Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Solve water quality problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing double-acid ferro-aluminum flocculating agent

InactiveCN101691252ALow priceEase of industrial productionWater/sewage treatment by flocculation/precipitationLiquid productSocial benefits

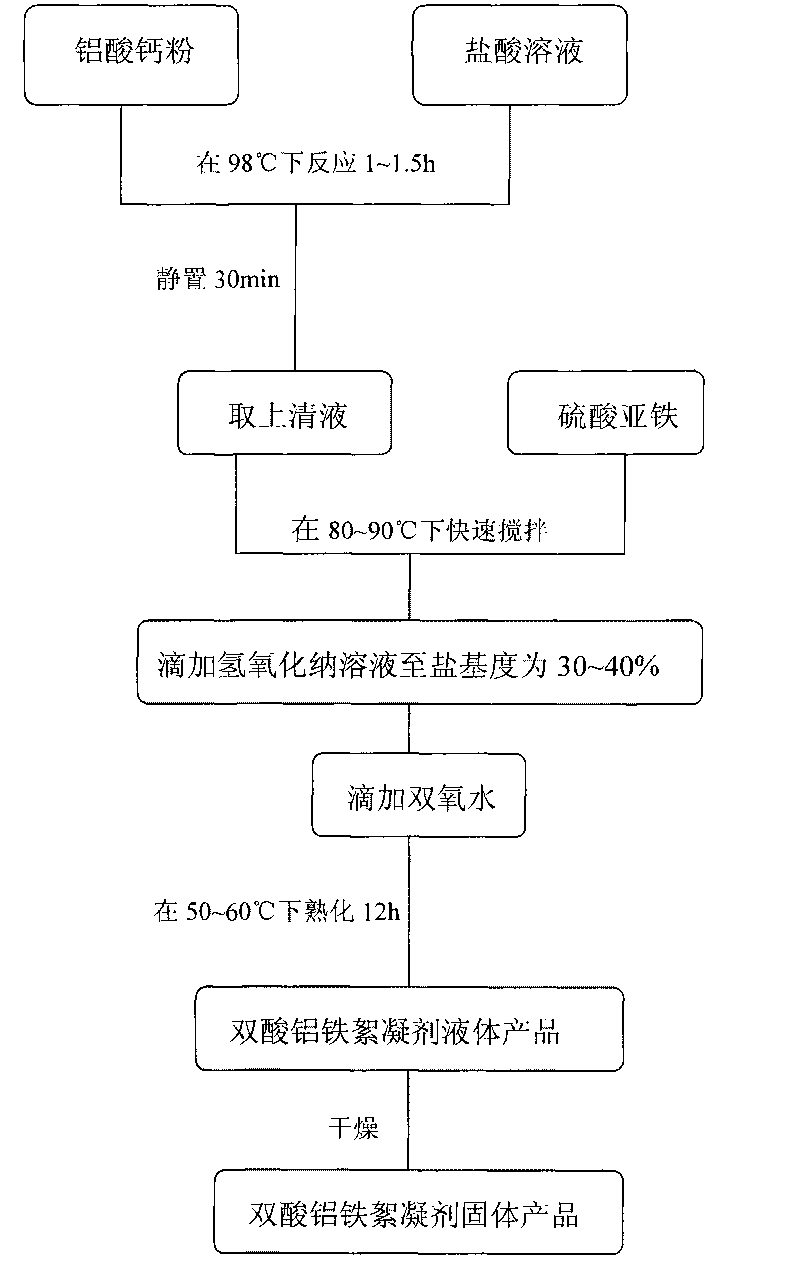

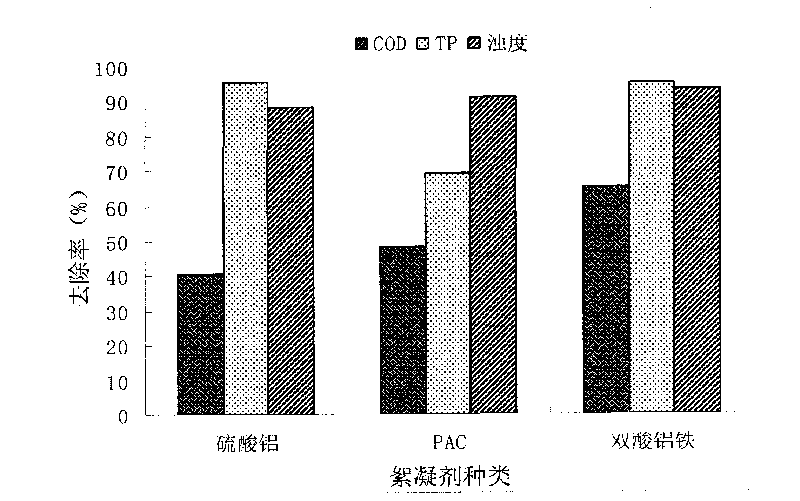

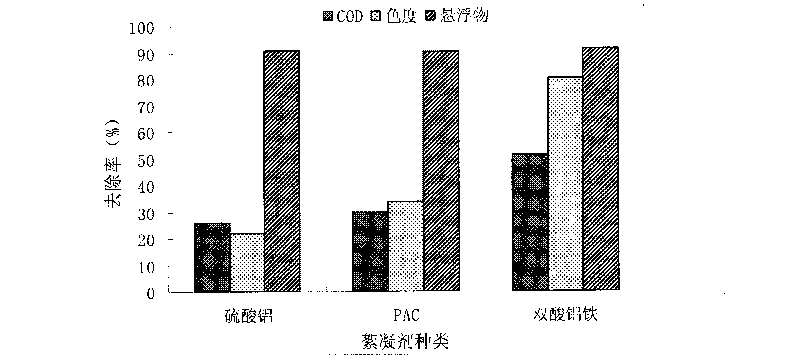

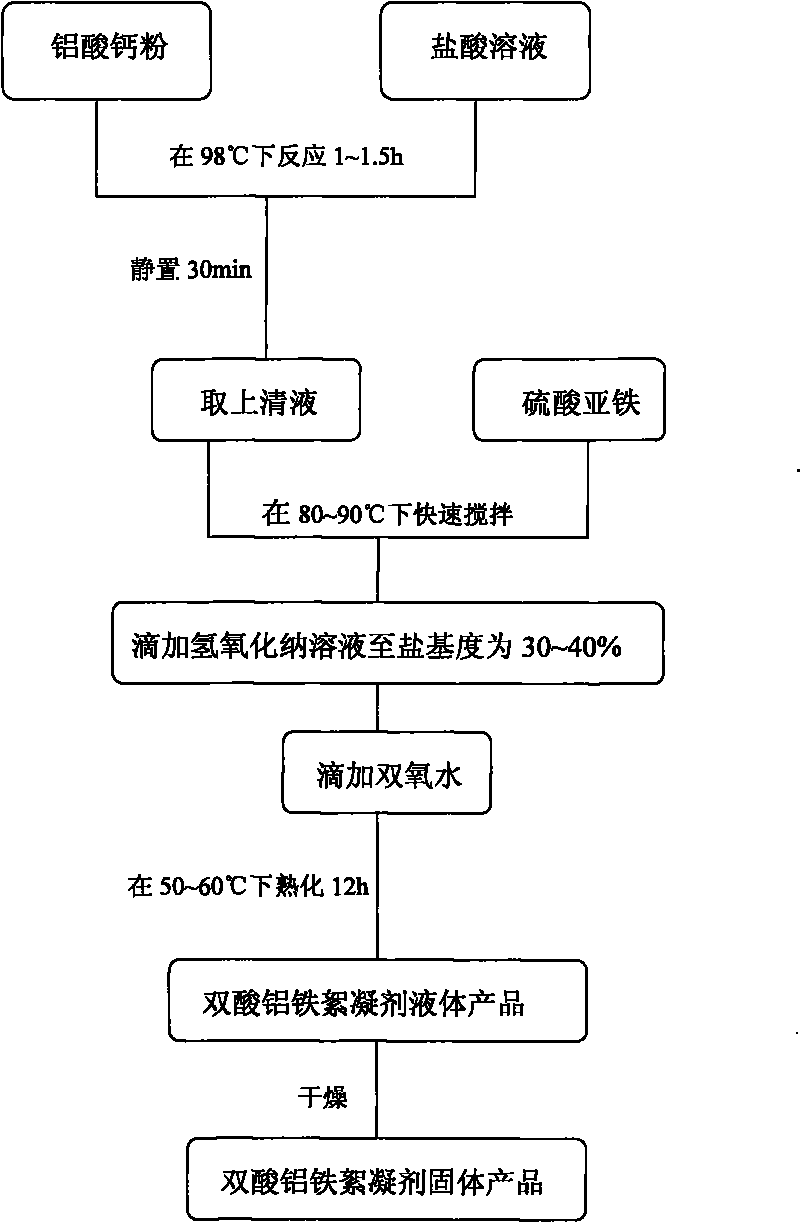

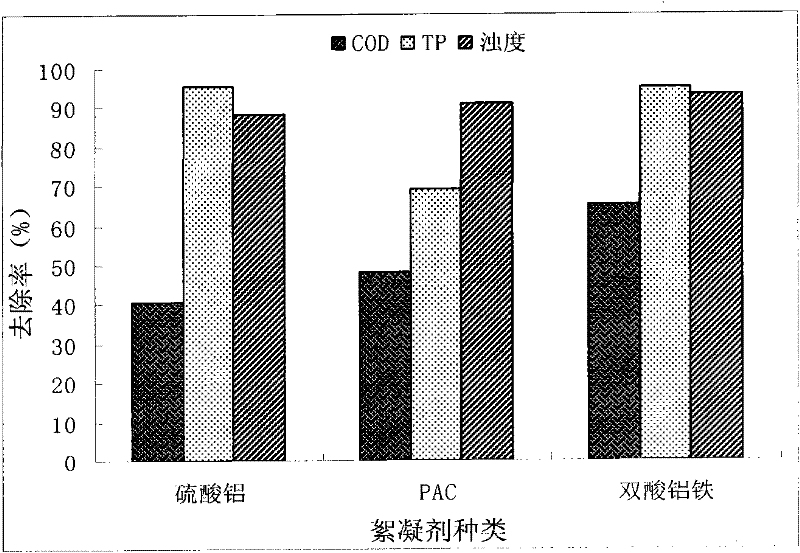

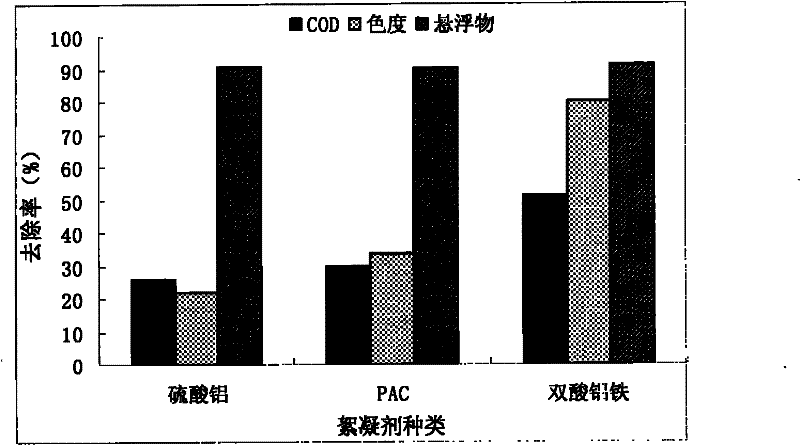

The invention discloses a method for preparing a double-acid ferro-aluminum flocculating agent, which relates to a process for preparing the double-acid ferro-aluminum flocculating agent by using calcium aluminate powder. The method comprises the following steps of: taking the calcium aluminate powder of which the particle size is smaller than 60 meshes, putting the calcium aluminate powder into a hydrochloric acid solution in a part mass ratio of the hydrochloric acid solution to the calcium aluminate powder of 3-5:1, reacting the two materials at a temperature of 98 DEG C for 1 to 1.5 hours, standing the mixture for 30 minutes, and then taking a supernatant to obtain AlCl3 liquid; adding ferrous sulfate to the mixture in a part mass ratio of the calcium aluminate powder to the ferrous sulfate of 9-11:1 at a temperature of between 80 and 90 DEG C, dropwise adding a sodium hydroxide solution of which the concentration is 0.5 mol / L into the mixture after 15 minutes, dropping oxyful into the mixture in a part mass ratio of the ferrous sulfate to the oxyful of 1:1-1.5 when the basicity is 30 to 40 percent, stirring the mixture continuously for 15 to 20 minutes, and then curing the mixture at a temperature of between 50 and 60 DEG C for 12 hours to obtain a liquid product of the double-acid ferro-aluminum flocculating agent; and drying the liquid product of the double-acid ferro-aluminum flocculating agent to obtain a double-acid ferro-aluminum solid product. Tests show that in the solid product, Al2O3 is over 30 percent, the total iron is over 1 percent, the insoluble substances is less than 1 percent, and other indexes accord with the national standards. The method has a simple process and a low cost, and the prepared product has a good coagulation effect and high economic and social benefits.

Owner:TONGJI UNIV

Automatic filling machine

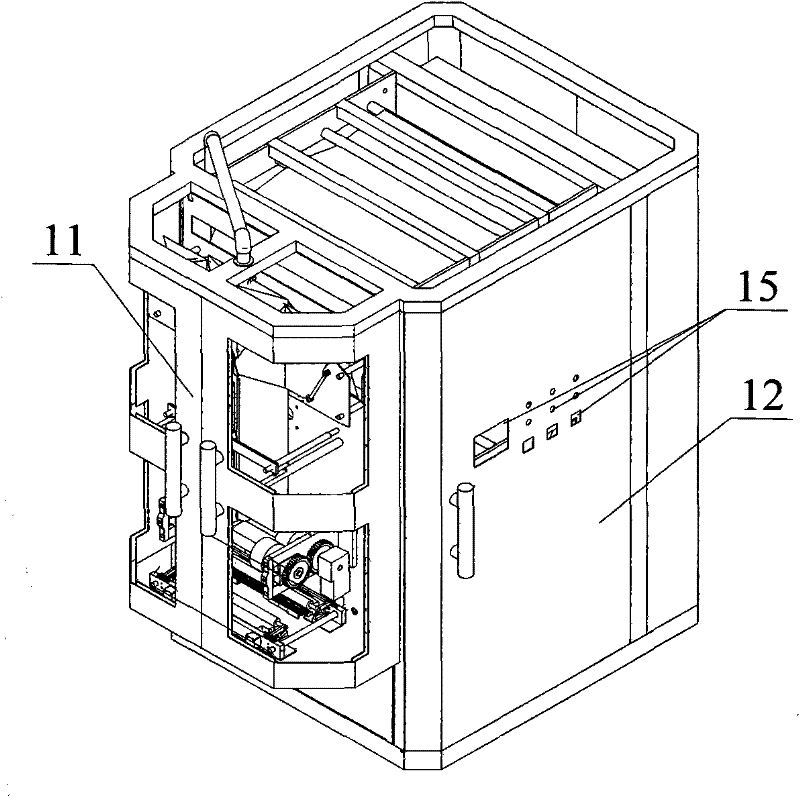

ActiveCN102442628ANo manual operationRealize automatic controlBottle-handling machinesEngineeringElectric control

The invention discloses an automatic filling machine, which comprises a machine frame and an electric control device. A film rolling device for storing and releasing a film, a film connecting device for connecting the film, a disinfecting and cleaning device for disinfecting and cleaning the pulled film, a filling device for filling liquid in a film bag, a forming device for turning and rolling the film into a cylindrical structure, a vertical sealing device for vertically piecing and sealing the cylindrical film, a film pulling device for pulling the film to move and a transverse closing andcutting device for transversely closing and cutting the cylindrical film are arranged on the machine frame in turn. The automatic filling machine provided by the invention is high in production efficiency, lower in cost and high in automation degree.

Owner:SHENZHEN ANGEL DRINKING WATER IND GRP

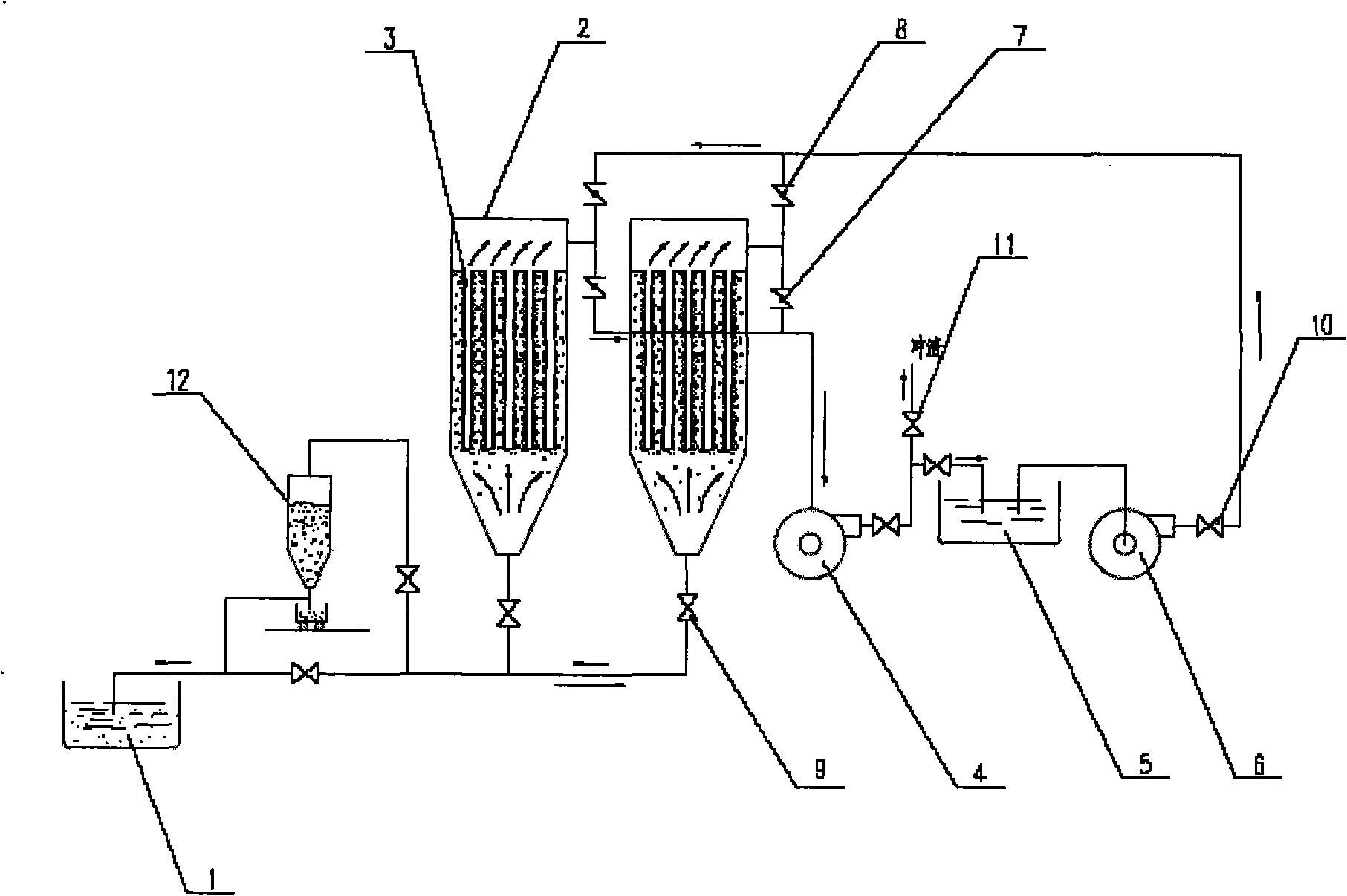

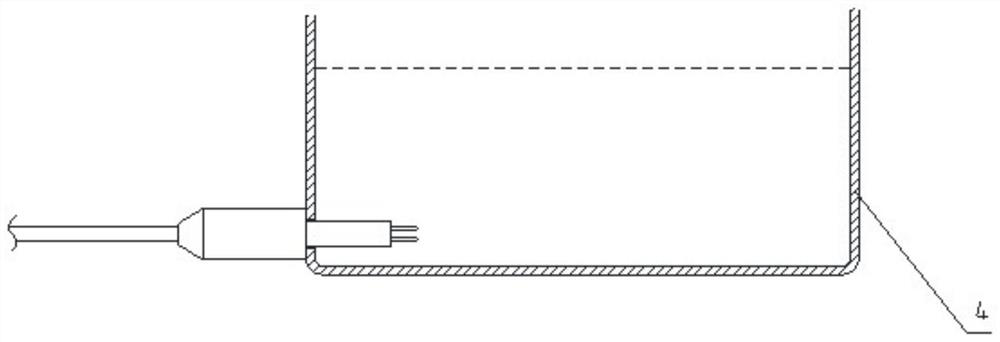

Blast furnace slag flushing water purification system and method thereof

ActiveCN101564616ASolve water quality problemsPerfect slag flushing processGravity filtersFiltration circuitsSlagWater flow

The invention discloses a blast furnace slag flushing water purification system and a method thereof, pertaining to the technical field of blast furnace ironmaking in the iron and steel industry. The system comprises a slag water tank, a filter, a filter pump, a clear water reservoir, a back flush water pump, a filter butterfly valve, a back flush butterfly valve and a matched valve and a slag bin for back flushing. One or a plurality of filters are arranged for purifying slag flushing water containing suspended fine slag and are internally provided with filter elements which are arranged in order; though the equipment is small, the filter area is much larger than that in a bottom filter method; the back flush water pump is used for reversely injecting the clear water in a clear water flow flushing filter element for removing the slag on the surface and recovering the filtering quality. The filter pump can be integrated with the slag flushing pump in the existing slag treatment system, thus being capable of filtering and flushing slag simultaneously with one pump. The blast furnace slag flushing water purification system and the method thereof have the advantages of good purification effect and high filter velocity, therefore, the filter area is small, the volume of the equipment is small, the operation is easy and the maintenance is convenient.

Owner:BEIJING SHOUGANG INT ENG TECH

Water supply method of shared water dispensers

InactiveCN110070674AEasy to useAdjust selling price in real timeApparatus for dispensing fluids/granular materialsApparatus for hiring articlesComputer scienceCloud server

The invention belongs to the field of water dispensers, and relates to a water supply method of shared water dispensers. The method adopts a cloud server, the water dispensers connected with the cloudsever, and user terminals, wherein quick response (QR) code labels in one-to-one correspondence with the water dispensers are adhered to the surfaces of the corresponding water dispensers; and the user terminals scan the QR code labels to establish connection with the cloud server. The method provided by the invention has the advantage that a water intaking process is convenient and quick.

Owner:广东七芯净化科技有限公司

Mining intelligent frequency-converting unattended emulsion pump station system

InactiveCN103899509ARealize unattendedCutting costsPump controlPump installationsEmulsionEngineering

The invention discloses a mining intelligent frequency-converting unattended emulsion pump station system creatively. The mining intelligent frequency-converting unattended emulsion pump station system is characterized by comprising a fed-water processing portion, an emulsion pump station portion, a frequency-converting control cabinet portion, a PLC detection and control portion and a high-pressure filtering and automatic backwash device. The work processes of the fed-water processing portion, the emulsion pump station portion, the frequency-converting control box portion, the PLC detection and control portion and the high-pressure filtering and automatic backwash device are all controlled by a PLC.

Owner:山东新煤格林尼泵业科技有限公司

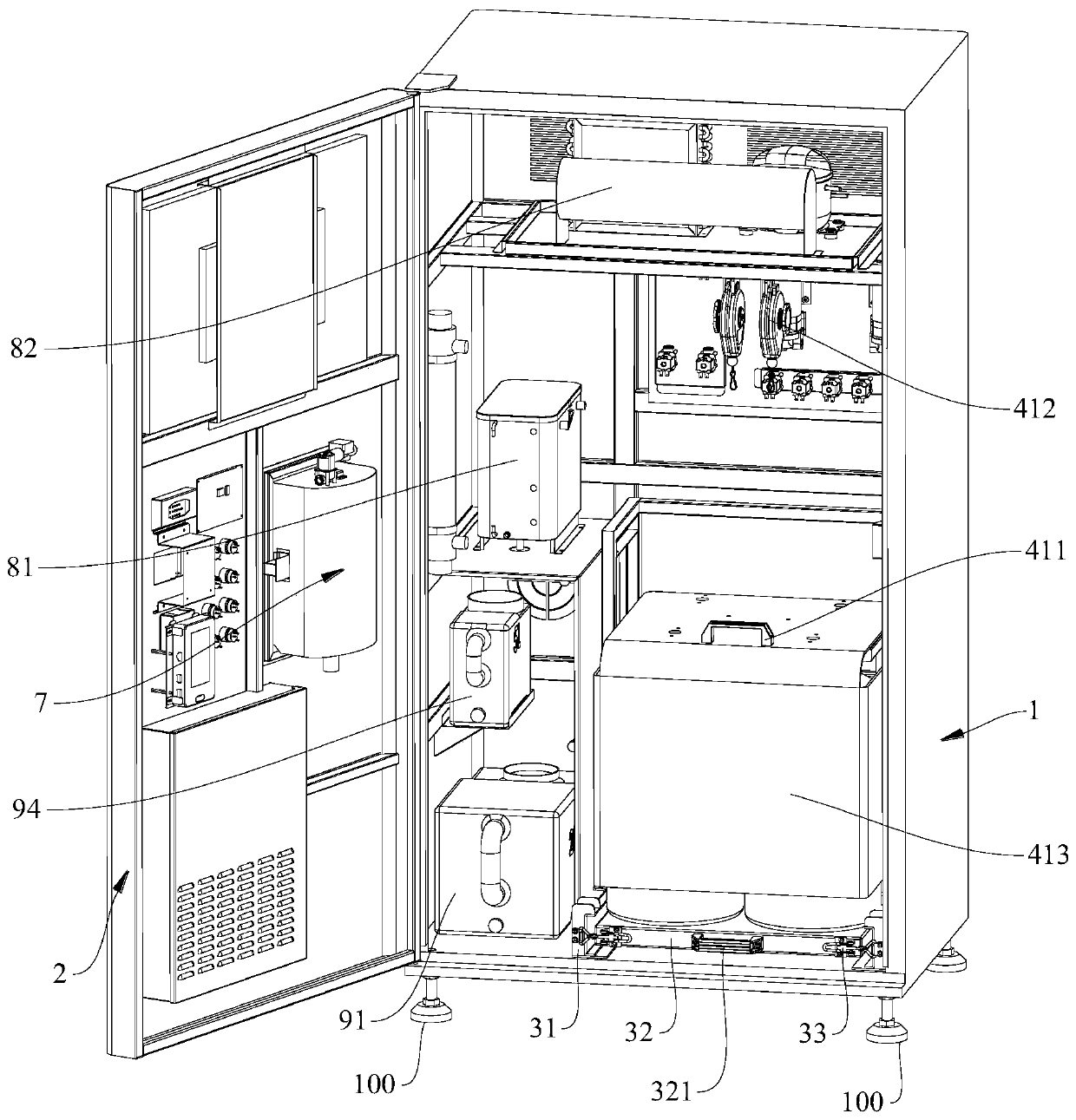

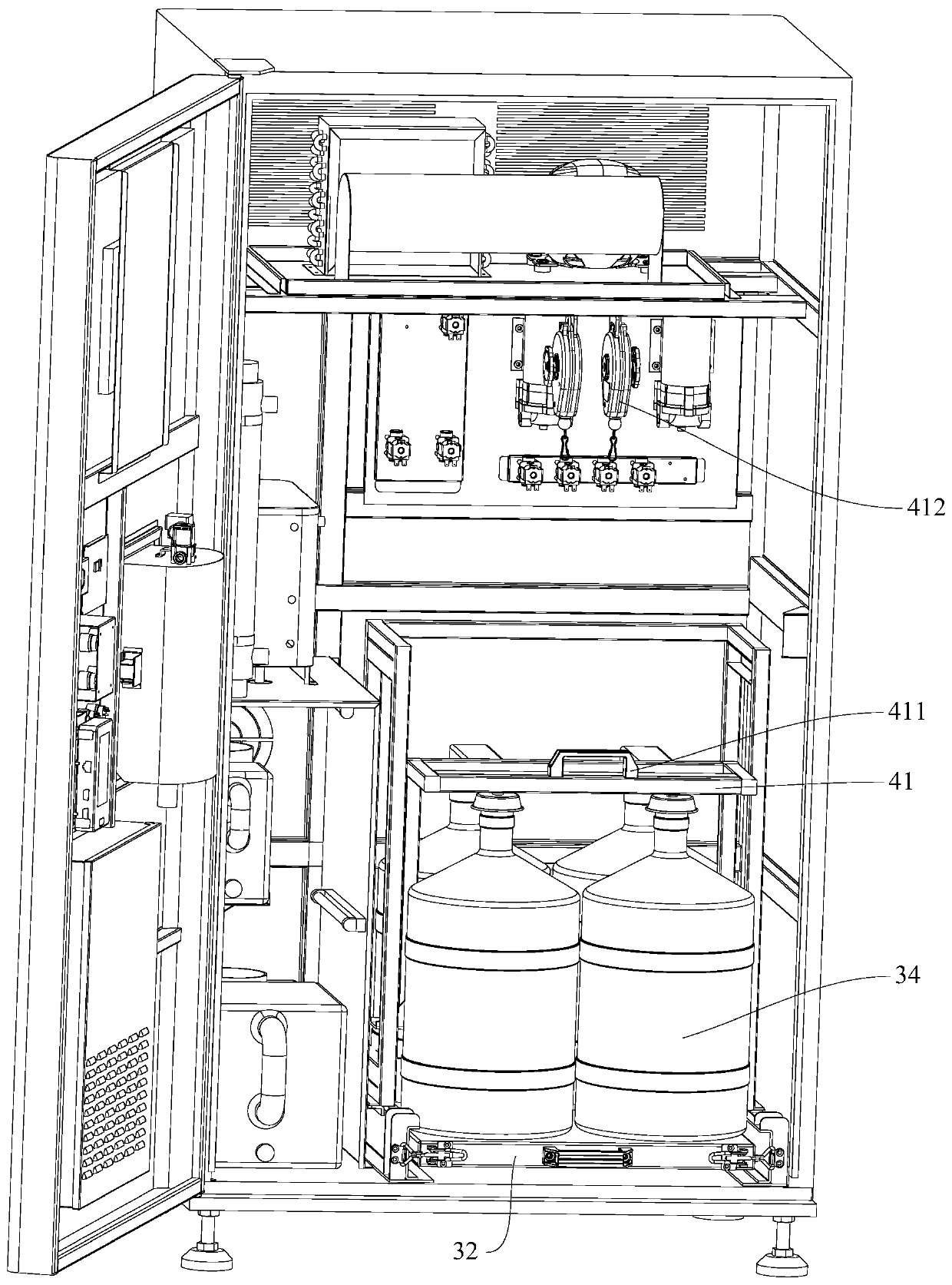

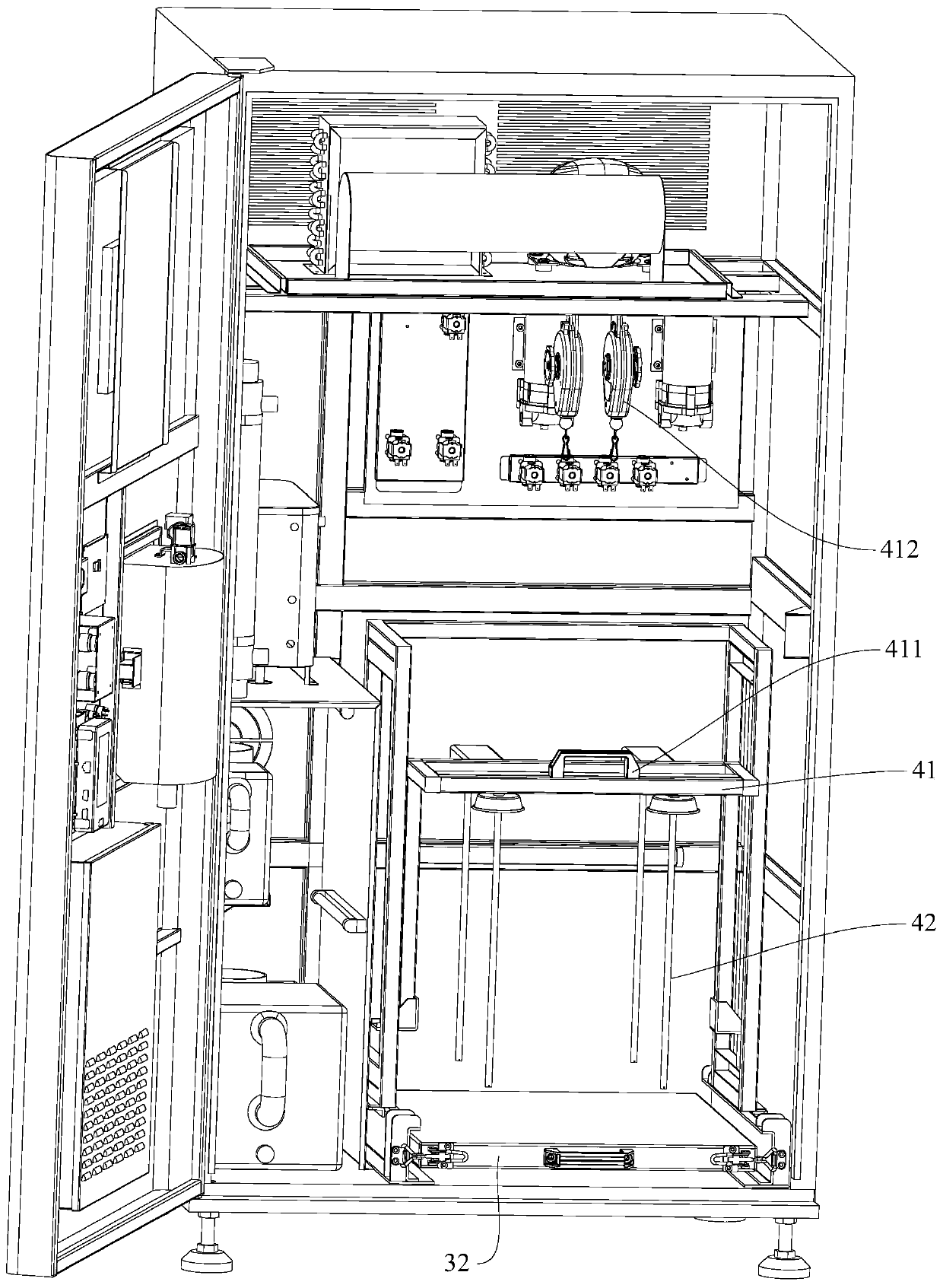

Barreled water vending machine

InactiveCN110097701AEasy to replaceReduce usageLighting and heating apparatusRefrigeration devicesWater storage tankEngineering

The invention discloses a barreled water vending machine comprising a cabinet body and a cabinet door. A support assembly, a pumping assembly, a water storage tank, a first water pump, a drinking water pipeline, a drinking water filling zone and a control device. The support assembly includes a slide rail, a support plate and a lock catch support plate, wherein the support plate and the lock catchsupport plate can slide along the slide rail. A lock catch is used for fixing the support plate and the slide rail. A barreled water barrel with drinking water loaded is arranged on the support plate. The pumping assembly includes a guide column, a handle frame and a straw; the straw is connected to the handle frame and can make synchronous movement with the handle frame. The first water pump isconfigured to pump drinking water in the barreled water barrel to the water storage tank by the straw. The drinking water pipeline includes a water feeding pipe; a discharging pipe is arranged in thedrinking water filling zone; a first end of the water feeding pipe is communicated with the water storage tank; a second end of the water feeding pipe is communicated with a first end of the discharging pipe; and a second end of the discharging pipe is used for discharging water. The invention aims at providing a barreled water vending machine that is capable of selling water in a barrel without using a filter element.

Owner:TECH LEADER ENG

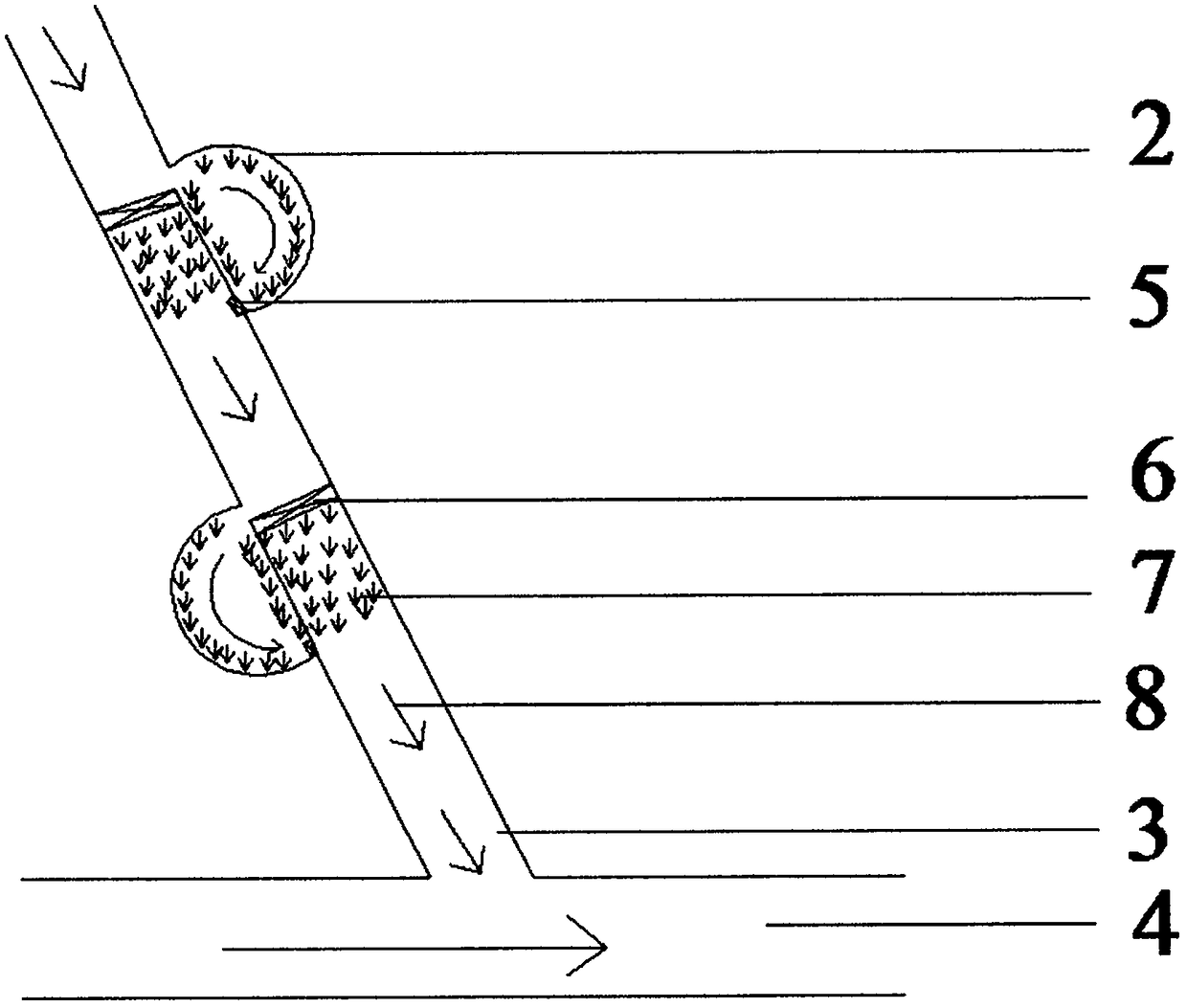

Method for treating rural rivers through multi-stage ecological pond

InactiveCN108623007ASolve water quality problemsReduce construction costsWater treatment parameter controlWater contaminantsEngineeringTherapeutic effect

The invention discloses a method for treating rural rivers through multi-stage ecological pond. According to the method, the multi-stage ecological pond comprise multi-stage ecological pond systems, each ecological pond system is arranged on the two sides of one rural river, and is arranged at intervals in the flow direction of the corresponding rural river and comprises ecological ponds, overflowdams and water gates, each ecological pond is a semi-circular flow channel, the two ends of each ecological pond are communicated with the corresponding rural river, aquatic plants are planted all around in each ecological pond, an aerating device is arranged in each ecological pond, meanwhile, fishes are bred in each ecological pond, and each overflow dam is located in the corresponding rural river and is used for forcing river water to flow into the corresponding ecological pond. The method for treating the rural rivers through the multi-stage ecological pond systems fully relies on an ecological treatment technology and has the advantages of being low in construction and maintenance cost, good in treatment effect, free of secondary pollution, simple in later-period operation management, capable of beautifying the landscape and the like; and in addition, the problem of rural river pollution can be solved, and the water quality problem caused by the fact that the rural rivers flow toa downstream main stream can be effectively solved.

Owner:山东君成环境检测有限公司

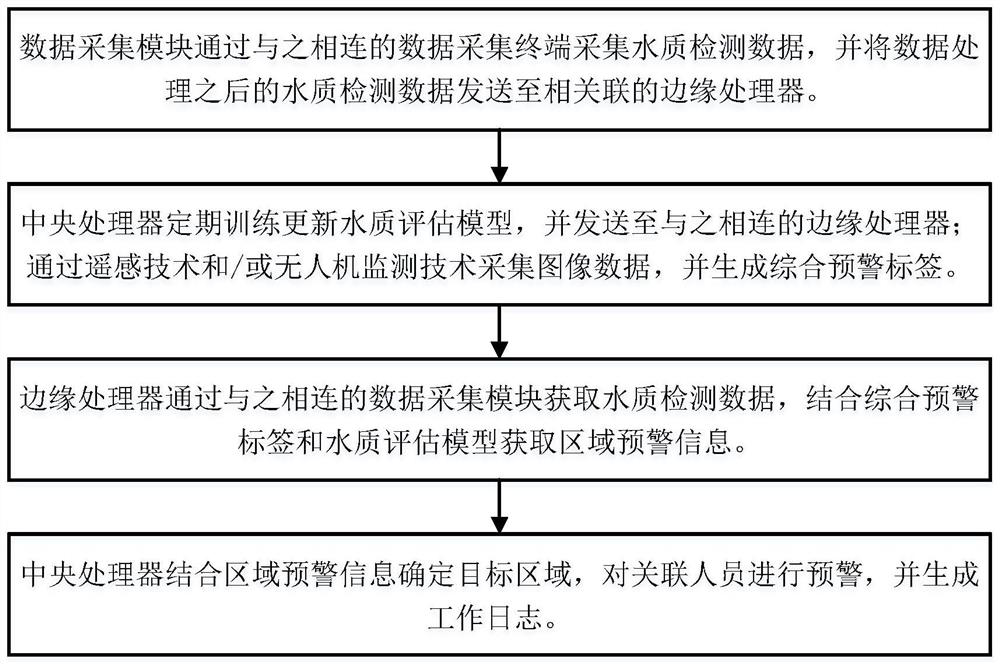

Intelligent river leader patrolling system

ActiveCN114417981AGuaranteed accuracyLow costGeneral water supply conservationCharacter and pattern recognitionEnvironmental resource managementData acquisition

The invention discloses an intelligent river chief patrol system, relates to the technical field of water environment monitoring, and solves the technical problems that the river chief patrol system in the prior art is realized through an unmanned aerial vehicle, so that the accuracy of a water quality detection result cannot be ensured, and early warning is not in place. Comprising a central processor, an edge processor, a data acquisition module and a data acquisition terminal, according to the invention, a remote sensing technology, an unmanned aerial vehicle monitoring technology and an artificial intelligence model are combined, and water quality detection is carried out on a river in a patrol detection area or the water quality detection is directly carried out on the river in the patrol detection area on the basis of large-scale data; the cost can be reduced, and the accuracy of a water quality detection result is ensured; the water quality detection result is obtained through the artificial intelligence model, the target area is obtained according to the water quality detection result, and then the associated personnel in the target area are determined according to the associated personnel determination rule; the responsibility limit can be determined, and the water quality problem can be solved in time.

Owner:安徽新宇环保科技股份有限公司

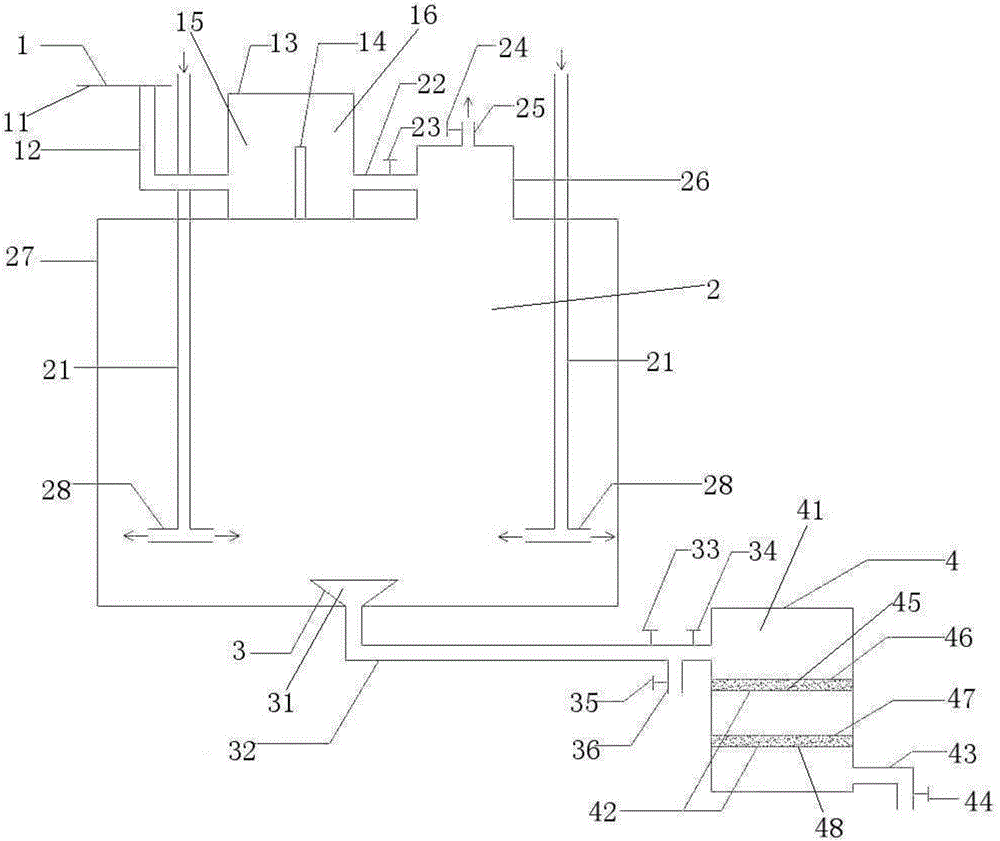

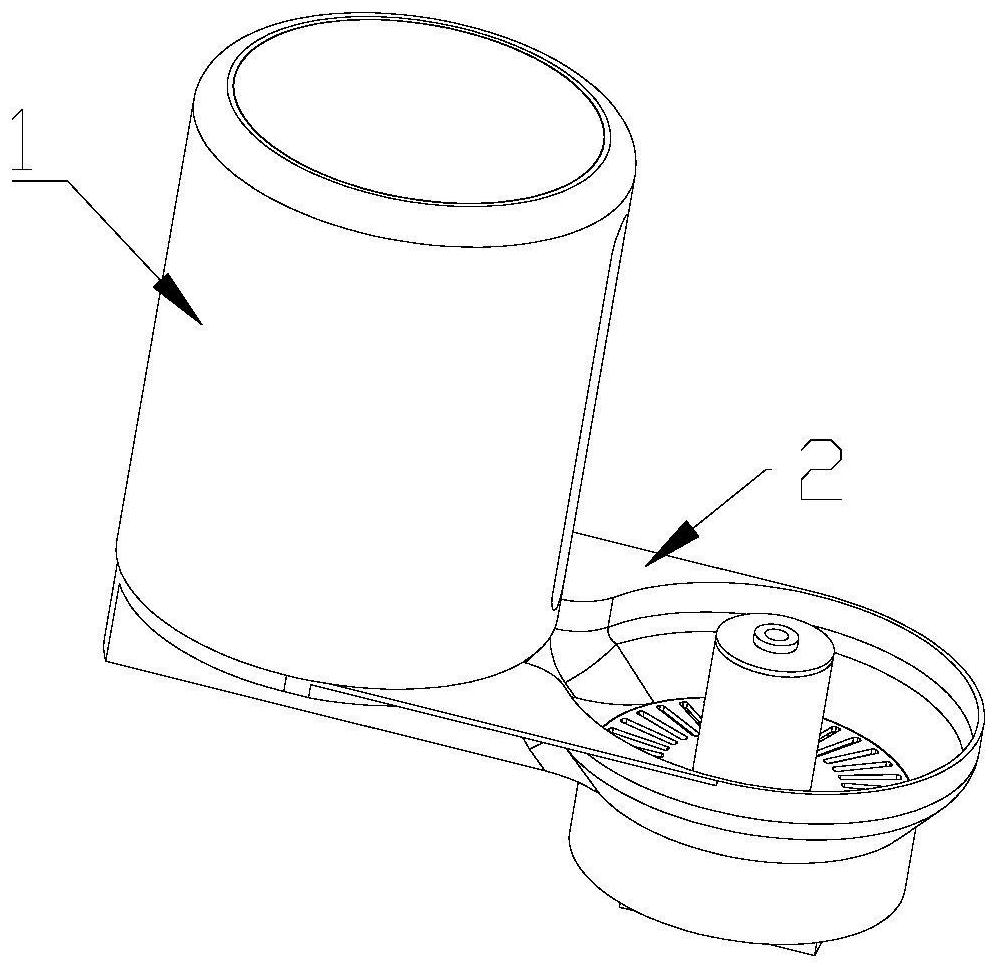

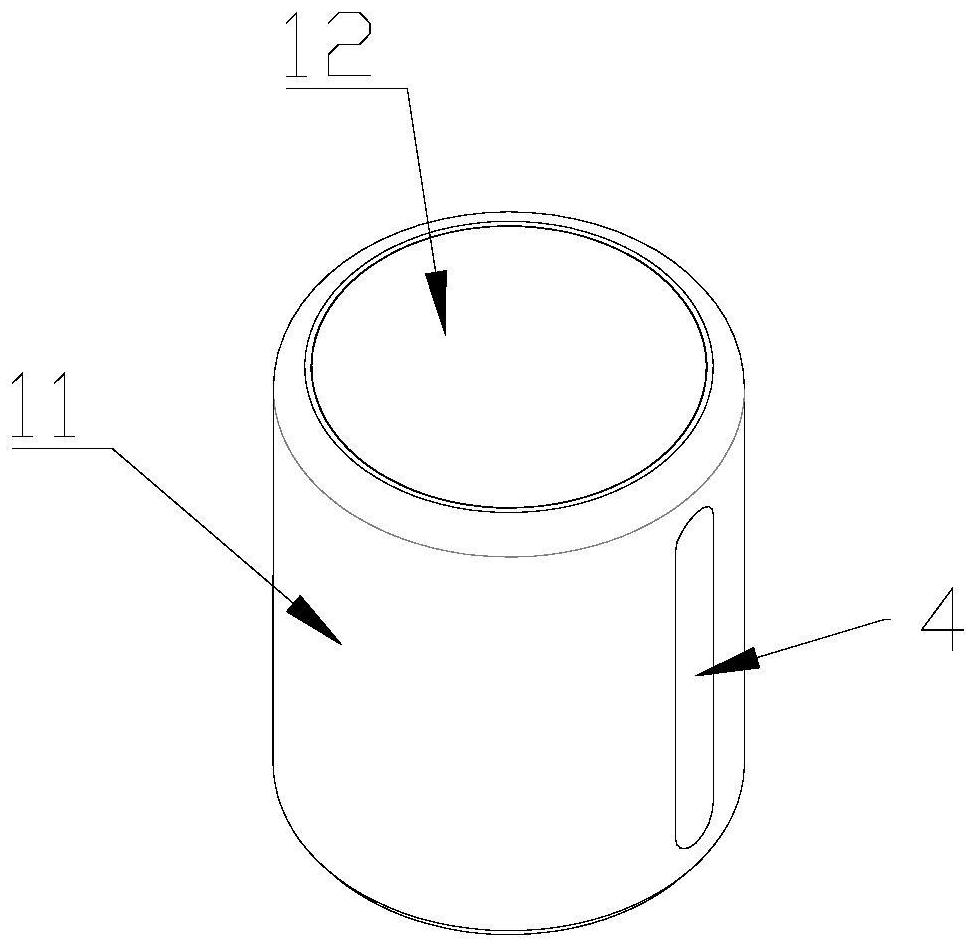

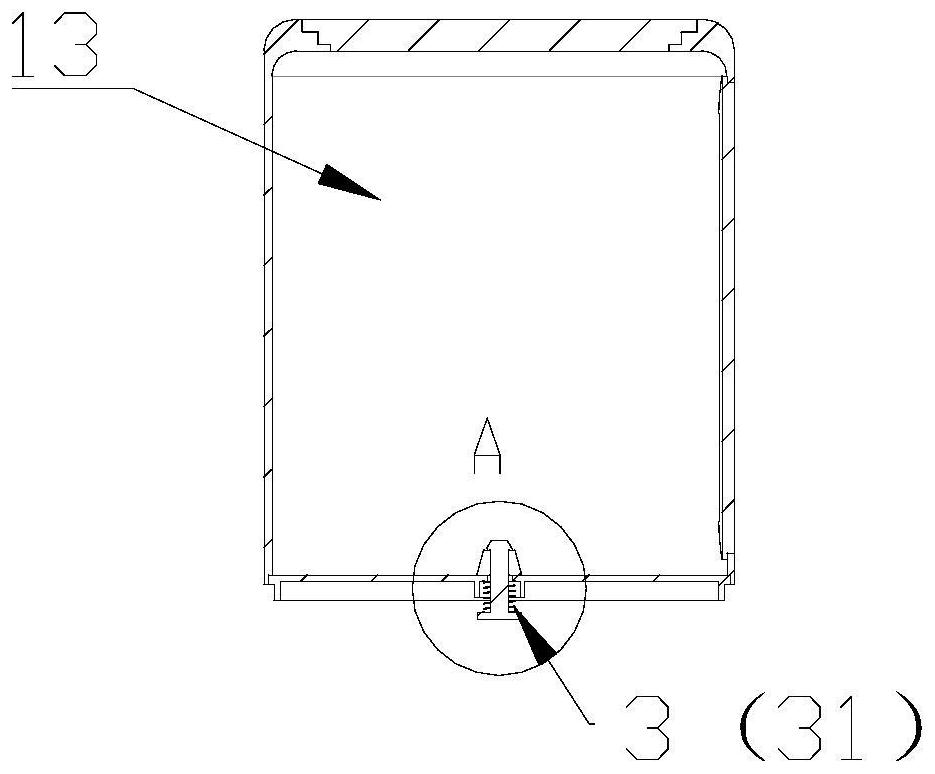

Negative pressure self-disturbance anti-contamination water-purifying water cellar

InactiveCN104452875AAchieve self-purification functionMeet drinking water standardsGeneral water supply conservationWater aerationEngineeringGuide tube

The invention discloses a negative pressure self-disturbance anti-contamination water-purifying water cellar. The water cellar is characterized by comprising a water collecting and filtering device (1), a cellar body anti-contamination water-purifying device (2), a water collecting and guiding component (3) and a purification water-taking device (4). Multiple air guiding tubes (21) are arranged on the cellar body anti-contamination water-purifying device (2), the upper ends of the air guiding tubes (21) are communicated with the outside, the lower ends of the air guiding tubes (21) are located inside the cellar body anti-contamination water-purifying device (2), and the water collecting and guiding component (3) comprises a water guiding opening (31) which is used for guiding water inside the cellar body anti-contamination water-purifying device (2) into the water collecting and guiding component (3) in a self-disturbance mode. With rainwater as a treatment carrier, the negative pressure self-disturbance anti-contamination water-purifying water cellar achieves cyclic utilization, is efficient and environmentally friendly and meets the requirements of ecological water utilization; meanwhile, the water cellar is simple and compact in structure, low in cost, affordable and easy to obtain.

Owner:HOHAI UNIV

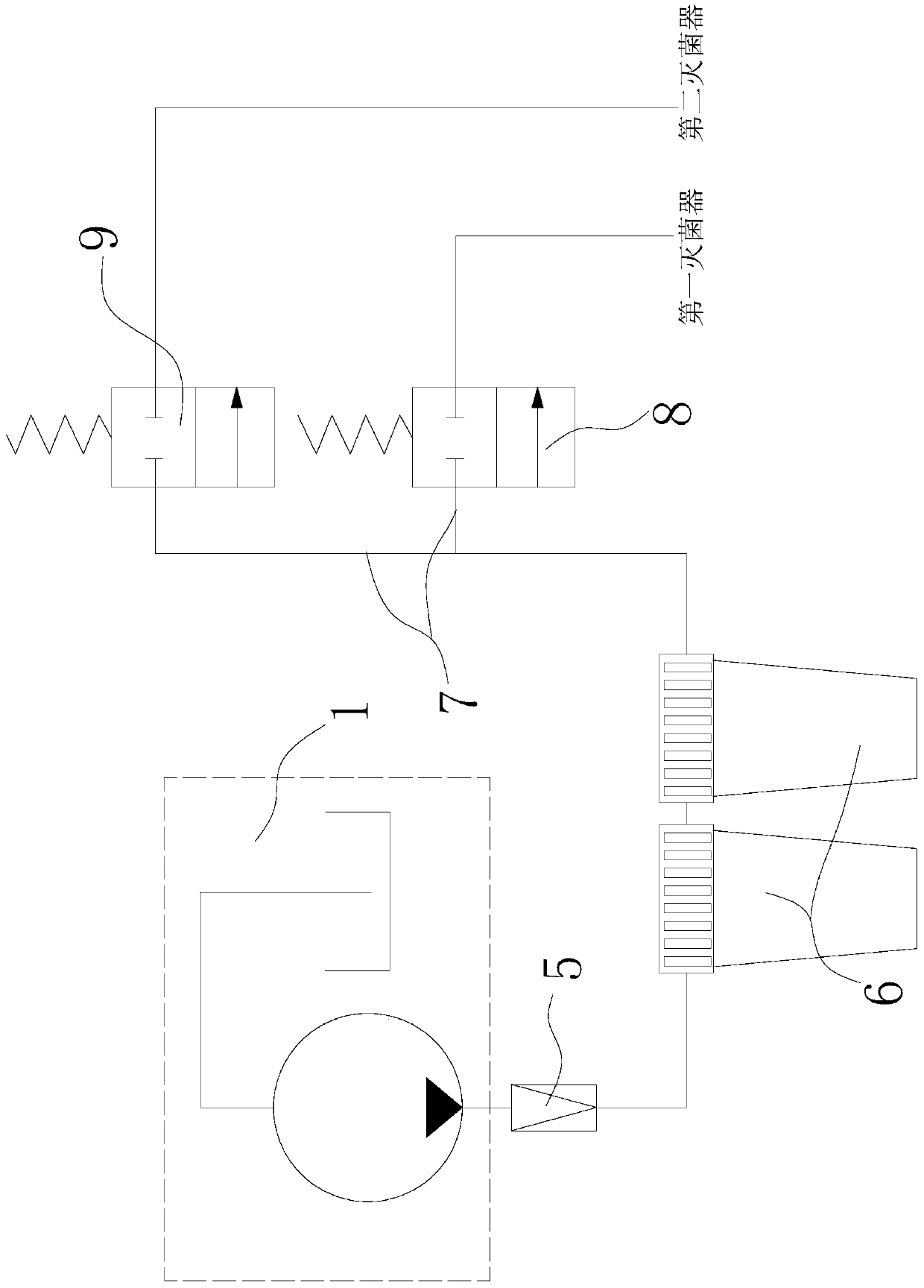

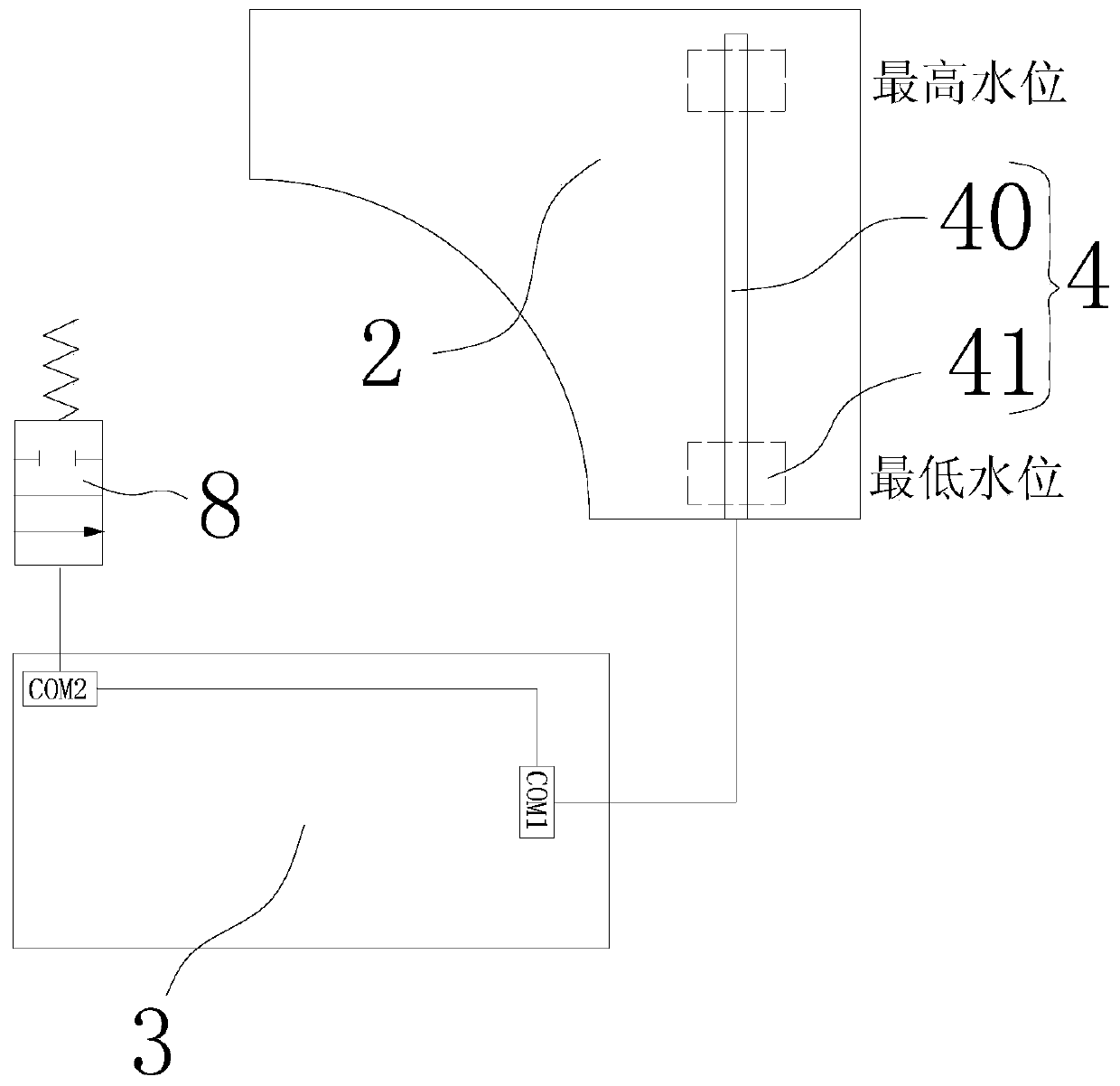

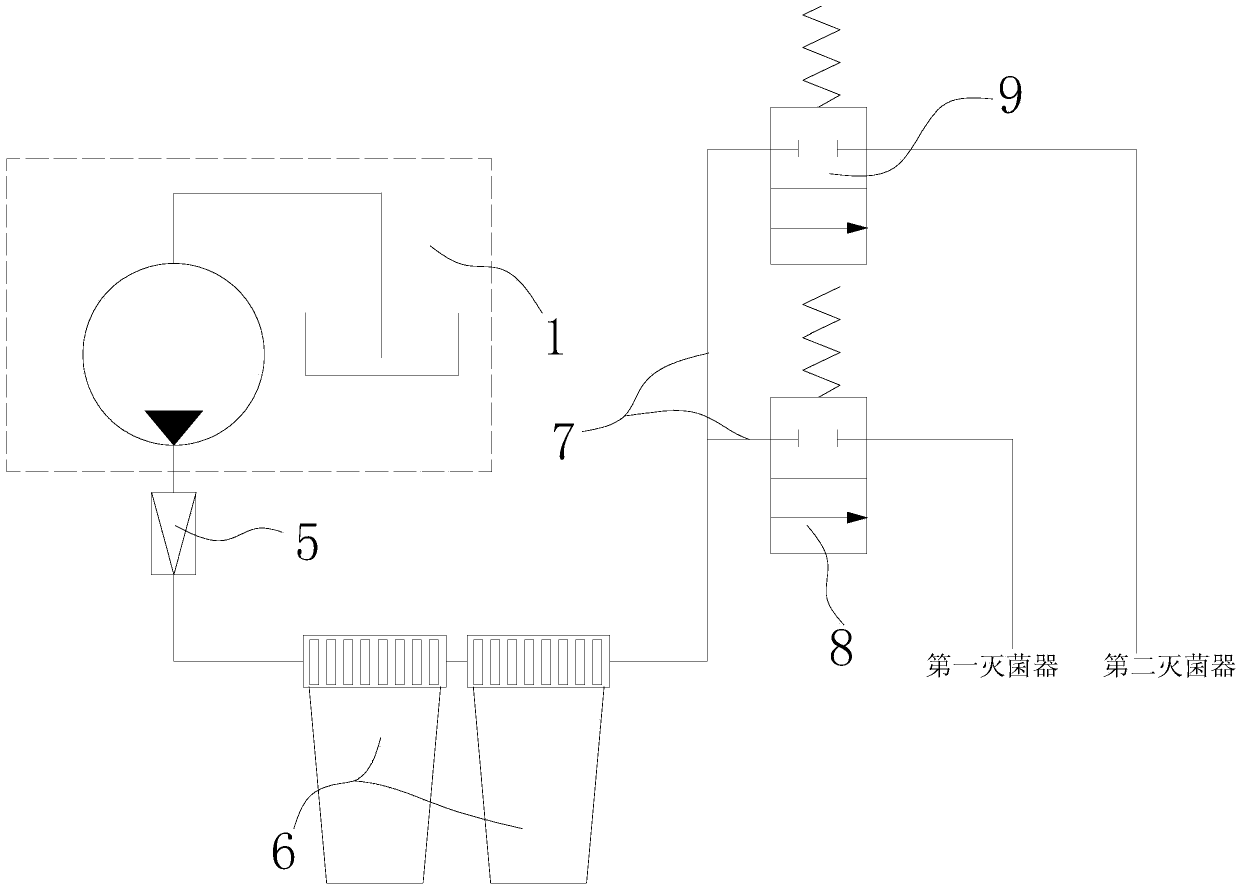

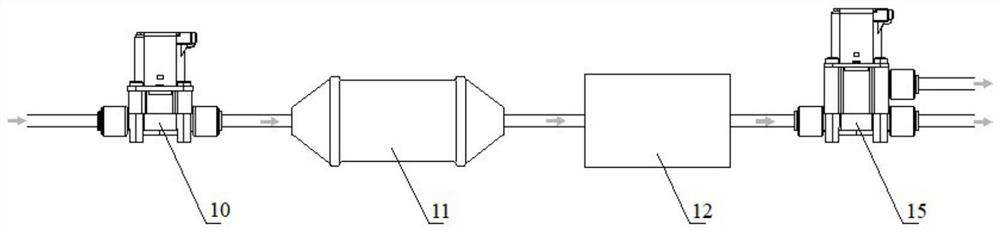

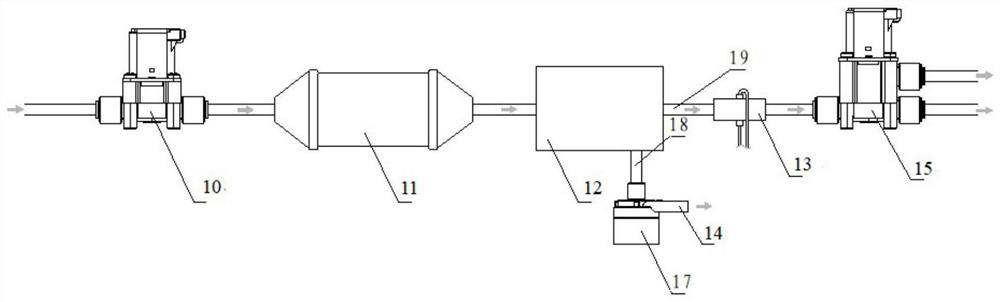

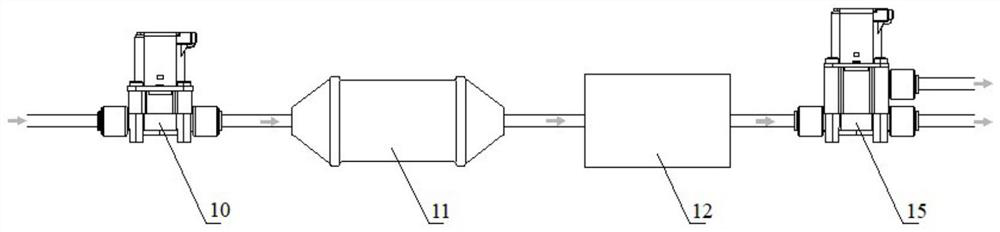

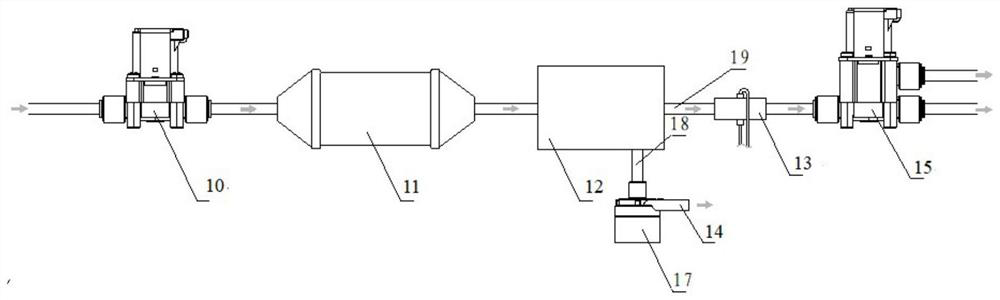

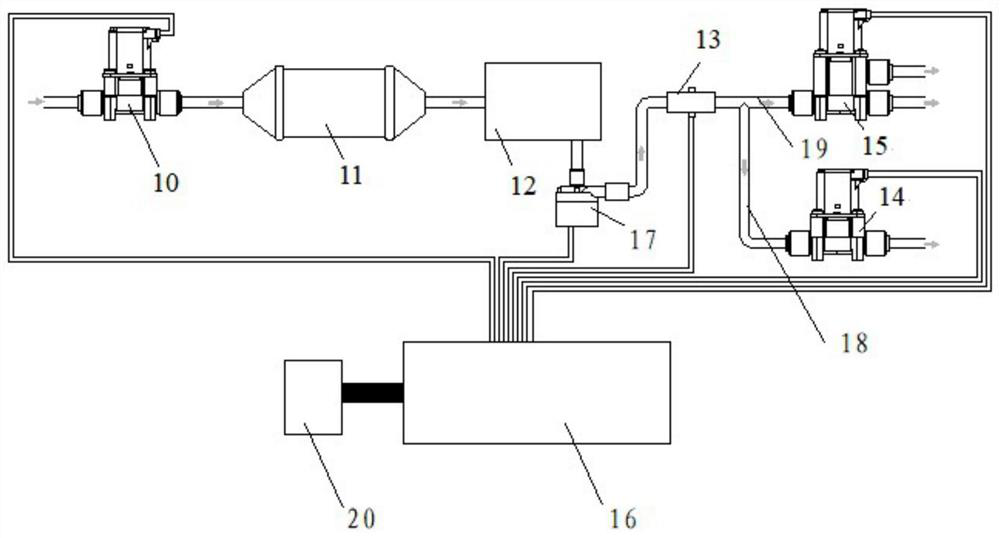

Automatic water supply system used for steam sterilizer

PendingCN109847076ASolve water quality problemsImprove work efficiencyLavatory sanitoryHeatElectricityWater source

The present invention provides an automatic water supply system used for a steam sterilizer. The automatic water supply system comprises a water source water supply system for automatically pumping water, a water purification tank and a circuit board arranged in the steam sterilizer, the water purification tank is provided with a water level sensor, and the water level sensor is electrically connected with a first communication port arranged on the circuit board; the water source water supply system is connected with a pressure reducing valve and a water filtering device; the water filtering device is connected with two water supply pipelines; each water supply pipeline is also respectively provided with a solenoid valve electrically connected with the circuit board in the steam sterilizerand convenient for controlling opening and closing of the water supply pipelines, and the circuit board is provided with a second communication port electrically connected with the solenoid valves; through the water level sensor and the solenoid valves and under control of the circuit board, water is automatically added to the water purification tank; and automatic water filtration solves a waterquality problem of water supply by the sterilizer, besides, a fully automatic water supply function effectively solves a water supply problem of the sterilizer, and the automatic water supply systemincreases working efficiency of medical staff and saves costs of water supply.

Owner:珠海西格医疗设备有限公司

A kind of urban river gushing water quality purification system and purification method

ActiveCN105330107BReduce pollutionEfficient removalWater resource protectionMultistage water/sewage treatmentChemical industryPurification methods

The invention discloses a water quality purification system for an urban river. The river is divided into three treatment areas according to the water quality condition of the urban river, namely an agricultural farming waste water treatment area, a treatment area of branch rivers polluted by waste water from the chemical industry and a domestic waste water treatment area, the water quality purification system for the urban river comprises a sludge cleaning device, biological earthworms, a first biological dam, a second biological dam, a third biological dam and an ecological floating island. According to the water quality purification system and process for the urban river, an integral treatment scheme and a segmented treatment principle are adopted, the river is divided into three segments for segmented treatment, all treatment units are matched reasonably, conditions are created actively for gradually lowering pollution of the river, the ecological system is established artificially, the self-cleaning capacity of the river is gradually restored, all the areas are subjected to targeted treatment according to actual conditions, investment and operating cost are low, and the purifying effect is good. The invention further discloses a water quality purification method for the urban river.

Owner:广州市天瑞环保科技有限公司

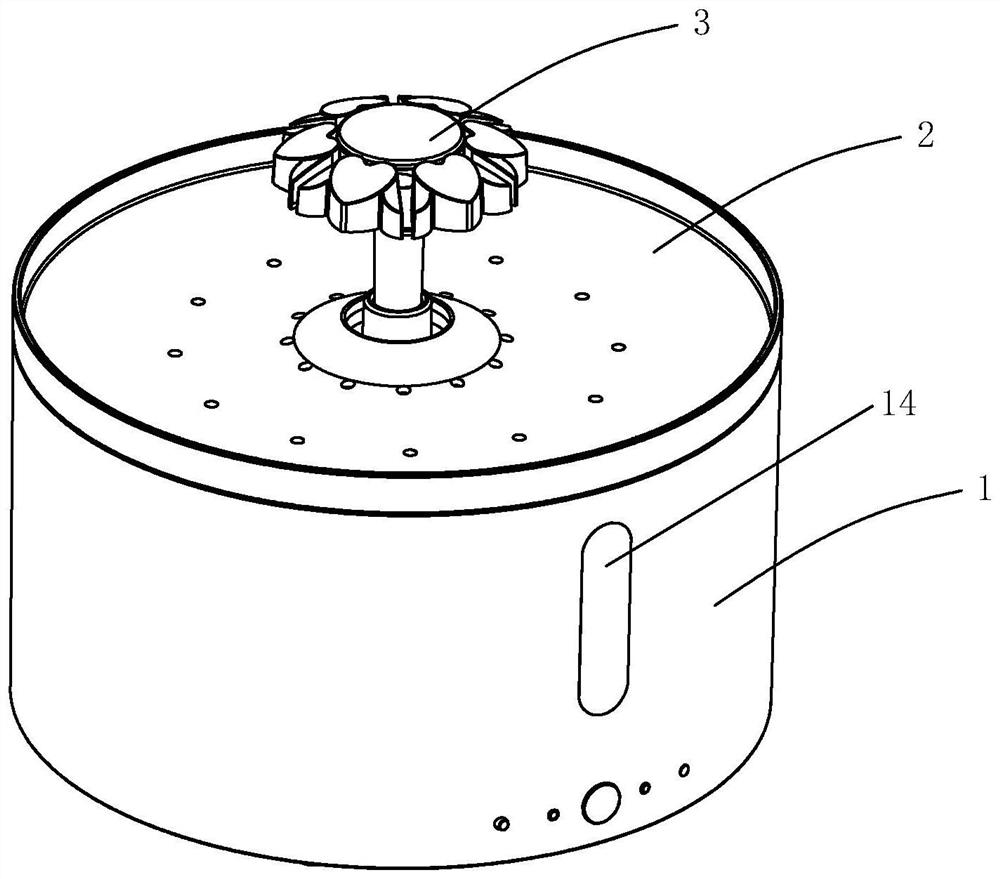

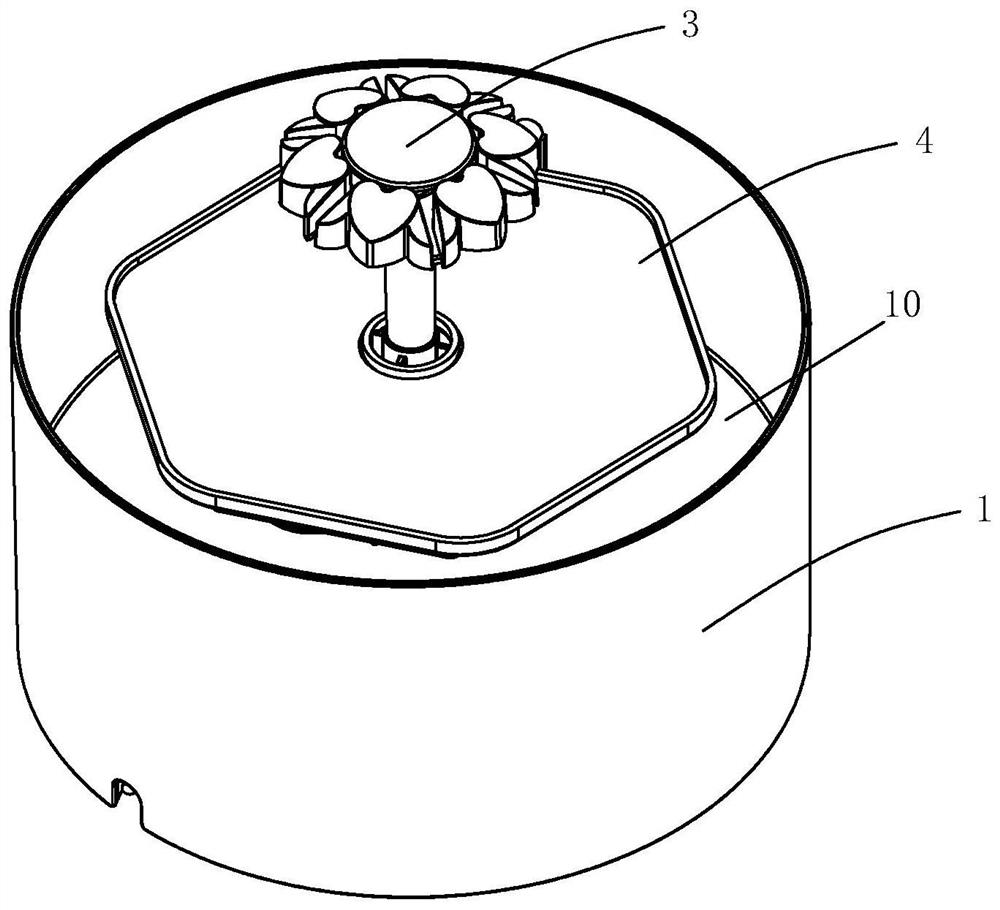

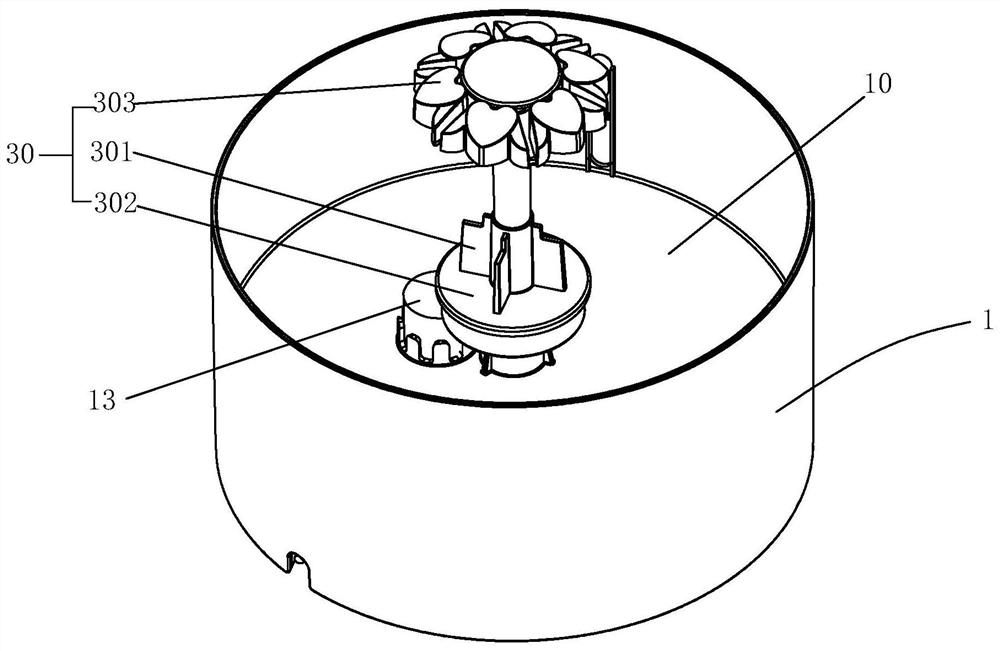

Water dispenser for pets

PendingCN113349085ASolve drinking water quality problemsSolve water quality problemsAnimal watering devicesTreatment involving filtrationWater storageWater storage tank

The invention provides a water dispenser for pets, which comprises a water storage tank, a water dispensing tray, a circulating water supply module and a backflow filtering module, a water storage cavity used for storing water is formed in the water storage tank, and the circulating water supply module is arranged on the water storage tank and used for filtering water in the water storage cavity and then conveying the filtered water to the water dispensing tray for the pets to drink, the water dispensing tray is provided with a backflow structure communicating with the water storage cavity, and the backflow filtering module is arranged in the water storage cavity and used for receiving water flowing back from the backflow structure and filtering the water into the water storage cavity 10. The water dispenser has the advantages of being simple in structure and reasonable in design, the purpose of purifying water is achieved through multi-stage circulating filtering, the problem of water quality of drinking water for the pets can be solved, and healthy water drinking is guaranteed.

Owner:JIETAI PURIFICATION TECH CO LTD

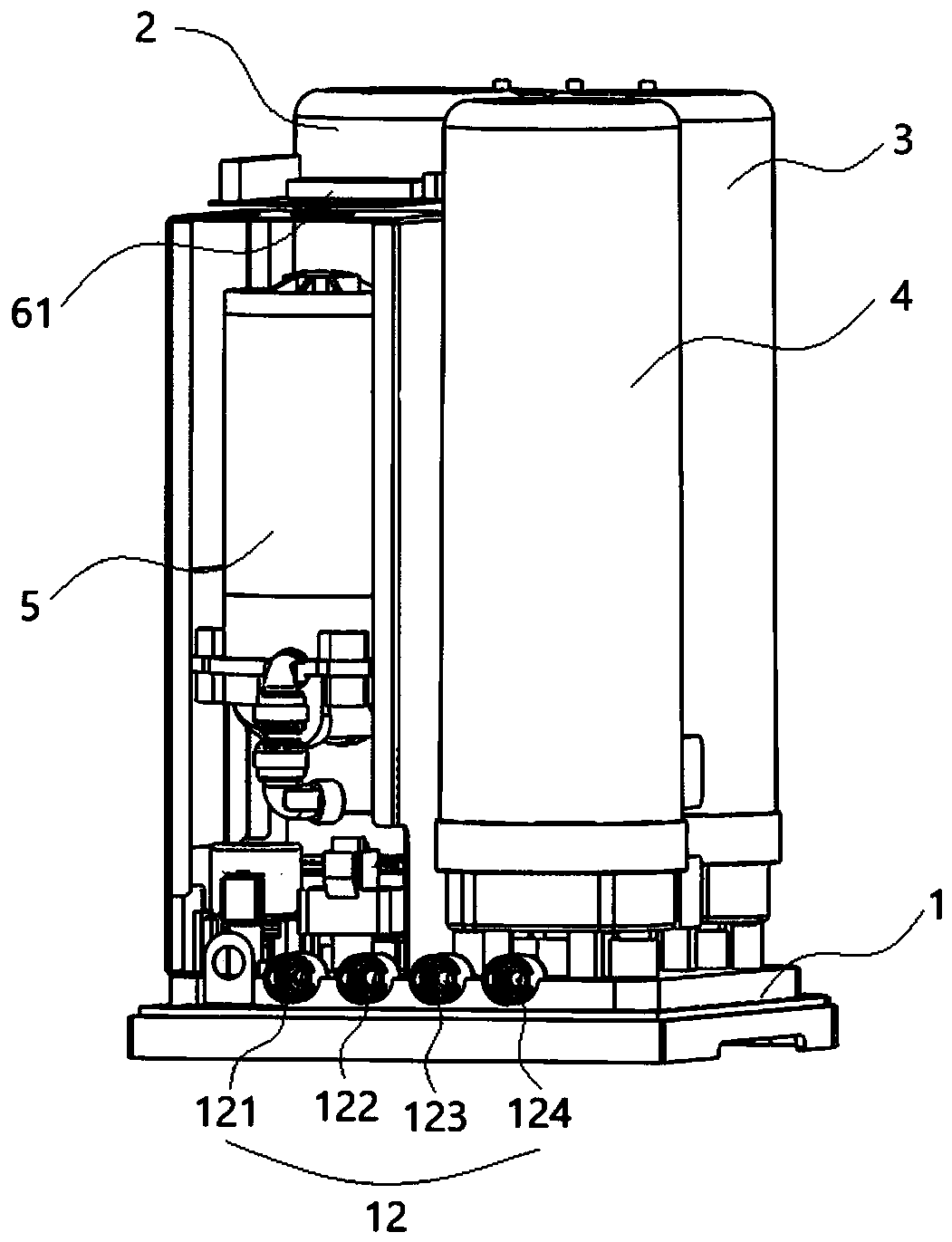

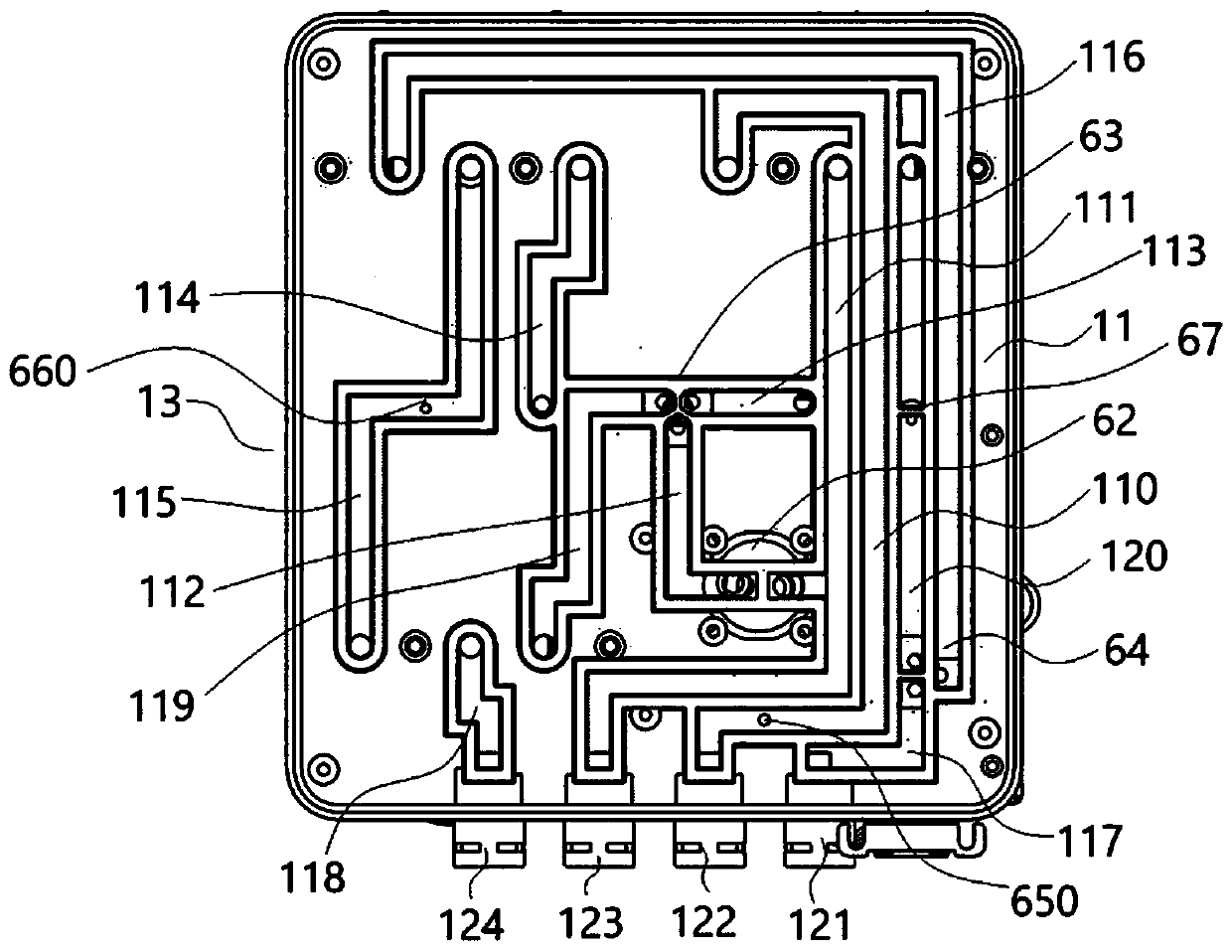

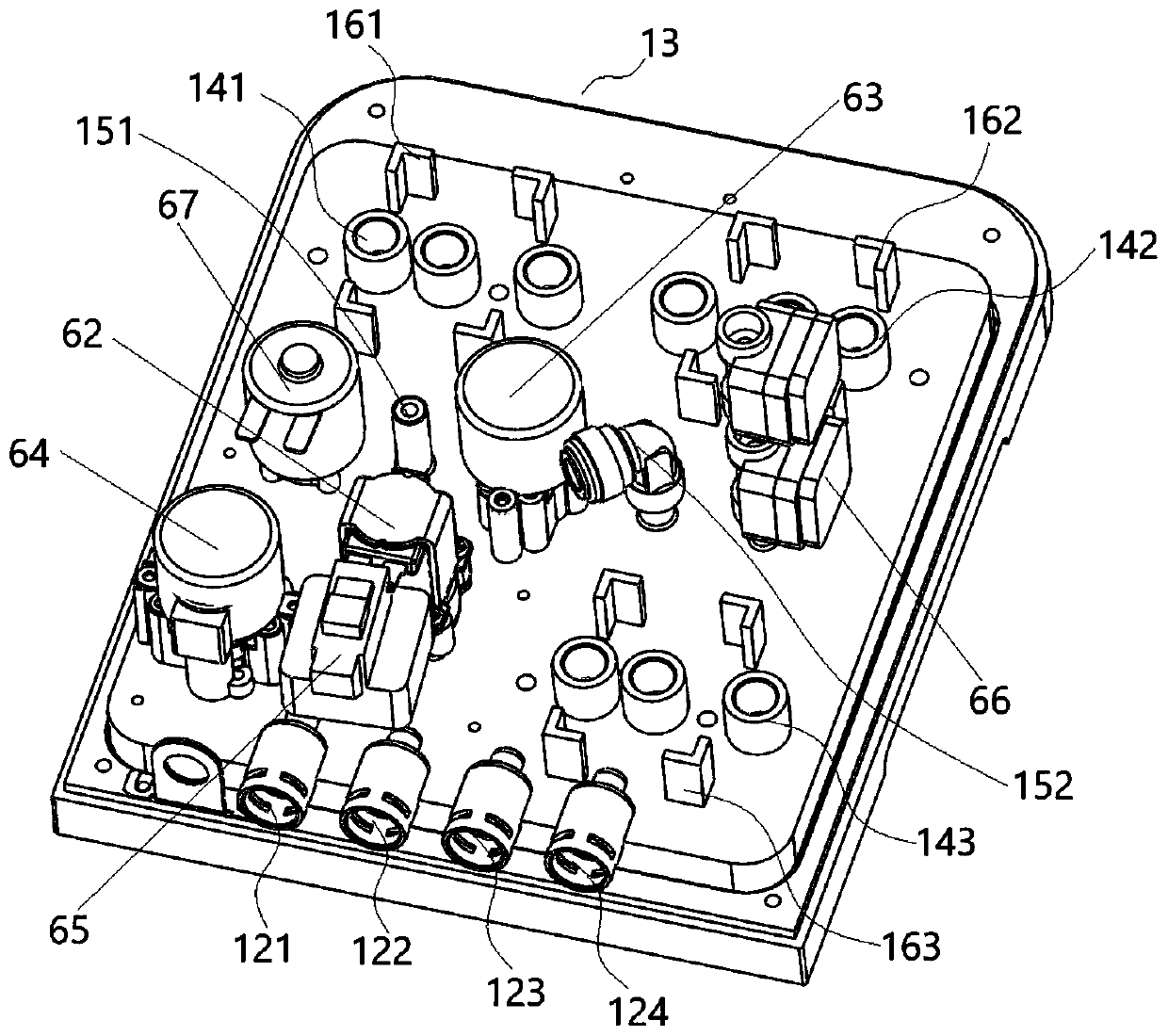

Integrated water purifier

PendingCN110615505ASimplify the assembly processLow costUltrafiltrationWater/sewage treatment bu osmosis/dialysisEngineeringElectric control

The invention provides an integrated water purifier. The integrated water purifier comprises a filtering and washing device, a pressurizing device and an electric control valve device, and further comprises a base, wherein a plurality of water channels are formed in the base; the filtering and washing device, the pressurizing device and the electric control valve device are installed on the base;water inlets and water outlets of all the devices are communicated with one another through the water channels or external pipelines; and an external waterway joint is also arranged on the base. According to the integrated water purifier disclosed by the invention, the water channels are arranged in the base, so that the mode that the existing water purifier is connected with each filter element through a complex external pipeline is replaced, the production and assembly processes of the whole water purifier are greatly simplified, and the cost is saved; and meanwhile, the whole water purifieris more intensive, the occupied space of the whole water purifier is reduced, and the water purifier is more convenient to place.

Owner:浙江诺水科技发展有限公司

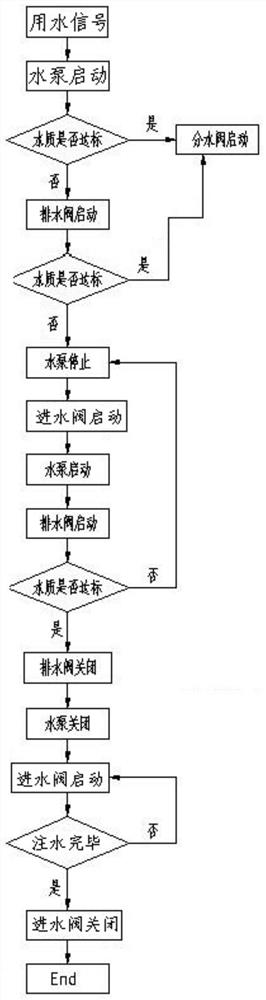

Water supply system water quality monitoring method, water supply system and refrigerating device

InactiveCN111827413AImprove safety and hygieneAvoid breedingIce productionService pipe systemsWater dischargeWater rinsing

The invention relates to the technical field of water supply system water quality monitoring and provides a water supply system water quality monitoring method, a water supply system and a refrigerating device. The water supply system water quality monitoring method includes the steps that water is conveyed to a water outlet pipe of the water supply system in a controlled manner; water quality parameters in the water outlet pipe are obtained; whether the water quality parameters reach the standard or not is judged; if the water quality parameters reach the standard, monitoring is over; if thewater quality parameters do not reach the standard, the next step is conducted; water is discharged out of the water supply system in a controlled manner; and the above water quality parameter obtaining, water quality parameter judging and water discharging processes are repeated till the water quality parameters reach the standard. By means of the method, the water quality parameters in the wateroutlet pipe can be monitored in real time, the water in the water supply system is discharged in the controlled manner when the water quality parameters exceed the standard, and organic matter breeding and precipitating are avoided. In addition, by means of the method, water discharging flushing of the water supply system can be avoided when the water supply system is not used for a long time, the operation difficulty is lowered, and the use convenience of users is improved.

Owner:HEFEI HUALING CO LTD +2

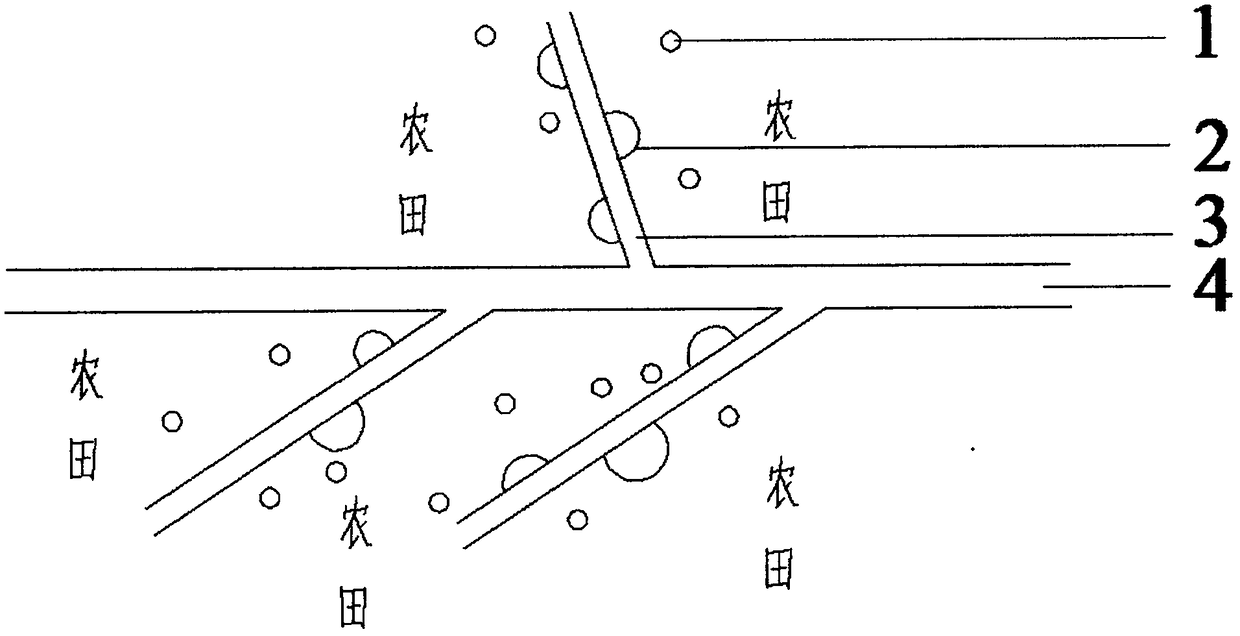

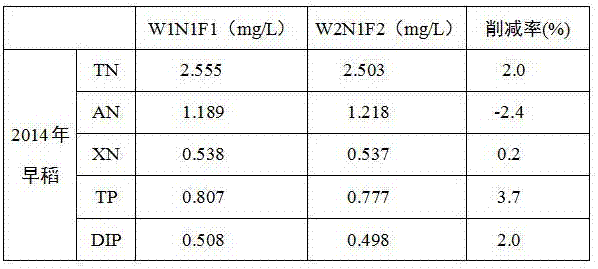

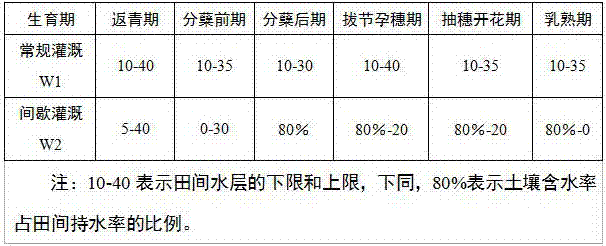

Method for reducing non-point source pollutants of farmland

PendingCN107055797AReduce churnIncrease profitWater treatment parameter controlSustainable biological treatmentEnvironmental engineeringDitch

The invention discloses a method for reducing non-point source pollutants of a farmland. The method comprises the following steps: S1, reducing nitrogen and phosphorus loss of the farmland through adopting a manner of combining intermittent irrigation and split application; S2, enabling water drained from the farmland to flow into an optimized water drainage grass ditch and filtering; S3, enabling water drained from the water drainage grass ditch to flow into a pond wetland and precipitating and absorbing the pollutants by water plants; S4, enabling water drained from the pond wetland to flow into a backbone ecological ditch and purifying the water drained from the wetland again.

Owner:GUANGXI COLLEGE OF WATER RESOURCES & ELECTRIC POWER

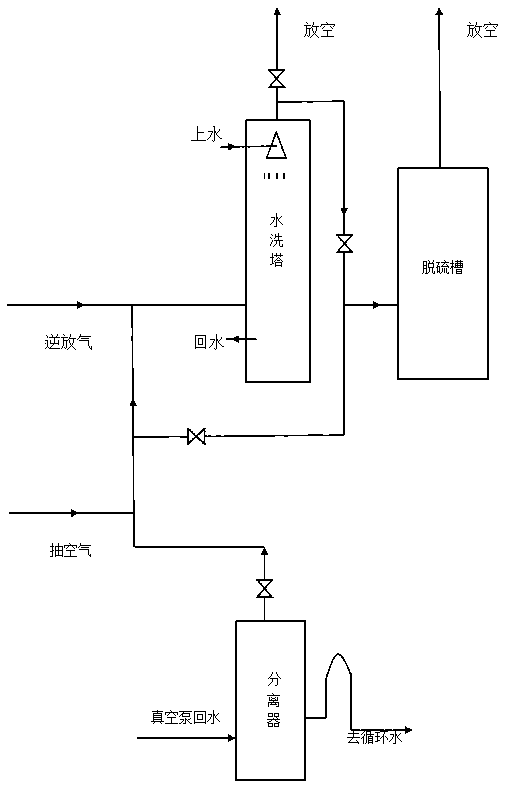

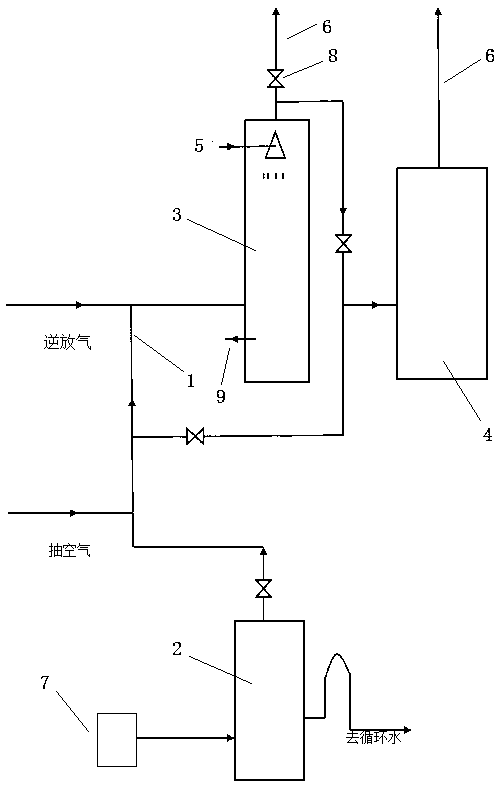

Purification method for pressure swing adsorption decarbonized evacuated gas and purification device thereof

InactiveCN109589743AEfficient purificationNo increased loadGas treatmentDispersed particle separationActivated carbonPurification methods

The invention discloses a purification method for pressure swing adsorption decarbonized evacuated gas and a purification device thereof. The evacuated gas is purified effectively by adding a washingstep behind an original gas evacuating step, carrying out gas-liquid separation on return water of a vacuum pump, controlling the liquid level of a water seal pipe through a U-shaped bend of a separator, ejecting the evacuated gas after gas-water separation from the top of the separator, feeding the evacuated gas into a post-section washing tower and a desulfurizer successively together, feeding the evacuated gas into a washing tower to be washed and purified and adsorbing and purifying acidic gas such as H2S in the evacuated gas by activated carbon, so that the environmental influence is reduced.

Owner:ANHUI JINGHE IND

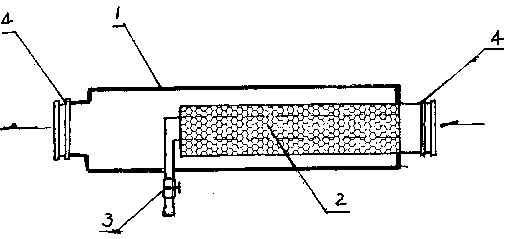

Water purification device

InactiveCN110947221ASolve water quality problemsGravity filtersStationary filtering element filtersEnvironmental engineeringWater pipe

The invention discloses a water purification device of a roadheader. The water purification device comprises a dustproof water pipe with a diameter of 5 inches and a length of 500 mm, wherein a cylindrical interlayer type high-pressure metal filter with a diameter of 3 inches and a length of 300 mm is welded in the water inlet side of the dustproof water pipe, the end head of the high-pressure metal filter is welded with a 5 / 8 steel pipe to be connected with an impurity filtering valve on the side wall of the dustproof water pipe, and the two ends of the dustproof water pipe are respectively welded with a quick connector with a diameter of 16 mm. The water purification device is compact in structure, good in adaptability, light, easy to operate, safe and reliable, and solves the water purification problem.

Owner:湘潭微动农业发展有限公司

Water supply system and refrigerator

ActiveCN111830027AImprove safety and hygieneAvoid breedingLighting and heating apparatusDomestic refrigeratorsWater basedIcebox

The invention relates to the technical field of water supply systems and provides a water supply system and a refrigerator. The water supply system comprises a water container and a water outlet pipeline connected with the water container, and a water quality detection device and a drainage device are arranged on the water outlet pipeline. The water supply system further comprises a controller, the water quality detection device acquires water quality parameters in the water outlet pipeline and sends the water quality parameters to the controller, and the controller controls the drainage device to be started according to the water quality parameters. According to the water supply system, the water quality of the water supply system can be detected, once the water quality is detected to beunqualified, the water supply system can control the drainage device to drain water based on the detection result, breeding and deposition of organic matters in the water supply system are avoided, the water quality problem is fundamentally prevented, the safety and sanitation of the water supply system are improved, and the health of users is guaranteed. Even if the water supply system is not used for a long time, the water supply system does not need to be drained and flushed by a user when the water supply system is started again, so that the operation difficulty is reduced, and the convenience of use by the user is improved.

Owner:HEFEI HUALING CO LTD +2

Environment-friendly control technology for tail water of sandstone factory

InactiveCN108793354AEliminate drug residue hazardsGood for transportationSludge treatment by de-watering/drying/thickeningNature of treatment waterWater supplyLand resources

The invention discloses an environment-friendly control technology for tail water of a sandstone factory. The environment-friendly control technology comprises the following steps of (1) washing of sandstone: washing the sandstone for building engineering, and collecting the tail water after washing; (2) separating and concentrating: separating and settling the tail water in step (1) by concentrating equipment, producing mud containing fine particles and siltized matter and primary clean water, conveying the mud into dewatering equipment of a press filter to make cakes, and returning the primary clean water back to a water supply system for further use; (3) primary dewatering and cake making: dewatering the settled mud in step (2) for the first time by a primary belt type press filter, andproducing primary dewatering mud cake and secondary clean water; (4) secondary dewatering and cake making: dewatering the primary dewatering mud cake in step (3) for the second time by a secondary belt type press filter, and producing secondary dewatering mud cake and secondary clean water; selecting a land for the secondary dewatering mud cake, storing for further use, and returning the secondary clean water back to the water supply system for further use. The environment-friendly control technology has the advantage that the pollution to the environment by the tail water and the occupationof land resources are fundamentally eliminated.

Owner:乔静梅

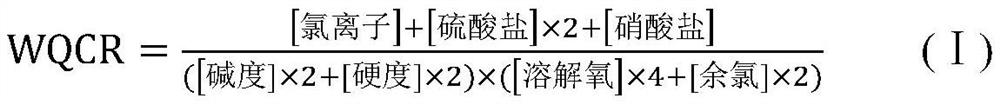

Judgment method for the cause of water quality change in the water source switching area of the water supply network

ActiveCN109001391BAccurately determine the cause of water quality changesDetermine the cause of water quality changesTesting waterWater useWater volume

The invention provides a method for judging the cause of water quality change in a water source switching area of a water supply pipe network, including measuring the ratio of water quality parameters and the change ratio of dissolved iron during the peak water use period of the water quality change pipe section, the stagnation period at night, and the change ratio of dissolved iron. 比值 , soluble iron 变化比值 0.7‑1.3, turbidity 比值 , total iron 比值 ≤0.5, the water quality change is that the sediment in the pipeline is brought into the water due to the change of the hydraulic condition, and the pipeline is flushed with a large amount of water; if residual chlorine 比值 ≤0.5, turbidity 比值 , total iron 比值 ≥1, soluble iron 变化比值 <0.7, the water quality change is the release of iron as the main substance in the pipeline, gradually increase the proportion of new water sources, and improve the adaptability of the pipeline. This method quickly and accurately judges and analyzes the causes of water quality changes when the water quality of the water supply pipe network changes, and provides solutions to ensure the normal water supply and water safety of the water supply pipe network in the area where the water source is switched. Stability has important guiding significance, it is convenient and easy to implement, simple and fast.

Owner:北京市自来水集团有限责任公司技术研究院

Method for preparing double-acid ferro-aluminum flocculating agent

InactiveCN101691252BLow priceEase of industrial productionSedimentation separationWater/sewage treatment by flocculation/precipitationLiquid productSocial benefits

The invention discloses a method for preparing a double-acid ferro-aluminum flocculating agent, which relates to a process for preparing the double-acid ferro-aluminum flocculating agent by using calcium aluminate powder. The method comprises the following steps of: taking the calcium aluminate powder of which the particle size is smaller than 60 meshes, putting the calcium aluminate powder into a hydrochloric acid solution in a part mass ratio of the hydrochloric acid solution to the calcium aluminate powder of 3-5:1, reacting the two materials at a temperature of 98 DEG C for 1 to 1.5 hours, standing the mixture for 30 minutes, and then taking a supernatant to obtain AlCl3 liquid; adding ferrous sulfate to the mixture in a part mass ratio of the calcium aluminate powder to the ferrous sulfate of 9-11:1 at a temperature of between 80 and 90 DEG C, dropwise adding a sodium hydroxide solution of which the concentration is 0.5 mol / L into the mixture after 15 minutes, dropping oxyful into the mixture in a part mass ratio of the ferrous sulfate to the oxyful of 1:1-1.5 when the basicity is 30 to 40 percent, stirring the mixture continuously for 15 to 20 minutes, and then curing the mixture at a temperature of between 50 and 60 DEG C for 12 hours to obtain a liquid product of the double-acid ferro-aluminum flocculating agent; and drying the liquid product of the double-acid ferro-aluminum flocculating agent to obtain a double-acid ferro-aluminum solid product. Tests show that in the solid product, Al2Cl3 is over 30 percent, the total iron is over 1 percent, the insoluble substances is less than 1 percent, and other indexes accord with the national standards. The method has a simple process and a low cost, and the prepared product has a good flocculation effect and high economic and social benefits.

Owner:TONGJI UNIV

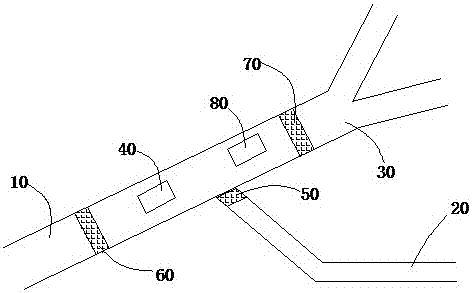

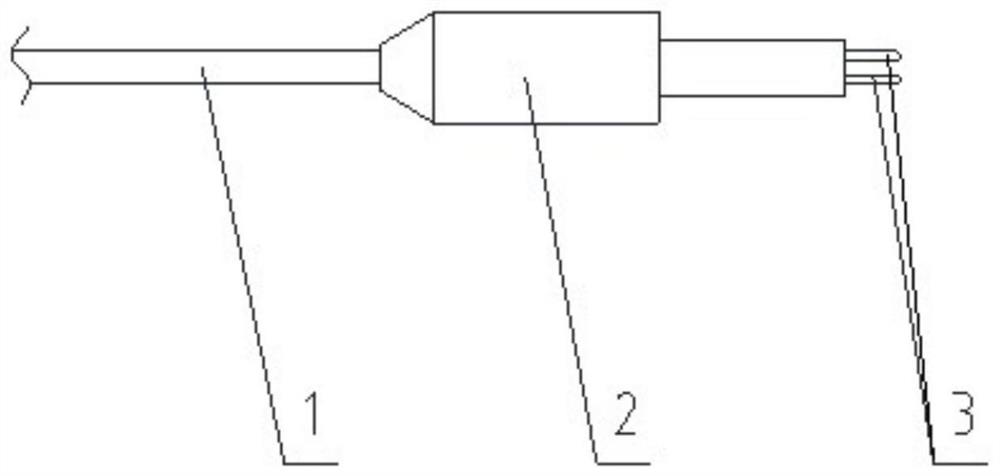

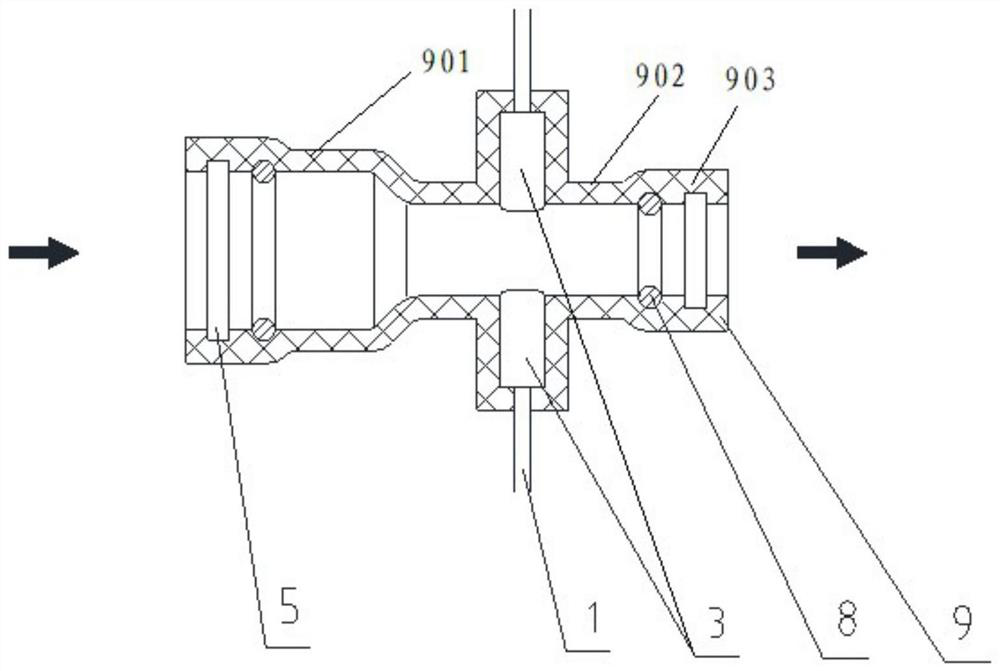

Water quality detection device, refrigerator water supply system and refrigerator

ActiveCN111830085BImprove detection accuracyExtended service lifeDomestic cooling apparatusLighting and heating apparatusIceboxWater flow

The invention relates to the technical field of water quality detection, and provides a water quality detection device, a refrigerator water supply system and a refrigerator. The water quality detection device includes an installation pipeline and a water quality detection probe. The installation pipeline includes a water inlet pipe section, a water outlet pipe section and a connecting pipe section connecting the water inlet pipe section and the water outlet pipe section. The flow rate of the water pipe section; the water quality detection probe is installed on the connecting pipe section and extends into the connecting pipe section. The water quality detection device avoids being combined with the water tank, thereby avoiding leakage at the joint. In addition, since the flow velocity in the connecting pipe section is greater than the flow velocity in the water inlet pipe section, the water flow in the connecting pipe section is locally accelerated, so that the water quality detection probe inserted into the connecting pipe section is washed by the water flow, and impurities are deposited on the surface of the water quality detection probe. Improve detection accuracy. Since the water quality detection probe is not affected by the accumulation of impurities, the service life of the water quality detection device can be extended.

Owner:HEFEI HUALING CO LTD +2

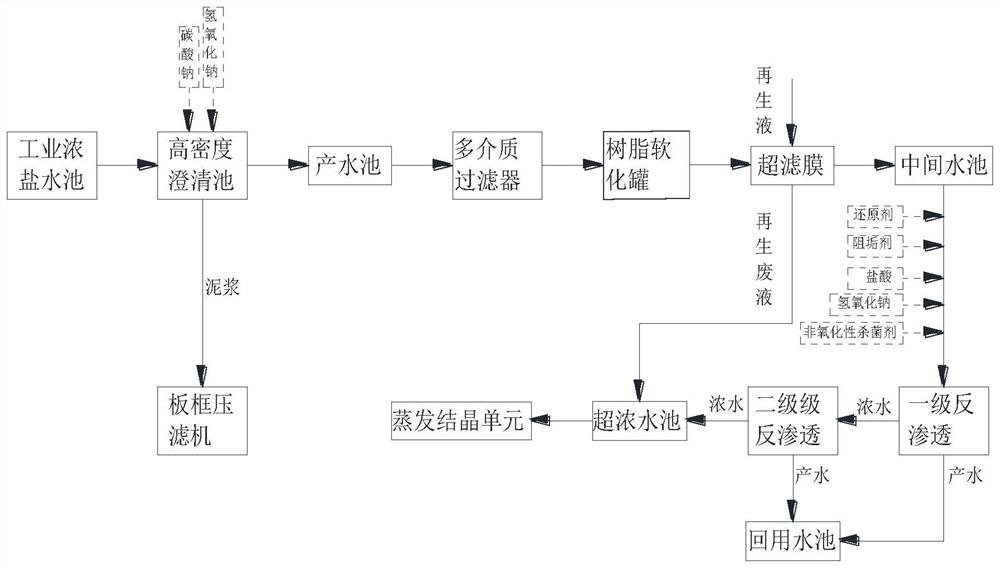

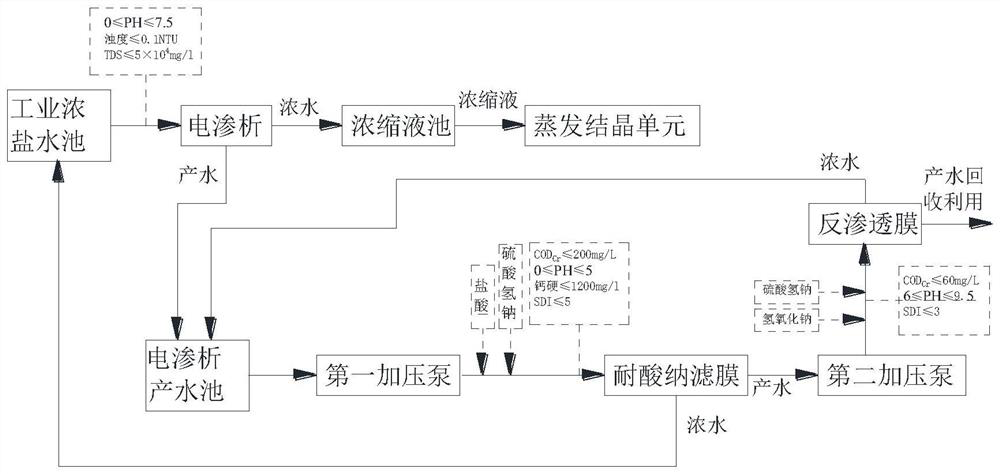

Industrial strong brine zero discharge treatment system and method

PendingCN114716083AAchieving Zero EmissionsSatisfy the water inlet conditionGeneral water supply conservationWater/sewage treatment by ion-exchangeReverse osmosisProcess engineering

The invention relates to an industrial strong brine zero discharge treatment system which comprises an industrial strong brine tank, an electrodialysis device, a concentrated solution tank and an evaporative crystallization unit which are sequentially connected, an electrodialysis produced water outlet is connected with an electrodialysis produced water tank, and the electrodialysis produced water tank is sequentially connected with a first pressure pump, an acid-resistant nanofiltration membrane, a second pressure pump and a reverse osmosis membrane. And finally, the concentrated water of the reverse osmosis membrane is returned to the electrodialysis water producing tank from a water outlet, and the concentrated water of the acid-resistant nanofiltration membrane is returned to the industrial concentrated brine tank. The invention further relates to a treatment method using the treatment system. According to the invention, the industrial strong brine is concentrated by using a simple and low-cost method, the final produced water is recycled, and the rest of super strong brine is evaporated and crystallized, so that the purpose of zero emission of strong brine is achieved.

Owner:TANGSHAN IRON & STEEL GROUP +2

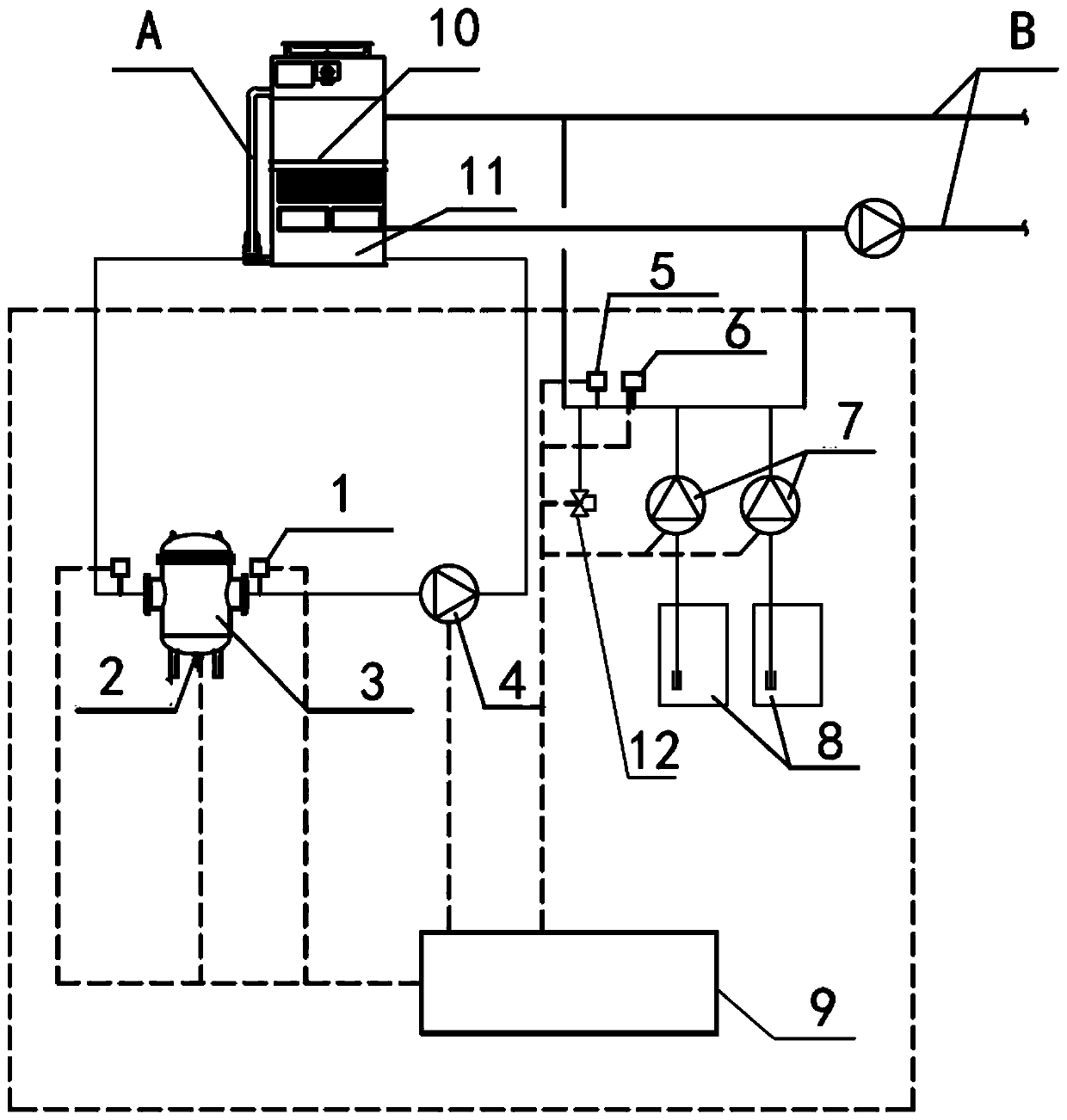

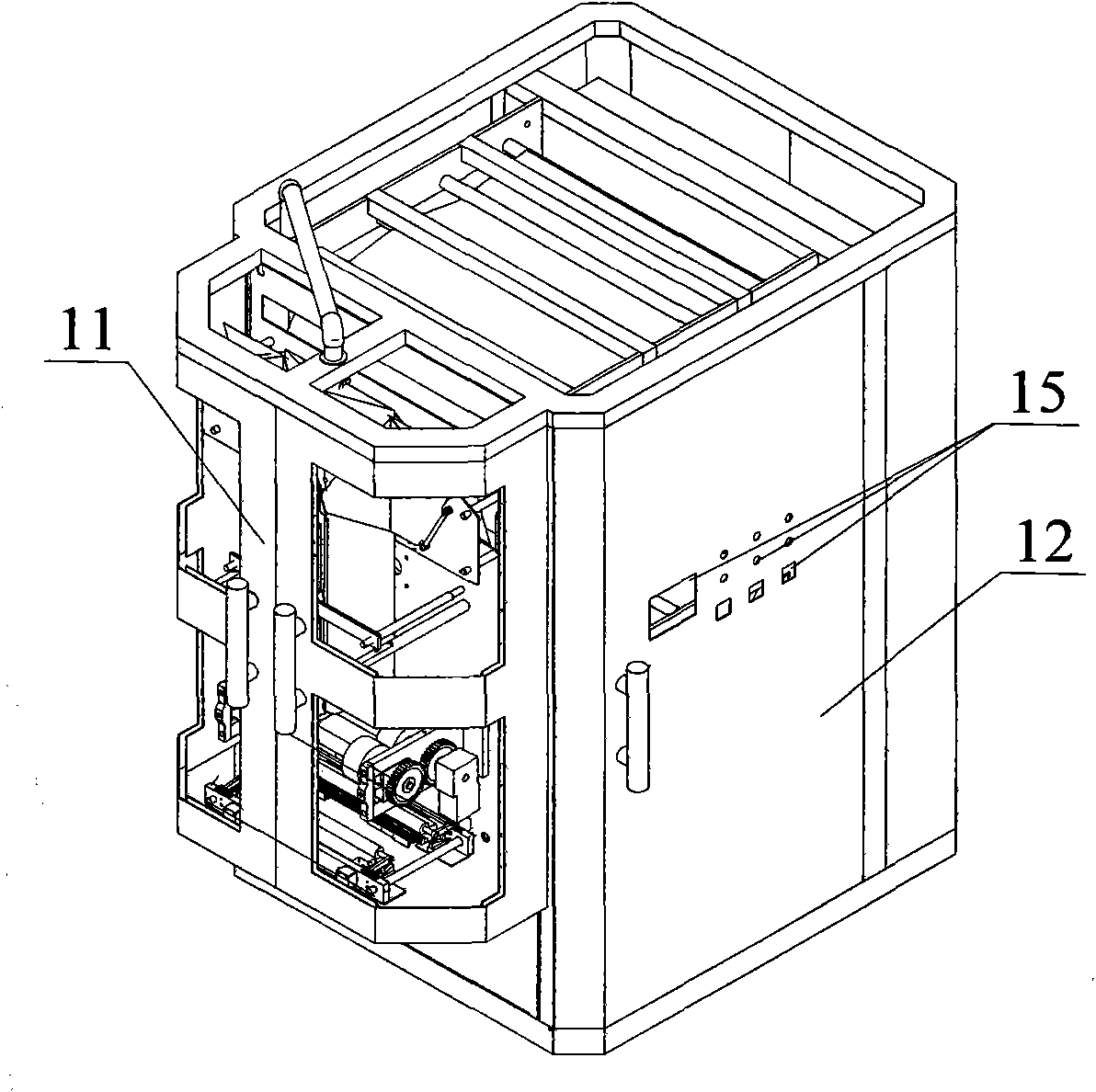

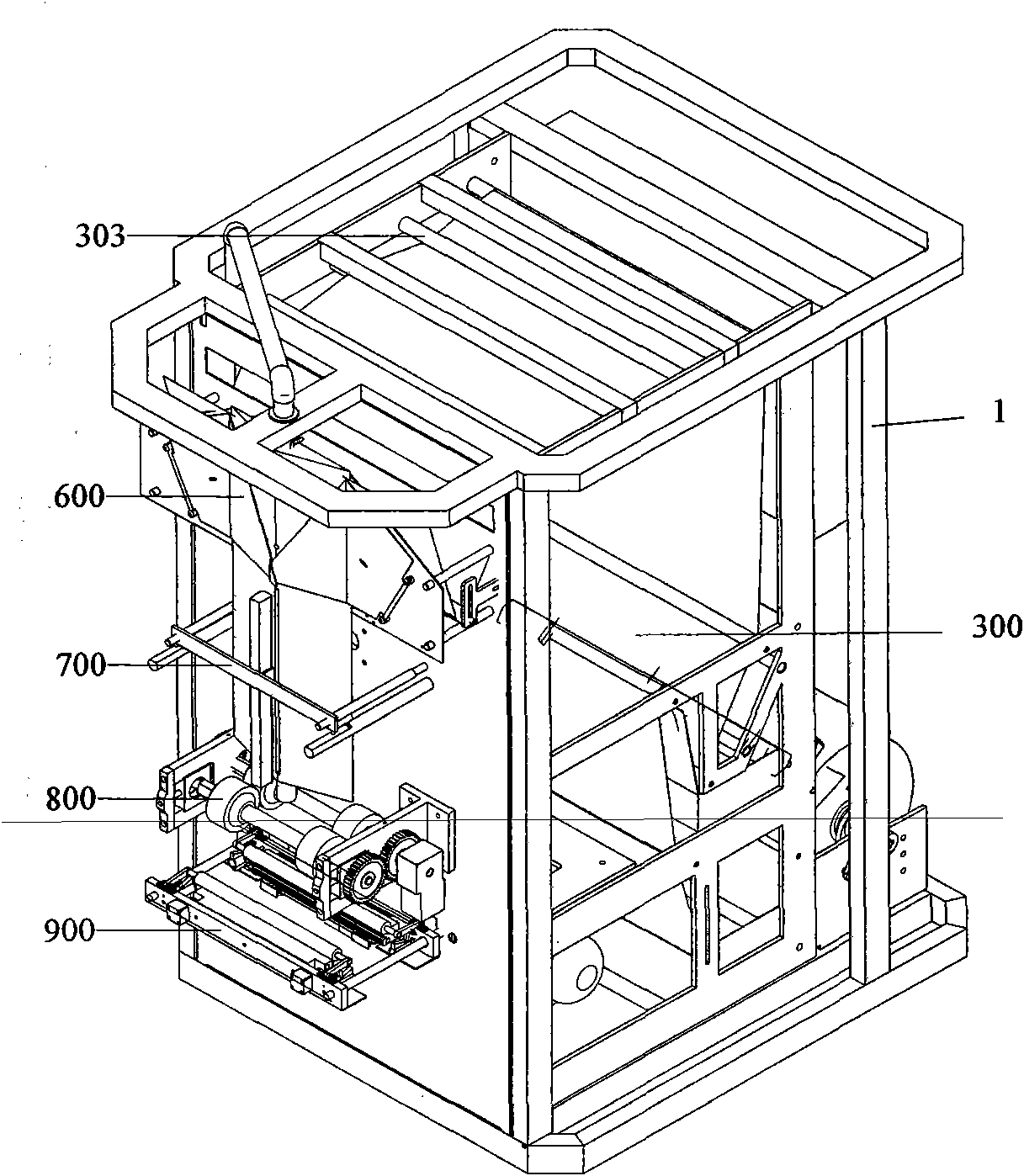

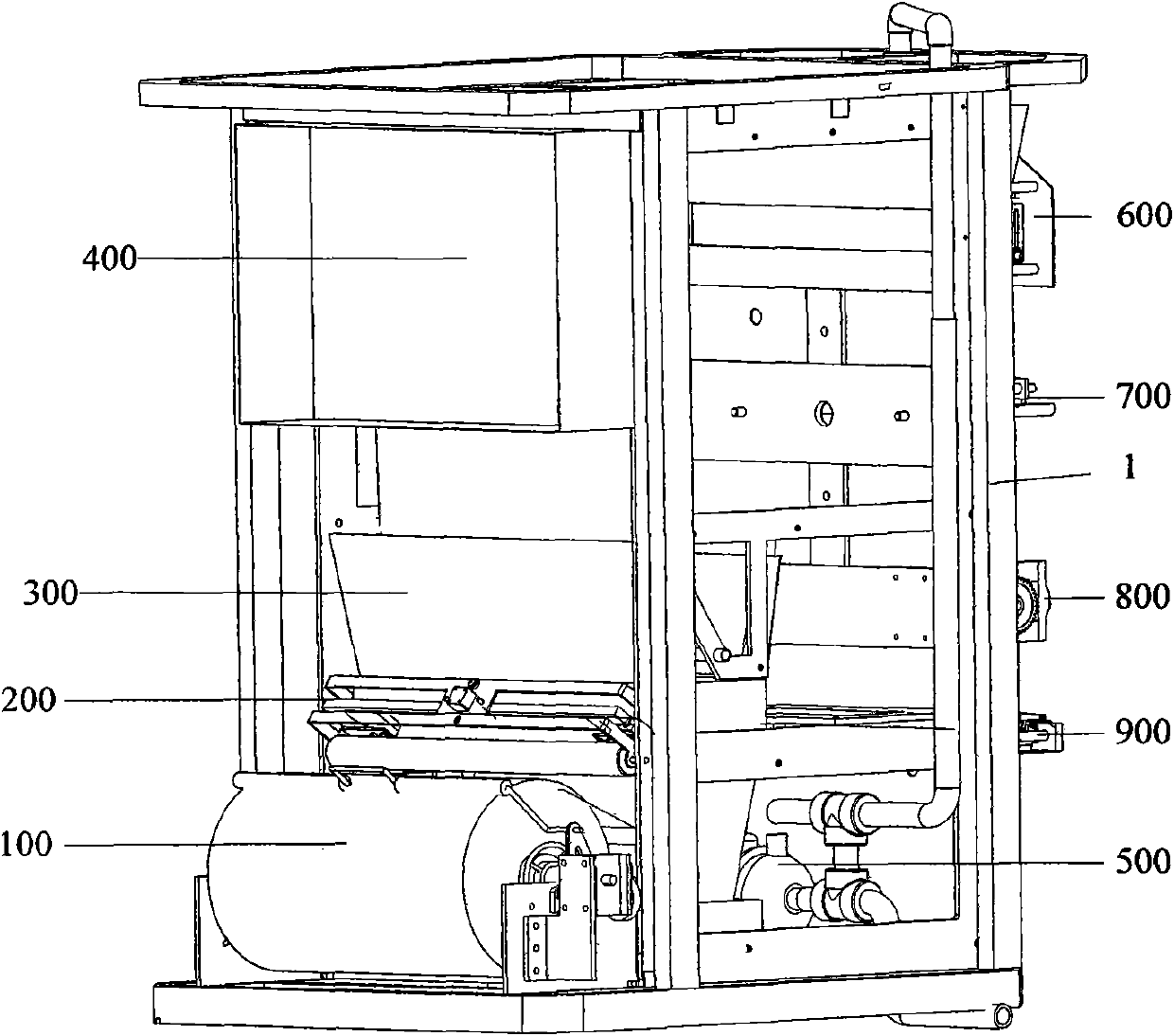

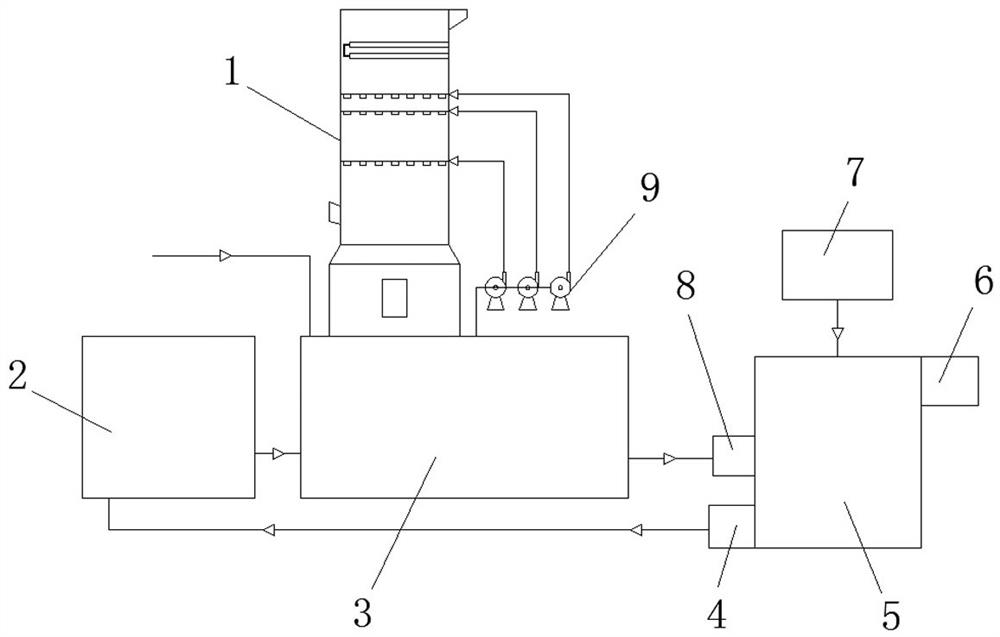

Outer circulating and inner circulating comprehensive water treatment device of closed cooling tower

PendingCN110921920AReduce heat transfer efficiencyImprove heat transfer efficiencyWater treatment parameter controlTreatment involving filtrationCooling towerSump pump

The invention relates to an outer circulating and inner circulating comprehensive water treatment device of a closed cooling tower. The device comprises an inner circulating water treatment assembly,an outer circulating water treatment assembly and a controller, the inner circulating water treatment assembly comprises a water quality detection assembly and a water quality adjusting assembly; thedetection end of the water quality detection assembly is arranged at an inner circulating liquid outlet; the water quality adjusting assembly is connected with an inner circulating liquid inlet; the outer circulating water treatment assembly comprises a sewage pump and a spiral sewage discharging device, a water inlet and a water outlet are formed in the spiral sewage discharging device, the waterinlet of the spiral sewage discharging device is connected with an outer circulating liquid outlet, the water outlet of the spiral sewage discharging device is connected with a water inlet end of thesewage pump, and the water outlet end of the sewage pump is connected with an outer circulating liquid inlet. Compared with the prior art, the spiral sewage discharging device is adopted to treat outer circulating dirt, the blockage degree of the spiral sewage discharging device is calculated through the pressure difference, overhauling is reminded, the conductivity of inner circulating water isadjusted through a chemical cylinder and a metering pump, and the water quality problem of inner circulating and outer circulating of the closed cooling tower can be solved at the same time.

Owner:上海九瀚机电设备有限公司

Automatic filling machine

ActiveCN102442628BNo manual operationRealize automatic controlBottle-handling machinesEngineeringElectric control

The invention discloses an automatic filling machine, which comprises a machine frame and an electric control device. A film rolling device for storing and releasing a film, a film connecting device for connecting the film, a disinfecting and cleaning device for disinfecting and cleaning the pulled film, a filling device for filling liquid in a film bag, a forming device for turning and rolling the film into a cylindrical structure, a vertical sealing device for vertically piecing and sealing the cylindrical film, a film pulling device for pulling the film to move and a transverse closing and cutting device for transversely closing and cutting the cylindrical film are arranged on the machine frame in turn. The automatic filling machine provided by the invention is high in production efficiency, lower in cost and high in automation degree.

Owner:SHENZHEN ANGEL DRINKING WATER IND GRP

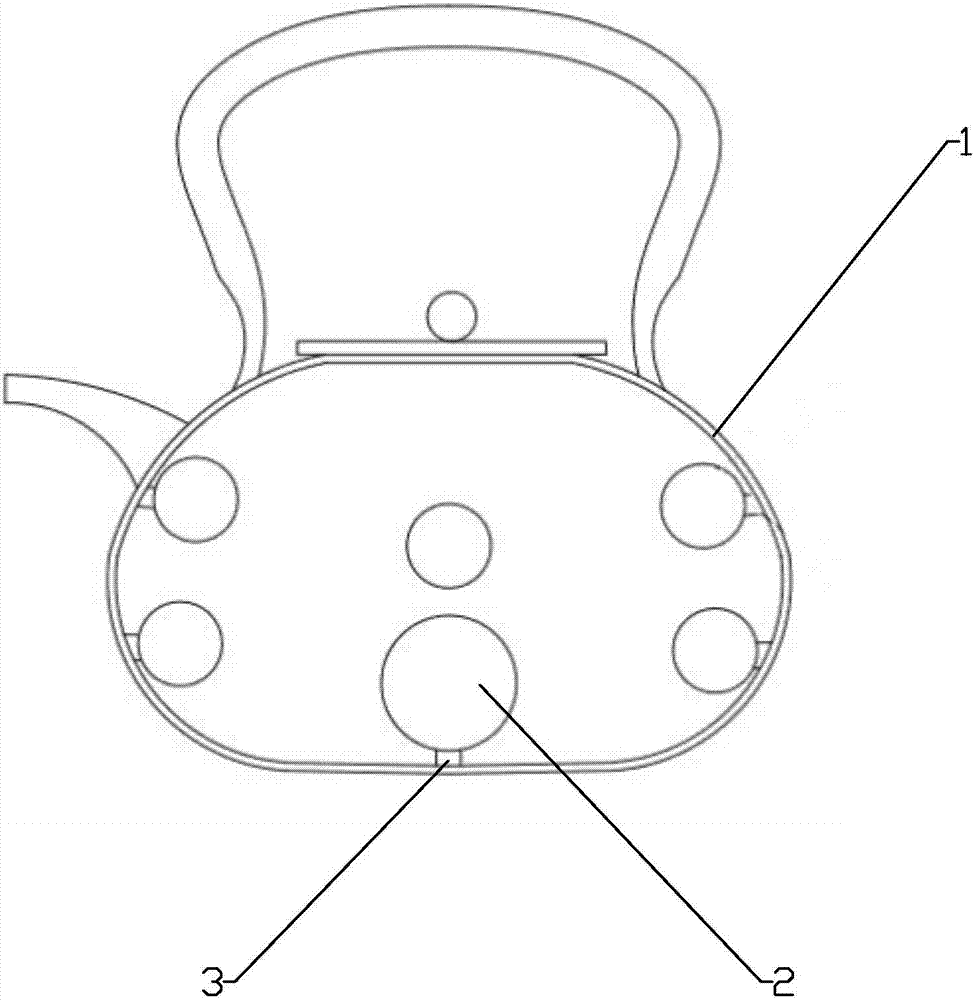

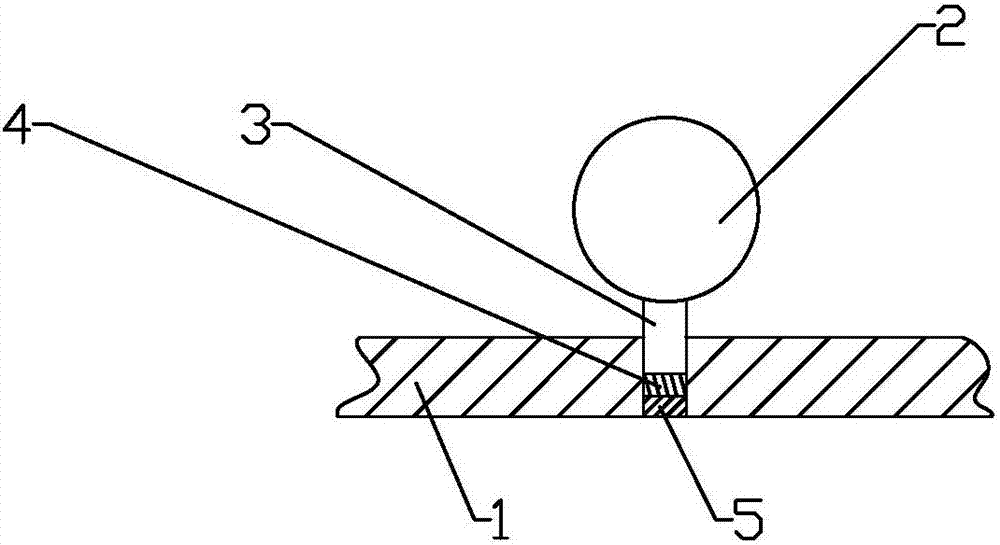

Method for making iron kettle with silver

InactiveCN107468051AThe taste is thick, full and smoothSolve water quality problemsCooking-vessel materialsWater-boiling vesselsWater qualityMaterials science

The invention discloses a method for making an iron kettle with silver. The method comprises the following steps that a mounting hole is formed in a blank iron kettle body; a body and a bulge arranged on the body and matched with the mounting hole are processed on a silver body; the silver body is placed in the iron kettle body, and the bulge is clamped in the mounting hole. According to the method for making the iron kettle with the silver, the mounting hole is formed in the iron kettle body, the silver body is provided with the bulge, and the bulge is clamped in the mounting hole, so that the advantages of iron kettles are maintained, and the iron kettle makes water sweet, good in taste, and thick, full and smooth in mouth feel; meanwhile, sterilization and freshness preservation are achieved, the water quality problem is solved, and the iron kettle is simple in structure and very suitable for people's daily usage.

Owner:开平曜宸五金制品有限公司

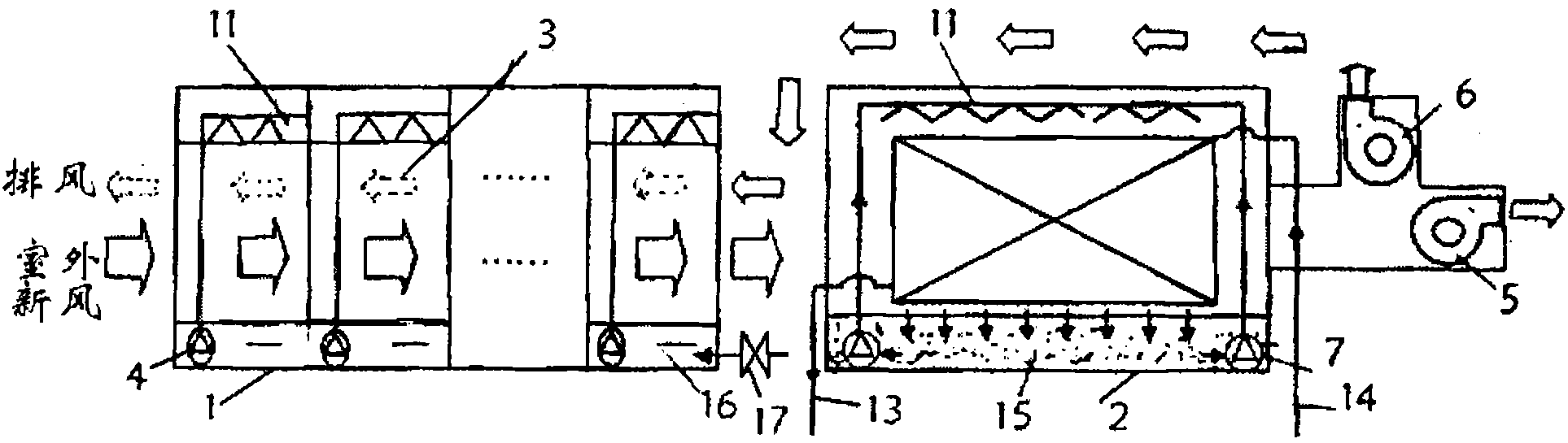

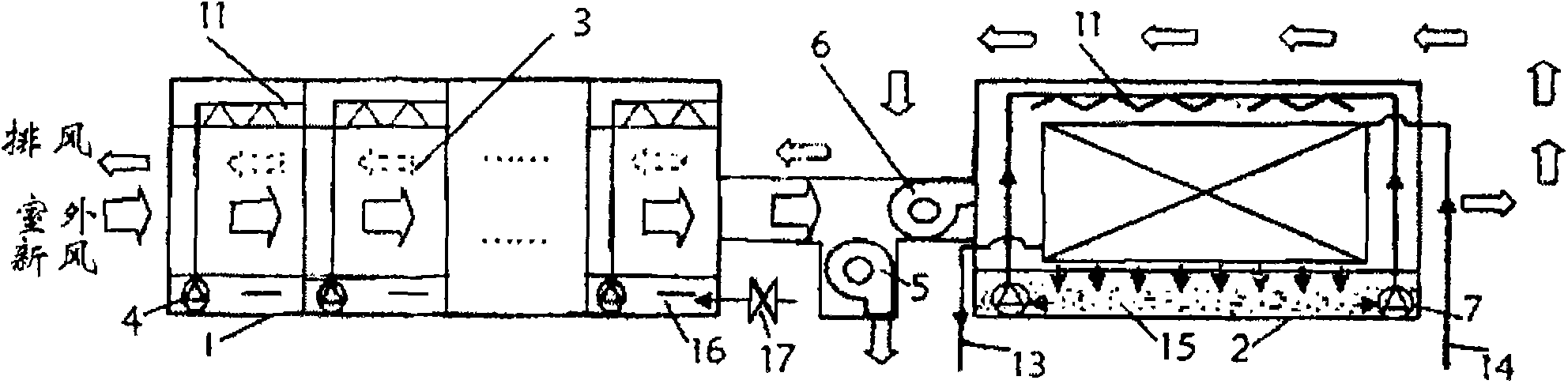

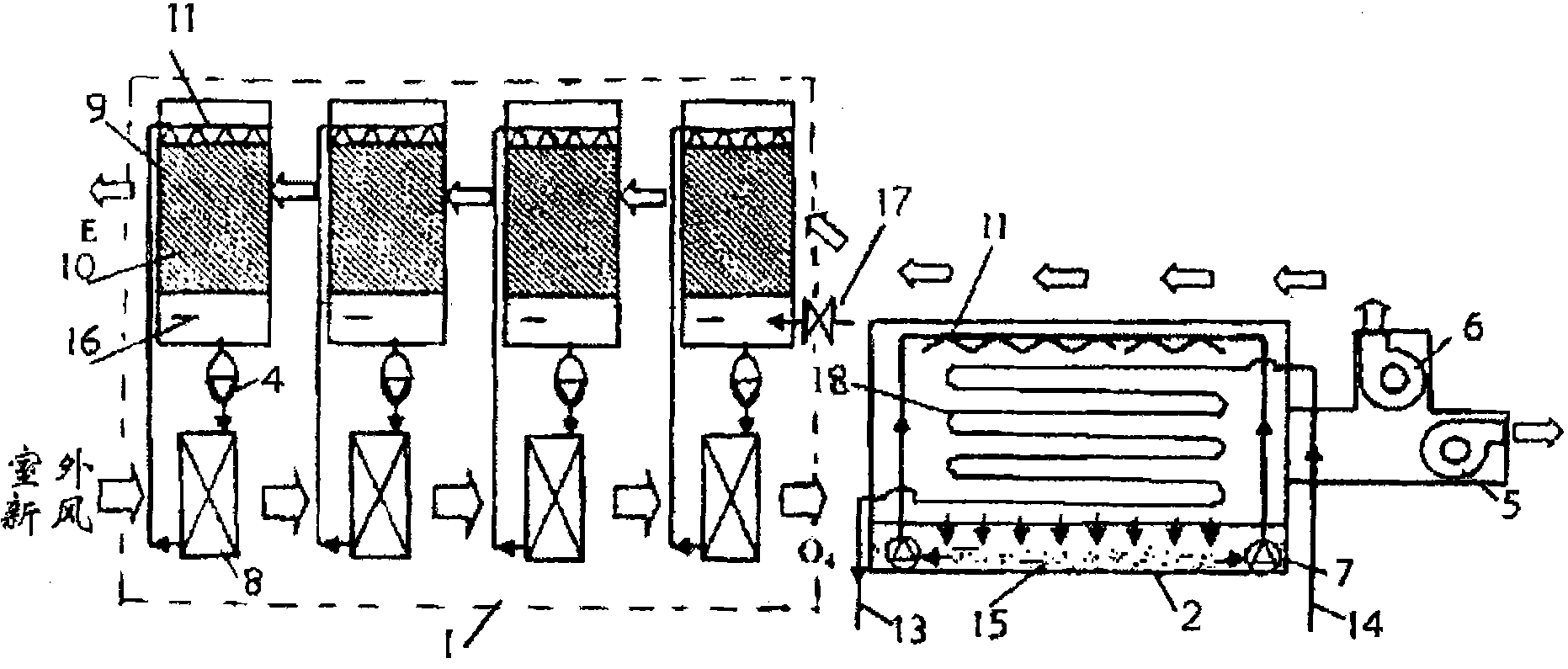

Indirect evaporation refrigerating method and device capable of generating cold water and cold wind meanwhile

ActiveCN101251285BAchieve recyclingResolving mismatches caused by non-linearityLighting and heating apparatusAir conditioning systemsEvaporative coolerFresh air

The invention discloses an indirect evaporation cooling method of generating cold water and cold wind at the same time and a device, belonging to the energy technical field and relating to an evaporation cooling type cold supply. Fresh air firstly enters a multistage evaporation cooling type heat recoverer, is performed with a wet cooling by an exhaust air evaporation cooling process, etc., then enters an evaporation cooler which generates the cold water and the cold wind at the same time and is performed with a direct evaporation cooling by contacting spray water; part of outlet air of the evaporation cooler is outputted to a user, while another part of the wind is used as exhaust air which is exhausted outdoor via cooling inlet air during multistage evaporation cooling process. In the evaporation cooler, the cold water is outputted after circulated and cold water of the user is cooled by the spray water and an air evaporation cooling process; a temperature of outlet water is lower than a wet bulb temperature of inlet air. The invention outputs the cold water for the user and the fresh air at a lower temperature at the same time, solves a mismatching of a flow ratio of air and water in a sensible heat transferring process and a heat and moisture exchanging process, and solves the mismatching caused by a non linearity of a saturated line through a multistage device; a cold water side for the user can be a closed system, and application situations for a unit can be more widely.

Owner:TSINGHUA UNIV +1

Water drinking assembly and pet water dispenser thereof

PendingCN114403037AReduce pollutionSolve water quality problemsAnimal watering devicesWater circulationWater drinking

The invention provides a water drinking assembly and a pet water dispenser thereof, relates to the technical field of pet supplies, and solves the technical problem that water in a water storage tank is polluted due to the fact that water in the water storage tank is circularly mixed with water flowing back from a water drinking tray in the prior art. The water drinking assembly comprises a water storage tank, a water drinking tray assembly and an isolating and blocking structure, the isolating and blocking structure is arranged between the water storage tank and the water drinking tray assembly, a water storage cavity is formed in the water storage tank, and a mounting part used for containing the water storage tank and a water drinking trough allowing a pet to drink water are formed in the water drinking tray assembly. The water storage tank is installed above the drinking water tray assembly, an isolation plugging structure is arranged between a water outlet of the water storage cavity and the installation part, the isolation plugging structure has a plugging state and an opening state, and the isolation plugging structure in the plugging state can close the water outlet of the water storage cavity so as to prevent water in the water storage cavity from flowing into the drinking water trough. The isolation plugging structure in the open state can open the water outlet of the water storage cavity so that water in the water storage cavity can flow out to the drinking trough.

Owner:BEIJING KITTEN & PUPPY TECH CO LTD

Industrial lime desulfurization technical process and device thereof

InactiveCN111686563ASolve efficiency problemsSolving labor-intensiveDispersed particle separationFlue gasProcess engineering

The invention discloses an industrial lime desulfurization technical process and a device thereof, and relates to the field of lime desulfurization. Aiming at problems that the existing industrial lime desulfurization efficiency is low and labor consumption is high, a technical scheme is provided, wherein the device includes an absorption column, a circulating pump circulating pool, a filter press, a lime bin and a lime pool, the absorption column is mounted at the top end of the circulating pool, three circulating pumps with the same structure are mounted around the absorption column, water inlets of the circulating pumps are connected with the circulating pool, water outlets of the circulating pumps are connected with the absorption column, and one side of the circulating pool is connected with the filter press. According to the invention, flue gas particles generated by desulfurized water can be solved, the problem of water quality of desulfurized water can be solved, the phenomenonof discharge of desulfurized water is solved, the desulfurized water can be recycled for a long time, resources are saved, the problems of scaling and blockage of a desulfurization pipeline and a spray head are effectively controlled, the desulfurization efficiency is improved, the manual operation time is reduced, and the process and the device are suitable for popularization.

Owner:山东诺帆电气设备有限公司

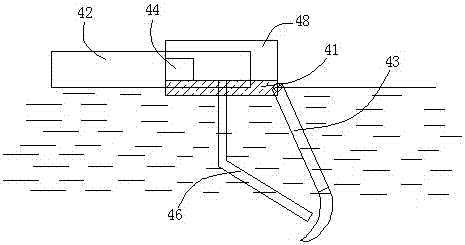

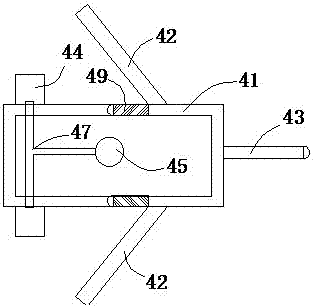

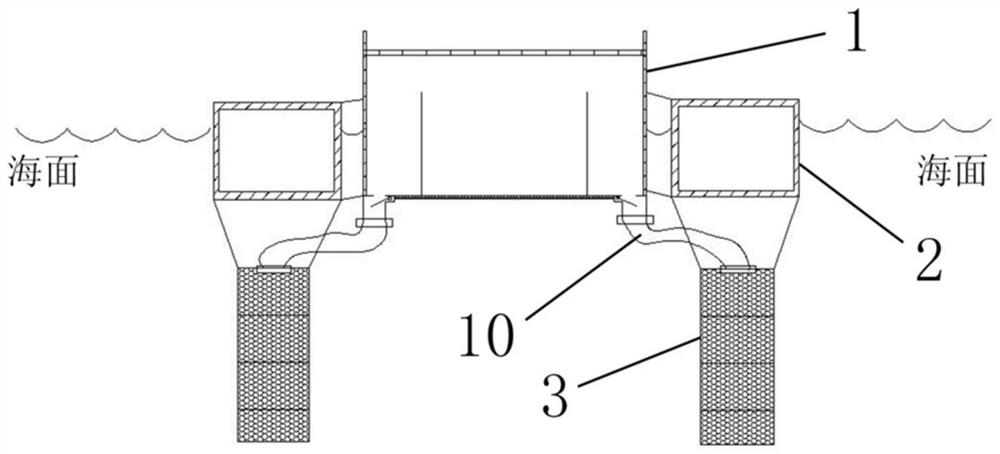

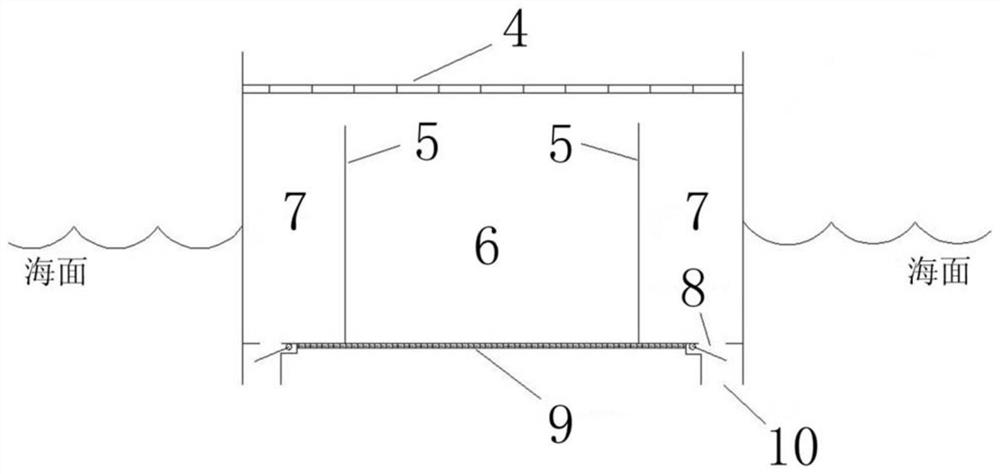

A wave-driven shellfish automatic feeding culture device and culture method

ActiveCN109349189BSolve water quality problemsReduce energy consumptionClimate change adaptationPisciculture and aquariaSea wavesZoology

The invention discloses an ocean-wave-driven shellfish automatic feeding and breeding device and a breeding method. The device includes a bait cultivation floating tank, an ordinary floating tank and a breeding net cage. The common floating tank; the lower part of the common floating tank hangs the culture net cage; the top of the box body of the bait cultivation floating tank is provided with a light-transmitting protective net, and the inside of the tank is divided into 3 areas by a partition, and the middle area is The main breeding room, the areas on both sides are feeding rooms; the bottom of the main breeding room is provided with a water-permeable filter screen that bait cannot pass through, and the water-permeable filter screen extends to the bottom of the feeding room. To pass through the door, connected with the culture net cage by pipeline. Compared with land cultivation methods, it reduces energy consumption, simplifies the shellfish cultivation process, has sufficient and adjustable light, and continuous feeding driven by waves reduces the density requirements for cultivation and reduces pollution to seawater.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com