System and method for producing high-purity vanadium pentoxide through clean chlorination of vanadium resources

A technology of vanadium pentoxide and resources, which is applied in the field of clean chlorination of vanadium resources to produce high-purity vanadium pentoxide, which can solve the problems of ecological environment impact, cost increase, and environmental problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

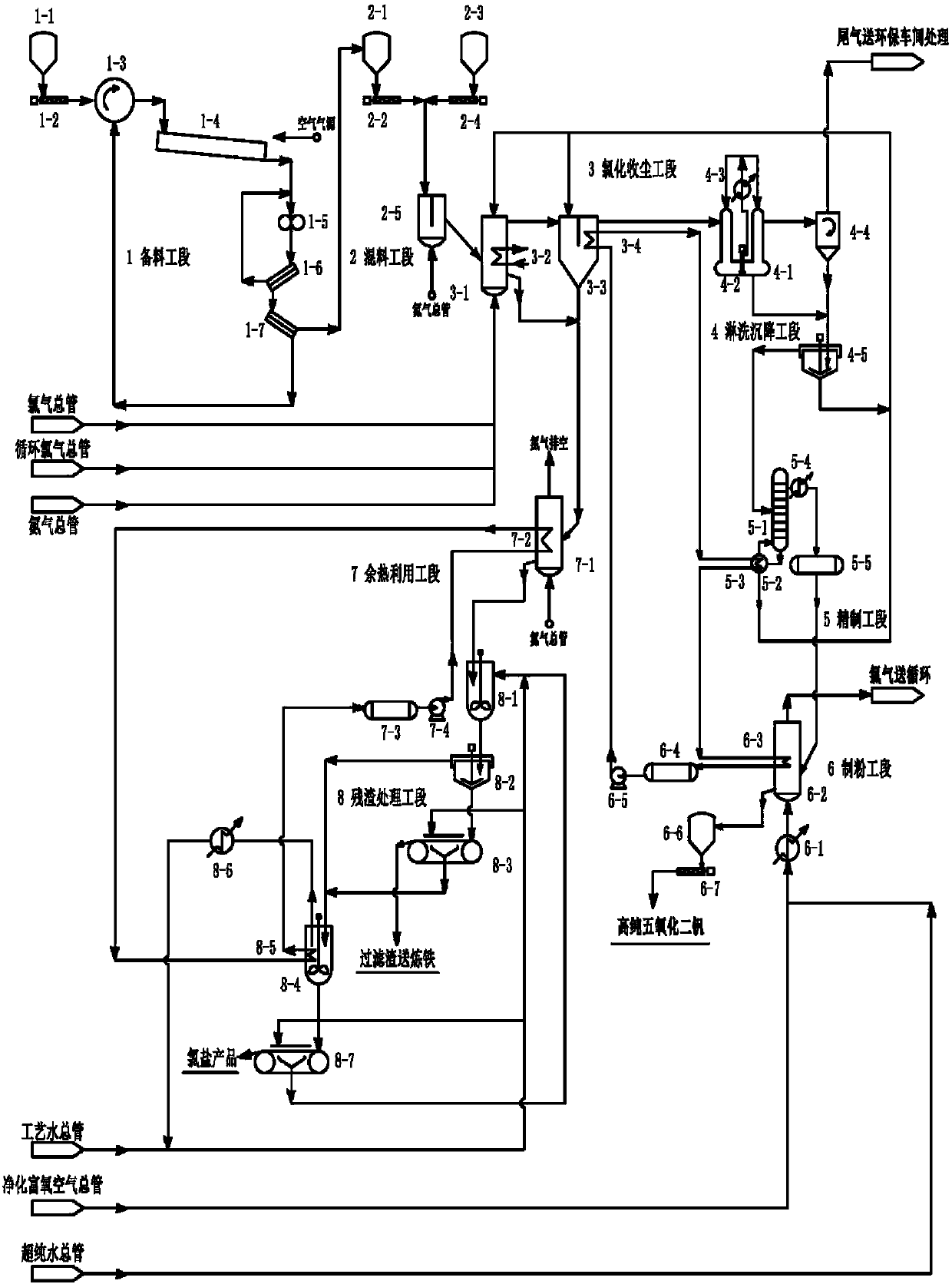

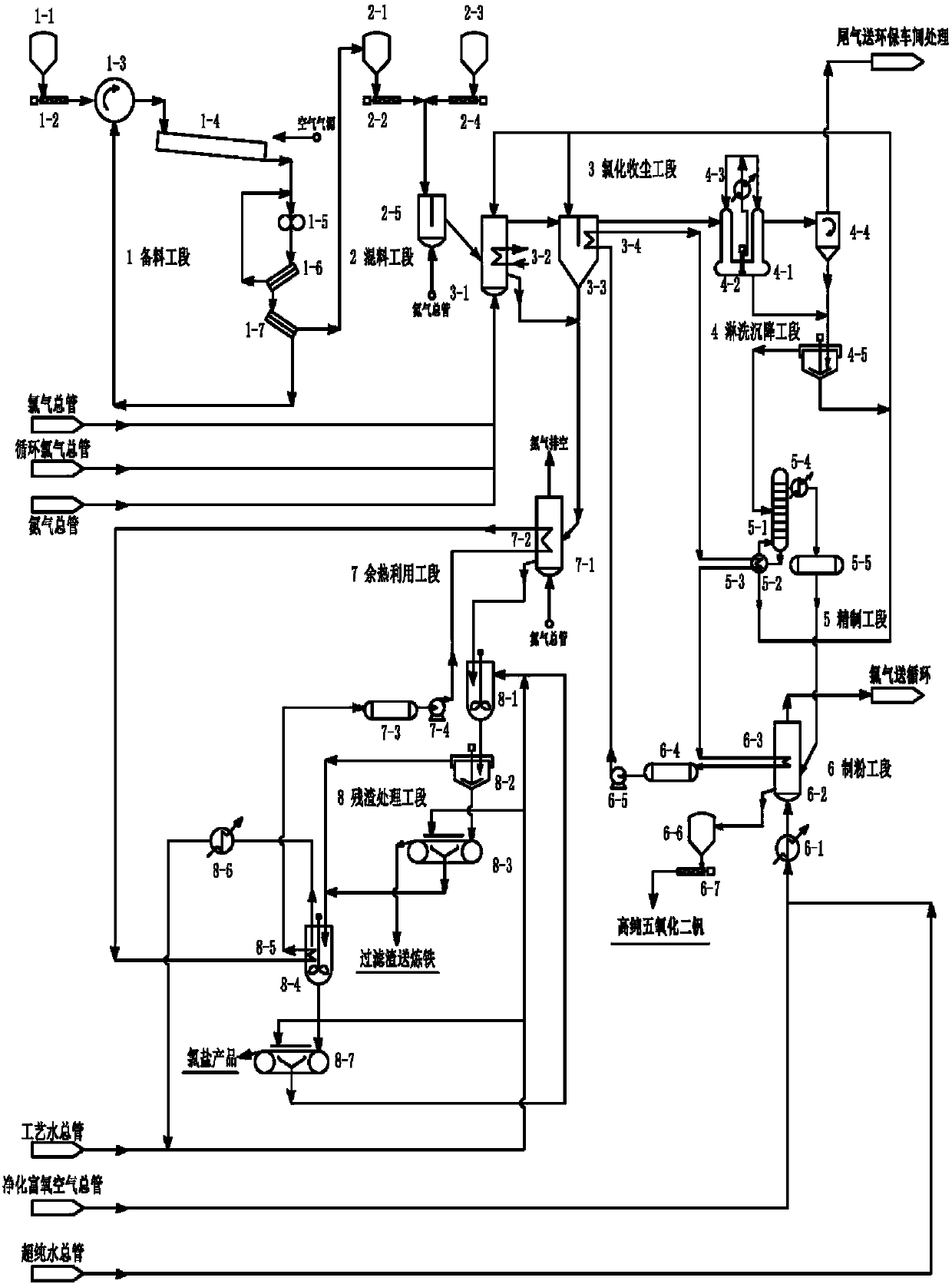

[0077] combine figure 1 A system for producing high-purity vanadium pentoxide by clean chlorination of vanadium resources used in this embodiment includes a material preparation section 1, a mixing section 2, a chlorination and dust collection section 3, a leaching and sedimentation section 4, and a refining section 5 , milling section 6, waste heat utilization section 7 and residue treatment section 8;

[0078] Material preparation section 1 includes vanadium resource silo 1-1, vanadium resource screw feeder 1-2, disc granulator 1-3, oxidation roasting rotary kiln 1-4, double roller machine 1-5, coarse grain screening machine 1-6 and fine particle screening machine 1-7;

[0079] Mixing section 2 includes screening vanadium resource bin 2-1, screening vanadium resource feeder 2-2, carbon source bin 2-3, carbon source feeder 2-4 and fluidized bed mixer 2 -5;

[0080] Chlorination dust collection section 3 includes chlorination furnace 3-1, chlorination furnace heat exchanger...

Embodiment 2

[0095] Adopt the system described in embodiment 1, present embodiment provides a kind of method for producing high-purity vanadium pentoxide, comprises the following steps:

[0096] The vanadium resources in the vanadium resource silo 1-1 enter the disc granulator 1-3 through the vanadium resource screw feeder 1-2 for granulation treatment; the vanadium resources after granulation treatment are sequentially oxidized and roasted in the rotary kiln 1- 4 Ore phase reforming, crushing by roller machine 1-5, screening by coarse screening machine 1-6 and fine screening machine 1-7, and then entering into screening vanadium resource bin 2-1; the oxidation roasting rotary kiln 1 -4 The operating temperature is 400°C to 1000°C; the vanadium resources in the vanadium resource silo 2-1 and the carbon source in the carbon source silo 2-3 are screened through the vanadium resource feeder 2-2 and the carbon source respectively. The source feeder 2-4 enters the fluidized bed mixer 2-5 at the...

Embodiment 3

[0101] In this example, vanadium slag is used as raw material, and the processing capacity is 200kg / h. High-purity vanadium pentoxide product is prepared through processes such as material preparation, material mixing, chlorination and dust collection, leaching and sedimentation, refining, and milling. Utilization and residue treatment to realize industrial waste energy utilization and residue dechlorination treatment.

[0102] In the oxidative roasting rotary kiln 1-4, the oxidative roasting temperature is 400°C; in the fluidized bed mixer 2-5, the dosage of activated carbon is 25% of the mass of the sieved vanadium slag; The chlorination temperature is 950°C, the operating gas velocity of the chlorination furnace is 4.00m / s, and pure chlorine gas is used as the chlorination medium; in the pulverizing reactor, the water vapor introduced into the catalytic oxidation process is 0.05% of the mass of vanadyl trichloride, Reaction temperature is 120 ℃, and the mass fraction of oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com