Method for preparing high-temperature flexible LaNiO3 conductive film by sol-gel method

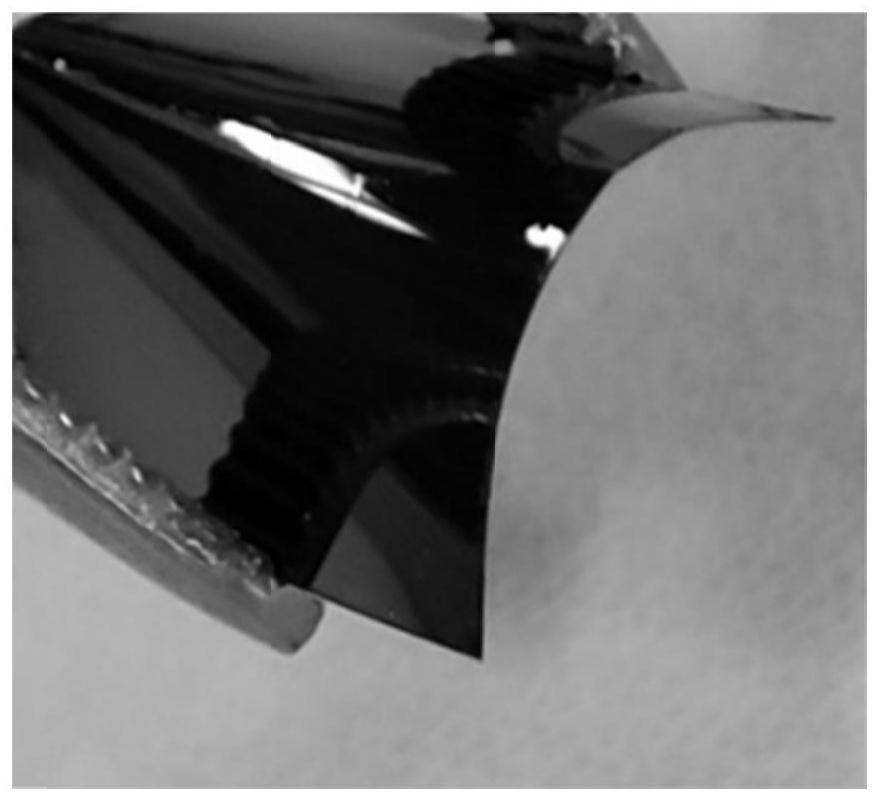

A high-temperature flexible and conductive film technology, which is applied to the conductive layer, circuit, and electrical components on the insulating carrier, can solve the problems of drastic changes in pH value, increased energy consumption, and increased volatilization too fast, and achieves excellent flexibility. Evaporation speed and the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

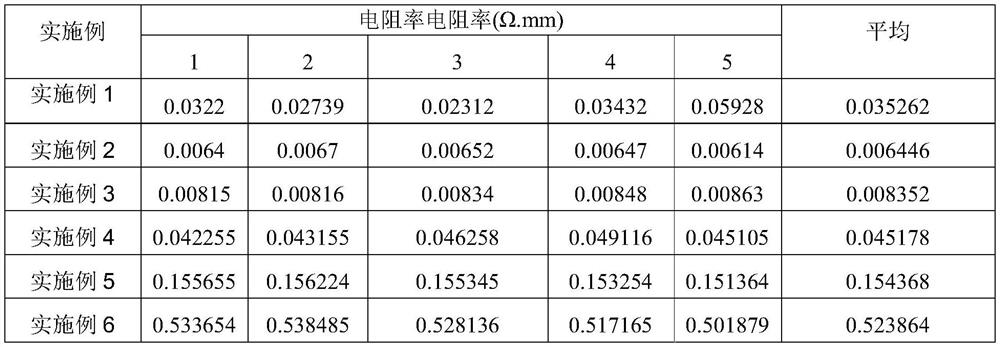

Embodiment 1

[0030] Step 1: Select an inorganic fluorophlogopite (F-Mica) substrate as the base, and rinse the cut mica substrate with a washing bottle filled with absolute ethanol.

[0031] Step 2: Place the clean inorganic fluorophlogopite (F-Mica) substrate in an ultraviolet irradiator for 30 minutes to make the surface of the substrate reach "atomic cleanliness".

[0032] Step 3: Put La(NO 3 ) 5 ·6H 2 O.C 4 H 6 NiO 4 ·4H 2 O was dissolved in ethylene glycol methyl ether in a molar ratio of 1:1, then acetic anhydride was added to the mixed solution to adjust the viscosity, and after magnetic stirring for 90 min, stable LaNiO with a metal ion concentration of 0.6 mol / L was obtained 3 Precursor solution, wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1.

[0033] Step 4: Spin Coating LaNiO on Inorganic Fluorophlogopite (F-Mica) Substrate by Spin Coating 3 Precursor to prepare thin films. The glue mixing speed is low speed 800r / min for 15s, 4100r...

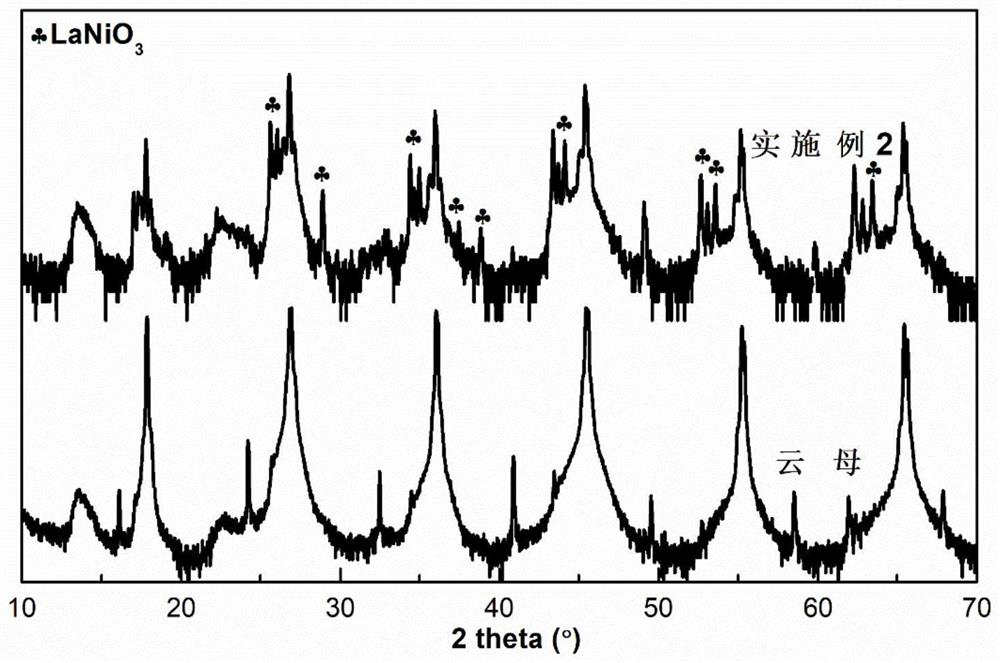

Embodiment 2

[0036] Step 1: Select an inorganic fluorophlogopite (F-Mica) substrate as the base, and rinse the cut mica substrate with a washing bottle filled with absolute ethanol.

[0037] Step 2: Place the clean inorganic fluorophlogopite (F-Mica) substrate in an ultraviolet irradiator for 30 minutes to make the surface of the substrate reach "atomic cleanliness".

[0038] Step 3: Put La(NO 3 ) 5 ·6H 2 O.C 4 H 6 NiO 4 ·4H 2 O was dissolved in ethylene glycol methyl ether in a molar ratio of 1:1, then acetic anhydride was added to the mixed solution to adjust the viscosity, and after magnetic stirring for 90 min, stable LaNiO with a metal ion concentration of 0.6 mol / L was obtained 3 Precursor solution, wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1.

[0039] Step 4: Spin Coating LaNiO on Inorganic Fluorophlogopite (F-Mica) Substrate by Spin Coating 3 Precursor to prepare thin films. The glue mixing speed is low speed 800r / min for 15s, 4100r...

Embodiment 3

[0042] Step 1: Select an inorganic fluorophlogopite (F-Mica) substrate as the base, and rinse the cut mica substrate with a washing bottle filled with absolute ethanol.

[0043] Step 2: Place the clean inorganic fluorophlogopite (F-Mica) substrate in an ultraviolet irradiator for 30 minutes to make the surface of the substrate reach "atomic cleanliness".

[0044] Step 3: Put La(NO 3 ) 5 ·6H 2 O.C 4 H 6 NiO 4 ·4H 2 O was dissolved in ethylene glycol methyl ether in a molar ratio of 1:1, then acetic anhydride was added to the mixed solution to adjust the viscosity, and after magnetic stirring for 90 min, stable LaNiO with a metal ion concentration of 0.6 mol / L was obtained 3 Precursor solution, wherein the volume ratio of ethylene glycol methyl ether and acetic anhydride is 3:1.

[0045] Step 4: Spin Coating LaNiO on Inorganic Fluorophlogopite (F-Mica) Substrate by Spin Coating 3 Precursor to prepare thin films. The glue mixing speed is low speed 800r / min for 15s, 4100r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com