Preparation method and application of photoinitiator intermediate

A photoinitiator and intermediate technology, applied in the field of preparation of photoinitiator intermediates, can solve the problems of poor α-chlorination selectivity, complicated recovery operation, and high cost of bromine, so as to improve chlorination selectivity and increase production The effect of reducing the efficiency and reducing the process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

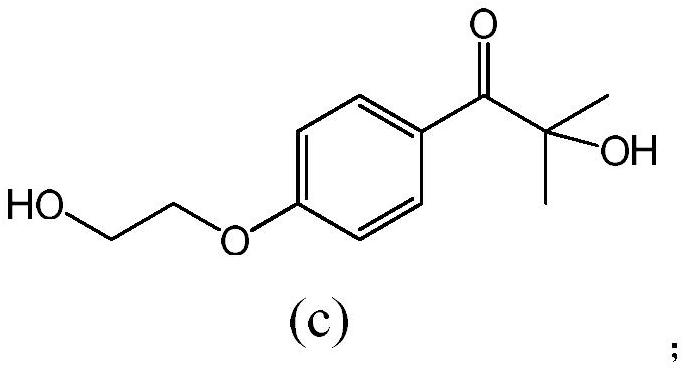

[0079] This embodiment provides a kind of preparation method of photoinitiator 2959, specifically comprises:

[0080] (1) Friedel-Crafts reaction:

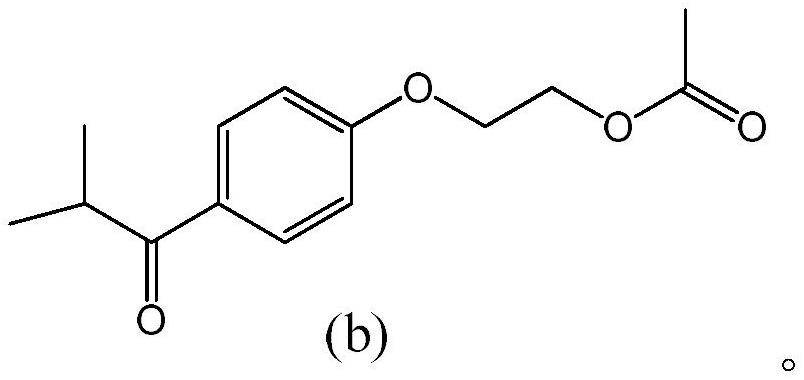

[0081] 36g (0.2mol) 2-phenoxyethyl acetate is dissolved in 70g chlorobenzene, obtains 2-phenoxyethyl acetate solution, connects tail gas absorption device (absorbent is ice water), at-3 ℃, Add 56g (0.42mol) of anhydrous aluminum trichloride to the above solution, stir for 0.5h; then raise the temperature to 3°C, with stirring, add 21.3g (0.2mol) of isobutyryl chloride dropwise, the dropwise addition is completed in 2h, and keep warm for 6h , cooling the reaction solution to -3°C, adding it to the ice water of the tail gas absorption device for hydrolysis, stirring for 0.5h, standing for stratification, separating the organic phase, washing with water, to obtain a solution of the compound of formula b;

[0082] (2) Chlorination reaction:

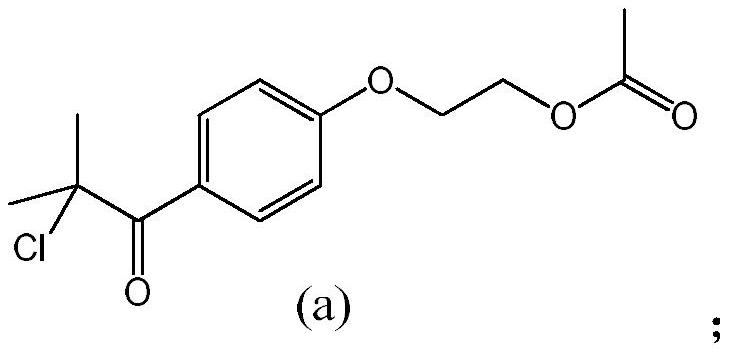

[0083] At 0°C, the solution of the compound of formula b obtained by the Friedel-Crafts rea...

Embodiment 2

[0091] The difference between this embodiment and embodiment 1 is only that the sulfuric acid phase obtained in step (2) is used in step (1), and other parameters and conditions are exactly the same as in embodiment 1.

[0092] The photoinitiator 2959 product obtained in this example is a white solid with a purity of 99.0% and a yield of 89.5%.

Embodiment 3

[0094] The difference between this embodiment and Example 1 is only that the sulfuric acid of 70g 50% is replaced by the sulfuric acid of 54g 65% in the step (2), and other parameters and conditions are exactly the same as in Example 1.

[0095] The photoinitiator 2959 product obtained in this example is a white solid with a purity of 99.0% and a yield of 89.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com