Method of Preparing Metal Matrix Composite and Coating Layer and Bulk Prepared Thereby

a technology of metal matrix composite and coating layer, which is applied in the direction of coatings, sustainable transportation, molten spray coatings, etc., can solve the problems of high cost of high temperature operation and safety securing problems of facilities, inhibit the formation of intermetallic compounds, and inappropriate hardening, etc., to achieve excellent mechanical strength, improve high temperature strength, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

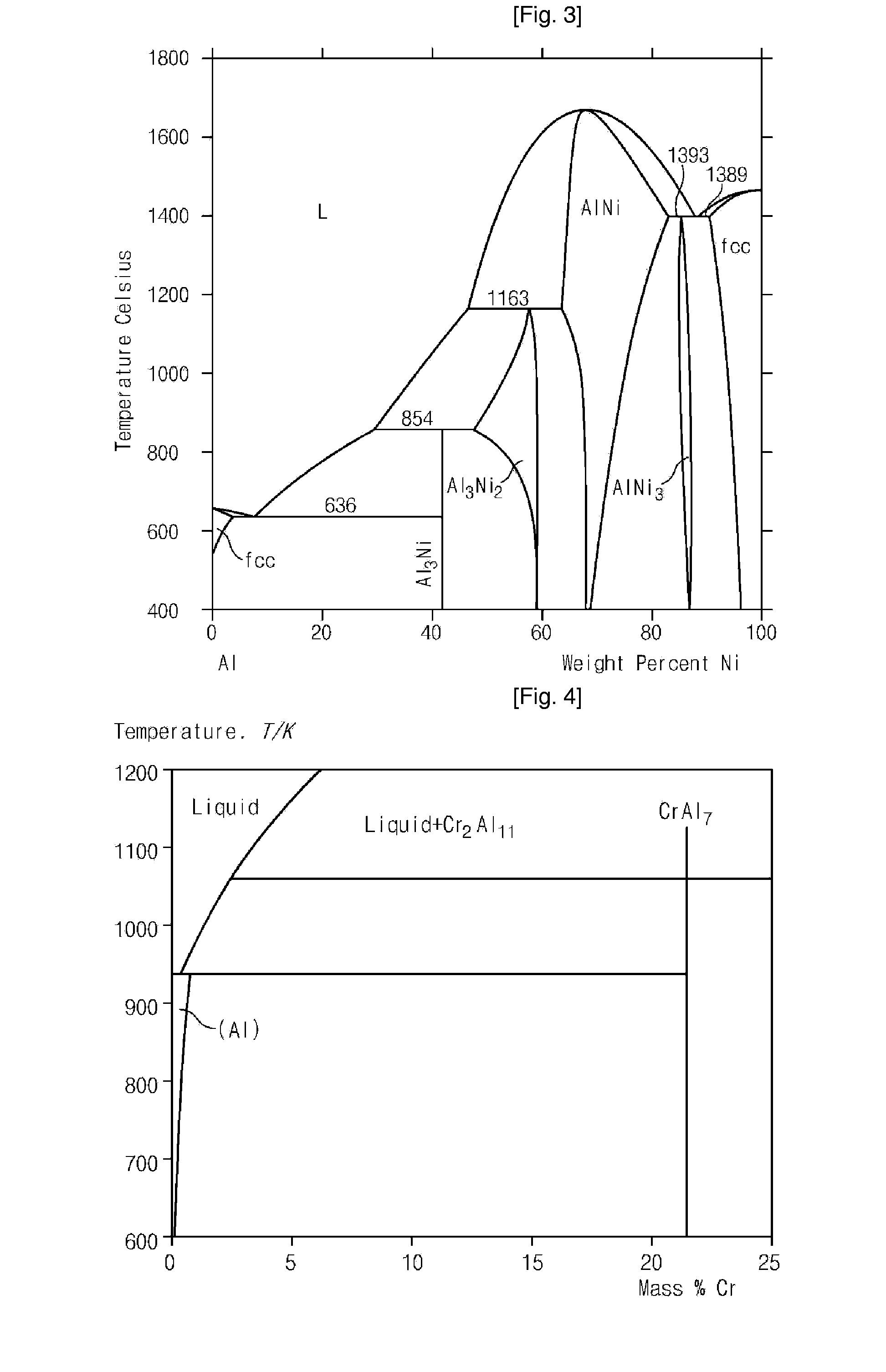

[0090]Mixed metal powders where a weight ratio of Al powder having an average particle diameter of 77 um and Ni powder having an average particle diameter of 3 um is 90:10 (Al-10% Ni) and 75:25 (Al-25% Ni), respectively were prepared and SiC powder having an average particle diameter of 35 um was mixed therewith in an amount of 5 parts by weight of 100 parts by weight of the mixed metal powder thereby to prepare the final mixed powder. The mixed powder was inserted into a nozzle having an aperture of 4×6 mm and a throat gap of 1 mm as a standard laval type nozzle in the conditions of air as a compression gas, 7 atm and flow of transportation gas of 330° C. whereby a coating layer was prepared. The prepared coating was subject to thermal treatment for four hours at about 450° C., 500° C. and 550° C. The thermal treatment was carried out under nitrogen atmosphere. With the surface of the thermally treated substrate, its X-ray diffraction patterns were determined and the results were d...

example 2

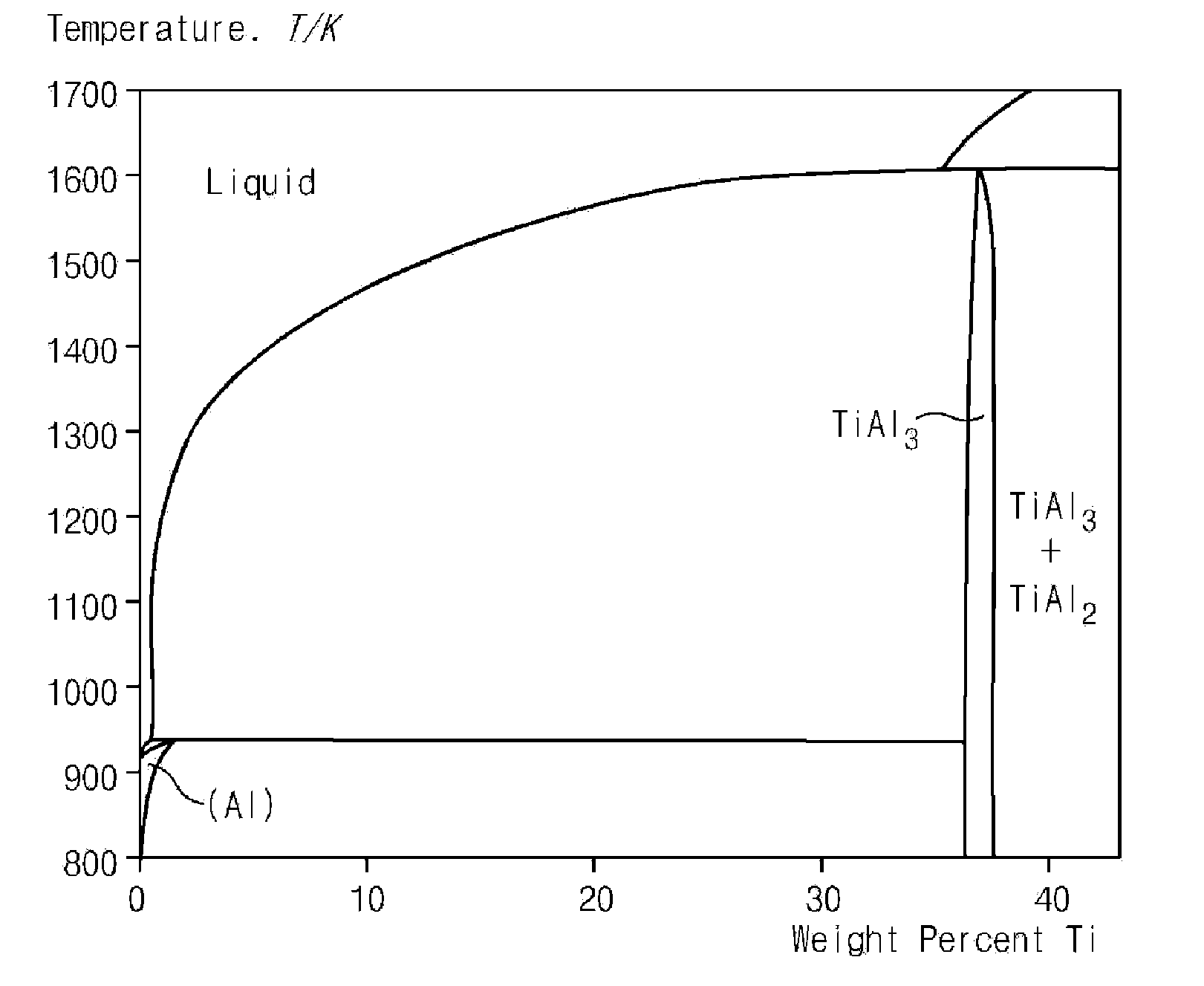

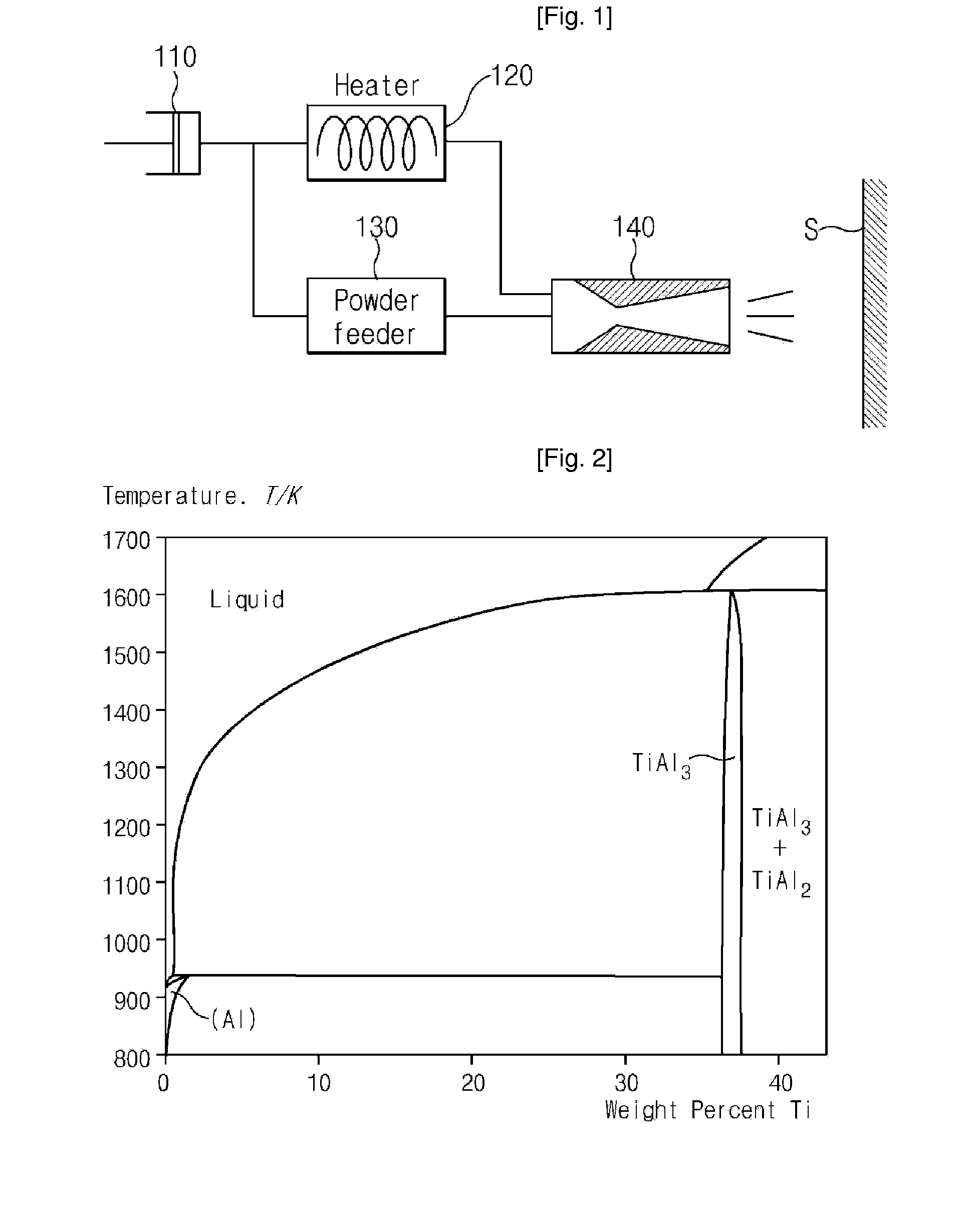

[0093]Mixed metal powders where a weight ratio of Al powder having an average particle diameter of 43 um and Ti powder having an average particle diameter of 43 um is 90:10 (Al-10% Ti) and 75:25 (Al-25% Ti), respectively were prepared and SiC powder having an average particle diameter of 35 um was mixed therewith in an amount of 5 parts by weight of 100 parts by weight of the mixed metal powder thereby to prepare the final mixed powder. The mixed powder was inserted into a nozzle having an aperture of 4×6 mm and a throat gap of 1 mm as a standard laval type nozzle in the conditions of air as a compression gas, 7 atm and flow of transportation gas of 330° C. whereby a coating layer was prepared. The prepared coating was subject to thermal treatment for four hours at about 450° C., 500° C., 550° C. and 630° C. The thermal treatment was carried out under nitrogen atmosphere. With the surface of the thermally treated substrate, its X-ray diffraction patterns were determined and the resu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com