Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70 results about "Alkylation unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An alkylation unit (alky) is one of the conversion processes used in petroleum refineries. It is used to convert isobutane and low-molecular-weight alkenes (primarily a mixture of propene and butene) into alkylate, a high octane gasoline component. The process occurs in the presence of an acid such as sulfuric acid or hydrofluoric acid (HF) as catalyst. Depending on the acid used, the unit is called a sulfuric acid alkylation unit (SAAU) or hydrofluoric acid alkylation unit (HFAU). In short, the alky produces a high-quality gasoline blending stock by combining two shorter hydrocarbon molecules into one longer chain gasoline-range molecule by mixing isobutane with a light olefin such as propylene or butylene from the refinery's fluid catalytic cracking unit (FCCU) in the presence of an acid catalyst.

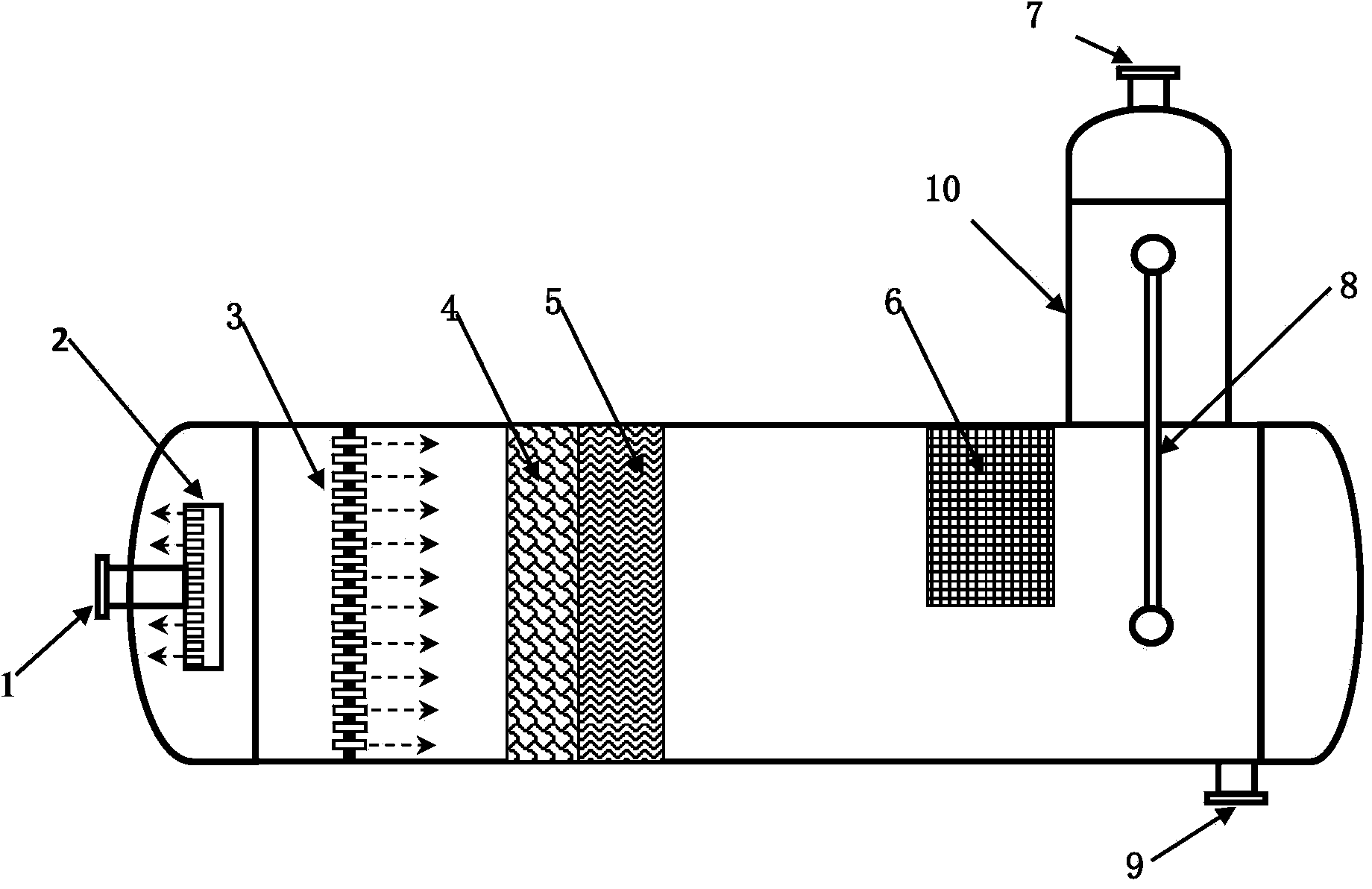

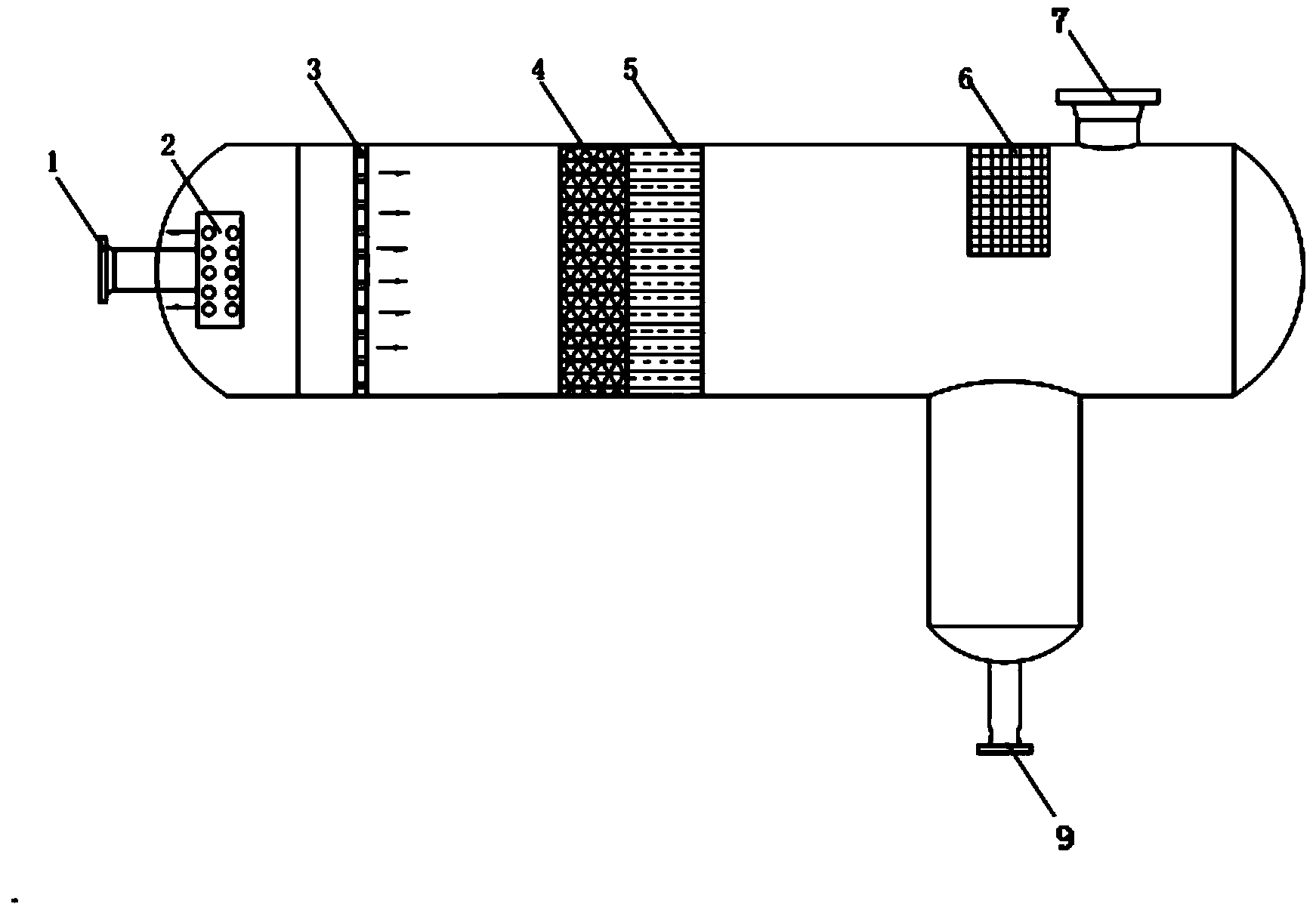

Efficient coalescence-separation equipment for alkylating device

ActiveCN103723790AIncrease contact channelTake advantage ofFatty/oily/floating substances removal devicesWater contaminantsNanofiberOil water

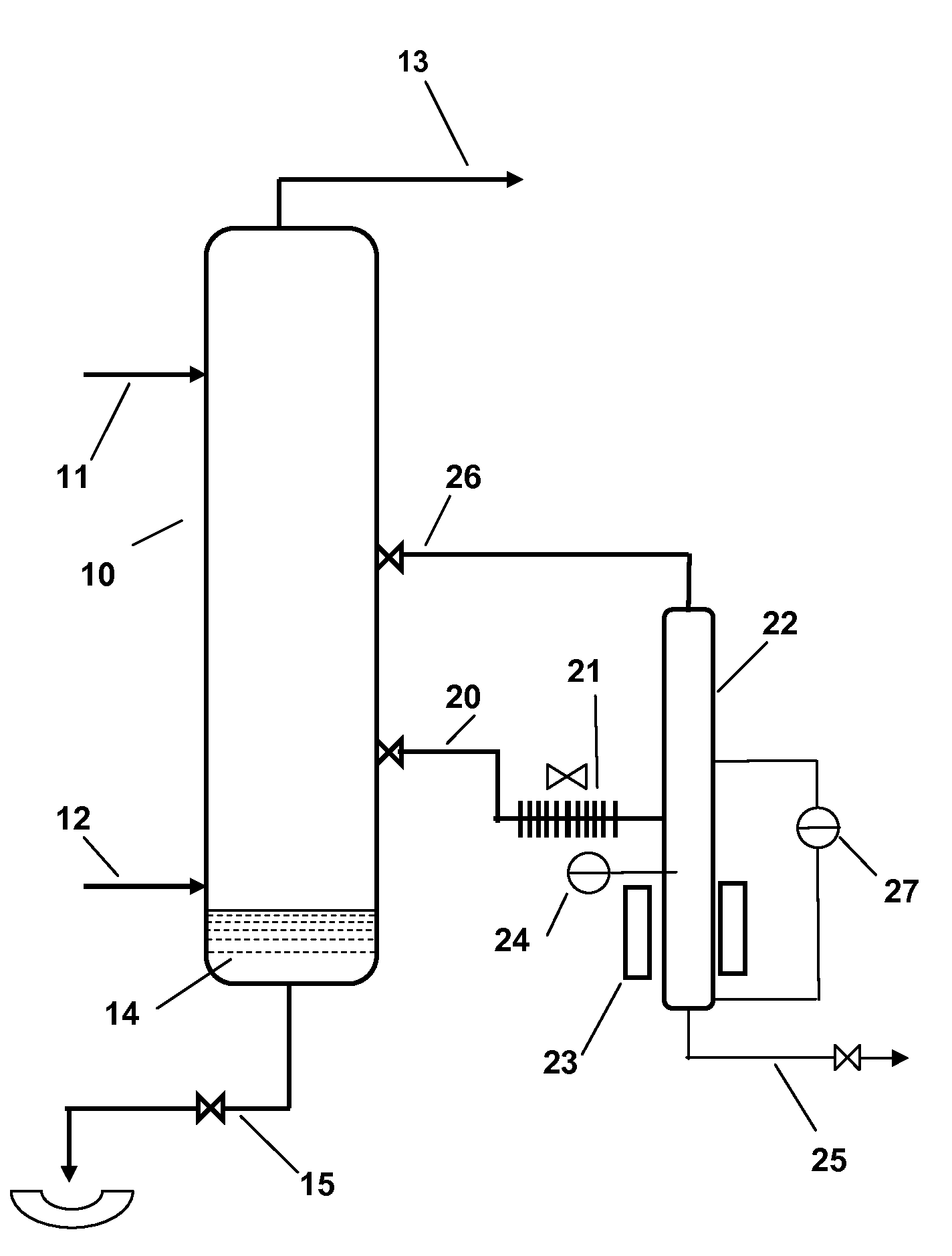

The invention discloses efficient coalescence-separation equipment for an alkylating device, and belongs to the field of oil-water separation of petrochemical industry. The efficient coalescence-separation equipment comprises a housing and an internal part; a mixed liquid inlet part, a water (acid) phase outlet part, and an oil phase outlet part are formed in the housing; a liquid distributor is arranged at the mixed liquid inlet part; an oil collecting chamber above which an oil phase outlet is formed is arranged at the oil phase outlet part; a rectifying and uniform distributing device, a coarse graining coalescence section, a modified corrugated and reinforced separation section and a nanofiber deep separation section are arranged in the housing along the direction the mixed liquid flows; a position gauge is also arranged in the housing. According to the efficient coalescence-separation equipment for the alkylating device, the shallow pool theory and coarse graining technology are integrated, so that high oil-water (-acid) separation efficiency can be realized; compared with the existing single filler oil-water separation equipment, the efficient coalescence-separation equipment, disclosed by the invention, has obvious characteristics of being high in separation efficiency, high in processing capability, high in operation flexibility, small in floor area, small in one-time investment for equipment, etc.

Owner:SHANGHAI MISU ENVIRONMENTAL PROTECTION TECHCO LTD +2

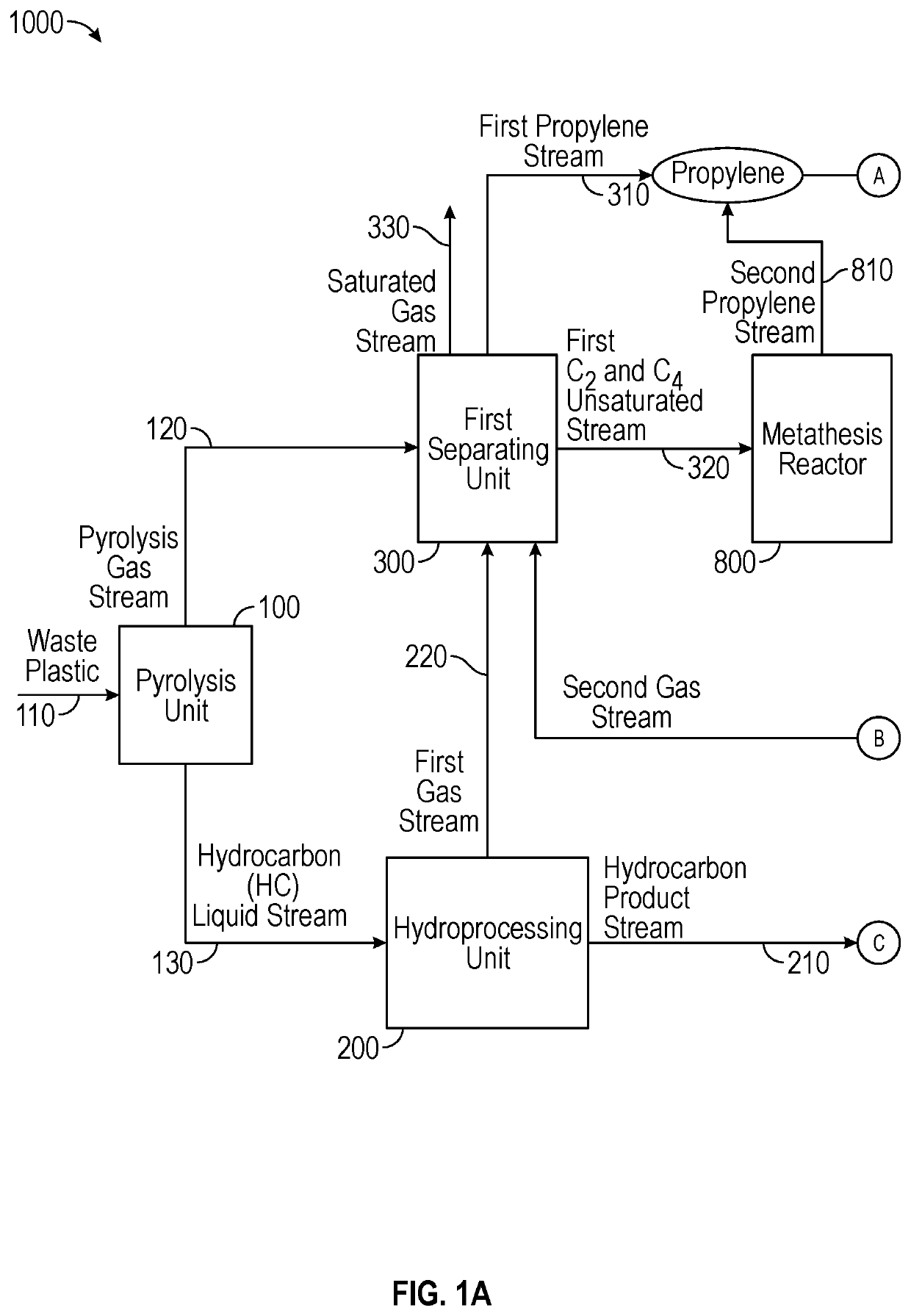

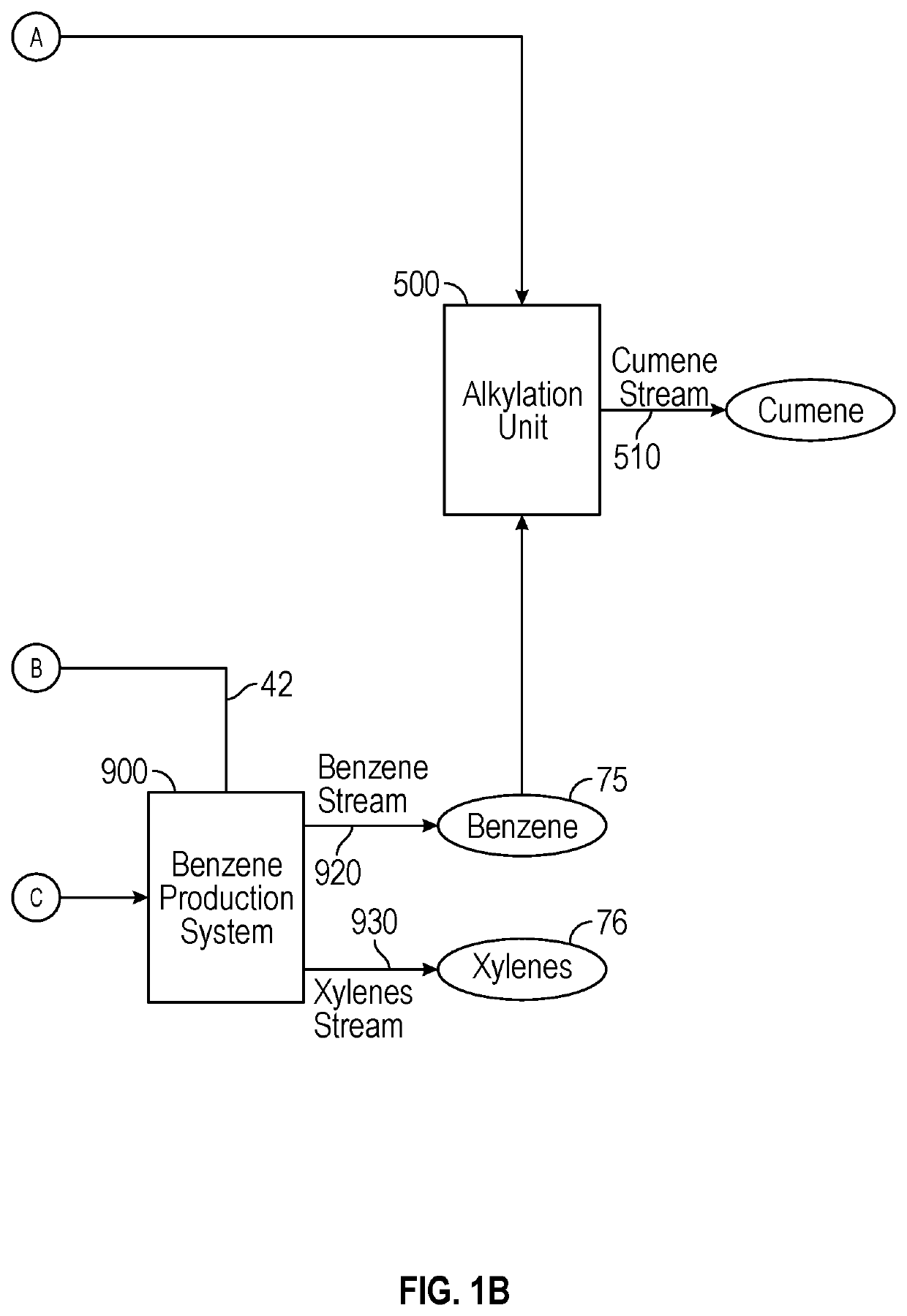

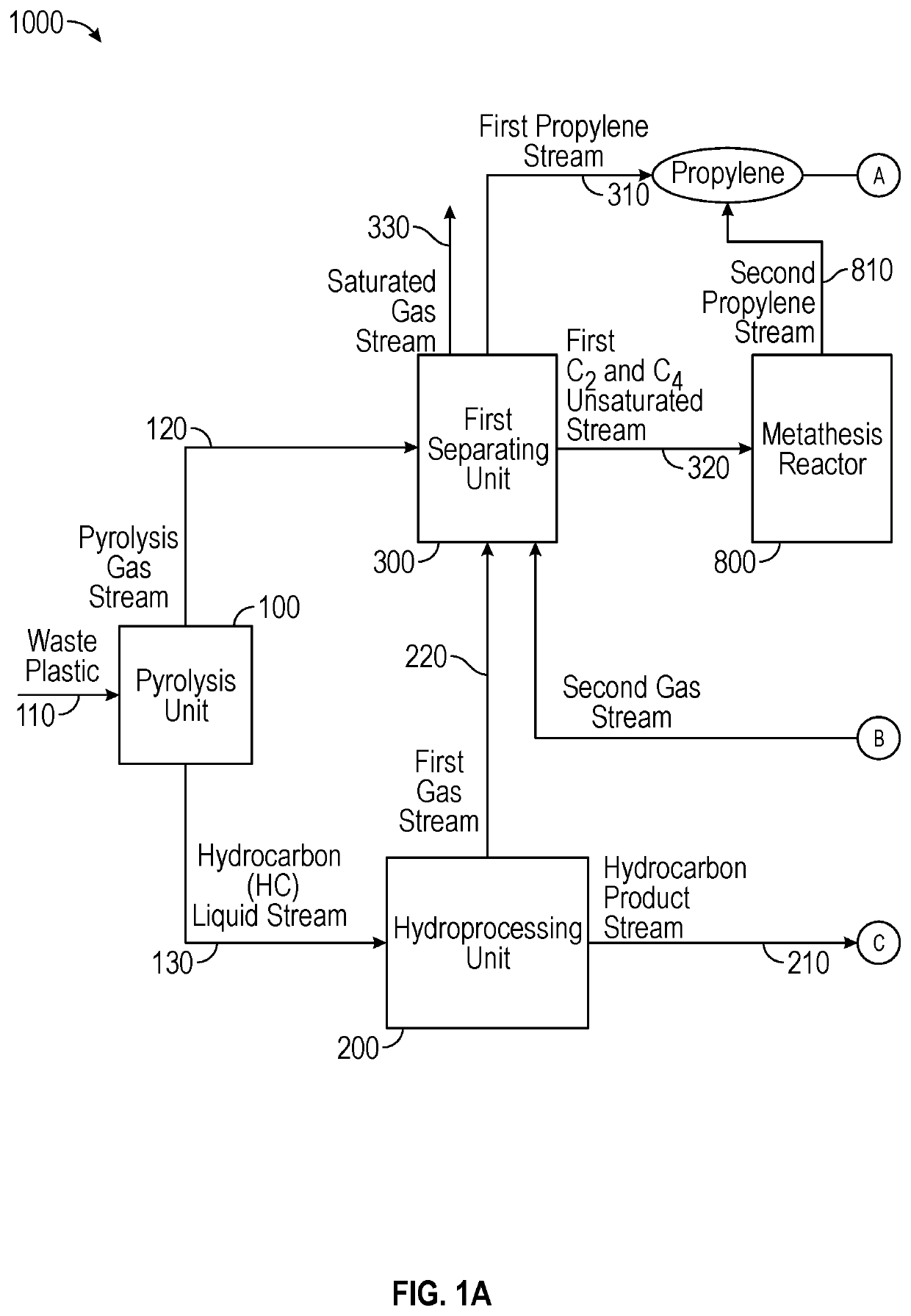

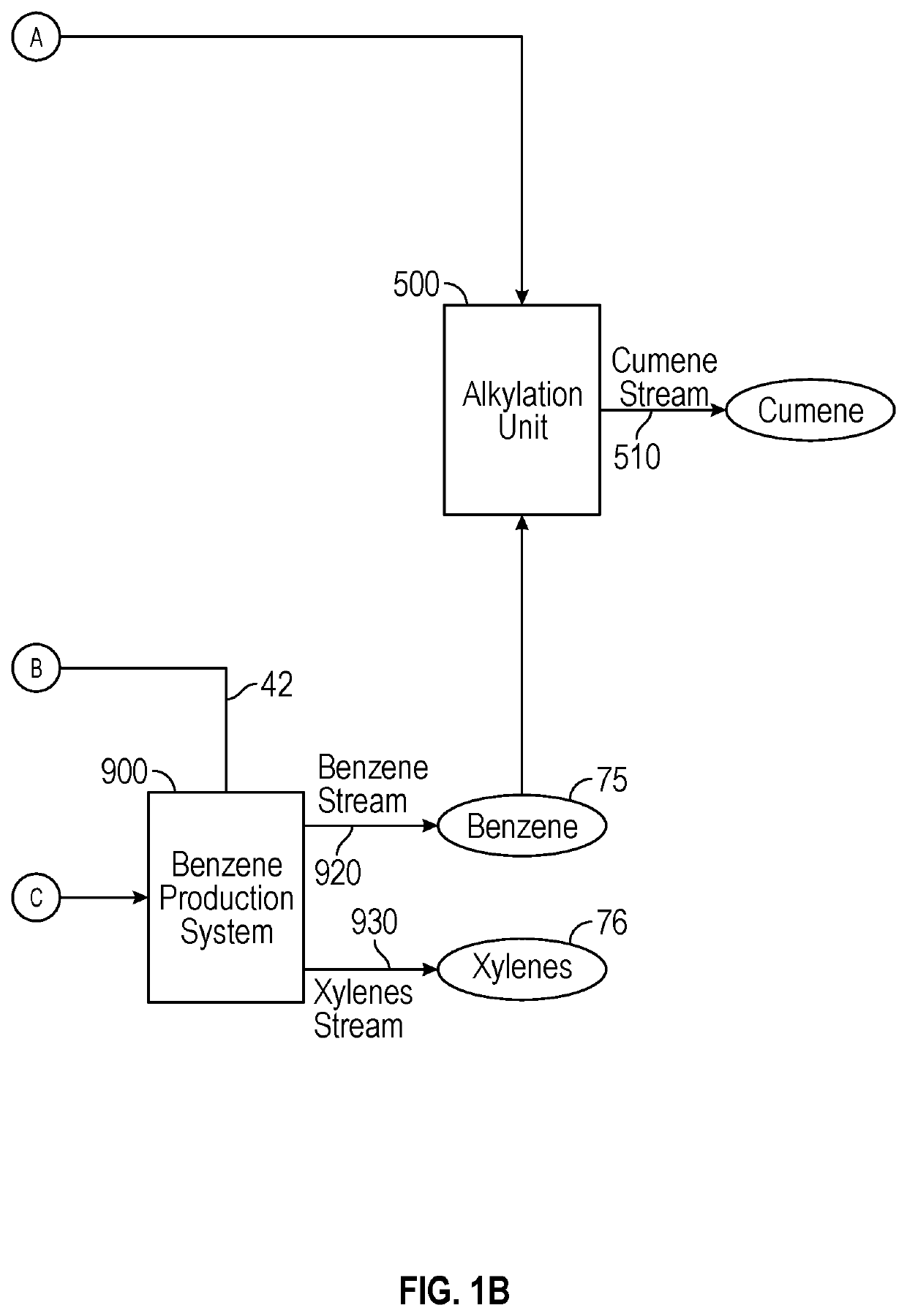

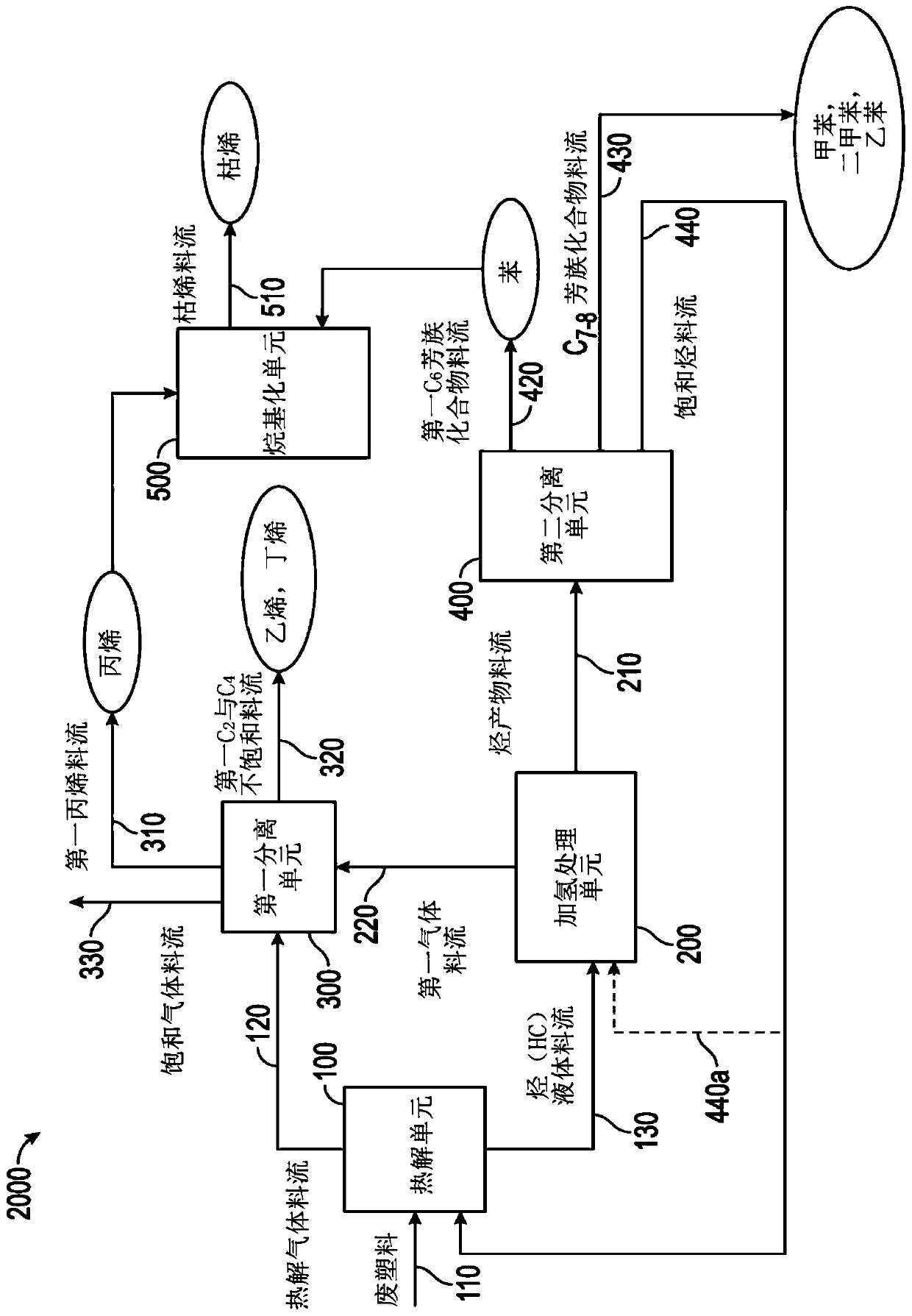

Conversion of waste plastic to propylene and cumene

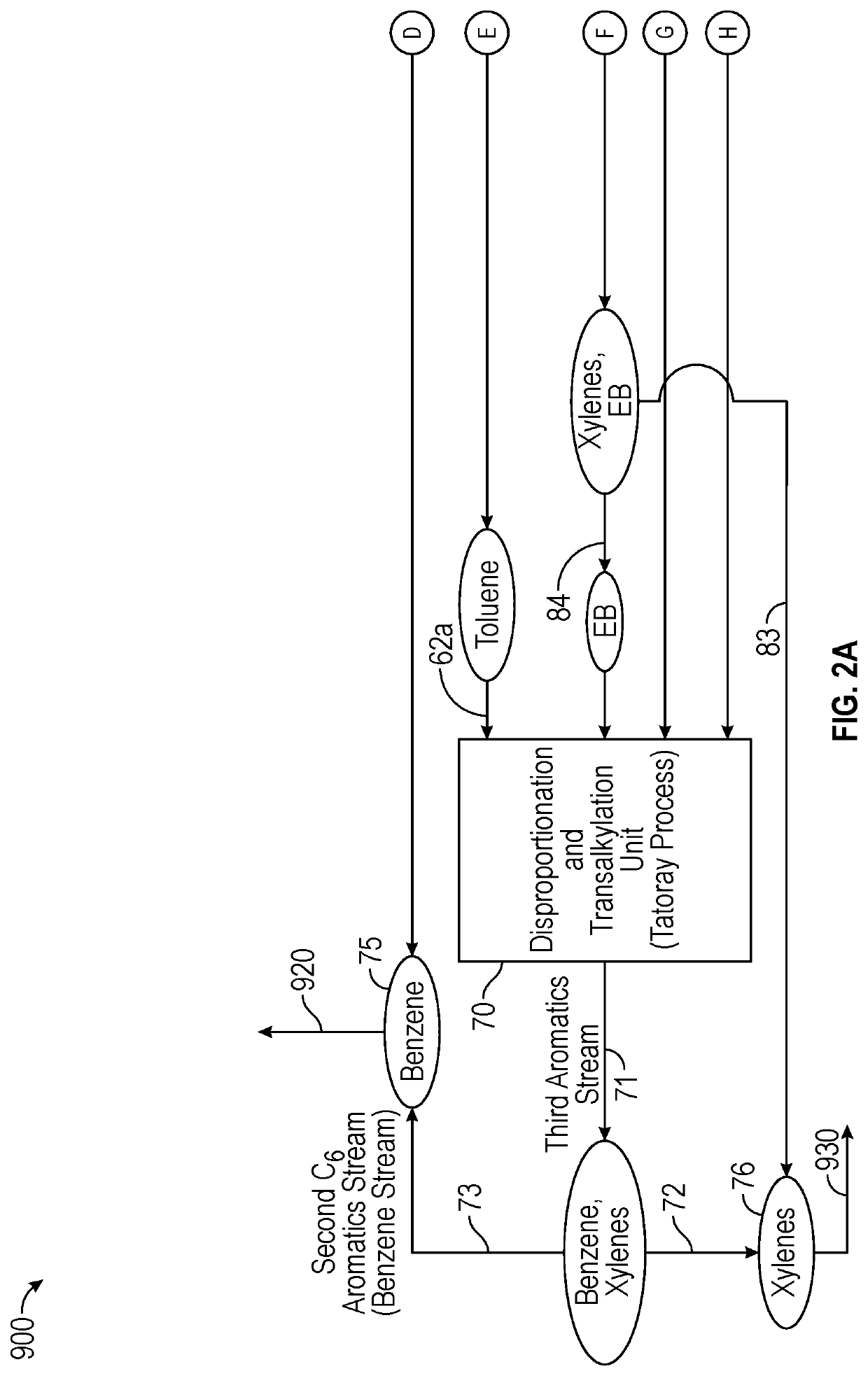

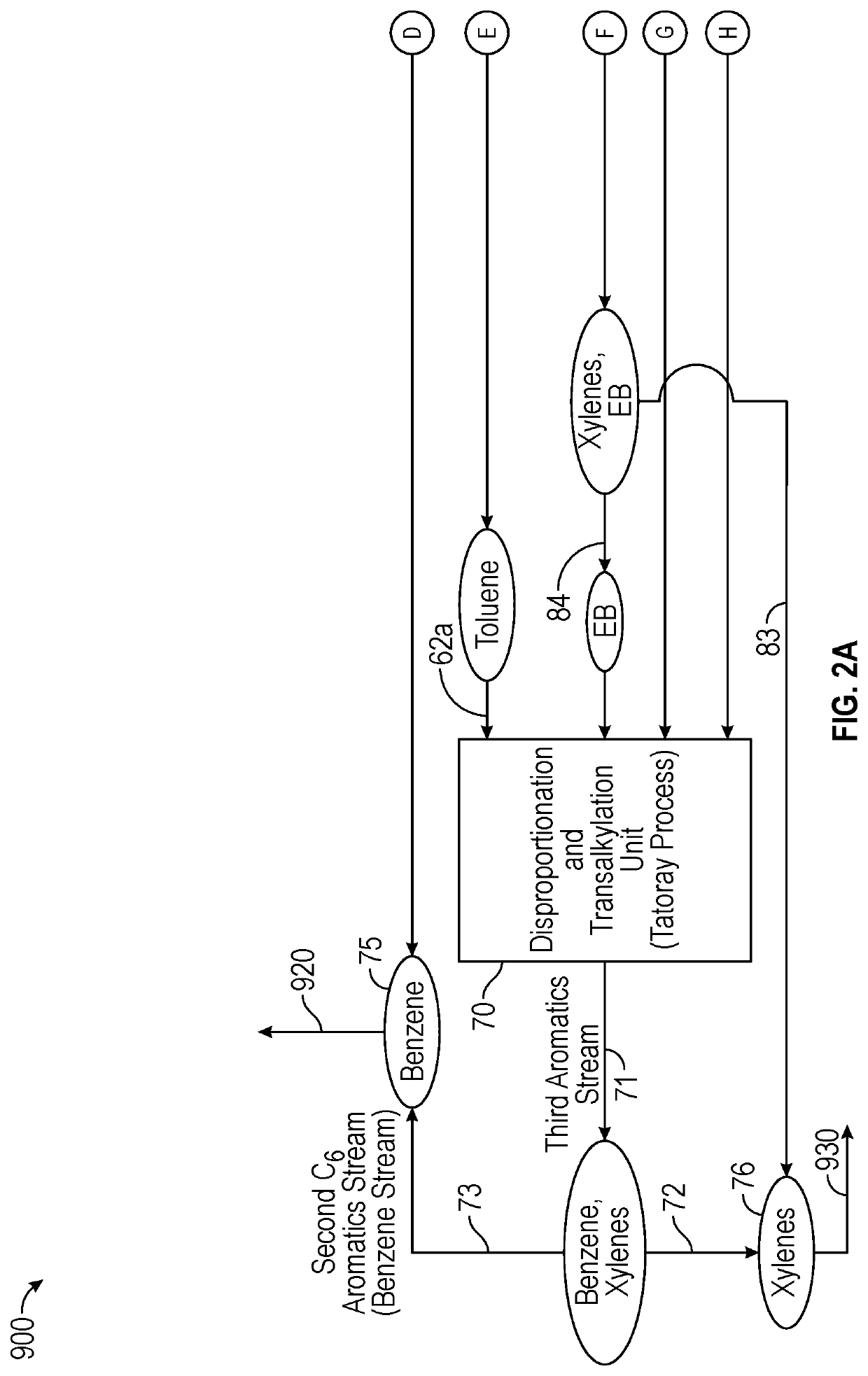

A process for producing cumene comprising converting plastics to hydrocarbon liquid and pyrolysis gas; feeding hydrocarbon liquid to hydroprocessor to yield hydrocarbon product and first gas stream; feeding hydrocarbon product to reforming unit to produce reforming product, second gas stream, and hydrogen; separating reforming product into non-aromatics recycle stream and second aromatics stream (C6+ aromatics); recycling non-aromatics recycle stream to reforming unit; separating second aromatics stream into benzene, C7, C8, C9, C10, and C11+ aromatics; contacting C7, C9, and / or C10 aromatics with a disproportionation&transalkylation catalyst / H2 to yield benzene&xylenes; conveying C11+ aromatics to hydroprocessor; introducing pyrolysis gas, first and / or second gas stream to first separator to produce first propylene stream, first C2&C4 unsaturated stream, and saturated gas (H2 and C1-4 saturated hydrocarbons); introducing first C2&C4 unsaturated stream to metathesis reactor to produce second propylene stream; and feeding benzene, and first and / or second propylene stream to alkylation unit to produce cumene.

Owner:SABIC GLOBAL TECH BV

Integrated Process for the Production of P-Xylene

ActiveUS20100228066A1High energy consumptionImprove concentrationHydrocarbon by isomerisationMolecular sieve catalystsIsomerizationHydrogen

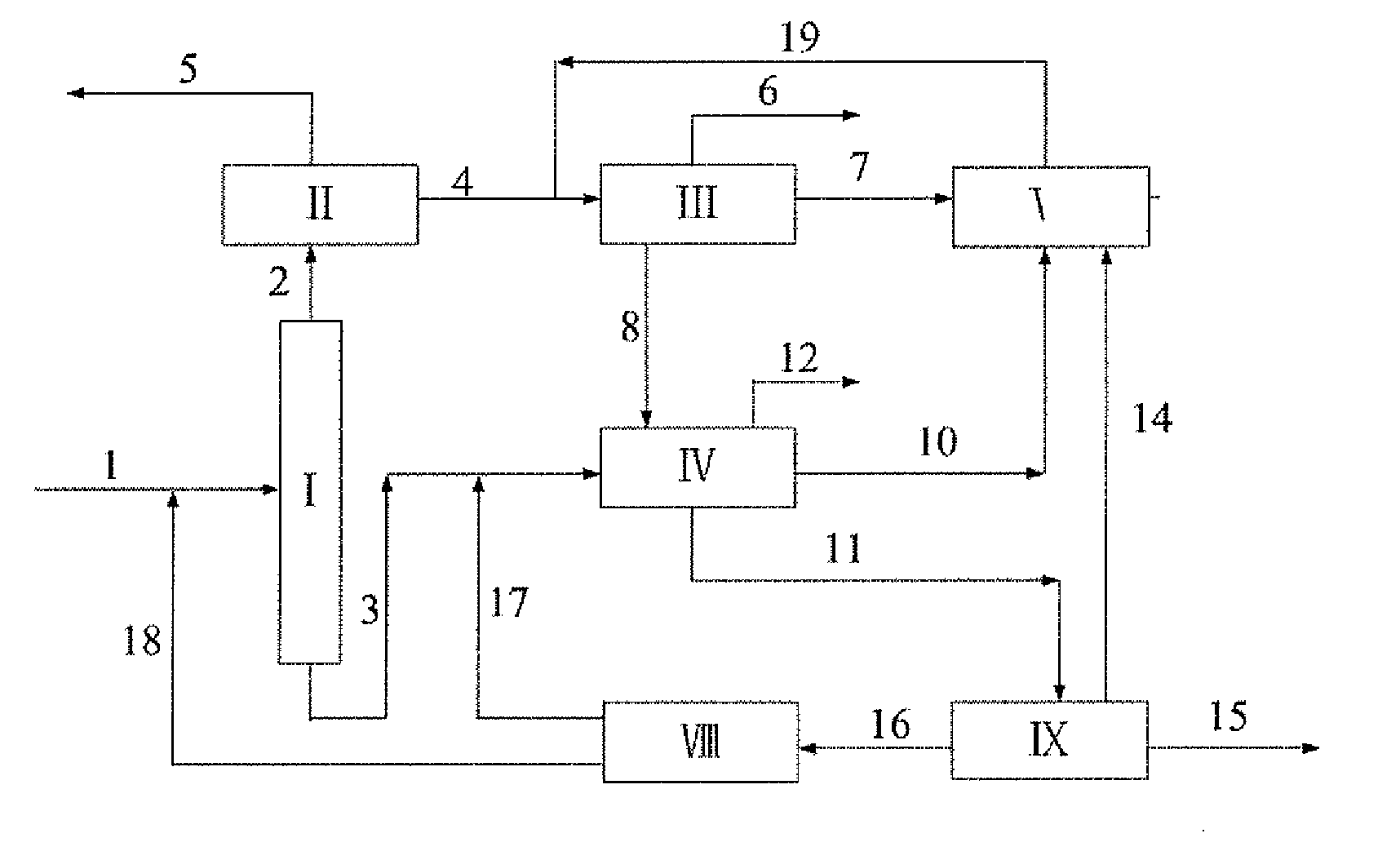

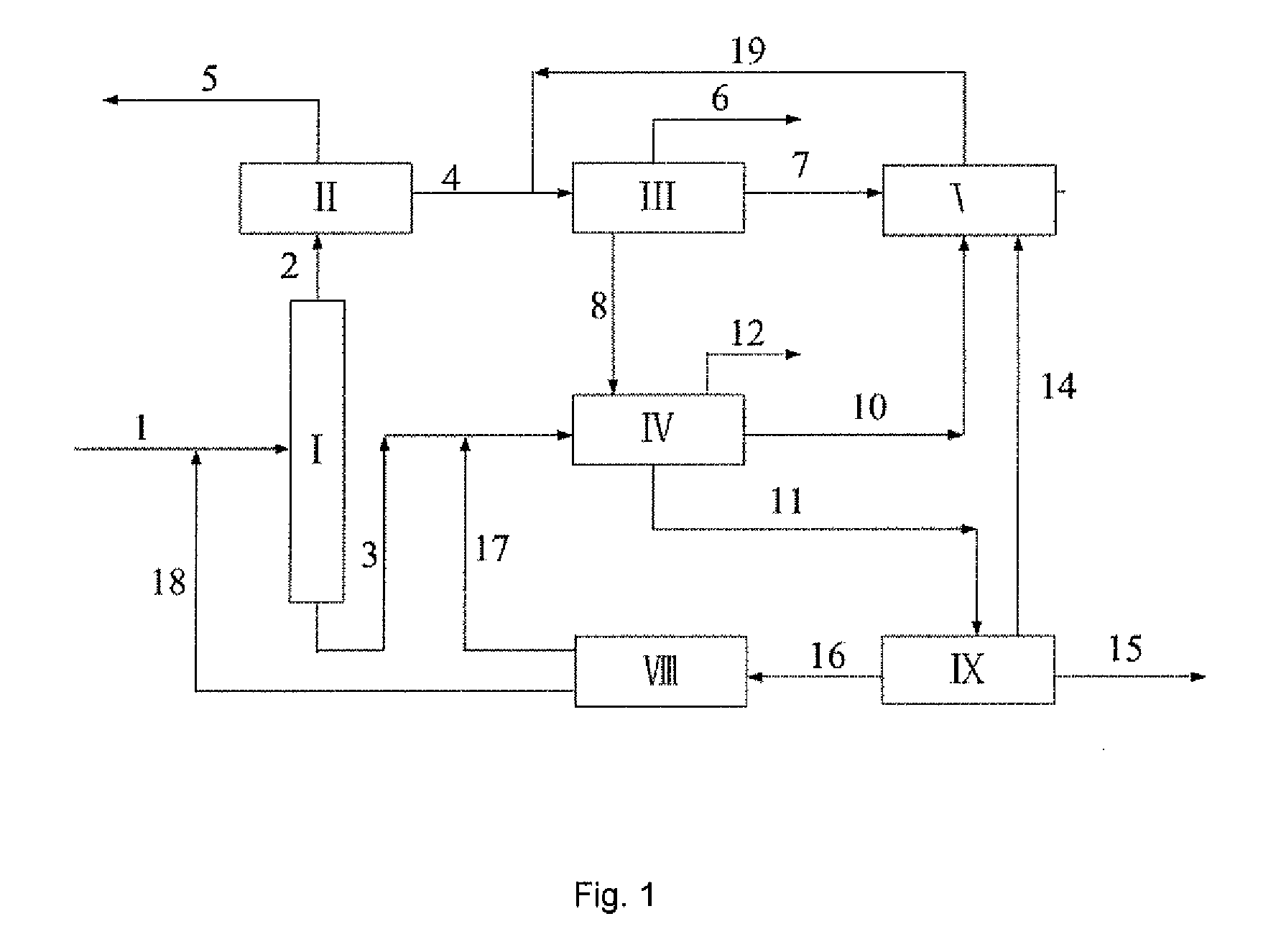

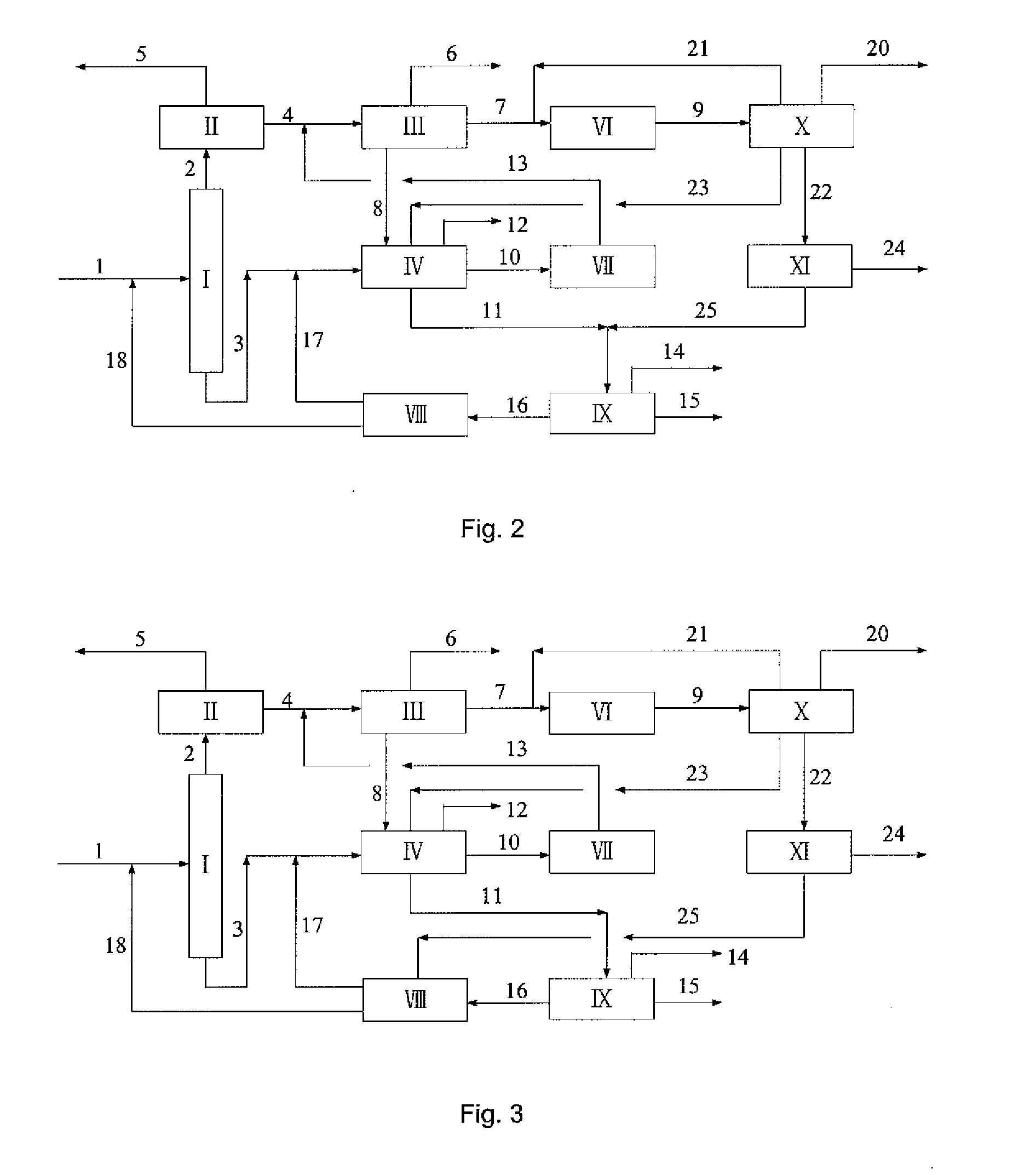

The present invention provides an integrated process for the production of p-xylene, comprising the steps of A) separating a mixed feedstock containing benzene, toluene, C8 aromatic hydrocarbons, C9 and higher aromatic hydrocarbons, and non-aromatic hydrocarbons from a reforming unit, to obtain a first benzene stream, a first toluene stream, a first C8 aromatic hydrocarbon stream, a stream of C9 and higher aromatic hydrocarbons, and a stream of non-aromatic hydrocarbons; B) feeding the stream of C9 and higher aromatic hydrocarbons from step A) to a C9 and higher aromatic hydrocarbon dealkylation unit, where dealkylation reaction occurs in the presence of hydrogen, and separating the reaction effluent to obtain a second benzene stream, a second toluene stream, and a second C8 aromatic hydrocarbon stream; C) feeding both the first toluene stream and the second toluene stream to a toluene selective disproportionation unit, where toluene selective disproportionation reaction occurs in the presence of hydrogen to produce a stream containing C8 aromatic hydrocarbons including p-xylene and benzene, which stream is separated to obtain a third C8 aromatic hydrocarbon stream, a third toluene stream, and a third benzene stream, with the third toluene stream being returned to an inlet of this unit; D) feeding both the first C8 aromatic hydrocarbon stream and the second C8 aromatic hydrocarbon stream to an adsorption separation unit, to obtain a first p-xylene product stream and a fifth C8 aromatic hydrocarbon stream, with the fifth C8 aromatic hydrocarbon stream being passed to an isomerization unit; E) feeding the third C8 aromatic hydrocarbon stream to a crystallization separation unit, to obtain a fourth C8 aromatic hydrocarbon stream and a second p-xylene product stream, with the fourth C8 aromatic hydrocarbon stream being passed to the adsorption separation unit or the isomerization unit; and F) feeding an effluent of the isomerization unit to an inlet of the adsorption separation unit.

Owner:CHINA PETROCHEMICAL CORP +1

Apparatus for Producing Ethylbenzene or Cumene

ActiveUS20080289946A1Thermal non-catalytic crackingDistillation regulation/controlAlkylation unitDistillation

The apparatus includes an alkylation unit connected to a first benzene recycle conduit, a feed conduit and an alkylation effluent conduit; a transalkylation unit connected to an polyalkylbenzene recycle conduit, a second benzene recycle conduit, and a transalkylation effluent conduit. A dividing wall distillation column is in fluid communication with the transalkylation effluent conduit, the alkylation effluent conduit, a product stream, a bottoms stream conduit and first and second benzene recycle conduits. A polyalkylbenzene fractionation column is connected to the bottoms stream conduit, the polyalkylbenzene recycle conduit and a heavy component conduit.

Owner:UOP LLC

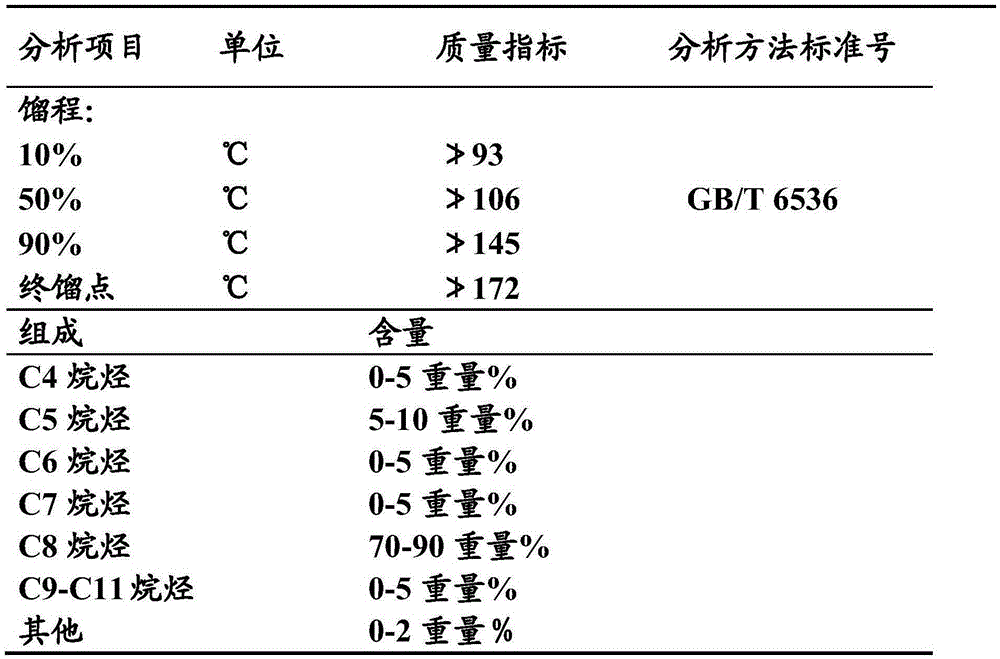

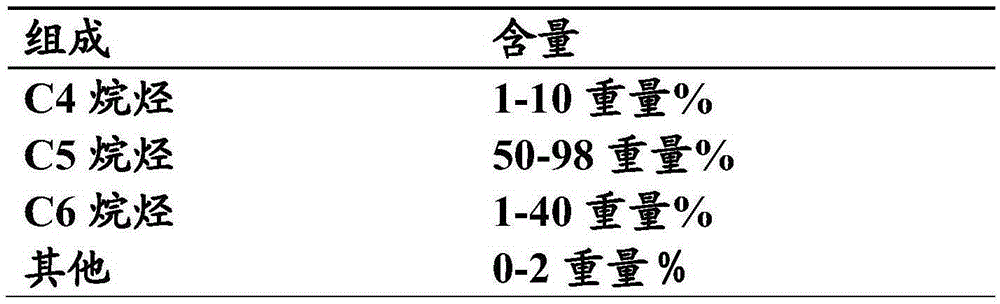

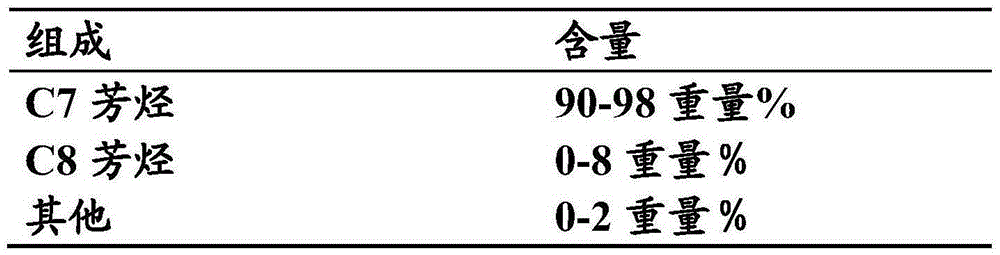

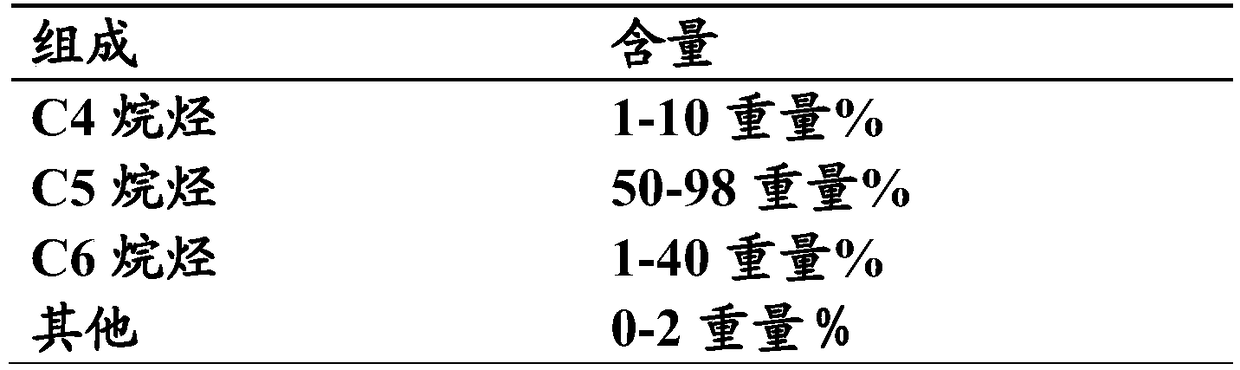

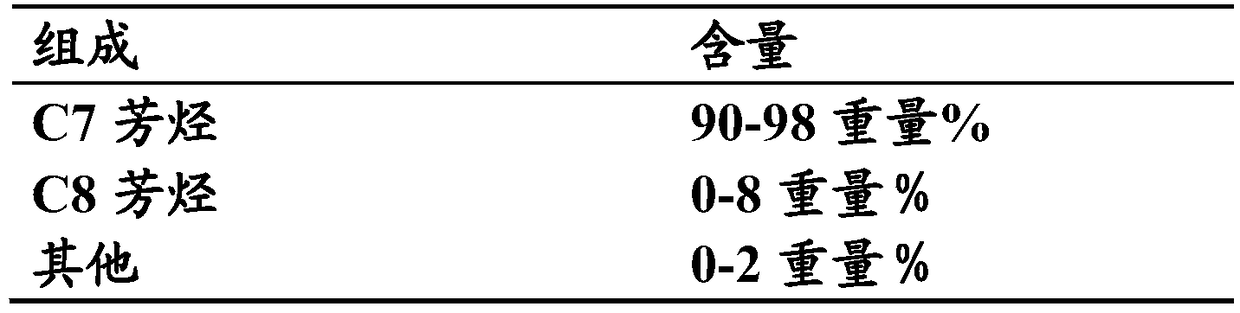

Lead-free aviation gasoline and preparation method thereof

ActiveCN106590773AAppropriate distillation rangeFulfil requirementsLiquid carbonaceous fuelsAviationAlkylation unit

The invention relates to lead-free aviation gasoline. The lead-free aviation gasoline contains components as follows: A) 55wt%-90wt% of alkylation unit oil, B) 5wt%-15wt% of pentane component oil, C) 0-20wt% of C7 aromatic component oil, D) 0-15wt% of cumene and E) 0-15wt% of an alkyl ether antiknock agent, wherein the alkylation unit oil is prepared from a reaction product distillate C4 obtained through alkylation of 1-butene and / or 2-butene and iso-butane as well as light components shown in the specification; the content of arylamine compounds in the lead-free aviation gasoline does not exceed 0.5wt%, and further, the lead-free aviation gasoline contains lead which does not exceed 0.01 g / L and contains at least one of the component C and the component D. The gasoline does not contain the arylamine compounds basically, so that environmental pollution caused by the aviation gasoline is greatly reduced, moreover, an octane value and a heat value realize good balance, a net heating value at least reaches 43.5 MJ / kg, and a motor octane value is not smaller than 91.

Owner:CHINA PETROLEUM & CHEM CORP

P-xylene fluid catalyst prepared by performing alkylation of methylbenzene methyl alcohol and preparation method thereof

ActiveCN103638963AMole lowEasy to handleMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationAlkyl transferAlkaline earth metal

The invention discloses a p-xylene fluid catalyst prepared by performing alkylation of methylbenzene methyl alcohol and a preparation method of the p-xylene fluid catalyst. The p-xylene fluid catalyst is prepared by modeling mixed spray of ZSM-5, matrix and amorphous binding agent, modifying by alkaline-earth metals, non-metals or / and rare earth metals and modifying by a siloxy group compound to prepare corresponding catalysts. The catalyst is used in methylbenzene methyl alcohol alkylation reaction; based on full conversion of methanol, methylbenzene conversion rate is more than 20 percent, and the once through yield of p-xylene in the product is up to 25 percent.

Owner:陕西煤化工技术工程中心有限公司

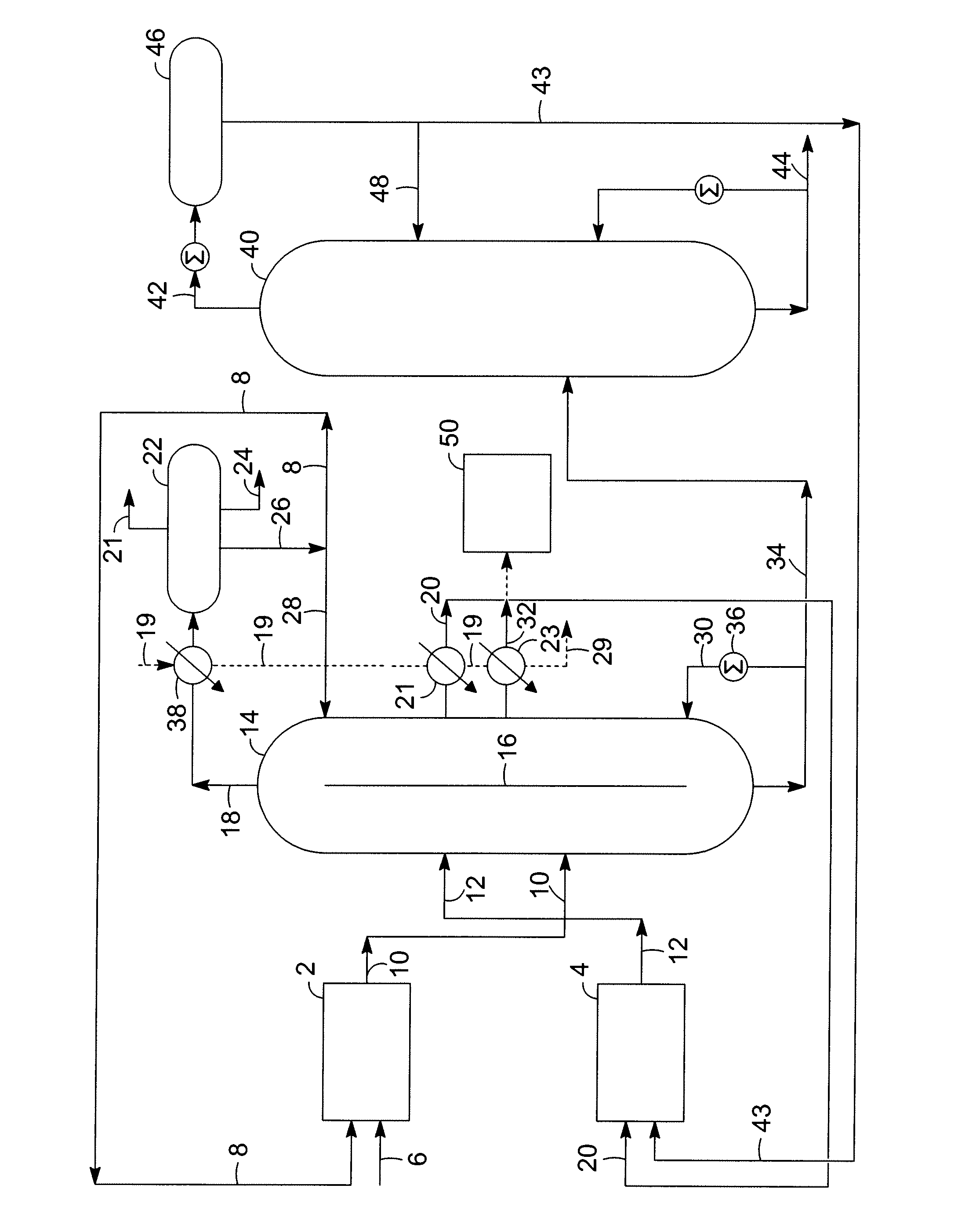

Process for the preparation of alkylate and middle distillate

InactiveUS20100076096A1High yieldTreatment with plural serial cracking stages onlyCatalytic crackingAlkylation unitReaction zone

A process for the preparation of alkylate and middle distillate, the process comprising: (a) catalytically cracking a first hydrocarbon feedstock by contacting the feedstock with a cracking catalyst comprising a shape-selective additive at a temperature in the range of from 450 to 650° C. within a riser or downcomer reaction zone to yield a first cracked product comprising middle distillate and a spent cracking catalyst; (b) regenerating the spent cracking catalyst to yield a regenerated cracking catalyst; (c) contacting, within a second reaction zone, at least part of the regenerated cracking catalyst obtained in step (b) with a second hydrocarbon feedstock at a temperature in the range of from 500 to 800° C. to yield a second cracked product and a used regenerated catalyst, the second feedstock comprising at least 70 wt % C5+ hydrocarbons obtained in a Fischer-Tropsch hydrocarbon synthesis process; (d) using the used regenerated catalyst as at least part of the cracking catalyst in step (a); and (e) alkylating at least a portion of the second cracked product in an alkylation unit to obtain alkylate.

Owner:SHELL OIL CO

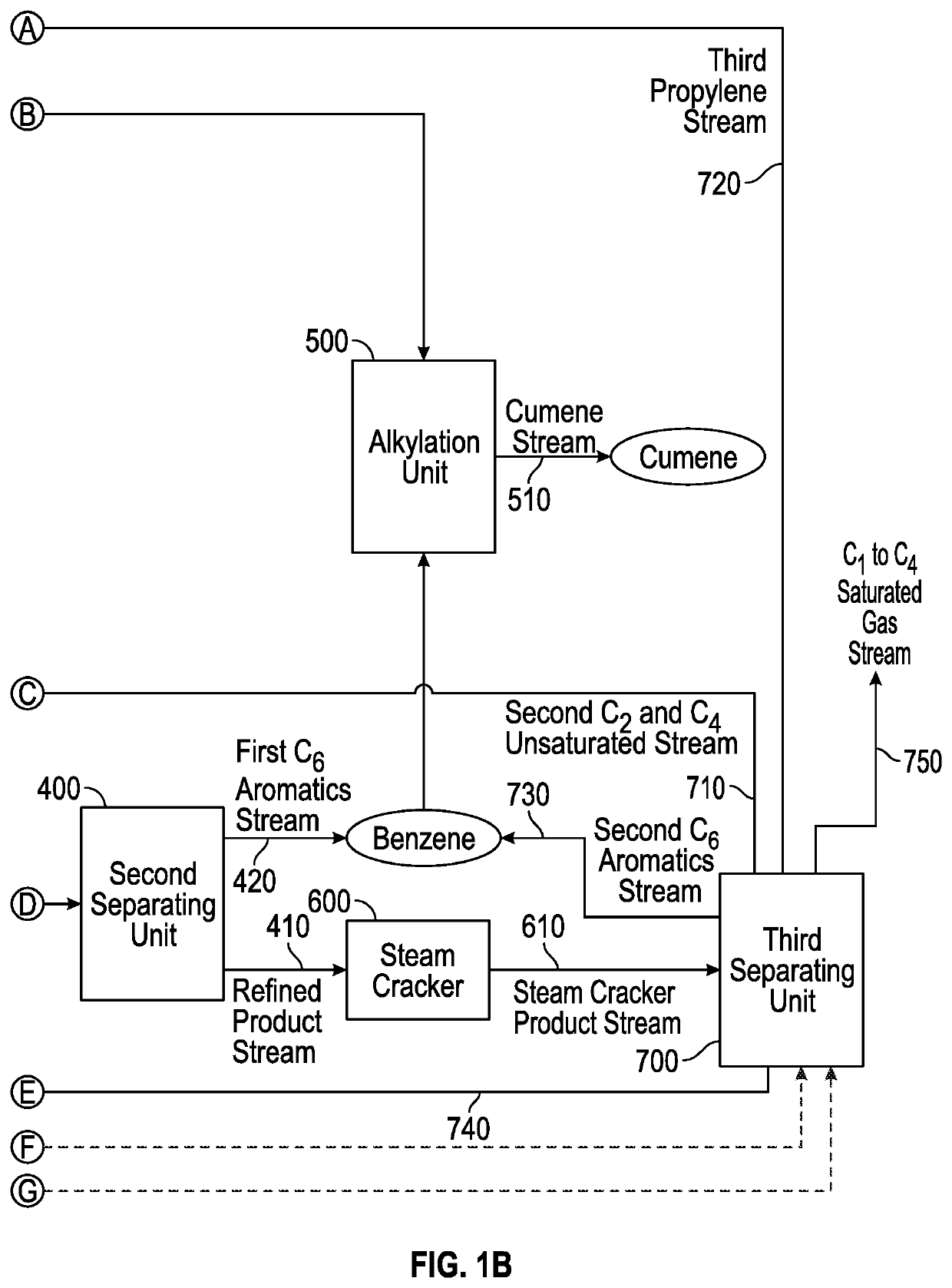

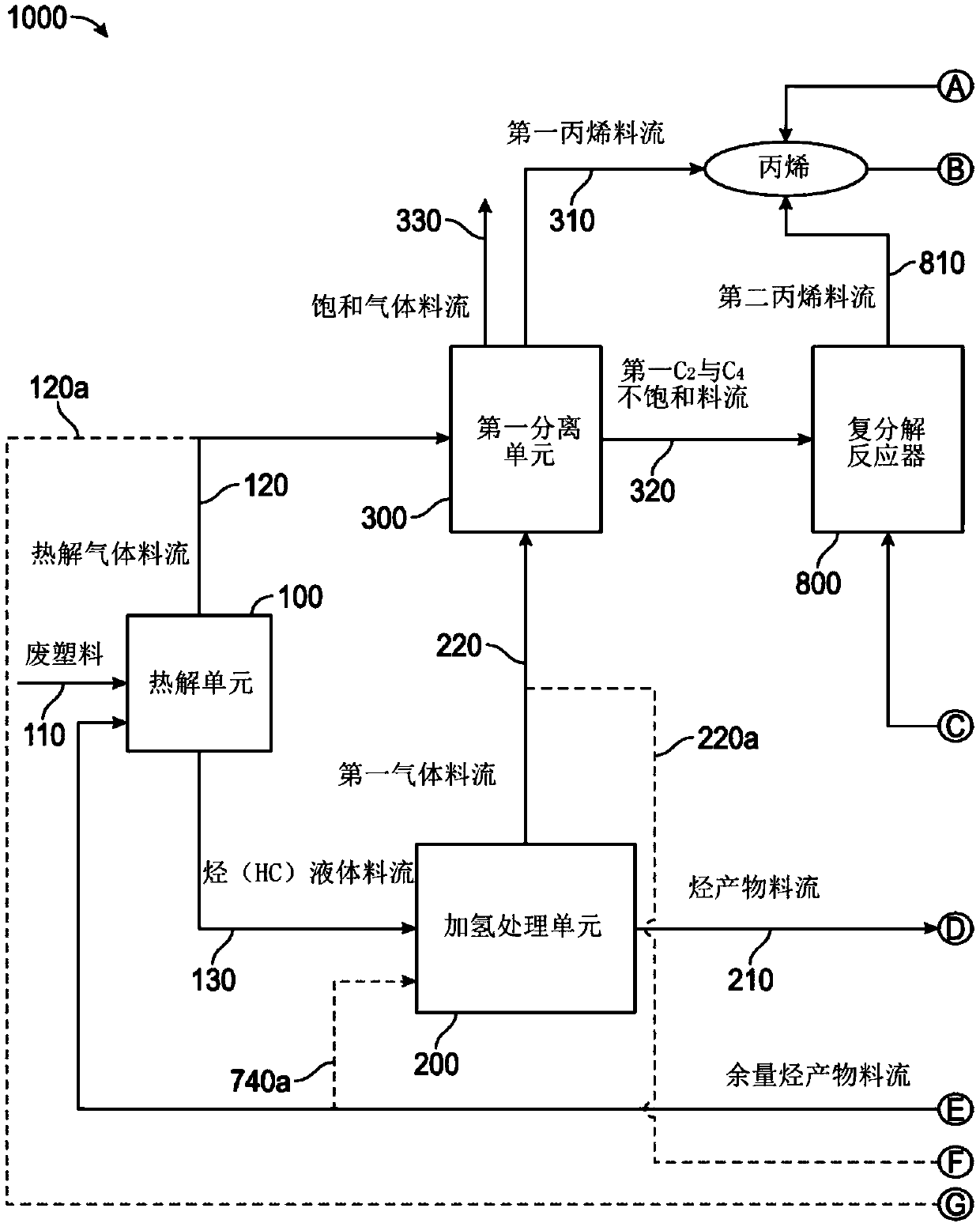

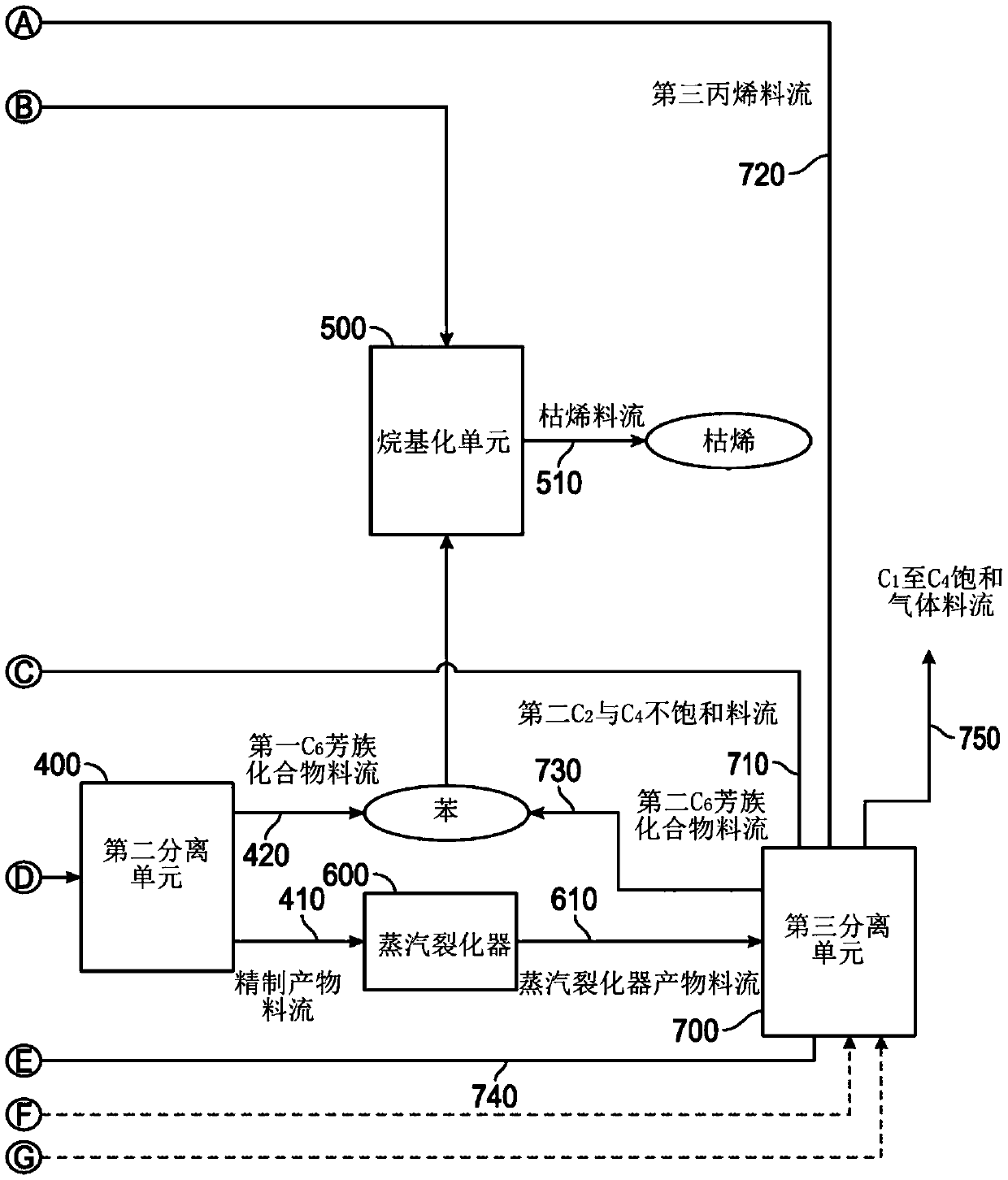

Conversion of waste plastic to propylene and cumene

ActiveUS20200017772A1Hydrocarbon by metathesis reactionHydrocarbon oil crackingHydrocotyle bowlesioidesAlkylation unit

A process for producing propylene and cumene comprising converting plastics to hydrocarbon liquid and pyrolysis gas in pyrolyzer; feeding hydrocarbon liquid to hydroprocessor to yield hydrocarbon product and first gas stream; introducing hydrocarbon product to second separator to produce first C6 aromatics and refined product; feeding refined product to steam cracker to produce steam cracker product; introducing steam cracker product to third separator to produce second C6 aromatics, third propylene stream, second C2&C4 unsaturated stream, C1-4 saturated gas, and balance hydrocarbons product; introducing pyrolysis gas and / or first gas stream to first separator to produce first propylene stream, first C2&C4 unsaturated stream, and saturated gas stream; feeding first and / or second C2&C4 unsaturated stream to metathesis reactor to produce second propylene stream; feeding first and / or second C6 aromatics, and first, second, and / or third propylene stream to alkylation unit to produce cumene; and conveying balance hydrocarbons product to pyrolyzer and / or hydroprocessor.

Owner:SABIC GLOBAL TECH BV

Aromatic hydrocarbon liquid phase alkylation method

ActiveCN103539600AImprove stabilityReduce olefin contentHydrocarbonsBulk chemical productionAlkaneAlkylation unit

The invention relates to an aromatic hydrocarbon liquid phase alkylation method, for mainly solving the problem that a catalyst is easily inactivated and poor in stability in the prior art. According to the technical scheme, a mixture containing saturated alkane, aromatic hydrocarbon and olefin is taken as a raw material, silicon-aluminum crystal zeolite is taken as a catalyst, and the raw material comes into contact with the catalyst to react to generate an alkylation liquid containing alkylbenzene and polyalkylbenzene under the conditions that the reaction temperature is 100-210 DEG C, the reaction pressure is 1.5-5.0MPa, the mole ratio of aromatic hydrocarbon to olefin is 1:10 and the weight space velocity of olefin is 0.1-1.0 hour<-1>, wherein the saturated alkane is at least one of ethane, propane, n-butane, iso-butane, pentane, cyclopentane, methylcyclopentane, hexane or cyclohexane, and the content of the saturated alkane is 1-80% of the weight of the reaction mixture. Due to adoption of the technical scheme, the problem in the prior art is well solved. The aromatic hydrocarbon liquid phase alkylation method can be applied to industrial production of aromatic hydrocarbon liquid phase alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

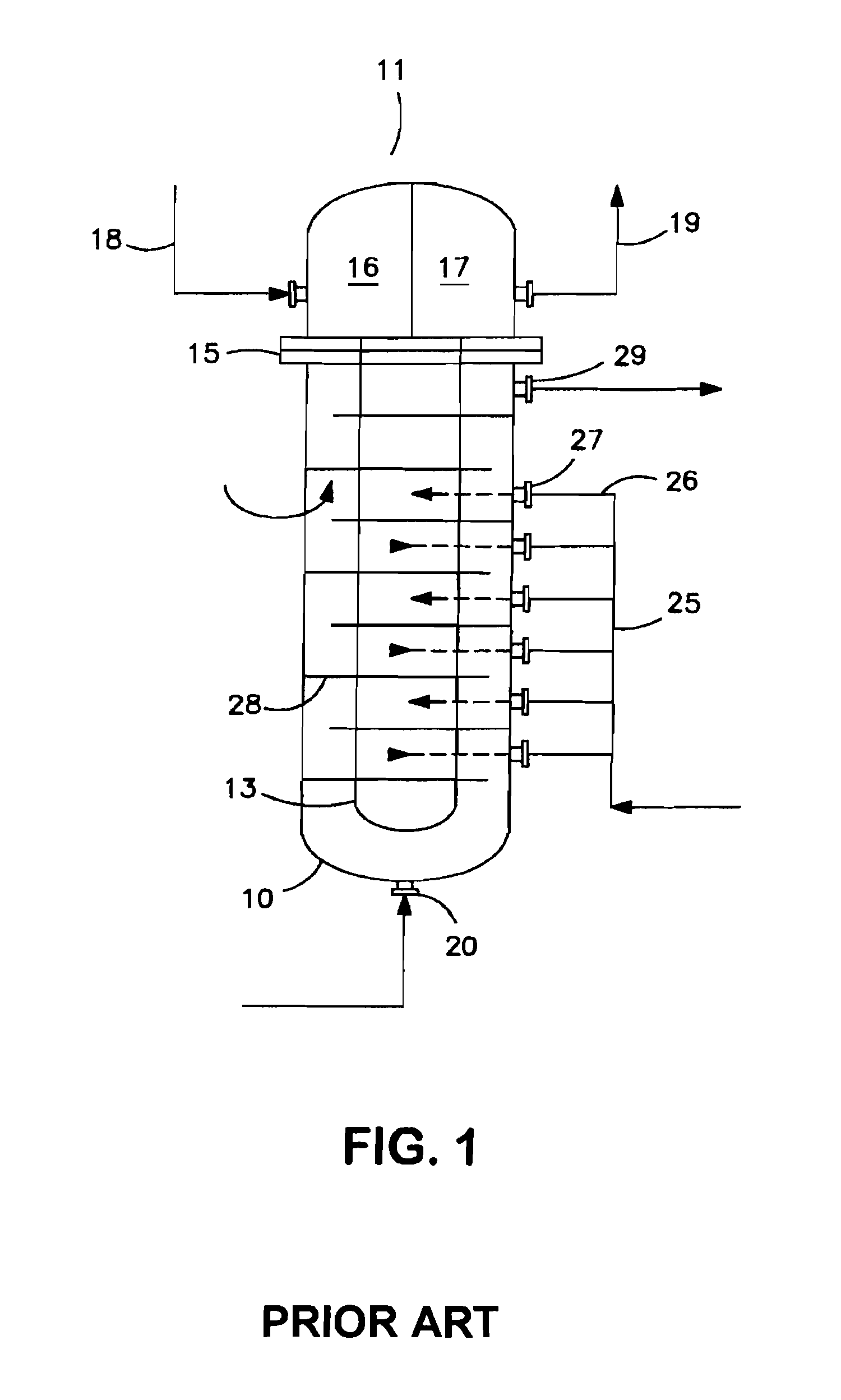

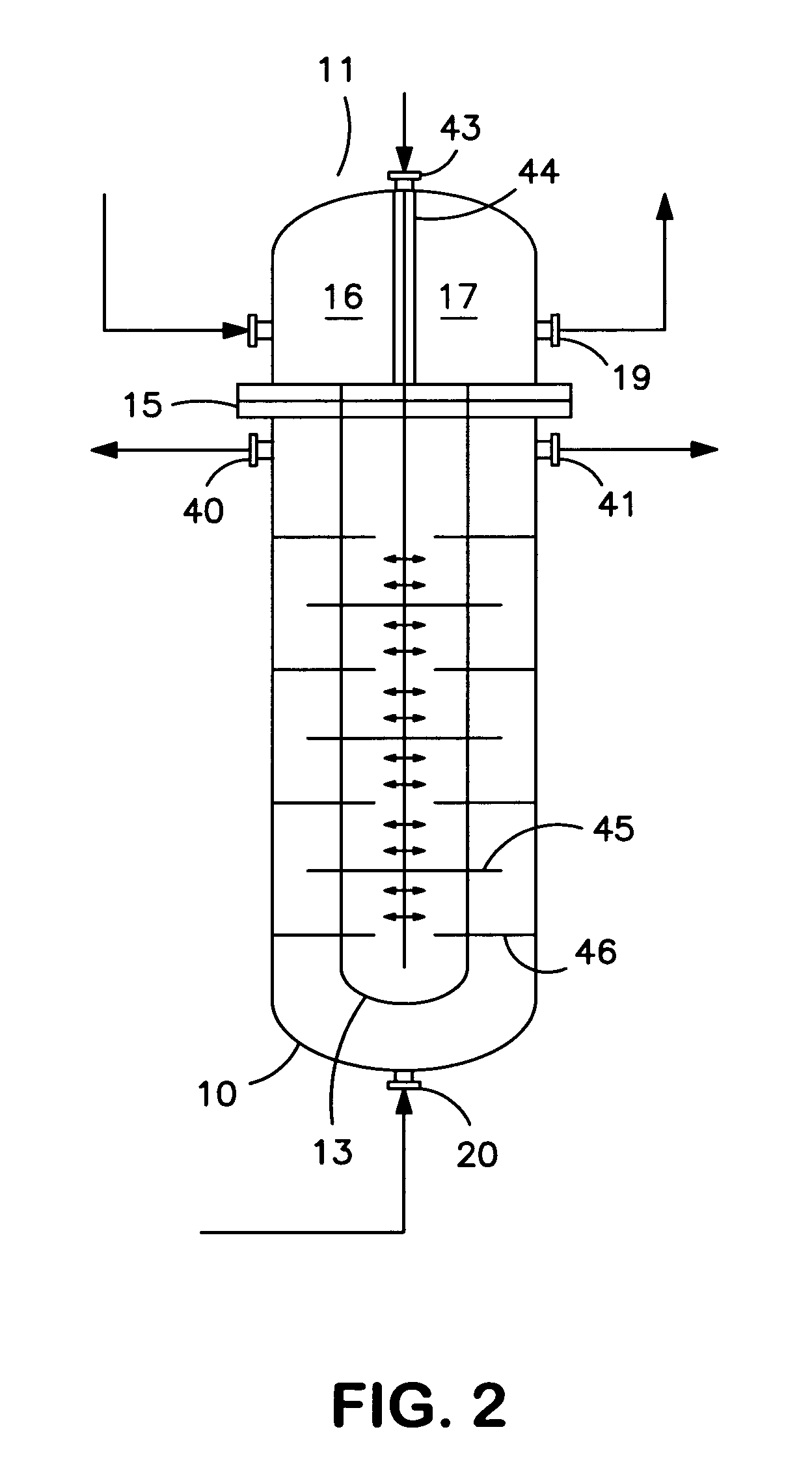

HF alkylation reactor

InactiveUS7947232B2Physical/chemical process catalystsChemical/physical/physico-chemical reactor detailsAlkyl transferShell and tube heat exchanger

Owner:EXXON RES & ENG CO

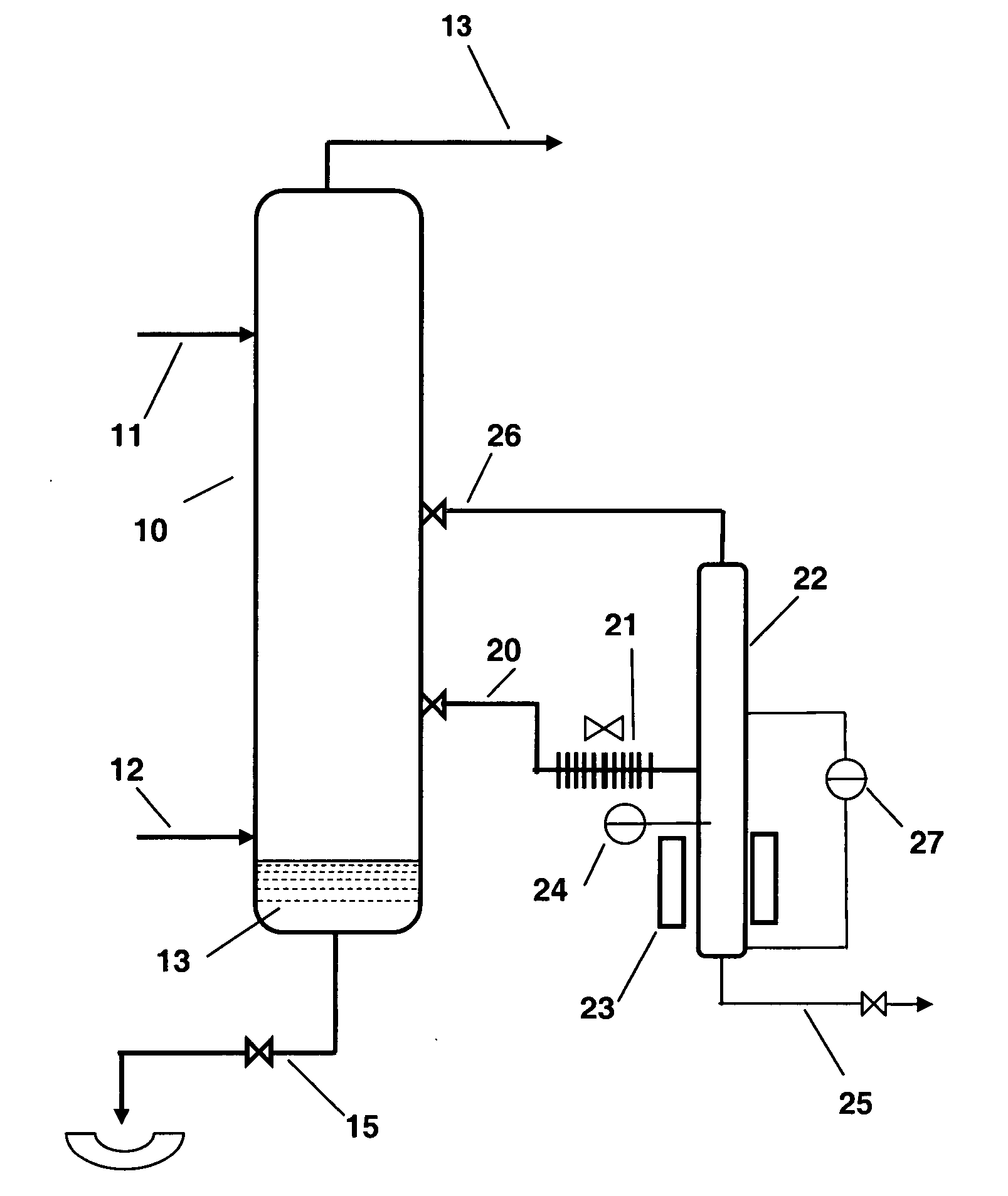

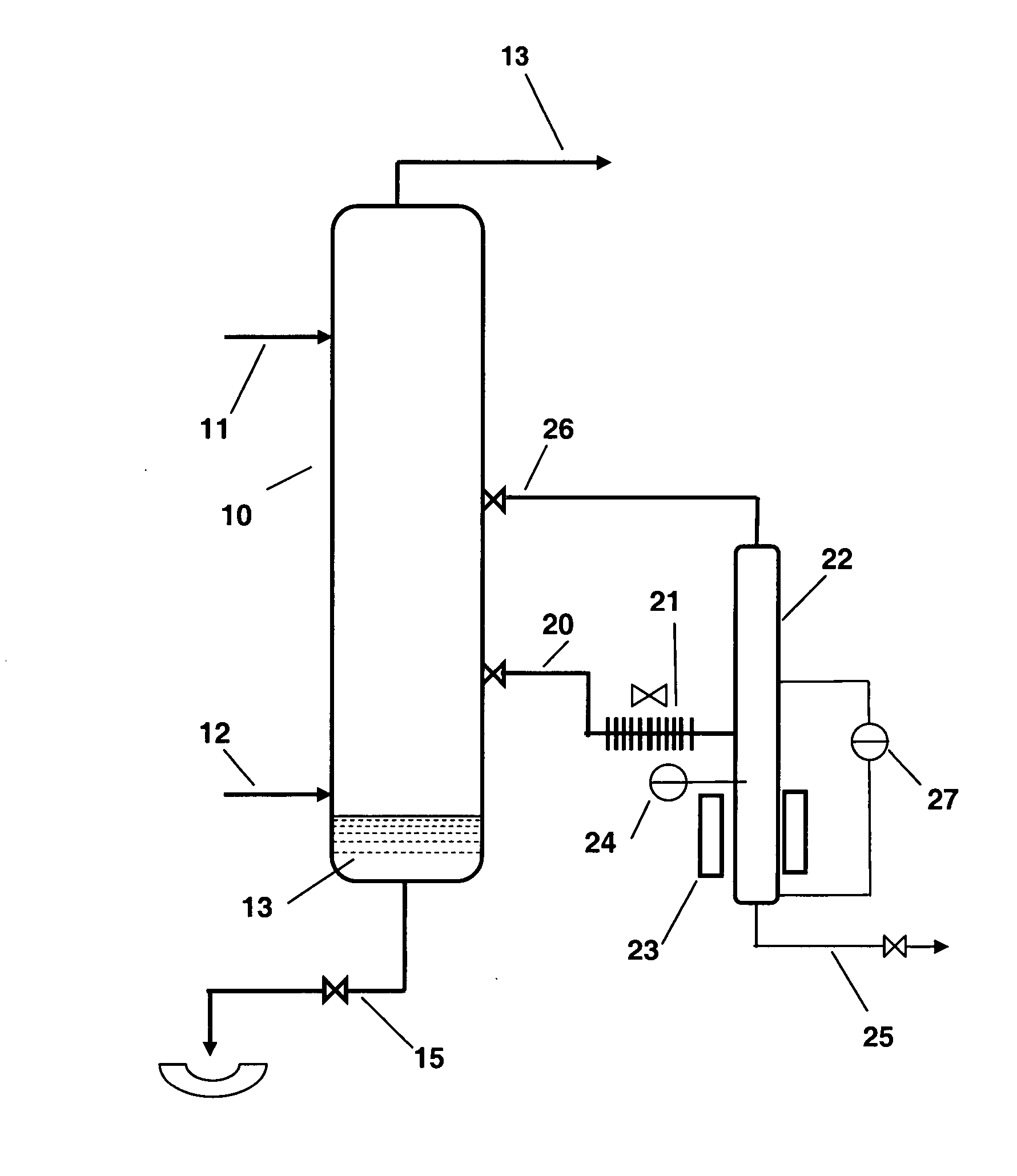

HF alkylation process with acid regeneration

InactiveUS20090029846A1Low costHydrogen fluorideStationary tubular conduit assembliesAlkyl transferDistillation

The regeneration of HF alkylation acid in an alkylation unit is improved by withdrawing a vapor stream from the HF regenerator tower and condensing the stream to form a liquid fraction which is accumulated in a side distillation zone; the collected liquid fraction, comprising HF acid, water and some stripping medium is distilled in a batch or continuous type operation to drive off the HF acid (along with stripping medium) and the vapor is returned to the regenerator-stripper vessel. The distillation of the sidedraw liquid is continued until the composition of the liquid attains the azeotropic value or as near to that value as desired. The azeotrope, comprising water and acid can then be dropped out of the distillation vessel for disposal by neutralization in the conventional way.

Owner:EXXON RES & ENG CO

Apparatus for producing ethylbenzene or cumene

ActiveUS7713386B2Thermal non-catalytic crackingDistillation regulation/controlAlkylation unitDistillation

The apparatus includes an alkylation unit connected to a first benzene recycle conduit, a feed conduit and an alkylation effluent conduit; a transalkylation unit connected to an polyalkylbenzene recycle conduit, a second benzene recycle conduit, and a transalkylation effluent conduit. A dividing wall distillation column is in fluid communication with the transalkylation effluent conduit, the alkylation effluent conduit, a product stream, a bottoms stream conduit and first and second benzene recycle conduits. A polyalkylbenzene fractionation column is connected to the bottoms stream conduit, the polyalkylbenzene recycle conduit and a heavy component conduit.

Owner:UOP LLC

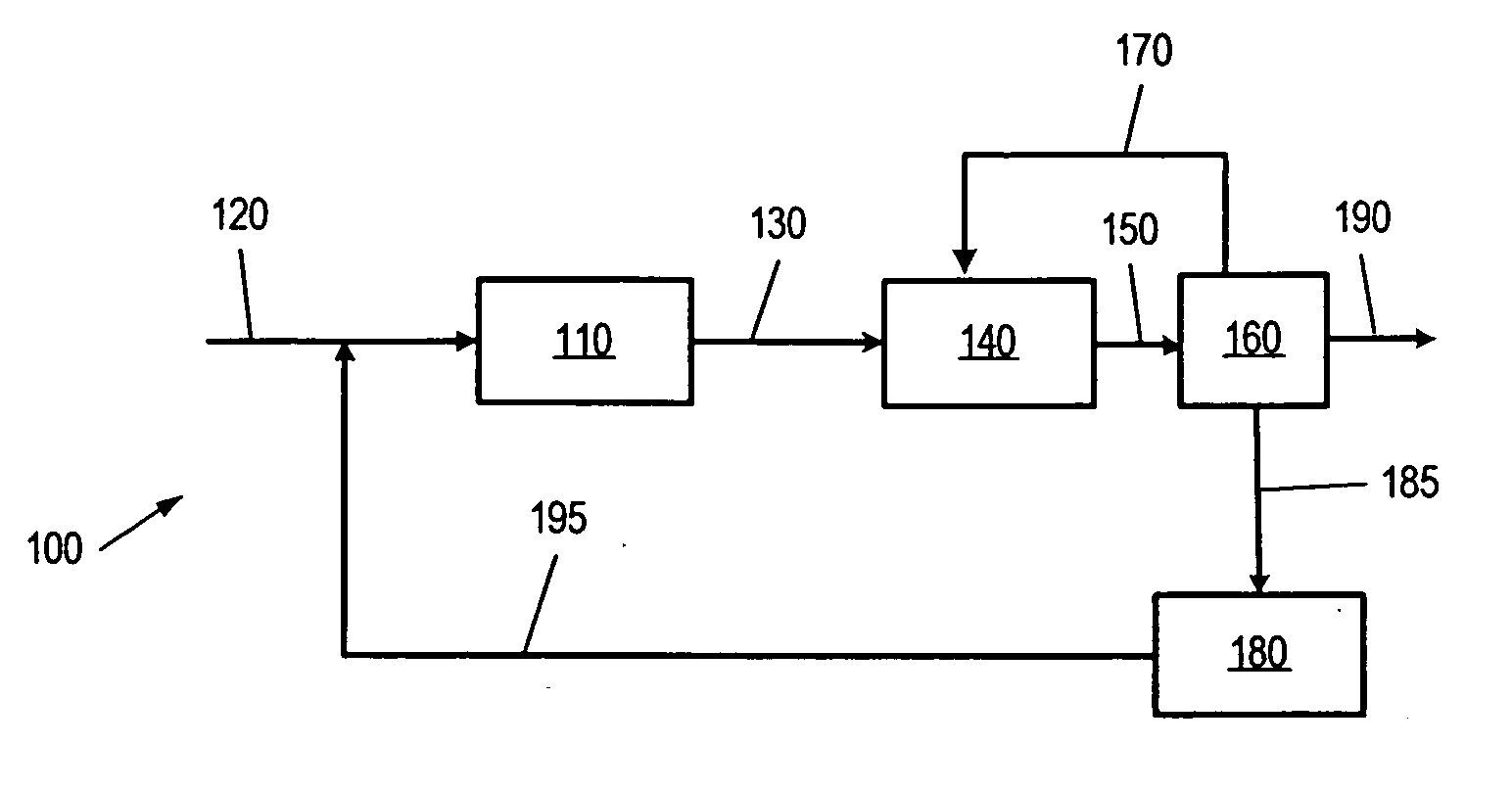

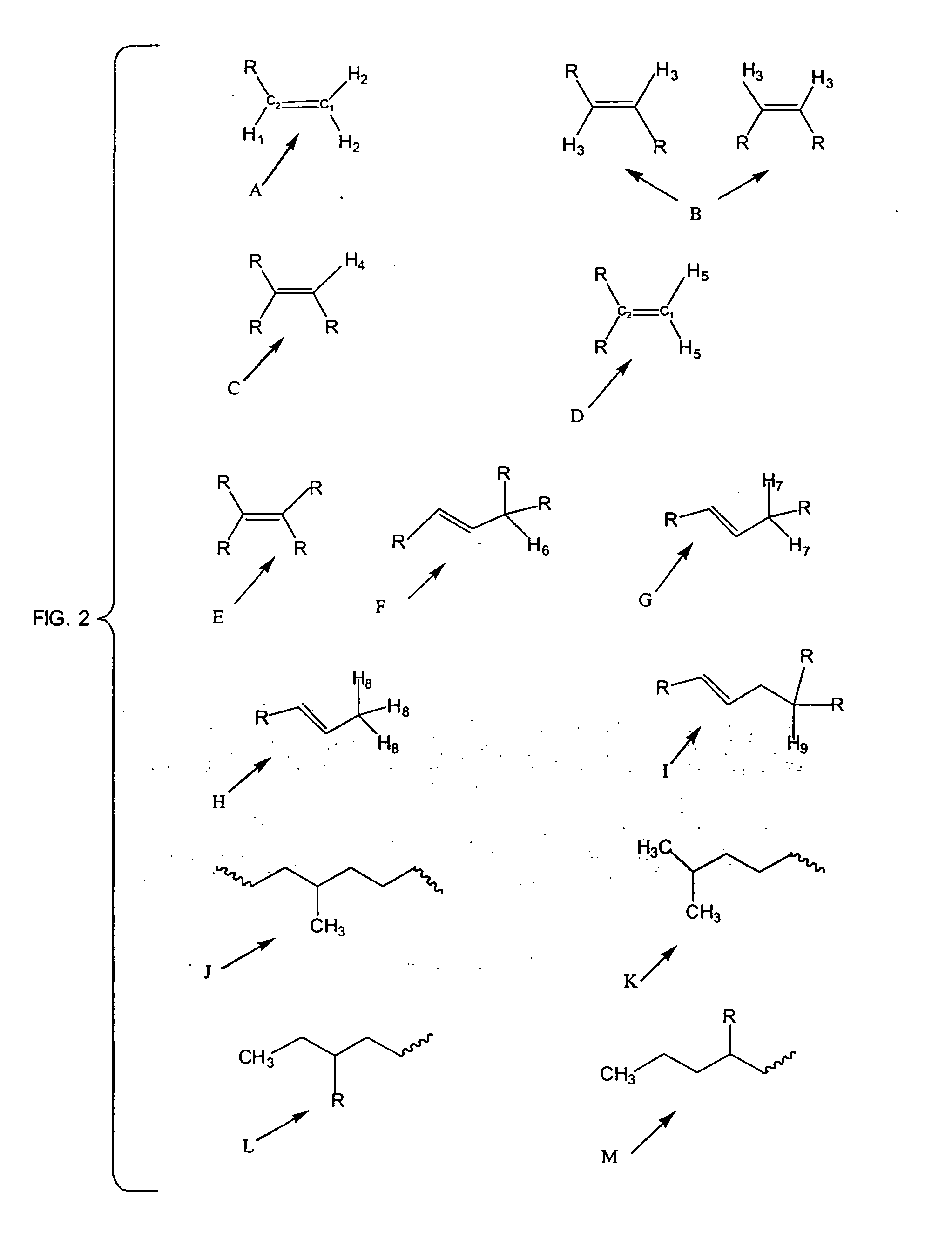

Methods of preparing branched alkyl aromatic hydrocarbons

InactiveUS20060224028A1Refining to change hydrocarbon structural skeletonHydrocarbonsAlkyl transferIsomerization

Systems and methods to produce branched alkyl aromatic hydrocarbons are described. Systems may include an olefin isomerization unit, an olefin dimerization unit, a dehydrogenation-isomerization unit, an alkylation unit, a dehydrogenation unit, a hydrogenation unit and / or combinations thereof. Methods for producing branched alkyl aromatic hydrocarbons may include isomerization of olefins in a process stream. The isomerized olefins may be used to alkylate aromatic hydrocarbons. After alkylation of the aromatic hydrocarbons, unreacted components from the alkylation process may be separated from the alkyl aromatic hydrocarbons. The unreacted components from the alkylation process may be recycled back into a process stream or sent to other processing units.

Owner:AYOUB PAUL MARIE +3

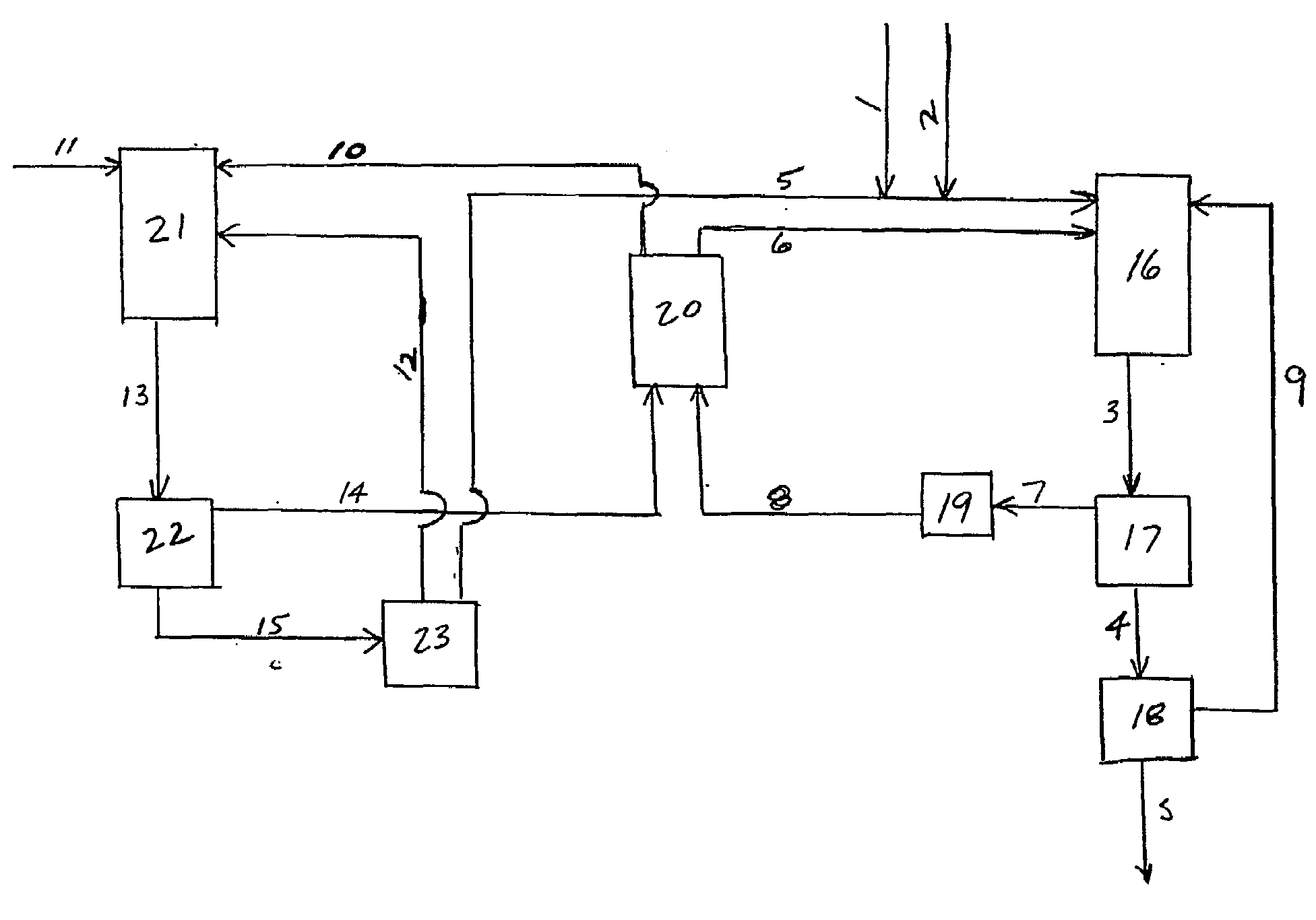

Dehydrogenation of ethylbenzene and ethane using mixed metal oxide or sulfated zirconia catalysts to produce styrene

InactiveUS20090036721A1Reducing and eliminating needSpeed up the conversion processCatalystsHydrocarbon preparation catalystsLithiumAlkylation unit

Methods are described for the simultaneous dehydrogenation of ethylbenzene and ethane in the presence of oxygen or carbon dioxide via a mixed metal oxide (MMO) catalyst or lithium-promoted sulfated zirconia catalyst to prepare styrene monomer from benzene and ethane. An alkylation unit produces ethyl benzene from ethylene and benzene, and an oxydehydrogenation unit produces styrene and ethylene from ethane, ethylbenzene and an oxidizing agent such as oxygen or carbon dioxide. The ethylene produced in the oxydehydrogenation unit is separated and used as feed to the alkylation unit.

Owner:LUMMUS TECH INC +1

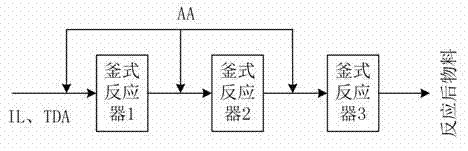

Method for synthesizing diethyltoluenediamine through alkylation of toluenediamine catalyzed by ionic liquid

InactiveCN102807493AReduce security risksFlexible processAmino preparation from aminesHydrogen halidePtru catalyst

The invention discloses a method for synthesizing diethyltoluenediamine through alkylation of toluenediamine catalyzed by ionic liquid. The method is characterized in that toluenediamine and alkylation reagents such as chloroethane and ethylene are used as raw materials, and acidic ionic liquid is used as catalyst; positive ions of the ionic liquid catalyst come from hydrogen halide of amine containing alkyl, or hydrogen halide of phosphorus containing alkyl or halide containing imidazole or a pyridine ring, and negative ions come from one or more metal halides. The method has the advantages of low reaction temperature and reaction pressure, short reaction time, safer process, high toluenediamine conversion rate and high diethyltoluenediamine selectivity. The invention additionally discloses an alkylation device for synthesizing diethyltoluenediamine under the catalytic effect of ionic liquid. The alkylation device at least comprises a reaction unit, a separation unit and a fractionation unit.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Method for adjusting product composition during coked crude benzene refining

InactiveCN101628846AIncrease productionReduce outputMolecular sieve catalystsDistillation purification/separationAlkyl transferMolecular sieve

The invention relates to a method for adjusting product composition during coked crude benzene refining. Coked crude benzene hydrogenated oil is premixed with alkylation reagent methanol. The mixture undergoes heat exchange with a material leaving an alkylation reactor and then is heated. After the temperature of the mixture reaches a reaction temperature, in the presence of a molecular sieve based catalyst, the mixture undergoes alkylation reaction so as to obtain a product. After the alkylation reaction is completed, the product is cooled by water and then undergo extraction, rectification and separation so as to obtain benzene, toluene and xylene, which leave the reaction system as target products. The method has simple procedures and can achieve the aim of reducing the benzene production amount and increasing the production amount of the toluene and the xylene by only increasing an alkylation unit without changing the main low-temperature hydrofining procedures of coked crude benzene.

Owner:山西恒扬科技有限公司 +1

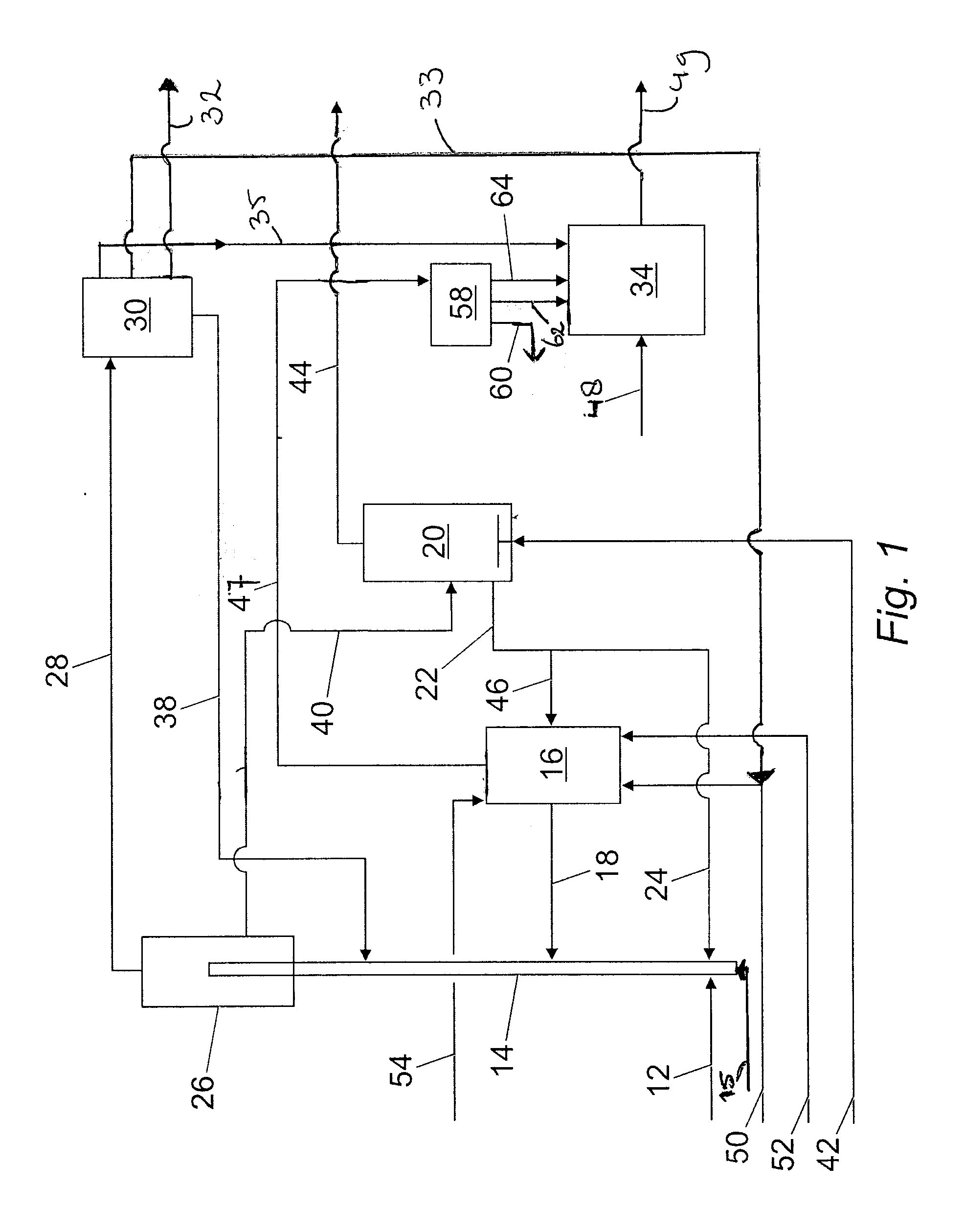

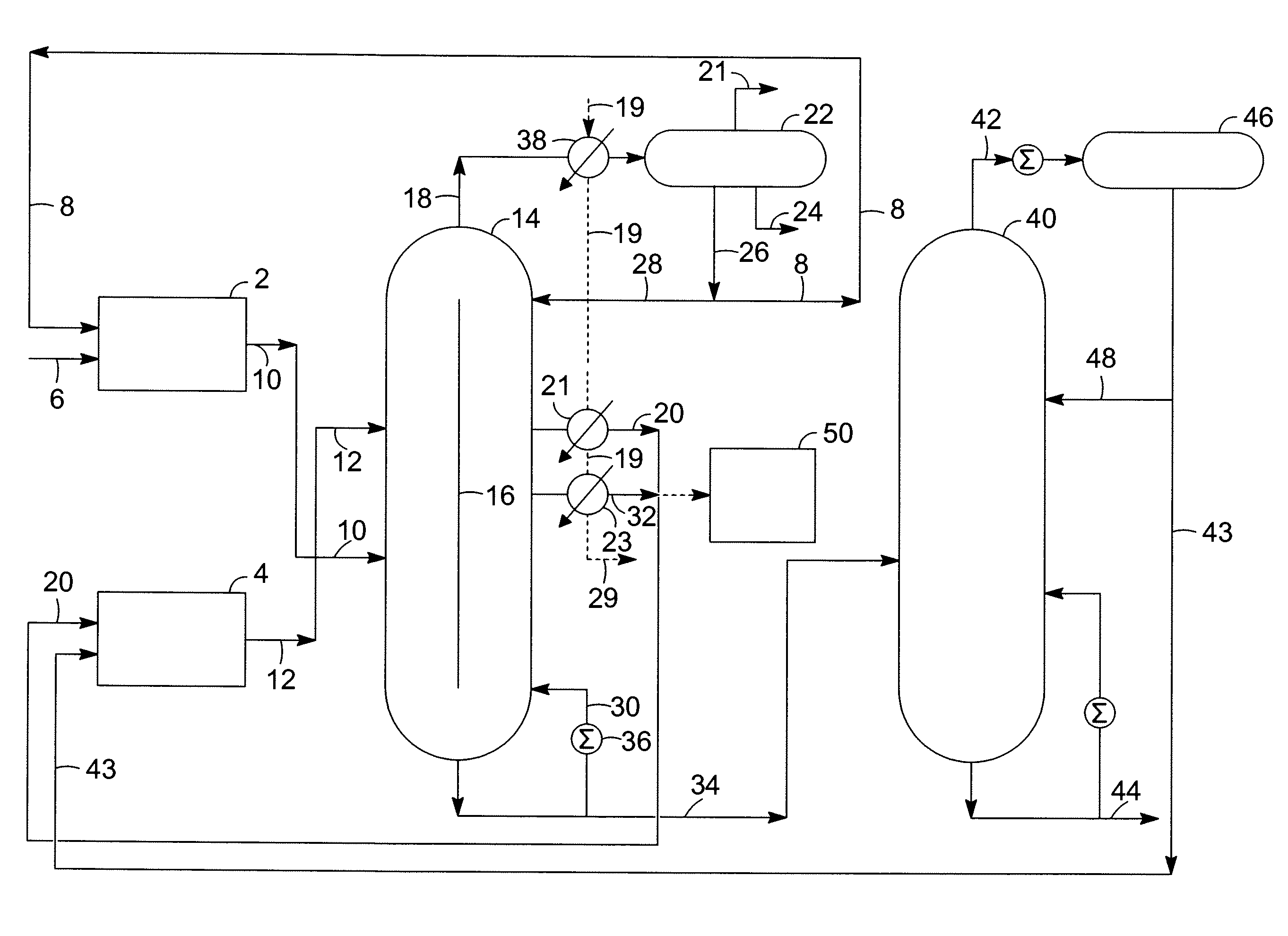

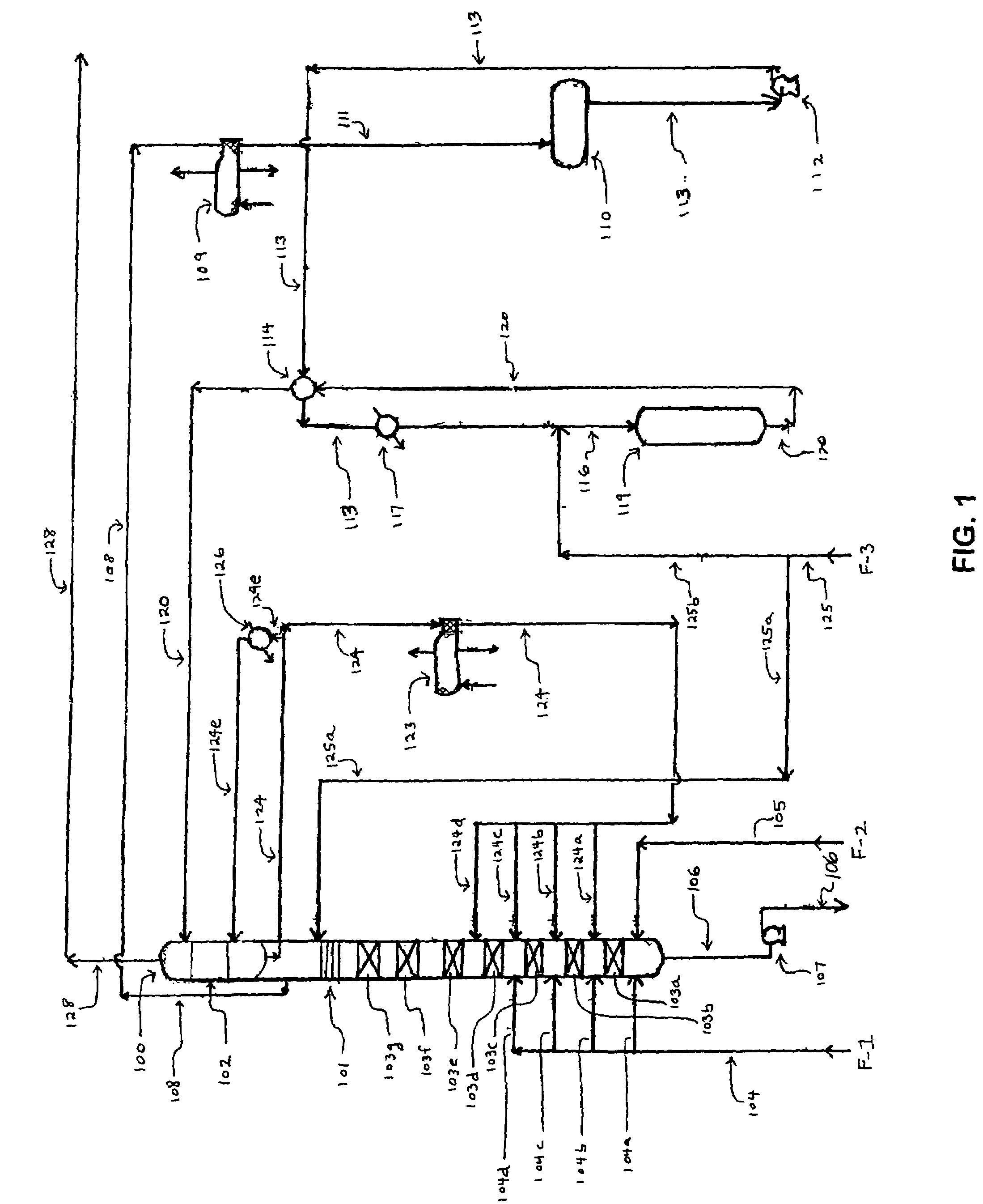

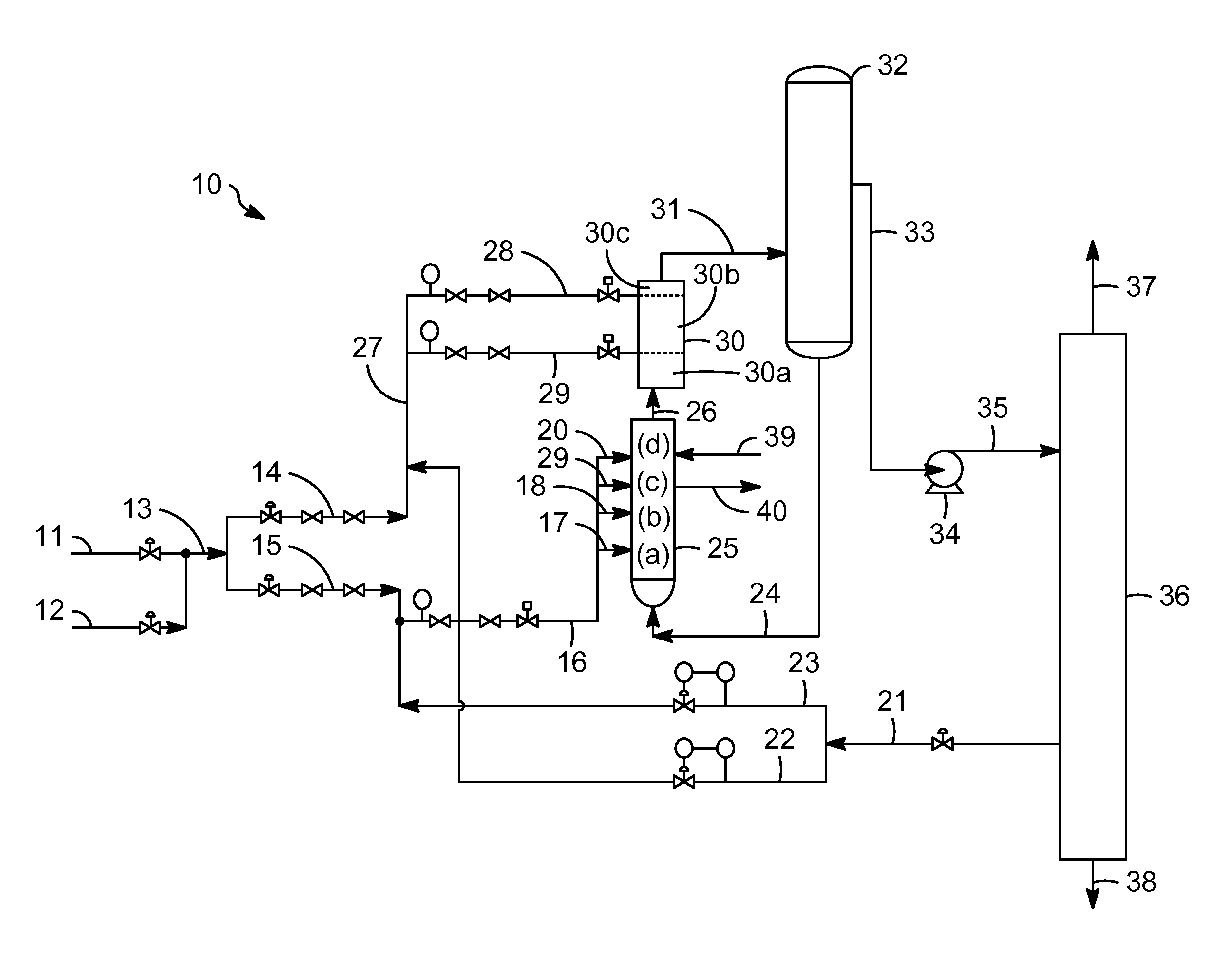

Alkylation process for increased conversion and reduced catalyst use

InactiveUS20080021252A1Improve productivityIncrease the number ofChemical industryHydrocarbonsAlkyl transferAlkylation unit

The invention relates to a process for the production of alkylated aromatic compounds comprising introducing olefin and aromatic compounds into at least first and second vertically spaced catalytic reaction zones in an alkylation unit under alkylation reaction conditions to provide an alkylated product, wherein the second catalytic reaction zone is positioned above the first catalytic reaction zone; wherein aromatic compound from each of the at least first and second catalytic reaction zones are contacted with a cooling means for re-condensing at least a portion of the aromatic compounds vaporized from the exothermic heat of reaction of the alkylation process; and wherein the olefin is introduced into the at least first and second catalytic reaction zones via respective first and second olefin feed streams at respective olefin feed rates such as to maintain olefin partial pressures at inlets to at least first and second catalytic reaction zones which vary by less than about ten percent. The invention additionally relates to an apparatus for practicing the alkylation process of the invention.

Owner:LUMMUS TECH INC

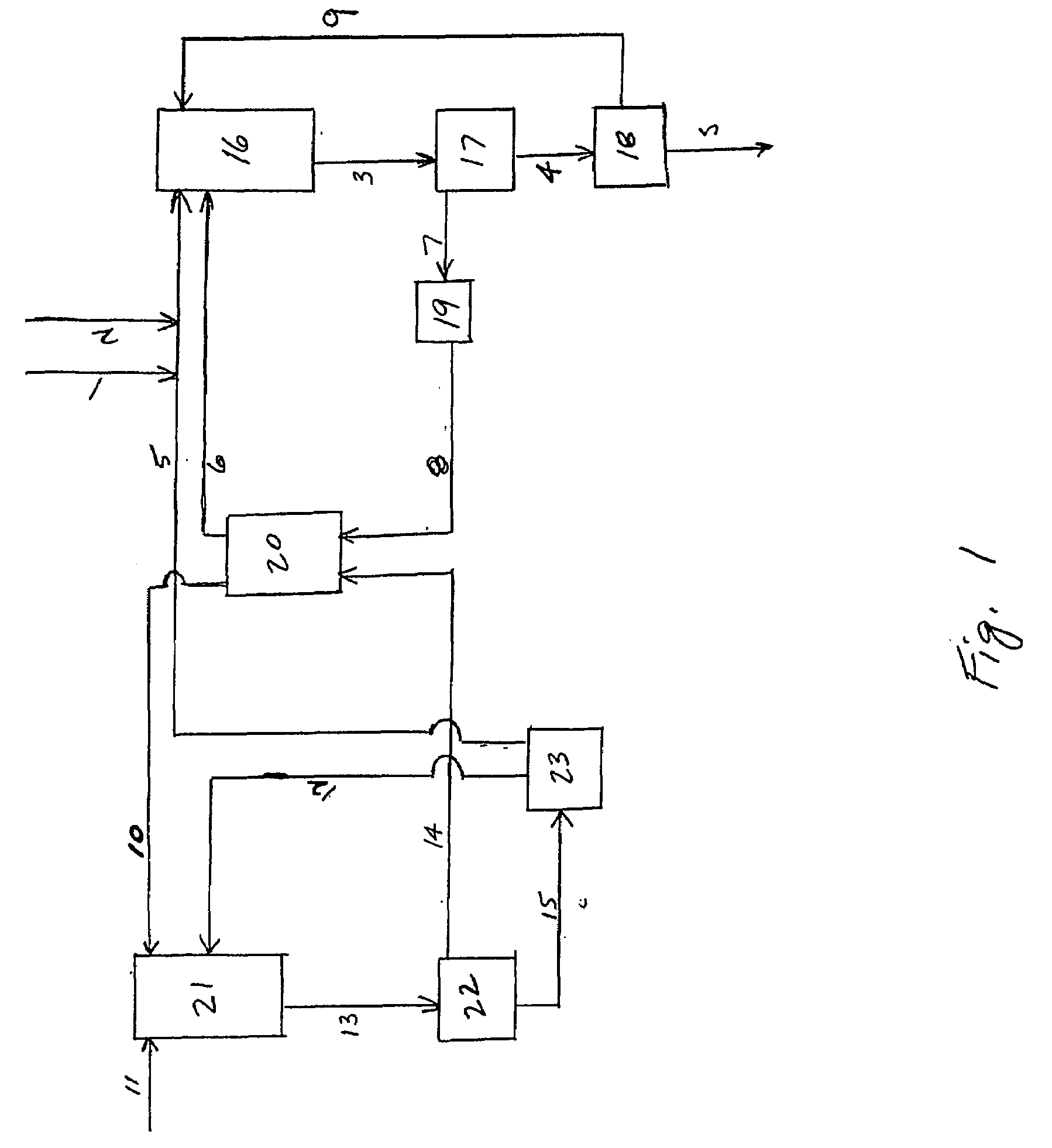

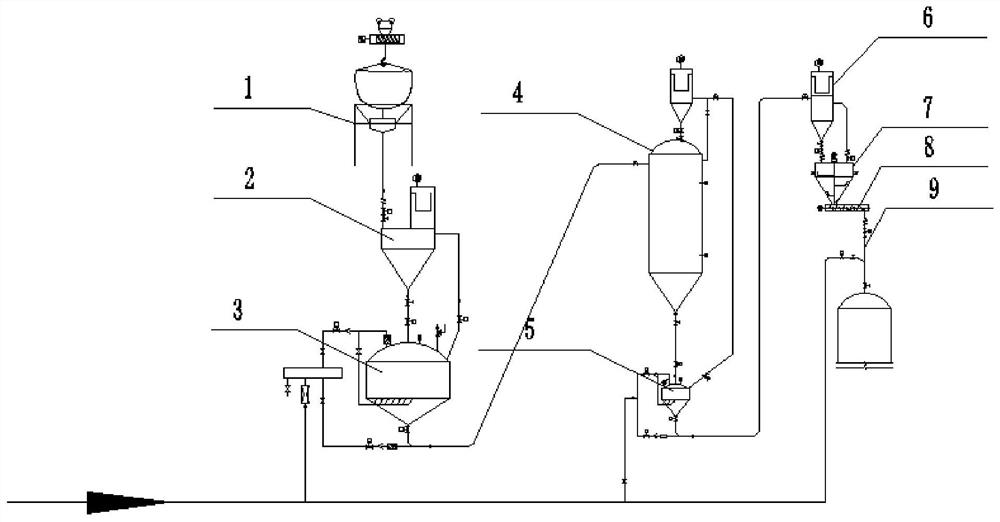

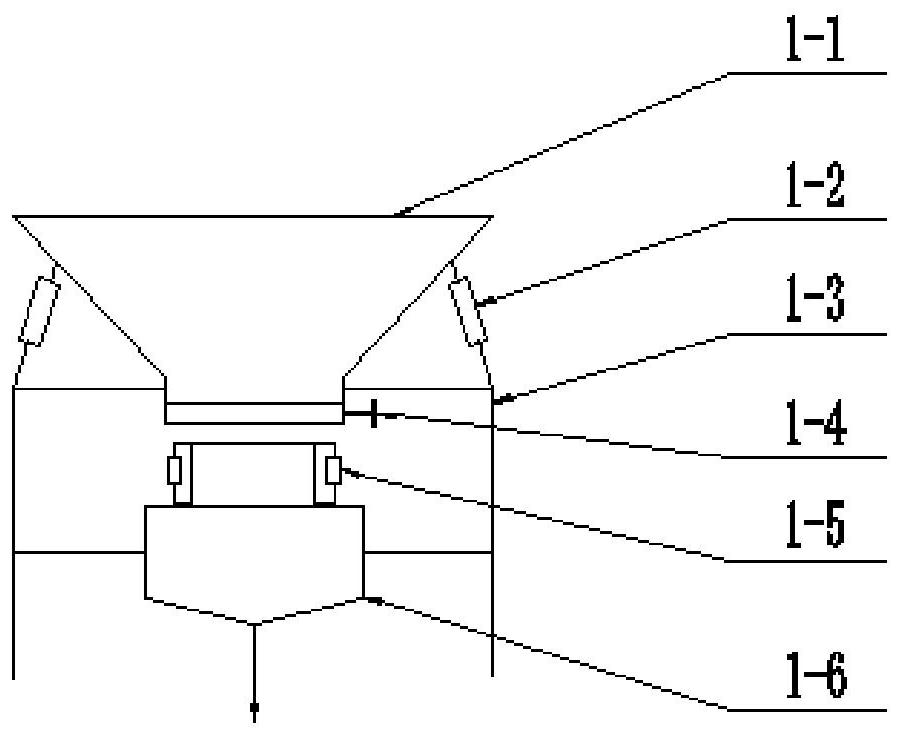

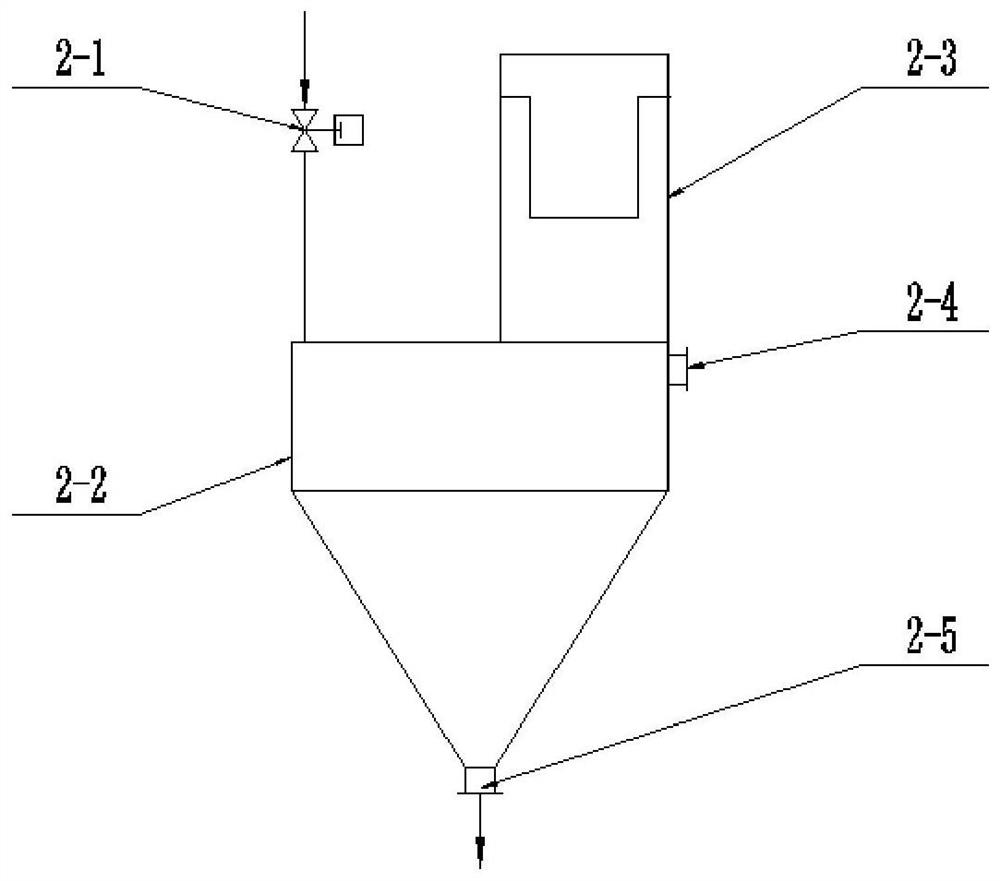

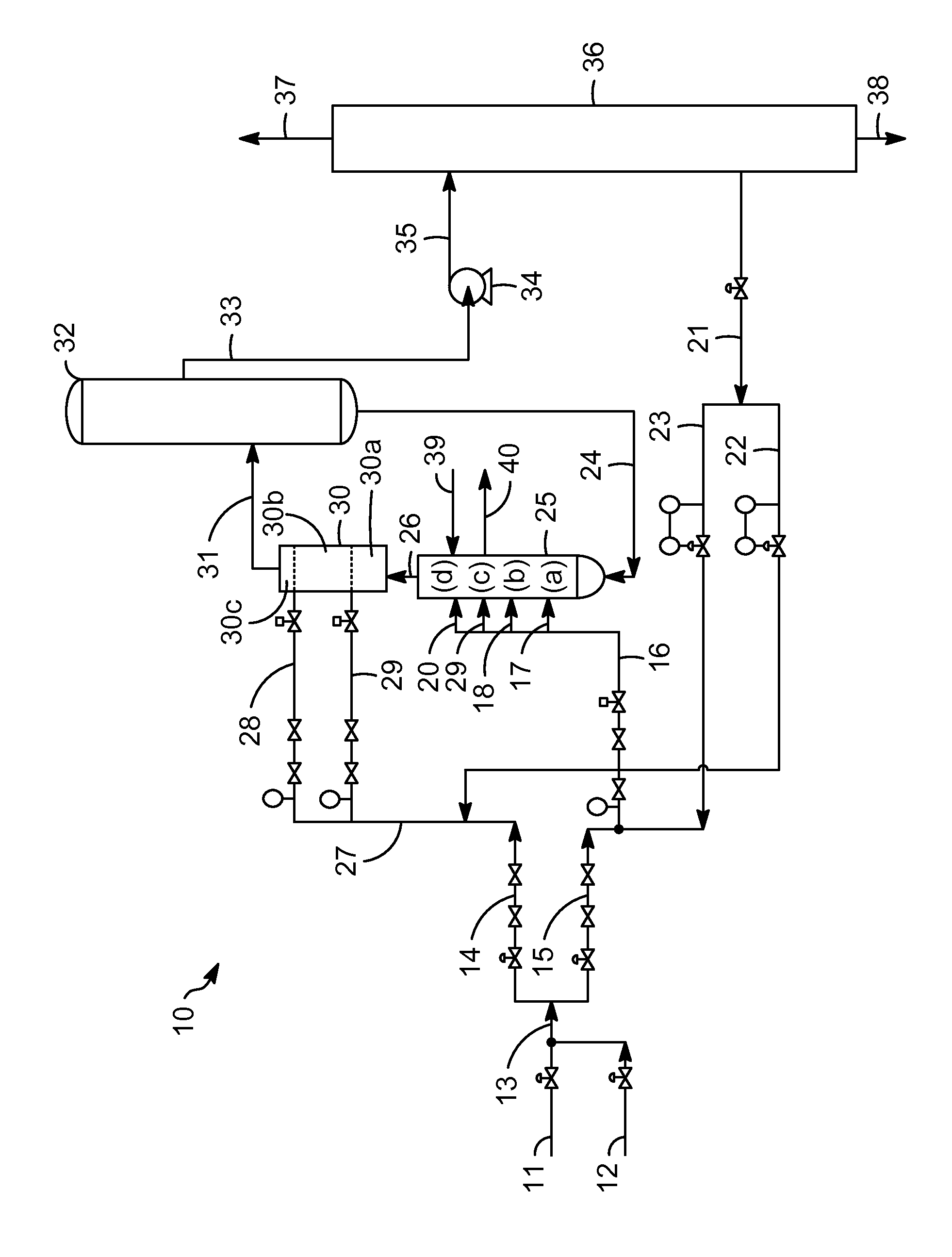

Normal-pressure continuous quantitative feeding system for alkylating device active agent

The invention relates to a normal-pressure continuous quantitative feeding system for an alkylating device active agent, and belongs to the technical field of petrochemical engineering. The system comprises a closed unloader, an active agent buffering and micro-negative-pressure dust removal unit, closed dense-phase conveying equipment, an active agent storing and filtering unit, small automatic feeding, metering and conveying equipment, a temporary storing and dust removal unit, a weighing, metering and anti-bonding unit, a double-helix continuous quantitative feeding unit and an emergency shutdown cutting-off unit. According to the normal-pressure continuous quantitative feeding system for the alkylating device active agent, the problems that the active agent is needed to be accurately added and metered, hydrocarbon gas in a reaction kettle is caked and hung on the wall after being in contact with the active agent, and a pipeline is easily blocked are solved; and the problems of environmental pollution and occupational injury to operators caused by active agent dust leakage during agent loading are fundamentally solved.

Owner:BEIJING LIKONPEC TECH

Refinery plant byproduct C4 hydrocarbon and liquefied gas comprehensive processing and utilizing device and method

ActiveCN108117482ARealize processing and utilizationReduce energy consumptionLiquid hydrocarbon mixtures productionHydrocarbonsAlkylation unitDehydrogenation

Owner:BEIJING PETROCHEM ENG

Conversion of waste plastic to propylene and cumene

ActiveUS10858593B2Hydrocarbon by metathesis reactionLiquid hydrocarbon mixture productionPtru catalystAlkylation unit

A process for producing cumene comprising converting plastics to hydrocarbon liquid and pyrolysis gas; feeding hydrocarbon liquid to hydroprocessor to yield hydrocarbon product and first gas stream; feeding hydrocarbon product to reforming unit to produce reforming product, second gas stream, and hydrogen; separating reforming product into non-aromatics recycle stream and second aromatics stream (C6+ aromatics); recycling non-aromatics recycle stream to reforming unit; separating second aromatics stream into benzene, C7, C8, C9, C10, and C11+ aromatics; contacting C7, C9, and / or C10 aromatics with a disproportionation&transalkylation catalyst / H2 to yield benzene&xylenes; conveying C11+ aromatics to hydroprocessor; introducing pyrolysis gas, first and / or second gas stream to first separator to produce first propylene stream, first C2&C4 unsaturated stream, and saturated gas (H2 and C1-4 saturated hydrocarbons); introducing first C2&C4 unsaturated stream to metathesis reactor to produce second propylene stream; and feeding benzene, and first and / or second propylene stream to alkylation unit to produce cumene.

Owner:SABIC GLOBAL TECH BV

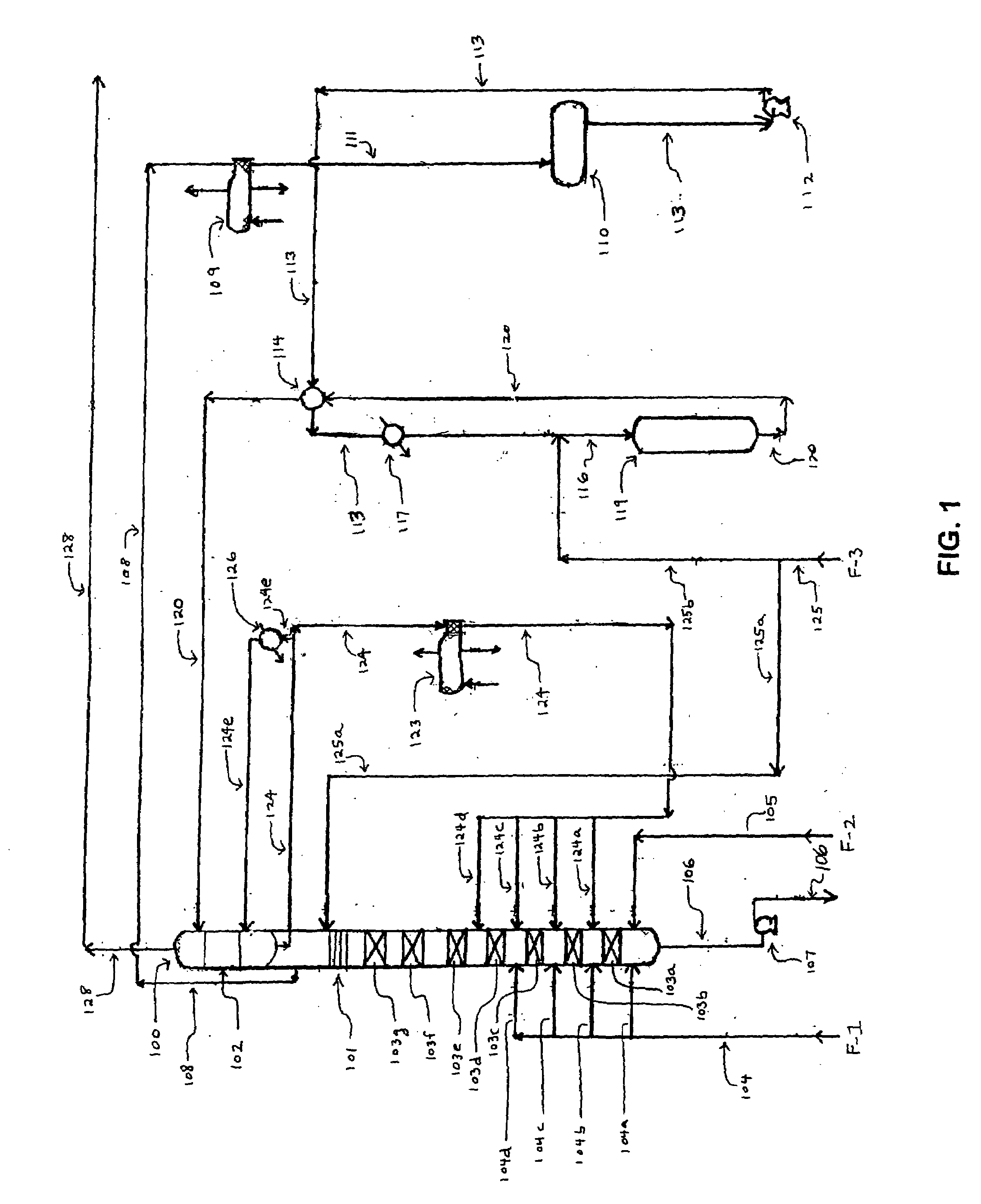

Alkylation process for increased conversion and reduced catalyst use

InactiveUS7632974B2Uniform and optimal/beneficial distributionUniform flowChemical industryHydrocarbonsAlkyl transferAlkylation unit

The invention relates to a process for the production of alkylated aromatic compounds comprising introducing olefin and aromatic compounds into at least first and second vertically spaced catalytic reaction zones in an alkylation unit under alkylation reaction conditions to provide an alkylated product, wherein the second catalytic reaction zone is positioned above the first catalytic reaction zone; wherein aromatic compound from each of the at least first and second catalytic reaction zones are contacted with a cooling means for re-condensing at least a portion of the aromatic compounds vaporized from the exothermic heat of reaction of the alkylation process; and wherein the olefin is introduced into the at least first and second catalytic reaction zones via respective first and second olefin feed streams at respective olefin feed rates such as to maintain olefin partial pressures at inlets to at least first and second catalytic reaction zones which vary by less than about ten percent. The invention additionally relates to an apparatus for practicing the alkylation process of the invention.

Owner:LUMMUS TECH INC

Alkylation processes using liquid lewis acid catalysts

ActiveUS20180127335A1Organic-compounds/hydrides/coordination-complexes catalystsCatalystsAlkaneAlkyl transfer

An alkylation process is described. The alkylation process includes contacting a feed comprising a paraffin or an aromatic with an olefin feed in the presence of a liquid Lewis acid catalyst in an alkylation reaction zone under alkylation conditions to form a reaction mixture comprising alkylation products and the liquid Lewis acid catalyst. The liquid Lewis acid catalyst is the liquid reaction product of a donor molecule and a metal halide. The alkylation products are separated from the liquid Lewis acid catalyst and recovered.

Owner:UOP LLC

Type-Y molecular sieve absorbent as well as preparation method and method for removing sulfur dioxide in iso-butane

InactiveCN108311098AHigh removal rateOther chemical processesAluminium silicatesAlkyl transferMolecular sieve

The invention provides a type-Y molecular sieve absorbent as well as a preparation method and method for removing sulfur dioxide in iso-butane. The preparation method of the type-Y molecular sieve absorbent comprises the following steps: performing the de-acidification for a vector to obtain the de-acidified vector; performing the ion exchange loading for the de-acidified vector and a chloride ofa transitional metal to obtain a semi-finished product of the transitional metal type-Y molecular sieve absorbent; drying the semi-finished product of the transitional metal type-Y molecular sieve absorbent, roasting, and obtaining the transitional metal type-Y molecular sieve absorbent; and a loading amount of the transitional metal type-Y molecular sieve absorbent is 0.8 to 9.0 percent. The transitional metal type-Y molecular sieve absorbent provided by the invention is adopted to remove the sulfur dioxide in iso-butane which is incompletely reacted in an alkylation apparatus, the removal rate is higher, and the content of the sulfur dioxide in the iso-butane which is not reacted in the alkylation apparatus can be removed to be 1 mg / kg or more.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Conversion of waste plastic to propylene and cumene

ActiveCN110139846AHydrocarbon by metathesis reactionHydrocarbon oil crackingAlkylation unitHydrogen treatment

Owner:SABIC GLOBAL TECH BV

A kind of unleaded aviation gasoline and preparation method thereof

ActiveCN106590773BAppropriate distillation rangeFulfil requirementsLiquid carbonaceous fuelsAviationAlkylation unit

The invention relates to lead-free aviation gasoline. The lead-free aviation gasoline contains components as follows: A) 55wt%-90wt% of alkylation unit oil, B) 5wt%-15wt% of pentane component oil, C) 0-20wt% of C7 aromatic component oil, D) 0-15wt% of cumene and E) 0-15wt% of an alkyl ether antiknock agent, wherein the alkylation unit oil is prepared from a reaction product distillate C4 obtained through alkylation of 1-butene and / or 2-butene and iso-butane as well as light components shown in the specification; the content of arylamine compounds in the lead-free aviation gasoline does not exceed 0.5wt%, and further, the lead-free aviation gasoline contains lead which does not exceed 0.01 g / L and contains at least one of the component C and the component D. The gasoline does not contain the arylamine compounds basically, so that environmental pollution caused by the aviation gasoline is greatly reduced, moreover, an octane value and a heat value realize good balance, a net heating value at least reaches 43.5 MJ / kg, and a motor octane value is not smaller than 91.

Owner:CHINA PETROLEUM & CHEM CORP

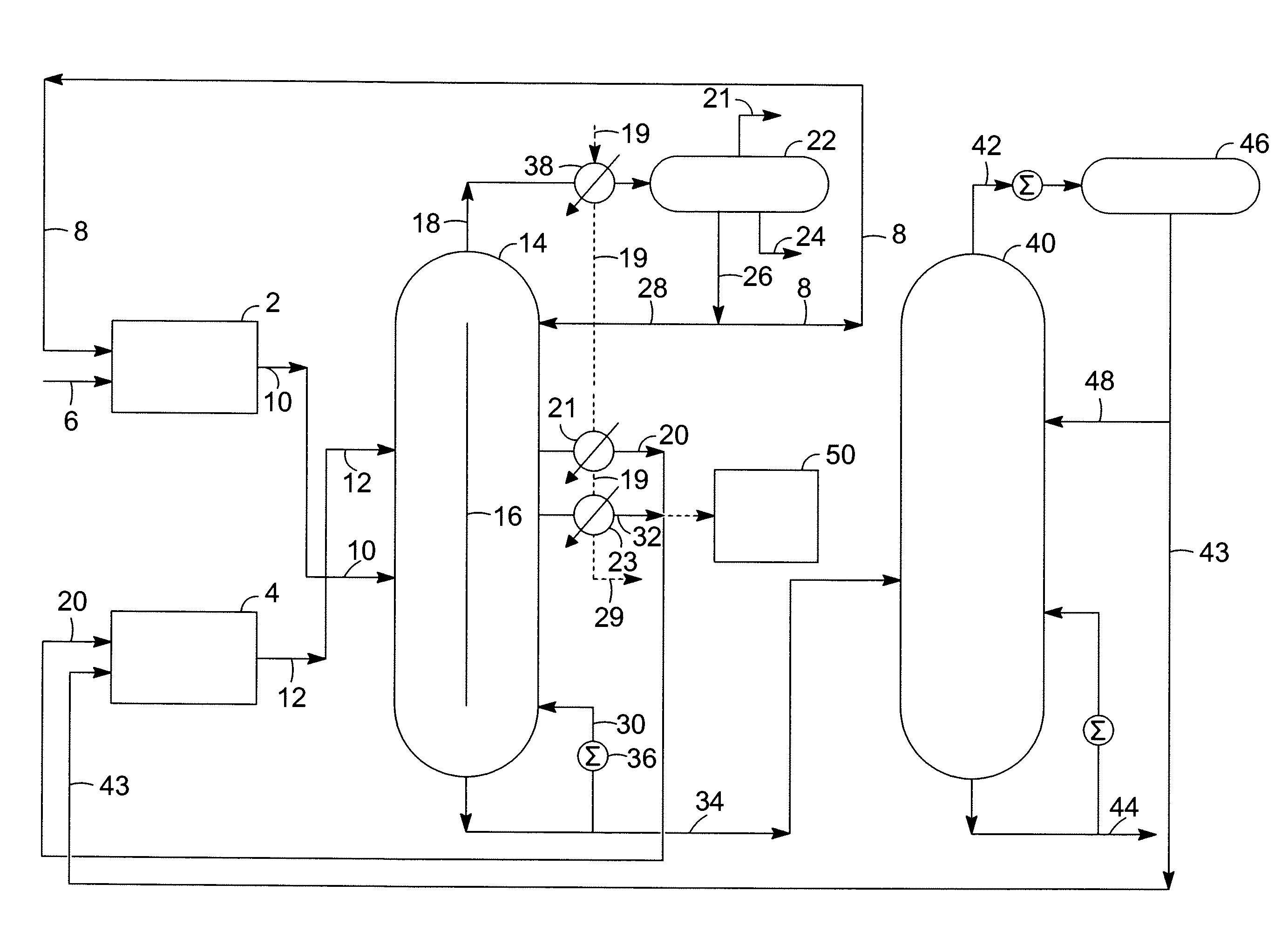

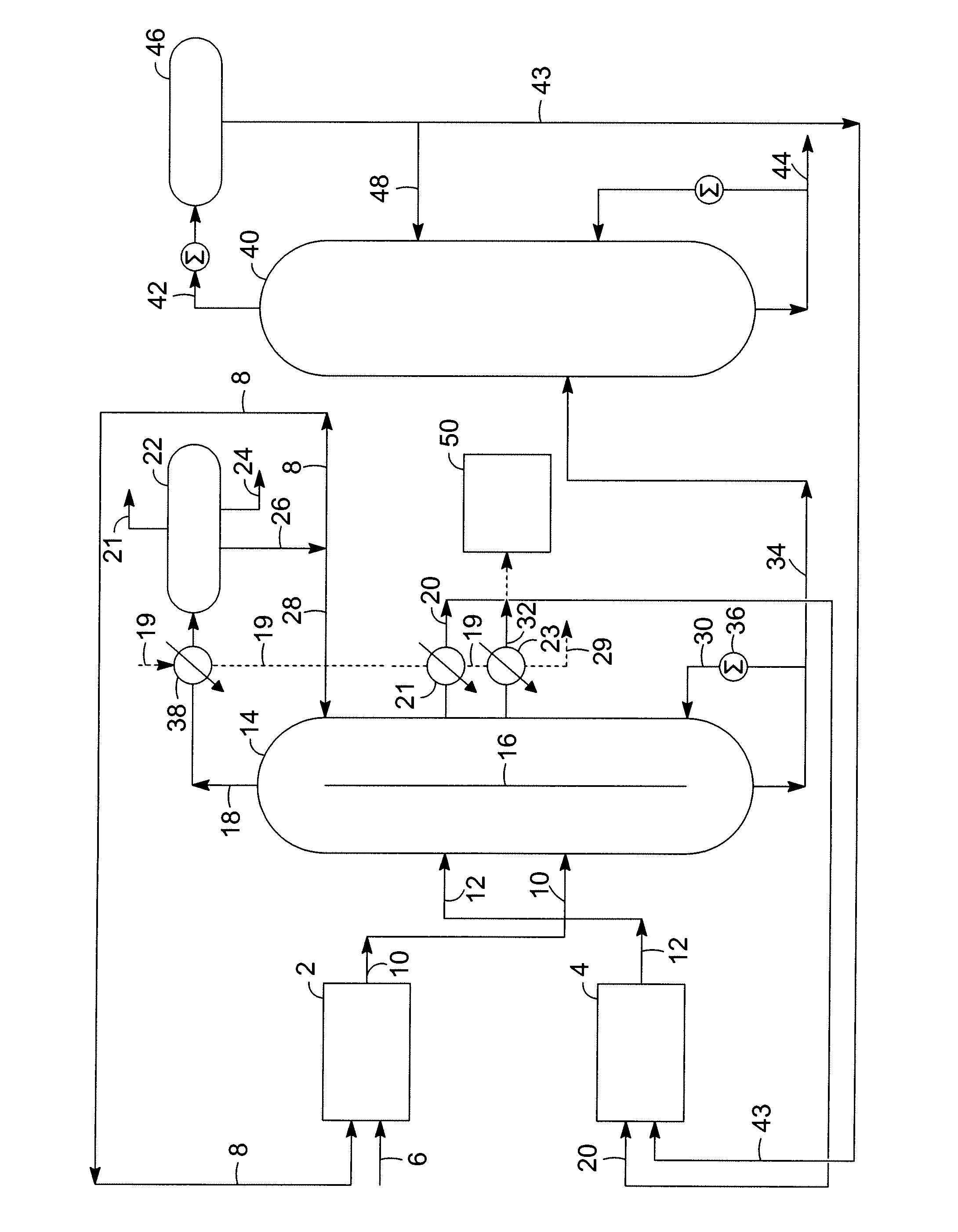

Alkylation unit

ActiveUS8246921B2Minimize corrosion and subsequent deteriorationPhysical/chemical process catalystsCatalystsAlkylation unitFractionation

One exemplary embodiment can be an alkylation unit. The alkylation unit can include at least one alkylation reaction zone having an alkylation catalyst, at least one cooler communicating with the at least one alkylation reaction zone, a settler communicating with the at least one alkylation reaction zone and the at least one cooler, a fractionation zone receiving an effluent from the settler passing through a line, and a boot coupled to a substantially horizontal portion of the line. Generally, the boot receives an effluent portion rich in the alkylation catalyst.

Owner:UOP LLC

Alkylation unit and method of modifying

ActiveUS8124034B2Use minimizedIncrease unit capacityHydrocarbonsChemical/physical/physico-chemical stationary reactorsAlkyl transferAlkylation unit

One exemplary embodiment can be a method of modifying an alkylation unit to increase capacity. The method may include combining a first alkylation zone with a second alkylation zone. Generally, the first alkylation zone includes a first settler having a height and a width. Typically, the width is greater than the height. In addition, the second alkylation zone may have a second settler having a height and a width. Usually, the height is greater than the width.

Owner:UOP LLC

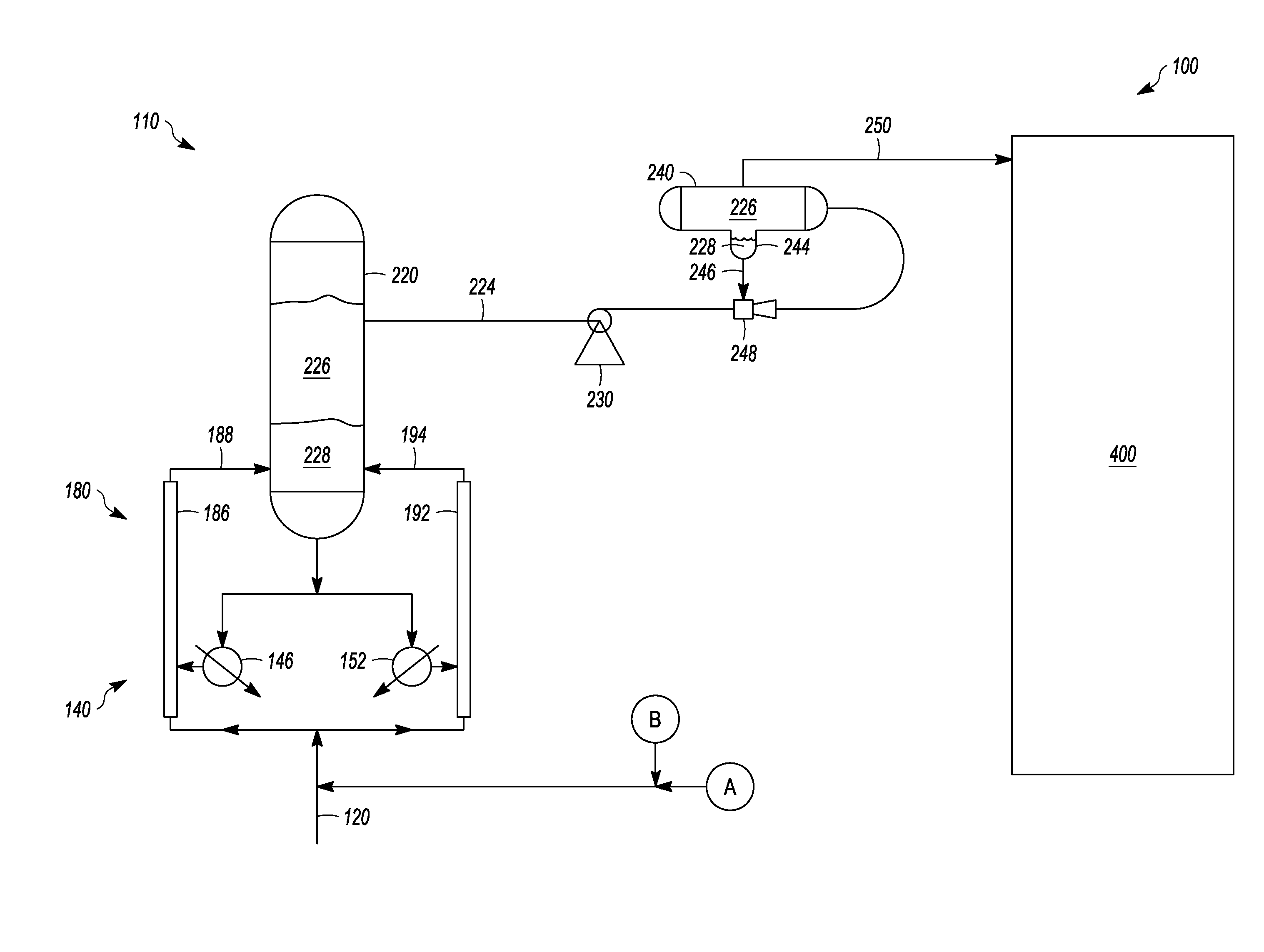

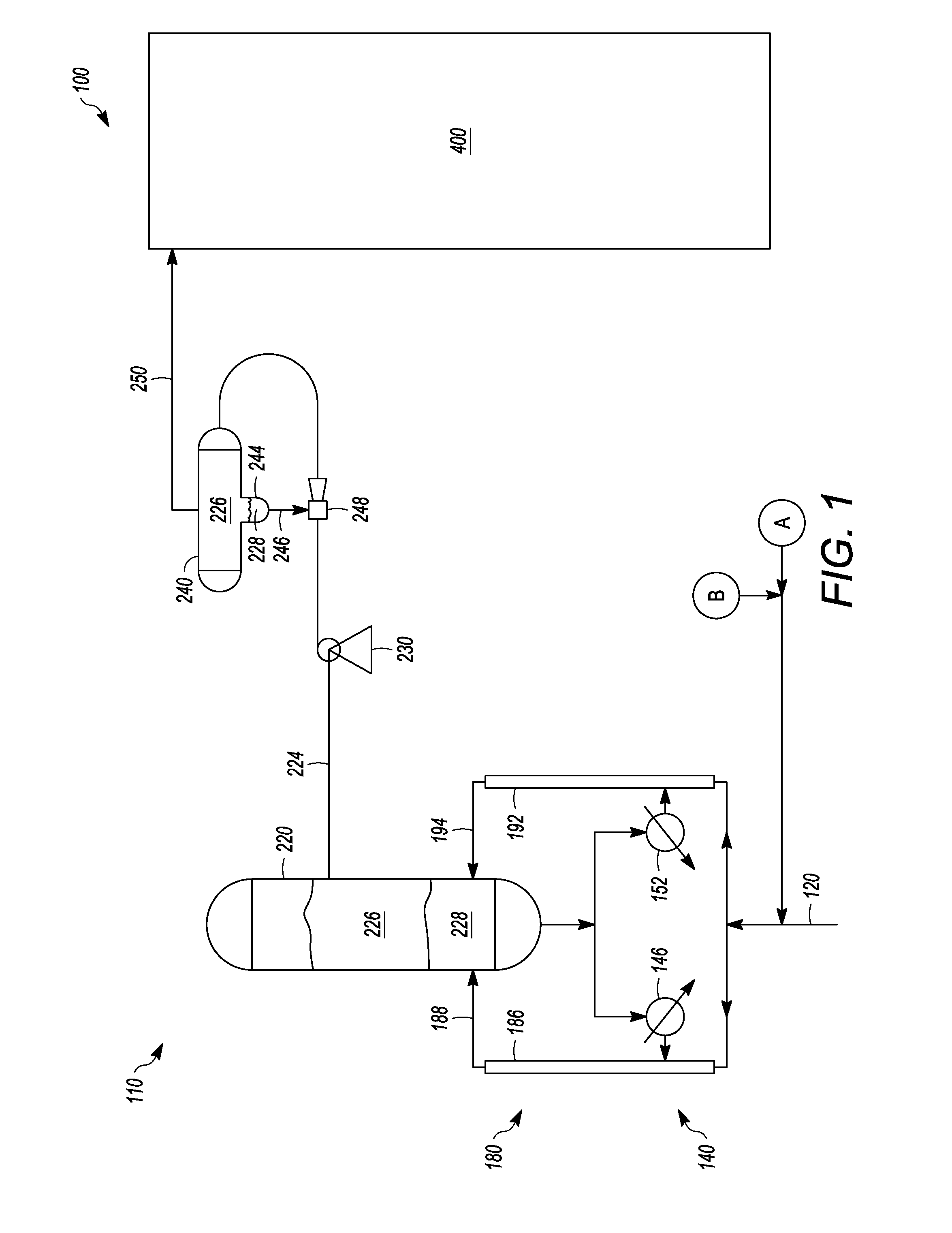

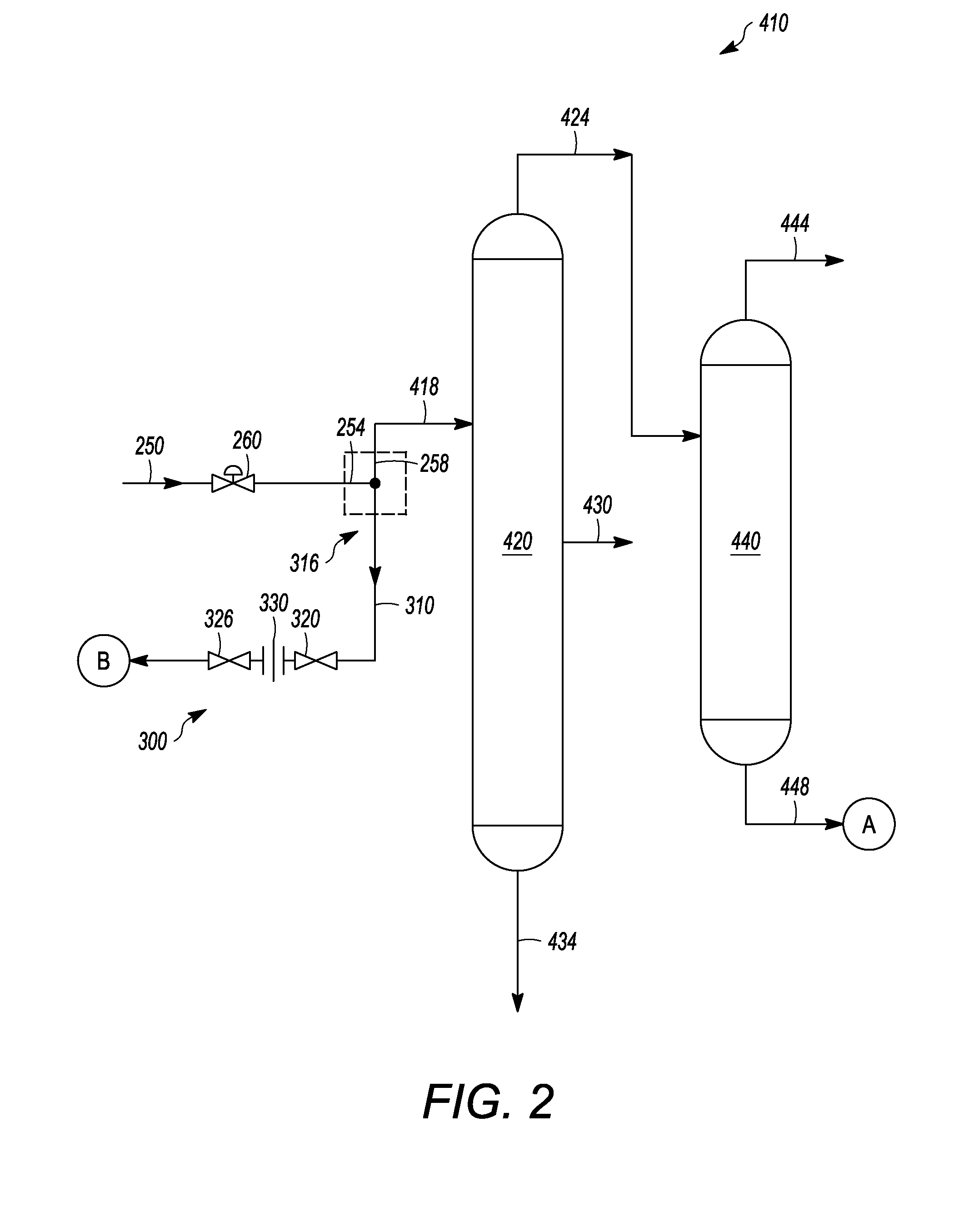

Alkylation unit and process

ActiveUS20150196894A1Increase unit capacityMinimizing octane loss.CatalystsHydrocarbon preparation catalystsAlkaneAlkyl transfer

A process for producing alkylated hydrocarbons includes the steps of: (a) combining a first feed stream comprising an olefin and an isoparaffin with an alkylation catalyst stream in a first alkylation reactor, (b) removing heat of reaction from the first alkylation reactor, (c) passing an effluent of the first alkylation reactor to a first reaction zone of a second alkylation reactor operating adiabatically to thereby form a first reaction zone effluent, (d) passing the first reaction zone effluent to a second reaction zone of the second alkylation reactor for mixture with a second feed stream comprising an olefin and an isoparaffin, and (e) passing an effluent of the second alkylation reactor to a settler for separation into a hydrocarbon stream and an alkylation catalyst effluent stream. An alkylation unit for carrying out the process is also disclosed.

Owner:UOP LLC

Alkylation unit and process relating thereto

ActiveUS20100076234A1Corrosion minimizationMinimize subsequent deteriorationPhysical/chemical process catalystsHydrocarbons from unsaturated hydrocarbon additionAlkyl transferAlkylation unit

One exemplary embodiment can be an alkylation unit. The alkylation unit can include at least one alkylation reaction zone having an alkylation catalyst, at least one cooler communicating with the at least one alkylation reaction zone, a settler communicating with the at least one alkylation reaction zone and the at least one cooler, a fractionation zone receiving an effluent from the settler passing through a line, and a boot coupled to a substantially horizontal portion of the line. Generally, the boot receives an effluent portion rich in the alkylation catalyst.

Owner:UOP LLC

HF alkylation process with acid regeneration

InactiveUS7847142B2Low costHydrogen fluorideStationary tubular conduit assembliesAlkyl transferDistillation

The regeneration of HF alkylation acid in an alkylation unit is improved by withdrawing a vapor stream from the HF regenerator tower and condensing the stream to form a liquid fraction which is accumulated in a side distillation zone; the collected liquid fraction, comprising HF acid, water and some stripping medium is distilled in a batch or continuous type operation to drive off the HF acid (along with stripping medium) and the vapor is returned to the regenerator-stripper vessel. The distillation of the sidedraw liquid is continued until the composition of the liquid attains the azeotropic value or as near to that value as desired. The azeotrope, comprising water and acid can then be dropped out of the distillation vessel for disposal by neutralization in the conventional way.

Owner:EXXON RES & ENG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com