Flavone polyphenol drug self-emulsifying composition, preparation method of flavonoid polyphenol drug self-emulsifying composition, drug composition and application

A technology of polyphenols and compositions, which is applied in the field of self-emulsifying compositions of flavonoids and polyphenols, can solve problems such as drug precipitation, difficulty in further increasing the drug loading of baicalein, and inability to meet the requirements of drug loading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

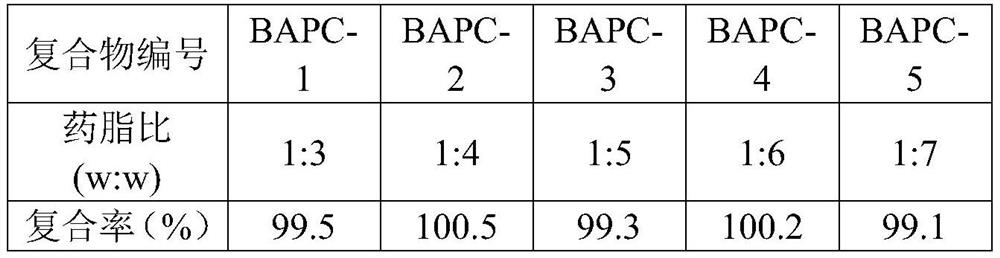

[0066] Embodiment 1 adopts different medicine lipid ratio (baicalein crude drug and soybean phospholipid mass ratio) to prepare baicalein-phospholipid compound compound.

[0067] Precisely weigh the baicalein raw material drug and soybean lecithin according to the drug-to-lipid ratio in Table 1, place them in a 1000ml rotary steamer, add an appropriate amount of tetrahydrofuran, mix and shake well, and wait until the baicalein raw material drug and phospholipid are completely dissolved and the compound solution is clarified, place

[0068] After 15-30 minutes, place it on a rotary evaporator, and evaporate the solvent at 40°C. After the object in the rotary steaming bottle foams and becomes honeycomb, continue rotary steaming for 1 to 2 hours. After the preparation is completed, put it in a drying oven and dry it for 3 days. Gently scrape off the solid baicalein-phospholipid complex and place it in the drying oven Save it for later use.

[0069] Table 1 Prescriptions of b...

Embodiment 2

[0071] Embodiment 2 adopts different organic solvents to prepare baicalein-phospholipid complex

[0072] Using the same method as in Example 1, the difference is: the mass ratio (w / w) of baicalein crude drug to soybean lecithin is 1:3.5, and ethyl acetate, methyl alcohol, acetone, ethanol, and dehydrated alcohol are respectively used , n-propanol, isopropanol, n-butanol, isobutanol, tert-butanol, ethyl ether, methyl ethyl ether, dioxane, butanone, petroleum ether, hexane, cyclohexane, dichloromethane , chloroform, carbon tetrachloride, DMSO, and DMF were used as reaction solvents to prepare baicalein-phospholipid complexes, and the complex rate was investigated.

[0073] The results show that when the above-mentioned organic solvent is used as the reaction solvent, the recombination rates of all the obtained baicalein-phospholipid complexes are greater than 80%.

Embodiment 3

[0074] Embodiment 3 adopts different phospholipids to prepare baicalein-phospholipid complex

[0075] Using the same method as in Example 1, the difference is: the mass ratio (w / w) of baicalein crude drug to phospholipids is 1:3.5, and natural phospholipids are respectively adopted: egg yolk phospholipids or soybean phospholipids, etc., or synthetic phospholipids: Phosphoglycerides, sphingomyelin, phosphatidylcholine, phosphatidylethanolamine, phosphatidylserine, phosphatidylinositol, phosphatidylglycerol, glycerol phosphatidic acid, distearoylphosphatidylcholine, dipalmitoylphosphatidylcholine, Dipalmitoylphosphatidylethanolamine or dimyristoylphosphatidylcholine were used as lipid materials to prepare baicalein-phospholipid complexes, and the complex rates were investigated respectively.

[0076] The results show that the recombination rates of all baicalein-phospholipid complexes prepared by using the above-mentioned phospholipids are above 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Drug loading | aaaaa | aaaaa |

| Drug loading | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com