Blast furnace slag flushing water purification system and method thereof

A blast furnace slag flushing water and purification system technology, which is applied in the field of blast furnace slag flushing water purification and blast furnace slag flushing water purification system, can solve the problems of unclean separation of slag and water, complicated operation, and large area occupied by the bottom filtration method. Good purification effect, small equipment size, and small filter area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

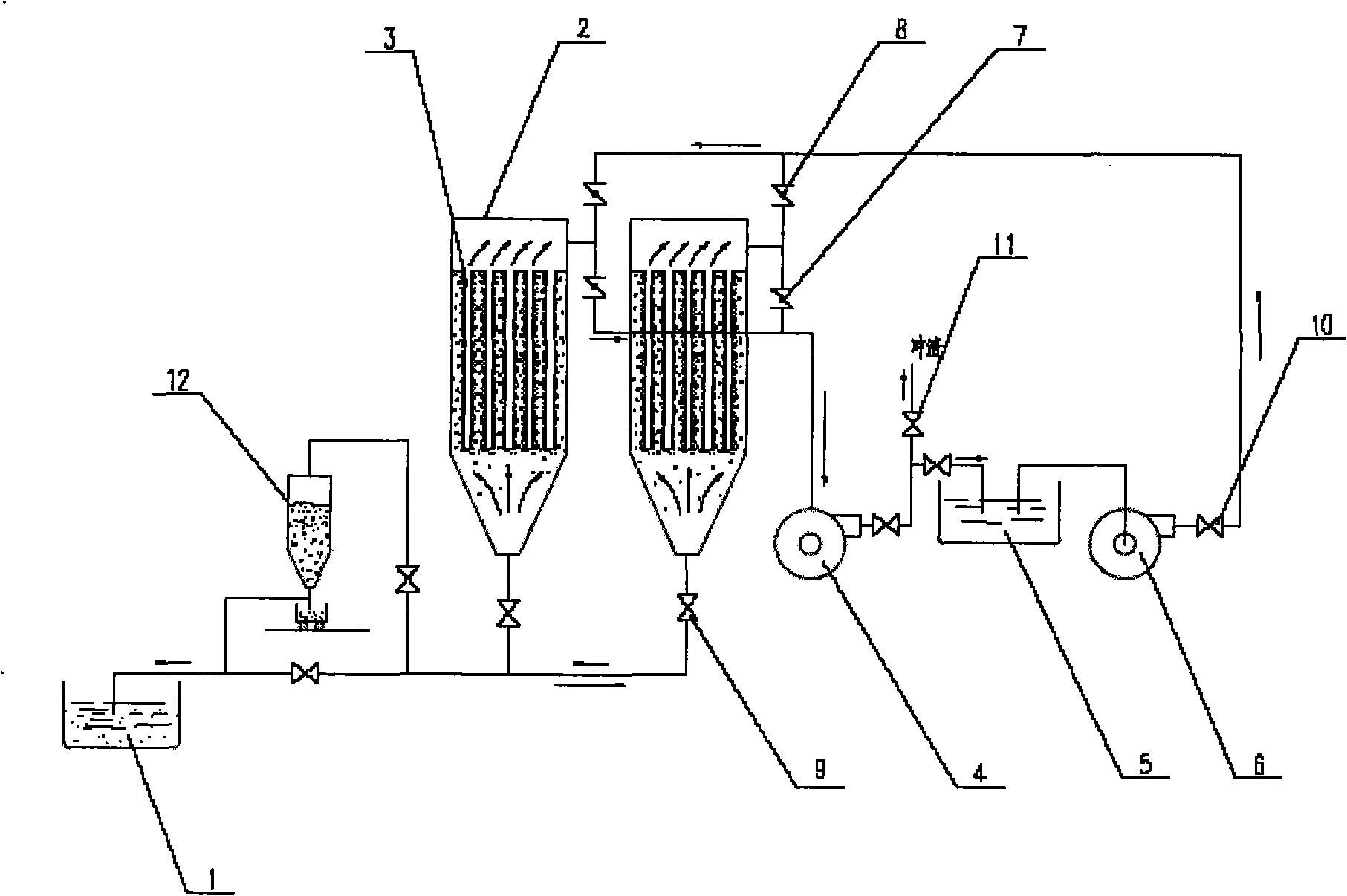

[0022] exist figure 1 The structure of the medium slag-containing pool 1 and the filter equipment 2 are cylindrical pressure-resistant containers, and the cylindrical filter elements 3 are arranged in an orderly manner. The slag-containing water enters the filter 2 from the lower part through the ball valve 9 to be filtered and purified; the water flow depends on the filter water pump. 4 drive, continuous purification; the effluent enters the clean water pool 5 for storage. It is also possible to combine the filter water pump 4 with the slag flushing pump of the existing slag treatment system, and flush the slag while filtering; the outer surface of the filter element increases with the thickness of the slag layer, and the loss of water flow resistance continues to increase, and reverse backwashing is performed after reaching the set value At this time, the filter butterfly valve 7 is closed, and the backwash butterfly valve 8 is opened. With the help of the backwash water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com