Quick-drying adhesive for BOPP adhesive tape and preparation method thereof

A technology of quick-drying adhesives and tapes, applied in the field of quick-drying adhesives, which can solve the problems of slow drying and poor film-forming property of BOPP tapes, and achieve the effects of increased drying speed, improved drying time, and increased quick-drying properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

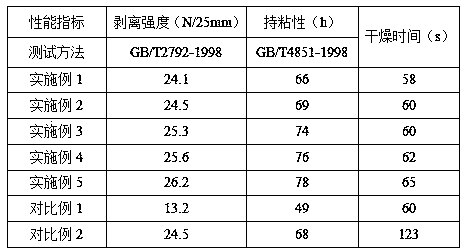

Examples

Embodiment 1

[0017] A quick-drying adhesive for BOPP adhesive tape, prepared from the following components by weight: 70 parts of butyl acrylate, 15 parts of hydroxyethyl acrylate, 10 parts of vinyl acetate, 70 parts of deionized water, 0.5 parts of sodium lauryl sulfate 1.5 parts of alkylphenol polyoxyethylene ether, 0.02 parts of hexadecane, 0.4 parts of ammonium persulfate, 0.1 parts of ammonia water, 0.05 parts of tert-butyl hydroperoxide, 0.05 parts of sodium formaldehyde sulfoxylate, p-tert-butylphenol aldehyde 10 parts of resin, 2 parts of allyl modified alkylphenolic resin, 6 parts of barium sulfate, 3 parts of tung oil.

[0018] The preparation method of the above-mentioned quick-drying adhesive for BOPP adhesive tape is as follows: (1) After dissolving sodium lauryl sulfate and hexadecane with 1 / 2 weight part of deionized water, then butyl acrylate, hydroxyethyl acrylate, Add vinyl acetate and mix and stir for 20 minutes to obtain a uniformly mixed pre-emulsion; (2) Dissolve the ...

Embodiment 2

[0020] A quick-drying adhesive for BOPP adhesive tape, prepared from the following components by weight: 110 parts of butyl acrylate, 5 parts of hydroxyethyl acrylate, 15 parts of vinyl acetate, 90 parts of deionized water, 1.5 parts of sodium lauryl sulfate Parts, 0.7 parts of alkylphenol polyoxyethylene ether, 0.06 parts of hexadecane, 1 part of ammonium persulfate, 0.5 parts of ammonia water, 0.3 parts of tert-butyl hydroperoxide, 0.3 parts of sodium formaldehyde sulfoxylate, p-tert-butylphenol aldehyde 5 parts of resin, 8 parts of allyl modified alkylphenolic resin, 2 parts of barium sulfate, 8 parts of tung oil.

[0021] The preparation method of the above-mentioned quick-drying adhesive for BOPP adhesive tape is as follows: (1) After dissolving sodium lauryl sulfate and hexadecane with 1 / 2 weight part of deionized water, then butyl acrylate, hydroxyethyl acrylate, Add vinyl acetate and mix and stir for 40 minutes to obtain a uniformly mixed pre-emulsion; (2) Dissolve the...

Embodiment 3

[0023] A quick-drying adhesive for BOPP adhesive tape, prepared from the following components by weight: 80 parts of butyl acrylate, 12 parts of hydroxyethyl acrylate, 11 parts of vinyl acetate, 75 parts of deionized water, 1.2 parts of sodium lauryl sulfate 1 part, 1 part of alkylphenol polyoxyethylene ether, 0.03 part of hexadecane, 0.5 part of ammonium persulfate, 0.2 part of ammonia water, 0.1 part of tert-butyl hydroperoxide, 0.1 part of sodium formaldehyde sulfoxylate, p-tert-butylphenol aldehyde 6 parts of resin, 3 parts of allyl modified alkylphenolic resin, 5 parts of barium sulfate, 4 parts of tung oil.

[0024] The preparation method of the above-mentioned quick-drying adhesive for BOPP adhesive tape is as follows: (1) After dissolving sodium lauryl sulfate and hexadecane with 1 / 2 weight part of deionized water, then butyl acrylate, hydroxyethyl acrylate, Add vinyl acetate and mix and stir for 25 minutes to obtain a uniformly mixed pre-emulsion; (2) Dissolve the alk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com