Modified material on surface of high-temperature component and preparation method of cladding layer of modified material

A technology for surface modification and high-temperature components, which is applied in the field of surface modification materials and cladding layer preparation of high-temperature components. It can solve the problems of complex equipment, large residual stress, and difficulty in controlling component ratios, and achieve molten pool heating and cooling. Fast speed, excellent high temperature oxidation resistance, uniform and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

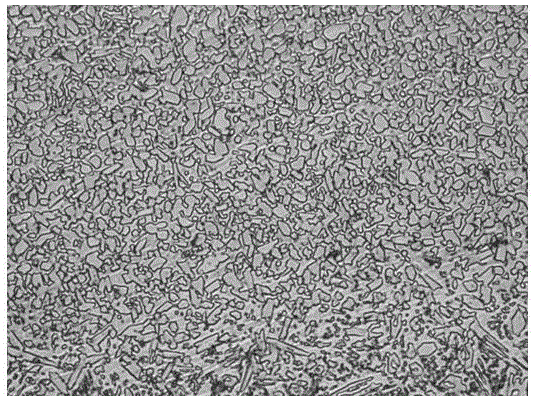

Embodiment 1

[0037] The surface modification material of high-temperature parts in this embodiment is composed of five element powders of Ti, Al, Hf, Ta and W; the components and molar percentages are 35% of Ti powder, 35% of Al powder, 15% of Hf powder, and 8% of Ta powder. %, W powder 7%, the average particle size of Ti powder, Al powder, Hf powder, Ta powder and W powder is 75 μm; and the mass of various element powders is weighed with an analytical electronic scale, and the total mass of the mixed powder is 50 g.

[0038] The preparation method of the cladding layer of the surface modification material of the high temperature component described in this embodiment comprises the following steps:

[0039] (1) Use TC4 (Ti-6Al-4V) as the base material, use mechanical grinding to remove oxides, use acetone to remove oil stains, and use ultrasonic alcohol to clean, dry and set aside;

[0040] (2) After weighing each component in proportion, carry out vacuum ball milling to make them fully mi...

Embodiment 2

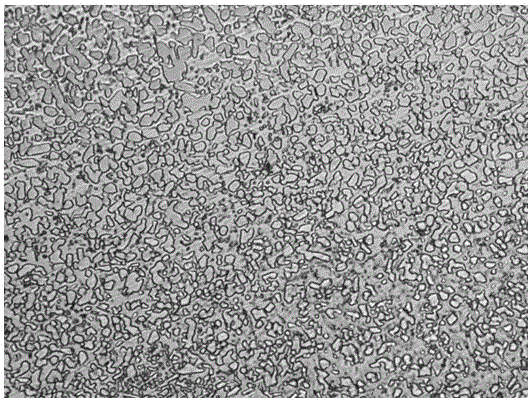

[0045] Example 2: The material for surface modification of high-temperature components in this example is composed of five element powders of Ti, Al, Hf, Ta, and W; the components and their molar percentages are Ti powder 40%, Al powder 35%, and Hf powder 15% , Ta powder 5%, W powder 5%, the average particle diameter of Ti powder, Al powder, Hf powder, Ta powder and W powder is 80 μm; The mass is 50g.

[0046] The preparation method of the cladding layer of the surface modification material of the high-temperature parts in this embodiment includes the following steps:

[0047] (1) Use TC4 (Ti-6Al-4V) as the base material, use mechanical grinding to remove oxides, use acetone to remove oil stains, and use ultrasonic alcohol to clean, dry and set aside;

[0048] (2) After weighing each component in proportion, carry out vacuum ball milling to make them fully mixed evenly, ball milling parameters: ball milling speed is 55r / min, ball to material ratio is 18:1, ball milling time i...

Embodiment 3

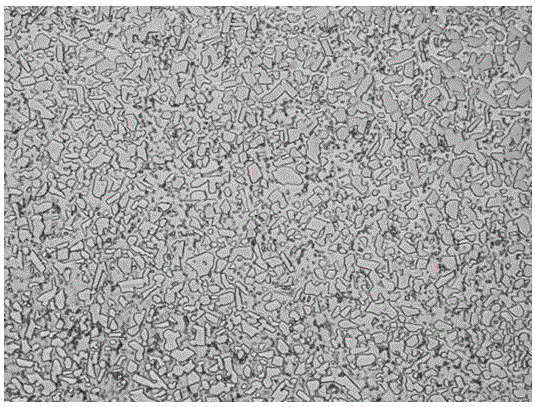

[0053] Example 3: The surface modification material of high-temperature parts in this example is composed of five element powders of Ti, Al, Hf, Ta and W; the components and mole percentages are 40% of Ti powder, 40% of Al powder, and 8% of Hf powder , Ta powder 6%, W powder 6%, the average particle diameter of Ti powder, Al powder, Hf powder, Ta powder and W powder is 85 μ m; The mass is 50g.

[0054] The preparation method of the cladding layer of the surface modification material of the high temperature component described in this embodiment comprises the following steps:

[0055] (1) Use TC4 (Ti-6Al-4V) as the base material, use mechanical grinding to remove oxides, use acetone to remove oil stains, and use ultrasonic alcohol to clean, dry and set aside;

[0056] (2) After weighing each component in proportion, carry out vacuum ball milling to make them fully mixed evenly, ball milling parameters: ball milling speed is 50r / min, ball to material ratio is 17:1, ball milling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average hardness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

| Average hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com