PC thin film material and preparation method thereof

A thin film material, mass fraction technology, applied in the field of PC thin film material and its preparation, can solve the problems of poor solvent resistance, poor stress crack resistance, low flame retardant grade, etc., and achieve good film forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

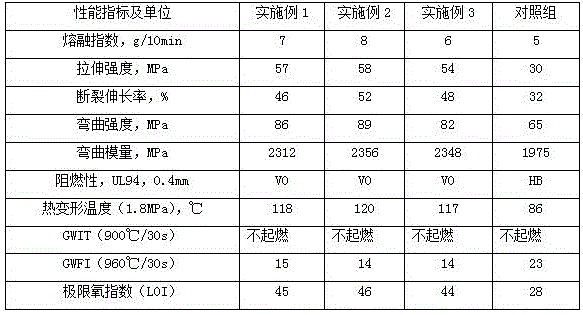

Examples

Embodiment 1

[0019] The PC film material in this embodiment is composed of the following components in parts by mass: 100 parts of PC, 12 parts of cobalt aluminate, 14 parts of magnesium hydroxide, 10 parts of stannous octoate, 8 parts of silane coupling agent, methyl acrylate 14 parts of ester, 10 parts of talcum powder, 8 parts of antimony trioxide, 14 parts of polybutylene terephthalate, 10 parts of benzoyl peroxide, 8 parts of potassium persulfate, 14 parts of hydroxypropyl methylcellulose 10 parts, 10 parts of p-tertoctylphenol, 10 parts of white carbon black, 8 parts of barium stearate, 14 parts of benzyl silicone oil, 10 parts of graphite powder, 8 parts of molybdenum disulfide, 14 parts of Fischer-Tropsch wax, alkyl 10 parts of sodium benzenesulfonate.

[0020] The above-mentioned PC has a refractive index of 1.58-1.64, a transmittance of 85-90%, a weight-average molecular weight of ≥30,000, and a melt index of 1-5g / 10min (according to ASTM standards, test conditions: 300°C / 1.2Kg)....

Embodiment 2

[0028] The PC film material in this embodiment is composed of the following components in parts by mass: 110 parts of PC, 14 parts of cobalt aluminate, 16 parts of magnesium hydroxide, 12 parts of stannous octoate, 10 parts of silane coupling agent, methyl acrylate 16 parts of ester, 12 parts of talcum powder, 10 parts of antimony trioxide, 16 parts of polybutylene terephthalate, 12 parts of benzoyl peroxide, 10 parts of potassium persulfate, 16 parts of hydroxypropyl methylcellulose 12 parts, 12 parts of p-tertoctylphenol, 12 parts of white carbon black, 10 parts of barium stearate, 16 parts of benzyl silicone oil, 12 parts of graphite powder, 10 parts of molybdenum disulfide, 16 parts of Fischer-Tropsch wax, alkyl 12 parts of sodium benzenesulfonate.

[0029] The above-mentioned PC has a refractive index of 1.58-1.64, a transmittance of 85-90%, a weight-average molecular weight of ≥30,000, and a melt index of 1-5g / 10min (according to ASTM standards, test conditions: 300°C / 1....

Embodiment 3

[0037]The PC film material in this embodiment is composed of the following components in parts by mass: 120 parts of PC, 16 parts of cobalt aluminate, 18 parts of magnesium hydroxide, 14 parts of stannous octoate, 12 parts of silane coupling agent, methyl acrylate 18 parts of ester, 14 parts of talcum powder, 12 parts of antimony trioxide, 18 parts of polybutylene terephthalate, 14 parts of benzoyl peroxide, 12 parts of potassium persulfate, 18 parts of hydroxypropyl methylcellulose 14 parts, 14 parts of p-tertoctylphenol, 14 parts of white carbon black, 12 parts of barium stearate, 18 parts of benzyl silicone oil, 14 parts of graphite powder, 12 parts of molybdenum disulfide, 18 parts of Fischer-Tropsch wax, alkyl 14 parts of sodium benzenesulfonate.

[0038] The above-mentioned PC has a refractive index of 1.58-1.64, a transmittance of 85-90%, a weight-average molecular weight of ≥30,000, and a melt index of 1-5g / 10min (according to ASTM standards, test conditions: 300°C / 1.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com