Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Small opening and closing torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

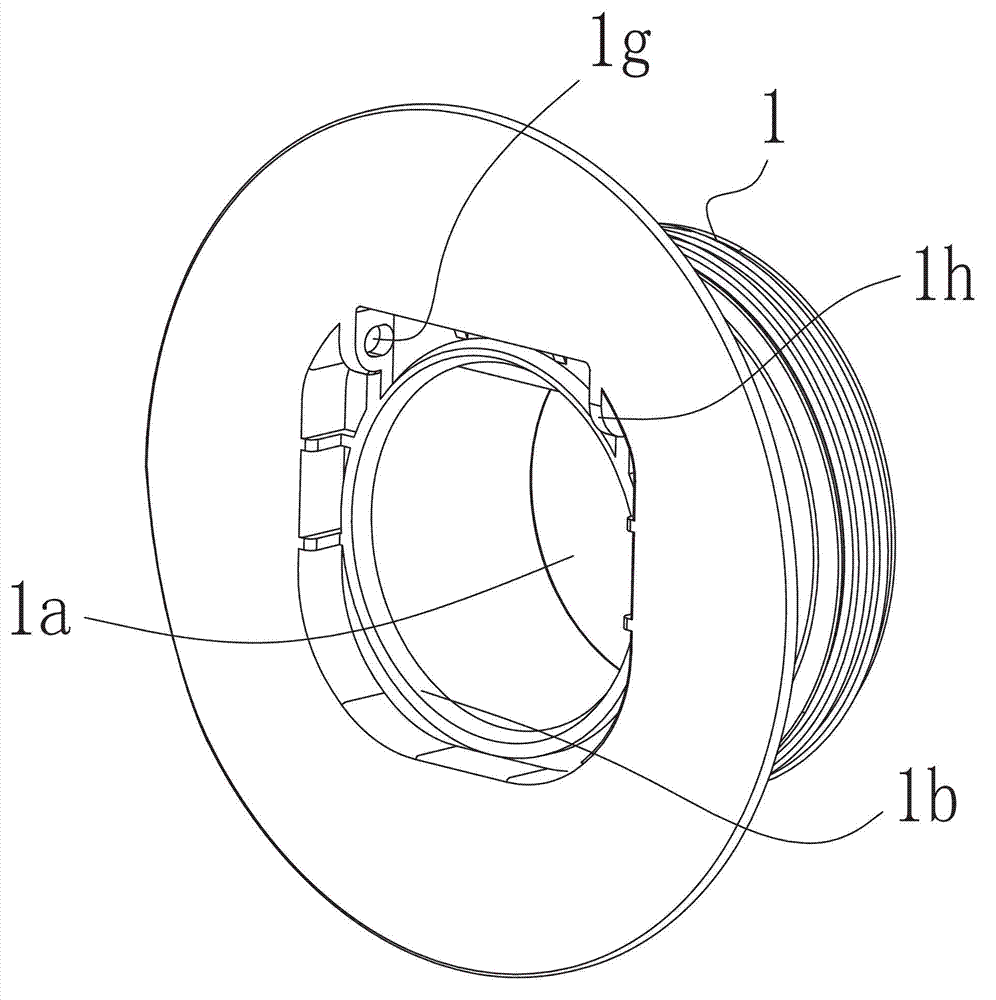

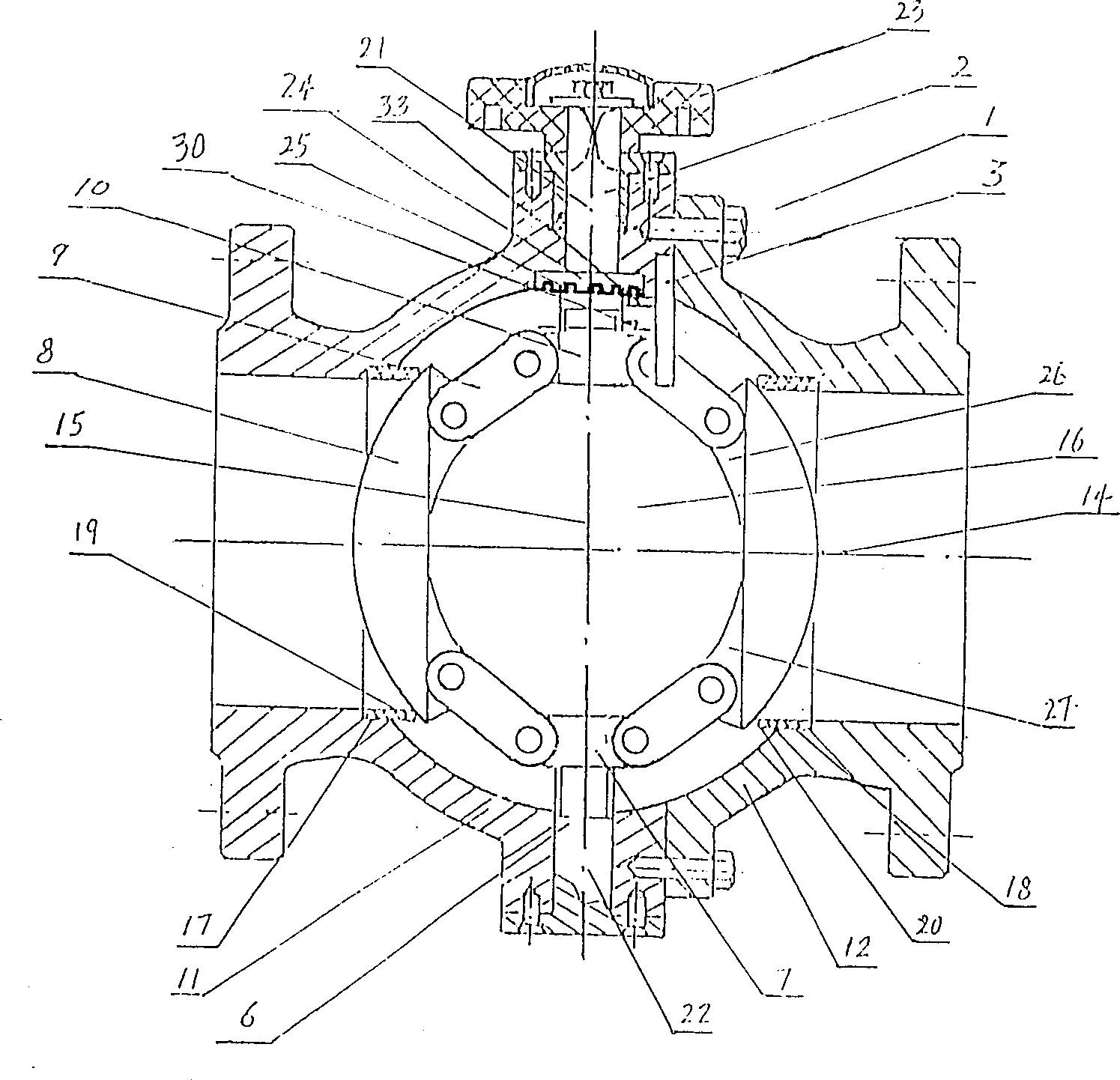

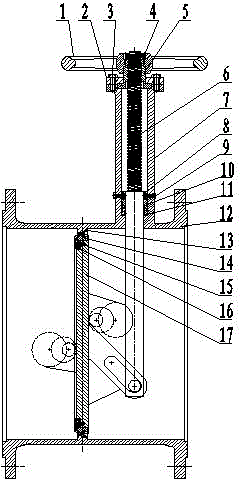

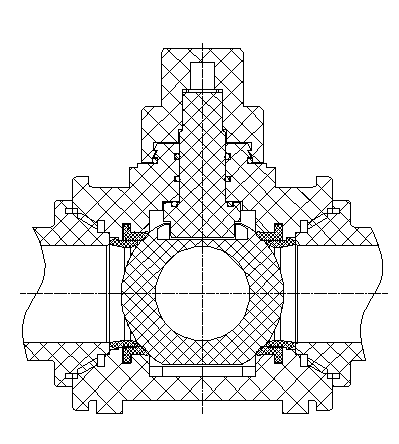

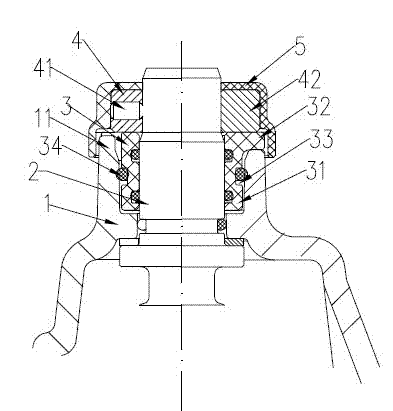

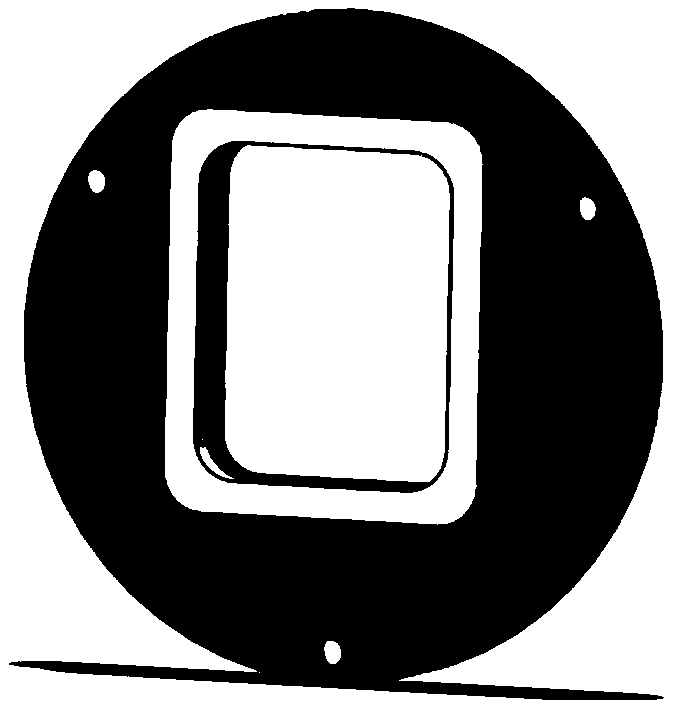

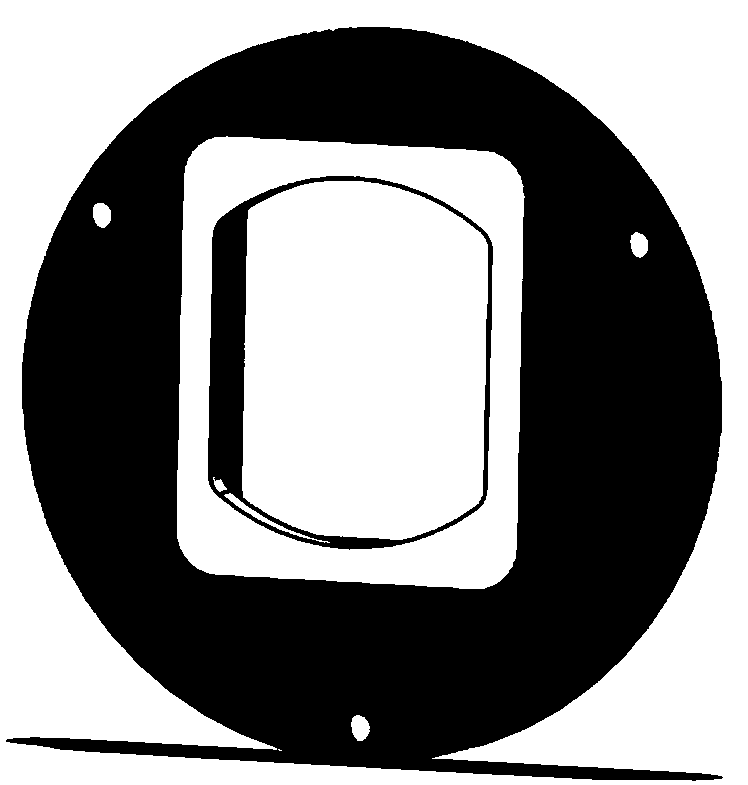

Non-abrasion hard-sealing butterfly valve

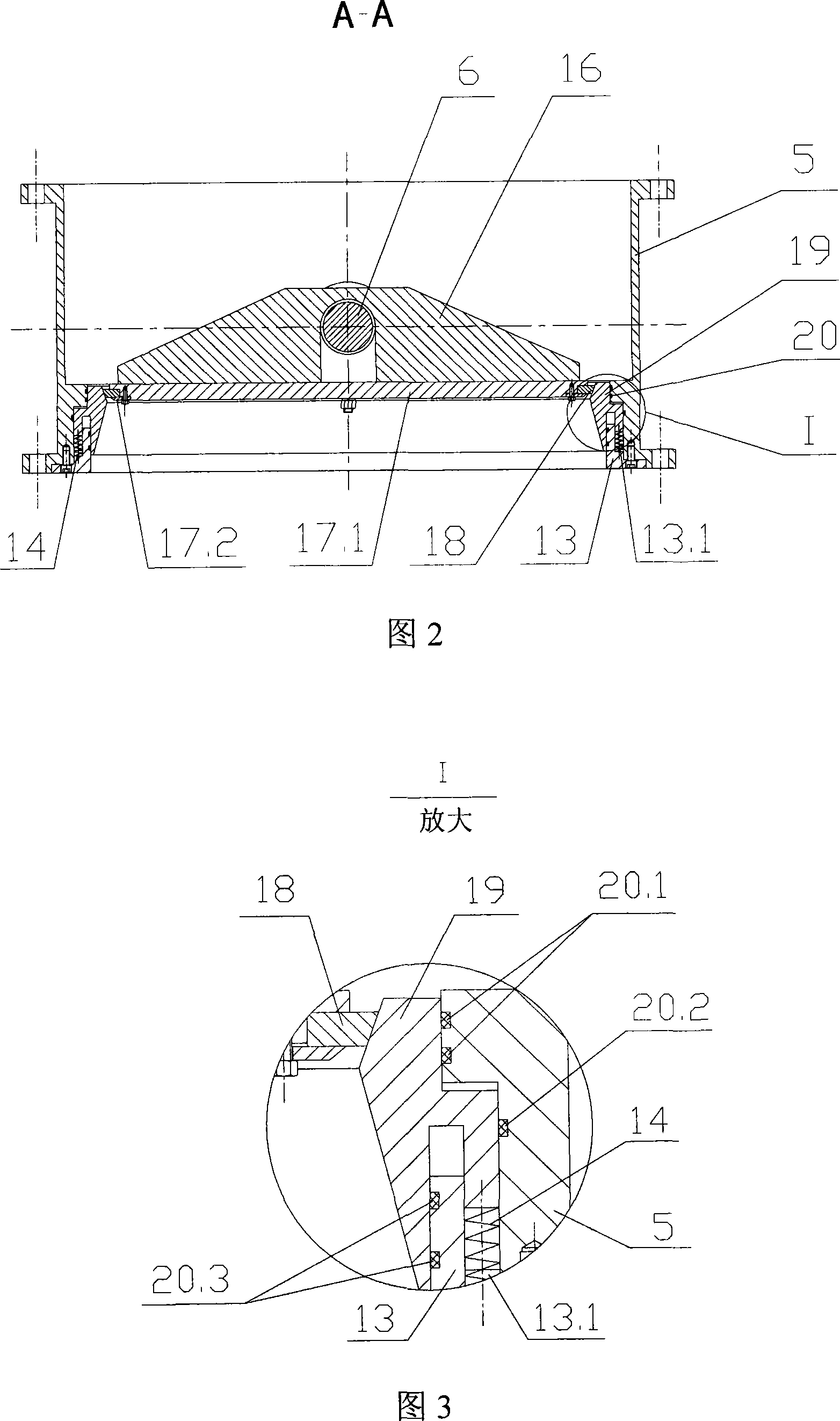

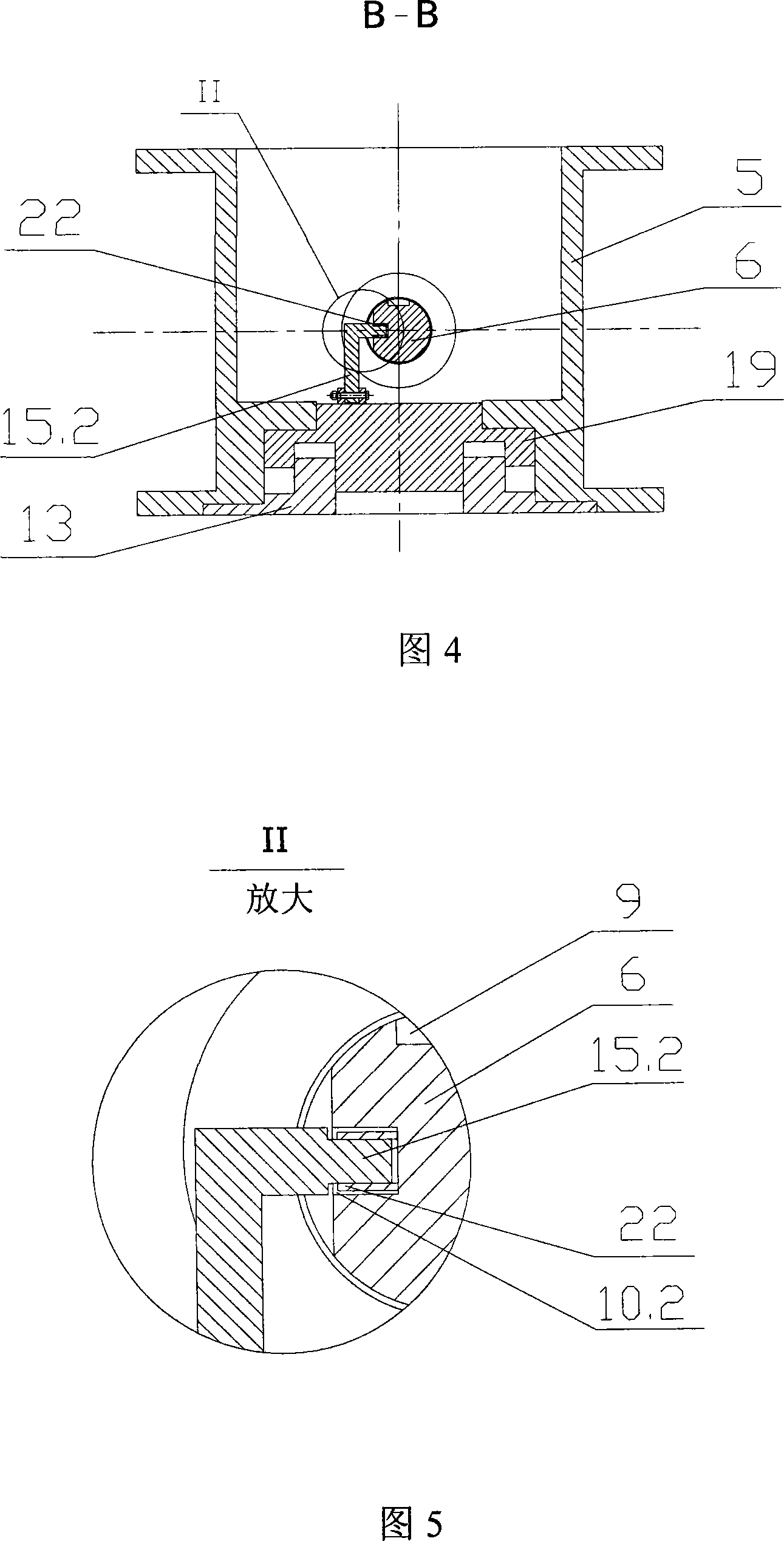

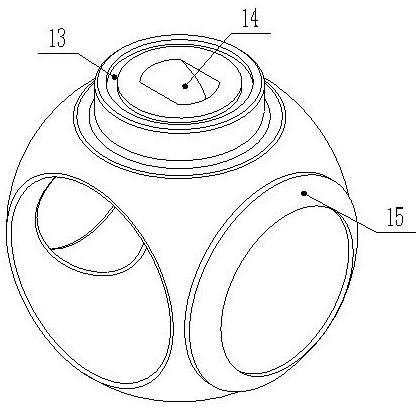

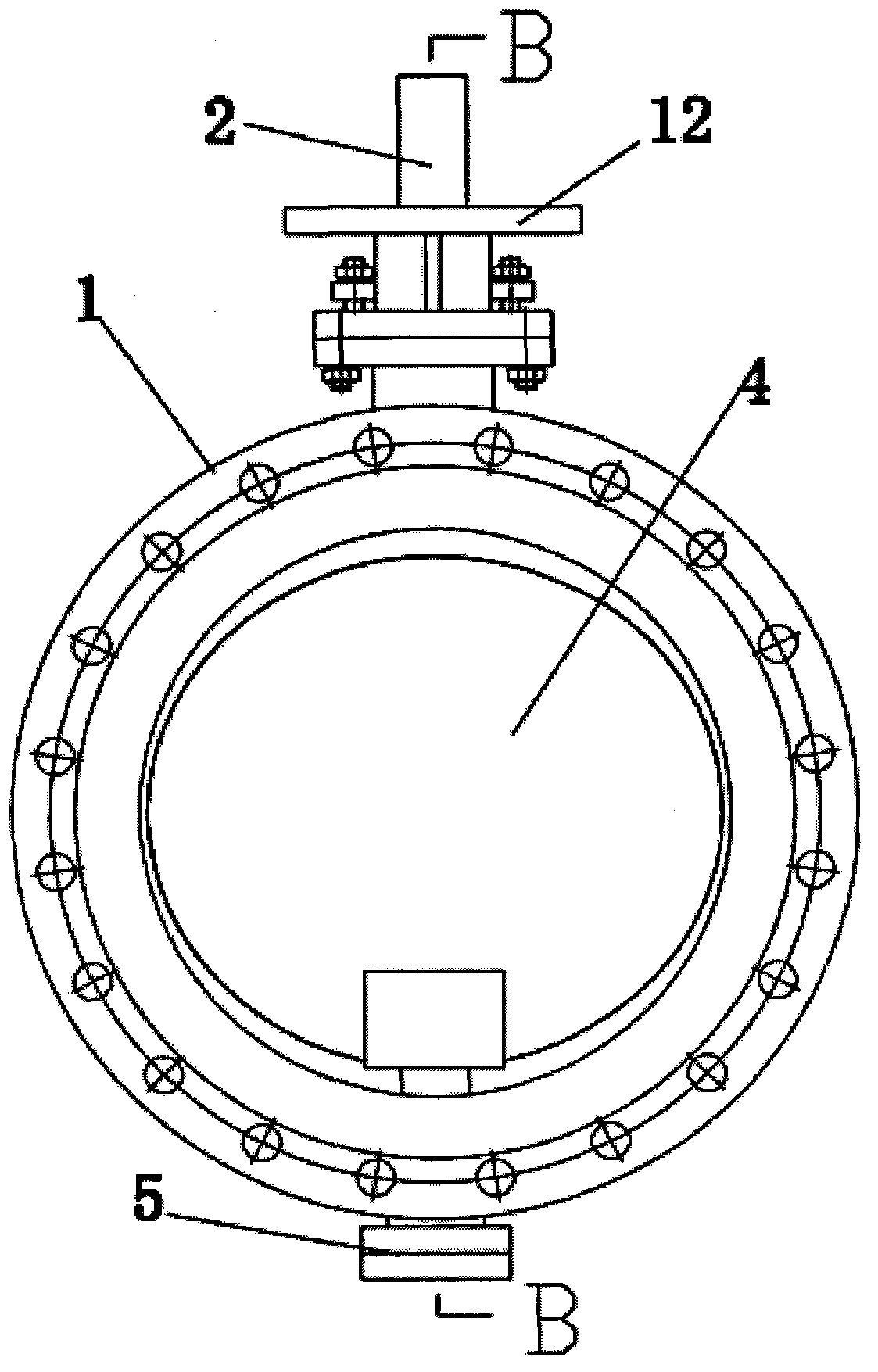

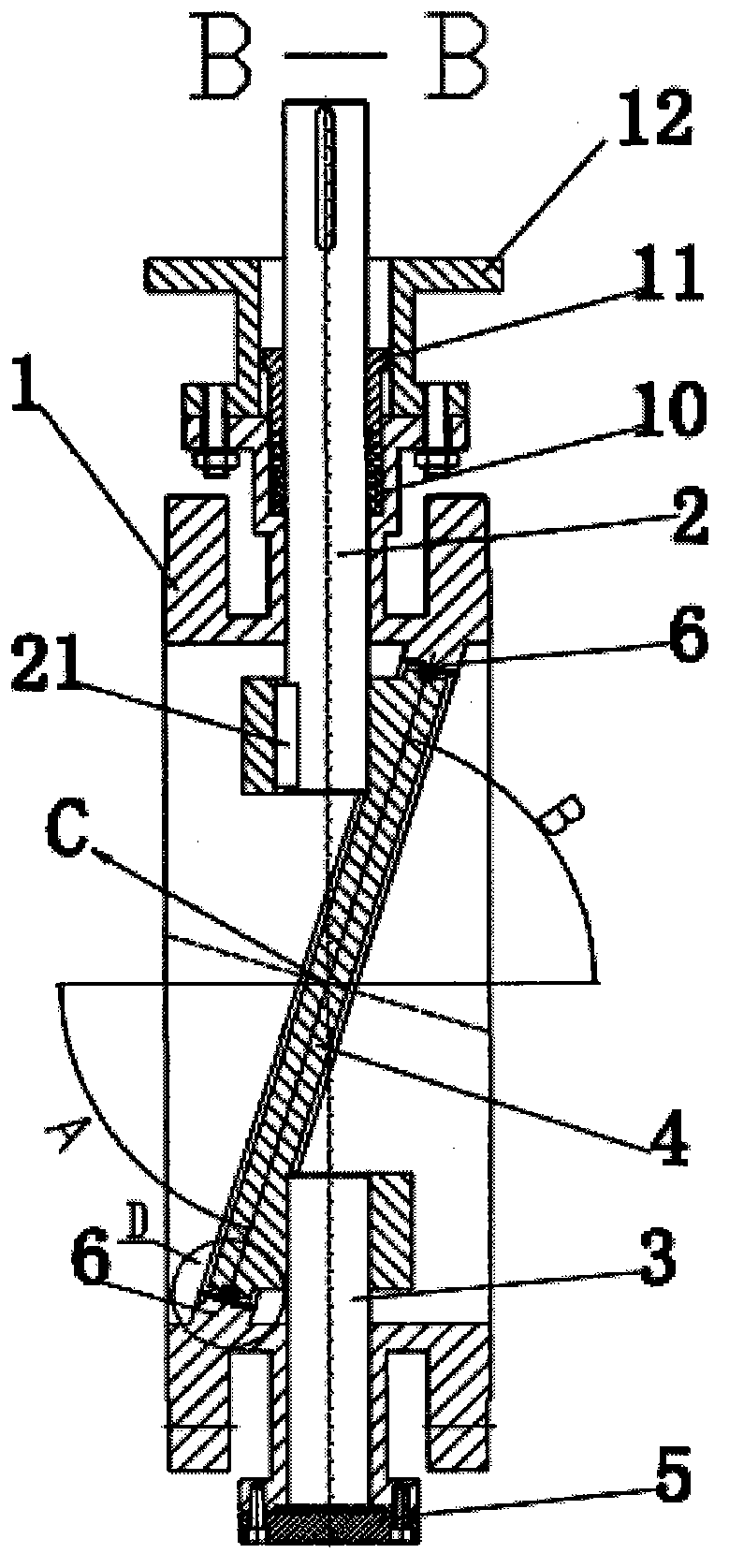

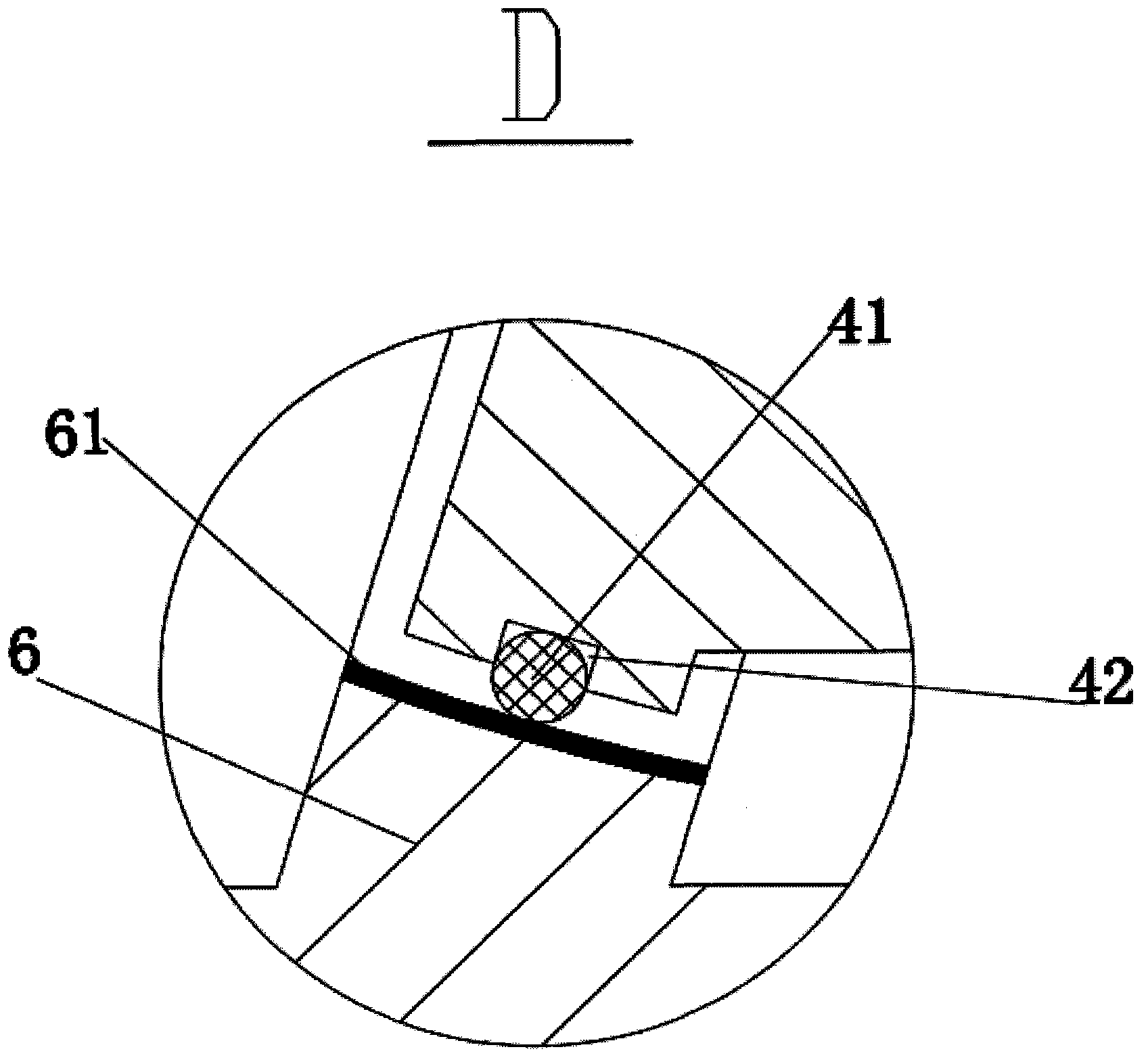

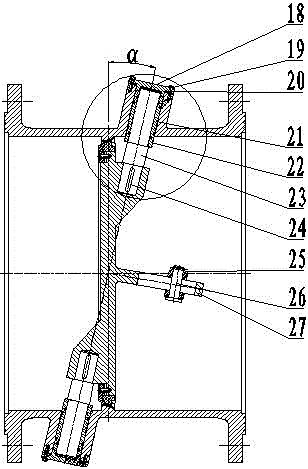

The invention relates to a non-loss hard seal butterfly valve which consists of a valve body, a valve rod, a butterfly plate and a valve seat. The invention is characterized in that the valve seat can be a movable valve seat which can axially move along the inner wall of the valve body; one side of the valve body is provided with a lateral body; seal rings are arranged both between the valve seat and the valve body, between the valve seat and the lateral body; a seal component is fixed on a butterfly plate frame; moving fit clearances are reserved between an inner side surface and an outer side surface of the valve seat, between the valve body and the lateral body; a spring is arranged between an outer end surface of the valve seat and the lateral body, an inner end surface of the valve seat is connected with the valve rod through a push rod; an inner end surface of the lateral body is provided with a spring; an upper end and a lower end of the valve rod are respectively provided with a curved slot; an upper curved slot and a lower curved slot are respectively formed by a skewed slot and an arc slot; the middle part of the valve rod is also provided with a long keyway, and an upper sliding key and a lower sliding key which are respectively fixed on an upper connecting seat and a lower connecting seat, and the upper connecting seat and the lower connecting seat are respectively fixed on the butterfly plate; the push rod consists of an upper push rod and a lower push rod, one end of the upper push rod and one end of the lower push rod are both provided with a roller, one end of the lower push rod is embedded in the lower curved slot and capable of sliding, while the other end of the lower push rod is hinged with the inner end surface of the movable valve seat; the upper push rod and the lower push rod are symmetrically arranged; a uni-eccentric structure is formed between a butterfly plate rotating axis and a seal pair plane.

Owner:HEBEI UNIV OF TECH

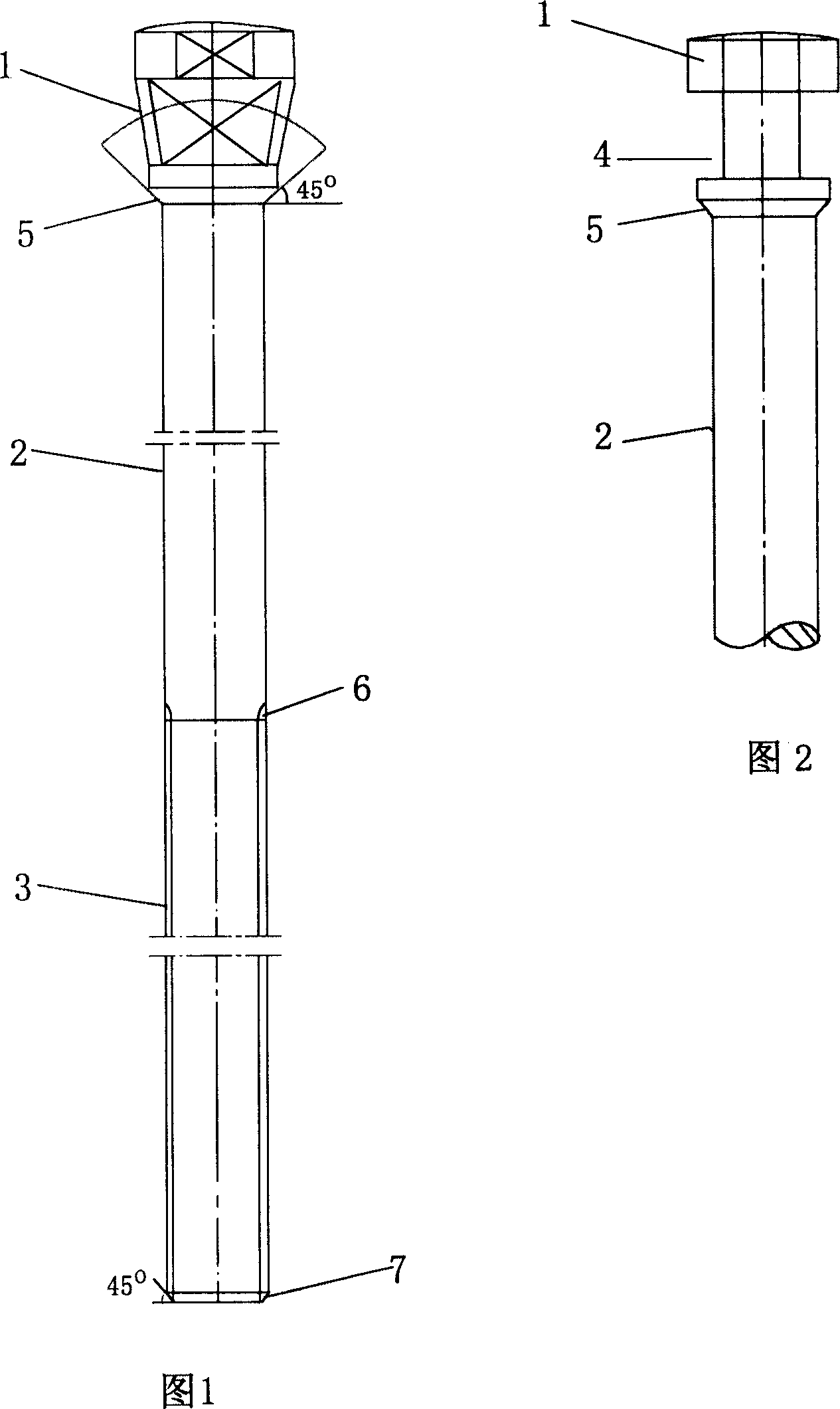

Valve rod forging and cold extruding formation process

The present invention relates to forging technology, and is especially valve rod forging and cold extruding formation process. The valve rod as the part of valve is one rod, and has one thicker end with slots as the head, the other end with thread and one middle part of smooth rod. The formation process includes the steps of cutting rod, end chamfering, slotting in the head, chamfering the sealing surface, chamfering the root of the thread part, cold extruding threads, rolling the smooth rod, etc. The production process has saving in material, high production efficiency and low cost.

Owner:朱志远

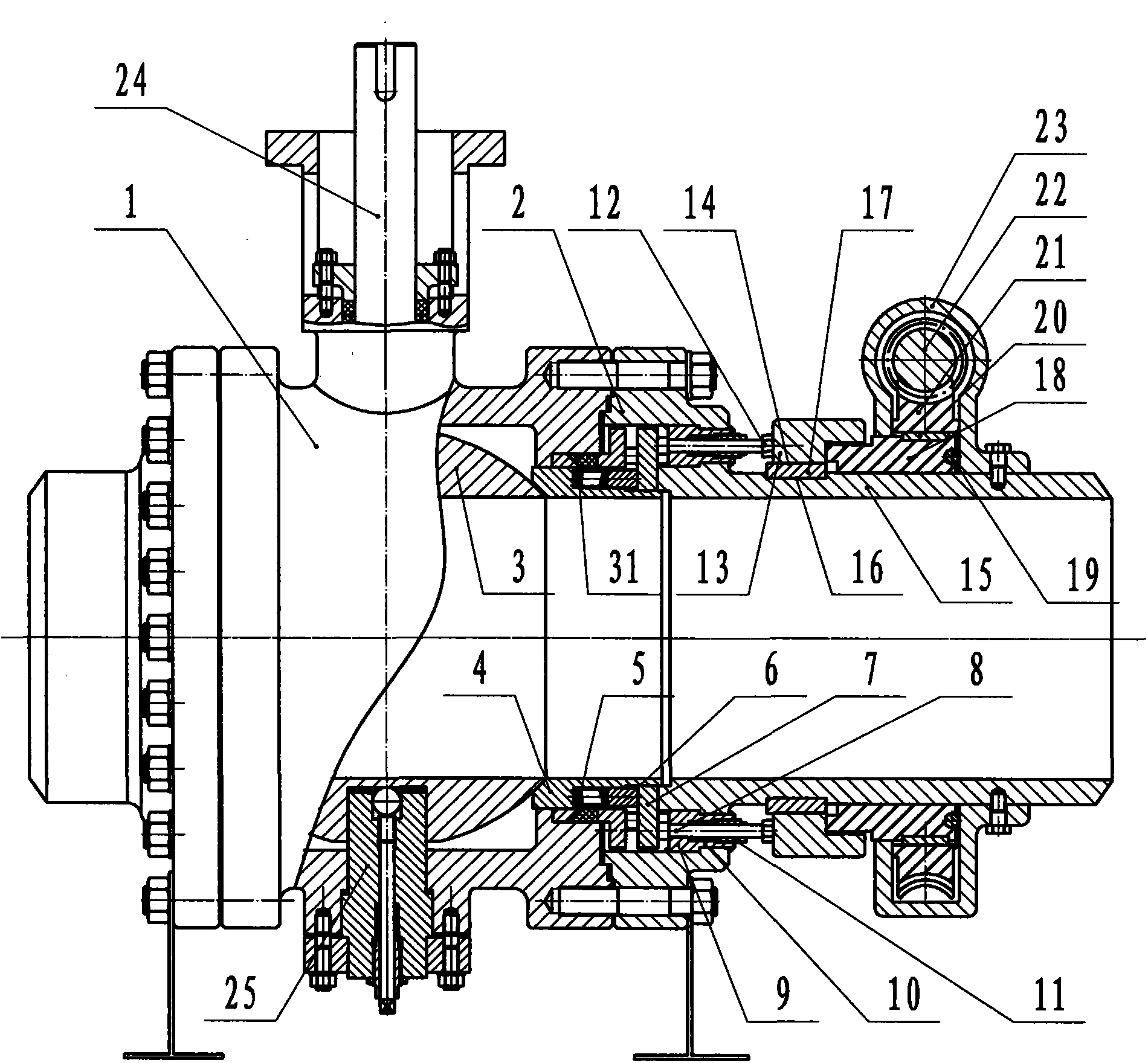

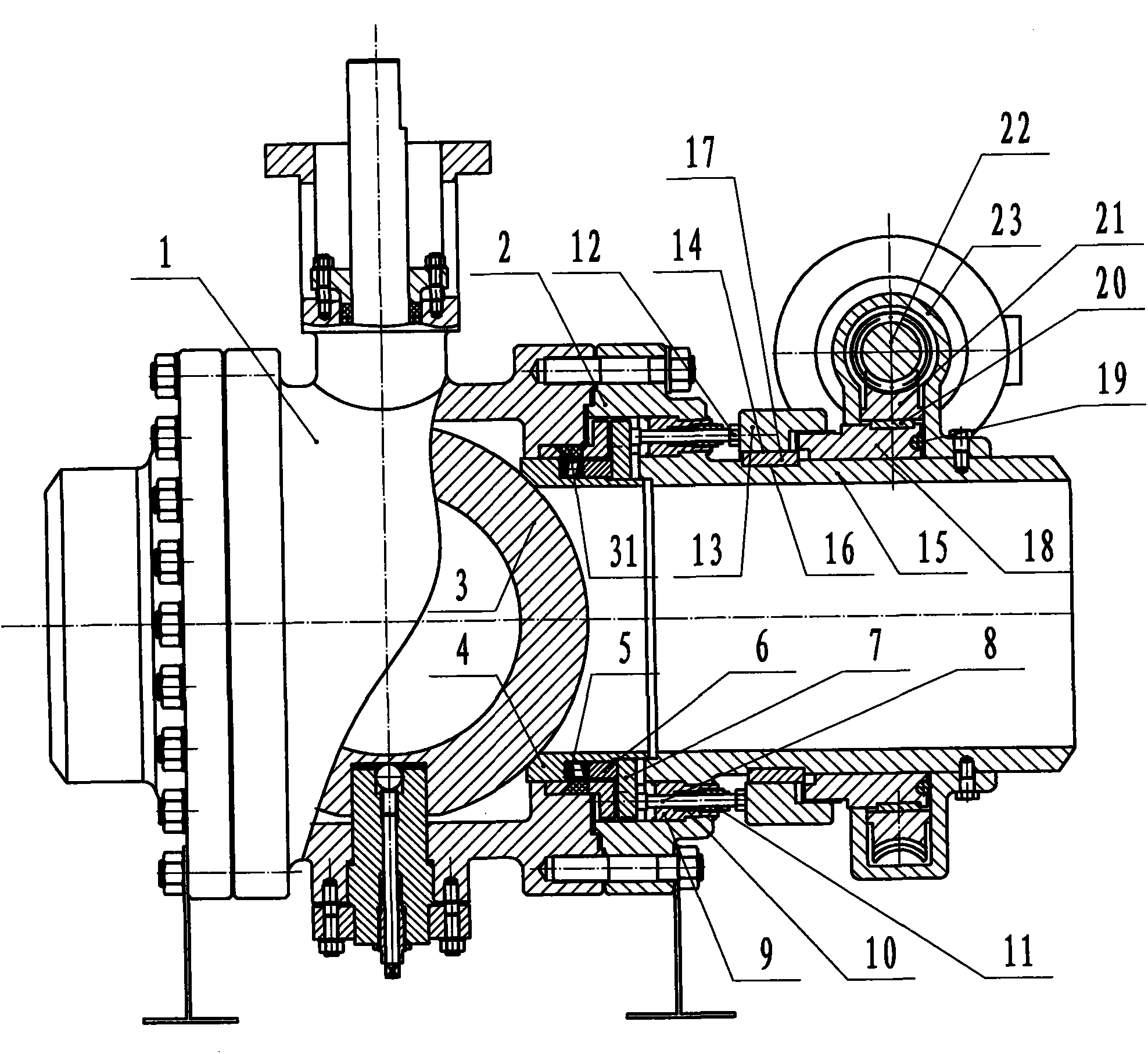

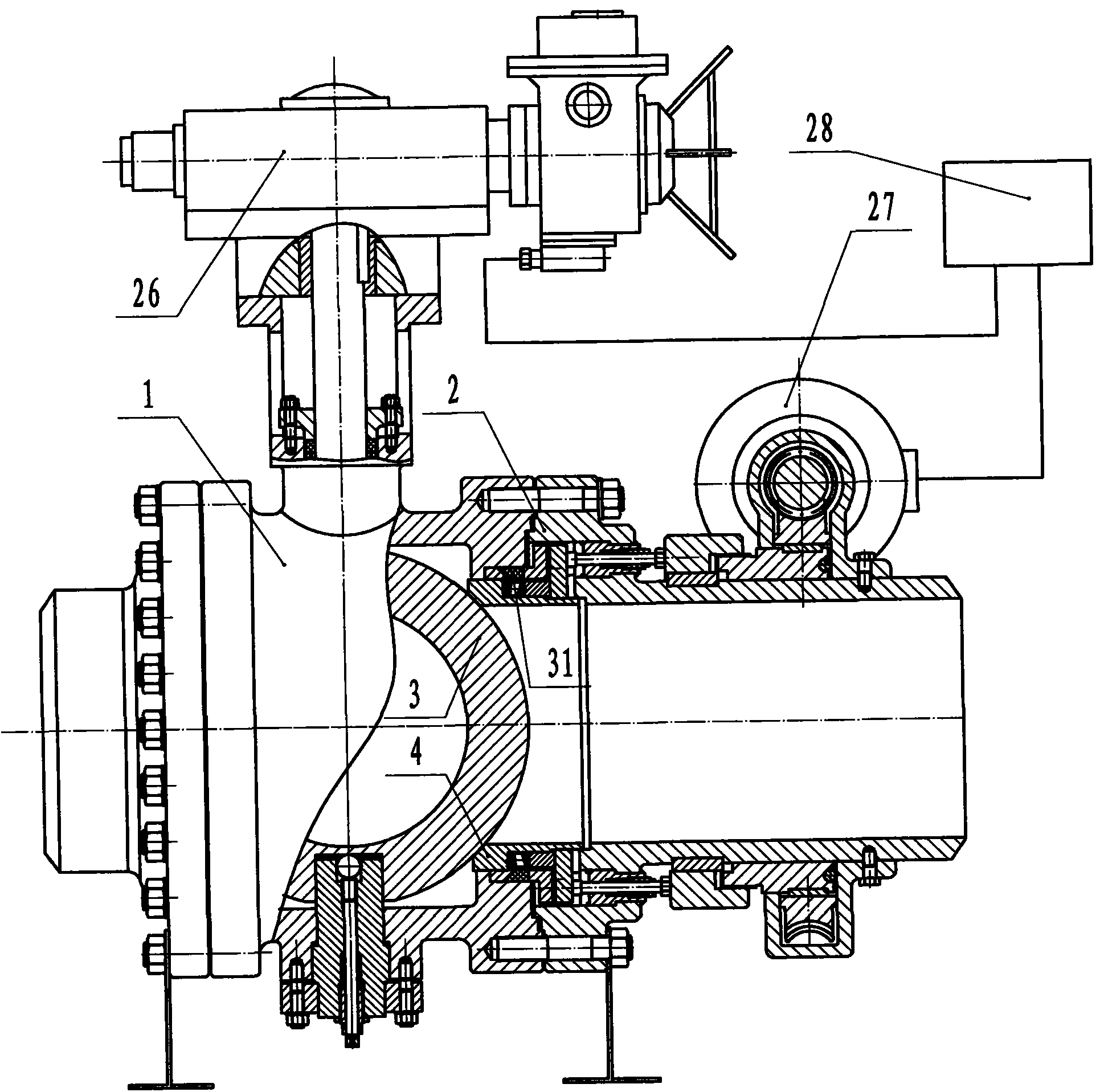

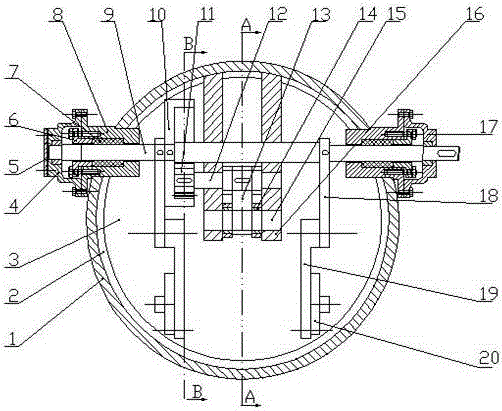

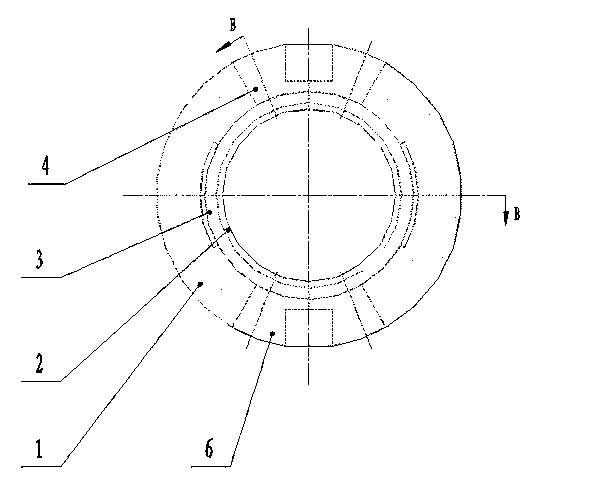

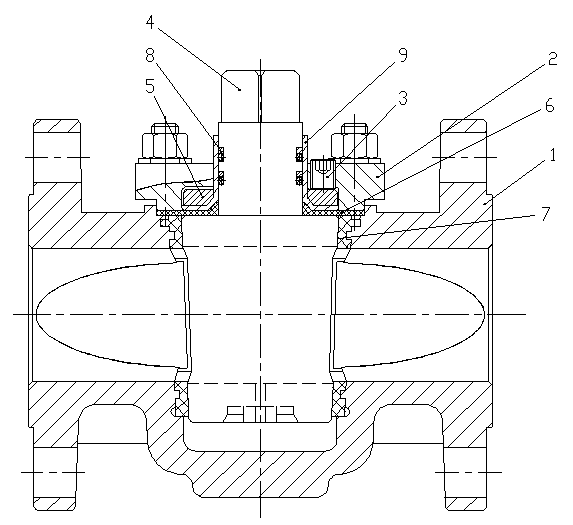

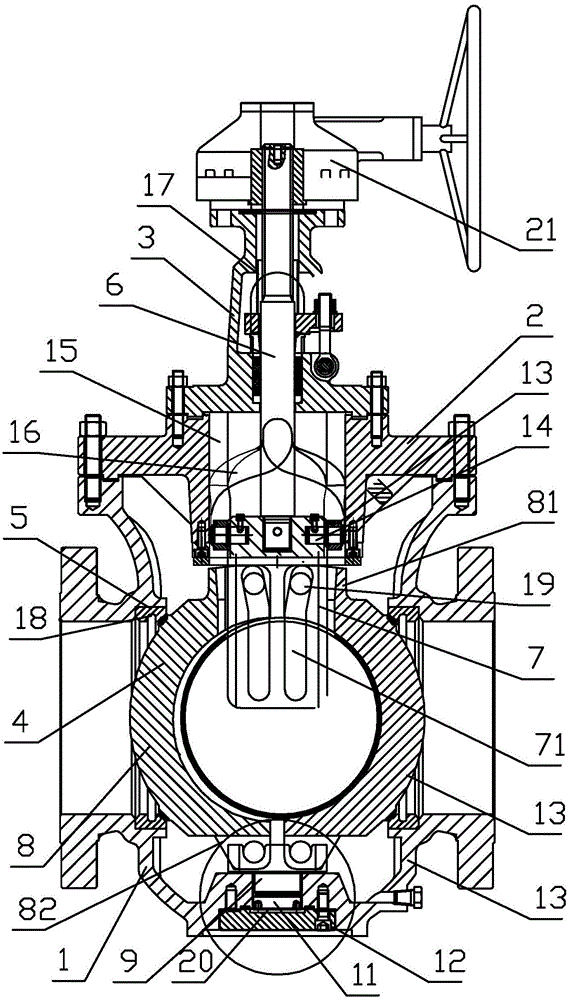

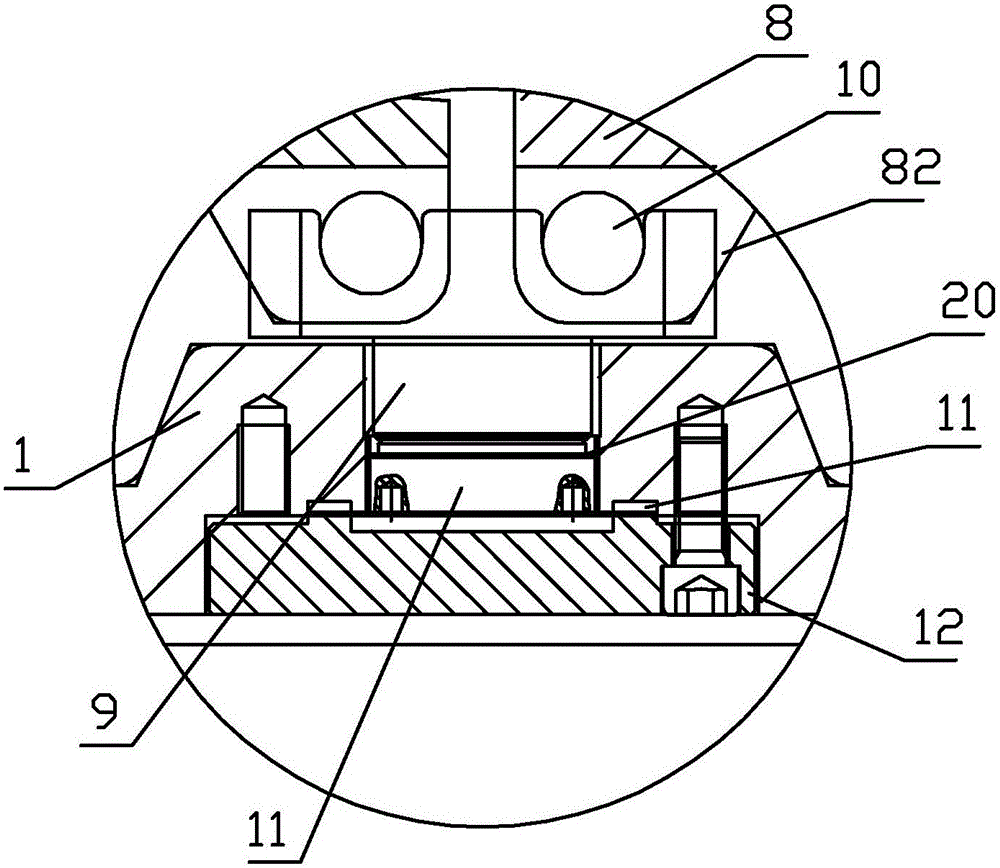

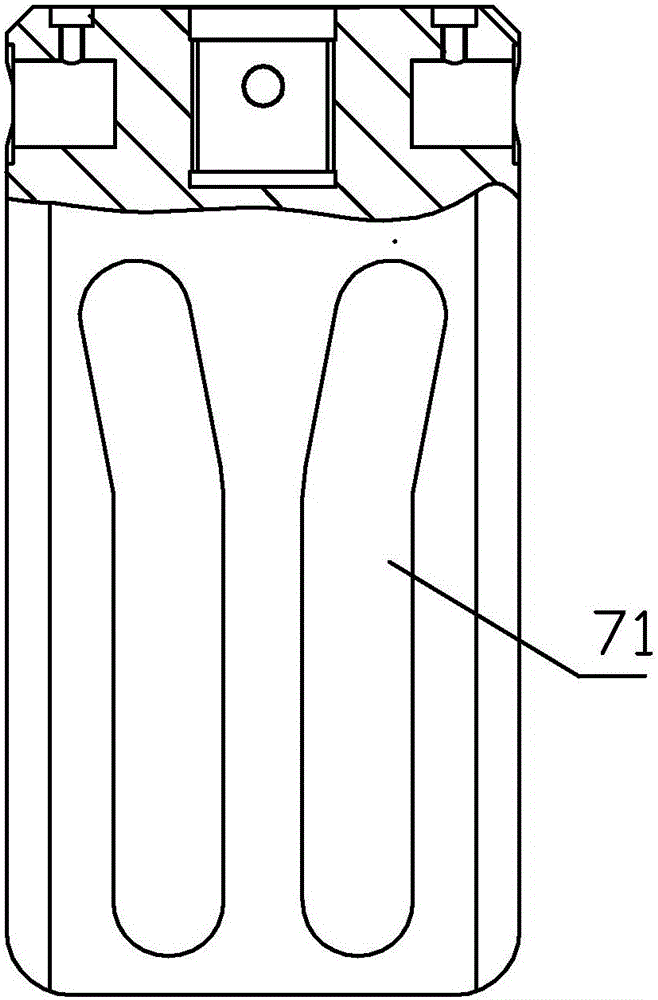

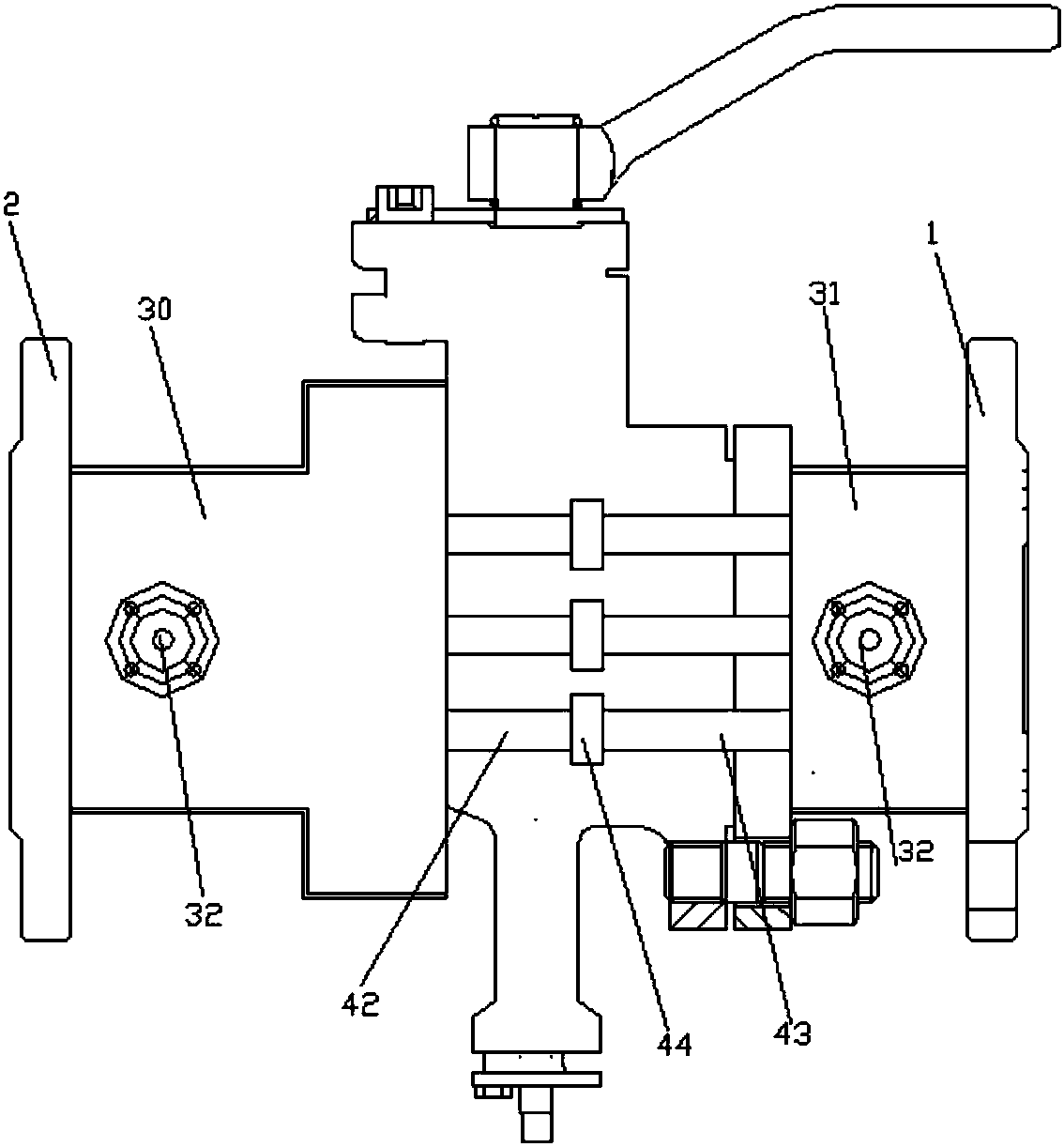

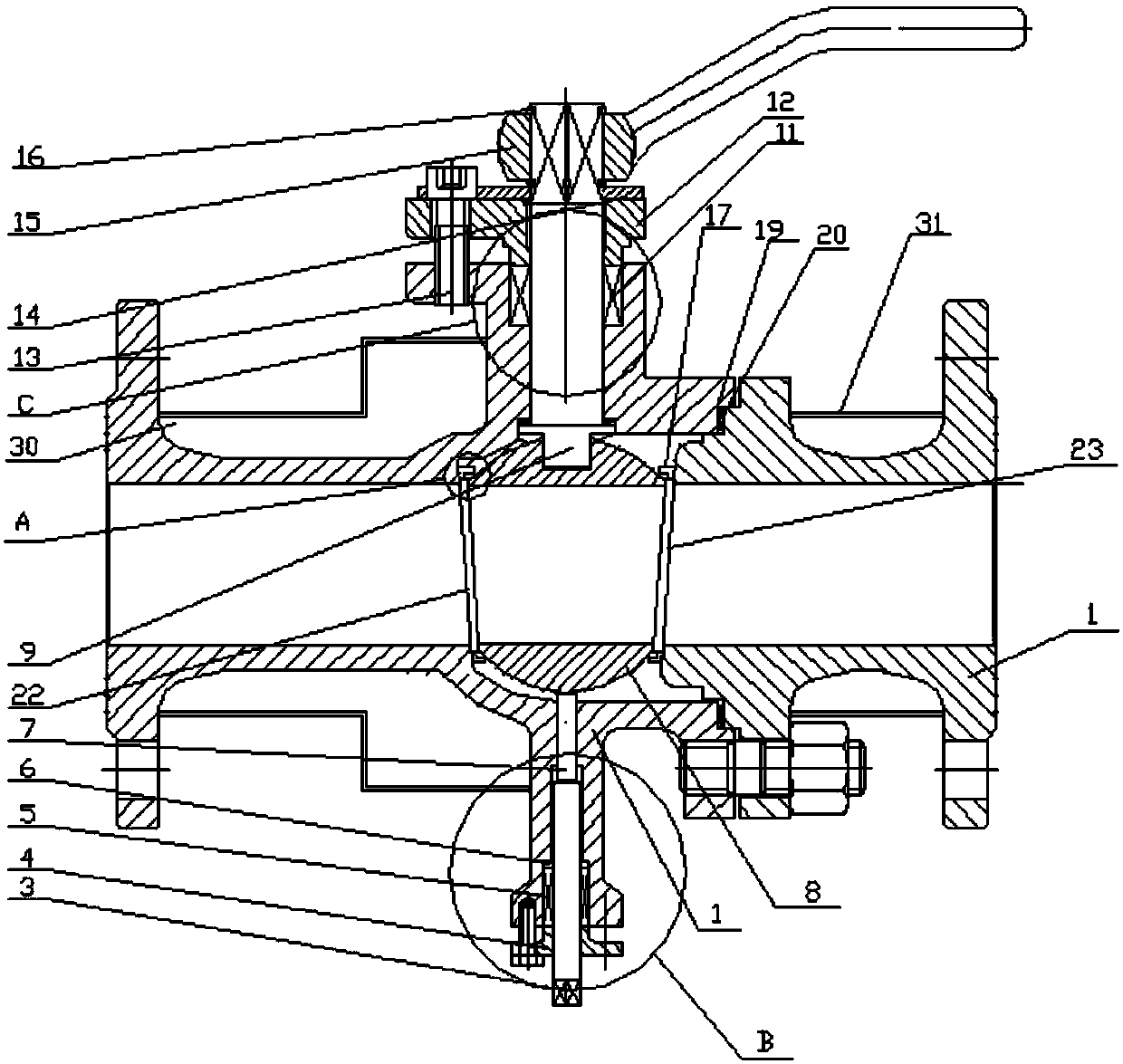

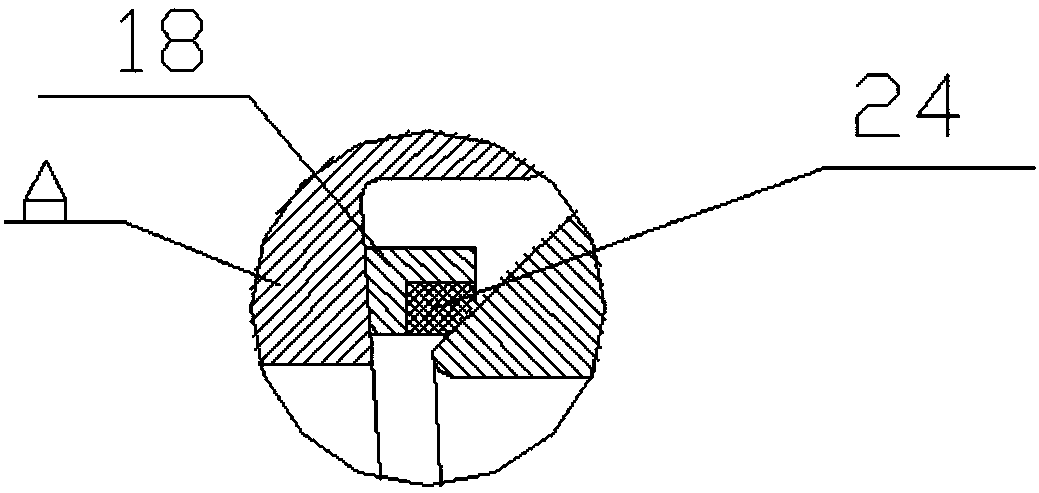

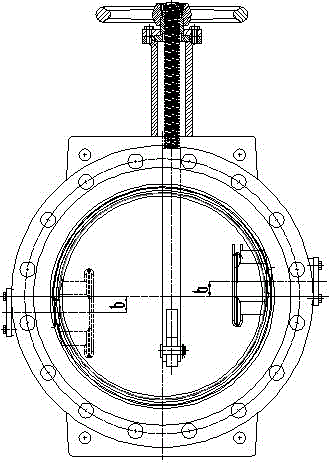

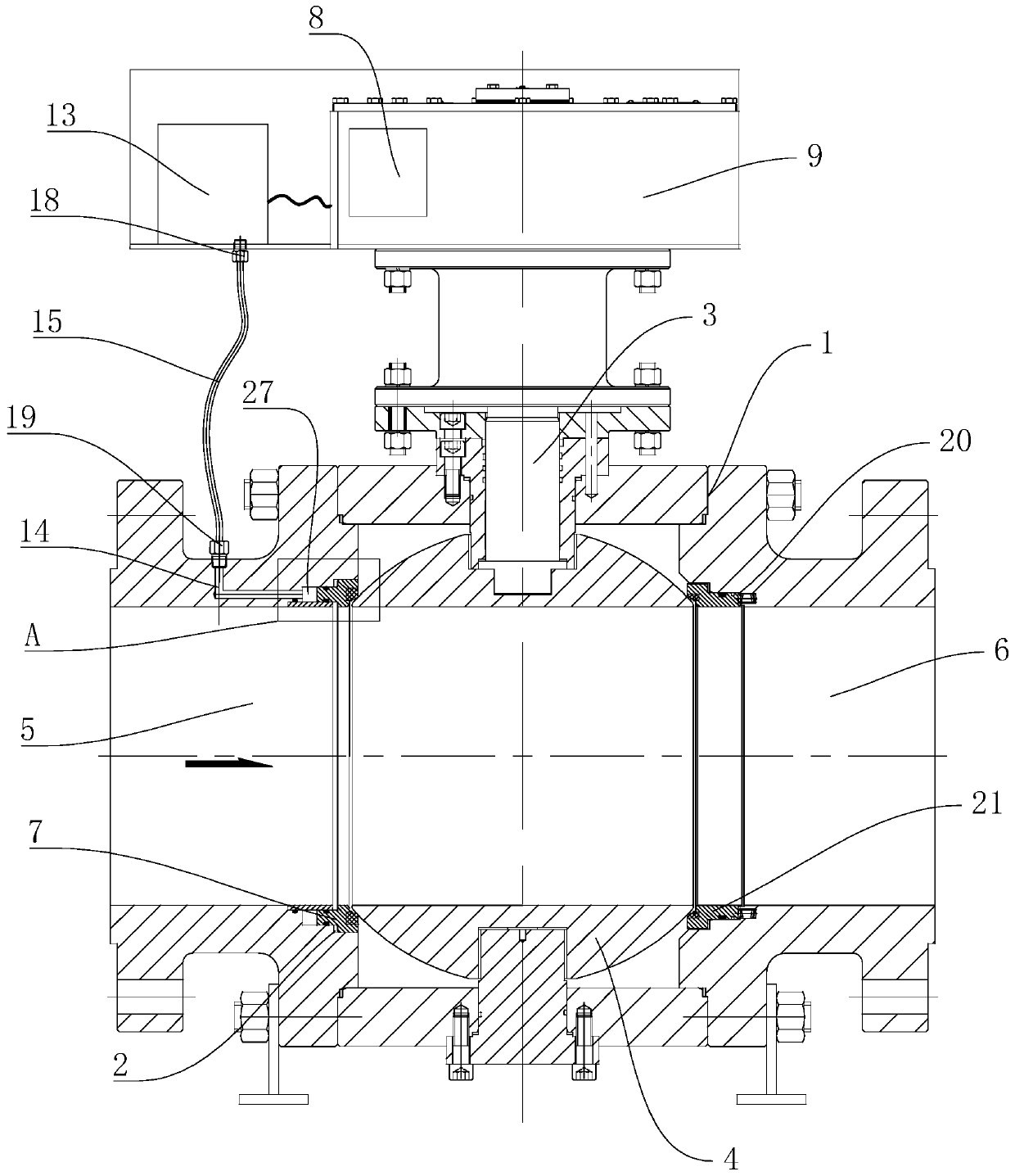

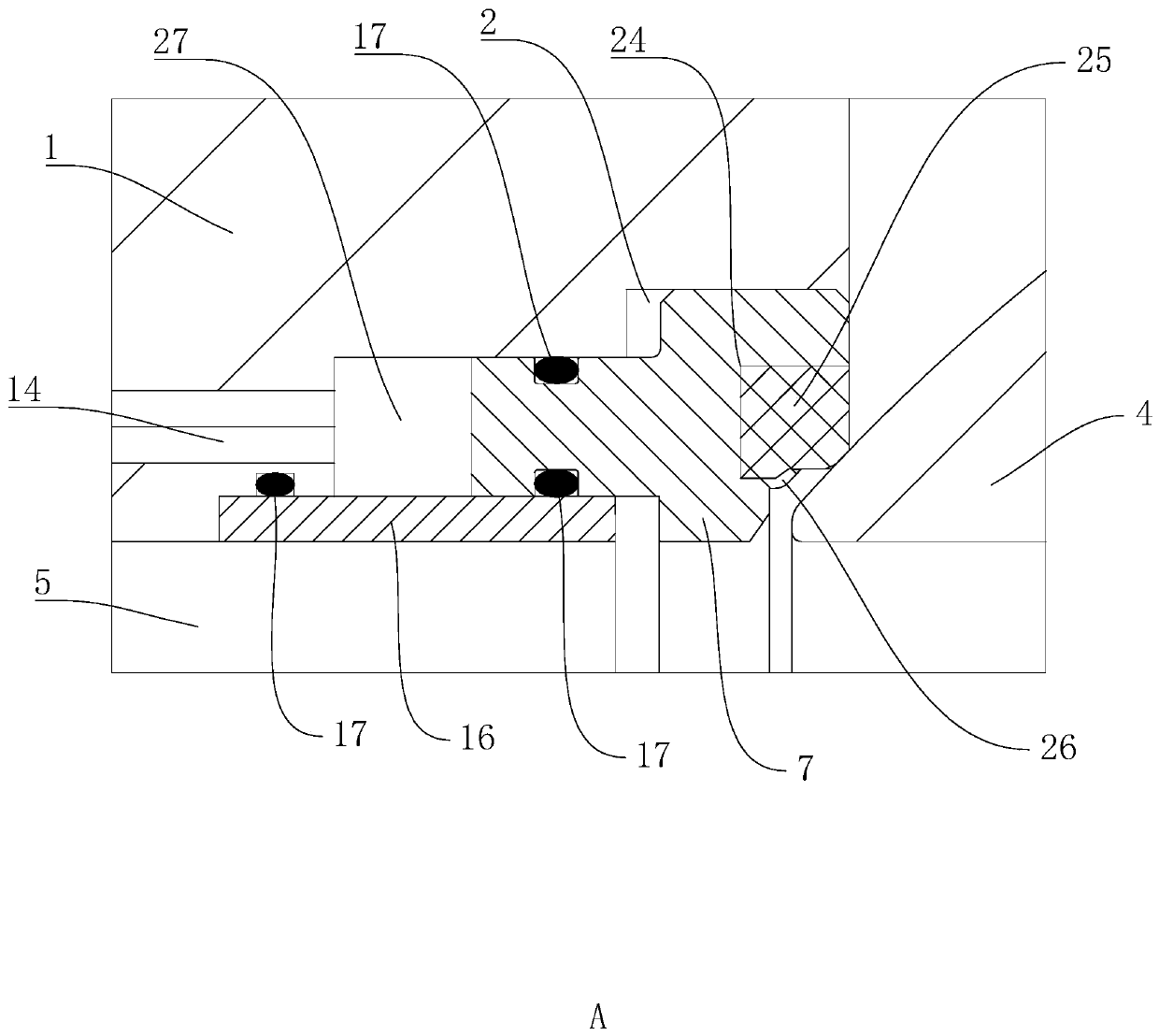

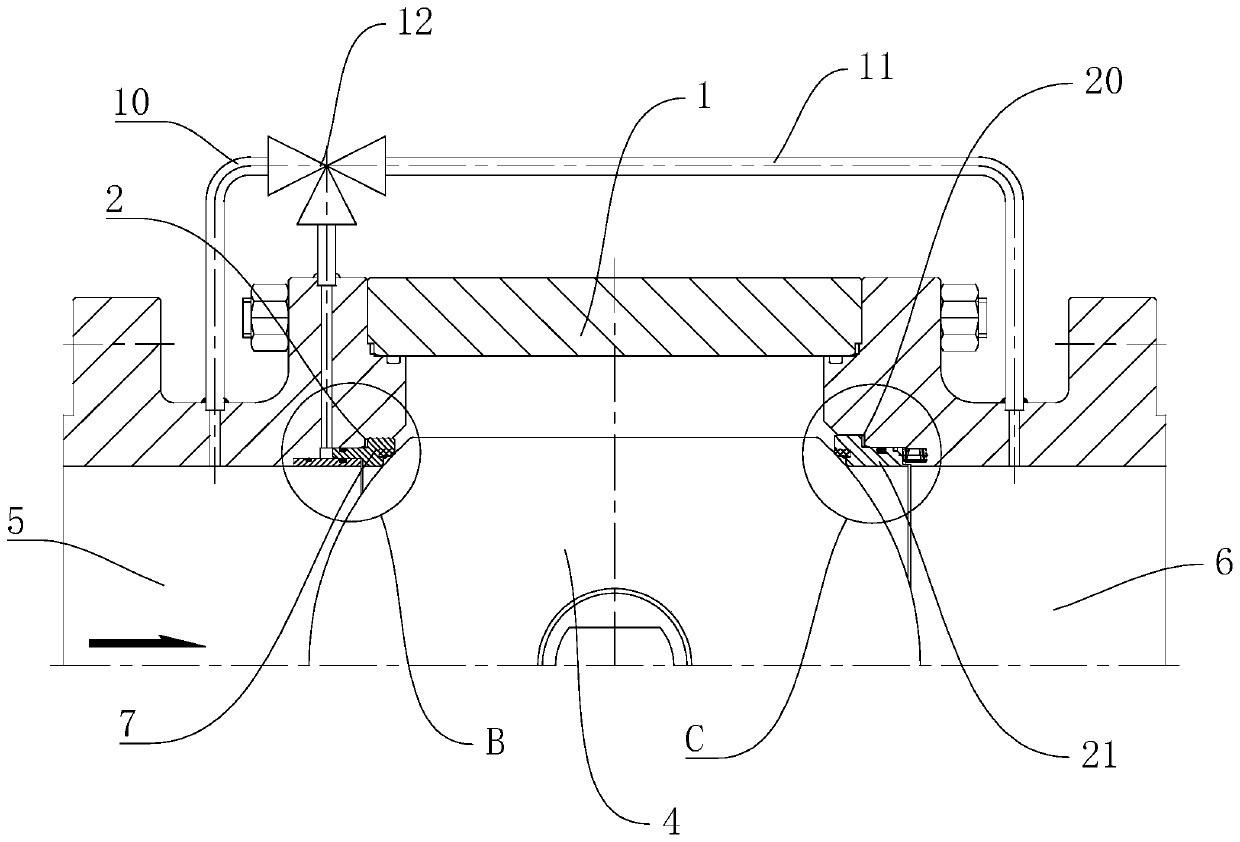

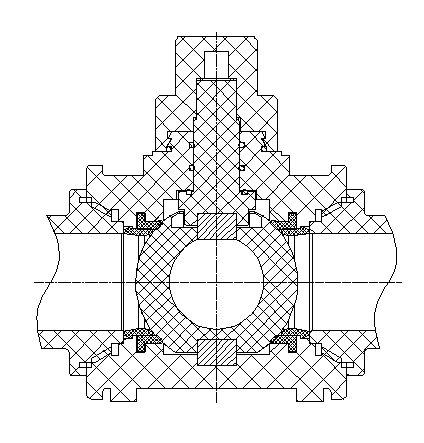

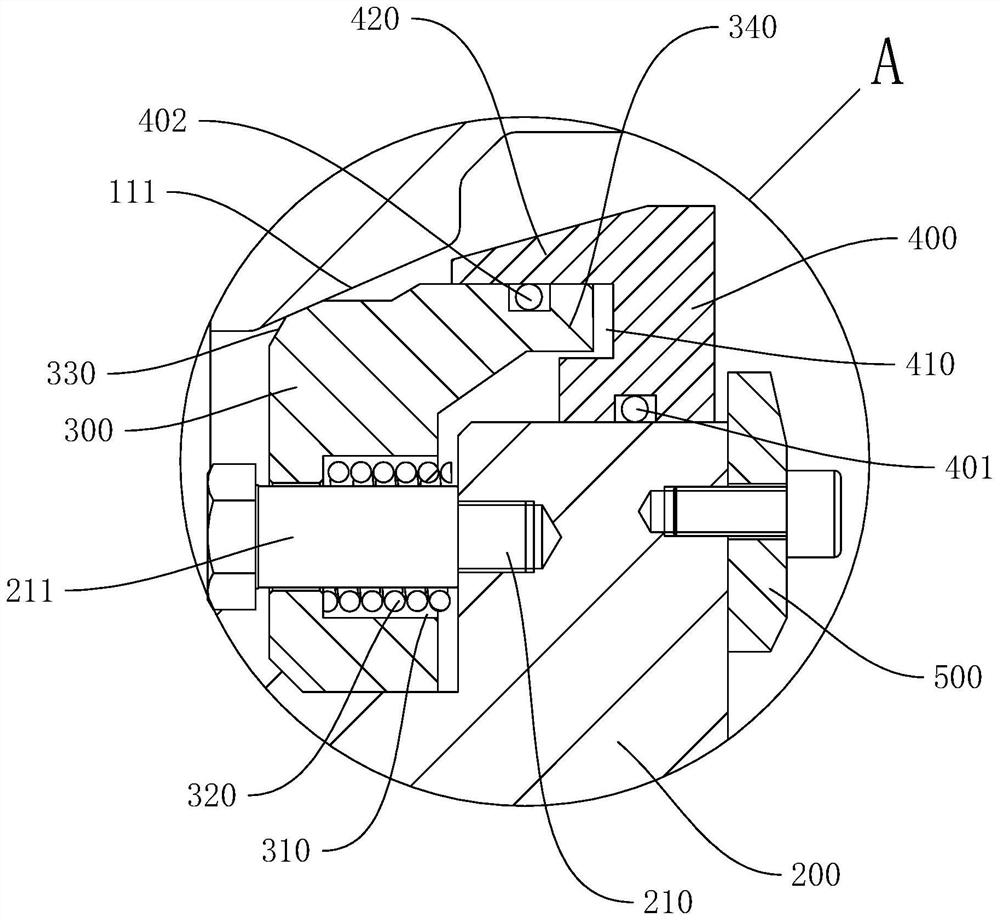

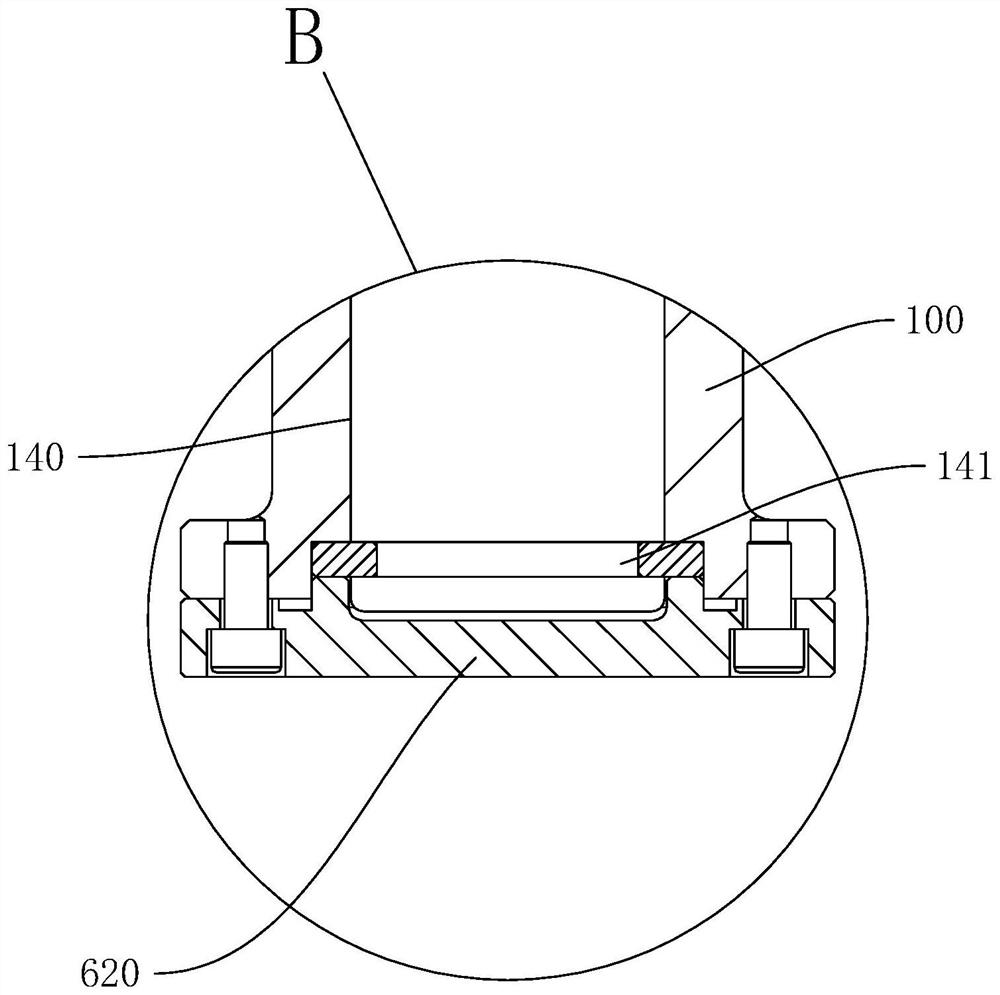

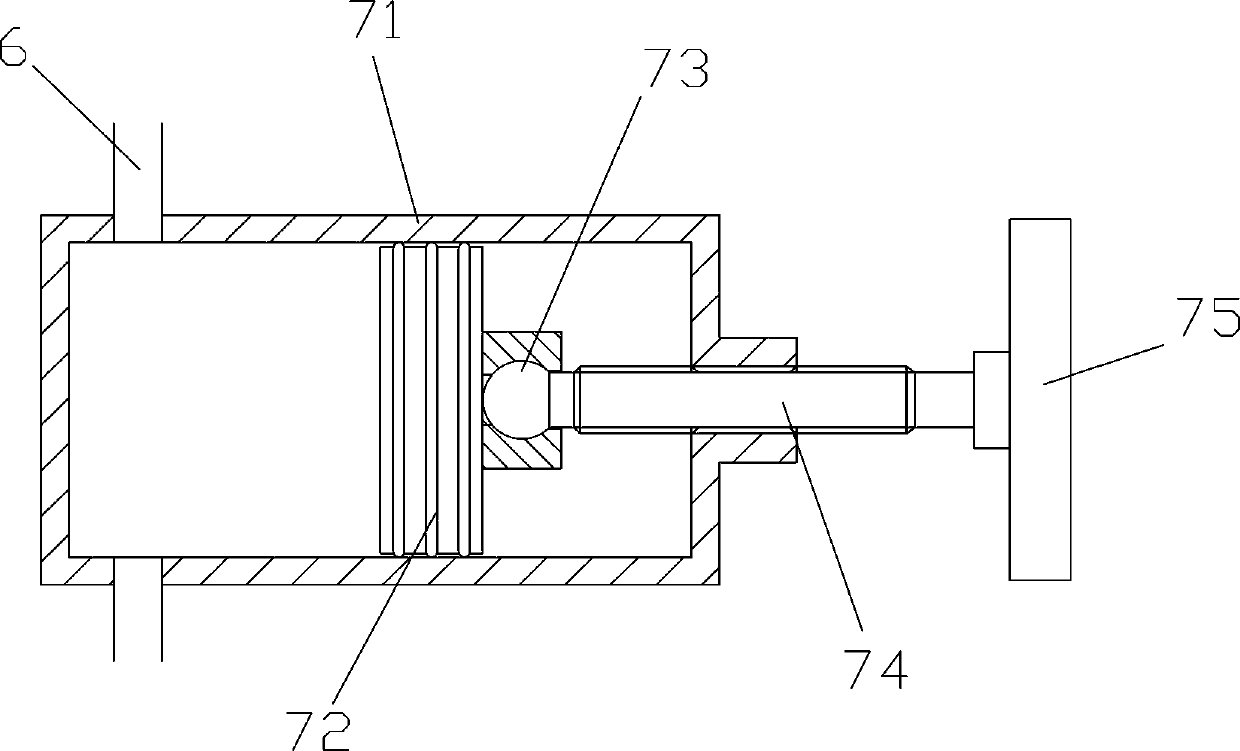

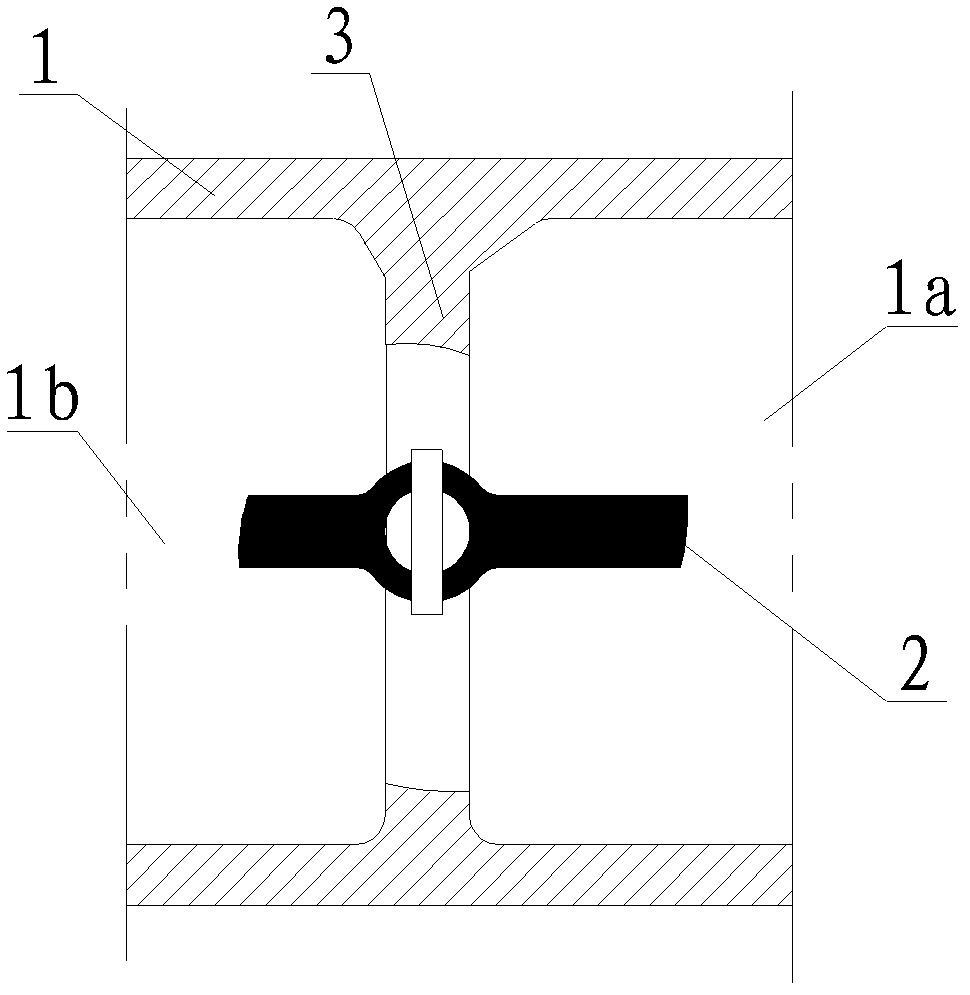

Forced sealing ball valve

ActiveCN103727260AReduce heavy wearSmall opening and closing torquePlug valvesOperating means/releasing devices for valvesLinear motionAutomatic control

The invention discloses a ball valve, and particularly relates to a forced sealing ball valve. The forced sealing ball valve comprises a valve body, an auxiliary valve body, a ball body, a valve seat and an auxiliary valve body fluid pipeline. A stud-nut driving type forced sealing device is arranged on the outer circle of the auxiliary valve body fluid pipeline, wherein a worm wheel and a driving stud are connected through a flat key. When the driving stud rotates, an axial sliding key groove of a driven nut screwed with the driving stud is made to conduct axial linear motion along a guiding key on the auxiliary valve body fluid pipeline, so that the needed sealing specific pressure is produced between the valve seat and the ball body in a valve cavity through the pressure produced outside via the pressure transferring. Thus, low-torque opening and closing and forced sealing are achieved. Related motion processes of the stud-nut driving type forced sealing device and an electric actuator are achieved through an automatic control system in the opening and closing process and the sealing process. According to the structure of the forced sealing ball valve, the selected corresponding materials can be suitable for various severe fluid and environments.

Owner:JIANGSU QUANHANG VALVE CO LTD

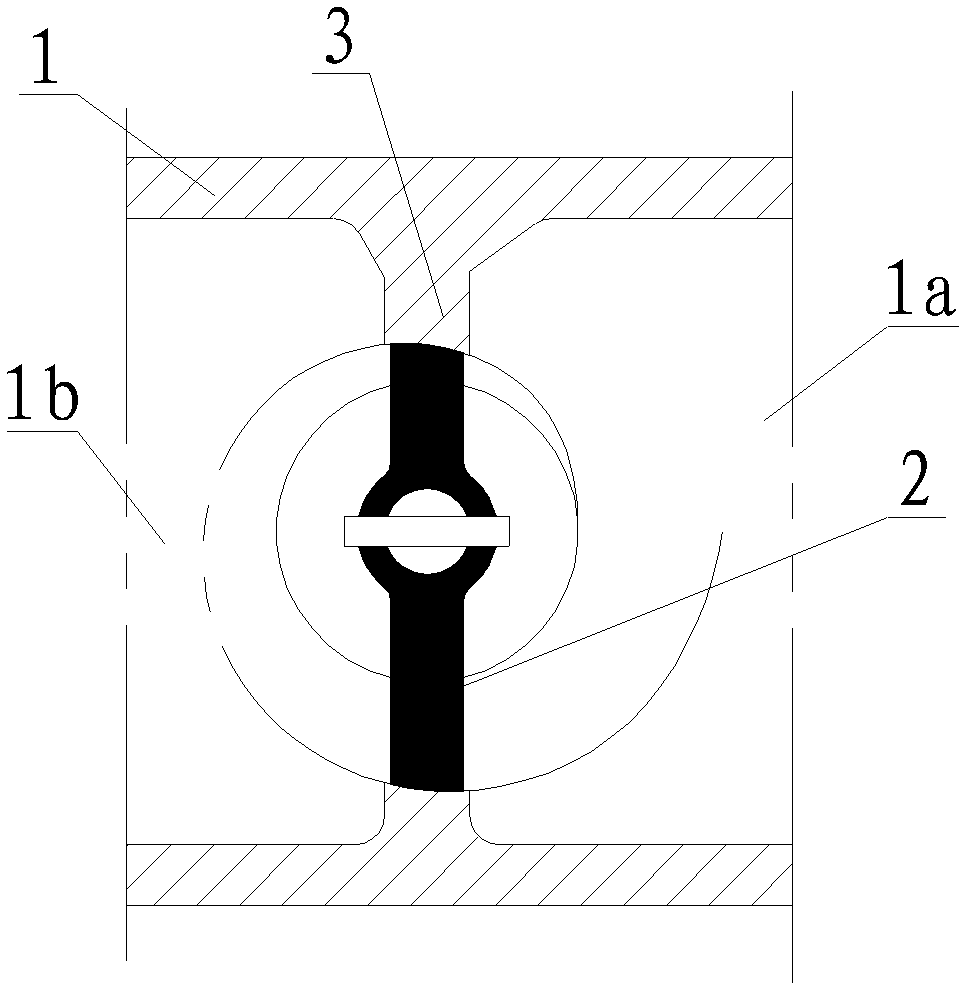

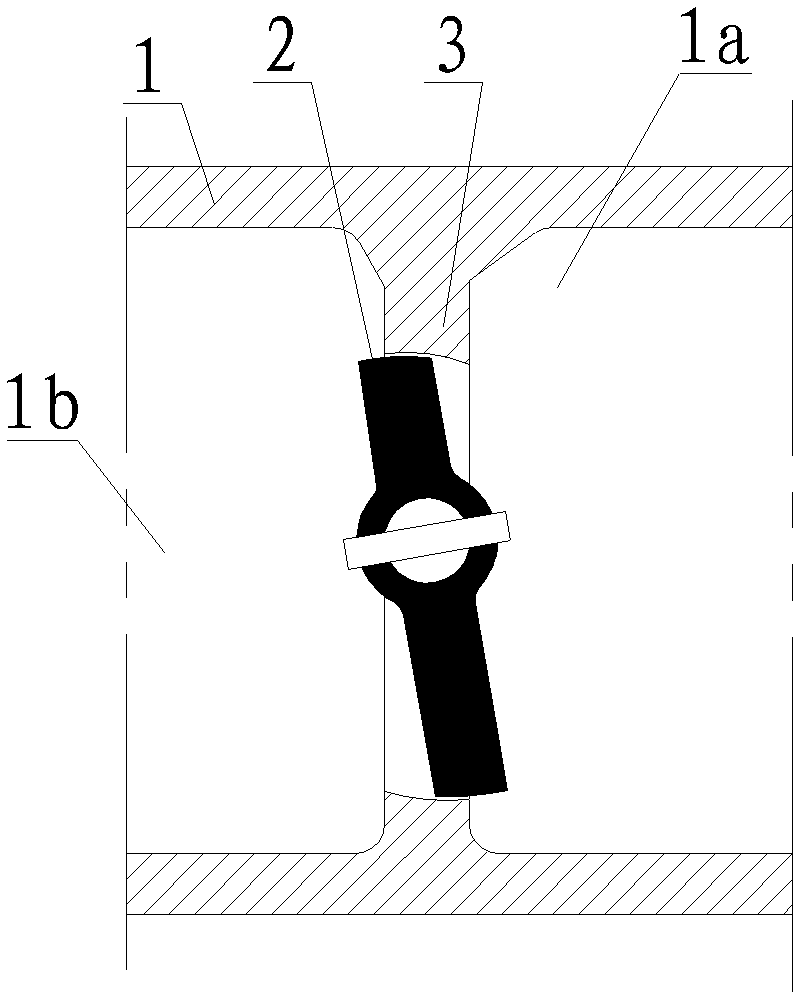

Valve with articulated valve core

ActiveCN103090023AHigh trafficSimple structureOperating means/releasing devices for valvesLift valveEngineeringClosed state

The invention discloses a valve with an articulated valve core. The valve with the articulated valve core comprises a handle, a valve rod, a valve body, the valve core, a transmission piece, a seal ring and a valve cover. The valve body is a shell body which is provided with a valve rod hole and a channel, and the channel is provided with an inlet and an outlet. The valve core is connected with the valve body through a hinge so that the valve core can rotate around a rotary axial line of the hinge, and the valve core is provided with a locking column and a connecting hole. A locking hook is arranged at the bottom end of the valve rod, and a rotary hole is formed in the bottom of the valve rod. Two ends of the transmission piece are respectively provided with a rotary head, one of the rotary heads is connected with the connecting hole of the valve core, and the other of the rotary heads is connected with the rotary hole of the valve rod, so rotary motion of the valve rod is transmitted to the valve core through the transmission piece to control opening and closing of the valve core. When the valve is in a closed state, the valve core is locked to the valve body through the locking hook and the locking column. The valve with the articulated valve core has the advantages of being compact in structure, small in opening moment of force, large in opening angle, large in flow, and the like.

Owner:SHANGHAI HONGYAN RETURNABLE TRANSIT PACKAGINGS CO LTD

Ball valve

InactiveCN1337535ASmall opening and closing torqueFlexible opening and closingPlug valvesScrew threadFriction Problem

The present invention relates to a ball valve, its valve rod and left-hand screw thread end of its uspporting shaft are respectively equipped with an upper nut and a lower nut which respectively possess a pair of symmetrical lugs, and two lugs positioned on same side of said upper nut and lower nut are respectively hinge-connected with one end of one link joint, and another end of the link joint is hinge-connected with half-valve core with spherical external surface of said side, and the upper end surface of upper nut possesses a ring groove in which can open-ended spring is fixedly mounted, a positioing pin is inserted into valve cavity, and on the positioning pin a press plate is fixedly mounted. The opening and closing processes of said valve are implemented by means of separation and contact of two semi-spherical valve cores and valve seat seal component, they do not produce friction, so that said ball valve has no leakage and its service life is long as compared with existent ball valve.

Owner:甘靖

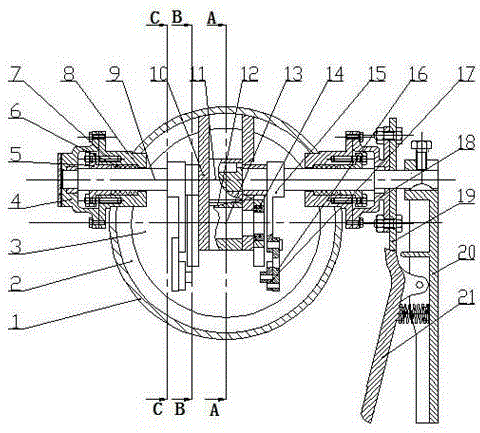

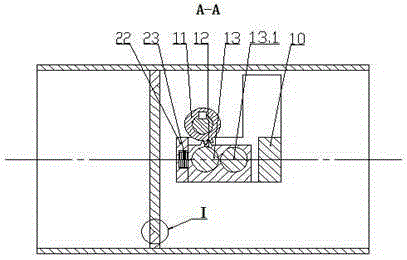

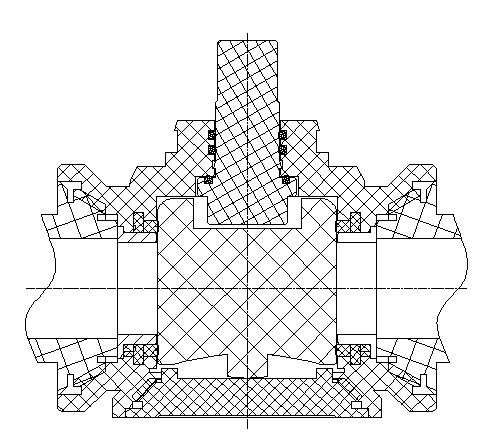

Double-rocker friction-free hard seal butterfly valve

ActiveCN105221768AImprove performanceReduce modelOperating means/releasing devices for valvesLift valveEngineeringMovable type

The invention discloses a double-rocker friction-free hard seal butterfly valve. The butterfly valve is characterized by comprising a valve body, a valve main body, a valve seat, a main valve shaft, a small valve shaft, a guide shaft, a guide groove, a butterfly plate, an incomplete big gear, a pinion, a shifting rod, a linkage rod, an intermittent mechanism and a drive device, wherein a through hole is formed in the valve main body, a valve neck is welded at the through hole, meanwhile, the valve seat is welded in the inner circle surface of the valve main body, and the outer circle surface of the valve seat is conical; the butterfly plate is of an annular structure, a movable butterfly plate with a hard seal ring is installed at the outer circle position of the butterfly plate, the movable type is a movement structural manner that the butterfly plate is capable of horizontally moving in the axial direction of the valve main body first, and then rotating by taking the guide shaft as a centre, and the butterfly plate is opened in a zero-friction mode, the butterfly plate is connected with the guide shaft, a self-lubricating shaft sleeve is installed at the junction of the butterfly plate and the guide shaft through interference fit, the self-lubricating shaft sleeve is in clearance fit with the guide shaft, and the guide shaft is installed in the guide groove; and a compression spring is installed in the guide groove.

Owner:HEBEI UNIV OF TECH +1

Scouring-resistant wear-resistant corrosion-resistant mid-high pressure ceramic ball valve and manufacturing method thereof

ActiveCN103291951AEasy processing and assemblyImprove wear resistancePlug valvesValve housingsCorrosion resistantWear resistant

The invention relates to a scouring-resistant wear-resistant corrosion-resistant mid-high pressure ceramic ball valve for a medium conveying pipeline, and a manufacturing method of the scouring-resistant wear-resistant corrosion-resistant mid-high pressure ceramic ball valve. A scouring-resistant wear-resistant corrosion-resistant mid-high pressure ceramic ball body is used as a ceramic ball body of the ceramic ball valve. A ceramic inner bushing is mounted on the inner side of a steel cylinder through a hot shrinkage process. Dovetail inlaying grooves are formed in the outer side face of the steel cylinder and a spherical surface ceramic inlaying sheet respectively. The dovetail inlaying grooves are meshed with each other. The spherical surface ceramic inlaying sheet is tightly combined with the steel cylinder. The ceramic ball body is arranged in a middle valve body between a left valve body and a right valve body. An upper steel valve rod and a lower steel valve rod are both directly connected with a steel ball body through a valve rod base which is fastened through bolts. Two ceramic valve seats are arranged on the left valve body and the right valve body respectively. Therefore, perfect combination between the steel cylinder and a ceramic material is realized; the ceramic ball valve has the advantages of being resistant to scouring, wear, corrosion and high pressure; the service life of the ceramic ball valve is greatly prolonged; meanwhile, demands on mid-high pressure large-caliber ceramic ball valves can be satisfied.

Owner:梅森阀门江苏有限公司

Plug valve of seal structure

ActiveCN103195944APrevent leakageReduce contact surfacePlug valvesEngineeringPolytetrafluoroethylene

The invention relates to a plug valve of a seal structure. The plug valve comprises a valve body, a valve cover, a plug rod, a pressing plate and a valve seat and is characterized by further comprising a pressing sleeve, a seal pad and a seal cup. The pressing sleeve is disposed on the outer surface of the plug rod. One end of the pressing sleeve extends to a position below the pressing plate. The bottom of the pressing sleeve is tightly pressed by the pressing plate. The middle of the pressing sleeve is tightly pressed by the valve cover and the pressing plate. The seal pad is disposed on the valve body. The excircle of the seal pad is located between the valve body and the valve cover and tightly pressed by the two. An inner circle of the seal pad is closely butted against the root of the plug rod and tightly pressed by the pressing sleeve. The seal cup is disposed on the plug rod, located between the pressing sleeve and the plug rod, and comprises an O-shaped ring and a PTFE (polytetrafluoroethylene) cup which are disposed on the plug rod, wherein the PTFE cup is located on the O-shaped ring. The plug valve is simple in structure, reasonable in design, convenient to use, reliable in seal performance and good in seal effect. contact face between the seal cup and the plug rod is low, and valve opening and closing torque is low.

Owner:ZHEJIANG WANLONG MACHINERY

Five-eccentric butterfly valve

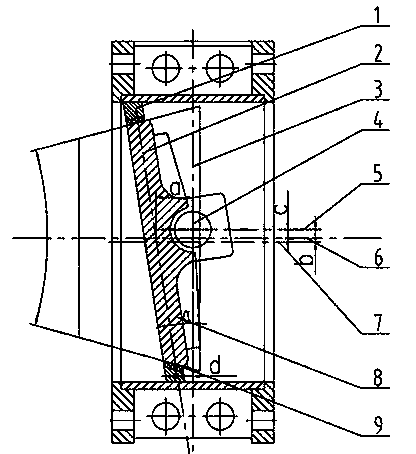

Provided is a five-eccentric butterfly valve. An eccentric distance a is formed between a symmetrical central face of a sealing face of the valve and an axial central face of a rotating shaft, an eccentric distance b is formed between a flow channel central face and the radial central face of the rotating shaft, angle offset of an angle alpha is formed between the sealing face and the axial central face of the rotating shaft, an eccentric distance c is formed between the axial line of an oval cone frustum and the radial central face of the rotating shaft, and an eccentric distance d is formed between a sealing face at the lower end of the oval cone frustum and the axial central face of the rotating shaft. The five-eccentric butterfly valve has the advantages that the eccentric distance b between the flow channel central face and the radial central face of the rotating shaft can be reduced by adjusting the size of the parameter c and the parameter d through a mathematical analysis method, namely, the opening and closing torque of the valve can be reduced effectively, energy can be saved, consumption can be reduced, and cost can be lowered. The existence of the angle alpha is discovered through the research of the angle alpha formed by the sealing face and the axial central face of the rotating shaft, the sealing face of the valve is an inclined face, the opening angle and the closing angle of the valve are small, the opening speed and the closing speed are high, sealing specific pressure is even, sealing is reliable, safety of equipment is ensured, and the service life is prolonged.

Owner:JIANGSU SHENTONG VALVE

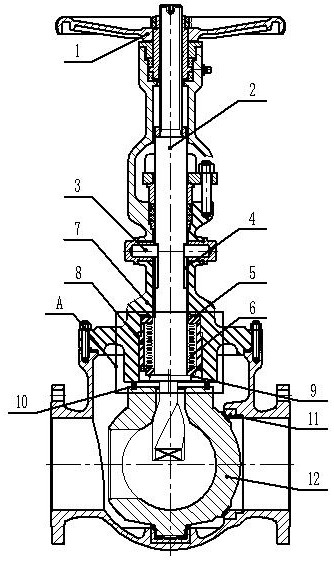

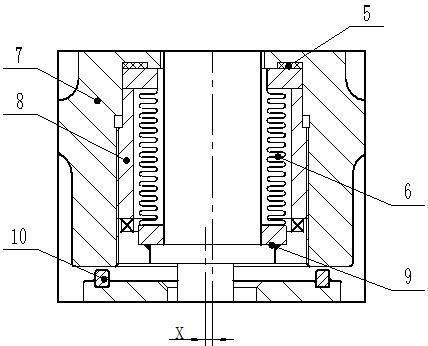

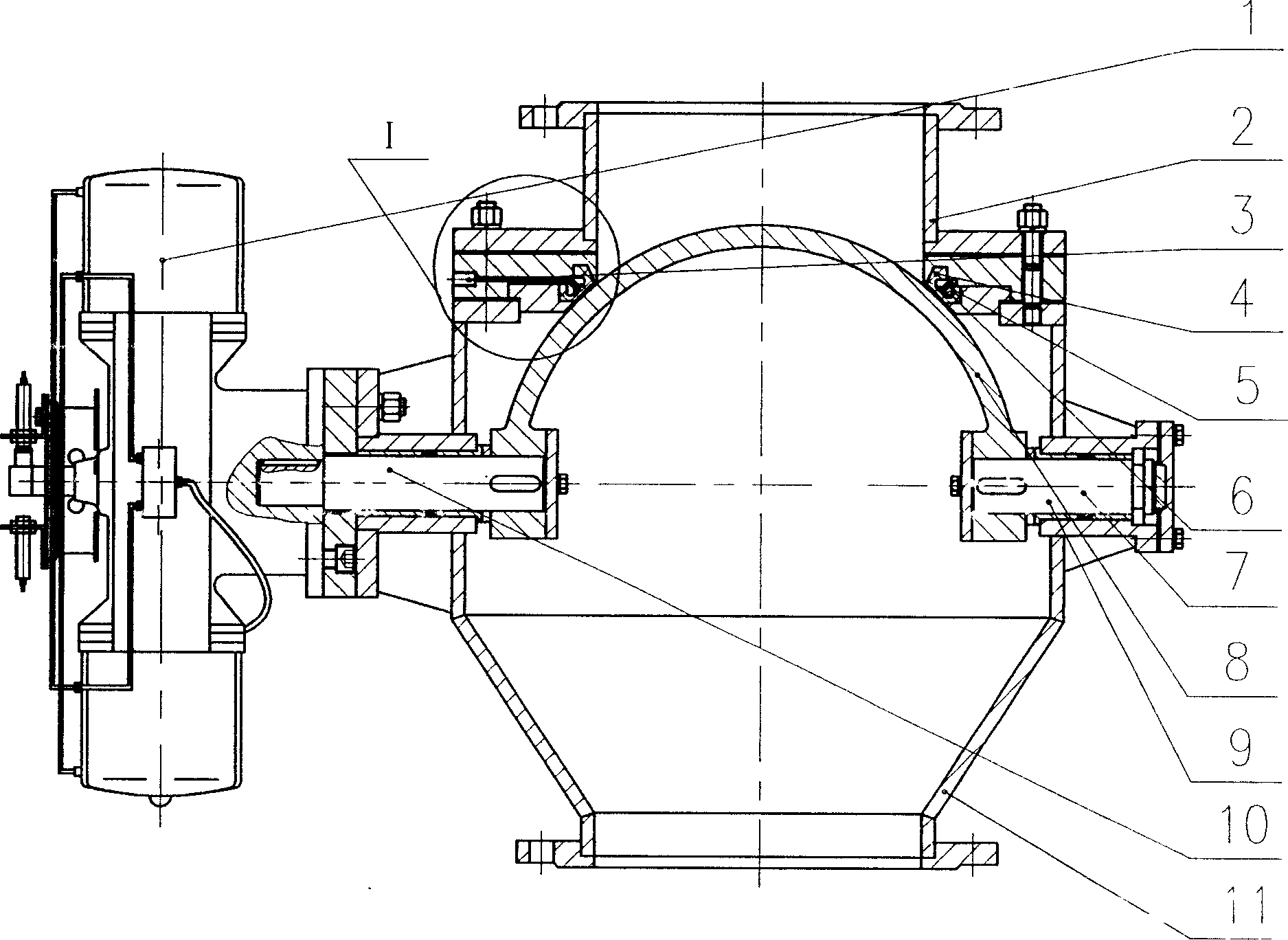

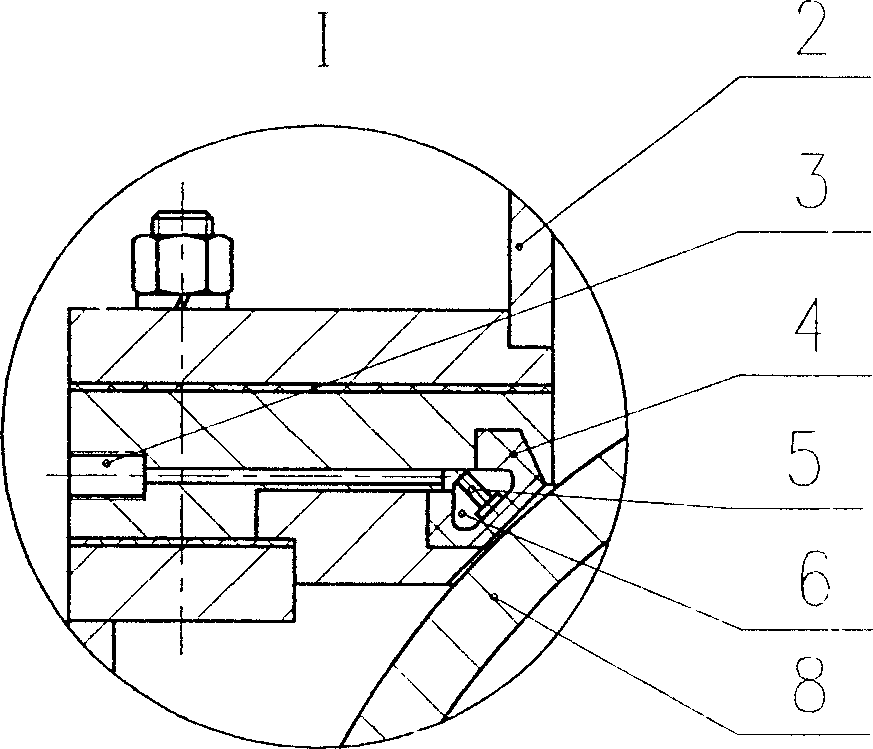

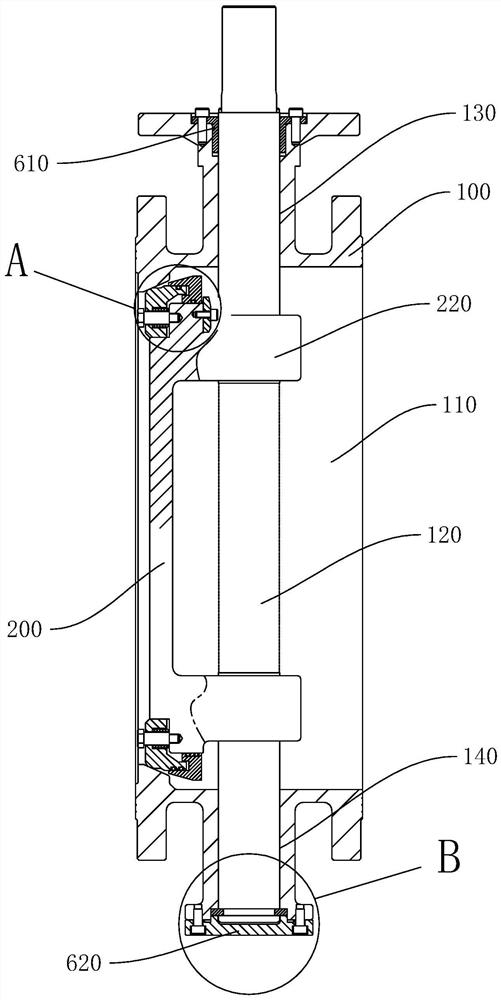

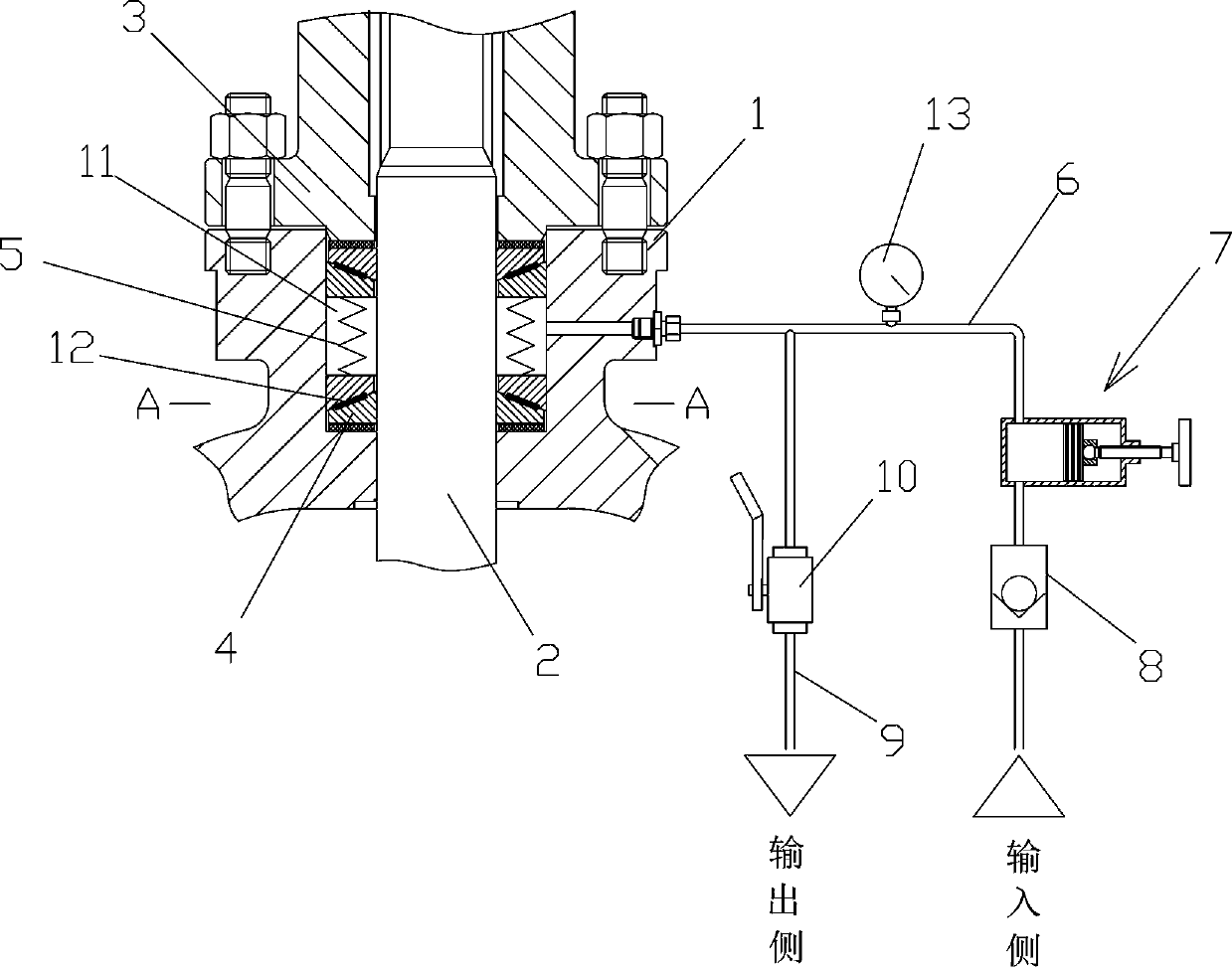

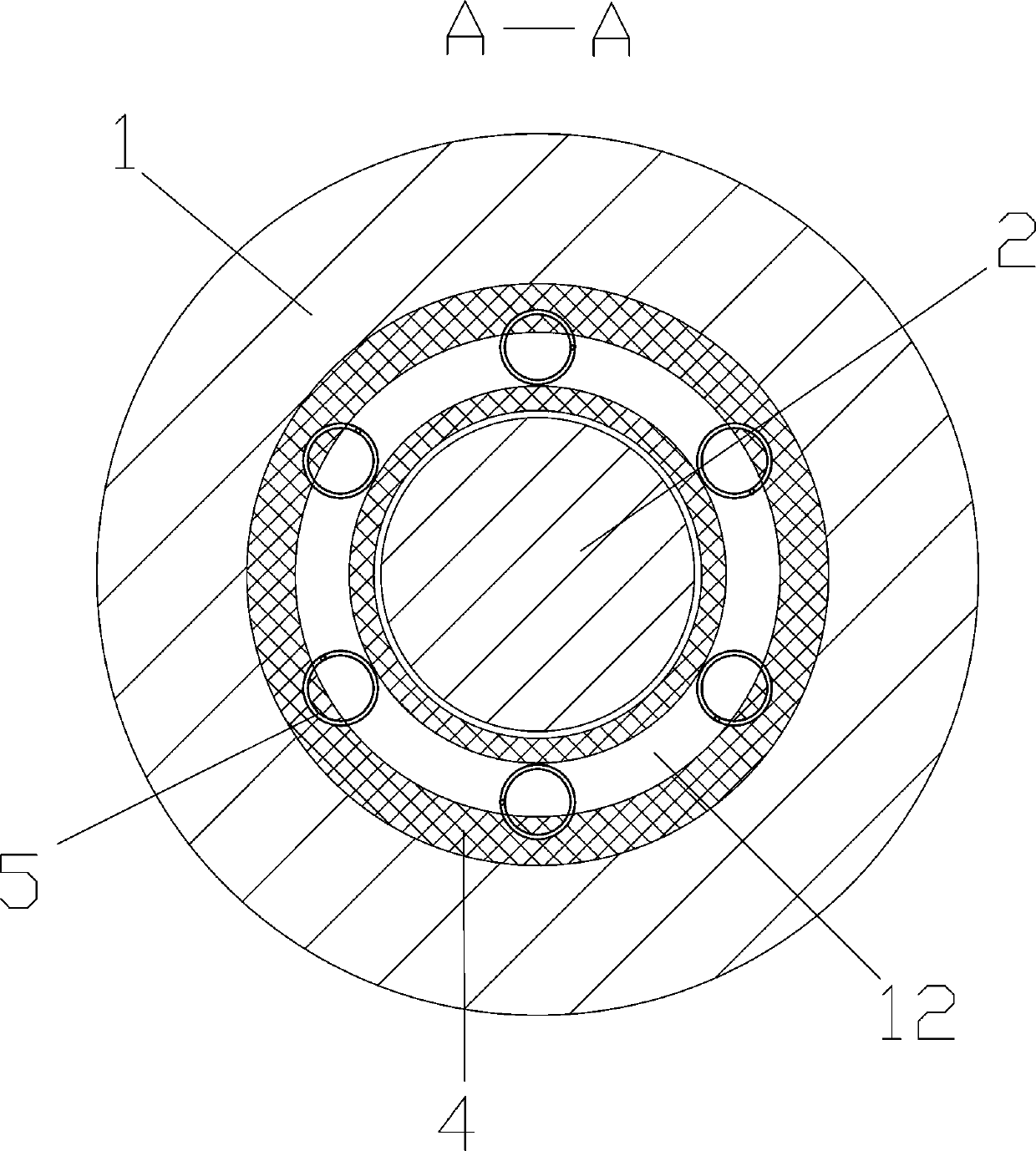

Underwater flat gate valve for sea bottom christmas tree

PendingCN108443524AReduce processing cumbersome proceduresRealize online replacement and maintenanceSlide valveValve housingsCorrosionRelief valve

The invention relates to an underwater flat gate valve for a sea bottom christmas tree. The underwater flat gate valve comprises a valve body, a valve cover, a gate plate, a support and a valve seat.A first sealing structure is arranged between the valve body and the valve cover. A second sealing structure is arranged between the valve seat and the valve body. A third sealing structure is arranged between the valve cover and a valve rod. A gasket ring and a valve rod nut are mounted in the support, and the valve rod stretches out of the valve cover to penetrate the gasket ring to be in threaded connection with the valve rod nut. The upper end of the valve rod nut is connected with a drive sleeve, the drive sleeve is connected with an upper valve rod, and the upper valve rod is connected with a valve position indication mechanism. The upper valve rod is connected with an ROV connector through a supporting bearing. A pre-pressing disc spring for providing initial specific pressure is mounted on the valve seat. A pressure relief channel extending in the upstream direction is arranged in the valve body, and a one-way pressure relief valve is mounted on an inner channel of a valve cavity of the valve body. A gate plate guide mechanism is detachably mounted at the symmetric positions of the middle of the valve seat. The underwater flat gate valve has the advantages that sealing performance is good, and the functions of gate plate guide and start and stop compensation are achieved; and meanwhile, for gate plate and valve seat hardening treatment, the corrosion resisting strengthis improved, corrosion resistance is high, and the service life is long.

Owner:天津祥嘉流体控制系统有限公司

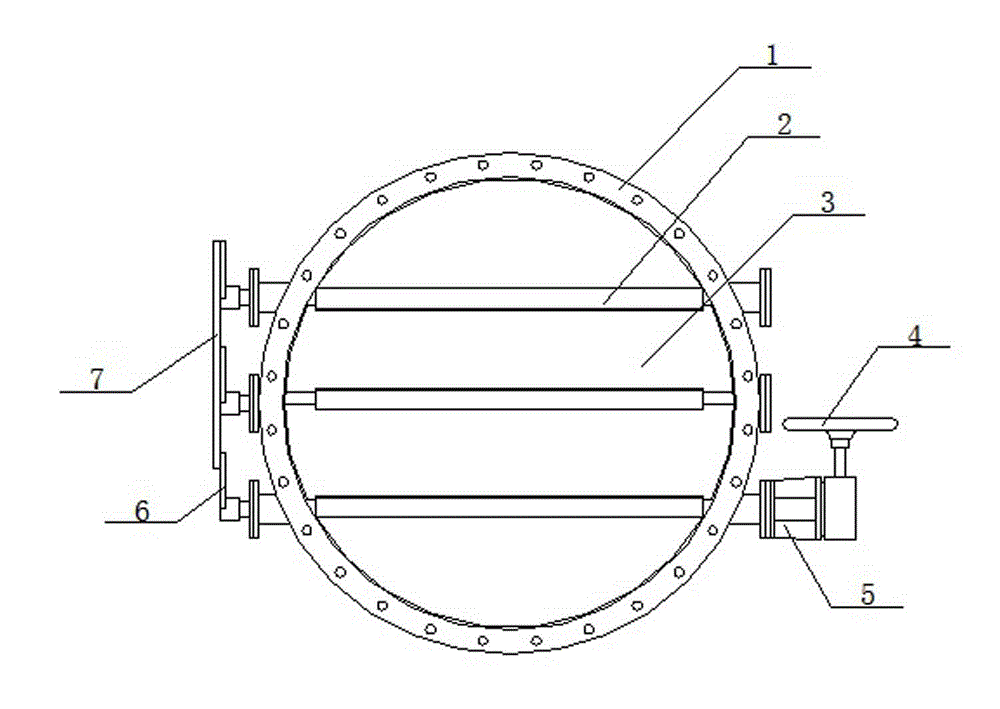

Manual louver valve

InactiveCN103335115AEvenly distributedReasonable designLift valveValve housingsAir volumeRotary valve

The invention discloses a manual louver valve which relates to the technical field of valves. The manual louver valve comprises a valve body; at least one rotary valve shaft is arranged in the valve body; a valve plate is fixedly arranged on the valve shaft; the valve plate is matched with the valve body; a hand wheel is arranged outside the valve body; one end of the valve shaft extends out of the valve body, and is connected with the hand wheel through a crank; the other end of the valve shaft extends out of the valve body and is connected with one end of a tension rod; and the other end of the tension rod is connected with a connecting rod. According to the manual louver valve, the design is reasonable, the airflow is uniformlyshunted due to a multi-leaf and multi-shaft design, the flow resistance is small, the opening and closing torque is small, the action is flexible and reasonable, the air volume can be effectively controlled, the energy is fully utilized so that a working system is in the best state, and the valve is ideal airflow regulating equipment in various air duct systems.

Owner:NANTONG XUYANG MACHINERY MFG

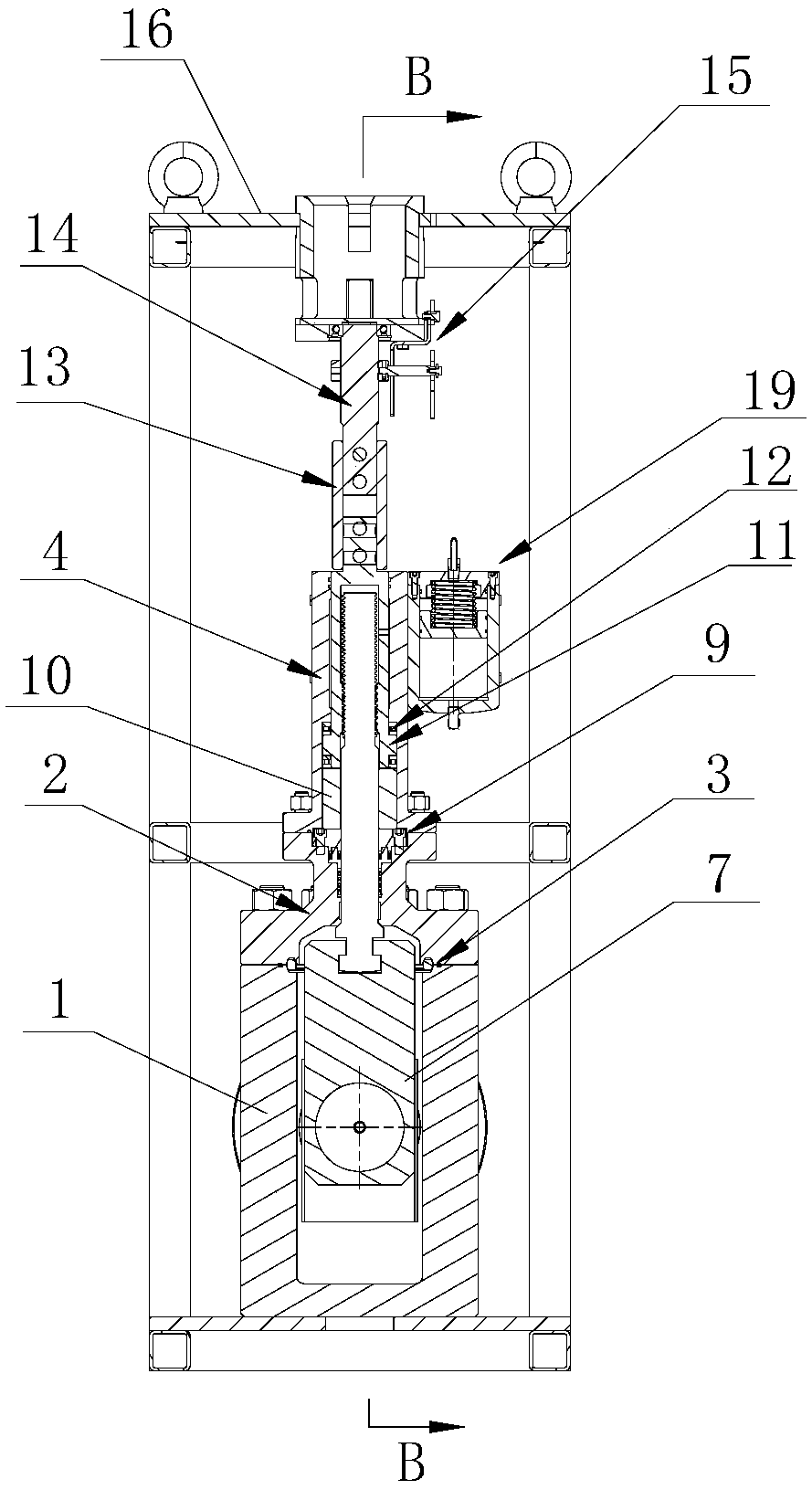

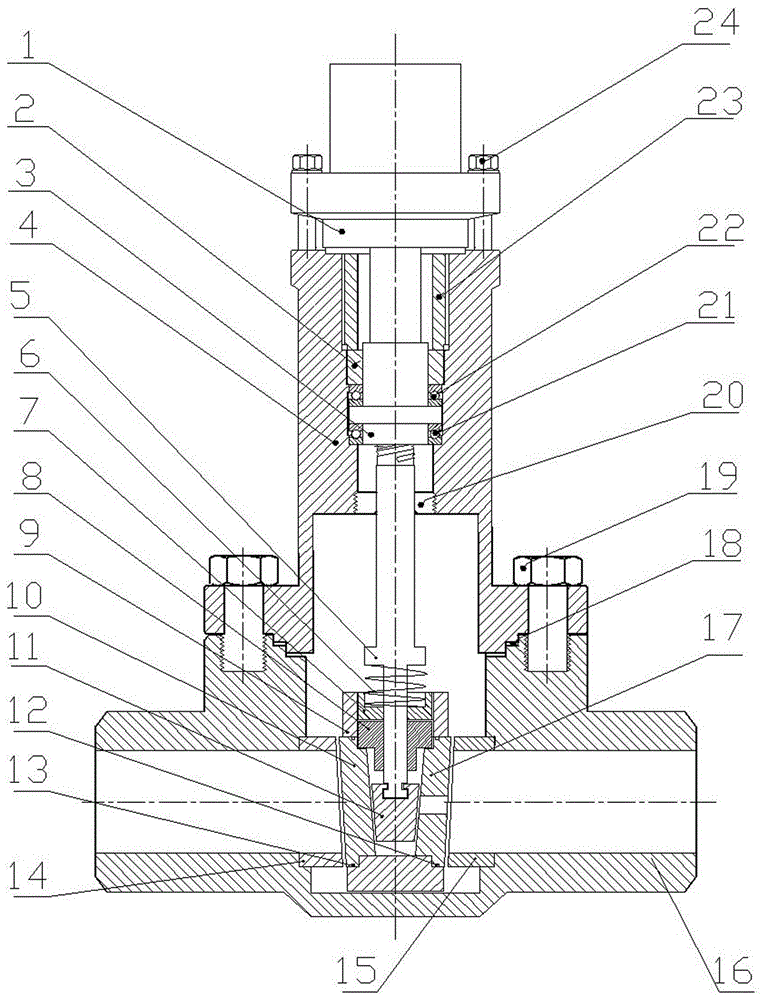

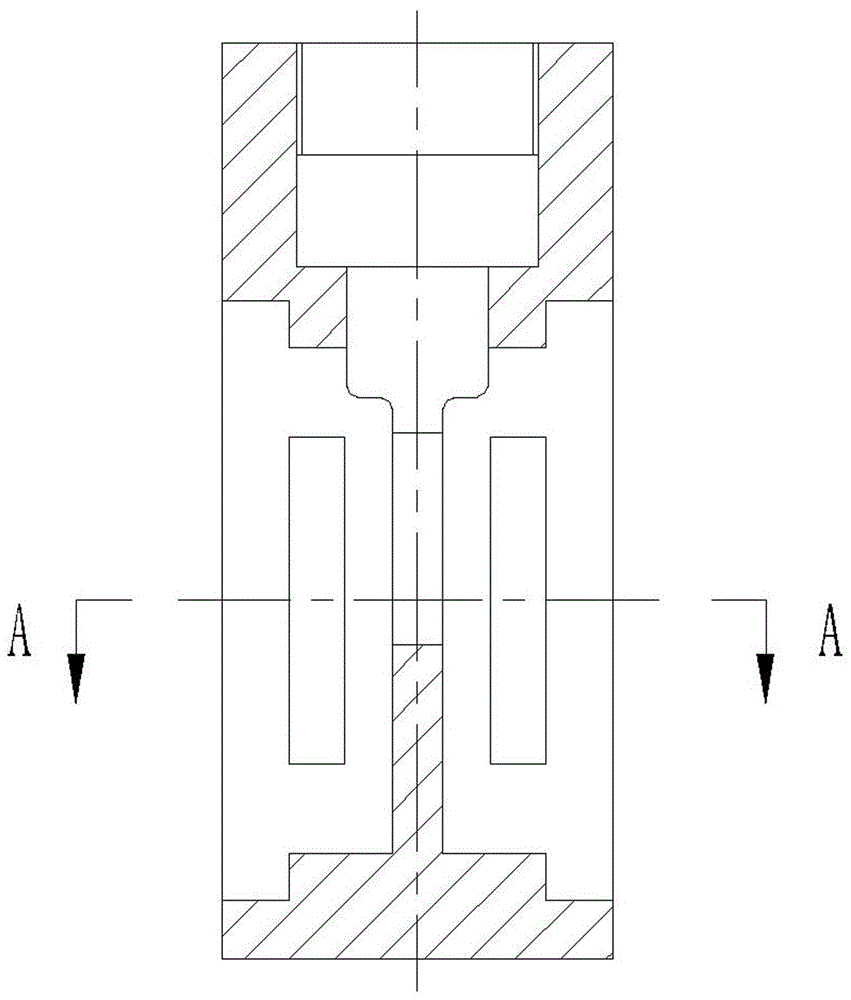

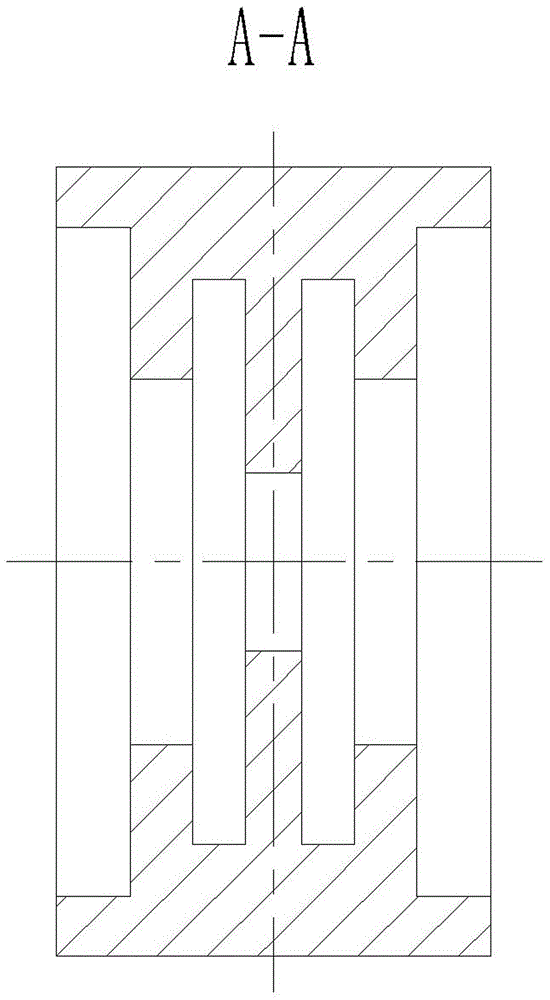

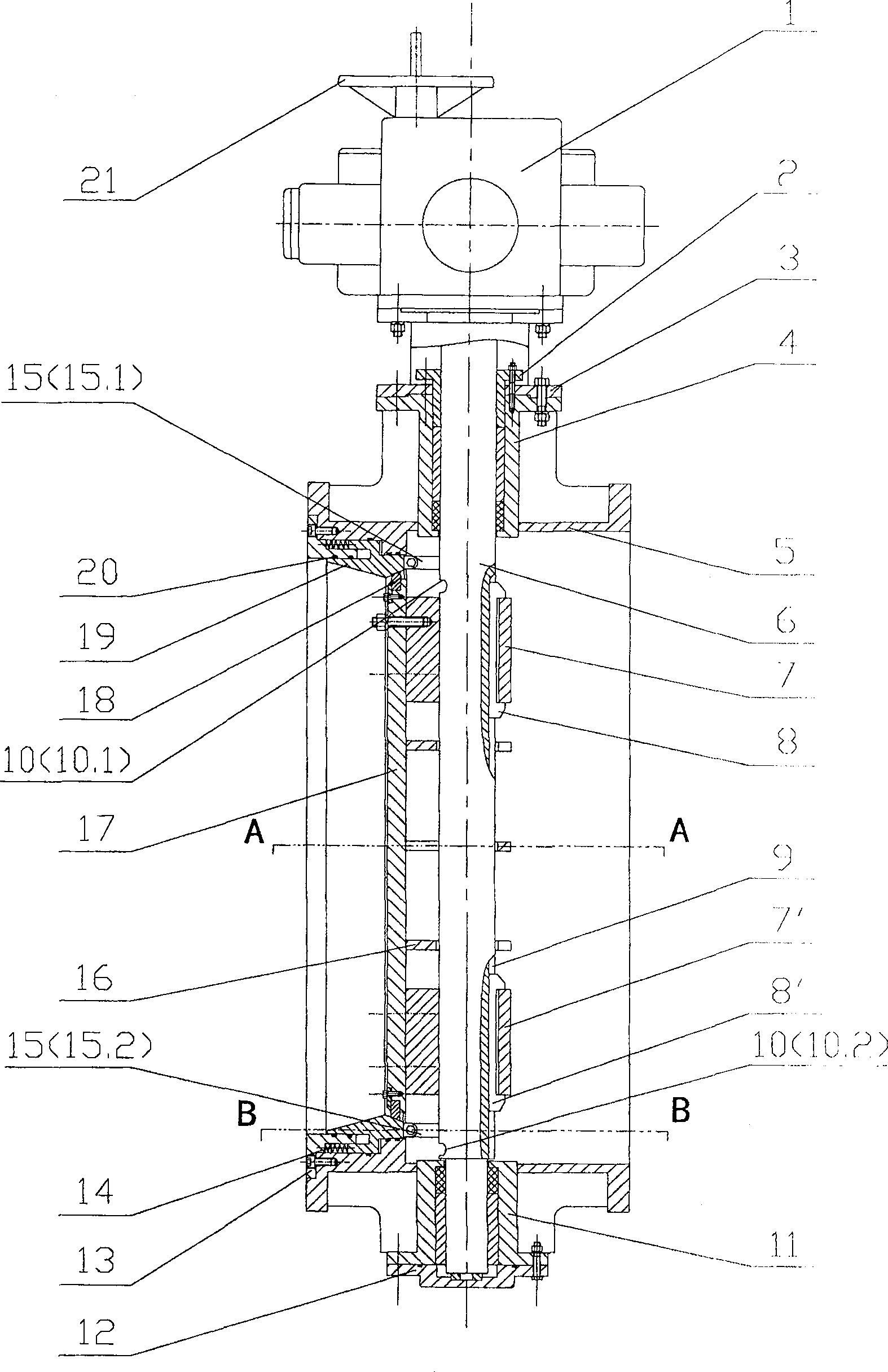

Double-drive movable double-wedge-surface gate plate step-by-step action type gate valve

ActiveCN106763849AReduced risk of breakageSmall opening and closing torqueOperating means/releasing devices for valvesSlide valveEngineeringPressure difference

The invention discloses a double-drive movable double-wedge-surface gate plate step-by-step action type gate valve which comprises a valve body, a valve deck, an electric device, a valve rod and a movable gate plate. According to the double-drive movable double-wedge-surface gate plate step-by-step action type gate valve, the electric device is used for driving the valve rod to stretch and contract. A pivot gate plate and the movable gate plate are driven to seal or open holes in a front valve seat of the valve and a rear valve seat of the valve in a wedge-shaped manner, and therefore the purpose of opening and closing the gate valve is achieved. In order to reduce operation force borne by the valve rod, a hole is formed in the middle portion of a second movable gate plate, so that when the gate valve needs to be opened, the pressure difference is built between an inner cavity and an outer cavity through the hole so as to reduce friction force between the movable gate plate and a valve seat, and the movable gate plate can disengage from the valve seat before opening. Thus, operation force is reduced, and an operation mechanism is not likely to be damaged; and the strength of operation elements in the gate valve can be designed to be lower, and therefore the size of the appearance of the gate valve is reduced, or the service life of the gate valve is prolonged. Due to the connecting manner of the pilot valve and the movable gate valve, the pilot valve and the movable gate valve are convenient to demount, and meanwhile replacement after abrasion is also facilitated.

Owner:ANSHAN SOLENOID VALVE

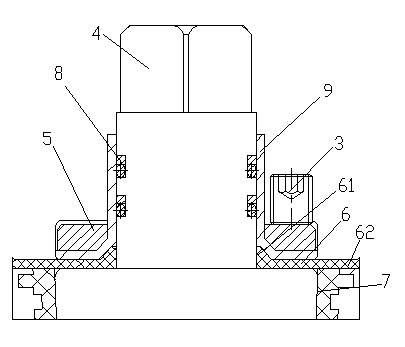

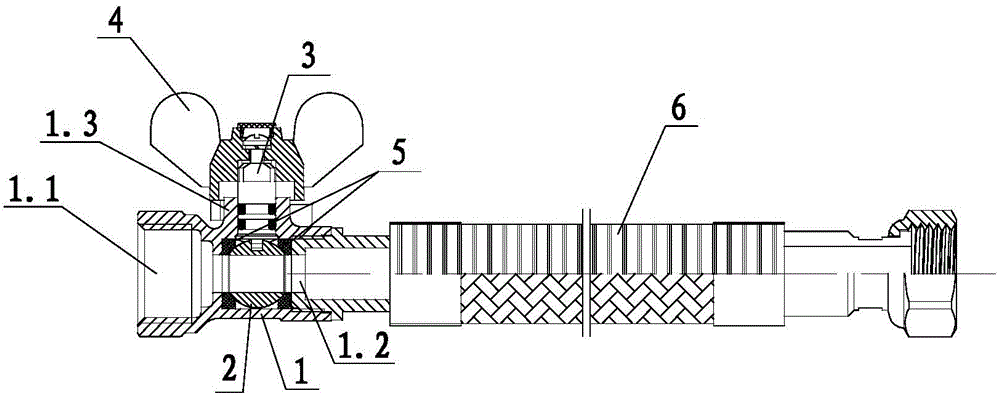

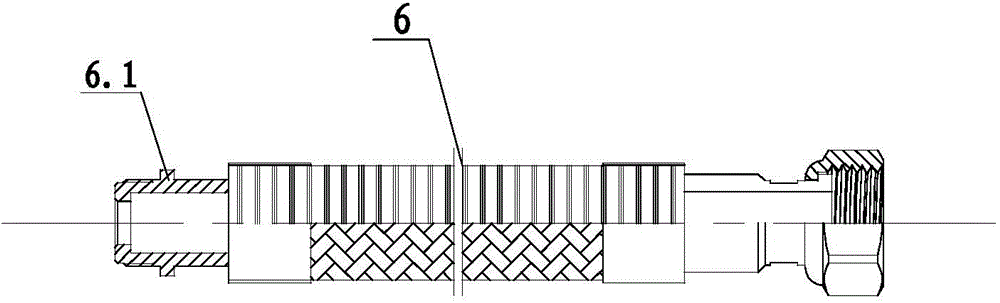

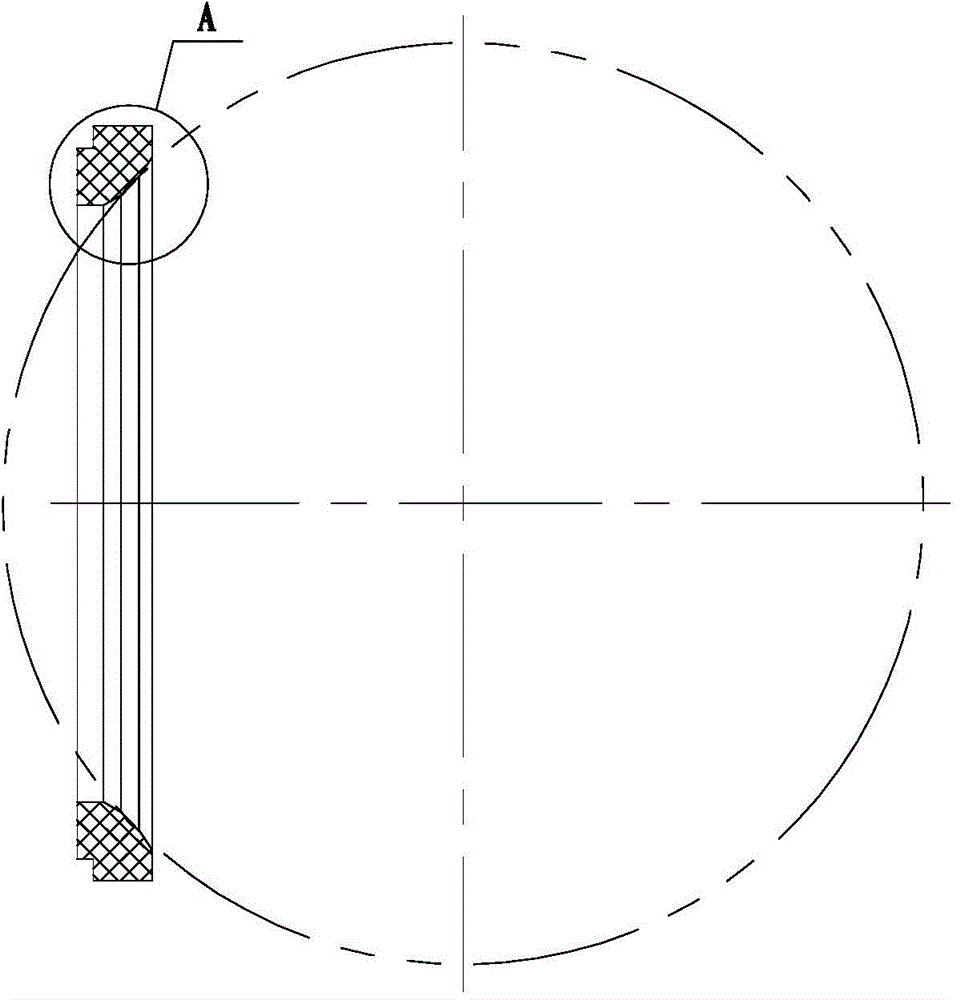

Combined type ball valve provided with corrugated pipe

InactiveCN104696540AReduce external leakage pointsEliminates the risk of air leaksPlug valvesValve housingsEngineeringBall valve

The invention discloses a combined type ball valve provided with a corrugated pipe. The combined type ball valve comprises a valve body (1) provided with an inlet end (1.1) and an outlet end (1.2) as well as a valve core (2), wherein the valve core (2) is mounted in the valve body (1); sealing pieces (5) are arranged on two sides of the valve core (2); one end of the corrugated pipe (6) is fixedly connected with the outlet end of the valve body (1); and the end surface of one end of the corrugated pipe (6) is propped against the sealing piece (5) close to the outlet end (1.2) of the valve body (1). With the adoption of the combined type ball valve provided with the corrugated pipe, the external leakage point between the corrugated pipe and the ball valve can be eliminated.

Owner:NINGBO ZHIQING INDAL

Corrugated pipe track ball valve

PendingCN113719633AImprove sealingGuaranteed detachabilitySpindle sealingsPlug valvesClassical mechanicsEngineering

A corrugated pipe track ball valve comprises a valve rod, a valve cover, a valve seat and a ball body, a corrugated pipe is arranged between the valve rod and the valve cover, a valve cover nut is arranged on the outer side of the corrugated pipe, the valve cover nut is matched with the valve cover through a thread pair, a positioning shoulder welded to the corrugated pipe is arranged on the lower portion of the valve rod, and a guide pin is arranged on the valve cover. The valve rod is provided with a guide rail groove matched with the guide pin, the guide rail groove is linear, the upper portion of the ball body is provided with a 90-degree spiral groove hole, the lower end of the valve rod is provided with a 90-degree spiral guide rail matched with the 90-degree spiral groove hole, the central axis of the 90-degree spiral guide rail and the axis of the valve rod are provided with eccentricity, and the upper end face of the ball body is provided with an annular groove. And a thrust collar is embedded in the annular groove. The corrugated pipe track ball valve has the beneficial effects that many defects of a general ball valve are overcome through a simple and effective movement mode, no friction exists in the opening and closing process, zero leakage is achieved during closing, no friction exists between the ball body and the valve seat during opening and closing, and the opening and closing torque of the valve is reduced.

Owner:JIANGSU SHENTONG VALVE

Bidirectional sealing butterfly valve

The invention discloses a bidirectional sealing butterfly valve, which comprises a valve body, an upper valve rod and a lower valve rod in the valve body, a valve seat positioned in the valve body, and a butterfly plate and an end cover which are arranged in the valve body, wherein one end of the upper valve rod is arranged outside the valve body, the other end of the upper valve rod is connected with the butterfly plate in the valve body, and one end of the lower valve rod is matched with the end cover to be fixed. The bidirectional sealing butterfly valve is characterized in that the other end of the lower valve rod is connected and fixed with the butterfly plate through a key, the valve seat is arranged at the upper side and the lower side in the valve body in an inclined mode, an upper periphery end surface of the valve seat is a valve seat sealing surface, an outer end surface of the butterfly plate is in clearance fit with the inclined valve seat sealing surface, a periphery ring surface of the butterfly plate is processed into an annular groove structure, a sealing piece is arranged in the annular groove structure, and the sealing piece and the inclined valve seat are in line contact. The bidirectional sealing butterfly valve disclosed by the invention has a small number of valve parts and is simple in assembly process, and working hours and material are saved; the valve can be sealed bidirectionally and reliably with zero leakage; and the valve has a lower opening-closing torque and long service life.

Owner:NAISEN VALVE IND

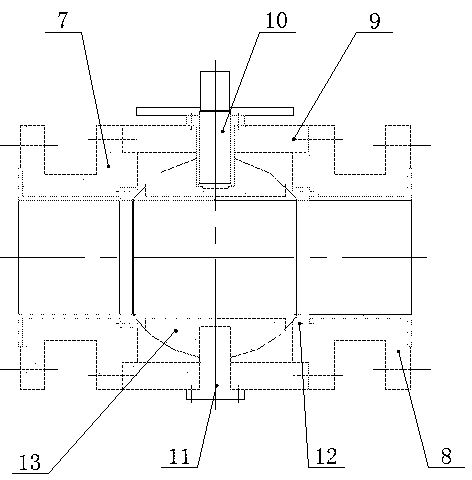

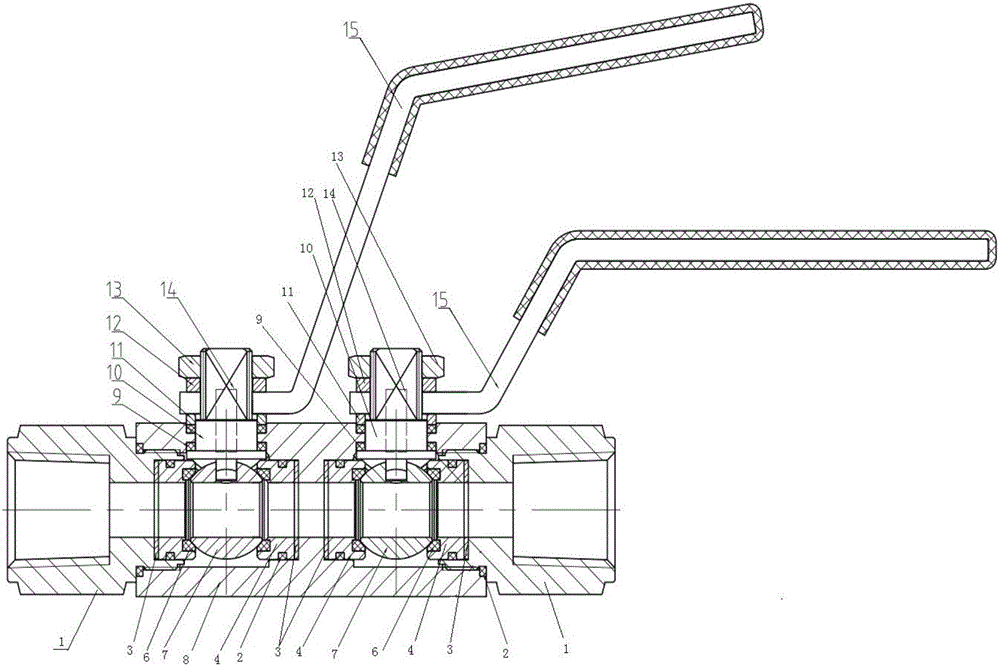

Belleville spring loaded automatic compensation double-ball valve

The invention discloses a belleville spring loaded automatic compensation double-ball valve. The belleville spring loaded automatic compensation double-ball valve comprises a valve body (8) and two ball valve assemblies which are installed inside the valve body (8) and are the same in structure. Each ball valve assembly comprises a supporting base (4), a valve seat (6) installed inside the supporting base (4) and a valve ball (7) installed on the valve seat (6); belleville springs (3) are placed on the two sides of the supporting base (4); a valve rod (10) is connected to the upper end of the valve ball (7); a filler (9) is installed between the valve body (8) and the valve rod (10); a filler pressing ring (11) is installed on the filler (9); the upper end of the valve rod (10) is connected with a hexagonal nut (13) and a handle (15); and end connectors (1) are screwed to the two ends of the valve body (8). According to the belleville spring loaded automatic compensation double-ball valve, the structure design is reasonable; the sealing performance is high; the service life is long; the structure of the double ball valve assemblies is adopted; and when one ball valve leaks, the other ball valve can serve as an emergency cut-off valve to be used.

Owner:JIANGSU JINGWEI VALVE

Air bag valve

A gasbag valve comprises a valve body, a valve cover, upper and lower valve shafts, a drive device, a spool, an end cap and a seal ring. The valve body is connected with the valve cover via bolts. The spool is supported in the valve body by the upper and lower valve shafts. In the valve body is mounted the seal ring, in which is inlaid a metal lining ring with several radial through-holes. An air inlet is set on the valve body. Outside the air inlet there is compression air and the inside of the air inlet is in communication with the metal lining ring. The seal ring is made of acrylonitrile rubber or silicon rubber.

Owner:JIANGSU SHENTONG VALVE

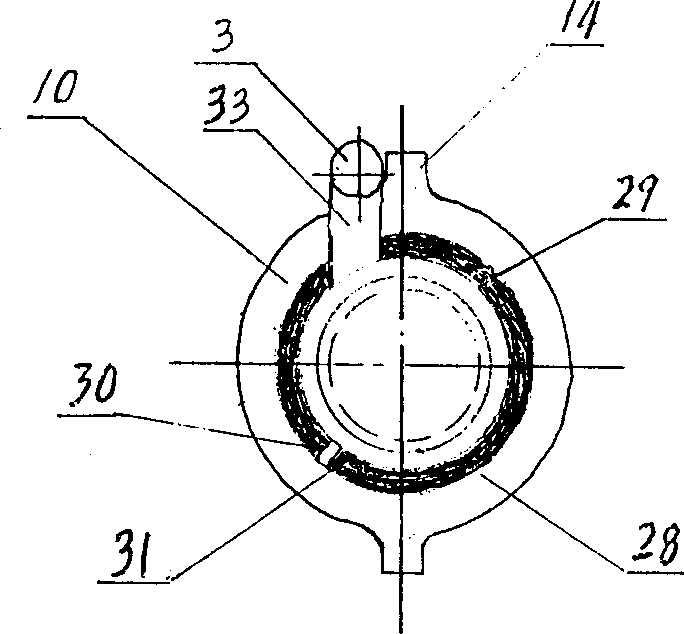

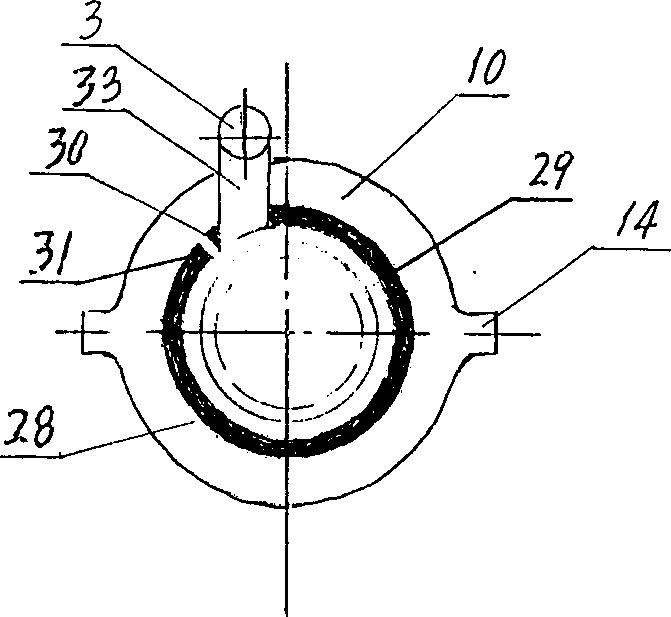

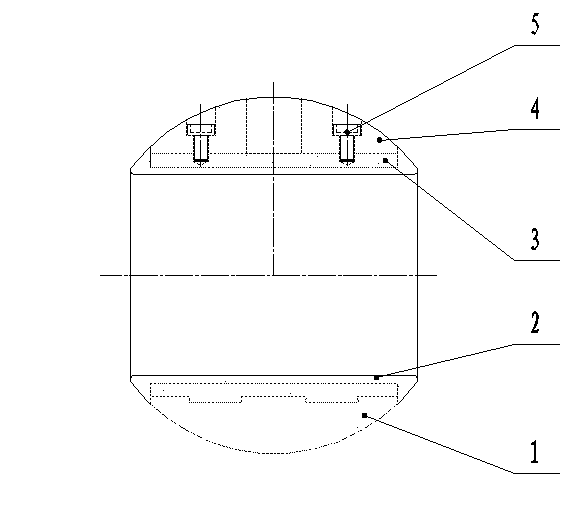

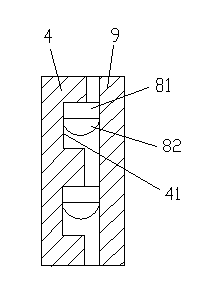

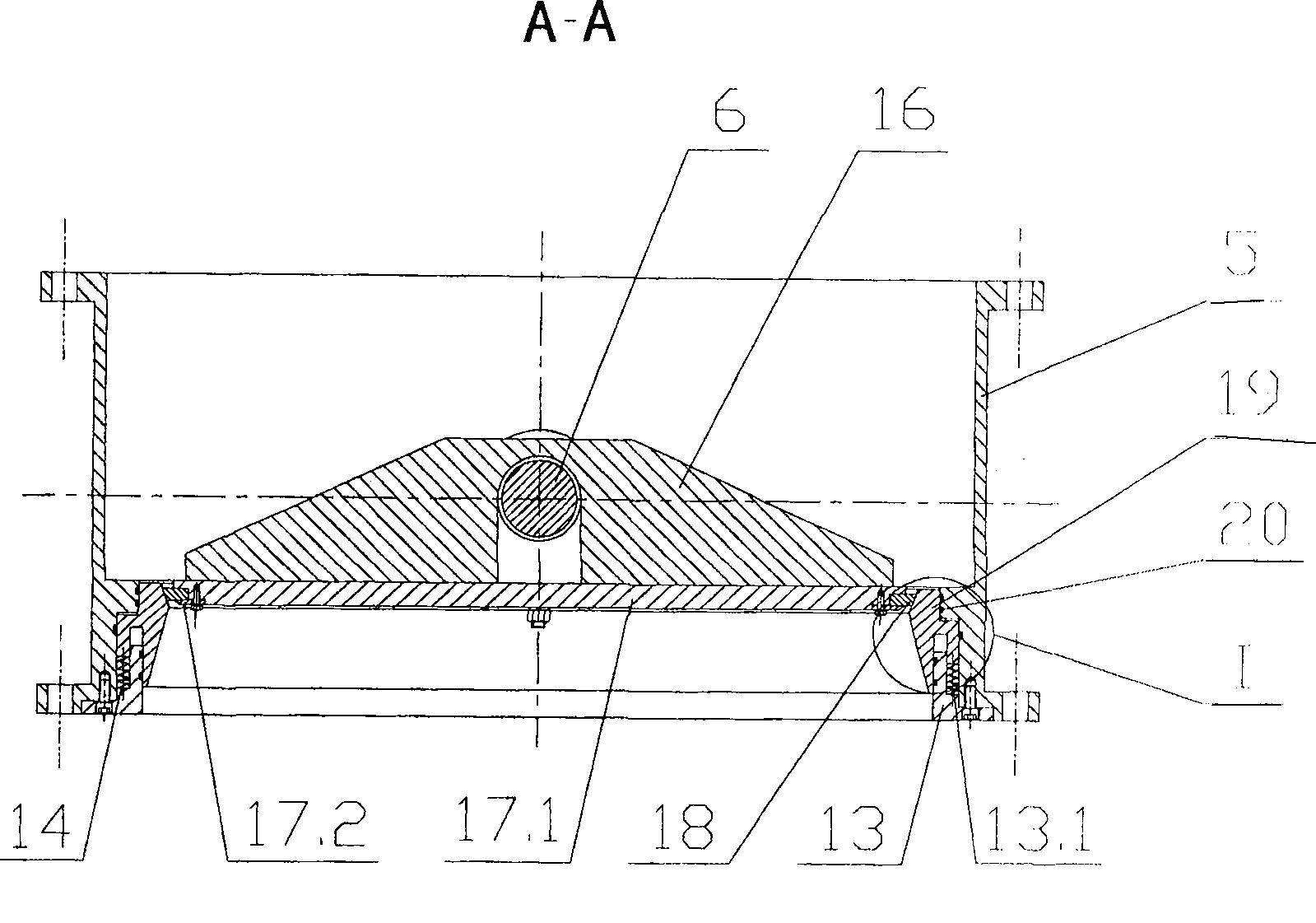

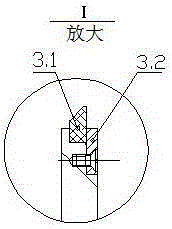

Non-abrasion hard-sealing butterfly valve

The invention relates to a wear-free hard-sealed butterfly valve, which includes a valve body, a valve rod, a butterfly plate and a valve seat, and is characterized in that the valve seat is a movable valve seat that can move axially along the inner wall of the valve body; one side of the valve body There is a side body; a sealing ring is installed between the valve seat, the valve body and the side body; the seal is fastened on the butterfly plate frame; there is a moving fit gap between the inner and outer sides of the valve seat and the valve body and the side body , there is a spring between the outer end surface of the valve seat and the side body, and the inner end surface is connected with the valve stem through a push rod; There is a long keyway in the middle of the valve stem, and there are upper and lower keys respectively fixed on the upper and lower connecting seats, and the upper and lower connecting seats are respectively fastened on the butterfly plate; the push rod It includes upper and lower push rods, one end of which is equipped with a roller, one end of the lower push rod is embedded in the lower curved groove, and can slide, and the other end is hinged with the inner end surface of the movable valve seat; the upper push rod and the lower push rod are installed symmetrically ; There is a single eccentric structure between the disc rotation axis and the sealing plane.

Owner:HEBEI UNIV OF TECH

Top entry ball valve

The invention relates to a top entry ball valve and mainly solves the problem that an existing top entry ball valve is complex to open and close, has limited applicable range and has high cost. A valve body and a bonnet form a cavity which is provided with a valve element and a valve seat inside, a support is connected to the upper end of the bonnet, the valve element comprises a valve stem, a switch block and a ball composed of two half-balls, the lower end of the valve stem is fixedly connected with the switch block, the switch block is connected with the upper end of the ball composed of the half-balls, the lower end of the ball composed of the half-balls is connected with a fork rotary shaft through a lower pin, the lower end of the fork rotary shaft is provided with an adjusting structure, two roller sets are connected to the upper portion of the switch block and are inserted respectively in spiral grooves of the bonne which have a spiral groove slide bushing, the upper end of the valve stem is sleeved with a dust cover, and the valve seat is provided with a channel. The top entry ball valve has good sealing performance, the valve element moves up and down as a whole during opening and closing so that the structure is simple, the top entry ball valve is applicable to a medium with impurities or particles, is widely applicable, and has small opening and closing torque, low manufacture cost and long service life.

Owner:TINGYU GRP ZHEJIANG FLUID CONTROL EQUIP

Two-piece type soft sealing and jacket heat preserving wedge type ball valve

PendingCN107940008AImprove detachabilitySealing automatic adjustmentPlug valvesThermal insulationTetrafluoroethyleneEngineering

The invention provides a two-piece type soft sealing and jacket heat preserving wedge type ball valve. The ball valve comprises a left valve body, a right valve body and an adjusting screw rod. The ball valve has the advantages of being simple in structure and good in heat preservation performance and sealing performance; through a double-bevel-type sealing pair of a first inclined surface and a second inclined surface, a center hole of the ball and the first inclined surface form an included angle of 5 degrees, and the center hole of the ball and the second inclined surface also form the included angle of 5 degrees so that the sealing performance among valve seats, the valve bodies and a ball body can be automatically adjusted; metal valve seat lining rings are arranged on the valve seat,the valve seat is made of polytetrafluoroethylene material, so that plastic deformation of the valve seat is prevented, and flushing of a medium on the valve seat is reduced; the adjusting screw rodis arranged at the bottom and is used for driving an ejector rod to move, so that abrasion of the valve seat is reduced, and the service life of the valve is prolonged; and a first heat preservation jacket is connected with a second heat preservation jacket through pipeline flanges, so that the detachability of the heat preservation jackets is realized, use is convenient, and the heat preservationperformance of the ball valve is ensured.

Owner:YANGZHONG VALVE FACTORY CO LTD

Bi-directional soft seal butterfly valve opened and closed through screw

ActiveCN104832660AShort opening and closing timeSmall opening and closing torqueLift valveValve housingsEngineeringButterfly valve

The invention discloses a bi-directional soft seal butterfly valve opened and closed through a screw. The butterfly valve comprises a hand wheel, a copper nut, the screw, a valve body bracket, a valve body, a valve body sealing seat, a valve plate sealing ring, a valve plate and valve shafts; when the valve plate is in a closed state, the plane, where the valve plate is positioned, and the screw are eccentric; a valve plate rocking handle is fixedly connected with the center of the valve plate; the screw and the valve plate rocking handle are connected through a pin shaft; the two valve shafts are respectively positioned on the two sides of the valve plate and form the angles alpha with the plane, where the valve plate is positioned when the valve plate is in the closed state; one valve shaft is positioned above the horizontal center axis of the valve plate; the other valve shaft is positioned below the horizontal center axis of the valve plate; and the eccentricity of the two valve shafts and the horizontal center axis of the valve plate in the closed state is b. The butterfly valve has the benefits as follows: the opening and closing are carried out through the screw, the opening and closing time is short, the opening and closing torque is less, and opening and closing are obvious; compared with worm gear case processing, the processing of the butterfly valve is simpler, the production cost is low, clamping during opening and closing does not occur and the valve plate can be opened fully.

Owner:ANHUI TONGDU FLOW TECH

Zero-friction hard seal butterfly valve

ActiveCN105221767AExtended service lifeAvoid frictionOperating means/releasing devices for valvesLift valveInterference fitEngineering

The invention discloses a zero-friction hard seal butterfly valve. The zero-friction hard seal butterfly valve is characterized in that the butterfly valve comprises a valve opening, a valve body, a valve seat, a disc, a valve shaft, a guide groove, an incomplete gear, a rack, a guide shaft No.1, a guide shaft No.2, a self-lubricating shaft sleeve, a linkage rod, an intermittent mechanism, a driving handle and a seal device, a through hole is formed in the valve body, a valve neck is welded at the part of the through hole, the valve seat is welded on the inner circumferential surface of the valve body, and the outer circumferential surface of the valve seat is a conical surface; the disc is a moving type disc and adopts a ring structure, a hard seal ring is mounted at the outer circle part of the disc, and the movement type refers to a motion structural mode that the disc can first make transverse movement along the axial direction of the valve body and then rotate with the guide shaft No.1 as a center and is opened in a zero friction manner; the disc is connected with the guide shaft No.1; the guide shaft No.1 is mounted in the guide groove and penetrates through the rack, and the guide shaft No.1 is also in interference fit with the rack at the connecting part; and the guide shaft No.2 is also mounted in the guide groove.

Owner:JIANGSU HUATAI ELECTRIC POWER ELECTRONICS INSTR

Opening and closing sealing surface separation ball valve

The invention discloses an opening and closing sealing surface separation ball valve. The ball valve comprises an automatic control and execution mechanism, a valve body, a flow channel and an upstream mounting groove; a valve rod is mounted on the valve body; an opening and closing piece is arranged on the valve rod and divides the flow channel into an inlet flow channel and an outlet flow channel; an upstream valve seat is glidingly arranged in the upstream mounting groove; the automatic control and execution mechanism comprises a controller and an actuator electrically connected with the controller; a closed driving cavity is formed between the upstream mounting groove and the upstream valve seat; the inlet flow channel communicates with the closed driving cavity through a first pipeline; the outlet flow channel communicates with a second pipeline; a switching piece for switching the medium flow direction is arranged between the first pipeline and the second pipeline; and a controlcomponent for controlling the pressure inside the closed driving cavity is arranged on the outer side of the valve body. The ball valve has the advantages and effects as follows: the upstream valve seat adopts the special valve seat adopting the detachable structure, the opening and closing torque of the valve can be reduced, the service life of the valve can be prolonged, and the better sealing effect can be achieved.

Owner:FANGZHENG VALVE GRP

Valve element stationary type PE fuel gas plug valve

InactiveCN103363143AAvoid chronic stressSmall opening and closing torquePlug valvesPlug valveFuel gas

The invention relates to the technical field of pipelines, particularly to a valve element stationary type PE fuel gas plug valve which comprises a valve element base I, a valve element base II, a valve element arranged on the valve element base I, a valve body arranged on the valve element base II, a valve rod arranged in the valve body, a sealing socket and a supporting seat, wherein the sealing socket and the supporting seat form an assembling unit in a vulcanized manner, the assembling unit is arranged on the valve body, and an avoiding groove is formed in the valve element. The valve element stationary type PE fuel gas plug valve is simple in structure and stable in performance, and can effectively prevent the sealing socket from being pressed for a long time and reduce start-and-stop torque of the valve body.

Owner:LIANSU TECH DEV GUIYANG

Bidirectional hard sealing rotary ball valve

PendingCN114321430AReduce frictionSmall opening and closing torqueSpindle sealingsPlug valvesEngineeringButterfly valve

The invention discloses a two-way hard sealing rotary ball valve which comprises a valve body, a valve seat is arranged in the valve body, and a valve shaft capable of rotating around the axis of the valve shaft is arranged in the valve body in a penetrating mode; the valve plate is arranged on the valve shaft in a sleeving mode, and the valve shaft rotates to drive the valve plate to rotate synchronously; the valve plate is provided with a floating valve element, a floating ring and a limiting block, the floating valve element can be connected with the valve seat in a sealed mode to control the valve body to be closed, the floating ring can abut against the floating valve element to improve the sealing pressure of the floating valve element and the valve seat, and the limiting block is used for conducting sliding limiting on the floating ring. And the sealing structure is mounted on the valve body and used for sealing the joint of the valve shaft and the valve body. According to the two-way hard sealing rotary ball valve, the friction force of the sealing face can be effectively reduced, the opening and closing torque of the valve is reduced so as to prolong the service life of equipment, meanwhile, the valve structure is simplified, the valve body and a valve body of a conventional one-way butterfly valve can be commonly used, and the production, manufacturing and maintenance cost is reduced.

Owner:HUNAN PUMP VALVE MFG CO LTD

Valve shaft sealing device

InactiveCN111350871AAchieve sealingSmall opening and closing torqueSpindle sealingsValve housingsRubber ringPressure rise

The invention discloses a valve shaft sealing device. The valve shaft sealing device comprises a valve body, a valve shaft and a gland; an annular cutting groove is formed in the valve body around thevalve shaft, an opening in the upper end of the cutting groove is blocked by the gland, two expansion assemblies are arranged in the cutting groove, the two expansion assemblies are connected with aplurality of springs, and the springs push the two expansion assemblies to abut against the gland and the bottom face of the cutting groove correspondingly; the cutting groove communicates with the input end of the valve body through a liquid inlet pipe; each expansion assembly comprises two rubber rings, and the end faces, making contact with each other, of the two rubber rings are inclined faces. The valve shaft sealing device is used for solving the problems that the pipeline pressure rises and pipeline distribution medium leaks from the valve shaft.

Owner:HUBEI TAIHE PETROCHEM EQUIP

Brake vale

InactiveCN104747744AVibration reliefEase eccentricitySpindle sealingsSlide valveEngineeringMechanical engineering

The invention provides a brake valve. The brake vale comprises a valve cover, a valve rod arranged in the valve cover, a valve rod sealing sleeve embedded between the valve cover and the valve rod in a sleeved manner and a sealing mechanism. The top end of the sealing mechanism plays a role in sealing and dust prevention. A locating portion is arranged on the valve cover, and a locating groove matched with the locating portion for locating is arranged on the valve rod sealing sleeve; and a plurality of sealing grooves are formed in the valve rod sealing sleeve, and sealing rings are arranged in the sealing grooves. The sealing mode between the valve rod sealing sleeve and the valve cover is changed, vibration and eccentricity of the valve rod in the motion process can be effectively relieved, open and close torque of the valve is reduced, and the service life of a part is prolonged.

Owner:ANHUI REDSTAR VALVE

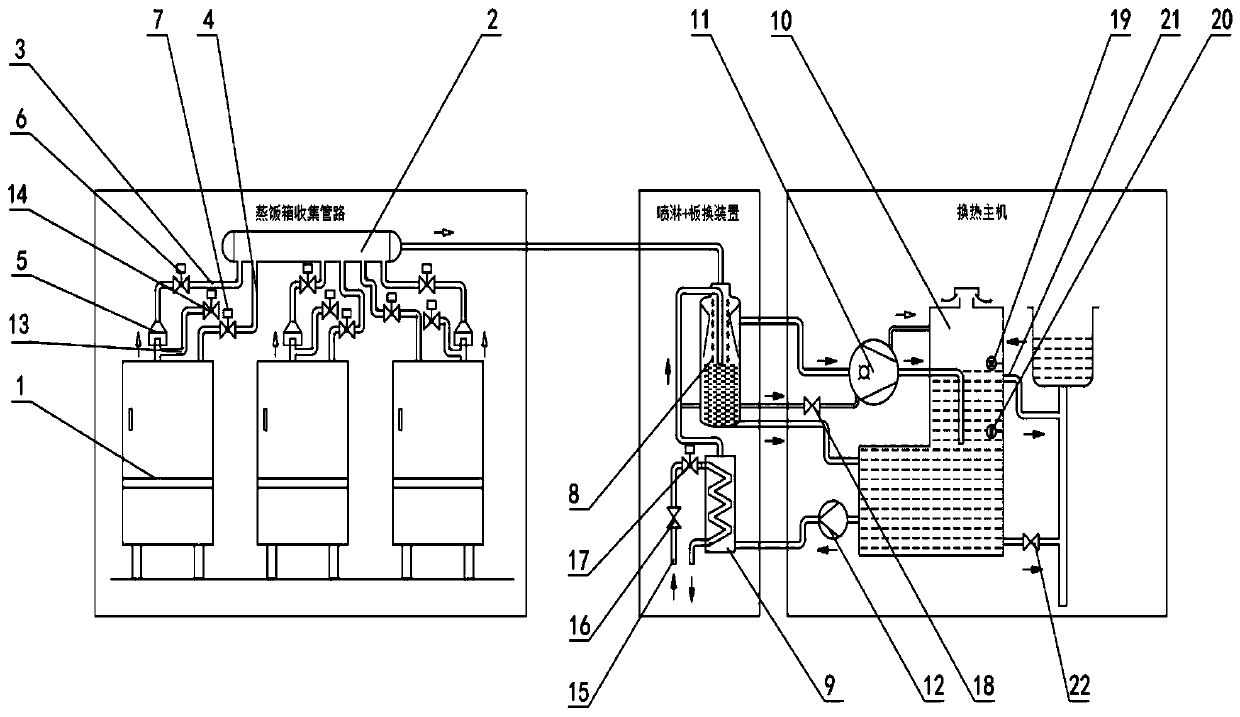

Ship kitchen steam collecting and processing device and working method thereof

ActiveCN110793346AEffective in handling steamConserve fresh water resourcesSteam generation heating methodsAuxillariesMachine partsWorking environment

The invention discloses a ship kitchen steam collecting and processing device and a working method thereof. The device comprises a rice steaming box collecting pipeline part, a spraying and plate exchanging device part and a heat exchanging main machine part. According to the ship kitchen steam collecting and processing device, the effect of processing steam is remarkable; and compared with a traditional method of directly discharging the steam into air in a natural ventilation mode, the ship kitchen steam collecting and processing device has the advantages that a large amount of fresh water resources are saved, the working efficiency is effectively improved, meanwhile, the working environment is improved to a certain extent, and the safety of personnel is improved. The device is suitablefor simultaneous use of a plurality of rice steaming boxes.

Owner:JIANGSU UNIV OF SCI & TECH

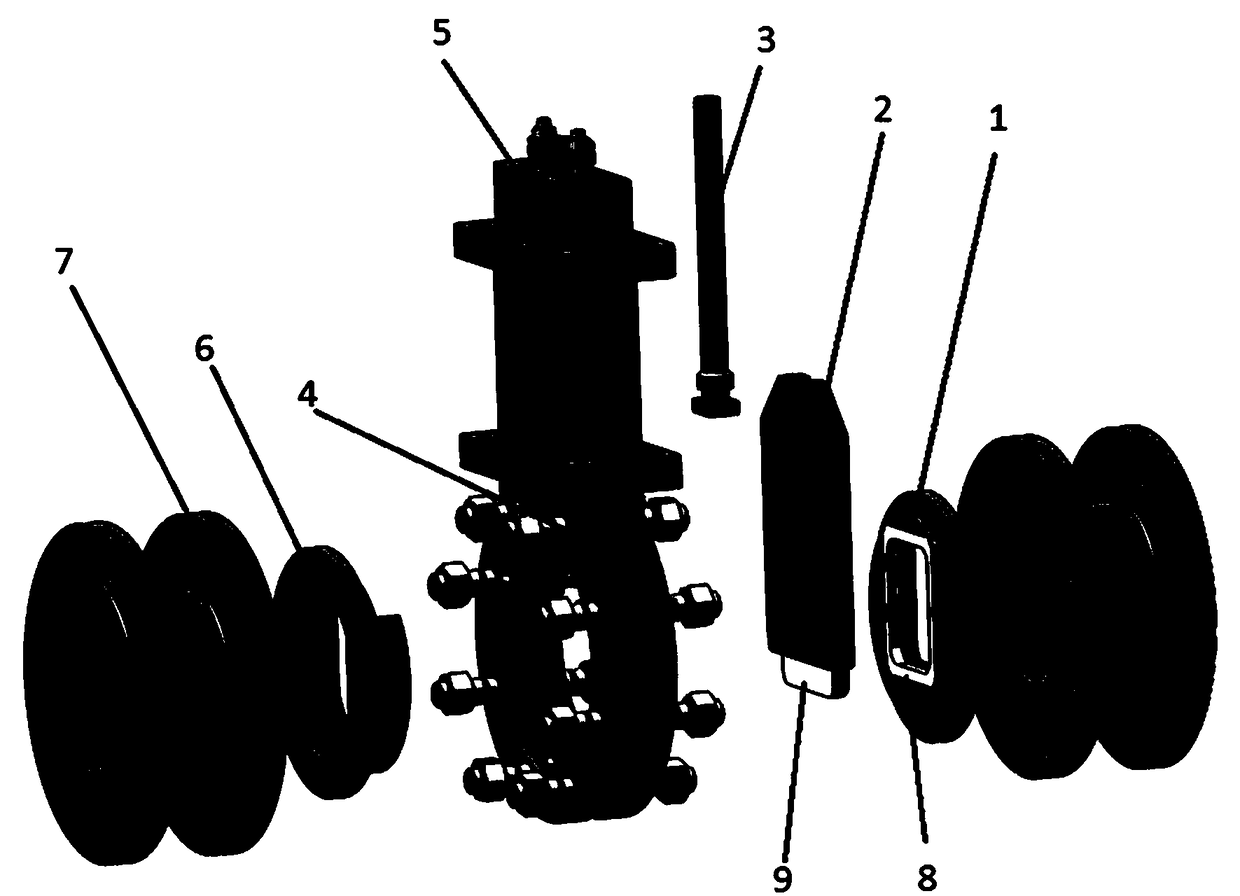

Ceramic slide valve

The invention discloses a ceramic slide valve. The ceramic slide valve comprises a round plate valve seat (1), a slide block (2), a valve rod (3), a valve body (4), an upper platform (5), a valve bodyliner (6) and a flange (7); the valve body liner (6) is arranged in the valve body (4); the lower end of the valve rod (3) is connected with the upper end of the slide block (2) in a matched mode; and the slide block (2) drives a ceramic valve core (9) to move up and down on one side of a ceramic valve seat (8) inlaid in the round plate valve seat (1), and is in plain sealing with the edge of a runner hole of the round plate valve seat (1), and throttling, starting and stopping of fluid are achieved.

Owner:YANTAI KINGWAY SCI & TECH

Seal valve with no-wear helical surface

InactiveCN102384312AAffect the service lifeExtended service lifeValve housingsEngineeringSpiral line

The invention discloses a seal valve with a no-wear helical surface, belonging to the technical field of valves. The main points of the seal valve are as follows: the seal valve comprises a valve body; the valve body is provided with a medium inlet and a medium outlet; a valve core and a valve base are movable arranged in the valve body, wherein when the valve core and the valve base are closed, the contour line of the transverse section of the contact face of the valve core and valve base is part of a same constant speed spiral line; when the valve core and the valve base are closed, the valve core rotates outward along the constant speed spiral line, the valve core is disengaged from the valve base, and the valve is opened; and when the valve core is disengaged from the valve base, the valve core rotates inward along the constant speed spiral line, the valve core and the valve base form a contact seal, and the valve is closed. The invention aims at providing a seal valve with a no-wear helical surface, which has a simple structure, small volume and high sealing reliability, and the seal valve is used for controlling the medium flowing in a pipeline.

Owner:GUANGDONG PEARL FLUID MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com