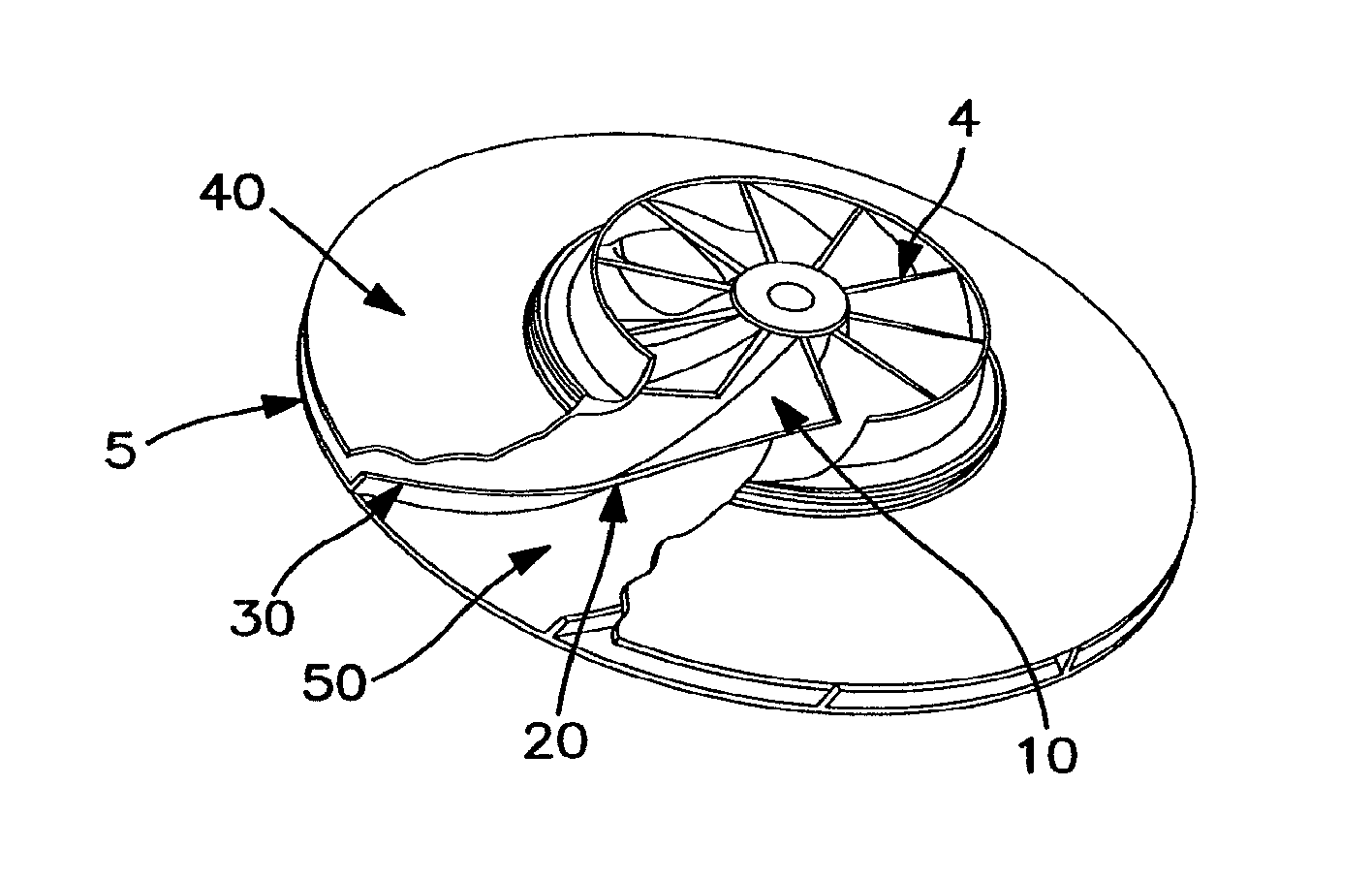

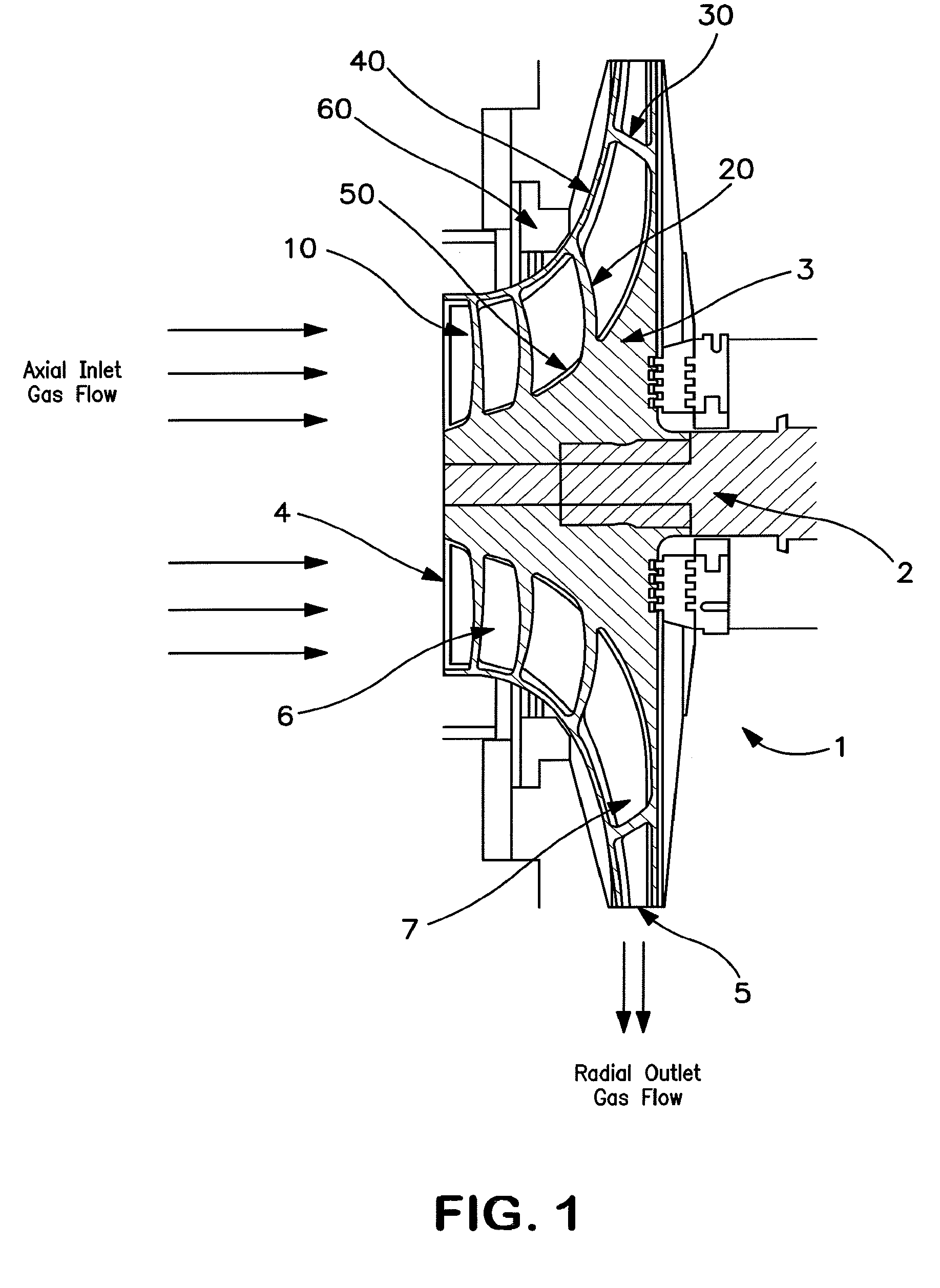

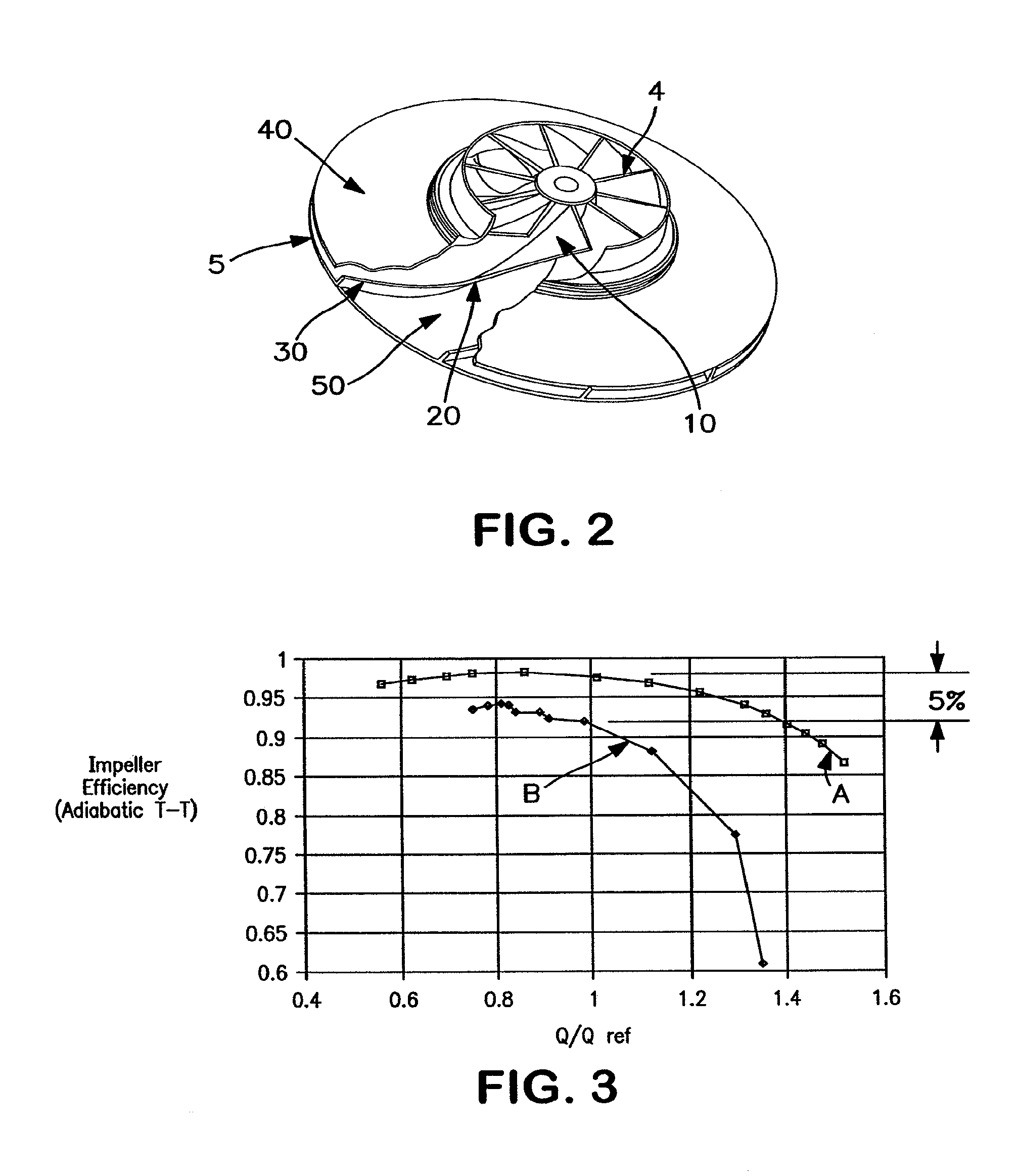

Compressor with large diameter shrouded three dimensional impeller

A compressor having a defined large diameter impeller having an integral shroud and having a three dimensional gas flow path defined by the impeller hub surface, blades and the shroud and having a large axially oriented inlet or inducer section with aggressive inducer blades, a defined outlet section geometry, and continuous blade geometries between the inlet and outlet sections.

Owner:PRAXAIR TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com