Composite electrolyte membrane and its preparation method and application

A technology of composite electrolyte membrane and mass ratio, which is applied in the direction of electrolyte, solid electrolyte, non-aqueous electrolyte, etc., can solve the problems of poor contact wettability of electrode materials, complex overall molding process, and limitation of practical application, so as to improve electrochemical performance, Effects of improving safety and stability and improving chain segment kinematics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

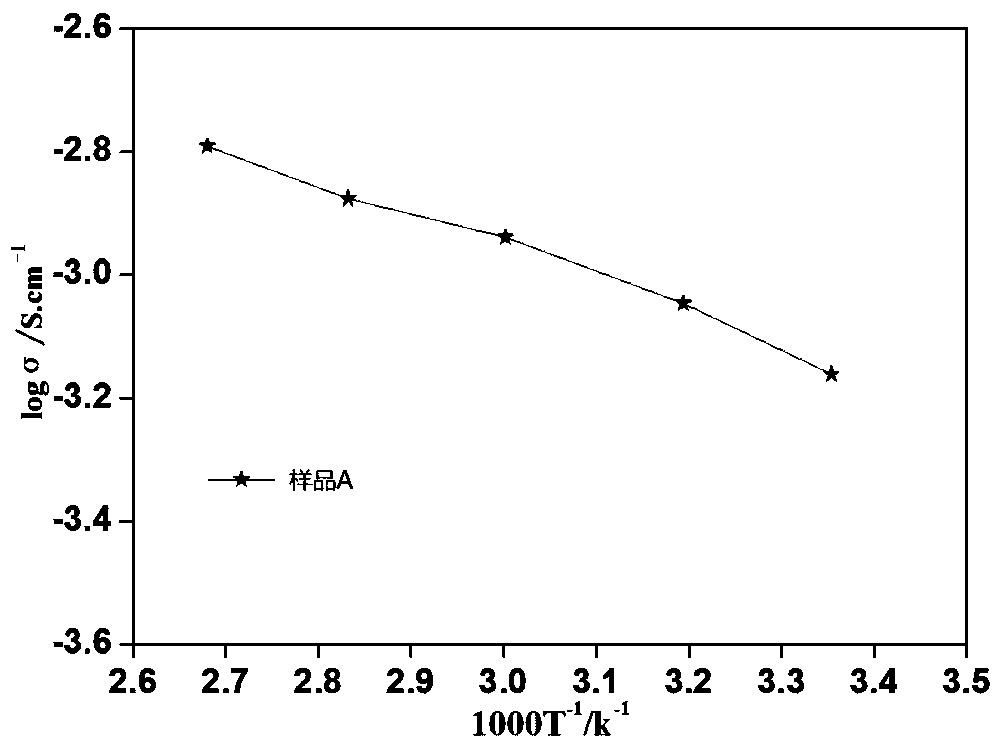

[0049] A kind of composite electrolyte membrane, this composite electrolyte membrane is a gel state composite electrolyte membrane, is made of SiO 2 , polyvinylidene fluoride hexafluoropropylene [P(VDF-HFP)], lithium bis(trifluoromethylsulfonyl)imide (LiTFSI), bis(trifluoromethylsulfonyl) 1-ethyl-3-methyl Made of imidazole (EMITFSI), among which P(VDF-HFP), LiTFSI, EMITFSI, SiO 2 The mass ratio is 1:1:1.4:0.2.

[0050] A method for preparing the composite electrolyte membrane in the above-mentioned embodiment, comprising the following steps:

[0051] (1) Add P(VDF-HFP) into methyl ethyl ketone, and magnetically stir at 50°C for 30 min to obtain a polyvinylidene fluoride hexafluoropropylene solution with a mass fraction of 6.7%.

[0052] (2) Under the protection of argon atmosphere, according to P(VDF-HFP), LiTFSI, EMITFSI, SiO 2 The mass ratio is 1:1:1.4:0.2, respectively weigh the polyvinylidene fluoride hexafluoropropylene solution, LiTFSI, EMITFSI and SiO 2 , then mix t...

Embodiment 2

[0054] A composite electrolyte membrane, the composite electrolyte membrane is a solid composite electrolyte membrane, made of Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 (LAGP), polyvinylidene fluoride hexafluoropropylene [P(VDF-HFP)], lithium bis(trifluoromethylsulfonyl)imide (LiTFSI), bis(trifluoromethylsulfonyl)1-ethyl- 3-Methylimidazole (EMITFSI), wherein the mass ratio of P(VDF-HFP), LiTFSI, EMITFSI, LAGP is 1:1:1.4:1.

[0055] A method for preparing the composite electrolyte membrane in the above-mentioned embodiment, comprising the following steps:

[0056] (1) Preparation of LAGP: Molar percentage, Li 2 CO 3 、GeO 2 、Al 2 o 3 , NH 4 h 2 PO 4 19.75%: 37.04%: 6.17%: 37.04%, weigh Li 2 CO 3 、GeO 2 、Al 2 o 3 and NH 4 h 2 PO 4 , and then put them in an agate ball mill jar and grind them evenly, put them into a platinum crucible and heat them to 700°C, keep them warm for 1h, then raise the temperature to 1500°C at 5°C / min, keep them warm for 2h, and cool them rapidly ...

Embodiment 3

[0060] A composite electrolyte membrane, the composite electrolyte membrane is a solid composite electrolyte membrane, made of Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 (LAGP), polyvinylidene fluoride hexafluoropropylene [P(VDF-HFP)], lithium bis(trifluoromethylsulfonyl)imide (LiTFSI), bis(trifluoromethylsulfonyl)1-ethyl- Made of 3-methylimidazole (EMITFSI), wherein the mass ratio of P(VDF-HFP), LiTFSI, EMITFSI, and LAGP is 1:1:1.4:1.5.

[0061] A method for preparing the composite electrolyte membrane in the above-mentioned embodiment, comprising the following steps:

[0062] (1) Preparation of LAGP: Same as Example 2.

[0063] (2) Add P(VDF-HFP) into methyl ethyl ketone and magnetically stir at 50°C for 30 min to obtain a polyvinylidene fluoride hexafluoropropylene solution with a mass fraction of 6.7%.

[0064] (3) Under the protection of argon atmosphere, according to the mass ratio of P(VDF-HFP), LiTFSI, EMITFSI, LAGP is 1:1:1.4:1.5, respectively weigh the polyvinylidene fluor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com