High-entropy alloy material and preparation method thereof

A technology of high-entropy alloys and copper-based alloys, which is applied in the coating process and coating of metal materials, can solve the problems of poor strength and wear resistance, and achieve high friction resistance, high temperature oxidation resistance, and good high temperature The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A high-entropy alloy material and a preparation method thereof, comprising the following steps:

[0027] High entropy alloy powder, the amount of each component is: 15% Cu, 23% Ta, 22% Nb, 20% Hf, 20% Zr.

[0028] (1) Calculate the mass of each component according to the atomic ratio, and then accurately weigh each component, and then use a vacuum arc melting furnace to perform repeated melting for 5 times to obtain a block high-entropy alloy.

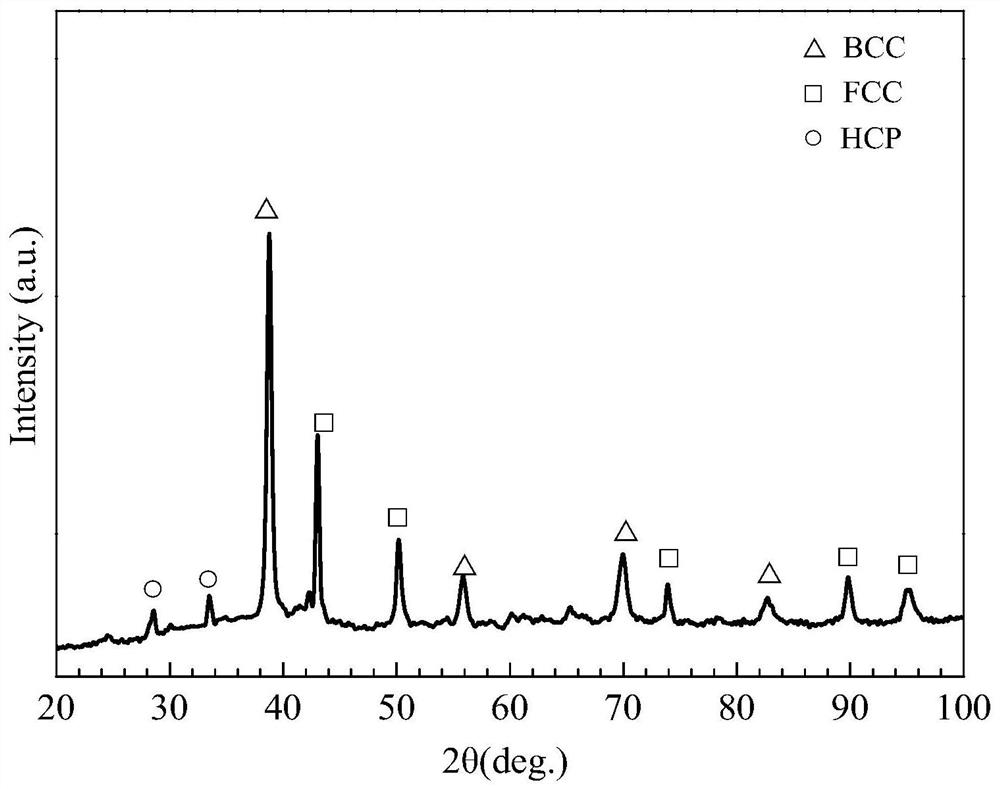

[0029] (2) Grinding the massive high-entropy alloy obtained in step (1) with a vibration mill, and sieving to obtain 200-400 mesh high-entropy alloy powder. The obtained powder is tested by X-ray diffractometer and the obtained spectra are as follows: figure 2 , it can be seen that the powder structure mainly contains BCC, FCC and HCP structures.

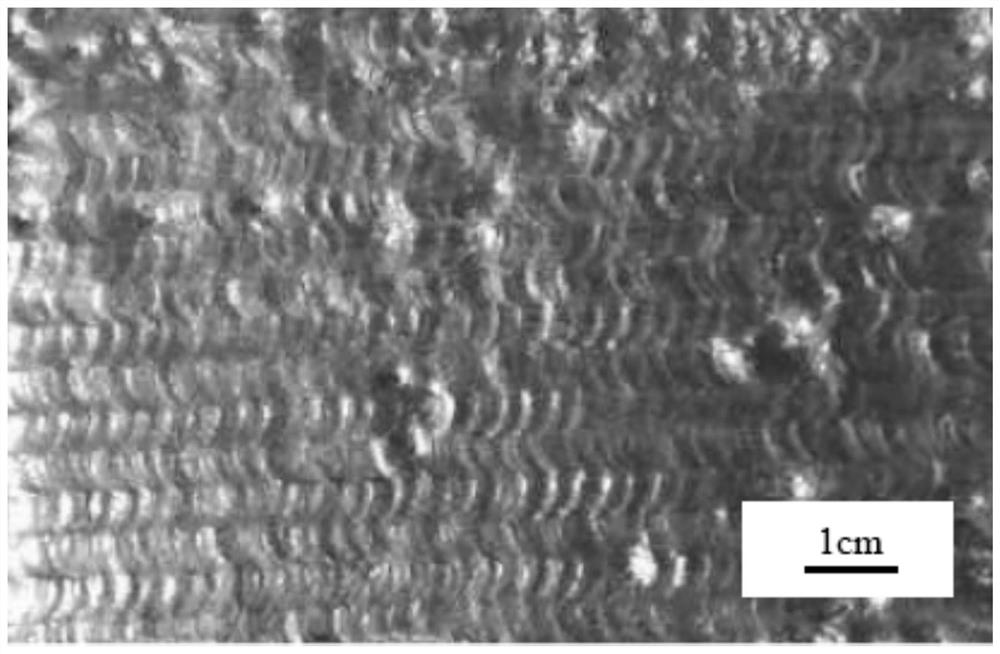

[0030] The bulk high-entropy alloy is obtained by smelting in a vacuum arc melting furnace, and the high-entropy alloy powder is made by vibratory grinding, and then prefabricated ...

Embodiment 2

[0038] A high-entropy alloy material and a preparation method thereof, comprising the following steps:

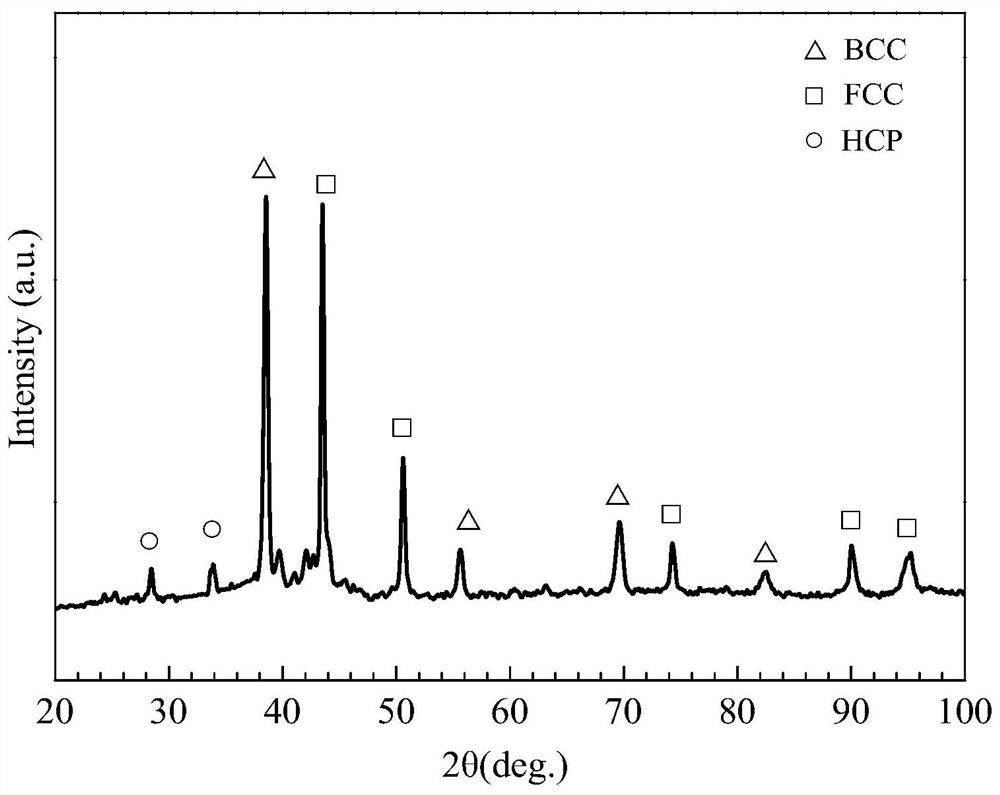

[0039] High-entropy alloy powder, the amount of each component is: 20% Cu, 20% Ta, 20% Nb, 20% Hf, 20% Zr.

[0040] (1) Calculate the mass of each component according to the atomic ratio, and then accurately weigh each component, and then use a vacuum arc melting furnace to perform repeated melting for 5 times to obtain a block high-entropy alloy.

[0041] (2) The massive high-entropy alloy obtained in step (1) is pulverized by a vibrating mill, and sieved to obtain 200-400 mesh high-entropy alloy powder.

[0042] (3) Polish the pure copper substrate to remove the oxide layer, and then clean it with alcohol.

[0043] (4) The alloy powder material obtained in step (2) is made into a paste using absolute ethanol as a binding agent, and evenly prefabricated on the surface of the base material after step (3) to form a prefabricated layer. The thickness of the prefabricated pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com