Automatic assembly apparatus system and method for automobile door lock

An automatic assembly device and a technology for car door locks, which are applied to measurement devices, optical devices, general control systems, etc., can solve the problems of small assembly parts of car door locks, unable to meet mass production, and low degree of automation. Maintainability, ease of transportation and maintenance, effect of solving low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In conjunction with the accompanying drawings, the present invention will be described in detail below through specific embodiments.

[0043] One, the design basis of the present invention is:

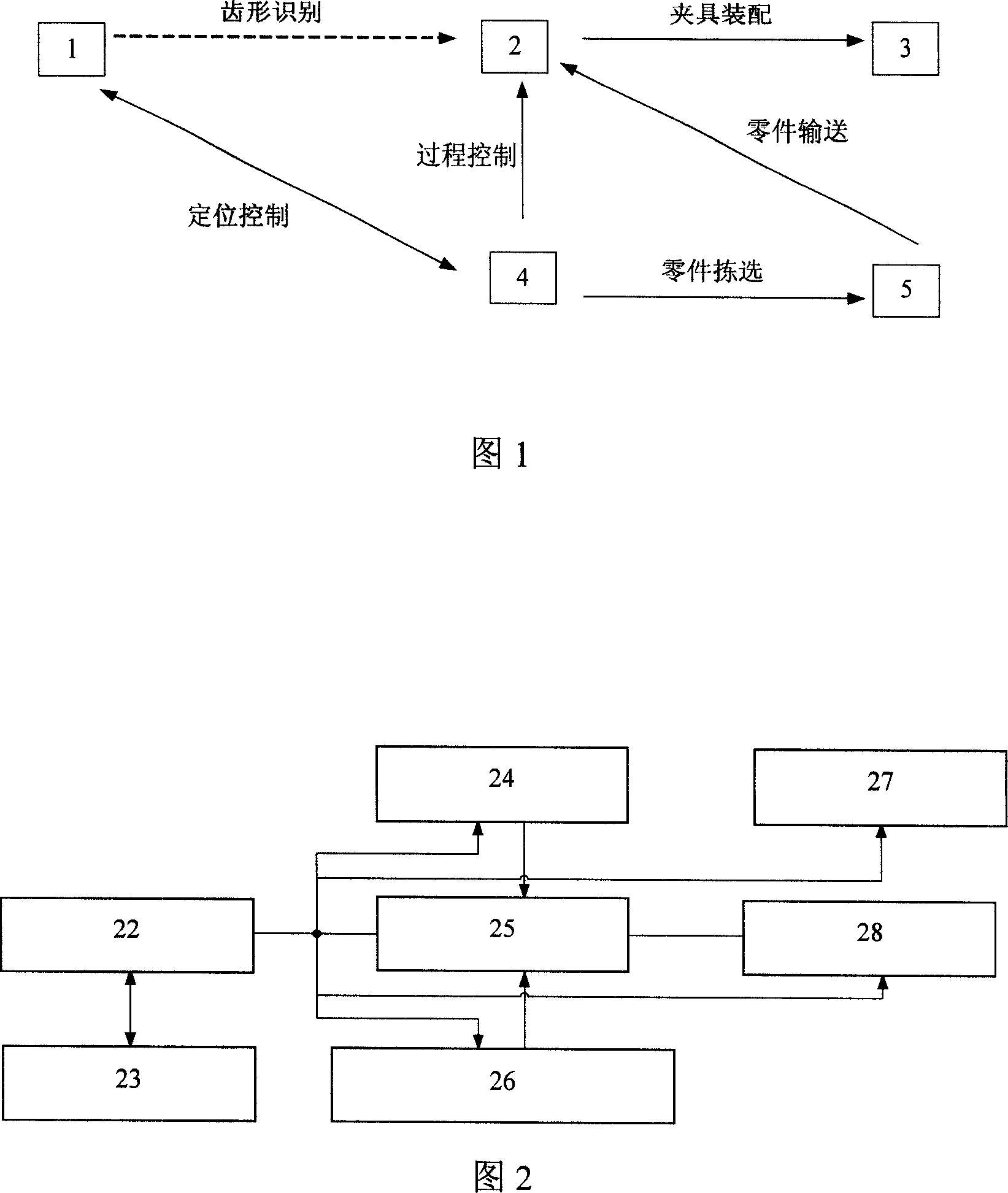

[0044] 1. Flexible Assembly System (FAS) is a new production mode developed for the characteristics of small batch and multi-variety production. It enables enterprises to adapt to the assembly of new products in the shortest time, and greatly improves the flexibility and adaptability of enterprises. , to meet the rapidly changing and uncertain requirements of the current market demand. FAS is a highly automated assembly system. It generally has three automation systems: assembly, material delivery, and control. Its flexibility is mainly reflected in the variable assembly objects, process flow, and production cycle. The entire assembly process is mainly composed of product design (DFA), assembly sequence, assembly task, assembly execution, and assembly inspection. Among them, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com