Automatic filling machine

A filling machine and automatic technology, applied in the field of automatic filling machines, can solve the problems of asymmetric molding, low yield, unsealed, etc., and achieve the effects of improving production efficiency, reducing production costs, and uniform rotation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

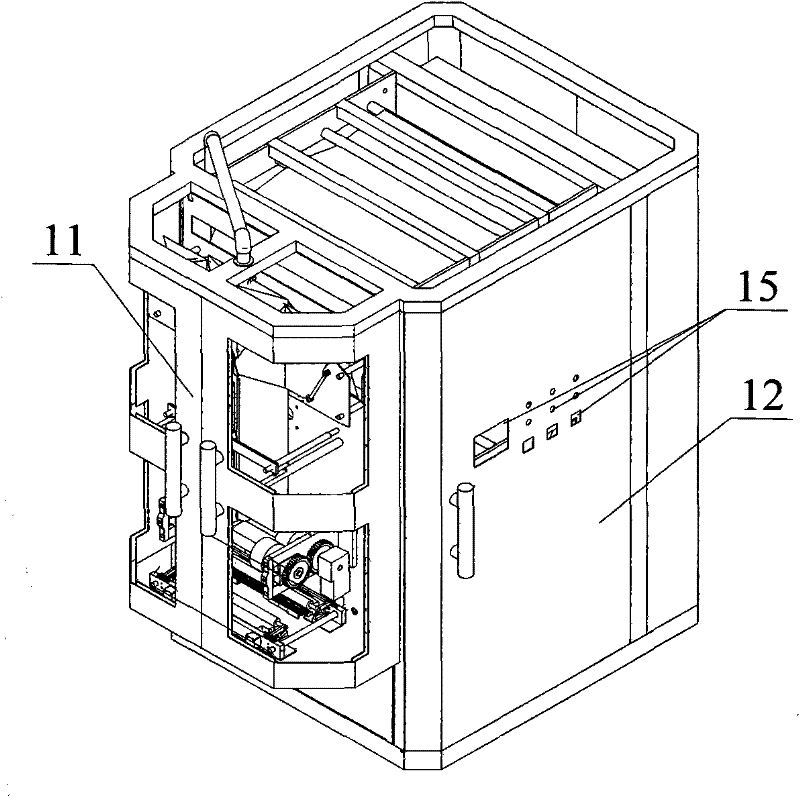

[0049] Such as figure 1 , 2 As shown in , 3, and 4, an automatic filling machine includes a frame 1 and an electric control device 400. On the frame 1, a film roll device 100 for storing and releasing films, and a splicing device for splicing films are arranged in sequence. Membrane device 200, a disinfection and cleaning device 300 for disinfecting and cleaning the stretched film, a filling device 500 for filling liquid into a film bag, a forming device 600 for turning the film into a cylindrical shape, and a cylindrical shape The vertical sealing device 700 for sealing the vertical seam (or middle seam) of the film, the film pulling device 800 for pulling the film to move, and the horizontal sealing and cutting device 900 for laterally sealing and cutting the tubular film. According to the size of the space where the equipment is located, the above-mentioned devices can be arranged horizontally or vertically, but since the opening of the film bag is upward during filling, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com