Two-piece type soft sealing and jacket heat preserving wedge type ball valve

A soft-sealing, two-piece technology, applied in the field of valves, can solve problems such as inability to play a role in heat preservation, single ball valve heat preservation form, poor valve maintenance performance, etc., to achieve detachability, prevent plastic deformation, and good heat preservation and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

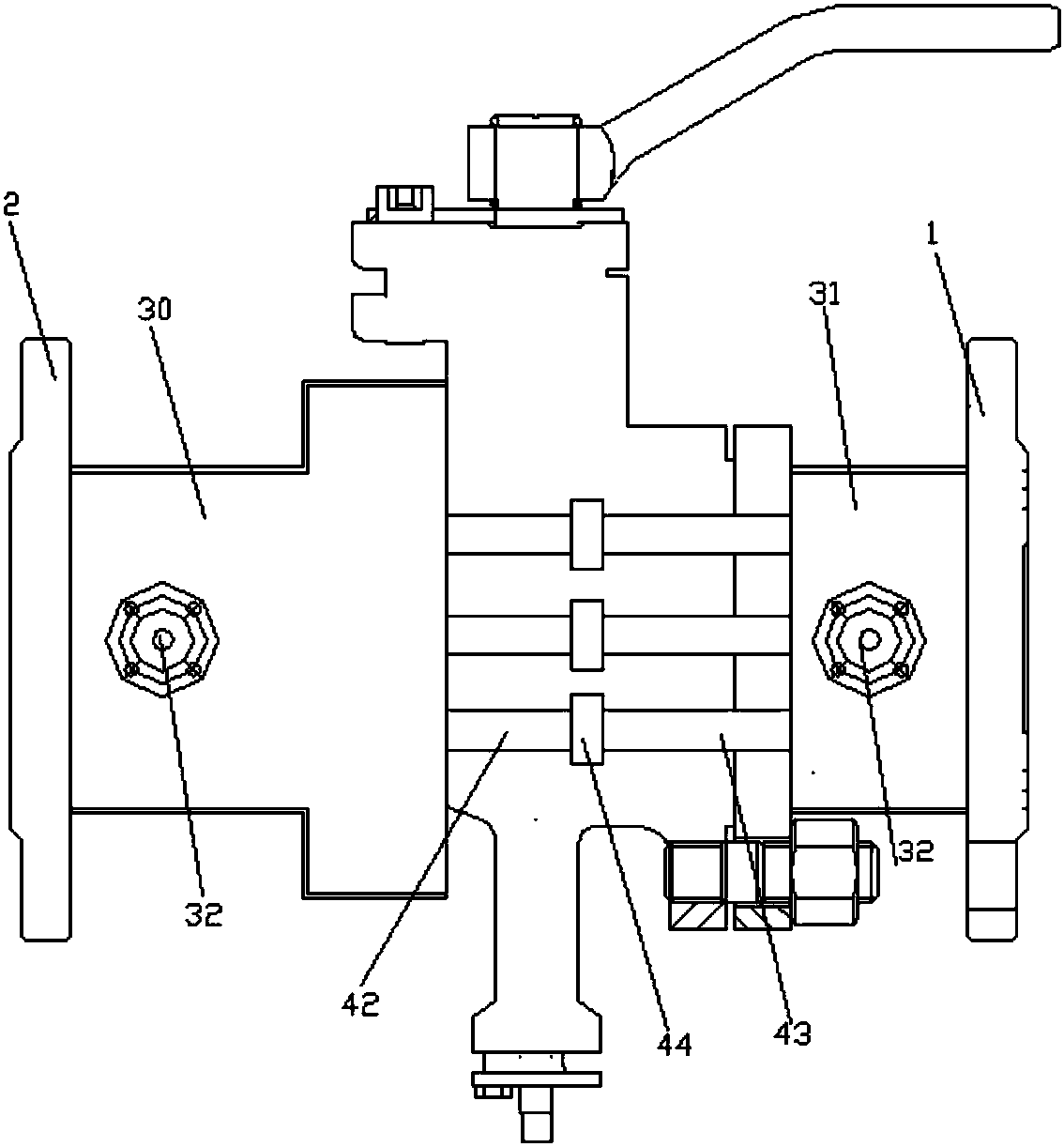

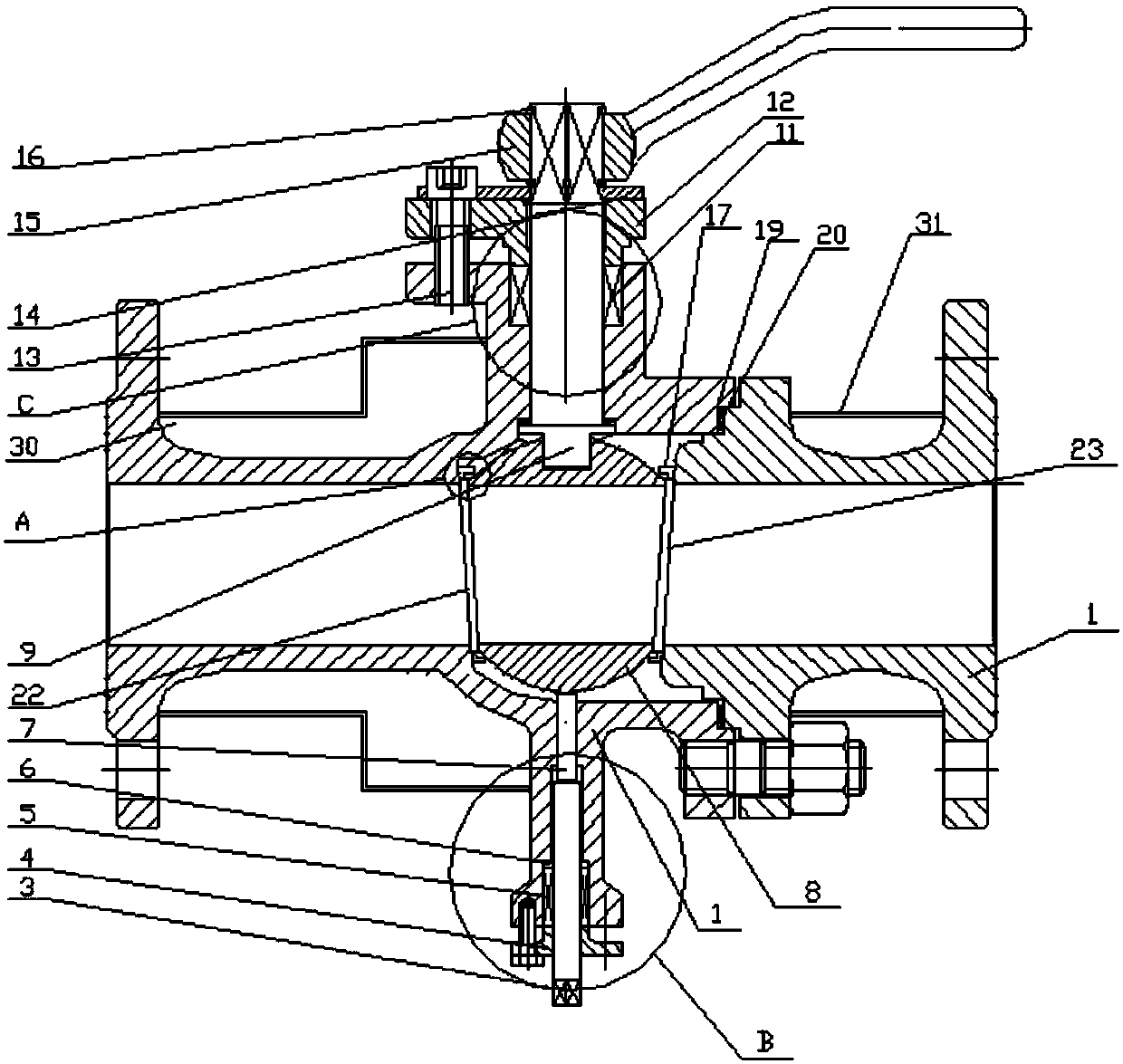

[0022] A two-piece soft-sealed jacket insulation wedge ball valve, including a left valve body 2, a right valve body 1, and an adjusting screw 3;

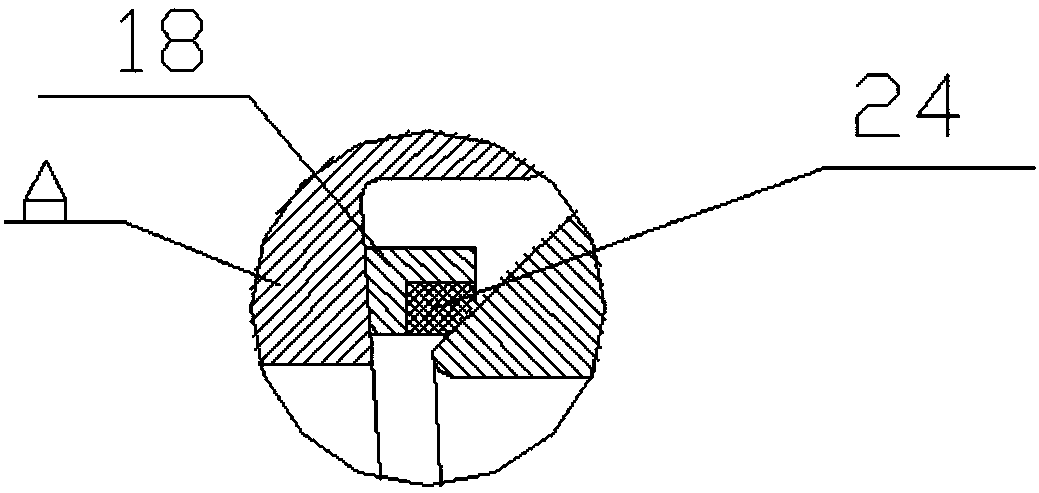

[0023] The right end surface of the left valve body 2 is provided with a first stepped surface 19, the left valve body 2 is provided with a center through hole, and the left valve body 2 is provided with a first inclined plane 22, and the first inclined plane 22 and the central axis of the circle center through hole The included angle is 5°; the left end surface of the right valve body 1 is provided with a second step surface 20, the right valve body 1 is provided with a center through hole, and the right valve body 1 is provided with a second inclined surface 23, and the second inclined surface The included angle between 23 and the central axis of the center through hole is 5°; the left valve body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com