Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Smash all round" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

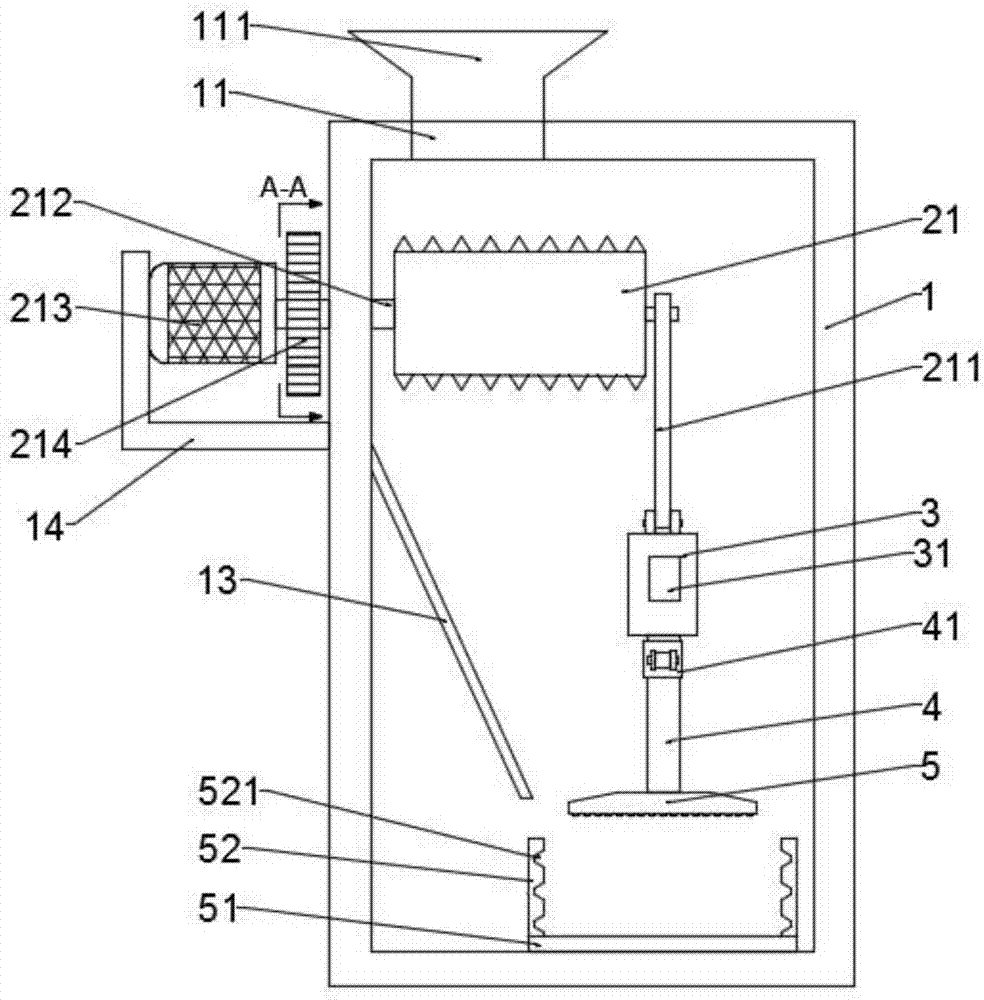

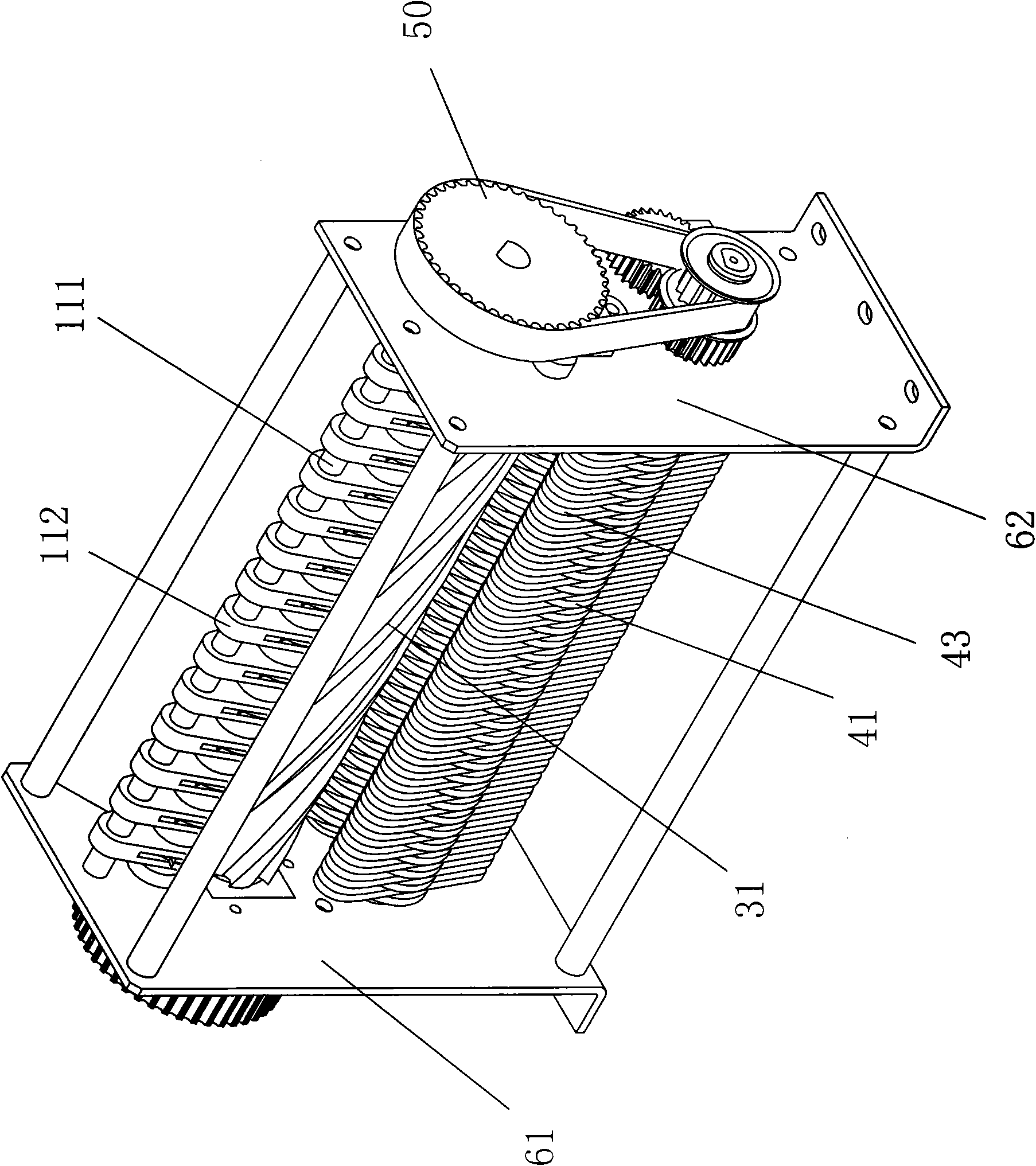

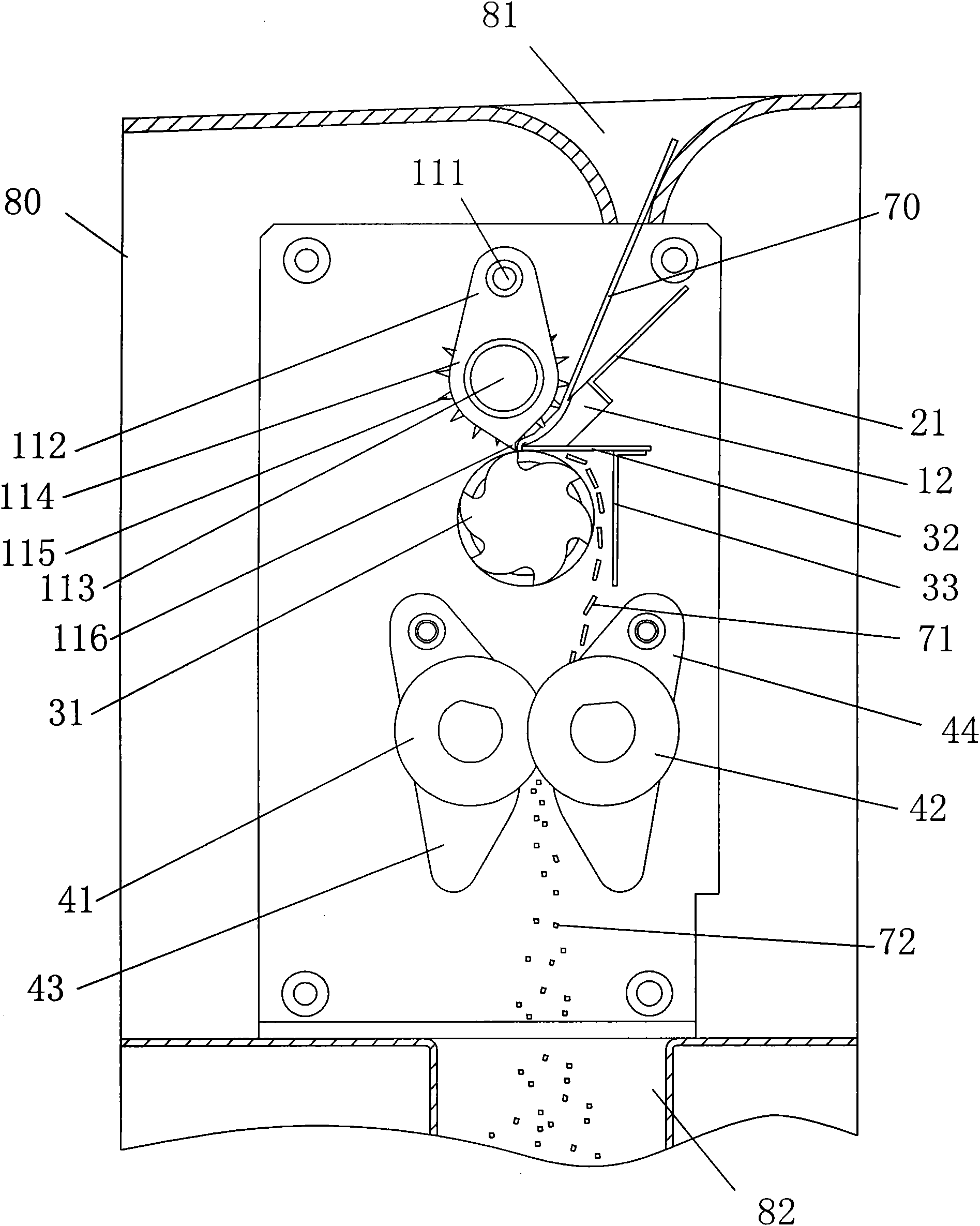

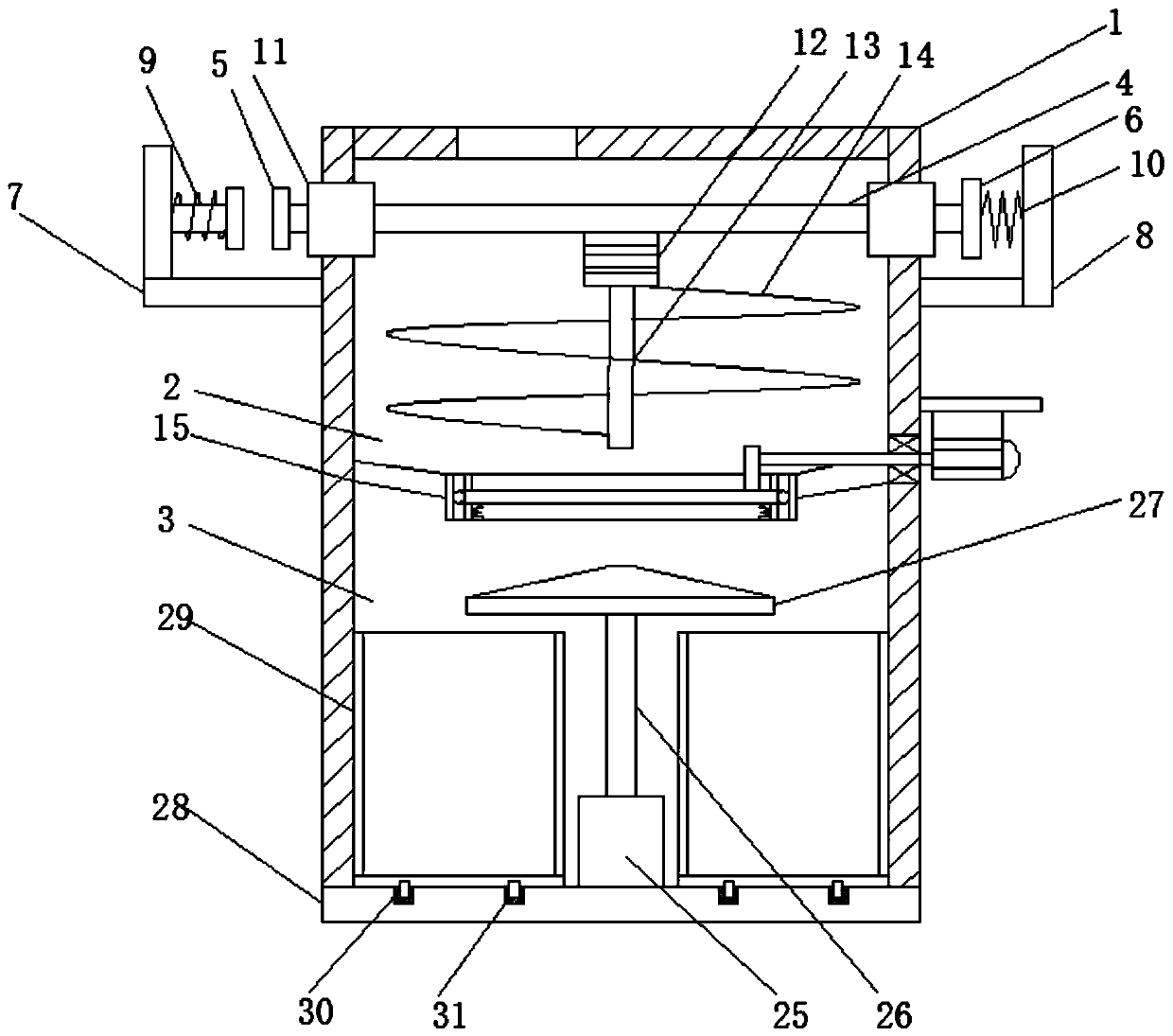

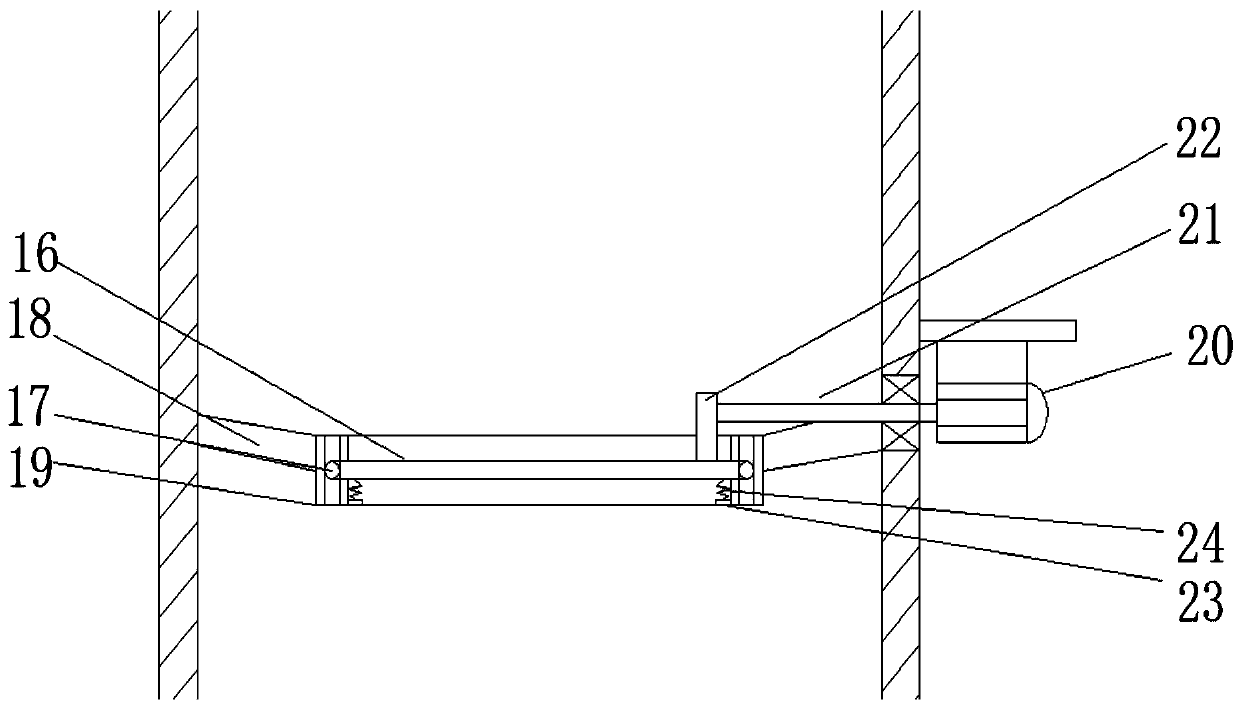

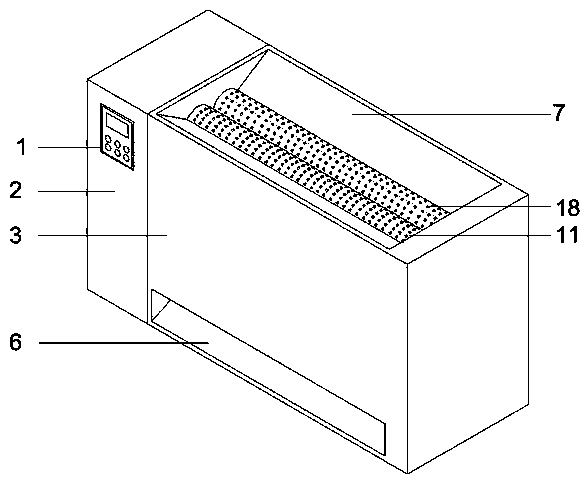

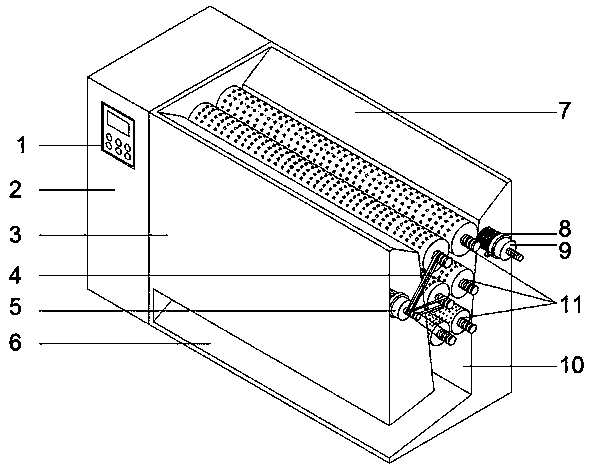

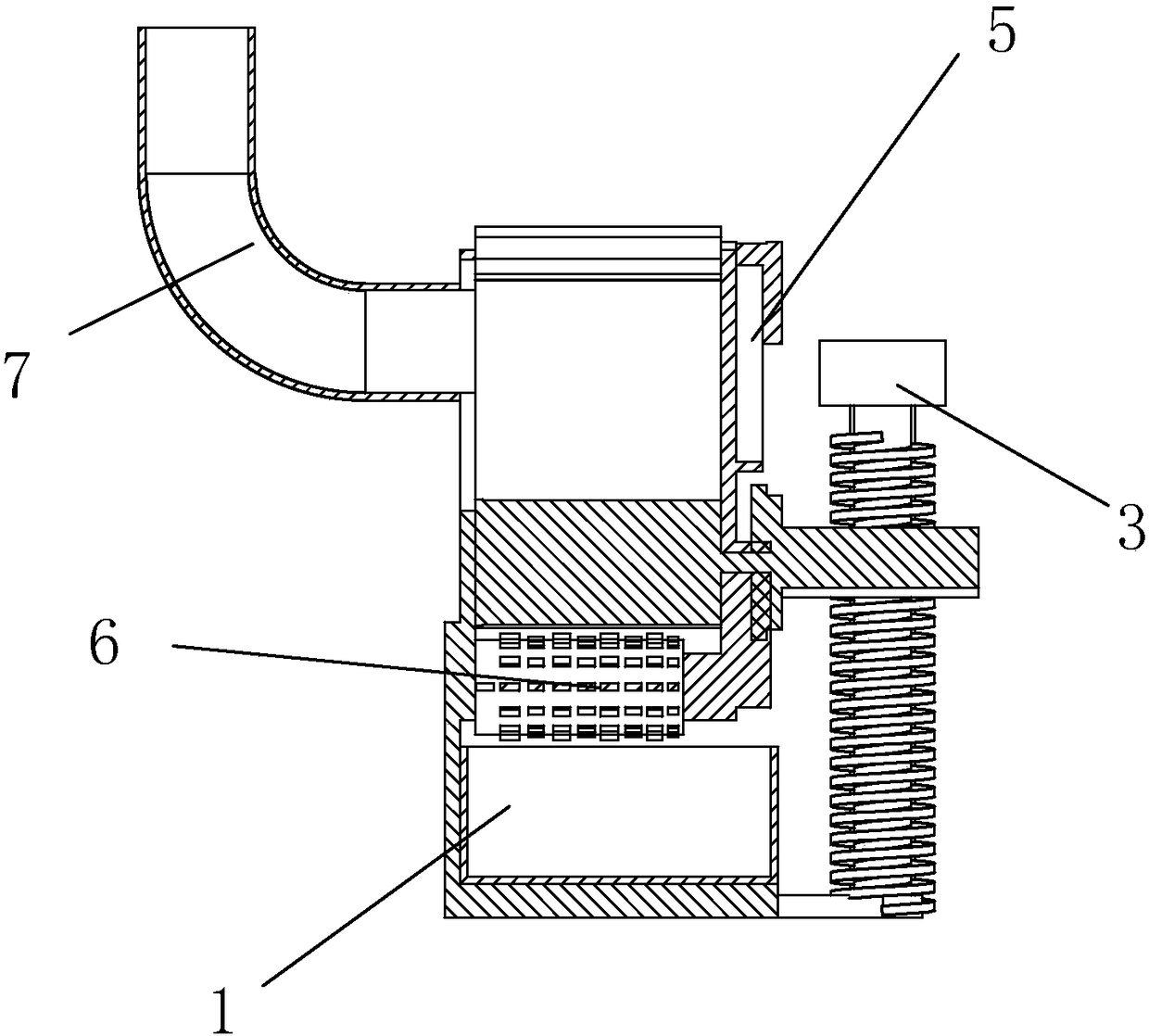

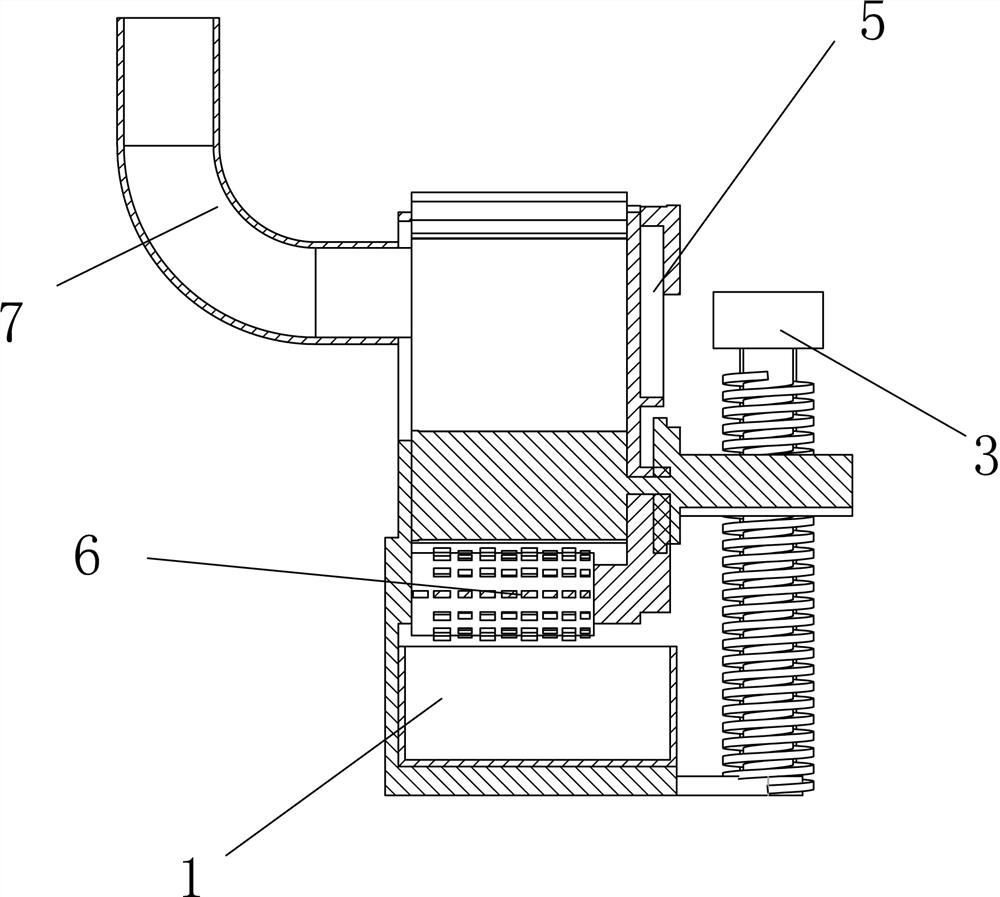

Shredder

ActiveCN102463179ALow costImprove practicalityGrain treatmentsPulp and paper industrySmall particles

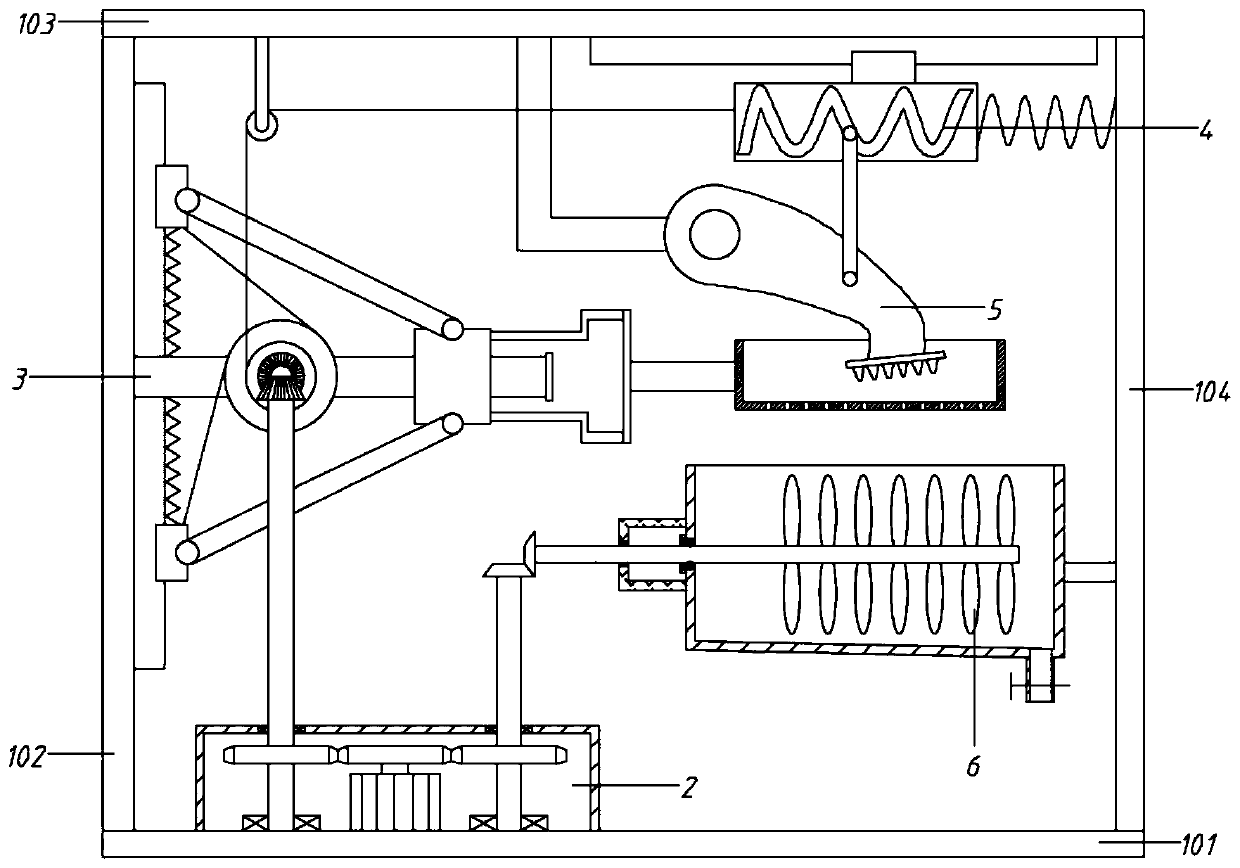

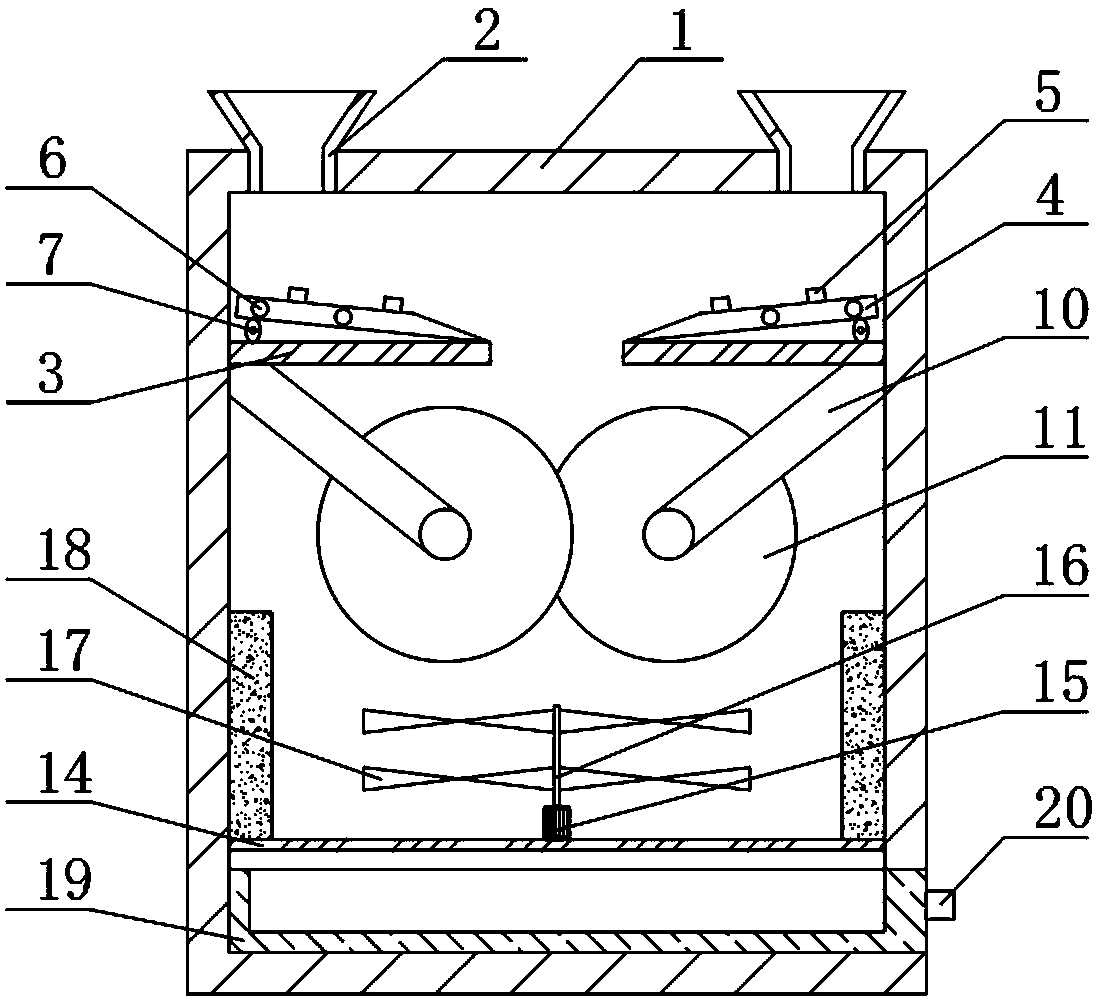

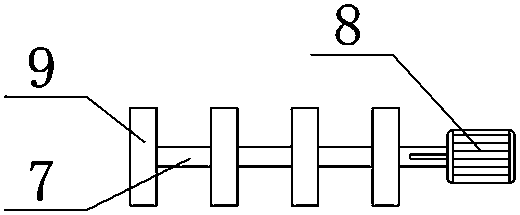

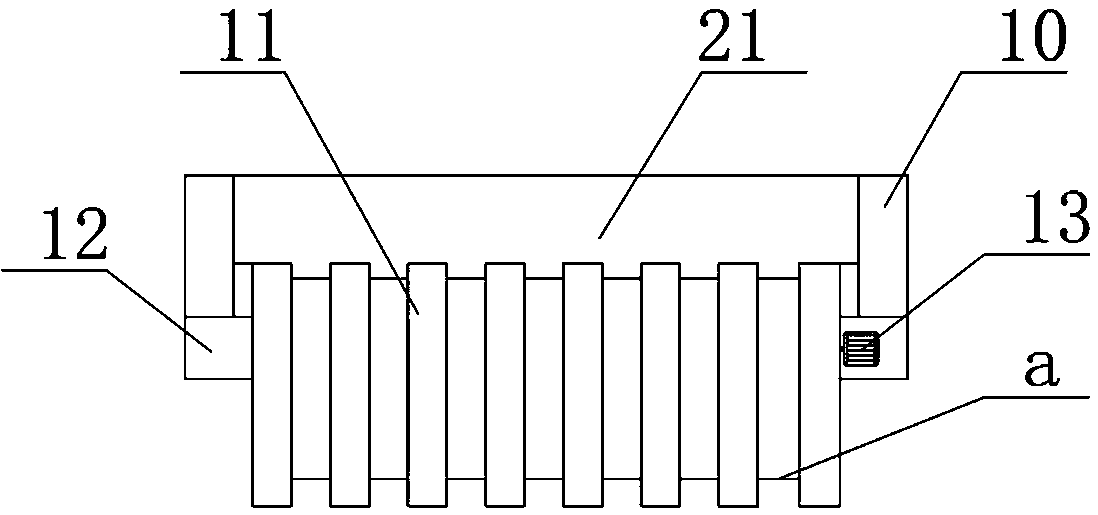

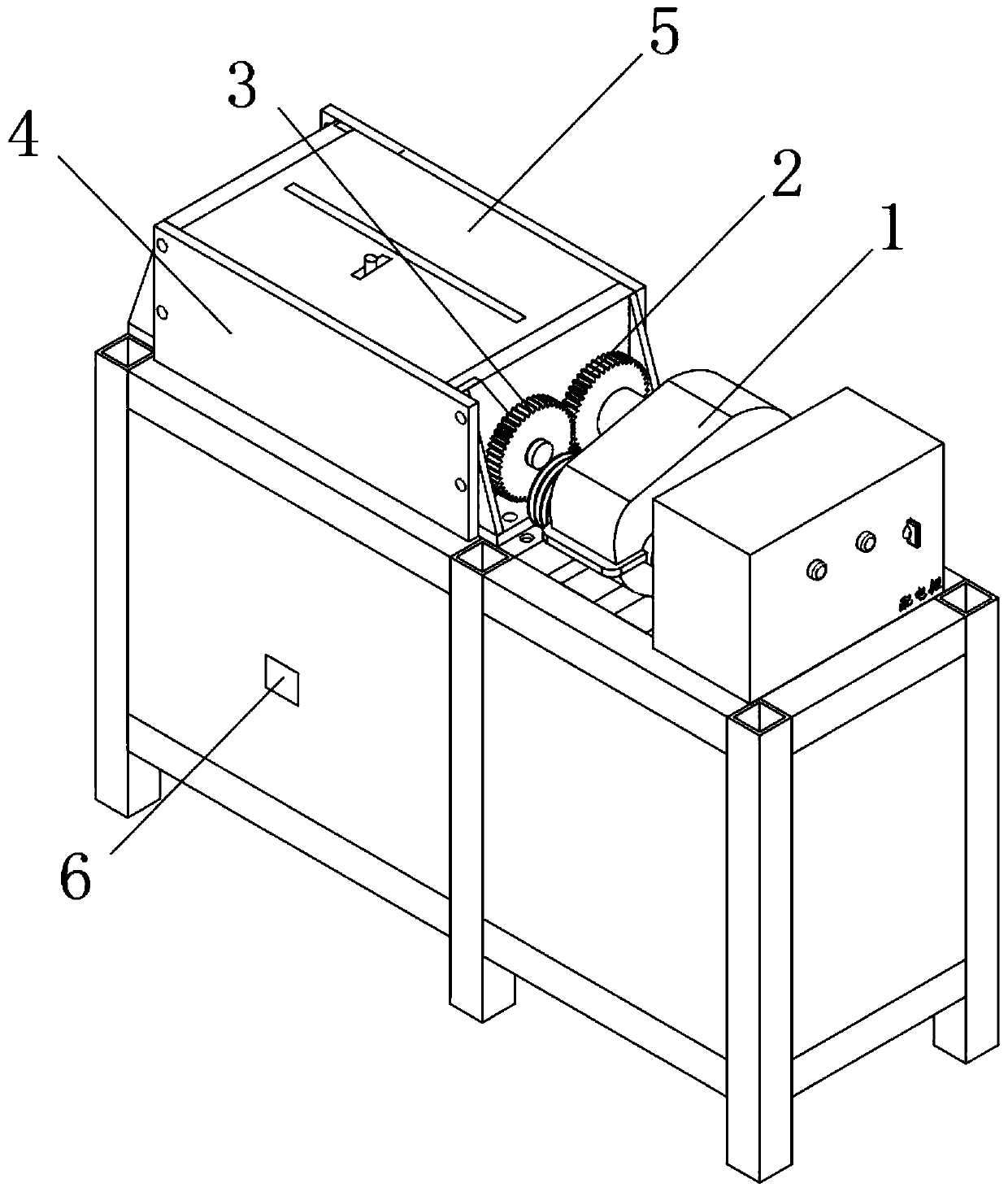

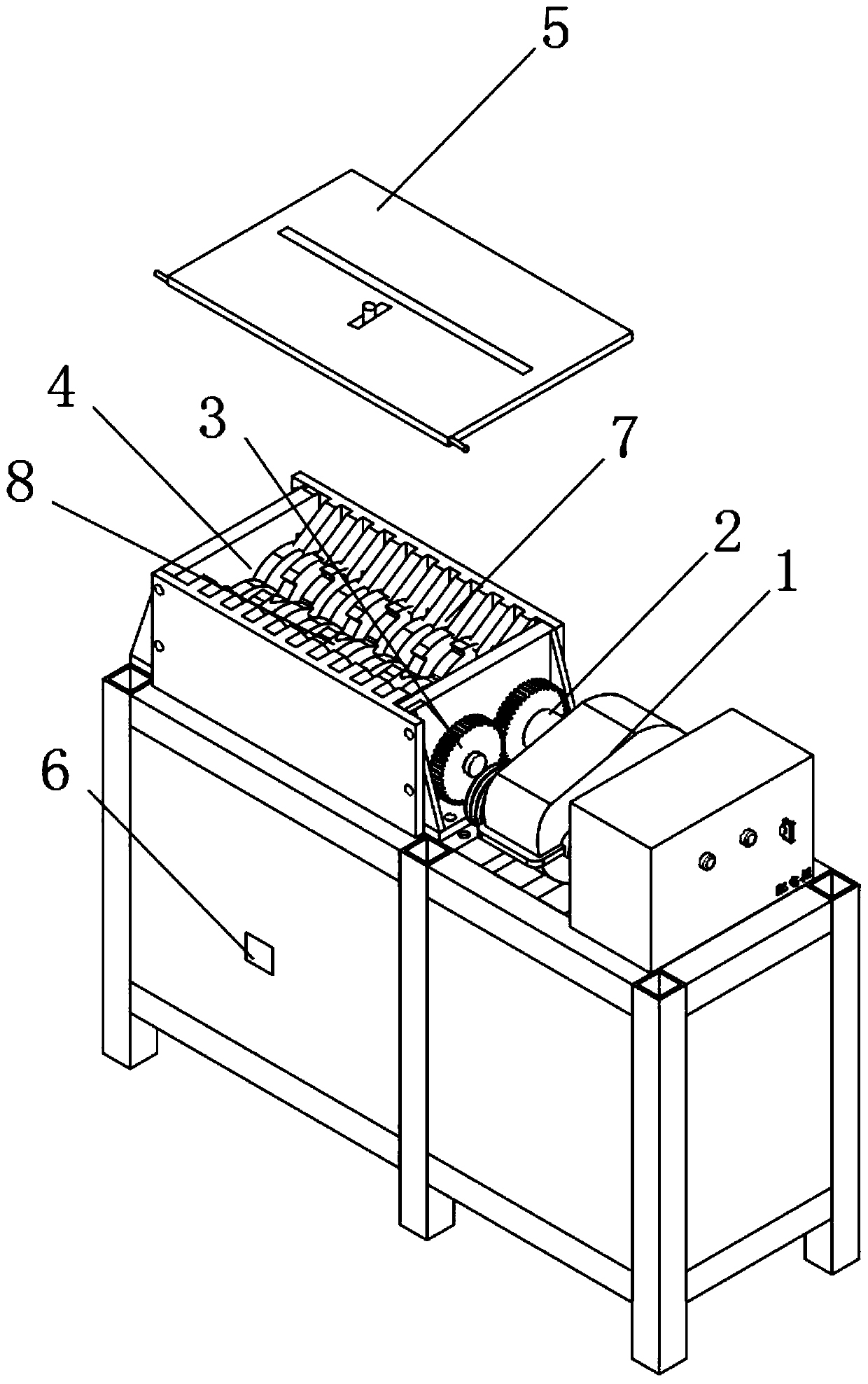

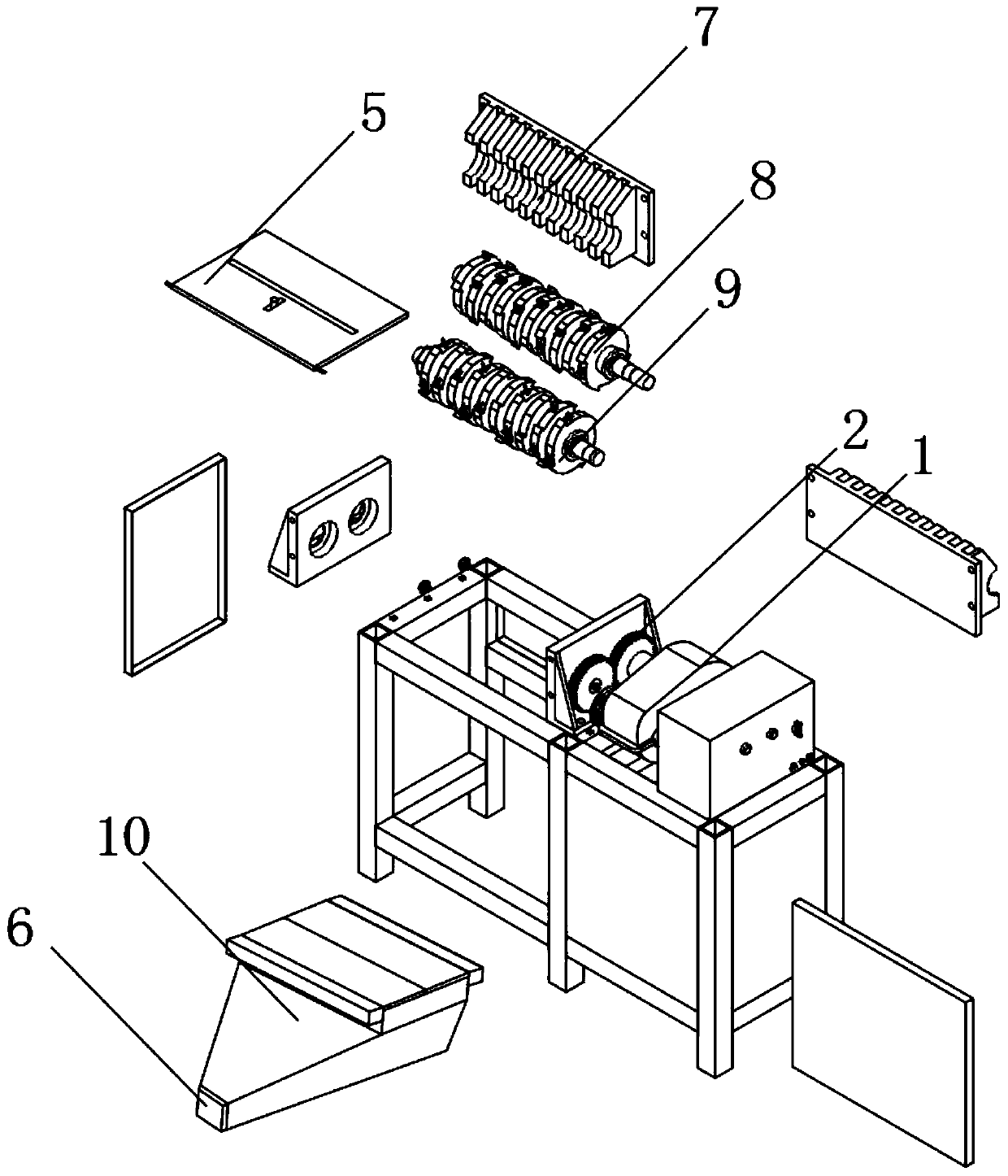

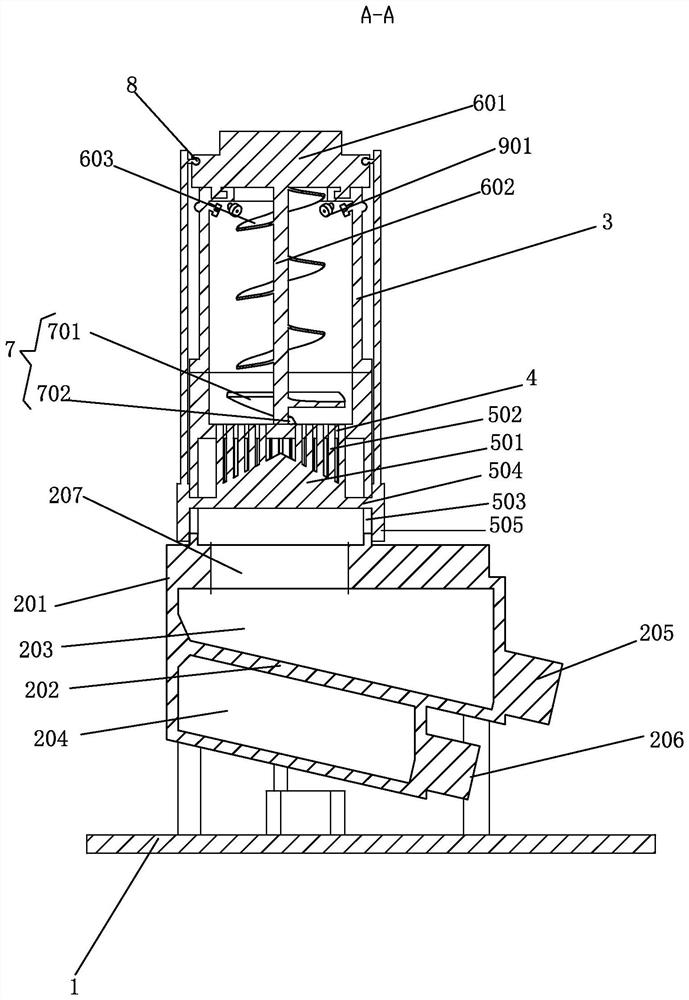

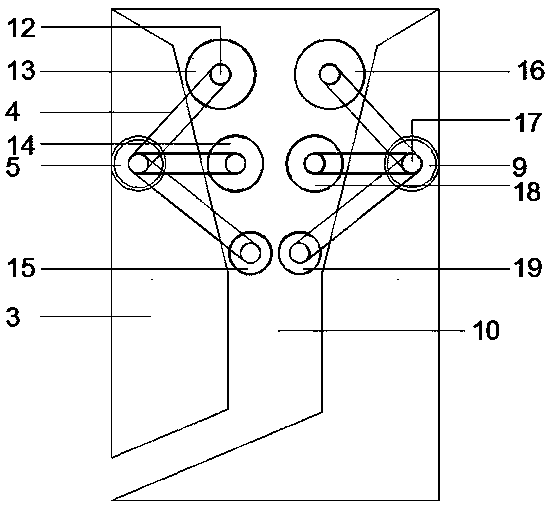

The invention discloses a shredder, comprising a housing. A paper inlet and a paper outlet are respectively arranged on top and bottom of the housing. A paper guiding mechanism for drawing and conveying paper, a transverse paper cutting mechanism for cutting paper into transverse strips and a vertical paper cutting mechanism for cutting the transverse strips into particles are arranged in the housing. The transverse paper cutting mechanism is arranged under the paper guiding mechanism; the vertical paper cutting mechanism is arranged under the transverse paper cutting mechanism; the paper guiding mechanism, the transverse paper cutting mechanism and the vertical paper cutting mechanism are all connected with a transmission mechanism; the paper inlet is arranged corresponding to the paper guiding mechanism, and the paper outlet is arranged corresponding to the vertical paper cutting mechanism. The shredder of the invention can crush paper into small particles rapidly and carry out effective crushing and destroy on paper, and is simple and convenient for operation.

Owner:BEIJING HESHENGDA INFORMATION SECURITY TECH

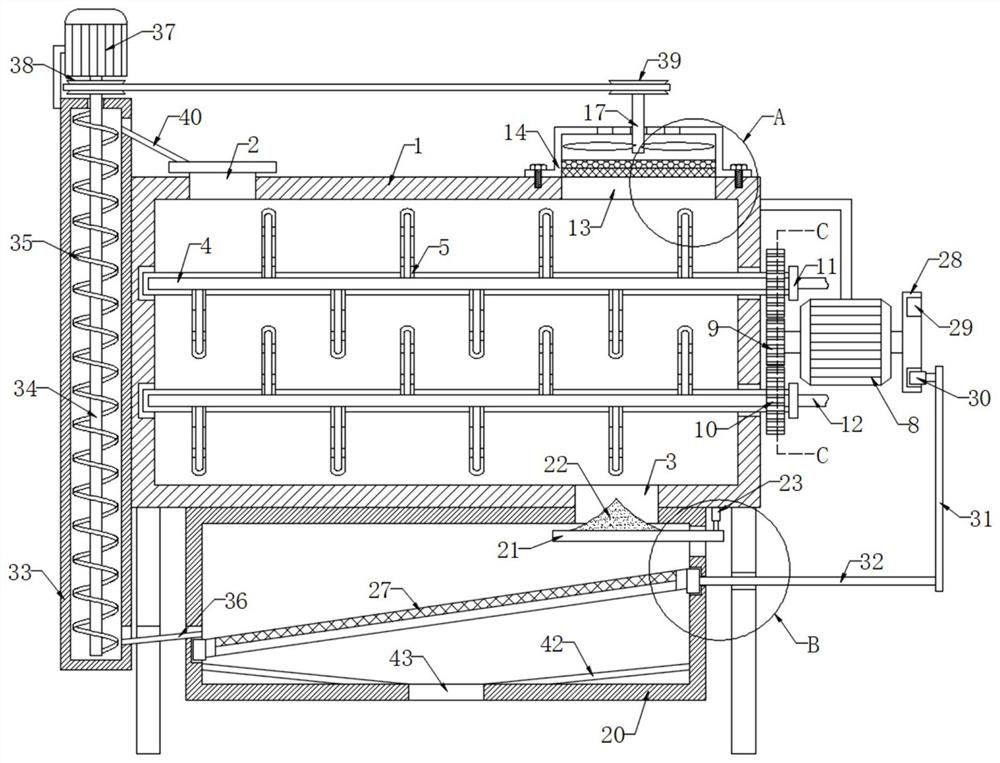

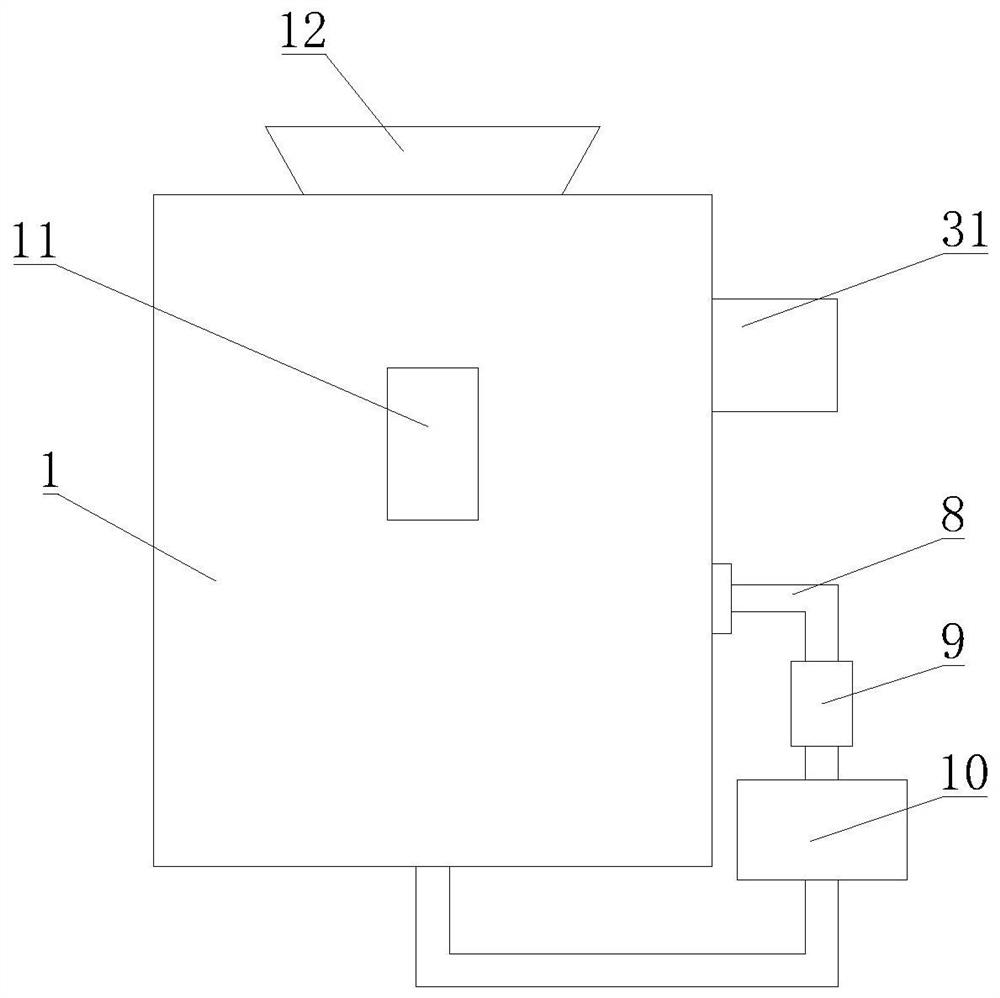

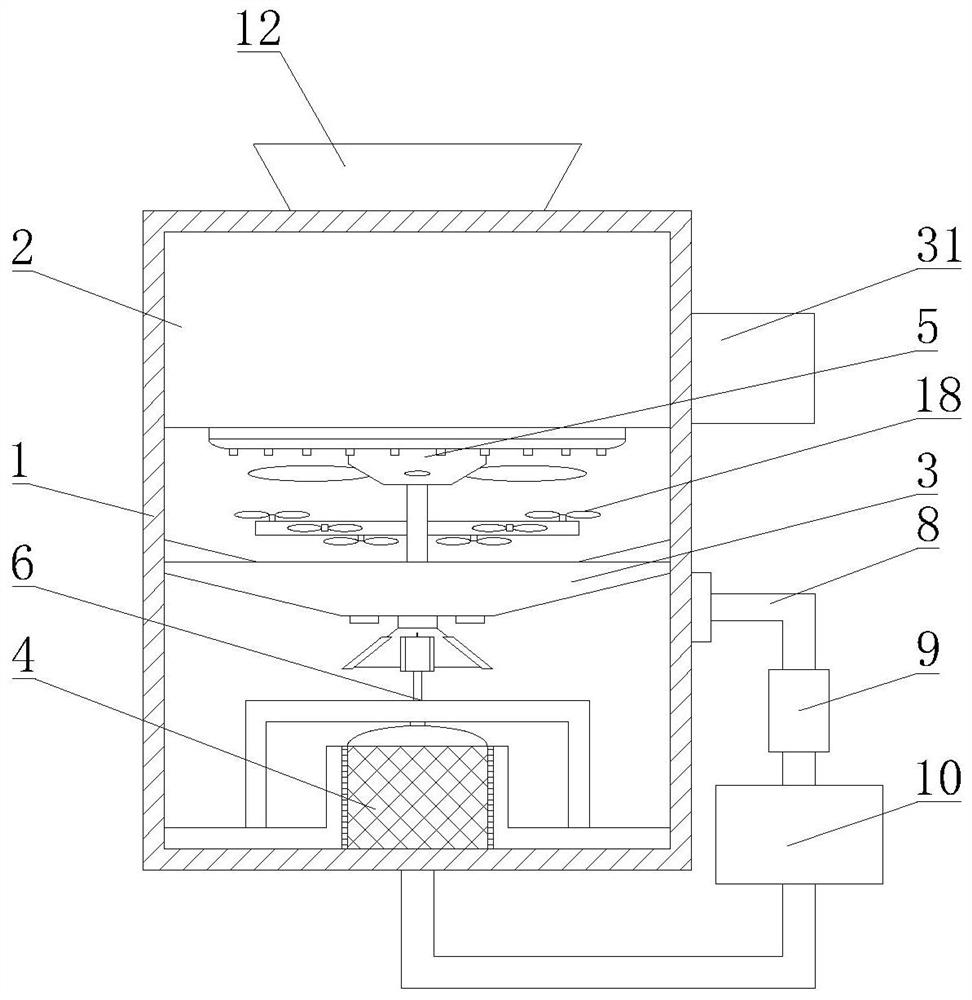

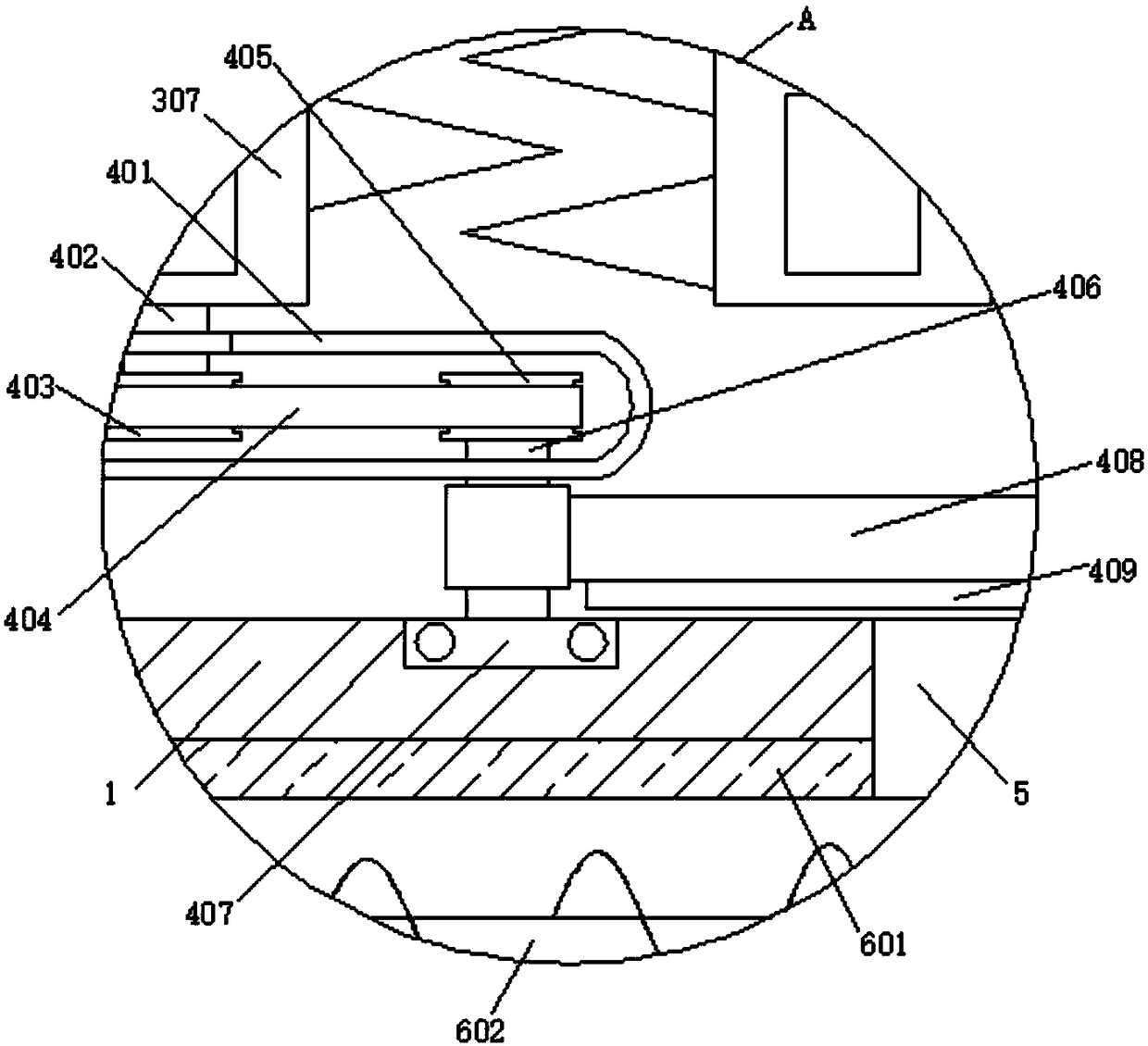

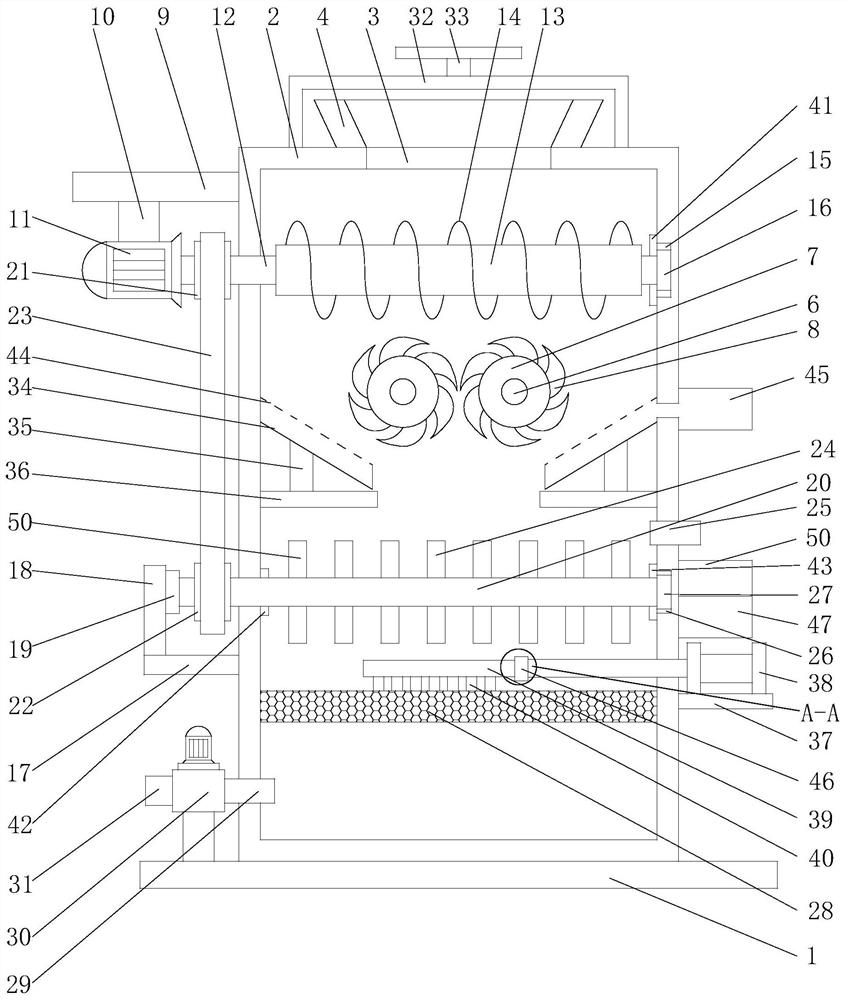

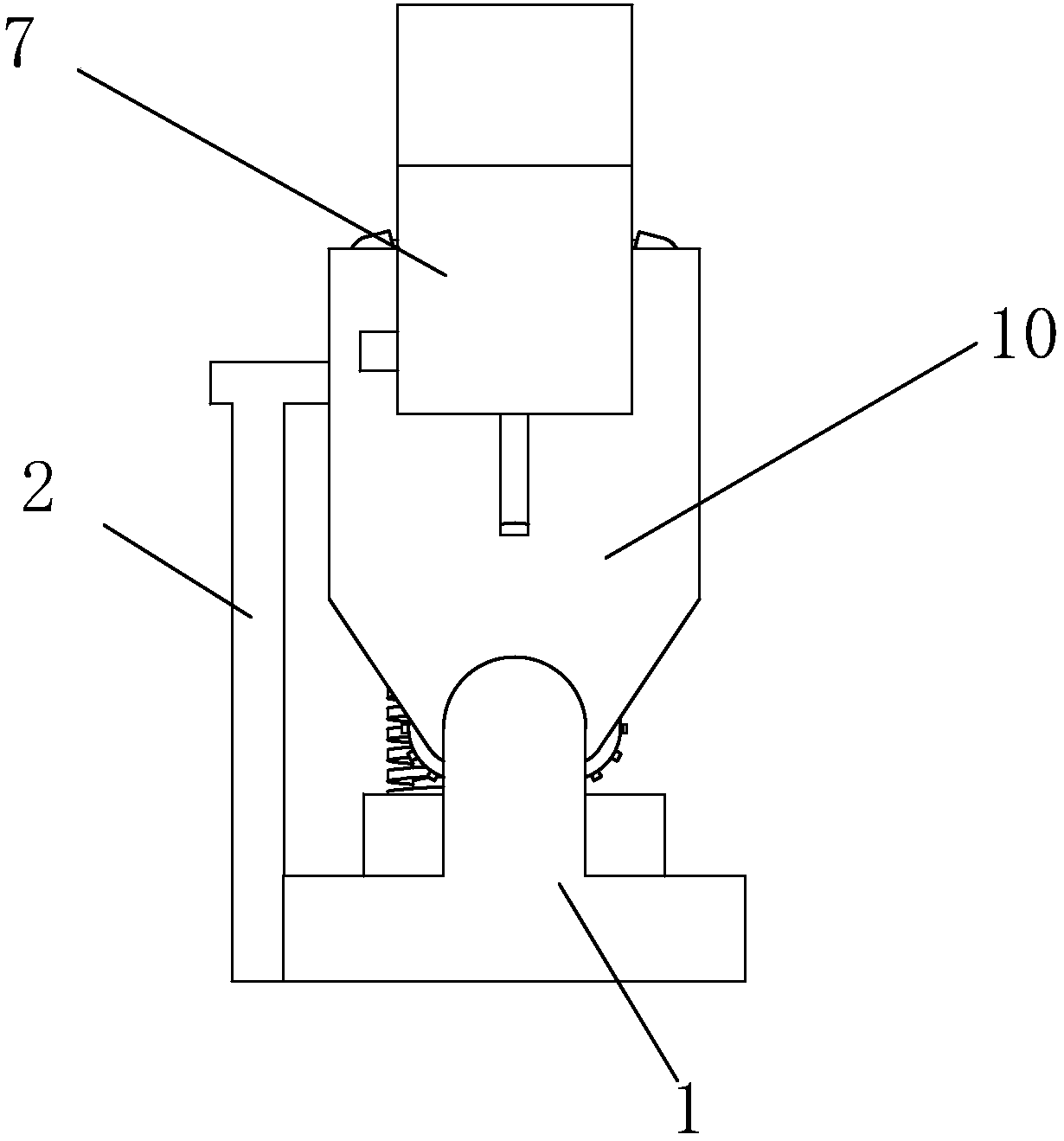

Material processing and feeding device used for animal husbandry

InactiveCN105557533AShorten the preparation cycleImprove processing efficiencyFeeding-stuffAnimal feeding devicesFood safetyEngineering

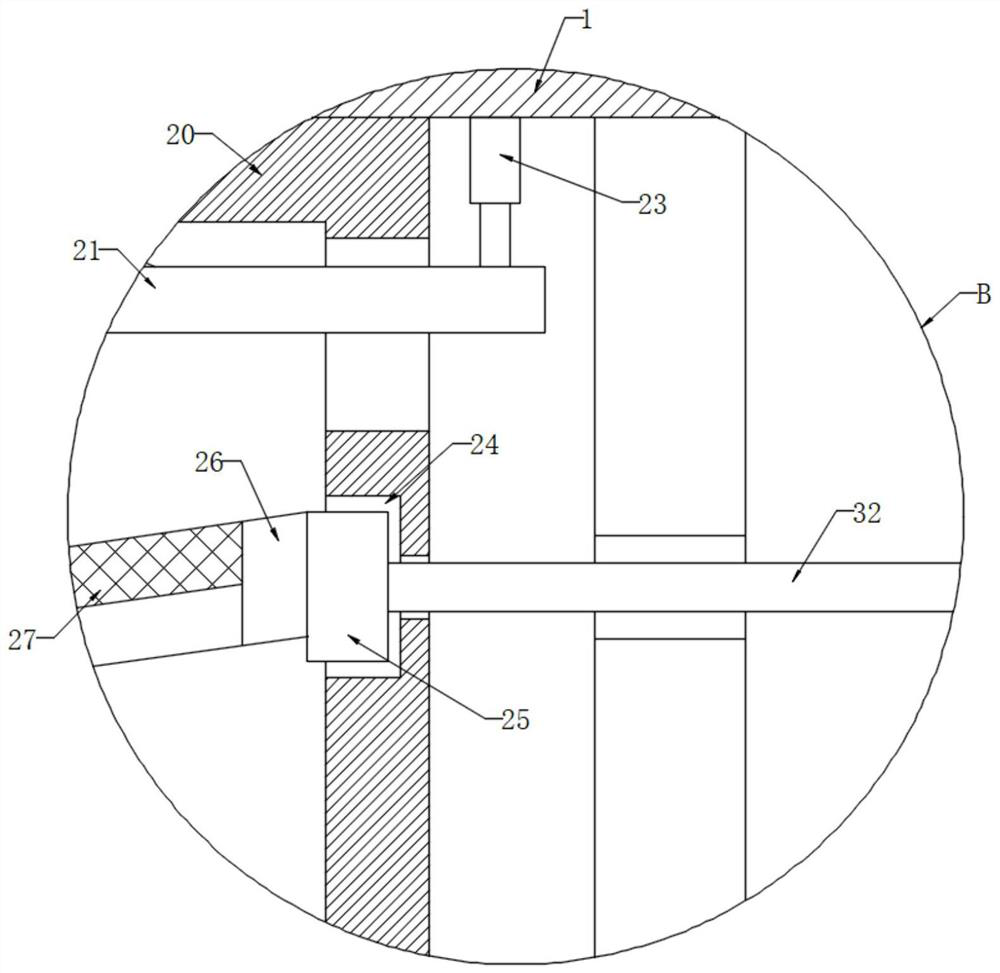

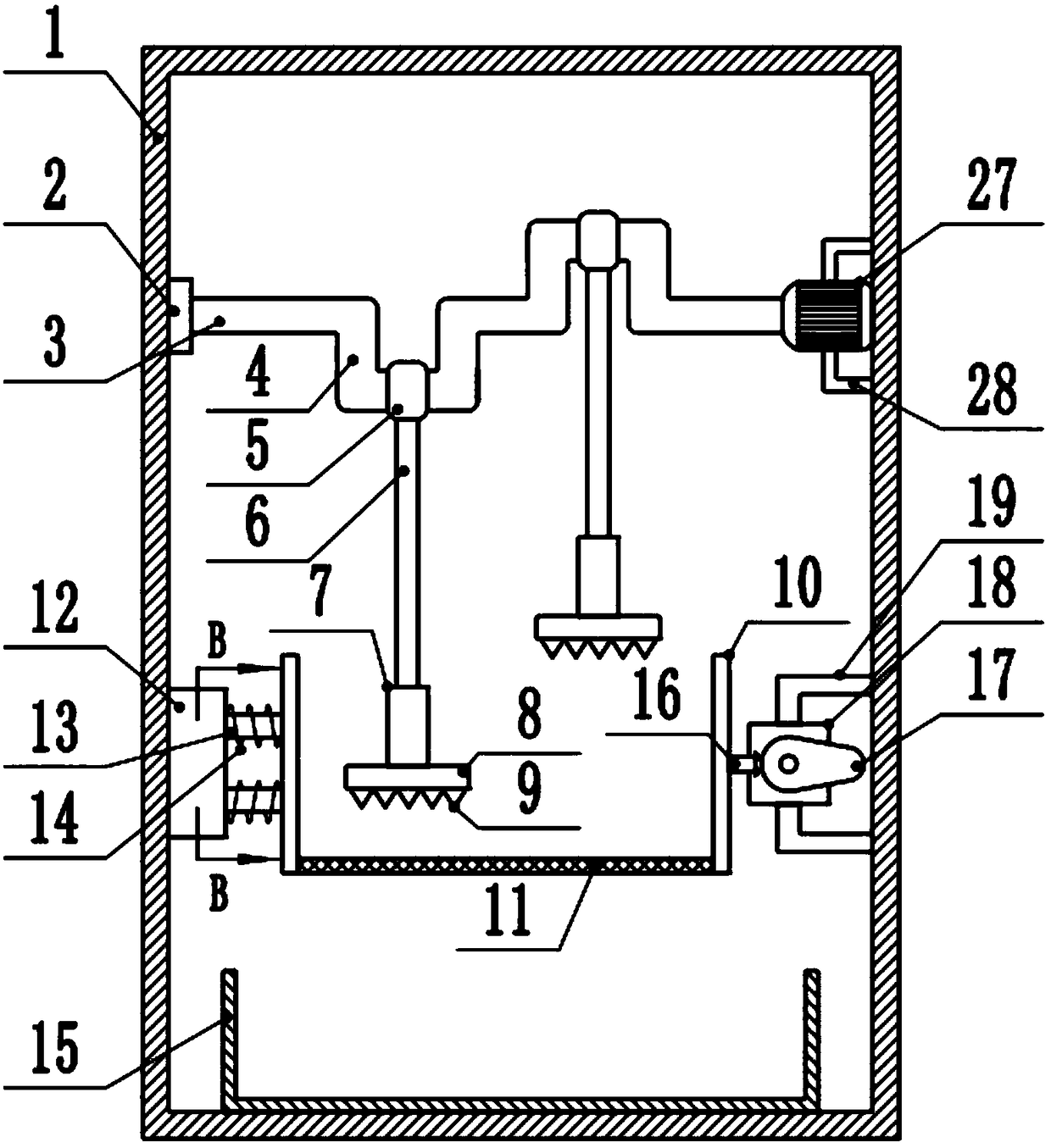

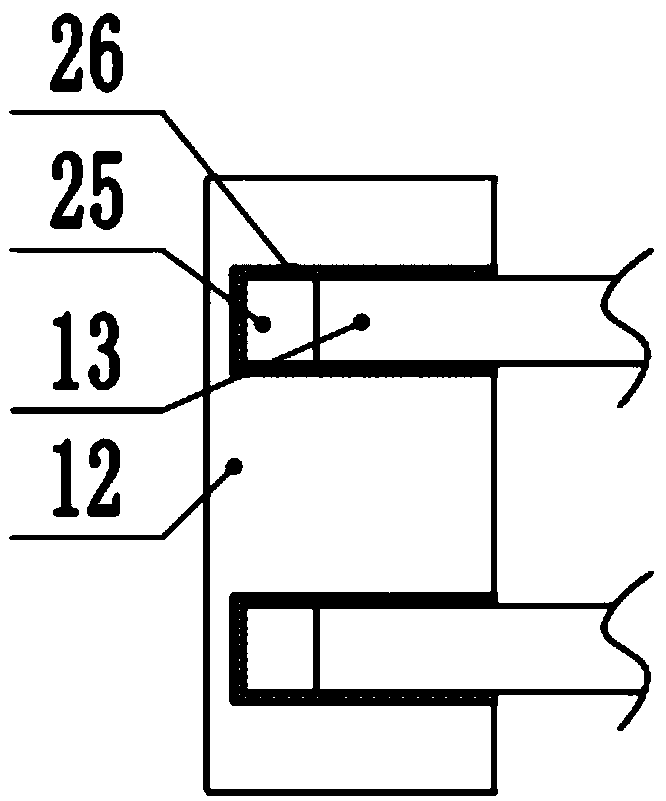

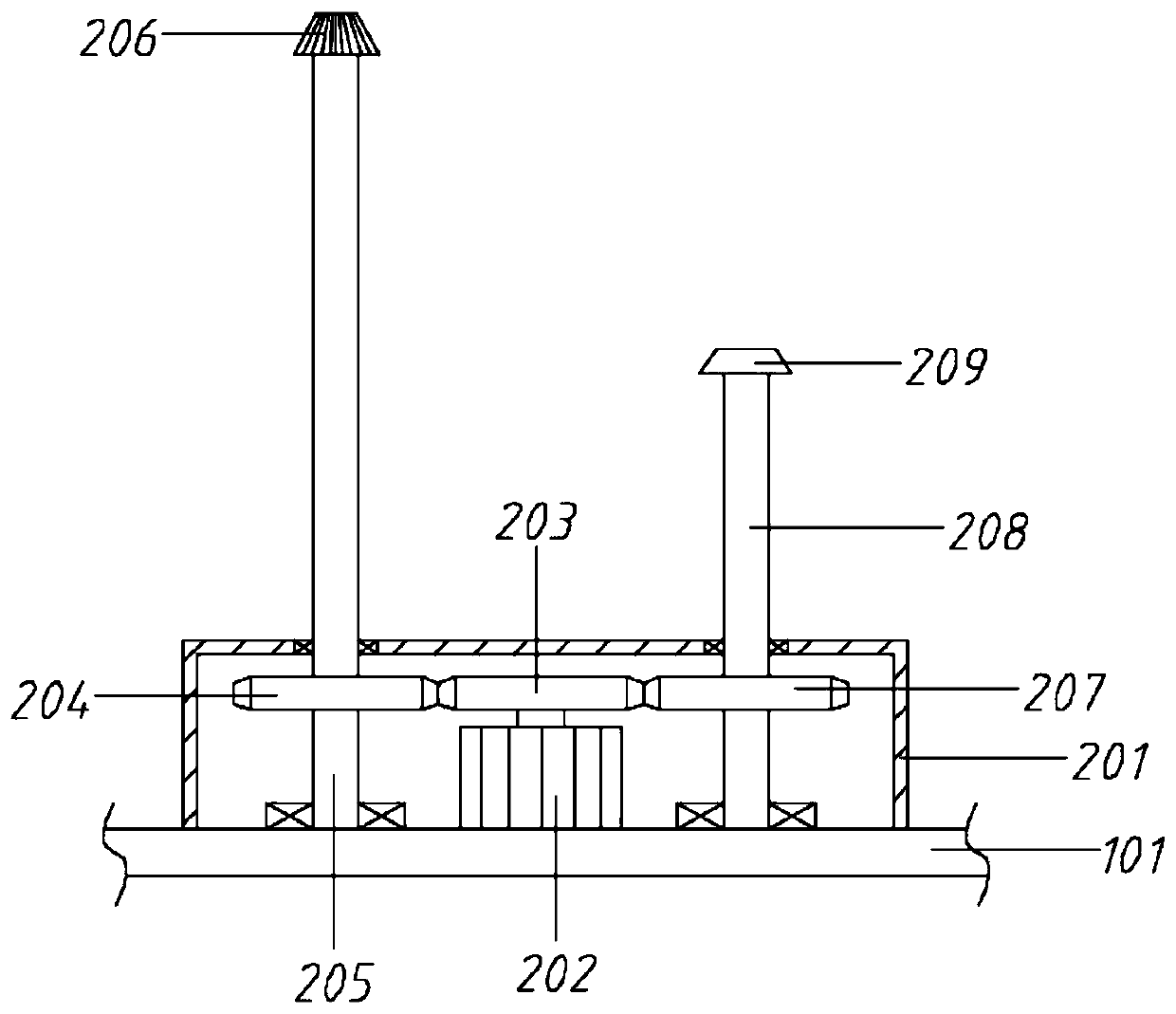

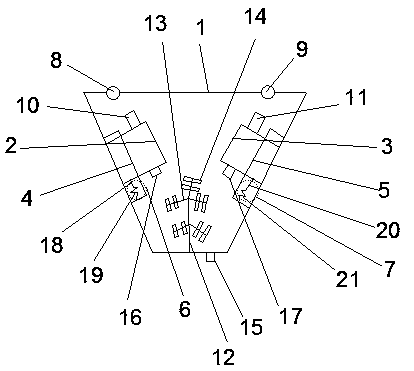

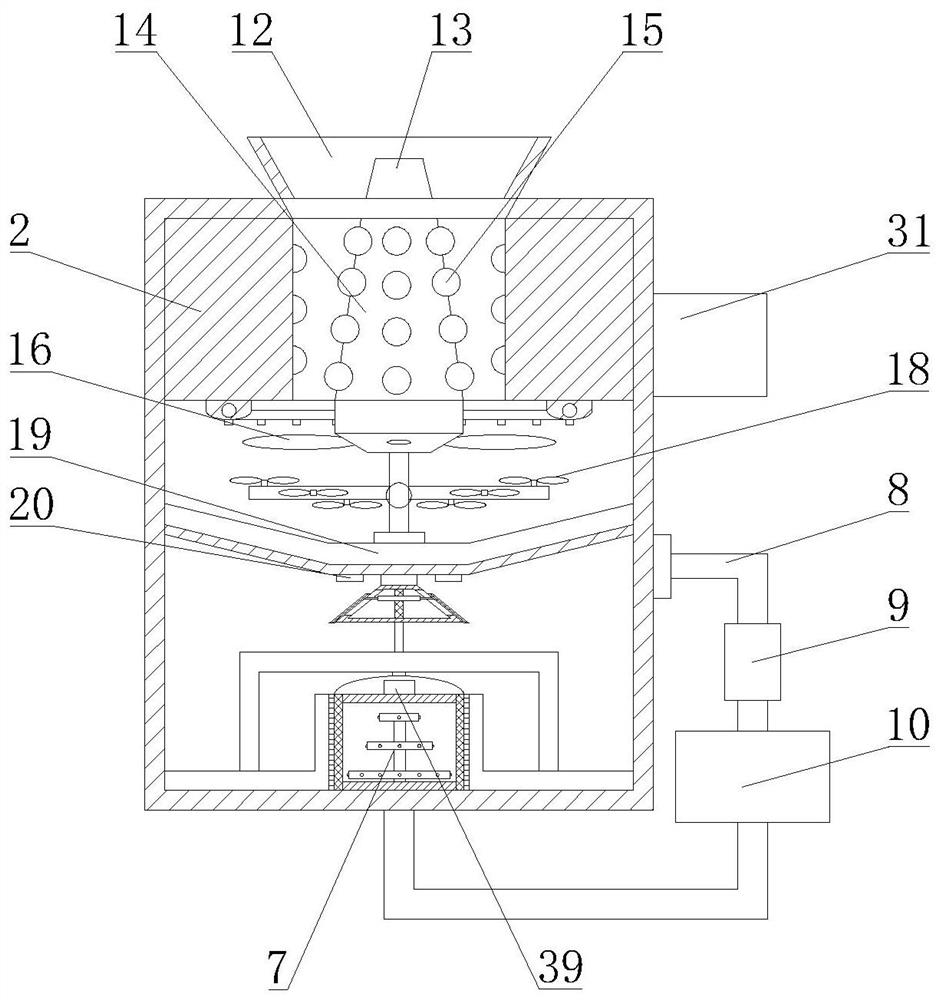

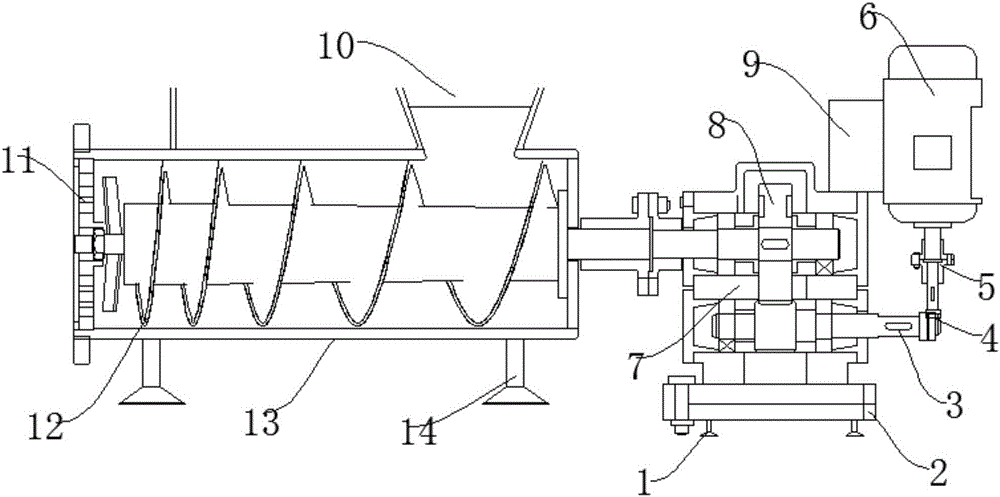

The invention discloses a material processing and feeding device used for animal husbandry. The material processing and feeding device used for the animal husbandry comprises a smashing cavity, wherein a smashing turntable body is fixedly arranged inside the smashing cavity by virtue of a power rotating shaft, a central serrated plate is arranged on the power rotating shaft, a pretreatment cavity is arranged at the top of the smashing cavity, a microwave sterilization device is arranged on the outer side wall of the smashing cavity, a bottom baffle is arranged below a semi-circular screen, the lower surfaces of the two ends of the bottom baffle are connected with a lifting cylinder, a discharging and weighing sensor is arranged at the bottom of a blanking cavity, a feeding weighing sensor is arranged at the bottom of a feeding channel, and a screw conveying bucket is also arranged at one side of the smashing cavity. The material processing and feeding device used for the animal husbandry can carry out pre-smashing treatment on materials, three cutting tools jointly act for carrying out comprehensively smashing on the materials, the bottom baffle can prevent the accumulation phenomenon and also can guarantee accurate supply of food, and the microwave sterilization device can carry out sterilization and disinfection treatment on the materials, so that food safety of feeds is improved.

Owner:郑焕刚

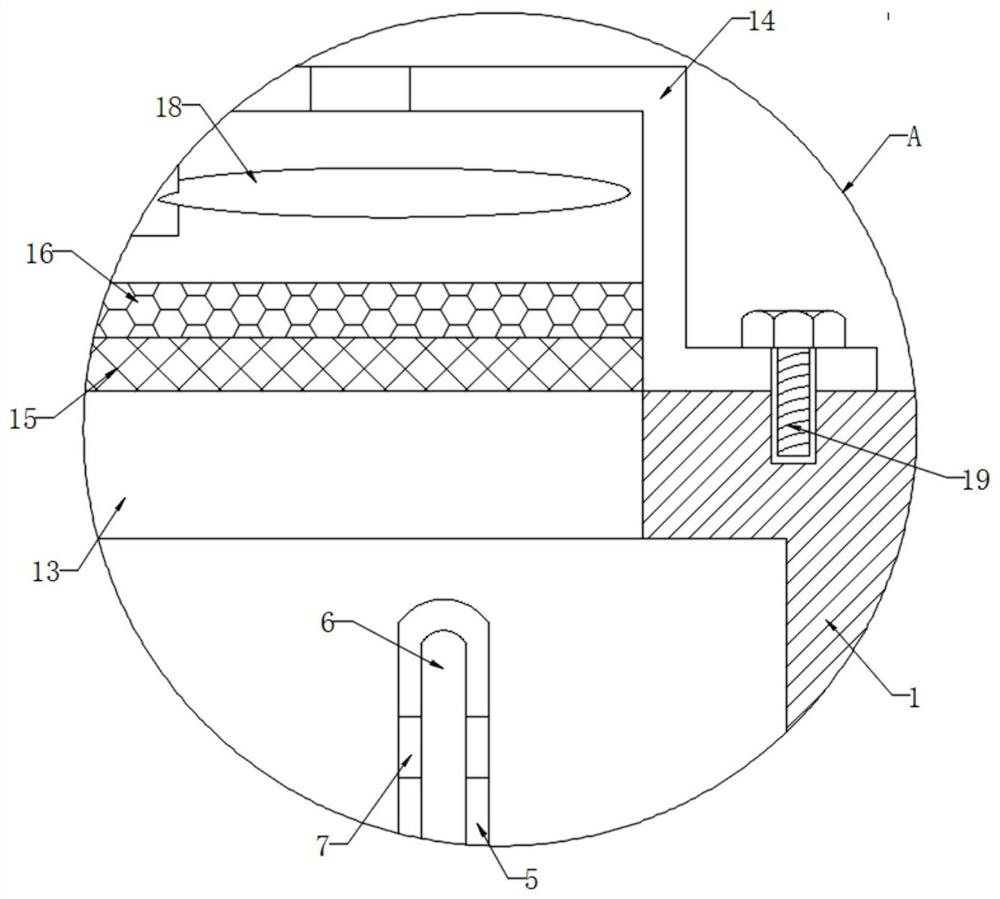

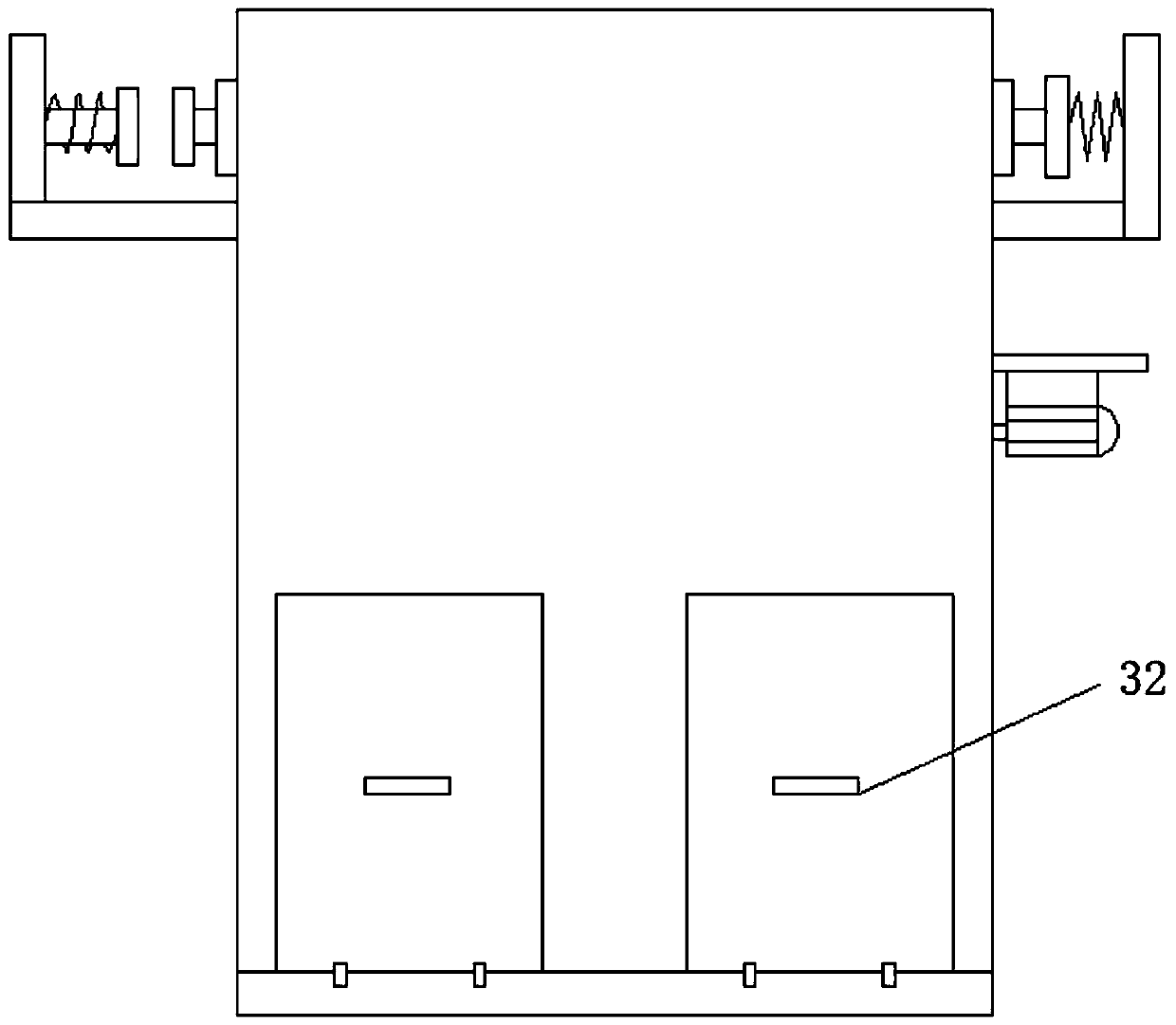

Waste paper recovery device with high recovery efficiency

ActiveCN109482303ASolve the problem of low recycling efficiencyFully processedGrain treatmentsStationary filtering element filtersDrive wheelPulp and paper industry

The invention discloses a waste paper recovery device with high recovery efficiency. The device comprises a base plate; the top of the base plate is fixedly connected with a machine shell; a materialpassing port is formed in the top of the inner wall of the machine shell; the top of the machine shell is fixedly connected with a material passing hopper matched with the material passing port; and two crushing motors are fixedly connected to the back surface of the machine shell. Through cooperation of the crushing motors, crushing rotating shafts, crushing wheels, crushing blades, breaking motors, breaking rotating shafts, breaking wheels, breaking blades, a first bearing, a second bearing, a stirring rotating shaft, a driving wheel, a driven wheel, a belt, stirring blades, a third bearing,a filter screen and a discharge pump, the device solves the problem of lower recovery efficiency in a common waste paper recovery device, fully treats waste papers in the waste paper treatment process, enables paper pulp to become fine and smooth through stirring, filters the paper pulp by the filter screen to improve the uniformity, and achieves more convenience for the waste paper recovery work.

Owner:SUZHOU BATAO INFORMATION TECH CO LTD

Multi-stage efficient stone breaking device

InactiveCN107377161ABroken comprehensiveImprove crushing efficiencyGrain treatmentsAgricultural engineeringEngineering

Owner:六安市金安区一元通包装设计中心(普通合伙)

Double-circulation type soil pollution treatment device

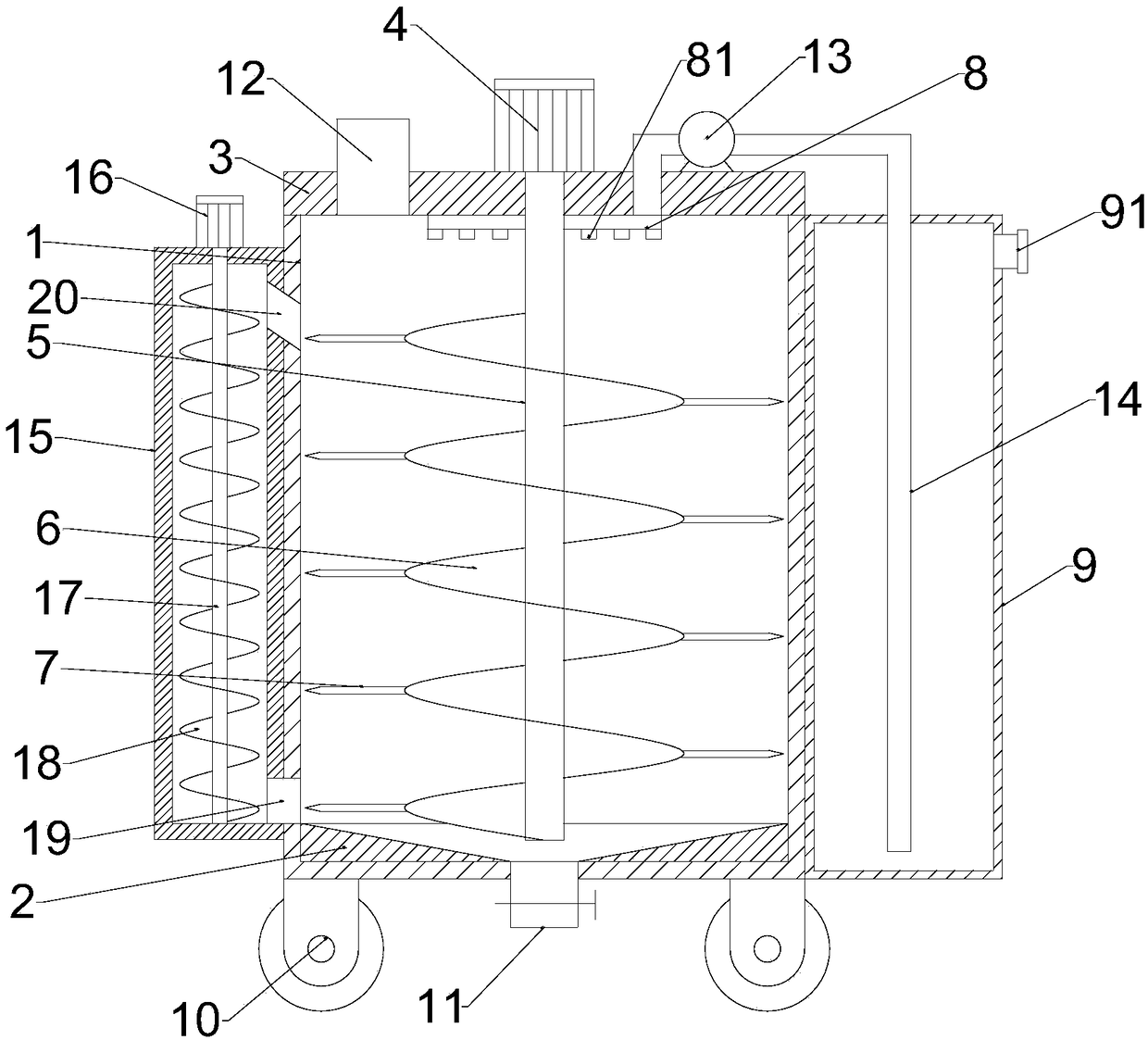

InactiveCN108273838AImprove mixing efficiencyImprove uniformityRotary stirring mixersTransportation and packagingSpiral bladeLiquid storage tank

The invention discloses a double-circulation type soil pollution treatment device. The device comprises a processing shell, a liquid storage tank and a circulation cavity, a bottom plate is arranged at the bottom of the processing shell, an upper cover is arranged at the upper end of the processing shell, the middle of the upper cover is sequentially provided with a first motor, a stirring shaft,a spiral blade and crushing blades, and a spray pipe and high-speed wide-angle spray heads are arranged at the lower end of the upper cover; and the liquid storage tank is arranged on the right wall of the processing shell, walking wheels and a discharging pipeline are arranged at the lower end of the processing shell, a feeding pipeline and a liquid pump are arranged on the upper cover, the circulation cavity is formed in the left wall of the processing shell, the circulation cavity is provided with a second motor, a lifting rotating shaft and a circulating lifting blade, and a circulation material outlet and a circulation material return opening are connected between the circulation cavity and the processing shell. According to the device, soil can be efficiently crushed, the soil crushing and treating efficiency can be further improved through internal and external double lifting circulation, the high-speed wide-angle spray heads are used cooperatively to spray an agent, effective and full mixing can be achieved, and the treatment of soil pollution can be efficiently completed.

Owner:李子琦

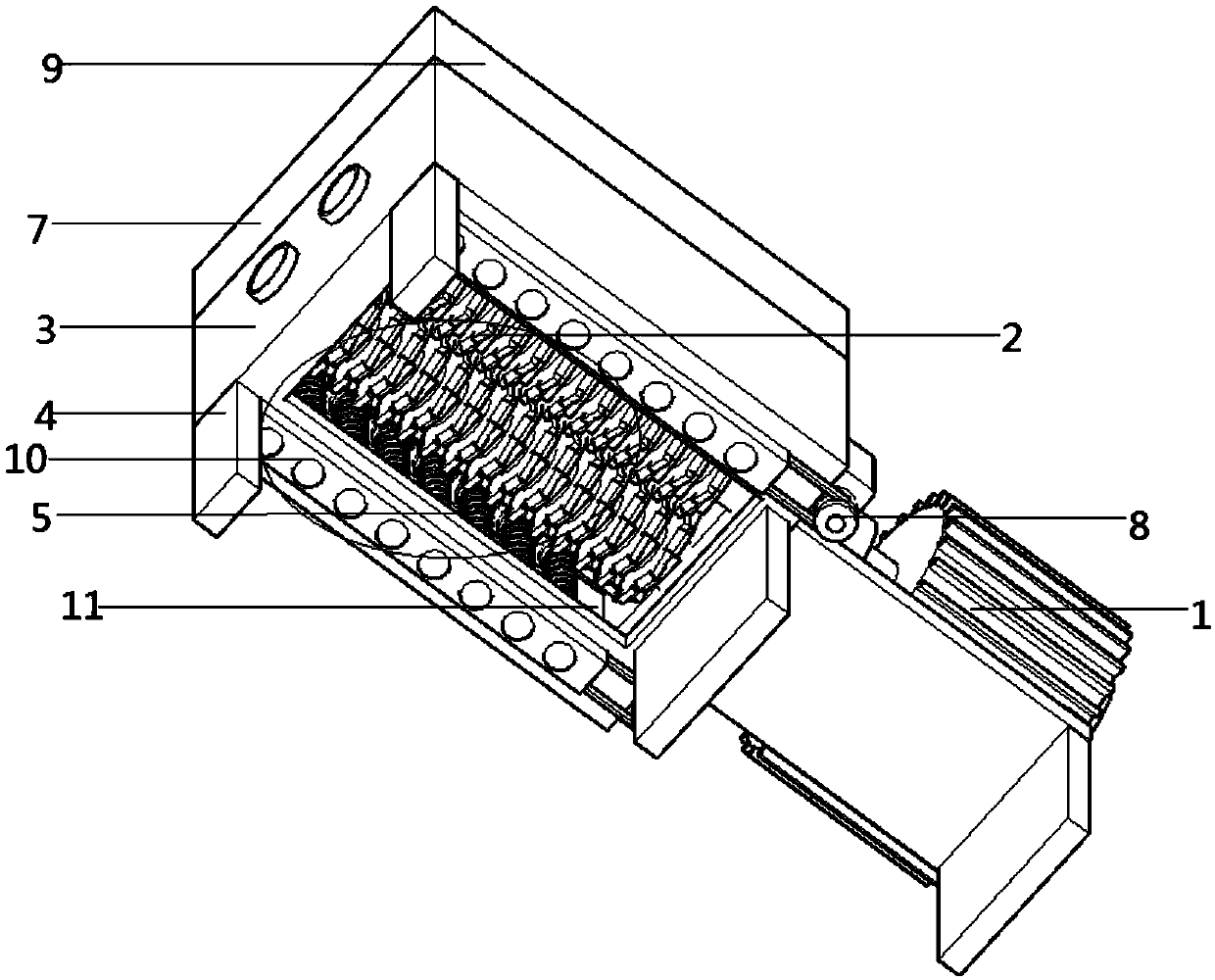

Waste material treatment device for new energy automobile battery production

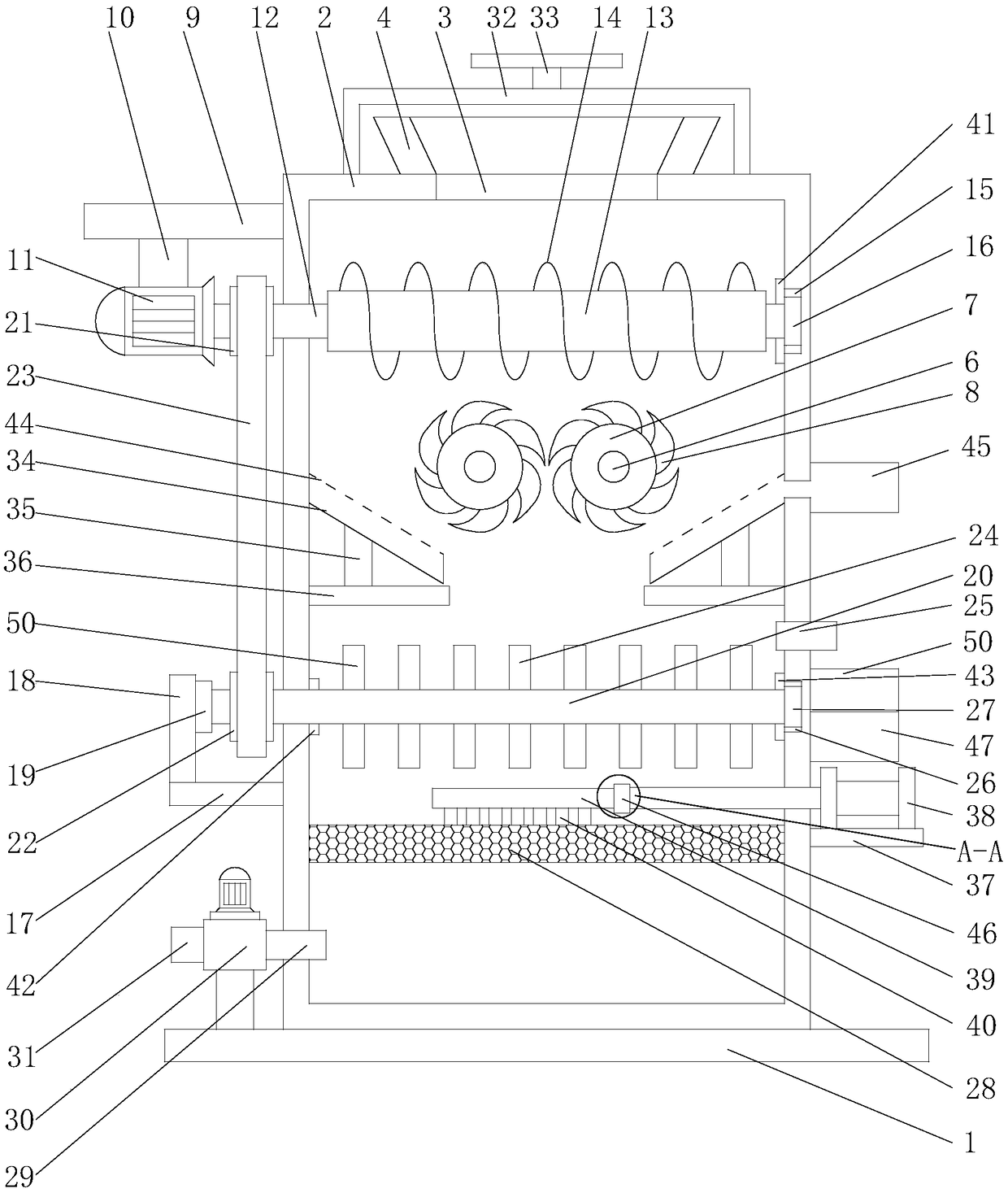

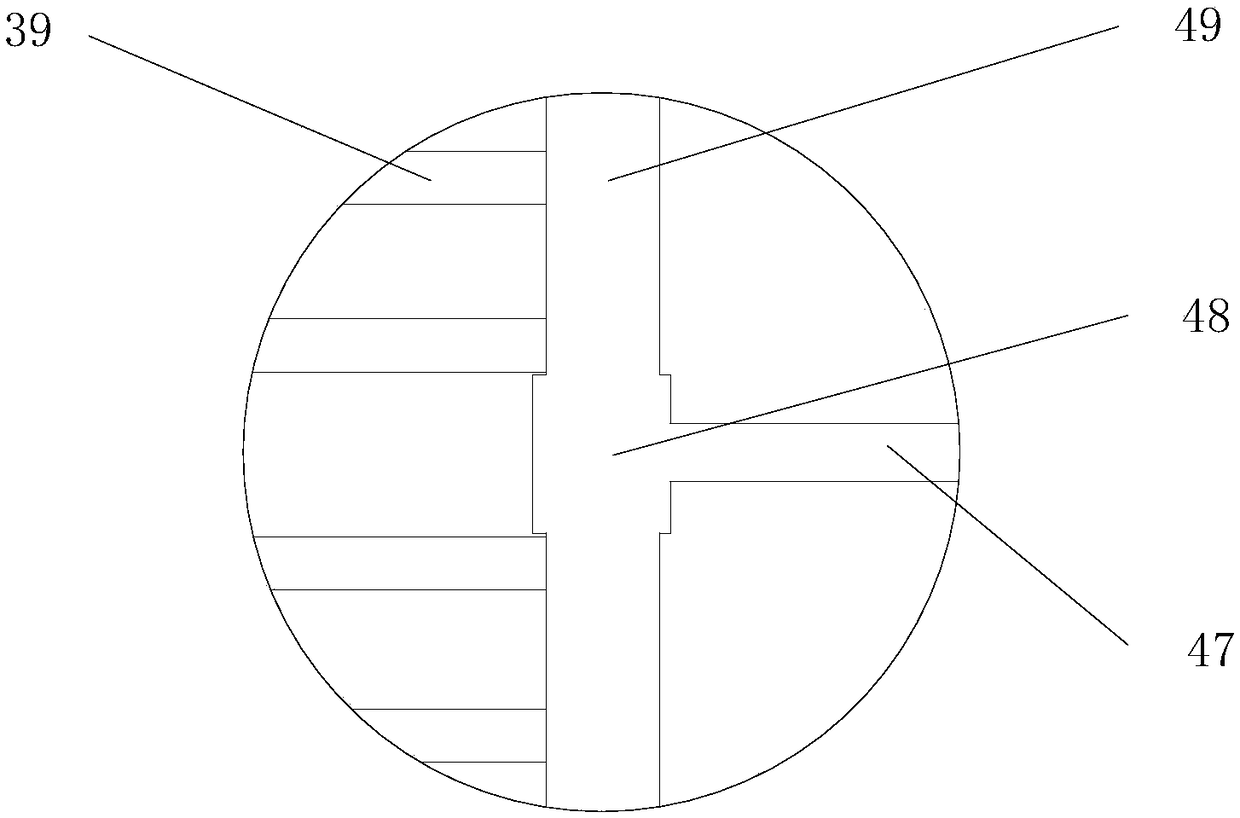

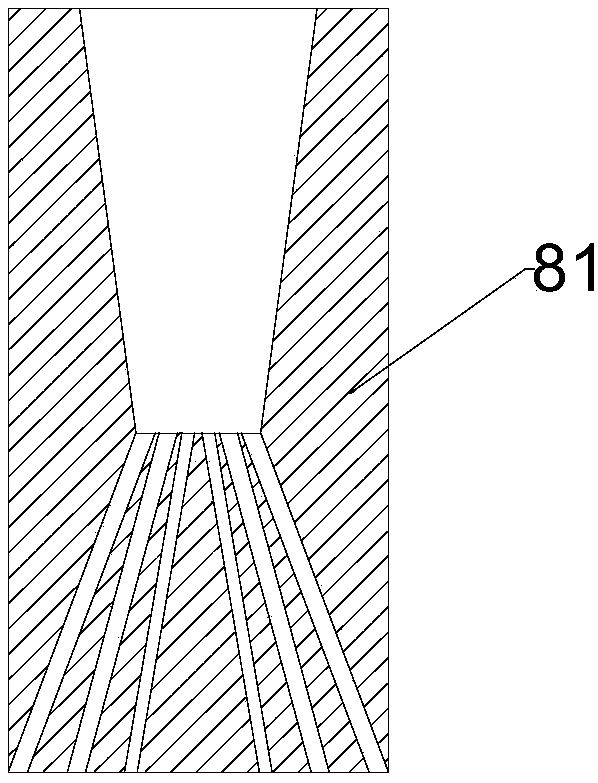

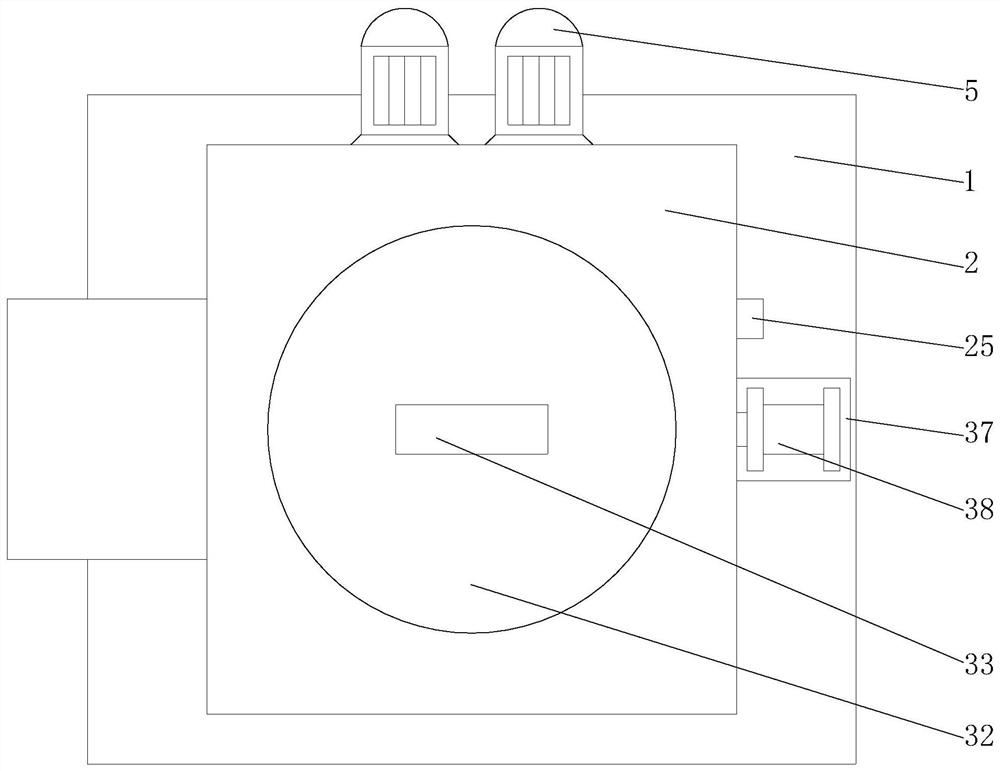

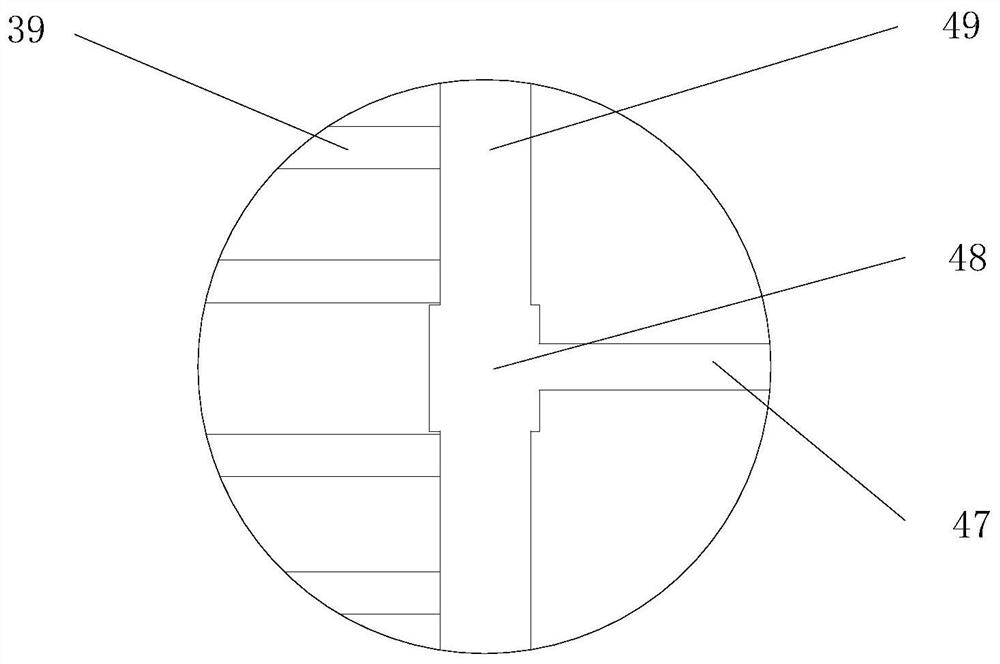

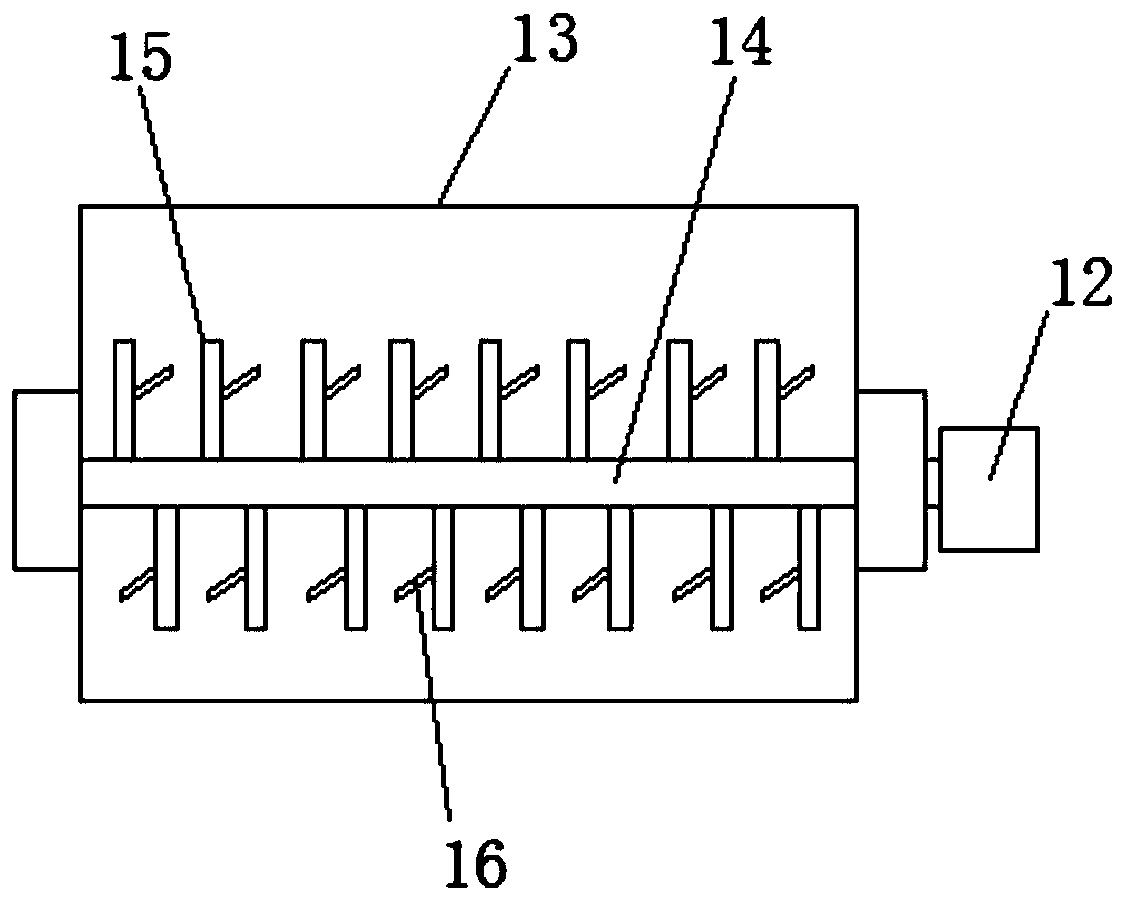

InactiveCN111940078ASmash all roundImprove crushing efficiencyDispersed particle filtrationDrying gas arrangementsAutomotive batteryNew energy

The invention discloses a waste material treatment device for new energy automobile battery production. The waste material treatment device for new energy automobile battery production comprises a smashing box; two hollow rotating shafts are symmetrically and rotationally connected to the inner wall of the smashing box; a double-shaft motor is fixedly connected to the side wall of the smashing boxthrough a support; and a first driving mechanism for driving the two hollow rotating shafts to rotate synchronously is installed on the double-shaft motor. According to the waste material treatment device for new energy automobile battery production, smashing knives on the side walls of the two hollow rotating shafts are arranged in a staggered mode so that the smashing knives can be used for comprehensively smashing waste batteries when rotating, the smashing efficiency is high, hot gas is introduced into the inner walls of the hollow rotating shafts through a hot gas pipe and is sprayed outfrom the positions of through holes, drying of water on the waste batteries is facilitated, and the smashing efficiency is further improved; unqualified waste batteries are conveyed upwards through auger spiral blades and flow out from a feeding plate to enter the smashing box again to be smashed, the situation that unqualified waste batteries after screening are manually poured in again from a feeding port, and the labor intensity is reduced is avoided, and the recycling treatment efficiency of the waste batteries is improved.

Owner:WUHU INST OF TECH

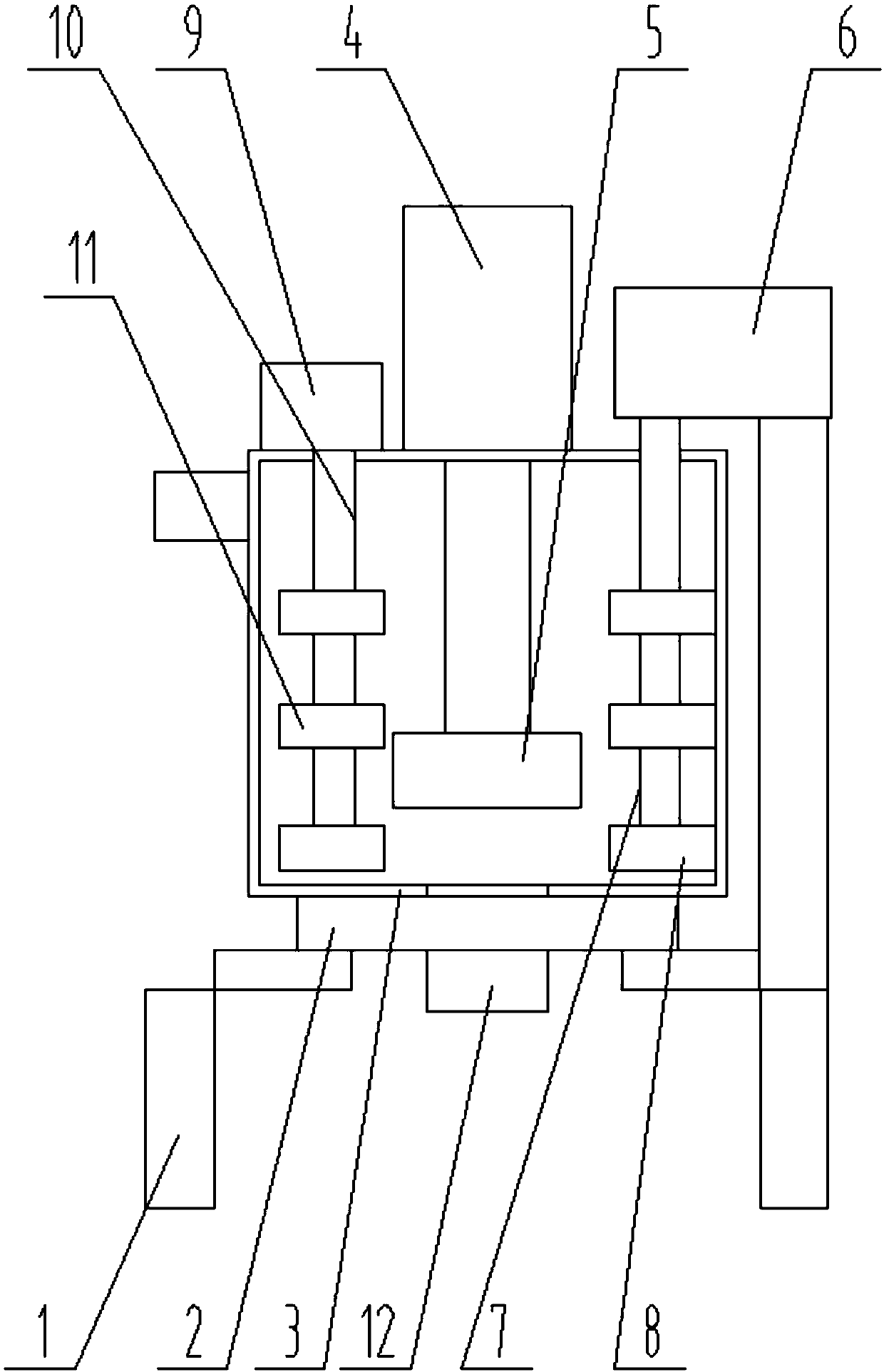

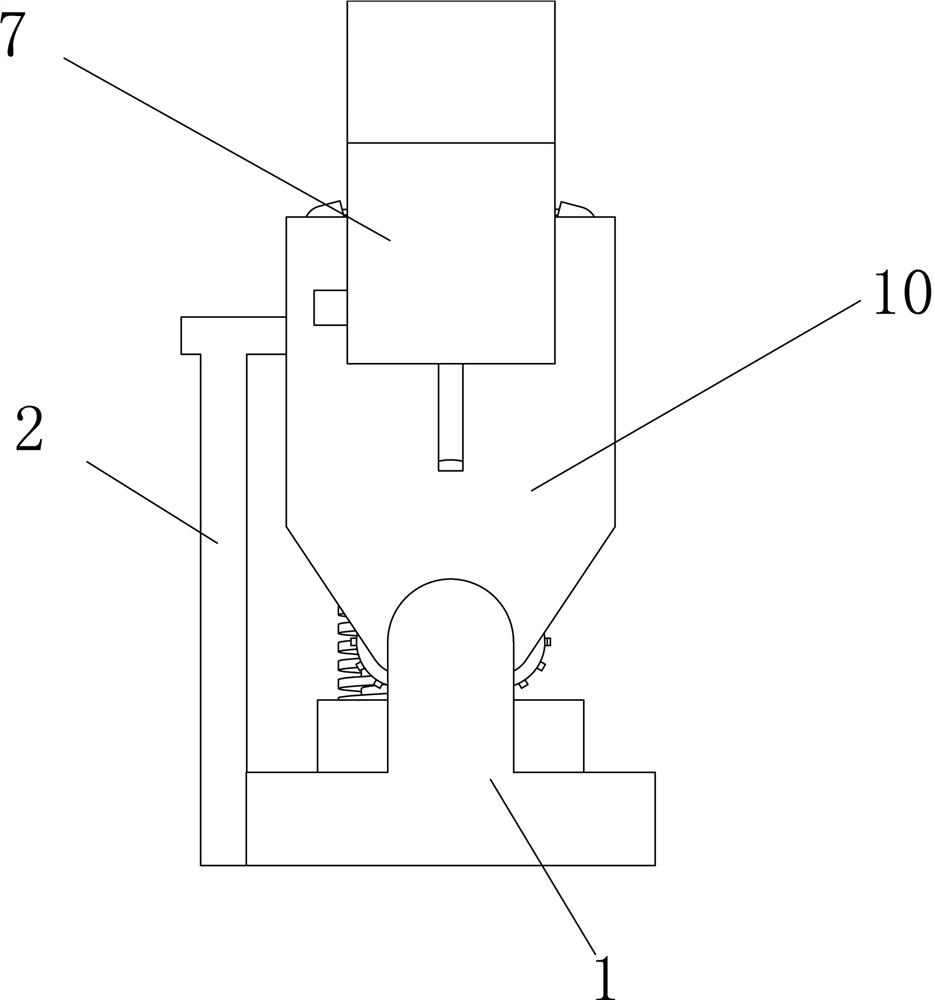

Caked lime recycling and reusing device for building construction

InactiveCN109433307ASmash all roundSmash thoroughlySievingScreeningArchitectural engineeringExtrusion

The invention discloses a caked lime recycling and reusing device for building construction, and relates to the field of buildings. The caked lime recycling and reusing device comprises a processing box; the upper part of a left-side box body in the processing box is fixedly connected with a shaft sleeve; the interior of the middle of the surface of the right side of the shaft sleeve is slidably connected with a rotating rod; the right end of the rotating rod is connected with a rotating motor; bulges are fixedly connected to the upper parts and the lower parts of the left and right sides of the middle of the rotating rod correspondingly; the outer surfaces of the middles of the bulges are slidably connected with rotating shafts; the lower parts of the outer surfaces of the rotating shaftsare fixedly connected with connecting rods; the lower ends of the connecting rods are connected with connecting seats; the lower surfaces of the connecting seats are fixedly connected with extrusionplates; the lower surfaces of the extrusion plates are fixedly connected with crushing teeth; and a crushing and screening box is arranged below the crushing teeth, and the lower surface of the crushing and screening box is fixedly connected with a screening plate. Caked lime can be comprehensively and thoroughly crushed, the crushing effect is very good, crushing and screening are simultaneouslyconducted, thus the recycling and treating efficiency of the caked lime is greatly improved, and practicability is high.

Owner:HENAN HUANQIU AVIATION EQUIP TECH CO LTD

Efficient rapid dissolving equipment for rare earth production

The invention relates to the technical field of dissolving equipment for rare earth production, in particular to efficient rapid dissolving equipment for rare earth production. A servo motor is adopted and controlled to drive a first gear to rotate forwards and backwards, a first bevel gear and a second bevel gear are driven to rotate through transmission, one bevel gear serves as a power source of a reciprocating assembly, and the other bevel gear serves as a power source of a stirring assembly. And when the first bevel gear rotates, the second bevel gear is driven to rotate, and a first take-up wheel rotates to carry out take-up and pay-off. A first-class pull rope is synchronously tightened or loosened under the action of the first take-up wheel, and the first-class pull rope is matchedwith a first-class spring to drive a sliding sleeve to move in the axial direction of a sliding rod through a push-pull rod. The first bevel gear rotates forwards and reversely, namely, the sliding sleeve reciprocates, so that a moving plate moves along with the first bevel gear, a crushing groove moves left and right, and comprehensive crushing is achieved through cooperation with a crushing assembly; and when the second bevel gear rotates, the stirring assembly is driven to work, so that stirring blades generate a stirring and mixing effect to realize rapid dissolution.

Owner:安徽延创通讯科技有限公司

Broken stone leveling device based on internal punching pressure for broken stone roads

InactiveCN108589500AIncrease the rolling pressureIncrease the crushing strengthRoads maintainencePunchingCrushed stone

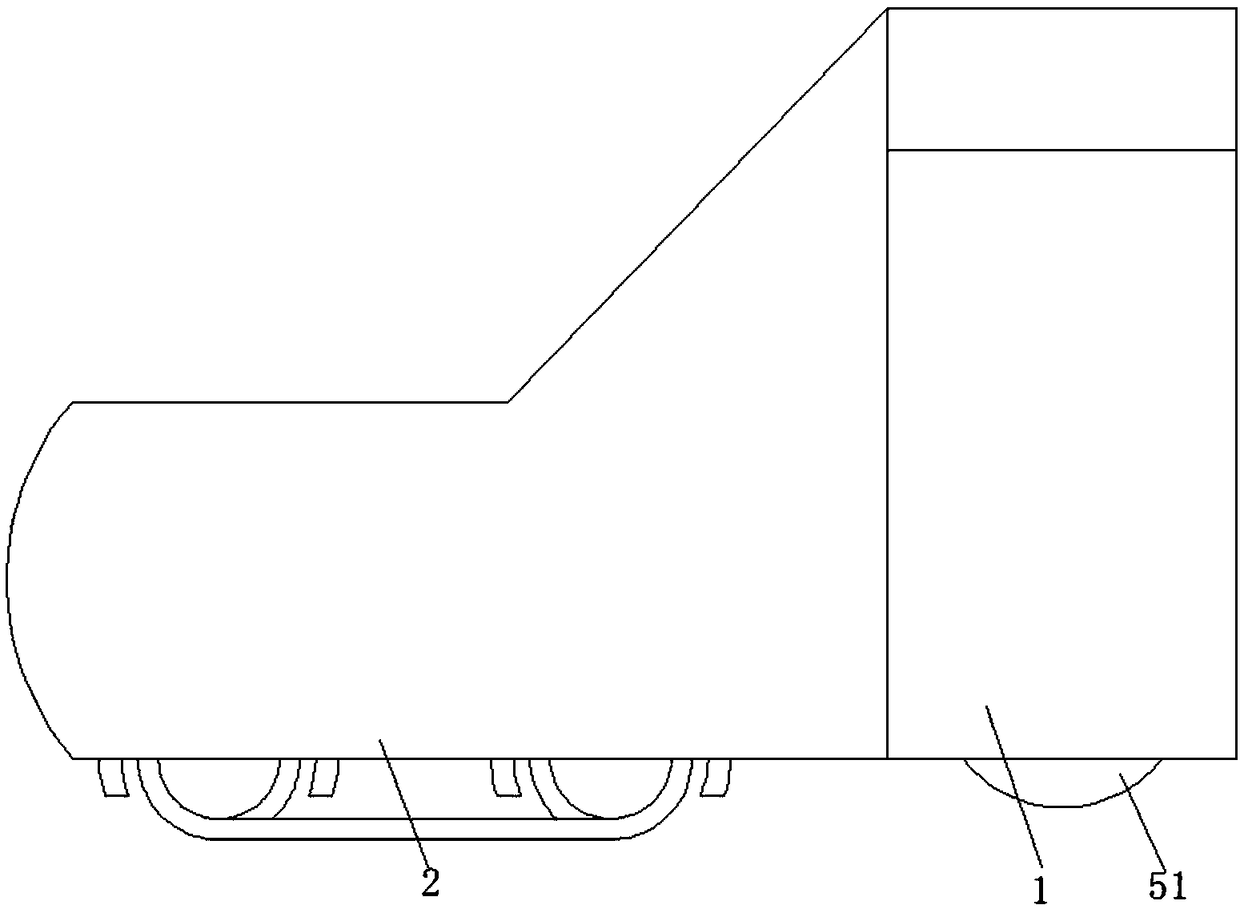

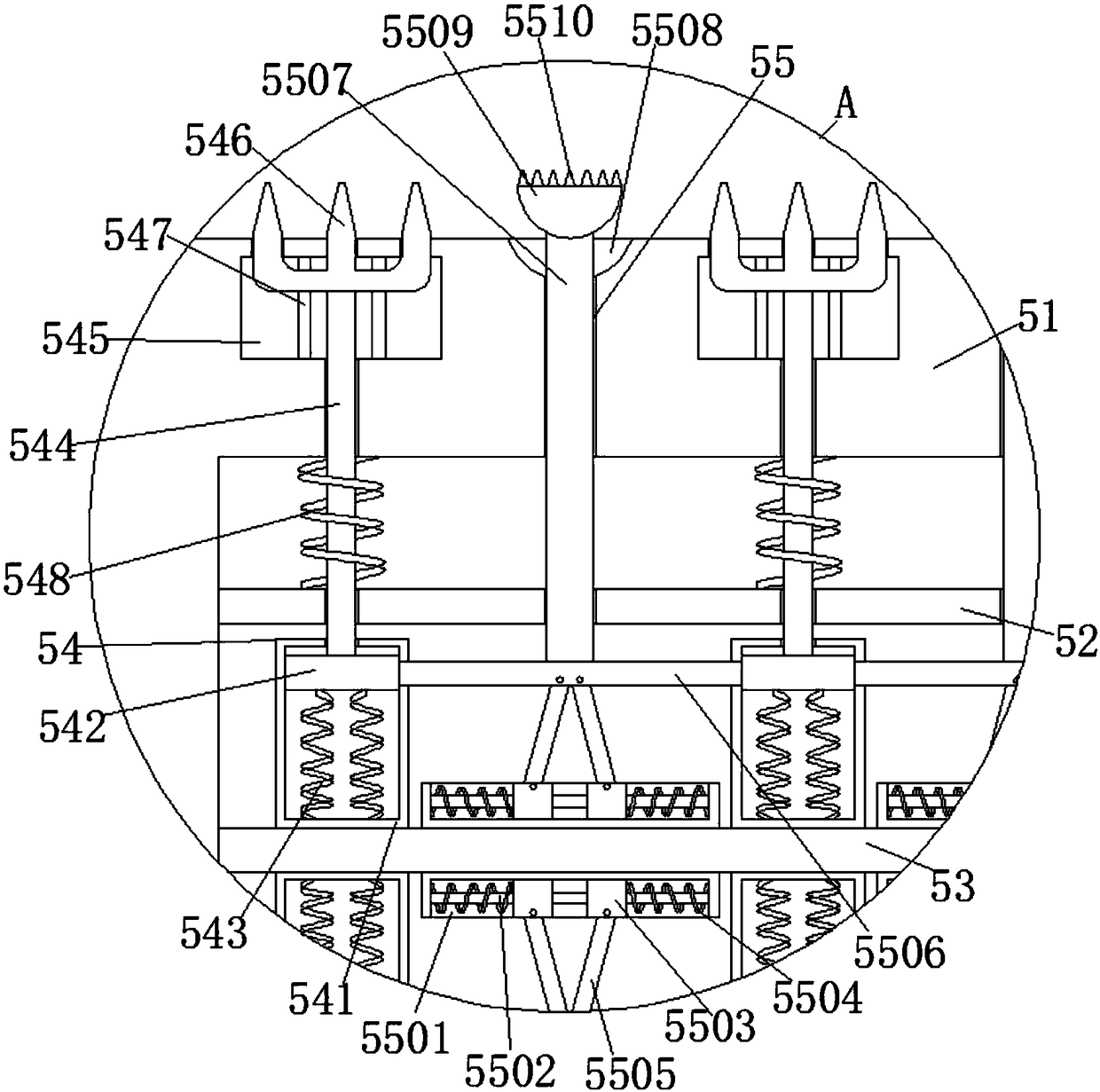

The invention relates to the technical field of leveling machines for broken stone roads, in particular to a broken stone leveling device based on internal punching pressure for the broken stone roads. The technical problem that the broken stone roads cannot be conveniently leveled by a press machine is solved. The broken stone leveling device comprises a front machine box; a thrust mechanism is fixedly connected to the back face of the front machine box; a driving mechanism is arranged at the top of the inner wall of the front machine box; two sides of the bottom of the driving mechanism arefixedly connected with the two sides of the inner wall of the front machine box correspondingly; and movable driving devices are fixedly connected to two sides of the front machine box. When smashingteeth are in contact with broken stones, a rod jaw is cooperated, and therefore contacting areas between the smashing teeth and the stones are increased, the stones can be smashed more thoroughly andmore comprehensively; and intervals between the rod jaw and the smashing teeth are reserved to reduce resistance when a hollow roller rotates.

Owner:当涂县金龙凤科技股份有限公司

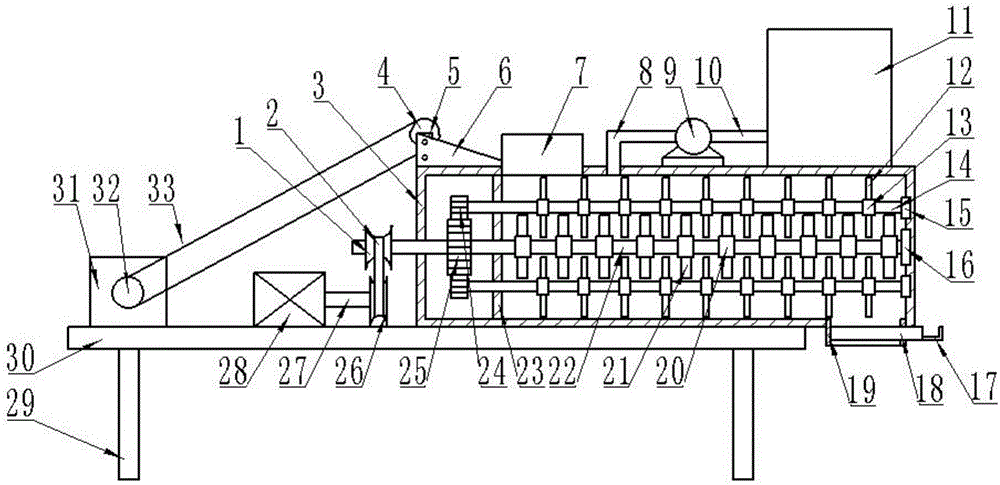

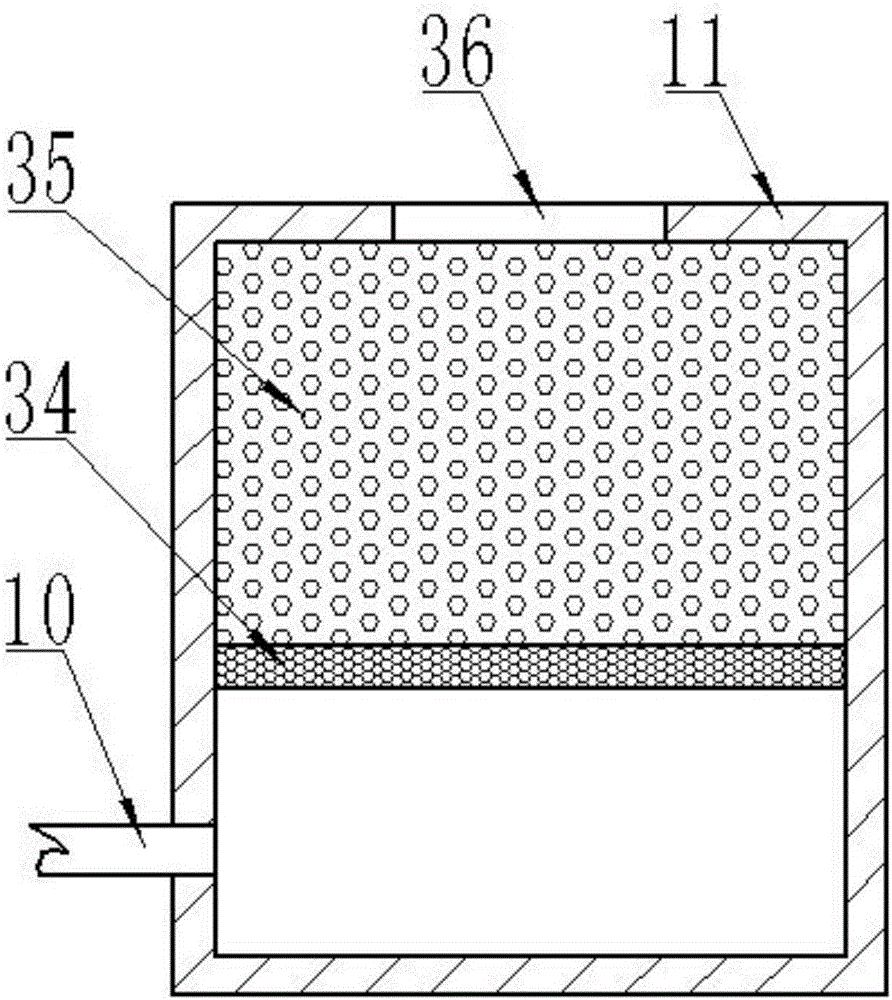

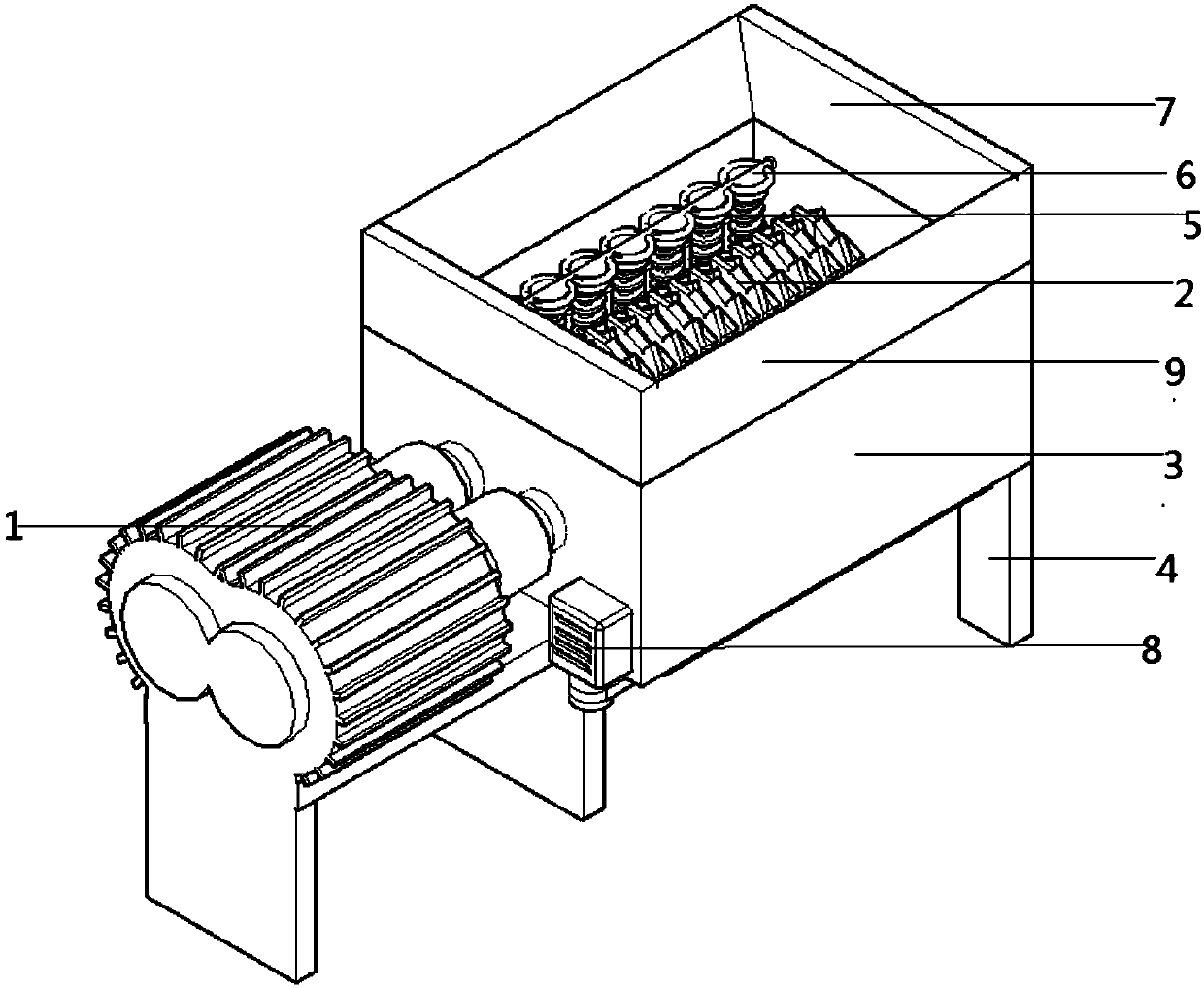

Feed processing raw material crushing device

InactiveCN107736639ADry comprehensiveDry completelyFeeding-stuffGrain treatmentsEconomic benefitsEngineering

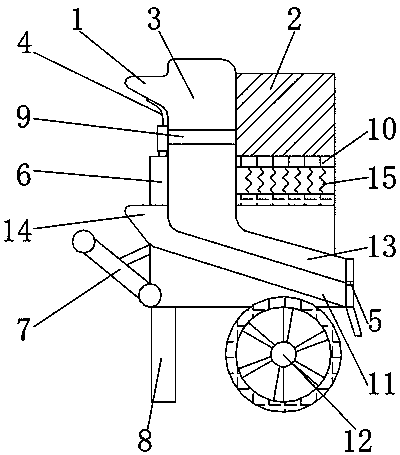

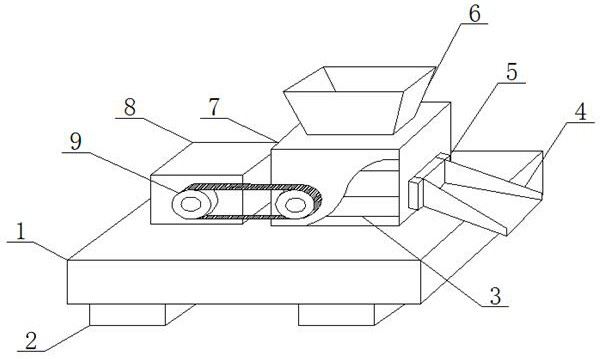

The invention relates to the technical field of feed processing, in particular to a raw material crushing device for feed processing, which includes a housing and a connecting rod. A feeding hopper is fixedly connected to the top of the housing, and a drying plate is arranged below the feeding hopper. The inner side of the drying plate is fixedly connected with a horizontally arranged heating wire, the top of the drying plate is fixedly connected with a gear lever, and the bottom of the drying plate is provided with a horizontally arranged support plate, and one end of the support plate is connected to the housing Fixedly connected, the outer top of the support plate is rotatably connected with an elliptical runner, the bottom end of the support plate is fixedly connected with a connecting rod, the bottom end of the connecting rod is fixedly connected with a second rotating shaft, and the second rotating shaft One end is fixedly connected with a second motor, and the inner side of the second motor is rotatably connected with a runner, which is conducive to improving the completion rate of products and increasing work efficiency, has huge economic benefits and broad market prospects, and is worthy of popularization and use.

Owner:邛崃驰阳农牧科技有限公司

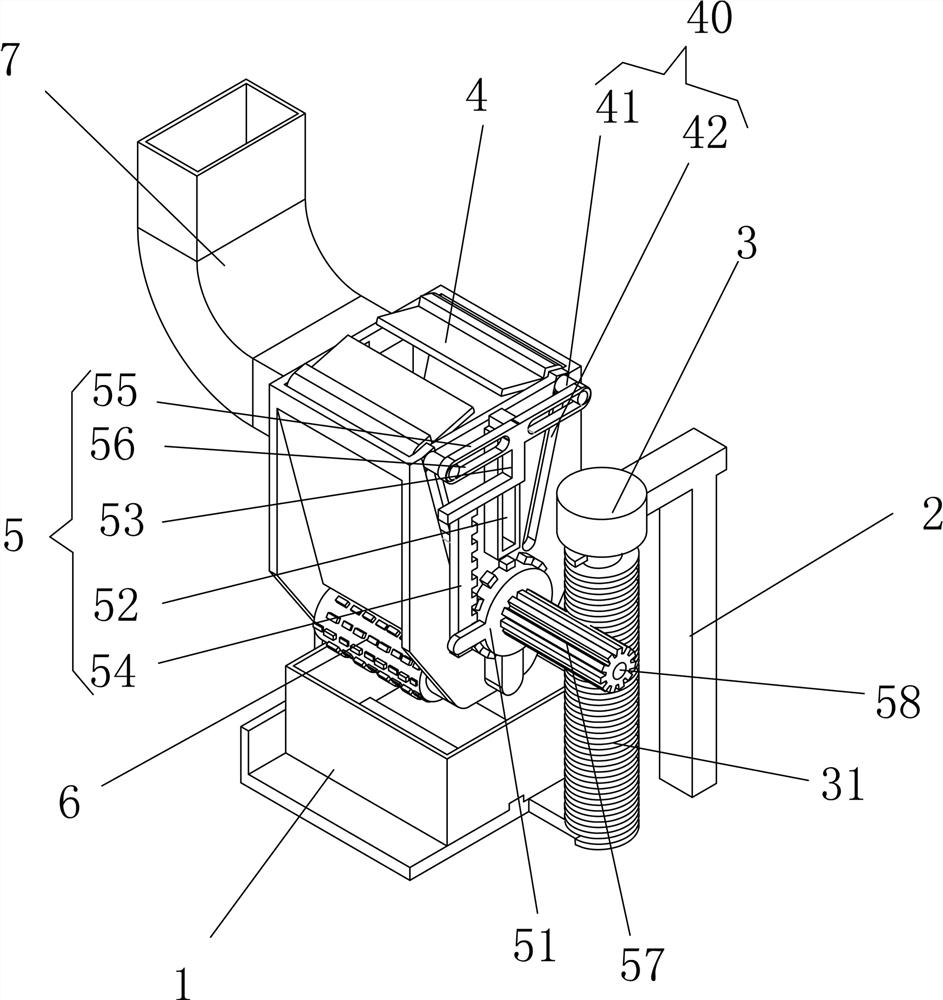

Pulverizer with full pulverizing function

InactiveCN108543600AReasonable structureMake sure to smashGrain treatmentsEngineeringMaterial storage

The invention discloses a pulverizer with a full pulverizing function. The pulverizer structurally comprises a conical shell, a first material storage chamber and a second material storage chamber, wherein a first guide rail is arranged at one side of the conical shell, a second guide rail is arranged at the other side of the conical shell, a first elastic module is arranged at the bottom end of the first guide rail, a second elastic module is arranged at the bottom end of the second guide rail, the first material storage chamber is fixed at one side of the conical shell through the first guide rail, the second material storage chamber is fixed at the other side of the conical shell through the second guide rail, a first feeding opening and a second feeding opening are formed in the top ofthe conical shell, a rotating shaft is arranged inside the conical shell, a plurality of layers of triangle rotating rods are arranged on the rotating shaft from top to bottom, a plurality of bladesare distributed on the rotating rods, and a discharging opening is formed in the bottom of the conical shell. The pulverizer has a reasonable structure, and the insufficient pulverizing of materials caused by excessive feeding is prevented through the control of the feeding of the first material storage chamber and the second material storage chamber.

Owner:如皋市昌旭机械制造有限公司

Garbage crushing device capable of realizing automatic loading degassing

InactiveCN106622539ASmash all roundCrushed fullyGas treatmentDispersed particle separationEngineeringMechanical engineering

The invention provides a garbage crushing device capable of realizing automatic loading degassing. The garbage crushing device comprises a loading device, a crushing device and a degassing device, wherein the loading device comprises an unloading plate and a first motor; the first motor is fixedly arranged on the left side surface of a base; the unloading plate is fixedly arranged on a second rotary wheel fixing frame through a bolt and communicates with a charge barrel; the crushing device comprises a crushing box, second crushing blades and first crushing blades; the crushing box is arranged on the base; the first crushing blades are fixedly arranged at the two sides of a first fixing sleeve; the second crushing blades are fixedly arranged at the two sides of a second fixing sleeve; the degassing device comprises an air extraction pump and a degassing box; the air extraction pump is fixedly arranged on the crushing box; and the degassing box is fixedly arranged on the crushing box and at the right side of the air extraction pump. The device provided by the invention is capable of adequately crushing garbage and carrying out absorption and purification on peculiar-smell gases discharged from the crushing box through loading of a conveying belt, thus saving labour and achieving high working efficiency.

Owner:河南微服网络科技有限公司

Traditional Chinese medicine active ingredient extraction equipment

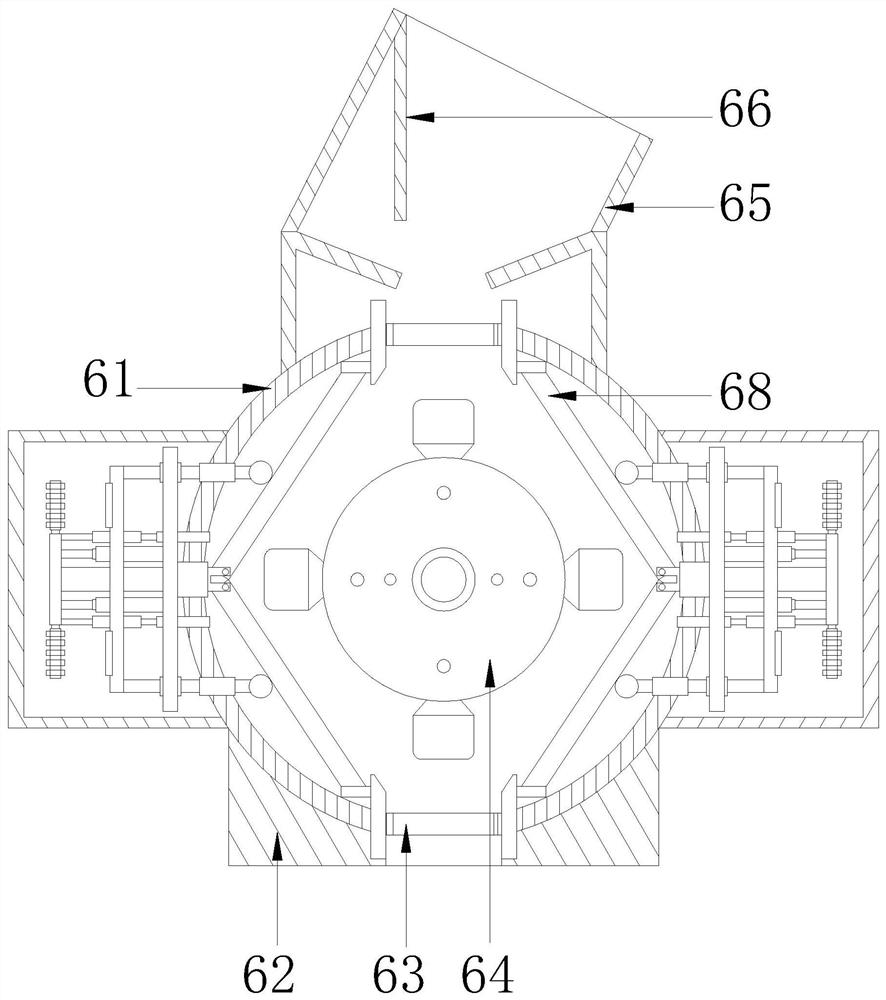

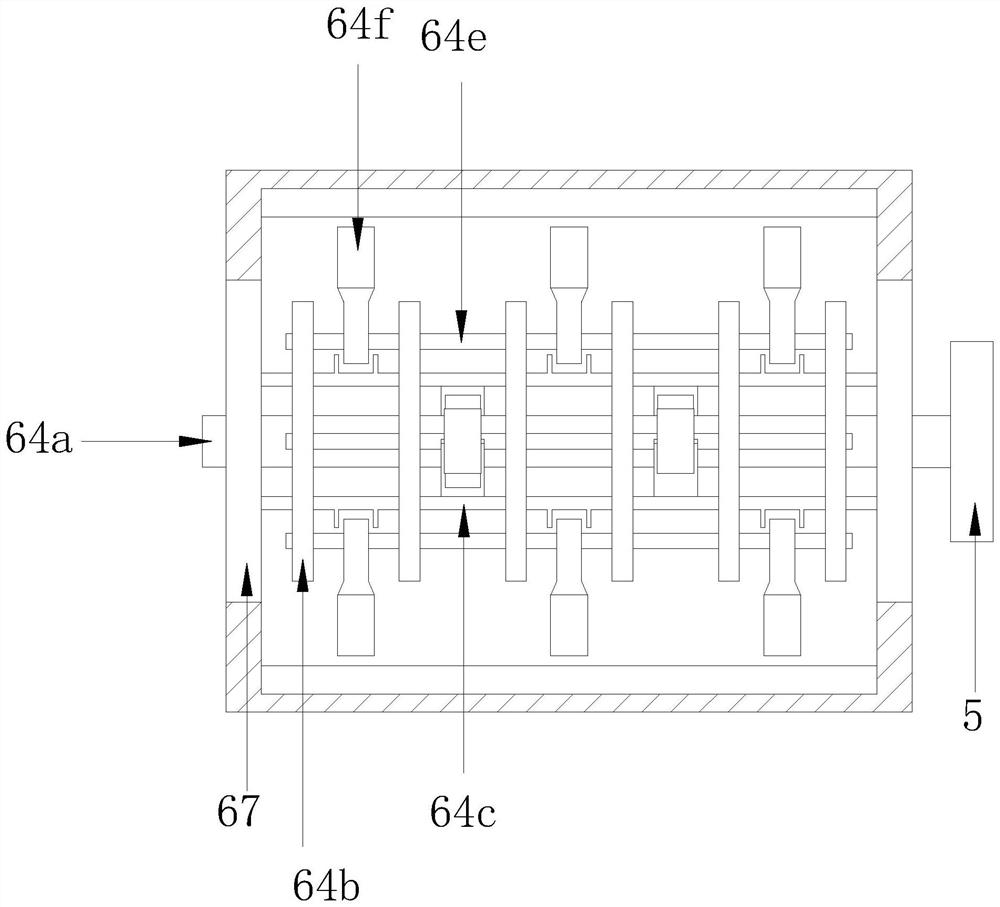

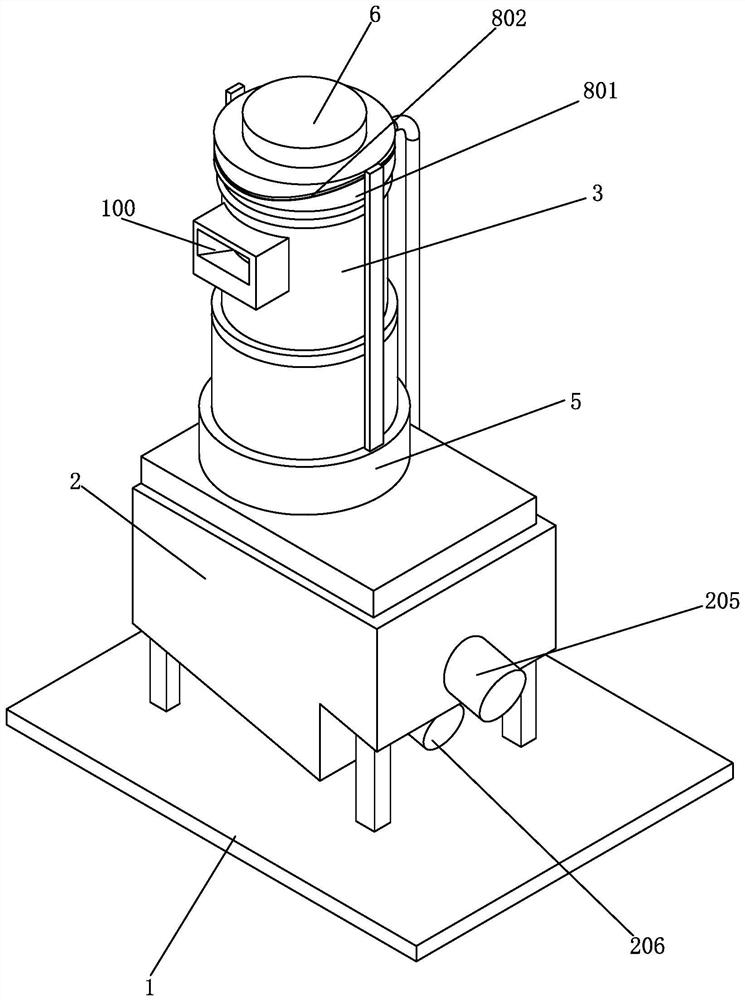

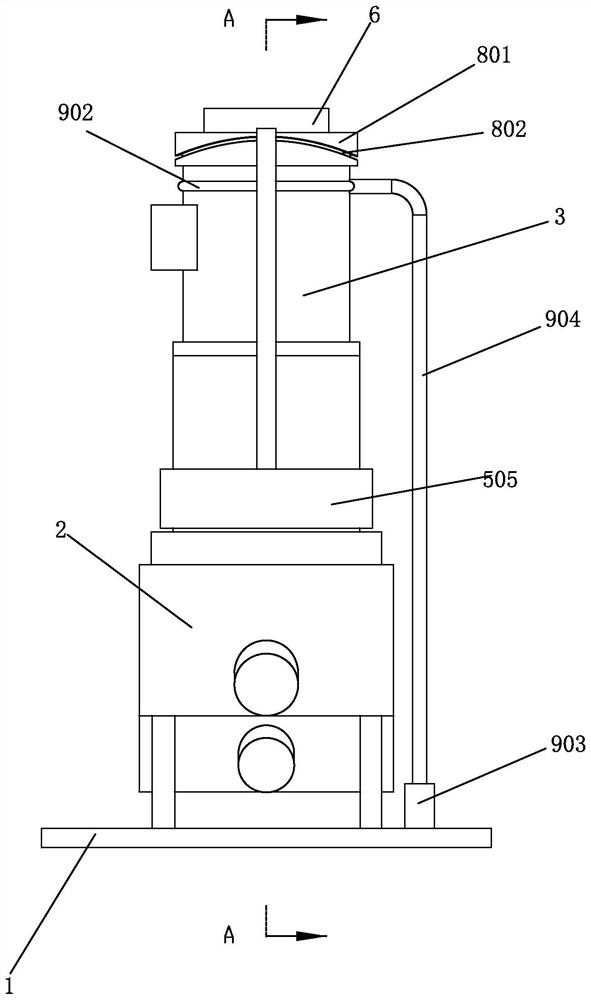

ActiveCN113457207ARealize batch crushingImprove crushing effectMixersGas solvent extractionPharmacy technologyPharmacy

The invention relates to the technical field of pharmacy, in particular to traditional Chinese medicine active ingredient extraction equipment. The equipment comprises a tank body, a material guiding cylinder, a material guiding cover, a filtering cylinder, a crushing assembly, a material guiding and mixing assembly, a steam outlet piece, a communicating pipe, a condenser, a steam generator and a controller, the material guiding cover, the material guide cover and the filter cartridge are sequentially arranged in the tank body from top to bottom; the crushing assembly is arranged on the tank body; the material guiding and mixing assembly is arranged outside the filter cartridge; the steam outlet piece is arranged in the filter cartridge; the communicating pipe is communicated with the steam outlet piece and the tank body; and the steam generator and the controller are arranged on the communicating pipe. The crushing assembly is arranged, batch crushing is achieved, and the crushing effect and efficiency are improved; an overturning frame and an airflow generation ring are arranged to cooperate for exhausting, the crushing speed is increased, and crushing is more comprehensive; a material guiding and mixing assembly is arranged, so that traditional Chinese medicine powder and extract liquor are fully mixed, and the extraction rate is finally increased.

Owner:谷地广东农业研究有限公司

Carbendazim wettable powder and preparation process thereof

InactiveCN110037043AImprove fungicidal performanceResponse mix comprehensiveBiocideFungicidesBlack liquorFilling materials

The invention discloses carbendazim wettable powder. The carbendazim wettable powder is prepared by the following raw materials, by mass percent: 36%-42% of carbendazim, 0.5%-1.8% of a wetting agent,7.2%-7.8% of a dispersant, and 12%-32% of a filling material. The beneficial effects of the carbendazim wettable powder and the preparation process thereof are that when the dispersant contained in the wettable powder is prepared, phenol or derivatives of phenol are added and a phenolic hydroxyl group is introduced, which improves the reaction activity of lignin in pulping black liquor and the temperature resistance of the product, ensures that the raw materials are reacted and mixed more comprehensively when the wettable powder is prepared and improves the antifungal performance of the wettable powder. An ultrafine grinding mechanism used in the preparation process of the invention crushes and pulverizes the raw materials by rotating a rotary grinding wheel between a rotary grinding discI and a rotary grinding disc II in opposite directions. Moreover, multiple arc-shaped scraping knives arranged on the rotary grinding wheels with equal radians scrap the raw materials into a grindinggroove for extrusion and crushing so as to crush the raw materials more comprehensively, thoroughly and finely, which improves the quality of the crushing of the raw materials.

Owner:苏农(广德)生物科技有限公司

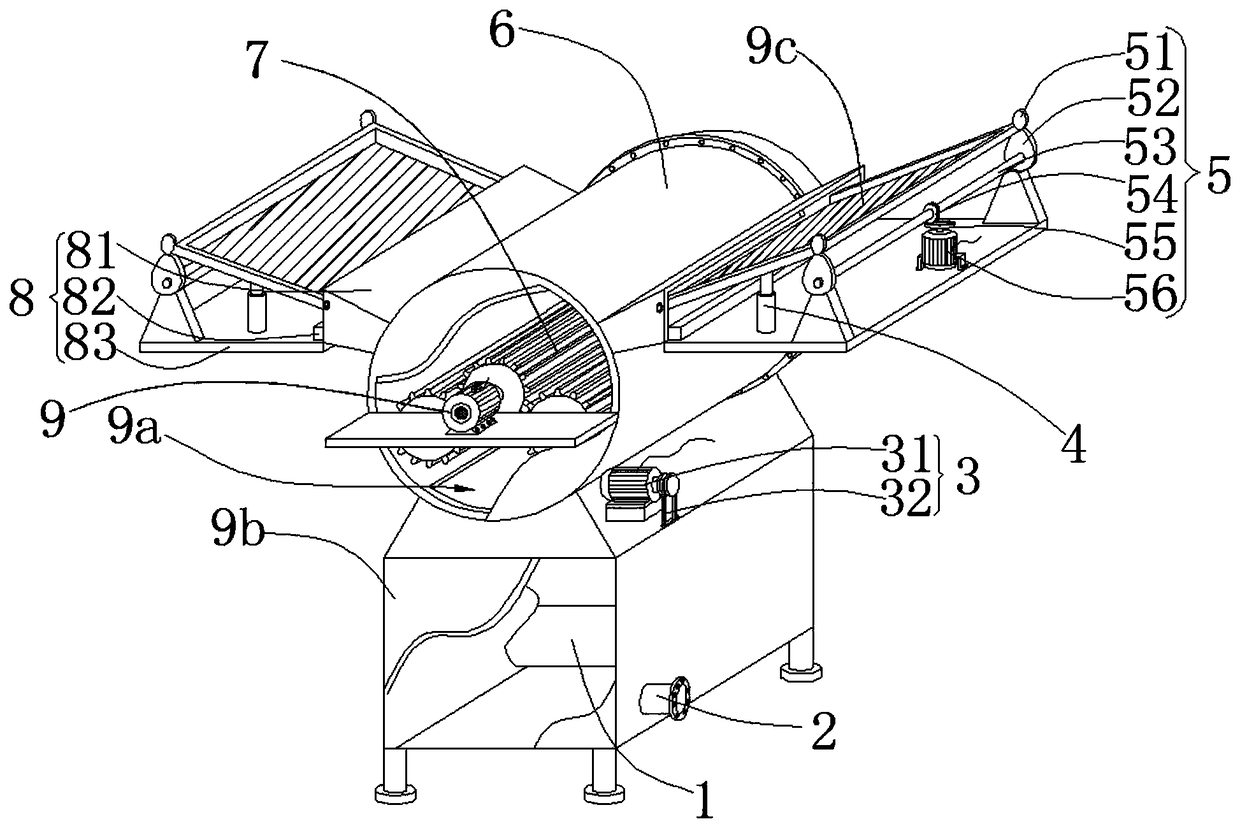

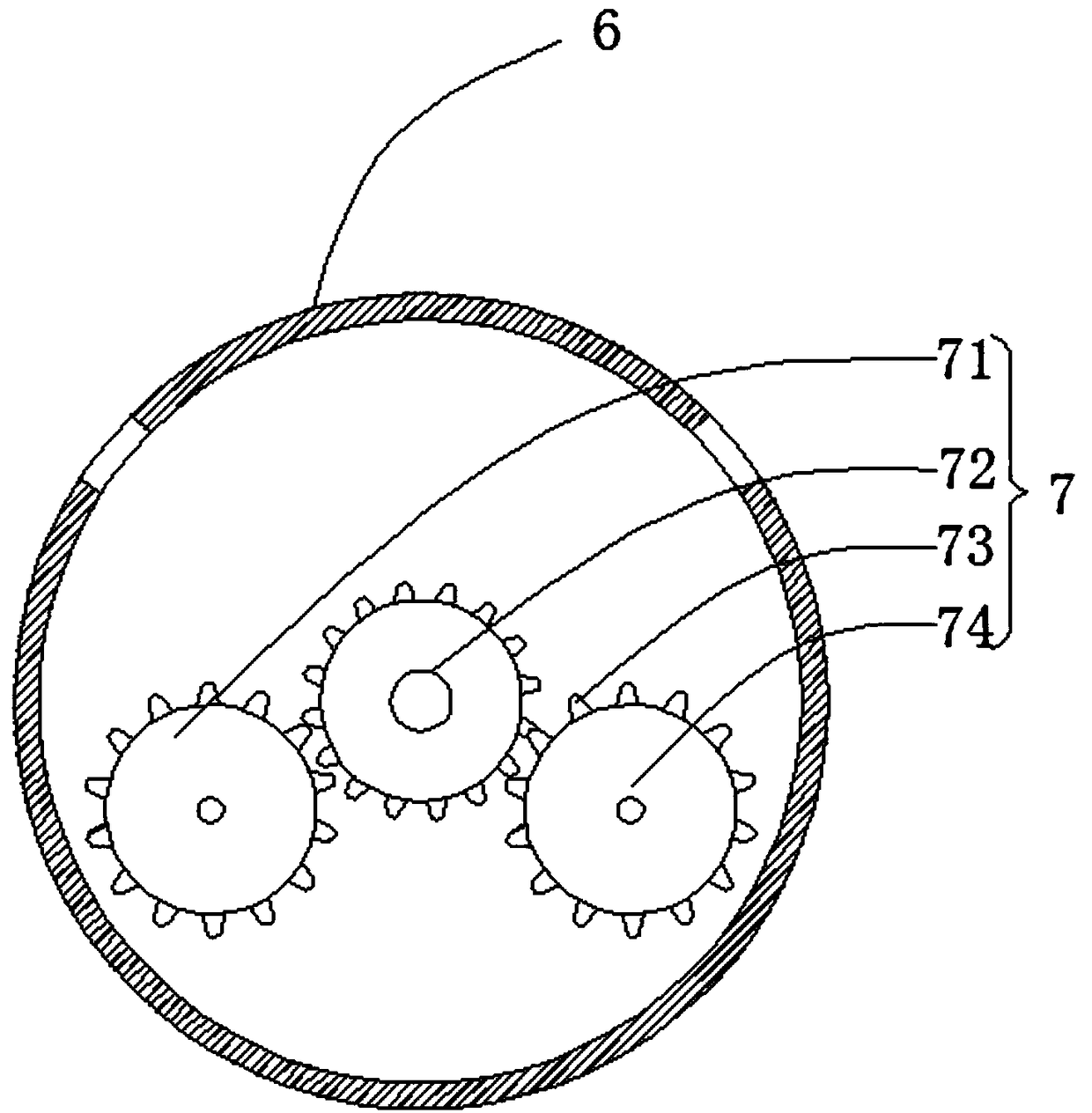

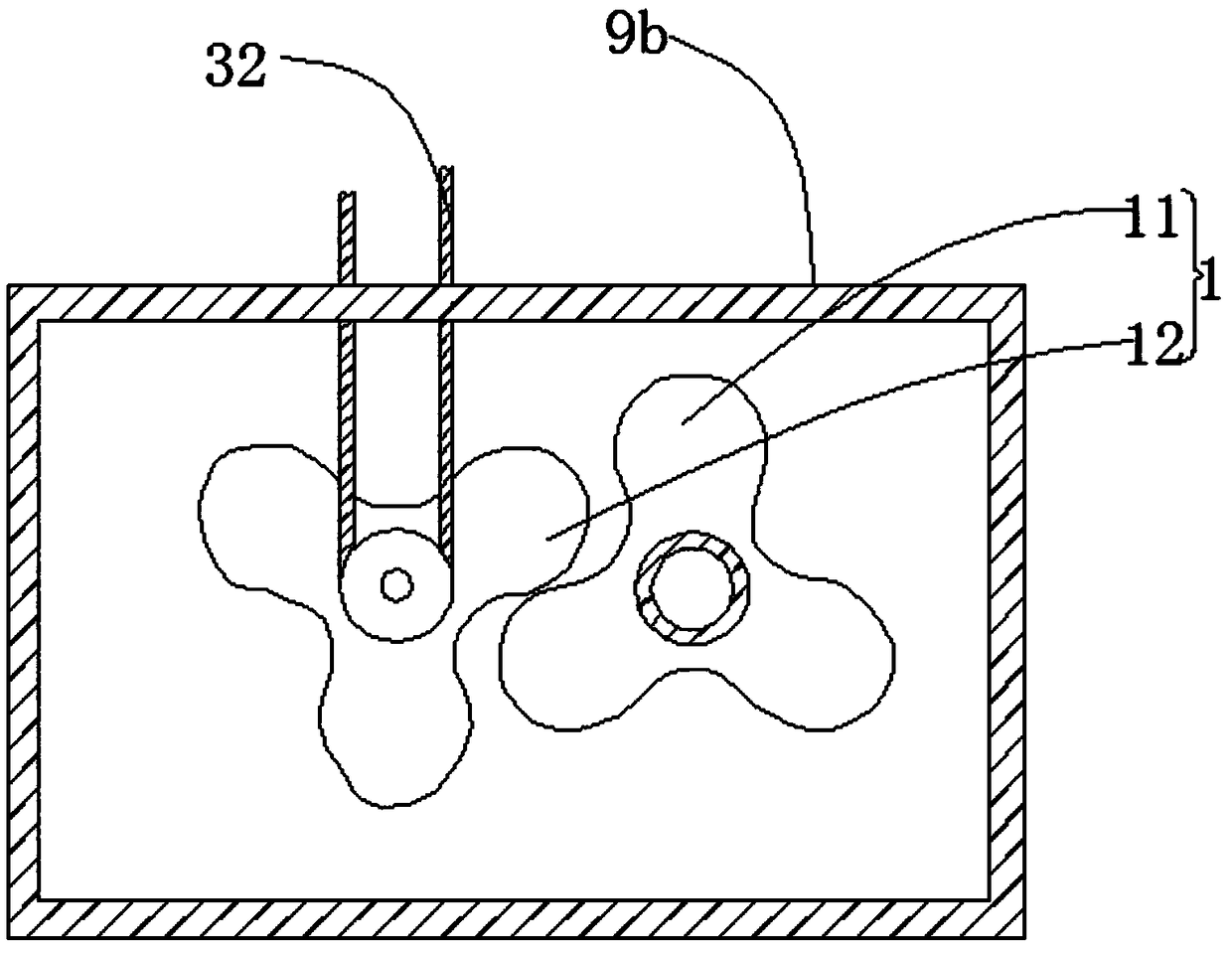

Regeneration process of waste paper

InactiveCN108691227AAvoid enteringAvoid cloggingPaper recyclingRaw material divisionElectric machinerySlurry

The invention relates to the technical field of waste paper regeneration, in particular to a regeneration process of waste paper, wherein the pulping system used in the process comprises a stirring mechanism, a slurry discharge pipe, a driving mechanism, a resetting mechanism, a feeding mechanism, a crushing barrel, a crushing mechanism, a fixing mechanism, a third motor and a paper discharge port, a stirring barrel and a partition plate, the fixing mechanism is matched with the feeding mechanism and the partition plate, the waste paper is placed on the surface of the partition plate to connect the second motor with the power supply, the protrusions at the two ends of the rotating shaft are in conflict with a fixed disc, the partition plate is driven to shake, the surface of the partitionplate which is obliquely arranged is fixedly connected with striker plates at equal intervals, the stirring barrel is prevented from being blocked, a second roller column in the stirring barrel is rotatably connected with the third motor, the second roller column is matched with a first roller column and a second roller column in the crushing barrel, the first roller column, the second roller column and the third roller column are in triangular distribution, the surfaces of the first roller column, the second roller column and the third roller column are equidistantly provided with crushing sheets, the crushing is more comprehensive, and the crushing efficiency is improved.

Owner:谢响玲

Shredder

ActiveCN102463179BLow costImprove practicalityGrain treatmentsPulp and paper industrySmall particles

Owner:BEIJING HESHENGDA INFORMATION SECURITY TECH

White radish wringing machine for making steamed stuffed buns with white radish fillings

InactiveCN108936439AEasy to manufactureDelicious tasteFood shapingGrain treatmentsShape changeBiology

The invention relates to the technical field of food processing, in particular to a white radish wringing machine for making steamed stuffed buns with white radish fillings, and aims to solve the technical problem that in the prior art, wringing the white radish fillings is time-consuming, labor-consuming, and low in working efficiency. In order to solve the technical problems, the invention provides the white radish wringing machine for making steamed stuffed buns with white radish fillings. The white radish wringing machine comprises a machine body, wherein a blocking frame is fixedly connected to the top of the machine body; a shape changing mechanism is arranged in the blocking frame; the bottom of the shape changing mechanism penetrates through and extends into the inner part of the machine body; a position pushing mechanism is arranged on the inner bottom wall of the machine body; and a white radish wringing mechanism is fixedly connected to the bottom of the machine body. According to the white radish wringing machine disclosed by the invention, the white radish wringing mechanism is driven by a power transmission mechanism to work and operate, and moisture in the white radish fillings is wringed, so that time and labor are saved, the working efficiency is improved, and the made steamed stuffed buns with white radish fillings are more delicious in mouth feel.

Owner:张孟齐

Environment-friendly construction waste crusher

ActiveCN113680455ASmash all roundCrushed fullyGrain treatmentsTransmission beltArchitectural engineering

The invention discloses an environment-friendly construction waste crusher. The environment-friendly construction waste crusher structurally comprises a motor, a first transmission wheel, a supporting leg column, a base, a second transmission wheel, a crusher body and a transmission belt, and has the beneficial effects that through the structural design of a sliding groove disc and a push rod, the sliding groove disc serves as a static part, the push rod serves as a dynamic part, a hammer head has the left-right displacement function in the rotating process, the hammer head can comprehensively crush the construction waste in a crushing cavity, crushing of the construction waste is more sufficient, crushing and discharging of the construction waste are facilitated, a counterattack adjusting device can control the distance matching degree of a counterattack plate and the hammer head by controlling stretching and retracting of a hydraulic telescopic rod, and the crushing effect of the construction waste is improved; and meanwhile, the crushing size and the crushing speed of the construction waste can be accurately controlled, the recoil force and the vibration force of the counterattack plate are reduced, the crushing effect is further enhanced, and meanwhile mechanical damage to the hydraulic telescopic rod and the motor is reduced.

Owner:NANJING KISEN INT ENG

Classified crushing treatment equipment for food waste

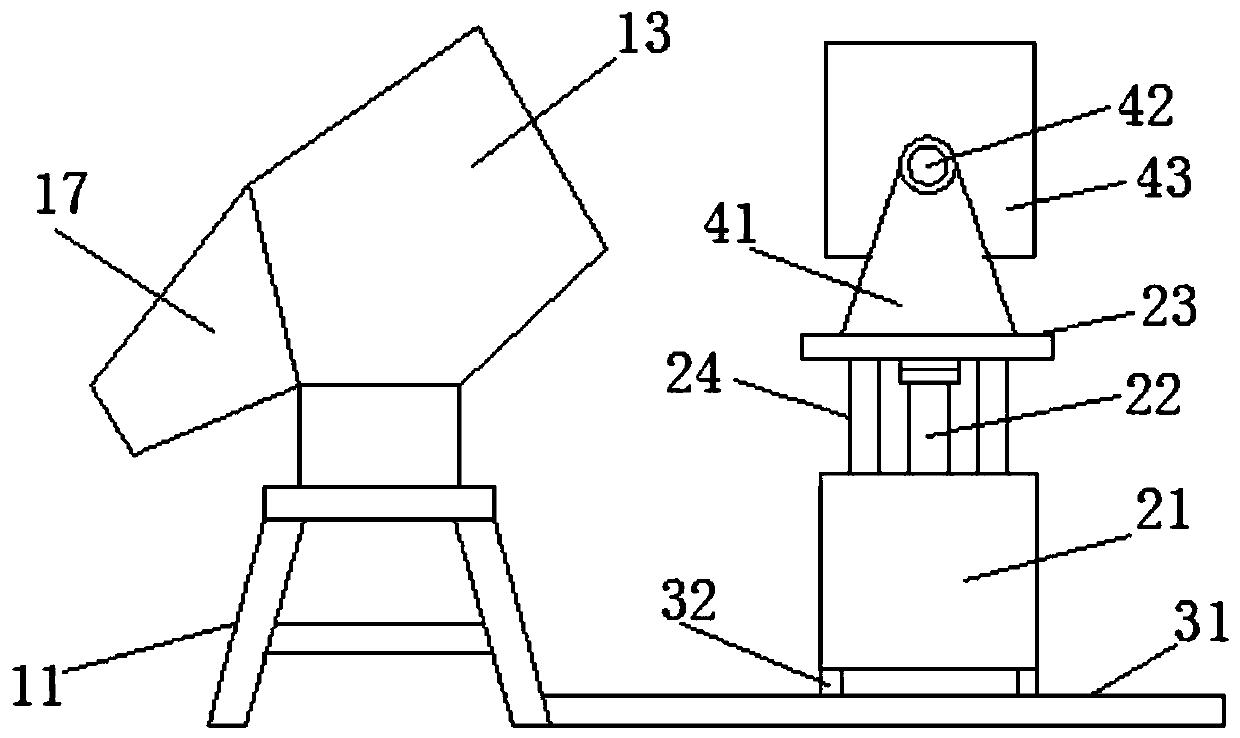

InactiveCN114178012AAvoid cloggingSmash all roundGrain treatmentsEnvironmental engineeringMechanical engineering

The invention discloses food waste classification crushing treatment equipment which comprises a base, a solid-liquid separation device is arranged on the base, a crushing barrel is arranged on the solid-liquid separation device, a screening net is arranged in the crushing barrel, and a screening net dredging mechanism used for dredging the screening net is arranged in the crushing barrel. A crushing assembly is arranged in the crushing barrel, a crushed object scraping structure tightly attached to the upper surface of the screening net is arranged on the crushing assembly, and a linkage mechanism for driving the screening net dredging mechanism to work when the crushing assembly works is arranged between the crushing assembly and the screening net dredging mechanism. According to the food waste crushing device, food waste can be crushed thoroughly and automatically leave the crushing barrel, food waste which is not crushed continuously remains in the crushing barrel to be crushed, meanwhile, a scraping structure is arranged, the food waste can be scraped and crushed again, the crushing quality is guaranteed, and meanwhile, a structure for preventing the screening net from being blocked is arranged, so that the stability of the working process is guaranteed.

Owner:SHENZHEN YIHUAXING ELECTRONICS

Plastic collecting device for energy conservation and environment protection

InactiveCN110385180ASmall footprintSave time and effort to collectGrain treatmentsEngineeringEnergy conservation

The invention discloses a plastic collecting device for energy conservation and environment protection. The plastic collecting device comprises a first feeding port, a first maintenance port is formedin the lower left corner of the first feeding port, the right side of the first feeding port of the plastic collecting device is fixedly connected with a feeding baffle plate, moreover, a crushing port is formed in the lower end of the feeding baffle plate, the lower end of the crushing port is fixedly connected with a first slide way, a second checking port is arranged on the left side of the crushing port of the plastic collecting device, moreover, a second feeding port is formed in the lower end of the second checking port, a driving device is arranged on the right side of the crushing port, a rubber pad is arranged at the lower end of the driving device of the plastic collecting device, moreover, a spring is fixedly connected to the lower end of the rubber pad, a second slide way is fixedly connected to the lower end of the second feeding port, a hand pushing frame is arranged at the lower left corner of the second feeding port of the plastic collecting device, and a supporting frame is arranged at the lower end of the hand pushing frame. According to the plastic collecting device for energy conservation and environment protection, the plastic collecting device is arranged ona trolley so that people can save more time and labor when the plastic is collected, moreover, a plastic crushing machine is arranged so that the plastic can be crushed when the plastic is collected,and then people can collect more plastic garbage.

Owner:宁夏澍侍信息科技有限公司

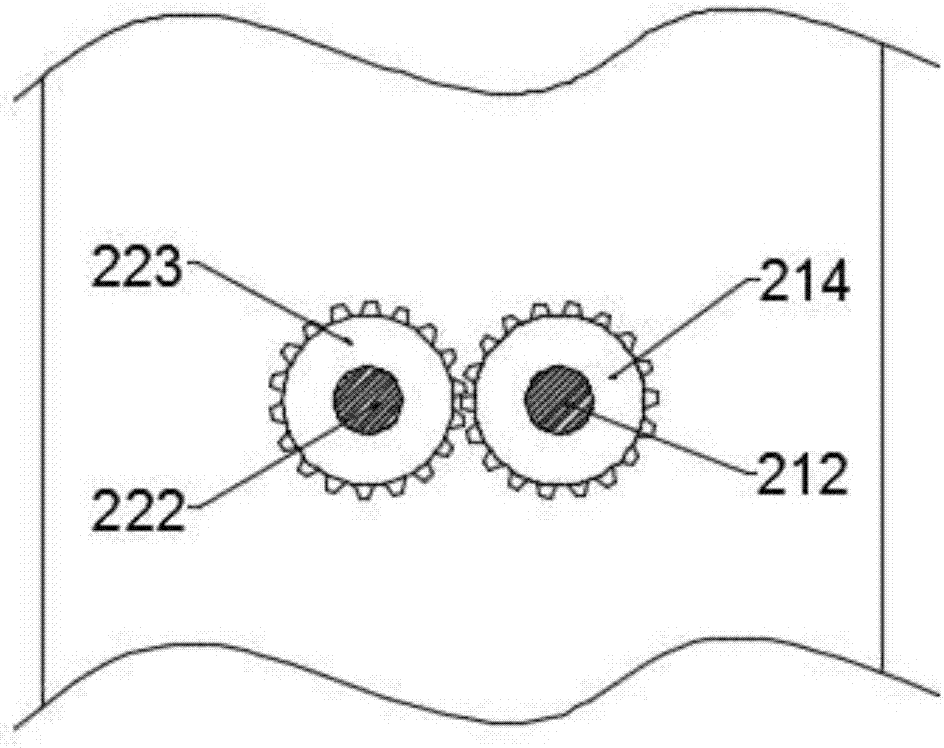

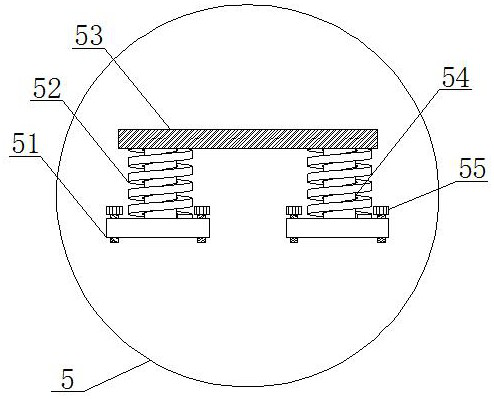

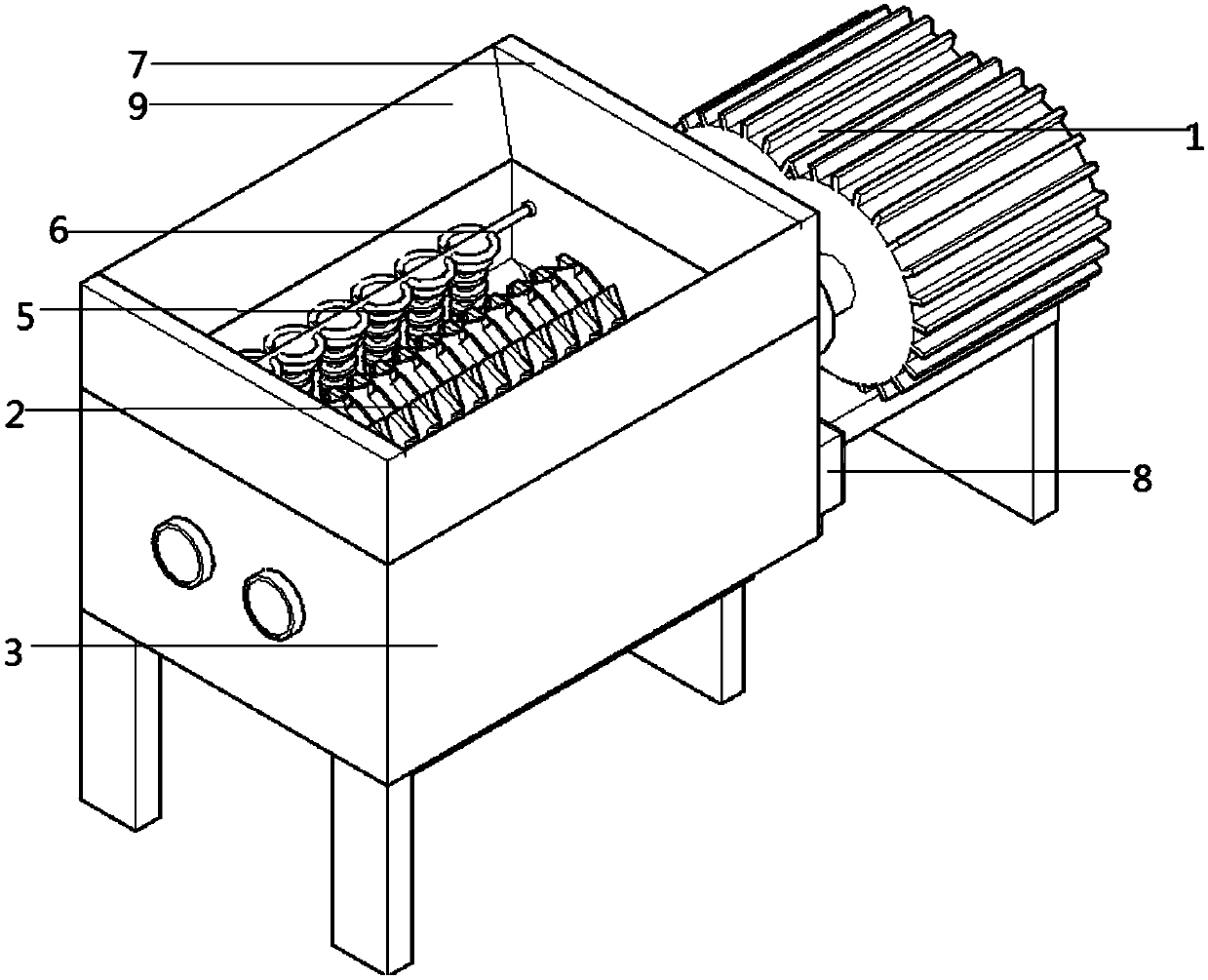

Feed grinder for animal husbandry equipment

InactiveCN111715373AEasy to crushSmash all roundFeeding-stuffGrain treatmentsAnimal scienceGear wheel

The invnetion relates to a feed grinder for animal husbandry equipment. The feed grinder comprises supporting legs and a base, the base is installed at the upper ends of the supporting legs, the supporting legs are connected with the base in a welded mode, a motor box is arranged on the left side of the upper end of the base, the base is fixedly connected with the motor box through bolts, the surface of the left side of the motor box is provided with a motor rotating shaft throug a connecting rod. According to the feed grinder, a connecting piece is arranged in the grinder, under the action ofthe connecting piece, vibration generated during work cannot damage a component, a hard spring is arranged on the periphery of the outer portion of a telescopic supporting rod, the hard spring has compressibility, and the hard spring can unload borne force; in addition, two crushing gears are arranged, so that thorough crushing of feed is facilitated when the feed is processed and crushed, and better crushing is achieved; and meanwhile, the space is better utilized, and more feed is crushed in the same time.

Owner:陈洁

A waste paper recycling device with high recycling efficiency

ActiveCN109482303BSolve the problem of low recycling efficiencyFully processedGrain treatmentsStationary filtering element filtersDrive wheelElectric machine

Owner:SUZHOU BATAO INFORMATION TECH CO LTD

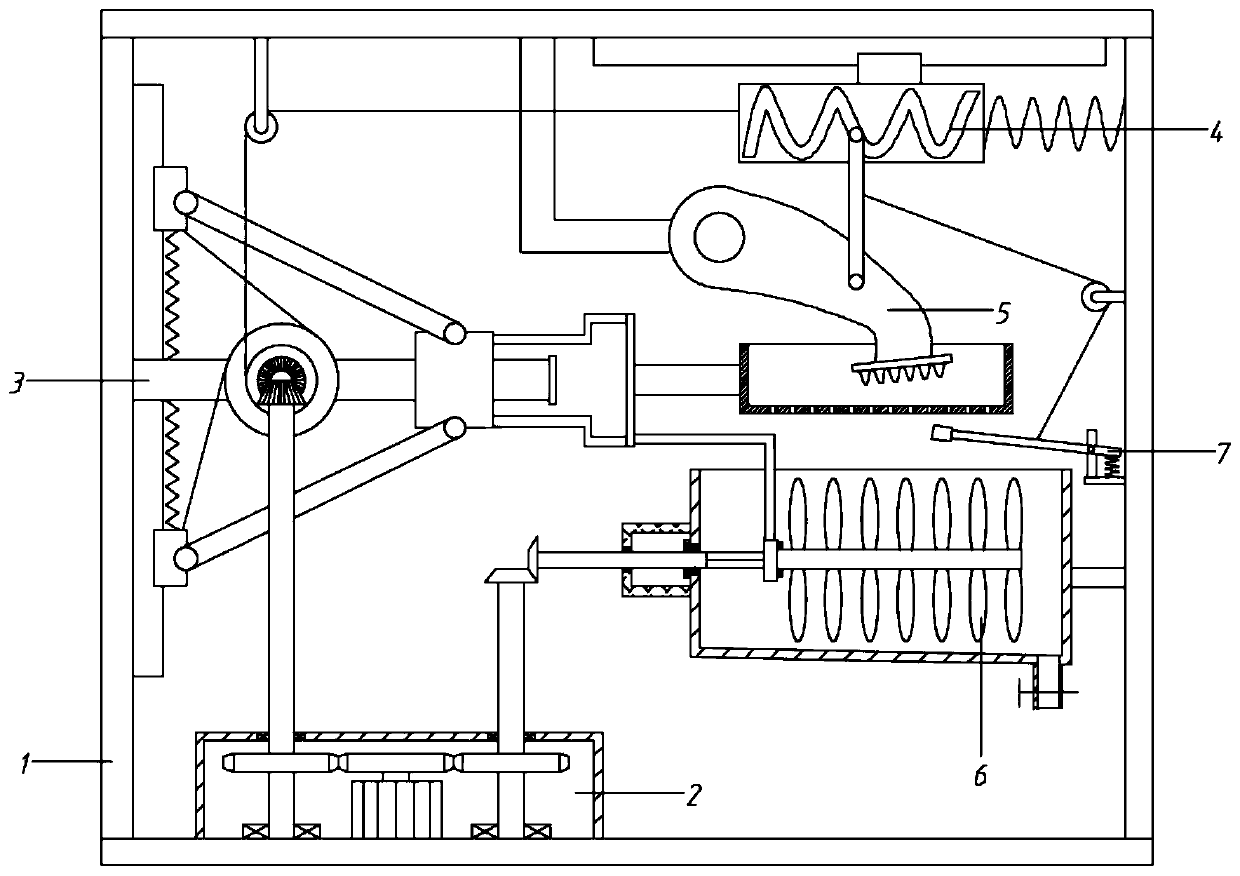

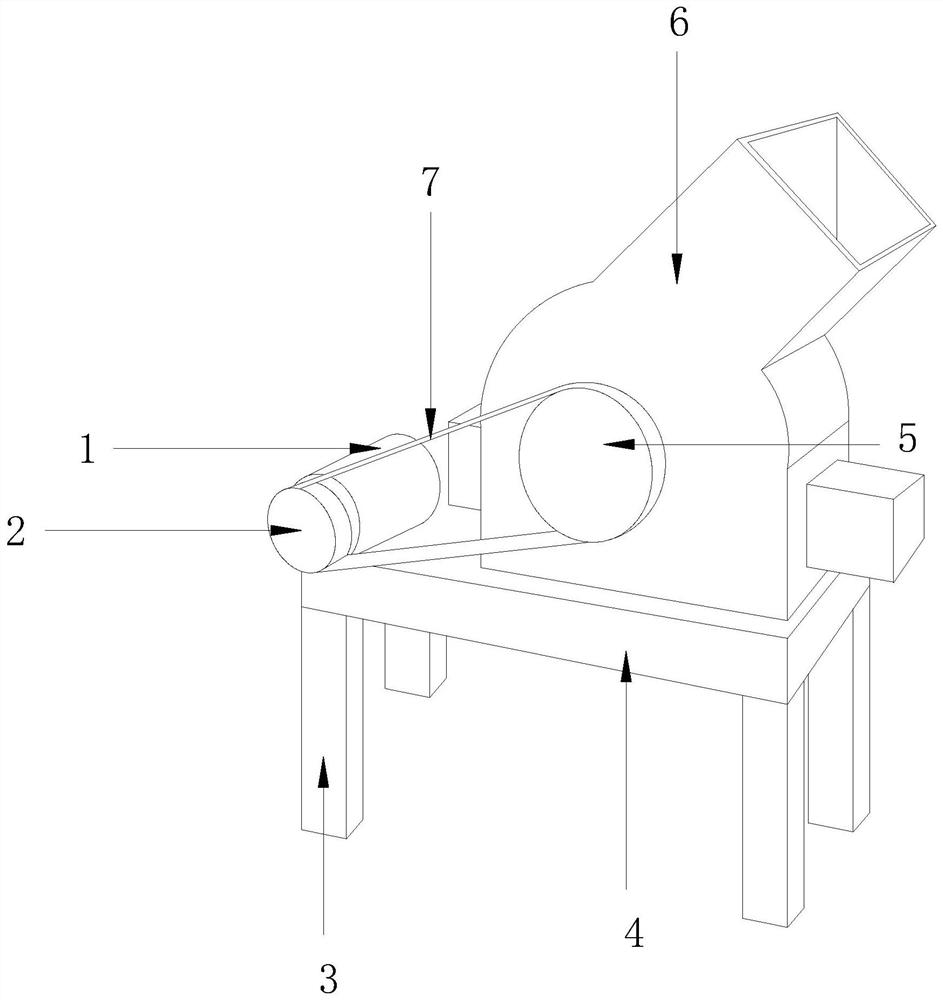

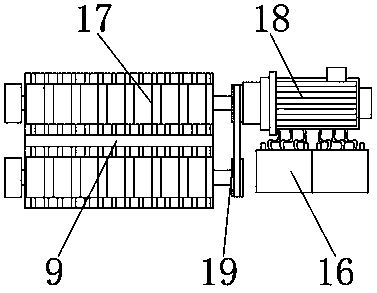

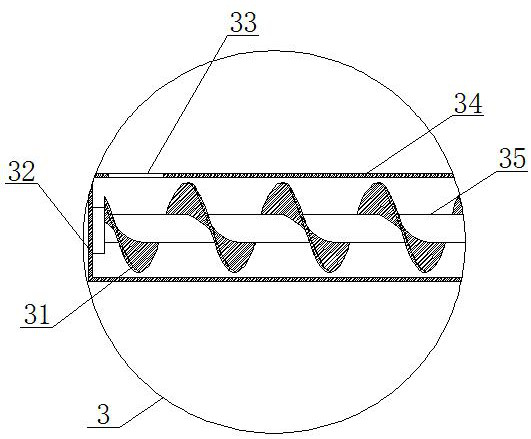

Novel crushing heavy calcium powder equipment

The invention discloses novel crushing heavy calcium powder equipment, and relates to the field of heavy calcium powder production equipment. The novel crushing heavy calcium powder equipment comprises a main body support frame (1), a cylindrical roller shaft (2), a pulverizer (3), a press machine (4), an insert (5), a first crushing motor (6), a first long rod (7), a group crushing disc A (8) anda heavy calcium powder output channel (12), wherein the pulverizer (3) are correspondingly provided with a feeding port, a discharging port, a press rod passing hole and a group of long rod passing holes; the bottom of the pulverizer (3) is movably arranged on the press rod passing hole; the press machine (4) is arranged at the top of the pulverizer (3); and a press rod of the press machine (4) penetrates through the press rod passing hole. The invention provides the novel crushing heavy calcium powder equipment which is multiple in crushing, high in precision, high in efficiency, and has very good practical value.

Owner:刘果

A feed processing device that is convenient for sieving and retrieving materials

The invention discloses a feed processing device facilitating material screening and taking. The feed processing device comprises a box body. The box body is divided into a processing chamber and a material receiving chamber. A material screening device is arranged between the processing chamber and the material receiving chamber. A fixed rod is arranged on the upper portion of an inner cavity ofthe processing chamber, and the left and right sides of the fixed rod both penetrate through the outer wall of the processing chamber. A metal block is mounted at the left end of the fixed rod, and aconnecting block is mounted at the right end of the fixed rod. A first fixed frame and a second fixed frame are mounted at the left and right ends of the processing chamber correspondingly. An electromagnet is mounted on the first fixed frame and located on the left of the metal block. A spring is arranged between the second fixed frame and the connecting block for connection. A cam is designed for transmission, so that a material screening net vibrates up and down along a sliding chute, thus, the material screening efficiency is improved, and blocking of a net opening of the screening net isavoided.

Owner:江苏大正饲料科技有限公司

Coal pulverizer

The invention relates to a coal pulverizer. The coal pulverizer comprises a motor power switch, a circuit cabinet, a pulverizing box, a conveying belt, a first motor, a coal outlet, a coal inlet, a motor ferrule, a second motor, a coal passage and a pulverizing power unit, wherein the circuit cabinet is connected with the pulverizing box through welding, the motor power switch is arranged on the circuit cabinet and is connected with the first motor and the second motor through wires, and the first motor and the second motor are mounted in the pulverizing box through the motor ferrule. The coalpulverizer is good in pulverizing effect and suitable for popularization and application.

Owner:滕州市凡廷自动化设备有限公司

Full-automatic plastic pulverizer for plastic mould factory

InactiveCN106042221AImprove crushing efficiencySmash all roundPlastic recyclingGrain treatmentsCouplingFixed frame

The invention discloses a full-automatic plastic pulverizer for a plastic mould factory. The full-automatic plastic pulverizer comprises bottom fixed suckers, a base, a coupling, a transmission shaft and a mixing bin. The base is arranged on the bottom fixed suckers. A rotating shaft is arranged above the base. A bevel gear is arranged on the rotating shaft. The coupling is arranged on the bevel gear. A drive motor is arranged on the coupling. A fixing frame is arranged at the lower part of the drive motor. The transmission shaft is arranged below the fixing frame. An oil tank is arranged at the lower part of the transmission shaft. The mixing bin is arranged beside the oil tank. A rotary knife is arranged in the mixing bin. A protective net is arranged beside the rotary knife. A pouring bucket is arranged above the protective net. Lifting footings are arranged below the pouring bucket. The full-automatic plastic pulverizer has the beneficial effects that the pulverizing efficiency is improved greatly, any plastic products can be pulverized, and pulverizing is complete and thorough.

Owner:XUZHOU BEIER ELECTRIC CO LTD

Automatic waste pulverizer

The invention provides an automatic waste pulverizer. The automatic waste pulverizer comprises a feeding mechanism and a pulverizing mechanism, wherein the feeding mechanism comprises a translating assembly, a vertical lifting assembly, and a shuffling assembly; the translating assembly is connected with the vertical lifting assembly; the shuffling assembly is arranged on the vertical lifting assembly; the pulverizing mechanism includes a rack, a pulverizing motor arranged on the rack, a pulverizing chamber, a tool holder arranged in the pulverizing chamber, and pulverizing cutters arranged onthe tool holder; the pulverizing motor and the tool holder are in transmission connection; the pulverizing chamber includes a feeding port and a discharging port; the pulverizing cutters include maincutters arranged perpendicular to the tool holder and auxiliary cutters arranged obliquely to the tool holder; the auxiliary cutters are arranged on the main cutters; and the main cutters are evenlyarranged along the outer diameter of the rack. By means of the automatic waste pulverizer, the automatic feeding of waste is achieved, the grade of scrap pulverization is higher, the smashing effect is better, and thus the smashed waste is transported and recycled conveniently.

Owner:苏州冬宝光电科技有限公司

Smasher provided with auxiliary propelling

The invention discloses a smasher provided with auxiliary propelling. The smasher comprises a bottom board, a stand is arranged on one side of the bottom board, and the smasher is characterized in that a driving motor with the direction facing down is arranged on the stand, a material preparing box body is arranged on the bottom board, a plurality of extrusion boards are arranged in the material preparing box body, a guiding mechanism is arranged between the extrusion boards and the outer wall of the material preparing box body, and a driving device capable of driving the extrusion boards to press downwards is arranged between the driving motor and the outer wall of the extrusion boards. The smasher can increase the pressure in the smashing process, can smash all-roundly, improves the smashing quality, brings convenience for human, and is simple in structure and convenient to use.

Owner:金华凡惠装饰工程有限公司

A shredder equipped with auxiliary propulsion

The invention discloses a smasher provided with auxiliary propelling. The smasher comprises a bottom board, a stand is arranged on one side of the bottom board, and the smasher is characterized in that a driving motor with the direction facing down is arranged on the stand, a material preparing box body is arranged on the bottom board, a plurality of extrusion boards are arranged in the material preparing box body, a guiding mechanism is arranged between the extrusion boards and the outer wall of the material preparing box body, and a driving device capable of driving the extrusion boards to press downwards is arranged between the driving motor and the outer wall of the extrusion boards. The smasher can increase the pressure in the smashing process, can smash all-roundly, improves the smashing quality, brings convenience for human, and is simple in structure and convenient to use.

Owner:金华凡惠装饰工程有限公司

Coal crushing device of coal mine

PendingCN107755043AAvoid missingSmash all roundRotary stirring mixersTransportation and packagingEngineeringFront and back ends

The invention provides a coal crushing device of a coal mine. The coal crushing device comprises a primary motor, a cutting body and an accommodating hole. Supporting legs are fixedly welded at the bottom of the primary motor and a shell; each of the bottoms of auxiliary stirring groups is rotatably connected to a stirring group transmission body, and each stirring group transmission body is rotatably connected to a stirring motor arranged on the side wall of the left end of the shell. The crushing rotary shafts are arranged in a staggered manner, wherein the crushing rotary shaft at the frontend is close to the left end while the crushing rotary shaft at the back end is close to the right end, and the staggering distance between the crushing rotary shafts is a distance of a crushing sheet, so that when coal is crushed, a full crushing surface is achieved, the coal is fully crushed, and no coal is missed; moreover, with the auxiliary stirring groups at the front and back ends of the inner wall of the shell, coal cinder on two sides can be centralized toward the crushing rotary shafts under the action of the auxiliary stirring groups, and the front and back shafts of the primary motor rotate reversely.

Owner:GUIZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com