Purification method for pressure swing adsorption decarbonized evacuated gas and purification device thereof

A pressure swing adsorption and purification device technology, which is applied in chemical instruments and methods, separation methods, degassed water/sewage treatment, etc., can solve problems such as hidden dangers in safe operation of equipment, ineffective purification and recovery, and corrosion of peripheral equipment. Achieve the effects of reducing environmental impact, solving backwater quality problems, and purifying the surrounding environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

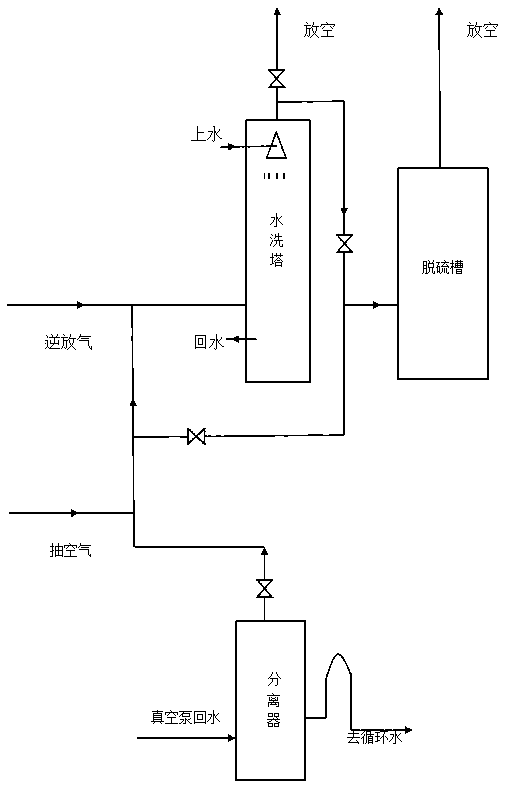

[0024] Such as figure 1 As shown, the present embodiment provides a method for purifying air by PSA decarburization, comprising the following steps:

[0025] Step 1: After the pressure swing adsorption device absorbs the raw material gas, the gas generated by reverse discharge enters the venting main pipe;

[0026] Step 2: The pressure swing adsorption device absorbs the raw material gas and the gas generated by the evacuation pump enters the vent main pipe;

[0027] Step 3: The evacuation pump adopts the water ring type, and the return water of the vacuum pump contains some CO 2 Waiting for the gas, the gas-liquid separation is carried out through the separator, and the separated gas enters the venting main pipe;

[0028] Step 4: The merged vented air enters the water washing tower, and the demineralized water is sprayed down from the upper part of the water washing tower, and is in reverse contact with the vented air to absorb the residual acid gas in the vented air, and t...

Embodiment 2

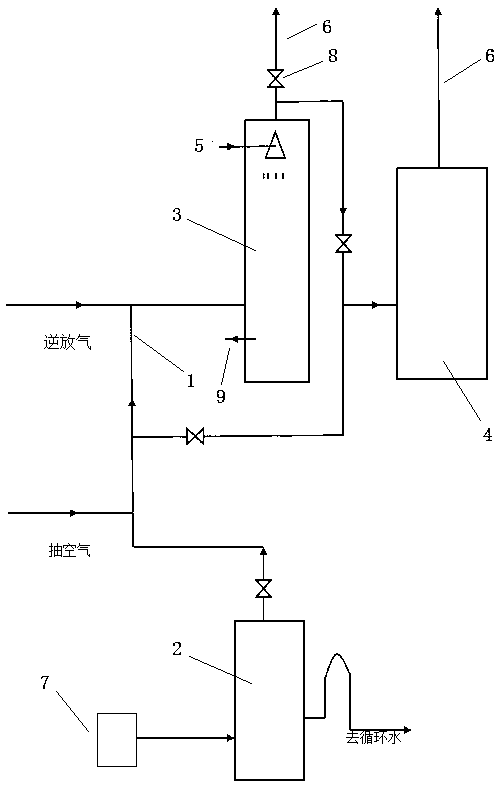

[0034] Such as figure 2 As shown, the present embodiment provides an air purification device, which includes a venting main pipe 1, a separator 2, a water washing tower 3 and a desulfurization tank 4, and the pressure swing adsorption device reversely releases the gas generated after absorbing the raw material gas and the variable The pressure adsorption device absorbs the raw material gas and the gas produced by the evacuation pump is respectively introduced into the venting main pipe 1, and the other end of the venting main pipe 1 is connected to the bottom of the water washing tower 3, and the desulfurization tank 4 is provided with pipeline, and a spray head 5 is arranged on the top of the water washing tower 3, and an emptying pipe 6 is arranged on the top of the water washing tower 3 and the desulfurization tank 4, and the return water of the vacuum pump 7 is received by the separator 2 , and the gas after gas-liquid separation is transported to the vent main pipe 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com